Process for manufacturing multielement composition high silica glass fibre fixed-length yarn

A high-silica glass fiber fixed-length and manufacturing process technology, applied in the field of high temperature resistant materials, to achieve the effect of reasonable process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

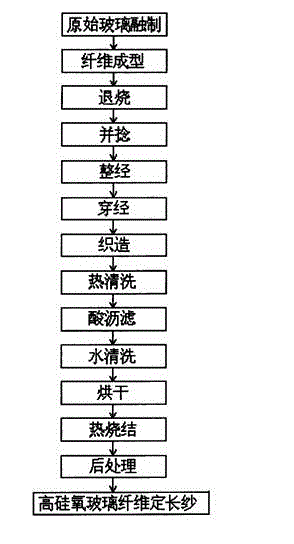

[0020] see figure 1 , the multi-component high-silica glass fiber staple yarn manufacturing process includes the following steps:

[0021] ①. Using the original glass with sodium-boron-silicon ternary composition as the raw material, the fiber is formed through melting and processing.

[0022] ②. Make yarn bundles by cooling down, twisting, warping and drawing-in in sequence.

[0023] ③. Place the yarn bundle on the creel, control the temperature at 96-98° C., and treat it with steam for 5 hours.

[0024] ④. Put the heat-treated yarn bundle on the creel, then place the creel in the acid leaching tank, inject hydrochloric acid with a concentration of 3.2mol / L into the acid leaching tank for circulation, and perform leaching treatment .

[0025] ⑤. The yarn bundle after the acid leaching treatment is sprayed with water at 25-35° C., and the surface pH value is detected to be 6.7-6.8 to complete the water washing treatment.

[0026] ⑥. Dry at 100-120°C, and then perform post-...

Embodiment 2

[0030] The manufacturing process of multi-component high-silica glass fiber cut-to-length yarn includes the following steps:

[0031] ①. Using the original glass with sodium-boron-silicon ternary composition as the raw material, the fiber is formed through melting and processing.

[0032] ②. Make yarn bundles by cooling down, twisting, warping and drawing-in in sequence.

[0033] ③. Place the yarn bundle on the creel, control the temperature at 97-99° C., and treat it with steam for 5 hours.

[0034] ④. Put the heat-treated yarn bundle on the creel, then place the creel in the acid leaching tank, inject hydrochloric acid with a concentration of 3.2mol / L into the acid leaching tank for circulation, and perform leaching treatment .

[0035] ⑤. The yarn bundle after the acid leaching treatment is sprayed with water at 32-39° C., and the surface pH value is detected to be 6.6-6.7 to complete the water washing treatment.

[0036] ⑥. Dry at 120-140°C, and then perform post-proces...

Embodiment 3

[0039] The manufacturing process of multi-component high-silica glass fiber cut-to-length yarn includes the following steps:

[0040] ①. Using the original glass with sodium-boron-silicon ternary composition as the raw material, the fiber is formed through melting and processing.

[0041] ②. Make yarn bundles by cooling down, twisting, warping and drawing-in in sequence.

[0042] ③. Place the yarn bundle on the creel, control the temperature at 97-98° C., and treat it with steam for 5 hours.

[0043] ④. Put the heat-treated yarn bundle on the creel, then place the creel in the acid leaching tank, inject hydrochloric acid with a concentration of 3.2mol / L into the acid leaching tank for circulation, and perform leaching treatment .

[0044] ⑤. The yarn bundle after the acid leaching treatment is sprayed with water at 35-36° C., and the surface pH value is detected to be 6.5-6.6 to complete the water washing treatment.

[0045] ⑥. Dry at 130-150°C, and then perform post-proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com