A filling support method for enhancing the processing rigidity of thin-walled parts

A technology for processing and supporting thin-walled parts, which is used in metal processing equipment, metal processing mechanical parts, supports, etc., can solve the problems of weakly rigid thin-walled parts and affect the surface quality of the workpiece, and achieves low shrinkage, low cost, The effect of good bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

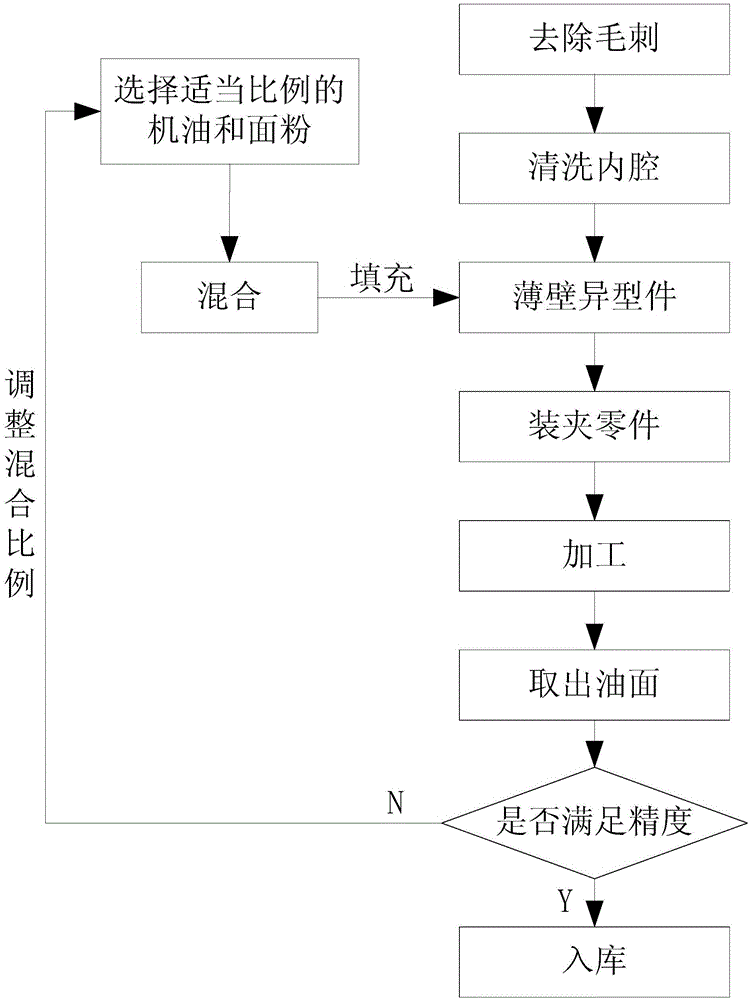

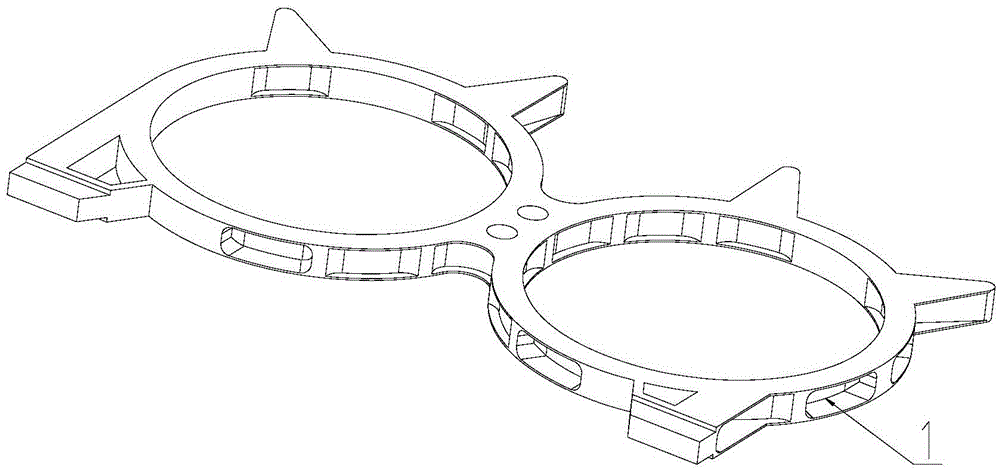

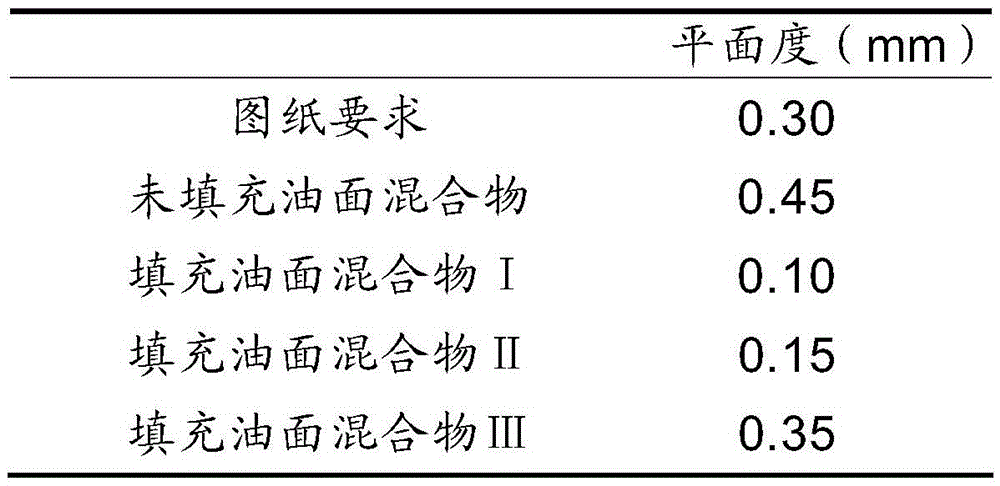

[0038] (1) According to the size of the round beam of the instrument board, make three oil-surface mixtures with different mass ratios, that is, weigh 600g of engine oil, 2000g of flour to be made into oil-surface mixture I, and weigh 800g of machine oil and 2000g of flour to be prepared into oil-surface mixture II , weigh 900g of engine oil and 2000g of flour to be made into oil-noodle mixture III;

[0039] (2) Put the flour into the measuring container, sprinkle engine oil on the flour gradually, and keep kneading the flour with your hands at the same time, so that the engine oil and the flour are in full contact until there is no remaining dry flour, and store the prepared oil-surface mixture in a sealed container. environment;

[0040] (3) Use a scraper to remove the burr of the part, and wipe the surface of the groove of the part with a non-woven cloth moistened with alcohol to remove oil and metal chips;

[0041] (4) According to the size of the part groove, the oil sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com