Three-stage carbon-nitrogen-boron ternary gas deep co-infiltration method for low carbon nickel molybdenum steel

A ternary gas, nickel-molybdenum steel technology, applied in coating, solid-state diffusion coating, metal material coating process, etc., can solve the problem that cannot meet the requirements of high hardness and high wear resistance, deep infiltration of N or co-infiltration technology Insufficient, affecting the impact toughness performance indicators and other problems, to achieve the effect of good hardness, fatigue life improvement, hardness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

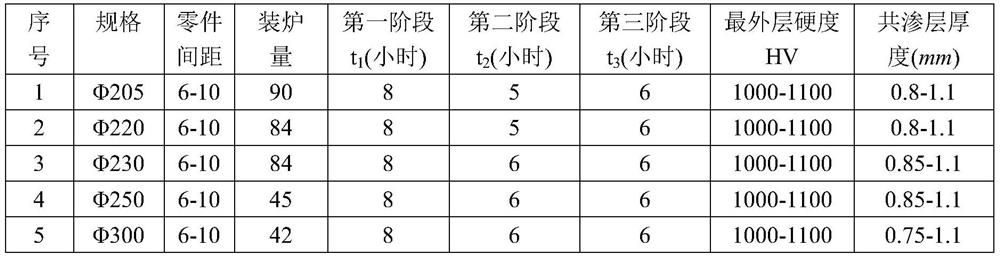

Image

Examples

Embodiment 1

[0020] This embodiment includes the following steps:

[0021] (1) Prepare a boron-donating agent, by weight percentage, 2% of lanthanum oxide rare earth, 5% of boron carbide, 15% of potassium fluoroborate, and the balance is silicon carbide, uniformly mixed and bonded and dried into a solid block; in addition, Prepare the carbon-nitrogen co-infiltration solution, the co-infiltration solution is calculated by mass percentage, and is composed of 50% carbonamide, 40% sodium carbonate and 10% sodium chloride;

[0022] (2) The 20Ni to be processed 4 The Mo steel drill bit workpiece is placed in a drop-controlled carburizing furnace, heated to 860°C, and exhausted for 1 hour;

[0023] (3) The three-stage co-infiltration method is used to carry out the gas three-component deep co-infiltration process

[0024] 3.1. The first stage is mainly carburizing. The initial heating temperature is 860°C for 2 hours and then carburizing. Among them, methanol is 40 drops / minute, kerosene is 120...

Embodiment 2

[0033] This embodiment includes the following steps:

[0034] (1) Prepare a boron-donating agent, by weight percentage, 2% of lanthanum oxide rare earth, 5% of boron carbide, 15% of potassium fluoroborate, and the balance is silicon carbide, uniformly mixed and bonded and dried into a solid block; in addition, Prepare the carbon-nitrogen co-infiltration solution, the co-infiltration solution is calculated by mass percentage, and is composed of 50% carbonamide, 40% sodium carbonate and 10% sodium chloride;

[0035] (2) The 20Ni to be processed 4 The Mo steel drill bit workpiece is placed in a drop-controlled carburizing furnace, heated to 860°C, and exhausted for 1 hour;

[0036] (3) The three-stage co-infiltration method is used to carry out the gas three-component deep co-infiltration process

[0037] 3.1. The first stage is mainly carburizing. The initial heating temperature is 860°C for 2 hours and then carburizing. Among them, methanol is 40 drops / minute, kerosene is 120...

Embodiment 3

[0046] This embodiment includes the following steps:

[0047] (1) Prepare a boron-donating agent, by weight percentage, lanthanum oxide rare earth 2.5%, boron carbide 10%, potassium fluoroborate 15%, and the balance is silicon carbide, uniformly mixed and bonded and dried into a solid block; in addition, Prepare the carbon-nitrogen co-infiltration solution, the co-infiltration solution is calculated by mass percentage, and is composed of 50% carbonamide, 40% sodium carbonate and 10% sodium chloride;

[0048] (2) The 20Ni to be processed 4 The Mo steel drill bit workpiece is placed in a drop-controlled carburizing furnace, heated to 860°C, and exhausted for 1 hour;

[0049] (3) The three-stage co-infiltration method is used to carry out the gas three-component deep co-infiltration process

[0050] 3.1. The first stage is mainly carburizing. The initial heating temperature is 860°C for 2 hours and then carburizing. Among them, methanol is 40 drops / minute, kerosene is 140 drops...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com