Photo-moisture curing adhesive with high-efficiency moisture barrier property and ultralow water absorption

A technology for curing resins and reactive diluents, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., which can solve the requirements of low water absorption, limited applications, and the inability of light and moisture curing technology to meet water vapor barrier Requirements and other issues, to achieve excellent heat and humidity resistance, ultra-low water absorption, high-efficiency water vapor barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

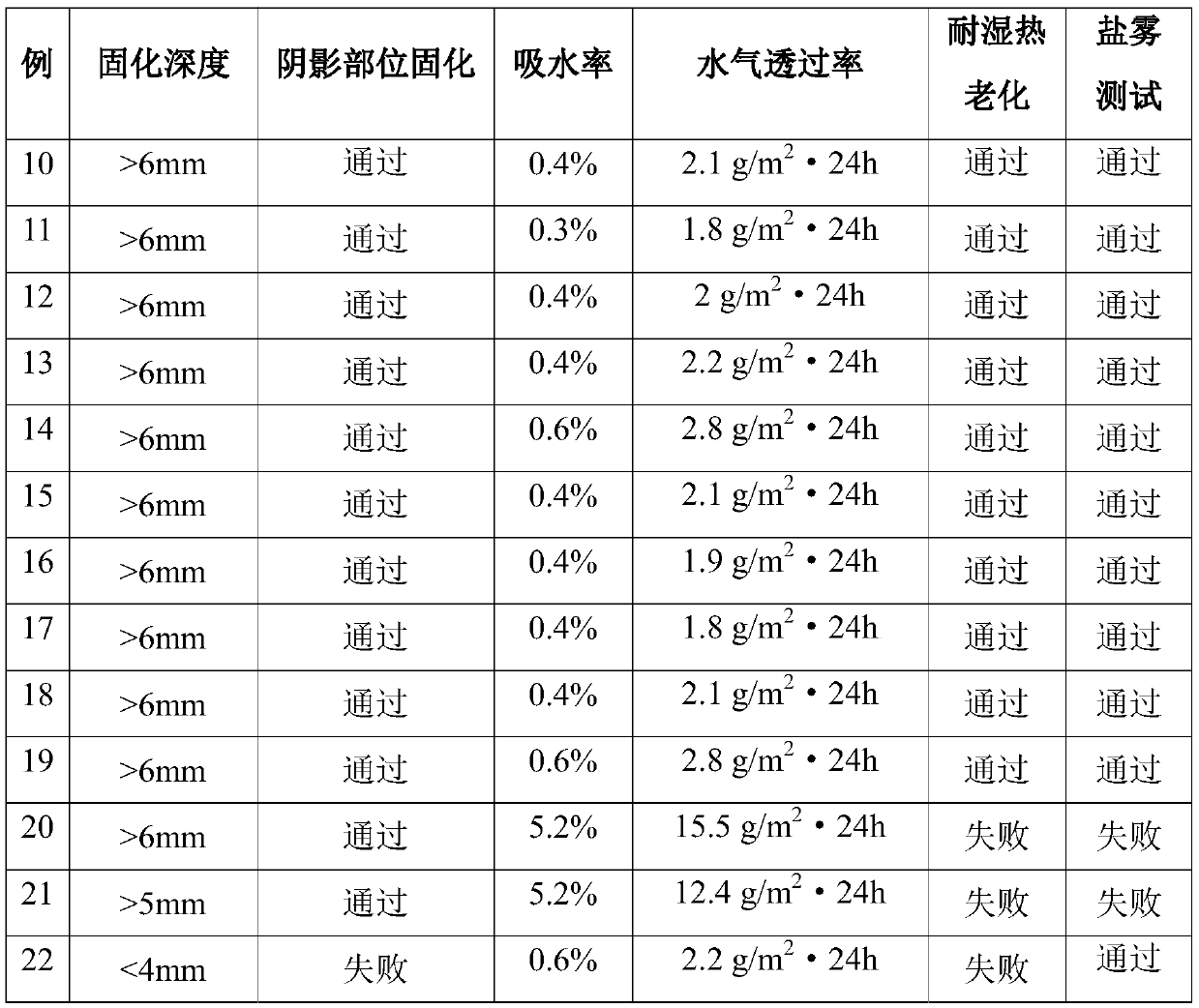

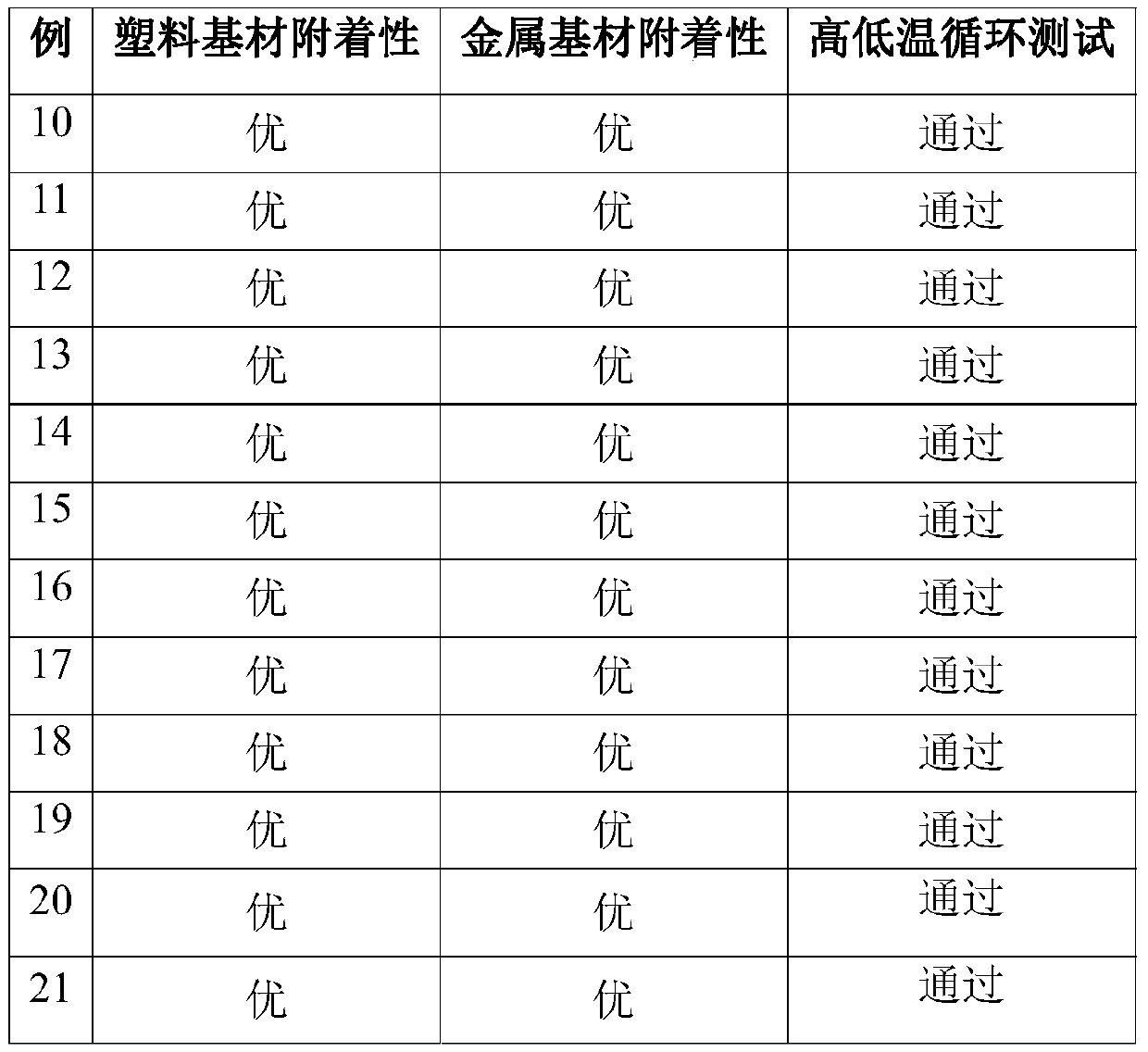

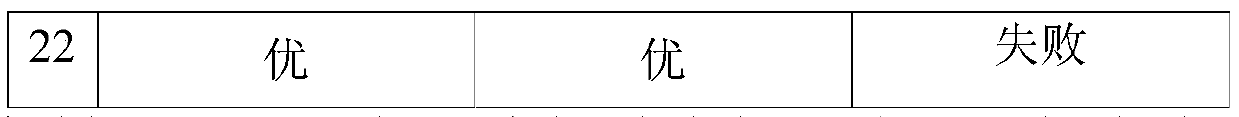

Examples

preparation example Construction

[0088] The preparation method of the cured resin in the present application can be any one known to those skilled in the art, such as heating and blending.

[0089] In some embodiments, the preparation method of described cured resin comprises the following steps:

[0090] a. put the polymer polyol into the reactor, and heat and dehydrate under vacuum;

[0091] b. Put in polyisocyanate after returning to normal pressure, heat and stir to react;

[0092] c. Put in hydroxyl-containing acrylate, heat and stir to react, and discharge.

[0093] The second aspect of the present invention provides a light-moisture-curing adhesive with high-efficiency moisture barrier properties and ultra-low water absorption. In parts by weight, its preparation raw materials include: 5-70 parts of the above-mentioned light-moisture-curable resin , 0-40 parts of the above-mentioned photocurable resin, 10-60 parts of reactive diluent, 0.5-10 parts of photoinitiator, and 0-20 parts of functional auxilia...

Embodiment 1

[0120] Embodiment 1 provides a kind of curing resin, and its preparation raw material comprises polymer polyol, polyisocyanate, hydroxyl-containing acrylate; The weight ratio of described polymer polyol, polyisocyanate, hydroxyl-containing acrylate is 20:2.8 :1.

[0121] The polymer polyol is hydroxyl-containing polybutadiene, the number average molecular weight is 2900, the hydroxyl functionality is 2.4, and the hydroxyl value is 46 mgKOH / g. In its molecular structure, 1,2-structure, cis-1,4 The molar ratio of -structure, trans-1,4-structure in the polymer is 1.1:2.9:1.

[0122] The polyisocyanate is hexamethylene diisocyanate; the hydroxyl-containing acrylate is hydroxyethyl methacrylate.

[0123] The raw materials for preparing the cured resin also include an antioxidant; the antioxidant is antioxidant 1010 (CAS No.: 128-37-0); the weight ratio of the antioxidant to acrylate is 0.1:1.

[0124] This example also provides the preparation method of above-mentioned cured resi...

Embodiment 2

[0130] Embodiment 2 provides a kind of curing resin, and its preparation raw material comprises polymer polyol, polyisocyanate, hydroxyl-containing acrylate; The weight ratio of described polymer polyol, polyisocyanate, hydroxyl-containing acrylate is 50:5.5 :1.

[0131] The polymer polyol is hydroxyl-containing hydrogenated polybutadiene, the number-average molecular weight is 2000, the hydroxyl functionality is 1.9, the hydroxyl value is 53.3mgKOH / g, and the double bond hydrogenation rate is 100%. In its molecular structure, 1, The molar ratio of 2-structure and 1,4-structure in the polymer is 60 / 40.

[0132] The polyisocyanate is hexamethylene diisocyanate; the hydroxyl-containing acrylate is hydroxyethyl methacrylate.

[0133] The raw materials for preparing the cured resin also include an antioxidant; the antioxidant is antioxidant 1010 (CAS No.: 128-37-0); the weight ratio of the antioxidant to acrylate is 0.25:1.

[0134] This example also provides the preparation met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com