Method and equipment for manufacturing metal part with embedded FRID (Radio Frequency Identification) label with SLM (Selective Laser Melting)

A technology of metal parts and labels, applied in the field of special laser processing technology and equipment, to achieve the effect of increasing radio frequency distance, overcoming interference and shielding, and improving manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

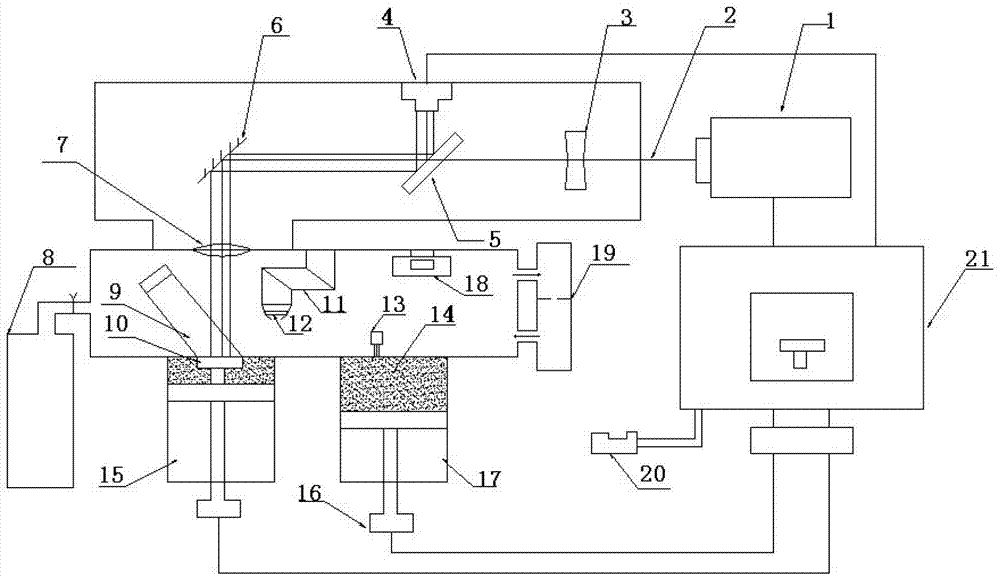

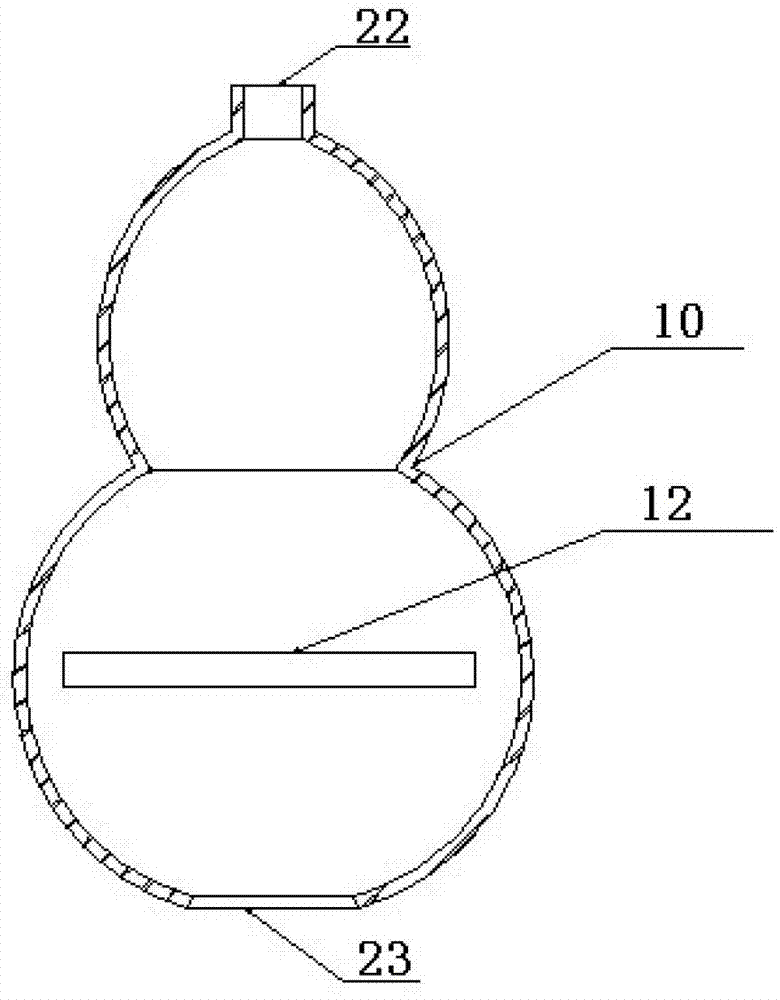

[0048] Such as figure 1 , 2 shown. The SLM of the present invention manufactures equipment with embedded RFID tag metal parts, including a beam focusing system, a near-wavelength coaxial visual positioning system, a tag embedding system, a powder laying system, and a gas protection system;

[0049] The beam focusing system includes a fiber laser 1, a beam expander 3, a scanning galvanometer 6, and an F-θ combination lens 7 sequentially connected in an optical path;

[0050] The near-wavelength coaxial visual positioning system includes a coated reflective lens 5, an industrial CCD4 and an illuminating device 9 for illuminating the metal part 10 to be processed; the coated reflective lens 5 is arranged between the beam expander 3 and the scanning galvanometer 6 In the light path; The industrial CCD4 is arranged on the top of the coated mirror 5;

[0051] The powder laying system includes a molding cylinder 15, a powder spreading scraper 13, a powder cylinder 17, a lifting pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com