Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56 results about "Hafnium powder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A METAL SOURCE, LLC is a distributor of high purity metal powders and compounds including Hafnium metals. Hafnium round bars in diameter ranges from 0.035 inches to 4 inches. Hafnium sheet thickness ranges from 0.0005 inches to 0.500 inches. Hafnium round tube OD ranges from 0.005 inches to 0.500 inches. Hafnium powder is also in our inventory.

Method of manufacturing high purity zirconium and hafnium

InactiveUS6861030B2Guaranteed uptimeGuaranteed performanceCellsSemiconductor/solid-state device detailsImpuritySemiconductor

The present invention relates to high-purity zirconium or hafnium with minimal impurities, particularly where the content of alkali metal elements such as Na, K; radioactive elements such as U, Th; transitional metals or heavy metals or high melting point metal elements such as Fe, Ni, Co, Cr, Cu, Mo, Ta, V; and gas components such as C, O, etc. is extremely reduced, as well as to an inexpensive manufacturing method of such high-purity zirconium or hafnium, thereby reducing the impurities hindering the guarantee of the operational performance of semiconductors. The present invention further relates to an inexpensive and safe manufacturing method of high-purity zirconium or hafnium powder from hydrogenated high-purity zirconium or hafnium powder.

Owner:JX NIPPON MINING& METALS CORP

Superfine high-purity hafnium powder as well as preparation method and application thereof

The invention relates to superfine high-purity hafnium powder as well as a preparation method and an application thereof. The grain size of the superfine high-purity hafnium powder is less than 1 micron; the purity reaches above 99.99%; the total content of metal impurities is less than 100ppm; and the oxygen content is less than 0.2%. The preparation method comprises the following steps: a) uniformly mixing hafnium oxide powder with reducing agent powder at a molar ratio of 1:1 to 1:6, and filling a mixture into a crucible; b) placing the crucible into a reaction tank, covering with a cover, then vacuumizing, filling argon for washing, heating and reducing, and performing constant-temperature insulation reduction; c) vacuumizing, filling argon again, and cooling under the argon protection; and d) washing: firstly, washing with an acid, then washing with deionized water, and screening and drying the obtained product, thereby obtaining the product of the superfine high-purity hafnium powder. The oxide generated by the method provided by the invention is capable of protecting hafnium powder, is anti-explosion and is safe and controllable.

Owner:有研资源环境技术研究院(北京)有限公司

Preparing method of low-oxygen large-dimension high-purity hafnium powder

The invention relates to a preparing method of low-oxygen large-dimension high-purity hafnium powder. The purity of the low-oxygen large-dimension high-purity hafnium powder is as high as 99.99 weight percent, the oxygen content is less than 0.2 percent, and the granularity is greater than 1mu. m. A preparing process comprises the following steps that a, hafnium oxide powder, reducing agents and molten salt are contained into a crucible; b, the crucible is placed into a reaction tank, vacuum pumping is carried out after the device is sealed, then, argon gas is filled for washing, heating reduction is carried out, then, constant-temperature heat-insulation reduction is carried out, and cooling and furnace discharging are carried out after the reduction completion; c, obtained products are firstly washed by acid and are then washed by de-ionized water, then, sieving and drying are carried out, and the low-oxygen large-dimension high-purity hafnium powder can be obtained. The molten salt system adopted by the method provided by the invention has the advantages that the oxygen content in the hafnium powder can be effectively removed, meanwhile, the dimension of the hafnium powder can be controlled, the friction spontaneous combustion of the hafnium powder is prevented, and safety and controllability are realized.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Method for preparing low-oxygen high-pure metal hafnium powder

ActiveCN104646659ALow content of interstitial elementsGuaranteed complete deoxygenationCrucibleMolten salt

The invention relates to a method for preparing low-oxygen high-pure metal hafnium powder; the low-oxygen high-pure metal hafnium powder has the purity of greater than 99.5wt% and the oxygen content being smaller than 0.15 wt%. The preparation method comprises the following steps: a. filling metal hafnium powder, a deoxidizing agent and a molten salt into a crucible; b, putting the crucible into a reaction tank, sealing the equipment, vacuumizing and inflating argon gas to wash the crucible, heating and deoxidizing, then performing constant-temperature and thermal-insulating deoxidization, cooling and discharging at the end of the deoxidization; c, pickling the discharged product, then washing with de-ionized water, sieving and drying the obtained product, namely, the product of the low-oxygen high-pure metal hafnium powder. The molten salt system is capable of effectively removing impurities in the metal hafnium powder, in particular, remarkably reducing the oxygen content in the hafnium powder; and the prepared low-oxygen high-pure metal hafnium powder satisfies the material requirement of high-end products.

Owner:有研资源环境技术研究院(北京)有限公司

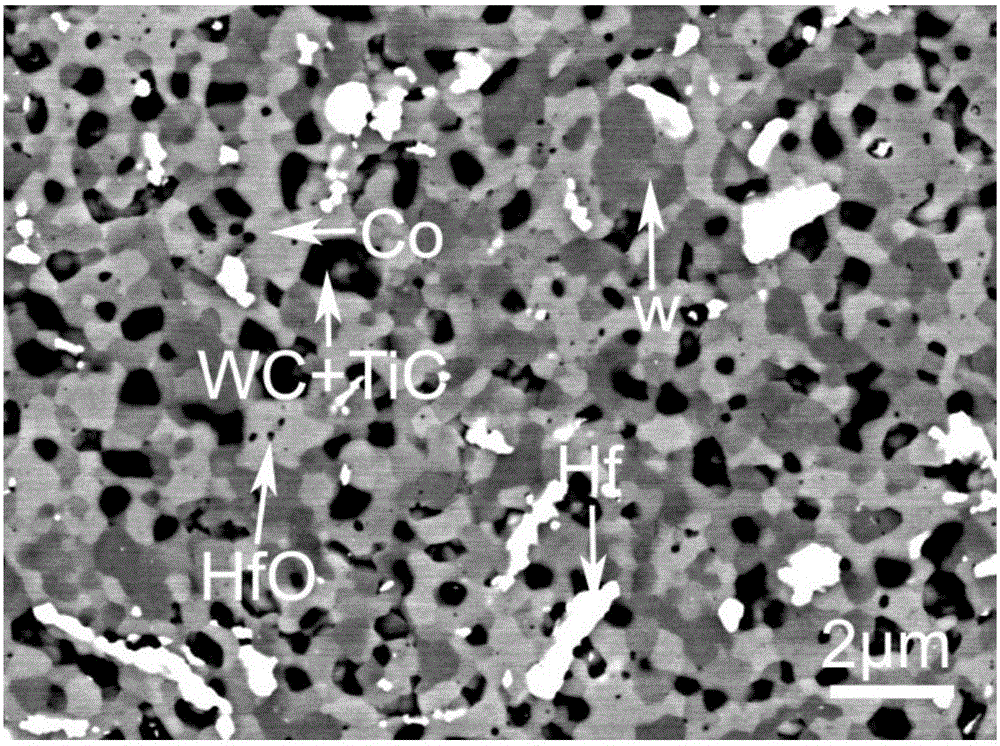

W-WC-TiC-Hf-Co alloy rod and preparation method thereof

The invention discloses a W-WC-TiC-Hf-Co alloy rod and a preparation method thereof, and relates to the technical field of alloy materials. The W-WC-TiC-Hf-Co alloy rod is prepared from the following raw materials in percentage by mass: 1 to 5 percent of WC, 2 to 8 percent of TiC, 1 to 5 percent of Hf, 1 to 5 percent of Co and the balance of W and unavoidable impurities; the preparation method of the W-WC-TiC-Hf-Co alloy rod comprises the following steps: (1) uniformly mixing tungsten powder, tungsten carbide powder, titanium carbide powder, hafnium powder and cobalt powder by adopting a wet ball milling method, and performing vacuum drying to obtain mixed powder; (2) performing vacuum sintering to obtain a sintering body; (3) smelting 2 to 5 times by electron beams to obtain an ingot; (4) performing thermal extruding to obtain a semi-finished rod blank; (5) performing thermal extruding to obtain an alloy rod. The W-WC-TiC-Hf-Co alloy rod disclosed by the invention has high hardness, high strength and excellent comprehensive mechanical properties, and has wide application prospect in aerospace field, national defence industry, electronic information, energy resources and the like.

Owner:XIAN HUASHAN METAL PROD CO LTD

Method for improving content of hafnium in tantalum tungsten alloy

The invention discloses a method for improving the content of hafnium in tantalum tungsten alloy. The method comprises the following steps of I, uniformly mixing a tantalum powder, a tungsten powder and a hafnium powder according to the designed content to obtain mixed powder; 2, pressing the mixed powder into a blank strip; 3, carrying out vacuum high-temperature sintering on the blank strip, soas to obtain a sintered blank strip; 4, carrying out two-time vacuum electron beam smelting on the sintered blank strip to obtain the tantalum tungsten alloy. According to the method, the raw materialpowder is pre-alloyed by virtue of high-temperature vacuum sintering, the argon protection is timely carried out in the cooling process, the volatilization of hafnium is effectively reduced, different smelting speeds are adopted in the two-time rapid vacuum electron beam smelting process, so that the hafnium element is prevented from being drawn out in a large amount, the homogenization of the tantalum tungsten alloy is promoted, so that a large amount of volatilization of hafnium elements is further avoided, and the mass content of hafnium in the final tantalum tungsten alloy is more than 80% of the design content.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

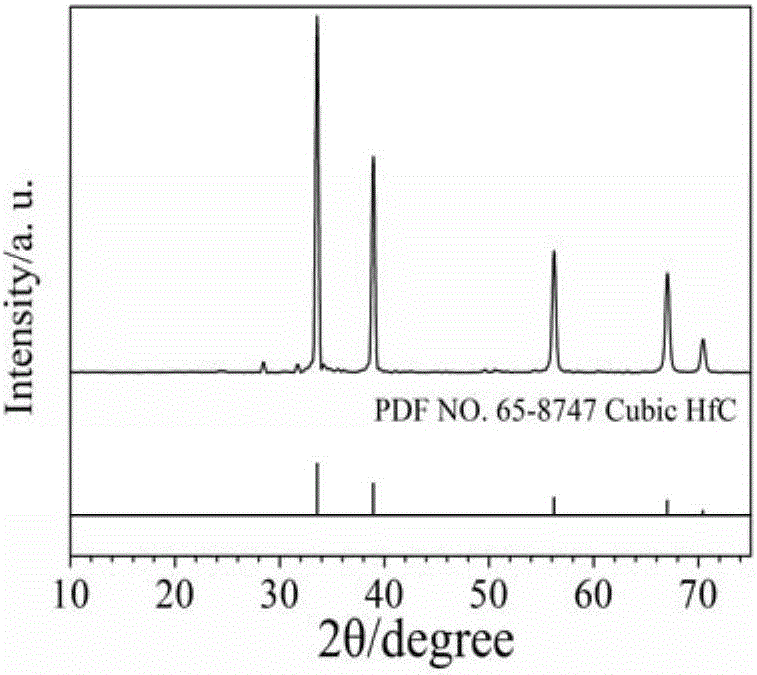

Method for preparing superhigh temperature carbonized hafnium ceramic nano-powder

ActiveCN106588018AGood dispersionSolve the problem of difficult sinteringMaterial nanotechnologyDispersityRoom temperature

The invention relates to a method for preparing superhigh temperature carbonized hafnium ceramic nano-powder. Anhydrous saccharose is evenly dispersed in deionized water, a mixed template is added, stirring is carried out, an even and transparent precursor solution is obtained, and the solution is poured into a hydrothermal still; the hydrothermal still is placed in an electric heating air blowing drying box for reacting after being sealed, then the product is cooled to room temperature, and filtering, separation, washing and drying are carried out; finally, the product is mixed with hafnium powder, a vacuum carburizing reaction is carried out, and HfC nano particles are prepared. Compared with the prior art, the prepared carbonized hafnium ceramic nano-powder is good in crystallinity and dispersity and controllable in morphology.

Owner:SHANGHAI JIAO TONG UNIV

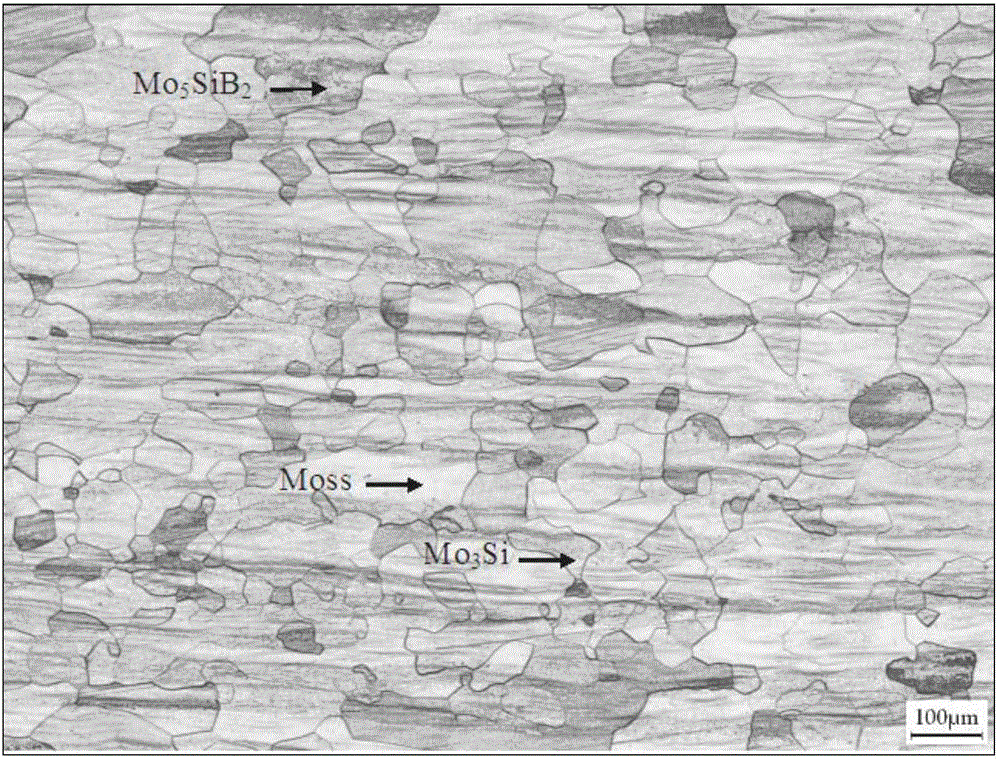

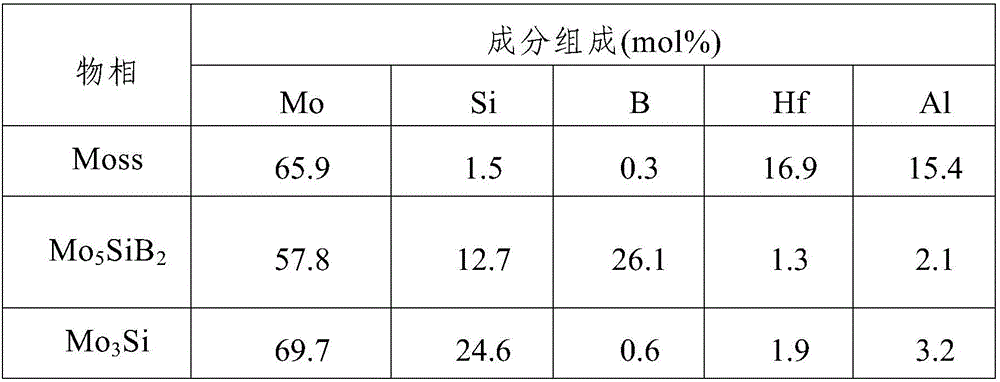

Mo-Si-B-Hf-Al alloy bar and preparation method thereof

The invention provides a Mo-Si-B-Hf-Al alloy bar. The Mo-Si-B-Hf-Al alloy bar is composed of the following ingredients in atomic percent: 6-18% of Si, 7-19% of B, 5-15% of Hf, 6-14% of Al and the balance Mo and inevitable impurities. The invention further provides a method for preparing the alloy bar. The method comprises the following steps: 1. uniformly mixing silicon powder, boron powder, hafnium powder, aluminium powder and molybdenum powder by means of wet ball-milling, carrying out vacuum drying, and then obtaining a mixed powder; 2. sintering to obtain a sintered body; 3. carrying out vacuum self-consuming arc melting to obtain a cast ingot; 4. carrying out hot extrusion to obtain a semi-finished bar billet; and 5. carrying out hot extrusion to obtain the Mo-Si-B-Hf-Al alloy bar. The Mo-Si-B-Hf-Al alloy bar provided by the invention has the characteristics of being low in oxygen content, high in strength, resistant to oxidation, high in room-temperature fracture toughness, and the like, and can be applied to a high-temperature oxidation atmosphere.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Electrolytic aluminum liquid microalloyed hexabasic intermediate alloy and preparation and use method thereof

The invention discloses electrolytic aluminum liquid microalloyed hexabasic intermediate alloy and a preparation and use method thereof. The electrolytic aluminum liquid microalloyed hexabasic intermediate alloy comprises the following components in percentage by mass: 1-6 percent of Sc, 1-5 percent of Zr, 0.1-3 percent of Ti, 1-6 percent of Hf, 6-12 percent of La and balance of aluminum. The preparation method comprises the following steps of: 1) well preparing high-purity aluminum, Sc2O3 powder, a fused salt system, high-purity sponge zirconium powder, high-purity sponge titanium powder, high-purity hafnium powder, metal lanthanum blocks and covering agents according to the mass percent of the components of the intermediate alloy; 2) conducting aluminothermic reduction to the Sc2O3 powder, the high-purity aluminum and the fused salt system at 950-980DEG C and preserving heat; 3) wrapping the hafnium powder by using an aluminum foil, adding the hafnium powder into aluminum liquid, agitating the mixture, heating the mixture to 1150 plus or minus 20DEG C and preserving heat; and 4) slagging off, taking and pouring alloy solution into a new crucible for continuous smelting, heating the alloy solution to 970 plus or minus 20DEG C, adding the sponge zirconium powder, the sponge titanium powder and the metal lanthanum blocks, adding the covering agents, preserving heat, conducting high-intensity ultrasonic treatment, conducting refining, degassing and deslagging, pouring the obtained alloy liquid in an iron mold and obtaining an intermediate alloy cast ingot after cooling.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

Stable-structure welding wire without copper plating coating

The invention provides a stable-structure welding wire without a copper plating coating. The stable-structure welding wire comprises a welding wire base body and a coating layer, wherein the coating layer comprises the following raw materials in parts by weight: 30-60 parts of iron alloy powder, 15-30 parts of titanium and titanium dioxide powder, 2-8 parts of calcium carbonate powder, 2-8 parts of magnesium carbonate powder, 0.5-8 parts of manganese oxide powder, 2-15 parts of silicon nitride powder, 0.5-1.5 parts of rare earth, 2-6 parts of modified attapulgite, 0.09-1.9 parts of germanium powder and 0.06-0.95 part of hafnium powder. The stable-structure welding wire without the copper plating coating, provided by the invention, has the advantages of good wear resistance, good arc stability, and the like.

Owner:安徽飞弧焊业股份有限公司

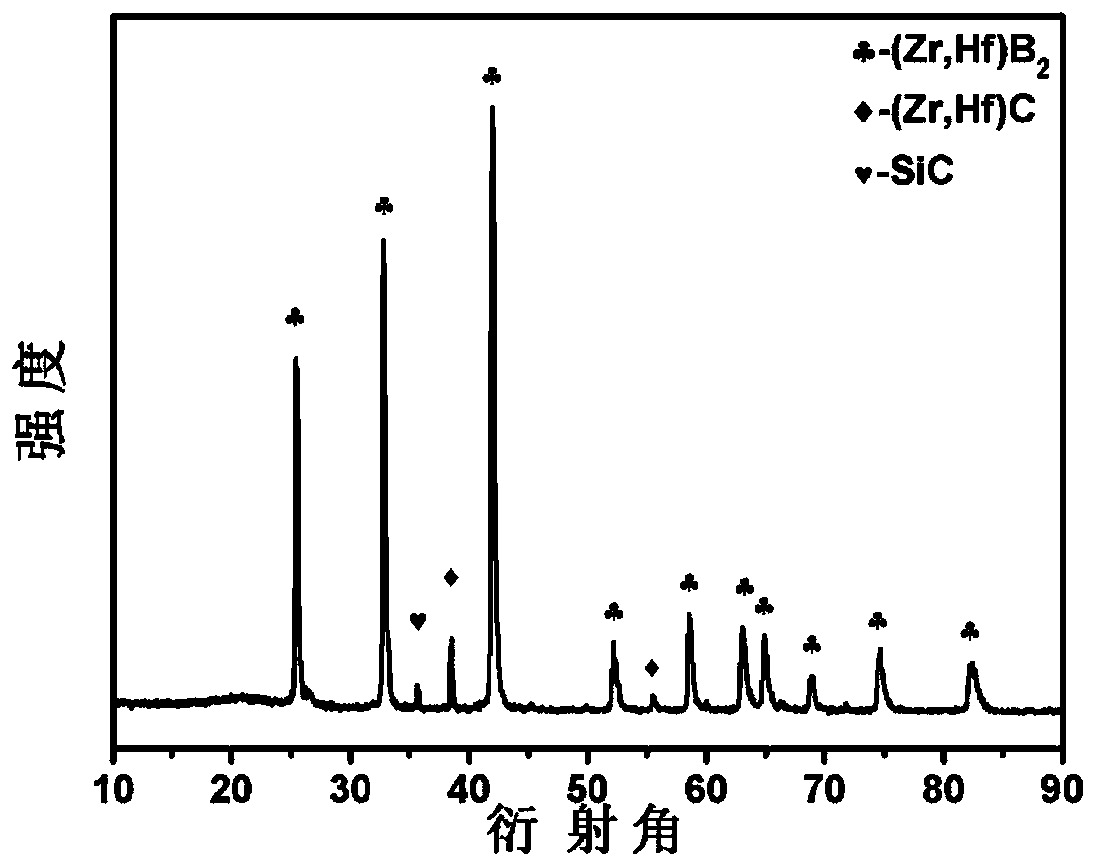

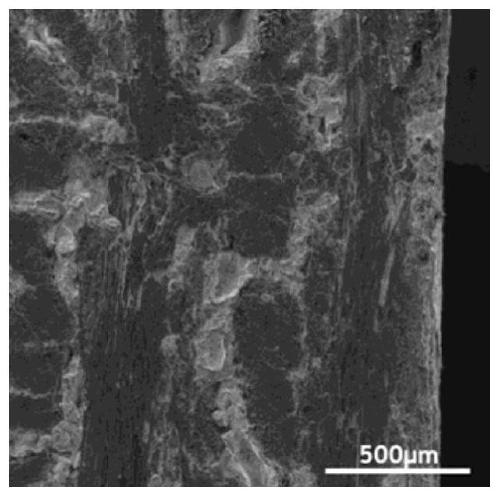

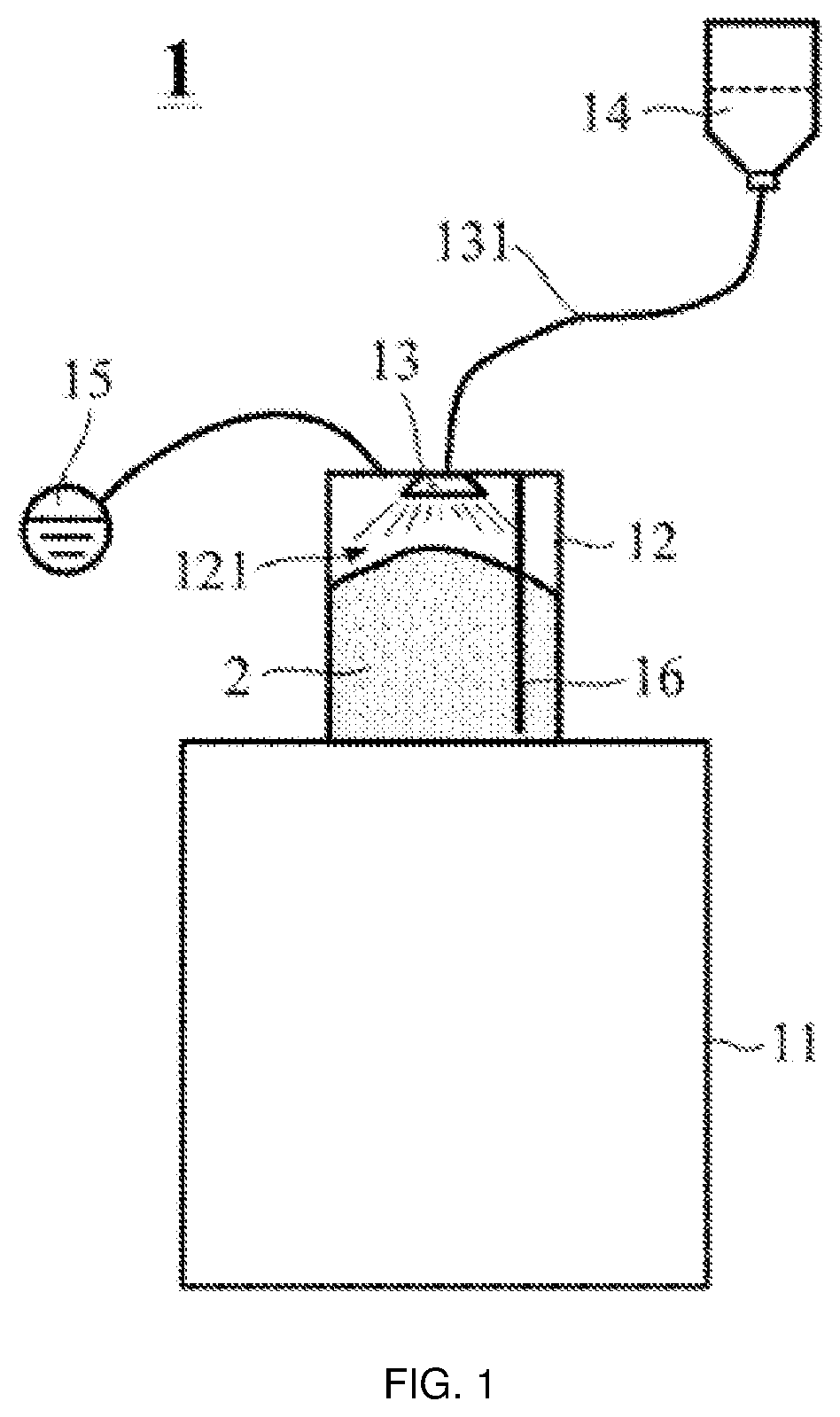

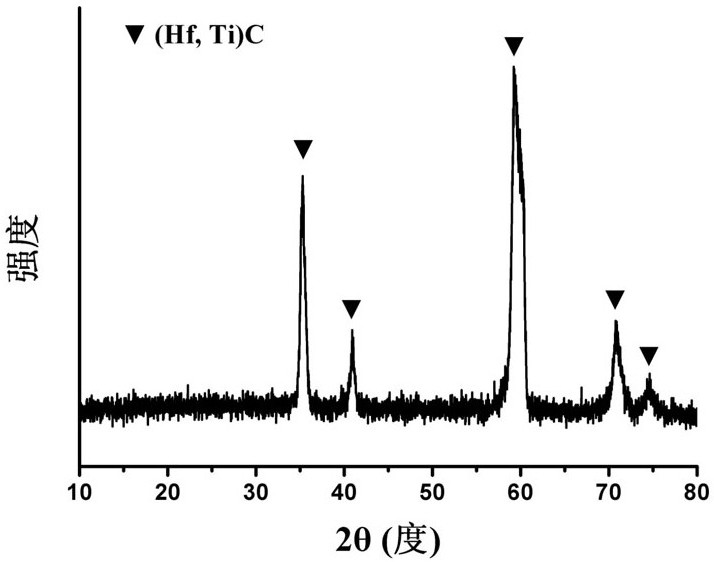

(Zr, Hf)B-SiC ceramic modified C/C composite material and preparation method thereof

The invention discloses a (Zr, Hf)B-SiC ceramic modified C / C composite material and a preparation method thereof. The method includes: performing high-energy ball milling on zirconium and hafnium powders to prepare a Zr / Hf alloy, then performing reactive melt infiltration on a high-temperature treated C / C composite material and the Zr / Hf alloy to prepare a Zr / Hf carbide modified C / C composite material; then placing a powder material, containing boron and silicon, in a carbonization furnace, burying the Zr / Hf alloy modified C / C composite material in the powder material containing boron and silicon, performing thermal treatment on the materials for 1-4 h at 1800-2100 DEG C to obtain the (Zr, Hf)B-SiC ceramic modified C / C composite material. The composite material is high in ceramic content and has excellent combination between the carbon substrate and ceramic phase. Oxidized products, such as B2O3, SiO2, ZrO2 and HfO2, in the (Zr, Hf)B and SiC have excellent chemical compatibility and synergistic anti-oxidizing performance, so that the composite material has excellent anti-ablation performance.

Owner:WUHAN UNIV OF SCI & TECH

Method for preparing oxidation resisting molybdenum product

ActiveCN106521408AImprove toughnessAvoid brittle defectsRare earth metal oxides/hydroxidesMolten spray coatingCeriumOxidation resistant

The invention discloses a method for preparing an oxidation resisting molybdenum product. The method comprises a step of manufacturing a first-order molybdenum product and a step of spraying the surface of the first-order molybdenum product to prepare an oxidation resisting co-doped molybdenum product, wherein silicon powder, hafnium powder, boron carbide and nanometer cerium dioxide are used for dispersing molybdenum to prepare the first-order molybdenum product; the first-order molybdenum product is dispersed to contain a high-temperature phase and alloy elements inside; heat-stable oxide particles are formed in the oxidation process; an oxide film is formed on the surface of the product in the oxidation process to stop continuous erosion of oxygen to the molybdenum product; and an oxidation resisting layer is sprayed on the surface of the first-order molybdenum product, and is tightly combined with a dispersing layer to largely delay the internal dispersion path of the oxidized molybdenum product.

Owner:LUOYANG KEWEI MOLYBDENUM & TUNGSTEN

Method for preparing metal hafnium powder through vacuum carbon reduction

The invention belongs to the technical field of vacuum metallurgy, discloses a method for preparing high-purity metal hafnium powder through hafnium dioxide vacuum carbon thermal reduction, and in particular, provides a method for preparing metal hafnium powder through reducing hafnium dioxide by graphite powder in vacuum. The method has the advantages of simple production process, low equipment investment, high metal yield of 95-98%, low production cost and prominent economic benefit, and is a process with low cost and high yield and suitable for large-scale preparation of high-purity and fine-granularity metal hafnium powder.

Owner:湖南华威景程材料科技有限公司

Ignition powder, preparation method therefor and use thereof, and airbag gas generator

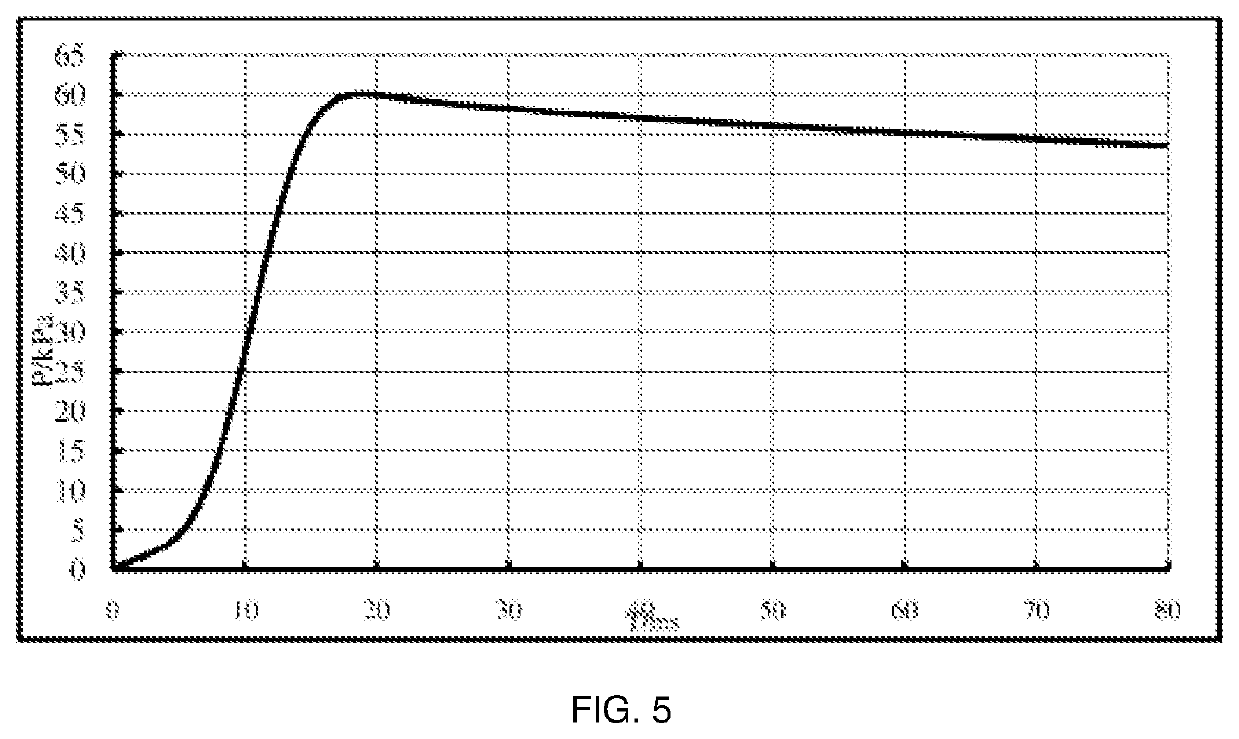

PendingUS20220055966A1Eliminate static electricityPedestrian/occupant safety arrangementPyrophoric compositionsCopper nitrateEngineering

Disclosed are an ignition powder, a preparation method therefor and a use thereof, and an airbag gas generator, which belong to the technical field of ignition powders. The raw materials of the ignition powder include the following components in percentages by mass: potassium perchlorate. 30%˜50%; basic copper nitrate: 5%˜20%; a fuel: 15%˜60%; a metal oxide: 1%˜25%; and a metal powder: 1%˜25%, wherein the metal powder is at least one of a titanium powder, a magnesium powder, a copper powder, an iron powder, a zirconium powder, a hafnium powder, a tungsten powder or a silicon powder.

Owner:HUBEI HANGPENG CHEM POWER TECH

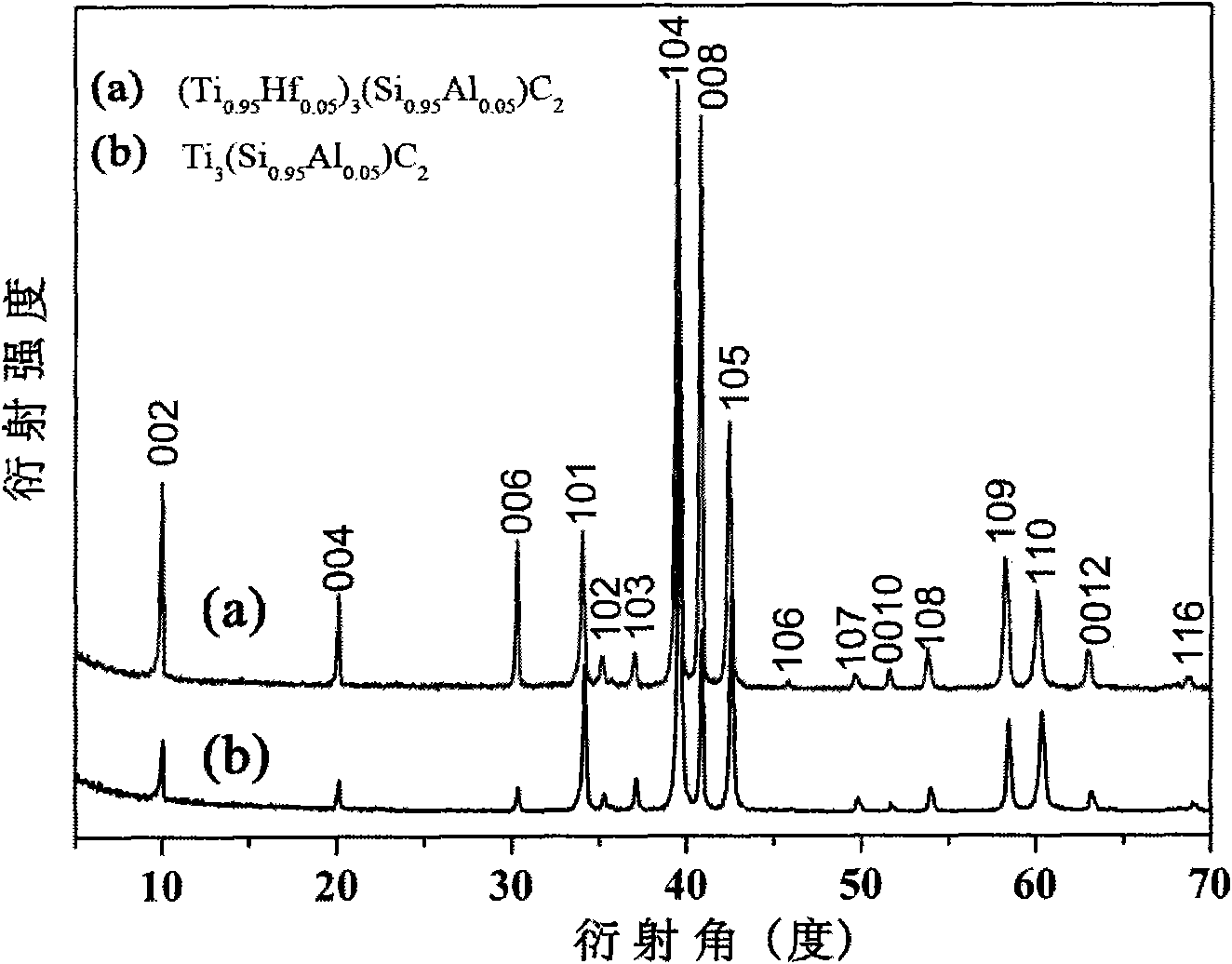

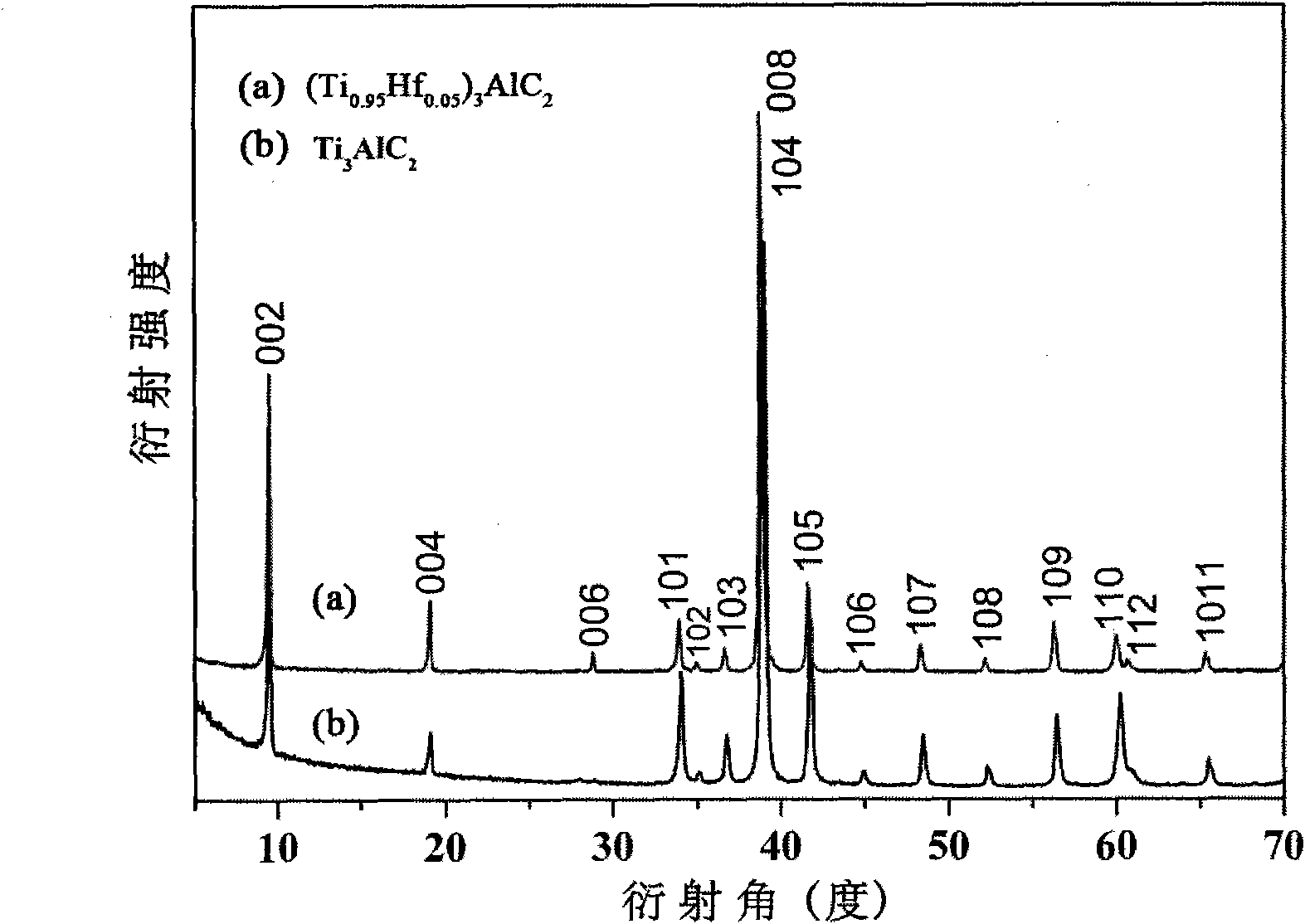

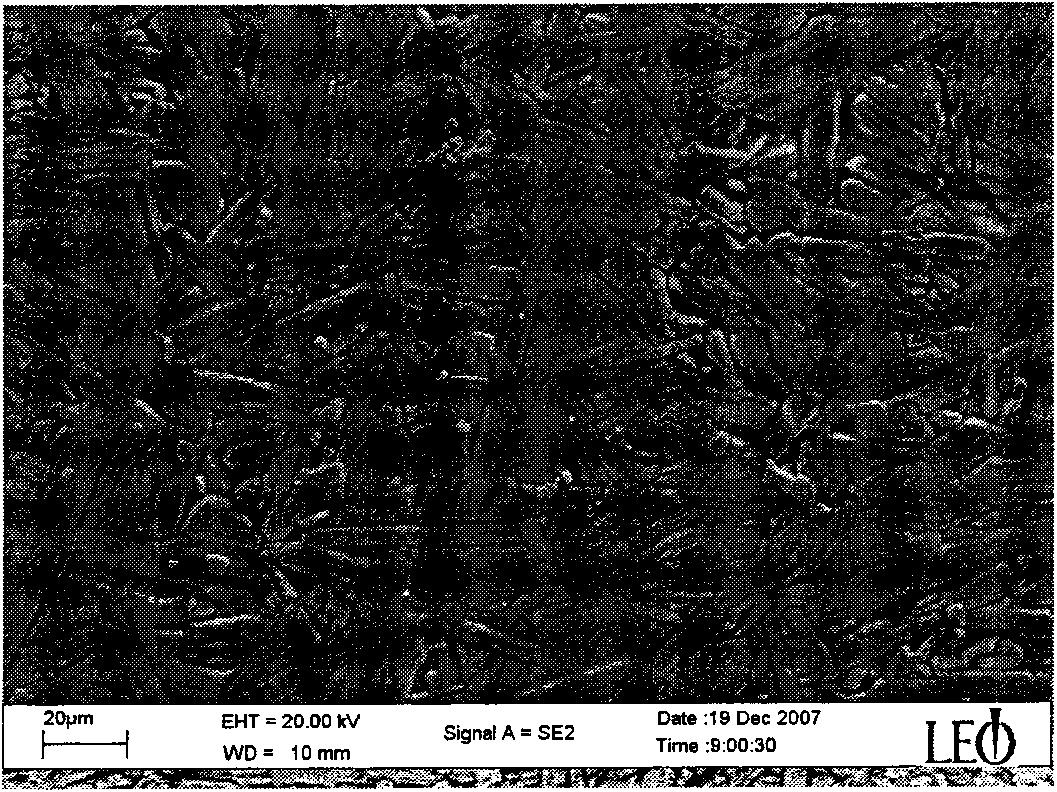

Ti-Hf-Si-Al-C, Ti-Hf-Al-C and Ti-Zr-Al-C solid solution material and preparation method thereof

The invention relates to a ceramic solid solution material and a preparation method thereof, in particular to a Ti-Hf-Si-Al-C, Ti-Hf-Al-C and Ti-Zr-Al-C solid solution material and a preparation method thereof. The method adopts elemental powder to synthesize Ti-Hf-Si-Al-C (Ti1-xHfx)3(Si1-yAly)C2, Ti-Hf-Al-C (Ti1-xHfx)3AlC2 and Ti-Zr-Al-C solid solution (Ti1-xZrx)3AlC2 in situ, where the numeric area of x is more than 0 and less than or equal to 0.07, and the numeric area of y is more than 0 and less than or equal to 0.10. The method comprises the following steps: firstly, mixing titanium powder, hafnium powder, zirconium powder, silicon powder, aluminum powder and graphite powder which serve as raw materials by a physical mechanical method; filling the mixture in a graphite mold for cold press molding; sintering the mixture in a hot-pressing furnace in which protective atmosphere is introduced to obtain the Ti-Hf-Si-Al-C, Ti-Hf-Al-C and Ti-Zr-Al-C solid solution material. In the invention, the Ti-Hf-Si-Al-C, Ti-Hf-Al-C and Ti-Zr-Al-C solid solution material with high purity, high compactness, high toughness, high hardness, good mechanical performance and other excellent comprehensive performances can be prepared at lower temperature and shorter time.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

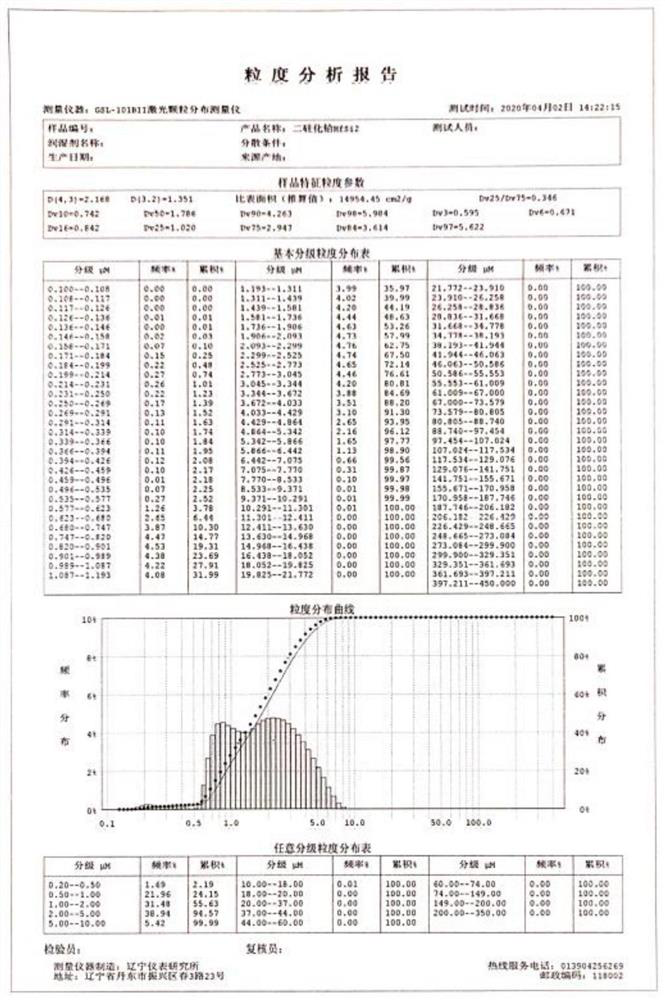

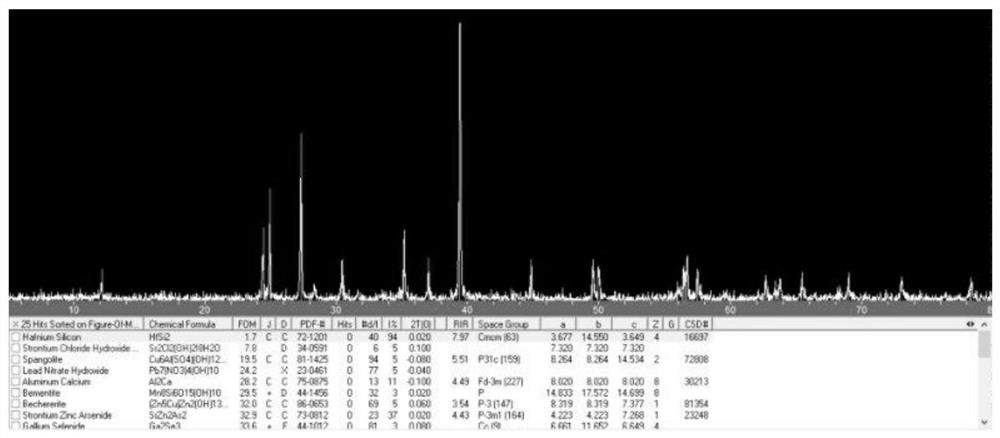

Production process of hafnium disilicide

The invention discloses a production process of hafnium disilicide. The production process comprises the following steps: ball-milling and mixing zirconium dioxide powder and silicon powder under a vacuum condition, briquetting by using a hydraulic machine, sintering and finishing in a vacuum sintering furnace, removing white silicon dioxide powder coated on the surface of hafnium, ball-milling ina vacuum ball mill, adding sodium hydroxide, adding distilled water with the temperature of 60 DEG C, and drying to obtain silicon-containing hafnium powder; detecting the content of silicon in the silicon-containing hafnium powder, adding silicon powder according to the content of silicon in the hafnium powder, carrying out ball milling for 5 hours in a vacuum ball mill under the protection of inert argon, putting into a vacuum self-propagating combustion furnace, vacuumizing, heating a thermal electrode, igniting the hafnium powder, making the hafnium powder and the silicon powder carry outa self-propagating combination reaction to obtain hafnium disilicide. Hafnium dioxide powder is used as a raw material, and the raw material cost is lower than sponge hafnium cost; according to the method, the whole process is reasonable in technology and suitable for industrial production, the obtained hafnium disilicide product is high in purity, and the alloying degree can reach 100%.

Owner:辽宁中色新材科技有限公司

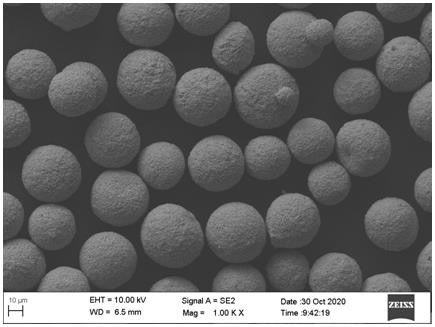

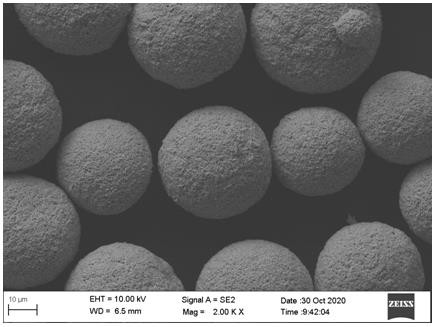

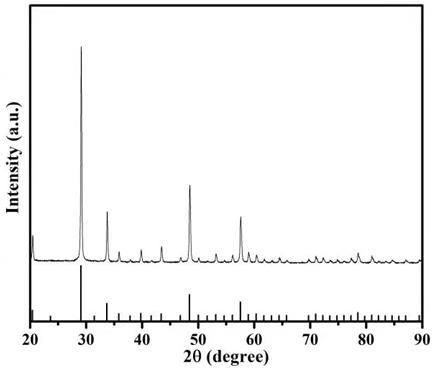

Yttrium-stabilized zirconium oxide hafnium powder for thermal spraying and preparation method thereof

PendingCN112851337AReduce hard agglomeratesIncrease service temperatureSpray GranulationPhysical chemistry

The invention discloses yttrium-stabilized zirconium oxide hafnium powder for thermal spraying and a preparation method of the yttrium-stabilized zirconium oxide hafnium powder. The preparation method comprises the following steps: firstly, preparing a yttrium-stabilized zirconium oxide hafnium precursor, then carrying out primary calcination, ball milling, sanding and spray granulation to prepare yttrium-stabilized zirconium oxide hafnium granulated powder, and finally, carrying out secondary calcination and screening to prepare the yttrium-stabilized zirconium oxide hafnium powder for thermal spraying. The yttrium-stabilized zirconium oxide hafnium powder is prepared by using ammonium bicarbonate as a precipitator, so that hard agglomeration during calcination is reduced; the yttrium-stabilized zirconium oxide hafnium powder is used as a thermal barrier coating material, and compared with traditional yttrium-stabilized zirconium oxide powder, the service temperature of the coating is increased; the content proportion of zirconium and hafnium in the yttrium-stabilized zirconium oxide hafnium powder for thermal spraying is controllable, and compared with yttrium-stabilized hafnium oxide powder, the raw material cost is reduced.

Owner:QUANNAN JINGXIN ENVIRONMENTAL PROTECTION MATERIALCO LTD +1

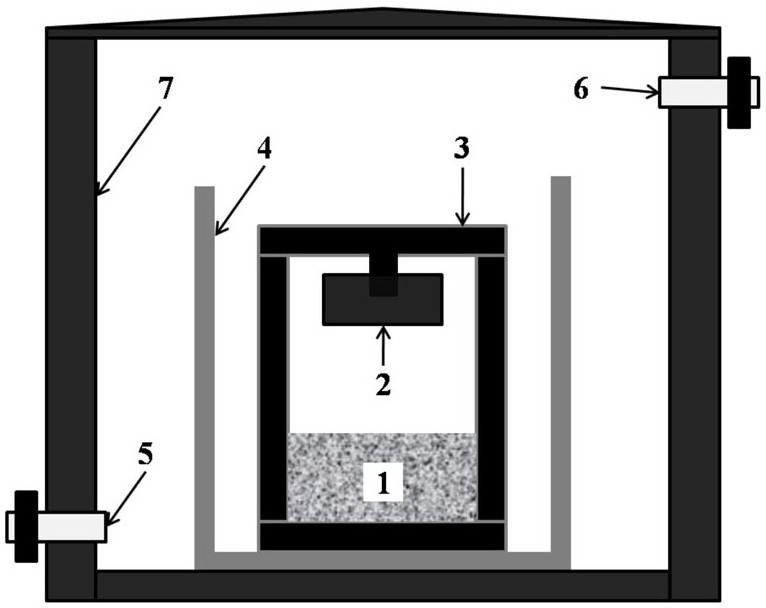

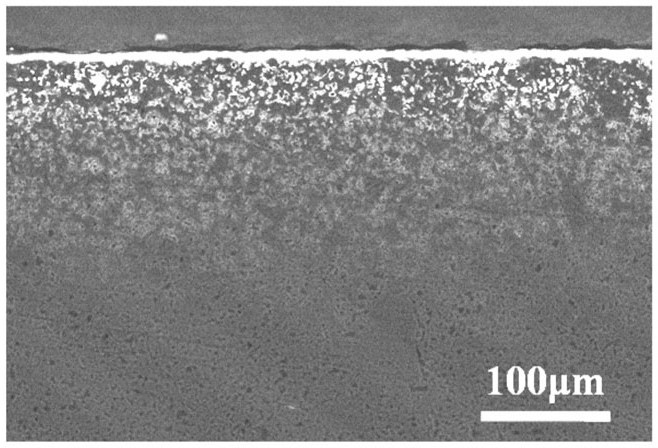

In-situ preparation method of HfC-based ternary carbide gradient coating on surface of carbon material

The invention discloses an in-situ preparation method of an HfC-based ternary carbide gradient coating on the surface of a carbon material. The method comprises the following steps: taking the carbonmaterial as a matrix, hafnium powder or a mixture of the hafnium powder and hafnium oxide powder as a hafnium source, TiO2 as a titanium source, ZrO2 as a zirconium source and ammonium chloride powderas an active agent, uniformly mixing one of the titanium source and the zirconium source with the hafnium source and the active agent to obtain a penetrating agent; placing the penetrating agent in areaction container, and placing the carbon material matrix above the penetrating agent; putting the reaction container with the penetrating agent and the carbon material matrix into a vacuum furnace,repeatedly vacuumizing and introducing inert gas until the pressure in the furnace is close to normal pressure; and heating to 1250-1500 DEG C, keeping the temperature, and cooling to obtain the product. The method is simple and convenient, low in cost and high in operability, and the prepared coating is good in combination with a matrix, good in thermal shock resistance and high in melting point.

Owner:NAT UNIV OF DEFENSE TECH

Preparation method of metal hafnium raw material for iodization

The invention relates to a preparation method of a metal hafnium raw material for iodization. The preparation method of the metal hafnium raw material for iodization comprises the following steps: firstly, pressing hafnium powder into a green compact; drying the obtained green compact; loading the green compact into a crucible, and carrying out vacuum sintering in a vacuum tungsten wire furnace; obtaining loose and porous hafnium raw material with even pores, wherein the purity of hafnium is above 95wt%, the total content of gas and metal impurities is less than 5wt%, the hydrogen content is less than 1000ppm, and the hafnium raw material is used for iodization. The preparation method of the metal hafnium raw material for iodization, which is disclosed by the invention, is safe and controllable and is favorable for the iodization operation, and the iodization efficiency is improved.

Owner:有研资源环境技术研究院(北京)有限公司

Preparation method of high-strength powder austenitic stainless steel

ActiveCN112935265AReduce adverse effectsReduce carbon contentNuclear energy generationTransportation and packagingSS - Stainless steelTitanium

The invention discloses a preparation method of high-strength powder austenitic stainless steel and belongs to the field of powder metallurgy. According to the method, a titanium-containing stainless steel powder prepared through water-gas combined atomization is taken as a raw material, zirconium-hafnium powder is added to serve as a carbon fixing agent and an oxygen fixing agent, and the zirconium-hafnium powder and atomized steel powder are subjected to high-energy ball milling, forming, sintering and heat treatment, so as to obtain a high-strength powder stainless steel product. Zirconium, hafnium and titanium belong to elements of the same family and are similar in chemical property, when zirconium, hafnium and titanium are added into a stainless steel system, intergranular corrosion can be further prevented, meanwhile, Ti, Zr (Hf) and O form an ordered phase in the sintering and heat treatment process, so that the effects of reducing the oxygen content of a steel matrix and strengthening a second phase are achieved, the plasticity of the steel matrix is improved, meanwhile, the material strength is greatly improved, and the high-strength powder stainless steel product is obtained. The preparation method has the advantages of simple preparation process, no need of additional equipment, high production efficiency, no pollution or inclusion, excellent performance and the like.

Owner:UNIV OF SCI & TECH BEIJING

High-melting-point titanium alloy and preparation method thereof

The invention discloses high-melting-point titanium alloy and a preparation method thereof. The high-melting-point titanium alloy is composed of, by mass fraction, 30-45 parts of titanium sponge particles, 10-15 parts of copper powder, 10-15 parts of iron powder, 5-8 parts of tungsten powder, 5-8 parts of molybdenum powder, 5-6 parts of niobium powder, 3-5 parts of tantalum powder, 3-4 parts of vanadium powder, 1-2 parts of zirconium powder, 1-2 parts of rhenium powder and 1-2 parts of hafnium powder. The titanium alloy prepared through the preparation method is stable in composition.

Owner:钦州市钦南区科学技术情报研究所

Wear-resisting flux-cored wire

The invention relates to the field of flux-cored wires, in particular to a wear-resisting flux-cored wire. The flux-cored wire comprises the following components of, in percentage by mass, 30-42% of rutile, 4-7% of quartz, 2-5% of magnesia, 3-6% of potassium fluoride, 11-14% of nickel powder, 5-8% of medium-carbon ferrochromium, 6-9% of silicon-manganese alloy, 8-11% of feldspar, 1-5% of fluorite,4-7% of graphite and the balance of hafnium powder. Compared with a conventional flux-cored wire, the flux-cored wire is more wear-resisting.

Owner:CHANGZHOU HEDA OIL PUMP

Deep-penetration flux-cored stranded welding wire, preparation method thereof, and welding method

The invention discloses a deep-penetration flux-cored stranded welding wire which comprises a flux core and an outer shell coated on the outer side of the flux core. The outer shell is made of cold-rolled low-carbon steel; and the flux core is prepared from the components in parts by weight: 20 to 30 parts of rutile, 5 to 10 parts of quartz, 1 to 5 parts of magnesia, 1 to 3 parts of aluminosilicate, 2 to 6 parts of cobalt powder, 1 to 4 parts of silicon carbide, 1 to 3 parts of manganese metal, 1 to 3 parts of molybdenum powder, 2 to 6 parts of iron powder, 0.5 to 4.5 parts of titanium powder,1 to 1.5 parts of aluminite powder, 0.2 to 0.6 part of hafnium powder, 1 to 2 parts of chromium powder, 0.5 to 1.5 parts of yttrium powder, 0.1 to 0.8 part of niobium powder, and 1 to 2 parts of tungsten powder. The invention discloses a preparation method of the deep-penetration flux-cored stranded welding wire. The preparation method of the deep-penetration flux-cored stranded welding wire comprises the following steps of processing cold-rolled low-carbon steel through a molding roller so as to form a U-shaped groove, mixing the flux core components, filling into the U-shaped groove, then rolling into a tubular shape, wiredrawing, and stranding to form the deep-penetration flux-cored stranded welding wire.

Owner:河北联之捷焊业科技有限公司

Piston material containing cobalt and preparation method thereof

The invention discloses a piston material containing cobalt, and further discloses a preparation method of the piston material containing cobalt. The piston material containing cobalt comprises the following raw materials of, by weight, 160-200 parts of aluminum powder, 20-30 parts of silica powder, 2-4 parts of magnesium powder, 2-4 parts of copper powder, 2-4 parts of hafnium powder, 3-5 parts of nickel, 3-5 parts of chrome and 3-5 parts of cobalt. The preparation method of the piston material containing cobalt comprises the following steps that the raw materials of the piston material are weighed correspondingly by weight; the raw materials of the piston material are subjected to ball-milling, pass through a screening net after ball-milling is conducted, and are mixed, and a mixed raw material is obtained; the mixed raw material is poured into a mold, the mold is placed in a vacuum environment for high-temperature smelting, and after cooling is conducted, the piston material containing cobalt is obtained. The piston material containing cobalt and the preparation method thereof have the advantages that alloy elements which have a greater influence on high-temperature performanceare added according to a certain proportion to adjust the proportion, so that the high-temperature strength and the high-temperature thermal stability of the material are improved, and finally the piston material containing cobalt is obtained, wherein the piston material has high-temperature tensile resistance, thermal corrosion resistance, fatigue resistance and abrasion resistance.

Owner:安徽浩丰实业有限公司

Tungsten-containing composite piston material, and preparation method thereof

The invention discloses a tungsten-containing composite piston material comprising, by weight, 5-6 parts of silicon powder, 0.6-0.9 part of magnesium powder, 0.15-0.35 part of manganese powder, 0.1-0.2 part of tungsten powder, 8-10 parts of silicon carbide powder, 4-5 parts of molybdenum disulfide, 0.6-0.8 parts of hafnium powder and 90-98 parts of aluminum powder. The invention further disclosesa preparation method of the tungsten-containing composite piston material. The preparation method comprises the step (1) of weighing raw materials; the step (2) of ball-milling, sieving and mixing thesilicon powder, the magnesium disulfide, the manganese powder, the tungsten powder, the hafnium powder and the aluminum powder; the step (3) of heating the silicon carbide powder and holding the temperature, and forming silicon dioxide on the surface layer after the silicon carbide powder reacts with oxygen fully; the step (4) of heating and degassing the mixed materials, holding the temperatureand cooling the mixed materials again, then adding the molybdenum disulfide and the silicon carbide to the mixed materials, and stirring the mixtures so that the tungsten-containing composite piston material is obtained. According to the tungsten-containing composite piston material and the preparation method thereof, by adding alloy elements with great influence on high-temperature performance and wear resistance proportionally and adjusting the proportion, the high-temperature strength and wear resistance of the materials are improved.

Owner:安徽宝泰汽车部件有限公司

A method for preparing anti-oxidation molybdenum products

ActiveCN106521408BImprove toughnessAvoid brittle defectsRare earth metal oxides/hydroxidesMolten spray coatingCeriumOxidation resistant

The invention discloses a method for preparing an oxidation resisting molybdenum product. The method comprises a step of manufacturing a first-order molybdenum product and a step of spraying the surface of the first-order molybdenum product to prepare an oxidation resisting co-doped molybdenum product, wherein silicon powder, hafnium powder, boron carbide and nanometer cerium dioxide are used for dispersing molybdenum to prepare the first-order molybdenum product; the first-order molybdenum product is dispersed to contain a high-temperature phase and alloy elements inside; heat-stable oxide particles are formed in the oxidation process; an oxide film is formed on the surface of the product in the oxidation process to stop continuous erosion of oxygen to the molybdenum product; and an oxidation resisting layer is sprayed on the surface of the first-order molybdenum product, and is tightly combined with a dispersing layer to largely delay the internal dispersion path of the oxidized molybdenum product.

Owner:LUOYANG KEWEI MOLYBDENUM & TUNGSTEN

Method for preparing high-performance powder metallurgy titanium and titanium alloy by recovering residual titanium

A method for recovering and preparing high-performance powder metallurgy titanium and titanium alloys from residual titanium belongs to the field of powder metallurgy titanium. The invention uses the leftover materials, cutting materials, recycled processing materials or titanium chips of titanium and titanium alloys as raw materials. After cleaning and crushing, the hydrodehydrogenation process is used to obtain fine hydrogenated dehydrogenated titanium powder, and zirconium and hafnium powder are added as an oxygen-fixing agent. Zirconium hafnium powder and HDH titanium powder are mixed evenly, and then formed and sintered to obtain high-performance powder metallurgy titanium products. Zirconium, hafnium and titanium belong to the same group of elements with similar chemical properties, which hinder the sintering. During the sintering process, the three elements of Ti, Zr(Hf), and O form an ordered phase, which can reduce the oxygen content of the titanium matrix and strengthen it. Improve the plasticity of the titanium matrix and greatly increase the strength of the material, and then obtain high-performance powder metallurgy titanium and titanium alloy products. The preparation process of the present invention is simple, no additional equipment is required, and the recovery and utilization rate of residual titanium is high, which is of great significance to the low cost and green recycling of the titanium industry.

Owner:UNIV OF SCI & TECH BEIJING

Lanthanum-containing composite piston material, and preparation method thereof

The invention discloses a lanthanum-containing composite piston material comprising, by weight, 10-13 parts of silicon powder, 1-2 parts of magnesium powder, 0.1-0.2 part of lanthanum powder, 5.2-5.8parts of silicon carbide powder, 1.2-1.8 parts of molybdenum disulfide, 0.15-0.18 part of hafnium powder and 74-84 parts of aluminum powder. The invention further discloses a preparation method of thelanthanum-containing composite piston material. The preparation method comprises the step (1) of weighing raw materials; the step (2) of ball-milling, sieving and mixing the silicon powder, the magnesium disulfide, the lanthanum powder, the hafnium powder and the aluminum powder; the step (3) of heating the silicon carbide powder and holding the temperature, and forming silicon dioxide on the surface layer after the silicon carbide powder reacts with oxygen fully; and the step (4) of heating and degassing the mixed materials, holding the temperature and cooling the mixed materials again, thenadding the molybdenum disulfide and the silicon carbide to the mixed materials, and stirring the mixtures so that the lanthanum-containing composite piston material is obtained. According to the lanthanum-containing composite piston material and the preparation method thereof, by adding alloy elements with great influence on high-temperature performance and wear resistance proportionally and adjusting the proportion, the high-temperature strength and wear resistance of the materials are improved.

Owner:安徽宝泰汽车部件有限公司

A kind of vacuum carbon reduction prepares the method for metal hafnium powder

The invention belongs to the technical field of vacuum metallurgy, discloses a method for preparing high-purity metal hafnium powder through hafnium dioxide vacuum carbon thermal reduction, and in particular, provides a method for preparing metal hafnium powder through reducing hafnium dioxide by graphite powder in vacuum. The method has the advantages of simple production process, low equipment investment, high metal yield of 95-98%, low production cost and prominent economic benefit, and is a process with low cost and high yield and suitable for large-scale preparation of high-purity and fine-granularity metal hafnium powder.

Owner:湖南华威景程材料科技有限公司

High-strength durable car die material and preparation method thereof

The invention discloses a high-strength durable car die material and a preparation method thereof, and belongs to the technical field of die material preparation. The high-strength durable car die material comprises the following raw materials including a chromium ingot, an iron block, carbon powder, copper powder, hafnium powder, molybdenum powder, nickel powder, a tungsten block, titanium powder, cobalt powder, tantalum powder, sulfur powder, phosphorus powder, nanometer titanium carbide, nanometer tungsten carbide, tungsten silicide and tungsten powder. The high-strength durable car die material is prepared through the steps of smelting, spheroidizing, refining desulfuration, deoxidation, pouring, heat treatment and the like. The high-strength durable car die material has excellent strength, hardness, toughness and heat resistant performance.

Owner:CHANGSHA QIUDIANBING INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com