Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Reduce hard agglomerates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Synthetic method of visible light catalyst Bi2MoO6

InactiveCN101254463AEvenly dispersedSmall particle sizeMetal/metal-oxides/metal-hydroxide catalystsMolybdateSynthesis methods

A synthetic method of a novel visible light photocatalyst Bi2MoO6 (bismuth molybdate) is provided. The method includes the following steps: weighing Bi(NO3)3*5H2O and (NH4)6Mo7O24*4H2O solids at the theoretical ratio by mass of 14:1, dispersing the weighed solids into an appropriate amount of deionized water, stirring to obtain white curdy precipitates, placing the precipitates in a magnetic stirrer and stirring at normal temperature for 30 minutes, subjecting to ultrasonic treatment with a ultrasonic generator for 30 minutes to allow intensively mixing, allowing reactions of the treated white precipitates at 150-200 DEG C under sealed conditions, filtering the reaction product to collect flavescent precipitates, washing, drying, and grinding to obtain Bi2MoO6 (bismuth molybdate) photocatalyst. The photocatalyst has good photodegradation effect on target pollutants; and when the temperature of hydrothermal synthesis is 160 DEG C, the removal rate of target pollutant 4BS after photodegradation for 90 minutes reaches 99.5%. The inventive synthetic method has the advantages of simple process and low requirement for equipment, and is suitable for the synthesis of highly-active visible light photocatalyst Bi2MoO6 (bismuth molybdate).

Owner:NANJING UNIV

Method for preparing nano-catalyst copper chromite and copper ferrite

InactiveCN101367044AHigh puritySmall particle sizeMetal/metal-oxides/metal-hydroxide catalystsWater bathsNano catalyst

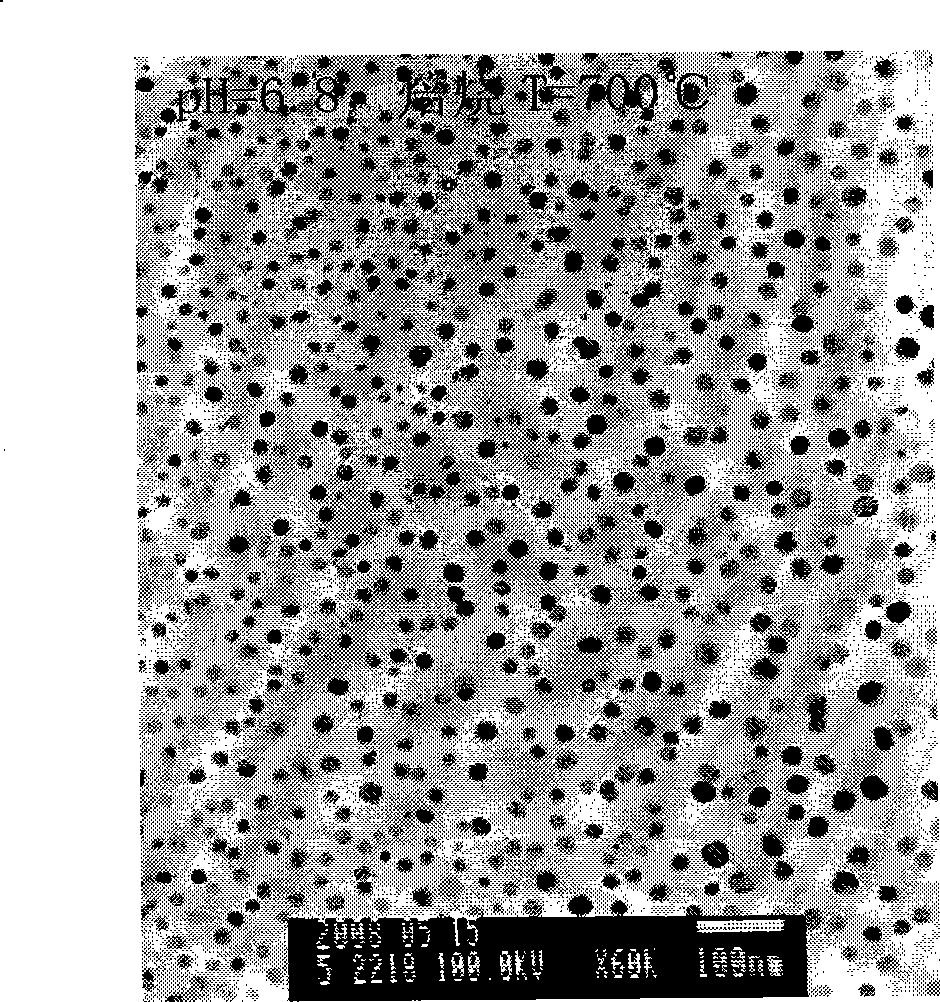

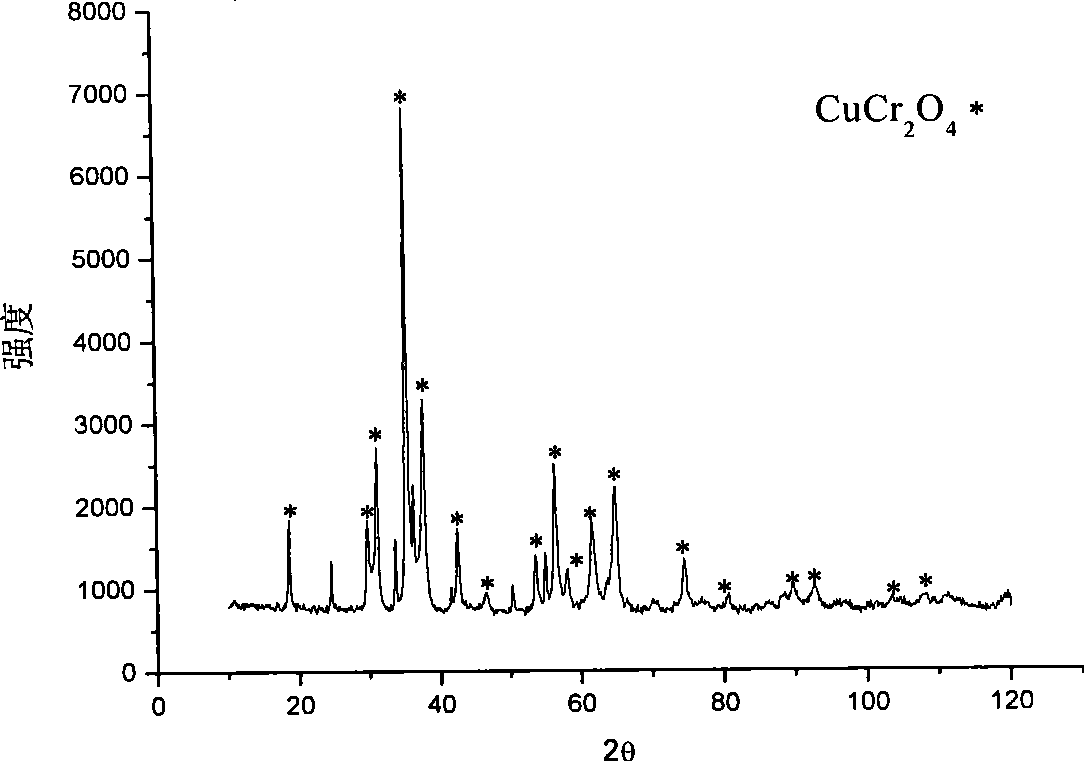

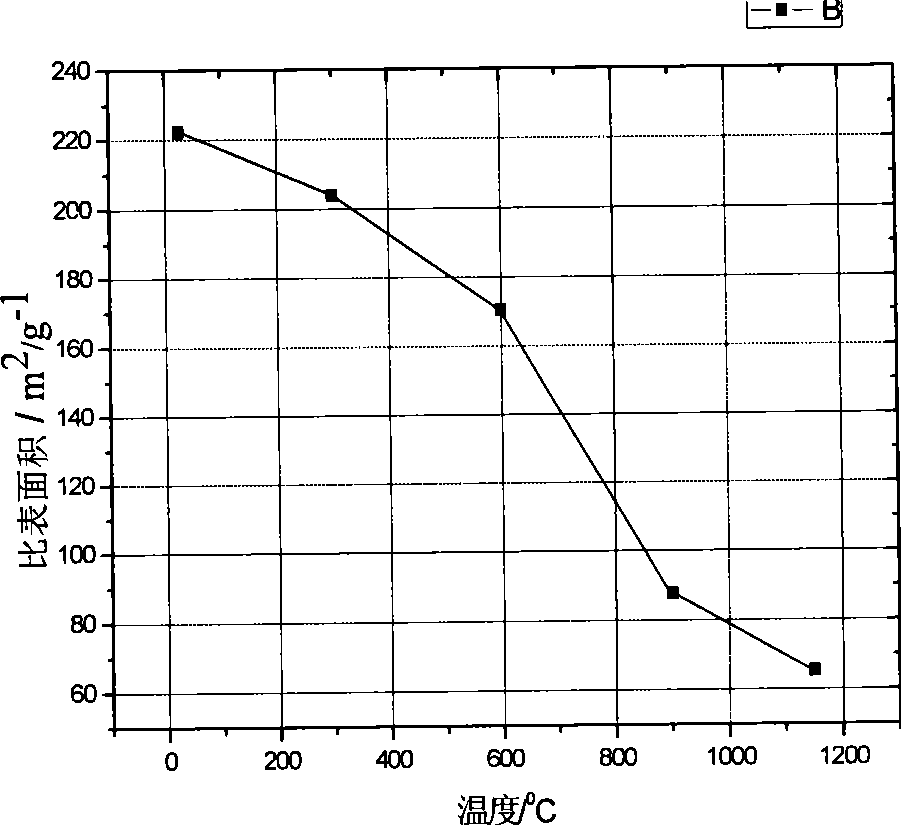

The invention discloses a method for preparing a nano-size catalyst of copper chromite and copper ferrite, and belongs to the technical field of nano-size catalyst preparation. The method of the invention comprises a sol-gel process and a vacuum freezing drying (VFD) process. Firstly, a mixed solution is prepared from a soluble copper salt and a soluble chromium salt or iron salt, added with a surface active agent, and mixed uniformly, and then the system is added with a precipitating agent to carry out precipitation reaction under the condition that the pH value is between 6.8 and 9.5, then is kept stand, aged, washed and melted in a water bath for 2 to 8 hours at a temperature of between 70 and 95 DEG C, thus sol is obtained; then the sol is subjected to freezing drying in a vacuum freezing dryer to obtain dried gel which is a precursor of the catalyst; finally, the dried gel is roasted to obtain the nano-size catalyst of copper chromite (CuCr2O4) or copper ferrite (CuFe2O4). The catalyst prepared by the method has the advantages of high purity, small grain diameter, good dispersivity, high catalytic activity, and the like.

Owner:TSINGHUA UNIV

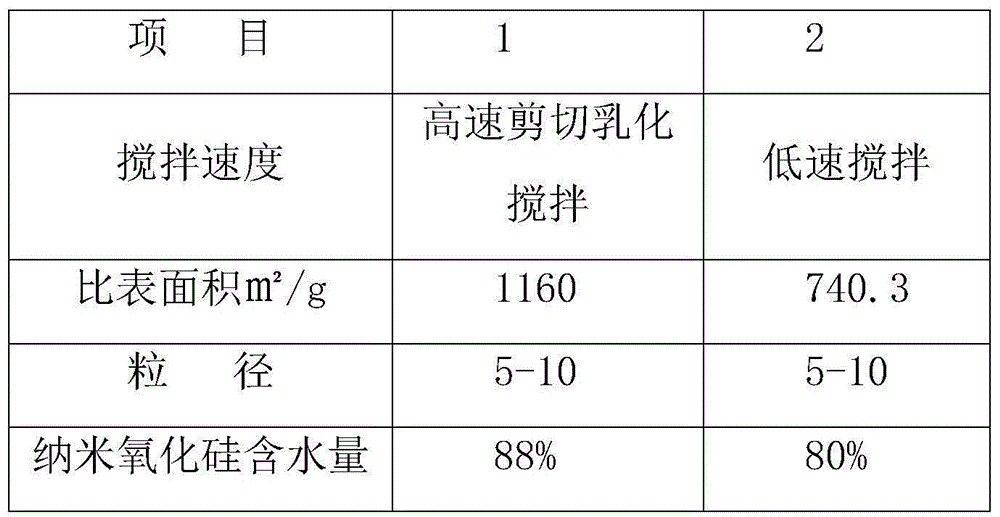

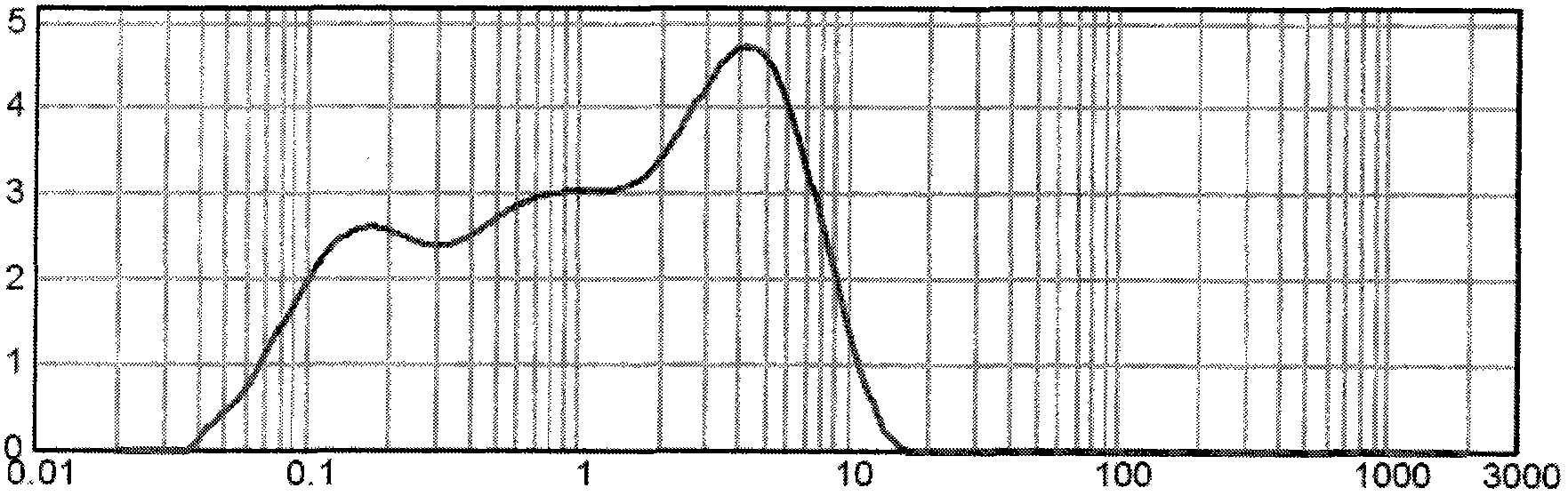

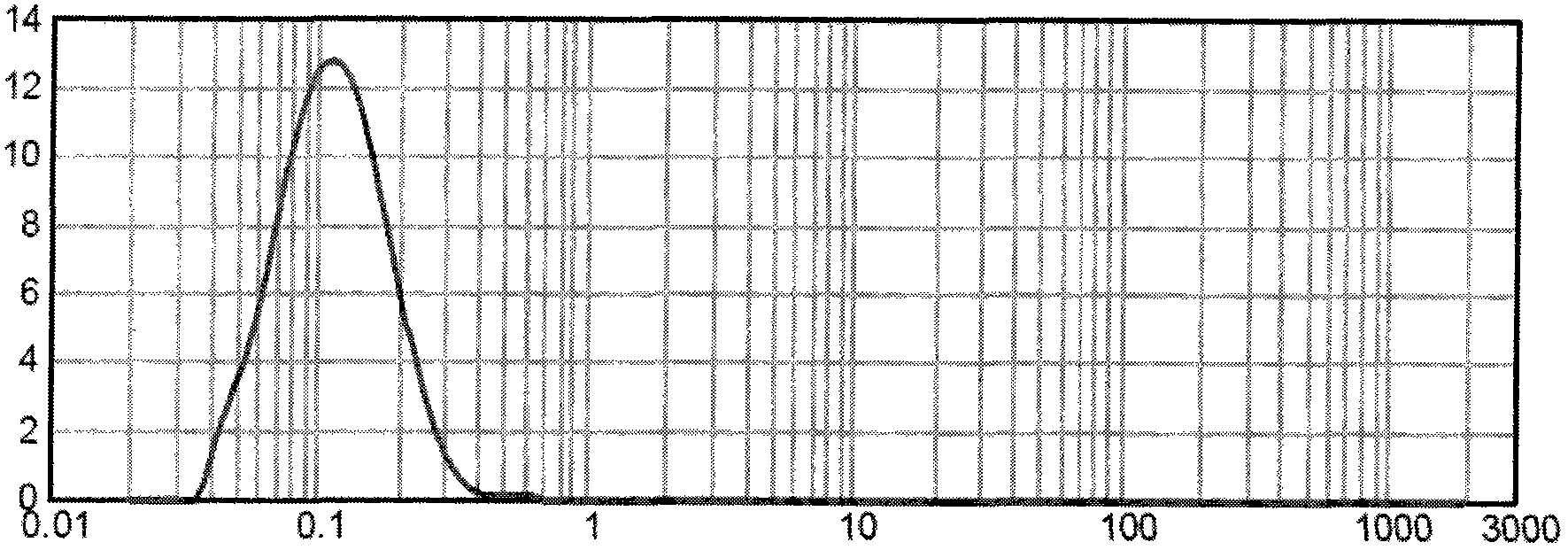

Small-particle-size ultrahigh-specific-area nano silicon oxide

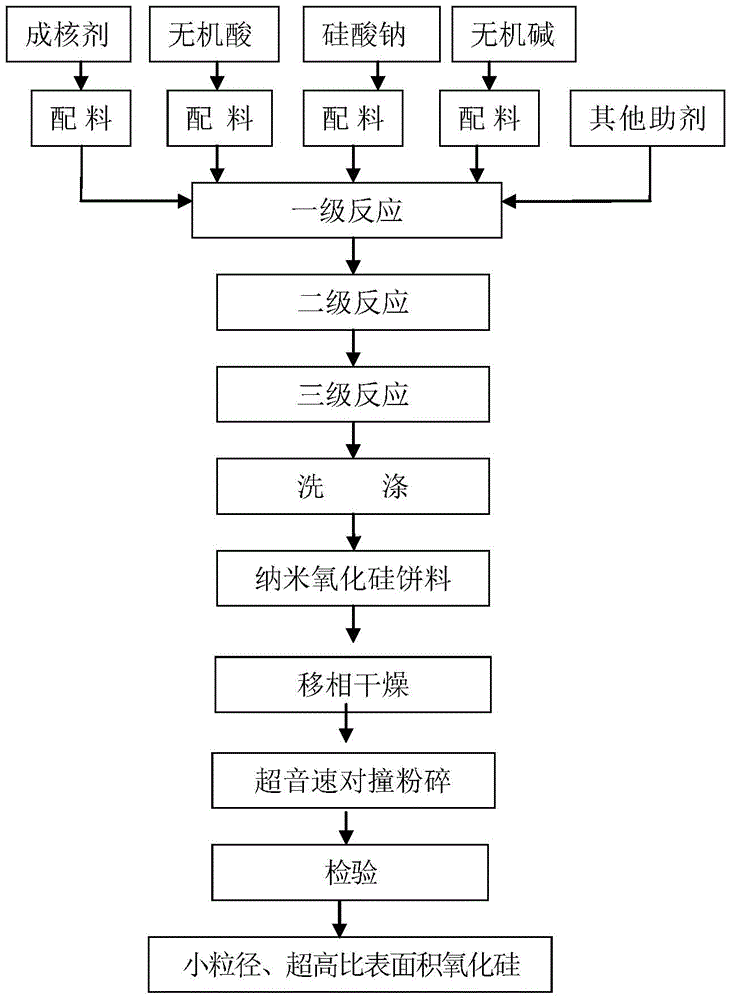

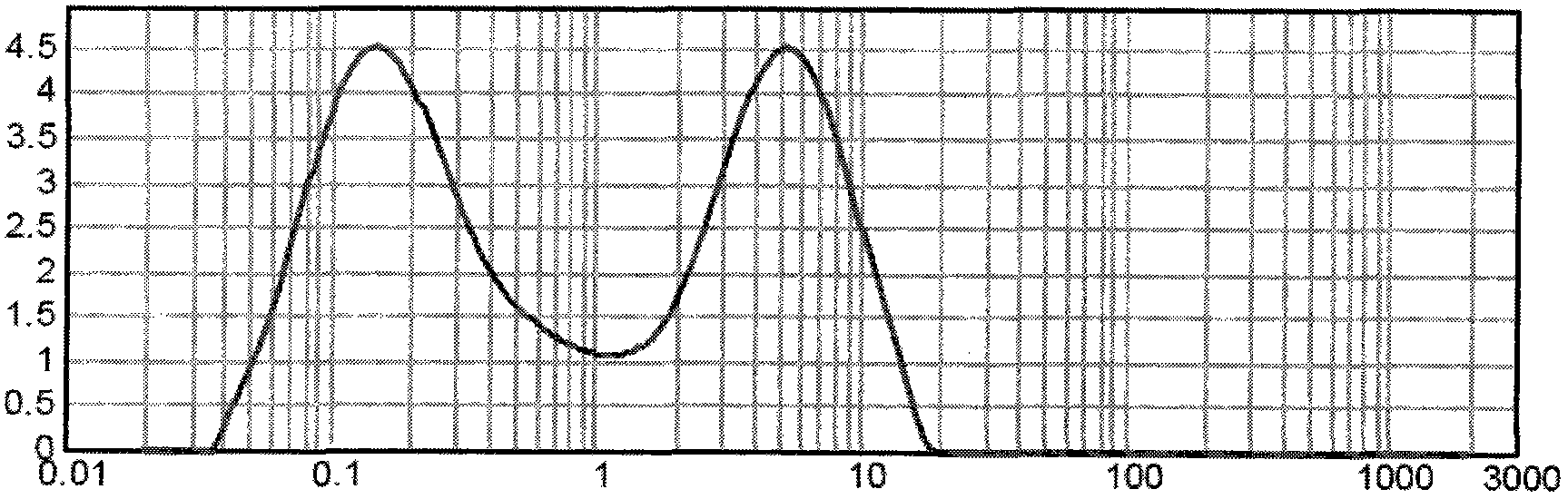

ActiveCN104828828AConcentration Stable EquilibriumLow reaction temperatureSilicaNanotechnologyStrong acidsOxide

The invention discloses a small-particle-size ultrahigh-specific-area nano silicon oxide which is prepared by the following steps: adding metered inorganic acid, water glass, a nucleator, a dispersing agent and pure water into a reaction vessel, and emulsifying and stirring by high-speed shearing to perform primary reaction; added metered primary reaction product, inorganic acid and a nucleator into a reaction vessel, stirring at low speed to perform secondary reaction; regulating the pH value of the reaction product after secondary reaction to less than 3, and carrying out aging reaction under such conditions to stably form the particles; and carrying out deacidifying-desalting washing on the product under strong acid conditions to obtain the small-particle-size ultrahigh-specific-area nano silicon oxide. The particle size of the nano silicon oxide can reach 5-10nm, and the specific area is up to 600-1160 m<2> / g. The nano silicon oxide has small particle size and ultrahigh specific area, and thus, has excellent effects when being applied to multiple fields.

Owner:上饶市安纳拓新材料有限公司

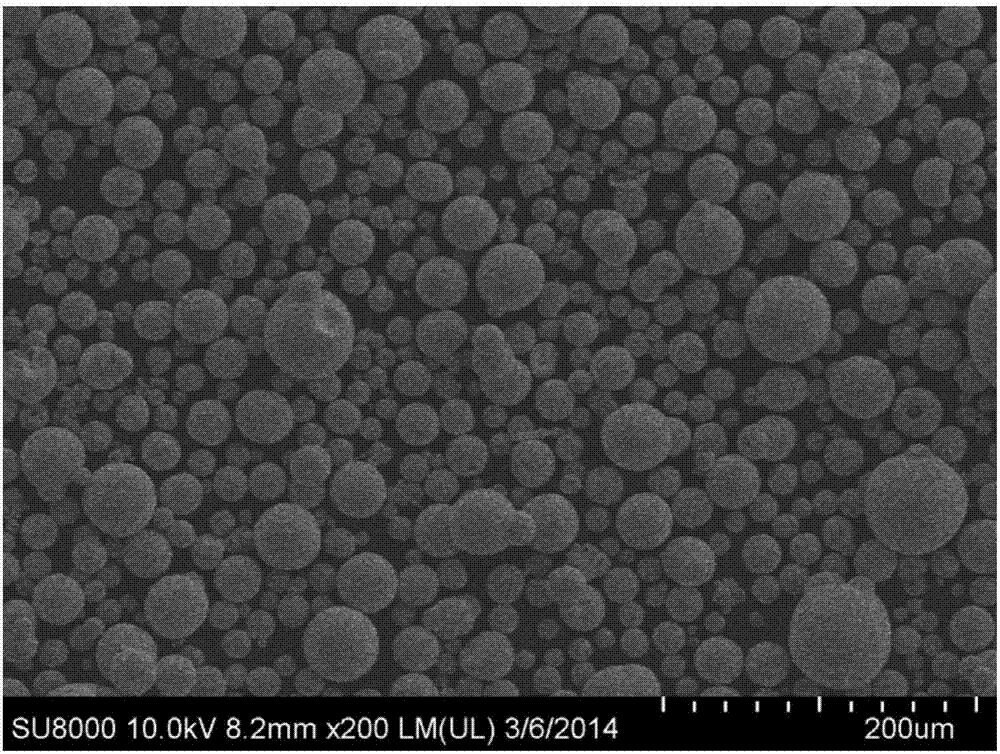

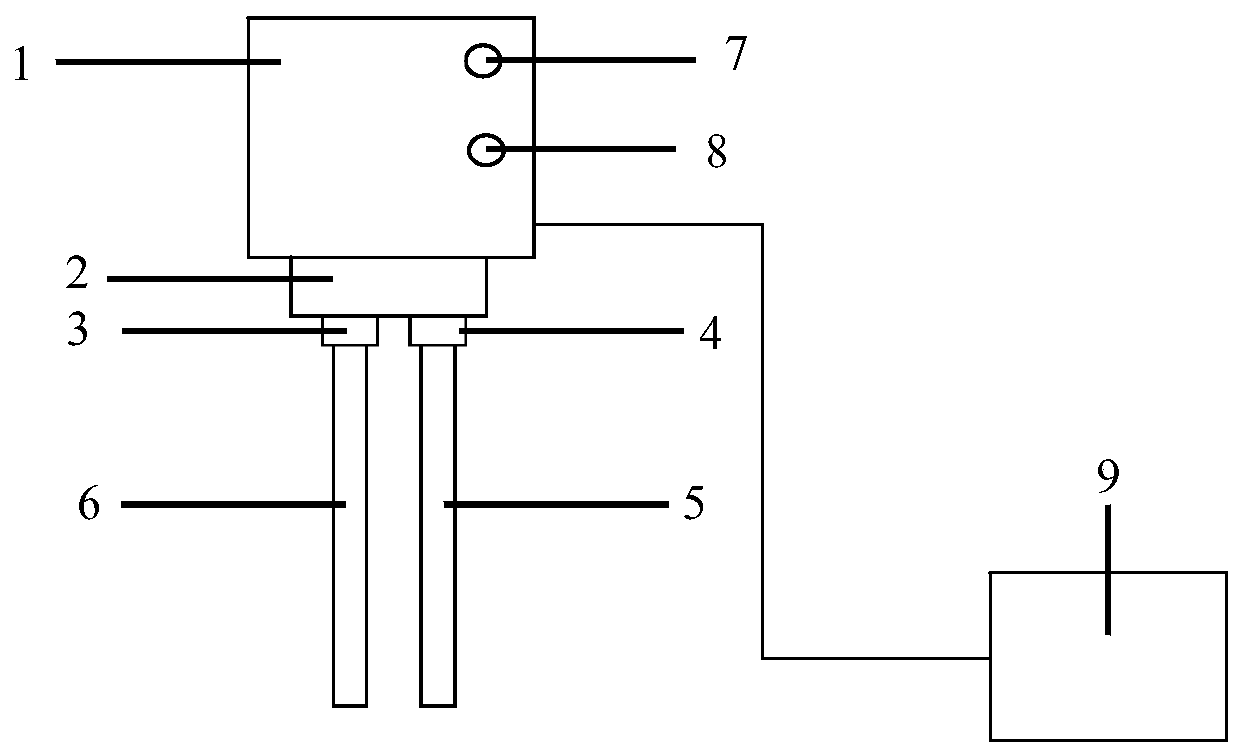

Aftertreatment method for doped nano-zirconia powder

ActiveCN102701279AHigh densityHigh transparencyMaterial nanotechnologyZirconium oxidesFreeze dryAgglomerate

The invention provides an aftertreatment method for doped nano-zirconia powder through spray freeze drying. The nano-powder prepared by the aftertreatment method has the advantages of regular shape, a few hard agglomerates, small particle size, low uniform sintering temperature and the like, and a nano-ceramic material which has the advantages of high density, strength, toughness, light-transmitting property and reliability and the like can be prepared. By the method, personalized nano-zirconia powder with small using amount can be prepared by introducing an additive in the aftertreatment process.

Owner:LIAONING UPCERA CO LTD

Hydrothermal method for synthesizing visible light catalyst SnWO4

InactiveCN101745381AEvenly dispersedSmall particle sizeCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsUltrasonic cavitationDissolution

The invention relates to a synthesizing method of a visible light catalyst SnWO4 (stannous wolframate), comprising the following steps: respectively adding SnCl2.2H2O and Na2WO4.2H2O which have the same substance amount to equivalent deionized water to be dissolved; mixing two solutions after dissolution; sufficiently stirring so as to obtain flaxen creaming; reacting an obtained reaction mixture containing the flaxen creaming at 120-200 DEG C for 24 hours in a sealing state; and filtering, collecting, washing, drying and grinding obtained rufous sediments after reaction so as to obtain the visible light catalyst SnWO4. The invention adopts ultrasonic preprocessing, has simple equipment, uniformly disperses the reaction mixture through ultrasonic cavitation action, reduces the grain diameter of the visible light catalyst SnWO4, enlarges the specific surface area and can enhance the light catalytic activity of the visible light catalyst SnWO4; a hydrothermal method can directly obtain well-crystallized powder without high-temperature calcination and crystallization and has lower synthesizing temperature and low equipment requirement; and in addition, the visible light catalyst SnWO4 (stannous wolframate) prepared by the method has high activity.

Owner:NANJING UNIV

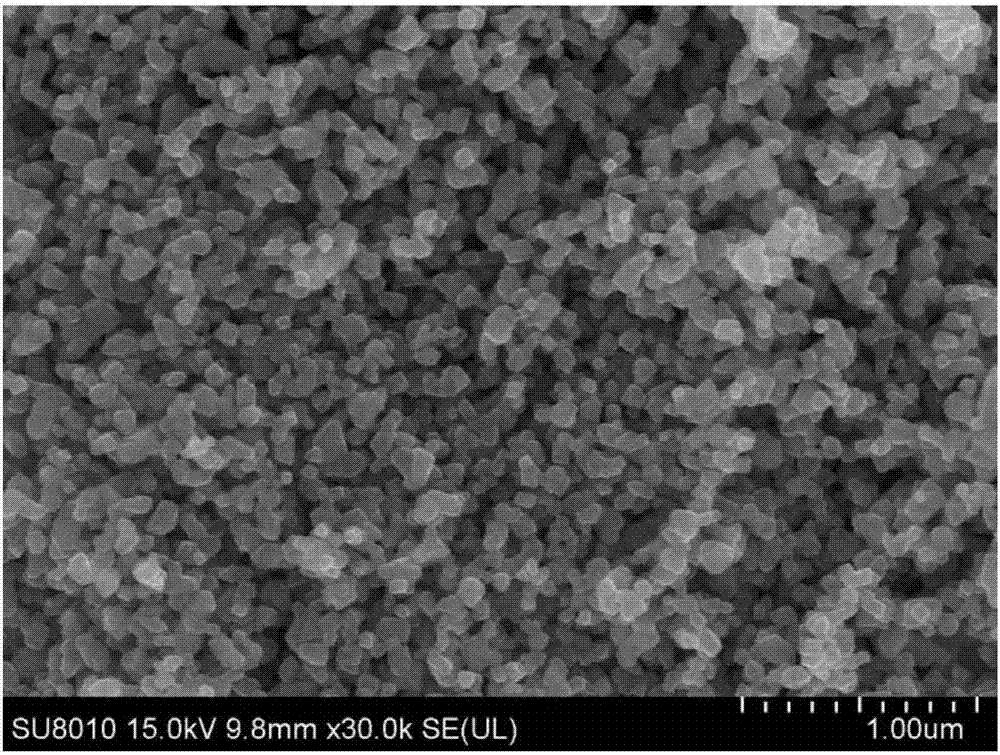

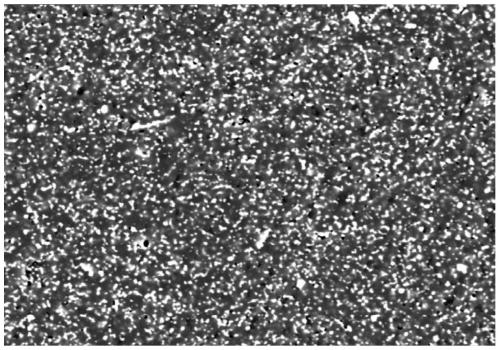

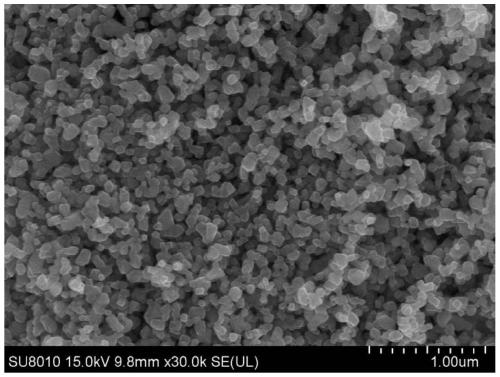

Preparation method of indium tin oxide composite powder

ActiveCN106882835AReduce agglomerationReduce hard agglomeratesMaterial nanotechnologyGallium/indium/thallium compoundsIndiumIndium tin oxide

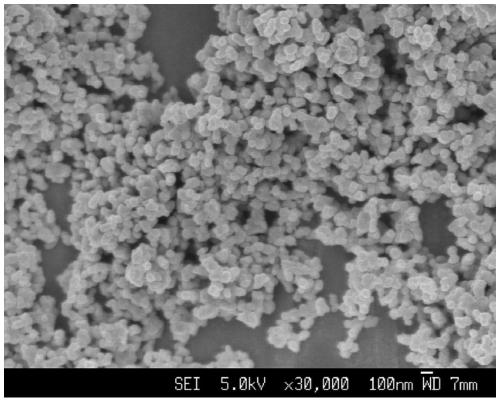

The invention discloses a preparation method of indium tin oxide composite powder, belonging to the technical field of preparation of indium tin oxide composite powder. The method comprises the following steps: preparation of mixed salt liquid: putting an InCl3 liquid and an SnCl4 liquid into a reaction kettle according to the In2O3:SnO2 weight ratio of 9:1, and uniformly mixing; addition of dispersing agents: adding polyvinylpyrrolidone, beta-alanine and ethanediol according to the weight ratio of 2:1:3, and adding more than 20% excessive of urea; coprecipitation reaction: gradually heating to 60-90 DEG C, keeping the temperature while continuously stirring until the In<3+> in the reaction solution is completely precipitated, carrying out ultrasonic treatment for 1 hour, continuing stirring, and aging to obtain an indium tin precipitate; and washing, drying, grinding, screening and carrying out high-temperature calcination to obtain the high-sintering-activity nano indium tin oxide composite powder. The indium tin oxide composite powder prepared by the method has the advantages of less hard aggregation and favorable flowability, and is easy for pressure molding.

Owner:ANHUI TUOJITAI NOVEL CERAMIC TECH

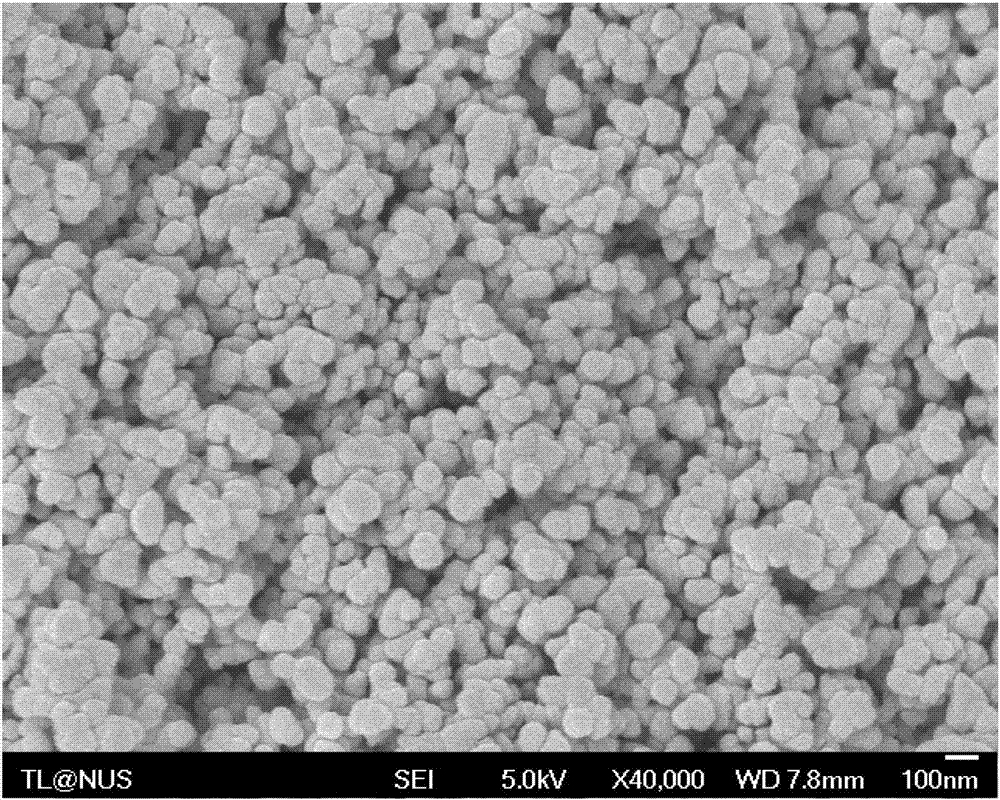

High-sensitivity alcohol-sensitive gas sensor, preparation method thereof, and preparation method of mesoporous SnO2 material

ActiveCN104310306APromote crystallizationReduce hard agglomeratesMaterial nanotechnologyIndividual molecule manipulationAir atmosphereSlurry

The invention discloses a preparation method of a mesoporous SnO2 material. The preparation method comprises the following steps of dissolving 3.1g of CTAB (Cetyl Trimethyl Ammonium Bromide) into 40mL of water to obtain a surfactant solution; adding 0.11g of dodecylamine into the surfactant solution; adding a prepared ammonia water solution into a mixed solution to obtain a template agent solution; dissolving 10.5g of SnCl4.5H2O into 80mL of water and adding the prepared solution into the template agent solution to obtain a white slurry-like solution; performing reaction on the white slurry-like solution at the temperature of 160 DEG C for 12h, roasting the treated white slurry-like solution in air atmosphere, and preserving heat for 1h to prepare the mesoporous SnO2 material. The invention further discloses a high-sensitivity alcohol-sensitive gas sensor and a preparation method thereof. Impurities and structural defects caused by after-treatment such as high-temperature calcination or ball milling can be avoided, high-temperature roasting crystallization is not needed, and hard powder agglomeration which is difficult to avoid in the high-temperature roasting process is reduced.

Owner:XIAN TECHNOLOGICAL UNIV

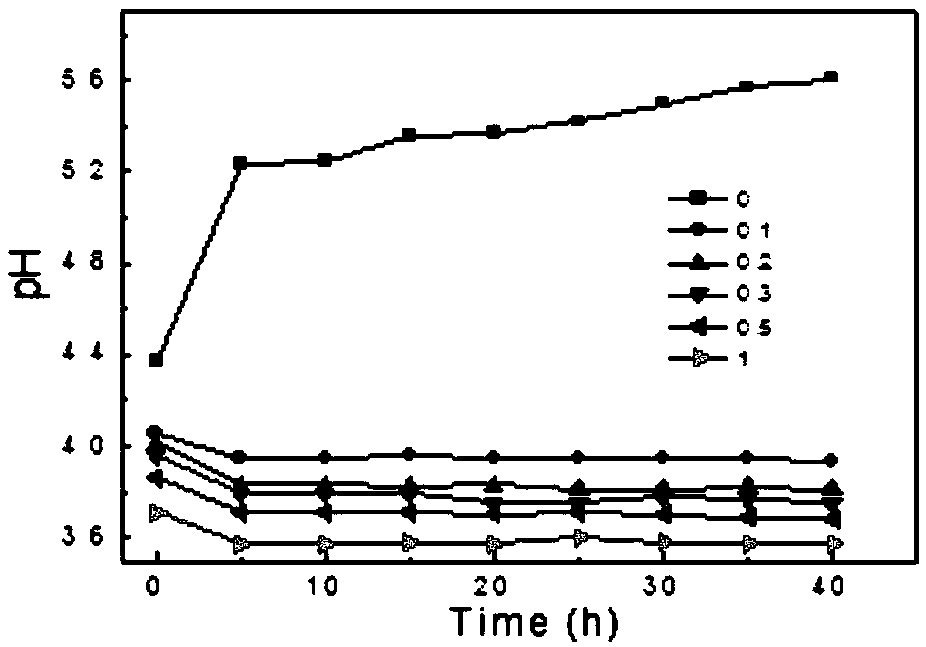

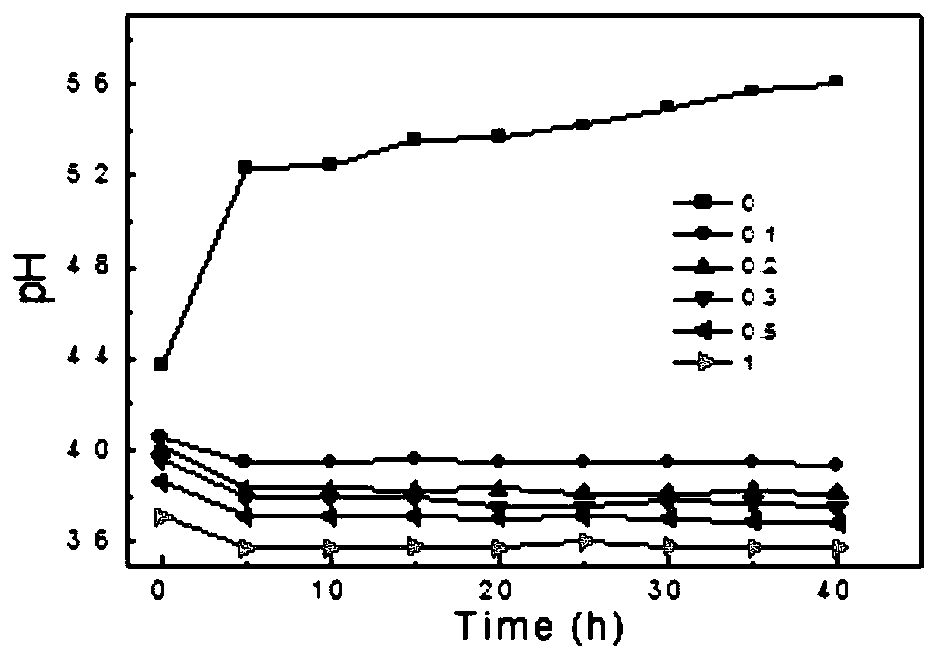

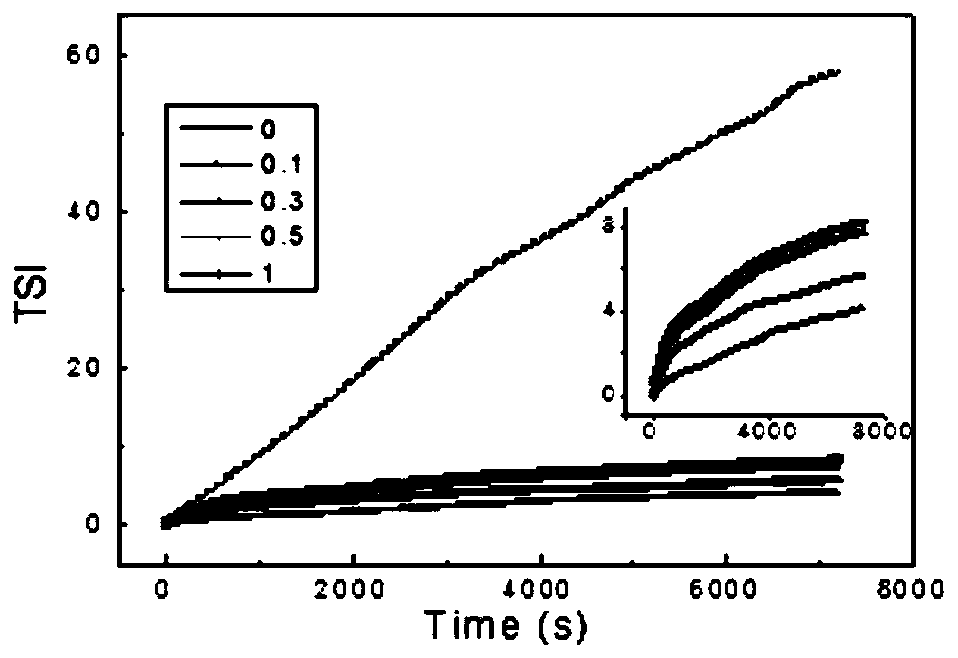

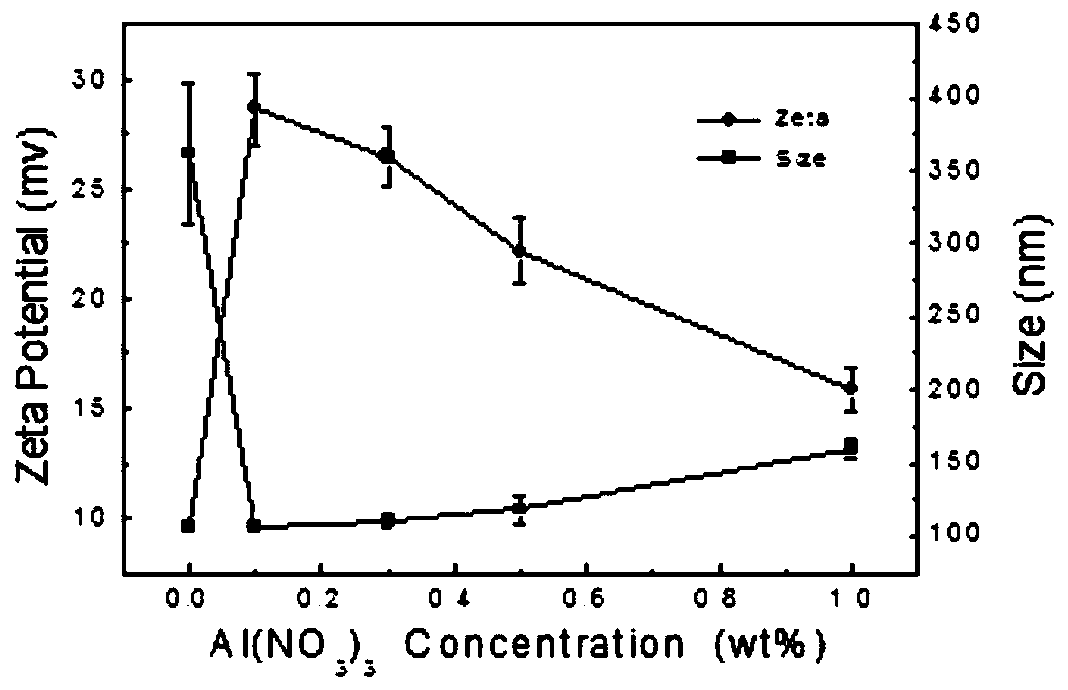

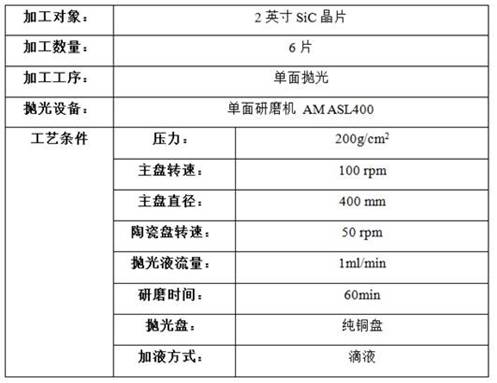

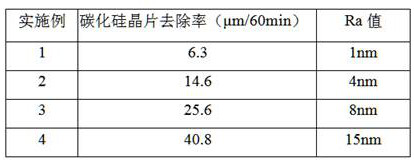

Method for preparing silicon carbide chemical mechanical polishing solution with improved pH stability

ActiveCN109321141AEvenly dispersedGuaranteed stabilityPolishing compositions with abrasivesDispersion stabilityOrganic acid

The invention provides a method for preparing a silicon carbide chemical mechanical polishing solution with improved pH stability. The preparation method comprises the following steps: performing surface modification on a high-hardness grinding material dispersion solution by using a surface modifier, and successively adding a pH stabilizer and an oxidant, wherein the surface modifier is organic acid. The stability of the pH value of the polishing solution can be well kept in the chemical mechanical polishing process, and the polishing solution is good in dispersion stability and uniform in dispersion. Since the pH stabilizer is added into the preparation method of the polishing solution, the pH value stability of the polishing solution in the chemical mechanical polishing process is higher, the organic acid surface modifier in the polishing solution is used for performing the surface modification on the high-hardness grinding material dispersion solution, so that the polishing solution is unlikely to have hard agglomeration. The polishing solution of the invention is pollution-free to the environment, and can be used in a circular feeding way.

Owner:SICC CO LTD

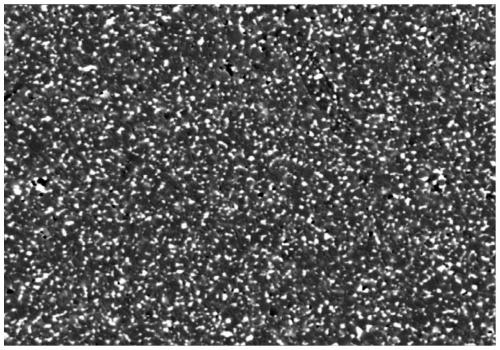

Preparation method of high-dispersibility ITO powder

ActiveCN107098378ASimple structureGood dispersionGallium/indium/thallium compoundsTin oxidesIndiumFiltration

The invention discloses a preparation method of high-dispersibility ITO powder and belongs to the technical field of preparation of indium tin oxide composite powder. The method comprises the steps of adding metal In to a HNO3 solution for completely dissolving; weighing SnCl4.5H2O white crystal at the mass ratio of In2O3 to SnO2 being 9:1, adding the SnCl4.5H2O white crystal to an indium salt solution and stirring evenly to prepare a mixed salt solution; adding a composite dispersing agent to a NH4AC buffer solution; dropwise adding ammonia water and a mixed salt solution to the buffer solution at the same time, thereby generating a indium-tin hydroxide precursor; reacting completely, ageing and carrying out suction filtration, washing the obtained indium-tin hydroxide precursor with water and an organic solvent separately; standing the washed indium-tin hydroxide precursor at room temperature and naturally airing; and calcining at a high temperature for 4h to obtain yellow ITO powder. The ITO powder prepared by adopting the preparation method has few hard agglomerates, and is good in mobility and easy to shape by pressing.

Owner:ANHUI TUOJITAI NOVEL CERAMIC TECH

High-purity high-sintering active indium tin oxide mixed powder preparation method

ActiveCN107140949APrevent coagulationReduce severe reunionMaterial nanotechnologyVacuum evaporation coatingAmmonium hydroxideIndium

The invention discloses a high-sintering active indium tin oxide mixed powder preparation method. The method particularly comprises the steps that high-activity nano SnO2 powder is prepared, wherein a compound dispersing agent is dissolved into water, an appropriate amount of SnCl4 is added, stirring is conducted till the mixture is completely transparent, and clarification is conducted; stirring is kept, an appropriate amount of ammonium hydroxide is added, a tin-containing precursor is obtained, after the precursor is placed in a high pressure reaction kettle to be subjected to hydrothermal treatment, sediment is taken out to be washed repeatedly, dried and subjected to low temperature thermal treatment, and nano SnO2 powder is obtained; metal indium is dissolved into hydrochloric acid, a InCl3 aqueous solution is generated, and a method similar to the method for synthesizing SnO2 powder is used for preparing nano In2O3 powder; the prepared InCl3 is mixed with SnO2 in proportion, PVA is added, by means of a spray drying technology, mixed indium tin oxide granulation powder which is less in aggregation, good in liquidity and prone to pressure molding is obtained, and the preparation method can be suitable for preparing high-end ITO target materials.

Owner:ANHUI TUOJITAI NOVEL CERAMIC TECH

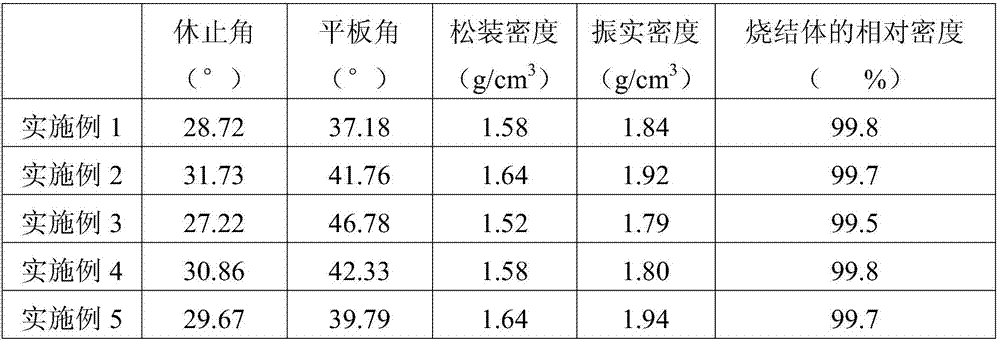

Preparation method of low-cost and high-densification ITO target material

The invention discloses a preparation method of a low-cost and high-densification ITO target material. The preparation method comprises the following steps: weighing metal In, adding into an HNO3 solution for complete dissolving, weighing SnCl4.5H2O white crystals, and adding into an indium salt solution, so as to prepare a mixed salt solution; preparing a NH4AC buffer solution, and adding a compound dispersing agent into the buffer solution; simultaneously dropwise adding ammonia water and the mixed salt solution into the buffer solution, so as to generate an indium-tin hydroxide precursor; after the reaction is complete, ageing, carrying out suction filtration, and respectively washing with water and an organic solvent; standing at room temperature for naturally airing; calcining at a high temperature for 4 hours, so as to obtain yellow ITO powder; and granulating the ITO powder, carrying out prepressing formation, so as to obtain a green body, and carrying out degreasing and sintering, so as to obtain the high-purity and high-density ITO target material. The ITO powder prepared in a preparation process of the preparation method has the characteristics of low sintering temperature and short time under a pressureless sintering condition and can be used for preparing the ITO target material which approaches to theoretical density and has relatively low porosity.

Owner:ANHUI TUOJITAI NOVEL CERAMIC TECH

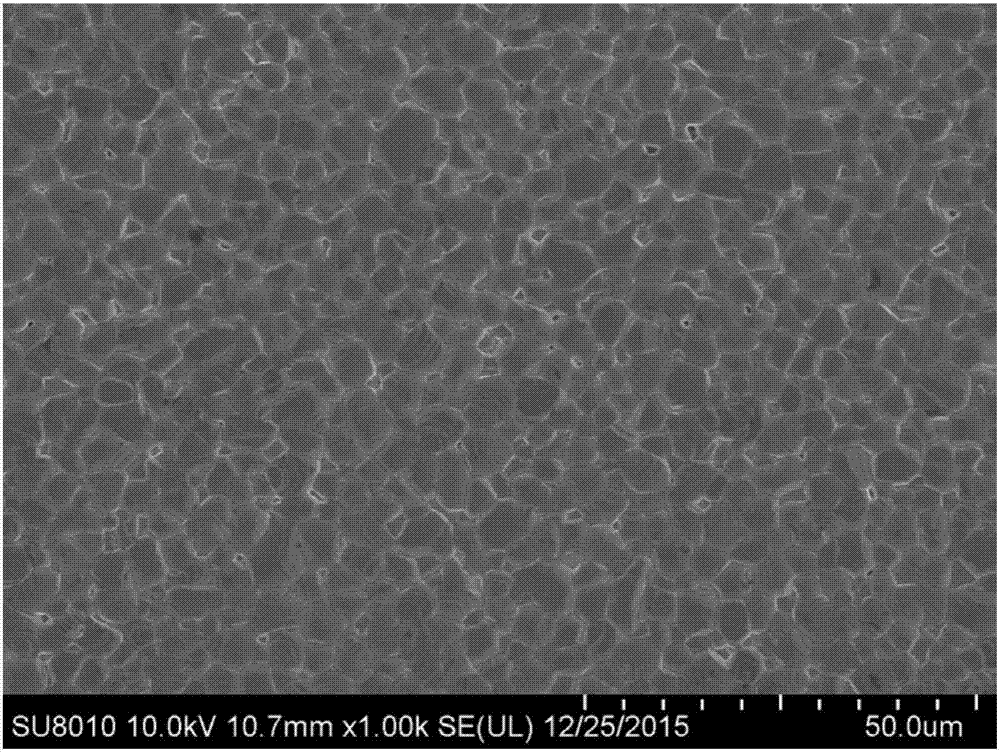

Preparation method of cerium-stabilized zirconia-toughened alumina ceramic material

The invention discloses a preparation method of a cerium-stabilized zirconia-toughened alumina ceramic material. The preparation method comprises adding water to zirconium oxychloride octahydrate andcerium nitrate hexahydrate to prepare solutions, mixing the solutions evenly to form a mixed solution, and dropwise adding ammonia water; after flocculent precipitate occurs, adding a surfactant; fixing a modified electric adsorbing device above a precipitate mixed solution container, and removing surplus Cl-, NH4+, OH- and NO3- in the solution by stirring and adsorbing through the electric adsorbing device; sucking all supernate, and dewatering the rest precipitate to obtain a precursor; adding absolute ethyl alcohol into the precursor, stirring well, adding nano alumina powder, carrying outball milling, drying, grinding, screening, and calcining to obtain zirconia-toughened alumina ceramic powder; after shaping, sintering to obtain the cerium-stabilized zirconia-toughened alumina ceramic material. The preparation method has shorter preparation cycle of powder, the powder can have less chances for hard aggregation due to 'salt bridge', and component uniformity and purity are guaranteed for the powder.

Owner:SOUTH CHINA UNIV OF TECH

A method for preparing silicon carbide chemical mechanical polishing fluid with improved pH stability

ActiveCN109321141BEvenly dispersedGuaranteed stabilityPolishing compositions with abrasivesOrganic acidDispersion stability

The invention provides a method for preparing a silicon carbide chemical mechanical polishing solution with improved pH stability. The preparation method comprises the following steps: performing surface modification on a high-hardness grinding material dispersion solution by using a surface modifier, and successively adding a pH stabilizer and an oxidant, wherein the surface modifier is organic acid. The stability of the pH value of the polishing solution can be well kept in the chemical mechanical polishing process, and the polishing solution is good in dispersion stability and uniform in dispersion. Since the pH stabilizer is added into the preparation method of the polishing solution, the pH value stability of the polishing solution in the chemical mechanical polishing process is higher, the organic acid surface modifier in the polishing solution is used for performing the surface modification on the high-hardness grinding material dispersion solution, so that the polishing solution is unlikely to have hard agglomeration. The polishing solution of the invention is pollution-free to the environment, and can be used in a circular feeding way.

Owner:SICC CO LTD

Diamond polishing solution for rough polishing of silicon carbide wafers and preparation method

InactiveCN112480825AEfficient removalIncrease profitPolishing compositions with abrasivesCarbide siliconWafering

The invention provides a diamond polishing solution for rough polishing of a silicon carbide wafer and a preparation method. The diamond polishing solution comprises the following components in percentage by weight: 0.1-1% of a diamond abrasive, 3-10% of an oiliness agent, 0.1-0.4% of a dispersing agent, 0.1-0.5% of modified urea solution, 0.1-0.5% of an activating agent and the balance of basic solvent. By adopting the abrasive two-step treatment method, the utilization rate of the polycrystalline diamond powder can be effectively increased, and meanwhile, the problem of scratching caused byoversize particles and hard aggregates in the polishing solution is effectively reduced; the modified urea solution is adopted as an organic suspending agent, the polishing solution has no obvious layering phenomenon after being placed for a long time, and compared with inorganic suspending agents such as hydrophobic modified fumed silica and organic bentonite, polishing scraps are not prone to adhering to a polishing disc and are easy to clean.

Owner:HENAN UNION ABRASIVES

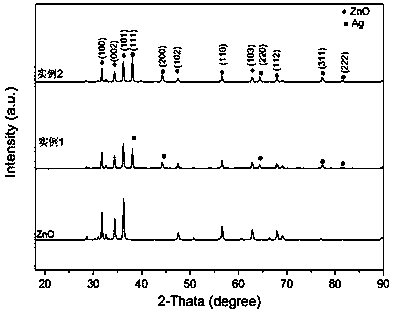

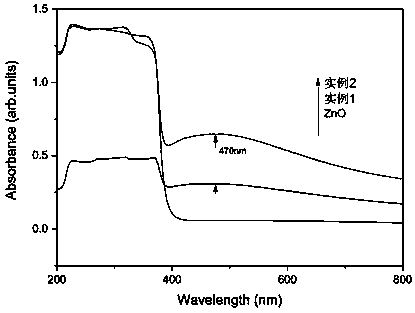

Preparation method of precious metal silver loaded nano-zinc oxide powder

InactiveCN110404533AAvoid hard clumpingReduce hard agglomeratesMaterial nanotechnologyWater/sewage treatment by irradiationDispersityPollution

The invention discloses a preparation method of precious metal silver loaded nano-zinc oxide powder. The preparation method comprises the steps that a water-soluble polymer, zinc nitrate hexahydrate and silver nitrate are taken as raw materials, and through a simple mixing reaction, a gel solution with a certain concentration is prepared; a brown spumescence intermediate is obtained through freezedrying, and finally, calcination is conducted to obtain a silver-zinc oxide target product. Through the entropy effect generated by abundant chain conformations of the water-soluble polymer and strong hydrogen bond association generated by hydrophilic groups on a chain and hydroxyl on the surfaces of particles, dispersion of zinc oxide and silver nanoparticles in a polymer aqueous solution is promoted, and thus nano silver particle loaded zinc oxide with high dispersity is obtained. The preparation technique is simple in process, the prepared powder is good in dispersity, hard agglomeration of the particles is less, the nano silver particle loaded zinc oxide with the high utilization rate and the high dispersity is obtained, the use amount of silver is decreased, raw materials are low incost and easy to obtain, the environment-friendly and pollution-free effects are realized, and the preparation method of the precious metal silver loaded nano-zinc oxide powder is suitable for industrial production.

Owner:BEIJING UNIV OF CHEM TECH

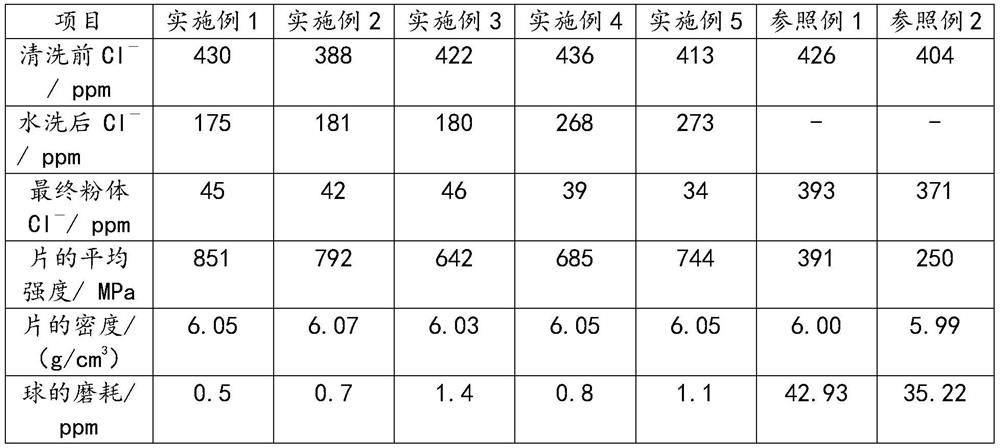

Method for removing Cl <-> in zirconium oxide powder

The invention relates to the field of zirconium oxide ceramic powder preparation, in particular to a method for removing Cl <-> in zirconium oxide powder, which is characterized by comprising the following steps: S1, putting zirconium salt into water, stirring and heating to prepare a zirconium salt solution; s2, mixing the zirconium salt solution and ammonia water, adjusting the pH value to 7-7.5, continuously adding the ammonia water solution, adjusting the pH value of the solution to 9-10, and stirring the mixture to prepare slurry; s3, washing the slurry until the content of Cl <-> in the slurry is lower than 300ppm, and then carrying out filter pressing to obtain a filter cake; s4, calcining the filter cake to obtain calcined powder; and S5, mixing the calcined powder with a hot acid solution, carrying out ball milling and sand milling, carrying out spray granulation, and sieving the granules to obtain the zirconium oxide powder. According to the method, hot acid is added during ball milling of the calcined powder to break the acid-base balance of a solution, so that the powder is further cleaned, the content of Cl <-> in the powder is reduced, and hard agglomeration of the powder can be obviously reduced; therefore, the purity, sintering activity and the like of the powder can be improved, the permeability probability of parts made of the powder can be obviously improved, the sintering temperature can be reduced, and the cost can be saved.

Owner:ZHEJIANG JINKUN ZIRCONIUM IND

Particle size control method of ceramic powder prepared by wet chemical method

InactiveCN103833377AReduce the degree of reunionReduce agglomeration particle sizeMetallurgySolid particle

The invention discloses a particle size control method of ceramic powder prepared by a wet chemical method. The particle size control method comprises the following steps: adding a combustible to initial powder prepared by a wet chemical method, uniformly mixing, drying, and calcining so as to obtain the ceramic powder, wherein the combustible is a solid particle combustible which can be completely burned off at a temperature which is below calcination temperature and is free of fusion and remained ash. The particle size control method is simple, convenient, easy to operate, economical and practicable; and the sintering degree among nano-powder particles in a calcination process can be controlled by adding the combustible, so as to reduce and control agglomeration particle sizes of nano-powder, so that the nanometer ceramic powder with uniform compositions and controlled particle sizes is realistically and effectively obtained.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Method for preparing tantalum-potassium composite oxide photocatalyst

InactiveCN101569858AOperational securitySimple processWater/sewage treatment by irradiationWater contaminantsMuffle furnaceComposite oxide

The invention relates to a method for preparing a tantalum-potassium composite oxide photocatalyst. The method for preparing the tantalum-potassium composite oxide photocatalyst is characterized by comprising the following steps: 1) according to a mol ratio of Ta2O5 to KOH between 1 to 2 and 1 to 20, selecting Ta2O5 and KOH to prepare white tantalic acid precipitate; 2) adding oxalic acid to form water-soluble oxalic acid solution of tantalum; 3) adding potassium nitrate and citric acid to form mixed solution; 4) adding glycol as an esterification agent into the mixed solution to generate a sticky frothy brown substance; 5) further coking the obtained brown substance for 3 to 4 hours in a muffle furnace at 450 DEG C, and grinding the coked substance to obtain a precursor of a tantalum-potassium composite oxide; and 6) baking the precursor of the tantalum-potassium composite oxide for 1 to 8 hours at the temperature between 700 and 800 DEG C, cooling the baked precursor to room temperature and then grinding the cooled precursor to obtain the tantalum-potassium composite oxide photocatalyst. The method has the advantages of safe operation, simple process, low reaction temperature, short time and low cost.

Owner:WUHAN UNIV OF TECH

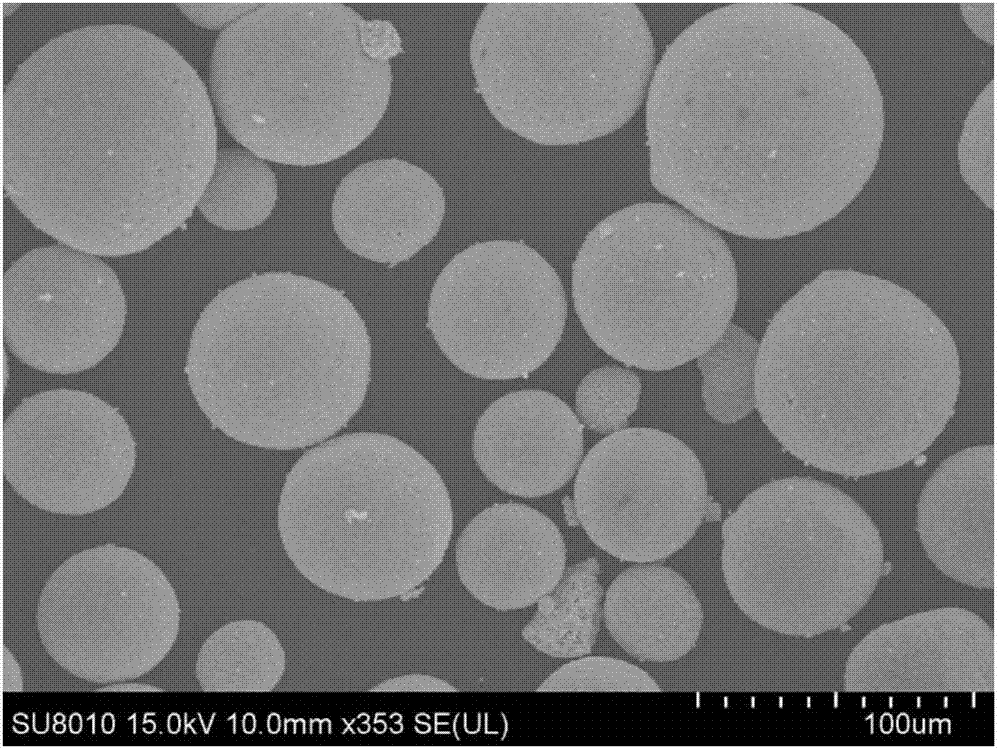

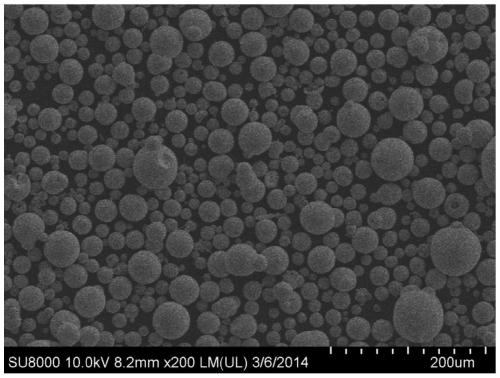

Yttrium-stabilized zirconium oxide hafnium powder for thermal spraying and preparation method thereof

PendingCN112851337AReduce hard agglomeratesIncrease service temperatureSpray GranulationPhysical chemistry

The invention discloses yttrium-stabilized zirconium oxide hafnium powder for thermal spraying and a preparation method of the yttrium-stabilized zirconium oxide hafnium powder. The preparation method comprises the following steps: firstly, preparing a yttrium-stabilized zirconium oxide hafnium precursor, then carrying out primary calcination, ball milling, sanding and spray granulation to prepare yttrium-stabilized zirconium oxide hafnium granulated powder, and finally, carrying out secondary calcination and screening to prepare the yttrium-stabilized zirconium oxide hafnium powder for thermal spraying. The yttrium-stabilized zirconium oxide hafnium powder is prepared by using ammonium bicarbonate as a precipitator, so that hard agglomeration during calcination is reduced; the yttrium-stabilized zirconium oxide hafnium powder is used as a thermal barrier coating material, and compared with traditional yttrium-stabilized zirconium oxide powder, the service temperature of the coating is increased; the content proportion of zirconium and hafnium in the yttrium-stabilized zirconium oxide hafnium powder for thermal spraying is controllable, and compared with yttrium-stabilized hafnium oxide powder, the raw material cost is reduced.

Owner:QUANNAN JINGXIN ENVIRONMENTAL PROTECTION MATERIALCO LTD +1

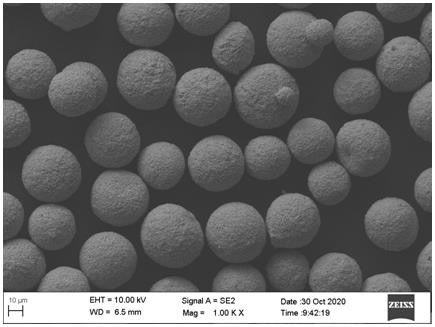

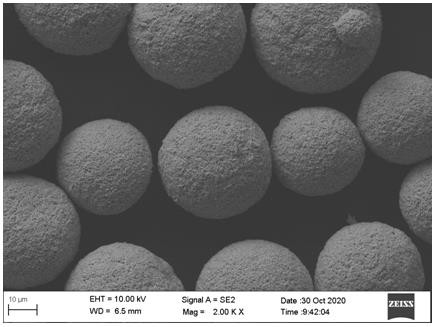

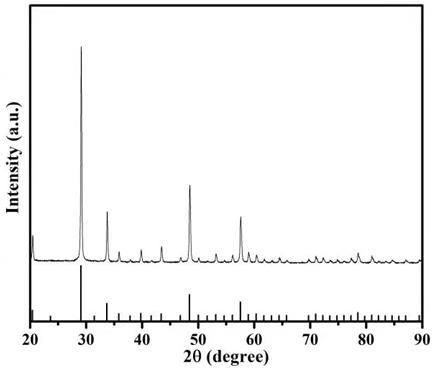

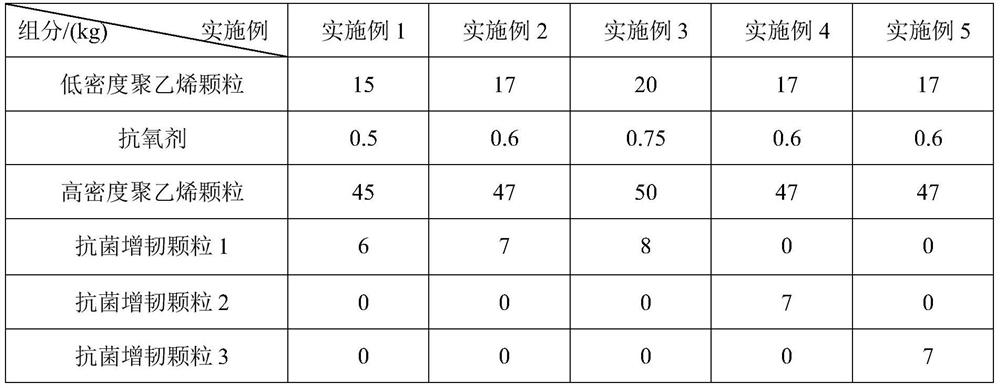

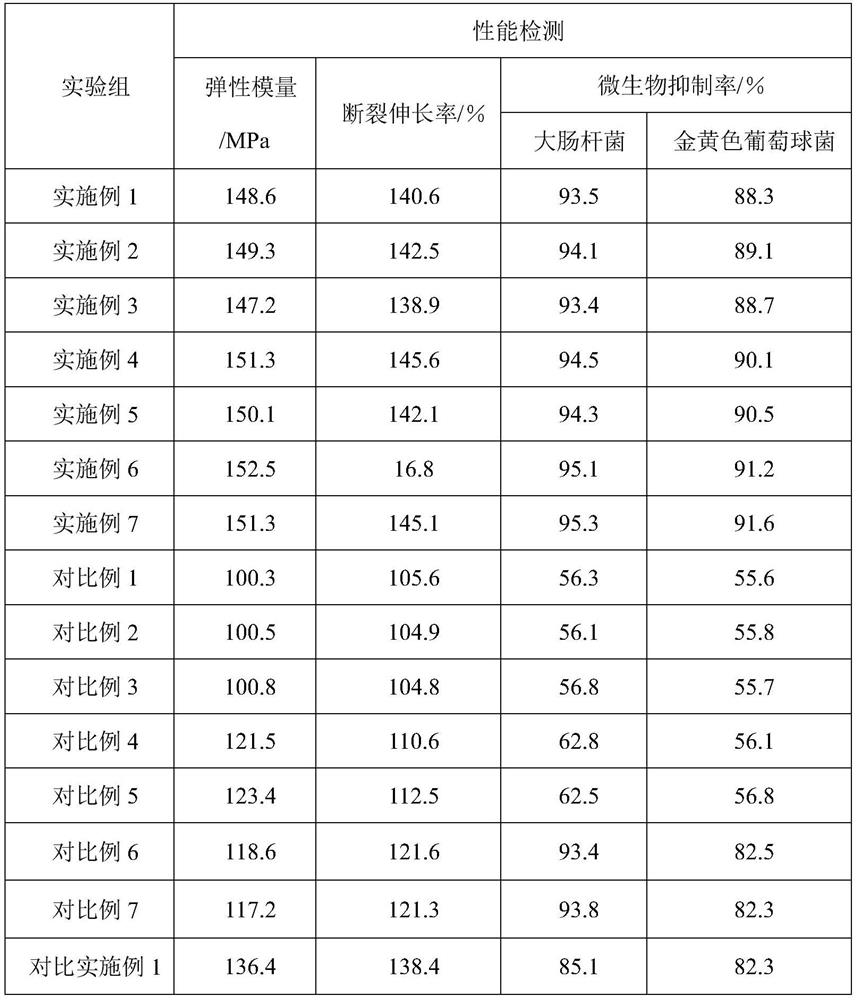

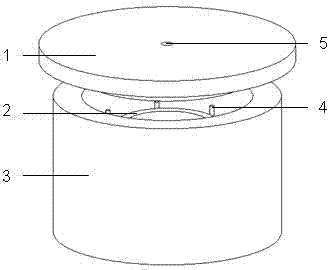

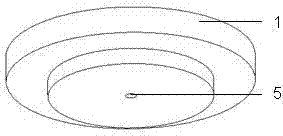

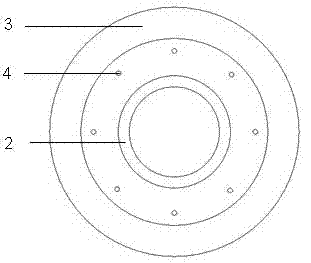

Antibacterial toughened polyethylene film and preparation method thereof

PendingCN113372642AImprove soft agglomerationEffective dispersionLow-density polyethylenePolymer science

The invention discloses an antibacterial toughening type polyethylene film and a preparation method thereof, the antibacterial toughening type polyethylene film comprises the following components in parts by weight: 45-50 parts of high density polyethylene particles, 15-20 parts of low density polyethylene particles, 0.5-0.75 part of an antioxidant, and 6-8 parts of antibacterial toughening particles; the antibacterial toughening particles are hydrotalcite particles prepared by metal oxide sol intercalation; and the preparation method comprises the following steps: stirring and mixing the low-density polyethylene particles, the antioxidant and the antibacterial toughening particles according to a formula, and collecting a mixed material; s2, extruding and granulating the mixed material, and collecting extruded particles; and S3, stirring and mixing the extruded particles and high-density polyethylene particles, extruding, blowing a film, and rolling to prepare the antibacterial toughened polyethylene film. The antibacterial toughening type polyethylene film can be used for fresh-keeping packaging and has excellent antibacterial performance and mechanical strength, and the mechanical strength of a polyethylene film fresh-keeping packaging material is improved.

Owner:北京冬曦既驾科技咨询有限公司

Mixed microwave sintering method of alpha-Al203 powder

InactiveCN102531014BFast sinteringSuitable for large-scale productionAluminium oxide/hydroxide preparationMicrowave cavityMaterials preparation

The invention belongs to the field of inorganic nonmetallic material preparation process technology, and discloses a mixed microwave sintering method of alpha-AL203 powder. The method comprises the following steps: putting precursor powder in an auxiliary heating insulation device, putting both the auxiliary heating insulation device and the precursor powder in a microwave cavity for sintering, firstly, turning on the microwave source, adjusting the microwave input power, and slowly heating up at an average speed of 6-30 DEG C / min; after dewatering, continuously adjusting the microwave input power, rapidly heating up at a speed of 20-100 DEG C / min, and meanwhile monitoring the reflection power; and after the reflection power is stable, maintaining the heating rate at 10-30 DEG C / min, heating up to a sintering temperature of 1000-1500 DEG C at a constant speed, keeping at the temperature for 2-20min, controlling the microwave input power, and rapidly cooling to room temperature at a constant speed of 6-30 DEG C / min to obtain alpha-AL203 powder product. The method of the invention combines traditional sintering and microwave sintering according to the wave adsorption property of oxides, so as to realize rapid sintering of alpha-AL203 powder. The method is low in cost, pollution-free, convenient and rapid, and is suitable for large-scale production of alpha-AL203 powder.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

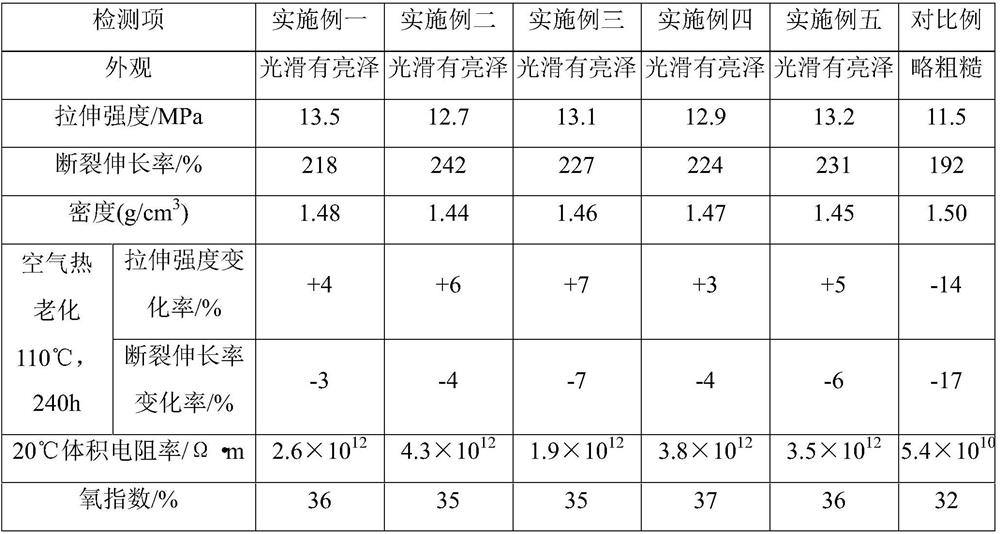

Smooth halogen-free low-smoke flame-retardant cable material and preparation method thereof

PendingCN112778616AGood dispersionImprove wear resistancePlastic/resin/waxes insulatorsNanotechnologyHalogenFire retardant

The invention discloses a smooth halogen-free low-smoke flame-retardant cable material and a preparation method thereof, and belongs to the technical field of cable materials. The preparation method comprises the following steps: preparing a high-dispersity flame retardant; jointly carrying out ultrasonic treatment on the prepared high-dispersity flame retardant and a slipping agent; mixing the high-dispersity flame retardant and the slipping agent which are subjected to ultrasonic treatment with other raw materials for banburying, extrusion and grain-sized dicing, and obtaining the slipping type halogen-free low-smoke flame-retardant cable material after cooling. According to the cable material, the high-dispersity flame retardant is prepared, and the high-dispersity flame retardant and the slipping agent are jointly subjected to ultrasonic treatment, so that the surface energy of the nano flame retardant powder is further weakened, the dispersing performance of the flame retardant and the slipping agent is improved, agglomeration of flame retardant particles is prevented, and the slipping performance and the surface glossiness of the cable material are further improved.

Owner:中广核拓普(四川)新材料有限公司

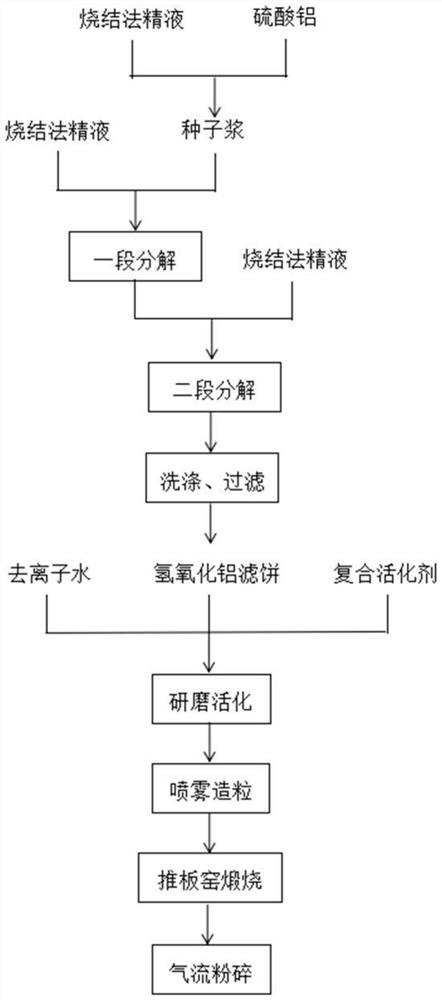

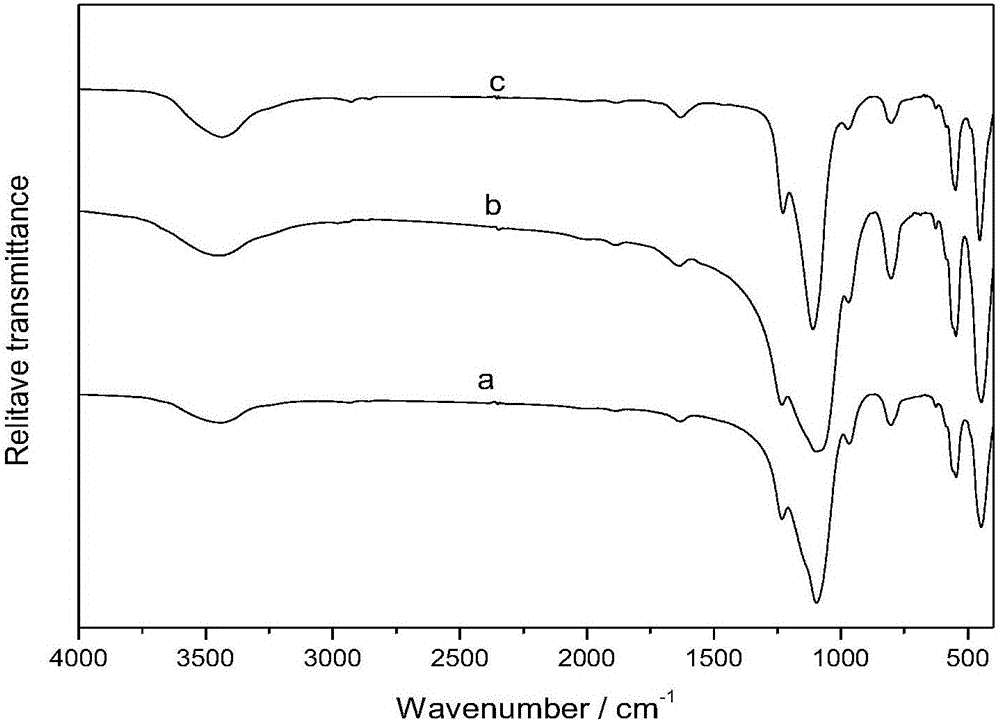

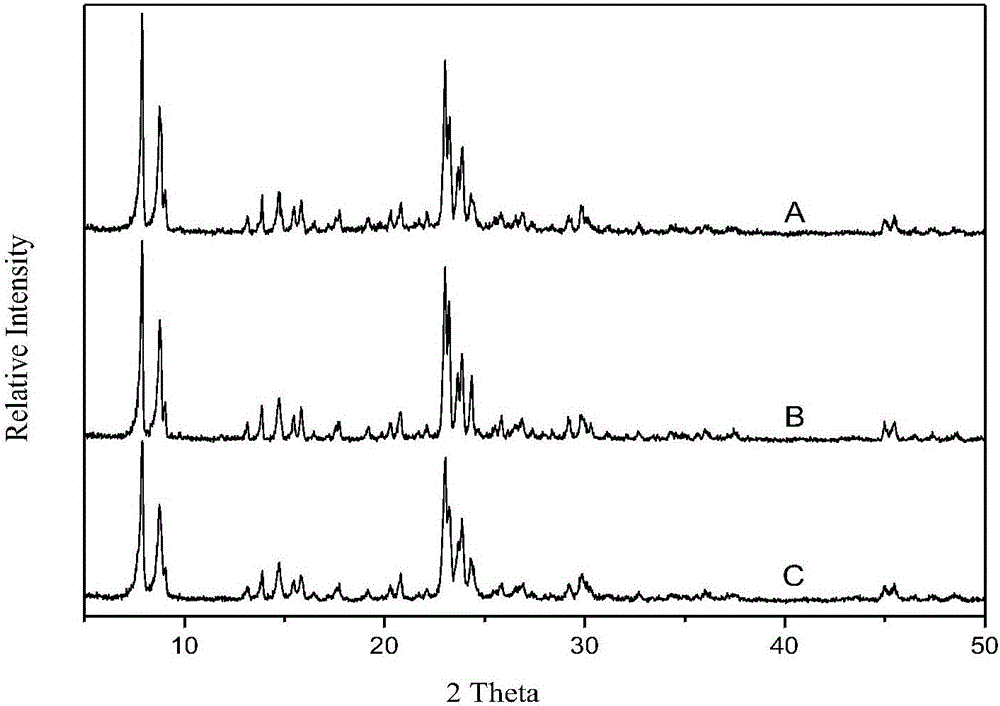

Preparation method of submicron small primary crystal alpha aluminum oxide for CMP (Chemical Mechanical Polishing) solution

PendingCN114655974ASmall granularityHigh purityAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationPolishing compositions with abrasivesAluminium hydroxideALUMINUM HYDROXIDE/MAGNESIUM HYDROXIDE

The invention discloses a preparation method of submicron small primary crystal alpha aluminum oxide for a CMP (chemical mechanical polishing) solution, which adopts a two-stage decomposition method to directly decompose aluminum hydroxide with the average particle size D50 of 0.5-1.2 mu m and the purity of more than 99.6%, the aluminum hydroxide is small in particle size and high in purity, and the difficulty of subsequent grinding and impurity removal is reduced; the preparation method comprises the following steps: adding a composite activator into prepared aluminum hydroxide slurry, grinding by a sand mill until the average particle size D50 is 0.3-1.0 [mu] m, activating, and carrying out spray granulation on the activated aluminum hydroxide slurry to obtain false agglomerated large particles with the average particle size D50 being 35-55 [mu] m, so that the aluminum hydroxide granulated powder and the activator can fully react in the calcining process; and hard agglomeration is reduced, so that the difficulty of airflow crushing of the alpha alumina powder after subsequent calcination is reduced. By adjusting a calcining process, the aluminum hydroxide powder after spray granulation is fed into a pushed slab kiln to be calcined at the temperature of 1100-1300 DEG C, so that the purity of the calcined aluminum oxide is greater than 99.9%, the alpha conversion rate is greater than 95%, the original grain size is 0.2-0.4 mu m, and the growth of the original crystal of the aluminum oxide can be effectively inhibited.

Owner:中铝中州铝业有限公司 +2

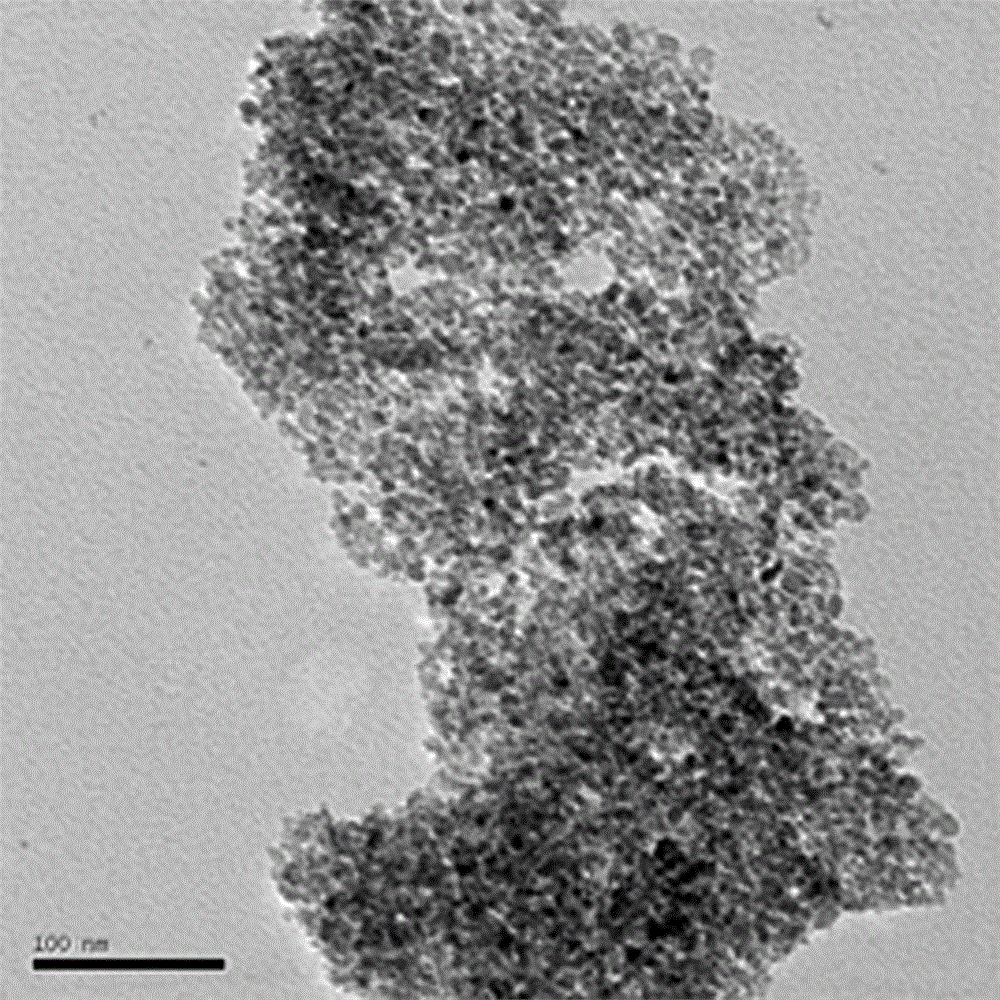

Method for preparing TS-1 titanium-silicon molecular sieve with nanoclusters

ActiveCN106115731AReduce the rate of hydrolysisIncrease contentCrystalline aluminosilicate zeolitesMolecular sieveFiltration

The invention relates to a method for preparing a TS-1 titanium-silicon molecular sieve with nanoclusters. The method includes the following steps that a template agent and a silicon source are mixed into A under 5-90 DEG C, an alkali source is recorded as B, and a titanium source is recorded as C; A, B and C are mixed in the ultrasonic environment and dropwise added into a beaker, and the pH value is kept to be 8-13; crystallization is carried out for 5-55 min in the normal-temperature and normal-pressure ultrasonic environment after titration is finished, and TS-1 nanoclusters are obtained through filtration; a template agent and an alkali source are mixed into D, and a silicon source and a titanium source are mixed into E; D is mixed with the dried nanoclusters under the anhydrous ultrasonic condition, E is added, mixed liquor F is obtained after titration is finished, F is transferred into a reaction kettle, 50-200 mL of water is added, the temperature is controlled to be 150-200 DEG C, washing, drying and roasting are carried out after crystallization is carried out for 12-120 h, and TS-1 is obtained. The method for preparing TS-1 is simple and good in repeatability and solves the problem of high production cost.

Owner:QINGDAO UNIV OF SCI & TECH

Preparation method of yttrium oxide spraying powder

The invention discloses a preparation method of yttrium oxide spraying powder. According to the invention,high-quality yttrium oxide powder is prepared by using a high-purity soluble yttrium raw material and a two-step process, wherein in the first step, an improved chemical coprecipitation method is used for preparing an yttrium oxide powder precursor, the precursor is subjected to heat treatment for thermal decomposition to obtain the yttrium oxide powder, and the process aims at controlling the particle size and size distribution of the powder, and in the second step, the obtained yttrium oxide powder is subjected to hydrothermal treatment through a hydrothermal method technology, the morphology of yttrium oxide powder particles is mainly improved, the yttrium oxide powder particles are spherical or approximately spherical, and the granularity agglomeration state of the powder is regulated and controlled by controlling key factors such as a mineralizer, a surface modifier, solid content and the like; and the prepared yttrium oxide powder is good in dispersity and relatively uniform in particle size distribution, and the yttrium oxide powder prepared by adopting the preparation method disclosed by the invention is less in hard agglomeration and good in flowability.

Owner:苏州科陶新材料有限公司

A kind of preparation method of highly dispersible ito powder

ActiveCN107098378BSimple structureGood dispersionGallium/indium/thallium compoundsTin oxidesIndiumFiltration

The invention discloses a preparation method of high-dispersibility ITO powder and belongs to the technical field of preparation of indium tin oxide composite powder. The method comprises the steps of adding metal In to a HNO3 solution for completely dissolving; weighing SnCl4.5H2O white crystal at the mass ratio of In2O3 to SnO2 being 9:1, adding the SnCl4.5H2O white crystal to an indium salt solution and stirring evenly to prepare a mixed salt solution; adding a composite dispersing agent to a NH4AC buffer solution; dropwise adding ammonia water and a mixed salt solution to the buffer solution at the same time, thereby generating a indium-tin hydroxide precursor; reacting completely, ageing and carrying out suction filtration, washing the obtained indium-tin hydroxide precursor with water and an organic solvent separately; standing the washed indium-tin hydroxide precursor at room temperature and naturally airing; and calcining at a high temperature for 4h to obtain yellow ITO powder. The ITO powder prepared by adopting the preparation method has few hard agglomerates, and is good in mobility and easy to shape by pressing.

Owner:ANHUI TUOJITAI NOVEL CERAMIC TECH

Preparation method of tin antimony oxide nanopowder

InactiveCN104261470BPromote generationEliminate hydrogen bondingMaterial nanotechnologyAntimony compoundsHigh concentrationSolvent

The invention discloses a preparation method of tin antimony oxide (ATO) nano powder. The preparation method comprises the following steps: by adopting antimony salt and tin salt as reaction raw materials, adopting ammonium hydrogen carbonate as a neutralization agent, adopting ammonium acetate as a cosolvent and adopting high-concentration ethanol as a reaction medium, performing solid-liquid heterophase coprecipitation reaction to generate Sn(OH)4 and NH4Cl mixed precipitates, performing filtration and vacuum drying, and then dissolving and dispersing a filter cake by using deionized water, then filtering, washing, dehydrating, drying, calcining and crushing to obtain the ATO nano powder. The preparation method disclosed by the invention is safe and environment-friendly, and is simple in process and low in cost; and an ATO nano powder product prepared by using the method disclosed by the invention is less in aggregate, uniform in doping, small in particle size and narrow in distribution range, and has excellent optical and electrical properties.

Owner:GUANGXI NATUO TECH CO LTD

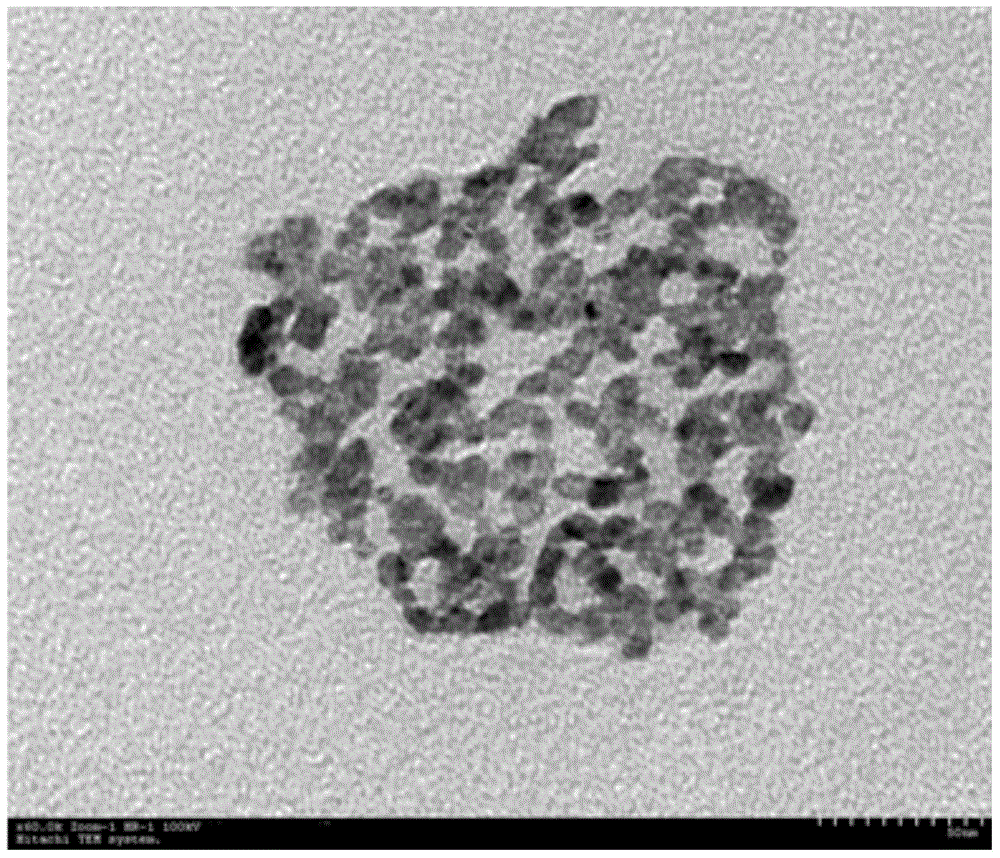

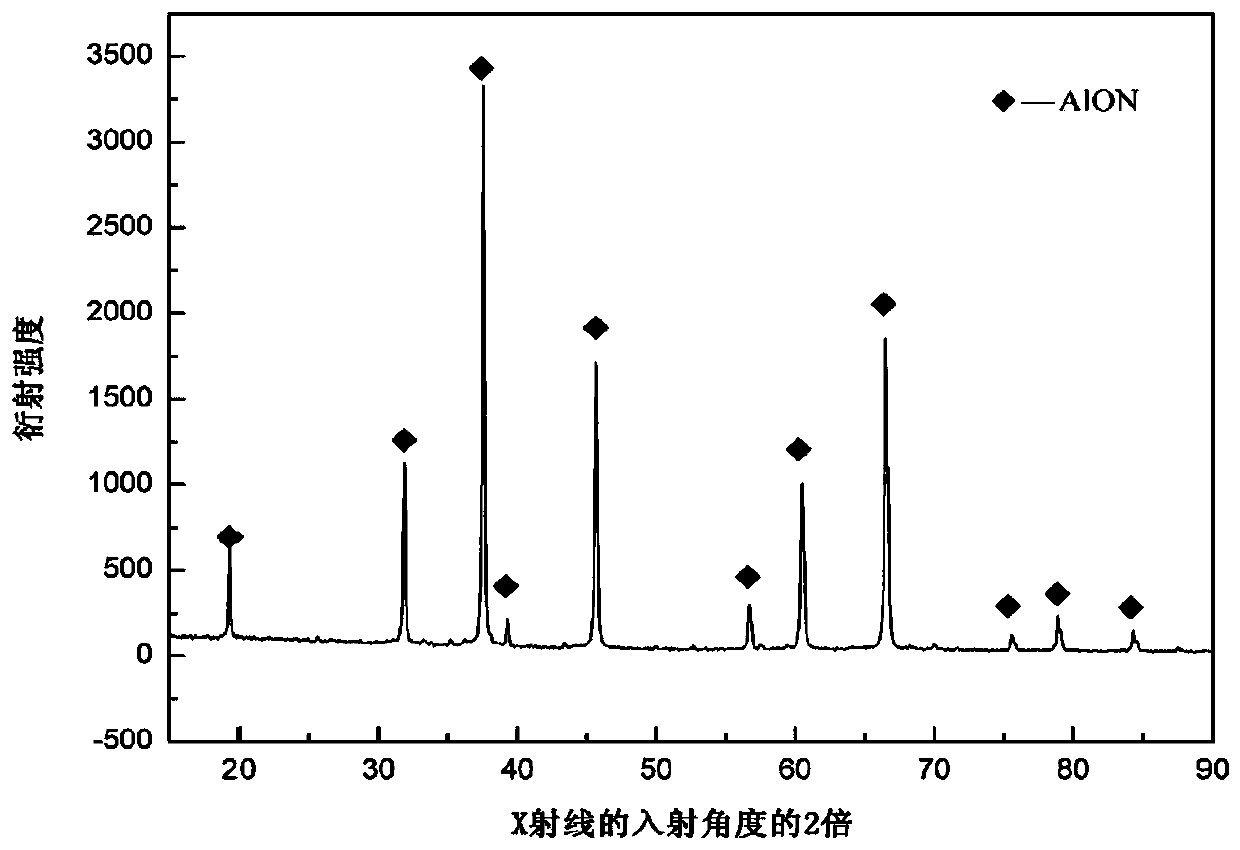

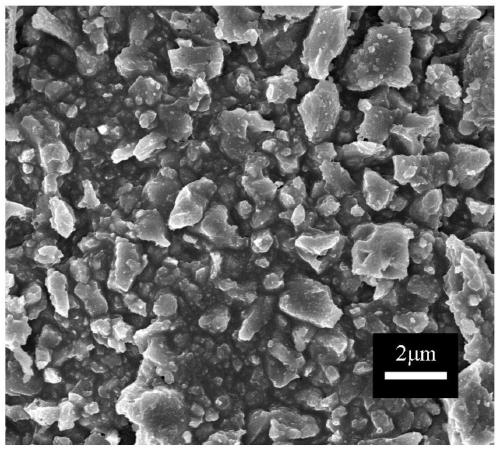

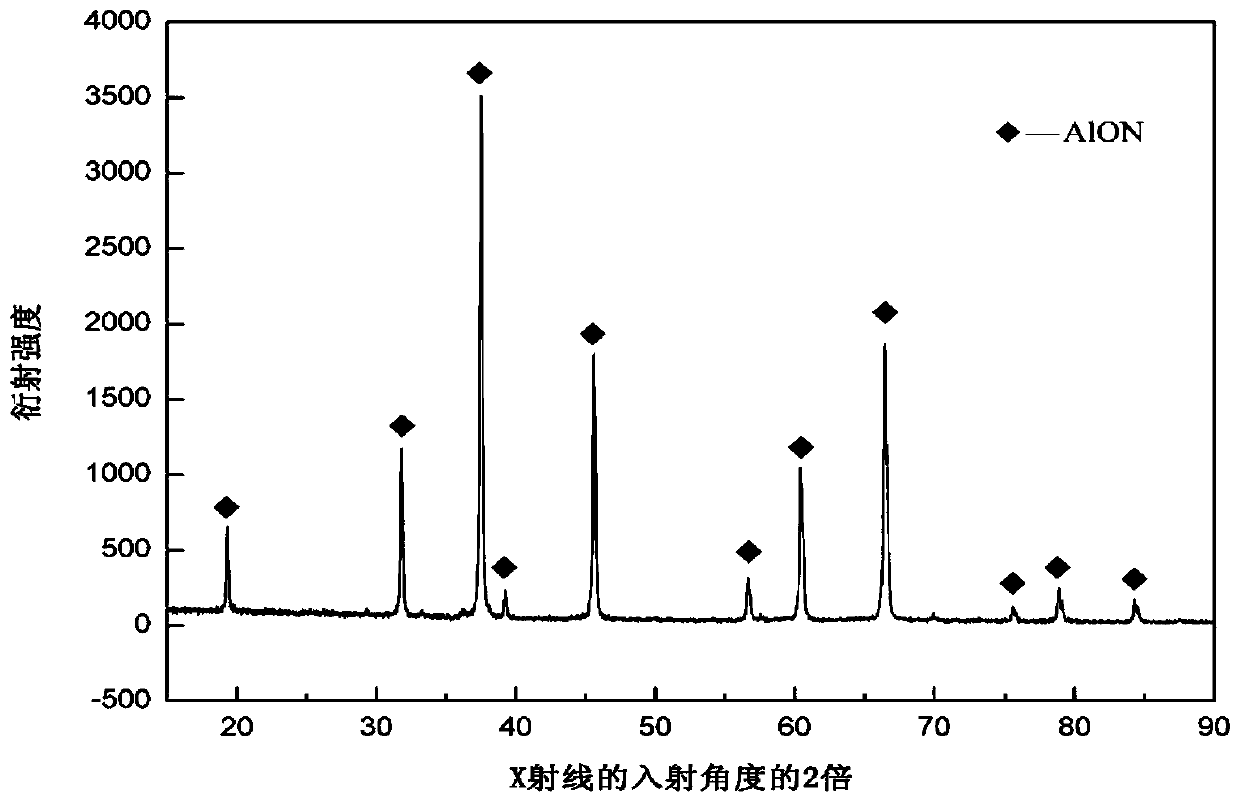

Aluminum oxynitride ceramic powder and preparation method thereof

The invention discloses aluminum oxynitride ceramic powder and a preparation method thereof. The aluminum oxynitride ceramic powder is Al5O6N. The preparation method comprises that an aluminum oxynitride precursor is prepared from organo-aluminium alcoholate and a saccharide compound as raw materials through a sol-gel method, the aluminum oxynitride precursor produces gamma-Al2O3 and carbon blackduring the heating process, a part of gamma-Al2O3 and carbon black undergo a carbothermal nitridation reduction reaction at 1350-1550 DEG C to produce AIN, and the AIN and the rest of gamma-Al2O3 undergo a high temperature solid-phase reaction at 1750-1850 DEG C to produce Al5O6N. The preparation method comprises (1) preparing an aluminum source and a carbon source, (2) preparing an AlON ceramic precursor and (3) carrying out stepwise heat treatment. The aluminum oxynitride ceramic powder has the characteristics of high purity and small and uniform particle sizes. Compared with the conventional solid phase synthesis method, the preparation method has the advantages of low synthesis temperature, simple preparation processes and low preparation cost.

Owner:NAT UNIV OF DEFENSE TECH

Silicon carbide chemical mechanical polishing liquid with improved pH stability and its application

ActiveCN109554119BEvenly dispersedGuaranteed stabilitySemiconductor/solid-state device manufacturingPolishing compositions with abrasivesCarbide siliconOxidizing agent

The invention provides a silicon carbide chemical mechanical polishing liquid with improved pH value stability, wherein the polishing liquid comprises an oxidizing agent, a high-hardness abrasive material and a pH value stabilizer, and the pH value stabilizer is aluminum nitrate. According to the present invention, the polishing liquid can well maintain the pH value stability during the chemical mechanical polishing, and has advantages of good dispersion stability and uniform dispersion; by adding the pH value stabilizer aluminum nitrate to the polishing liquid, the pH value stability of the polishing liquid during the chemical mechanical polishing is strong, and the polishing liquid is not easily subjected to hard agglomeration; and the polishing liquid is environmentally friendly, and can be used in a circulating material supply manner.

Owner:SICC CO LTD

A preparation method of high-purity, highly sintering active indium tin oxide mixed powder

ActiveCN107140949BReduce severe reunionPrevent coagulationMaterial nanotechnologyVacuum evaporation coatingIndiumPhysical chemistry

The invention discloses a high-sintering active indium tin oxide mixed powder preparation method. The method particularly comprises the steps that high-activity nano SnO2 powder is prepared, wherein a compound dispersing agent is dissolved into water, an appropriate amount of SnCl4 is added, stirring is conducted till the mixture is completely transparent, and clarification is conducted; stirring is kept, an appropriate amount of ammonium hydroxide is added, a tin-containing precursor is obtained, after the precursor is placed in a high pressure reaction kettle to be subjected to hydrothermal treatment, sediment is taken out to be washed repeatedly, dried and subjected to low temperature thermal treatment, and nano SnO2 powder is obtained; metal indium is dissolved into hydrochloric acid, a InCl3 aqueous solution is generated, and a method similar to the method for synthesizing SnO2 powder is used for preparing nano In2O3 powder; the prepared InCl3 is mixed with SnO2 in proportion, PVA is added, by means of a spray drying technology, mixed indium tin oxide granulation powder which is less in aggregation, good in liquidity and prone to pressure molding is obtained, and the preparation method can be suitable for preparing high-end ITO target materials.

Owner:ANHUI TUOJITAI NOVEL CERAMIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com