Method for preparing nano-catalyst copper chromite and copper ferrite

A nano-catalyst, copper salt technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of uneven powder particles, high catalytic activity, hard Less agglomeration and other problems, to achieve the effect of long service life, high catalytic activity, and less hard agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] (1) Preparation of sol:

[0034] a. Prepare a mixed solution of soluble copper salt and soluble chromium salt with a molar ratio of 1:2, wherein the concentration of copper salt is 0.1-0.5mol / L; add a surfactant with a mass percentage of 0.1%-5%, and stir evenly; Wherein soluble copper salt and soluble chromium salt adopt nitrate, sulfate or hydrochloride. The surfactant adopts polyethylene glycol, sodium tripolyphosphate, sodium hexametaphosphate or cetyltrimethylammonium bromide;

[0035] b. Add the precipitant aqueous solution to the mixed solution at a rate of 20-180ml / h until the pH of the system is 6.8-9.5, leave it for aging, centrifuge or filter and wash to obtain a precipitate; the precipitant used is ammonia water, ammonium carbonate, ammonium bicarbonate, sodium carbonate, sodium bicarbonate, or sodium hydroxide;

[0036] c. Add deionized water with a mass percentage of 8% to 40% to the obtained precipitate, and melt the gel in a constant temperature water ...

Embodiment 1

[0055] Prepare a mixed solution with a copper salt concentration of 0.1 mol / L according to the molar ratio of copper nitrate and chromium nitrate as 1:2, add 0.1% polyethylene glycol surfactant by mass percentage, and stir evenly. Ammonium bicarbonate aqueous solution was added to the mixed solution at a rate of 20ml / h until the pH of the system was 6.8, left to age for 8 hours, and washed by centrifugation. The obtained precipitate was added with 8% deionized water by mass, stirred evenly, and melted in a constant temperature water bath at 70° C. for 2 hours to obtain a sol. The sol is freeze-dried at -45° C. and a vacuum degree of 1 Pa by a vacuum freeze-drying method to obtain a precursor xerogel. Finally, the precursor xerogel was placed in a tube furnace, heated from room temperature to 350 °C at a rate of 3 °C / min, and kept for 1 h to obtain CuCr 2 o 4 Nano catalyst powder.

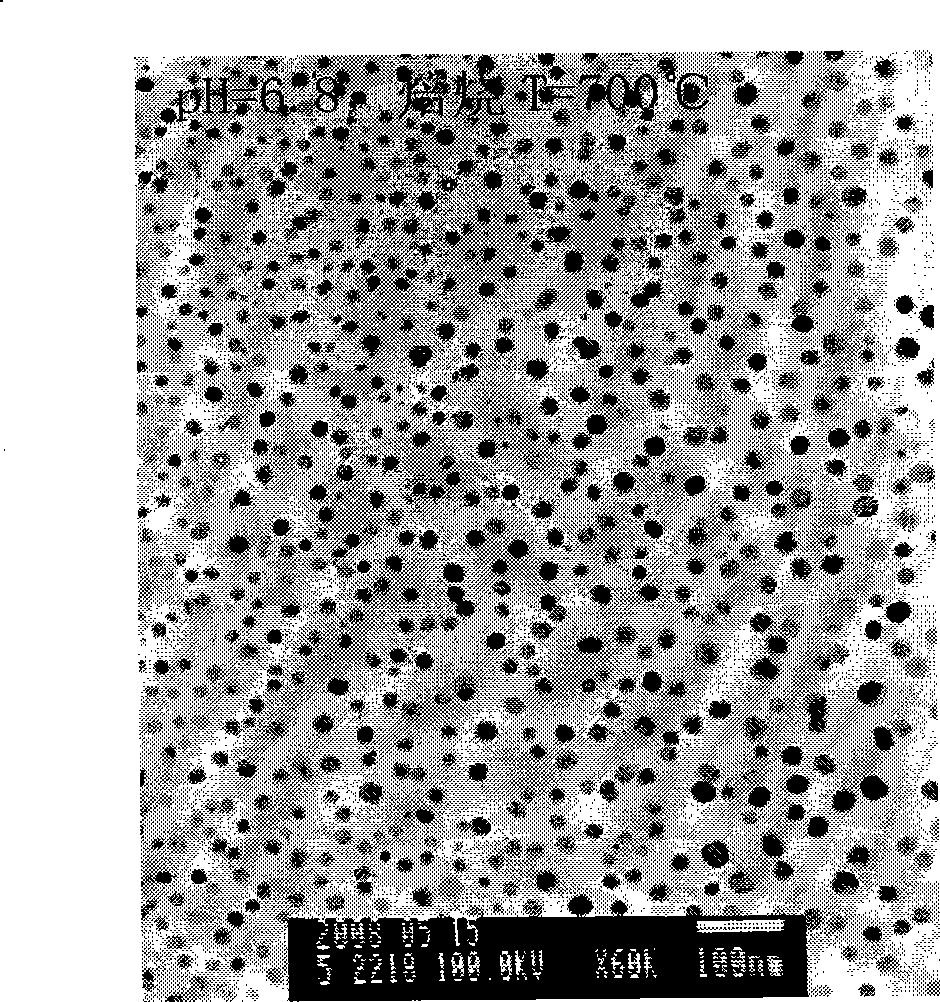

[0056] Depend on figure 1 From the TEM picture, we can see that the particle size of the cat...

Embodiment 2

[0058] Prepare a mixed solution with a copper salt concentration of 0.5 mol / L according to the molar ratio of copper sulfate to chromium sulfate of 1:2, add 0.1% by mass of sodium tripolyphosphate surfactant, and stir evenly. Add ammonia solution to the mixed solution at a rate of 180ml / h until the pH of the system is 9.5, let it stand for aging for 24 hours, and filter and wash. The obtained precipitate was added with 40% deionized water and stirred evenly, and the gel was melted in a constant temperature water bath at 95° C. for 8 hours to obtain a sol. The sol is freeze-dried at -80° C. under a vacuum degree of 30 Pa by a vacuum freeze-drying method to obtain a precursor xerogel. Finally, place the precursor xerogel in a muffle furnace, heat it from room temperature to 850°C at a rate of 15°C / min, and keep it for 8 hours to obtain CuCr 2 o 4 Nano catalyst powder.

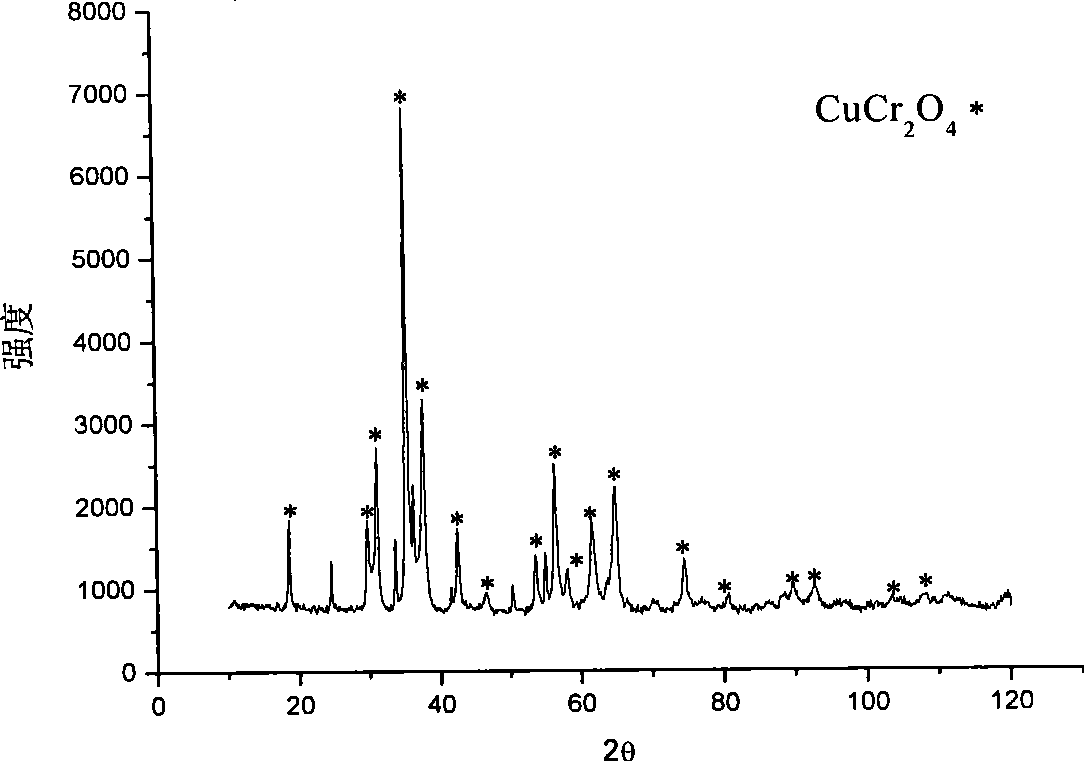

[0059] Depend on figure 2 From the XRD pattern, we can see that the peak shape of the catalyst prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

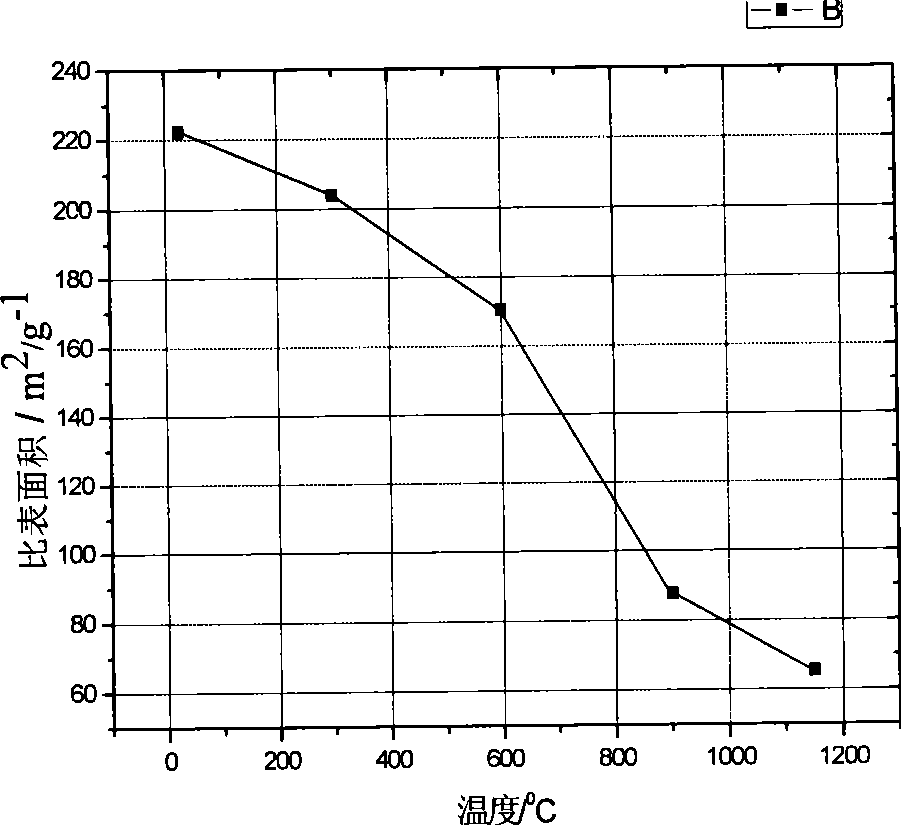

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com