Preparation method of indium tin oxide composite powder

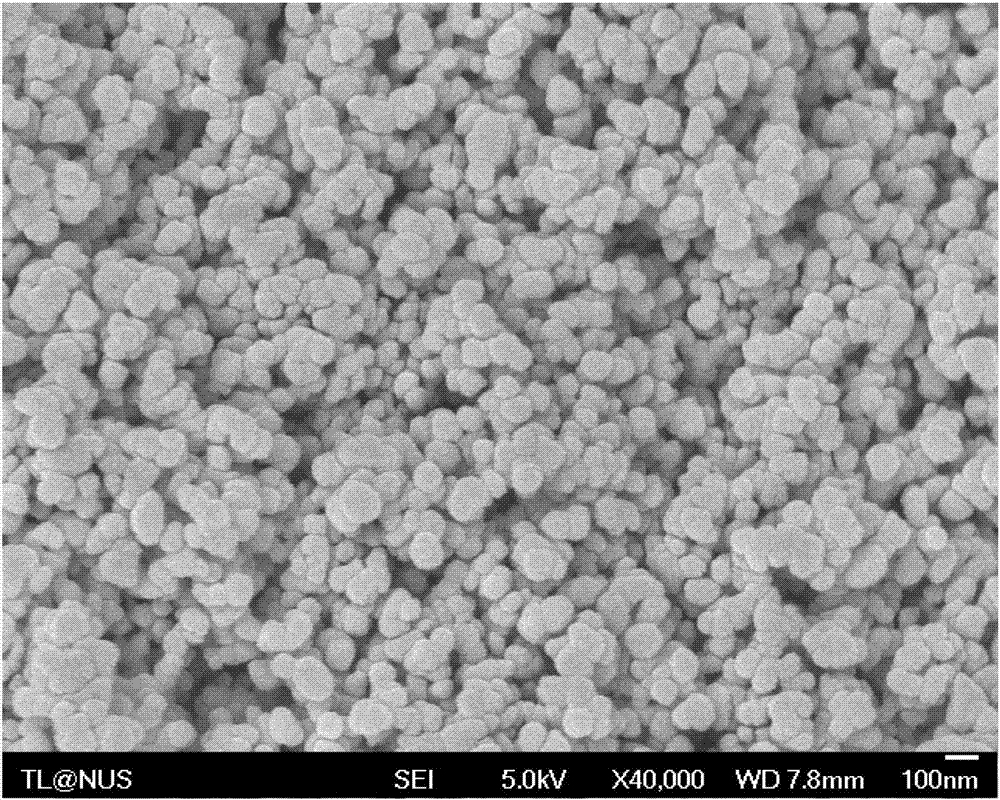

A technology of composite powder and indium tin oxide, which is applied in tin oxide, chemical instruments and methods, gallium/indium/thallium compounds, etc., can solve the problem of unsatisfactory dispersion of indium tin oxide composite powder, low sintering activity, and hard agglomeration More problems, to achieve the effect of less hard agglomeration, good fluidity, and reduce agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment provides a preparation method of indium tin oxide composite powder, comprising the following steps:

[0024] (1) Preparation of mixed salt solution and precipitation system: according to the weight ratio of In 2 o 3 : SnO 2 =9:1, measure the InCl whose mass concentration is 220g / L 3 Solution and SnCl with a mass concentration of 230g / L 4 The solution is placed in a reaction kettle, and then an excess of 20% urea is added, stirred and mixed evenly;

[0025] (2) Adding a dispersant: adding polyvinylpyrrolidone, β-alanine and polyethylene glycol at a weight ratio of 2:1:3; the amount of the dispersant is InCl 3 and SnCl 4 3.5% of the total amount;

[0026] (3) Co-precipitation reaction: Gradually raise the temperature to 70°C, and keep the constant temperature until In 3+ Until complete precipitation; Ultrasonic treatment for 1 hour, the frequency range of the ultrasonic wave is 50MHz, continue to stir and age for 12 hours to obtain metal precipitate...

Embodiment 2

[0032] This embodiment provides a preparation method of indium tin oxide composite powder, comprising the following steps:

[0033] (1) Preparation of mixed salt solution and precipitation system: according to the weight ratio of In 2 o 3 : SnO 2 =9:1, measure the InCl whose mass concentration is 200g / L 3 Solution and SnCl with a mass concentration of 250g / L 4 The solution is placed in a reaction kettle, and then an excess of 25% urea is added, stirred and mixed evenly;

[0034] (2) Adding a dispersant: adding polyvinylpyrrolidone, β-alanine and polyethylene glycol at a weight ratio of 2:1:3; the amount of the dispersant is InCl 3 and SnCl 4 4% of the total amount;

[0035] (3) Co-precipitation reaction: Gradually raise the temperature to 60°C, and keep the constant temperature until In 3+ Until complete precipitation, ultrasonic treatment for 1 hour, the frequency range of ultrasonic wave is 60MHz; continue to stir and age for 10 hours to obtain metal precipitates;

...

Embodiment 3

[0041] This embodiment provides a preparation method of indium tin oxide composite powder, comprising the following steps:

[0042] (1) Preparation of mixed salt solution and precipitation system: according to the weight ratio of In 2 o 3 : SnO 2 =9:1, measure the InCl whose mass concentration is 250g / L 3 Solution and SnCl with a mass concentration of 200g / L 4 The solution is placed in a reaction kettle, and then an excess of 28% urea is added, stirred and mixed evenly;

[0043] (2) Adding dispersant: adding polyvinylpyrrolidone, β-alanine and polyethylene glycol with a weight ratio of 2:1:3, the addition of the dispersant is InCl3 and SnCl 4 2% of the total amount;

[0044](3) Co-precipitation reaction: Gradually raise the temperature to 90°C, and keep the constant temperature until In 3+ Until complete precipitation, ultrasonic treatment for 1 hour, the frequency range of ultrasonic wave is 60MHz; continue to stir and age for 20 hours to obtain metal hydroxide;

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com