Preparation method of yttrium oxide spraying powder

A technology of yttrium oxide and powder, which is applied in the field of rare earth oxide powder preparation to achieve good dispersion, less hard agglomeration, and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The present invention is specifically described below in conjunction with the accompanying drawings, a preparation method of yttrium oxide spray powder, which adopts a two-step process to prepare high-quality yttrium oxide powder, comprising the following steps:

[0023] Step 1: Prepare the yttrium oxide powder precursor by using an improved chemical co-precipitation method, and perform thermal decomposition on the precursor to obtain the yttrium oxide powder; the preparation method of the yttrium oxide powder precursor adopts method 1 or method 2 .

[0024] Described method one concrete step is: high-purity Y 2 o 3 Dissolve powder in concentrated nitric acid to obtain yttrium nitrate solution, adjust its concentration to 0.01-1.0M with deionized water, use ammonia water and ammonium oxalate in the form of solution as precipitant and mix uniformly with yttrium nitrate solution for precipitation reaction, and the products are respectively hydroxide Yttrium and yttrium ...

Embodiment 1

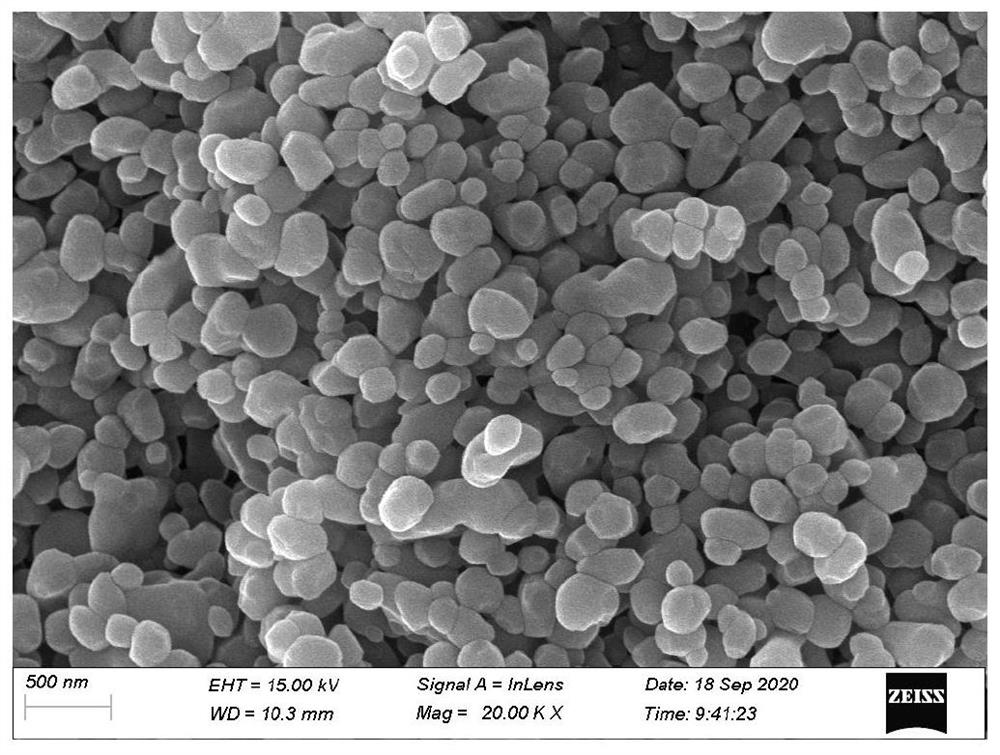

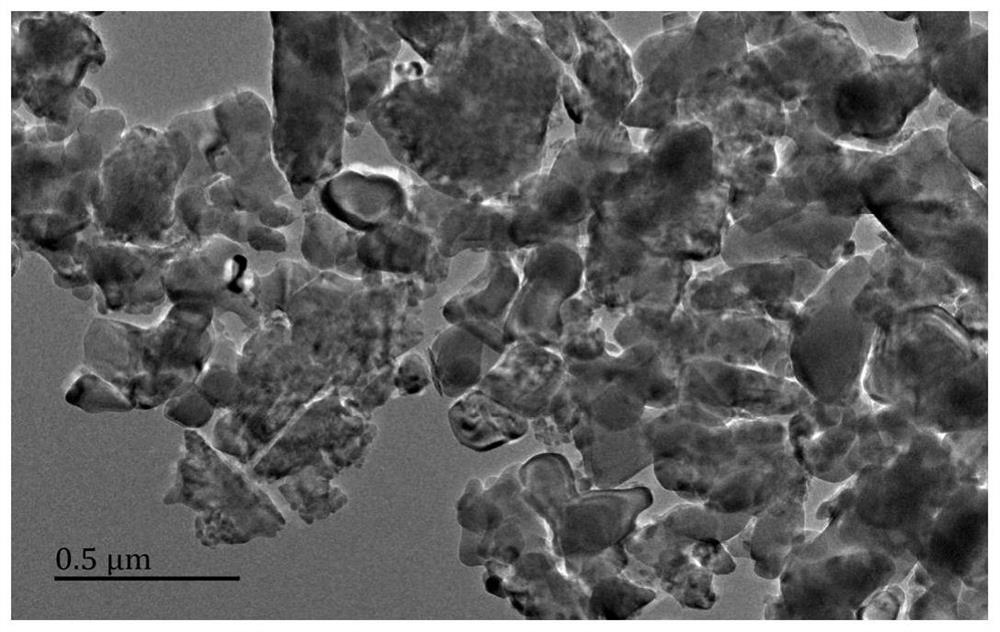

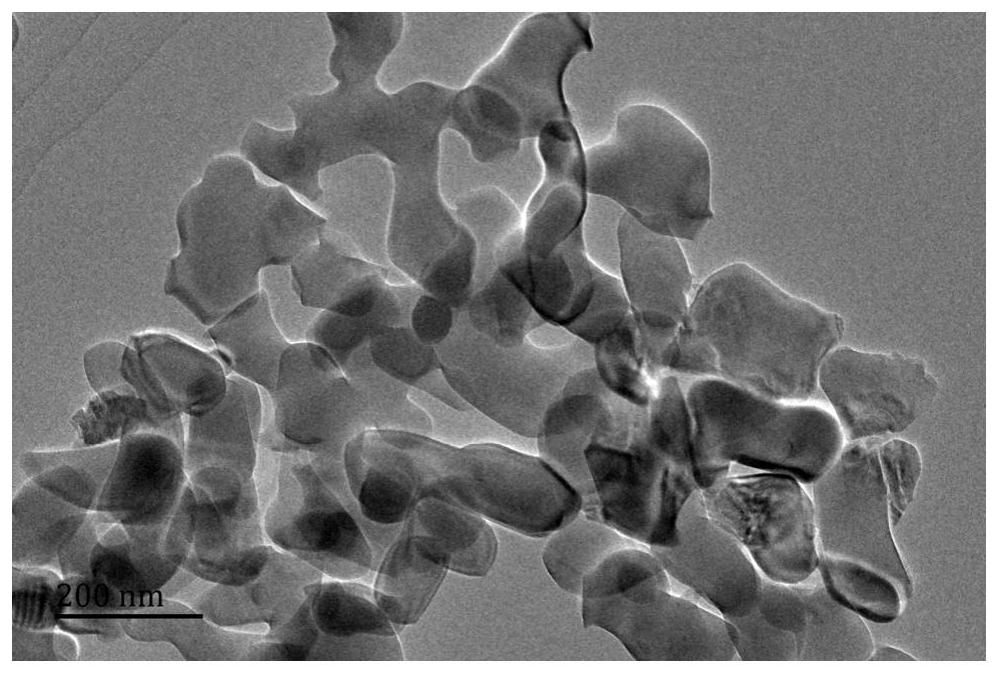

[0032] high purity Y 2 o 3 The powder is dissolved in concentrated nitric acid to obtain yttrium nitrate solution. During the dissolution process, continuous heating is required to accelerate its dissolution rate; after the dissolution is completed, the concentration is adjusted to 0.05M with deionized water. Aqueous ammonia solution is used as precipitating agent and yttrium nitrate solution is uniformly mixed for precipitation reaction, and the product is yttrium hydroxide. The obtained precipitate was filtered and cleaned, dried and pulverized into powder, and then heat-treated at a temperature of 800° C. for 12 hours and a heating rate of 0.5° C. / min. Gained yttrium oxide powder was dispersed into deionized water, and sodium hydroxide solution was added simultaneously and the concentration was adjusted at 5×10 -3 M; Wherein sodium hydroxide plays the role of mineralizer and surface modifier. Then carry out hydrothermal treatment, the temperature is 180 ℃, the time is 12...

Embodiment 2

[0034] High purity Y 2 o 3 The powder is dissolved in concentrated nitric acid to obtain a solution of yttrium nitrate. During the dissolution process, continuous heating is required to accelerate its dissolution rate; after the dissolution is completed, its concentration is adjusted to 0.1M with deionized water. Ammonium oxalate was dissolved in deionized water to make a solution, and the concentration of the solution was controlled at 0.5M. The prepared ammonium oxalate solution is used as a precipitating agent and uniformly mixed with the yttrium nitrate solution for precipitation reaction, and the product is yttrium oxalate. The obtained precipitate was filtered and cleaned, dried and pulverized into powder, and then heat-treated at a temperature of 800° C. for 12 hours and a heating rate of 1° C. / min. Gained yttrium oxide powder was dispersed into deionized water, while sodium hydroxide solution was added and the concentration was adjusted at 2×10 -2 M; Wherein sodium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com