Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Less gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

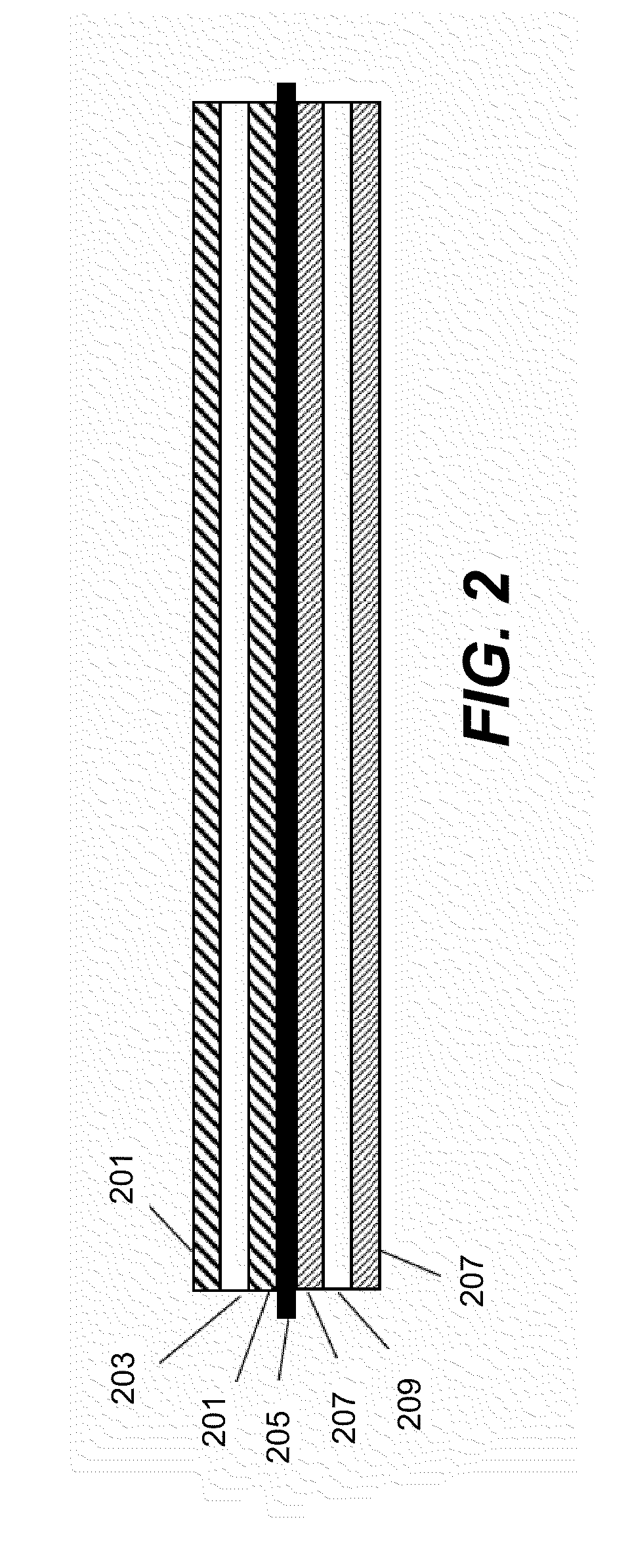

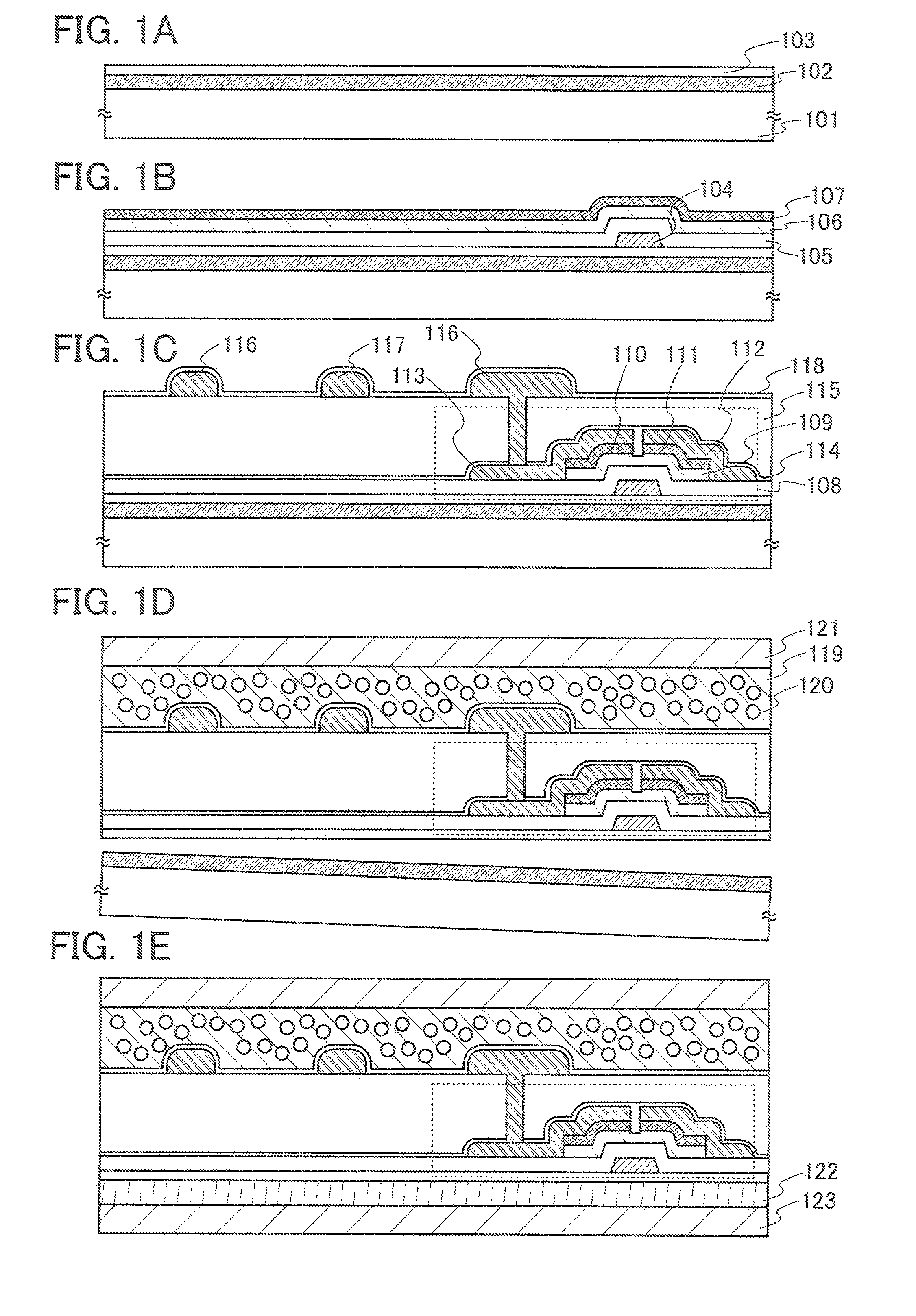

Method for manufacturing semiconductor device

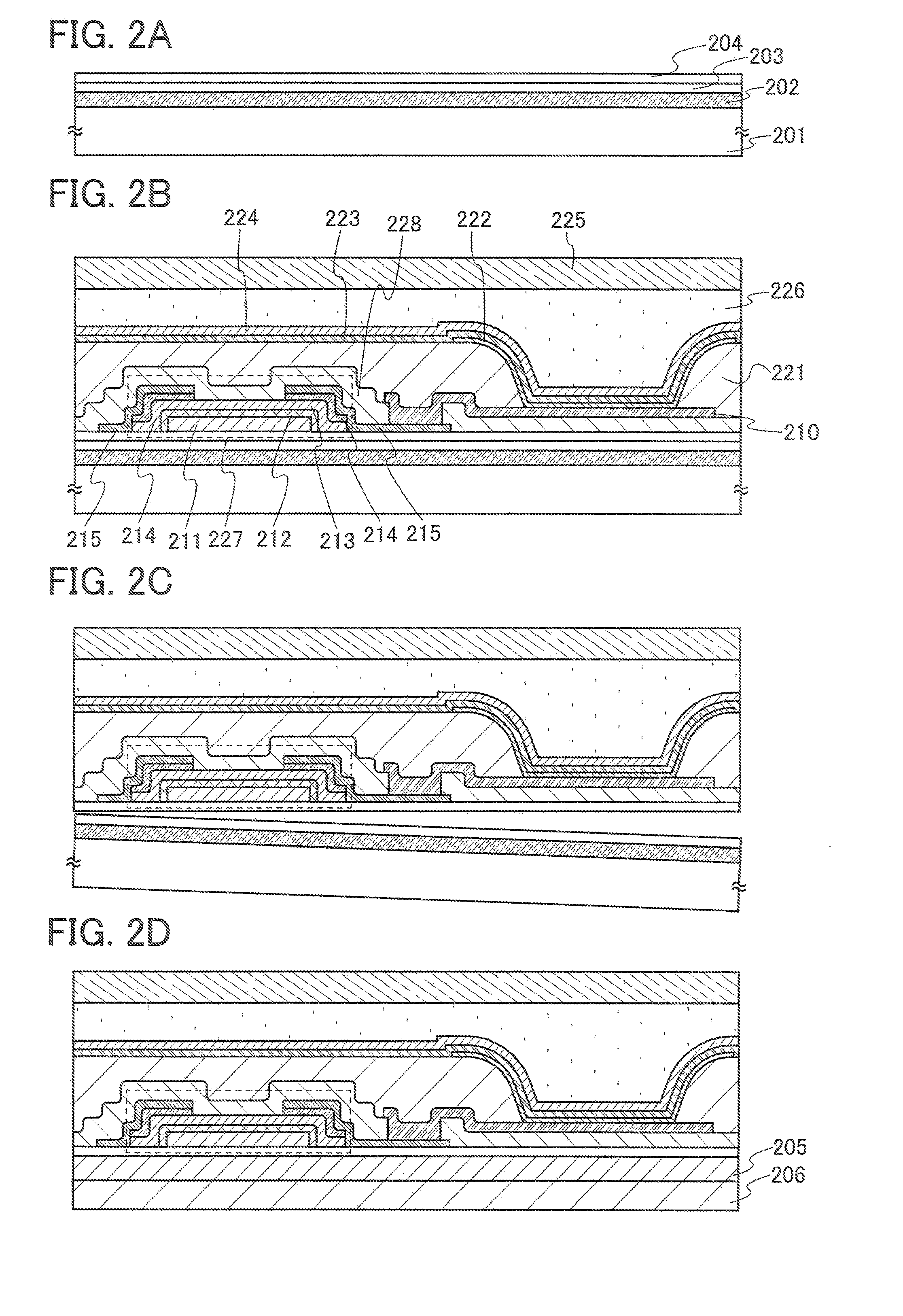

ActiveUS20070254456A1Process stabilityPoor heat resistanceFinal product manufactureSemiconductor/solid-state device detailsEngineeringPlastic film

A technique for peeling an element manufactured through a process at relatively low temperature (lower than 500° C.) from a substrate and transferring the element to a flexible substrate (typically, a plastic film). With the use of an existing manufacturing device for a large glass substrate, a molybdenum film (Mo film) is formed over a glass substrate, an oxide film is formed over the molybdenum film, and an element is formed over the oxide film through a process at relatively low temperature (lower than 500° C.). Then, the element is peeled from the glass substrate and transferred to a flexible substrate.

Owner:SEMICON ENERGY LAB CO LTD

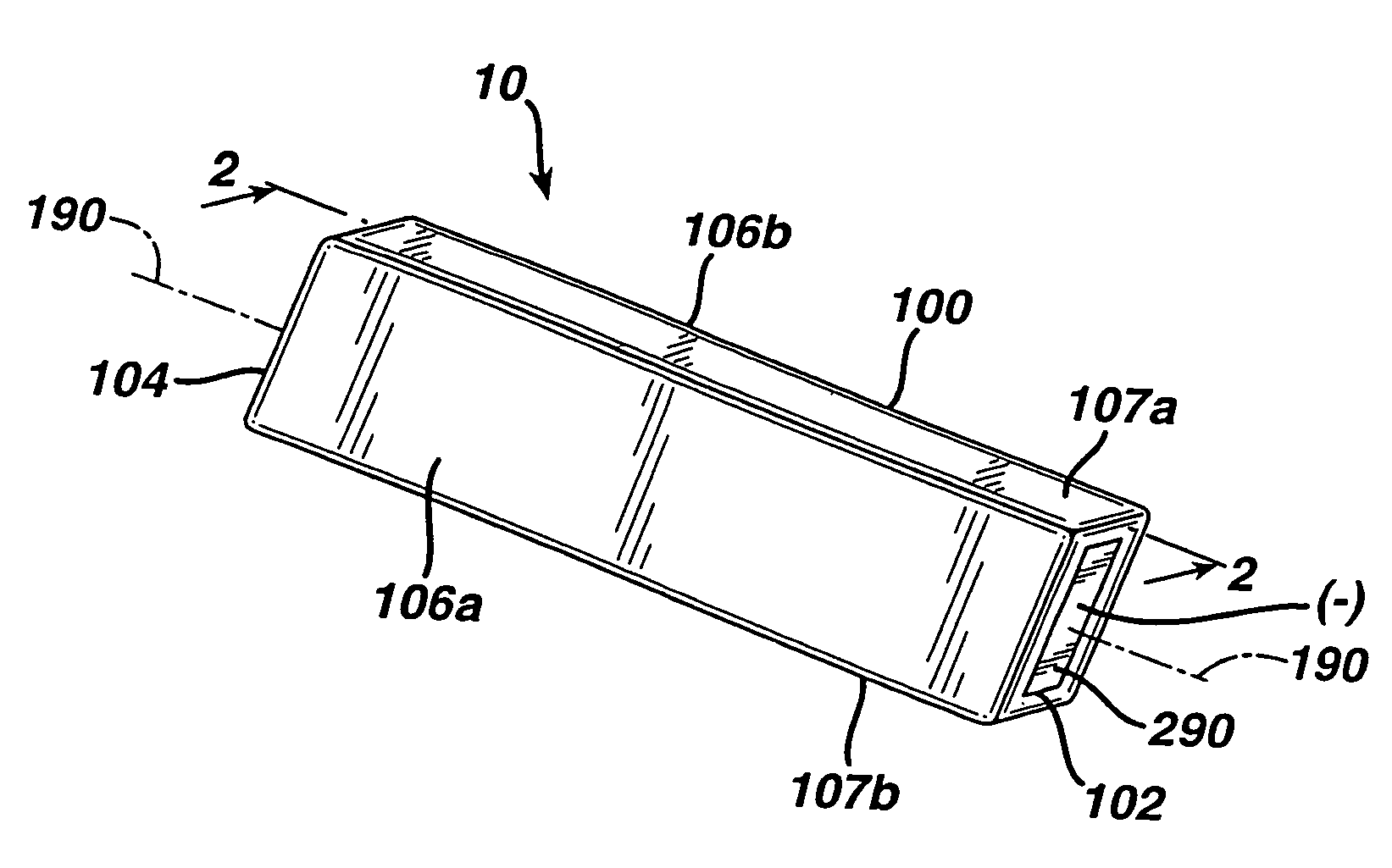

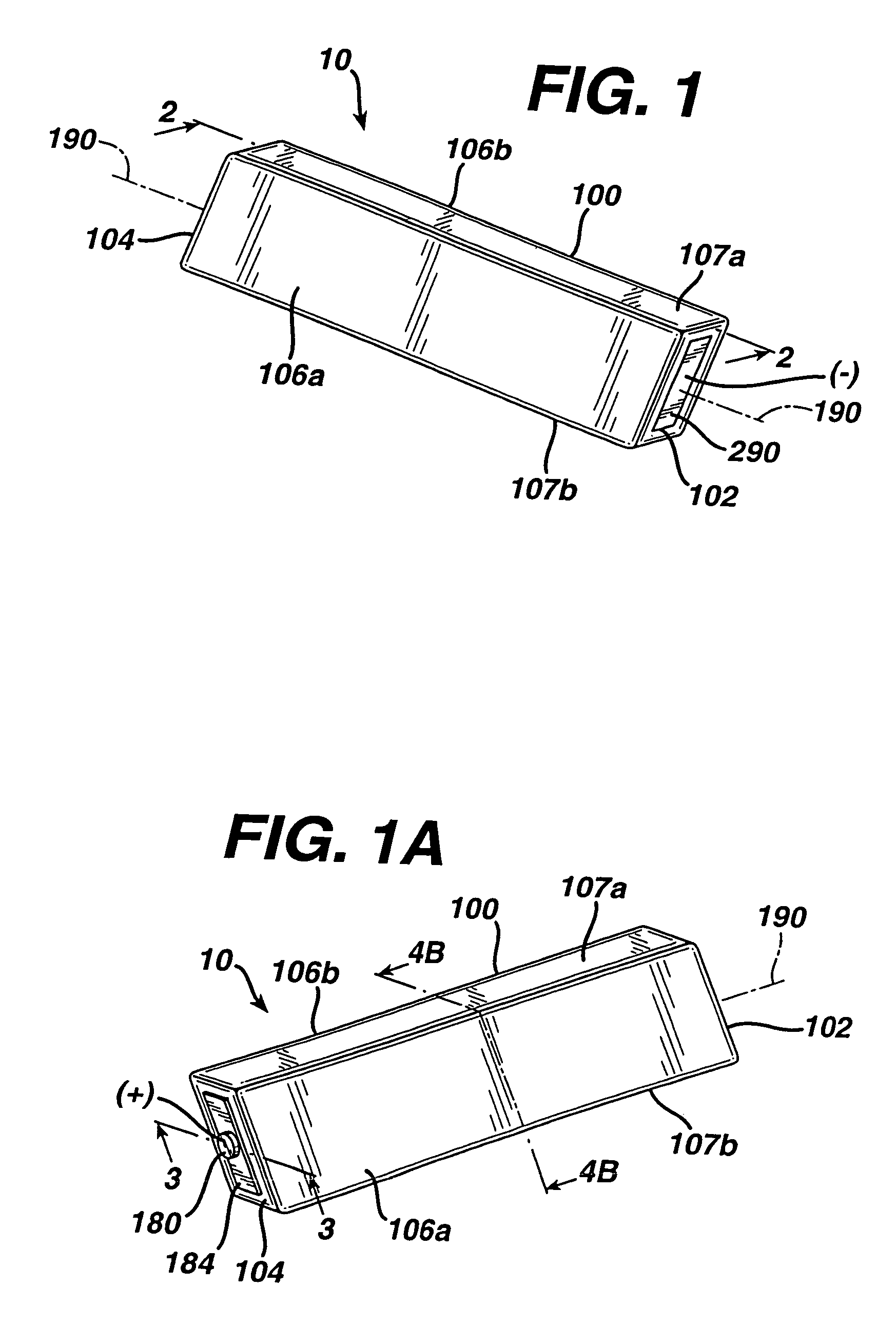

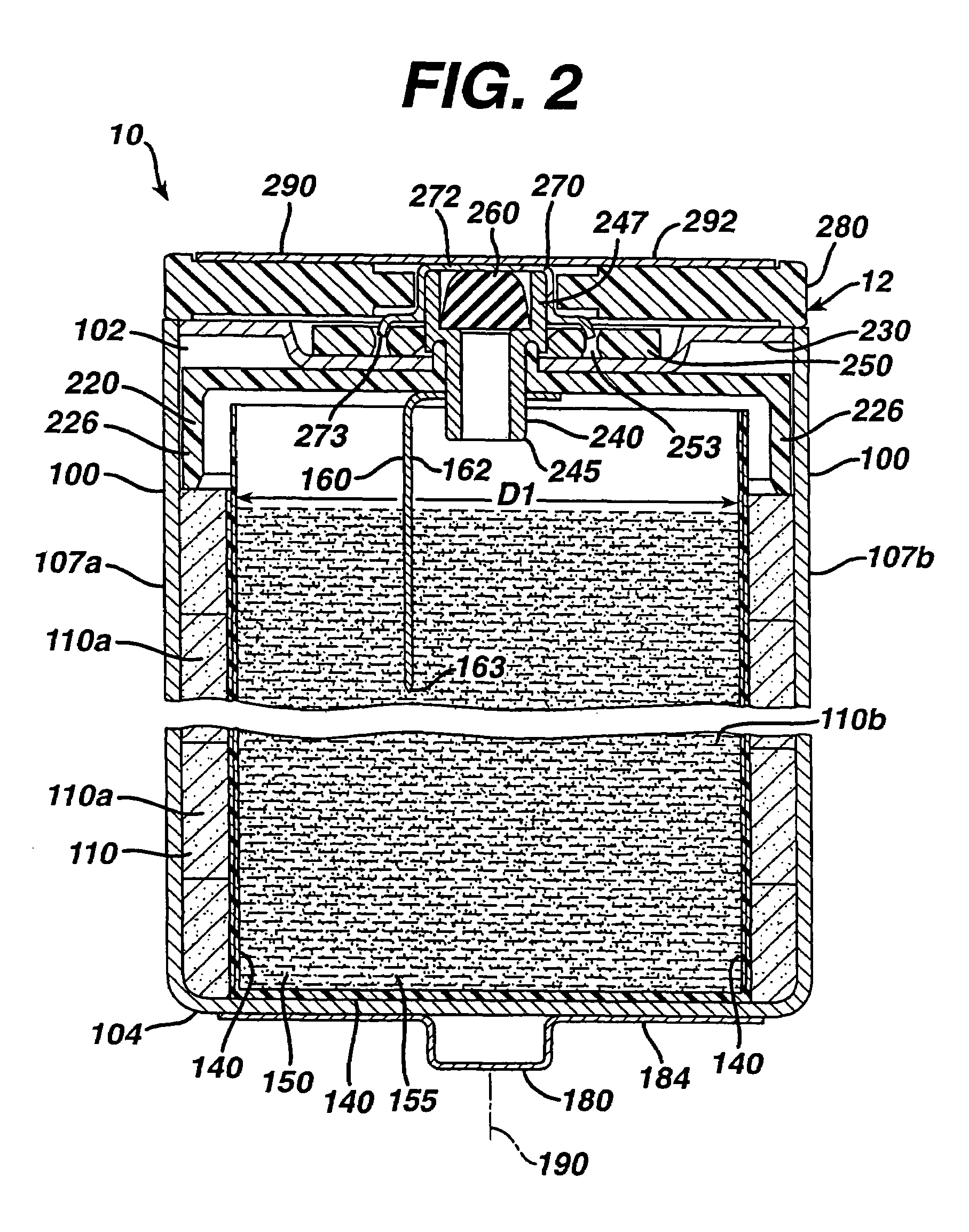

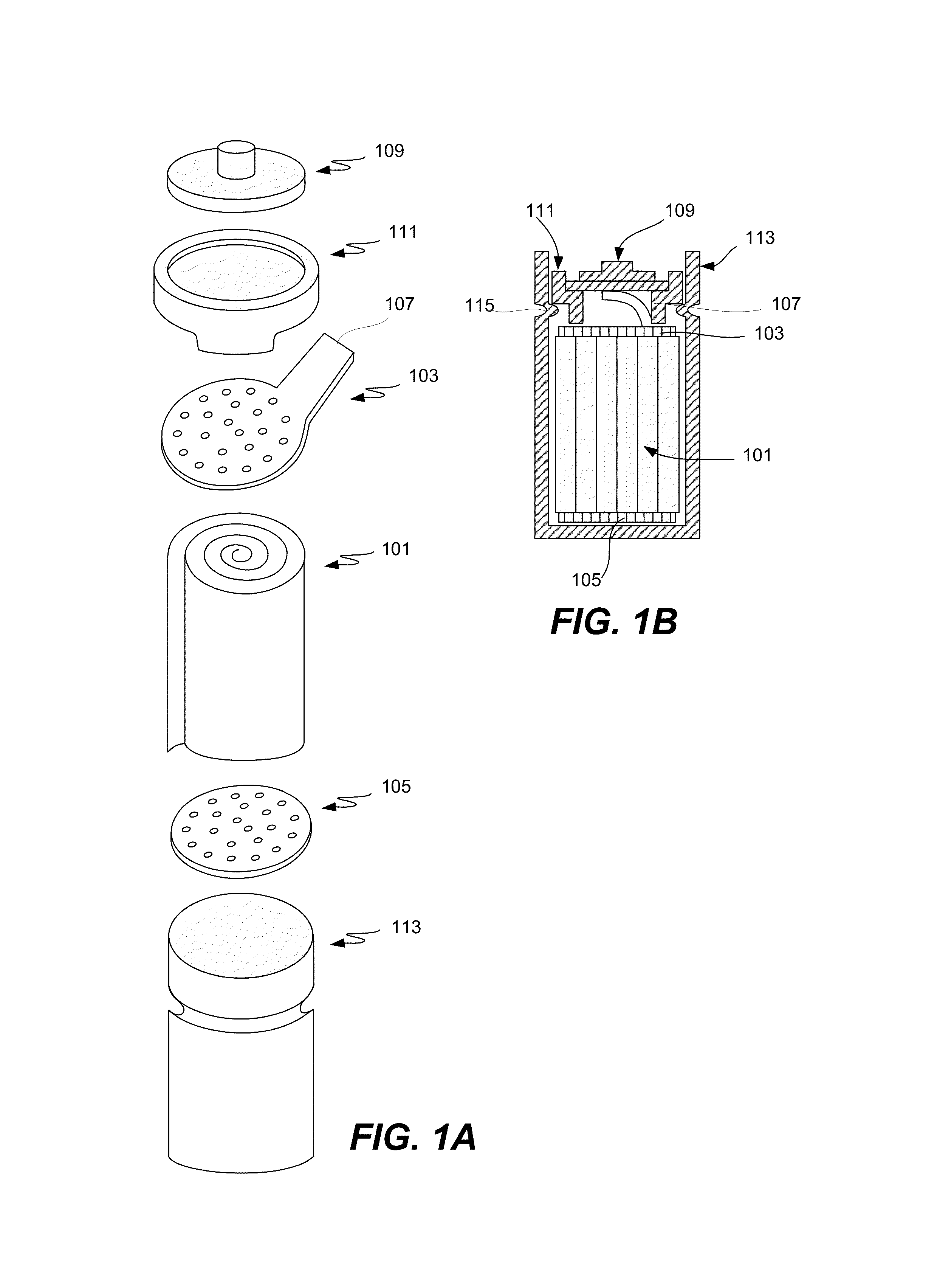

Alkaline cell with flat housing and nickel oxyhydroxide cathode

An alkaline cell having a flat casing, preferably of cuboid shape. The cell can have an anode comprising zinc and a cathode comprising nickel oxyhydroxide. The casing can have a relatively small overall thickness, typically between about 5 and 10 mm, but may be larger. Cell contents can be supplied through an open end in the casing and an end cap assembly inserted therein to seal the cell. The end cap assembly includes a vent mechanism, preferably a grooved vent, which can activate, when gas pressure within the cell reaches a threshold level typically between about 250 and 800 psig (1724×103 and 5515×103 pascal gage). The cell can have a supplemental vent mechanism such as a laser welded region on the surface of the casing which may activate at higher pressure levels.

Owner:DURACELL U S OPERATIONS

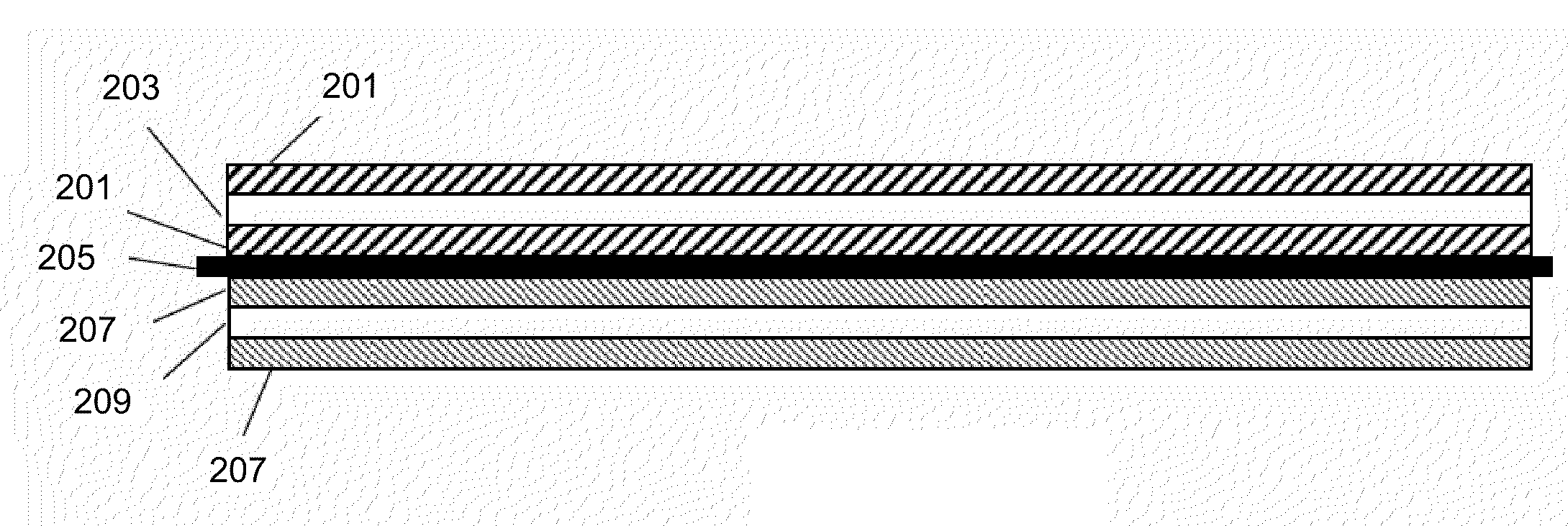

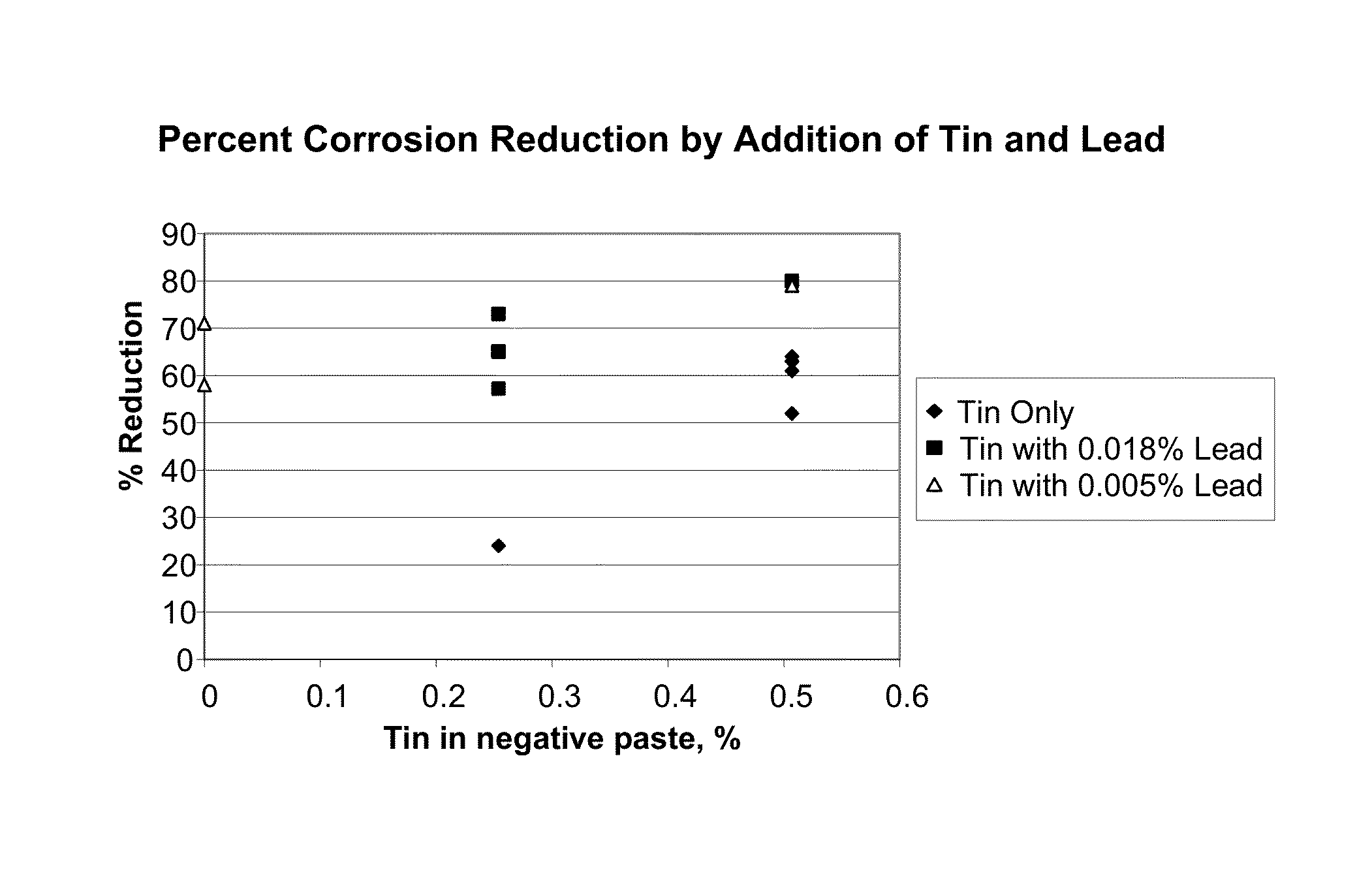

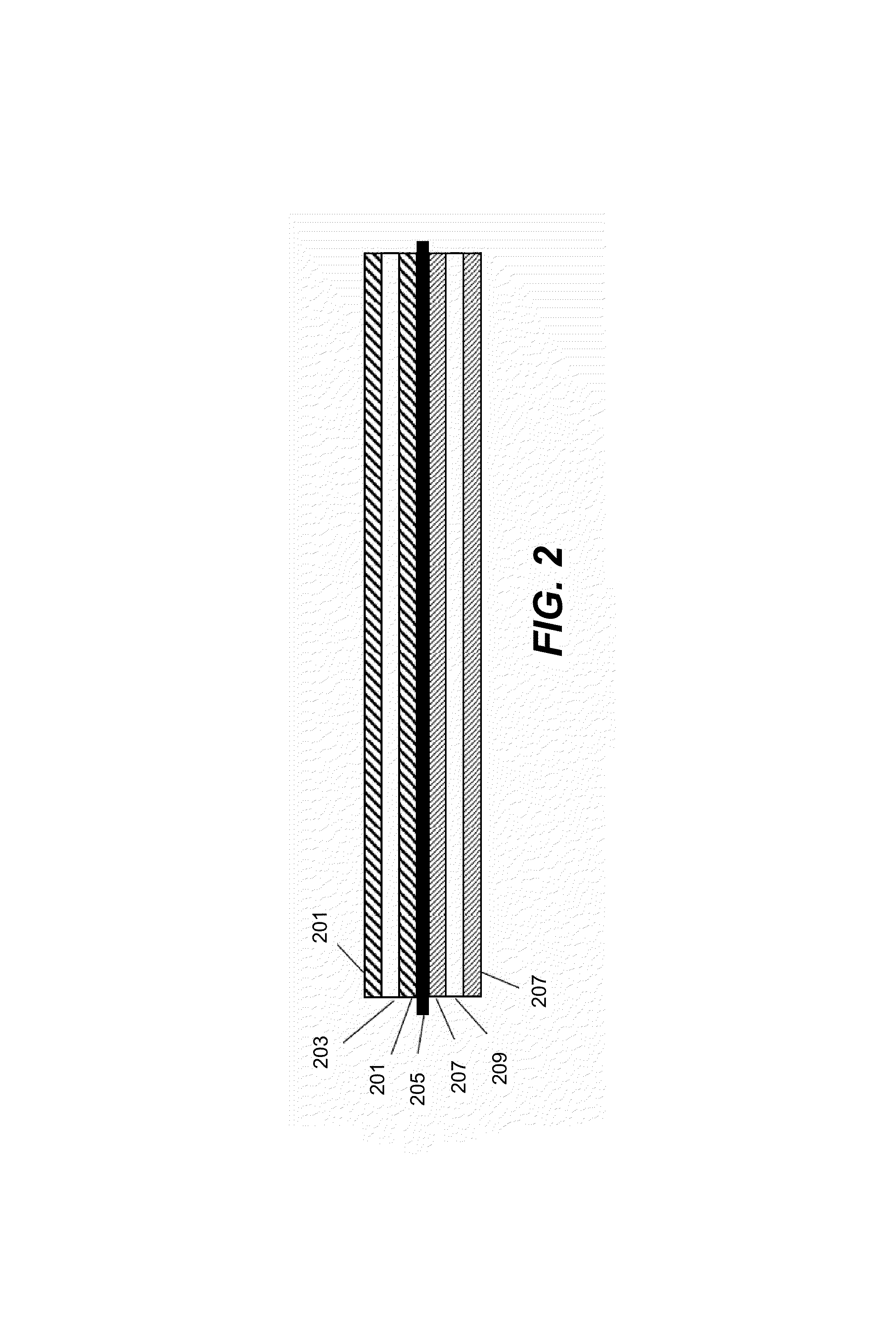

Pasted zinc electrode for rechargeable nickel-zinc batteries

ActiveUS20100291439A1High viscositySimple working processFinal product manufacturePrimary cellsZinc metalSlurry

Active material for a negative electrode of a rechargeable zinc alkaline electrochemical cell is made with zinc metal particles coated with tin and / or lead. The zinc particles may be coated by adding lead and tin salts to a slurry containing zinc particles, a thickening agent and water. The remaining zinc electrode constituents such as zinc oxide (ZnO), bismuth oxide (Bi2O3), a dispersing agent, and a binding agent such as Teflon are then added. The resulting slurry / paste has a stable viscosity and is easy to work with during manufacture of the zinc electrode. Further, the zinc electrode is much less prone to gassing when cobalt is present in the electrolyte. Cells manufactured from electrodes produced in accordance with this invention exhibit much less hydrogen gassing, by as much as 60-80%, than conventional cells. The cycle life and shelf life of the cells is also enhanced, as the zinc conductive matrix remains intact and shelf discharge is reduced.

Owner:ZINCFIVE POWER INC

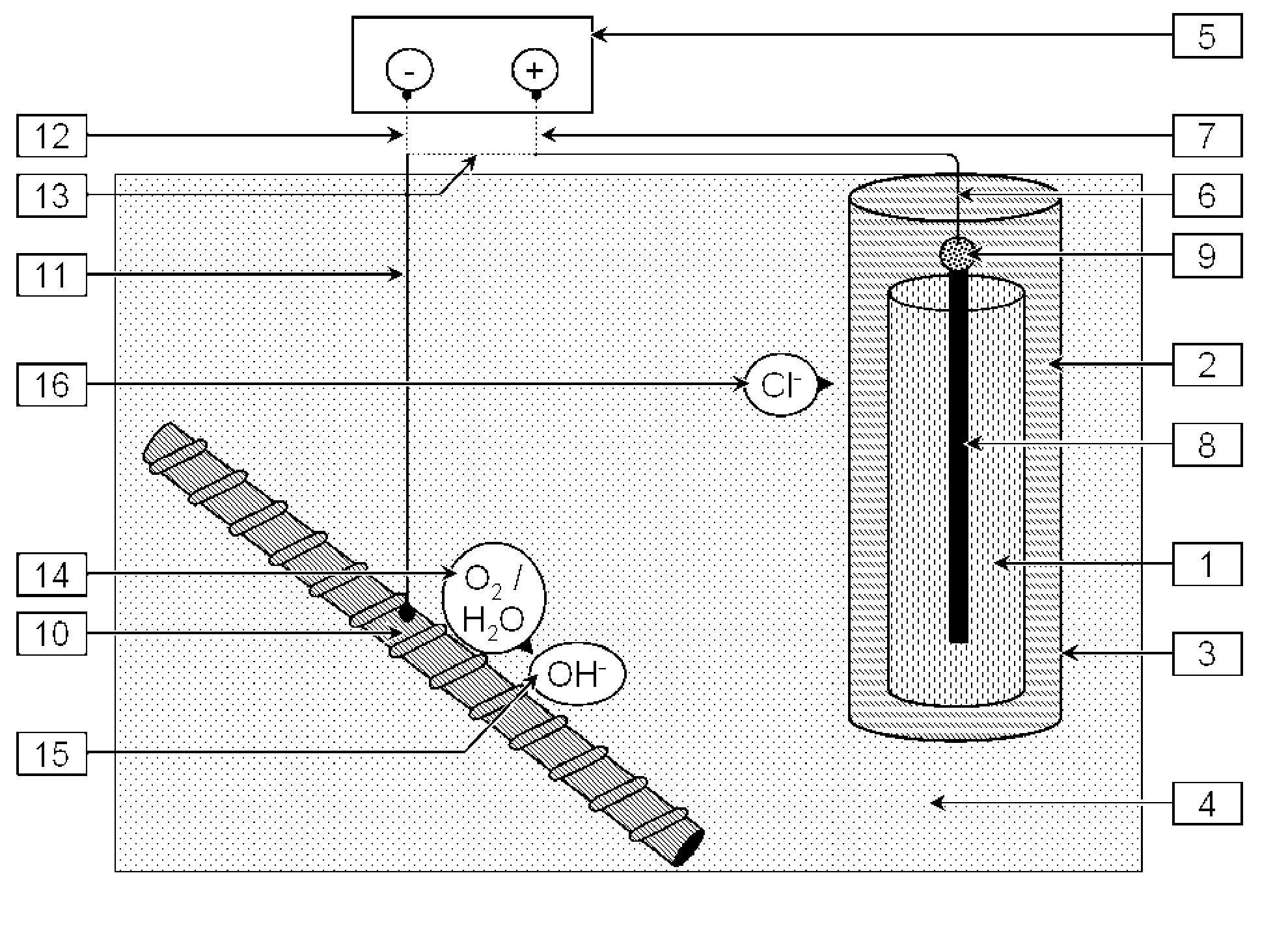

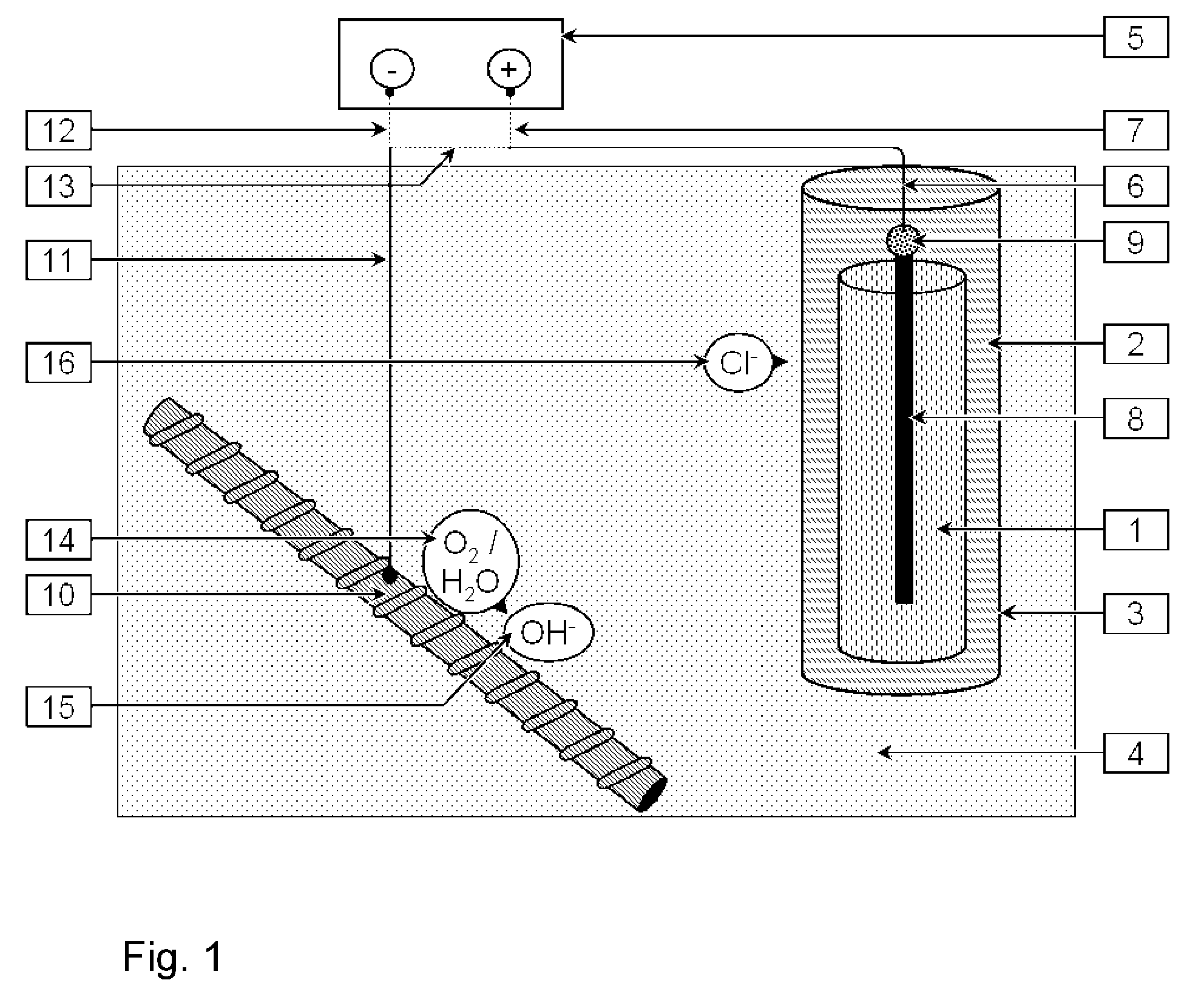

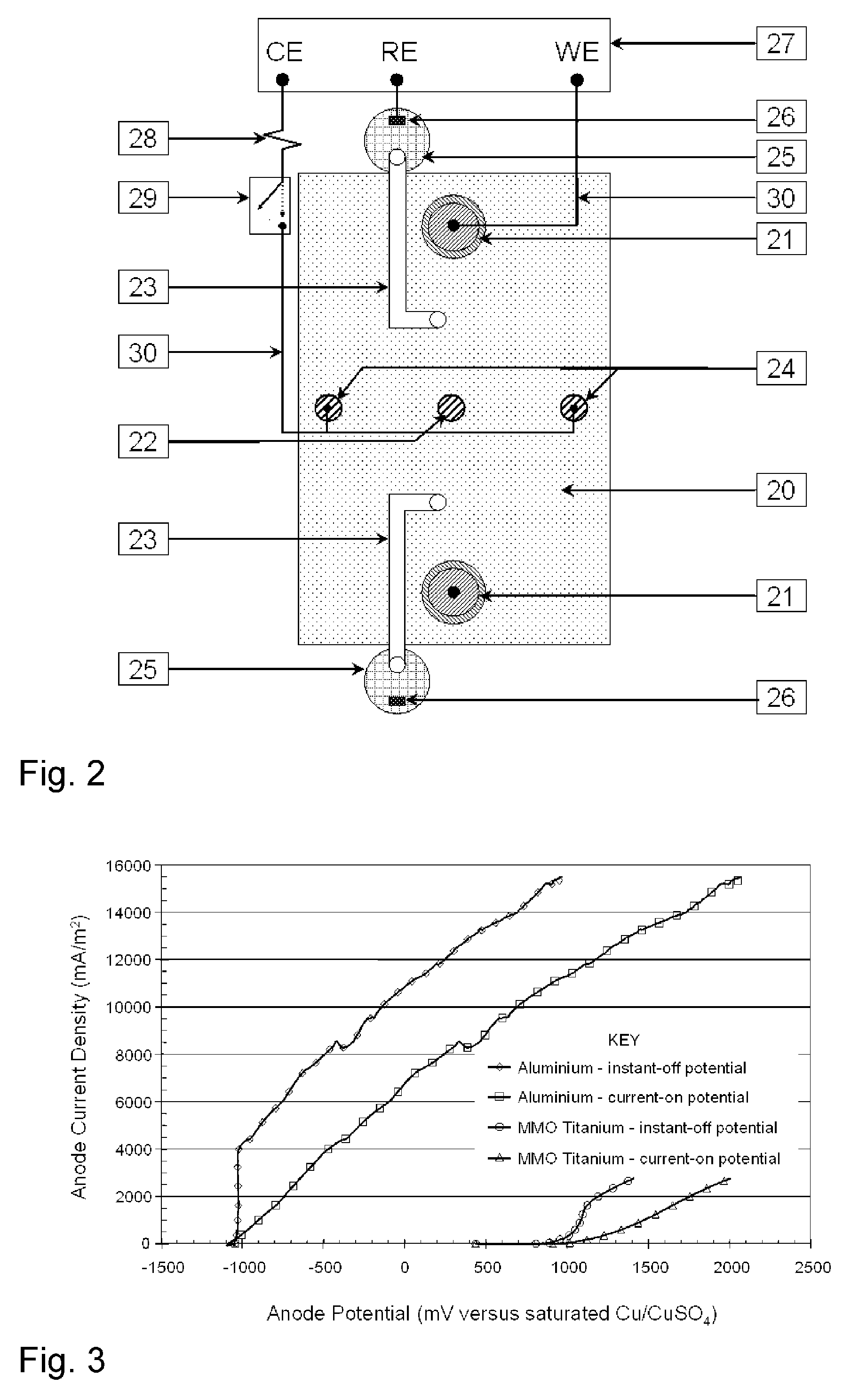

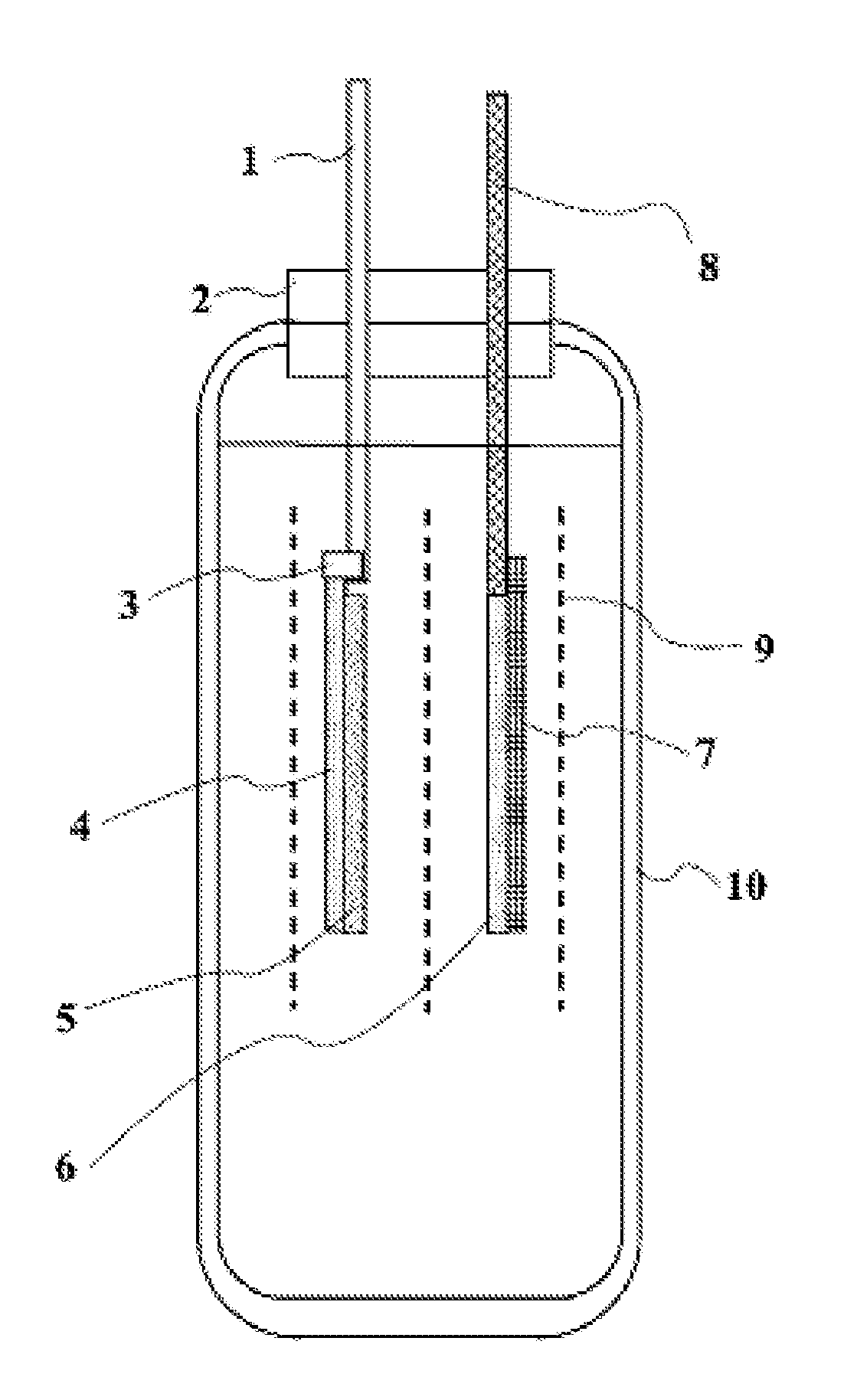

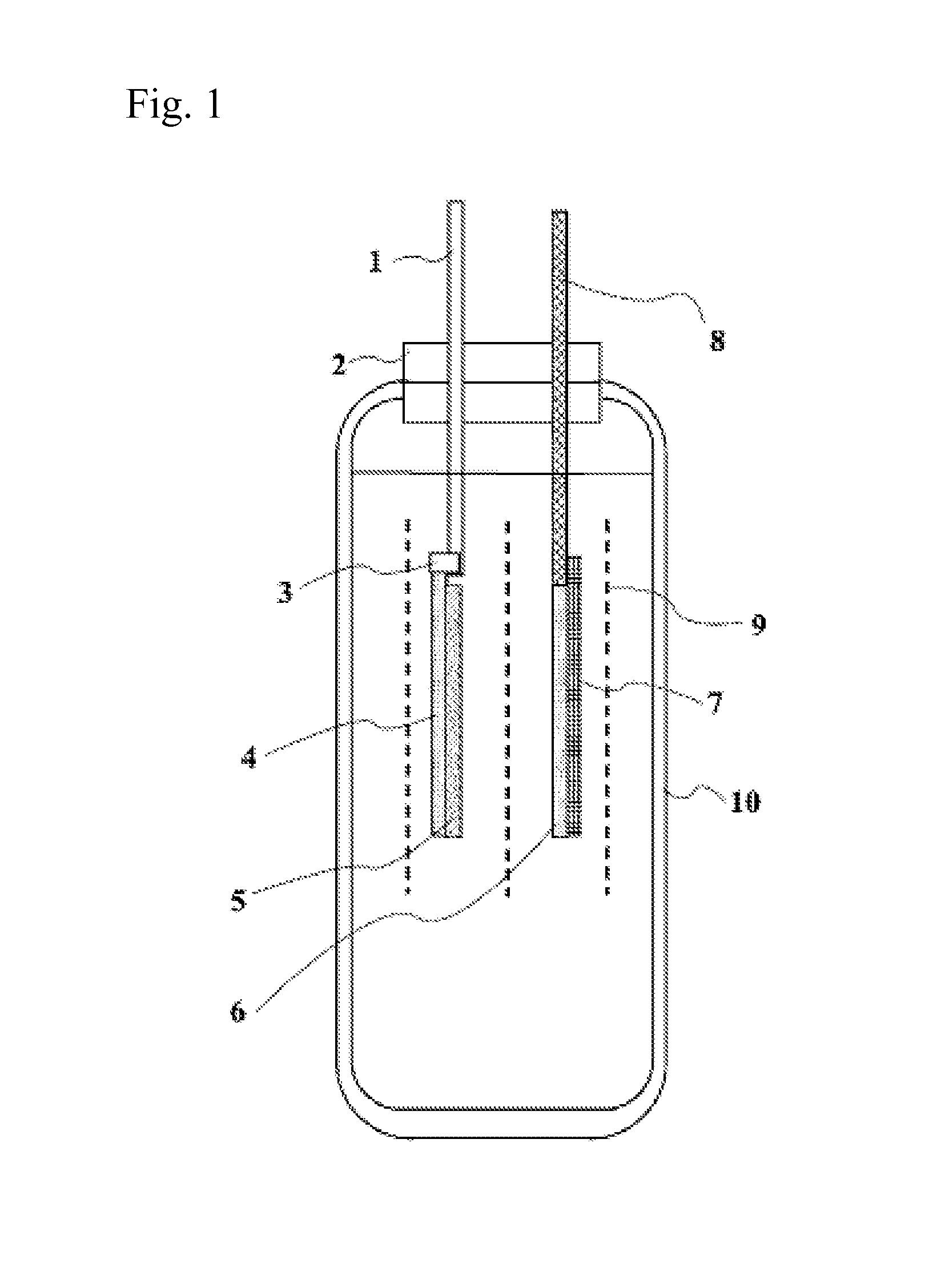

Treatment process for concrete

ActiveUS7909982B2Less driving voltageGenerate less acidCovering/liningsWallsChemical treatmentChloride

A single anode system used in multiple electrochemical treatments to control steel corrosion in concrete comprises a sacrificial metal that is capable of supporting high impressed anode current densities with an impressed current anode connection detail and a porous embedding material containing an electrolyte. Initially current is driven from the sacrificial metal [1] to the steel [10] using a power source [5] converting oxygen and water [14] into hydroxyl ions [15] on the steel and drawing chloride ions [16] into the porous material [2] around the anode such that corroding sites are moved from the steel to the anode restoring steel passivity and activating the anode. Cathodic prevention is then applied. This is preferably sacrificial cathodic prevention that is applied by disconnecting the power source and connecting the activated sacrificial anode directly to the steel.

Owner:GLASS +2

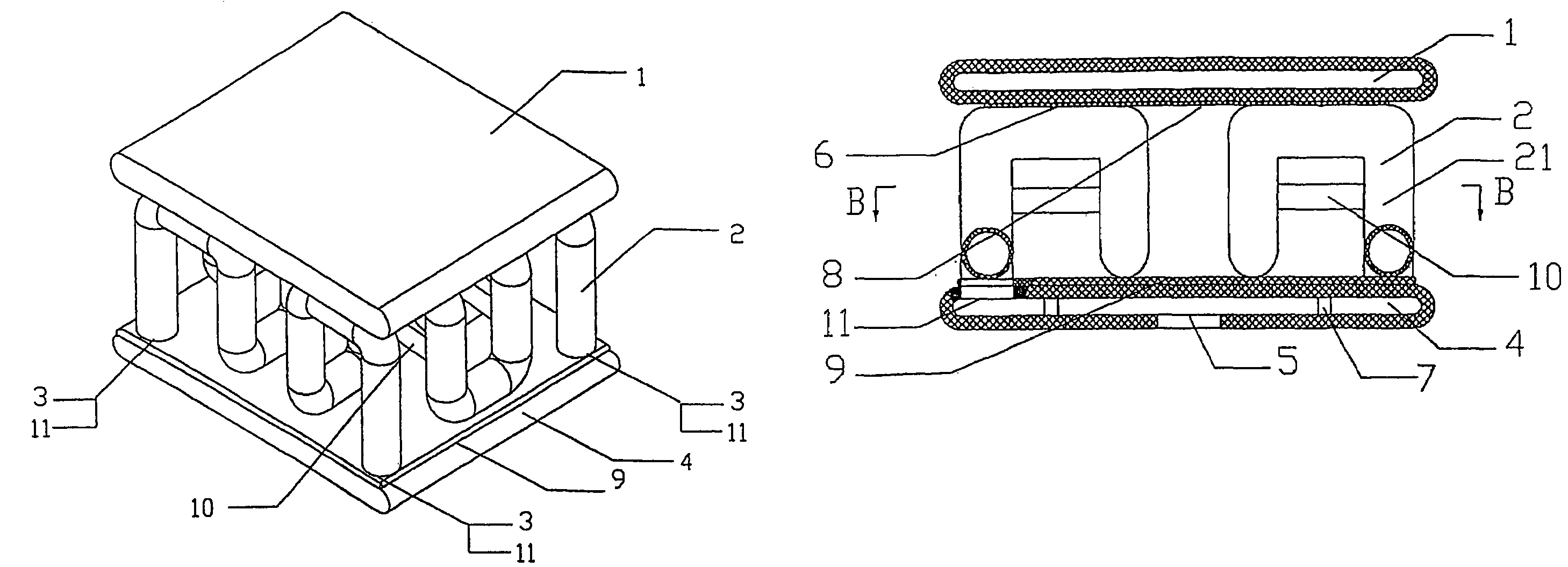

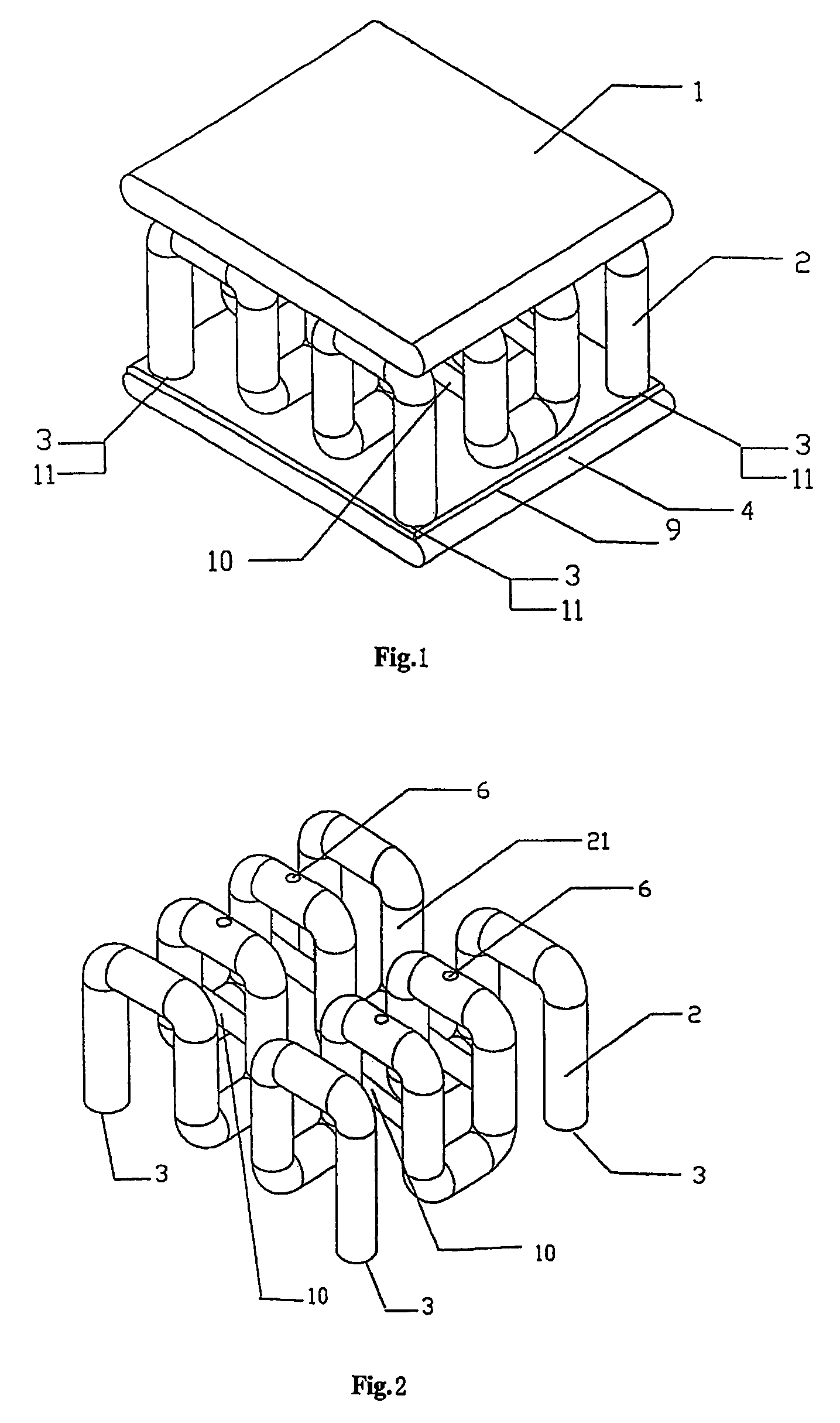

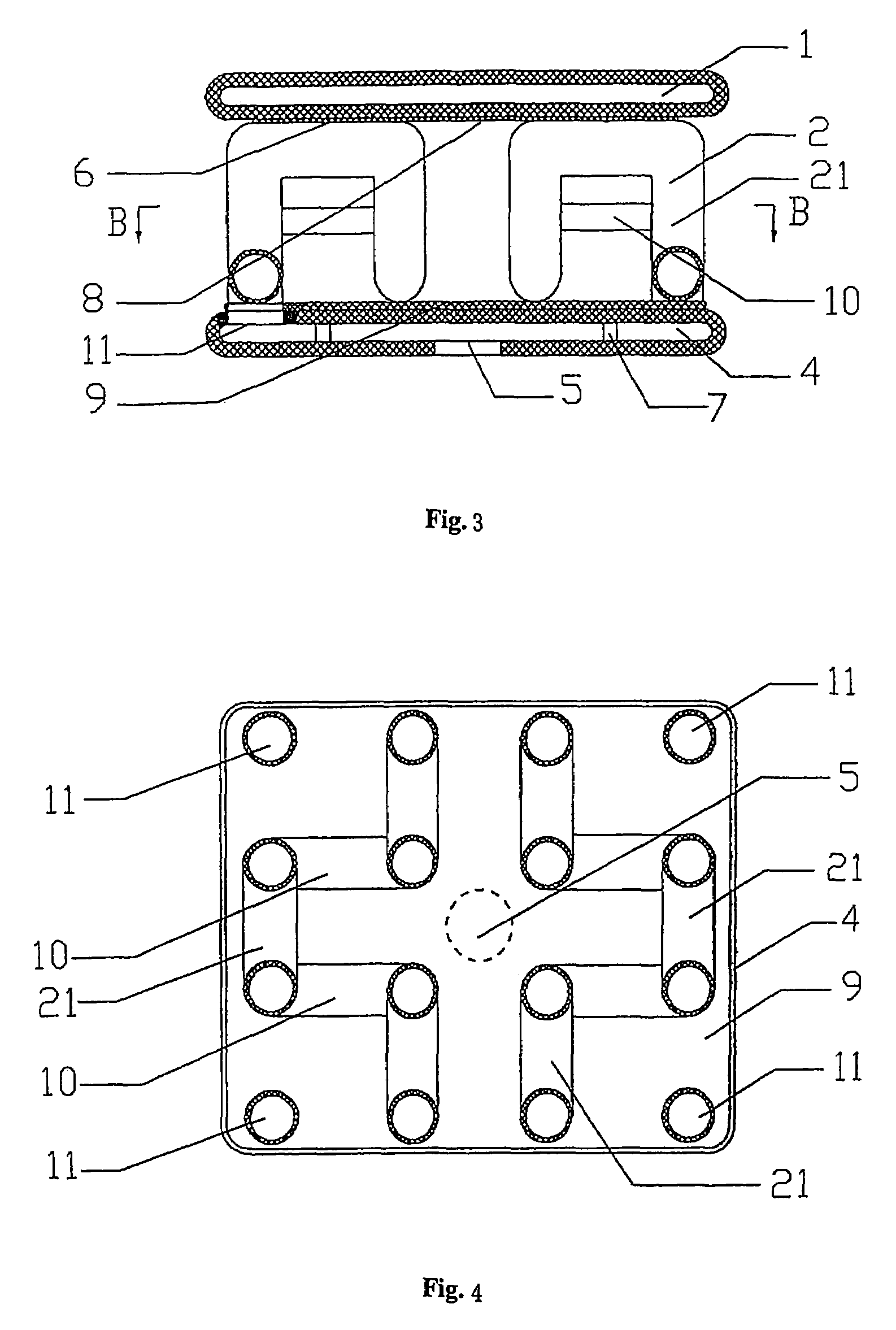

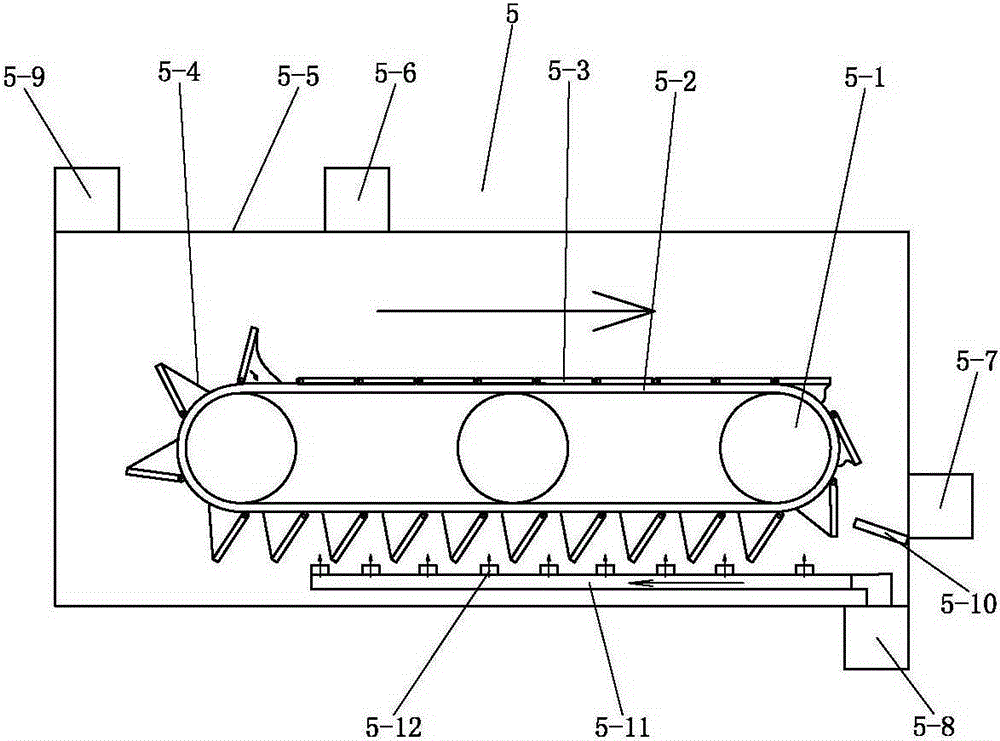

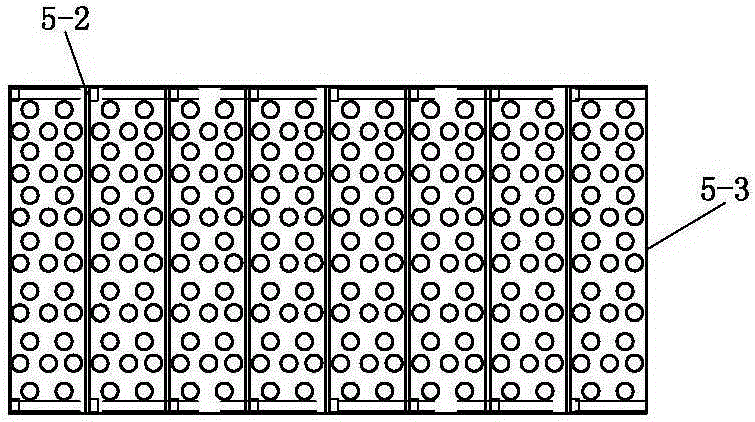

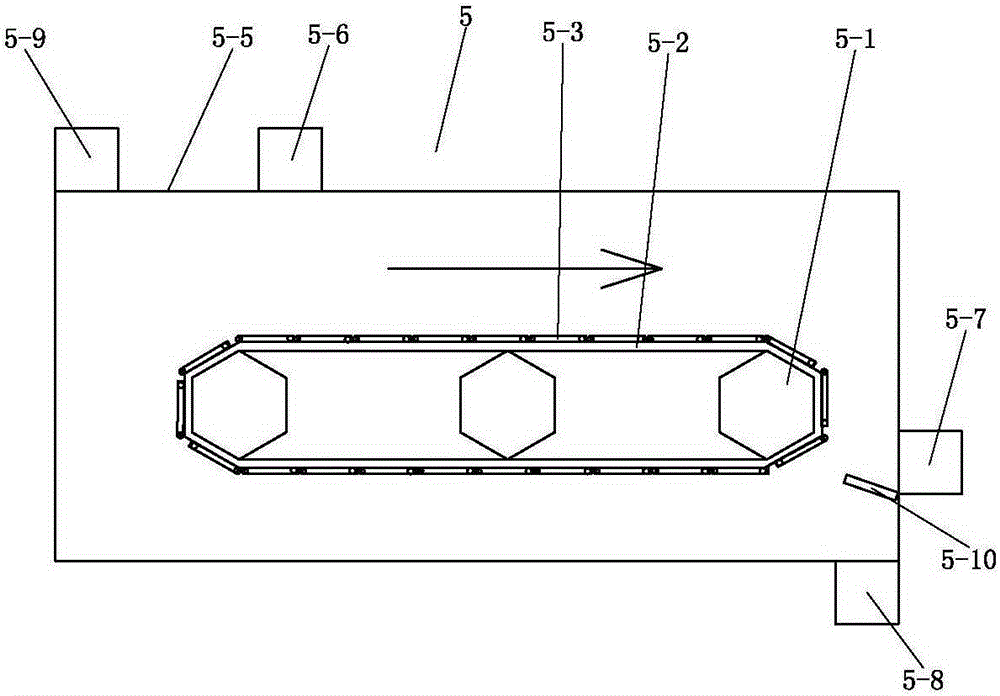

Sandwiched tubular airbags

ActiveUS7448644B2Less gasAvoid serious injuryPedestrian/occupant safety arrangementAirbag deploymentAutomotive engineering

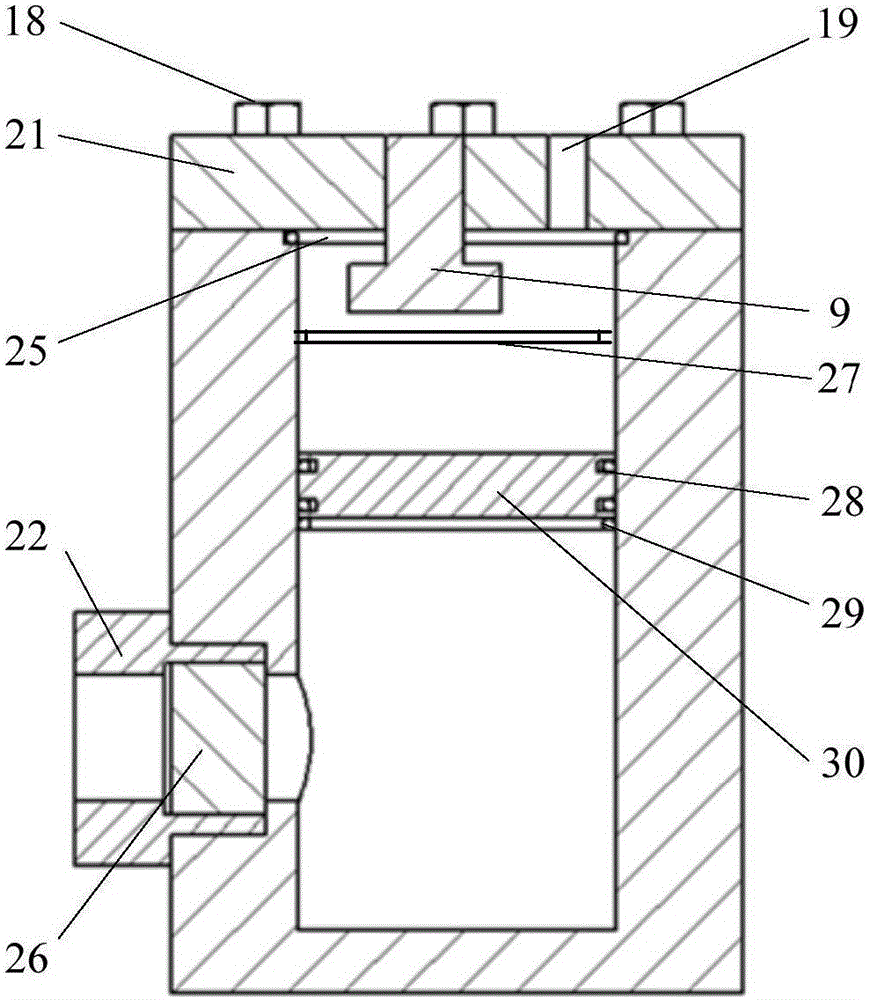

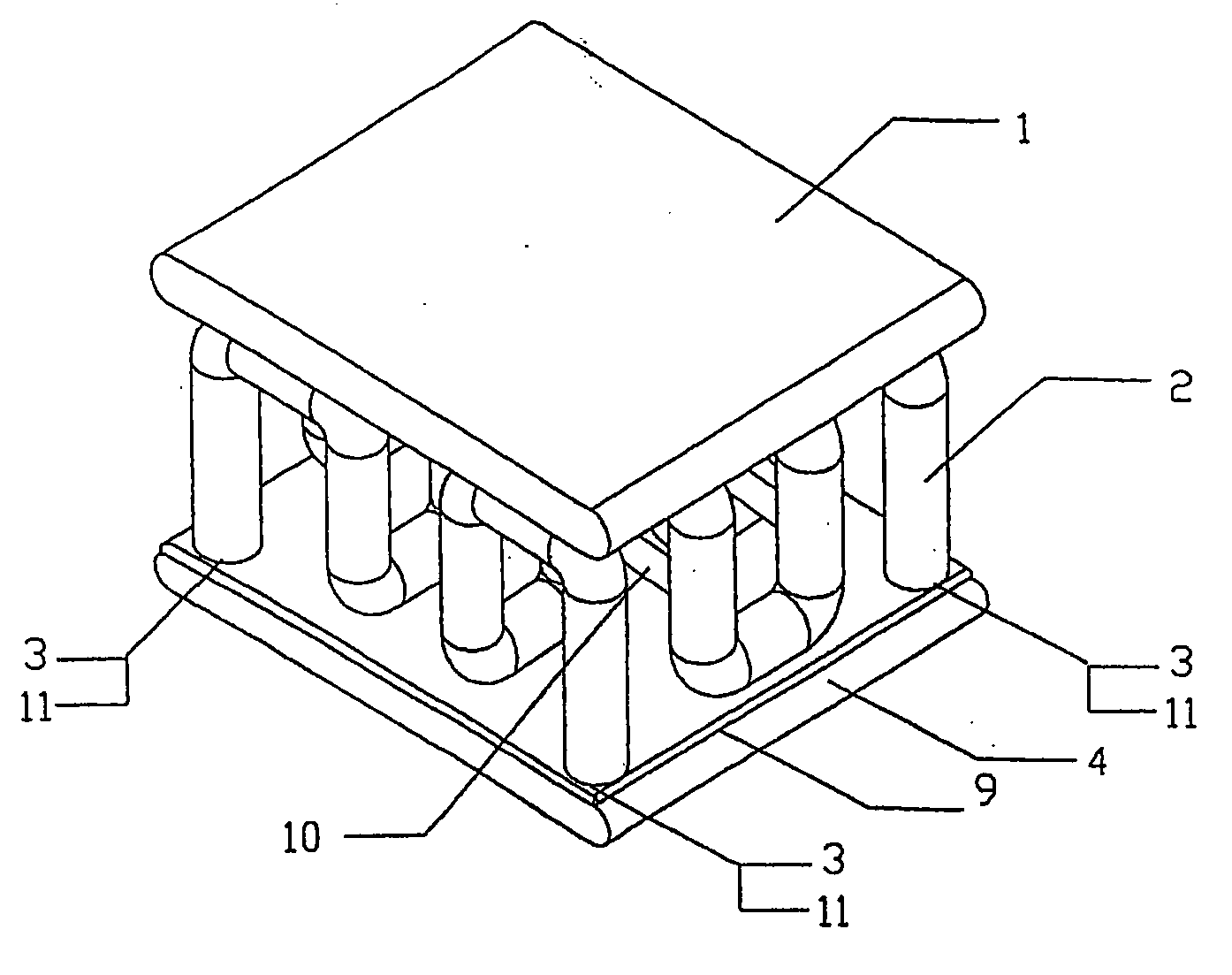

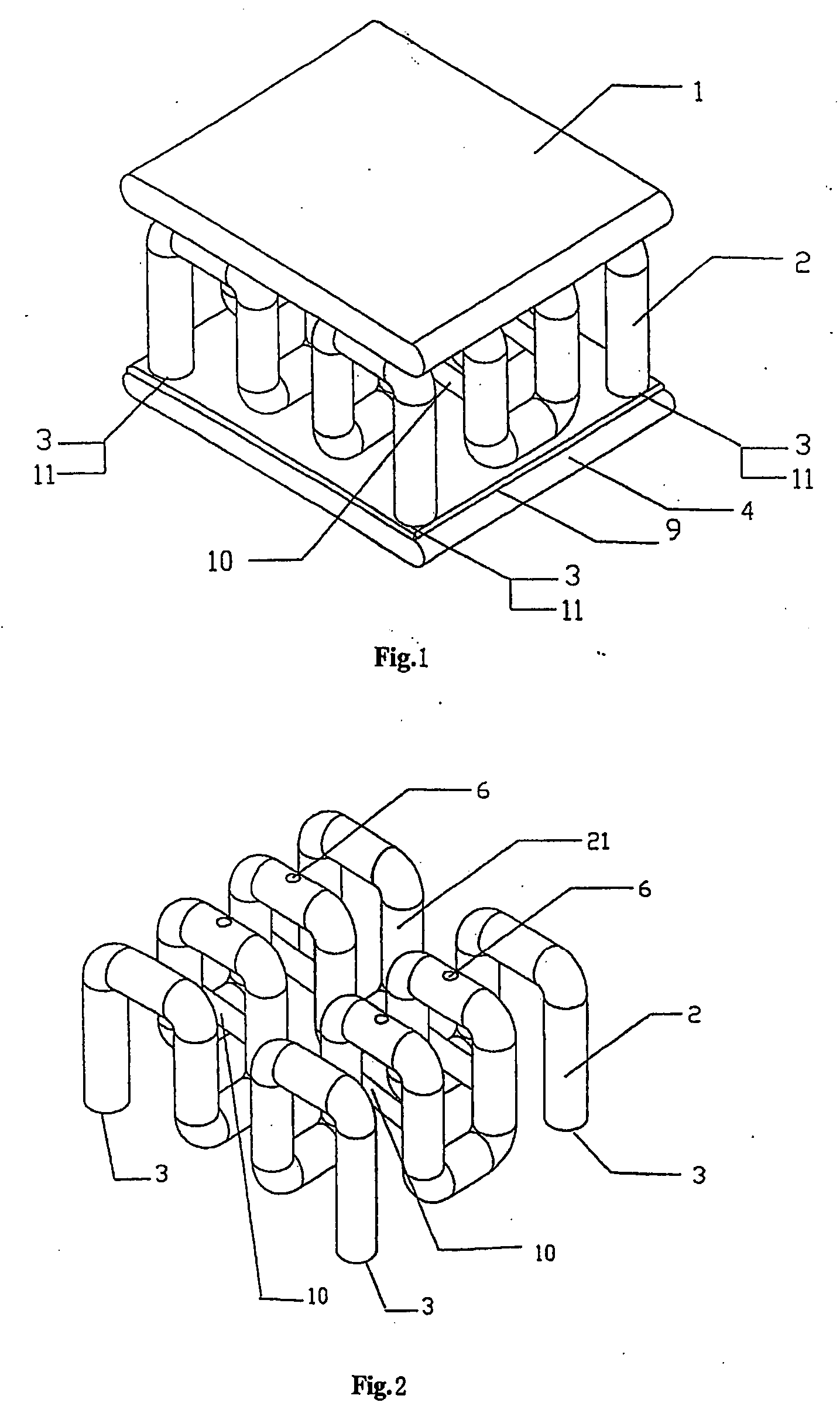

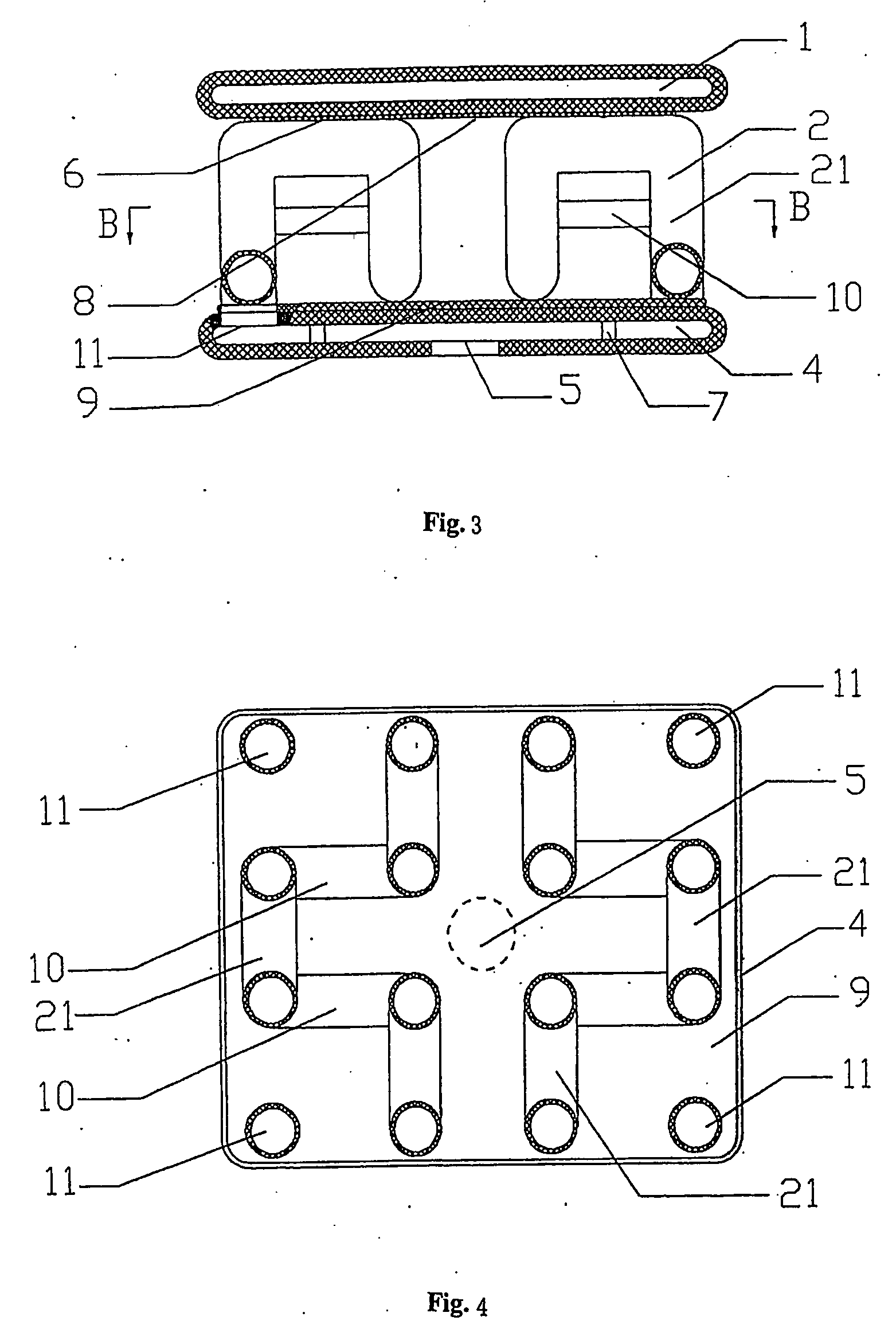

Sandwiched tubular safety airbags are disclosed. An example sandwiched tubular safety airbag comprises an air tube truss (2) formed by a bending hollow air tube (21), a lower air cushion (4) and an upper air cushion (1). The lower air cushion (4) is provided at the bottom of the air tube truss (2), and the upper air cushion (1) is provided on top of the air tube truss (2). An inlet opening (5) is provided on the bottom surface of the lower air cushion (4). The end openings of the hollow air tube (21) of the air tube truss (2) are charging openings (3) of the air tube truss (2). Charging holes (11) are provided at joints of the lower air cushion (4) with the charging openings (3) of the air tube truss (2). The top of the air tube truss (2) is provided with one or more discharging holes (6) communicating with the upper air cushion (1).

Owner:HUNAN UNIV STATE KEY LAB OF ADVANCED DESIGN & MFR FOR VEHICLE BODY

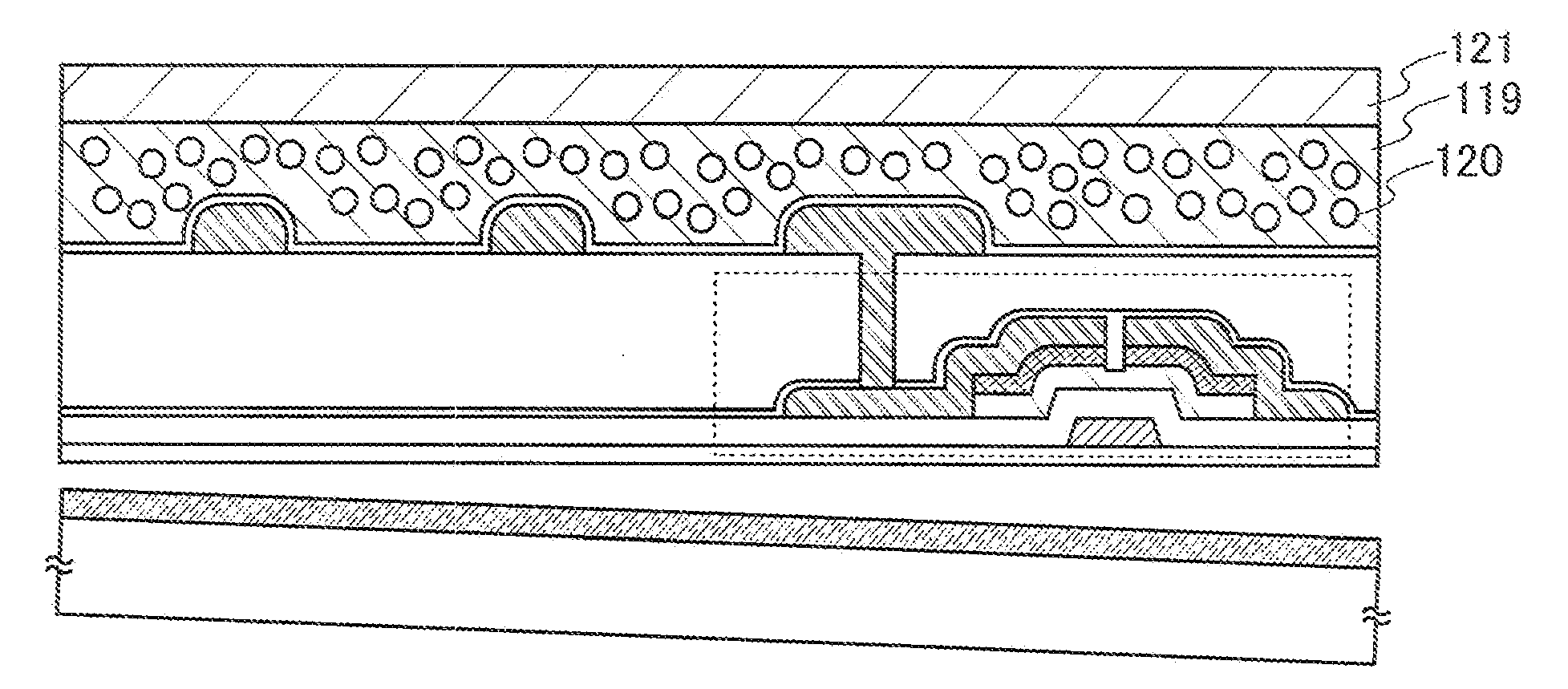

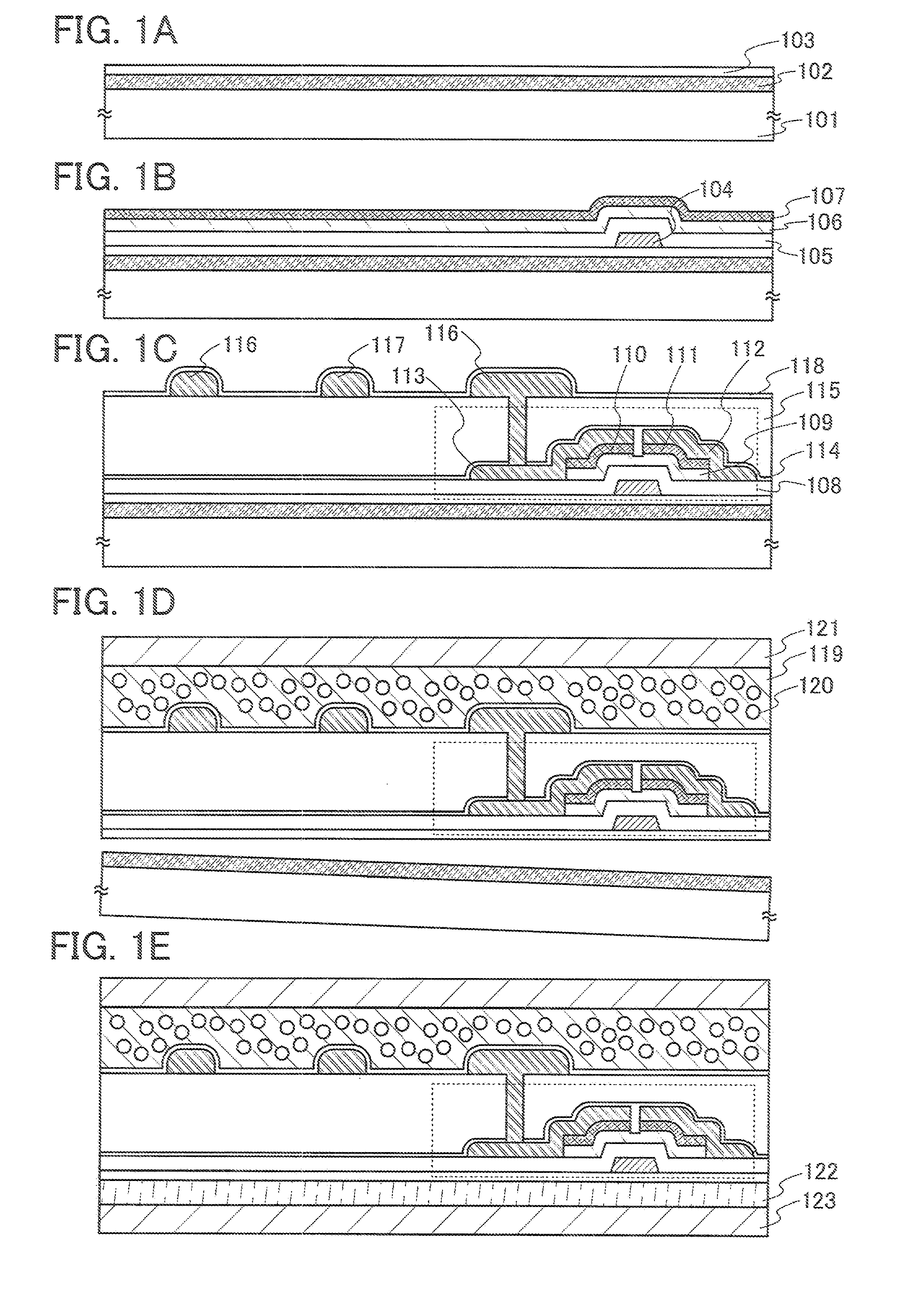

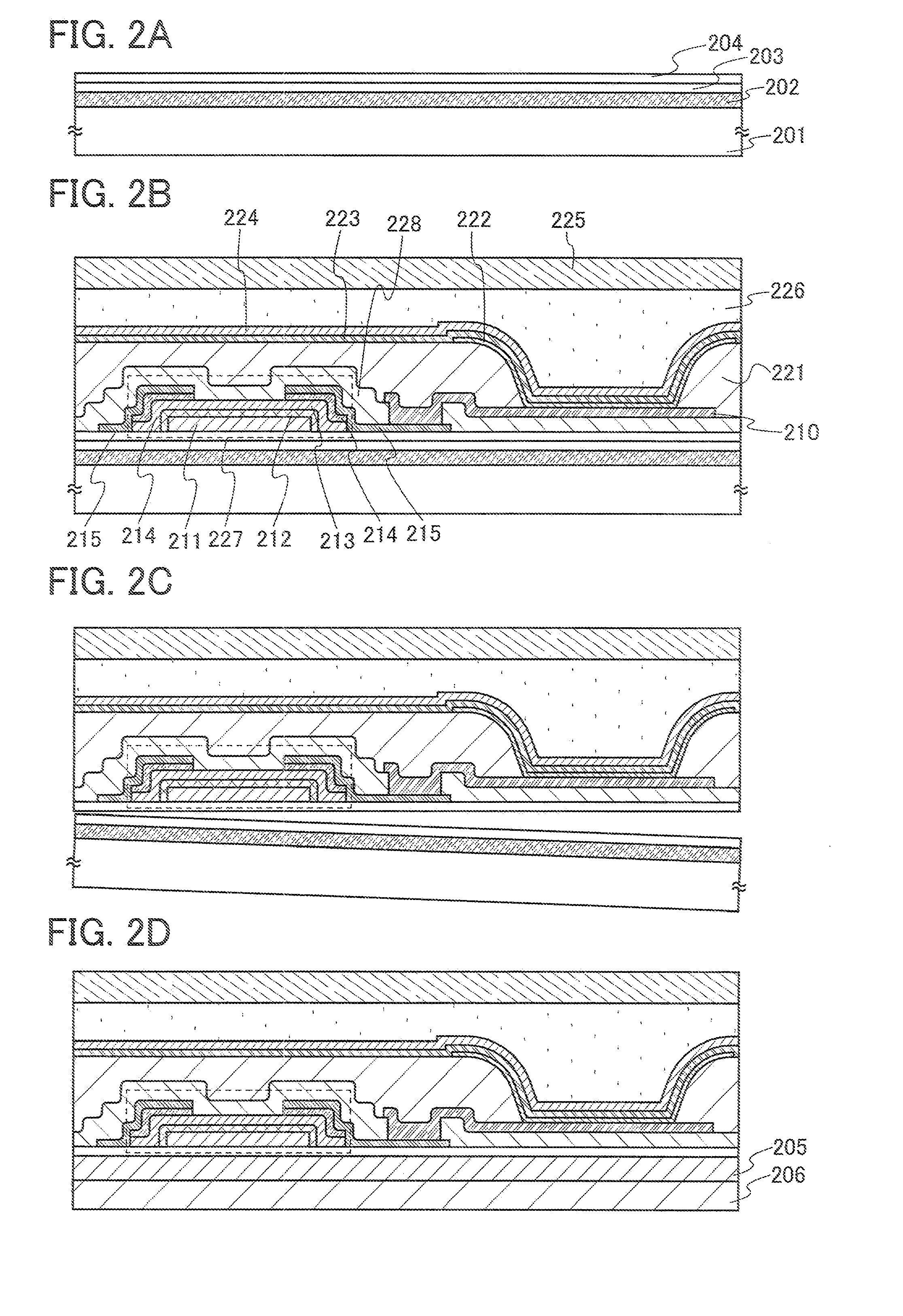

Method for manufacturing a semiconductor device using a flexible substrate

ActiveUS8900970B2Poor heat resistanceHigh yieldFinal product manufactureSemiconductor/solid-state device detailsPower semiconductor deviceEngineering

A technique for peeling an element manufactured through a process at relatively low temperature (lower than 500° C.) from a substrate and transferring the element to a flexible substrate (typically, a plastic film). With the use of an existing manufacturing device for a large glass substrate, a molybdenum film (Mo film) is formed over a glass substrate, an oxide film is formed over the molybdenum film, and an element is formed over the oxide film through a process at relatively low temperature (lower than 500° C.). Then, the element is peeled from the glass substrate and transferred to a flexible substrate.

Owner:SEMICON ENERGY LAB CO LTD

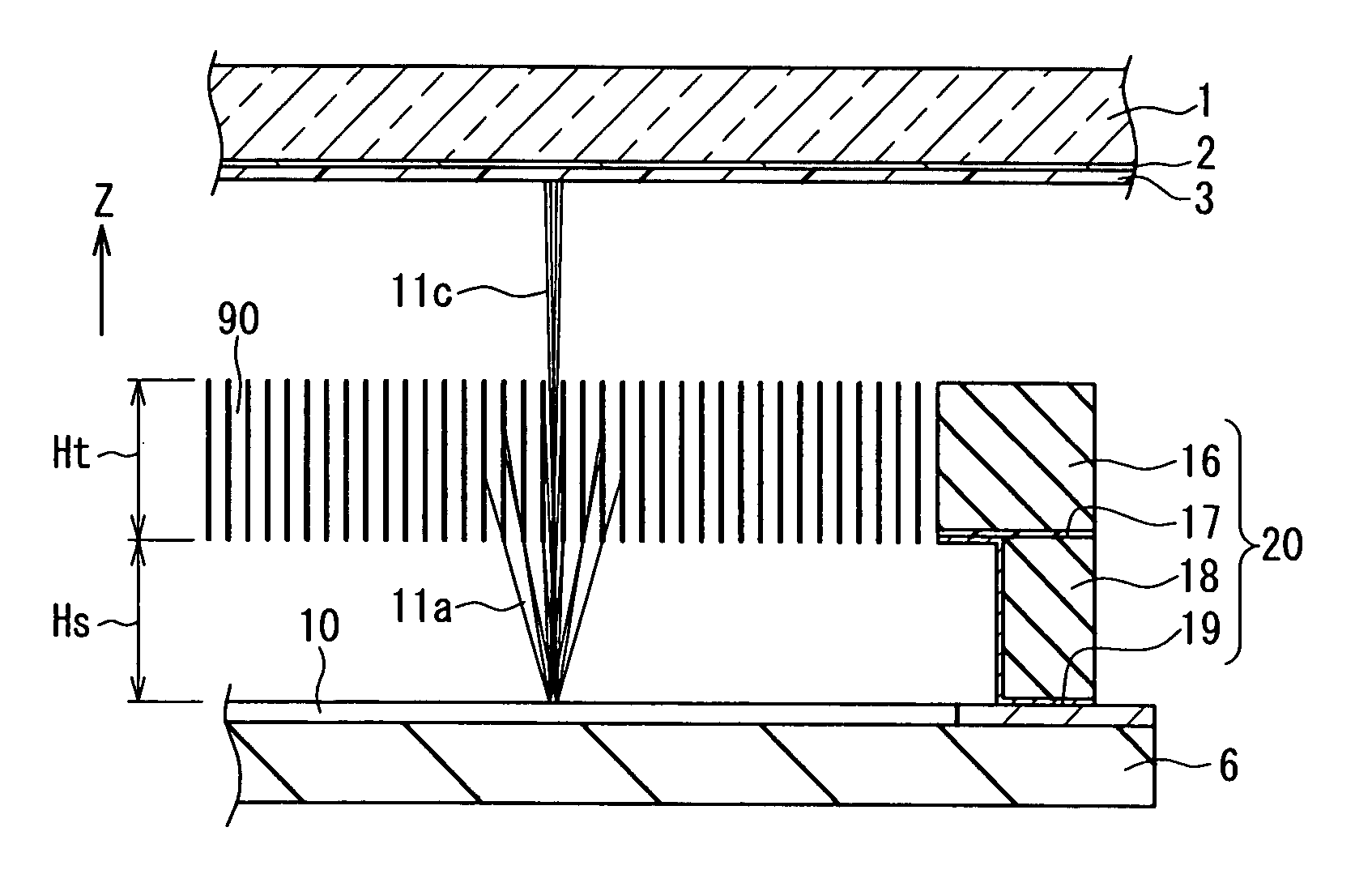

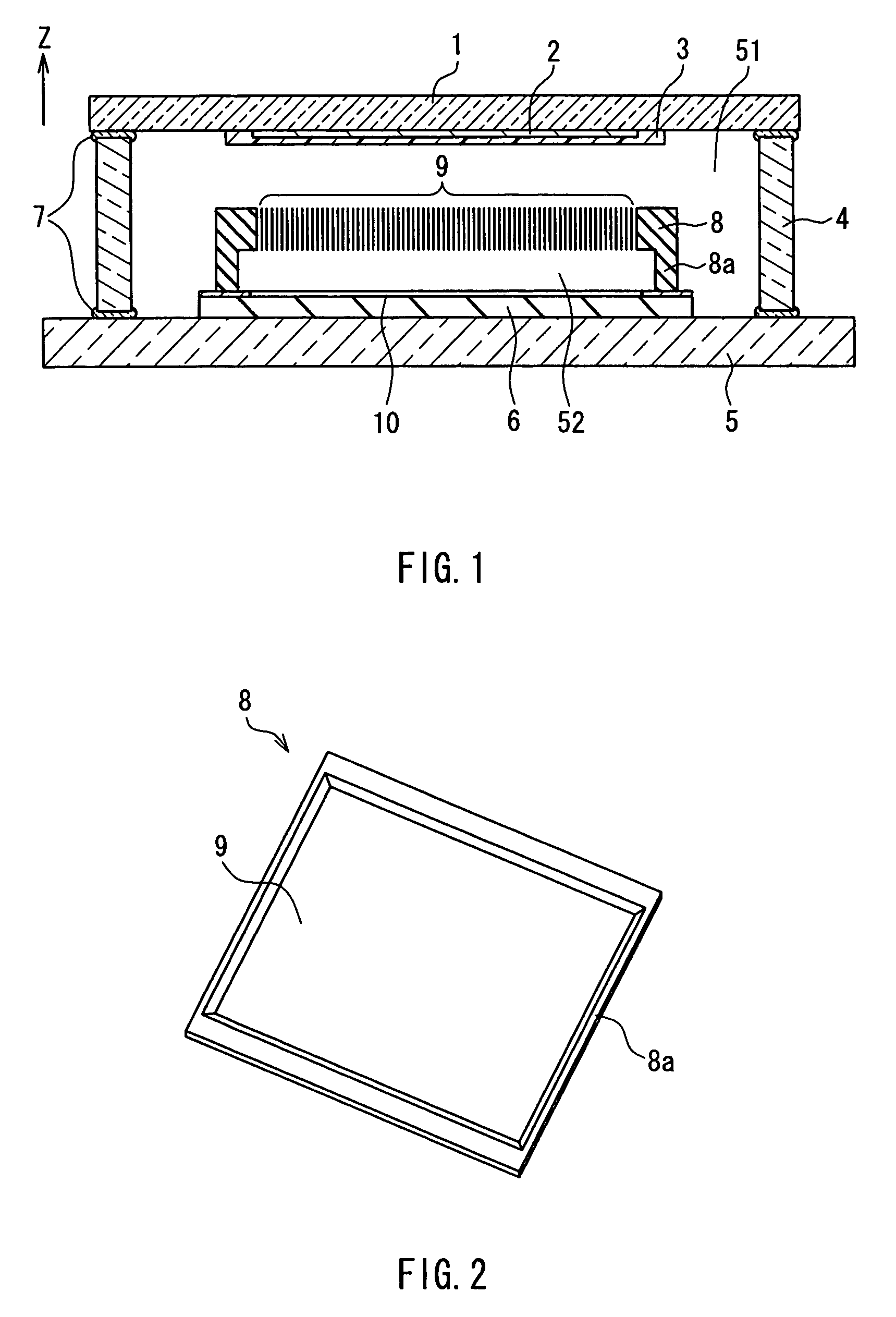

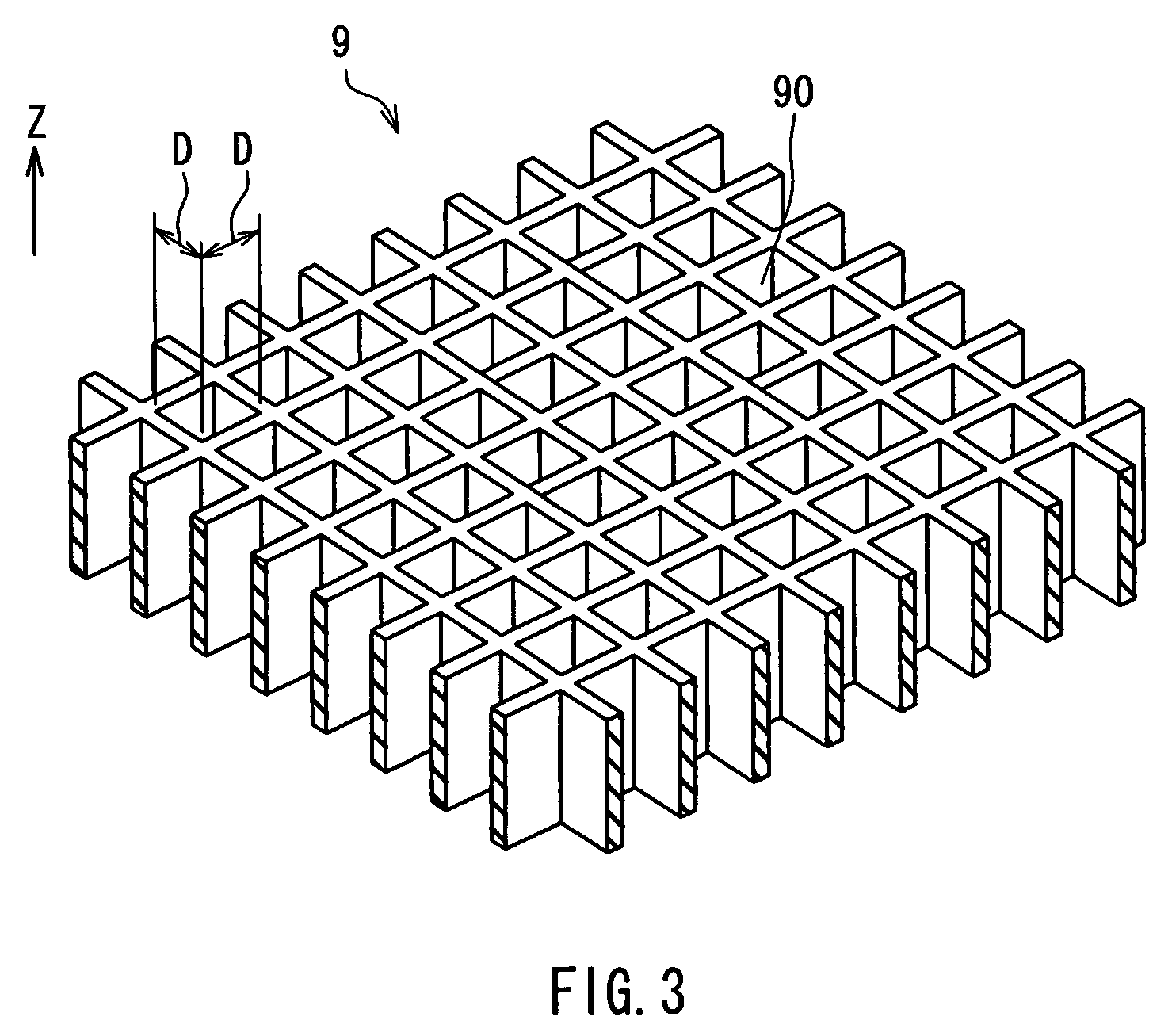

Mesh structure and field-emission electron source apparatus using the same

InactiveUS7825591B2Less gasHigh dimensional accuracyControl electrodesDischarge tube luminescnet screensElectron sourceParticle physics

An electron beam emitted from a field-emission electron source array passes through a plurality of through holes formed in a mesh structure and reaches a target. Each of the plurality of through holes in the mesh structure has an opening on a side of the field-emission electron source array and an electron beam passageway that continues from the opening. The mesh structure is formed of a silicon-containing material doped with a N-type or P-type material. In this way, it is possible to suppress a decrease in the amount of the electron beam reaching the target while securing a mechanical strength of an electrode provided with a large number of through holes, and suppress expansion of the electron beam on the target.

Owner:PANASONIC HEALTHCARE HLDG CO LTD +1

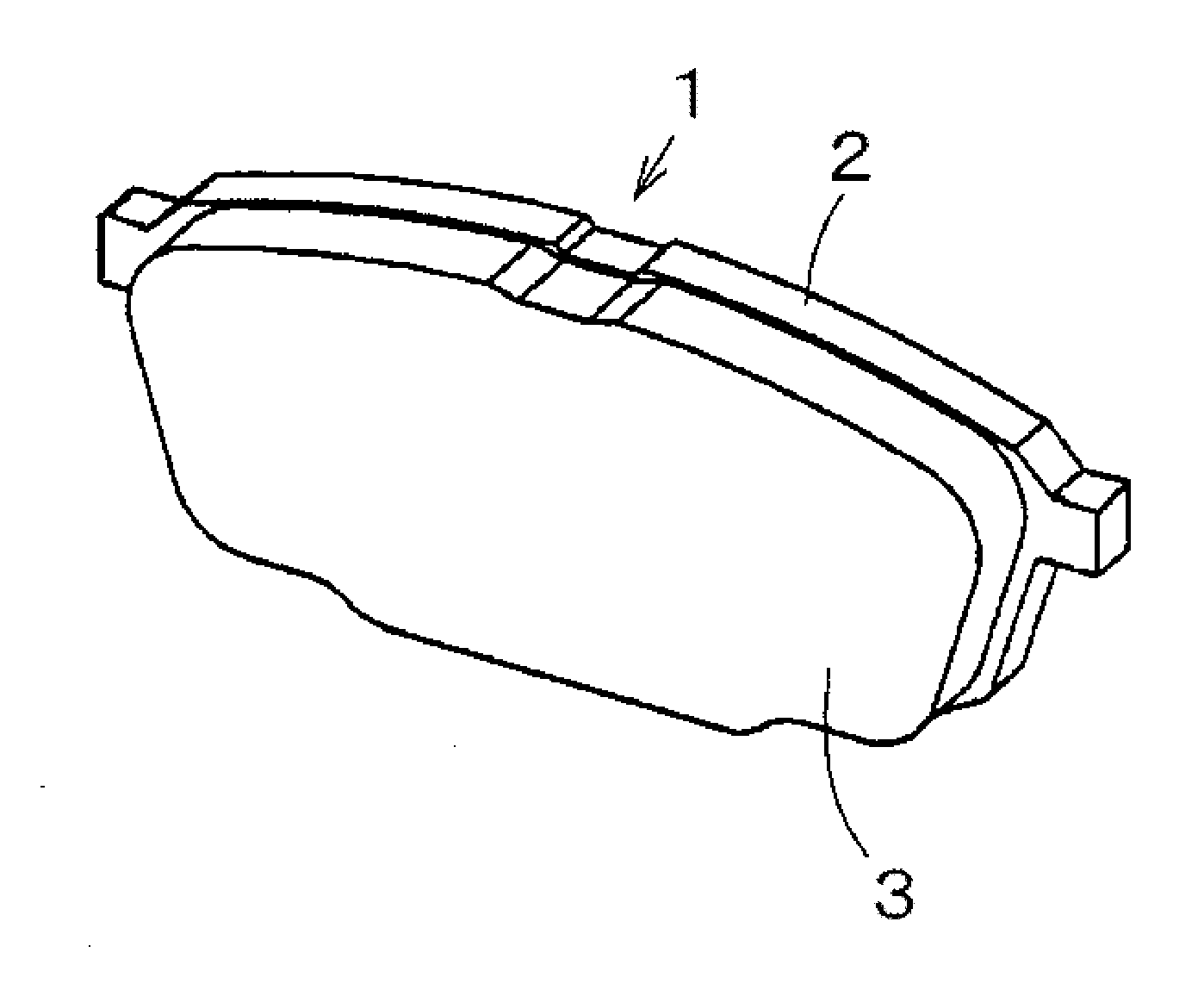

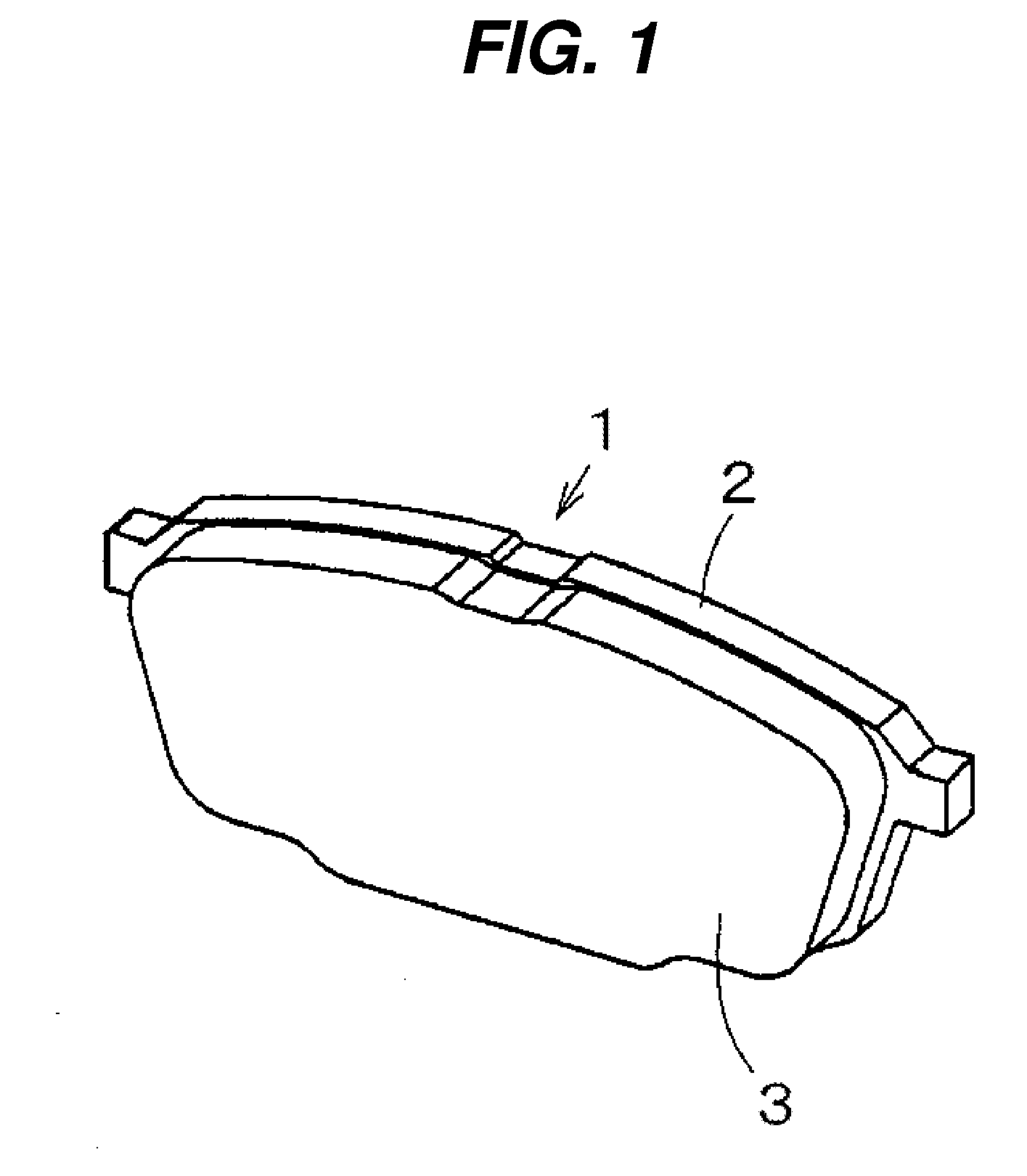

Disc brake pad

ActiveUS20110259686A1Effective formabilityEffective resistanceBraking membersFriction liningFiberMohs scale of mineral hardness

To provide a disc brake pad for a disc brake equipped with a metal disc rotor, having a friction material that includes a fiber base material, a binder, an abrasive material, and a frictional wear modifier, which effectively minimizes a sticking problem of the friction material and the disc rotor and simultaneously provides effective fading resistance, wear resistance, and formability. The friction material includes the fiber base material, binder, abrasive material, and frictional wear modifier, and friction material has the binder of 4.5-7.0 weight % relative to the gross friction material amount, aralkyl modified phenolic resin of at least 50 weight % relative to the binder amount, inorganic particles of 1-3 weight % as the abrasive material with 6-8 of Moh's hardness and average particle diameter of 10-200 μm. Furthermore, the friction material includes alkali metal titanate and / or alkali earth metal titanate of 20-30 weight %.

Owner:NISSHINBO BRAKE INC

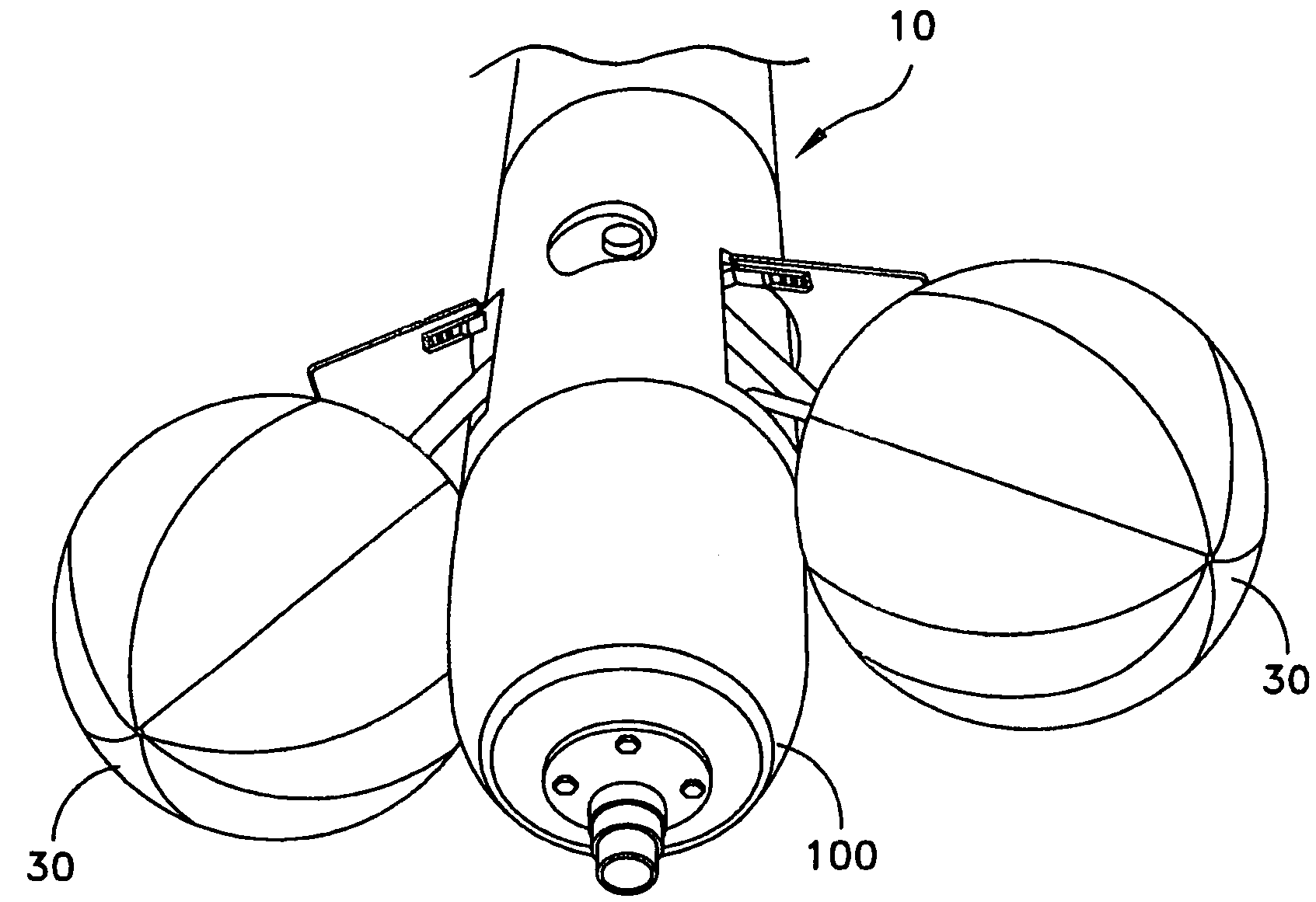

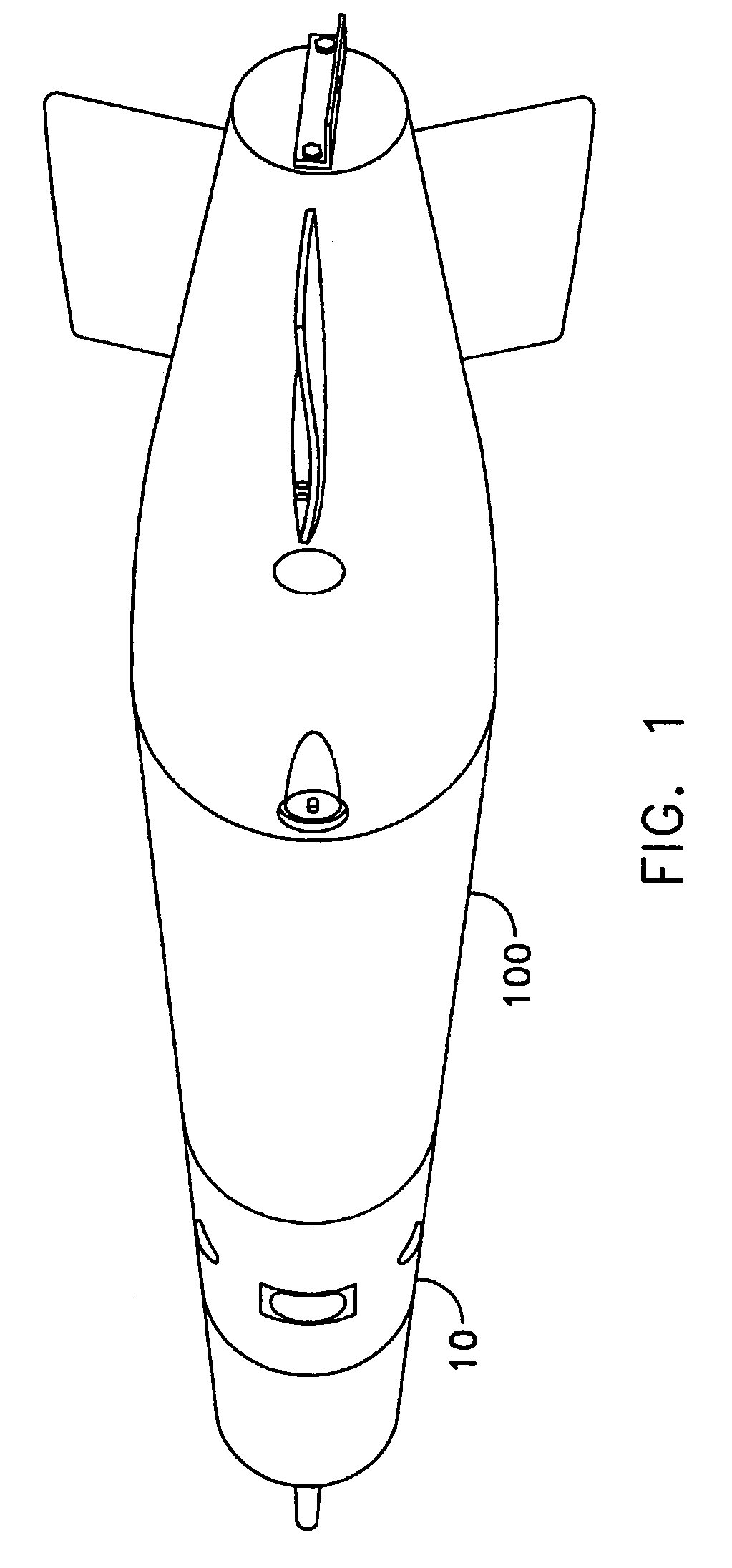

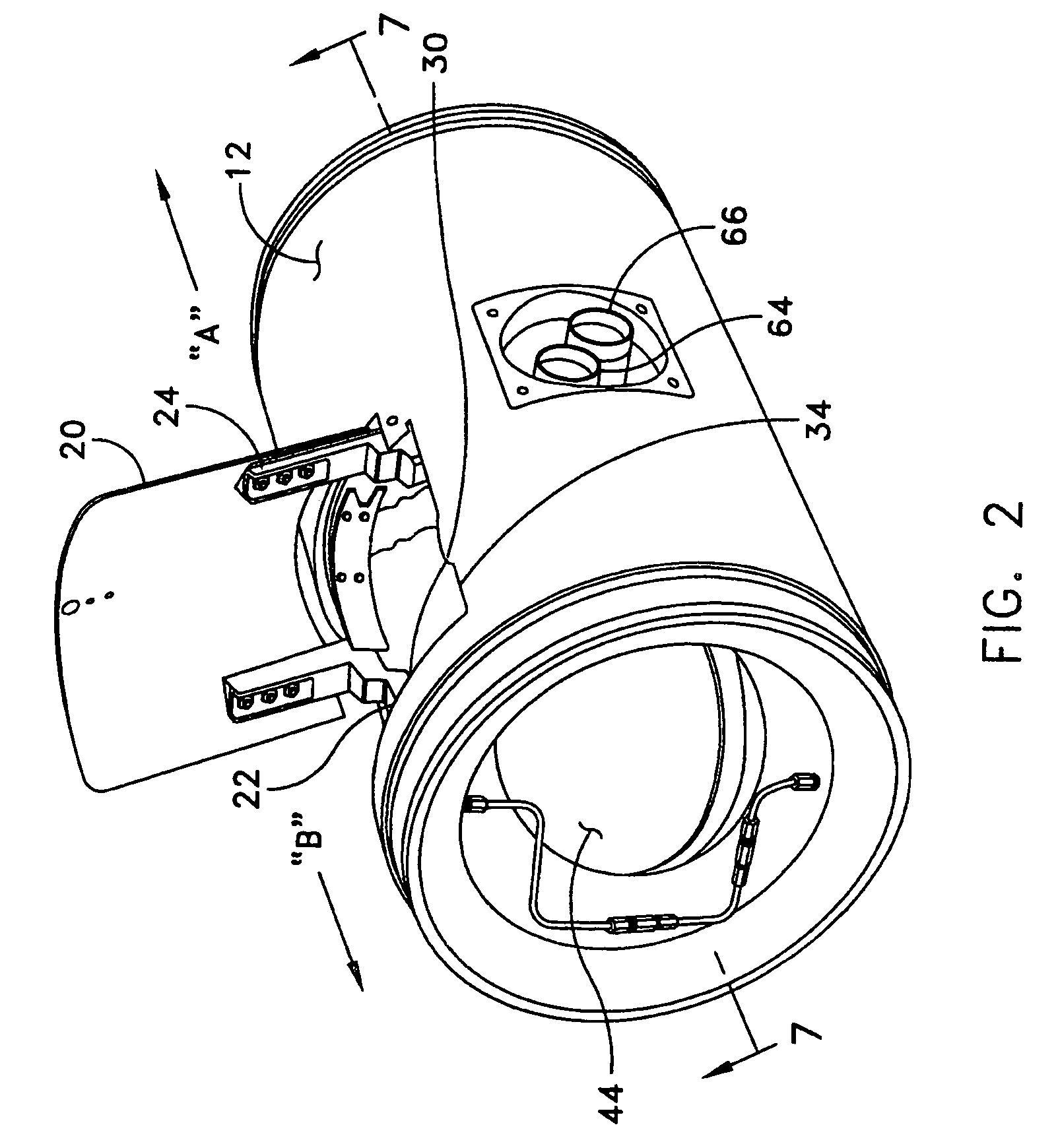

Underwater vehicle deceleration and positive buoyancy assembly

InactiveUS7250568B1Reduce depthShorten the timeMarine torpedoesSelf-propelled projectilesTerminal velocityHydrodynamic forces

An assembly for vehicle deceleration and buoyancy comprises a pair of doors enclosing flotation bags inflatable for buoyant recovery of the torpedo. In operation, the doors are controllably forced open to an initial angle off a longitudinal axis of the assembly to a fully-deployed position by hydrodynamic forces of the movement of the vehicle. From the doors blocking the hydrodynamic forces, the vehicle decelerates. The hydrodynamic braking action of the doors reduces the time required to reach terminal velocity, thus reducing the depth the vehicle sinks and enabling recovery with less gas required for inflation.

Owner:UNITED STATES OF AMERICA

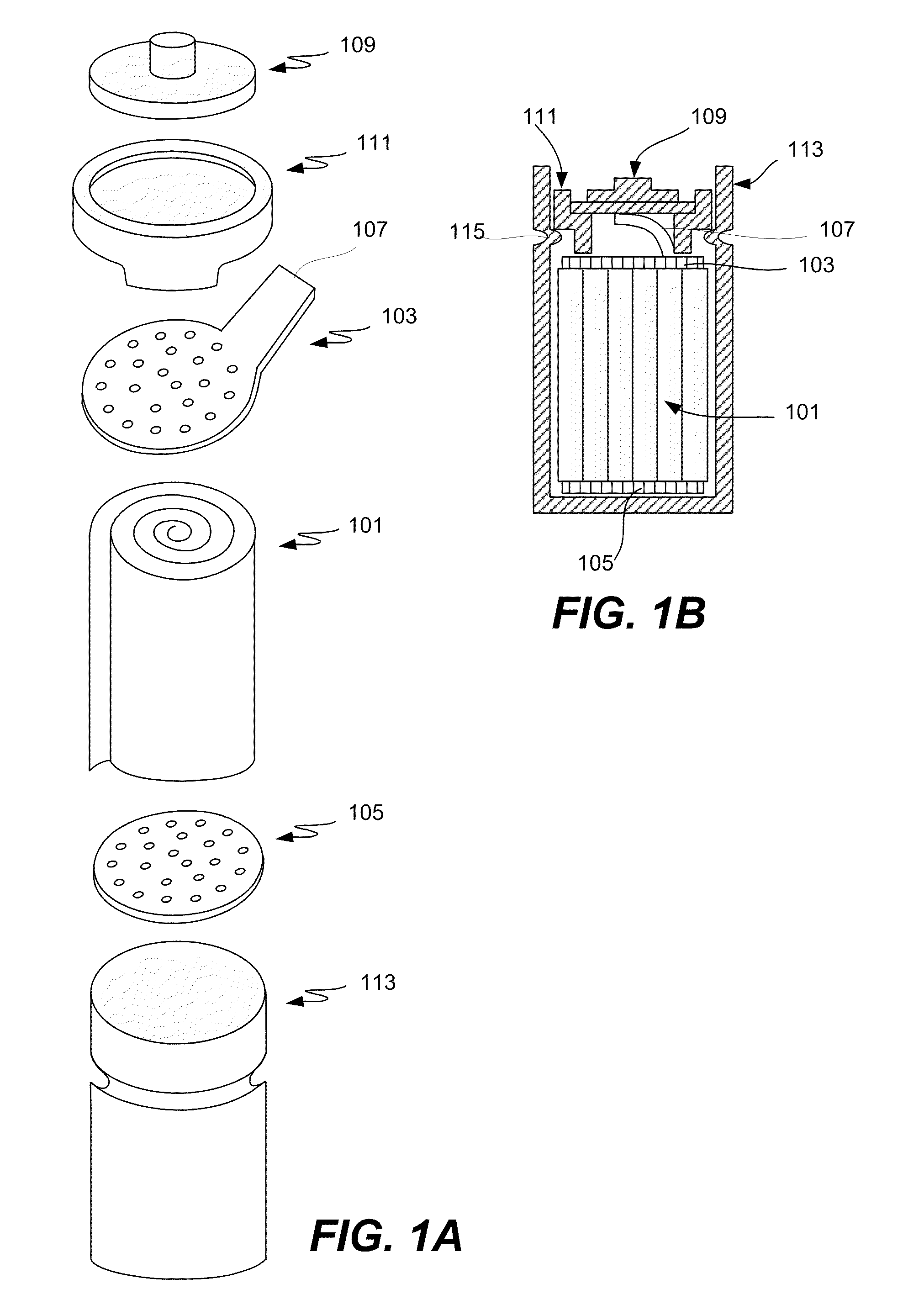

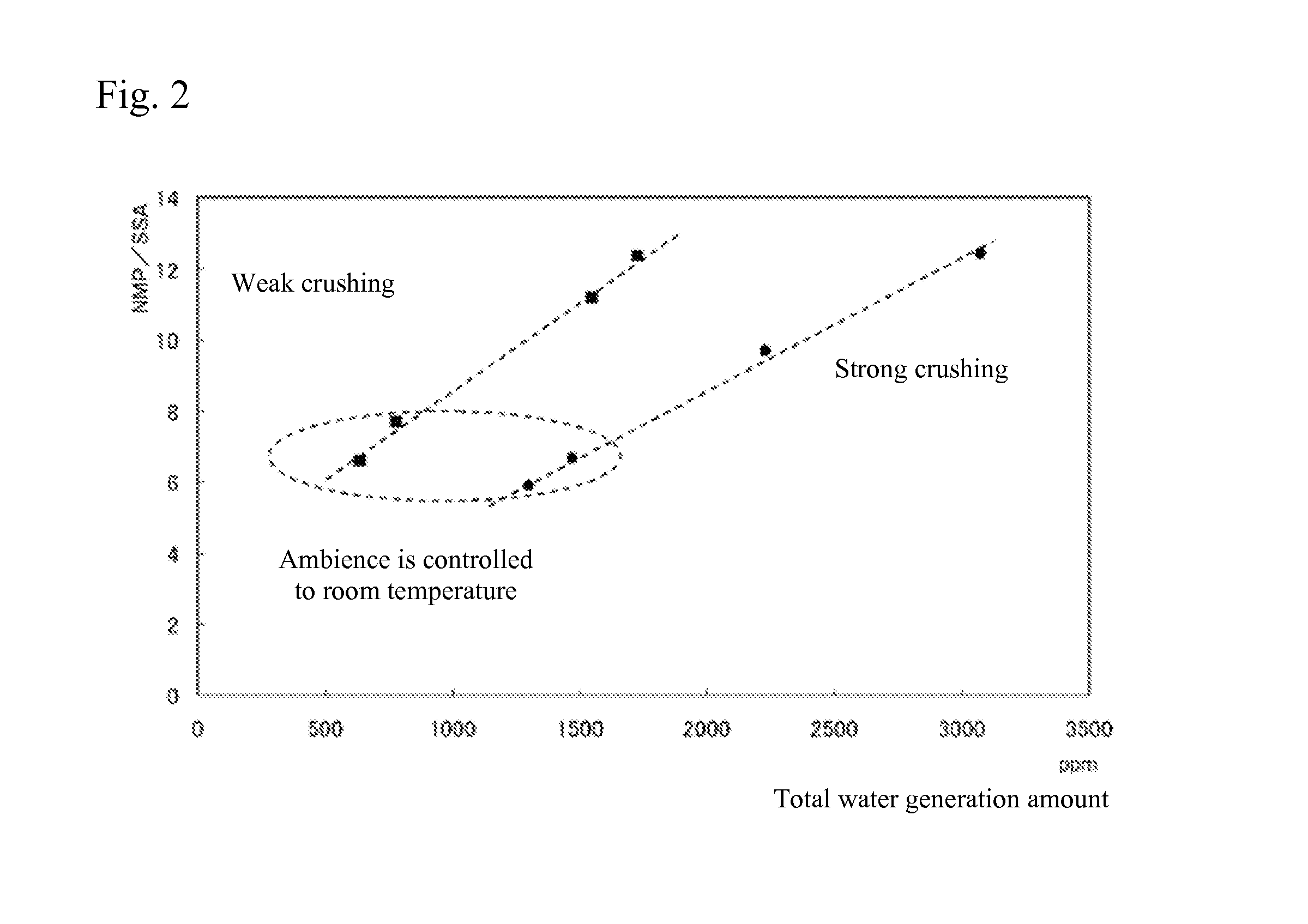

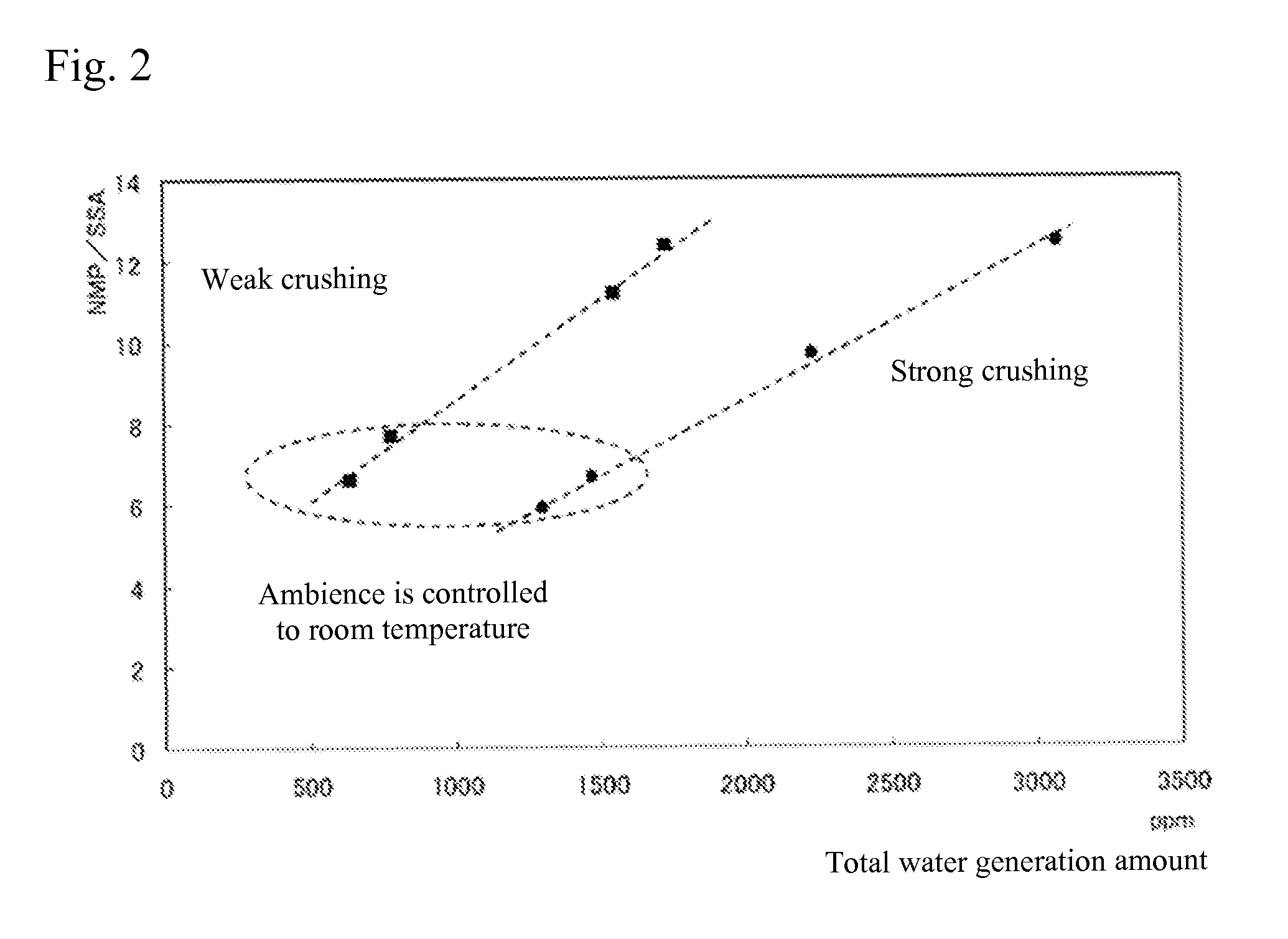

Lithium-titanium complex oxide and manufacturing method thereof, and battery electrode using same

ActiveUS20130343983A1Improve securityImprove stabilityAlkali titanatesCell electrodesTitaniumLithium compound

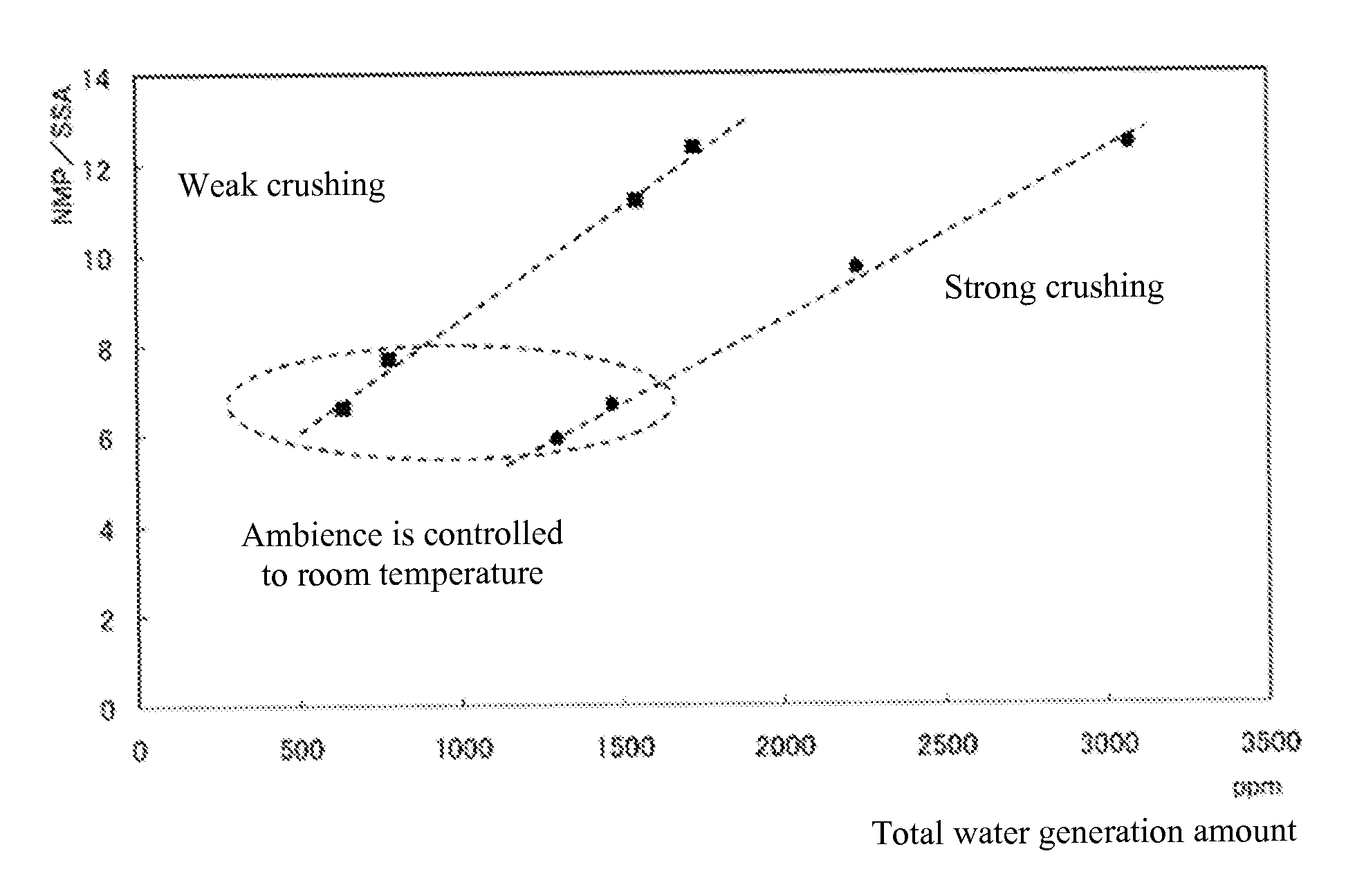

A lithium-titanium complex oxide whose total water generation amount and total carbon dioxide generation amount measured by thermal decomposition GC-MS are preferably 1500 wt ppm or less and 2000 wt ppm or less, respectively, is obtained by subjecting a mixture of titanium compound and lithium compound to a heat treatment at 600° C. or above, cooling the obtained reaction product to 50° C. or below, and then subjecting the cooled reaction product to a reheat treatment involving heating to the maximum temperature of 300 to 700° C. and then cooling, wherein the dew point of the ambience of the reheat treatment is controlled at −30° C. or below at a temperature of 200° C. or above.

Owner:TAIYO YUDEN KK

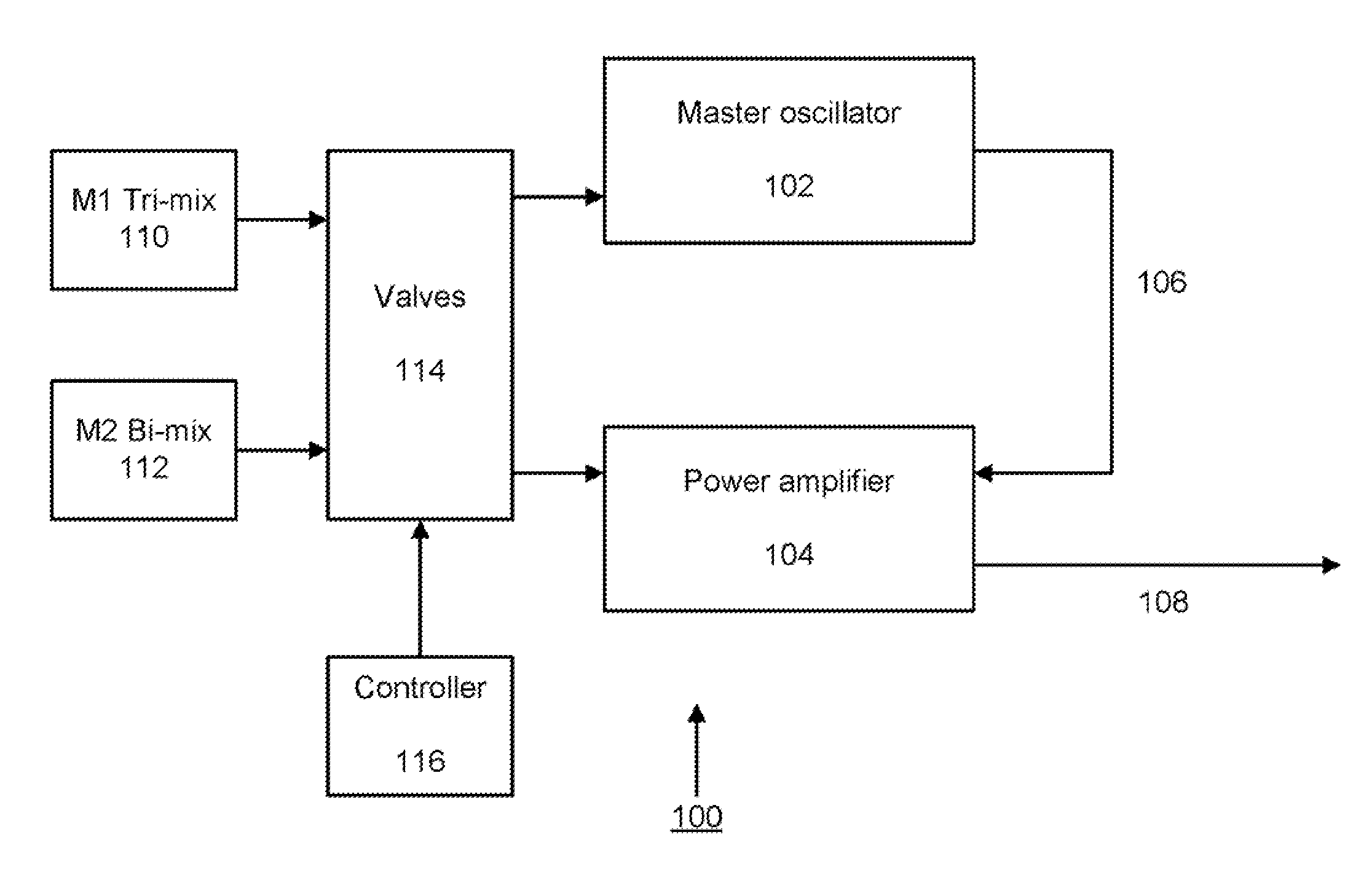

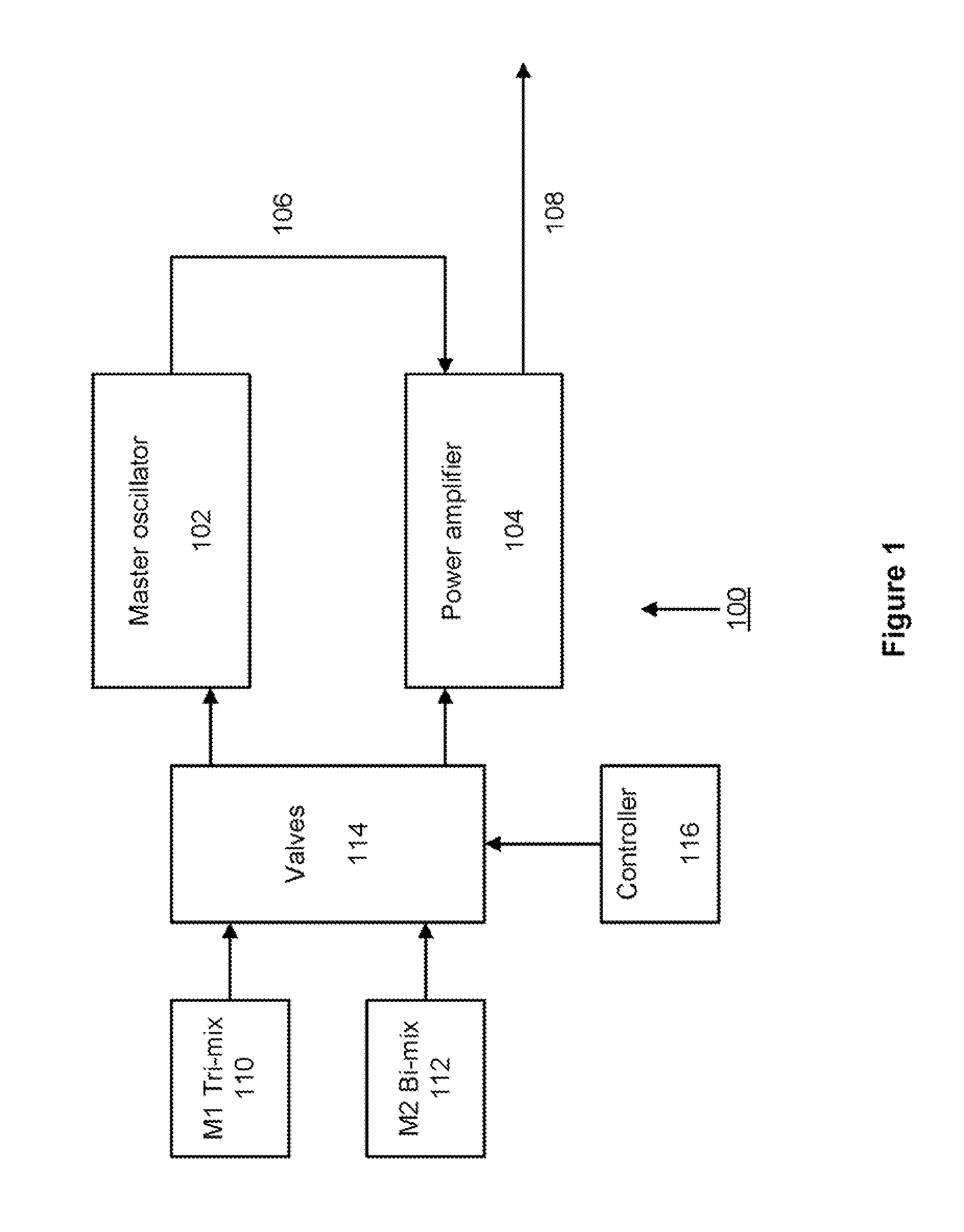

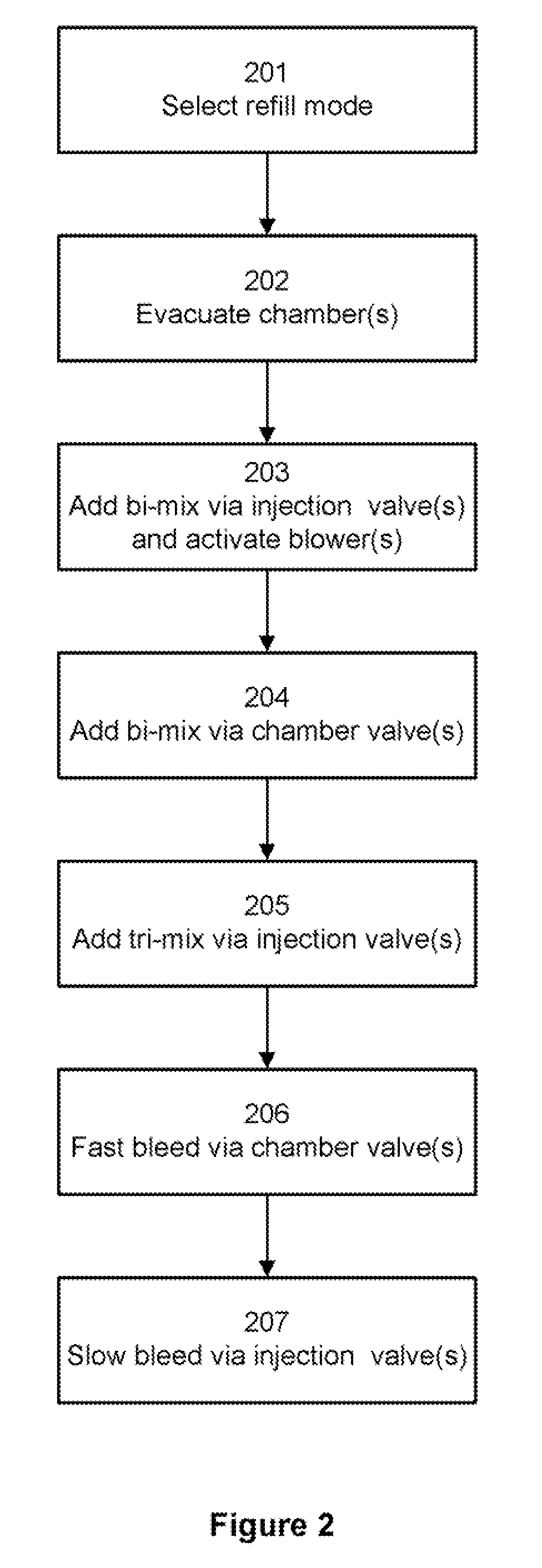

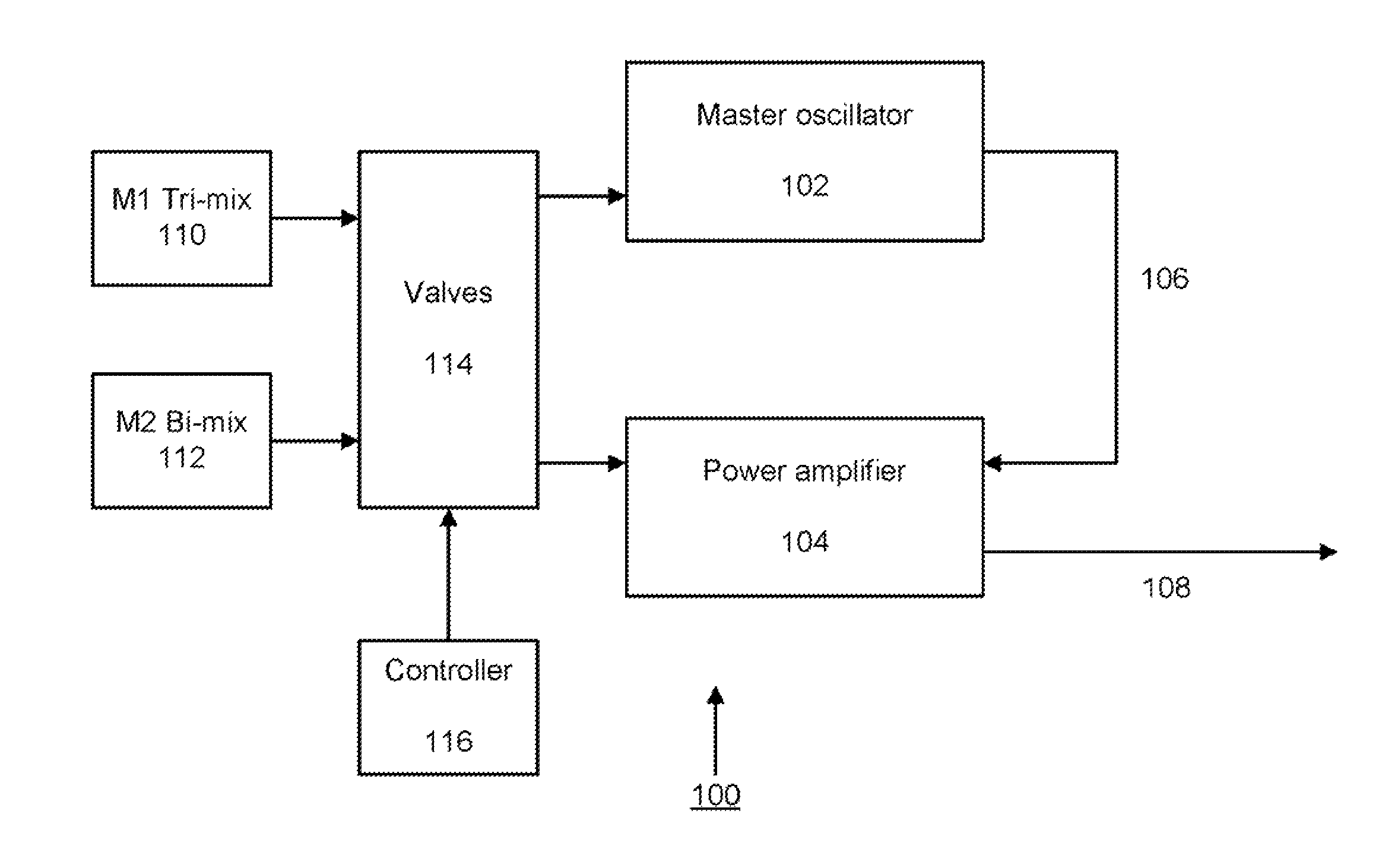

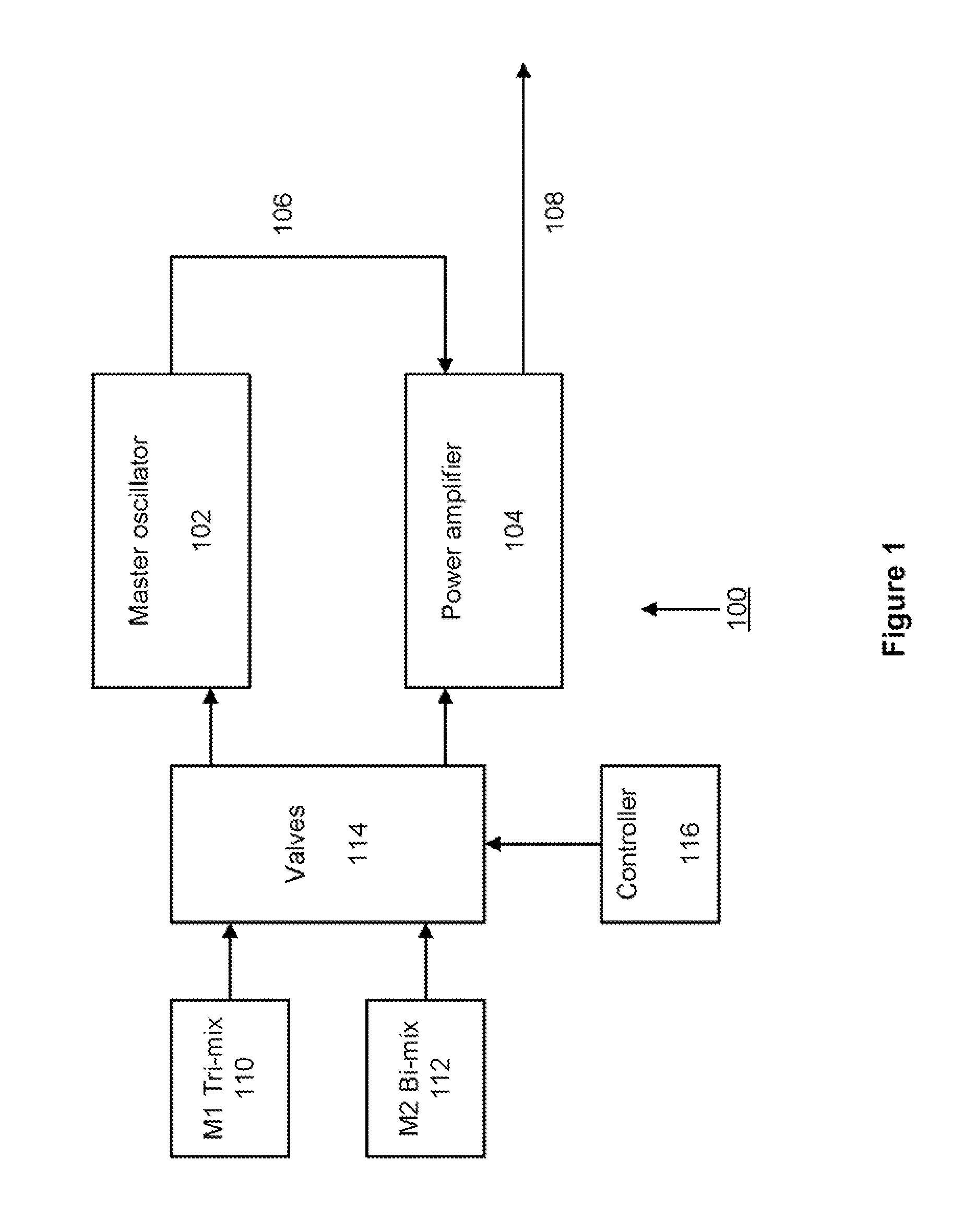

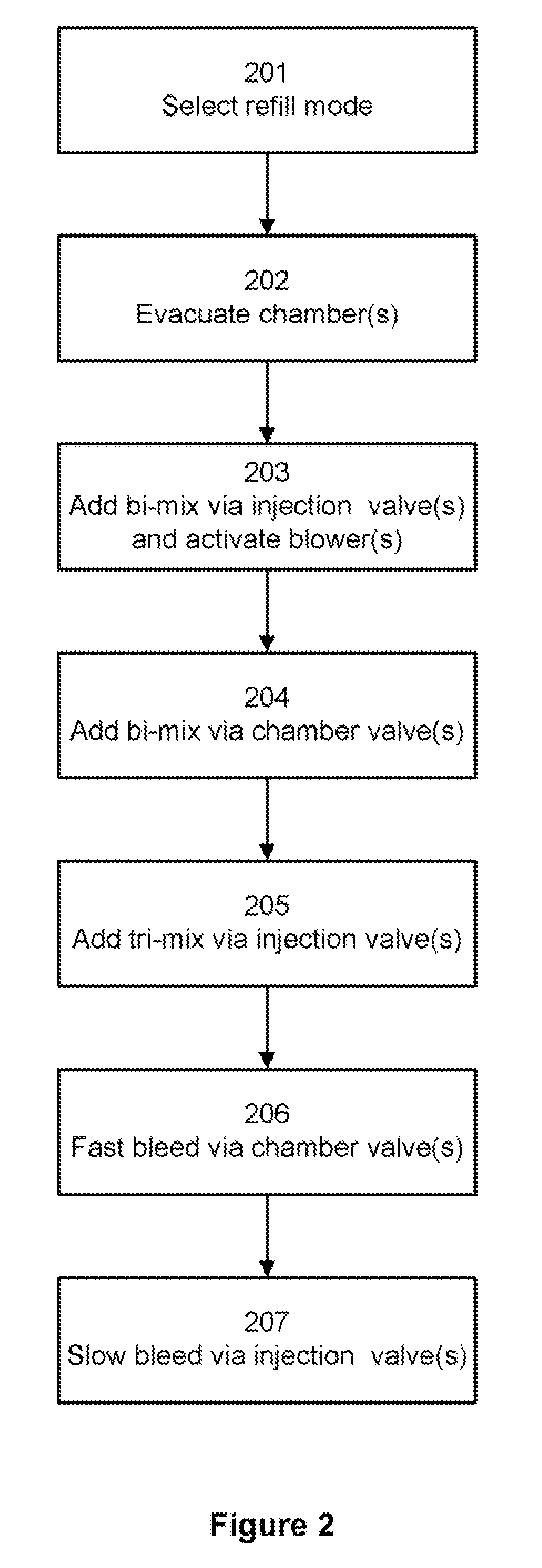

System and Method for High Accuracy Gas Refill in a Two Chamber Gas Discharge Laser System

ActiveUS20130000773A1Ensure correct executionLess gasPackaging by pressurising/gasifyingActive medium materialHalogenProcess engineering

Systems and methods for automatically performing a high accuracy gas refill in a laser chamber of a two chamber gas discharge laser such as an excimer laser are disclosed. Based upon a target pressure and halogen concentration that is either predetermined or entered by a user, and with no further user action, a non-halogen containing gas is added to the chamber to a first pressure, followed by the addition of halogen containing gas to a second pressure which is greater than a target pressure for the chamber, such that the halogen content in the gas at the second pressure is at a desired concentration. The gas in the chamber is bled until the pressure drops to the target pressure. The amount of non-halogen containing gas added is estimated automatically, and the amount of halogen containing gas is measured so that the desired concentration is obtained, taking into account both temperature and any gas remaining in the fill pipes from prior laser operation.

Owner:CYMER INC

Pasted zinc electrode for rechargeable nickel-zinc batteries

ActiveUS8501351B2High viscositySimple working processFinal product manufacturePrimary cellsElectrolytic agentElectrical battery

Active material for a negative electrode of a rechargeable zinc alkaline electrochemical cell is made with zinc metal particles coated with tin and / or lead. The zinc particles may be coated by adding lead and tin salts to a slurry containing zinc particles, a thickening agent and water. The remaining zinc electrode constituents such as zinc oxide (ZnO), bismuth oxide (Bi2O3), a dispersing agent, and a binding agent such as Teflon are then added. The resulting slurry / paste has a stable viscosity and is easy to work with during manufacture of the zinc electrode. Further, the zinc electrode is much less prone to gassing when cobalt is present in the electrolyte. Cells manufactured from electrodes produced in accordance with this invention exhibit much less hydrogen gassing, by as much as 60-80%, than conventional cells. The cycle life and shelf life of the cells is also enhanced, as the zinc conductive matrix remains intact and shelf discharge is reduced.

Owner:ZINCFIVE POWER INC

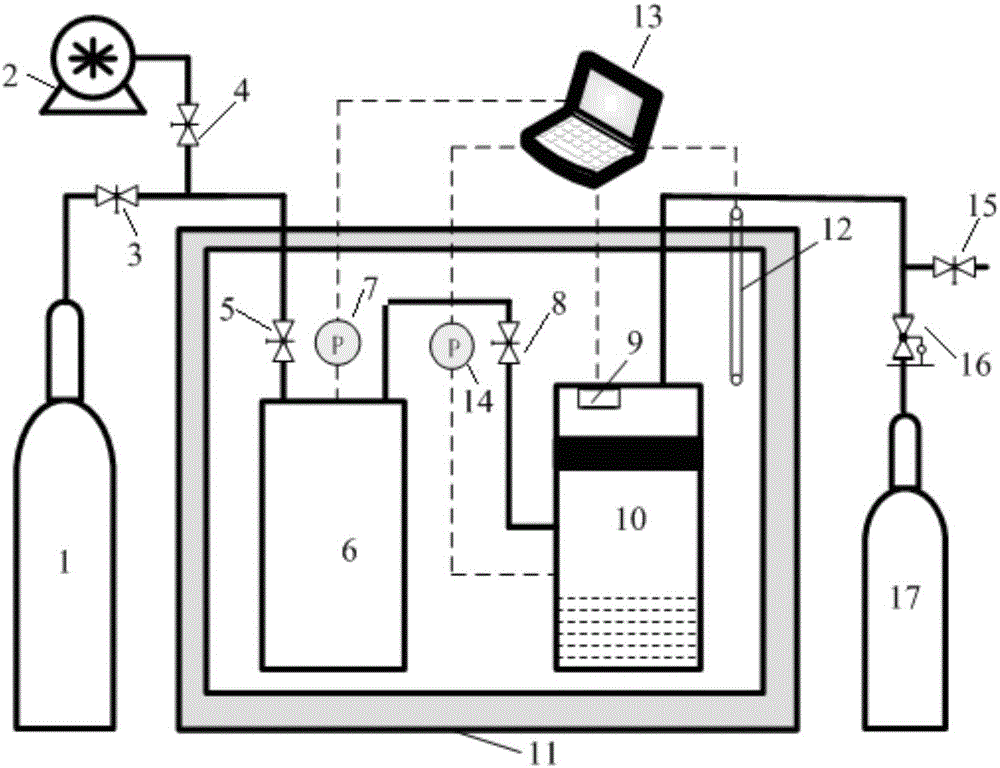

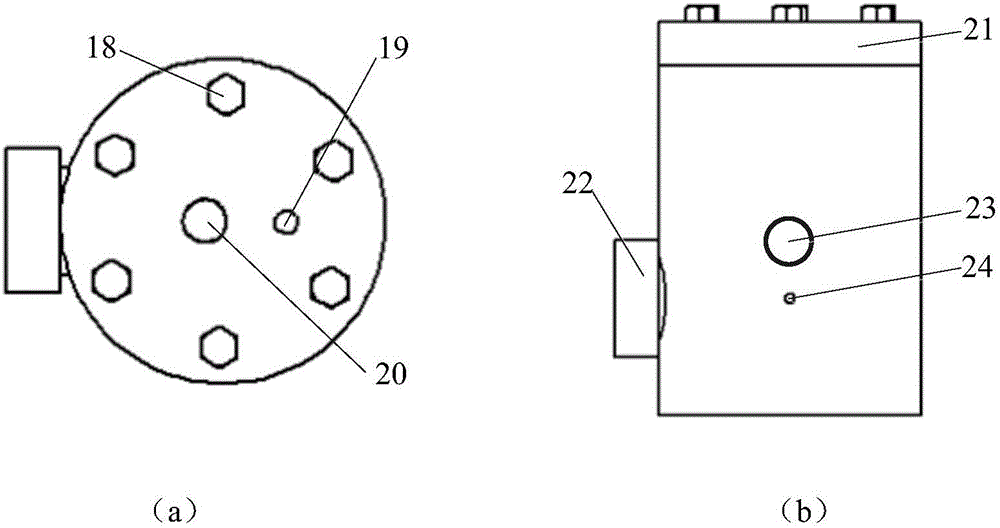

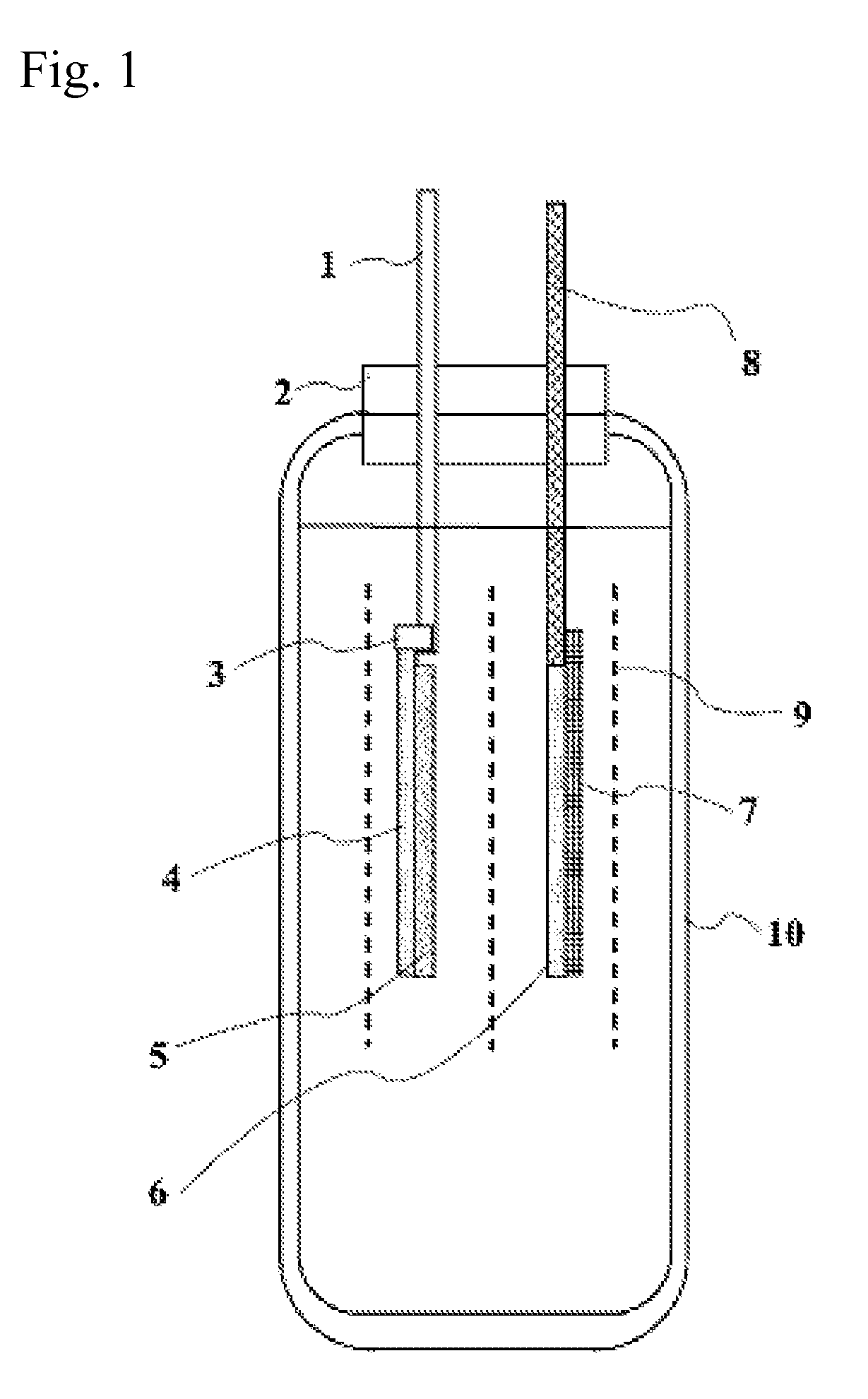

Device and method for measuring diffusion coefficients of variable-volume constant-pressure gas in liquid

ActiveCN106769689ARealize measurementLess liquidDiffusion analysisPlatinum resistanceMeasurement device

The invention discloses a device and method for measuring diffusion coefficients of variable-volume constant-pressure gas in liquid. The device mainly comprises a gas sample bottle, a gas cavity, a diffusion cavity, a thermostatic bath, a valve, a vacuum pump, a reducing valve, a displacement sensor, a pressure sensor, a platinum resistance thermometer and a data acquisition system, wherein the diffusion cavity adopts a visible window structure with quartz glass; the diffusion cavity is equipped with the pressure sensor and the displacement sensor; the pressure of the diffusion cavity is kept constantly by a movable piston and a pressure-controlled gas cylinder in the diffusion process; the movement distance of the movable piston in the measurement process is measured by the displacement sensor; diffusion data of the gas in the liquid are calculated and obtained through the Fick's second law. The device realizes measurement of diffusion data of the gas in the liquid at the constant pressure, and has the advantages of simple structure, low cost, convenience in operation and stable system.

Owner:XI AN JIAOTONG UNIV

Sandwiched tubular airbags

ActiveUS20070252367A1Less gasAvoid serious injuryPedestrian/occupant safety arrangementEngineeringAirbag

Sandwiched tubular safety airbags are disclosed. An example sandwiched tubular safety airbag comprises an air tube truss (2) formed by a bending hollow air tube (21), a lower air cushion (4) and an upper air cushion (1). The lower air cushion (4) is provided at the bottom of the air tube truss (2), and the upper air cushion (1) is provided on top of the air tube truss (2). An inlet opening (5) is provided on the bottom surface of the lower air cushion (4). The end openings of the hollow air tube (21) of the air tube truss (2) are charging openings (3) of the air tube truss (2). Charging holes (11) are provided at joints of the lower air cushion (4) with the charging openings (3) of the air tube truss (2). The top of the air tube truss (2) is provided with one or more discharging holes (6) communicating with the upper air cushion (1).

Owner:HUNAN UNIV STATE KEY LAB OF ADVANCED DESIGN & MFR FOR VEHICLE BODY

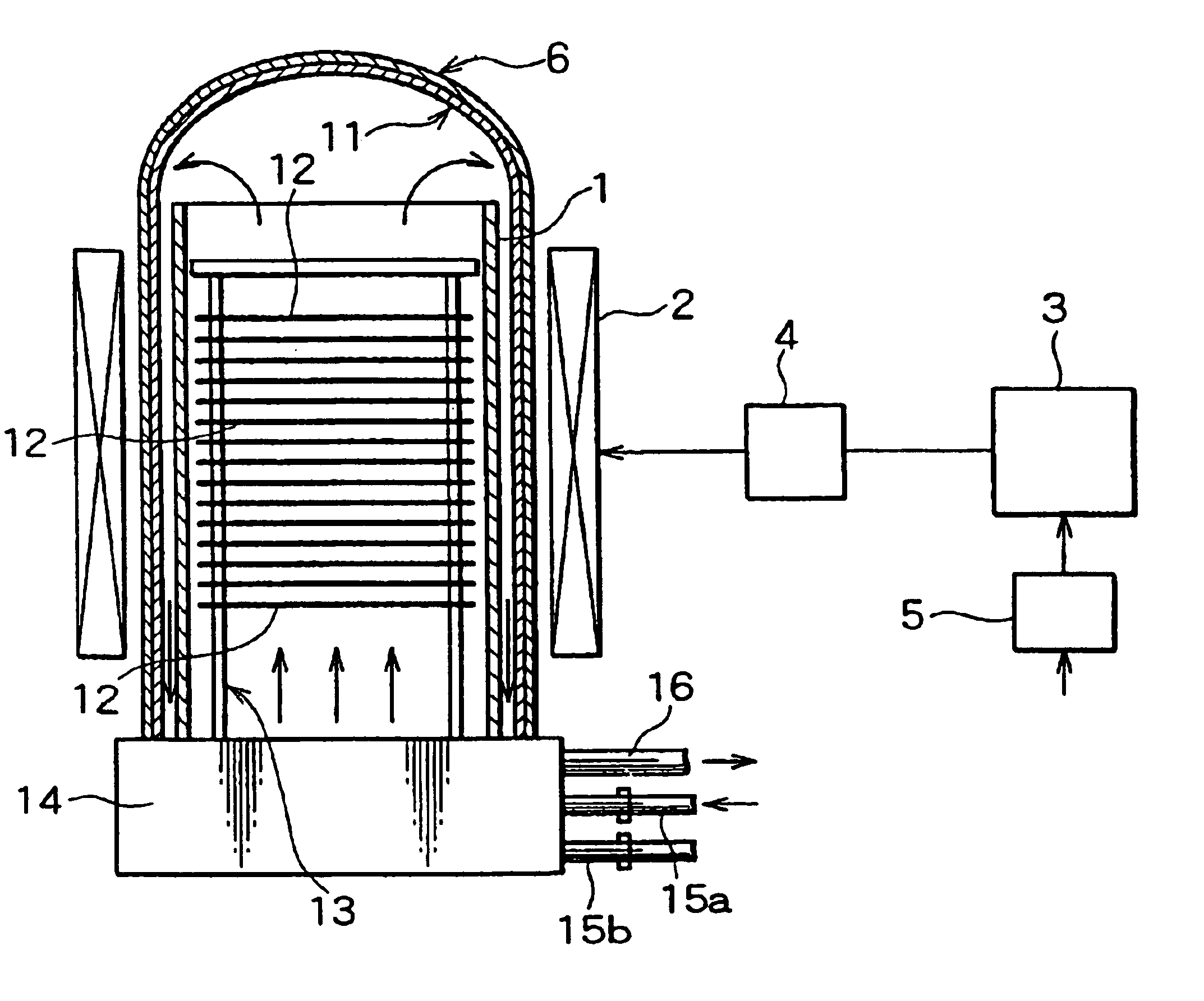

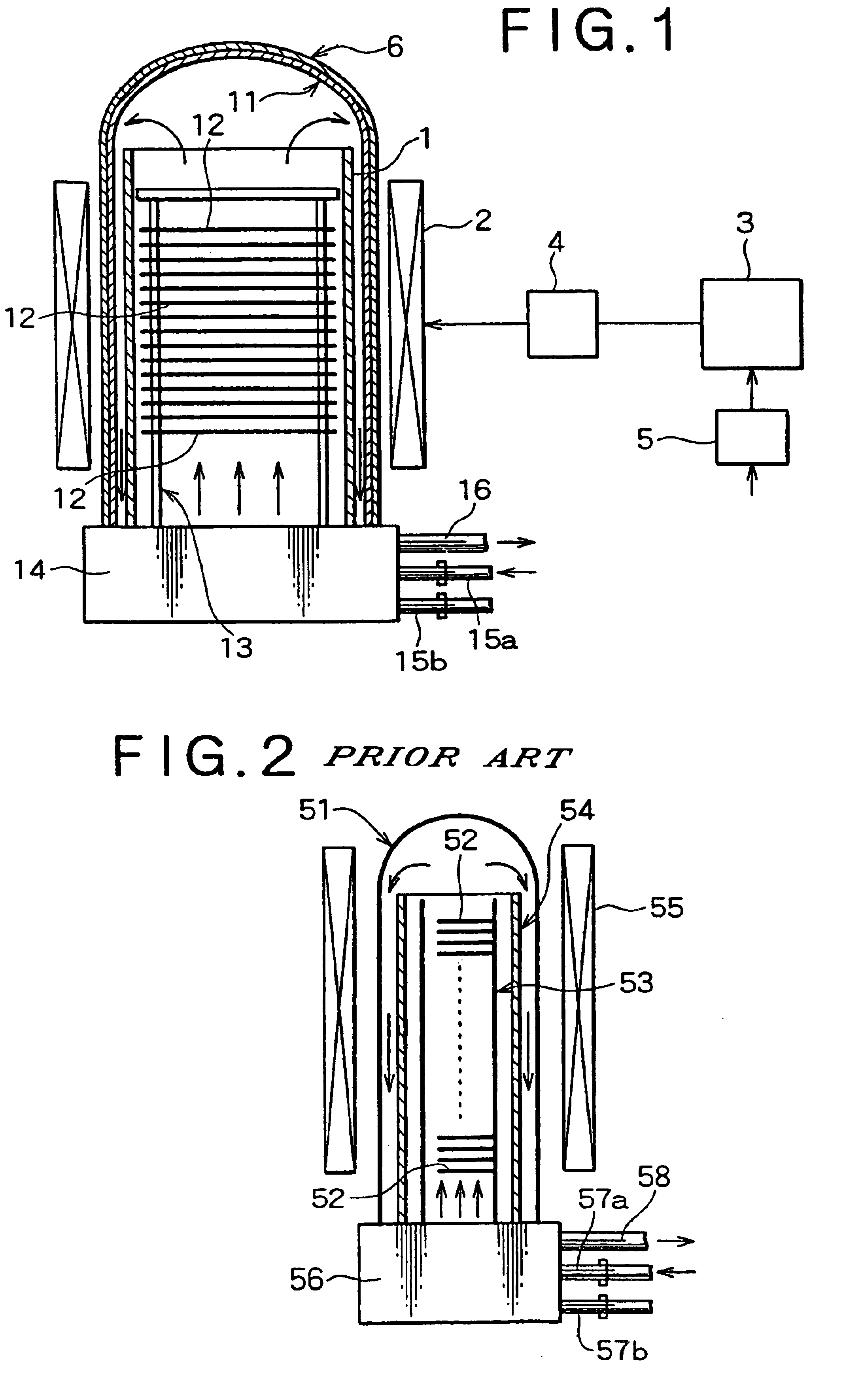

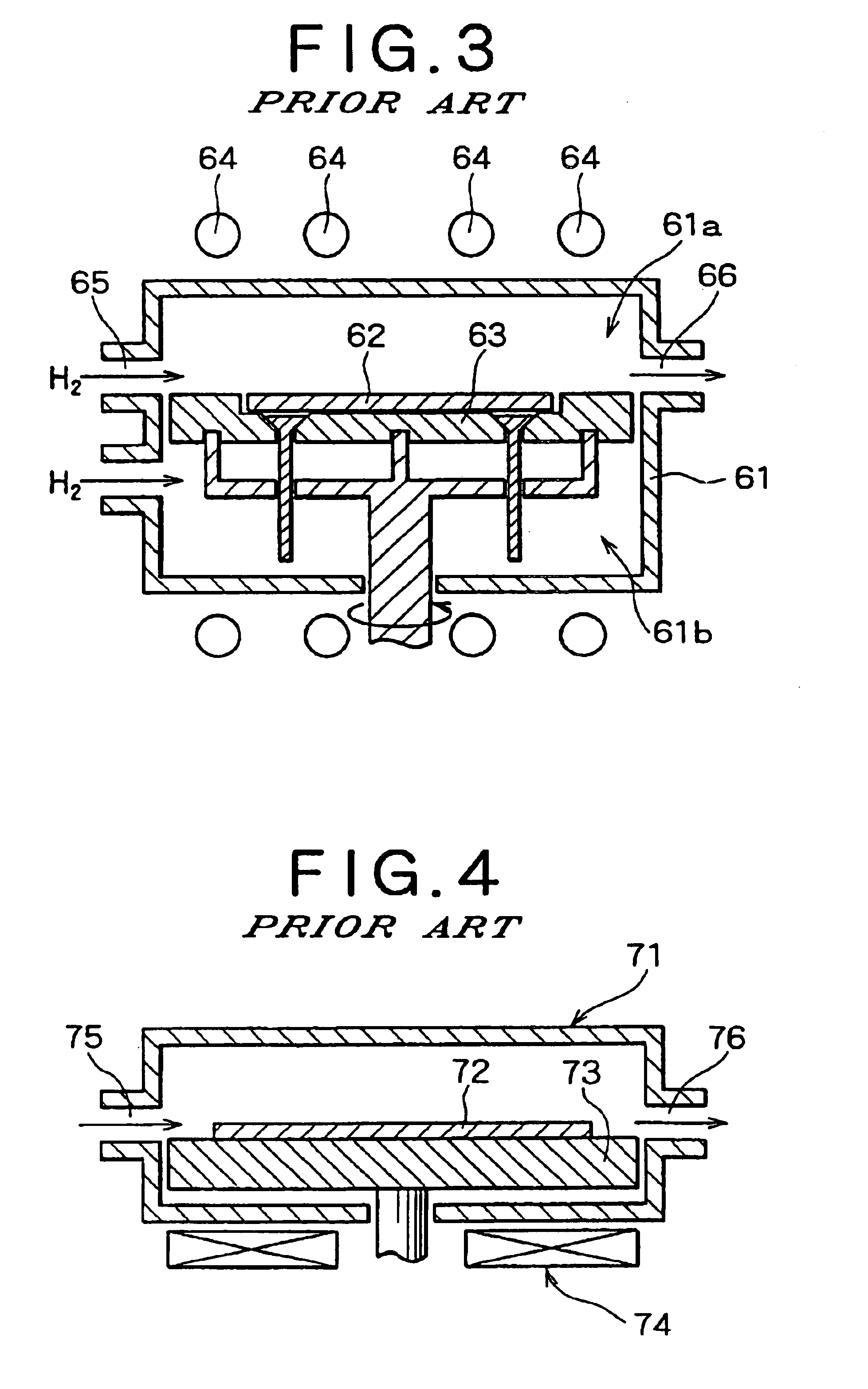

Heating apparatus using induction heating

InactiveUS6932872B2Temperature is raised and loweredIncrease volumeFurnaces without endless coreSemiconductor/solid-state device manufacturingIntegrated circuit manufacturingEngineering

A heating apparatus which is installed in a low pressure CVD system or annealing equipment for use in semiconductor integrated circuit manufacturing processes for heat-treating wafers on which IC's are to be formed, wherein wafers are uniformly heated, the temperature of wafers is rapidly raised and lowered, and wafers are processed in high volume, wherein the apparatus comprises a cylindrical body made of glass-like carbon placed inside a reactor, and a high-frequency induction coil which is placed outside the reactor and is for causing the cylindrical body made of glass-like carbon to produce heat and thereby heating wafers in the reactor.

Owner:KOBE STEEL LTD

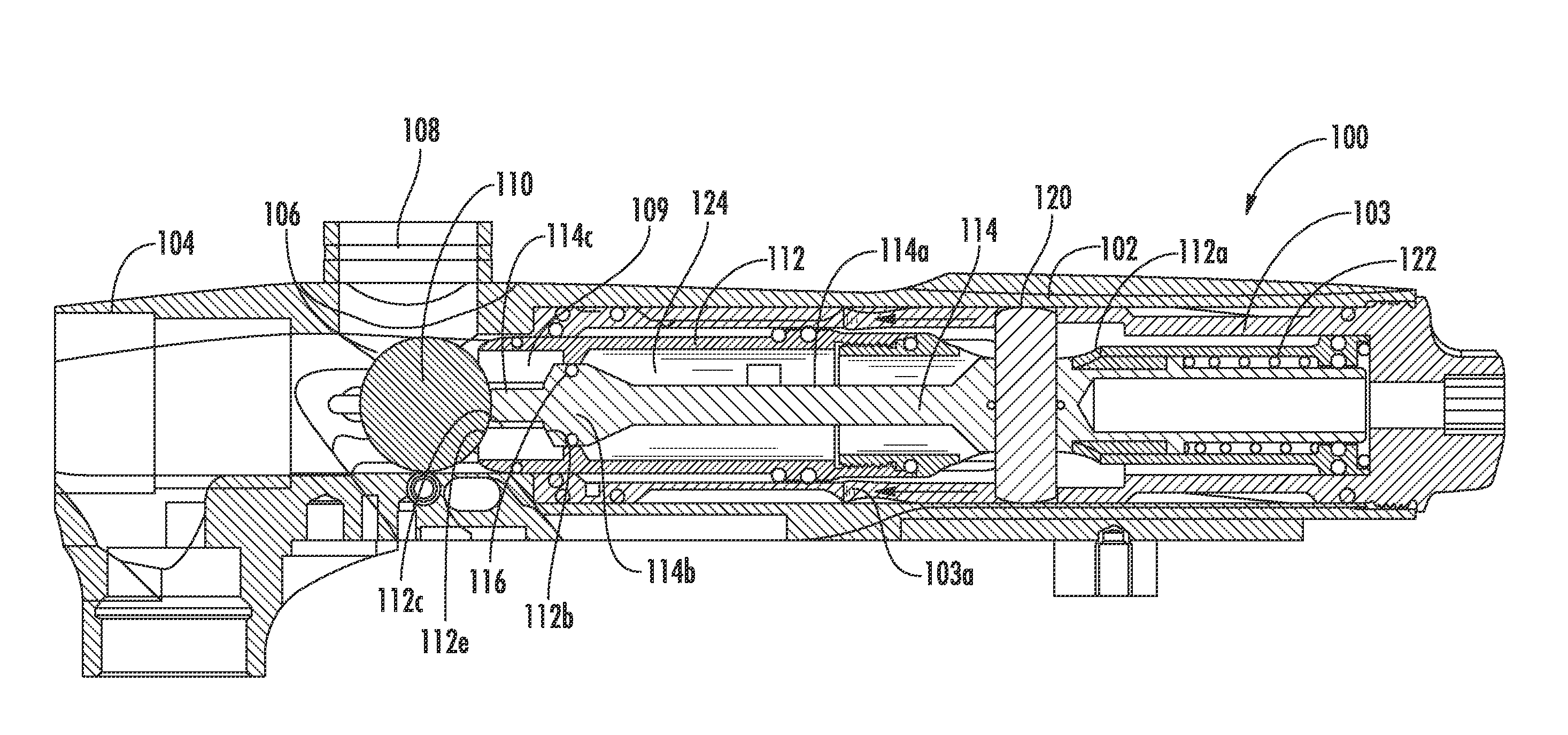

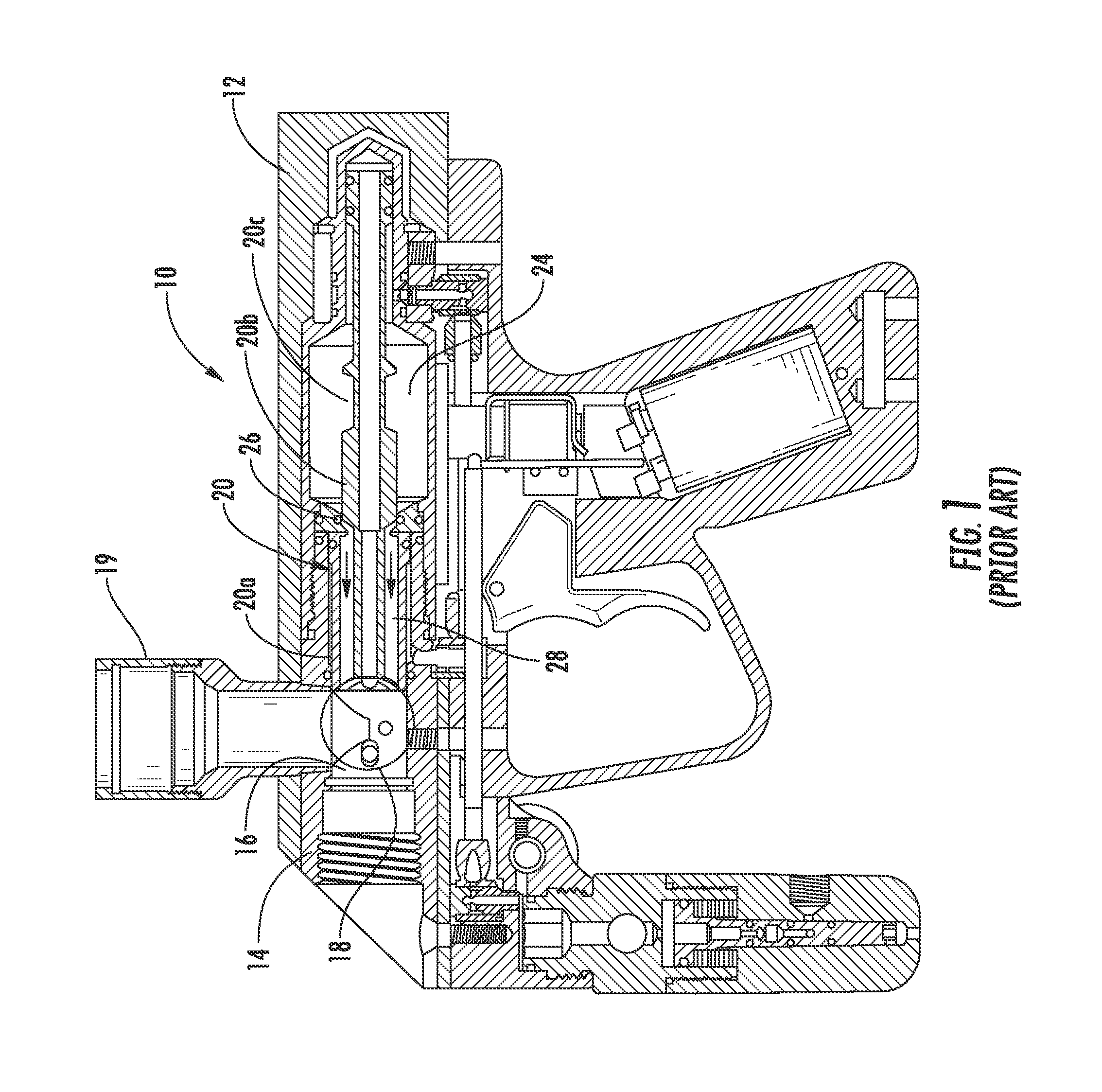

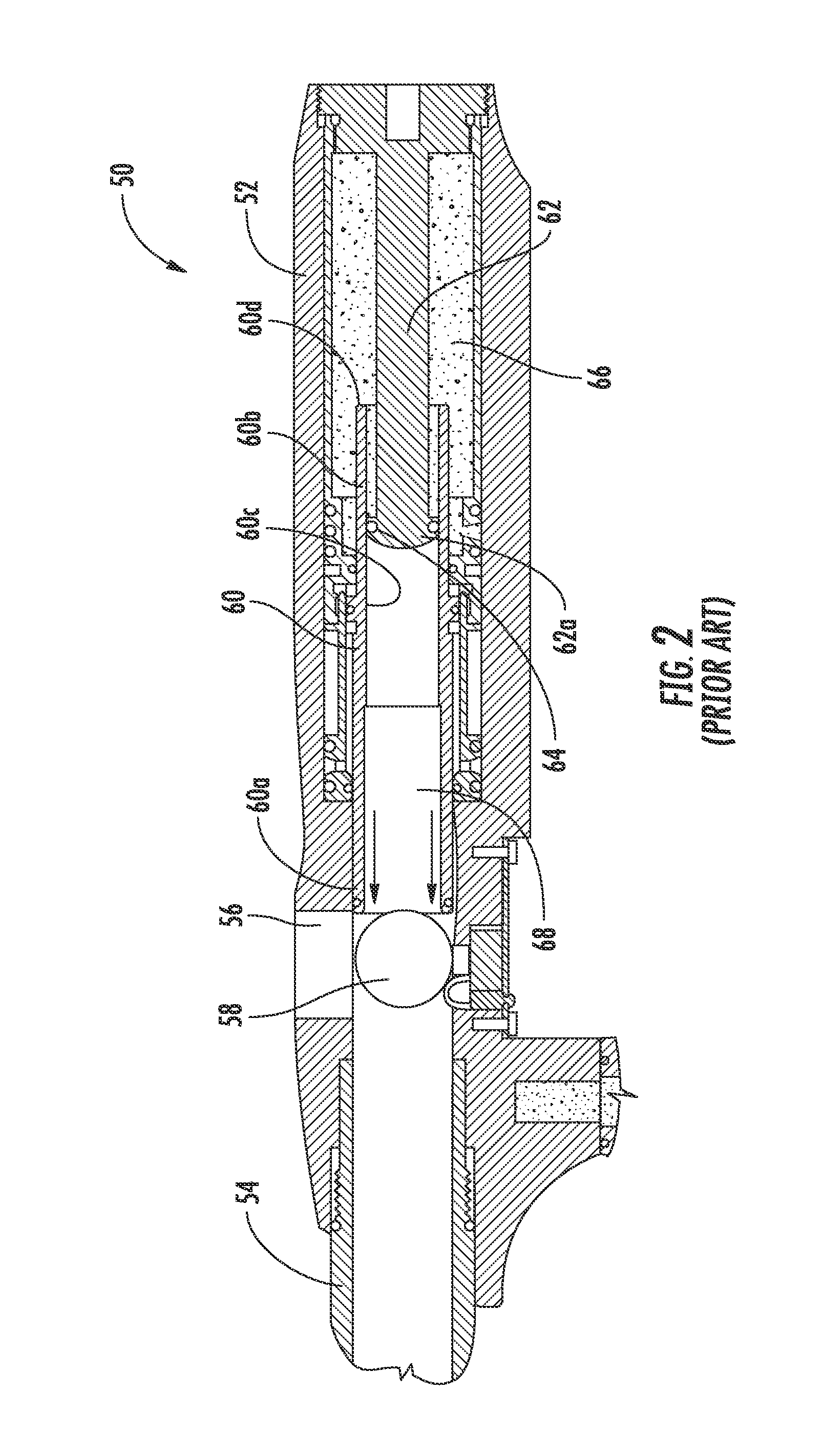

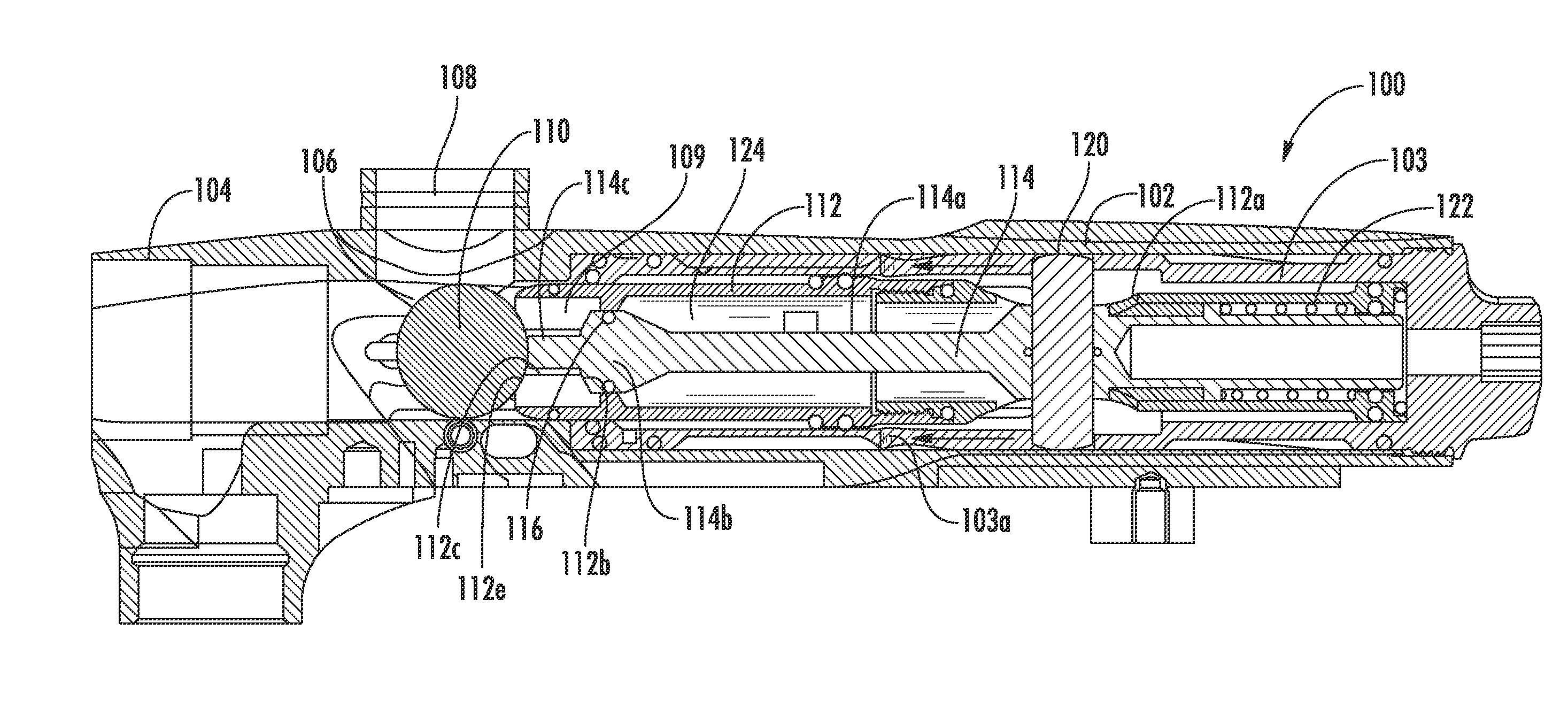

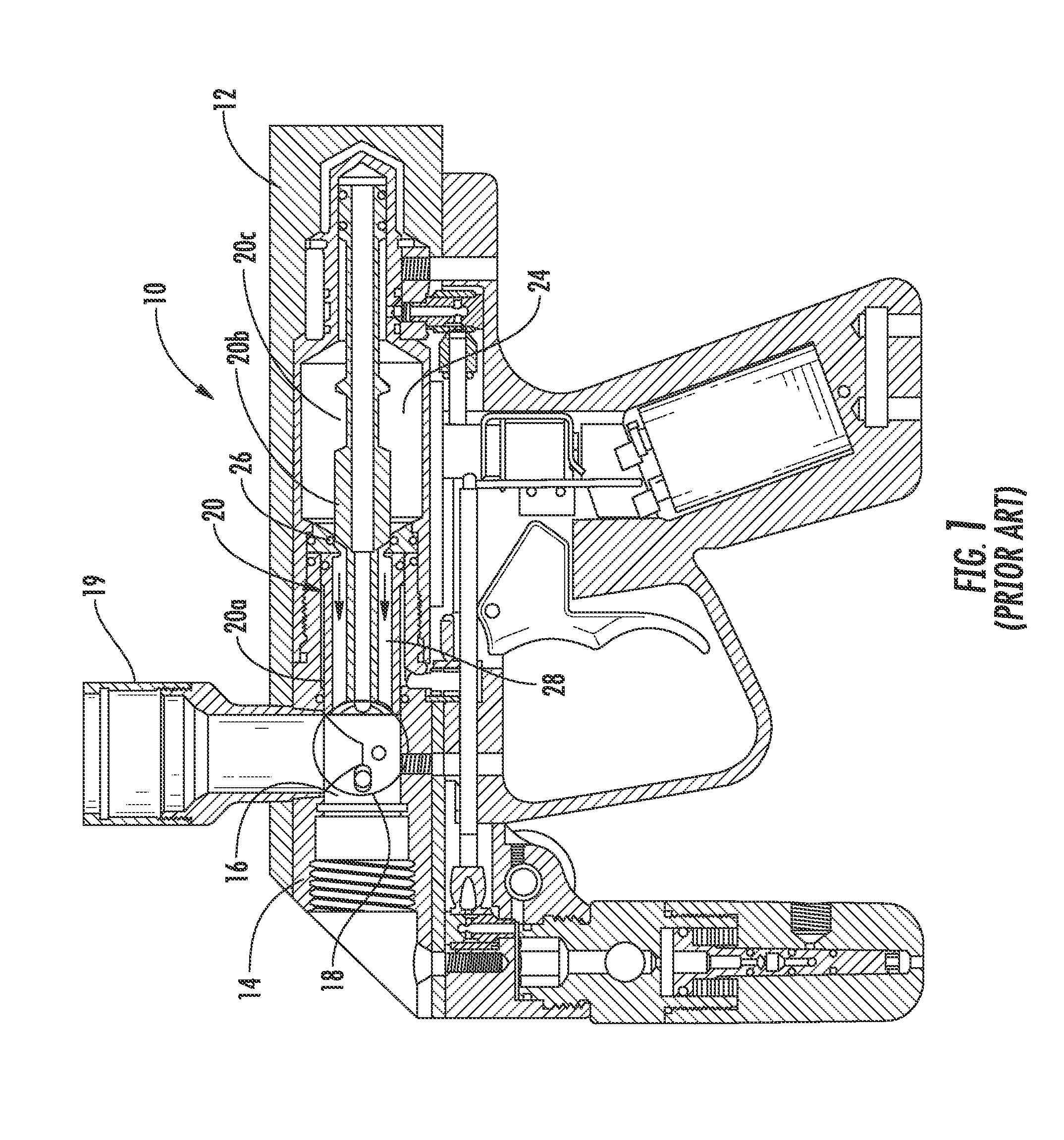

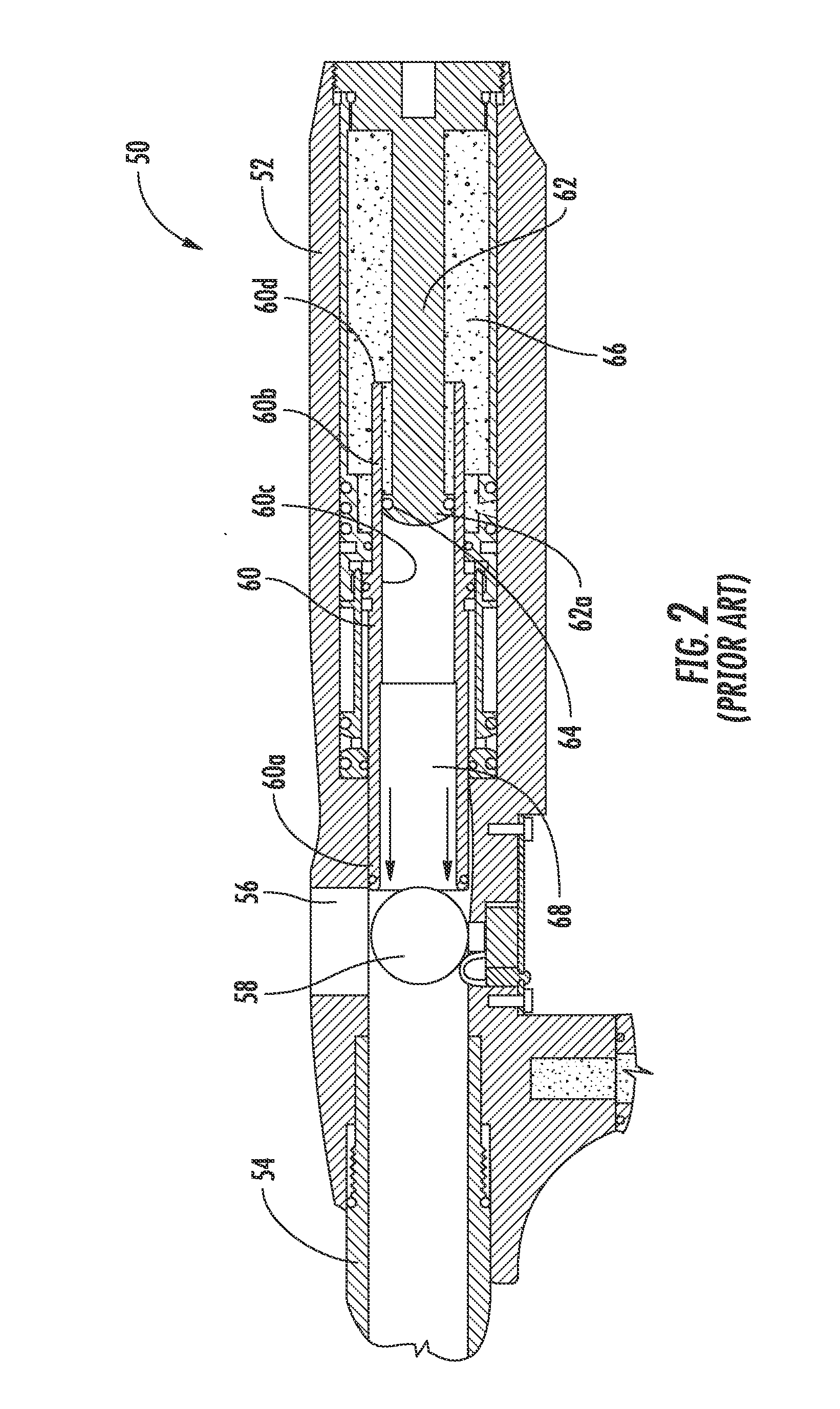

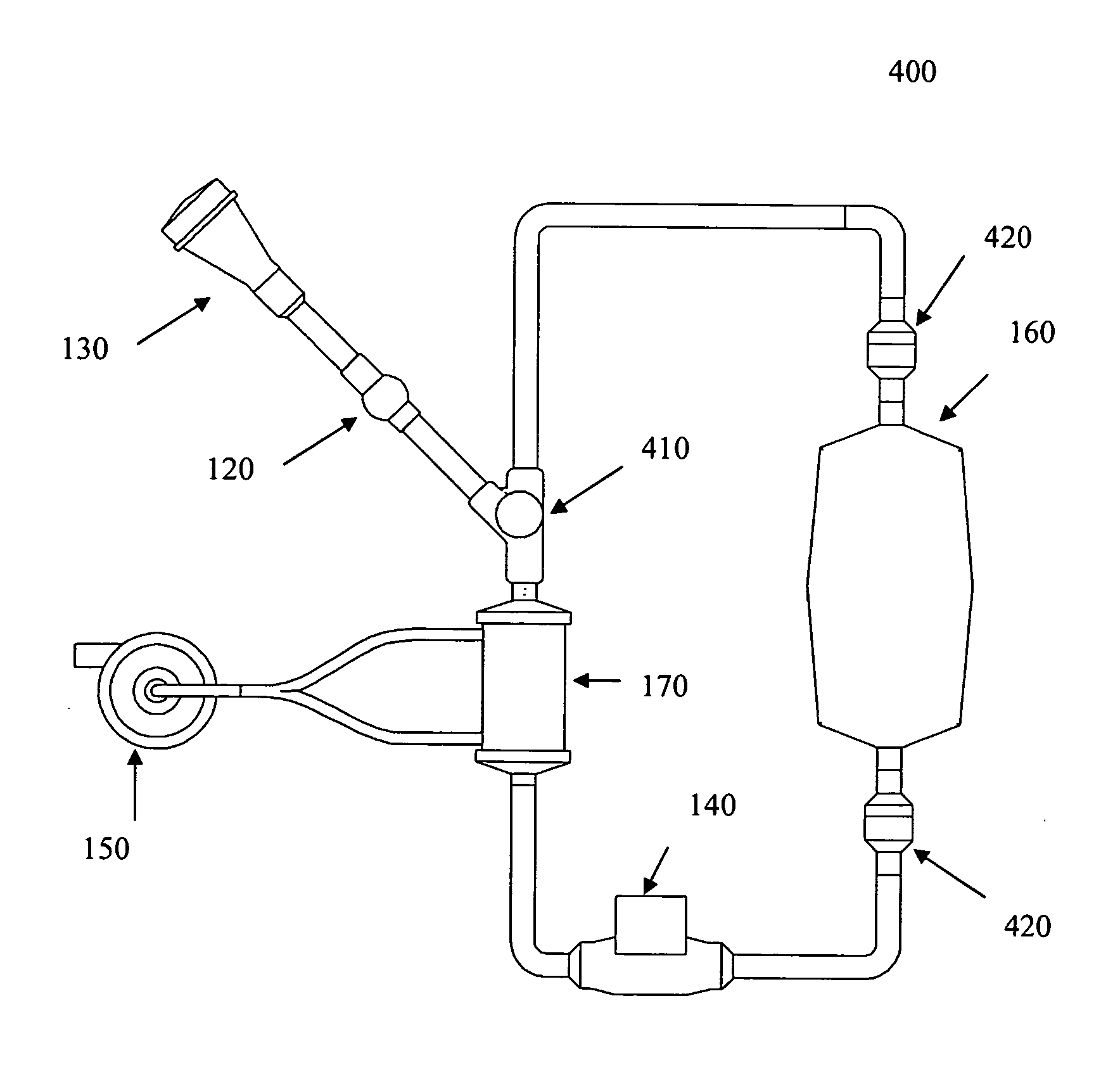

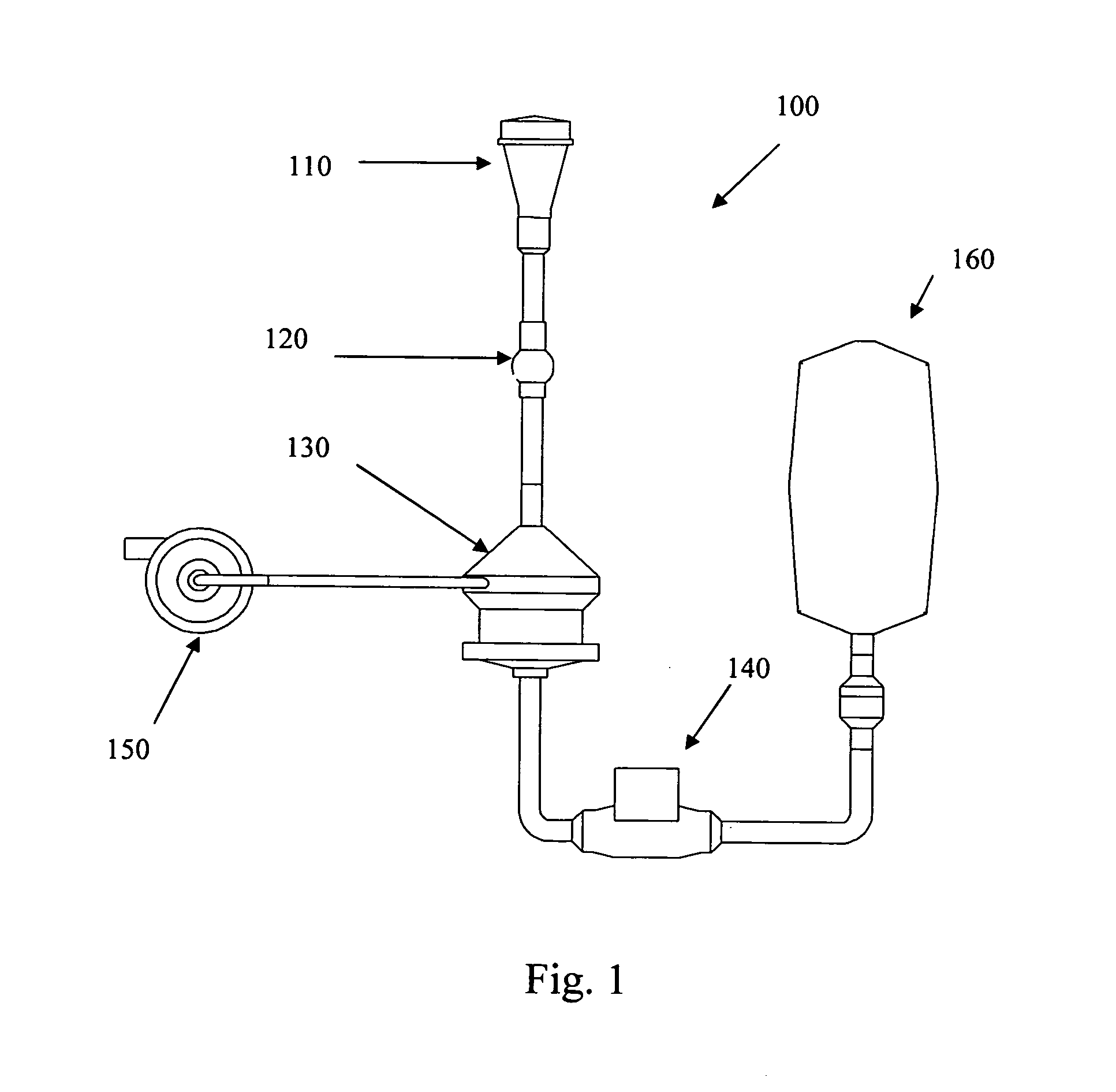

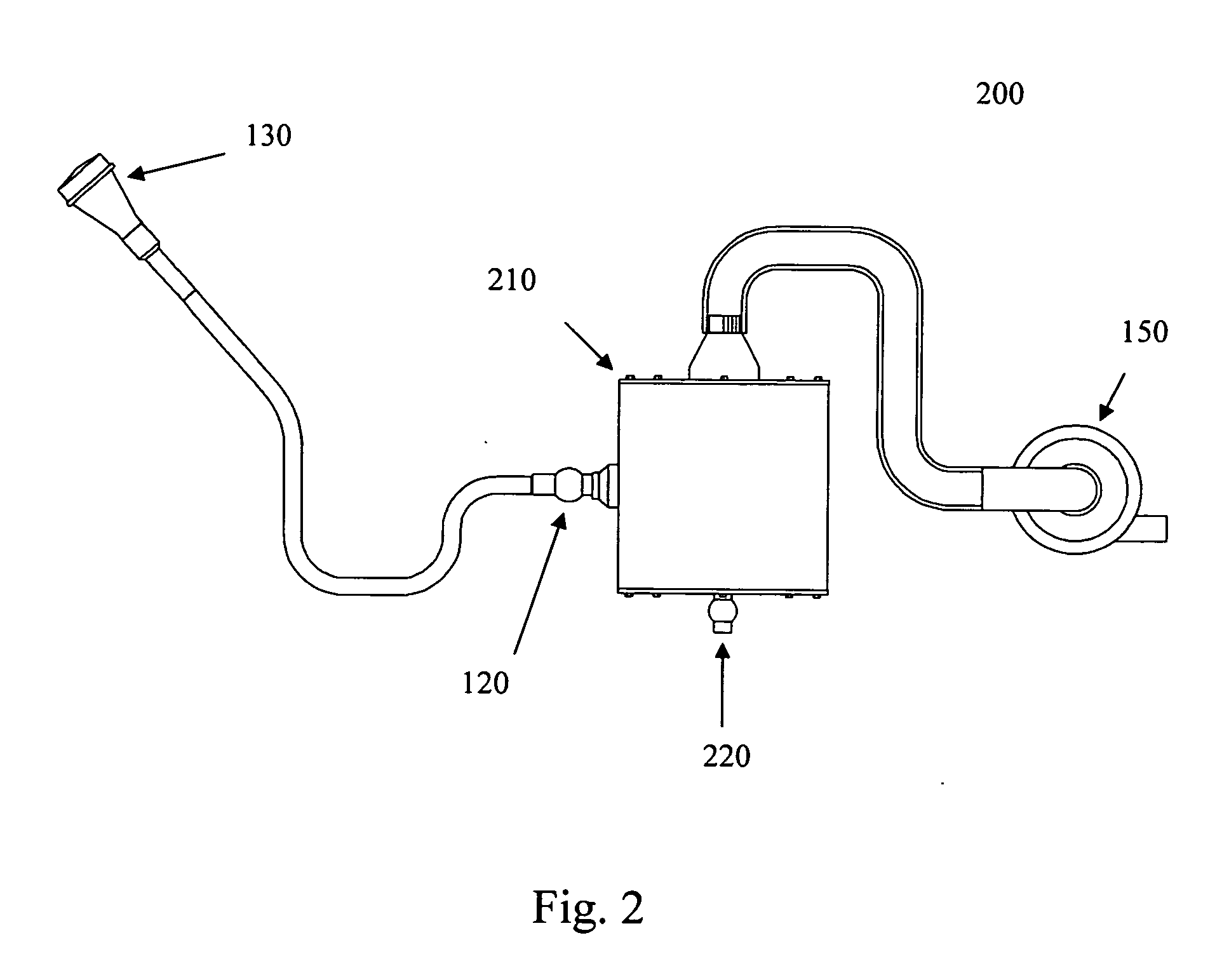

Bolt and valve mechanism that uses less gas

The proposed invention is a new bolt and gas release valve mechanism for a projectile launching device, such as a paintball marker, that uses significantly less gas per shot than prior art devices. The open gas chamber between the projectile, such as a paintball, and the gas release mechanism is eliminated thereby requiring much less gas to be used for each launch of a given projectile. Thus, only the launching gas to propel the projectile is needed and not the additional gas required to fill the chamber in the bolt directly behind the projectile. This enables desirably smaller gas supply tanks to be used during use to launch the same number of projectiles. Also, with the present invention, more projectiles can be launched using the same gas supply tank.

Owner:PLANET ECLIPSE

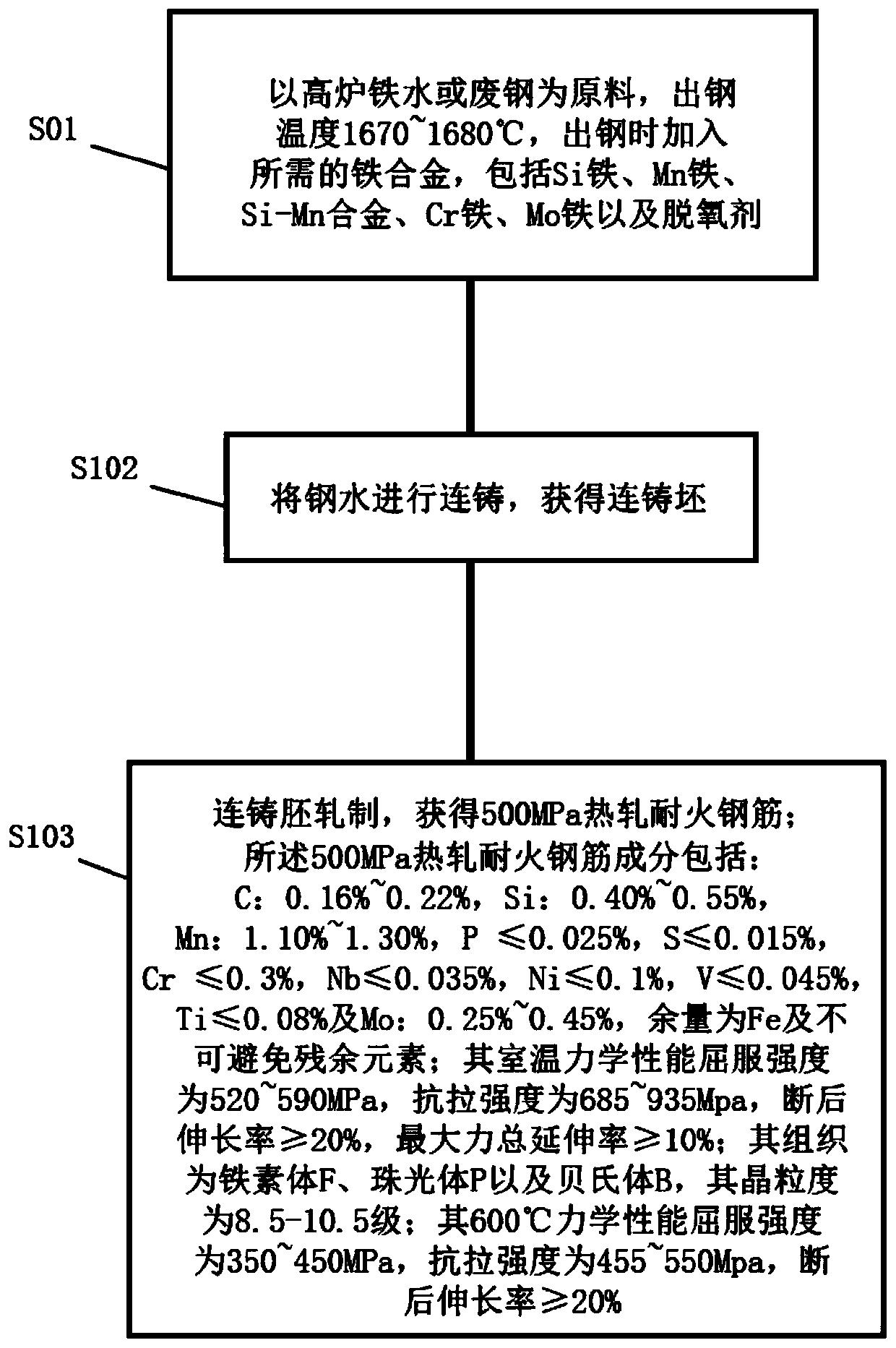

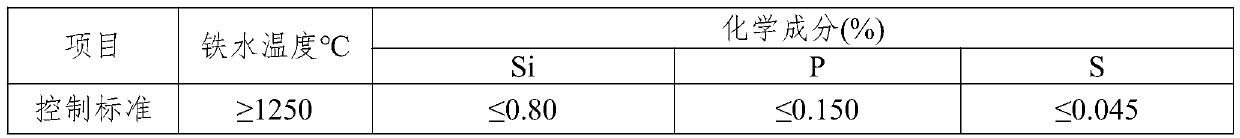

500MPa hot-rolled refractory steel bar and manufacturing method thereof

ActiveCN110923585AReasonable design of ingredientsTaking into account the room temperatureManufacturing convertersProcess efficiency improvementRebarUltimate tensile strength

The invention discloses a 500MPa hot-rolled refractory steel bar, of which the room-temperature mechanical property yield strength is 520-590 MPa, the tensile strength is 685-935 MPa, the percentage elongation after fracture is larger than or equal to 20%, and the maximum total elongation is larger than or equal to 10%. The 500MPa hot-rolled refractory steel bar comprises ferrite F, pearlite P andbainite B; the grain size is 8.5-10.5 grade; the mechanical property yield strength at 600 DEG C is 350-450 MPa; the tensile strength is 455-550 MPa; and the percentage elongation after fracture is larger than or equal to 20%. The invention further discloses a manufacturing method of the 500MPa hot-rolled refractory steel bar. The 500MPa hot-rolled refractory steel bar is reasonable in componentdesign; the requirements for room temperature and high temperature performance are considered; the quality of the refractory steel bar is improved; and application of the 500MPa hot-rolled refractorysteel bar is better popularized and promoted.

Owner:YANGCHUN NEW STEEL CO LTD +1

Rare earth strengthening aluminum alloy sheet for air conditioner radiator and preparation method of rare earth strengthening aluminum alloy sheet

InactiveCN104404318AHigh strengthImprove refining effectHeat exchange apparatusRare-earth elementSlag

The invention relates to a rare earth strengthening aluminum alloy sheet for an air conditioner radiator and a preparation method of the rare earth strengthening aluminum alloy sheet. The aluminum alloy sheet comprises the following chemical element compositions in percentage by weight: 0.45-0.75 of Si (silicon), 0.02-0.04 of La (lanthanum), 0.01-0.03 of Ce (cerium), 0.01-0.03 of Pr (praseodymium), 0.01-0.03 of Nd (neodymium), 0.24-0.49 of Ni (nickel), 2.03-2.69 of Mg (magnesium) and the balance of Al (aluminium). The aluminum alloy sheet disclosed by the invention uses magnesium and rare-earth elements, so that the strength of alloy is greatly strengthened, crystal grains are refined, gases and inclusions are reduced, and the aging temperature is low. The production method disclosed by the invention reduces the layering, peeling, bubbling and cracking probabilities of the aluminum alloy, and the rate of finished products is increased. The refining agent of the aluminum alloy sheet has a good refining effect, and the probabilities of air holes and slag inclusion are obviously reduced.

Owner:ANHUI TIANXIANG AIR CONDITIONING SCI & TECH CO LTD

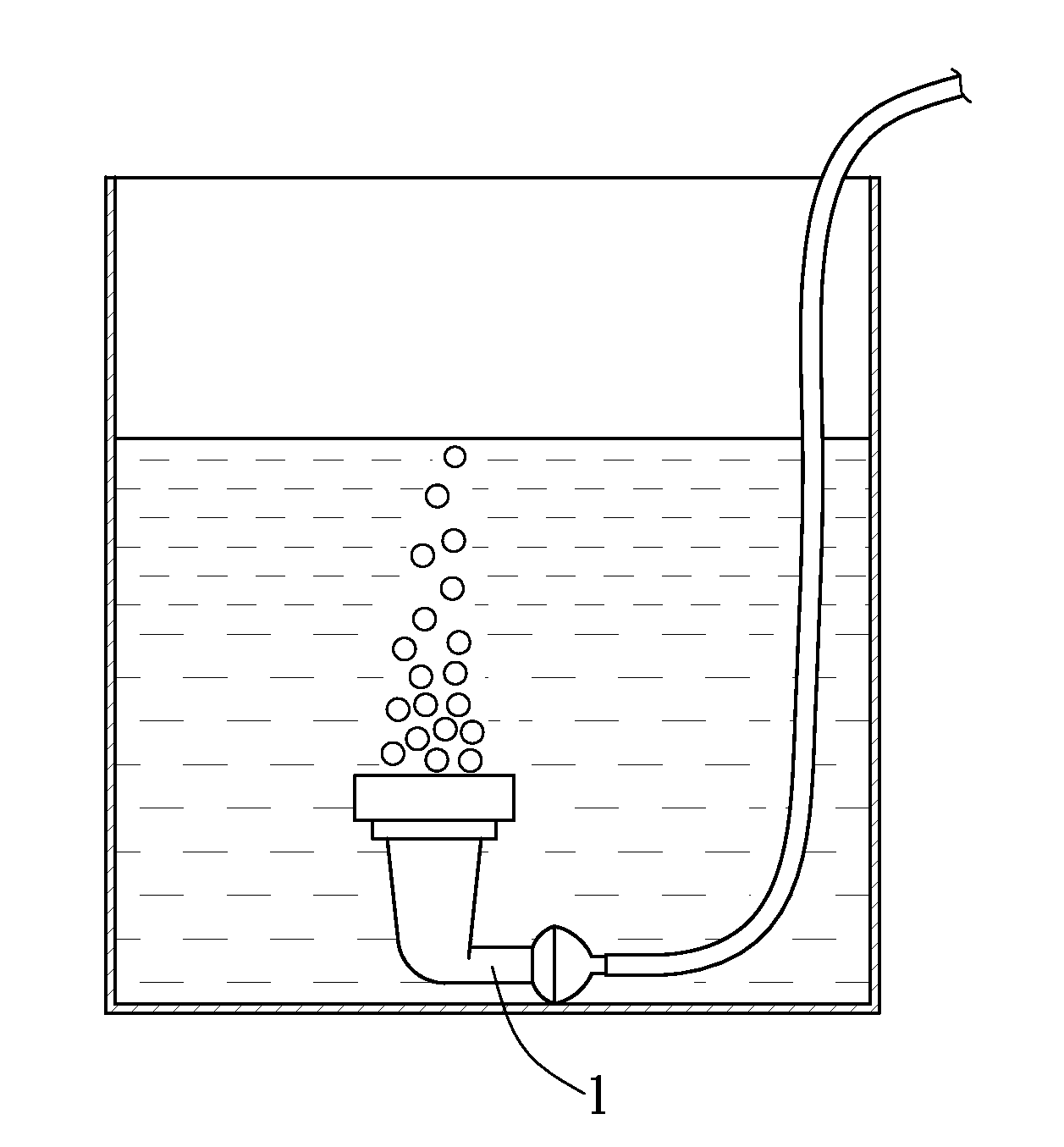

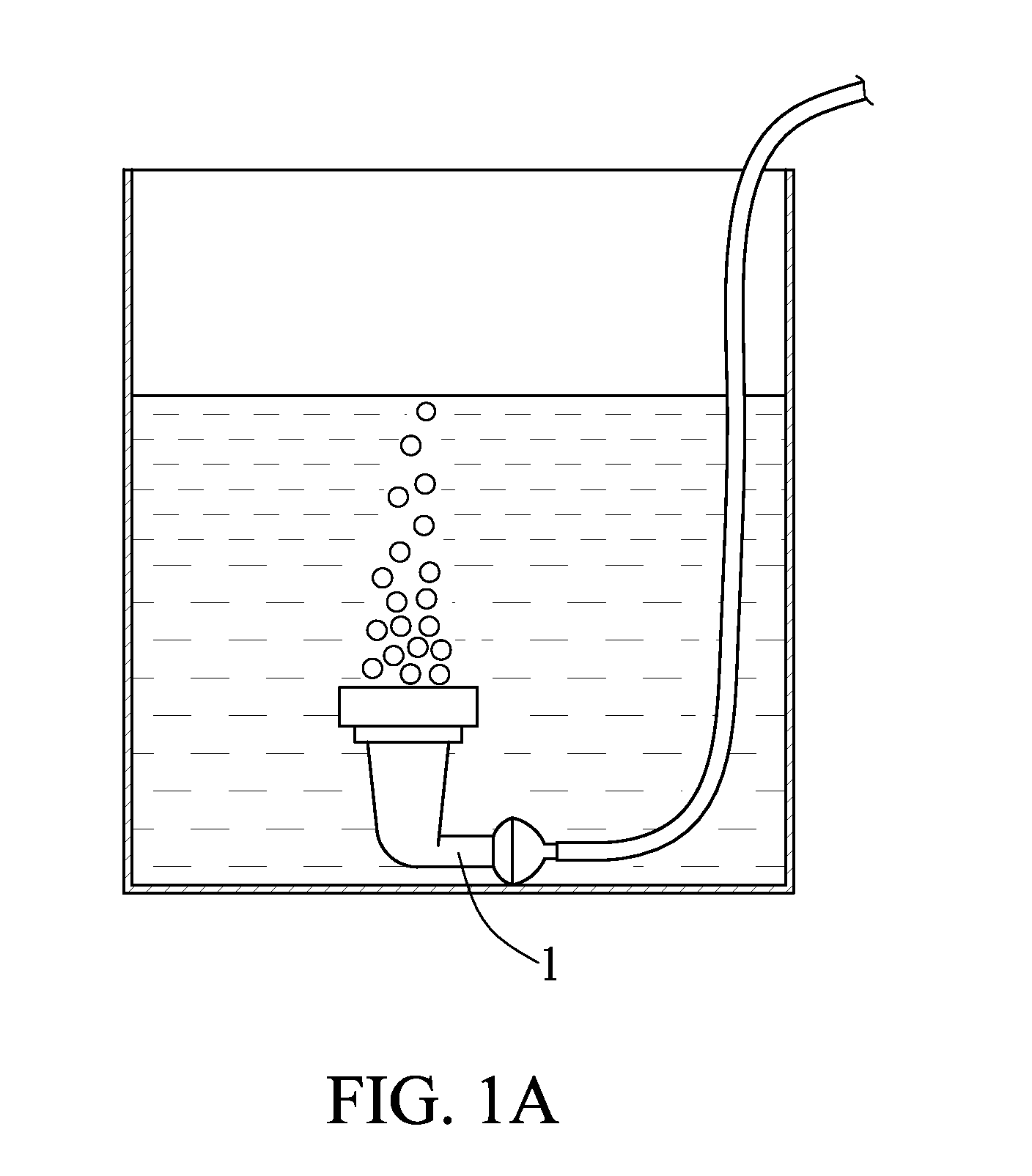

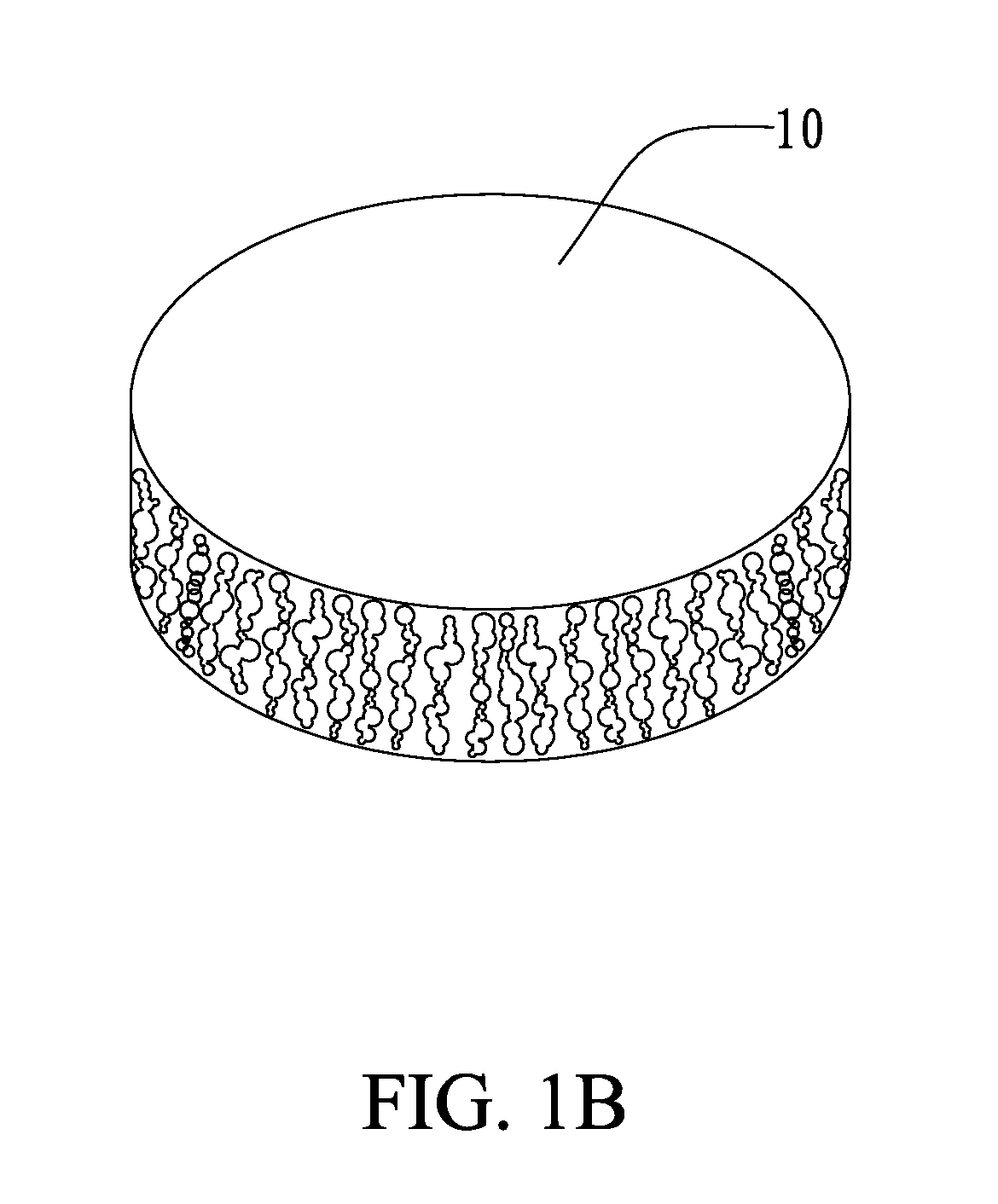

Difffuser, gas valve adapter thereof and method for generating micro bubbles thereof

InactiveUS20150272089A1Improve solubilityIncrease CO2 contentLighting and heating apparatusUsing liquid separation agentProcess engineeringGas supply

A diffuser including a gas supply, gas tank and micro-hole thin-film is provided. The gas tank may be coupled to the gas supply via a gas tube. The micro-hole thin-film has a plurality of micro holes and disposed at the gas outlet of the gas tank. The gas supply can transmit pressurized gas to the gas tank via the gas tube, and the pressurized gas will jet from the micro-hole thin-film to generate a great number of micro bubbles in the water.

Owner:QUATEK

Bolt and valve mechanism that uses less gas

Owner:PLANET ECLIPSE

Mixture of basic lead sulfates

ActiveUS20200075935A1Improved high rate battery performanceSmall sizeLead-acid accumulator electrodesLead sulfatesPhysical chemistryLead sulfate

A microporous lead-containing solid material is produced, which can serve as a carrier for desired materials into a reaction for various desired purposes. For example, if the microporous solid is impregnated with borax it tends to inhibit the growth of unduly large crystals of tetrabasic lead, which is useful in producing batteries having improved functional qualities.

Owner:MAYER GEORGE E

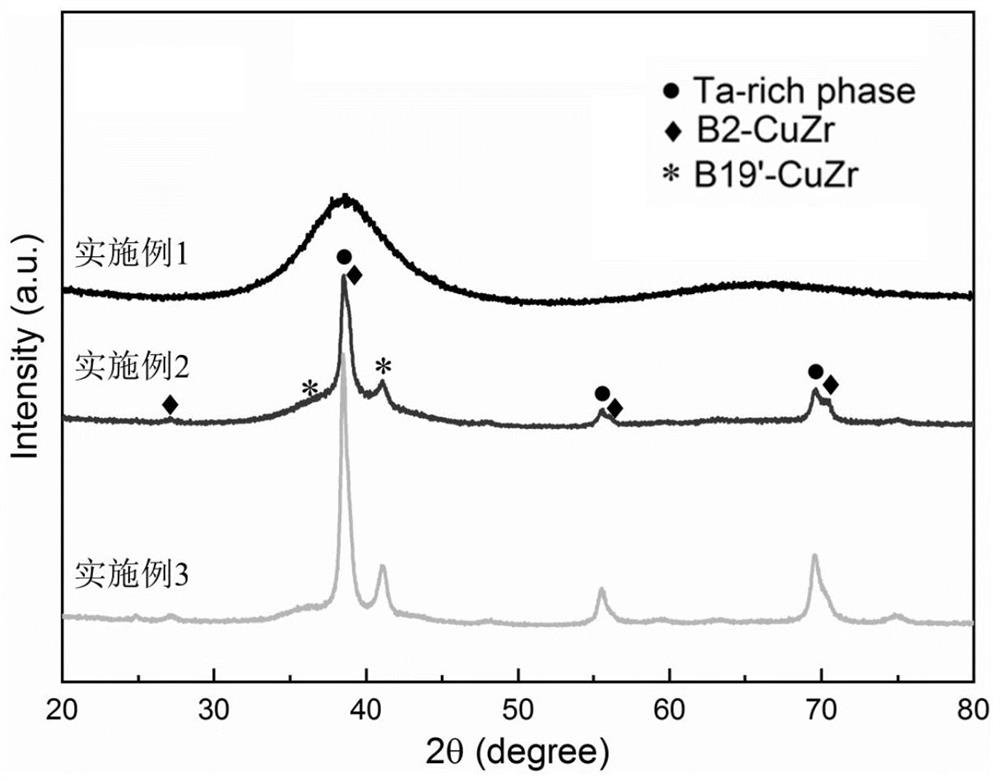

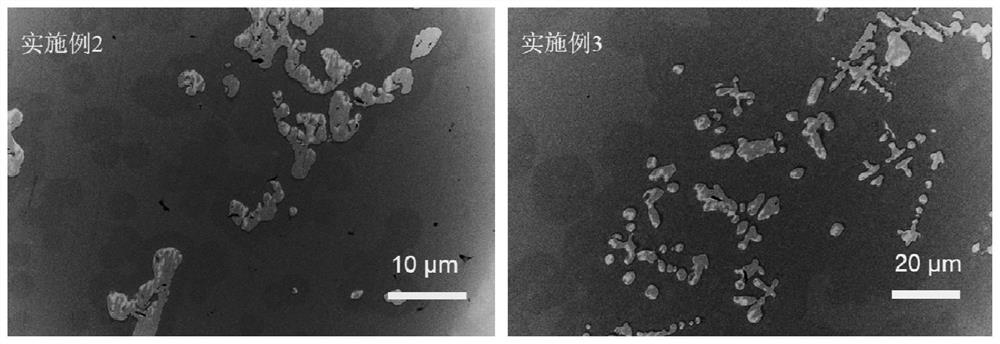

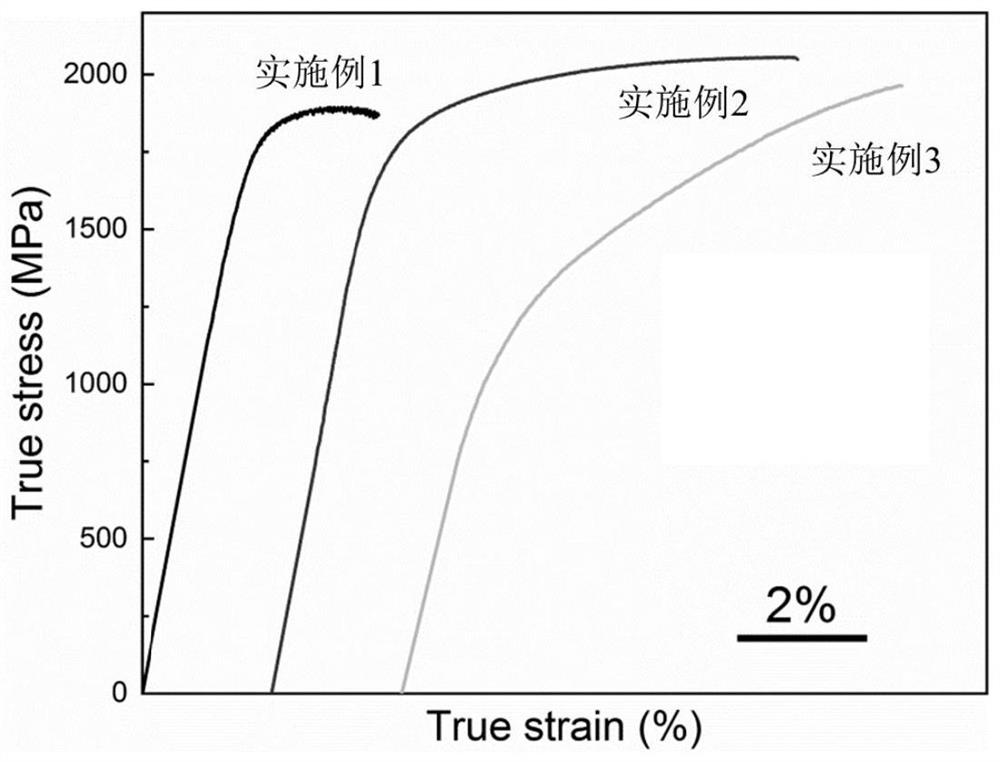

Mixed phase reinforced zirconium-based amorphous composite material and preparation method thereof

The invention belongs to the technical field of amorphous alloy composite materials, and particularly discloses a mixed phase reinforced zirconium-based amorphous composite material and a preparation method thereof. The composition expression of the composite material is (ZrCuAl<c>)<d>Ta<e>, a = b is larger than or equal to 0.46 and smaller than or equal to 0.475, c is larger than or equal to 0.05 and smaller than or equal to 0.08, and a + b + c is equal to 1; d and e are atomic percent, d is larger than or equal to 92 and smaller than 100, e is larger than 0 and smaller than or equal to 8, and d + e is equal to 100; and a matrix of the composite material is zirconium-based amorphous alloy, a reinforcing phase is a mixed phase of a core-shell structure, a Ta-rich phase is the core of the mixed phase, and a B2-CuZr phase and a B19 '-CuZr phase are the shell of the mixed phase. According to the mixed phase reinforced zirconium-based amorphous composite material and the preparation method thereof, the size of the B2-CuZr phase in the zirconium-based amorphous composite material is successfully refined, uniform distribution of the B2-CuZr phase is achieved, meanwhile, a core-shell mixed complex composite structure is introduced, the room-temperature comprehensive mechanical property of the zirconium-based amorphous composite material is further improved, and the application prospect of zirconium-based amorphous materials is expanded.

Owner:HUAZHONG UNIV OF SCI & TECH

Ni-Fe alloy sputtering target for forming magnetic thin films, magnetic thin film, and method of manufacturing the Ni-Fe alloy sputtering target

InactiveUS20010032686A1Less gasImprove magnetic propertiesPhotography auxillary processesSolvent extractionSputteringMetal impurities

An Ni-Fe alloy material suitable for forming a ferromagnetic Ni-Fe alloy thin film is provided. The magnetic thin film produces a small number of particles during sputtering, and excels in corrosion resistance and magnetic properties. A method of manufacturing an Ni-Fe alloy sputtering target used to make the thin film is also provided. In addition, an Ni-Fe alloy sputtering target for forming magnetic thin films is provided. The sputtering target is characterized in that it has: an oxygen content of 50 ppm or less; an S content of 10 ppm or less; a carbon content of 50 ppm or less, and a total content of metal impurities other than the alloy components of 50 ppm or less. Such an Ni-Fe alloy target can be produced by melting and alloying high-purity materials obtained by dissolving the raw materials in hydrochloric acid, and performing ion exchange, activated-charcoal treatment, and electrolytic refining.

Owner:JX NIPPON MINING & METALS CORP

System and method for high accuracy gas refill in a two chamber gas discharge laser system

ActiveUS8873600B2Ensure correct executionLess gasPackaging by pressurising/gasifyingActive medium materialHalogenProcess engineering

Owner:CYMER INC

Method for drying water-contained garbage by using afterheat of cement kiln system

ActiveCN105222601ASave energyIncrease the calorific value on a moisture basisDrying gas arrangementsIncreasing energy efficiencyDecompositionDrying time

The invention discloses a method for drying water-contained garbage by using afterheat of a cement kiln system. The method is to use tail gas having the afterheat in the cement kiln system for heating the water-contained garbage; and the water-contained garbage is heated for drying to form dried garbage. The cement kiln system comprises a cement kiln, a grate cooler and a generator; the cement kiln is provided with a decomposition furnace; the decomposition furnace is provided with a first-grade preheater; the heating of the water-contained garbage by using the tail gas having the afterheat in the cement kiln system is to lead out the tail gas having the afterheat in the first-grade preheater for heating the water-contained garbage, to lead out the tail gas having the afterheat in a low-temperature section of the grate cooler for heating the water-contained garbage and to lead out the tail gas having the afterheat in the generator for heating the water-contained garbage. The method can fully use abundant afterheat resource of the cement kiln for drying the water-contained garbage, can save a lot of energy for drying the water-contained garbage, shortens the drying time, decreases the drying floor area, and quickly improves the garbage wet base heat value.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES +1

Pig mane high pressure high temperature vacuum straightening and drying method

The high pressure, high temperature and vacuum bristle straightening and drying process includes water soaking, high temperature and high pressure straightening, vacuum drying and other steps. It features that the vacuum pump is used to make negative pressure state inside the container, so as to make water inside the connector and in bristle gasified and exhausted to atmosphere. The technological process is simple, convenient, low in water, power and gas consumption, short, high in product quality and environment friendly.

Owner:杨荣平

Urinal toilet concept

ActiveUS20120260802A1Less gasCosmonautic crew accomodationsIsotope separationCollection systemPeristaltic pump

A gas and liquid mixture separation and collection system for zero gravity operation that can be applied to a urinal toilet is disclosed. There is an inlet to receive the gas and liquid mixture. The mixture is directed to a filter having an air side. A vacuum pump on the air side of the filter generates a pressure delta to force the inlet flow. A peristaltic pump is used to transfer liquid away from the filter surface. In doing so, the flow on the liquid side of the membrane filter may contain some gas left over from the inlet flow mixture, but there is substantially less gas than in the gas and liquid mixture at the inlet. The filtered mixture is directed to an expandable collection bag that is attached to the air side of the filter so the filter process can be repeated to remove more gas from the mixture.

Owner:BIGELOW AEROSPACE

Lithium-titanium complex oxide and manufacturing method thereof, and battery electrode using same

ActiveUS8741172B2Drop in stabilityOperational stability can be improvedAlkali titanatesActive material electrodesTitaniumLithium compound

Owner:TAIYO YUDEN KK

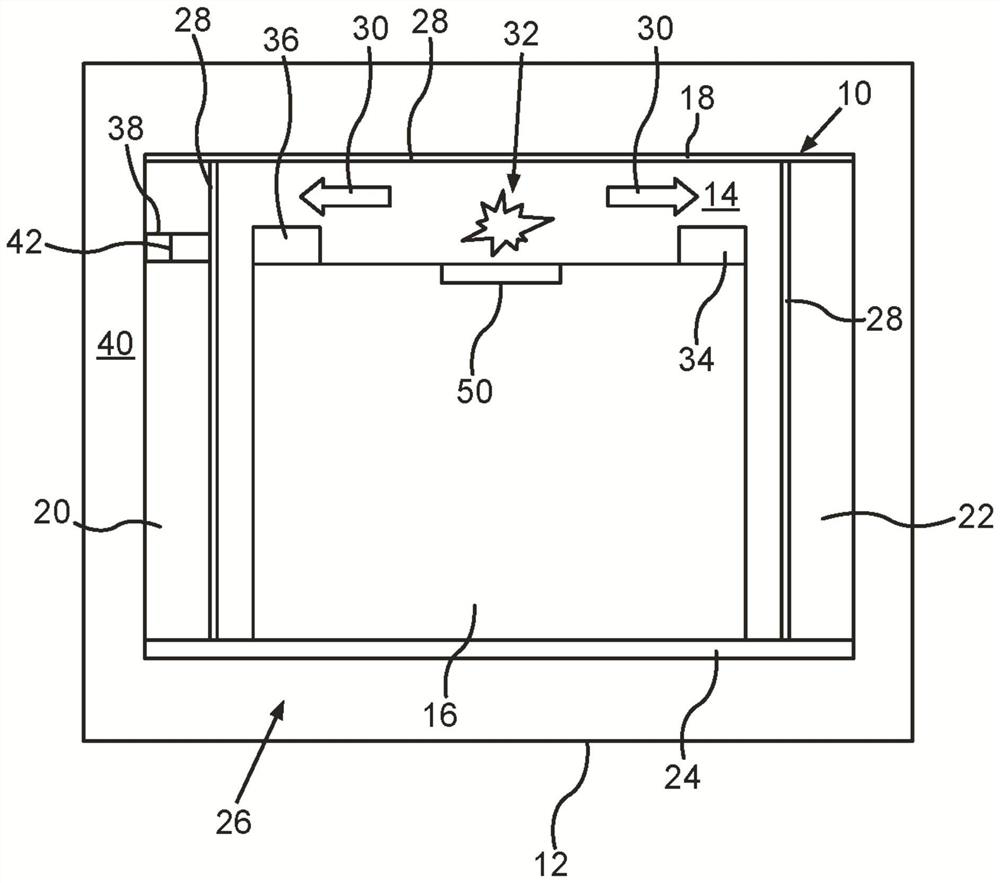

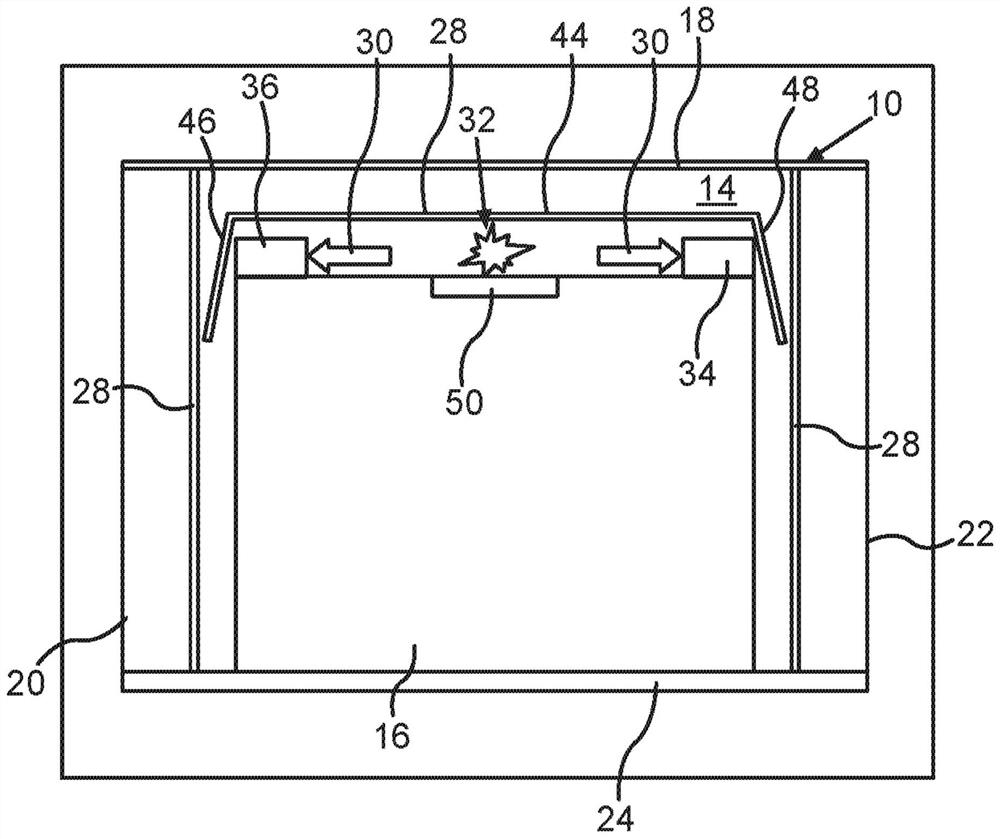

Battery housing for at least one battery cell and motor vehicle

PendingCN112397845AImprove protectionImprove fire performanceBattery isolationVehicular energy storageMechanical engineeringBattery cell

The invention relates to a battery housing (10) for at least one battery cell (16) of an electrical energy store (26) of an at least partially electrically operated motor vehicle (12), comprising an interior (14) of the battery housing (10), which interior is designed for arranging the at least one battery cell (16), the battery housing further comprises at least one protective layer (28) which isdesigned on at least one housing wall (18, 20, 22, 24) of the battery housing (10) and faces the interior (14), said protective layer (28) being designed as ceramic, glass or metal and being designedto generate an exhaust gas flow (30) when the battery cells (16) are evacuated (32) from the interior (14) of the battery housing (10). The invention also relates to a motor vehicle (12).

Owner:AUDI AG

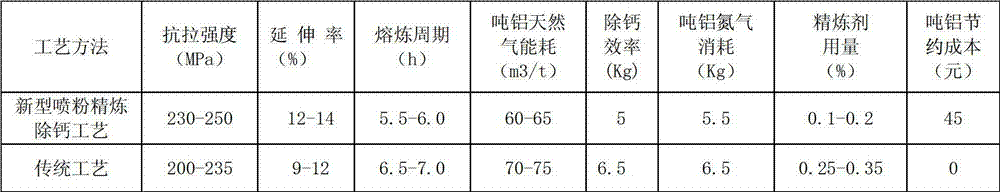

Powder spraying, refining and calcium removing method used for aluminium alloy material

The invention relates to a powder spraying, refining and calcium removing method used for an aluminium alloy material. The method provided by the invention comprises the following steps of: placing a mixture of a powdery refining agent and a calcium removing agent into a refining and powder spraying machine, adjusting the nitrogen flow, the refining agent and the calcium removing agent, directly spraying powder to the bottom of a smelting furnace by utilizing nitrogen as a carrier, and degassing and removing impurities and calcium while the nitrogen floats upward from the bottom of the smelting furnace. By utilizing the method provided by the invention, molten aluminium degassing, deslagging and calcium removing processes are carried out at the same time, the efficiency is high, the refining effect is better, the smelting time of aluminium alloy is greatly shortened, the energy consumption is saved, the labour productivity is improved, and the alloy quality is obviously improved.

Owner:天津新立中合金集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com