Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

468results about How to "Improve refining effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-conductivity aluminum alloy material for cable and preparation method thereof

InactiveCN101886198ALittle impact on electrical performanceEasy to stretchMetal/alloy conductorsRare-earth elementPliability

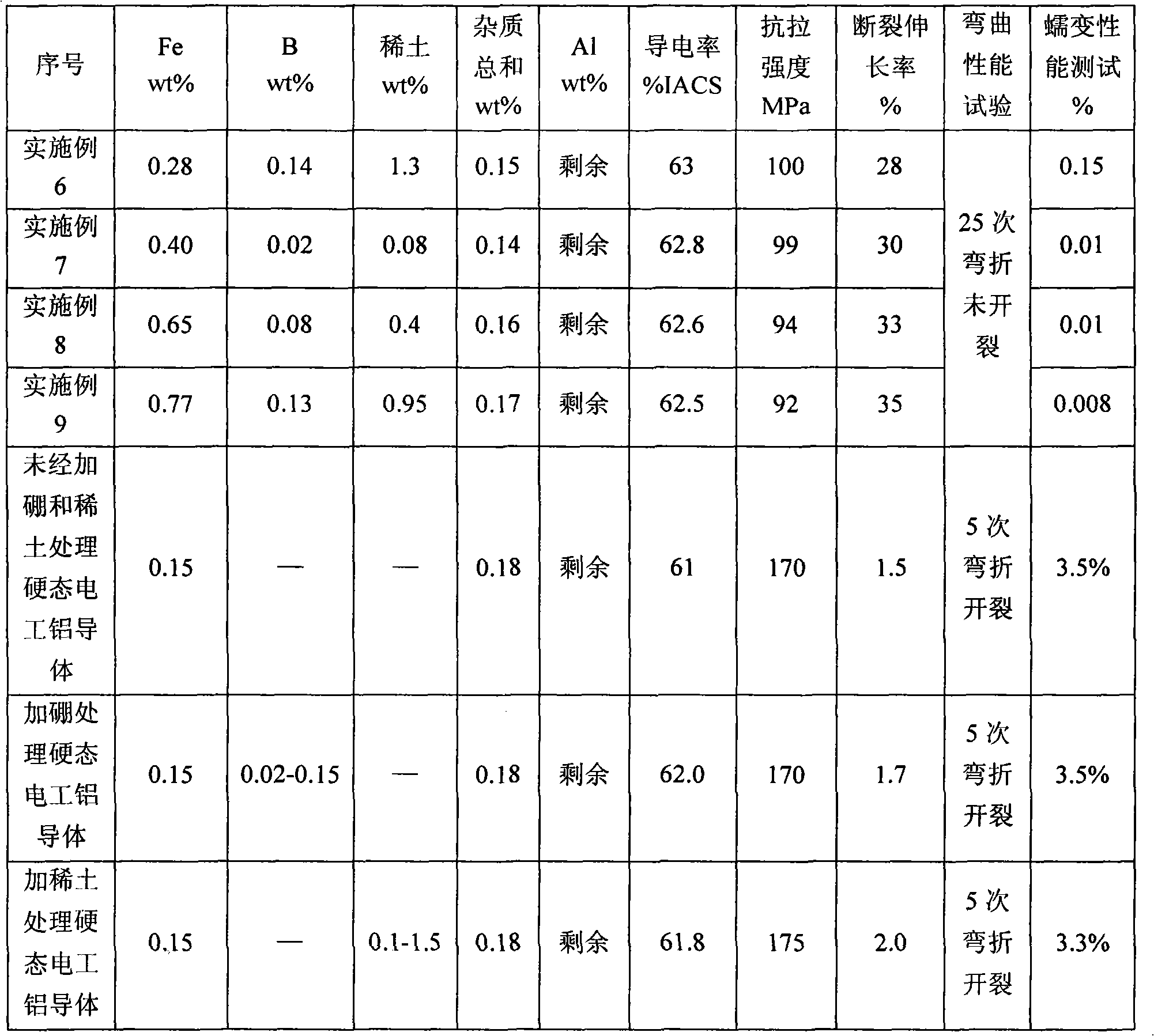

The invention relates to a high-conductivity aluminum alloy material for a cable and a preparation method thereof. The aluminum alloy material comprises the following components in percentage by weight: 0.25-0.80 percent of iron element, 0.02-0.15 percent of boron element, 0.1-1.5 percent of rare earth element and the balance of aluminum and inevitable impurities. The aluminum alloy is formed by adding an aluminum alloy intermediate alloy, an aluminum-boron alloy and an aluminum-rare earth intermediate alloy into an aluminum ingot of which the purity is more than 99.80 percent by weight and carrying out a casting process and annealing treatment on the mixture. Compared with a common electric aluminum conductor, the prepared aluminum alloy conductor has more excellent conductive performance and the conductivity reaching or exceeding 62.5 percent IACS (International Annealed Copper Standard); the aluminum alloy conductor treated by using a special process has excellent flexibility and creep resistance; and compared with a common electric aluminum conductor, the prepared aluminum alloy material used as a cable extrusion insulating lead core is more energy-saving and safer.

Owner:ANHUI JOY SENSE CABLE

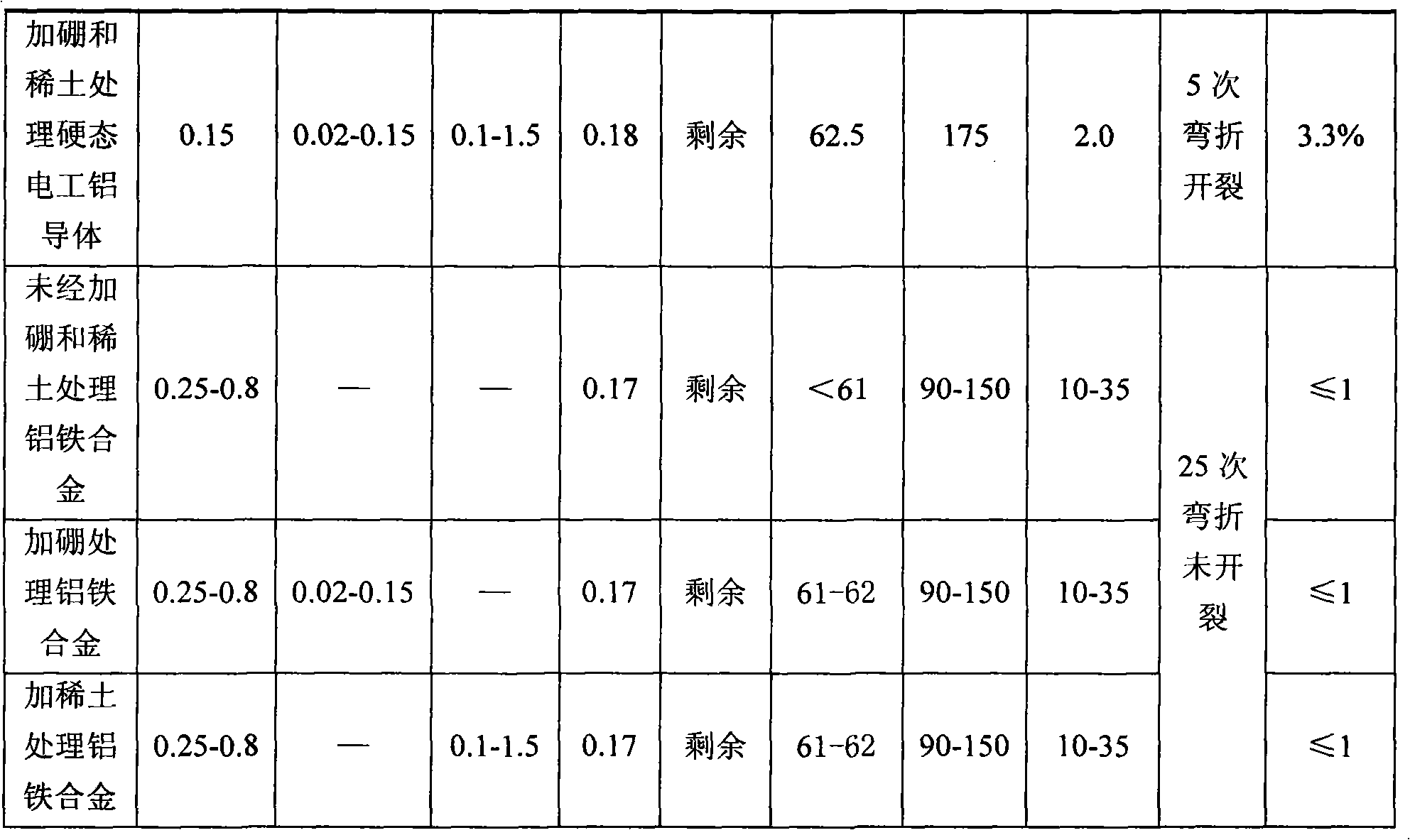

Substrate for solar cell and solar cell

InactiveUS20100218827A1Good pressure characteristicsImprove adhesionAnodisationPhotovoltaic energy generationSolar cellAnodic oxidation

A substrate for a solar cell having a metal substrate, a first insulating oxide film formed on the metal substrate by anodic oxidation, and a second insulating film, wherein the first insulating oxide film has pores and the pores are sealed with the second insulating film at a sealing ratio of 5 to 80%.

Owner:FUJIFILM CORP

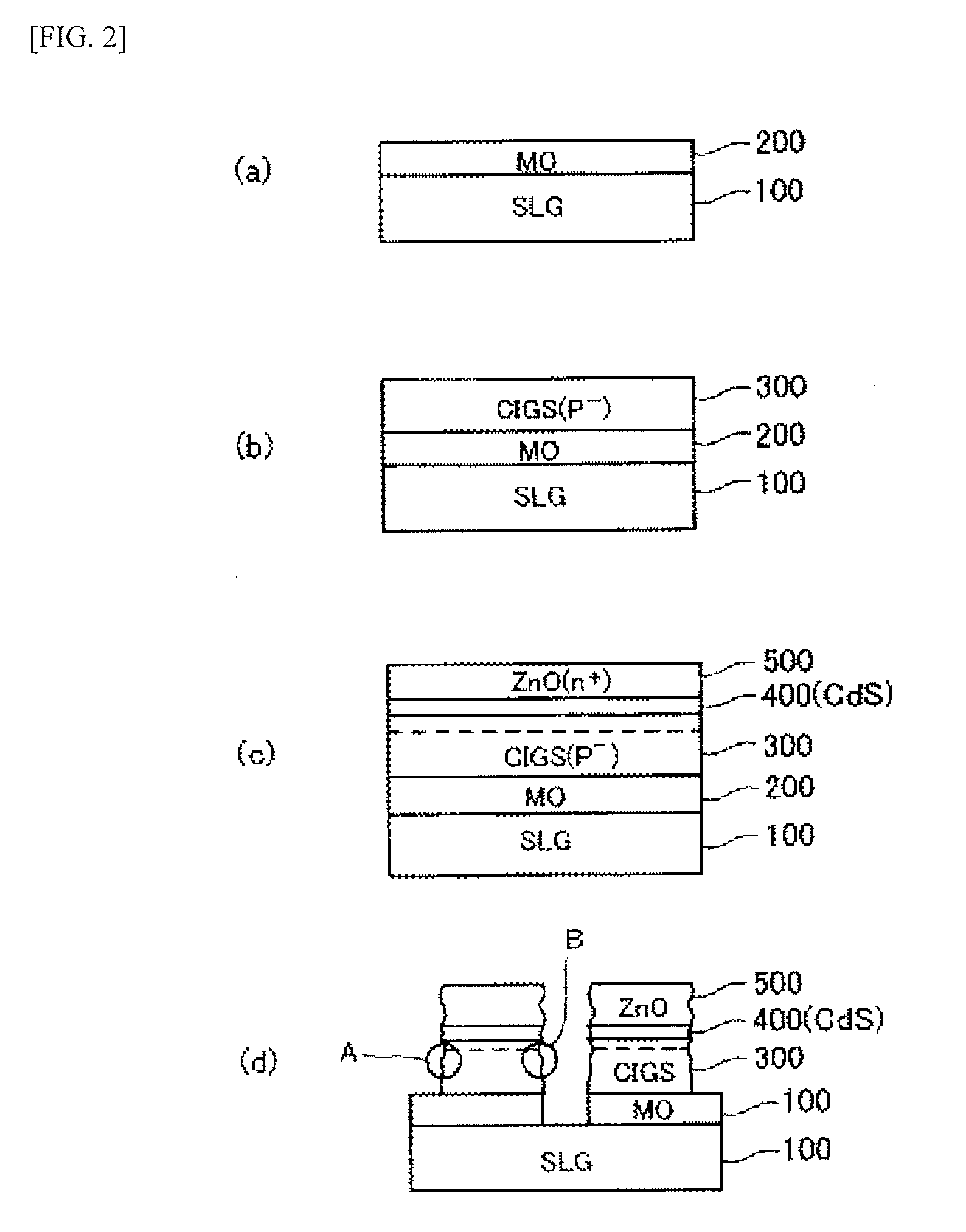

Production method of fructus monordicae extract with over 60% of mogroside V content

ActiveCN101690573APromote leachingEasy to separateCosmetic preparationsToilet preparationsSucroseAdditive ingredient

The invention provides a production method of fructus monordicae extract with over 60% of mogroside V content. In the method, the fresh momordica grosvenori is subjected to the following technique processes: smashing, saccharification, extraction by water, concentration, sedimentation and centrifugation, ion exchange resin refining, macroporous resin refining, concentration, aluminum oxide refining, concentration, spray drying and finishing product. The method can produce high-quality fructus monordicae extract products, reduce material loss, shorten period of production, increase product yield, lower production cost, and is suitable for industrial production. The mogroside V content in the fructus monordicae extract produced by the method is more than or equal to 60%; the fructus monordicae extract has high product purity, single composition, pure white color, good color and taste, fresh and cool sweet taste like that of sugar, simultaneously overcomes the technical problem for industrial production of the high-content and high-quality fructus monordicae extract, and successfully realizes large-scale production.

Owner:YONGZHOU YIDONG BIOTECH

Glass substrate for display and display

ActiveUS7763559B2Light weightImprove refining effectLiquid crystal compositionsAbsorbent padsDisplay deviceMetal

A glass substrate for a display, which is formed of a glass having a light weight and having high refinability with decreasing environmental burdens, the glass comprising, by mass %, 50 to 70% of SiO2, 5 to 18% of B2O3, 10 to 25% of Al2O3, 0 to 10% of MgO, 0 to 20% of CaO, 0 to 20% of SrO, 0 to 10% of BaO, 5 to 20% of RO (in which R is at least one member selected from the group consisting of Mg, Ca, Sr and Ba), and over 0.20% but not more than 2.0% of R′2O (in which R′ is at least one member selected from the group consisting of Li, Na and K), and containing, by mass %, 0.05 to 1.5% of oxide of metal that changes in valence number in a molten glass, and substantially containing none of As2O3, Sb2O3 and PbO.

Owner:AVANSTRATE INC

Refining agent for aluminum and aluminum alloy

ActiveCN101967565AAffect the service lifeWill not corrodeProcess efficiency improvementSlagPotassium

The invention relates to a refining agent for aluminum and aluminum alloy. The refining agent is characterized by mainly comprising the following components in percentage by mass: 30 to 85 percent of NaCl, 5 to 40 percent of Na2SiF6, 5 to 40 percent of Na2SO4, 2 to 20 percent of CaF2 and 0.5 to 5 percent of C6C16; and the refining agent also can comprise one or more of CaMg(CO3)2, Na3AlF6, Na2S2O3 and NaF. The potassium-free refining agent provided by the invention has good slag forming performance, strong gas and impurity removing capability and low cost; and the aluminum ash produced by refining the aluminum and the aluminum alloy through the refining agent can realize recycle.

Owner:江西广恒铝业有限公司

Al-Si-Cu-Zn-Sn-Ni aluminum-based brazing filler metal and preparation method thereof

InactiveCN102319963AReduce brittlenessImprove surface activityWelding/cutting media/materialsSoldering mediaSlagAlloy

The invention relates to an Al-Si-Cu-Zn-Sn-Ni aluminum-based brazing filler metal and a preparation method thereof. The components of the aluminum-based brazing filler metal are 7 to 13 percent by weight of Si, 5 to 11 percent by weight of Cu, 4 to 11 percent by weight of Zn, 1 to 6 percent by weight of Sn, 1 to 3 percent by weight of Ni, 0.02 to 0.3 percent by weight of Ce, 0.01 to 0.1 percent by weight of Sr, 0.01 to 0.2 percent by weight of Zr and the balance of Al. The process flow for preparing the aluminum-based brazing filler metal is that: pure aluminum is added into a graphite crucible and covered by flux for aluminum under the condition of 800 DEG C to 900 DEG C, and slag is removed after melting; the aluminum-based intermediate alloy of high-melting point elements and flux for aluminum are added at the same time, and melting, stirring and slag removal are carried out; the aluminum-based intermediate alloy of low-melting point elements is added under the protection of nitrogen, and melting and stirring are carried out; the mixture of argon and hexachloroethane is added to carry out refining, and standing and slag removal are carried out; the intermediate alloy of trace elements is added, and melting and stirring are carried out; secondary refining and slag removal are carried out; and under the protection of nitrogen, casting formation is carried out. The Al-Si-Cu-Zn-Sn-Ni aluminum-based brazing filler metal has the advantages of low melting point, high strength, high toughness, high corrosion-resistant property and good wetting property and spreadability.

Owner:GUILIN QINGTONG NON FERROUS METAL ARTS & CRAFTS MATERIAL DEV CO LTD

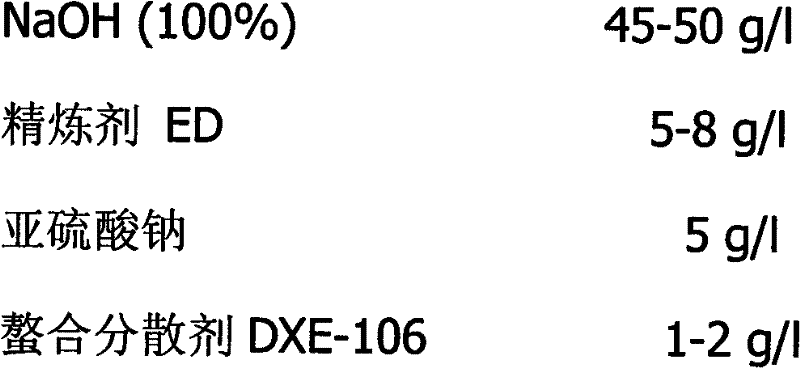

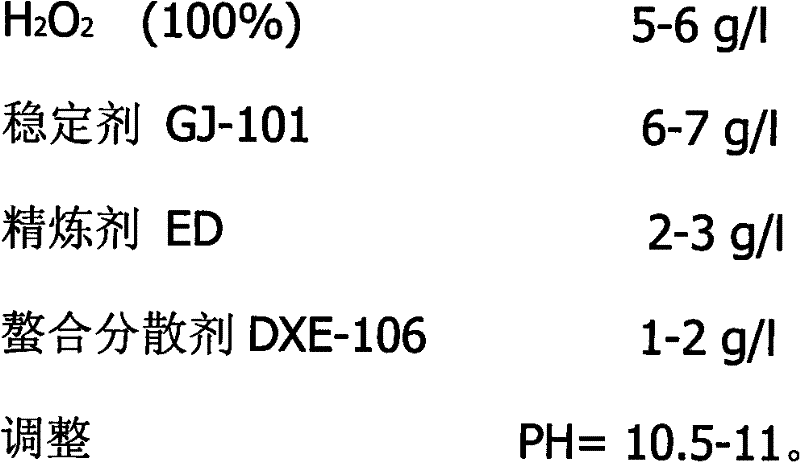

Low-temperature pretreatment process of full-cotton woven fabric

ActiveCN102220684AReduce qualityImprove refining effectBiochemical fibre treatmentDry-cleaning apparatus for textilesPulp and paper industryPre treatment

The invention relates to a continuous type low-temperature boiling-off and bleaching pretreatment process of full-cotton woven fabric. At present, the low-temperature boiling-off and bleaching of pre-treatment process exists, but are only the pre-treatment processing process for cotton and blended knitted fabric; research findings or patent documentation of pre-treatment process taking low-temperature boiling-off and bleaching of full-cotton woven fabric are not found at present. In the invention, hot water pre-treatment processing, biological enzyme processing, hot water washing and enzyme blanching and water washing process are firstly preformed on the full-cotton woven fabric, and then the low-temperature scouring and bleaching processing, the low-temperature steam bleaching processingand the water washing process are then performed to finish the pre-treatment of the cotton woven fabric. In the invention, the cotton woven fabric is pre-treated in combination with biological enzymedesizing and the low-temperature scouring and bleaching; the technology in the invention has a good effect without sizing agent residuals and residual cotton seed hulls, and the brightness achieves the effect of the traditional soda boiling and oxygenation bleaching technology.

Owner:HANGZHOU TRANSFAR FINE CHEM CO LTD +2

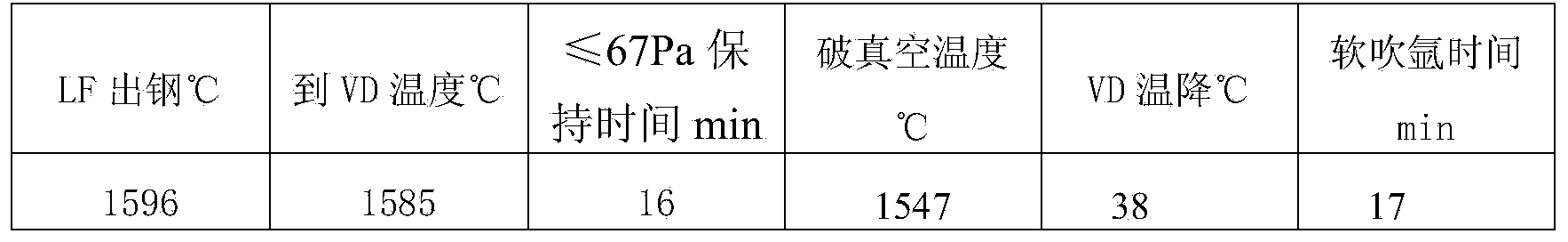

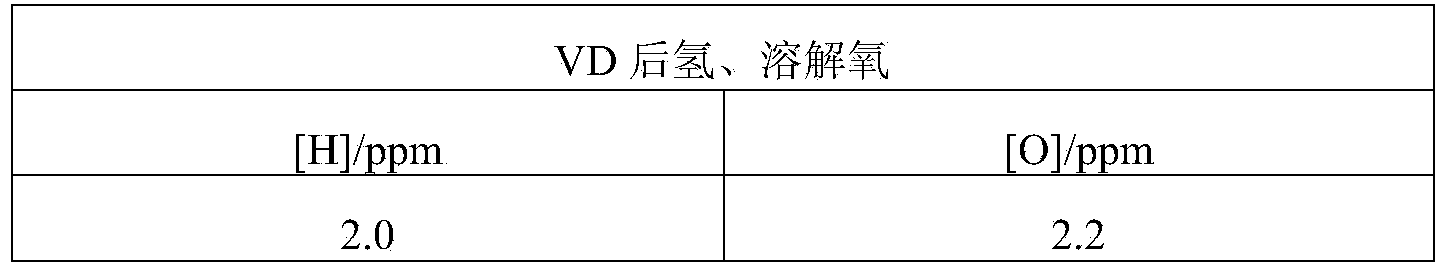

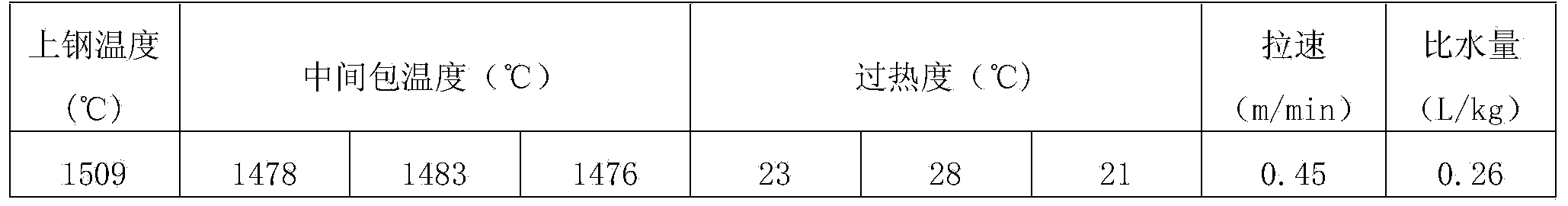

Method for preparing bearing steel

ActiveCN104178698AHarm reductionInhibit peroxidationProcess efficiency improvementElectric furnaceNon-metallic inclusionsOxygen content

The invention relates to a method for preparing bearing steel. The method comprises the following steps of smelting, and alloying; carrying out continuous casting; rolling; carrying out slow cooling, and the like. The chemical components in the bearing steel are controlled in percentage by weight as follows: 0.95%-1.05% of C, 0.20%-0.30% of Si, 0.30%-0.35% of Mn, 0.02%-0.05% of Mo, 1.45%-1.48% of Cr, 0.015%-0.035% of AlS, less than or equal to 0.05% of Cu, less than or equal to 0.025% of S, less than or equal to 0.025% of P, less than or equal to 0.05% of Ni, less than or equal to 12*10<-6> of [O], less than or equal to 2*10<-6> of [H] and the balance of Fe and inevitable impurities. According to the bearing steel produced through the method disclosed by the invention, the total oxygen content of a steel product can be stably controlled below 8 ppm, non-metallic inclusions are low in content and uniformly distributed, and good casting blank structure homogeneity, steel quality stability and anti-fatigue property and casting blank segregation grade reduction are achieved.

Owner:SHANDONG IRON & STEEL CO LTD

Pulp-grinding method for improving fibre brooming and application thereof in papermaking

InactiveCN101691700AEnhance brooming effectHigh strengthOther chemical processesPulp beating/refining methodsSodium BentonitePrecipitated calcium carbonate

The invention discloses a pulp-grinding method for improving fibre brooming, comprising the following steps: adding rigid filler to the pulp before grinding, and grinding after mixing the rigid filler and the pulp fibre, wherein the additive amount of the rigid filler accounts for 1%-30% of the total mass of the pulp; the rigid filler is any one or the mixture of several types of PCC, GCC, Talc, titanium pigment and bentonite of filler grade; and the rigid filler can also be fibrous mineral fibre. The adoption of the pulp-grinding method can improve devillicate brooming degree of the fibre, improve paper strength and interweaving, or can improve the ash content of paper and reduce fibre consumption under the condition of maintaining a considerable paper strength, and can reduce production cost and reduce the grinding energy consumption while protecting the environment.

Owner:GOLD EAST PAPER JIANGSU

New anti-fluffing and anti-pilling technology for polyester-cotton fabric under special standards

ActiveCN102561040AImprove refining effectReduce slipMercerising of indefinite length fabricsFibre treatmentPolyesterEngineering

The invention relates to the technical field of dyeing and finishing production of polyester-cotton anti-fluffing and anti-pilling fabrics. A new anti-fluffing and anti-pilling technology for a polyester-cotton fabric under special standards comprises the following steps of: (1) grey cloth seam turning, (2) primary singeing, (3) flat bleaching, (4) secondary singeing, (5) sizing, (6) mercerizing, (7) dyeing (dispersion / reduction), (8) finishing with a compound solution of ironing-free resin and an anti-fluffing and anti-pilling agent, (9) baking, (10) tentering, (11) pre-shrinking, (12) inspection, and (13) formation of a finished product. The product prepared by the technology meets the special quality requirement of customers for washing for 5 times, 30 minutes in each time, in hot water at 92 DEG C, the anti-fluffing and anti-pilling quality index of the fabric is detected, and the anti-fluffing and anti-pilling quality index of the product for clothes reaches the export standard, namely level 3-4.

Owner:辽宁宏润源印染有限公司

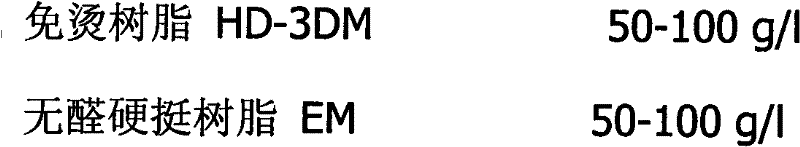

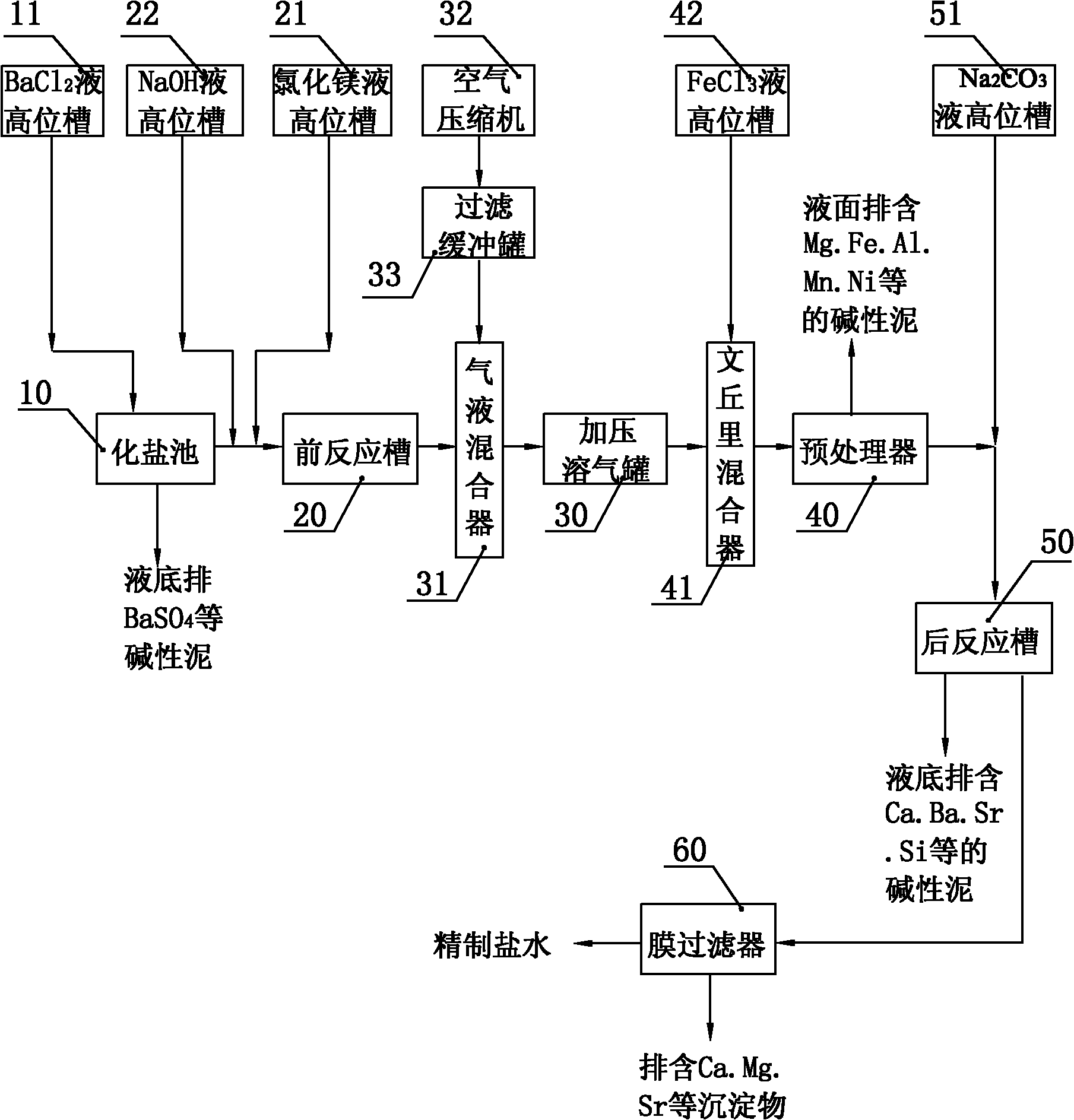

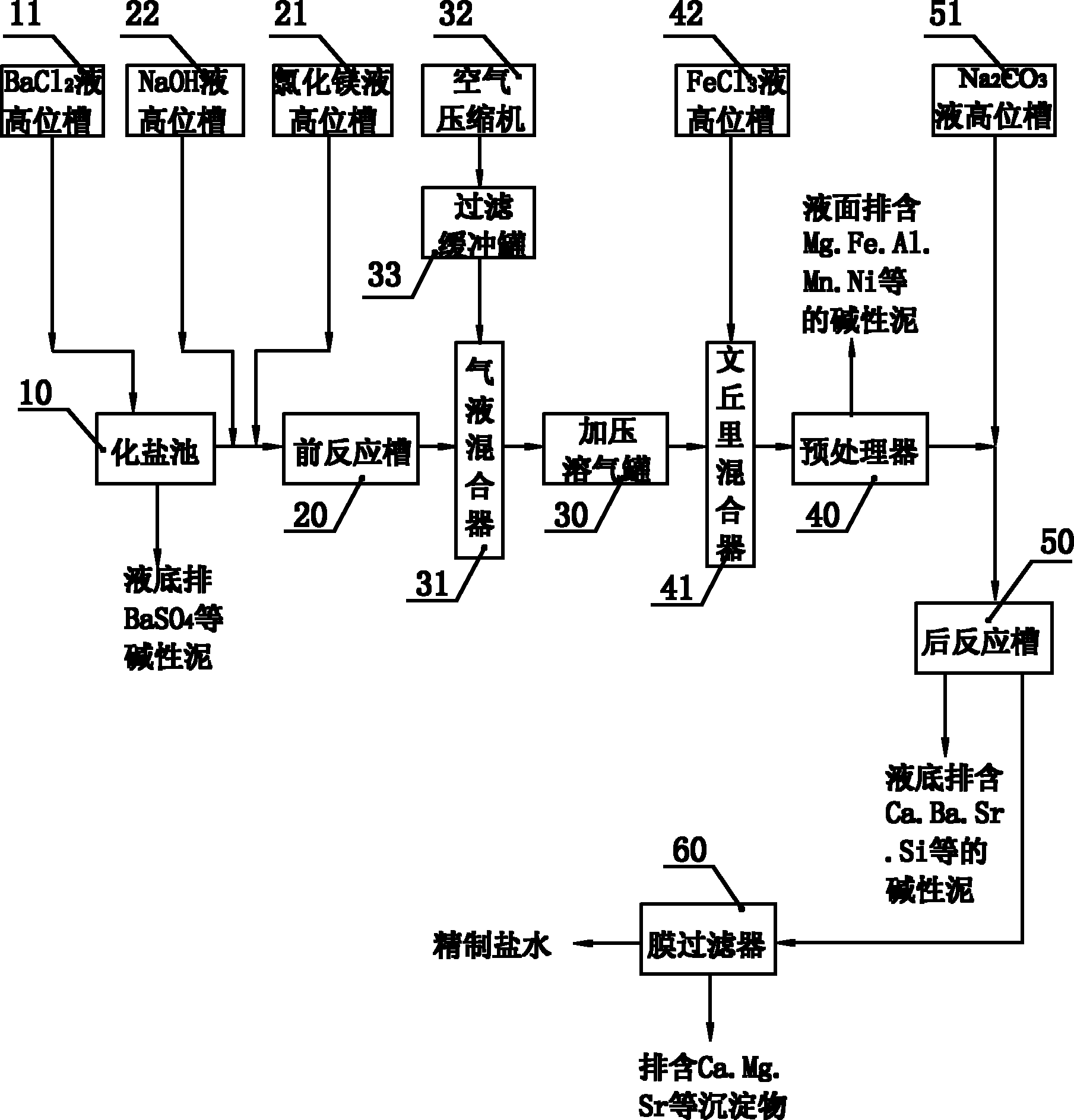

Method and system for refining crude brine

InactiveCN102120590AGood technical effectExcellent and unique refining effectAlkali metal halide purificationIon-exchange membranesSea salt

The invention relates to a method and a system for refining crude brine. The method comprises the following steps of: performing pre-reaction; pressurizing and dissolving gas; pretreating; performing post reaction; filtering by using a membrane; and filtering off residual slag particles by using a membrane filter to obtain the refined brine. By the method and the system for refining crude brine, under the condition of not introducing new impurities, various metal impurity ions are efficiently flocculated and precipitated, so that problems of great mineral salt impurity fluctuation and overproof Fe and Al ions are solved, the high quality of the finished brine product and the high-efficiency and normal operation of subsequent ion-exchange membrane electrolysis can be ensured, and the aim that mineral salt replaces sea salt to serve as chlor-alkali electrolysis raw salt is fulfilled; moreover, brine sludge emission and treatment cost can be obviously reduced, and the method and the system have good emission reduction effect and good environment-friendly property.

Owner:RUYUAN DONGYANGGUANG ELECTROCHEM FACTORY

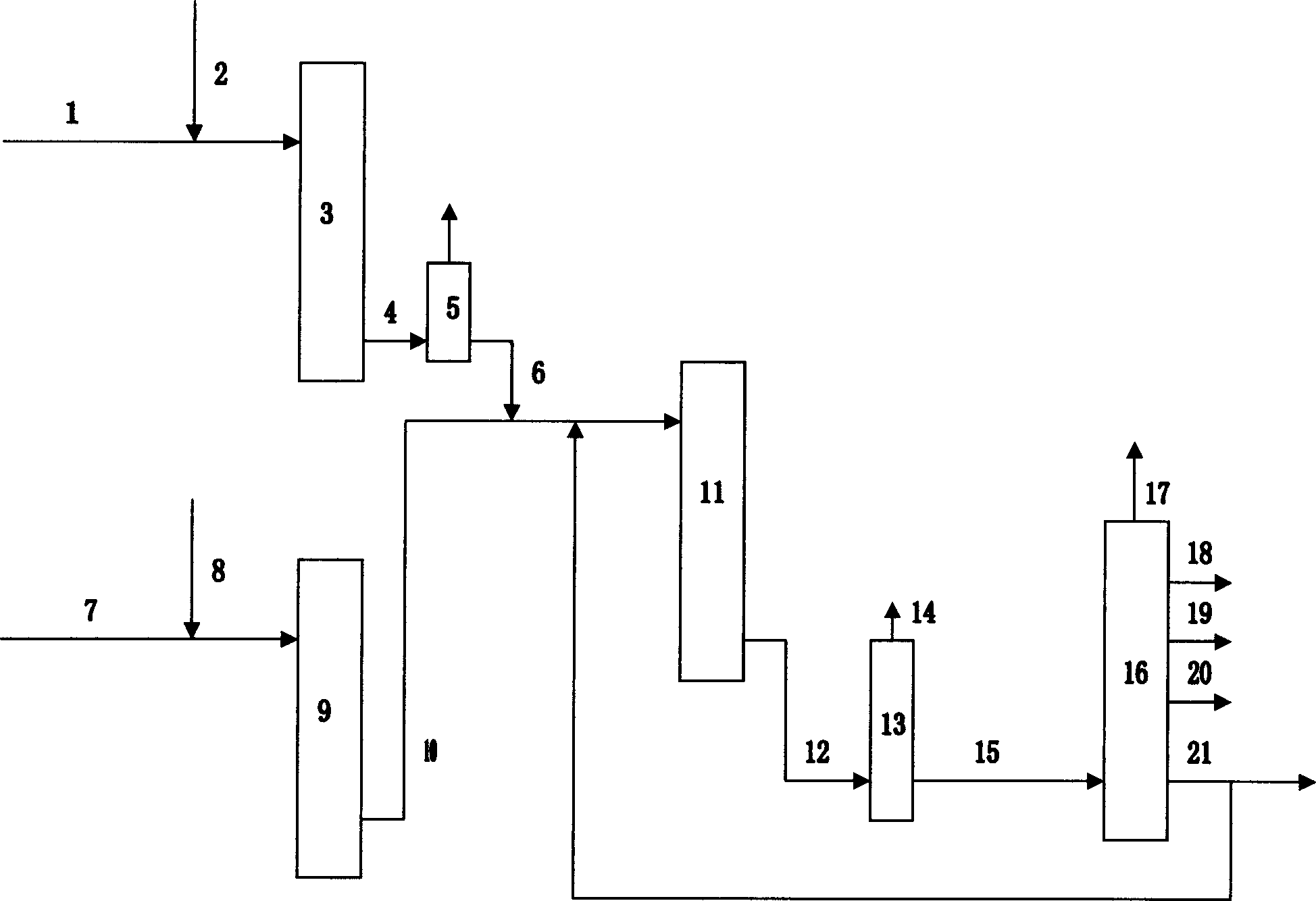

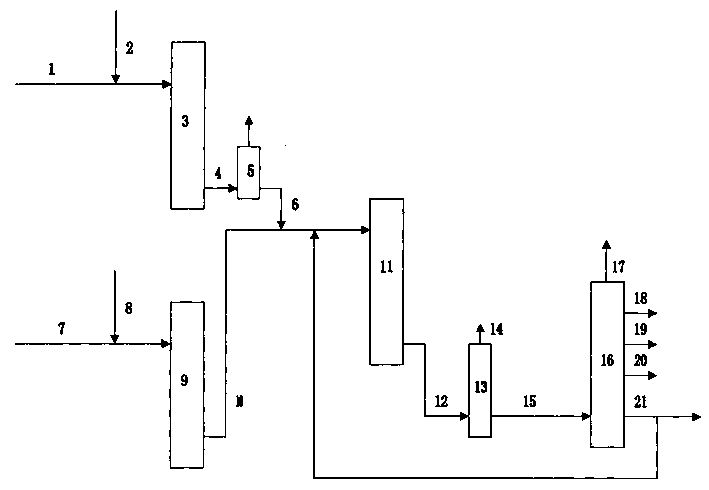

Industrial refining production method of rice bran oil and equipment thereof

InactiveCN101473873AProblems meeting refining requirementsImprove refining effectEdible oils/fatsSocial benefitsRice Bran Extract

The invention relates to a rice bran oil industrialized refining method and a device for implementing the method. The invention effectively satisfies the rice bran oil refining demands in the rice bran oil industrialized refining. The method is implemented by degumming with water, dewaxing, primary alkali refining, secondary alkali refining, cleaning with water, drying and decolorization, as well as deacidification and deodorization in turn. The device is characterized in that a first crude oil temporary storing tank is connected with a fourth oil pump sequentially through a first oil pump, a hydration kettle, a second oil pump, a pre-cooling tank, a third oil pump and a crystallizing tank, which are connected in series; the fourth oil pump is connected with a first oil refining caldron sequentially through a first frame filtering machine, a second crude oil temporary storing tank and a fifth oil pump; the first oil refining caldron is connected with the water-cleaning caldron sequentially through a sixth oil pump, a second oil refining caldron and a seventh oil pump; the water-cleaning caldron is connected with a decolorization oil pump, a second frame filtering machine, a decolorization oil tank and a deacidification and deodorization kettle through a drying and decolorization kettle; and the deacidification and deodorization kettle is connected with a polishing filter through a shielding pump and a condenser. The invention has the advantages of low production cost, high efficiency, good effect, capability in industrialized mass production and great economic and social benefit.

Owner:PUTIAN JIATENG FOOD IND

Ladle refining slag modifier, preparation method and slag modifying method

InactiveCN101519712AStrong fluxing effectImprove flux effectProcess efficiency improvementSteelmakingImpurity

The invention belongs to the technical field of steelmaking and refining, and discloses a ladle refining slag modifier, a preparation method and a slag modifying method. The slag modifier comprises the following chemical components in percentage by mass: 30 to 60 percent of CaO, 30 to 60 percent of Al2O3, 2 to 10 percent of MgO2, 2 to 10 percent of B2O3, and less than 8 percent of impurities. The slag modifying method using the slag modifier comprises that: the slag modifier is hoisted to the front of a refining furnace after a steelmaking furnace discharges steels, and then is directly fed into ladles, or the slag modifier can also be fed into the furnace along with other slags at a refining station; the components of modifying slag are determined according to the ladle residue amount and components, desulfuration amount and steel deoxidation product amount; and the modifying slag for controlling the ladle slag comprises the following components according to the adding amount: 48 to 54 percent of CaO, 26 to 32 percent of Al2O3, 6 to 8 percent of MgO, 2 to 4 percent of B2O3, and 0 to 8 percent of SiO2, wherein the modifying slag is better if the content of the SiO2 is lower. The slag modifier has the capabilities of quickly manufacturing the slag, improving desulfuration and deoxidation of the refining slag and accommodating and absorbing deoxidation products, and is simple to prepare and convenient to store, transport and use.

Owner:JIANGSU UNIV

Method for purifying industrial silicon through external refining

InactiveCN102583389AReduce energy consumptionIncrease productivityChemical industrySilicon compoundsSlagMelt temperature

The invention relates to a method for purifying industrial silicon through external refining, which comprises the following steps of: continuously introducing refined gas to a ladle before a submerged arc furnace releases a silicon melt to the ladle; then releasing the silicon melt into the ladle, heating in the ladle, controlling the temperature of the melt within a certain scope, adding a refining agent into the ladle for slag refining, adjusting the introducing flow rate, the pressure and the like of the refined gas along with the continuous increase of the quantity of the silicon melt in the ladle for external refining; and after the completion of the external refining, carrying out slag silicon separation and then pouring, i.e. the purification of the industrial silicon through the external refining is finished. Through the external refining process, a majority of metal impurities containing Al, Ca, Ti and Na and a part of B, P, S and C and other non-metallic impurities in the industrial silicon melt can be removed, and meanwhile, the effective components can be controlled for the subsequent purification of the industrial silicon, and high-quality raw materials are provided for solar grade silicon prepared by a metallurgical method. The method has the characteristics of full utilization, energy resource conservation, high production efficiency, less infrastructure investment, no environment pollution and the like.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of scouring agent for aluminum and aluminum alloy

The invention relates to a preparation method of a scouring agent for aluminum and an aluminum alloy, which comprises the following steps: firstly, selecting ingredients according to the following percentages by weight: 30-85% of NaCl, 5-40% of Na2SiF6, 5-40% of Na2SO4, 2-20% of CaF2 and 0.5-10% of C6Cl6; uniformly mixing and fully stirring the selected ingredients; placing the mixture into a crucible, carrying out overheat melting to eliminate crystal water, and preserving the temperature for 30-60 minutes; and finally, processing after cooling to obtain the scouring agent. The method has the advantages of simple process and low cost. The prepared scouring agent does not contain sylvite, so that sylvite can not be introduced into the scouring and purifying treatment procedures, and therefore, an aluminum electrolysis cell can not be seriously corroded as a result of the introduction of sylvite when aluminum ash is directly recycled in the cell.

Owner:包头市一禾稀土铝业科技材料有限公司

Slag adhesion preventing fluorine-free slag modifier for ladle refining, preparation method and using method

InactiveCN101519713AIncrease contentIncrease surface tensionProcess efficiency improvementSteelmakingPhosphor

The invention belongs to the field of steelmaking, and particularly discloses a fluorine-free slag modifier for preventing a ladle refining device from adhering slag, a preparation method and a using method. The slag modifier consists of active lime, bauxite and boric anhydride; and the slag modifier comprises the following chemical components in percentage by mass: 75 to 85 percent of CaO, 10 to 20 percent of Al2O3, 5 to 15 percent of B2O3, 0 to 8 percent of MgO, and the balance of impurities, wherein SiO2 is less than 7.0 percent, H2O is less than 0.05 percent, and the total amount of sulfur and phosphor is less than 0.01 percent. During use, in order to prevent a ladle from adhering the slag, the slag modifier is fed into the ladle in the later period of discharging steel from a steelmaking furnace, and in order to prevent an RH dip pipe or a CAS-OB dip cover and the like from dipping into the ladle device to adhere slag, the slag modifier is fed at a refining station. The slag modifier can effectively control the refining device from slag adhesion and improve the service life of a fireproof material, is favorable for reducing the contents of the sulfur, oxygen and impurities in the steel, and is simple to prepare and convenient to store, transport and use.

Owner:JIANGSU UNIV

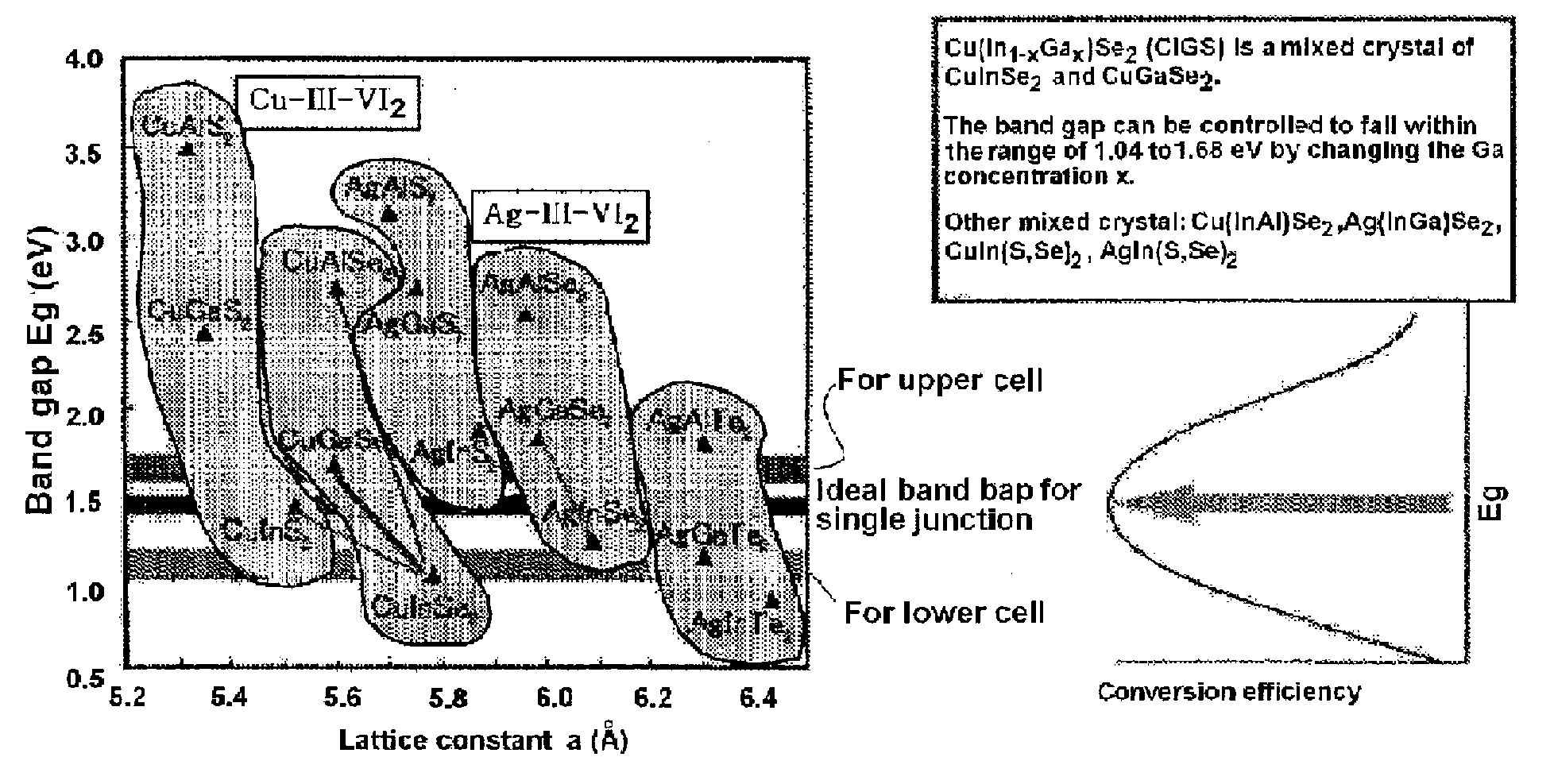

Solar cell

InactiveUS20100252110A1Improve refining effectImprove adhesionPhotovoltaic energy generationSemiconductor devicesSemiconductor materialsSurface roughness

A solar cell, comprising: a metal substrate having an insulating anodic oxidation film; and a photoelectric conversion layer provided on the metal substrate, whereon the anodic oxidation film has a surface roughness of 0.5 nm to 2 μm and the photoelectric conversion layer comprises a chalcopyrite semiconductor material having a band gap of 1.3 eV to 1.5 eV.

Owner:FUJIFILM CORP

Hydrocracking method for increasing quality of refined diesel oil

InactiveCN1488731AIncrease the volume ratioReduced inlet temperature requirementsTreatment with hydrotreatment processesSulfurHydrodesulfurization

The present invention discloses a hydrocracking process for raising refined diesel oil quality, and is mainly characterized by that the poor diesel oil is undergone the process of hydrodesulfurization treatment, then the desulfurized refined diesel oil is mixed with the refined hydrocracked raw material oil, and fed into the hydrocracking reactor, and the sulfur and nitrogen contents in the mixed oil of the refined diesel oil and refined hydrocracked raw material oil must meet the feeding requirements of hydrocracking reactor. As compared with existent technology said invention can utilize hydrocracking equipment to raise the quality of refined poor diesel oil and can obtain high-quality clean fuel.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of rear-earth magnesium alloy product

The invention relates to a preparation method of a rear-earth magnesium alloy product. The preparation method comprises the following steps of: placing dehydrated rear-earth chlorate in a melting electrolysis device; adding dehydrated magnesium chloride, potassium chloride and titanium dichloride for dispersing, mixing and carrying out melting electrolysis, so that rear-earth magnesium intermediate alloy is generated by co-electrodeposition of rear-earth ion and magnesium ion at a negative electrode; burdening and mixing the rear-earth magnesium intermediate alloy and the metal magnesium in a smelting device, wherein a molar ratio of the rear-earth metal to the magnesium is (0.1-1.0):100; heating up the rear-earth magnesium alloy mixture for melting, immersing the smelting agent inside the melt and stirring, increasing the temperature to 780 DEG C and stewing for 20 minutes for dividing the melt into an upper layer, a middle layer and a lower layer, wherein the middle melt layer is used as the rear-earth magnesium alloy melt; casting after pre-cooling, cooling and forming, and carrying out surface treatment after carrying out mechanical processing and thermal processing, so that a compact proactive film layer is covered on the surface of the rear-earth magnesium alloy product. The preparation method of the rear-earth magnesium alloy product is high in preparation efficiency, safe and reliable in process, environment-friendly and low in energy consumption.

Owner:YANGZHOU FENG MING METAL PROD

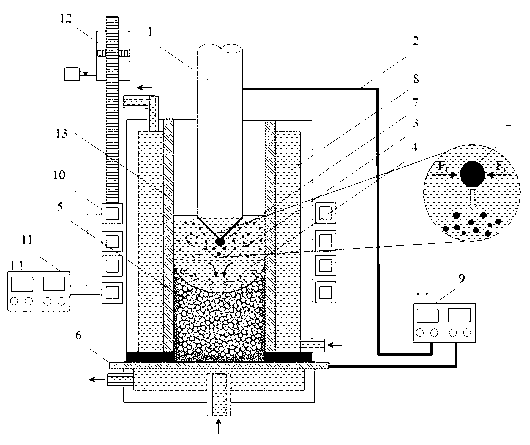

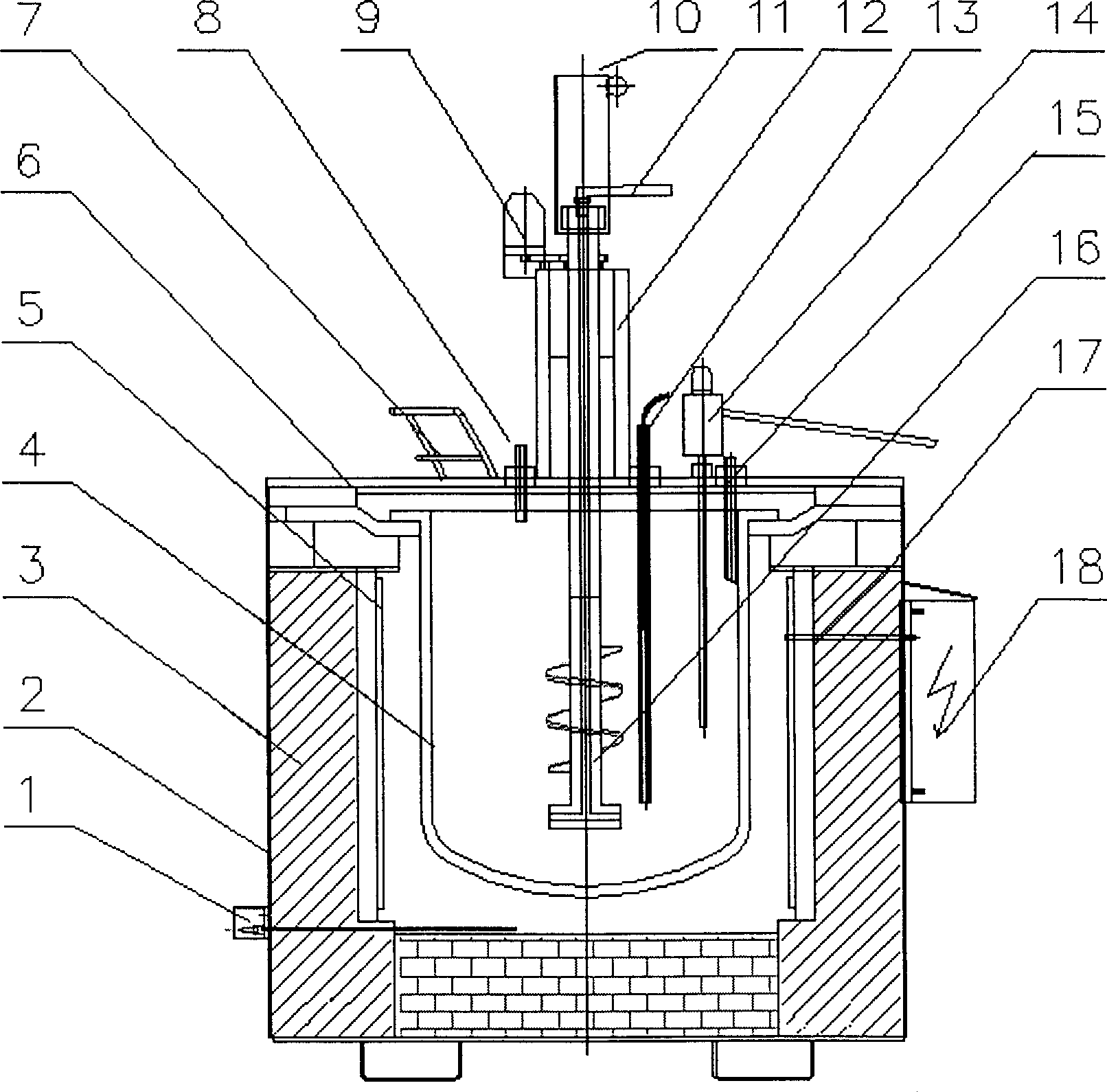

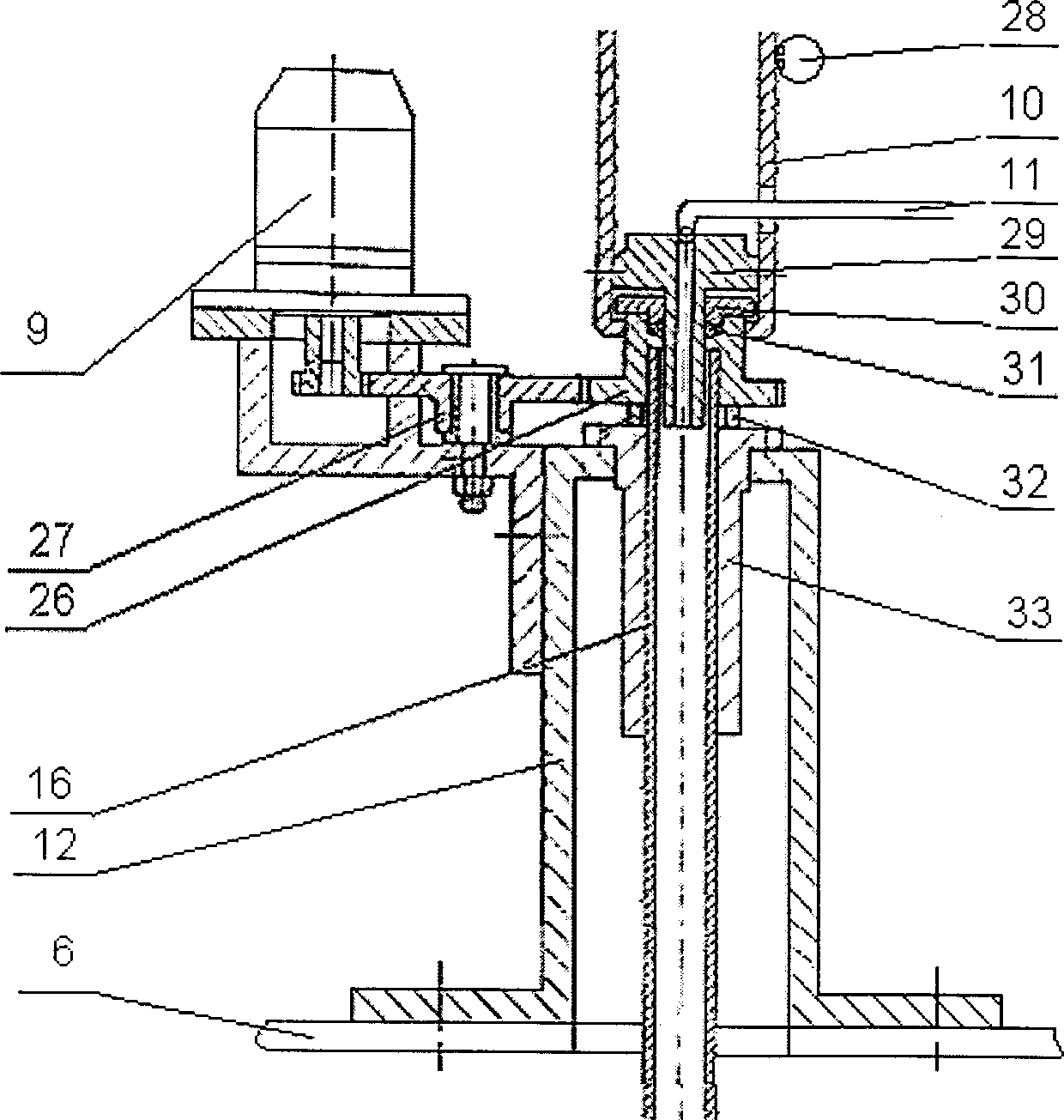

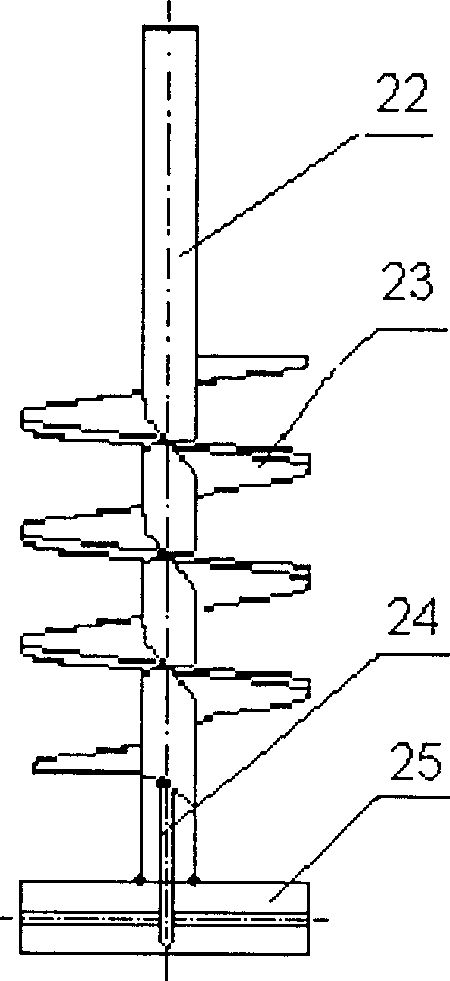

Magnesium alloy waste regenerator

InactiveCN1436865AReduce recycling costsImprove refining effectCrucible furnacesCombustionSpiral blade

The magnesium alloy waste regenerator consists of furnace body, feeding and discharge system and refining system. The apparatus has a stirrer comprising stirring rod with spiral blades and stirring head and these is a through hole in the stirring rod and the stirring head and connected to the refining gas passage via fixing flange. There are dynamic sealing structure in the upper part of the stirring rod and partitioned bin feeder comprising partitioned bin, rotary opened upper cover and withdrawable partition boards. The present invention can realize mechanical composite stirring of gas during refining and isolate magnesium alloy waste in smelting and refining from outside, and these results in less oxidation and combustion, saving in flux and protective gas, improved refining effect, regeneration quality and efficiency, low cost and less environmental pollution.

Owner:TSINGHUA UNIV

Extracting method for high-content sweet inulin A3

The utility model relates to a method for extracting high-content stevioside A3 glycoside, which includes six steps: (1) water extraction: the ground stevia rebaudiana is extracted with water and filtered; (2) resin separation: Filtrate passes through a macroporous resin column and is eluted by alcoholic solvent, stripping liquid passes through a duolite column, and effluent liquid is collected; (3) decolorization: decolourant is added into the effluent liquid, which is then filtered and dried to produce a crude product: (4) crystallization: the crude product is resolved into alcoholic solvent, kept static and filtered to obtain crystals; (5) recrystallization: alcoholic solvent is used again for multiple recrystallizations; (6) washing: the crude product is washed by anhydrous alcoholic solvent and dried to obtain the finished product. The purity of the produced high-content stevioside A3 glycoside is high, so the high-content stevioside A3 glycoside can better improve the taste, the quality and the grade of food, and the method is reasonable and can be easily implemented.

Owner:NINGBO GREEN HEALTH PHARMACEUTICAL CO LTD

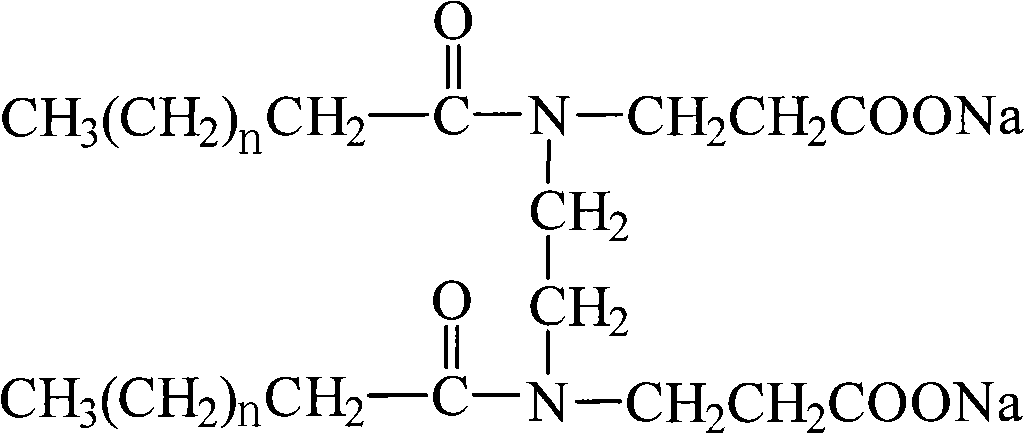

Silk broadcloth scouring agent

The invention relates to a finish process technology for textile, especially a scouring agent for real silk scouring and processing. According to the quality percentage, the ingredients scouring agent is 5-20% double-surfactant N,N'-dialkylamide and carboxylate sodium, 5-20% surfactant alkyl polyoxyethylene ether carboxylate, 2-10% maleic acid / acrylic acid copolymer, 2-10% fibroin protective agent, 1-10% inorganic salts, and water for the rest. The scouring agent take the double-surfactant as the essential component, so the surface activity and the solubility of the scouring agent are improved greatly, and the moistening and the scrubbing effect are strengthened; taking the alkyl polyoxyethylene ether carboxylate surfactant as a complex surfactant, the scouring agent has good emulsification and lime soap dispersing capacity, so as to enhances the scouring effect. At the same time, because amide bond exists in the molecular structure, the scouring agent has good hard water-resistant capacity and lime soap dispersing capacity, and has the advantages of improving the smooth feeling of the scoured textile, and enhancing the capillary effect.

Owner:SUZHOU UNIV

Low-titanium calcium aluminate and its preparing method

The low-titanium calcium aluminate product is produced with industrial alumina and its side product, calcite or limestone, fluorite and feldspar as material, and through crushing, mixing, smelting, cooling, crushing and sieving. The product has TiO2 content less than 0.5%, and is used as desulfurizing agent for smelting steel and fluorite substitute for smelting, especially in smelting special steel, low carbon steel and ultralow carbon steel with strict TiO2 content requirement.

Owner:大连环球矿产股份有限公司

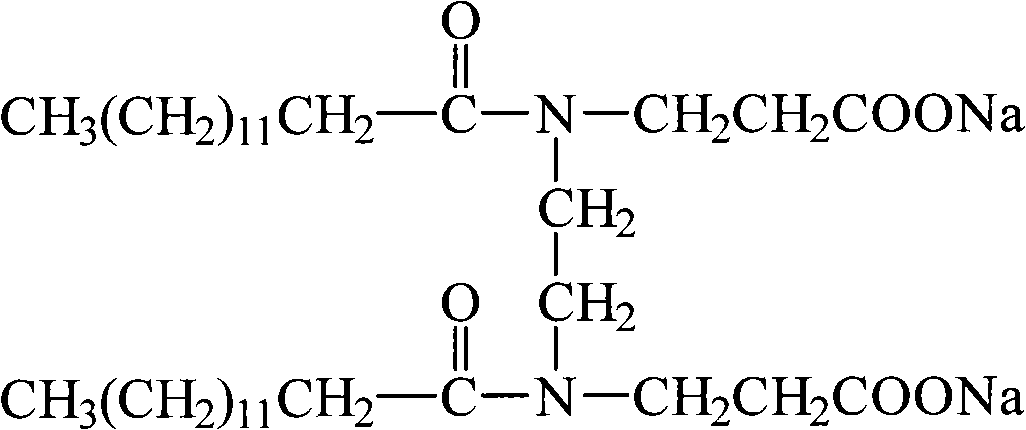

Preparing method of N-[2-(7- anisyl-1- naphthyl) ethide] acetamide

InactiveCN101759591AMeet the requirements of medicinal valueComply with purityOrganic active ingredientsNervous disorderDehydrogenationAntidepressants drugs

The present invention relates to a preparing method of agomelatine (N-[2-(7- anisyl-1- naphthyl) ethide] acetamide) of melatonin antidepressant drugs of commercial production. Firstly, 7- anisyl-1-tetralone is used as raw material, and is prepared into 2-(1,2,3,4- tetrahydrochysene-1- oxhydryl-7- methoxynaphthalene-1-base) acetonitrile in a cyanophoric way; then, 2-(1,2- dihydro-1-oxhydryl-7- methoxynaphthalene-1-base) acetonitrile is generated in an aromatization dehydrogenation way, and (7-- anisyl-1- naphthyl) acetonitrile is generated in a backflow reaction dehydrogenation way; finally, the agomelatine (N-[2-(7- anisyl-1- naphthyl) ethide] acetamide) is generated by reducing and acetylizing in a one-kettle way. The present invention has the advantages of high product purity, friendly environment, convenient operation and low cost, and is suitable for the commercial production.

Owner:ZHEJIANG HUAHAI PHARMA CO LTD

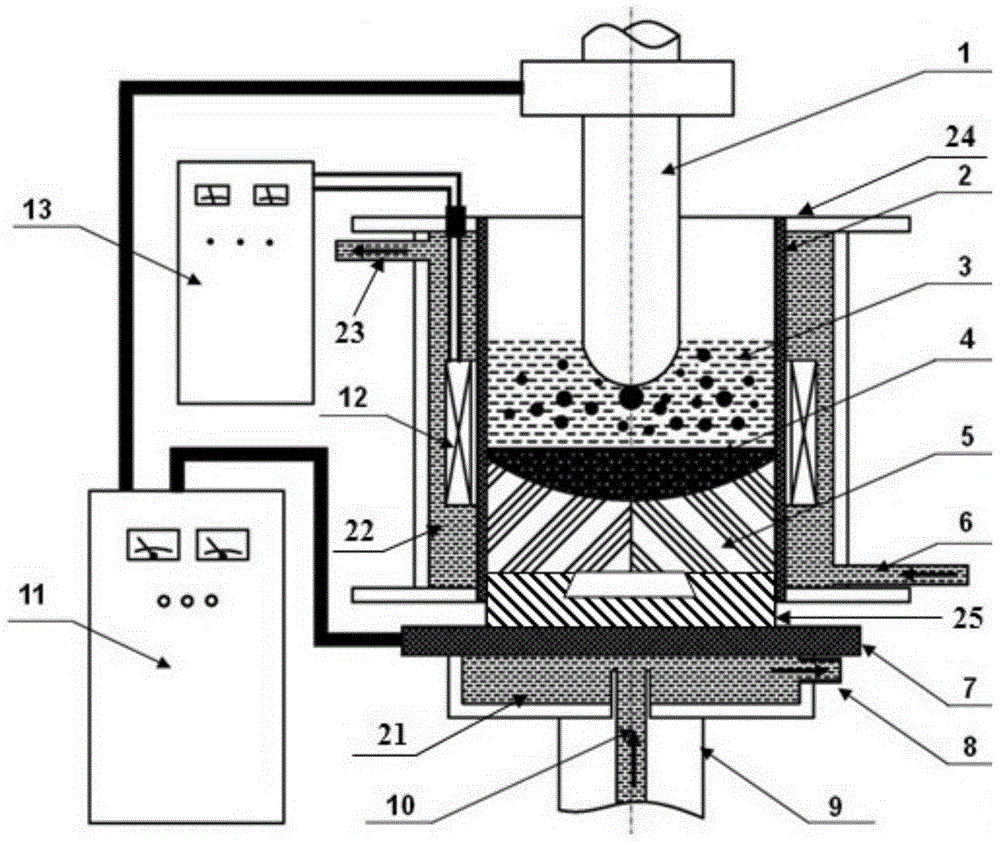

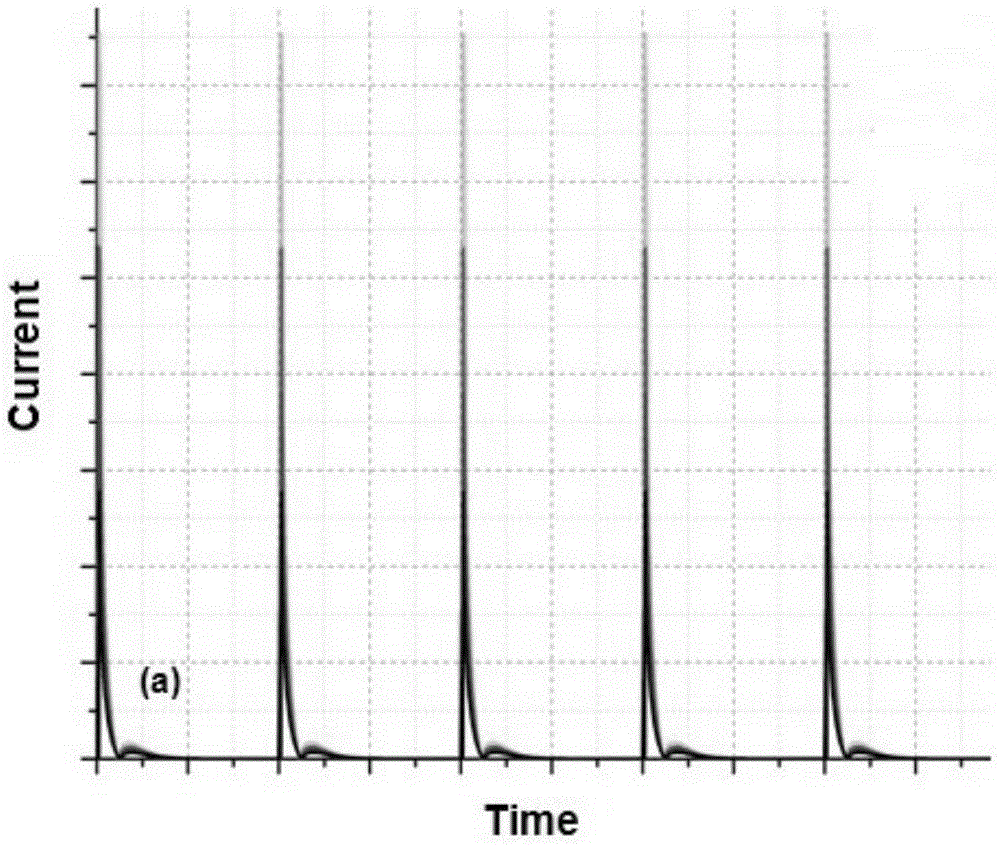

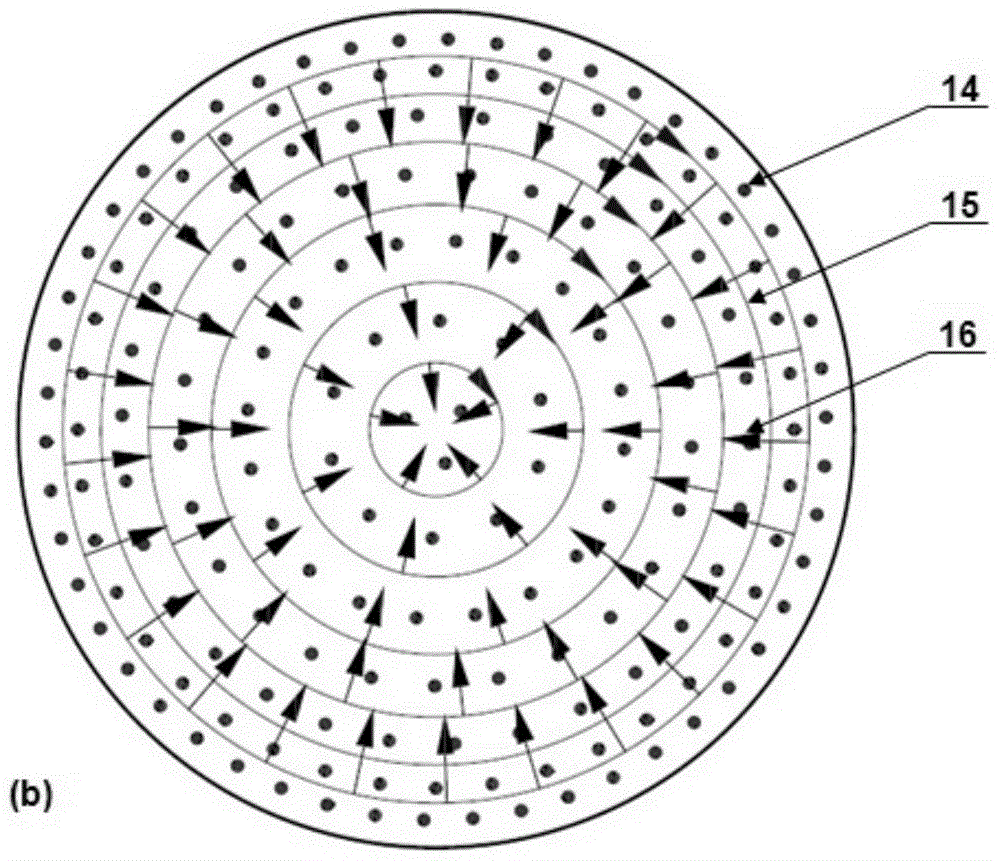

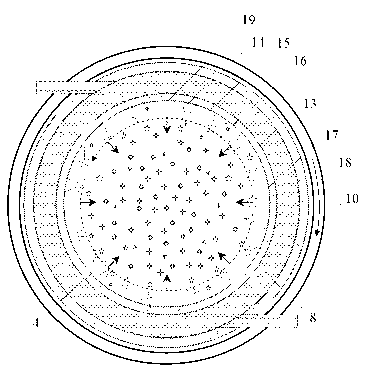

Method and device for casting electromagnetic compound control electroslag remelting fine grains

The invention relates to a method and a device for casting electromagnetic compound control electroslag remelting fine grains, and belongs to the field of preparation of metal materials. According to the method, metallic melt generates forced convection by using the action of exerted pulse magnetic field and periodic electromagnetic force which is generated by compounding of induced current in the melt and electroslag remelting current; a metal material solidification structure is fined; and composition segregation is reduced. Metal droplets can be crushed into fine liquid drops under the action of the electromagnetic force with direction and size in periodic change; the contact area and the contact time of the metal droplets and slag liquid are improved; and a good purification effect is achieved. The device comprises an electroslag remelting work power supply, a pulse power supply and an electromagnetic compound control electroslag remelting crystallizer, wherein the crystallizer is provided with a crystallizer red copper inner sleeve, a side cooling jacket, a bottom cooling jacket and a magnet exciting coil. The method and the device can be applied to electroslag remelting and refining of metal materials such as high-temperature alloy and high alloy steel; the alloy solidification structure can be fined; the segregation is reduced; the refining effect of the electroslag remelting process is improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for determining amount of slagging material and deoxidized alloy added into LF (Low-Frequency) refining furnace by use of reference heat method

ActiveCN103866088AProcessing data is accurateAvoid instabilityProcess efficiency improvementSlagInstability

The invention relates to a method for determining the amount of a slagging material and deoxidized alloy added into an LF refining furnace by use of a reference heat method. The method comprises the following steps: controlling the amount of slags discharged from a rotary furnace during a refining process, wherein the amount of the added synthetic slags is the same during a steel discharging process of the rotary furnace according to the same type of steel heat number; (1) acquiring data and building a database by use of a computer; and (2) using the database for determining the amount of the slagging material and the deoxidized alloy added into this type of steel LF refining furnace when the acquired data of a certain type of steel in the database is accumulated to be not less than 400 heat number. The method disclosed by the invention comprises steps of acquiring operation data, building the database and using the computer to process the data rapidly and accurately; the reference heat method absolutely can be used for replacing the existing slagging method for manually determining the amount of the added slagging material and has the advantages of solving the instability of manual determination, optimizing the refining effect, stabilizing the quality of refined liquid steel and promoting standardized operation.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

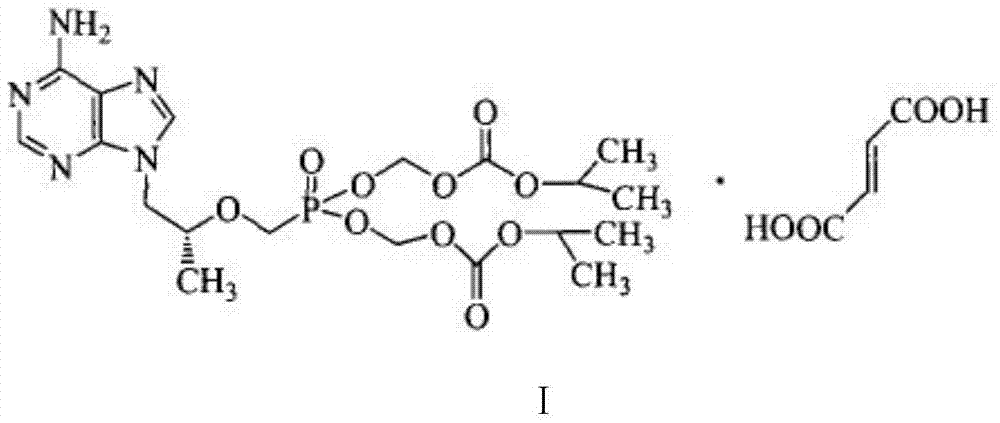

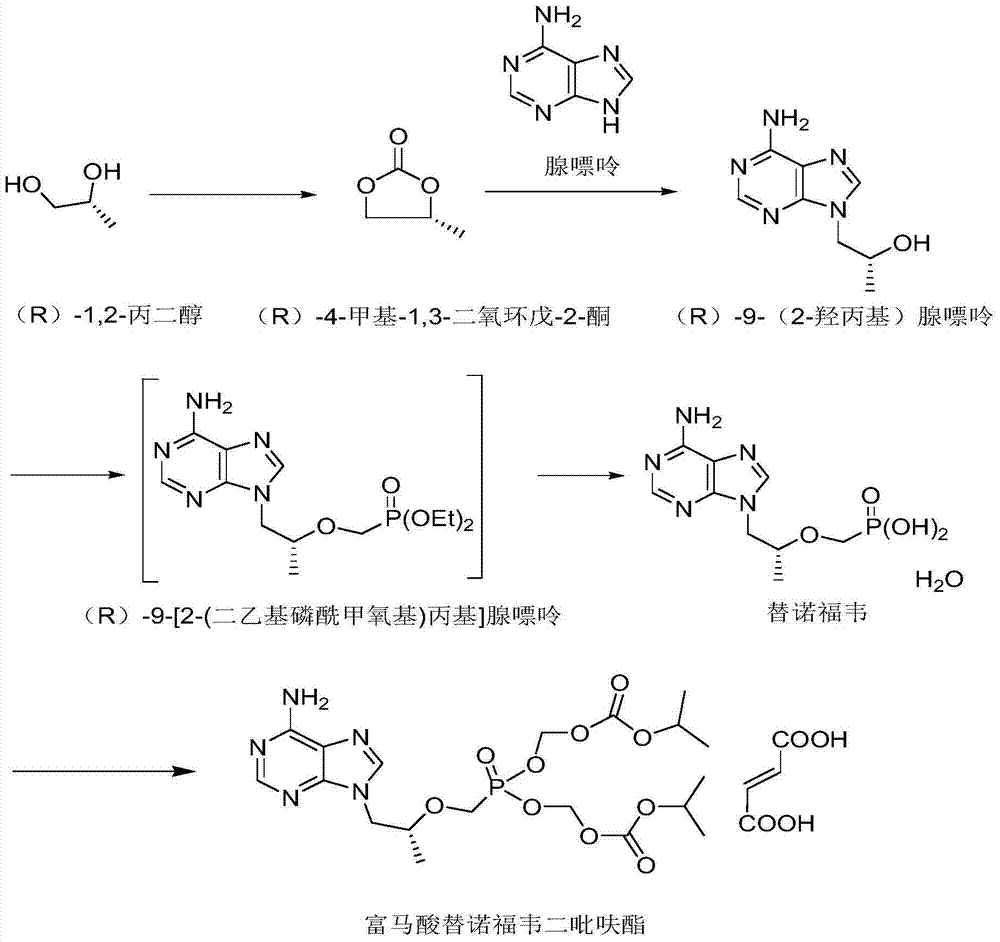

Tenofovir disoproxil fumarate synthesis method

InactiveCN104725423AHigh yieldHigh purityGroup 5/15 element organic compoundsSynthesis methodsReaction intermediate

The present invention belongs to the technical field of medicine, and relates to a tenofovir disoproxil fumarate synthesis method, wherein (R)-1,2-propanediol and carbonate are adopted as raw materials, and condensation, etherification, hydrolysis, esterification salification and other steps are performed to prepare the finished product. According to the present invention, the process improving and the reaction intermediate treatment are performed so as to easily achieve the reactions in the subsequent steps and the separation and purification, improve the yield and the corresponding purity of the target product, and obtain the tenofovir disoproxil fumarate meeting the medical standard.

Owner:SHANDONG NEWTIME PHARMA

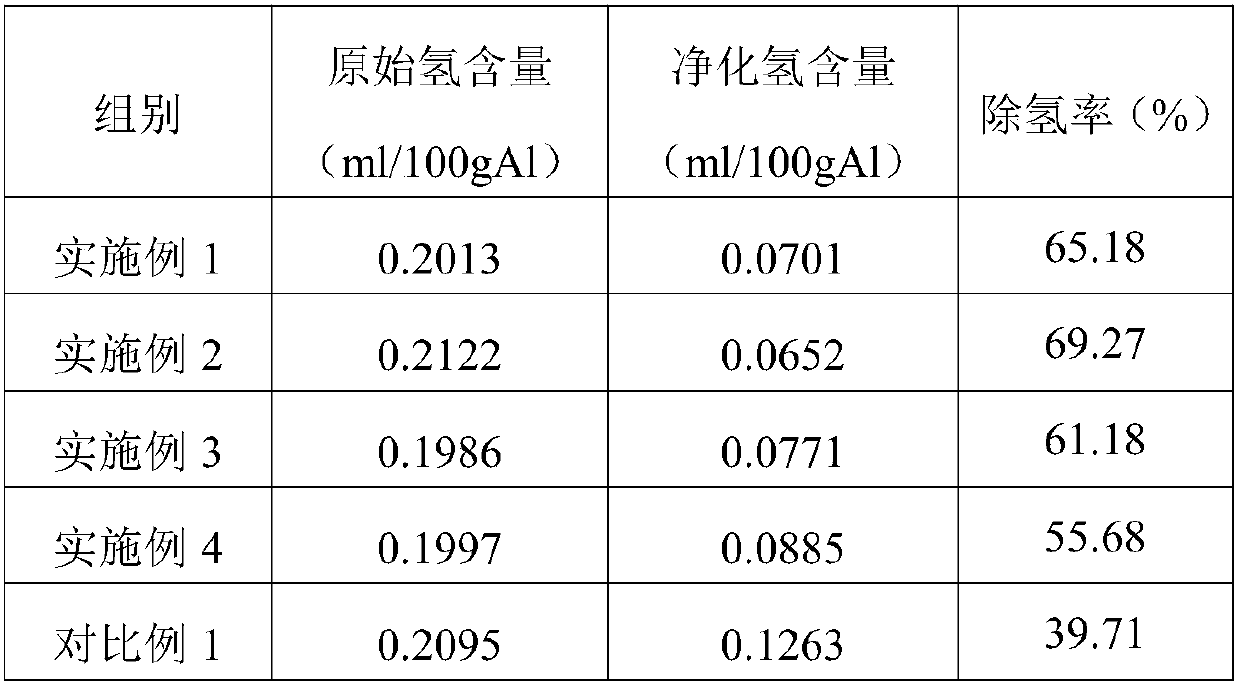

Purifying method of aluminum alloy melt

InactiveCN107805723ATo promote floatingImprove refining effectProcess efficiency improvementParticulatesSlag

The invention discloses a purifying method of aluminum alloy melt, and belongs to the technical field of aluminum alloy machining. The purifying method of the aluminum alloy melt comprises the steps that aluminum alloy raw materials in a crucible melting furnace are heated to 720-740 DEG C to prepare the melt; a switch of a movable rotating arm is turned on, so that the rotating arm rotates and stirs in the aluminum alloy melt at a constant speed, N2 and Cl2 mixing gas and a refining agent are introduced simultaneously, and meanwhile, floating slag on the surface of the aluminum alloy melt isremoved; after the aluminum alloy melt is smelt for 15-20 min, the melt is heated to 720-740 DEG C, and N2 and Ar mixing gas is introduced into the melt for exhausting; and after air exhausting is finished, slagging-off is conducted once again, after standing still is conducted for a period of time, filtering is conducted, and particulate impurities are removed. According to the purifying method of the aluminum alloy melt, a motor is used for driving rotation, big bubbles entering the melt are broken up into fine bubbles, and the refining effect is improved.

Owner:广西平果铝合金精密铸件有限公司

Method for controlling electroslag melting casting by added transient magnetic field and electroslag smelting casting device

The invention discloses a method for controlling electroslag melting casting by an added transient magnetic field. The method includes adding a transient magnetic field to a melting end of an electroslag remelting mother electrode, a liquid slag tank and a metal melting tank so that the transient magnetic field acts on large metal molten drops which are generated by initial melting at the tail end of the electrode and are converging to become big; under joint action of alternating lorentz force and pressure waves generated by the transient magnetic field, dispersing the metal molten drops in a burst manner into small metal molten drop groups, and randomly dispersing the small metal molten drop groups into the liquid slag tank to sufficiently contact with liquid slag after passing the liquid slag tank; after washing, enabling included foreign substances and impurities in the small metal molten drops to enter the liquid slag quickly, slowly settling and converging the foreign substances and impurities into the metal melting tank below the liquid slag tank, and finally crystallizing and solidifying to form solidified cast ingots. The invention further provides an electroslag melting casting device. By adding the transient magnetic field during electroslag melting casting and fining the molten drops by the aid of unique electromagnetic effect of the transient magnetic field, the purposes of improving refining efficiency, fining crystalline grains and reducing segregation of cast ingots are achieved, and industrial application value is realized.

Owner:SHANGHAI UNIV

Magnesium alloy rare earth compound flux and its production method

The present invention provides a magnesium alloy rare earth compound flux and its production method. Its composition includes (wt%) 40-55% of magnesium chloride, 15-25% of potassium chloride, 12-25% of sodium chloride, 1-6% of calcium chloride, 5-15% of calcium fluoride, 1-8% of barium chloride and 3-10% of rare earth activator. Said ivnention flux has high activity, proper melting point, density, viscosity and surface tension, and can greatly raise mechanical property of magnesium alloy and corrosion resistance.

Owner:SHANGHAI HAOHUA MOLD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparing method of N-[2-(7- anisyl-1- naphthyl) ethide] acetamide Preparing method of N-[2-(7- anisyl-1- naphthyl) ethide] acetamide](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/304a2a1f-93bf-4b9b-8f00-84c91fb25cf8/G2009101403386D0000012.PNG)

![Preparing method of N-[2-(7- anisyl-1- naphthyl) ethide] acetamide Preparing method of N-[2-(7- anisyl-1- naphthyl) ethide] acetamide](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/304a2a1f-93bf-4b9b-8f00-84c91fb25cf8/G2009101403386D0000031.PNG)

![Preparing method of N-[2-(7- anisyl-1- naphthyl) ethide] acetamide Preparing method of N-[2-(7- anisyl-1- naphthyl) ethide] acetamide](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/304a2a1f-93bf-4b9b-8f00-84c91fb25cf8/G2009101403386D0000051.PNG)