Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

216 results about "Hexachloroethane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hexachloroethane, also known as perchloroethane (PCA), C₂Cl₆, is a white crystalline solid at room temperature with a camphor-like odor. It has been used by the military in smoke compositions, such as base-eject smoke munitions (smoke grenades).

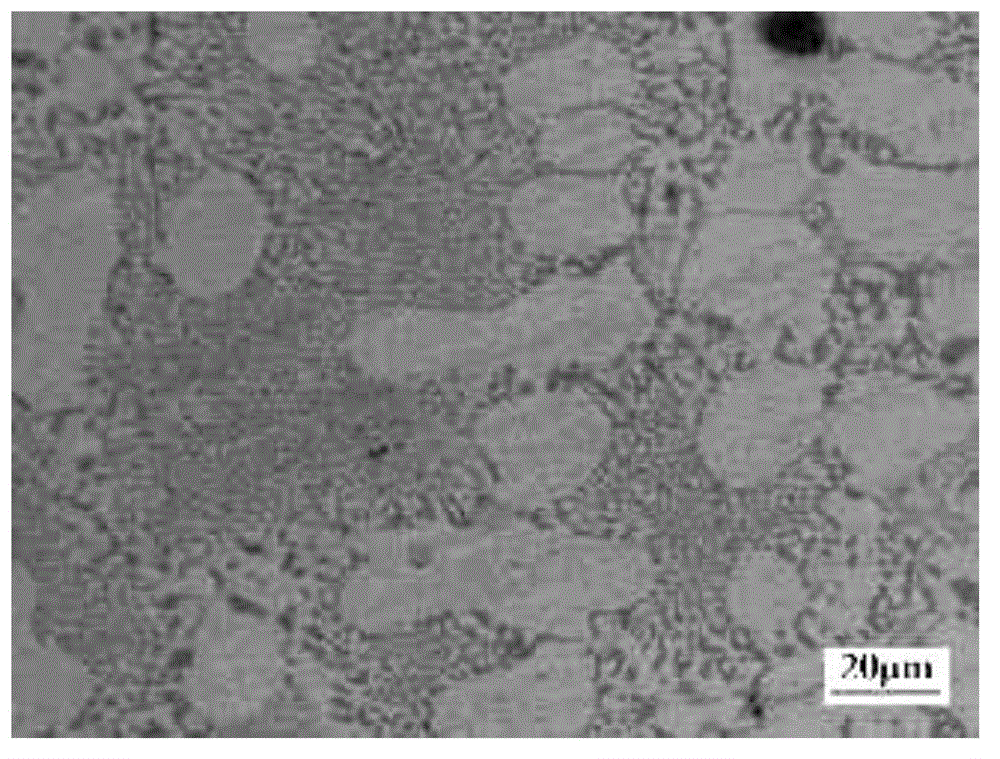

Aluminum-silicon based aluminum section and preparation technology thereof

The invention discloses an aluminum-silicon based aluminum section. The aluminum section is composed of, by weight, 5.0-14.0% of silicon, 0.2-0.7% of magnesium, less than 0.03% of boron, less than 0.06% of strontium, 0.1-6.55% of strengthening elements, less than 0.25% impurity elements, and the balance aluminum. The aluminum-silicon based aluminium section has the advantages of high strength, high hardness, good wear resistance, etc. the invention also discloses a preparation technology for the aluminum-silicon based aluminum section, which comprises a first step of adding aluminum-silicon alloy to a graphite crucible and heating the alloy to form melt; a second step of adding the magnesium, the silicon and the strengthening elements; a third step of adding hexachloroethane for refinement; a forth step of adding the strontium for deterioration, casting to a cast iron die to form an ingot casting; and a fifth step of hot extruding, hot rolling for deformation, solid solution treating and aging treating in sequence after annealing the ingot casting, thereby obtaining the aluminum-silicon based aluminum section. The preparation technology is simple.

Owner:SOUTHEAST UNIV

Al-Si-Cu-Zn-Sn-Ni aluminum-based brazing filler metal and preparation method thereof

InactiveCN102319963AReduce brittlenessImprove surface activityWelding/cutting media/materialsSoldering mediaSlagAlloy

The invention relates to an Al-Si-Cu-Zn-Sn-Ni aluminum-based brazing filler metal and a preparation method thereof. The components of the aluminum-based brazing filler metal are 7 to 13 percent by weight of Si, 5 to 11 percent by weight of Cu, 4 to 11 percent by weight of Zn, 1 to 6 percent by weight of Sn, 1 to 3 percent by weight of Ni, 0.02 to 0.3 percent by weight of Ce, 0.01 to 0.1 percent by weight of Sr, 0.01 to 0.2 percent by weight of Zr and the balance of Al. The process flow for preparing the aluminum-based brazing filler metal is that: pure aluminum is added into a graphite crucible and covered by flux for aluminum under the condition of 800 DEG C to 900 DEG C, and slag is removed after melting; the aluminum-based intermediate alloy of high-melting point elements and flux for aluminum are added at the same time, and melting, stirring and slag removal are carried out; the aluminum-based intermediate alloy of low-melting point elements is added under the protection of nitrogen, and melting and stirring are carried out; the mixture of argon and hexachloroethane is added to carry out refining, and standing and slag removal are carried out; the intermediate alloy of trace elements is added, and melting and stirring are carried out; secondary refining and slag removal are carried out; and under the protection of nitrogen, casting formation is carried out. The Al-Si-Cu-Zn-Sn-Ni aluminum-based brazing filler metal has the advantages of low melting point, high strength, high toughness, high corrosion-resistant property and good wetting property and spreadability.

Owner:GUILIN QINGTONG NON FERROUS METAL ARTS & CRAFTS MATERIAL DEV CO LTD

Grain refinement and modification master alloy for aluminum and aluminum alloy and method for preparing same

The invention discloses a grain refinement and modification master alloy for aluminum and an aluminum alloy, which comprises the following components by weight percentage: 3.0 to 10.0 percent of titanium, 1.0 to 3.0 percent of boron, 0.5 to 5.0 percent of strontium, 0.5 to 2.0 percent of cerium-enriched rare earth, and the balance of aluminum. The preparation method for the master alloy comprises the following steps: weighting potassium fluotitanate, potassium fluoborate, a mixed rare earth ingot, an alloy, and a pure aluminum ingot in proportion; drying the potassium fluotitanate and the potassium fluoborate; heating and melting the aluminum ingot and the aluminum rare earth ingot, adding the mixture of the potassium fluotitanate and the potassium fluoborate, and stirring until the melted mass is completely reacted; adding a Al-Sr master alloy, stirring, and performing heat preservation and slagging off; adding hexachloroethane and evenly stirring; and standing, performing heat preservation for 20 to 30 minutes, casting into an ingot and then extruding into a wire. The master alloy can be well combined with an interface of an aluminum matrix; the particle phase is evenly distributed; the grain size of the refinement phase is small; the activated Sr is enough to ensure the following modification; the conglobation of the refinement phase is effectively reduced, and the degradation is inhibited; and the preparation process is low in cost.

Owner:广州工业投资控股集团有限公司 +1

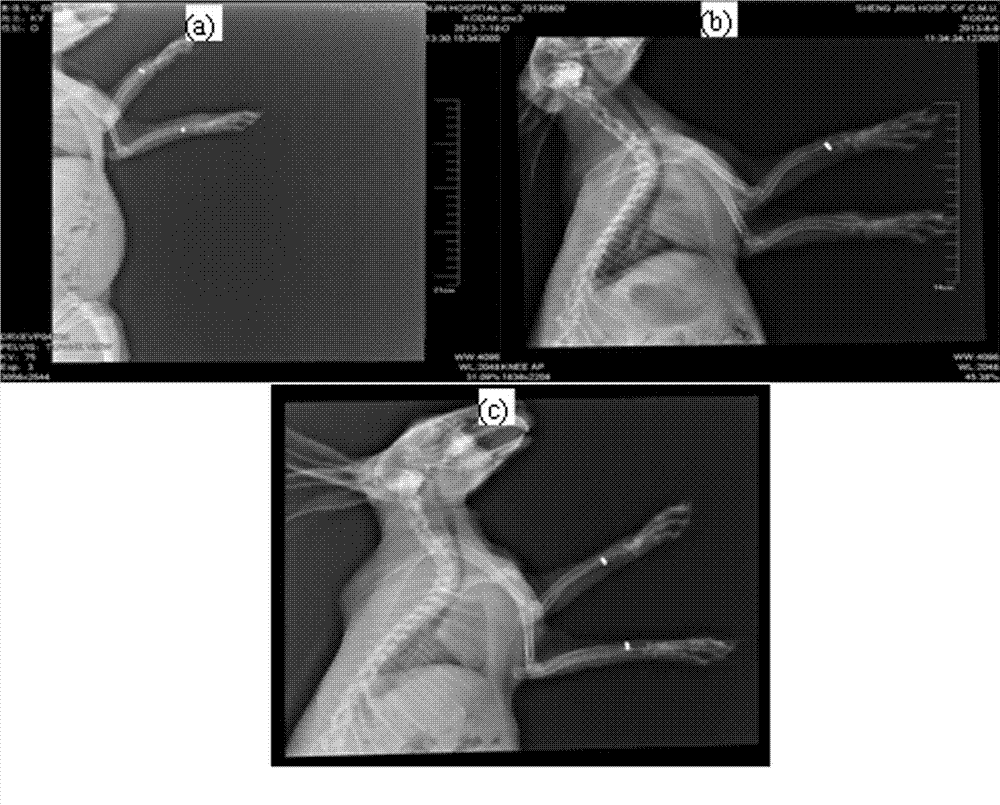

Medical biodegradable zinc alloy and preparation method thereof

The invention discloses a medical biodegradable zinc alloy and a preparation method thereof, belonging to the technical field of materials. The medical biodegradable zinc alloy comprises the following components in percentage by weight: 0.005-1% of Mg, 0.01-0.5% of Ag, 0.01-0.5% of Ca, 0.01-0.5% of Mn, less than or equal to 0.2% of inevitable impurities and the balance of Zn. The preparation method comprises the following steps: (1) heating pure metal zinc to be 520+ / -5 DEG C, dissolving, sequentially adding manganese metal, metallic silver, calcium metal and magnesium metal, and stirring till the components are uniformly mixed; (2) cooling to be 460+ / -5 DEG C, pressing hexachloroethane, keeping the temperature, and standing for 10-20 minutes; (3) keeping and reducing the temperature to be 440+ / -5 DEG C, and casting; (4) keeping the temperature to be 300+ / -5 DEG C for 100-200 minutes, heating to be 330-360 DEG C, keeping the temperature for 3-5 hours, and further water-cooling to be normal temperature; (5) keeping the temperature to be 150-350 DEG C for 20-40 minutes, subsequently performing high-temperature deformation, and air-cooling to be normal temperature; and (6) performing multiple times of normal temperature deformation-intermediate annealing, and finally air-cooling to be the normal temperature. The zinc alloy disclosed by the invention can be used for preparing various degradable medical devices which can meet different clinical use requirements.

Owner:NORTHEASTERN UNIV +1

Low-melting-point and high-strength aluminum-based brazing filler metal and preparation method thereof

InactiveCN102000924AReduce brittlenessReduce surface tensionWelding/cutting media/materialsSoldering mediaNitrogen gasToughness

The invention discloses a low-melting-point and high-strength aluminum-based brazing filler metal and a preparation method thereof. The brazing filler metal consists of the following components in percentage by mass: 6 to 13 percent of Si, 6 to 13 percent of Cu, 1 to 3 percent of Ni, 0.01 to 0.1 percent of Sr, 0.01 to 0.2 percent of Ti, 0.01 to 0.2 percent of Y and the balance of Al. The preparation method comprises the following steps of: weighing each component; adding the components into a graphite crucible melting furnace according to a certain sequence; melting and then refining twice, wherein argon gas and hexachloroethane are used as refining agents during the refining; introducing the hexachloroethane from bottom of solution by the argon gas, wherein the introduction pressure of the argon gas is 5 to 7KPa; and continuously casting solution which is subjected to the second refining process under the protection of nitrogen gas as required or performing gas atomization to form the aluminum-based brazing filler metal in different forms. The aluminum-based brazing filler metal prepared by the method has the superior characteristics of low melting point, high strength, toughness, wettability and spreadability and the like.

Owner:GUILIN QINGTONG NON FERROUS METAL ARTS & CRAFTS MATERIAL DEV CO LTD

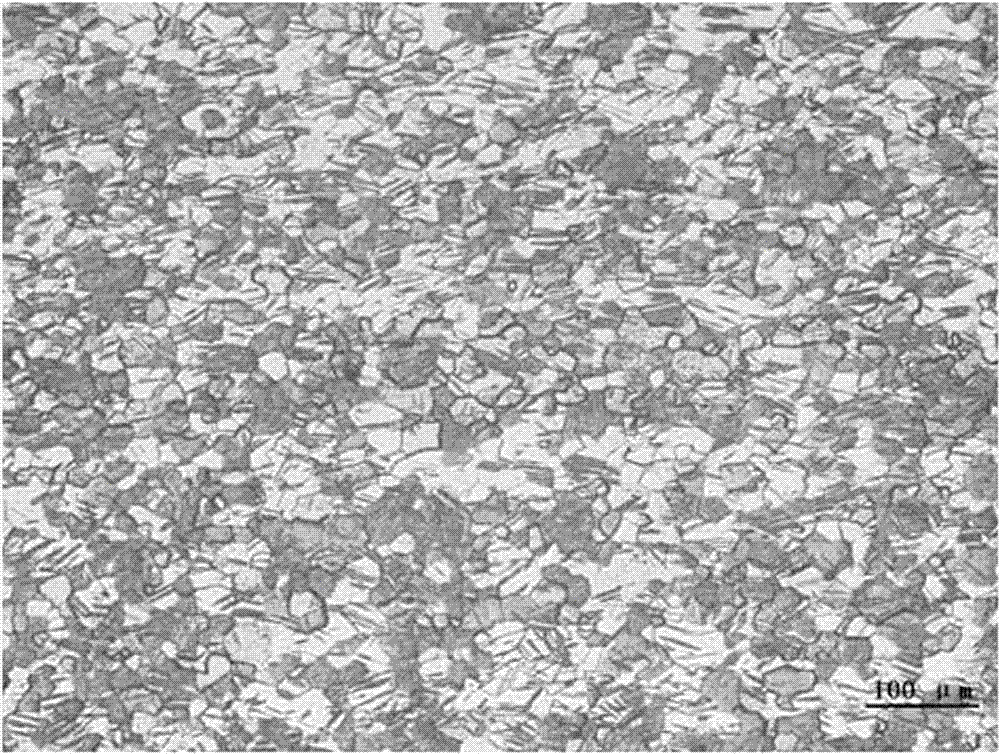

Aluminum alloy 7085 microalloyed with strontium and preparation method thereof

The invention discloses an aluminum alloy 7085 microalloyed with strontium, which is formed by microalloying aluminum alloy 7085 with a small amount of strontium. The alloy mainly comprises Al, Zn, Mg, Cu, Zr and Sr, wherein the mass percent of Zn is 7.0-7.95%, the mass percent of Mg is 1.41-1.80%, the mass percent of Cu is 1.50-1.59%, the mass percent of Zr is 0.138-0.148%, the mass percent of Sr is 0.0228-0.0237%, and the balance is Al and a small amount of impurity elements. The preparation process flow of the alloy is as follows: melting pure Al, sequentially adding Al-Cu intermediate alloy, Al-Sr intermediate alloy, Al-Zr intermediate alloy, pure Zn and pure Mg, melting, adding hexachloroethane for refining, standing and maintaining the temperature for 5-10 minutes, and then casting into ingots; and carrying out post treatments of annealing, stamping and soilid solution ageing on the alloy ingots formed by casting. The invention has the advantages of high rigidity, good exfoliation corrosion resistance and wide application range.

Owner:JIANGSU UNIV

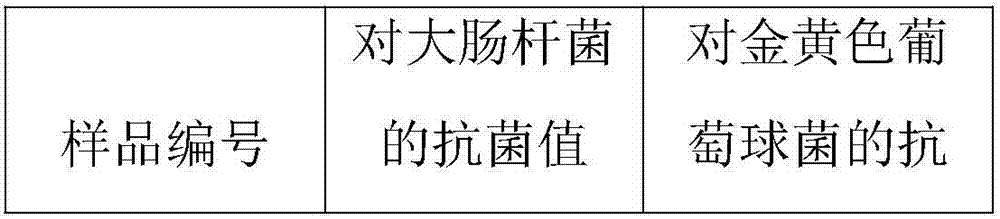

High-strength antibacterial aluminum alloy for aluminum alloy ladder and preparation method thereof

ActiveCN107201469AHigh hardnessImprove toughnessAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention relates to the technical field of aluminum alloy ladder preparation, and particularly relates to high-strength antibacterial aluminum alloy for an aluminum alloy ladder and a preparation method thereof. The aluminum alloy comprises a high-strength aluminum alloy matrix and a micro-arc oxidation film, wherein the micro-arc oxidation film is arranged on the surface of the aluminum alloy matrix, the weight of a hole sealing agent on the micro-arc oxidation film is 0.15 g / cm<2> to 0.90 g / cm<2>, and the hole sealing agent covers at least 92% of micropores in the micro-arc oxidation film. The preparation method comprises the steps of smelting metal, modifying, refining and degassing, pouring and forming and performing quenching treatment, aging treatment, micro-arc oxidation and hole sealing treatment, wherein in the step of modifying, nanometer modificators are uniformly dispersed into liquid alloy obtained by smelting; in the step of refining and degassing, 0.23% to 0.38% of hexachloroethane is added to the modified liquid alloy so as to refine and degas; and the aging treatment is divided into four-stage aging treatment. The aluminum alloy prepared by adopting the preparation method has the characteristics of high hardness, high strength, wear resistance, corrosion resistance, good anti-cracking performance, good antibacterial effect, difficulty in aging and deformation and long service life.

Owner:浙江洋铭实业有限公司

High-strength aluminum alloy welding wire and preparation method thereof

ActiveCN102114579ALight materialImprove performanceWelding/cutting media/materialsSoldering mediaSlagHeating temperature

The invention discloses a high-strength aluminum alloy welding wire which comprises the following chemical compositions in percentage by weight: 2.5-3.5 percent of Cu, 2.2-3.2 percent of Si, 0.1-0.25 percent of Ti, 0.1-0.25 percent of Zr, 0.1-0.2 percent of Mn and the balance of Al. The preparation method comprises the following steps: melting and ingot-casting raw materials so as to prepare intermediate alloy of Al-Cu50, Al-Mn10, Al-Si30, Al-Ti10 and Al-Zr10; pouring the pure aluminum ingot into a crucible according to composition proportion, raising temperature, adding and melting the intermediate alloy of Al-Mn10, Al-Cu50, Al-Ti10 and Al-Zr10 in sequence according to composition proportion after the aluminum ingot is entirely molten; after melting is finished, raising the temperature to 800 DEG C for heat preservation for 15 minutes, pressing hexachloroethane into the bottom of the alloy liquid with a graphite hood, stirring to conduct degassing and slagging, wherein the using amount of the hexachloroethane is 0.3-0.4 percent of the amount of a furnace, scattering a little amount of scouring agent to remove surface float slag after finishing slagging-off; continuing to raise the temperature to 820-850 DEG C, fully stirring, and discharging; conducting pull-casting to prepare high-strength aluminum alloy cast ingot; then taking out and sawing the cast ingot into segments and peeling; putting the cast ingot into an extruder at the heating temperature of 330-380 DEG C for extrusion; and conducting wiredrawing in a wiredrawer, and annealing in the drawing process, thus obtaining high-strength aluminum alloy welding wires when achieving the standard diameter.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

Die-cast aluminum alloy material and method for preparing same

The invention discloses novel high strength die-cast aluminum alloy material and a method for preparing the same. The novel die-cast aluminum alloy material takes the aluminum (Al) as the substrate and comprises the following elements by weight percent: 10-12 percent of silicon (Si), 0.5-1.0 percent of manganese (Mn), 0.5-3.0 percent of copper (Cu), 0-0.5 percent of titanium (Ti), 0.5 percent of ferrum (Fe) or less, 0-0.8 percent of other elements and the balance of aluminum (Al). The method for preparing the novel die-cast aluminum alloy material comprises the following steps: melting an pure aluminum ingot; keeping the heat of the melted pure aluminum ingot at 700-750 DEG C; adding the industrial Si, the industrial Cu, the Mn and the Ti to the melted pure aluminum ingot according to the formula, and stirring the industrial Si, the industrial Cu, the Mn, the Ti and the melted pure aluminum ingot with a mechanical stirrer; keeping the heat of the mixture for 30-60min; removing the slag and the gas with hexachloroethane for 10min; and modifying the mixture with the universal ternary modifier. Through improving the components of the die-cast aluminum alloy, the microstructure and the refined grain of the die-cast aluminum alloy in the crystallizing and the solidifying process are controlled, the morphology of the Si-Fe compound in the die-cast aluminum alloy is changed, the mechanical property of the die-cast part is improved, the elements in the die-cast aluminum alloy are dissolved in the substrate to form the solid solution, and the mechanical property of the die-cast aluminum alloy is improved.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

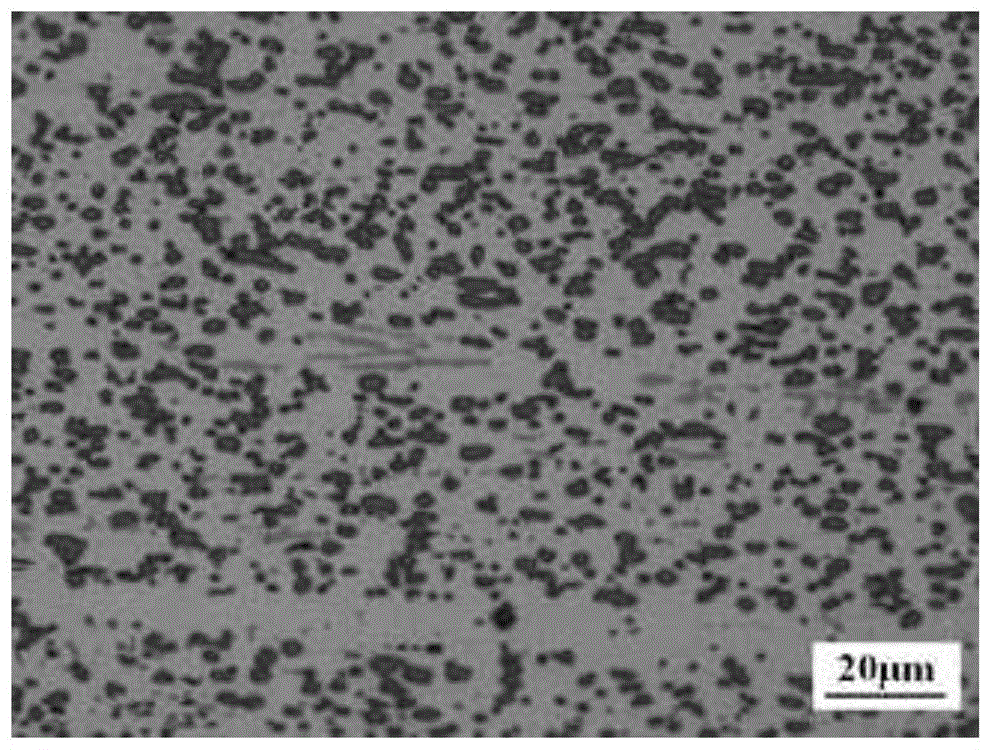

Compound 6013-type aluminum alloy microalloyed by zirconium and strontium and preparation method thereof

The invention discloses a 6013-type aluminum alloy microalloyed by zirconium and strontium, which mainly comprises Al, 1.22% to 1.52% of Mg, 0.90% to 1.15% of Si, 0.804% to 1.04% of Cu, 0.451% to 0.661% of Mn, 0.0311% to 0.135% of Zn, 0.0915% to 0.135% of Zr and 0.0157% to 0.0391% of Sr. The preparation method of the alloy comprises the steps of: melting pure Al; sequentially adding Al-Cu intermediate alloy, Al-Si intermediate alloy, Al-Mn intermediate alloy, Al-Zr intermediate alloy, Al-Sr intermediate alloy, pure Zn and pure Mn; melting and adding hexachloroethane for refining; standing and keeping the temperature for 5 to 10 minutes; removing residues; casting into ingots; and treating the cast ingots. The hardness of the alloy reaches 156.0 to 159.1 HV; the performance of resisting intergranular corrosion is in fourth level; and the performance of resisting exfoliation corrosion is not less than PB level. The alloy can be widely applied to the fields of modern aerospace, weaponry and the like, and has wide application prospect.

Owner:NANTONG JIANGZHONG PHOTOELECTRIC

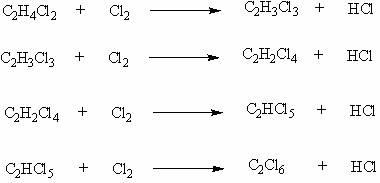

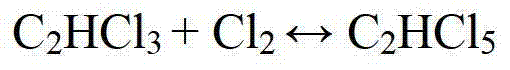

A kind of method that takes dichloroethane as raw material to produce trichloroethylene and tetrachloroethylene

InactiveCN102267863ATo satisfy the market's needsSimple processPreparation by hydrogen halide split-offTetrachloroethaneEthylene Dichloride

The invention relates to a method for preparing trichloroethylene and perchloroethylene from dichloroethane as a raw material. The existing method has the defects of difficult realization and large amount of investment. The method of the invention comprises the following steps that dichloroethane undergoes chlorination to produce a mixture of dichloroethane, trichloroethane, tetrachloroethane, pentachloroethane and hexachloroethane, and hydrogen chloride gas under a dichloroethane gaseous or liquid phase; the mixture is transferred into a rectifying tower to be rectified; a tetrachloroethane / pentachloroethane mixture fraction with a top temperature of 147 to 162 DEG C is collected; the collected tetrachloroethane / pentachloroethane mixture fraction is vaporized and then is fed into a fixedbed reactor to form a trichloroethylene / perchloroethylene gas mixture; the trichloroethylene / perchloroethylene gas mixture is condensed into a liquid mixture; the liquid mixture and hydroquinone are fed into a rectifying tower to be rectified; a fraction with a top temperature of 86 to 87.5 DEG C is collected to obtain trichloroethylene finished products; and a fraction with a top temperature of 120 to 121.5 DEG C is collected to obtain perchloroethylene finished products. The method has the advantages of simple process, good controllability, easy acquirement of raw materials, low cost and little or no process wastewater or waste residue.

Owner:内蒙古磐迅科技有限责任公司

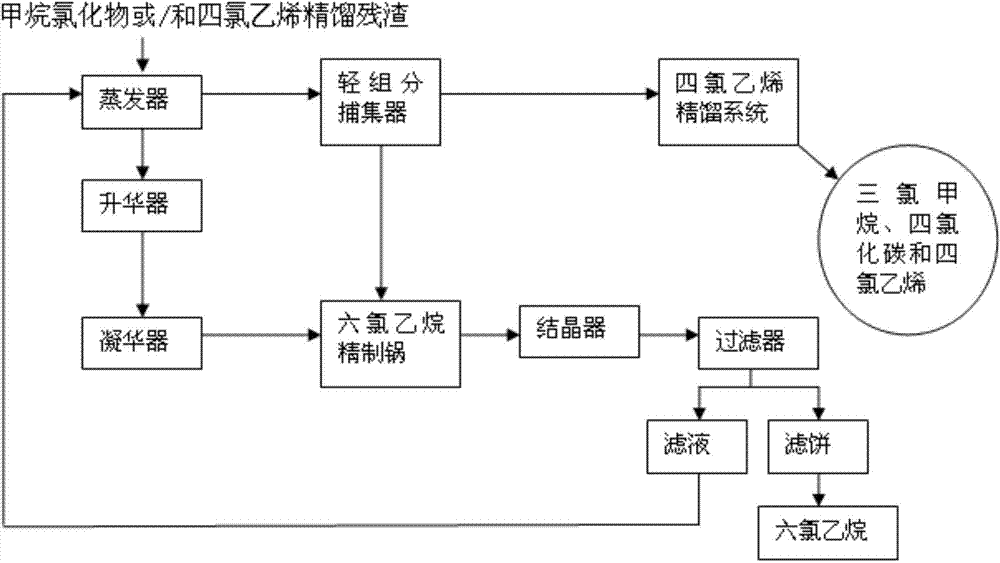

Method for recovering organic chloride from rectification residues of methane chloride or/and tetrachloroethylene

ActiveCN103787823AEfficient recyclingDisposal savingsHalogenated hydrocarbon separation/purificationOrganic chloride compoundEvaporation

Owner:山东中盛药化设备有限公司

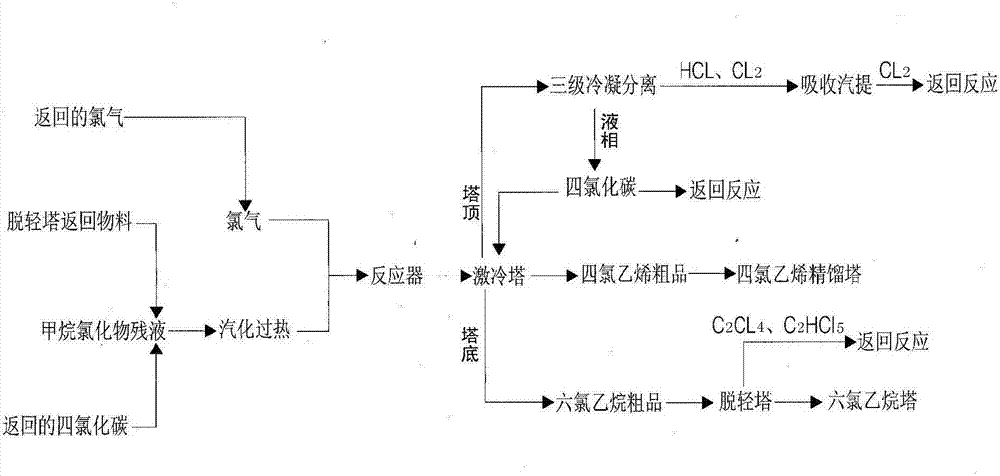

Production process for production of tetrachloroethylene and coproduction of hexachloroethane by using methane chloride residual liquid

ActiveCN103086839AAvoid pollutionIncrease profitabilityHalogenated hydrocarbon preparationGas phaseMixed gas

The invention discloses a production process for production of tetrachloroethylene and coproduction of hexachloroethane by using methane chloride residual liquid. According to the production process, the methane chloride residual liquid subjected to vaporization and overheating and excessive chlorine enter a reactor, the mixed gas after reaction enters a chilling tower, a tetrachloroethylene crude product in gas phase is extracted out from the top side line of the chilling tower, the gas containing carbon tetrachloride, excessive chlorine and hydrogen chloride passes through three stages of condensers and a separation tank in sequence, one part of condensed liquid-phase material carbon tetrachloride is used as chilling liquid, and the other part of condensed liquid-phase material carbon tetrachloride is returned to the system for reaction, so that the aim of consuming the methane chloride residual liquid through continuous circulation is achieved; hydrogen chloride and excessive chlorine are absorbed by using water and subjected to steam stripping, and chlorine is returned to the reaction system; the materials at the bottom of the chilling tower are treated in a lightness-removing column, so that the light components including tetrachloroethylene and pentachloroethane are separated and returned to the reactor for reaction; and hexachloroethane is subjected to rectification to obtain a hexachloroethane finished product. According to the production process, the methane chloride residual liquid is subjected to innocent treatment to prevent environmental pollution caused by improper treatment.

Owner:SHANDONG DONGYUE FLUO SILICON MATERIALS CO LTD

Al-Si-Cu-Zn low-melting-point aluminum-based brazing filler metal and preparing method of Al-Si-Cu-Zn low-melting-point aluminum-based brazing filler metal

InactiveCN103934591AGood brazing processLow melting pointWelding/cutting media/materialsSoldering mediaManganeseAlloy

Owner:SOUTH CHINA UNIV OF TECH

Continuous rheological extending forming method for preparing Al alloy tube

InactiveCN101224490ASignificant positive effectSolve process problemsMetal rolling arrangementsChemical compositionConductive materials

The invention relates to a continuous rheological extension forming method used for preparing an aluminium alloy pipe. The invention adopts a continuous extension forming device which mainly consists of a water cooling rotation roller, a fixed shoe plate, an extrusion forming die, a back pressing block and a base. The key point is that the invention is achieved by the steps that the chemical ingredients of the invention are 0.8% of an Mg, 0.7% of a Si, less than or equal to 0.1% of total impurity, and an Al with the residual quantity according to the mass percentage; a melting furnace is pre-heated to 700 DEG C when an aluminium ingot is added; an Al-Si master alloy is added when the temperature is 760 DEG C; the Mg is pressed into the melting body when the temperature is reduced to 720 DEG C; a refining is achieved by a hexachloroethane when the temperature is increased to 740 DEG C; after that, the melting body is covered and the temperature is increased and kept at 760-800 DEG C; finally, the aluminium alloy pipe is prepared by the continuous extension forming device of the melting body. The pipe tissue is uniform and fine; the tensile strength of T6 state is 300MPa, the elongation thereof is 10% and the equivalent conductivity is 54.38IACS. The invention has the advantages of high efficiency, saving energy, short process flow and fast effect. The product of the invention becomes the conductive material which is urgently required by power industry.

Owner:NORTHEASTERN UNIV

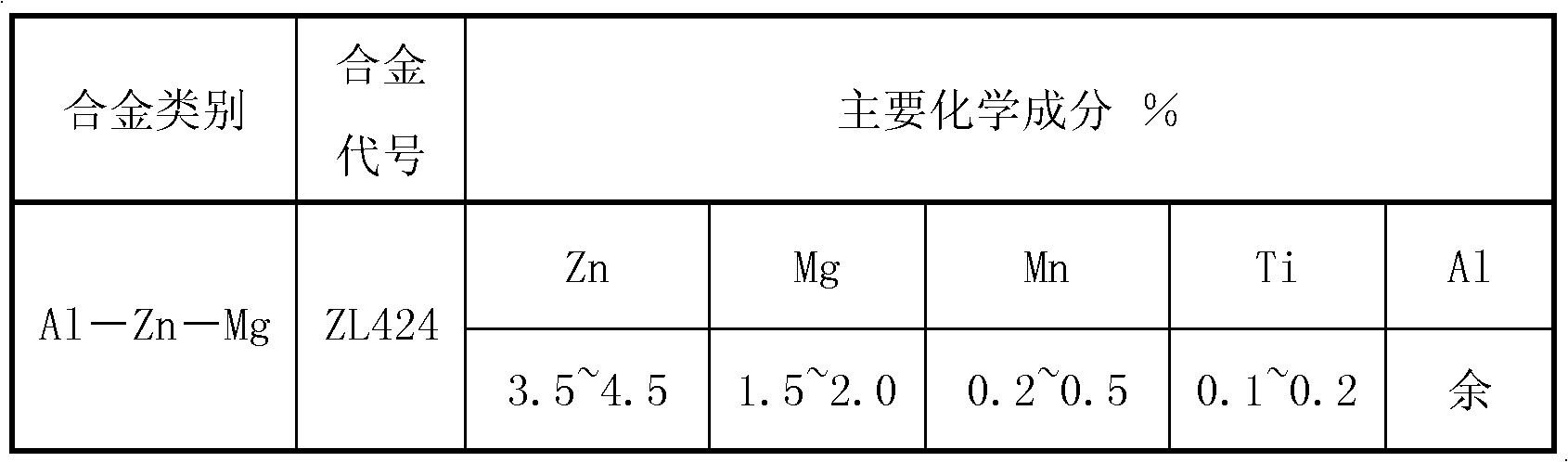

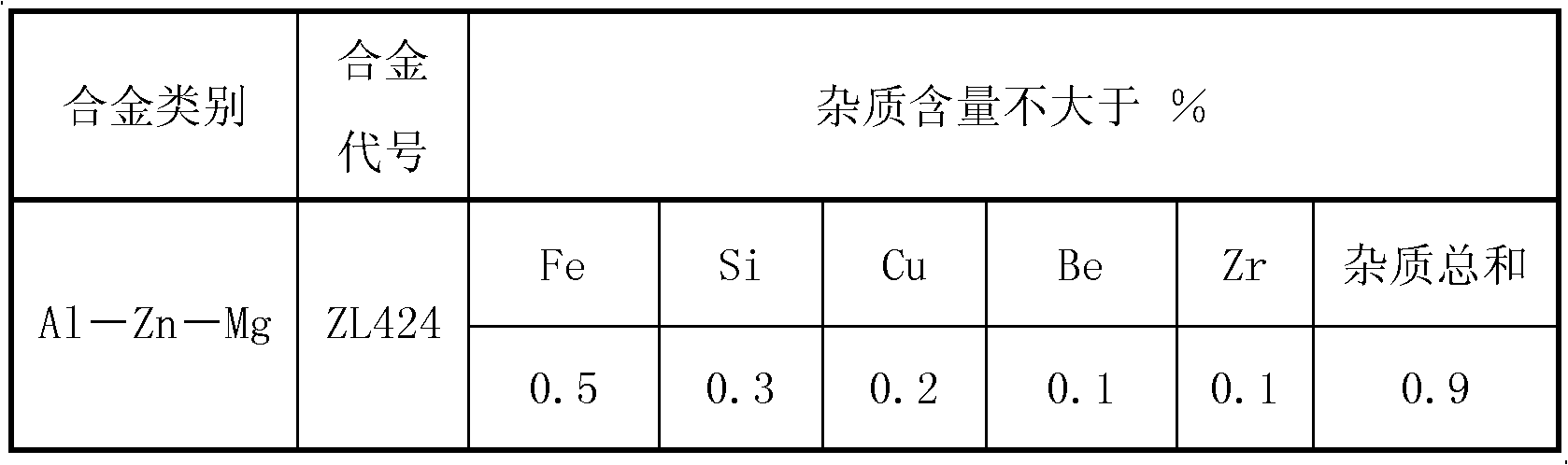

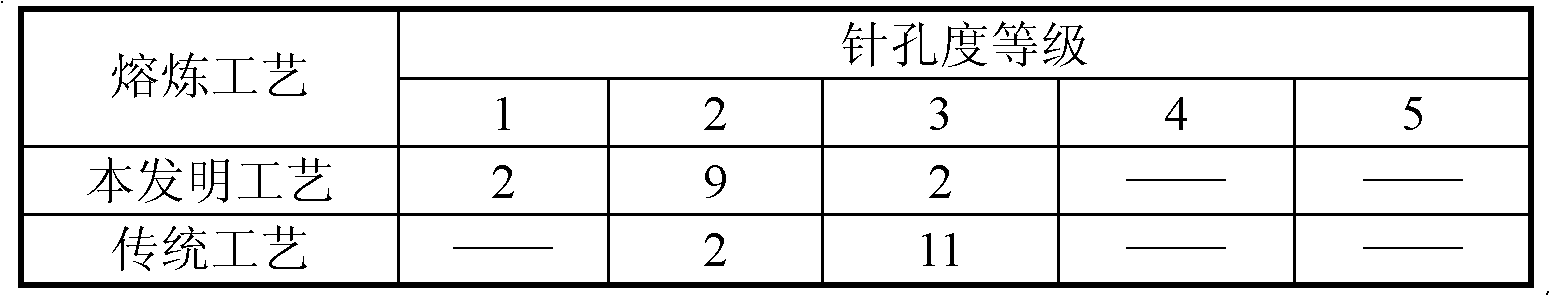

Technology for medium-frequency induction furnace to smelt ZL424 and aluminum casting alloy

ActiveCN102108453AImprove inner qualityImprove mechanical propertiesSmelting processMedium frequency

The invention relates to technology for a medium-frequency induction furnace to smelt ZL424 and aluminum casting alloy. The smelting process comprises the following steps: (1) primary refining: adopting hexachloroethane for primary refining; (2) secondary refining: adopting argon rotary injection for secondary refining; (3) filtering: adding a ceramic filter net between the primary refining and the secondary refining for purification. Alloy liquid is endowed with effects of good gas and slag removal effects, the difficulty that the defects such as easy generation of pin hole, shrinkage and the like are easily generated in the casting of aluminum alloy is solved, the alloy pinhole degree is greatly improved, the inherent quality of castings is improved, and the mechanical properties (such as tensile strength, elongation rate and hardness) can be improved evidently. In the manner of combining the secondary refining and purification process, the integral process is more reasonable, and the quality and the efficiency of aluminum casting alloy are effectively improved.

Owner:TIANJIN NAVIGATION INSTR RES INST

Composite melting agent for reinfing crystal grains of aluminium magnesium alloy and preparation thereof

A composite flux for fining the crystal grains of MgAl-series Mg alloy contains magnesium chloride, potassium chloride, sodium chloride, calcium chloride, calcium fluoride, barium chloride, hexachloroethane, magnesium carbonate and calcium (or strontium) carbonate. Its advantages are high effect and high chemical stability.

Owner:SHANGHAI HAOHUA MOLD

Preparation method of composite refining agent of aluminum alloy

The invention relates to a preparation method of a composite refining agent of an aluminum alloy, and belongs to the technology field of refining agent. The composite refining agent of the aluminum alloy prepared by the invention comprises chloride, fluoride and nitrate, wherein the chloride is the main component of the refining agent with high hygroscopicity; sodium chloride and potassium chloride have good coverage performance and are the basis of the refining agent; hexachloroethane is easy to store, easy to use, has a good purifying effect, and has a grain refining effect; since the loosehexachloroethane and aluminum alloy liquid will react violently, the hexachloroethane and sodium fluorosilicate are pressed together and granulated to improve the purification effect of the hexachloroethane; sodium fluoride can cause the oxide film to mechanically fall off and dissolve in the solvent, thereby playing a purifying function ; the addition of fluoride in the refining agent has an effect of adsorbing and dissolving aluminum oxide; the fluoride accelerates the process of adsorbing hydrogen and inclusions in an aluminum liquid by the refining agent, promotes the migration of the inclusions to the interface and improves the efficiency of the inclusion removal.

Owner:FOSHAN CHAOHONG NEW MATERIAL TECH CO LTD

High-efficiency aluminum alloy refining agent, as well as preparation method and usage method thereof

The invention provides a high-efficiency aluminum alloy refining agent, as well as a preparation method and a usage method thereof. The high-efficiency aluminum alloy refining agent comprises refining agent components including sodium chloride, potassium chloride, potassium fluosilicate, sodium fluoaluminate, light-weight sodium carbonate, calcium fluoride, hexachloroethane, sodium sulfate, potassium fluoaluminate and quartz sand. The preparation method of the high-efficiency aluminum alloy refining agent comprises the following steps: respectively weighing all the components according to the weight percentage of the refining agent components, and fully mixing to obtain the high-efficiency aluminum alloy refining agent. The usage method of the high-efficiency aluminum alloy refining agent comprises the following steps: placing the high-efficiency aluminum alloy refining agent into a refining tank, introducing nitrogen gas or argon gas into the refining tank when the temperature of aluminum alloy liquid achieves 700-740DEG C, and delivering the high-efficiency aluminum alloy refining agent into the aluminum alloy liquid. The high-efficiency aluminum alloy refining agent is strong in degassing and inclusion removal capabilities, high in reaction speed, high in deslagging efficiency and low in usage temperature. The preparation method and usage method of the high-efficiency aluminum alloy refining agent are simple and effective.

Owner:SICHUAN LANDE IND

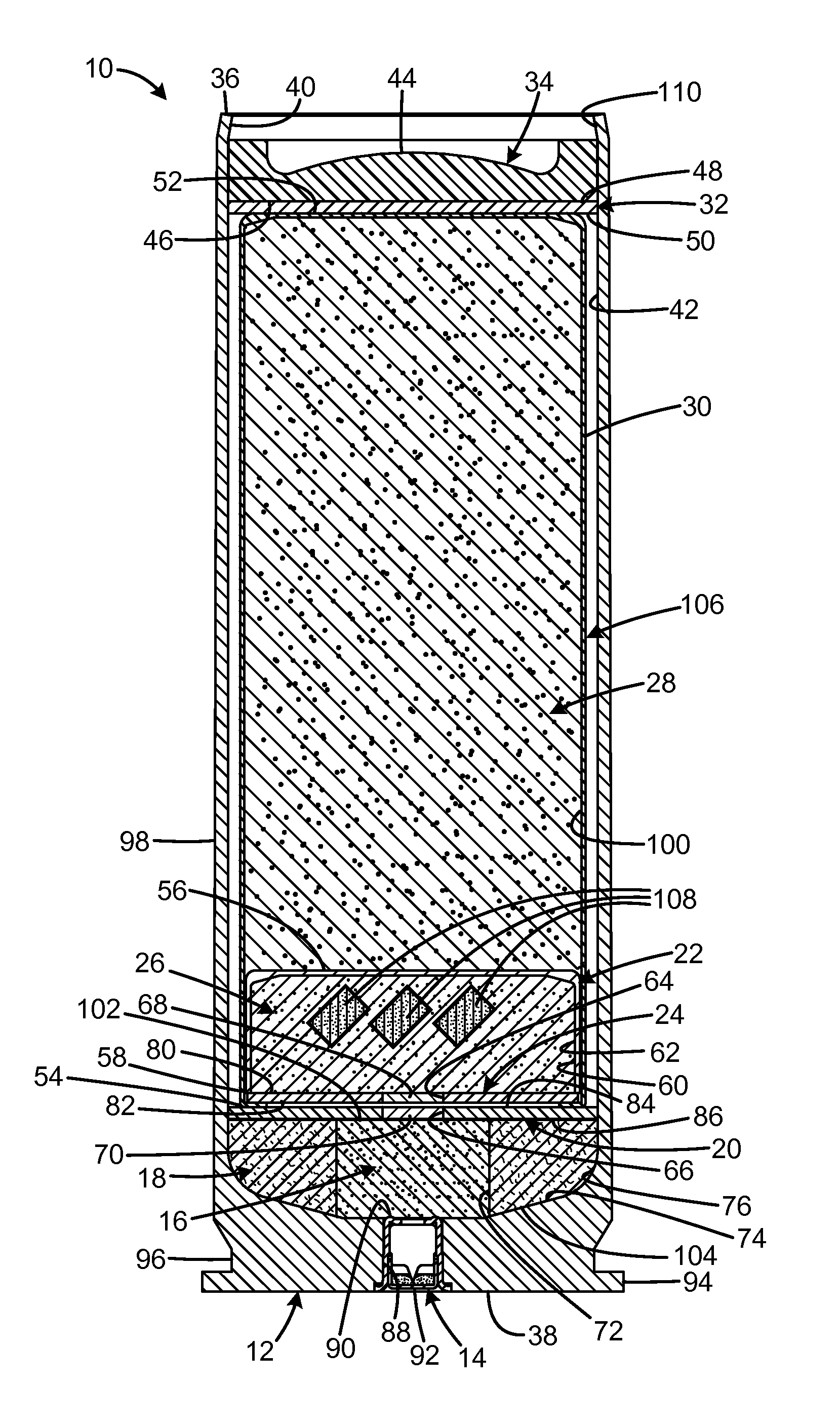

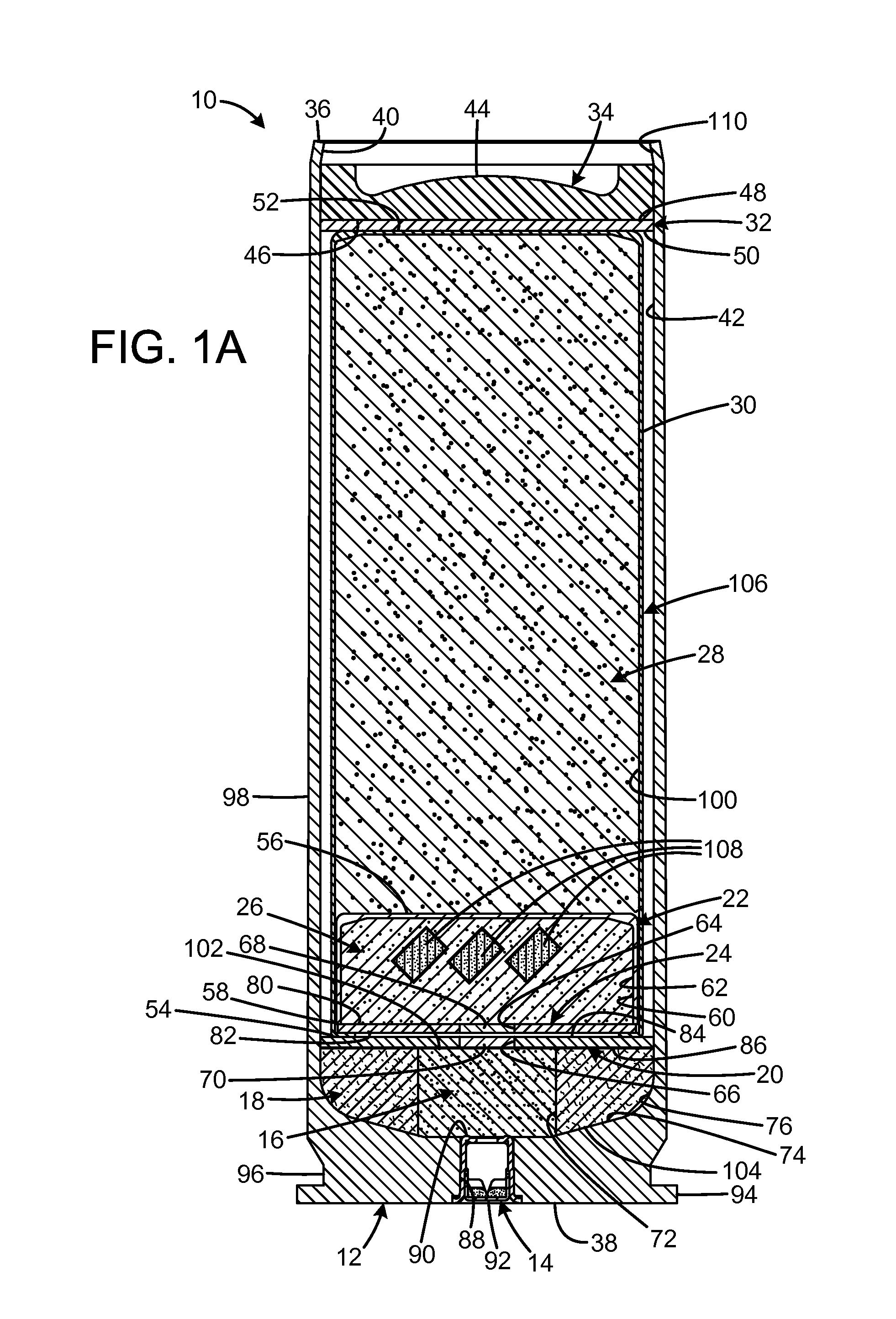

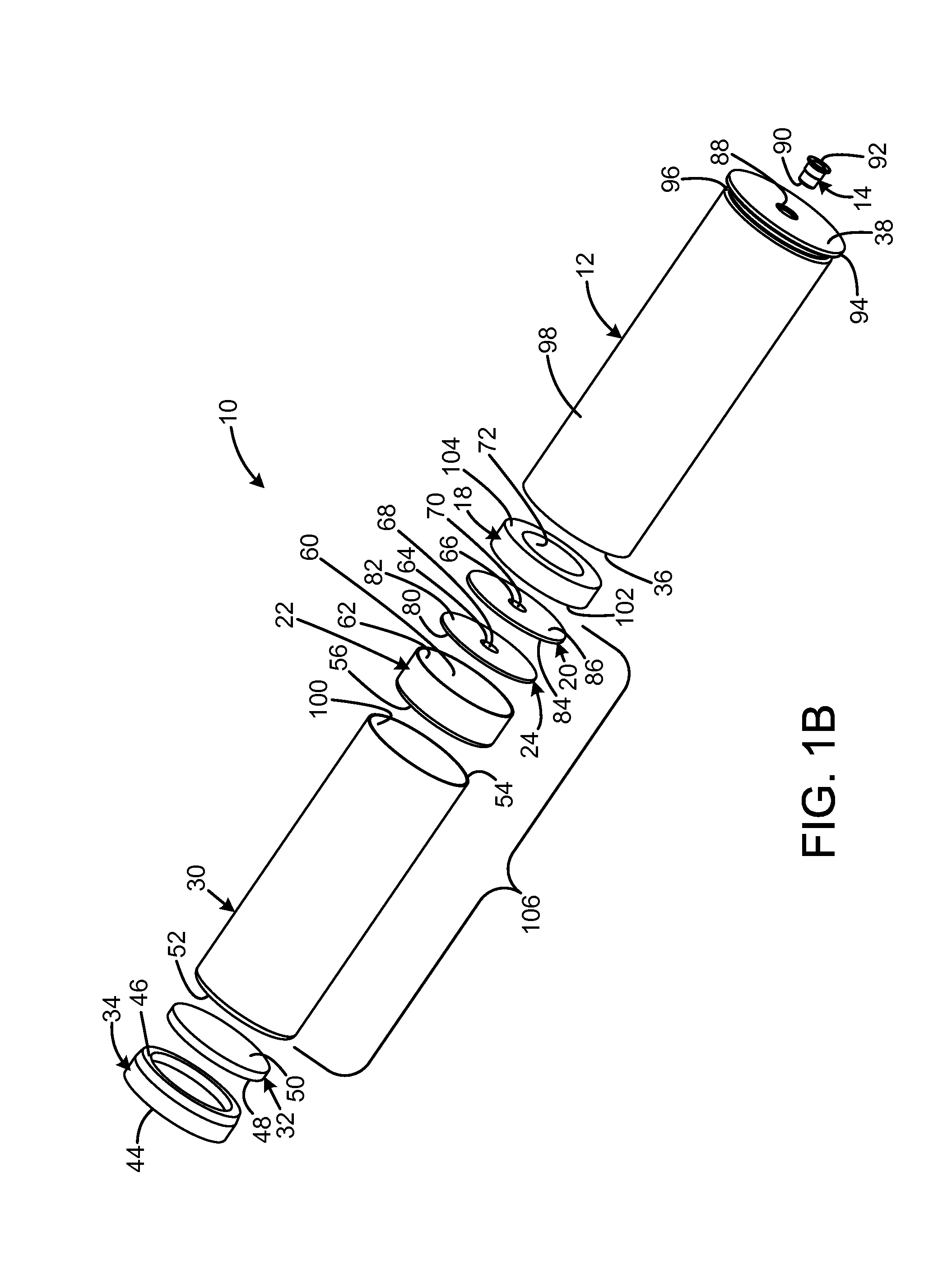

Launched Smoke Grenade

ActiveUS20130319278A1Great contributionAmmunition projectilesSmoke/mist generationSmokeless powderMechanical engineering

A launched smoke grenade has a cartridge case having a hollow interior that receives a primer and a propellant, a projectile received by the cartridge case, and the projectile including a smoke generation component and an ignition component. The smoke generation component and the ignition component may be separated by a barrier prior to admission of the ignition component. The ignition component may burn through the barrier to ignite the smoke generation component. The smoke generation component may include hexachloroethane. The propellant may be black powder or smokeless powder.

Owner:CSI PENN ARMS

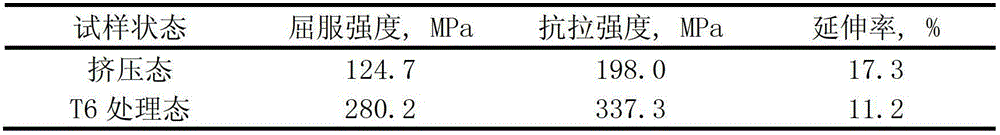

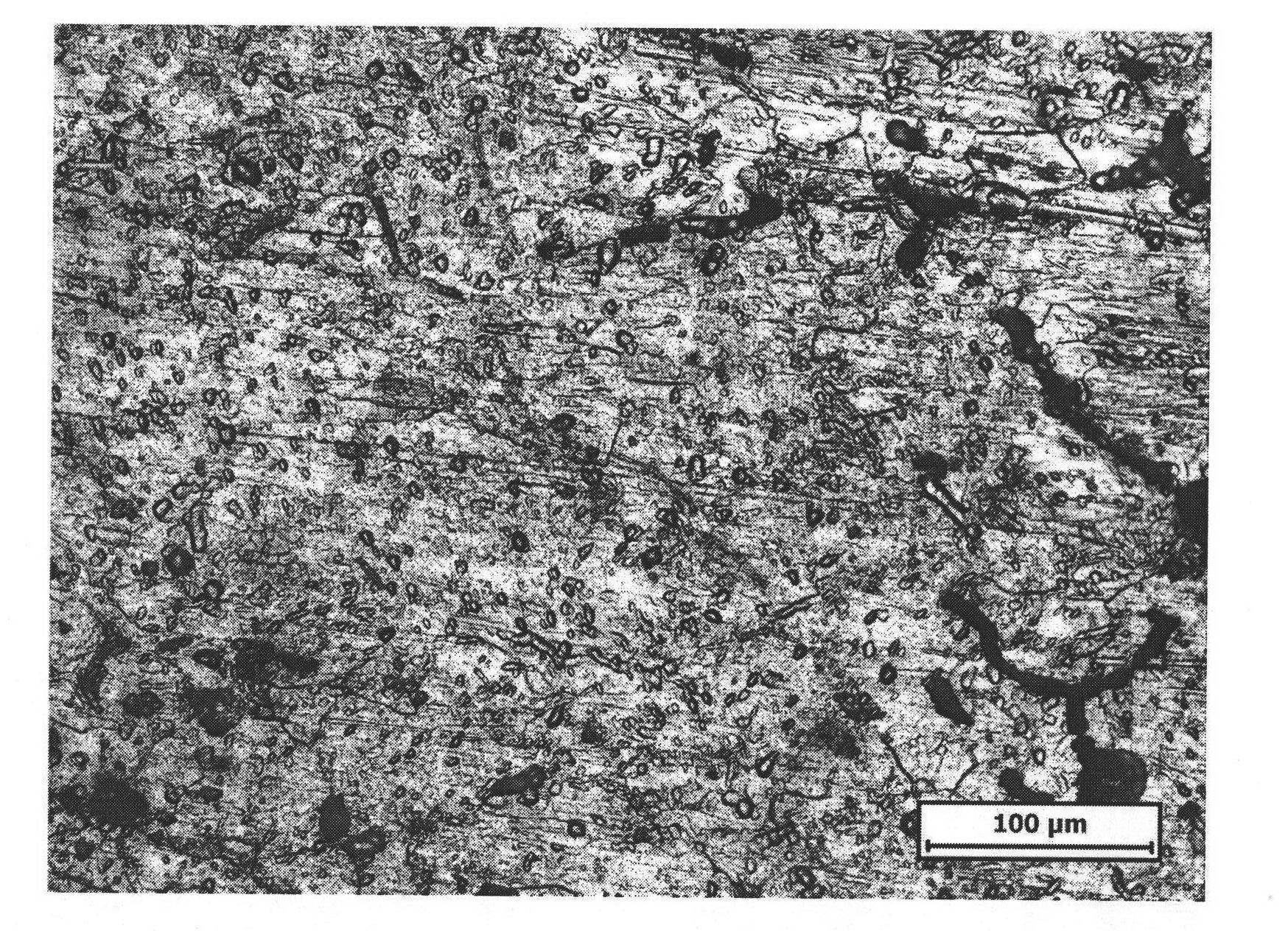

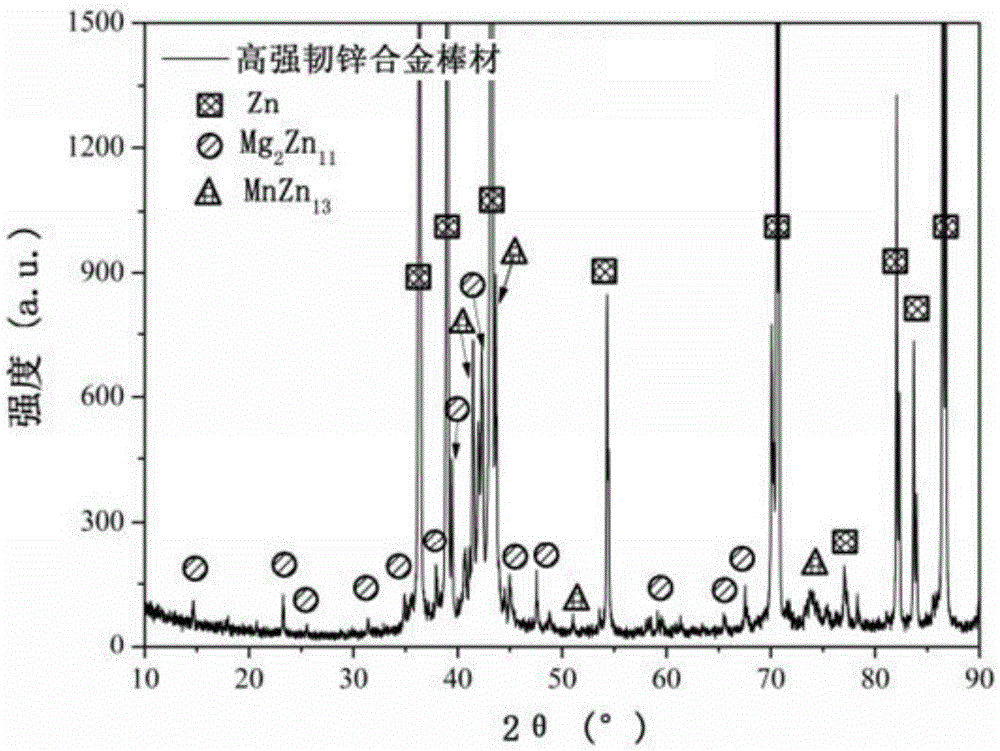

High-strength and high-tenacity zinc alloy bar/wire and preparation method thereof

The invention belongs to the technical field of alloy materials, and relates to a high-strength and high-tenacity zinc alloy bar / wire and a preparation method thereof. High-strength and high-tenacity zinc alloy compositions comprise, by mass percent, 0.5%-2% of Mn, 0.05%-1% of Mg, not larger than 0.3% of inevitable impurities and the balance Zn. The preparation method of the high-strength and high-tenacity zinc alloy bar / wire comprises the steps that batching is carried out according to the compositions, zinc alloy melt is obtained after melting, 0.3%-0.5% of hexachloroethane is added, casting is carried out at the temperature ranging from 430 DEG C to 470 DEG C, and a cylindrical cast ingot with the diameter ranging from 40 mm to 60 mm is obtained; the cast ingot is subjected to homogenization treatment, reverse hot extrusion is carried out at the temperature ranging from 140 DEG C to 310 DEG C, and the high-strength and high-tenacity zinc alloy bar is obtained; and the bar is subjected to room temperature drawing and intermediate annealing, and the high-strength and high-tenacity zinc alloy wire is obtained. The prepared high-strength and high-tenacity zinc alloy comprises few compositions, has the beneficial effects of being high in strength and tenacity, and is diversified in processing manner and wide in appearance dimension change range, and the corrosion rate of the alloy is 10%-25% of that of pure Zn under the same condition.

Owner:NORTHEASTERN UNIV

Wear-resistant copper alloy material and casting method thereof

The invention relates to a wear-resistant copper alloy material and a casting method thereof, wherein total seven raw materials, including an aluminum-copper alloy, a nickel plate, pure iron, electrolytic copper, metal manganese, hexachloroethane and cullet, are employed; the CuAl10Ni wear-resistant copper alloy material is obtained through the steps of stove charging, melting, sodium fluoroaluminate doping and sand mold test sample casting, casting molding and the like; and the mechanical properties of the obtained wear-resistant copper alloy material reach the following standards: yield strength B0.2: more than or equal to 270N / mm<2>; tensile strength Bb: more than or equal to 600N / mm<2>; elongation sigma5: more than or equal to 12%; and Brinell hardness HBW: more than or equal to 140; the wear-resistant copper alloy material is specially used for manufacture of the positioning guide sleeve of the air spring of a rail transit vehicle, and has excellent comprehensive mechanical properties, and extremely high abrasive resistance and corrosion resistance; and the service life of the wear-resistant copper alloy material is twice as long as that the service life of the traditional ZCuAl9Mn2(S) material.

Owner:株洲联诚集团铸业有限责任公司

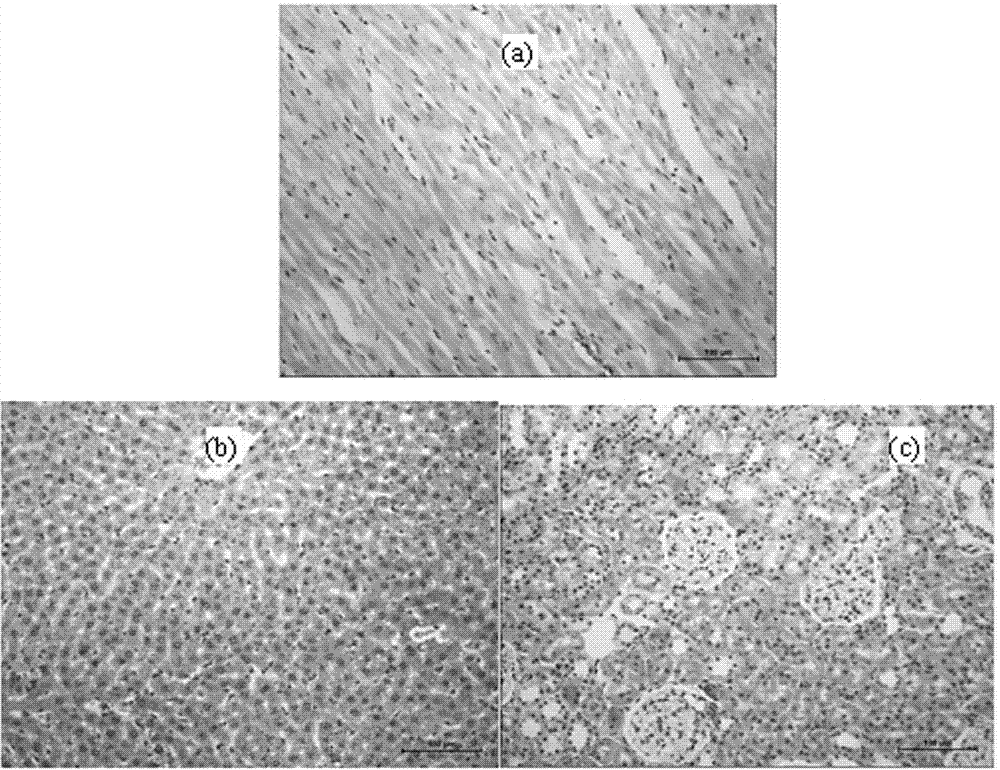

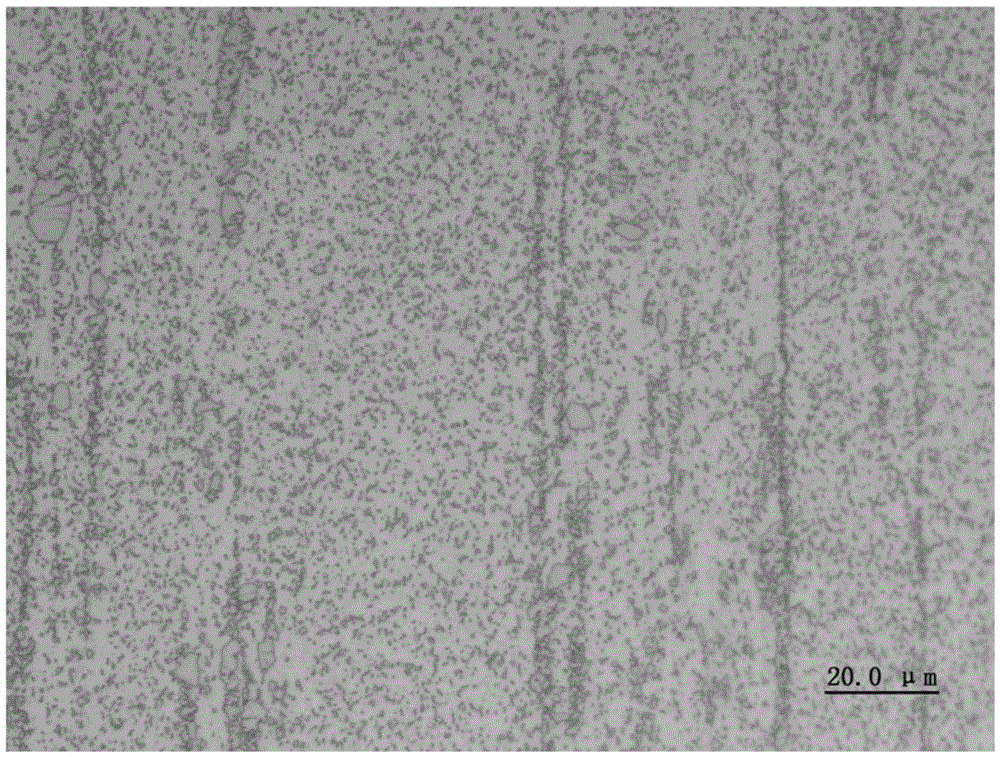

Manufacturing technology for rare earth-magnesium alloy

The invention belongs to the fields of metal materials and metallurgy, aims to solve the problems that impurities of alloy are hard to separate, ingredients are nonuniform, the utilization rate of rare earth element is low, precipitated rare earth phases are nonuniform, the segregation is more, and effects for the quality is great by adopting the manner that alloying, rare earth process, and casting are conducted in a pot during a conventional manufacturing technology process, and provides a manufacturing technology for rare earth-magnesium alloy. According to the manufacturing technology, conducting adding, refining, and degassing with hexachloroethane degassing agent of alloy element in a melting pot; and pouring into a second pot after standing for 30 min, adding rare earth, and standing and casing. A manufactured bar material has uniform and stable metallographic structure and clear crystal boundary; the product is without pore, shrinkage cavity and cold shut, and the surface is smooth and without rugosity; the purity, ingredients, and equilibrium of physical properties of the product are guaranteed, the grain size of the alloy is refined, very stable dispersed phase is precipitated, and the rigidity and the decay resistance of texture are improved; therefore, product performances are allowed to be superior to an ordinary alloy standard.

Owner:孝义市东义镁业有限公司 +1

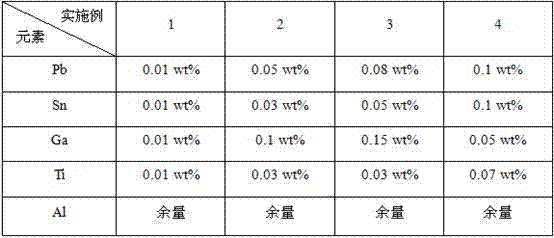

Aluminum alloy anode material, and casting method and application thereof

The invention discloses an aluminum alloy anode material, and a casting method and an application thereof. The aluminum alloy anode material is prepared through casting Pb, Sn, Ga, Ti and Al. The casting method concretely comprises the following steps: 1, refining alloy: (1) placing pure aluminum blocks in a shaft furnace in batches, and heating for melting the pure aluminum blocks; (2) adding trace metal elements into the high temperature shaft furnace after all the aluminum blocks are completely molten; (3) stirring all above components by a graphite rod after all the components are completely molten; and (4) adding hexachloroethane, and removing the waste residues in the molten aluminum; and 2, carrying out casting molding: (1) coating the internal surface of a die with a layer of a release agent, and carrying out heating and heat insulation; and (2) pouring the molten aluminum alloy into the die, and casting the aluminum alloy to form aluminum ingots. The aluminum alloy anode material has low overpotential and high hydrogen evolution overpotential, so an electrode made of the material has high electrochemical activity and high anode utilization efficiency during the running of a battery.

Owner:HARBIN INST OF TECH

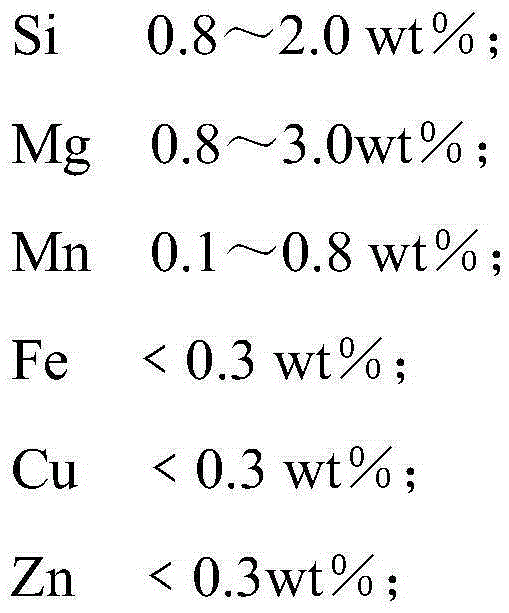

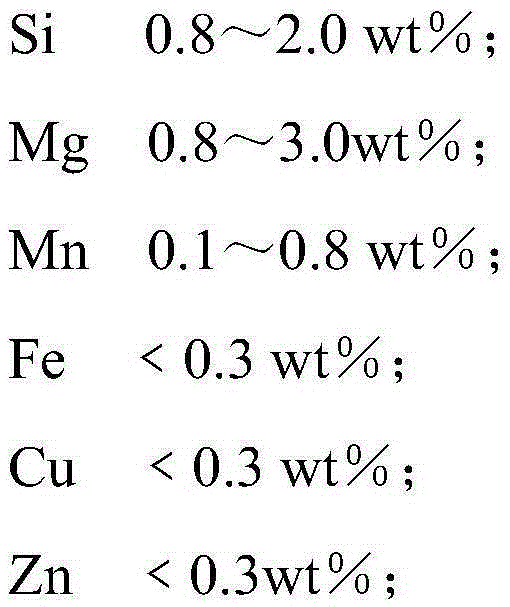

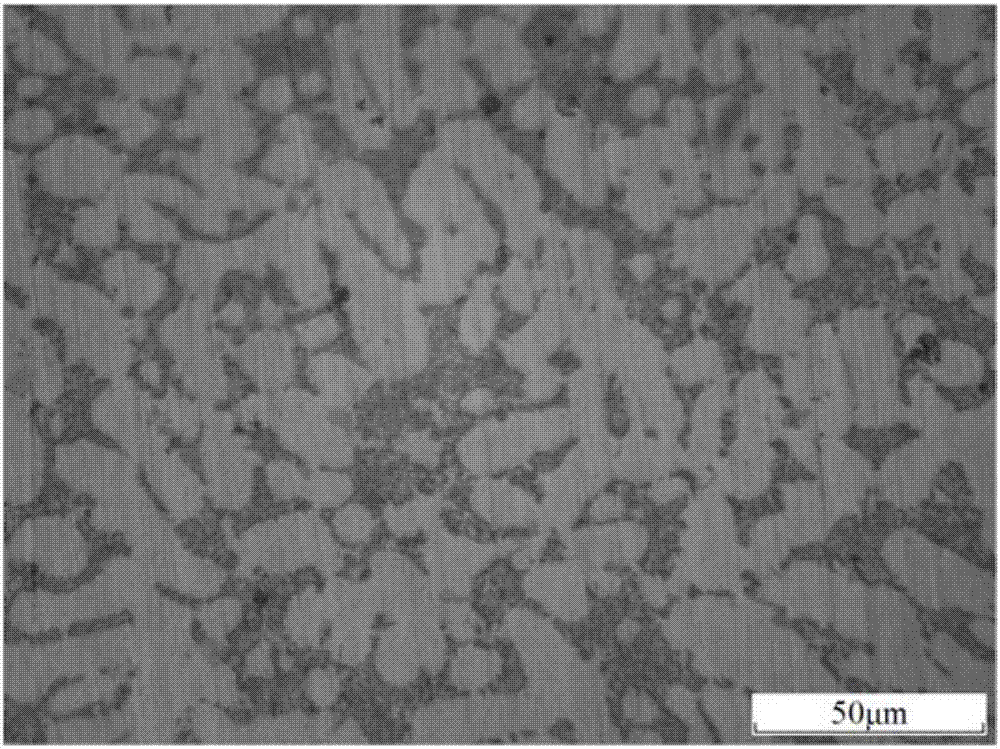

Cast aluminum alloy capable of being anodized and preparation method thereof

InactiveCN105420555AHighlight substantive featuresSignificant progressTrace elementUltimate tensile strength

The invention relates to cast aluminum alloy capable of being anodized and a preparation method thereof. The cast aluminum alloy capable of being anodized is prepared from, by weight, 0.8%-2.0% of Si, 0.8%-3.0% of Mg, 0.1%-0.8% of Mn, less than 0.3% of Fe, less than 0.3% of Cu, less than 0.3% of Zn, less than 0.05% of at least one of the trace elements including Ti, B, Re and Zr, and the balance Al. The preparation method comprises the steps that firstly, smelting is conducted, then degassing and refining are conducted, the smelting temperature is adjusted, hexachloroethane is added for degassing and refining, and purifying and slagging-off are conducted; secondly, modification and secondary refining are conducted, the smelting temperature is adjusted to be 730-750 DEG C, an Al-Sr modificator is added for modification treatment, the smelting temperature is adjusted to be 700-720 DEG C, degassing and refining agents are added, and slagging-off is conducted; and finally, pouring and casting are conducted. By the adoption of the cast aluminum alloy capable of being anodized and the preparation method thereof, the oxidation effect is more excellent, a film is thick, and the color and luster are uniform; by controlling the contents of the main alloy elements, the cast aluminum alloy has high strength and formability.

Owner:SUZHOU SANJI FOUNDRY EQUIP

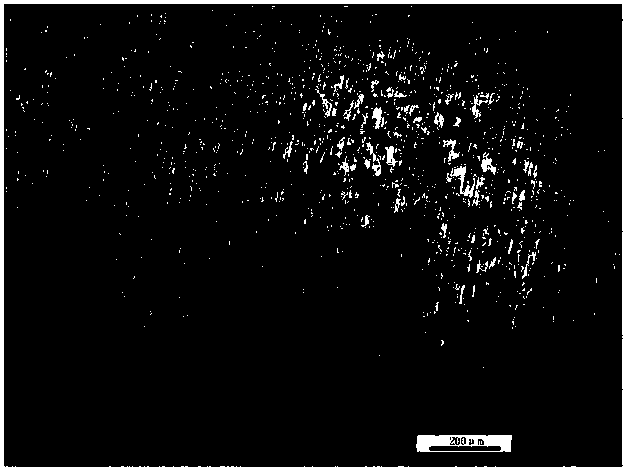

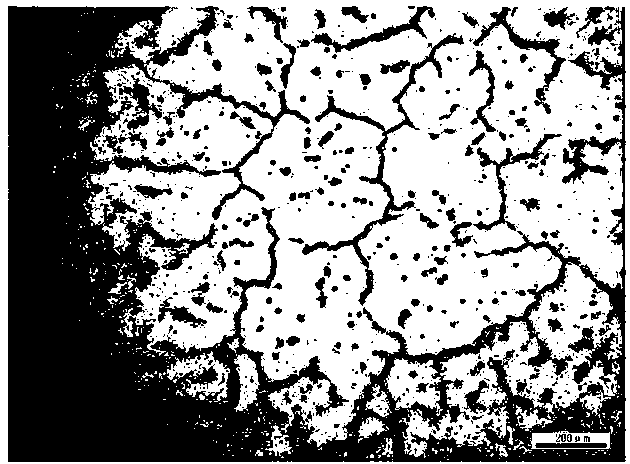

Al-30Si aluminum alloy containing Sr, B, Ti and Zr and preparation process thereof

The invention discloses a Al-30Si aluminum alloy containing Sr, B, Ti and Zr and a preparation process thereof. The high-silicon aluminum alloy is prepared by pouring an aluminum alloy molten mass at 750 DEG C into a metal mold with 200 DEG C in an atmospheric environment. The Al-30Si mother alloy is prepared by the following steps: smelting industrial pure aluminum with the purity of higher than 99.8 Wt% and silicon metal with the purity of higher than 99.5 Wt% in a graphite crucible by using a well-type resistance furnace, keeping the temperature at 850 DEG C for 4 hours, carrying out refining and degassing on the alloy liquid with hexachloroethane at 750 DEG C, and keeping the temperature for 30 minutes. The elements Sr, B, Ti and Zr are alloyed by respectively adding Al-10Sr, Al-5Ti-1B, Al-10Zr and other alloys at 720 DEG C and keeping the temperature for 30 minutes. The aluminum-silicon alloy comprises the following chemical components: 0.03-0.09 Wt% of Sr, 0.01-0.05 Wt% of B, 0.05-0.25 Wt% of Ti, 0.03-0.09 Wt% of Zr, 30 Wt% Si and the balance of Al. The tensile strength of the alloy is 149.4-245.4 MPa, the hardness is 37.5-82.1 HBW, and the resistivity is 0.107-0.127 ohm m.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

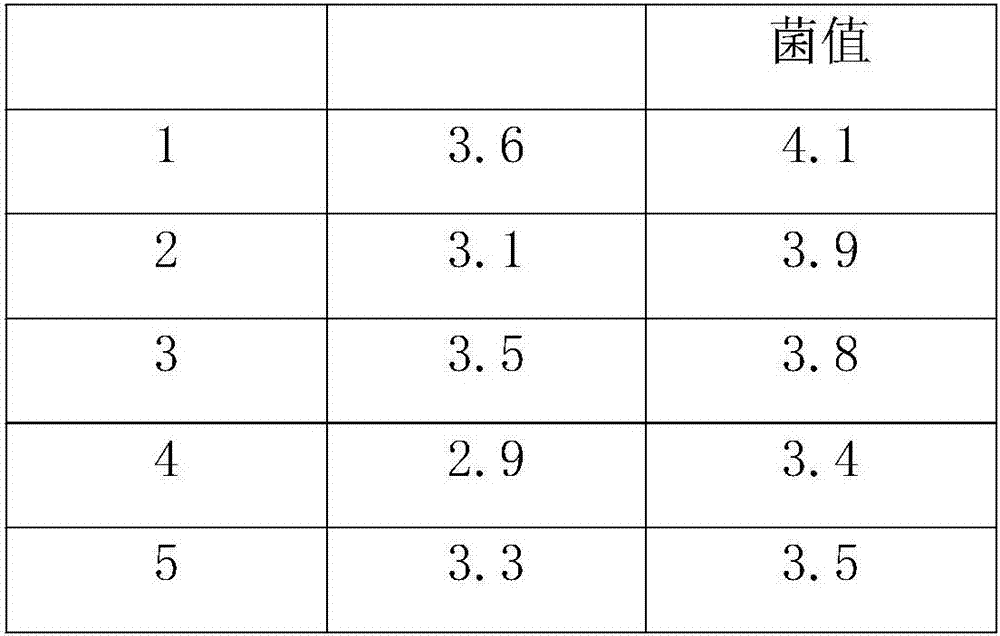

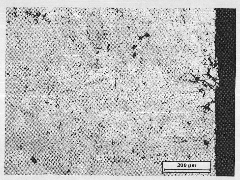

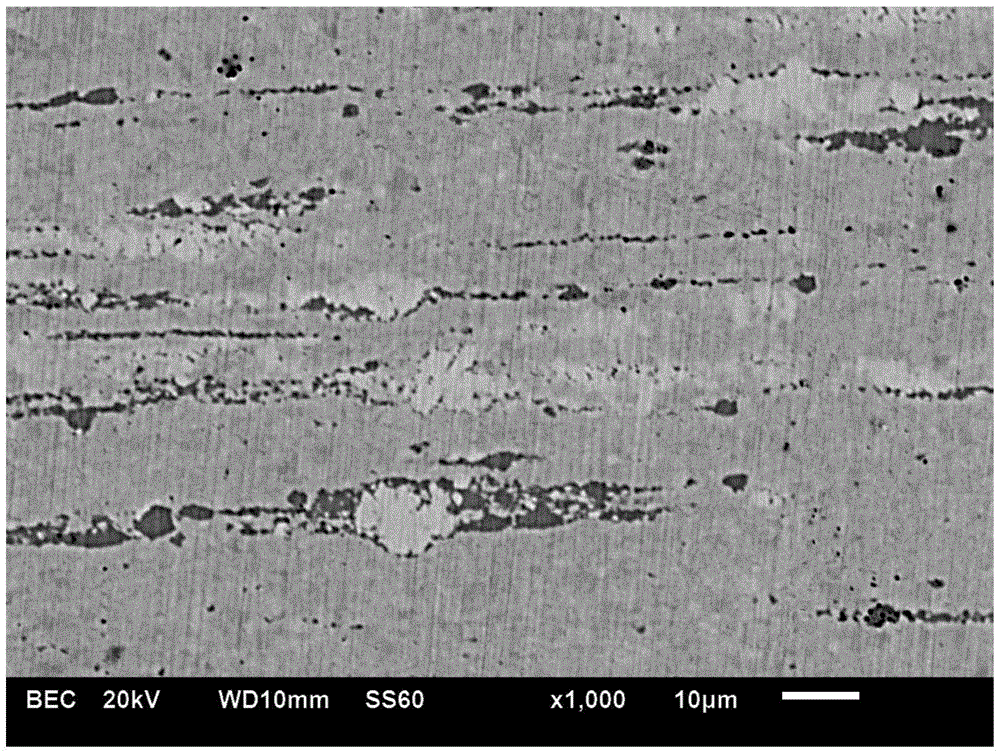

High-hardness corrosion-resistance aluminum-silicon-copper series cast aluminum alloy obtained through zirconium-strontium composite microalloying and magnesium alloying and preparing method

Disclosed is a high-hardness corrosion-resistance Al-Si-Cu series cast aluminum alloy obtained through Zr-Sr composite microalloying and Mg alloying. The high-hardness corrosion-resistance aluminum-copper-silicon cast aluminum alloy of the zirconium strontium composite microalloying and the magnesium alloying is characterized in that the aluminum alloy is mainly composed of aluminum (Al), silicon (Si), cuprum (Cu), magnesium (Mg), zirconium (Zr), strontium (Sr) and ferrum (Fe). A preparing method comprises sequentially the following steps that (1), pure Al and Al-Si intermediate alloy are molten and then are heated to 850 DEG C, and then Al-Cu, Al-Zr and Al-Sr intermediate alloy are added in sequence; and (2), after all intermediate alloys and metals are molten, the temperature is adjusted to 750 DEG C, and pure Mg is added; and after the pure Mg is molten, hexachloroethane is added for refining and degassing until no gas escapes, the melt is deslagged and cast into an ingot after standing and heat preservation for 5-10 min. According to the high-hardness corrosion-resistance aluminum-silicon-copper series cast aluminum alloy obtained through the zirconium-strontium composite microalloying and the magnesium alloying and the preparing method, the casting-state texture of the aluminum alloy is compact, the indoor temperature non-notch impacting tenacity average value is 16.35 J / cm2, the tensile strength is 262.132 MPa, the ductility is 5.645%, and meanwhile, the uniform corrosion rate is 0.321081508 mm / y when the aluminum alloy is soaked for 93 h in 3.5% NaCl water solution under the temperature of 37 DEG C.

Owner:JIANGSU UNIV

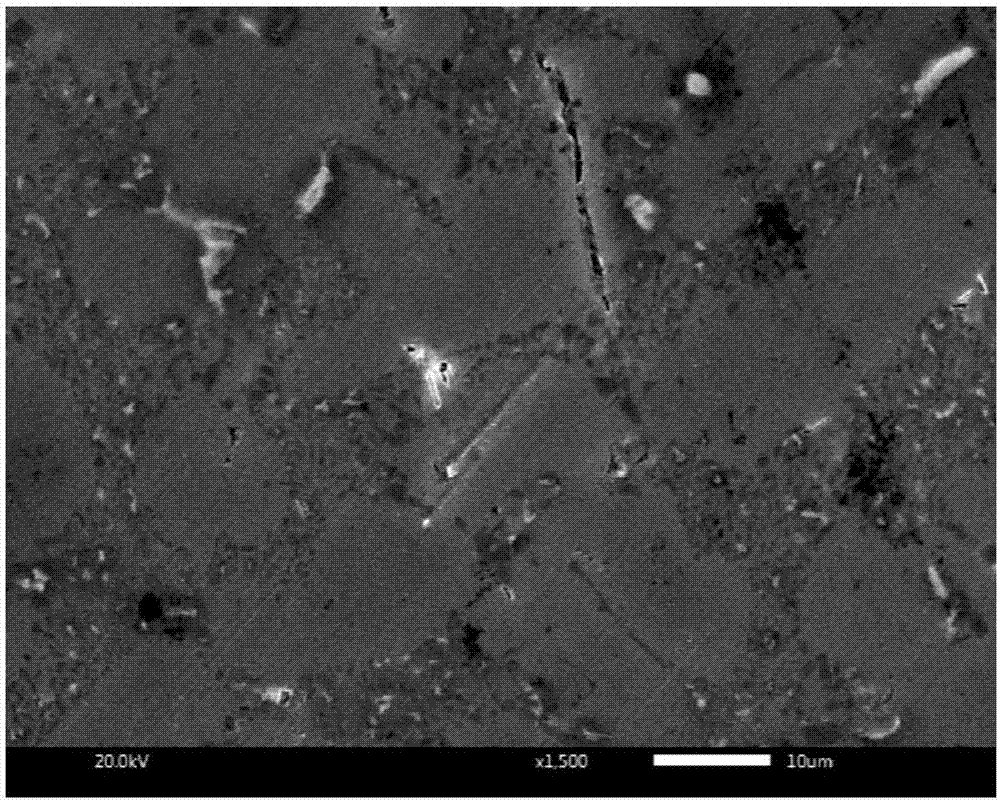

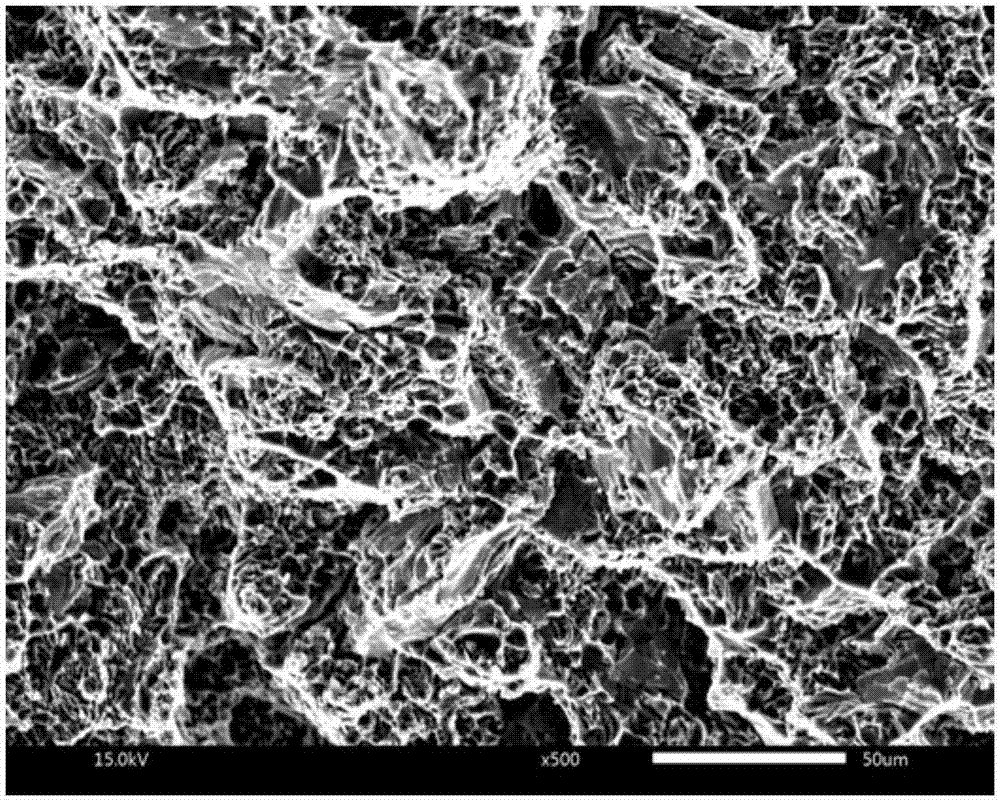

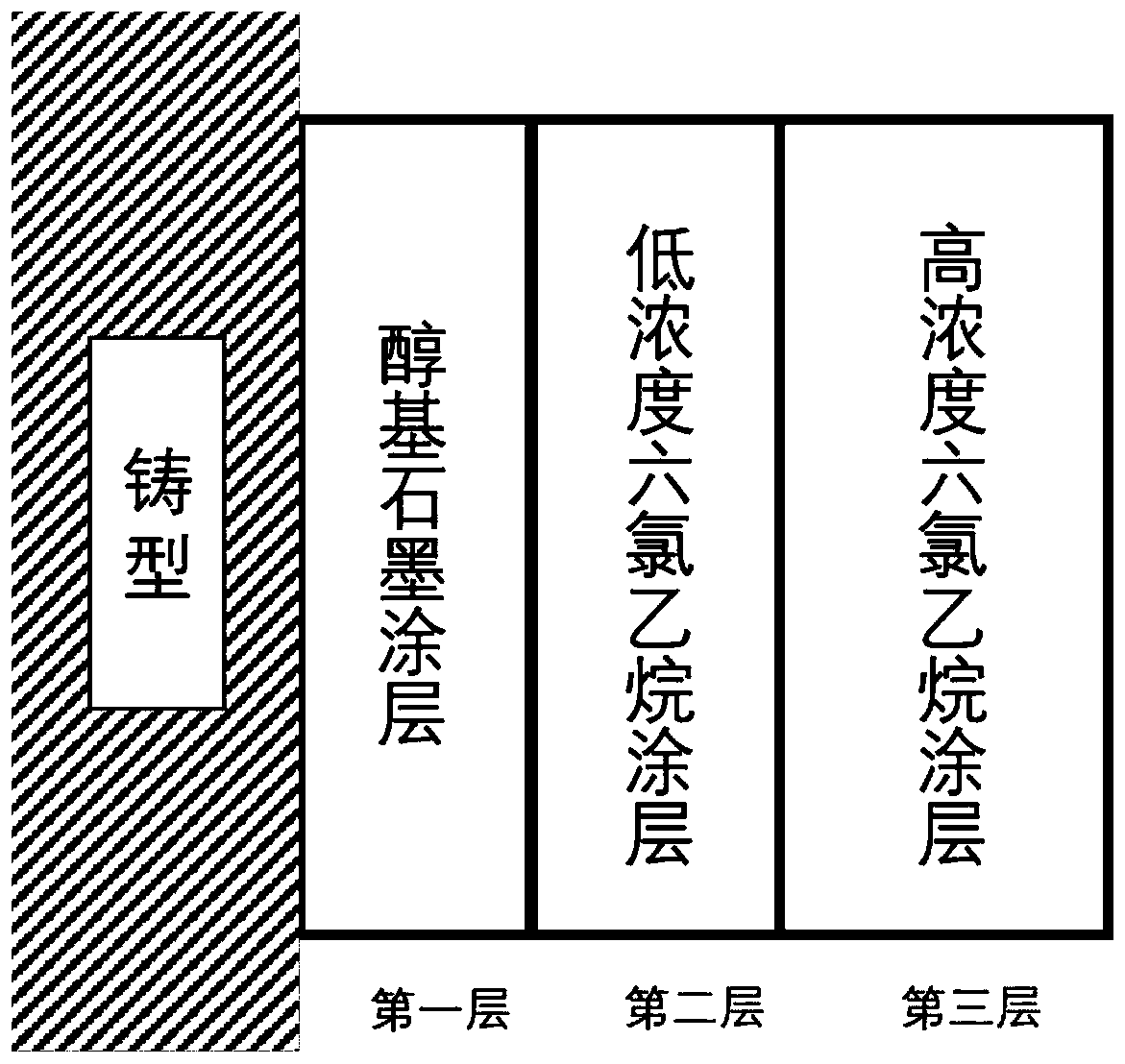

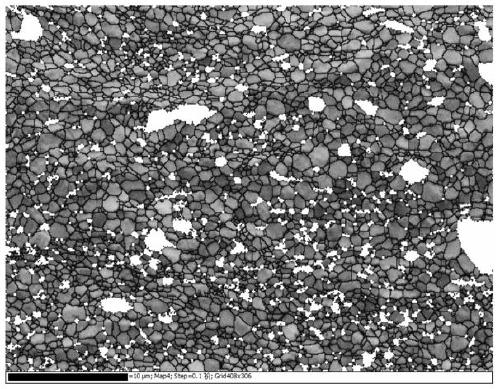

Multi-layer composite mold coating for aluminum-lithium alloy sand casting and coating method thereof

The invention discloses a multi-layer composite mold coating for aluminum-lithium alloy sand casting and a coating method thereof. The multi-layer composite coating comprises an alcohol-based graphitecoating, a low-concentration hexachloroethane coating and a high-concentration hexachloroethane coating which are sequentially arranged. The coating method adopts a combination manner of brushing andspraying, the alcohol-based graphite coating is brushed by adopting a brushing method, and the low-concentration hexachloroethane coating and the high-concentration hexachloroethane coating are sprayed by adopting a spraying method, and waited for natural volatilization and drying of the low-concentration hexachloroethane coating and the high-concentration hexachloroethane coating after the tlcohol-based graphite coating is ignited and dried. According to the coating, the hexachloroethane coating is added to react with aluminum lithium alloy melt to form an air film to prevent the alloy liquid from being in contact with a casting mold, and the problem that the high-activity lithium element is easy to react with a binder, a suspending agent, an auxiliary agent and the like in the sand moldand the coating in the aluminum lithium alloy sand mold casting process is solved. Meanwhile, the hexachloroethane coating can also generate a refining effect on the melt, deslagging and degassing are carried out, and the surface quality of the aluminum lithium alloy casting can be greatly improved.

Owner:SHANGHAI JIAO TONG UNIV

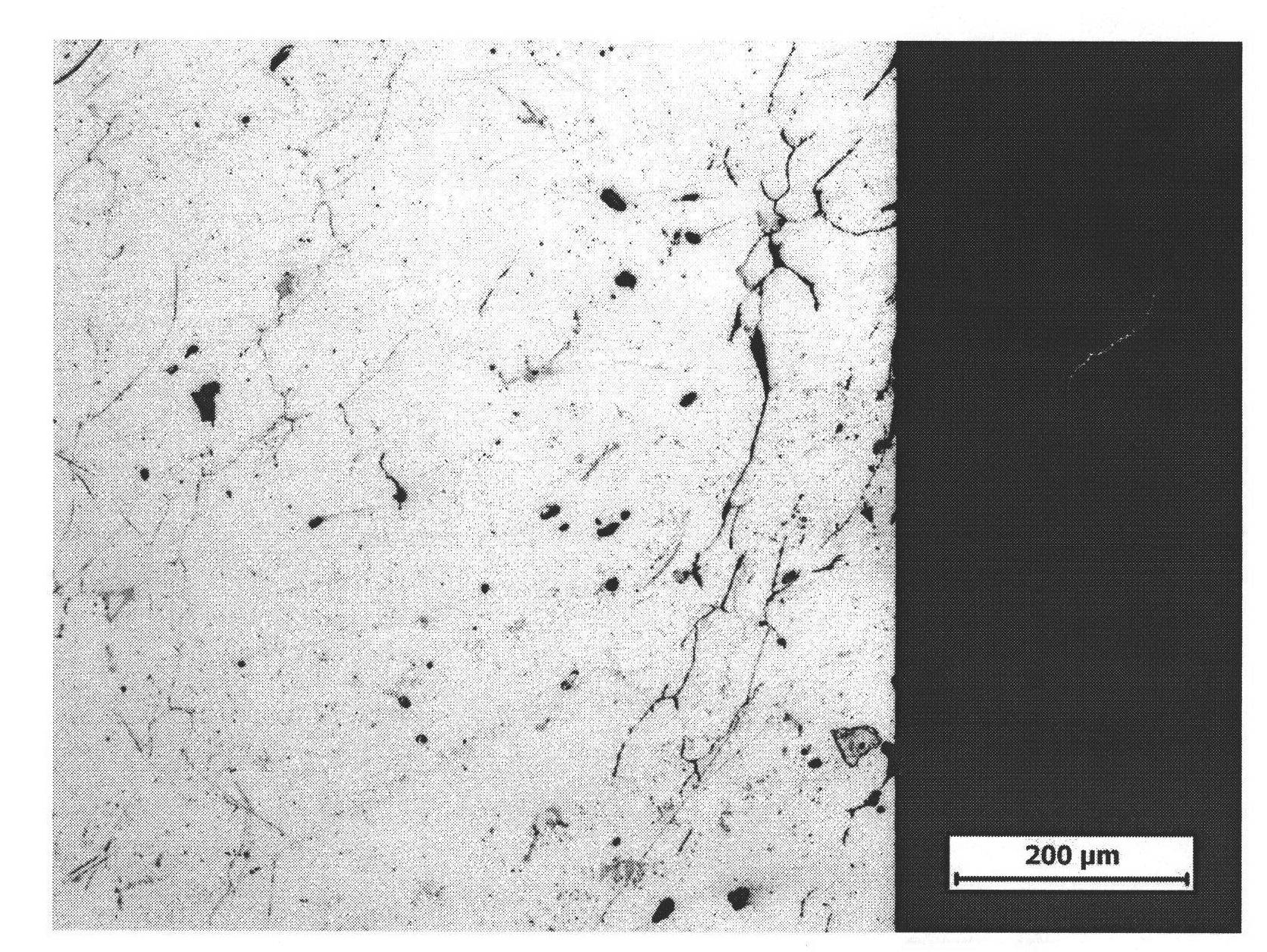

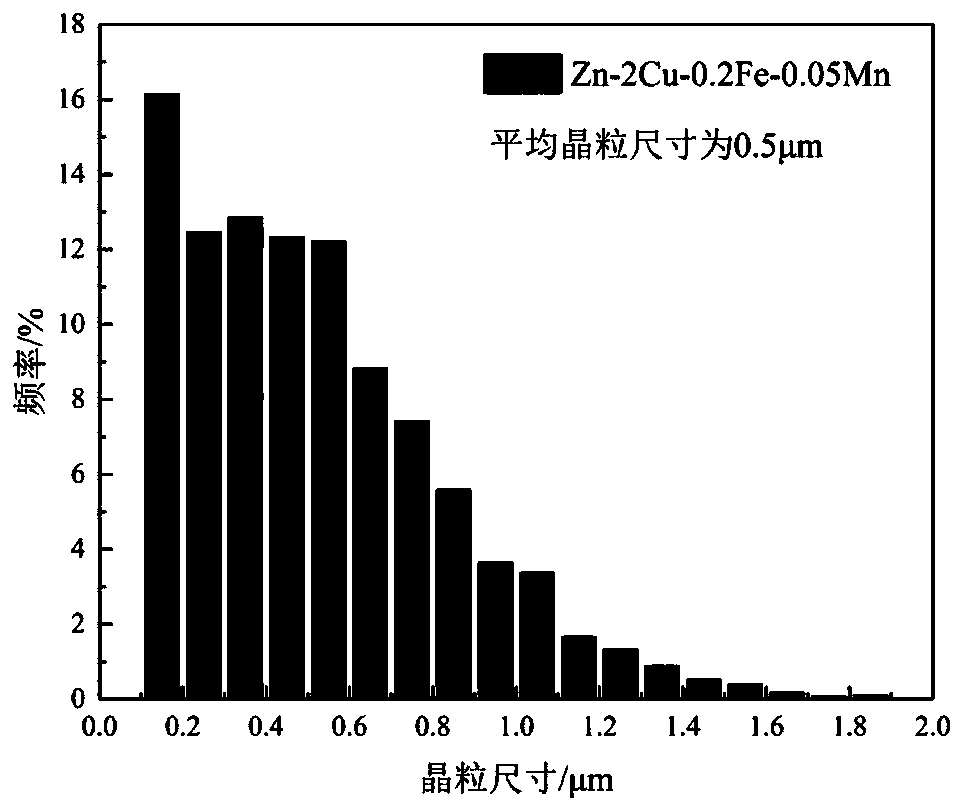

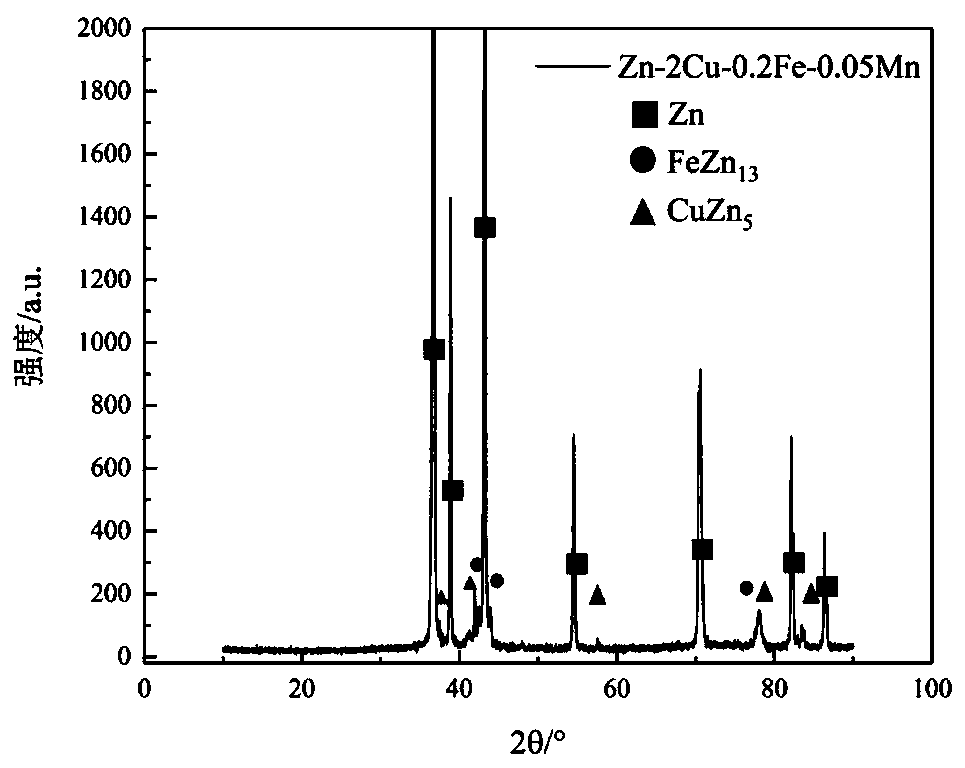

Zinc-based alloy bar/plate with room-temperature superplasticity and preparation method thereof

ActiveCN109735744ARoom temperature superplasticityRoom temperature superplasticZinc alloysDouble stage

The invention discloses a zinc-based alloy bar / plate with room-temperature superplasticity and a preparation method thereof. The zinc-based alloy bar / plate with the room-temperature superplasticity comprises the following components of, by the weight percent, 0.1-4% of Cu, 0.05-2% of Fe, 0.05-0.5% of Mn, less than or equal to 0.2% of inevitable impurities, and the balance Zn. The preparation method of the zinc-based alloy bar / plate with the room-temperature superplasticity comprises the following steps of heating and melting pure metallic zinc according to the proportion, adding metallic Cu and intermediate alloys sequentially, uniformly mixing melts to obtain a zinc alloy melt after all the metals are molten, cooling the zinc alloy melt, adding hexachloroethane, carrying out heat preservation, leaving the alloy melt to stand, cooling the alloy melt and casting the alloy melt into ingots, carrying out double-stage homogenization treatment, then carrying out heat treatment, and controlling relevant parameters to prepare the zinc-based alloy bar / plate with the room-temperature superplasticity. The preparation method of the zinc-based alloy bar / plate with the room-temperature superplasticity is simple in preparation process, a dynamic recrystallization process of alloys is controlled, and crystal grains are prevented from growing by pinning the grain boundary with second-phase particles, so that the crystal grains of basal bodies are markedly refined, the prepared zinc-based alloy bar / plate has high strength, high plasticity and good creep resistance and can meet application requirements in different fields.

Owner:NORTHEASTERN UNIV LIAONING

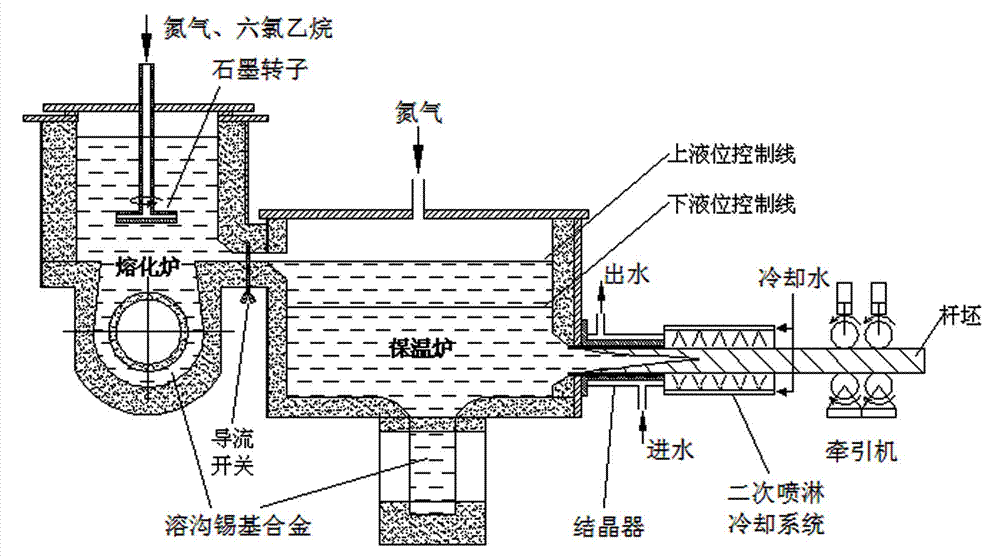

Preparation method of anaerobic tin based solder alloy

ActiveCN102776401AUniform temperatureUniform compositionWelding/cutting media/materialsSoldering mediaNitrogen gasElectronic industry

The invention belongs to the field of soft solder for soft solder welding in electronic industry, and in particular relates to a preparation method of an anaerobic tin based solder alloy. The method comprises the following steps of: (1) melting tin and alloy materials in a melting furnace, blowing, stirring and refining nitrogen and a hexachloroethane refining agent for 30-40 minutes, then standing for 15-20 minutes, and skimming the surface floating scruff, wherein the hexachloroethane refining agent accounts for 0.1-0.2% of the total weight of melt; (2) guiding a tin alloy liquid in the melting furnace into a temperature preservation furnace of 350-380 DEG C, introducing protective nitrogen, and guiding the tin alloy liquid by a traction rod through a crystallizer by a traction machine, wherein the water inlet temperature of cooling water in the crystallizer is 20-25 DEG C, and the water outlet temperature is 30-35 DEG C, and the traction speed is 0.3-0.5m / min; and (3) carrying out secondary spraying and cooling after traction instantly, thus the temperature of a rod blank is reduced to 30-50 DEG C, thereby obtaining a finished product finally. According to the invention, the tin based solder alloy which has high purity, is uniform in component, and has the oxygen content within 10ppm can be prepared, the production process is stable, and the continuous scale production can be realized.

Owner:云南锡业锡材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com