Manufacturing technology for rare earth-magnesium alloy

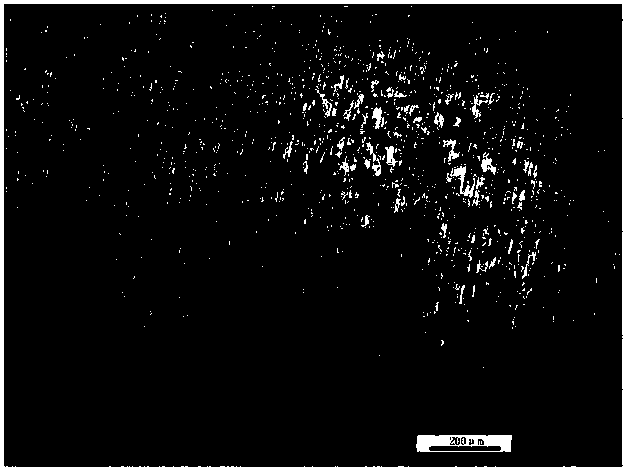

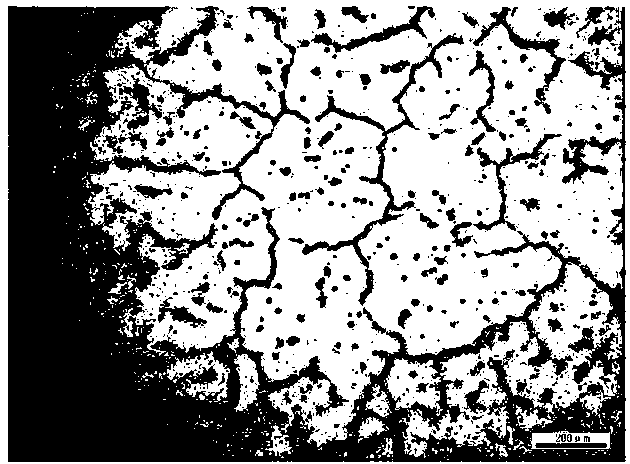

A production process and rare earth magnesium technology, applied in the field of production process of rare earth magnesium alloys, can solve the problems of difficult separation of impurities in the alloy, low utilization rate of rare earth elements, and great influence on quality, and achieve uniform and stable metallographic structure and product appearance. Smooth, wrinkle-free, guaranteed physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A kind of production technology of rare earth magnesium alloy, concrete steps are:

[0023] 1. Heating and cleaning of the melting furnace device: heat the crucible, add 2kg of 2# flux, and when the crucible is heated to dark red, clean all the bottom and surrounding areas of the crucible to ensure that there are no alloys, no oxides and other impurities in the crucible;

[0024] 2. Accurately weigh 500kg of high-quality magnesium ingot and preheat it to 180°C, put it into the melting furnace and melt for 3 hours;

[0025] 3. After the magnesium ingots are melted, the temperature of the melting furnace is raised to 680°C, add 9.5kg of zinc ingots with a temperature of 180°C and 4.8kg of manganese chloride, then raise the temperature of the melting furnace to 720°C, and install a mechanical stirring device to stir. The stirring speed is 50r / min and stirring for 20min, then adjust the stirring speed to 60r / min and stir for 10min; the content of manganese chloride must be ...

Embodiment 2

[0033] A kind of production technology of rare earth magnesium alloy, concrete steps are:

[0034] 1. Heating and cleaning of the melting furnace device: heat the crucible, add 3kg of 2# flux, and when the crucible is heated to dark red, clean it from the bottom of the crucible and its surroundings to ensure that there are no alloys, no oxides and other impurities in the crucible;

[0035] 2. Accurately weigh 500kg of high-quality magnesium ingot and preheat it to 200°C, put it into the melting furnace and melt for 2.5h;

[0036] 3. After the magnesium ingots are melted, the temperature of the melting furnace is raised to 670°C, add 9.5kg of zinc ingots with a temperature of 180°C and 4.8kg of manganese chloride, then raise the temperature of the melting furnace to 740°C, and install a mechanical stirring device to stir. The stirring speed is 50r / min and stirring for 20min, then adjust the stirring speed to 60r / min and stir for 10min; the content of manganese chloride must be ...

Embodiment 3

[0044] A kind of production technology of rare earth magnesium alloy, concrete steps are:

[0045] 1. Heating and cleaning of the melting furnace device: heat the crucible, add 2.5kg of 2# flux, and when the crucible is heated to dark red, clean it from the bottom of the crucible and its surroundings to ensure that there are no alloys, no oxides and other impurities in the crucible;

[0046] 2. Accurately weigh 500kg of high-quality magnesium ingot and preheat it to 220°C, put it into the melting furnace and melt for 3.5h;

[0047] 3. After the magnesium ingots are melted, the temperature of the melting furnace is raised to 690°C, add 9.5kg of zinc ingots with a temperature of 180°C and 4.8kg of manganese chloride, then raise the temperature of the melting furnace to 730°C, and install a mechanical stirring device to stir. The stirring speed is 50r / min and stirring for 20min, then adjust the stirring speed to 60r / min and stir for 10min; the content of manganese chloride must b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com