Method and system for refining crude brine

A refining method and refining system technology, applied in the field of chlor-alkali salt and its preparation process and equipment system, can solve the problems of expensive adsorption equipment, huge daily consumption of raw salt, and difficult transportation of sea salt, so as to ensure the energy efficiency and The effects of safe production, excellent and stable brine quality, and widening the selection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Embodiment of the refining system of the present invention:

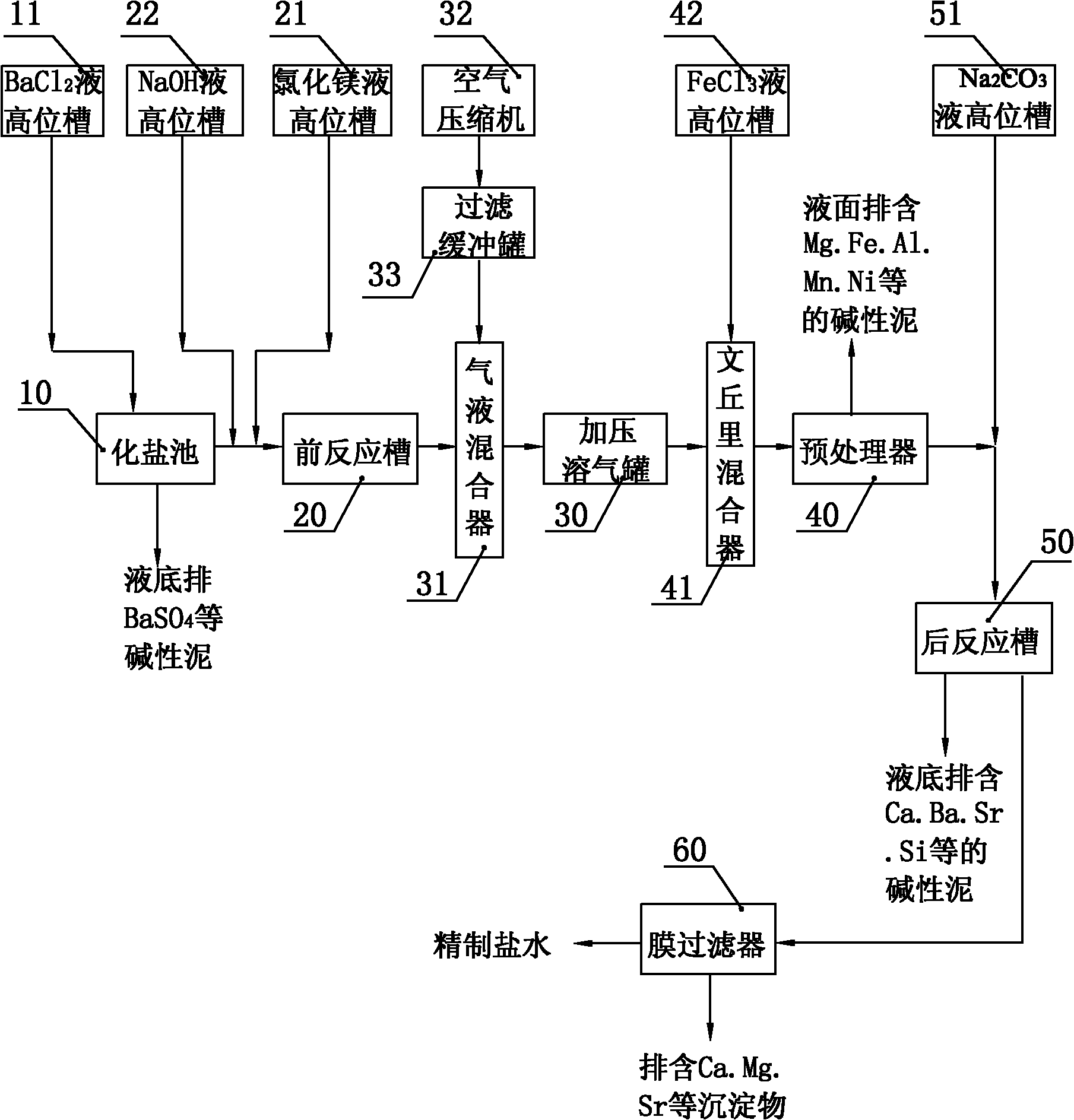

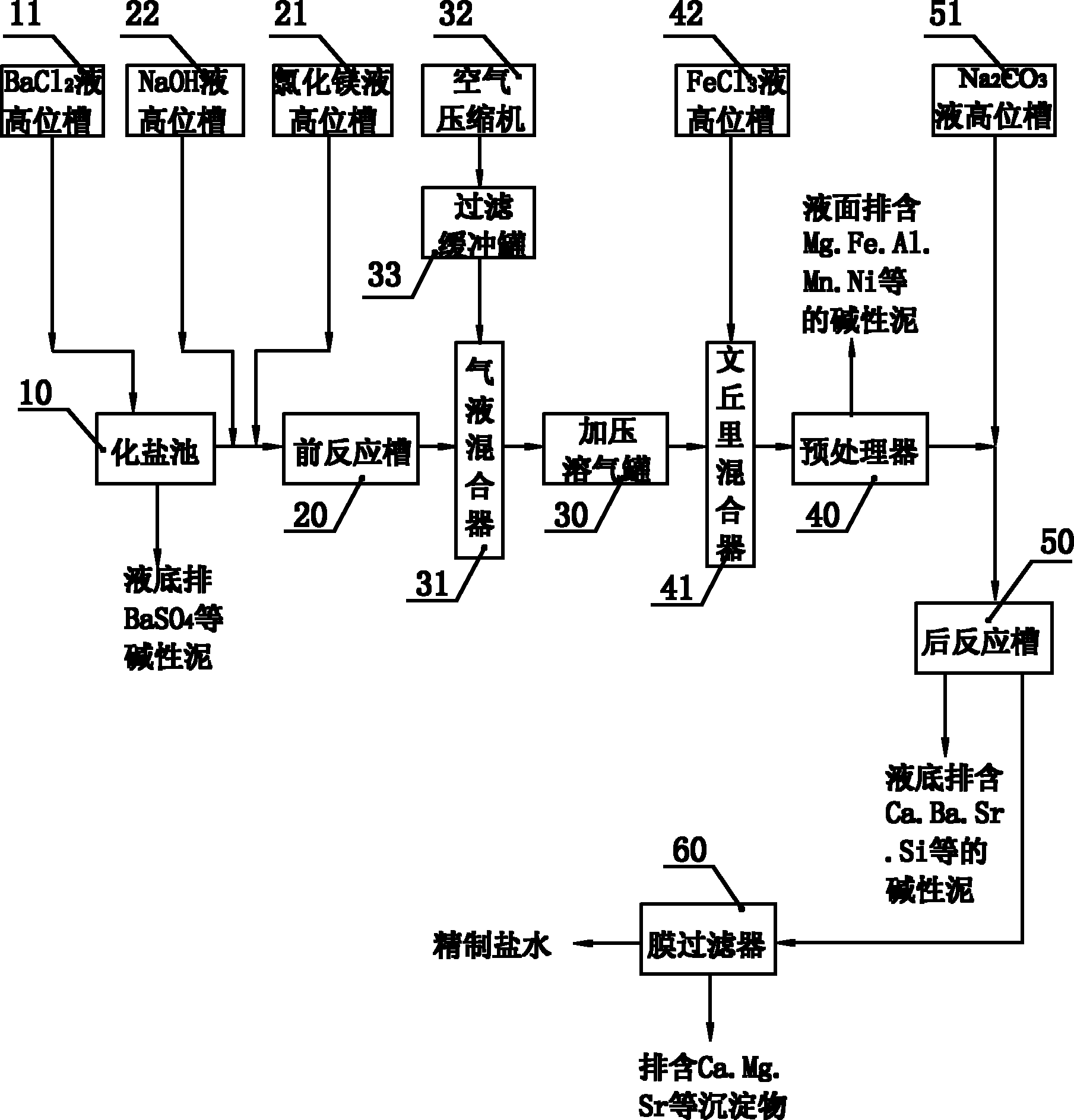

[0060] Such as figure 1 , which is a schematic diagram of the structure of the embodiment of the refining system using the above-mentioned crude brine refining method and its refining and impurity removal links. This embodiment of the refining system includes sequentially connected: a salt tank 10, a front reaction tank 20, a pressurized gas solution tank 30, a preprocessor 40, a rear reaction tank 50, and a membrane filter 60;

[0061] Also be provided with BaCl on the said chemical salt pond 10 2 Head tank 11 of the solution and its infusion pipe, from which BaSO is removed from the bottom 4 and other sedimentation; a baffle type settling tank (not shown) is also connected in series between the outlet of the salt salt tank 10 and the inlet of the front reaction tank 20.

[0062] The inlet of the front reaction tank 20 is also connected with the output pipe of the magnesium chloride solution head tank 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com