Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

158results about How to "Ensure productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

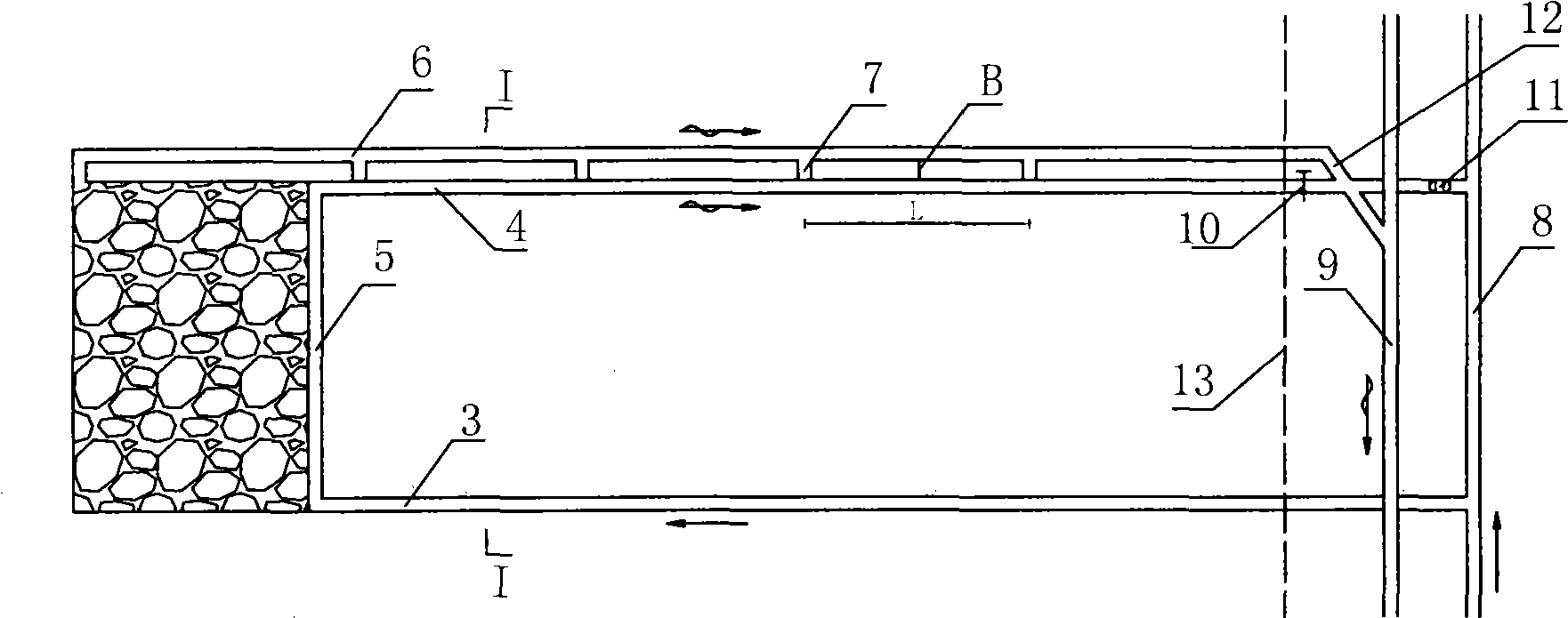

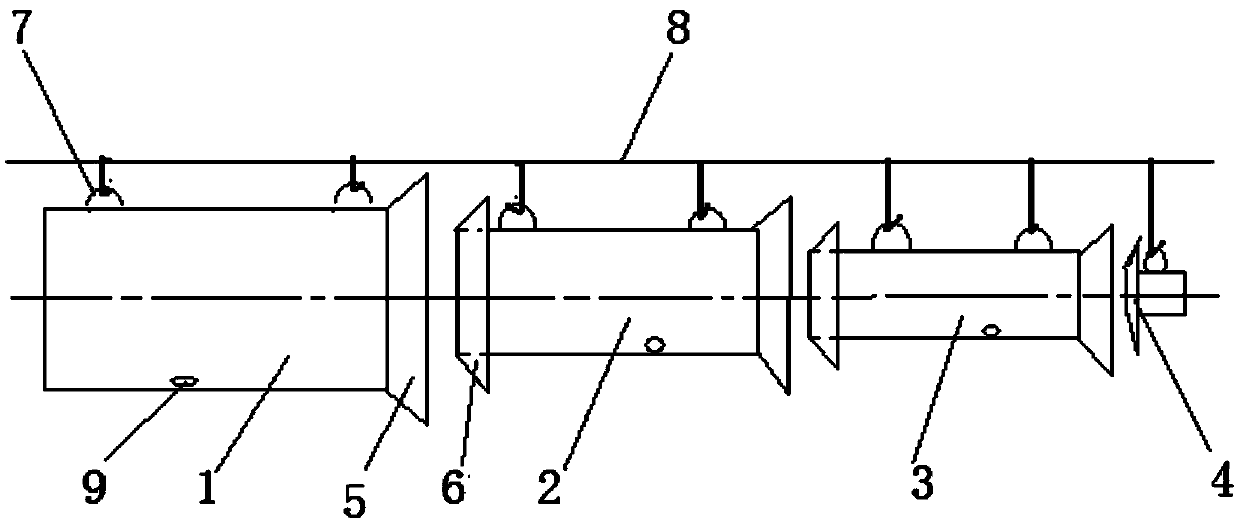

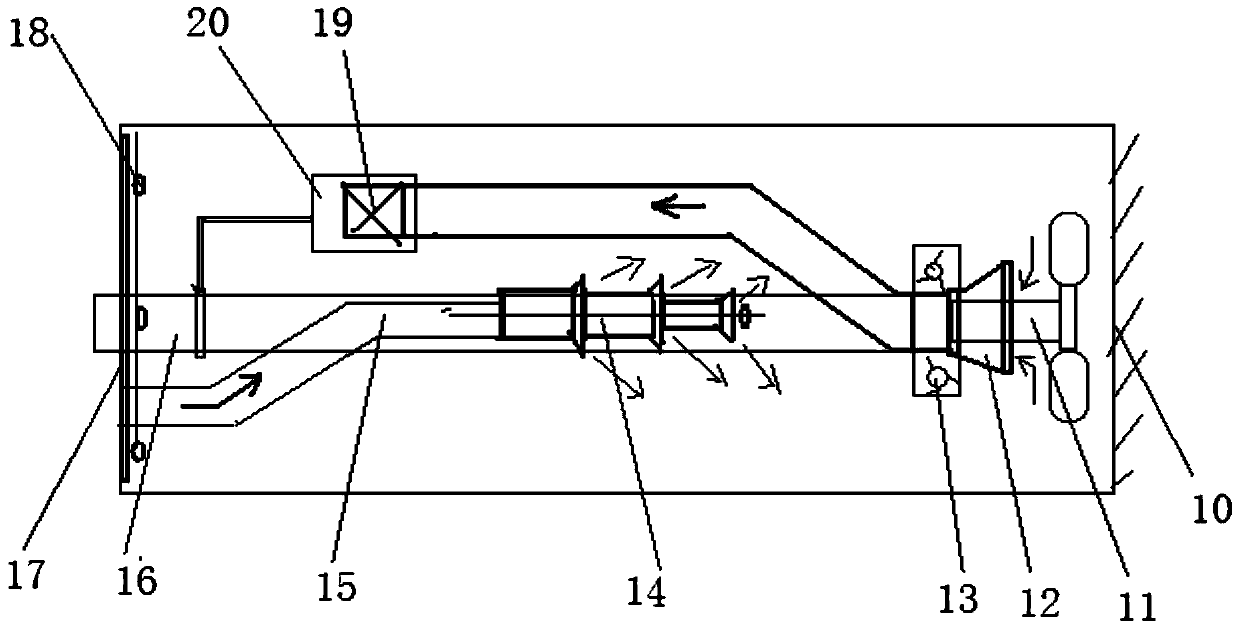

U+I type ventilating system for top-coal caving face

InactiveCN101498225AEfficient dischargeEliminate buildupUnderground miningSurface miningSpelunkingCoal dust

The invention provides a U+I type ventilation system for a work surface of top coal caving, which is an improvement of the arrangement of the U type, the U+L type and the E type or B type laneways and the ventilation systems in the prior art. An air intake way and an air return way of the work surface of top coal caving are arranged along a bottom board of a coal bed, and a regulation air door is arranged on the part of the air return way close to a big air return lane to control the reasonable ventilating parameter of the U+I type ventilating system. The invention is mainly characterized in that air exhausting lanes of top boards are arranged in parallel along the air return way with the parallel outward-staggered distance of 0 m to 5 m from the air return way to form the U+I type ventilating system of a one-intake and two-return mode. The invention fundamentally solves the problem of the accumulation of gas and coal dust on the upper section, the upper spatial angle and the gob area of the work surface of top coal caving, in particular the problem of the accumulation of the gas and the coal dust of the upper space of the upper gob area, provides a safe and high-effect ventilating system, and creates an excellent mechanical environment for realizing the exploitation of the top coal caving of small coal pillars and increasing the recovery rate of coal.

Owner:TAIYUAN UNIV OF TECH

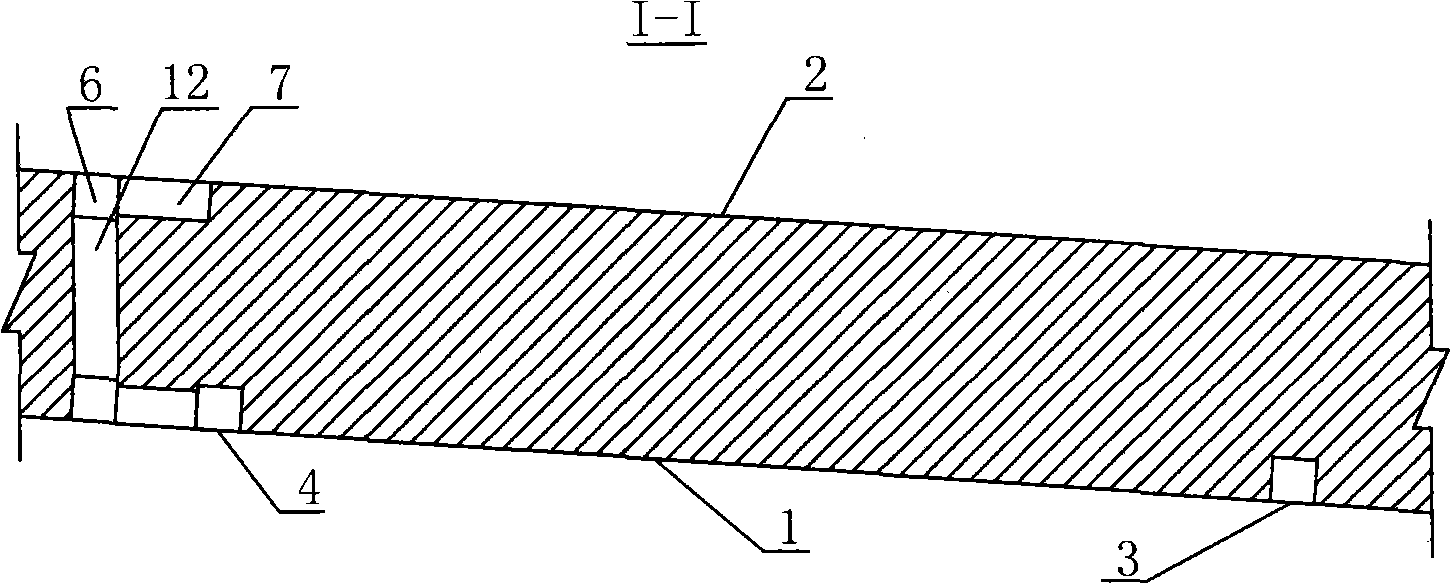

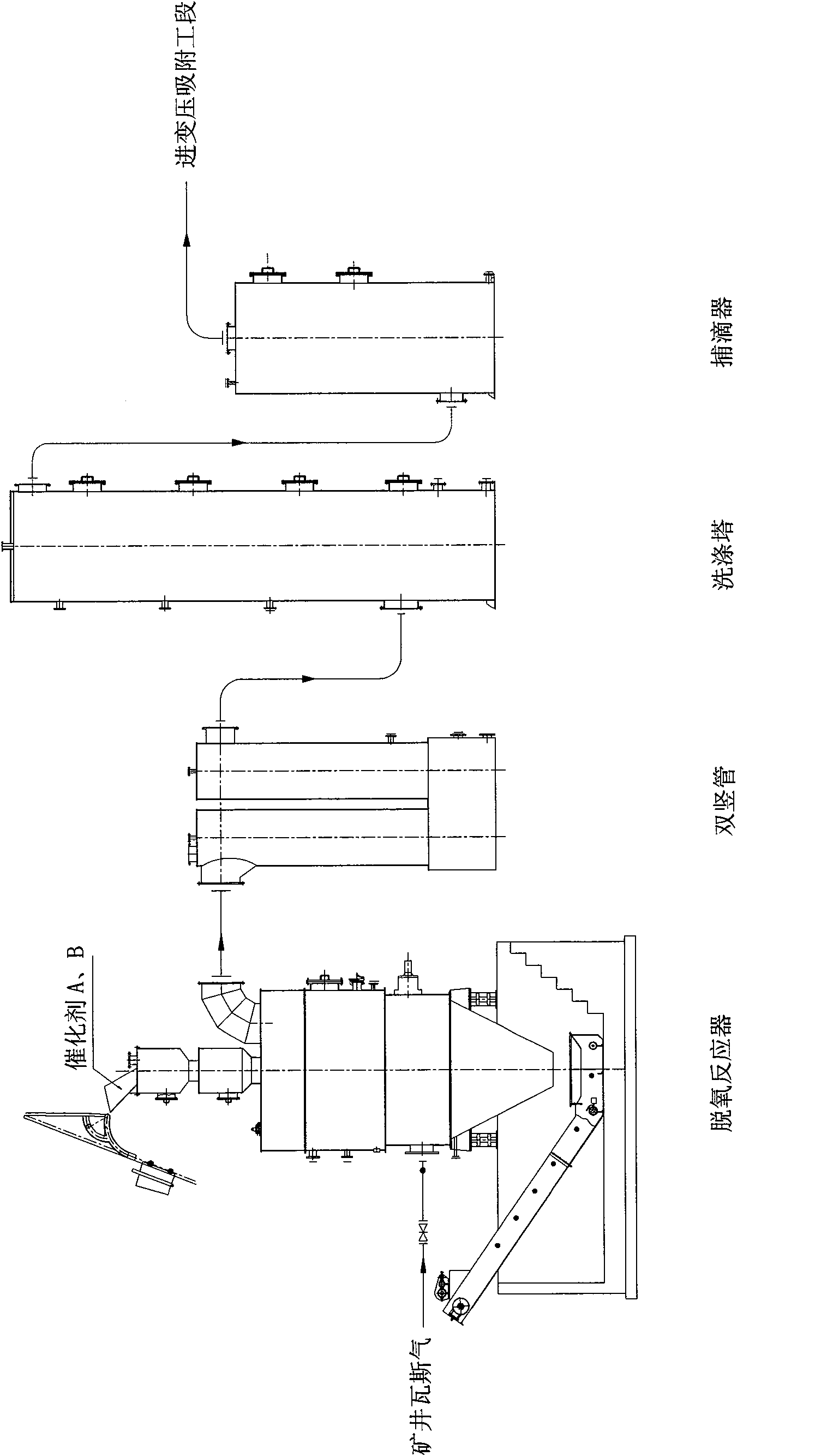

Method for deoxidizing and concentrating mine gas

InactiveCN101591579AEnsure productivityQuality assuranceGaseous fuelsCompressed natural gasCo2 absorption

The invention discloses a method for deoxidizing and concentrating a mine gas, which comprises: a step of deoxidization, in which a raw material gas is delivered into a deoxidization reactor so as to reduce oxygen in the raw material gas from about 10 volume percent to less than 1 volume percent by dense and dilute phase two-stage catalysis process in the deoxidization reactor; a step of system fluctuation control, in which software and hardware are used to monitor and process coal bed gas disturbance and gas composition change; a step of denitrification, in which a pressure swing adsorption denitrifying device is used to remove most nitrogen to purify the methane in a coal bed gas till the content of the methane is above 90 percent; a step of decarbonization, in which gas treated by the denitrification step is subjected to CO2 absorption by an amine method as well as H2S removal; and a step of compression, in which the decarbonized gas is compressed in a compression process, dehydrated and liquefied to be turned into a compressed natural gas or a liquefied natural gas.

Owner:赵昱

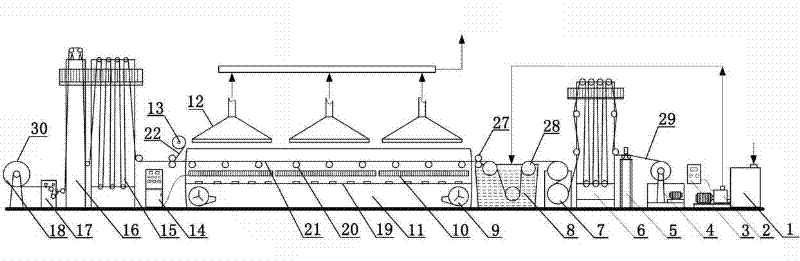

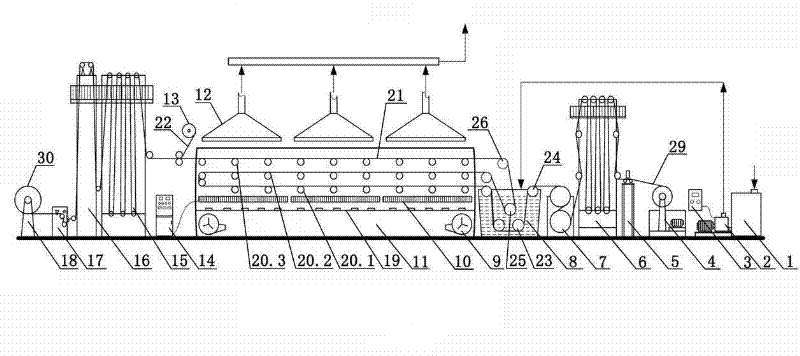

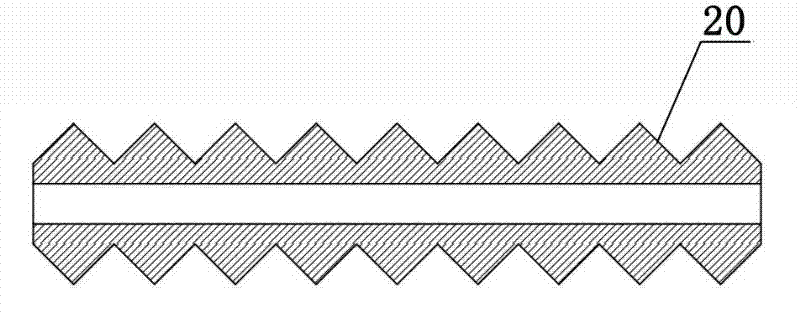

Production equipment and method of self-adhesive layer band

InactiveCN102350852AGuaranteed bondingControl UniformityLamination ancillary operationsFilm/foil adhesivesEngineeringError correcting

Production equipment and a method of a self-adhesive layer band. A base material is treated by a base material unfolding machine, a head-tail-overlapping machine, a base material buffering adjusting bracket and a base material dryer successively, enters into a gluing pool for gluing, then enters a dryer for drying; the dried base material is rolled with an isolated film on a surface thereof by a mulch applicator, cooled by a self-adhesive layer buffering adjusting bracket and adjusted by an automatic error correcting controller; then the base material can be packaged by a product winder and finally cut into dimensions required by production specifications by a cutting machine. After gluing, the base material is dried and returns to the gluing pool for a second gluing; and base material enters into the dryer again for drying after the second gluing, so as to increase peeling intensity of a self-adhesive waterproof coiled material and bonding strength of the material with a base, accelerate drying speed and increase product quality. According to the invention, base material treatment, gluing, drying, coating, cooling, rolling and packaging can be finished in a line, so as to realizeflexible operation, high degree of automation and good product quality.

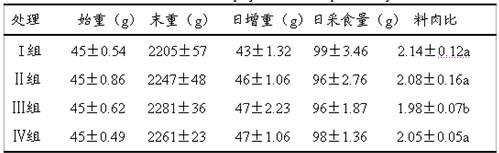

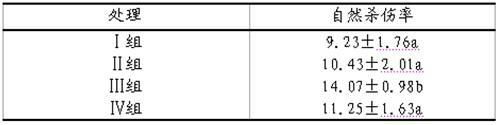

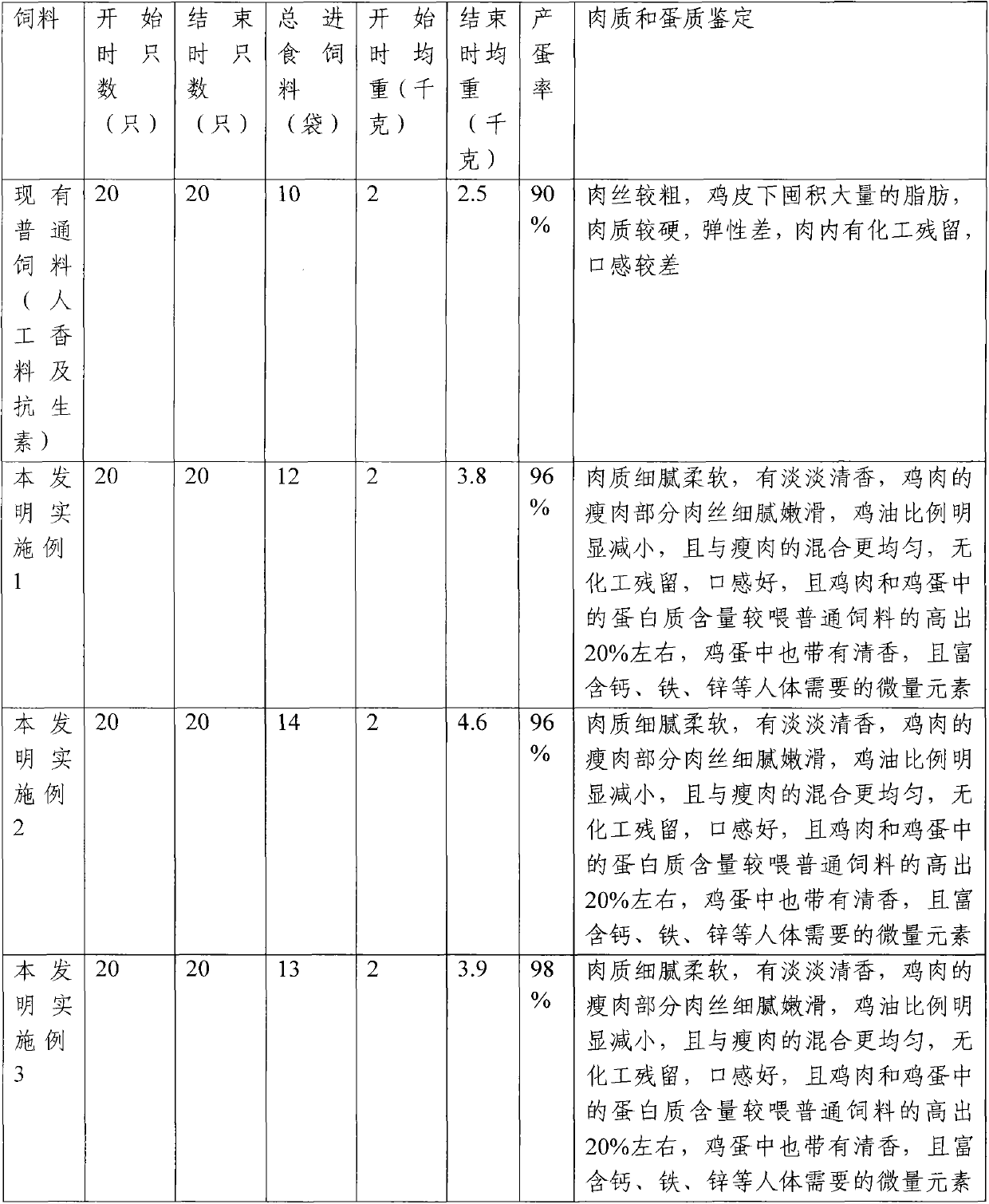

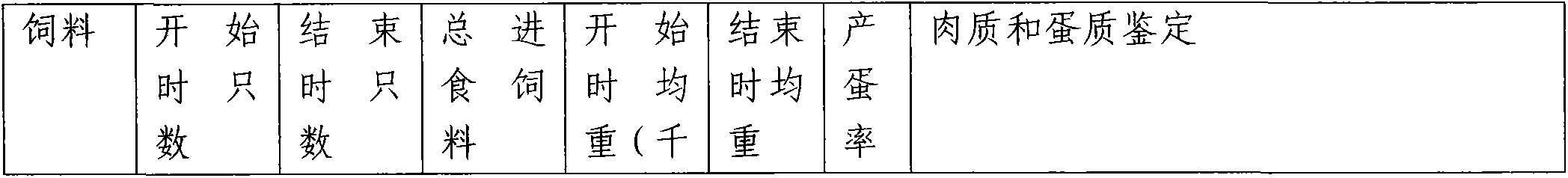

Plant polysaccharose additive premix feed for broiler chicken

InactiveCN102630853AImprove healthImprove production performanceAnimal feeding stuffAccessory food factorsAloinBiotechnology

The invention provides a plant polysaccharose additive premix feed for broiler chicken, which is prepared by a method comprising the following steps: extracting plant polysaccharose from aloes, and adding aloe polysaccharose into basic ration, wherein one hundred kilograms of basic ration is added with 0.10-0.50 kilogram of dry aloe polysaccharose powder. The plant polysaccharose additive premix feed has the advantages that the plant polysaccharose additive is a green and safe feed additive without toxicity, side effect and drug residue, and is favorable for the health of animals and human being. Compared with other additives, the plant polysaccharose additive has the advantages of low cost and favorable taste, the appetite of animals is enhanced, animals are promoted to grow, the immunity of animals is enhanced, the quality is improved, and the commodity value is improved; and the plant polysaccharose additive is a green and safe feed additive which is developed ideally.

Owner:SHANDONG NEW HOPE LIUHE GROUP

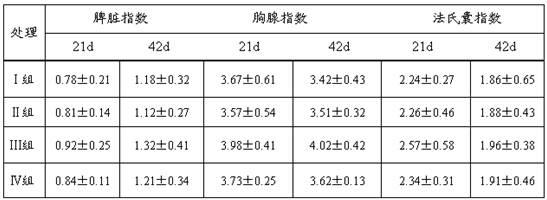

Automated production device for styrene-acrylic emulsion mixing and automated control method of automated production device

ActiveCN104014293AGuaranteed responseEnsure productivityChemical/physical/physico-chemical stationary reactorsTotal factory controlAutomatic controlEmulsion

The invention discloses an automated production device for styrene-acrylic emulsion mixing and an automated control method of the automated production device. The automated production device comprises a PLC (programmable logic control) system, a polymerization reaction kettle, an overhead acrylate tank, an overhead styrene tank and an overhead initiator tank, wherein a weight sensor is arranged at the bottom of each overhead tank and is connected with the PLC system; a control valve is arranged on each of an acrylate feeding pipe, a styrene feeding pipe and an initiator feeding pipe and is connected with the PLC system; a temperature sensor is arranged on the polymerization reaction kettle and is connected with the PLC system; a control valve is arranged on each of a heated steam pipe and a cooling water pipe and is connected with the PLC system. The automated control method comprises the step that the PLC system automatically adjusts an acrylate feeding control valve, a styrene feeding control valve, an initiator feeding control valve, a heated steam control valve and a cooling water control valve to control the feeding amount and the feeding speed of acrylate solution, styrene solution and an initiator solution and the temperature of the polymerization reaction kettle. The feeding amount and the feeding speed of materials and the flow of heated steam and cooling water are adjusted according to the change of reaction temperature by using the PLC system, so that the temperature of polymerization reaction is stable, and the production safety and the product quality are ensured.

Owner:湖北尚助化学有限公司

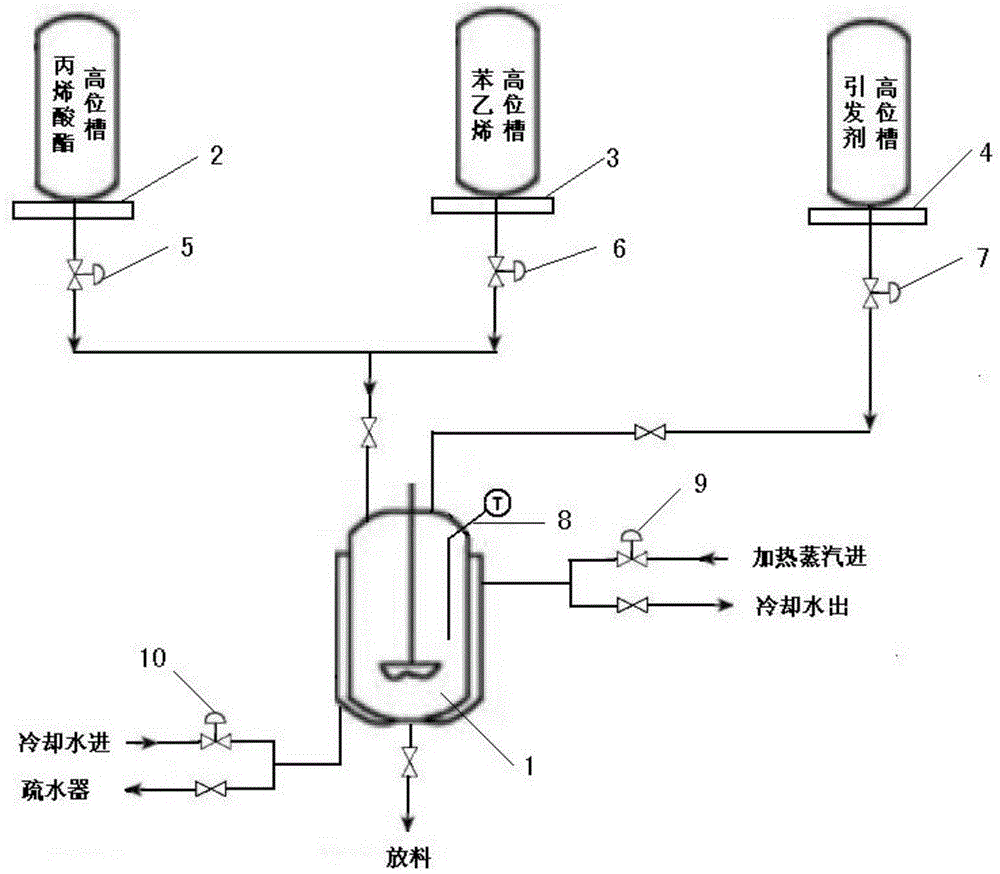

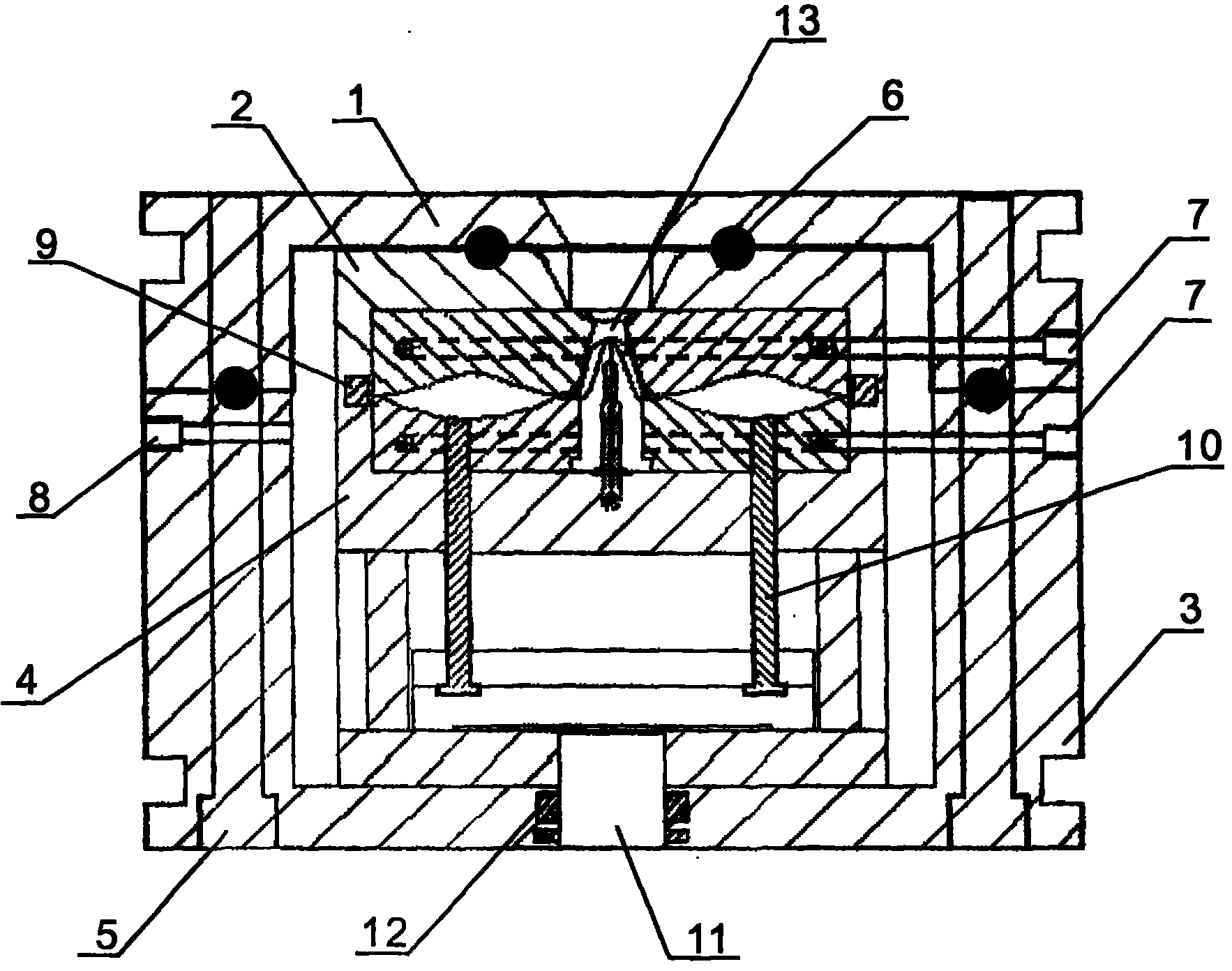

Fully sealed mold ultra-high vacuum die-casting and injection molding device and operation method

The invention relates to a fully sealed mold ultra-high vacuum die-casting and injection molding device and an operation method. A mold sealing box is arranged outside a mold in an ordinary die-casting and injection molding machine, a feed inlet of a mold cavity is provided with a sealing plug, and a micromesh screen is arranged in a vacuum-pumping pipe orifice of the mold cavity. A vacuum-pumping device is started for pumping out air in the sealing box and the mold cavity, liquid metal or plastic which is molten at high temperature firstly breaks through the sealing plug of the feed inlet from the feed inlet, smoothly flows into the mold cavity in an ultra-high vacuum state and flows in the ultra-high vacuum mold cavity in an accelerated manner, the cavity is rapidly filled with the liquid metal or the plastic for casting a workpiece, and when metal or plastic liquid which is molten at the high temperature is in contact with the edge of the vacuum-pumping pipe orifice of the mold cavity, the metal liquid or the plastic liquid is blocked by the micromesh screen arranged in the vacuum-pumping pipe orifice of the mold cavity for preventing the molten metal liquid or the plastic liquid from blocking a vacuum pipeline. A product which is formed by die-casting and injection molding through the device disclosed by the invention has the advantages of high precision, lower air hole level and high finished product rate.

Owner:增城市运豪五金塑料有限公司

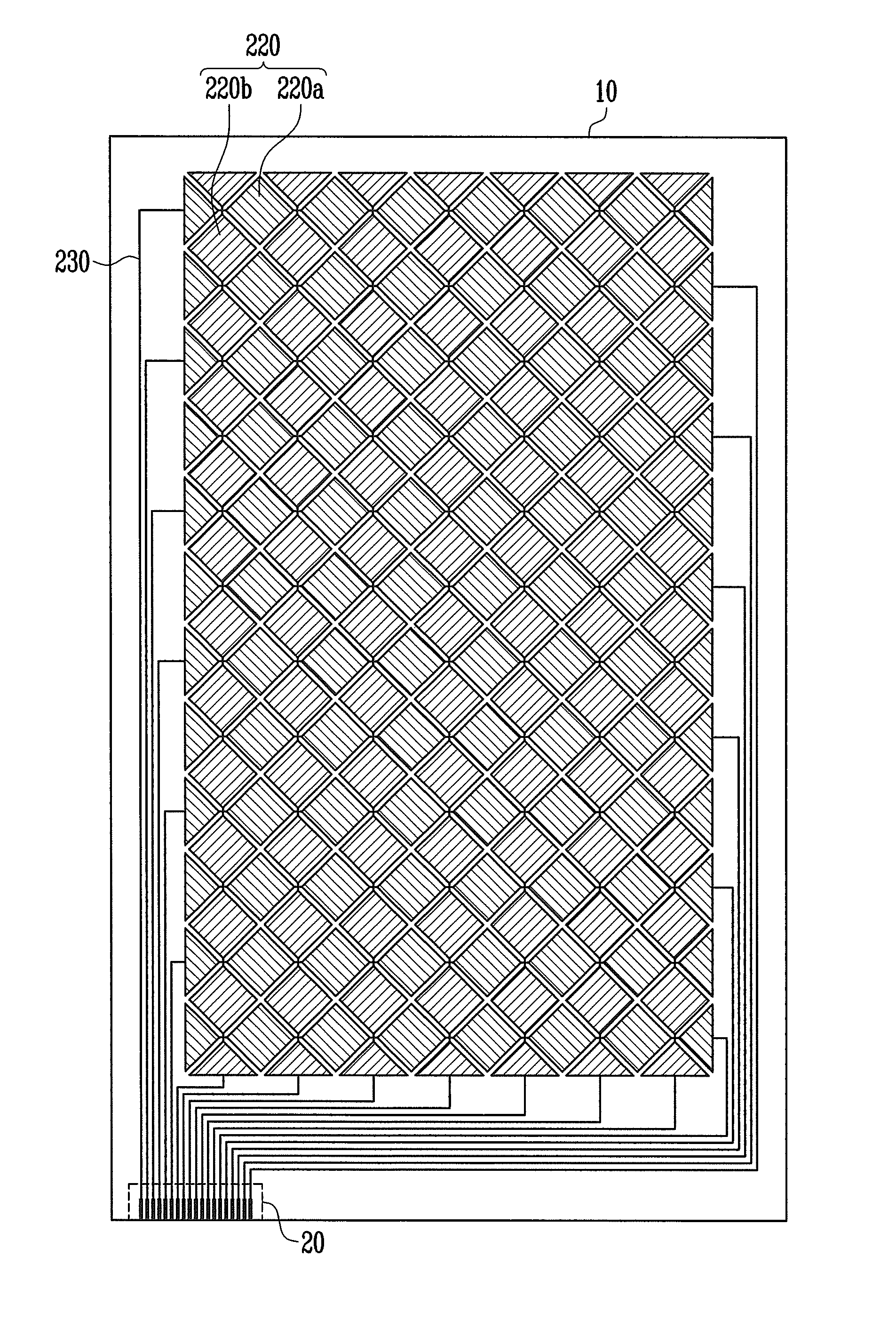

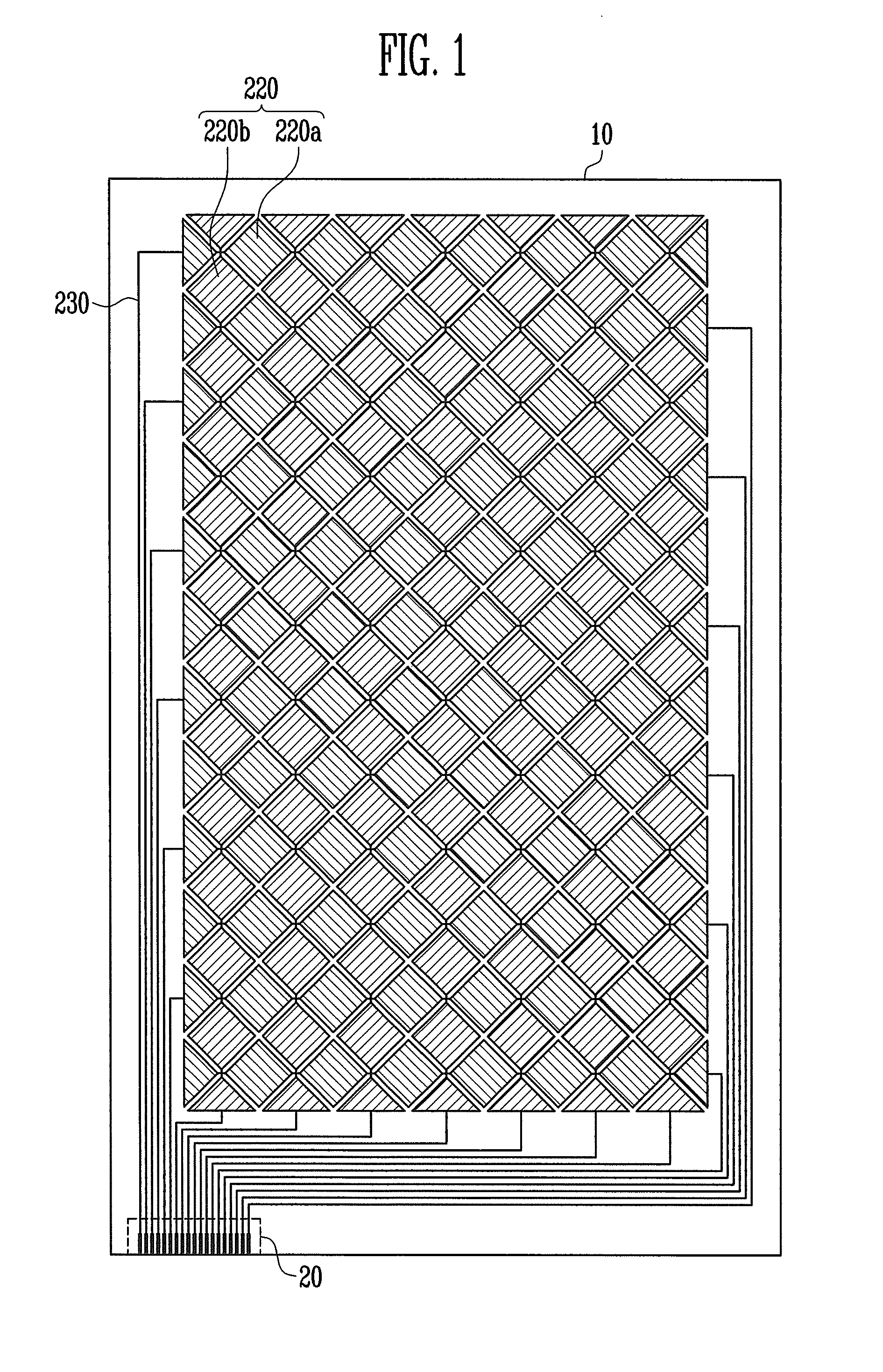

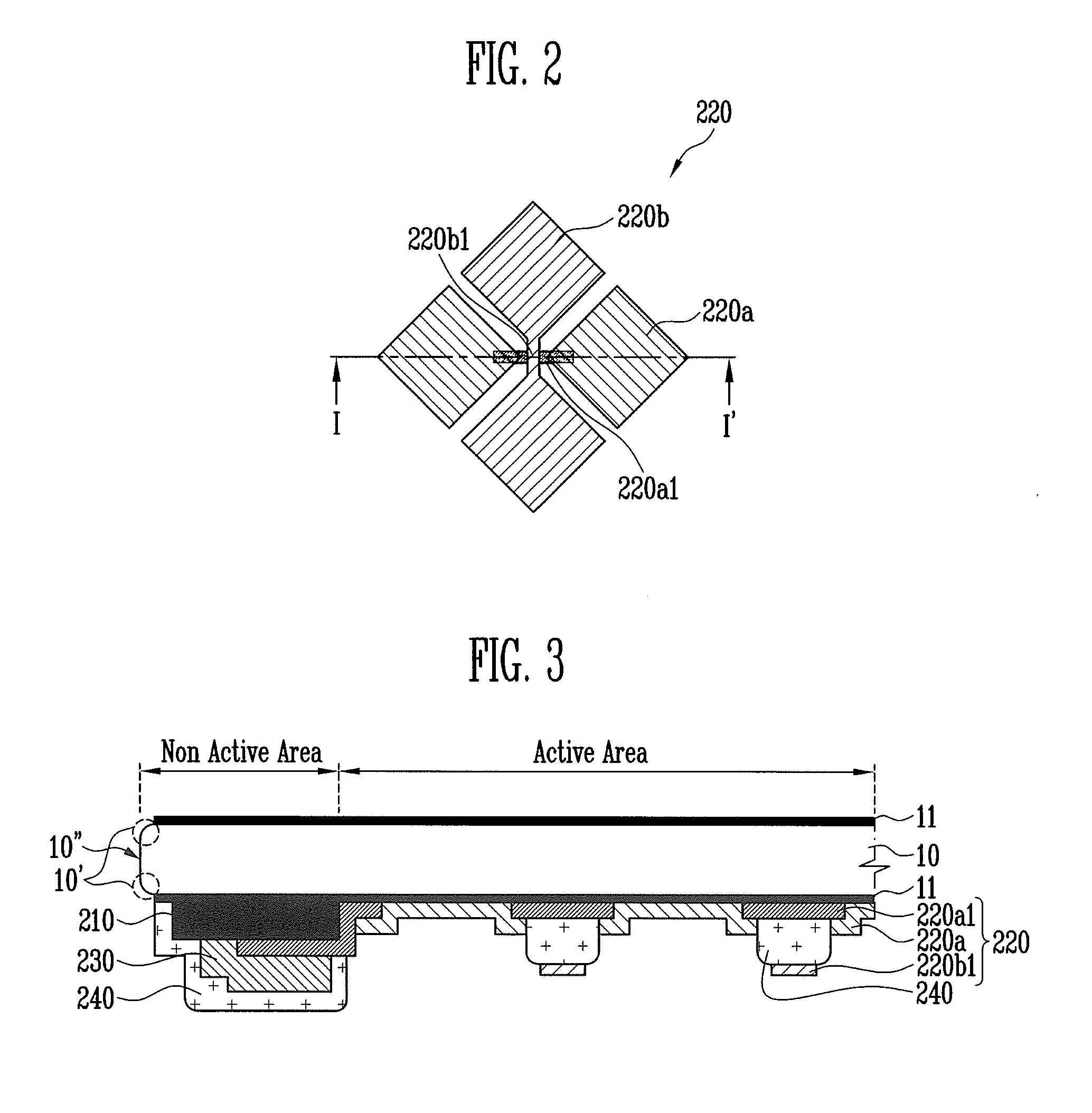

Touch screen panel and fabricating method for the same

ActiveUS20120120003A1Increase productivityHigh strengthLamination ancillary operationsControlling laminationCell regionTouchscreen

A method of fabricating a touch screen panel according to an embodiment of the present invention includes: forming a reinforcing layer on the top and the bottom of a glass substrate by reinforcing the entire surface of the glass substrate defining a plurality of unit cell regions; forming the touch screen panels in the unit cell regions on a side of the glass substrate with the reinforcing layers; cutting the reinforced glass substrate into the touch screen panels; forming passivation layers on the outer surfaces of the touch screen panels and sequentially stacking the touch screen panels; and simultaneously with the stacking, performing healing on the non-reinforced cut-sides of the stacked touch screen panels.

Owner:SAMSUNG DISPLAY CO LTD

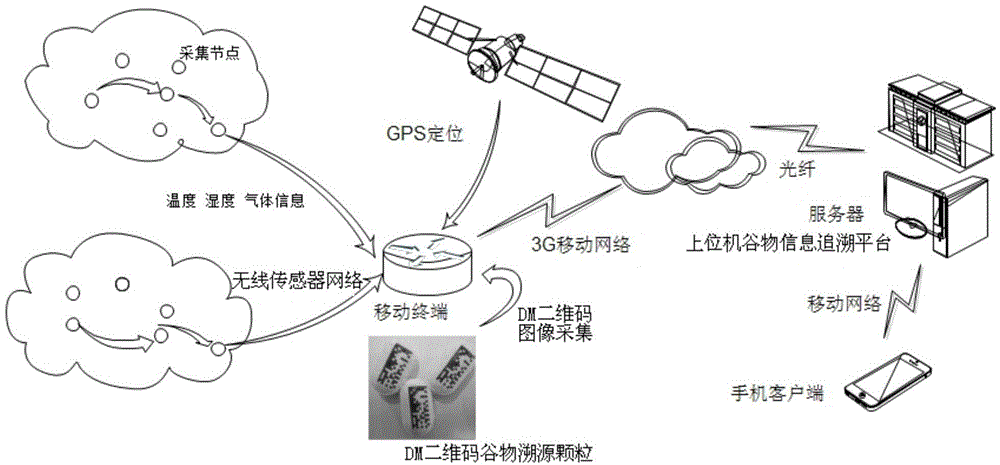

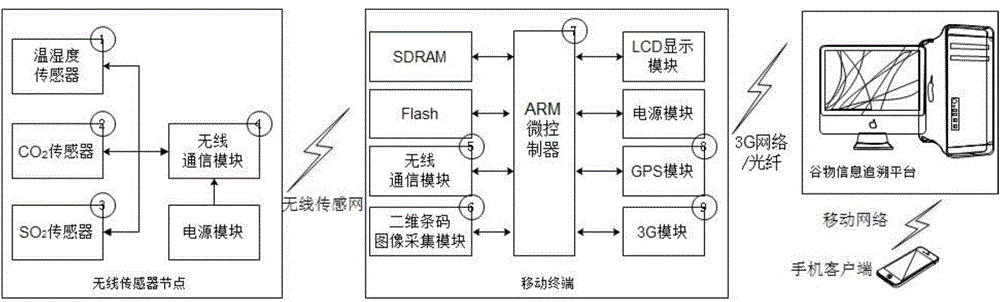

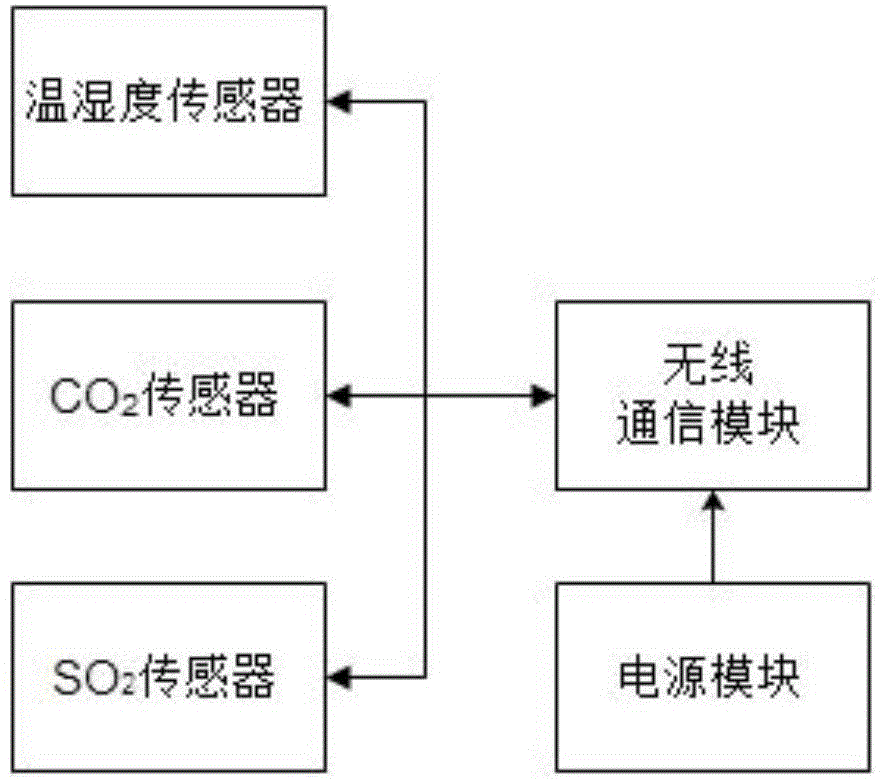

Precise information acquisition and tracing system and tracing method based on DM (Data Matrix) two-dimension code grain tracing particles

InactiveCN104867023AAccurate full traceabilityAccurately realize full traceabilityCo-operative working arrangementsCommerceGeneral Packet Radio ServiceThe Internet

The invention discloses a precise information acquisition and tracing system and a tracing method based on DM (Data Matrix) two-dimension code grain tracing particle, which take the food-grade DM two-dimension code grain tracing particles as a carrier of a grain producing area information identifier, and develop automatic acquisition and transmission based on information of each link for ARM (Advanced RISC Machines) grain tracing as a rapid full-range grain tracing system with low cost to provide an effective manner for guaranteeing the grain quality and the safety production. The tracing system comprises an environment information acquisition node, a wireless sensor network, a mobile terminal provided with a wireless communication module, a GPRS (General Packet Radio Service) locating module and a DM two-dimension code image capture module, and an upper computer grain information tracing platform. The upper computer grain information tracing platform recognizes and decodes a plurality of DM two-dimension code areas in received grain images to obtain grain production mark information, stores the grain production mark information, the grain environment information and the position information together, and publishes on the internet. A user can search related grain information through a mobile phone client.

Owner:NANJING AGRICULTURAL UNIVERSITY

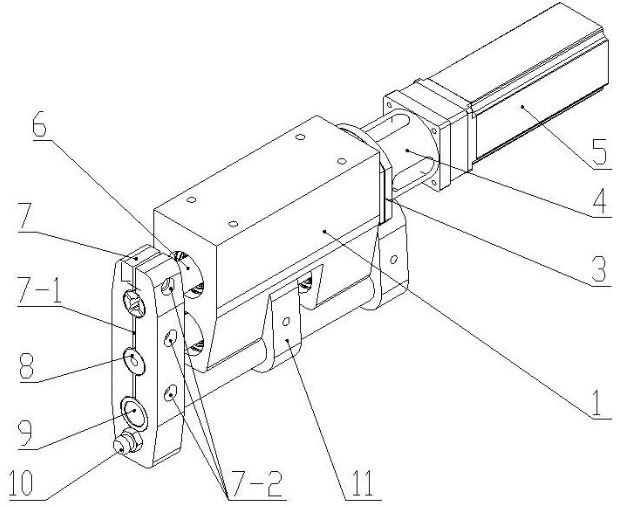

Electronic shift device

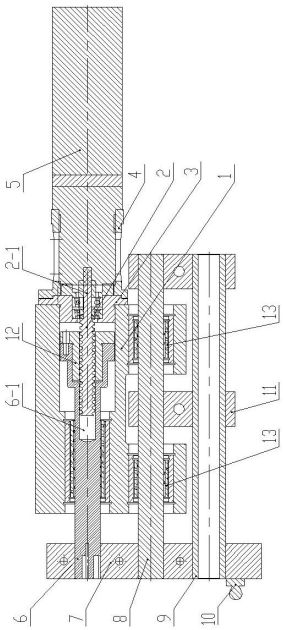

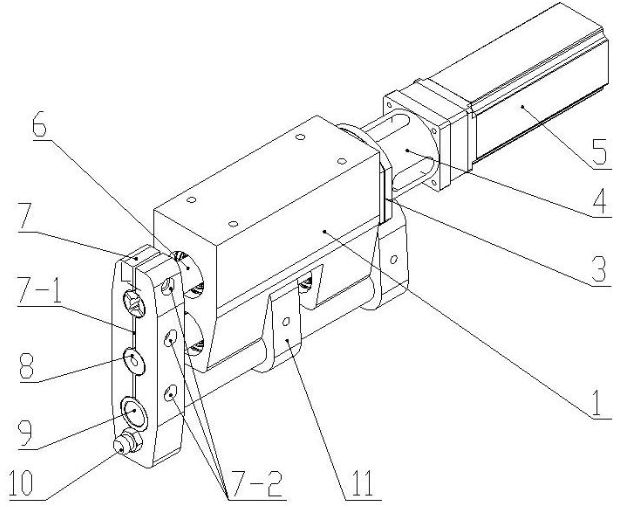

The invention relates to an electronic shift device, comprising a servo motor, a locomotory apparatus and a shift straining ring, wherein the locomotory apparatus comprises a main locomotory apparatus and an assistant locomotory apparatus, and the servo motor is fixedly installed on the main locomotory apparatus; the main locomotory apparatus comprises a guide holder, a connecting flange, a ball screw, a ball nut and a propeller shaft, wherein the connecting flange is fixedly installed on one end of the guide holder to be connected with the servo motor; the shift staining ring is positioned on the other end of the guide holder; the propeller shaft is positioned in the guide holder, one end of the propeller shaft is fixed with the shift straining ring, and a cavity is formed in the other end of the propeller shaft; the ball screw and the ball nut are fixed in the cavity; and the ball screw is connected with the connecting flange by a screw shaft on the end of the ball screw. The assistant locomotory apparatus comprises a spring shaft, a transition shaft, a linear bearing and an assistant straining ring, wherein one end of the spring shaft is fixed with the shift straining ring, the other end of the spring shaft is fixedly arranged on the assistant straining ring, and the transition shaft is installed in the guide holder by the linear bearing. The invention is favorable for ensuring product quality and maintenance, prevents dust from entering, has low cost, and simple and compact structure and improves the service life of products.

Owner:CHANGZHOU WUJIN WUYANG TEXTILE MACHINERY

Mixed pellet feed for over-sized fattening pigs and preparation method thereof

InactiveCN104489371AGuaranteed lean meatEmission reductionAnimal feeding stuffBiotechnologyAnimal science

The invention relates to mixed pellet feed for over-sized fattening pigs and a preparation method thereof, belonging to the technical field of pig feed. The mixed pellet feed is prepared from the following components in parts by weight: 500-600 parts of corn, 30-60 parts of bean pulp, 150-200 parts of corn DDGS (distillers dried grains with soluble), 150-200 parts of rice bran, 100-150 parts of middlings bran, 10-13 parts of mountain flour, 2.5-3.5 parts of salt, 0.5-1 part of choline, 3-4 parts of lysine hydrochloride, 1-1.5 parts of threonine, 0.2-0.3 part of an antioxidant, 0.4-1.5 parts of a mildew preventive, 10-20 parts of bentonite, 1-2 parts of calcium hydrogen phosphate, 8-10 parts of a vitamin premix and 8-10 parts of a trace element premix. On the premise of guaranteeing safety, the mixed pellet feed can be used for improving the production input and output efficiency, and achieving the purposes of improving feed conversion, pig meat quality and slaughter performance to meet the market needs.

Owner:TONGWEI

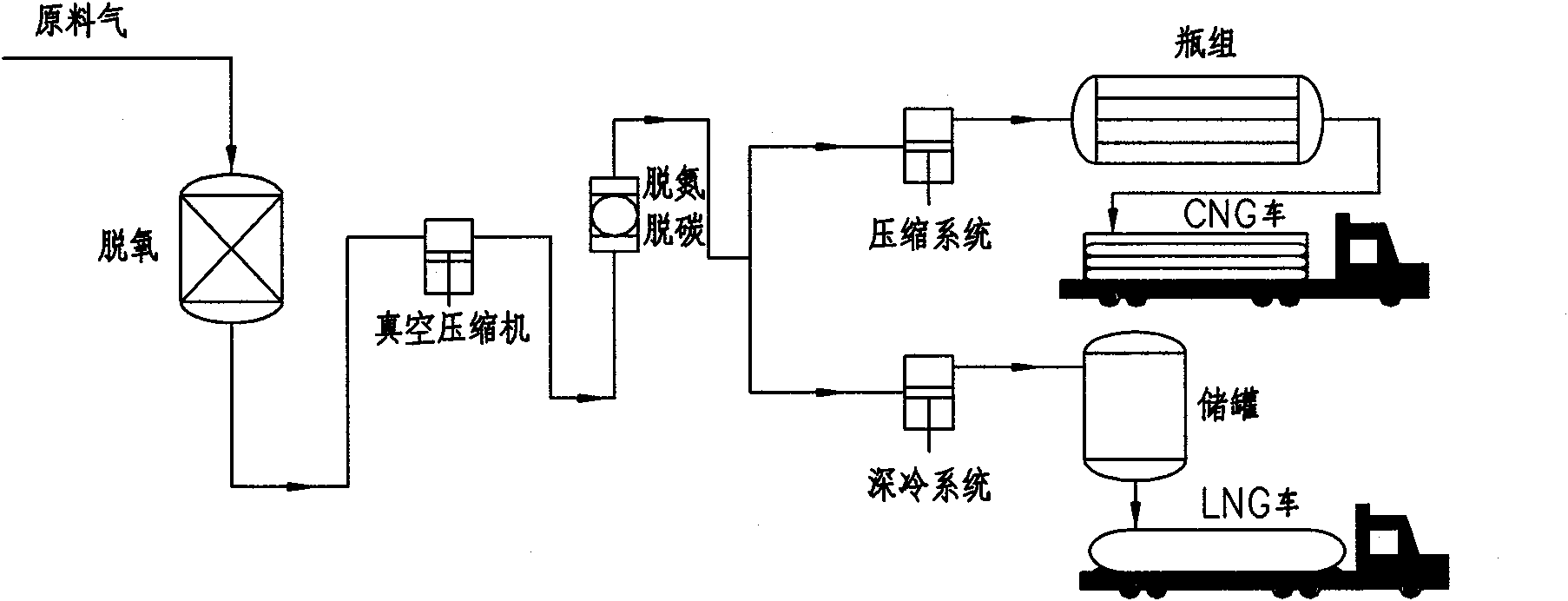

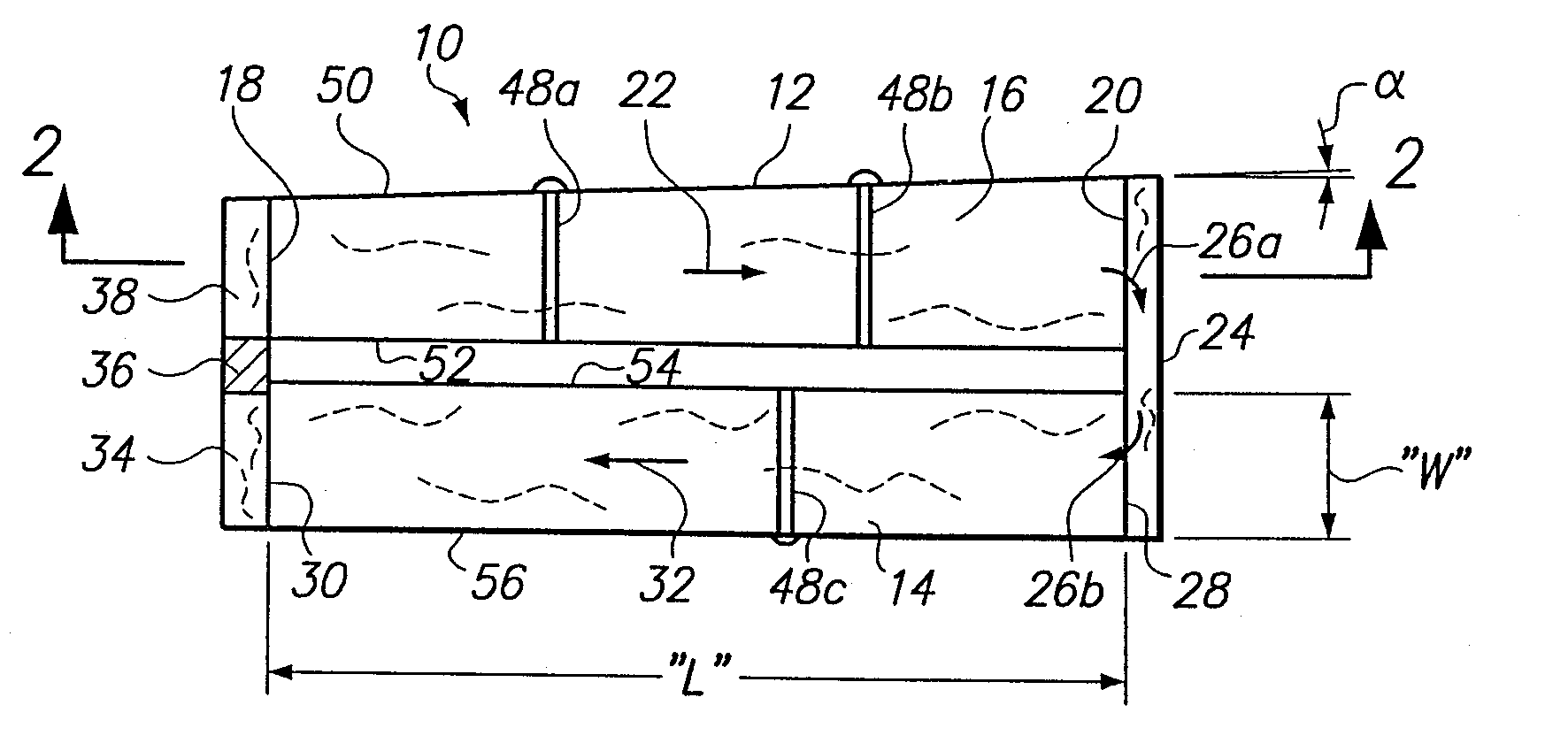

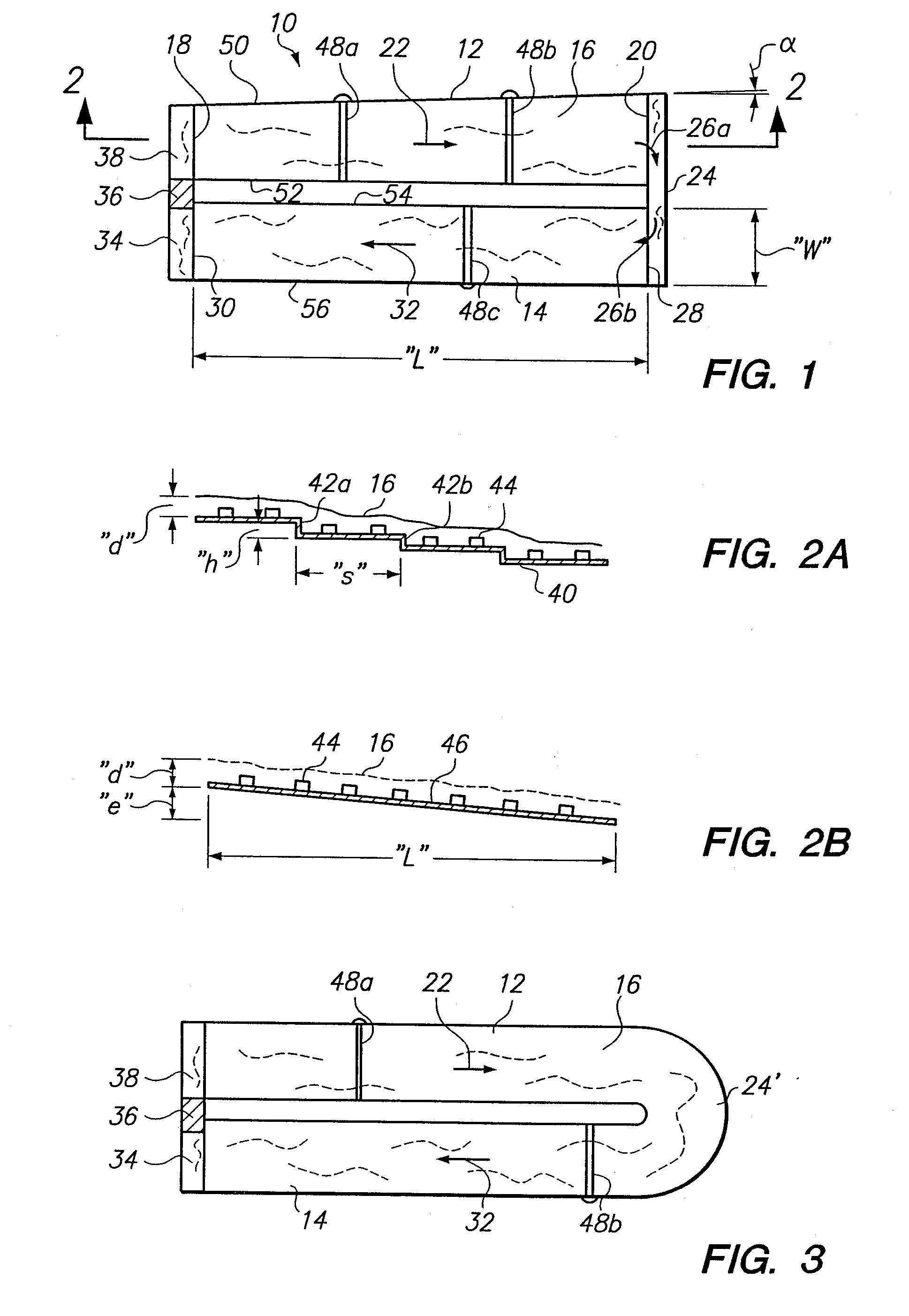

Microalgae Growth Pond Design

InactiveUS20110287531A1Ensure productivityBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringMicroalgae growth

A raceway pond for circulating microalgae in a fluid medium includes a plurality of interconnected channels. Each channel is straight and has a structured gradient, due to tilt or terracing, that moves the fluid medium along the raceway. In operation, the concentration of microalgae in the fluid medium is maintained substantially constant, and the depth of the fluid medium in the raceway is maintained below a pre-determined level.

Owner:GENERAL ATOMICS

Polyester fully-drawn slub yarn and preparation method thereof

InactiveCN102828278AGood orientationEnsure productivityNew-spun product collectionFilament forming substance formingPolyesterBreaking strength

The invention discloses a polyester fully-drawn slub yarn and a preparation method thereof. On the basis of not changing the conventional FDY (fully-drawn yarn) production device, the polyester fully-drawn slub yarn is produced by using a one-step method implemented through adding a polymethyl methacrylate additive (mass percentage: 0.5-3.0%) into a polyester chip and then carrying out drawing on an obtained mixture at a drawing speed of 4600-5000m / min. The radial fineness ratio of the obtained slub yarn is 1.20-1.60 / l, the length of a thick section of the slub yarn is 15-40mm, and the slub density is 5-15 / m; and the breaking strength is 2.70-3.40 cN / dtex, and the breaking elongation is 40-80%. The polyester fully-drawn slub yarn prepared by using the technical scheme of the invention has the characteristics of high output, low cost, good quality, stable performance, high added values of products, and obvious price-performance advantages, and achieves the purposes of energy conservation, emission reduction, environmental protection, clean production and benefit incensement.

Owner:SUZHOU UNIV

Method for controlling slag bonding of vacuum chamber

The invention discloses a method for controlling slag bonding of a vacuum chamber. The method comprises the following steps of: when IF (Intermediate Frequency) steel is produced, carrying out pressure control over an RH (Rockwell Hardness) furnace: controlling the pressure of the vacuum chamber to be 25KPa within 0 to 2min; controlling the pressure of the vacuum chamber to be 15KPa within 2 to 3min; and omitting the pressure control after 3 min; when medium carbon steel is produced and the mode of the process path of direct pouring on a machine after treatment by an LF (Ladle Refining) furnace is changed into the mode of direct pouring on a machine after treatment by the RF furnace, controlling the weight of the tapped carbon from the converter to be 0.03-0.06 percent; in the tapping process of the converter, adjusting components such as aluminum, silicon and manganese only; raising the tapping temperature by 10-15DEG C on the basis of an original process path of the LF furnace; reducing the temperature rise oxygen blowing amount of the RH furnace; ending the final deoxidation of the RH furnace; and adjusting the carbon component. Therefore, the splashing of molten steel is relieved; the slag bonding of the vacuum chamber is reduced; the blocking probability of an alloy blanking hopper is reduced; the labor intensity of operators is relieved and the influence caused by accumulated slag falling on the components of the molten steel is avoided and further the quality of the IF steel and smooth operation of the products are ensured.

Owner:ANGANG STEEL CO LTD

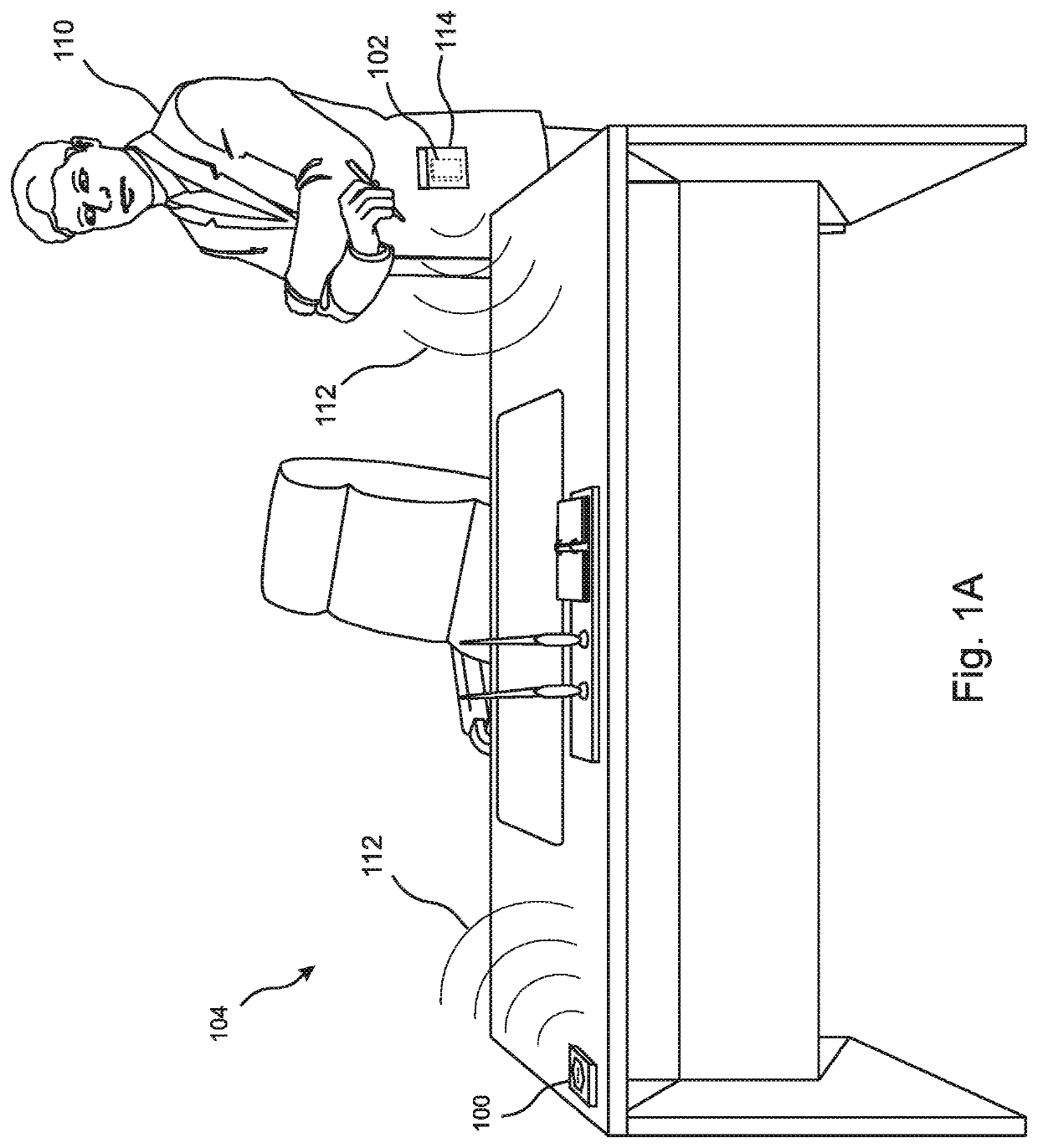

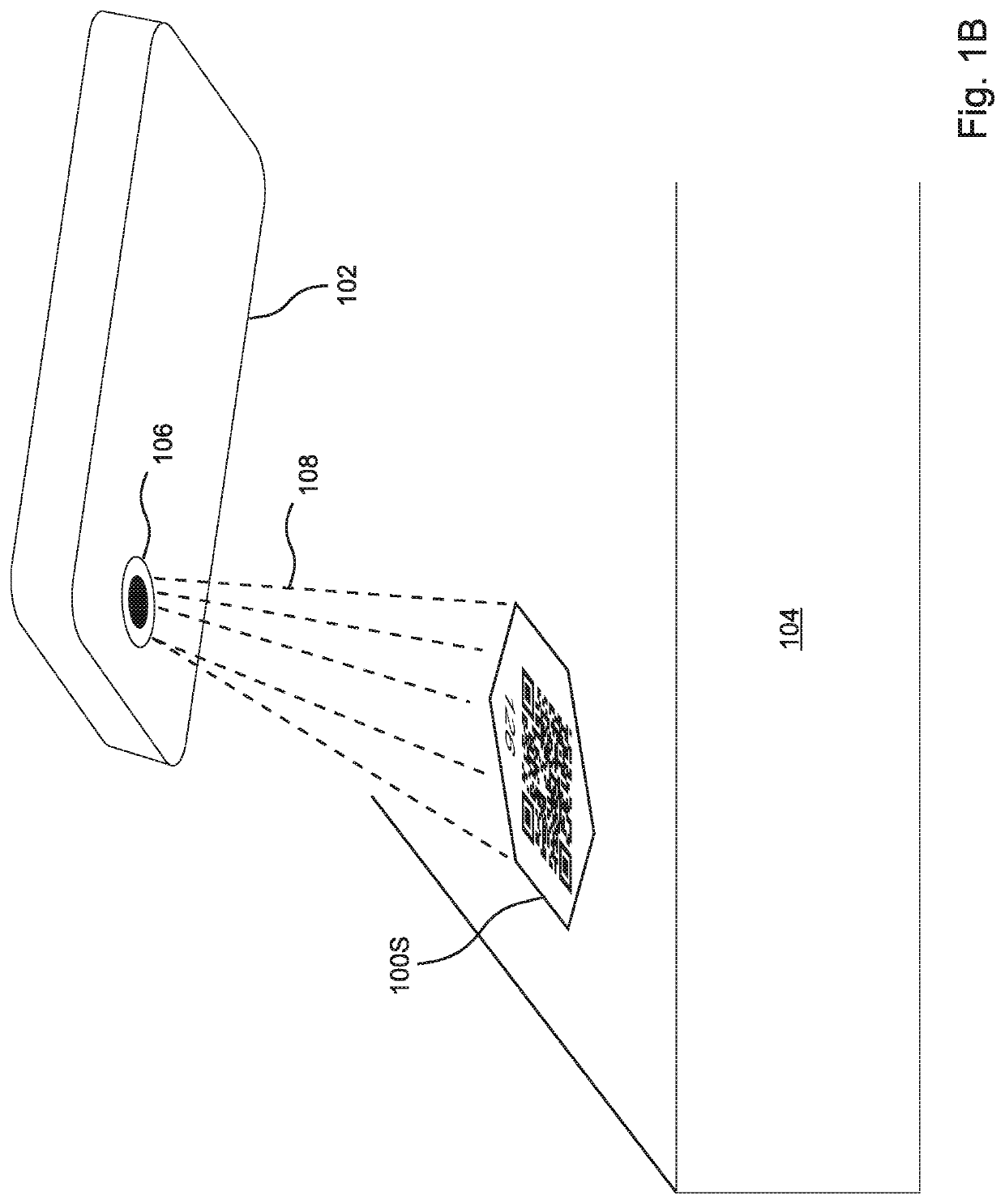

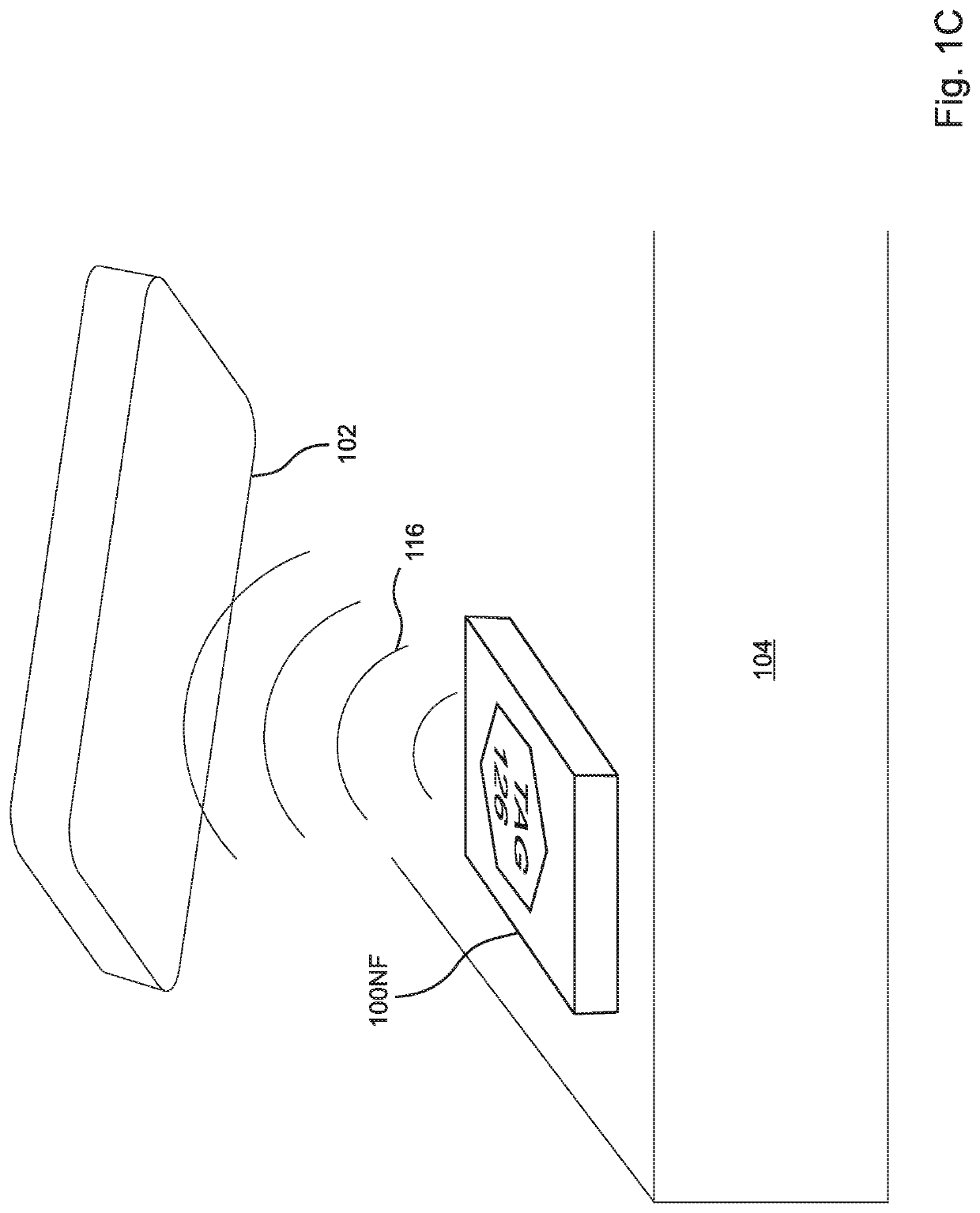

Apparatus and method for minimizing direct and indirect cross-contamination of pathogens between personnel within a workplace

ActiveUS20200304944A1Ensure safetyEnsure productivityParticular environment based servicesEpidemiological alert systemsMobile deviceServer

An apparatus and method of minimizing pathogen cross-contamination and enhancing infection mitigation at a workplace includes placing tags at selected locations, requiring at least some workplace personnel to carry mobile devices, and logging interactions between the mobile devices and tags as tapping events. Tags can be powered or unpowered. Tapping can include RF or Bluetooth communication, and / or indicia scanning. Tapping events can be wirelessly directed to a server by the tags and / or mobile devices. The logged tapping can be used to identify high risk locations, record user movements, monitor user compliance with assigned schedules and locations, and monitor compliance with specified sanitation schedules. During mitigation of an infection event, the logged tapping can be used to identify users at high risk of direct cross-contamination due to proximity to an infected user and / or surface-mitigated cross-contamination due to occupation of a location shortly after occupation thereof by the infected user.

Owner:INNOVET LLC

Polyvinyl chloride co-extrusion foaming furniture board and manufacturing method thereof

ActiveCN108384156AHigh hardnessHigh surface hardnessSynthetic resin layered productsPolyvinyl chlorideTriple superphosphate

The invention discloses a polyvinyl chloride co-extrusion foaming furniture board and a manufacturing method thereof, belongs to the technical field of polyvinyl chloride boards, and aims at solving the problems of high density, low hardness and toughness, and rough surface of the conventional product. The polyvinyl chloride co-extrusion foaming furniture board comprises a core layer and a surfacelayer, wherein the core layer comprises 60-80 parts of polyvinyl chloride SG8 type resin, 45-60 parts of triple superphosphate, 35-50 parts of recovery material, 5-6 parts of foaming conditioner P, 2.8-3.2 parts of a calcium-zinc stabilizer, 0.5-0.6 parts of an inner lubricating agent SP-60, 0.1-0.25 part of micronized polyethylene wax N-14P, 0.4-0.5 part of a plasticizer OA, a foaming agent anda pigment. The method comprises the following steps: preheating a heat mixing pot; sequentially adding chloroethylene resin, recovery material, calcium powder and the lubricating agent in sequence; heating; sequentially adding the foaming agent, the foaming conditioner and the rest materials; heating; cooling; extruding the materials to obtain the finished product through an extruder. The method is carried out to manufacture the furniture board.

Owner:SHANDONG HUIFENG NEW MATERIAL TECH CO LTD

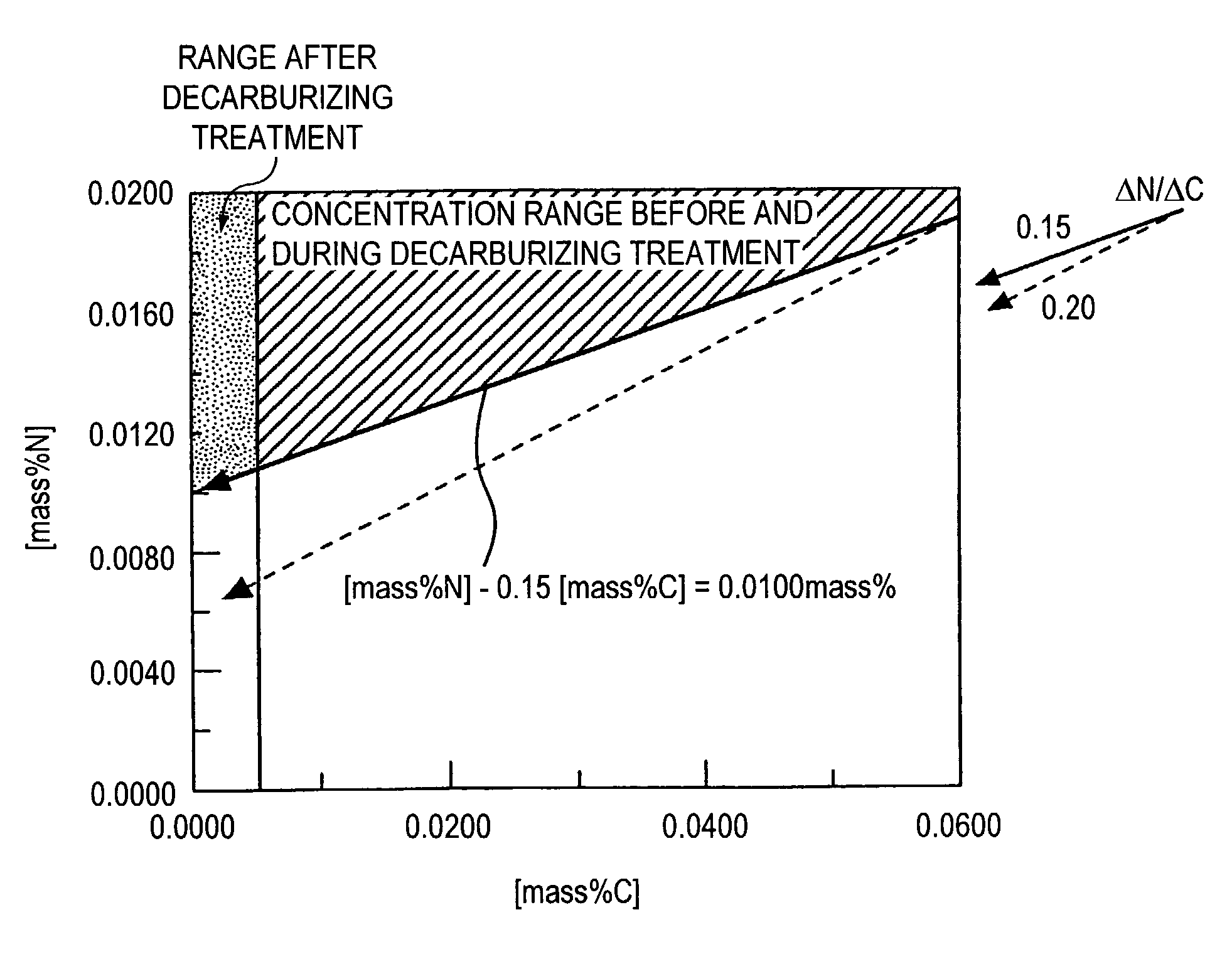

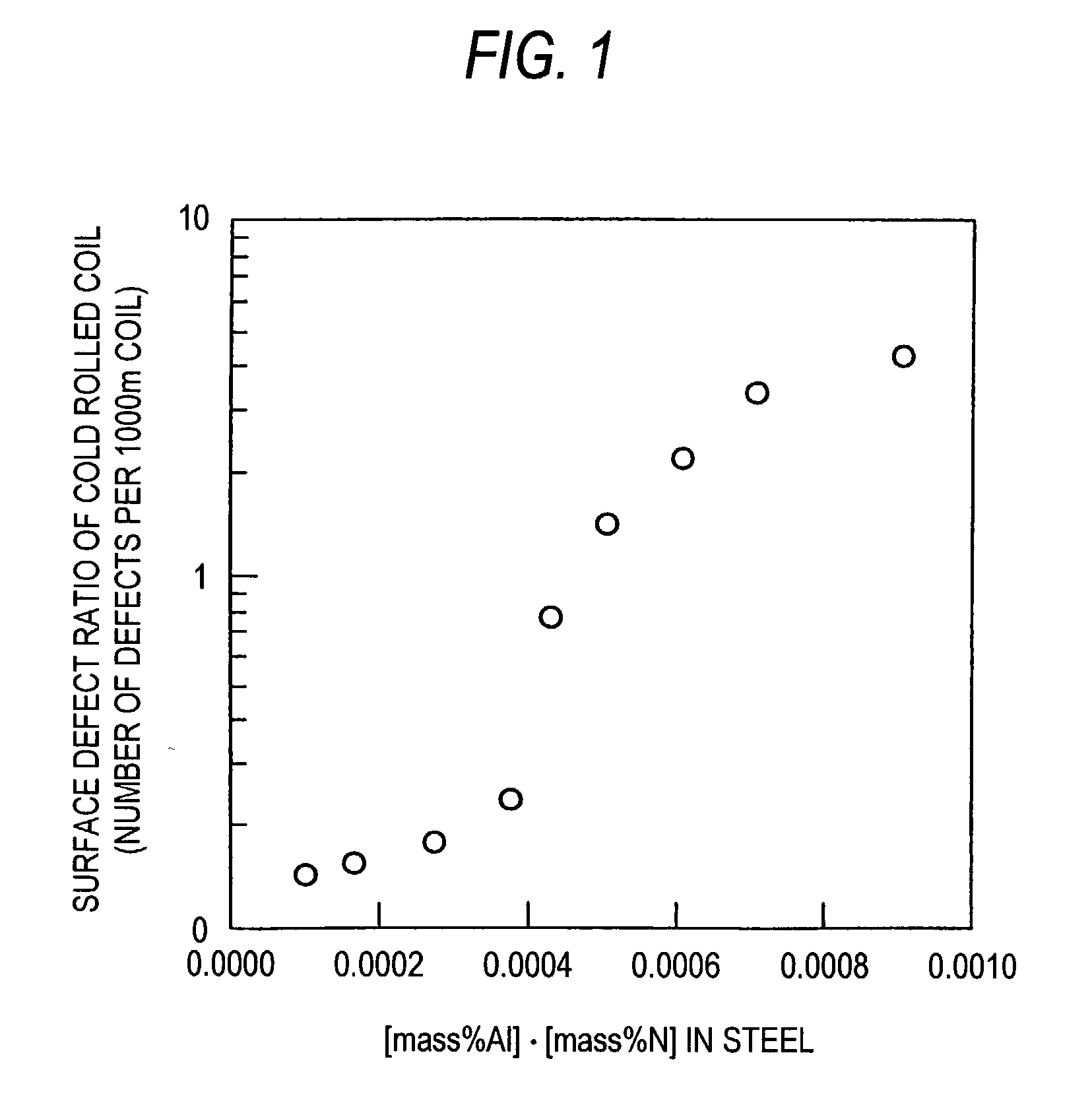

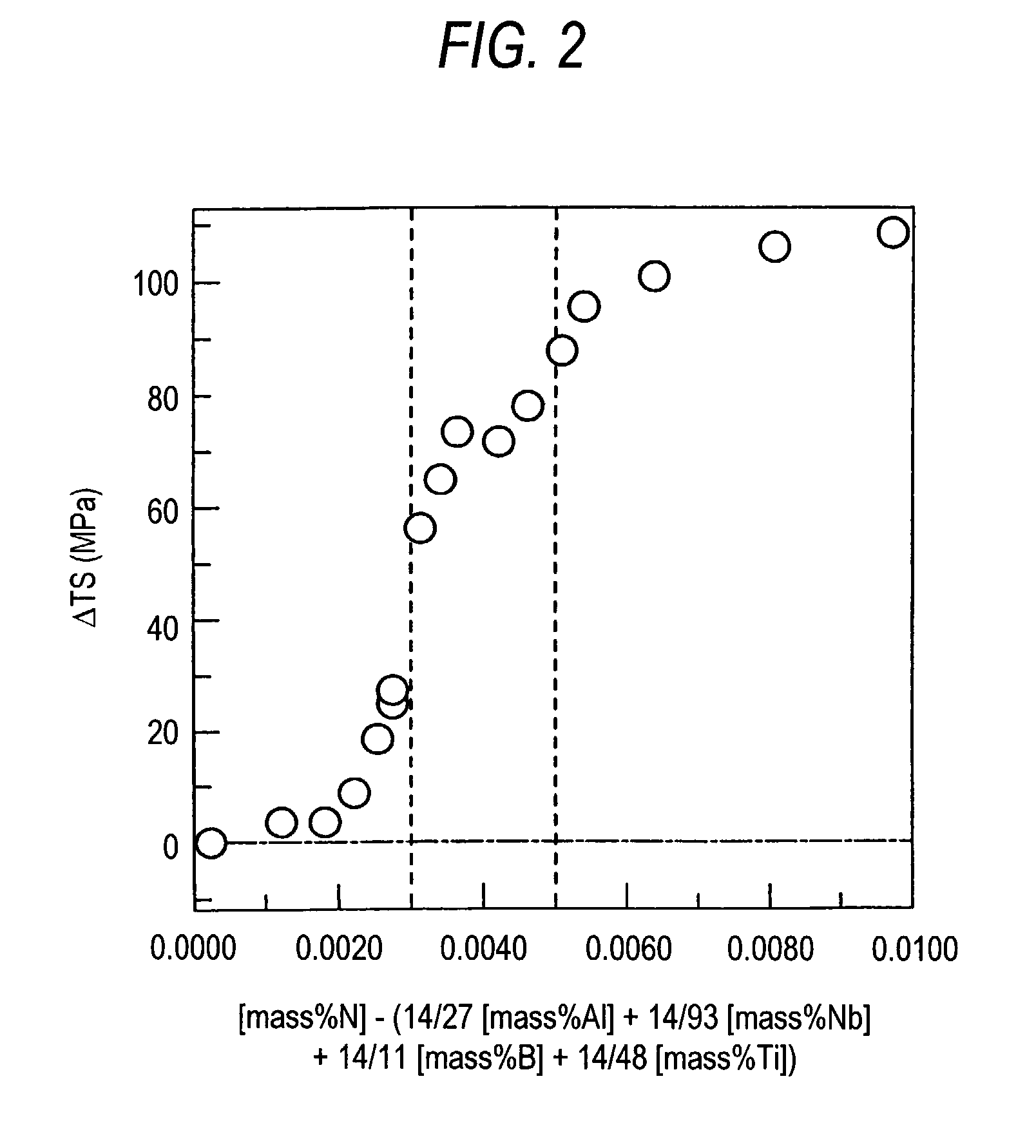

Process for producing high-nitrogen ultralow -carbon steel

A method of producing a high nitrogen, ultra low carbon steel suitable to rolling material for use in cold rolled steel sheets having excellent age hardening property by an age hardening treatment after forming by working, with no defects in slabs or steel sheets, reliably, at a reduced cost and with a high productivity is proposed. The method for producing a rolling material for use in ultra low carbon steel sheets at: C<=0.0050 mass % comprises; applying primary decarburization refining to molten iron from a blast furnace, then controlling the composition in the molten steel after primary decarburization refining to a range satisfying the following relation: [mass %N]-0.15 [mass %C]>=0.0060, subsequently conducting secondary decarburization refining to a ultra low carbon concentration region while suppressing denitridation using a vacuum degassing facility, then conducting deoxidation by Al and, further, controlling the composition such that [mass %Al].[mass %N]<=0.0004, N: 0.0050 to 0.0250 mass % and, preferably, with the amount of solid solute N being at a predetermined amount or more and then casting the molten steel continuously.

Owner:JFE STEEL CORP

Automatic butyl naphthalene sulfonate production device and automatic control method thereof

ActiveCN104014294AGuaranteed responseEnsure productivityChemical/physical/physico-chemical stationary reactorsSulfonic acid preparationSulfonateAutomatic control

The invention discloses an automatic butyl naphthalene sulfonate production device and an automatic control method thereof. The production device comprises a PLC (programmable logic controller), a fuming sulfuric acid elevated tank and a sulfonation reaction kettle, wherein the fuming sulfuric acid elevated tank is provided with a weight sensor and a feeding control valve and connected with the PLC; the sulfonation reaction kettle is provided with a temperature sensor and connected with the PLC; a heating vapor pipe, a cooling water pipe and a freezing salt water pipe are respectively provided with a control valve and connected with the PLC. The control method comprises the following steps: automatically adjusting and controlling the fuming sulfuric acid control valve, the freezing salt water control valve, the heating vapor control valve and the cooling water control valve by the PLC so as to control the dropwise adding speed of fuming sulfuric acid, controlling the initial temperature of the reaction kettle to be less than or equal to 30 DEG C and the reaction temperature to be 35 to 40 DEG C, heating the reaction kettle to 50 to 55 DEG C, preserving heat for 8h, and then cooling the reaction kettle to 40 DEG C, and standing for 5h. The charging speed of fuming sulfuric acid and the flow rate of freezing salt water, heating vapor and cooling water are adjusted by the PLC according to the variation of the reaction temperature, so that the sulfonation reaction temperature is stable, and the safety production and product quality can be guaranteed.

Owner:湖北尚助化学有限公司

Deodorizing method for chicken coop

InactiveCN102989307AReduce ammonia emissionsReduce chicken coop odorDispersed particle separationBird housingsChemistryCalcium superphosphate

The invention discloses a deodorizing method for a chicken coop. Calcium superphosphate is scattered on the ground in the chicken coop; calcium superphosphate and ammonia generated in chicken manure are reacted to generate tasteless solid ammonium phosphate, so that the emission of the ammonia in the chicken manure in the chicken coop is reduced; and therefore, the odour in the chicken coop is reduced; the environment in the chicken coop is improved; chickens are prevented from being attacked; and production performances of chickens are ensured.

Owner:DALIAN CHENGDE ANIMAL HUSBANDRY

Poultry feed

InactiveCN103989014AHealthy growthIncrease appetiteFood processingAnimal feeding stuffNutritionApocynum venetum

The invention discloses poultry feed which comprises the following raw materials in parts by weight: 60 parts of corn flour, 10 parts of soybean husks, 15 parts of fly ash, 12 parts of gardcnia sootepensis powder, 0.005 part of lepiota brunneoincarnata, 7 parts of chestnut shells, 0.01 part of walnut shell powder, 0.5 part of junci medulla, 0.02 part of amber, 0.3 part of apocynum venetum roots, 0.2 part of wild chrysanthemum flowers, 0.1 part of eel bones, 0.8 part of green tea, 0.02 part of alums, 0.01 part of vitamin E, 0.04 part of zinc oxide, 0.01 part of camphor, 0.5 part of butterflybush flowers, 1 part of common cnidium fruits, 0.01 part of otter livers, 5 parts of peanut shells, 0.1 part of gynostemma pentaphylla, 3 parts of alfalfa meal, 0.5 part of corn stigmas, 6 parts of rapeseed dregs, 0.5 part of rhizoma curculiginis and 1 part of rhizoma corydalis. The poultry feed disclosed by the invention meets a poultry demand on taste, and can greatly stimulate appetite and effectively promote rapid growth; the poultry, fed by the poultry feed, is good in meat quality, high in laying rate, rich in egg and meat nutrition, and good in egg and meat taste.

Owner:WENZHOU ZHONGPU TECH CONSULTATION

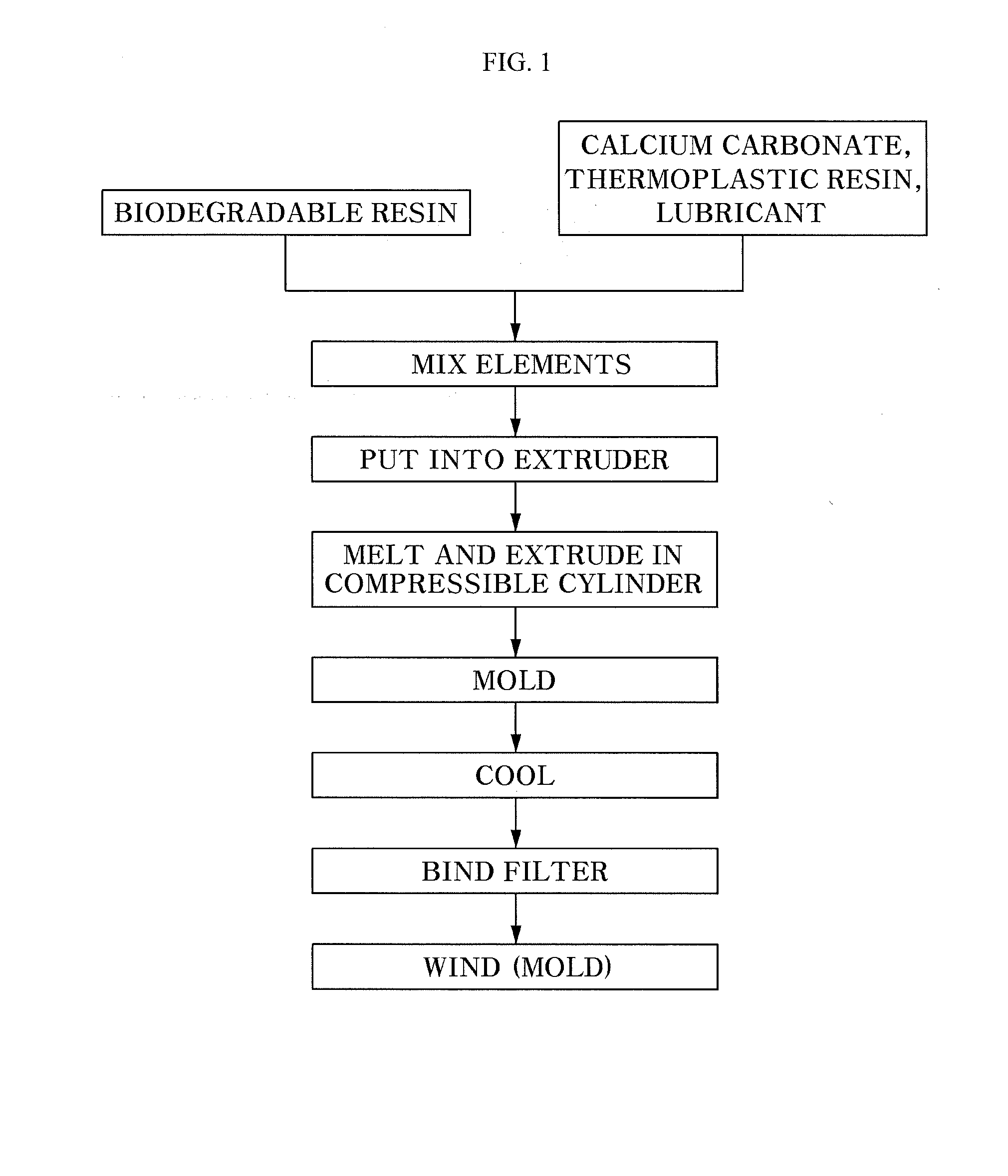

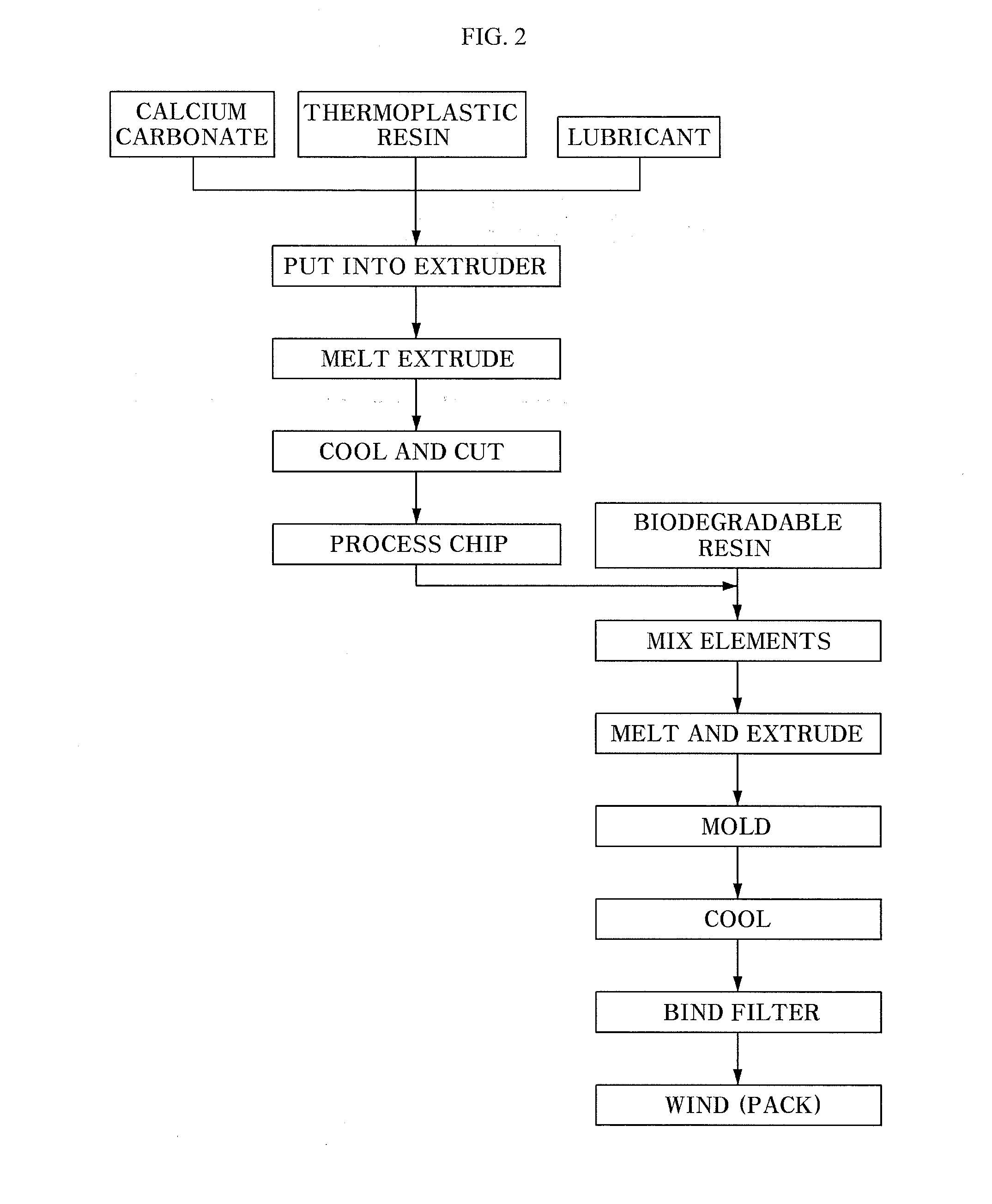

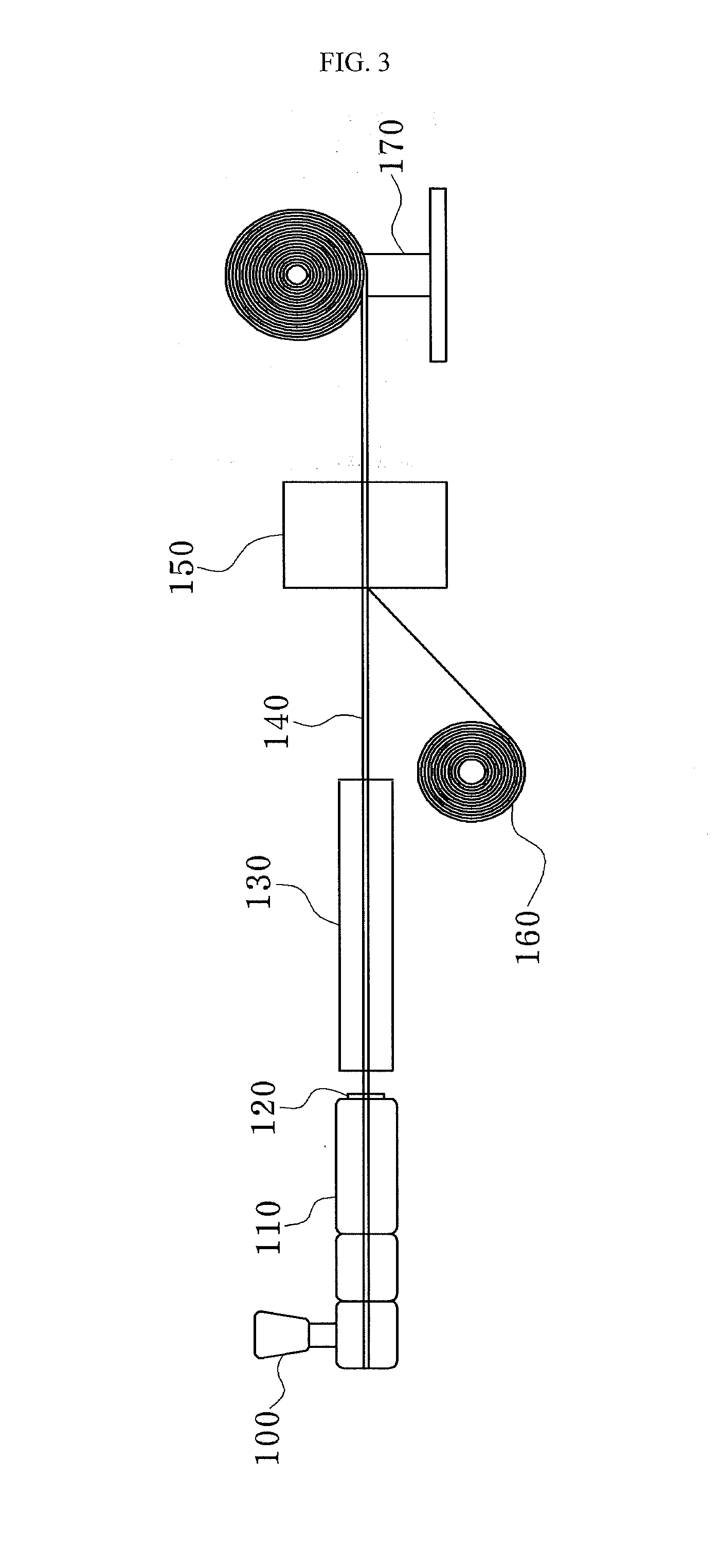

Biodegradable resin composition, and draining board core material and draining board produced therefrom

InactiveUS20140134380A1Strong process adaptabilityEnsure productivityLayered productsAnti-corrosive paintsProduction rateCalcium carbonate

A biodegradable resin composition is provided. More particularly, a biodegradable resin composition for a core of a drain board, which has excellent extrusion productivity and thus improves productivity by improving physical properties, for example, reducing contractibility and elasticity recovery, according to original characteristics of a biodegradable resin without degradation in biodegrability of the biodegradable resin by mixing the biodegradable resin with an additional material for improving processibility in suitable amounts, a core of a drain board using the same, and a method of manufacturing a drain board.The biodegradable resin composition is prepared by mixing 5 to 60 parts by weight of calcium carbonate, 1 to 10 parts by weight of a thermoplastic resin, and 0.1 to 5 parts by weight of a lubricant with respect to 100 parts by weight of a biodegradable polymer compound, or mixing 1 to 5 parts by weight of the additives, which are fowled in a pellet state to have 60 to 90 parts by weight of calcium carbonate, 5 to 15 parts by weight of a thermoplastic resin, and 1 to 5 parts by weight of a lubricant, with respect to 100 parts by weight of a biodegradable polymer compound.

Owner:LOTTE FINE CHEM CO LTD +1

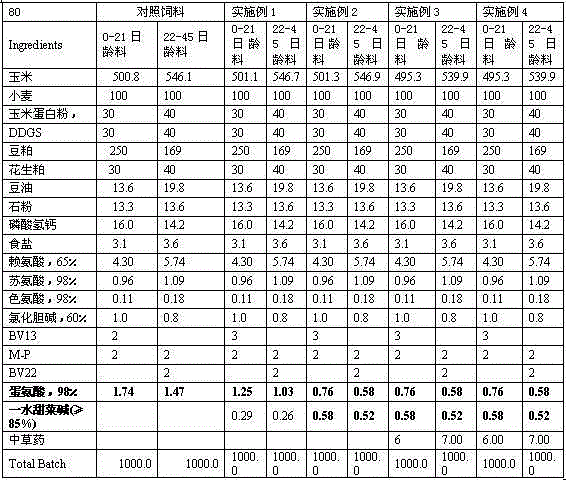

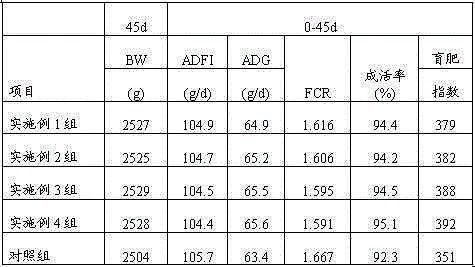

Two-stage broiler compound feed and preparing method thereof

The invention discloses two-stage broiler compound feed and a preparing method thereof. The compound feed comprises 0-21-day-old feed and 22-45-day-old feed. The two-stage broiler compound feed and the preparing method thereof have the advantages that matching is scientific, preparation is easy, feed cost is reduced, the nutritional requirement for broiler growth and development can be met, the utilization rate of feed is increased, and broiler growth is promoted; by the adoption of traditional Chinese medicine additives, the spleen and stomach can be strengthened, the appetite and digestion can be promoted, normal nutrient intake of broilers can be guaranteed on the premise that feed cost is reduced, and high broiler production performance is realized.

Owner:SHANDONG NEW HOPE LIUHE GROUP

Layer chicken premixing biochemical feed and preparation process thereof

InactiveCN101637226APromote growthImprove production performanceAnimal feeding stuffAccessory food factorsFish mealAnimal science

The invention relates to a layer chicken premixing biochemical feed and a preparation process thereof. Quite few of the prior chicken feed is added with bacillus, or even if the feed is added with thebacillus, the proportion is unreasonable. The layer chicken premixing biochemical feed comprises the following components in portion by weight: 3 portions of the bacillus, 4 portions of lactobacillus, 40 portions of small peptide, 5 portions of poultry complex vitamin, 8 portions of poultry complex mineral microelement, 225 portions of calcium hydrophosphate, 242 portions of calcium carbonate, 62portions of cooking salt, 210 portions of fish meal, and 167 portions of meat meal. The layer chicken premixing biochemical feed is used as a chicken feed and the preparation process is used as the process for preparing the chicken feed.

Owner:HARBIN QINGHE TECH

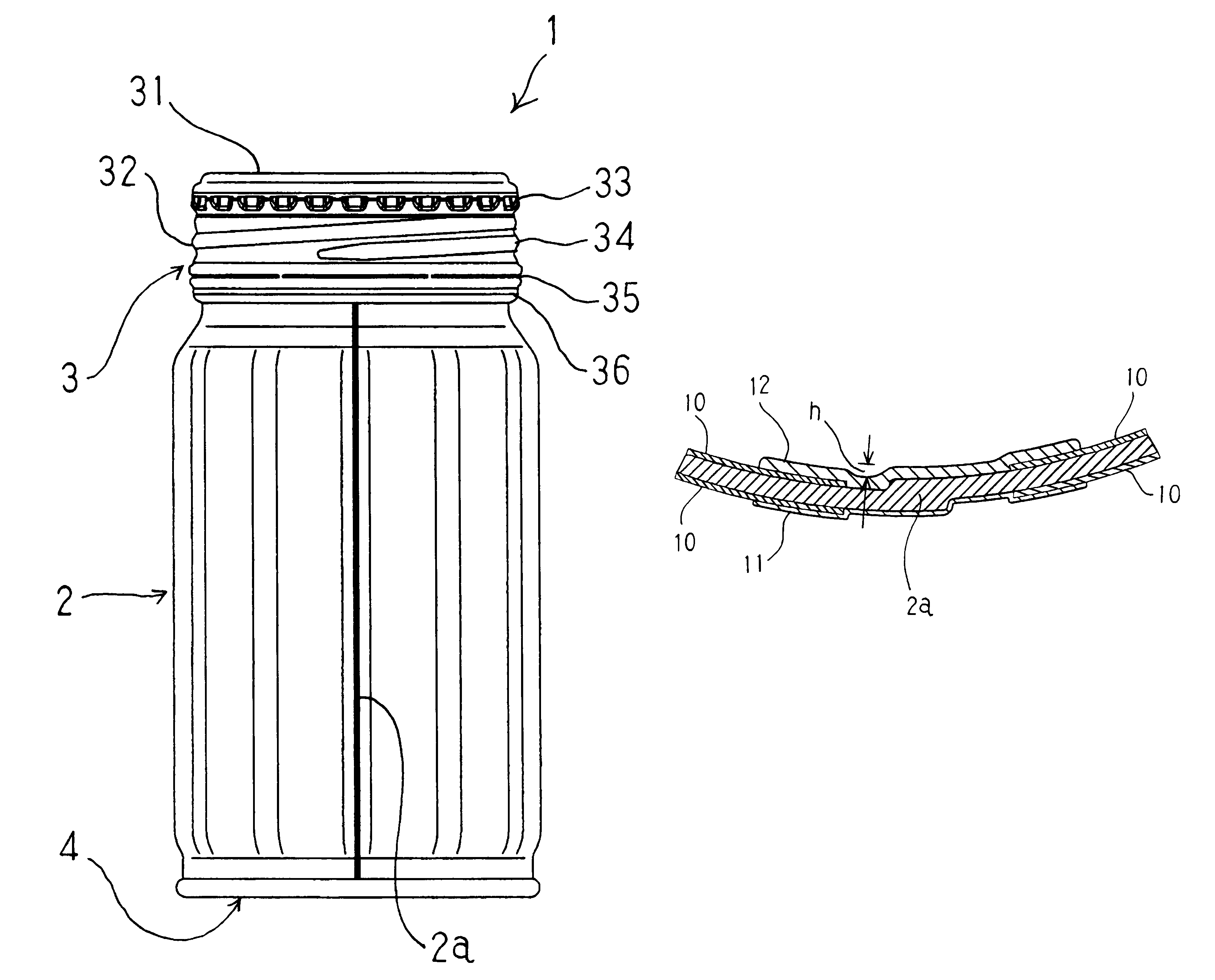

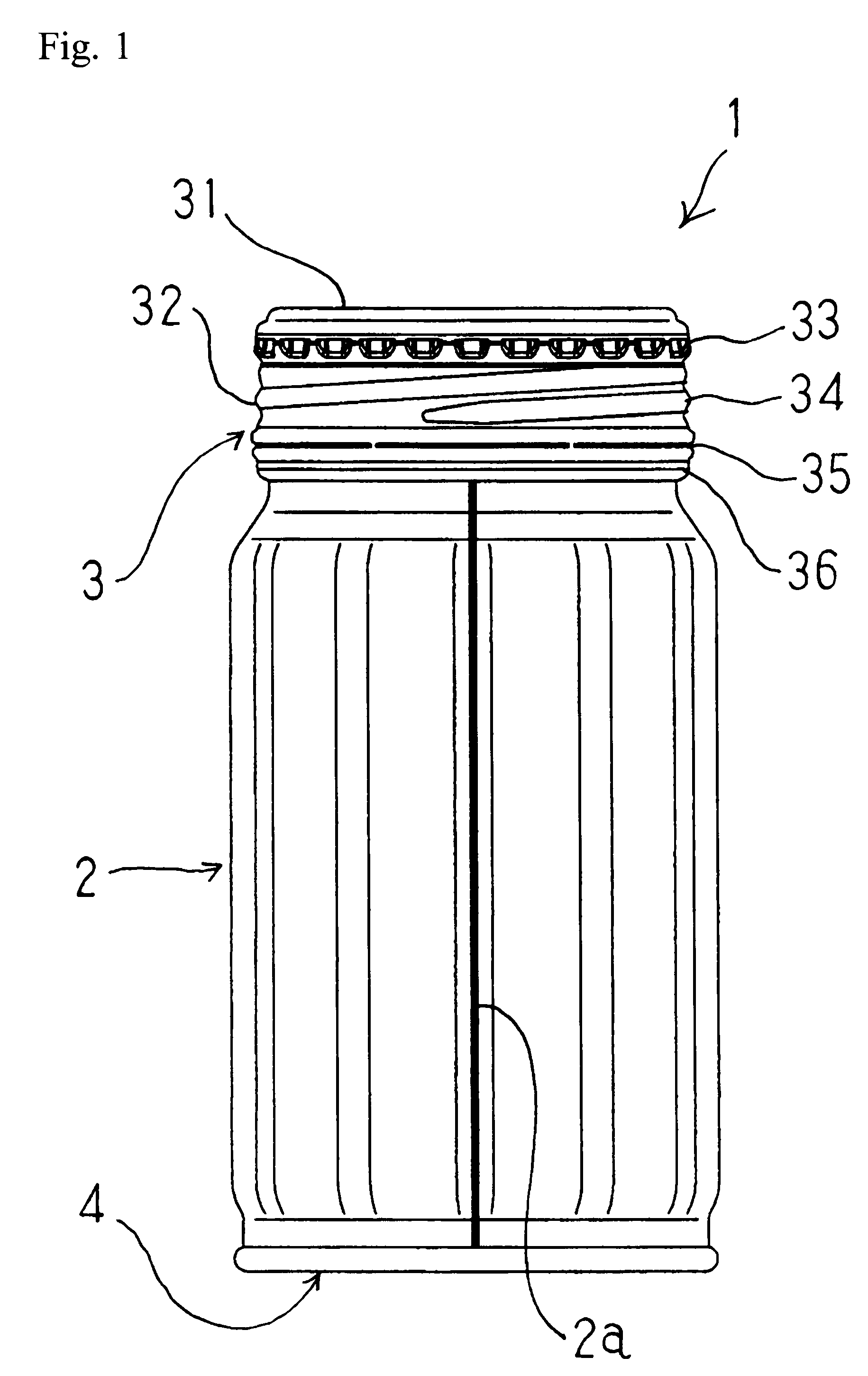

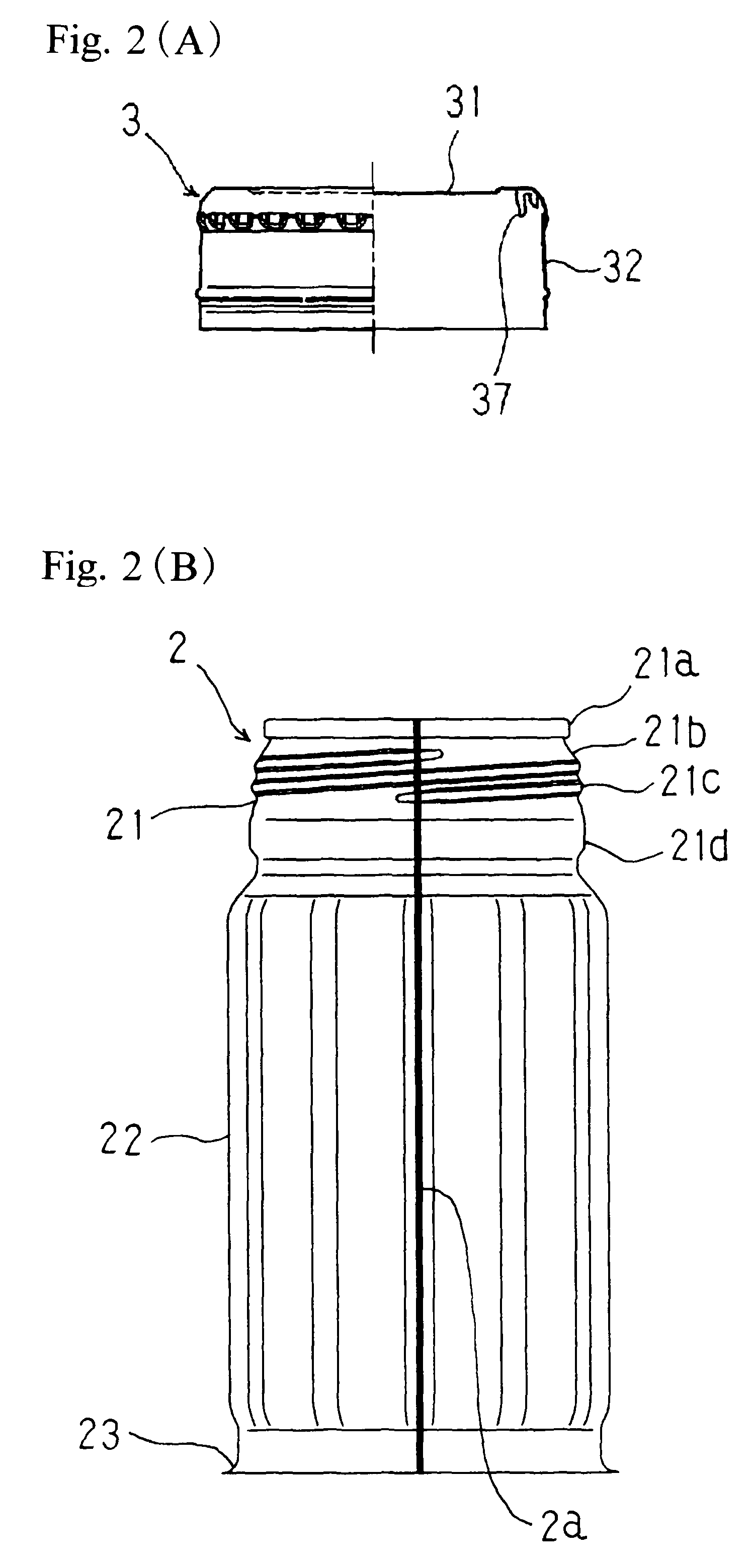

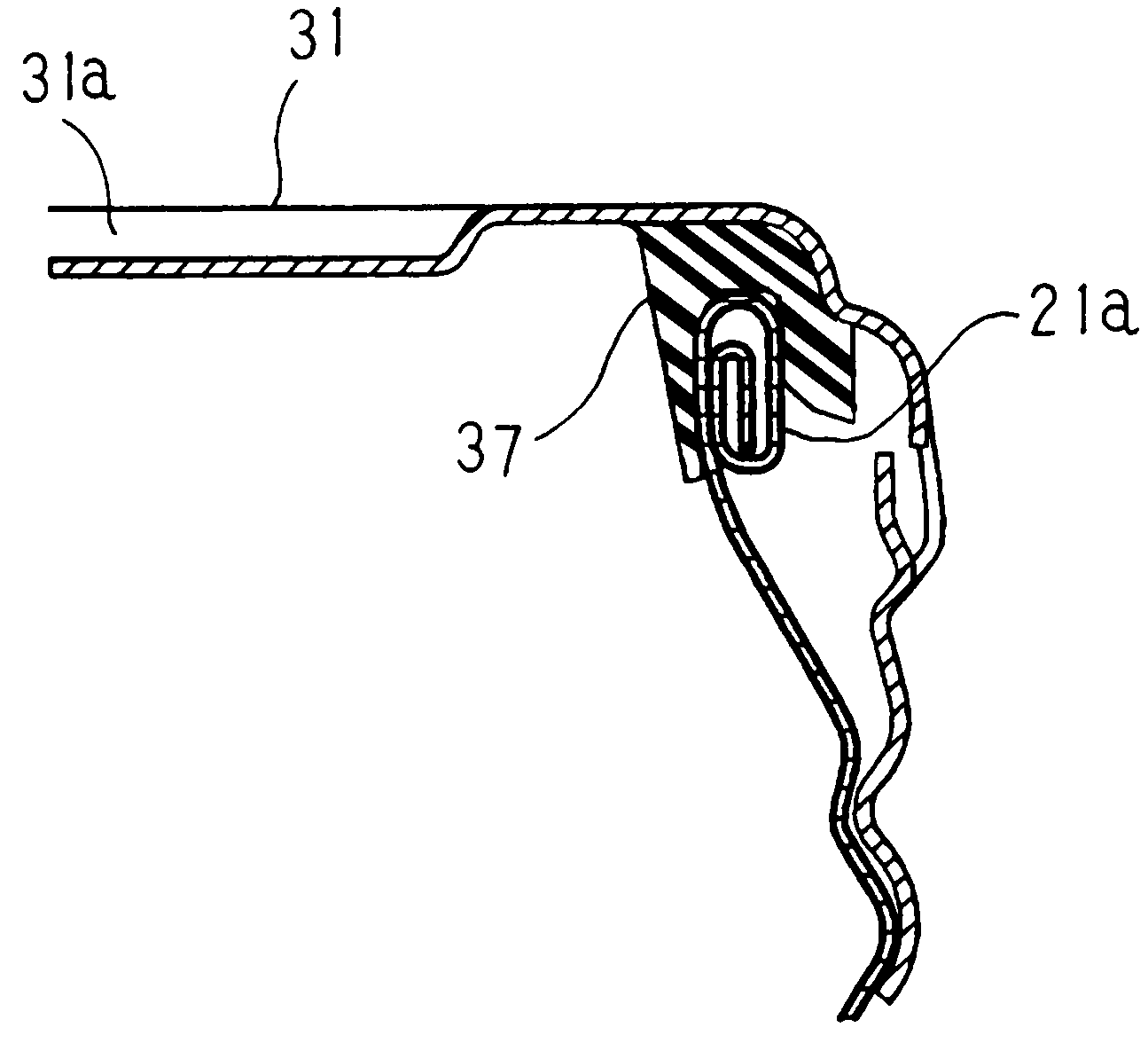

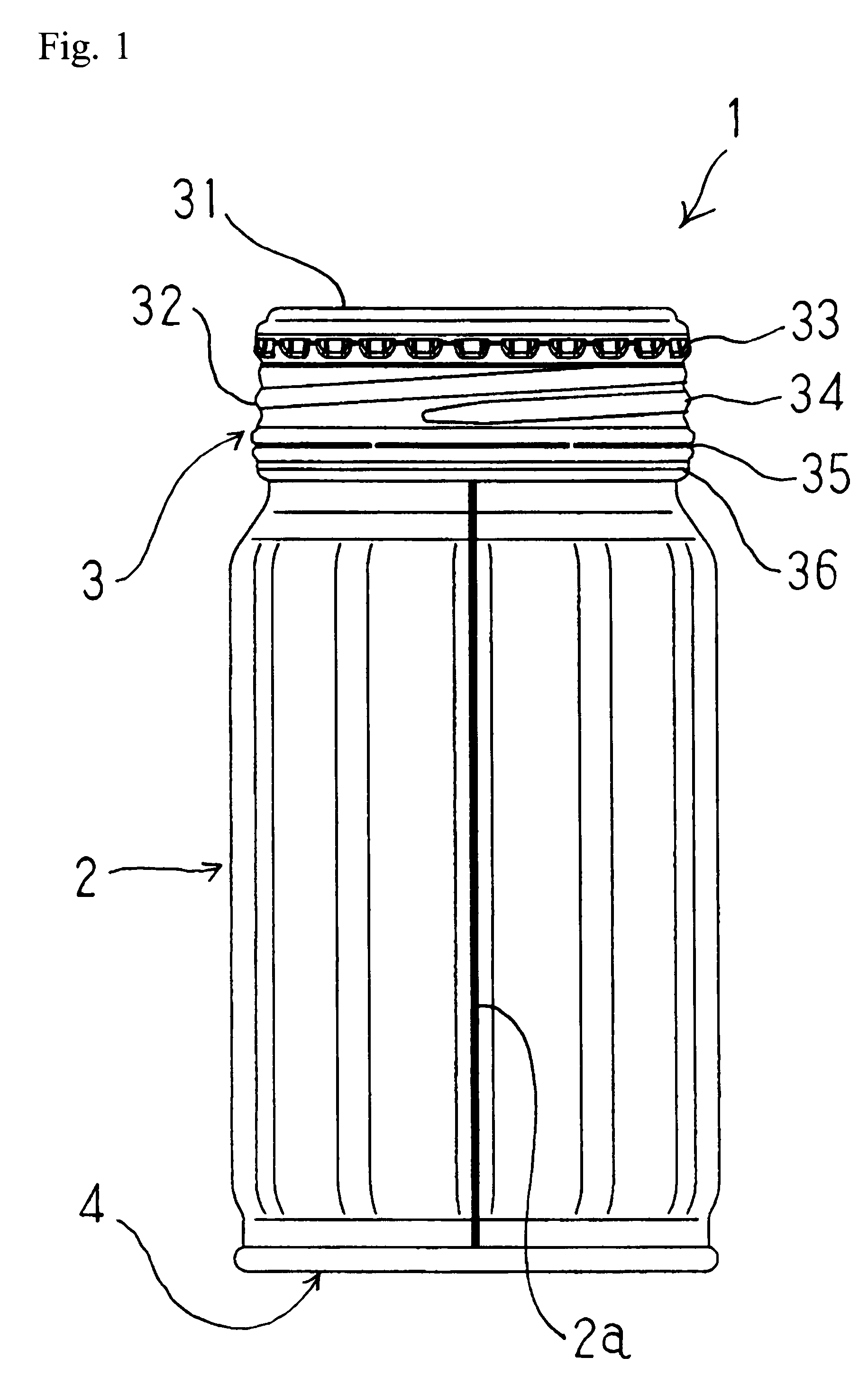

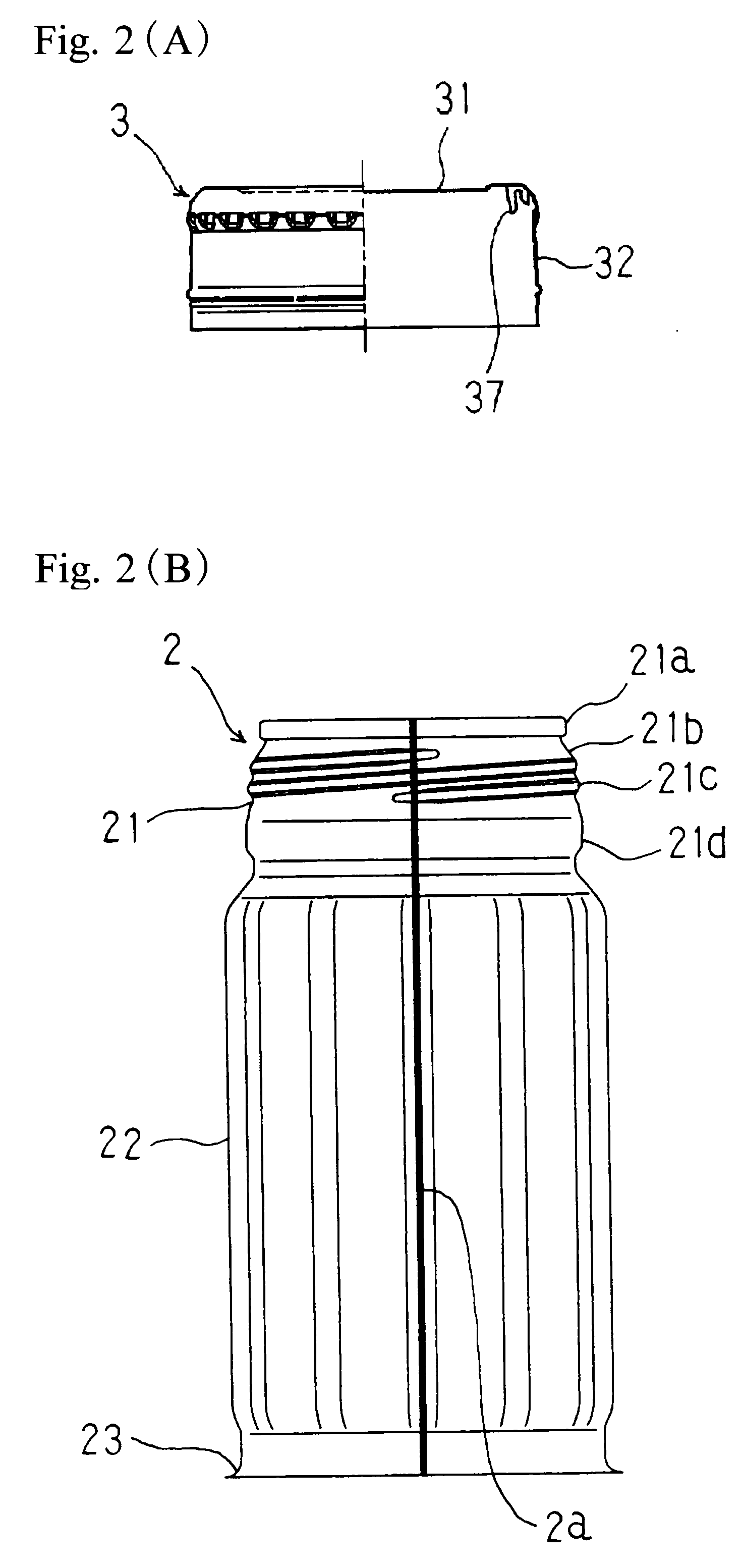

Can container

InactiveUS8181814B2Sufficient sealing abilityMinimize the differenceClosure capsRigid containersEngineeringWelding

To ensure sealing ability of a resealable can container formed of a welded can body between a curled portion of container mouth and a resin sealing liner, without degrading productivity and easiness to open the closure.The can body 2 is prepared by rolling a steel sheet and welding overlapped longitudinal edges of the steel sheet. In order to achieve the above-mentioned objective, a level difference of a welded portion 2a on the surface of a curled portion 21a is reduced smaller than that on the trunk portion 22, specifically, kept within the range of 15 to 100 μm, and a durometer hardness of the resin sealing liner is kept within the range of HDA 30 to 70 according to ISO 868 (or JIS-K7215).

Owner:DAIWA CAN

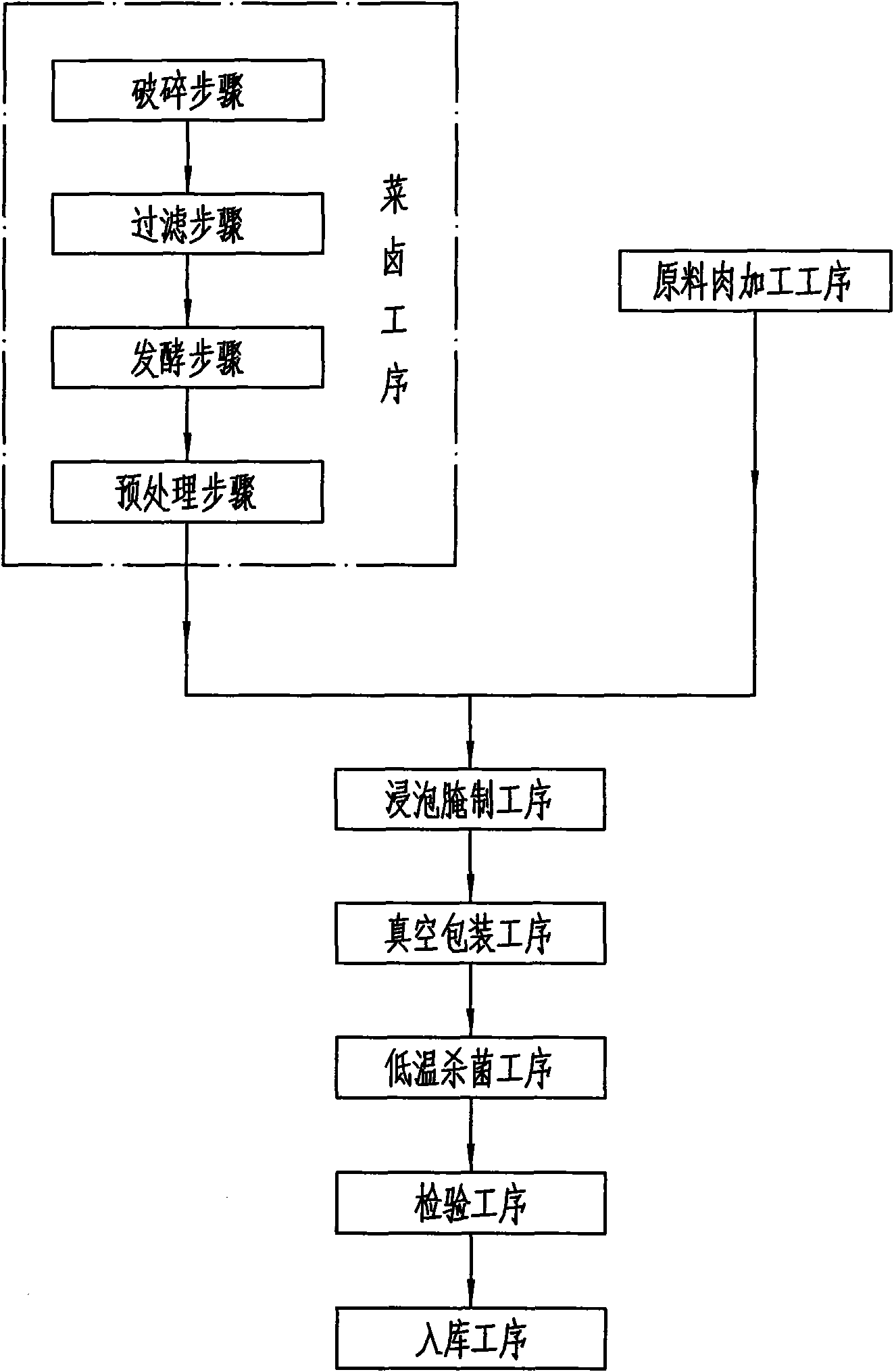

Method for processing vegetable-spiced animal meat products

InactiveCN101569421AImprove securityExtended shelf lifeFood preservationFood preparationSteepingRaw meat

The invention relates to a method for processing vegetable-stewed animal meat products. The method for processing vegetable-stewed meat products, which has the advantages of simple preparation, wide applicability and freedom from seasonal restriction, is not available at present. The method of the invention comprises the following procedures: preparing vegetable for stewing; processing raw meat; and steeping and pickling. The method has the following characteristics: (1) the procedure for preparing vegetable for stewing comprises the following steps: mincing, filtering, fermenting and pre-treating; (2) the procedure for processing the raw meat comprises the following steps: boiling the raw meat, putting rice wine with the weight being 1.8% to 2.2% of raw meat and ginger slices with the weight being 0.8% to 1.2% of raw meat, taking out and draining the raw meat, and naturally cooling the raw meat in a ventilating place to obtain the pre-boiled meat, wherein, the raw meat is boiled for 10 to 42 minutes in boiling water; and (3) the procedures for steeping and pickling comprise the following step: steeping the pre-boiled meat in step (2) in the vegetable for stewing in step (1). The invention has the advantages of simple process and low preparation cost, and the vegetable-stewed animal meat product prepared by the method of the invention has unique flavor and good taste.

Owner:ZHEJIANG QINGLIAN FOOD

Coal mine fully-mechanized excavation face short-distance comprehensive dedusting method

ActiveCN103742187ASuppress escapeImprove the working environment of the working faceDust removalFire preventionWaste management

The invention discloses a coal mine fully-mechanized excavation face short-distance comprehensive dedusting method. A dedusting fan is arranged on the fully-mechanized excavation face, and an air draft port of the dedusting fan is a horn mouth type air draft port. A multi-step wall-adhering air duct connected onto a forced draught fan air duct is arranged at the position within a 20meter distance from the fully-mechanized excavation face. One to two dust collecting nets covering the full face are arranged at the position of mobile belt conveyer tail of a fully-mechanized excavation machine, and automatic flushing water curtains are arranged on the dust collecting nets. A bearing trolley of the dedusting fan is connected with the mobile belt conveyer tail end of the fully-mechanized excavation machine. The dedusting fan is in linkage with the fully-mechanized excavation machine. Air pressures of three hard air duct sections are identical by adjusting distances between three hard air duct sections and a cambered surface air blocking round plate, accordingly two sides of the face backward form three directional air walls, and air flows carried with dust is completely flow into the dedusting fan. By adopting the coal mine fully-mechanized excavation face short-distance comprehensive dedusting method, the dust concentration of an operation place is reduced, the coal-dust explosion danger and dust phthisis morbidity are reduced, and safety production of a coal mine is ensured.

Owner:XINWEN MINING GROUP

Can container

InactiveUS20090101661A1Avoid Insufficient SealingSufficient sealing abilityClosure capsRigid containersProduction rateSheet steel

To ensure sealing ability of a resealable can container formed of a welded can body between a curled portion of container mouth and a resin sealing liner, without degrading productivity and easiness to open the closure.The can body 2 is prepared by rolling a steel sheet and welding overlapped longitudinal edges of the steel sheet. In order to achieve the above-mentioned objective, a level difference of a welded portion 2a on the surface of a curled portion 21a is reduced smaller than that on the trunk portion 22, specifically, kept within the range of 15 to 100 μm, and a durometer hardness of the resin sealing liner is kept within the range of HDA 30 to 70 according to ISO 868 (or JIS-K7215).

Owner:DAIWA CAN

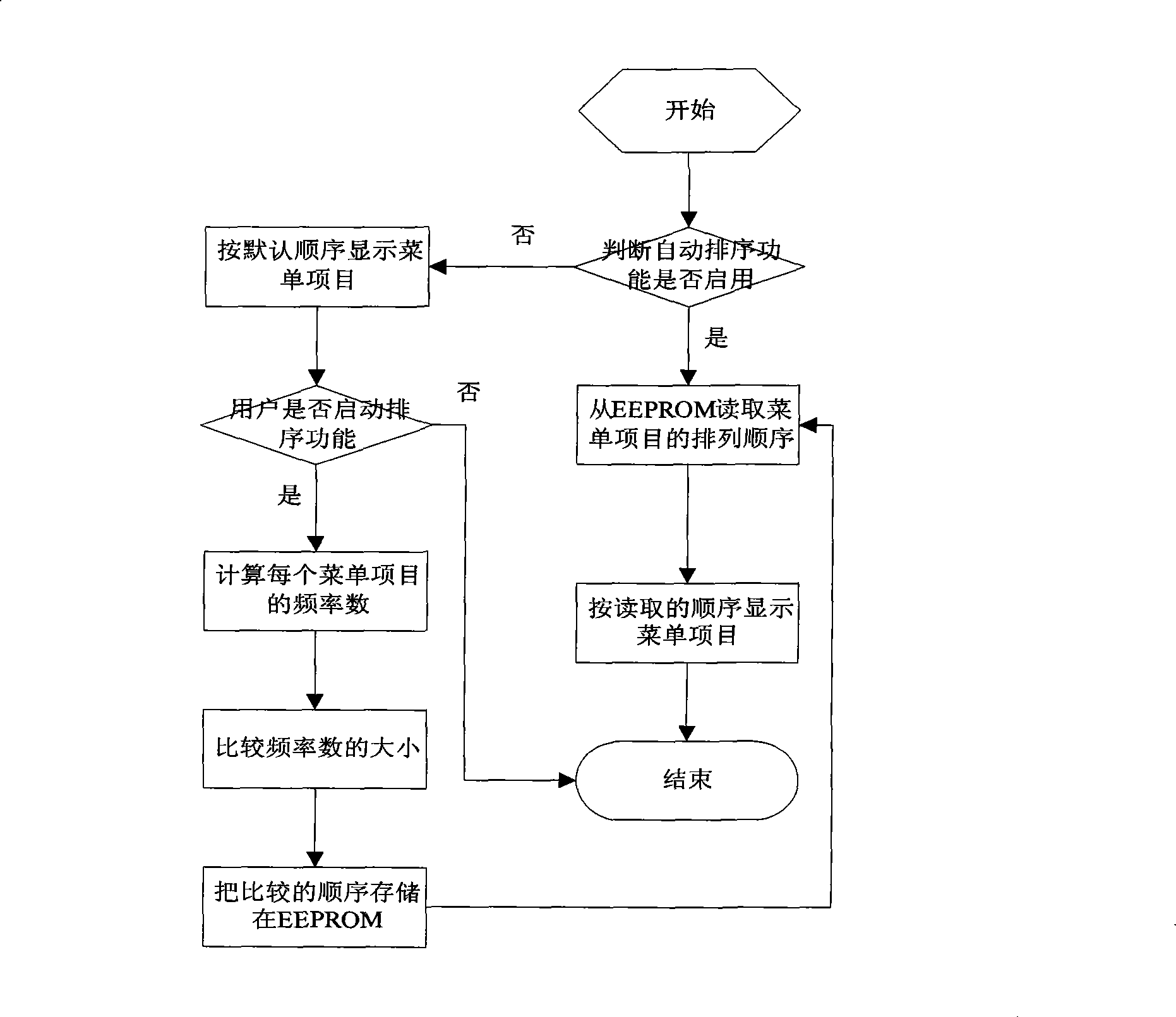

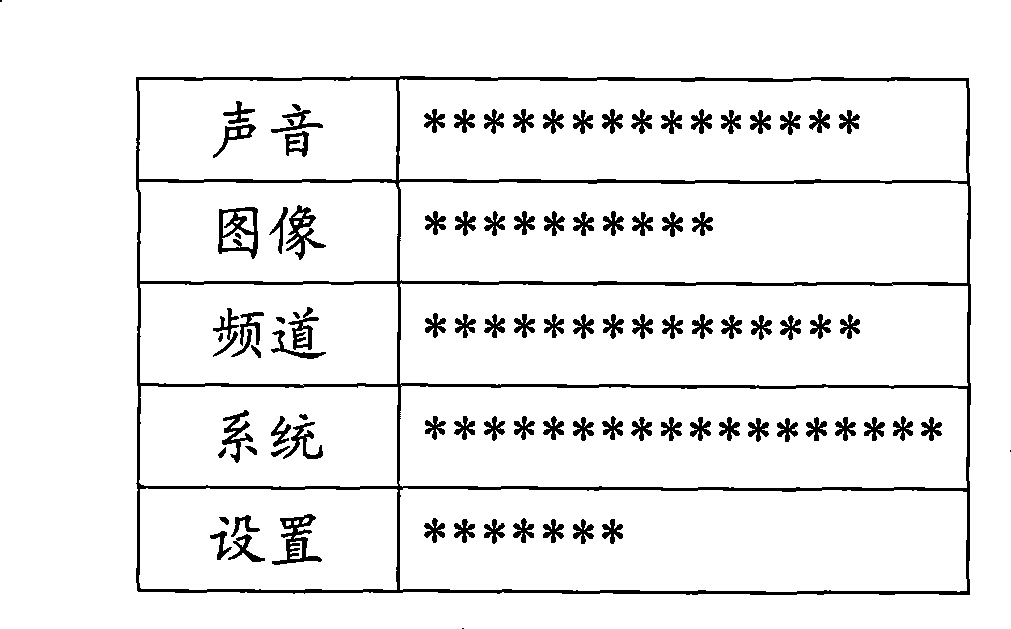

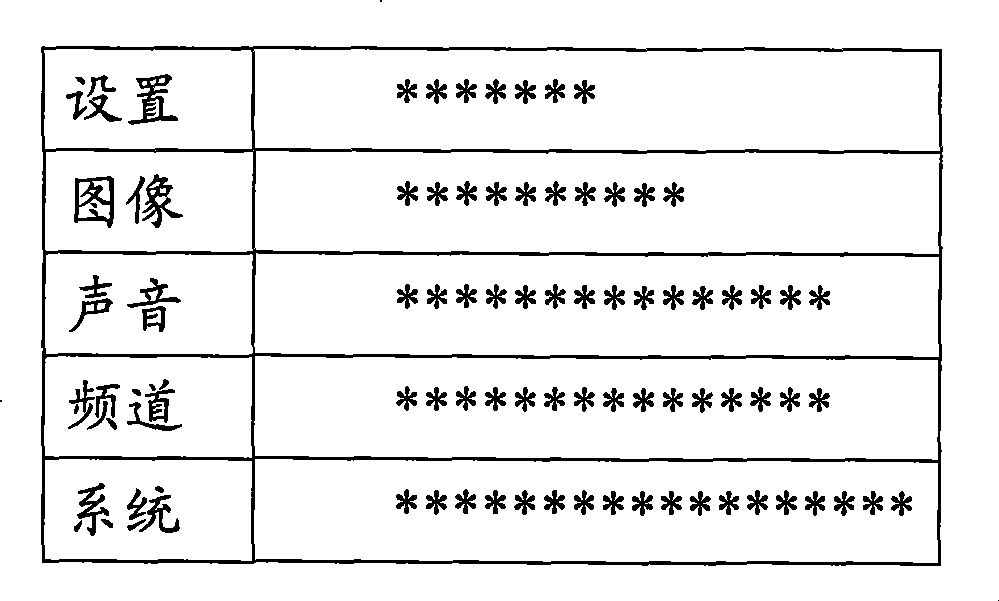

Method for television menu automatically ordering

InactiveCN101399937AEnsure productivityGuaranteed stabilityTelevision system detailsColor television detailsSystem configurationSingle chip

The invention discloses a TV menu automatic rank ordering method which is controlled by software program of single-chip machine chip in circuit of TV. The automatic rank ordering function of TV can make menu ranking according to use frequency of user and effectively facilitates user of different taste. The automatic rank ordering method of the invention adopts programming without changing system configuration of hardwares, effectively guarantee production, stability and quality reliability of TV.

Owner:TIANJIN SAMSUNG ELECTRONICS DISPLAY

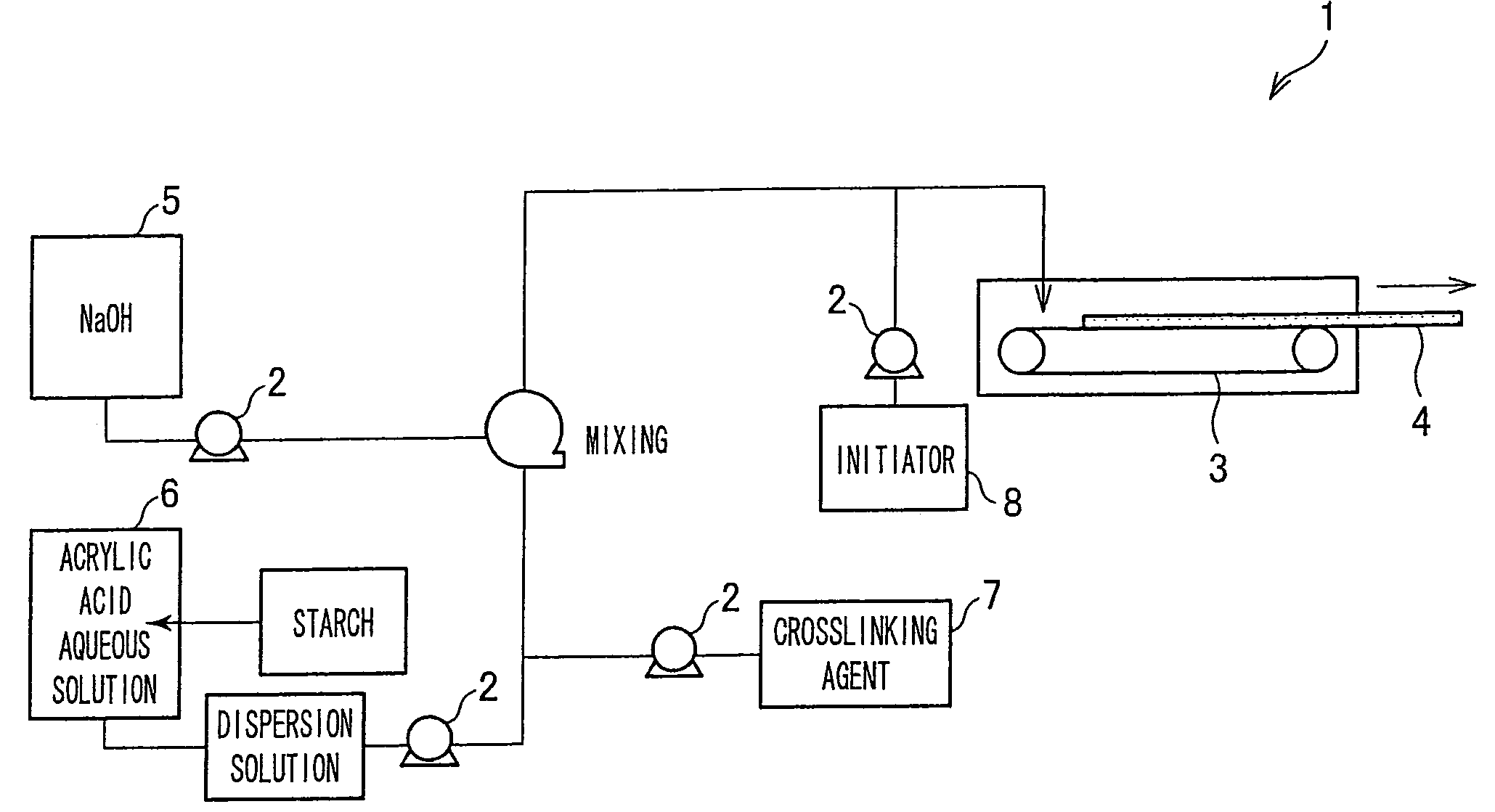

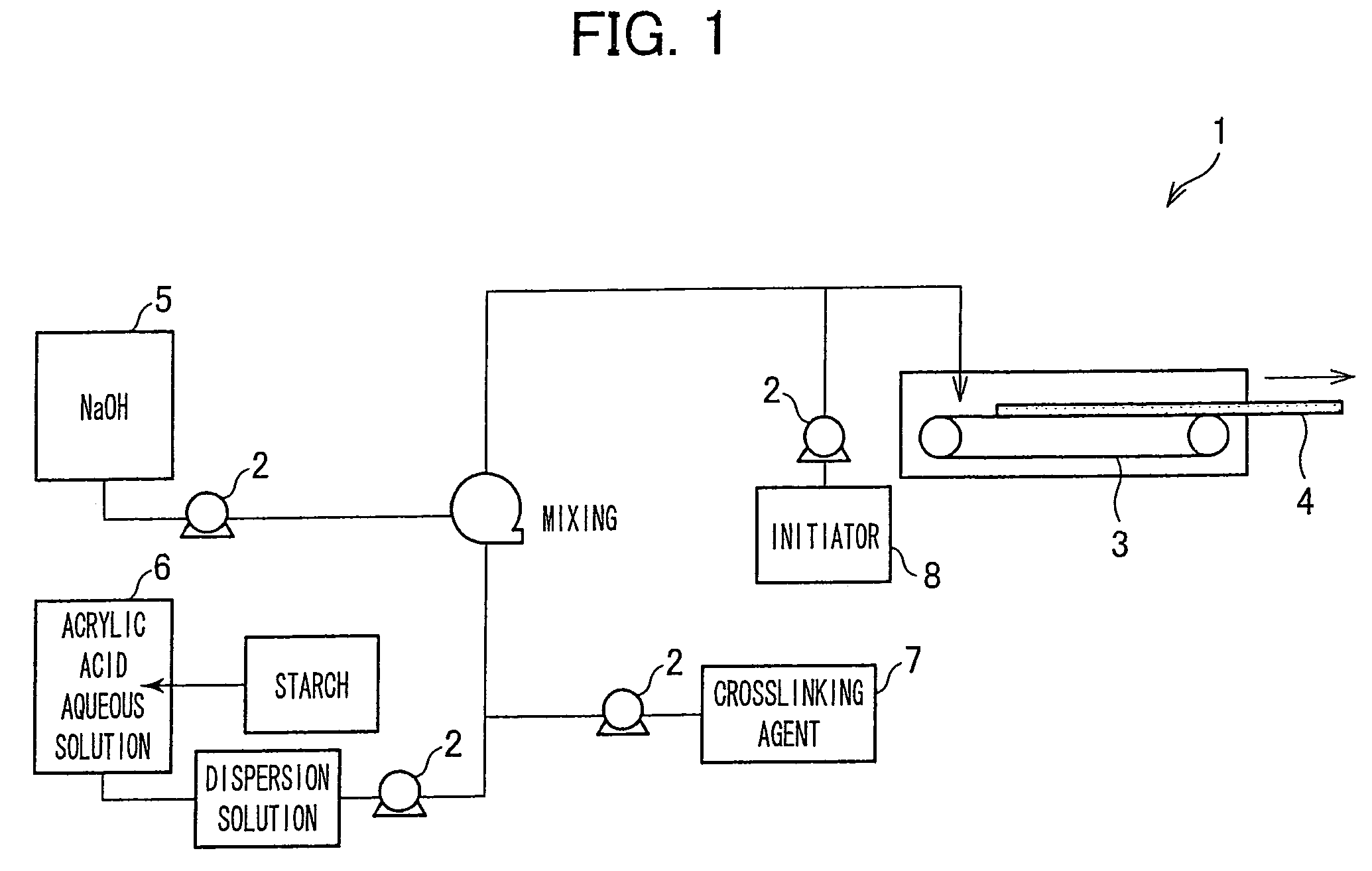

Production method for hydrophilic polymer

ActiveUS7816445B2Improve productivityHigh-performance hydrophilic polymerEmulsion paintsHydrophilic monomerProduction rate

The subject invention provides a hydrophilic polymer (water-absorbing resin) which is superior in performance and productivity. According to the production method of the present invention, a hydrophilichigh-molecular-weight compound is dispersed in an aqueous solution containing a hydrophilic monomer. The dispersed hydrophilic high-molecular-weight compound is dissolved by heat of neutralization (heat of hydration) and / or heat of polymerization generated in the process of producing a hydrophilic polymer.

Owner:NIPPON SHOKUBAI CO LTD

Soybean-meal-free laying-hen compound feed and preparation method thereof

InactiveCN104041711AGuaranteed production performanceReduce formulation costsFood processingAnimal feeding stuffNutrientEnzyme

The invention provides a soybean-meal-free laying-hen compound feed and a preparation method thereof. The soybean-meal-free laying-hen compound feed is formed by mixing the following ingredients by weight percent: 50 to 65 percent of corns, 5 to 10 percent of cotton meal, 1 to 5 percent of vegetable meal, 5 to 10 percent of DDGS, 1 to 4 percent of corn protein powder, 2 to 5 percent of hydrolyzed feather powder, 8 to 11 percent of middling flour and 3 to 6 percent of auxiliary additives. The invention provides the soybean-meal-free laying-hen compound feed in which nutrients are balanced and an ideal protein AA balance technology is adopted, appropriate miscellaneous meal enzyme is added and miscellaneous meal is adopted to completely replace the soybean meal; the invention also provides a preparation method of the soybean-meal-free laying-hen compound feed.

Owner:SHAANXI SHIYANG AGRI TECH

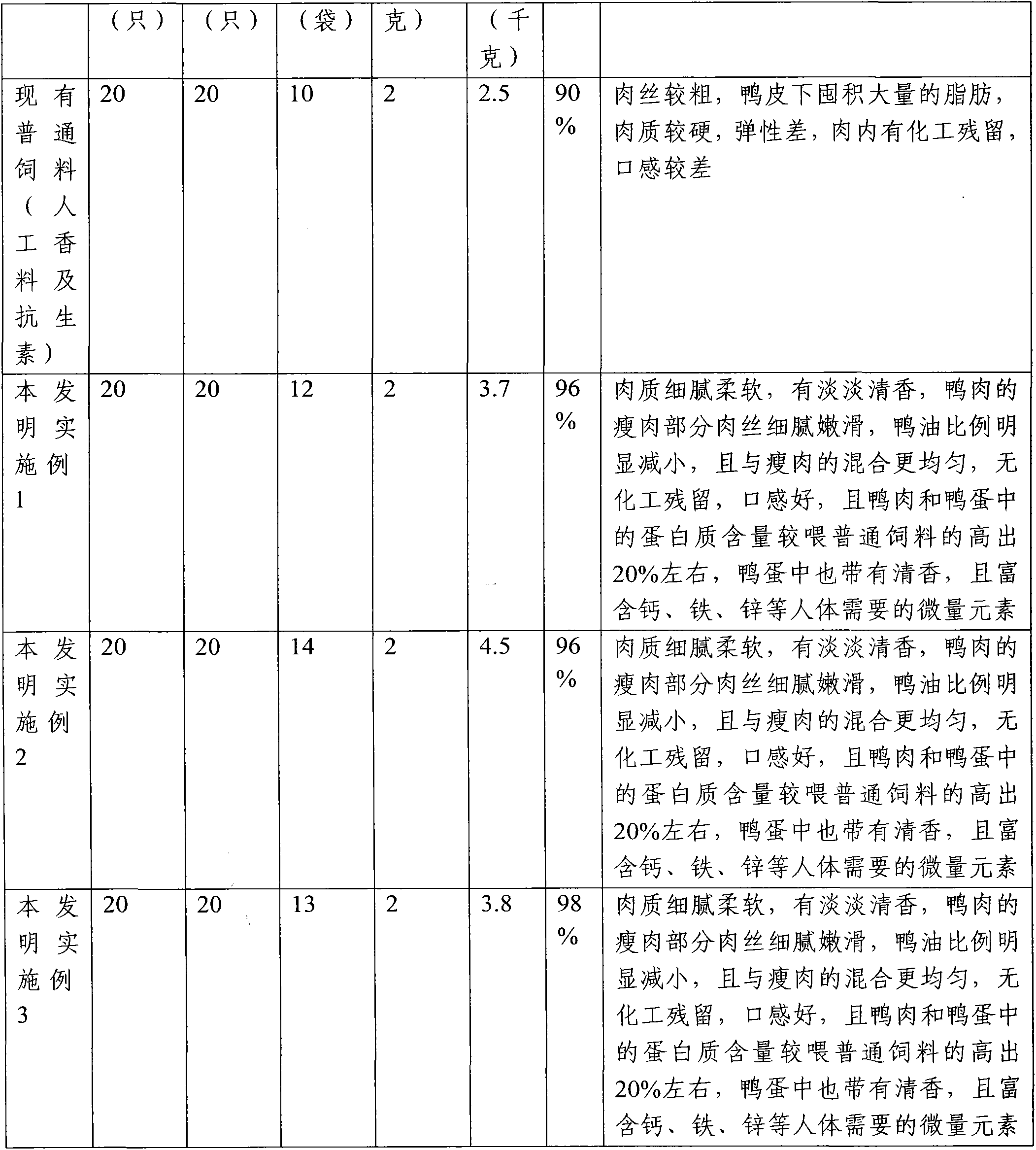

Duck feed

InactiveCN103918944AHealthy growthFresh appetiteFood processingAnimal feeding stuffApocynum venetumSoybean hulls

The invention discloses duck feed. The duck feed comprises following raw materials in parts by weight: 60 parts of corn flour, 10 parts of soybean hulls, 15 parts of fly ash, 12 parts of pepper hulls, 0.005 part of lepiota brunneo-incarnata chod et mart, 7 parts of Chinese chestnut hulls, 0.01 part of azedarach, 0.5 part of juncus effuses, 0.02 part of amber, 0.3 part of apocynum venetum root, 0.2 part of wild chrysanthemum flowers, 0.1 part of eel bone, 0.8 part of green tea, 0.02 part of alums, 0.01 part of vitamin E, 0.04 part of zinc oxide, 0.01 part of camphor, 0.5 part of buddleja officinalis, 1 part of fructus cnidii, 0.01 part of otter liver, 5 parts of peanut hulls, 0.1 part of gynostemma pentaphylla, 3 parts of alfalfa meal, 0.5 part of corn stigma, 6 parts of rapeseed meal and 1 part of epimedium brevicornu maxim. The duck feed is suitable for taste requirements of ducks and can arouse the great appetite of the ducks; the duck feed can be used for effectively accelerating the rapid growth of the ducks and has good meat quality and high laying rate; meat and eggs have abundant nutrition and good mouth feel; compared with ducks fed by the existing feed, the meat quality and the egg quality are more originally ecological and the edible safety is good.

Owner:WENZHOU ZHONGPU TECH CONSULTATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com