Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

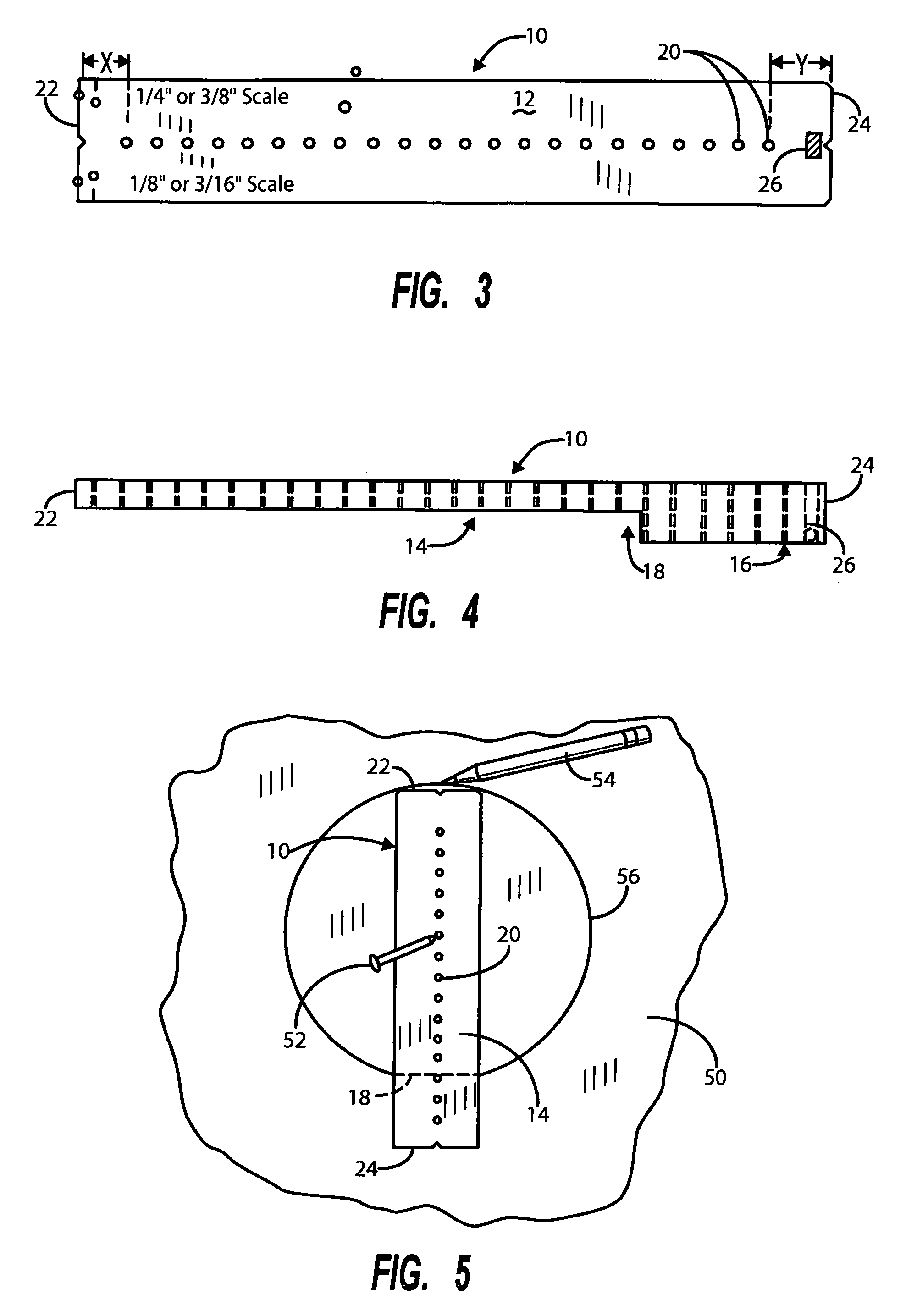

265 results about "Thick section" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

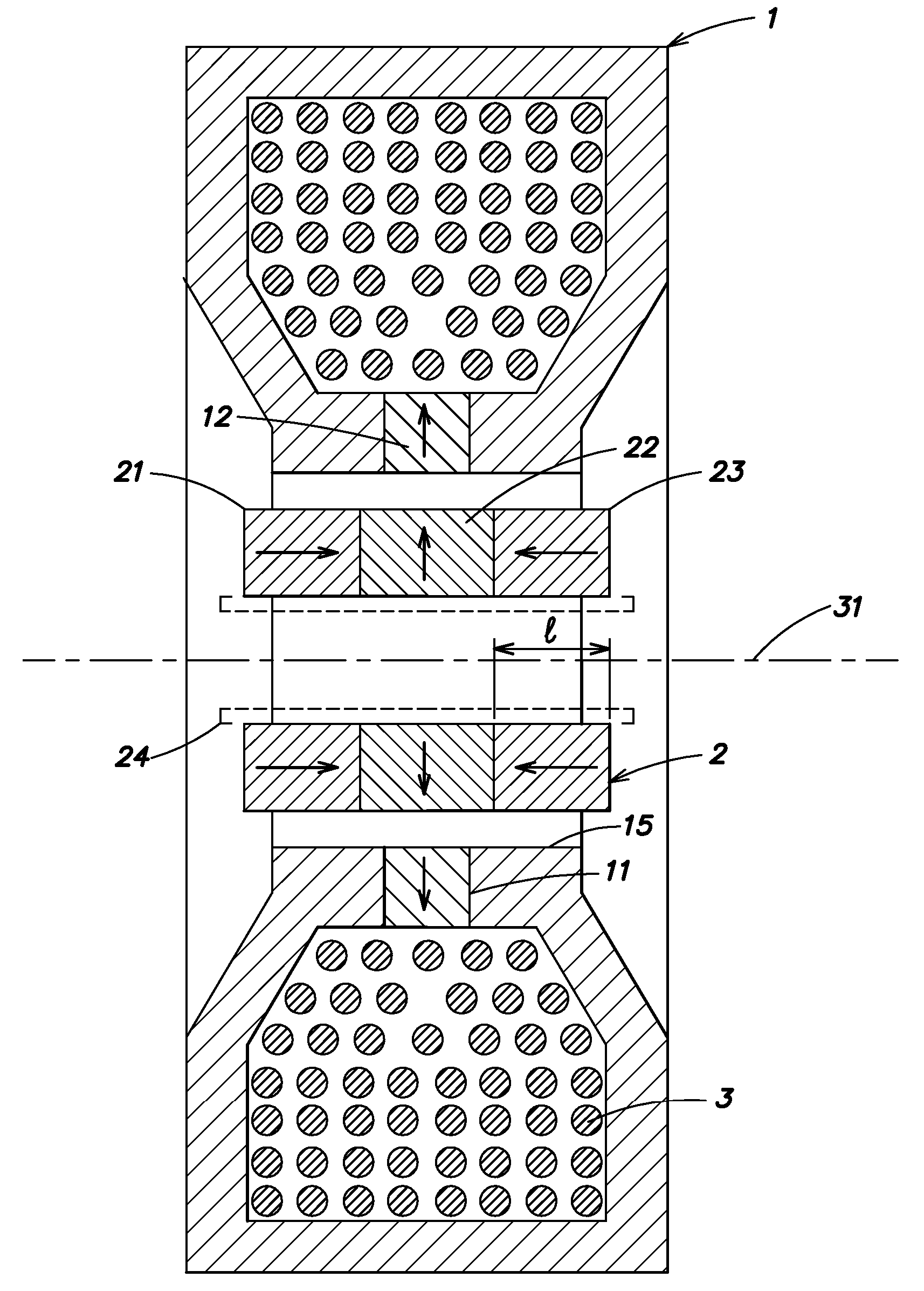

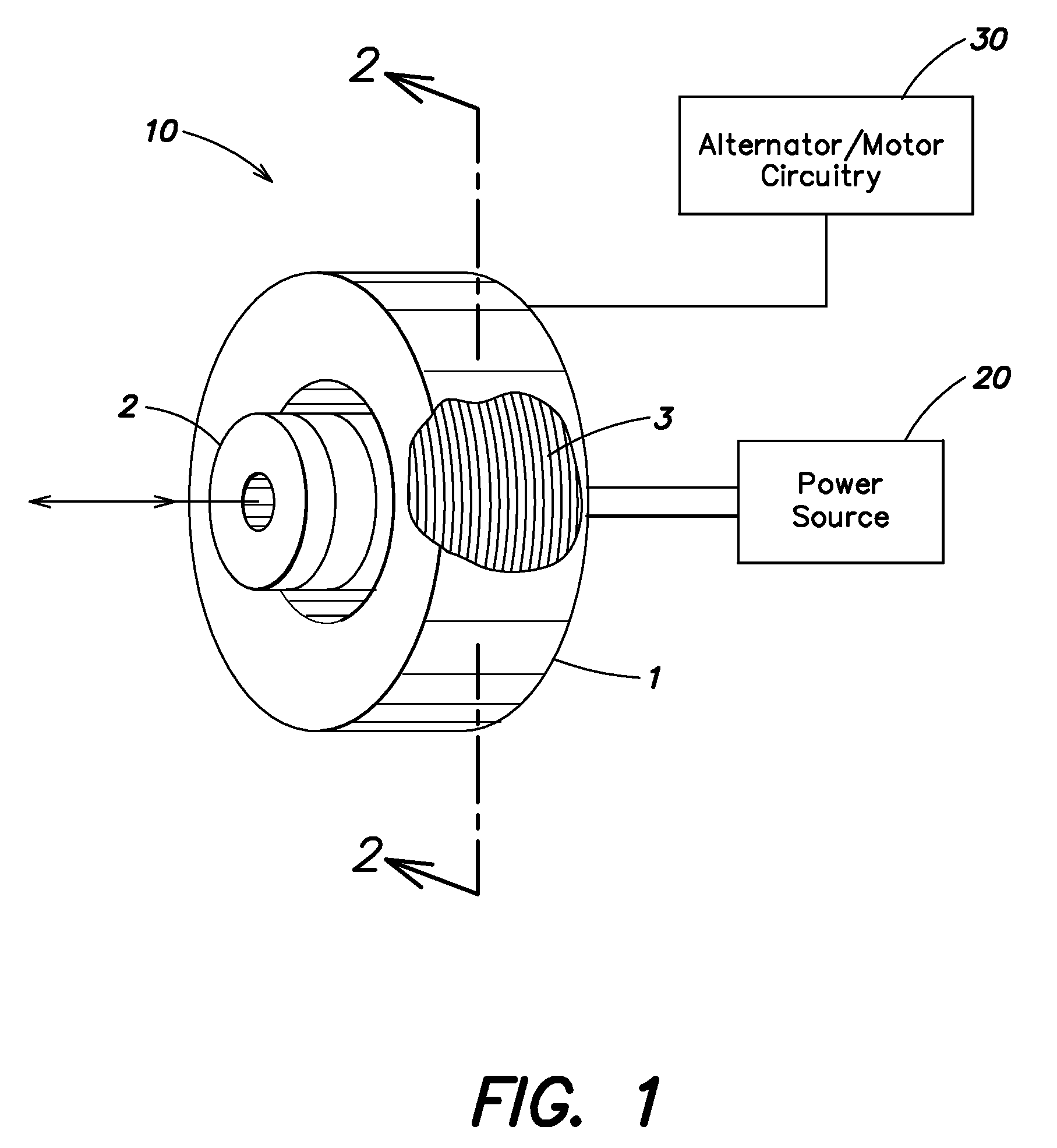

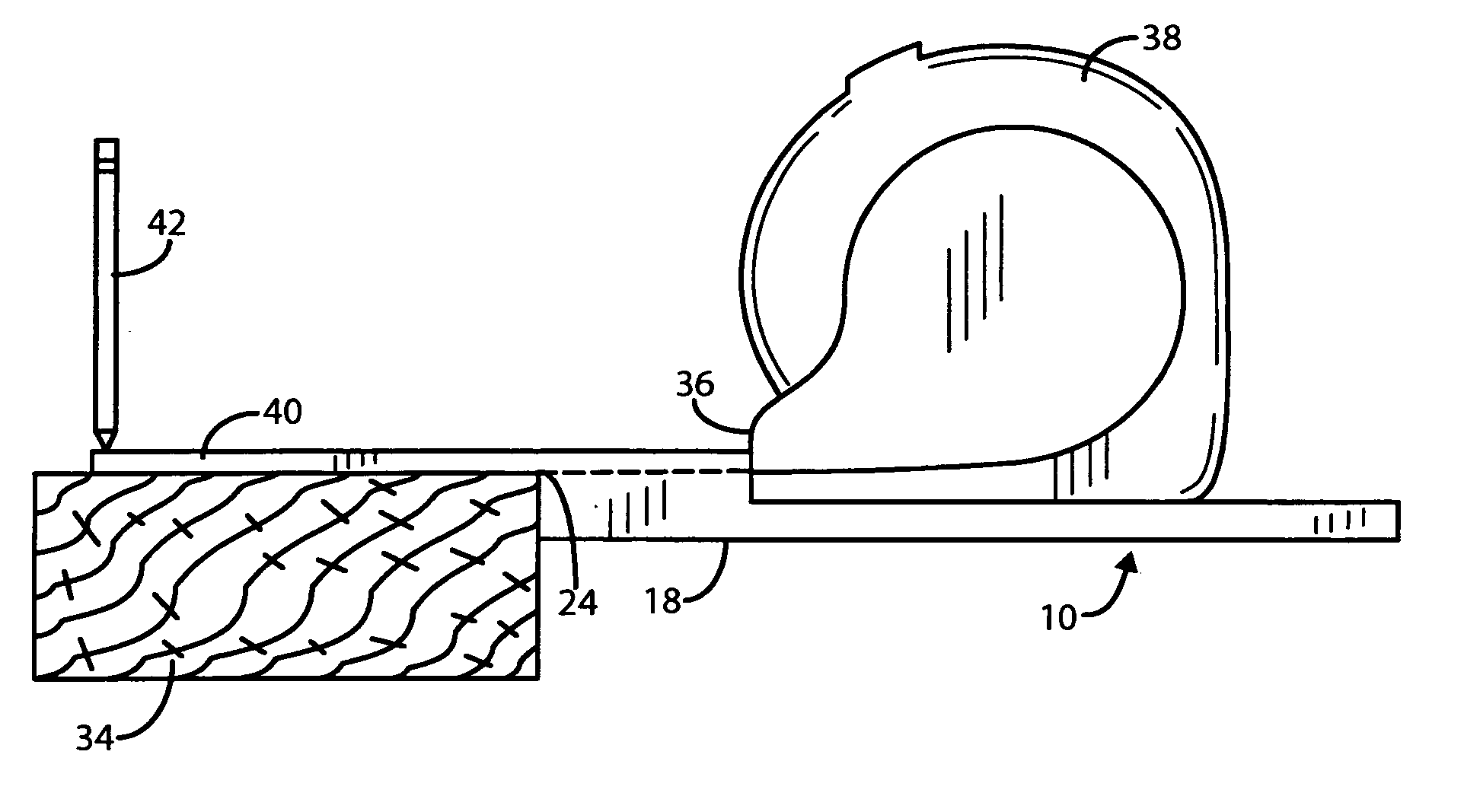

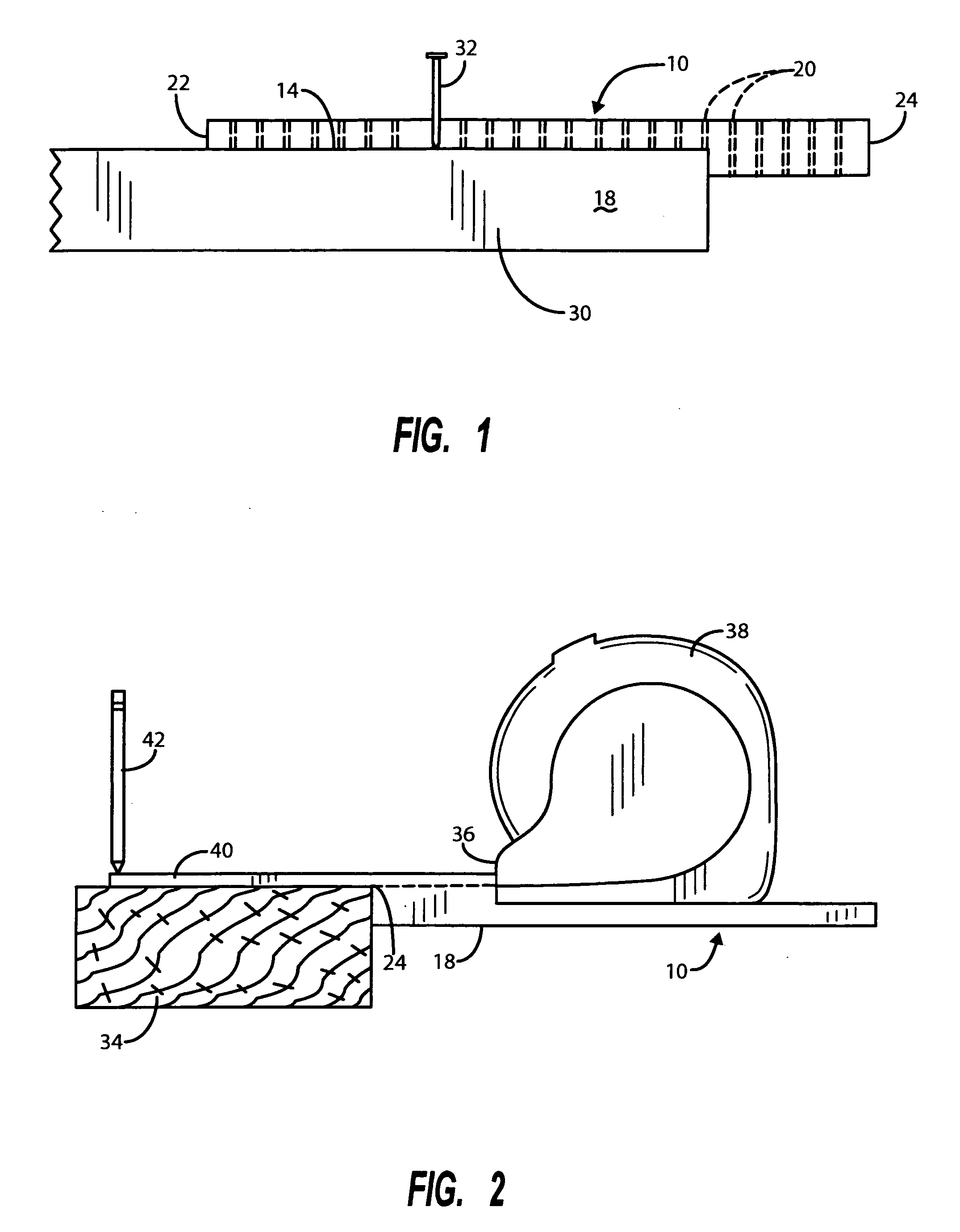

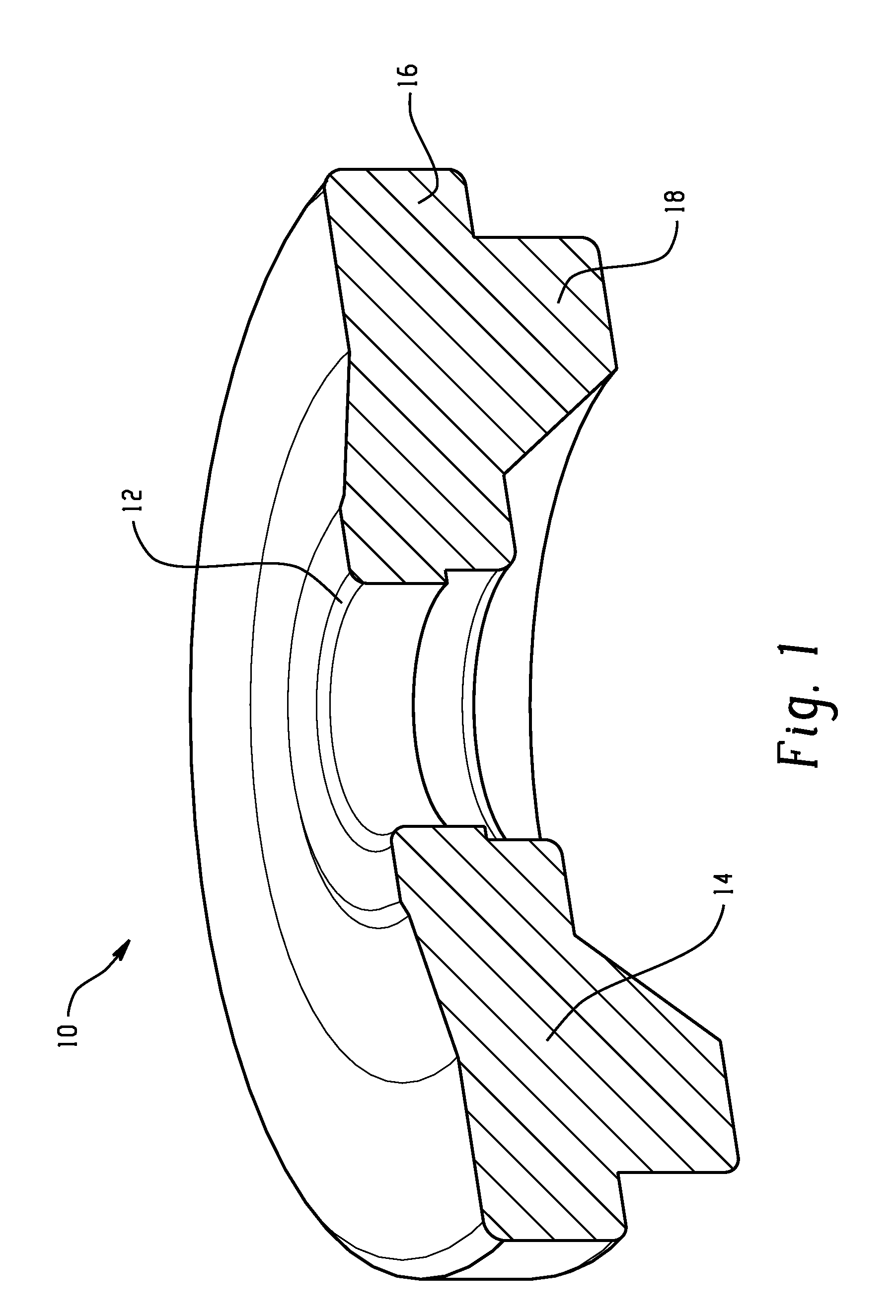

Linear electrical machine for electric power generation or motive drive

InactiveUS20070108850A1Increase magnet flux linkageImprove permeabilityMagnetic circuitPropulsion systemsAlternatorReciprocating motion

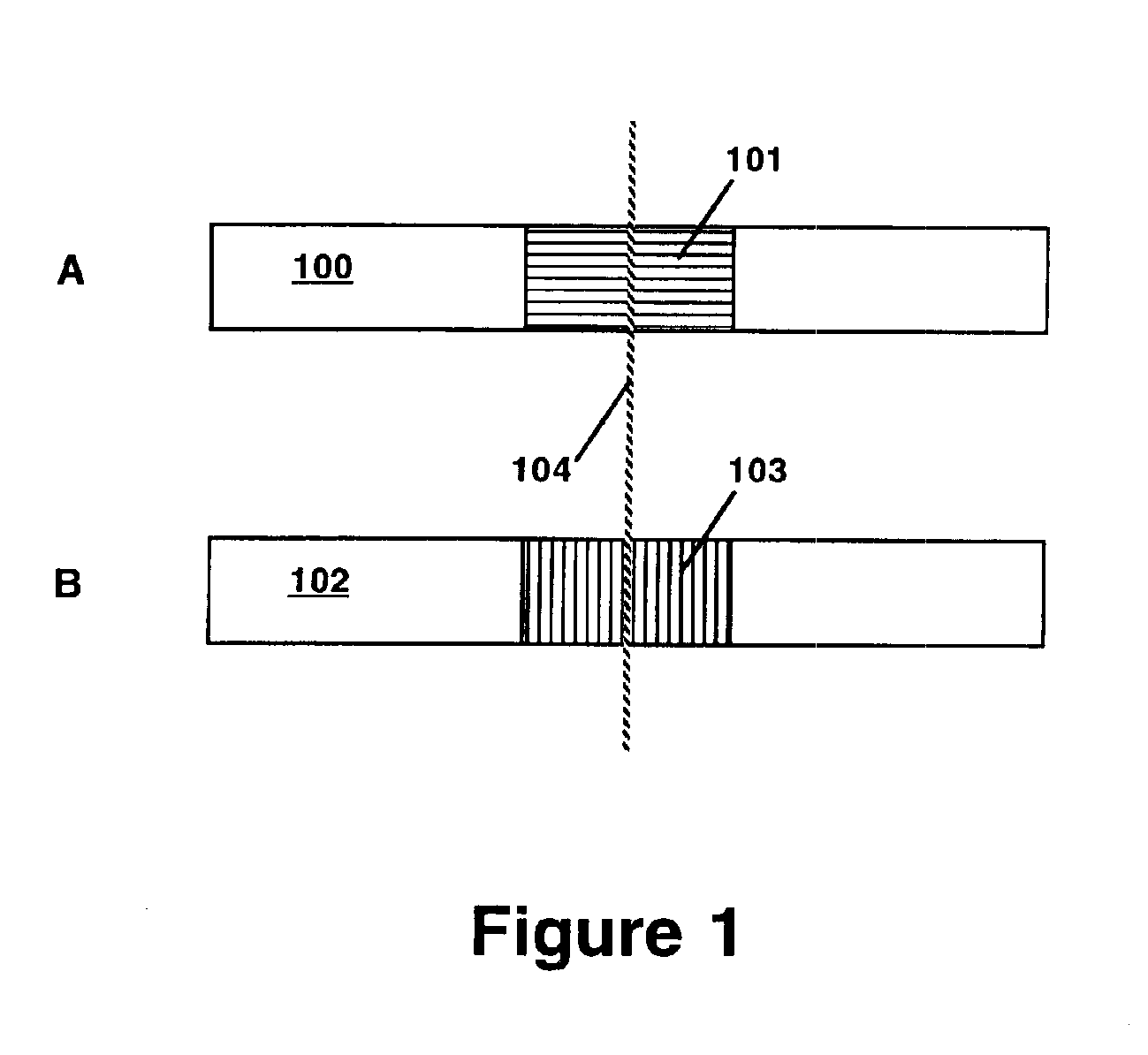

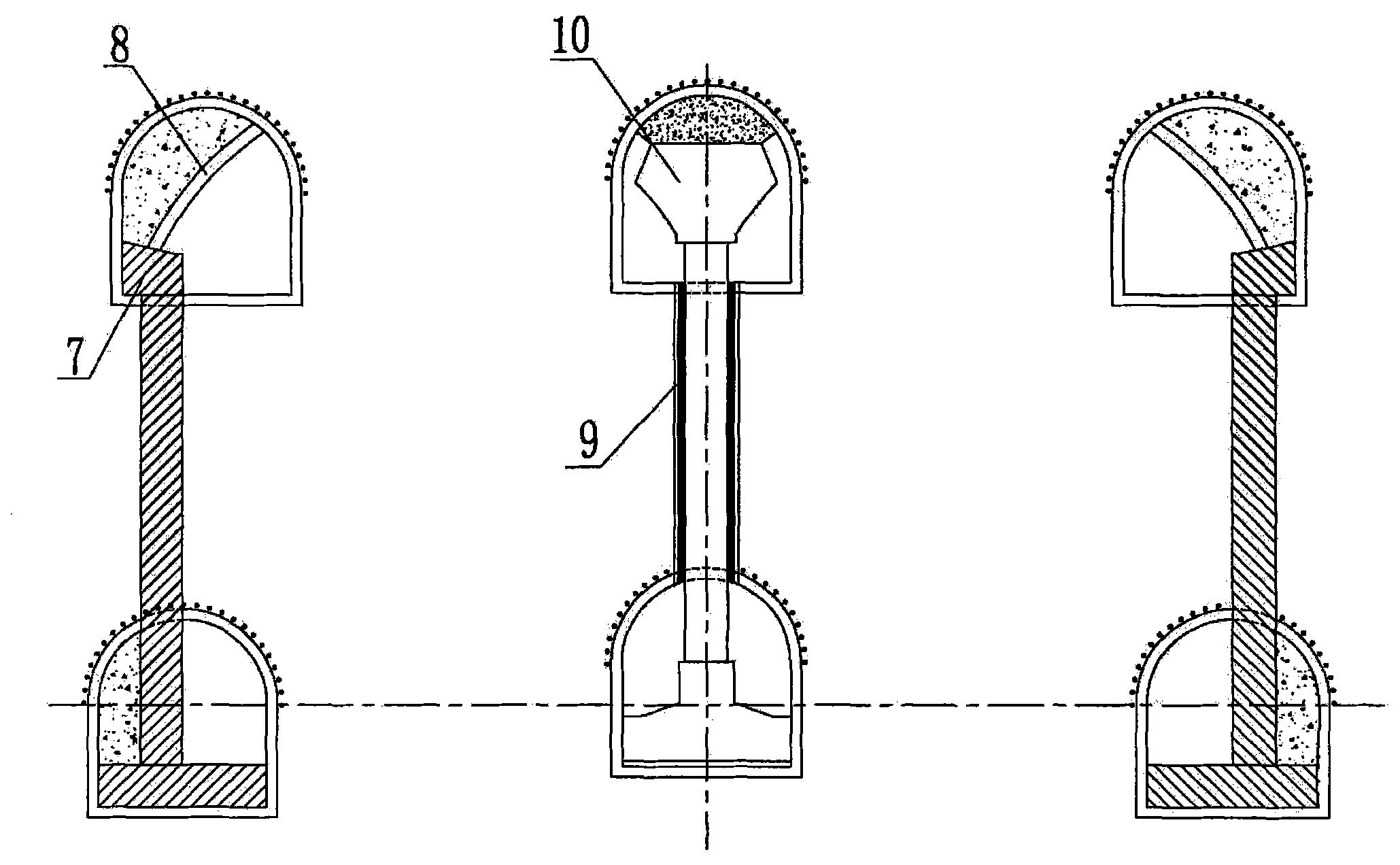

A linear electrical machine may function as an alternator or a motor. Three annular magnets may be provided that move relative to a core. The magnets may all have a different magnetic orientation. Two magnets may have a north pole oriented in a direction parallel to an axis along which the magnets move relative to the core. Another magnet may have a north pole oriented in a direction perpendicular to the axis. The core may include a plurality of ferromagnetic core elements; and a support structure composed of a composite material defining plural spaces, each for receiving one of the plurality of core elements. The core may further include a core shield disposed on the support structure substantially following a perimeter of the support structure defining an opening through which a reciprocating element can pass. Furthermore, the magnets may be supported in a reciprocating element having a low reluctance ferromagnetic frame there being a clearance gap between the machine core and the reciprocating element, the frame having a thicker section adjacent the gap, so as to desirably increase magnet flux linkage with an armature coil.

Owner:TIAX LLC

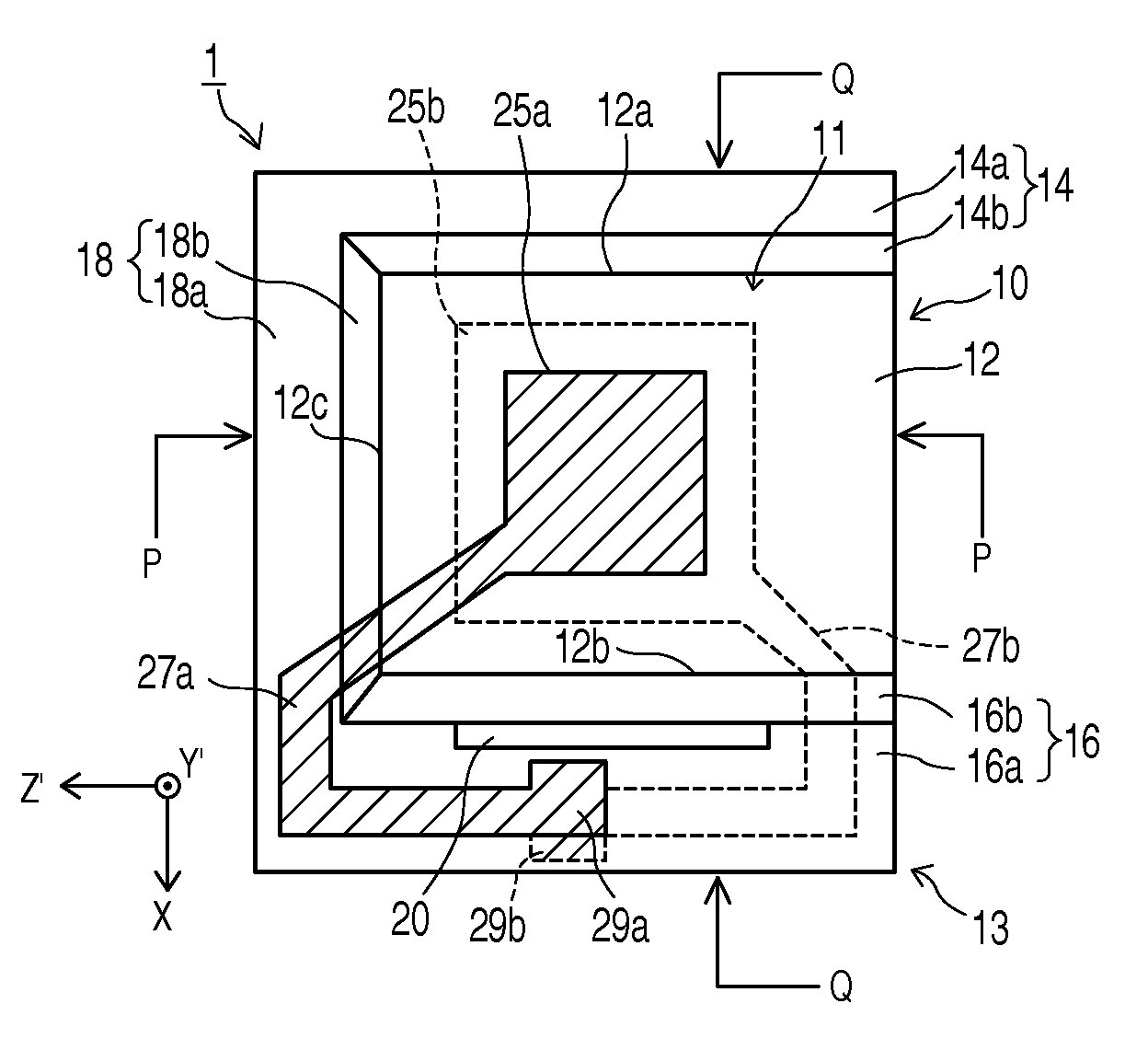

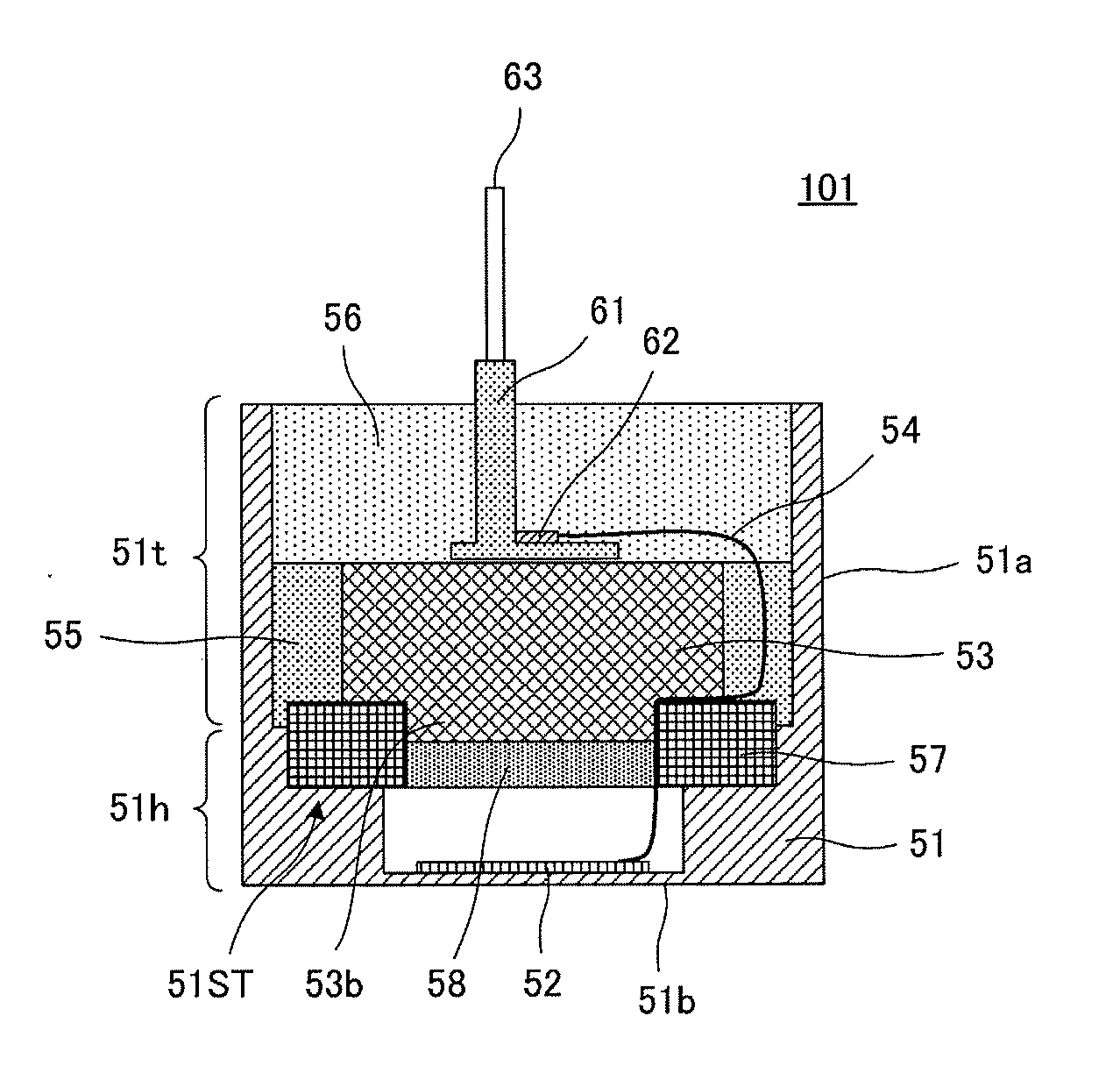

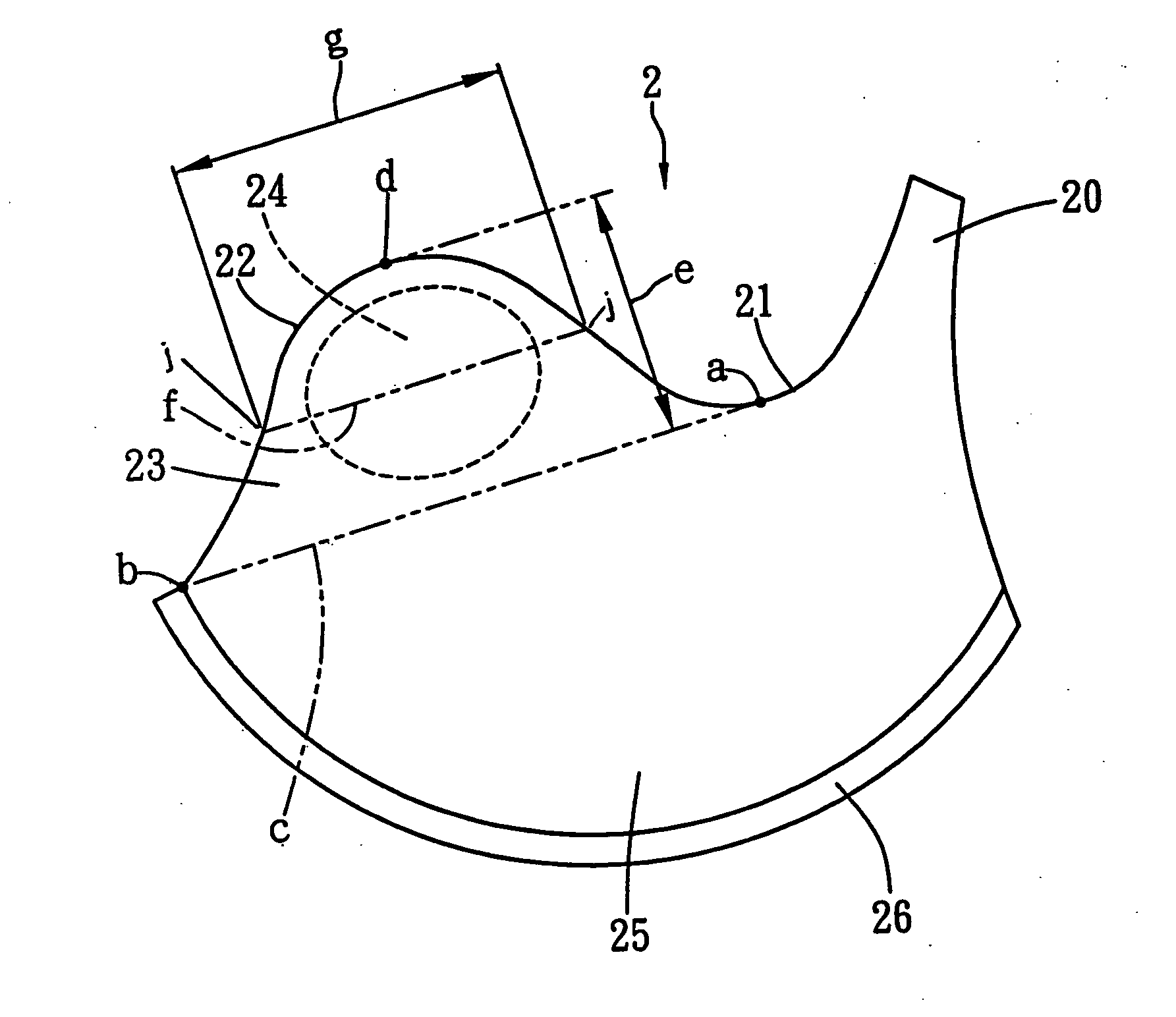

Piezoelectric vibration element, manufacturing method for piezoelectric vibration element, piezoelectric resonator, electronic device, and electronic apparatus

ActiveUS20120306321A1Spread of stress due to bonding and fixing can be suppressedAvoid smallPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksStress relaxationLead electrode

A piezoelectric vibration element includes a piezoelectric substrate including a thin vibration region and a thick section integrated along three sides excluding one side of the vibration region, excitation electrodes respectively arranged on the front and rear surfaces of the vibration region, and lead electrodes. The thick section includes a first thick section and a second thick section arranged to be opposed to each other across the vibration region and a third thick section connected between proximal ends of the first and second thick sections. The second thick section includes an inclined section connected to the one side of the vibration region, a second thick section main body connected to the other side of the inclined section, and at least one slit for stress relaxation.

Owner:SEIKO EPSON CORP

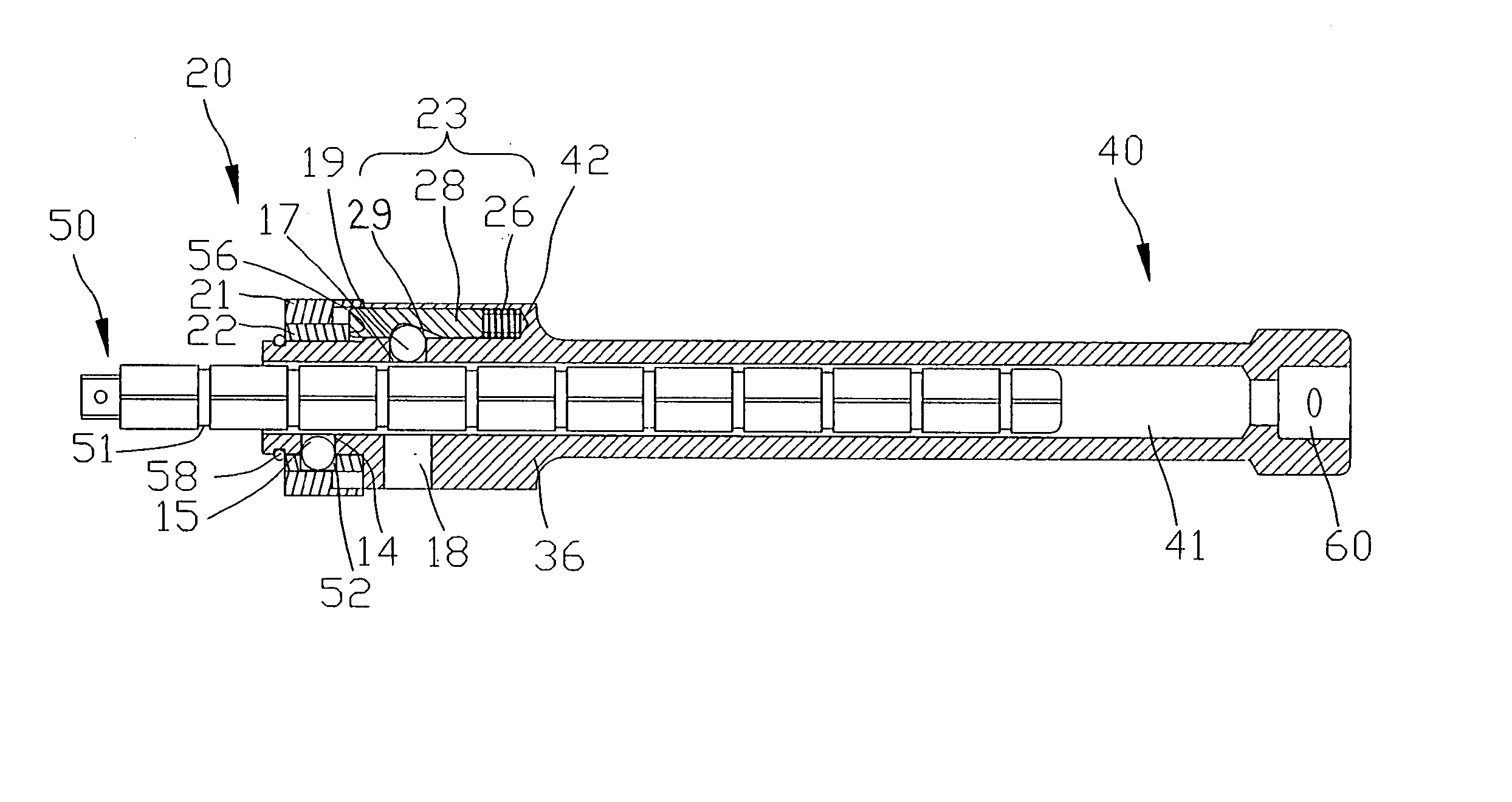

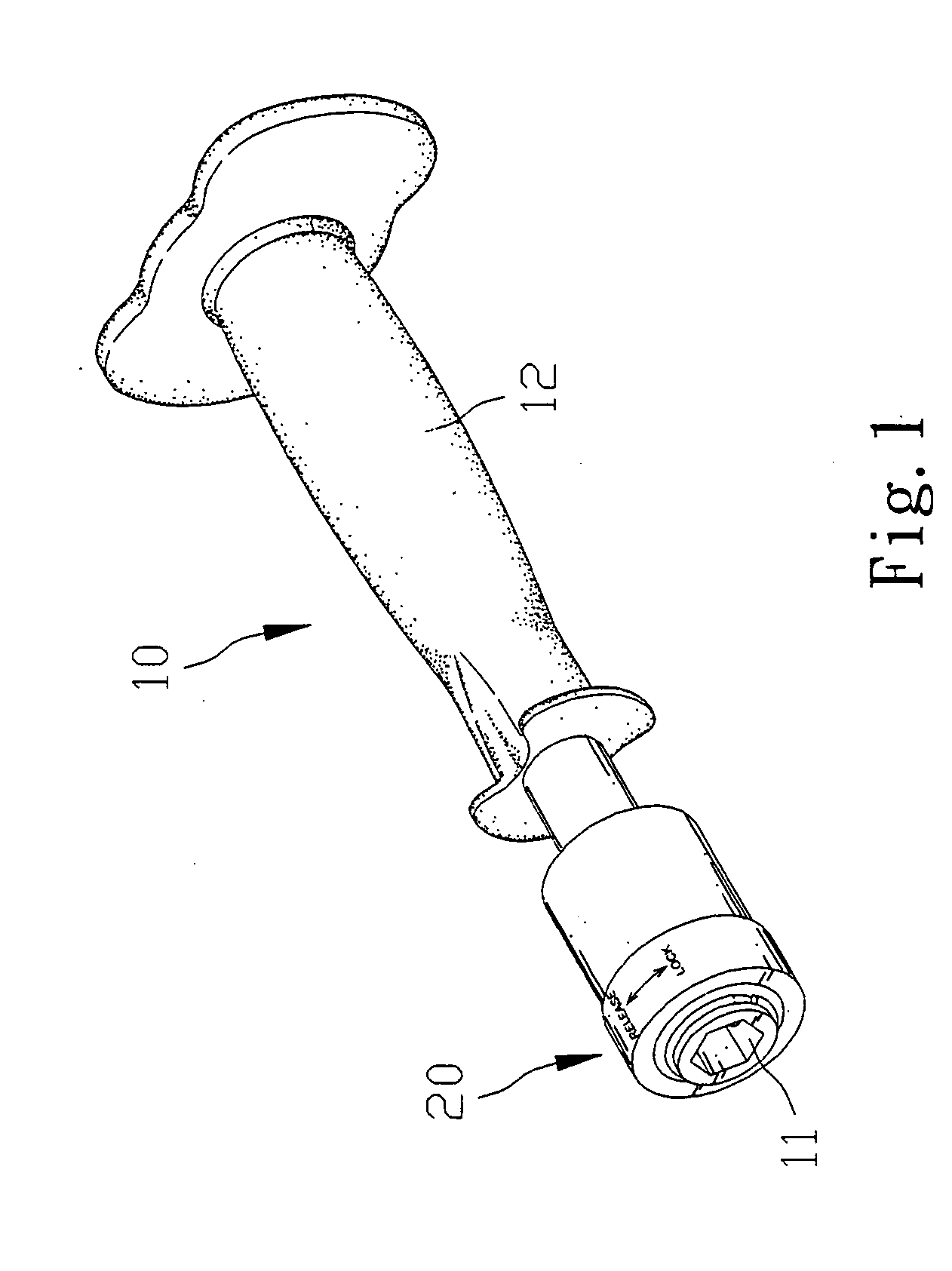

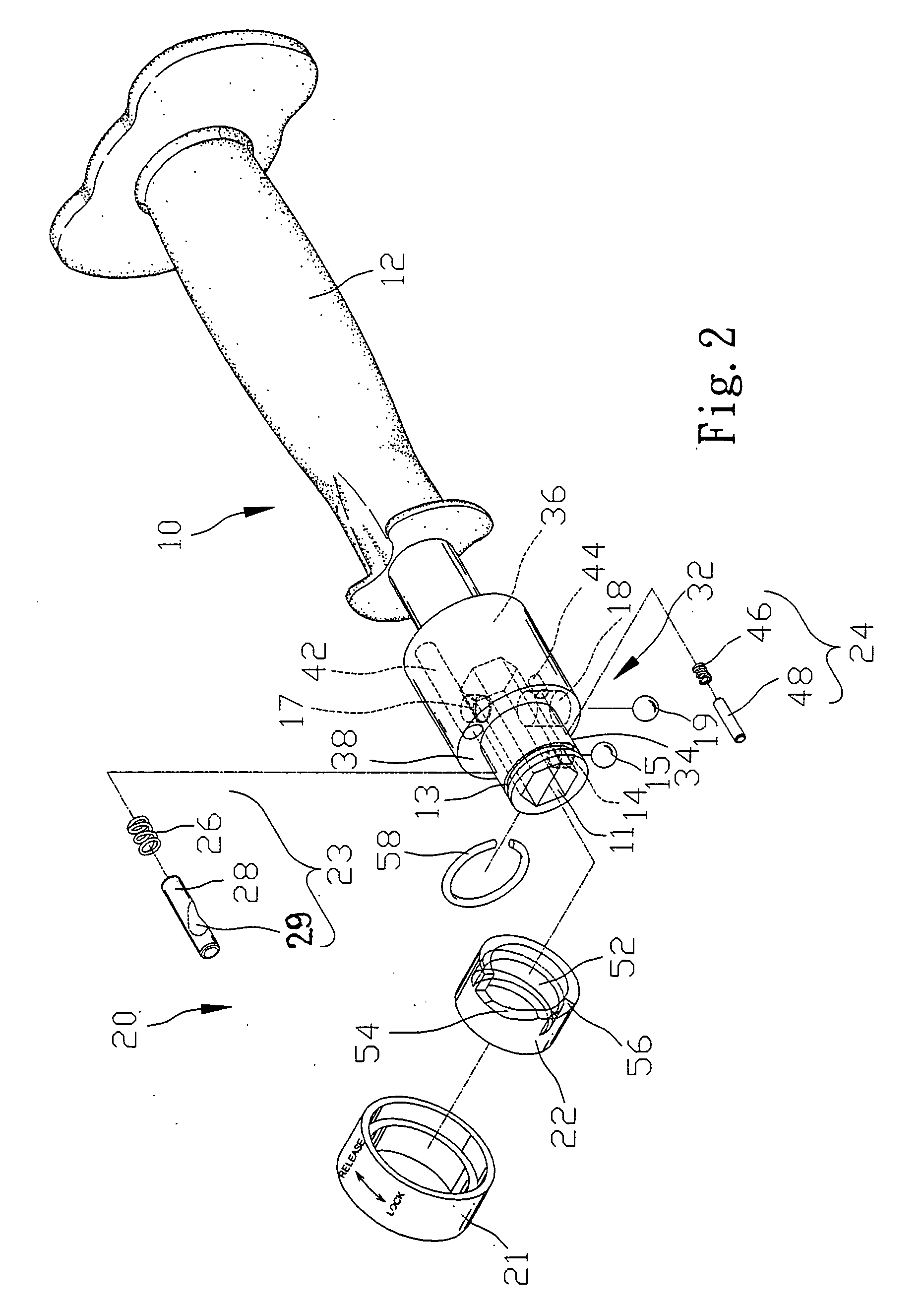

Tool including bit and handle

A handle is provided for use with a bit or extensive rod. The handle includes a socket. The socket includes a thin section, a thick section, an annular face between the thin and thick sections, an axial cavity and a radial aperture communicated with the axial cavity in the thin section. A detent is put in the radial aperture. A chuck is put on the socket for control over the detent.

Owner:LIOU MOU TANG

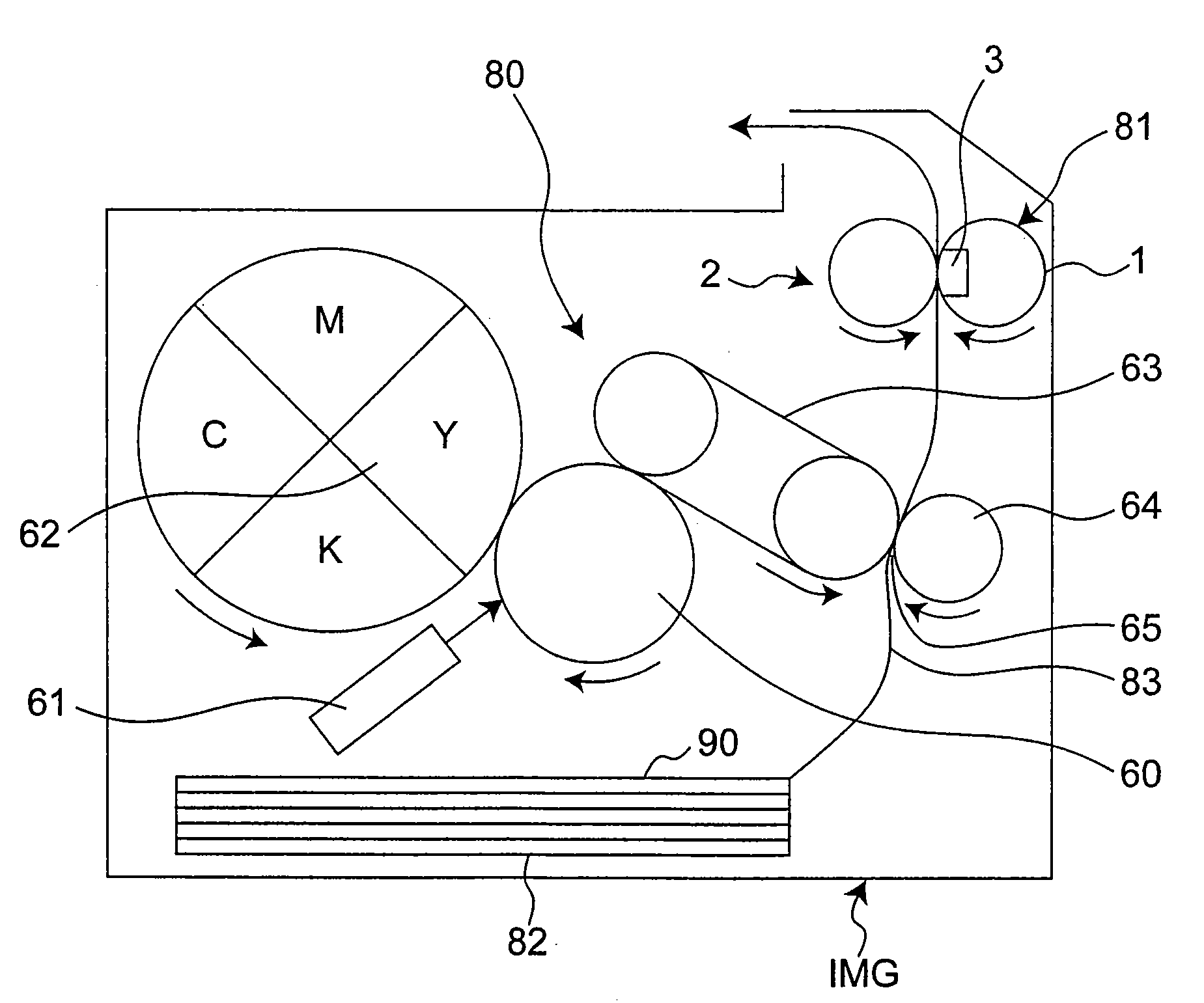

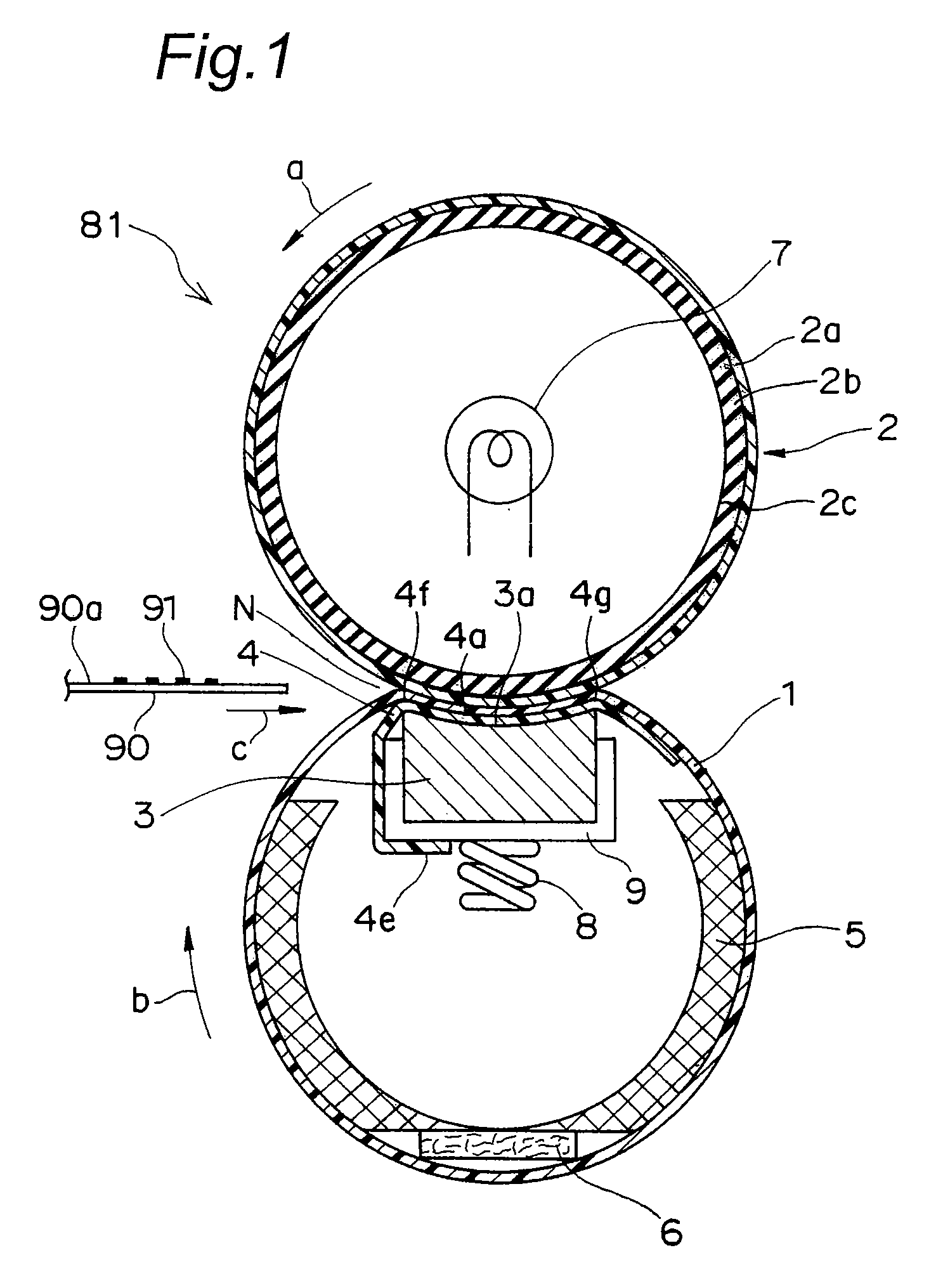

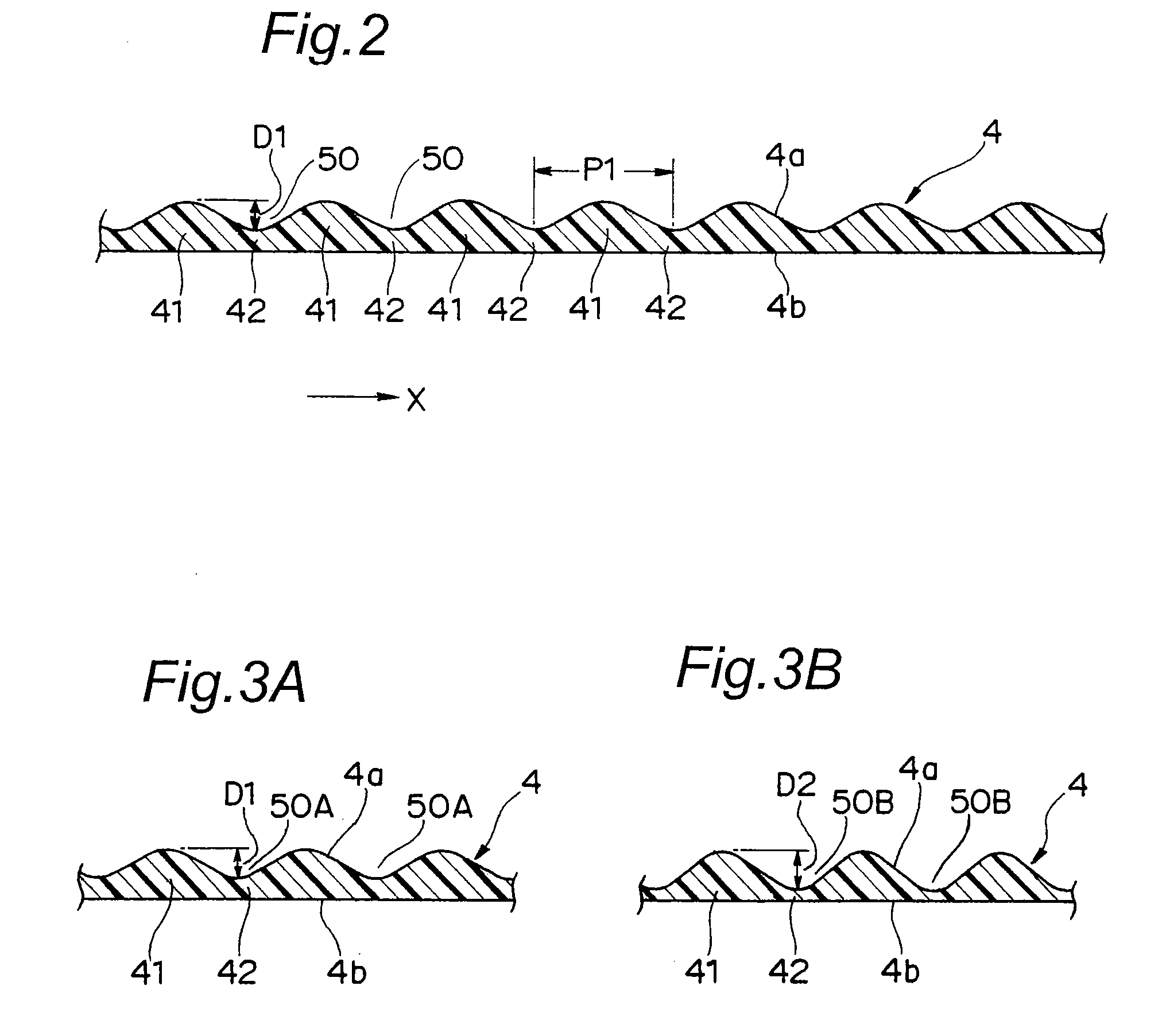

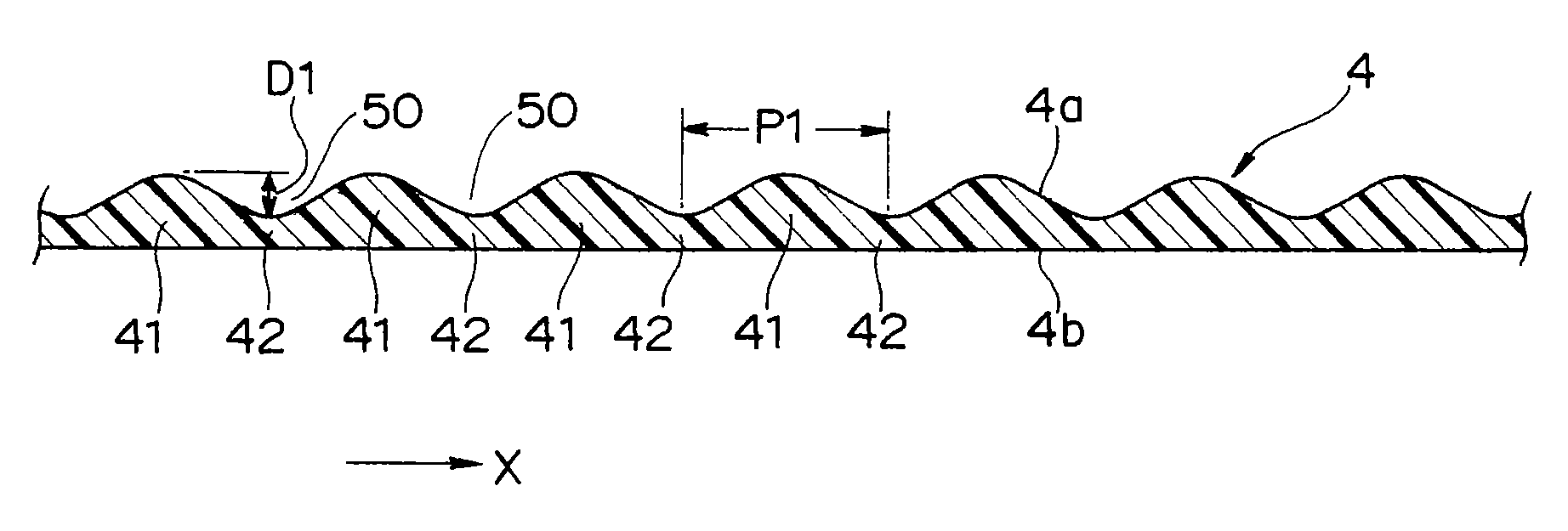

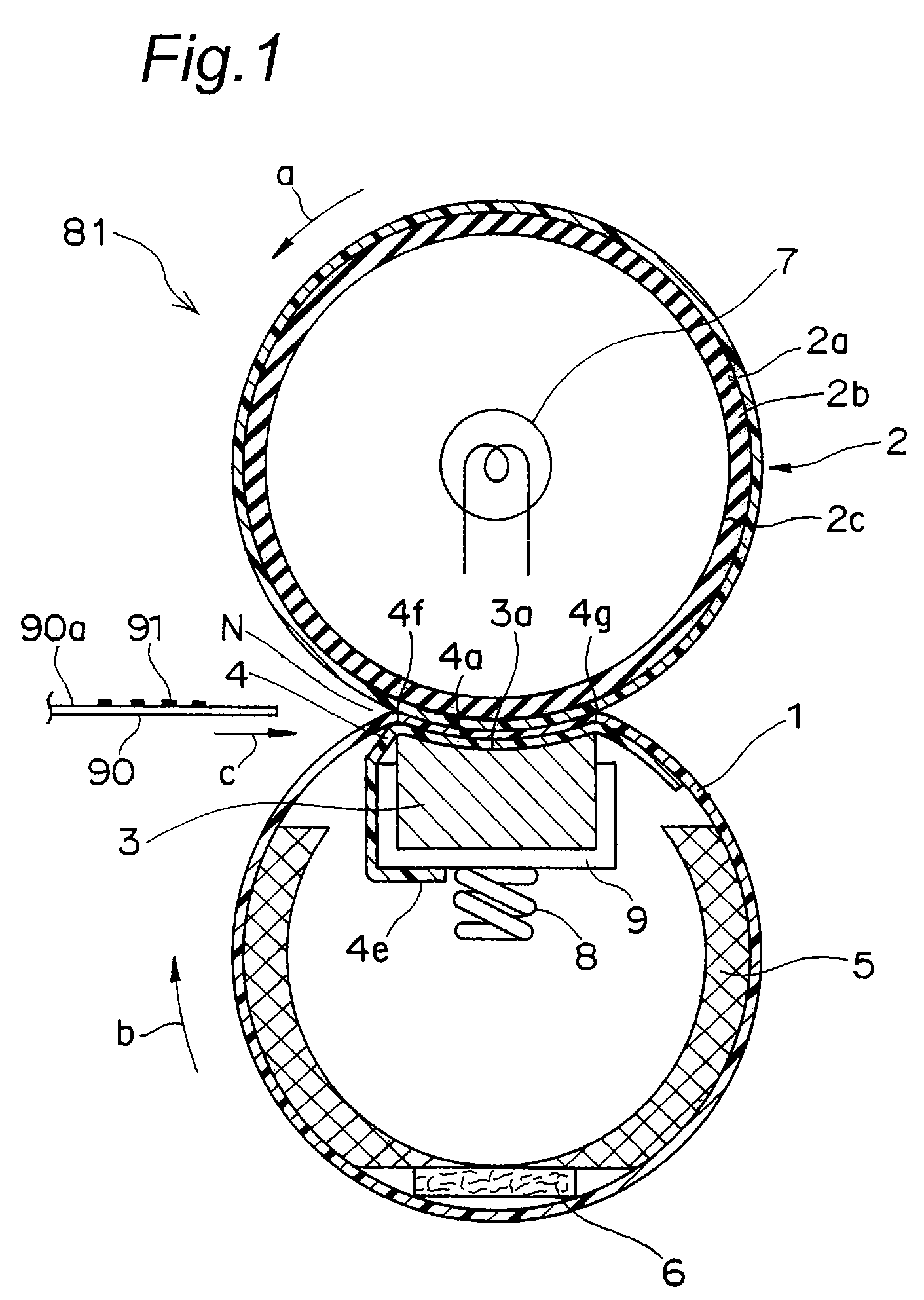

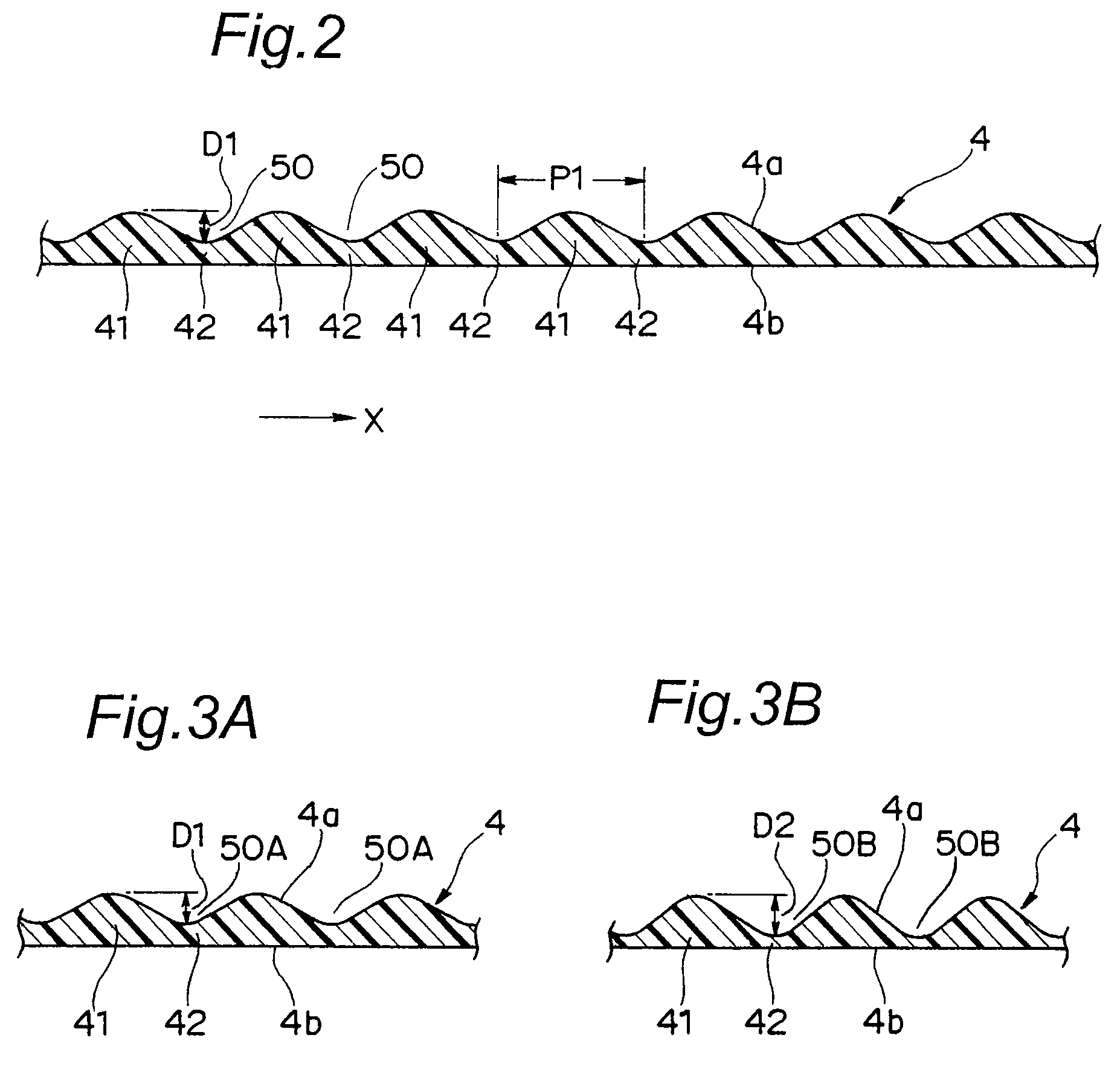

Sliding sheet for fixing devices, manufacturing method for same, fixing device, and image forming apparatus

ActiveUS20090014942A1Reduce manufacturing costShape stableElectrographic process apparatusRotary pressesEngineeringThin section

A sliding sheet for fixing devices in the present invention is inserted in between an endless belt constituting one member out of two members which form a nip section for fixing operation and a pressure member for pressing the endless belt from an inner surface side toward the other member out of the two members. The sliding sheet, which is made of a single resin, repeatedly has a thick section and a thin section at least with respect to a sliding direction of the endless belt due to substantial difference in resin amount per unit area corresponding to positions within a sheet surface.

Owner:KONICA MINOLTA BUSINESS TECH INC

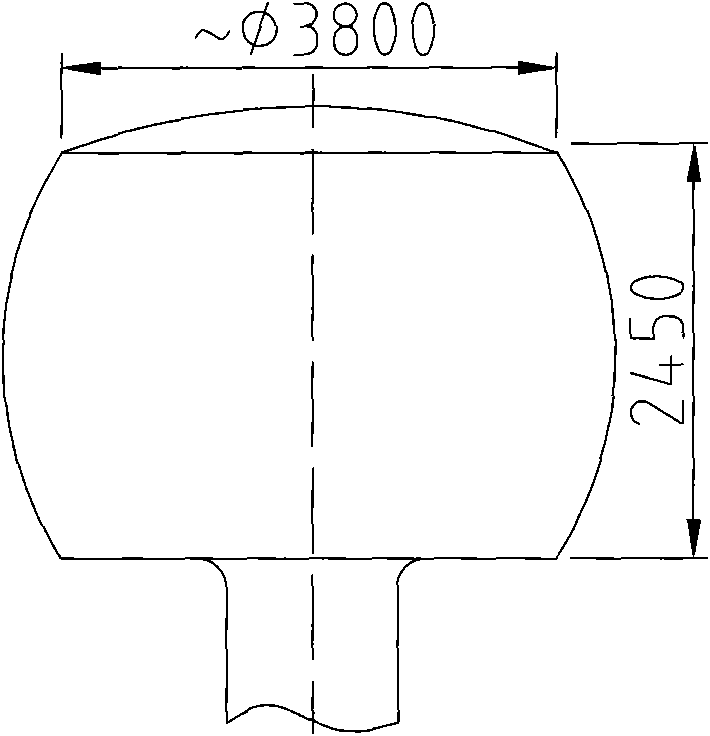

Forging method of tube sheet of nuclear power equipment

The invention discloses a forging method of tube sheets of nuclear power equipment, which forges SA-508 Grade 3 Class 2 dual vacuum steel ingots with the weight of 300+ / -20 tons by using a 165000 ton hydraulic press. The method comprises the following specific steps of step 1, first continuous upsetting, ensuring that the forging rate is 1.85; step 2, first extension by using a wide smashing and strong compressing method; step 3, second continuous upsetting, ensuring that the forging rate is 2.1; step 4, second extension; step 5, third continuous upsetting; step 6, forging and pressing by using a differential temperature compression method; immediately spraying frost to forging parts for cooling or carrying out wind cooling after the third continuous upsetting so that the surface of the forging part is cooled to 700 to 800 DEG C, and then forging by using the differential temperature compression method; and step 7, finally rotating 360 degrees for crossed forging. By carrying out continuous upsetting twice and combining the wide smashing and strong compressing method and the differential temperature compression method, the invention is capable of completely forging the forging part and obtaining uniform deformation of the forging part, and can integrally compress tube sheet forging parts with extremely thick sections from top to bottom so that the tube sheet forging parts havefine and uniform grains, and stable performance can meet requirement of fault detection and further meet various technical conditions of nuclear power tube sheets.

Owner:SHANGHAI ELECTRIC SHMP CASTING & FORGING CO LTD +1

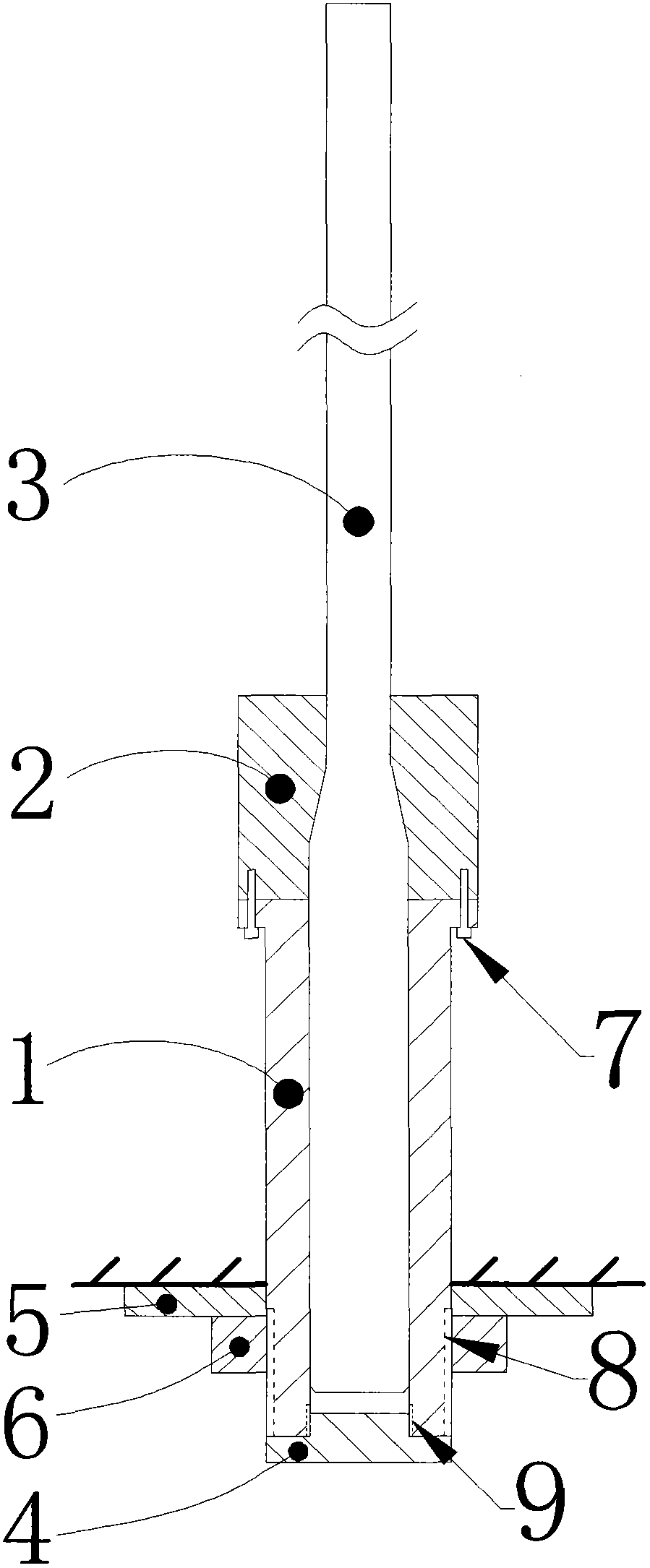

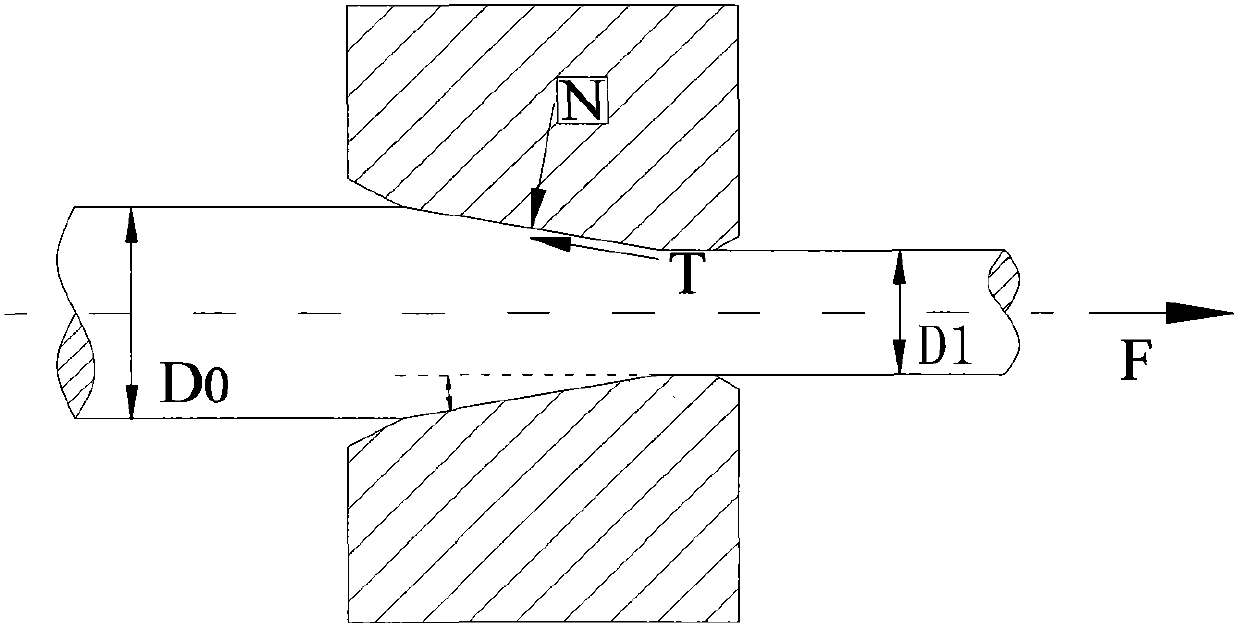

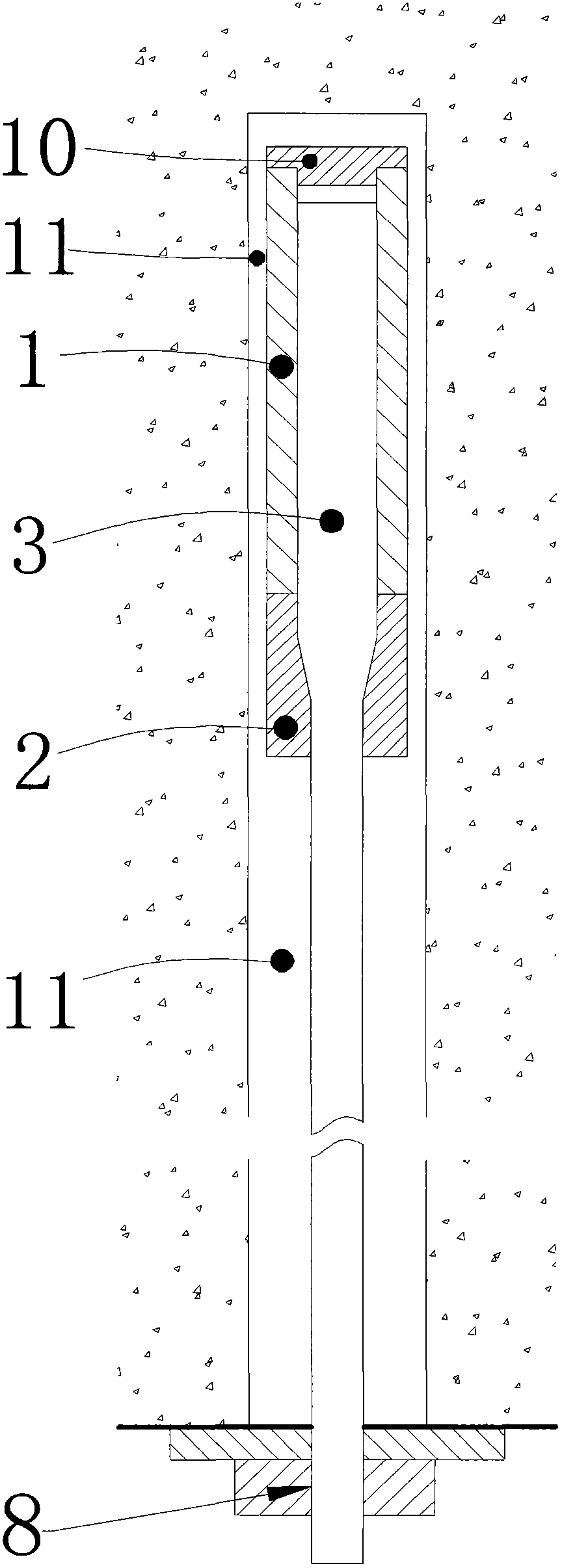

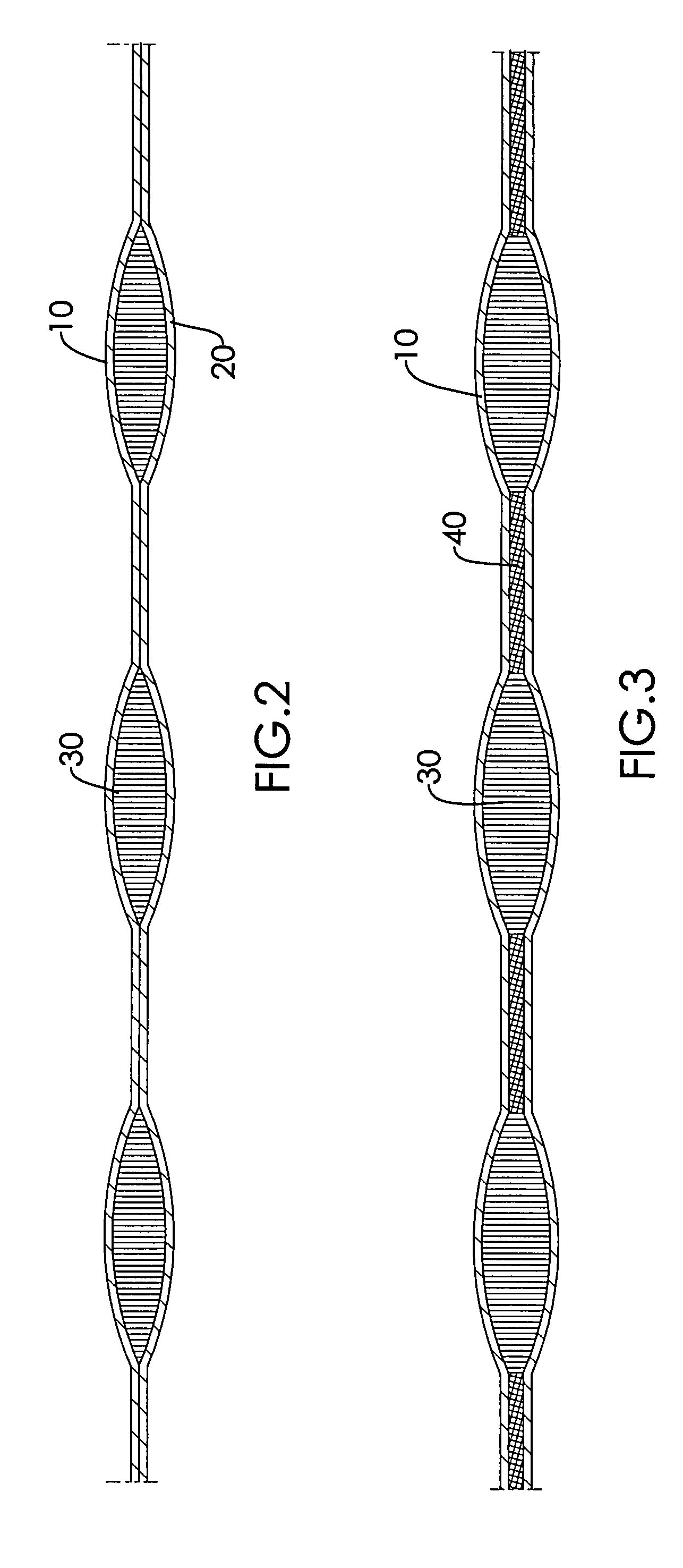

Novel high-strength constant-resistance large deformation anchor rod and using method thereof

InactiveCN102678148AConstant pull forceIncrease resistanceBulkheads/pilesAnchoring boltsLarge deformationScrew thread

The invention discloses a novel high-strength constant-resistance large deformation anchor rod and a using method thereof. An anchor rod body of the novel high-strength constant-resistance large deformation anchor rod comprises a cold-drawn rod body, a cylindrical sleeve and a wire drawing mold, wherein the diameter of one end of the cold-drawn rod body is greater than that of the other end, namely one thick section and one thin section; a cone-shaped section is formed between the thick section and the thin section; the surface of the thin section is provided with rib patterns; the cylindrical sleeve is connected with the wire drawing mold and is sleeved on the cold-drawn rod body; the wire drawing mold is a cone-shaped mold; the taper of the wire drawing mold is matched with the taper of the cone-shaped section; and the end head of the cylindrical sleeve or the end head of the cold-drawn rod body is provided with external threads for installing nuts. The anchor rod can stretch under stress and is not damaged when surrounding rock is subjected to large deformation, and the cold-drawn rod body has large displacement to adapt to deformation of the surrounding rock.

Owner:SHANDONG UNIV OF SCI & TECH

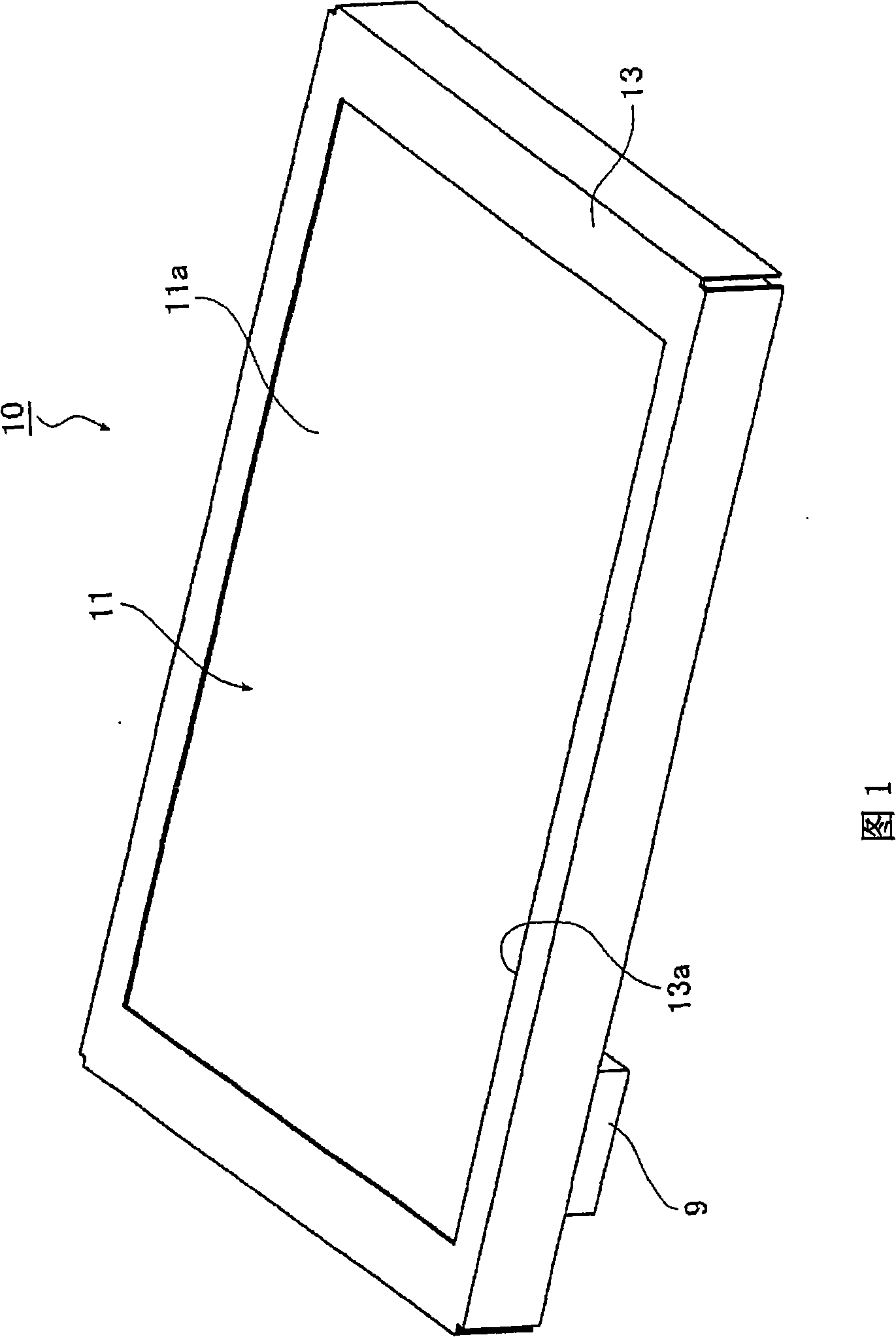

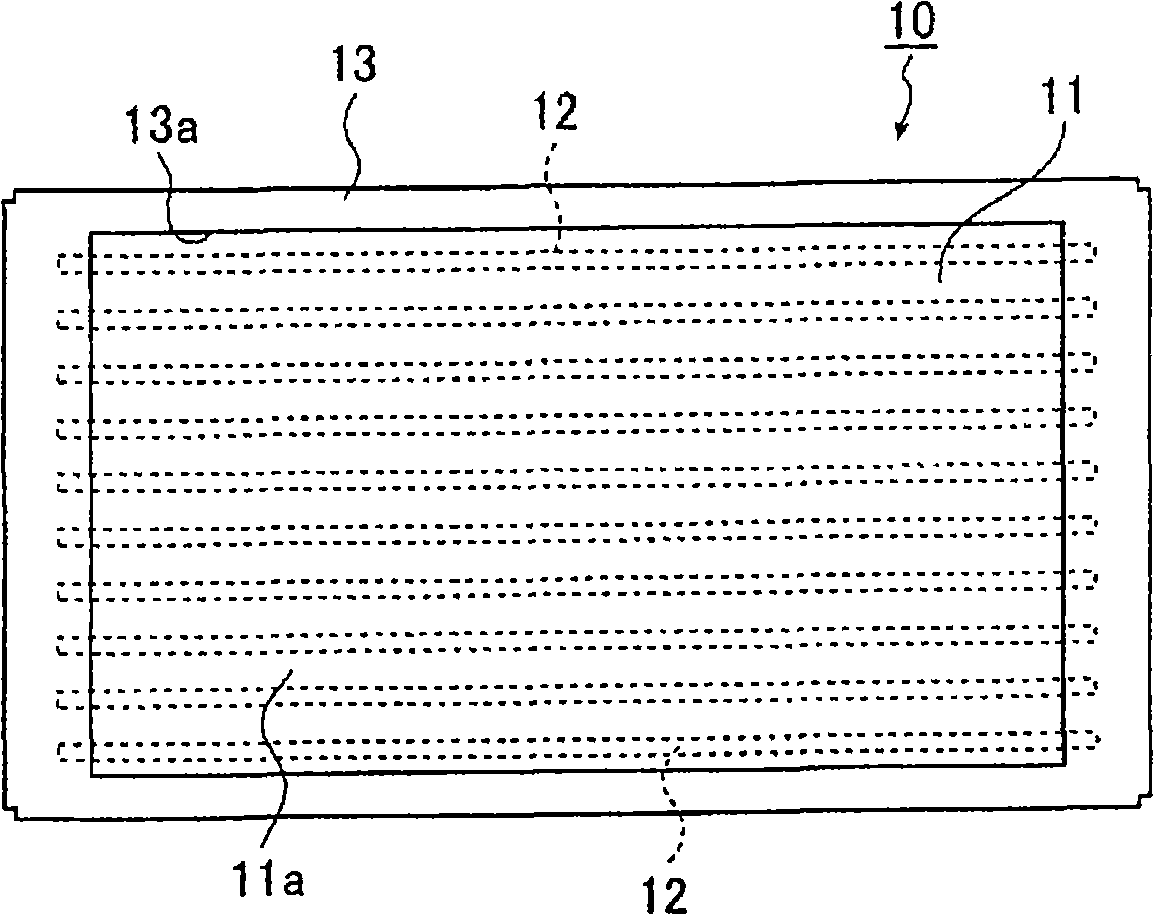

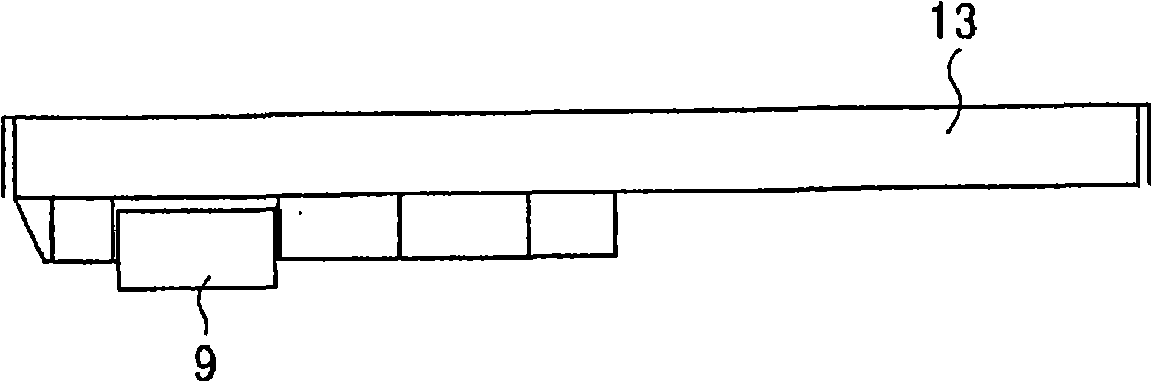

Unit light guide plate, light guide plate unit, planar illuminating device and liquid crystal display device

InactiveCN101495799AImprove injection efficiencySmall sizeMechanical apparatusPoint-like light sourceLiquid-crystal displayLight guide

A unit light guide plate and a light guide plate unit are provided with a light outputting surface; a thick section substantially at the center of the light outputting surface; a thin end sections formed on the both sides of the thick section; a half section of a parallel groove formed on the rear side of the light outputting surface for storing a linear light source; an inclined rear section which becomes thinner toward the thin end section from the thick section; and a scattering means for scattering light which enters the thin end section from the light source stored in the parallel groove and propagates inside the inclined rear section.Alternatively, the unit light guide plate is provided with a spot light source; a light outputting surface for outputting light; a rear surface facing the light outputting surface; side surfaces connected to the light outputting surface and the rear surface; a light entering section, which is arranged substantially at the center of the rear surface, with a spot light source arranged, and permits incident light to enter; and a scattering means for outputting the entered light from a light outputting surface. A distance between the light outputting surface and the rear surface increases as it separates from the light entering section. A planar illuminating device and a liquid crystal display device are provided by using such unit light guide plate and the light guide plate unit.

Owner:FUJIFILM CORP

OOCr13Ni5Mo ultralow-carbon martensitic stainless steel and producing method thereof

ActiveCN101104909AImprove stabilityImprove securityRoll mill control devicesMetal rolling arrangementsChemical compositionIngot casting

The invention discloses a 00Cr13Ni5Mo ultralow-carbon martensitic stainless steel and the manufacturing method thereof. The chemical components, by weight percentage, are as follows: C less than or equal to 0.03, Mn 0.50-1, Si less than or equal to 0.5, P less than or equal to 0.025, S less than or equal to 0.015, Cr 12-14, Ni 4.5-6, Mo 0.5-1, and Fe and inevitable impurity in balance. The manufacturing method mainly comprises, in order, primary smelting in an electric furnace, refining in a refining furnace, steel ingot casting, steel ingot annealing, forging rolling of blank, and heat treatment of blank. This type of steel has high strength, toughness and weldability; and has excellent resistance against erosion, wear and corrosion. The steel is mainly used, in large hydropower station, as key parts such as rotating wheel with thick section and good weldability and lower ring for hydropower station, and used as material for valve and gate valve systems.

Owner:ZHEJIANG DALONG ALLOY STEEL

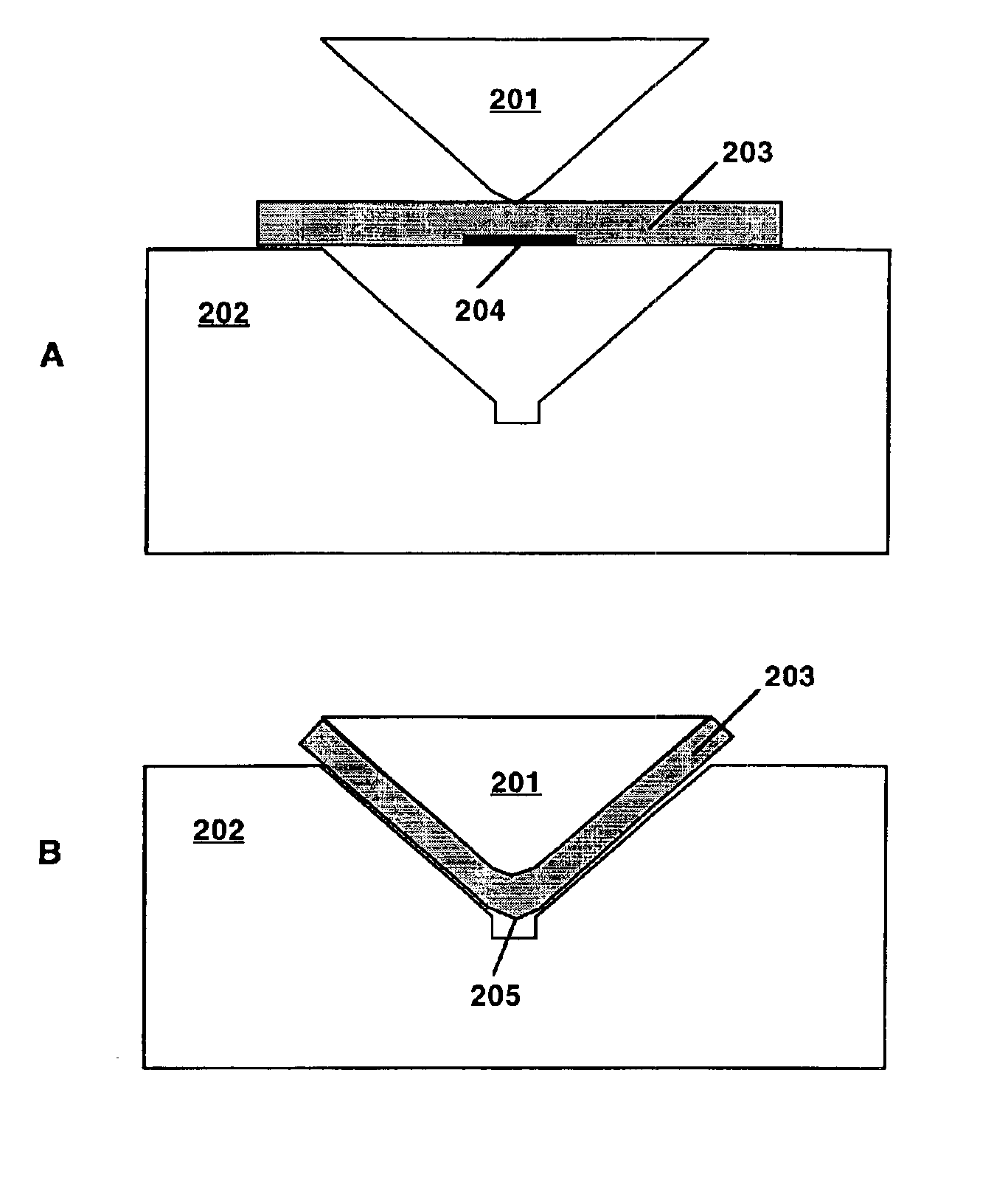

Thick-section metal forming via friction stir processing

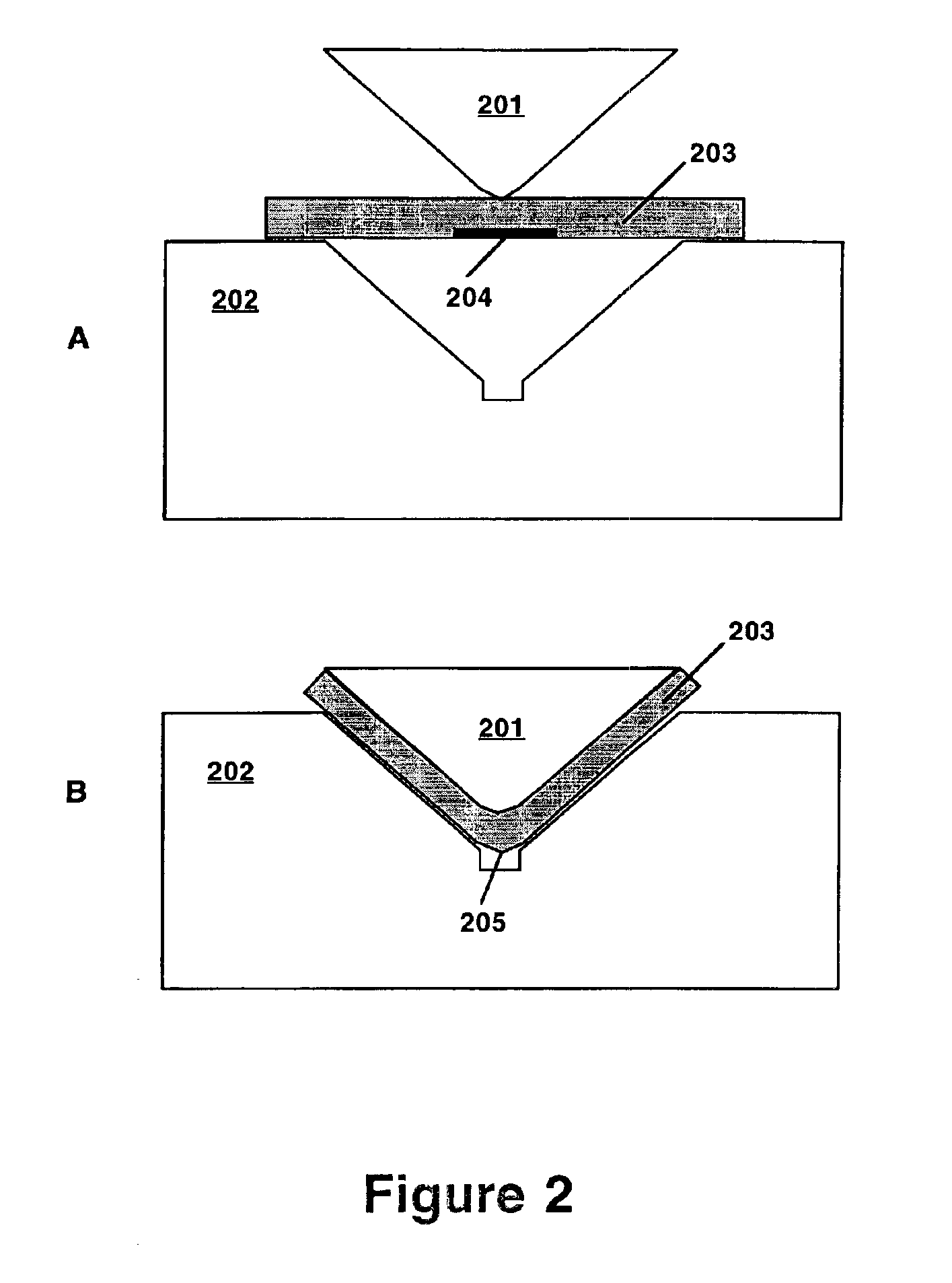

InactiveUS6866180B2Minimize formation of crackReduce flow stressWelding/cutting auxillary devicesAuxillary welding devicesMetal formingRoom temperature

Friction stir processing (FSP) modifies the surface microstructure of metals so that thick-section metal workpieces can be bent over large angles without formation of surface cracks. A thick 2519-T8 aluminum plate (25.4 mm thick and 50.8 mm wide) was friction stir processed across the pre-tensile surface to a depth of 6.3 mm, and was then bent at room temperature over a punch with radius 38.1 mm into a v-shaped die to an 80° bend angle. Whereas unprocessed workpieces of this type exhibited surface cracking at 31° bend angle and failed at 40° bend angle, no cracking was evident for the friction stir processed workpiece up to 80° bend angle.

Owner:TELEDYNE SCI & IMAGING

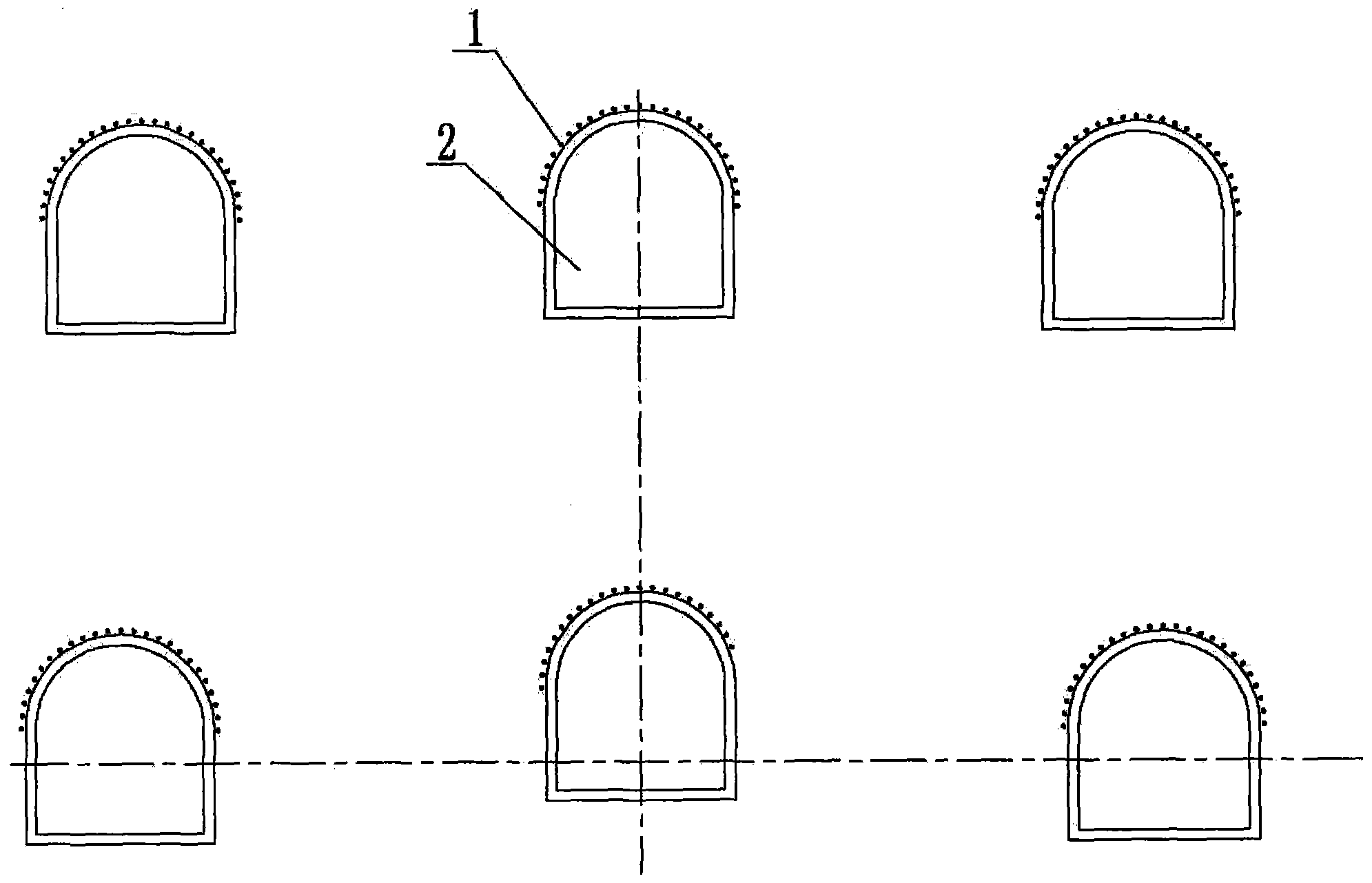

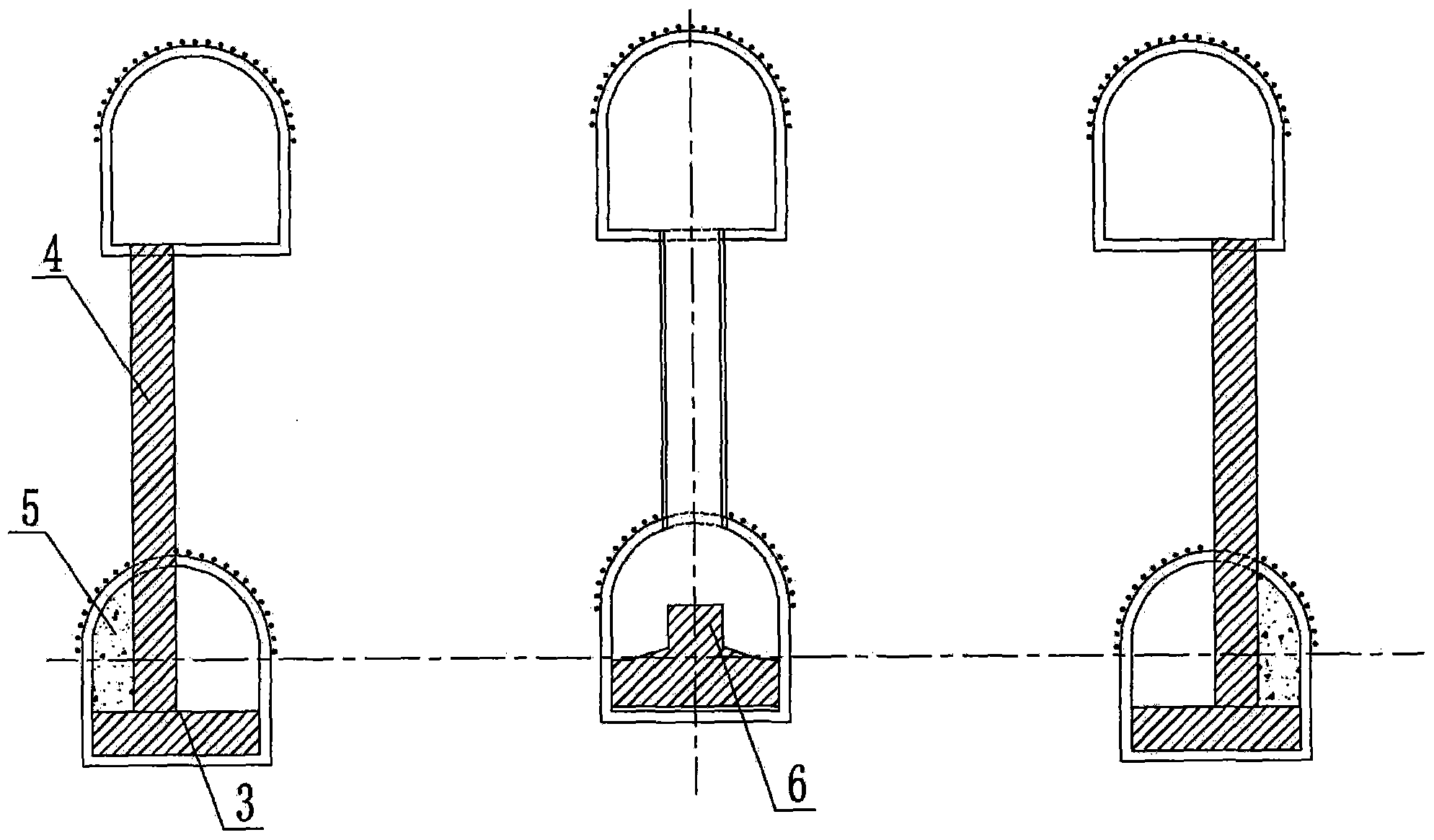

Construction method for subway station body

InactiveCN103821167AConstruction safetyConstruction method safetyArtificial islandsUnderwater structuresSubway stationUltimate tensile strength

The invention relates to a construction method for a subway station body. The construction method includes the following steps that pilot tunnels are excavated, and primary support is constructed; after cutthrough of each lower pilot tunnel, a strip-shaped foundation of each lower side pilot tunnel is constructed; pile top beams and large arch springings are constructed on the upper layer side pilot tunnels in a moulding mode; the inner side of the upper layer middle pilot tunnel is reinforced through a top longitudinal beam, a ground layer is reinforced through preliminary grouting in advance, and a soil body part I is excavated symmetrically left and right; a soil body part II is symmetrically excavated, and arch primary support is constructed; after cutthrough of the primary support, a medium partition, a waterproof plate and a protective layer are cut off in a segment mode through an inverted supporting method; excavation is downwards performed in a layered mode in the longitudinal direction of a subway station to the bottom elevation of a station hall plate; after medium plate concrete reaches design strength, excavation is downwards performed in a layered mode by 3.5 m along the longitudinal direction of the station; slope excavation is longitudinally performed downwards in a layered and segment mode to the position of 370 mm below the bottom elevation of the station hall plate according to the scale of 1:1, a thick section steel sprayed mixed cushion layer, a waterproof layer and a waterproof protective layer are constructed; a side wall waterproof layer is laid, and side wall concrete is poured; an inner structure is constructed to finish structure construction of the station. The construction method has the advantages of being high in efficiency, short in construction period, safe in construction and the like.

Owner:BEIJING MUNICIPAL CONSTR

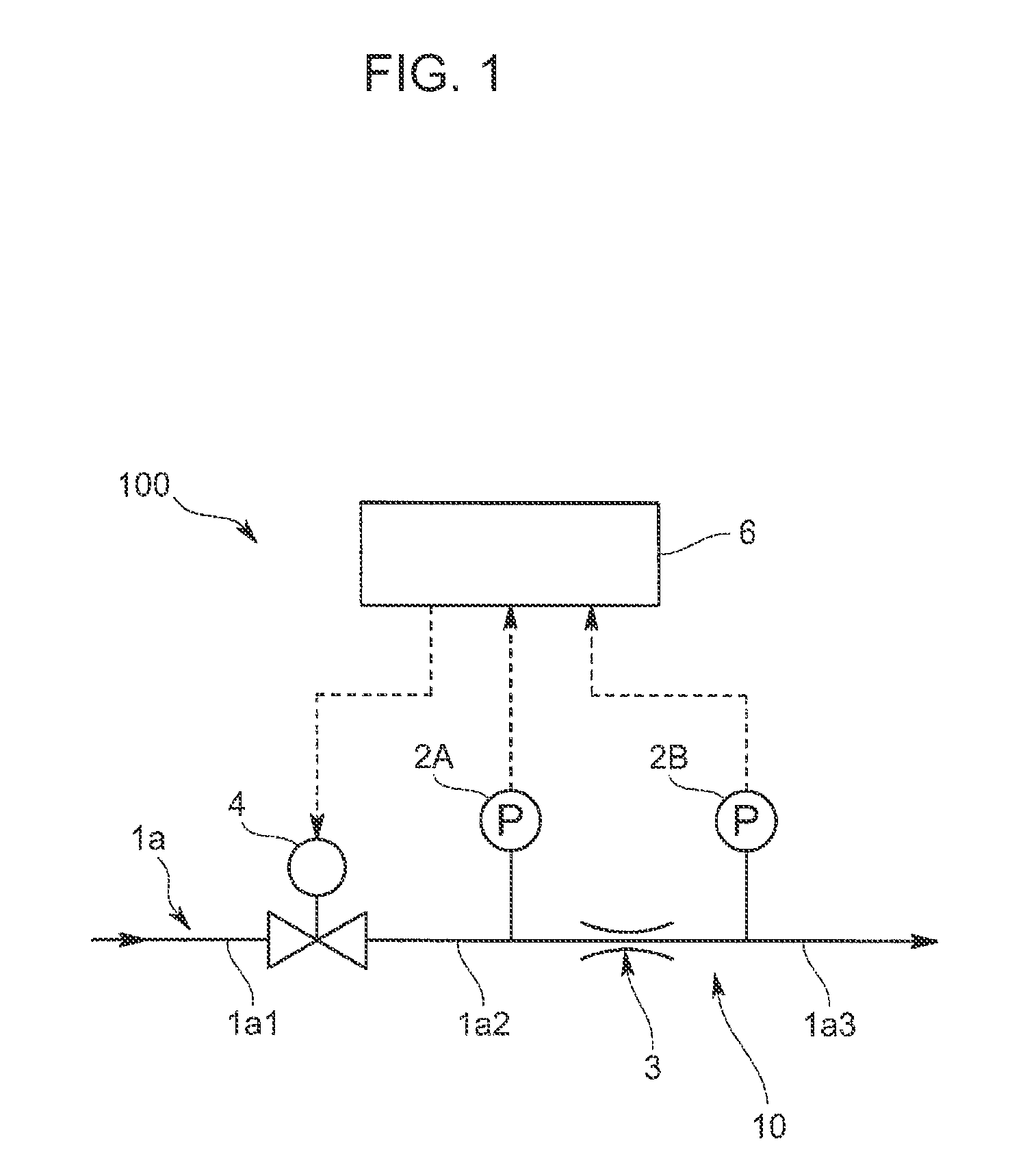

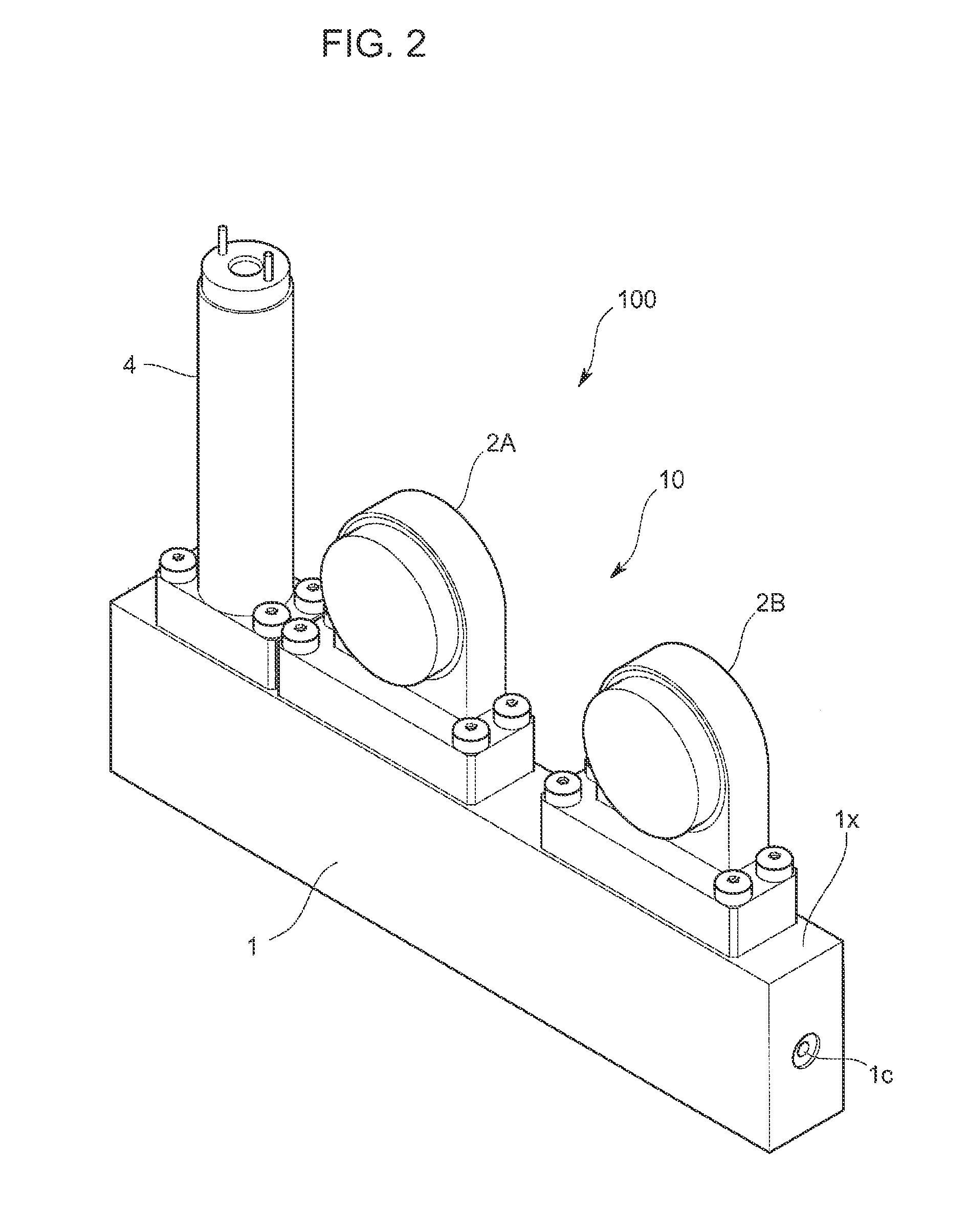

Fluid controller

ActiveUS8910656B2Reduce width dimensionMaintain mechanical strengthOperating means/releasing devices for valvesFlow control using electric meansFluid controlPressure sense

A fluid controller is disclosed, having a body unit, a fluid controlling valve, pressure sensors, and a casing. The fluid controlling valve is attached to a component part attachment face of the body unit. The pressure sensors are attached to the component part attachment face so that the pressure sensing surfaces thereof are positioned substantially perpendicular to the component part attachment face and substantially parallel to the longitudinal direction. On the lateral walls of the casing, the inner surfaces thereof are arranged to be uneven, so that such sections facing the fluid controlling valve and the pressure sensors are arranged to be thin sections, whereas at least a part of such a section that does not face the fluid controlling valve and the pressure sensors is arranged to be a thick section that is thicker than the thin sections.

Owner:HORIBA STEC CO LTD

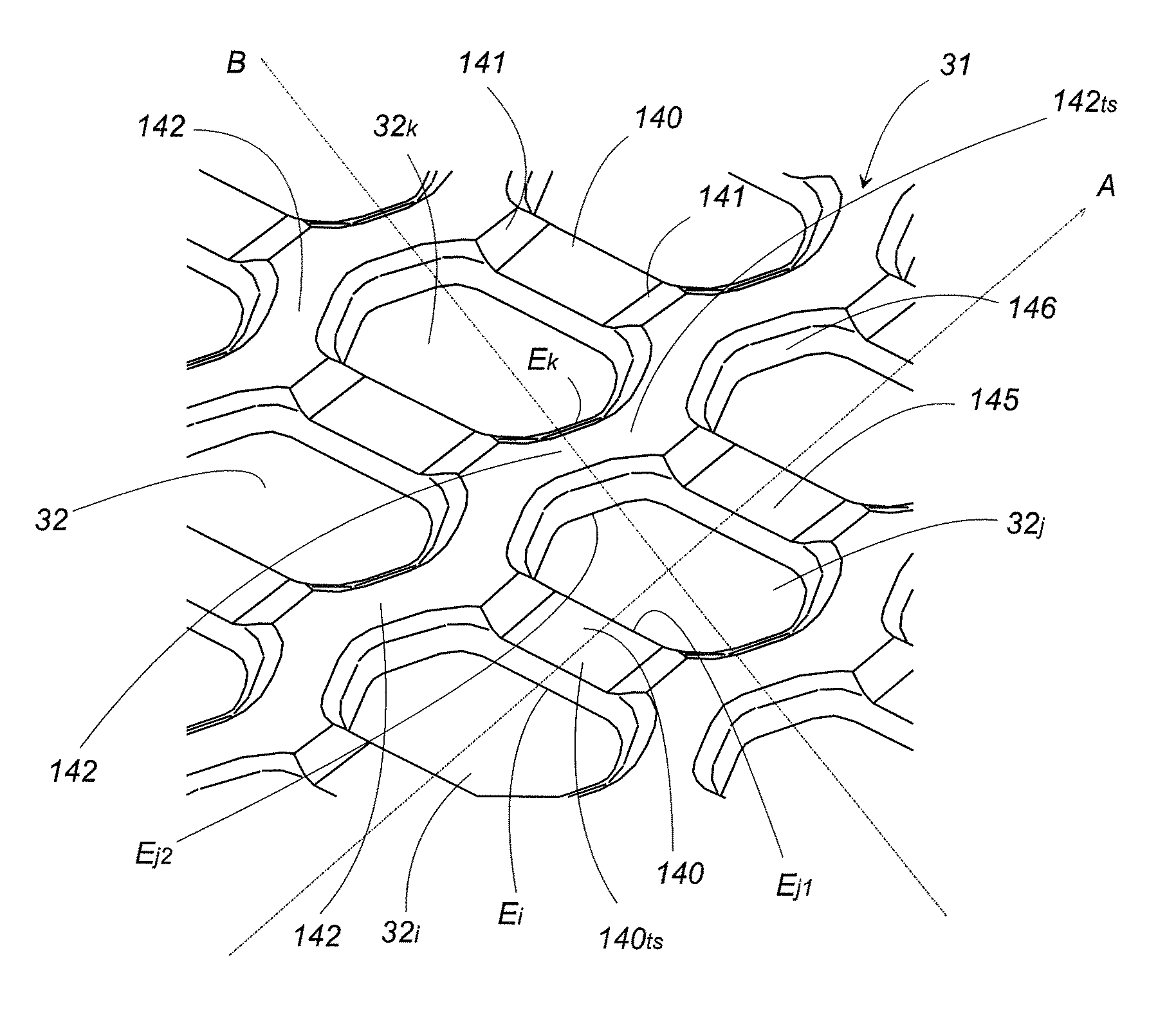

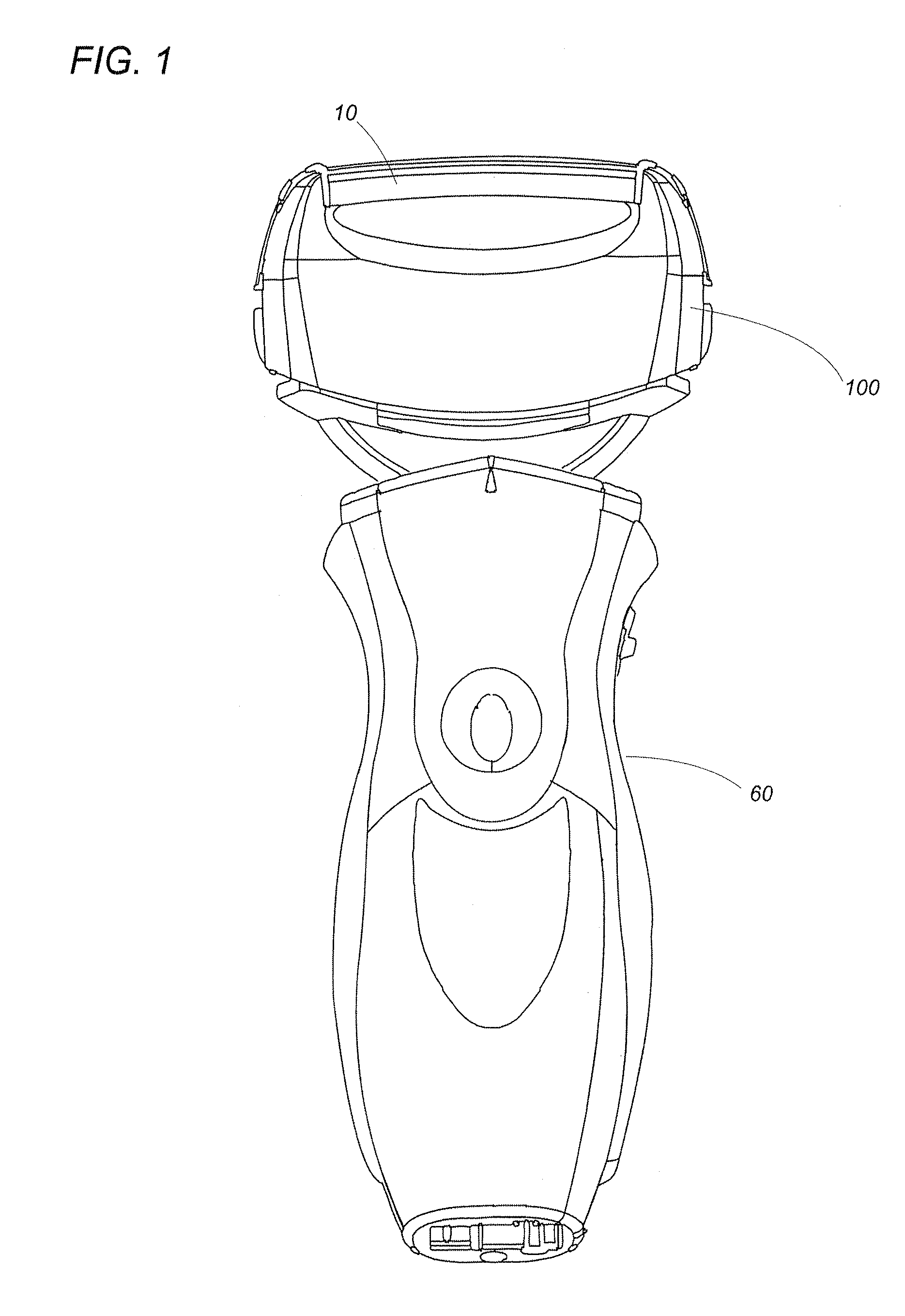

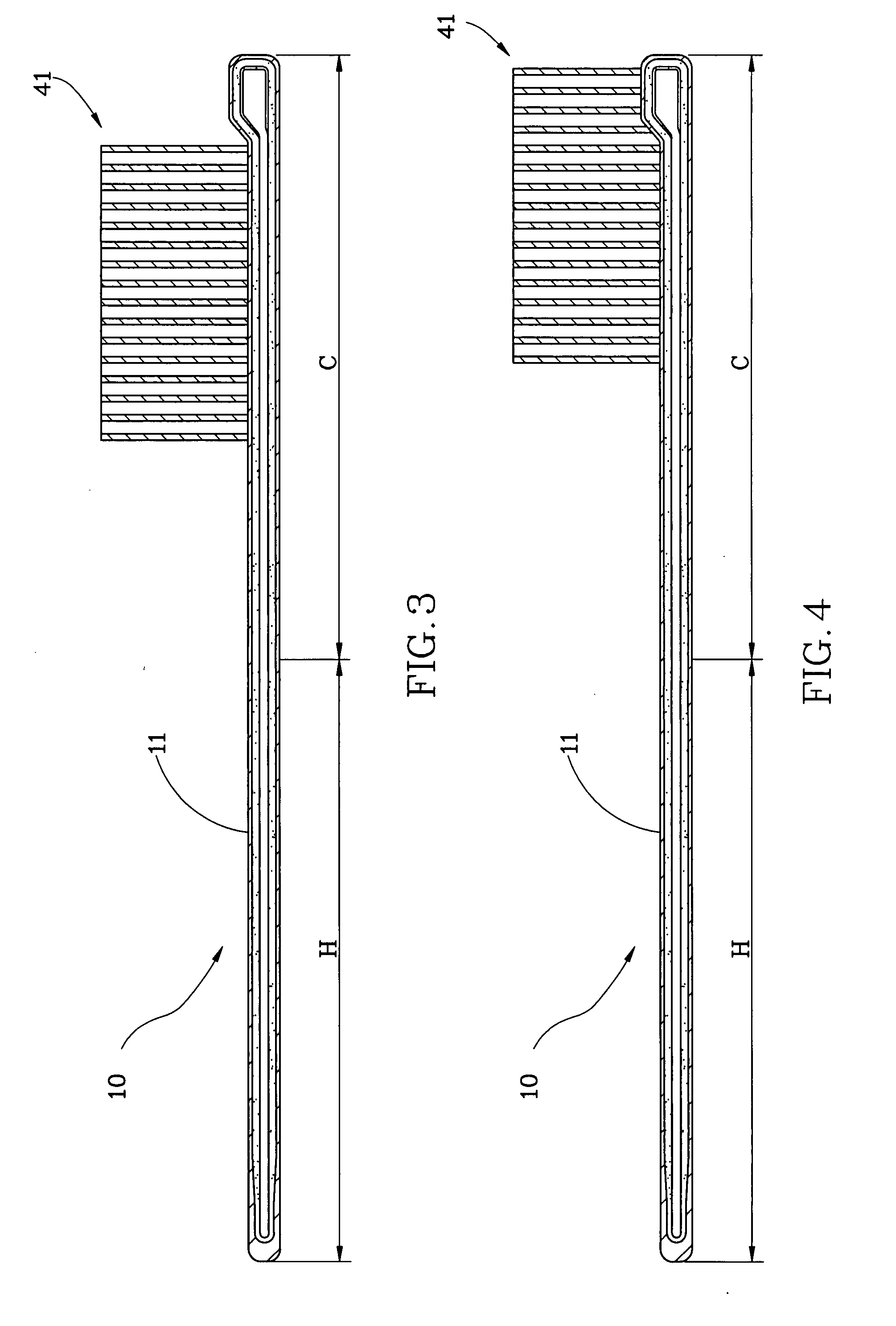

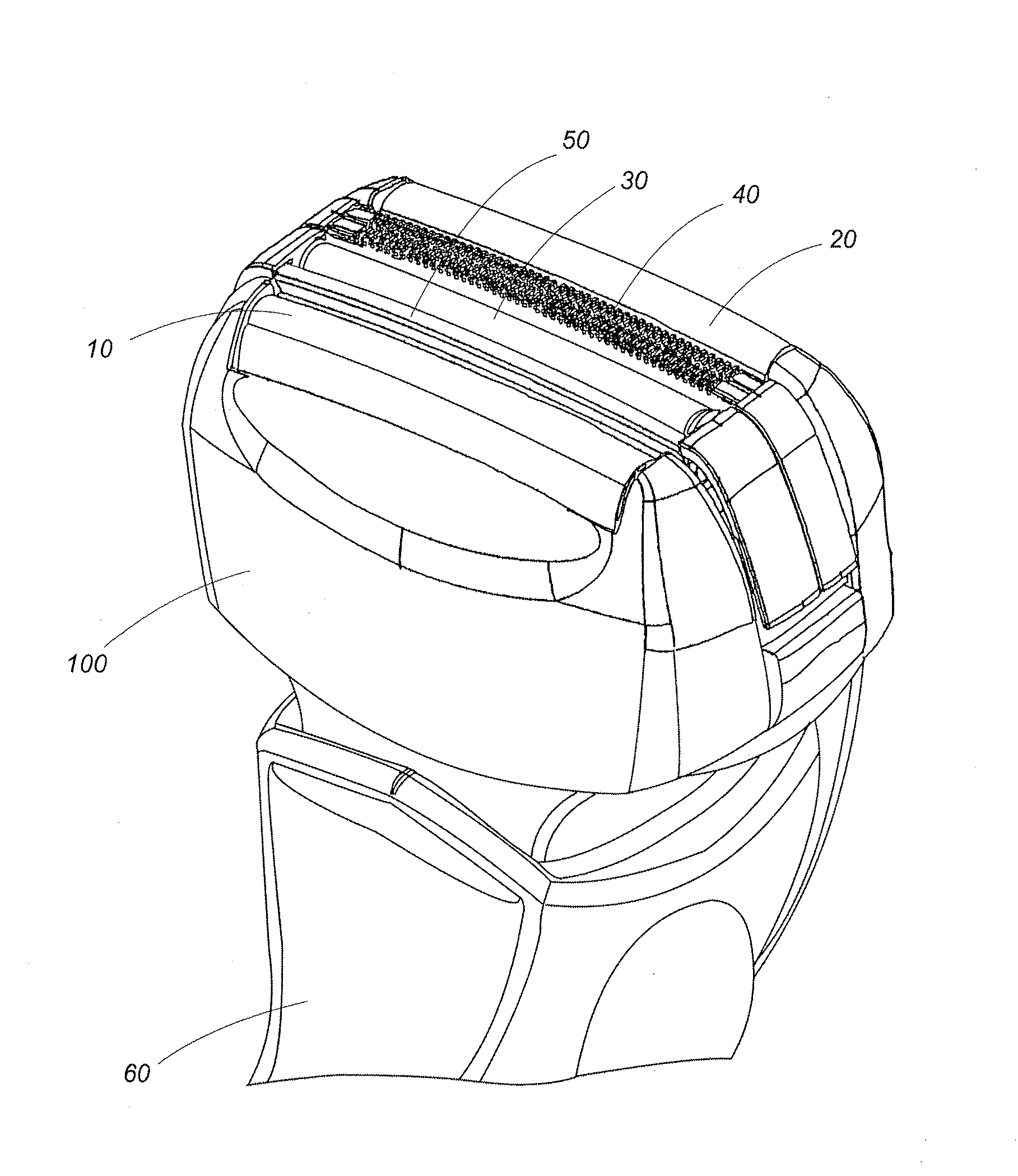

Shaving foil for a dry shaver

ActiveUS7730621B2Without causing skin irritationReduce thicknessMetal working apparatusRazor stropSkin contact

A shaving foil for a dry shaver has a plurality of perforation arranged in an array. The shaving foil is formed in its skin contact surface with a plurality of recesses which define a thin section of reduced thickness at the recesses, while leaving thick sections at the remainder of the foil. Each perforation is configured to have its circumference defined partly by the thin section and partly by the thick section. Both of the thin and thick sections can come into contact with a user's skin for smoothly guiding hairs into the perforations to make close shaving without irritating the skin, while the shaving foil is moved across the skin. Especially, the thin sections act to cut the hairs shorter than the thick section, as wall as to raise flattened hairs into the perforations for successfully cutting the flattened hairs.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Nodularizer for nodular iron with thick section

InactiveCN102002548AImprove mechanical propertiesSuppresses the formation of graphite distortionCeriumRare earth

The invention discloses a nodularizer for nodular iron with a thick section, and belongs to casting alloys. The nodularizer consists of elements of magnesium, silicon, barium, calcium, rare earth, antimony and iron, wherein the rare earth consists of cerium and yttrium; the nodularizer comprises 6 to 10 weight percent of magnesium, 40 to 48 weight percent of silicon, 5 to 6 weight percent of barium and calcium, 3 to 5 weight percent of rare earth, 0.4 to 0.7 weight percent of antimony and the balance of iron; the ratio of antimony to the rare earth is (8-14): 100; the 3 to 5 percent of rare earth contains 1.5 to 2.5 percent of cerium and 1.5 to 2.5 percent of yttrium; and the ratio of antimony to the cerium is (20-40): 100. After the nodularizer is applied, the nodular iron with the thick section can achieve satisfactory nodulizing effect within the curing time of 240 minutes, and the nodularizer particularly can inhibit graphite distortion in the nodular iron with the thick section.

Owner:HARBIN INST OF TECH

Thick section steel structure fireproof coating and construction technology thereof

InactiveCN104140707AHigh bonding strengthImprove water resistanceFireproof paintsSpecial surfacesInsulation layerFire - disasters

A thick section steel structure fireproof coating is characterized in that the thick section steel structure fireproof coating is composed of a fireproof coating, a binder and water according to a weight ratio of 1:0.08:1.2. The NH-AWS indoor thick section steel structure fireproof coating is a water-soluble coating, is prepared by compounding the inorganic binder with many flame-retardant heat insulation coatings, and a coat formed by the thick section steel structure fireproof coating can form a heat insulation layer after meeting fire, so a steel member is insulated and protected from heat in a fire hazard, and does not generate any harmful gases at a high temperature, and the strength of the steel member does not acutely decrease under the action of the high temperature of the fire hazard, thereby the collapse of buildings is avoided; and the NH-AWS indoor thick section steel structure fireproof coating has the advantages of high binding strength, excellent water resistance, good weather ability, light specific gravity, long fireproof time, and suitableness for the fireproof protection of the naked parts of steel structure buildings with high fireproof limit.

Owner:HENAN OASIS TECH GRP

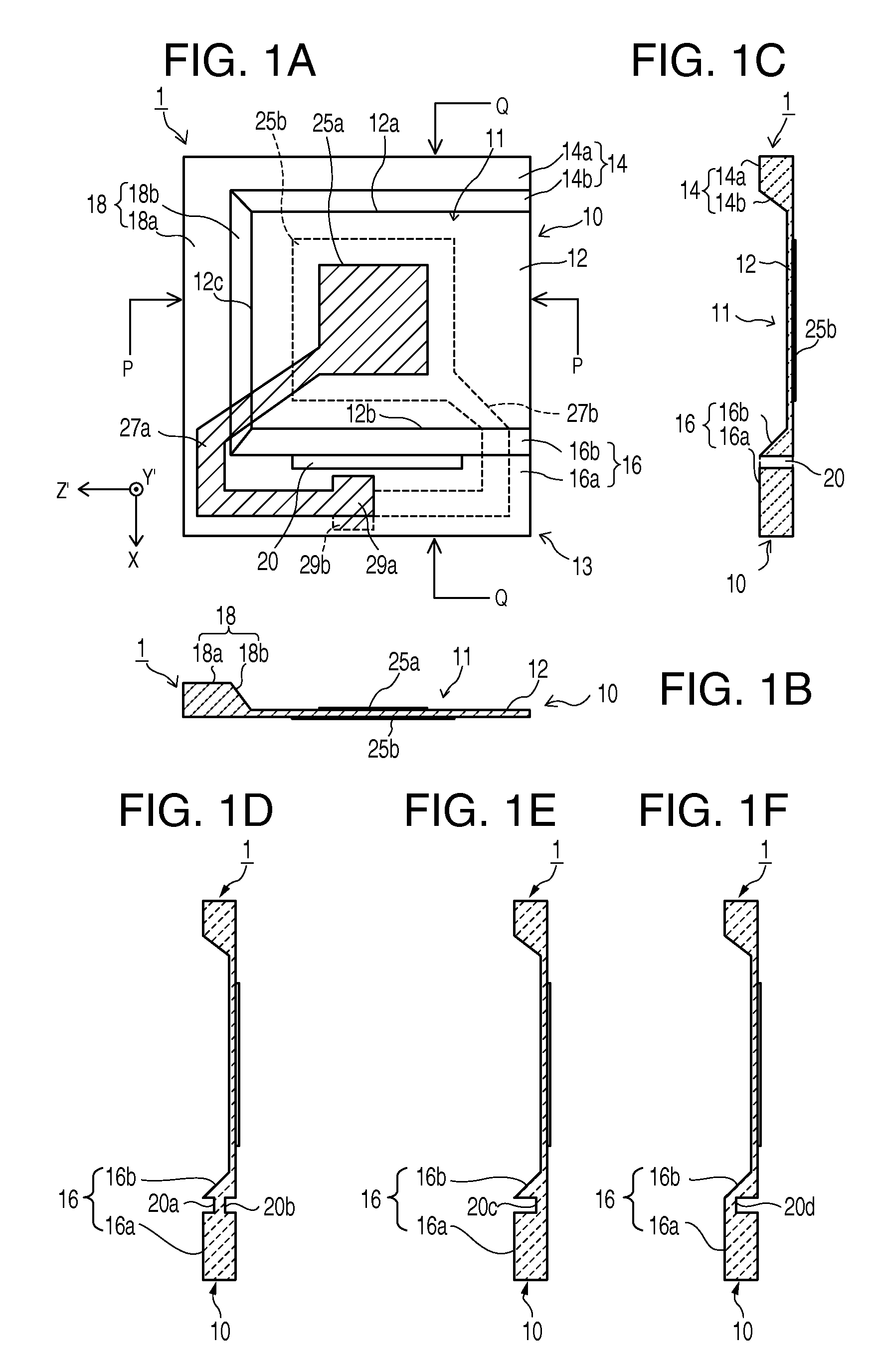

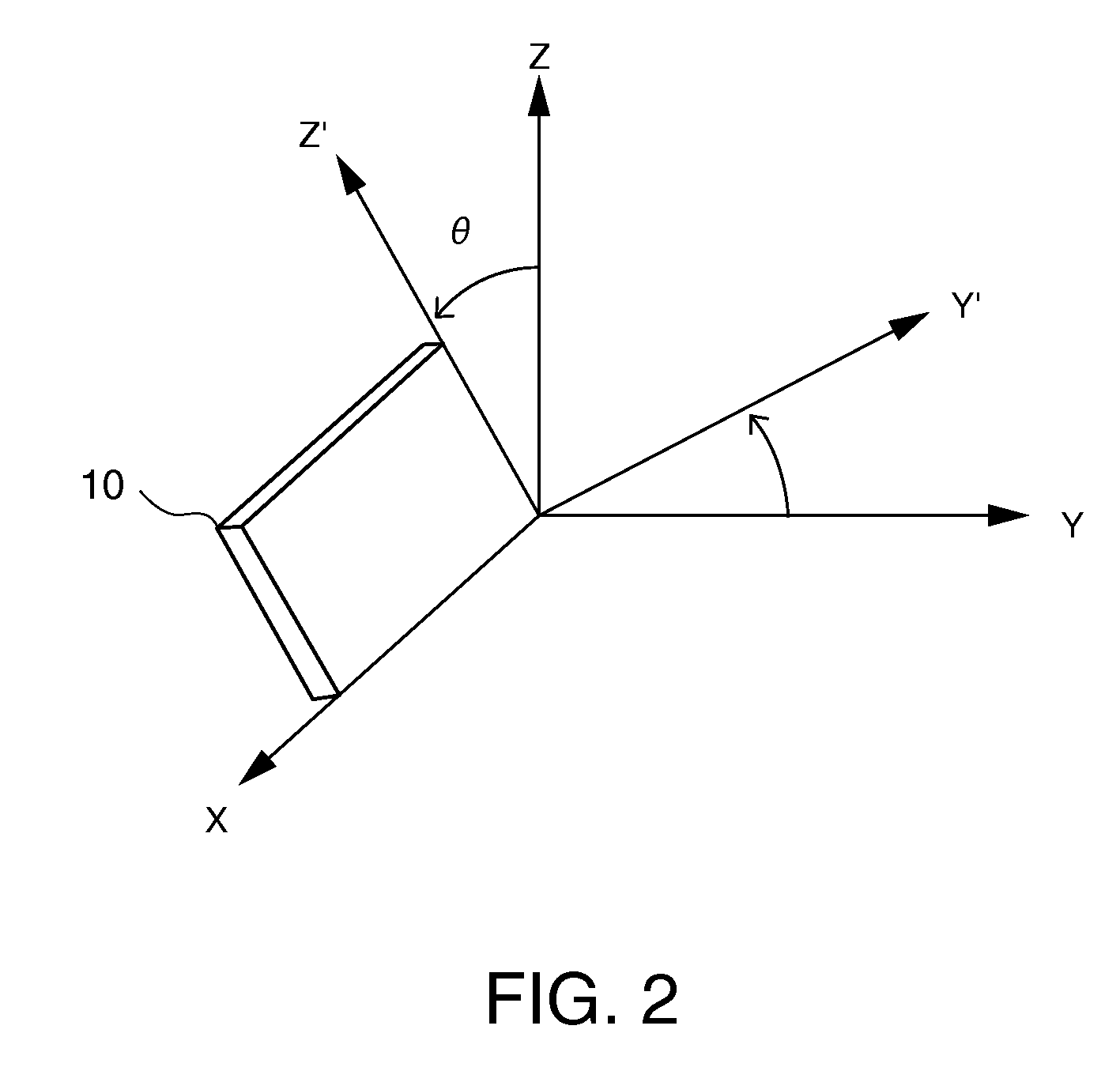

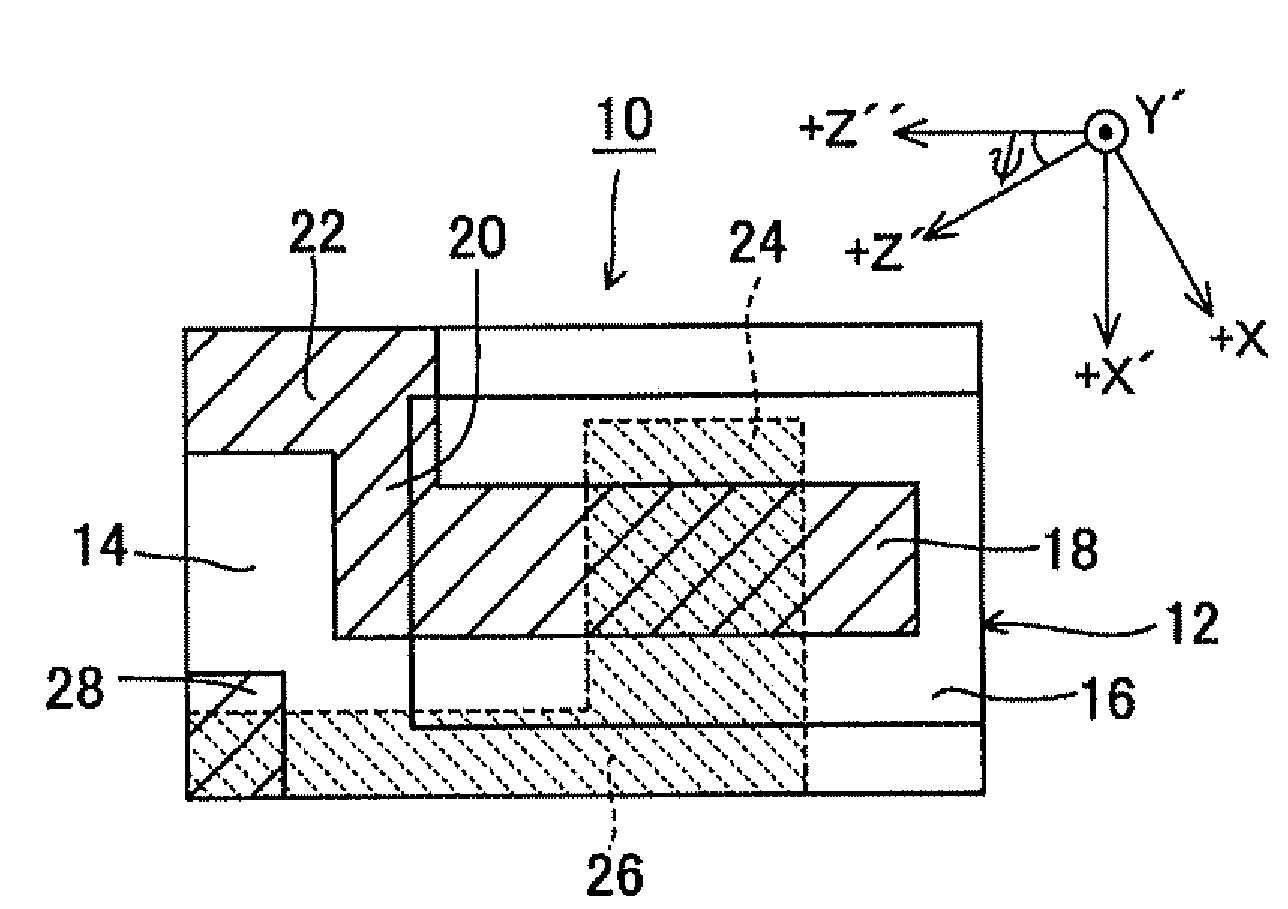

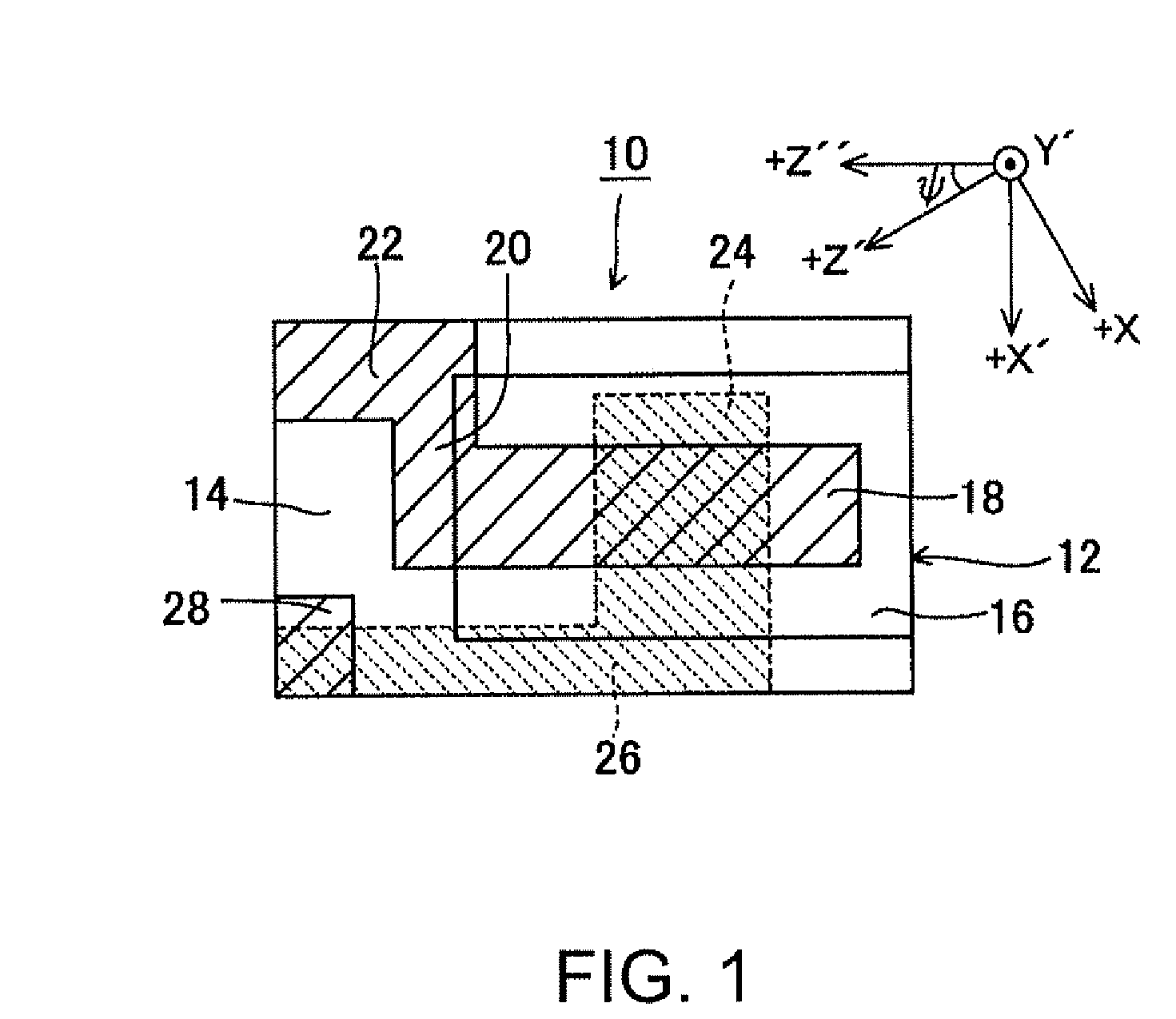

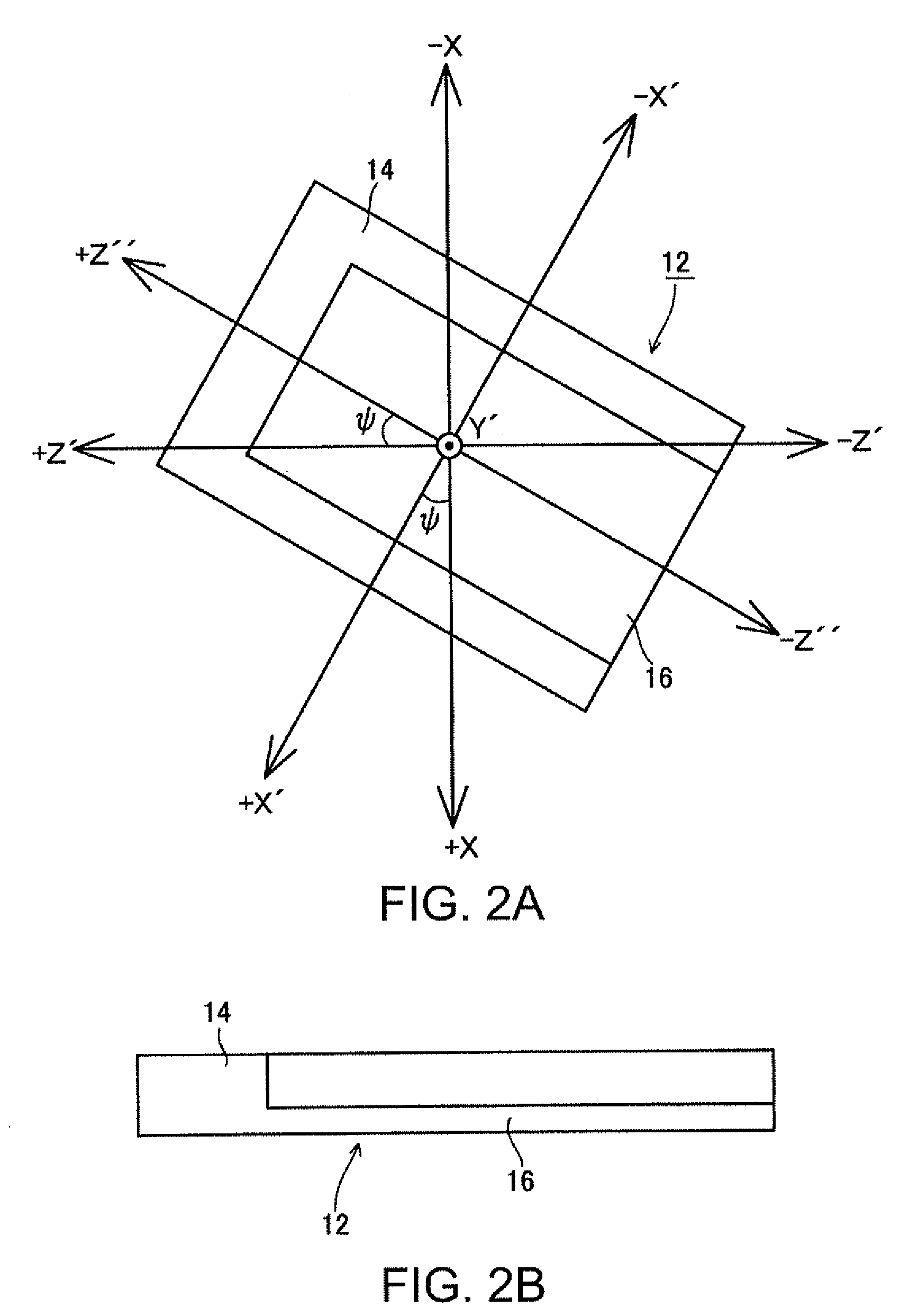

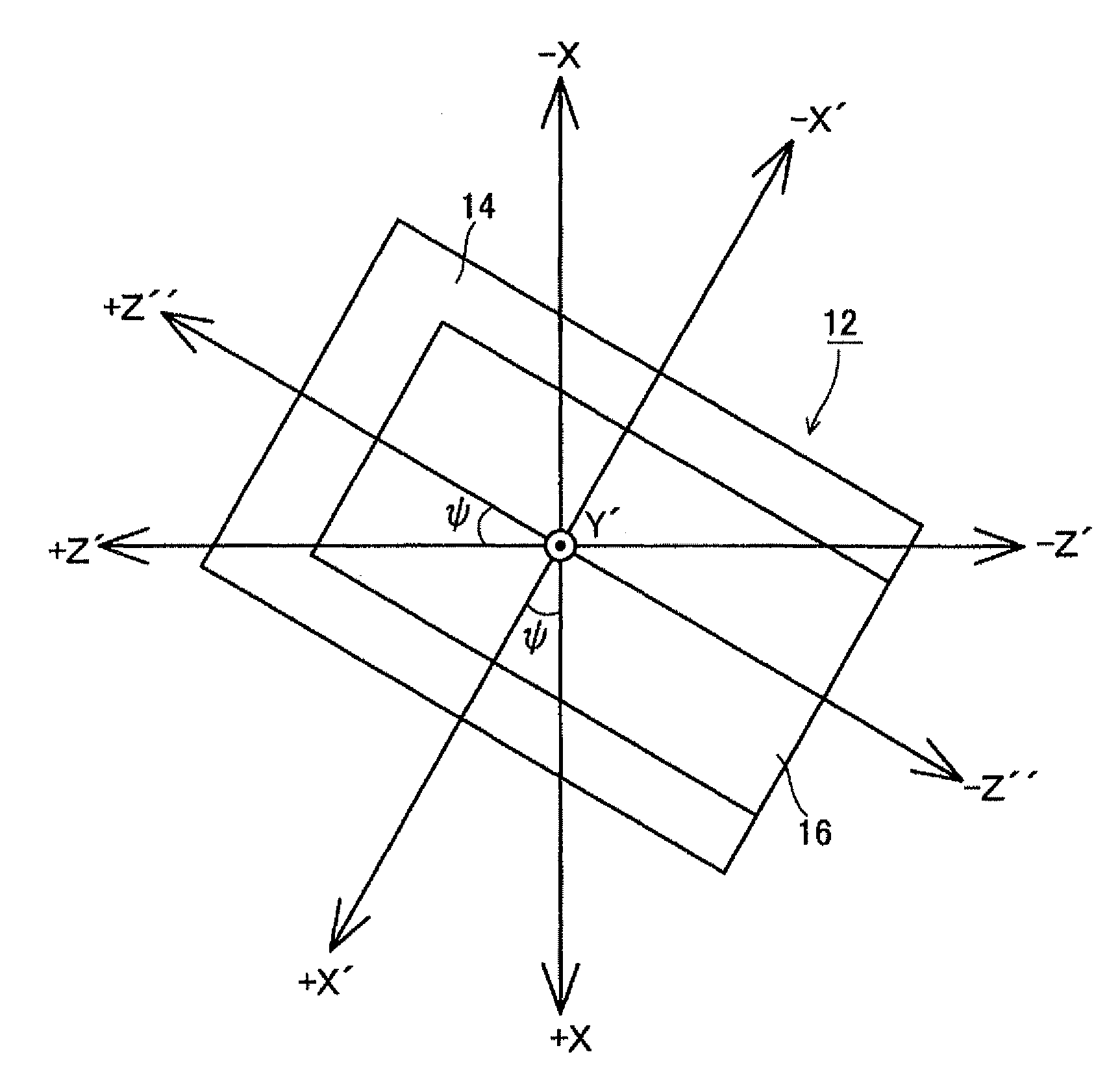

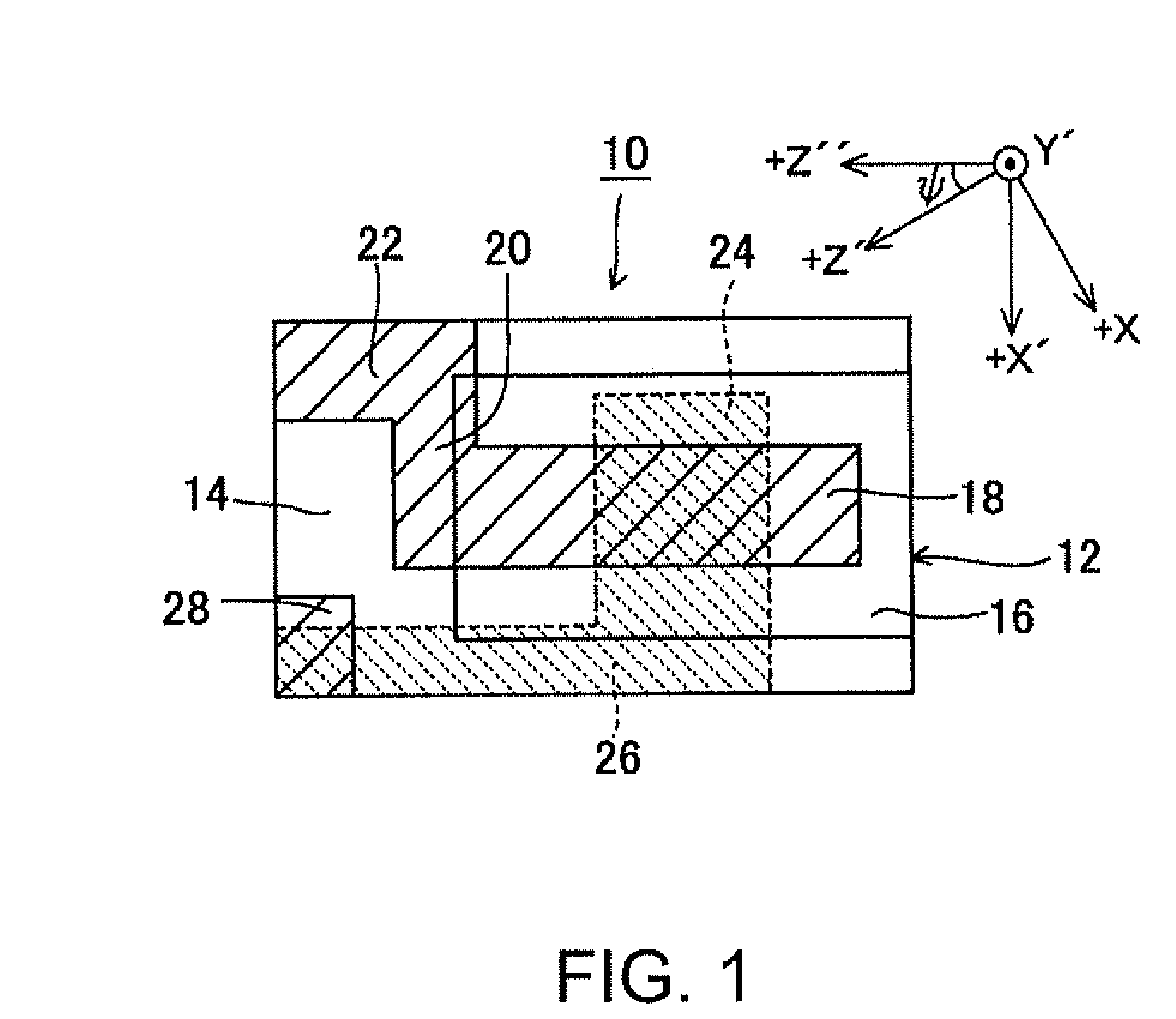

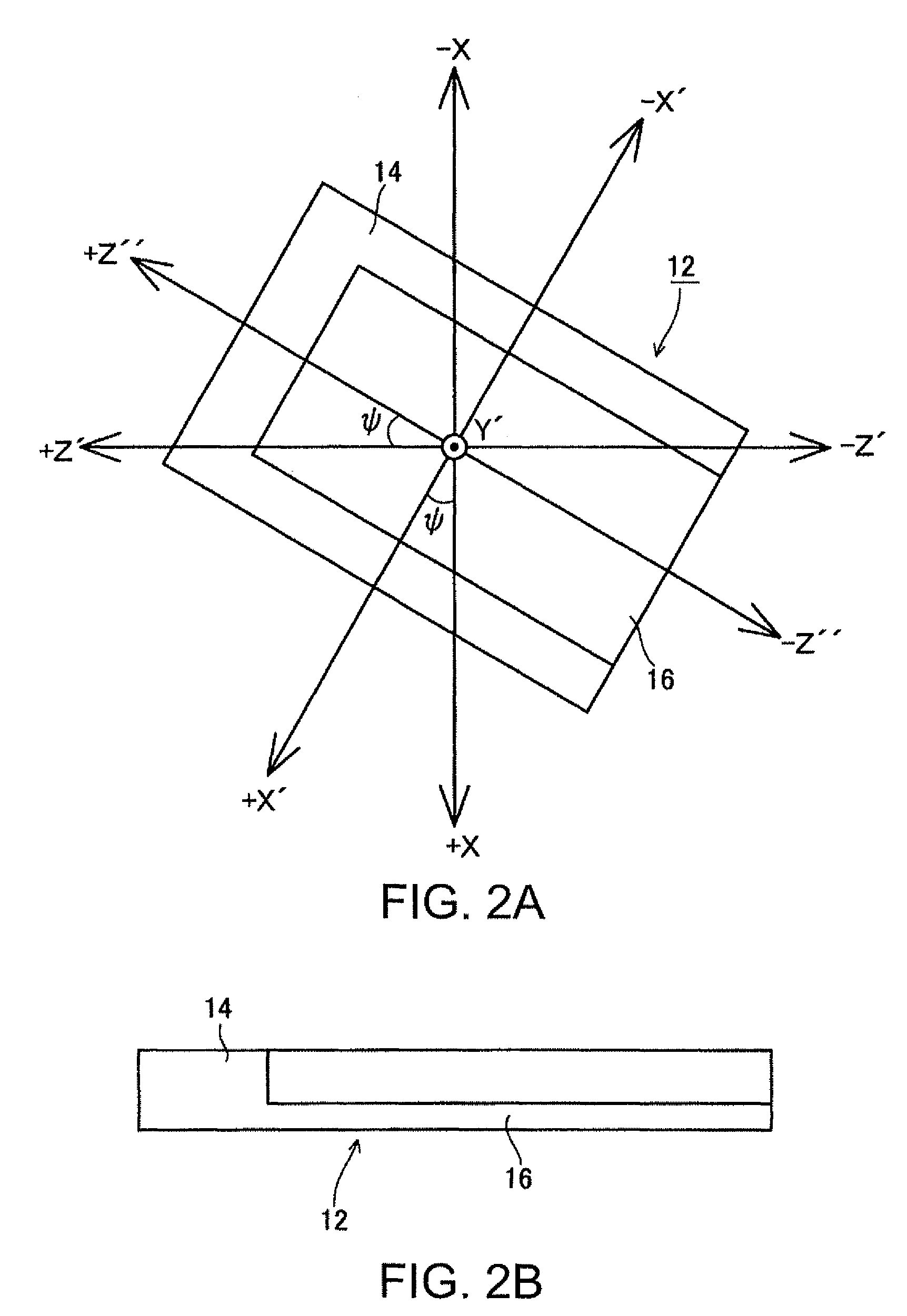

Quartz crystal resonator element, quartz crystal device, and method for producing quartz crystal resonator element

ActiveUS20090167117A1Improve batch productivityBig spacePiezoelectric/electrostrictive device manufacture/assemblyImpedence networksQuartz crystal resonatorEtching

A quartz crystal resonator element includes an AT-cut quartz crystal substrate, the substrate having edges parallel to each of a Z″ axis obtained by rotating a Z′ axis in a range of −120° to +60° about a Y axis and an X′ axis perpendicular to the Z″ axis when an angle formed by rotating a +Z′ axis in a direction of a +X axis about the Y′ axis is a positive rotation angle; a thin section that forms a resonating section; and a thick section adjacent to the resonating section, the thin section and the thick section being formed on the quartz crystal substrate by wet etching. The thin section is formed either on a main surface of the substrate corresponding to a +Y′-axis side or on a main surface of the substrate corresponding to a −Y′-axis side. When the thin section is formed by the etching on the main surface of the +Y′-axis side, the thick section is provided at at least a +Z″-axis-side end of the thin section, whereas when the thin section is formed by the etching on the main surface of the −Y′-axis side, the thick section is provided at at least a −Z″-axis-side end of the thin section.

Owner:SEIKO EPSON CORP

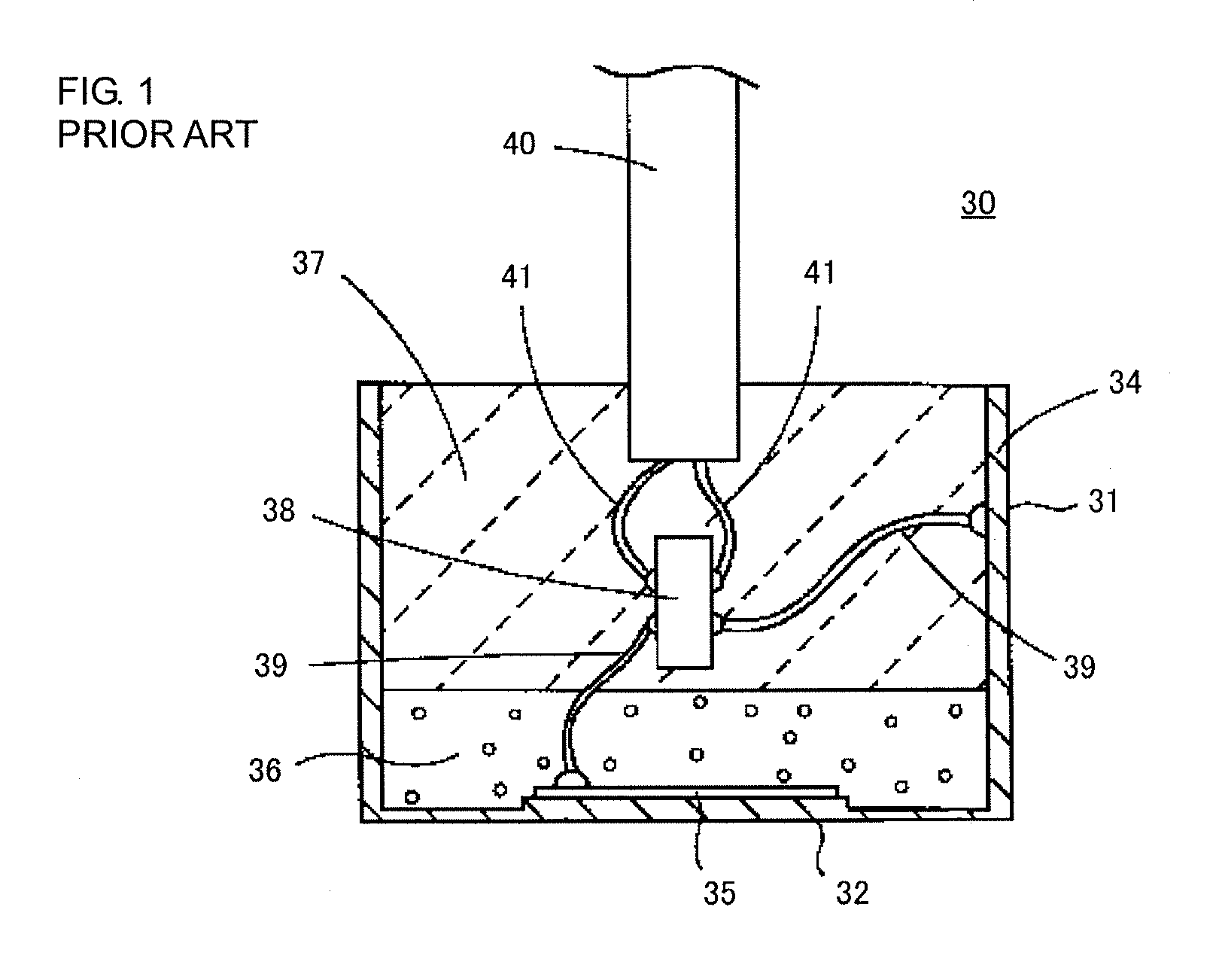

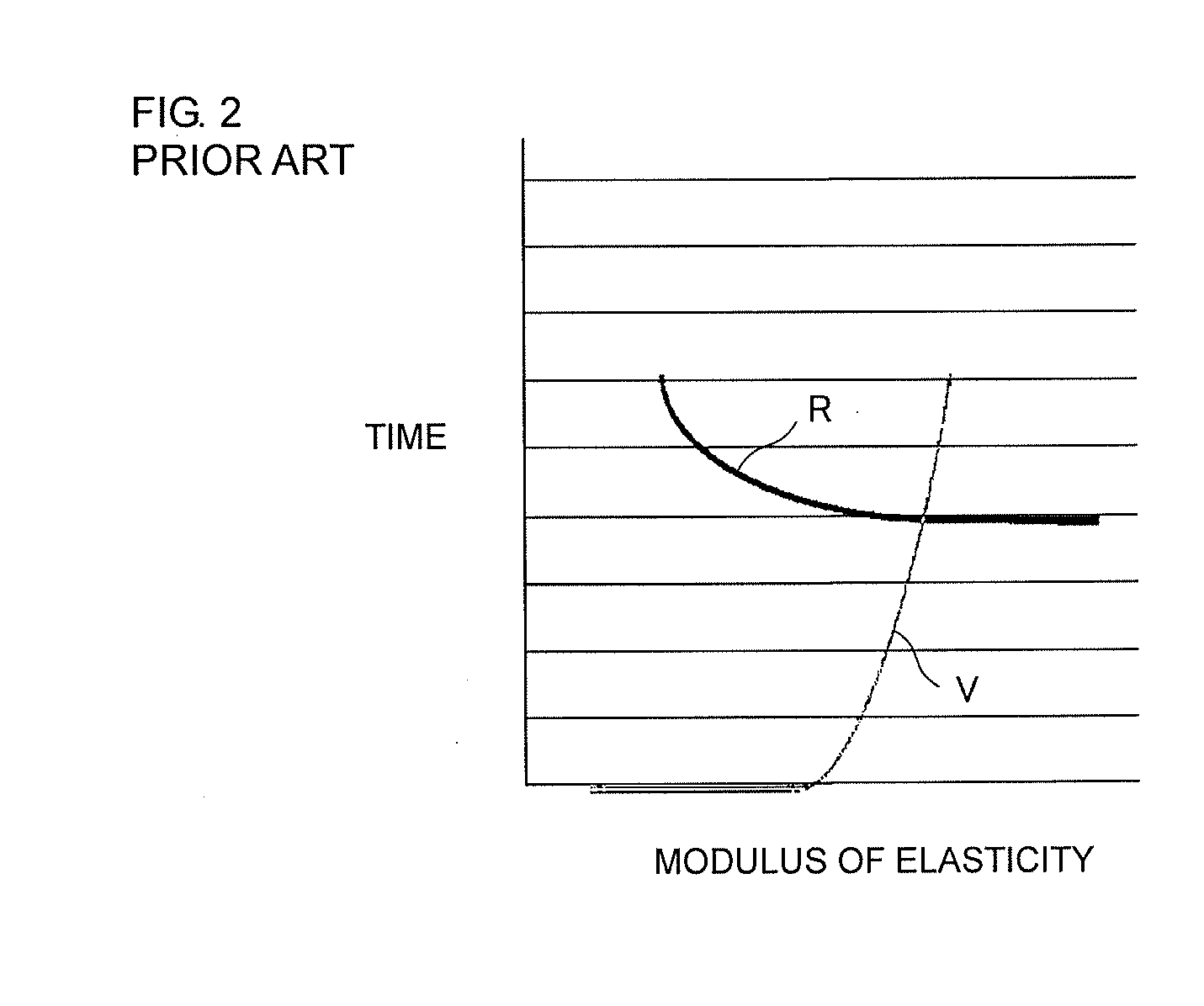

Ultrasonic Sensor

ActiveUS20110290584A1High sensitivityShort-range detectionWave based measurement systemsPiezoelectric/electrostriction/magnetostriction machinesUltrasonic sensorEngineering

An ultrasonic sensor includes a substantially cylindrical case including a bottom portion and a side wall portion and a plurality of members disposed within the case. A reinforcement having a substantially ring shape is fitted on a thick section in the case at a location that is not in contact with an inner surface of a thin section of the side wall portion. A piezoelectric element is attached to an inner bottom surface of the case. An elastic member is fitted on the reinforcement so as to cover a substantially ring-shaped opening region of the reinforcement. A gap between the elastic member and an inner circumferential surface of the case is filled with a first filler. The terminal holding member is placed on the elastic member. A surrounding region of the terminal holding member is filled with a second filler.

Owner:MURATA MFG CO LTD

Casting method of spheroidal graphite cast iron valve

ActiveCN108531803AStable productionReduce manufacturing costFoundry mouldsFurnace typesElectricitySlag

The invention discloses a casting method of a spheroidal graphite cast iron valve, and relates to the spheroidal graphite cast iron valve. The method comprises the steps of model making, modeling, smelting, pouring, heat treatment and obtaining of a finished product valve casting. Alloy elements are not added, the spheroidal graphite cast iron valve with the supersize can be stably produced, a dedicated slag blocking device is arranged at the front end of a transverse sprue, when molten iron of the transverse sprue is introduced into the front end, the slag blocking effect is achieved, it is ensured that a mold cavity is rapidly and stably filled with the molten iron, oxide inclusions are reduced, a heat preservation top riser is adopted, and is placed on the top of the valve, and castingfeeding, slag discharging and exhausting are facilitated; a chilling block is arranged at the position, on the large and thick section and the portion with the large wall thickness difference, in thecasting, chromite sand is used around an even core and a shaft head in a shaft hole of the casting, the upper portion of an annular belt is paved with chromite sand, it is ensured that the casting canbe subject to directional sequential solidification, and meanwhile, the casting surface quality is ensured, and the method is particularly suitable for making a spheroidal graphite cast iron water and electricity butterfly valve with the supersize and the large section.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

Quartz crystal resonator element, quartz crystal device, and method for producing quartz crystal resonator element

InactiveUS8026652B2Improve batch productivityBig spacePiezoelectric/electrostrictive device manufacture/assemblyImpedence networksQuartz crystal resonatorEtching

A quartz crystal resonator element includes an AT-cut quartz crystal substrate, the substrate having edges parallel to each of a Z″ axis obtained by rotating a Z′ axis in a range of −120° to +60° about a Y′ axis and an X′ axis perpendicular to the Z″ axis when an angle formed by rotating a +Z′ axis in a direction of a +X axis about the Y′ axis is a positive rotation angle; a thin section that forms a resonating section; and a thick section adjacent to the resonating section, the thin section and the thick section being formed on the quartz crystal substrate by wet etching. The thin section is formed either on a main surface of the substrate corresponding to a +Y′-axis side or on a main surface of the substrate corresponding to a −Y′-axis side. When the thin section is formed by the etching on the main surface of the +Y′-axis side, the thick section is provided at at least a +Z″-axis-side end of the thin section, whereas when the thin section is formed by the etching on the main surface of the −Y′-axis side, the thick section is provided at at least a −Z″-axis-side end of the thin section.

Owner:SEIKO EPSON CORP

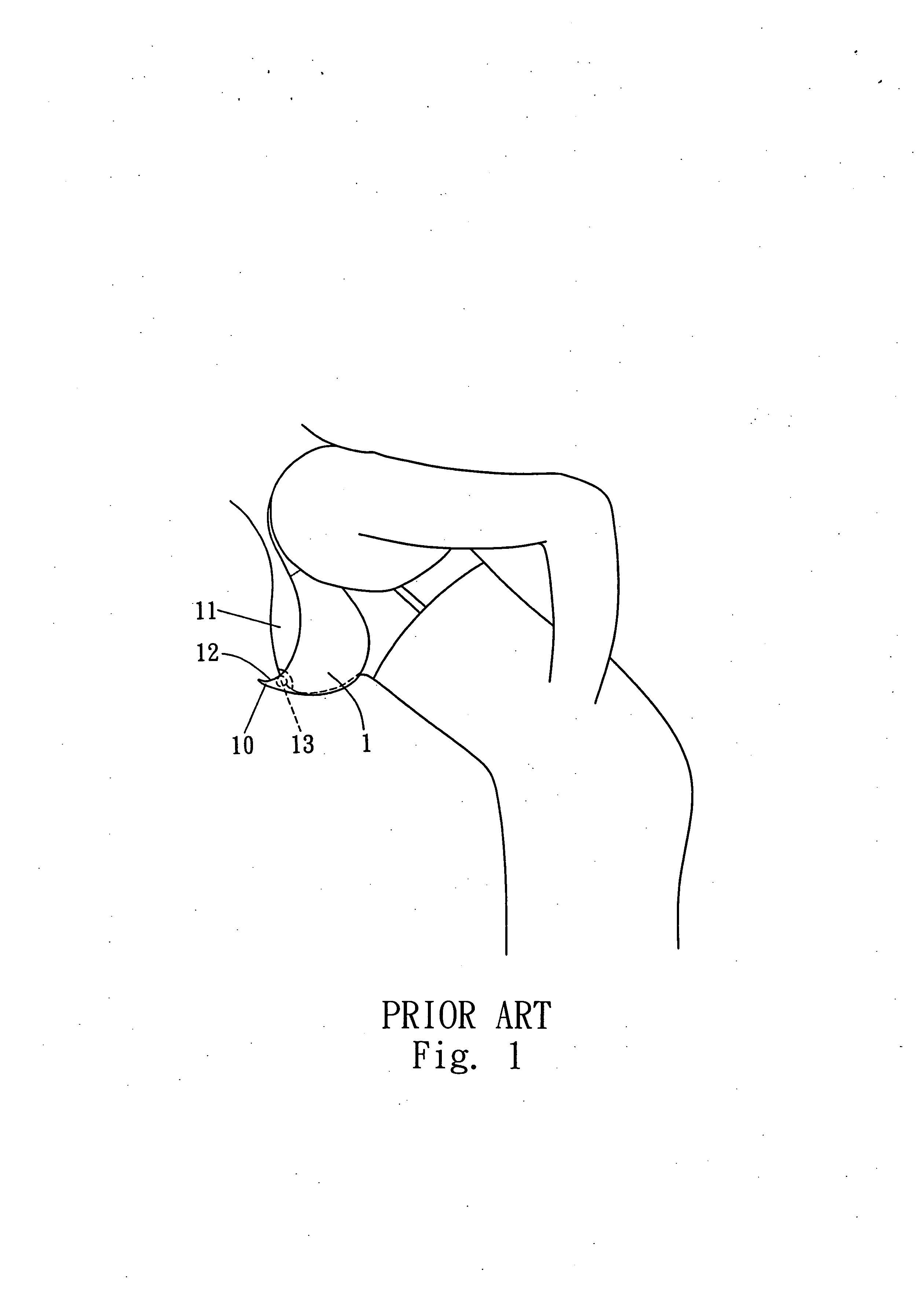

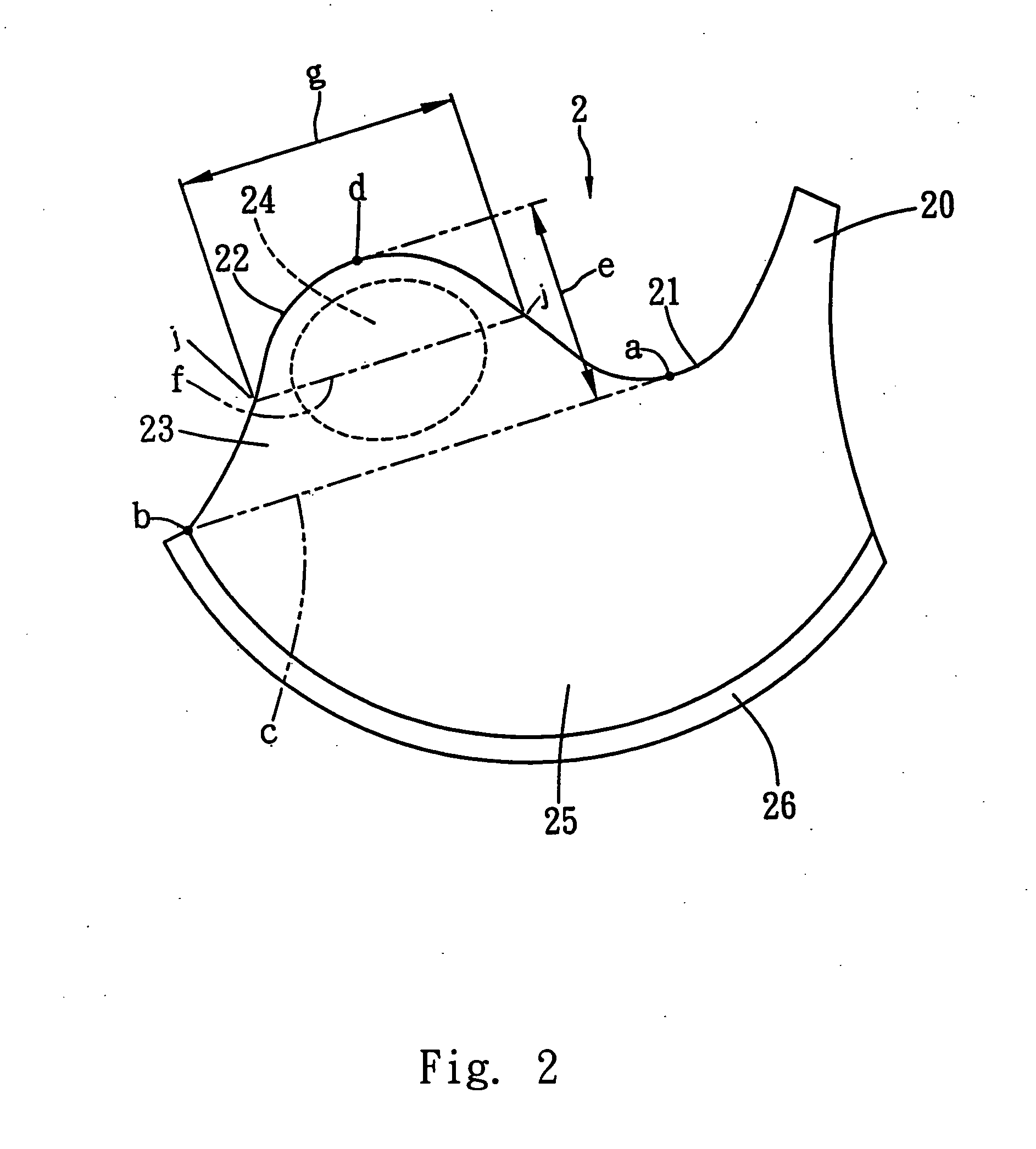

Inner bra cup

Owner:LIN SHIAN YI

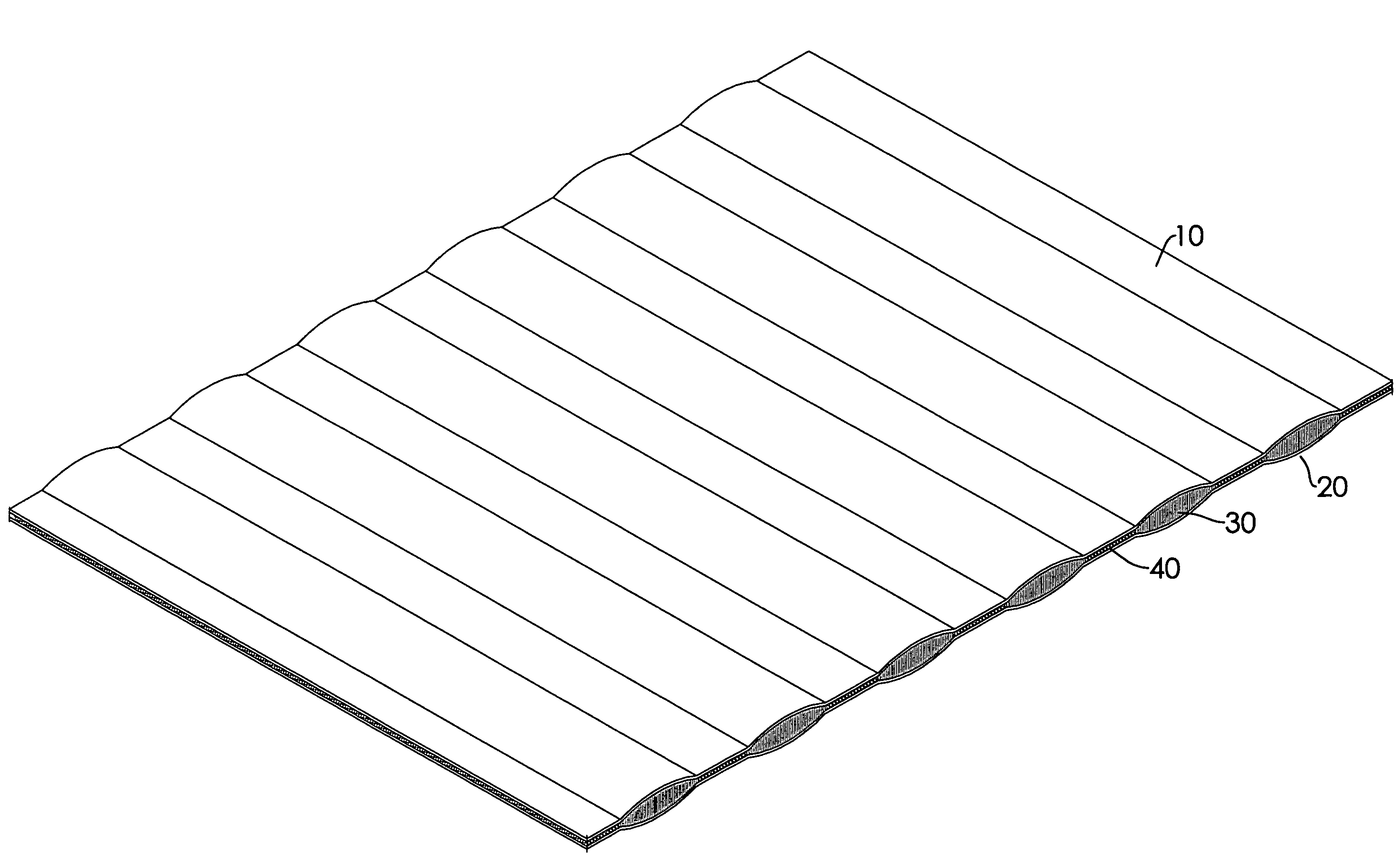

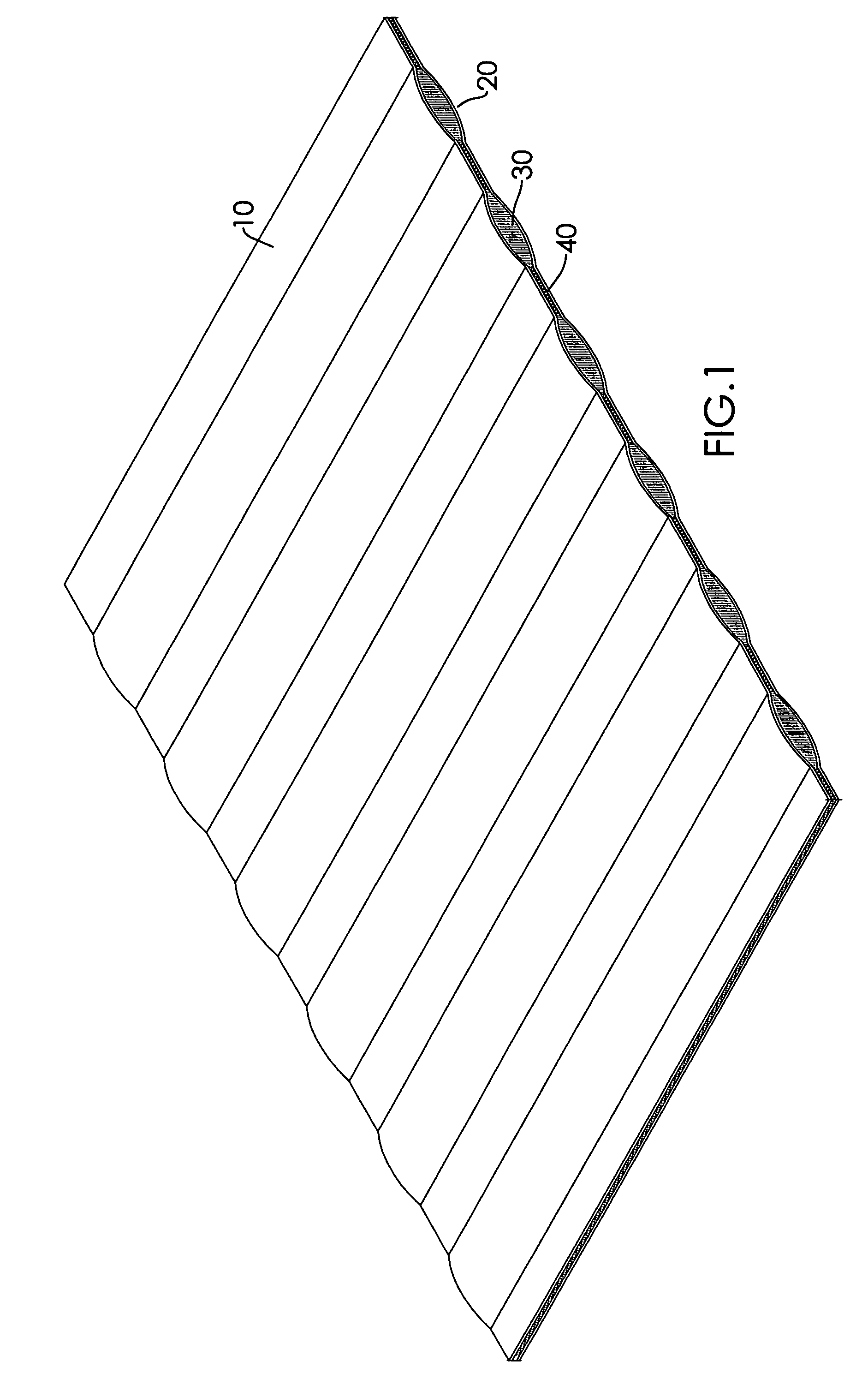

Fabric with different thicknesses

ActiveUS7380420B1Cost of of differentTime of of differentOrnamental textile articlesWarp knittingFiberYarn

A fabric with different thicknesses has an upper layer, a lower layer and at least one yarn layer made of firm yarn, connecting to and formed partially between the upper layer and the lower layer to from at least one thick section of the fabric. Multiple sections of the fabric without the at least one yarn layer are thin sections. Each of the at least one yarn layer is formed between two adjacent thin sections The fabric with different thicknesses is produced by a method comprising a mounting step, a forming step and a connecting step. The connecting step comprises connecting the upper layer partially to the lower layer by fibers to form the thin sections and connecting the upper layer to the lower layer by firm yarn to integrally form the at least one thick section to reduce the cost of the fabric.

Owner:RUEY TAY FIBER IND

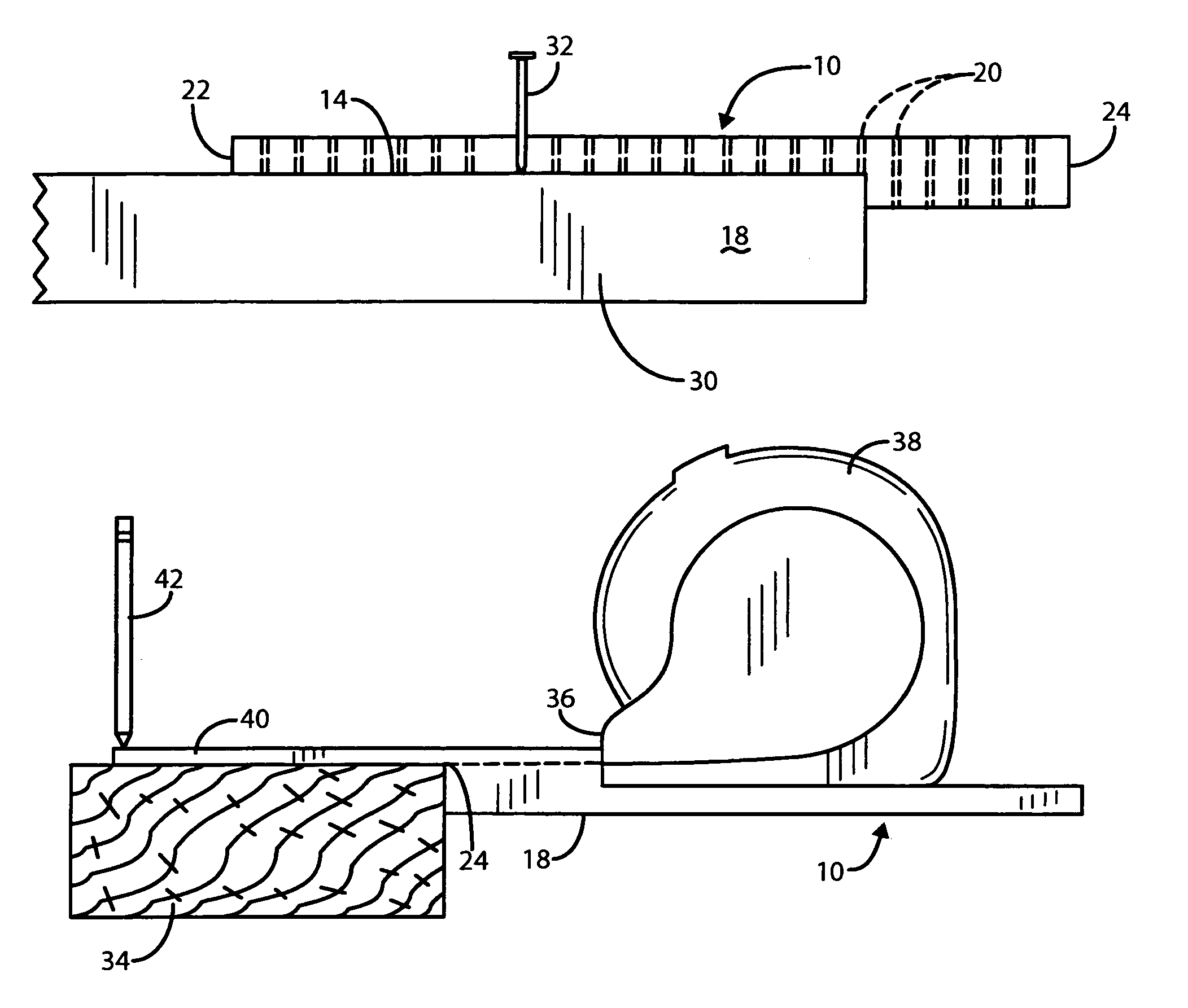

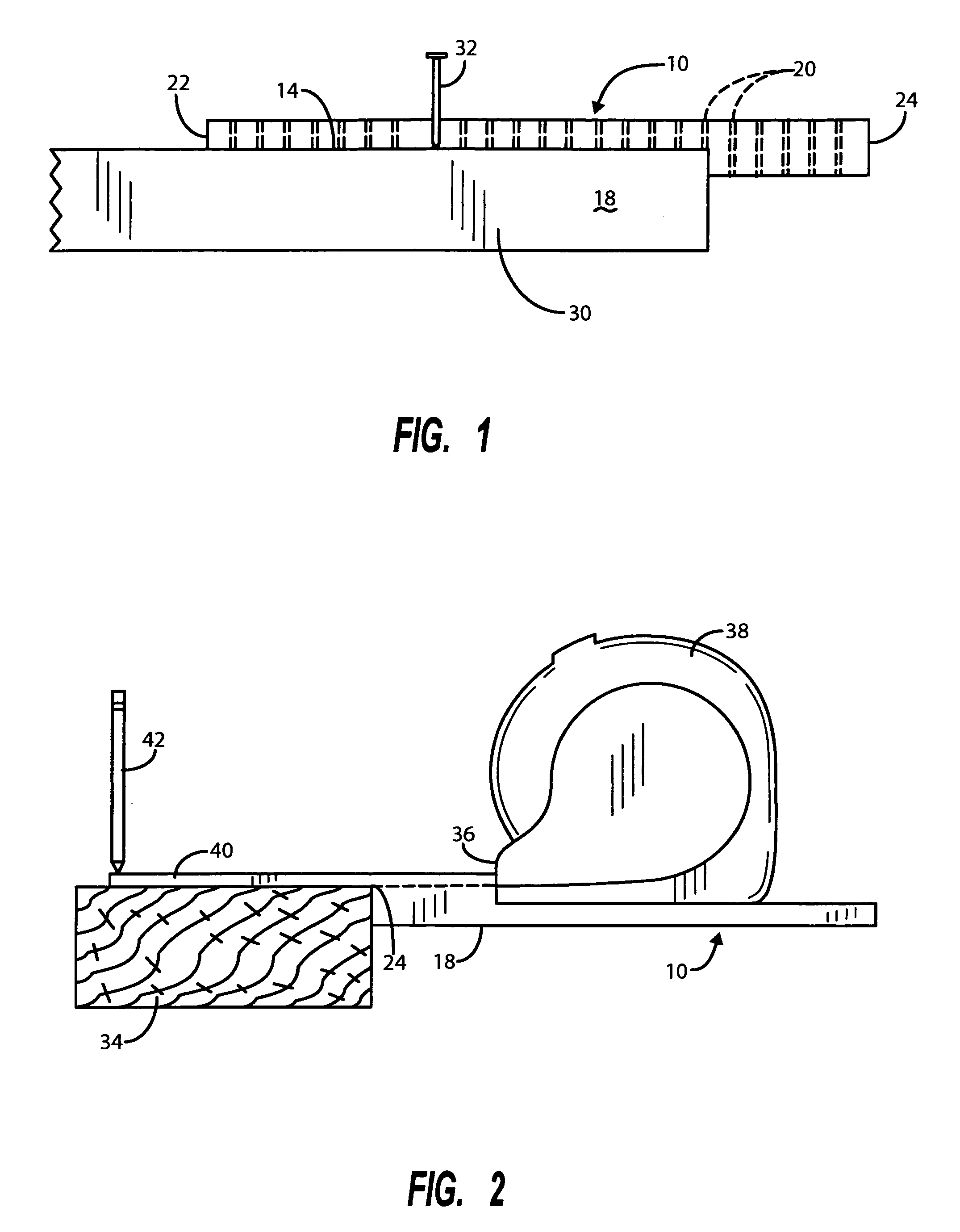

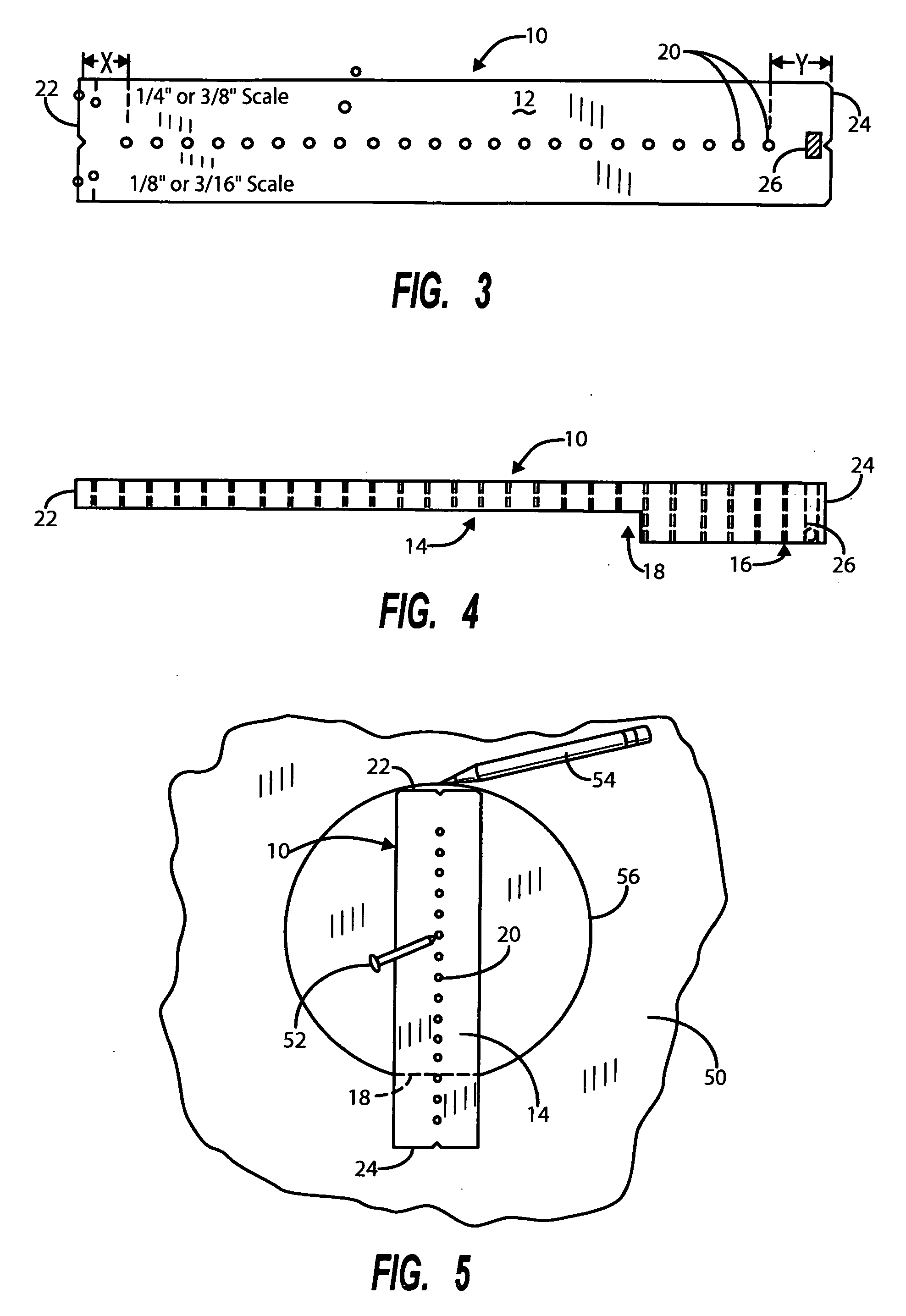

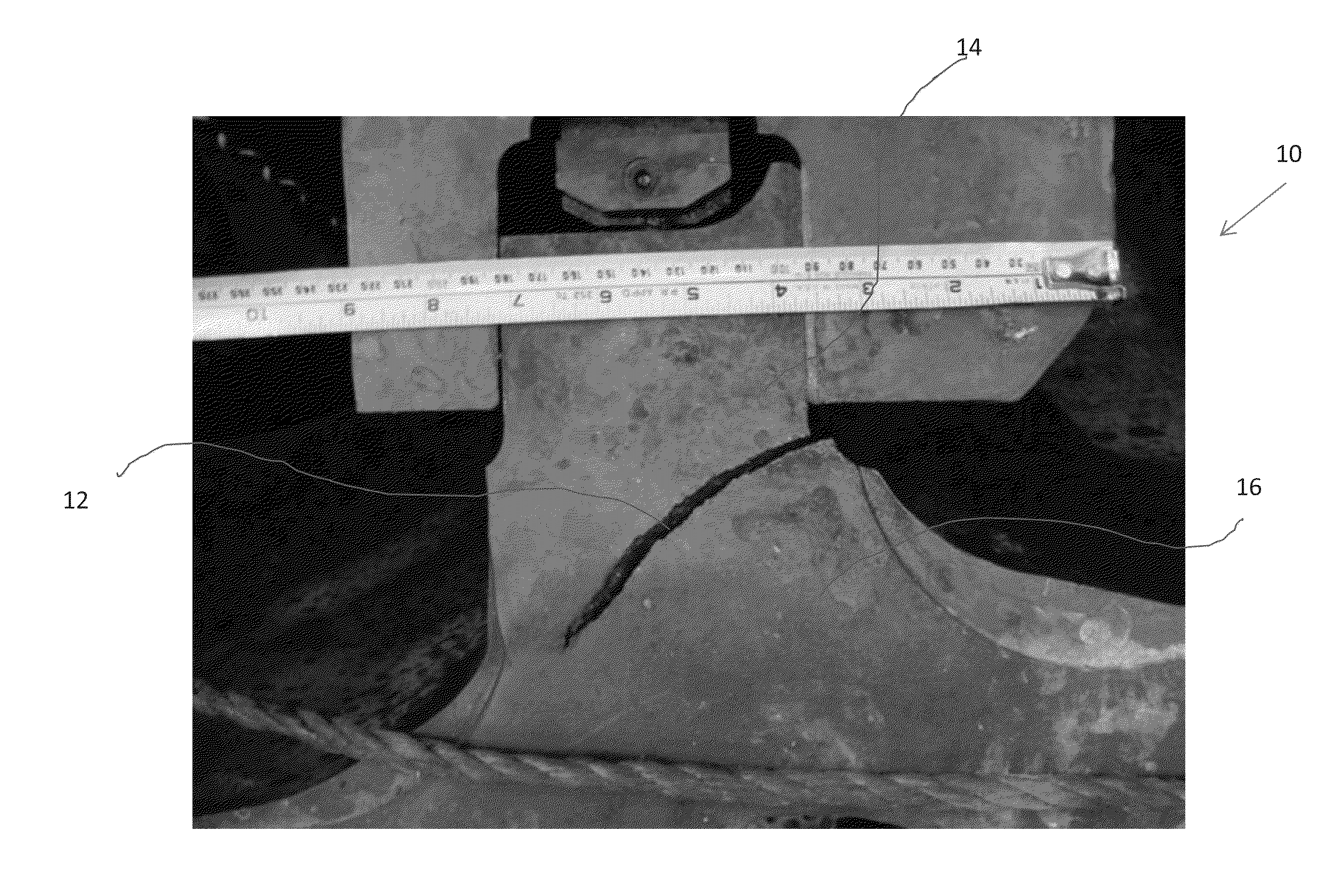

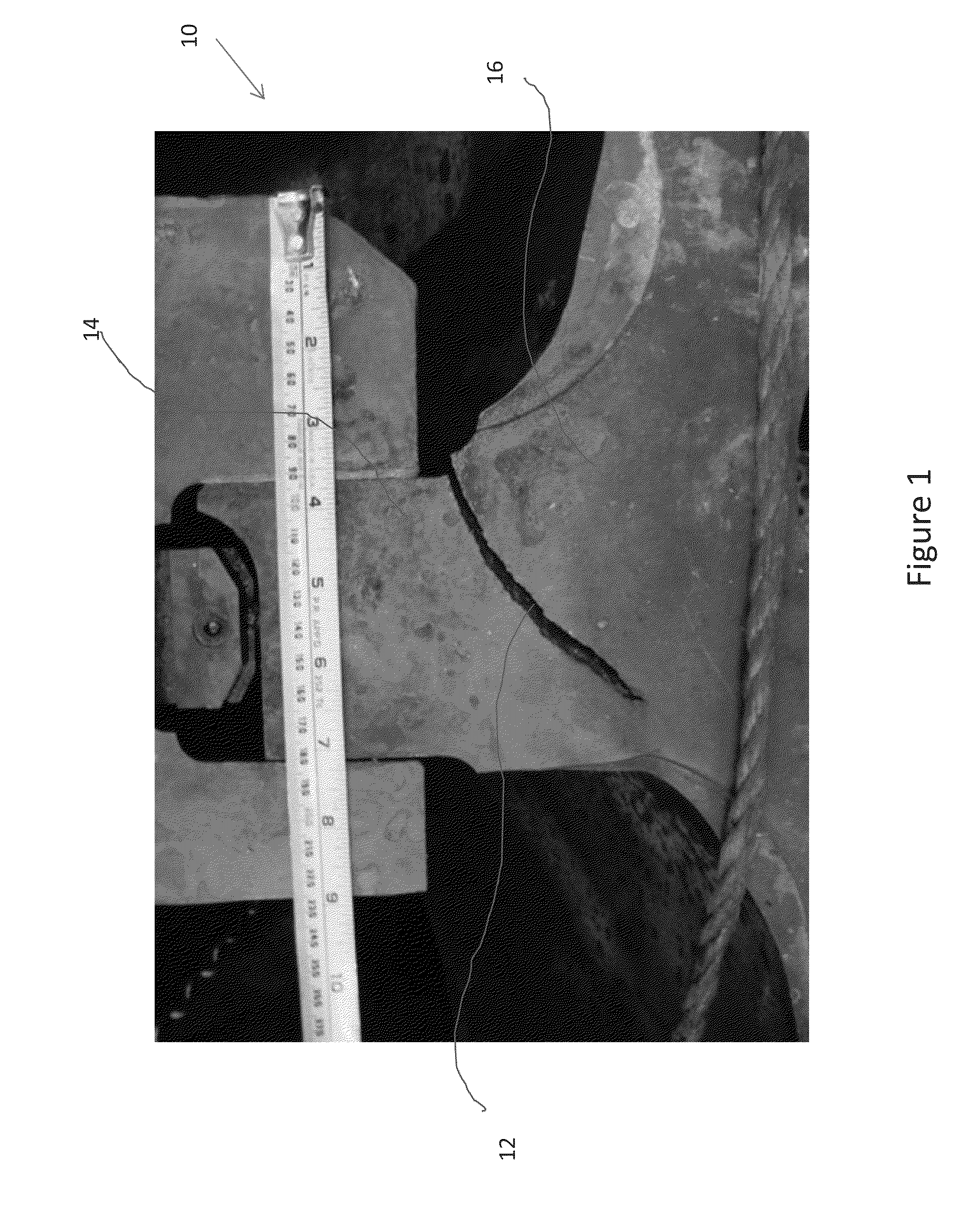

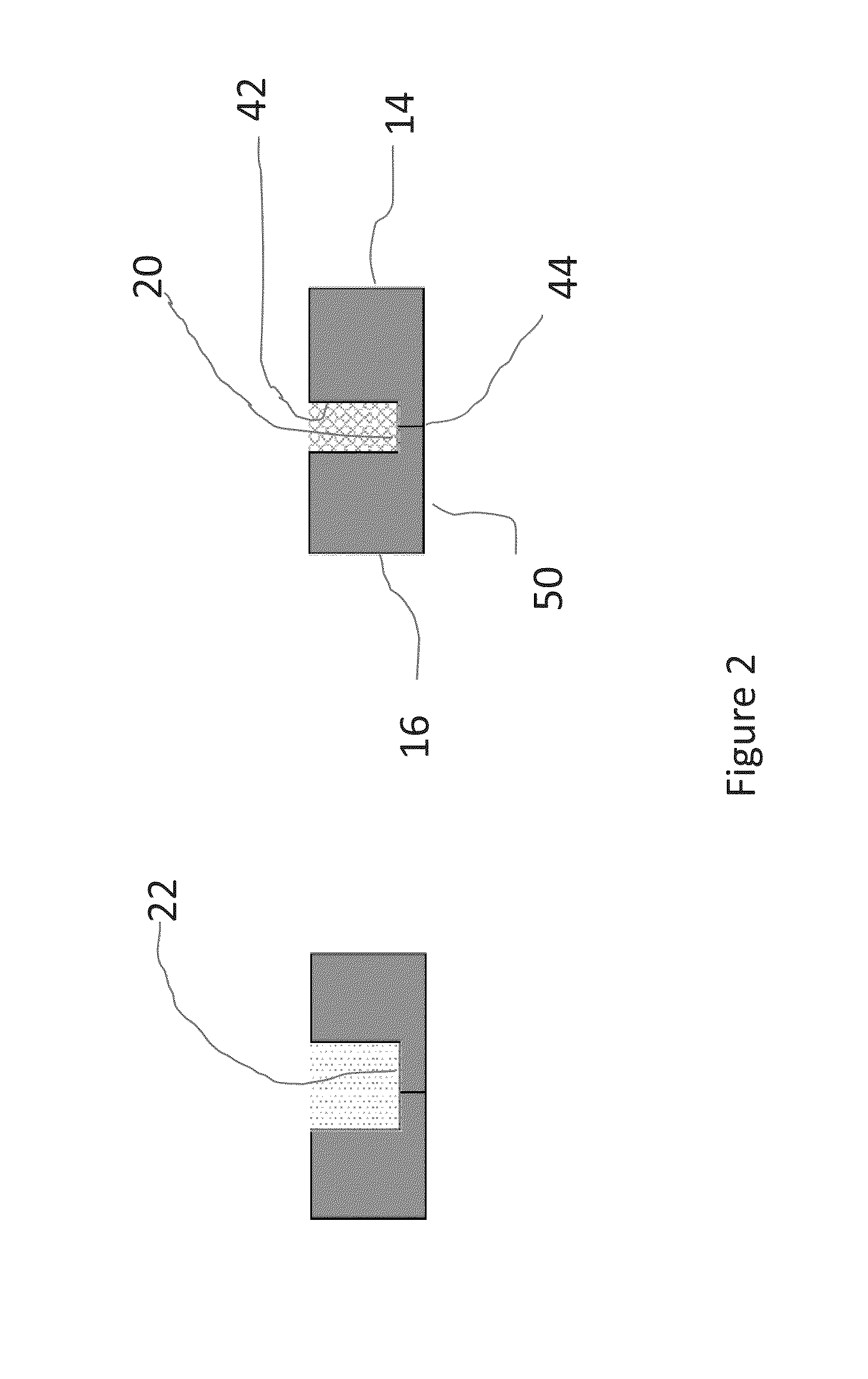

Measuring and marking guide tool

Owner:VICK DANIEL S

Sliding sheet for fixing devices, manufacturing method for same, fixing device, and image forming apparatus

ActiveUS8195072B2Reduce manufacturing costShape stableElectrographic process apparatusMetal working apparatusImage formationEngineering

A sliding sheet for fixing devices in the present invention is inserted in between an endless belt constituting one member out of two members which form a nip section for fixing operation and a pressure member for pressing the endless belt from an inner surface side toward the other member out of the two members. The sliding sheet, which is made of a single resin, repeatedly has a thick section and a thin section at least with respect to a sliding direction of the endless belt due to substantial difference in resin amount per unit area corresponding to positions within a sheet surface.

Owner:KONICA MINOLTA BUSINESS TECH INC

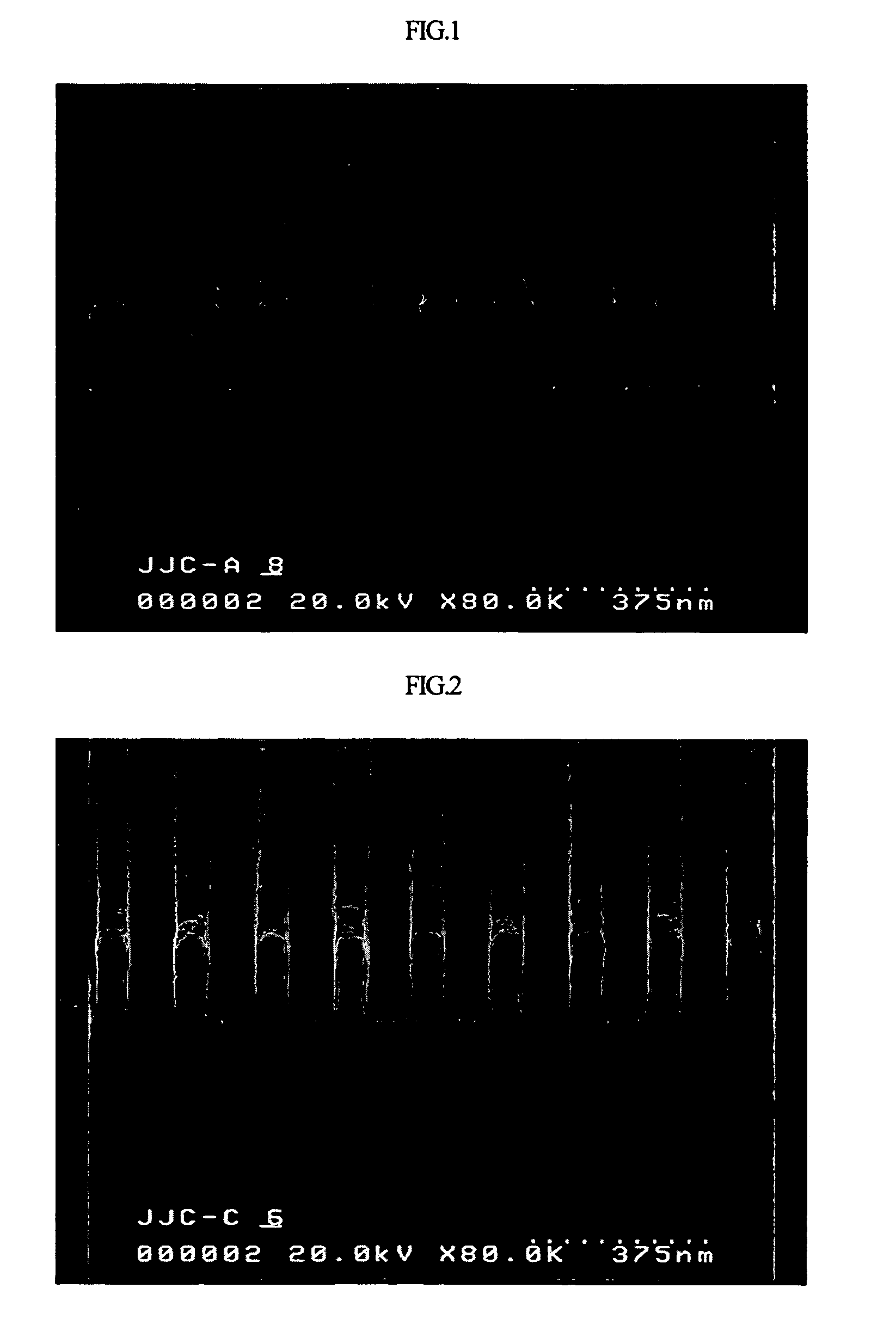

Top anti-reflective coating composition and method for pattern formation of semiconductor device using the same

ActiveUS20060046184A1Avoid interferenceEnable formationPhotomechanical apparatusSemiconductor/solid-state device manufacturingAnti-reflective coatingPhotosensitizer

Disclosed herein is a top anti-reflective coating composition which comprises a photoacid generator represented by Formula 1 below. wherein n is between 7 and 25. Since the top anti-reflective coating composition dissolves a portion of a photoacid generator present at the top of an underlying photosensitizer, particularly, upon formation of a top anti-reflective coating, it can prevent the top from being formed into a thick section. Therefore, the use of the anti-reflective coating composition enables the formation of a vertical pattern on a semiconductor device.

Owner:SK HYNIX INC

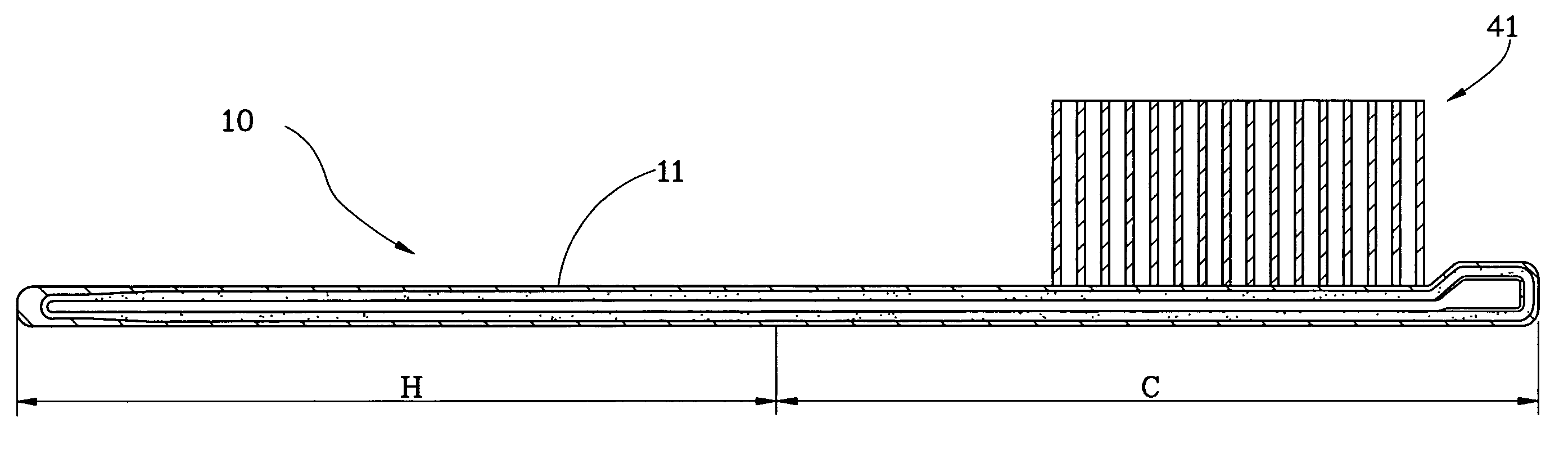

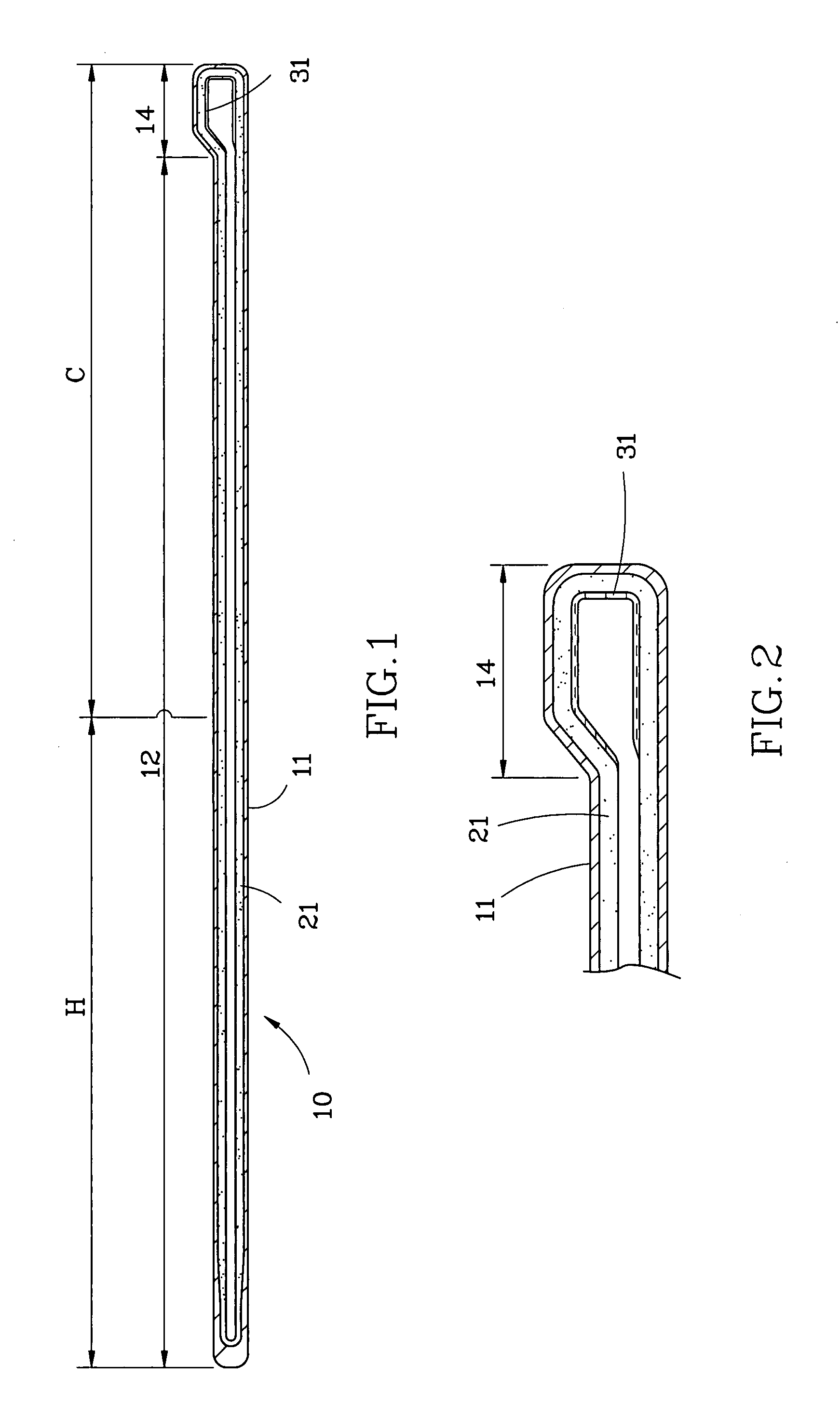

Flat heat pipe

InactiveUS20080245511A1Good characterSolve the real problemIndirect heat exchangersThick sectionEngineering

A flat heat pipe including: a tubular member having two sealed ends, a capillary wick being disposed at the internal sidewall of said tubular member and a liquid contained in said tubular member. Said tubular member defines a flat section and a thicker section at least. By the way, the present invention can solve the problem of the accumulated water inside the heat pipe of prior art and keeps a good efficiency of uniform temperature, and the radiation efficiency is better then the heat pipe of prior art.

Owner:TAI SOL ELECTRONICS

Shaving foil for a dry shaver

ActiveUS20080134523A1Without causing skin irritationReduce thicknessMetal working apparatusRazor stropSkin contact

A shaving foil for a dry shaver has a plurality of perforation arranged in an array. The shaving foil is formed in its skin contact surface with a plurality of recesses which define a thin section of reduced thickness at the recesses, while leaving thick sections at the remainder of the foil. Each perforation is configured to have its circumference defined partly by the thin section and partly by the thick section. Both of the thin and thick sections can come into contact with a user's skin for smoothly guiding hairs into the perforations to make close shaving without irritating the skin, while the shaving foil is moved across the skin. Especially, the thin sections act to cut the hairs shorter than the thick section, as wall as to raise flattened hairs into the perforations for successfully cutting the flattened hairs.

Owner:MATSUSHITA ELECTRIC WORKS LTD

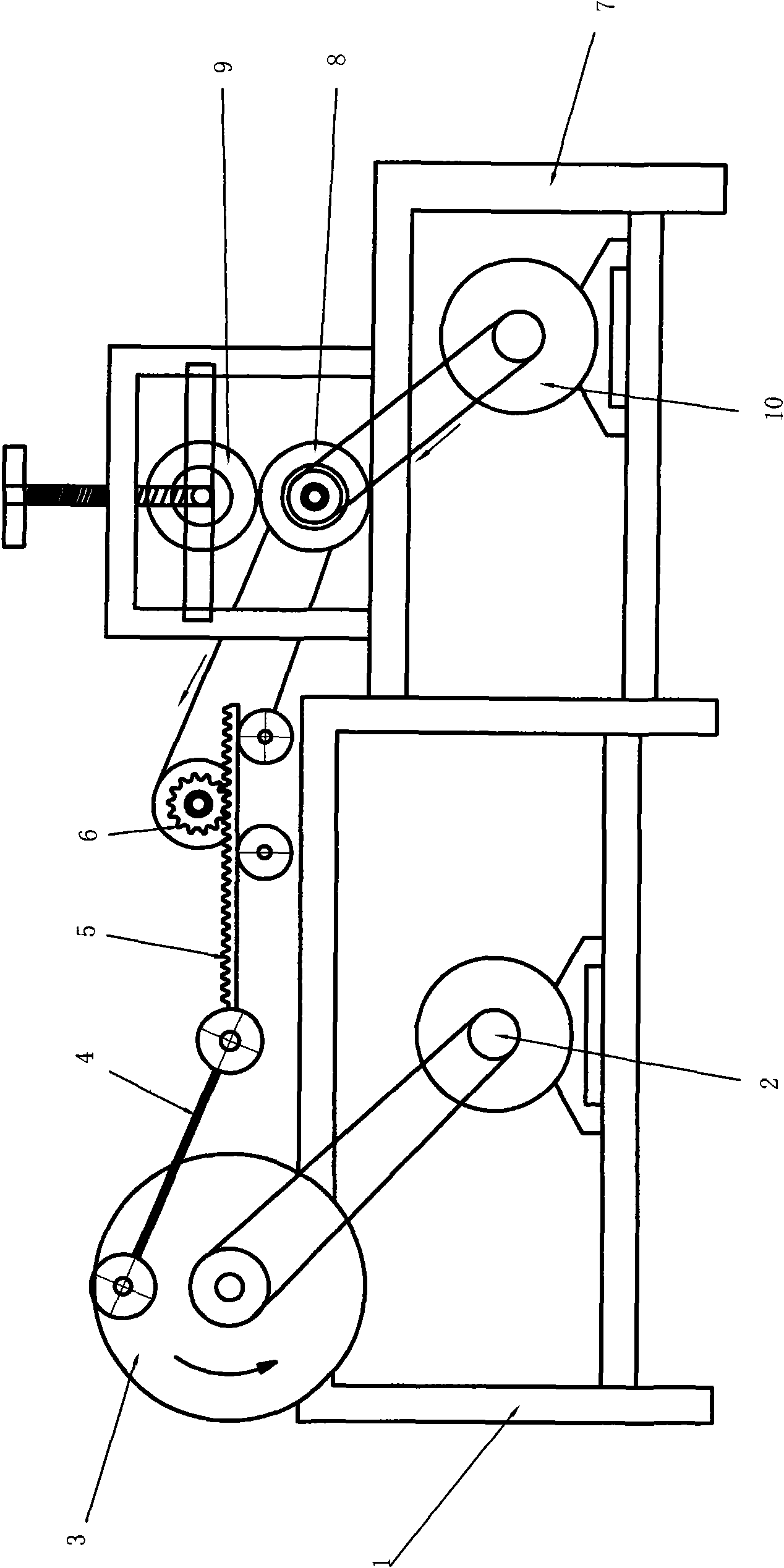

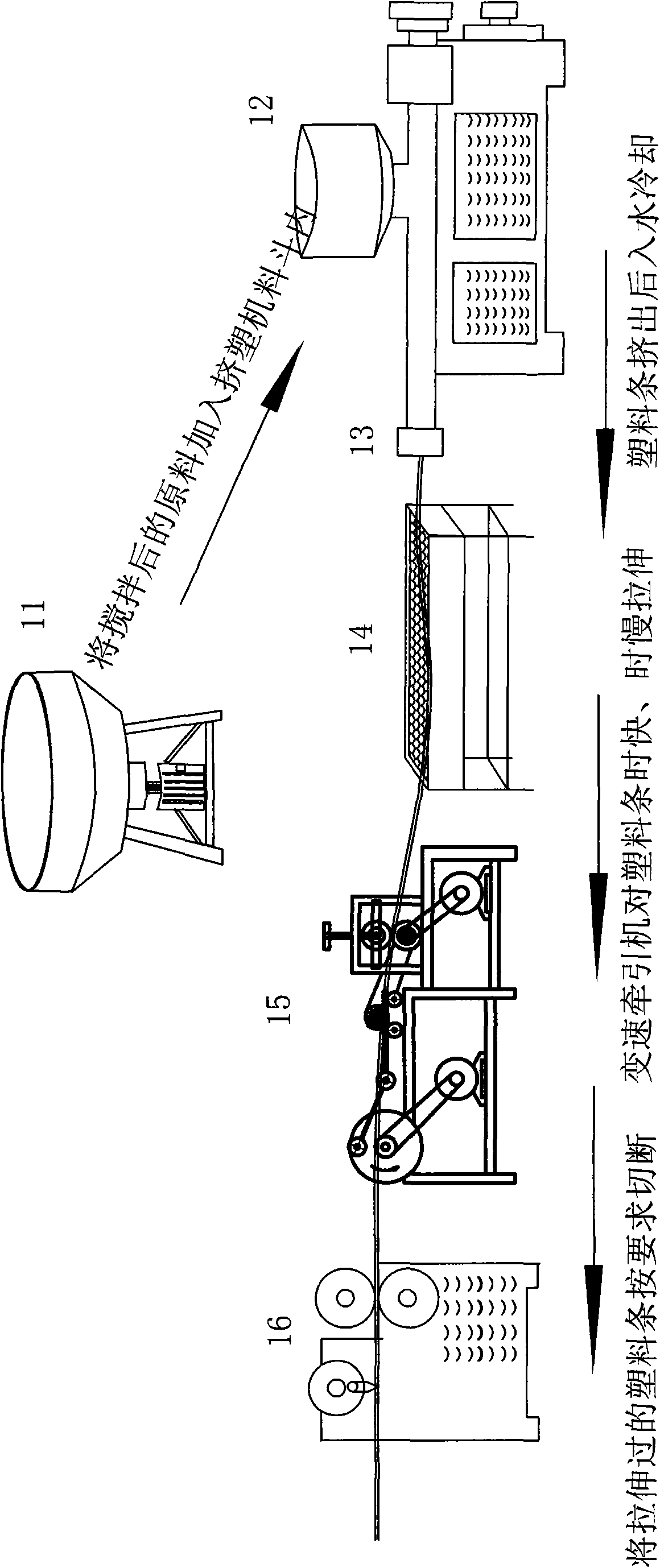

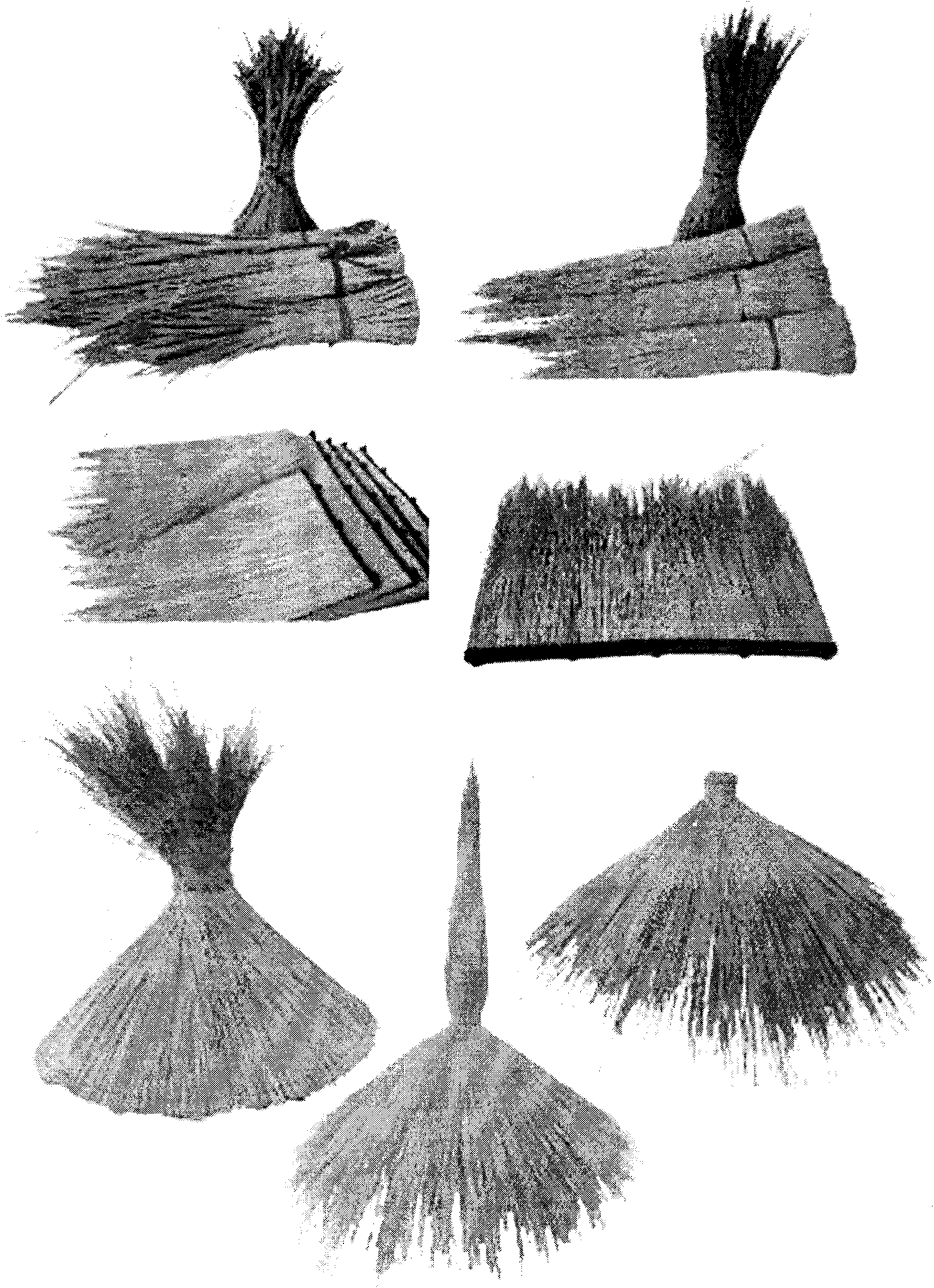

Plastic artificial grass and preparation method and preparation device thereof

ActiveCN101669691ANo pollutionBeautiful roofArtificial flowers and garlandsSpecial ornamental structuresPlasticizerUltraviolet

The invention relates to a plastic artificial grass which is exactly like grass and a preparation method and a preparation device thereof and the artificial grass adopts plastic as main material. Theplastic artificial grass comprises 100 parts of plastic raw material. The preparation method comprises the following steps: adding 1-10% of plasticizer, 1-10% of lubricant, 1-10% of stabilizer, 1-10%of flame retardant, 1-10% of ultraviolet resistant agent and 0.1-10% of pigment in the 100 parts of plastic raw material, mixing evenly, extruding with a plastic extruding machine, cooling, performingvariable-speed drawing to form plastic strips with thick sections and thin sections, and cutting at the thickest sections and the thinnest sections to form artificial grass stems each of which contains one thick end and one thin end. The prepared plastic strips can appear the same color of the real grass stems and bear wind, rain or ultraviolet ray, the plastic grass is durable and does not causepollution to the environment; in addition, the roof prepared with the product is beautiful and natural and can integrate with the environment with a sense of harmony.

Owner:YUZHOU CITY LVZHIZHOU GARDEN APPLIANCE MFG

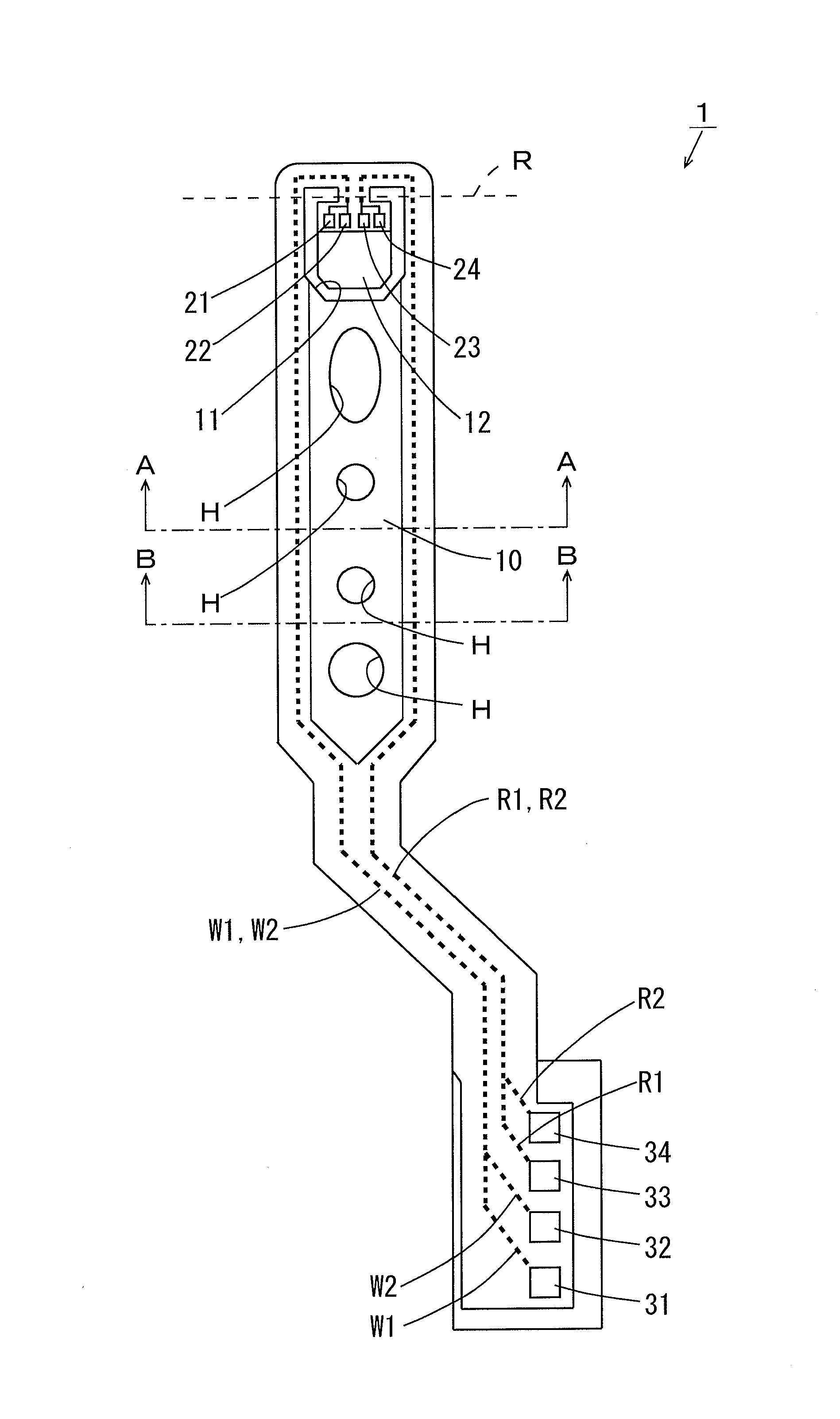

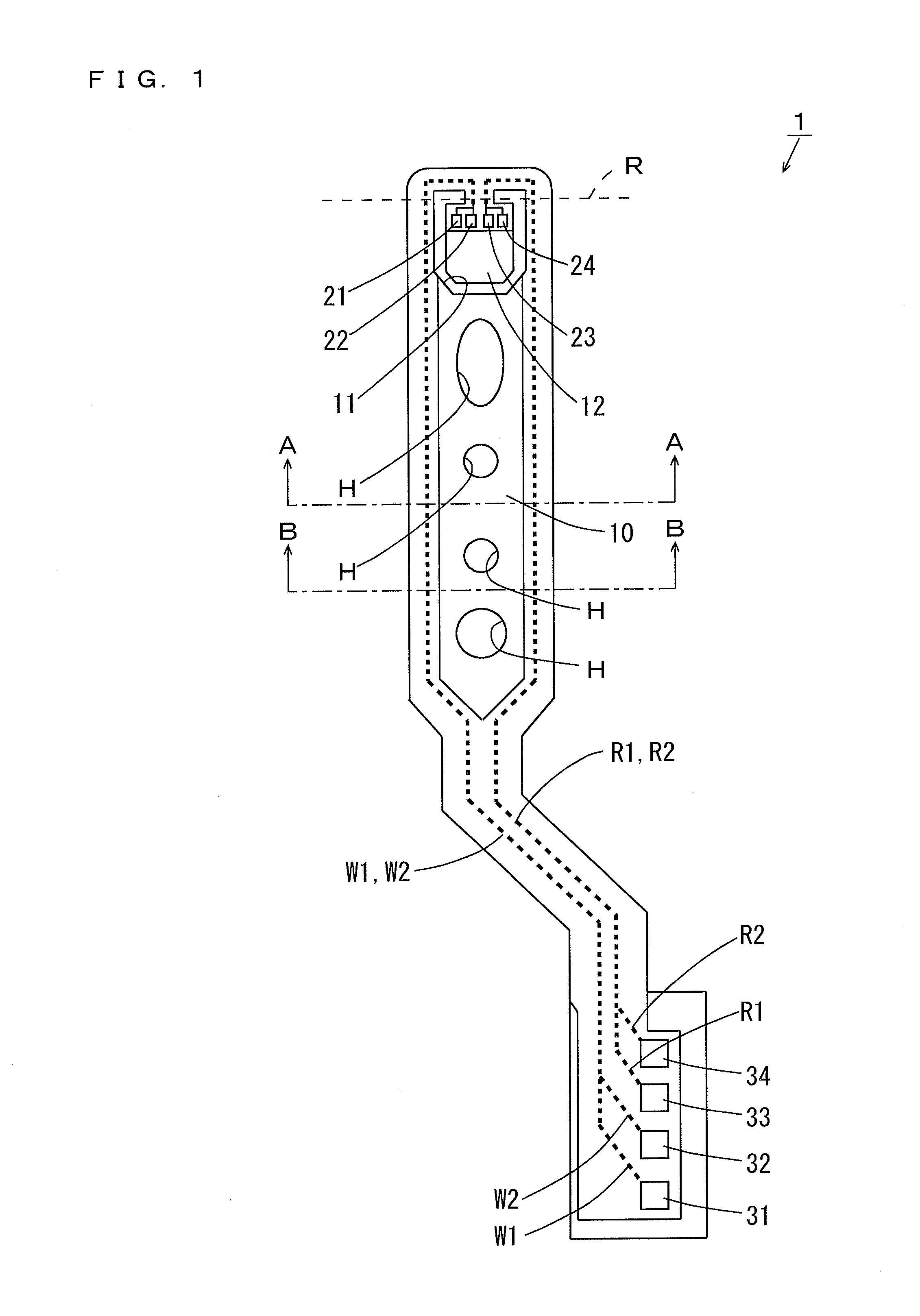

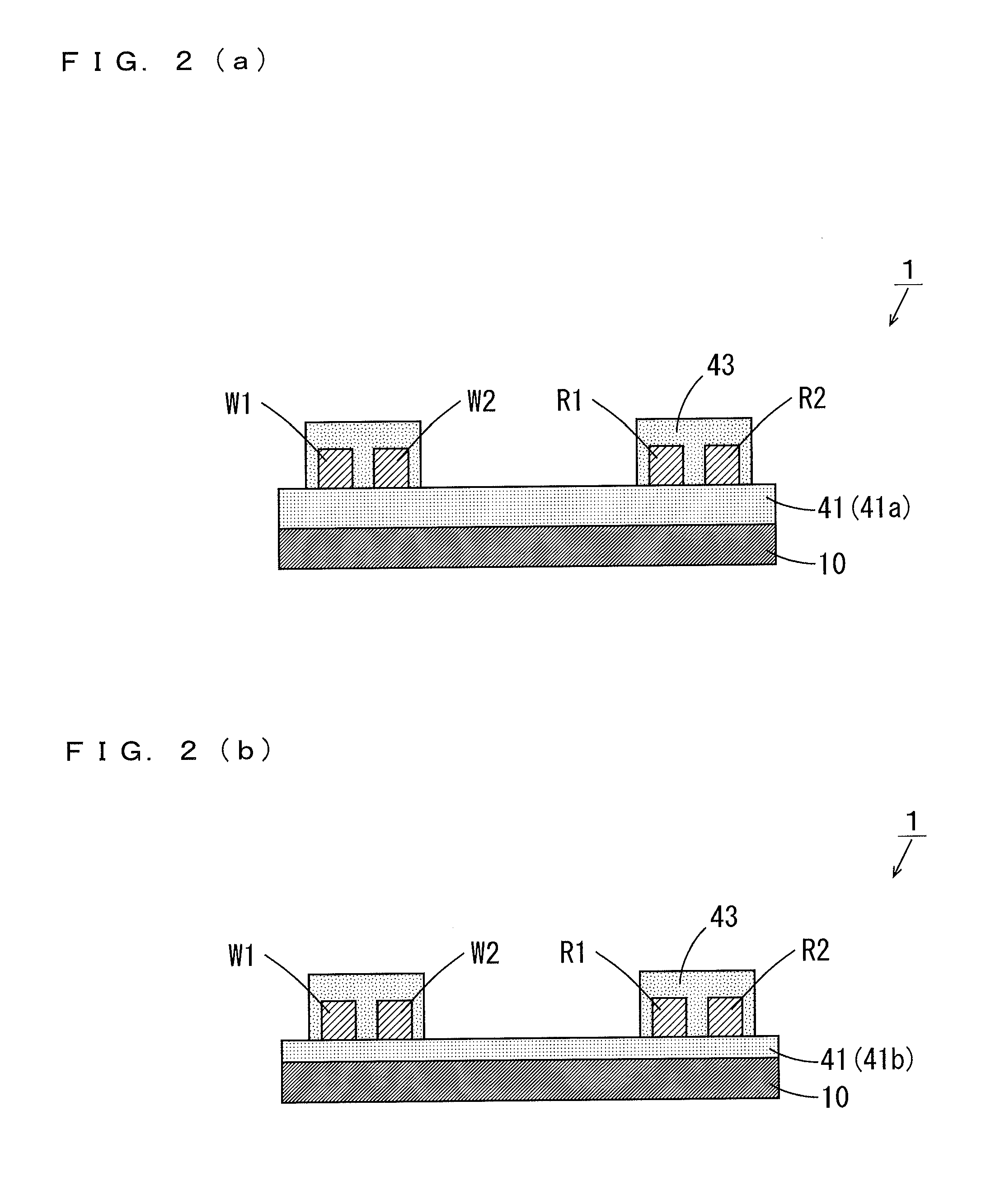

Suspension board with circuits and method for manufacturing the same

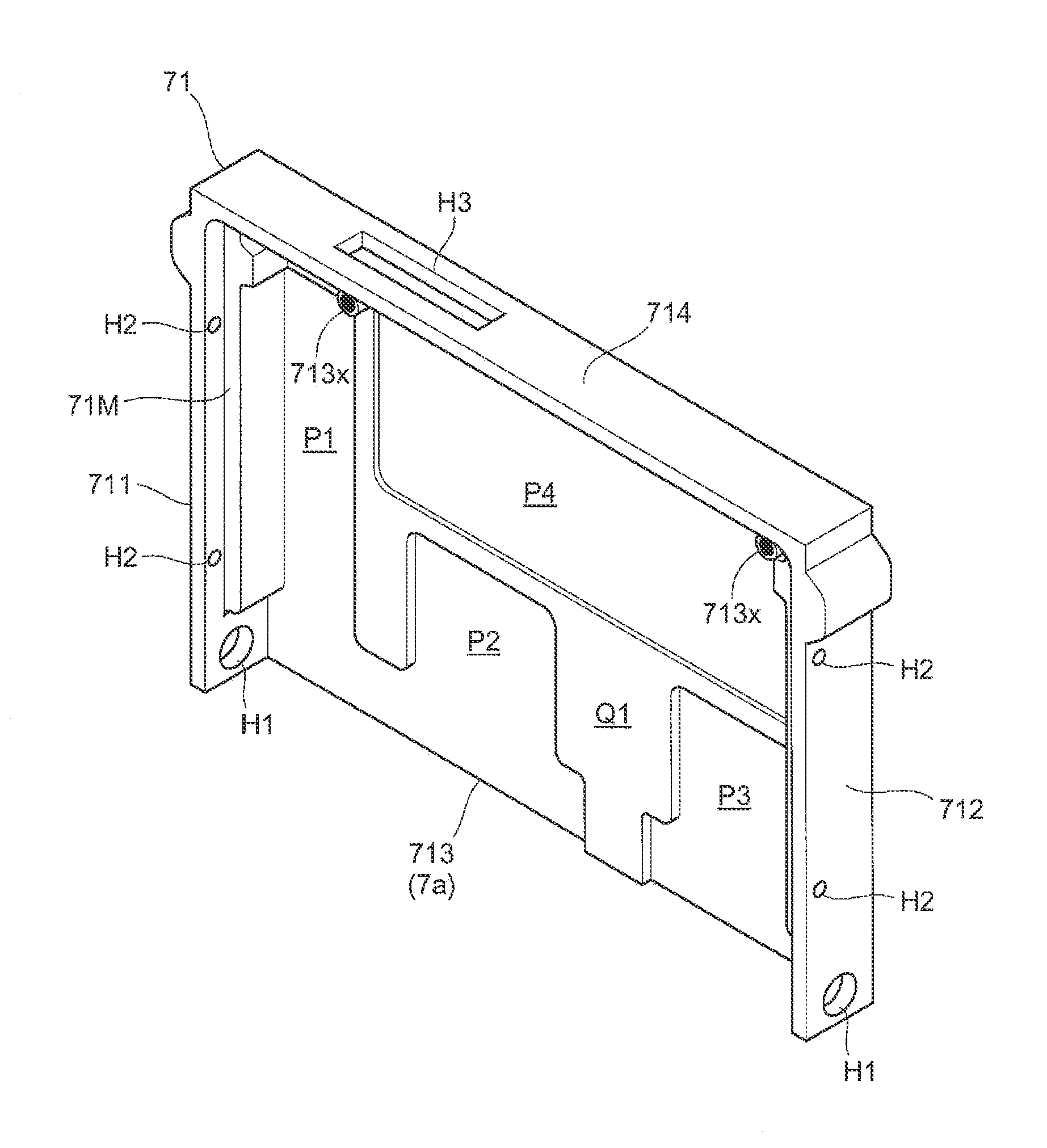

ActiveUS20140177106A1Increase flexibilityReduce rigidityCircuit bendability/stretchabilityElectrical connection between head and armHemt circuitsEngineering

A thick portion having a first thickness and a thin portion having a second thickness on a base insulating layer are formed on a conductive support substrate. The second thickness is smaller than the first thickness. A boundary surface is formed between an upper surface of the thick portion and an upper surface of the thin portion. A boundary line between the upper surface of the thick portion and the boundary surface extends in a first direction. Write wiring traces and read wiring traces are formed to extend on the thick portion and the thin portion of the base insulating layer. The lateral sides of the write wiring traces and the read wiring traces extend in a second direction that intersects with the first direction, and the second direction forms an angle of not less than 60 degrees and not more than 90 degrees with the first direction.

Owner:NITTO DENKO CORP

Measuring and marking guide tool

Owner:VICK DANIEL S

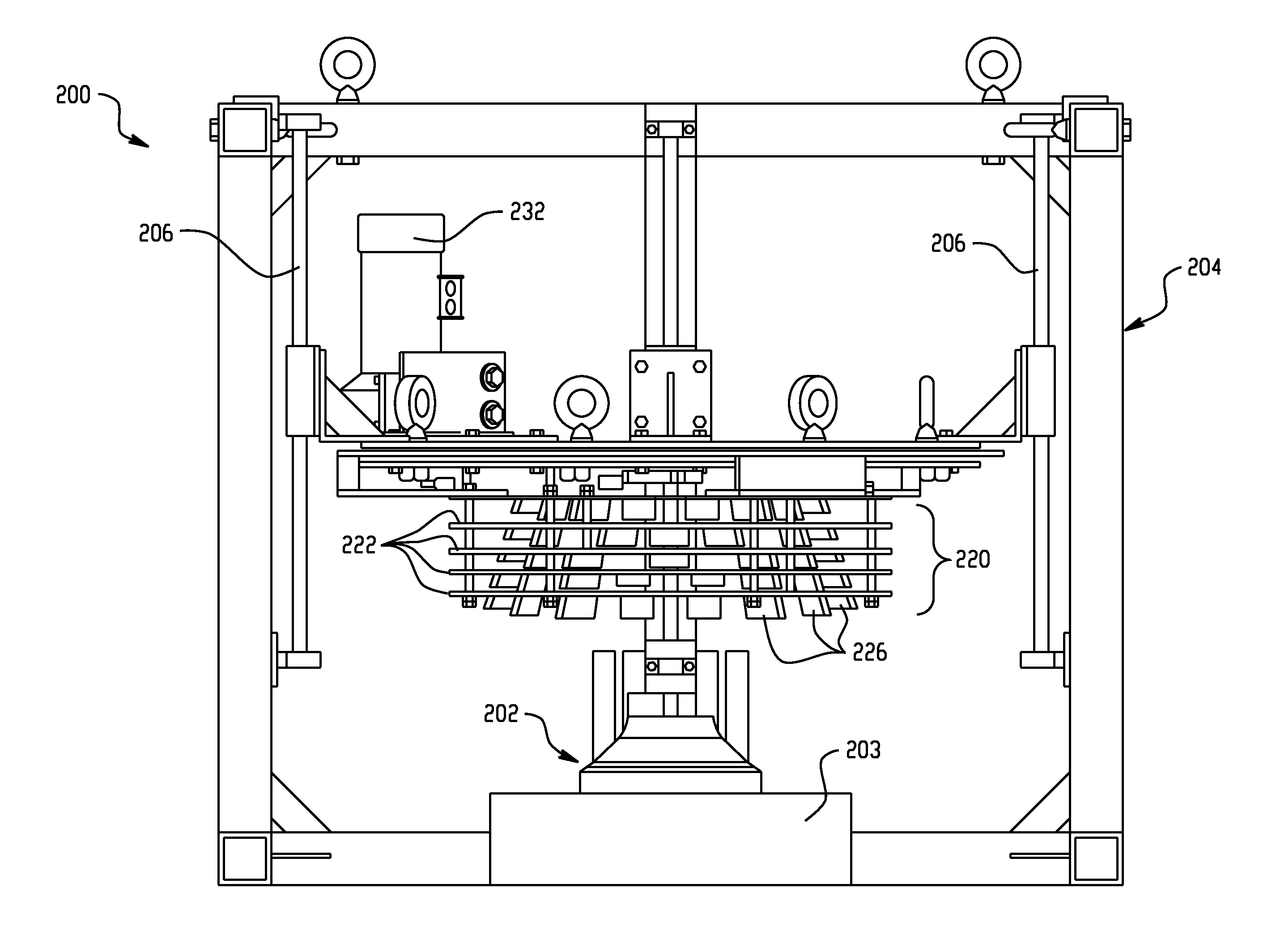

Cooling systems for heat-treated parts and methods of use

Owner:ARCONIC INC

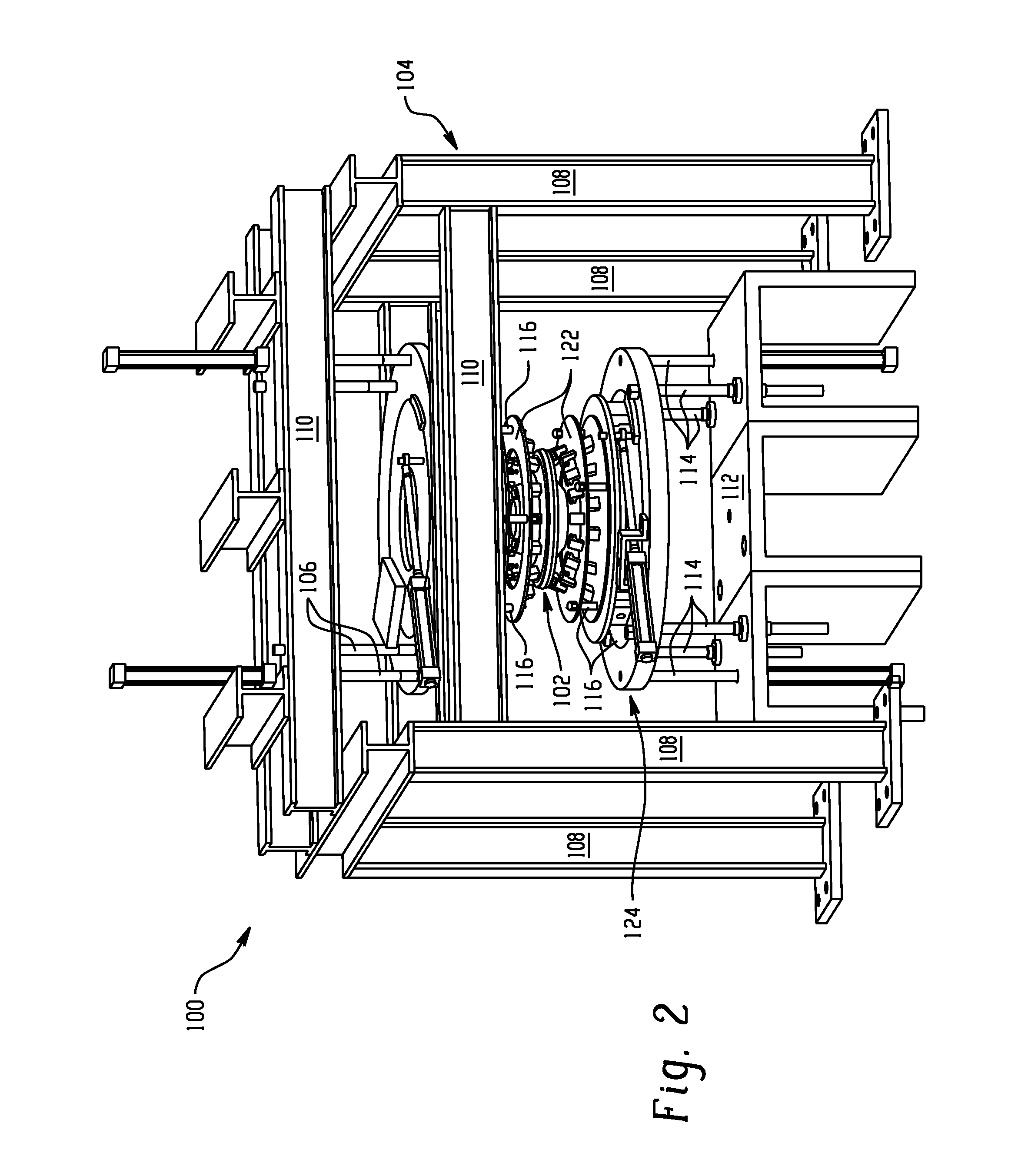

Welding process for repair of thick sections

InactiveUS20140042140A1Quantity minimizationFast welding speedTurbinesBlade accessoriesEngineeringDistortion

A double-sided tribrid welding technique and apparatus for root pass welding of narrow groove welds. The welding technique utilizes three welding devices. A welding apparatus on a backside of the weld joint may strike an arc on the backside of the weld joint; a welding apparatus on a narrow groove side of the weld may strike an arc within the narrow groove weld joint, while the remaining welding apparatus is a laser that can help establish a keyhole as a common pool of molten metal at the root without burning through the root. Once the arcs are struck substantially simultaneously and the laser is energized, the welding heads move simultaneously, the arc welders assisting in maintaining pre-heat temperature, while minimizing distortion and cracking. Adjusting arc weld parameters provides deformation on completion of the root pass so as to compensate for distortion due to metal shrinkage in subsequent passes.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com