Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1489results about How to "Shape stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

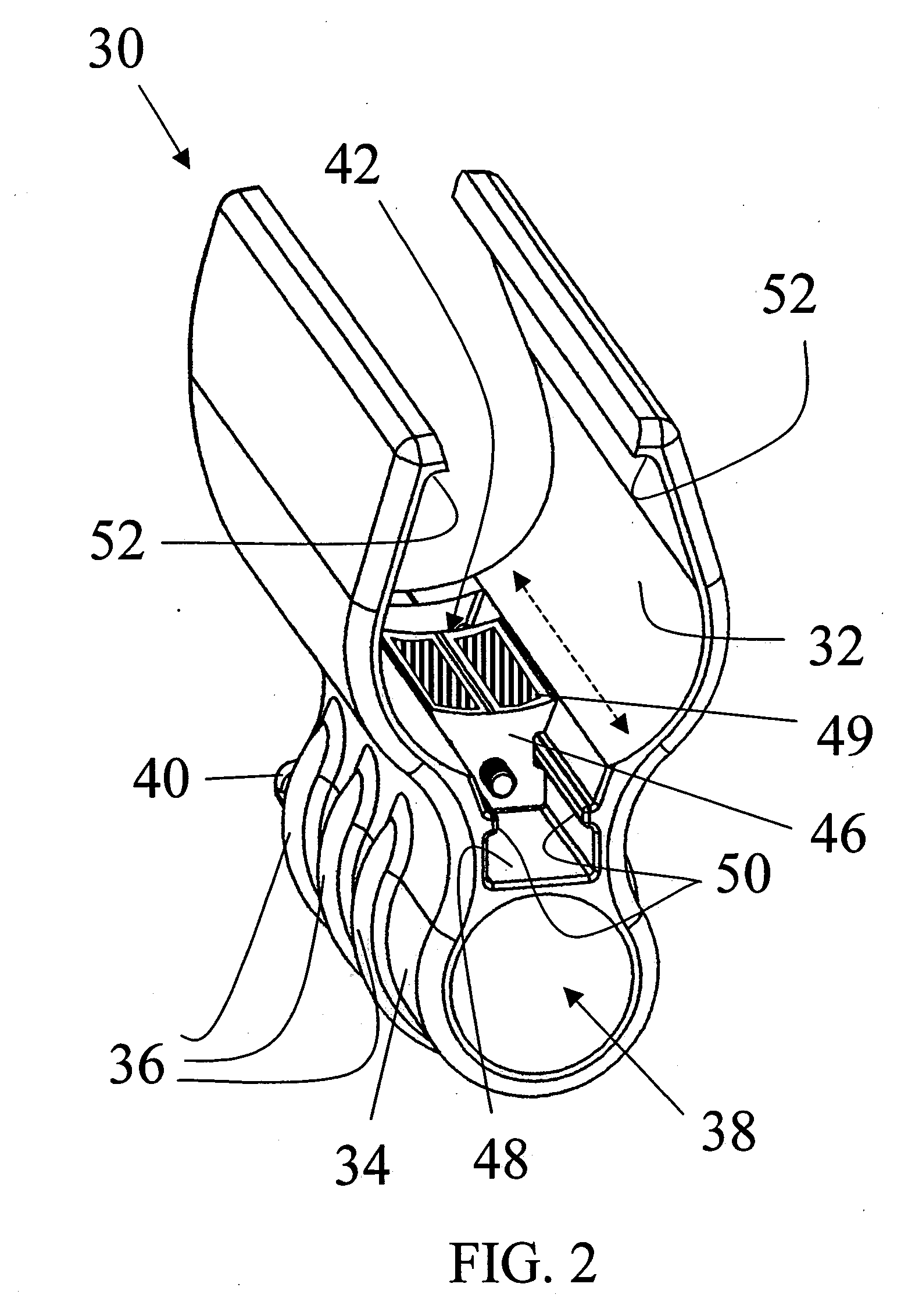

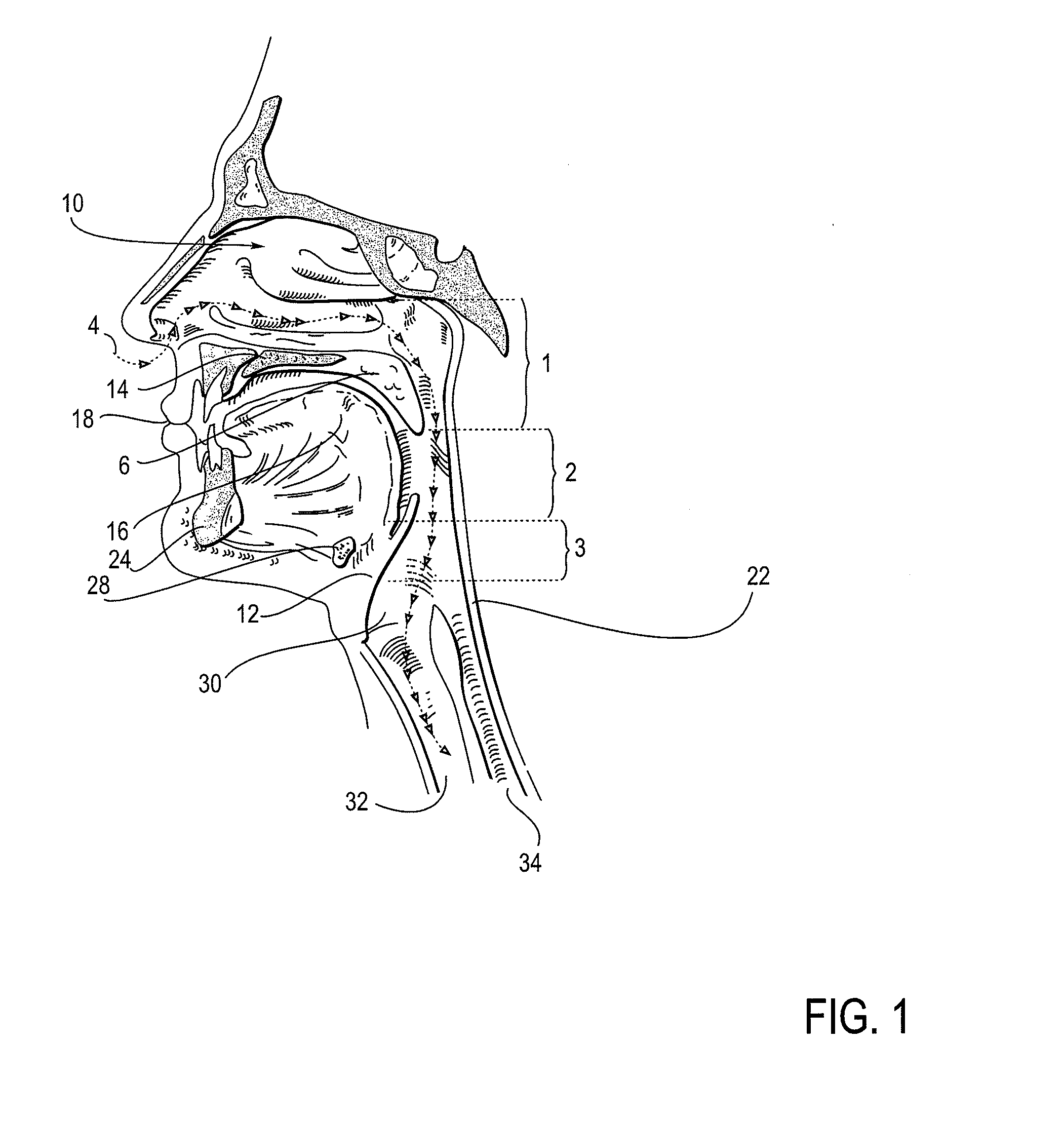

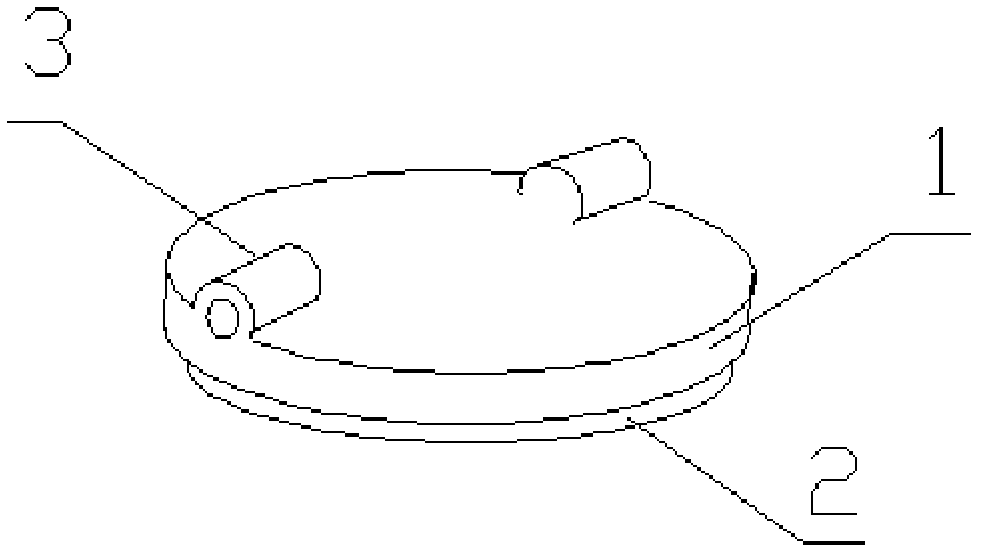

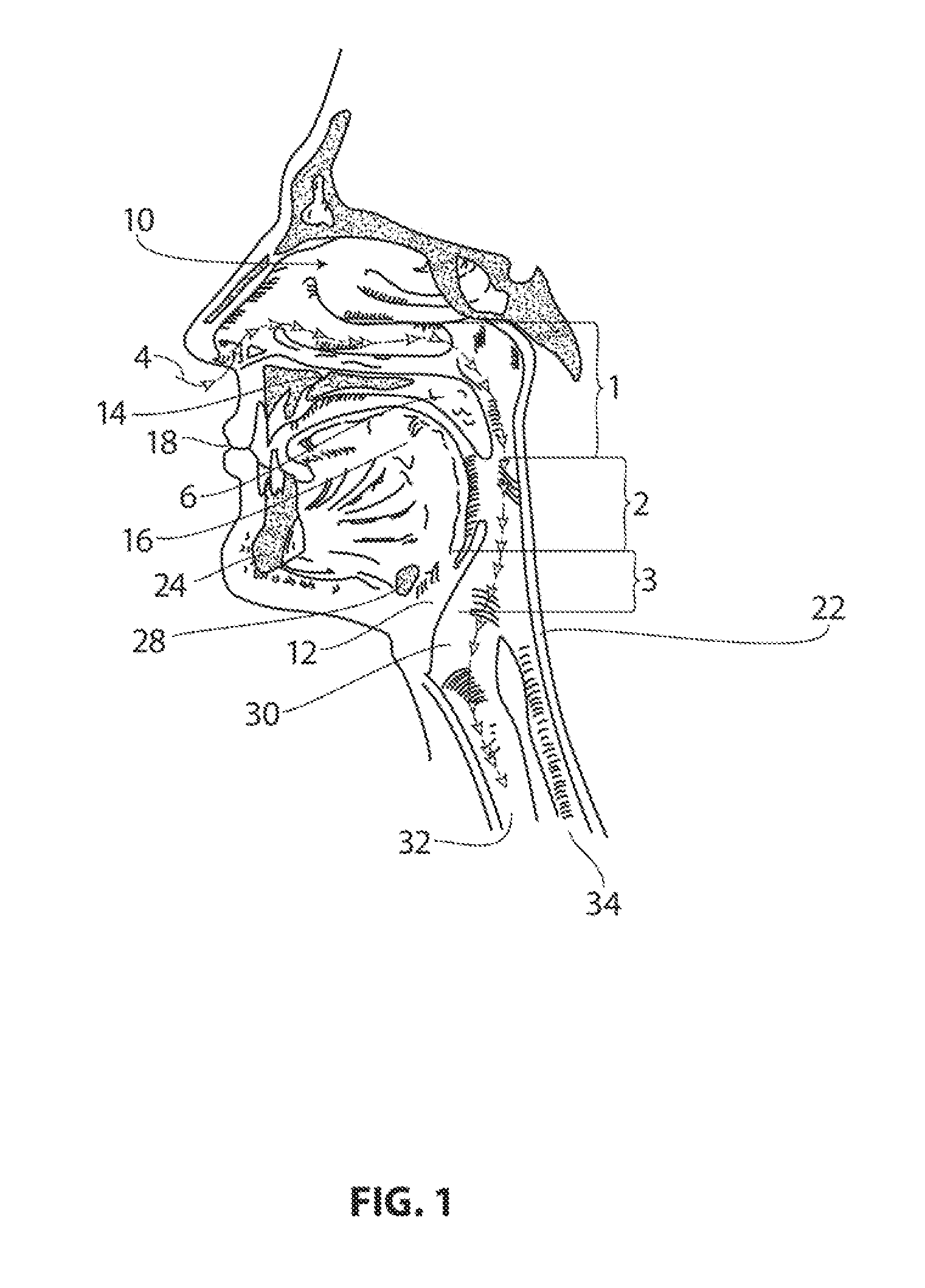

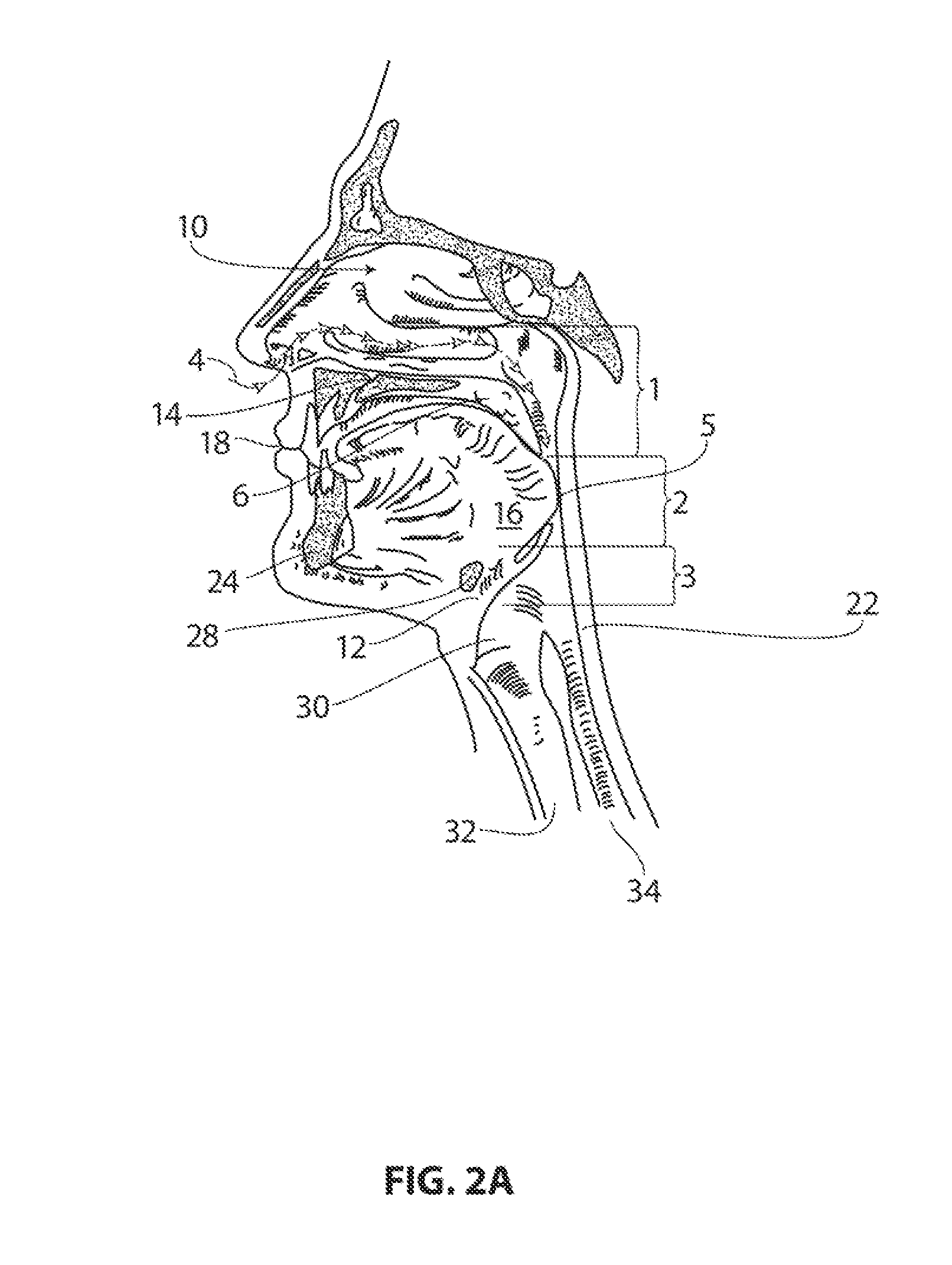

Mastopexy stabilization apparatus and method

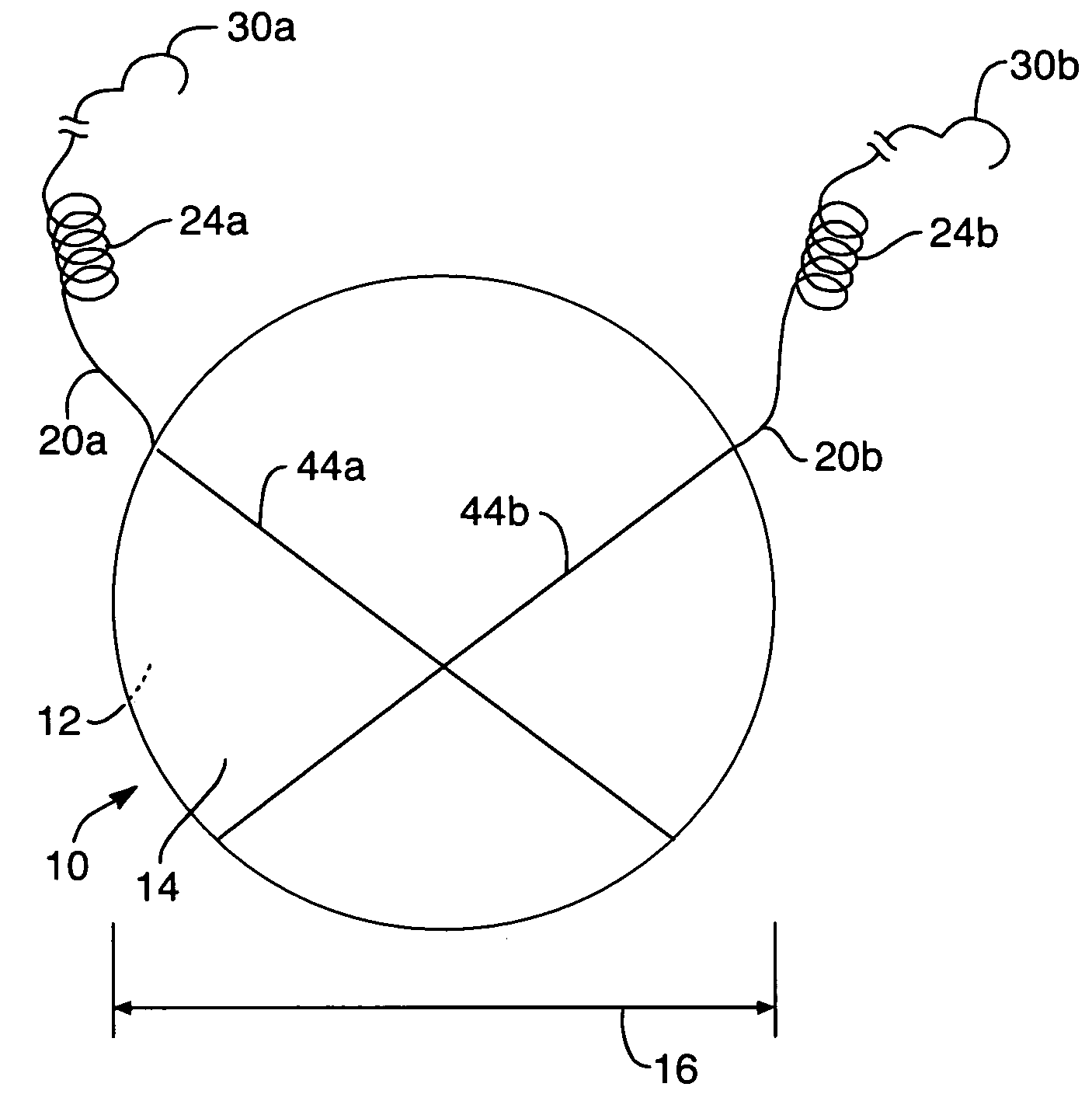

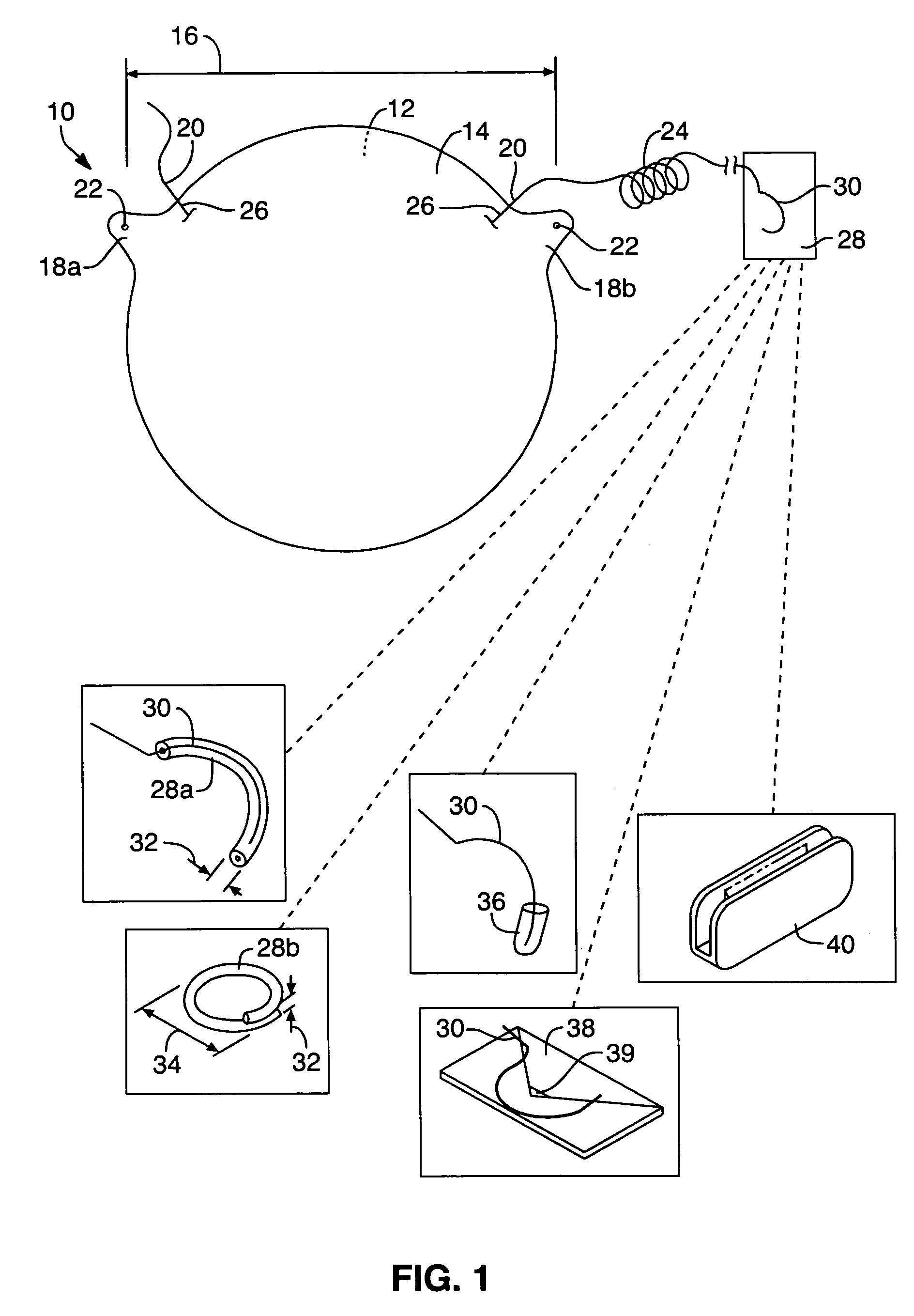

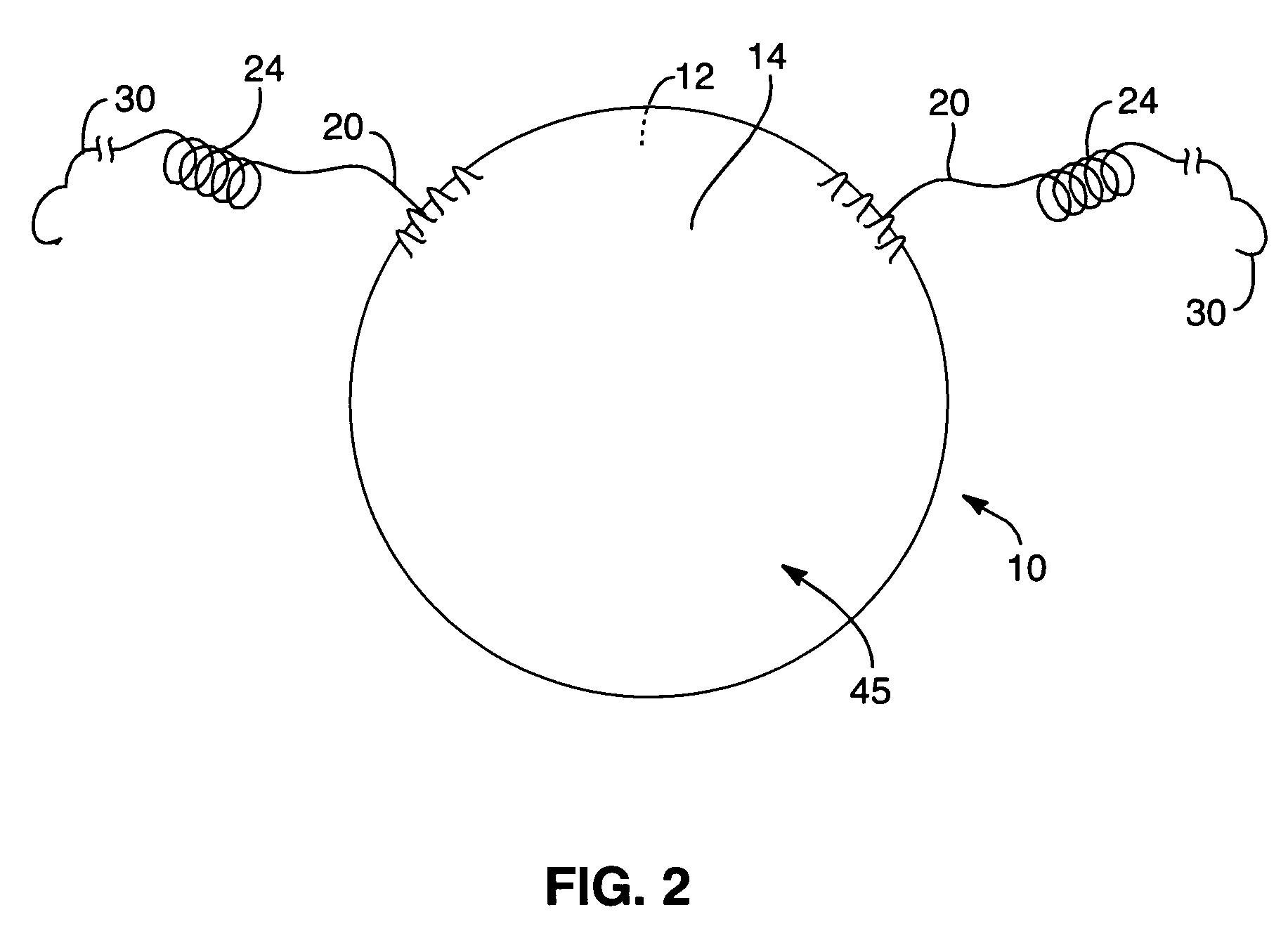

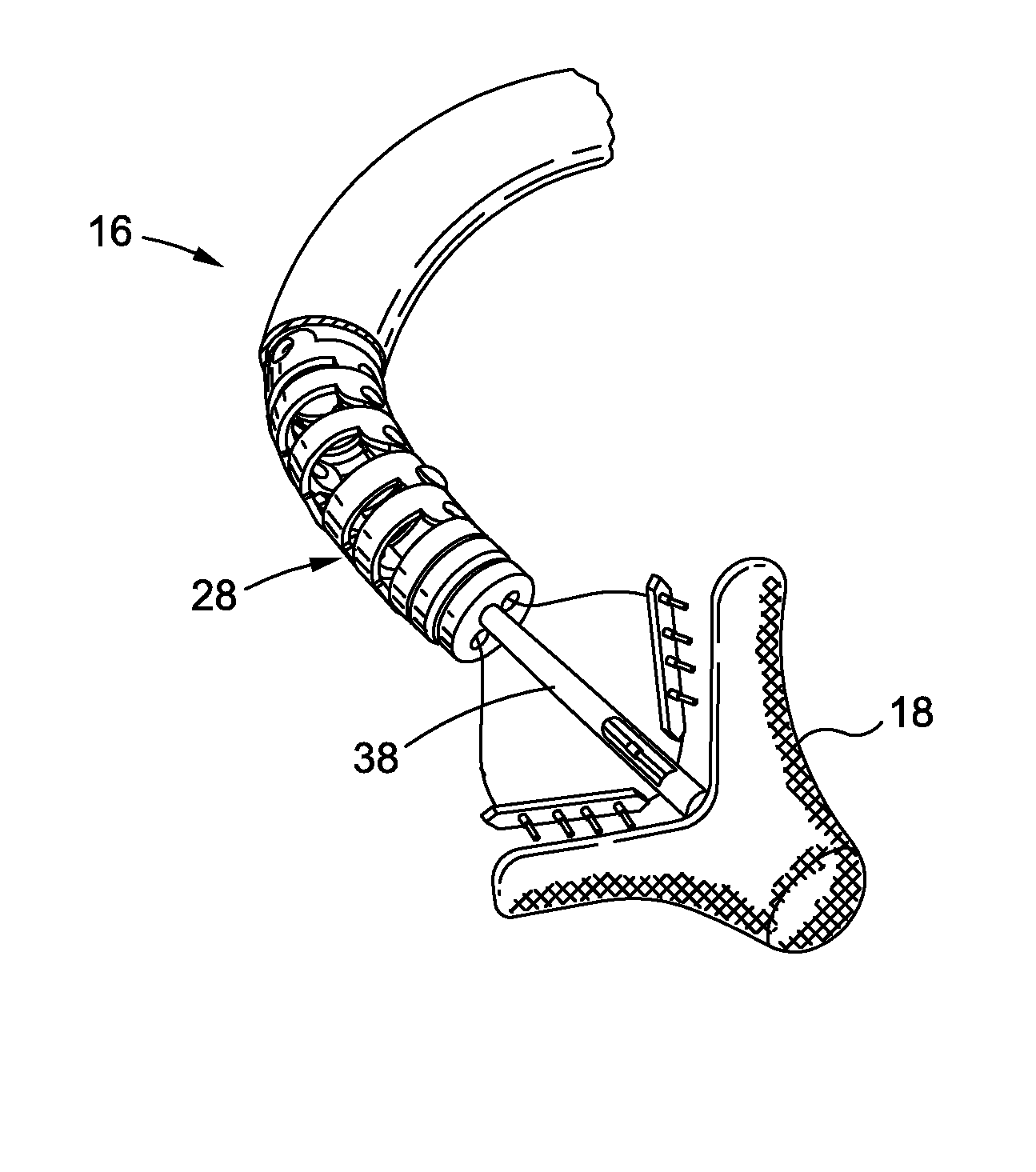

An apparatus and method for mastopexy surgeries correcting a ptosis condition caused by tissue stretching, in the breast as a result of pregnancy, time, aging, and the effects of gravity and athletic activity provide an implant having homogeneously formed connectors extending from inside an implant wall for anchoring to the chest wall or chest muscles of a patient. Embedded reinforcements and anchoring tabs or sutures may be readily oriented along a rib or other defining physiological location in order to provide immediate, permanent, and symmetric installation of implants in a mastopexy reconstruction.

Owner:SMITH LANE FIELDING +1

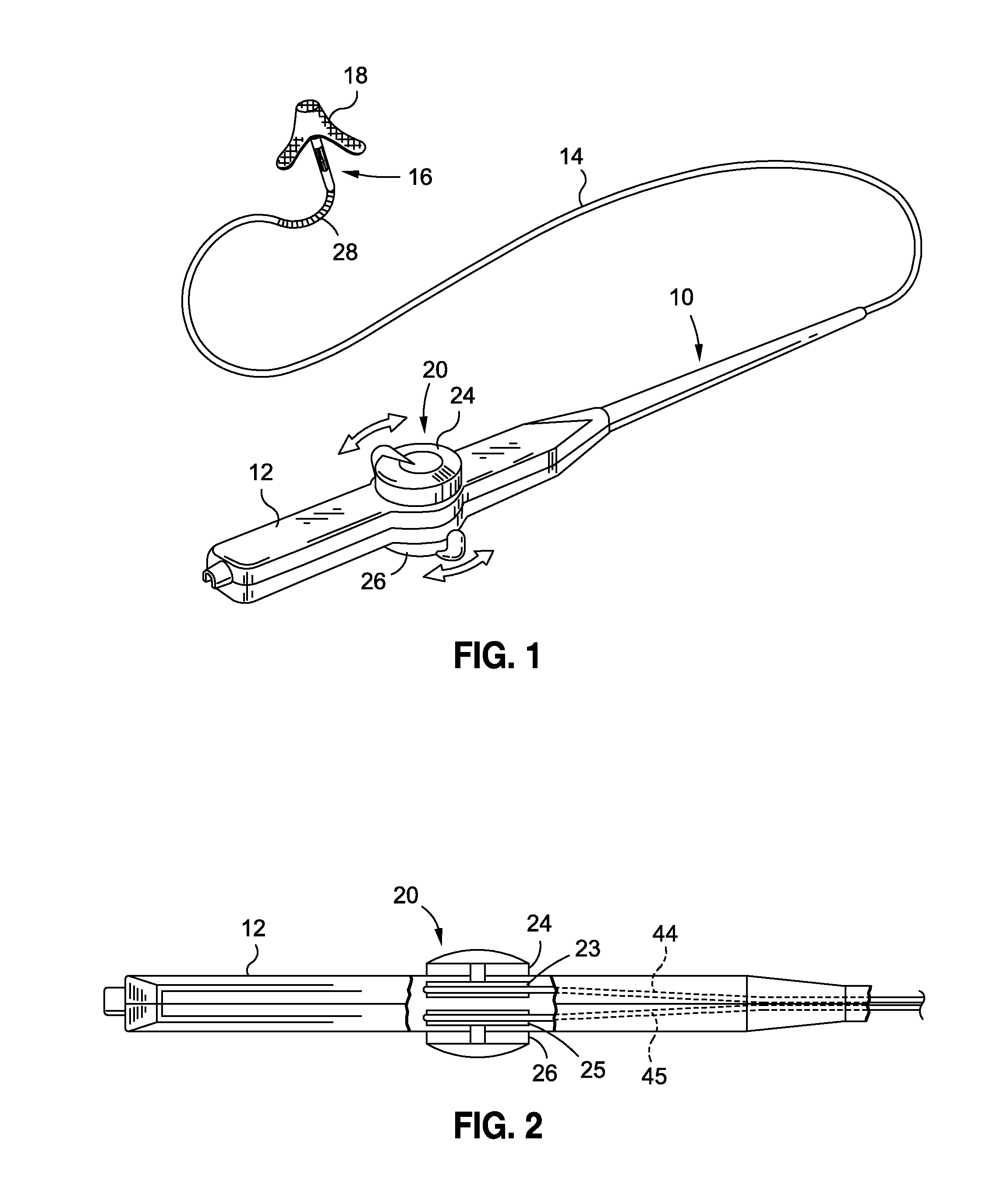

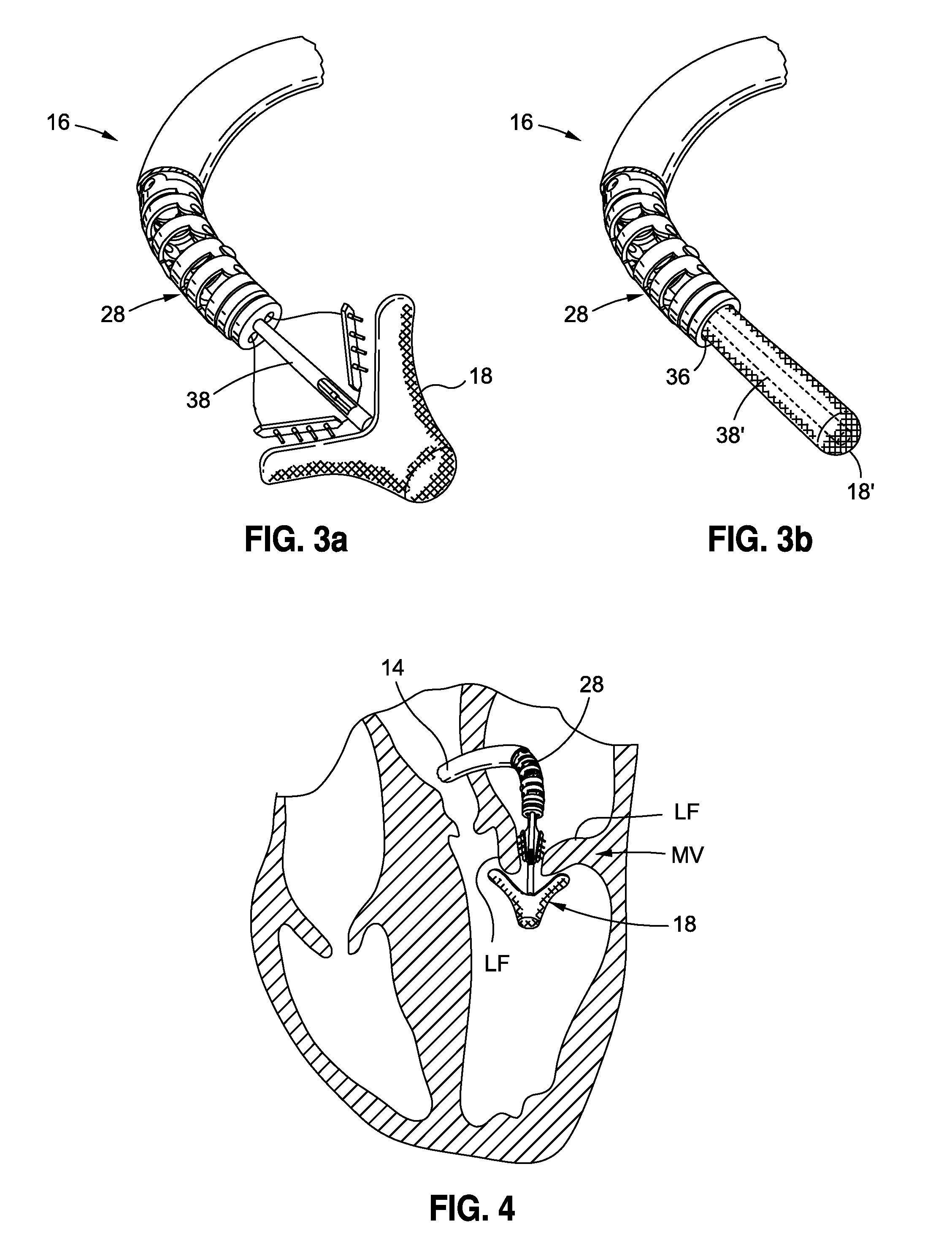

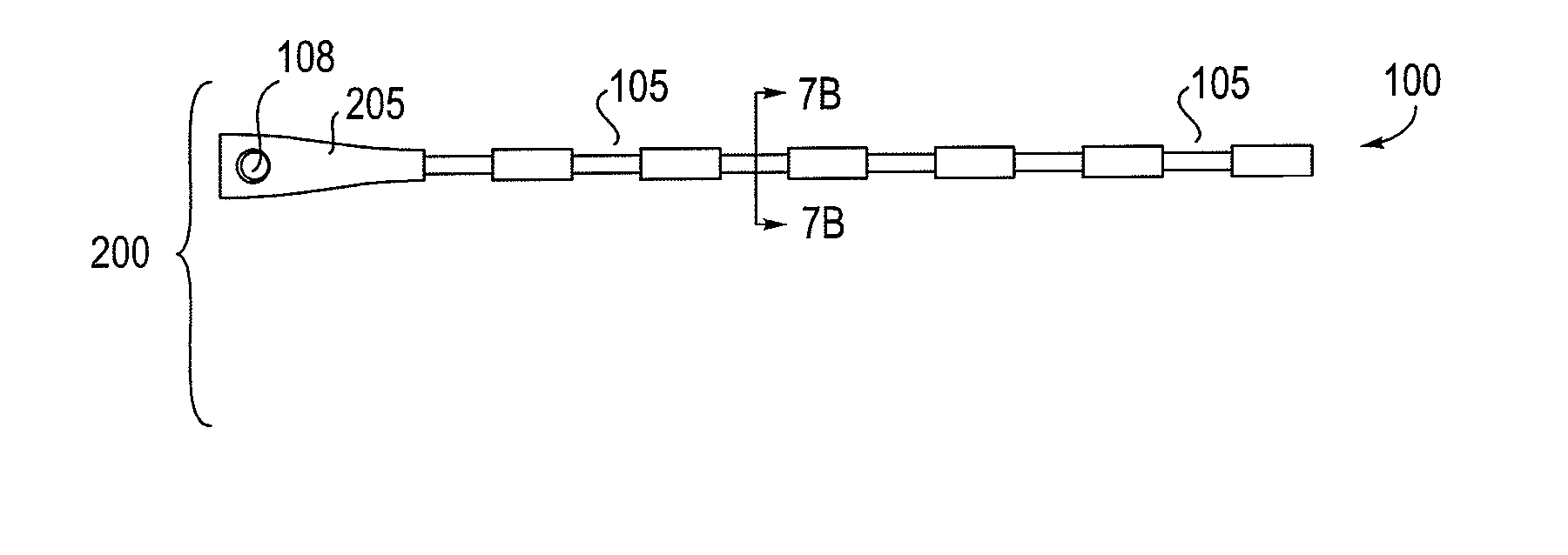

Steerable assembly for surgical catheter

ActiveUS20140135685A1Effective shapingDenies the surgeon the required degree of controlHeart valvesSurgeryCatheterTarsal Joint

A catheter configured for intraluminal delivery to a location in the body of a patient, the catheter comprising a steerable assembly comprising a first segment connected to a second segment; the first segment comprises first and second cylindrical elements connected to each other by a first revolute joint in a first single plane; the second segment comprises third and fourth cylindrical elements connected to each other by a second revolute joint in a second single plane, wherein the first single plane and the second single plane are offset by an angle from each other.

Owner:ABBOTT CARDIOVASCULAR

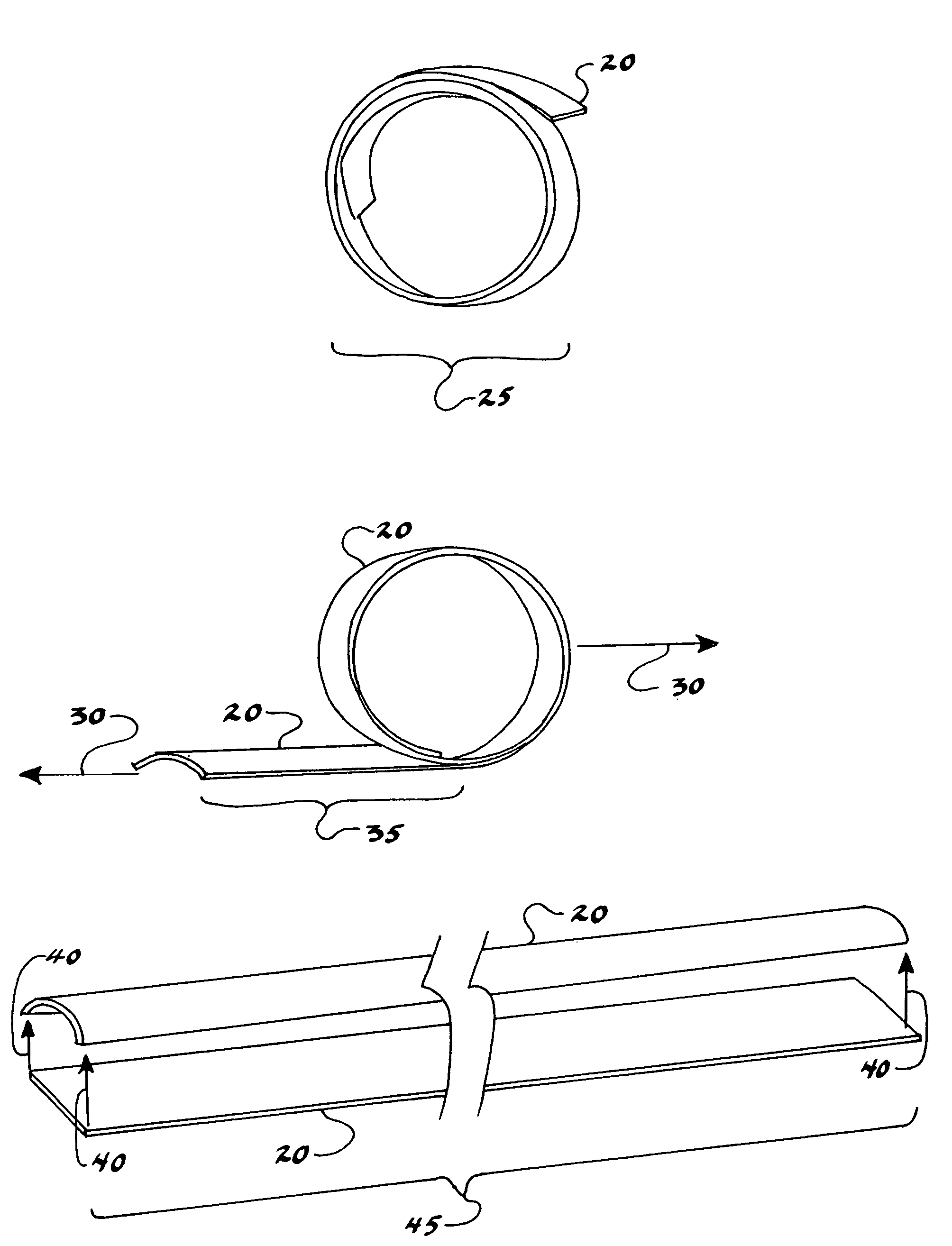

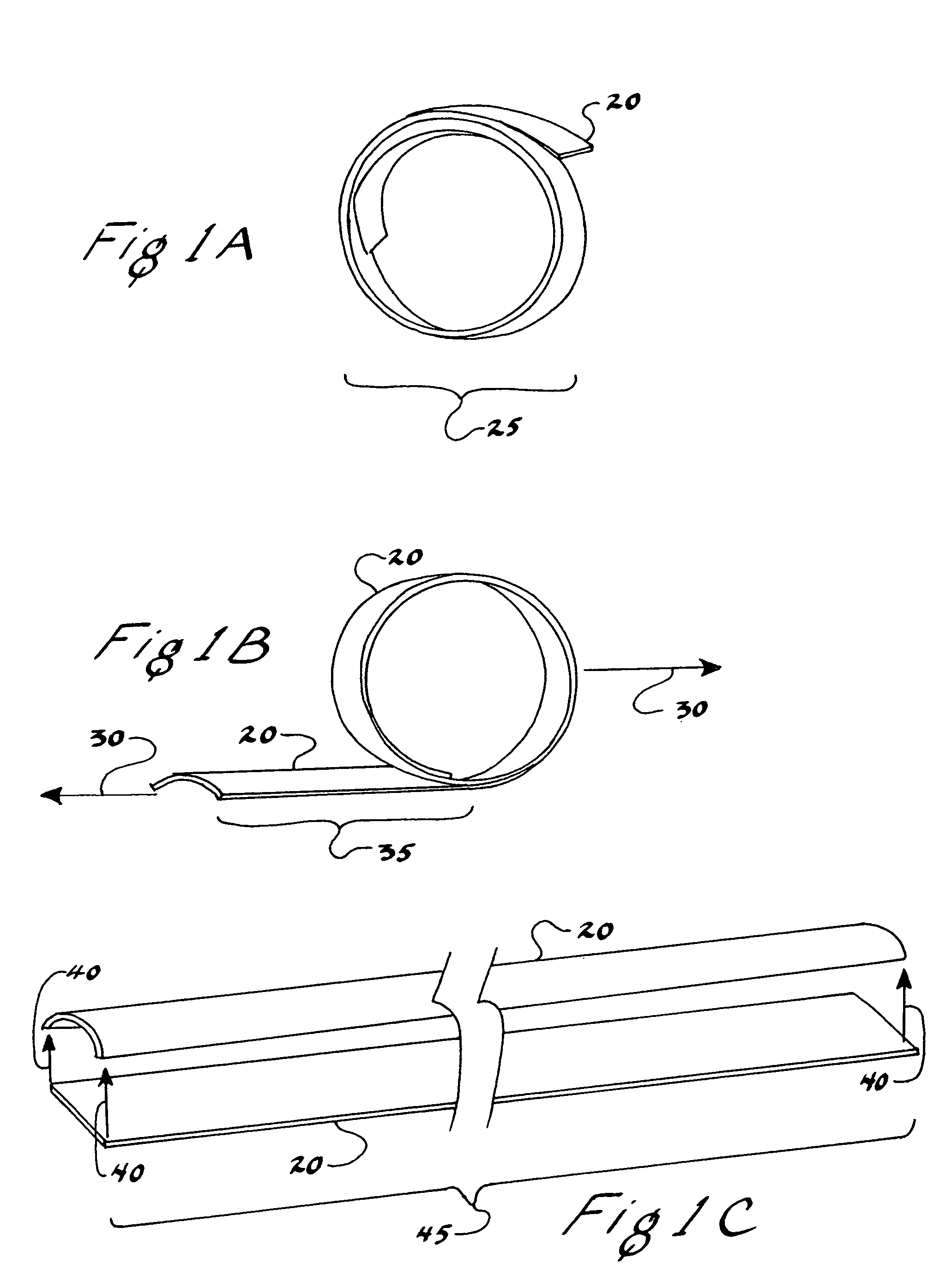

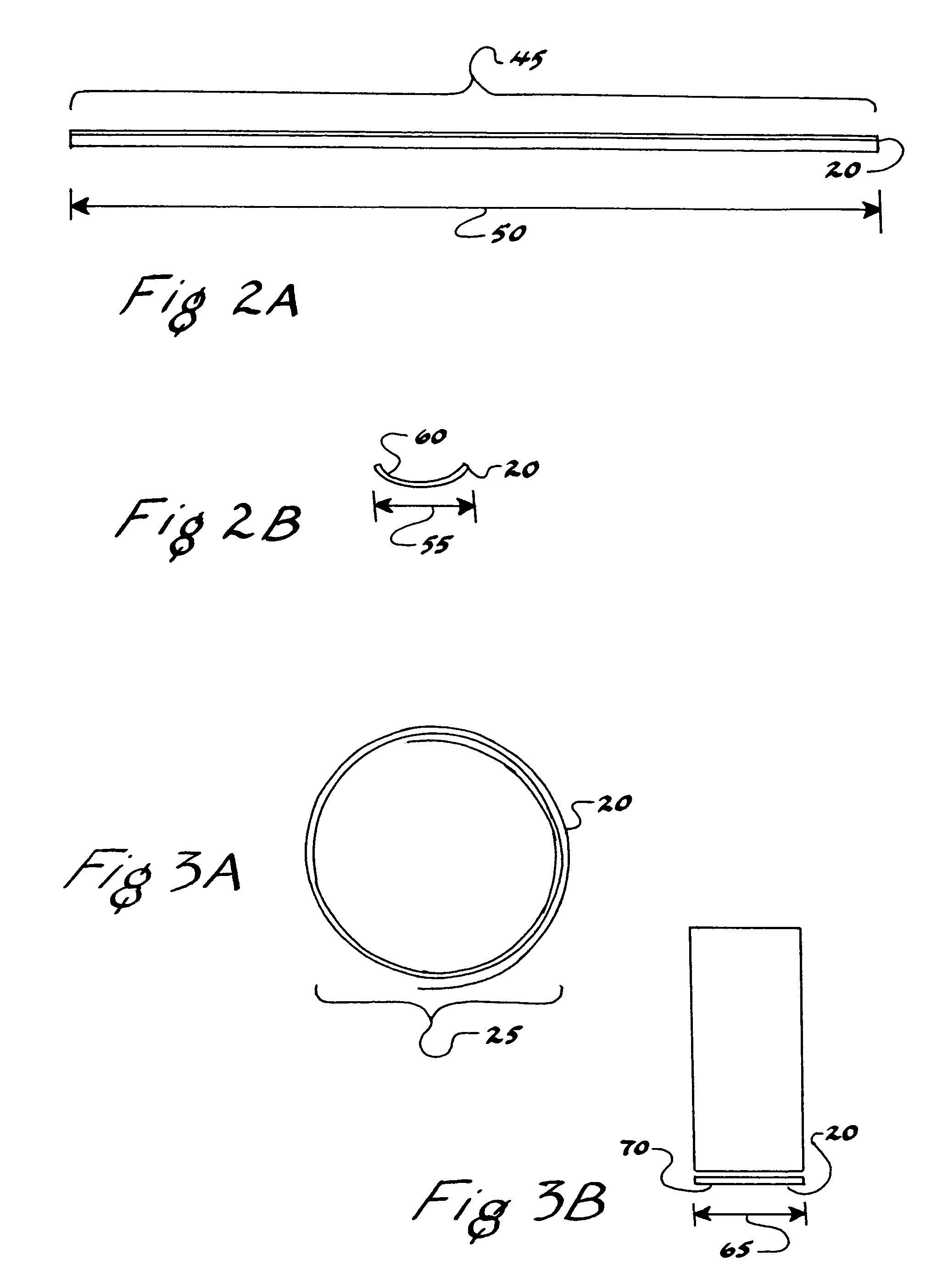

Devices incorporating a bi-stable ribbon spring

InactiveUS7347019B1Simple designSimplifying device device reliabilitySpringsBoardsBand shapeDual mode

A bi-stable snap action ribbon spring incorporated into self-latching, spring-loaded mechanisms. The dual mode stability of the spring eliminates the need for complex latching mechanisms thereby simplifying the device manufacture and device reliability. The spring is stable in either a linear or coiled state enabling the simplified design of rolling, hinging and feeding mechanisms. A plan or map rolling and presentation device incorporates a bi-stable snap action ribbon spring along with optional spring end caps and stiffening elements. The plan or map is driven to a stable coiled or stable rolled shape by the influence of the snap action spring. Application of the snap spring properties to a discreet length of a longer ribbon can create a hybrid bi-stable hinge mechanism. A convenient storage container utilizes the bi-stable characteristics of a snap action ribbon spring to create a container having a self-closing and captured lid. A can or drum feeder incorporates the bi-stable characteristics of a snap action ribbon spring to provide a device that reliably stores and presents cans such as soda cans.

Owner:SHAW EDWARD EMIL

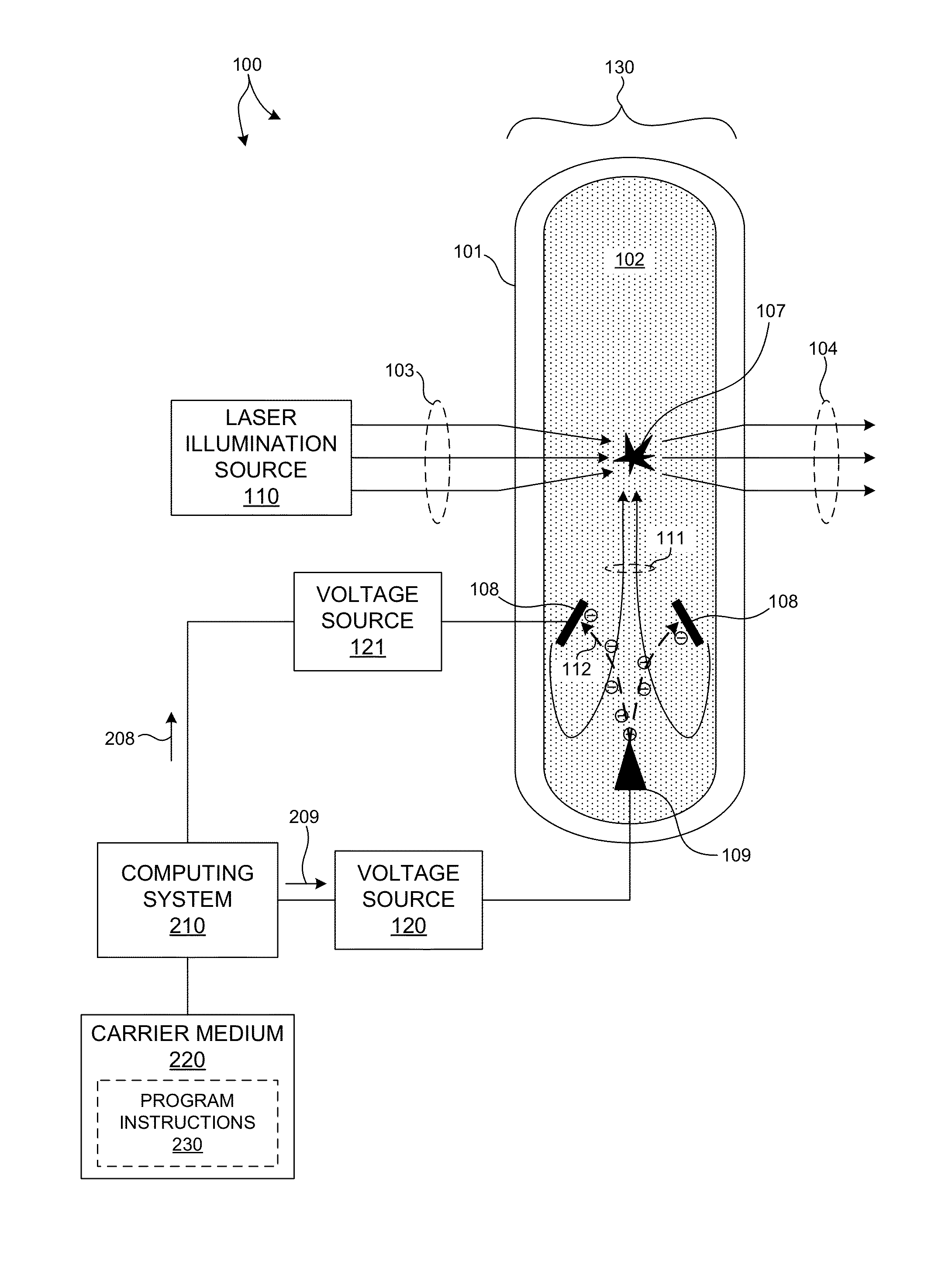

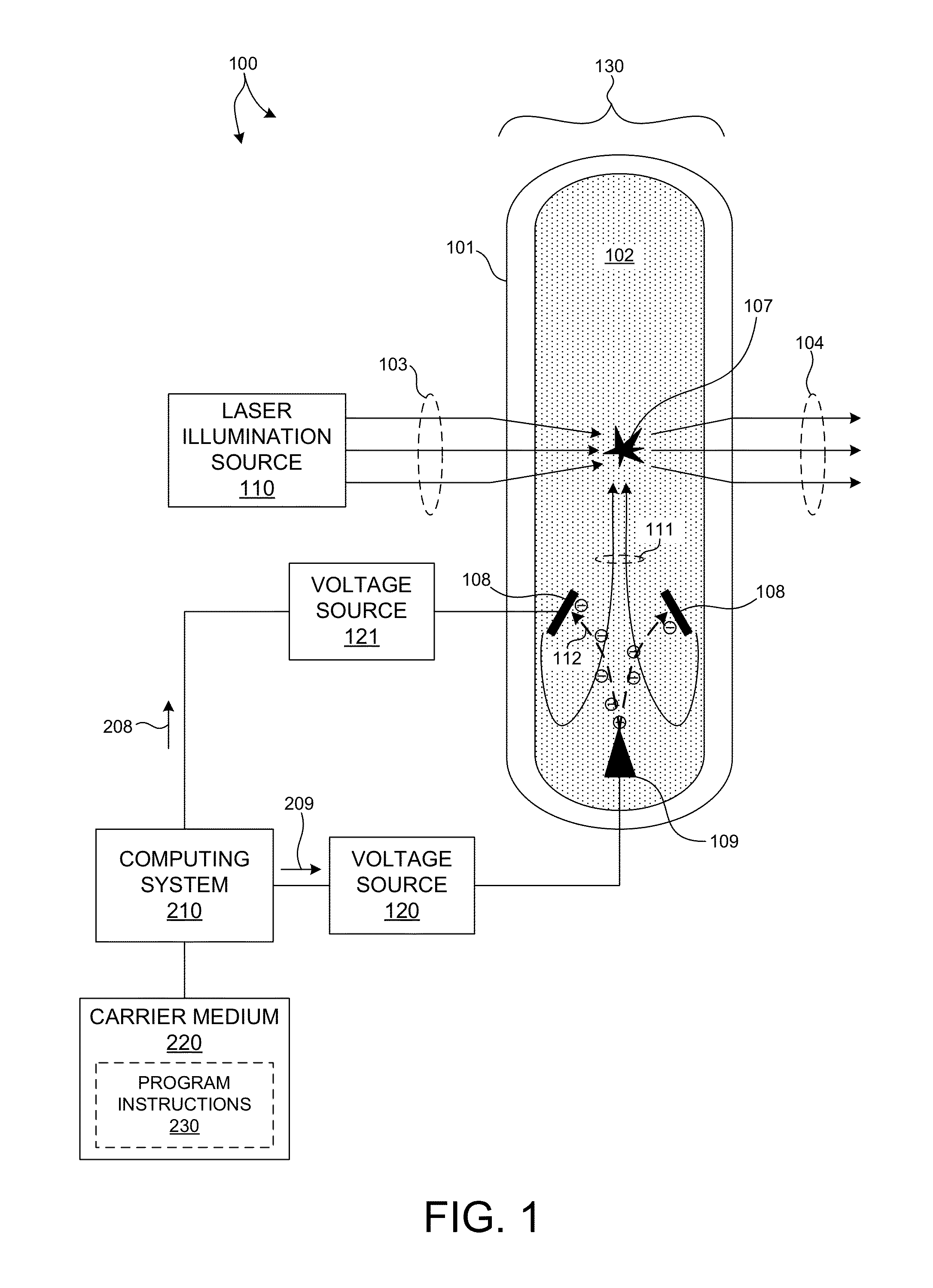

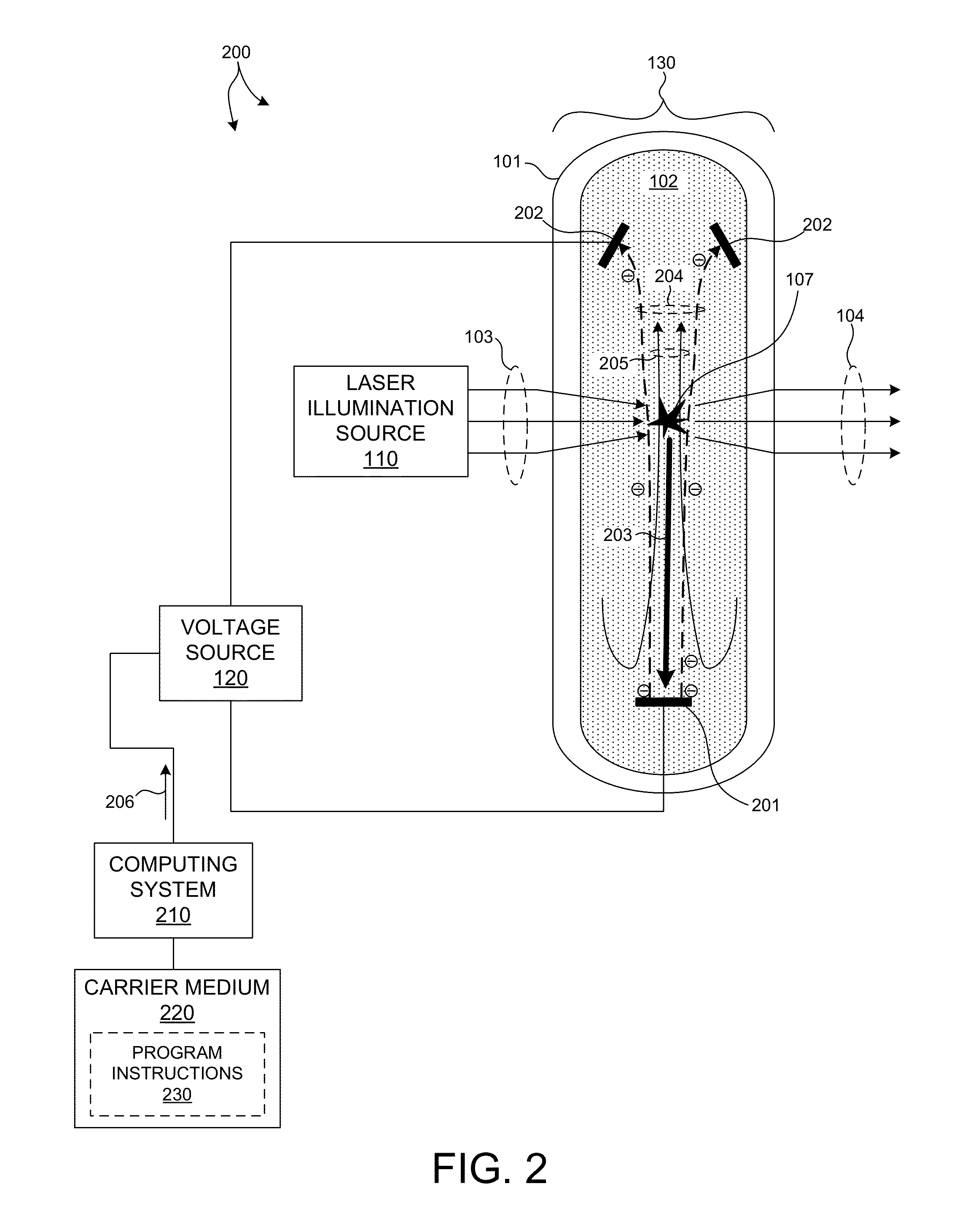

Laser Sustained Plasma Light Source With Electrically Induced Gas Flow

ActiveUS20130342105A1Increase control flexibilityImprove stabilityElectric discharge tubesElectric arc lampsAirflowVoltage

A laser sustained plasma light source includes a plasma bulb containing a working gas flow driven by an electric current sustained within the plasma bulb. Charged particles are introduced into the working gas of the plasma bulb. An arrangement of electrodes maintained at different voltage levels drive the charged particles through the working gas. The movement of the charged particles within the working gas causes the working gas to flow in the direction of movement of the charged particles by entrainment. The resulting working gas flow increases convection around the plasma and increases laser to plasma interaction. The working gas flow within the plasma bulb can be stabilized and controlled by control of the voltages present on the each of the electrodes. A more stable flow of working gas through the plasma contributes to a more stable plasma shape and position within the plasma bulb.

Owner:KLA TENCOR CORP

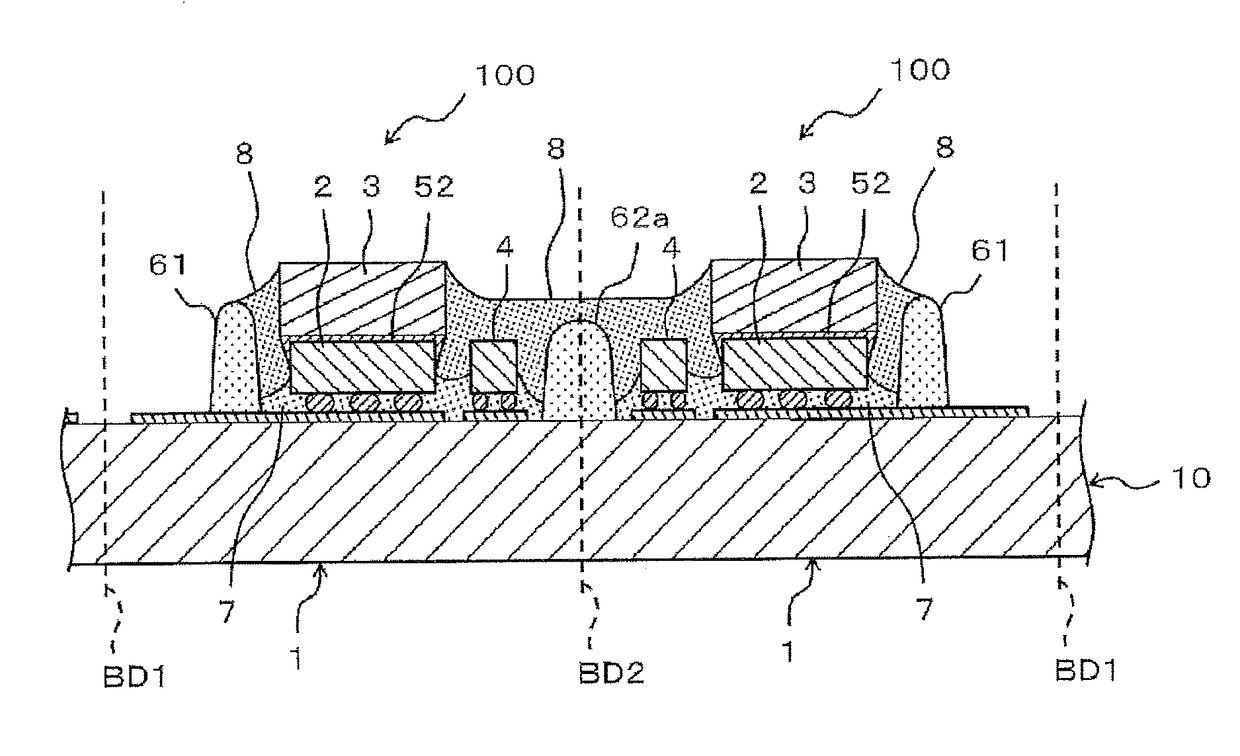

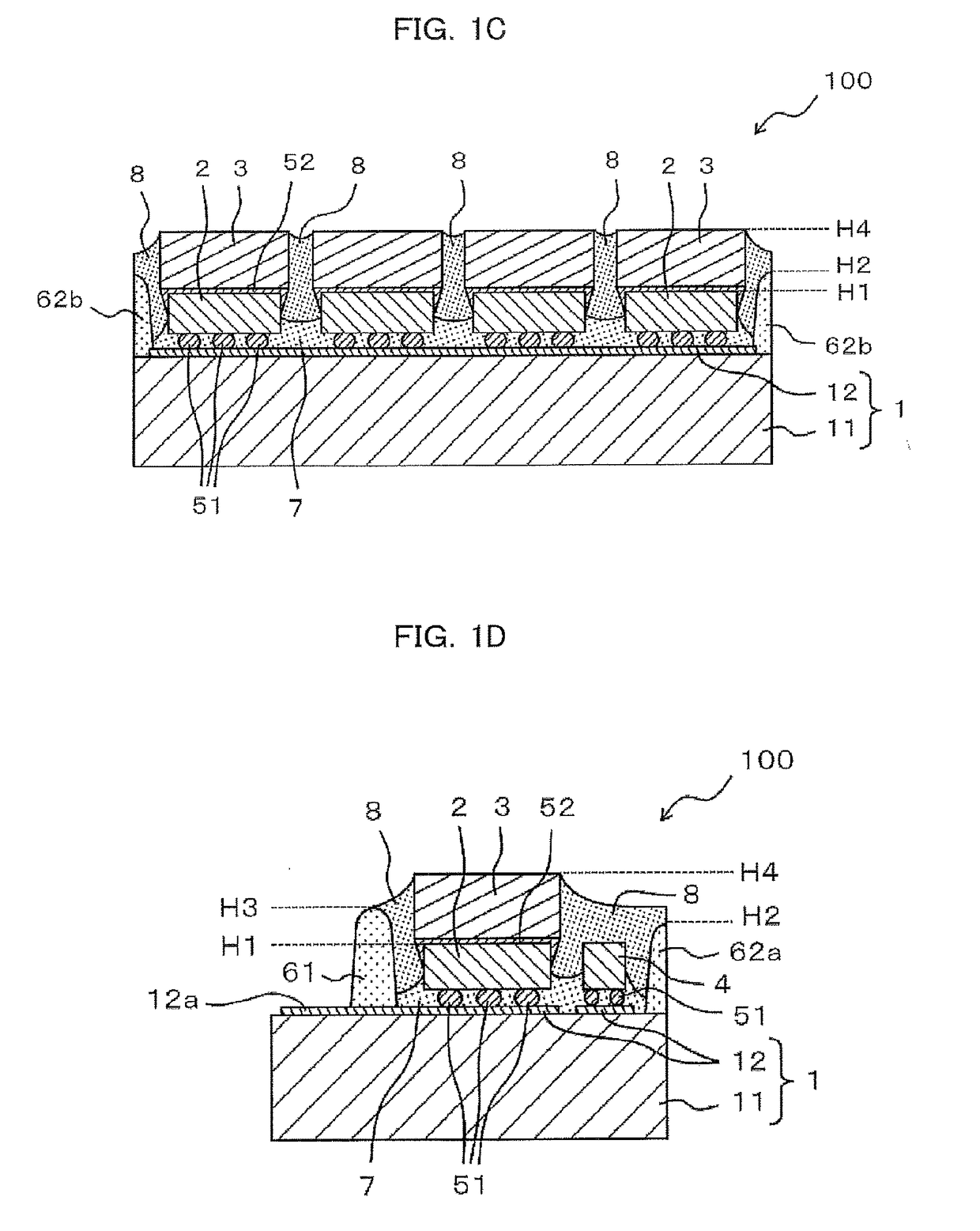

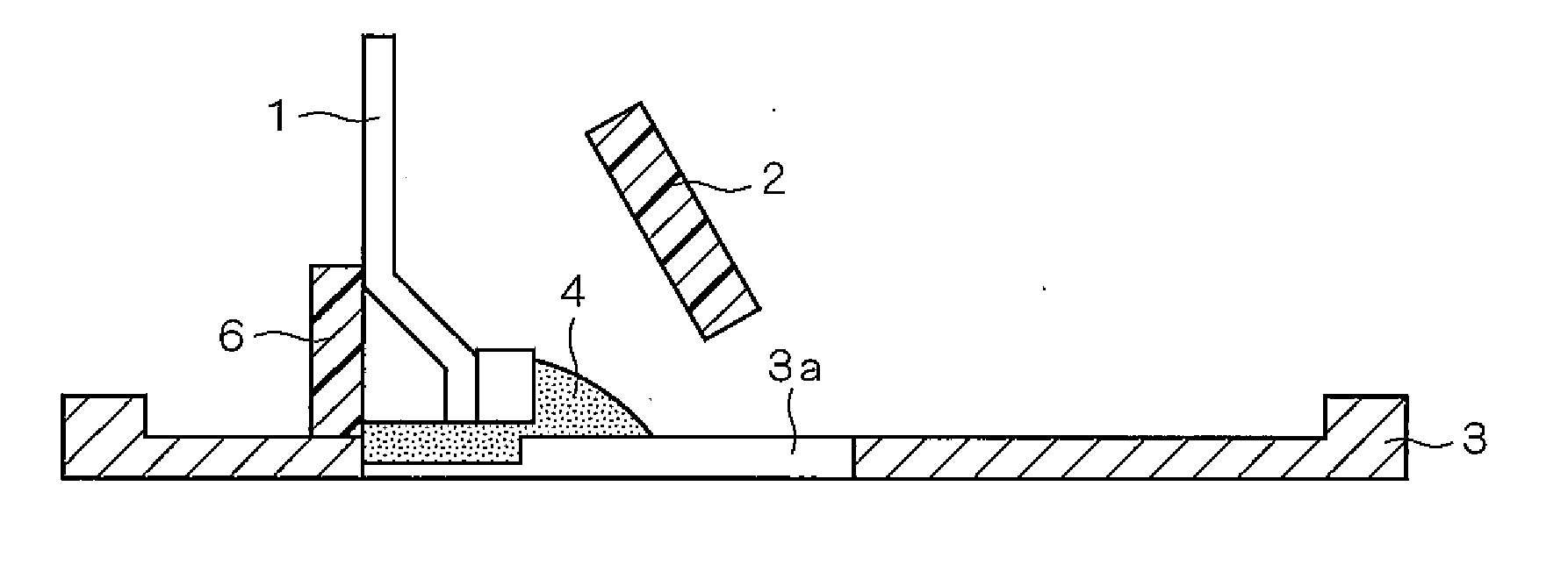

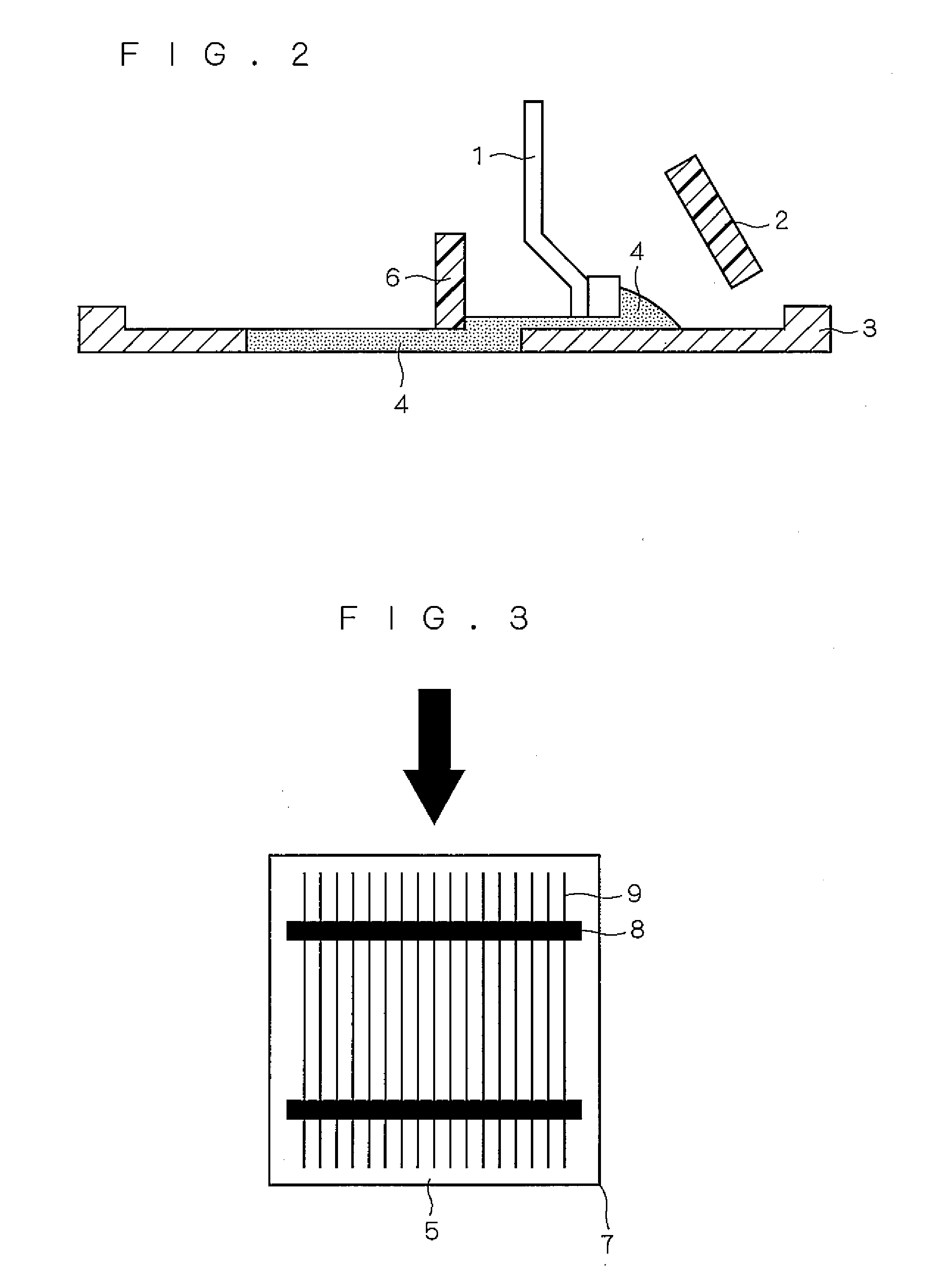

Method of manufacturing light emitting device

ActiveUS20170154880A1Shape stableLow costSemiconductor/solid-state device detailsSolid-state devicesEngineeringLight emitting device

A method of manufacturing a light emitting device includes: mounting light emitting elements on a collective substrate; arranging a first protruding member surrounding the light emitting elements; arranging a second protruding member between the light emitting elements; forming a cover member covering an upper end of the second protruding member, a lateral surface of each of the light emitting elements in a region surrounded by the first protruding member; and singulating the light emitting devices by cutting the cover member, the second protruding member, and the collective substrate at a portion including the second protruding member. The second protruding member is harder than the cover member. An upper end of the second protruding member is located lower than that of the first protruding member but higher than the upper surface of each of the light emitting elements.

Owner:NICHIA CORP

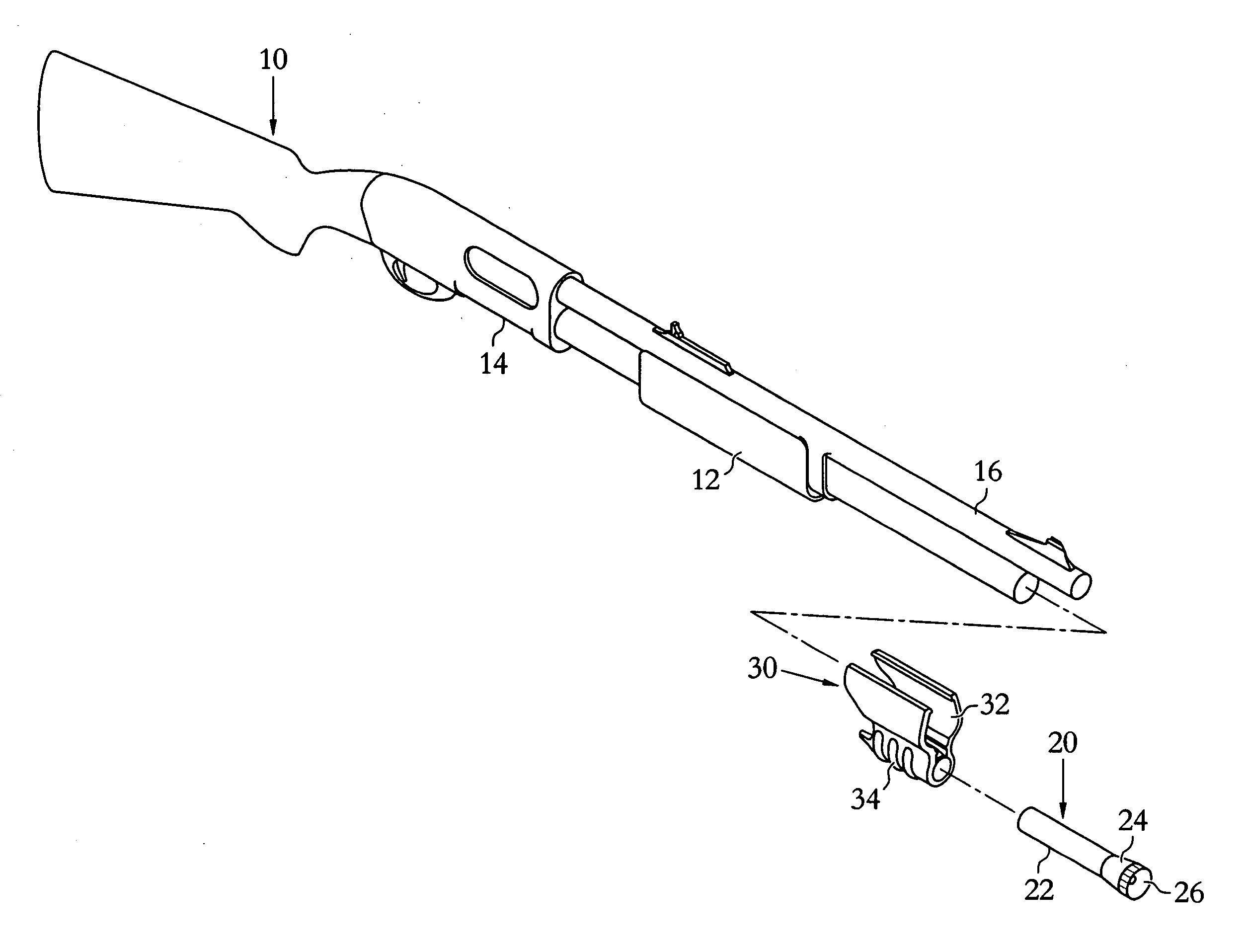

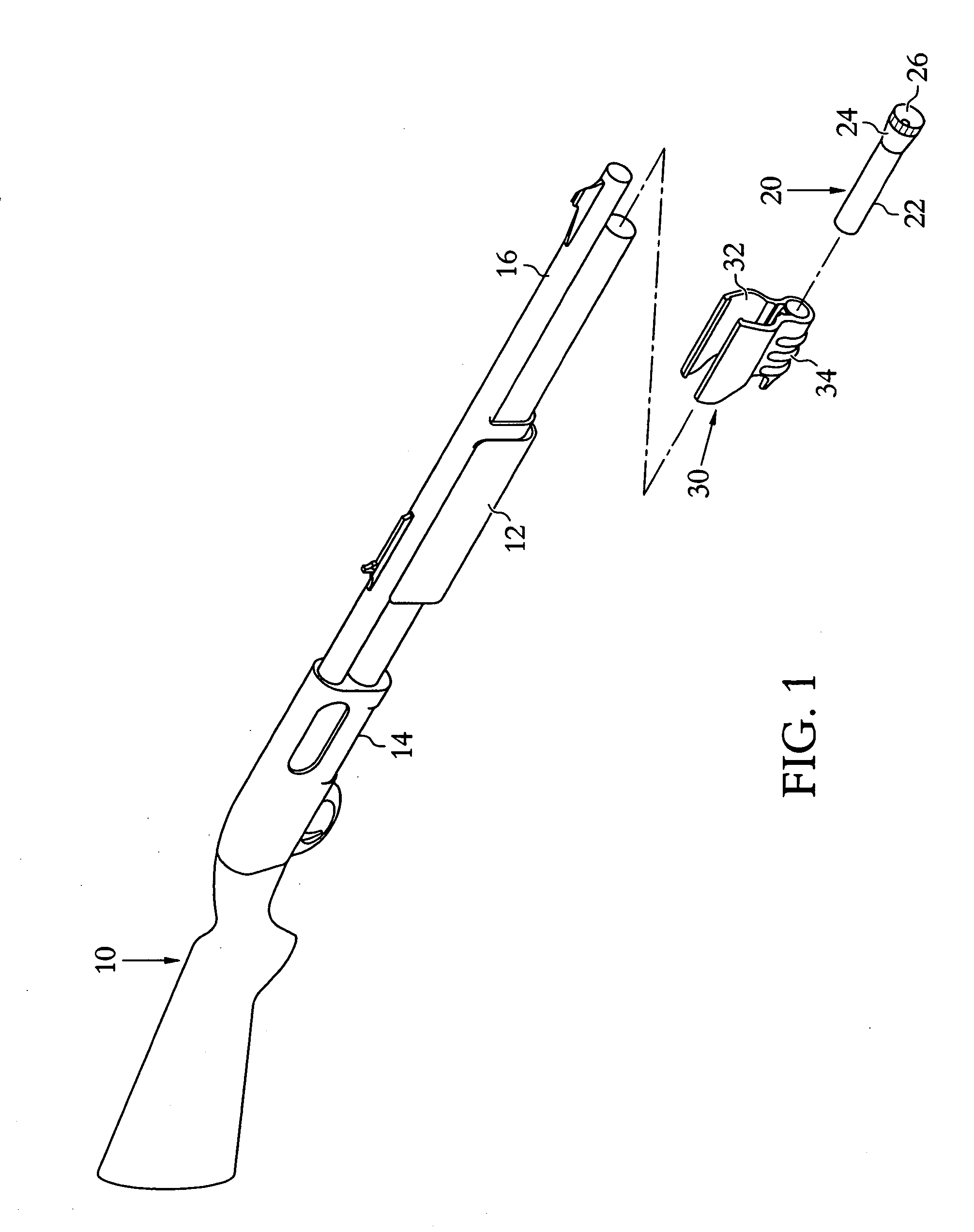

Removable integrated target-illuminating device holder and grip apparatus and method thereof

InactiveUS20070137087A1Quick installationShape stableCartridge extractorsSighting devicesInterference fitEngineering

A removable integrated target-illuminating device holder and grip apparatus and method thereof are disclosed. The apparatus mounts to an existing forestock of a weapon with an interference fit actuated by a single screw. The apparatus also includes a passage for receiving the barrel of a target illumination device. Resilient prongs are provided adjacent the rear of the passage to press the illumination device longitudinally along approximately the same axis as the weapon's barrel to prevent dislodgment upon movement of the weapon during handling or discharge, and to enable relatively quick, one-handed release and replacement of the entire illumination device.

Owner:DAYTAC

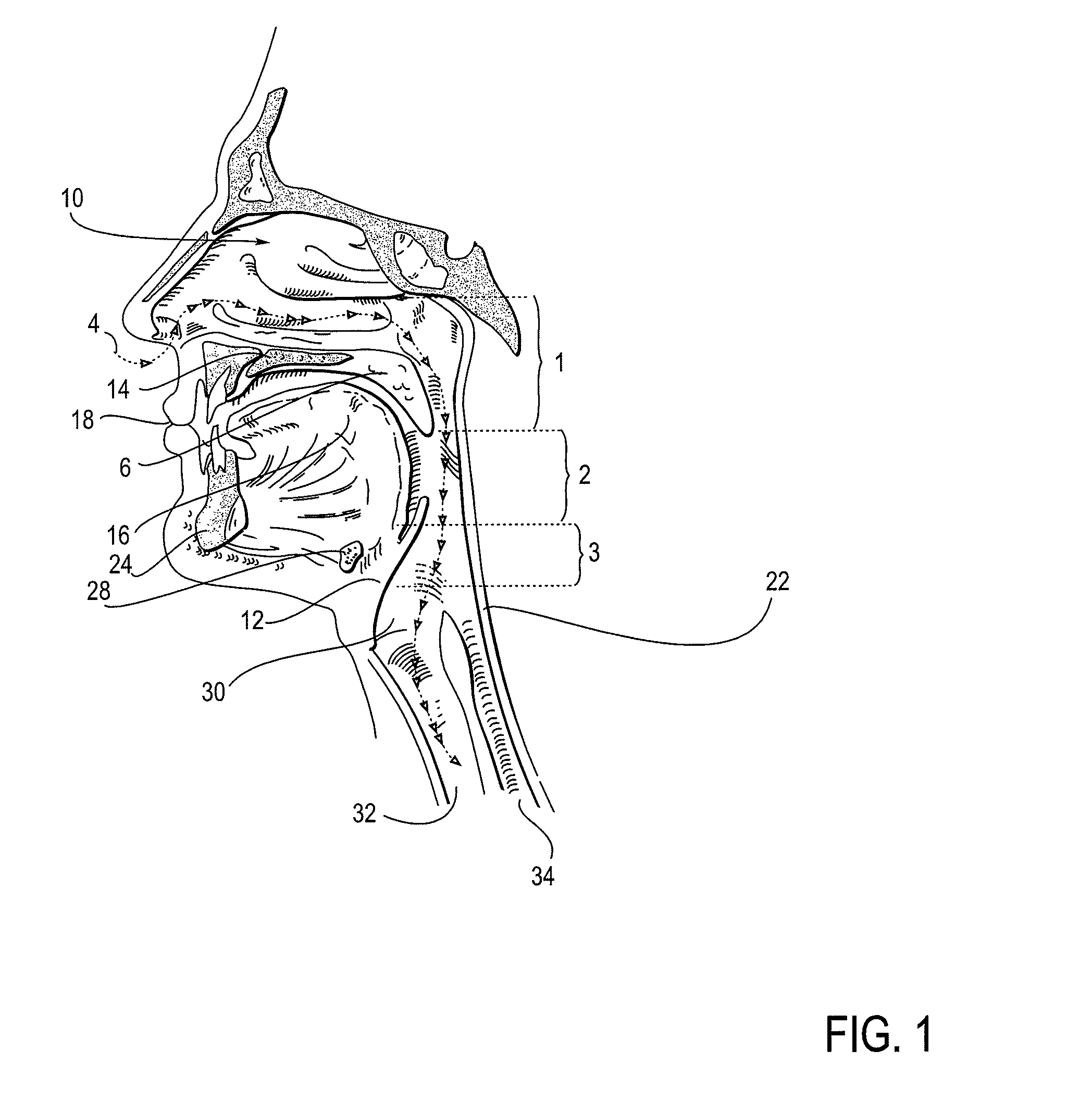

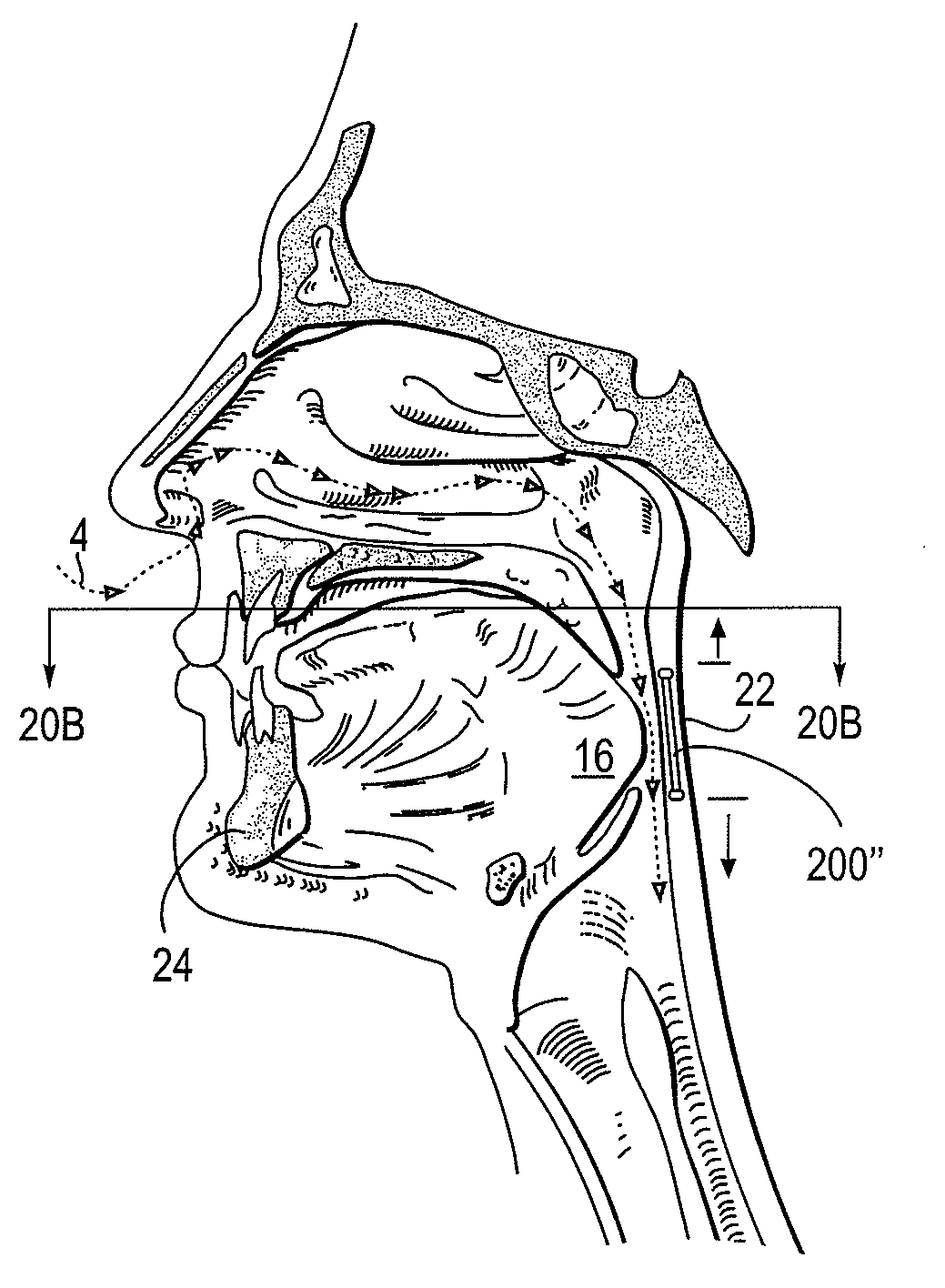

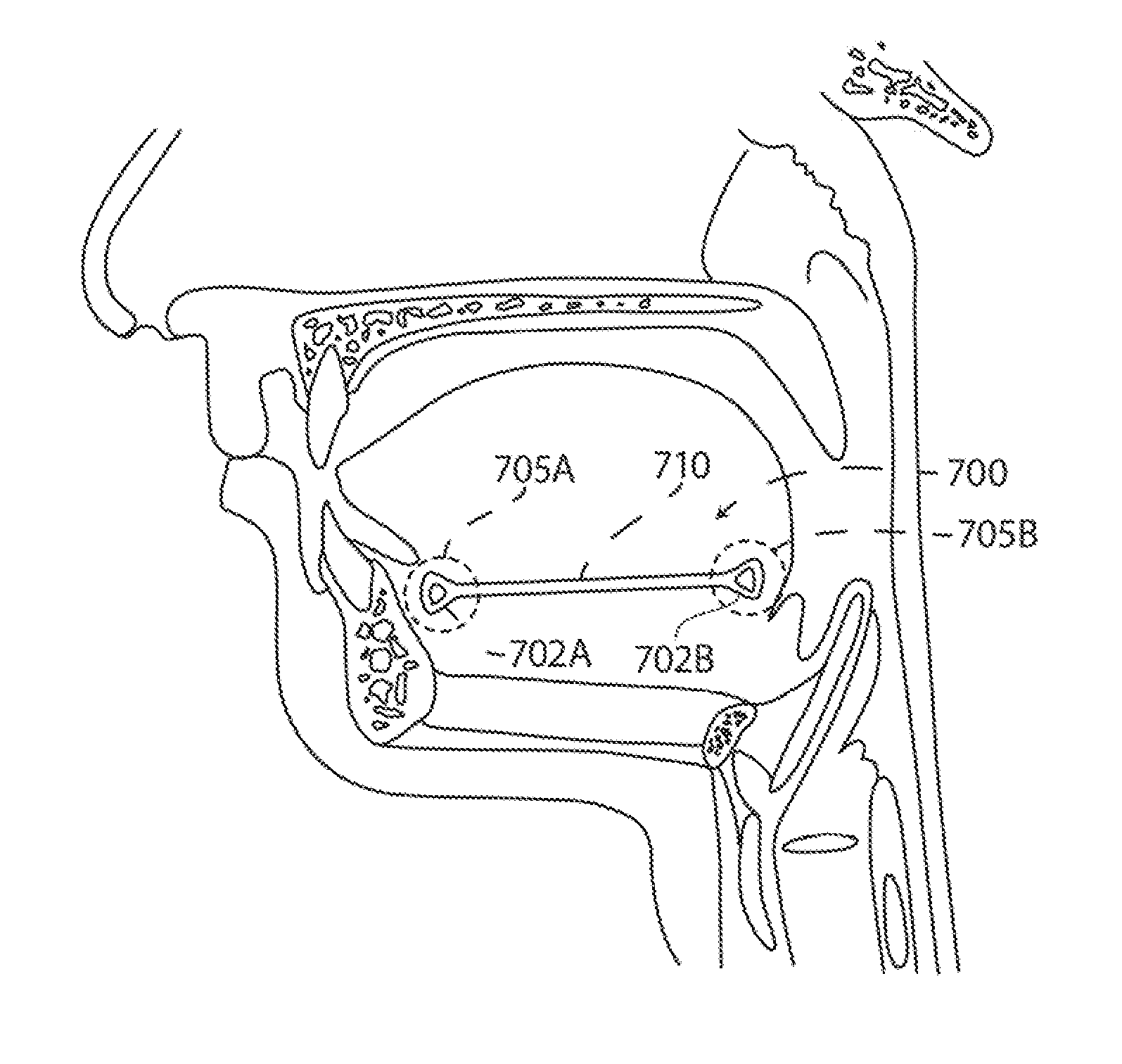

Partially erodable systems for treatment of obstructive sleep apnea

InactiveUS8167787B2Alleviating obstructive collapseReduce frequencyDiagnosticsSurgeryShape changeBiomedical engineering

The invention relates to devices and methods for reforming tissue surrounding the airway of a subject suffering from obstructive sleep apnea so as to open the airway and alleviate the occurrence of apneic events. Devices comprise a combination of resiliently deformable material and bioerodible material. The deformable portion of the device has a preferred shape that corresponds to the desired final shape of the device once placed in an airway. In making a transplant-ready device, however, the deformable portion is placed into a deformed shape and constrained in that shape by the bioerodible material. After implantation, the device gradually assumes the preferred shape as the constraining bioerodible material erodes. As the device gradually reforms toward the preferred shape, it reforms the tissue into the therapeutically desirable configuration. The gradual nature of the shape change generally stabilizes the device in the tissue, and supports tissue reforming into a stable configuration.

Owner:REVENT MEDICAL

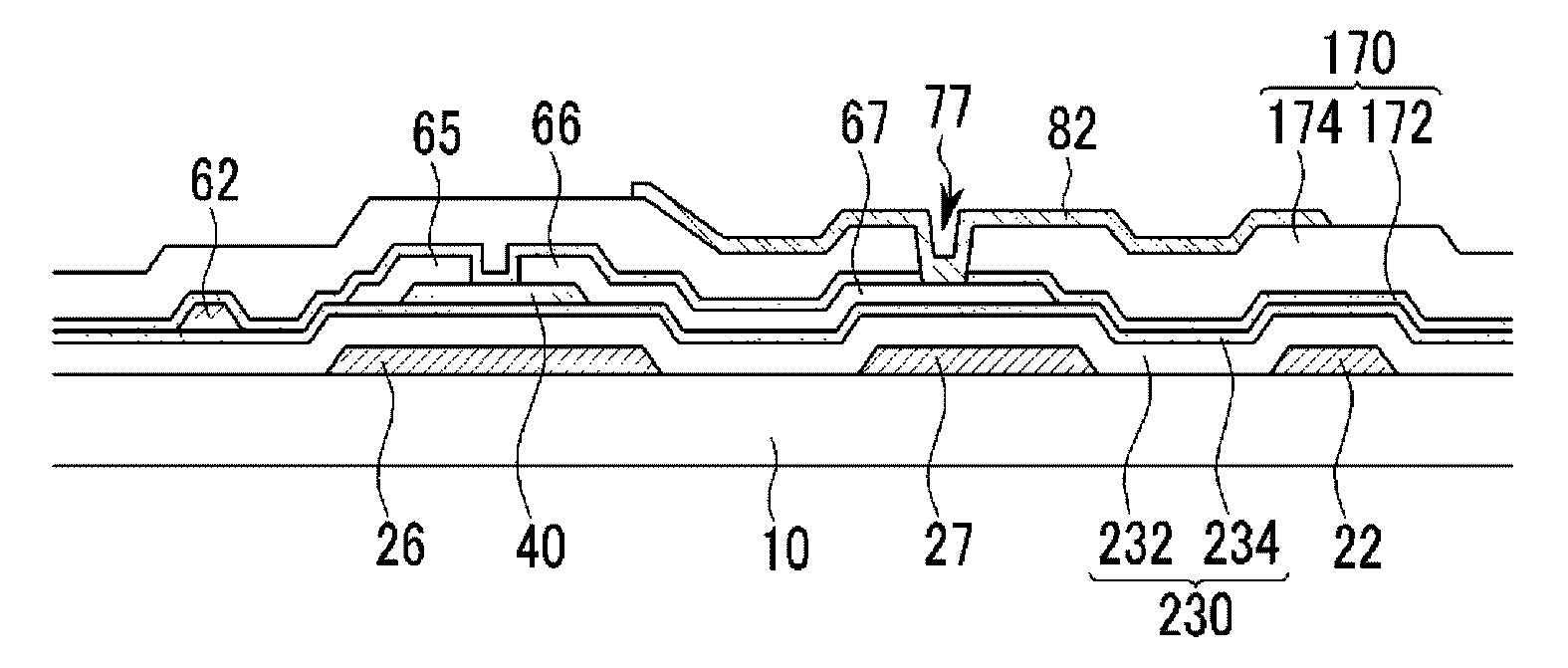

Thin film transistor display panel and manufacturing method of the same

ActiveUS20110297930A1Improve reliabilityShape stableTransistorSolid-state devicesDisplay deviceSemiconductor

A TFT display panel having a high charge mobility and making it possible to obtain uniform electric characteristics with respect to a large-area display is provided as well as a manufacturing method thereof. A TFT display panel includes a gate electrode formed on an insulation substrate, a first gate insulting layer formed of SiNx on the gate electrode, a second gate insulting layer formed of SiOx on the first gate insulting layer, an oxide semiconductor layer formed to overlap the gate electrode and having a channel part, and a passivation layer formed of SiOx on the oxide semiconductor layer and the gate electrode, and the passivation layer includes a contact hole exposing the drain electrode. The contact hole has a shape in which the passivation layer of a portion directly exposed together with a metal occupies an area smaller than the upper passivation layer.

Owner:SAMSUNG DISPLAY CO LTD

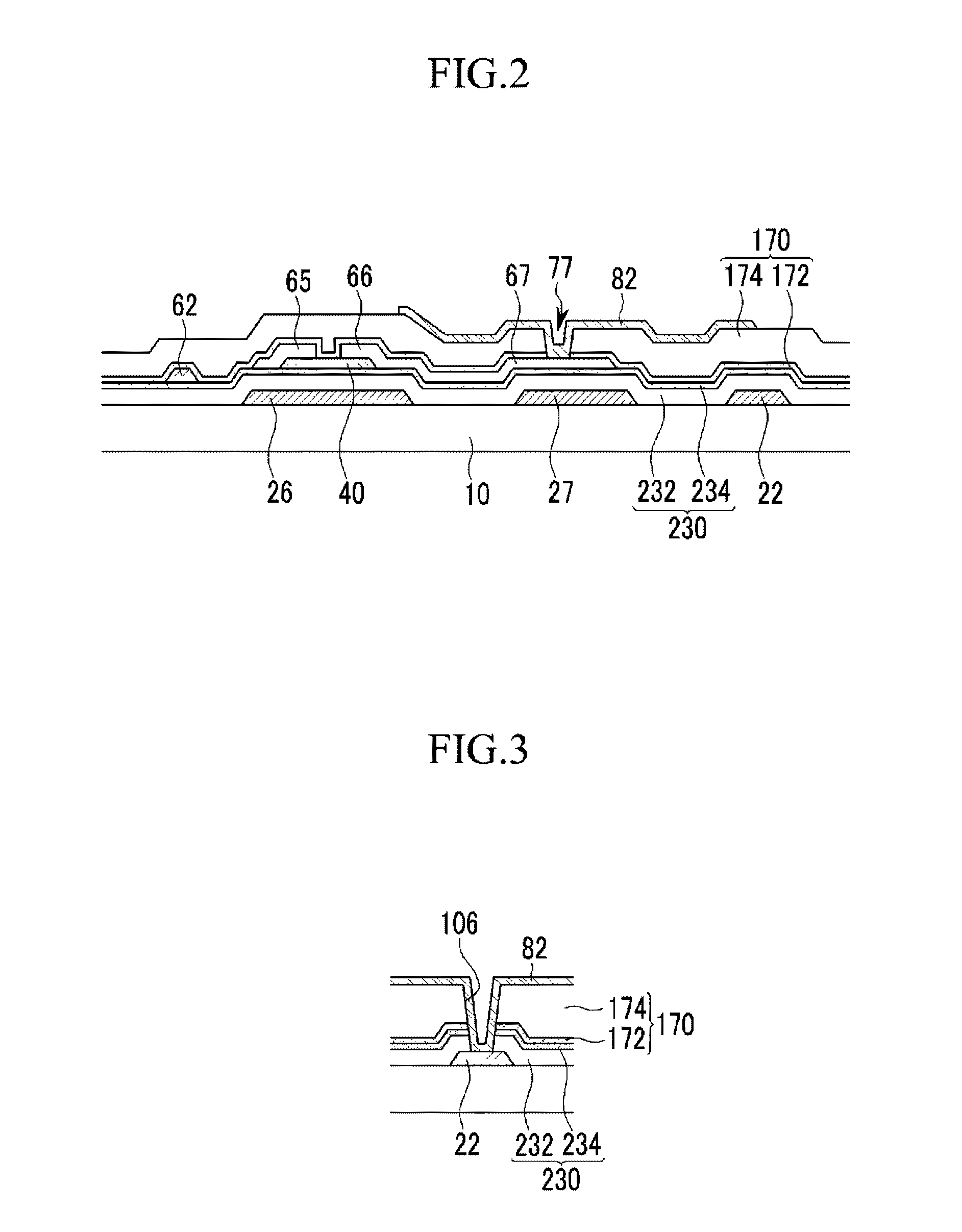

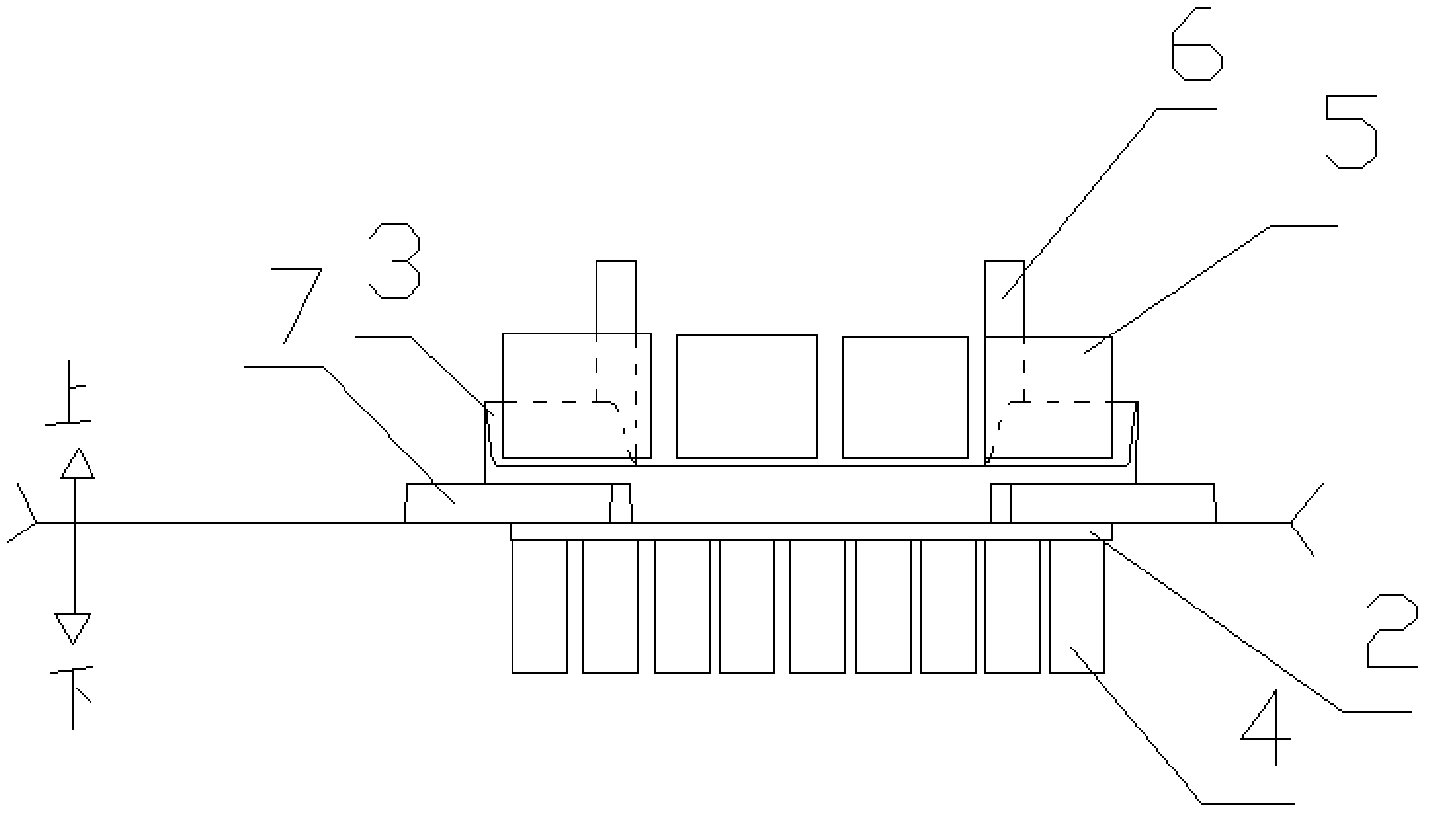

Contactless guide system for continuous web

InactiveUS6635111B1Easy to clean automaticallyShape stableLiquid surface applicatorsProjector film strip handlingMetallic materialsBiomedical engineering

Known devices for contactlessly guiding or treating continuous lines of material (1) have one chamber (2). A supply device (3) for a gaseous fluid is connected to said chamber (2), which has a gas-permeable wall (4). The outer surface (5) of said wall (4) is embodied as a guide surface for the line (1). According to the invention, the gas-permeable wall (4) is produced from a porous, metal-containing material with open pores which have an average diameter of less than 500 mum, preferably less than 100 mum, especially less than 20 mum. The porous material used for the guiding surface enables the line (1) to glide on a fluid pad of less than 1 mm. The losses of fluid on the surfaces not covered by the line (1) are very low.

Owner:BACHOFEN MEIER MASCHFAB

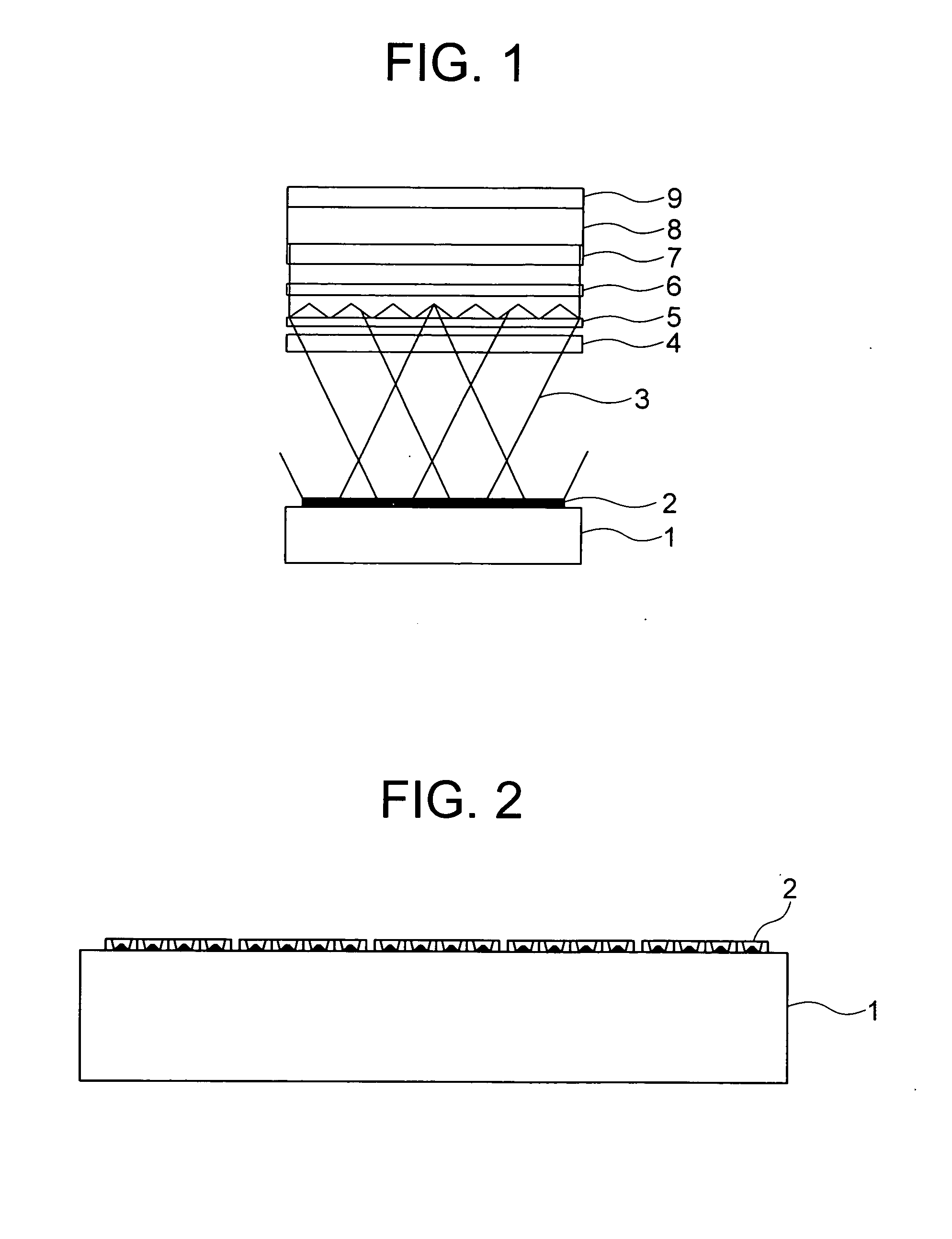

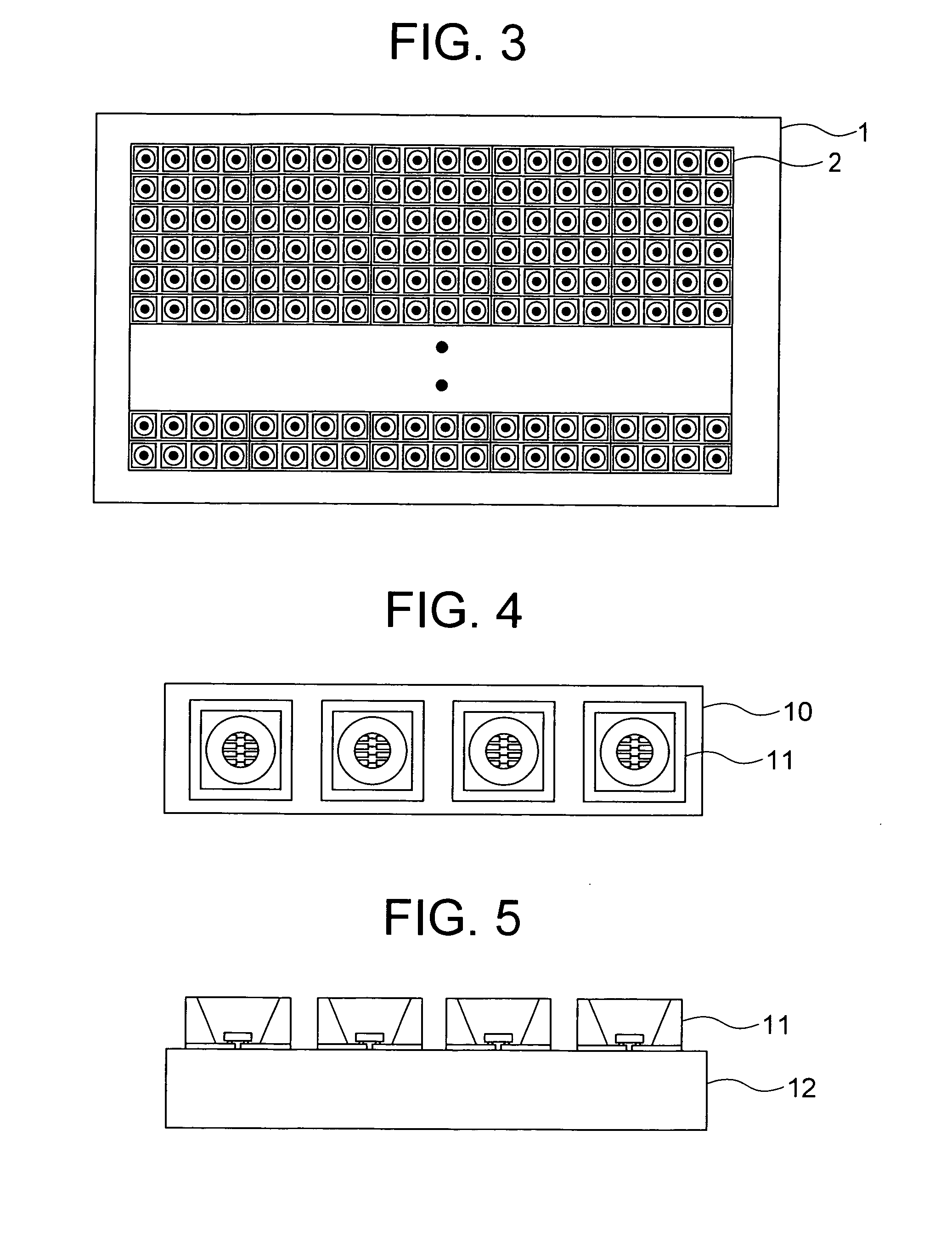

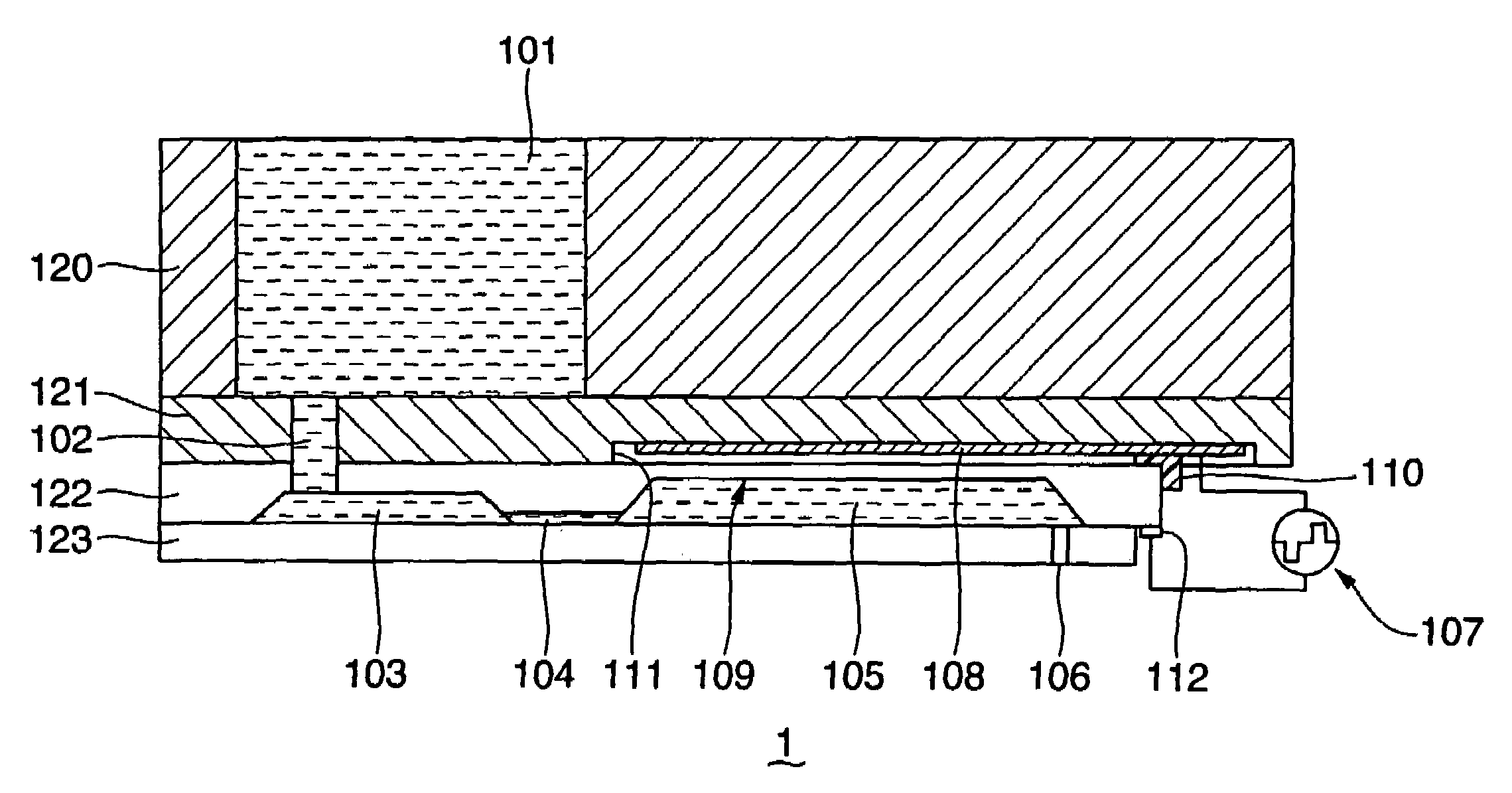

Liquid crystal display apparatus

ActiveUS20070085944A1Increase brightnessIncrease in sizeSolid-state devicesNon-linear opticsCold cathodeEngineering

A cold-cathode tube has hitherto been used as a backlight for supplying illumination to a liquid crystal television but recently, light emitting diode pieces have been used for a backlight of a large-size liquid crystal television. For the purpose of improving the emission efficiency, flip chip mounting of the light emitting diode piece is advantageous but the mounting yield is restricted by the piece size, electrode structure and wire pattern structure, facing situations having difficulties in realizing simplified mounting and reduction of costs of members. In a liquid crystal display apparatus having a liquid crystal panel, an optical system and a light source, the light source includes a light emitting element structure having positive and negative electrodes, at least one of them being plural, and wires mounted to the positive and negative electrodes through flip chip mounting by making electrical correspondence to individual regions of the positive and negative electrodes.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

Partially erodable systems for treatment of obstructive sleep apnea

InactiveUS20090177027A1Alleviating obstructive collapseReduce frequencyDiagnosticsSurgeryShape changeBiomedical engineering

The invention relates to devices and methods for reforming tissue surrounding the airway of a subject suffering from obstructive sleep apnea so as to open the airway and alleviate the occurrence of apneic events. Devices comprise a combination of resiliently deformable material and bioerodible material. The deformable portion of the device has a preferred shape that corresponds to the desired final shape of the device once placed in an airway. In making a transplant-ready device, however, the deformable portion is placed into a deformed shape and constrained in that shape by the bioerodible material. After implantation, the device gradually assumes the preferred shape as the constraining bioerodible material erodes. As the device gradually reforms toward the preferred shape, it reforms the tissue into the therapeutically desirable configuration. The gradual nature of the shape change generally stabilizes the device in the tissue, and supports tissue reforming into a stable configuration.

Owner:REVENT MEDICAL

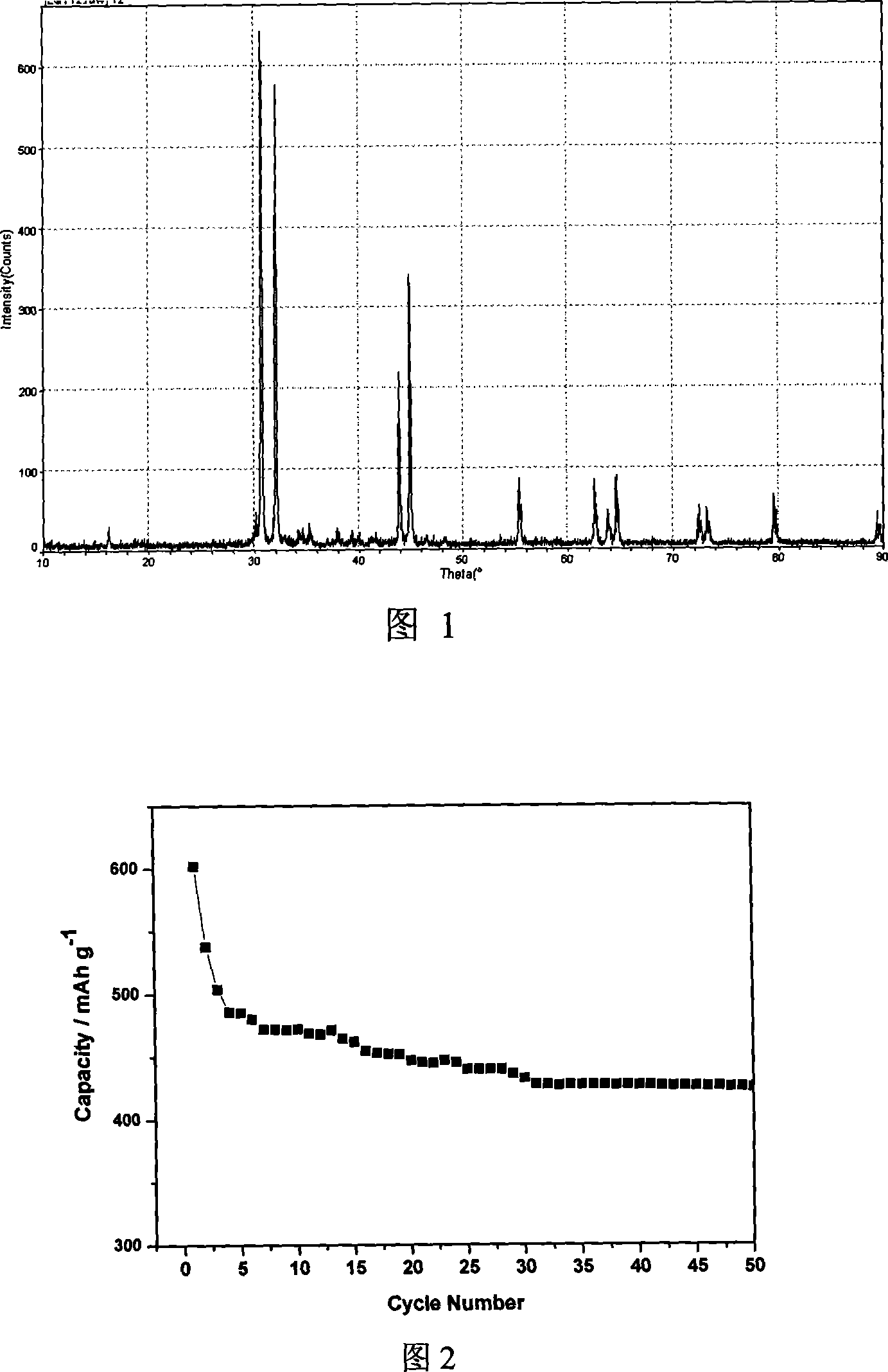

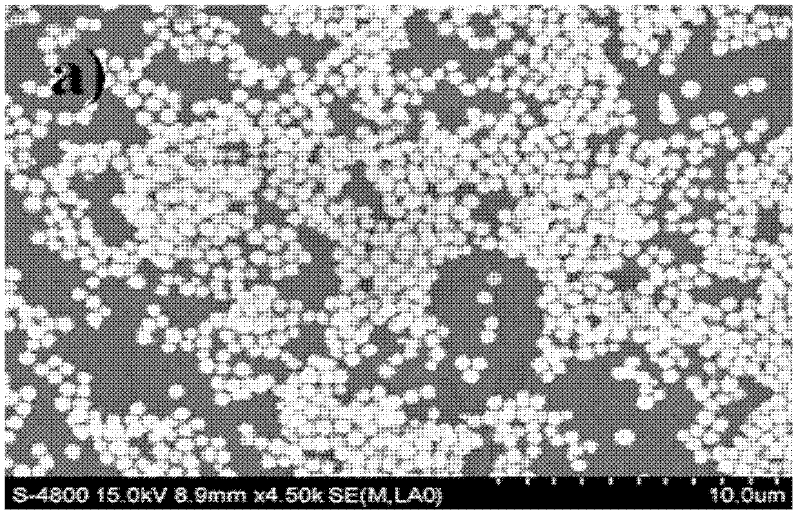

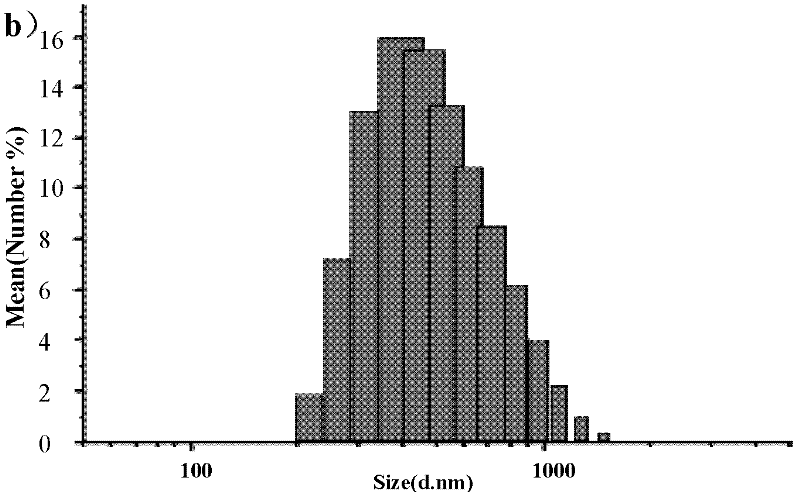

Tin carbon nanometer compound material for lithium ion battery and method for making same

InactiveCN101202340APromote circulationAlleviate volume changesElectrode manufacturing processesChemical/physical/physico-chemical processesMass ratioSodium-ion battery

The invention discloses a tin-carbon nano-composite and a preparation method which are used for a cathode of a li-ion battery. The steps of the preparation method are as follows: 1) dissoluble stannate or dissoluble tin salt is mixed uniformly with starch in order to obtain admixture; the mass ratio of starch and tin in the dissoluble stannate or tin in the dissoluble tin salt is 1:0.01 to 0.5; 2) the obtained admixture is arranged in inertia gas environment, heated to the temperature of 300 DEG C to 400 DEG C which is kept for 0-10 hours, and then heated to the temperature of 500 DEG C to 1000 DEG C which is kept for 0-10 hours and then cooled to obtain the tin-carbon nano-composite used for the cathode of the li-ion battery. The preparation method of the invention has simple process, low cost, high specific capacity and excellent circulation performance of obtained tin-carbon nano-composite.

Owner:GUANGXI NORMAL UNIV

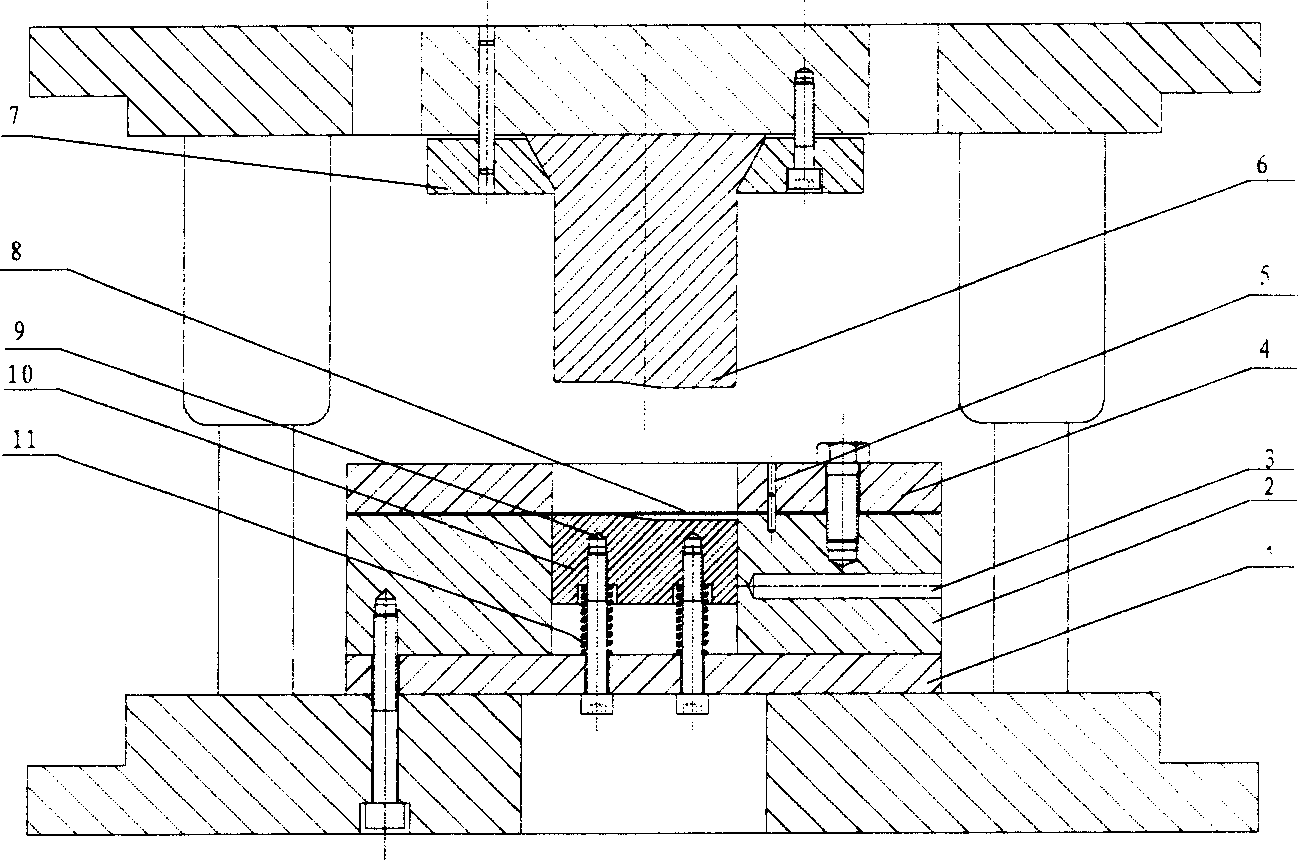

Mild hot formation method for making magnesium alloy shell of cell phone and mould specially for the same

A thermal shaping method for the Mg-alloy shell of mobile telephone features use of draw technology with a dedicated die set, which includes such steps as heating edge pressing ring and female die to 170-180 deg.C, coating lubricant onto die set and raw black of said Mg-alloy shell, heating the raw black, pre-heating the male die to 70-100 deg.C, and die pressing at 170-180 deg.C for drawing.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

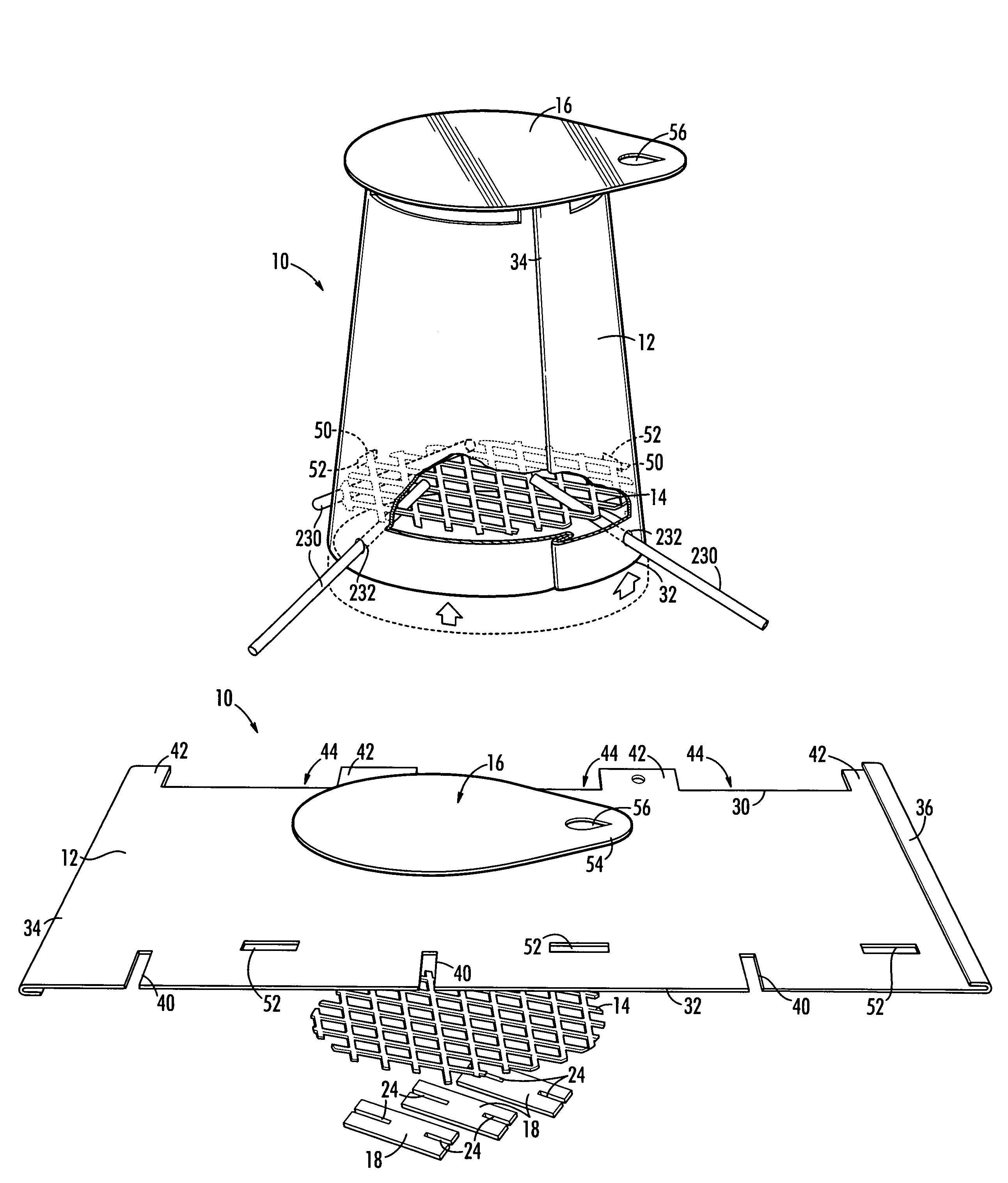

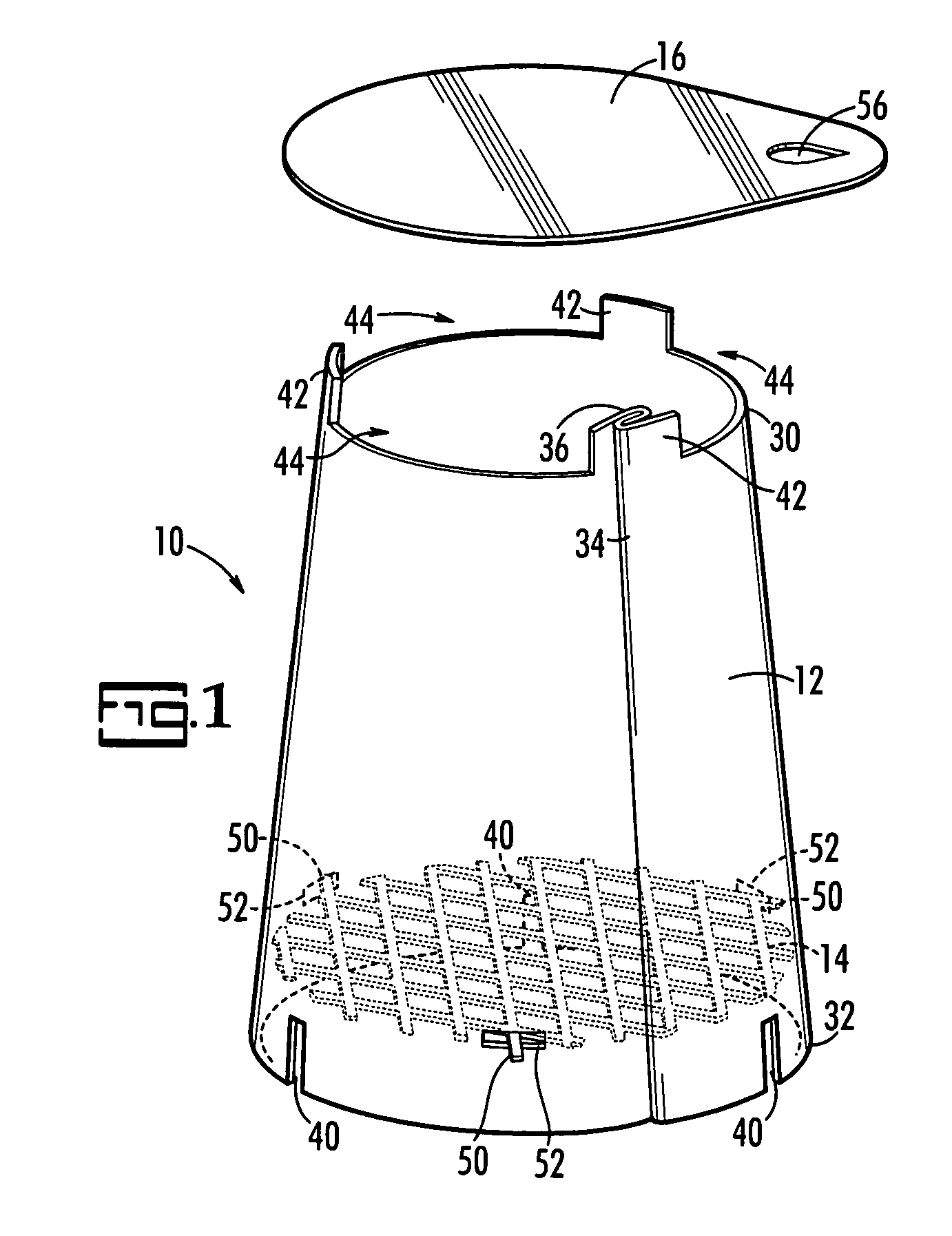

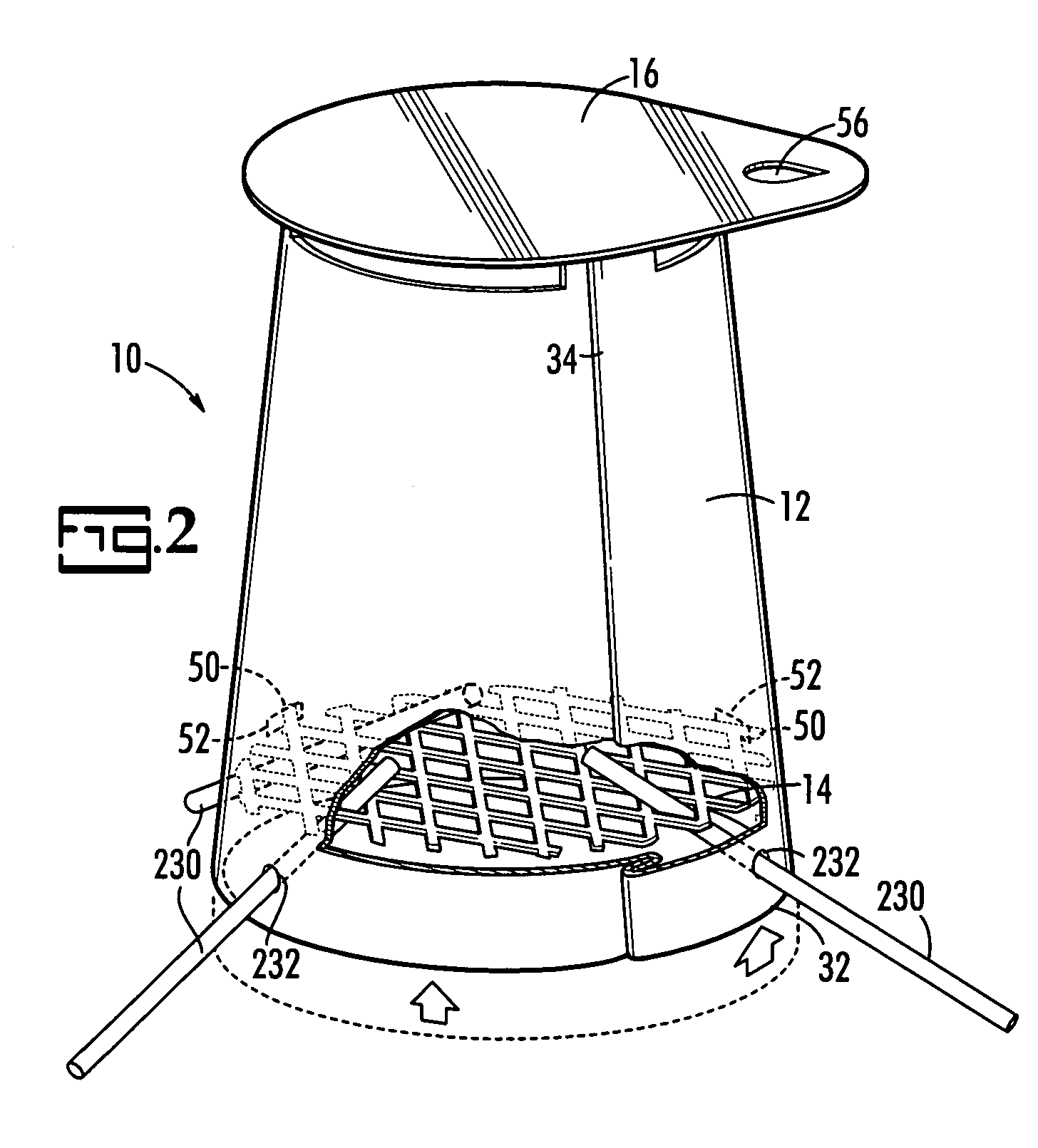

Portable stove

ActiveUS7107983B1Easy to carryEasy to storeDomestic stoves or rangesLighting and heating apparatusEngineeringMechanical engineering

A portable stove includes a frusto-conical body and a grid carried within the body together with an optional cooking surface for the smaller end of the body and stands to elevate the larger end of the body to facilitate establishing an air flow into the body. By rolling a flat piece of metal that has folds on both ends until the folded ends are interlocked, the stove's body is formed. Squeezing the formed body releases it to return to a flattened configuration for storage. The components of the stove can thus be stored in a compact configuration such as in a backpack. An optional oven includes a cooking chamber within a housing. The oven rests on the body and redistributes heat from the burning fuel inside the body to the cooking chamber base, body and lid so that it bakes evenly. The housing confines the heat to the chamber for improved cooking efficiency.

Owner:WEST JEFFREY C

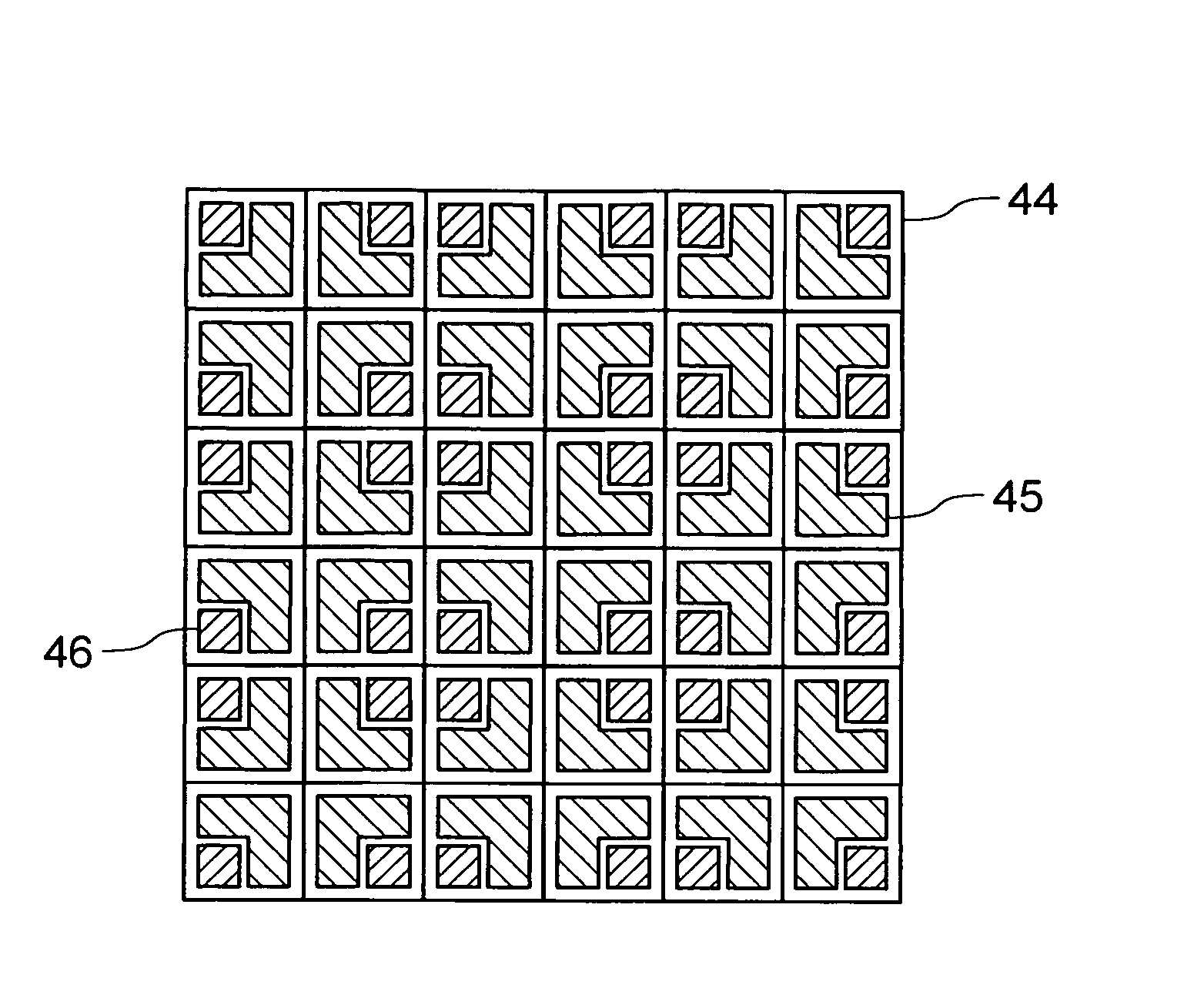

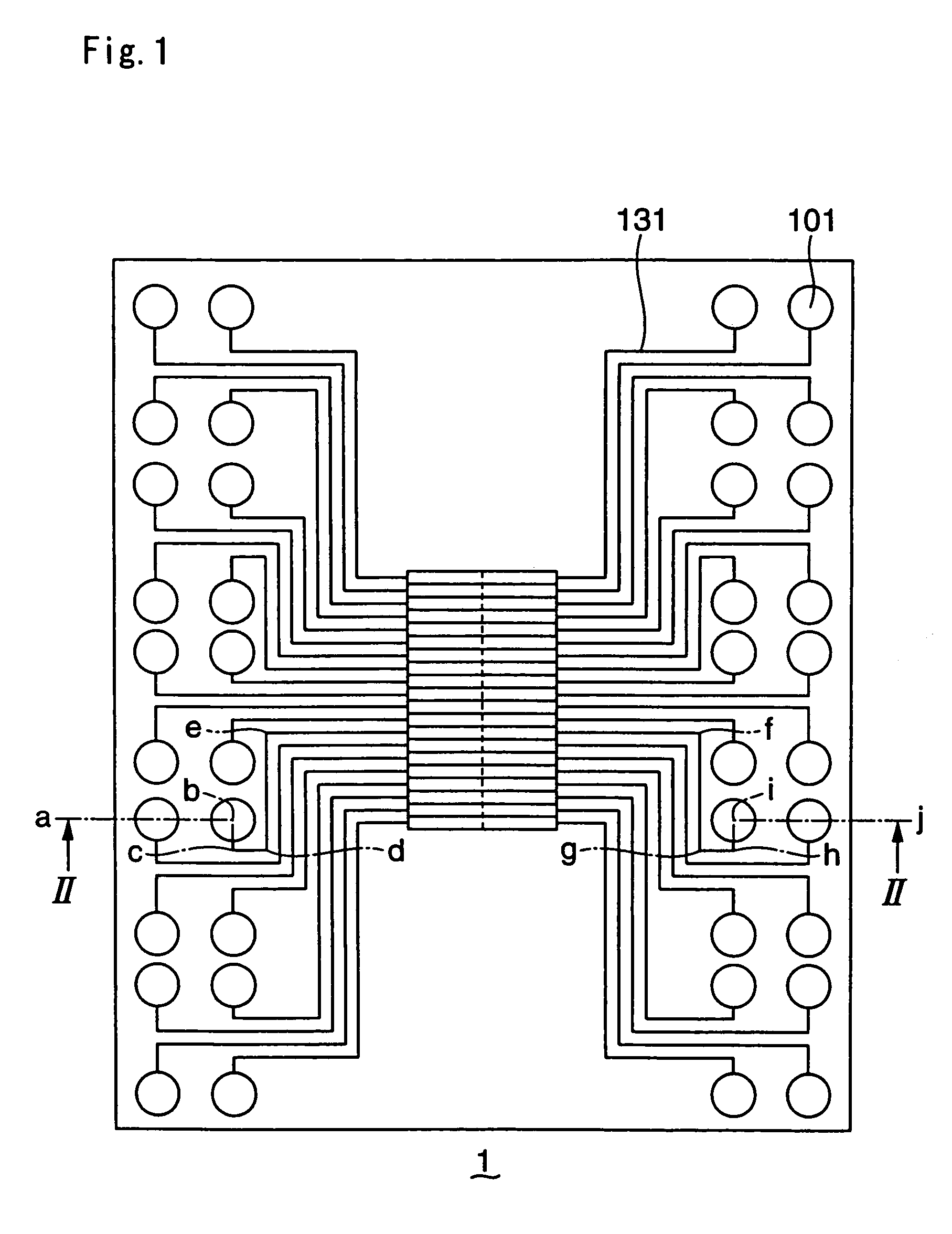

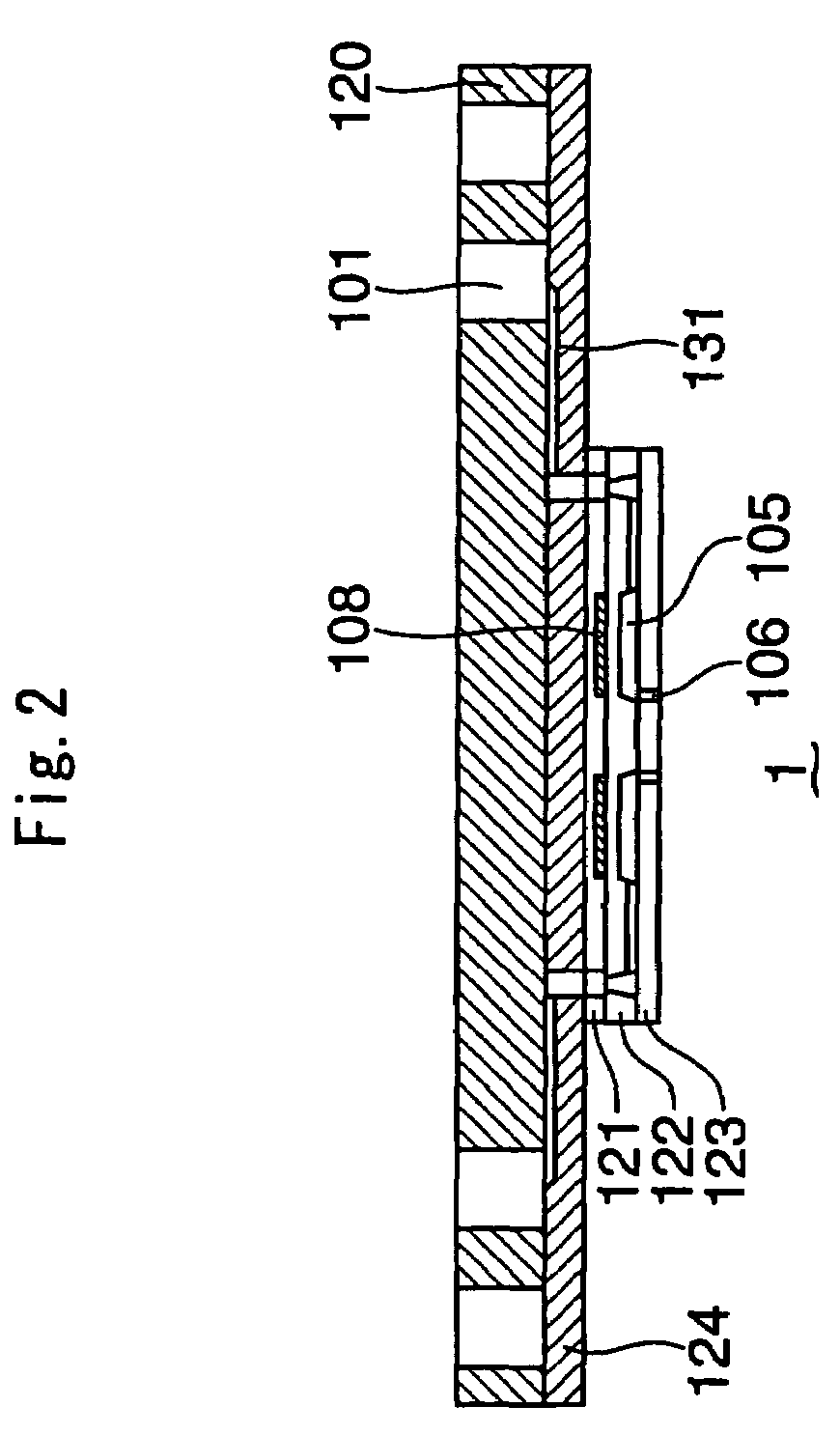

Droplet discharging head and microarray manufacturing method

InactiveUS7438860B2High densityShape stablePump componentsWithdrawing sample devicesElectricityPhosphorylcholine

It is an object of the present invention to provide a droplet discharging head suited to the discharge of a sample solution, and particularly one that contains a bio-related substance. This object is achieved by a droplet discharging head 1 for discharging a sample solution, wherein the portion of the inner walls of the droplet discharging head 1 that comes into contact with the sample solution is covered with a polymer composed of phosphorylcholine group-containing unsaturated compound units, or a copolymer including same. The droplet discharging head is preferably an electrostatic drive or piezoelectric drive type.

Owner:KAZUHIKO ISHIHARA +1

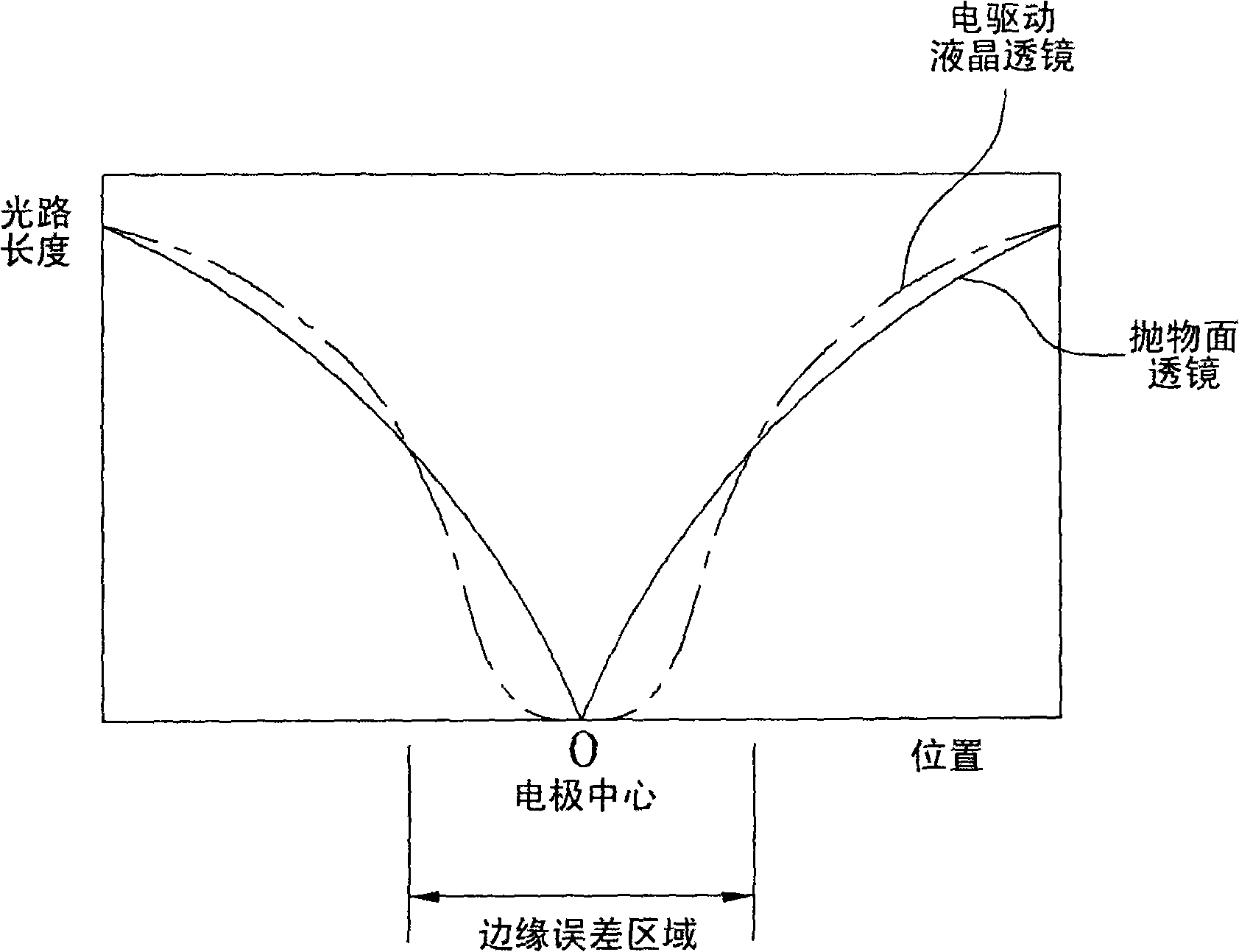

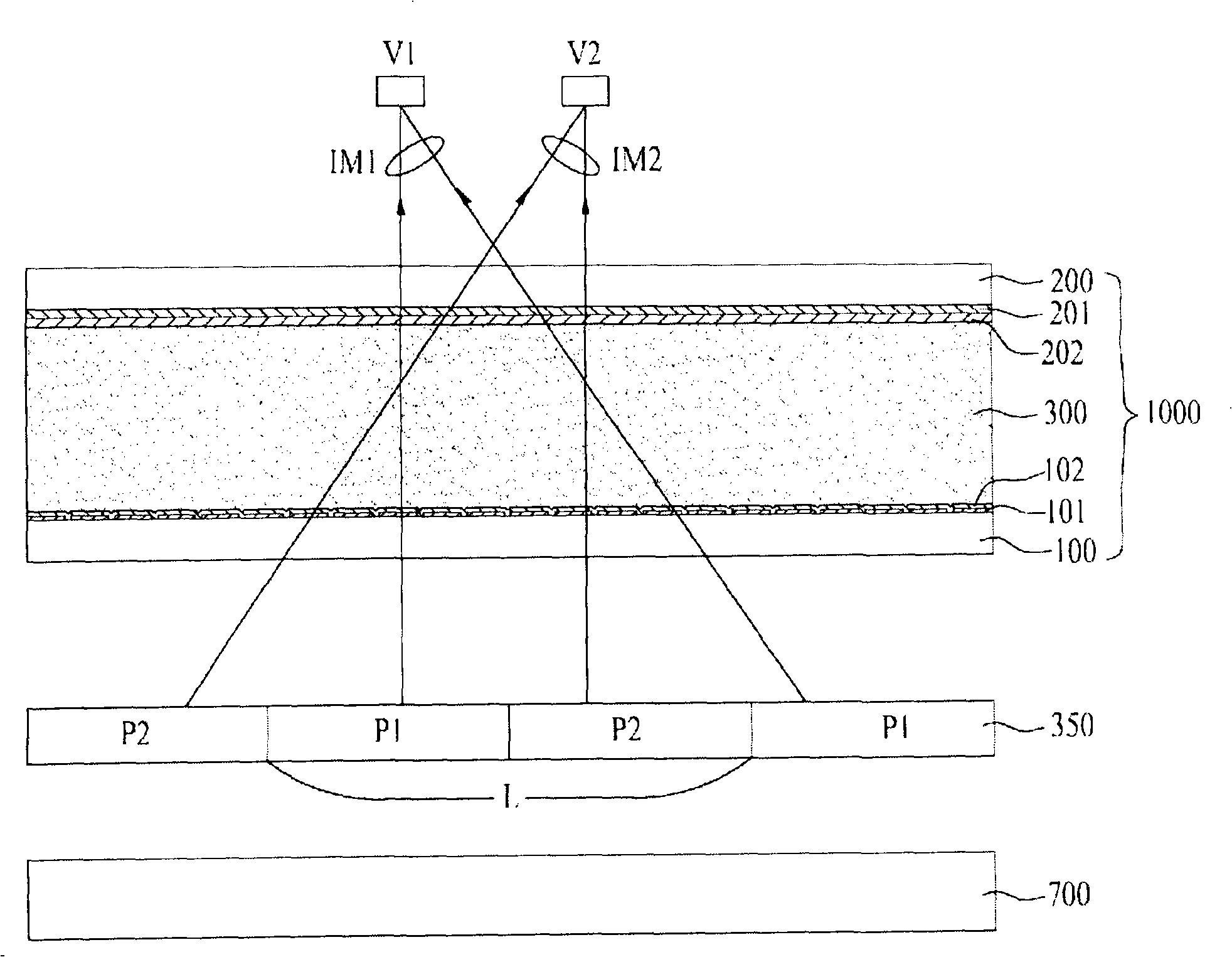

Electrically-driven liquid crystal lens and stereoscopic display device using the same

ActiveCN101344698AReduced box gapShape stableStatic indicating devicesSteroscopic systemsElectricityDisplay device

An electrically-driven liquid crystal lens, and a stereoscopic display device using the same, including first and second substrates arranged opposite each other and including an active region having a plurality of lens regions and a pad region defined at an outer rim of the active region, a plurality of first electrodes formed on the first substrate to correspond to the respective lens regions and spaced apart from one another, a second electrode formed on the entire surface of the second substrate, a voltage source to apply different voltages to the plurality of first electrodes, respectively, and to apply a ground voltage to the second electrode, and a liquid crystal layer interposed between the first substrate and the second substrate.

Owner:LG DISPLAY CO LTD

Confectionery product comprising agglomerated oil powder

InactiveUS20150157040A1Pleasant consumption experienceEasy to industrializeMilk preparationConfectioneryCross-linkAdditive ingredient

The invention relates to the use of oil powder and milk powders for the preparation of solid confectionery products wherein the oil powder is granulated together with the milk powder and other powder ingredients and then pressure agglomerated; to solid confectionery products comprising pressure agglomerated powder ingredients including an oil powder and a milk powder, wherein the oil powder comprises an inner core comprising an oil and an outer shell comprising a cross-linked emulsifier and to processes for the preparation thereof.

Owner:NESTEC SA

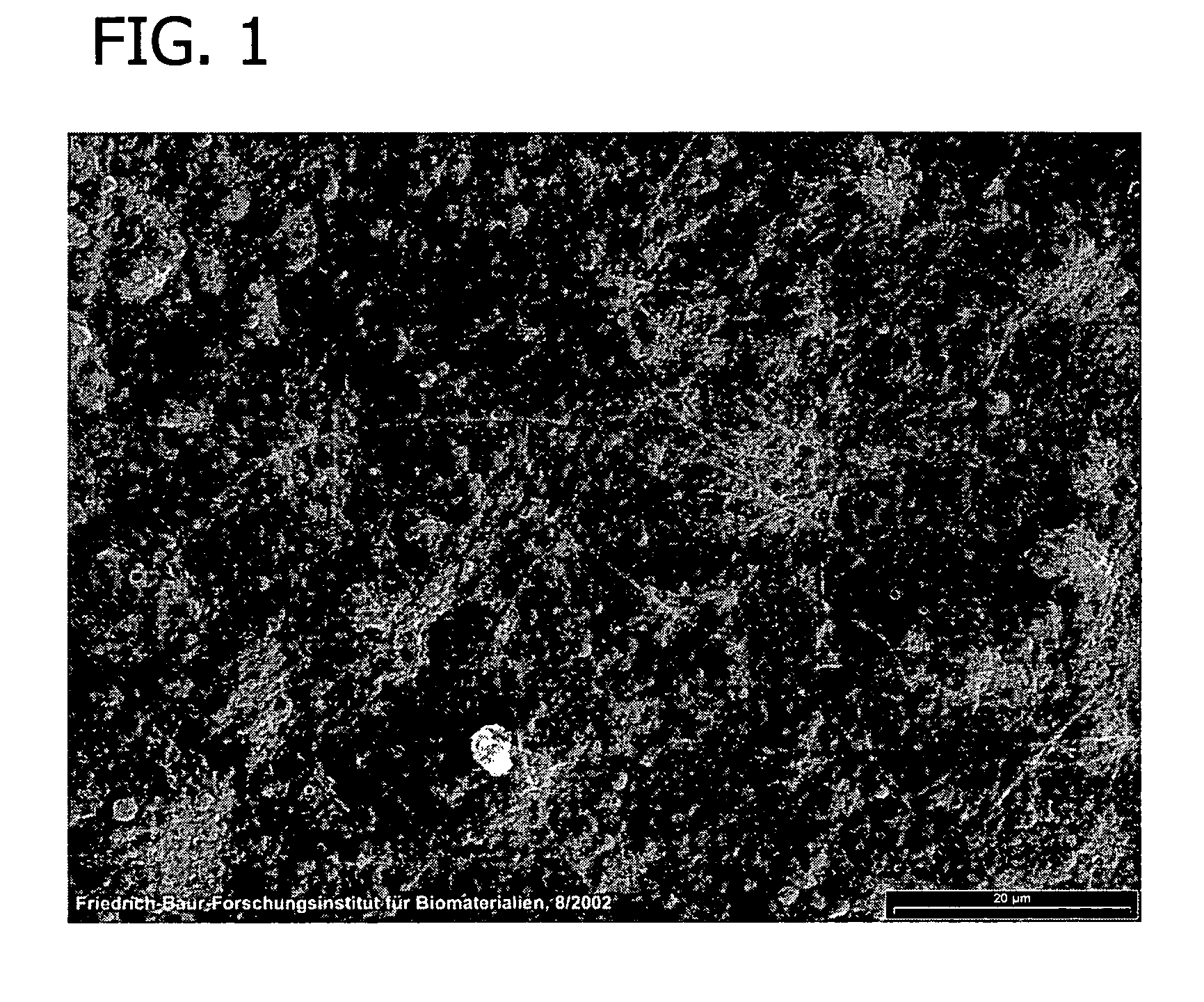

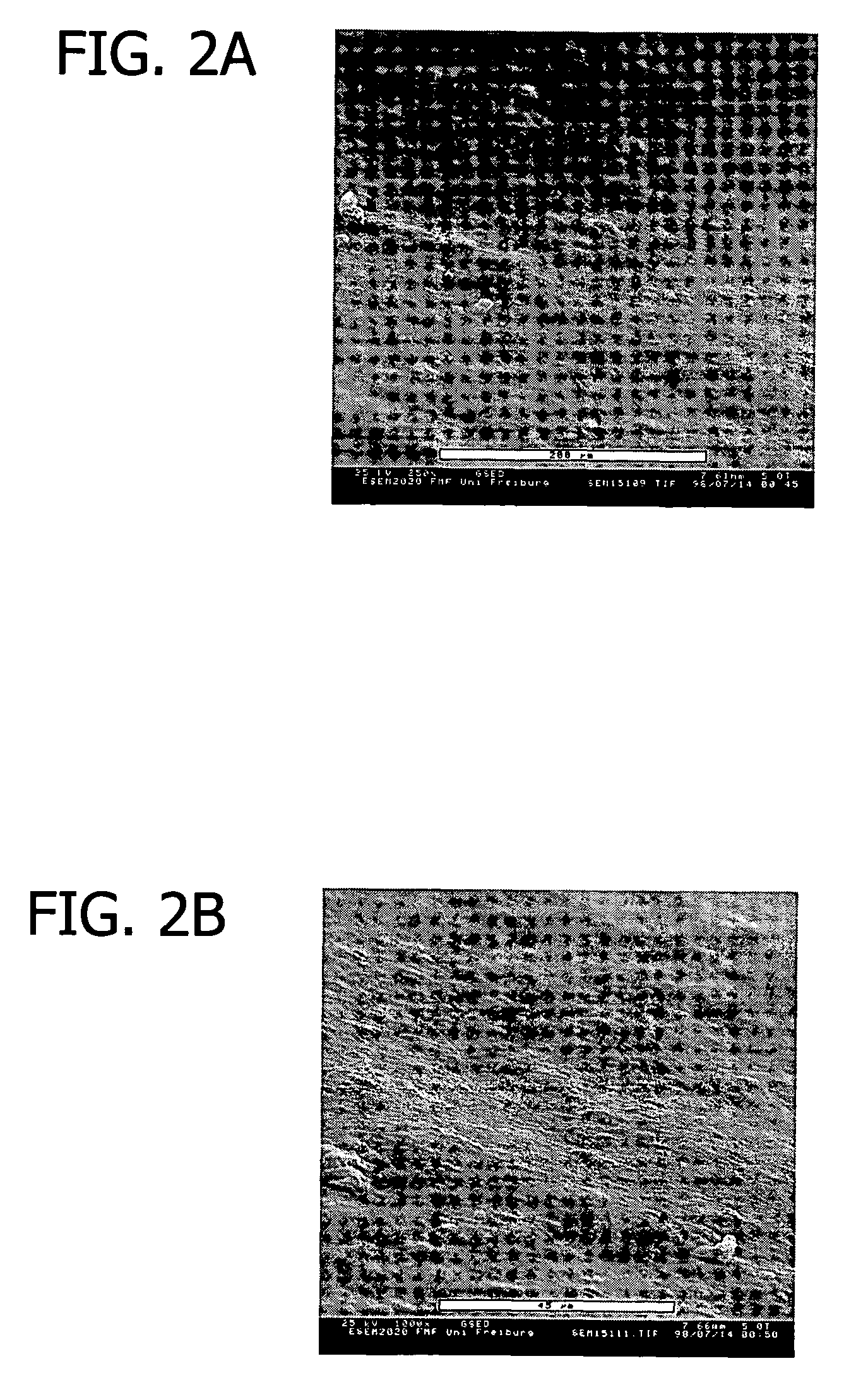

Methods for repairing and regenerating human dura mater

A method of using a substantially non-porous equine collagen foil to repair and regenerate dura mater tissue of mammals when the dura mater tissue is damaged as a result of injury, tumors, surgery, and the like. The non-porous equine collagen foil comprises collagen fibrils which provides a replacement dura mater composition that is elastic, liquid-tight, and which has a high tensile strength. The non-porous equine collagen foil is furthermore resorbable and provides a biomatrix, wherein a neodura is rapidly formed which becomes indistinguishable from the autologous dura mater in a matter of weeks. The process for making the equine collagen foil reduces the likelihood of disease transmission.

Owner:BAXTER INT INC +1

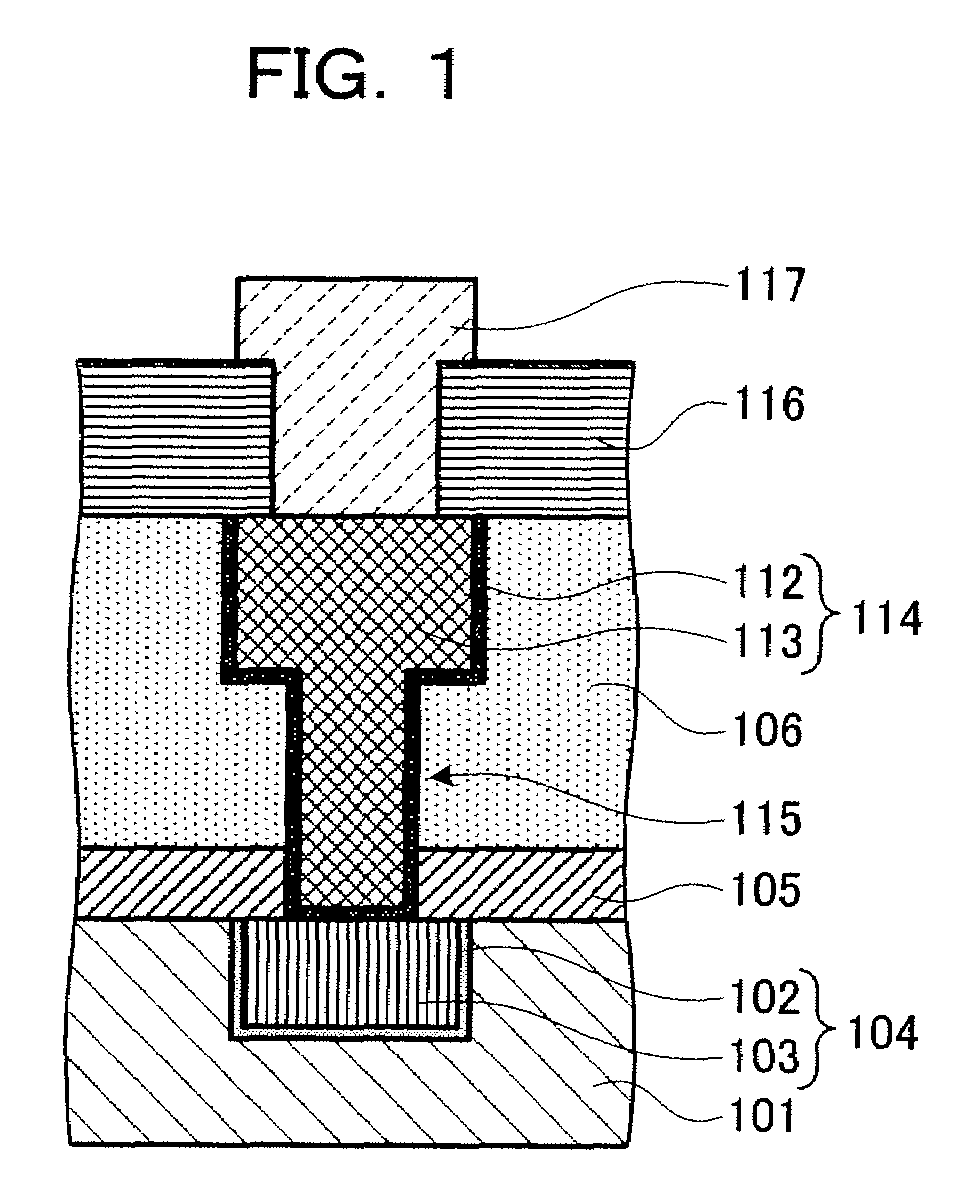

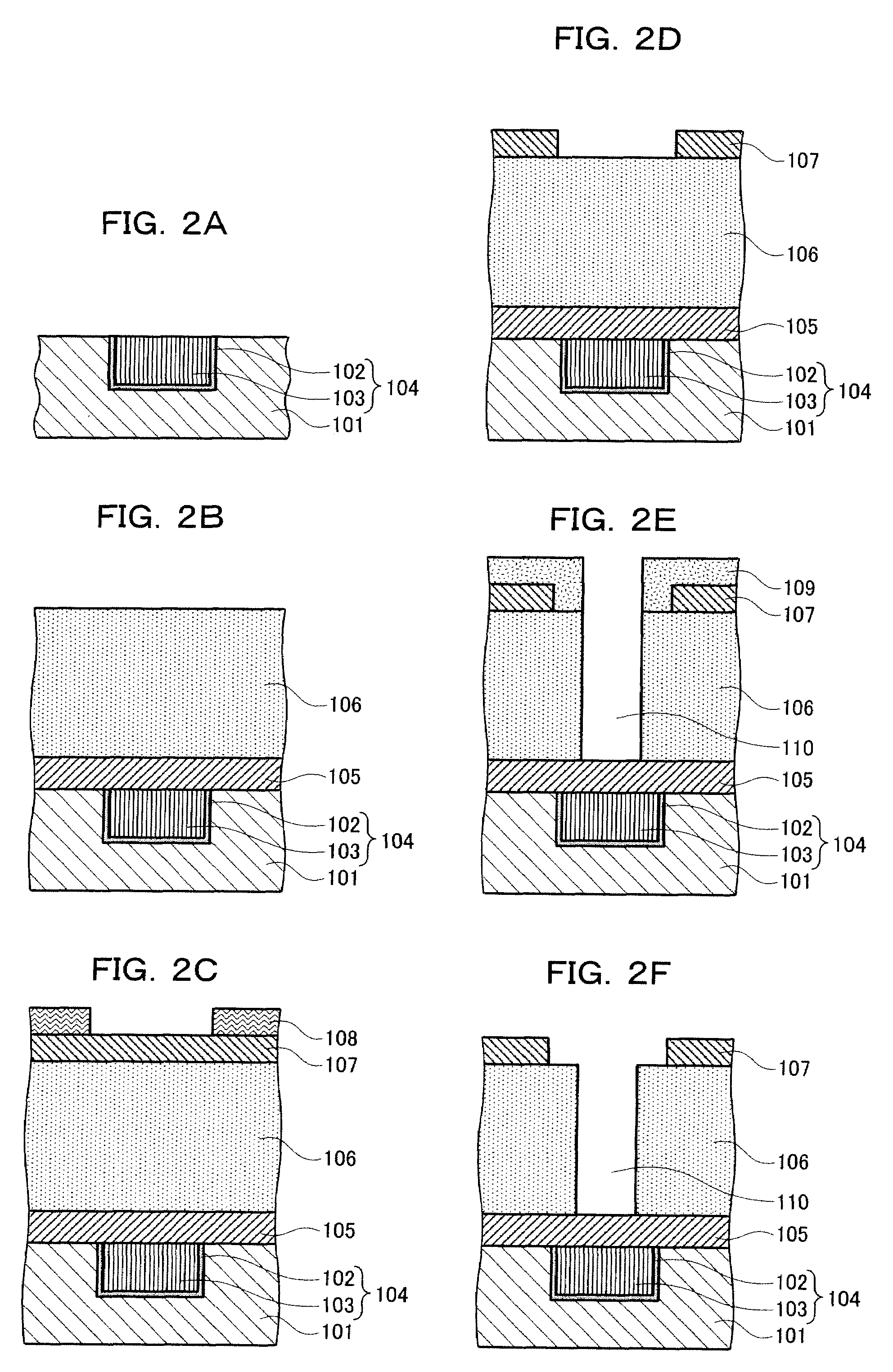

Method of manufacturing semiconductor device

ActiveUS7524752B2Shape stableReduce harmSemiconductor/solid-state device manufacturingEngineeringDielectric permittivity

In a method of manufacturing a semiconductor device which method is made up of a process of forming a wiring groove using a hard mask, a metal hard mask 107 is used to form a wiring groove 111, allowing the shape of the wiring groove 111 to be stabilized. Furthermore, a part or all of the metal hard mask 107 is removed before the formation of TaN and Cu layers in the wiring groove 111. This enables a reduction in possible damage, which may increase the dielectric constant of the surface of low-dielectric-constant film, and thus in possible inter-wire leakage current. As a result, a reliable semiconductor device can be provided.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

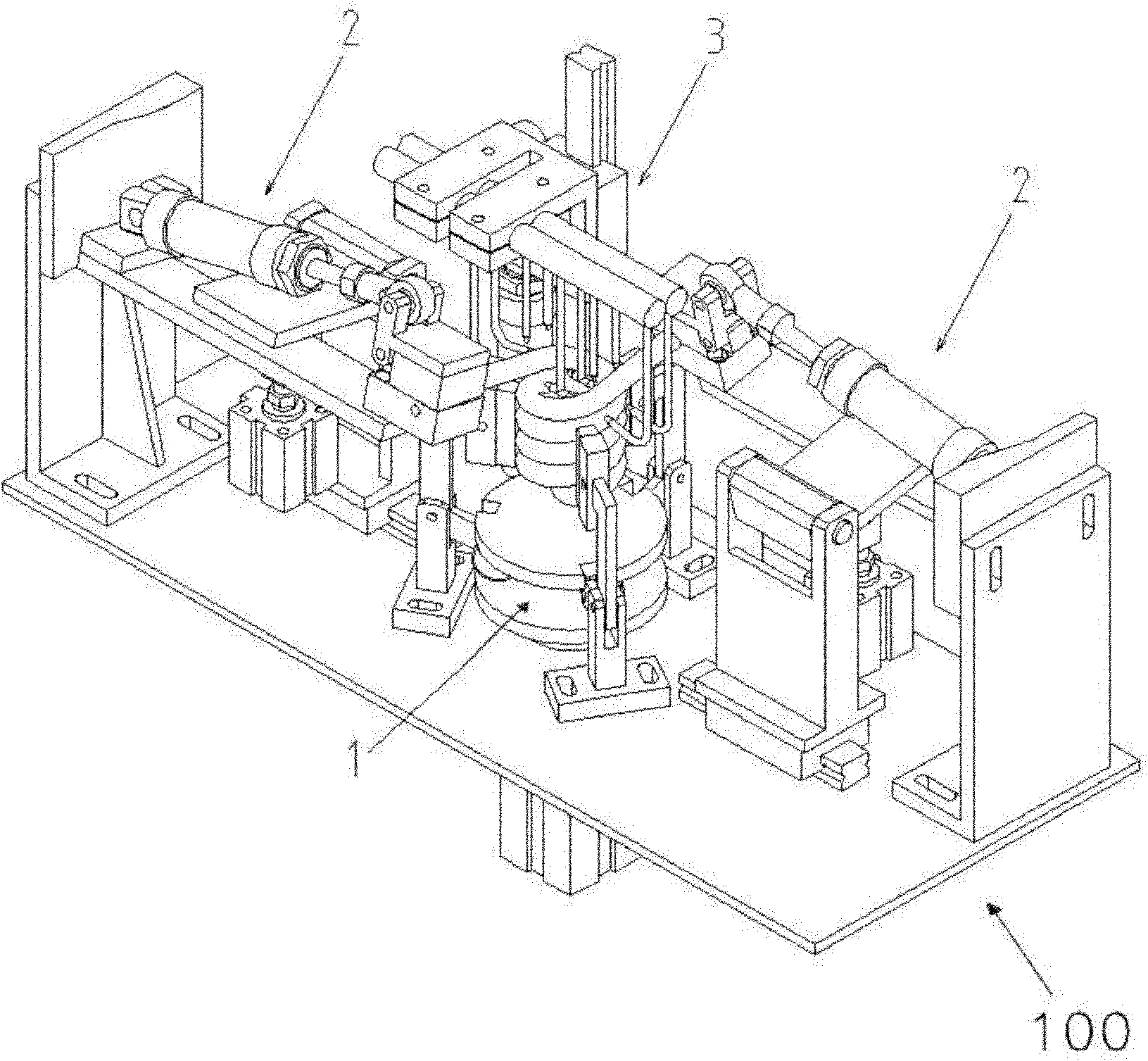

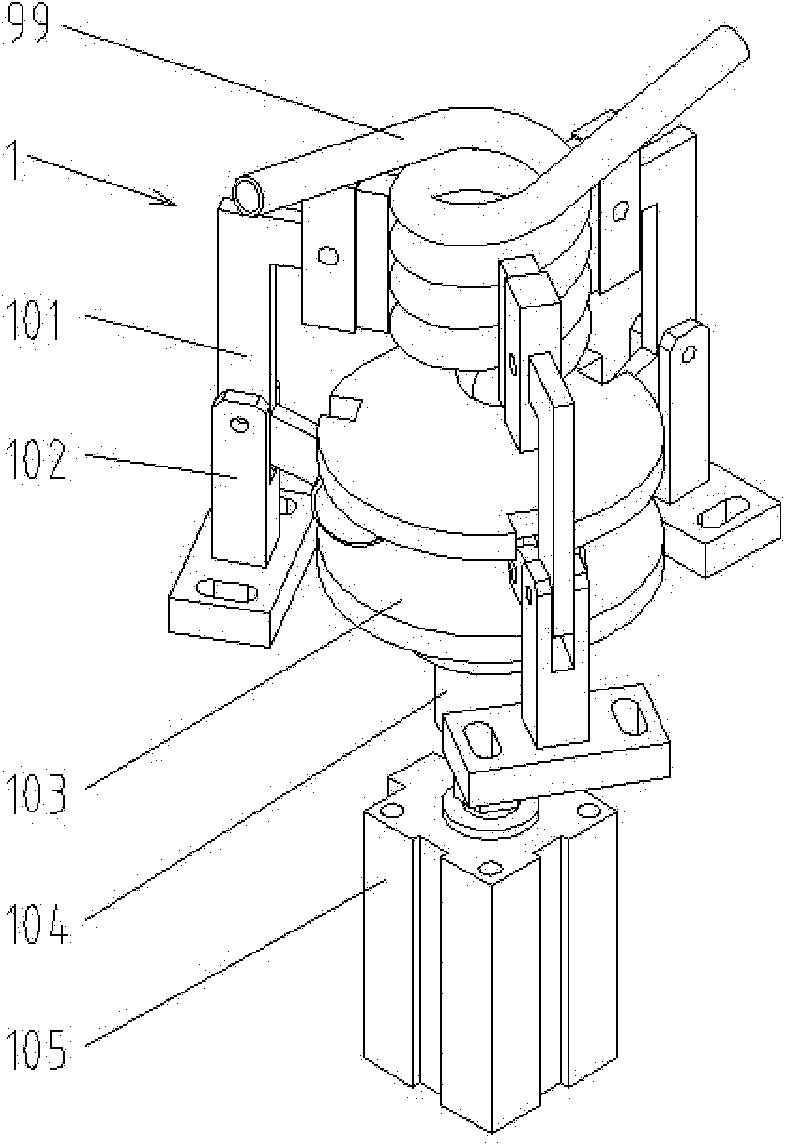

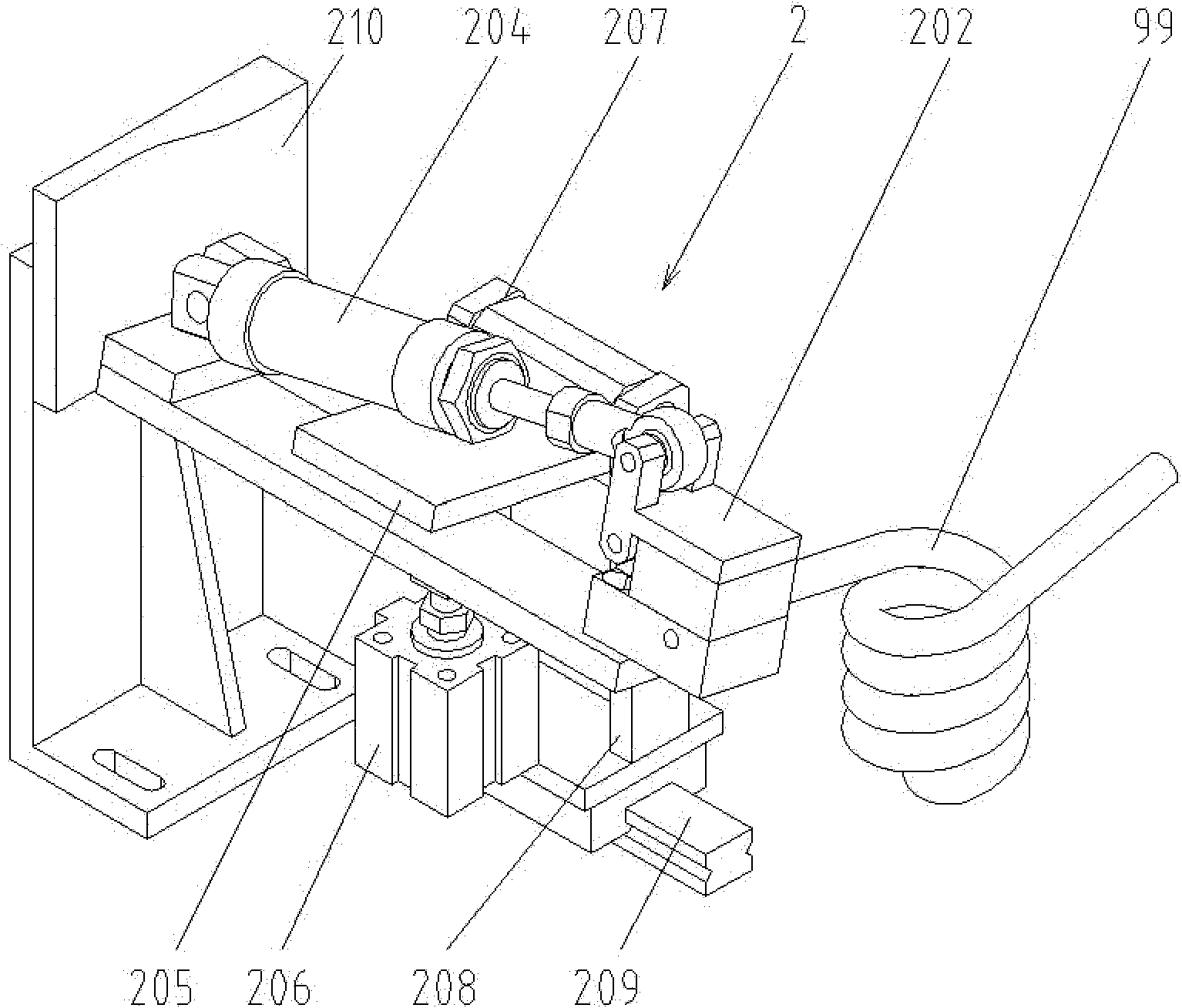

Bending machine for spiral light tube

InactiveCN102030463AReduce volumeLow costGlass reforming apparatusAutomatic controlProgrammable logic controller

The invention discloses a bending machine for a spiral light tube. The bending machine comprises a frame, a light tube clamping mechanism arranged on the frame, bending actuating mechanisms which are respectively arranged at two sides of the light tube clamping mechanism, a flame heating system arranged above the light tube clamping mechanism, and an automatic control system arranged in a distribution box outside the frame, wherein, the light tube clamping mechanism is used for fixing the current spiral light tubes of all specifications; the bending actuating mechanisms are positioned at the two sides of the light tube clamping mechanism and are used for clamping two pins and executing predetermined actions; the flame heating system is arranged above the light tube and is used for heating the designated positions of the pins and can slide up and down; and the automatic control system can carry out preset control on all the actions of the frame, and the main functional element of the automatic control system is a PLC (programmable logic controller). The bending machine has the advantages of single station, small volume, low cost and high production efficiency up to over twice as high as that in the case of manual operation, and is simple in operation.

Owner:宋云峰

Process for casting thick and large nodular cast iron valve plate

The invention provides a process for casting a thick and large nodular cast iron valve plate. The process comprises the following steps of: (1) manufacturing a mould; (2) manufacturing a casting mould and a sand core; (3) drying and integrating; (4) smelting; (5) pouring; and (6) shaking out and cleaning. In the process, a large number of external chilling blocks and sand separation chilling blocks are used on upper and lower surfaces of a casting for chilling, appropriate placing positions and thickness are selected, and shrinkage cavity and shrinkage porosity of the casting are effectively avoided; meanwhile, a good graphite balling state is ensured by quickly chilling, a feeding head is avoided, the casting is easy to clean, 5 percent of molten iron using amount is saved, and production cost is reduced; a semi-closed casting system is adopted by a casting system, an ingate is uniformly distributed around the casting mould, and the casting mould is slightly scoured, and a good residue stopping effect is achieved; and under the action of chilling of chilling blocks, the thick and large nodular cast iron casting which is smelted by a cupola furnace is good in moulded surface, and meets production requirements, offscourings and sand are avoided, and process yield is improved by 5.9 percent.

Owner:TIJIN YIJI MACHINERY

Conductive Paste, Solar Cell Manufactured Using Conductive Paste, Screen Printing Method and Solar Cell Formed Using Screen Printing Method

InactiveUS20070158621A1Avoid conductionSimple processConductive materialNon-conductive material with dispersed conductive materialConductive pasteScreen printing

Owner:KYOCERA CORP

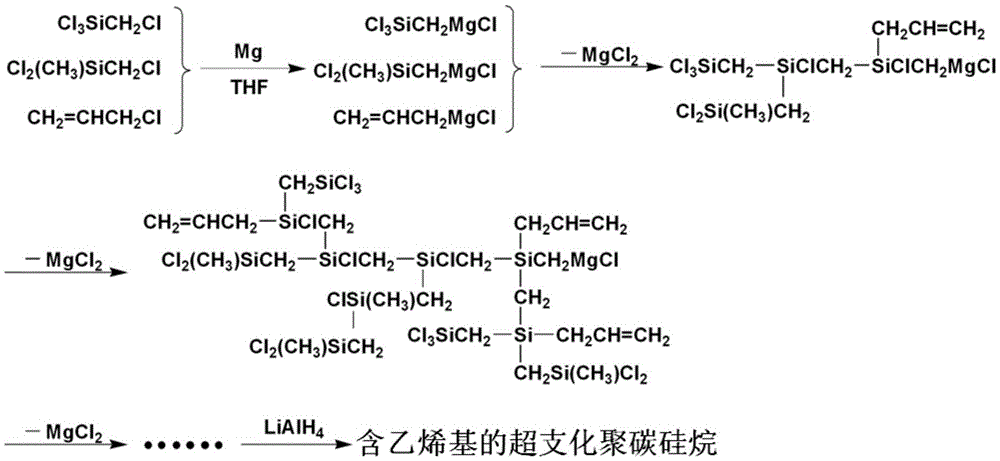

Photocuring material and application thereof

The invention relates to a photocuring material which comprises the following components in percentage by weight: 60-98% of hyperbranched polycarbosilane, 0-35% of active diluent, 0.1-8% of photoinitiator and 0-10% of additive, wherein the hyperbranched polycarbosilane contains an unsaturated double bond, and the number-average molecular weight of the hyperbranched polycarbosilane is 300-15,000; the unsaturated double bond is acryloyloxy, methylacryloyloxy, vinyl or allyl; and the content of the unsaturated double bond in the hyperbranched polycarbosilane is 1-30% by weight. The invention also relates to an application of the photocuring material in photocuring 3D printing and an application in preparation of a SiC component. The photocuring material provided by the invention has relatively low viscosity and is convenient to spray out of a nozzle of 3D printing equipment while the curing speed is high and the shrinkage rate in curing is little.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

1050 alloy CTO (computer-to-plate) substrate and preparation method thereof

The invention provides a 1050 alloy CTO (computer-to-plate) substrate which comprises the following components in percentage by mass: 0.28-0.32% of Fe, 0.08-0.12% of Si, at most 0.03% of Ti, at most 0.02% of Cu, at most 0.02% of Mn, at most 0.02% of Mg, at most 0.02% of Zn, at most 0.02% of V and the balance of Al. The invention also provides a preparation method of the 1050 alloy CTP substrate. A piezoelectric template control technique, a normal-temperature high-speed multichannel cast-rolling technique, a furnace-out Al-5Ti-B wire matching supersonic grain refinement technique and a continuous rolling technique are utilized to prepare the original cast-rolling structure with abundant uniform and fine crystal grains and dispersedly distributed diphase compounds at the grain boundary, and a processing structure with flat template quality and uniform deformation.

Owner:浙江中金铝业有限公司

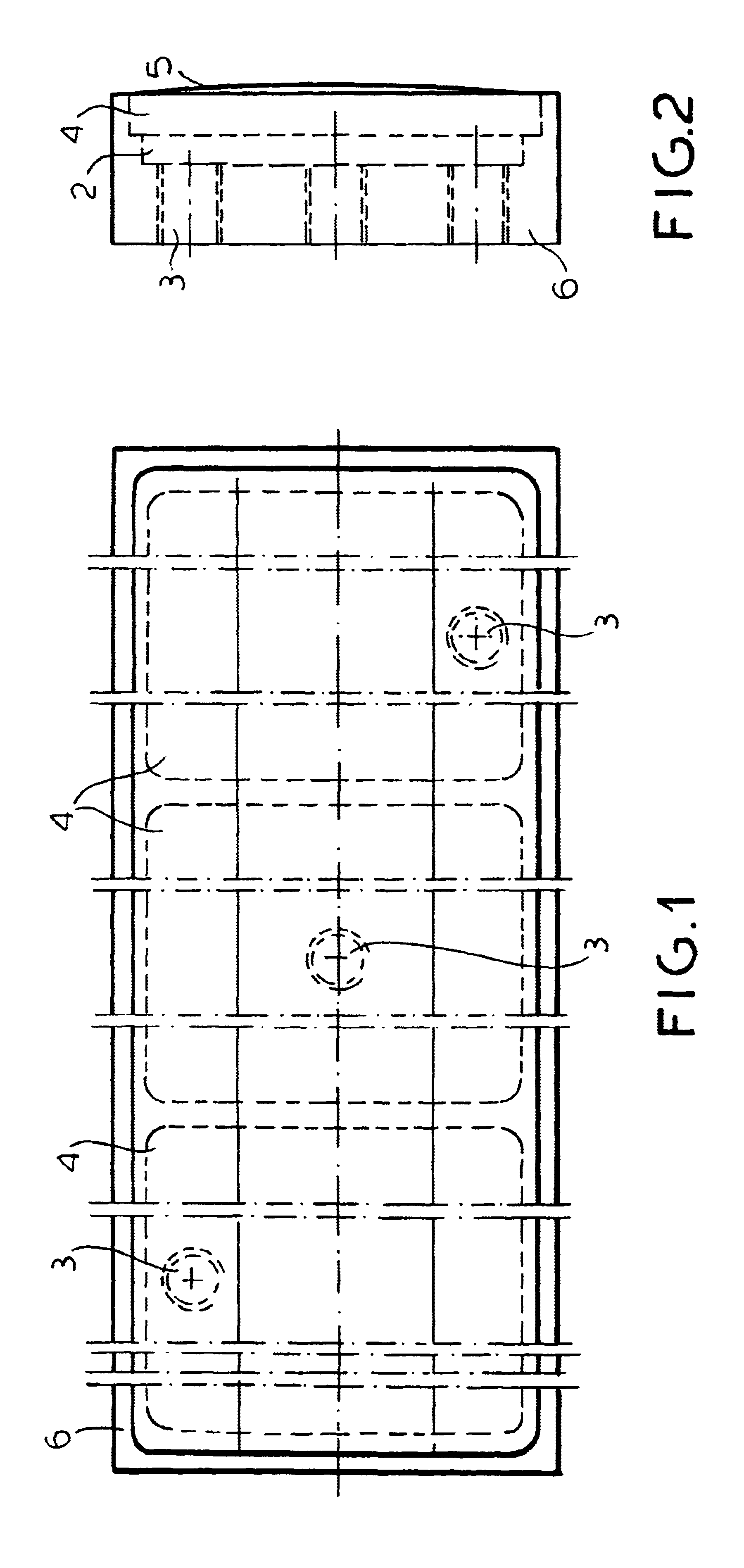

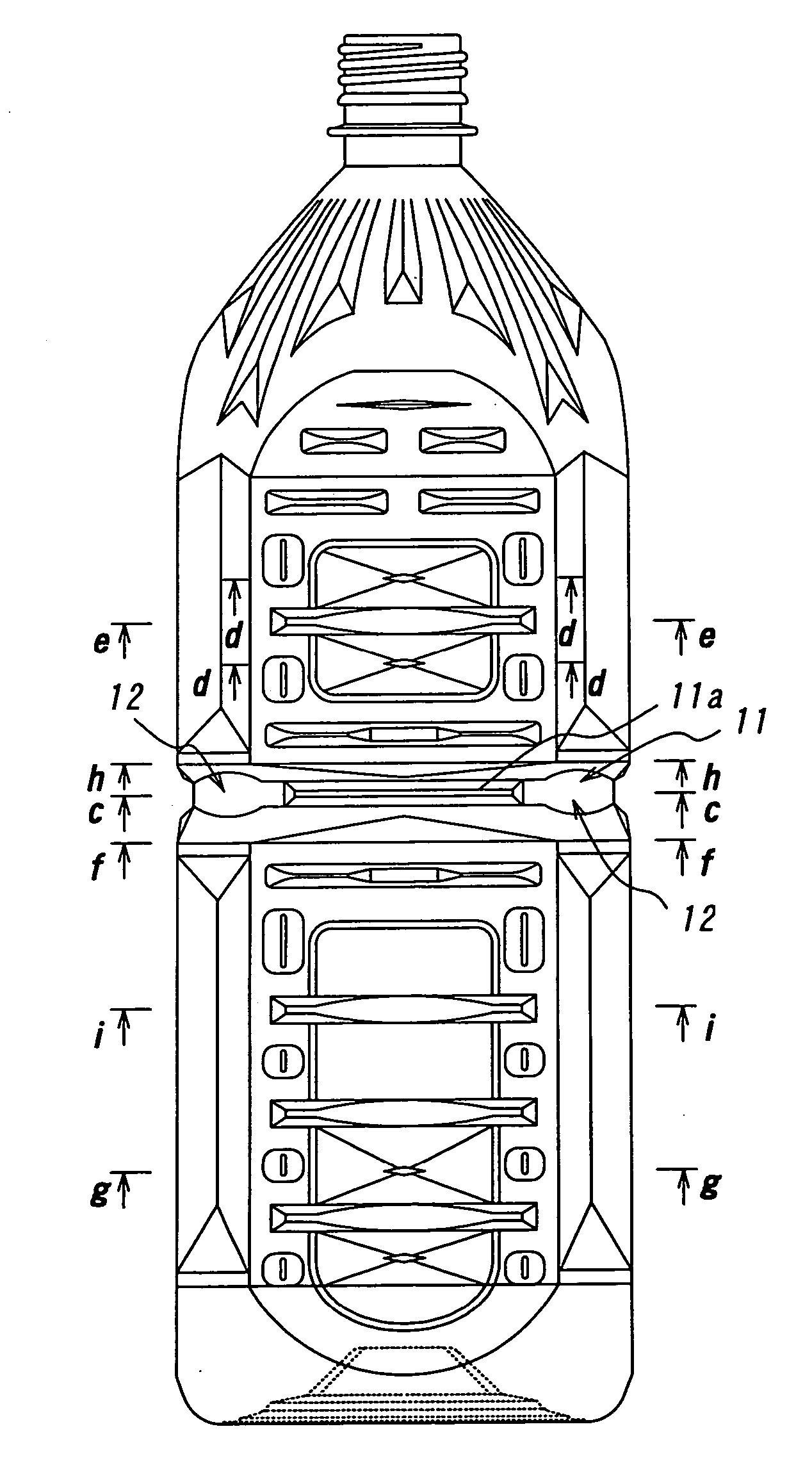

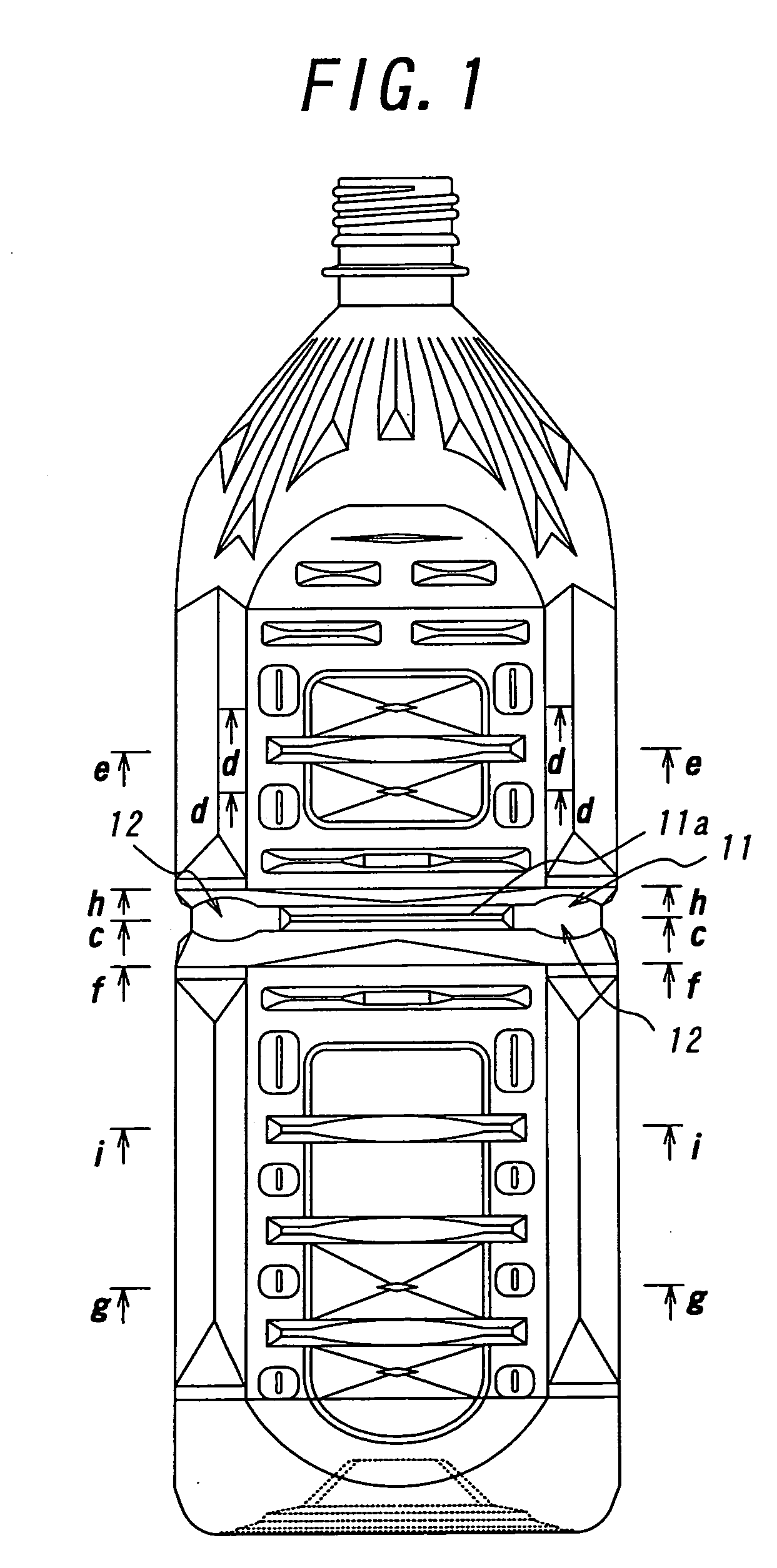

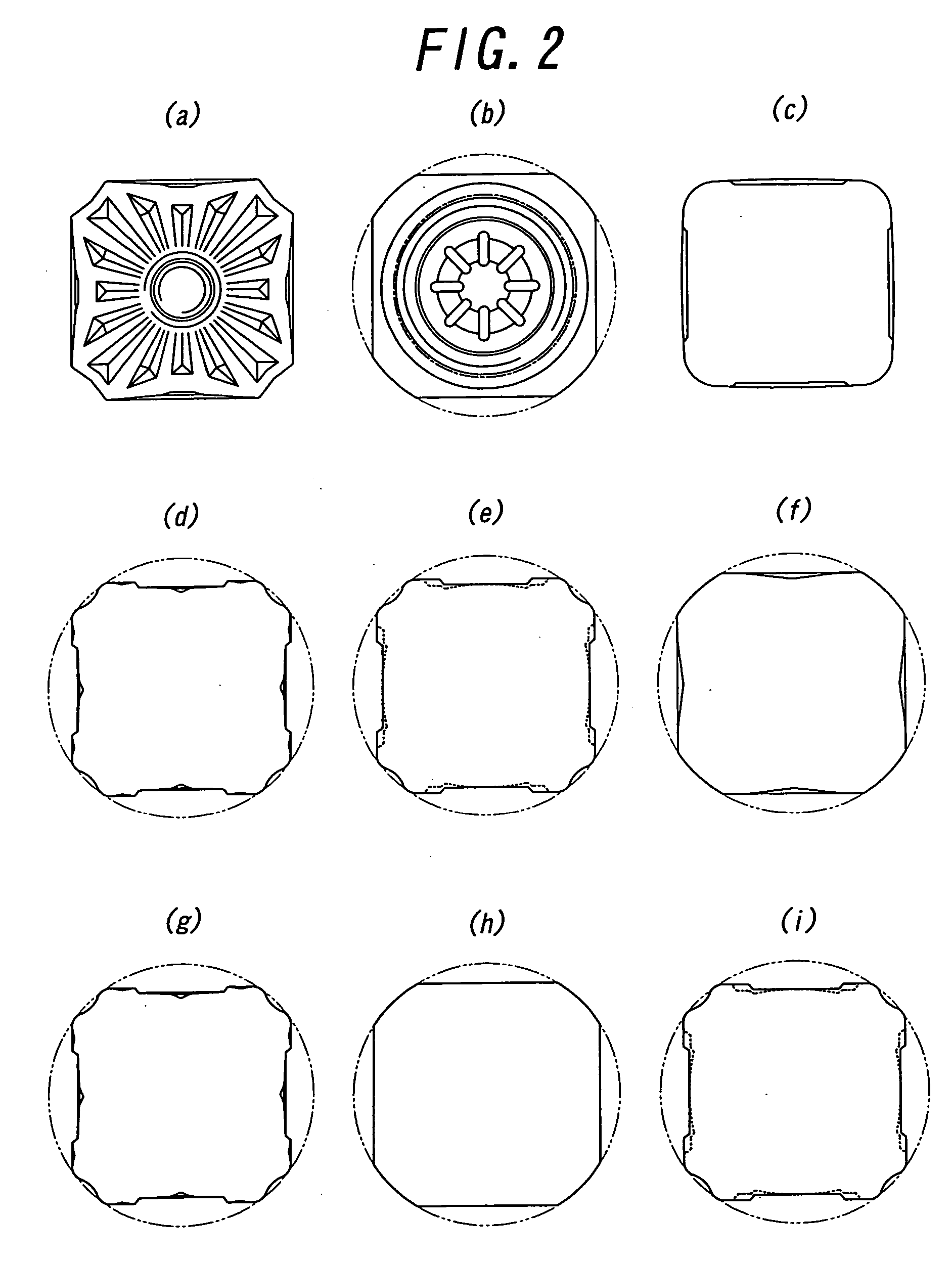

Synthetic resin container with shape retainability

InactiveUS20050045645A1Shape stableEffectively avoiding lowering of the rigidity of the containerBottlesLarge containersEngineeringSynthetic resin

The synthetic resin container according to the present invention has a waist dividing a container main body portion into upper and lower parts, wherein the waist is formed on an annular groove surrounding the main body portion to as to be convex toward the interior of the container. The annular groove has reinforcing ribs with a level higher than a groove bottom of the annular groove and lower than the surface of the main body portion. The container main body portion includes reinforcing lateral ribs each having a concave portion which is positioned at the same level as a surface of the container, which or forms a slight step relative to the surface of the container. The main body portion has a plurality of ridges converging toward the associated central convergent point, respectively, thereby defining multi-faceted concave walls inclined toward the associated convergent points, respectively.

Owner:YOSHINO KOGYOSHO CO LTD

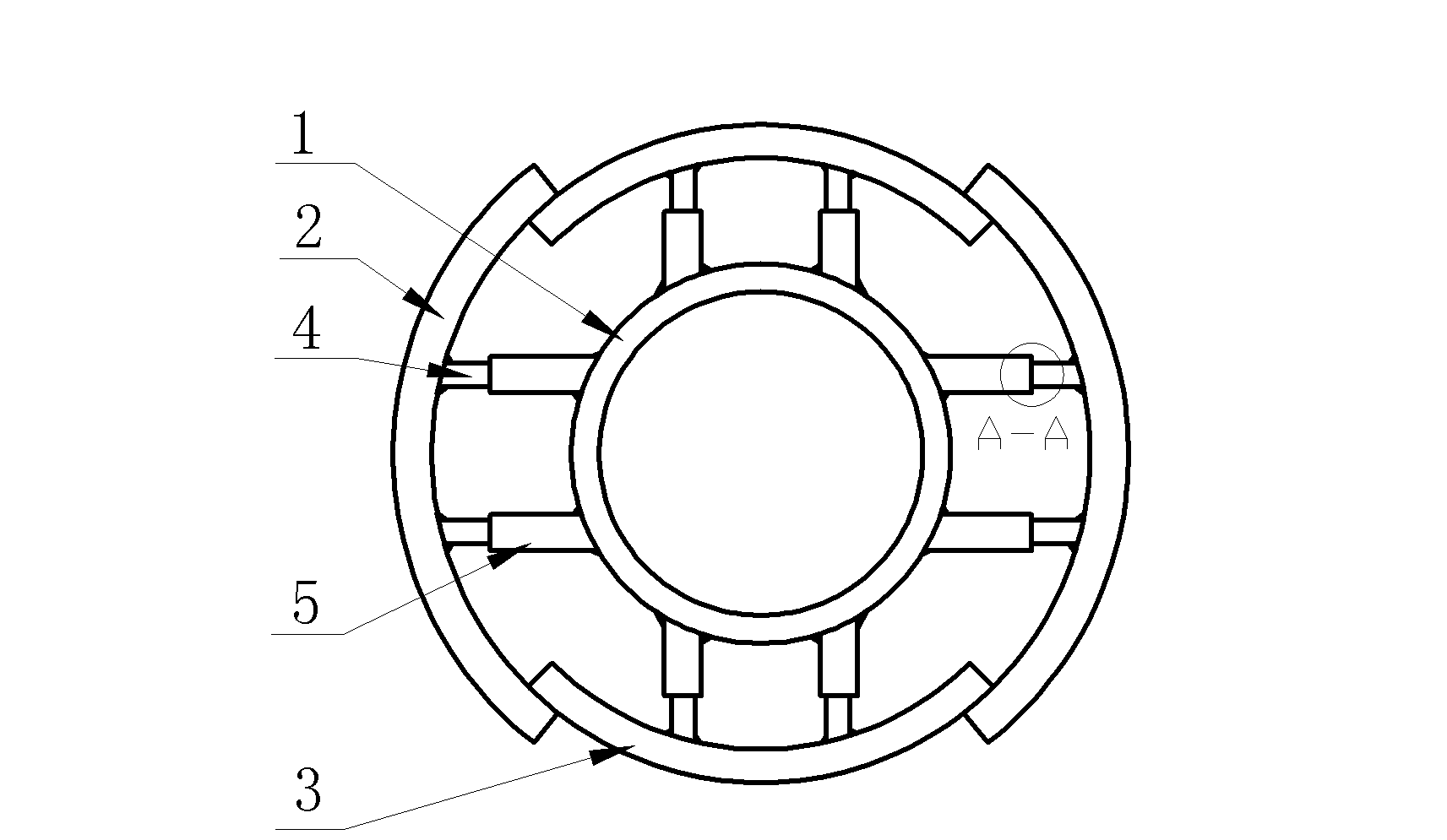

Casting method for thin-wall annular cast

The invention relates to a casting method, in particular relates to a casting method for a thin-wall annular cast. The casting method is characterized by comprising the following steps: simulating by a computer; determining a cast scheme; manufacturing a die; manufacturing a core box and a core skeleton; manufacturing a core; putting the core; modeling; opening the box; closing the box; pressing the box; pouring; cutting a dead head; carrying out thermal treatment; detecting a molded line; and carrying out relief grinding and shot blasting. The technical method disclosed by the invention is peculiar, the problem of the casting crack and deformation of the thin-wall annular cast can be solved, the sand metal ratio is lowered, the cost is saved, and the production period is shortened.

Owner:KOCEL EQUIP

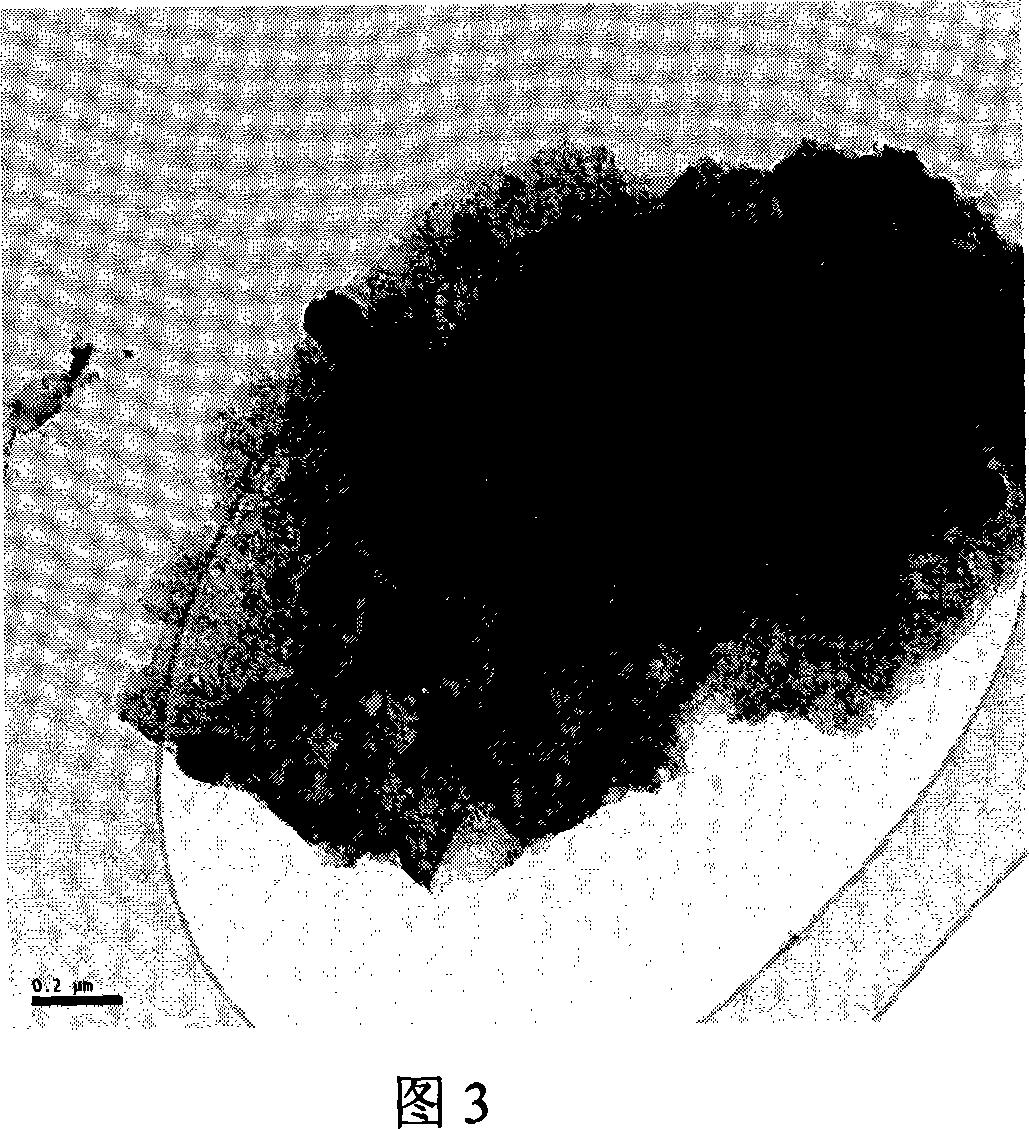

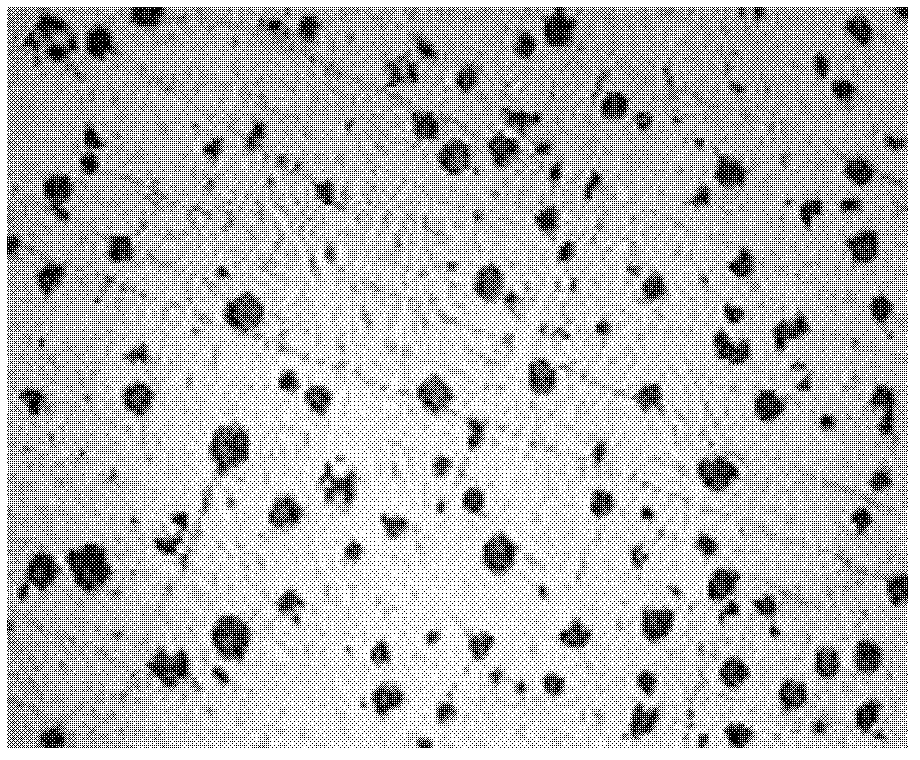

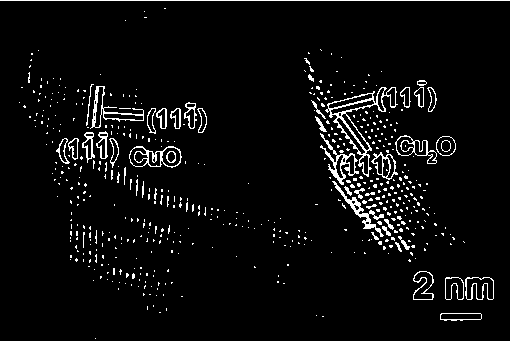

CuO-Cu2O/graphene nano compound material and preparation method thereof

InactiveCN103956473AShort reaction timeReduce energy consumptionMaterial nanotechnologyCell electrodesGraphene nanocompositesElectrochemistry

The invention discloses a CuO-Cu2O / graphene nano compound material and a preparation method thereof. The CuO-Cu2O / graphene nano compound material disclosed by the invention is characterized in that CuO-Cu2O nano spheres are uniformly dispersed on the surface of graphene, are of a hollow structure, and comprise CuO nano crystals and Cu2O nano crystals through mixing. The preparation method comprises the following steps: mixing a defined amount of a copper slat and graphite oxide, dispersing to form a uniform solution, and adding a defined amount of ammonia water for adjusting a pH value; then placing a mixed solution in a microwave reactor, and performing a microwave heating reaction to prepare a precursor; and finally, calcining the precursor in an inert atmosphere at a high temperature of 450-700 DEG C for 1-3 hours, and calcining the precursor in an air atmosphere at a low temperature of 150-250 DEG C for 1-2 hours to obtain the CuO-Cu2O / graphene nano compound material. The CuO-Cu2O / graphene nano compound material disclosed by the invention is simple in preparation process, low in cost, and good in electrochemical property, and can be applied to a lithium battery electrode.

Owner:ZHEJIANG NORMAL UNIVERSITY

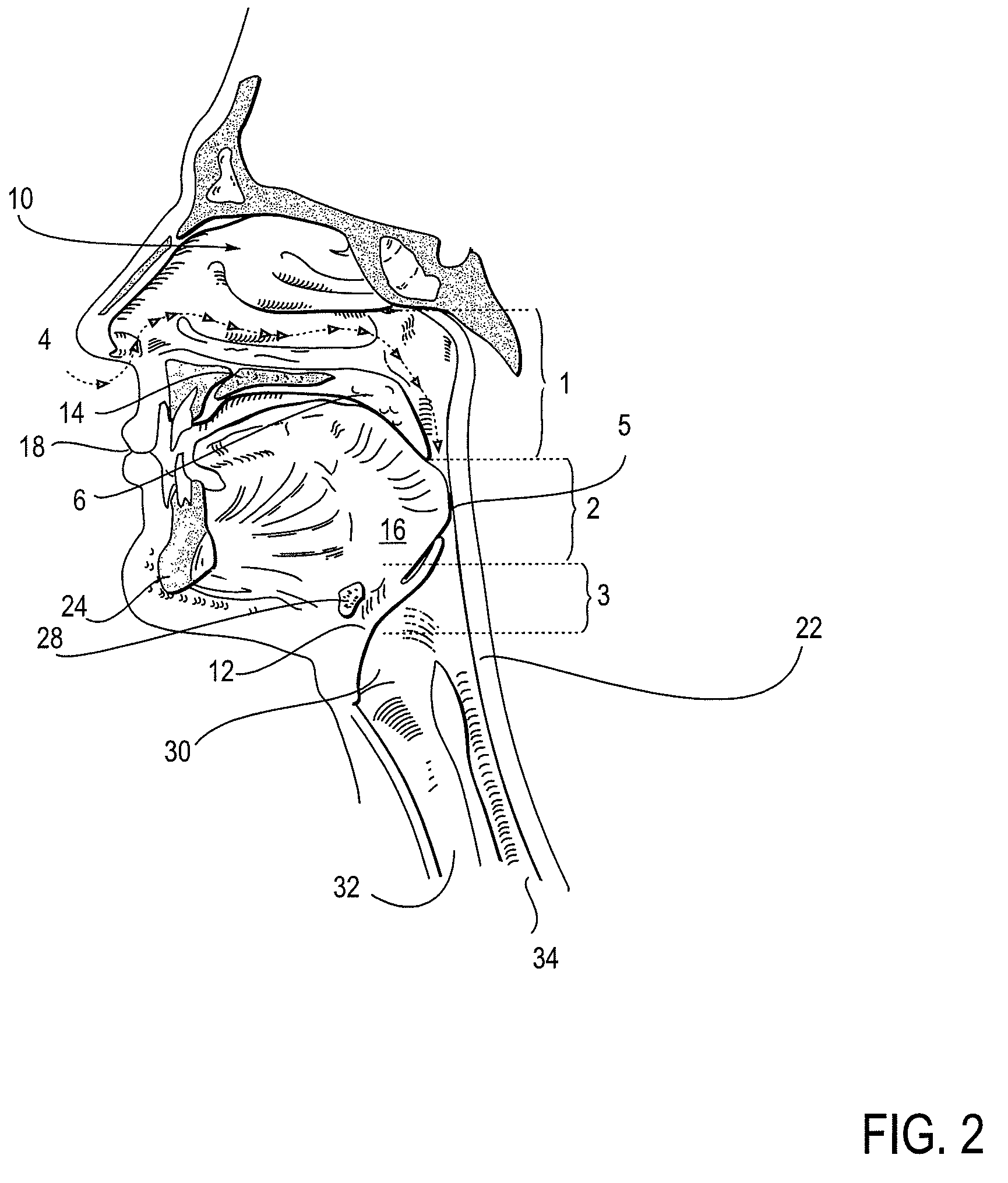

Systems and methods for treatment of sleep apnea

InactiveUS20110308530A1Alleviating obstructive collapseReduce frequencySnoring preventionNon-surgical orthopedic devicesDiseaseTreatment sleep

A system for treating an airway disorder is provided with an implant body configured to conform to an airway-interface tissue site in a manner compatible with normal physiological function of the site. In some embodiments, the implant body has first and second end portions and a medial portion. The implant body also includes a coupler configured to couple the end portions to one another such that the medial portion encircles targeted tissue. Methods of using such systems are also provided.

Owner:REVENT MEDICAL

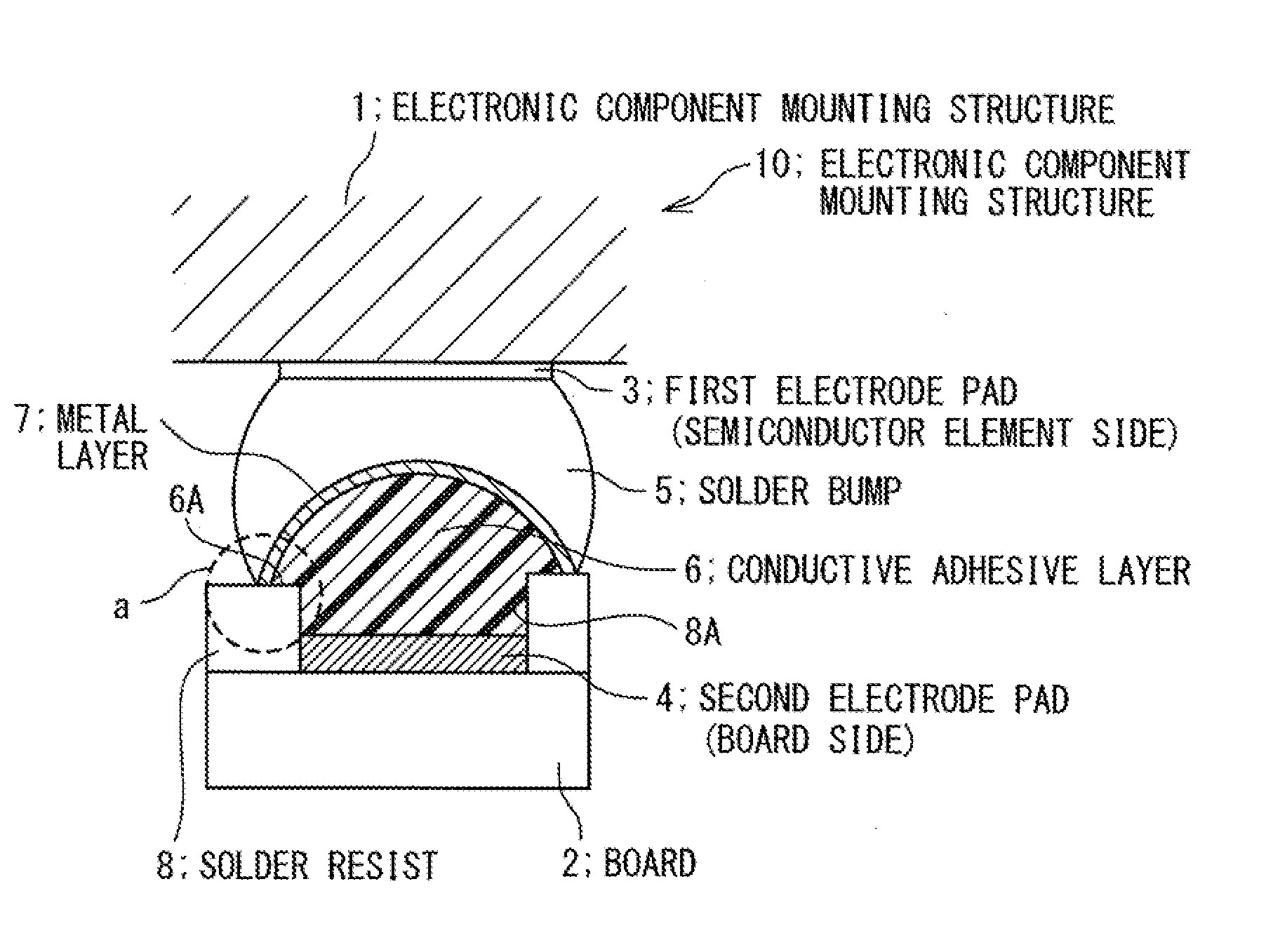

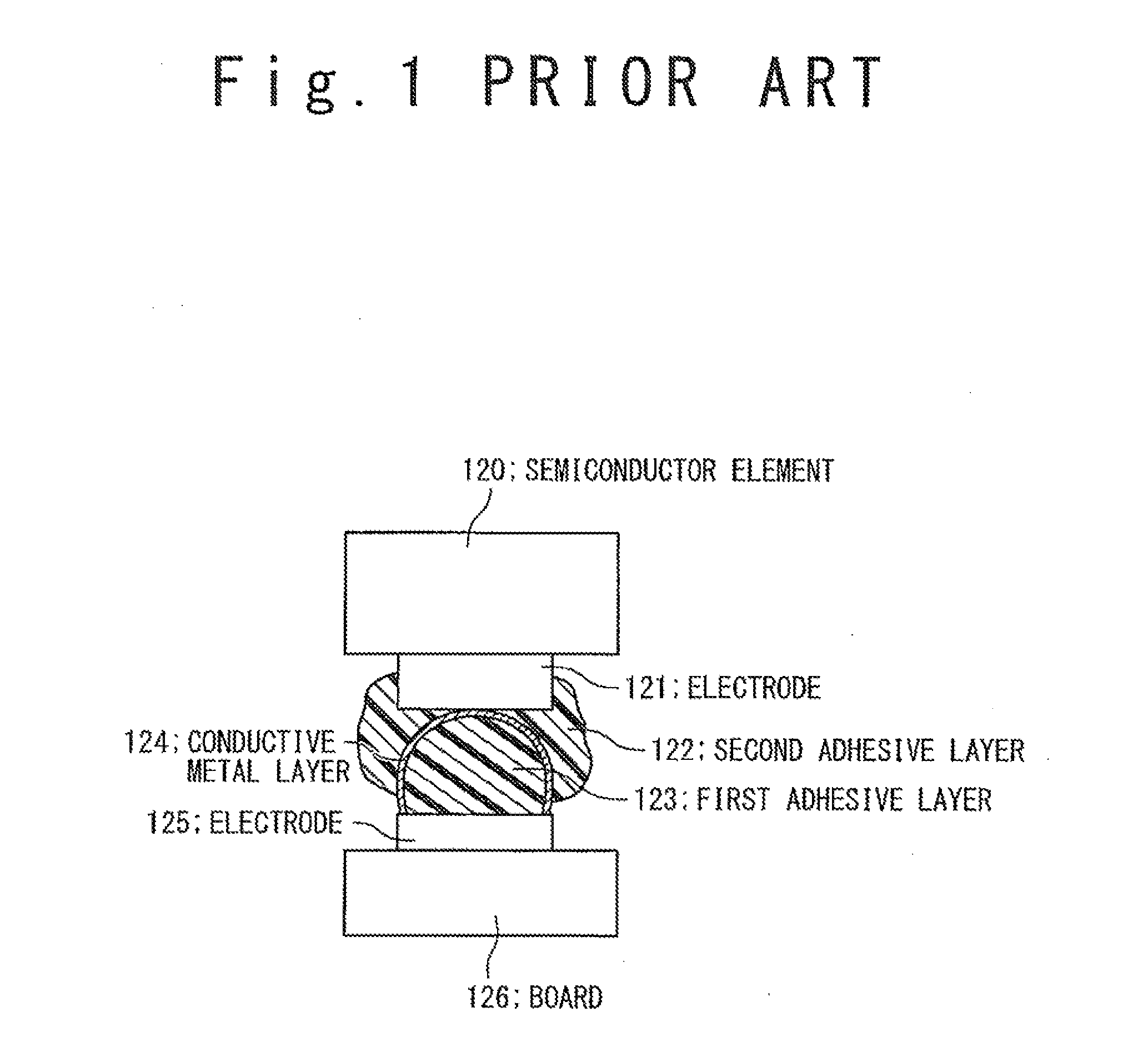

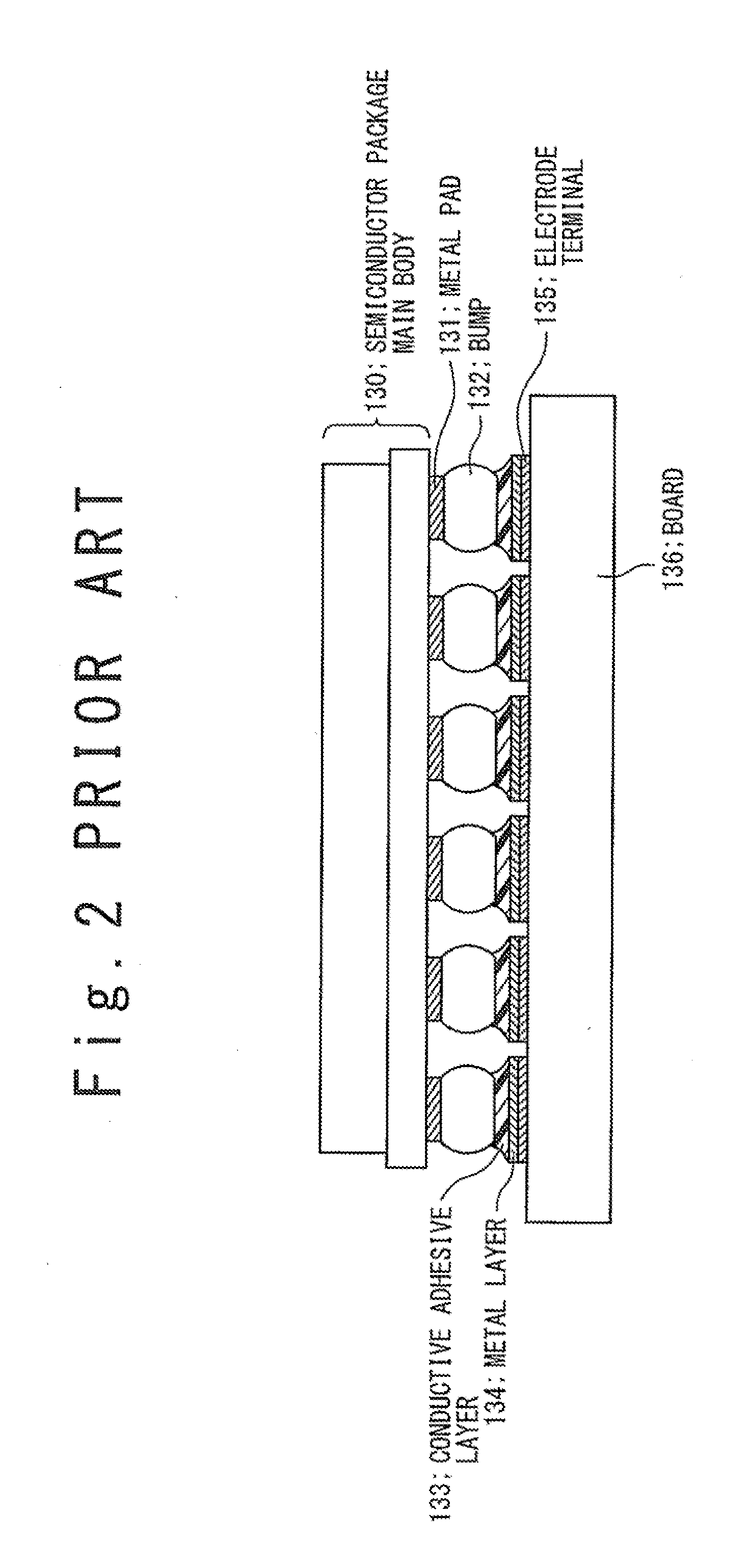

Electronic component mounting structure, electronic component mounting method, and electronic component mounting board

ActiveUS20100295177A1Firmly connectedIncrease freedomFinal product manufactureSemiconductor/solid-state device detailsResistConductive materials

In an electronic component mounting structure, a semiconductor element (an electronic component) provided with an electrode pad and a board provide with an electrode pad corresponding to the electrode pad are connected via a conductive material portion. On a surface of the board, there is formed solder resist having an opening regulating an area of the electrode pad. The conductive material portion is formed to protrude from a surface of the solder resist. An elastic coefficient of the conductive material portion is lower than that of the solder resist. A solder bump and the conductive material portion are connected via a metal layer. The conductive material portion is formed to have an area larger than that of the opening of the solder resist. An edge of the conductive material portion is adhered to a portion of the surface of the solder resist. Thus, in a case of mounting an electronic component on a board by flip-chip connection, a reliability of connection can be secured.

Owner:NEC CORP

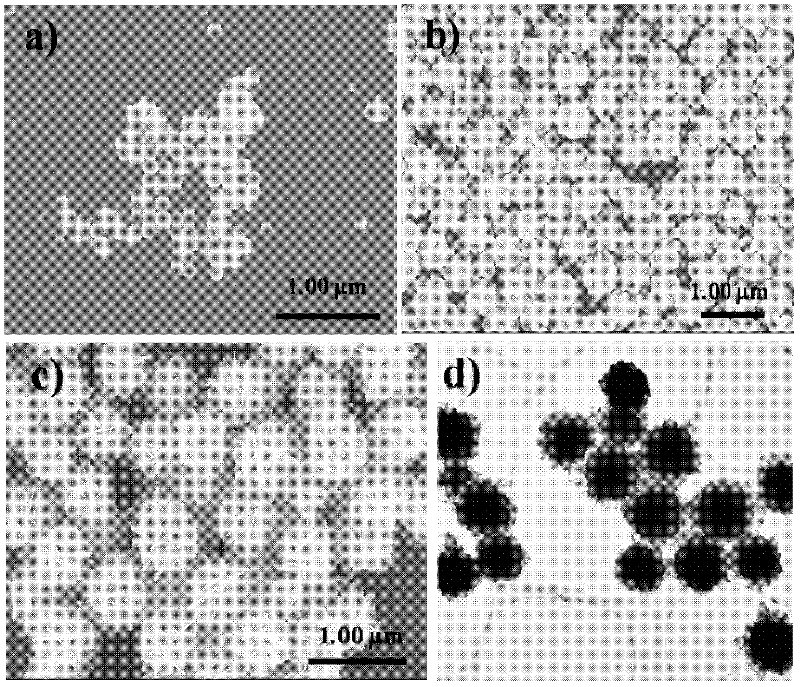

Method for preparing nano/micron gold hierarchical structure material

The invention discloses a method for preparing a gold hierarchical structure material. In the method, the nano / micron gold hierarchical structure material is prepared by reducing chloroauric acid at normal temperature, wherein a 'dendritic' surfactant C18N3 serves as a template and protective agent; and ascorbic acid serves as a reducing agent. Bubbles formed by the surfactant C18N3 serve as the template; and a C18N3 protected stable gold nano hierarchical structure is obtained through reduction by using the ascorbic acid. Compared with the conventional method, the method is simple and low incost; and the hierarchical structure prepared by the method has high monodispersity, controllable appearance and the like. The nano / micron gold hierarchical structures with different appearances can be obtained by simply adjusting the amount of the surfactant, the chloroauric acid and the ascorbic acid, and comprise three-dimensional gold nanostructures such as a gold nanocrystal with a pluralityof protrusions on the surface, nearly spherical hollow nanoparticles, a meatball-shaped structure, a spherical structure with rodlike protrusions on the surface, a nano / micron spherical structure with sheet-like surface and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com