Photocuring material and application thereof

A photocurable material, hyperbranched technology, applied in the direction of coating, can solve the problem of no report, etc., and achieve the effect of high crosslinking density, high wear resistance and chemical resistance, and good thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

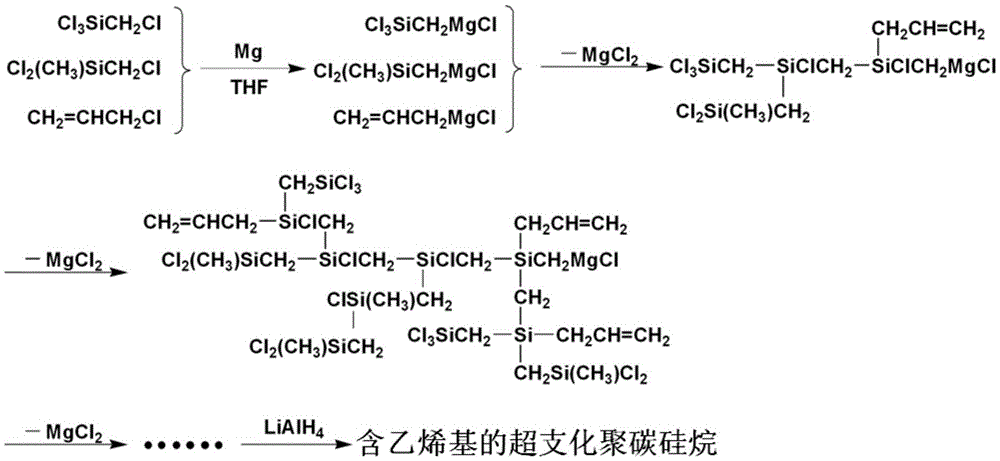

[0030] Step 1: Synthesis of vinyl-containing hyperbranched polycarbosilane

[0031] References (Chinese Chemical Letters, 2007, 18, 754-757.) to synthesize vinyl-containing hyperbranched polycarbosilane, the specific steps are: adding magnesium chips (1.04mol) to CH 2 =CHCH 2 Cl(0.12mol), Cl 3 SiCH 2 Cl (0.46mol) and Cl 2 Si(CH 3 )CH 2 Cl (0.23mol) in tetrahydrofuran (200mL) was reacted at 60°C for 12 hours, then lithium aluminum hydride (0.37mol) was added in an ice-water bath, and the reaction was continued at 60°C for 12 hours. After the reaction finished, the reaction solution was poured into the aqueous hydrochloric acid solution with a concentration of 4mol / L and stirred. After stirring for 2 hours, n-hexane (500mL) was added to the water, the layers were static, the organic phase was separated and dried with sodium sulfate, and finally Dry in vacuum at 60°C to obtain vinyl-containing hyperbranched polycarbosilane. The synthetic route is as follows (it should be n...

Embodiment 2

[0039] Step 1: Synthesis of acryloxy-containing hyperbranched polycarbosilane

[0040] References (Chinese Chemical Letters, 2007, 18, 754-757.), synthesis of hyperbranched polycarbosilane containing Si-Cl bonds, and then refer to literature (Polymer, 2006, 47, 1519–1525), to obtain hyperbranched polycarbosilane containing acryloyloxy groups Polycarbosilane, the specific steps are: adding magnesium chips (1.0mol) to the CH 3 CH 2 CH 2 Cl (0.20mol), Cl 3 SiCH 2 Cl (0.15mol), Cl 2 Si(CH 3 )CH 2 Cl (0.45mol) in tetrahydrofuran (200mL) was reacted at 60°C for 12 hours, then 2-hydroxyethyl acrylate (0.6mol) and pyridine (0.6mol) were added in an ice-water bath and reacted for 1.5 hours. After the reaction finishes, remove the insolubles by filtration, pour the filtrate into an aqueous hydrochloric acid solution with a concentration of 4mol / L and stir, after stirring for 2 hours, add n-hexane (500mL) to the water, separate the organic phases and use sulfuric acid Sodium dryi...

Embodiment 3

[0050] Step 1: Synthetic vinyl-containing hyperbranched polycarbosilane with reference to Example 1

[0051] Step 2: Preparation of photocurable materials

[0052] The formula of light-curing material is: hyperbranched polycarbosilane (82wt%) containing vinyl, active diluent tripropylene glycol diacrylate (10wt%), ultraviolet photoinitiator 1-hydroxycyclohexyl phenyl ketone ( 4wt%) and benzophenone (3.6wt%), co-initiator CN373 (0.4wt%). The above raw materials were mixed under light shielding and mechanically stirred at room temperature for 2 h.

[0053] Step 3: Light Curing 3D Printing

[0054] The above-mentioned light-curing material in the working chamber of the nozzle quickly forms small droplets, and then sprays onto the support material at a certain speed and frequency, and solidifies under the action of ultraviolet light (the light source is a 600W medium-pressure mercury lamp). Form a three-dimensional structure. After characterization, the Shore hardness is 86HD,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity at room temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com