Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

99results about How to "High ceramic yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel liquid polycarbosilane as well as preparation method and application thereof

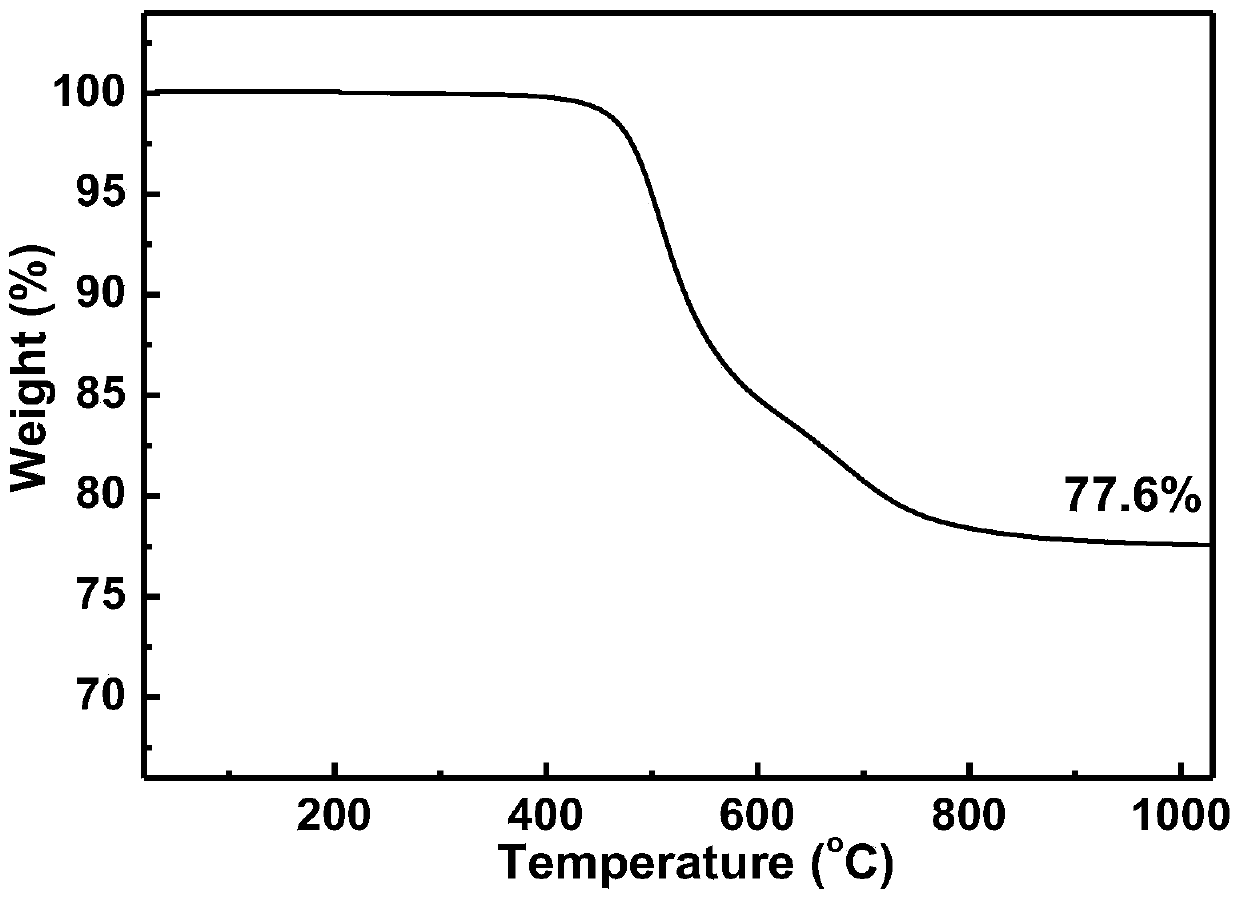

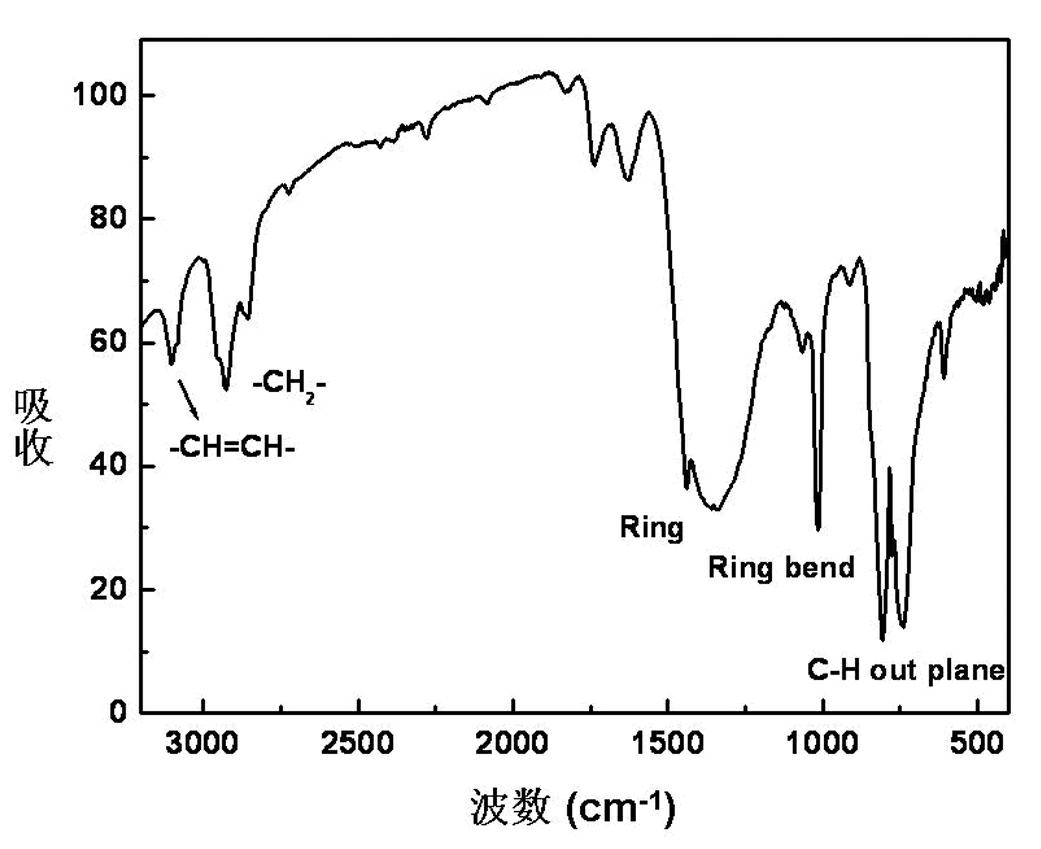

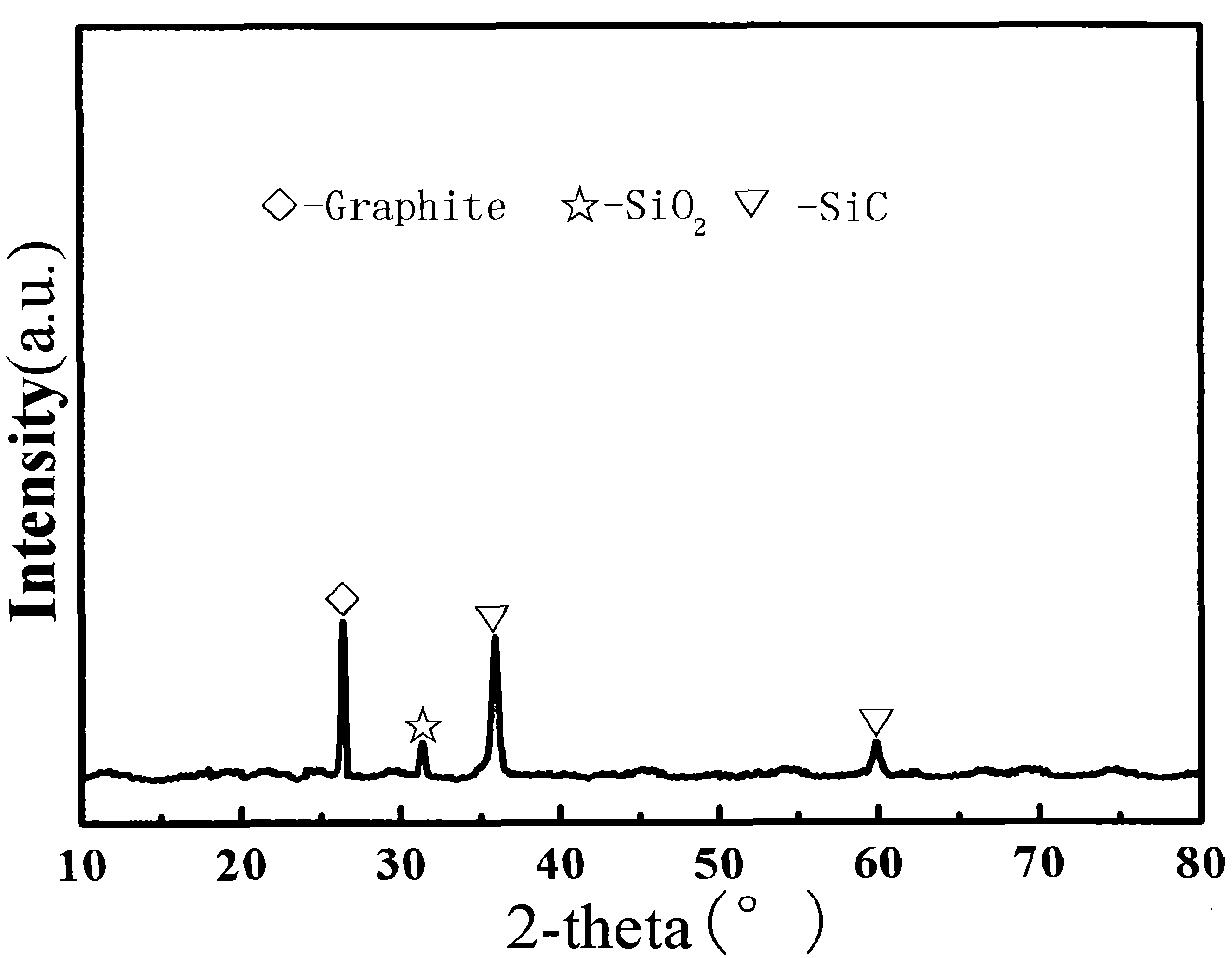

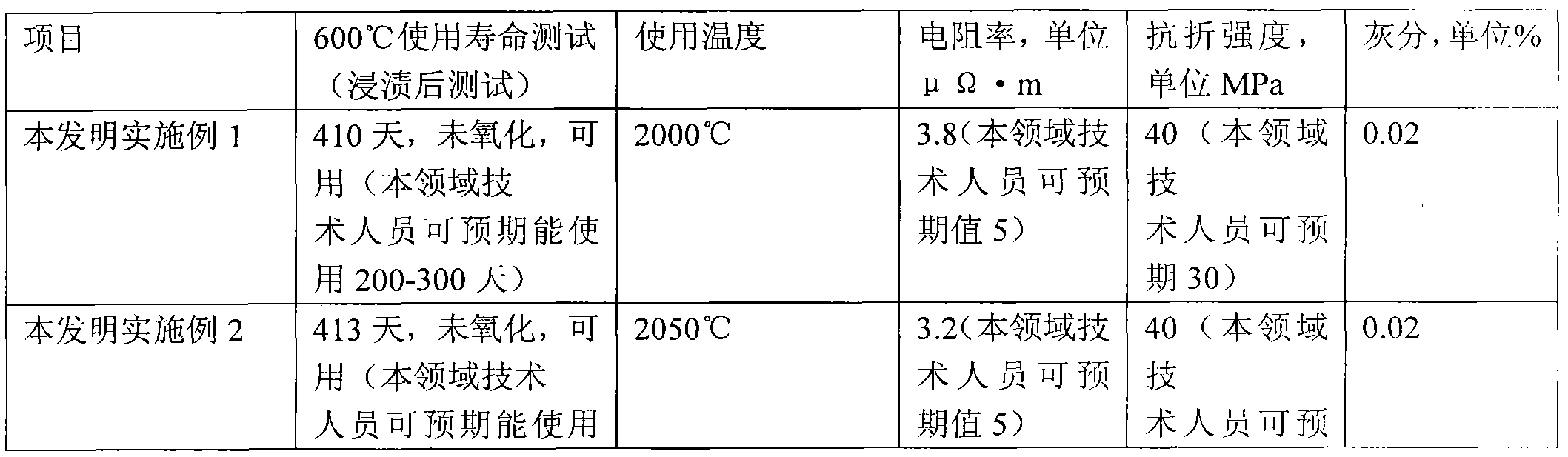

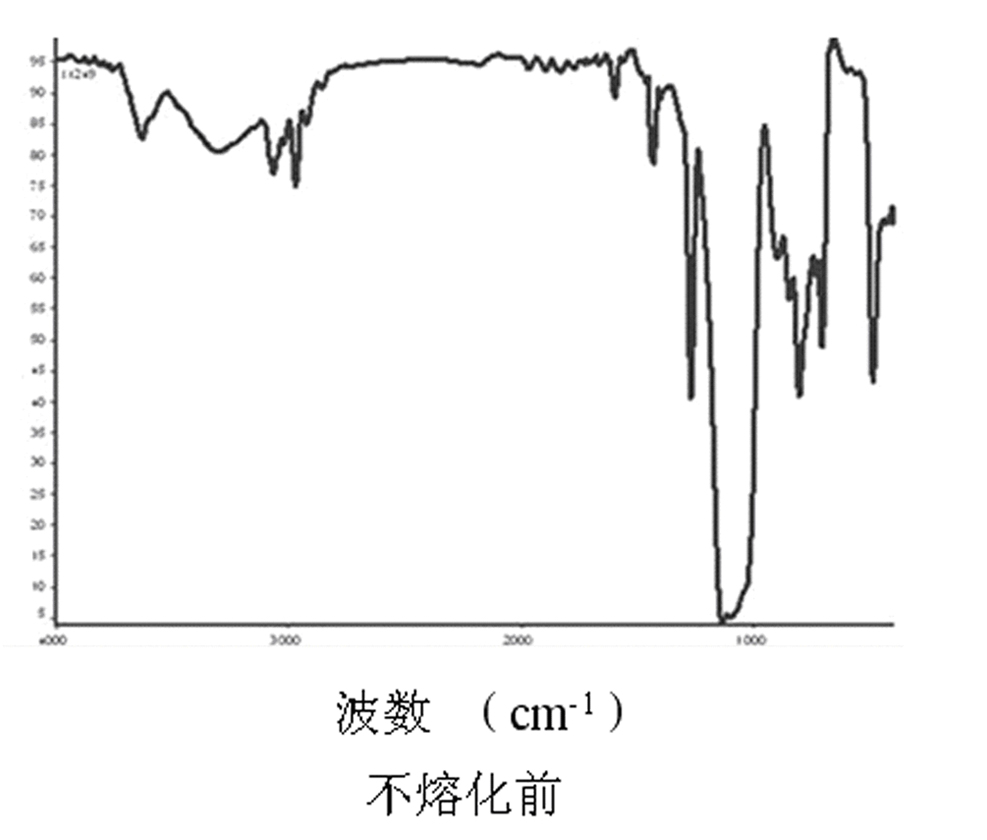

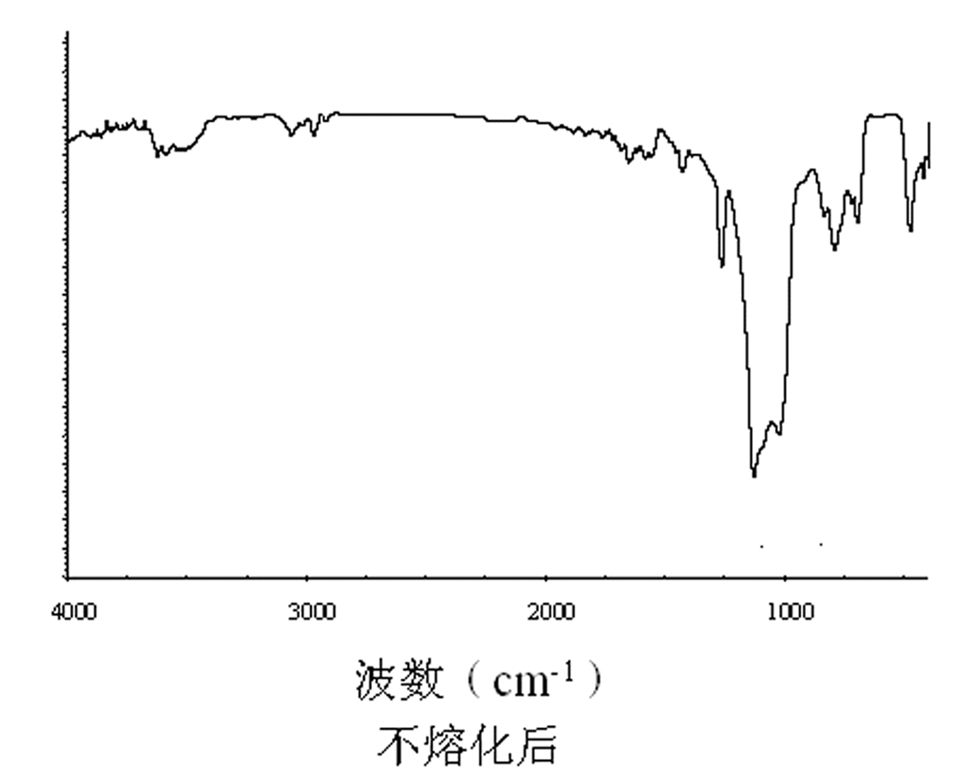

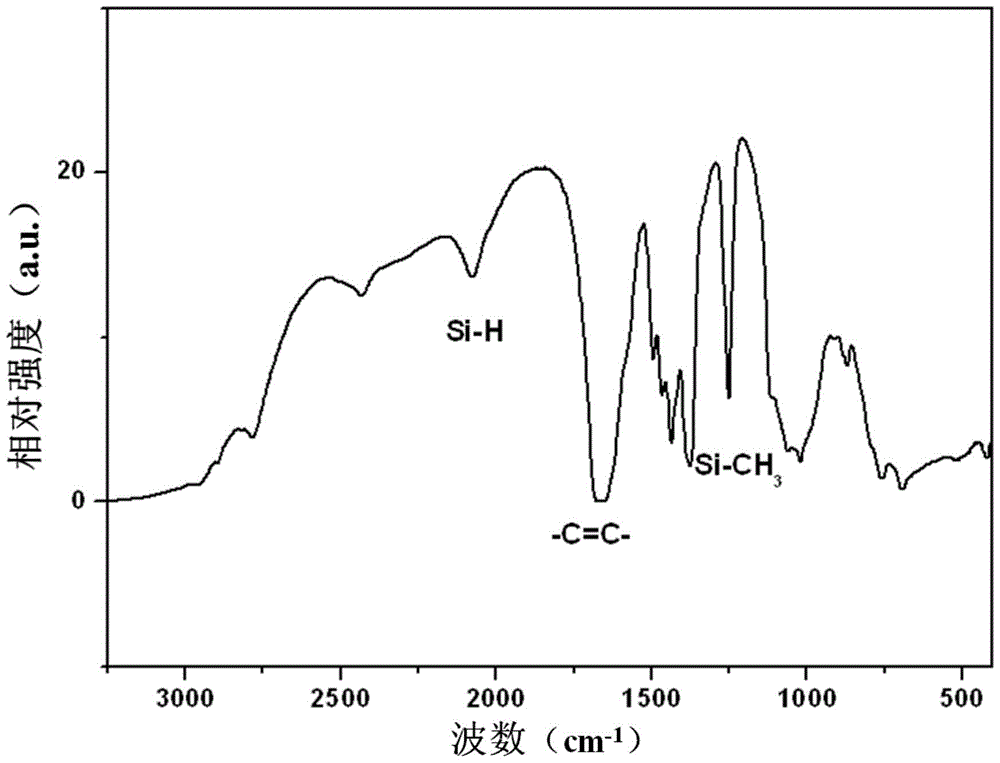

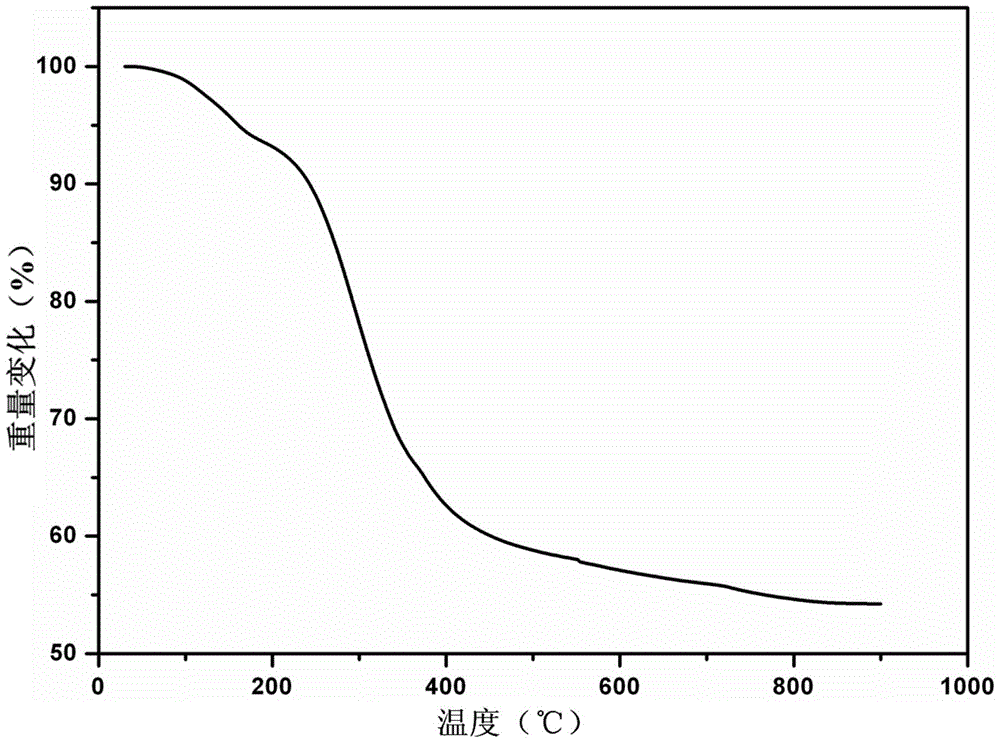

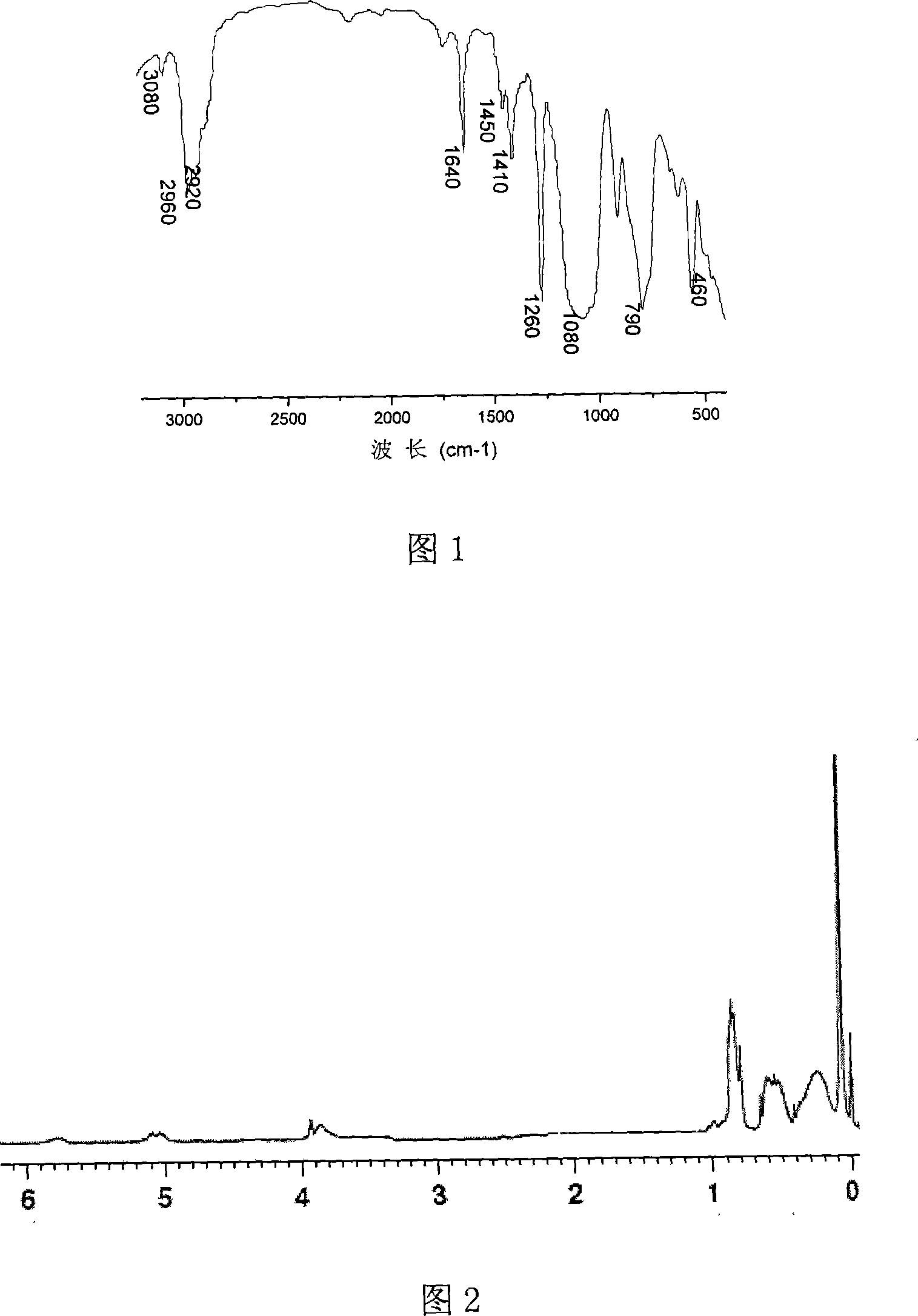

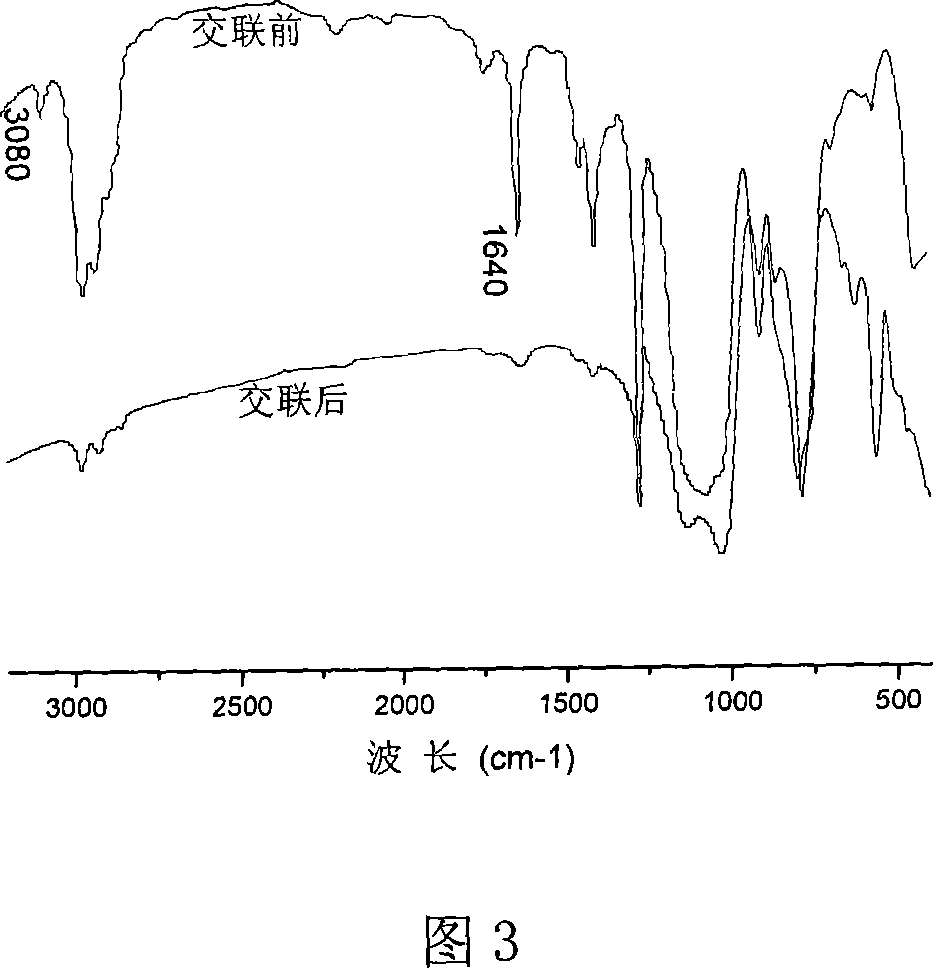

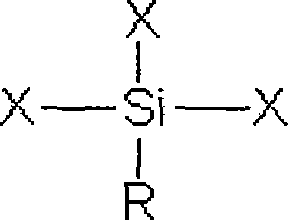

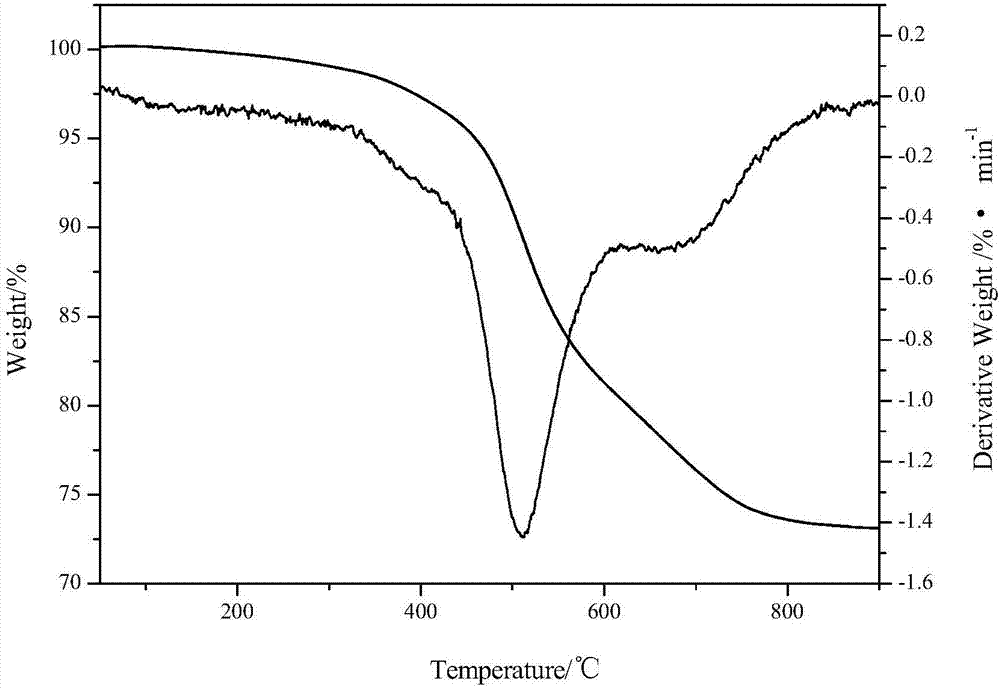

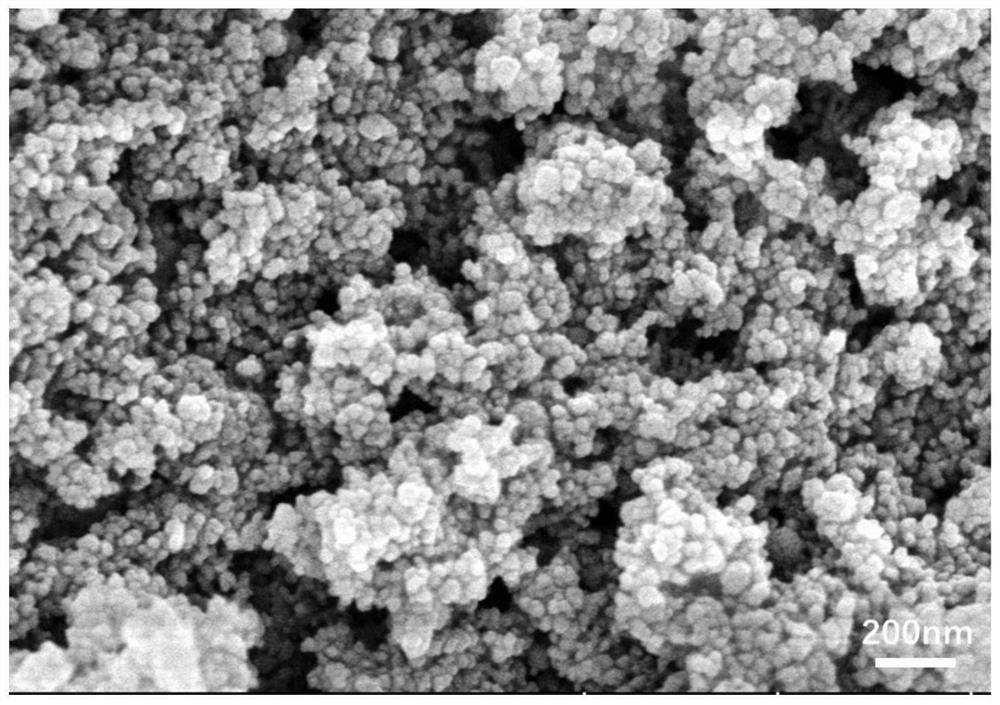

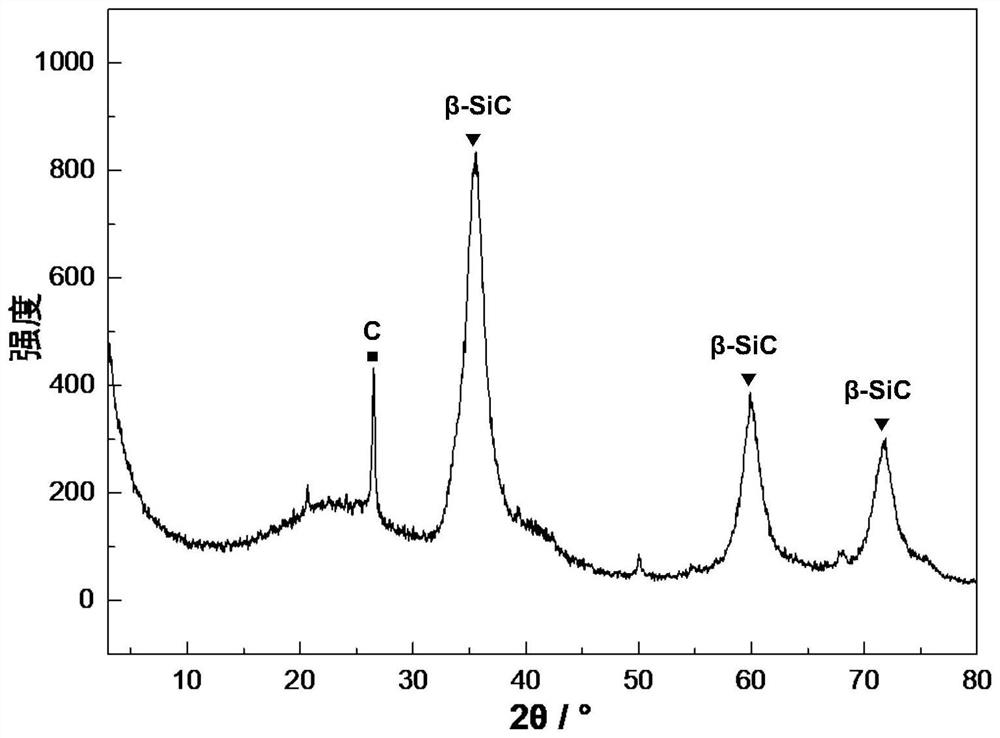

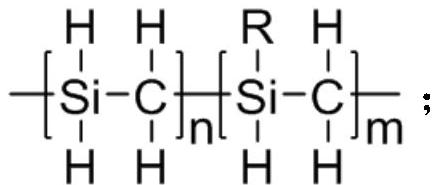

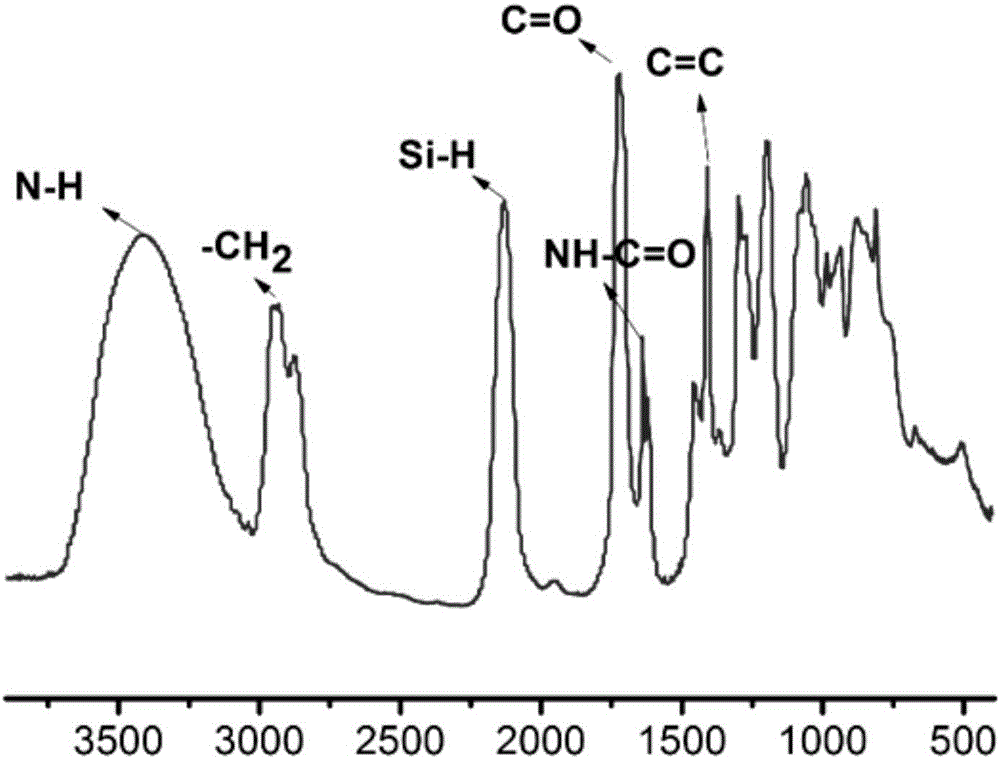

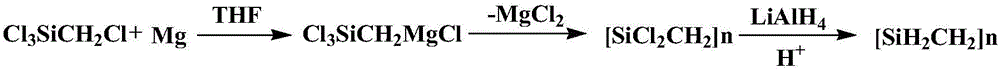

The invention discloses novel liquid polycarbosilane which is low in viscosity and high in storage stability and is crosslinkable, a preparation method of novel liquid polycarbosilane, and an application of novel liquid polycarbosilane. Polycarbosilane is prepared by adopting chloromethyl alkoxy silane or mixtures of chloromethyl alkoxy silane as raw materials by virtue of Grignard coupling reaction and reduction reaction, and the structure of polycarbosilane is shown in a formula (I) in the specification. The structure simultaneously contains Si-H bonds and unsaturated bonds such as C=C bonds, can be subjected to self-crosslinking and curing under a certain condition, has relatively high ceramic yield, and can be used as a silicon carbide precursor of a polymer precursor impregnation pyrolysis (PIP) process. Polycarbosilane disclosed by the invention is adjustable in structural composition, good in storage stability, low in viscosity and relatively low in boiling point, and has the utilization potentiality of being used as a silicon carbide ceramic precursor for chemical vapor deposition / chemical vapor infiltration (CVD / CVI). In addition, polycarbosilane can also be used for replacing commonly-used divinyl benzene to serve as a crosslinking agent of solid-state polycarbosilane (PCS).

Owner:淄博市临淄齐泉工贸有限公司

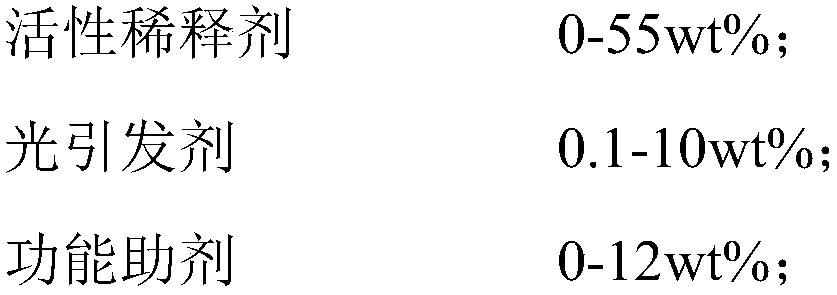

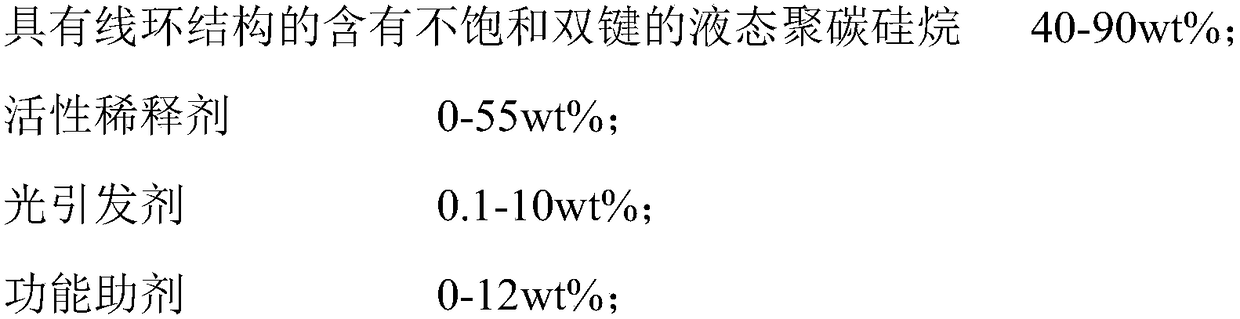

Photocuring material and application thereof

The invention relates to a photocuring material which comprises the following components in percentage by weight: 60-98% of hyperbranched polycarbosilane, 0-35% of active diluent, 0.1-8% of photoinitiator and 0-10% of additive, wherein the hyperbranched polycarbosilane contains an unsaturated double bond, and the number-average molecular weight of the hyperbranched polycarbosilane is 300-15,000; the unsaturated double bond is acryloyloxy, methylacryloyloxy, vinyl or allyl; and the content of the unsaturated double bond in the hyperbranched polycarbosilane is 1-30% by weight. The invention also relates to an application of the photocuring material in photocuring 3D printing and an application in preparation of a SiC component. The photocuring material provided by the invention has relatively low viscosity and is convenient to spray out of a nozzle of 3D printing equipment while the curing speed is high and the shrinkage rate in curing is little.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

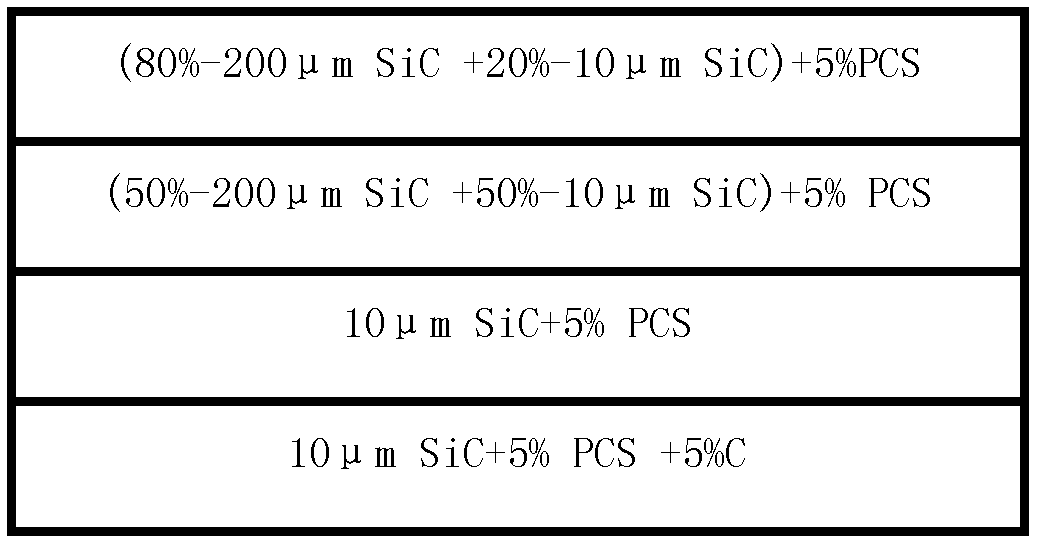

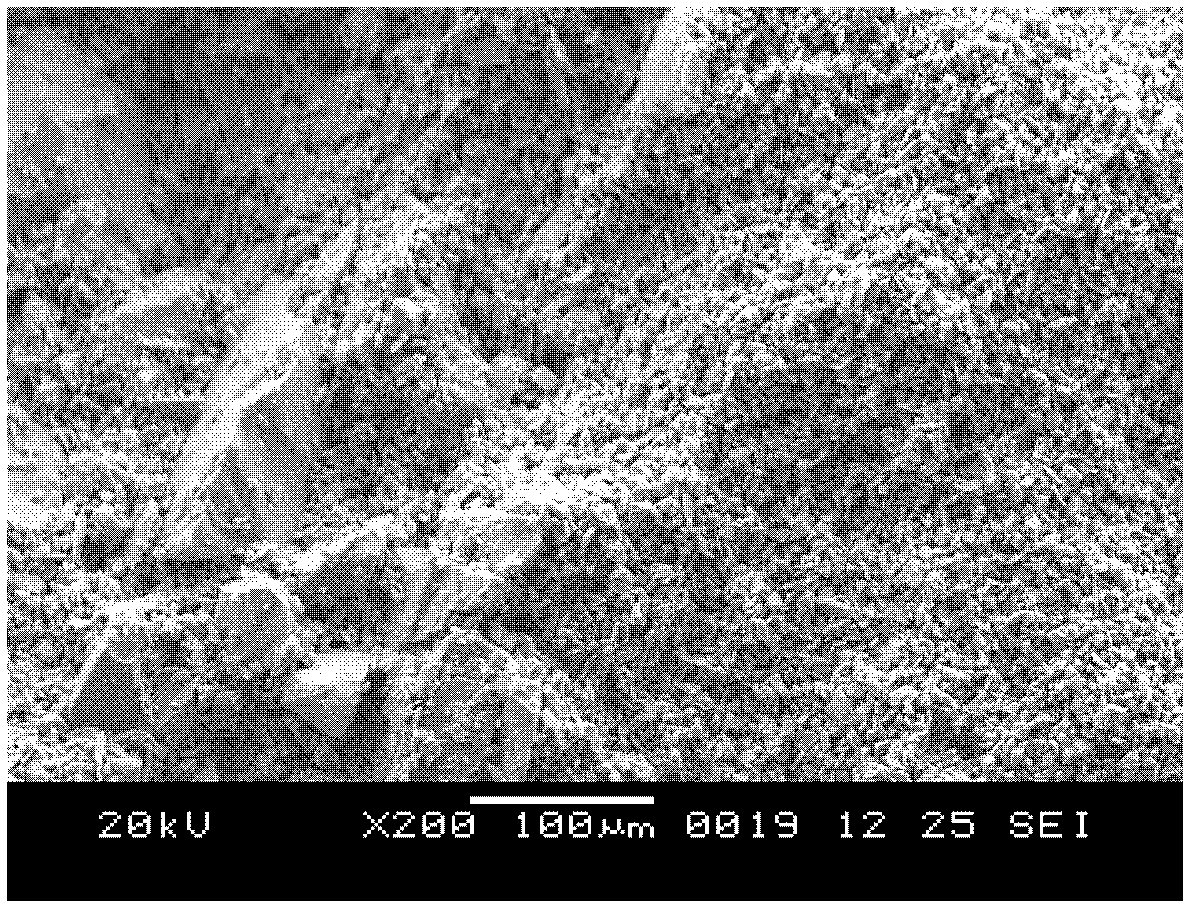

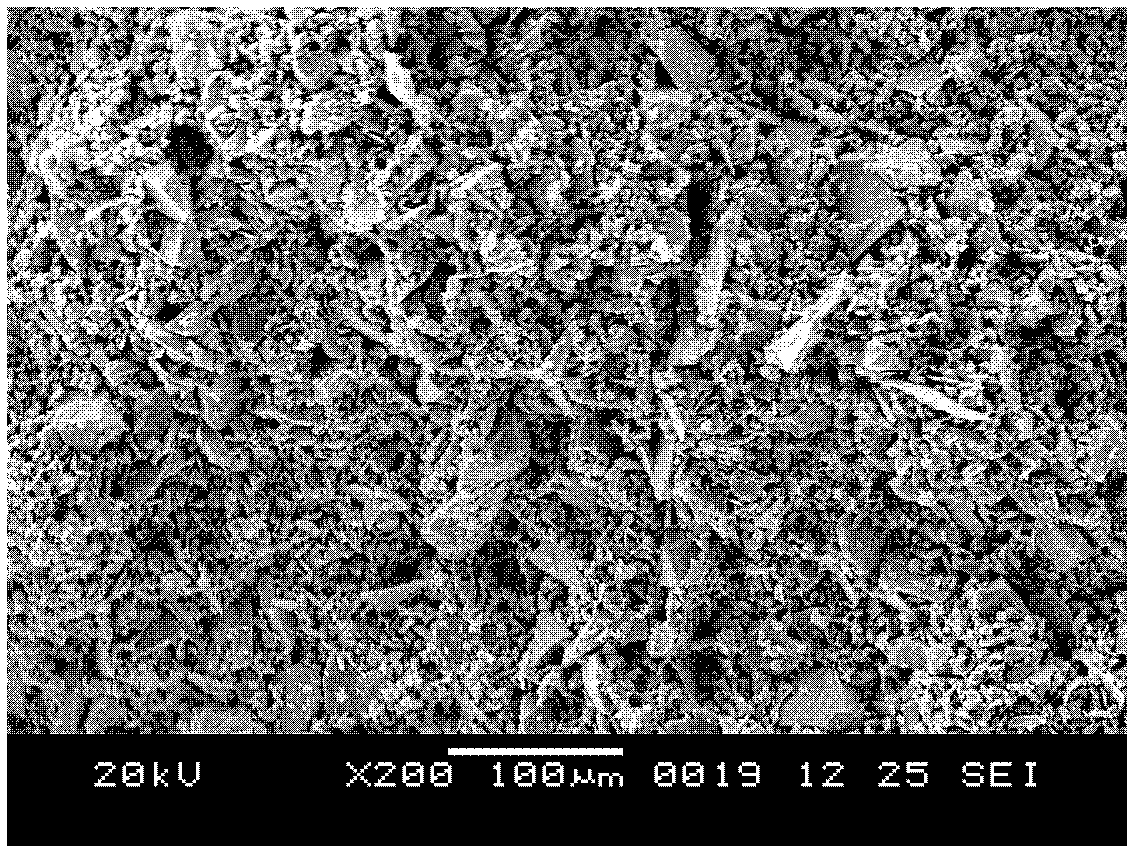

Pore gradient silicon carbide porous ceramic and preparation method thereof

The invention relates to a pore gradient silicon carbide porous ceramic and a preparation method thereof, and belongs to the technical field of preparation of porous ceramic. The pore gradient silicon carbide porous ceramic comprises polycarbosilane and silicon carbide powder, wherein a total weight of the silicon carbide powder is calculated as 100 parts, and the polycarbosilane accounts for 2-10 parts; the pore gradient silicon carbide porous ceramic can also comprise 5-15 parts of powdered carbon; the silicon carbide powder comprises fine silicon carbide powder, crude silicon carbide powder or a mixture of fine silicon carbide powder and crude silicon carbide powder. According to the invention, the pore gradient silicon carbide porous ceramic can be prepared at a low temperature; porous ceramic of various shapes can be prepared; a ceramic precursor has high ceramic yield; the prepared pore gradient silicon carbide porous ceramic has controllable three dimensional communicating pores, and distribution of which can be designed; and pore gradient silicon carbide porous ceramic in large size can be prepared.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Product prepared by light-curing rapid prototyping process and preparation method thereof

InactiveCN109280395AImprove mechanical propertiesHigh tensile strengthAdditive manufacturing apparatusLiquid lineDouble bond

The invention discloses a product and a preparation method thereof. The product is prepared by a light-curing rapid prototyping process, and a raw material used in the light-curing rapid prototyping process is a liquid photosensitive resin material. The product has an excellent mechanical property, and is high in tensile strength and tensile modulus, smooth and clean on surface, small in cure shrinkage, stable in size and good in mechanical property. The liquid photosensitive resin material contains liquid polycarbosilane having a line-ring structure and containing unsaturated double bond andis good in stability and easy to store, and the synthetic route of the material is green and environmentally friendly without corrosion; and a liquid line-ring polycarbosilane active group is large indensity, fast in curing speed, high in cured product strength, low in molecular weight and viscosity, good in fluidity and printable performance, and especially suitable for a 3D printing technologyof light-curing rapid prototyping.

Owner:BEIJING HENGCHUANG ADVANCED MATERIALS & ADDITIVE MFG INST CO LTD

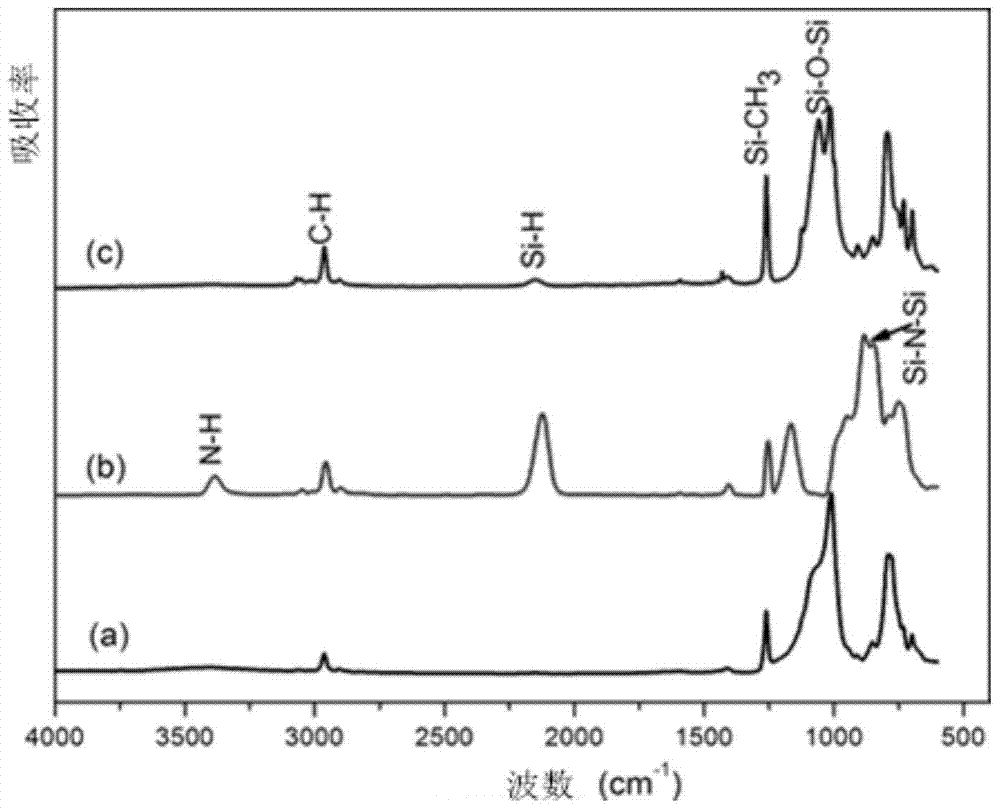

Preparation method for liquid polyborosilazane

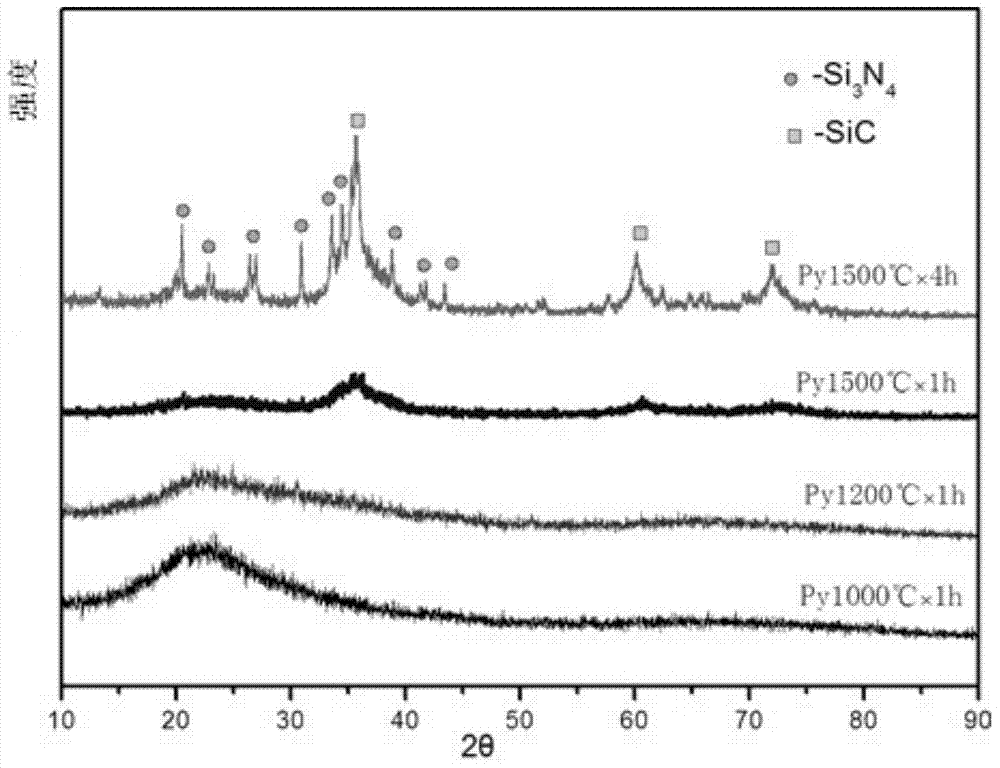

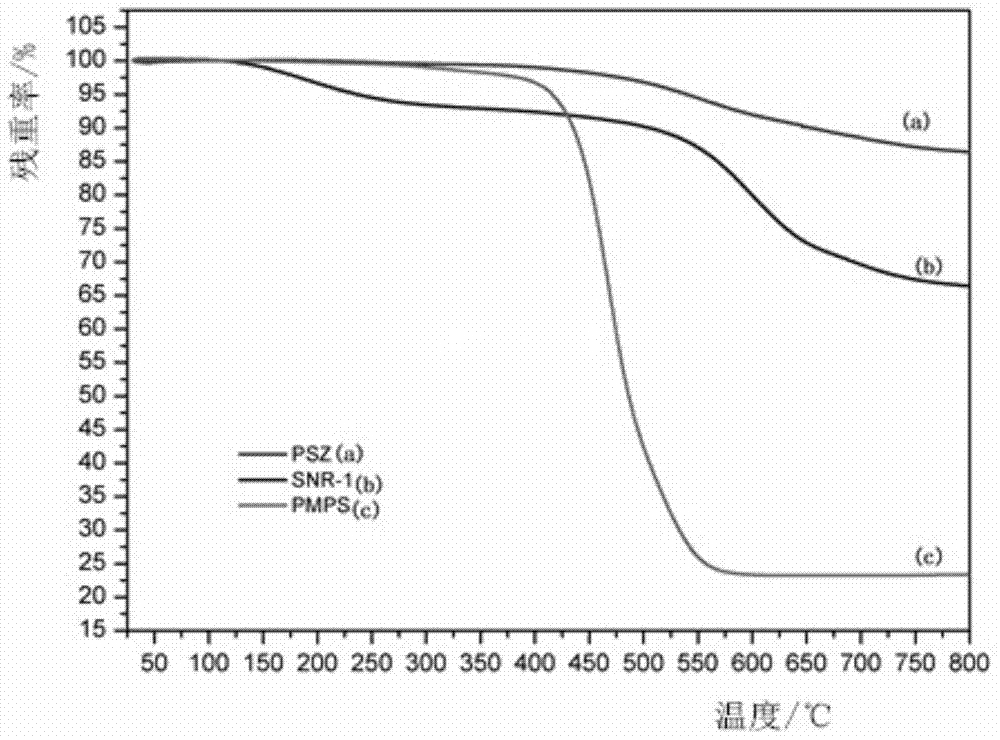

The invention relates to a preparation method for liquid polyborosilazane and belongs to the field of inorganic nonmetallic materials. The preparation method comprises the following steps: liquid polyborosilazane and 9-borabicyclo [3,3,1]-nonane are added in a solvent in inert atmosphere to obtain mixed solution, then the obtained mixed solution is hydroborated under the stirring condition, and then the solvent is removed after completion of hydroboration to obtain the liquid polyborosilazane. The preparation method solves the problems in the traditional polymer route that excessive cross-linking is easily caused in the hydroboration addition reaction, and solid polyborosilazane has poorer fluidity. The prepared liquid polyborosilazane has good fluidity and high ceramic yield and can be directly used for the high polymer infiltration and pyrolysis method for preparing SiBCN ceramic matrix composites.

Owner:XIAMEN UNIV

Catalytic rearrangement preparation method of polycarbosilane

ActiveCN105273199AHigh synthetic yieldStrong Lewis acidityFibre chemical featuresSilanesReaction temperature

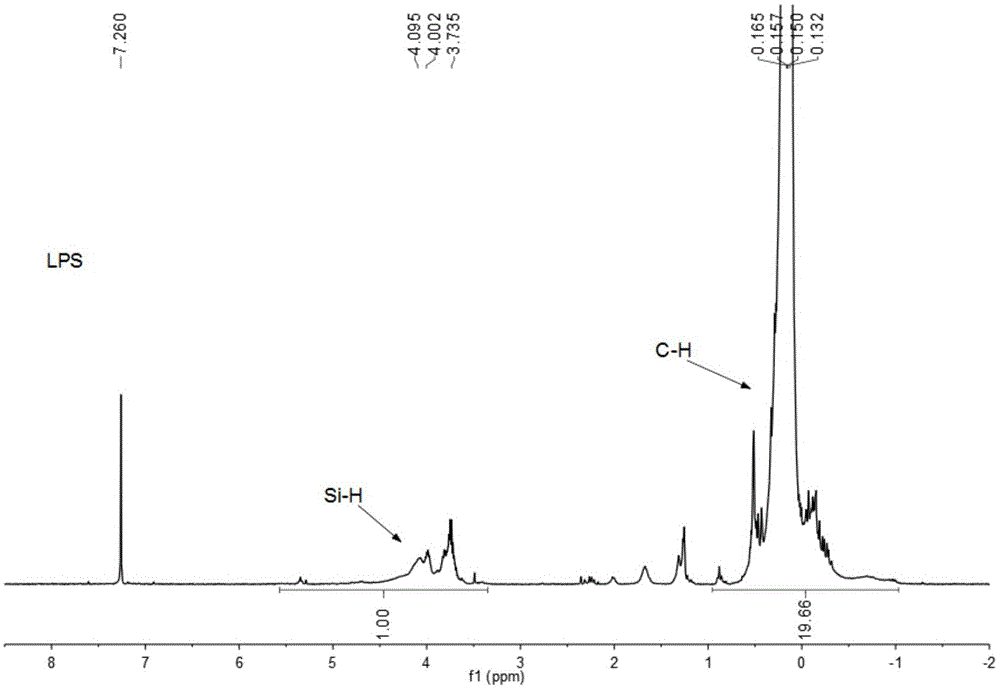

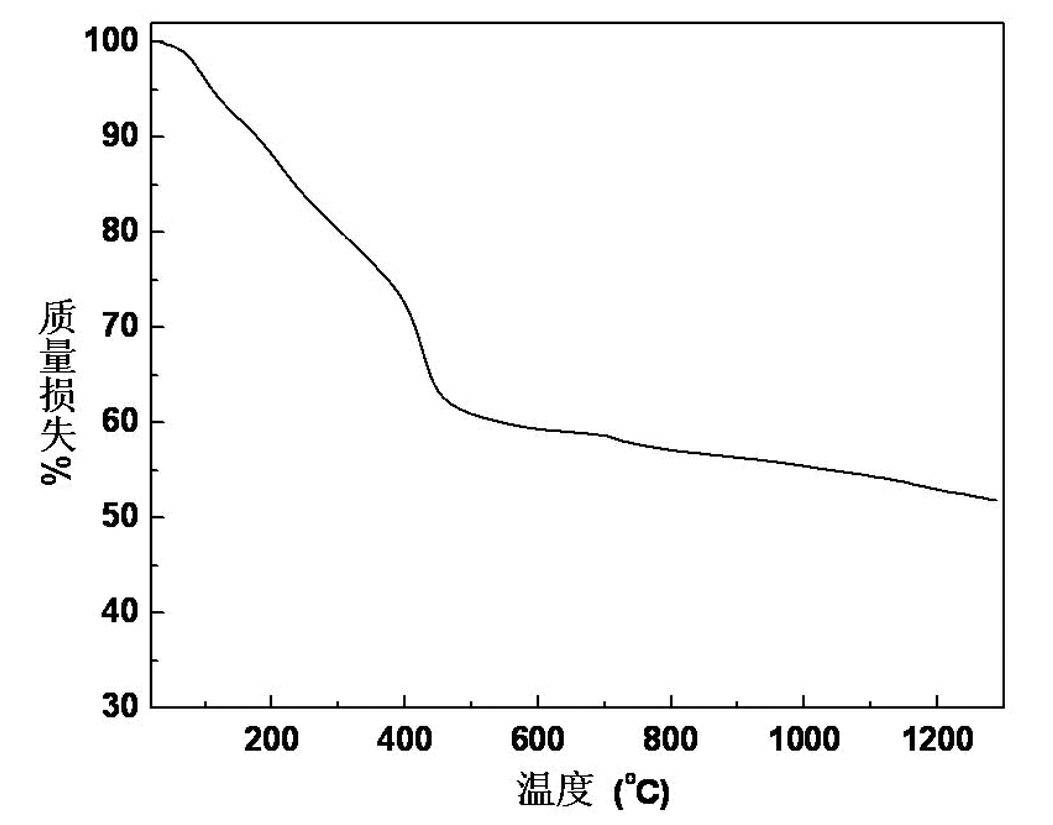

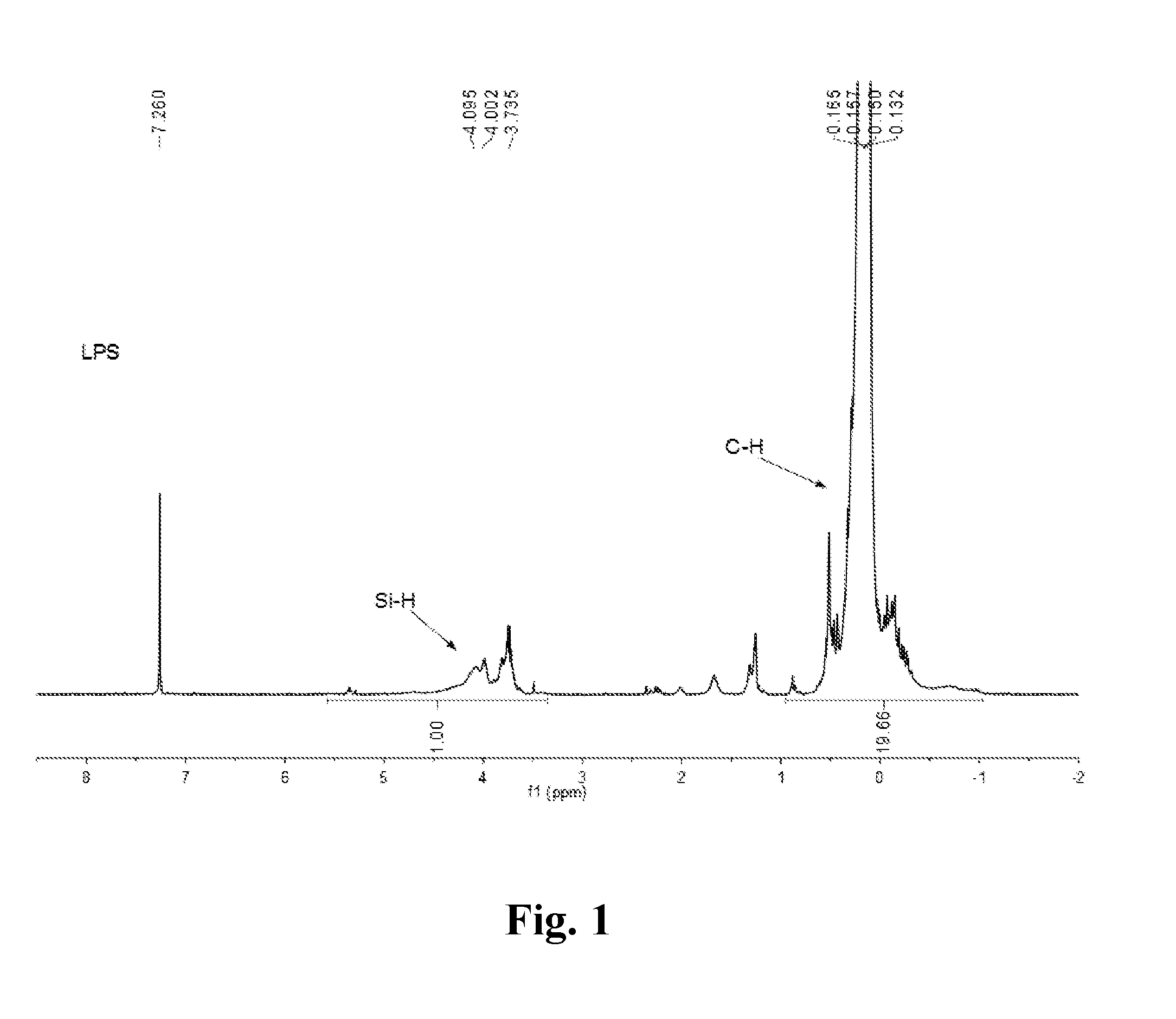

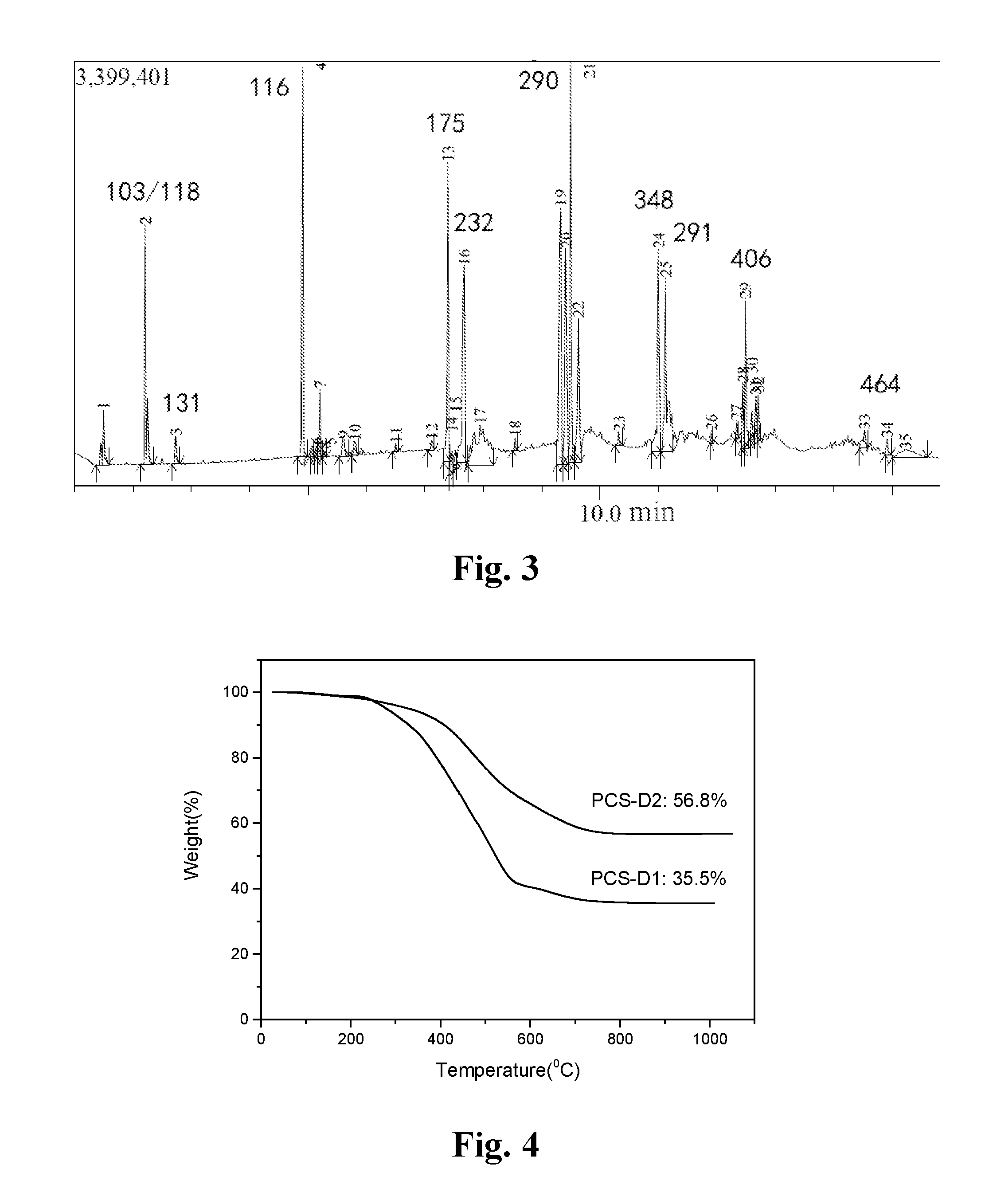

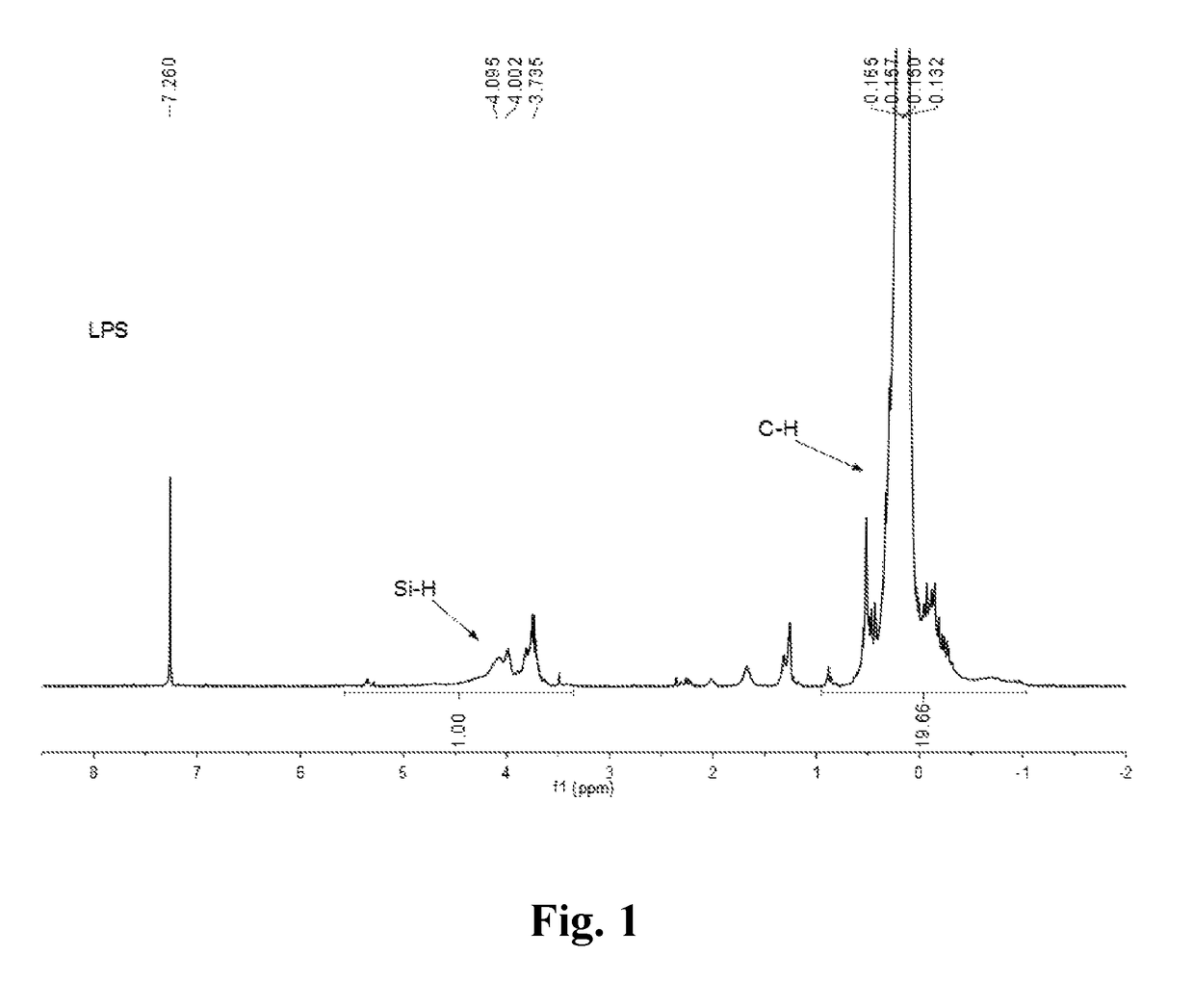

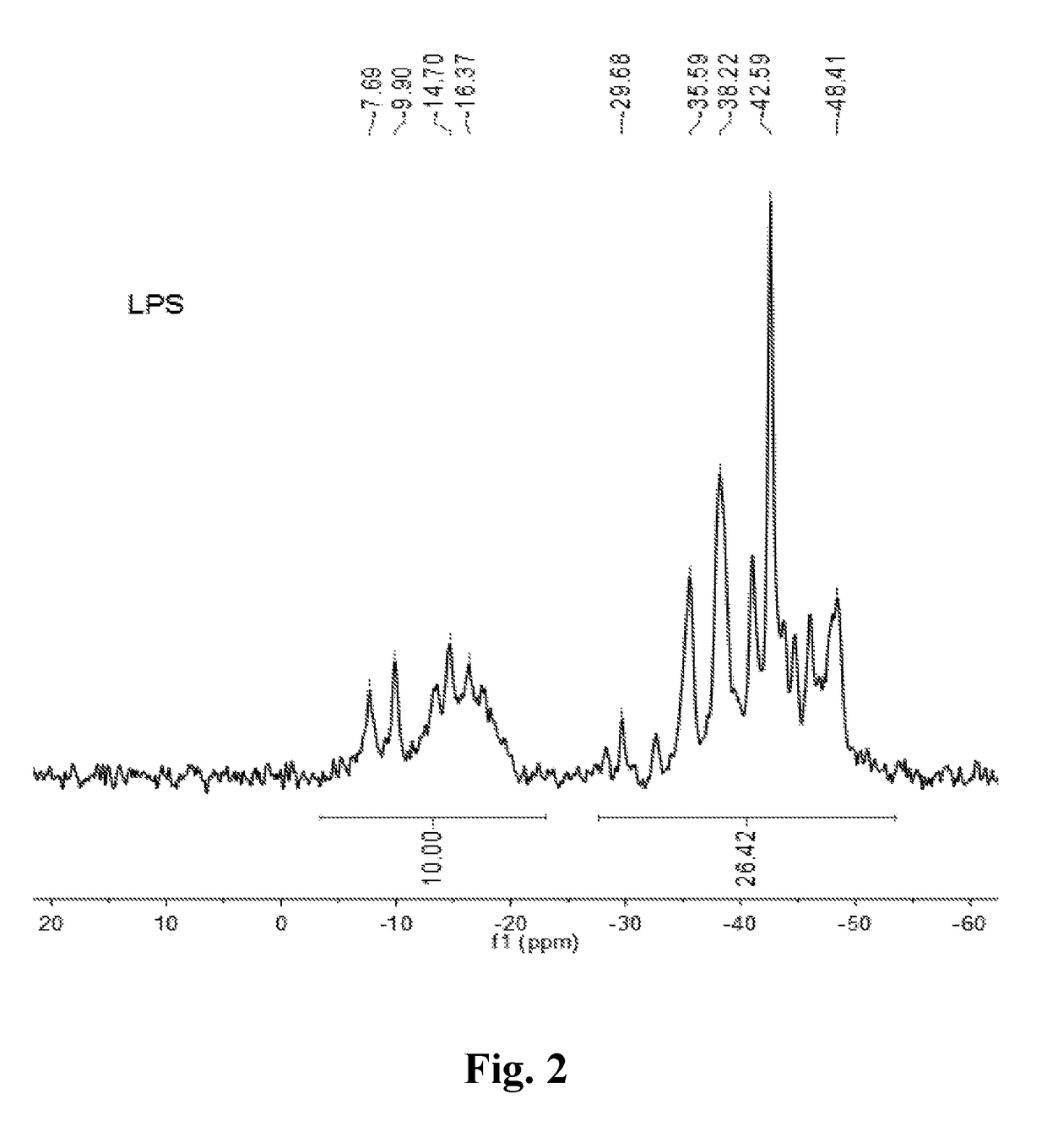

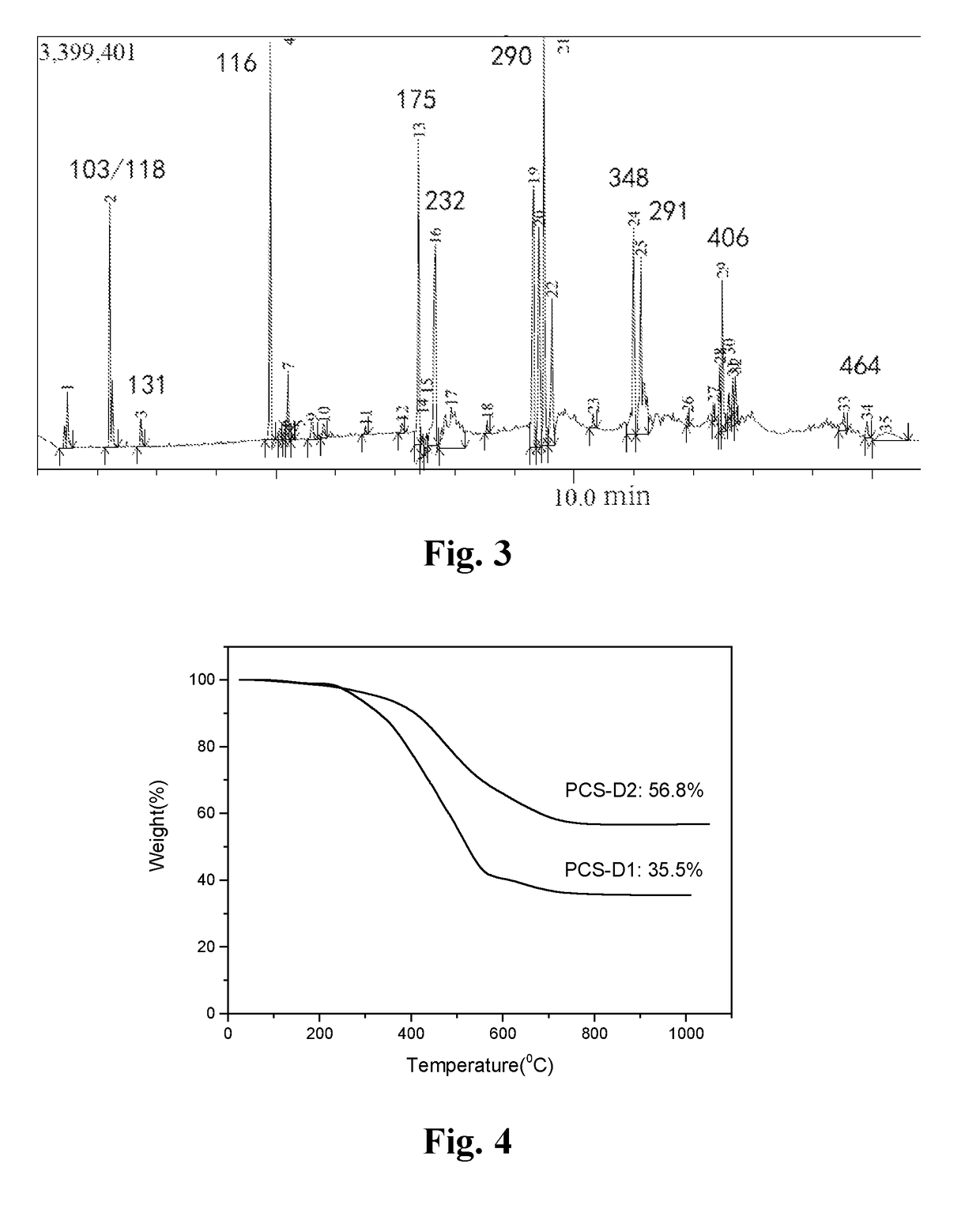

The invention relates to a method for preparing polycarbosilane through cracking rearrangement of a cyclic silane compound or chain polysilane under the catalytic effect of trace (lower than 1wt%) boron-containing catalyst. According to the invention, polydimethylsilane (PDMS) or a pyrolysis product thereof which is a liquid-state silane-carbosilane compound (LPS) is adopted as a raw material; lower than 1wt% (relative to the amount of the raw material) of the boron-containing catalyst is added; the temperature is gradually increased to a reaction temperature under a normal pressure or a high pressure, such that a pyrolysis / rearrangement reaction is carried out, and solid-state polycarbosilane (PCS) with relatively high ceramic yield is obtained. The method provided by the invention has the advantages of short reaction time, high synthesis yield, good product quality, simple equipment and safe operation. The prepared polycarbosilane is a SiC precursor polymer, and can be used in the preparations of SiC fiber and SiC-based composite materials.

Owner:INST OF CHEM CHINESE ACAD OF SCI

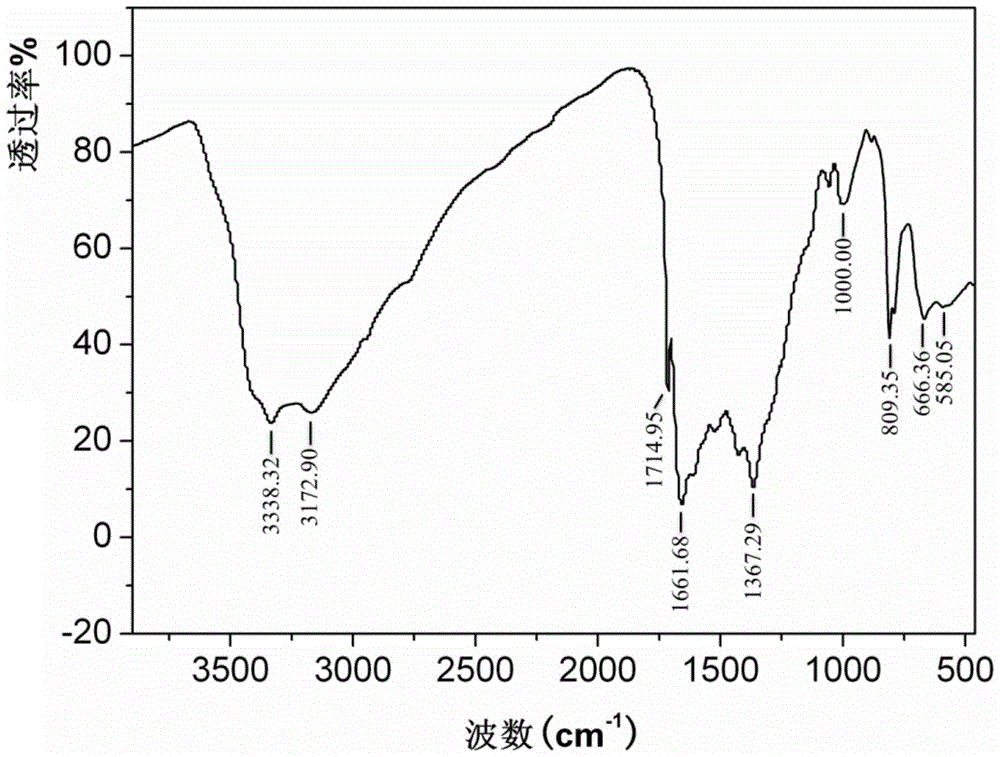

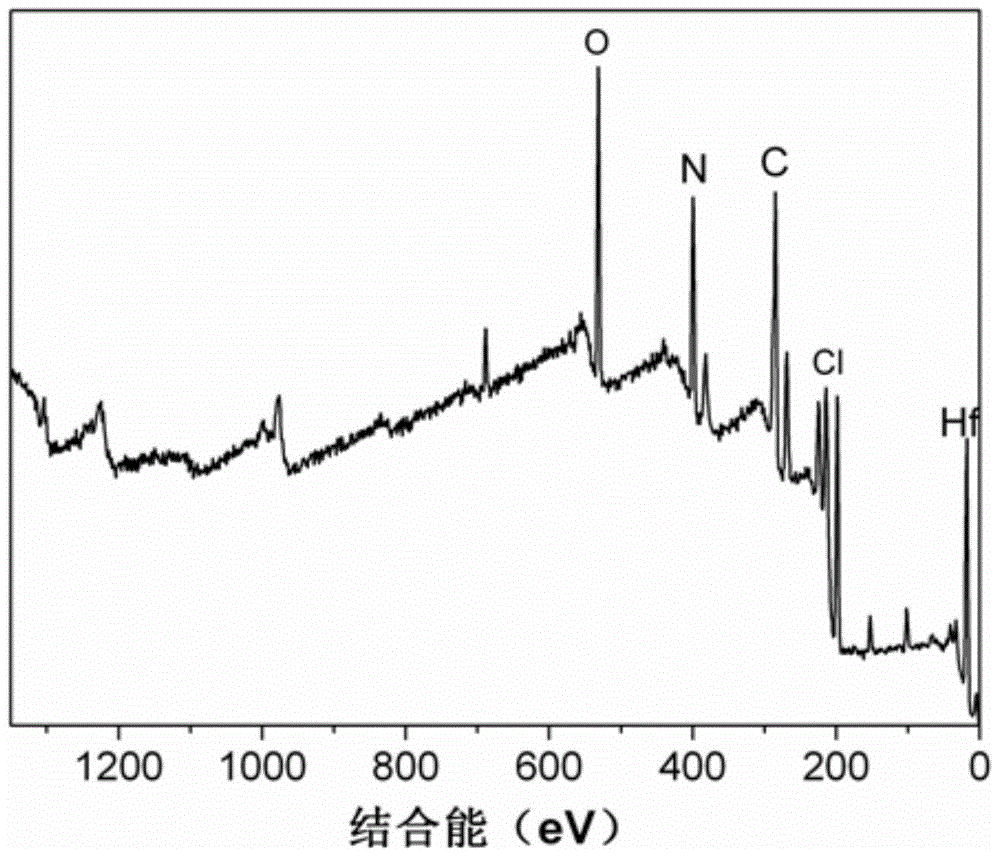

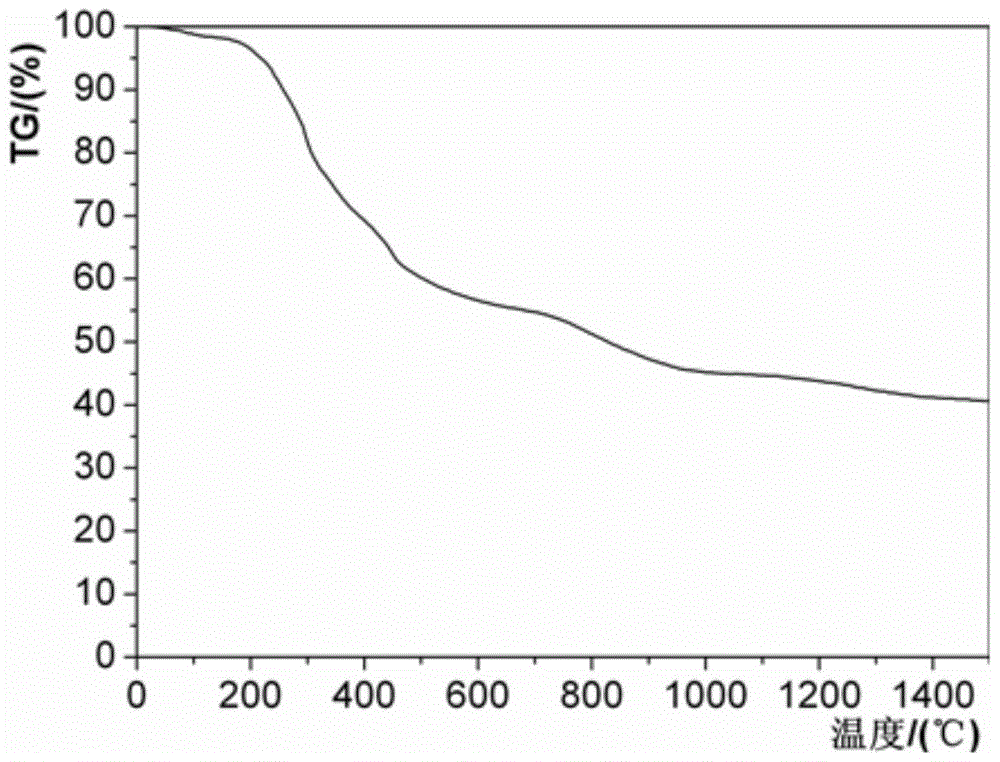

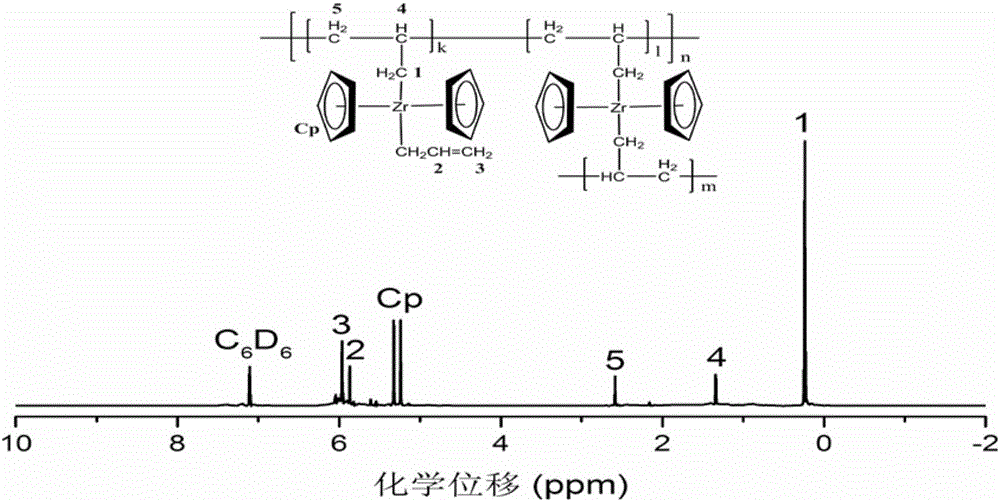

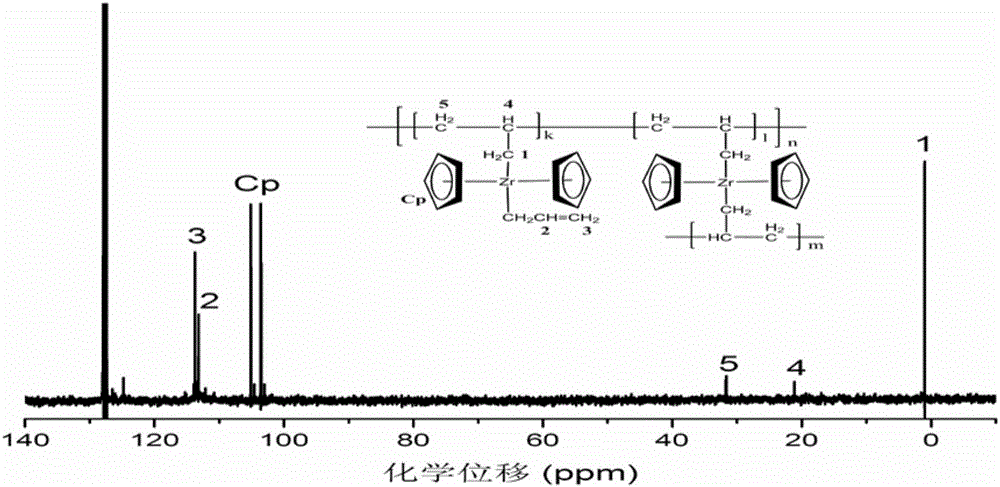

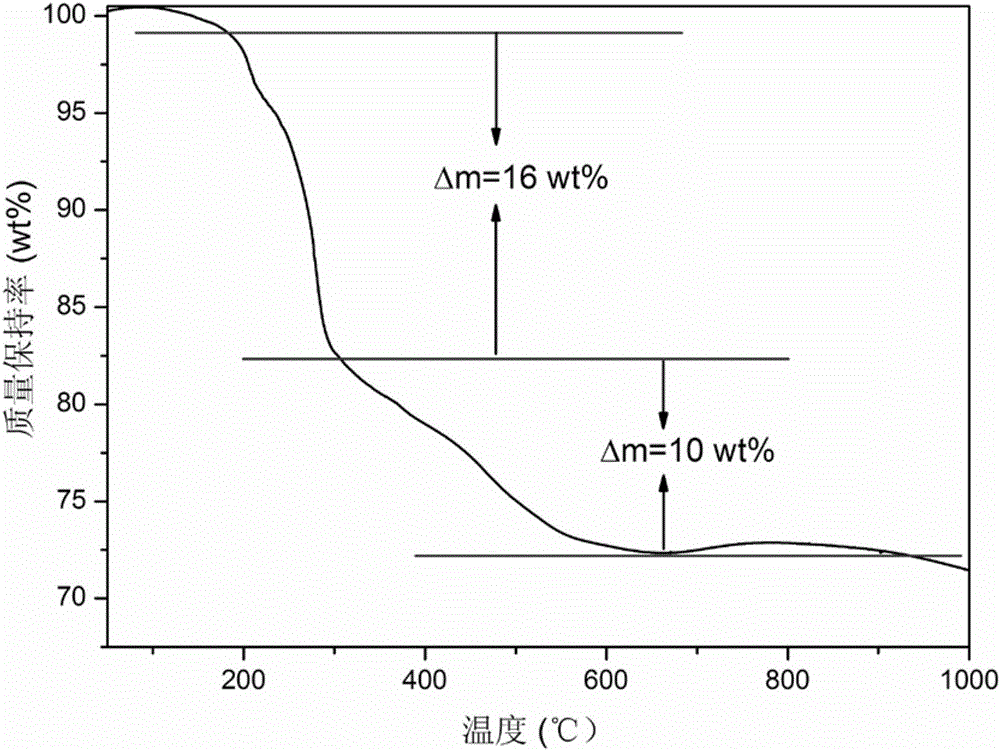

Organometallic polymer ceramic precursor, and preparation method and application thereof

ActiveCN102153760AHigh ultra-high temperature ceramic component contentHigh ultra-high temperature resistant component contentDouble bondHafnium

The invention relates to an organometallic polymer ceramic precursor, and a preparation method and application thereof. The organometallic polymer ceramic precursor is prepared by copolymerization of a double-bond-containing organometallic zirconium or titanium or hafnium monomer and a boron-containing monomer. By using the organometallic polymer ceramic precursor for preparing M(Zr,Ti,Hf)-B-C ceramic, the ceramic yield is up to 40-60%, and the content of the super-high-temperature-resistant component (ZrC / ZrB2,TiC / TiB2,HfC / HfB2) in the prepared ceramic material is higher than 70 wt%. When being treated at 2000 DEG C for 2 hours, the organometallic polymer ceramic precursor is not subjected to obvious weight loss, thereby having favorable high-temperature resistance.

Owner:NAT UNIV OF DEFENSE TECH

Method for preparing polycarbosilane by catalytic rearranging

This invention provides a method for preparing a polycarbosilane by decomposition and rearrangement a cyclic silane compound or chain polysilane under the catalysis of a boron-containing catalyst in a trace amount (less than 1 wt %). In the method, poly(dimethylsilane) (denoted as PDMS) or a thermal decomposition product thereof, i.e., a liquid silane-carbosilane compound (denoted as LPS), is used as the raw material, less than 1 wt % of the boron-containing catalyst (with respect to the amount of the raw material) is added, and then the temperature is gradually increased to the reaction temperature under atmospheric pressure or high pressure to perform the thermal decomposition / rearrangement reaction so as to obtain solid polycarbosilane (PCS) with a higher ceramic yield. This method has advantages, such as short reaction time, high synthetic yield, good product quality, simple equipment and safe operation; and the polycarbosilane prepared is a polymeric precursor for SiC, and can be used for the preparation of SiC fibres and SiC-based composite materials.

Owner:INST OF CHEM CHINESE ACAD OF SCI

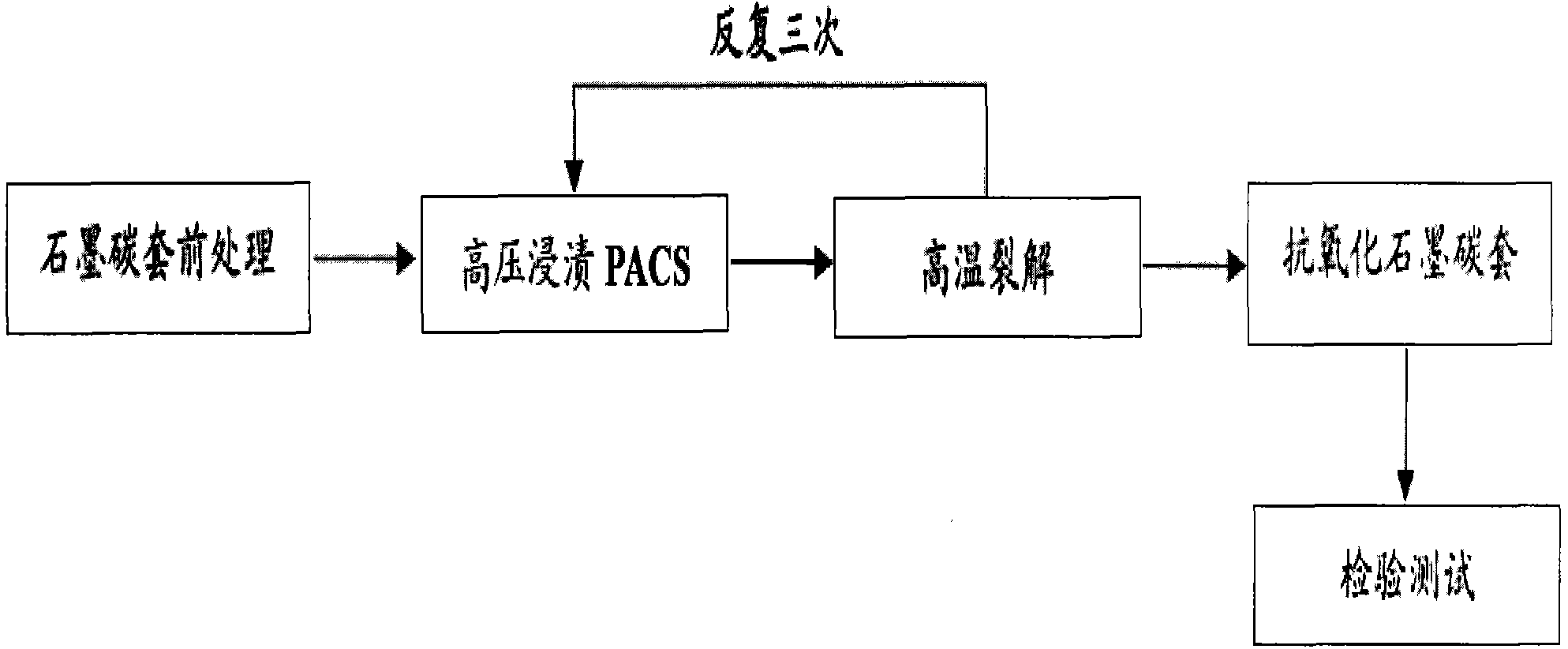

Graphite carbon sleeve gradient anti-oxidation coating and preparation method thereof

ActiveCN103435372AImprove antioxidant capacityImprove high temperature resistanceProduction rateGraphite carbon

The invention relates to a graphite carbon sleeve gradient anti-oxidation coating and a preparation method thereof. The preparation method comprises the following steps: the surface of a graphite carbon sleeve is pretreated; polyaluminocarbosilane (PACS) serves as a precursor for preparing the graphite carbon sleeve gradient anti-oxidation coating; the PACS has the advantages of high ceramic production rate and good effects of anti-oxidation and high temperature resistance; the pre-treated graphite carbon sleeve is immersed in a xylene solution of the PACS under the vacuum condition, kept under the vacuum condition for 1-10 min, macerated under the condition of pressurizing 10 MPa, dried and placed in an electric furnace, raised to 1,100-1,600 DEG C, and is cracked for preparing the graphite carbon sleeve gradient anti-oxidation coating.

Owner:江苏赛菲新材料有限公司

Cf/MC-SiC composite material and preparation method thereof

The invention discloses a Cf / MC-SiC composite material and a preparation method thereof. The Cf / MC-SiC composite material comprises a carbon fiber fabricated part, an MC substrate and an SiC substrate, wherein M is Zr or Hf, the MC substrate and the SiC substrate are uniformly filled in the holes of the carbon fiber fabricated part, in the Cf / MC-SiC composite material, the volume fraction of the MC substrate is 10%-20%, the volume fraction of the SiC substrate is 20%-30%, and the percentage of opening of 2%-10%. The preparation method comprises the following steps that (1) a precursor is soaked and split for preparing a Cf / MC blank; (2) a Cf / MC-C blank is prepared; (3) the Cf / MC-SiC composite material is prepared with a gas phase siliconizing method. The Cf / MC-SiC composite material has the advantages that the material is high in content of MC substrate, low in porosity, high in heat conductivity, excellent in oxidation resistance, ablation resistance and mechanical property and the like, and the preparation method is simple in technology and easy to implement.

Owner:NAT UNIV OF DEFENSE TECH

Polycarbosilane containing high-activity cross-linking groups and preparation method thereof

The invention discloses a preparation method of polycarbosilane containing high-activity cross-linking groups. The method comprises the following steps that after polycarbosilane, halogenated reagentsand solvents are mixed, a halogenation reaction is performed, and partially-halogenated polycarbosilane is obtained; the obtained polycarbosilane, an acid absorbent and a compound containing high-activity cross-linking groups are mixed and then stirred, and the polycarbosilane containing high-activity cross-linking groups is obtained through separation. The invention further discloses the polycarbosilane containing high-activity cross-linking groups prepared through the preparation method. The preparation method is low in reaction temperature and short in time, and adopts few side reactions,and the product with high purity can be obtained through centrifuging, concentrating and purifying in the follow-up steps. The introducing amount of cross-linking groups can be controlled by controlling the halogenation degree, the thermosetting or photo setting speed of the obtained polycarbosilane is increased, and the product can have the high ceramic yield.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

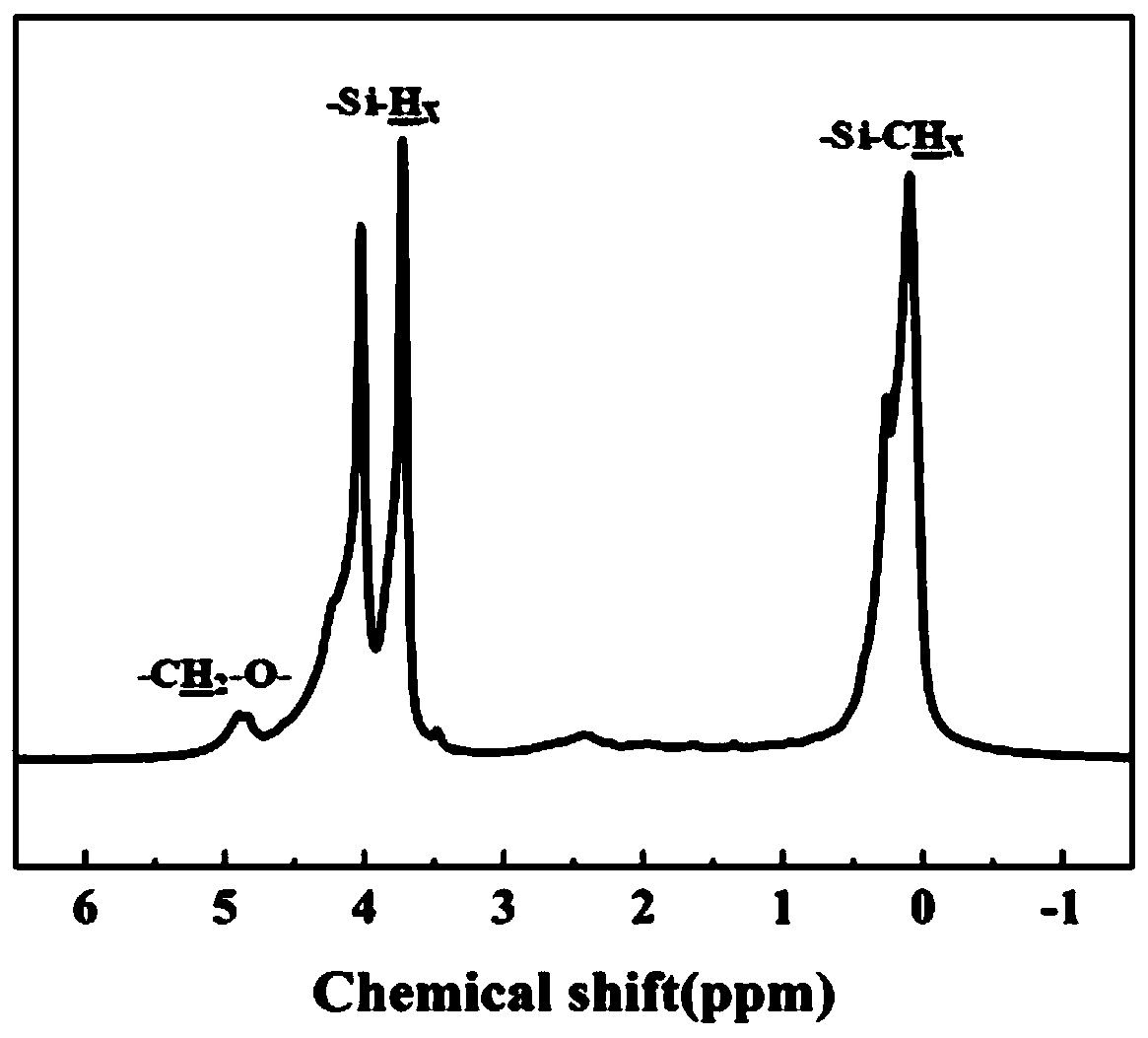

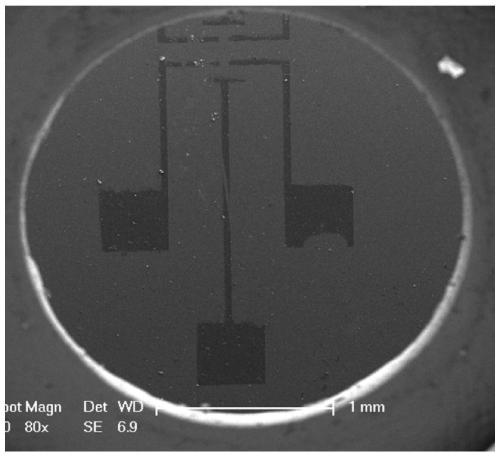

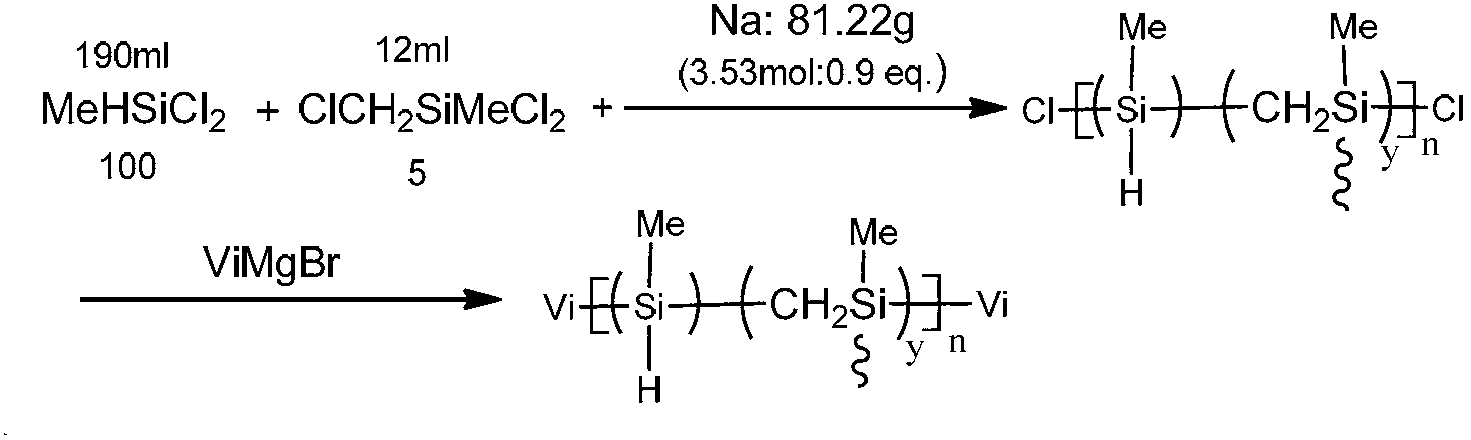

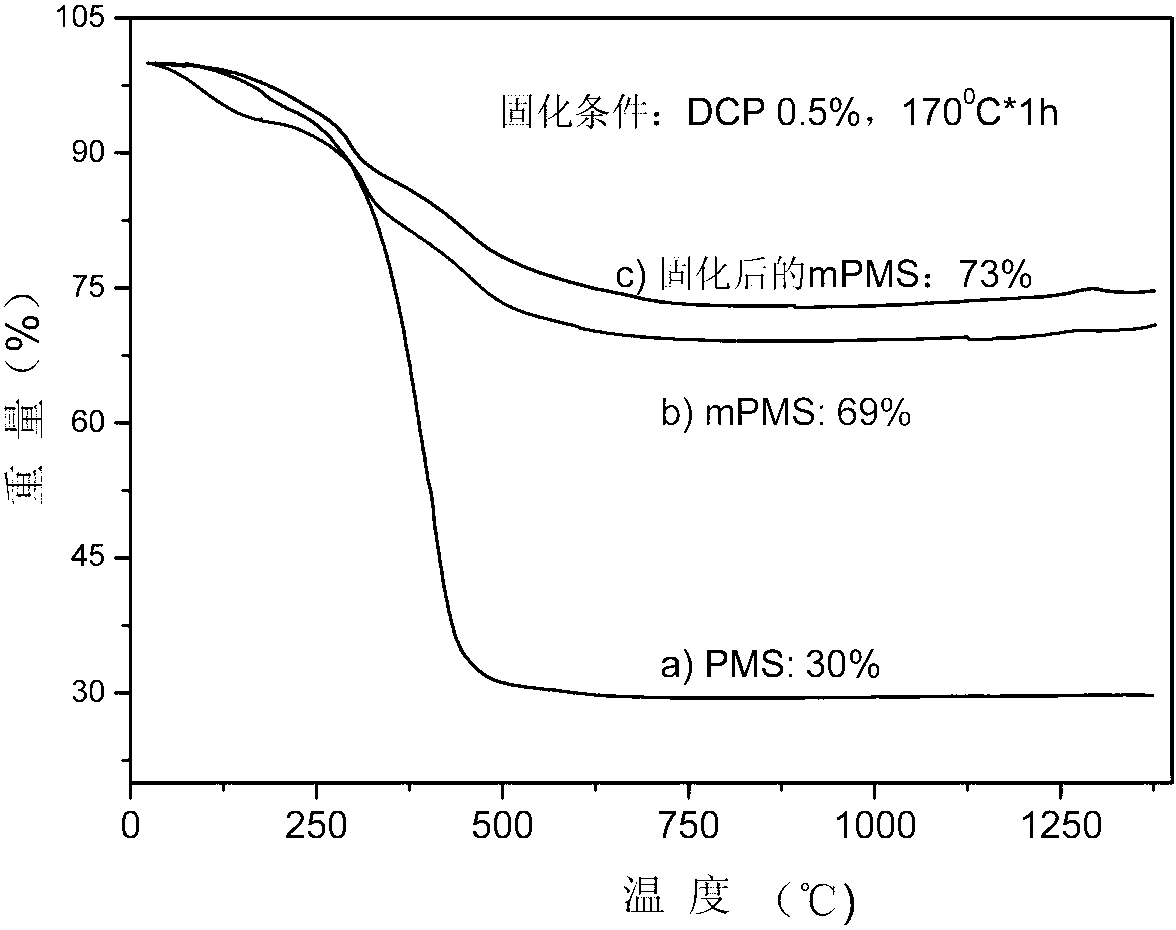

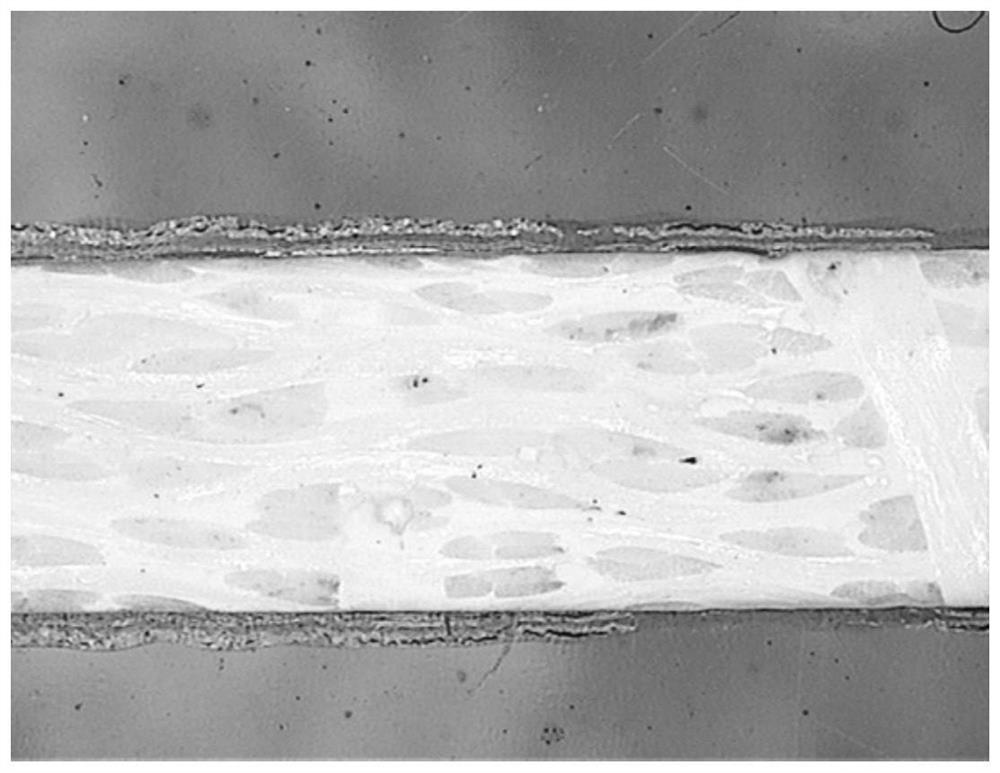

Poly(methylsilane-carbosilane) and preparation method thereof

The invention discloses poly(methylsilane-carbosilane) and a preparation method thereof. The structural formula of the poly(methylsilane-carbosilane) copolymer is shown in formula I which is shown in the specification, wherein x=0-0.2, y=0.03-0.2, z=0-0.25, n=10-30, R1 represents Me, Ph or C2-C8 aromatic hydrocarbon or alkane, R2 represents Me or H, and Y represents a group containing C-C unsaturated bond. The preparation method of the poly(methylsilane-carbosilane) comprises the following steps of: in an organic solvent, carrying out a Wurtz type condensation polymerization reaction on a chlorosilane monomer mixture and insufficient alkali metal to synthesize Si-Cl bond-containing intermediate polymer; and then obtaining liquid methylsilane-carbosilane copolymer containing a C-C unsaturated bond through a grignard coupling reaction. The poly(methylsilane-carbosilane) disclosed by the invention can be served as a silicon carbide ceramic precursor, has the advantages of high ceramic yield, good storage stability and adjustability in structure composition, and can be applied to precursors of ceramic coatings and block body materials, and impregnants of composite materials.

Owner:INST OF CHEM CHINESE ACAD OF SCI

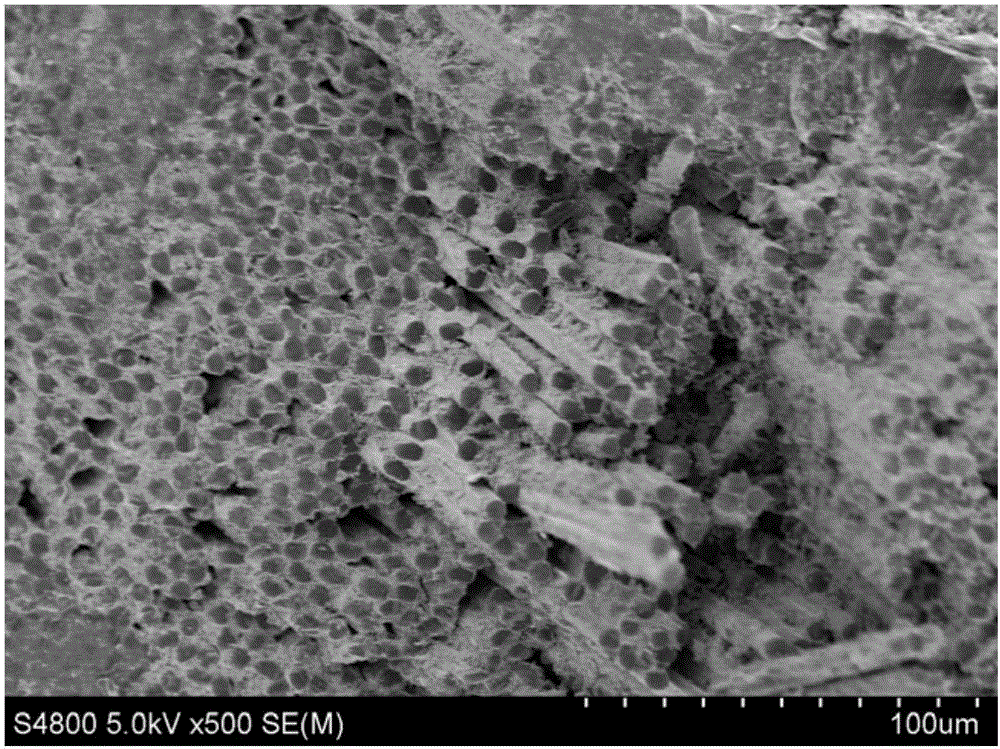

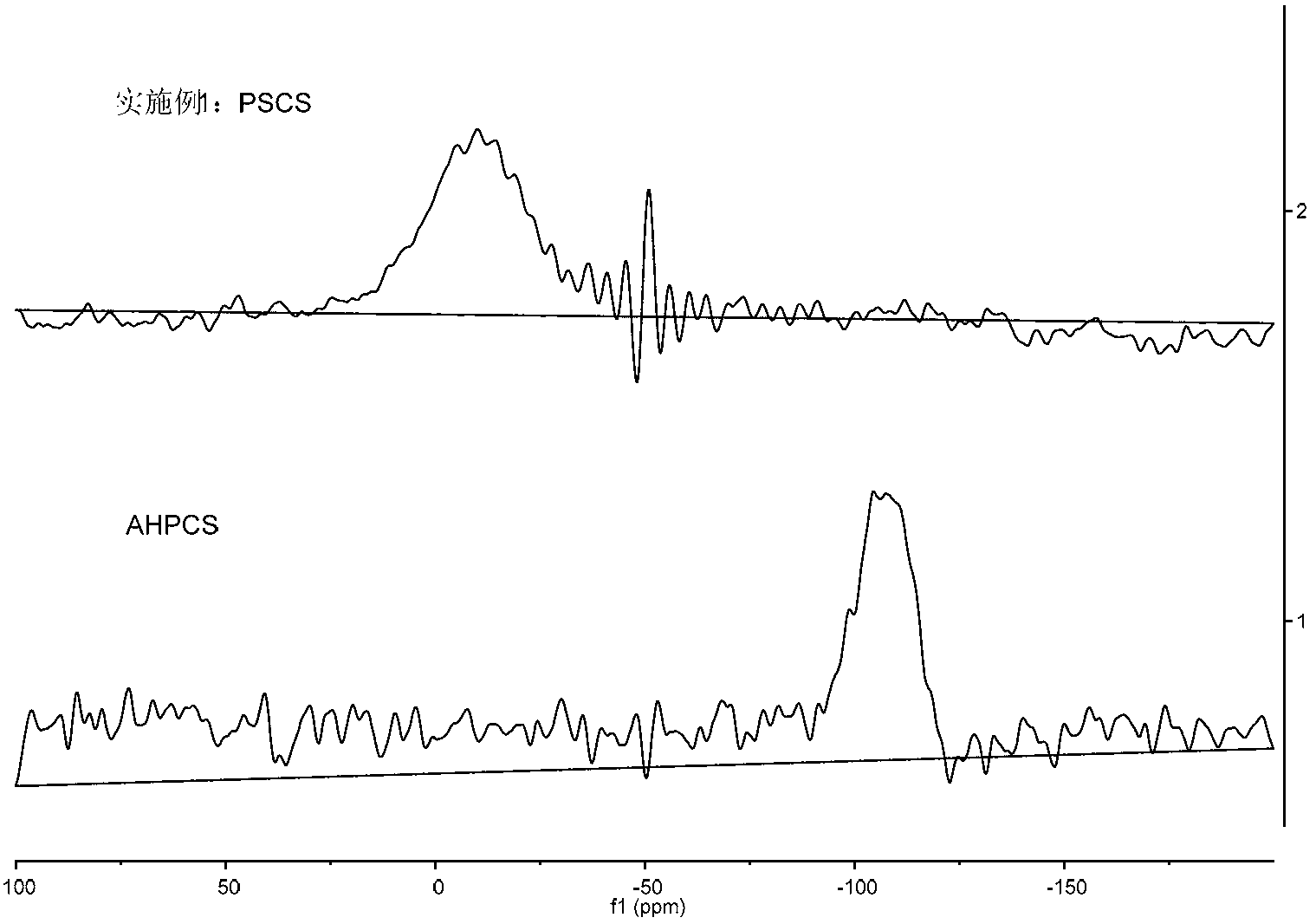

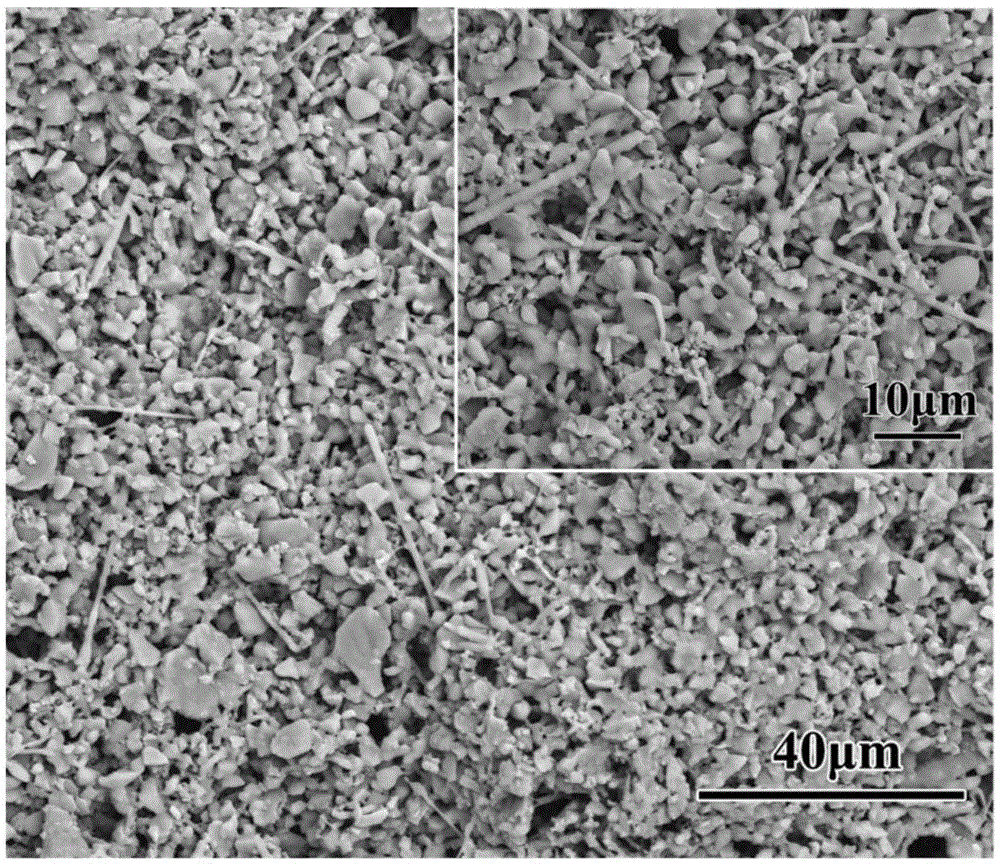

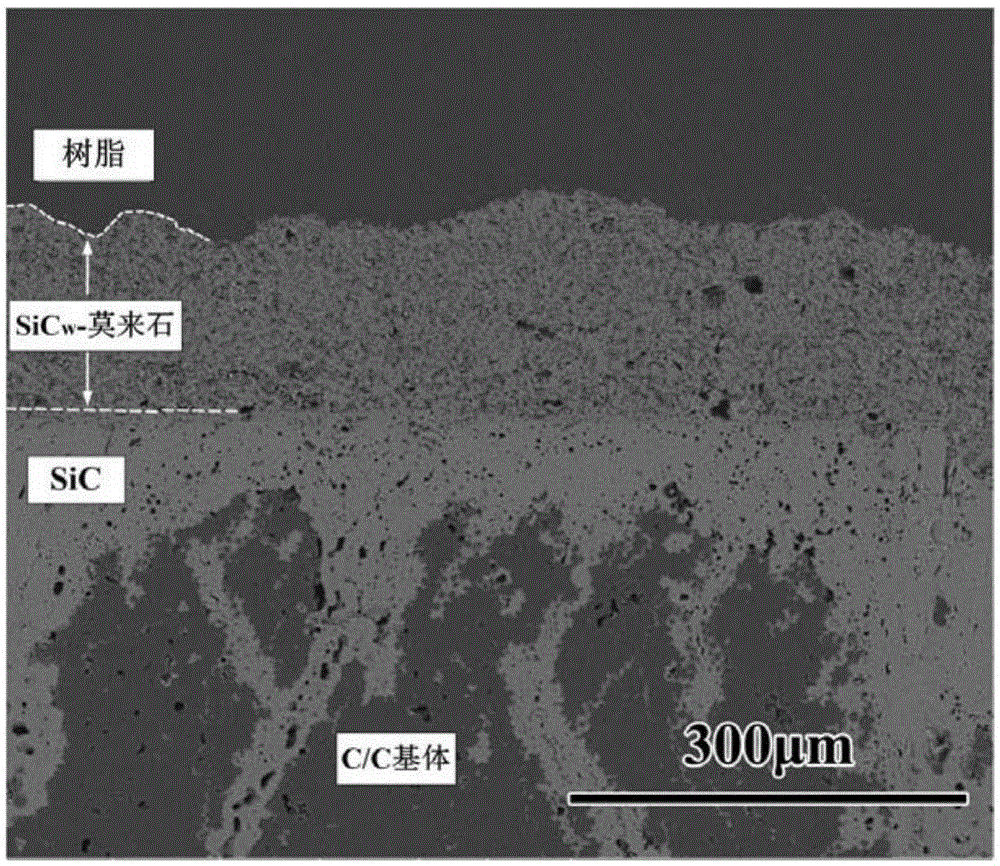

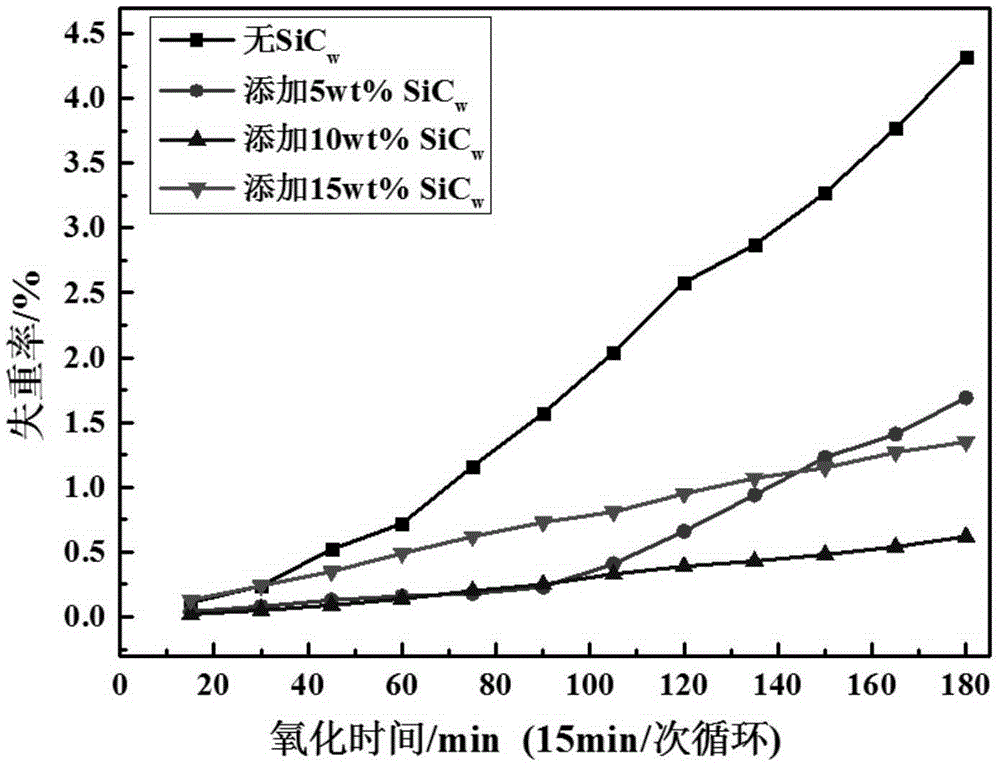

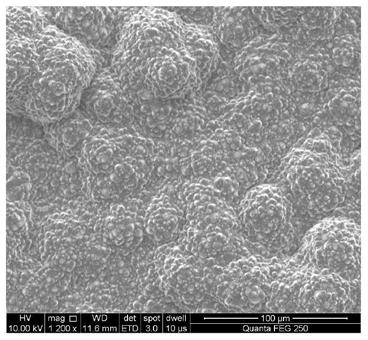

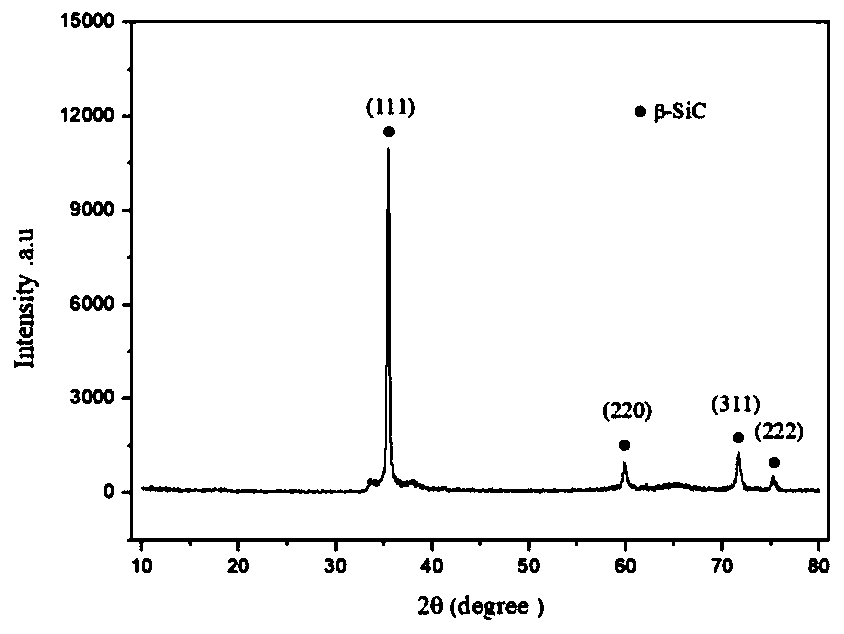

Preparation method of SiC whisker reinforced mullite anti-oxidation coating

The invention relates to a preparation method of a SiC whisker reinforced mullite anti-oxidation coating and belongs to the technical field of preparation of high-temperature anti-oxidation / anti-corrosion coatings. A preparation route comprises steps as follows: firstly, high-performance mullite precursor sol is synthesized with a sol-gel method, then SiC whiskers are dispersed uniformly into the mullite precursor sol in a manner of ultrasound and later ball-milling, a SiC whisker reinforced mullite coating precursor suspension is obtained, then the coating precursor suspension is applied to the surface of a substrate with a high-precision dip-coating process, and finally, the SiC whisker reinforced mullite coating can be obtained after coating sintering. The preparation method breaks through a preparation technology of a whisker reinforced high-temperature anti-oxidation composite coating on the basis of the sol-gel process, has the advantages of simple process, low cost, high efficiency, high substrate shape adaptability and the like and has broad development prospect.

Owner:CENT SOUTH UNIV

Method for preparing spinnable polysiloxane ceramic precursor for SiC fibers

The invention discloses a method for preparing a spinnable polysiloxane ceramic precursor for SiC fibers, which comprises the following steps of: (1) adding chlorosilane, chlorinated siloxane and dimethylbenzene into a neck flask according to a certain mass ratio; (2) vacuumizing the neck flask, introducing N2 for protection, slowly raising the temperature to 70-90DEG C, keeping constant temperature, simultaneously performing mechanical stirring, dripping aqueous solution of an alkaline substance, and continuously stirring for reaction for 6 to 24 hours at constant temperature under the protection of the N2; (3) standing reaction liquid to separate out water and impurities of the lower layer, and taking polysiloxane dimethylbenzene solution of the upper layer out; and (4) distilling the polysiloxane dimethylbenzene solution of the upper layer under reduced pressure to remove a dimethylbenzene solvent. The compound raw materials are mature industrial materials, and are wide in sources; the reaction process is easy to control, the preparation yield is high, and the product purity is high; and the prepared polysiloxane ceramic precursor is low in cost, higher in ceramic yield and good spinnability.

Owner:NAT UNIV OF DEFENSE TECH

Organometallic polymer composite ceramic precursor and preparation method and application thereof

ActiveCN105669982AImprove high temperature resistanceImprove oxidation resistanceComposite ceramicMaterials science

The invention provides an organometallic polymer composite ceramic precursor and a preparation method and application thereof.The organometallic polymer composite ceramic precursor can be used to prepare Zr-Si-C-N ceramics, the yield of the ceramics is 40-60%, no evident weight loss is discovered when the ceramics are processed at 2000 DEG C for 2 hours, and the ceramics are good in high temperature resistance.The ceramics are promising in application prospect in fields such as aviation and supersonic aircrafts.

Owner:NAT UNIV OF DEFENSE TECH

Method for synthesizing polysilane containing two bonds

The invention relates to a manufacture method for polysilane with double bond. It adopts electrochemical synthesis method, uses magnesium block as anode and cathode. Methyl trichlorosilane and allyl chloride are taking polymerization in tetrahydrofuran solution to compound polysilane with double bond. It has the advantages of mild reacting condition, easy to control, easy to operate, safe, high yield, short producing cycle. And it is suitable to be used in industrial in large.

Owner:SHANGHAI UNIV

Preparation method and application of HfC ceramic precursor

The invention provides a preparation method and application of an HfC ceramic precursor.The preparation method includes the steps of firstly, adding solvent into a reactor, adding organic hafnium compound and cyanamide organic matter, and vacuumizing and drying the reactor; secondly, rising the temperature, performing continuous stirring reaction under the protection of nitrogen atmosphere, and evaporating the reaction products to remove the solvent so as to obtain white solid.The HfC ceramic precursor prepared by the method is high in ceramic yield, good in high-temperature resistance and suitable for being used to prepare high-performance hafnium carbide ceramics and composite materials thereof, and the ultrahigh-temperature HfC component content of the ceramic materials prepared by the HfC ceramic precursor is higher than 79%.

Owner:NAT UNIV OF DEFENSE TECH

Ablation-resistant organosilicon composite, and preparation method and application thereof

ActiveCN104725879AIncrease elasticityImproves ablation resistanceInsulated cablesInsulated conductorsHydrogenVulcanization

The invention discloses an ablation-resistant organosilicon composite, and a preparation method and application thereof. The composite is a co-cured system of vinyl polymethylphenylsiloxane and silicic hydrovinyl polysilazane, and a silicic hydrogen addition or peroxide vulcanization system is adopted for vulcanization to obtain vulcanized rubber. The invention also discloses a preparation method and application of the composite. The ablation-resistant organosilicon composite has the characteristics of high high-temperature ceramic yield and favorable ablation resistance, and can be used for preparing heat insulating layers and fire-resisting cables of engines and the like.

Owner:SHANDONG UNIV

In-situ ceramization type anti-oxidant resin, resin matrix and ceramic material, as well as preparation method of resin

The invention relates to in-situ ceramization type anti-oxidant resin, resin matrix and ceramic material, as well as a preparation method of the resin. Carborane and silazane serve as raw materials, a solvent is not used in the preparation process, Diels-Alder addition reaction and cross-linking solidification are conducted through vinyl under the action of an initiator, the raw materials and the vinyl perform hydrosilylation reaction when the raw materials contain a Si-H group, and the two kinds of reaction form a compact three-dimensional space network structure, so that the resin has excellent heat resistance; micromolecular byproducts in the condensation polymerization process are avoided by utilizing vinyl addition and hydrosilylation reaction; in addition, the resin system has high oxidation resistance, can be subjected to in-situ ceramization under the action of high temperature, is high in ceramic yield, and can serve as a resin matrix or a ceramic precursor of a heat-resistant composite material to be applied to the fields of national defense, aviation, spaceflight and the like.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Preparation method of polymer precursor ceramic aerogel

The invention provides a preparation method of polymer precursor ceramic aerogel, which comprises the following steps of: under the protection of inert atmosphere, uniformly dispersing polycarbosilaneas a polymer precursor in an organic solvent to prepare a precursor solution; placing the precursor solution in an inert atmosphere, selectively adding a platinum catalyst, and carrying out a hydrosilylation reaction to obtain precursor gel; drying the precursor gel to obtain precursor aerogel; and placing the precursor aerogel in an inert atmosphere for high-temperature cracking to obtain the ceramic aerogel. According to the method, the used raw materials are simple in composition, the precursor synthesis process is simple, additional vinyl substances are avoided, and the obtained silicon carbide ceramic aerogel is low in oxygen content, high in purity, adjustable in C / Si ratio and high in ceramic yield.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

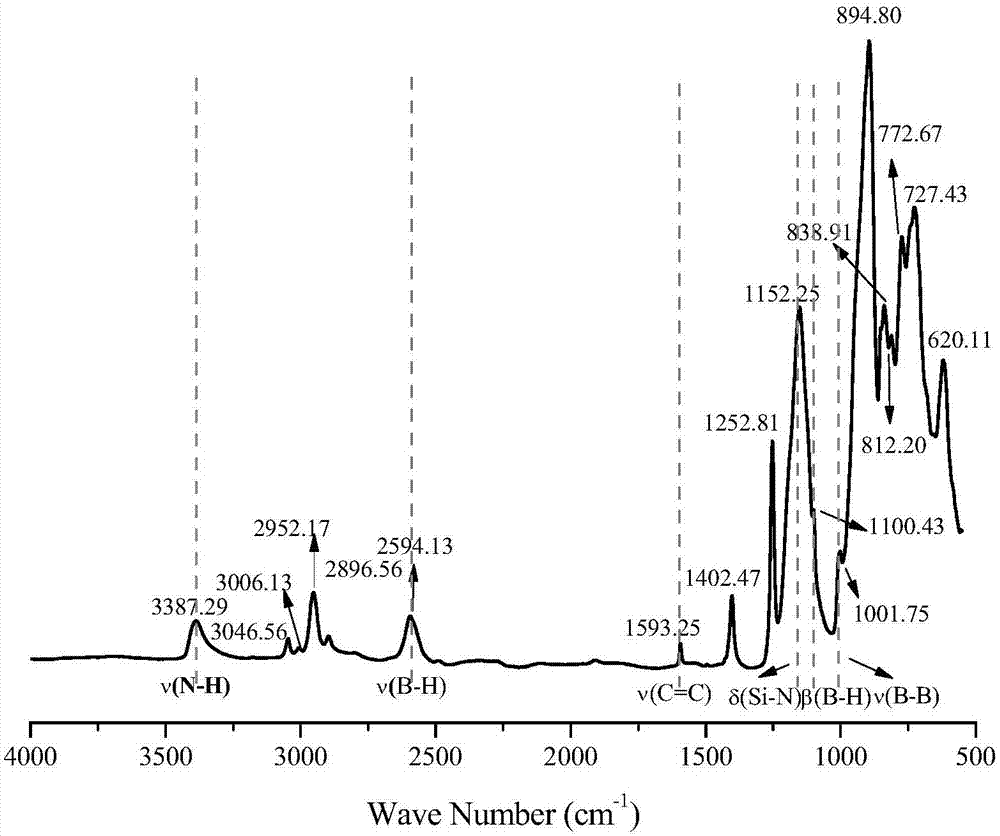

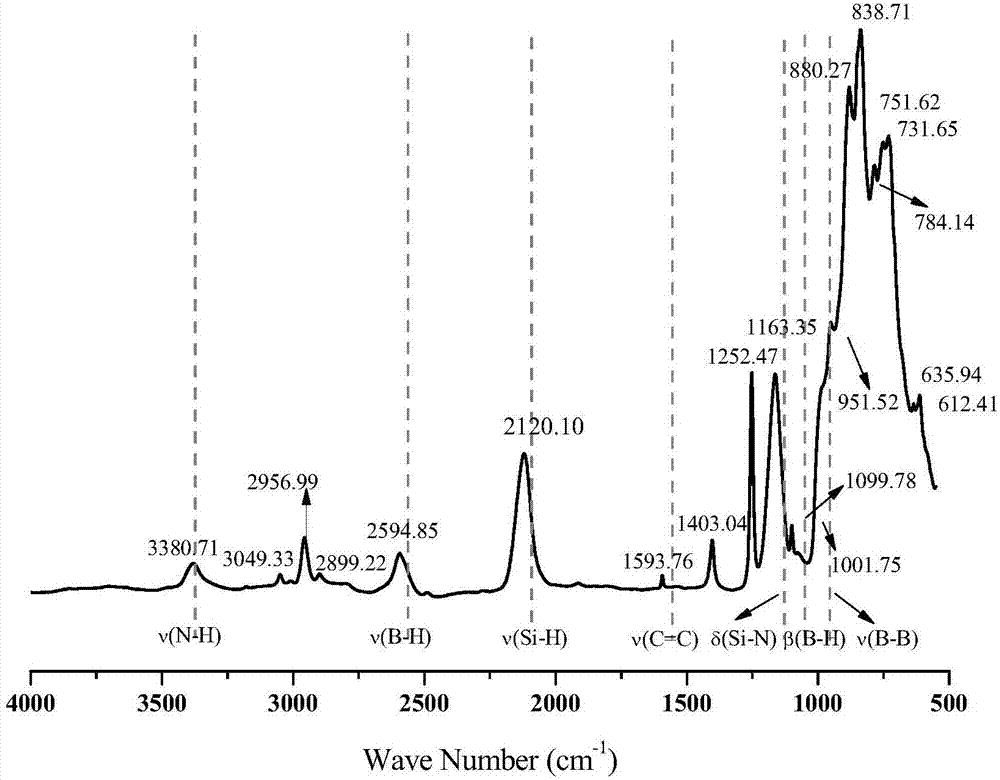

Silicon-boron-azane ceramic precursor polymer containing borazine and preparation method and application of polymer

The invention discloses a silicon-boron-azane ceramic precursor polymer containing borazine and a preparation method and application of the polymer. The silicon-boron-azane ceramic precursor polymer containing borazine has the structural characteristics that a molecular chain of the polymer has structures of borazine and silazane. The preparation method of the ceramic precursor polymer comprises the step that with ammonium chloride, organic primary amine, boron trihalide, dichlorosilane and ammonia gas as main raw materials, the silicon-boron-azane ceramic precursor polymer is synthesized through a three-step reaction under the protection of inert gas, wherein firstly, ammonium chloride or organic primary amine reacts with boron trihalide to synthesize b-trichloroborazine, secondly, b-trichloroborazine and a hydrocarbyl magnesium bromide Grignard reagent react with each other to obtain hydrocarbyl-substituted chloroborazine, and then hydrocarbyl-substituted chloroborazine and dichlorosilane are subjected to co-ammonolysis to synthesize the silicon-boron-azane ceramic precursor polymer. The silicon-boron-azane ceramic precursor polymer containing borazine is colorless or light yellow viscous liquid and is soluble in a common solvent and excellent in process performance. A precursor polymer solidified product can be pyrolyzed and transformed into ceramic, the yield of the ceramicis high, and the precursor polymer solidified product can be used for preparing silicon-boron-nitrogen ceramic-based composite materials.

Owner:EAST CHINA UNIV OF SCI & TECH

Three-dimensional aluminum oxide fiber woven part reinforced aluminum oxide composite material based on aqueous slurry impregnation process and preparation method of three-dimensional aluminum oxide fiber woven part reinforced aluminum oxide composite material

PendingCN112851386AOvercoming the problem of easy failure without fiber reinforcementGuaranteed deflectionOxide compositeAlumina composite

The invention relates to the technical field of continuous fiber reinforced ceramic matrix composite materials, and particularly discloses a three-dimensional aluminum oxide fiber woven part reinforced aluminum oxide composite material based on an aqueous slurry impregnation process, and the porosity of the composite material is 20-30%. A reinforced phase of the composite material is a continuous aluminum oxide fiber woven part, the woven part is in a fiber cloth sewing, two-dimensional and half or three-dimensional weaving mode, the mass content of alumina in alumina fibers is not lower than 70%, and the volume fraction of the fibers in the composite material is 40-45%. The aluminum oxide matrix of the composite material is prepared through the processes of multiple times of dipping, drying and sintering of water-based aluminum oxide powder slurry with high solid content and low viscosity, the solid content of the water-based aluminum oxide powder slurry is 30-40 vol%, the viscosity of the slurry is 5-30 mPas, the pH is 3-4.5, and the Zeta potential is 60-70 mV. The invention also provides a preparation method of the composite material. The reinforced fibers are arranged between the layers of the composite material, so that the integrity is good. The preparation method disclosed by the invention is simple in process, low in cost, good in environmental protection property and easy to realize large-scale industrialization.

Owner:NAT UNIV OF DEFENSE TECH

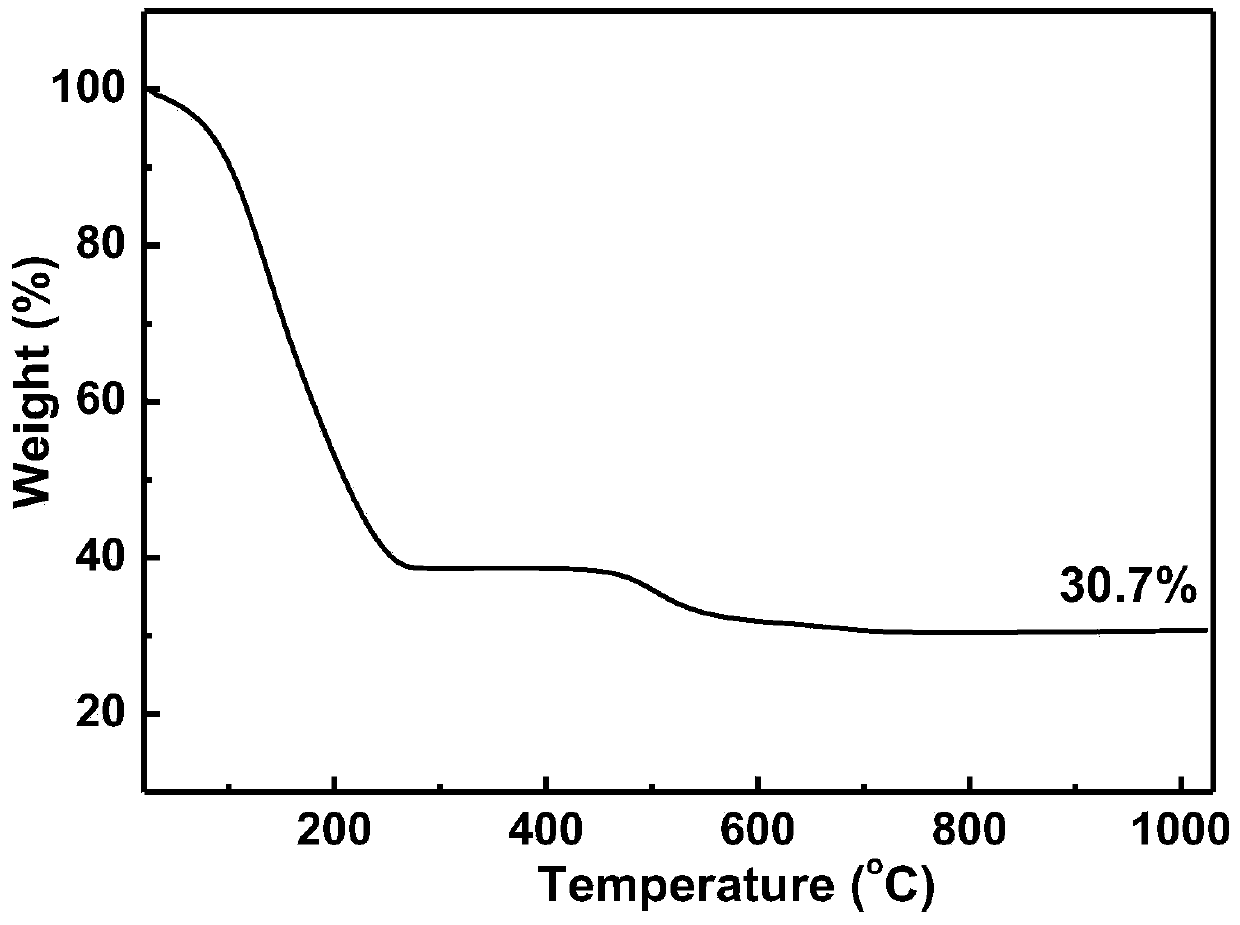

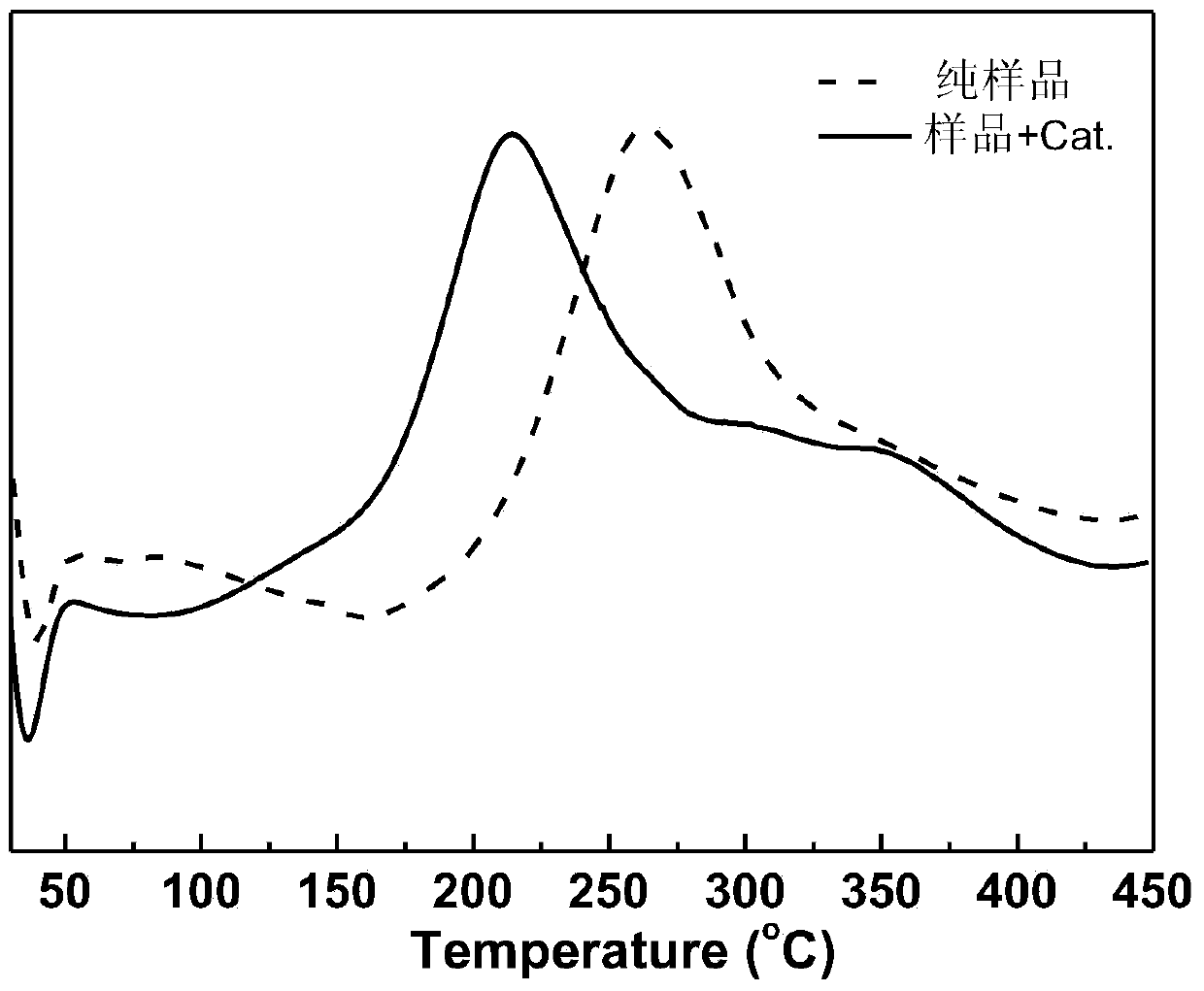

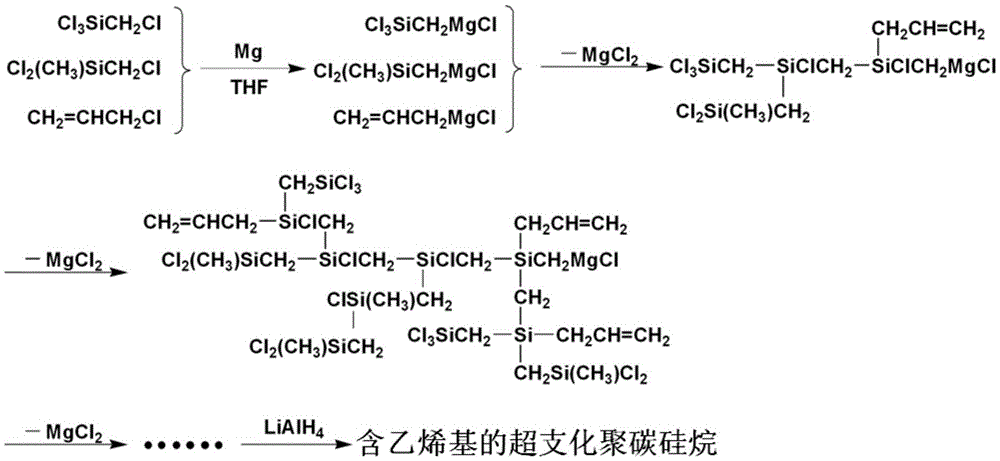

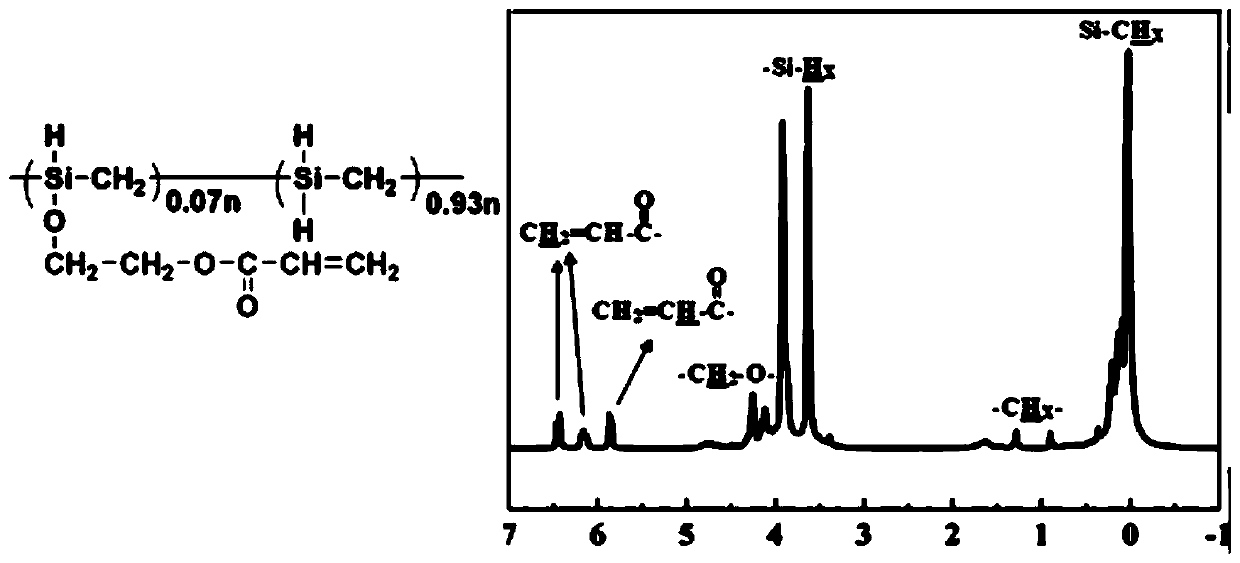

Preparation method for liquid hyperbranched polycarbosilane containing acryloyloxy group

The invention provides a preparation method for liquid hyperbranched polycarbosilane containing an acryloyloxy group. The liquid hyperbranched polycarbosilane containing the acryloyloxy group is prepared from liquid hyperbranched polycarbosilane containing a Si-H bond and an acryloyloxy compound containing a hydroxyl or mercapto group through a reaction without a catalyst or under the catalysis of halide of metallic Zn, Al, B, Sn, Cr, Co or Pd, oxide of alkali metal, hydroxide of alkali metal or organic base. The preparation method is simple and the content of the acryloyloxy group in the product can be controlled, so the ceramic yield of the product is improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Molybdenum disilicide/silicon carbide three-dimensional polymer precursor ceramic and preparation method thereof

The invention discloses molybdenum disilicide / silicon carbide three-dimensional polymer precursor ceramic and a preparation method thereof, belonging to preparation of ceramic materials. The preparation method comprises the following steps: putting precursor PVG powder into a graphite paper boat and carrying out high-temperature cracking under the protection of an inert atmosphere; mixing MoSi2, cracked SiC(rGO)p ceramic particles and the precursor PVG powder to form a MoSi2 / SiC(rGO)p / PVG mixture, carrying out ball milling and uniform mixing in an alcohol medium, and then drying the MoSi2 / SiC(rGO)p / PVG mixture in an oven; and loading the mixture into a mold for compression molding, conducing demolding to obtain a biscuit, putting the biscuit into an inert atmosphere tube furnace for high-temperature sintering, and conducting cooling along with the furnace to obtain black molybdenum disilicide / silicon carbide three-dimensional polymer precursor ceramic, namely 3D-SiC(rGO, MoSi2x) nanometer composite block ceramic for short, wherein x is the mass fraction of silicon carbide in the whole biscuit. The obtained ceramic is high in heat conductivity and electric conductivity and good in formability and component uniformity; and the preparation method is simple and economical in process.

Owner:中科德胜(常州)电子科技有限公司

Method for preparing polycarbosilane by catalytic rearranging

Owner:INST OF CHEM CHINESE ACAD OF SCI

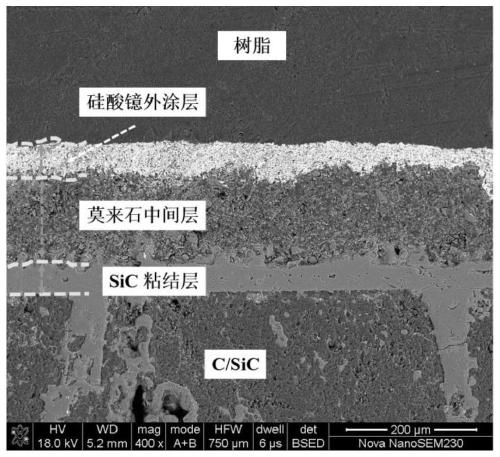

Environmental barrier coating as well as preparation method and application thereof

The invention provides an environmental barrier coating. The environmental barrier coating is composed of a SiC bonding layer, a mullite middle layer and an ytterbium silicate outer coating, which coat a C / SiC composite material and are sequentially arranged from inside to outside. The C / SiC composite material coated by a SiC coating is prepared by a secondary chemical vapor deposition (CVD) method; the mullite middle layer is prepared by combining a sol-gel method with an air spraying technology, and the ytterbium silicate outer coating is prepared by combining a solid phase sintering technology with an air spraying technology. Through a smart EBC coating system and a preparation process, the ytterbium silicate outer coating is prepared by combining a solid phase sintering technology withan air spraying technology for the first time, the mullite middle layer and the ytterbium silicate outer coating are tightly combined, and the coating is compact and free of cracks. The traditional sol-gel process is improved to a great extent, the defects of cracking, peeling and poor binding force in the sintering process of a coating prepared through a traditional sol-gel method are maximallyovercome, and the use requirements of large components and special-shaped parts can be met.

Owner:CENT SOUTH UNIV

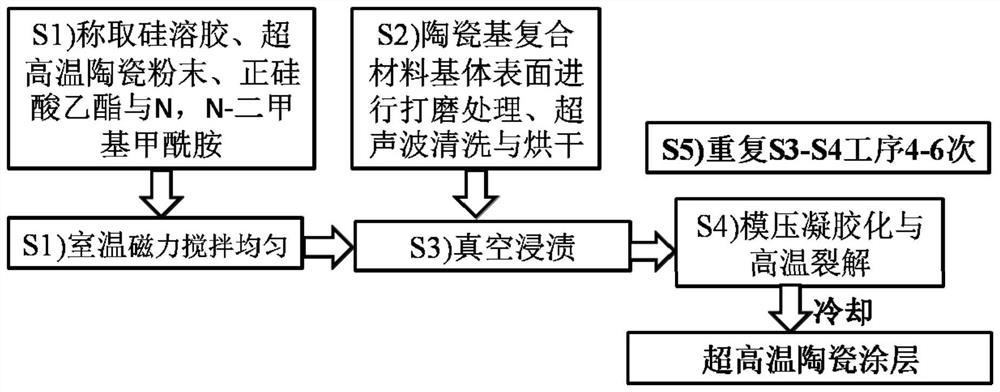

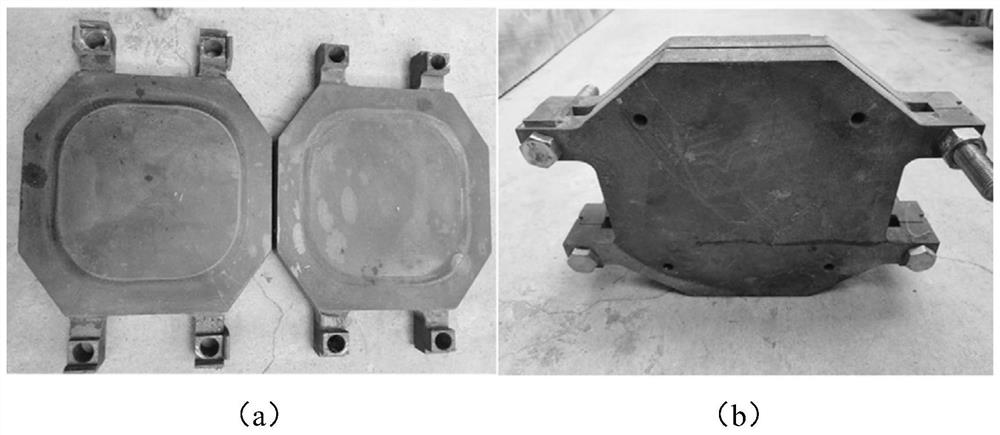

Preparation method of high-temperature-resistant coating for ceramic-based composite material

The invention belongs to the technical field of coating materials, and provides a preparation method of a high-temperature-resistant coating for a ceramic-based composite material. According to the invention, tetraethoxysilane and N,N-dimethylformamide are respectively used as an anti-gelling agent and a dispersing agent, and the coating is obtained on the surface of the ceramic-based composite material by adopting a process consisting of dipping, mould pressing low-temperature gelatinization and high-temperature cracking. The preparation method is short in preparation period and low in cost;the temperature of mold pressing low-temperature gelatinization and high-temperature cracking is lower than 1000 DEG C, so influence on the ceramic-based composite material is small; the strength retention rate of the material obtained after the obtained coating is oxidized at 1500 DEG C for 1 h is larger than or equal to 60%, so good high-temperature resistance is achieved; the coating is good inconsistency, has high binding force (larger than or equal to 10 MPa) with a matrix, presents good compactness and integrity and can be applied to the field of aerospace.

Owner:HUNAN UNIV OF HUMANITIES SCI & TECH

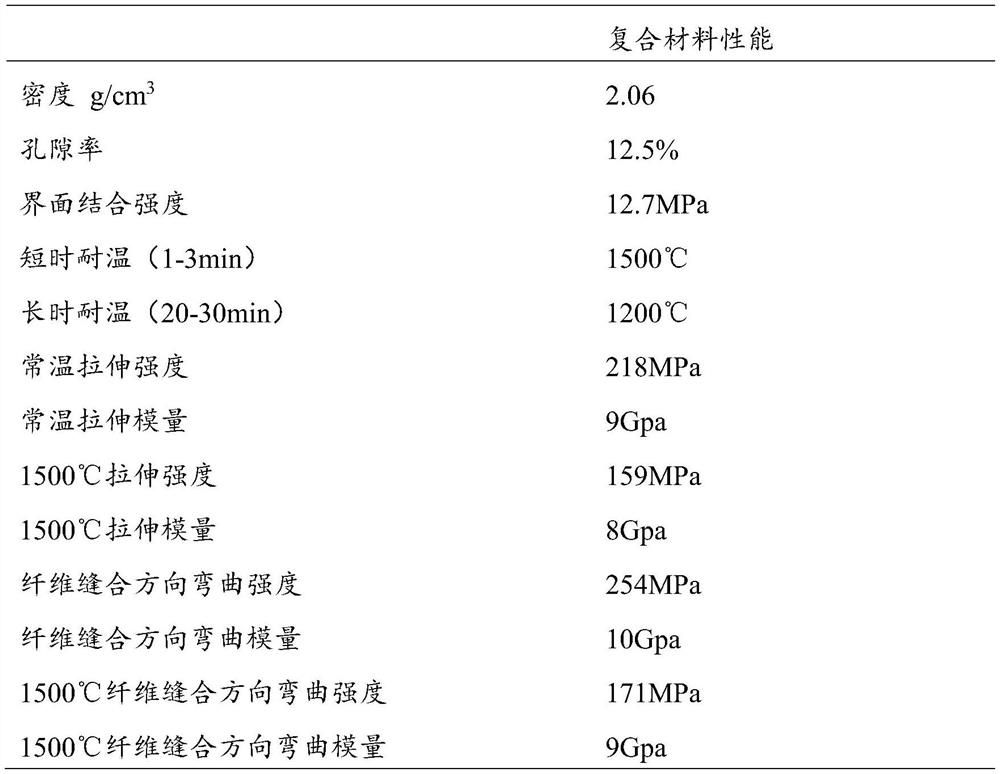

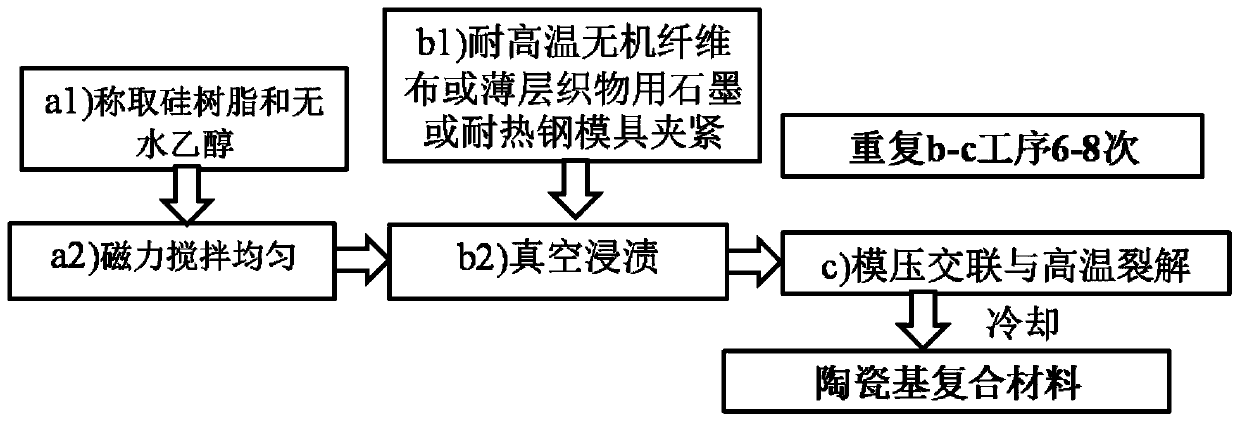

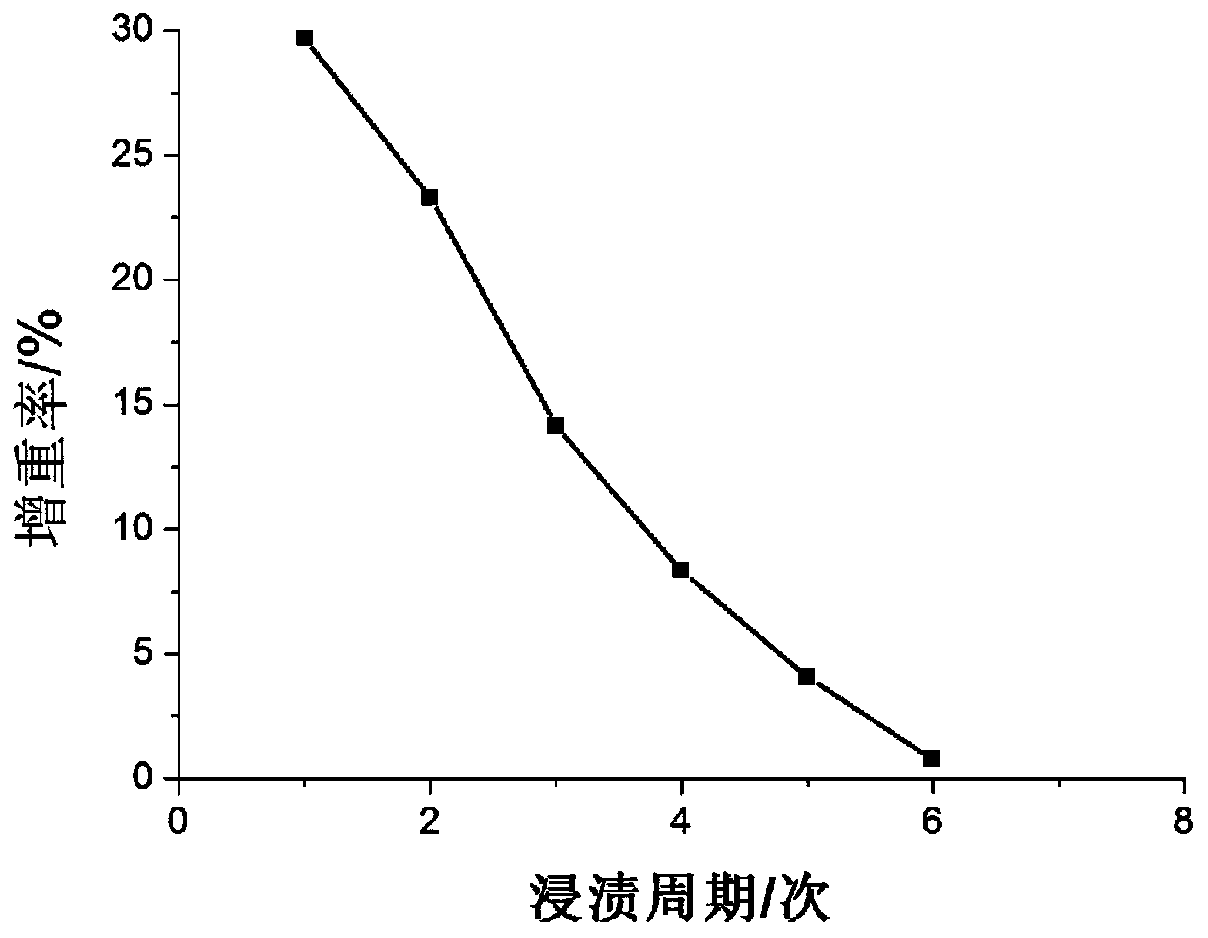

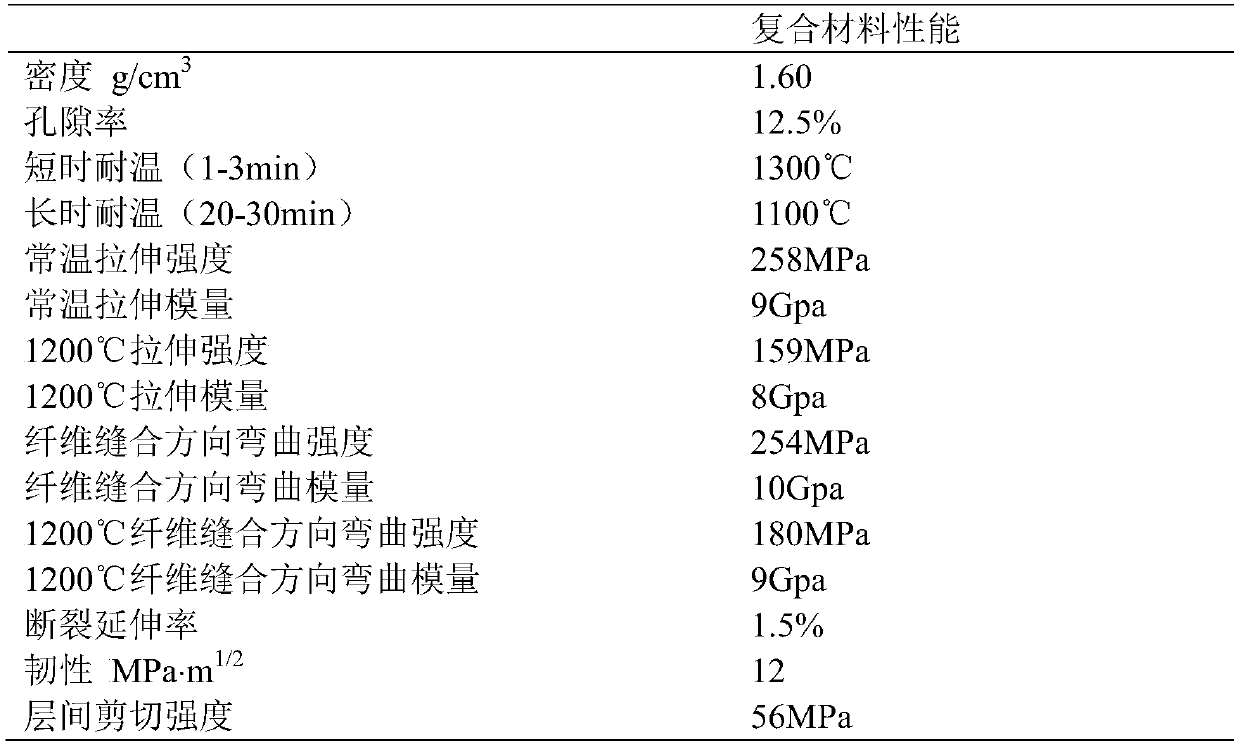

Ceramic-based composite material and preparation method thereof

InactiveCN110950662AHigh ceramic yieldQuality remains stableInterlaminar shearCeramic matrix composite

The invention discloses a ceramic-based composite material and a preparation method thereof. The density of the composite material is 1.60-1.80g / cm<3>, the porosity is 11.5-14.5%, the interlaminar shear strength is 55-56MPa, the tensile strength at 1500 DEG C reaches 100MPa, and the bending strength in the fiber sewing direction at 1500 DEG C reaches 130MPa. According to the preparation method, the ceramic-based composite material is prepared by adopting a precursor impregnation-mold pressing low-temperature crosslinking-high-temperature cracking method. The composite material provided by theinvention is low in density, high in interlaminar strength and high in tensile strength at 1500 DEG C, and can be applied to the field of aerospace. The preparation method provided by the invention isshort in preparation period and low in cost, the temperature of mold pressing low-temperature crosslinking-high-temperature cracking is lower than 1000 DEG C, and the influence on a fiber system is small.

Owner:NAT UNIV OF DEFENSE TECH

A kind of preparation method of high temperature resistant ceramic precursor binder

ActiveCN104194717BIncrease temperatureImprove high temperature resistanceNon-macromolecular adhesive additivesSilazaneOrganic solvent

The invention discloses a preparation method for a high-temperature-resistant ceramic precursor adhesive. The preparation method comprises the following steps of (1) adding metal sodium and methylbenzene into a three-opening flask with a condensation backflow device and a mechanical stirring device, heating to 80-120 DEG C under the protection of inert atmosphere, dropping methyl dichloresilane, preserving the heat of 80-140 DEG C for 2-4 hours after dropping is finished, and filtering and distilling to remove an organic solvent to obtain liquid polymethylsilane; (2) mixing liquid polymethylsilane and tetramethyldivinyldisilazane according to a mass ratio of 1:(1 to 10), preserving the heat of 100-250 DEG C for 1-10 hours under the protection of inert atmosphere, and obtaining a liquid polymethylsilane precursor; (3) respectively adding a micron-level inorganic filler and a nano-level inorganic filler into the liquid polymethylsilane precursor, and uniformly mixing to obtain the high-temperature-resistant ceramic precursor adhesive. The ceramic precursor adhesive is high in bonding strength and excellent in heat resistance, and has a wide application prospect in adhering of ceramic materials and carbon materials.

Owner:NAT UNIV OF DEFENSE TECH

Method for synthesizing soluble ZrC ceramic precursor polymer

The invention provides a method for synthesizing a soluble ZrC ceramic precursor polymer. According to the method, Cp2ZrCl2 or CpZrCl3 is taken as the zirconium source, a double-bond Grignard reagent such as the allyl Grignard reagent and 3-butene Grignard reagent is taken as the carbon source, and an activated monomer obtained through reaction of the zirconium source and the carbon source is polymerized through a proper initiator to obtain a soluble ZrC ceramic precursor. A ZrC superhigh temperature ceramic material can be obtained through high-temperature pyrolysis of the prepared ZrC ceramic precursor.

Owner:NAT UNIV OF DEFENSE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com