Organometallic polymer composite ceramic precursor and preparation method and application thereof

A multiphase ceramic and organometallic technology, which is applied in the field of organometallic polymer multiphase ceramic precursors and their preparation, can solve the problems of difficult and impossible to achieve effective infiltration, doping and bonding of ZrC ceramics, and achieve good resistance. high temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] Another aspect of the present invention also provides a kind of preparation method of above-mentioned precursor, comprises the following steps:

[0042] A4 monomers and B-type monomers undergo copolymerization reactions to prepare precursors;

[0043] The A4 monomer is zirconium tetraallylamide, titanium tetraallylamide or hafnium tetraallylamide; the type B monomer is polycarbosilane or polymethylsilane.

[0044]The organometallic polymer ceramic precursor of the present invention is prepared by copolymerizing organometallic zirconium A4 monomers containing double bonds and type B monomers. The A4 monomer here can be various types of organometallic zirconium monomers containing double bonds. Type B monomers can be various types of boron-containing monomers. The precursor can be prepared by reacting the two according to conventional copolymerization reaction conditions.

[0045] Preferably, the A4 monomer and the B-type monomer are mixed in a molar ratio of 4:1-16 fo...

Embodiment 1

[0068] Under nitrogen protection, add 1.1g of tetraallylamino zirconium (A4 monomer) and 50ml of toluene to the three-necked flask, and keep the temperature at -20°C; Body and PMS mass ratio is 1:6), reacted for 48 hours, the solution became viscous; add 100ml of n-hexane, precipitate and filter, dry at 80°C, remove solvent, and obtain Zr-Si-C-N organometallic polymer composite ceramic precursor Yellow block. Yield 72%.

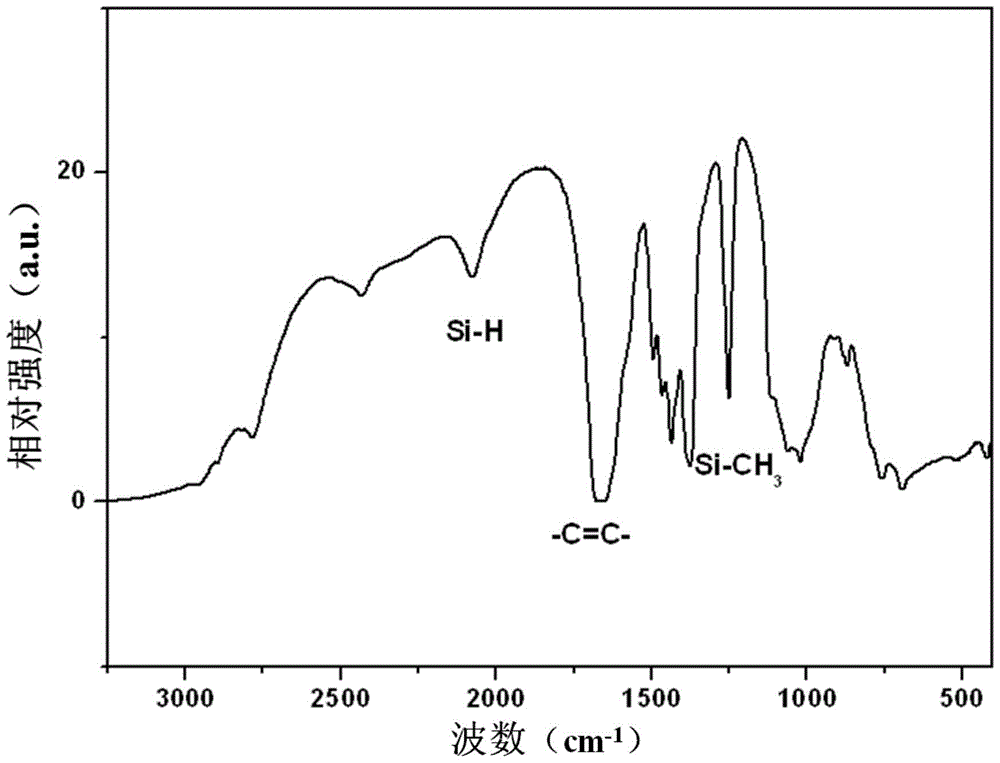

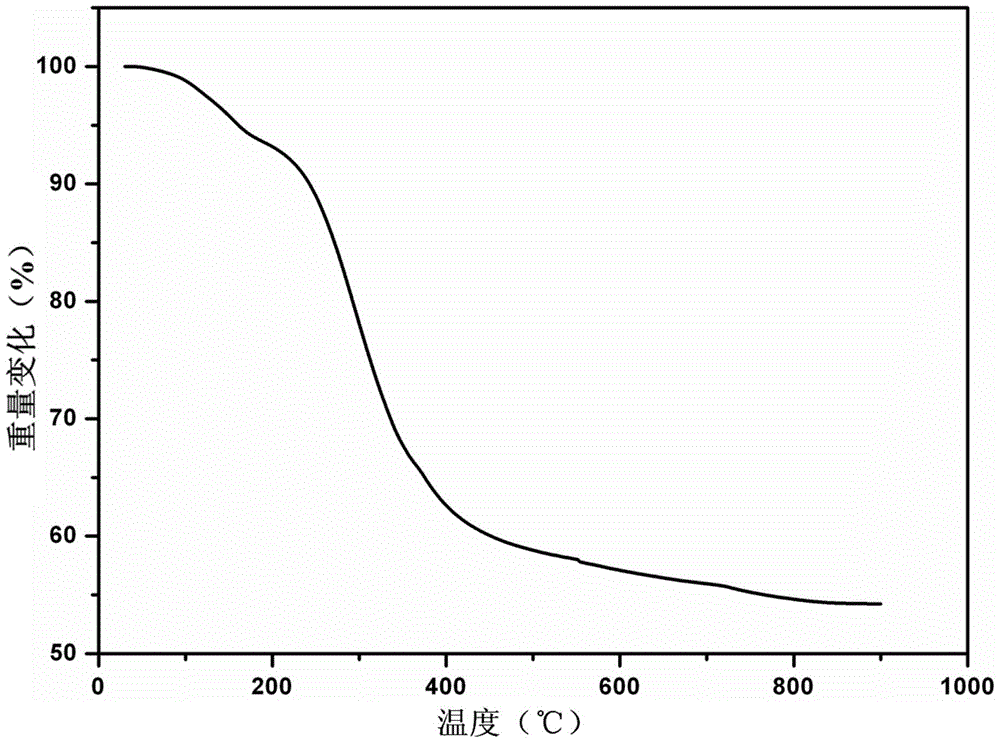

[0069] The resulting ceramic precursor polymer is soluble in DMF, NMP and DMSO. The structure of the precursor was characterized and tested by IR and TGA. In the IR spectrum, 1257cm-1 represents Si–CH 3 The vibration absorption peak of 1120cm -1 Represents the shock absorption peak of N–C (see figure 1 ). The vibrational peaks shown in the figure can prove that the structure of the precursor polymer is consistent with the molecular design. The TGA test result shows that this precursor polymer is in argon atmosphere, and the ceramic production rate of 14...

Embodiment 2

[0072] The difference from Example 1 is that the raw material A4 monomer is hafnium tetraallylamide, and the molar ratio to B monomer is 3:4, and the rest is the same as in Example 1. The obtained product is a light yellow block with a yield of 68%.

[0073] The resulting ceramic precursor polymer is soluble in DMF, NMP and DMSO. Put the Hf-Si-C-N ceramic precursor polymer in an inert atmosphere, crack it at a high temperature of 1400°C for 2 hours, and obtain Hf-Si-C-N ceramics with a yield of 62%. The ultra-high temperature resistant component HfC in the prepared ceramics The / SiC content reached 78%; no obvious weight loss was seen after 2 hours of treatment at 2000 °C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com