Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

286 results about "Methylsilane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

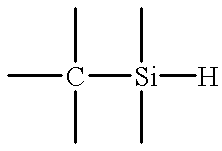

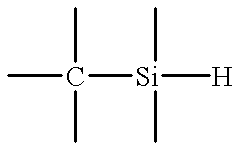

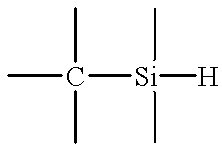

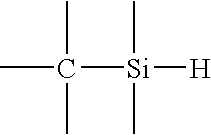

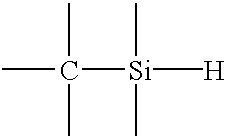

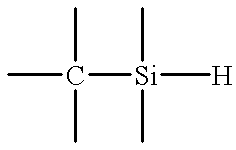

Methylsilane (CH₃-SiH₃) is a compound of silicon, carbon, and hydrogen. The reaction of methylsilane and Si⁺ produces several active organosilicon species.

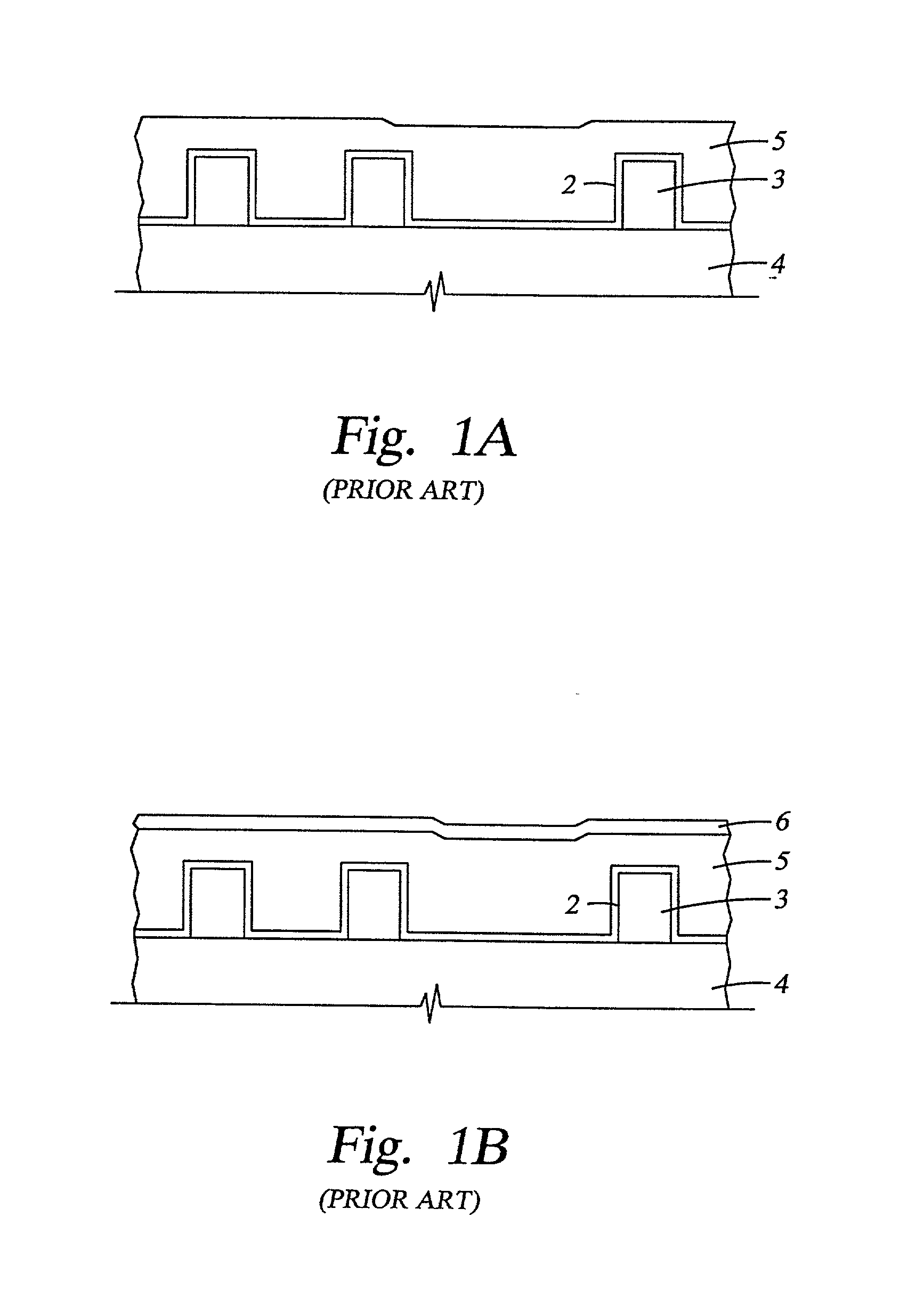

Method of depositing a low k dielectric with organo silane

InactiveUS6054379ASemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilane compoundsSilanes

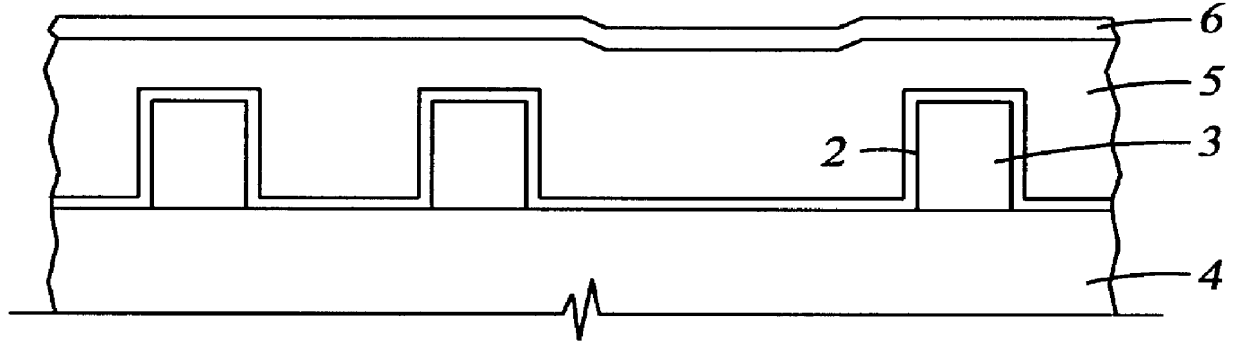

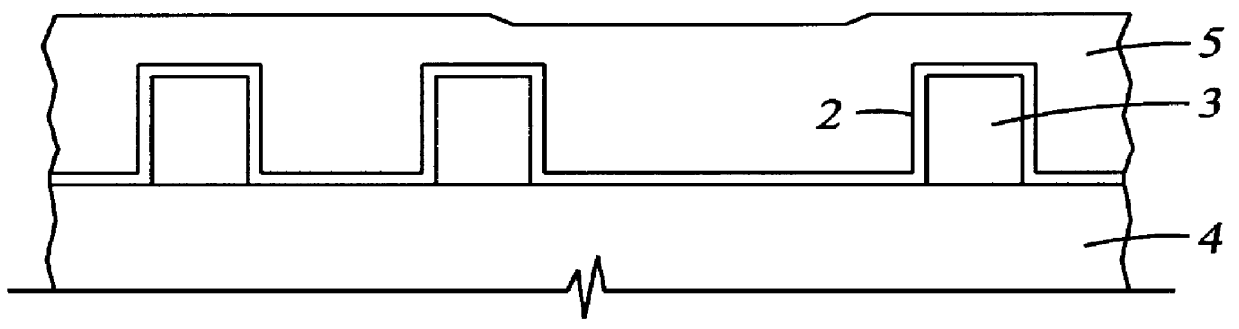

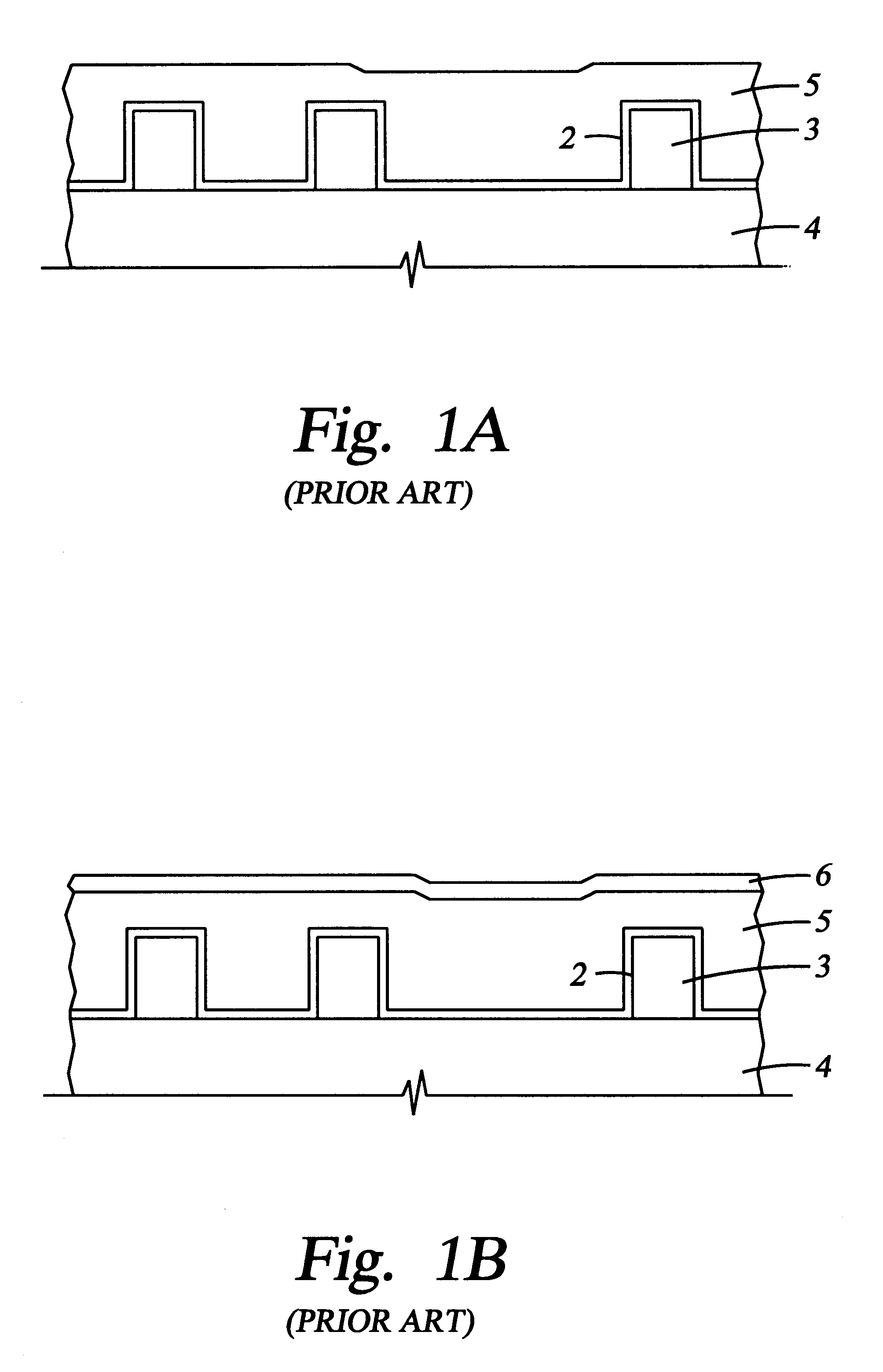

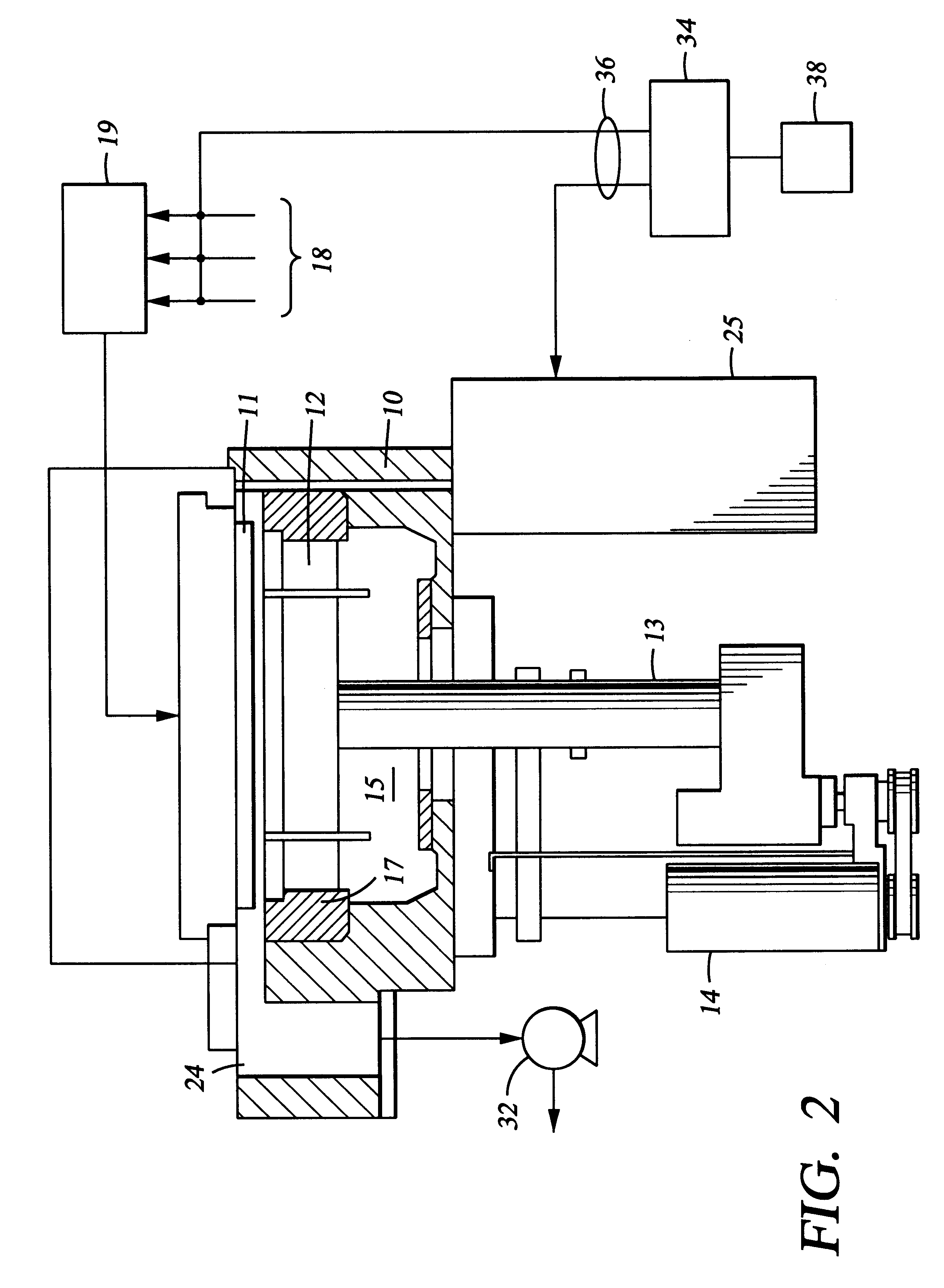

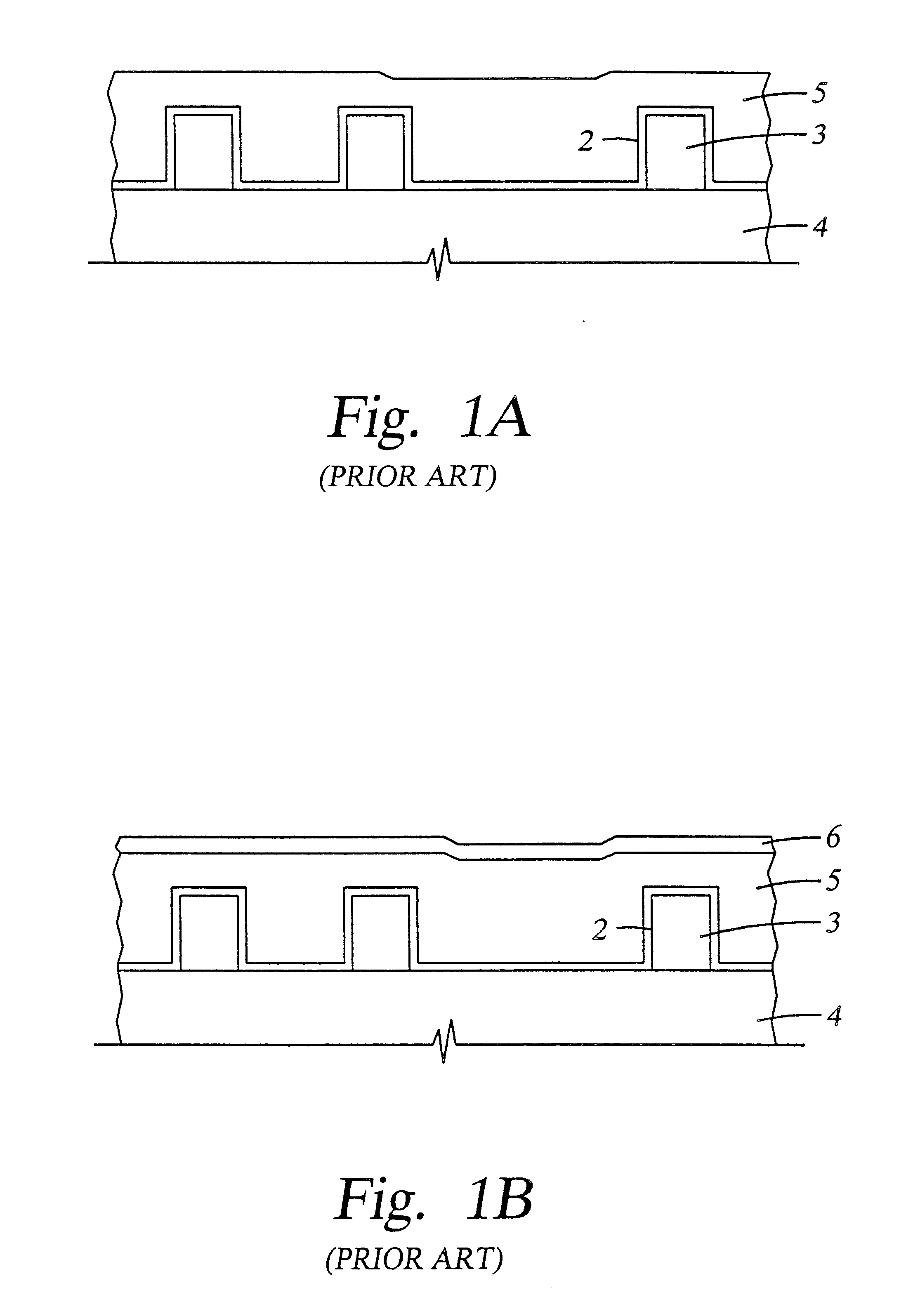

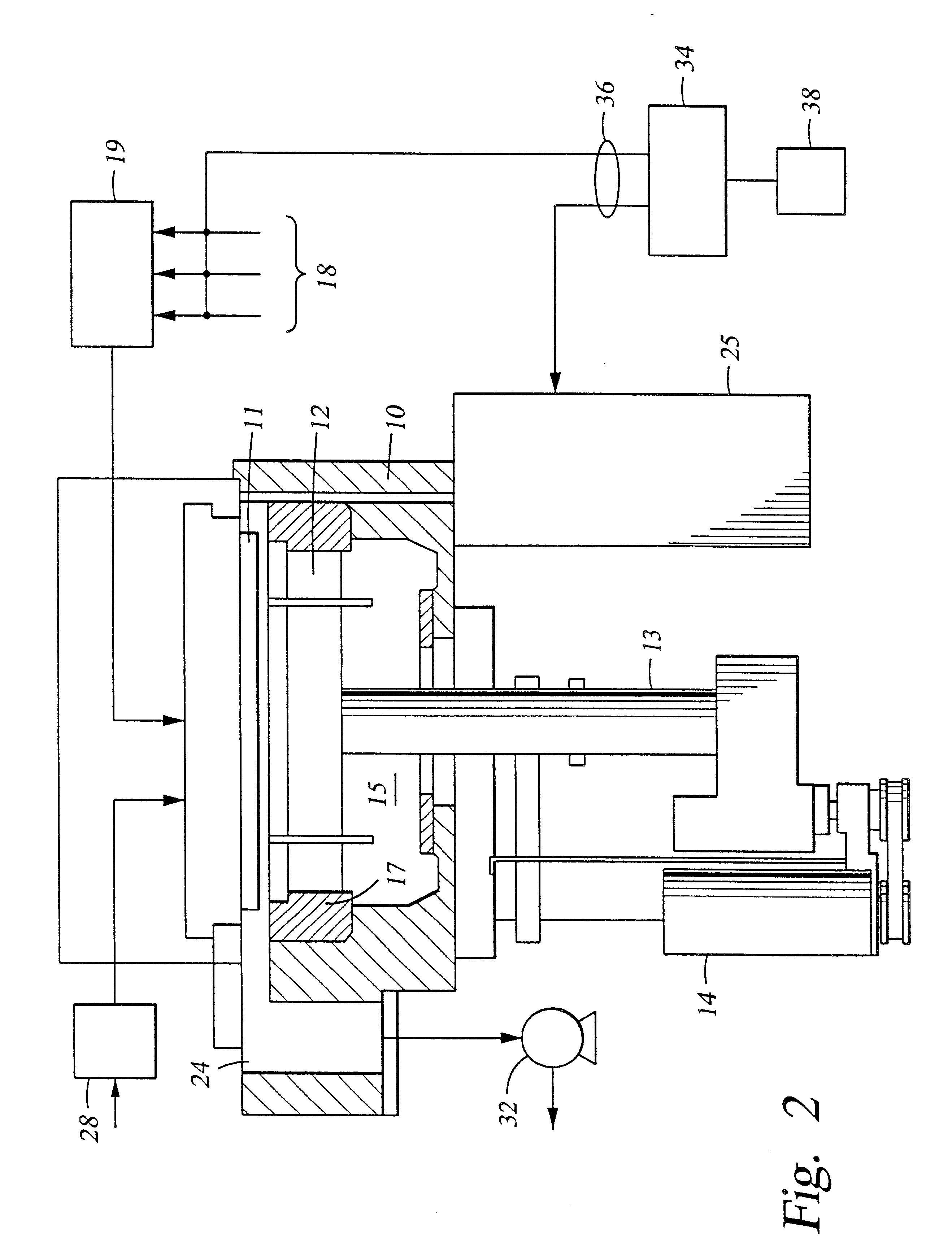

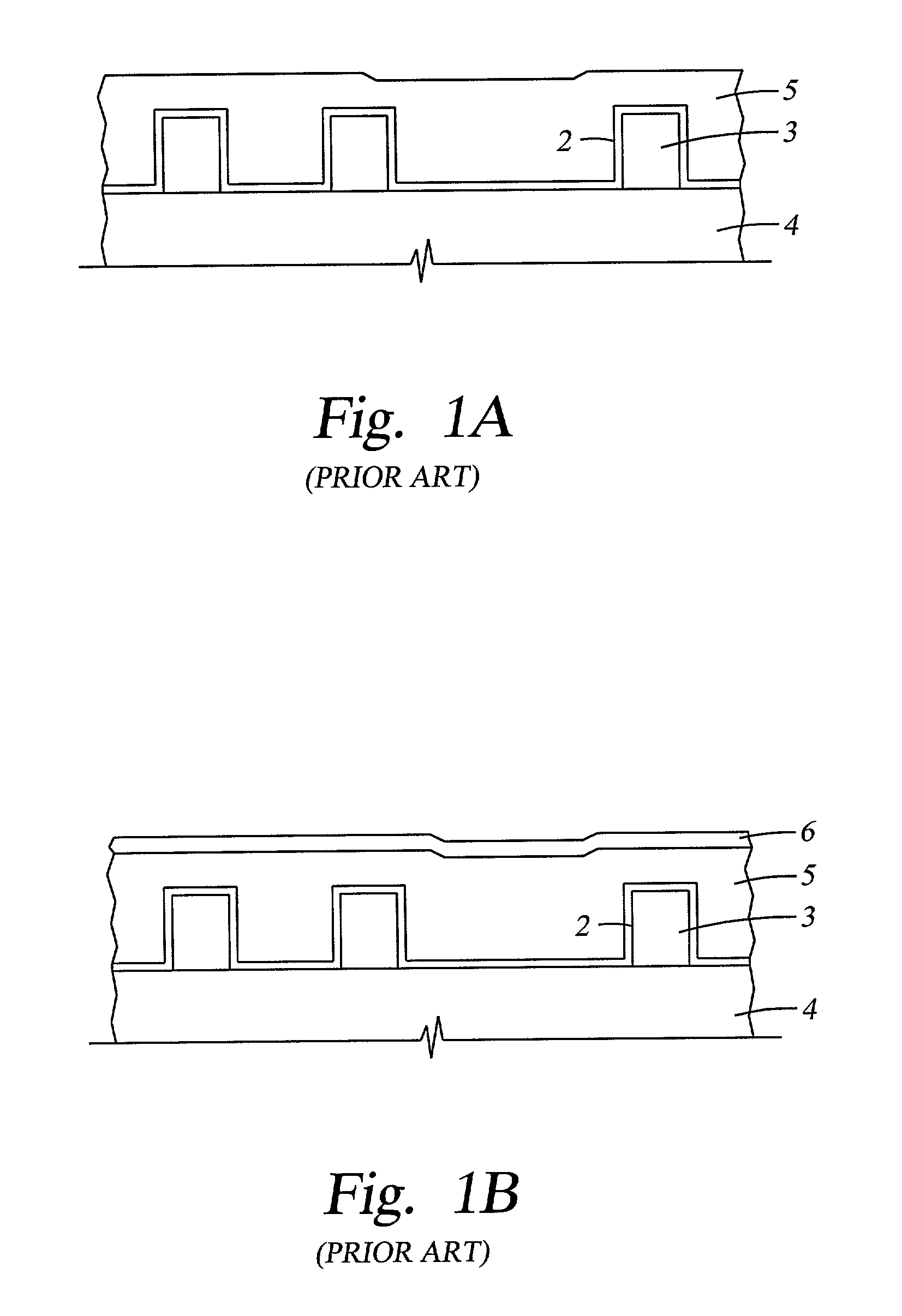

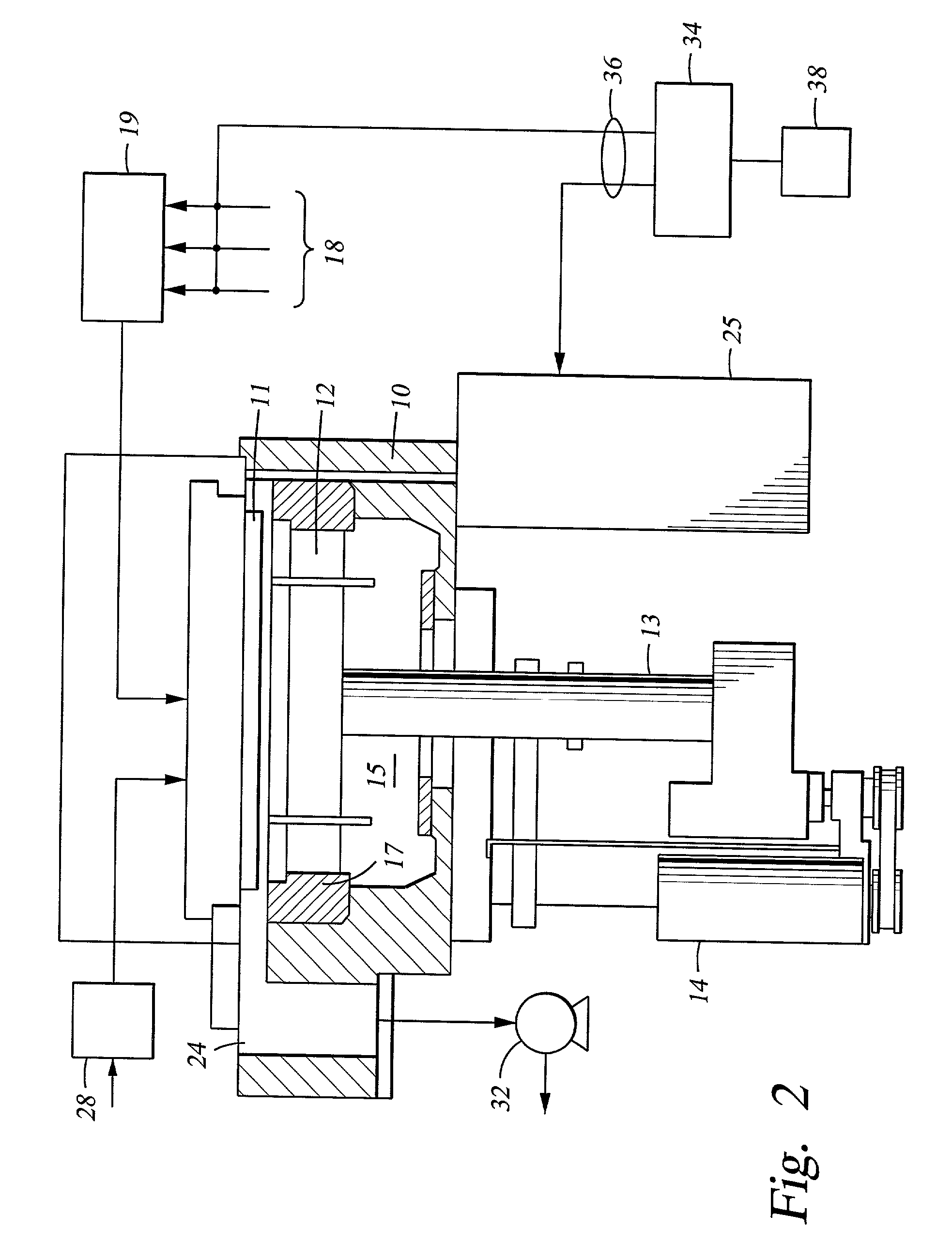

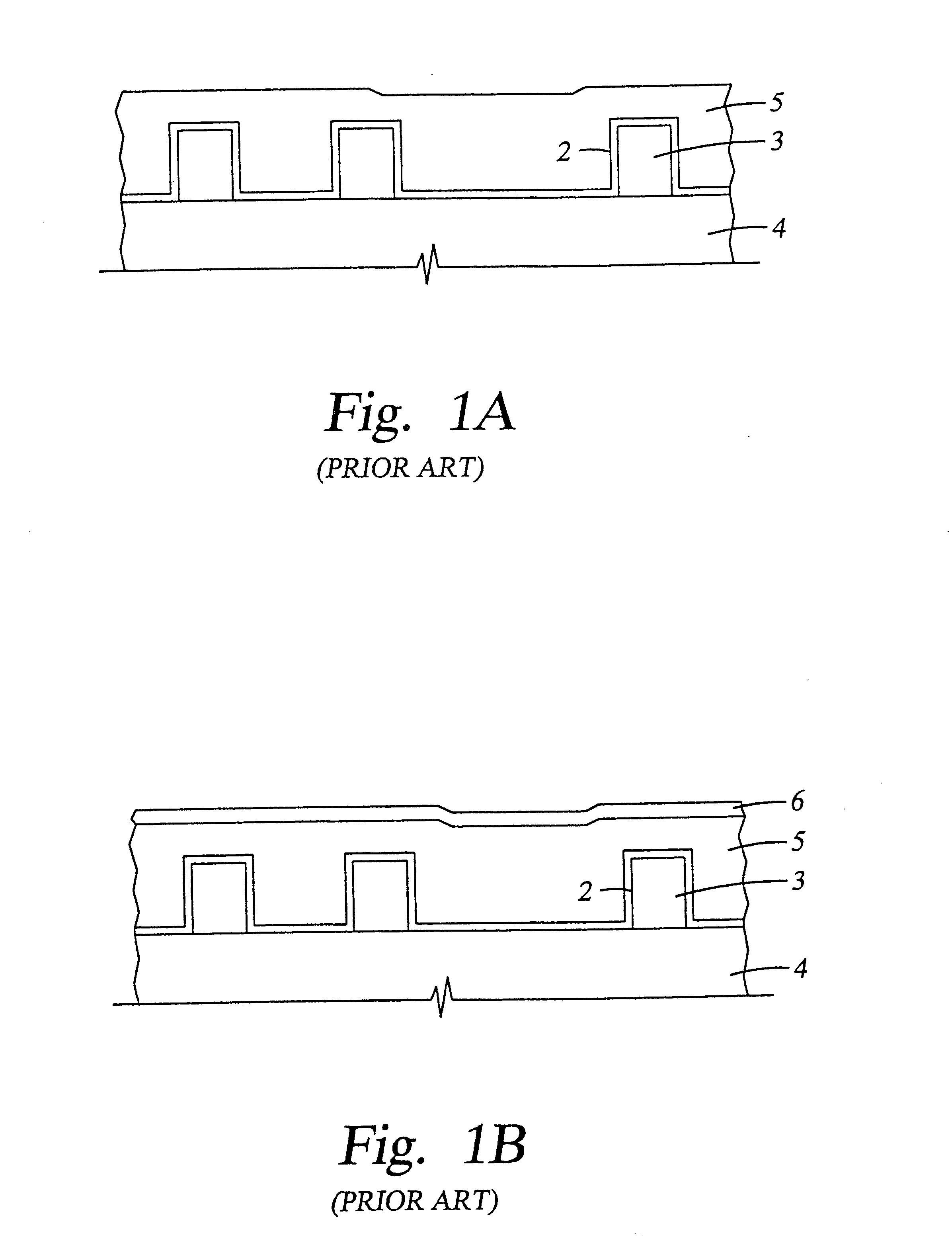

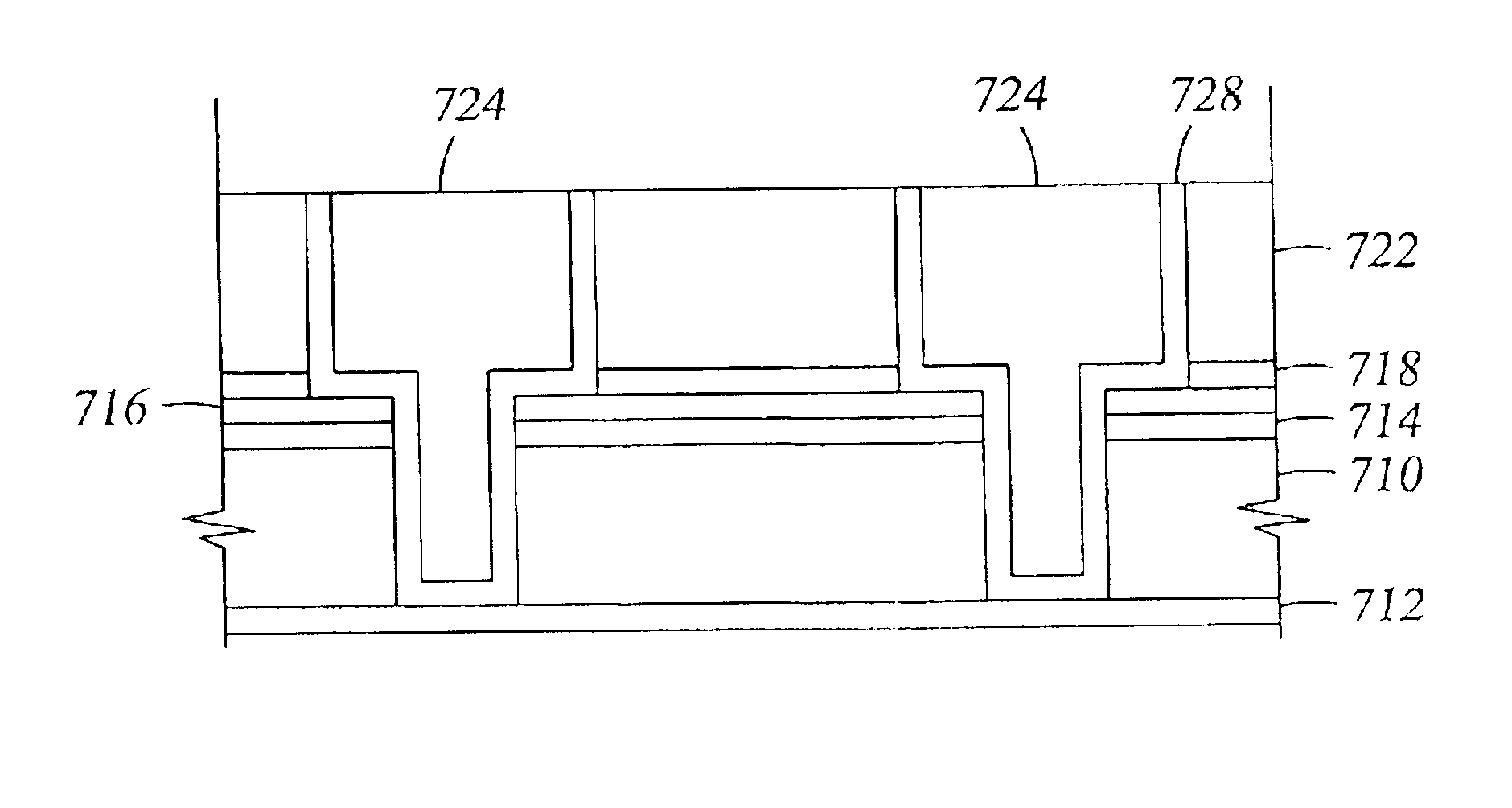

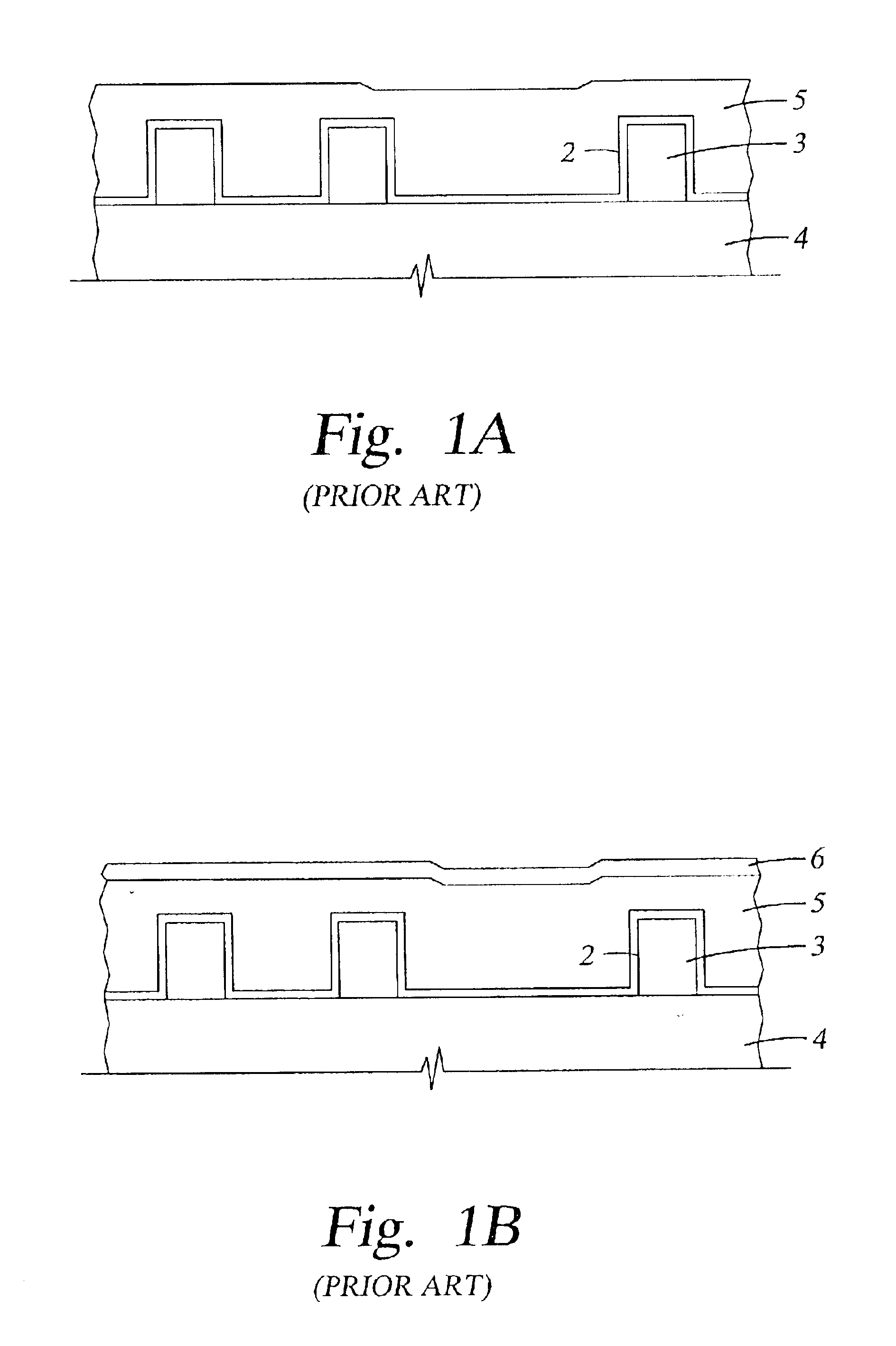

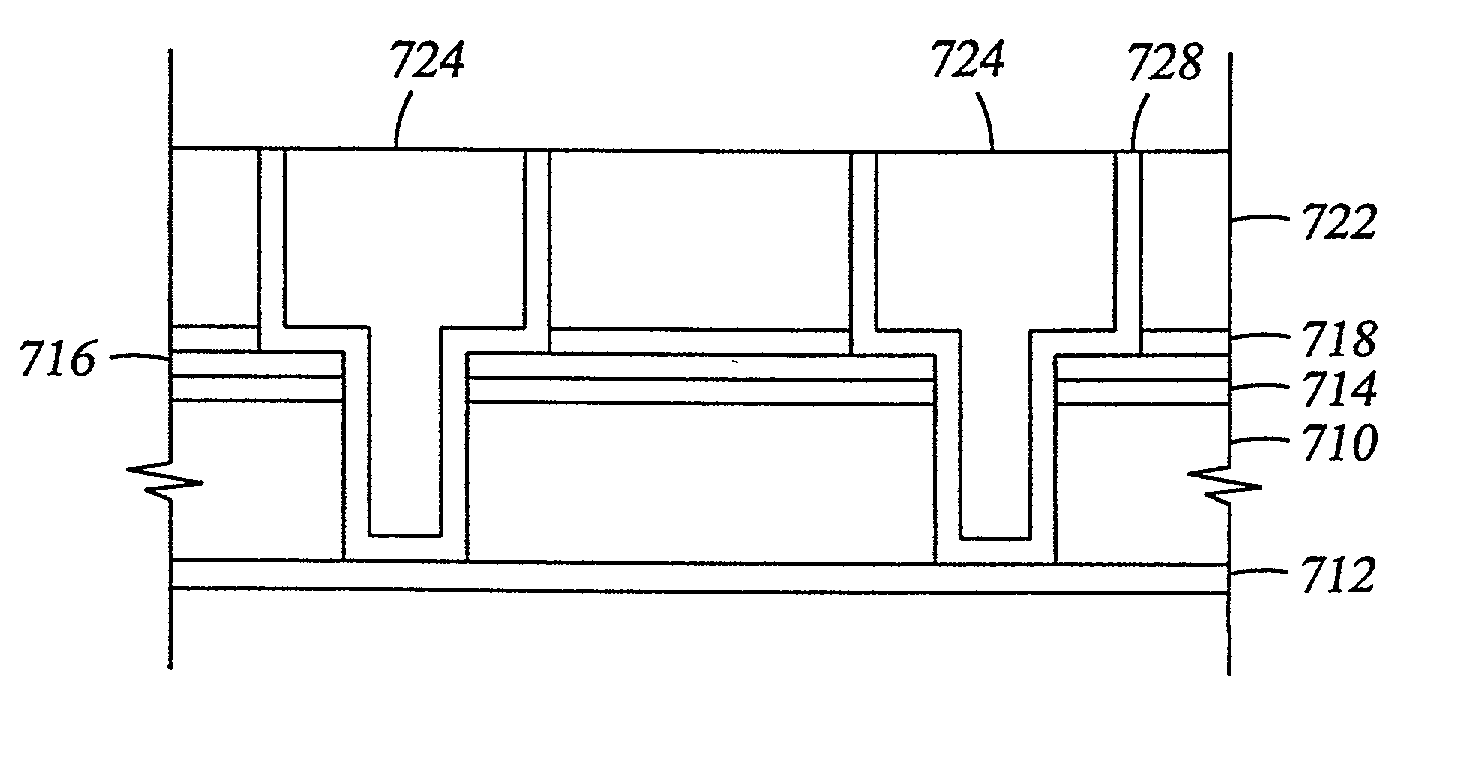

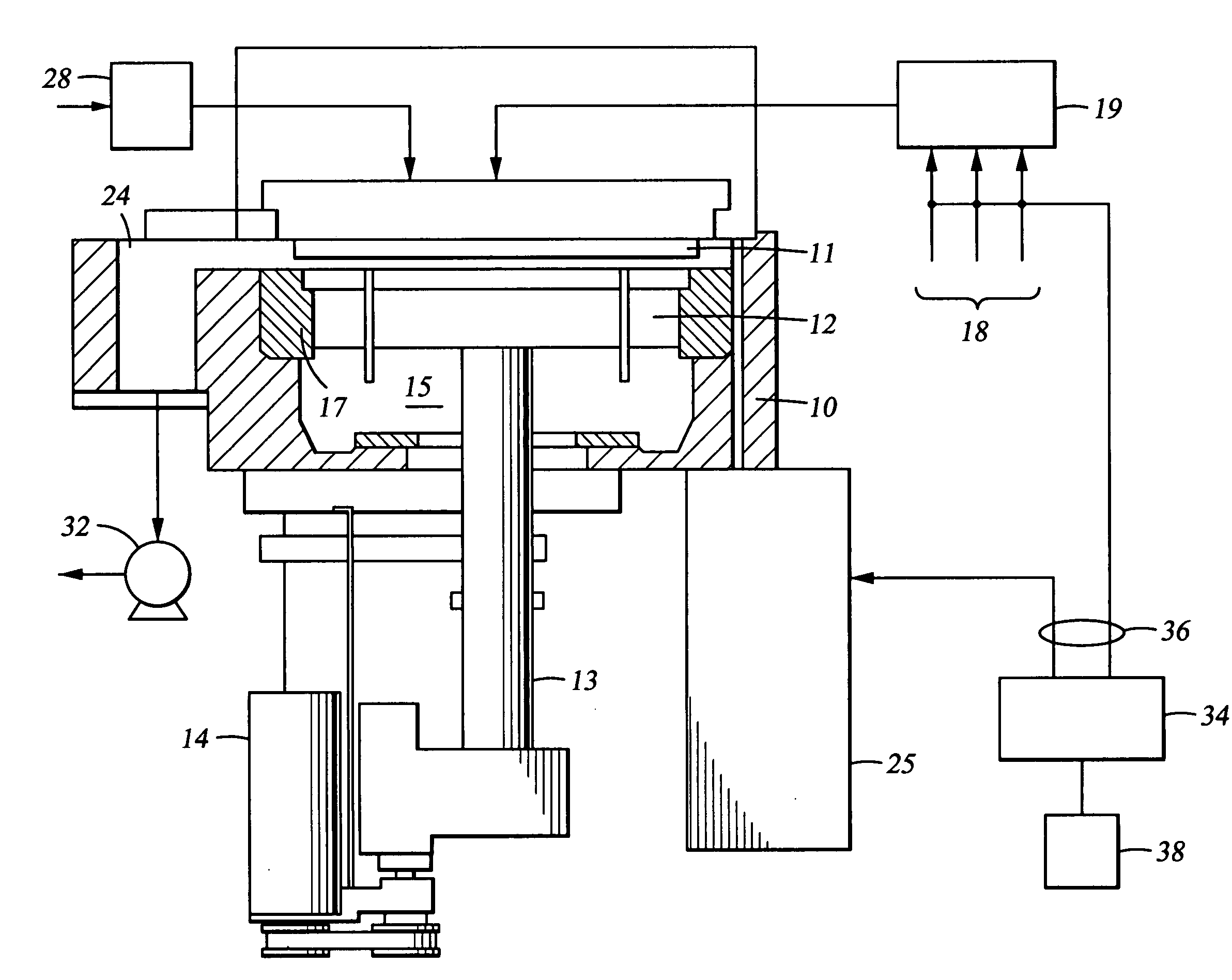

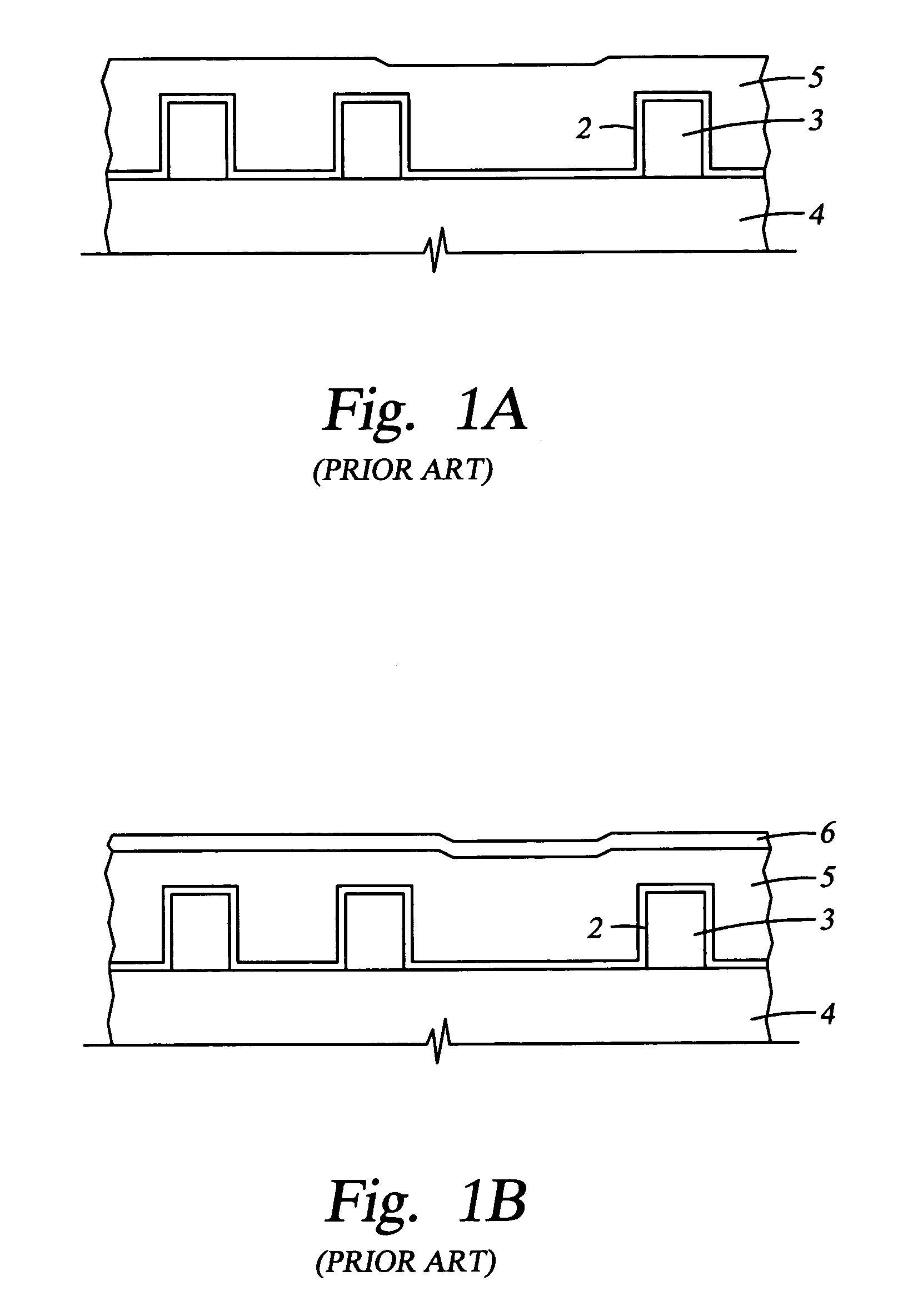

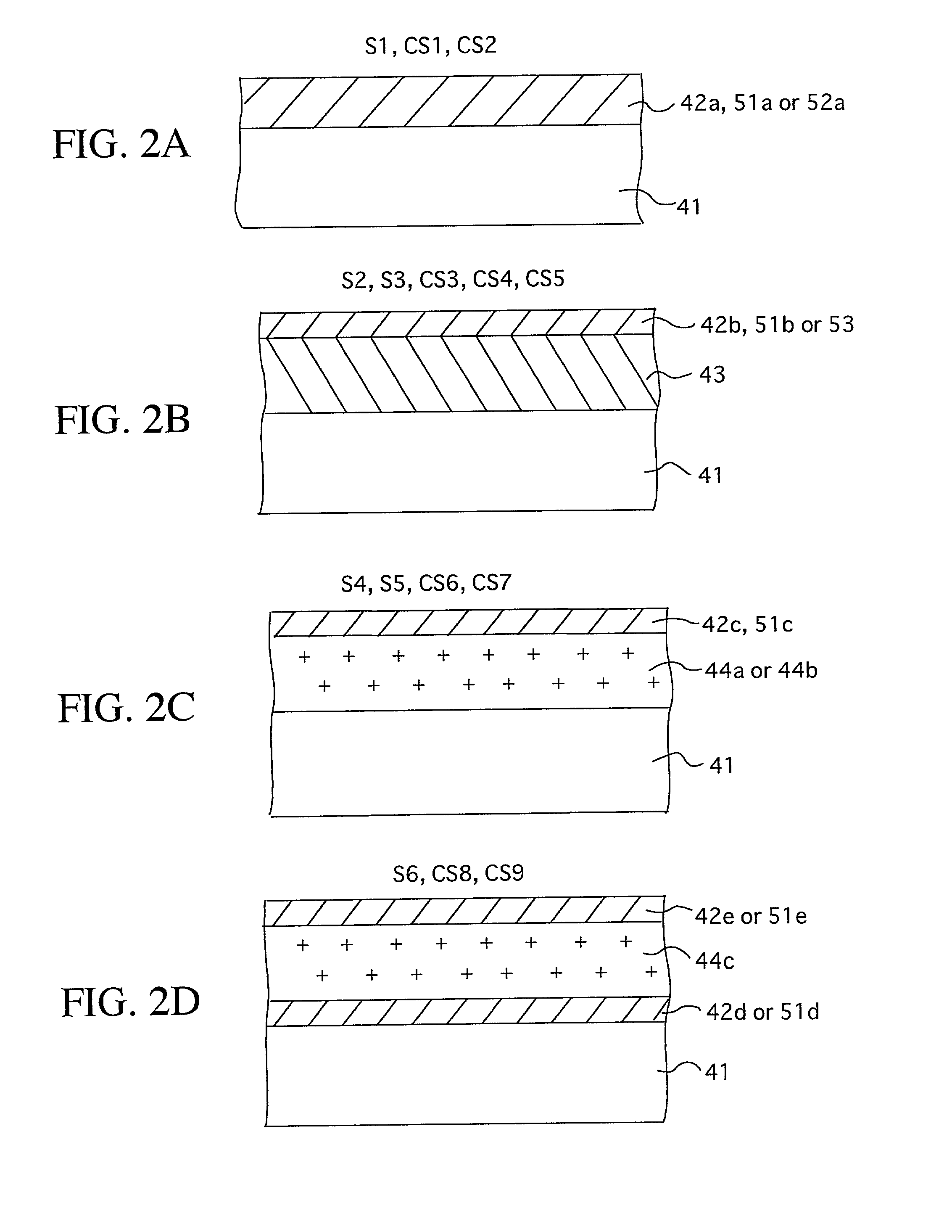

A method and apparatus for depositing a low dielectric constant film by reaction of an organo silane compound and an oxidizing gas. The oxidized organo silane film has excellent barrier properties for use as a liner or cap layer adjacent other dielectric layers. The oxidized organo silane film can also be used as an etch stop or an intermetal dielectric layer for fabricating dual damascene structures. The oxidized organo silane films also provide excellent adhesion between different dielectric layers. A preferred oxidized organo silane film is produced by reaction of methyl silane, CH3SiH3, and N2O.

Owner:APPLIED MATERIALS INC

CVD plasma assisted low dielectric constant films

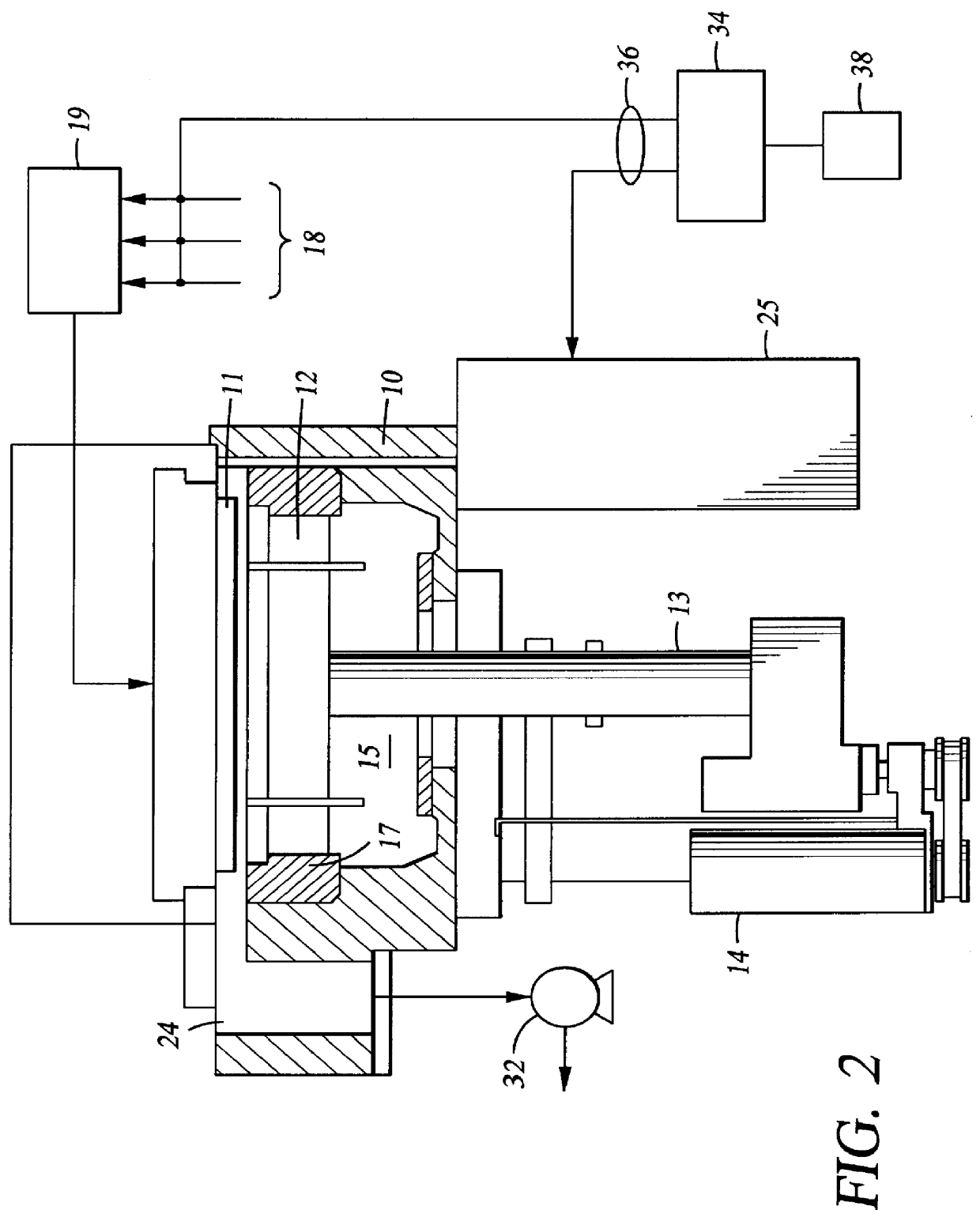

A method and apparatus for depositing a low dielectric constant film by reaction of an organosilane or organosiloxane compound and an oxidizing gas at a low RF power level from 10-250 W. The oxidized organosilane or organosiloxane film has good barrier properties for use as a liner or cap layer adjacent other dielectric layers. The oxidized organosilane or organosiloxane film may also be used as an etch stop or an intermetal dielectric layer for fabricating dual damascene structures. The oxidized organosilane or organosiloxane films also provide excellent adhesion between different dielectric layers. A preferred oxidized organosilane film is produced by reaction of methylsilane, CH3SiH3, or dimethylsilane, (CH3)2SiH2, and nitrous oxide, N2O, at an RF power level from about 10 to 200 W or a pulsed RF power level from about 20 to 250 W during 10-30% of the duty cycle.

Owner:APPLIED MATERIALS INC

Plasma processes for depositing low dielectric constant films

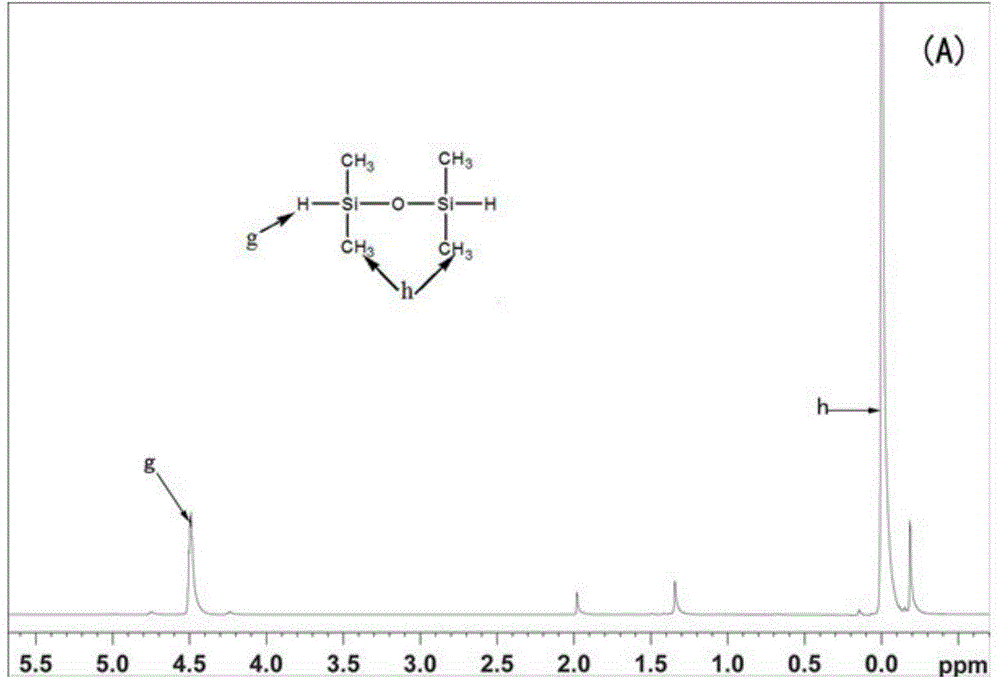

A method and apparatus for depositing a low dielectric constant film by reaction of an organosilicon compound and an oxidizing gas at a constant RF power level from about 10W to about 200W or a pulsed RF power level from about 20W to about 500W. Dissociation of the oxidizing gas can be increased prior to mixing with the organosilicon compound, preferably within a separate microwave chamber, to assist in controlling the carbon content of the deposited film. The oxidized organosilane or organosiloxane film has good barrier properties for use as a liner or cap layer adjacent other dielectric layers. The oxidized organosilane or organosiloxane film may also be used as an etch stop and an intermetal dielectric layer for fabricating dual damascene structures. The oxidized organosilane or organosiloxane films also provide excellent adhesion between different dielectric layers. A preferred oxidized organosilane film is produced by reaction of methylsilane, CH3SiH3, dimethylsilane, (CH3)2SiH2, or 1,1,3,3-tetramethyl-disiloxane, (CH3)2-SiH-O-SiH-(CH3)2, and nitrous oxide, N2O, at a constant RF power level from about 10W to about 150W, or a pulsed RF power level from about 20W to about 250W during 10% to 30% of the duty cycle.

Owner:APPLIED MATERIALS INC

Plasma processes for depositing low dielectric constant films

InactiveUS20010005546A1Semiconductor/solid-state device detailsSolid-state devicesDisiloxaneMicrowave

A method and apparatus for depositing a low dielectric constant film by reaction of an organosilicon compound and an oxidizing gas at a constant RF power level from about 10W to about 200W or a pulsed RF power level from about 20W to about 500W. Dissociation of the oxidizing gas can be increased prior to mixing with the organosilicon compound, preferably within a separate microwave chamber, to assist in controlling the carbon content of the deposited film. The oxidized organosilane or organosiloxane film has good barrier properties for use as a liner or cap layer adjacent other dielectric layers. The oxidized organosilane or organosiloxane film may also be used as an etch stop and an intermetal dielectric layer for fabricating dual damascene structures. The oxidized organosilane or organosiloxane films also provide excellent adhesion between different dielectric layers. A preferred oxidized organosilane film is produced by reaction of methylsilane, CH3SiH3, dimethylsilane, (CH3)2SiH2, or 1,1,3,3-tetramethyl-disiloxane, (CH3)2-SiH-O-SiH-(CH3)2, and nitrous oxide, N2O, at a constant RF power level from about 10W to about 150W, or a pulsed RF power level from about 20W to about 250W during 10% to 30% of the duty cycle.

Owner:APPLIED MATERIALS INC

Computer readable medium for holding a program for performing plasma-assisted CVD of low dielectric constant films formed from organosilane compounds

A method and apparatus for depositing a low dielectric constant film by reaction of an organosilane or organosiloxane compound and an oxidizing gas at a low RF power level from 10-250 W. The oxidized organosilane or organosiloxane film has good barrier properties for use as a liner or cap layer adjacent other dielectric layers. The oxidized organosilane or organosiloxane film may also be used as an etch stop or an intermetal dielectric layer for fabricating dual damascene structures. The oxidized organosilane or organosiloxane films also provide excellent adhesion between different dielectric layers. A preferred oxidized organosilane film is produced by reaction of methylsilane, CH3SiH3, or dimethylsilane, (CH3)2SiH2, and nitrous oxide, N2O, at an RF power level from about 10 to 200 W or a pulsed RF power level from about 20 to 250 W during 10-30% of the duty cycle.

Owner:APPLIED MATERIALS INC

CVD plasma assisted low dielectric constant films

InactiveUS6800571B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingDimethylsilaneNitrous oxide

A method and apparatus for depositing a low dielectric constant film by reaction of an organosilane or organosiloxane compound and an oxidizing gas at a low RF power level from 10-250 W. The oxidized organosilane or organosiloxane film has good barrier properties for use as a liner or cap layer adjacent other dielectric layers. The oxidized organosilane or organosiloxane film may also be used as an etch stop or an intermetal dielectric layer for fabricating dual damascene structures. The oxidized organosilane or organosiloxane films also provide excellent adhesion between different dielectric layers. A preferred oxidized organosilane film is produced by reaction of methylsilane, CH3SiH3, or dimethylsilane, (CH3)2SiH2, and nitrous oxide, N2O, at an RF power level from about 10 to 200 W or a pulsed RF power level from about 20 to 250 W during 10-30% of the duty cycle.

Owner:APPLIED MATERIALS INC

A low dielectric constant film produced from silicon compounds comprising silicon-carbon bonds

InactiveUS20020000670A1Semiconductor/solid-state device detailsSolid-state devicesSilane compoundsSilanes

A method and apparatus for depositing a low dielectric constant film by reaction of an organo silane compound and an oxidizing gas. The oxidized organo silane film has excellent barrier properties for use as a liner or cap layer adjacent other dielectric layers. The oxidized organo silane film can also be used as an etch stop or an intermetal dielectric layer for fabricating dual damascene structures. The oxidized organo silane films also provide excellent adhesion between different dielectric layers. A preferred oxidized organo silane film is produced by reaction of methyl silane, CH3SiH3, and N2O.

Owner:APPLIED MATERIALS INC

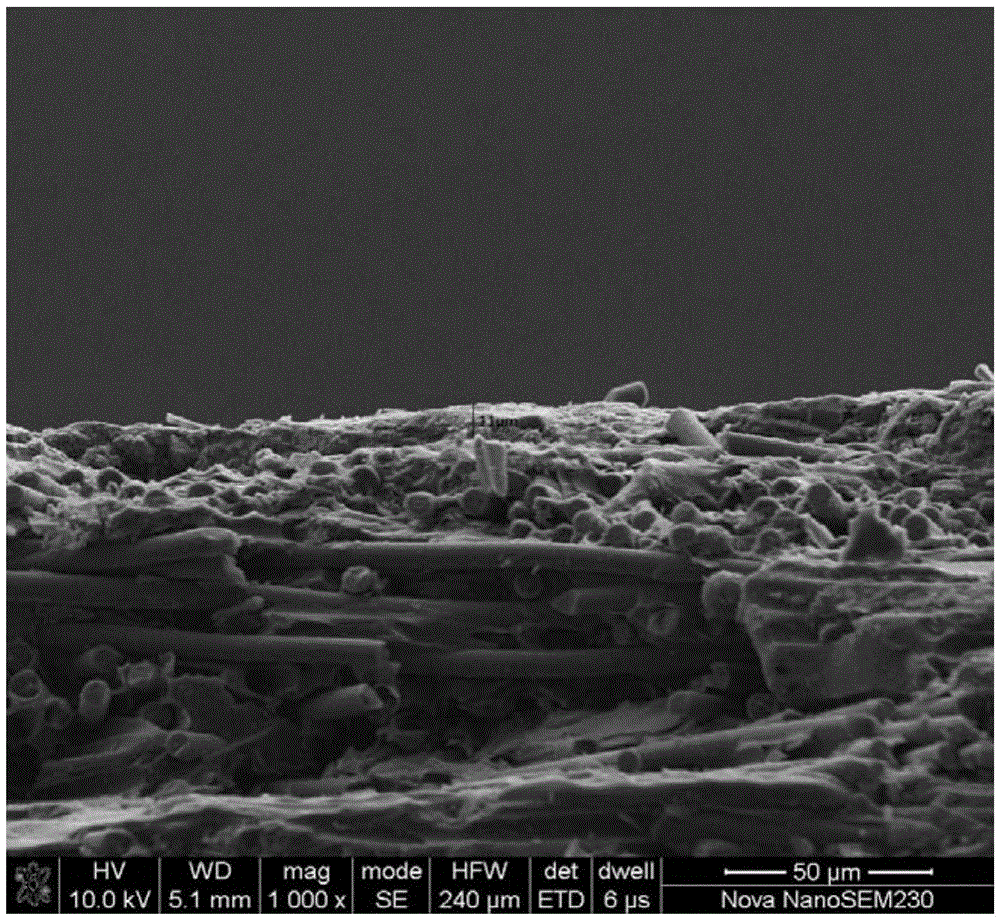

Method for preparing silica aerogel composite material by adopting chloride-free and alcohol-free process

The invention discloses a method for preparing a silica aerogel composite material by adopting a chloride-free and alcohol-free process. The method comprises the following steps: S1, adopting a water-based silicon source as a raw material, regulating the pH value of sol with a chloridion-free acid, adding an additive after desalting, and uniformly stirring to obtain a first mixed solution; S2, immersing a fiber reinforced material into the first mixed solution, and completing gel curing; S3, standing the obtained composite gel material so as to obtain an aged composite gel material; S4, placing the aged composite gel material in a chloride-free and alcohol-free displacer to realize uniform solution infiltration; S5, performing surface methylsilane modification on the composite gel by usinga chloride-free surface modifier; S6, drying the modified composite gel, thereby obtaining the silica aerogel composite material. The invention provides a method for preparing the silica aerogel composite material without any chloride ion or alcohol substance in the formula.

Owner:SHENZHEN AEROGEL TECH CO LTD

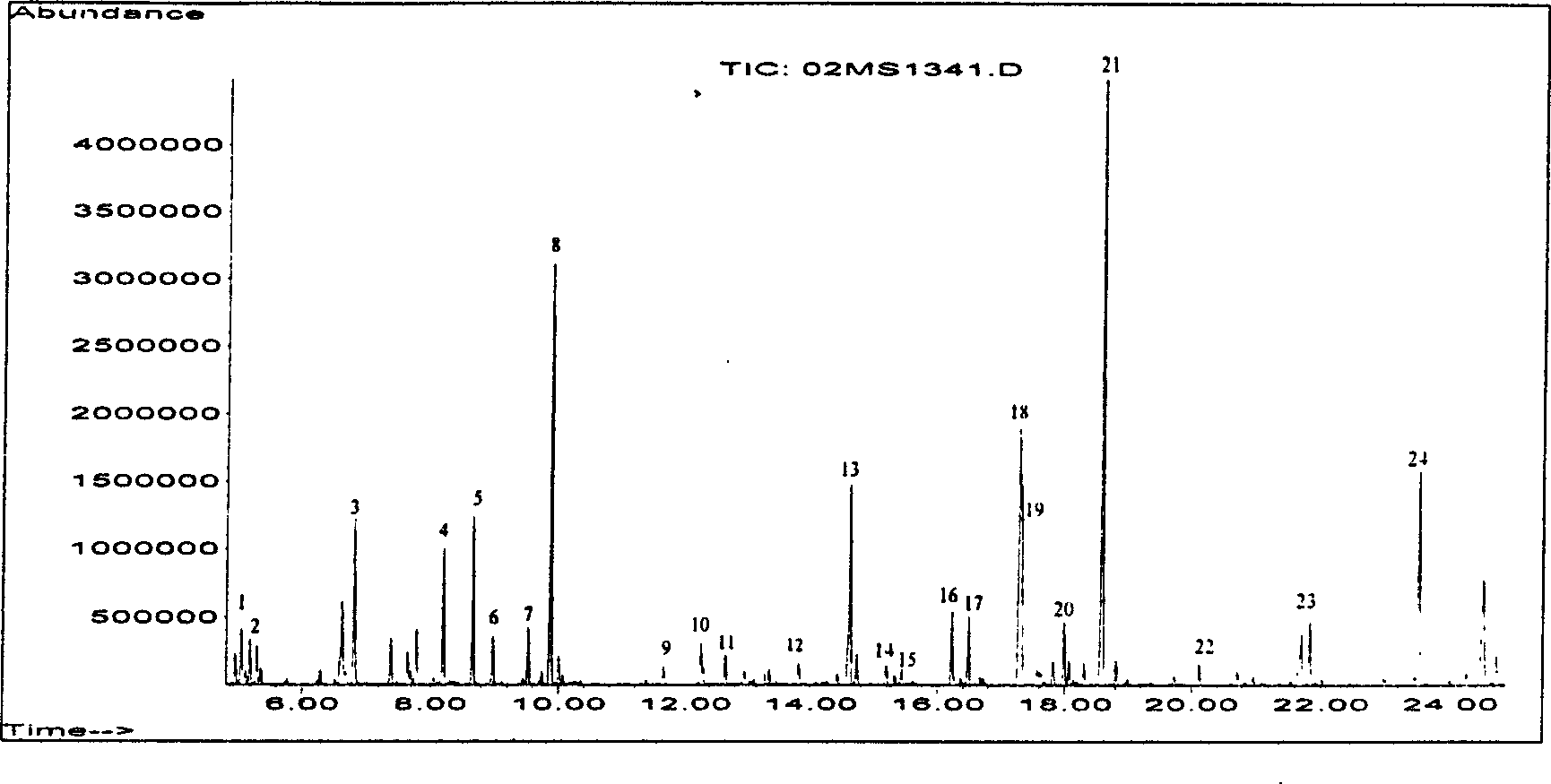

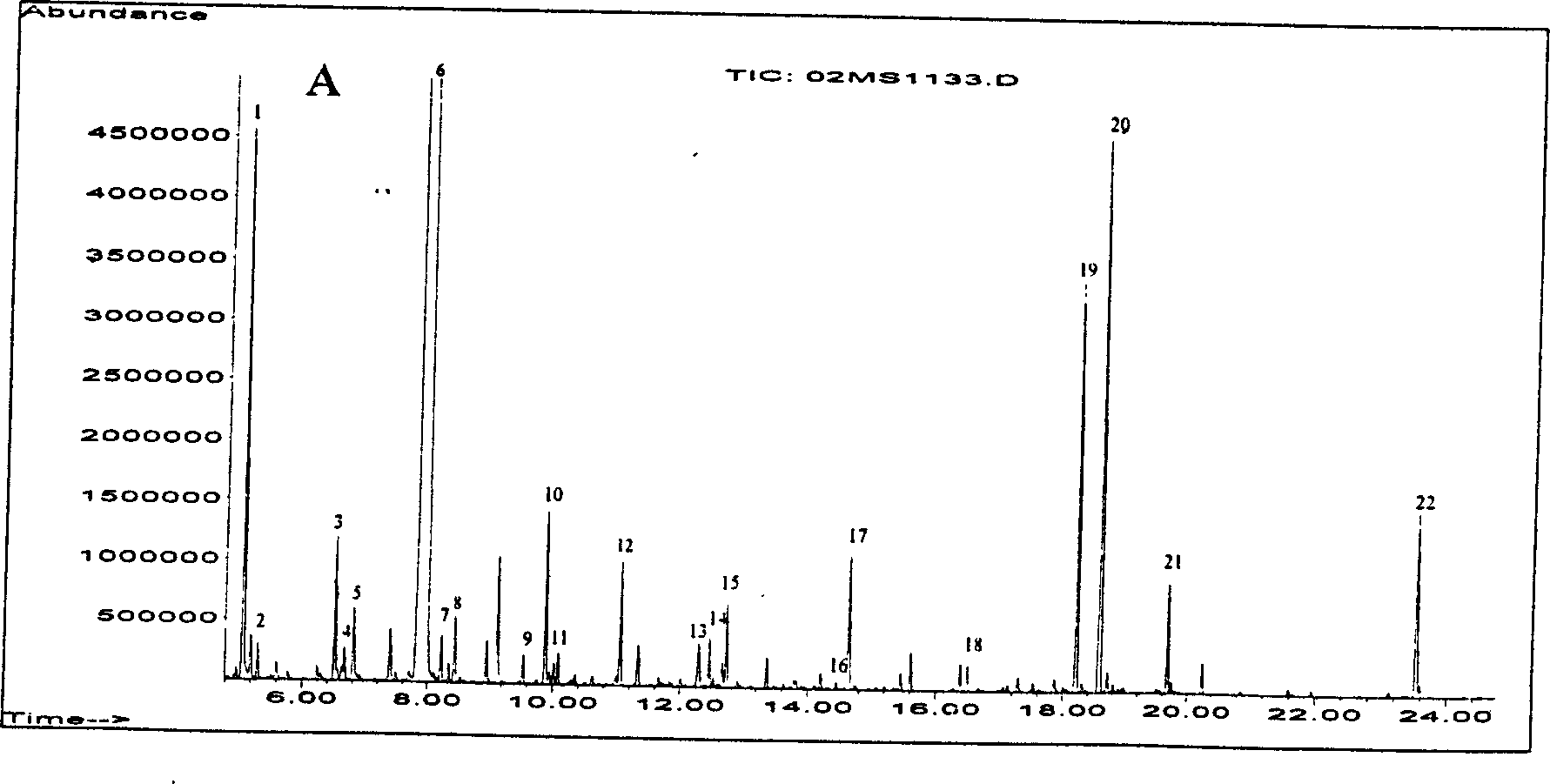

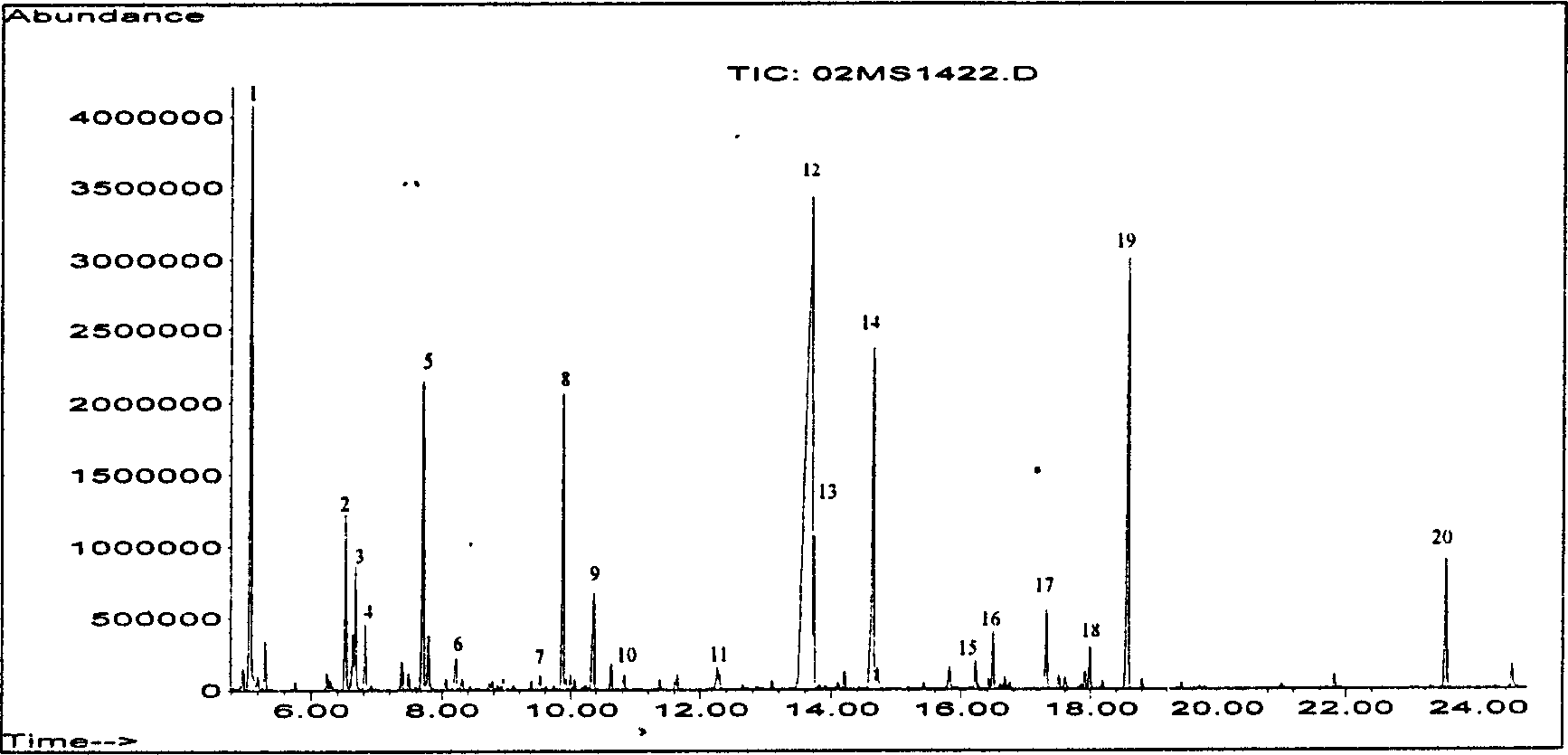

Method for detecting organic acid/amino acid metabolic product by filter paper shect gas chromatography-mass spectrum analysis

The present invention discloses filter paper sheet gas chromatography-mass spectrum analysis process of organic acid / amino acid metabolic product in urine. The process includes elution of urine collected with filter paper, oximation reaction, extraction, methyl silane derivation, and united detection with chromatographic instrument and mass spectrograph. The process of the present invention is superior in that the filter paper collection of urine favors remote analysis of genetic metabolic diseases; the oximation reaction processing favors alpha-ketonic acid detection for diagnosis of branched chain ketonic acid metabolic disorder; the extraction has high recovery rate of organic acid / amino acid metabolic product, high repeatability, less chromatographic impurity peaks and no pollution to chromatographic capillary column and mass spectrographic ion source; and the united detection is suitable for screening analysis of great amount of samples.

Owner:TONGJI HOSPITAL ATTACHED TO TONGJI MEDICAL COLLEGE HUAZHONG SCI TECH

CVD plasma assisted low dielectric constant films

InactiveUS20030124859A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingDimethylsilaneNitrous oxide

A method and apparatus for depositing a low dielectric constant film by reaction of an organosilane or organosiloxane compound and an oxidizing gas at a low RF power level from 10-250 W. The oxidized organosilane or organosiloxane film has good barrier properties for use as a liner or cap layer adjacent other dielectric layers. The oxidized organosilane or organosiloxane film may also be used as an etch stop or an intermetal dielectric layer for fabricating dual damascene structures. The oxidized organosilane or organosiloxane films also provide excellent adhesion between different dielectric layers. A preferred oxidized organosilane film is produced by reaction of methylsilane, CH3SiH3, or dimethylsilane, (CH3)2SiH2, and nitrous oxide, N2O, at an RF power level from about 10 to 200 W or a pulsed RF power level from about 20 to 250 W during 10-30% of the duty cycle.

Owner:APPLIED MATERIALS INC

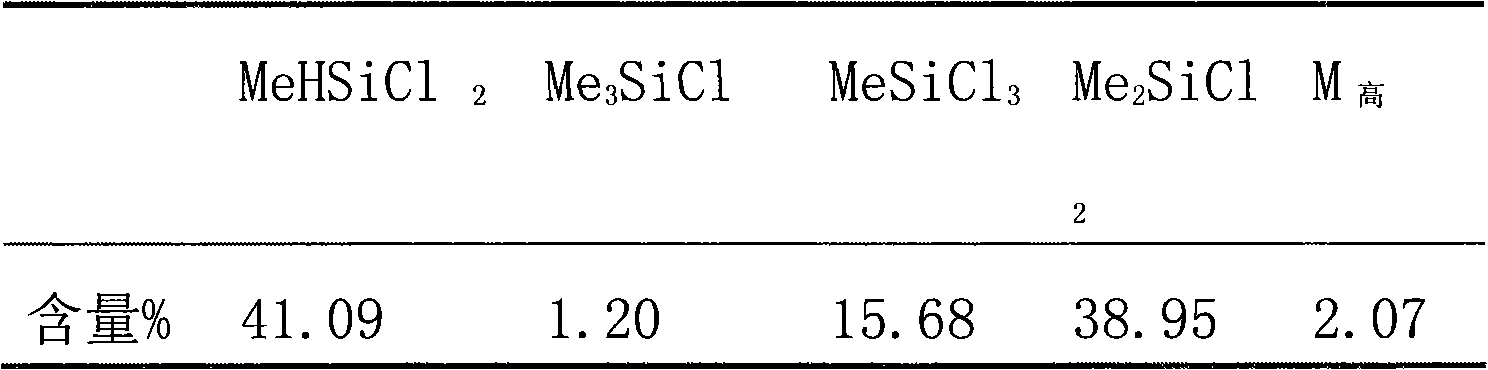

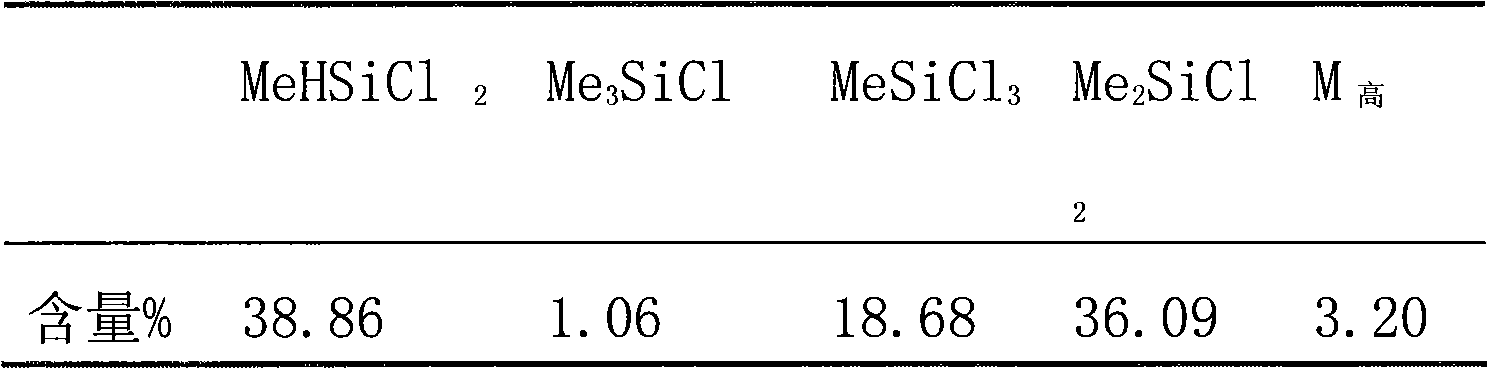

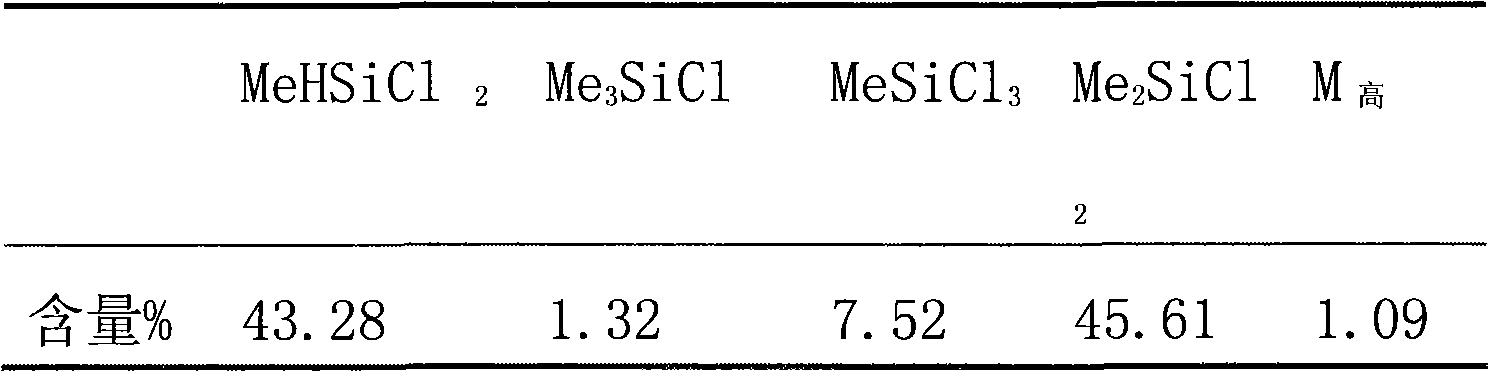

Method for cracking treatment of organic silicon waste residue slurry

The invention relates to method for the cracking treatment of waste residues slurry produced in a synthesis process of an organic silicone monomer. The comehtod comprises: adding a high-boiling material of the same mass into a organic silicon waste residue slurry liquid and solid mixture containing 20 percent of solid to prepare a cracking feed solution, wherein a catalyst is tri-n-butylamine andthe cracking reaction temperature is 80 to 160 DEG C; and introducing HCl gas, wherein the ratio of the feed speeds of the hydrogen chloride and the raw material mixed liquid is 1:1.05-1:1.12. The method has the advantages that: the residue slurry containing 20 percent of solid is used in combination with the high-boiling material, so a monosilane product can be separated directly in a cracking process; the conversion rate is over 70 percent; the selectivity of dimethyldichlorosilane is over 35 percent; the selectivity of methylsilane is over 40 percent; and the slurry residue obtained after cracking having certain liquidity and can be further treated.

Owner:PETROCHINA CO LTD

Coating process for lotus leaf-like diamond film

InactiveCN103469205AReduce stressToo much dopingSolid state diffusion coatingChemical vapor deposition coatingWear resistantGas phase

The invention relates to a coating process for a lotus leaf-like diamond film. According to the process, gases such as octafluorocyclobutane, monomethylsilane and dimethylsilane are introduced into a vacuum tank, denpending on plasma immersion ion deposition equipment; and the lotus leaf-like diamond film is coated on a workpiece surface by a plasma-enhanced chemical vapor deposition method. The coating process mainly comprises five steps of plasma cleaning, plasma nitriding, transition layer plating, diamond-like plating and lotus leaf-like film plating. The lotus leaf-like diamond film has very high hardness. Since the lotus leaf-like diamond film has a structure similar to the surface of the lotus leaf, the lotus leaf-like diamond film has extremely low surface energy. In consideration of high wear-resistant and hydrophobic properties of the lotus leaf-like diamond film, the lotus leaf-like diamond film can be successfully applied in the fields such as coal mine screen meshes, metal molds, aerospace aircraft wings and oil pipelines.

Owner:HEFEI YONGXIN PLASMA TECH

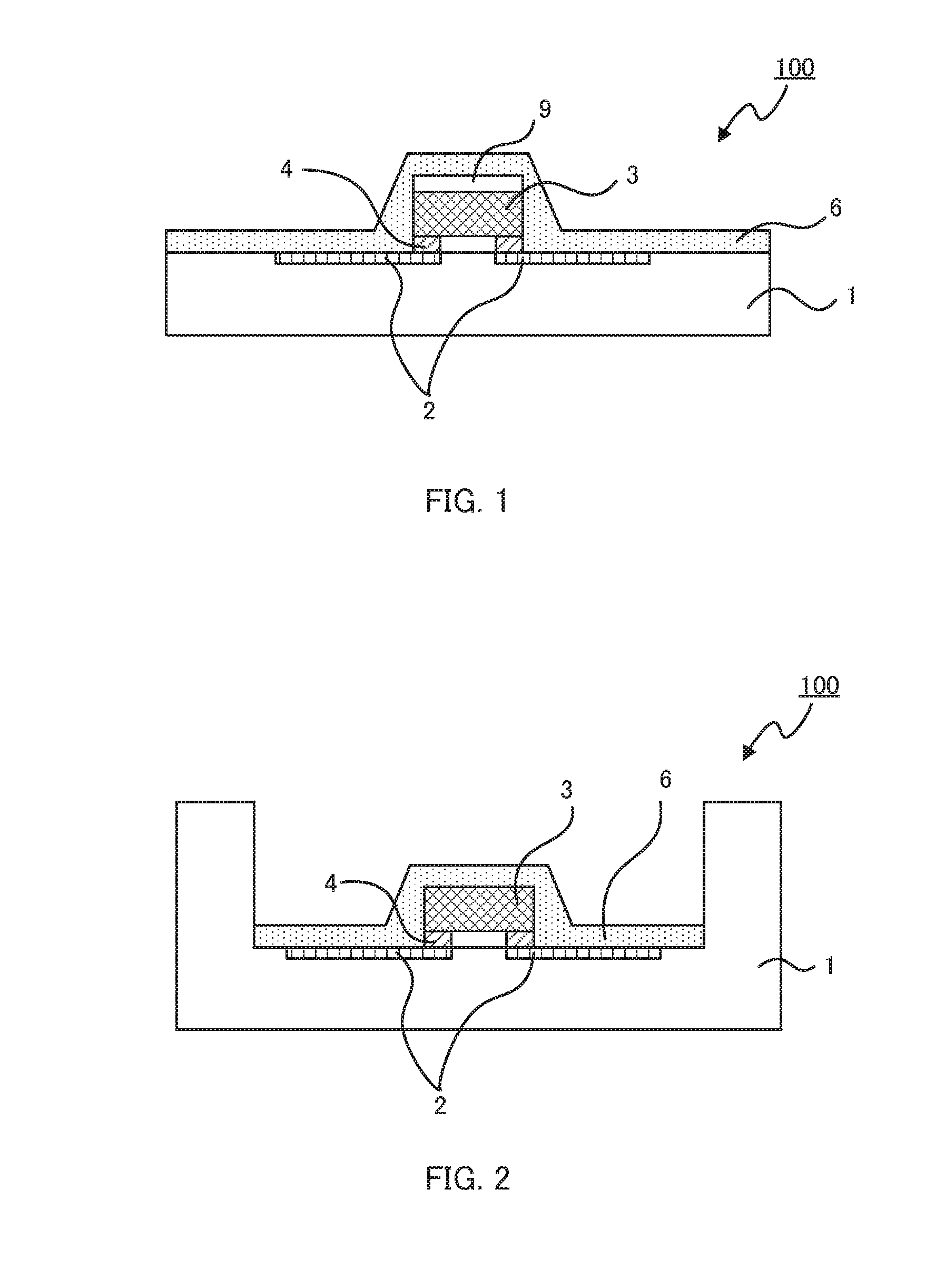

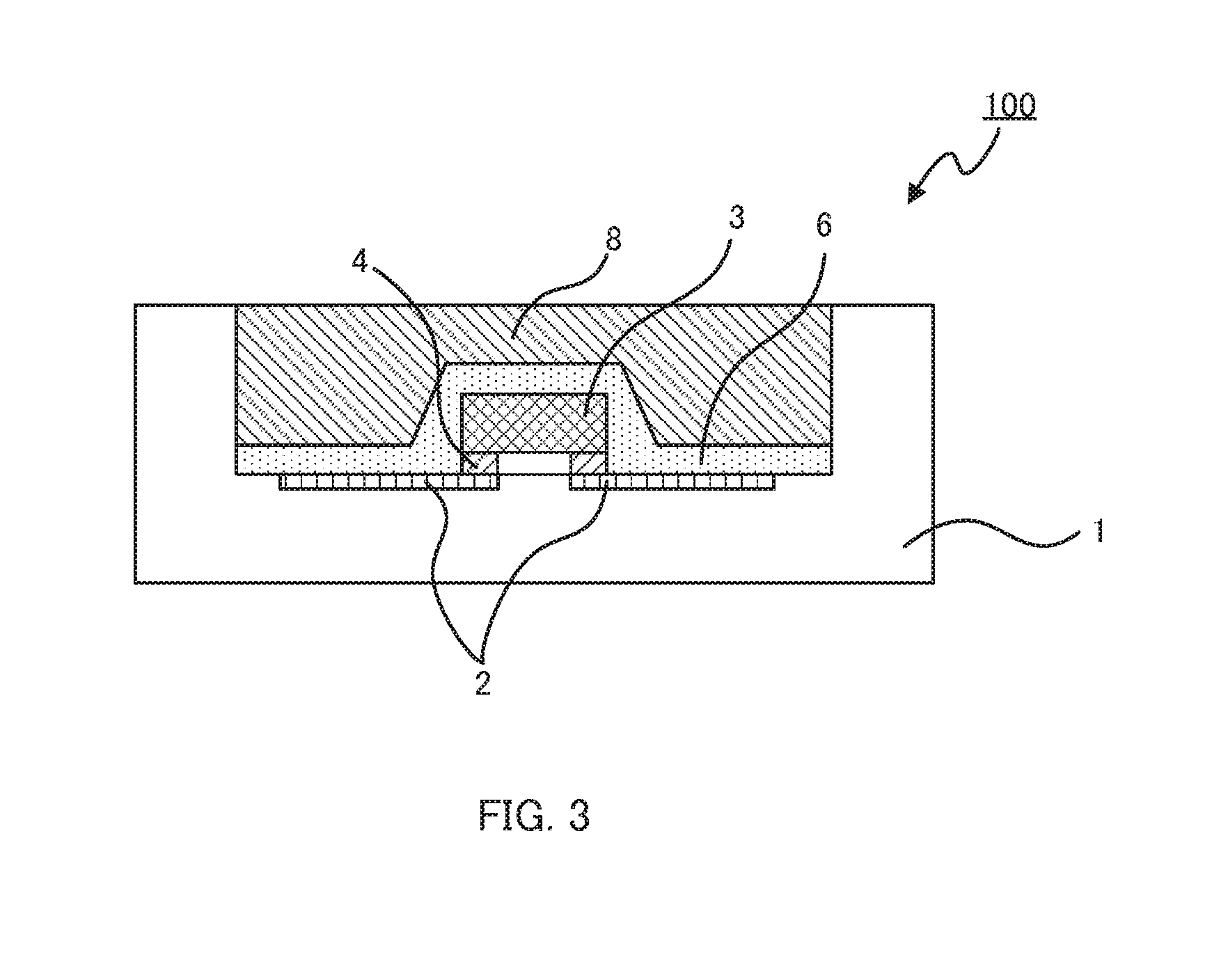

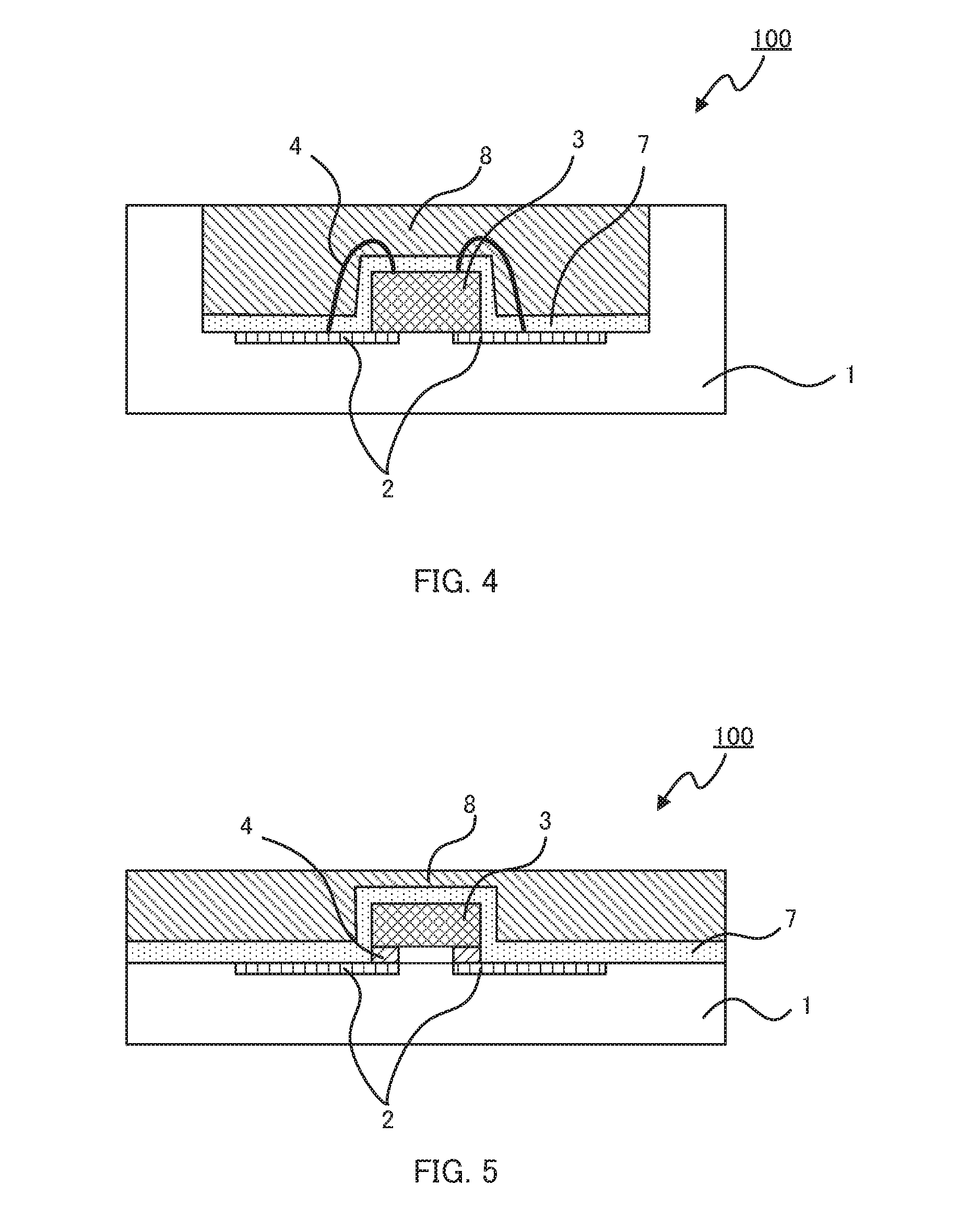

Sealant for LED device, LED device, and method for producing LED device

InactiveUS20150221837A1Improve adhesionHigh sulfide gas resistanceOther chemical processesSolid-state devicesSilane compoundsSilanes

The objective of the present invention is to provide a sealant for an LED device capable of forming a sealing layer having a high level of light extraction, outstanding resistance to sulfidizing gas, and not giving rise to cracking or peeling even when used for extended periods, as well as an LED device employing the same. In order to attain at least one of the abovementioned objective, a sealant for an LED device reflecting one aspect of the present invention contains 100 mass parts of a 1000-3000 mass average molecular weight polysiloxane polymerized from a trifunctional monomethyl silane compound and a tetrafunctional silane compound, 5 mass parts to 100 mass parts of an organometallic compound comprising a metal alkoxide or metal chelate containing a Group 4 or Group 13 metal, and a solvent.

Owner:KONICA MINOLTA INC

Preparation method for high-temperature-resistant ceramic precursor adhesive

ActiveCN104194717AIncrease temperatureImprove high temperature resistanceNon-macromolecular adhesive additivesSilazaneOrganic solvent

The invention discloses a preparation method for a high-temperature-resistant ceramic precursor adhesive. The preparation method comprises the following steps of (1) adding metal sodium and methylbenzene into a three-opening flask with a condensation backflow device and a mechanical stirring device, heating to 80-120 DEG C under the protection of inert atmosphere, dropping methyl dichloresilane, preserving the heat of 80-140 DEG C for 2-4 hours after dropping is finished, and filtering and distilling to remove an organic solvent to obtain liquid polymethylsilane; (2) mixing liquid polymethylsilane and tetramethyldivinyldisilazane according to a mass ratio of 1:(1 to 10), preserving the heat of 100-250 DEG C for 1-10 hours under the protection of inert atmosphere, and obtaining a liquid polymethylsilane precursor; (3) respectively adding a micron-level inorganic filler and a nano-level inorganic filler into the liquid polymethylsilane precursor, and uniformly mixing to obtain the high-temperature-resistant ceramic precursor adhesive. The ceramic precursor adhesive is high in bonding strength and excellent in heat resistance, and has a wide application prospect in adhering of ceramic materials and carbon materials.

Owner:NAT UNIV OF DEFENSE TECH

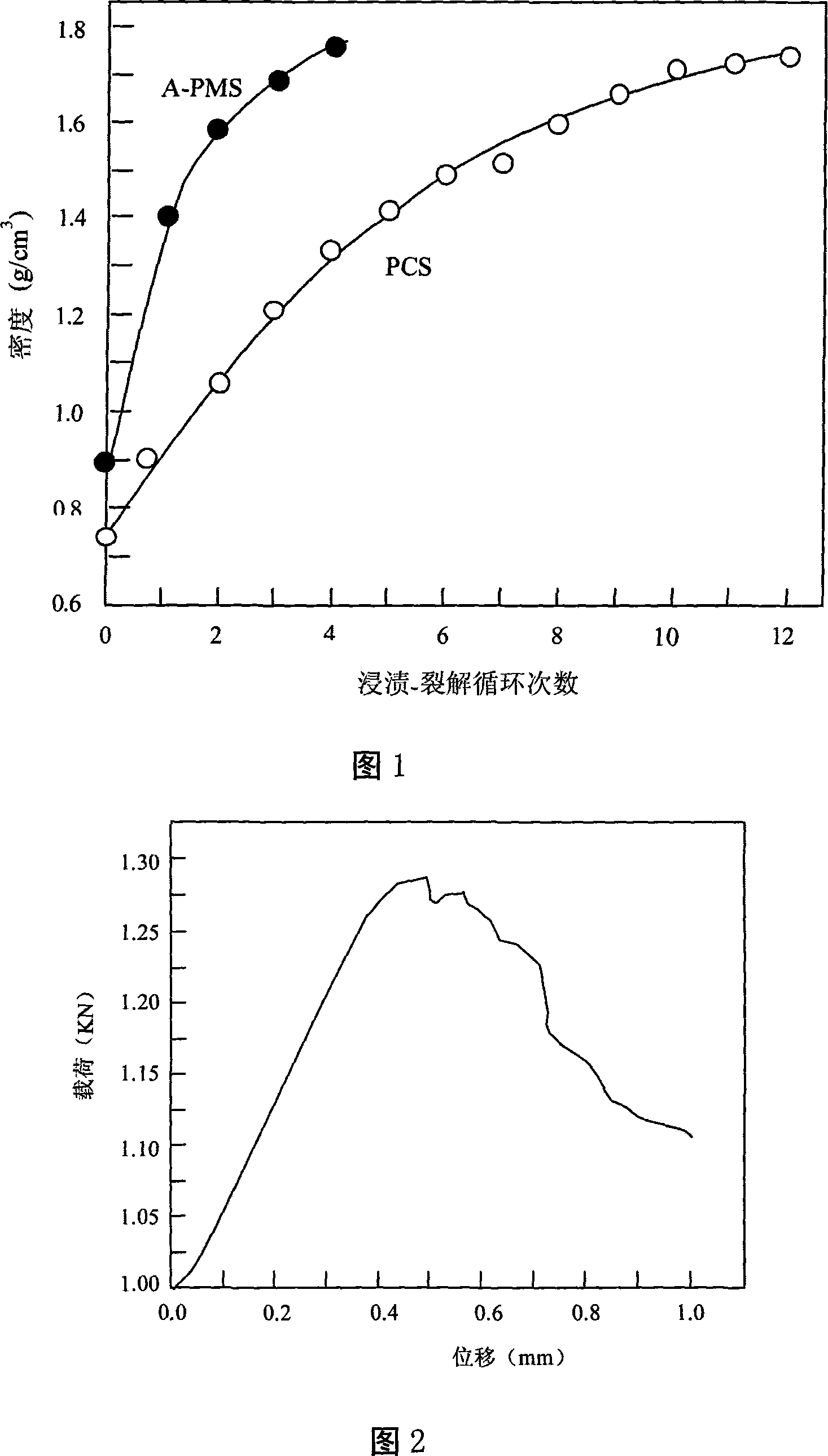

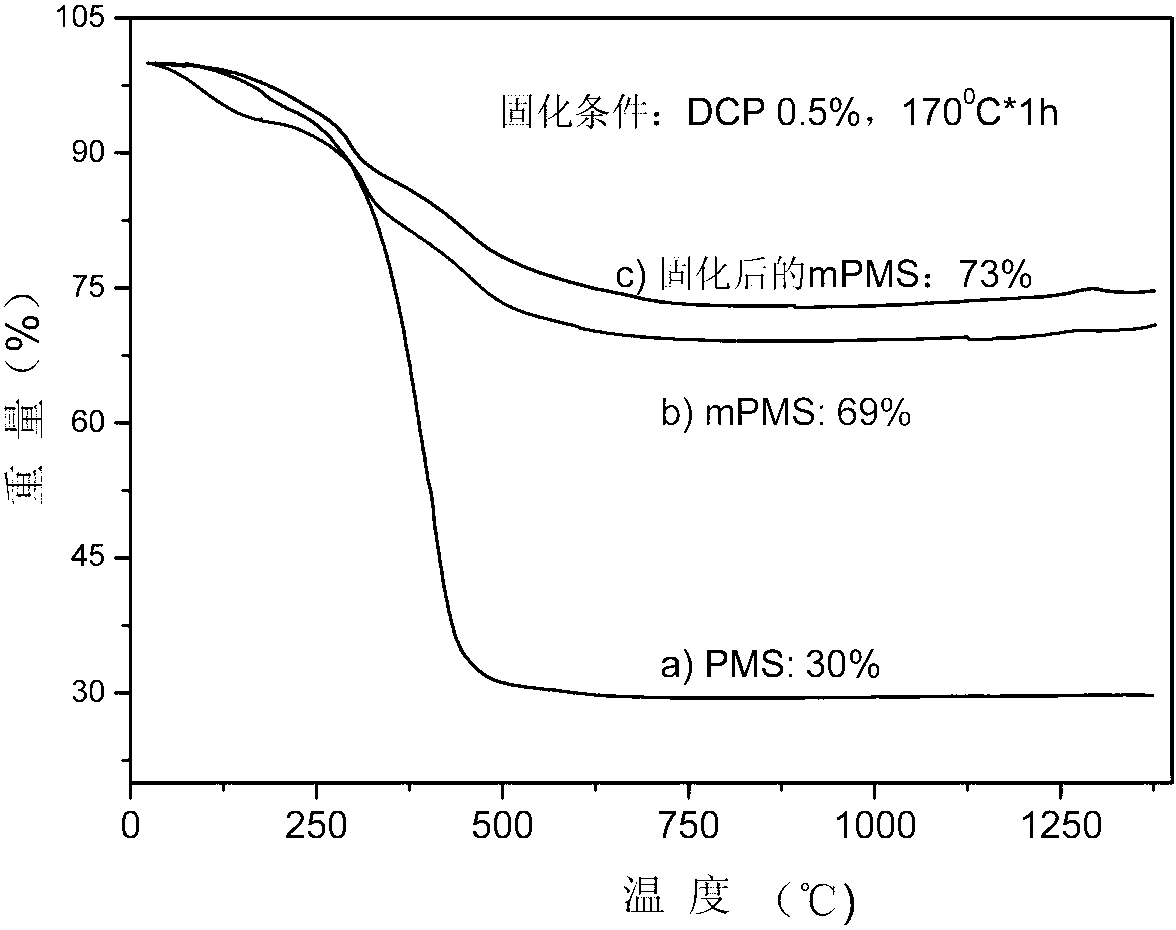

Metal modified polymethyl silicane, preparation method and application thereof

The invention discloses a metallic modified polymethyl siloxane, process for preparation and application. The metallic modified polymethyl siloxane regards the polymethyl siloxane as the matrix polymer, metallic chloride as the cross linking agent, oxosilane compound as the accelerant and synthesizes a metallic modified polymethyl siloxane harbinger body polymeric compound via removing hydrochloride which is liquid state in the normal temperature, wherein the mean molecular weight of the metallic modified polymethyl siloxane harbinger body polymeric compound is between 400 and 1000, the ceramic yield is 60-80%, the metallic modified polymethyl siloxane harbinger body polymeric compound can be solidified at 300-400 DEG C, the solidified ceramic yield can achieve more than 95%. The invention can be used for preparing the ceramic group composite material in PIP technology, which can shorten the dipping cycle frequency, reduces the material cost, guarantees the carborundum basal body of the product and has ideal silicon carbide ratio.

Owner:NAT UNIV OF DEFENSE TECH

Plasma processes for depositing low dielectric constant films

A method and apparatus for depositing a low dielectric constant film by reaction of an organosilicon compound and an oxidizing gas at a constant RF power level from about 10W to about 200W or a pulsed RF power level from about 20W to about 500W. Dissociation of the oxidizing gas can be increased prior to mixing with the organosilicon compound, preferably within a separate microwave chamber, to assist in controlling the carbon content of the deposited film. The oxidized organosilane or organosiloxane film has good barrier properties for use as a liner or cap layer adjacent other dielectric layers. The oxidized organosilane or organosiloxane film may also be used as an etch stop and an intermetal dielectric layer for fabricating dual damascene structures. The oxidized organosilane or organosiloxane films also provide excellent adhesion between different dielectric layers. A preferred oxidized organosilane film is produced by reaction of methylsilane, CH3SiH3, dimethylsilane, (CH3)2SiH2, or 1,1,3,3-tetramethyl-disiloxane, (CH3)2-SiH-O-SiH-(CH3)2, and nitrous oxide, N2O, at a constant RF power level from about 10W to about 150W, or a pulsed RF power level from about 20W to about 250W during 10% to 30% of the duty cycle.

Owner:APPLIED MATERIALS INC

Anti-hard water composite water-soluble fertilizer and preparation method thereof

InactiveCN102584470AHigh nutrient contentStrong resistance to hard waterFertilizer mixturesCarrageenanCopper sulfate

The invention discloses an anti-hard water composite water-soluble fertilizer and a preparation method of the anti-hard water composite water-soluble fertilizer. The existing composite water-soluble fertilizer is low in hard water resistance and cannot be used in saline-alkali areas. The anti-hard water composite water-soluble fertilizer contains the following components: 30-50% of nitrogen, phosphorus and potassium, 0.5-2% of microelements including iron, manganese, copper, zinc, molybdenum and boron, 3-8% of humic acid, and water for the rest. The preparation method of the anti-hard water composite water-soluble fertilizer comprises the following steps: taking weathered coal, sulfuric acid, phosphoric acid, nitric acid, ammonium nitrate, potassium hydroxide and potassium nitrate as main materials; taking potassium pyrophosphate, polyvinylpyrrolidone, polyacrylamide, ammonium polyphosphate, sodium dodecyl sulfate, methylsilane, xanthan gum, carrageenan and konjac gum mixture as an auxiliary anti-hard water slow release agent; taking ferrous sulfate, zinc sulfate, potassium borate, copper sulfate, manganese sulfate and ammonium molybdate as microelement additives; degrading, modifying, chelating, stabilizing and the like to obtain the anti-hard water composite water-soluble fertilizer. The anti-hard water composite water-soluble fertilizer is high in utilization rate, stable in product shape, convenient to use, resistant to hard water and the like, and is suitable for saline-alkali areas with harder water.

Owner:HANGZHOU QIUSHI INTPROP CONSULTATION & SERVICE

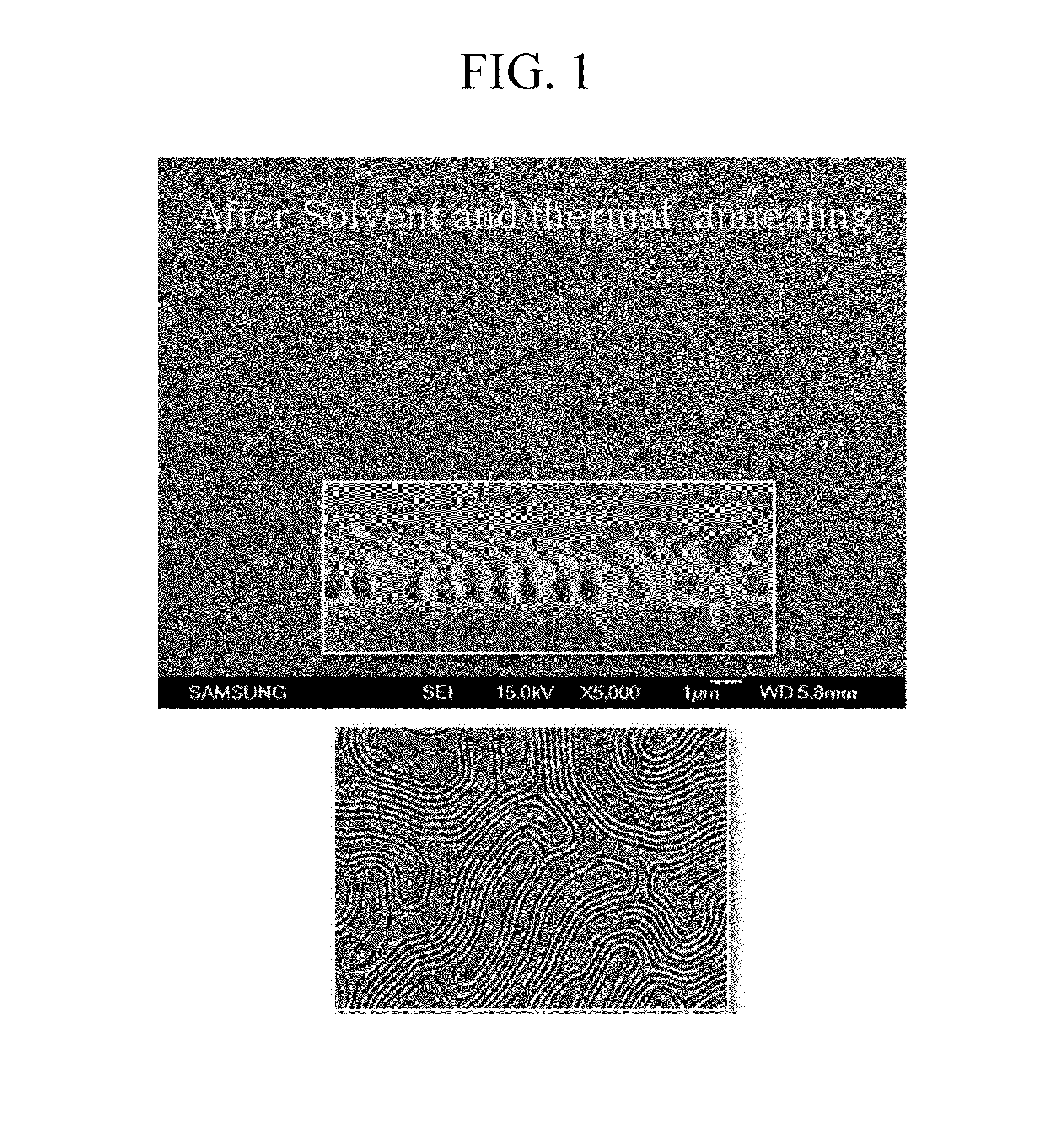

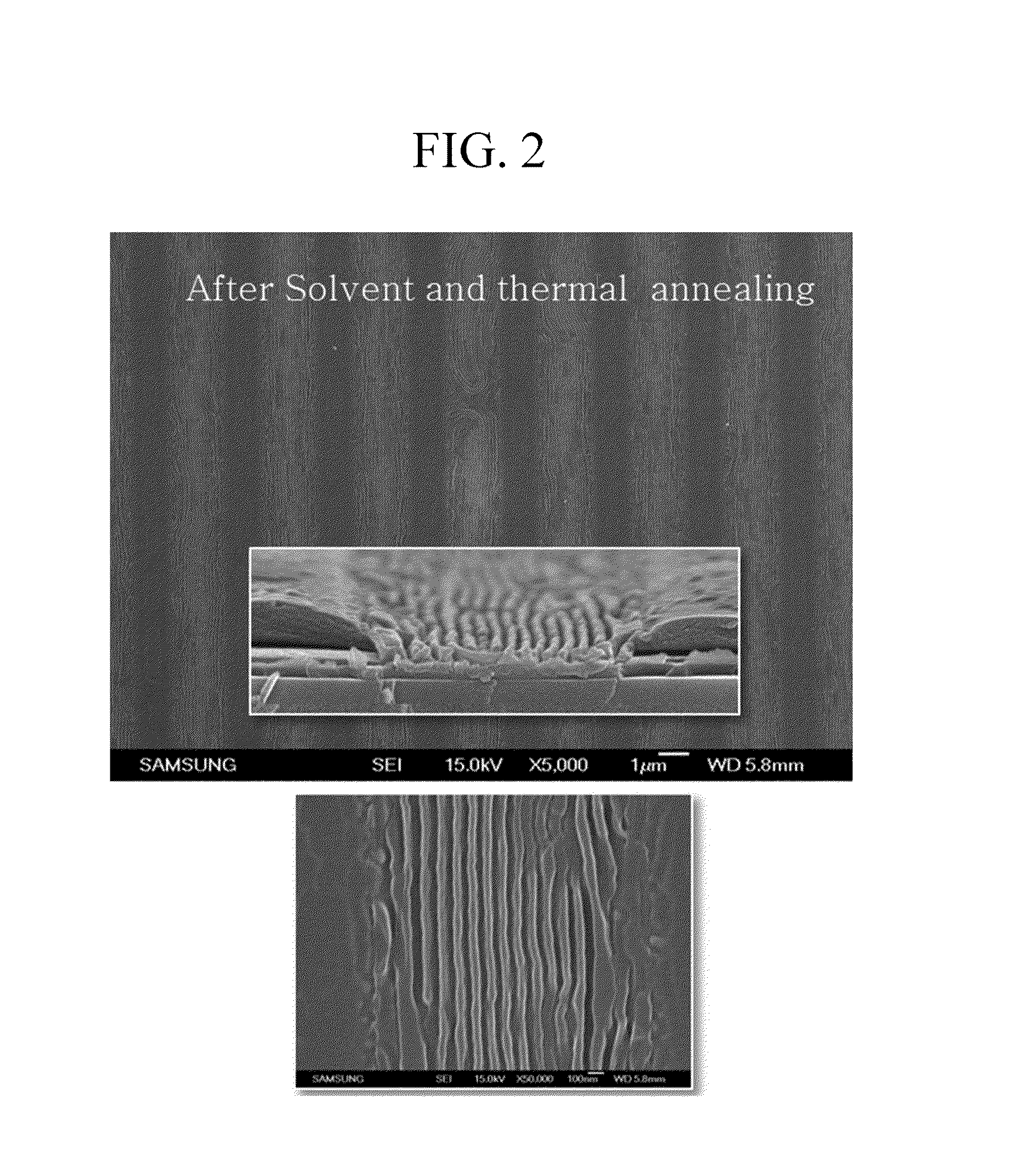

Block copolymer, method of forming the same, and method of forming pattern

ActiveUS20140197132A1Increase separation speedAvoid processing timeDecorative surface effectsFootwearPolyethylene oxideHydrogen

A block copolymer is provided. The block copolymer according to an exemplary embodiment includes a first block represented by Chemical Formula 1 and a second block represented by Chemical Formula 2:wherein COM1 and COM2 are independently selected from a polystyrene moiety, polymethylmethacrylate moiety, polyethylene oxide moiety, polyvinylpyridine moiety, polydimethylsiloxane moiety, polyferrocenyldimethylsilane moiety, and polyisoprene moiety, R1 is hydrogen or an alkyl group with 1 to 10 carbon atoms, Ph is a phenyl group, a is 1 to 50, R2 is hydrogen or an alkyl group with 1 to 10 carbon atoms, and b is 1 to 50.

Owner:SAMSUNG DISPLAY CO LTD +2

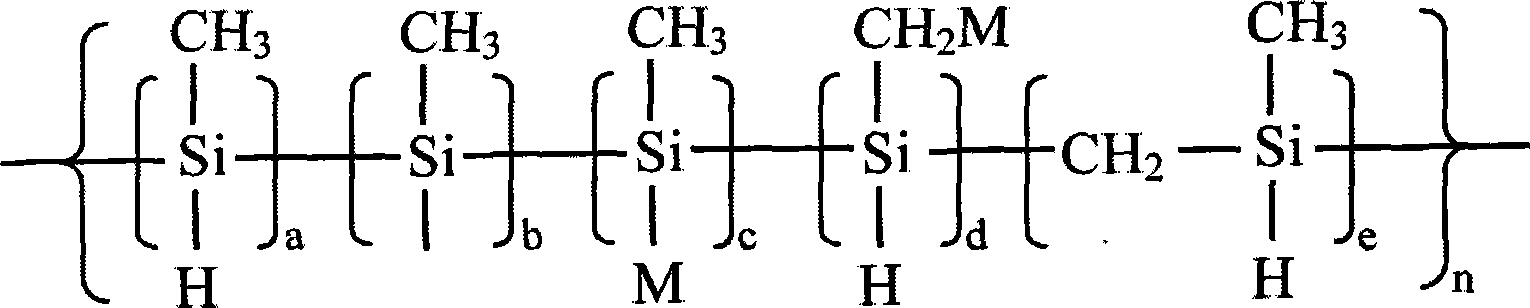

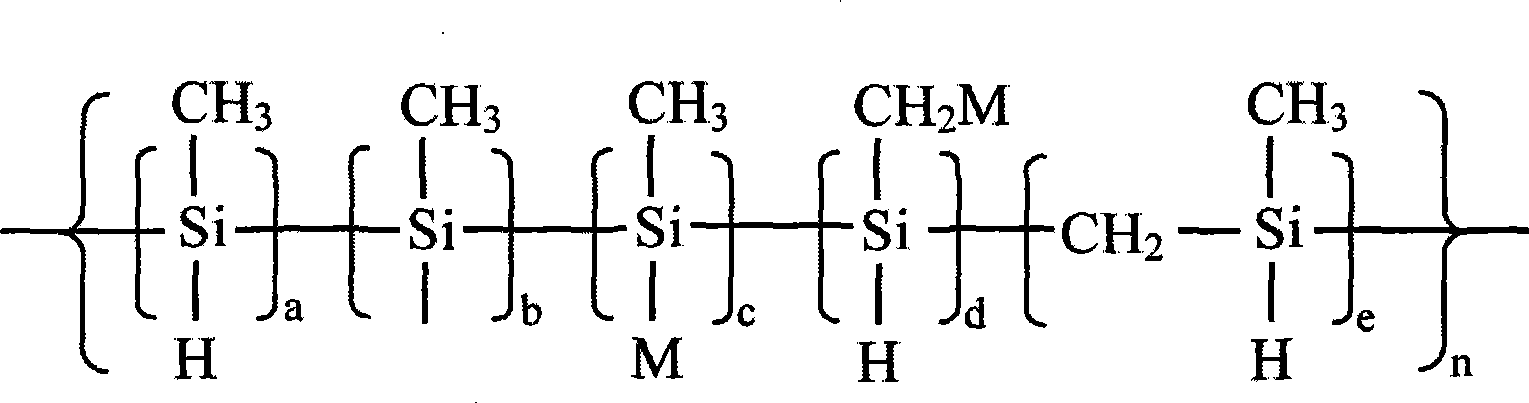

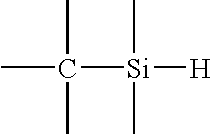

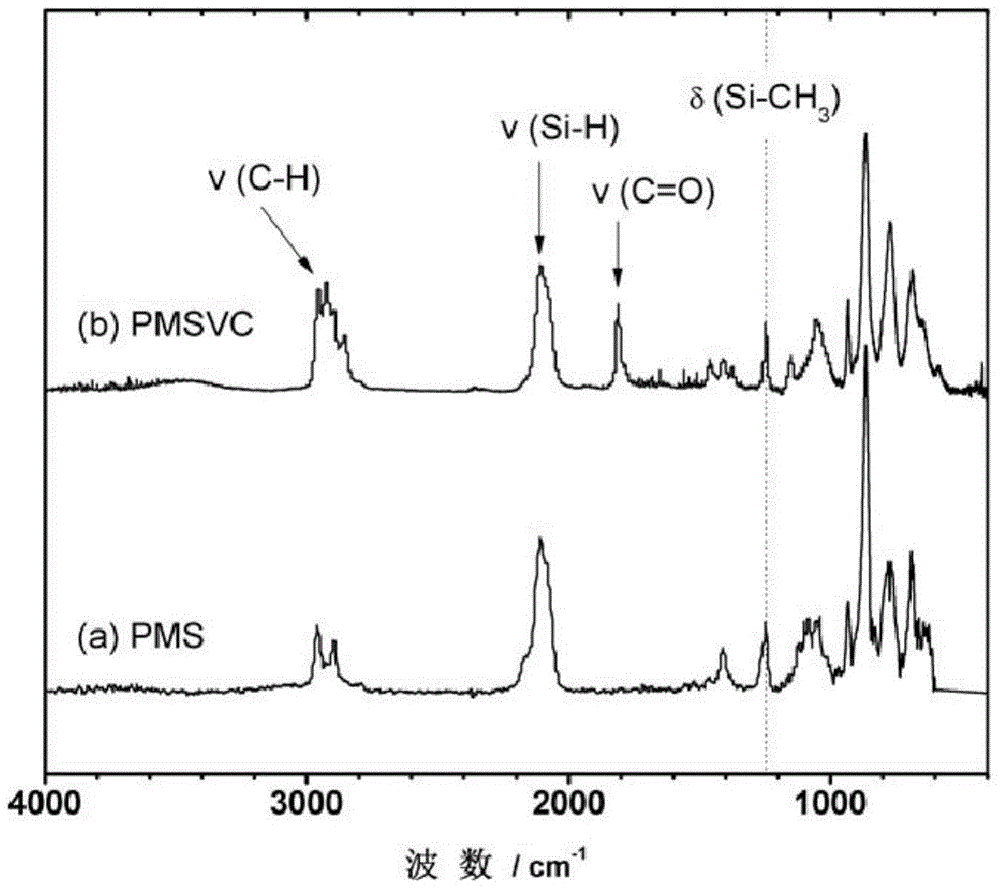

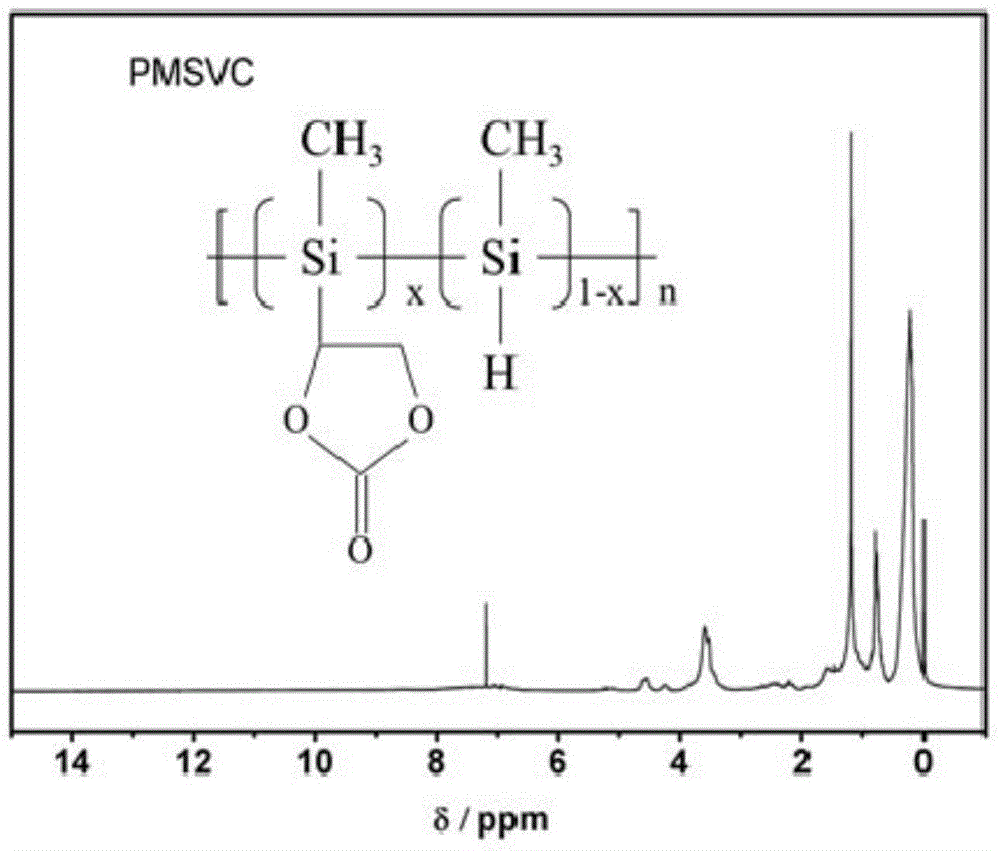

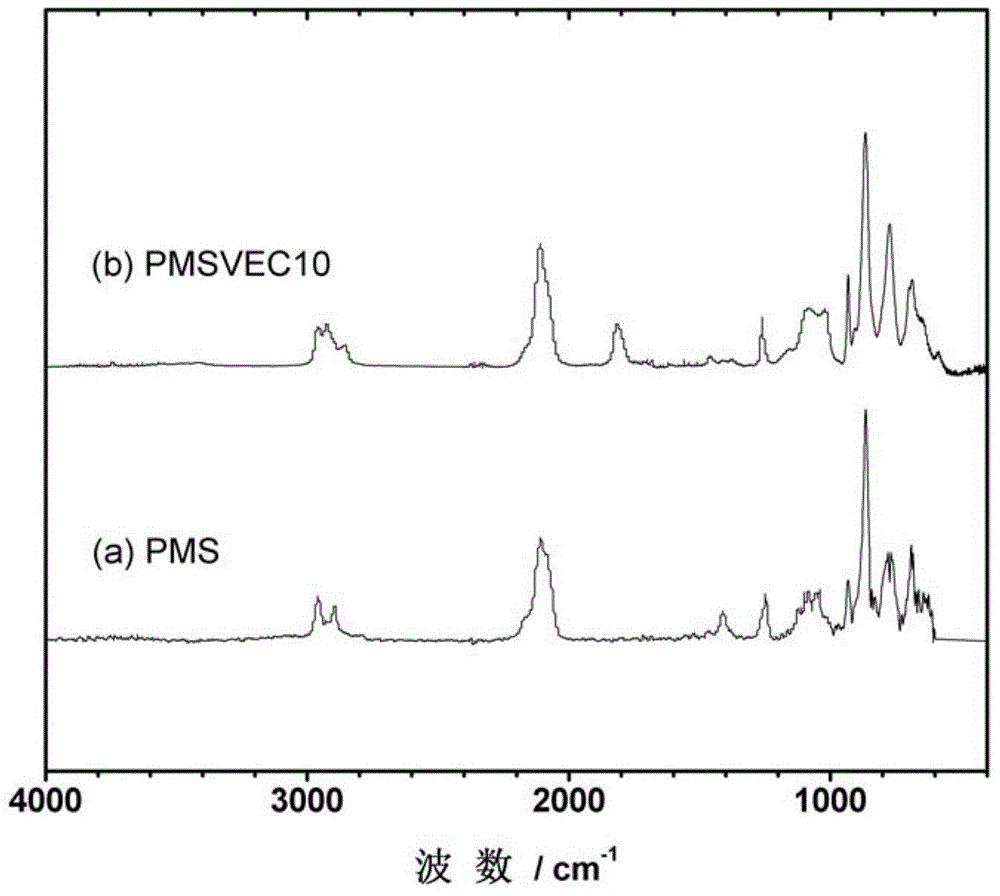

Grafted polysilane compound, preparation method and application of grafted polysilane compound in battery electrolyte

ActiveCN104448324AImprove charge and discharge cycle stabilitySuppression of attenuation lossSecondary cellsHydrogenStructural formula

The invention discloses a grafted polysilane compound, a preparation method and an application of the grafted polysilane compound. A chemical structural formula of the grafted polysilane compound can be expressed with the following formula as shown in the specification, wherein the polymerization degree n is 18-23; the quantity m of -CH2- chain links is 0-6; and the grafted replacement rate x is 0-0.8. The invention also provides a preparation method of the grafted polysilane compound. The method comprises the following step: grafting a vinylene carbonate compound on a branch chain of poly-hydrogen methylsilane through hydrosilicenae addition reaction, so as to obtain grafted polysilane. The grafted polysilane compound provided by the invention can be applied to the battery electrolyte as a stabilizer, thus the charge and discharge cycling stability of the battery at a high temperature is improved.

Owner:NAT UNIV OF DEFENSE TECH +1

Preparation method for ceramic precursor binder allowed to be cured at room temperature

ActiveCN104232017AAchieving room temperature curingGood adhesionNon-macromolecular adhesive additivesOrganic solventToluene

The invention discloses a preparation method for a ceramic precursor binder allowed to be cured at the room temperature. The preparation method comprises the following steps: firstly, adding metallic sodium and methylbenzene in a three-mouth flask with a condensation flux device and a mechanical stirring device; heating the mixture to 80-120DEG C under the protection of inert gases, and dropping methyl dichloresilane; after the dropping is finished, preserving the heat at the temperature of 80-120DEG C for 4-12 hours, filtering, distilling and removing an organic solvent to obtain liquid polysilane; secondly, performing heat preservation on the liquid polysilane and 2,4,6,8-tetramethyl-2,4,6,8-tetravinyl cyclotetrasiloxane at the temperature of 80-160DEG C under the protection of the inert gases for 1-6 hours to obtain a liquid siloxane polycarbonate precursor; thirdly, uniformly mixing the liquid siloxane polycarbonate precursor with boron carbide powder, glass powder and a compound containing platinum to obtain the ceramic precursor binder. By using the preparation method disclosed by the invention, the ceramic precursor binder which can be cured at the room temperature and has excellent temperature resistance and binding performance can be prepared.

Owner:NAT UNIV OF DEFENSE TECH

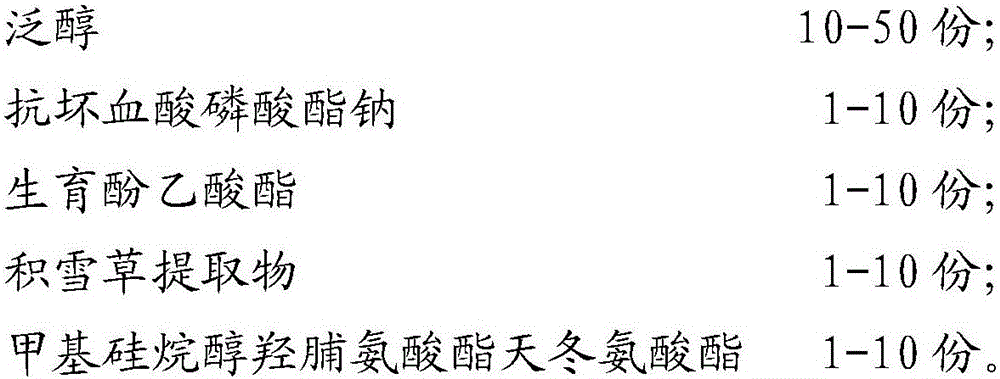

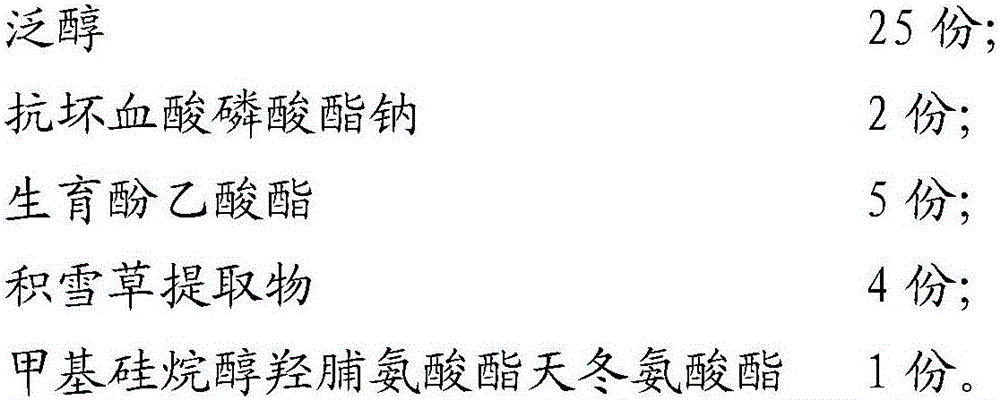

Composition for preventing stretch marks, stretch mark cream and the preparation method

InactiveCN106265310ASafeEfficientCosmetic preparationsToilet preparationsFiberCentella asiatica extract

The invention relates to the field of skin care and in particular relates to a composition for preventing stretch marks, a stretch mark cream and the preparation method. The composition for preventing stretch marks, includes by weight the following constituents: panthenol 10-50 parts; ascorbic acid sodium phosphate 1-10 parts; tocopheryl acetate 1-10 parts; centella asiatica extract 1-10 parts; methylsilanol hydroxyproline ester aspartate 1-10 parts. The selected raw materials in the method are commonly used qualified cosmetic constituents, and do not contain chemical peeling agent and exfoliating ingredients, the safety is high; the formula composition is carefully designed for stretch marks and the repair, it keeps the skin elastic and soft, strengthens the skin elasticity; the composition penetrates deep into the skin, nourishes and repairs; it prevents the degeneration of elastic fibers, collagen fiber and proteoglycan, stimulates and regulates fibroblast cell division, helps the regeneration of epidermal and dermal cells, prevents stretch marks.

Owner:TIANJIN TIANSHI BIOLOGICAL DEV

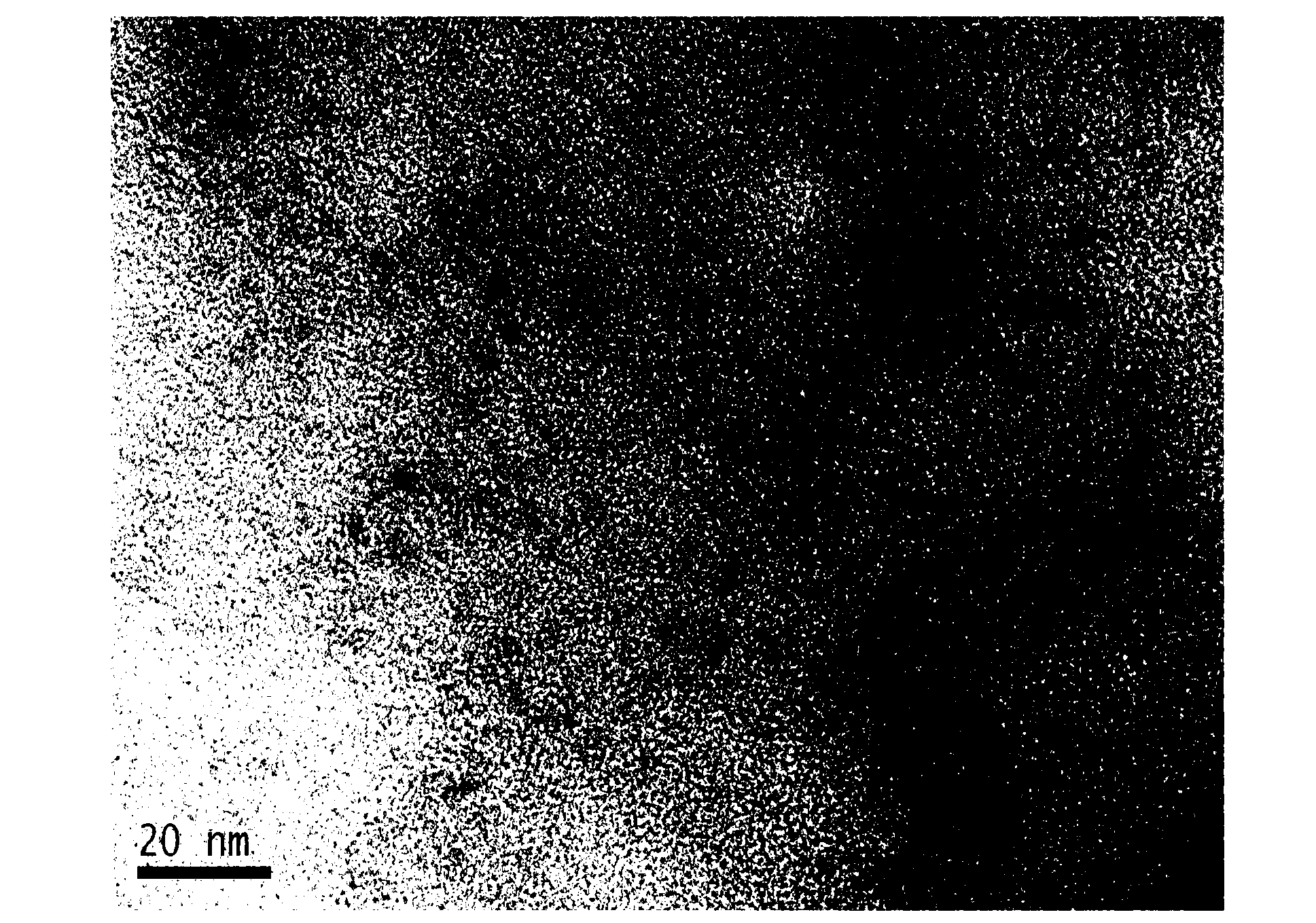

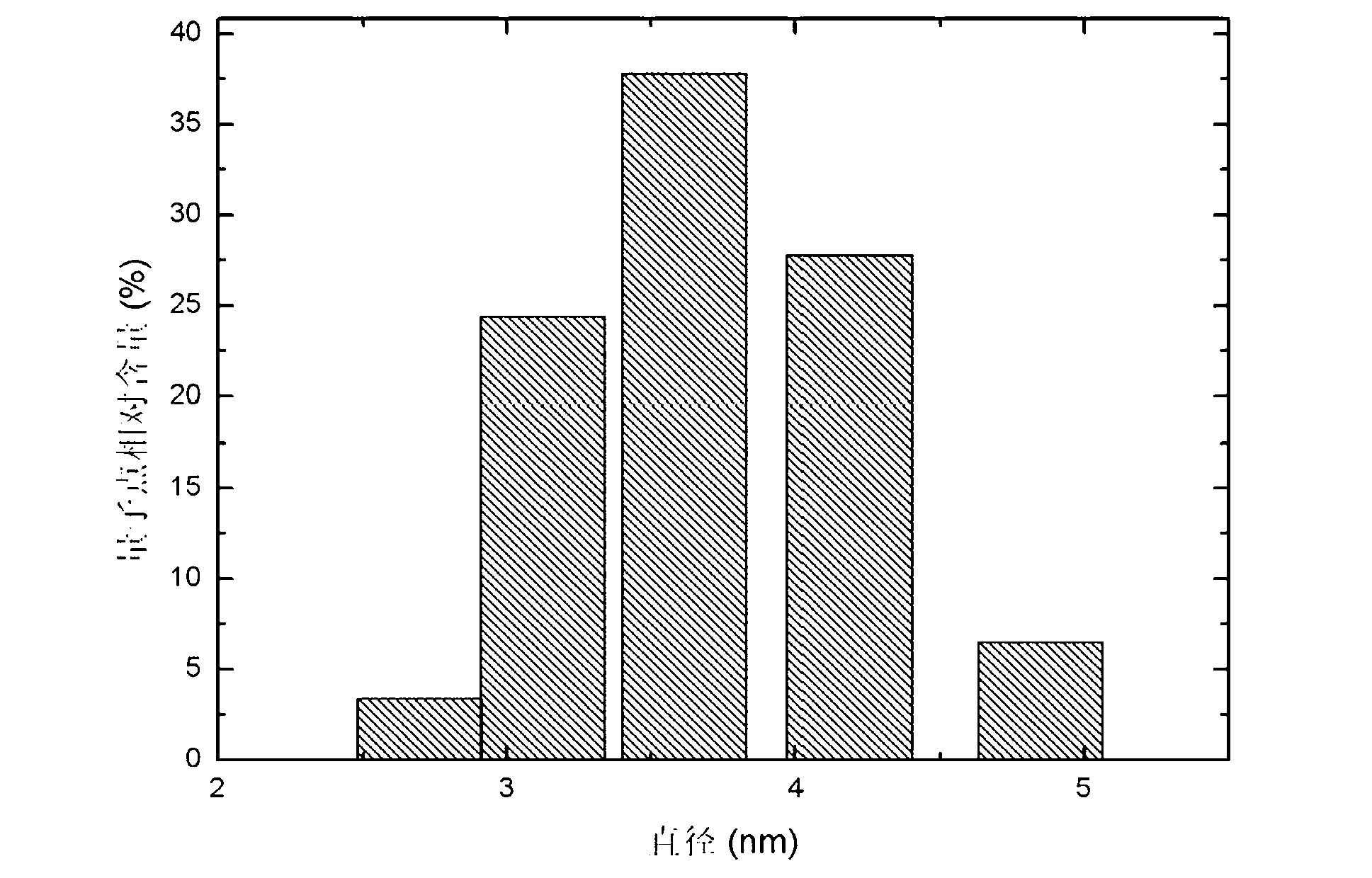

Silicon carbide quantum dot and preparation method thereof

InactiveCN103194224AThe synthesis steps are simpleEasy to operateSilicon carbideLuminescent compositionsFreeze-dryingToluene

The invention discloses a silicon carbide quantum dot and a preparation method thereof. The silicon carbide quantum dot is similar to a ball shape, the granularity of the silicon carbide quantum is normally distributed in the range of 2.5nm to 5.5nm, the excitation wavelength of the silicon carbide quantum dot is 250nm to 400nm, the emission wavelength is 350nm to 450nm, and the fluorescent spectrum peak is 380nm, 400nm and 420nm. The preparation method of the silicon carbide quantum dot comprises the following steps of mixing polymethylsilane and toluene solvent according to a mass ratio of 0.5 to 10: 600, heating the mixture in a high-pressure kettle to 500 DEG C to 600 DEG C through a program, and naturally cooling the mixture after preserving heat for 1h to 5h; and filtering the prepared toluene liquid containing the silicon carbide quantum dot, and freeze-drying or centrifuging the filter liquid at a high speed to obtain the silicon carbide quantum dot. The granularity distribution of the silicon carbide quantum dot is concentrated, the luminescence is strong and stable, and the preparation method is simple, easy and environment-friendly.

Owner:NAT UNIV OF DEFENSE TECH

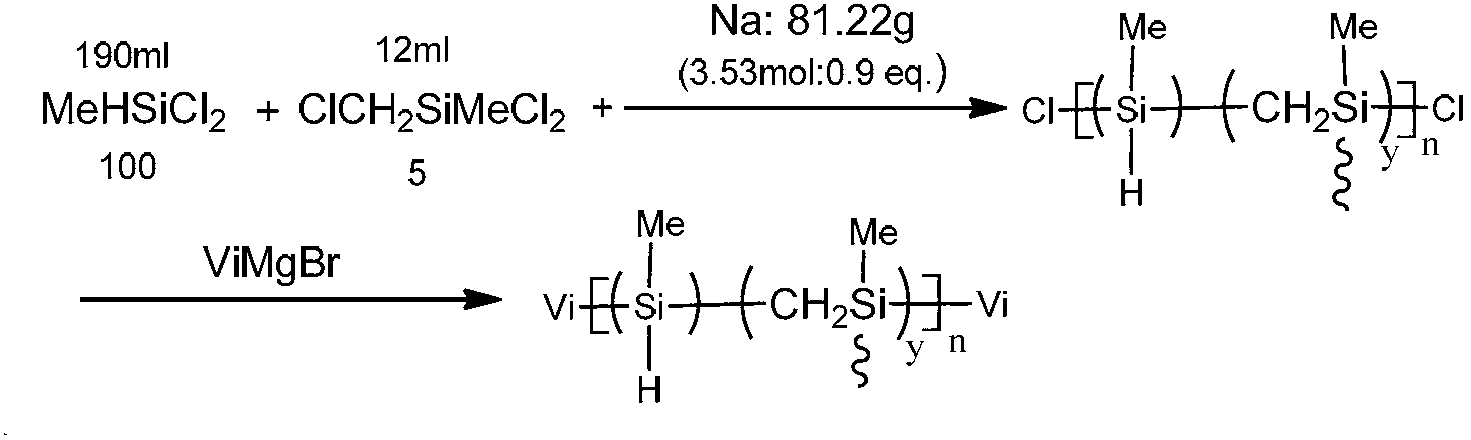

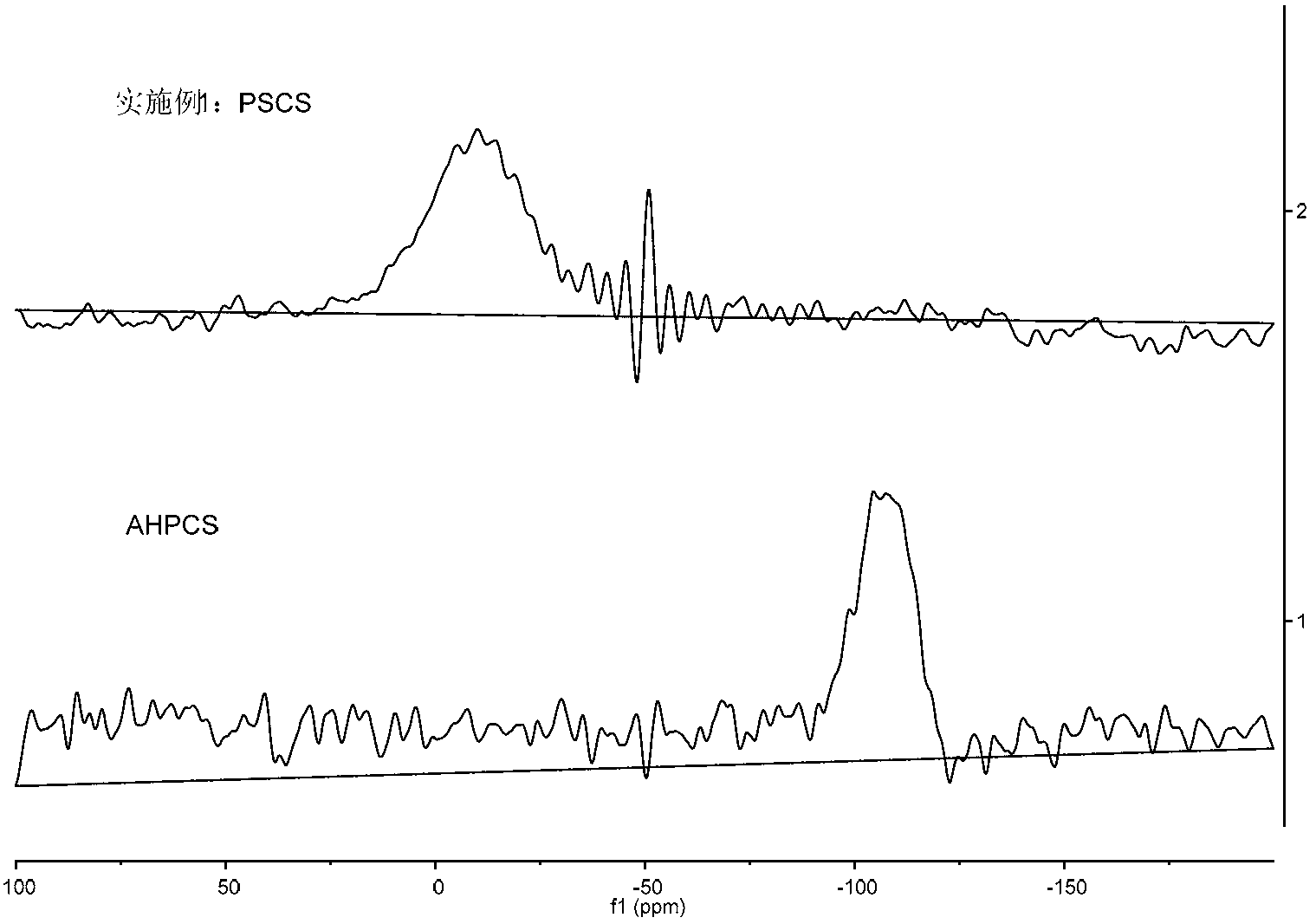

Poly(methylsilane-carbosilane) and preparation method thereof

The invention discloses poly(methylsilane-carbosilane) and a preparation method thereof. The structural formula of the poly(methylsilane-carbosilane) copolymer is shown in formula I which is shown in the specification, wherein x=0-0.2, y=0.03-0.2, z=0-0.25, n=10-30, R1 represents Me, Ph or C2-C8 aromatic hydrocarbon or alkane, R2 represents Me or H, and Y represents a group containing C-C unsaturated bond. The preparation method of the poly(methylsilane-carbosilane) comprises the following steps of: in an organic solvent, carrying out a Wurtz type condensation polymerization reaction on a chlorosilane monomer mixture and insufficient alkali metal to synthesize Si-Cl bond-containing intermediate polymer; and then obtaining liquid methylsilane-carbosilane copolymer containing a C-C unsaturated bond through a grignard coupling reaction. The poly(methylsilane-carbosilane) disclosed by the invention can be served as a silicon carbide ceramic precursor, has the advantages of high ceramic yield, good storage stability and adjustability in structure composition, and can be applied to precursors of ceramic coatings and block body materials, and impregnants of composite materials.

Owner:INST OF CHEM CHINESE ACAD OF SCI

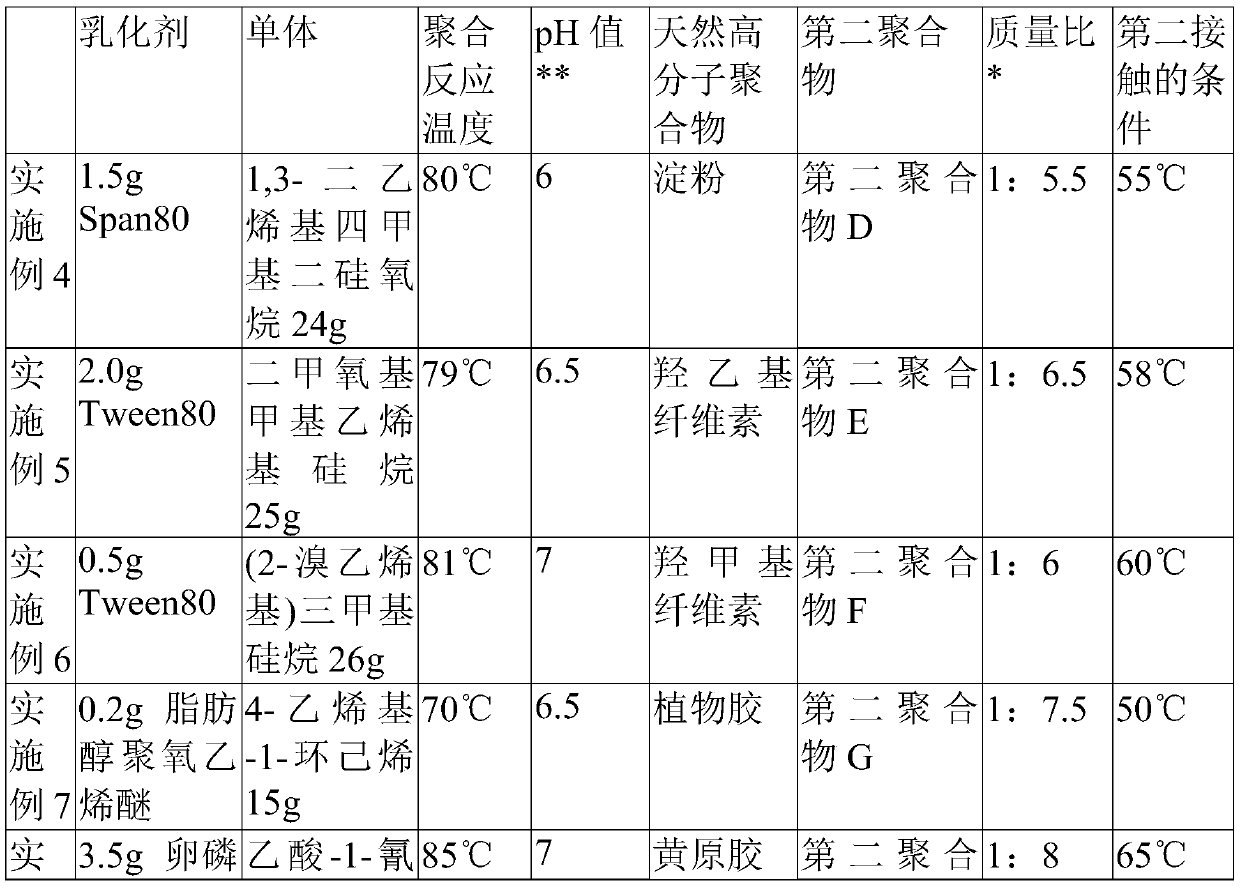

Filtrate reducer and preparation method thereof, and water-based drilling fluid and application thereof

The invention relates to the technical field of oil exploitation, and discloses a filtrate reducer and a preparation method thereof, and a water-based drilling fluid and application thereof. The filtrate reducer comprises a first polymer and a second polymer, wherein the first polymer is a natural high-molecular polymer; the second polymer is prepared by carrying out a polymerization reaction on an emulsifier and a monomer in the presence of an initiator; and the monomer is one or more selected from a group consisting of methyl-4-vinylbenzoate, dimethoxymethylvinylsilane, 1,3-divinyltetramethyldisiloxane, (2-bromovinyl)trimethylsilane, 4-vinyl-1-cyclohexene and acetic acid-1-cyano-2-propenyl ester. The water-based drilling fluid containing the filtrate reducer has salt resistance and high-temperature resistance, meets the requirement for the environmental protection properties of no toxicity and easy degradation, and also has tackifying and shear strength improving properties.

Owner:CHINA PETROCHEMICAL CORP +3

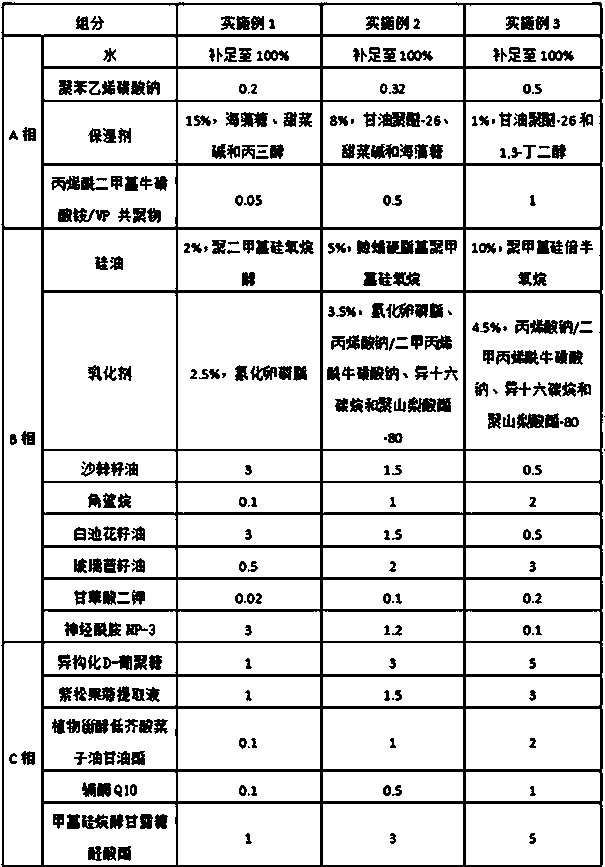

Facial care product for repairing sensitive skin and resisting initial aging

InactiveCN111067832AImprove the damaged stateEnhanced sensitivityCosmetic preparationsToilet preparationsSuspending AgentsHippophae

The invention belongs to the field of daily chemicals. A facial care product for repairing sensitive skin and resisting initial aging comprises the following components: an echinacea purpurea extract,a moisturizer, a carbohydrate isomer, borago officinalis seed oil, hippophae rhamnoides seed oil, squalane, limnanthes alba seed oil, sodium polystyrene sulfonate, a thickening suspending agent, silicone oil, an emulsifier, dipotassium glycyrrhizinate, a phytosteryl canola glyceride, ceramide NP-3, coenzyme Q10, methylsilanol mannuronate and water. The care product of the invention can increase skin moisture content, reduces skin moisture loss, and provides long-term water supplement and moisturizing effects; repairs skin barrier, helps skin resist surfactant stimulation and ultraviolet damage, and has anti-inflammatory and anti-allergic effects; has good anti-oxidant effects, tightens and revitalizes skin, prevents wrinkles and resists wrinkles, and effectively delays skin aging; and canform a protective film on the skin surface, and effectively resists initial aging while repairing sensitive skin.

Owner:OPAL COSMETICS HUIZHOU

Preparation method of graphite/SiC composite material

ActiveCN105481477AExcellent high temperature oxidation resistanceExcellent thermal shock resistancePorosityMaterials preparation

The invention discloses a preparation method of a graphite / SiC composite material, and belongs to the technical field of C / SiC composite material preparation. The preparation method adopts graphite the density of which is 1.6-1.85g / cm<3> as a raw material, and comprises the steps: firstly, carrying out soaking, curing, pyrolysis and Si / C reaction to obtain a pre-finished product the density of which is 1.95-2.05g / cm<3>; secondly, carrying out enrichment-pyrolysis on polymethyl silane in a graphite container to obtain a graphite / SiC pre-finished product with an amorphous silicon carbide coating; and finally, carrying out sintering to obtain a graphite / SiC finished product with a beta silicon carbide coating. The porosity of the finished product provided by the invention is less than or equal to 2%, and the problem of cracking when the product is used at a high temperature is avoided.

Owner:HUNAN BOWANG CARBON CERAMIC CO LTD

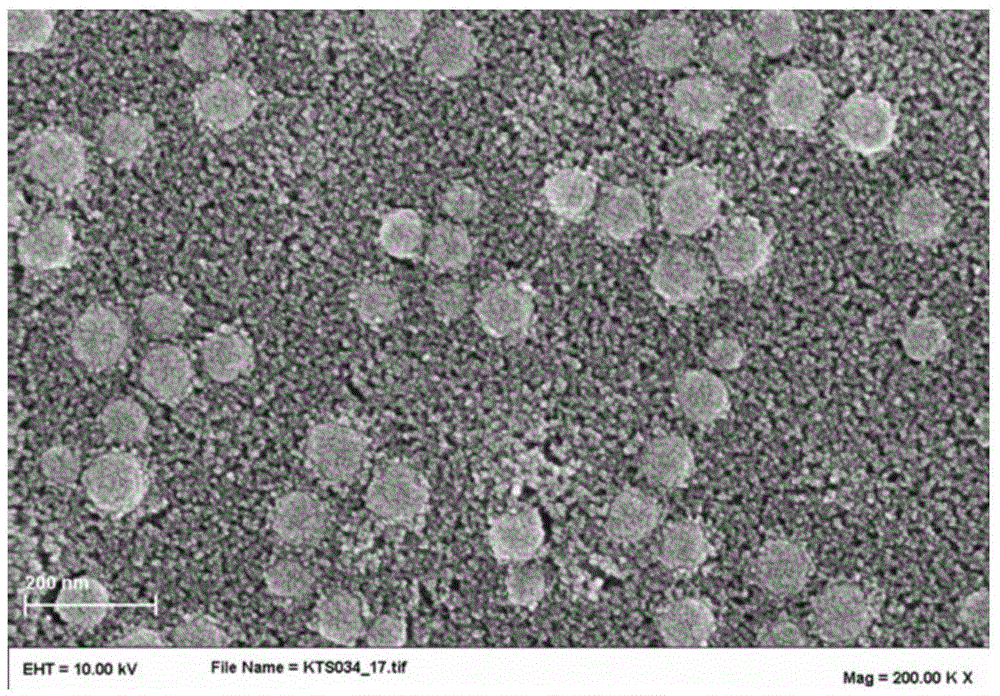

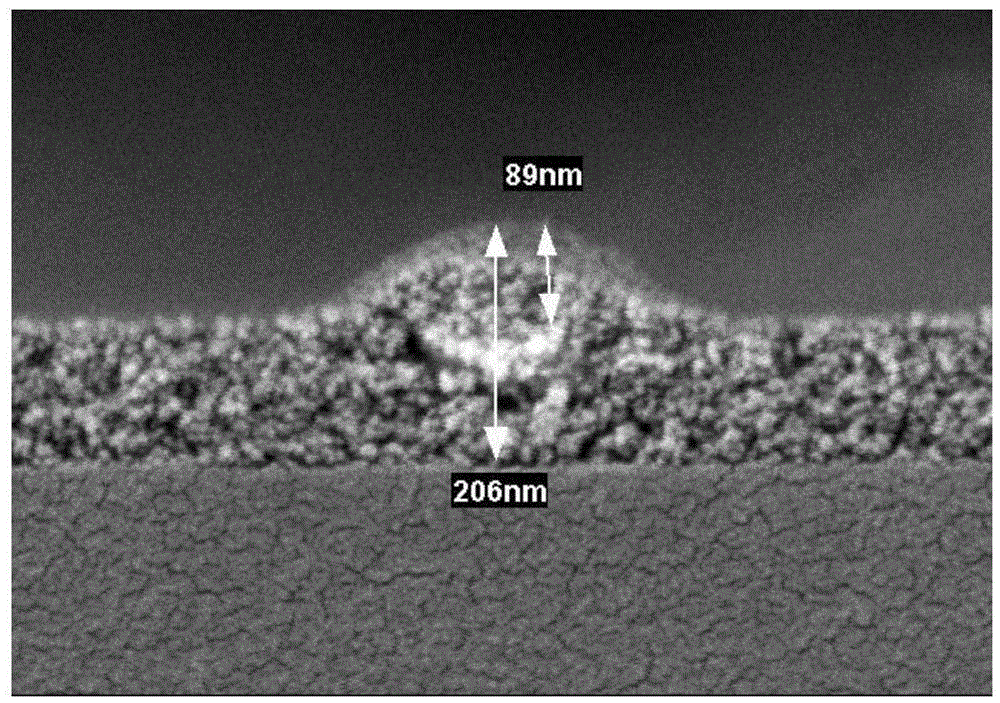

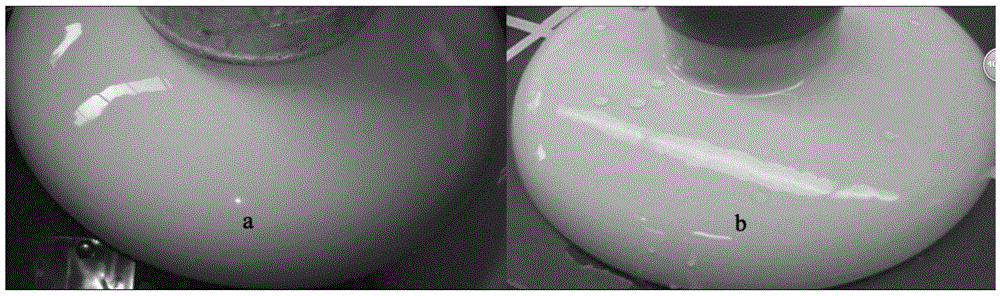

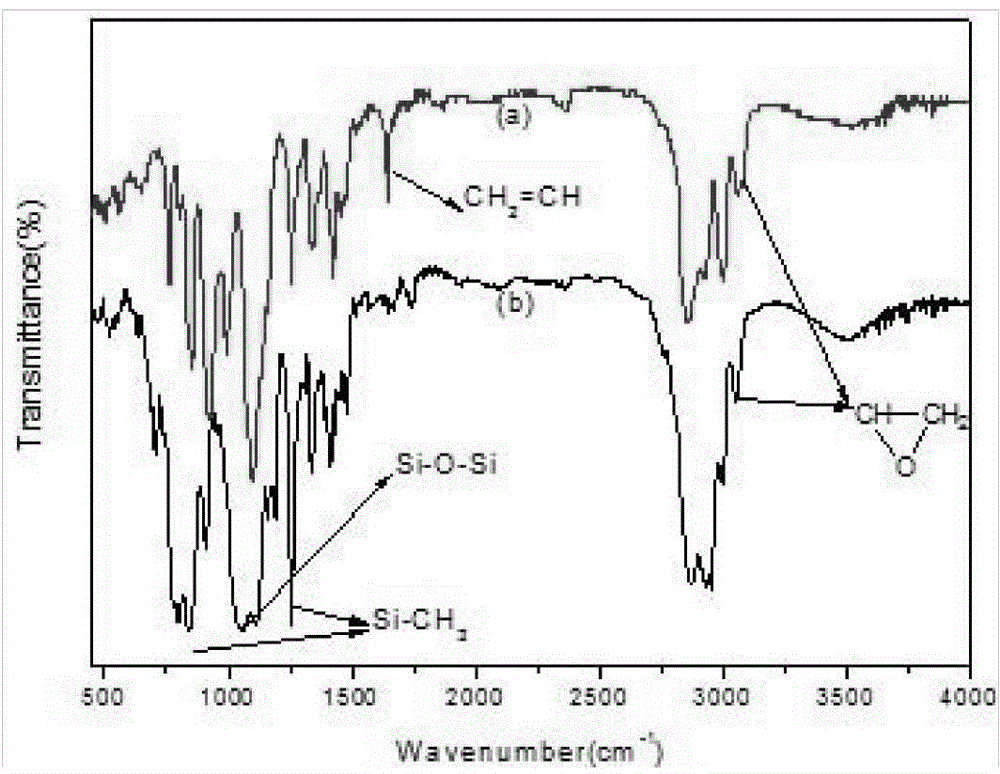

Inorganic hydrophobic antifouling glaze used for porcelain insulator as well as preparation method and application thereof

The invention relates to an inorganic hydrophobic antifouling glaze used for a porcelain insulator as well as a preparation method and an application thereof and belongs to the technical field of improvement of glazes used for the porcelain insulators. The inorganic hydrophobic antifouling glaze used for the porcelain insulator is prepared from the following raw materials in percentage by weight: 3-14% of silica sol, 0.5-4% of methylsilane, 12-21% of acetic acid and 75-89% of propyl alcohol. The inorganic hydrophobic antifouling glaze used for the porcelain insulator is simple in formula, hydrophilicity of the surface of the traditional porcelain insulator is changed, antifouling property is improved, and the inorganic hydrophobic antifouling glaze used for the porcelain insulator has the advantages of aging resistance, scour resistance, good weather resistance, high strength and long life. The invention also provides a simple preparation method and an application of the inorganic hydrophobic antifouling glaze.

Owner:SINOMA JIANGXI ELECTRICAL PORCELAIN ELECTRIC CO LTD

Separation analyzing method for lipophilicity extraction in agricultural waste

InactiveCN1560626AReduce usageSimple and fast operationComponent separationTrimethylsilyl chlorideOrganic solvent

The invention discloses a separating and analyzing method for lipophilic extracted substances from the agricultural waste, introduces a method using double-trimethyl silicane group fluoroform acetamide and trimethyl chlorosilane to carry on methyl silicane process after the lipophilic extracted substances is extracted through organic solvent, then using high temperature Rtx-1 capillary to carry on gas phase chromatogram analysis, determining the content and composition of the lipophiltic extracted substances.

Owner:SOUTH CHINA UNIV OF TECH

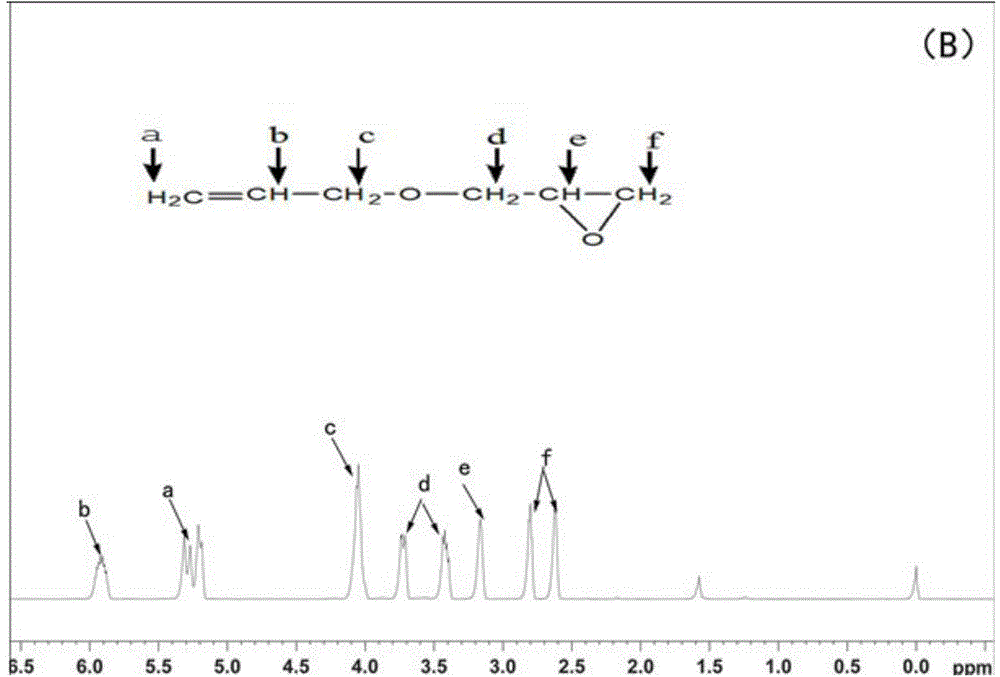

Synthesis method of three-terminal epoxy-modified silicone oil

The invention relates to a synthesis method of three-terminal epoxy-modified silicone oil, and relates to the field of chemistry. The three-terminal epoxy-modified silicone oil is synthesized through two steps. Tetramethyl disiloxane and allyl glycidyl ether are adopted as raw materials; chloroplatinic acid-isopropanol is adopted as a catalyst; and 1,3-diglycidoxypropyl-1,1,3,3-tetramethyl disiloxane with epoxy groups on two terminals is synthesized through a hydrosilylation reaction. The 1,3-diglycidoxypropyl-1,1,3,3-tetramethyl disiloxane is adopted as a capping agent; octamethyl cyclotetrasiloxane and 3-glycidylpropyl(dimethoxy)methylsilane are adopted as raw materials; tetramethyl ammonium hydroxide is adopted as a catalyst; and epoxy-modified silicone oil with epoxy groups on three terminals is synthesized through a bulk polymerization method. Through controlling a reaction material ratio, products with different molecular weights can be prepared. According to the invention, modified silicon oil with epoxy groups on three terminals is synthesized for a first time. Reaction activity is enhanced, and high-temperature resistance is improved.

Owner:CHANGCHUN UNIV OF TECH

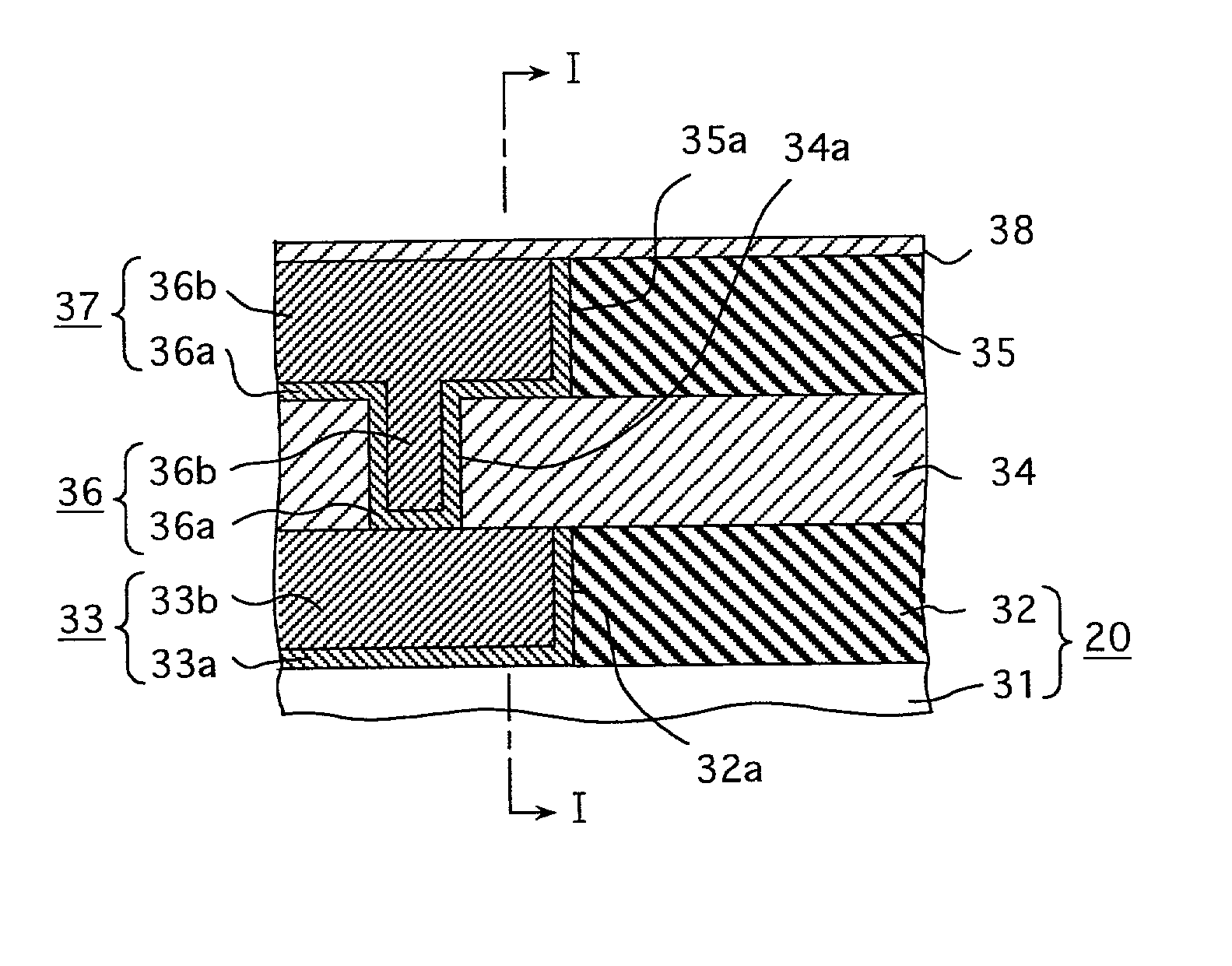

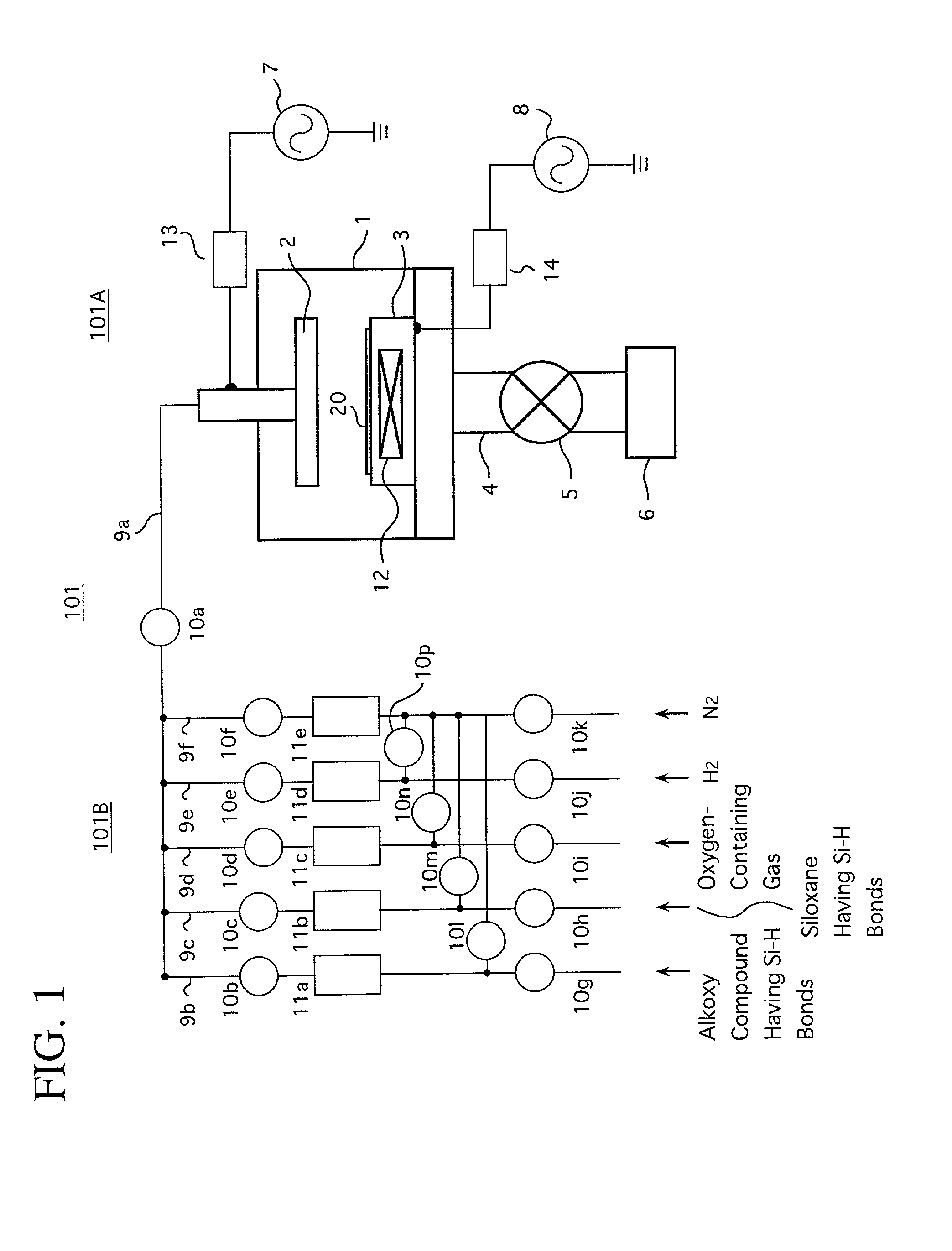

Semiconductor device and semiconductor device manufacturing method

InactiveUS20020011672A1Semiconductor/solid-state device detailsSolid-state devicesForming gasDevice material

The present invention relates to a semiconductor device manufacturing method of forming an inter-wiring layer insulating film having a low dielectric constant to cover a copper wiring. In construction, in a semiconductor device manufacturing method of forming an insulating film 34 having a low dielectric constant on a substrate 20, the insulating film 34 is formed by plasmanizing a film forming gas, that consists of at least any one of alkyl compound having siloxane bonds and methylsilane (SiHn(CH3)4-n: n=0, 1, 2, 3), any one oxygen-containing gas selected from a group consisting of N2O, H2O, and CO2, and ammonia (NH3) to react.

Owner:CANON SALES CO +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com