Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

518 results about "Vinylsilane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

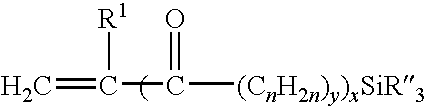

Vinylsilane refers to an organosilicon compound with chemical formula CH₂=CHSiH₃. It is a derivative of silane (SiH₄). The compound, which is a colorless gas, is mainly of theoretical interest.

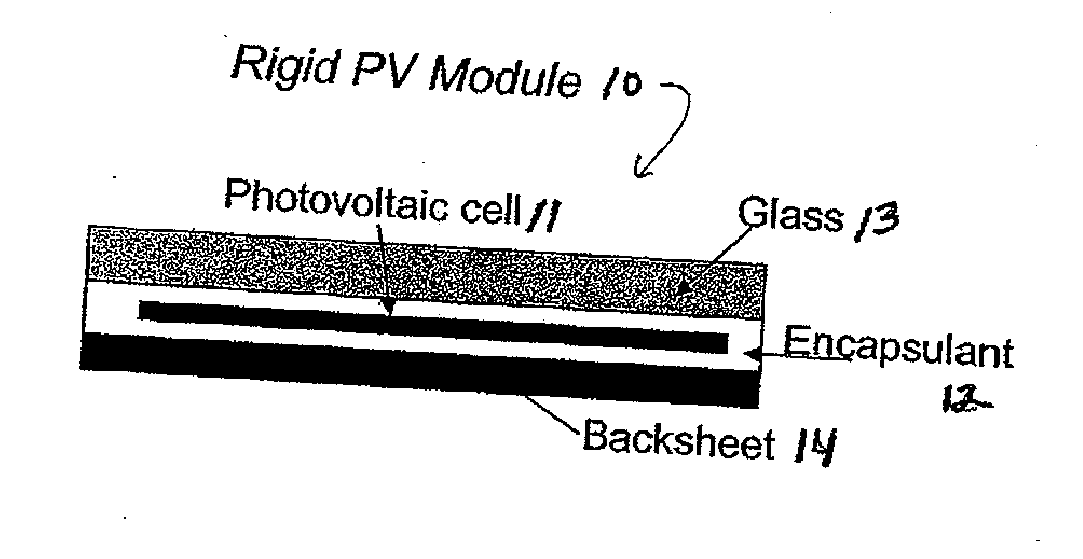

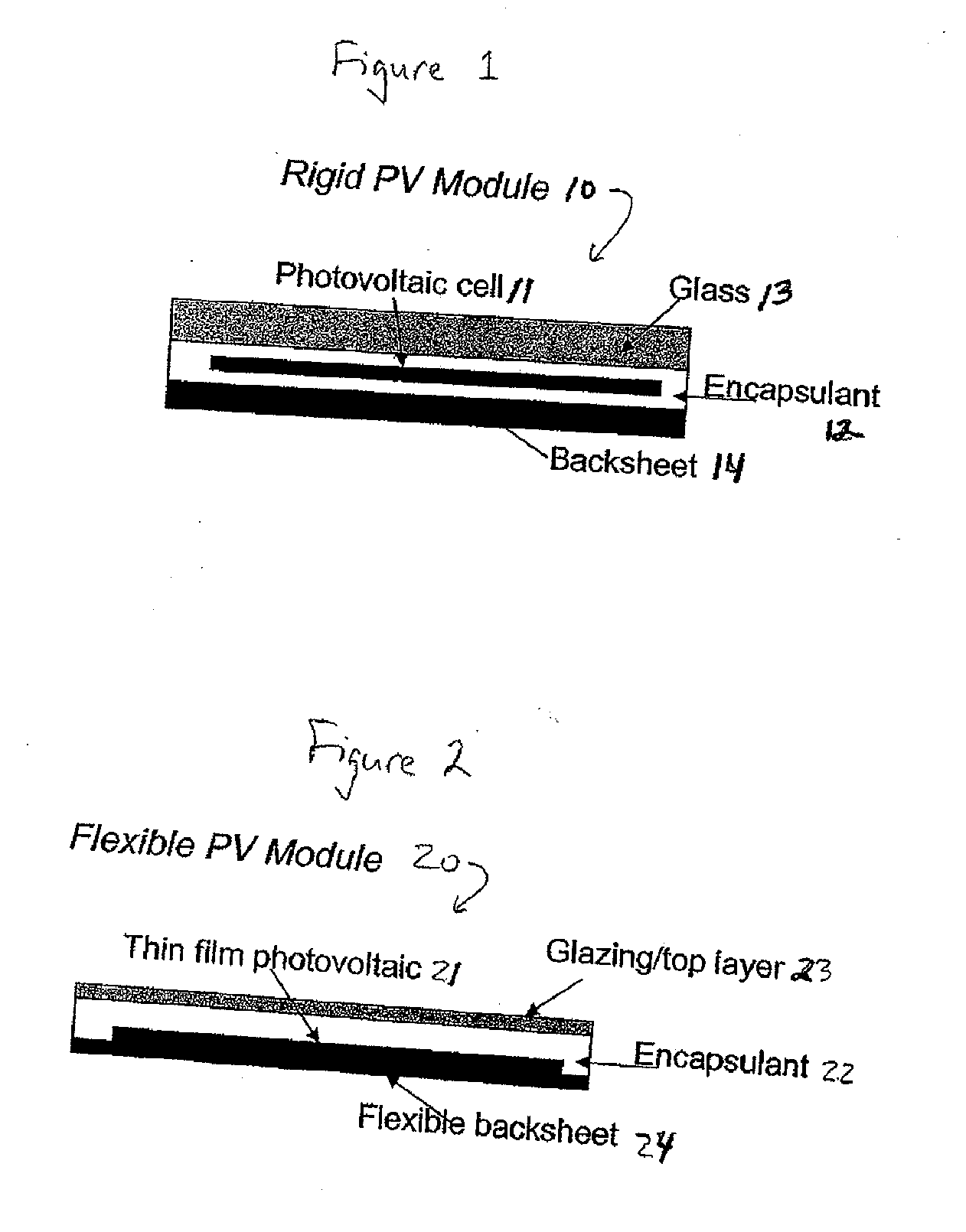

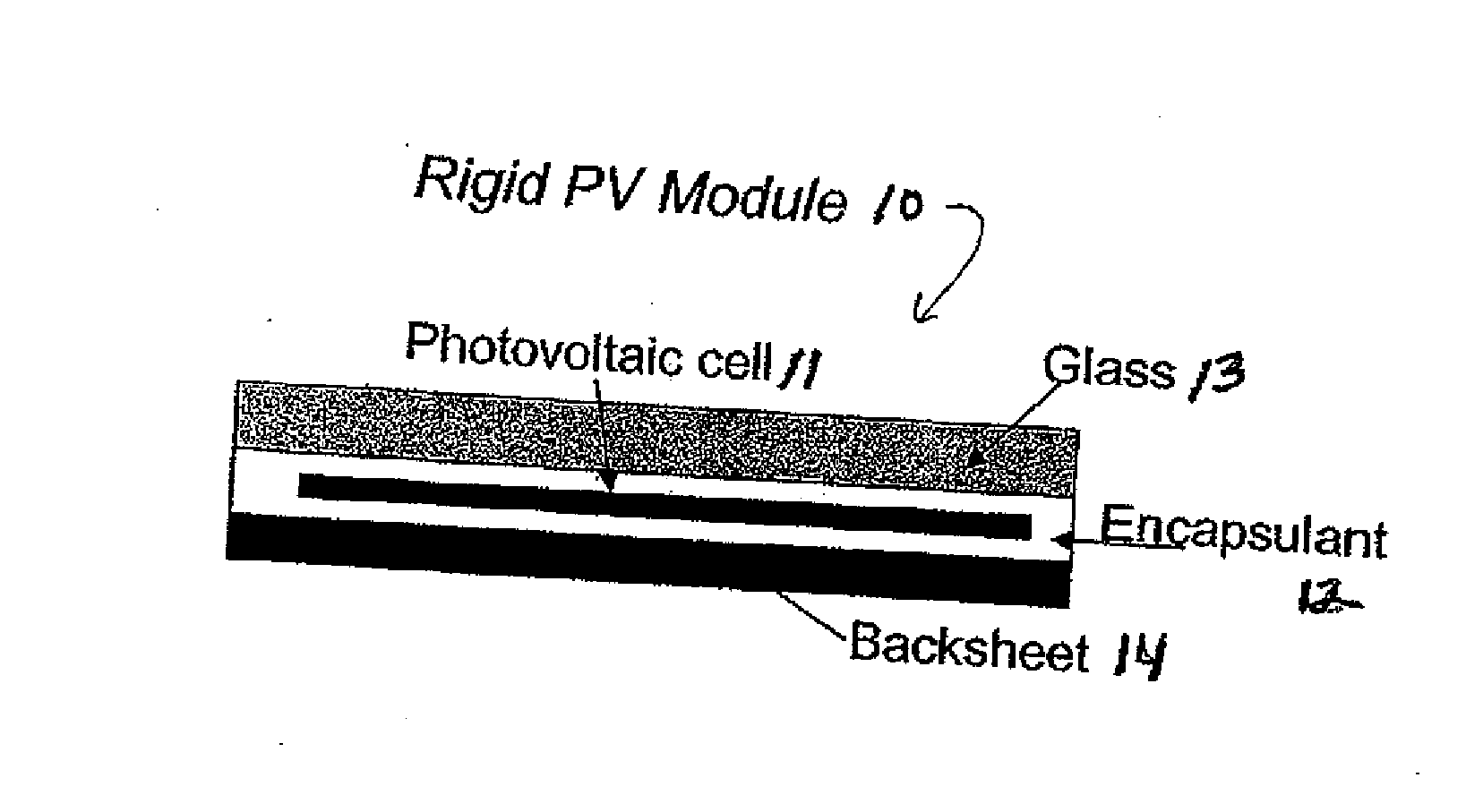

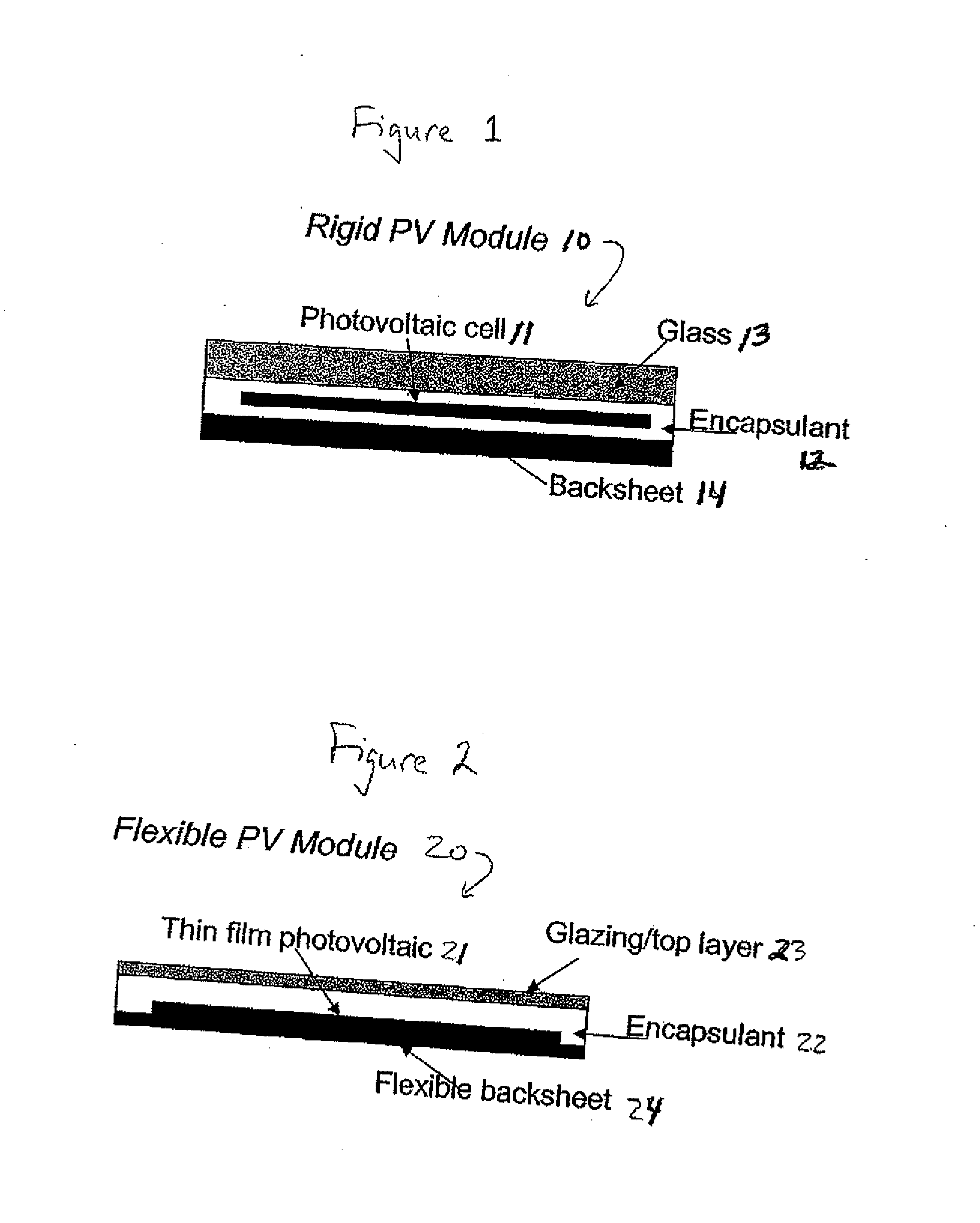

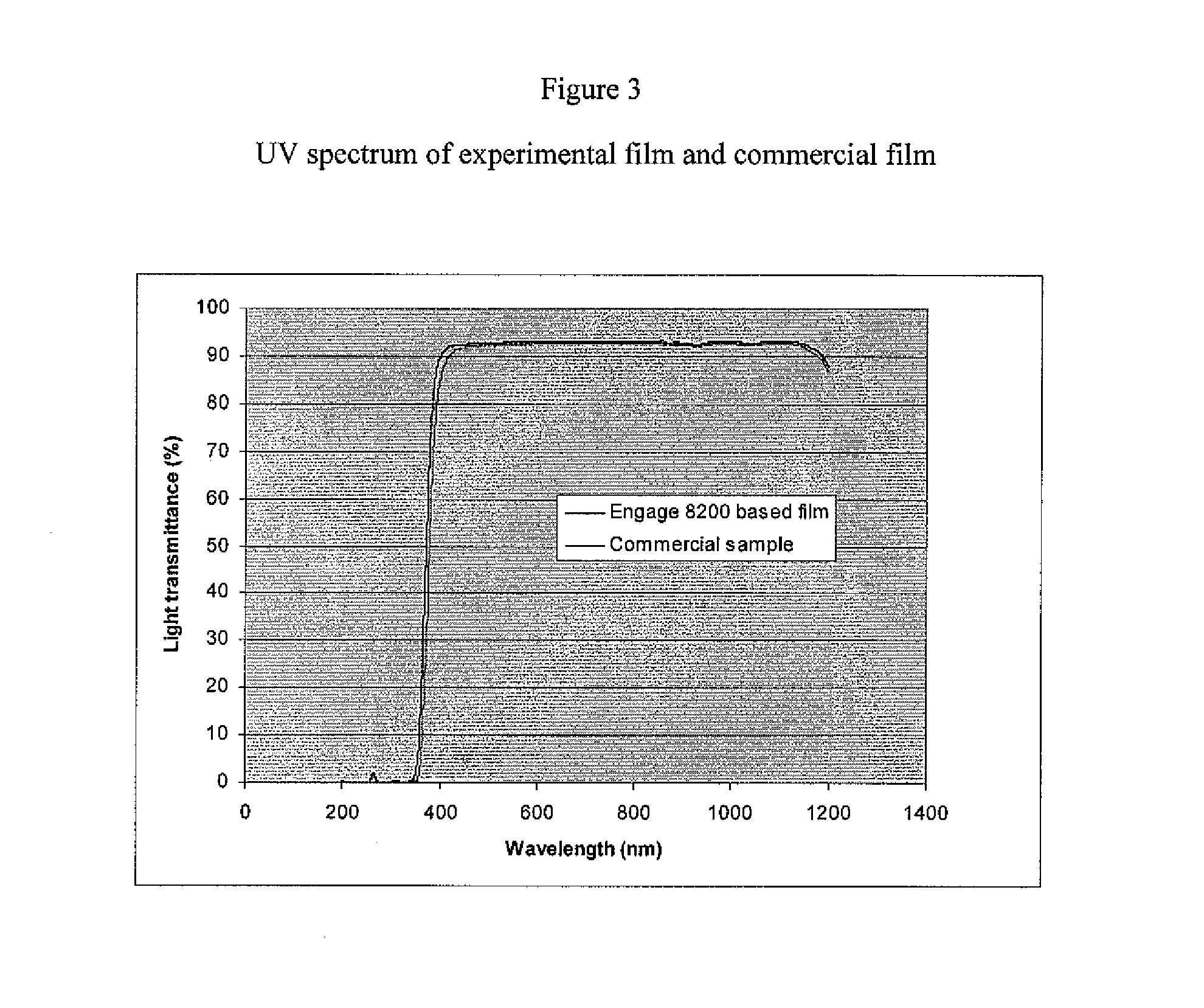

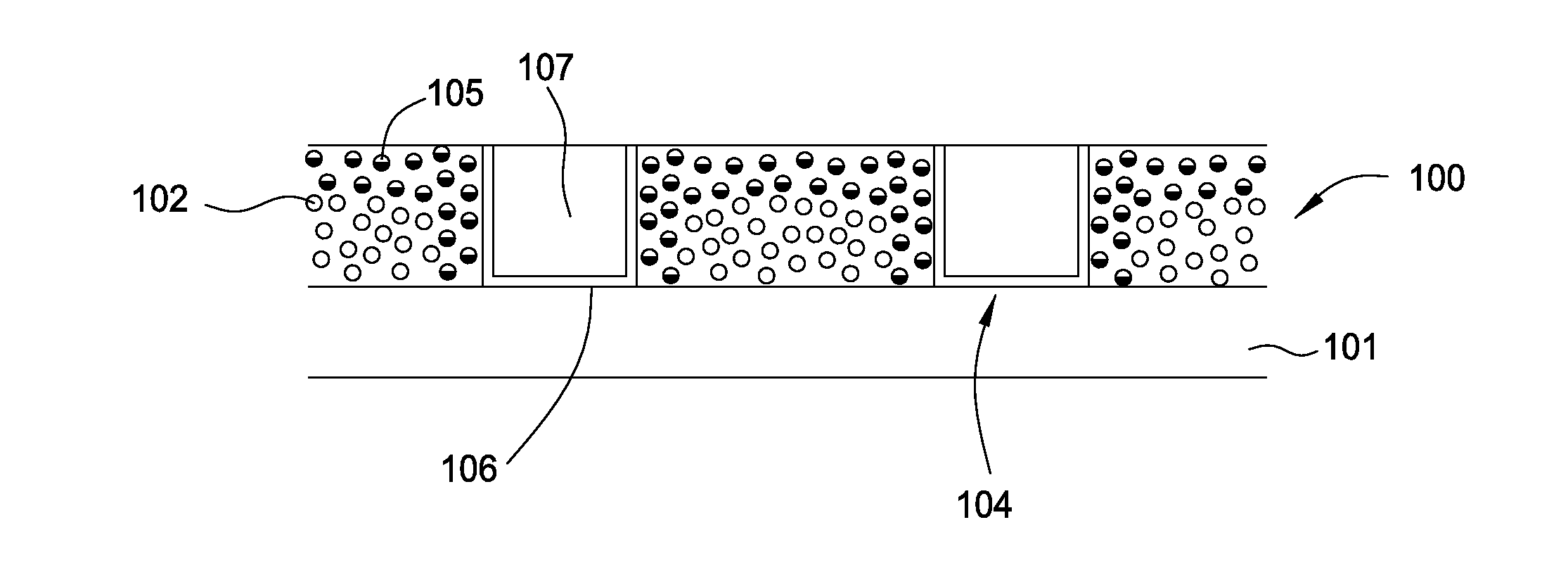

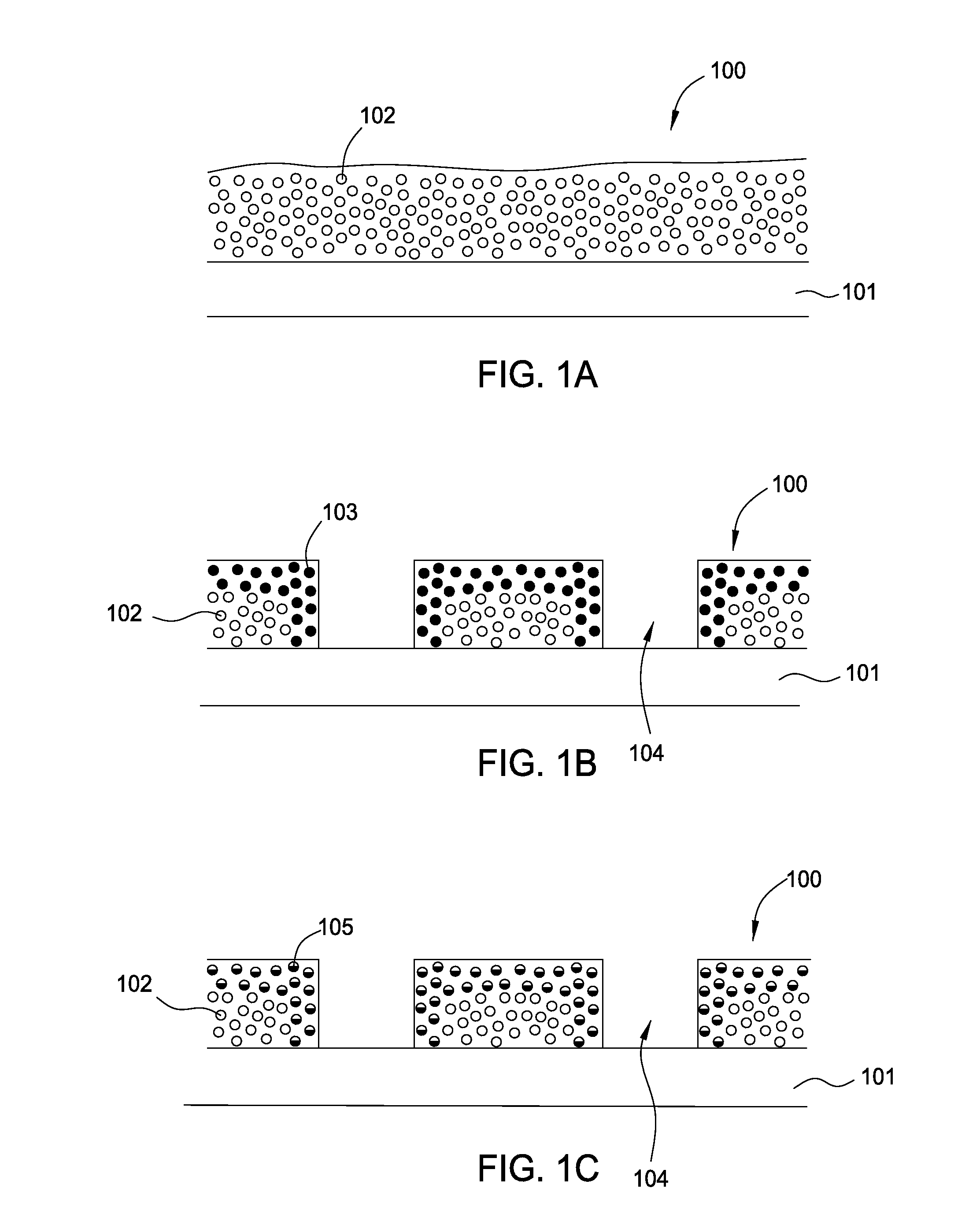

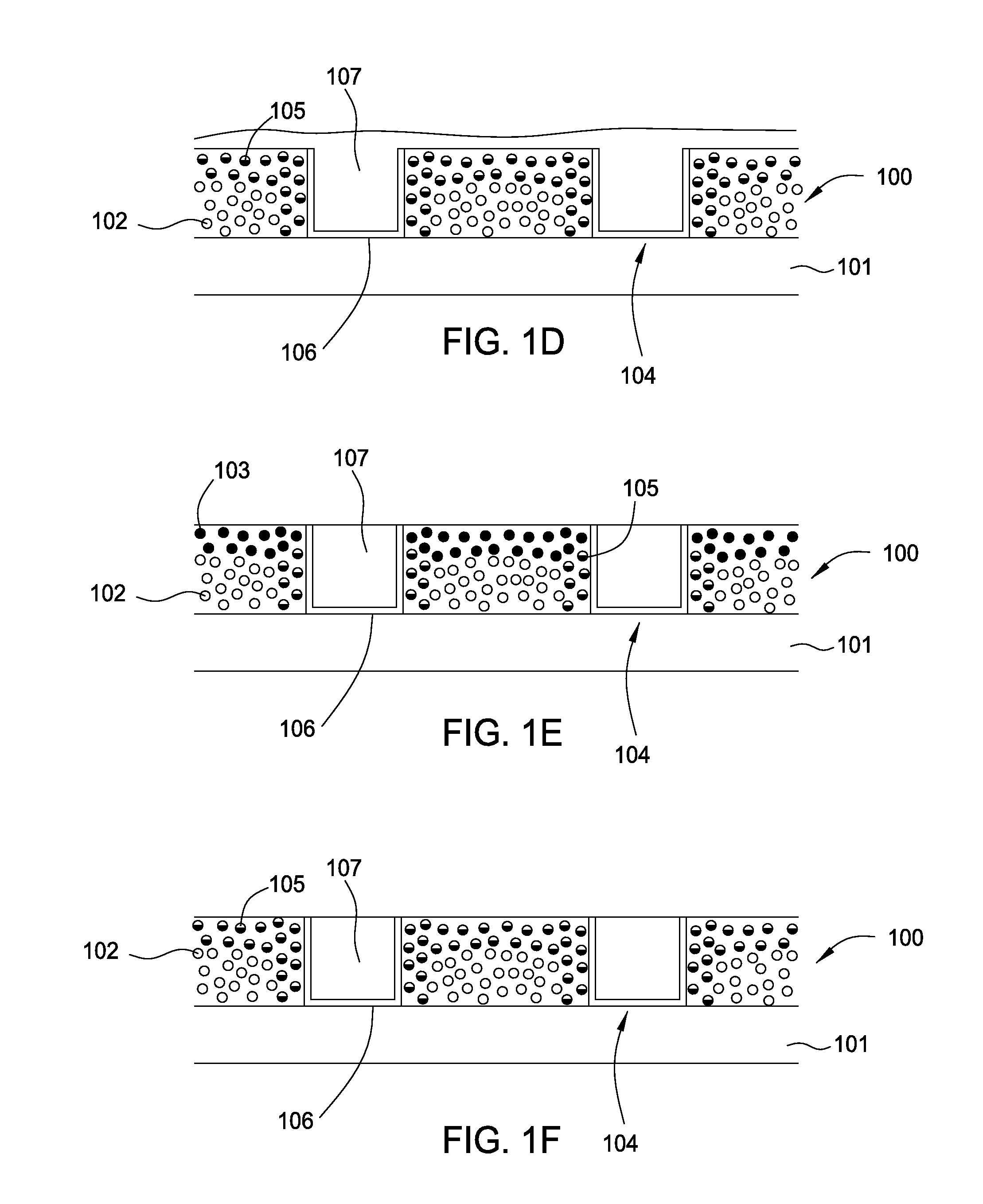

Electronic device module comprising polyolefin copolymer with low unsaturation and optional vinyl silane

InactiveUS20110290317A1Improve adhesionHigh processing temperatureGlass/slag layered productsPhotovoltaic energy generationPolymer sciencePolyolefin

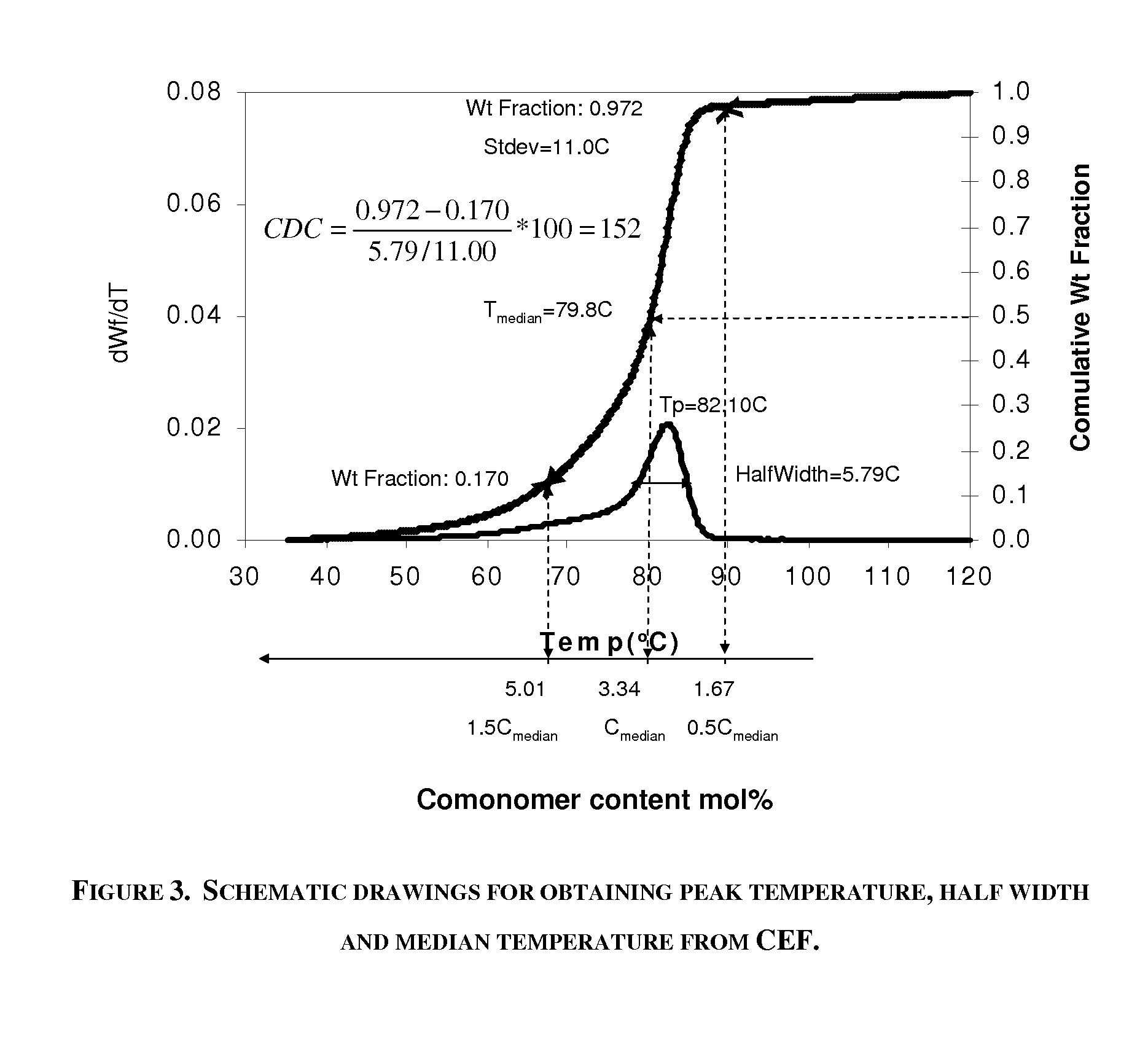

An electronic device module comprising:A. At least one electronic device, e.g., a solar cell, andB. A polymeric material in intimate contact with at least one surface of the electronic device, the polymeric material comprising (1) an ethylene-based polymer composition characterized by a Comonomer Distribution Constant greater than about 45, more preferably greater than 50, most preferably greater than 95, and as high as 400, preferably as high as 200, wherein the composition has less than 120 total unsaturation unit / 1,000,000C, preferably the ethylene-based polymer compositions comprise up to about 3 long chain branches / 1000 carbons, more preferably from about 0.01 to about 3 long chain branches / 1000 carbons; the ethylene-based polymer composition can have a ZSVR of at least 2; the ethylene-based polymer compositions can be further characterized by comprising less than 20 vinylidene unsaturation unit / 1,000,000C; the ethylene-based polymer compositions can have a bimodal molecular weight distribution (MWD) or a multi-modal MWD; the ethylene-based polymer compositions can have a comonomer distribution profile comprising a mono or bimodal distribution from 35° C. to 120° C., excluding purge; the ethylene-based polymer compositions can comprise a single DSC melting peak; the ethylene-based polymer compositions can comprise a weight average molecular weight (Mw) from about 17,000 to about 220,000, (2) optionally, a vinyl silane, (3) optionally, a free radical initiator, e.g., a peroxide or azo compound, or a photoinitiator, e.g., benzophenone, and (4) optionally, a co-agent.

Owner:NAUMOVITZ JOHN +3

Electronic Device Module Comprising Polyolefin Copolymer

ActiveUS20080078445A1Improve adhesionHigh processing temperaturePV power plantsElectrical equipmentPolyolefinSilanes

An electronic device module comprising: A. At least one electronic device, e.g., a solar cell, and B. A polymeric material in intimate contact with at least one surface of the electronic device, the polymeric material comprising (1) a polyolefin copolymer with at least one of (a) a density of less than about 0.90 g / cc, (b) a 2% secant modulus of less than about 150 megaPascal (mPa) as measured by ASTM D-882-02), (c) a melt point of less than about 95 C, (d) an α-olefin content of at least about 15 and less than about 50 wt % based on the weight of the polymer, (e) a Tg of less than about −35 C, and (f) a SCBDI of at least about 50, (2) optionally, free radical initiator, e.g., a peroxide or azo compound, or a photoinitiator, e.g., benzophenone, and (3) optionally, a co-agent. Typically, the polyolefin copolymer is an ethylene / α-olefin copolymer. Optionally, the polymeric material can further comprise a vinyl silane and / or a scorch inhibitor, and the copolymer can remain uncrosslinked or be crosslinked.

Owner:DOW GLOBAL TECH LLC

Method of treating metals using vinyl silanes and multi-silyl-functional silanes in admixture

InactiveUS6071566AImprove adhesionImprove solubilityGroup 4/14 element organic compoundsFibre treatmentSilyleneSilanes

The present invention relates to a method of treating a metal substrate to provide permanent corrosion resistance. The method comprises applying a solution containing one or more vinyl silanes in admixture with one or more multi-silyl-functional silanes to a metal substrate in order to form a coating. The method is particularly suitable for use on zinc coated surfaces.

Owner:CHEMETALL PLC

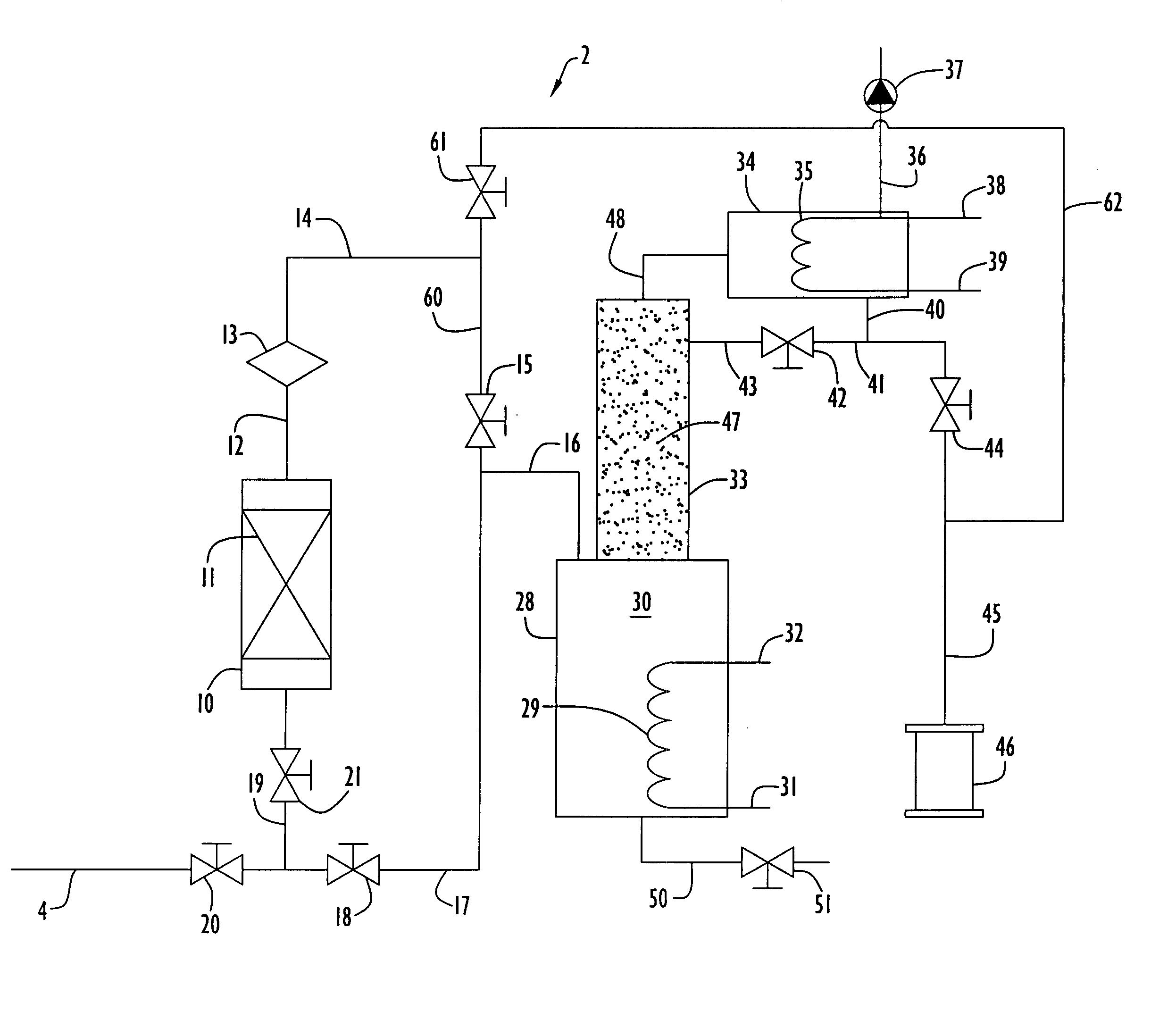

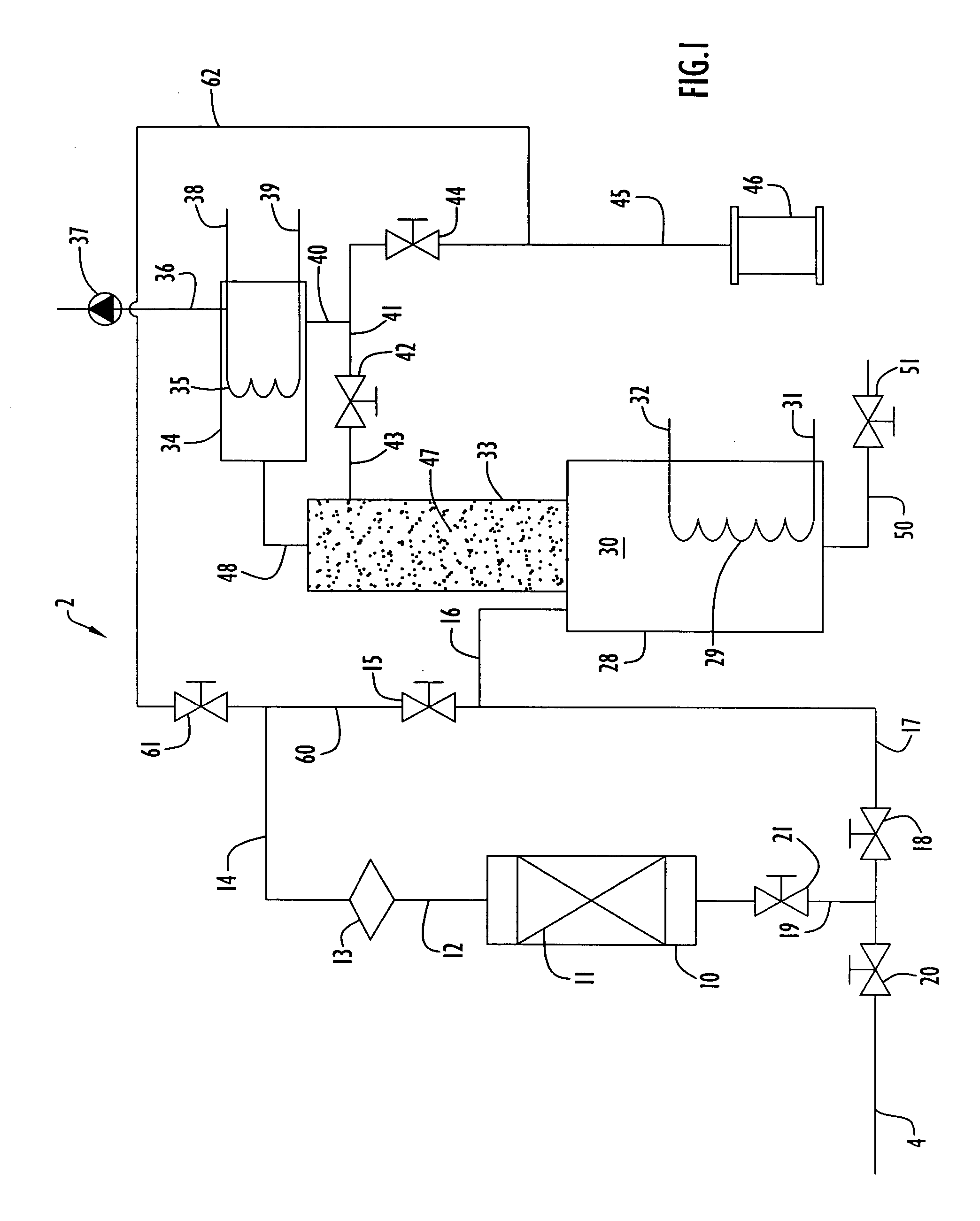

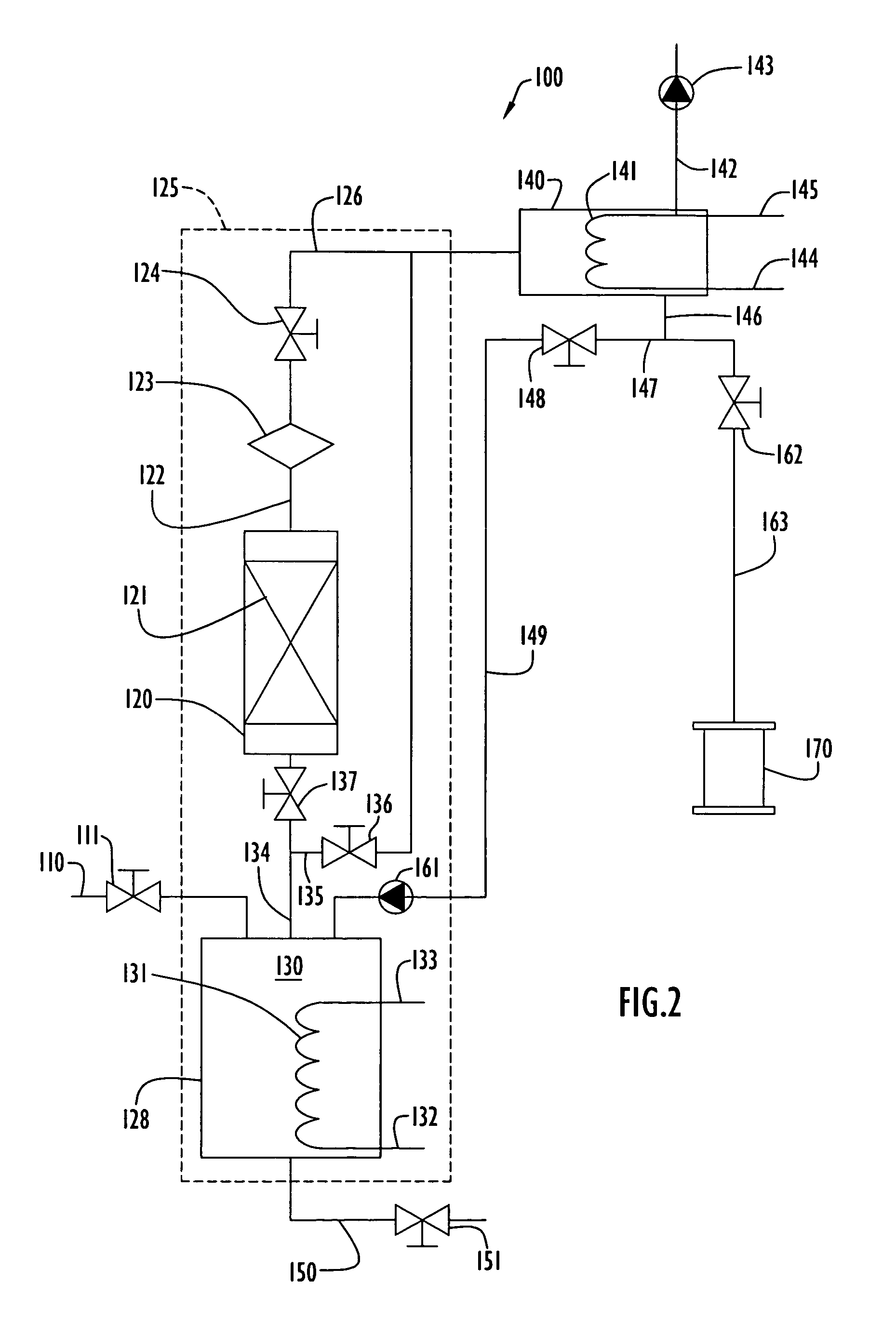

Purification of silicon-containing materials

InactiveUS20050054211A1Impurities increaseSilicon organic compoundsSemiconductor/solid-state device manufacturingSilanesLiquid state

Systems and methods of purifying a silicon-containing material include the step of directing the silicon-containing material in a liquid state through an adsorption unit including an adsorbent material to facilitate adsorption of at least one component from the silicon-containing material. Alternatively, the silicon-containing material is directed, in liquid state and / or gaseous state, through two or more purification units, including an adsorption unit, a vaporization unit, a filter unit and a condenser. The silicon-containing material can be a low-k silicon-containing material such as trimethylsilane, tetramethylsilane, dimethyldimethoxysilane, tetramethylcyclotetrasiloxane, octamethylcyclotetrasiloxane, dimethylphenyl silane, and dimethyldivinyl silane.

Owner:XU MINDI +2

Silane coatings for metal

InactiveUS20050058843A1Improve corrosion resistanceAvoid corrosionLiquid surface applicatorsFibre treatmentSilyleneSilanes

Owner:UNIVERSITY OF CINCINNATI

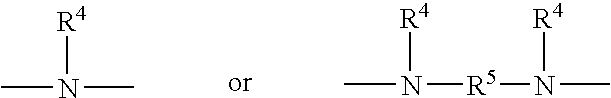

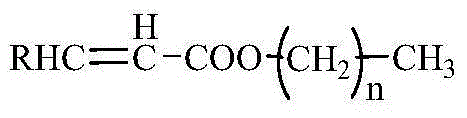

Preparation method and application of main chain fracture type polyacrylic acid silane ester resin

ActiveCN103396513AEfficient regulated releaseMake sure to keepAntifouling/underwater paintsPaints with biocidesPolyesterPolymer science

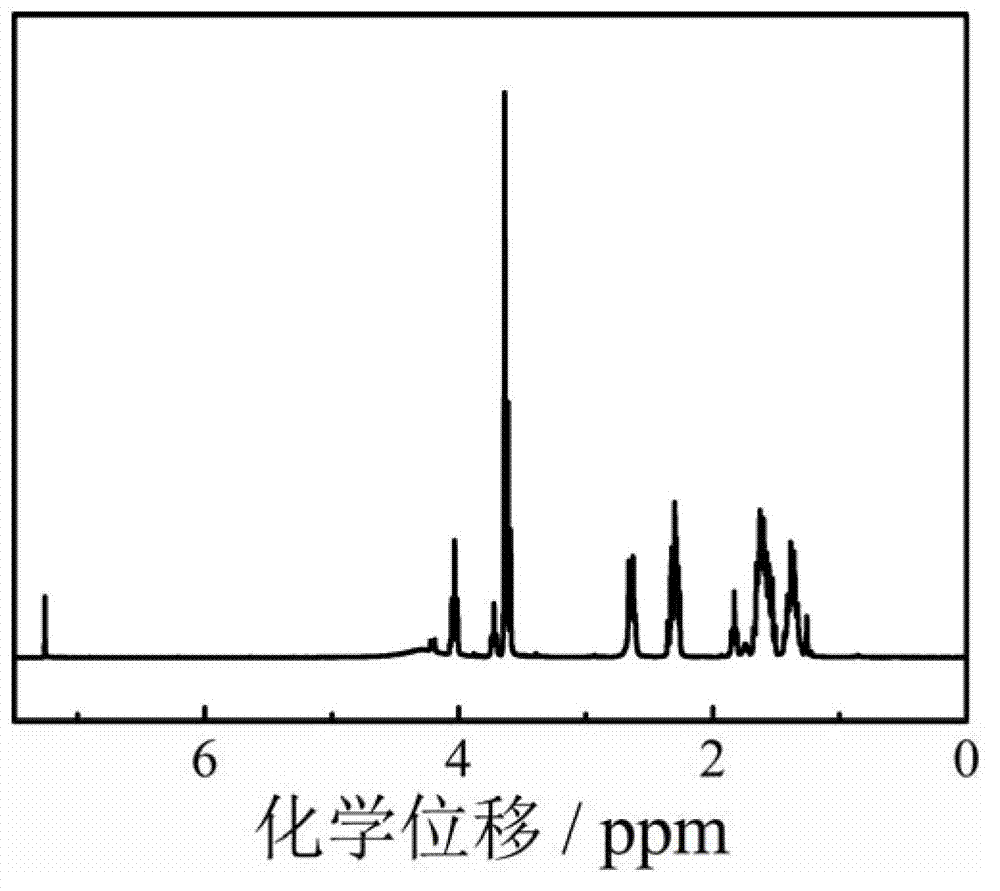

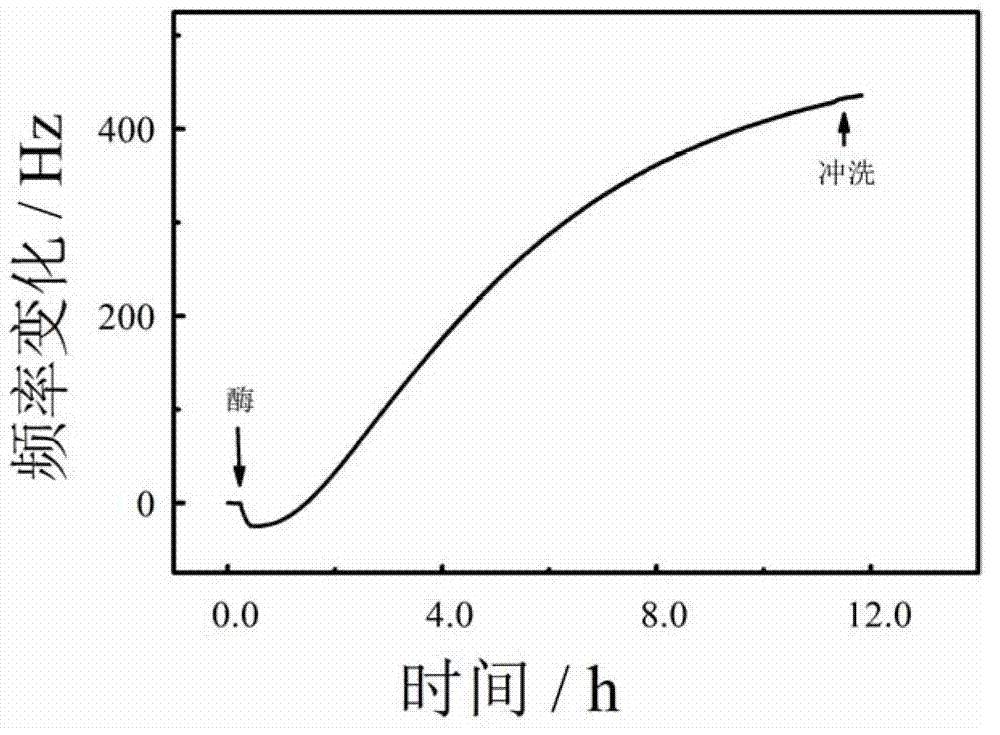

The invention discloses a preparation method and an application of main chain fracture type polyacrylic acid silane ester resin. The method comprises the following steps of: mixing a cyclic monomer, a vinyl monomer and a vinyl silane ester monomer in a solvent according to a proportion, and then, adding a composite initiator accounting for 0.01-5% of the total mass percent of the monomers, and reacting at a temperature of 25-150 DEG C under the protection of argon or nitrogen to prepare the main chain fracture type polyacrylic acid silane ester resin; and the monomers are composed of 5-95wt% of cyclic monomer, 0-90wt% of vinyl monomer and 5-95wt% of vinyl silane ester monomer. According to the resin obtained by the invention, the side chain silane ester can hydrolyze under the action of seawater and the polyester chain segment of a main chain can generate chain scission under the action of seawater, thereby solving the dependence of traditional self-polishing materials on navigational speed, effectively regulating and controlling a stain-proofing agent to release at a constant speed, maintaining active substances on the coating surface of a ship and well meeting the anti-fouling requirements of ships, submarines and offshore production platform facilities with low navigational speeds.

Owner:SOUTH CHINA UNIV OF TECH

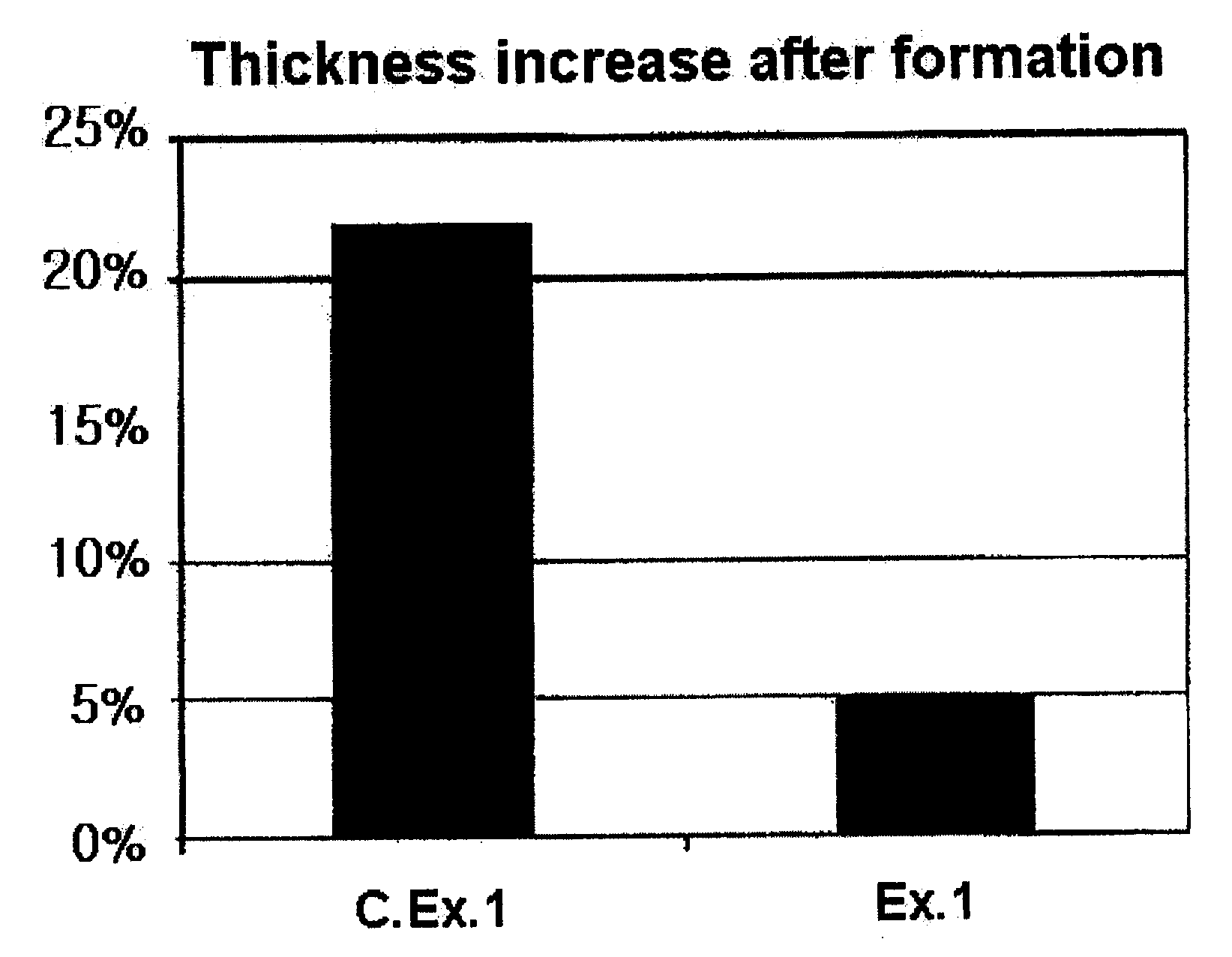

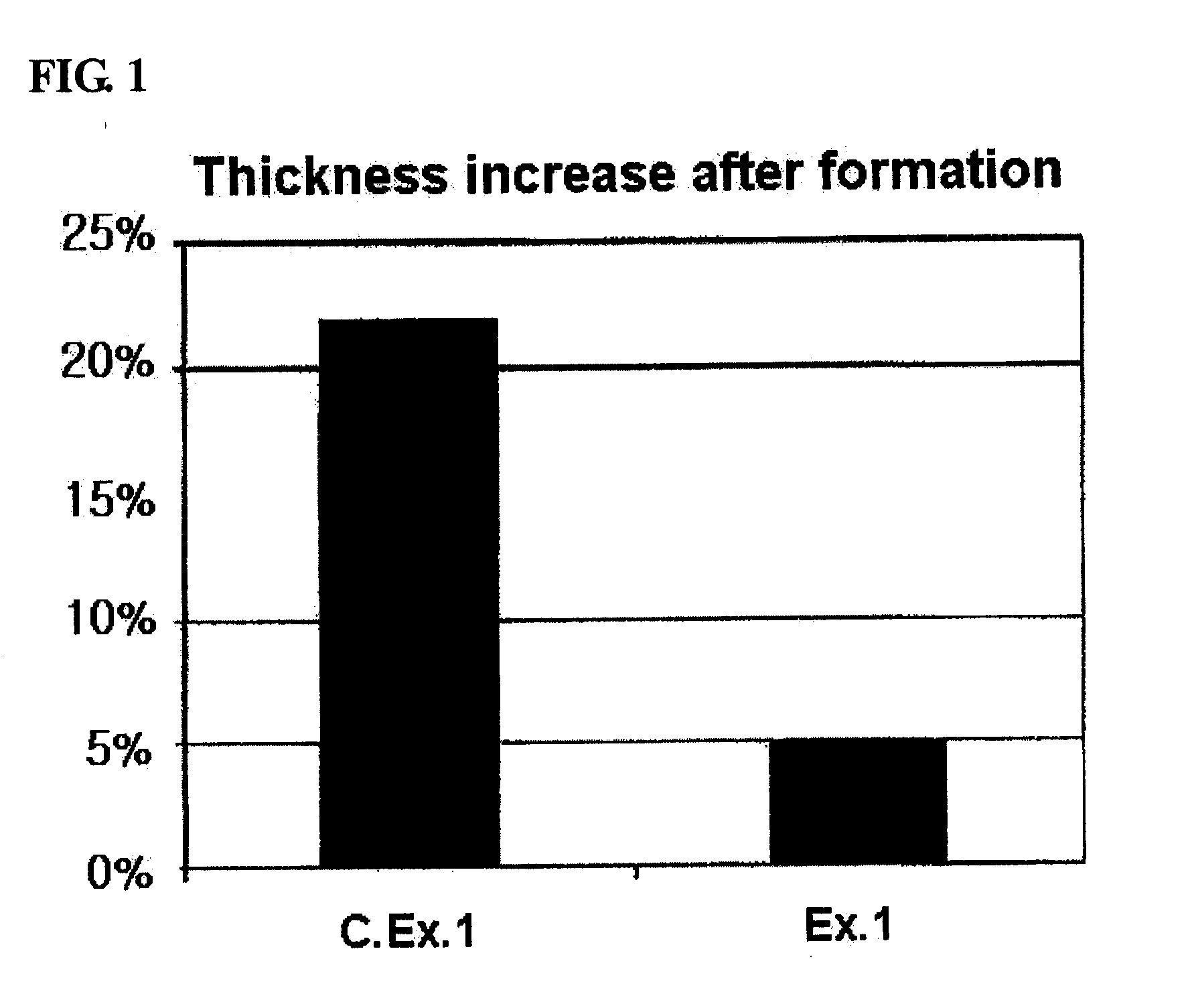

Fabrication of lithium secondary battery

ActiveUS20100024204A1Extend battery lifeSimple methodFinal product manufacturePrimary cellsSilanesPre-charge

A method of fabricating a lithium secondary battery, which improves charge-discharge characteristics, lifespan, and temperature characteristics of the battery and which includes interposing a separator between a positive electrode plate and a negative electrode plate, thus manufacturing an electrode assembly; housing the electrode assembly in a battery case, introducing an additive-containing electrolytic solution, and then sealing the battery case; subjecting the sealed battery case to pre-charging, and then removing gas generated by the pre-charging; subjecting the battery case to formation; and removing gas generated by the formation, wherein the additive is one or more selected from among LiF2BC2O4, 3,9-divinyl-2,4,8,10-tetraoxaspiro[5,5]undecane, LiBC(C2O4)2, poly(ethyleneglycol)borate and derivatives thereof, halogen-substituted carbonate, and vinyl silane, and the pre-charging is conducted in a range of 10% or less of a battery capacity.

Owner:SK ON CO LTD

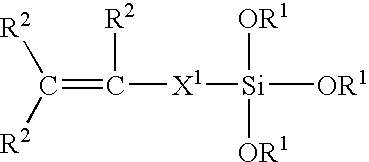

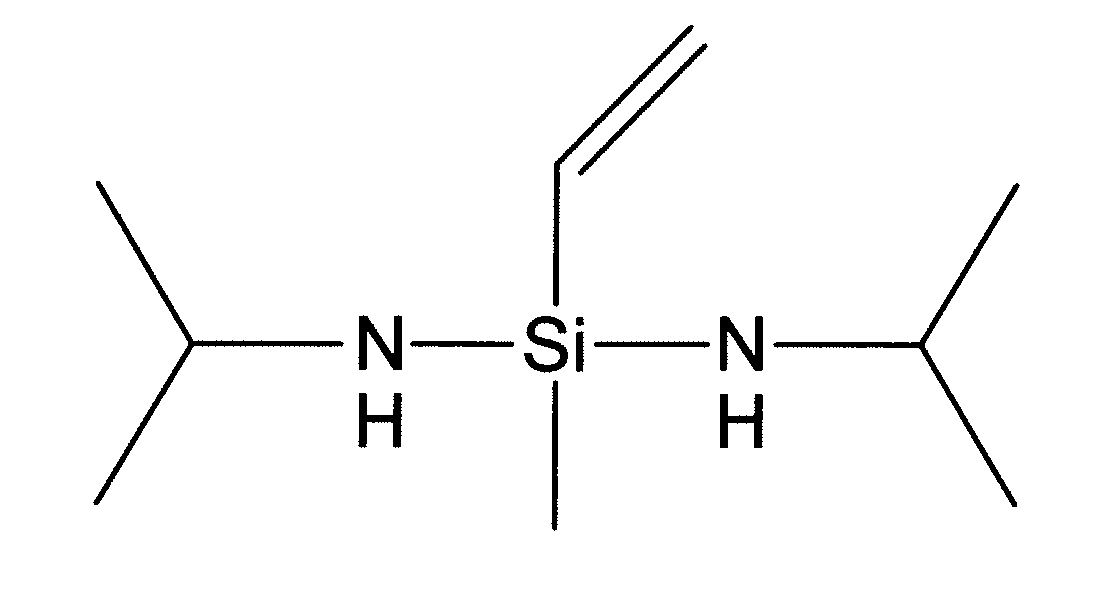

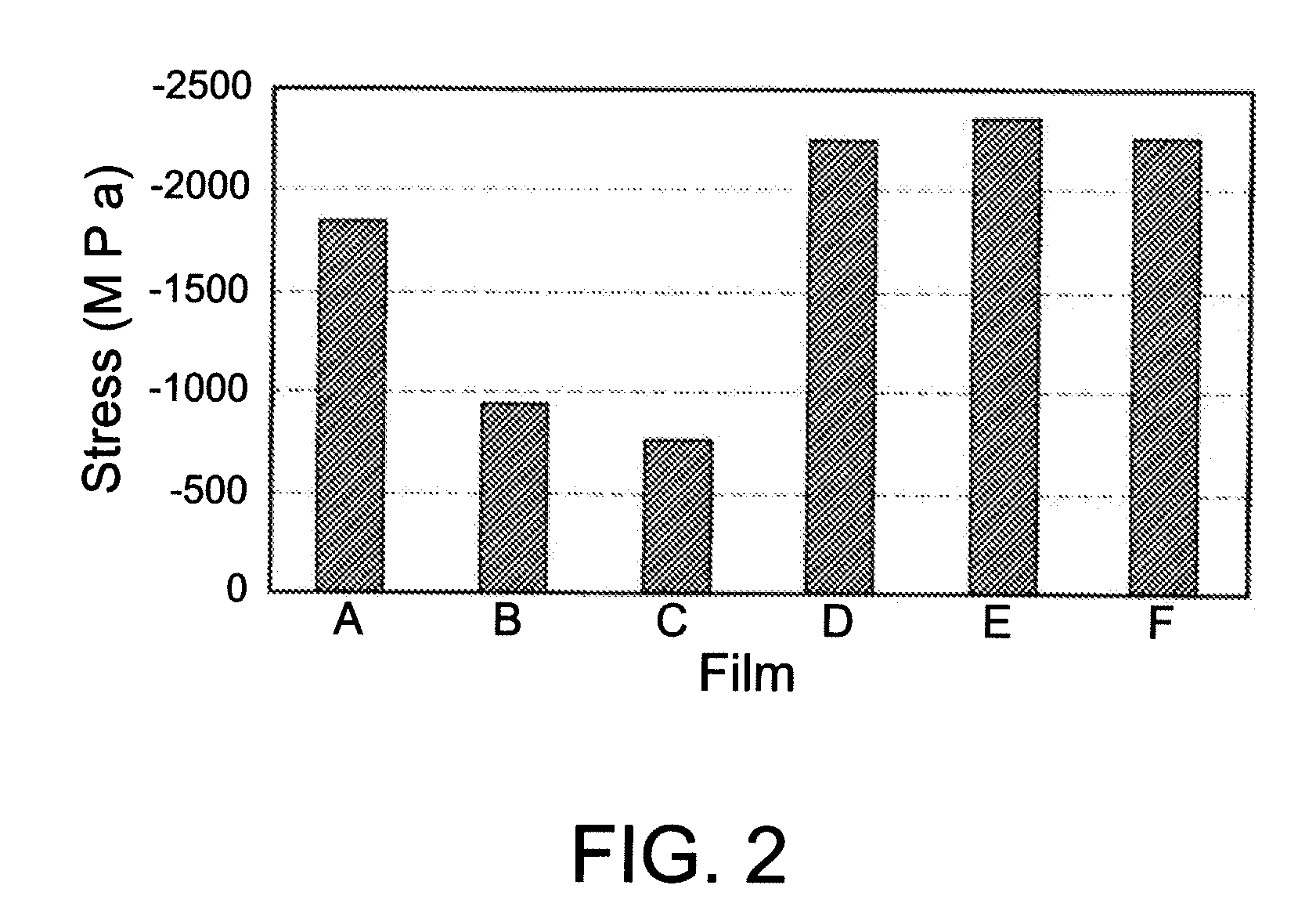

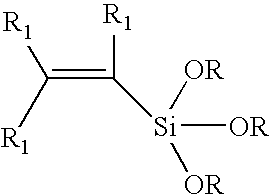

Amino Vinylsilane Precursors for Stressed SiN Films

InactiveUS20100120262A1Increase intrinsic compressive stressEnhanced vapor depositionSilicon organic compoundsSemiconductor/solid-state device manufacturingAlkaneHydrogen

The present invention is a method to increase the intrinsic compressive stress in plasma enhanced chemical vapor deposition (PECVD) silicon nitride (SiN) and silicon carbonitride (SiCN) thin films, comprising depositing the film from an amino vinylsilane-based precursor. More specifically the present invention uses the amino vinylsilane-based precursor selected from the formula: [RR1N]xSiR3y(R2)z, where x+y+z=4, x=1-3, y=0-2, and z=1-3; R, R1 and R3 can be hydrogen, C1 to C10 alkane, alkene, or C4 to C12 aromatic; each R2 is a vinyl, allyl or vinyl-containing functional group.

Owner:VERSUM MATERIALS US LLC

Hydroxyl acrylic acid emulsion with microgel nuclear structure and preparation process and application thereof

A hydroxyacrylic acid emulsion with micro gel core structure is prepared through copolymerization of vinylsilane coupling agent on acrylate monomer to obtain hydrophobic micro gel cores, copolymerization of hydroxyvinyl monomer on acrylate monomer on the surface of said core to become hydrophilic shell, and preparing emulsion. A process for preparing water-soluble dual-component polyurethane used for paint is also disclosed.

Owner:SOUTH CHINA UNIV OF TECH

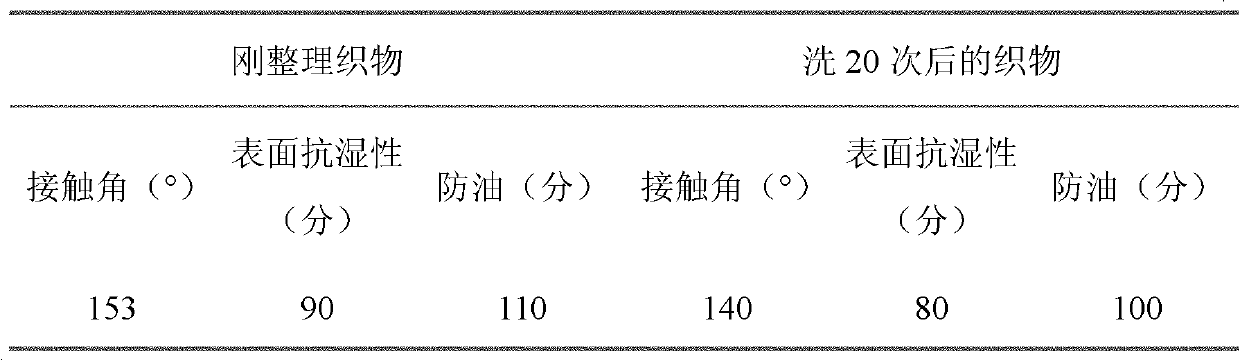

Organic-inorganic composite emulsion water-and-oil-repellent finishing agent and application thereof

ActiveCN102002128AReduce usageReduce pollutionVegetal fibresAnimal fibresDispersion stabilityActive agent

The invention relates to an organic-inorganic composite emulsion water-and-oil-repellent finishing agent and the application thereof. The preparation method of the finishing agent comprises the following steps of: (1) adding deionized water, composite surface active agent and an ethylene-contained silane coupling agent to a container provided with a stirrer, a reflux condensing tube and a thermometer, stirring at a high speed, adding ammonia, continuously and rapidly stirring and making the material react to obtain a functionalized nano SiO2 aqueous dispersion; and (2) adding the functionalized nano SiO2 aqueous dispersion and parts of monomer emulsified in advance and an initiator to the container provided with the stirrer, the reflux condensing tube and the thermometer, increasing the temperature, slowly dipping the rest monomer emulsified in advance and a fluorinated acrylate monomer, simultaneously dipping the rest initiator, cooling and adjusting the pH value to be 7-8. The finishing agent of the invention has favorable dispersion stability as well as favorable water and oil repellence when applied to textiles, and the preparation method is simple and suitable for industrial production.

Owner:DONGHUA UNIV +1

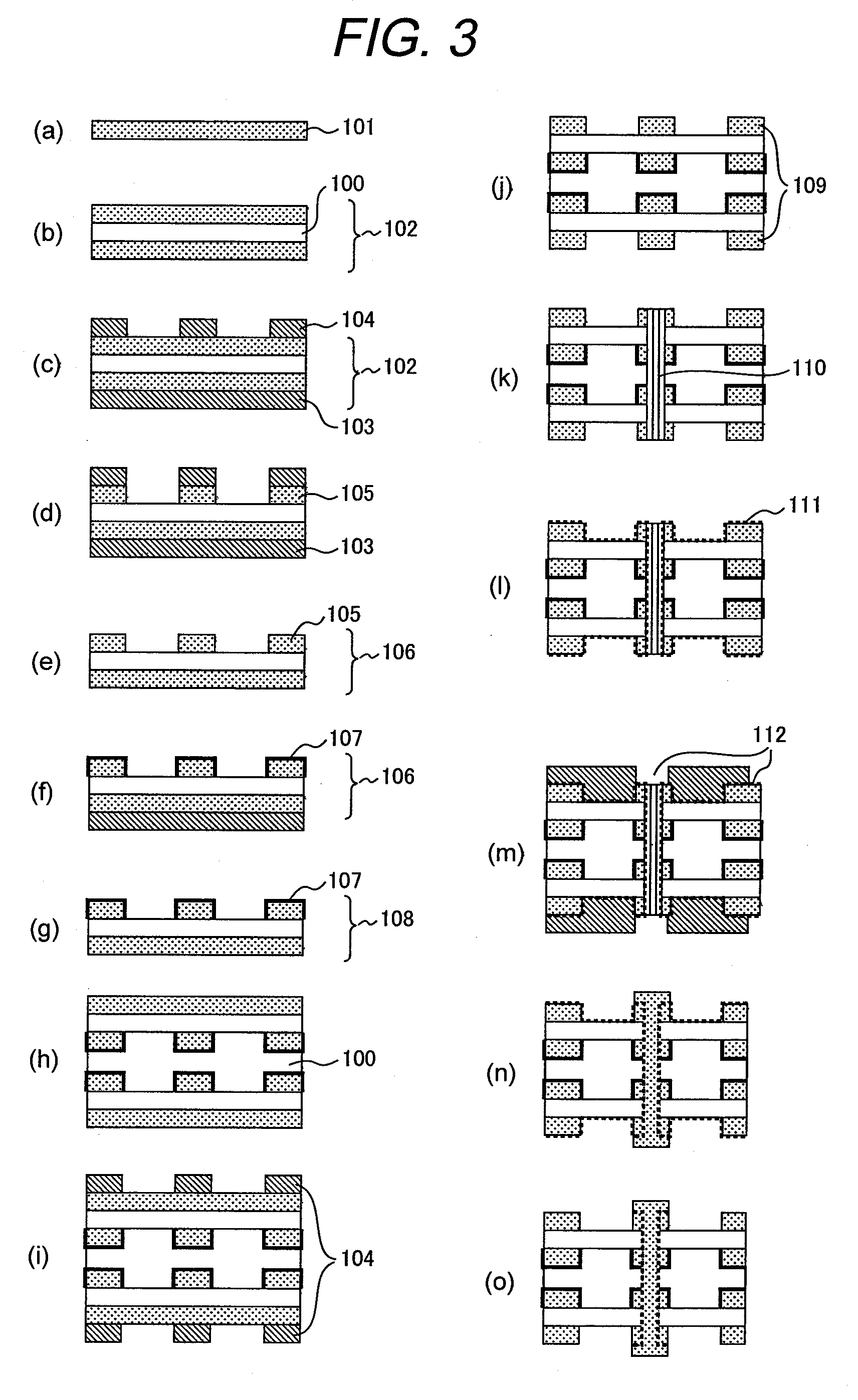

Low dielectric loss wiring board, multilayer wiring board, copper foil and laminate

InactiveUS20110088933A1The material is lowEasy to peelInsulating substrate metal adhesion improvementPrinted circuit aspectsCross-linkDouble bond

A wiring board comprising a copper wiring, and an insulating layer which is a cured product of a resin composition containing a compound having a carbon-carbon unsaturated double bond as a cross-linking component,the wiring board having a surface-treated layer formed on one or both sides of the copper wiring, andthe surface-treated layer having a metal layer (A) containing at least one metallic component selected from the group consisting of tin, zinc, nickel, chromium, cobalt and aluminium,an oxide and / or hydroxide layer (B) of the metallic component on the metal layer (A),an amino-silane coupling agent layer (C) having an amino group in its structure on the oxide and / or hydroxide layer (B), anda vinyl-silane coupling agent layer (D) having a carbon-carbon unsaturated double bond on the amino-silane coupling agent layer (C).

Owner:HITACHI LTD

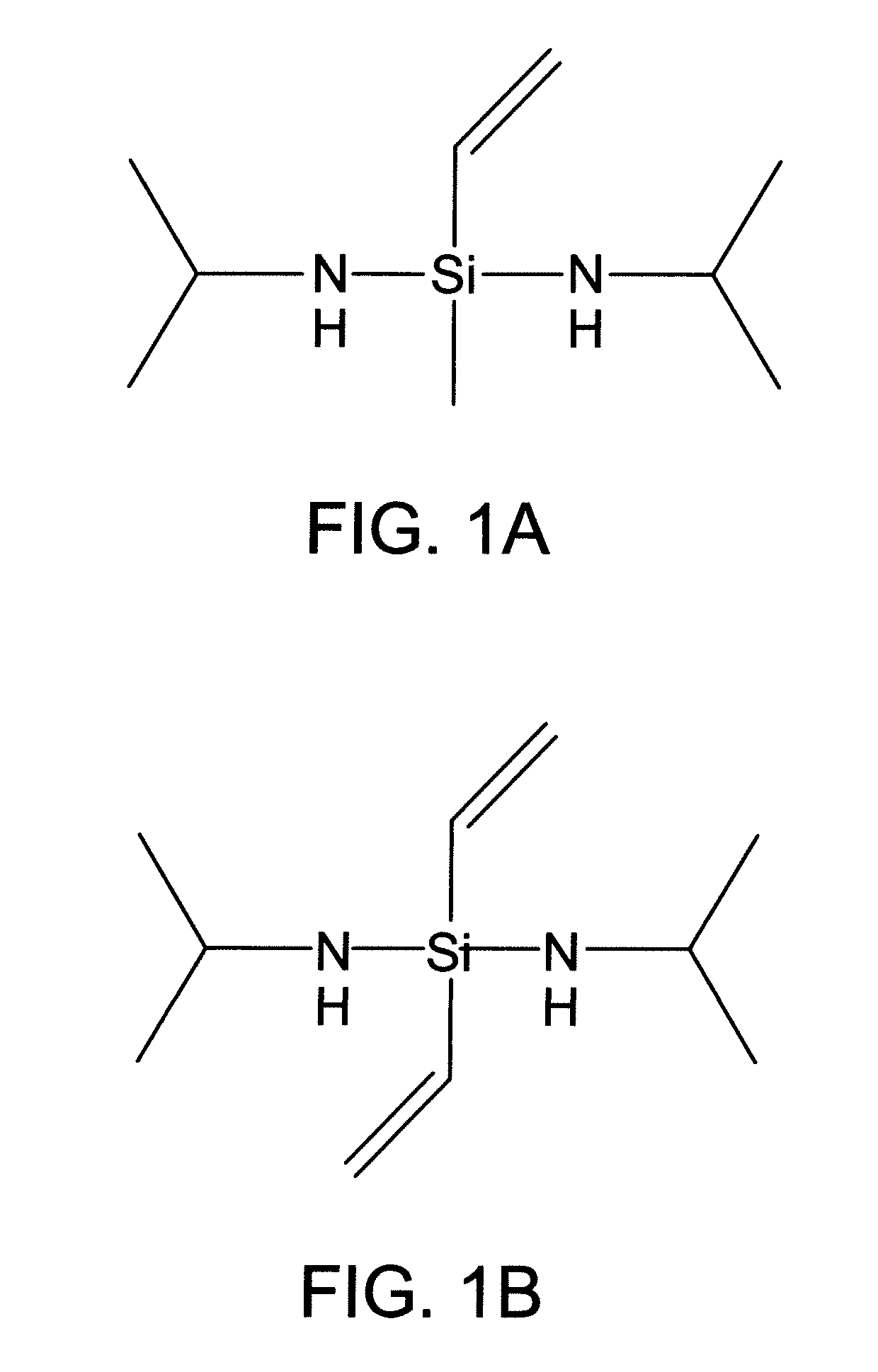

Low-k dielectric damage repair by vapor-phase chemical exposure

ActiveUS20140004717A1Dielectric constant be lowerSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseSilanes

A method for repairing and lowering the dielectric constant of low-k dielectric layers used in semiconductor fabrication is provided. In one implementation, a method of repairing a damaged low-k dielectric layer comprising exposing the porous low-k dielectric layer to a vinyl silane containing compound and optionally exposing the porous low-k dielectric layer to an ultraviolet (UV) cure process.

Owner:APPLIED MATERIALS INC

Process for copolymerizing ethylene with vinylsilanes

Owner:EQUSR CHEM LP

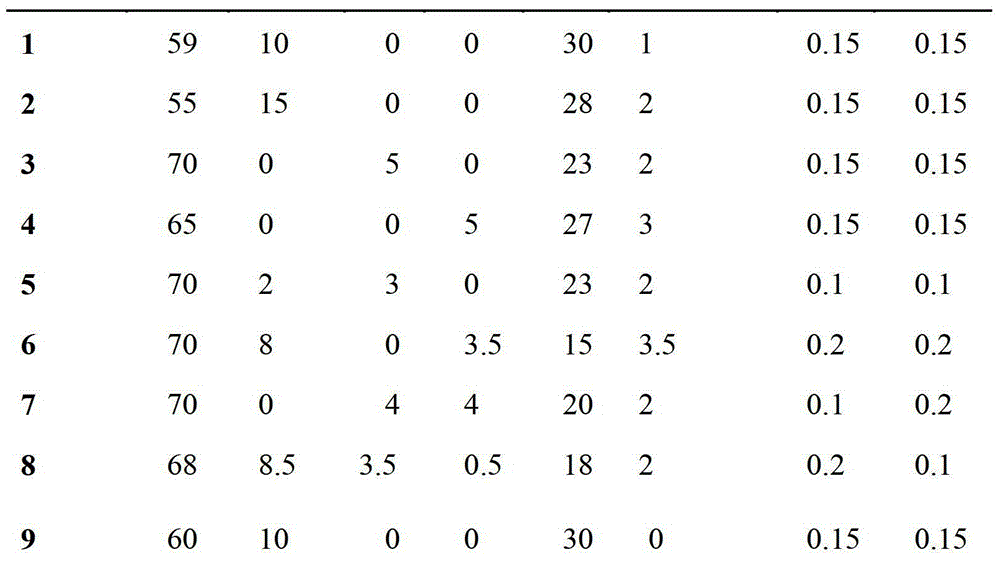

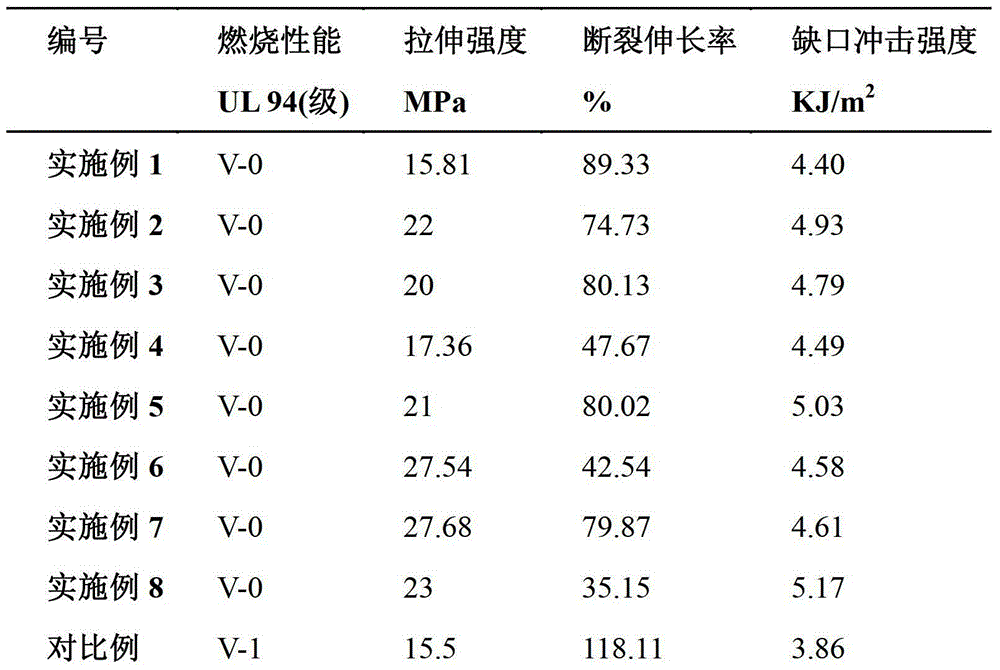

Modified intumescent flame-retardant polypropylene composition and preparation method thereof

InactiveCN103333406AImprove flame retardant performanceImprove mechanical propertiesPolymer scienceVinylsilane

The invention discloses a modified intumescent flame-retardant polypropylene composition and a preparation method thereof. The modified intumescent flame-retardant polypropylene composition is prepared from the following raw materials in parts by weight: 55-70 parts of polypropylene, 5-15 parts of toughener, 15-30 parts of compound intumescent flame retardant (IFR), 1-3.5 parts of nano zinc oxide, 0.1-0.2 part of vinyl silane coupling agent and 0.1-0.2 part of polyethylene wax. The preparation method comprises the following steps: proportionally preparing ammonium polyphosphate, bis-pentaerythritol and melamine into an IFR, drying, and mixing the nano zinc oxide, compound IFR, vinyl silane coupling agent and polyethylene wax to obtain the compound flame retardant; and mixing the surface-modified compound flame retardant, polypropylene and toughener, and extruding and granulating by a triple-screw extruder to obtain the modified intumescent flame-retardant polypropylene composition. The modified intumescent flame-retardant polypropylene composition disclosed by the invention can obviously enhance the flame-retardant efficiency of the IFR, and greatly enhances the mechanical properties of the polypropylene composition.

Owner:SOUTH CHINA UNIV OF TECH

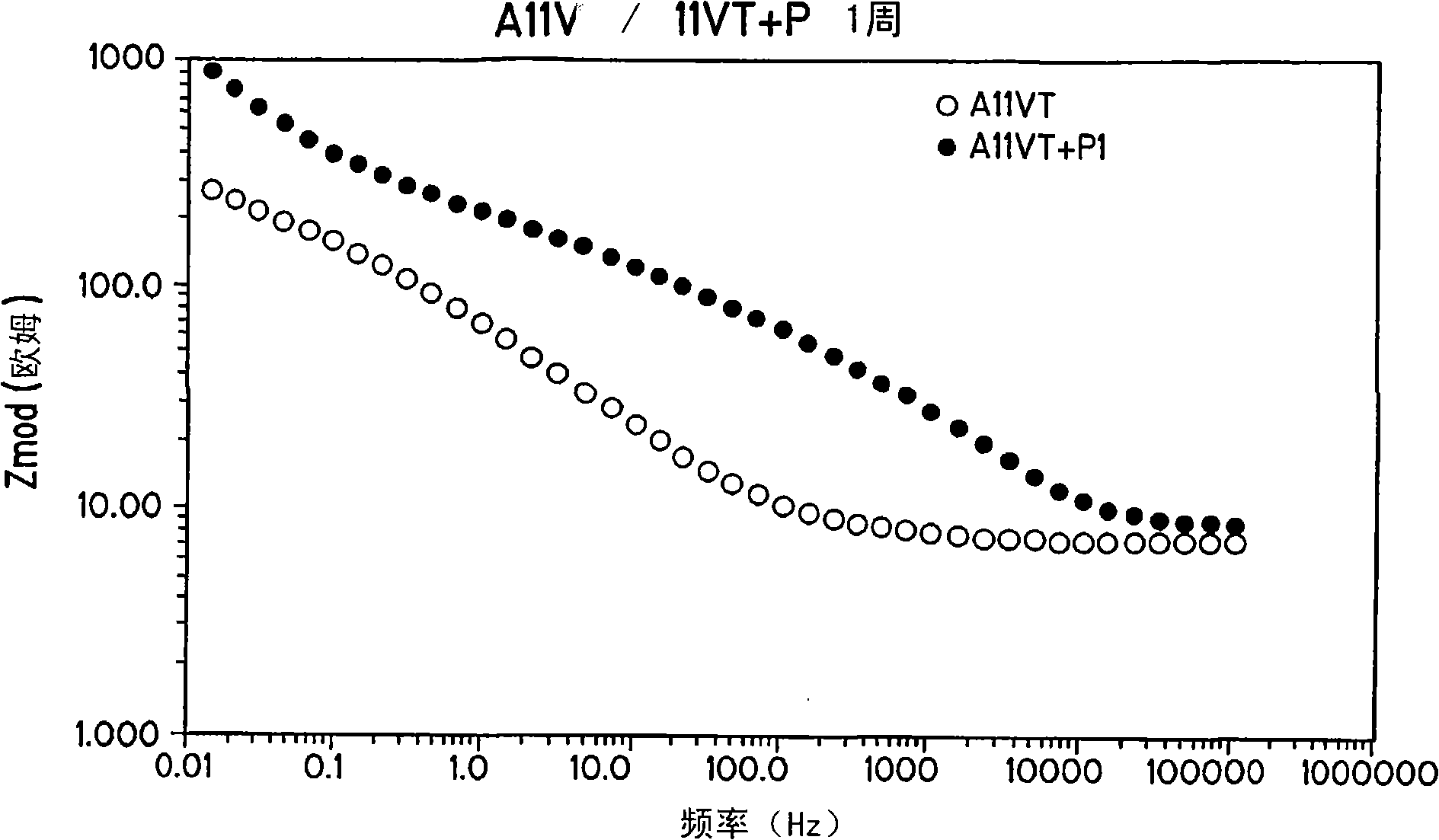

Silane crosslinked structure-introduced fuel-cell polymer electrolyte membrane and fuel-cell electrode assembly having the same

InactiveUS20100040927A1Improve antioxidant capacitySuitable for useSolid electrolytesFinal product manufacturePolymer electrolytesFuel cells

An object is to provide an electrolyte membrane that maintains excellent cell characteristics for a long time under high temperature and low water retention, as this is the most important point in fuel cells.A process for producing a polymer electrolyte membrane for fuel cells is provided, which process comprises in sequence: forming graft molecular chains by graft-polymerization of a vinyl silane coupling agent on a polymer film substrate that has phenyl groups capable of holding sulfonic acid groups; introducing sulfonic acid groups into phenyl groups contained in the graft molecular chains; and hydrolyzing and condensing alkoxy groups contained in the graft molecular chains so that a silane crosslinked structure is introduced between the graft molecular chains. A polymer electrolyte membrane produced by the process is also provided.

Owner:JAPAN ATOMIC ENERGY AGENCY INDEPENDANT ADMINISTRATIVE CORP +1

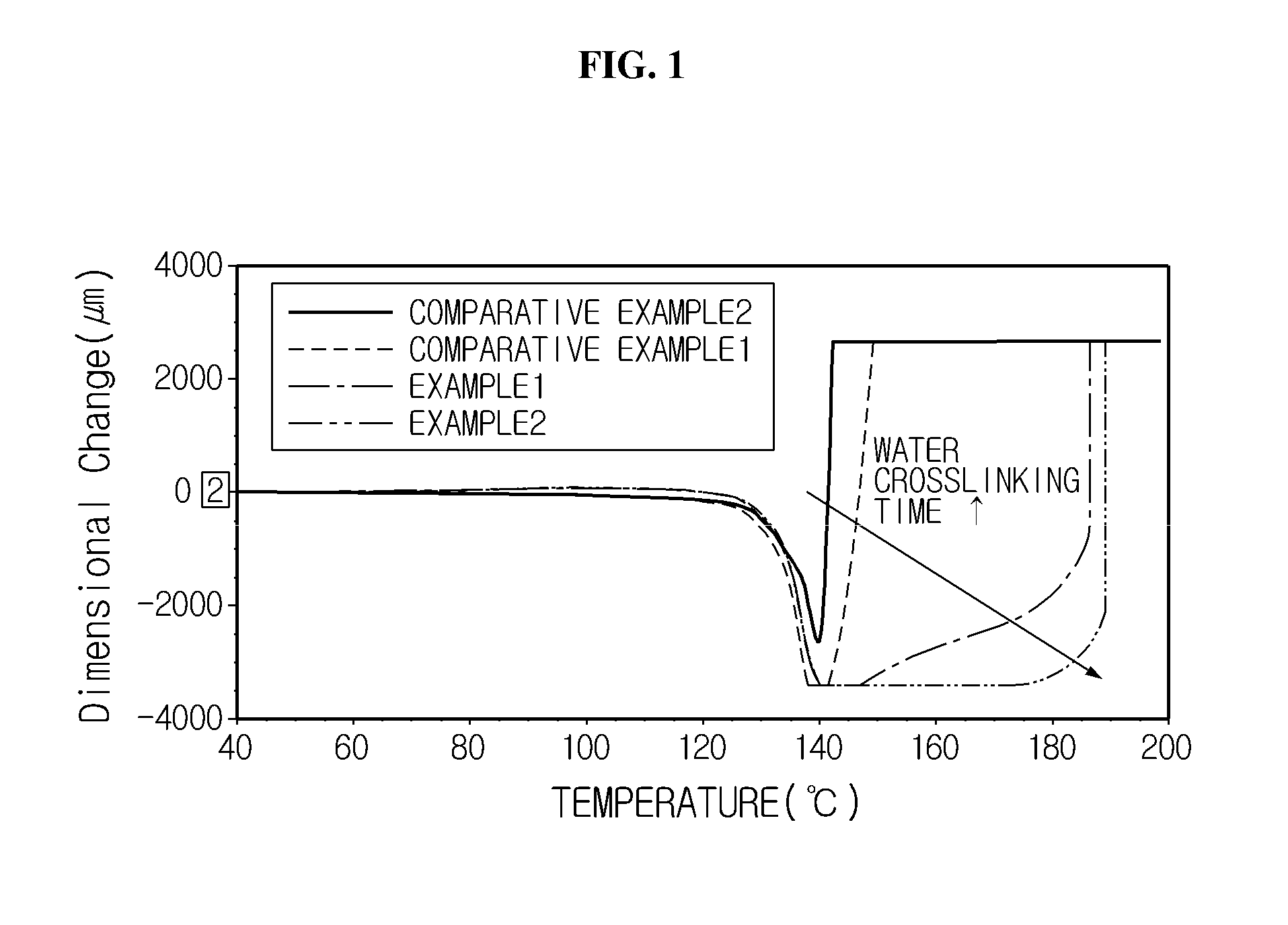

Crosslinked polyolefin separator and method of preparing the same

ActiveUS20160126518A1Improve high temperature stabilityImprove heat resistanceButtonsCeramic shaping apparatusPolymer sciencePolyolefin

Disclosed is a method of preparing a crosslinked polyolefin separator including preparing a silane grafted polyolefin solution using a polyolefin having a weight average molecular weight higher than or equal to 200,000, a diluent, an alkoxy group containing vinylsilane, and an initiator, forming the silane grafted polyolefin solution in a sheet shape and stretching, extracting the diluent from the stretched sheet to produce a porous membrane, and crosslinking the porous membrane in the presence of water, and a crosslinked polyolefin separator.

Owner:LG CHEM LTD

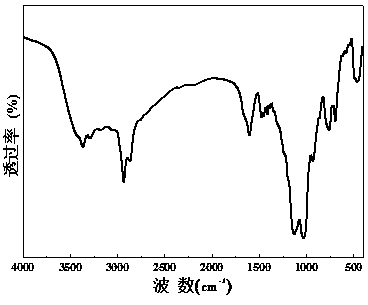

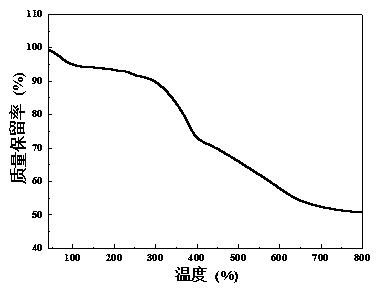

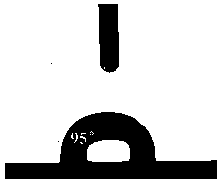

Hybridization structured polysiloxane flame retardant and preparation method thereof

The invention discloses a hybridization structured polysiloxane flame retardant and a preparation method thereof. The hybridization structured polysiloxane flame retardant is prepared by enabling hydrogen-containing silicone oil, allyl glycidyl ether, vinyl silane substances, phosphorus-containing active substances and a silane coupling agent to react with one another under the action of a catalyst. The flame retardant comprises a great amount of organic groups such as benzene rings, a relatively long -Si-O-Si-main chain and a hybridization structure, has hydrophobicity, is relatively high in thermal stability, comprises a great number of elements such as carbon, nitrogen, phosphorus and silicon, can be used as a carbon source and a gas source in an intumescent system, meanwhile has a synergistic flame retardant effect of multiple flame-retardant elements, is good in carbonization property and high in flame-retardant efficiency, the contact angle of the composition is up to 95 DEG C, the compatibility of the composition and a high polymer can be improved, and processing requirements of the high polymer can be met.

Owner:TAIYUAN UNIV OF TECH

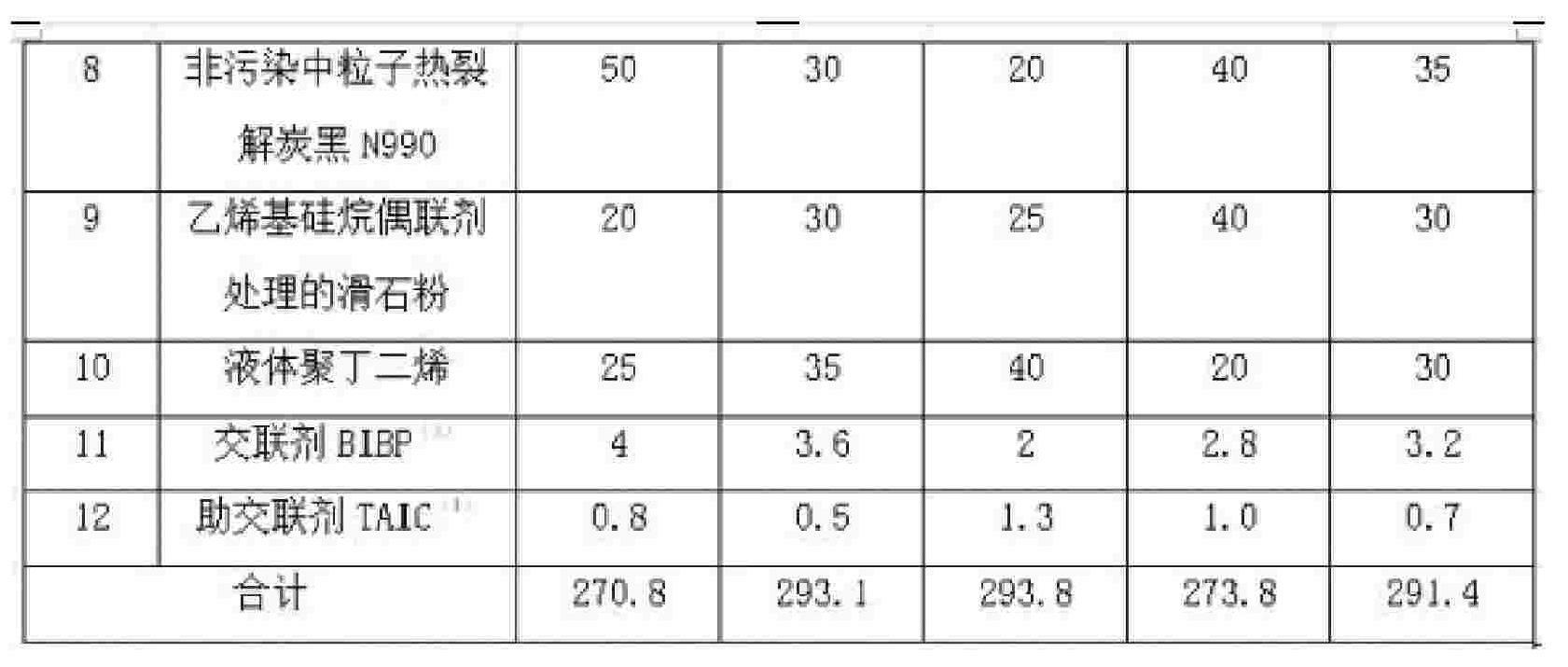

Formula of rubber hose of peroxide vulcanization radiator

ActiveCN101812204ALow pressure denaturationImprove high temperature resistanceFlexible pipesPolymer scienceVulcanization

The invention relates to a formula of a rubber hose of a peroxide vulcanization radiator, comprising the following ingredients by weight percent: ternary ethylene propylene rubber 100, zinc oxide 5-15, polyethylene glycol 2-4, stearic acid 0.5-1.5, age resister (445) 0.5-2, age resister MMBZ 0.5-2, fast extruding furnace black (N550) 50-90, non-polluted intermediate-particle thermal black (N990) 20-50, talcum powder treated with vinylsilane coupling agent 20-40, liquid polybutadiene 20-40, crosslinking agent BIBP 2-4 and crosslinking aid TAIC 0.5-1.3.Compared with the rubber hose of a sulphur vulcanization radiator, the rubber hose of the peroxide vulcanization radiator has more excellent heat-resistant and ageing-resistant properties, very good cooling liquid resistant property, electrical insulation property and press deformation property, better meeting the demand of water pipes of traditional radiators for automobiles.

Owner:TIANJIN PENGYI GRP CO LTD

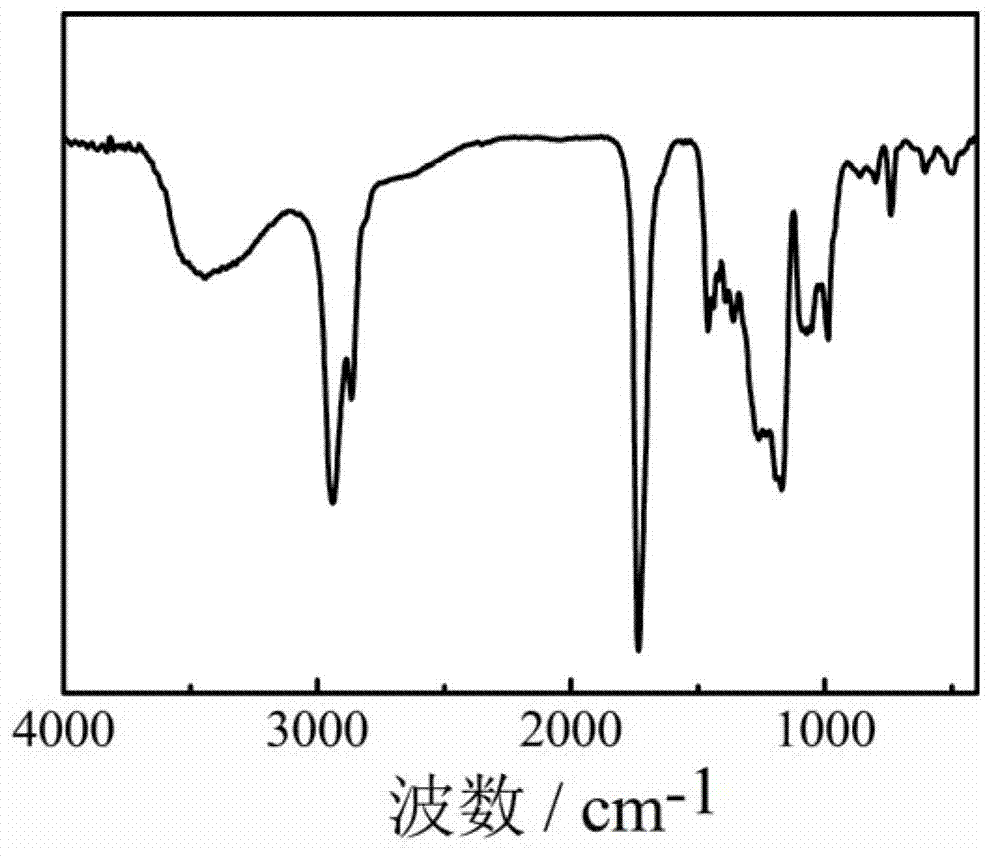

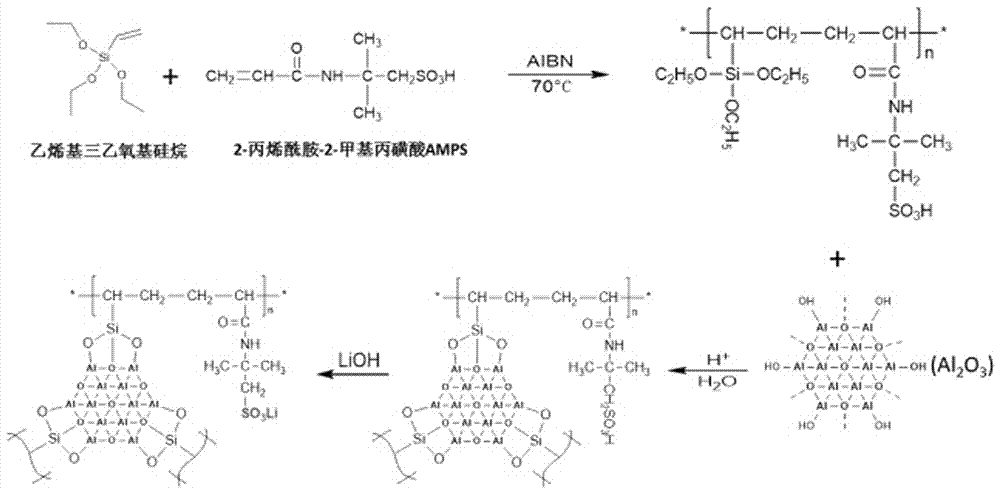

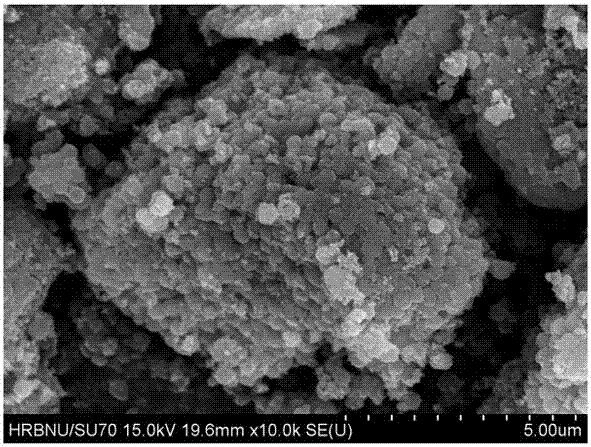

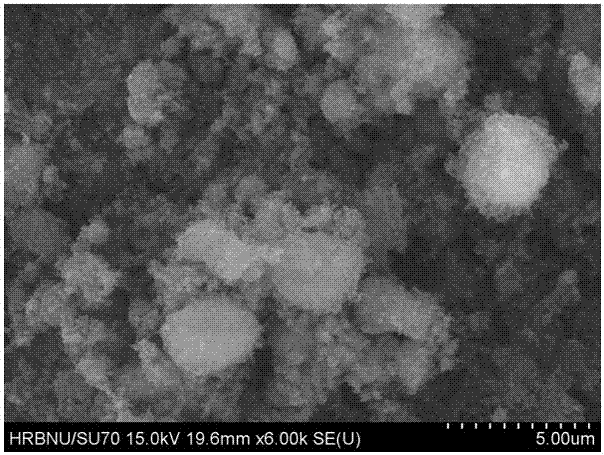

Surface-modified inorganic nanoparticles as well as preparation method and application thereof

ActiveCN107134590AGood dispersionEvenly dispersedMaterial nanotechnologySolid electrolytesDispersityMetal oxide nanoparticles

The invention discloses surface-modified inorganic nanoparticles as well as a preparation method and application thereof. The surface-modified inorganic nanoparticles are composed of a core of inorganic metal oxide nanoparticles and amphipathic organic segments grafted on the surface of the particles, wherein the amphipathic organic segments grafted on the surface of the particles account for 0.1-50% of total mass of the surface-modified inorganic nanoparticles; the inorganic metal oxide nanoparticles refer to one or several in aluminum oxide, silicon dioxide, titanium dioxide, zirconium dioxide and zinc oxide inorganic nanoparticles; and the amphipathic organic segments are produced from a vinyl silicane coupling agent and 2-acrylamido--methylpropane sulfonic acid through solution polymerization. The surface-modified inorganic nanoparticles can be used for preparing polymer electrolyte. Therefore, the inorganic nanoparticles are high in dispersity in a polymer matrix, and the prepared polymer electrolyte is high in lyotropic property, high in ionic conductivity and stable in electrochemical performance.

Owner:浙江久功新能源科技有限公司

Method for producing hollow microsphere modified fluoro-silicone emulsion and outer wall heat-insulating coating thereof

ActiveCN101805433AGood weather resistanceImprove performanceReflecting/signal paintsMicrosphereSolvent

The invention relates to a building outer wall heat-insulating coating, in particular to a method for producing hollow microsphere modified fluoro-silicone emulsion and outer wall heat-insulating coating thereof. Hollow microspheres are added into aqueous solution containing vinylsilane coupling agent and uniformly stirred, so that hollow microsphere dispersion with the solid content of 20 percent to 60 percent is produced, and the hollow microsphere dispersion, deionized water, buffer and emulsifier are uniformly mixed and then added with fluorin, silicon acrylate mixed monomer and initiator to carry out reaction, so that the hollow microsphere modified fluoro-silicone emulsion is produced. The hollow microsphere modified fluoro-silicone emulsion is uniformly mixed with bactericide, dispersing agent, wetting agent, cosolvent and defoamer and then added with thickening agent, so that the outer wall heat-insulating coating is produced. The outer wall heat-insulating coating has the advantages of excellent comprehensive performance, outstanding heat-insulating, stain-resistant and weather-resistant properties and convenient construction, and therefore has a broad market prospect.

Owner:武汉双虎涂料股份有限公司

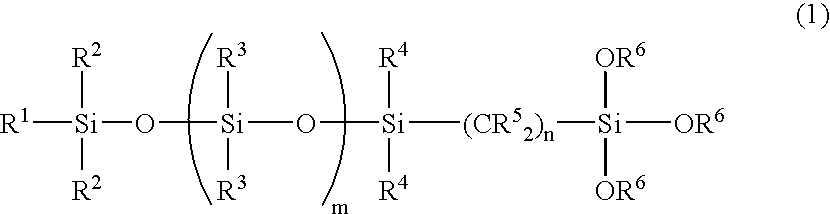

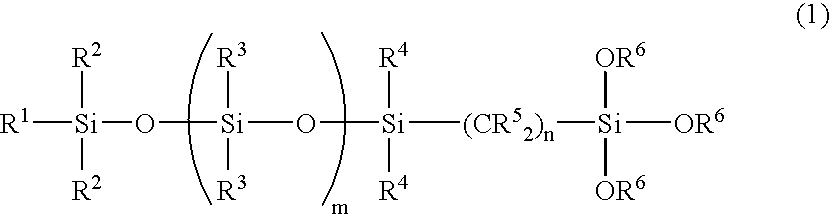

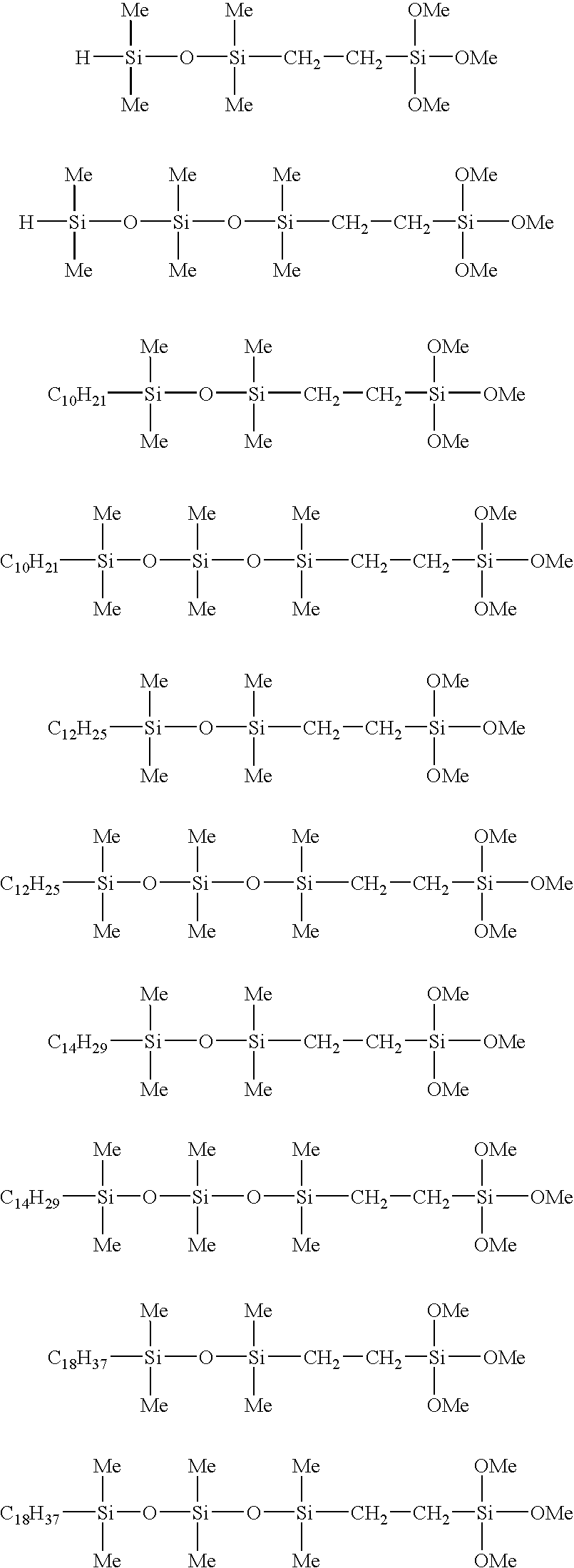

Organosilicon compound

InactiveUS20070290202A1Promote wettingHigh viscositySilicon organic compoundsSolid-state devicesSilyleneHydrosilylation

Provided is a novel organosilicon compound which functions as a silane coupling agent (wetter) that enables a silicone to be filled with a large quantity of a filler.The organosilicon compound is represented by a general formula (1)wherein, R1 represents a hydrogen atom, or an unsubstituted or substituted monovalent hydrocarbon group, R2 to R4 represent identical or different unsubstituted or substituted monovalent hydrocarbon groups, each R5 represents, independently, a hydrogen atom, or an unsubstituted or substituted monovalent hydrocarbon group, each R6 represents, independently, an identical or different unsubstituted or substituted monovalent organic group, m represents an integer from 0 to 4, and n represents an integer from 2 to 20; as well as a method of producing the above organosilicon compound, wherein a one end organohydrogensilyl-terminated organopolysiloxane is produced by reacting an organohydrogensiloxane with a vinylsilane or an alkenyltriorganooxysilane in the presence of a hydrosilylation catalyst, and optionally this one end organohydrogensilyl-terminated organopolysiloxane is then reacted with an alkene in the presence of a hydrosilylation catalyst.

Owner:SHIN ETSU CHEM IND CO LTD

Preparation method of acrylic thickening agents with inorganic clay as cross-linking agent

The invention belongs to the field of new materials and particularly relates to a preparation method of acrylic thickening agents with inorganic clay as a cross-linking agent. According to the method, a silane coupling agent is adopted for modifying the inorganic clay, vinyl is introduced on the surface of the inorganic clay, and then the acrylic thickening agents are prepared through inverse emulsion polymerization by taking vinyl silane coupling agent modified inorganic clay as the cross-linking agent, an acrylic monomer as a main monomer and a hydrophobic long-chain monomer as a functional monomer for improving the electrolyte resistance of the thickening agents. The thickening agent is low in price and has excellent thickening performance and salt tolerance.

Owner:CHANGZHOU XIAOGUO INFORMATION SERVICES

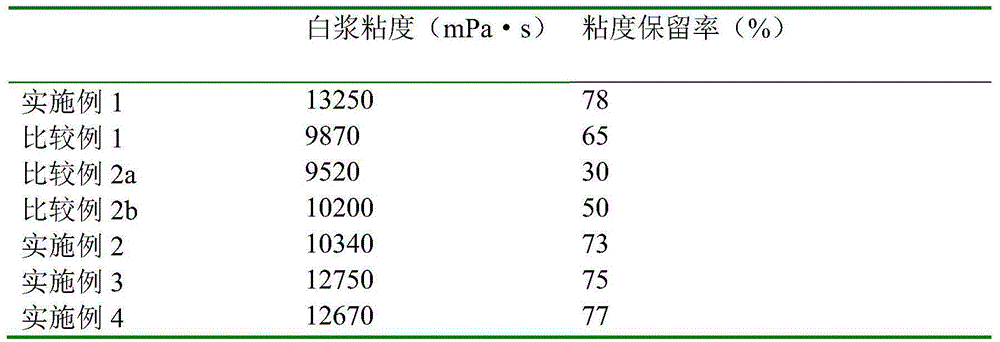

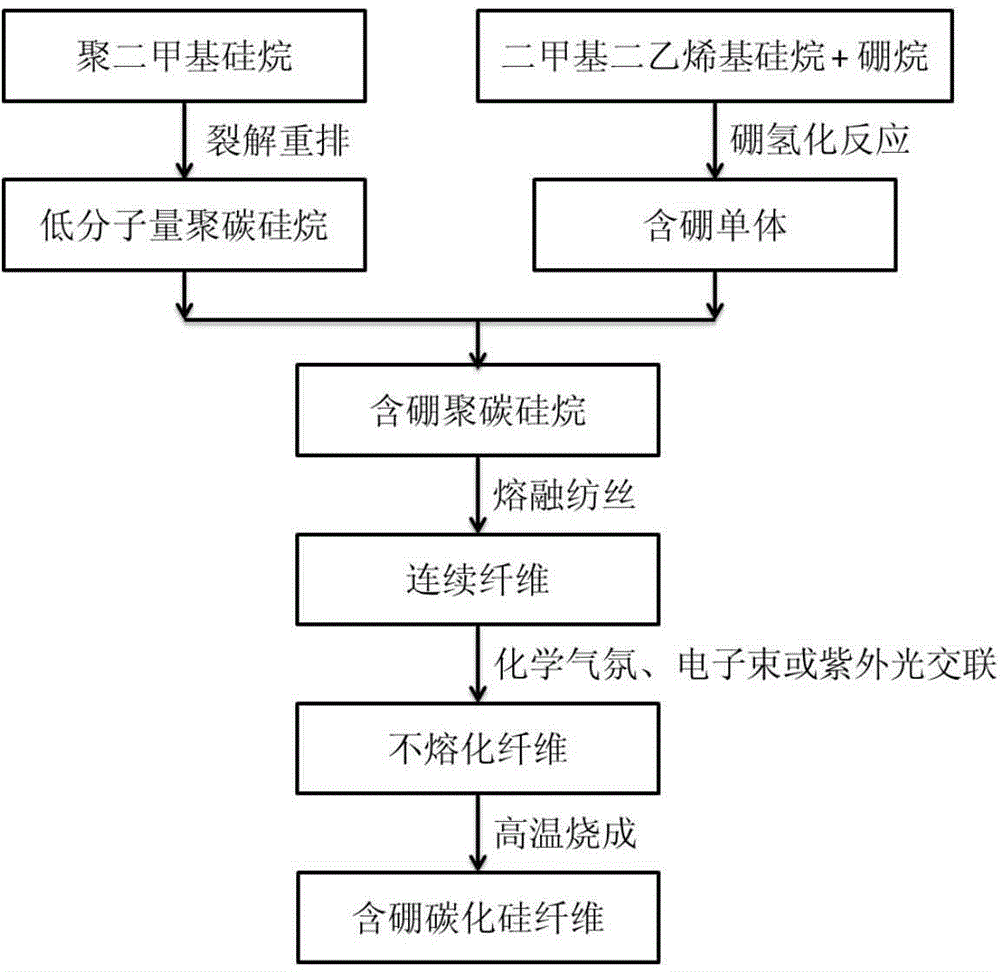

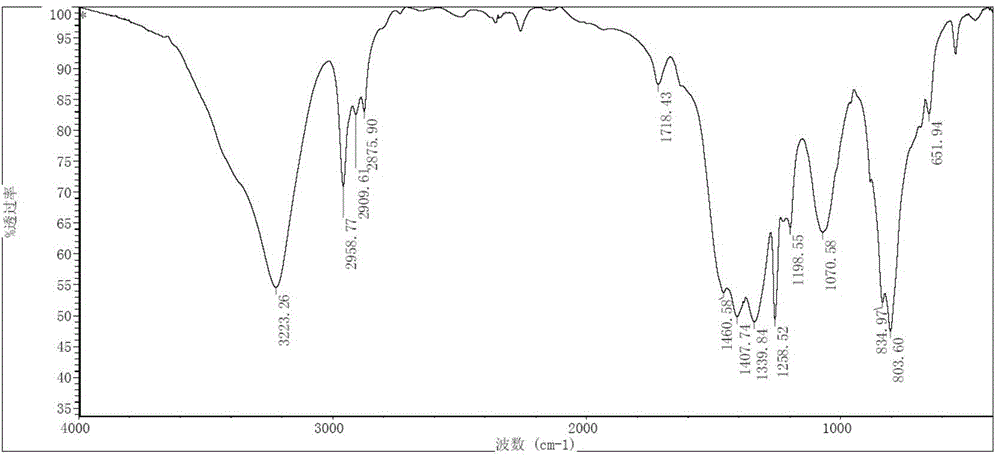

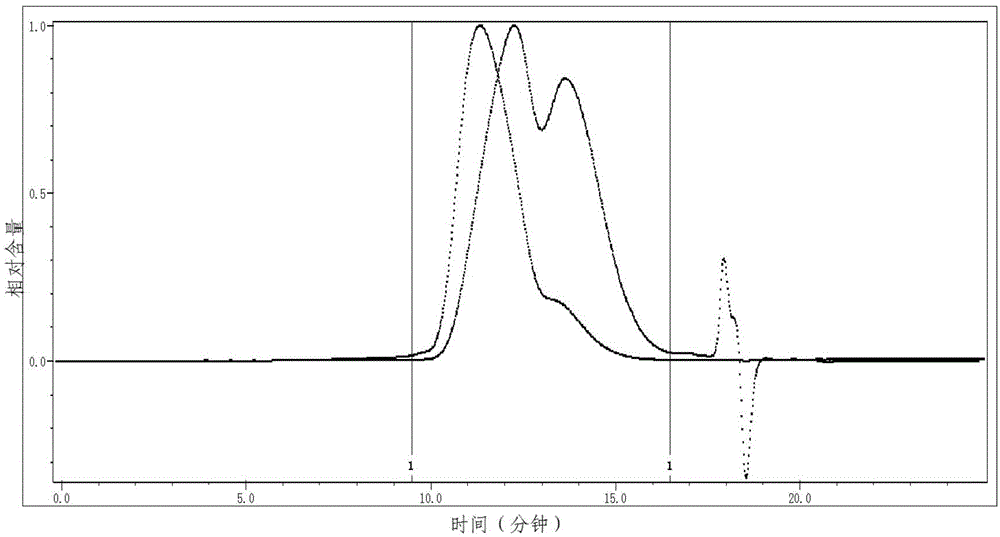

Preparation method of boron-containing silicon carbide fiber

The invention discloses a preparation method of boron-containing silicon carbide fiber. The preparation method comprises the following steps: mixing dimethyldivinylsilane with borane in a ratio of (3-1): 1 under the protection of nitrogen at room temperature, segmentally heating and preserving heat, and distilling to obtain a boron-containing monomer; dissolving LPCS into dimethylbenzene with weight equal to that of the LPCS, adding the boron-containing monomer, segmentally heating and preserving heat, distilling for 0.5-2 h at 20-100 Pa to remove low molecular compounds, and cooling to room temperature to obtain boron-containing polycarbosilane; putting the boron-containing polycarbosilane into a spinning melting barrel, heating till a uniform melt under the protection of nitrogen, performing melt spinning to obtain continuous fiber, and preparing into unmelted fiber; heating the unmelted fiber to 900-1100 DEG C, ceramizing the unmelted fiber, and further preserving heat at 1400-1800 DEG C. The boron-containing polycarbosilane prepared by the preparation method is not sensitive to air and humidity, has good melt spinning performance, and avoids toxicity of an unmelted boron-containing atmosphere and equipment corrosion caused by the unmelted boron-containing atmosphere.

Owner:NAT UNIV OF DEFENSE TECH

Radiation curing sealant for packaging eyeglass nameplate or ornament

InactiveCN101928370AFast curing timeIncrease productivityOther chemical processesPolyureas/polyurethane adhesivesPolyesterAntioxidant

The invention provides a radiation curing sealant for packaging an eyeglass nameplate or an ornament. The radiation curing sealant comprises the following components in percentage by weight: 30 to 70 percent of urethane acrylate low polymer, 10 to 50 percent of urethane acrylate, 0 to 40 percent of reactive diluent, 0.2 to 8 percent of photo-initiator, 0.1 to 5 percent of silane coupling agent, 0 to 2 percent of antioxidant and 0 to 2 percent of antifoaming agent, wherein the reactive diluent is mono (bi / multi)-functional group acrylic ester; the photo-initiator is a cracking initiator, a hydrogen abstraction initiator or the combination of the cracking initiator and the hydrogen abstraction initiator; and the silane coupling agent is a mixture selected from one or more of epoxy silane, vinyl silane and (methyl) propylene acyloxy silane. When the sealant is used, the sealant is directly injected into a groove for accommodating the eyeglass nameplate or the ornament without sealant mixing. The sealant can be cured rapidly under the irradiation of ultraviolet light and packaging is further finished, so that production efficiency is improved greatly; simultaneously, energy is saved and raw material cost is lowered.

Owner:DONGGUAN POWERBOND NEW MATERIALS TECH DEV

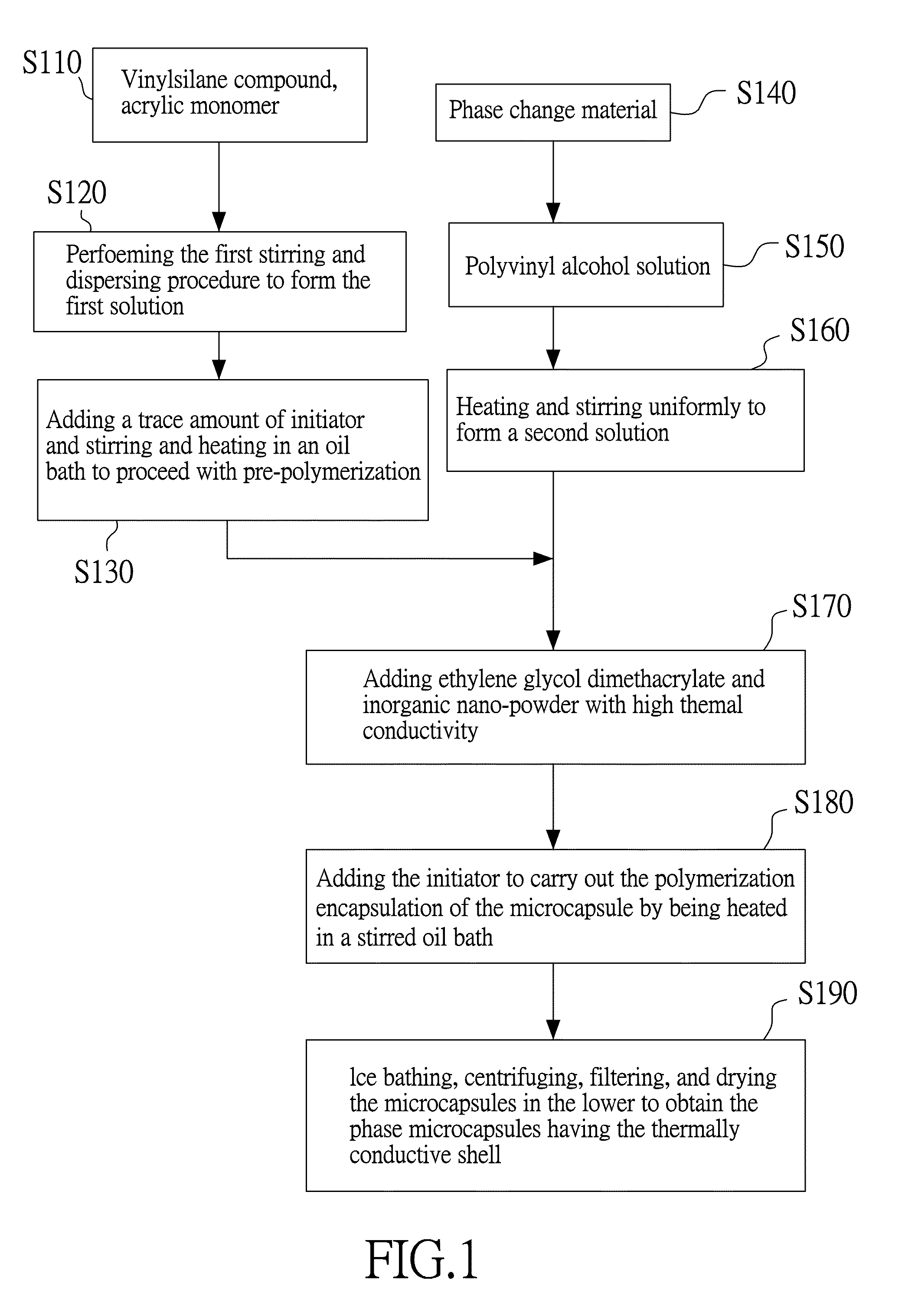

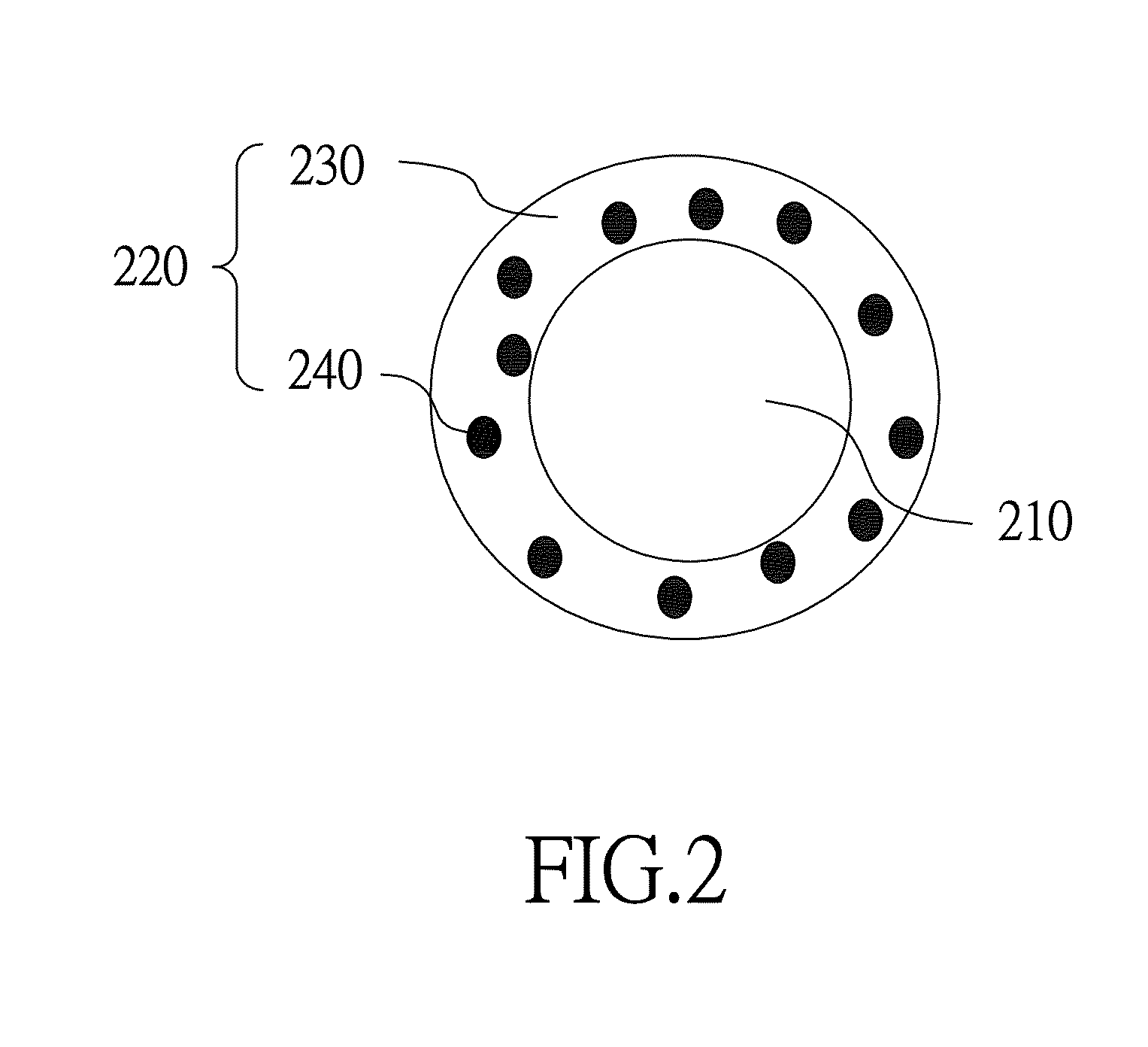

Process for preparing phase change microcapsule having thermally conductive shell

ActiveUS20160151757A1Speeding up absorptionSpeed up the releaseHeat storage plantsHeat-exchange elementsElectrical polarityConductive materials

A process for preparing a phase change microcapsule having a thermally conductive shell is introduced. The thermal conductivity of the encapsulation materials for the phase change microcapsules is increased by adding thermally conductive nano-materials. The vinylsilane compound is polymerized with the acrylic monomer to form the copolymer first, and then the thermally conductive inorganic material is added. Thereafter, the phase change microcapsule having the phase change material as the core and the thermally conductive material-containing copolymer as the shell is prepared. The polar functional groups on the surface of the thermally conductive inorganic material condense with the vinylsilane compound to form chemical bonding, thereby substantially increasing the compatibility between the thermally conductive inorganic material and the copolymer. Therefore, the thermally conductive material can be dispersed stably during the encapsulation of the microcapsules, and the phase change microcapsule having the thermally conductive shell can be obtained successfully.

Owner:NAT CHUNG SHAN INST SCI & TECH

Preparation method of polyhedral oligomeric silsesquioxane-grafted carbon fiber reinforcement

InactiveCN105778153AImprove surface roughnessHigh grafting rateCarbon fibresCarbon fibersSilsesquioxane

The invention relates to a preparation method of a polyhedral oligomeric silsesquioxane-grafted carbon fiber reinforcement. The preparation method comprises the following steps of firstly, grafting a vinyl silane coupling agent onto the carbon fiber surface which is acidified by a hydrolysis method; then, generating a click reaction between introduced vinyl on the carbon fiber surface and sulfydryl on the sulfydryl polyhedral oligomeric silsesquioxane, so as to obtain the polyhedral oligomeric silsesquioxane-grafted carbon fiber reinforcement. After the polyhedral oligomeric silsesquioxane is introduced onto the carbon fiber surface, the wettability between the carbon fiber and the resin is improved, and the interfacial strength between the carbon fiber and the resin is improved. The preparation method has the advantages that the process is simple, the reaction time is short, the byproduct has no toxicity, and the scaled production is favorably realized.

Owner:NANCHANG HANGKONG UNIVERSITY

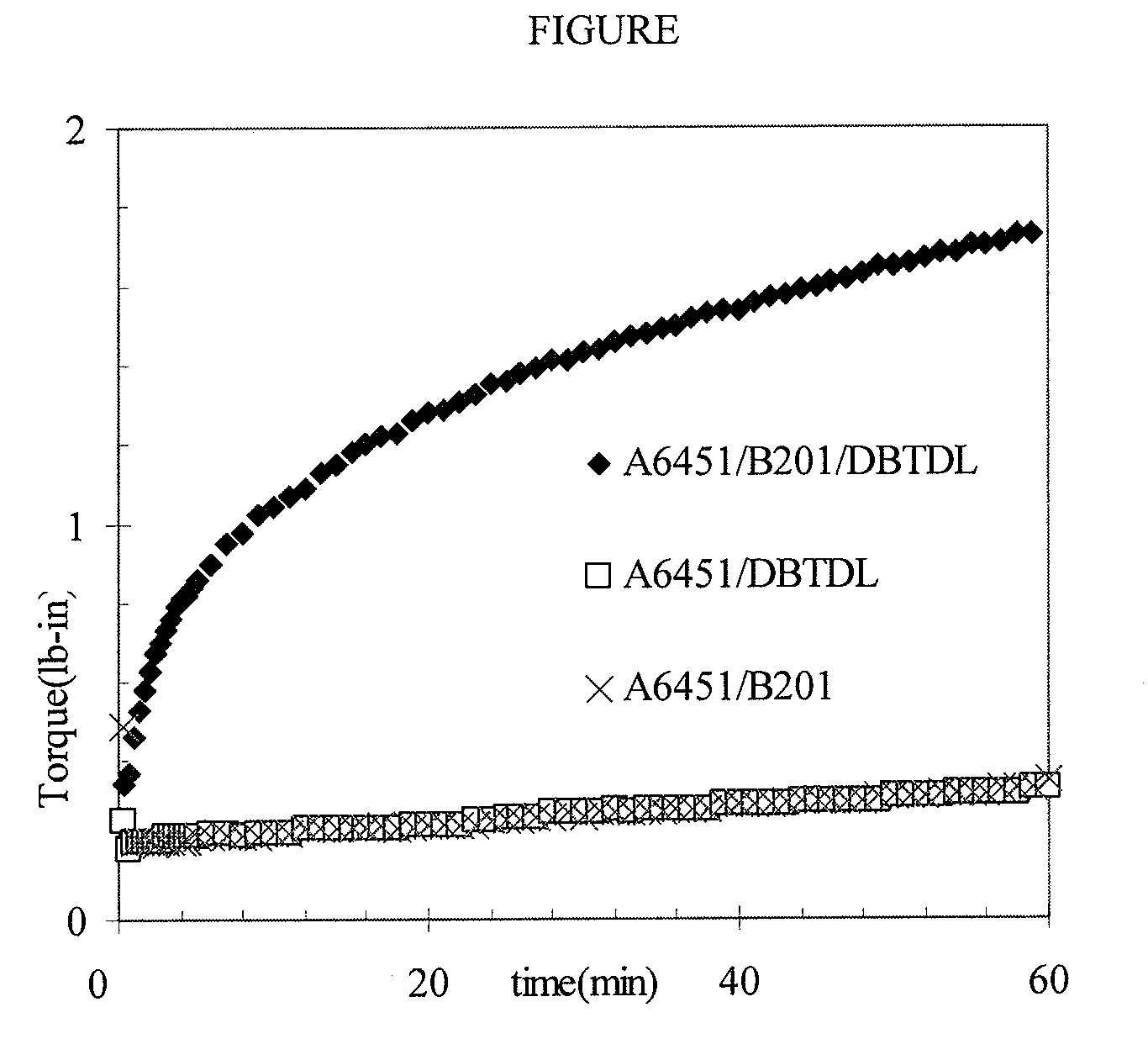

Catalyst System for Moisture Cure of Ethylene-Vinylsilane Copolymers

Ethylene-vinylsilane copolymers are moisture-cured under ambient conditions using a synergistic combination of at least one Lewis acid and at least one Brønsted acid or at least one Lewis base and at least one Brønsted base. Preferably the catalyst system comprises a Lewis acid, e.g., dibutyltin dilaurate, in combination with a Brønsted acid, e.g., sulfonic acid. The Lewis acid or base and the Brønsted acid or base is present in the catalyst system at a molar ratio of Lewis acid / base to Brønsted acid / base of 1:10 to 10:1.

Owner:DOW GLOBAL TECH LLC

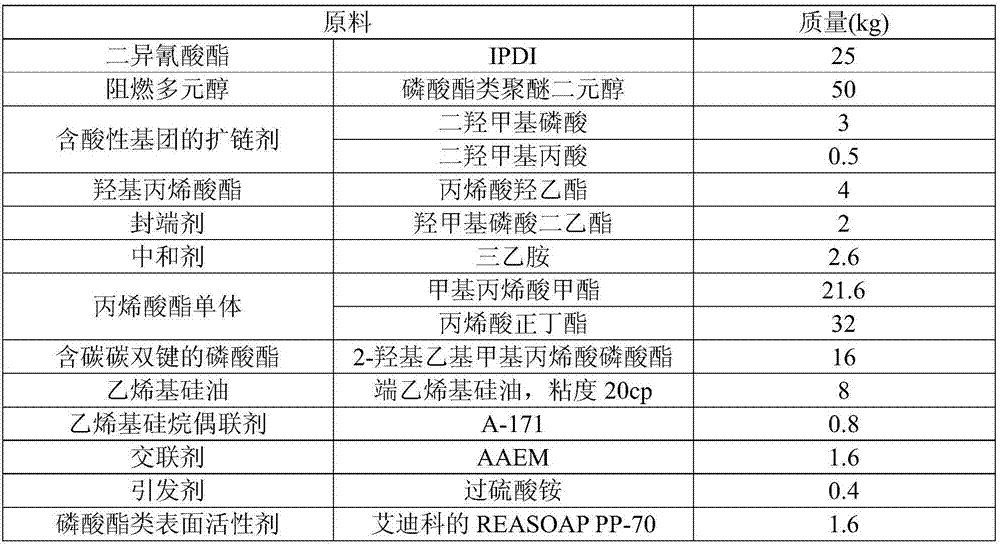

A waterborne polyurethane-acrylate copolymer emulsion and a preparing method thereof

A waterborne polyurethane-acrylate copolymer emulsion and a preparing method thereof are disclosed. The emulsion is prepared by preparing a phosphorus containing waterborne polyurethane emulsion containing carbon-carbon double bonds from diisocyanate, a flame-retardant polyol, a non-flame-retardant polyol, a chain extender containing an acidic group, hydroxyl acrylate and an end-capping agent through a chemical grafting method; and then subjecting acrylate, phosphate containing a carbon-carbon double bond, vinyl silicone oil, a vinyl silane coupling agent and an acrylic acid type crosslinking agent which are adopted as raw materials to emulsion polymerization under protection of a phosphate surfactant. The copolymer emulsion has a high solid content, time for drying the copolymer emulsion is short, and a product after the copolymer emulsion is dried has good flame retardance and resistance to thermal decomposition.

Owner:DONGGUAN CTL NEW MATERIAL TECH

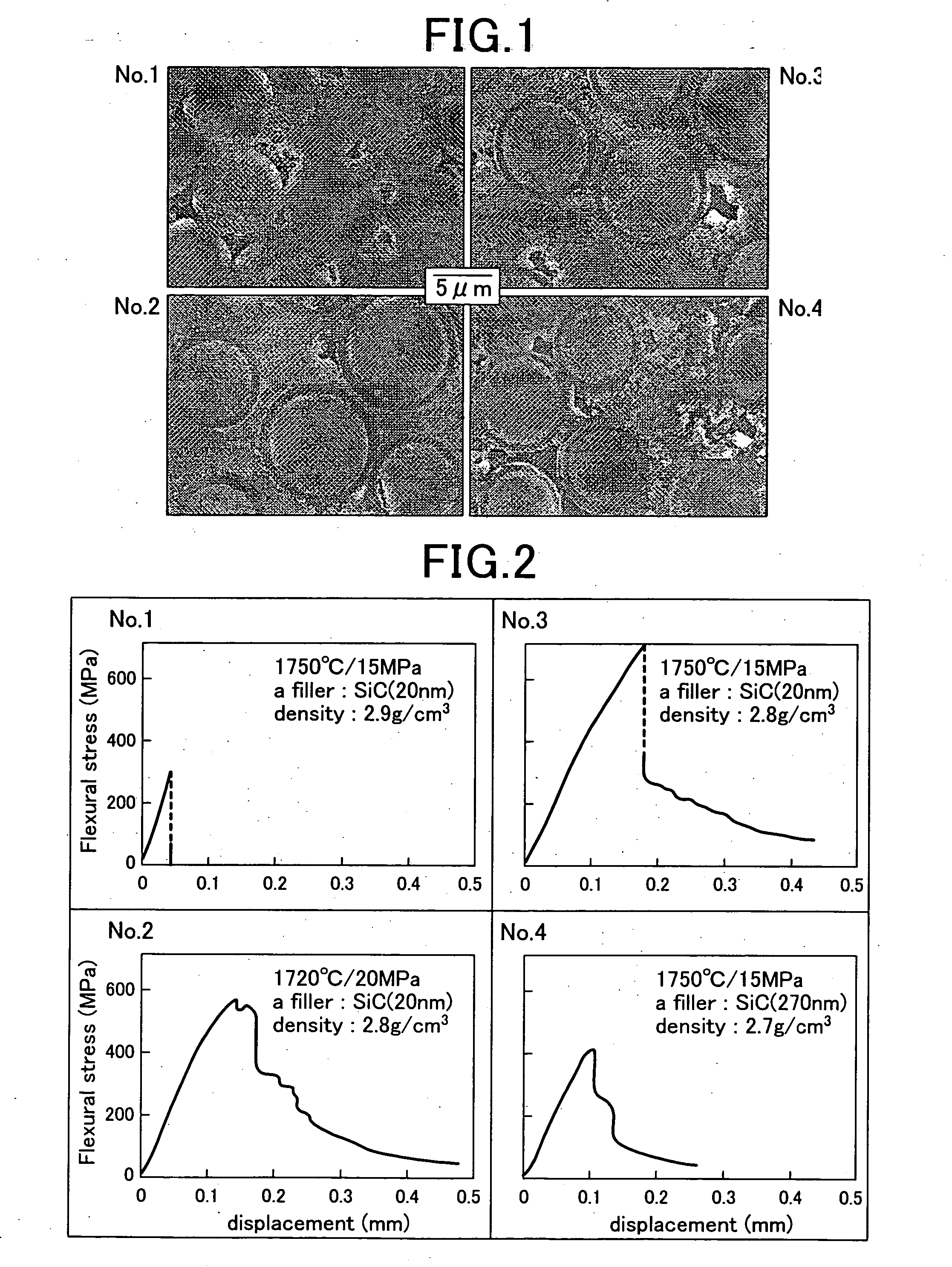

Method for producing sic fiber-reinforced sic composite material

InactiveUS20050001361A1Compact structureHigh strengthMaterial nanotechnologyLamination ancillary operationsSlurrySilicon dioxide

A preformed of SiC fiber, which is coated with one or more of C, BN and SiC, is impregnated with a slurry, which suspends fine SiC powder and a sintering additive therein. The impregnated preform is hot-pressed at 1600-1800° C. with a pressure of 10 MPa or more. The sintering additive may be one or more of Al2O3, Y2O3, SiO2 and CaO. The slurry may futher contain a silicone polymer selected from polycarbosilane, polyvinylsilane and polymethylsilane. Reaction of SiC fiber with a matrix is inhibited by the coating, so as to manufacture a SiC fiber-reinforced SiC-matrix composite remarkably improved in mechanical properties.

Owner:JAPAN SCI & TECH CORP

Silane coating compositions and methods of use thereof

A method of treating a substrate, such as a metal surface, by application of a silane coating composition containing at least one water-soluble or dispersible silane and a polymeric resin, which may be provided as a water-based dispersion of polymeric resin, the polymeric resin being present in an amount less than 10% by weight of the composition to slow the rate of corrosion of the metal surface and / or to promote adhesion of rubber thereto. The at least one silane can include a bis-amino silane, a vinyl silane, a bis-sulfur silane, or mixtures thereof and the polymeric resin may include an epoxy resin, acrylate resin, polyurethane resin, novolac resin, or mixtures thereof. The silane coating compositions may be either water or solvent based.

Owner:UNIVERSITY OF CINCINNATI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com