Preparation method and application of main chain fracture type polyacrylic acid silane ester resin

一种聚丙烯酸、主链断裂的技术,应用在硅烷酯树脂领域,能够解决很难达到自抛光效果等问题,达到均匀和彻底水解抛光、改善溶解性、优异减阻性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

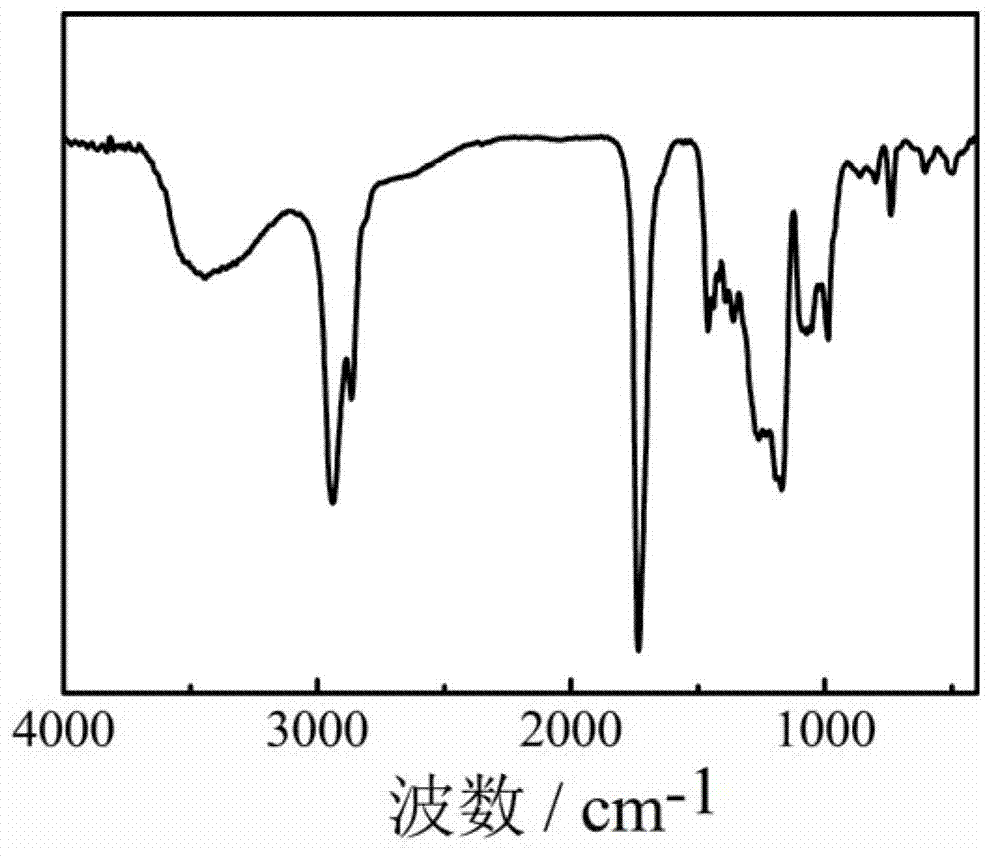

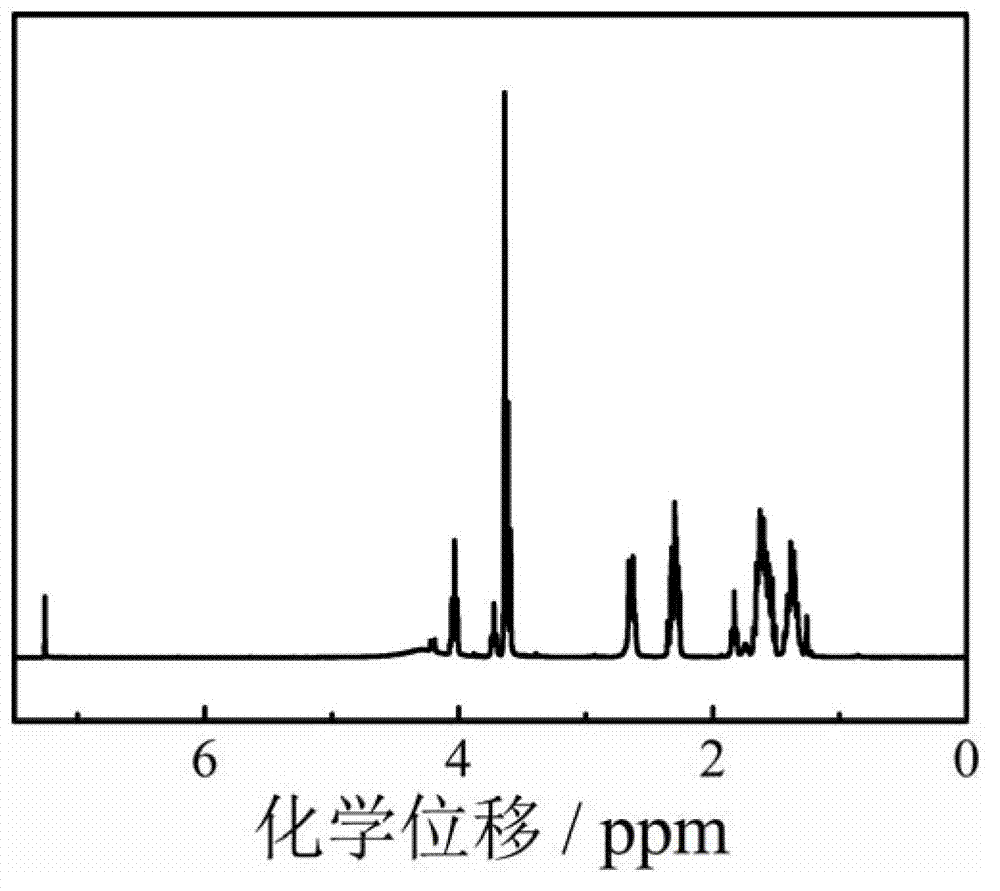

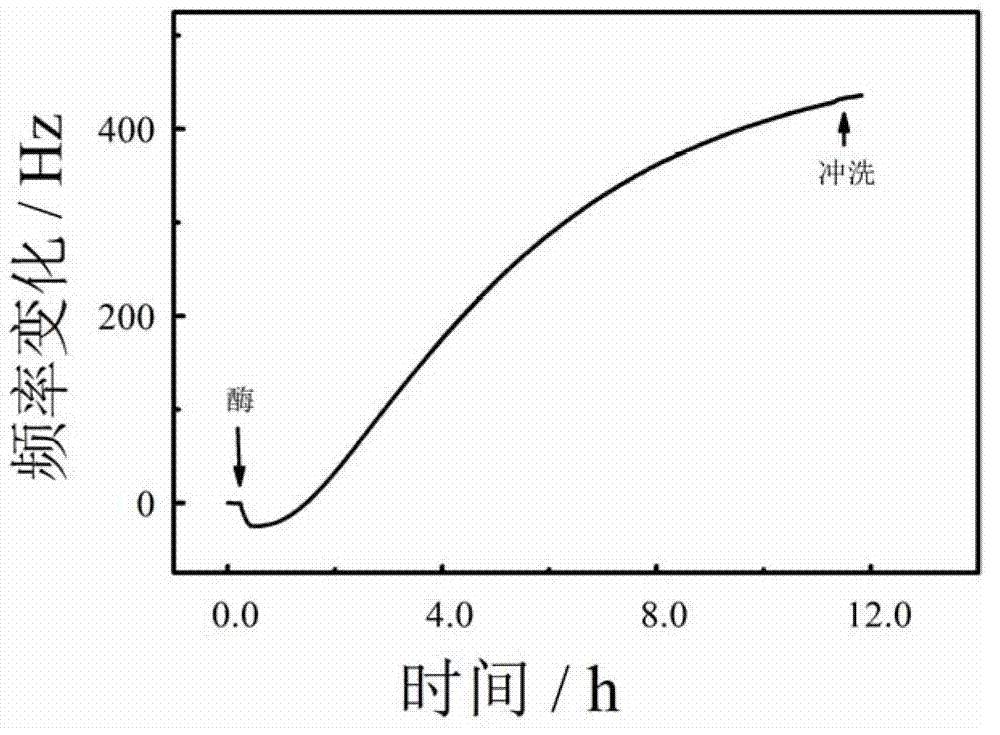

Embodiment 1

[0029] Add 50g of caprolactone, 50g of trimethylsilyl methacrylate, 0.1g of methanol and 100mL of xylene into a dry 250mL three-neck flask with a stirrer and a thermometer, add 100μL of phosphazene (t‐BuP 4 ) in n-hexane solution, reacted at 25°C for 6h, precipitated in methanol, and dried in vacuum to obtain poly(caprolactone-trimethylsilyl methacrylate), with a yield of 90%. from figure 1 1730cm appears in the infrared spectrum ‐1 (corresponding to the ester group absorption peak of caprolactone), 2860cm ‐1 (corresponds to the CH of caprolactone 2 absorption peak) and 2950cm ‐1 (corresponding to the CH of the silane ester 3 absorption peak), indicating that the target product was successfully synthesized. figure 2 The chemical shift δ=0.87 in the NMR spectrum (corresponding to the CH of the silane ester 3 absorption peak) and δ=1.32‐1.45ppm, 1.55‐1.72ppm, 2.25‐2.40ppm, 3.98‐4.17ppm appeared four peaks (corresponding to the CH of caprolactone 2 absorption peak), furth...

Embodiment 2

[0033] Add 10g lactide, 90g triisopropylsilyl acrylate, 0.01g diethylene glycol and 100mL tetrahydrofuran into a 250mL sealed tube, freeze with liquid nitrogen, replace nitrogen three times and inject 70μL of t-BuP under nitrogen atmosphere 4 n-hexane solution, melted and sealed, reacted at 60°C for 2h, then precipitated in 100mL of methanol, dried in vacuum for 12h, the yield was 94%, and the number average molecular weight was 1.5×10 by gel permeation chromatography. 4 g / mol. 20g of this polymer was stirred and mixed with 120g of cuprous oxide, 20g of pyridine triphenylborane, 10g of iron oxide red and 30g of methyl isobutyl ketone to prepare a marine antifouling paint. By brushing, a film was formed on the epoxy resin board, and a shallow sea hanging board experiment was carried out in Xiamen Sea (2012.4-2013.2), and no marine organisms grew for 10 months.

Embodiment 3

[0035] Add 180g of ethylene carbonate, 10g of tri-n-butylsilyl acrylate, 10g of methyl methacrylate, 0.02g of methanol into a 500mL three-necked flask, freeze with liquid nitrogen, replace the nitrogen three times, and quickly inject 70 μL of t-BuP4 under a nitrogen atmosphere n-hexane solution, reacted at 150°C for 12h. After the reaction, precipitated in methanol, filtered, vacuum-dried, the yield was 90%, and its number-average molecular weight detected by gel permeation chromatography was 2.4×10 4 g / mol. The polymer 30g, with 40g cuprous oxide, 7g 4,5-dichloro-2-n-octyl-4-isothiazolin-3-one, 7g zinc oxide, 6g calcium carbonate, 3g bentonite, and 7g butyl Ketones are stirred and mixed to make marine antifouling coatings. By brushing, a film was formed on the epoxy resin board, and a shallow sea hanging board experiment was carried out in Xiamen Sea (2012.4-2013.4), and no marine organisms grew for 12 months.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com