Preparation method of acrylic thickening agents with inorganic clay as cross-linking agent

A technology of inorganic clay and acrylic acid, applied in the field of new materials, can solve the problems of reduced thickening effect, poor electrolyte resistance, application limitation, etc., and achieve the effect of reducing cost and improving thickening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

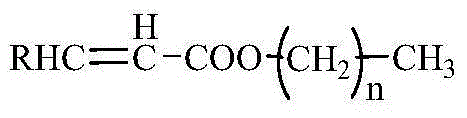

Image

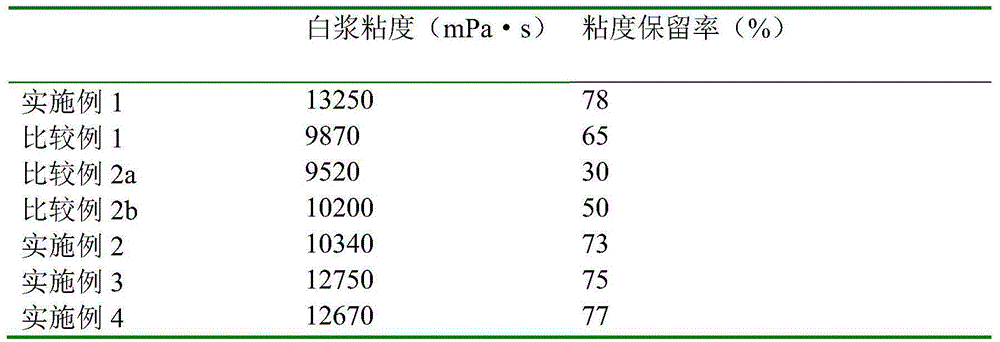

Examples

Embodiment 1

[0020] (1) Add 2mol / LNaCl solution in the round-bottomed flask, then add bentonite, the mass volume ratio of bentonite and sodium chloride solution is 1:40 in g / mL, stir for 6h, discard the supernatant, wash the precipitate, Vacuum-dry at 50°C to obtain sodium-based bentonite, grind the sample, pass through a 200-mesh sieve, and set aside.

[0021] (2) Disperse sodium bentonite in toluene with a solid-to-liquid mass ratio of 1:10, disperse it ultrasonically for 10 minutes, add vinyltriethoxysilane dropwise, and the mass ratio of silane coupling agent to sodium bentonite is 2:1, Use glacial acetic acid to adjust the pH value of the system to 4.0, and react at 70°C for 10h. After the reaction, remove the solvent, vacuum dry, grind, and pass through a 200-mesh sieve to obtain the silane coupling agent-modified bentonite.

[0022] (3) Place the four-necked flask in a cold water bath, add acrylic acid, cetyl acrylate, silane coupling agent modified bentonite, cetyl acrylate and si...

Embodiment 2

[0030] (1) Add 2mol / L NaCl solution to the round bottom flask, then add attapulgite, the mass volume ratio of attapulgite to sodium chloride solution is 1:80 in g / mL, stir for 8h, and discard the supernatant , washed the precipitate, and vacuum-dried at 80°C to obtain sodium-based attapulgite. The sample was ground, passed through a 200-mesh sieve, and set aside.

[0031] (2) Disperse sodium-based attapulgite in xylene at a solid-to-liquid mass ratio of 1:30, disperse it ultrasonically for 30 minutes, and add vinyltrimethoxysilane dropwise. The mass ratio of silane coupling agent to sodium-based attapulgite is 5:1, use glacial acetic acid to adjust the pH value of the system to 5.0, and react at 100°C for 6h. After the reaction, remove the solvent, vacuum dry, grind, and pass through a 200-mesh sieve to obtain the silane coupling agent-modified attapulgite.

[0032] (3) Place the four-necked flask in a cold water bath, add methacrylic acid, myristyl methacrylate, silane coupl...

Embodiment 3

[0034] (1) Add 2mol / LNaCl solution in the round bottom flask, then add kaolin, the mass volume ratio of kaolin and sodium chloride solution is 1:60 in g / mL, stir 7h, discard supernatant, wash precipitation, Vacuum-dry at 70°C to obtain sodium-based kaolin, grind the sample, pass through a 200-mesh sieve, and set aside.

[0035] (2) Disperse sodium-based kaolin in toluene at a solid-to-liquid mass ratio of 1:20, disperse it ultrasonically for 20 minutes, add vinyl tris(β-methoxyethoxy)silane, silane coupling agent and the quality of sodium-based kaolin The ratio was 4:1, the pH value of the system was adjusted to 4.5 with glacial acetic acid, and the reaction was carried out at 80°C for 8 hours. After the reaction, the solvent is removed, vacuum-dried, ground, and passed through a 200-mesh sieve to obtain silane coupling agent-modified kaolin.

[0036](3) Place the four-necked flask in a cold water bath, add itaconic acid, dodecyl acrylate, silane coupling agent modified kaoli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com