Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

282results about How to "Improve electrolyte resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-corrosion, anti-puncture and anti-short circuit melting through aluminum-plastic packaging film for lithium battery and manufacture method thereof

ActiveCN102602081AExcellent electrolyte resistanceAvoid corrosionLamination ancillary operationsLaminationPlastic packagingElectrical battery

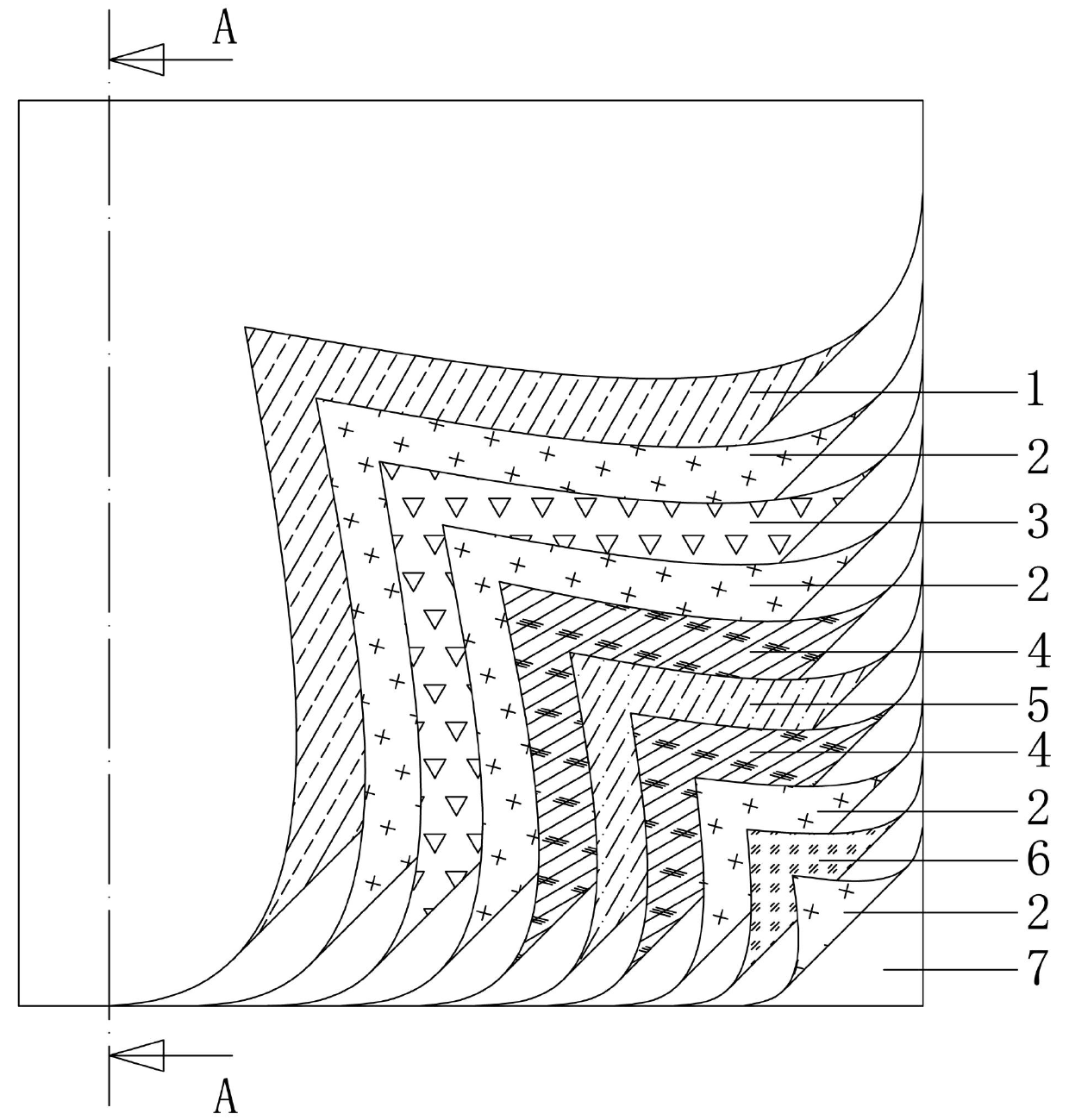

The invention discloses an anti-corrosion, anti-puncture and anti-short circuit melting through aluminum-plastic packaging film for lithium battery and a manufacture method thereof. The aluminum-plastic packaging film has a layer structure, comprises at least seven layers which are respectively to be a protecting layer A, an adhesive layer, a coating material layer, an aluminum foil layer, another coating material layer, another coating material layer and a heat-seal layer, and further comprises a protecting layer B arranged on the protecting layer A by the adhesive layer and / or a protecting layer C arranged between the coating material layer and the adhesive layer at the lower surface of the aluminum foil layer through another adhesive layer. According to the invention, the corrosion of electrolyte can be effectively stopped, the anti-puncture intensity, the tensile strength and the wear-resistant property of the aluminum-plastic film can be improved, the yield and the reliability of the battery can be improved, the heat-seal short circuit caused by the improper operation or the abnormal temperature of a machine during heat sealing can be completely avoided, and the service life of the battery can be greatly prolonged, so that the invention is high in reliability.

Owner:东莞市金恒晟新材料科技有限公司

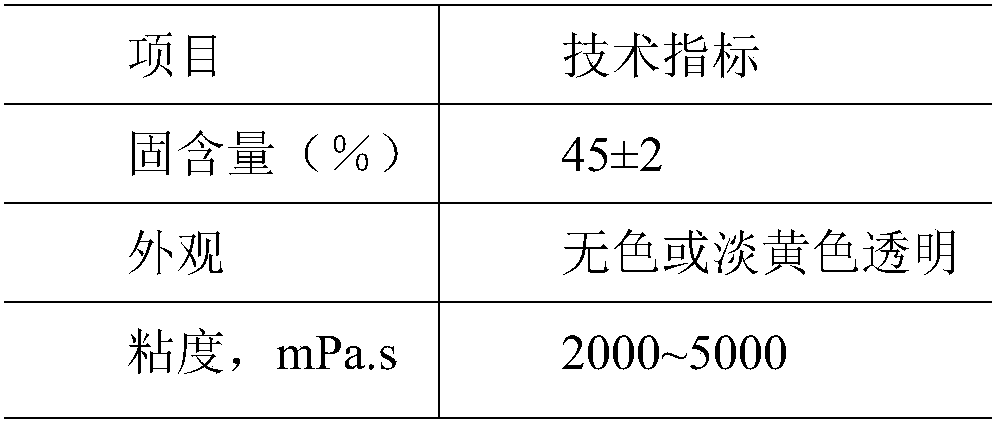

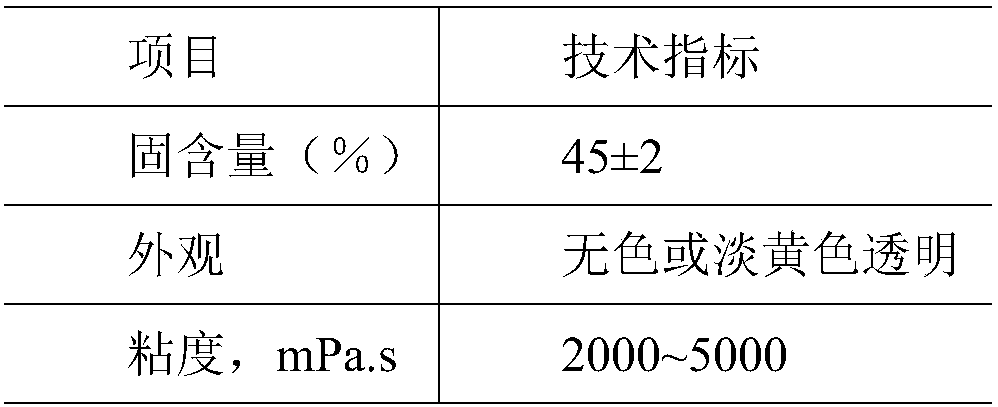

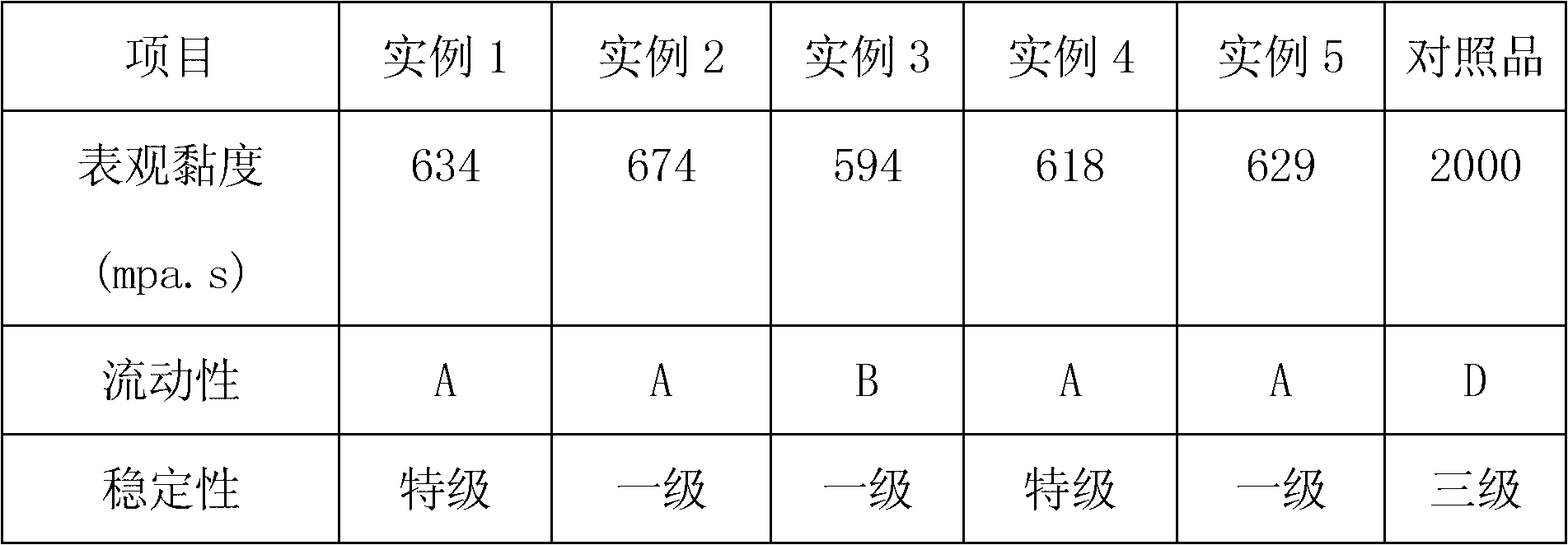

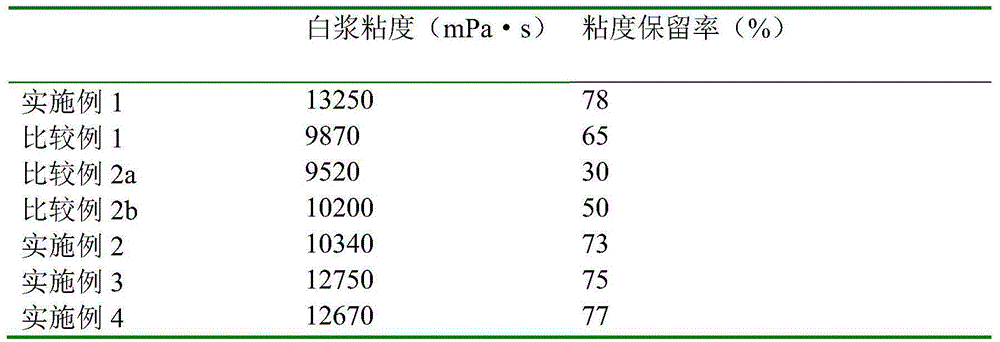

Paint thickener for printing and preparation method thereof

The invention discloses a paint thickener for printing and a preparation method thereof. The preparation method comprises the following steps: using unsaturated and acidic monomers, crosslinking agent, unsaturated compound and functional monomers to perform inverse emulsion polymerization in hydrocarbon solvent under the action of initiator and oil-soluble emulsifier and performing inverse emulsion, wherein unsaturated and acidic monomers are neutralized before the polymerization. The paint thickener for printing of the invention has excellent thickening ability and electrolyte tolerance performance, high colour yield and soft hand feeling.

Owner:HANGZHOU TRANSFAR FINE CHEM CO LTD +1

Binder for electrode material containing semi-ipn of polyvinyl alcohol and polyurethane and lithium secondary battery employed with the same

ActiveUS20100047693A1High bonding strengthImprove electrolyte resistanceSilver accumulatorsConductive materialInterpenetrating polymer networkCurrent collector

Provided is a binder for an electrode mix containing a semi-interpenetrating polymer network (semi-IPN) of polyvinyl alcohol and polyurethane, wherein the polyurethane is mixed to crosslink with the polyvinyl alcohol to form semi-IPN, and a lithium secondary battery comprising the same. The binder has superior adhesion to the electrode, excellent electrolyte resistance and improved elongation percentage, and therefore it is possible to prevent exfoliation or separation of electrode active materials from current collectors which occurs during repeated charge / discharge cycles. As a result, the capacity or power out of secondary batteries can be maintained at a constant level.

Owner:LG CHEM LTD

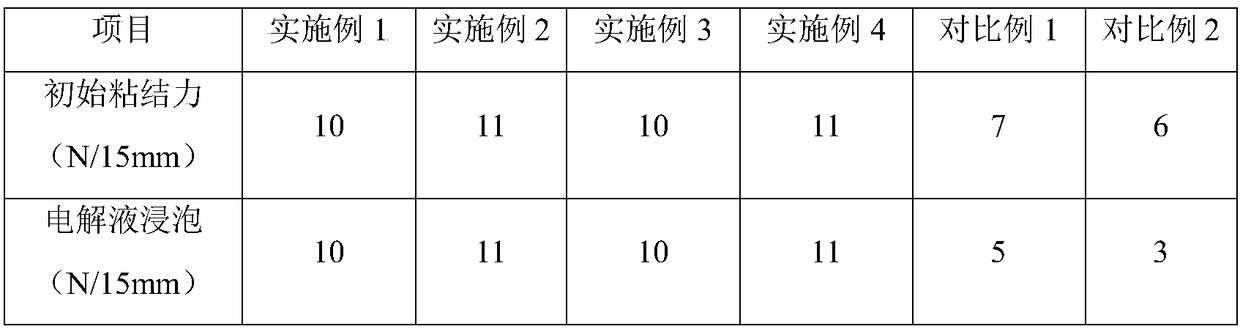

Polyacrylate solvent-type acid-base-resistant pressure-sensitive adhesive tape and preparation method and application thereof

InactiveCN108485556AHigh temperature resistant, acid and alkali resistantImprove performanceNon-macromolecular adhesive additivesEster polymer adhesivesPolymer scienceFunctional monomer

The invention belongs to the technical field of an adhesive and adhesive tape for lithium ion batteries and discloses a polyacrylate solvent-type acid-base-resistant pressure-sensitive adhesive tape and a preparation method and application thereof. The preparation method comprises mixing a hard monomer, a soft monomer and a functional monomer, adding a chain transfer agent and a solvent into the mixture, adding an initiator to cause a reaction, adding a curing agent and color paste into the reaction product, and carrying out coating and drying to obtain the polyacrylate solvent-type acid-base-resistant pressure-sensitive adhesive. The mass ratio of the hard monomer, the soft monomer to the functional monomer is (80 to 95): (1 to 15): (2 to 5). The pressure-sensitive adhesive can resist acid and alkali corrosion and is particularly resistant to corrosion of weakly acidic lithium ion battery electrolytes. The pressure-sensitive adhesive and tape have excellent high-temperature and electrolyte resistance, can meet the performance requirements of large power lithium-ion battery tapes and have high cost performance.

Owner:东莞市方恩电子材料科技有限公司

Binder for electrodes of lithium secondary batteries, and lithium secondary battery which uses electrode produced using binder for electrodes of lithium secondary batteries

ActiveCN104115316AExcellent charge and discharge characteristicsExcellent adhesionCell electrodesLi-accumulatorsLithiumHydrogen

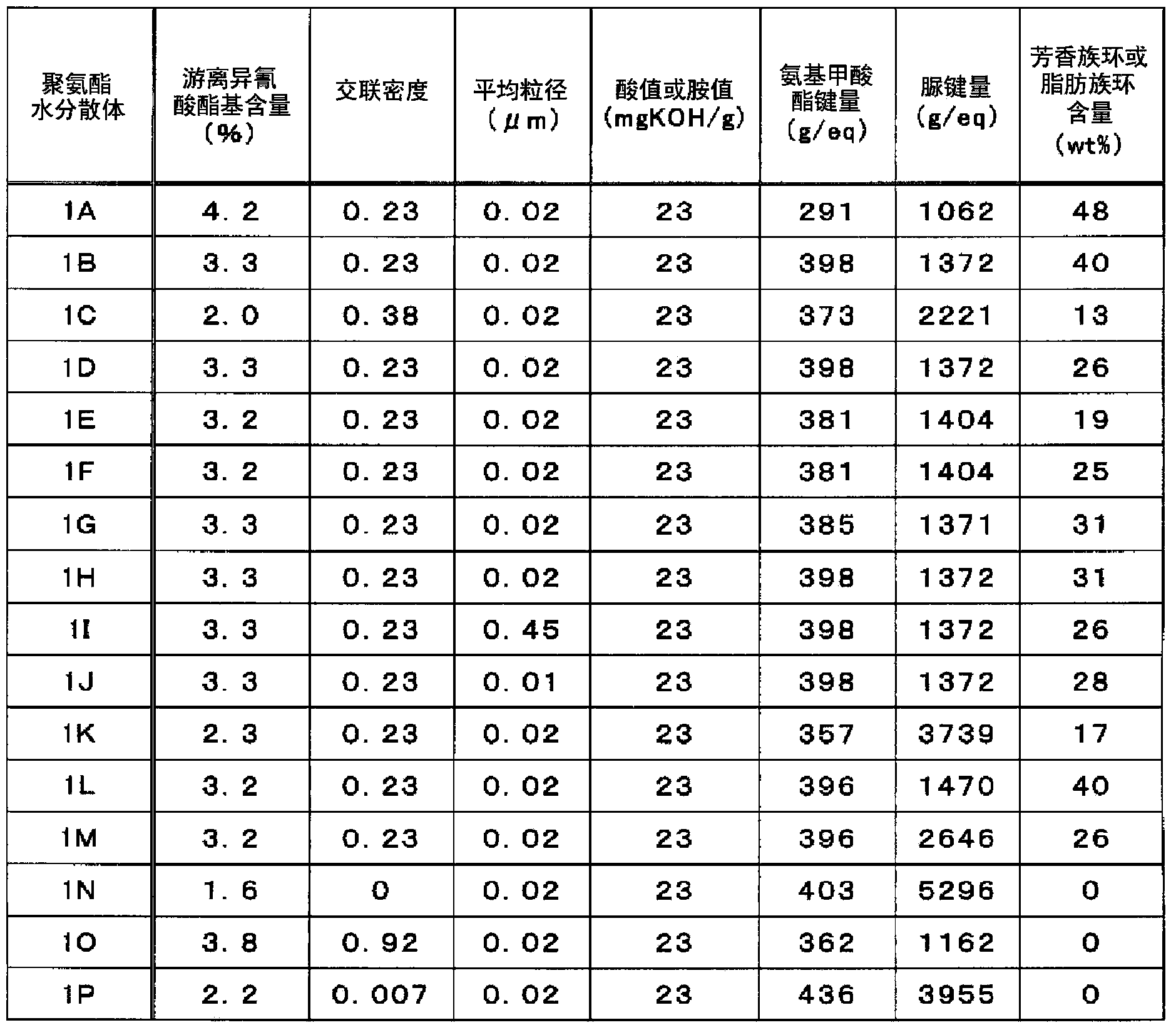

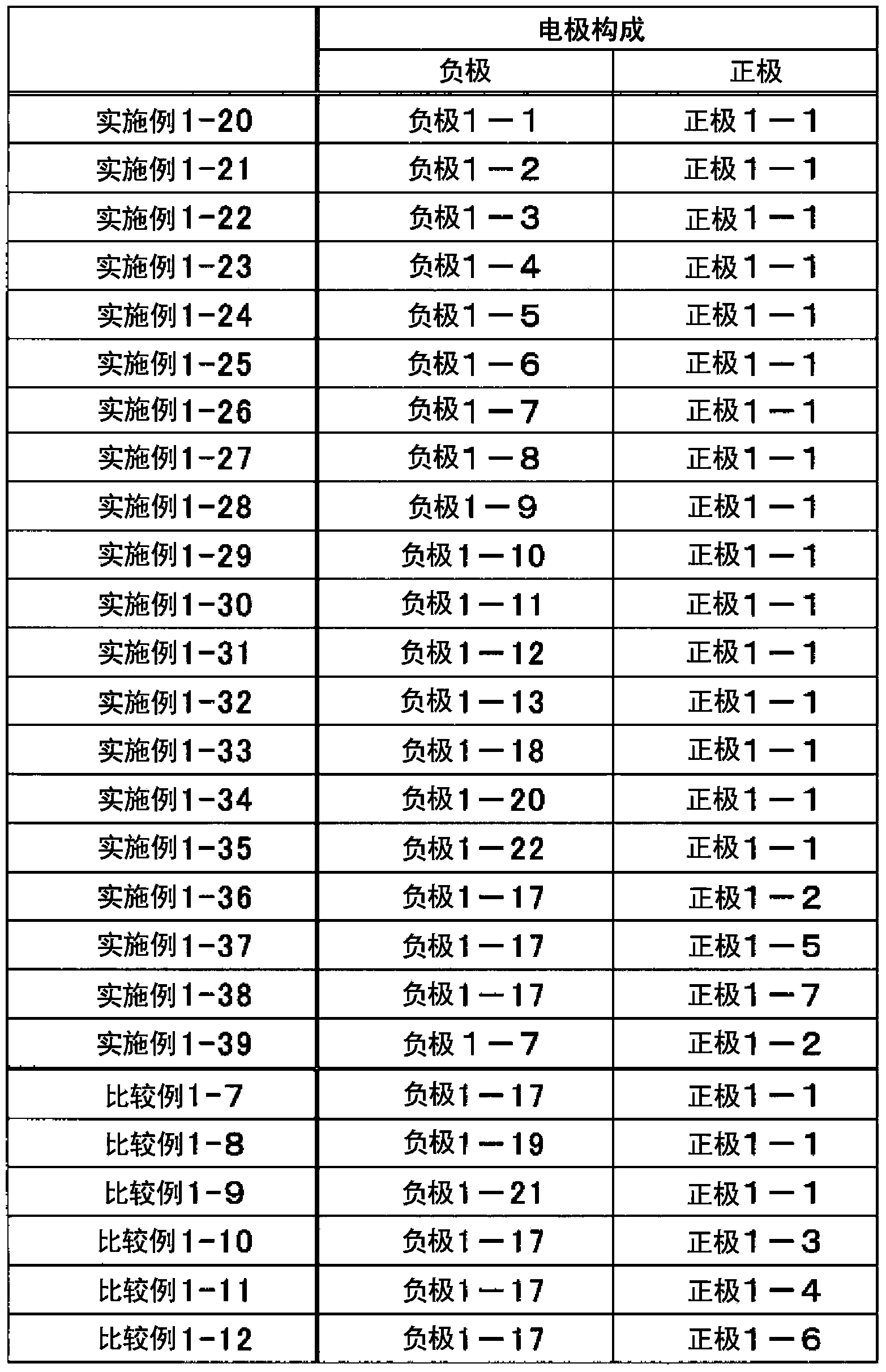

Provided are: a binder which exhibits high adhesion to a collector and is not separated during pressing, and has high flexibility, excellent binding properties and excellent electrolyte solution resistance; and a lithium secondary battery which uses an electrode that is produced using the binder, and has excellent charge / discharge characteristics. There is used a binder for electrodes, which contains (A) a polyisocyanate, (B) a compound having two or more active hydrogen groups, (C) a compound having one or more active hydrogen groups and one or more hydrophilic groups, and (D) an aqueous resin composition that contains, as an aqueous dispersion, a hydrophilic group-containing polyurethane that is formed of a chain extender, or an aqueous resin composition that is obtained by emulsifying an unsaturated polymerizable monomer polymer by means of the above-mentioned hydrophilic group-containing polyurethane.

Owner:DAI ICHI KOGYO SEIYAKU CO LTD

Aqueous liquid composition, aqueous coating liquid, functional coating film and composite material

ActiveUS20150179357A1Sufficient viscosityImprove adhesionCosmetic preparationsStarch dervative coatingsWater basedPVA - Polyvinyl alcohol

Provided is an aqueous liquid composition including a water-based medium containing water, a polymer having at least one type of groups selected from hydroxyl groups and amino groups, and phosphonobutanetricarboxylic acid. The polymer is at least one polymer selected from the group consisting of a polysaccharide, polyamino acid, polyvinyl alcohol, polyallylamine, polyvinylamine, a polyamidine, a polyethylenimine, and their derivatives.

Owner:DAINICHISEIKA COLOR & CHEM MFG CO LTD

Preparation method of anion sulfonate type coal water slurry dispersant

The invention discloses a preparation method of an anion sulfonate type coal water slurry dispersant. A terpolymer is prepared from an anion monomer and a sulfonate monomer as reaction monomers under the action of an initiator and a chain transfer agent through free radical polymerization. By using the dispersant obtained by the preparation method disclosed by the invention, coal water slurry with solid content of 60-70% has excellent dispersion and stabilization effects; and the dispersant is suitable for various coal species, in particular slurrying of coal with poor quality.

Owner:SHAANXI UNIV OF SCI & TECH

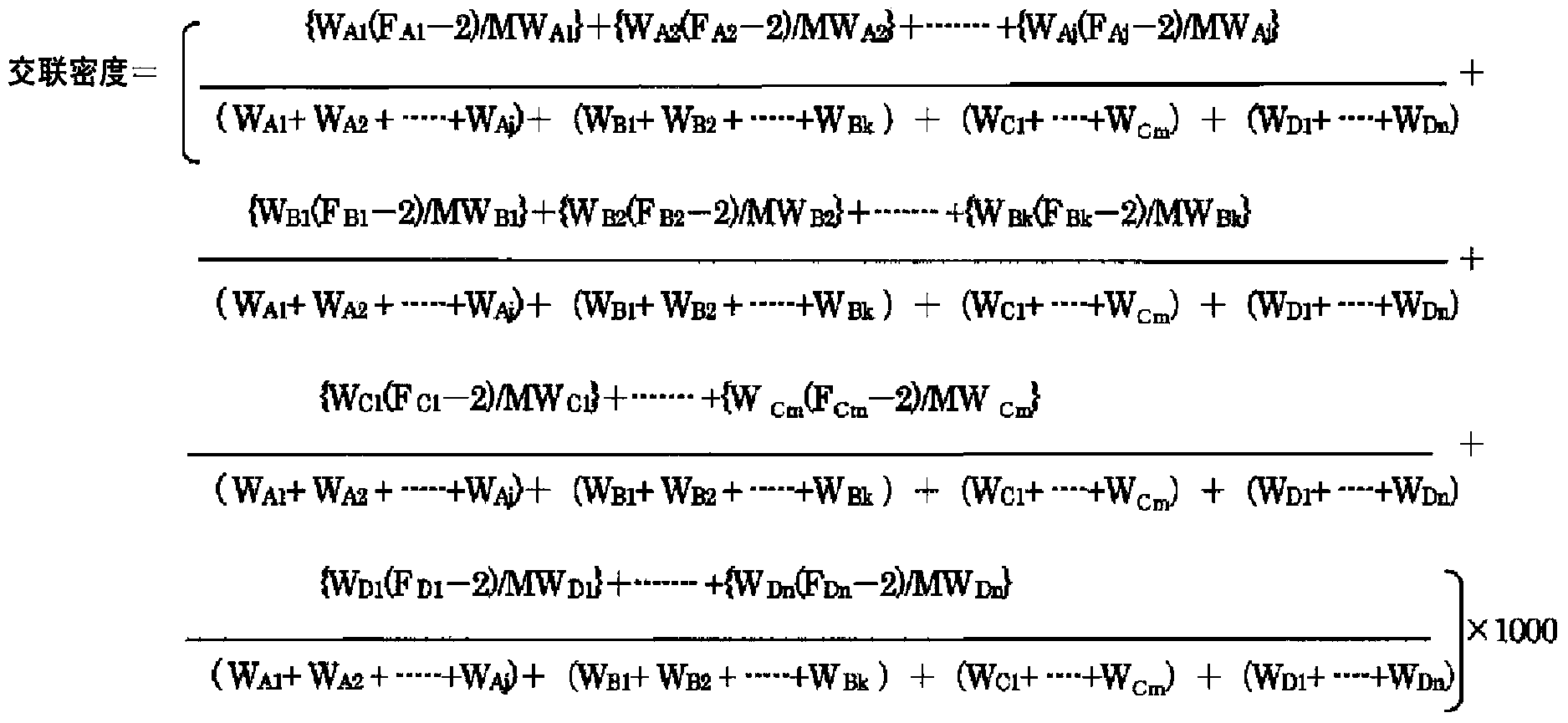

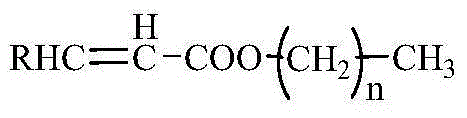

Preparation method of acrylic thickening agents with inorganic clay as cross-linking agent

The invention belongs to the field of new materials and particularly relates to a preparation method of acrylic thickening agents with inorganic clay as a cross-linking agent. According to the method, a silane coupling agent is adopted for modifying the inorganic clay, vinyl is introduced on the surface of the inorganic clay, and then the acrylic thickening agents are prepared through inverse emulsion polymerization by taking vinyl silane coupling agent modified inorganic clay as the cross-linking agent, an acrylic monomer as a main monomer and a hydrophobic long-chain monomer as a functional monomer for improving the electrolyte resistance of the thickening agents. The thickening agent is low in price and has excellent thickening performance and salt tolerance.

Owner:CHANGZHOU XIAOGUO INFORMATION SERVICES

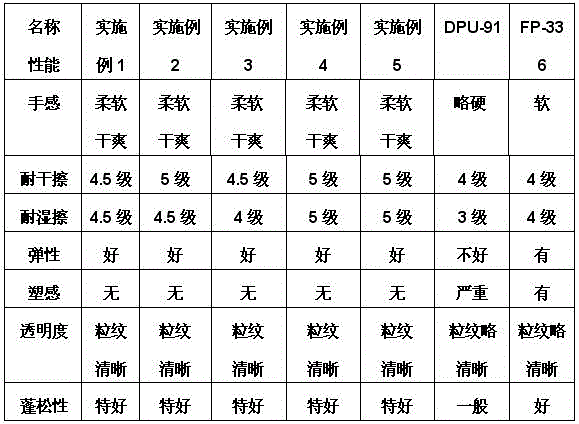

Non-ionic waterborne polyurethane coating agent for leather and preparation method thereof

ActiveCN106752829AHigh fastnessImprove electrolyte resistancePolyurea/polyurethane coatingsLeather surface finishingIsophoroneDiol

The invention provides a non-ionic waterborne polyurethane coating agent for leather and a preparation method thereof. The coating agent is prepared from 20-50 parts of isophorone diisocyanate, 5-35 parts of hexamethylene diisocyanate, 10-30 parts of polytetramethylene glycol, 40-70 parts of polycarbonate diols, 3-10 parts of methoxypolyethylene glycols, 25-35 parts of acetone, 10-20 parts of chain extender, 5-20 parts of a small molecule chain extender, and 150-500 parts of deionized water. The preparation method comprises the following steps: carrying out pre-polymerization reaction, chain extension reaction, emulsification reaction and chain extension reaction. The coating agent is used for leather finishing, and has the advantages of being fluffy, dry and high in elasticity, softness, high fastness and no plastic feeling.

Owner:LIAONING FIXED STAR FINE CHEM

Aqueous liquid composition, aqueous coating, functional coating film, and composite material

ActiveUS20130316231A1Sufficient viscosityImprove adhesionElectrolytic capacitorsGroup 5/15 element organic compoundsWater basedViscosity

An aqueous liquid composition contains a water-based medium containing water, a polymer having at least one type of groups selected from hydroxyl groups and amino groups, and phosphonobutanetricarboxylic acid. The aqueous liquid composition contains low-cost materials having low environmental load, can retain adequate viscosity even when stored over a long term, and can form a functional coating film having excellent adhesiveness to a base material and superb durability, solvent resistance and waterproofness and capable of exhibiting various functions led by electrical conductivity and hydrophilicity.

Owner:DAINICHISEIKA COLOR & CHEM MFG CO LTD

Flexible package aluminum-plastic film material for lithium battery

InactiveCN104241556AImprove ductilityGood mechanical propertiesSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsPolyesterElectrolytic agent

The invention relates to a flexible package aluminum-plastic film material for a lithium battery. The flexible package aluminum-plastic film material for the lithium battery comprises a layer structure, wherein the layer structure comprises an aluminum-based layer (AL) in the middle and layers on the inner side and the outer side of the aluminum-based layer, wherein a novel functional adhesive resin layer (AD), a polyester layer (PET), a novel functional adhesive resin layer (AD) and a copolymer propylene layer (CPP) are sequentially distributed on the inner side from inside to outside; a polyester layer (PET), a novel functional adhesive resin layer (AD) and a homopolymer propylene layer (PP) are sequentially distributed on the outer side from inside to outside. The polyester layer (PET) is used as a functional barrier layer and has the stable chemical performance and high electrolyte resistance; the copolymer propylene layer (CPP) is used as a functional material layer and has the high electrolyte resistance, heat-sealing performance and high heat-sealing strength; the novel functional adhesive resin layer (AD) is made of a PP material and has the strong adhesive fastness with the aluminum-based layer (AL), the polyester layer (PET), the homopolymer propylene layer (PP) and the copolymer propylene layer (CPP). The layering can not occur by adopting a casting process technology.

Owner:广东赛洋科技有限公司

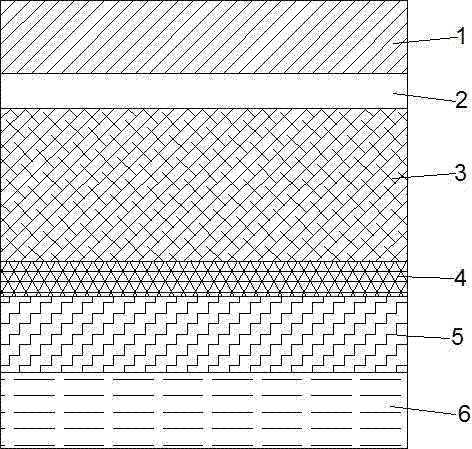

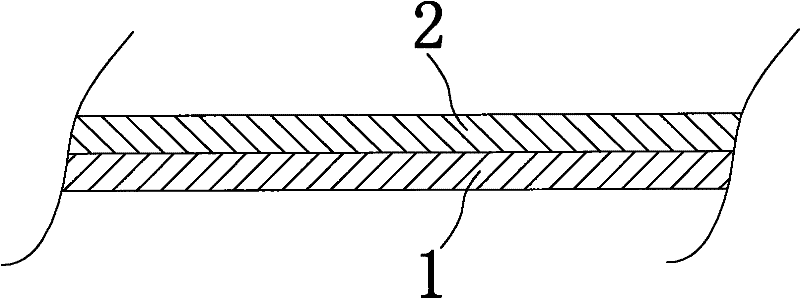

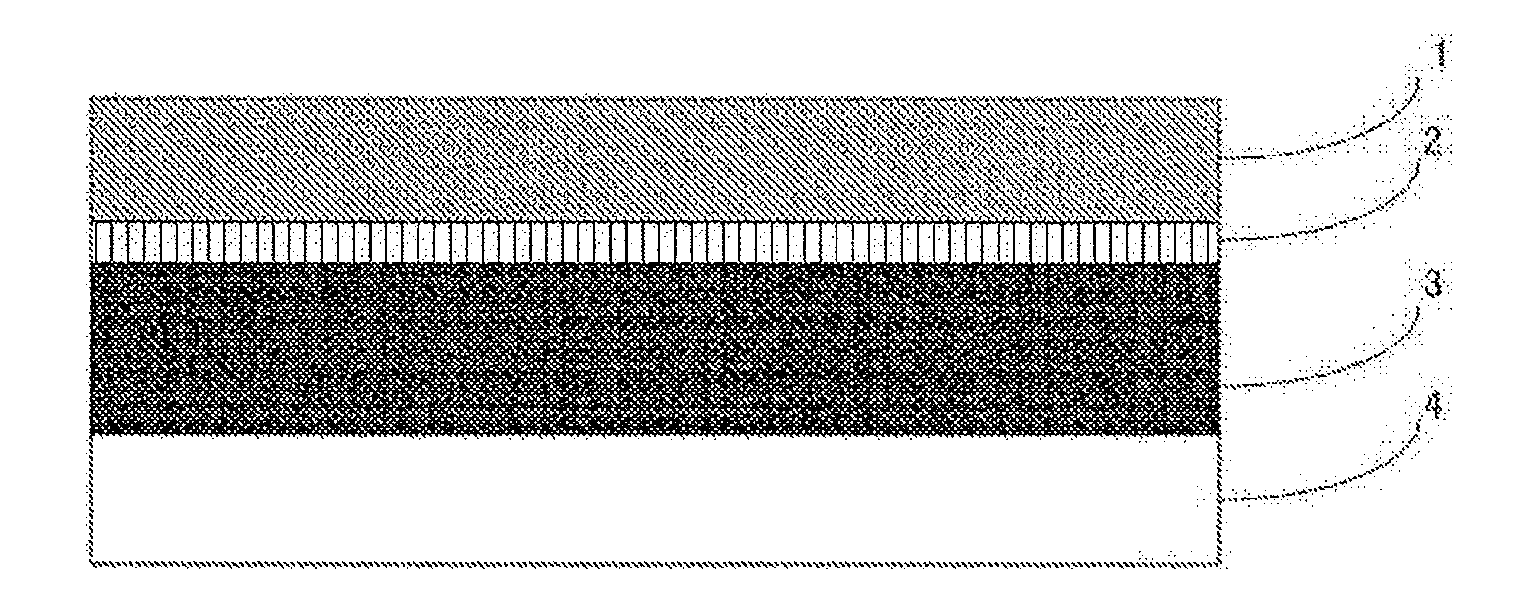

Corrosion resistant aluminum plastic film for lithium battery packaging

PendingCN108000986AImprove mechanical propertiesImprove electrolyte resistanceElectrical equipmentMetal layered productsPolyolefinCo extrusion

The invention discloses a corrosion resistant aluminum plastic film for lithium battery packaging, which mainly comprises a protective layer, an aluminum foil layer and a heat-seal layer. The corrosion resistant aluminum plastic film is characterized in that: the protective layer and the aluminum foil layer are bonded and combined by a cementing layer, the aluminum foil layer and the heat-seal layer are combined by hot pressing; the aluminum foil layer is subjected to surface treatment by adopting anodic oxidation before bonding combination and hot pressing combination; the material of the heat-seal layer is a three-layer co-extrusion polyolefin composite membrane, of which the inner layer is a bonding layer, the middle layer is a structural layer and the outer layer is a blocked layer; the thickness of the protective layer is 10 to 50mu m, the thickness of the aluminum foil layer is 20 to 80mu m and the thickness of the heat-seal layer is 20 to 120mu m. The product, the aluminum plastic film, has the advantages of higher electrolyte resistance property, and package bonding power, and is suitable for high performance lithium battery packaging.

Owner:SHANGHAI HIUV NEW MATERIALS

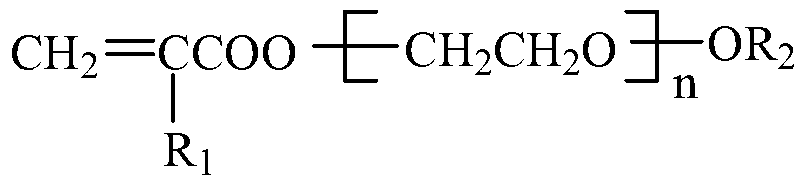

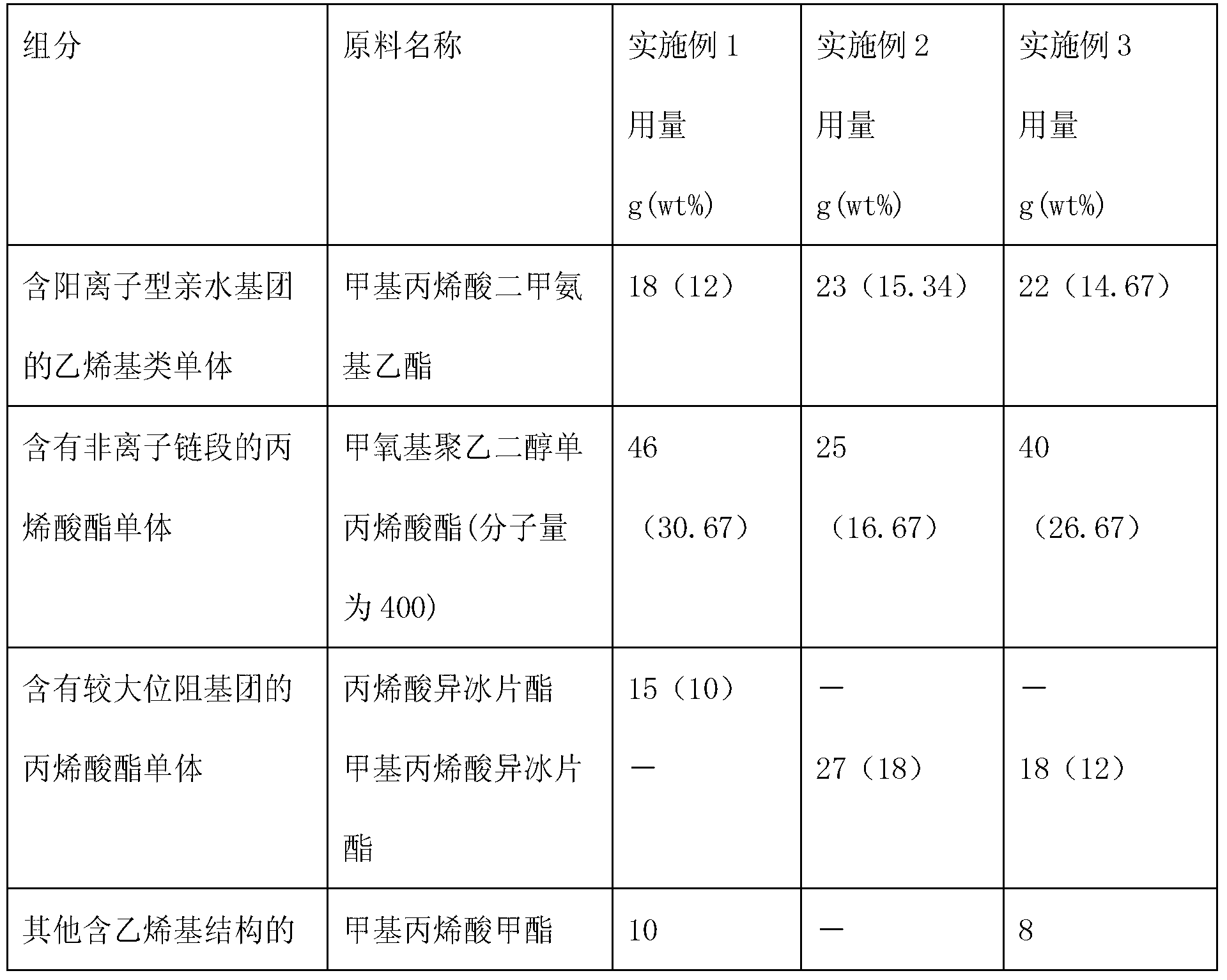

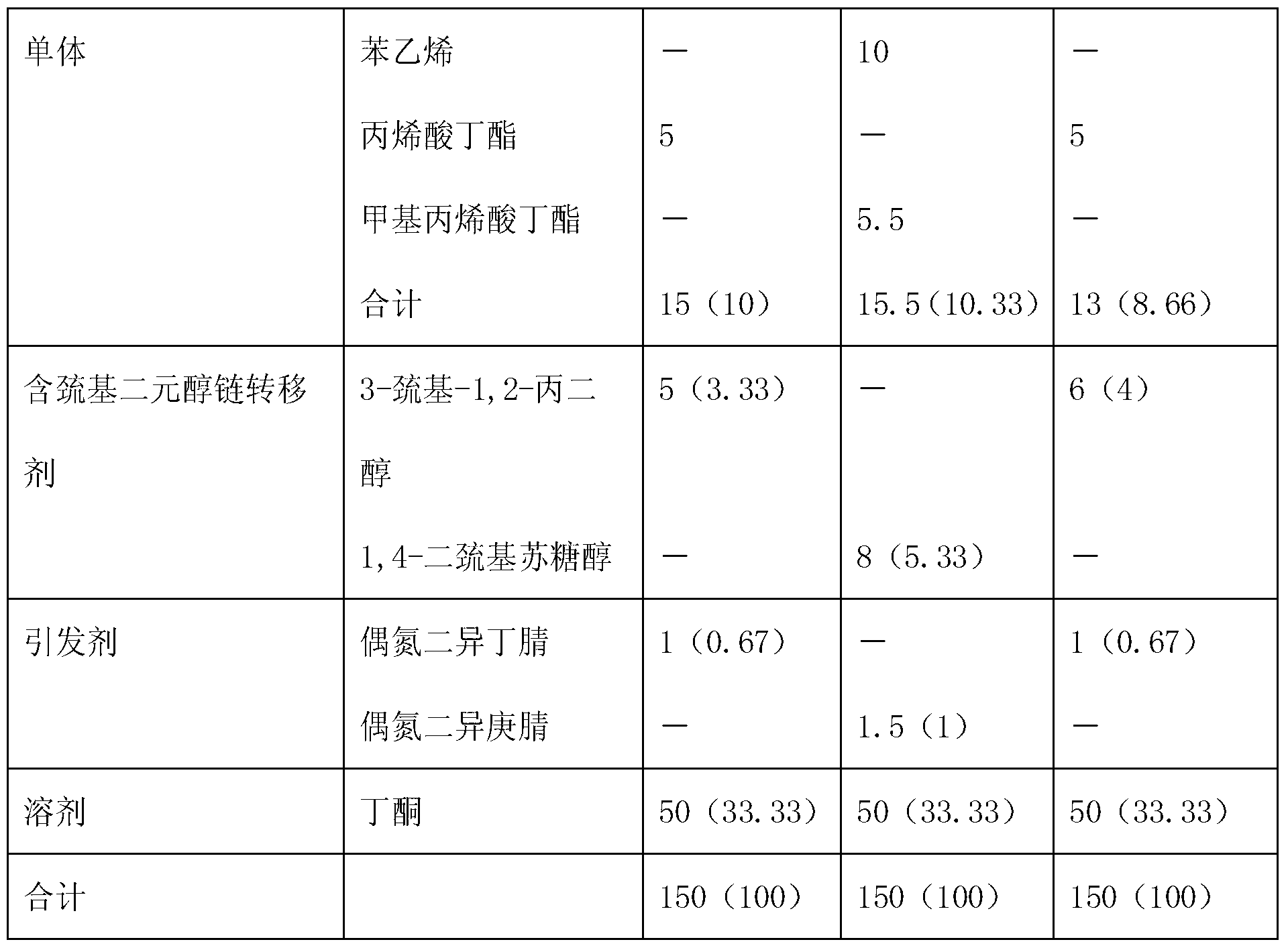

Preparation method of composite emulsion of cation-nonionic waterborne polyurethane-polyacrylate

The invention relates to a preparation method of composite emulsion of cation-nonionic waterborne polyurethane-polyacrylate. The method comprises the following steps of: in synthesis polyurethane reaction, accessing polyacrylate containing terminated hydroxyl into a polyurethane molecular chain through the contained terminated hydroxyl, and forming a side chain of a polyurethane molecule, so as to obtain the composite emulsion combined with a chemical bond, wherein the side chain of the polyacrylate containing the terminated hydroxyl includes a cationic hydrophilic group, a non-ionic segment and a large-resistance group; preparing the polyacrylate containing terminated hydroxyl by using a uniform dripping method in preparation, and then neutralizing and emulsifying to obtain the composite emulsion of cation-nonionic waterborne polyurethane-polyacrylate after reacting with common high-molecular polyol, isocyanate, a crosslinking agent and a common chain extender. The prepared composite emulsion integrates dual advantages of the polyurethane and polyacrylate materials, especially has excellent storage stability and electrolyte resistance, simultaneously has good water resistance and excellent mechanical property, and can be widely applied to the fields such as painting, ink, a binder and the like.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

Special adhesive tape for energy storage and power lithium battery and production method of special adhesive tape

ActiveCN103333629APaste firmlyImprove puncture strengthNon-macromolecular adhesive additivesFilm/foil adhesivesEpoxyPolyester

The invention relates to a special adhesive tape for an energy-storage or power lithium battery and a production method of the special adhesive tape. The adhesive tape comprises an adhesive layer, a hardened coating layer, a base layer and a release layer which are sequentially distributed. The base layer is a polyester thin film. The hardened coating layer is an epoxy resin layer and is coated on the front surface of the base layer. The release layer is a single-component non-silicon release agent coating layer and is arranged on the back surface of the base layer. The adhesive layer is arranged on the outer surface of the hardened coating layer. The adhesive tape is provided with a four-layer structure and each layer has a respective function, wherein the adhesive layer is in direct contact with the terminating part of the battery and has the characteristics that the adhesive layer is firm in bonding, is electrolyte-resistant and halogen-free and satisfies (RoHS) Restriction of Hazardous Substances requirements and the like; the hardened coating layer further improves the puncture strength of the base layer; the base layer can be prevented from being punctured by burrs on pole pieces; the release layer has an excellent adhering property and a quick drying performance similar to the base layer. The special adhesive tape for an energy-storage or power lithium battery has the advantages that the adhesive tape is environmentally-friendly, the RoHS requirements are satisfied, the electrolyte resistance is good and the like, and is mainly used for the insulation and the protection of the terminating part of the lithium battery.

Owner:佛山市顺德区永创翔亿电子材料有限公司

Passivation solution for soft roll lithium battery and packaging material of soft roll lithium battery

InactiveCN108179407AHigh bonding strengthAvoid destructionMetallic material coating processesCell component detailsOrganic acidAluminum foil

The invention relates to a passivation solution for a soft roll lithium battery and a packaging material of the soft roll lithium battery. The passivation solution comprises, by weight part, 0.3 to 1part of a metallic compound, 0.5 to 2 parts of organic acid, 0.5 to 2 parts of film forming polymer, 0.1 to 1 part of bonding resin and 100 to 200 parts of water. The invention further relates to a packaging material for the soft roll lithium battery. The packaging material is composed of a heat resisting layer, a first adhesive layer, an aluminum foil surface passivation treatment layer, an aluminum foil layer, an aluminum foil surface passivation treatment layer, a second adhesive layer and a heat seal layer. The aluminum foil surface passivation treatment layer is formed by coating of the passivation solution on the surface of the aluminum foil. The problem that in the long-term electrolyte resistance operation, bonding performance between the aluminum foil layer and the heat seal layeris seriously reduced or layered is solved, and the service life of the soft roll lithium battery is prolonged.

Owner:乐凯胶片股份有限公司

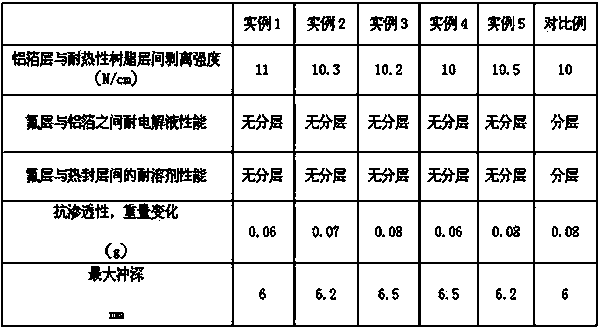

Flexible package aluminum-plastic membrane applied to lithium ion battery

ActiveCN104201298AGood solvent resistanceImprove electrolyte resistanceJackets/cases materialsMetal layered productsAluminum foilLithium-ion battery

The invention belongs to the technical field of novel energy resources and in particular relates to a flexible package aluminum-plastic membrane applied to a lithium ion battery. The aluminum-plastic membrane is of a layer structure and comprises a heat-resistant resin layer, an adhesive layer, an aluminum foil layer, an adhesive resin layer 1, a fluorine membrane layer, an adhesive resin layer 2 and a heat sealing layer in sequence from top to bottom; the surface of the heat-resistant resin layer treated by in a corona manner is coated with the adhesive layer; the other surface of the adhesive layer is compounded with a passivated aluminum foil; the surface of the aluminum foil is compounded with the fluorine membrane layer treated in the corona manner when the adhesive resin layer 1 is hot extruded on the surface of the aluminum foil; the other surface of the fluorine membrane layer is compounded with the hot sealing layer when the adhesive resin layer 2 is hot extruded on the other surface of the fluorine membrane layer. The aluminum-plastic membrane provided by the invention is good in interlayer adhesive performance; the service life of the lithium ion battery can be prolonged.

Owner:乐凯胶片股份有限公司

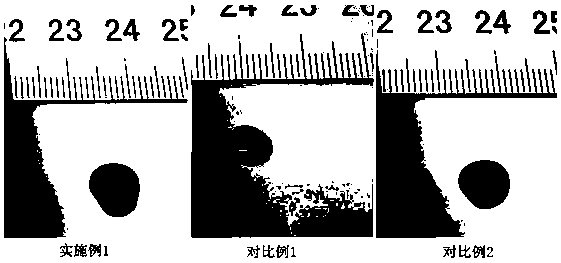

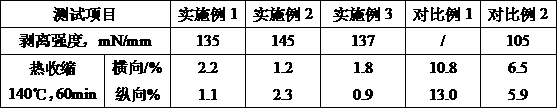

Preparation method of heat-resistant lithium battery diaphragm

ActiveCN108467503AImprove adhesionLess prone to dusting problemsFireproof paintsSecondary cellsWater basedAdhesive

The invention discloses a preparation method of a heat-resistant lithium battery diaphragm. The preparation method comprises the steps that an inorganic material and a dispersing agent are added intodeionized water, and the mixture is ground to obtain a uniform solution; then a suspension stabilizer, a defoaming agent, a wetting agent, a surfactant, a first adhesive and a second adhesive are added, low-speed dispersing is carried out, and water-based ceramic slurry is obtained; after a base diaphragm is coated with the slurry, the heat-resistant lithium battery diaphragm is obtained. The diaphragm has a relatively good liquid absorption rate, peel strength and thermal stability.

Owner:瑞固新能(上海)材料科技有限公司

Aluminum-plastic composite film for flexible packaging of lithium battery

ActiveCN107825773AStrong bondExtended service lifeSynthetic resin layered productsMacromolecular adhesive additivesComposite filmPolyolefin

The invention discloses an aluminum-plastic composite film for flexible packaging of a lithium battery. The aluminum-plastic composite film comprises a wear-resistant layer, a first bonding layer, analuminum foil layer, a passivation layer, a second bonding layer having corrosion resistance and a heat sealing layer which are sequentially arranged from the outside to the inside, and the passivation layer comprises, by weight, 100 parts of acrylic resin, 5-15 parts of a chromium-containing compound, 1-5 parts of a phenyltrimethylsilane coupling agent, 1-5 parts of a titanate coupling agent and30-50 parts of water; and the second bonding layer having corrosion resistance includes, by weight, 100 parts of acid-modified polyolefin resin, 1-5 parts of an epoxy system curing agent, 1-5 parts offluorine-containing micro-powder, 10-20 parts of a cyclohexane solvent and 20-40 parts of a butanone solvent. The aluminum-plastic composite film has the advantages of obviously improved electrolyteresistance, stability in bonding among the first bonding layer, the aluminum foil layer, the passivation layer, the second bonding layer having corrosion resistance and the heat sealing layer, high deep-drawing intensity and long service life.

Owner:ZHEJIANG GREEN NEW MATERIALS

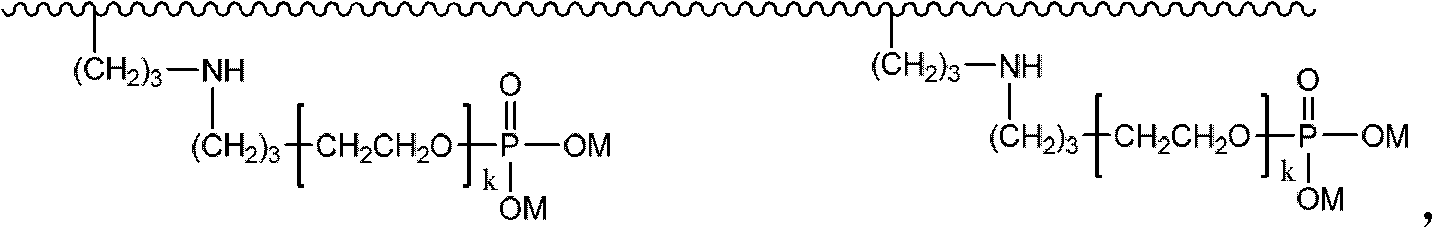

Phosphate leather fat liquoring agent and preparation method thereof

The invention provides a phosphate leather fat liquoring agent and a preparation method thereof. A phosphorylated polyether modified aminosilicone leather fat liquoring agent is prepared by modifying aminosilicone with allyl polyether and P2O5 serving as raw materials. An active group phosphate radical in a molecular structure can react with an amino group in a leather fiber structure, and can be tightly combined with chromium in chrome tanned leather in the form of a coordination bond, so that a phosphorylation product can be stored in leather fiber for a long time, and leather is endowed with certain flame retardance and antistatic property. A certain quantity of hydrophilic oxyethyl groups are introduced onto the molecular structure, so that the properties of water solubility, acid resistance, electrolyte resistance and the like of aminosilicone are improved effectively, and the self-emulsifying property of aminosilicone is enhanced. Aminosilicone is a leather fat liquoring agent per se, and can be used for endowing leather with higher flexibility and fullness and enhancing the physical and mechanical properties such as tear resistance, thickening rate and the like of the leather; and the leather fat liquoring agent with the structure has higher development and application values.

Owner:SHAANXI UNIV OF SCI & TECH

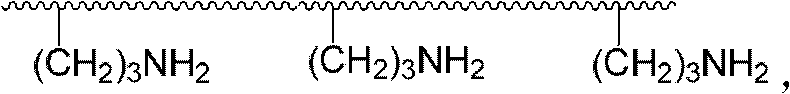

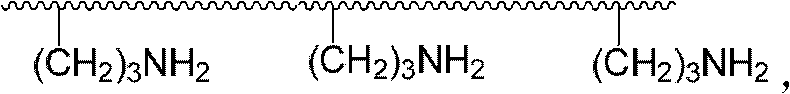

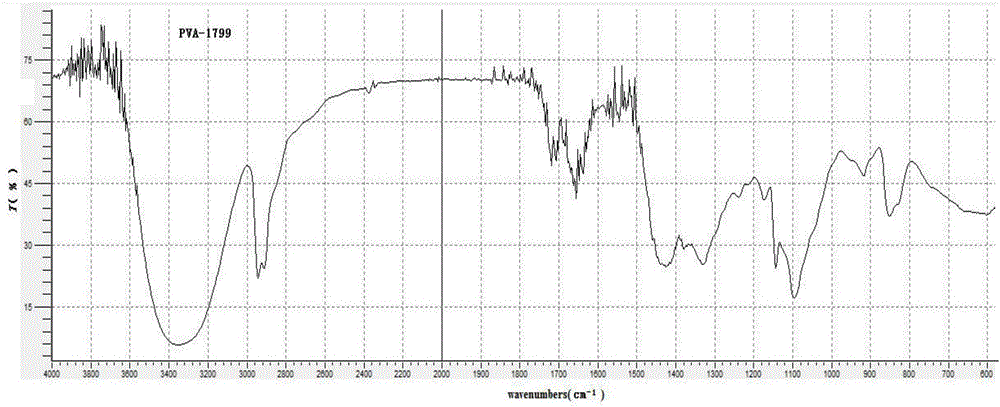

Modified polyvinyl alcohol copolymer and preparation thereof as well as gel polymer electrolyte

ActiveCN106832135AEasy to prepareProcess stabilityHybrid capacitor electrolytesWater bathsCross-link

The invention particularly discloses a modified polyvinyl alcohol copolymer and a preparation method thereof, and gel polymer electrolyte containing the modified polyvinyl alcohol copolymer. The preparation method of the modified polyvinyl alcohol copolymer comprises the following steps: weighing a polyvinyl alcohol solid; adding water and swelling; after raising the temperature and dissolving, heating in a water bath at 40 DEG C to 45 DEG C; introducing argon gas and adding N-vinylpyrrolidone and a functional monomer; and after uniformly stirring, adding an acidic cerium ion solution and reacting for 3h to 5h to prepare the modified polyvinyl alcohol copolymer. The modified polyvinyl alcohol copolymer has a good electrolyte resisting performance. The neutral and alkaline gel polymer electrolyte with ideal mechanical properties and capacitive properties is prepared by taking the modified polyvinyl alcohol copolymer as a matrix material, taking glutaraldehyde or borax as a cross-linking agent and adding a proper amount of electrolyte (LiCl or LiOH); and the moisture content in gel is adjusted, and meets good application requirements in a flexible solid-state super-capacitor.

Owner:GUANGDONG PHARMA UNIV

Textile printing thickening agent and production process thereof

InactiveCN105735007AStrong structural viscosityGood dispersionDyeing processTextile printerOil phase

The invention discloses a textile printing thickening agent. The textile printing thickening agent is prepared by processing the following raw materials in parts by weight: 150-220 parts of acrylic acid, 20-60 parts of methacrylic acid, 50-80 parts of acrylamide, 1-10 parts of octadecyl acrylate, 0.01-0.5 part of N,N'-methylene-bisacrylamide, 120-250 parts of white oil or aviation kerosene, 15-50 parts of sorbitan monooleate, 0.2-2 parts of an initiator, 0.01-1 part of sodium hydrogensulfite, 10-50 parts of fatty alcohol polyoxyethylene ether, 5-50 parts of hydrophilic silicon oil and 200-500 parts of a sodium hydroxide solution. The thickening agent has good water holding performance, strong electrolyte resistance capability and high color yield. A production process comprises the following steps of: (1) neutralizing the acrylic acid and the methacrylic acid until the pH value is 5.2-6.5; (2) adding the acrylamide, the N,N'-methylene-bisacrylamide and the initiator to prepare a water phase; (3) mixing the white oil or the aviation kerosene, the sorbitan monooleate and the octadecyl acrylate to form an oil phase; and (4) adding the water phase into the oil phase and emulsifying, and adding sodium hydrogensulfite to carry out a polymerization reaction; and (5) adding the fatty alcohol polyoxyethylene ether and the hydrophilic silicon oil and mixing.

Owner:HEFEI JUHE RADIAL CHEM TECH

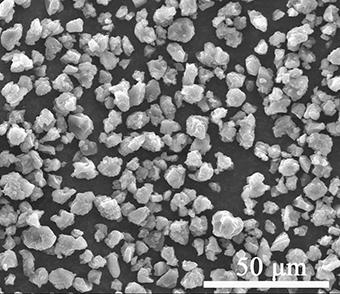

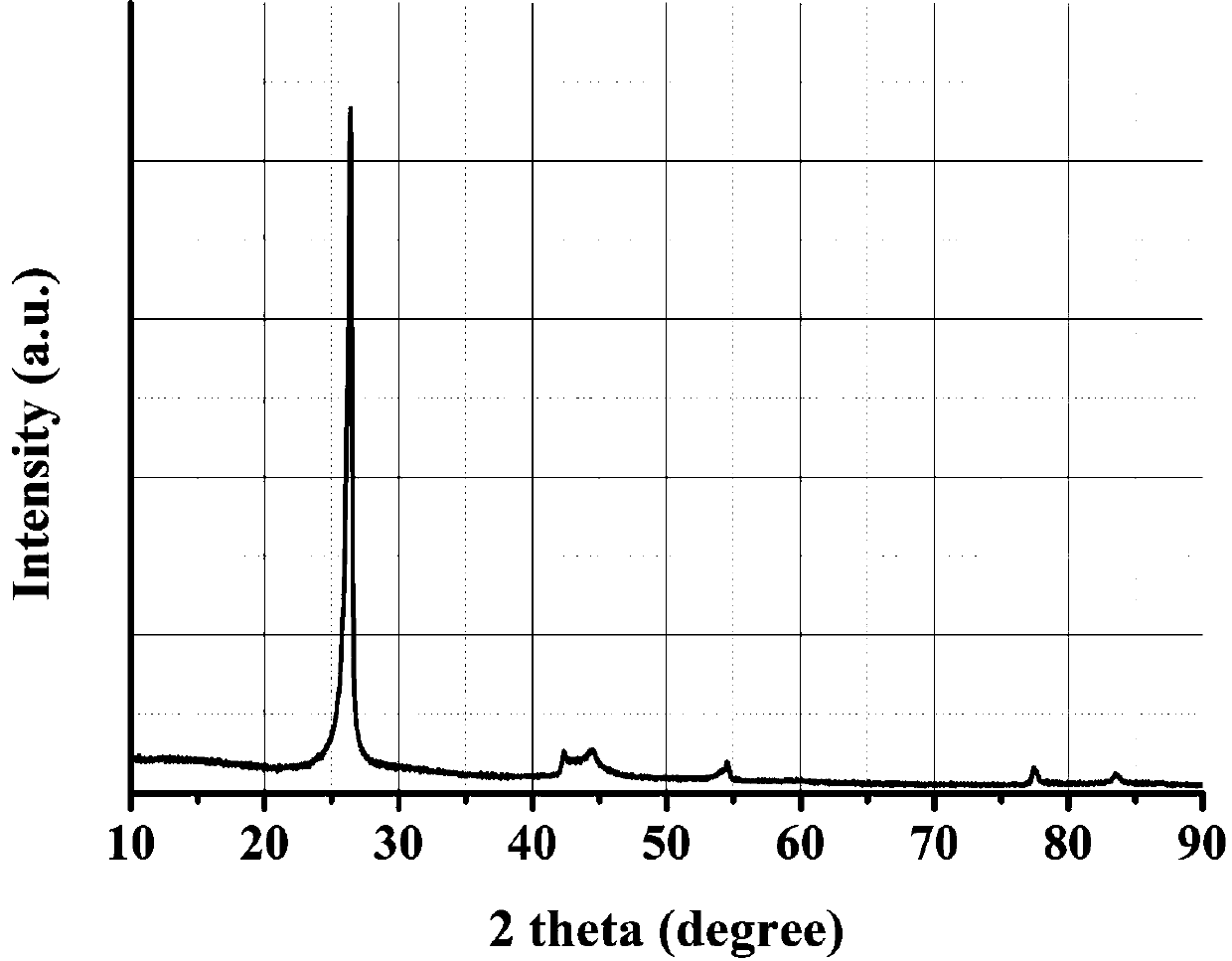

Hard carbon-like graphite cathode material for high-rate lithium ion battery and preparation method thereof

ActiveCN109626352AStable material structureAvoid anisotropySecondary cellsNegative electrodesChemistryPyrolysis

The invention relates to a hard carbon-like graphite cathode material for a high-rate lithium ion battery and a preparation method thereof. The preparation method comprises the following steps of S1,crushing a thermoplastic polymer to obtain polymer powders; S2, dispersing polymer powders in an aqueous solution containing an oxidizing agent and a surfactant for liquid-phase low-temperature oxidation reaction crosslinking, and then pyrolyzing to obtain an oxygen-rich carbon precursor; S3, crushing and graphitizing the oxygen-rich carbon precursor to obtain hard carbon-like graphitized carbon powders; S4, depolymerizing and screening the hard carbon-like graphitized carbon powders to obtain the hard carbon-like graphite cathode material. According to the preparation method, the thermoplastic polymer is used as a raw material, the isotropic oxygen-rich carbon precursor is obtained through liquid-phase low-temperature oxidation crosslinking and pyrolysis treatment, and then the hard carbon-like graphite negative electrode material with low orientation degree and large interlayer spacing is obtained through graphitization treatment, so that the charge-discharge rate performance of thematerial is improved; and when the material is used in the lithium ion battery, the charge-discharge rate can reach more than 15C.

Owner:SHANGHAI SHANSHAN TECH CO LTD

Termination adhesive tape and manufacture method thereof

InactiveCN102250562AMeet application needsLow costFilm/foil adhesivesEster polymer adhesivesIsooctyl acrylateBenzoyl peroxide

The invention relates to the technical field of adhesive tapes, and particularly relates to a termination adhesive tape and a manufacture method thereof. The termination adhesive tape comprises a base tape and a glue layer located on the base tape, wherein the glue layer is an acrylic glue layer, which is composed of the following raw materials in parts by weight: 1-5 parts of butyl acrylate, 5-12 parts of vinyl acetate, 40-60 parts of ethyl acetate, 20-35 parts of iso-octyl acrylate, 0.5-2 parts of hydroxyethyl methacrylate, 1-3 parts of acrylic acid, 2-4 parts of toluene and 0.1-0.4 part of benzoyl peroxide. The manufacture method sequentially comprises the following steps: A. preparing the acrylic glue: titrating toluene-dissolved benzoyl peroxide used as an initiator to a mixed solution of butyl acrylate, vinyl acetate, ethyl acetate, iso-octyl acrylate, hydroxyethyl methacrylate and acrylic acid at the temperature of 80 DEG C, and ensuring the titration time of 2 hours and self-reaction time of 2.5 hours; and B. applying the acrylic glue on the base tape, sequentially drying, cooling and coiling. The termination adhesive tape provided by the invention has the advantages of low cost, beautiful appearance, simple manufacture process and good electrolyte resistance.

Owner:东莞市苏粤电子包装材料有限公司

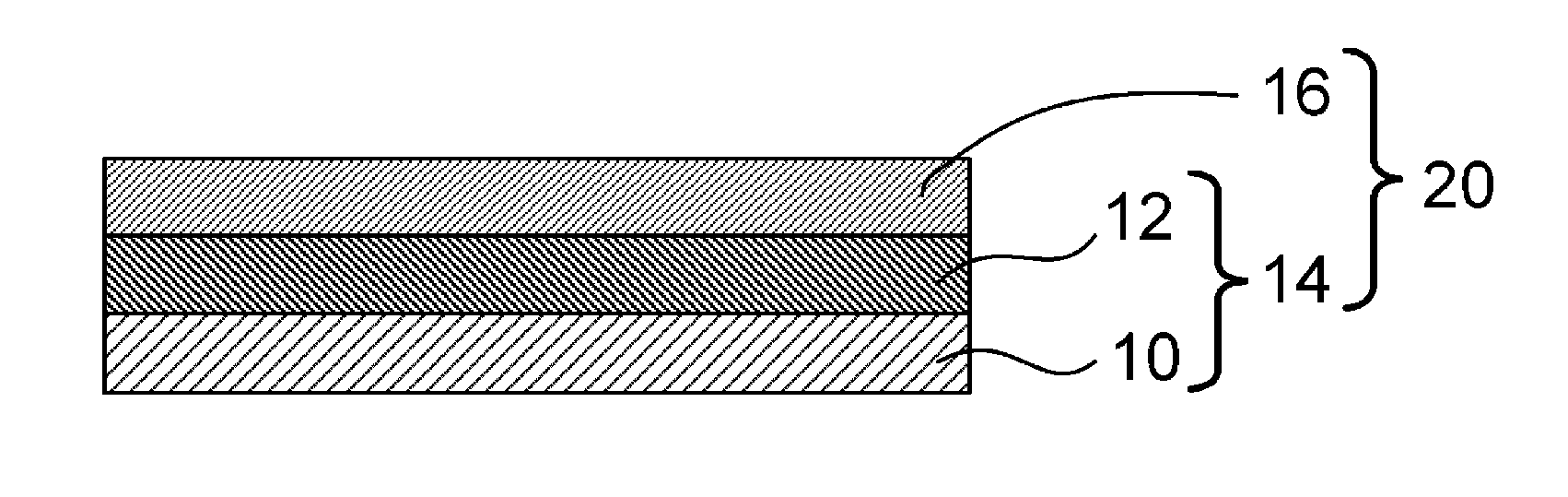

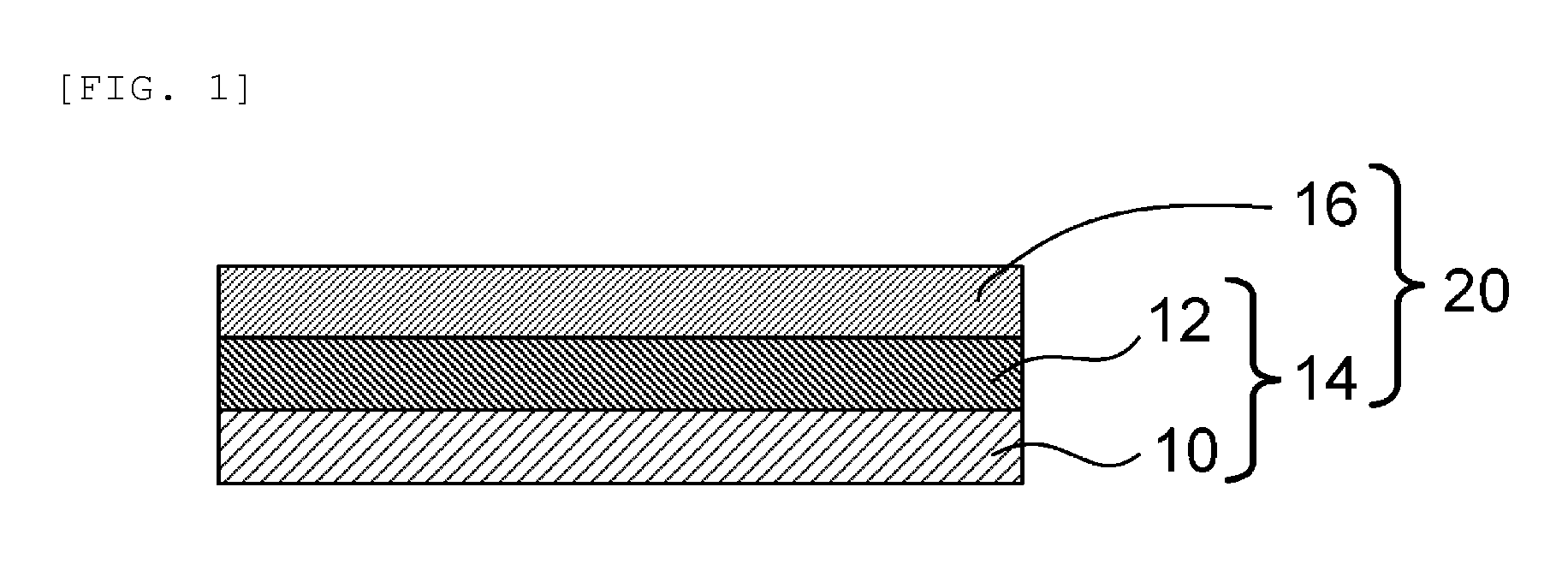

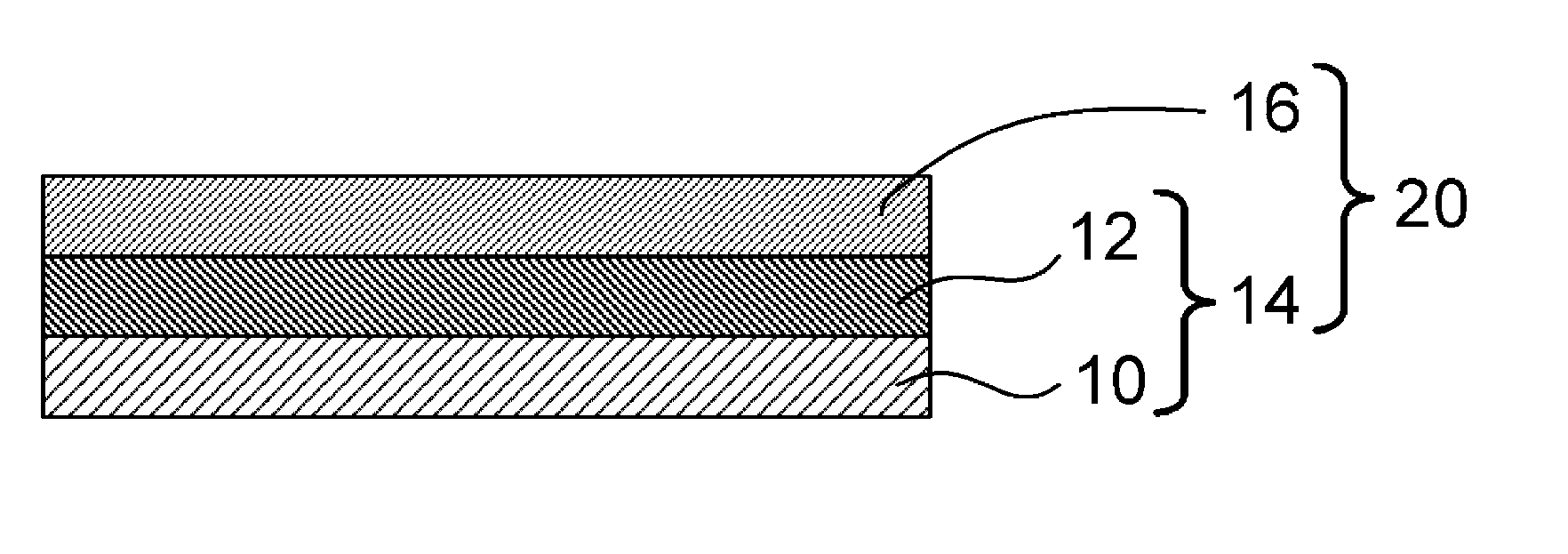

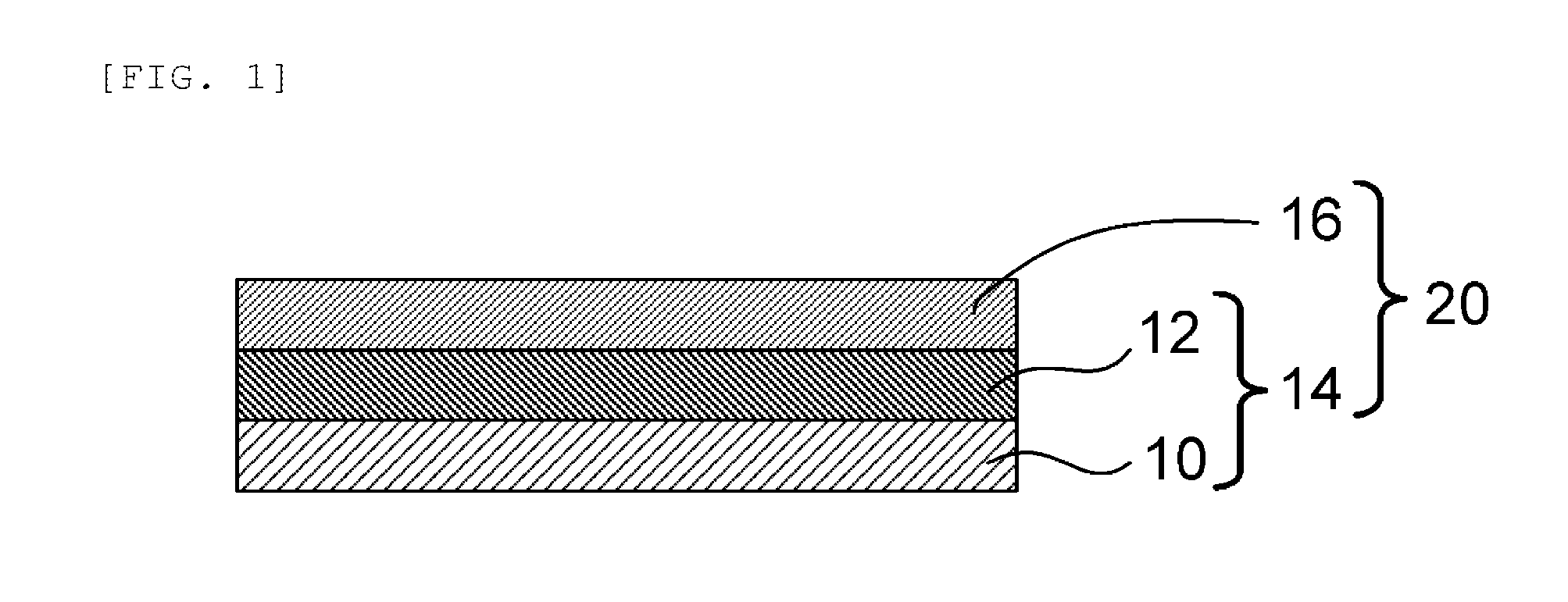

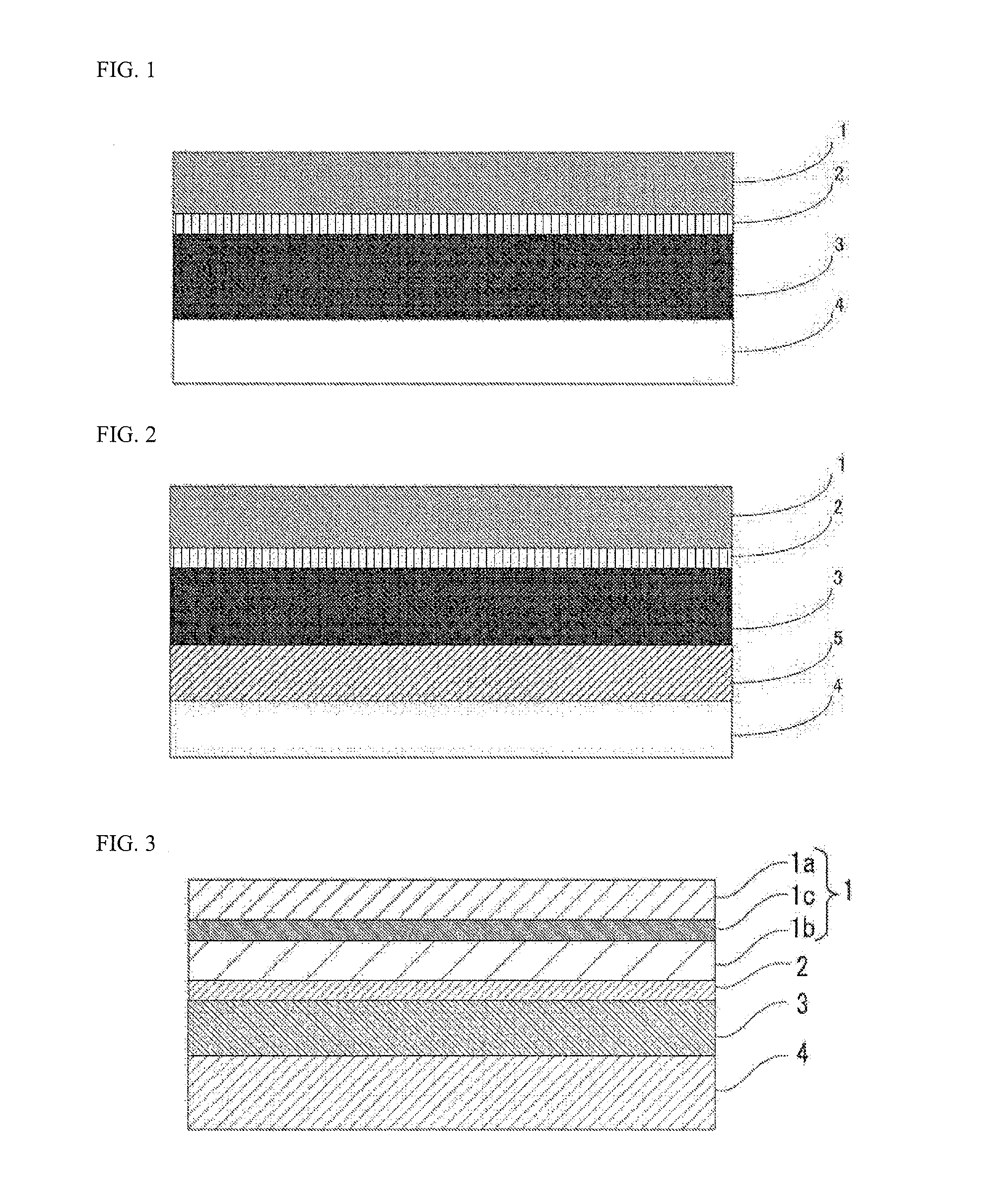

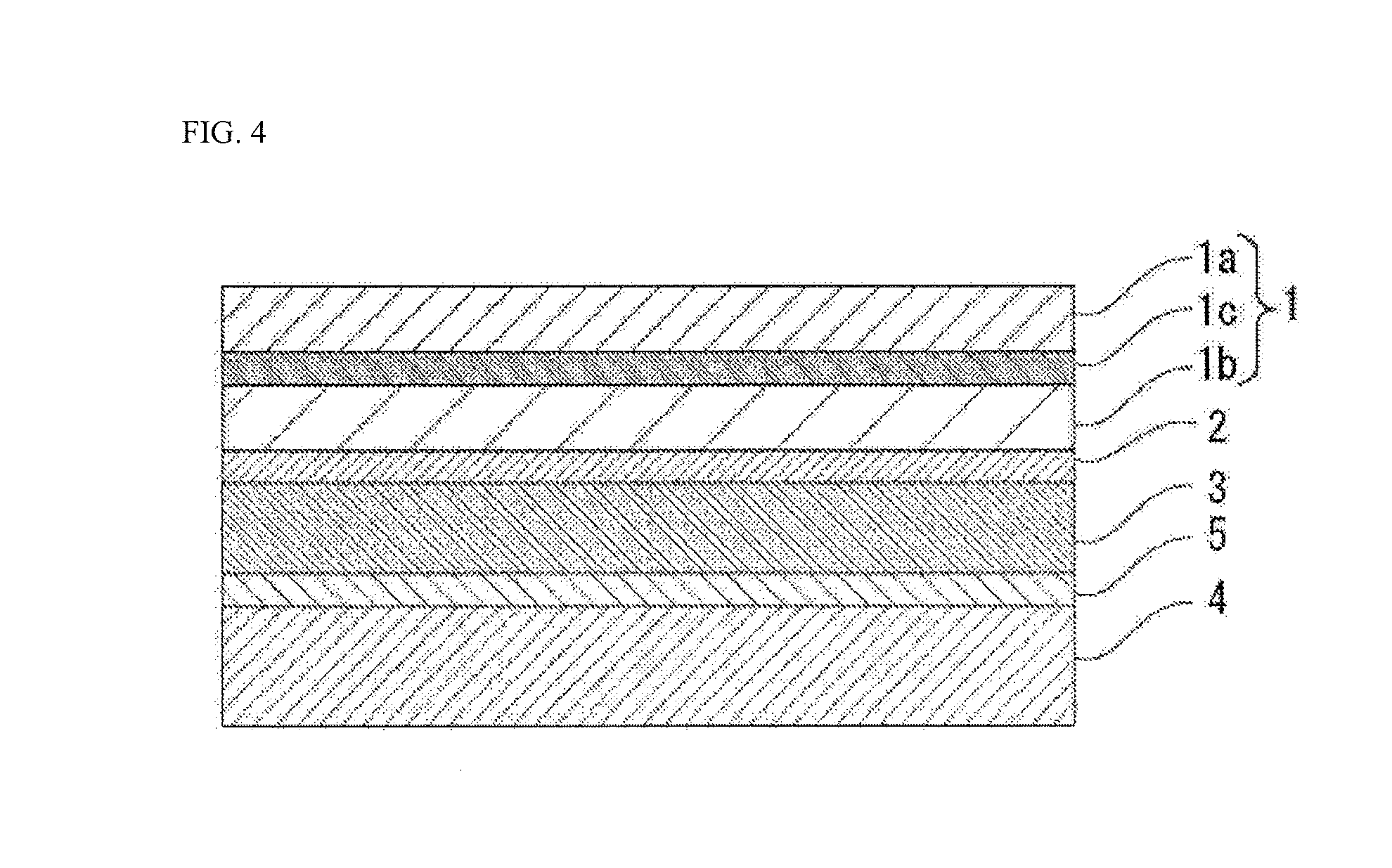

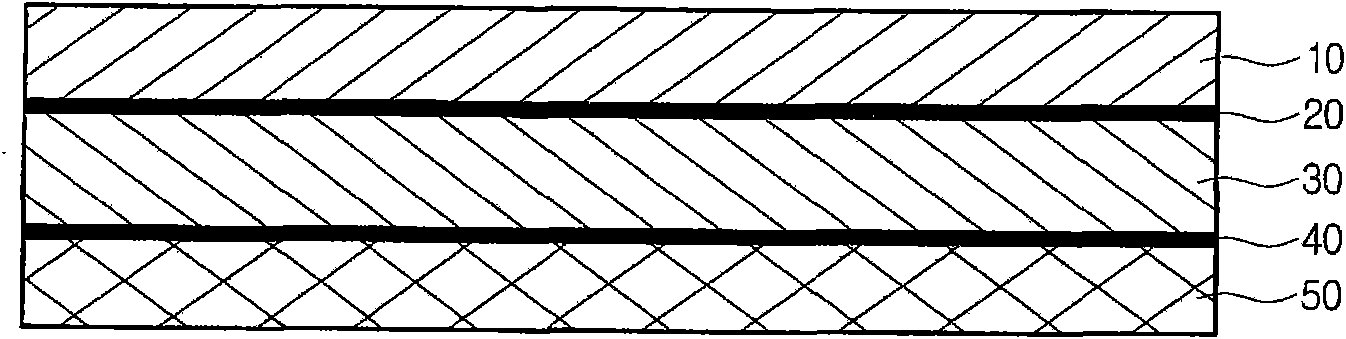

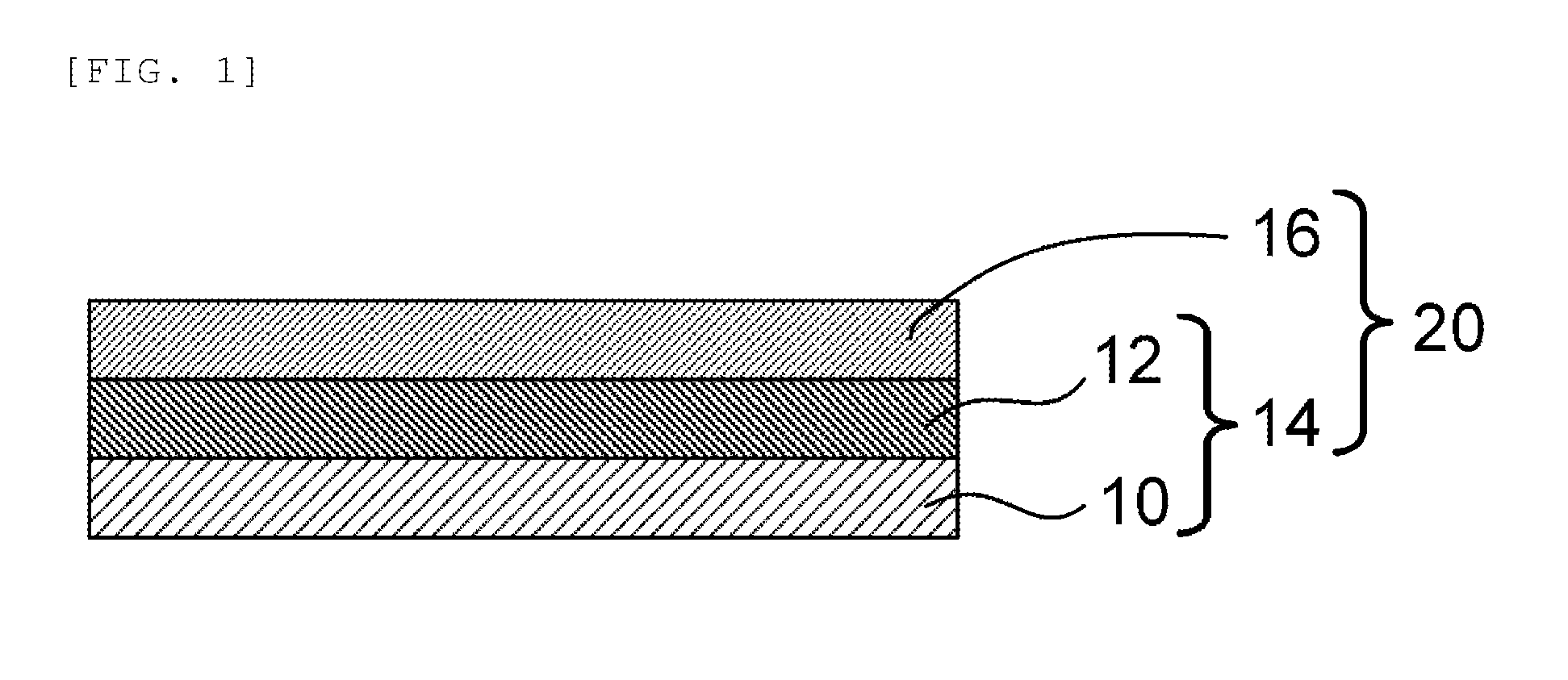

Battery-packaging material

ActiveUS20160301040A1Excellent moldabilityImprove productivityFinal product manufactureSynthetic resin layered productsPolyesterTensile testing

To provide a technique for a battery-packaging material made of a film-form laminate in which at least a base material layer, an adhesive layer, a metal layer, and a sealant layer are laminated successively, wherein: electrolytic solution resistance is further improved by including a polyester film in the base material layer; cracks and pinholes are less likely to be created at the time of forming the polyester-film-including base material layer; and formability is improved. This battery-packaging material is made of a laminate in which at least a base material layer, an adhesive layer, a metal layer, and a sealant layer are laminated successively, wherein: the base material layer includes a polyester film; and the metal layer is an aluminum foil in which the 0.2% proof stress at the time of performing a tensile test in a direction parallel to the rolling direction is from 55 to 140 N / mm2.

Owner:DAI NIPPON PRINTING CO LTD

Adhesive for aluminum battery packaging aluminum plastic film, aluminum plastic film and preparation method of aluminum plastic film

InactiveCN109337620AGood solvent resistanceImprove acid resistanceNon-macromolecular adhesive additivesVinyl aromatic copolymer adhesivesElastomerEpoxy

The invention provides an adhesive for an aluminum battery packaging aluminum plastic film, the aluminum plastic film and a preparation method of the aluminum plastic film. The adhesive at least comprises the following components in percentage by mass: 10-15% of a main resin, 1-3% of a curing agent, 0.5-1%of a tackifying resin, 0.1-0.5% of an anti-hydrolysis agent and 65-90% of a solvent, whereinthe main resin comprises one or more of maleic anhydride modified styrene, polypropylene and a polyolefin elastomer; the curing agent comprises a mixture of one or more polymers in an epoxy resin system. In the aluminum plastic film, the adhesive is coated on the surface of an adhesive layer of a cast polypropylene film, and dried to serve as an inner adhesive layer. The inner adhesive layer is used for dry compounding of an aluminum foil layer of the aluminum battery packaging aluminum plastic film and the cast polypropylene layer, so that aluminum plastic film products have high adhesion andelectrolyte resistance; in addition, the adhesive has a relatively long storage cycle.

Owner:JIANGXI RUIERGY NEW MATERIAL TECH CO LTD

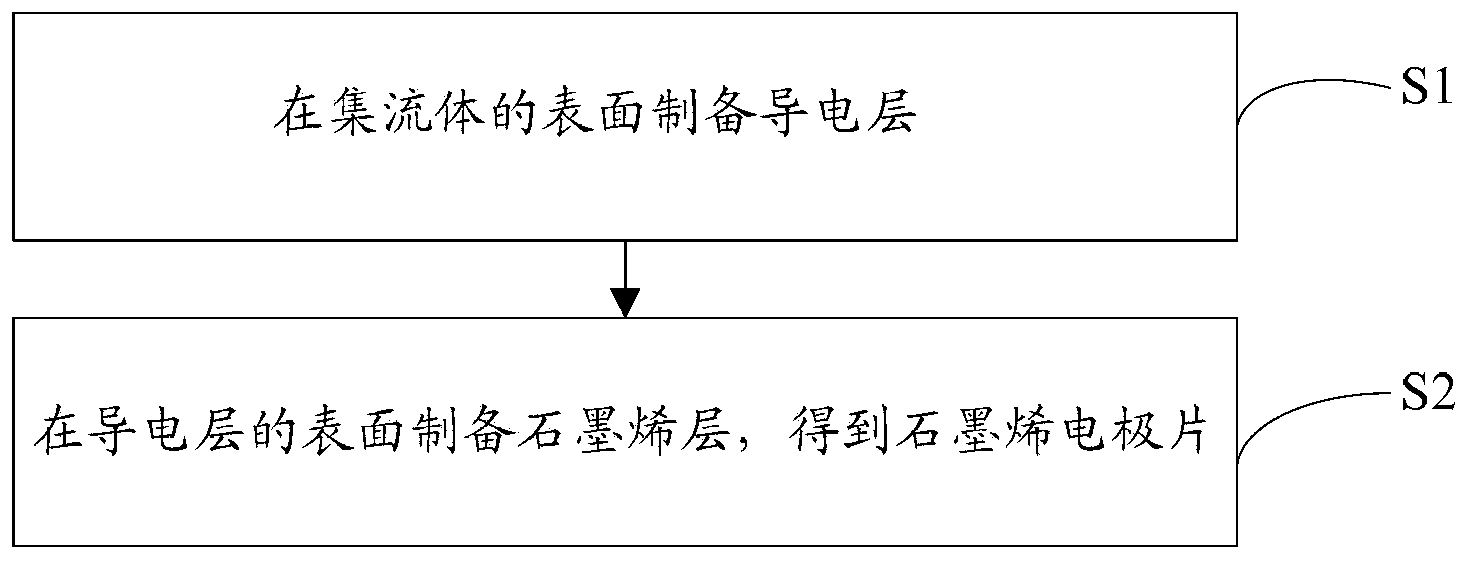

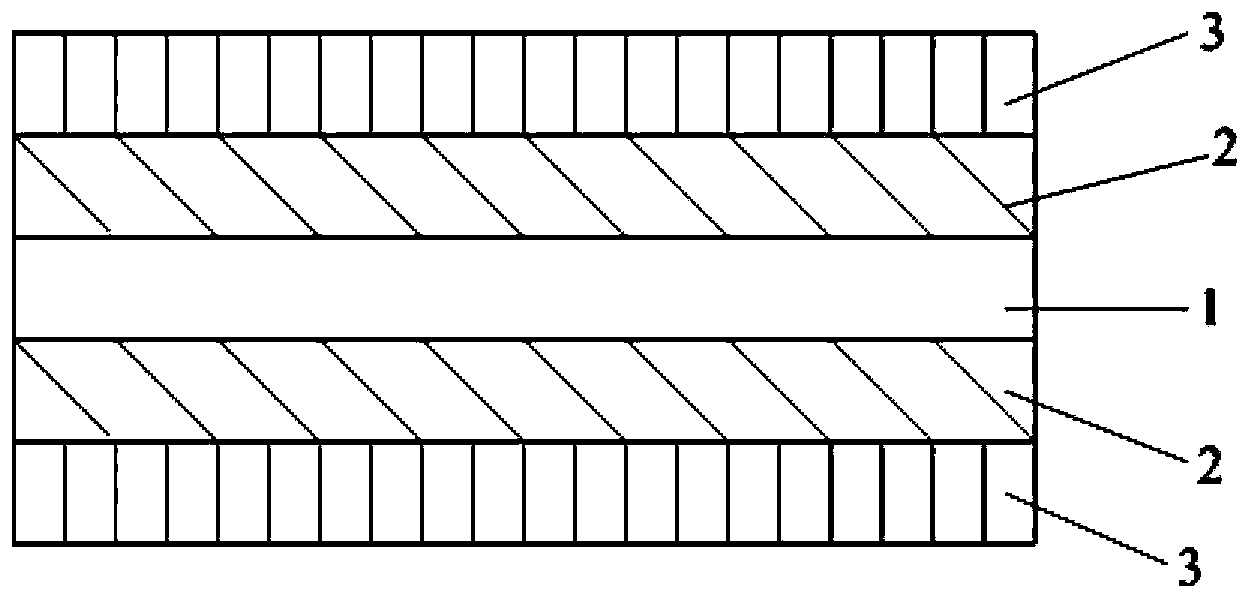

Graphene electrode plate, and preparation method and application thereof

InactiveCN103839695AReduce expansionLow elongationHybrid capacitor electrodesHybrid/EDL manufactureCyclic processDying processes

The invention belongs to an electrochemical material and discloses a graphene electrode plate, and a preparation method and application thereof. The preparation method of the graphene electrode plate includes: preparing a conductive layer, which is made of materials of alginate and a conductive agent, on a current collector; and preparing a graphene layer, which is made of materials of graphene, a conductive agent and the alginate, on the surface of the conductive layer which undergoes a drying process and performing a dying process and then obtaining the graphene electrode plate. In the preparation method for the graphene electrode plate, uniform carboxyl groups are distributed evenly on a chain structure of the alginate and the carboxyl groups in the alginate are capable of forming chemical bonds with hydroxyl groups on different graphene-plate layers so that a bonding force between the graphene plate layers is reinforced and conductivity between the graphene plate layers is improved and thus the rate performance is improved; and low reaction activity between the alginate and an electrolyte, and an excellent electrolyte resistance characteristic reduce irreversible consumption of the electrolyte on the surfaces of cathode active material particles in a cyclic process so that the long cyclic performance of a cell is ensured.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

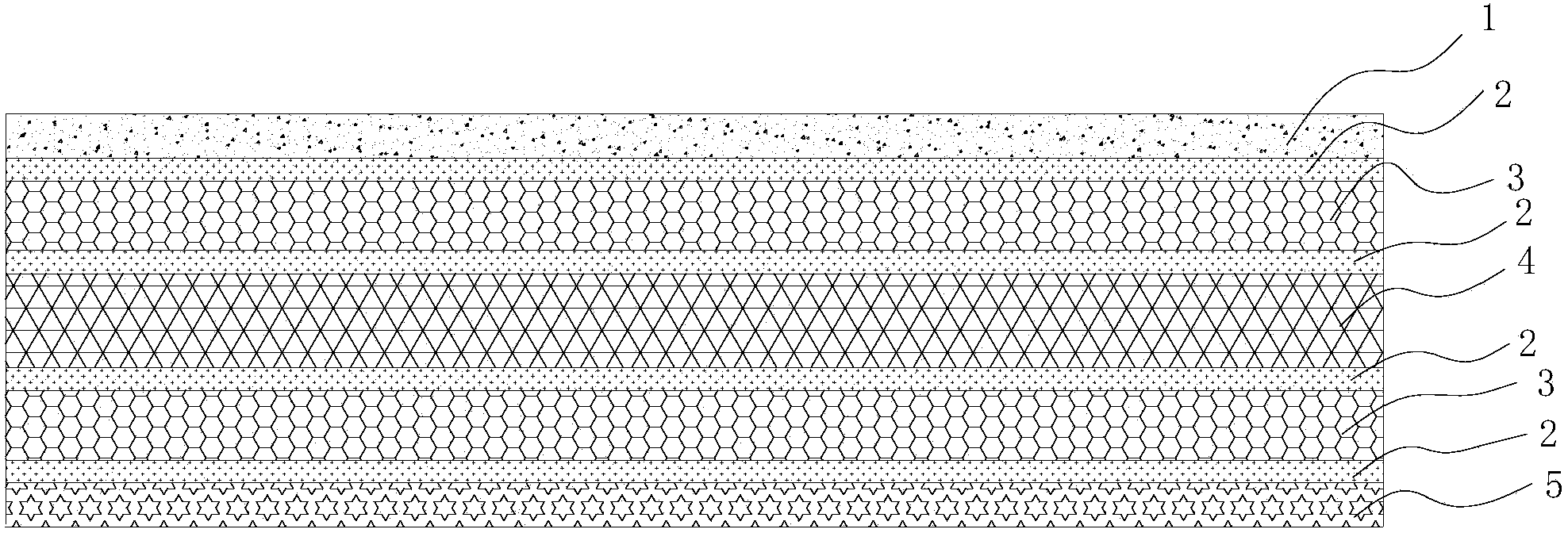

Aluminum-plastic composite film for lithium ion battery soft package and manufacturing method of aluminum-plastic composite film

InactiveCN106346904AHigh peel strengthImprove machinabilitySynthetic resin layered productsLaminationComposite filmConductive materials

The invention discloses an aluminum-plastic composite film for a lithium ion battery soft package and a manufacturing method of the aluminum-plastic composite film. A surface protecting layer, a heat-conductive material layer, an upper adhesion layer, an upper passivation barrier layer, an aluminum film layer, a lower passivation barrier layer, a lower adhesion layer and a CPP composite film layer are successively superposed on a heat-conductive aluminum-plastic film. The aluminum-plastic composite film for the lithium ion battery soft package comprises the following steps: pretreating double surfaces of a substrate material; coating a pretreated surface of the substrate material with coating; washing the surface of an aluminum foil with water; and coating the upper passivation barrier layer, the lower passivation barrier layer, the upper adhesion layer and the lower adhesion layer. The aluminum-plastic composite film for the lithium ion battery soft package has high strength, airtightness, barrier property, acid and alkali resistance and electrolyte resistance, and meanwhile, facilitates heat conduction. The aluminum foil layer and the heat-conductive material layer have the advantages of quite high stripping strength, machining property, shielding effectiveness and barrier property, good bending property and tensile property, and excellent heat conduction property.

Owner:南通樱川薄膜科技有限公司

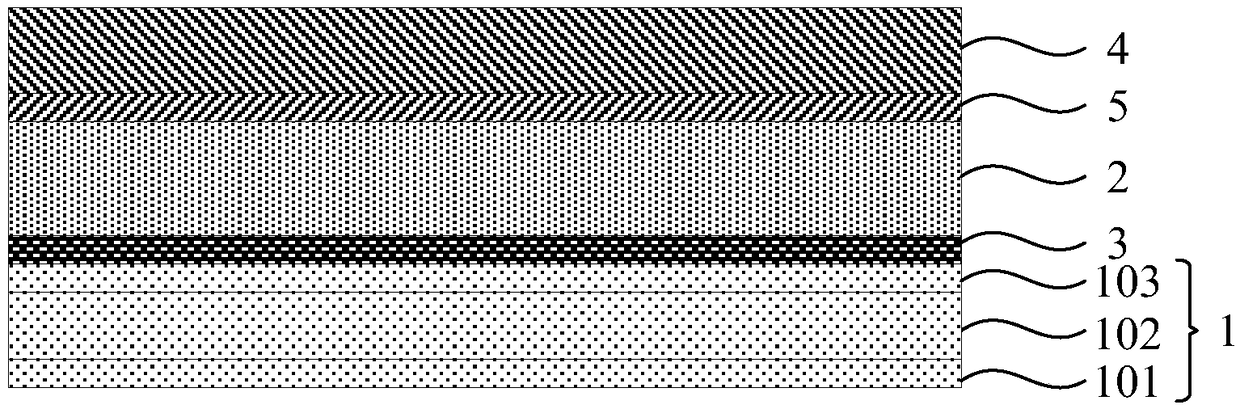

Pouch for packing cell and method for preparing the same

ActiveCN101563221AAvoid corrosionAvoid delaminationSynthetic resin layered productsMetal layered productsLithiumProcess efficiency

Provided are a pouch for packing a cell such as a lithium secondary cell or a portable storage battery and a method for preparing the same. The pouch for packing a cell such as a lithium secondary cell or a portable storage battery according to the present invention has drastically improved electrolyte resistance, which is particularly required for a cell pouch, and, therefore, is capable of preventing the corrosion of the barrier layer by the electrolyte and preventing de- lamination of the sealant layer from the barrier layer. Further, the pouch for packing a cell according to the present invention it is capable of protecting the cell safely, is shaped freely, has superior barrier property, moldability, impact resistance, air(oxygen) penetration resistance, moisture permeation resistanceand piercing strength, reduces manufacturing time, improves process efficiency, reduces cost, and is lightweight.

Owner:YOULCHON CHEM

Aqueous liquid composition, aqueous coating, functional coating film, and composite material

InactiveUS20130316232A1Sufficient viscosityImprove adhesionMaterial nanotechnologyCosmetic preparationsWater basedViscosity

An aqueous liquid composition contains a water-based medium containing water, chitosan and / or a chitosan derivative, and a polymeric acid, and has a pH of not higher than 4.5. The aqueous liquid composition contains low-cost materials having low environmental load, can retain adequate viscosity even when stored over a long term, and can form a functional coating film having excellent adhesiveness to a base material and superb durability, solvent resistance and waterproofness and capable of exhibiting various functions led by electrical conductivity and hydrophilicity.

Owner:DAINICHISEIKA COLOR & CHEM MFG CO LTD

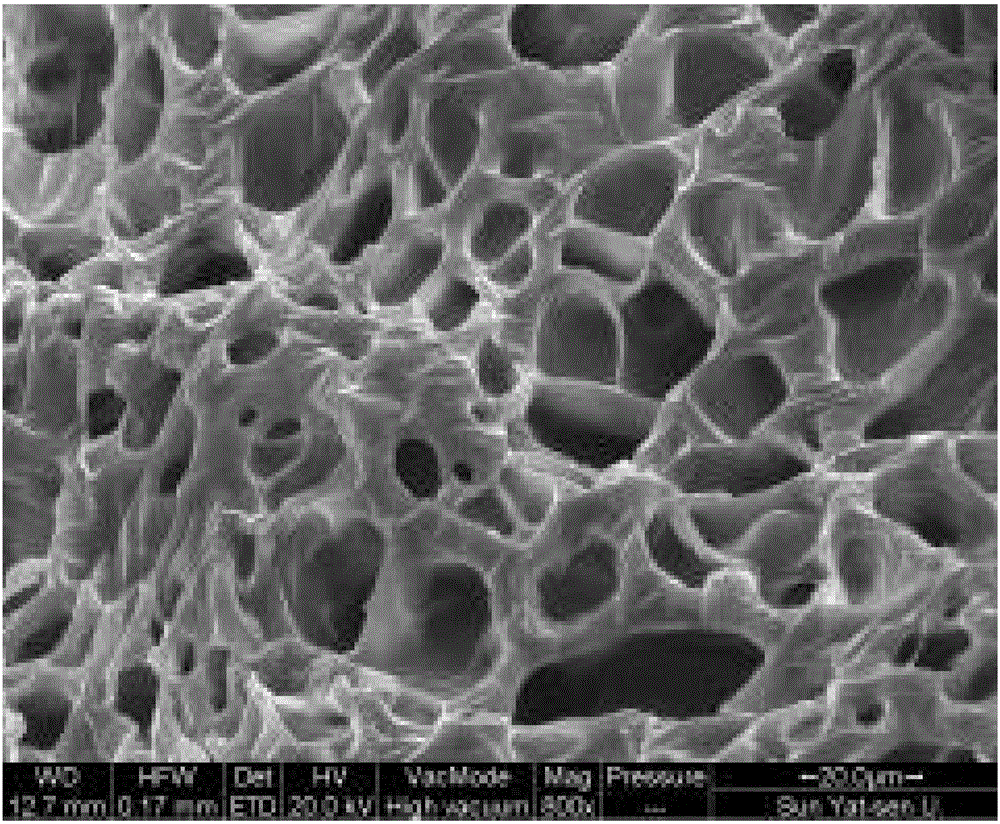

Highly corrosion-resistant porous metal member

ActiveCN102255084AImprove electrolyte resistanceAccelerated corrosionCapacitor terminalsElectrode carriers/collectorsAlloyBoron

A porous metal member composed of an alloy at least containing nickel and tungsten is provided. The alloy may contain 50 to 80 wt % of nickel and 20 to 50 wt % of tungsten and may further contain 10 wt % or less of phosphorus and / or 10 wt % or less of boron. Such a porous metal member can be produced by, for example, making a porous base such as a urethane foam be electrically conductive, forming an alloy film containing nickel and tungsten, then removing the porous base from the alloy film, and subsequently reducing the alloy.

Owner:SUMITOMO ELECTRIC IND LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com