Hard carbon-like graphite cathode material for high-rate lithium ion battery and preparation method thereof

A lithium-ion battery, graphite anode technology, applied in battery electrodes, carbon preparation/purification, negative electrodes, etc., can solve the problems of poor fast charge and discharge performance, high crystallinity, small interlayer spacing, etc., to achieve stable product properties, The effect of high retention and large carbon layer spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The present embodiment provides a kind of hard carbon graphite negative electrode material for high-rate lithium-ion batteries, and its preparation method (all the other embodiments are the same) comprises the following preparation steps:

[0055] S1: Grinding the thermoplastic polymer to a micron size to obtain a polymer powder;

[0056] S2: Disperse the polymer powder in an aqueous solution containing an oxidizing agent and a surfactant, carry out a liquid-phase low-temperature oxidation reaction under stirring conditions at 80-180°C, cross-link to obtain an oxidized product, and then pyrolyze the oxidized product to obtain oxygen-enriched carbon Precursor; the mass ratio of the polymer powder to the oxidizing agent is 100:20-50;

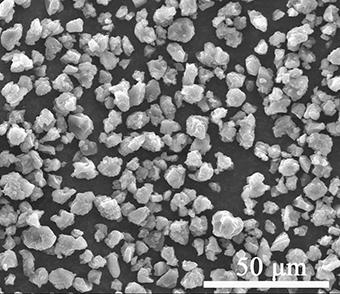

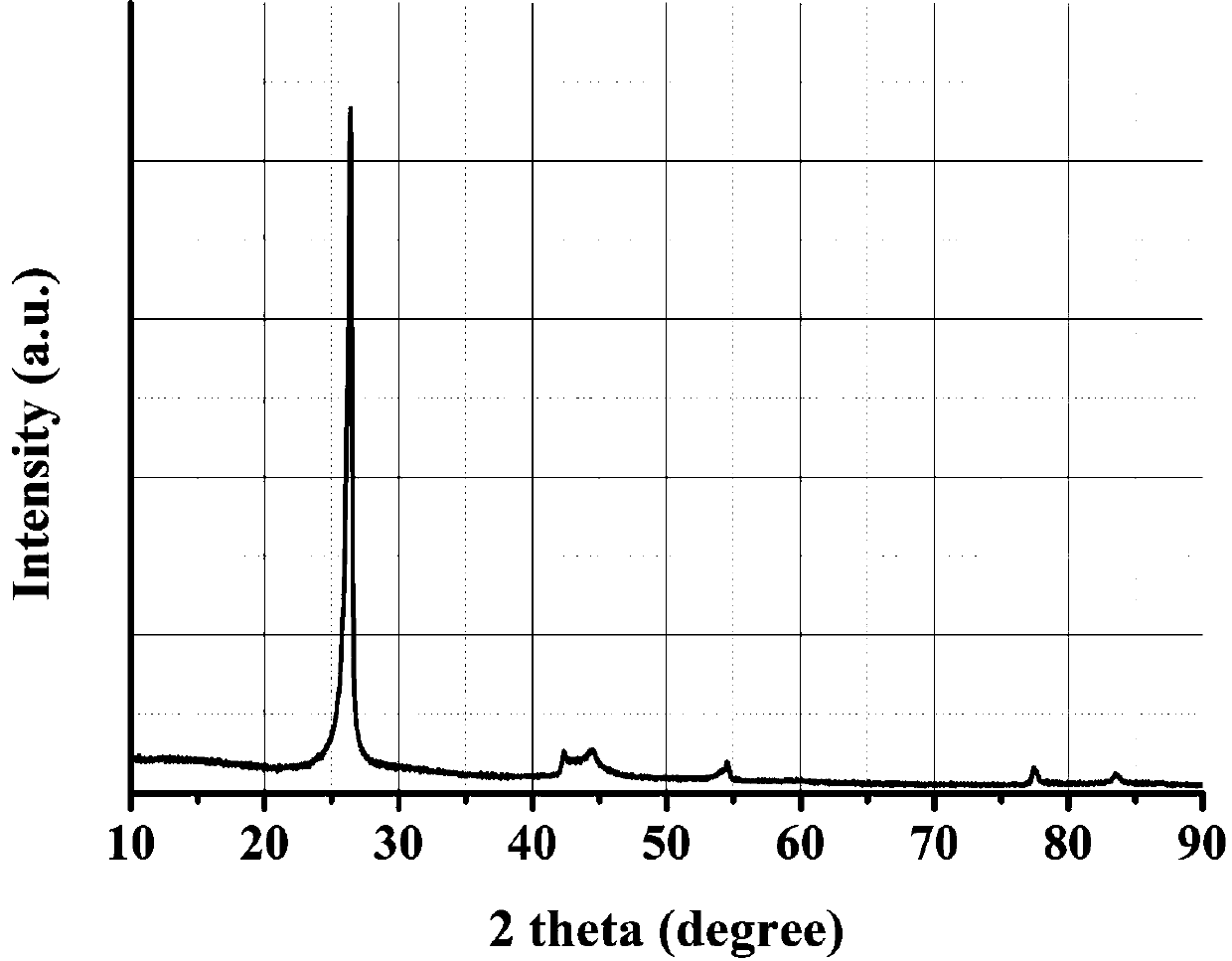

[0057] S3: Pulverize the oxygen-rich carbon precursor and graphitize it to obtain a hard carbon-like graphitized carbon powder;

[0058] S4: depolymerize and sieve the hard carbon-like graphitized carbon powder to obtain the hard carbon-li...

Embodiment 2

[0062] This embodiment provides a hard carbon-like graphite negative electrode material for a high-rate lithium-ion battery, which is prepared by the following preparation method.

[0063] The high-temperature coal tar pitch (softening point is 250°C) is pulverized by air flow to make a powder with a volume average particle diameter D50 of 5 μm; Mix to make a water slurry with a solid content of 50%, and dry it in a heated stirring tank at 180°C for 4 hours to carry out oxidation reaction, and discharge it after cooling to room temperature to obtain oxidized asphalt powder; then put it into a rotary kiln and Under the protection of nitrogen, the temperature was raised to 1000°C for 2 hours, and the temperature was lowered to room temperature to discharge; then it was crushed by air flow to make a powder with a volume average particle size D50 of 8 μm, and it was carried out at 2800°C under the protection of an inert gas. Graphitization at high temperature for 12 hours, cooling...

Embodiment 3

[0065] This embodiment provides a hard carbon-like graphite negative electrode material for a high-rate lithium-ion battery, which is prepared by the following preparation method.

[0066] The coumarone resin is pulverized by airflow to make a powder with a volume average particle diameter D50 of 5 μm; the obtained resin powder is mixed with nitric acid and Tween 20 with a mass concentration of 20% according to a mass ratio of 100:30:2 Make a water slurry with a solid content of 50% and dry it in a heated stirring tank at 100°C for 8 hours for oxidation reaction. After cooling to room temperature, the oxidized resin powder is obtained; then put it into a rotary kiln and protect it under nitrogen Heat up to 1000°C at 2°C / min for 2 hours, cool down to room temperature and discharge; then use jet milling to make a powder with a volume average particle size D50 of 8 μm, and graphitize at 2600°C under the protection of an inert gas High-temperature treatment for 24 hours, cooling t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Volume average particle size | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com