Lithium battery positive electrode, preparation method thereof, lithium battery, power supply system and electric equipment

A technology of power supply system and lithium battery, which is applied in the direction of lithium battery, battery electrode, non-aqueous electrolyte battery electrode, etc., can solve the problem of timely monitoring and suppression of battery thermal runaway, increase the contact resistance between current collector and active material, Problems such as battery rate performance are greatly affected, to achieve the effect of preventing temperature rise, suppressing collapse, and stabilizing product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

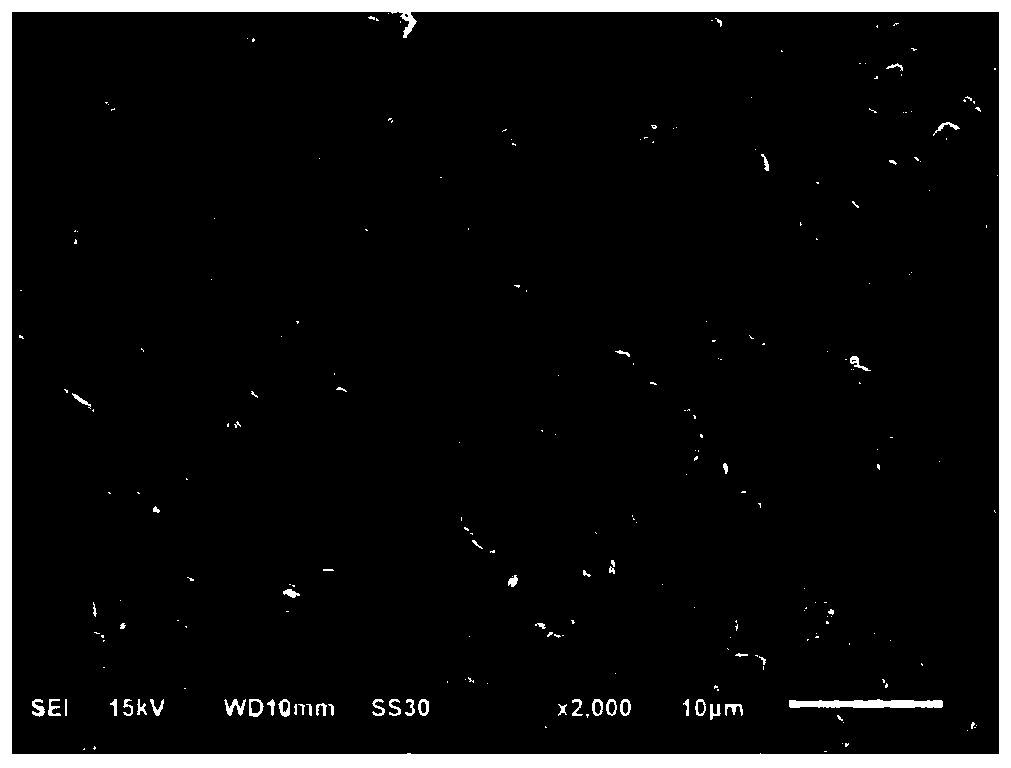

Image

Examples

Embodiment 1

[0055] With polytetrafluoroethylene as binder, acetylene black as conductive agent, LiNi 0.6 co 0.2 mn 0.2 o 2 It is the active substance, the mass ratio of the active substance, acetylene black, and PVDF is 92:4:4, mix well and grind evenly in an agate mortar, and drop into NMP solvent. After grinding for 60 minutes, the slurry was scraped on the aluminum foil of the current collector, and vacuum-dried at 100° C. for 8 hours to obtain a positive electrode substrate.

[0056] Then it is placed in the vacuum reaction chamber of the magnetron sputtering equipment, and the background vacuum pressure of the vacuum chamber is 6.0×10 - 4 Pa, under the sputtering power of 60W, perform radio frequency magnetron sputtering coating, and BaPbO with a purity of not less than 99.95wt% 3 The target is placed in the pressure groove of the hydraulic press and pressed into a thin target as the sputtering source. The surface of the positive electrode is sputtered and coated by the magnetro...

Embodiment 2

[0058] With polytetrafluoroethylene as binder, acetylene black as conductive agent, LiNi 0.8 co 0.15 Al 0.05 o 2 It is the active substance, and the mass ratio of the active substance, acetylene black, and PVDF is 90:4:6, mix well and grind evenly in an agate mortar, and drop into NMP solvent. After grinding for 80 minutes, the slurry was scraped on the current collector aluminum foil, and vacuum-dried at 100° C. for 6 hours to obtain a positive electrode substrate.

[0059] Then it is placed in the vacuum reaction chamber of the magnetron sputtering equipment, and the background vacuum pressure of the vacuum chamber is 2.0×10 - 4 Pa, under the sputtering power of 40W, perform radio frequency magnetron sputtering coating, and BaPbO with a purity of not less than 99.95wt% 3 The target is placed in the pressure groove of the hydraulic press and pressed into a thin target as the sputtering source. The surface of the positive electrode is sputtered and coated by the magnetron...

Embodiment 3

[0061] With polytetrafluoroethylene as binder, acetylene black as conductive agent, LiFePO 4 It is the active substance, the mass ratio of the active substance, acetylene black, and PVDF is 88:6:6, mix well and grind evenly in an agate mortar, and drop into NMP solvent. After grinding for 80 minutes, the slurry was scraped on the aluminum foil of the current collector, and vacuum-dried at 100° C. for 10 hours to obtain a positive electrode substrate.

[0062] Then it is placed in the vacuum reaction chamber of the magnetron sputtering equipment, and the background vacuum pressure of the vacuum chamber is 5.0×10 - 4 Pa, under the sputtering power of 80W, the radio frequency magnetron sputtering coating was carried out, and the BaPbO with a purity of 99.99wt% 3 The target is placed in the pressure groove of the hydraulic press and pressed into a thin target as the sputtering source. The surface of the positive electrode is sputtered and coated by the magnetron sputtering metho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com