Graphene electrode plate, and preparation method and application thereof

A graphene electrode and graphene technology, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of reduced electrode life and electrochemical performance, powder drop, and poor adhesion. Achieve good electrolyte resistance, less contact resistance, and reduce irreversible consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

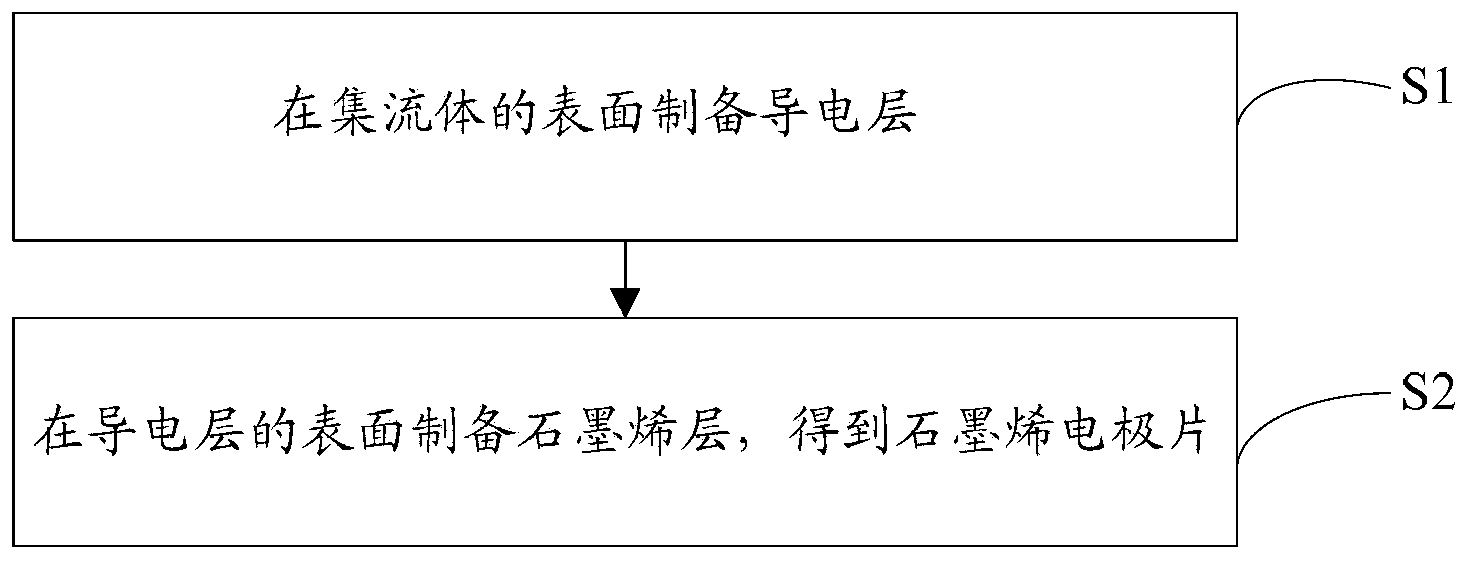

Method used

Image

Examples

preparation example Construction

[0030] In the preparation process of the above-mentioned graphene electrode sheets, the alginate is sodium alginate and / or potassium alginate, and the two stereoisomers L-guluronic acid (G section) and The ratio G / M of D-mannuronic acid (section M) is less than or equal to 1.5, and the calcium impurity contained in the alginate is less than or equal to 0.3%. If the G segment content in the molecular sequence is too high, on the one hand, the homopolymeric G segment structure is prone to chelation with calcium impurities, making the alginic acid chains tightly bound and synergistically stronger, and finally forms a gel; on the other hand, The brittleness of sodium alginate (or potassium) with high G / M ratio is enhanced after film formation, and the processing of pole pieces is more difficult; moreover, the impedance of pole pieces prepared with high G / M ratio sodium (or potassium) is higher than that of low G / M ratio of sodium alginate (or potassium) prepared pole piece, which...

Embodiment 1

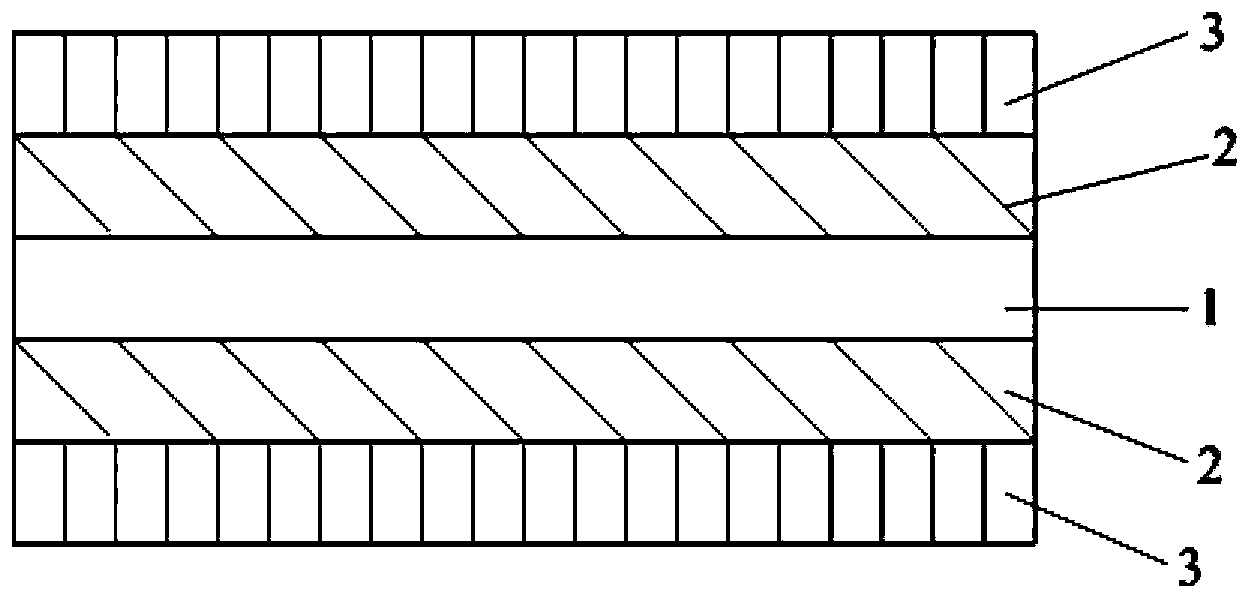

[0044] According to the mass percentage, add 90% conductive agent and 10% sodium alginate binder into water, stir evenly to form a conductive layer slurry, and evenly coat the conductive layer slurry on one side of aluminum foil with a coating thickness of 3 μm Thick, then put it into an oven, dry at 80°C for 12 hours, and then apply the same process to the other side of the aluminum foil to coat a conductive layer, in which water accounts for 60% of the total slurry weight.

[0045] According to the mass percentage, 90% graphite, 5% conductive agent, and 5% alginate binder are added into water, stirred evenly to form a graphene slurry, and the graphene slurry is evenly coated on the conductive layer, The coating thickness is 50 μm, then put it into an oven, and dry it at 80 ° C for 12 hours, and then apply the graphene slurry layer on the other side of the conductive layer by the same process to obtain a graphene electrode sheet; wherein water occupies 60% of the total slurry...

Embodiment 2

[0048] According to the mass percentage, add 99% conductive agent and 1% potassium alginate binder into water, stir evenly to form a conductive layer slurry, and evenly coat the conductive layer slurry on one copper foil with a coating thickness of 10 μm thick, then put it into an oven, dry at 100°C for 6 hours, and then apply the same process on the other side of the copper foil to coat a conductive layer, in which water accounts for 60% of the total slurry weight.

[0049] According to the mass percentage, add 96% graphene, 2% conductive agent, and 2% potassium alginate binder into water, stir evenly to form a graphene slurry, and evenly coat the graphene slurry on the conductive layer , the coating thickness is 300 μm thick, then put it into an oven, dry at 100 ° C for 6 hours, and then apply the same process to the other side of the conductive layer to coat the graphene slurry layer to obtain a graphene electrode sheet, wherein Water was 60% by weight of the total slurry. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coating thickness | aaaaa | aaaaa |

| Coating thickness | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com