Anti-corrosion, anti-puncture and anti-short circuit melting through aluminum-plastic packaging film for lithium battery and manufacture method thereof

A kind of aluminum-plastic packaging film, corrosion-resistant technology, used in circuits, battery pack parts, chemical instruments and methods, etc. Problems such as low puncture strength, to achieve the effect of improving puncture resistance, improving corrosion resistance, and excellent electrolyte resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

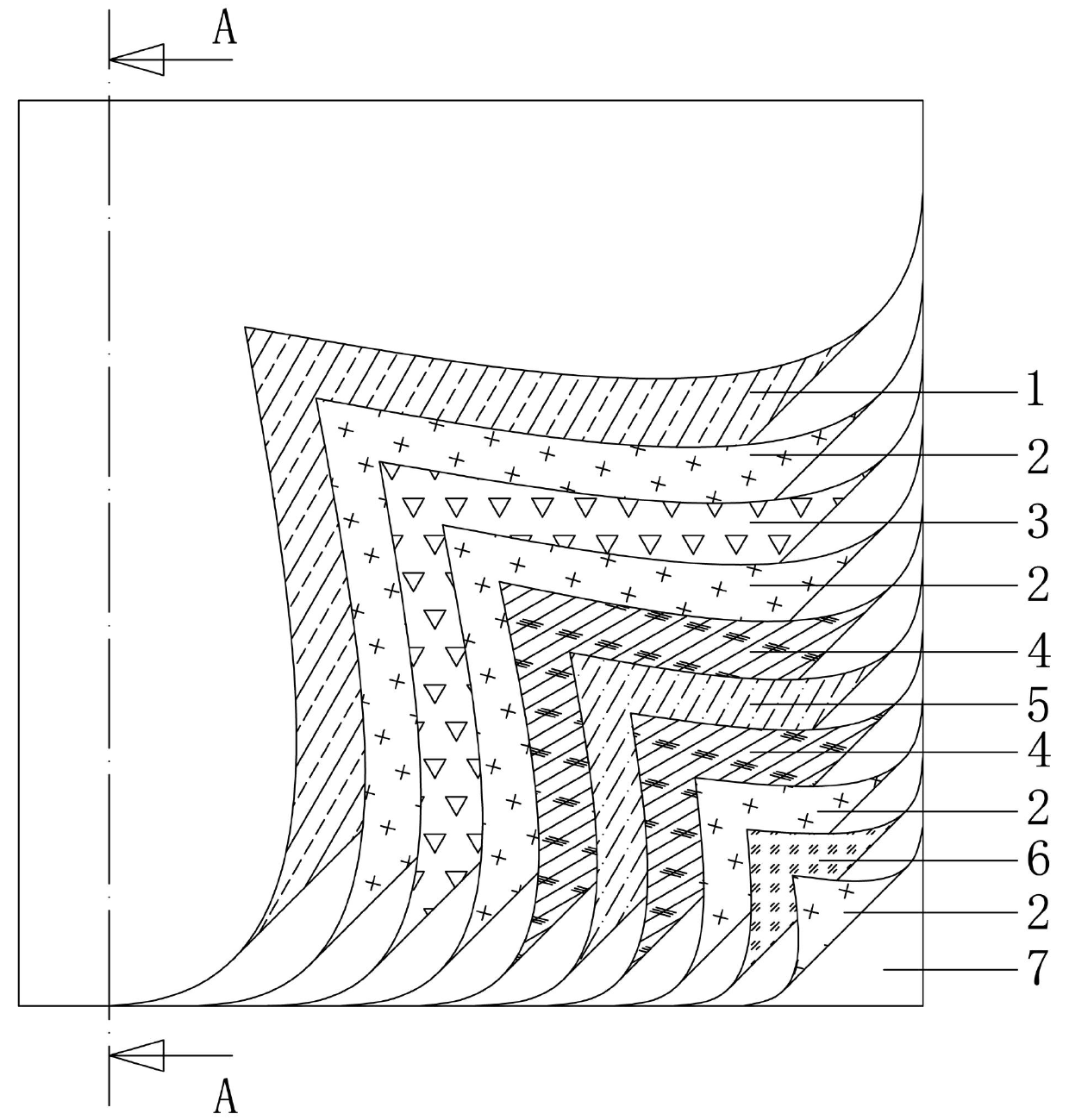

Image

Examples

specific Embodiment 1

[0048] First, take the acid-modified polypropylene resin and mold it through a co-extrusion casting machine to prepare an acid-modified polypropylene film (co-extrusion cast non-stretch film) with a thickness of 30 microns for use; secondly, take the thickness Nylon (PA, Polyamide) with a thickness of 25 microns, polyimide (PI, Polyimide) film with a thickness of 30 microns, polyethylene terephthalate (PET) with a thickness of 20 microns , Polyethylene Terephthalate) film as a spare; then, take an annealed soft high-formability aluminum foil (Al) with a thickness of 40 microns as the aluminum foil layer 4, and coat a layer of thickness on both sides of the aluminum foil layer 4 by gravure printing A solvent made of 99% polymethyl methacrylate (PMMA, PolymethylMethacrylate) dissolved in 1% ethyl acetate to form a corrosion-resistant coating layer 4 with a thickness of 3 microns; Aluminum foil layer 4 is coated with 4 micron thick modified polyurethane and curing agent (wherein,...

specific Embodiment 2

[0053] First, the ethylene-acrylate copolymer resin (EEA) is molded by a co-extrusion casting machine to prepare an ethylene-acrylate copolymer film (co-extrusion casting fee stretch film) with a thickness of 40 microns for use; Secondly, take nylon (PA) with a thickness of 15 microns, polyethylene terephthalate (PET) film with a thickness of 30 microns, and polyimide (PI) film with a thickness of 40 microns for backup; Next, take the annealed soft high-formability aluminum foil (Al) with a thickness of 40 microns as the aluminum foil layer 4, and coat a layer of 85% polyformaldehyde with a thickness of 3 microns on both sides of the aluminum foil layer 4 by dip coating. Methyl acrylate (PMMA) and polyvinylidene fluoride (PVDF) are mixed at a ratio of 1:1 and dissolved in a solvent made of 15% ethyl acetate to form a corrosion-resistant coating layer 4; One side of the aluminum foil layer 4 is coated with a self-polymer of 2 microns of modified polyurethane and curing agent po...

specific Embodiment 3

[0058] First, take acid-modified polypropylene resin, ethylene-acrylate copolymer, metal ion cross-linked polyethylene resin, copolymer of ethylene and acrylic acid derivatives, and copolymer of ethylene and methacrylic acid derivatives through a co-extrusion casting machine Forming to make a five-layer co-extruded film (co-extruded cast non-stretched film) with a thickness of 45 microns for use; then, take a polyethylene terephthalate film (PET) with a thickness of 30 microns , a polyethylene terephthalate film (PET) with a thickness of 20 microns and a polyaryl ketone resin film with a thickness of 15 microns for use; then, take an annealed soft-state high-formability film with a thickness of 30 microns Aluminum foil (Al) is used as the aluminum foil layer 4, which is made of 90% polymethyl methacrylate (PMMA) dissolved in 10% ethyl acetate with a thickness of 1 micron on both sides of the aluminum foil layer 4 by dip coating. solvent to form a corrosion-resistant paint laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com