Flexible composite plastic film, and preparation method and test method thereof

A plastic film and flexible technology, applied in the field of flexible composite plastic film, can solve the problems of metal layer and plastic film detachment, increase battery self-discharge rate, battery capacity attenuation, etc., achieve the same size and thickness, and resist electrolyte Enhanced sex, well-tolerated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

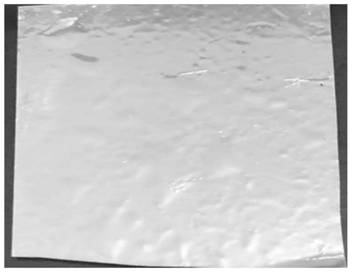

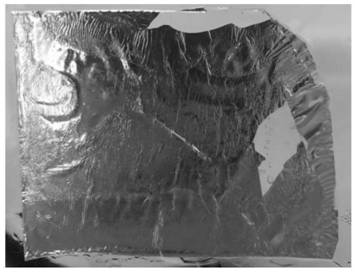

Embodiment 1

[0049] A flexible composite plastic film, including a 6μm thick PET plastic film layer, a 50nm aluminum oxide intermediate reinforcement layer is evaporated on both sides of the PET layer, a 1um thick metal aluminum layer is evaporated outside the aluminum oxide layer, and finally the metal aluminum layer A 100nm aluminum oxide resistive layer is evaporated on the upper and lower surfaces. A method for preparing a flexible composite plastic film resistant to electrolyte erosion, the preparation method comprising the steps of:

[0050] (1) Select a suitable plastic film for surface oil removal and pre-drying treatment;

[0051] (2) carry out plasma treatment to the plastic film after drying, the power of surface plasma treatment is 8kW;

[0052] (3) Coating intermediate reinforcing layers on both sides of the plastic film layer by magnetron sputtering, wherein the coating power is 200kW, the substrate transmission speed is 15m / min, and the argon speed is 25L / min;

[0053] (4)...

Embodiment 2

[0064] A flexible composite plastic film, including a 4.5 μm thick OPP film layer, on both sides of the OPP layer, magnetron sputtering a 10nm silicon oxide intermediate reinforcement layer, 500nm metal aluminum layer is evaporated outside the silicon oxide layer, and finally evaporated on the surface Plating 20nm aluminum oxide resist layer. A method for preparing a flexible composite plastic film resistant to electrolyte erosion, the preparation method comprising the steps of:

[0065] (1) Carry out surface oil stain removal and pre-drying treatment on the OPP plastic film;

[0066] (2) carry out plasma treatment to the plastic film after drying, the power of surface plasma treatment is 5kW;

[0067] (3) Coating an intermediate reinforcement layer on both sides of the plastic film layer by magnetron sputtering, wherein the coating power is 150kW, the substrate transmission speed is 10m / min, and the argon speed is 20L / min;

[0068] (4) Deposit a metal layer on the outside o...

Embodiment 3

[0079] A flexible composite plastic film, including a PI film layer with a thickness of 20 μm, a 500nm aluminum oxide intermediate reinforcement layer is evaporated on both sides of the PI layer, a 3000nm metal aluminum layer is evaporated outside the aluminum oxide layer, and finally a 500nm oxide oxide layer is evaporated on the surface Aluminum resistant layer. A method for preparing a flexible composite plastic film resistant to electrolyte erosion, the preparation method comprising the steps of:

[0080] (1) Carry out surface oil stain removal and pre-drying treatment to PI plastic film;

[0081] (2) carry out plasma treatment to the plastic film after drying, the power of surface plasma treatment is 15kW;

[0082] (3) Coating an intermediate reinforcement layer on both sides of the plastic film layer by evaporation and coating, the evaporation boat wire feeding speed is 800mm / min, the cooling system temperature is -30°C, and the film running speed is 8m / s;

[0083] (4)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com