Termination adhesive tape and manufacture method thereof

A technology for terminating tapes and production methods, applied in the directions of adhesives, adhesive types, film/sheet adhesives, etc., can solve the problems of corrosion, complex production process, high cost, and achieve good electrolyte resistance. Simple production process and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

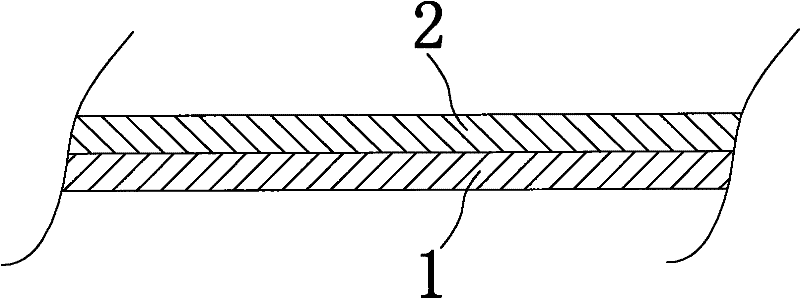

[0022] refer to figure 1 As shown, this embodiment of the present invention includes a base tape 1 and a glue layer 2 disposed on the base tape 1 .

[0023] The above-mentioned glue layer 2 is an acrylic glue layer, and the specific raw materials and weight of the acrylic glue layer in the present embodiment are:

[0024] Butyl acrylate 3 kg;

[0025] Vinyl acetate 9 kg;

[0026] 52 kg of ethyl acetate;

[0027] 28 kg of isooctyl acrylate;

[0028] Hydroxyethyl methacrylate 1.5 kg;

[0029] Acrylic acid 2 kg;

[0030] 3 kg of toluene;

[0031] Benzoyl Peroxide 0.3 kg.

[0032] An appropriate amount of green pigment and 1.2 kg of polycyanoisolate are added to the acrylic glue layer.

[0033] The steps of the method for making the above-mentioned termination tape are as follows:

[0034] A. Make acrylic glue;

[0035] Use 3 kilograms of to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com