Phosphate leather fat liquoring agent and preparation method thereof

A technology of leather fatliquor and phosphate esters, applied in leather impregnation, small raw hide/big raw hide/leather/fur treatment, small raw hide/large raw hide/leather skin/fur chemical treatment, etc., can solve demulsification, bleaching, etc. Oil and other problems to achieve the effect of improving water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The first step: allyl polyether modified amino silicone oil

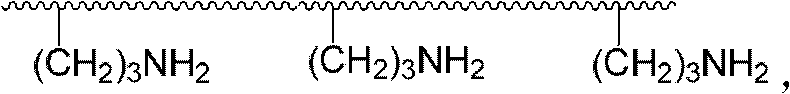

[0033] Add 450 parts of allyl polyether and 1000 parts of amino silicone oil in parts by mass into a reactor equipped with a stirrer, condenser and thermometer, mix well, heat up, react at 60°C for 10 hours, cool to room temperature, and obtain activity Polyether modified amino silicone oil, the allyl polyether is APEG-500; the structural formula of the amino silicone oil is

[0034]

[0035] Indicates the siloxane chain, the amino value of amino silicone oil is 0.9mmol / g;

[0036] Step 2: Phosphorylation

[0037] Control the temperature at 30°C, slowly add 63.9 parts of P 2 o 5 , the feeding time is 1h, and then the temperature is slowly raised to 65°C, and the constant temperature is reacted for 5.5h to obtain phosphorylated polyether modified amino silicone oil;

[0038] Step Three: Neutralization

[0039] After the second step, neutralize the system with an alkaline aqueous solution until the pH...

Embodiment 2

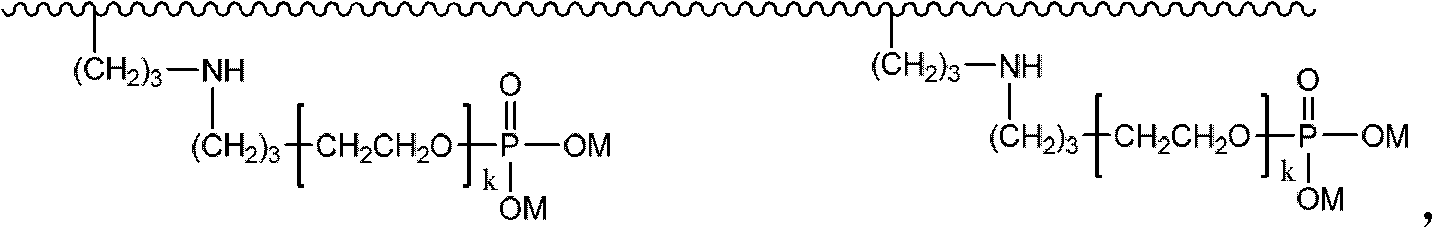

[0041] The first step: allyl polyether modified amino silicone oil

[0042] Add 490 parts of allyl polyether and 1000 parts of amino silicone oil in parts by mass into a reactor equipped with a stirrer, condenser and thermometer, mix well, heat up, react at 60°C for 10 hours, cool to room temperature, and obtain activity Polyether modified amino silicone oil, the allyl polyether is APEG-700; the structural formula of the amino silicone oil is

[0043]

[0044] Indicates the siloxane chain, the amino value of amino silicone oil is 0.7mmol / g;

[0045] Step 2: Phosphorylation

[0046] Control the temperature at 20°C, slowly add 49.7 parts of P in batches to the reactor after the first step 2 o 5 , the feeding time is 1.5h, then the temperature is slowly raised to 60°C, and the constant temperature is reacted for 6h to obtain phosphorylated polyether modified amino silicone oil;

[0047] Step Three: Neutralization

[0048] After the second step, neutralize the system wit...

Embodiment 3

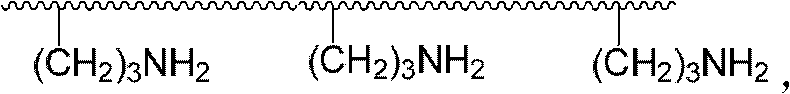

[0050] The first step: allyl polyether modified amino silicone oil

[0051] Add 500 parts of allyl polyether and 1000 parts of amino silicone oil in parts by mass into a reactor equipped with a stirrer, condenser and thermometer, mix well, heat up, react at 80°C for 6 hours, cool to room temperature, and obtain activity Polyether modified amino silicone oil, the allyl polyether is APEG-1000; the structural formula of the amino silicone oil is

[0052]

[0053] Indicates the siloxane chain, the amino value of amino silicone oil is 0.5mmol / g;

[0054] Step 2: Phosphorylation

[0055] Control the temperature at 25°C, slowly add 35.5 parts of P in batches to the reactor after the first step 2 o 5 , the feeding time is 2 hours, and then the temperature is slowly raised to 80 ° C, and the temperature is reacted for 3 hours to obtain phosphorylated polyether modified amino silicone oil;

[0056] Step Three: Neutralization

[0057]After the second step, neutralize the system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com