Highly corrosion-resistant porous metal member

A technology of metal porous bodies and alloys, which is applied in electrode carriers/current collectors, electrolytic capacitors, electrical components, etc., can solve the problems of low strength of stainless steel porous bodies, expensive stainless steel powder, and impractical use, and achieve excellent electrolyte resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

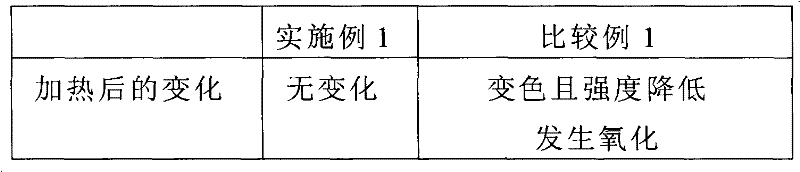

Embodiment 1

[0055] A polyurethane sheet (polyurethane foam) having a thickness of 1.5 mm was used as the porous resin sheet. The surface of the chip was treated by immersing the chip in a mixture of 400 g / L chromium trioxide and 400 g / L sulfuric acid at 60° C. for 1 minute. As a result of the surface treatment, the flakes have an anchoring effect on the conductive coating to be formed, thereby achieving strong adhesion of the flakes to the conductive coating.

[0056] Carbon powder having a particle diameter of 0.01 to 20 μm was dispersed in 80 g of a 10% styrene acrylic synthetic resin aqueous solution to prepare a carbon coating solution.

[0057] The polyurethane sheet is then continuously immersed in the coating solution, squeezed with a roller and then dried to make the polyurethane sheet conductive.

[0058] The polyurethane flakes are then electroplated with nickel-tungsten. The polyurethane portion on the resulting part was removed by heat treatment. Thus a composition with 65%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com