Formula of rubber hose of peroxide vulcanization radiator

A peroxide and radiator technology, applied in the direction of hoses, pipes, pipes/pipe joints/pipe fittings, etc., can solve the requirements that cannot meet the requirements of low pressure change, high temperature resistance, coolant resistance and electrical resistance of automobile radiator hoses , harsh and other issues, to achieve good high temperature resistance and electrical resistance, low pressure denaturation effect

Active Publication Date: 2010-08-25

TIANJIN PENGYI GRP CO LTD

View PDF0 Cites 22 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

With the development of the automobile industry, the radiator hose, one of the important parts of the automobile, has higher and higher requirements for it; the sulfur vulcanization system used in the EPDM radiator hose used in the past can no longer meet the requirements. The requirements for low pressure change, high temperature resistance, coolant resistance and electrical resistance of automobile radiator hoses, so peroxide vulcanized radiator hoses came into being

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

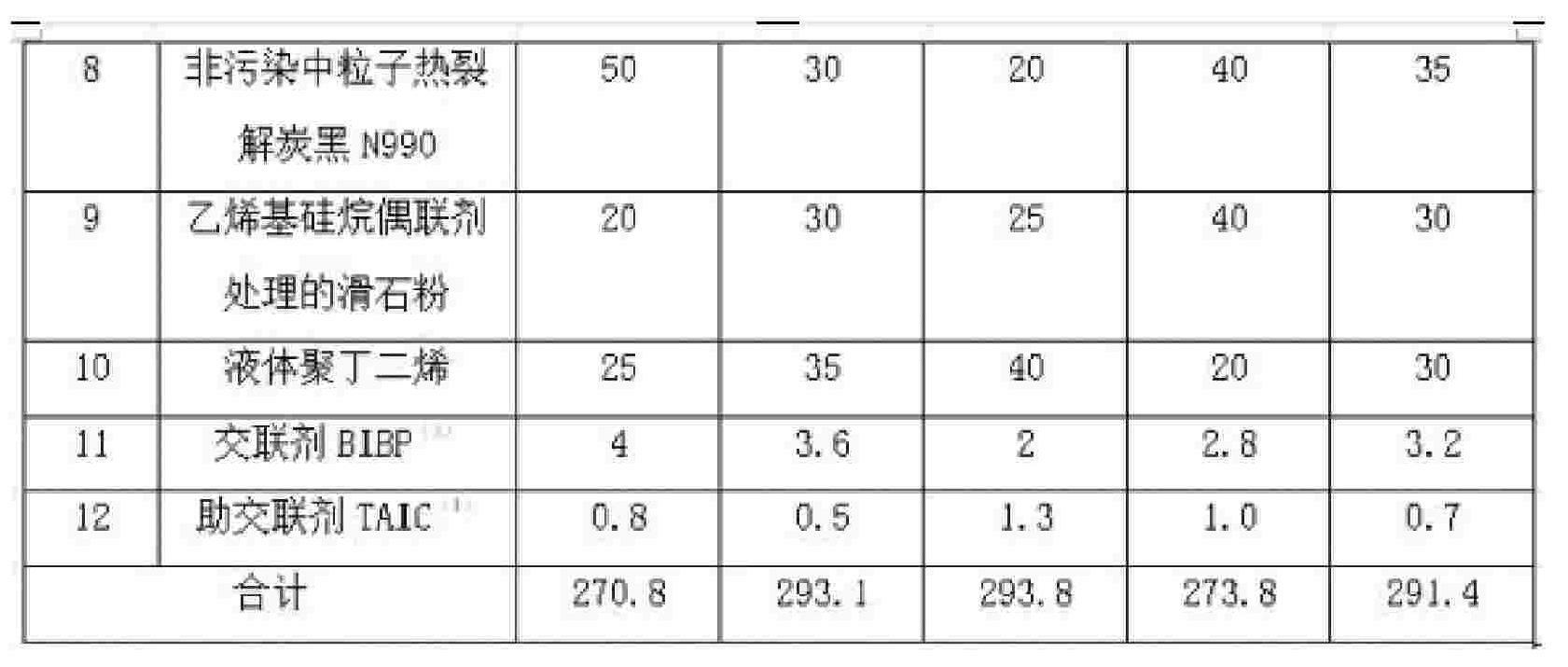

The invention relates to a formula of a rubber hose of a peroxide vulcanization radiator, comprising the following ingredients by weight percent: ternary ethylene propylene rubber 100, zinc oxide 5-15, polyethylene glycol 2-4, stearic acid 0.5-1.5, age resister (445) 0.5-2, age resister MMBZ 0.5-2, fast extruding furnace black (N550) 50-90, non-polluted intermediate-particle thermal black (N990) 20-50, talcum powder treated with vinylsilane coupling agent 20-40, liquid polybutadiene 20-40, crosslinking agent BIBP 2-4 and crosslinking aid TAIC 0.5-1.3.Compared with the rubber hose of a sulphur vulcanization radiator, the rubber hose of the peroxide vulcanization radiator has more excellent heat-resistant and ageing-resistant properties, very good cooling liquid resistant property, electrical insulation property and press deformation property, better meeting the demand of water pipes of traditional radiators for automobiles.

Description

technical field The invention relates to a formula of rubber, in particular to a formula of peroxide vulcanized radiator rubber hose. Background technique Automobile rubber hose refers to the rubber hose products used in the three parts of the chassis, engine and body, which are divided into seven systems: oil transportation, gas transportation, drive, control, brake, radiator and heating and cooling. The role of power transmission. Among them, radiator hose is one of the main products. Automobile radiator hose is one of the main uses of EPDM rubber. With the development of the automobile industry, the radiator hose, one of the important parts of the automobile, has higher and higher requirements for it; the sulfur vulcanization system used in the EPDM radiator hose used in the past can no longer meet the requirements. The requirements for low pressure change, high temperature resistance, coolant resistance and electrical resistance of automobile radiator hoses, so perox...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L23/16C08L71/08C08L47/00C08K13/06C08K3/22C08K5/09C08K3/04C08K9/06C08K3/34C08K5/14C08K5/37C08K5/18F16L11/04

Inventor 张洪起张桂林

Owner TIANJIN PENGYI GRP CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com