Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

467 results about "Polysilane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polysilanes are organosilicon compounds with the formula (R₂Si)ₙ. They are relatives of traditional organic polymers but their backbones are composed of silicon atoms. They exhibit distinctive optical and electrical properties. They are mainly used industrially as precursors to silicon carbide.

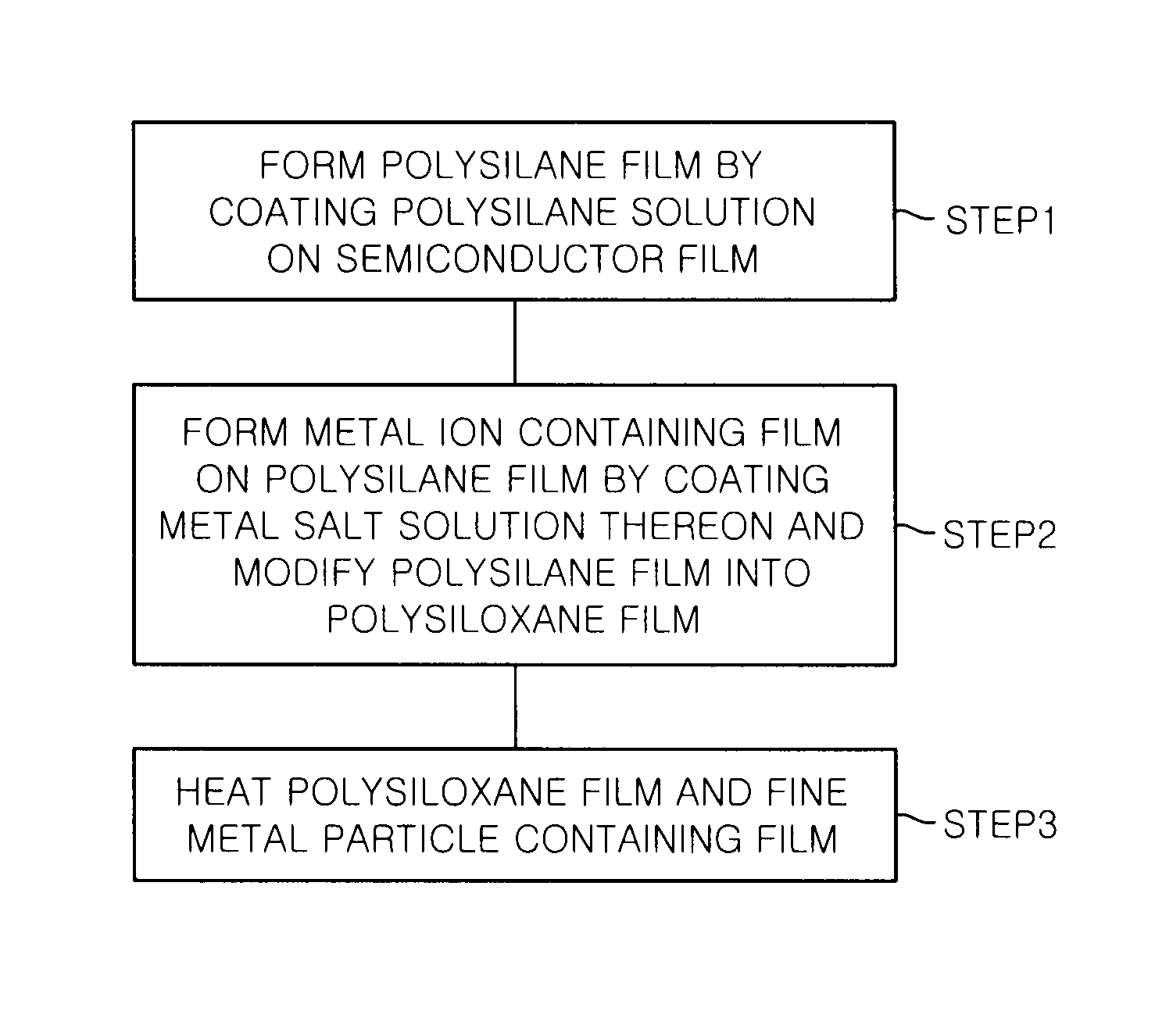

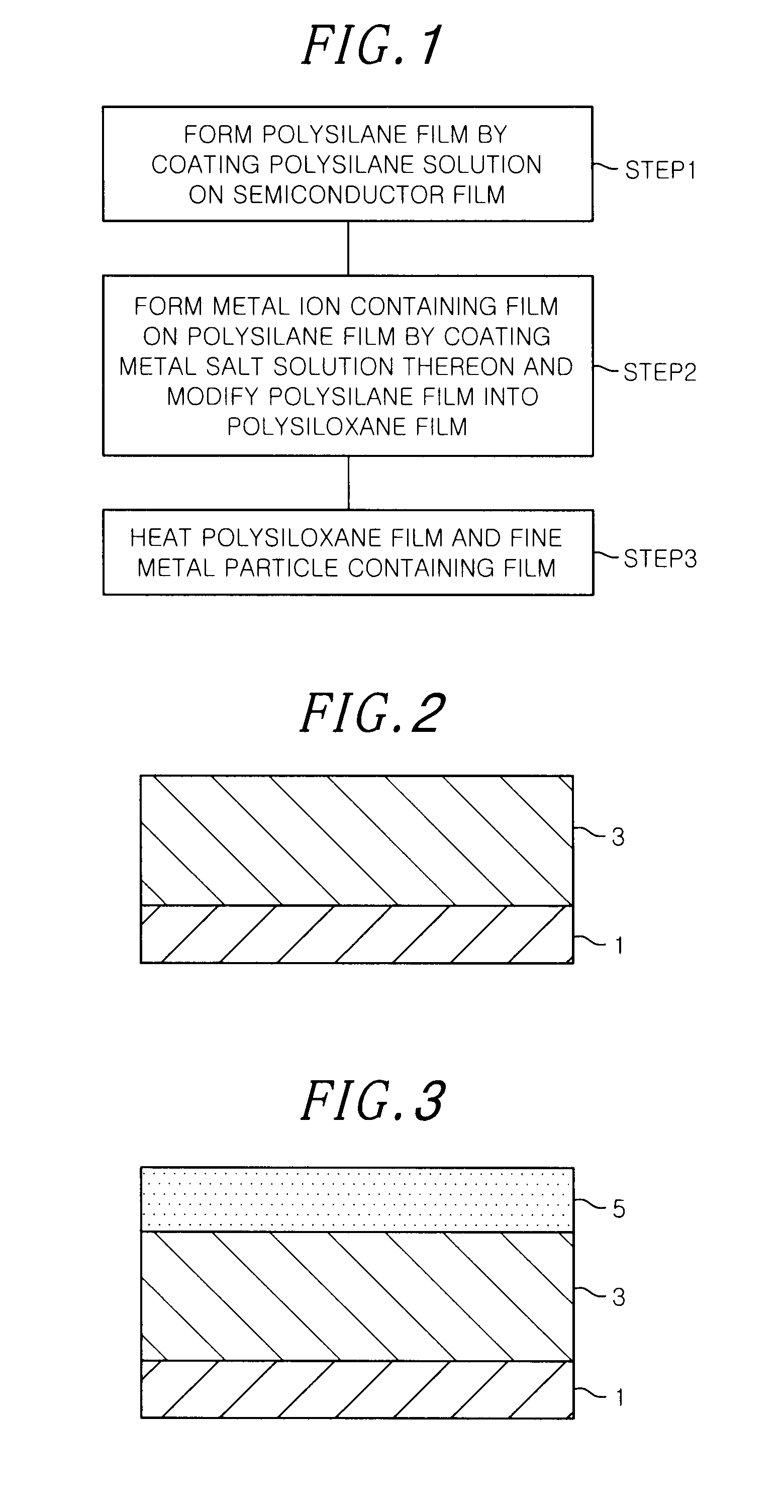

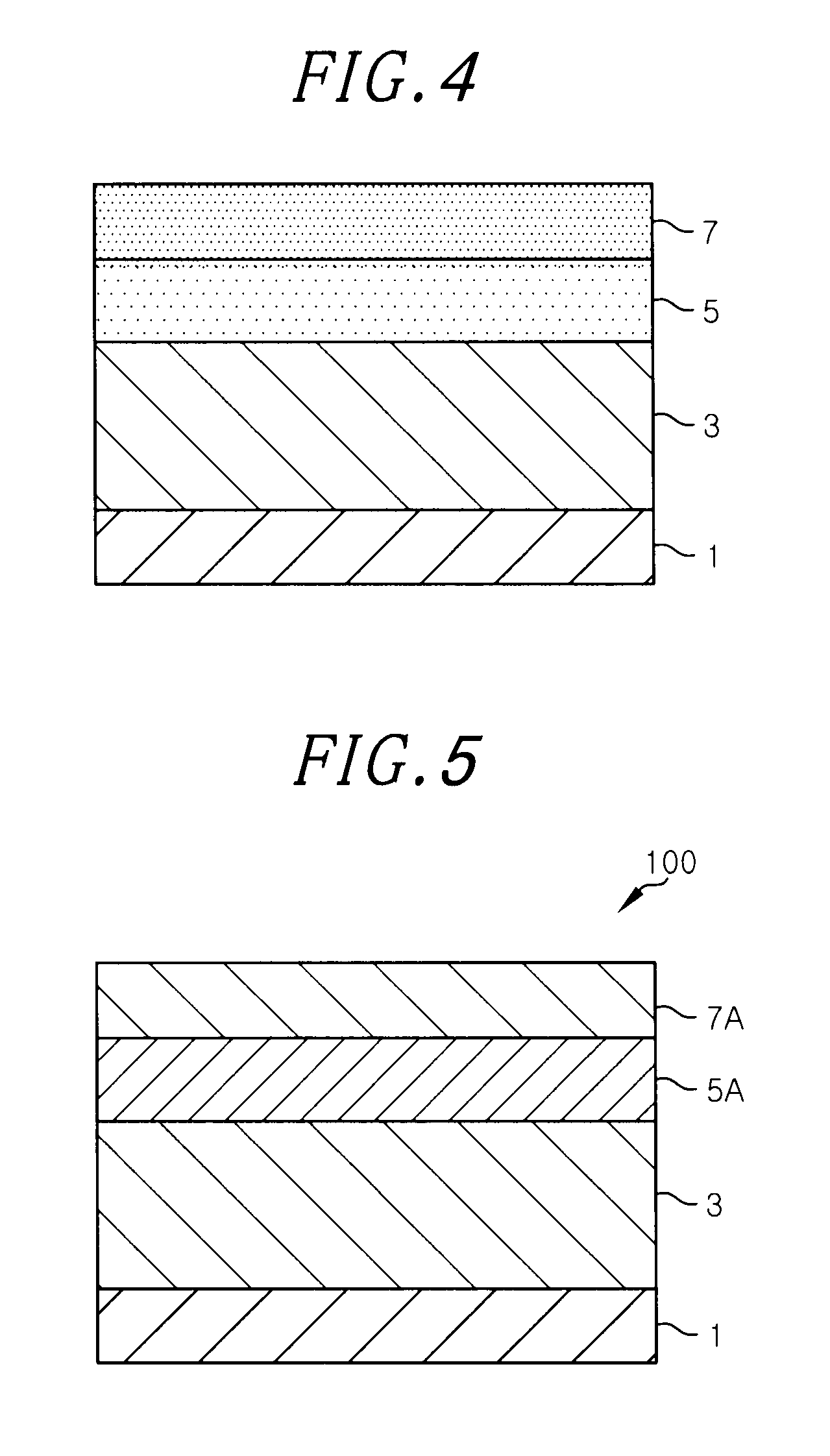

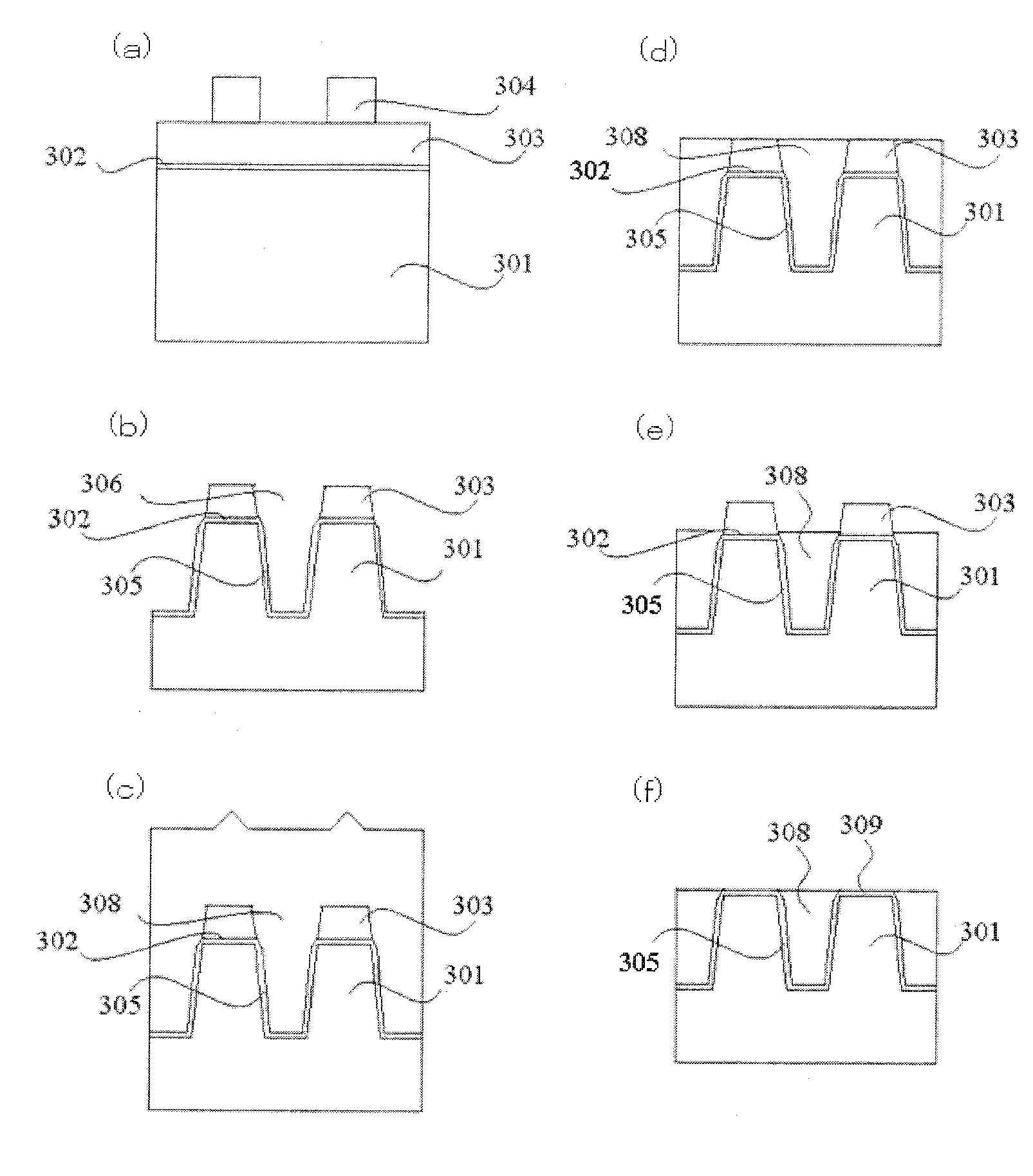

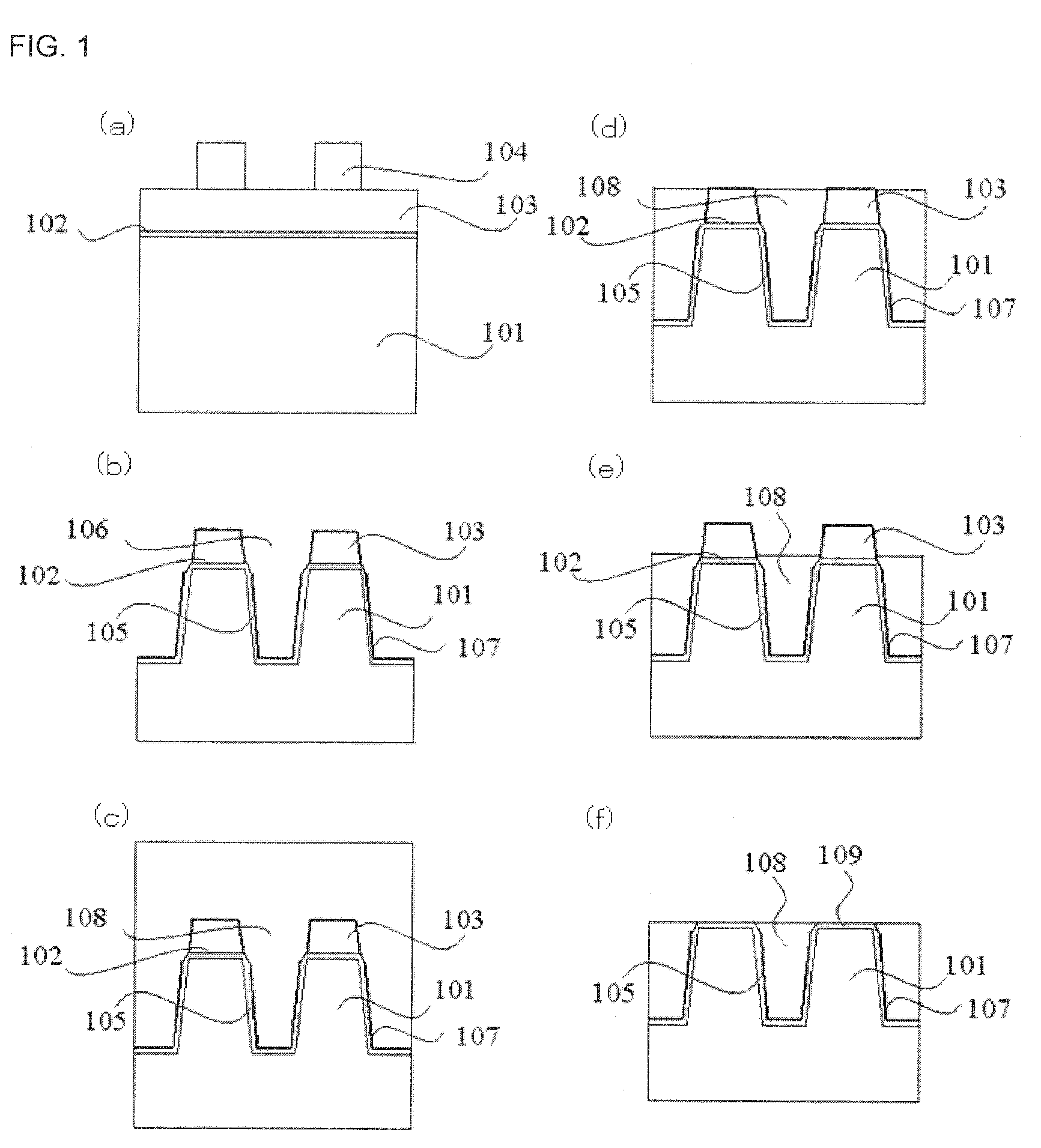

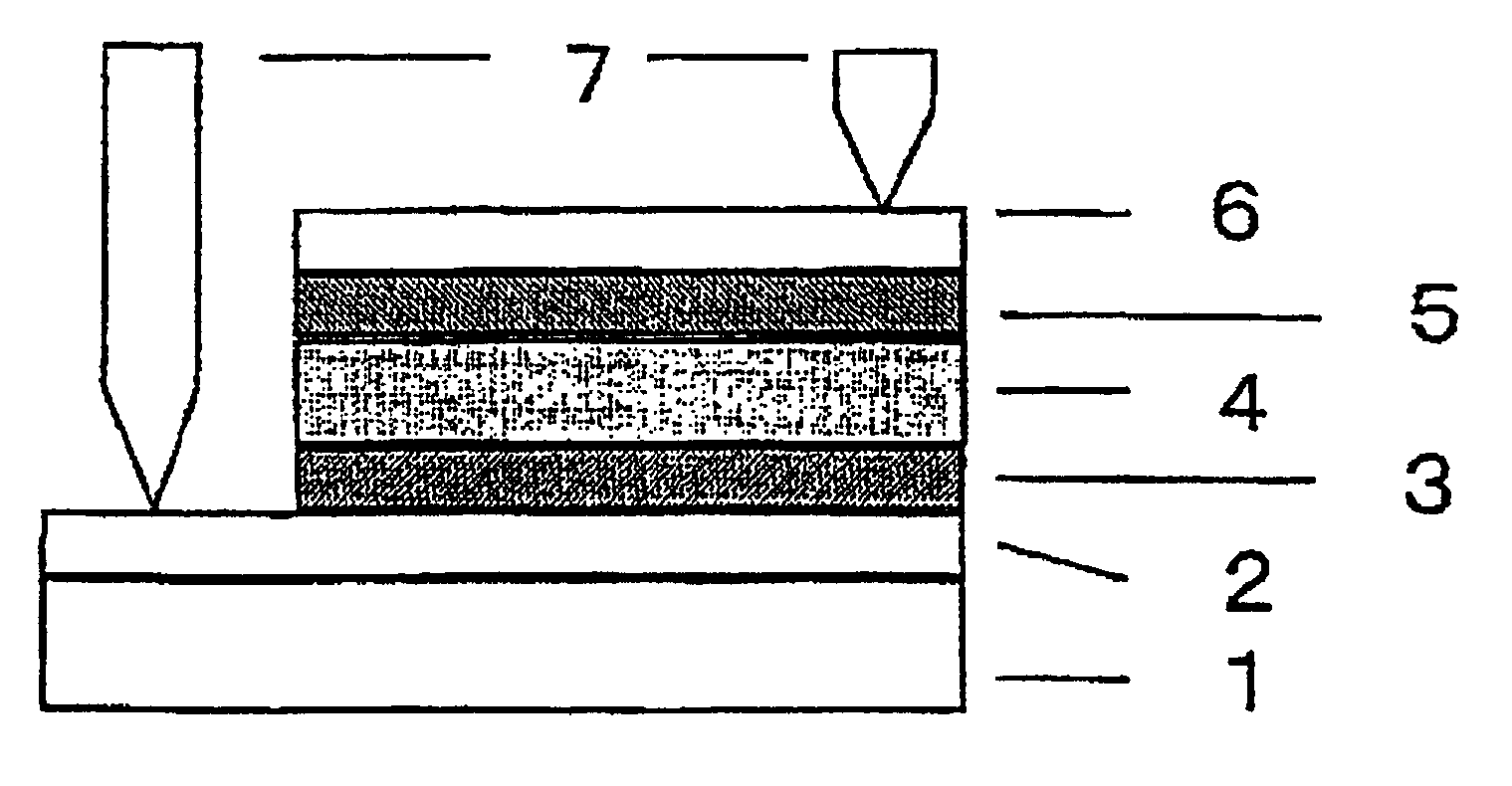

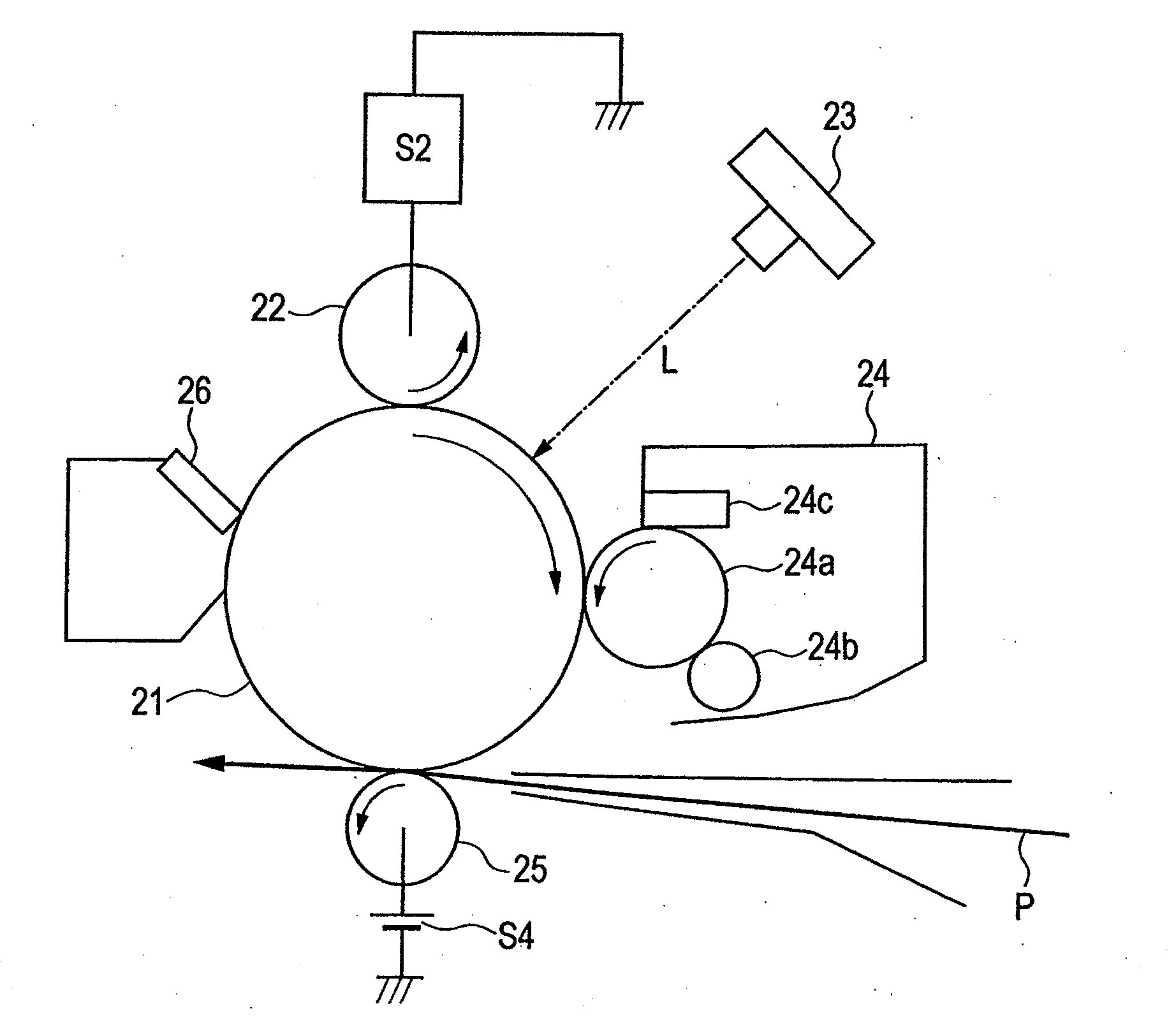

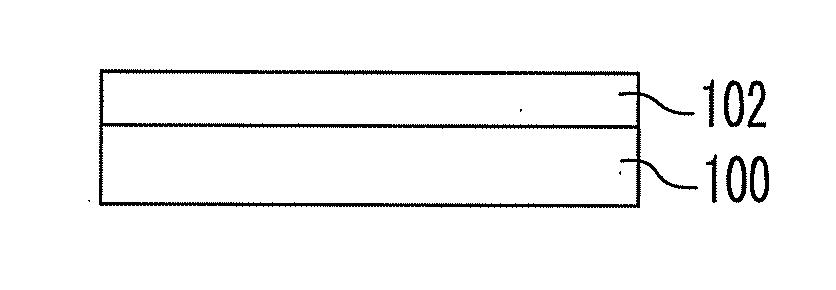

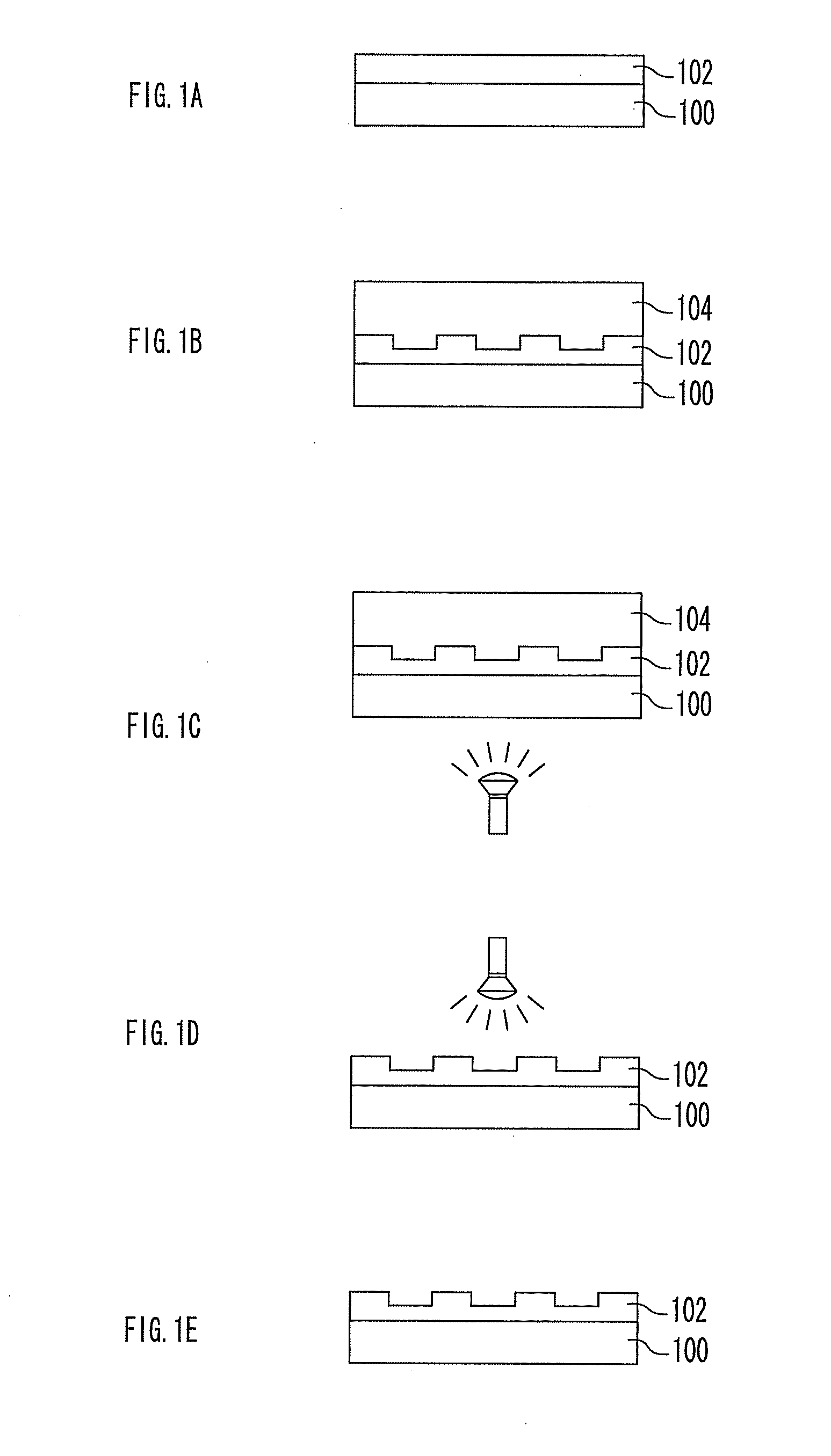

Film forming method, semiconductor device, manufacturing method thereof and substrate processing apparatus therefor

InactiveUS8785311B2Solid-state devicesSemiconductor/solid-state device manufacturingSemiconductor materialsSilanes

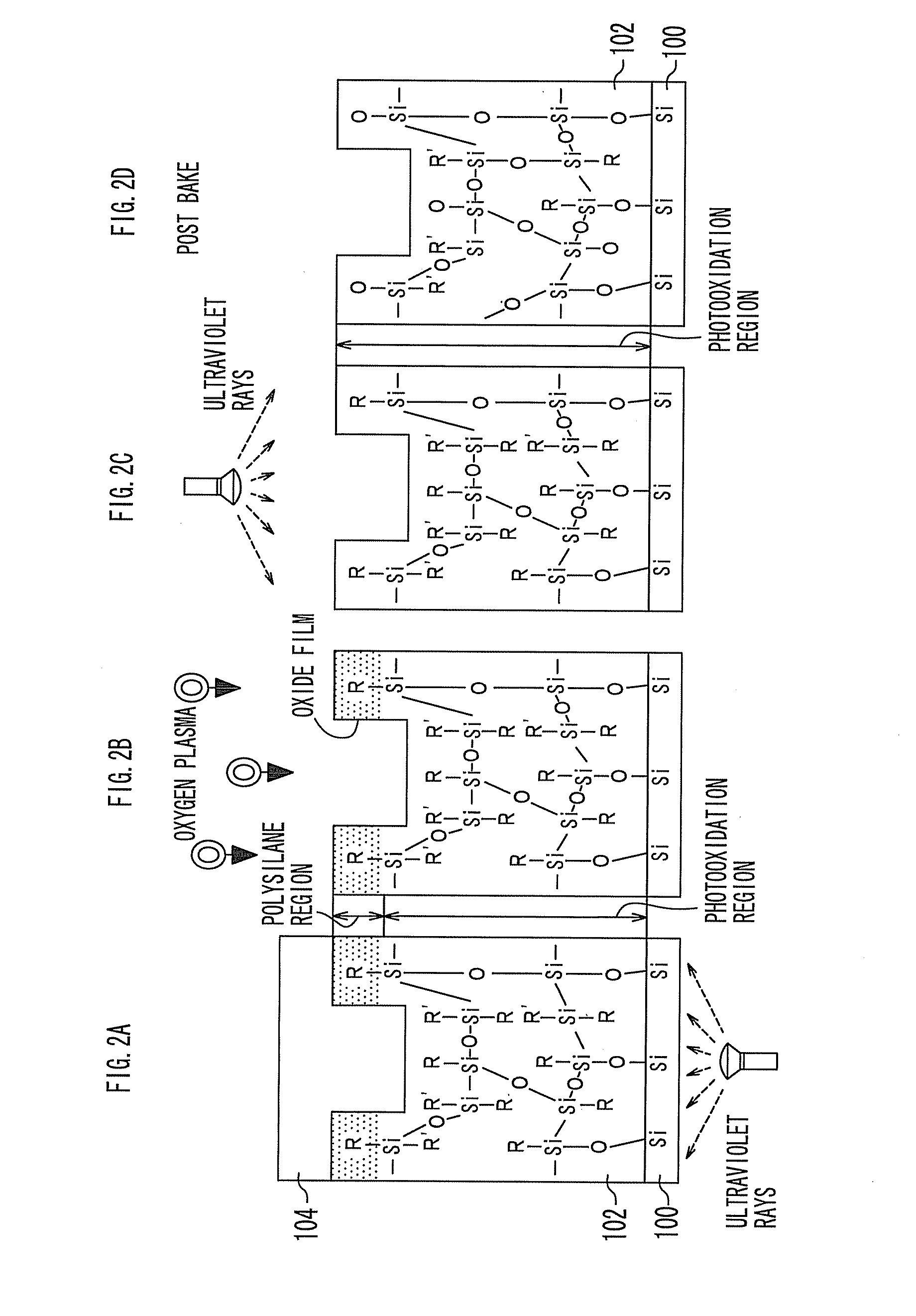

In a method for forming a stacked substrate of a MOS (Metal Oxide Semiconductor) structure including an oxide film serving as a gate insulating film formed on a semiconductor material layer having a film or substrate shape; and a conductive film serving as a gate electrode formed on the oxide film, a polysilane film on the semiconductor material layer is formed by coating a polysilane solution on a surface of a substrate to which the semiconductor material layer is exposed. A film containing metal ions is formed on the polysilane film by coating a metal salt solution thereon, and the polysilane film and the film containing metal ions are respectively modified into a polysiloxane film and a film containing fine metal particles to form the stacked substrate.

Owner:TOKYO ELECTRON LTD

Porous SiC-bodies with micro-channels and process for their fabrication

InactiveUS20060121266A1Large effective internal surface areaImprove filtering effectInternal combustion piston enginesLayered productsParticulatesCellulose

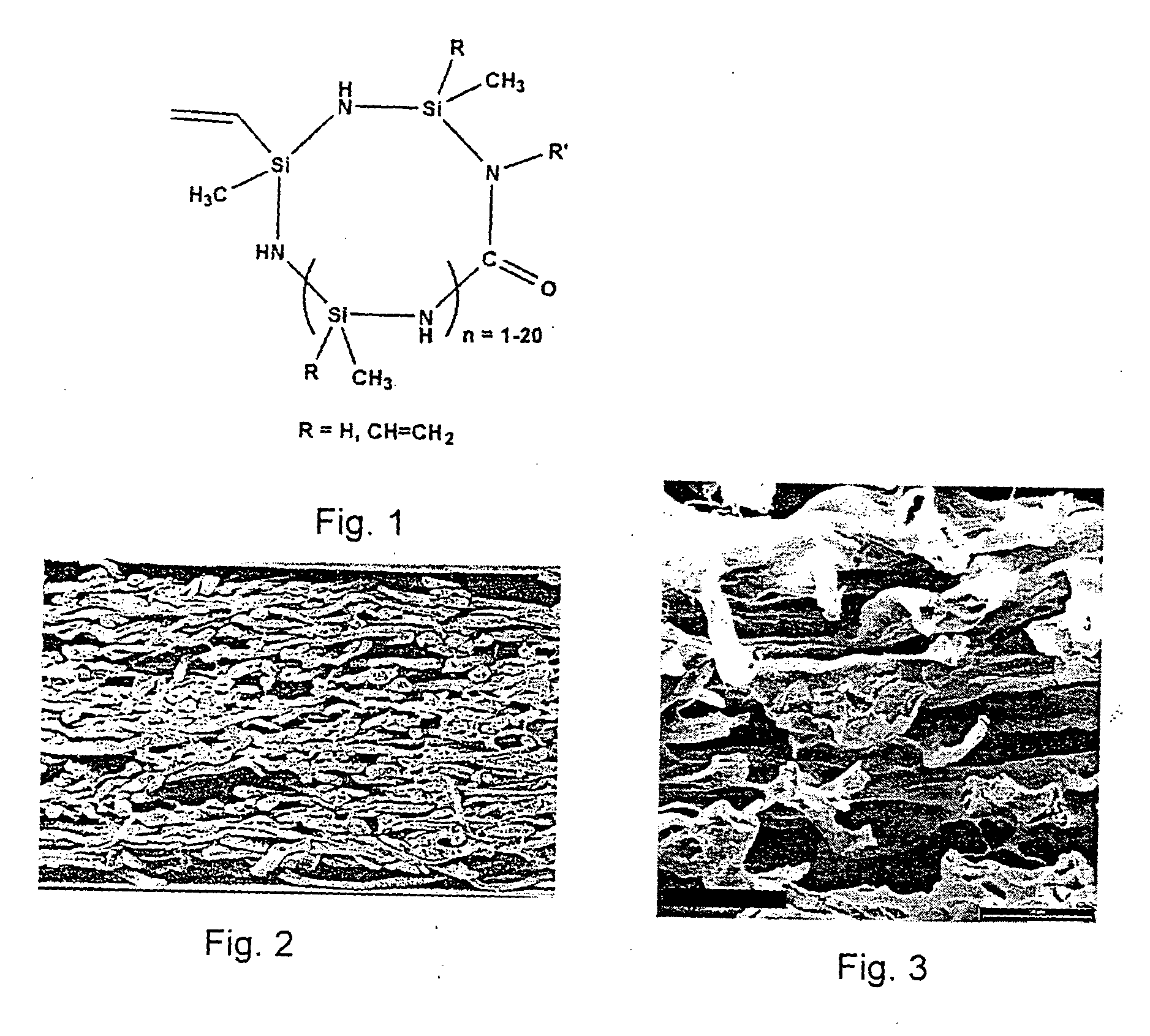

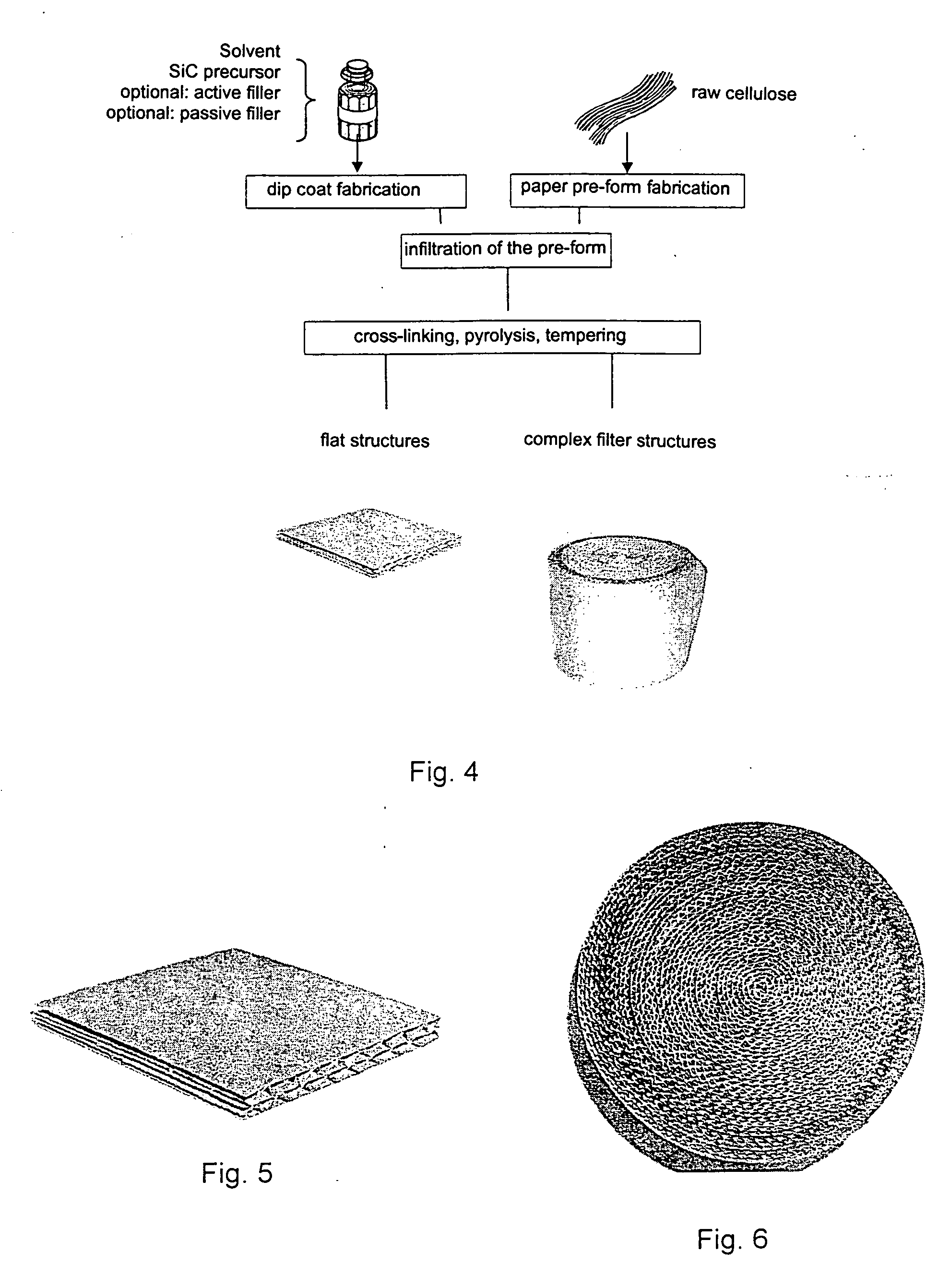

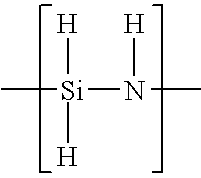

Process for the fabrication of porous bodies mainly constituted by SiC containing ceramic with a microstructure which is interfused with micro-channels which consists of the process steps a) Provision of a pre-body made from cellulose or pulp b) Fabrication of an infiltration solution or a slurry consisting of (A) solvent, polysilazane, polysilane and / or polycarbosilane or (B) solvent, polysilazane and / or polysilane as well as active metallic fillers and / or passive ceramic fillers. c) Infiltrating the body with infiltration solution or slurry d) Cross-linking of the polysilazane, polycarbosilane and / or polysilane while generating a solid green body e) Ceramization through pyrolysis of the green body in an inert-gas atmosphere. f) Removal of residual carbon with an oxidizing thermal process, thereof producible catalyst carriers or carbon particulate filters as well as Porous ceramic which is made from at least 80% SiC in which the porous ceramic features a microstructure with micro-channels consisting mainly of SiC coated micro-channels featuring an average diameter between 1 and 25 μm and webs of SiC located between the micro-channels as well as additional ceramic materials with a content below 20 wt %.

Owner:DAIMLER AG

Polysilane-containing coating solution

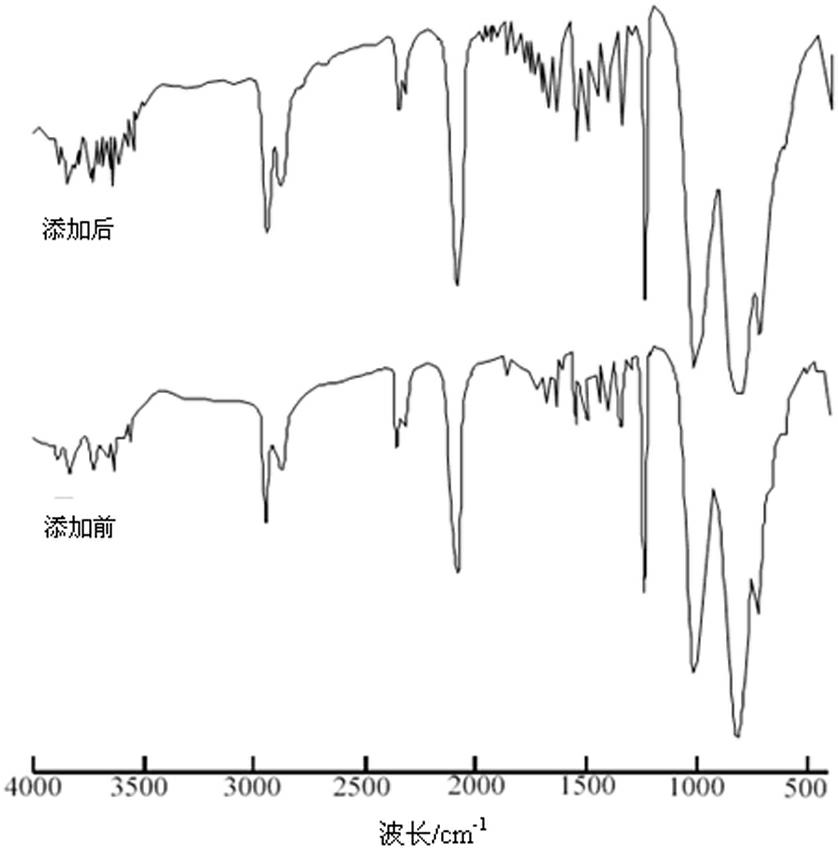

InactiveUS20050279255A1Easy-to-clean propertyLow shrinkageFireproof paintsImpression capsBrickSolvent

A coating solution comprising 0.1 to 35% by weight of an inorganic or organic polysilazane having repeating units represented by the general formula below and soluble in a solvent and 0.1 to 10% by weight of catalyst such as 4,4′-trimethylenebis(1-methylpiperidine) based on a pure polysilazane content. By applying the coating solution onto the surface of base materials such as metals, plastics, glass, ceramic, wood, cement, mortar, bricks, etc., a silica coating strongly adhered to the base materials can be formed excellent in corrosion resistance and anti-scratch properties and simultaneously excellent in characteristics such as abrasion resistant, long-lasting anti-fouling properties, wetting properties to water, sealing properties, chemical resistance, oxidation resistance, physical barrier effect, heat resistance, fire resistance and antistatic properties.

Owner:CLARIANT INT LTD

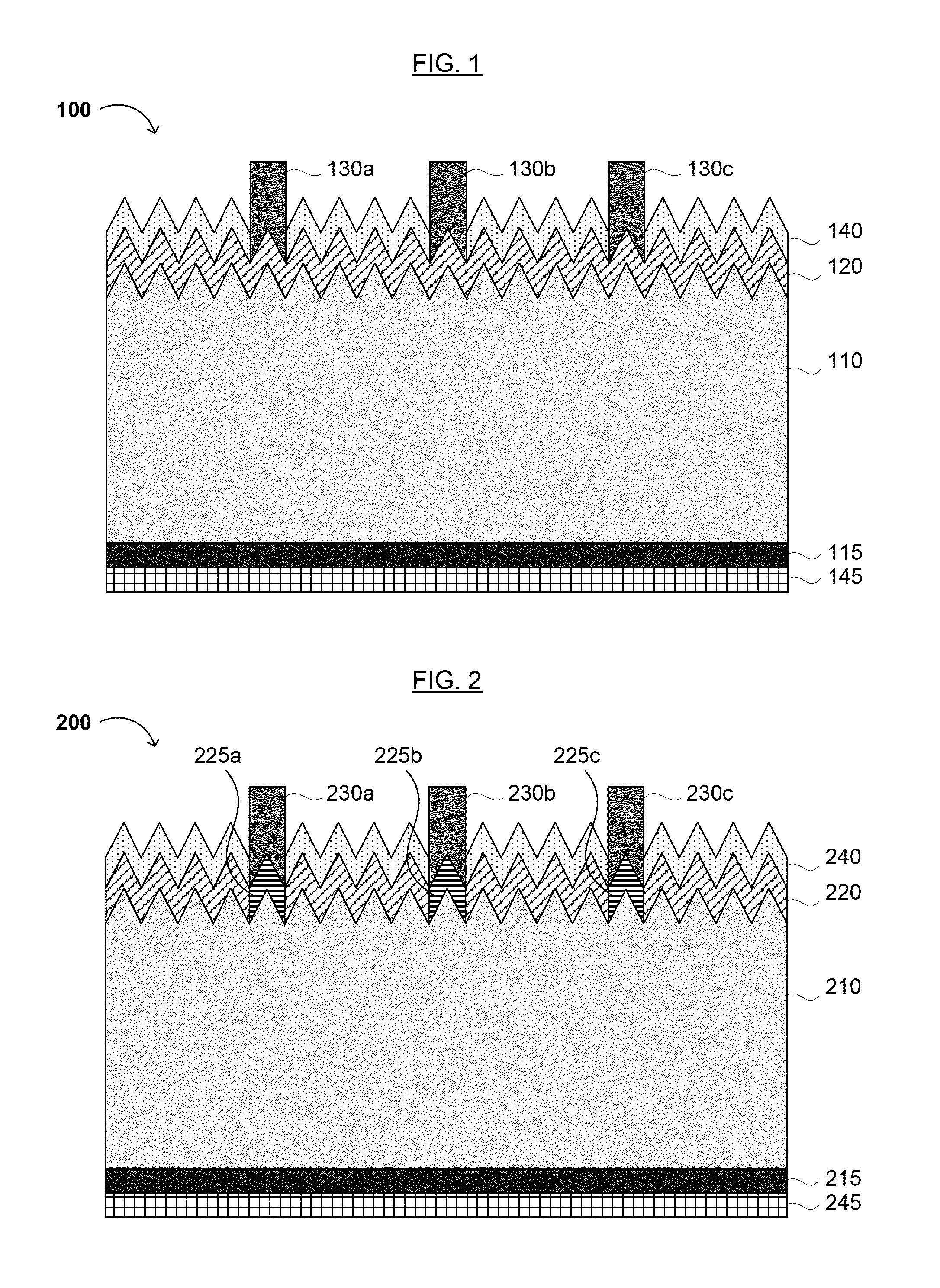

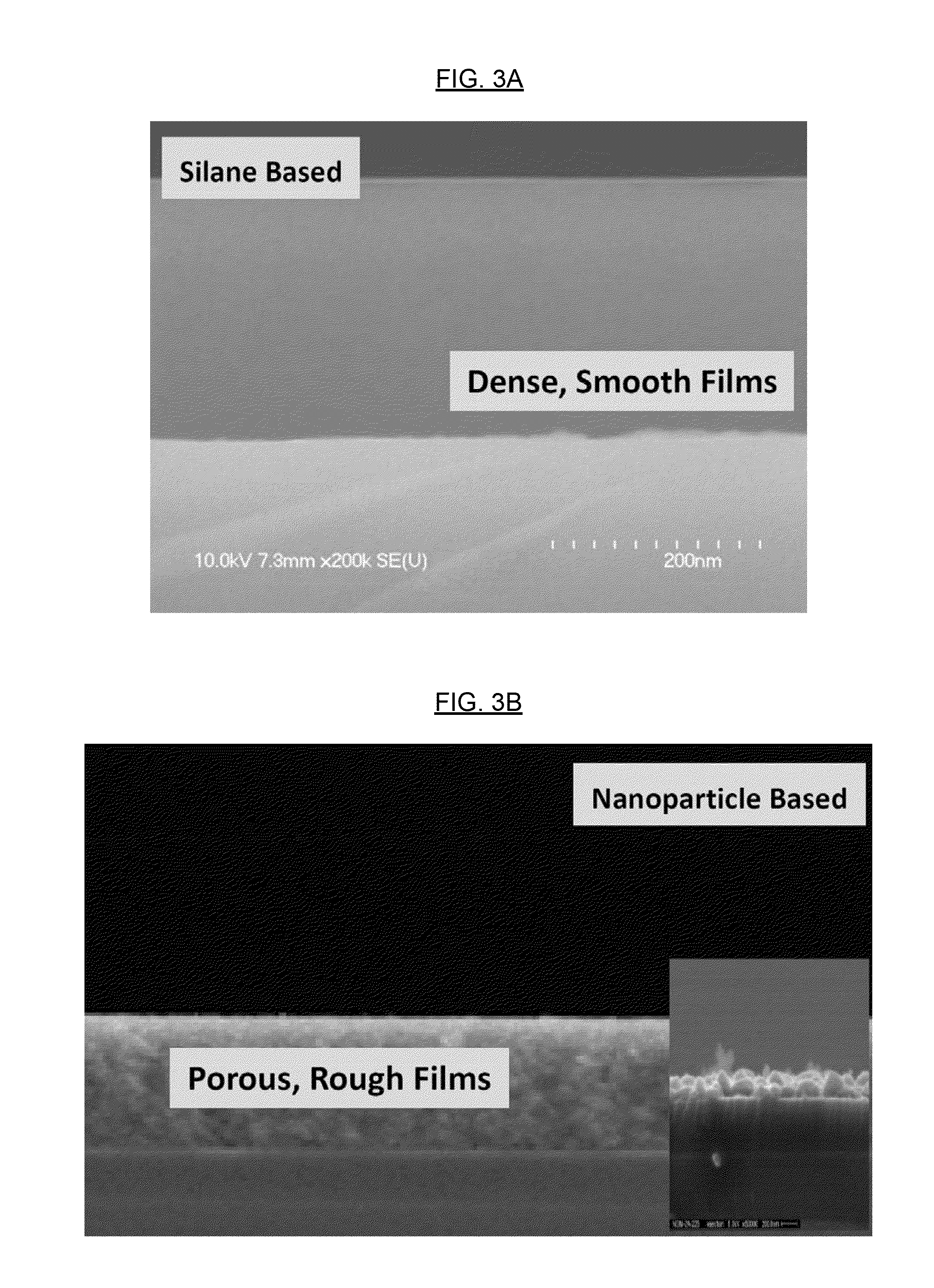

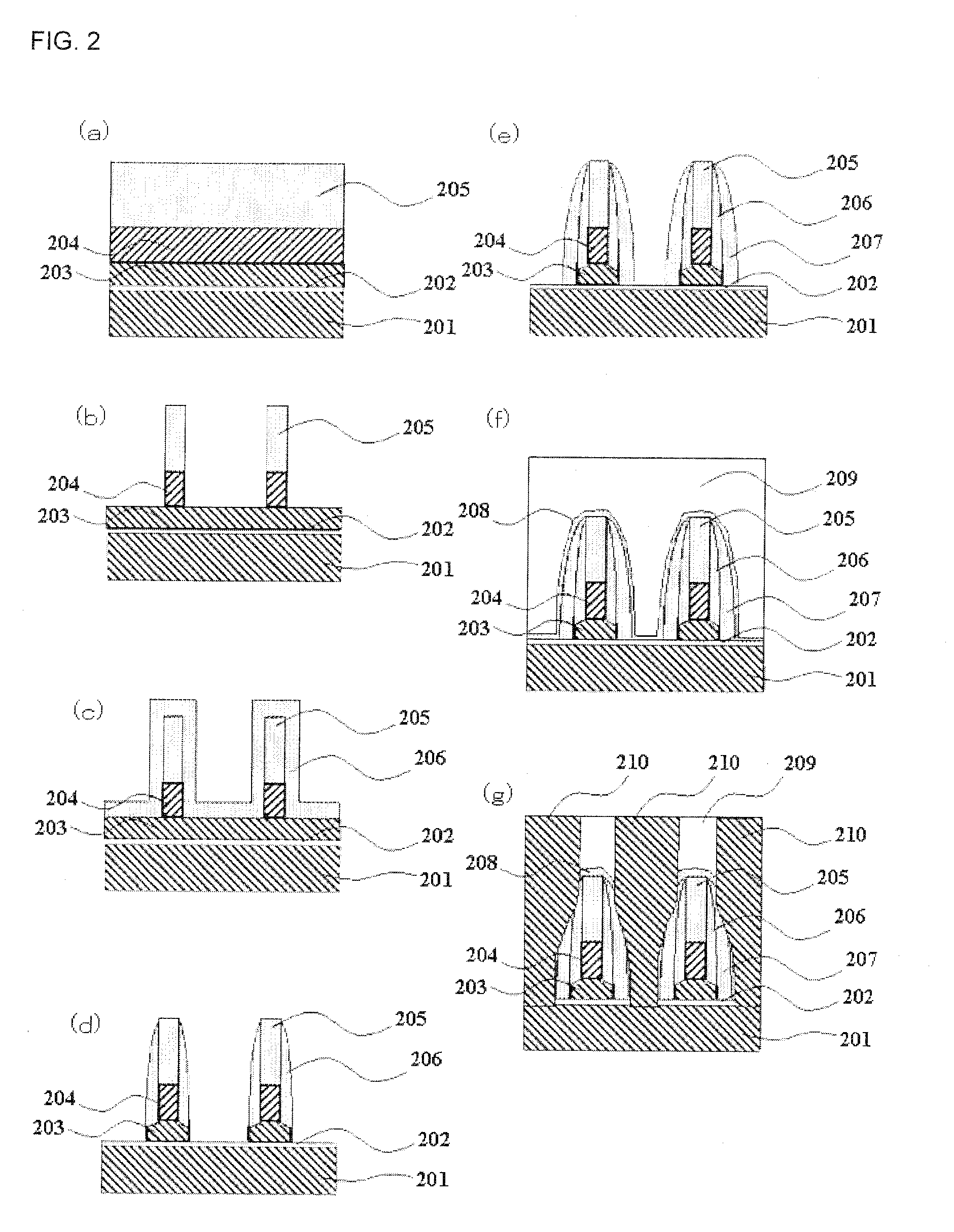

Epitaxial Structures, Methods of Forming the Same, and Devices Including the Same

ActiveUS20110240997A1Wide particle size distributionSintering property becomes poorFinal product manufactureSemiconductor/solid-state device manufacturingOptoelectronicsSubstrate surface

Epitaxial structures, methods of making epitaxial structures, and devices incorporating such epitaxial structures are disclosed. The methods and the structures employ a liquid-phase Group IVA semiconductor element precursor ink (e.g., including a cyclo- and / or polysilane) and have a relatively good film quality (e.g., texture, density and / or purity). The Group IVA semiconductor element precursor ink forms an epitaxial film or feature when deposited on a (poly)crystalline substrate surface and heated sufficiently for the Group IVA semiconductor precursor film or feature to adopt the (poly)crystalline structure of the substrate surface. Devices incorporating a selective emitter that includes the present epitaxial structure may exhibit improved power conversion efficiency relative to a device having a selective emitter made without such a structure due to the improved film quality and / or the perfect interface formed in regions between the epitaxial film and contacts formed on the film.

Owner:ENSURGE MICROPOWER ASA

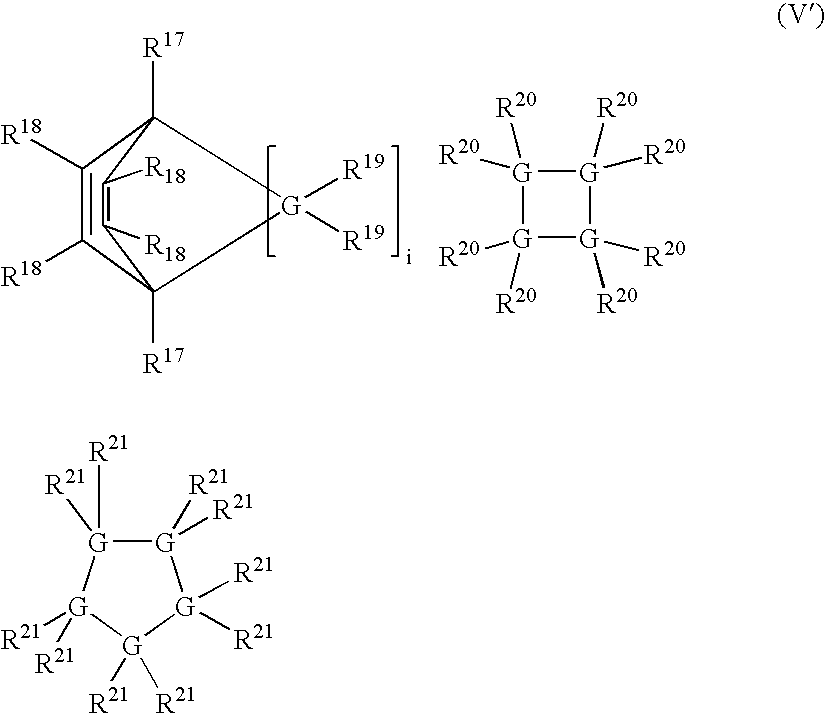

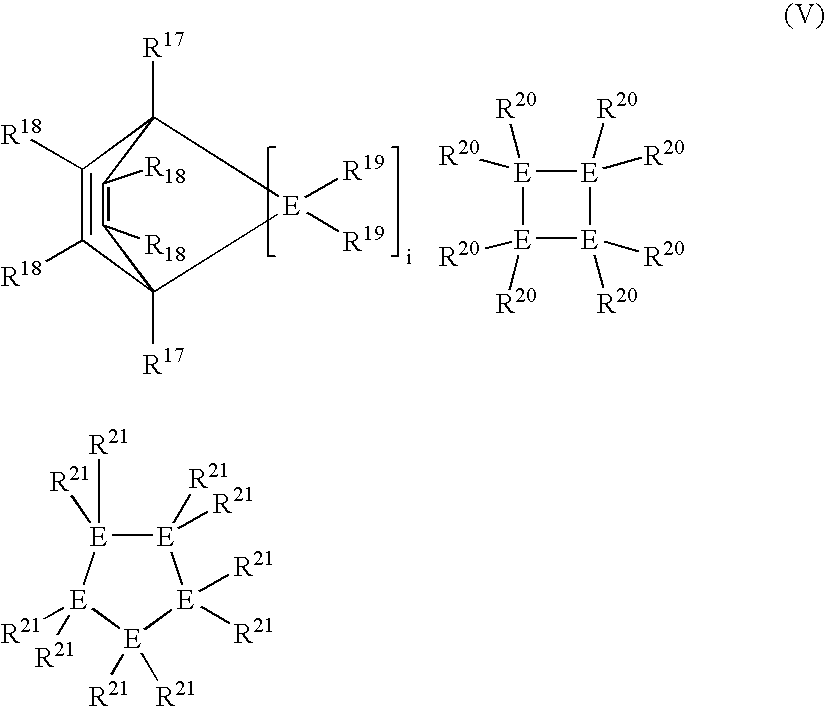

Linear and cross-linked high molecular weight polysilanes, polygermanes, and copolymers thereof, compositions containing the same, and methods of making and using such compounds and compositions

Methods are disclosed of making linear and cross-linked, HMW (high molecular weight) polysilanes and polygermanes, polyperhydrosilanes and polyperhydrogermanes, functional liquids containing the same, and methods of using the liquids in a range of desirable applications. The silane and germane polymers are generally composed of chains of Si and / or Ge substituted with R′ substituents, where each instance of R′ is, for example, independently hydrogen, halogen, alkenyl, alkynyl, hydrocarbyl, aromatic hydrocarbyl, heterocyclic aromatic hydrocarbyl, SiR″3, GeR″3, PR″2, OR″, NR″2, or SR″; where each instance of R″ is independently hydrogen or hydrocarbyl. The cross-linked polymers can be synthesized by dehalogenative coupling or dehydrocoupling. The linear polymers can be synthesized by ring-opening polymerization. The polymers can be further modified by halogenation and / or reaction with the source of hydride to furnish perhydrosilane and perhydrogermane polymers, which are used in liquid ink formulations. The synthesis allows for tuning of the liquid properties (e.g., viscosity, volatility, and surface tension). The liquids can be used for deposition of films and bodies by spincoating, inkjetting, dropcasting, etc., with or without the use of UV irradiation. The deposited films can be converted into amorphous and polycrystalline silicon or germanium, and silicon or germanium oxide or nitride by curing at 400-600 DEG C. and (optionally) laser- or heat-induced crystallization (and / or dopant activation, when dopant is present).

Owner:ENSURGE MICROPOWER ASA

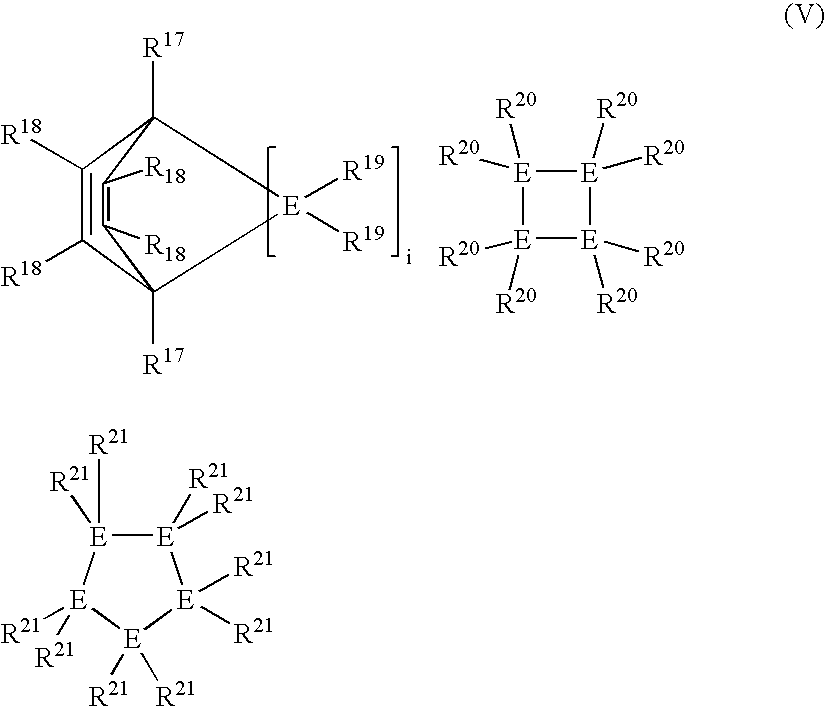

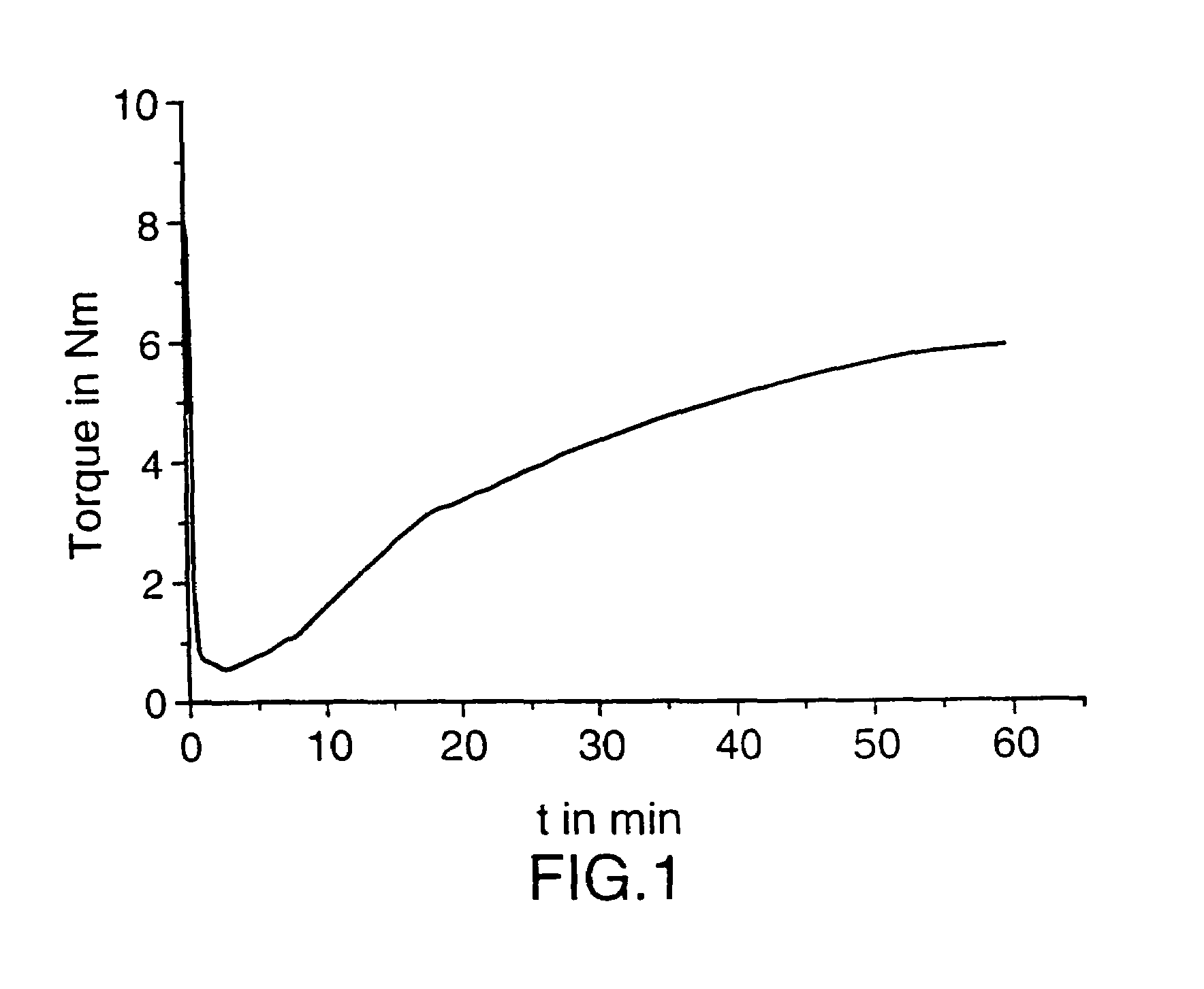

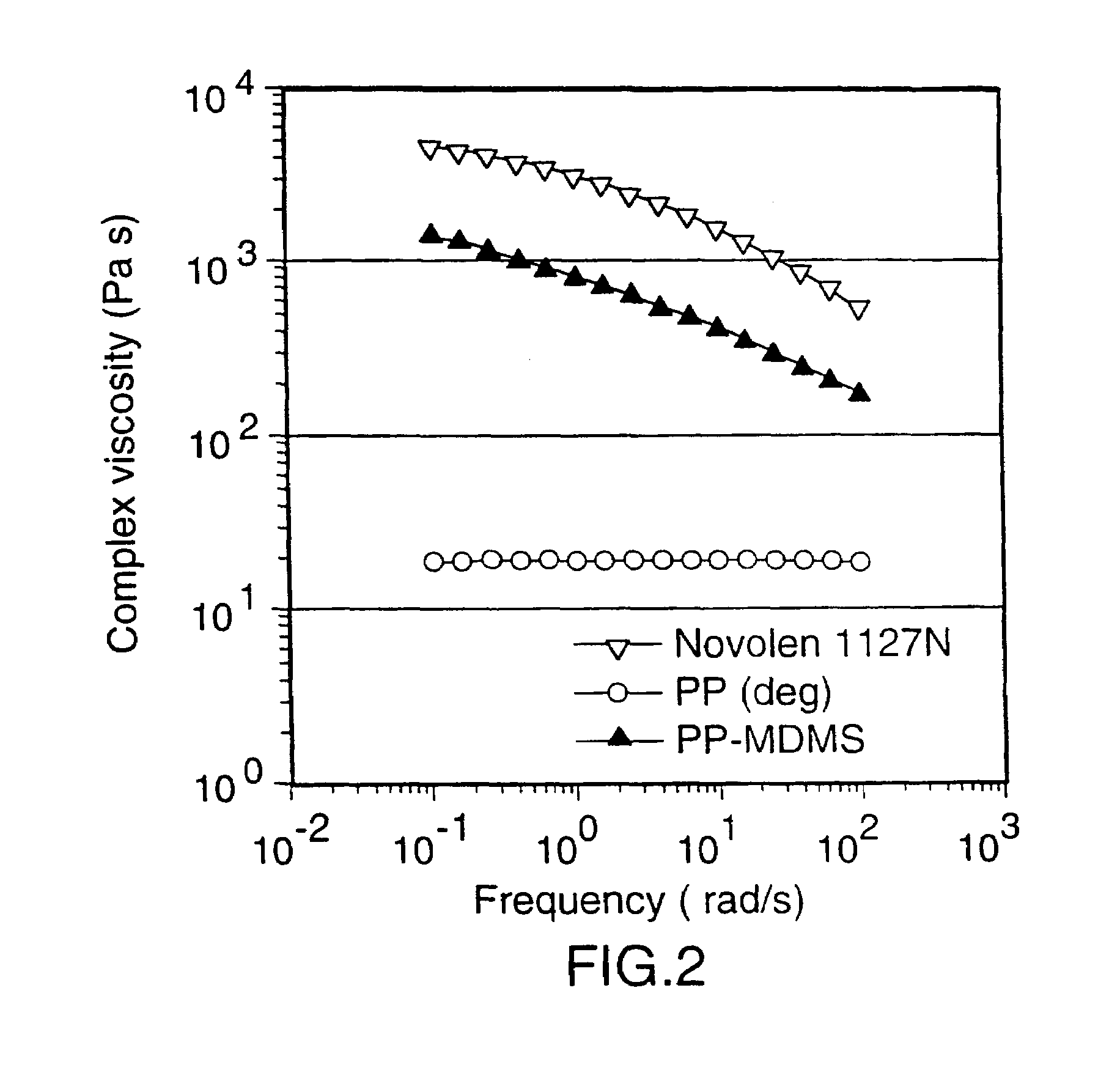

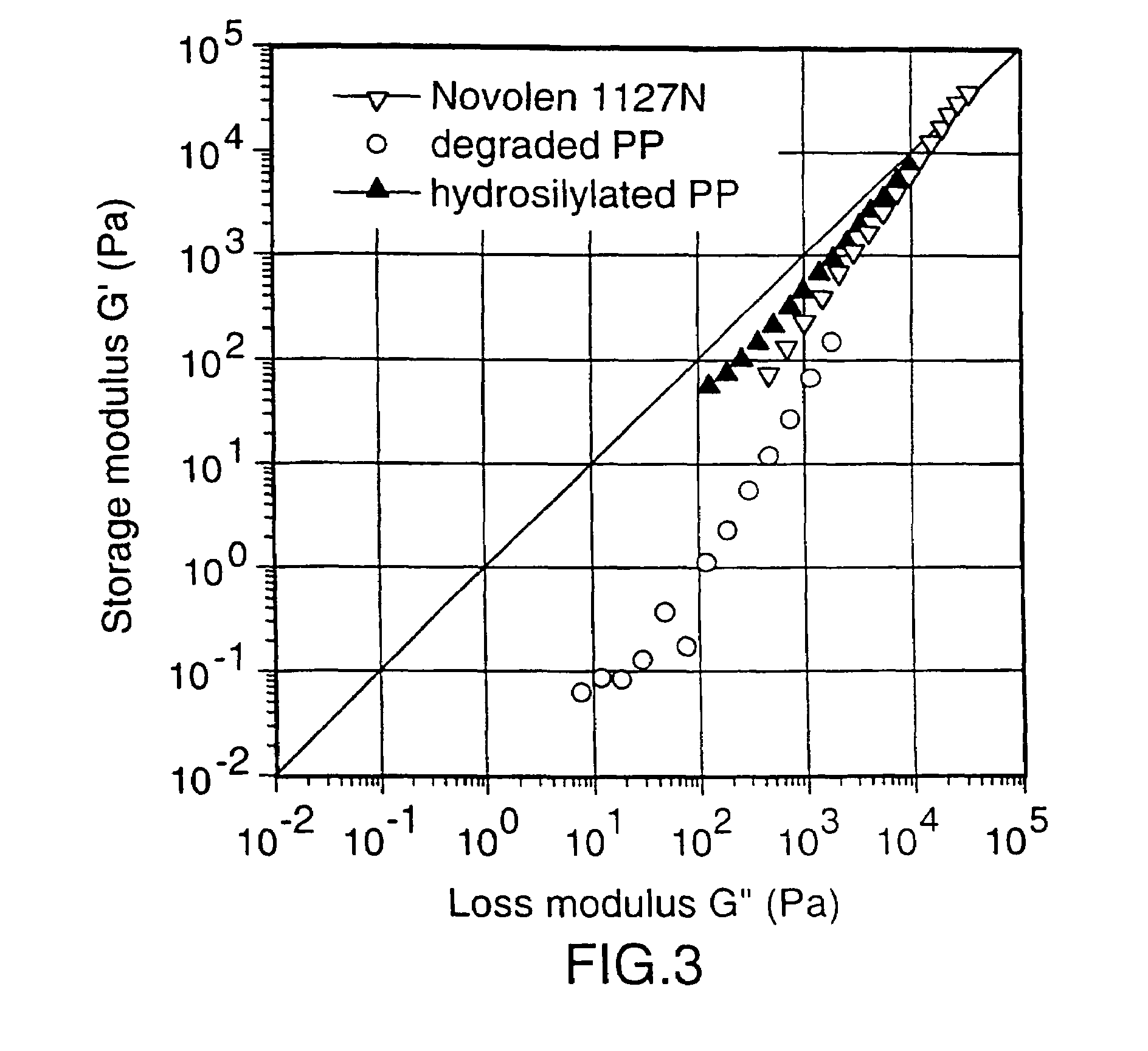

Melt phase hydrosilylation of polypropylene

InactiveUS7247385B1Synthetic resin layered productsChemical/physical/physico-chemical stationary reactorsHydrosilylationPolypropylene

Branched copolymers of polypropylene (PP) and polysilanes are prepared by procedures involving melt phase hydrosilylation. Such branched copolymers may be formed in situ during the melt phase hydrosilylation or may be prepared by subsequent processing. The branched copolymers exhibit superior properties.

Owner:UNIVERSITY OF WATERLOO

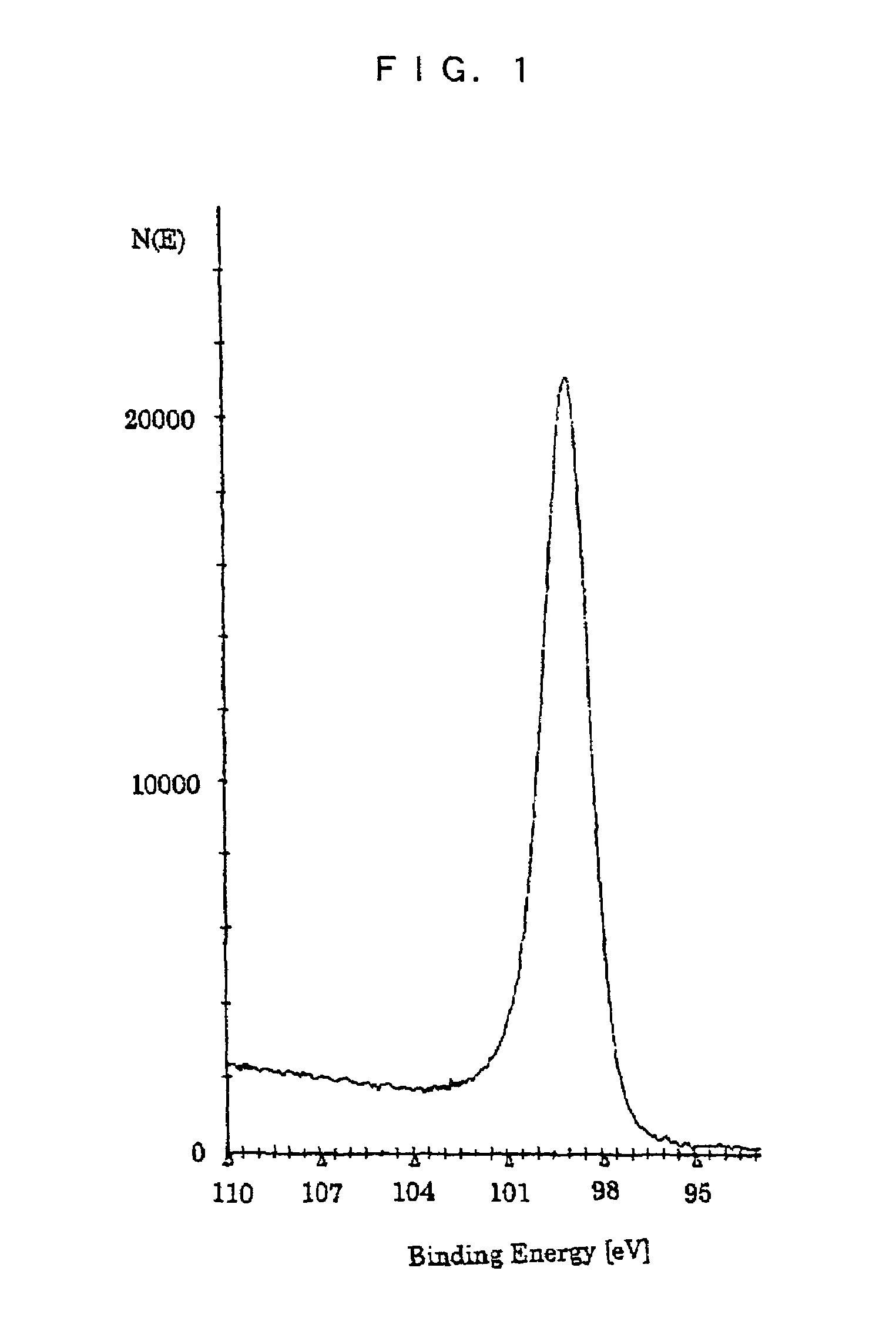

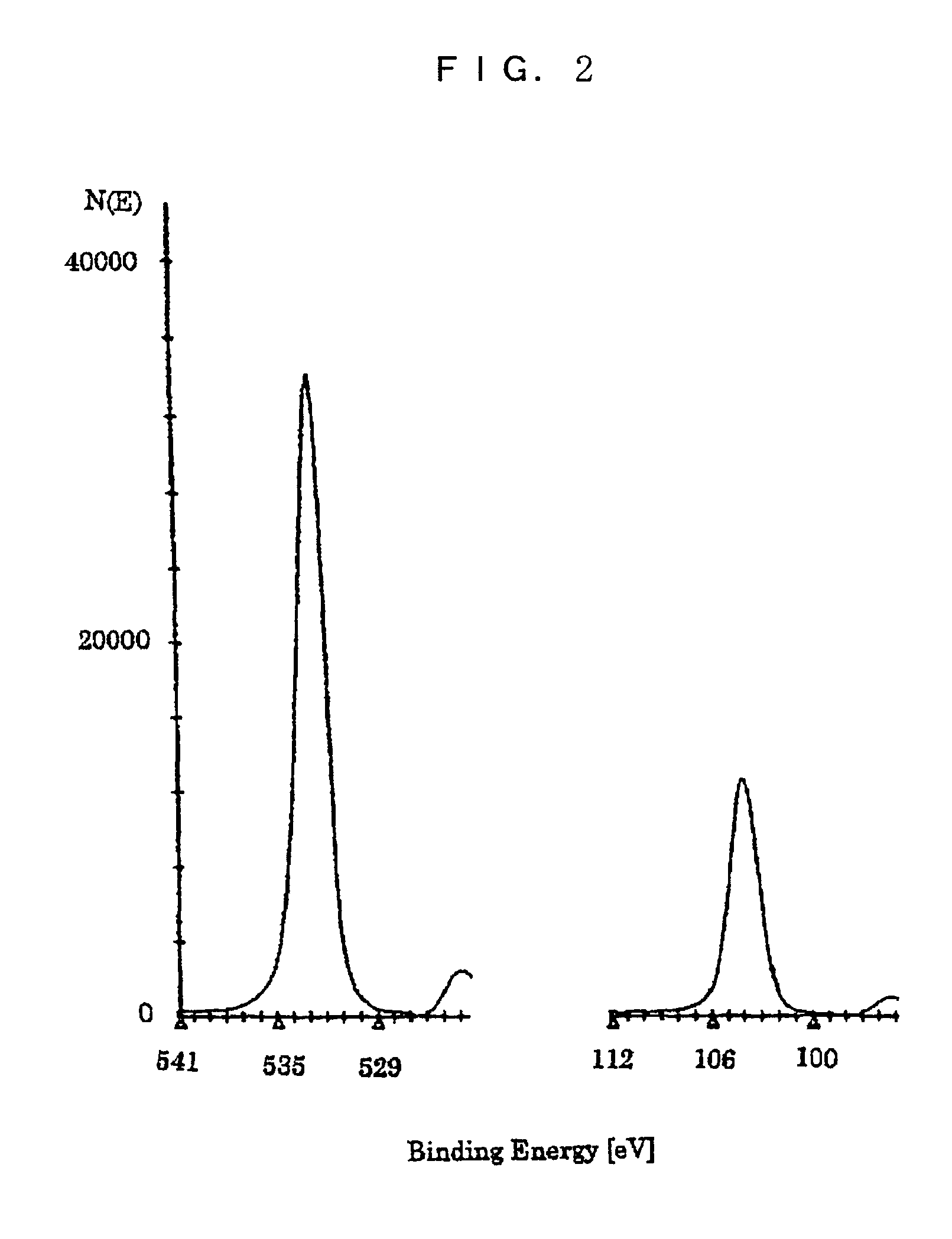

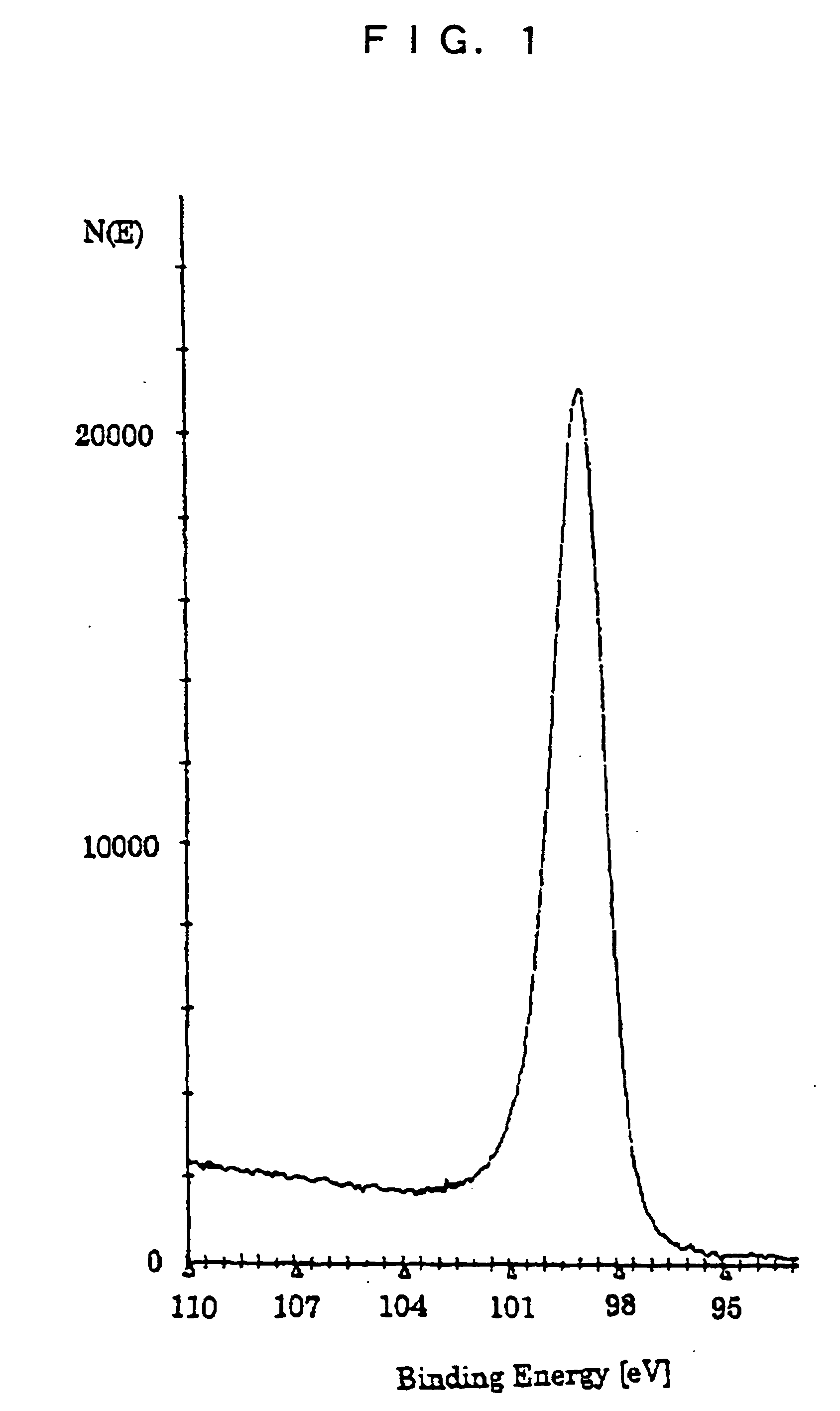

Process for the formation of silicon oxide films

InactiveUS6517911B1Well formedRadiation applicationsVacuum evaporation coatingDielectricHydrogen atom

There is provided a process for forming a silicon oxide film which is useful as an electrical insulating film, dielectric film or protective film as used in LSI, thin-film transistor, photoelectric converter, photosensitive body and the like. The process comprises forming a coating film from a polysilane compound represented by the formula SinRm (wherein n is an integer of 3 or more, m is an integer of n to 2n+2, and a plurality of R's are independently a hydrogen atom or an alkyl group) and oxidizing the coating film to form the silicon oxide film.

Owner:JSR CORPORATIOON

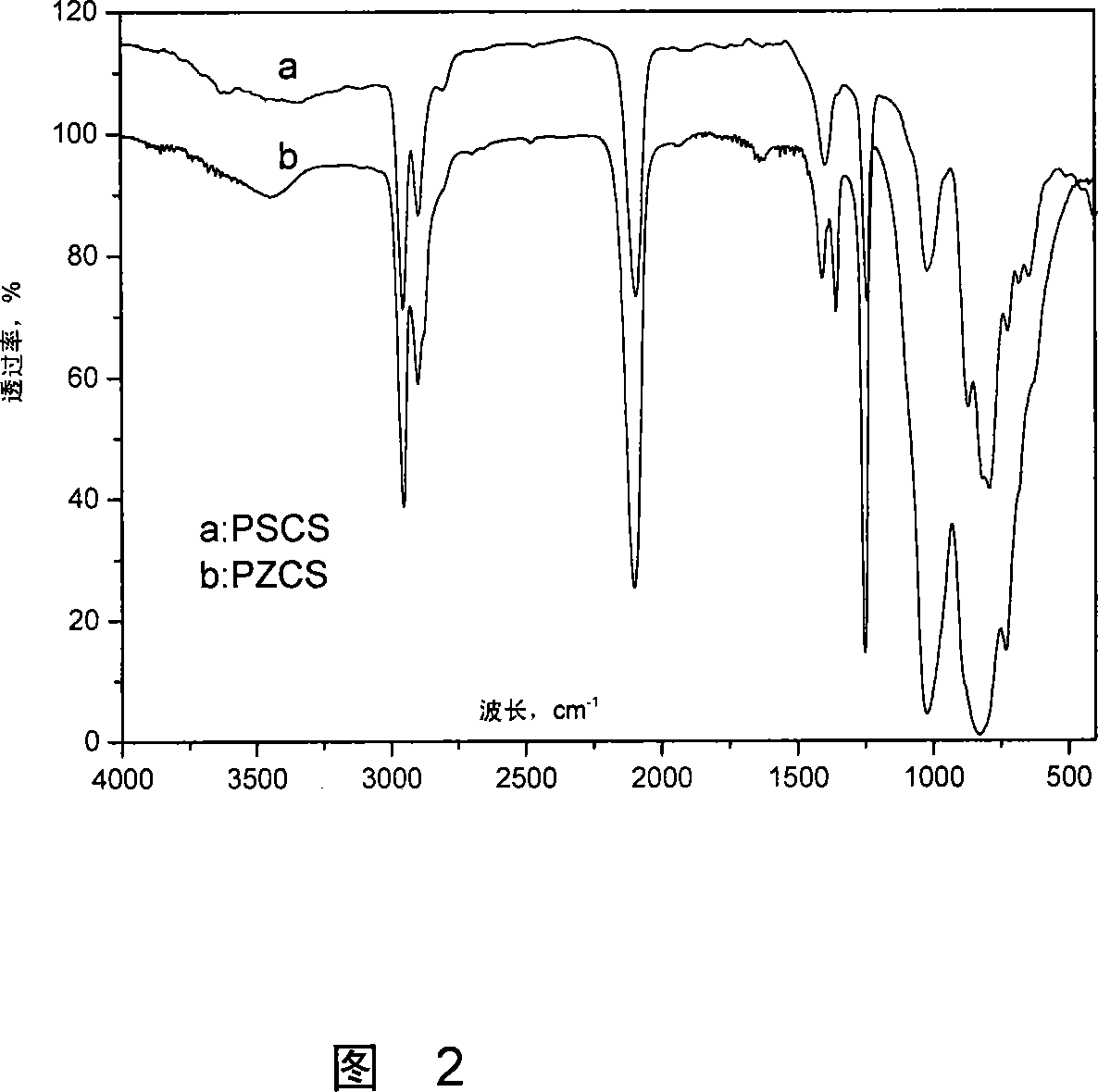

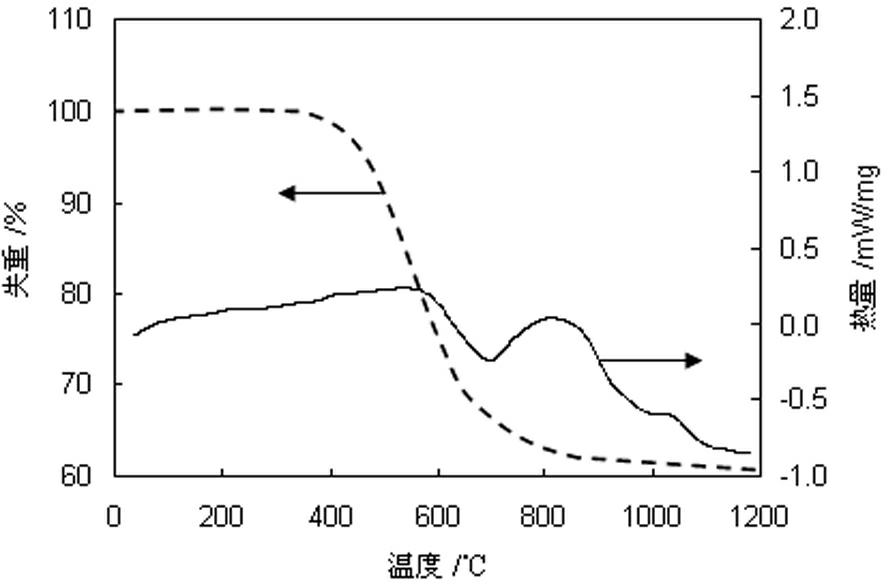

Method and equipment for preparing precursor body of poly carbon silane ceramics of containing zirconium

This invention discloses method and apparatus for preparing polycarbosilane ceramic precursor containing Zr. The method comprises: utilizing low molecular weight polymer with S-H bonds (polysilane, polycarbosilane or poly(dimethyl silane)) as the raw material, organic metallic compound containing Zr as the additive, and Ar, N2 or their mixture as the protective atmosphere, and pyrolyzing at high temperatures and normal pressure to obtain Zr-containing SiC ceramic precursor PZCS. The pyrolysis apparatus comprises a three-necked flask in the heater, a pyrolysis column in the electric heating jacket, a condensing tube, a separatory funnel, and a vacuum system seam. The method is simple, and can control the content and properties of Zr in the precursor and the ceramic. The product has such advantages as high purity, high remoldability, and high heat resistance.

Owner:NAT UNIV OF DEFENSE TECH

Coating composition for forming oxide film and method for producing semiconductor device using the same

InactiveUS20080305611A1Increase ratingsSuppress the volume expansion coefficientSemiconductor/solid-state device manufacturingCoatingsDielectricPolysilane

A coating composition for forming an oxide film, which can suppress the phenomenon of an increased wet etching rate caused by a part of the SOG film embedded inside a groove becoming low-density, and which can suppress the volume expansion coefficient to a low level, and a method for producing a semiconductor device using the same are provided. An oxide film is formed inside a groove by: coating a coating composition for forming an oxide film, which contains a polysilazane or a hydrogenated silsesquioxane, and a polysilane, on a substrate having a groove; and thereafter heat treatment in an oxidizing atmosphere. This method is suitable for forming a device isolation region and a wiring interlayer dielectric film.

Owner:ELPIDA MEMORY INC

Silane composition, silicon film forming method and solar cell production method

InactiveUS7067069B2Increase the areaFormed with easeSilicon organic compoundsSilicaSilane compoundsSilylene

A silane composition for preparing a semiconductor thin films of a solar cell is disclosed. The silane composition contains a polysilane compound represented by the formula SinRm (n is an integer of 3 or more, m is an integer of n to (2n+2) and an m number of R's are each independently a hydrogen atom, alkyl group, phenyl group or halogen atom, with the proviso that when all the m number of R's are hydrogen atoms and m=2n, n is an integer of 7 or more), and at least one silane compound selected from cyclopentasilane, cyclohexasilane and silylcyclopentasilane.

Owner:JSR CORPORATIOON

Silane composition, silicon film forming method and solar cell production method

InactiveUS20060185712A1Increase the areaFormed with easeSilicon organic compoundsPV power plantsSilyleneSilanes

A silane composition for preparing a semiconductor thin films of a solar cell is disclosed. The silane composition contains a polysilane compound represented by the formula SinRm (n is an integer of 3 or more, m is an integer of n to (2n+2) and an m number of R's are each independently a hydrogen atom, alkyl group, phenyl group or halogen atom, with the proviso that when all the m number of R's are hydrogen atoms and m=2n, n is an integer of 7 or more), and at least one silane compound selected from cyclopentasilane, cyclohexasilane and silylcyclopentasilane.

Owner:JSR CORPORATIOON

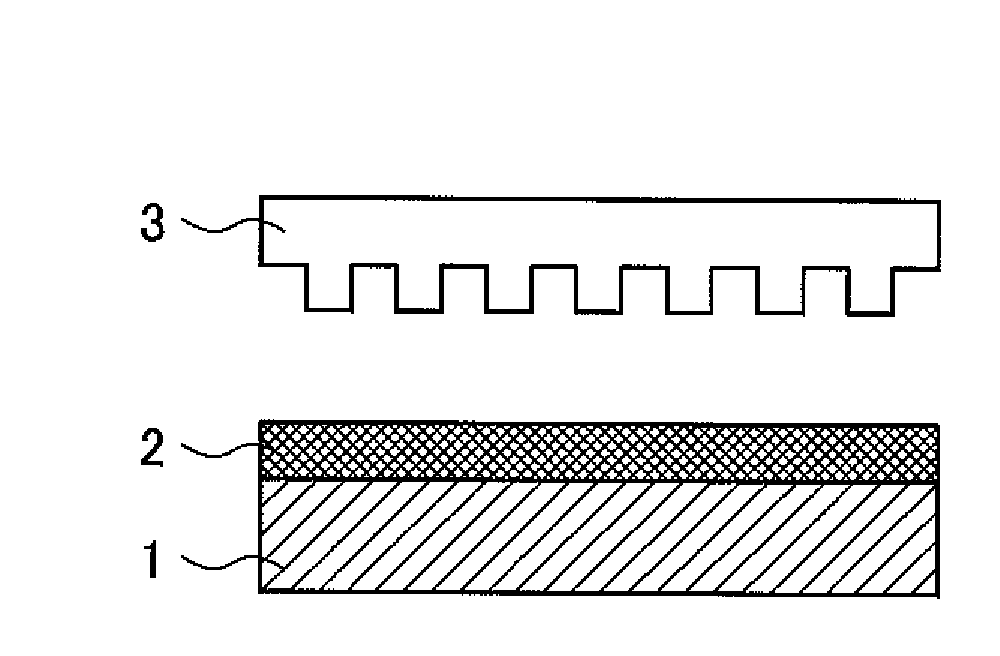

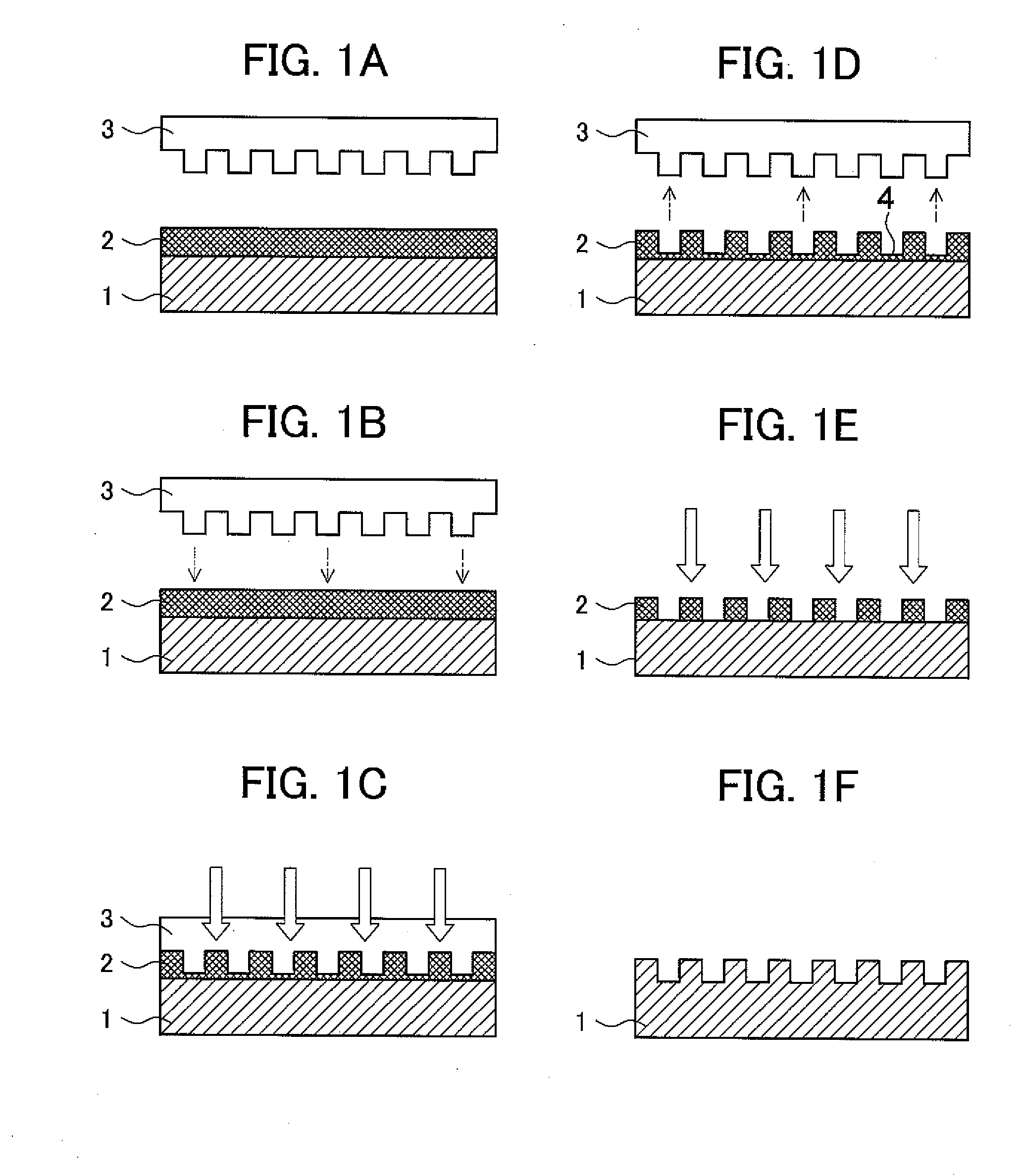

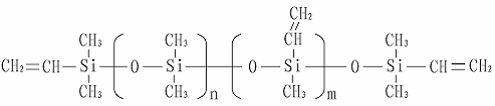

Film forming composition for nanoimprinting and method for pattern formation

InactiveUS20090263631A1Improve the immunityBroaden your optionsDecorative surface effectsOrnamental structuresResistNanostructure

This invention provides a film forming composition for nanoimprinting, which has excellent resistance to etching with oxygen gas, can prevent the separation of a transfer pattern, can eliminate a problem of a holing time on a substrate, and is also excellent in transferability, and photosensitive resist, a nanostructure, a method for pattern formation using the same, and a program for realizing the method for pattern formation. The film forming composition for nanoimprinting comprises a polymeric silicon compound having the function of causing a photocuring reaction. Preferably, the polymeric silicon compound has a functional group cleavable as a result of response to electromagnetic waves and causes a curing reaction upon exposure to electromagnetic waves. More preferred are siloxane polymer compounds, silicon carbide polymer compounds, polysilane polymer compounds, and silazane polymer compounds, or any mixture thereof.

Owner:TOKYO OHKA KOGYO CO LTD

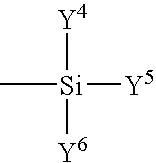

Method of rendering substrates oil and water repellent with a fluorochemical oligomeric silane

InactiveUS7166329B2Lower levelIncreased durabilityOther chemical processesFibre treatmentArylPolymer science

A fluorochemical composition comprising of organic solvent and fluorochemical oligomer represented by the general formula:X-MfnMhmMar-Gwherein X represents the residue of an initiator or hydrogen; Mf represents units derived from fluorinated monomers; Mh represents units derived from a non-fluorinated monomers; Ma represents units having a silyl group represented by the formula:wherein each of Y4, Y5 and Y6 independently represents an alkyl group, an aryl group or a hydrolyzable group; G is a monovalent organic group comprising the residue of a chain transfer agent; n represents a value of 1 to 100; m represents a value of 0 to 100;r represents a value of 0 to 100; and n+m+r is at least 2.

Owner:3M INNOVATIVE PROPERTIES CO

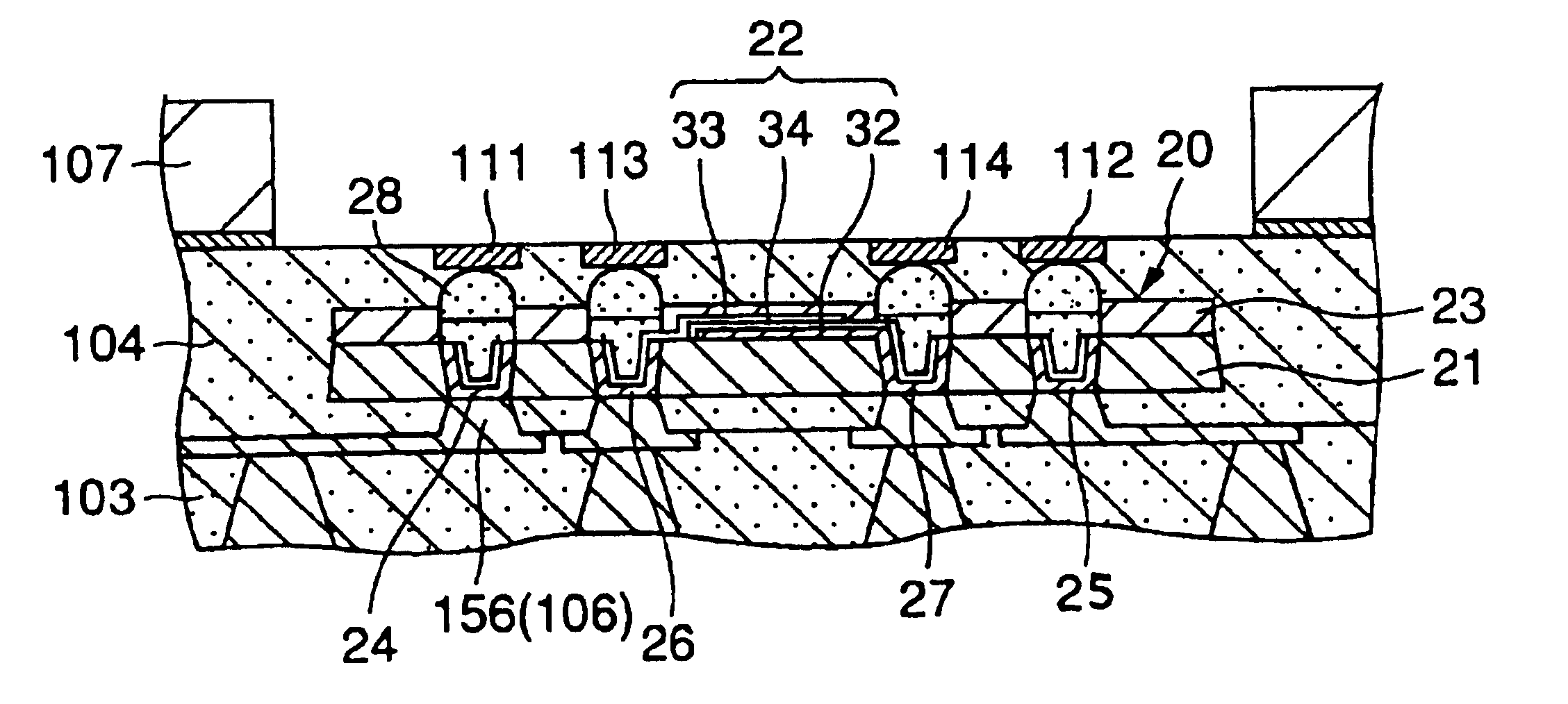

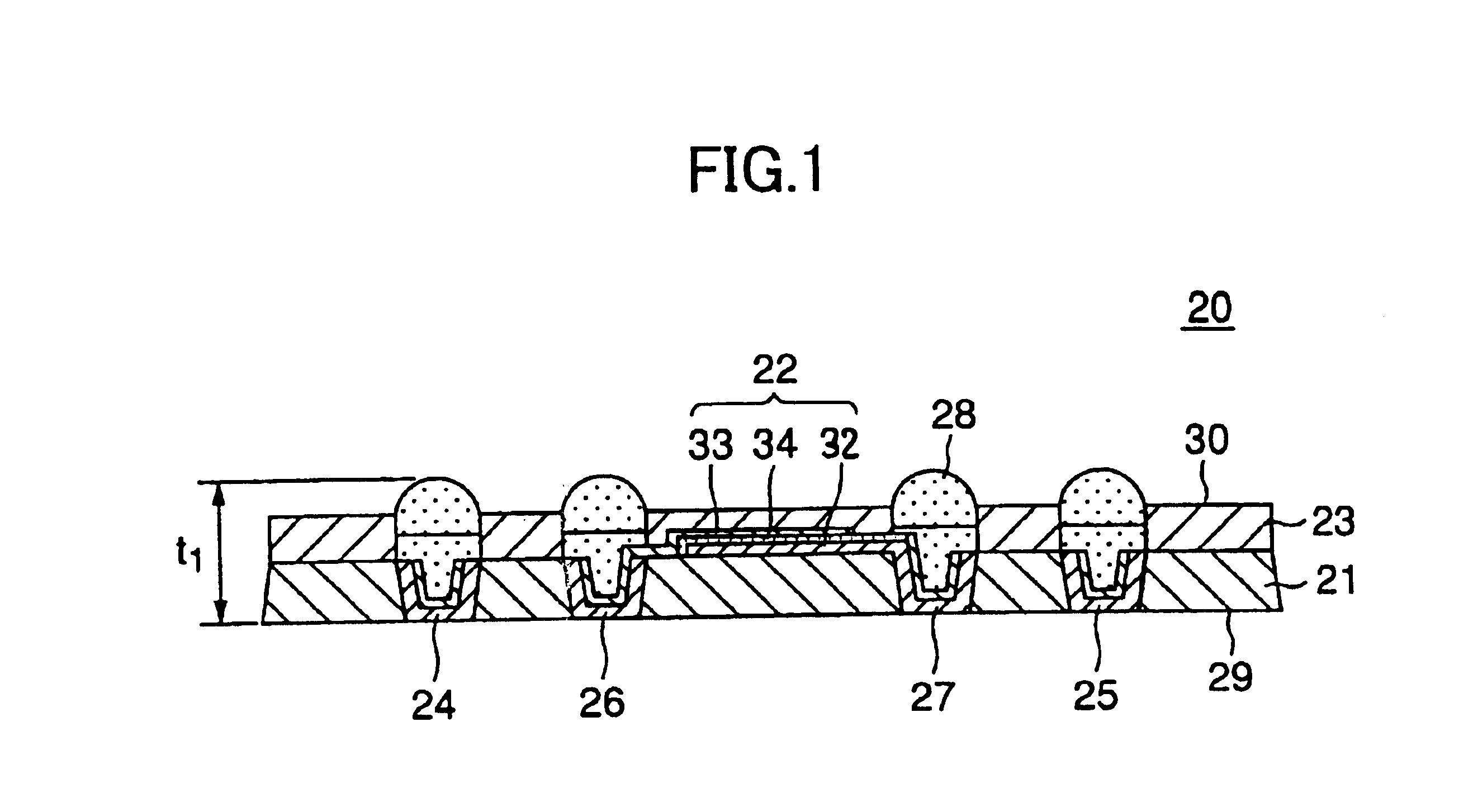

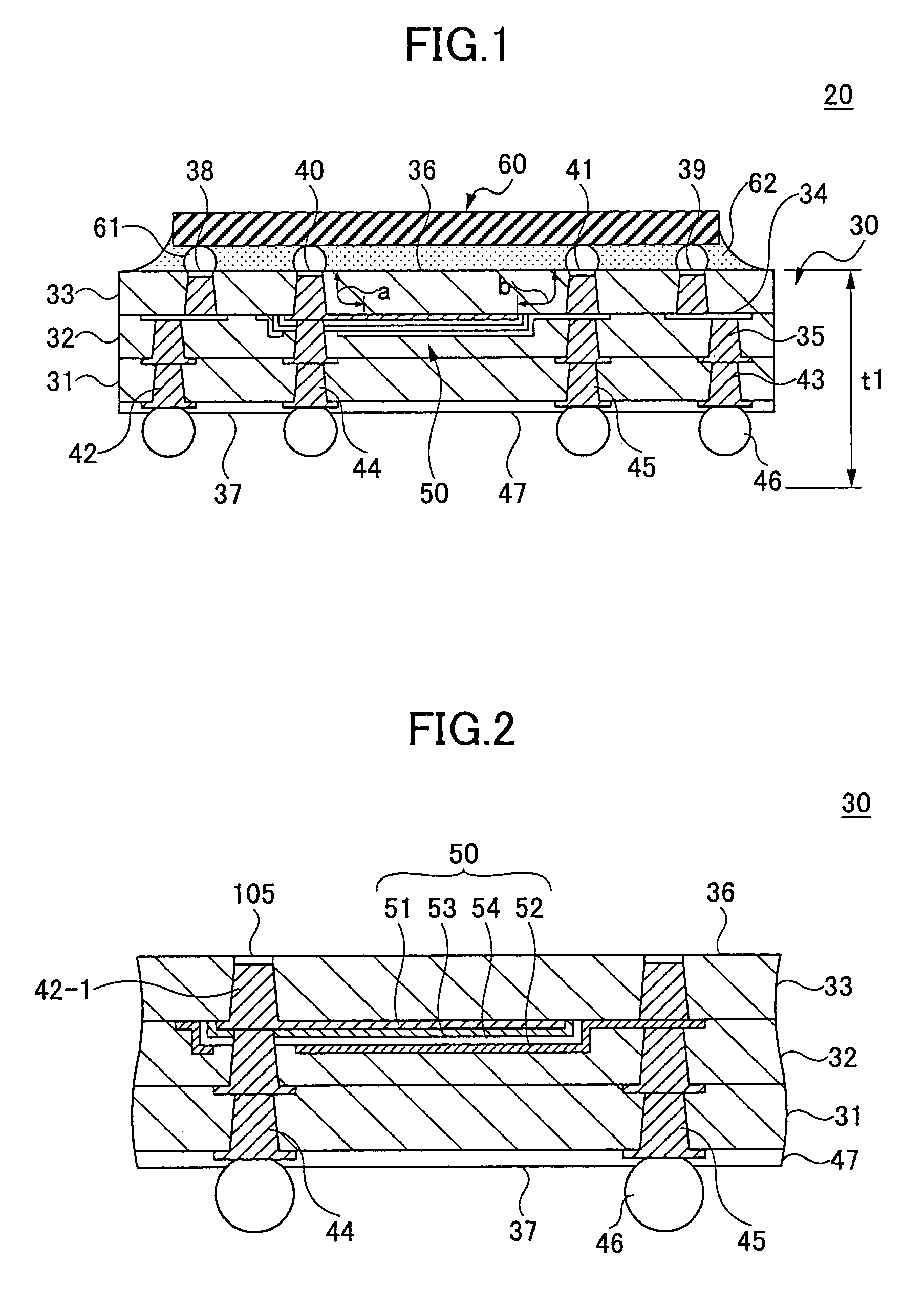

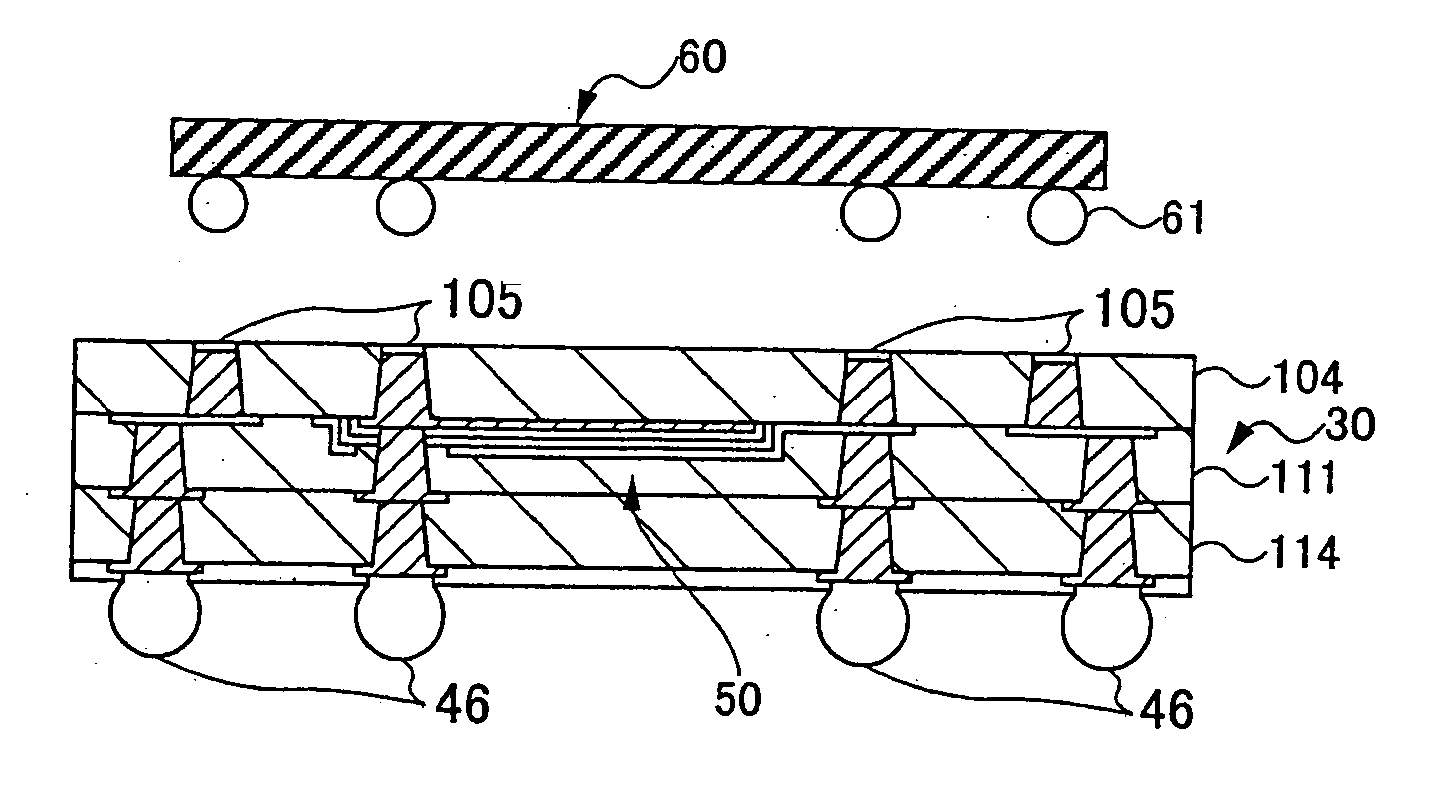

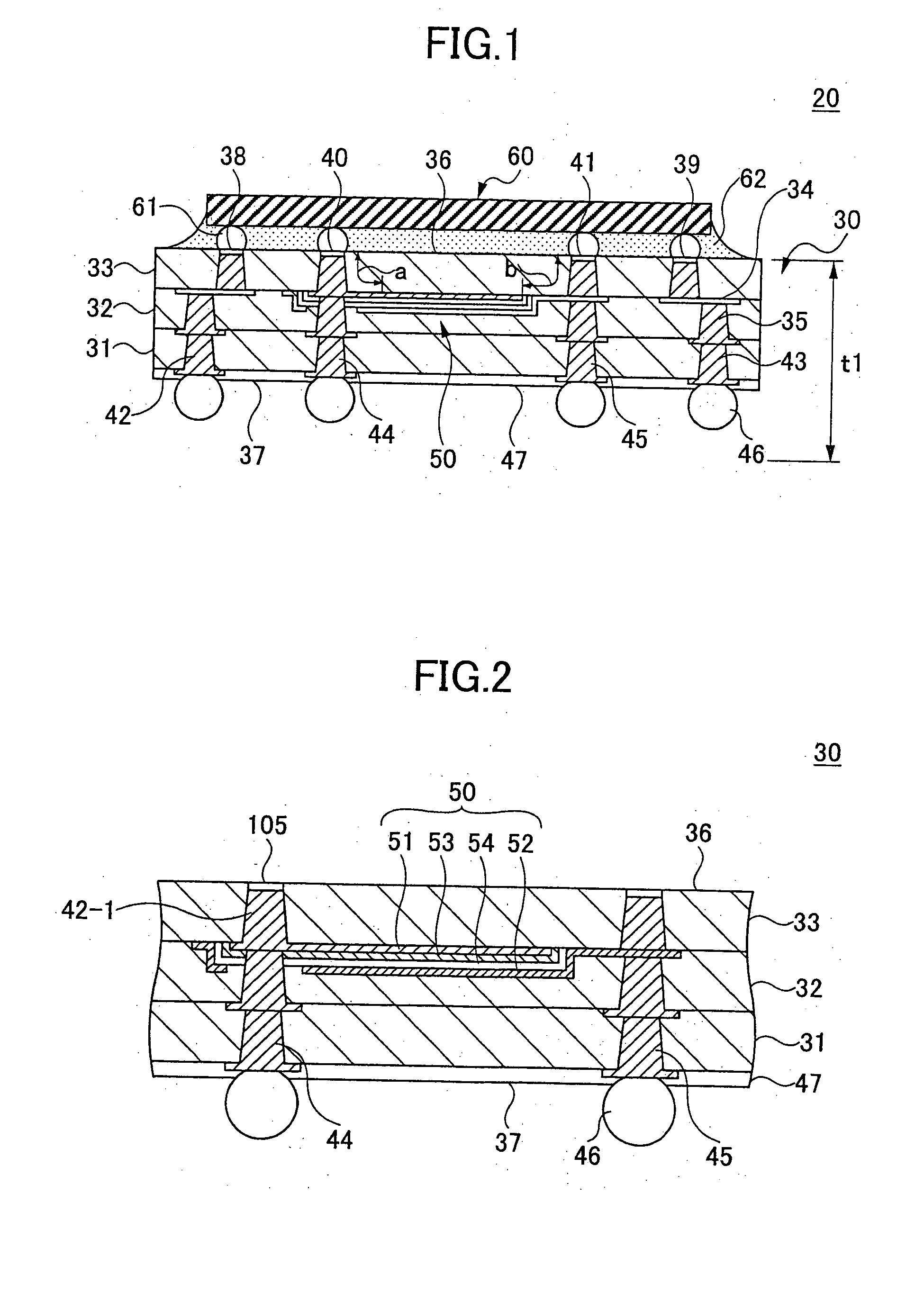

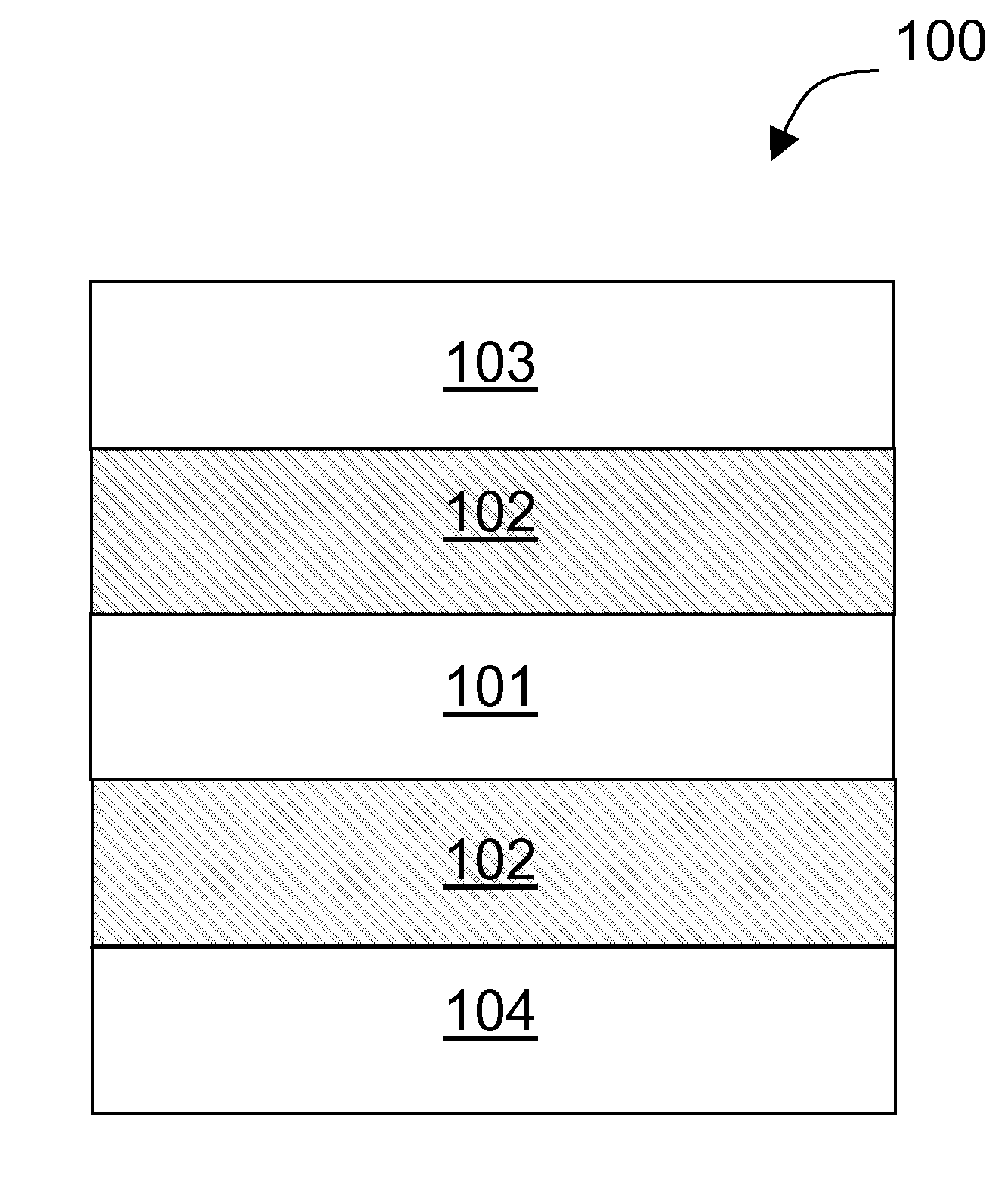

Capacitor and manufacturing method thereof, semiconductor device and substrate for a semiconductor device

ActiveUS6897544B2Reduce thicknessDistanceTransistorSemiconductor/solid-state device detailsDielectric membranePolysilane

A capacitor includes a capacitor part formed of a dielectric film sandwiched by a pair of electrodes and a support body formed of a film of an organic polysilane. The support body is provided so as to support the capacitor part thereon.

Owner:SHINKO ELECTRIC IND CO LTD

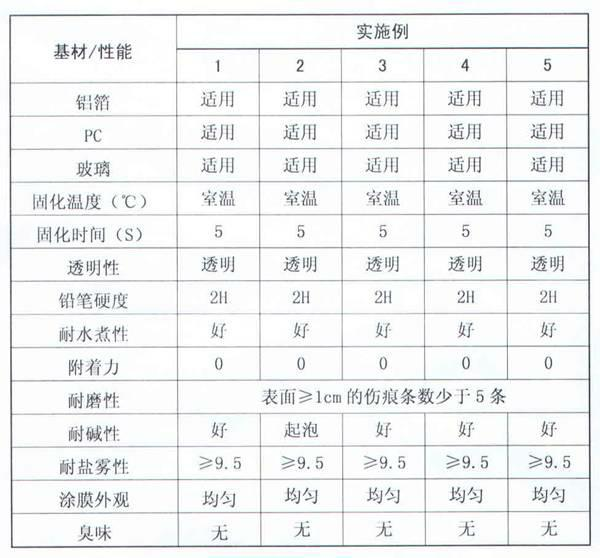

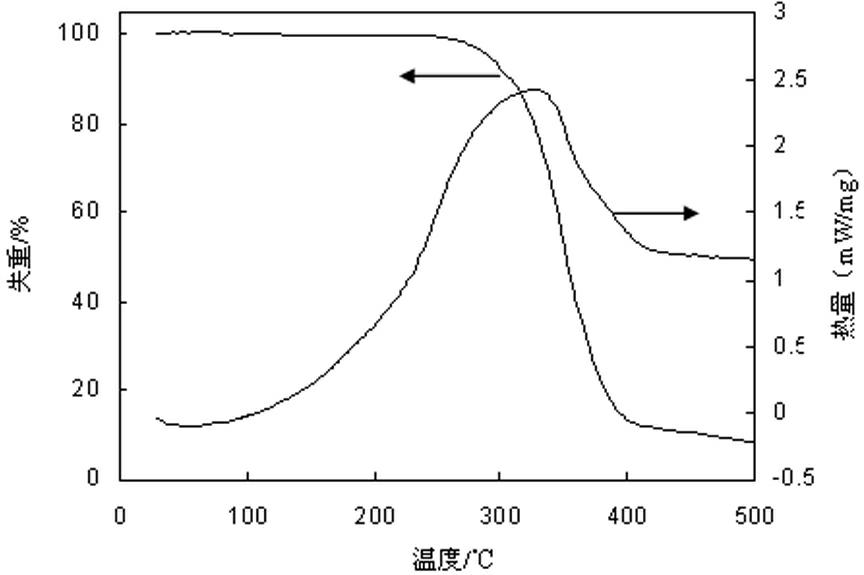

Organosilicon-modified polyurethane-acrylic ester photocurable coating and preparation method thereof

InactiveCN102559038AUniform particle size distributionSmall particle sizePolyurea/polyurethane coatingsPolymer scienceUrethane acrylate

The invention relates to an organosilicon-modified polyurethane-acrylic ester photocurable coating and a preparation method thereof. The photocurable coating comprises the following components in percentage by weight: 25 to 60 percent of polyurethane-acrylic ester, 20 to 55 percent of organic polysilane, 5 to 15 percent of solvent, 1 to 5 percent of photoinitiator and 0.05 to 4.5 percent of aid. The preparation method comprises the following steps of: weighing the organic polysilane according to the amount of a formula, putting into a container, sequentially adding a polyurethane-acrylic ester photocurable resin, the solvent and the aid, mixing uniformly, adding the photoinitiator, stirring uniformly to obtain an ultraviolet-photocurable coating, and preserving in a dark place. The ultraviolet-photocurable coating composition can be coated on base materials such as plastics, metals, glass and the like; a coating subjected to ultraviolet photocuring has excellent wear resistance and mechanical properties; and meanwhile, the coating has excellent adhesion, water resistance, salt fog resistance and alkali resistance.

Owner:CHANGSHA YUANPENG CHEM TECH

Method for synthetizing polycarbosilane under atmospheric pressure

InactiveCN102120822AIncrease the concentration of free radicalsStructure will not changeNitrogen atmosphereReaction temperature

A method for synthetizing polycarbosilane under the atmospheric pressure comprises the following steps: under the protection of high purity nitrogen, cracking solid raw material-polydimethylsilane at above 360 DEG C in nitrogen atmosphere to convert to liquid polysilane; (2) adding solid powdery raw material-polydimethylsilane which accounts for 15-100wt% of liquid polysilane in liquid polysilane, stirring evenly, sealing, heating to 280-330 DEG C under the protection of high purity nitrogen, reacting for 2-6h; and (3) performing temperature programming to 370-420 DEG C, and reacting for 6-12h and cooling. The method has low reaction temperature, the synthetic yield is more than 60%; the structure of precursor polycarbosilane (PCS) can not be changed; the equipment is simple; and large-scale synthesis is easy to realize and synthetic steps are less.

Owner:NAT UNIV OF DEFENSE TECH

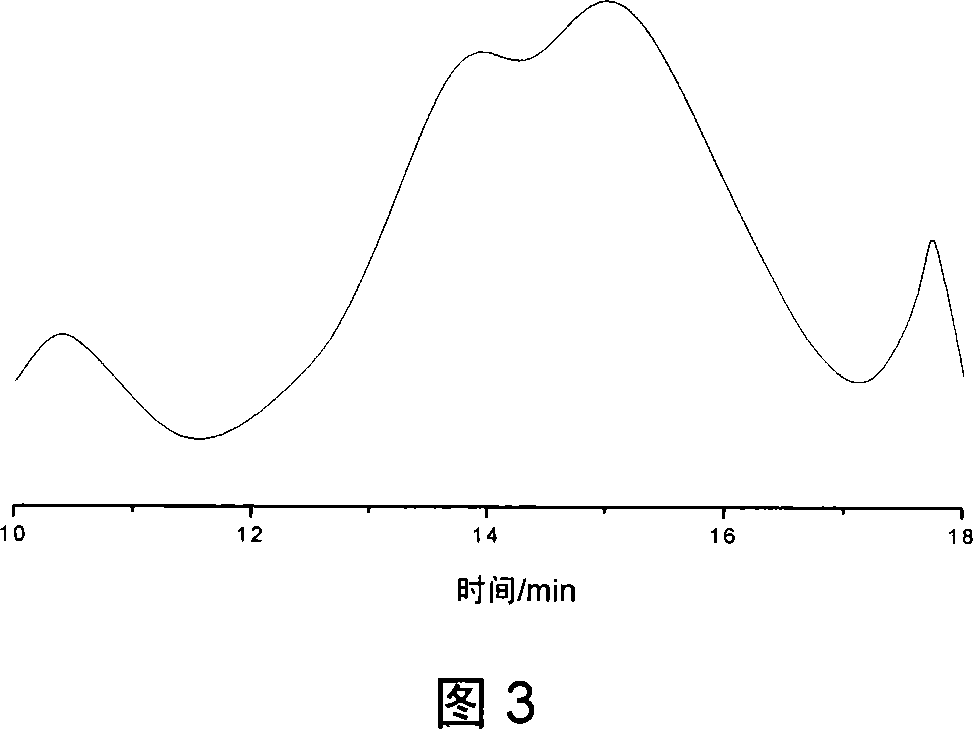

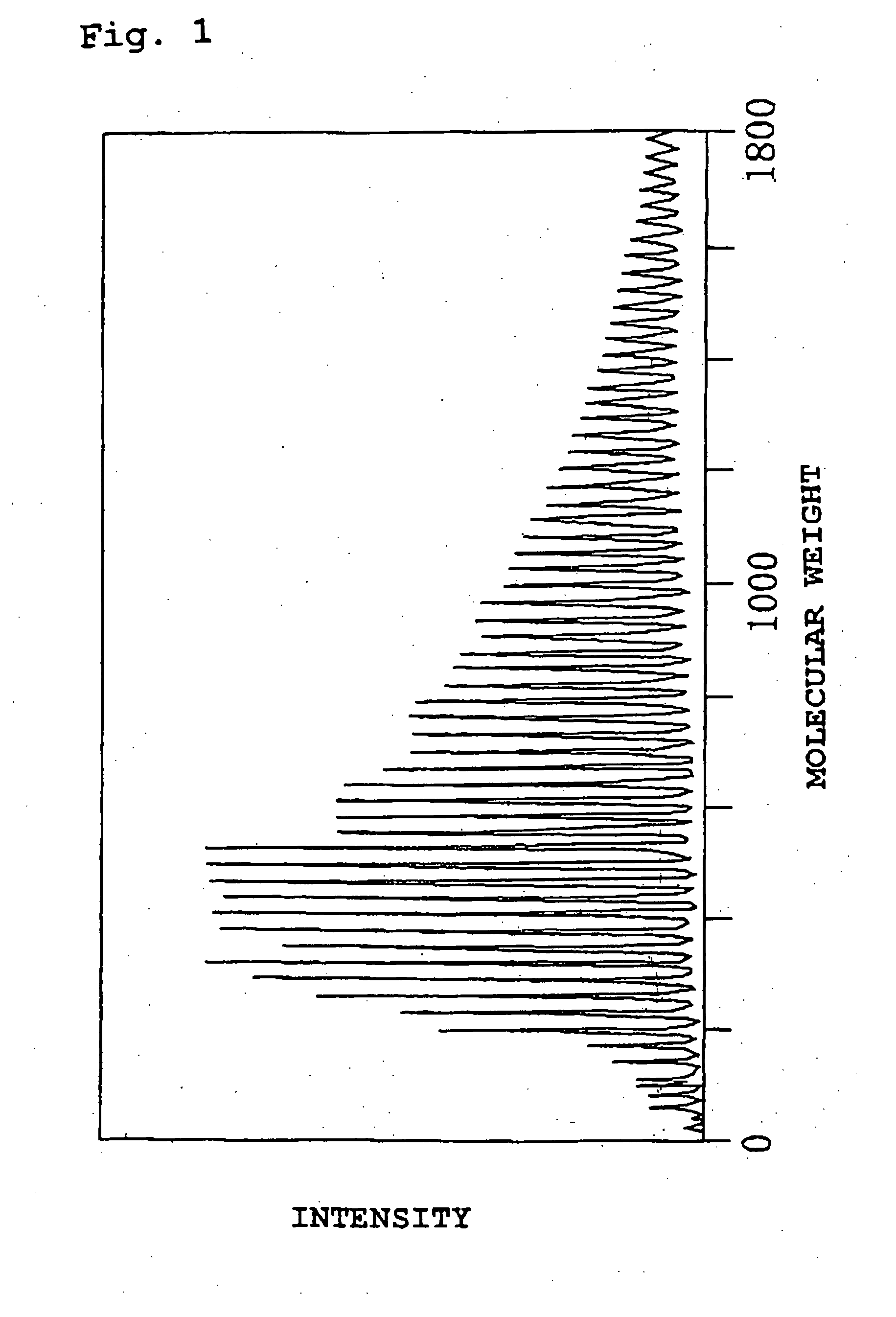

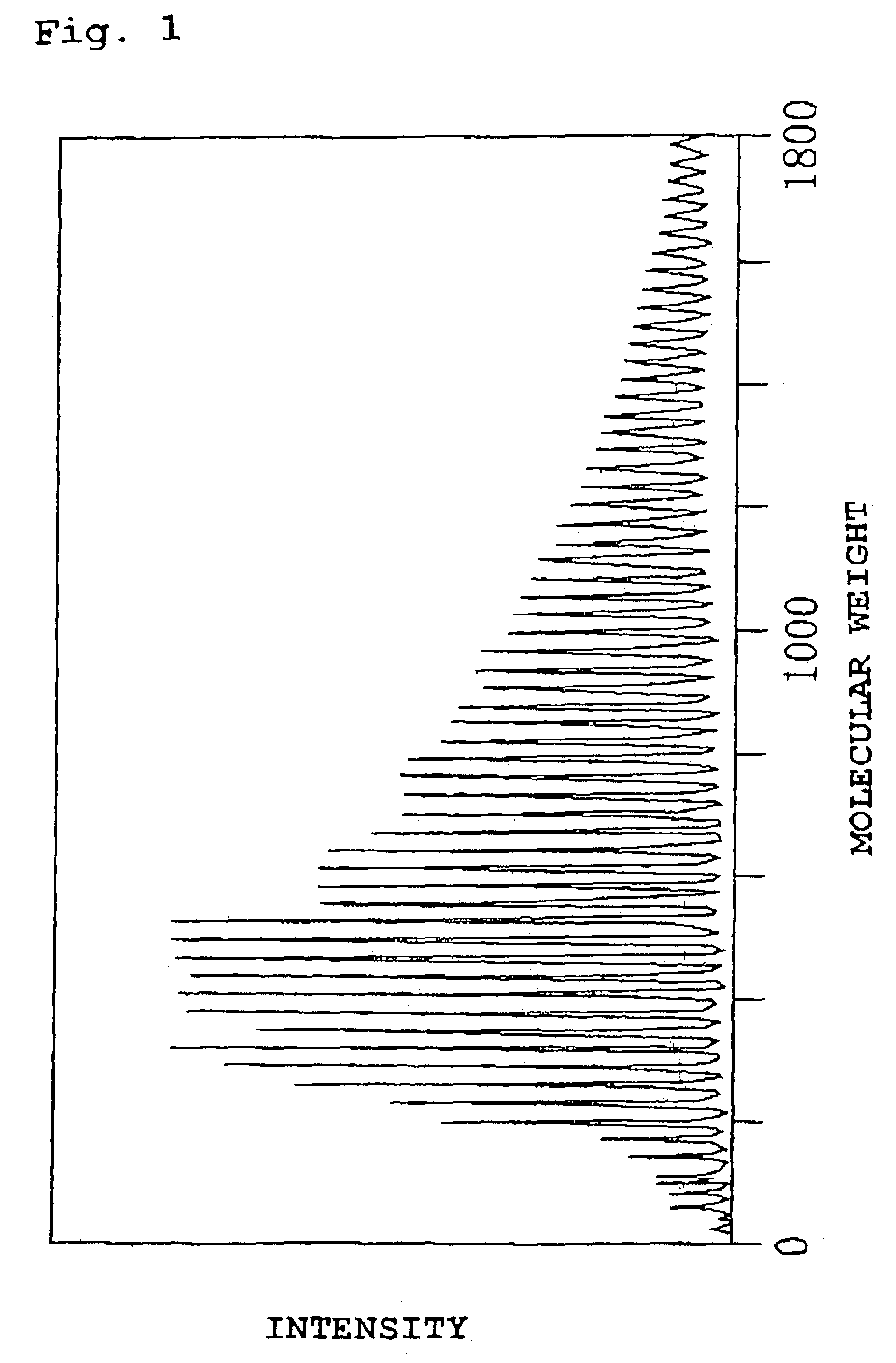

High order silane composition, and method of forming silicon film using the composition

InactiveUS20070190265A1Well formedHigh molecular weightPretreated surfacesSilicon hydridesBoiling pointUltraviolet lights

It is an object of the present invention to provide a high order silane composition that contains a polysilane having a higher molecular weight than conventionally, this being from the viewpoints of wettability when applying onto a substrate, boiling point and safety, and hence in particular enables a high-quality silicon film to be formed easily, and also a method of forming an excellent silicon film using the composition. The present invention attains this object by providing a high order silane composition containing a polysilane obtained through photopolymerization by irradiating a solution of a photopolymerizable silane or a photopolymerizable like-liquid silane with ultraviolet light. Moreover, the present invention provides a method of forming a silicon film comprising the step of applying such a high order silane composition onto a substrate.

Owner:AOKI TAKASHI +4

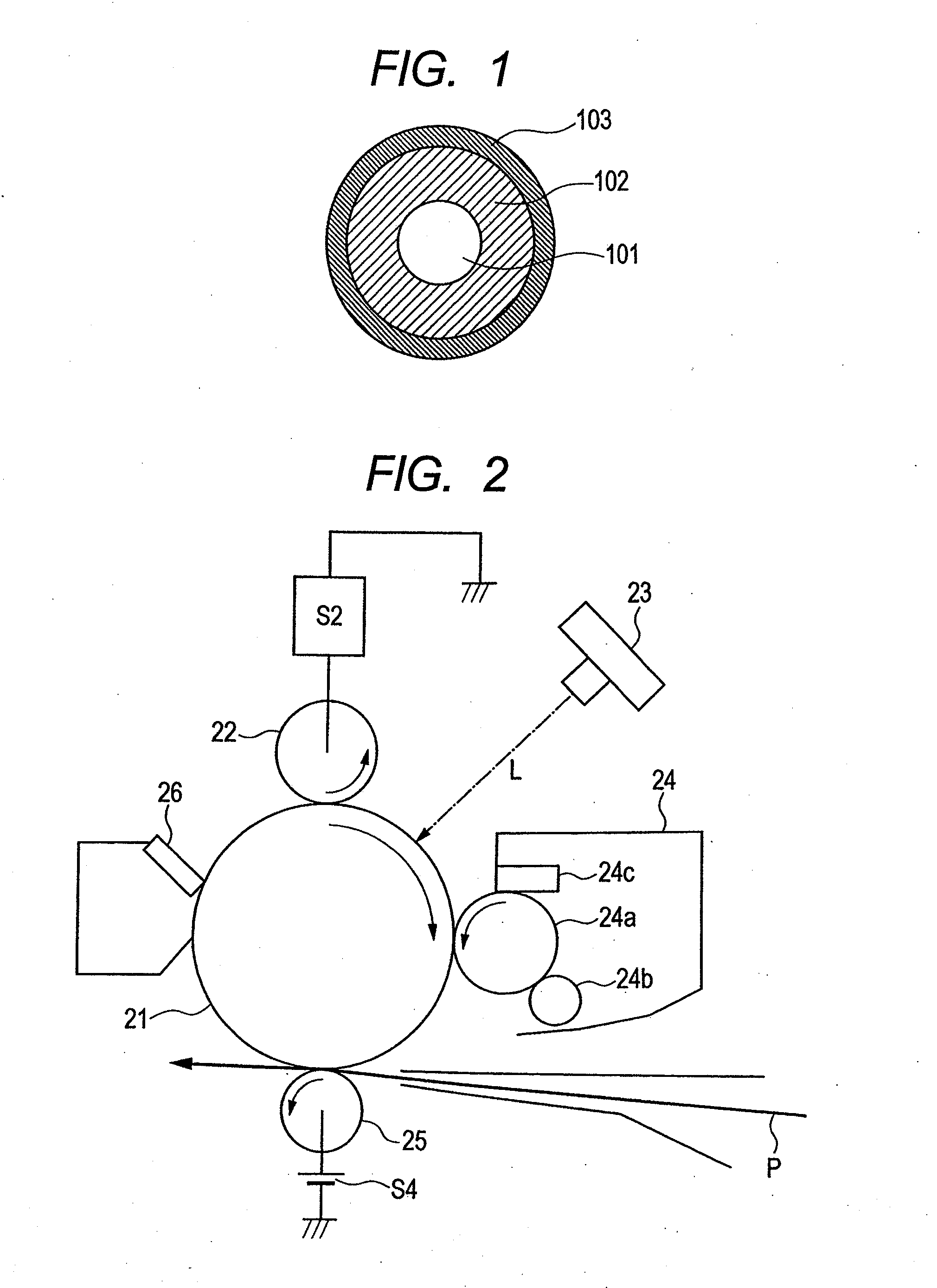

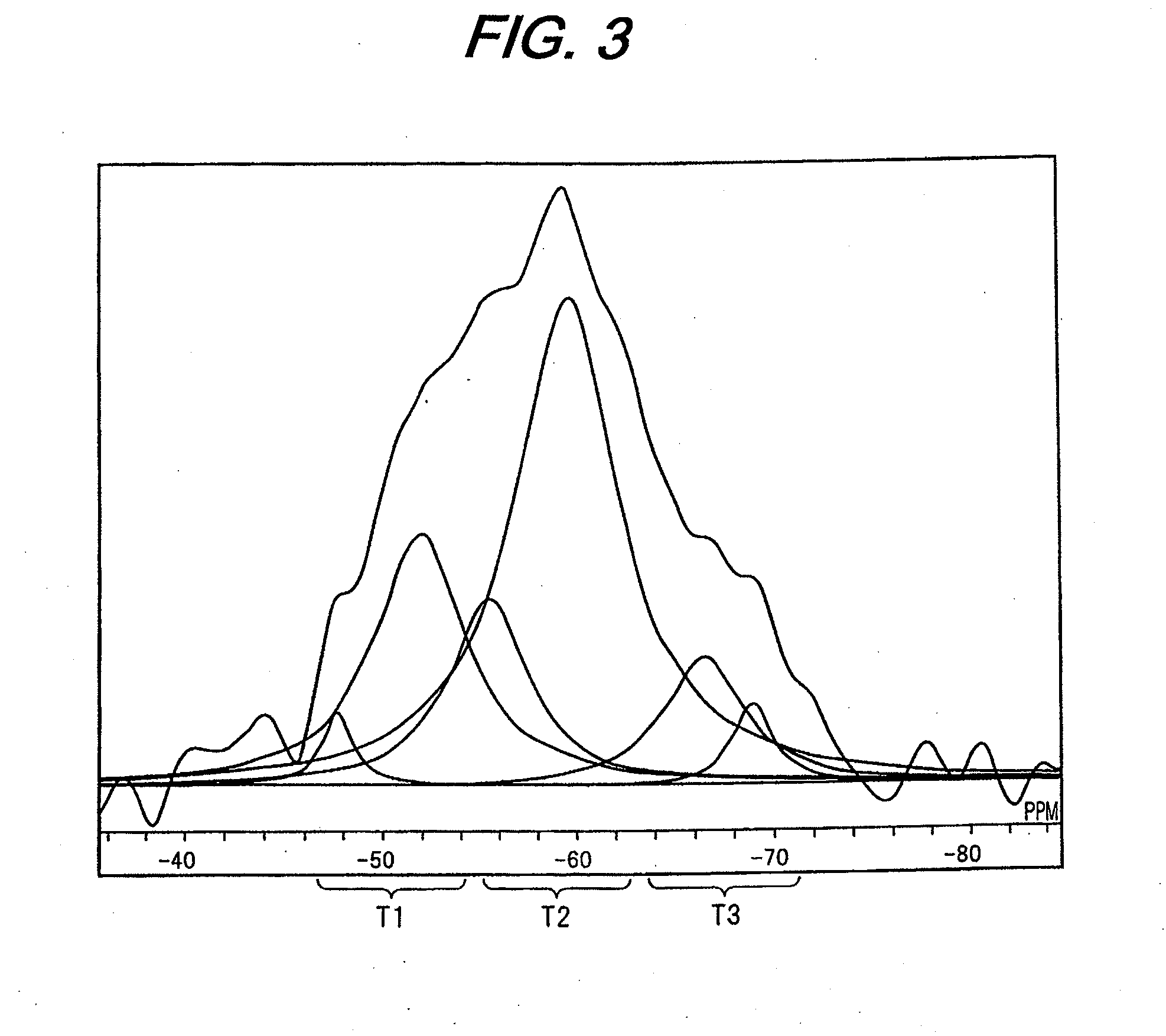

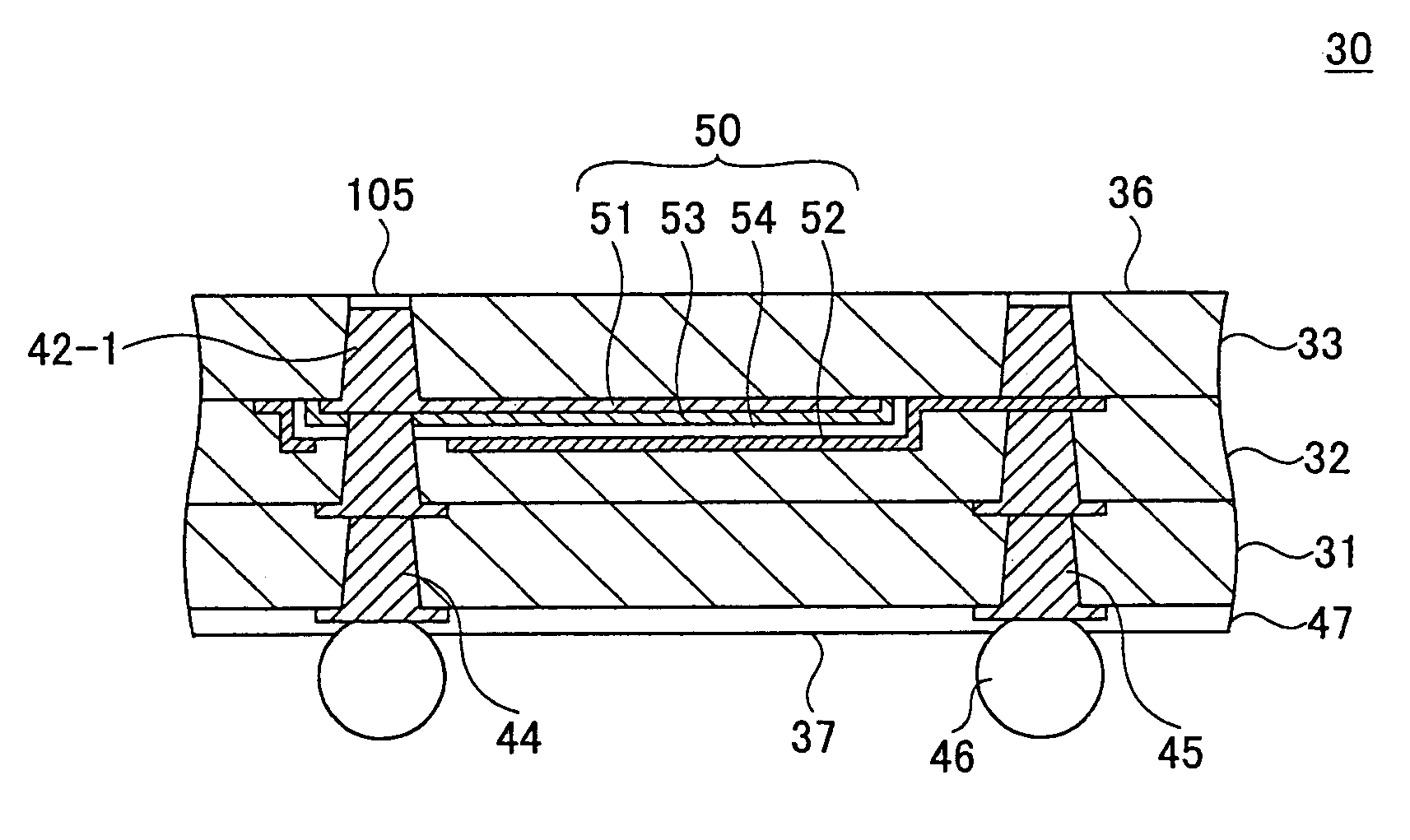

Charging member, process cartridge and electrophotographic apparatus

InactiveUS20130004206A1Improve charging effectNot easy to changeElectrographic process apparatusCorona dischargeSurface layerElectron

A charging member for electrophotographic apparatus is provided which has a superior charging performance for the electrophotographic photosensitive member and also can not easily change with time in charging performance. The charging member has a substrate, an elastic layer and a surface layer, which surface layer contains a high-molecular compound having an Si—O—Ti linkage in the molecular structure and a cyclic polysilane represented by the general formula (7) defined in the specification, and the high-molecular compound has a constituent unit represented by the general formula (1) and a constituent unit represented by the following formula (2) which are defined in the specification.

Owner:CANON KK

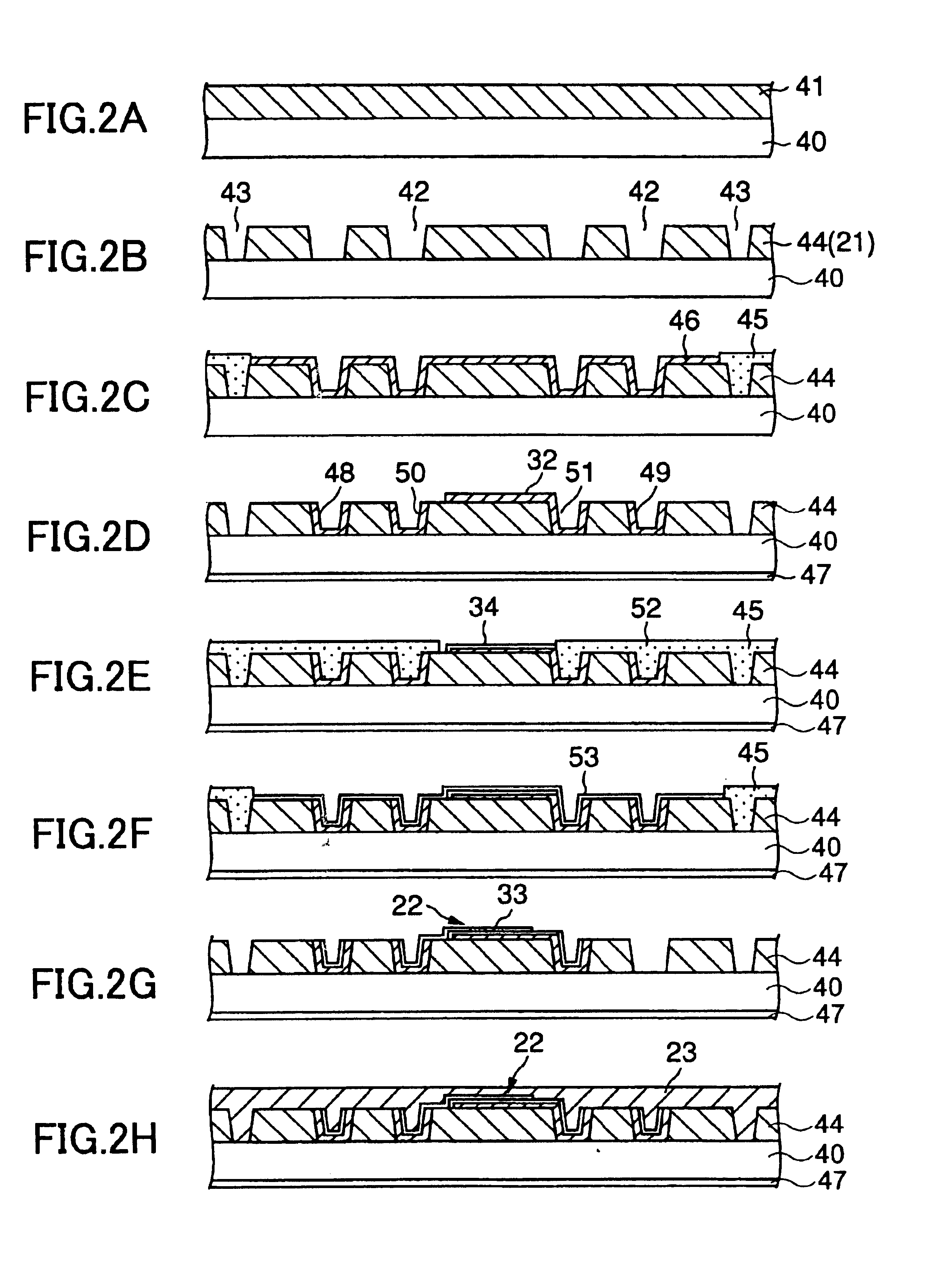

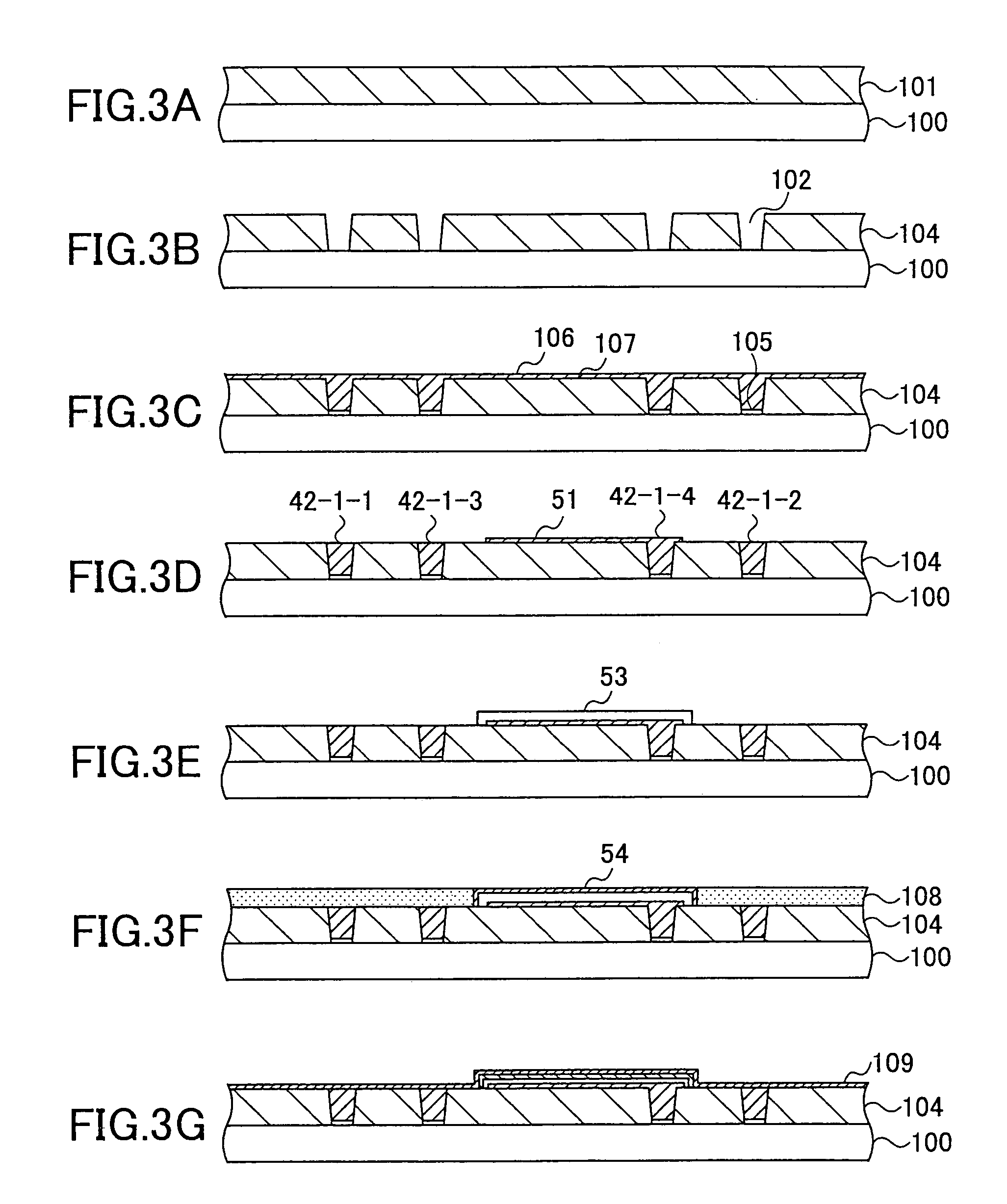

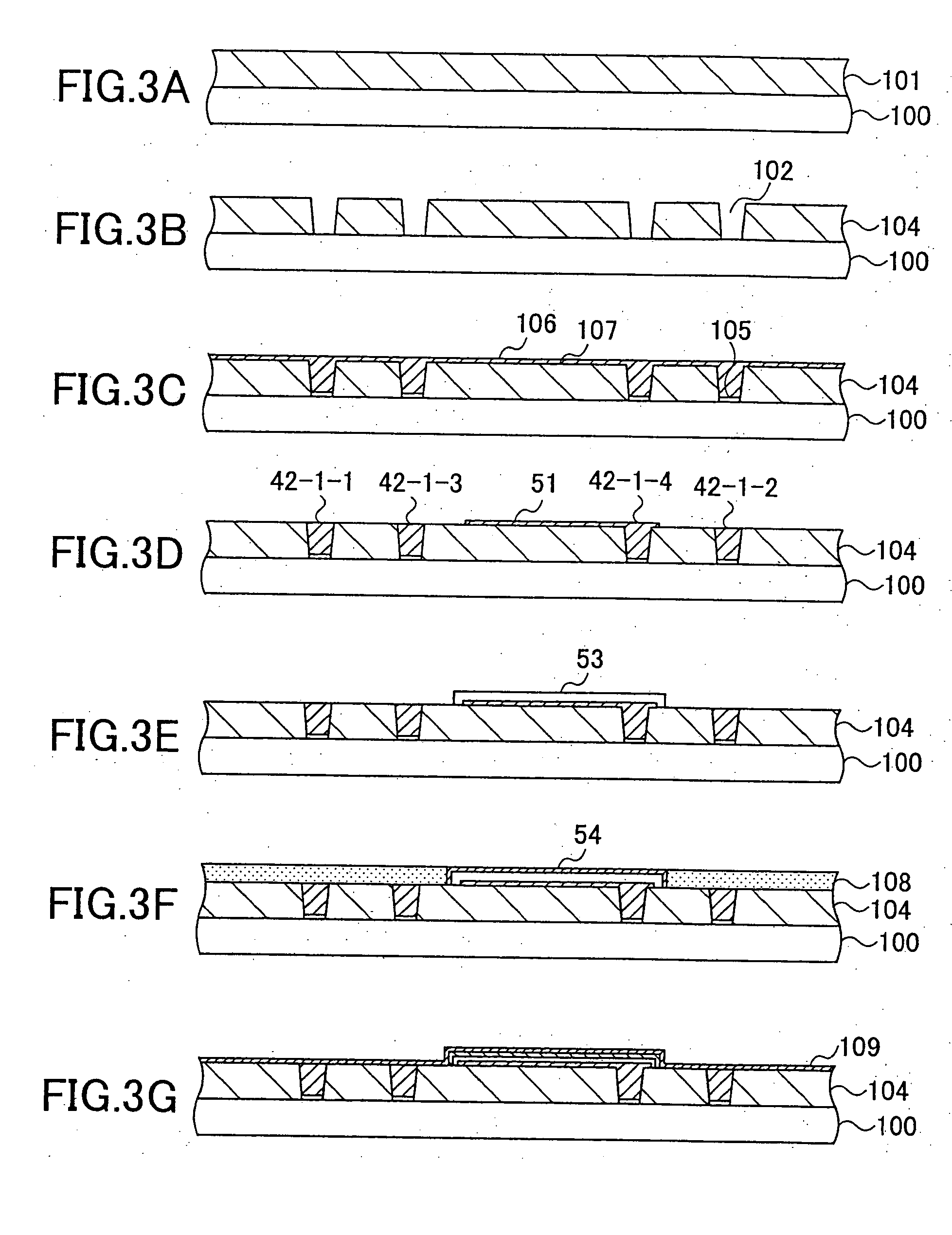

Substrate for carrying a semiconductor chip and a manufacturing method thereof

ActiveUS6998308B2Average thicknessInductance, of the substrate is reducedSemiconductor/solid-state device detailsPrinted circuit aspectsInsulation layerSemiconductor chip

A substrate includes a plurality of insulation layers forming a laminated structure and a built-in capacitor formed in the laminated structure, wherein the laminated structure includes a layer of baked organic polysilane.

Owner:SHINKO ELECTRIC IND CO LTD

Substrate for carrying a semiconductor chip and a manufacturing method thereof

InactiveUS20050185382A1Easy and efficientEasily and efficiently obtainedSemiconductor/solid-state device detailsPrinted circuit aspectsInsulation layerSemiconductor chip

A substrate includes a plurality of insulation layers forming a laminated structure and a built-in capacitor formed in the laminated structure, wherein the laminated structure includes a layer of baked organic polysilane.

Owner:OOI KIYOSHI +1

High order silane composition, and method of forming silicon film using the composition

InactiveUS7223802B2Well formedHigh molecular weightSilicon hydridesSemiconductor/solid-state device manufacturingBoiling pointUltraviolet lights

It is an object of the present invention to provide a high order silane composition that contains a polysilane having a higher molecular weight than conventionally, this being from the viewpoints of wettability when applying onto a substrate, boiling point and safety, and hence in particular enables a high-quality silicon film to be formed easily, and also a method of forming an excellent silicon film using the composition. The present invention attains this object by providing a high order silane composition containing a polysilane obtained through photopolymerization by irradiating a solution of a photopolymerizable silane or a photopolymerizable like-liquid silane with ultraviolet light. Moreover, the present invention provides a method of forming a silicon film comprising the step of applying such a high order silane composition onto a substrate.

Owner:SEIKO EPSON CORP

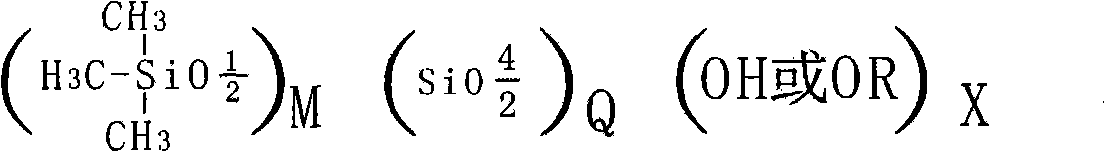

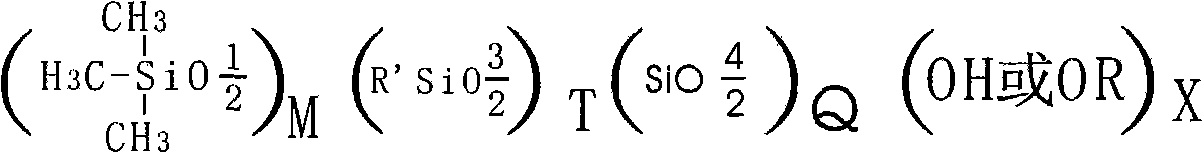

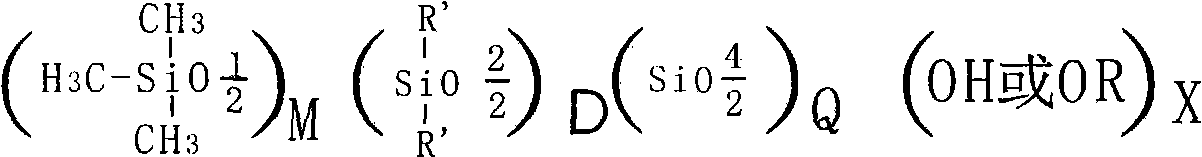

Silicone-type coatings and preparation method thereof

The invention discloses a preparation method of silicone-type coatings prepared by mixing a silicone component A containing hydroxyl or alkoxy, a silicone oil component B containing linear terminated-hydroxyl, a white carbon black component C, a cross-linking agent component D, a catalyst component E and a tackifier component F. The invention is used for preparing various insulated moisture-curedcoatings with different kinds of viscosity, strength and toughness and strong adhesion by synthesizing various forms of silicones containing hydroxyl or alkoxy and mutually collocating terminated-hydroxyl linear polysilane. The silicone-type coatings have better protection performance and have favorable protection efficacy of resisting water, dampness, shock, aging, dust and corrosion, insulating, and the like for various electronic components, circuit boards and live devices.

Owner:陈俊光

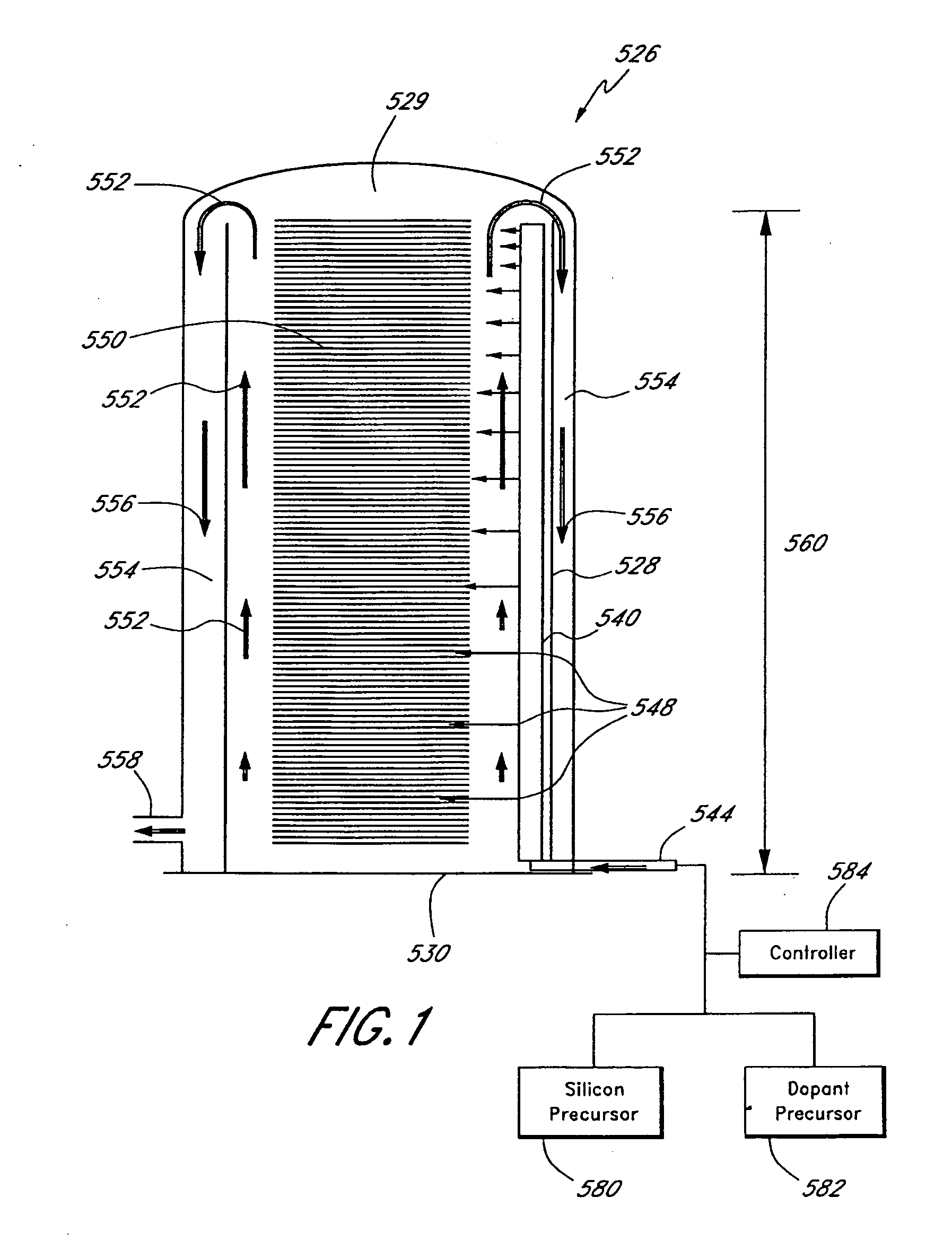

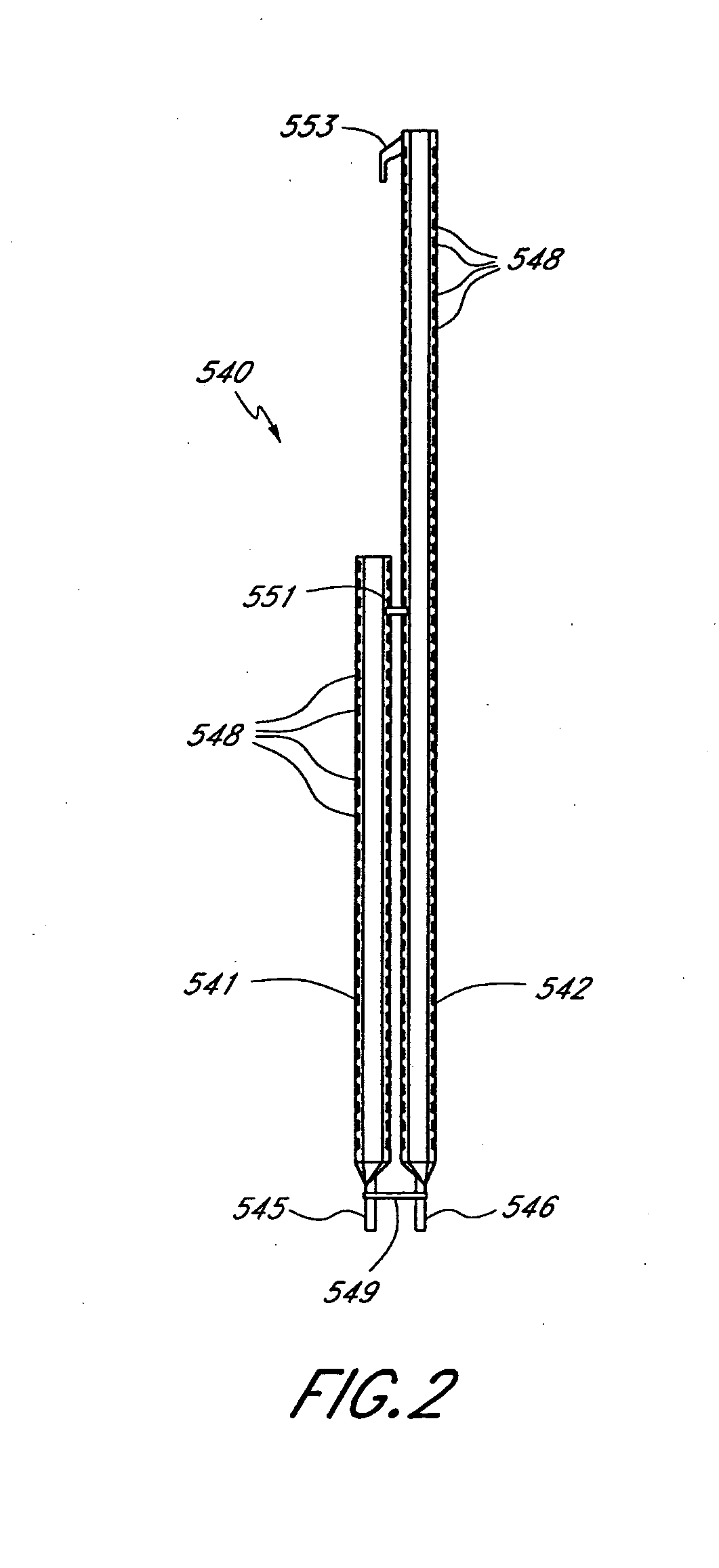

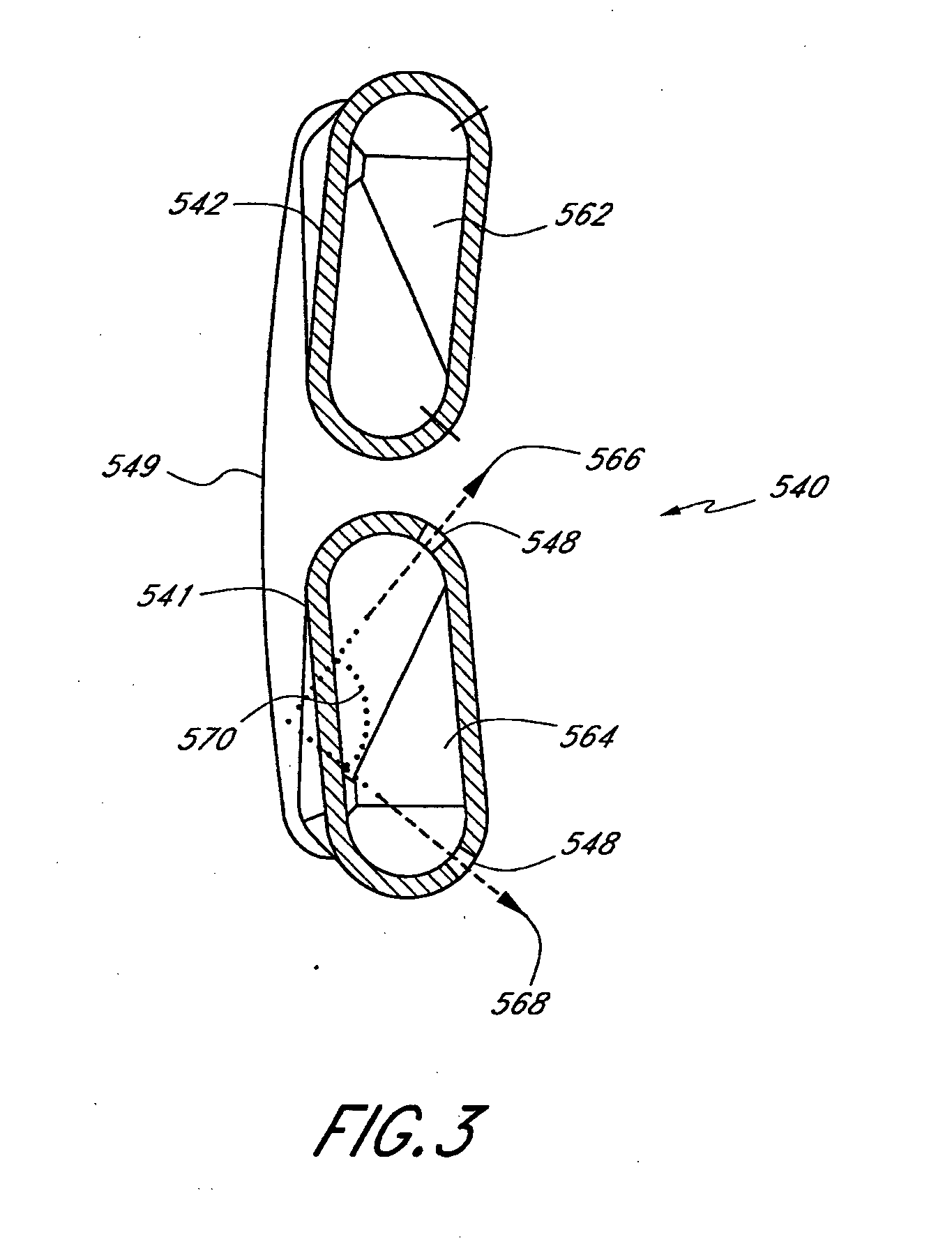

Low temperature doped silicon layer formation

ActiveUS20070141812A1Polycrystalline material growthSemiconductor/solid-state device manufacturingDopantPhosphine

A doped silicon layer is formed in a batch process chamber at low temperatures. The silicon precursor for the silicon layer formation is a polysilane, such as trisilane, and the dopant precursor is an n-type dopant, such as phosphine. The silicon precursor can be flowed into the process chamber with the flow of the dopant precursor or separately from the flow of the dopant precursor. Surprisingly, deposition rate is independent of dopant precursor flow, while dopant incorporation linearly increases with the dopant precursor flow.

Owner:ASM INTERNATIONAL

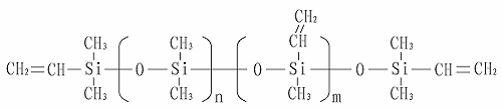

Resin Composition for LED Encapsulation

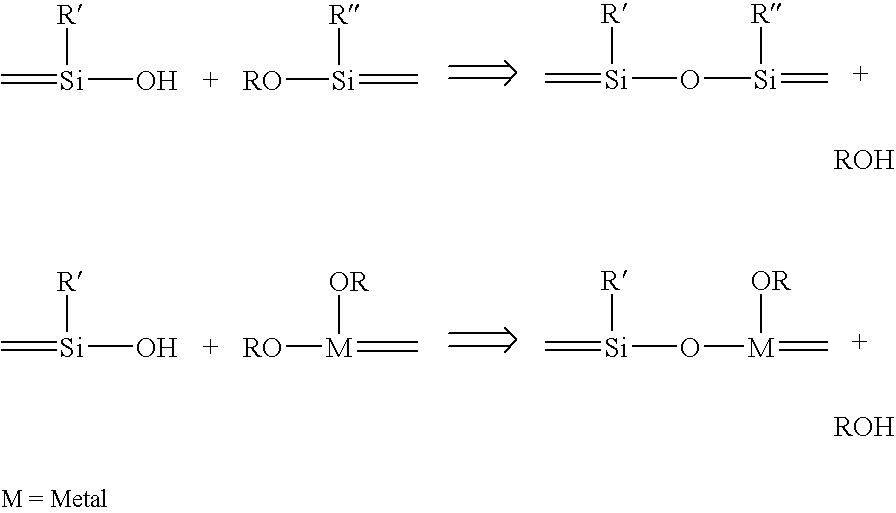

InactiveUS20100025724A1Improve stabilityImprove mechanical propertiesPhotomechanical apparatusSemiconductor devicesNetwork structureOrganic group

Disclosed is a resin composition for LED encapsulation including an organic oligosiloxane hybrid prepared by non-hydrolytic condensation of organoalkoxysilane. More particularly, the resin composition for LED encapsulation includes an organic oligosiloxane hybrid prepared by non-hydrolytic condensation of organoalkoxysilane with organosilanediol or non-hydrolytic condensation of a mixture containing organoalkoxysilane and metal alkoxide with organosilanediol. The prepared organic oligosilane hybrid has an inorganic network structure with a high degree of condensation and contains at least one organic group or organic functional group. In addition, an encapsulated LED fabricated using the above resin composition for LED encapsulation is provided.

Owner:KOREA ADVANCED INST OF SCI & TECH

Low-temperature adhesive undercoat composition

InactiveUS20100043945A1Good adhesion promotionAdhesive processes with surface pretreatmentLaminationAdhesiveAdduct

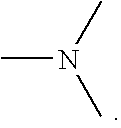

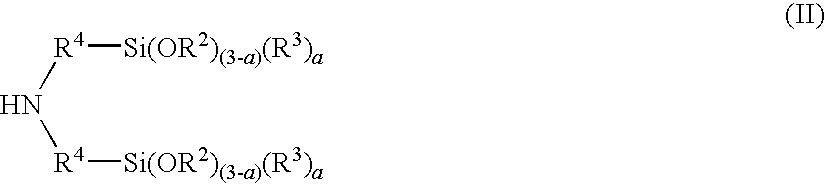

A method for producing an adhesive undercoat on a substrate S1 with a substrate temperature of lower than 5° C. The adhesive undercoat composition comprises at least one mercaptosilane MS or an adduct of mercaptosilane and either at least one polysilane PSA, comprising at least one secondary or tertiary amino group, or at least one polysilane PS and at least one aminosilane AS, comprising at least one secondary or tertiary amino group. This method is particularly suited for the gluing of glass, particularly of glass ceramics, preferably for repairing windows of motor vehicles in cold temperatures.

Owner:SIKA TECH AG

Preparation method of near-stoichiometric silicon carbide fiber

ActiveCN102634867AHigh softening pointAvoid fusible problemsArtificial filament heat treatmentMelt spinning methodsCarbon fibersSynthetic Polymeric Macromolecules

The invention relates to a preparation method of a near-stoichiometric silicon carbide fiber, which comprises the following steps: (1) catalytically synthesizing HPCS: synthesizing high-molecular-weight polycarbosilane HPCS under the catalysis of metal by using liquid polycarbosilane or liquid polysilane as the material; (2) preparing a continuous HPCS fiber through melt spinning; (3) preparing an infusible fiber; (4) decarburizing: removing redundant carbon in the infusible fiber in a reducing atmosphere, thus forming a near-stoichiometric fiber; and (5) firing: carrying out high-temperature firing densification on the decarburized fiber under the protection of an inert atmosphere, thus obtaining a near-stoichiometric continuous SiC fiber. The preparation method can improve the performance of the composite material; the equipment and the process are simple; and the preparation method can be implemented by conventional fiber production equipment, can be easily industrialized and can promote the application of the SiC fiber.

Owner:NAT UNIV OF DEFENSE TECH

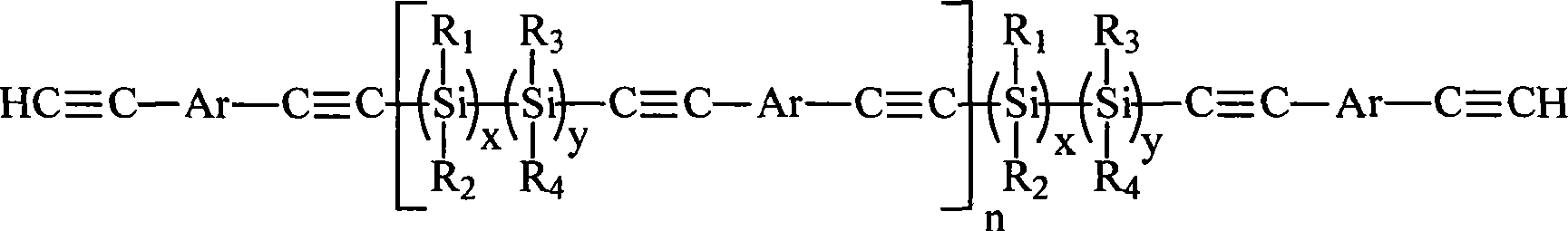

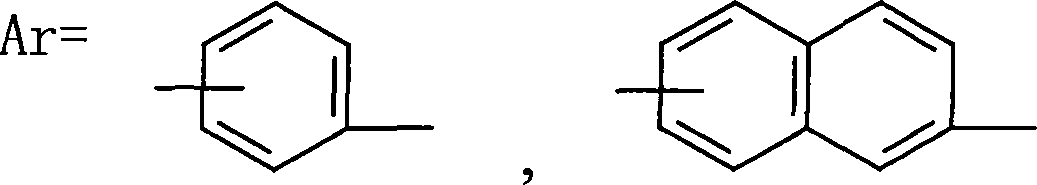

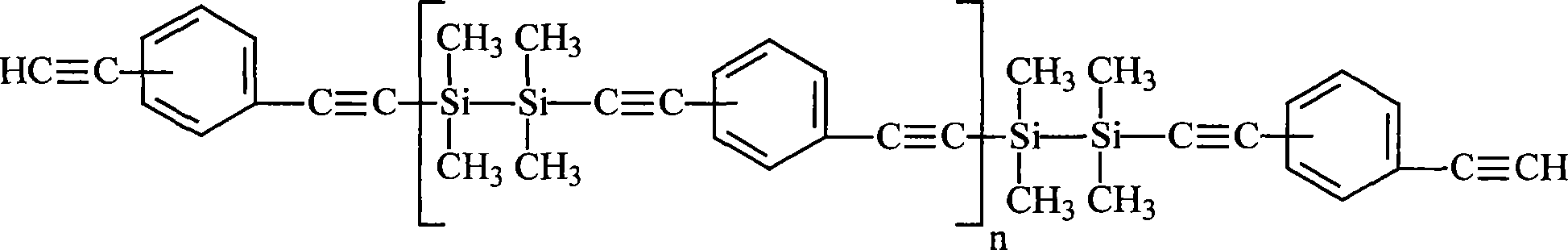

Aryne resin containing polysilicone and preparation method thereof

The invention relates to a polysilane-containing aryne resin represented as right, wherein n is 0-20, x and y are 0-20, R1, R2, R3 and R4 are CH3 and C6H5, or R1 is H, R2, R3 and R4 are CH3 and C6H5, or R1 and R3 are H, R2 and R4 are CH3 and C6H5. The preparation method of polysilane-containing aryne resin uses aryne Grignard reagent to be reacted with terminated chlorine polysilane, while terminated chlorine polysilane is prepared by chlorination process and sodium condensation method. The inventive polysilane-containing aryne resin has better processing character, mechnical character, heat endurance, oxidation resistance and fire-retardancy, which can form ceramic material in high temperature and own better cementation with reinforcing fiber, with wide application in resin substrate and ceramic boving precursor.

Owner:EAST CHINA UNIV OF SCI & TECH

Metallizable and Metallized Polyolefin Films and a Process of Making Same

InactiveUS20110195259A1Good metal adhesionAcceptable barrier propertyPlastic/resin/waxes insulatorsSynthetic resin layered productsPolysilanePolyolefin

Owner:JINDAL FILMS AMERICAS LLC

Light emitting diode (LED) high-power encapsulation silica gel

The invention relates to a light emitting diode (LED) high-power encapsulation silica gel, which consists of gel A and gel B in parts by weight, wherein the gel A comprises an ingredient of a resin part, and the gel B comprises an ingredient of a cross linking agent part, wherein the gel A comprises ingredients consisting of 100 parts of vinyl phenyl polysiloxane, 50 to 100 parts of vinyl polysiloxane and 0.02 to 2 parts of catalysts, the gel B comprises ingredients consisting of 100 parts of hydrogen phenyl polysiloxane, 50 to 100 parts of hydrogen polysiloxane and 0.01 to 2 parts of polymerization inhibitors, catalysts are platinum catalysts with the platinum content between 1000 and 7000ppm, and the polymerization inhibitors are alkynol substances. The LED high-power encapsulation silica gel provided by the invention adopts the storage modes of the gel A and the gel B, the production process is simple and can be easily implemented, the storage is convenient without special requirements, the storage life is long, and the silica gel is favorable for production. In the use process, the silica gel formed through simple mixing has the advantages of strong bonding force, high intensity, high light transmission rate, good light refractivity and excellent high-temperature-resistance and aging-resistance capability.

Owner:东莞市永固绝缘材料有限公司

Method of manufacturing a replica mold and a replica mold

InactiveUS20080203271A1Good chemical resistanceHigh hardnessNanoinformaticsPhotomechanical apparatusHeat resistanceHardness

There are provided a replica mold which is excellent in transferring a pattern of a master mold, and also has notably excellent hardness, transparency, heat resistance and chemical resistance, and a simple and inexpensive method of manufacturing the replica mold. A method of manufacturing a replica mold according to the present invention includes the steps of: applying, to a substrate, a replica mold material containing a polysilane and a silicone compound; pressing a master mold on which a predetermined minute pattern has been formed to the replica mold material which has been applied to the substrate; irradiating energy rays from a side of the substrate while the master mold is contacted by press with the replica mold material; releasing the master mold; and irradiating the replica mold material with energy rays from a side to which the master mold has been pressed.

Owner:RIKEN +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com