Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

157results about How to "Average thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

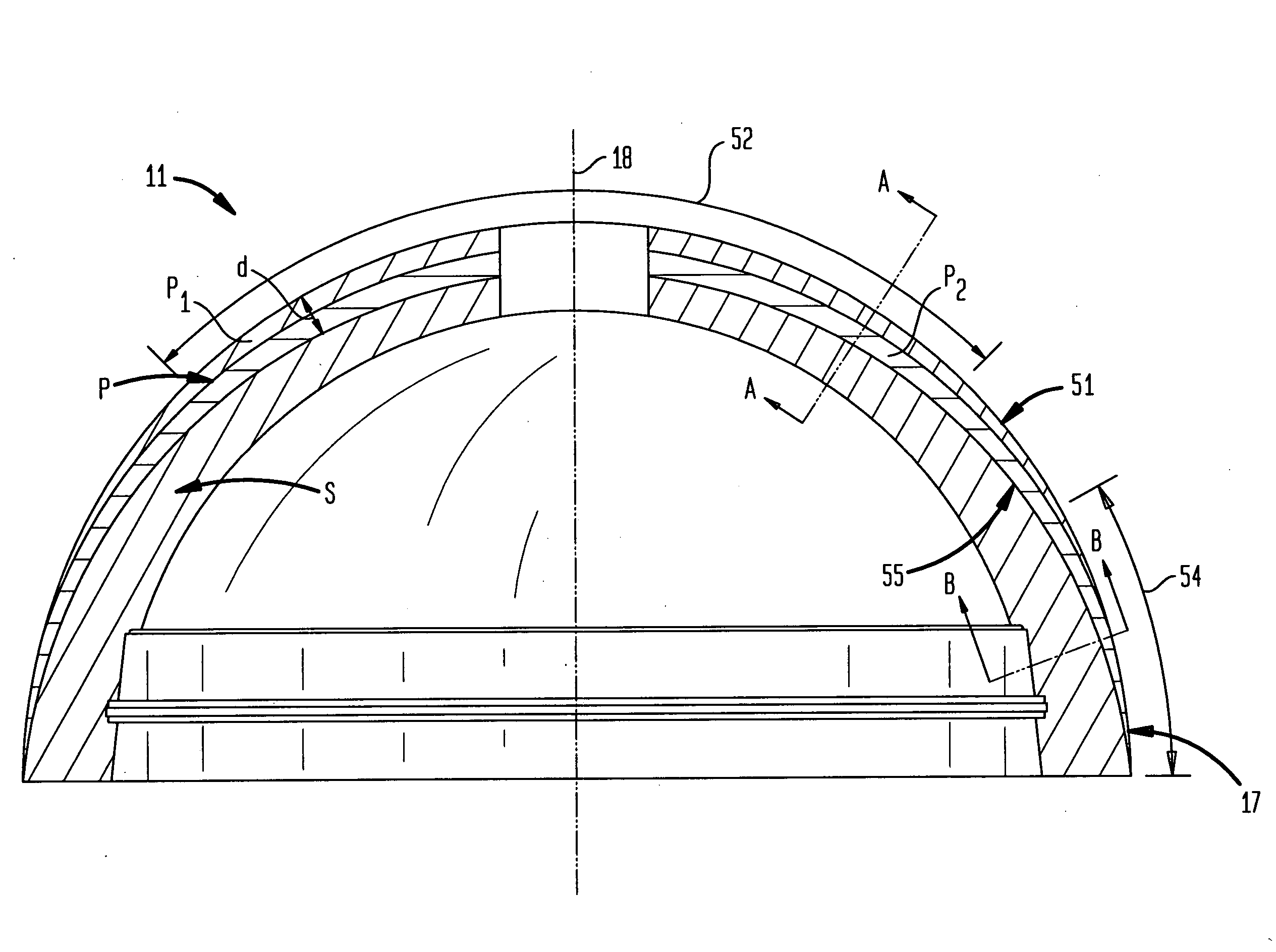

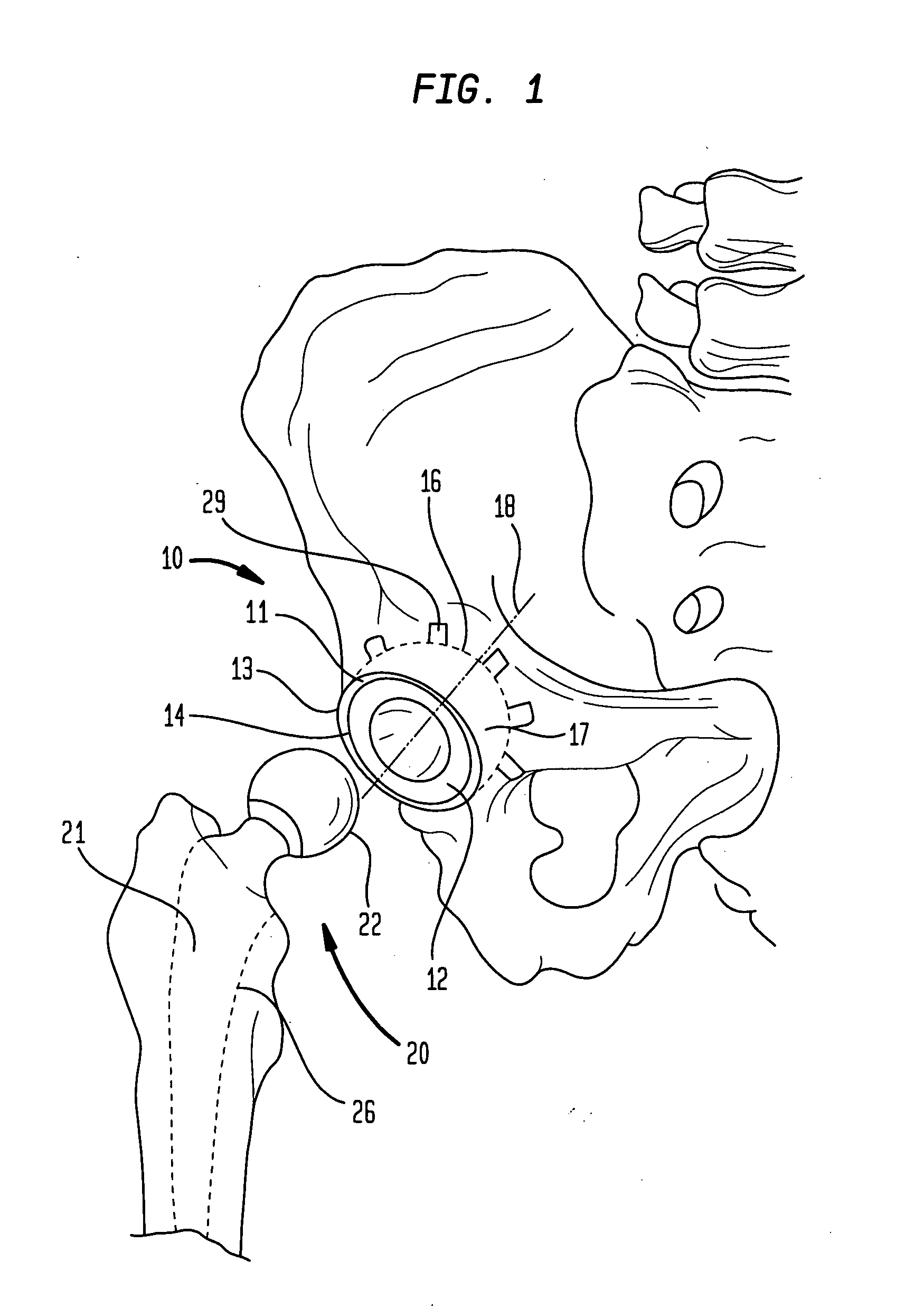

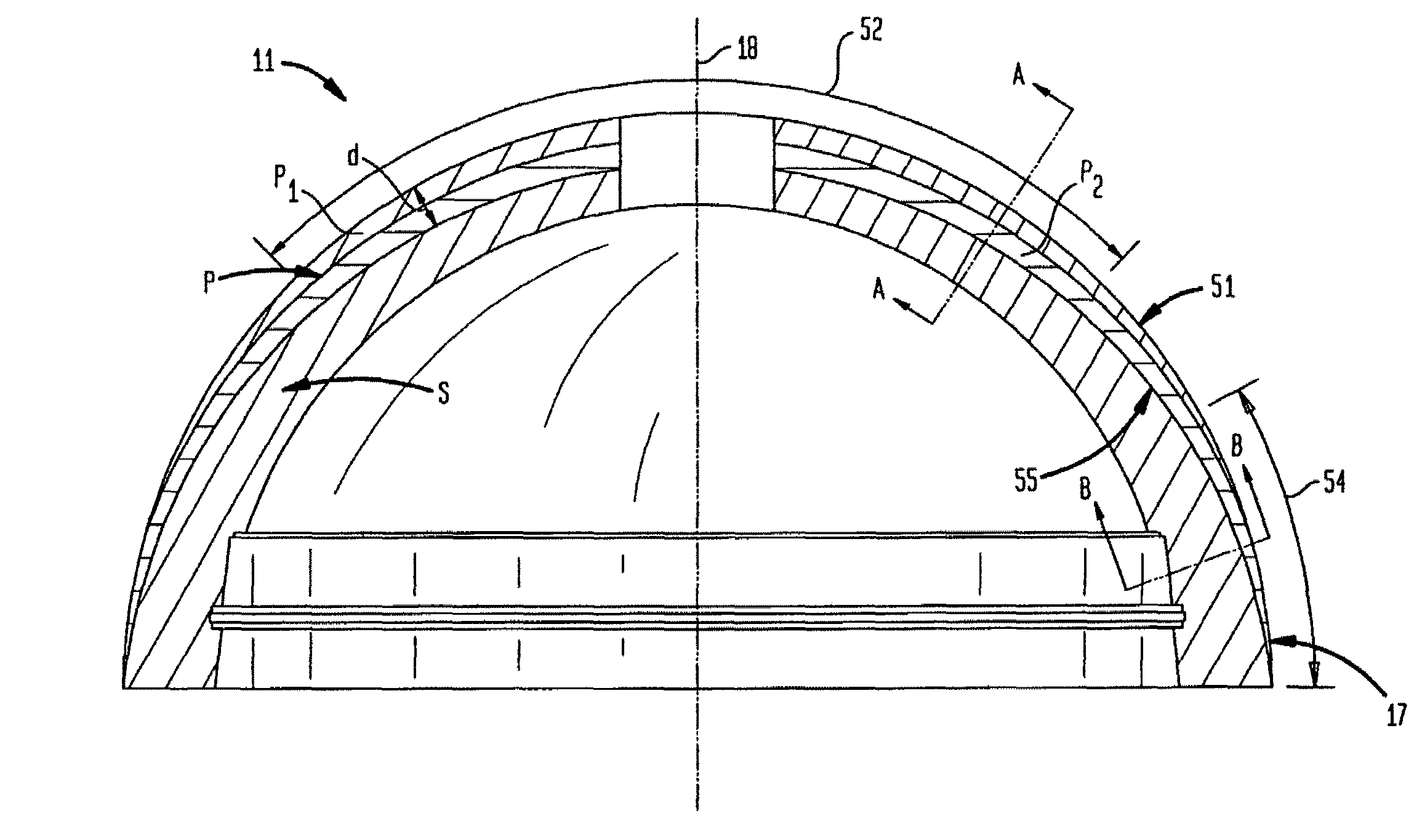

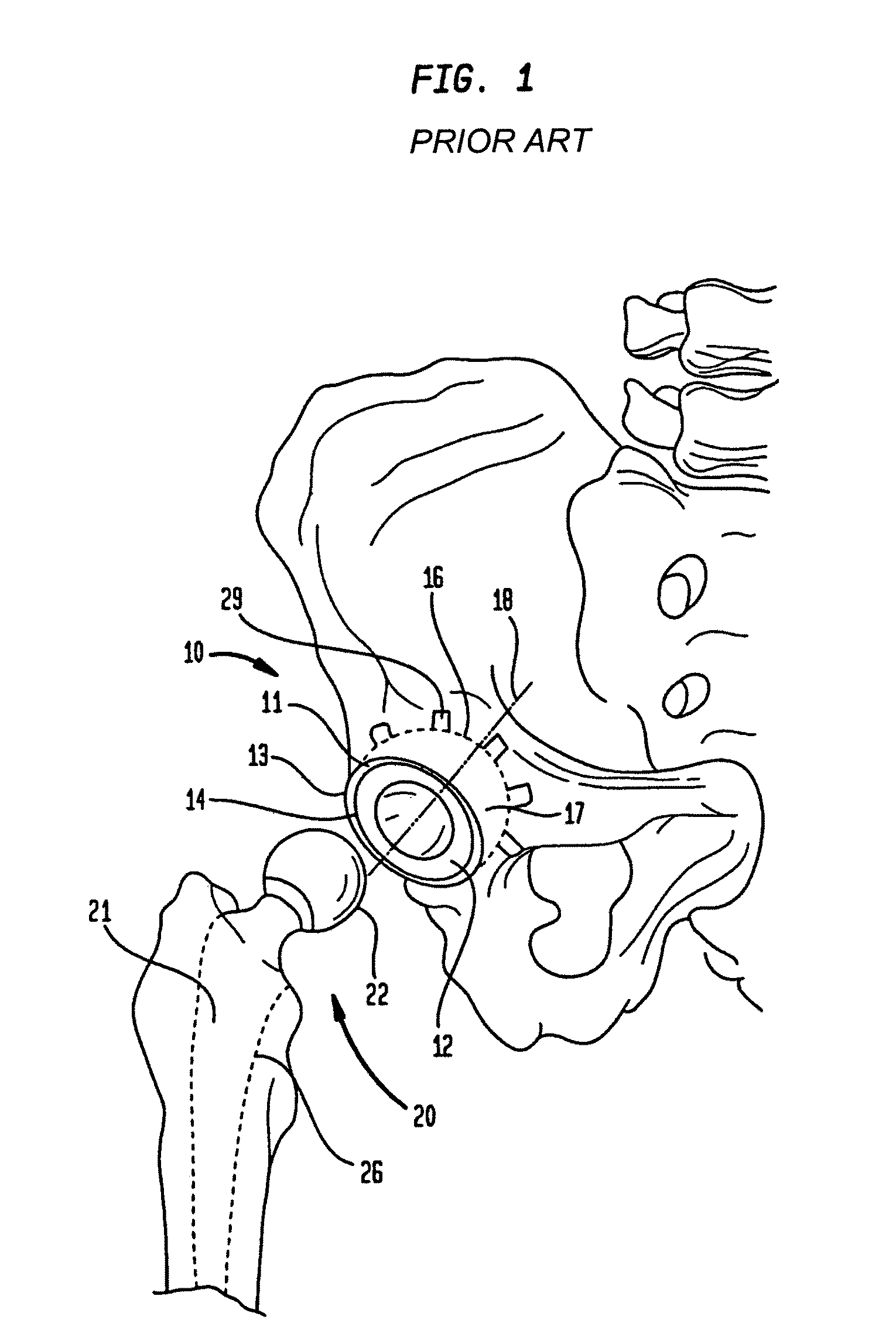

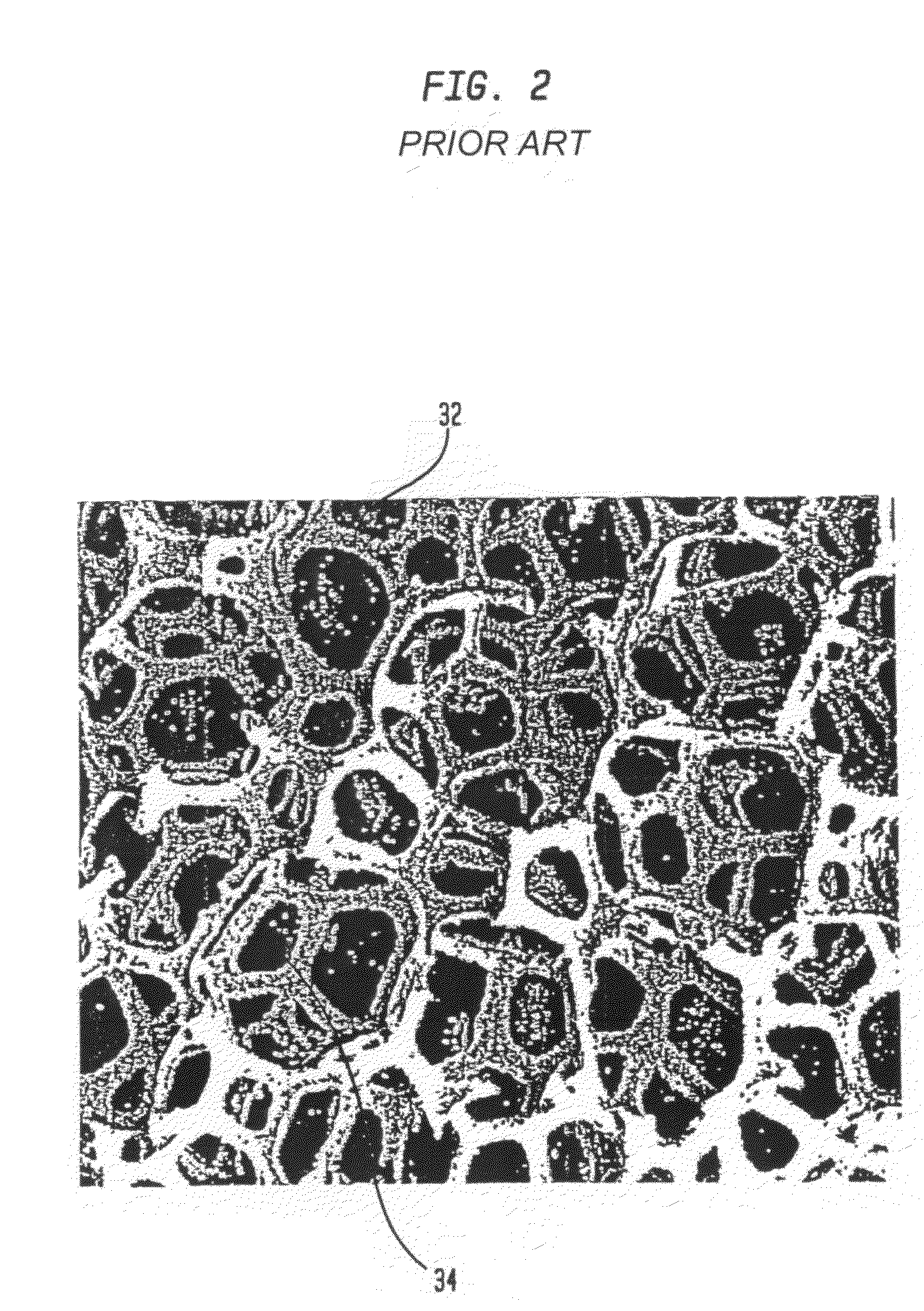

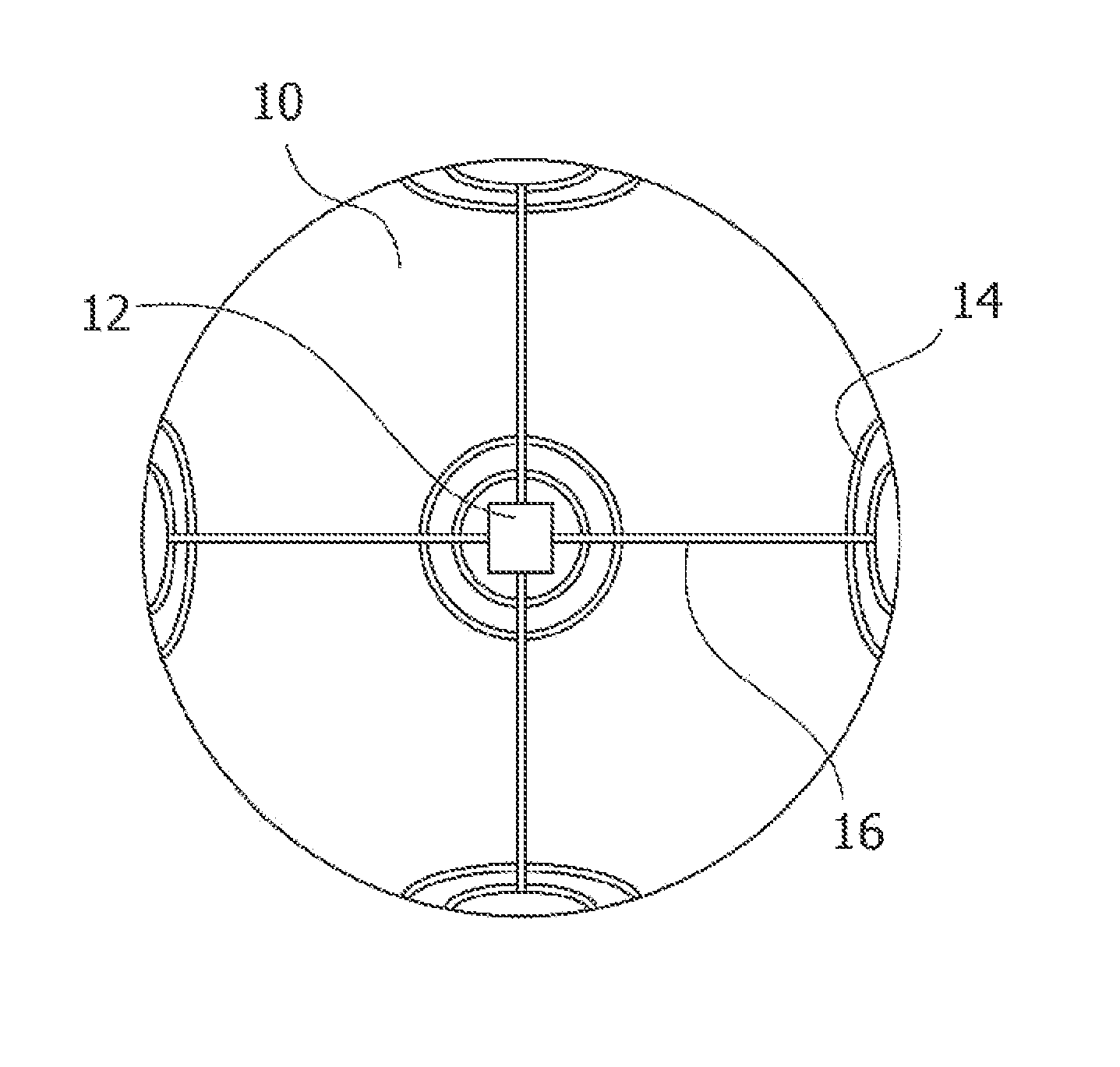

Gradient porous implant

ActiveUS20070150068A1Optimize performanceOptimizes various mechanical and biological requirements of the implants performanceAdditive manufacturing apparatusBone implantPorous metalMedical treatment

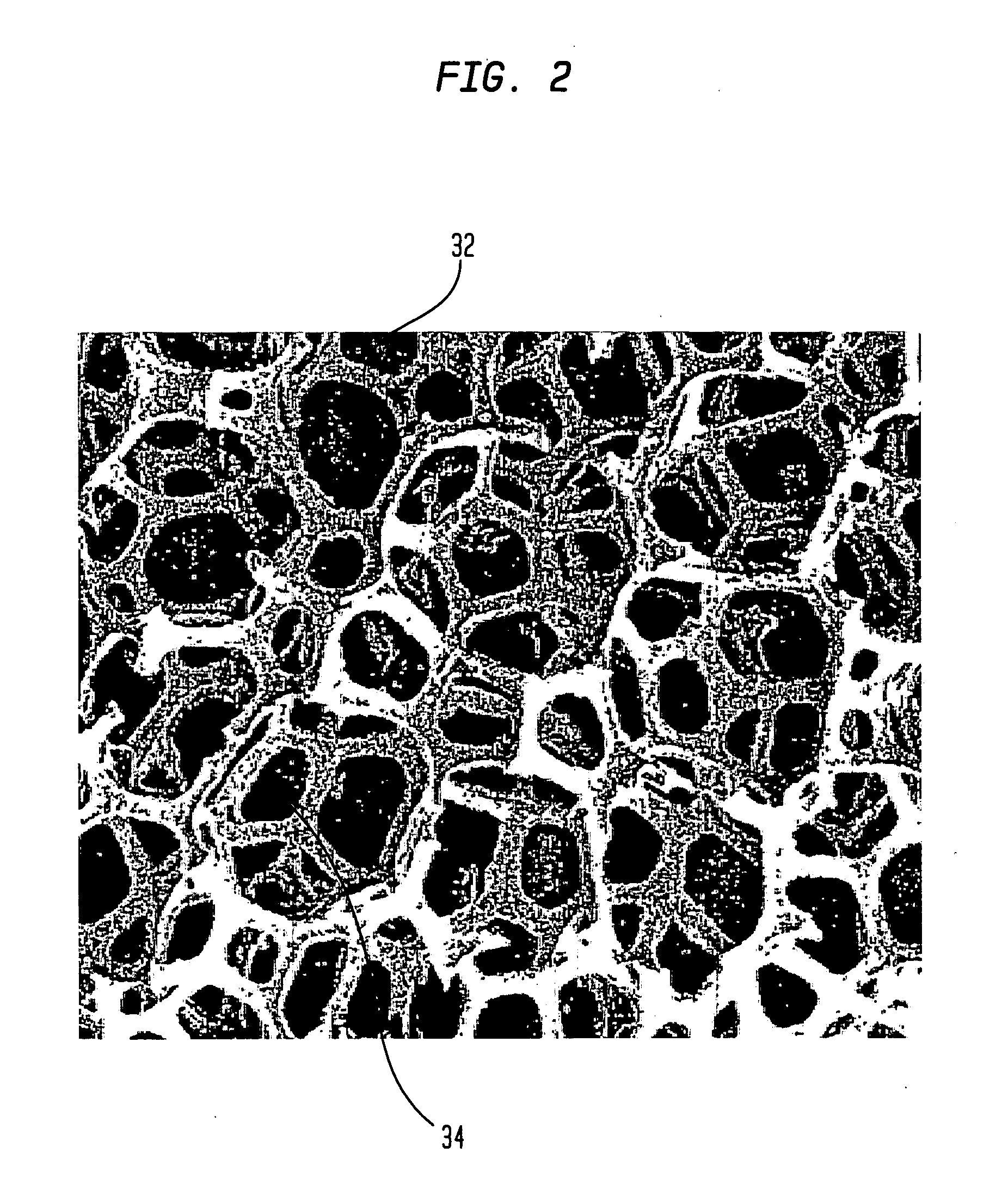

An implantable medical device includes a porous metal foam or foam-like structure having pores defined by metal struts or webs wherein the porous structure has directionally controlled pore characteristics. The pore characteristics controlled include one or more of the metal structure porosity, pore size, pore shape, pore size distribution and strut thickness. The pore characteristics may vary in one or more directions throughout the structure. Preferably the pore characteristics are controlled to match the porous metal structure to various mechanical and biological requirements of different regions of the structure in order to optimize aspects of the implants performance and may vary not only over the surface of the porous structure but through the depth of the porous structure. The thickness of the porous metal structure may also be modified to establish a thickness profile that optimizes mechanical and biological requirements of the implants performance. Acetabular cup embodiments of the invention are described. Various methods of manufacturing implants having directionally controlled pore characteristics are described.

Owner:HOWMEDICA OSTEONICS CORP

Gradient porous implant

ActiveUS7578851B2Optimizes various mechanical and biological requirements of the implants performanceIncreasing the thicknessAdditive manufacturing apparatusBone implantPorous implantMedical device

An implantable medical device includes a porous metal foam or foam-like structure having pores defined by metal struts or webs wherein the porous structure has directionally controlled pore characteristics. The pore characteristics controlled include one or more of the metal structure porosity, pore size, pore shape, pore size distribution and strut thickness. The pore characteristics may vary in one or more directions throughout the structure. Preferably the pore characteristics are controlled to match the porous metal structure to various mechanical and biological requirements of different regions of the structure in order to optimize aspects of the implants performance and may vary not only over the surface of the porous structure but through the depth of the porous structure. The thickness of the porous metal structure may also be modified to establish a thickness profile that optimizes mechanical and biological requirements of the implants performance. Acetabular cup embodiments of the invention are described. Various methods of manufacturing implants having directionally controlled pore characteristics are described.

Owner:HOWMEDICA OSTEONICS CORP

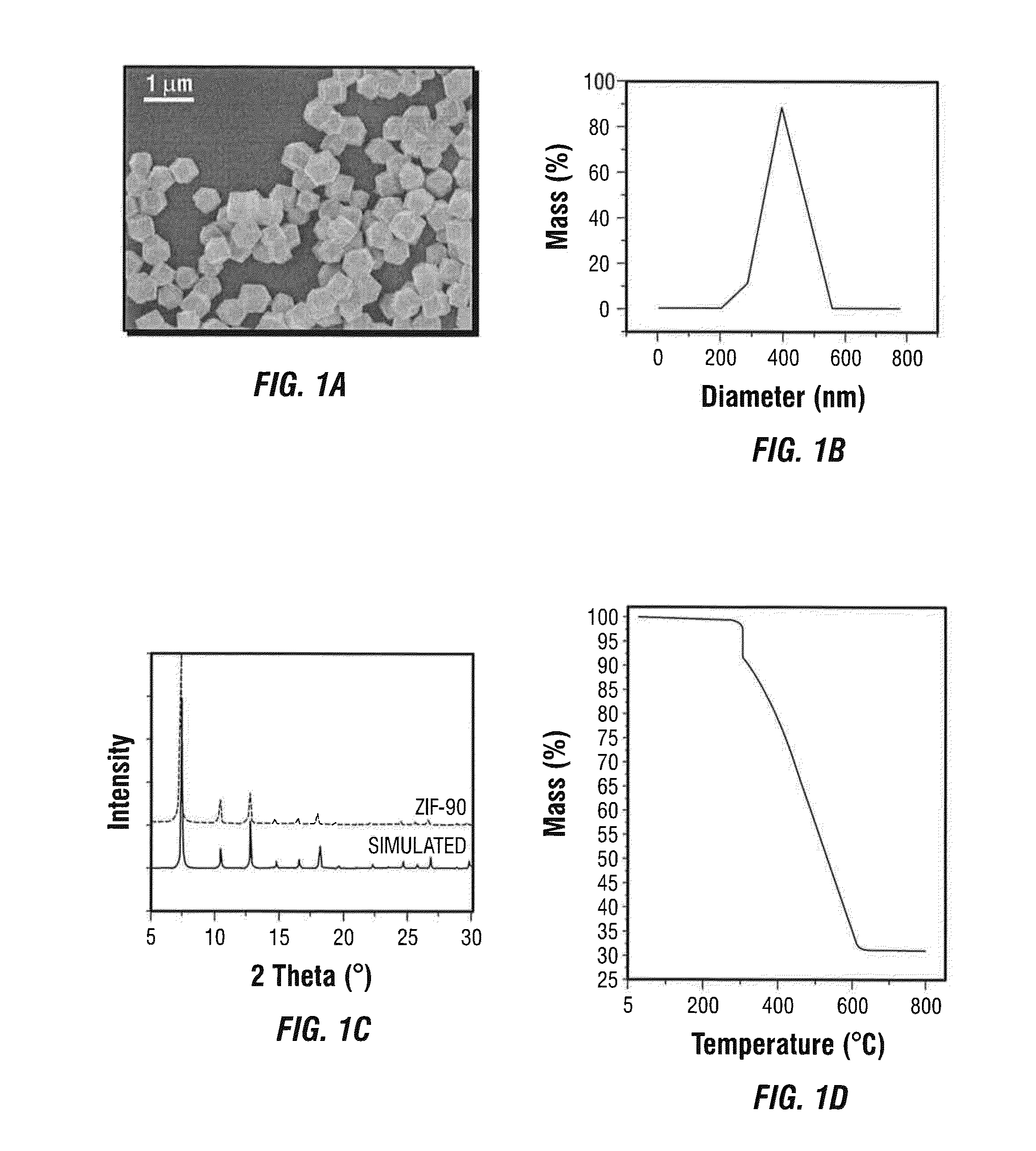

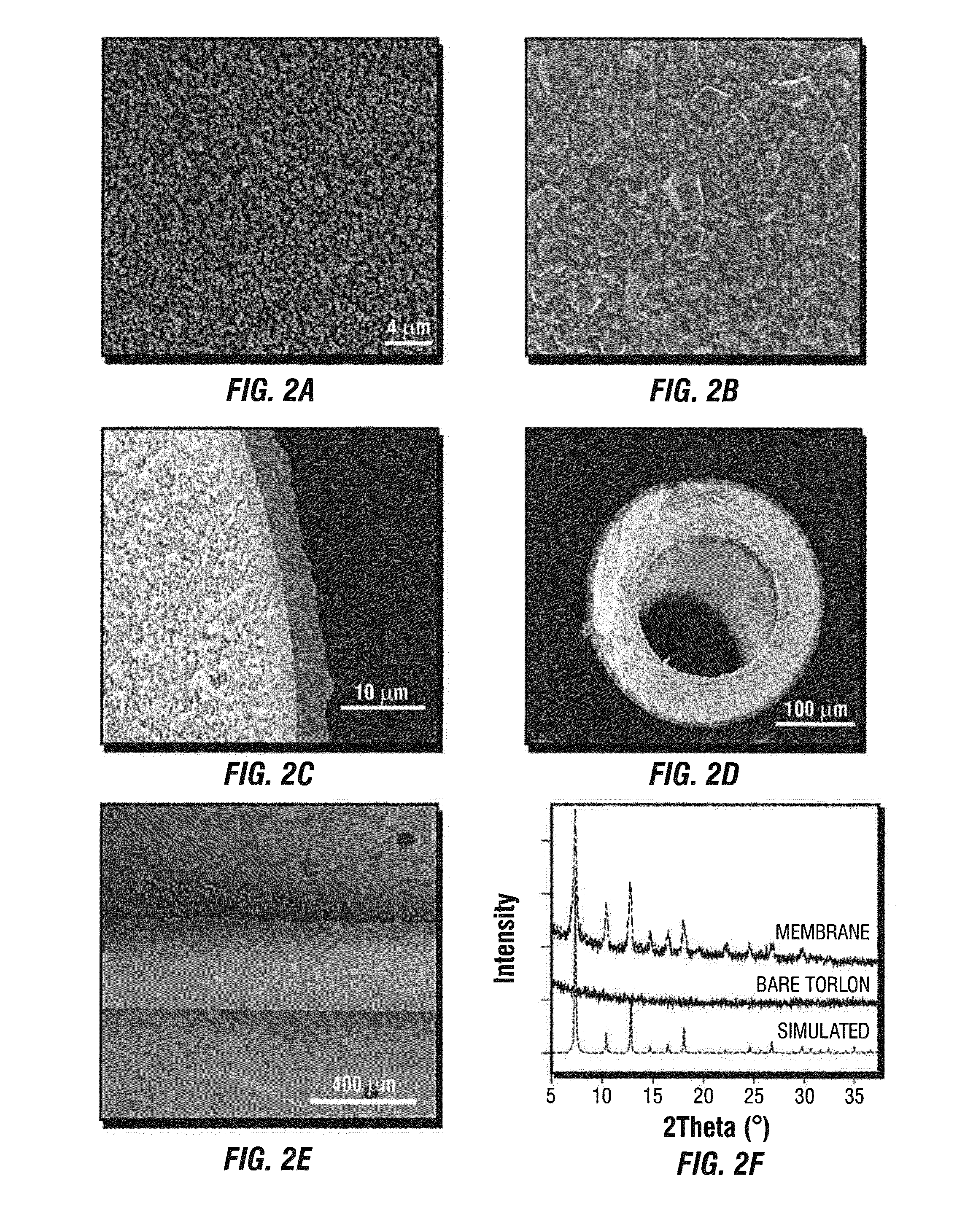

Metal-organic framework supported on porous polymer

ActiveUS20130313193A1Degrade polymer structureDegrade pore structureSemi-permeable membranesGas treatmentHollow fibreMetal-organic framework

The growth of continuous MOF membranes on porous polymeric supports is reported, wherein a dip-coating procedure is used to deposit a layer of seed MOF nanocrystals on the surfaces of porous polymers, preferably in the form of hollow fibers, and polycrystalline MOF membranes are subsequently grown at temperatures as low as 65° C. from precursor solutions. The present work opens the road to inexpensive and scalable fabrication of MOF membranes for large-scale separation applications.

Owner:GEORGIA TECH RES CORP

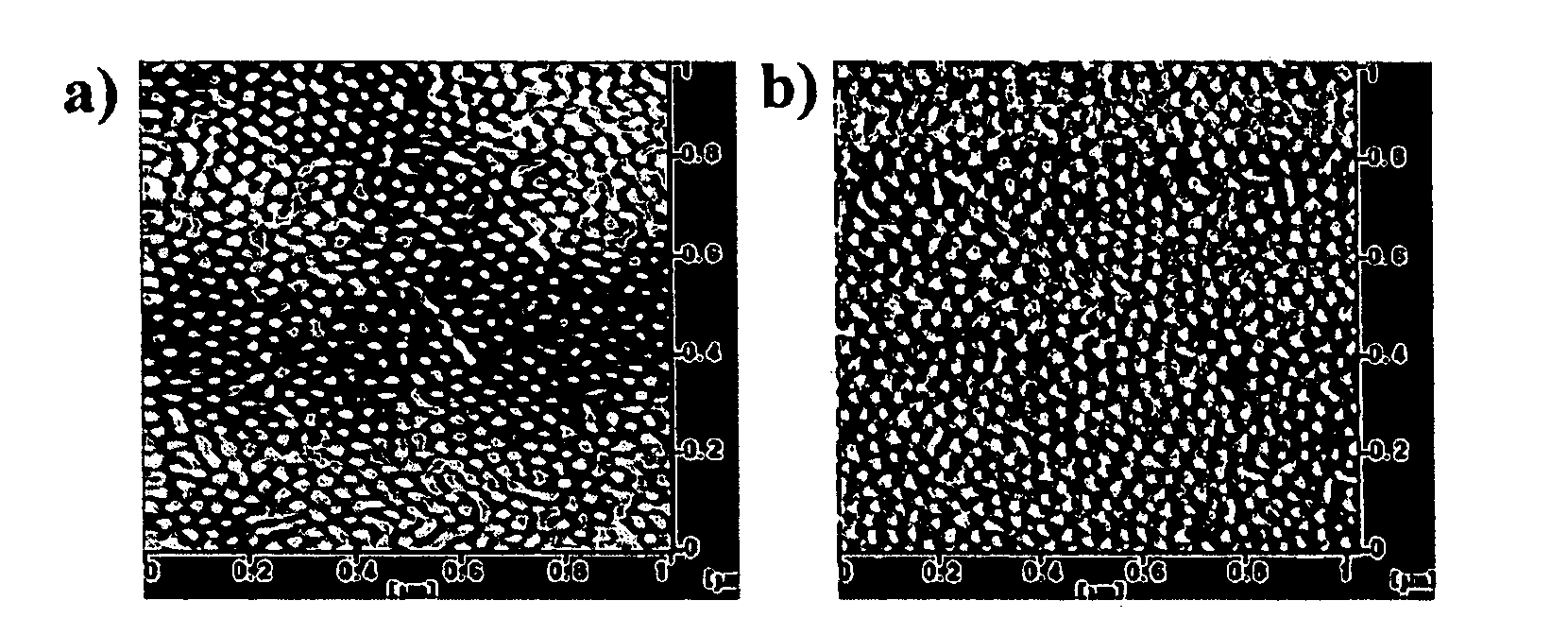

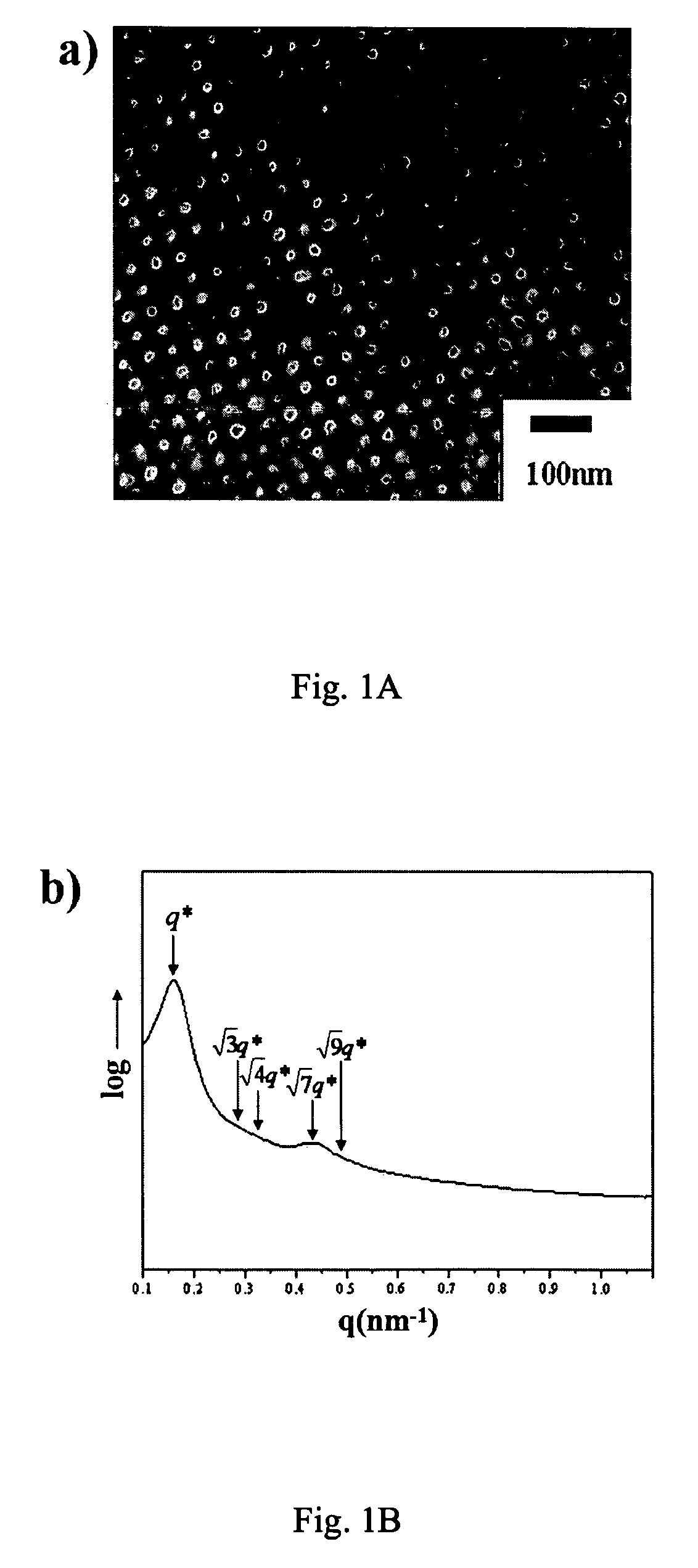

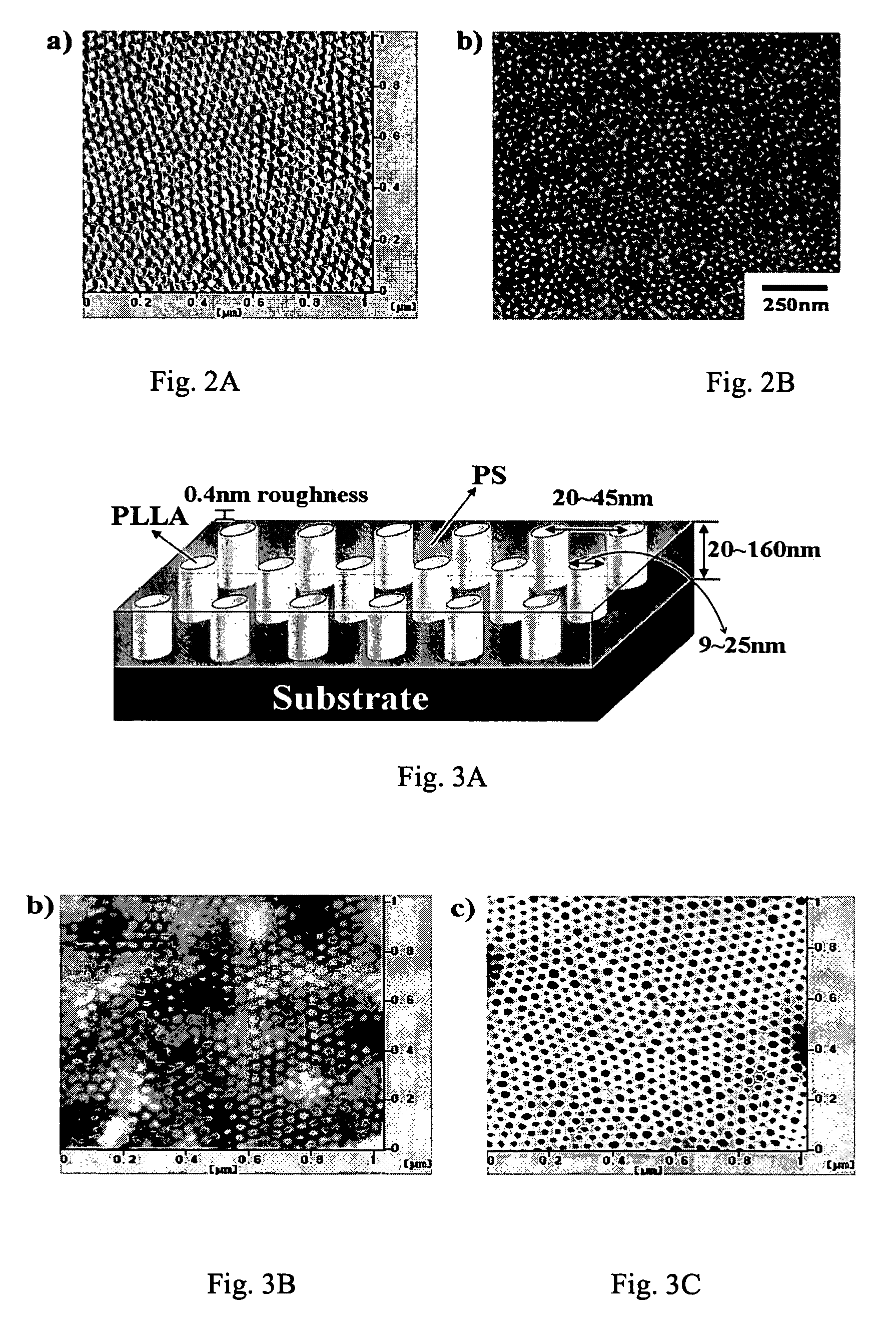

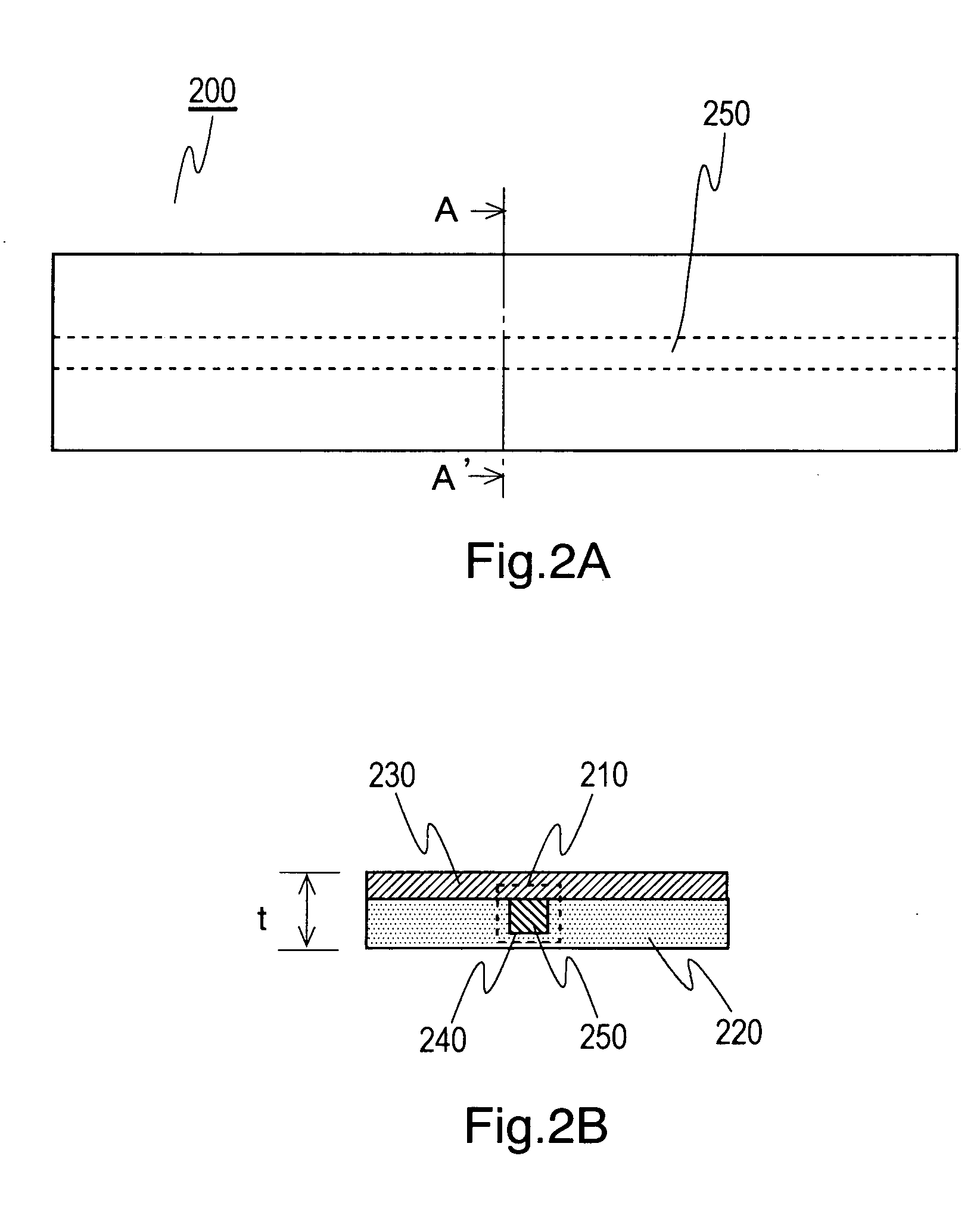

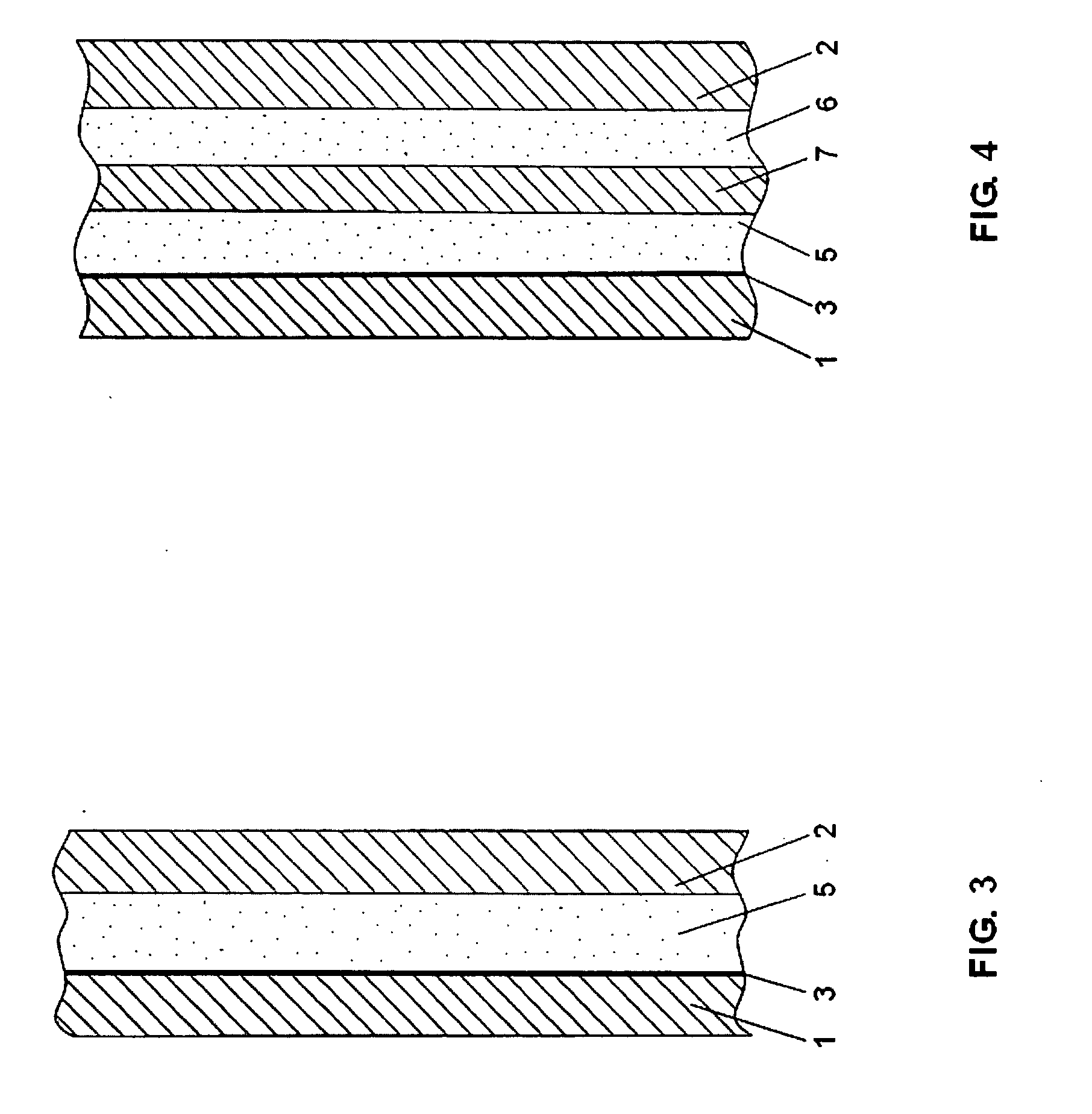

Nanopatterned templates from oriented degradable diblock copolymer thin films

InactiveUS7632544B2Improve applicabilityAverage thicknessMaterial nanotechnologyDecorative surface effectsCylindrical channelPolymer science

A nanopatterned template for use in manufacturing nanoscale objects. The nanopatterned template contains a nanoporous thin film with a periodically ordered porous geomorphology which is made from a process comprising the steps of: (a) using a block copolymerization process to prepare a block copolymer comprising first and second polymer blocks, the first and second polymer blocks being incompatible with each other; (b) forming a thin film under conditions such that the first polymer blocks form into a periodically ordered topology; and (c) selectively degrading the first polymer blocks to cause the thin film to become a nanoporous material with a periodically ordered porous geomorphology. In a preferred embodiment, the block copolymer is poly(styrene)-poly(L-lactide) (PS-PLLA) chiral block copolymer, the first polymer is poly(L-lactide), and the second polymer is polystyrene. Experimental results show that the first polymer blocks can be formed into a hexagonal cylindrical geomorphology with its axis perpendicular to a surface of the thin film. After hydrolysis to selectively degrade the first polymer blocks, a thin film having a series of repeated nanoscale hexagonal-cylindrical channels is obtained.

Owner:IND TECH RES INST

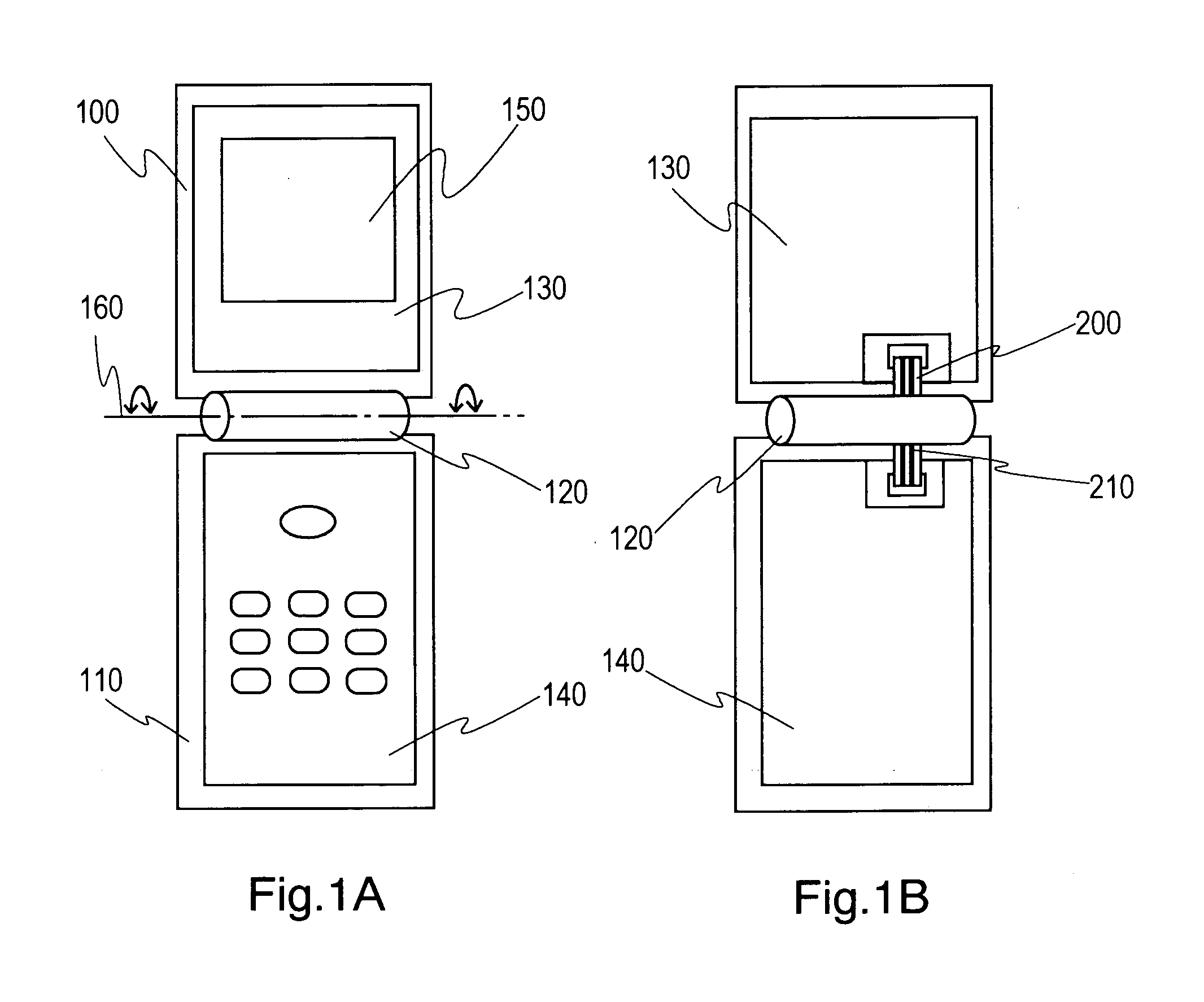

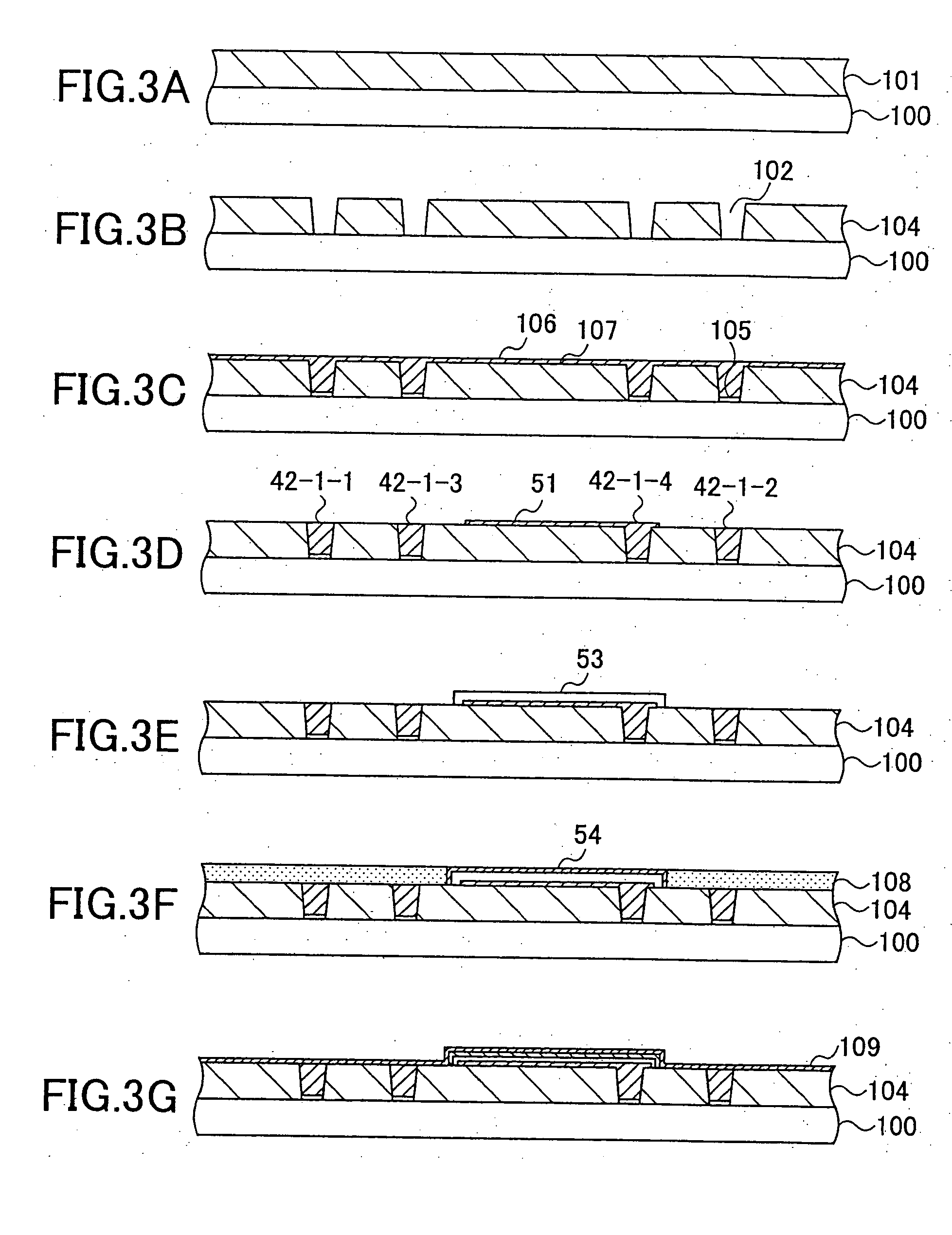

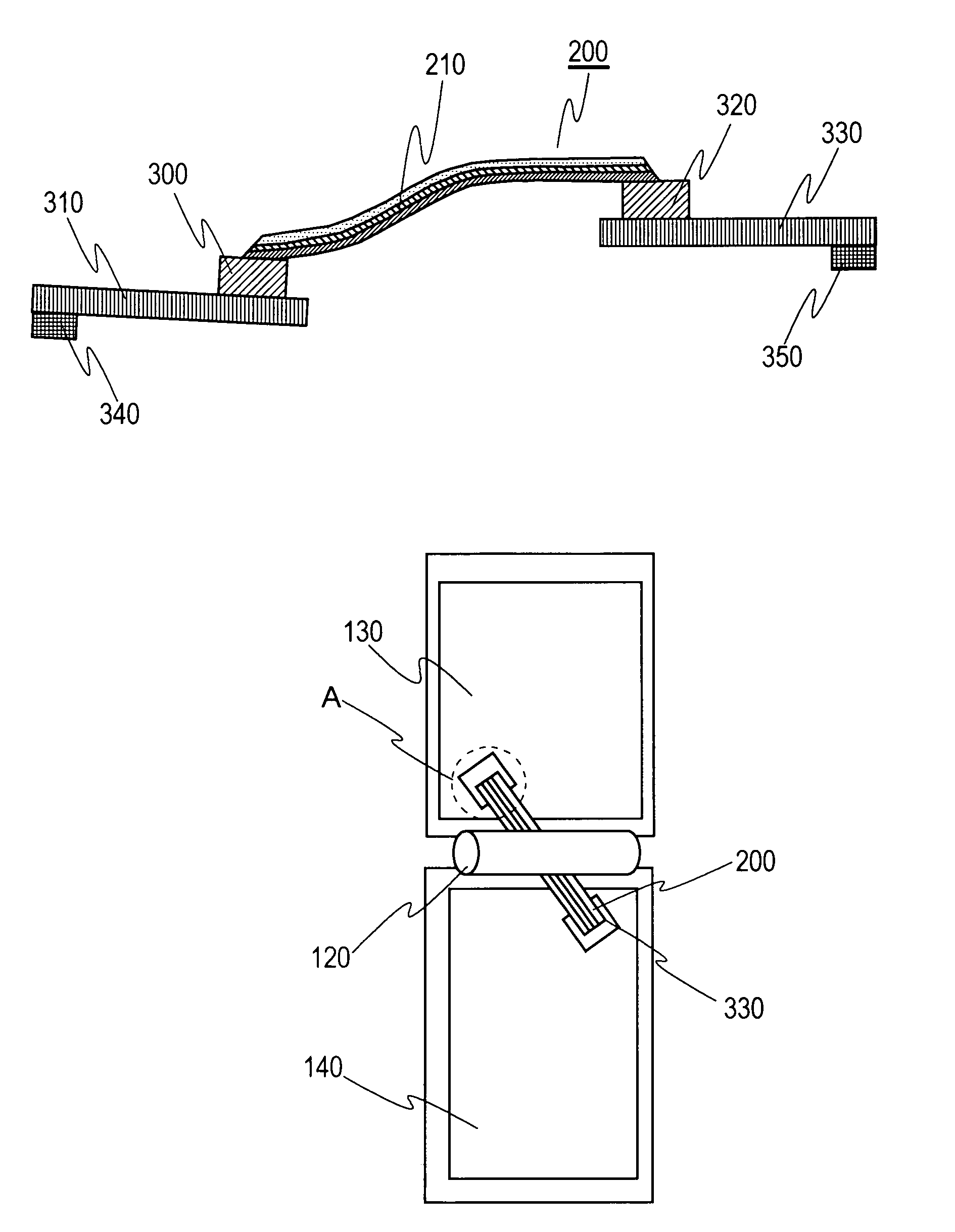

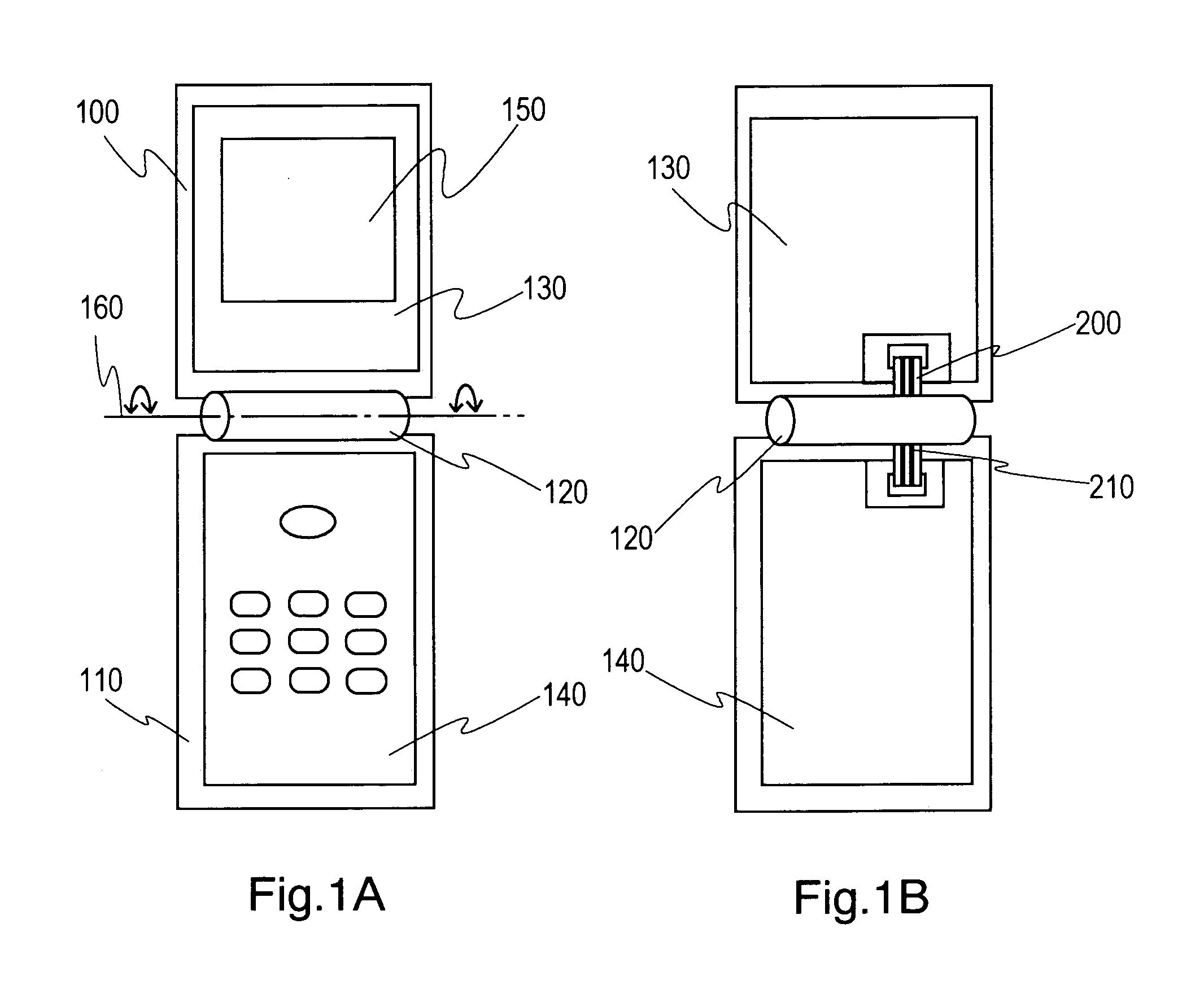

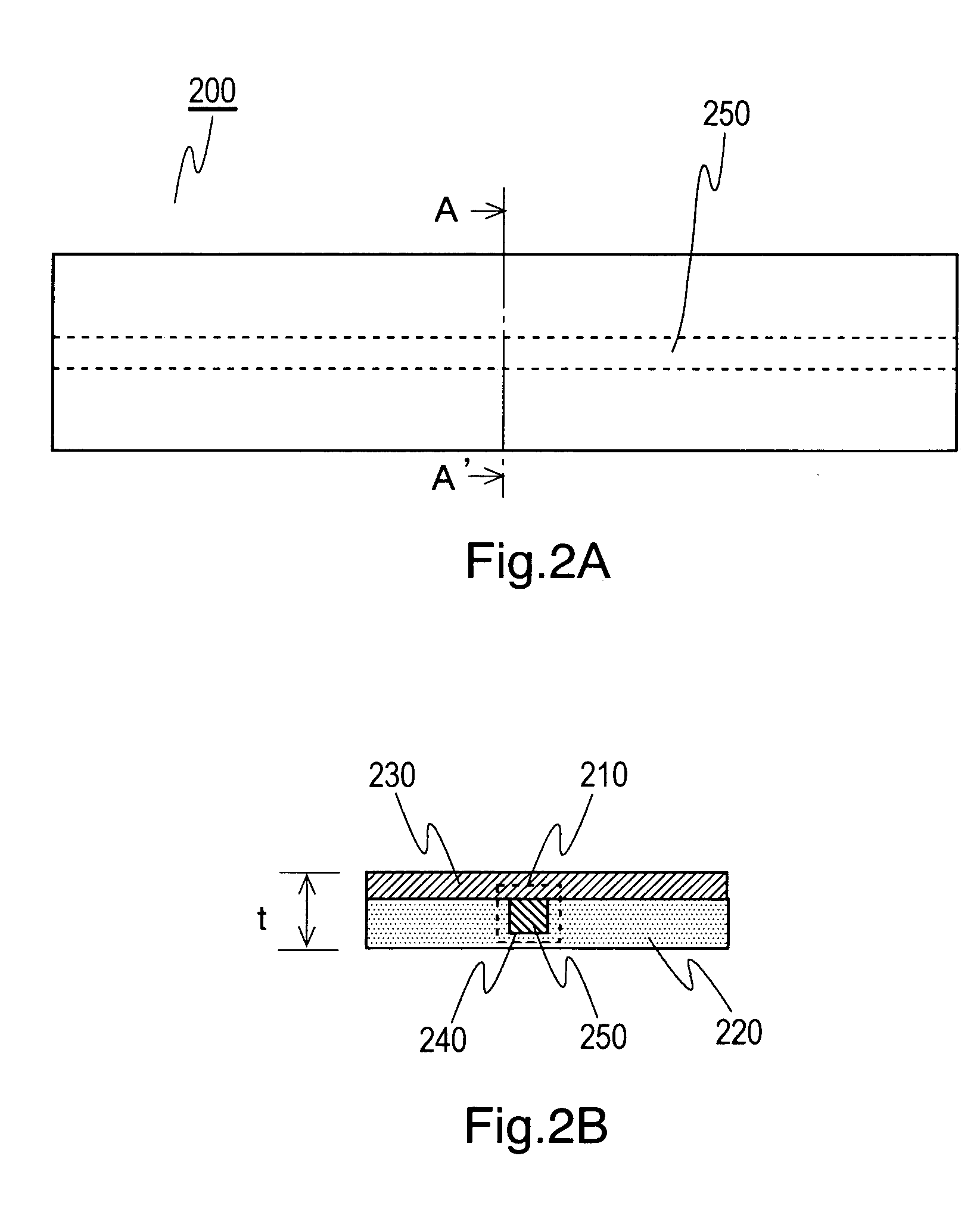

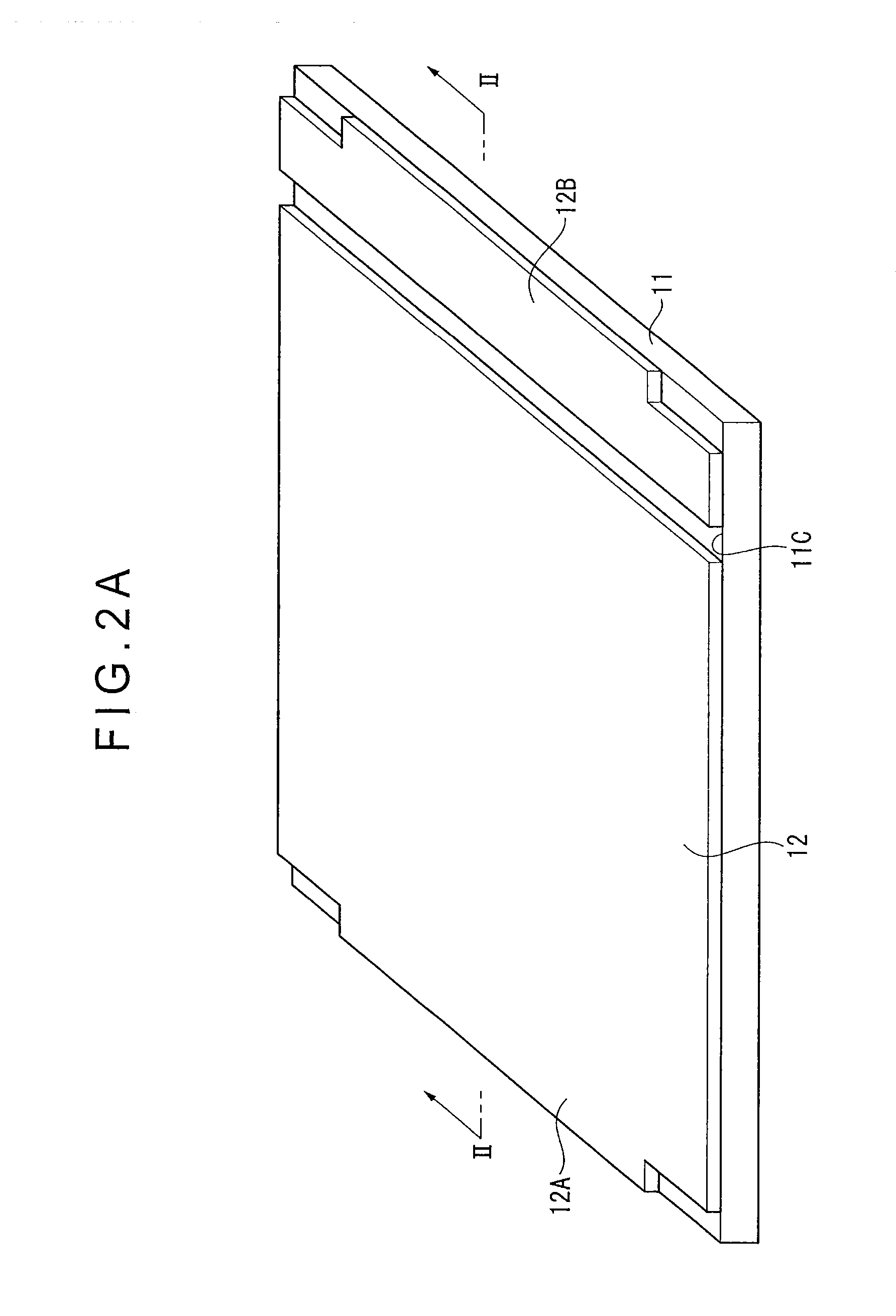

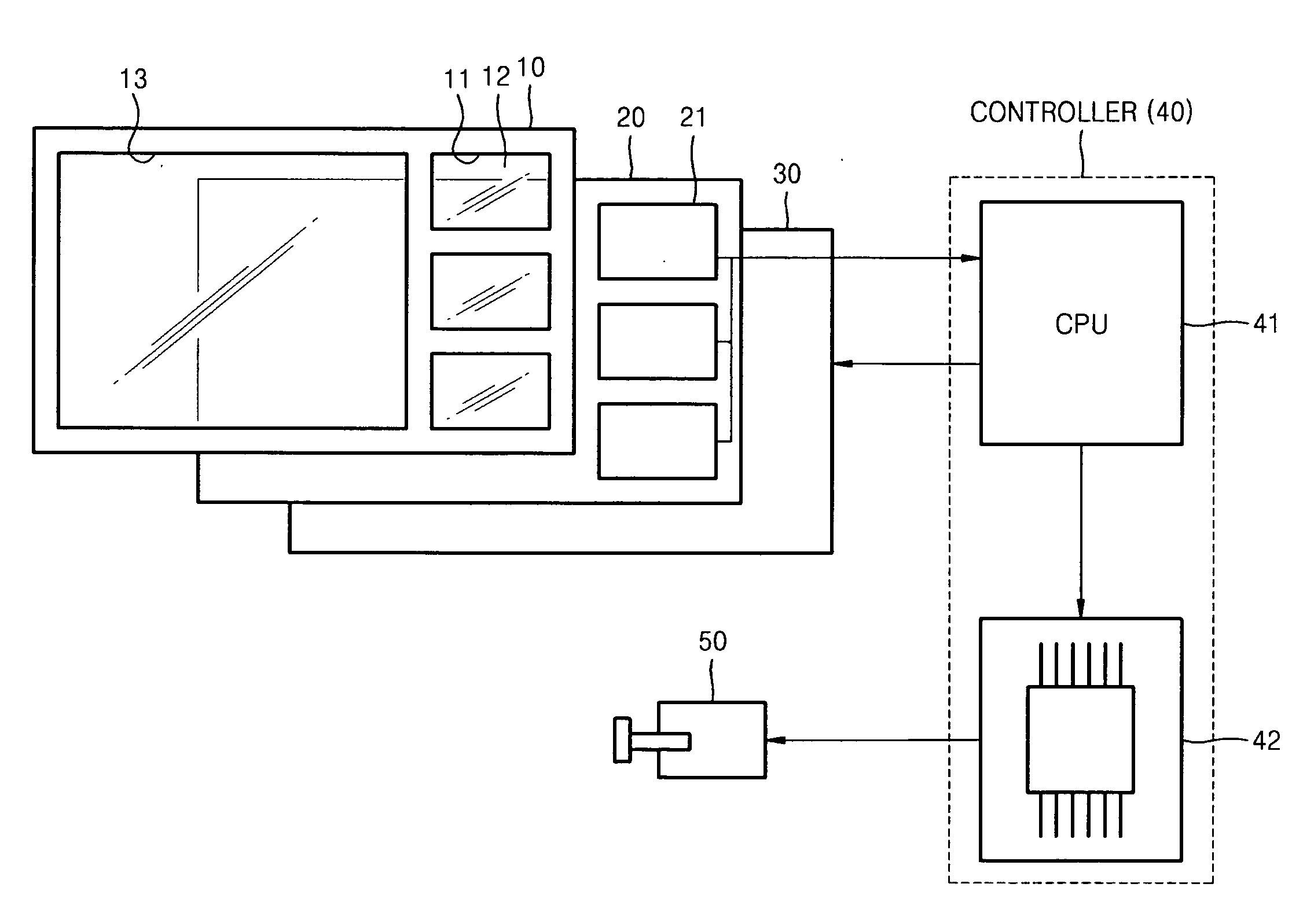

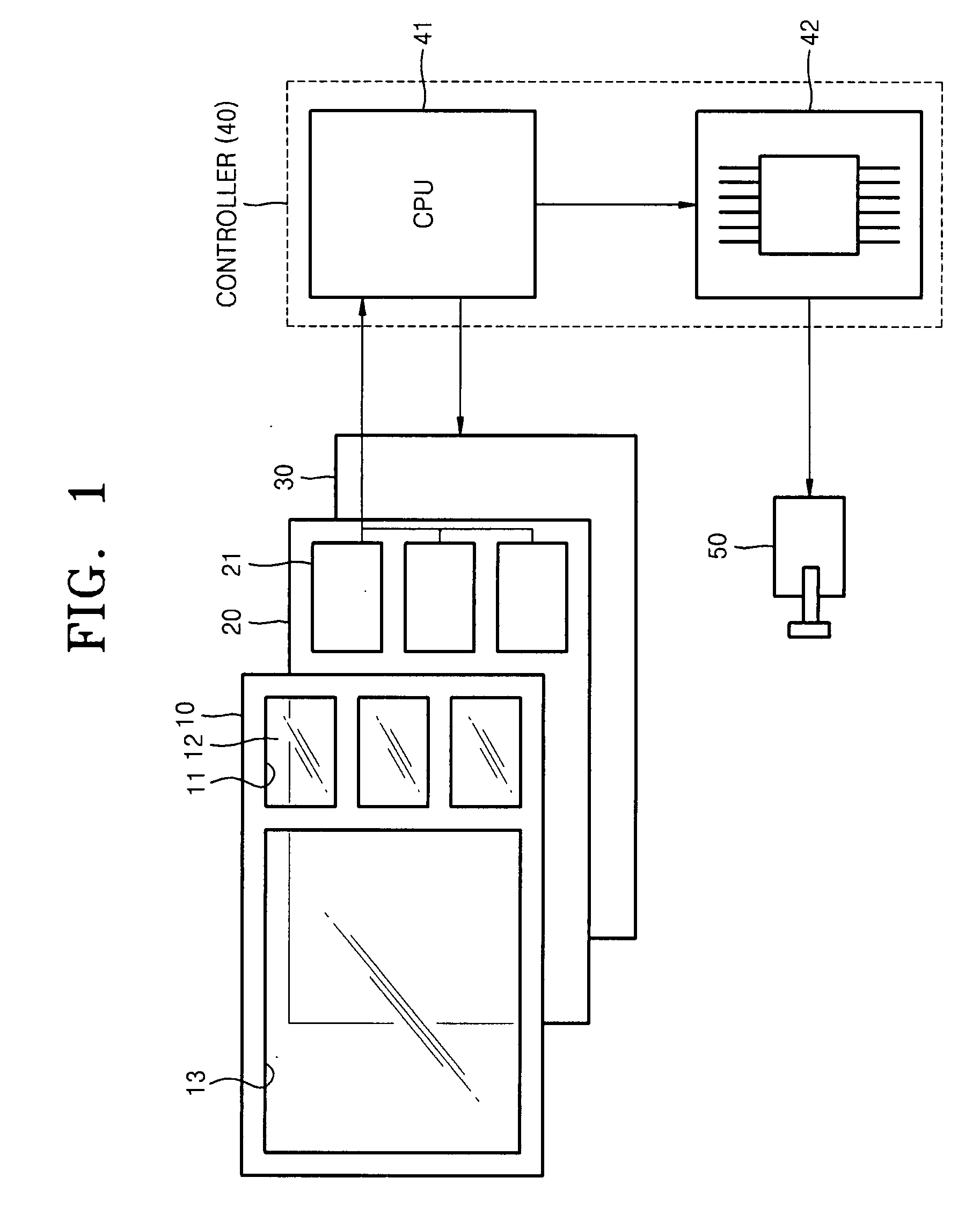

Portable device

ActiveUS20050201693A1Improve portabilityAverage thicknessPrinted circuit detailsCoupling light guidesEngineeringWaveguide

Provided is a portable device having such a configuration that a plurality of housings are connected functionally, wherein the thickness of a connection section between the housings is reduced so that the portability is improved. The portable device comprising: a first housing; a first board provided in the first housing; a second housing; a second board provided in the second housing; a connection section for connecting the first housing with the second housing in such a manner that the irrelative position can be changed; and an optical waveguide film having at least one optical waveguide for connecting the first board with the second board through optical wiring.

Owner:PANASONIC CORP

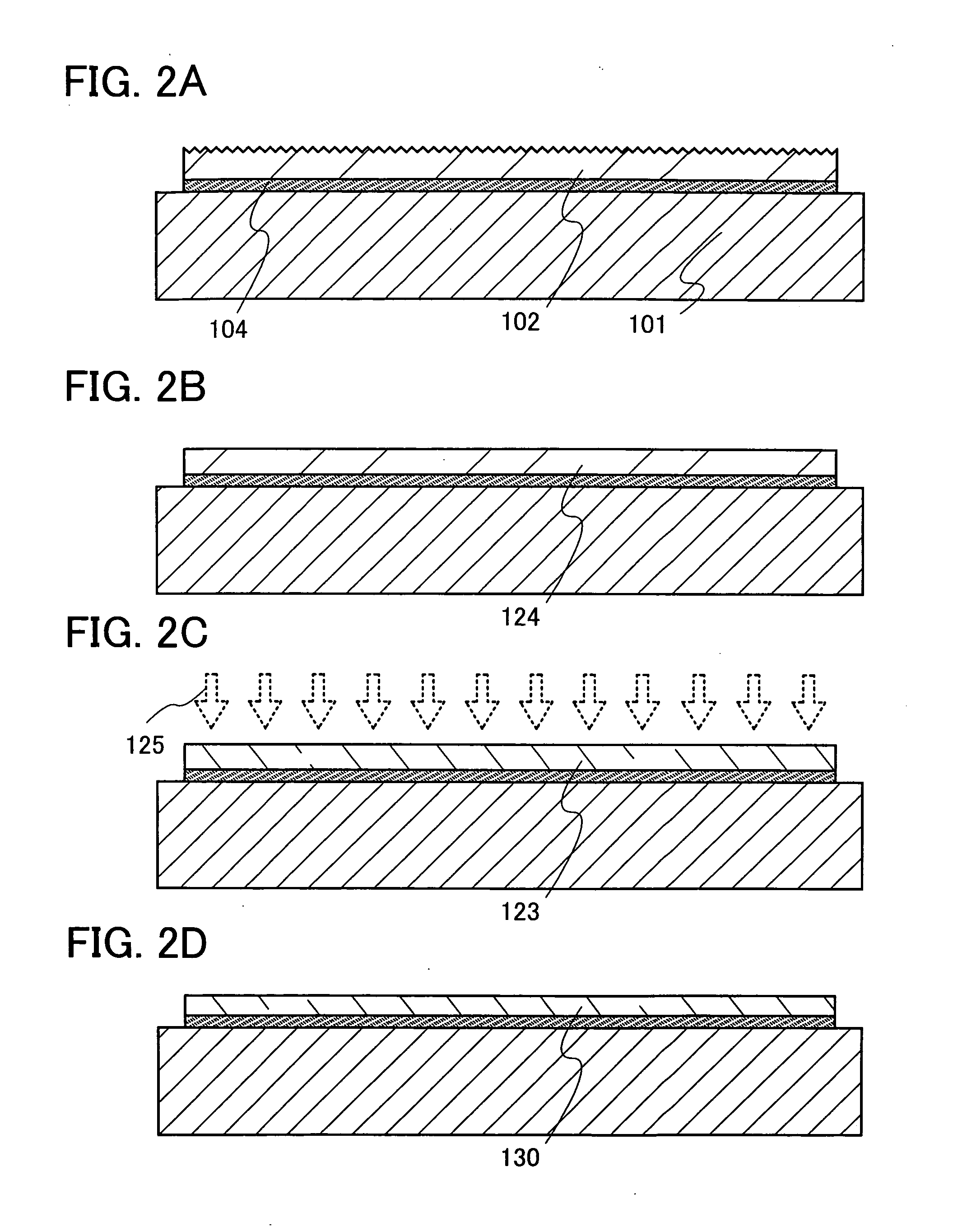

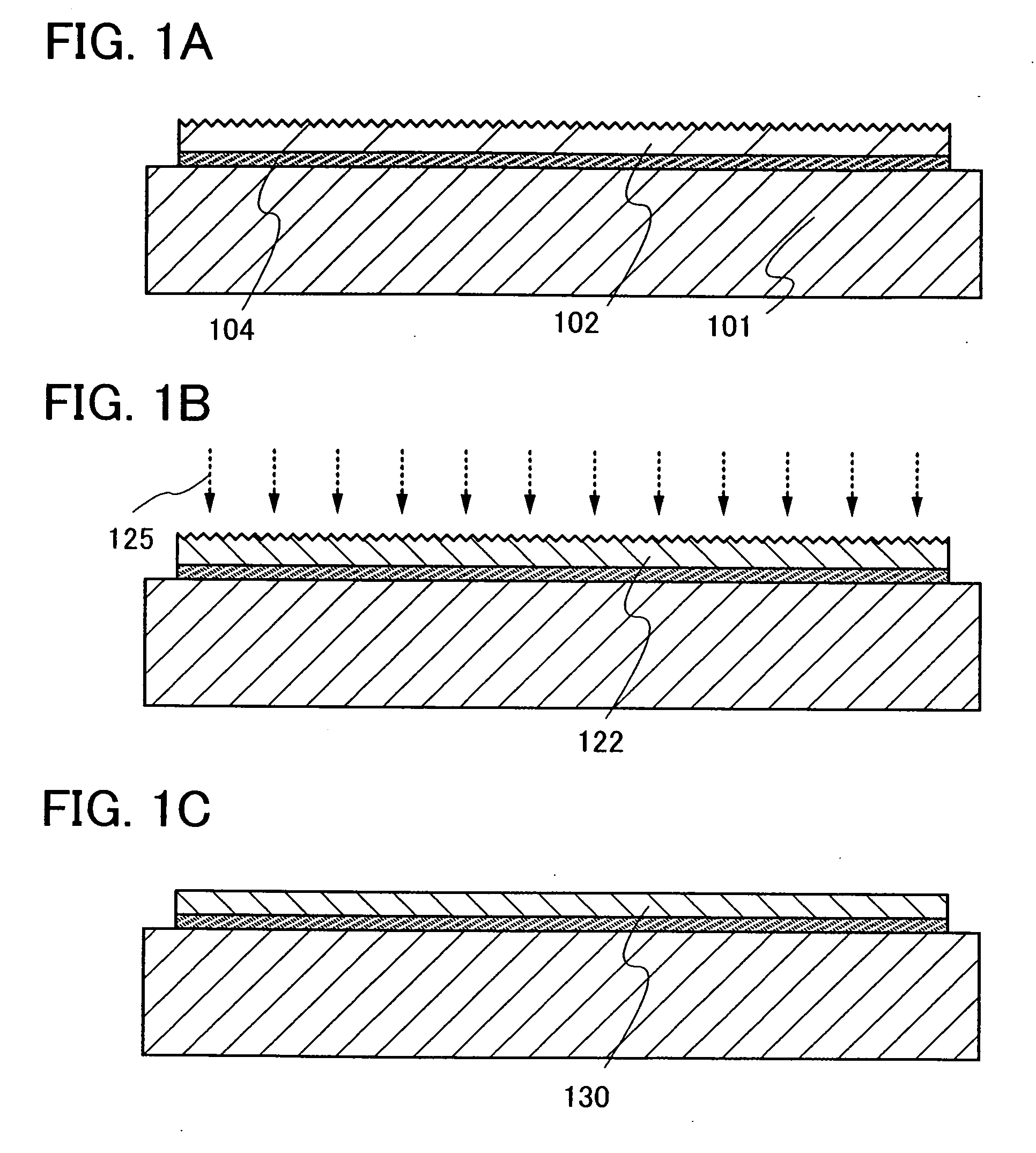

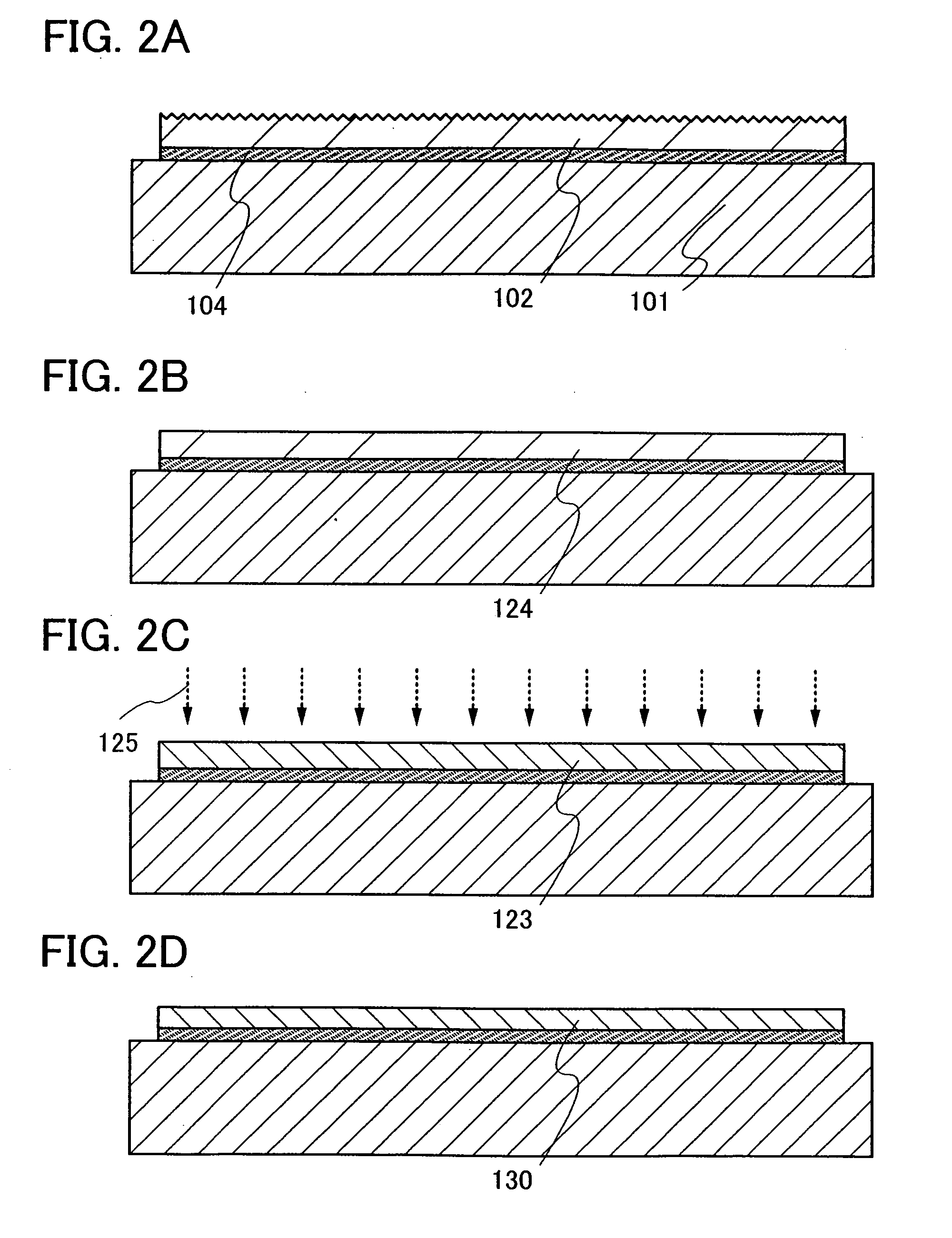

Method for manufacturing SOI substrate and method for manufacturing semiconductor device

InactiveUS20090004764A1Good planarityImprove performanceTransistorElectroluminescent light sourcesHigh energySingle crystal

To provide a method for manufacturing an SOI substrate provided with a single-crystal semiconductor layer which is suitable for practical use even when a substrate of which heat-resistant temperature is low, such as a glass substrate, is used, and to manufacture a highly reliable semiconductor device using such an SOI substrate. A semiconductor layer, which is separated from a semiconductor substrate and bonded to a supporting substrate having an insulating surface, is heated by supplying high energy by using at least one kind of particles having the high energy, and polishing treatment is performed on the heated surface of the semiconductor layer. At least part of a region of the semiconductor layer can be melted by the heat treatment by supplying high energy to reduce crystal defects in the semiconductor layer. Further, the surface of the semiconductor layer can be polished and planarized by the polishing treatment.

Owner:SEMICON ENERGY LAB CO LTD

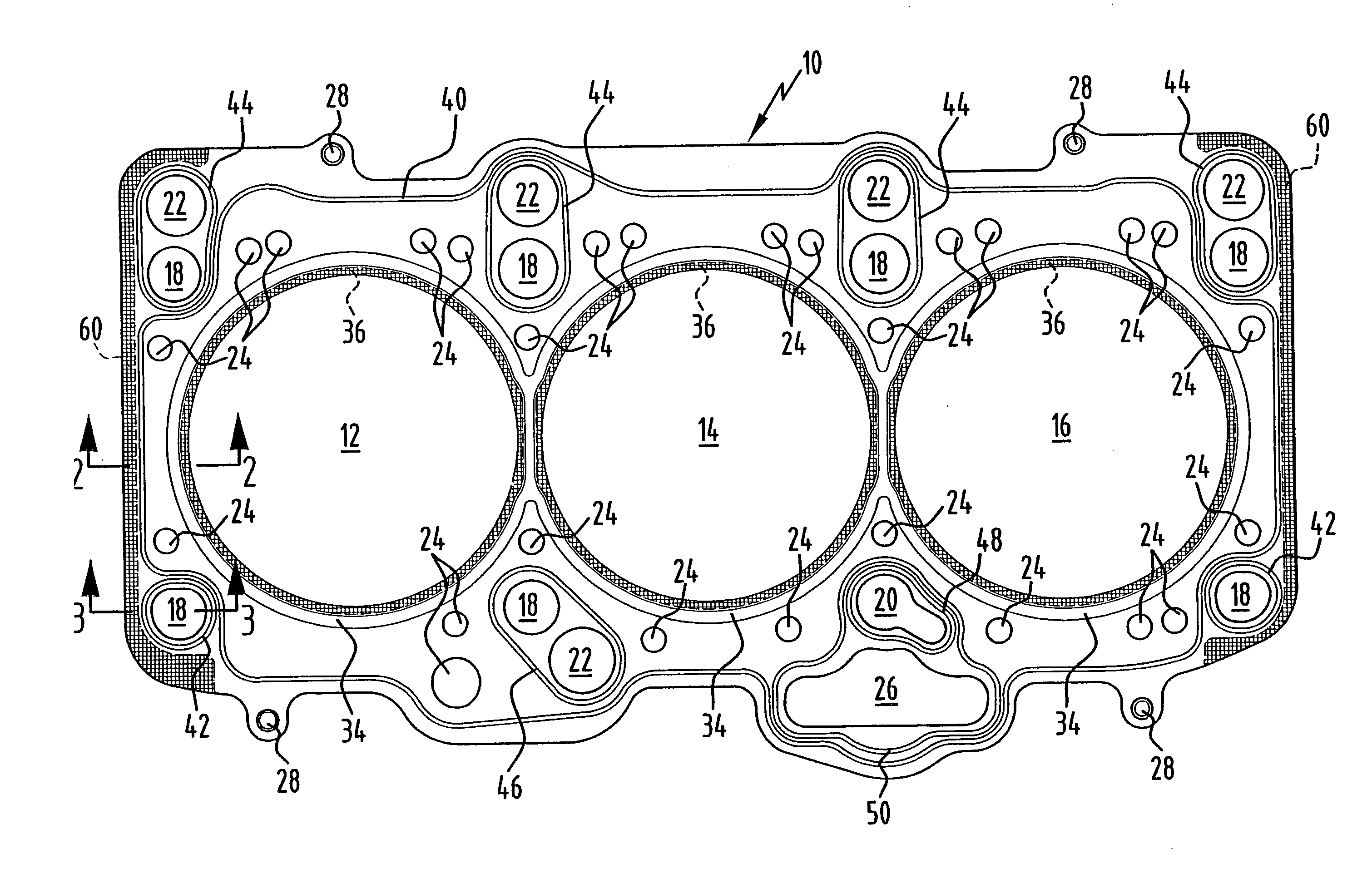

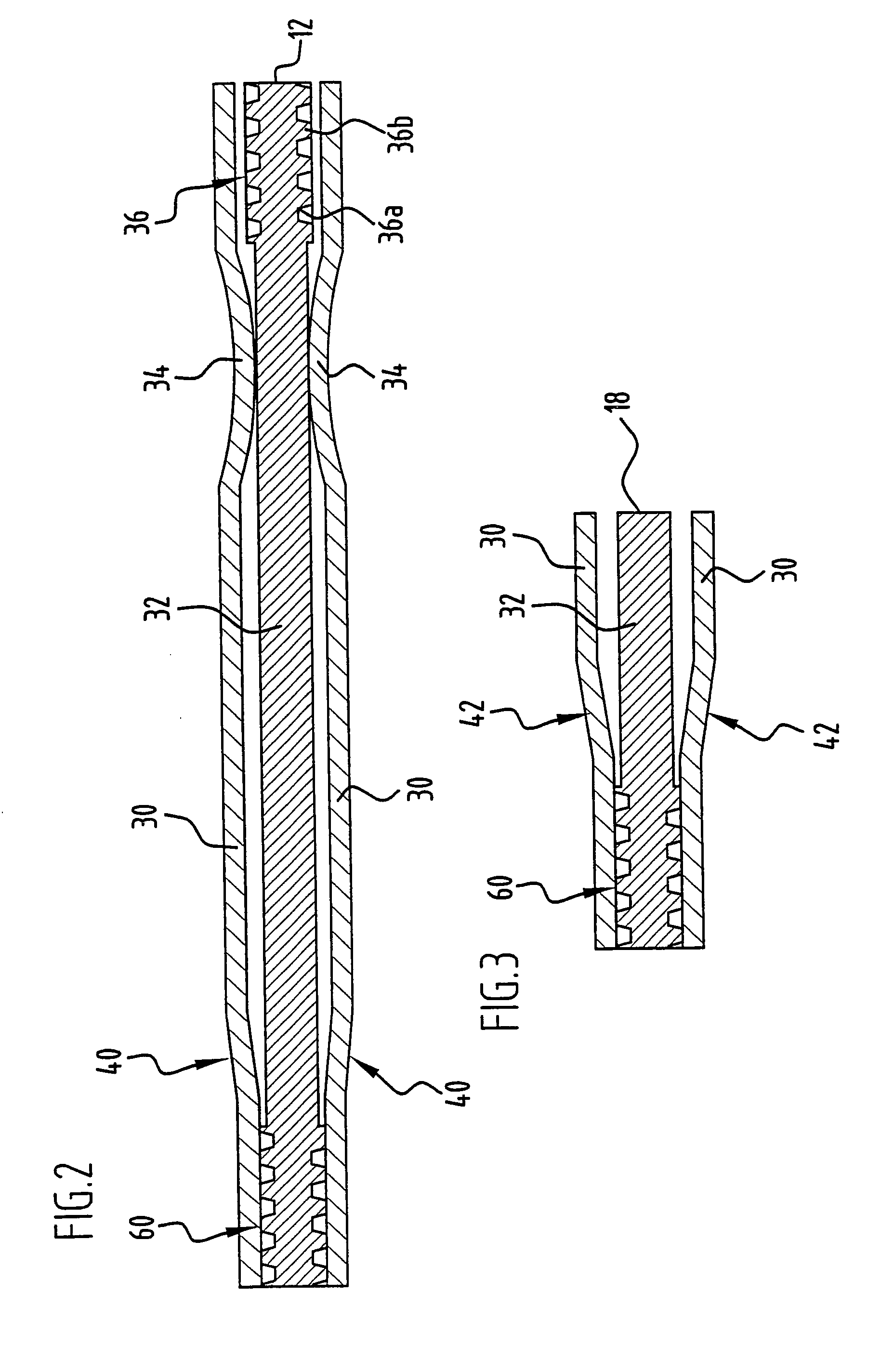

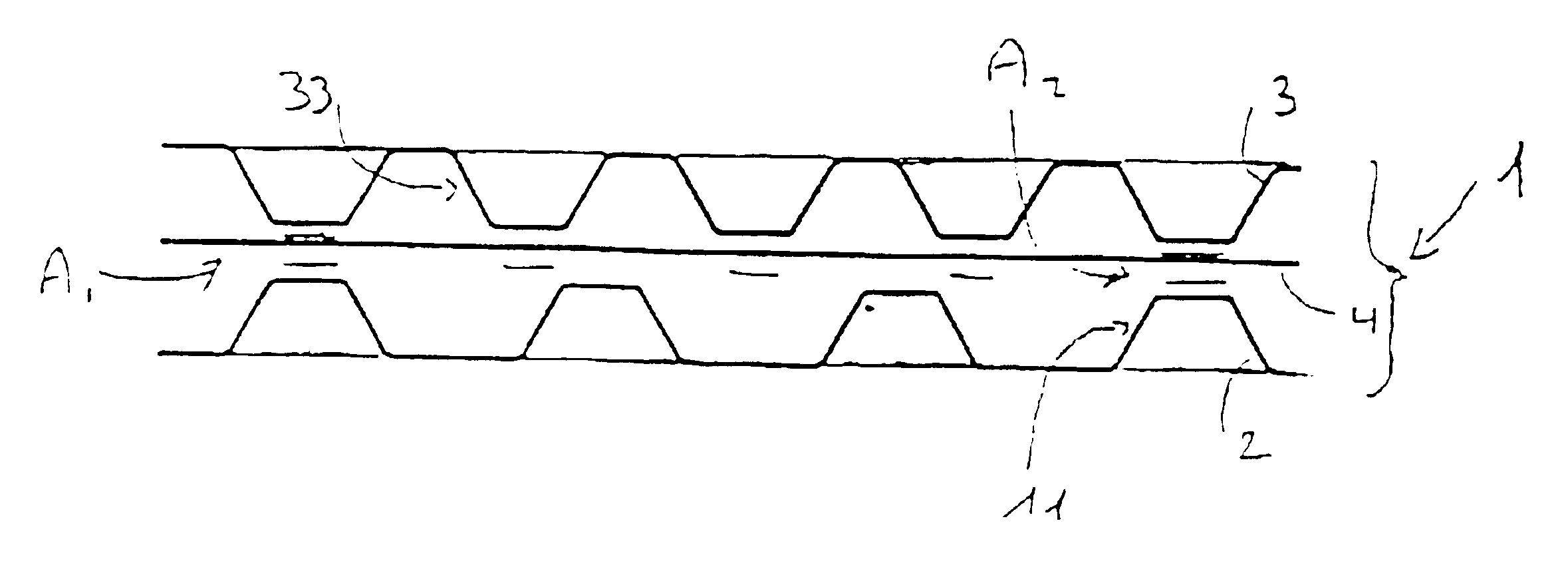

Cylinder head gasket

InactiveUS20050206091A1Average thicknessIncreasing the thicknessEngine sealsSealing arrangements for enginesCombustion chamberCylinder head

Cylinder head gasket with a gasket plate formed by at least one layer of sheet metal and at least one combustion chamber aperture which is enclosed by a sealing device serving the purpose of sealing the combustion chamber, wherein in order to reduce any warpages of an engine block and / or of a cylinder head a supporting device is provided radially outside the sealing device on the gasket plate; so that the supporting device can be produced in a material-saving and procedurally reliable manner, the supporting device has an area of the sheet-metal layer which is thickened by way of embossing and does not enclose any of the apertures of the gasket to be sealed completely or almost completely and has at least one embossed supporting bead with a meandering shape or a two-dimensional pattern of cup-like recesses and associated elevations.

Owner:ELRINGKLINGER AG

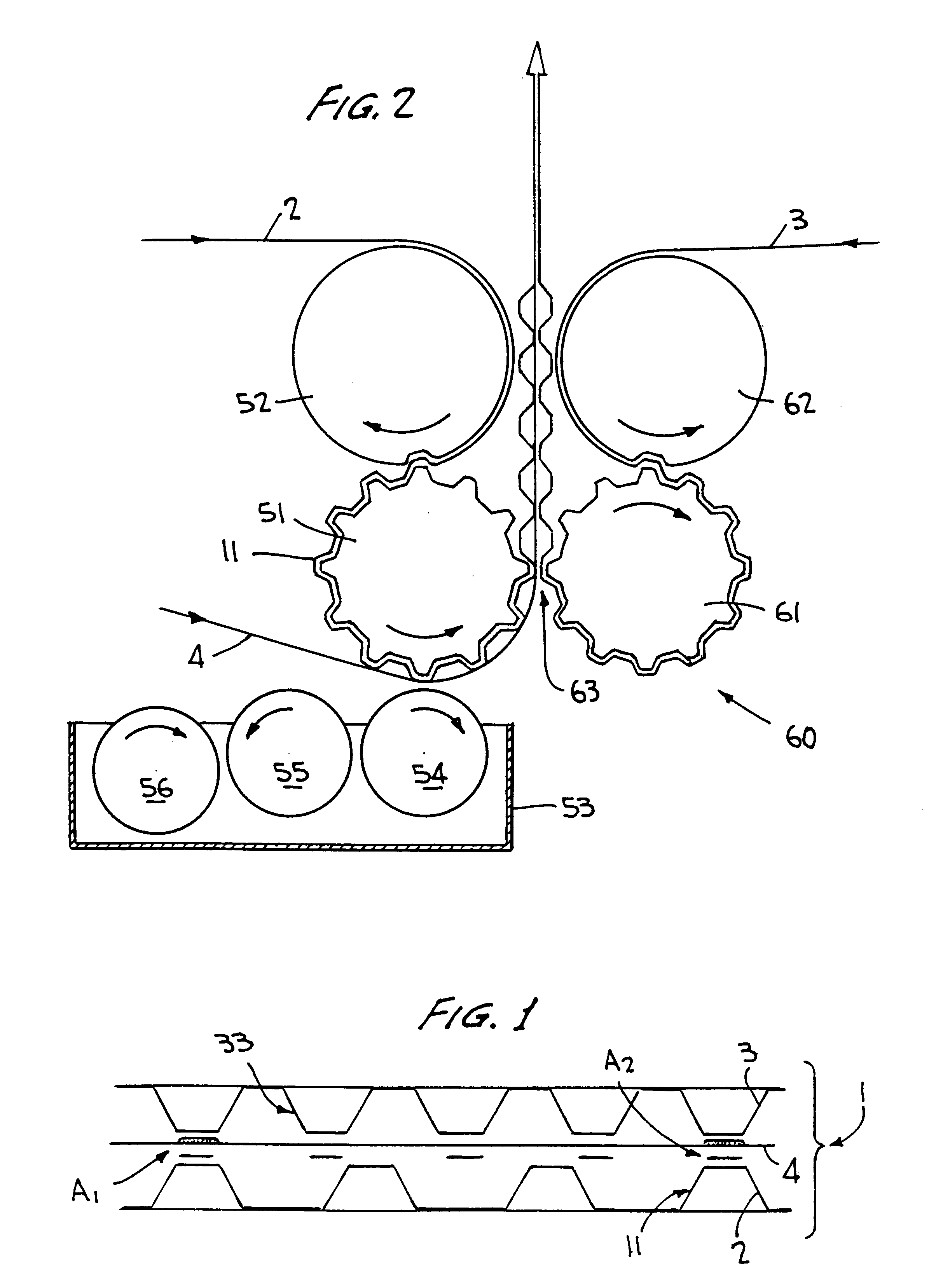

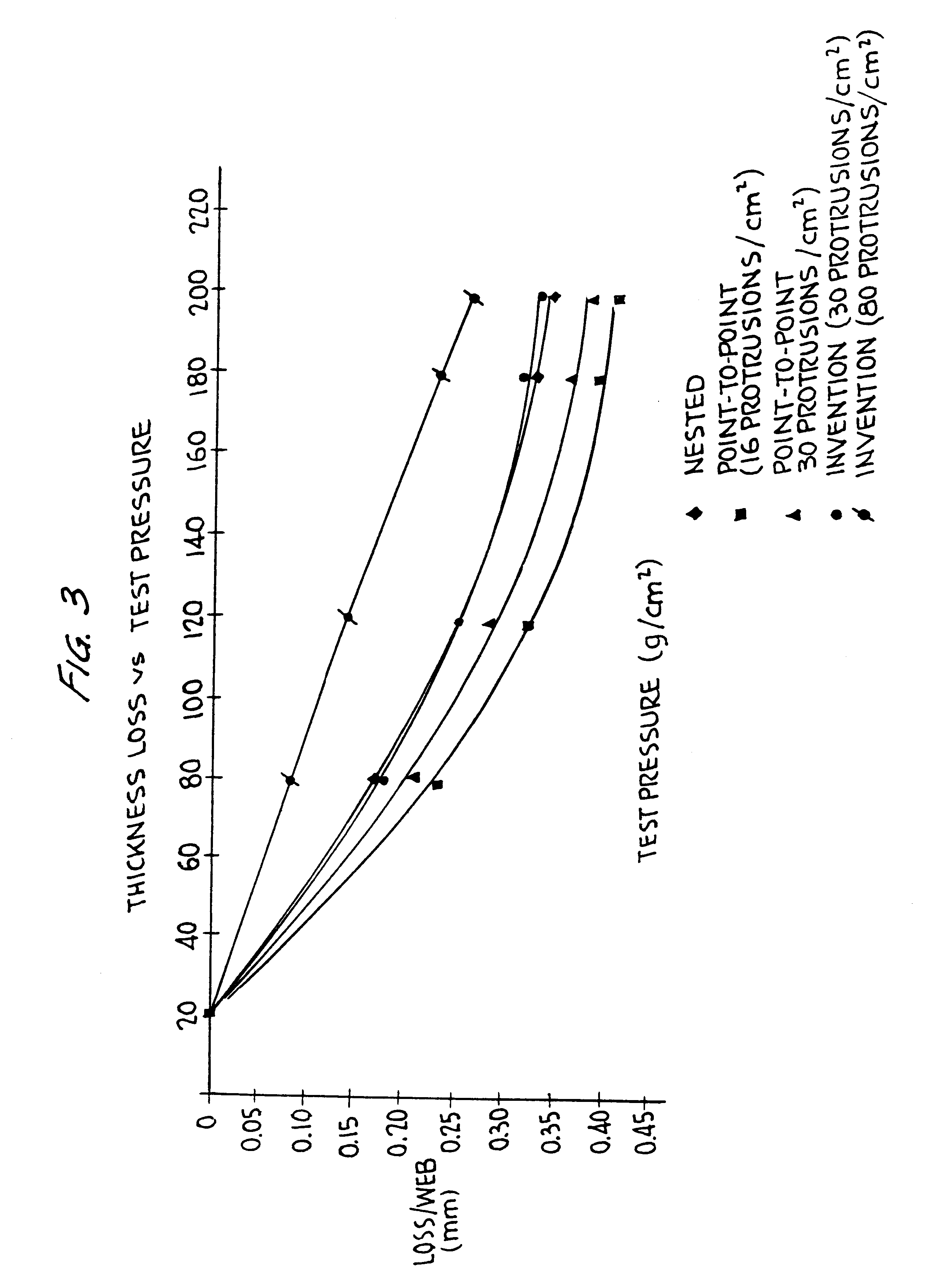

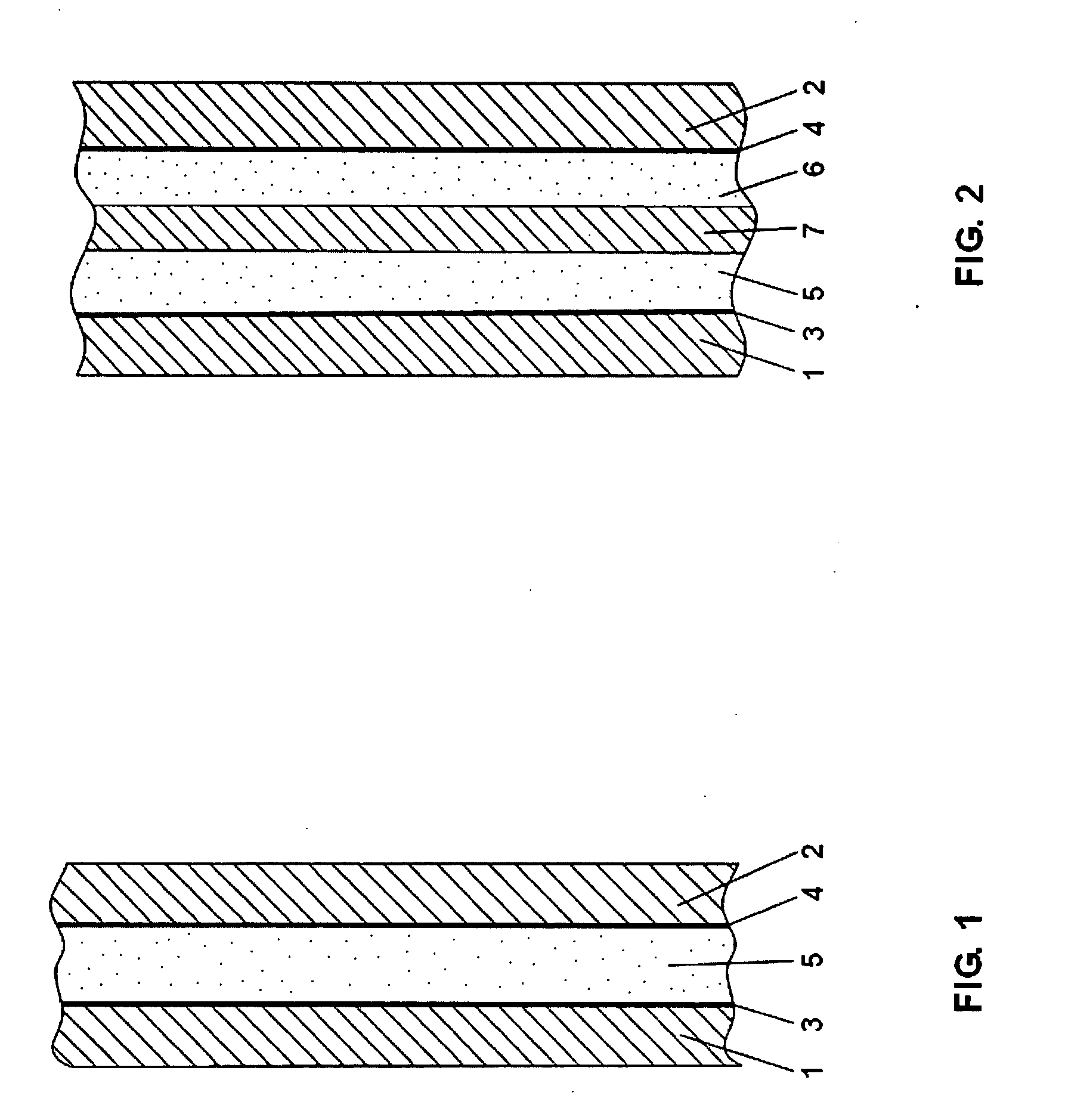

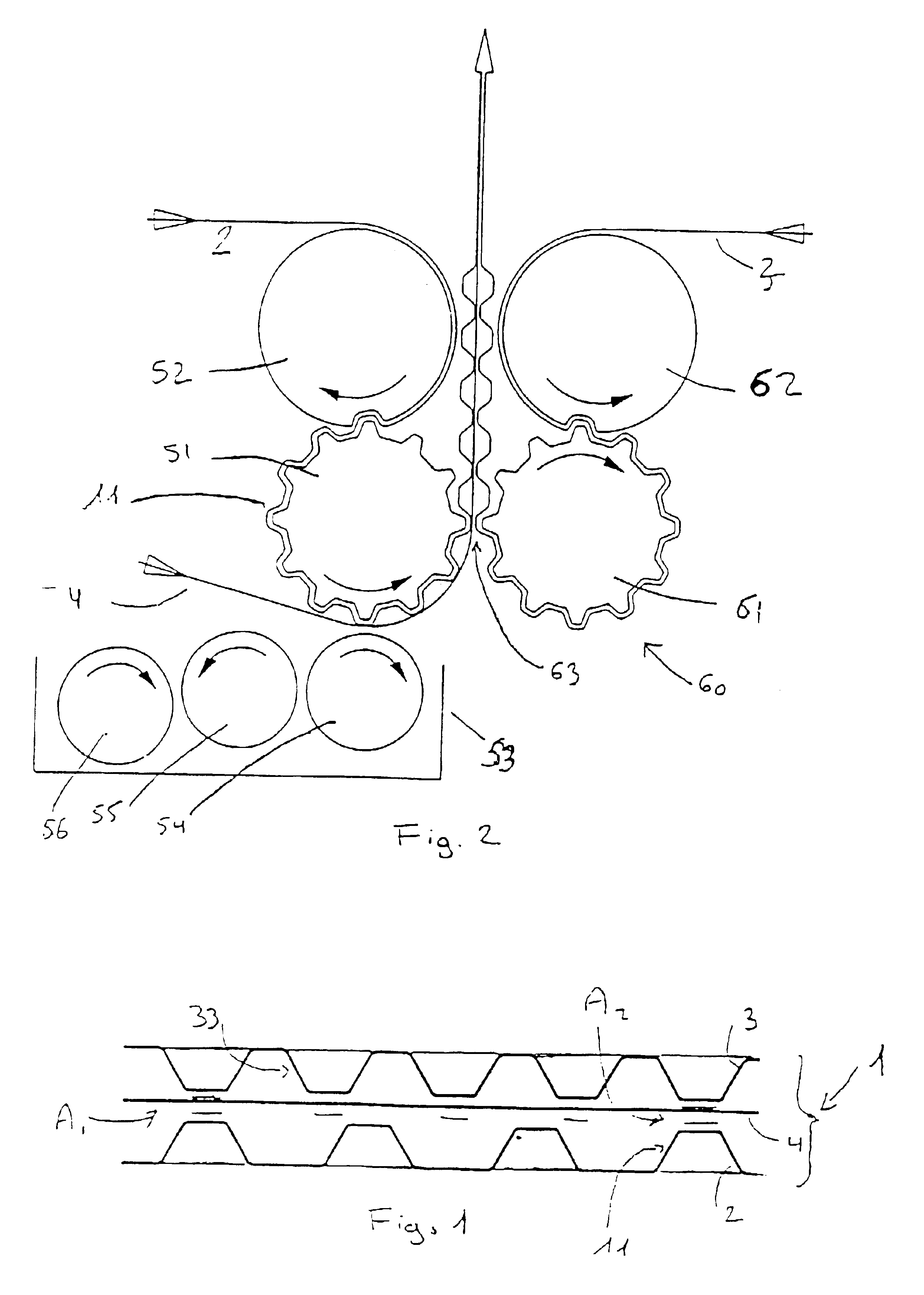

Three ply absorbent paper product and method of making

InactiveUS6599614B1Feel goodGood flexibilityNatural cellulose pulp/paperMechanical working/deformationAdhesiveEngineering

The invention concerns an absorbent paper product with basic weight of about 36 to about 105 g / m2 comprising at least three pleats, a first and second outer embossed pleats each comprising raised patterns consisting at least partially of discrete protuberances oriented towards the inside of the structure and a non-embossed central pleat, the pleats being associated by linking the distal surfaces of at least part of the protuberances of each of the outer pleats to the central pleat. The invention is characterised in that each of the embossed outer pleats is linked by means of an adhesive to said central pleat, and at least one of the pleats has a pattern density more than 30 protuberances per cm2.

Owner:FORT JAMES FRANCE

Electronic Pen Device

InactiveUS20080165162A1Improve finenessAverage thicknessTransmission systemsCharacter and pattern recognitionUltrasonic sensorTransducer

Various electronic pen devices are disclosed herein. In one embodiment, an electronic pen with an improved ultrasound transducer (i.e. transmitter or receiver) is provided. In one embodiment an electronic pen with an improved ‘pen up / pen down’ detector is provided In one embodiment, an electronic pen with an improved structure for transmitting infrared light is provided. In one embodiment, an improved electronic pen that may be operated in pen mode or mouse mode is provided.

Owner:PEGASUS TECH LTD

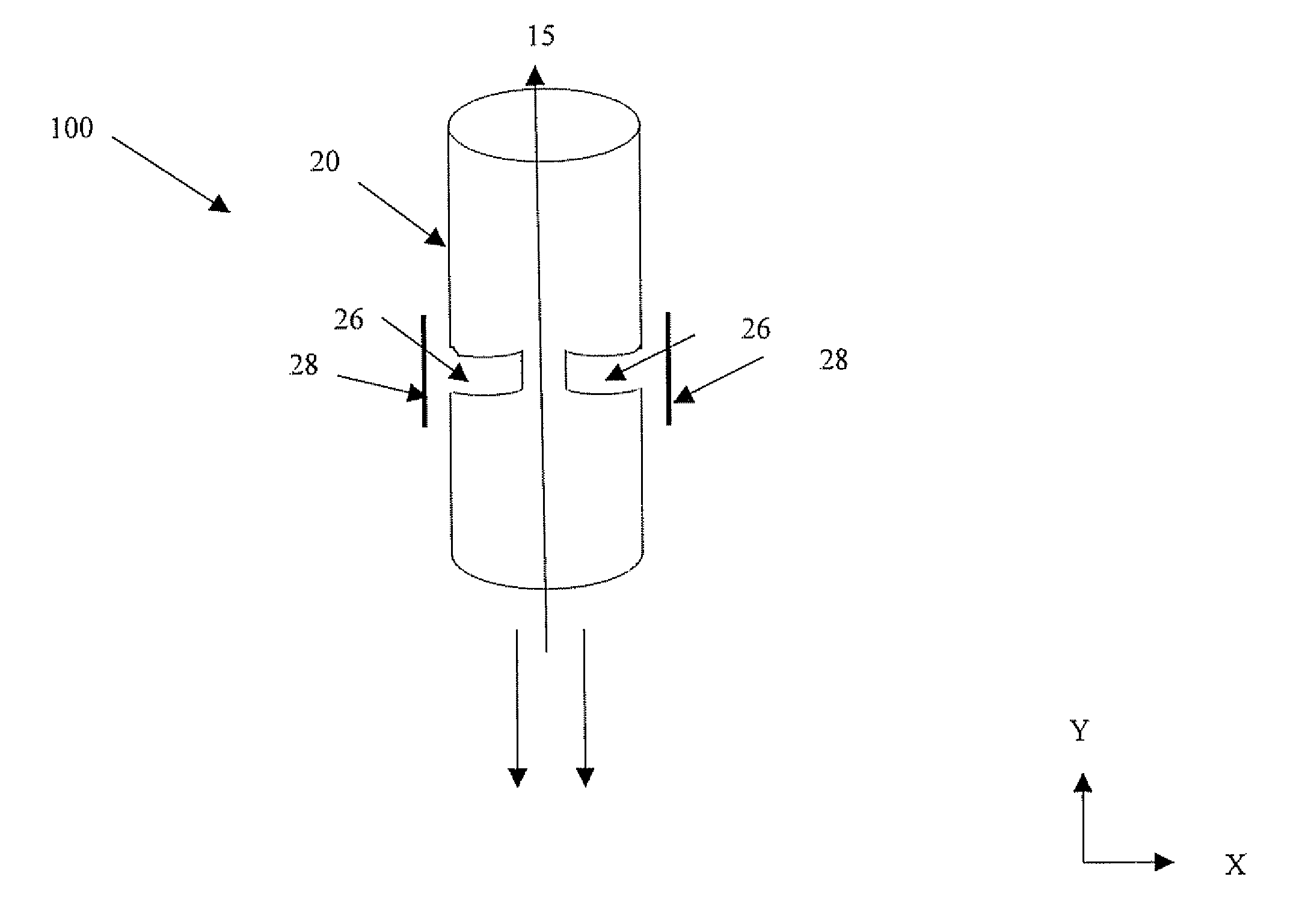

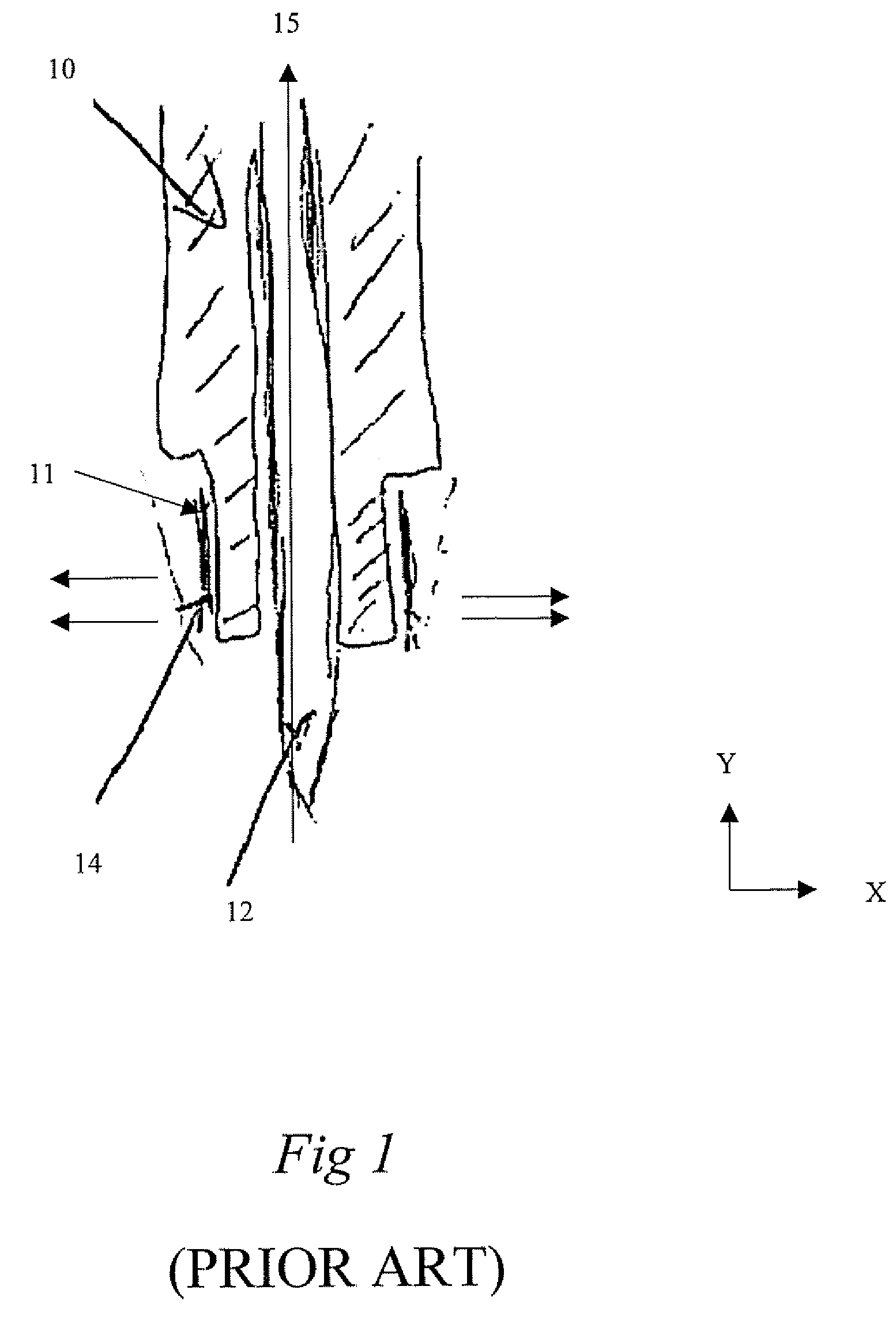

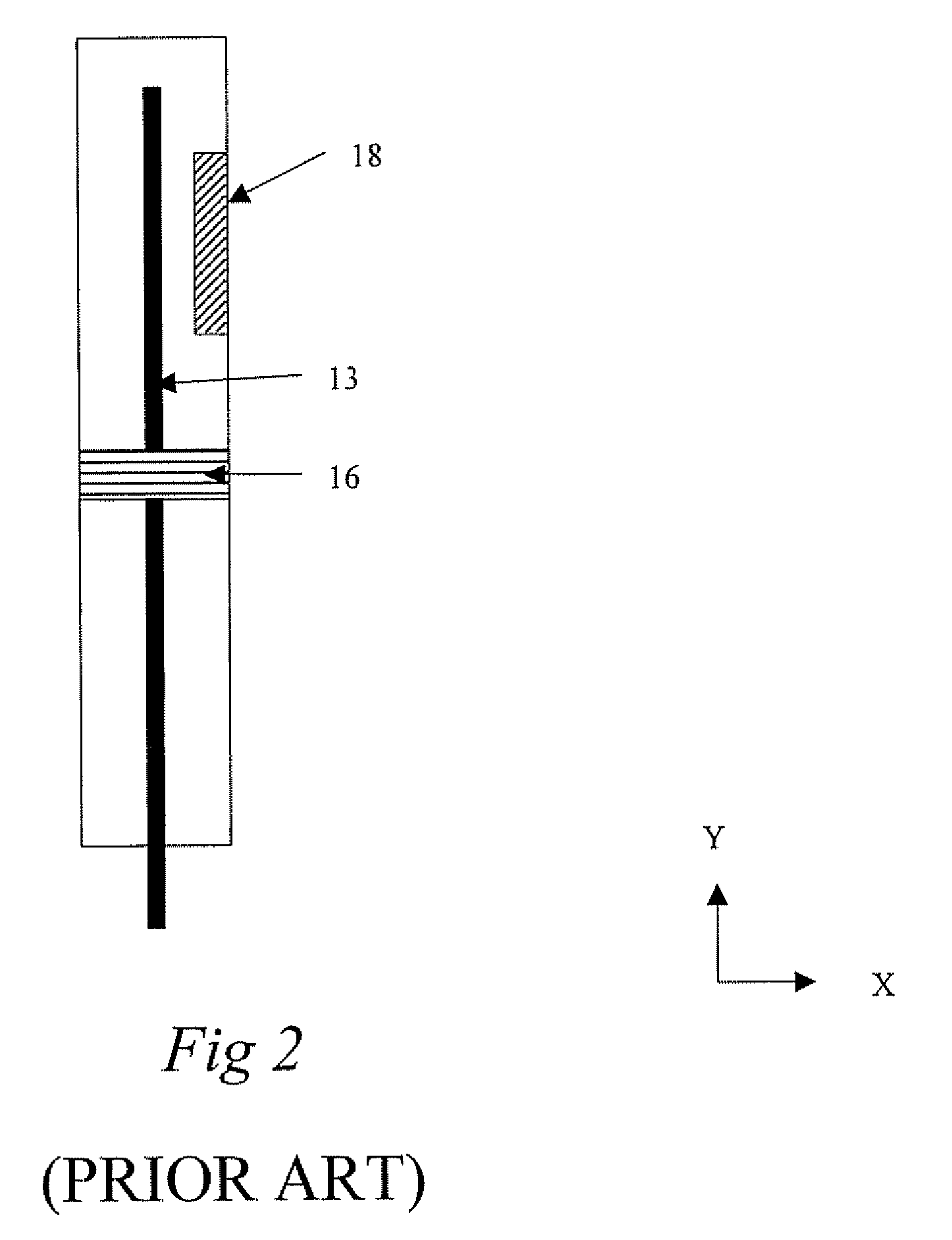

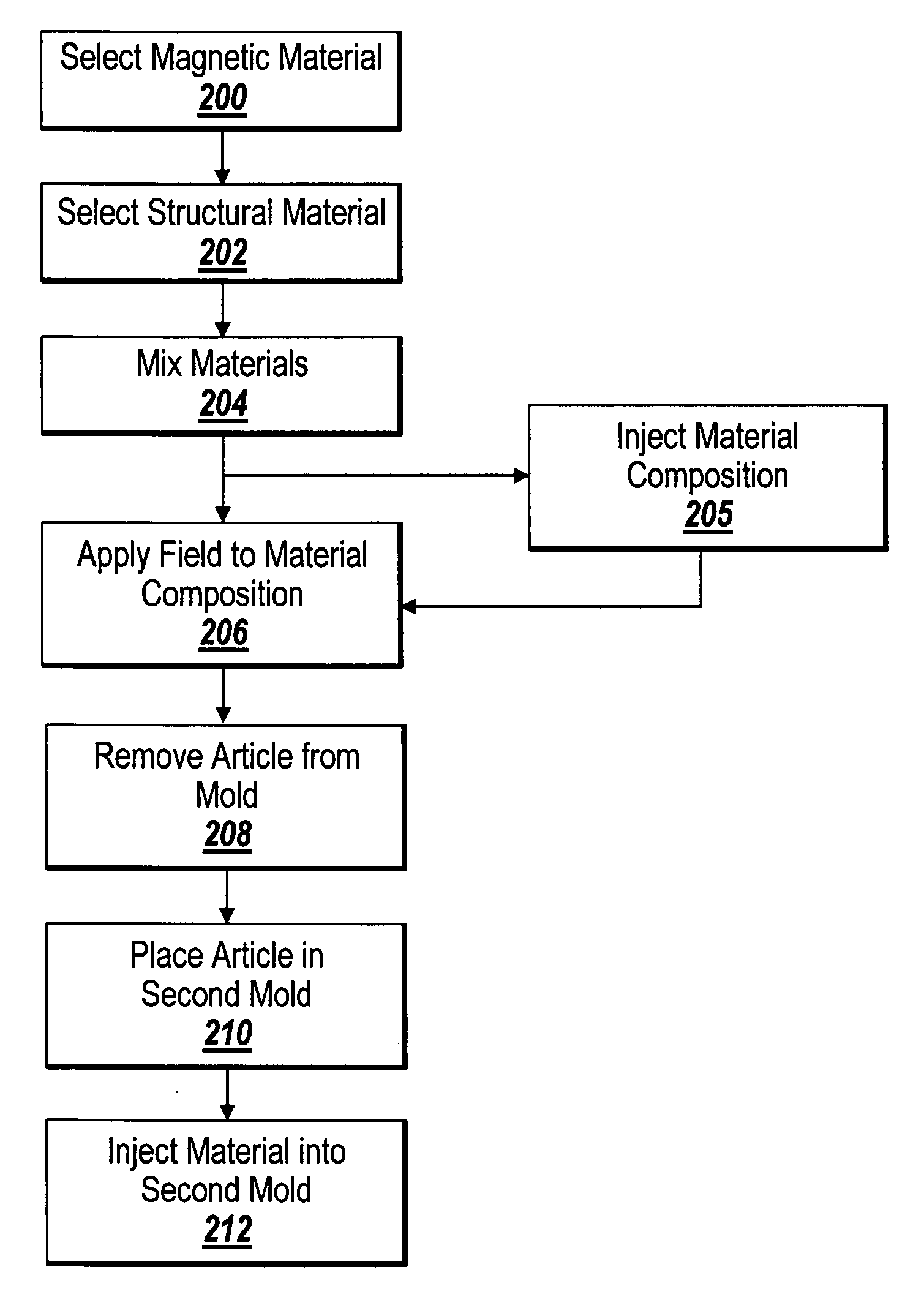

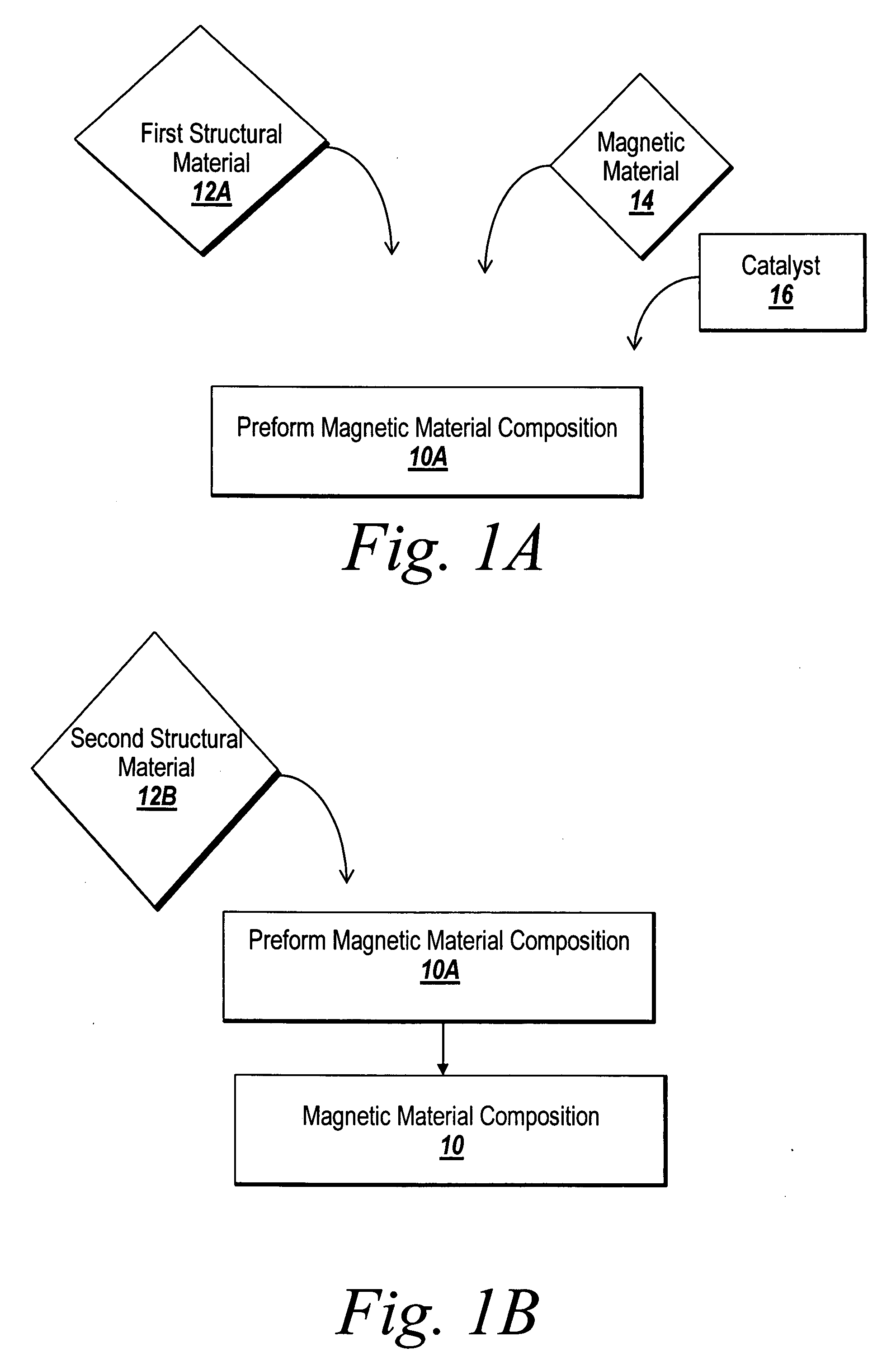

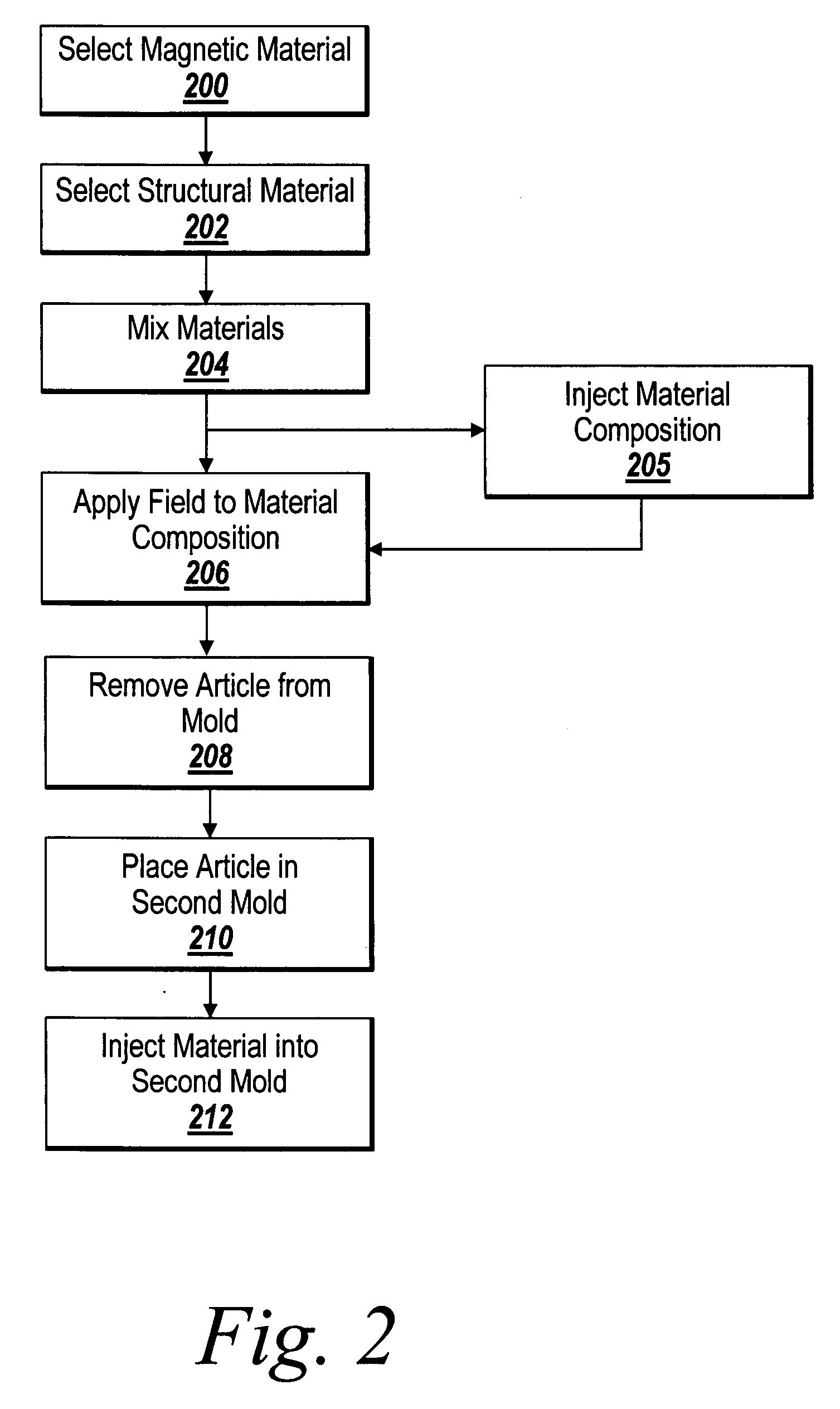

Magnetic composites

InactiveUS20080044680A1Improve magnetic strengthReduce materialConfectioneryInorganic material magnetismEpoxyMagnetite Nanoparticles

The present invention discloses methods and magnetic material composites capable of withstanding one or more loads without the need for a substructure to provide structural support thereto. The magnetic composites are formable from composites such as epoxies, resins, plastics and the like together with rare earth or other magnetic or magnetizable compounds, or magnetic nano-particles to form structural magnetic composites. The magnetic composites have one or more portions with an aggregation of the magnetic material and one or more portions free of or substantially free of the magnetic material. The magnetic composites are suitable for use to form components of electrical motors, generators, pumps, fans, paints, coatings and parts or derivatives thereof.

Owner:MAGLEV TECH LLC

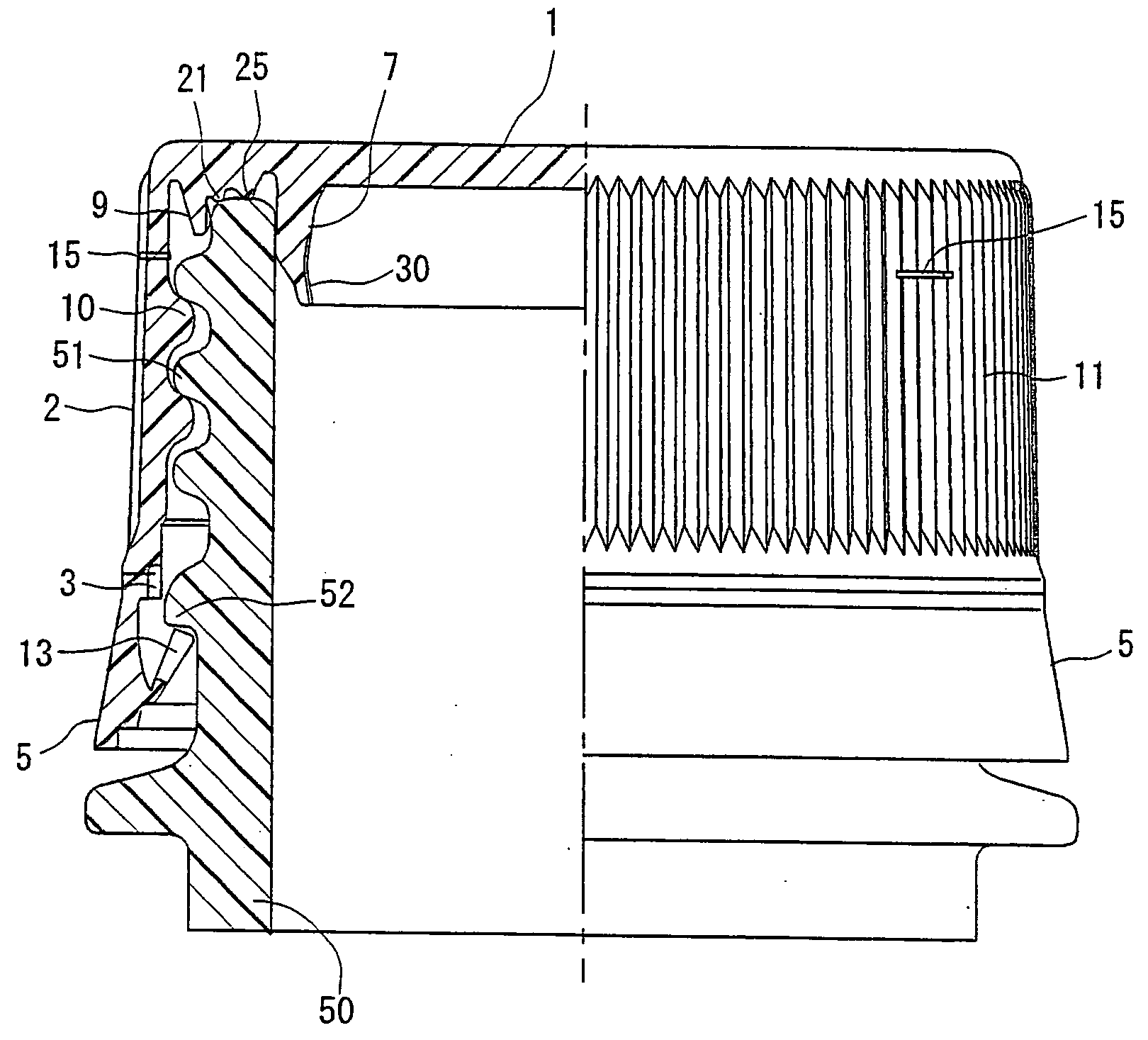

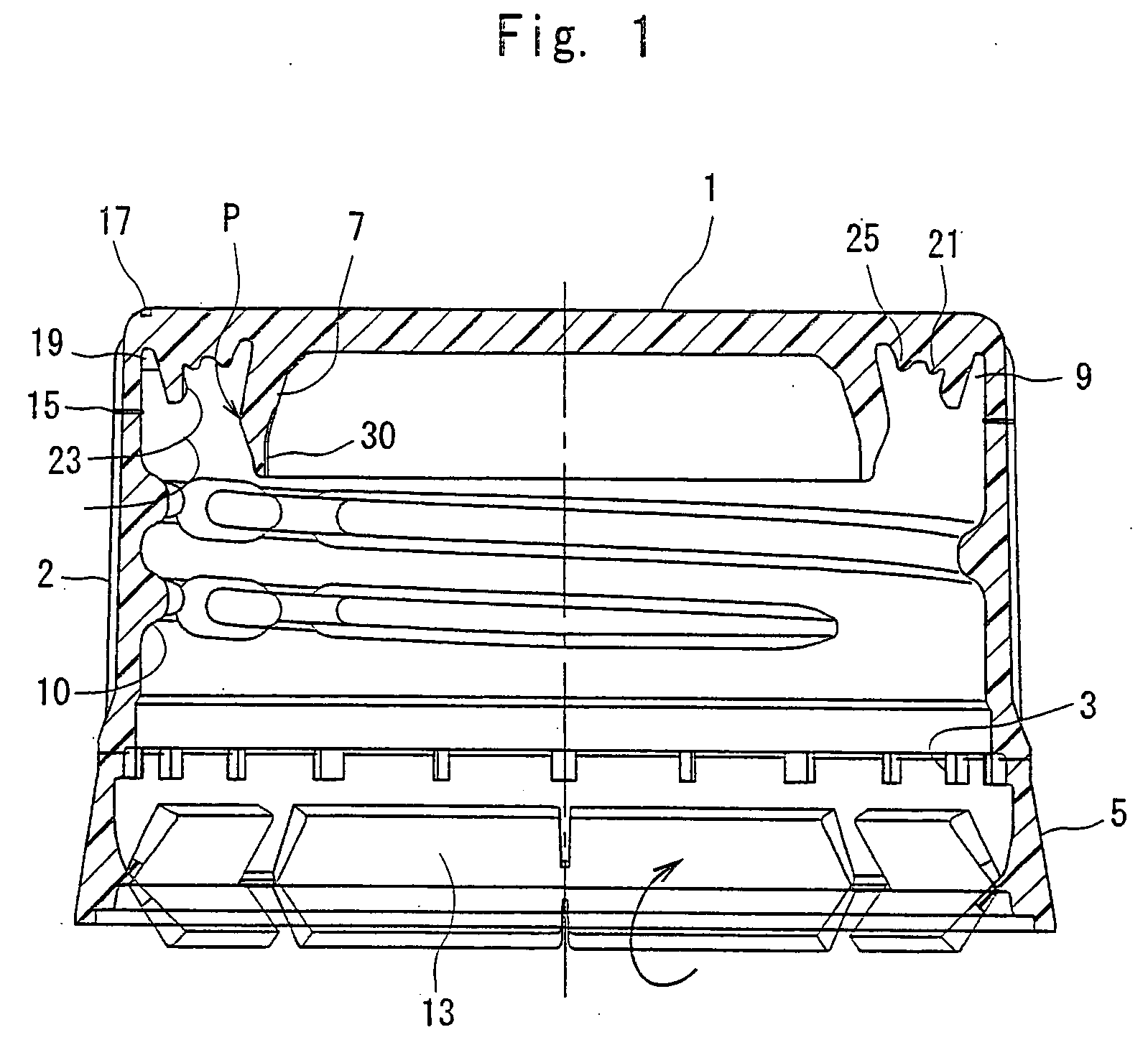

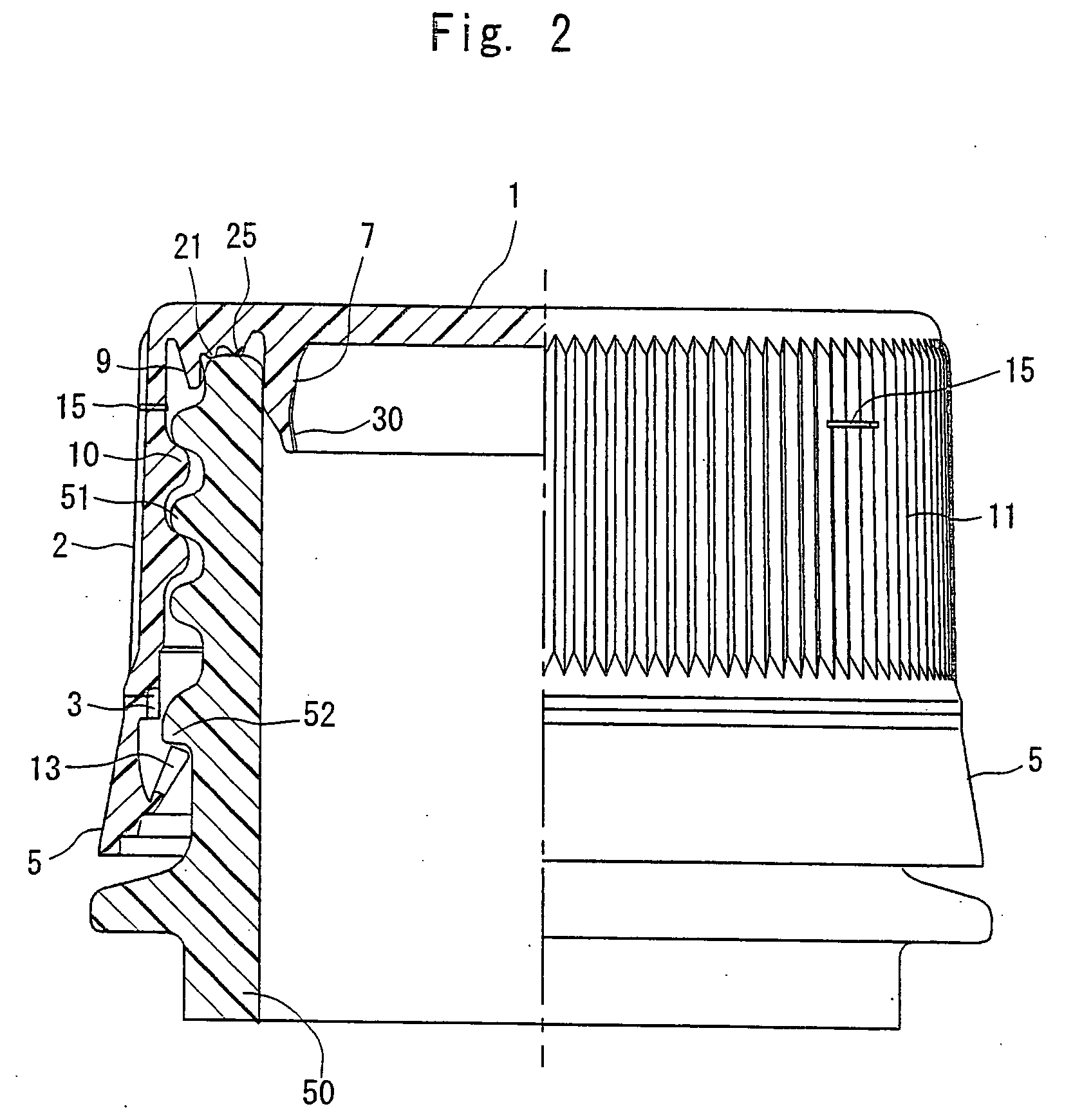

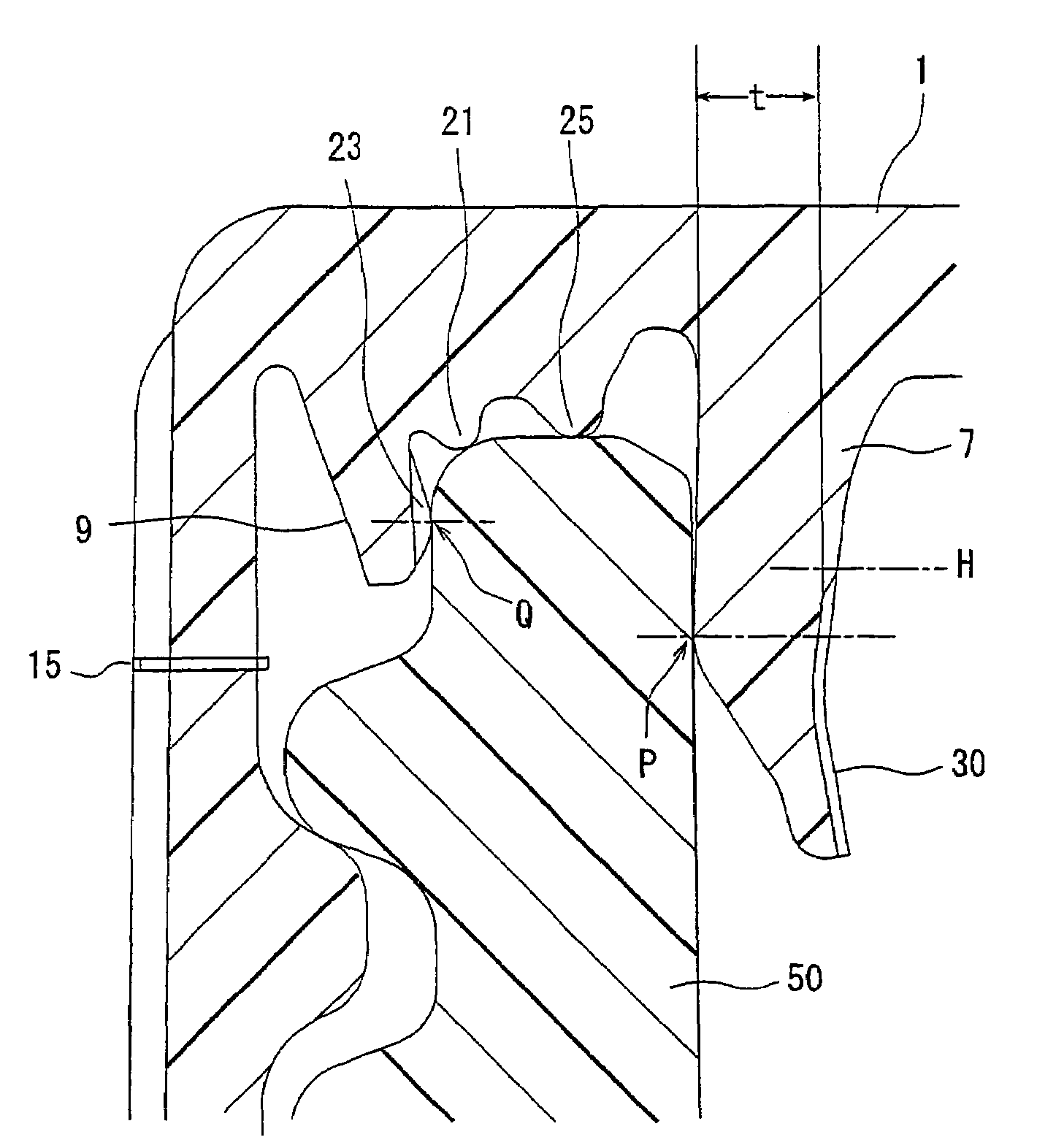

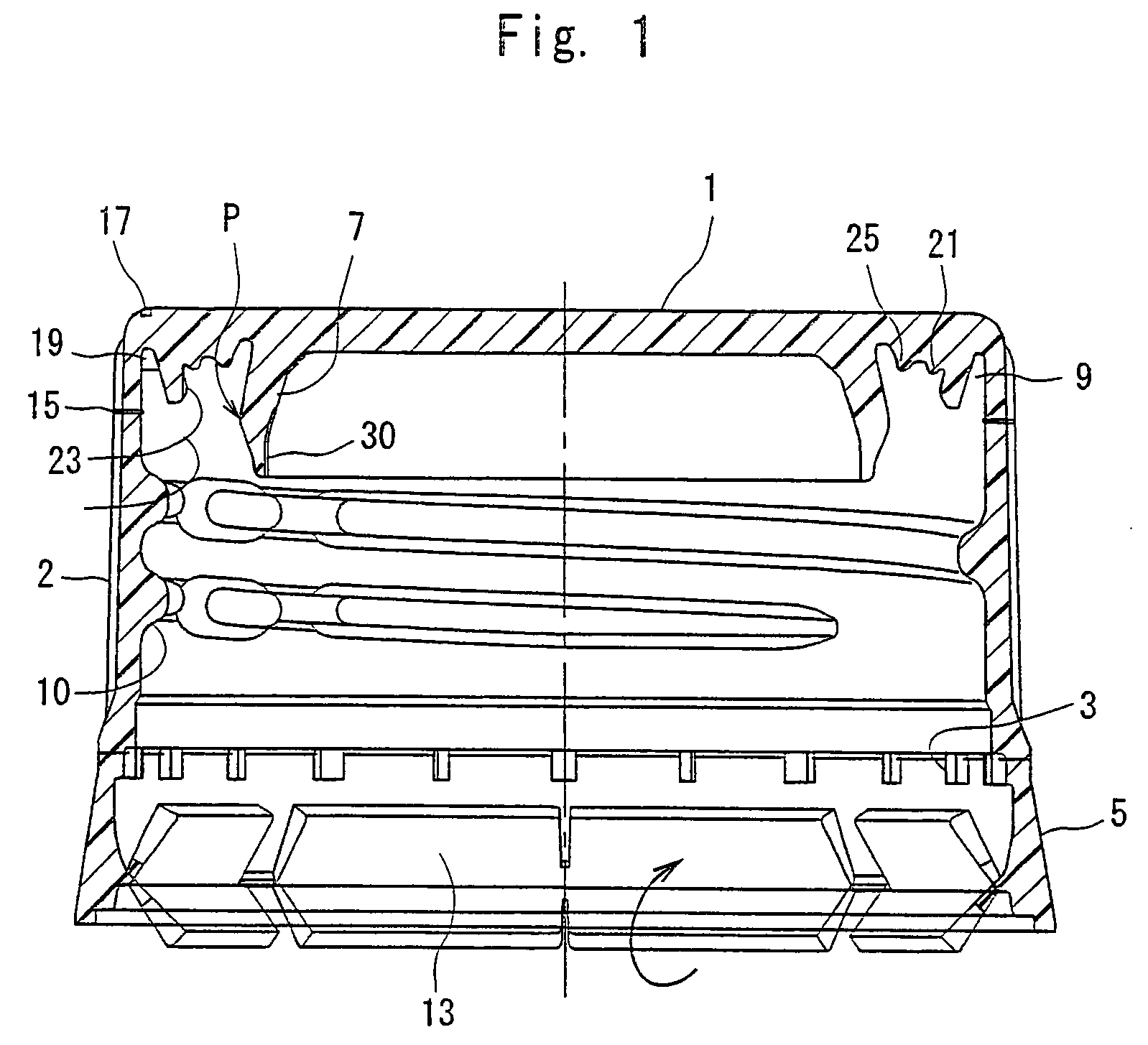

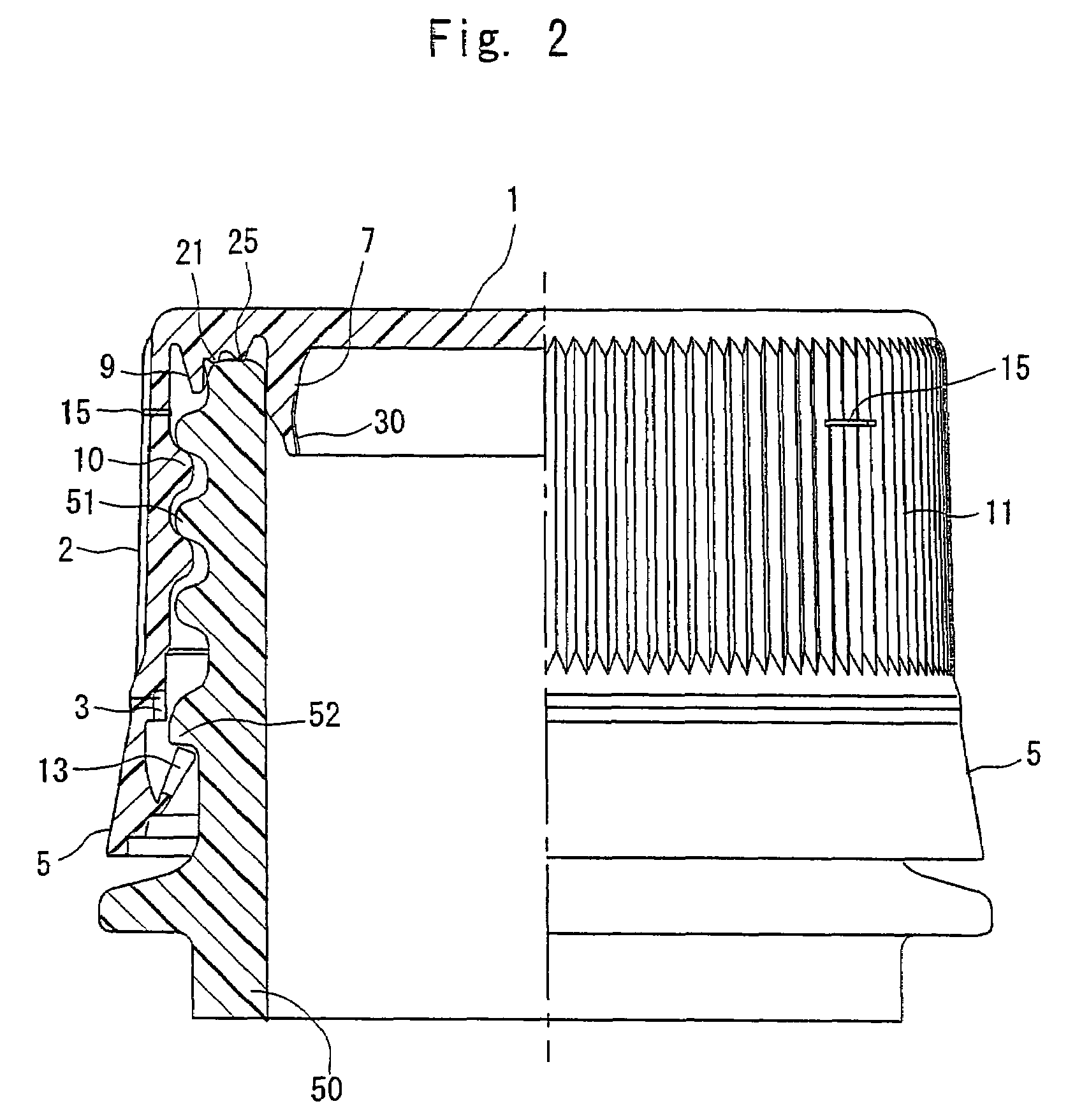

Plastic cap featuring excellent sealing and venting

A plastic cap comprising a top panel and a skirt hanging down from the peripheral edge of the top panel, the inner surface of the top panel forming an inner ring that forms a seal upon coming into intimate contact with the inner surface of the wall of the mouth of a container, and the inner surface of skirt forming a screw thread that comes into engagement with a screw thread formed on the outer surface of the wall of the mouth of the container, wherein a slender recessed portion is formed in a number of at least one in the inner surface of said inner ring extending upward from an end thereof. The cap features both excellent sealing and excellent venting.

Owner:TOYO SEIKAN KAISHA LTD +1

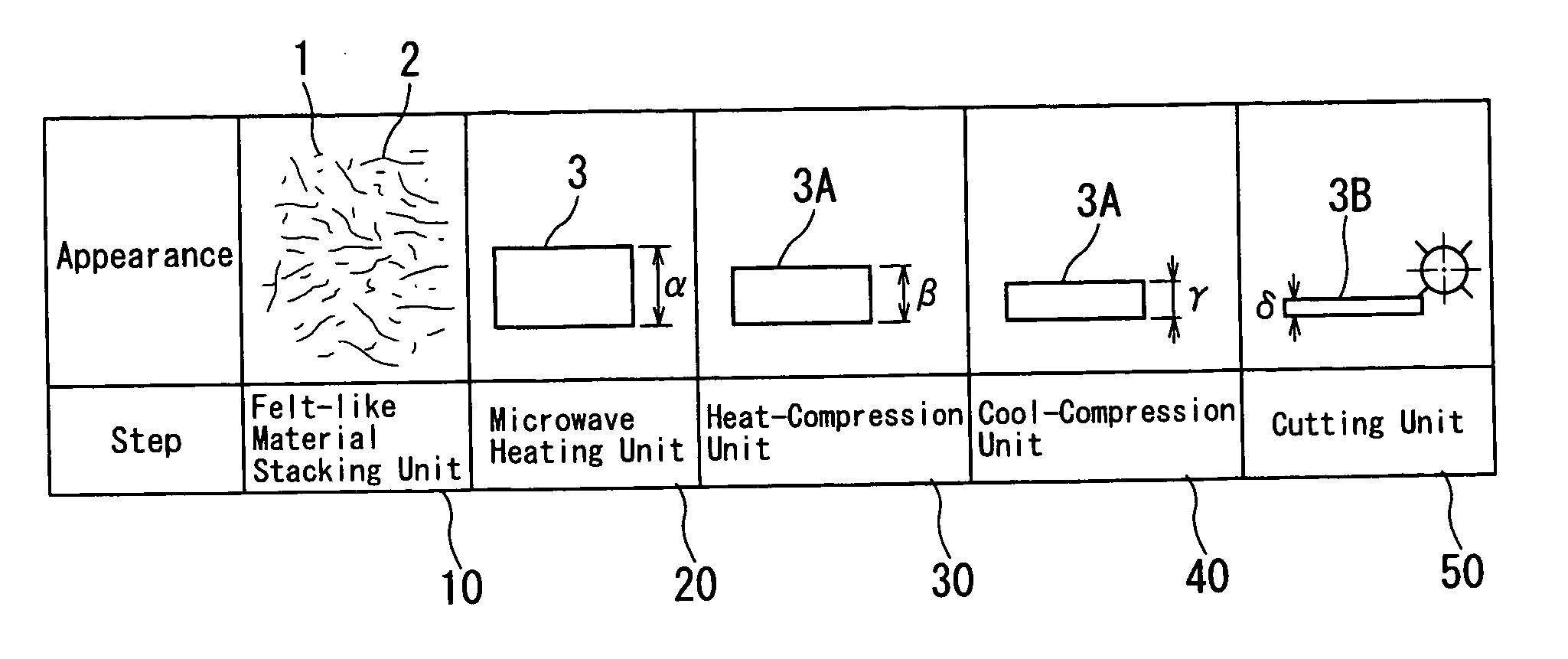

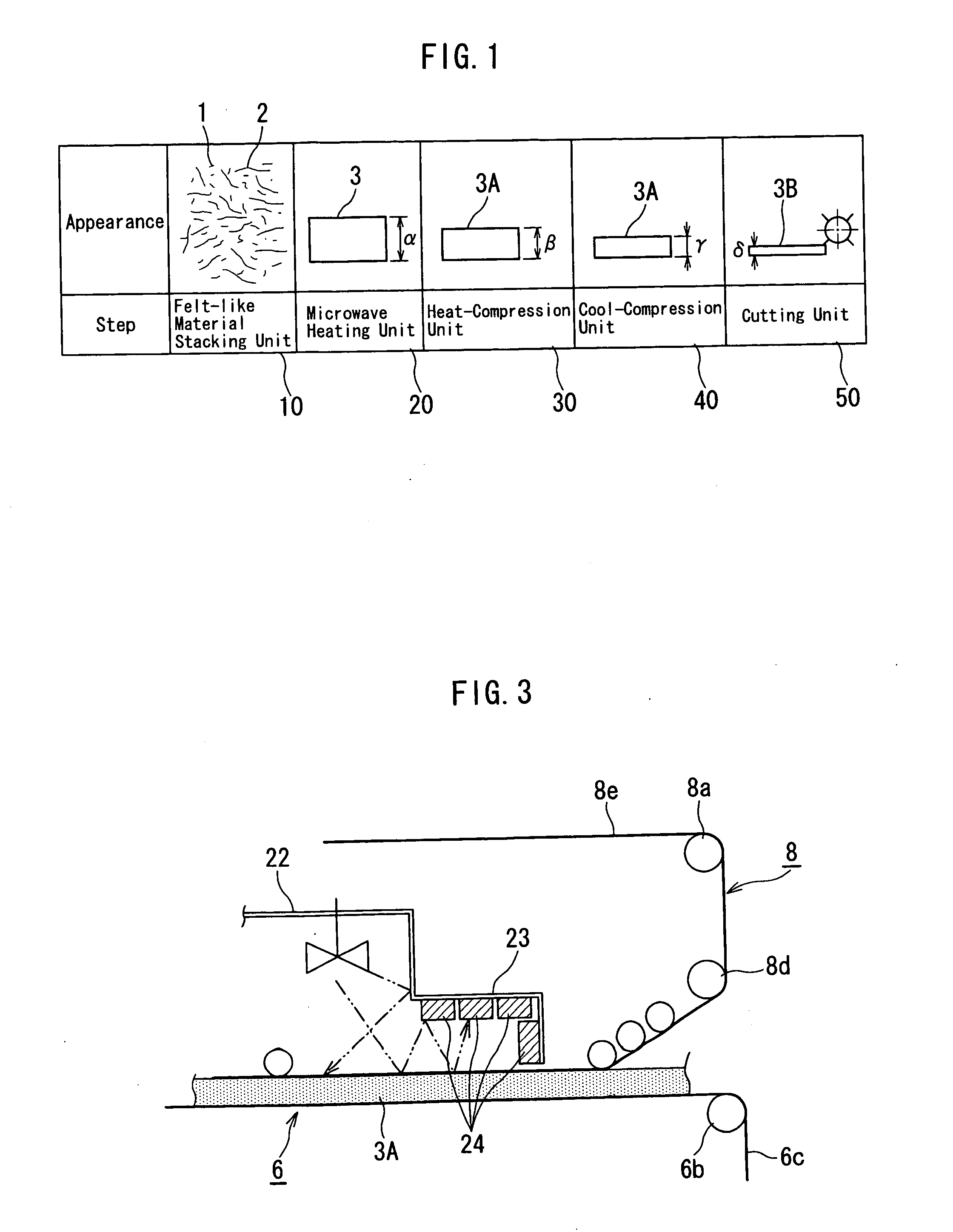

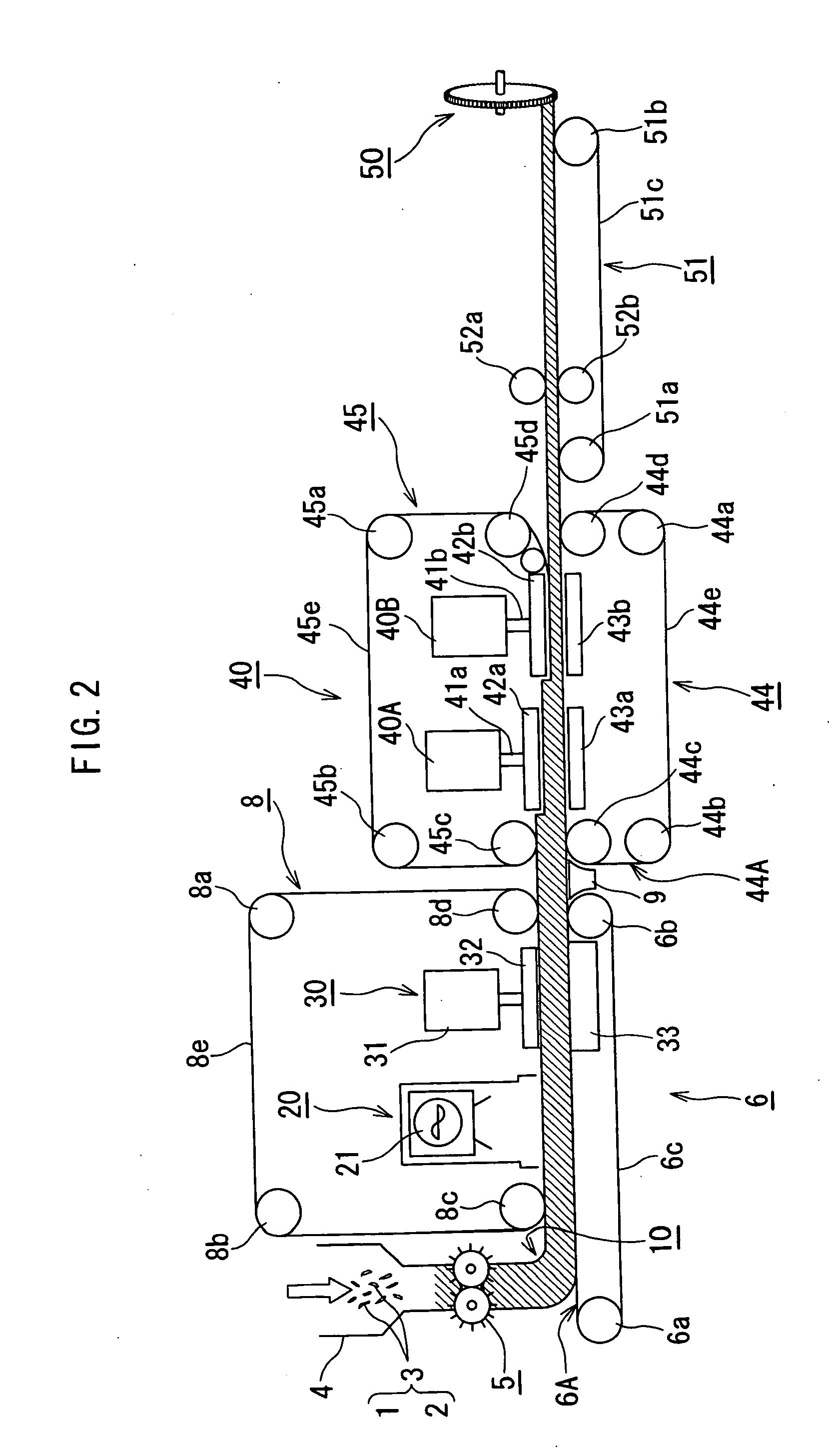

Plastic fiber molding, manufacturing method of plastic fiber molding and manufacturing apparatus for plastic fiber board

InactiveUS20050238865A1Increase physical strengthStrengthDielectric heatingConfectioneryPlant fibrePlastic fiber

Plastic fibers and plant fiber such as thinned woods, scrap woods of buildings, stumps, branches or barks are stirred and mixed with each other into a felt-like material. Microwaves are radiated on the felt-like fiber mixture material. After a sufficient temperature is ensured for the felt-like fiber mixture material of low density by the microwave radiation, the fiber mixture material is fed to a pair of upper and lower pressure plates and compressed thereat. The fiber mixture material is rapidly compressed by the pressure plates so as to be melted and integrated. Then, the fiber mixture material is cooled so as to be further packed by such cooling, thereby becoming a stronger plastic fiber board.

Owner:TOPIA

Method of Pultrusion Employing Multiple Resins

InactiveUS20090023870A1Maintain durabilityMaintain strengthSynthetic resin layered productsEngineeringPolyresin

There is provided a method of pultrusion using multiple resins. In the method a continuous interior reinforcement layer and a continuous exterior reinforcement layer are supplied and the interior reinforcement layer is infused with a first resin and then combined with the exterior reinforcement layer to form a pultrusion reinforcement structure. The pultrusion reinforcement structure passes into an infusion die where a second resin infuses the exterior reinforcement layer, and then passes into a curing die to cure the resins and form a composite article. The second resin comprises an aliphatic isocyanate polyurethane resin with a greater concentration of aliphatic isocyanate than is present in the first resin to give the composite article superior UV resistance. A pultruded composite article produced by the pultrusion method is also provided.

Owner:RESIN SYST

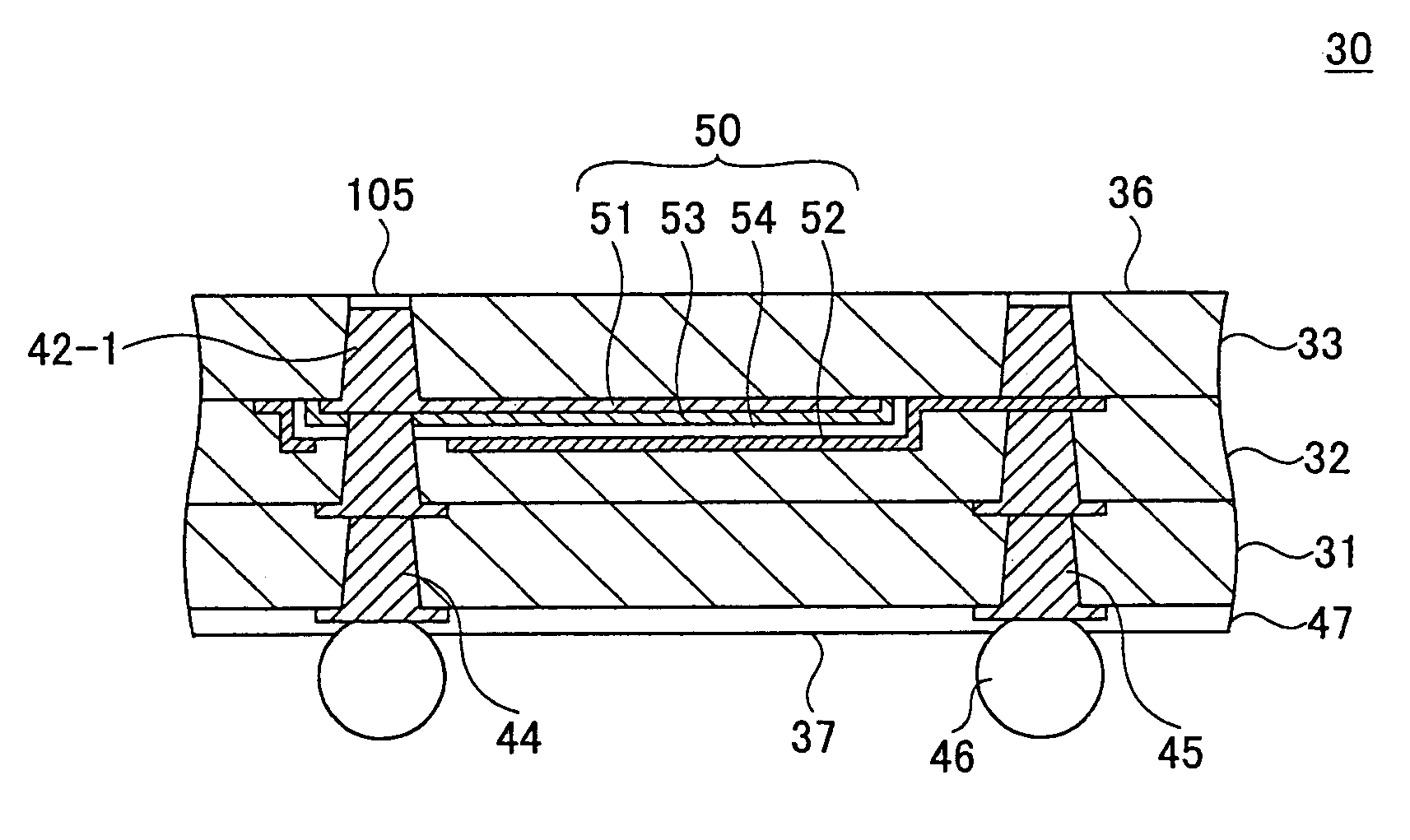

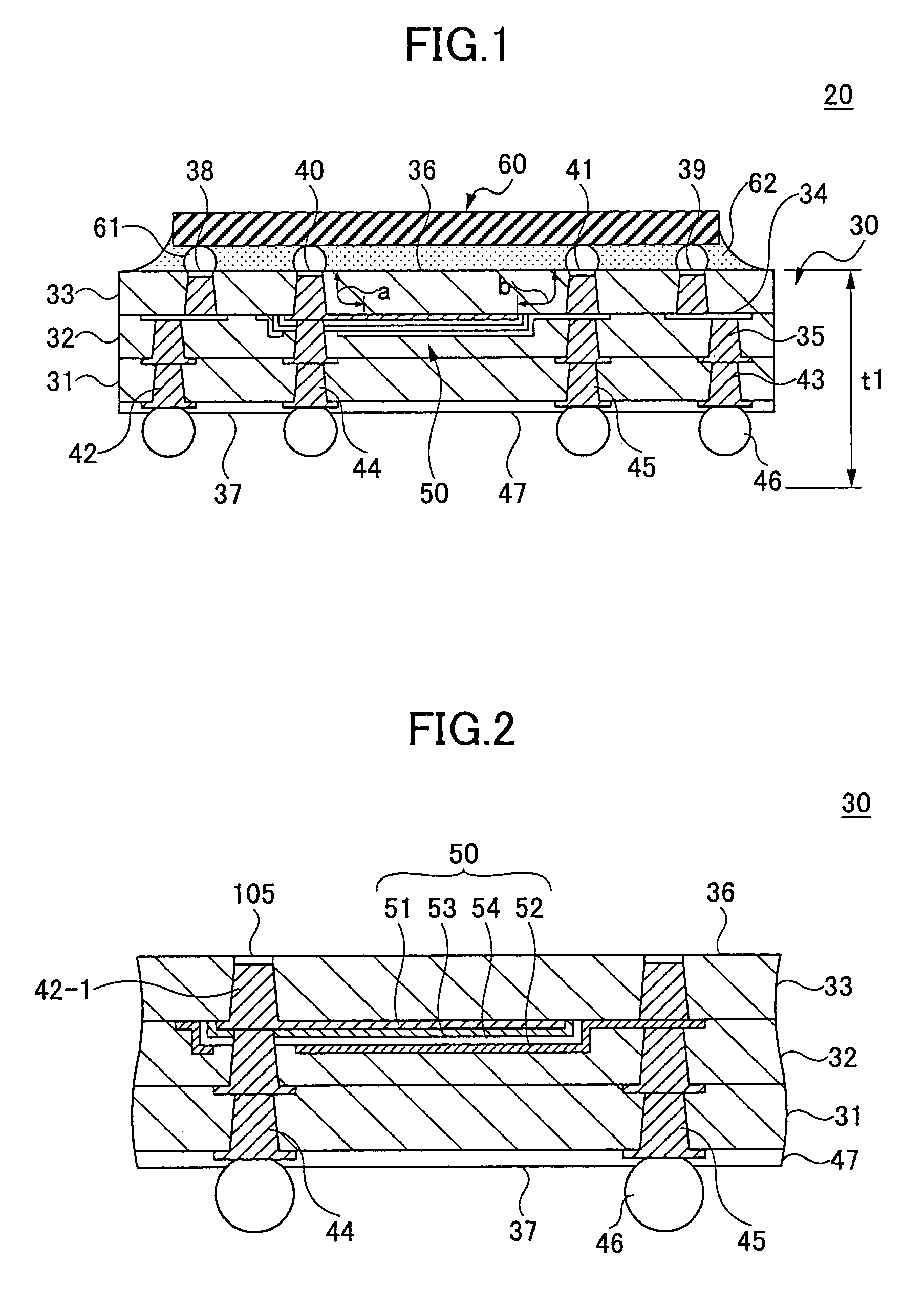

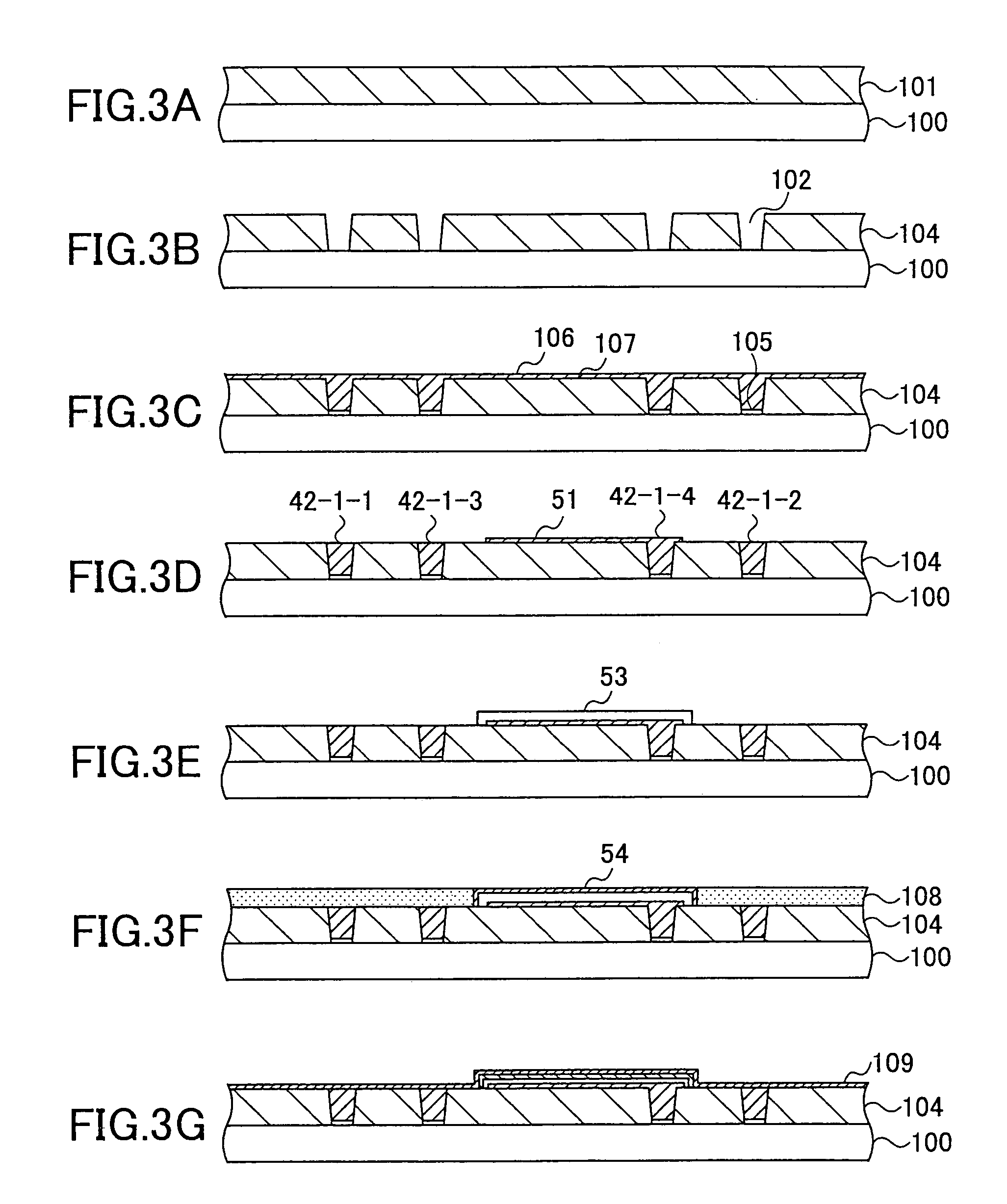

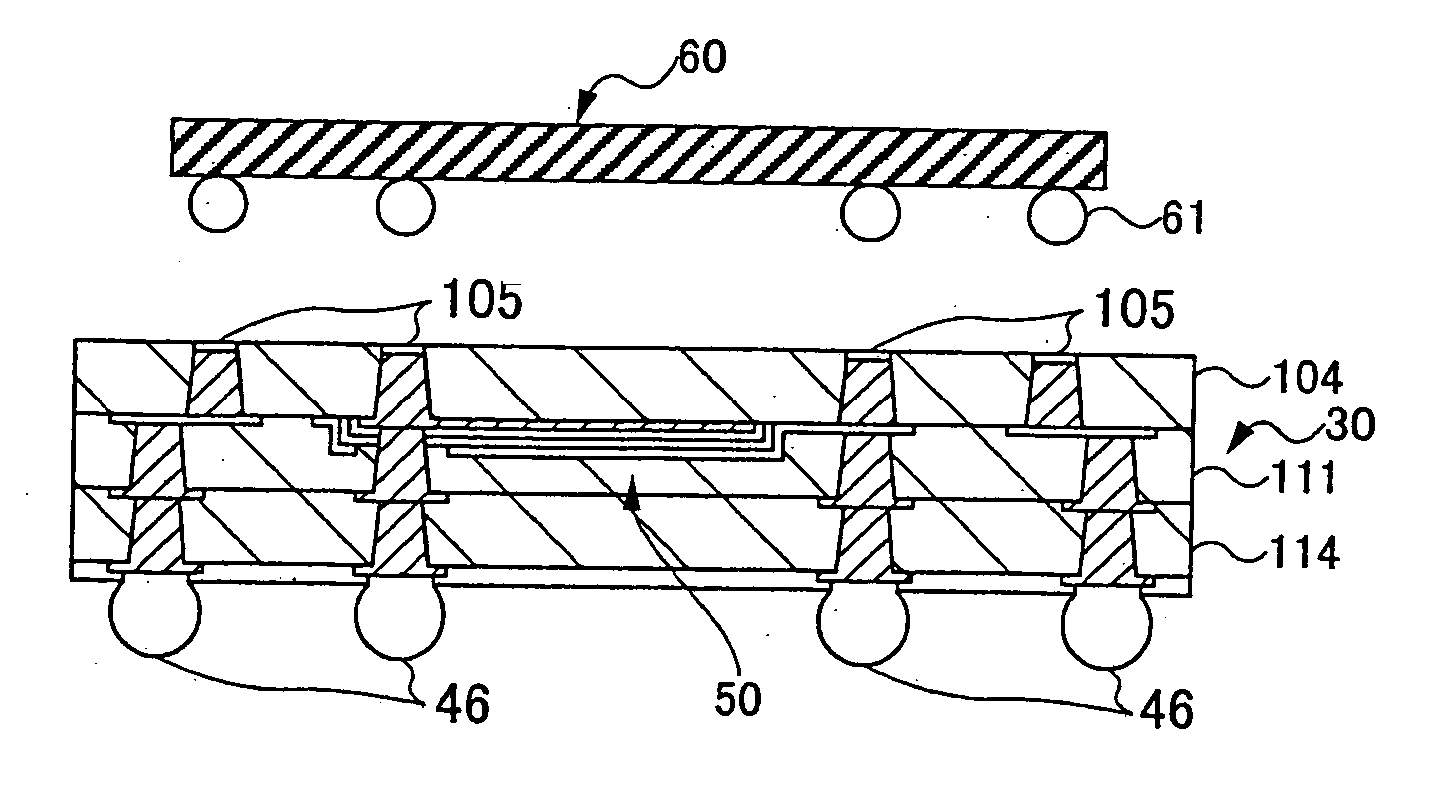

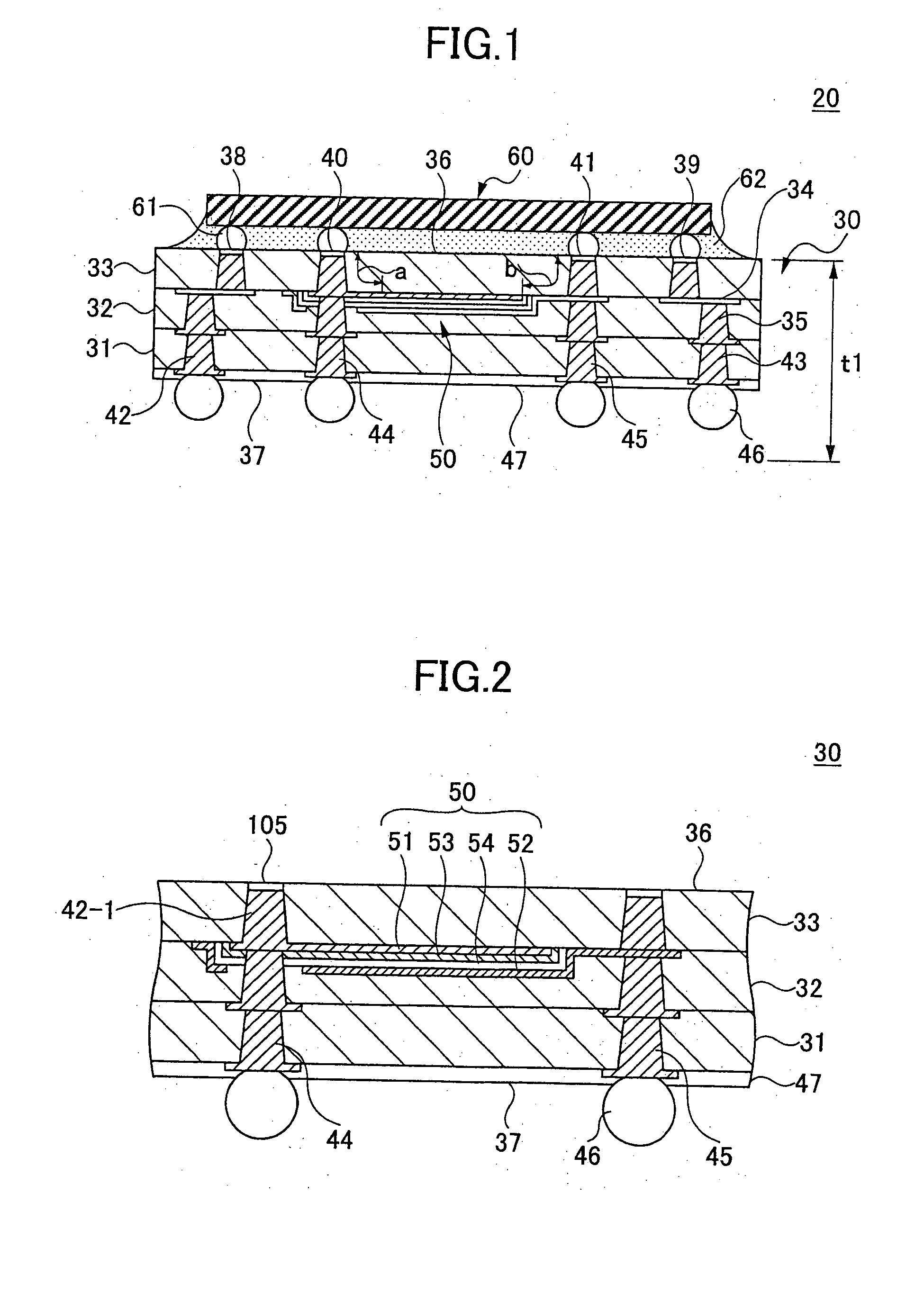

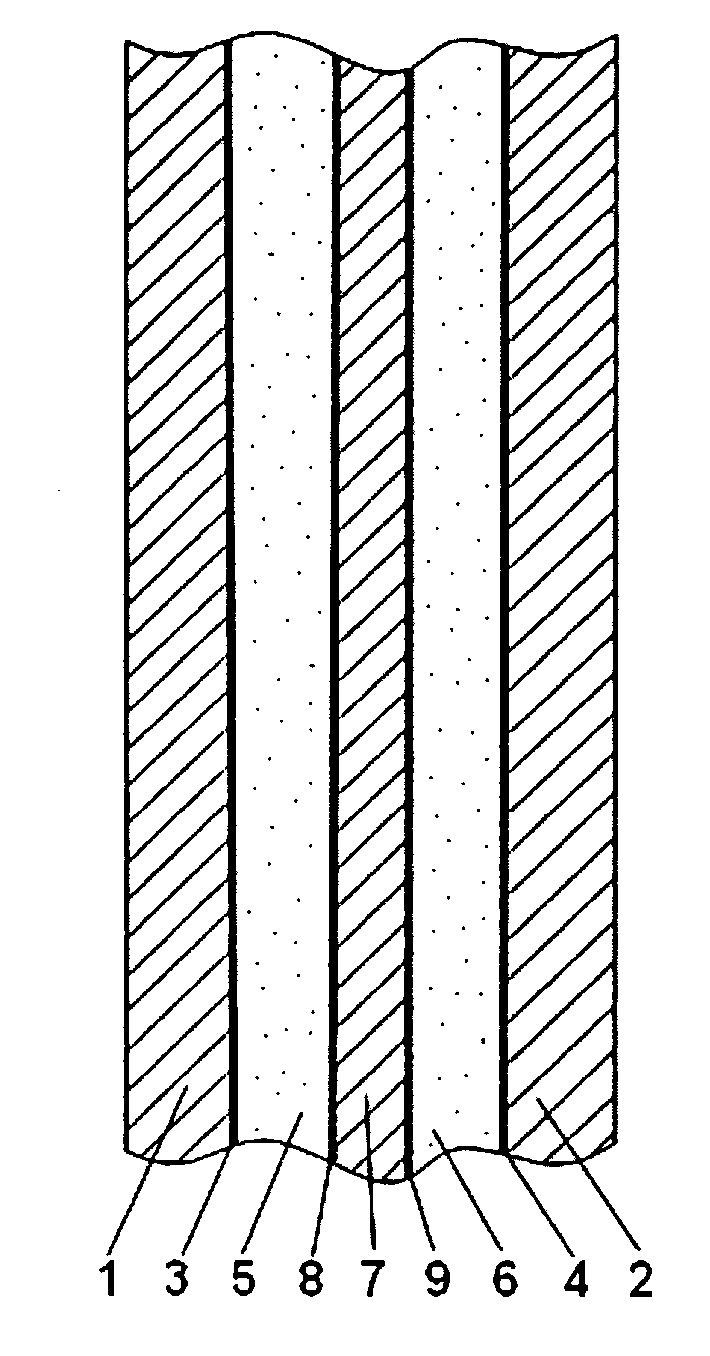

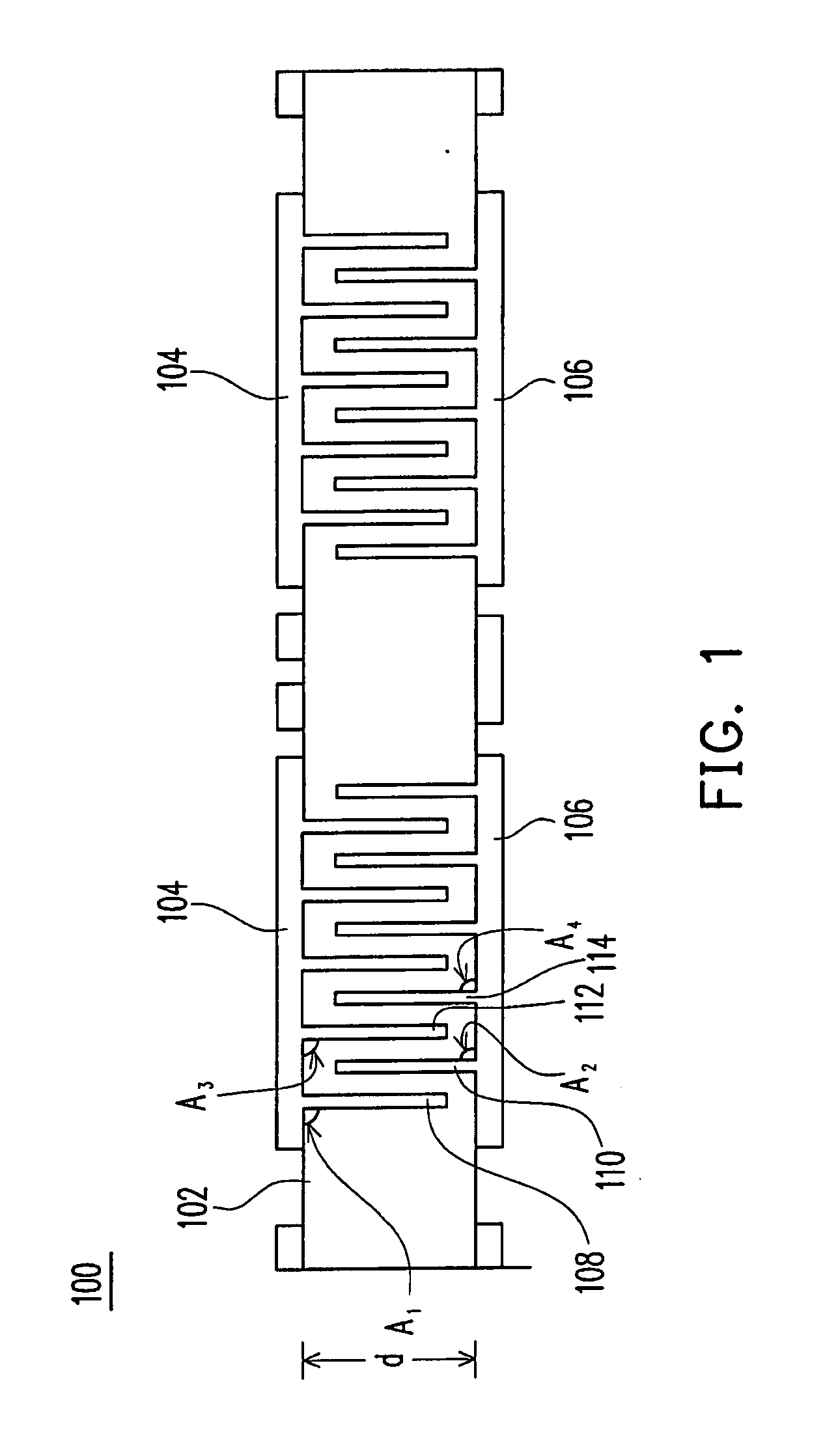

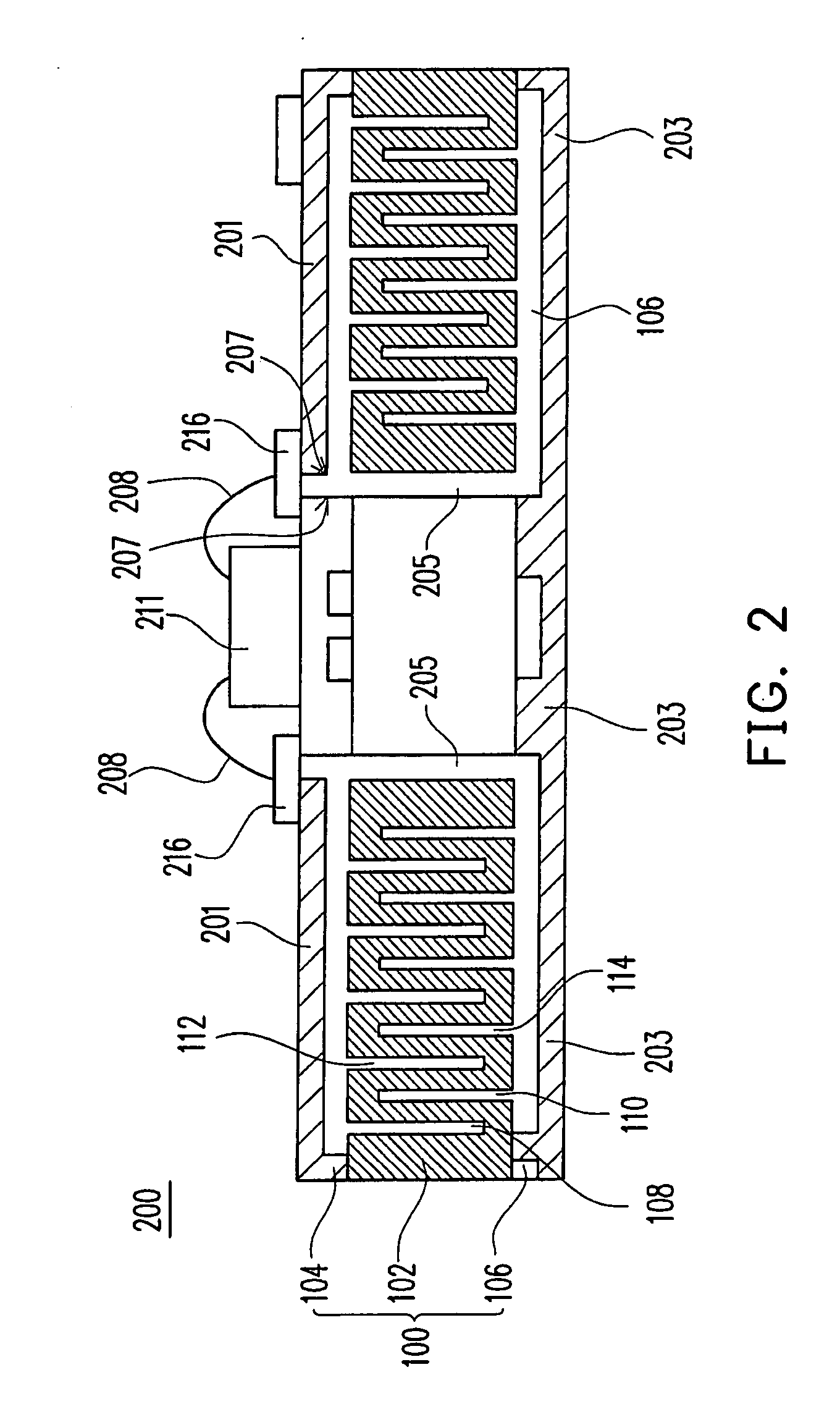

Substrate for carrying a semiconductor chip and a manufacturing method thereof

ActiveUS6998308B2Average thicknessInductance, of the substrate is reducedSemiconductor/solid-state device detailsPrinted circuit aspectsInsulation layerSemiconductor chip

A substrate includes a plurality of insulation layers forming a laminated structure and a built-in capacitor formed in the laminated structure, wherein the laminated structure includes a layer of baked organic polysilane.

Owner:SHINKO ELECTRIC IND CO LTD

Plastic cap featuring excellent sealing and venting

A plastic cap comprising a top panel and a skirt hanging down from the peripheral edge of the top panel, the inner surface of the top panel forming an inner ring that forms a seal upon coming into intimate contact with the inner surface of the wall of the mouth of a container, and the inner surface of skirt forming a screw thread that comes into engagement with a screw thread formed on the outer surface of the wall of the mouth of the container, wherein a slender recessed portion is formed in a number of at least one in the inner surface of said inner ring extending upward from an end thereof. The cap features both excellent sealing and excellent venting.

Owner:TOYO SEIKAN KAISHA LTD +1

Substrate for carrying a semiconductor chip and a manufacturing method thereof

InactiveUS20050185382A1Easy and efficientEasily and efficiently obtainedSemiconductor/solid-state device detailsPrinted circuit aspectsInsulation layerSemiconductor chip

A substrate includes a plurality of insulation layers forming a laminated structure and a built-in capacitor formed in the laminated structure, wherein the laminated structure includes a layer of baked organic polysilane.

Owner:OOI KIYOSHI +1

Fire resistant glazing assembly with additional functions

InactiveUS20090246426A1CostIncreased durabilityFireproof doorsUnits with parallel planesGlass windowPrivacy protection

A fire resistant glazing assembly with various additional functions in impact safety, solar control, bullet and blast resistance, burglary and forced entry resistance, natural disaster protection, decoration and aesthetics, privacy protection, sound insulation and signal defense security. The fire resistant glazing assembly comprises: (a) two or more glass sheets that are parallel and spaced-apart from each other, the distance between any two adjacent glass sheets is from 1 mm to 40 mm; (b) one plastic film that is adhered onto one of opposite surfaces of the glass sheets or more plastic films that are respectively adhered onto more opposite surfaces of the glass sheets; (c) one or more intumescent interlayers that are between the glass sheets and bond with the glass sheet or the plastic film adhered onto the glass sheet. The fire resistant glazing assembly achieves various additional functions by means of different plastic films existing inside the glazing assembly. The adopted plastic film is compatible with fire resistant glazing assembly and has at least one specific function in safety and security, solar control, decoration and aesthetics, privacy protection, sound insulation and signal defense security.

Owner:WU HAIJIANG

Package structure with embedded capacitor, fabricating process thereof and applications of the same

InactiveUS20080180878A1Save circuit layout spaceReduce distanceSemiconductor/solid-state device detailsPrinted circuit aspectsDielectric layerCapacitor

A package structure with an embedded capacitor, a fabricating process thereof and applications of the same are provided, wherein the package structure includes a dielectric layer, a first conductive layer, a second conductive layer, a first embedded plate and a second embedded plate. The dielectric layer has a thickness. The first conductive layer with a first potential is located on one side of the dielectric layer. The second conductive layer with a second potential is located on the dielectric layer at the other side thereof opposite to the first conductive layer. The first embedded plate and the second embedded plate that are embedded in the dielectric layer are separated at a distance, wherein the first embedded plate is electrically connected with the first conductive layer, and the second embedded plate is electrically connected with the second conductive layer.

Owner:ADVANCED SEMICON ENG INC

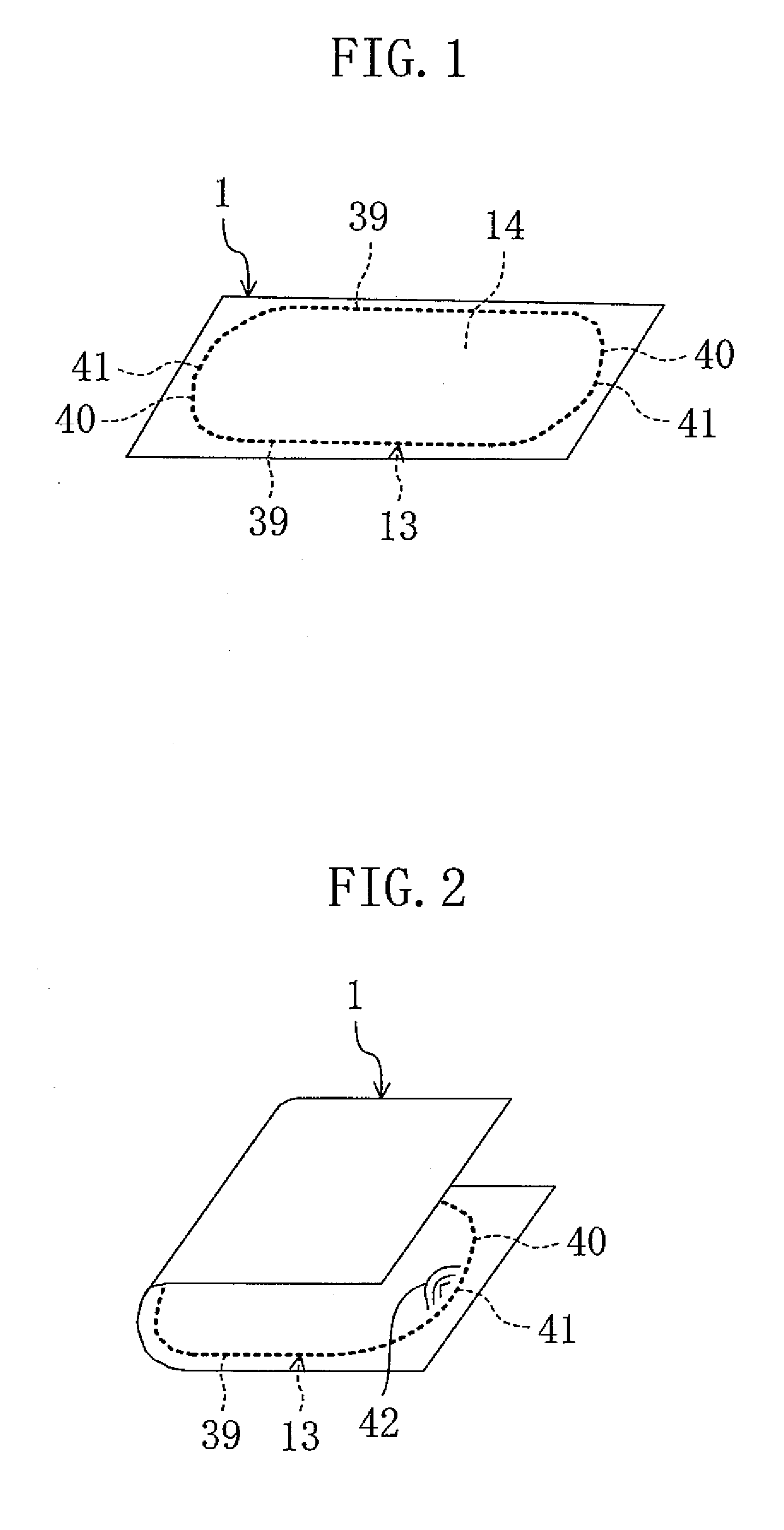

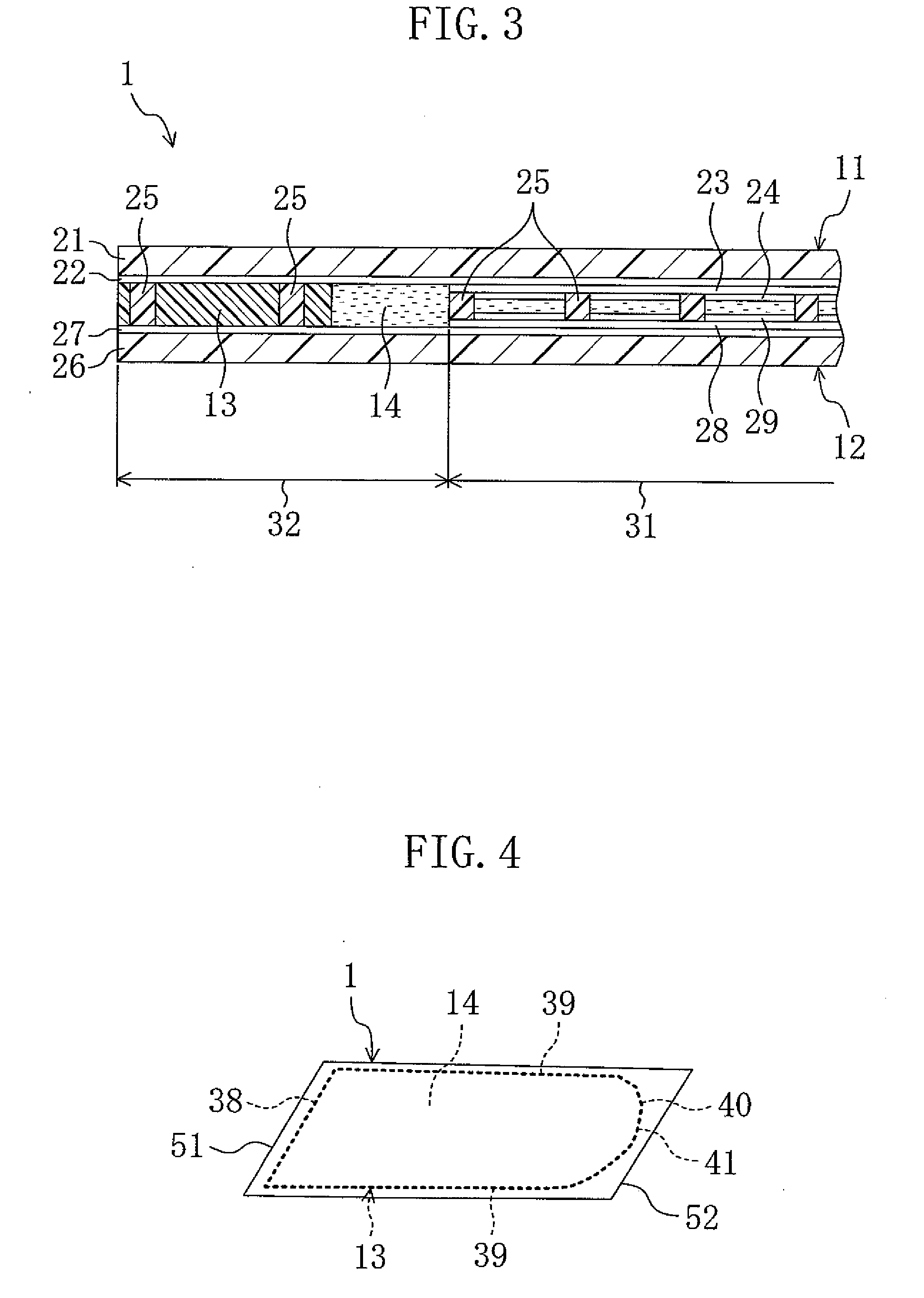

Flexible display device

InactiveUS20100238098A1Reduce sealReduce layeringStatic indicating devicesNon-linear opticsDisplay deviceEngineering

A display device includes a display medium layer positioned between a flexible first substrate and a flexible second substrate, and a sealing member arranged to surround the display medium layer between the first substrate and the second substrate. The sealing member includes a curved portion that is curved so as to protrude outward toward a side opposite to the display medium layer as viewed from a direction normal to a surface of the first substrate in a flat state.

Owner:SHARP KK

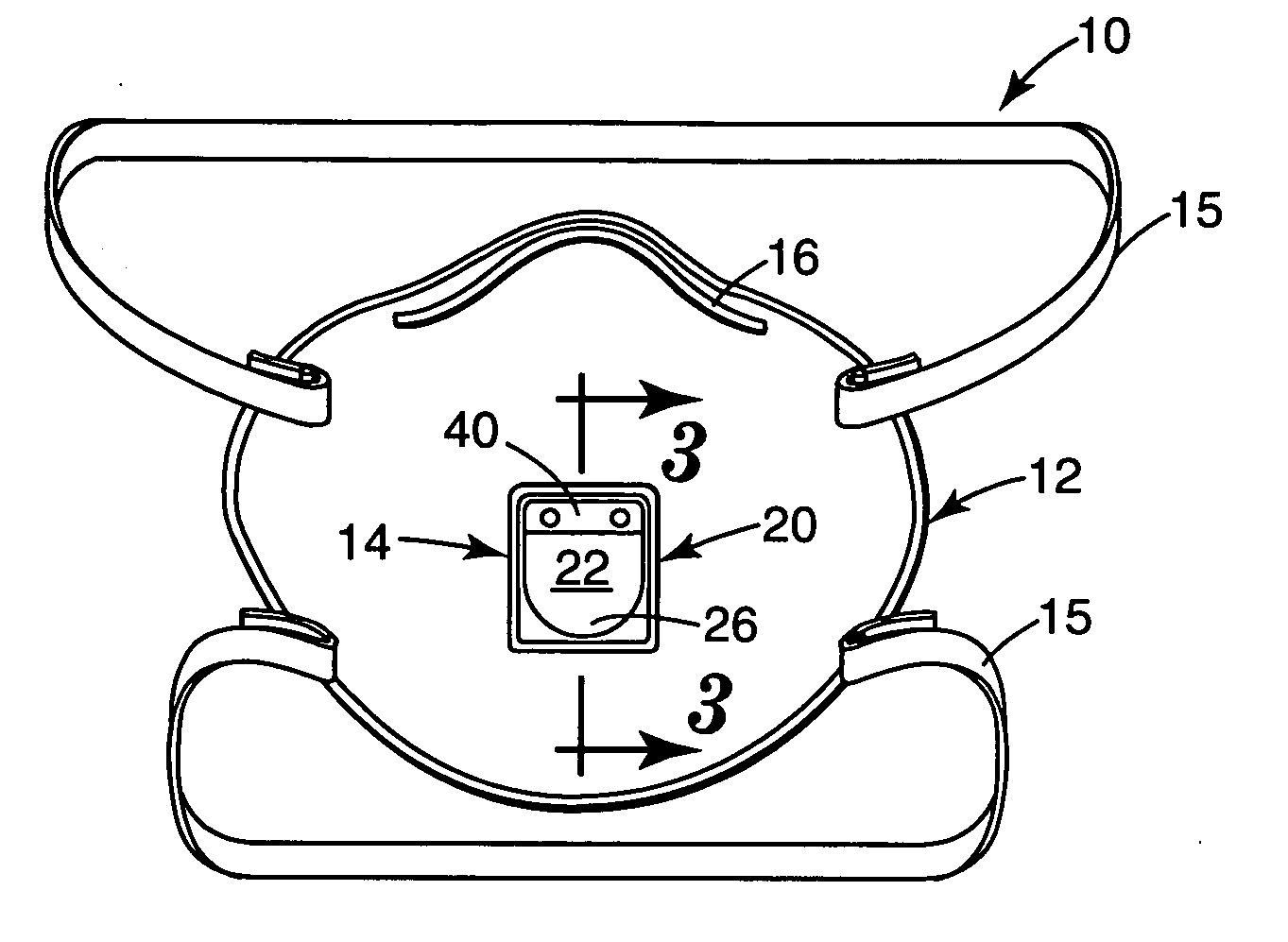

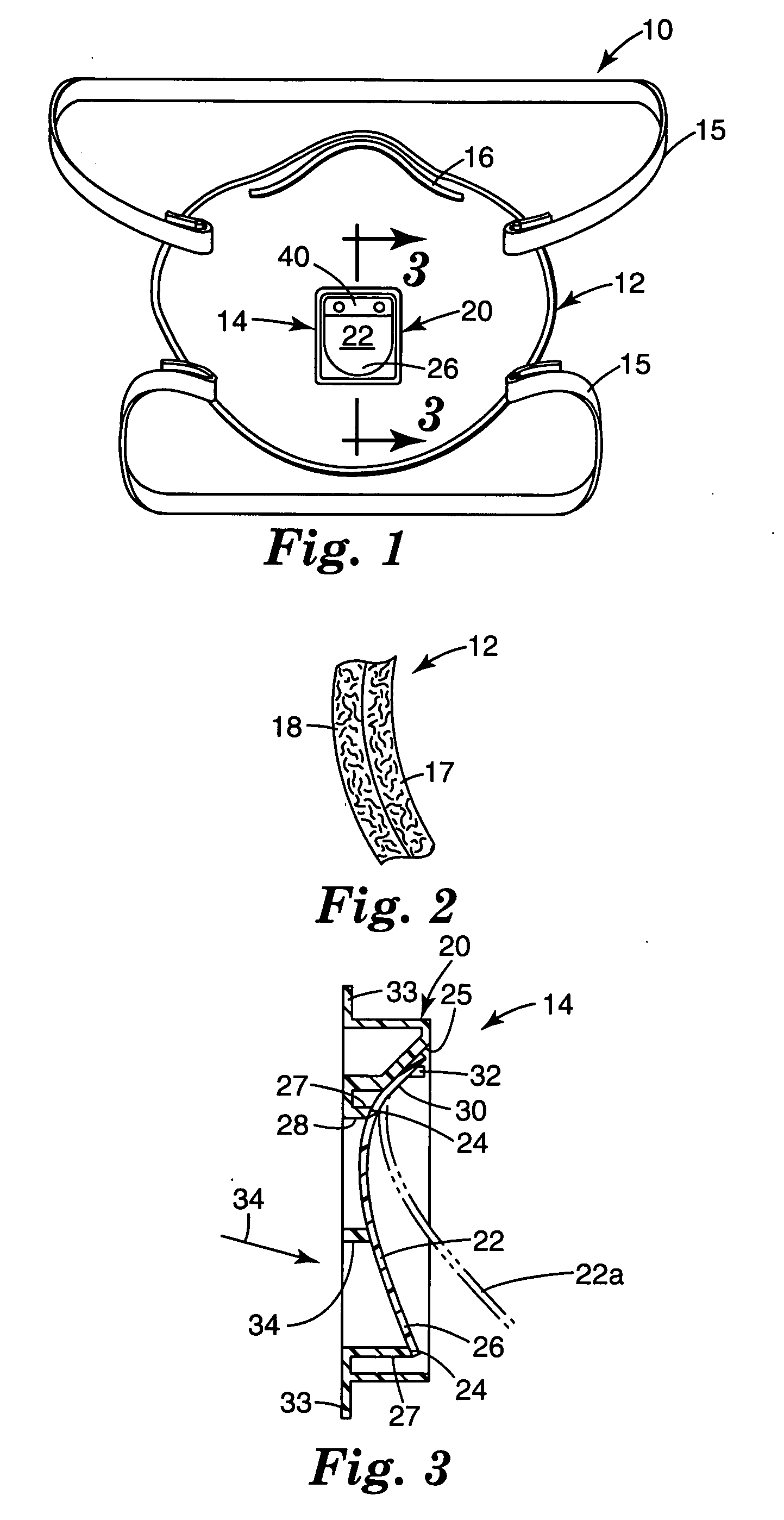

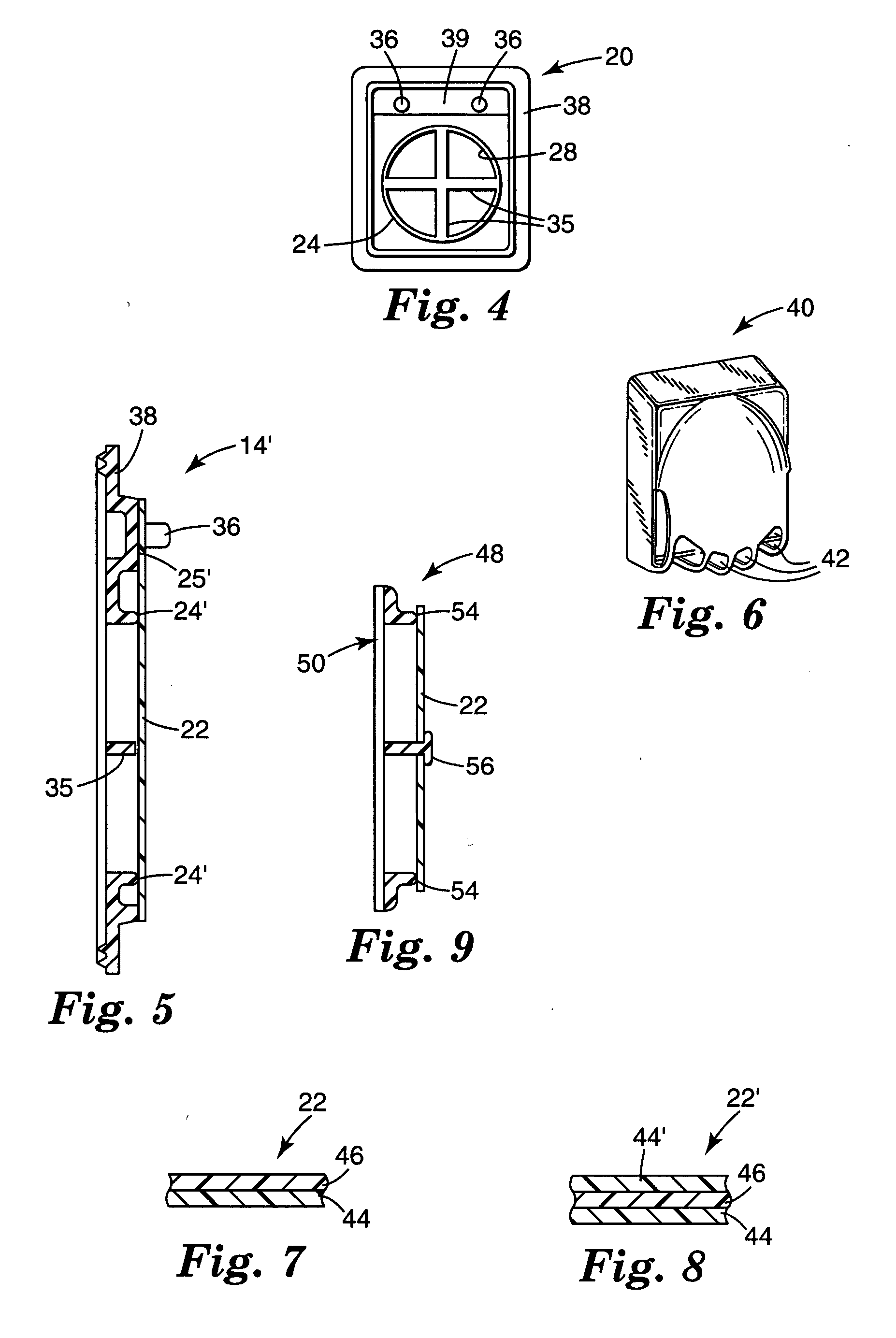

Exhalation and inhalation valves that have a multi-layered flexible flap

InactiveUS20050155607A1Improve comfortEasy to openBreathing filtersBreathing masksEngineeringRespiratory mask

Exhalation and inhalation valves that are sized and adapted to fit on a mask body of a personal respiratory protection device. The exhalation and inhalation valves comprise a valve seat that has a seal surface and an orifice through which an exhale flow stream may pass to leave the interior gas space. A flexible flap is mounted to the valve seat such that the flap makes contact with the seal surface when the valve is in its closed position and such that the flap can flex away from the seal surface during an exhalation to allow exhaled air to pass through the orifice to ultimately enter an exterior gas space. The flexible flap has at least first and second juxtaposed layers where at least one of the layers is stiffer or has a different elastic modulus than the other layer. These valves provide extraordinarily lower pressure drop in use, and they operate more efficiently and require less actuation power to operate. The end user therefore derives greater comfort when wearing a respiratory mask that uses the inventive valve.

Owner:3M INNOVATIVE PROPERTIES CO

Foam Production Method

A foam production method including an irradiating step in which an active energy beam is irradiated onto a foamable composition containing an acid generating agent, which generates an acid, or a base generating agent, which generates a base, due to an action of an active energy beam, and containing a compound which has a decomposable / foamable functional group, which decomposes and eliminates one or more kinds of volatile substances with a low boiling point by reacting with the acid or base; and a subsequent foaming step in which the foamable composition is foamed under controlled pressure in a temperature region where the volatile substances with a low boiling point are decomposed and being eliminated.

Owner:OJI PAPER CO LTD

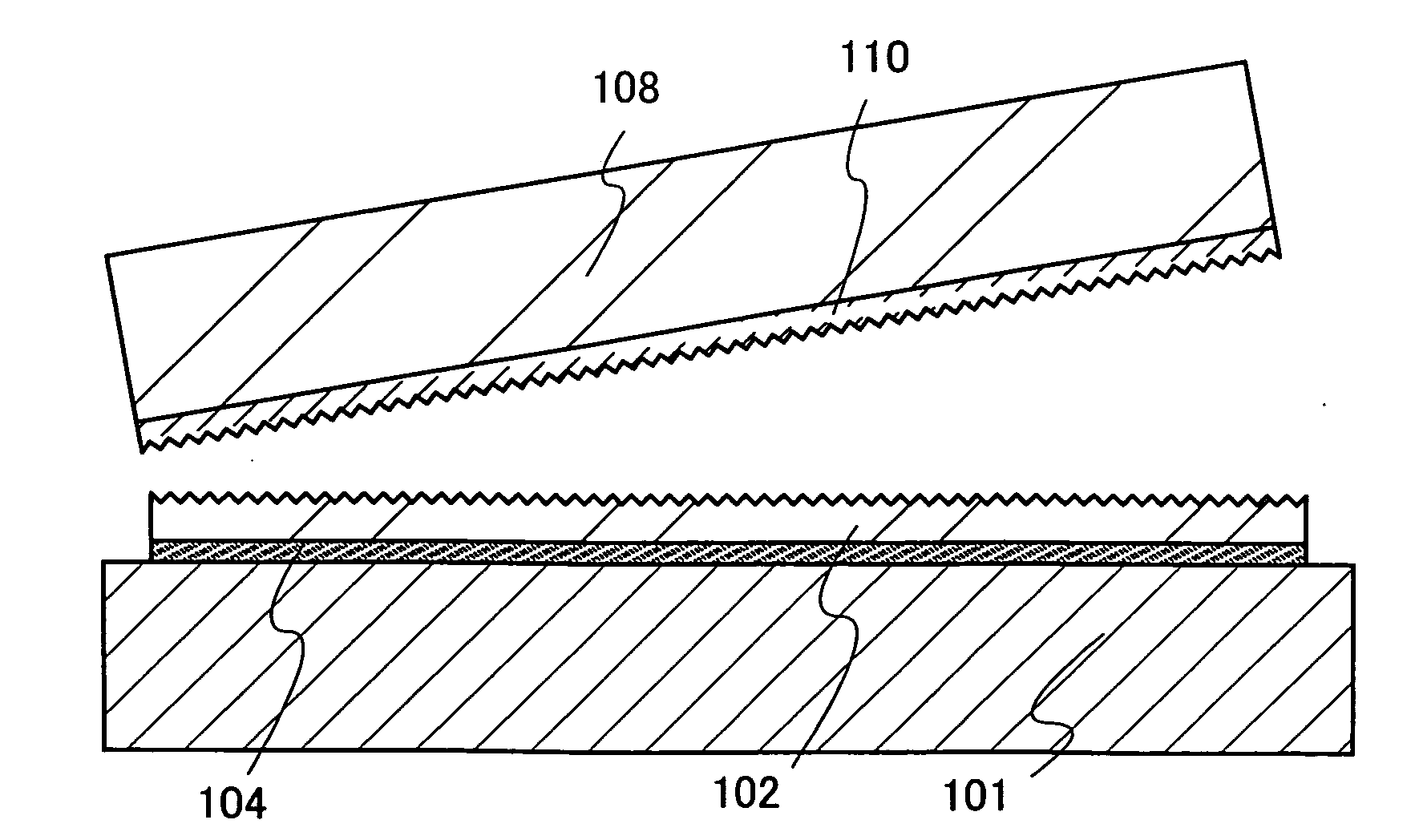

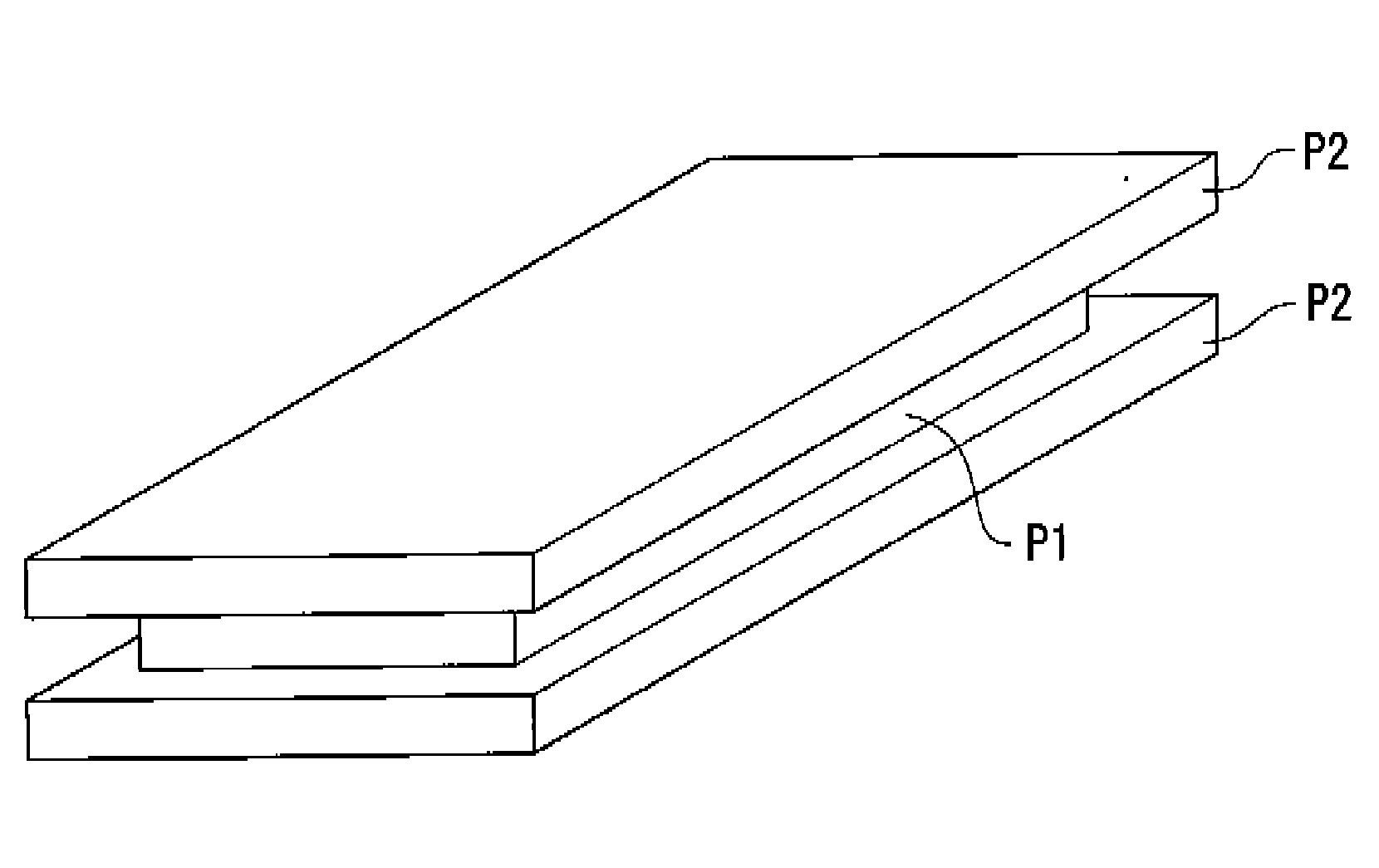

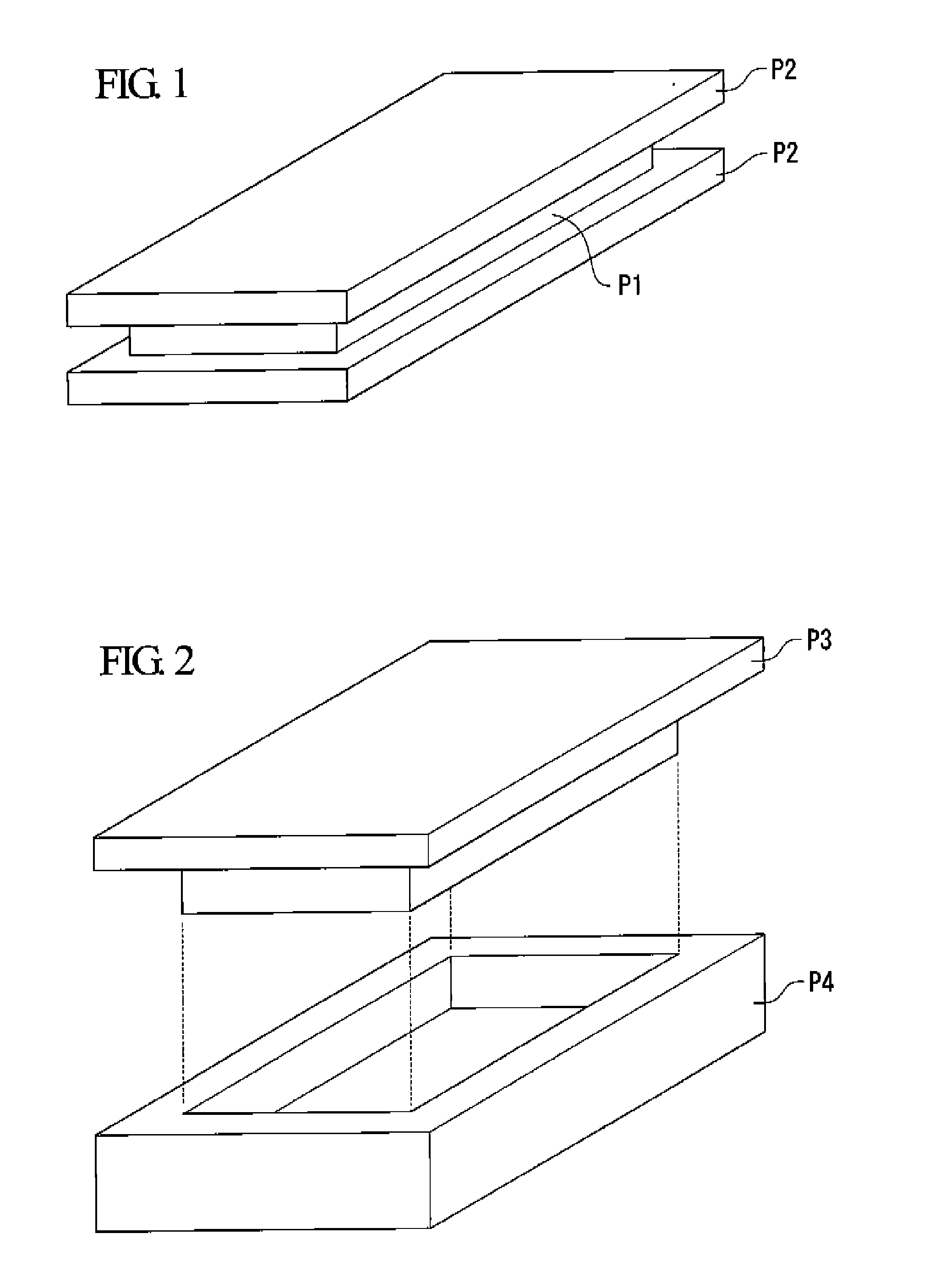

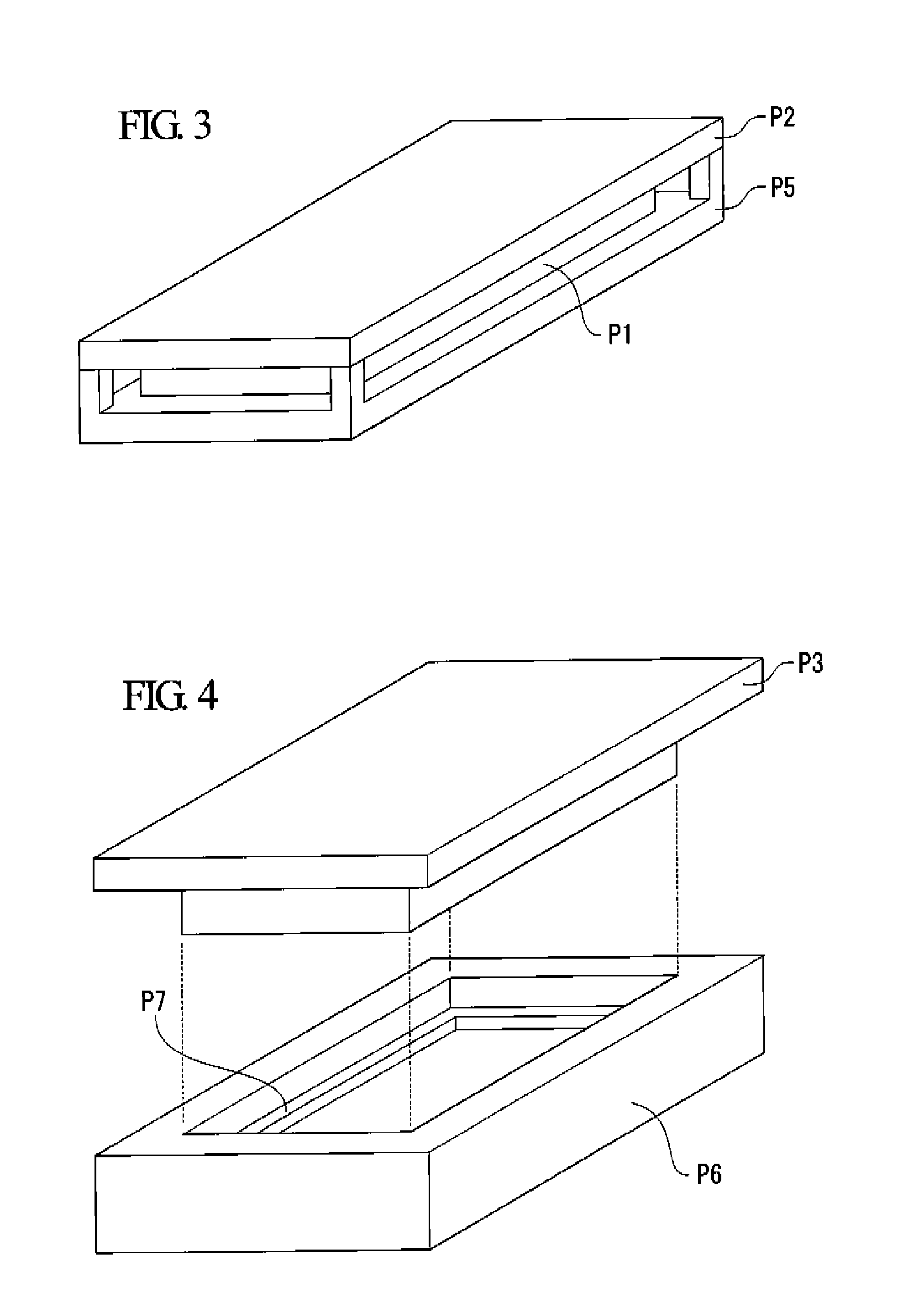

Portable device

ActiveUS7184617B2Average thicknessImprove portabilityPrinted circuit detailsCoupling light guidesOn boardEngineering

A portable device has a configuration such that a plurality of housings are connected functionally, wherein the thickness of a connection section between the housings is reduced so that the portability is improved. The portable device includes a first housing; a first board provided in the first housing; a second housing; a second board provided in the second housing; a connection section for connecting the first housing with the second housing in such a manner that their relative position can be changed; and an optical waveguide film having at least one optical waveguide for connecting the first board with the second board through optical wiring.

Owner:PANASONIC CORP

Photoelectric conversion device, and process for manufacturing photoelectric conversion device

InactiveUS20130221341A1Avoid mixingSealedFinal product manufactureSolid-state devicesOrganic layerAuxiliary electrode

A photoelectric conversion device includes a first substrate, a first electrode, an organic layer, a second electrode and a second substrate that are provided in this order. An auxiliary electrode is interposed between the first electrode and the organic layer. When the photoelectric conversion device is seen in a cross section taken in a thickness direction of the first substrate, a thickness of the auxiliary electrode is greater than a thickness of the organic layer.

Owner:IDEMITSU KOSAN CO LTD

Three-ply absorbent paper product and method of making

InactiveUS6805766B1Feel goodGood flexibilityNatural cellulose pulp/paperMechanical working/deformationAdhesiveEngineering

Owner:GEORGIA PACIFIC FRANCE SAS

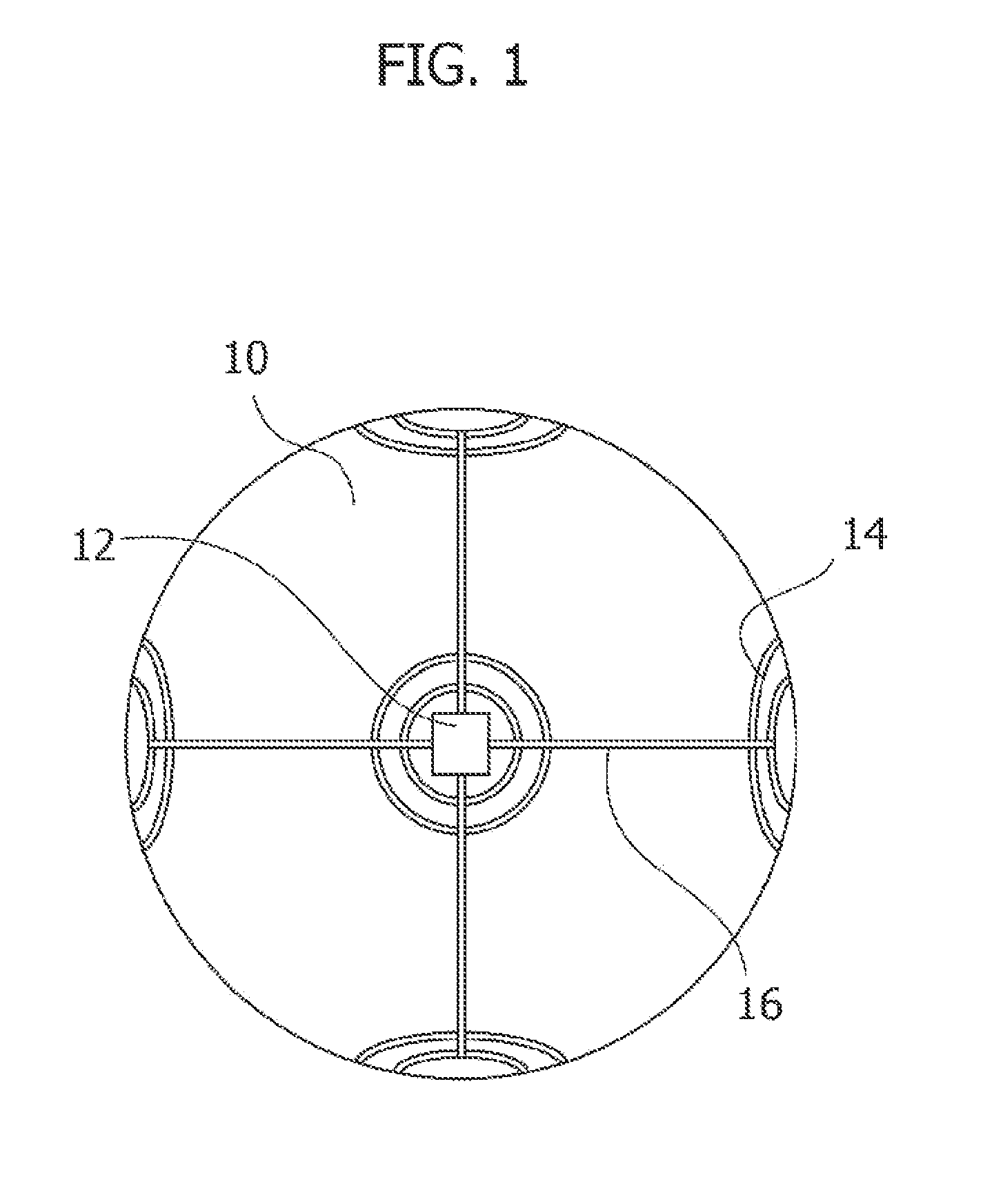

Golf ball with RFID system

InactiveUS20130196788A1Improve heat resistanceAvoid signalingPrinted electric component incorporationGolf ballsInter layerRadio frequency signal

A golf ball has a radio-frequency identification (RFID) circuit for storing ID information therein, the RFID circuit formed of conductive ink; and an antenna for communicating by using radio frequency signals, the antenna connected to the RFID circuit. The antenna may be formed of conductive ink or paste. The RFID circuit and the antenna may be formed on the surface of the golf ball. The golf ball may further include a core layer, a cover layer disposed on the outside of the core layer, and optionally, an intermediate layer disposed between the core layer and the cover layer. The core or intermediate layer has a groove on the surface thereof, and the RFID circuit and the antenna may be formed within the groove.

Owner:BRIDGESTONE SPORTS

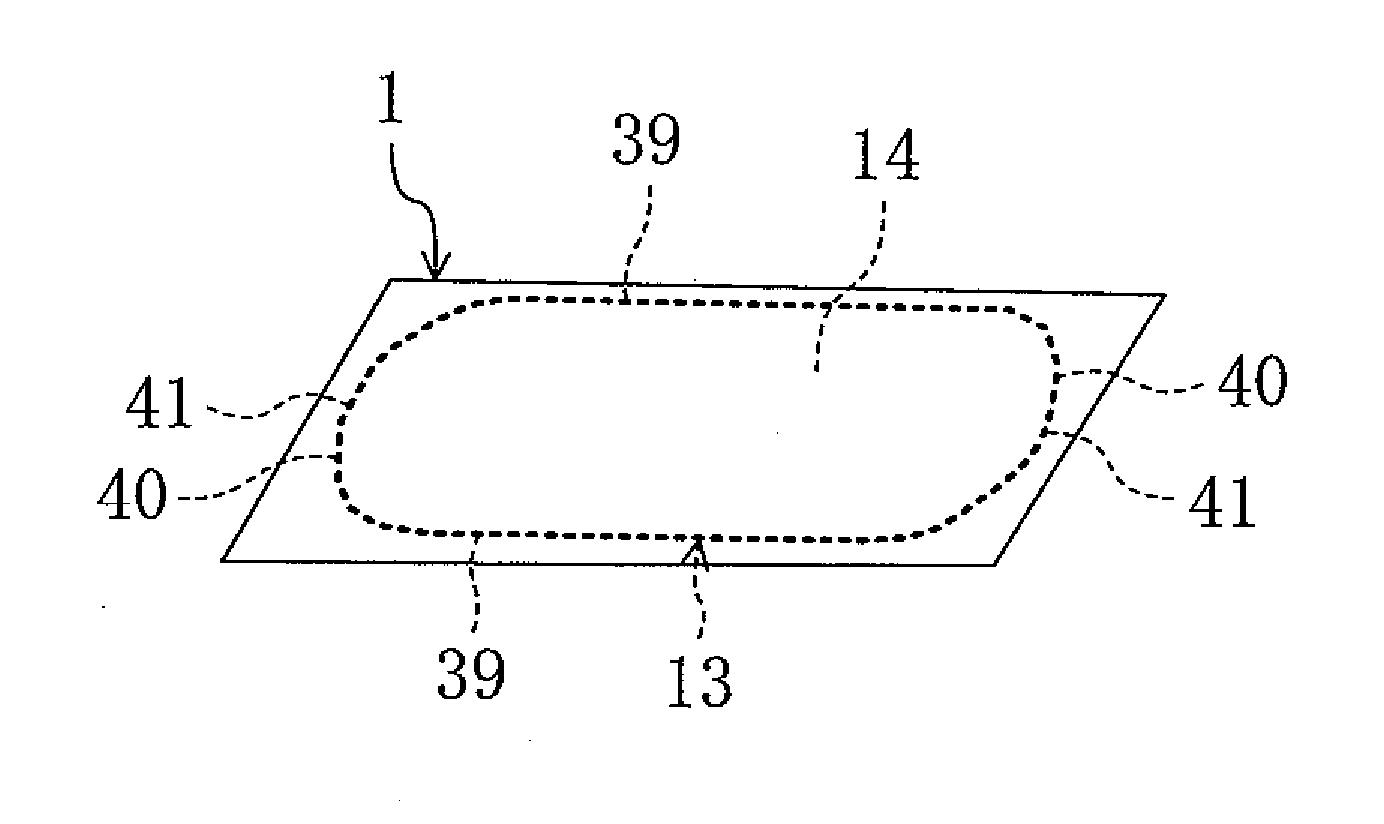

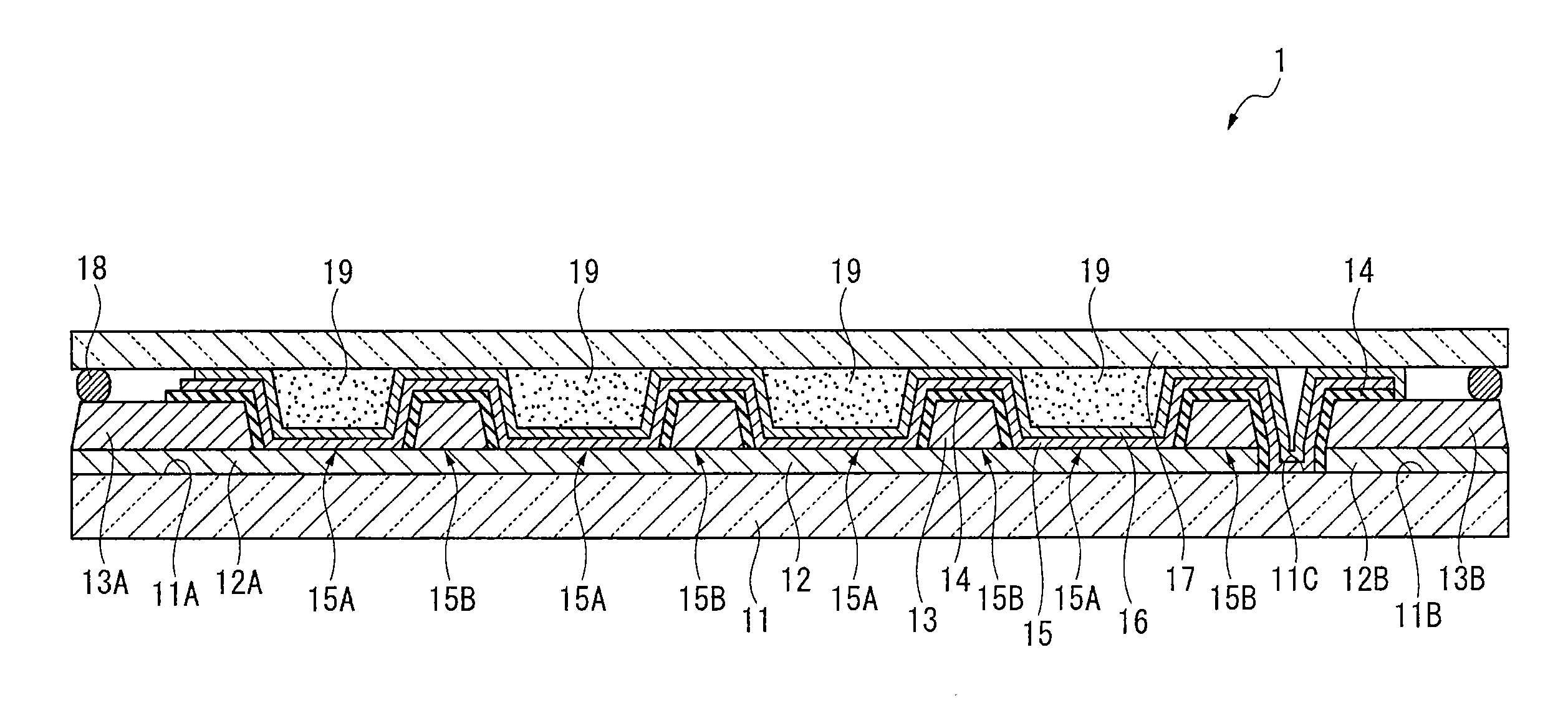

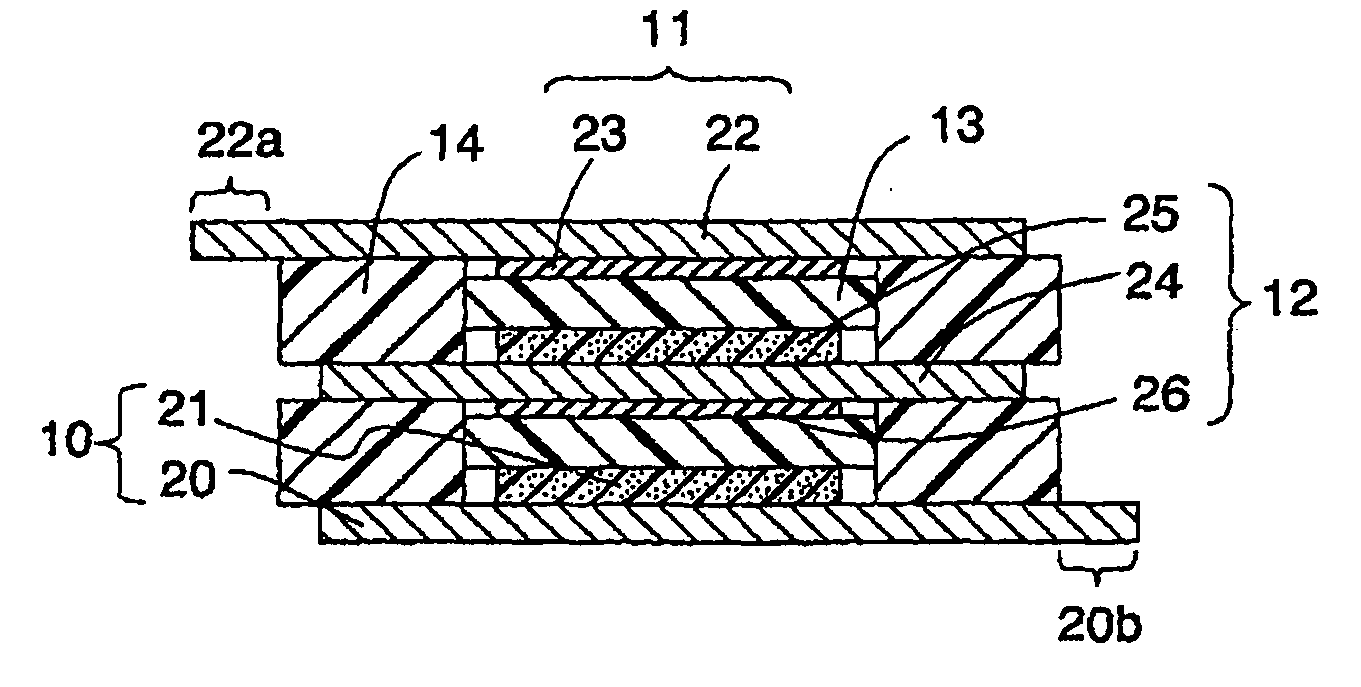

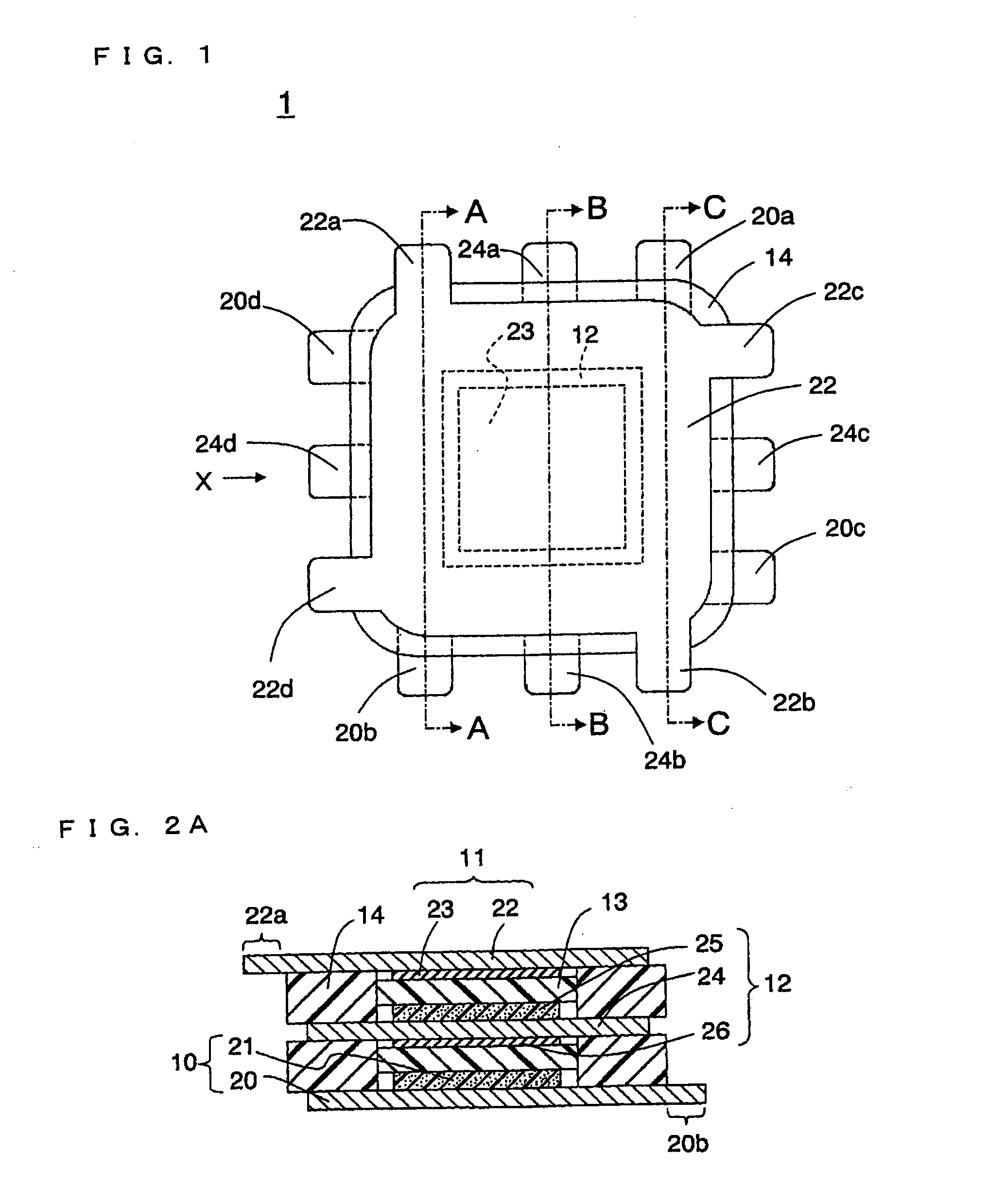

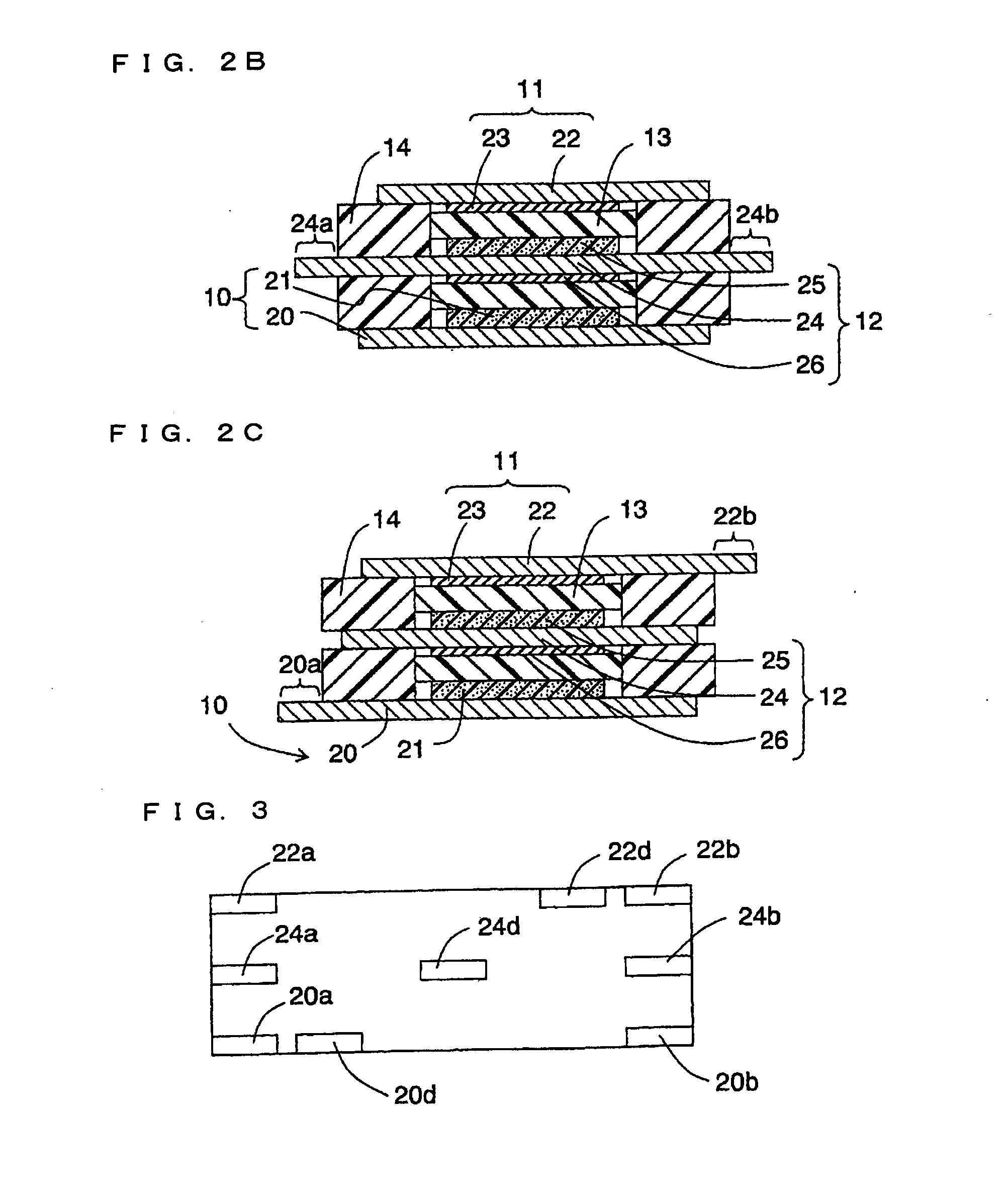

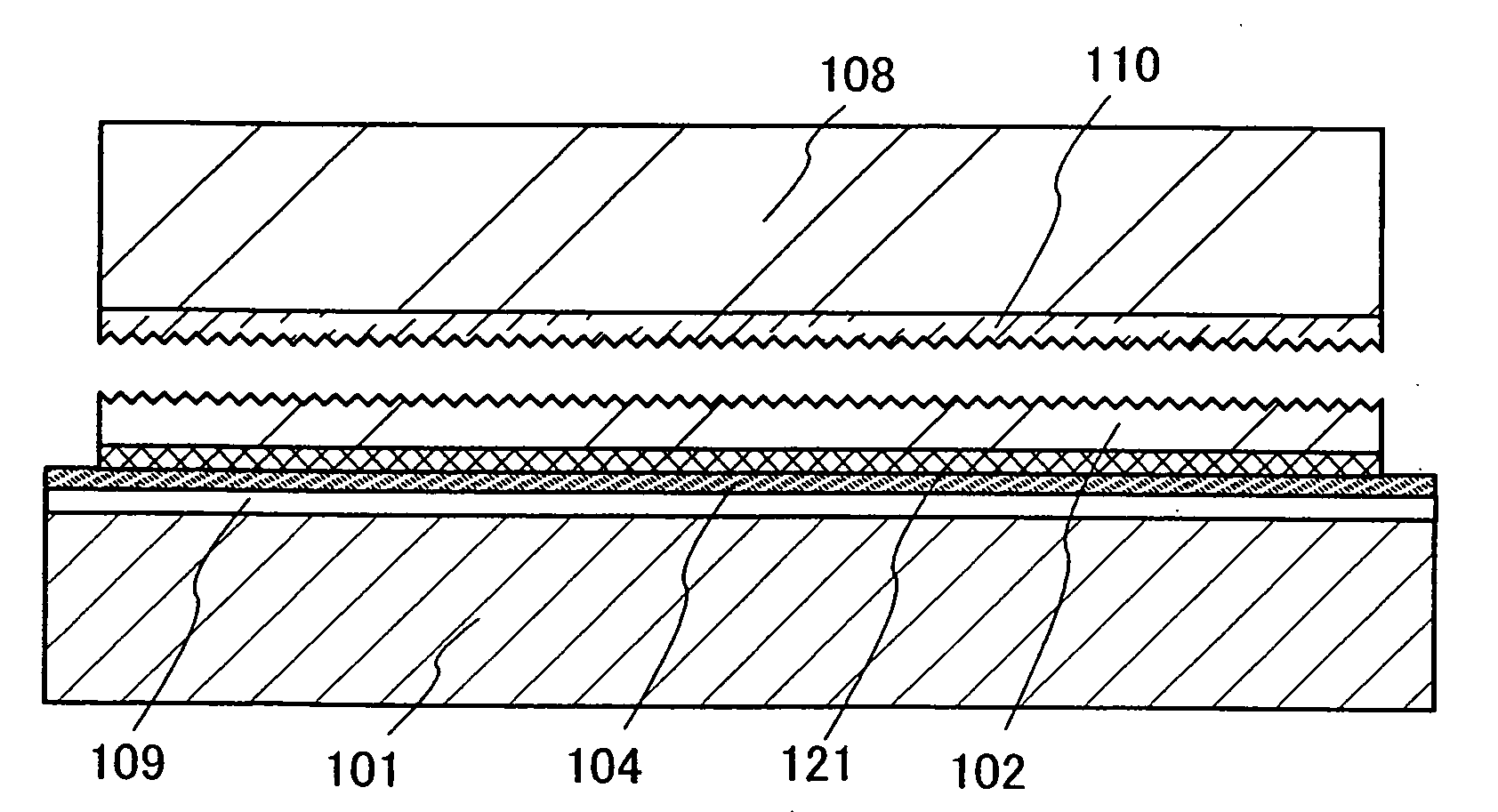

Bipolar battery

InactiveUS20110014520A1Ensure electrical connection reliabilityReduce the possibilityFinal product manufactureElectrode carriers/collectorsEngineeringElectrolyte

The present invention relates to a bipolar battery. It is an object of the present invention to provide a bipolar battery having a good productivity and a high reliability of the electrical connection with an apparatus when the battery is attached to various apparatuses. A bipolar battery 1 of the present invention includes a positive electrode 10, a negative electrode 11, a bipolar electrode 12, an electrolyte-containing separator 13, and a sealing member 14. Current collectors 20, 22, and 24 of the positive electrode 10, the negative electrode 11, and the bipolar electrode 12 are respectively provided with at least two projections 20a to 20d, 22a to 22d, and 24a to 24d, and these projections project from peripheral portions of the current collectors.

Owner:PANASONIC CORP

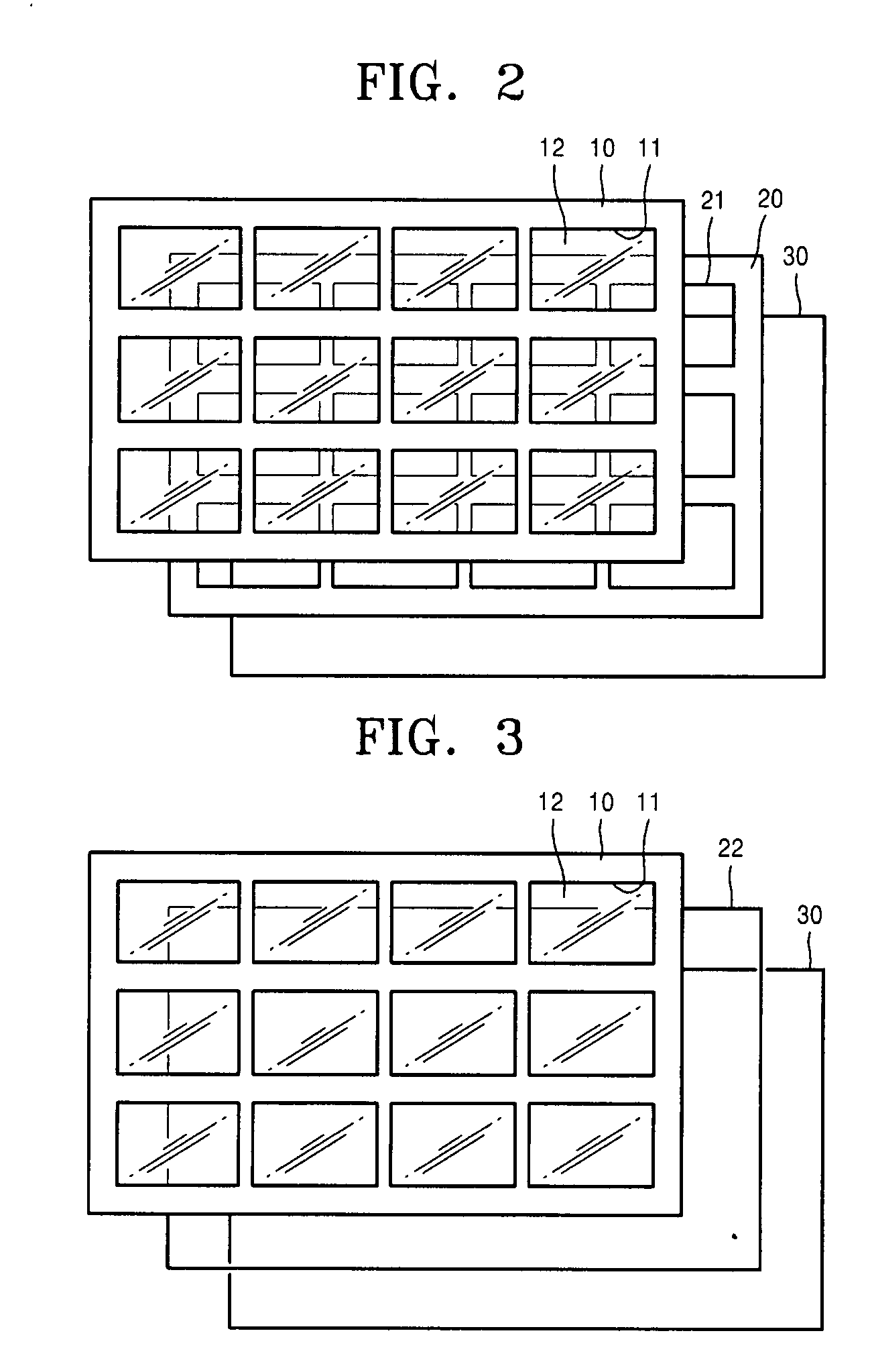

Input device with display buttons and portable electronic device having the same

InactiveUS20070296694A1Reduce the possibilityComfortable operation feeling of a button pressDigital data processing detailsCathode-ray tube indicatorsKey pressingHuman–computer interaction

Provided are an input device with display buttons and a portable electronic device having the same. The input device with display buttons may include a button frame having at least one button window; a touch interface, which is disposed below the button frame and generates a signal by sensing a user's touch on each of the button windows; a display panel, which is disposed below the touch interface and provides an image corresponding to each of the button windows; and an operation feeling generator generating mechanical vibration in response to the signal input from the touch interface. The portable electronic device may include the input device with display buttons.

Owner:SAMSUNG ELECTRONICS CO LTD

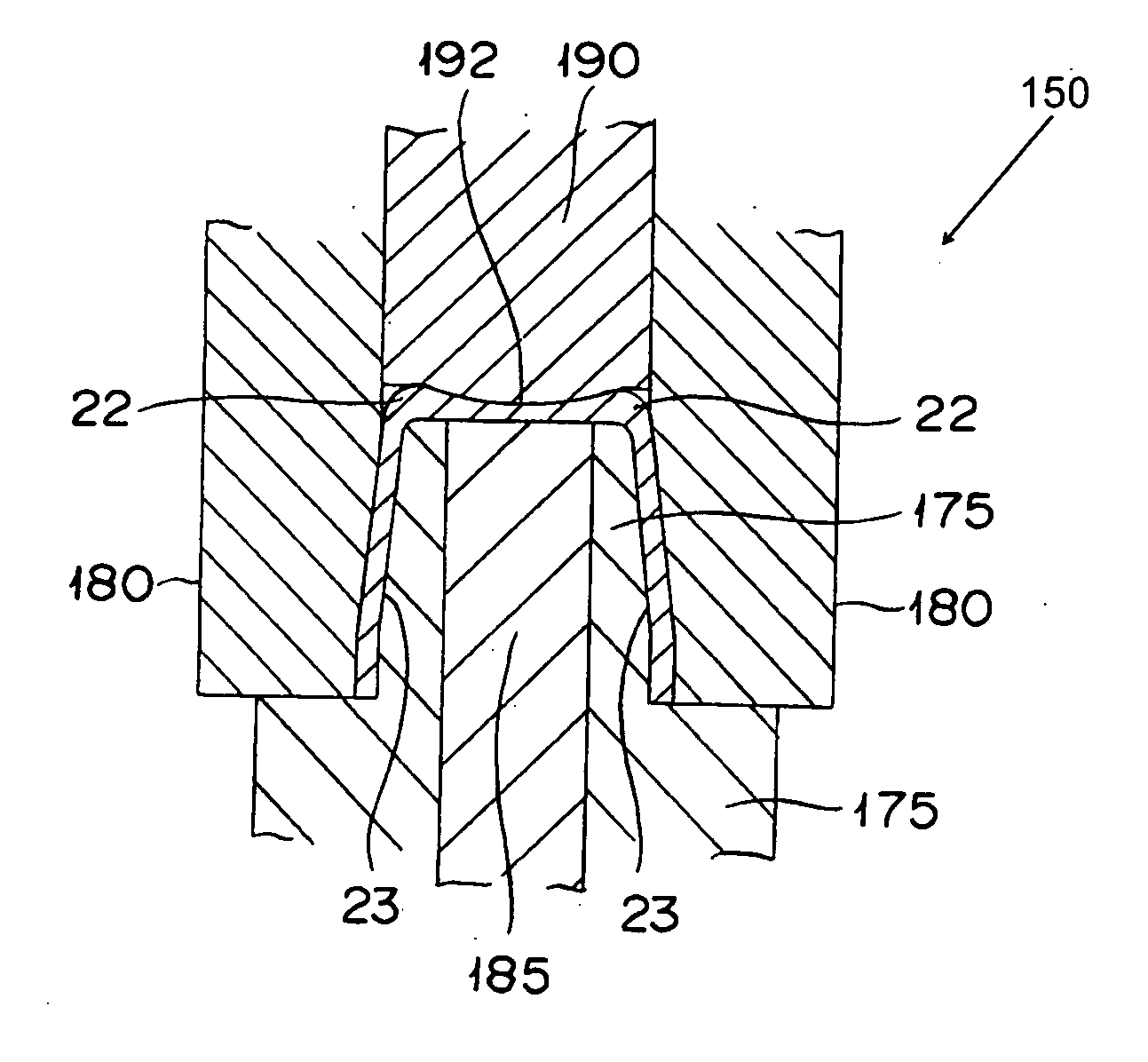

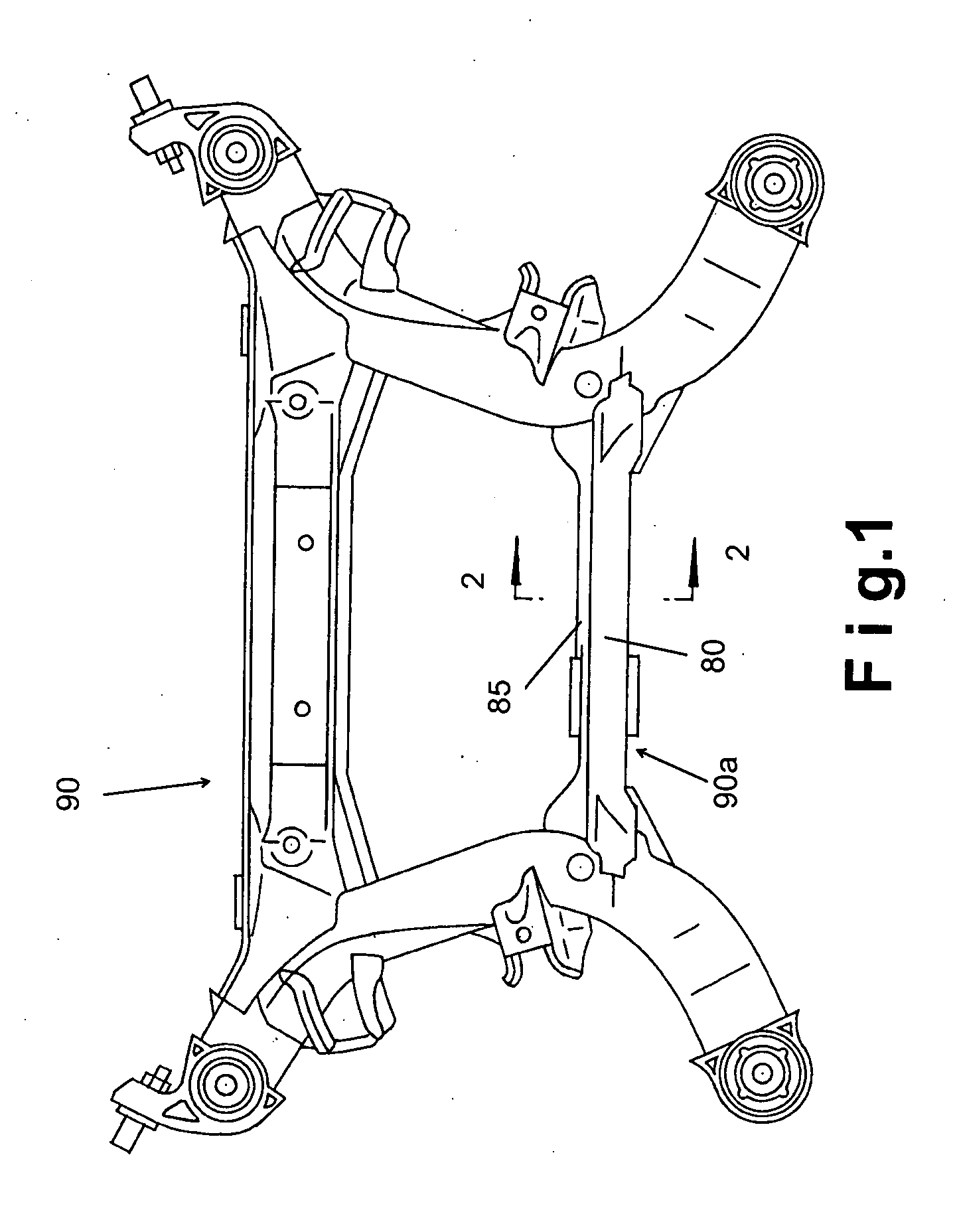

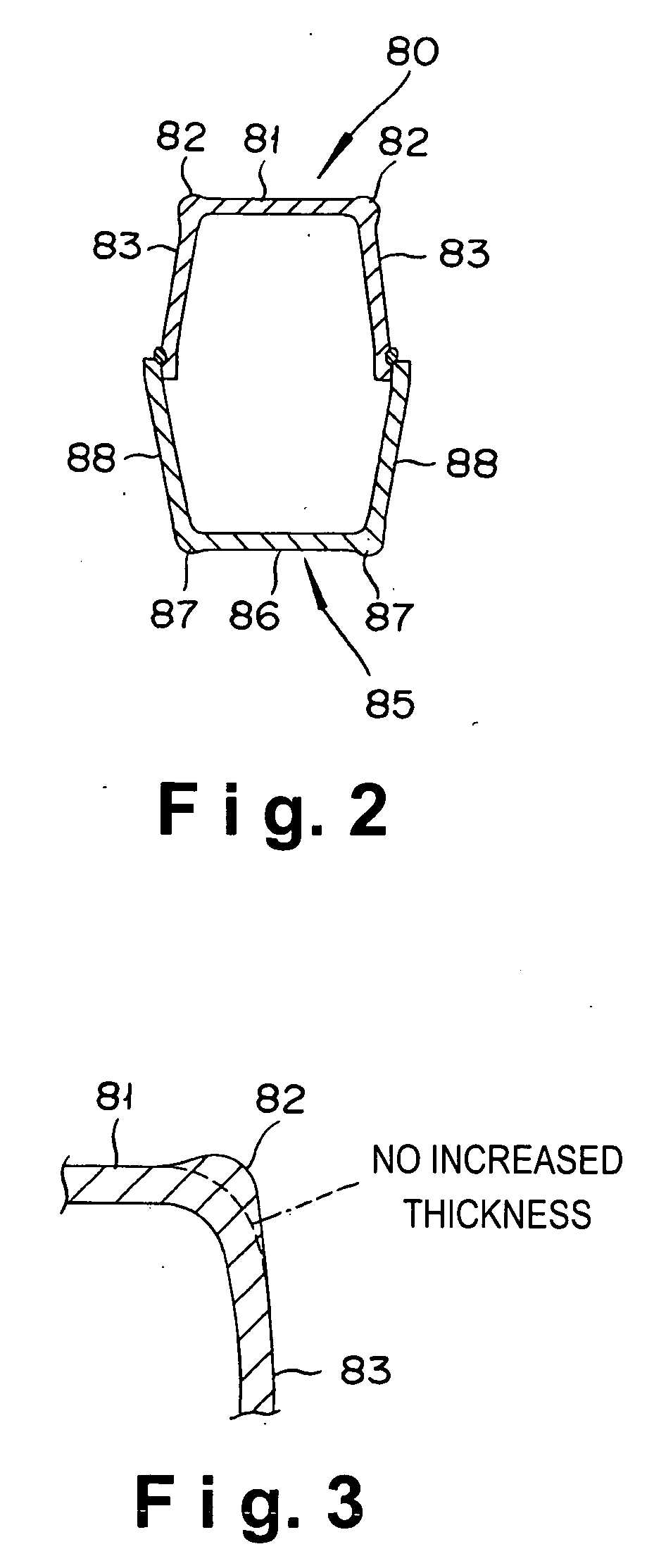

Press-formed member having corner portion, press-formed member manufacturing apparatus and press-formed member manufacturing method

InactiveUS20070125149A1Increase production capacityReduce thicknessForging/hammering/pressing machinesVehicle componentsManufactured apparatusMechanical engineering

A press-formed member includes a first wall with a first thickness, a second wall with a second thickness, and a first corner portion. The first corner portion is disposed between the first and second walls, with the first corner portion having an increased thickness formed by pressure-forming such that the increased thickness of the first corner portion is larger than the first and second thicknesses of the first and second walls adjacent to the first corner portion. In a manufacturing method for the press-formed member, a preliminary body structure to be deformed is provided, and the thickness of the first corner portion of the preliminary body structure is increased by applying pressure to the preliminary body structure.

Owner:NISSAN MOTOR CO LTD

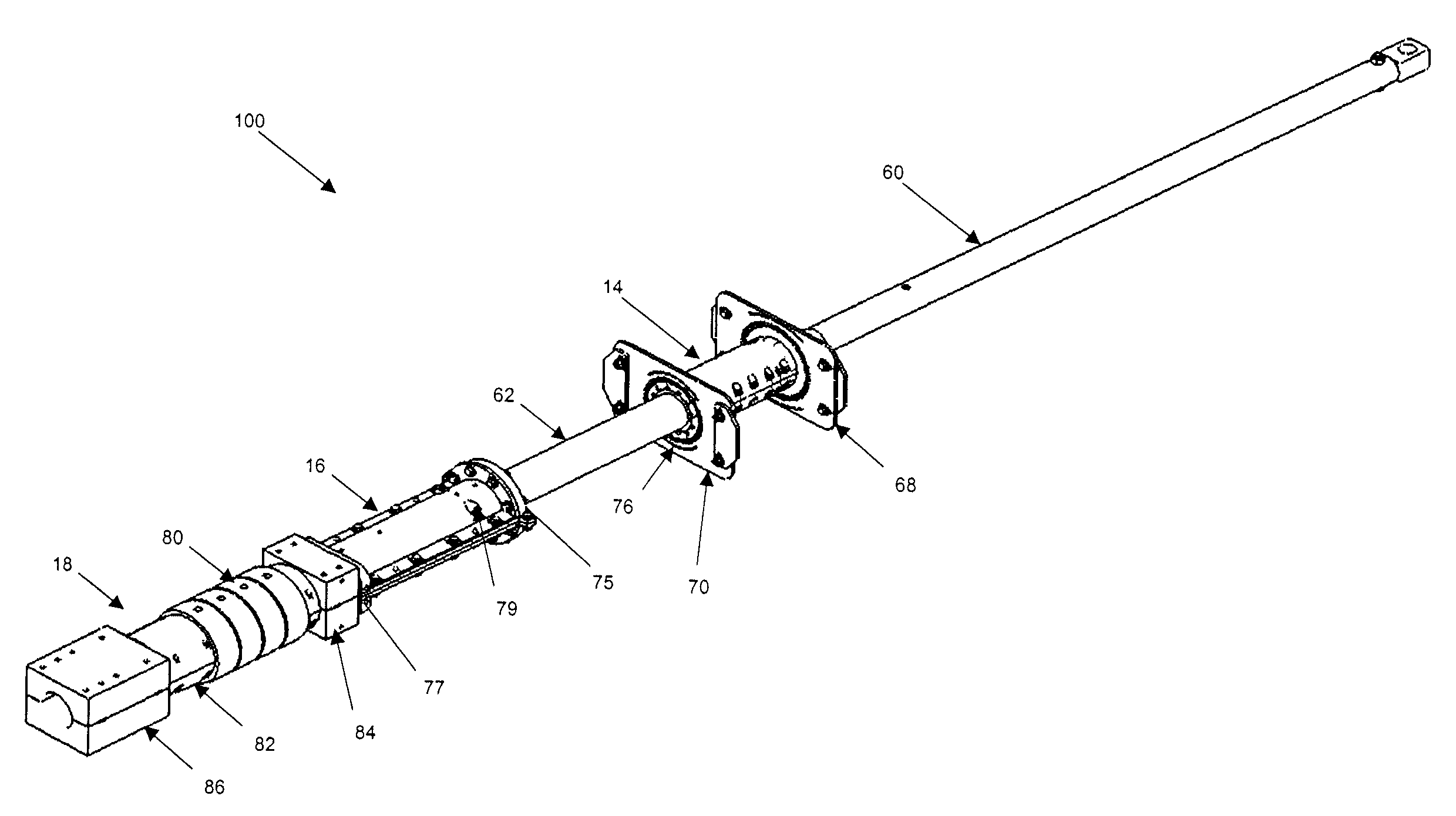

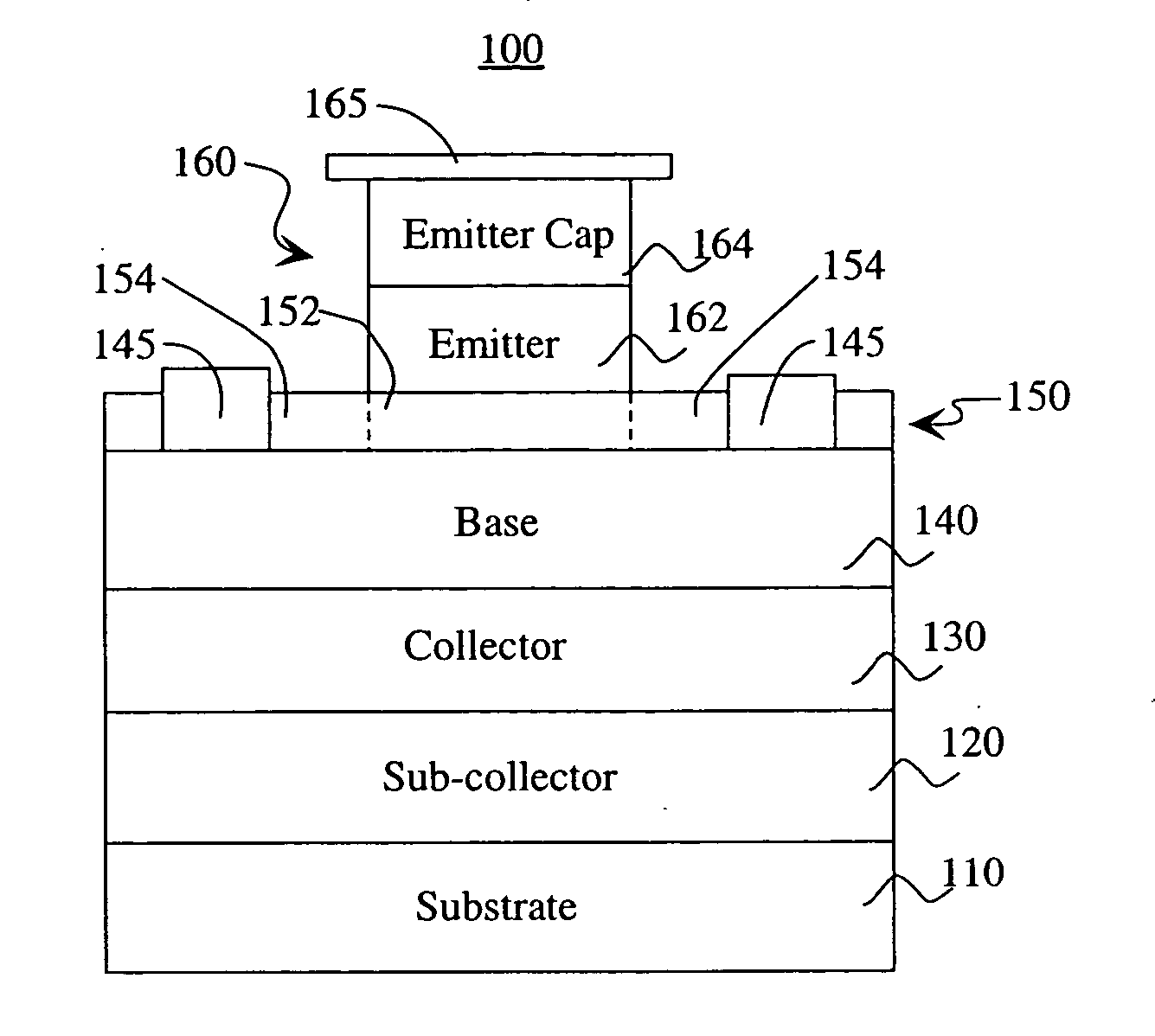

Semiconductor structure for a heterojunction bipolar transistor and a method of making same

InactiveUS20050035370A1Convenient lengthTotal lengthSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor materialsSemiconductor structure

An InP based NPN heterojunction bipolar transistor (HBT) having an emitter mesa; a base layer; an emitter ledge layer located above the base layer and below the emitter mesa, the emitter ledge layer having an intrinsic region located beneath the emitter mesa and an extrinsic region located outside the intrinsic region, the extrinsic region made of depleted semiconductor material; and base contacts formed within a portion of the extrinsic region of the emitter ledge layer and spaced at selected distances from the emitter mesa, wherein the base contacts electrically contact the base layer, and wherein the base contacts and the emitter ledge layer are disposed to cover an upper surface of the base layer so that there are no gaps in the emitter ledge layer between the base contacts and the emitter mesa to leave the upper surface of the base layer exposed.

Owner:HRL LAB

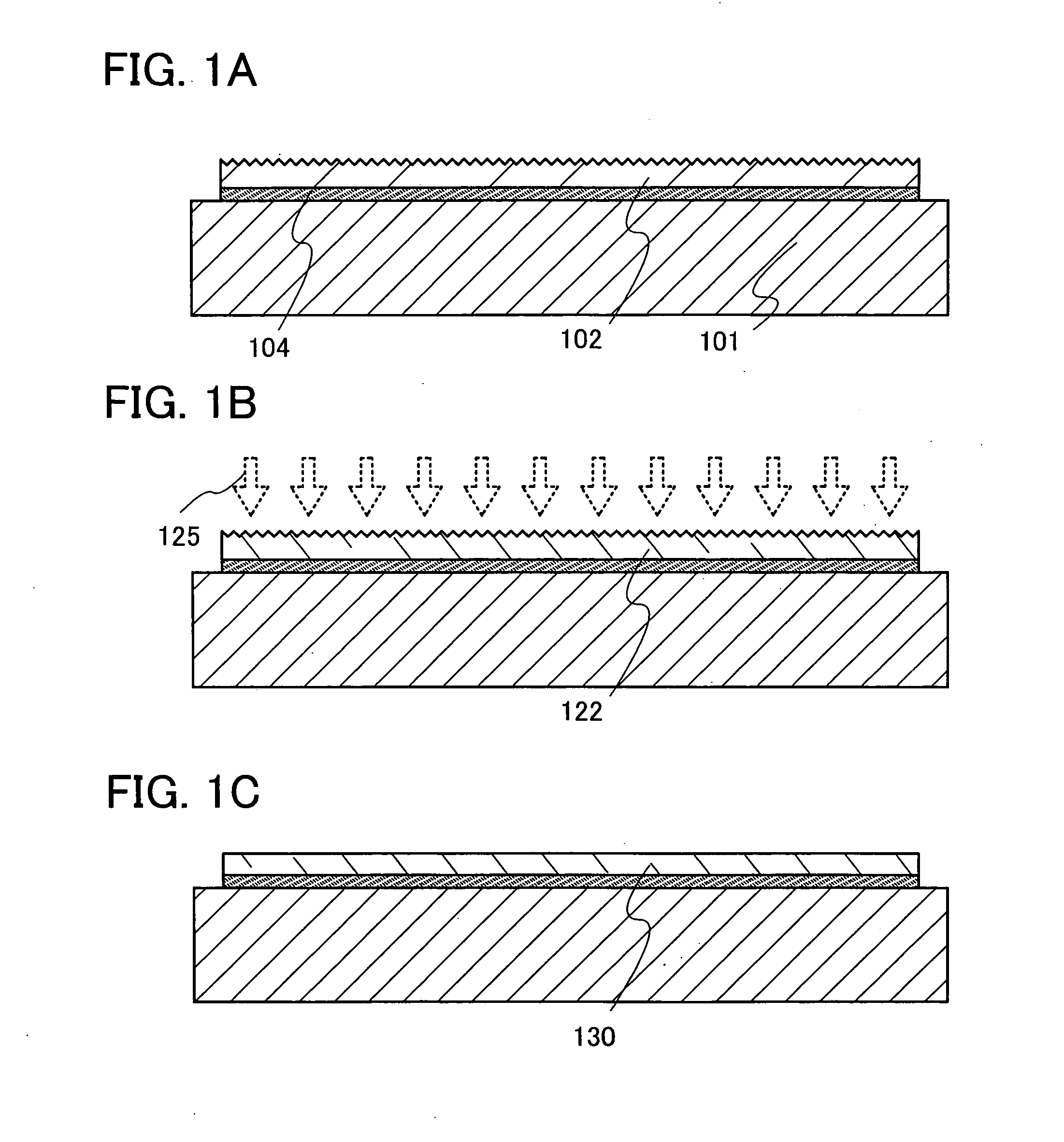

Method of manufacturing an SOI substrate and method of manufacturing a semiconductor device

InactiveUS20090004878A1Good planarityImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingSingle crystalSoi substrate

It is an object of the present invention is to provide a method of manufacturing an SOI substrate provided with a single-crystal semiconductor layer which can be practically used even when a substrate having a low heat-resistant temperature, such as a glass substrate or the like, is used, and further, to manufacture a semiconductor device with high reliability by using such an SOI substrate. A semiconductor layer which is separated from a semiconductor substrate and bonded to a supporting substrate having an insulating surface is irradiated with electromagnetic waves, and the surface of the semiconductor layer is subjected to polishing treatment. At least part of a region of the semiconductor layer is melted by irradiation with electromagnetic waves, and a crystal defect in the semiconductor layer can be reduced. Further, the surface of the semiconductor layer can be polished and planarized by polishing treatment.

Owner:SEMICON ENERGY LAB CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com