Substrate for carrying a semiconductor chip and a manufacturing method thereof

a technology of semiconductor chips and substrates, which is applied in the direction of printed capacitor incorporation, printed electric component incorporation, electrical apparatus construction details, etc., can solve the problems of increasing the difficulty of reducing the inductance between the decoupling capacitor b>14/b> and the semiconductor chip b>12/b> mounted on the substrate b>11/b>, and the difficulty of supply of stabilized electric power, particularly the supply of stabilized voltage, to increase the difficulty rate a semiconductor chips mounted on the semiconductor chip and substrate and semiconductor chip and semiconductor chip substrate and semiconductor chip and semiconductor chip and semiconductor chip and substrate and semiconductor chip and manufacturing method which is applied in the field of semiconductor chip and manufacturing method, which is applied in the field of semiconductor chip and semiconductor chip and manufacturing method, and achieves the effect of semiconductor chip and the supply of stable electric power and the a semiconductor chip and semiconductor chip technology, applied in the field of semiconductor chip and substrate technology, which is applied in the field of semiconductor chip substrate technology, which is applied in the field of semiconductor chip and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

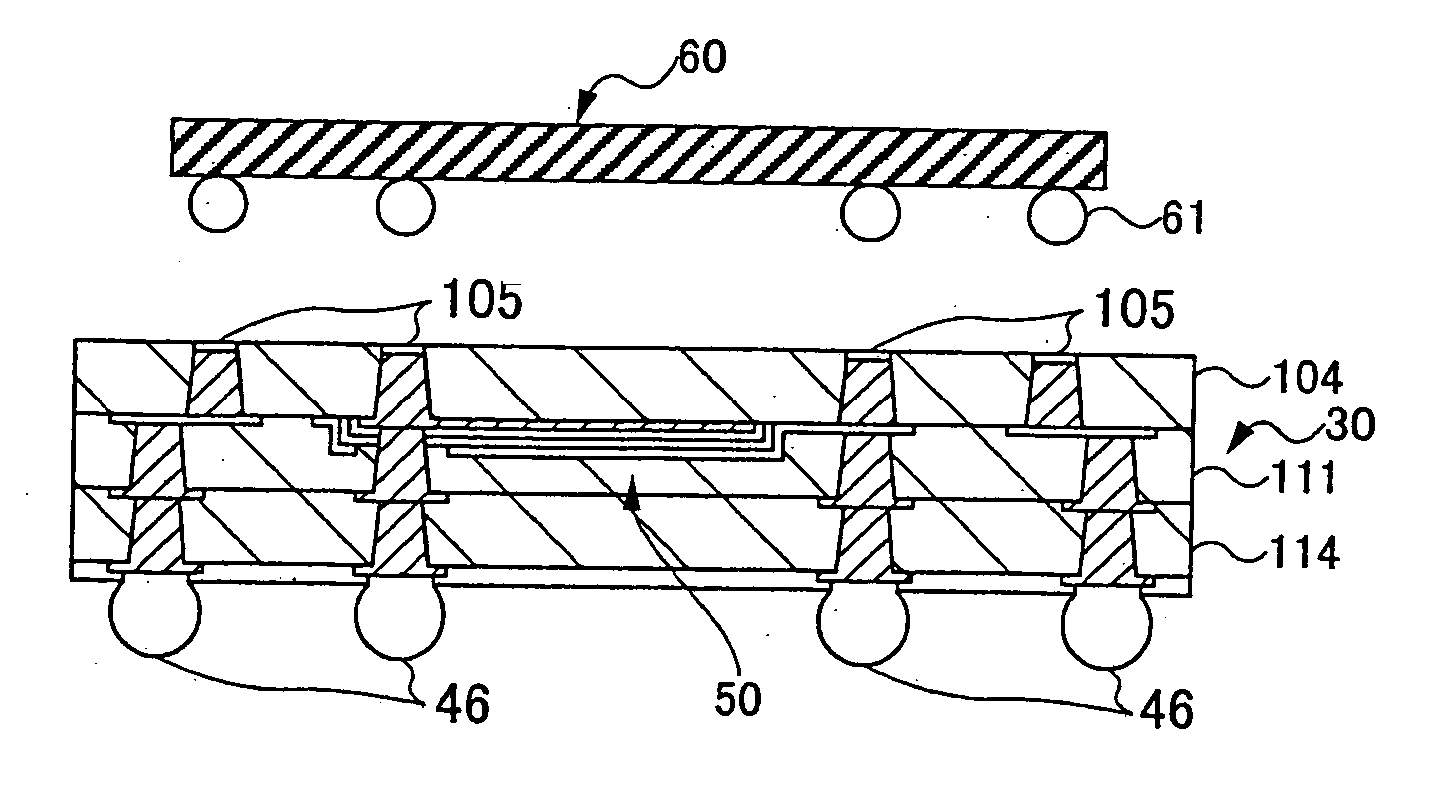

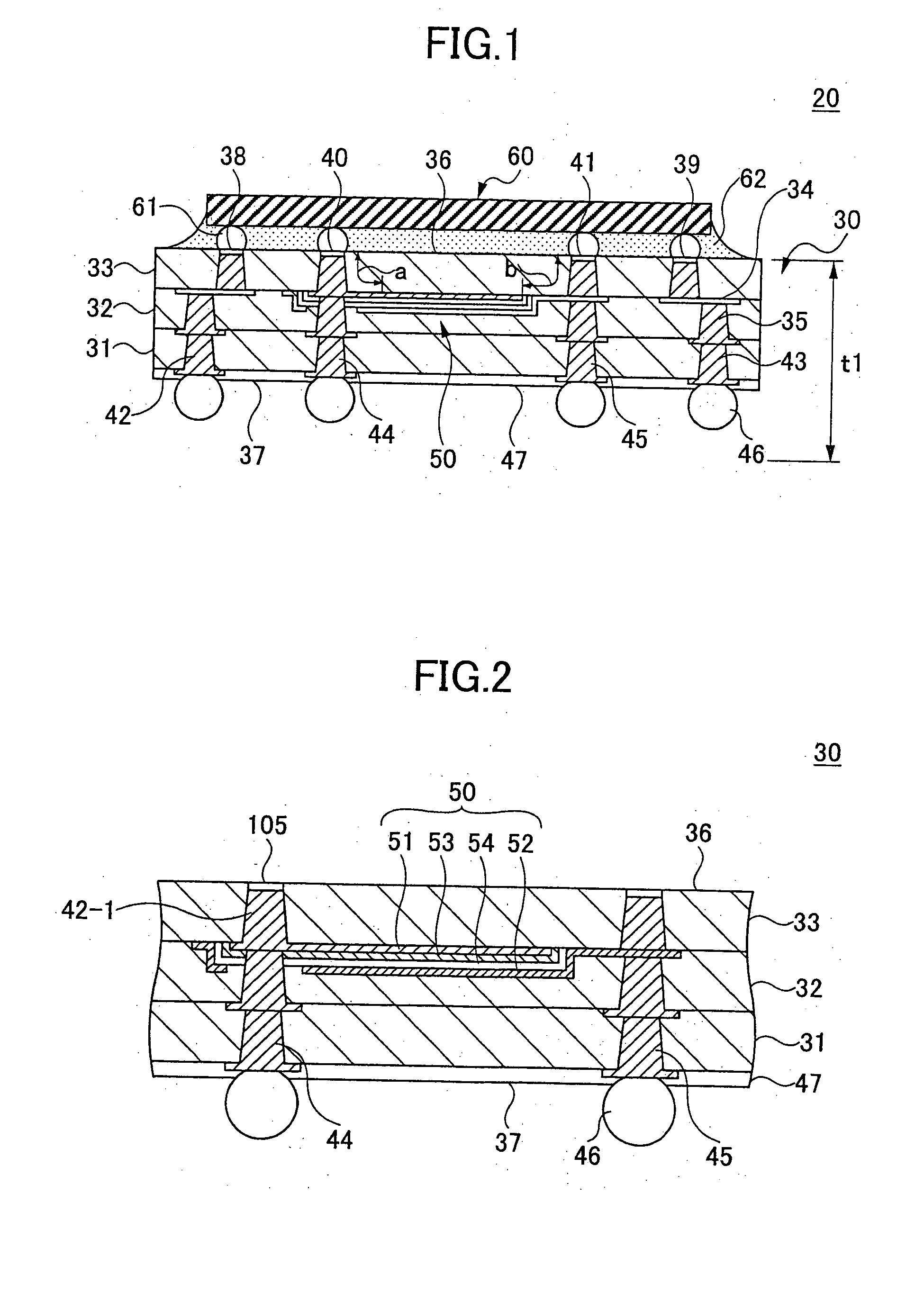

[0031]FIG. 1 shows the construction of a semiconductor device 20 according to a first embodiment of the present invention.

[0032] Referring to FIG. 1, the semiconductor device 20 is a so-called ball-grid type device and includes a semiconductor chip 60 flip-chip mounted on a chip-mounting surface 36 of a chip-mounting substrate 30 by way of bumps 61, wherein the semiconductor chip 60 is adhered to the chip-mounting substrate 30 by an underfill resin layer 62. Thereby, it should be noted that the bumps 61 on the bottom surface of the semiconductor chip 60 make an engagement with corresponding terminals exposed at the foregoing surface 36 including signal terminals 38 and 39, a power terminal 40, and a ground terminal 41.

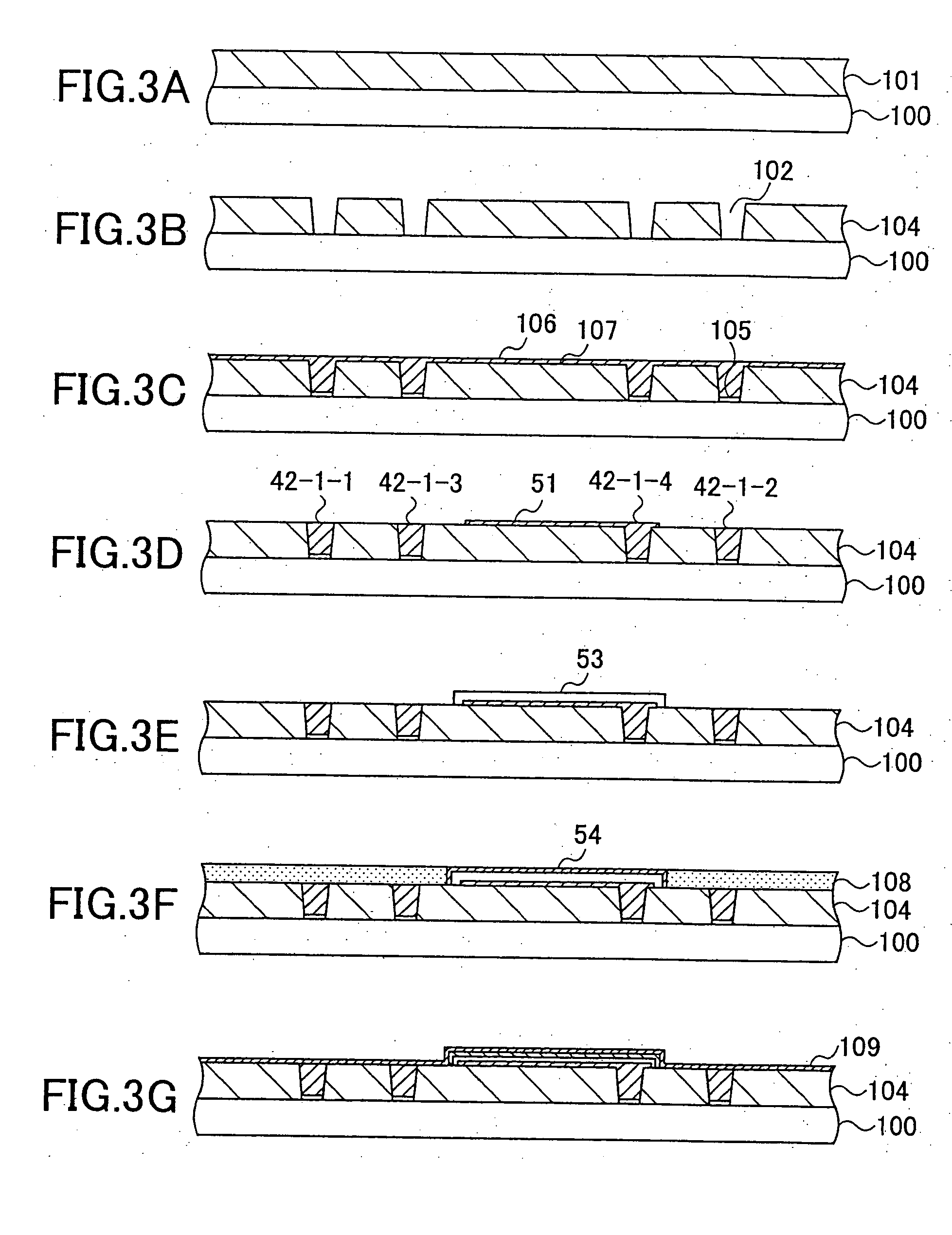

[0033] As will be explained later, the chip-mounting substrate 30 is formed by a single-side build-up process and forms a multiplayer circuit substrate including lamination of insulation layers 31, 32 and 33. The substrate 30 is defined by the foregoing chip-mounting...

second embodiment

[0085]FIG. 7 shows a semiconductor device 20B according to a second embodiment of the present invention.

[0086] Referring to FIG. 7, the semiconductor device 20B has a construction similar to the semiconductor device 20 of FIG. 1 except that a chip-mounting substrate 30B is used in place of the chip-mounting substrate 30. In FIG. 7, those parts corresponding to the parts described previously are designated by the same reference numerals added with a suffix B.

[0087] As will be explained later, the chip-mounting substrate 30B is a multilayer circuit substrate formed by a both-side buildup method and thus includes, in addition to the insulation layers 33, 32 and 31 built up in the A1 direction, insulation layers 140 and 141 that are built up in the A2 direction. The chip-mounting substrate 30B has a chip-mounting surface 36B at the top side thereof and a mounting surface 37 at the bottom surface thereof.

[0088] Similarly as before, the decoupling capacitor 50 is formed between the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com