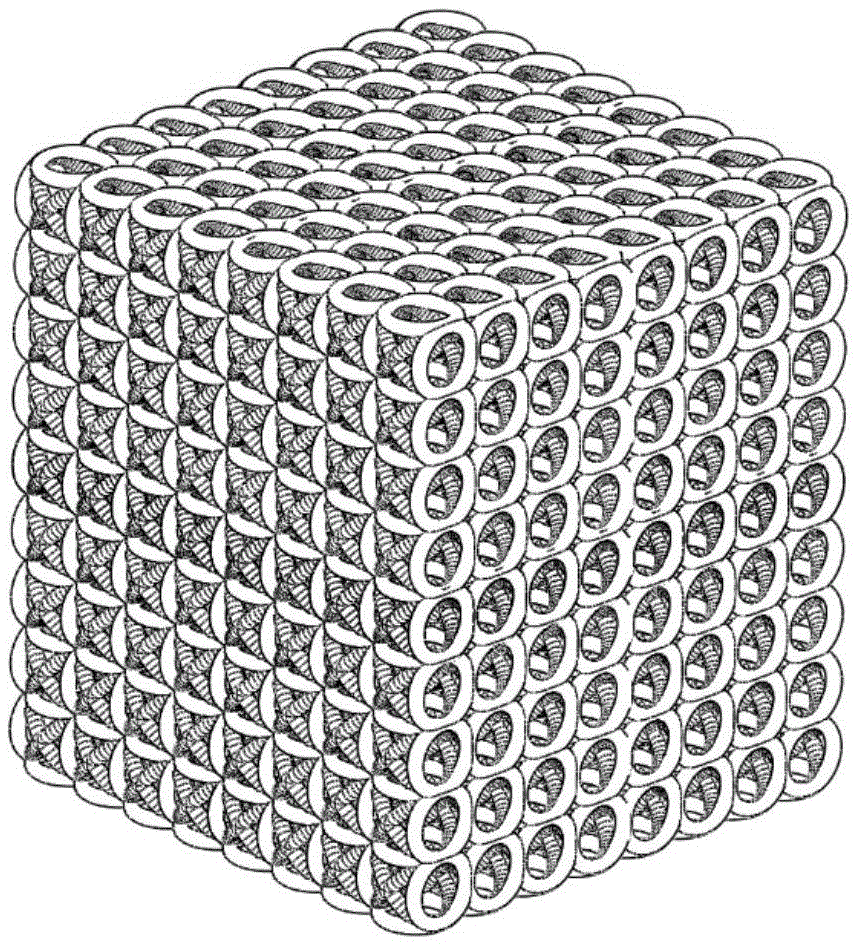

Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

78 results about "Porous implant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Medpor porous polyethylene implant is a highly stable and somewhat flexible porous alloplast that has been shown to exhibit rapid tissue ingrowth into its pores. A total of 116 Medpor implants were placed in 70 patients over a four-year period.

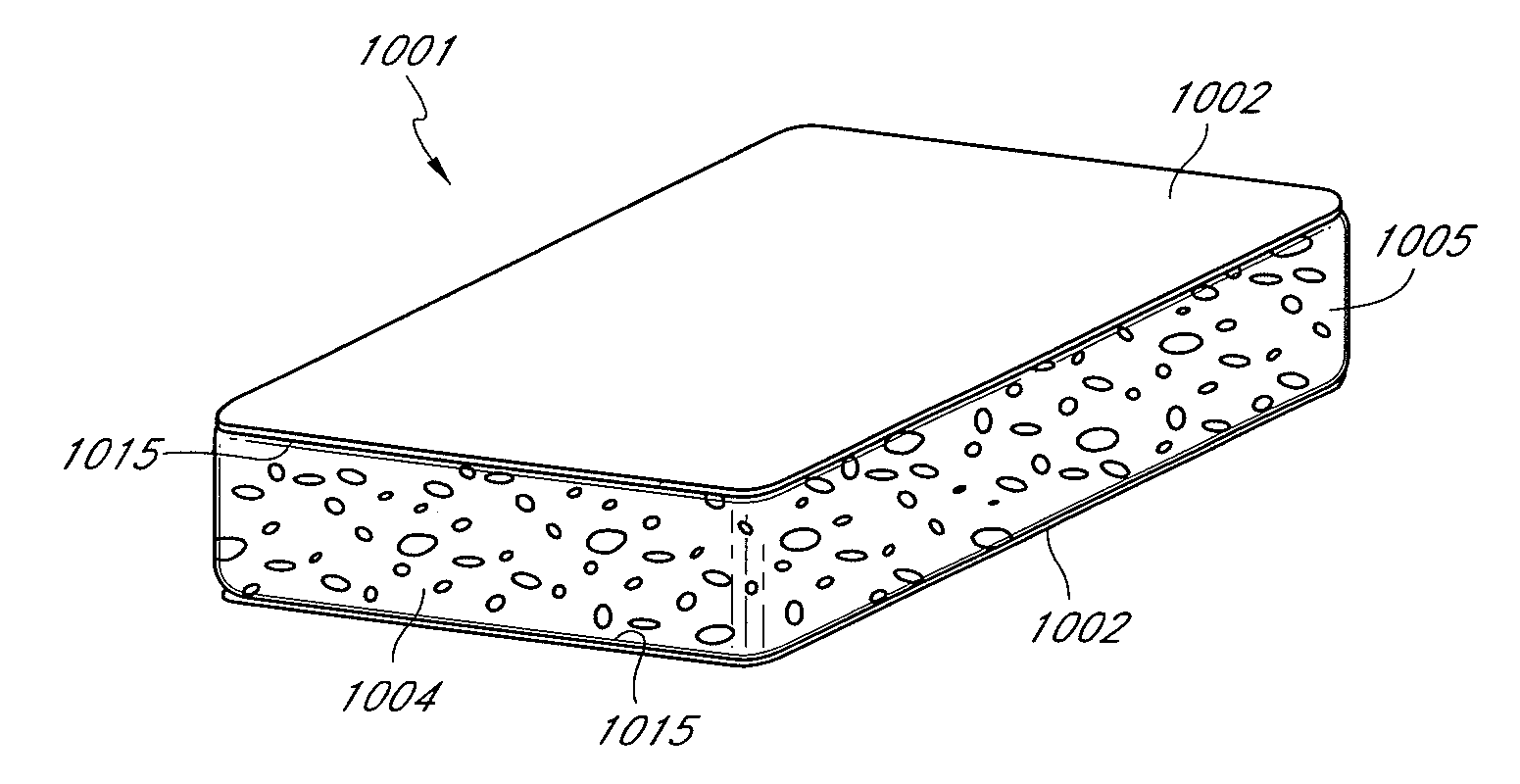

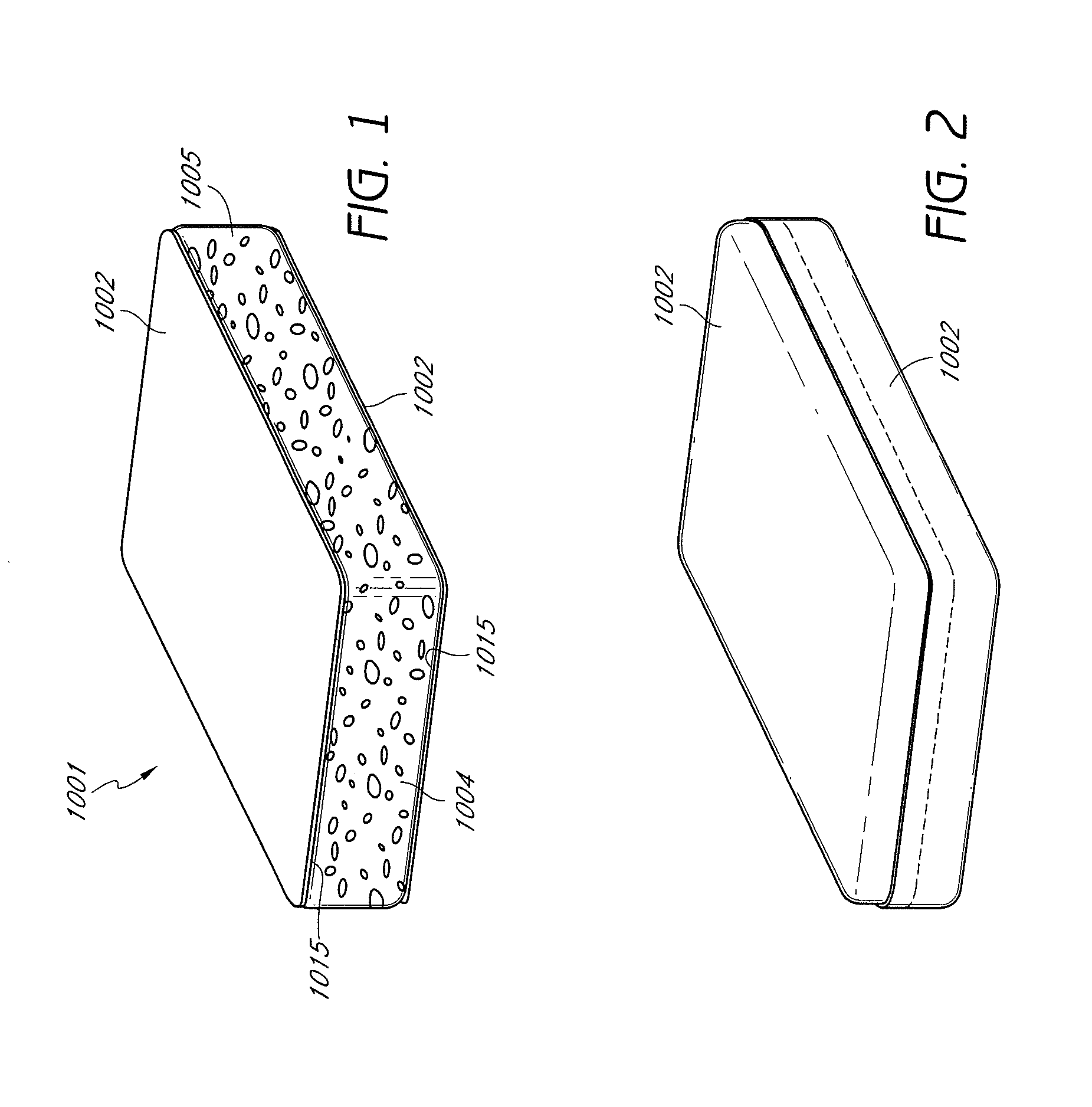

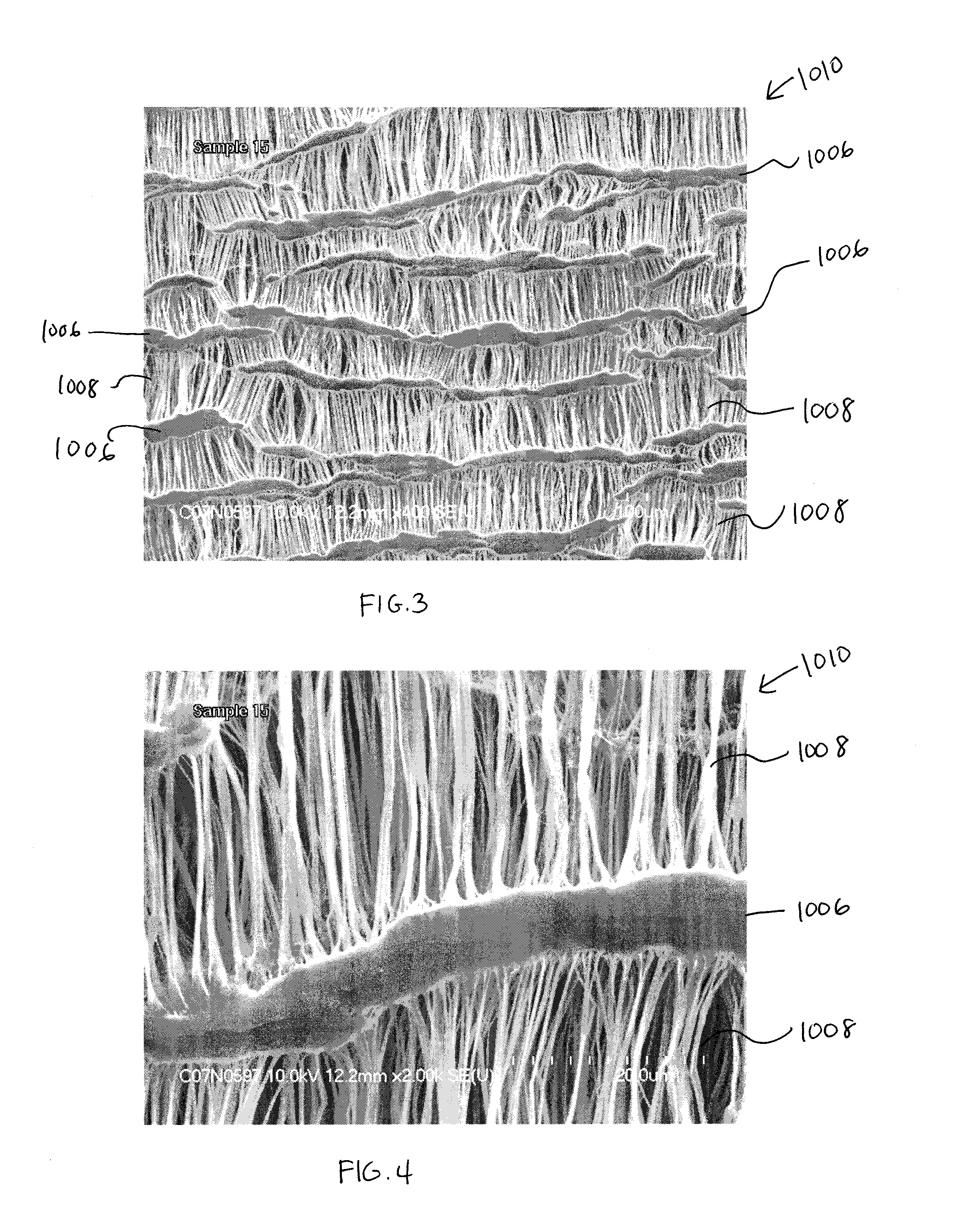

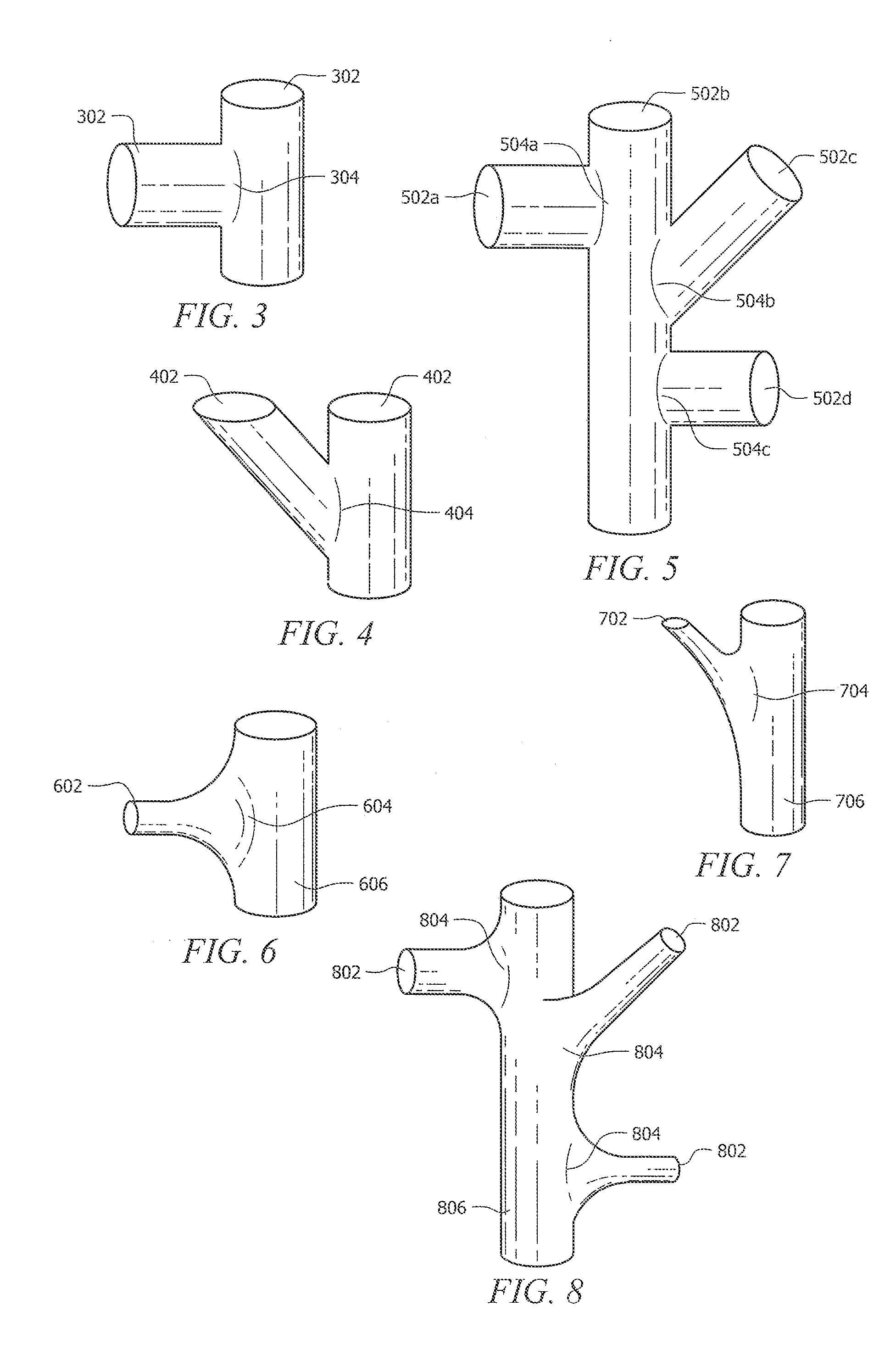

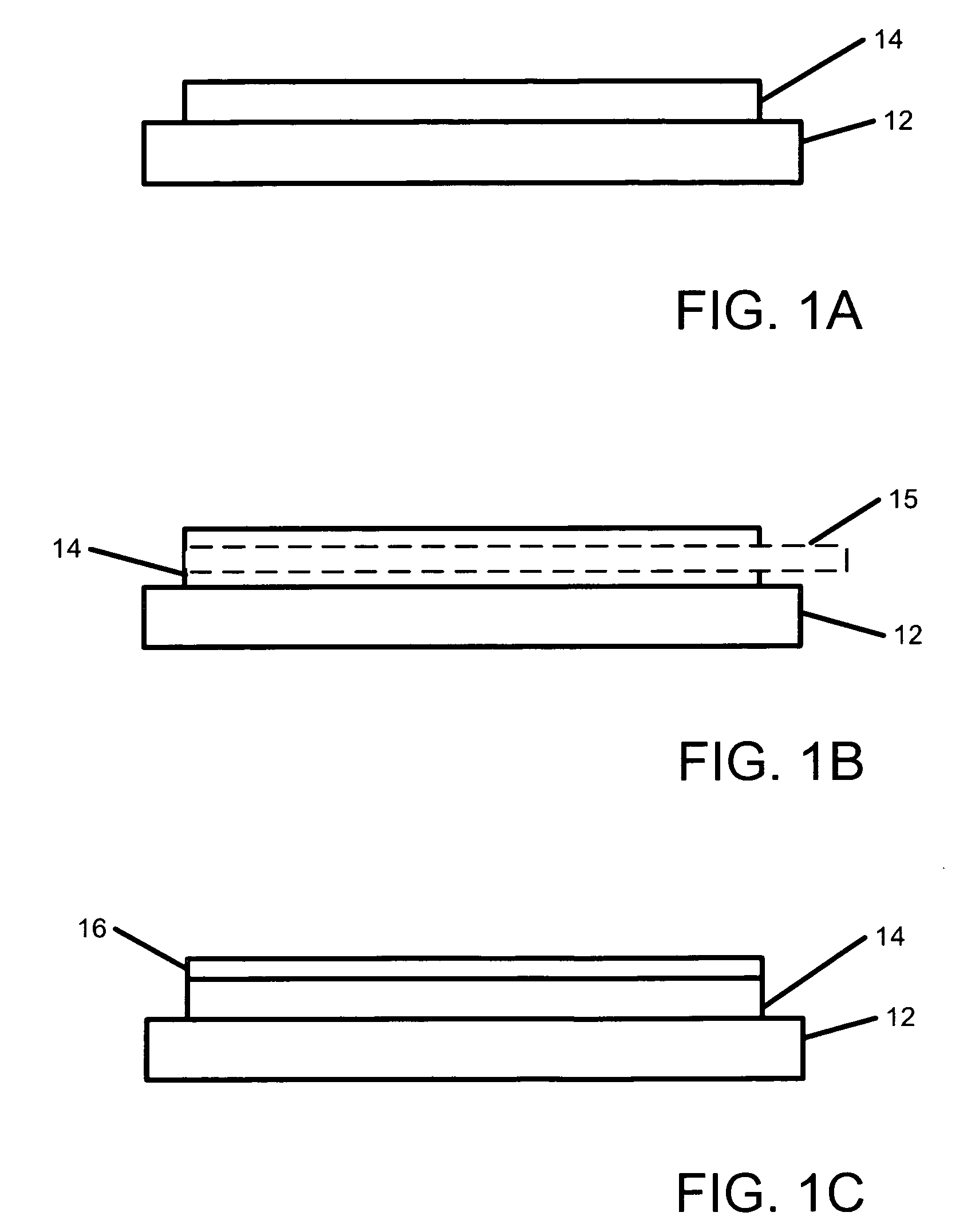

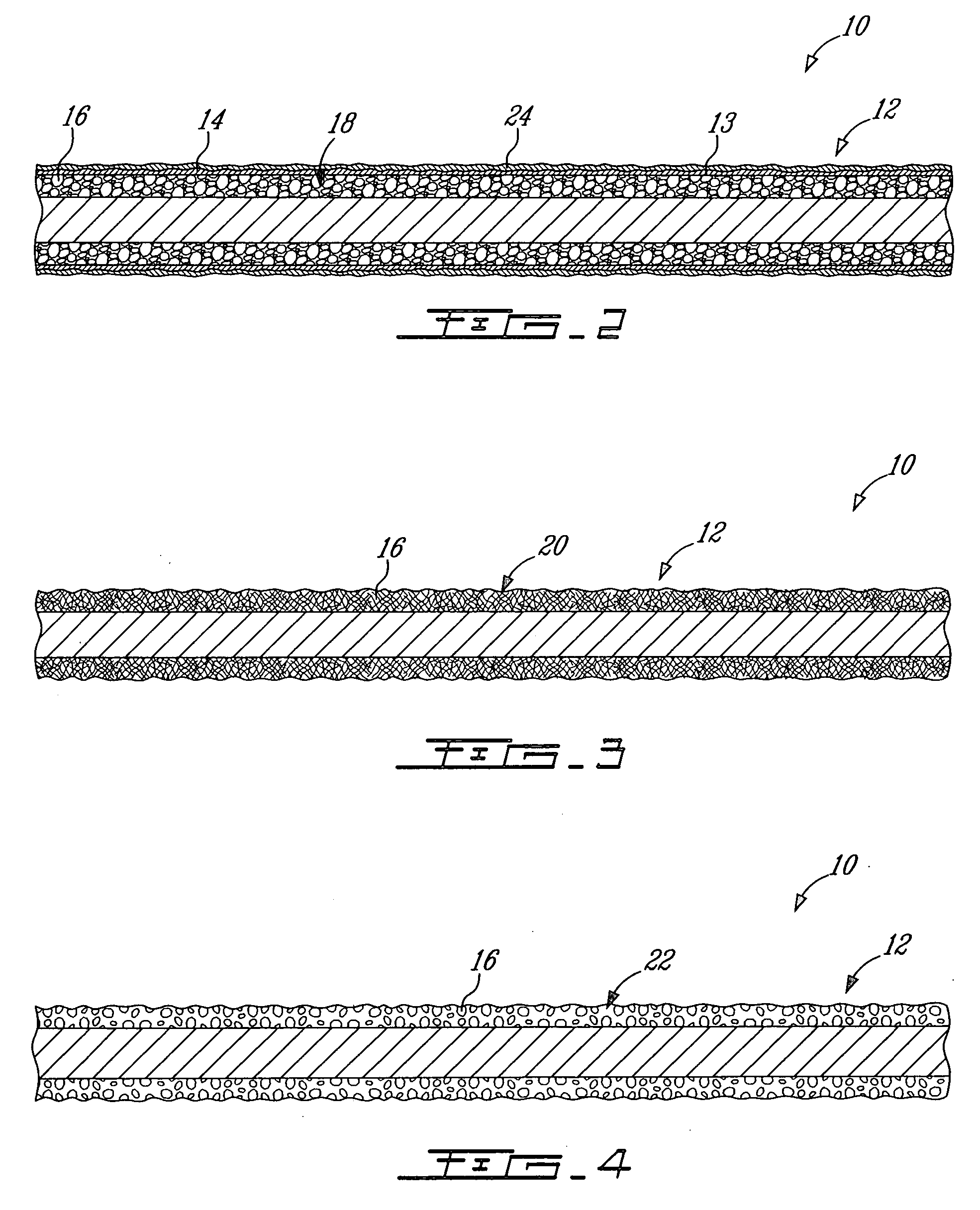

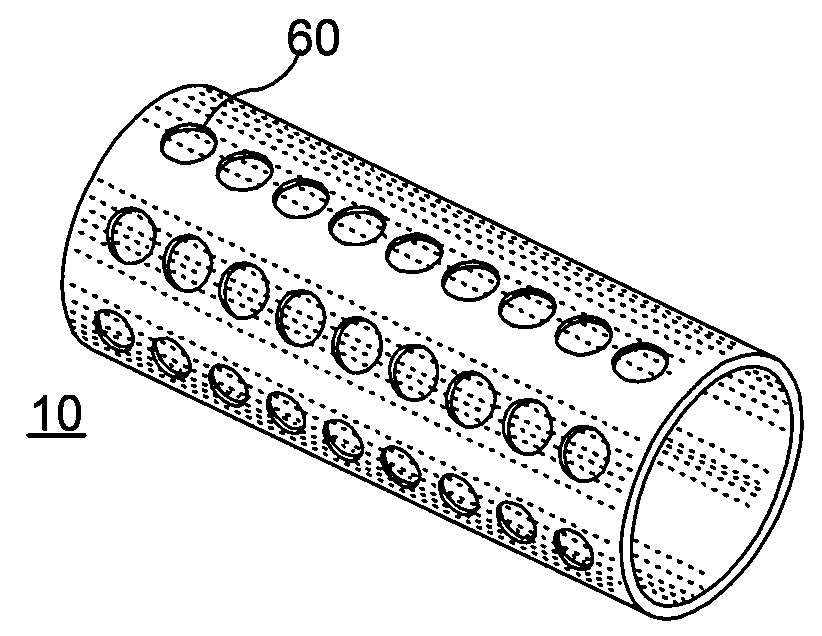

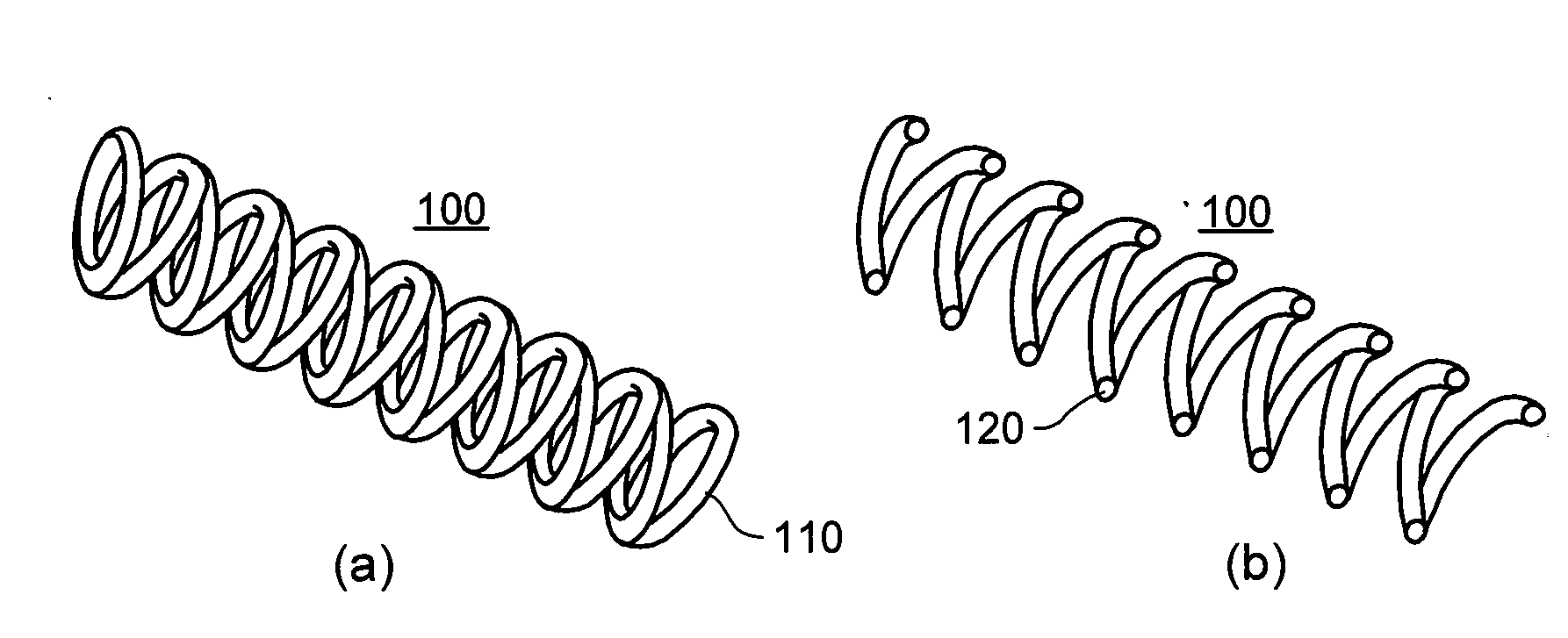

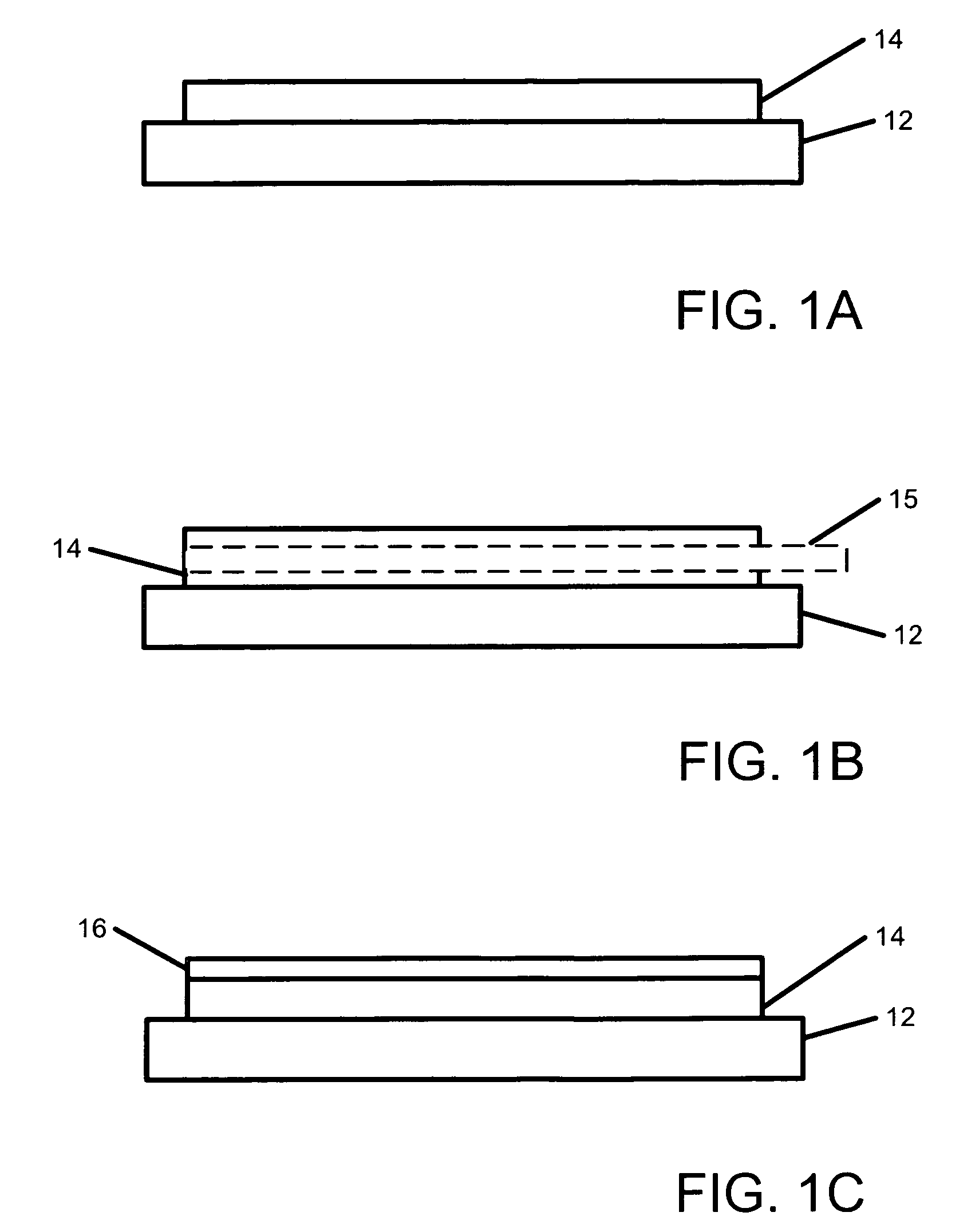

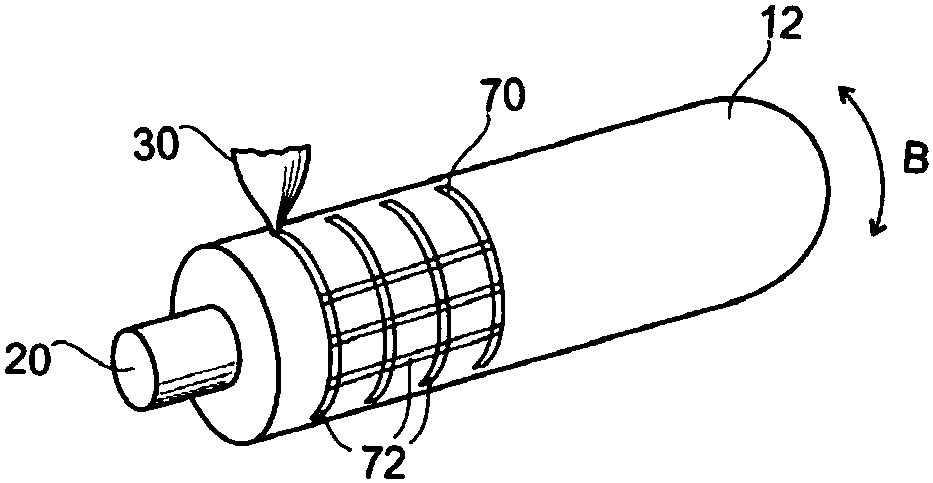

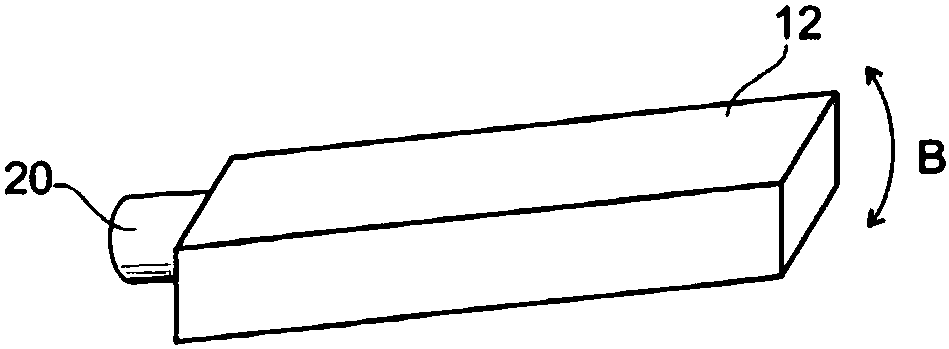

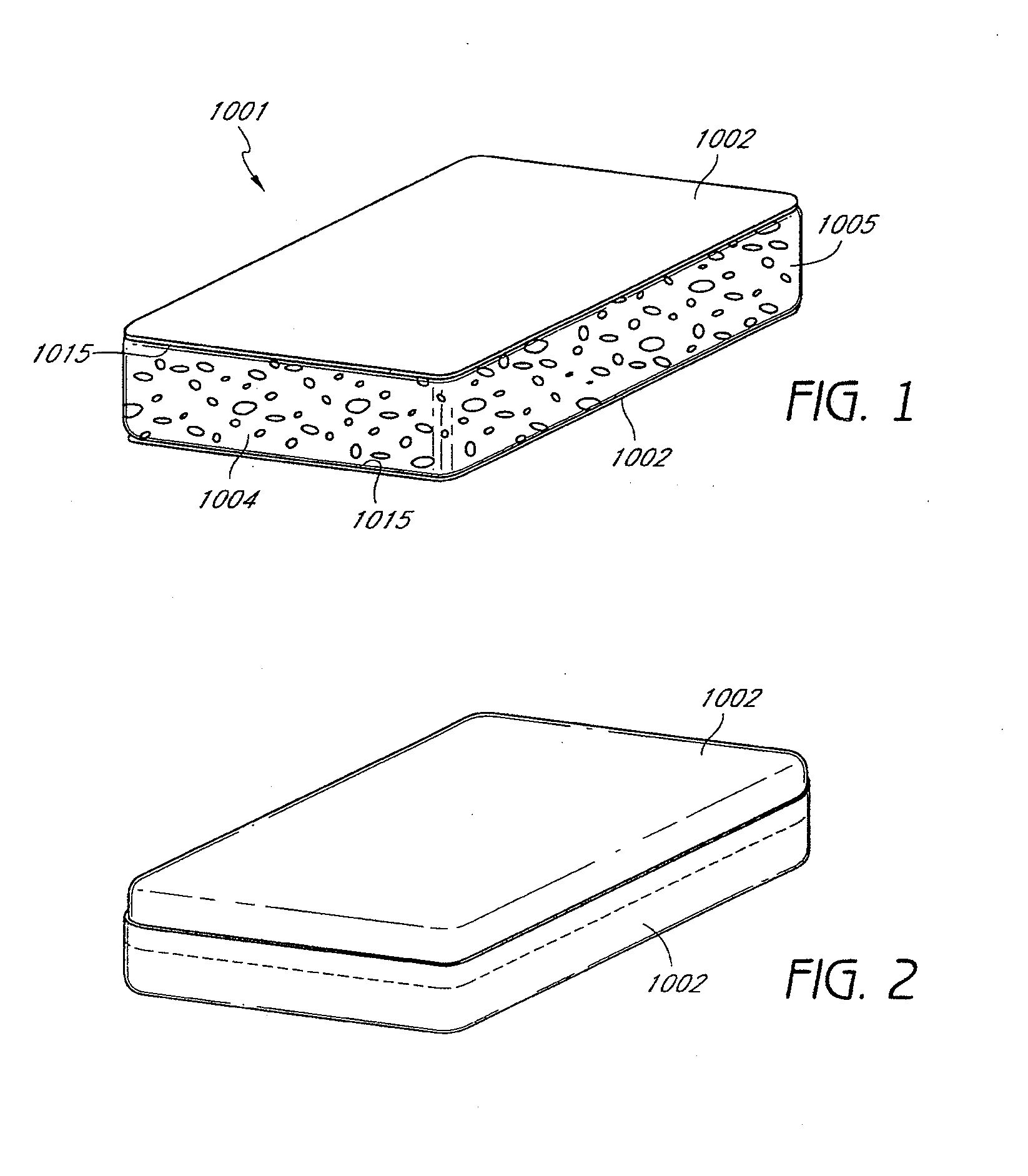

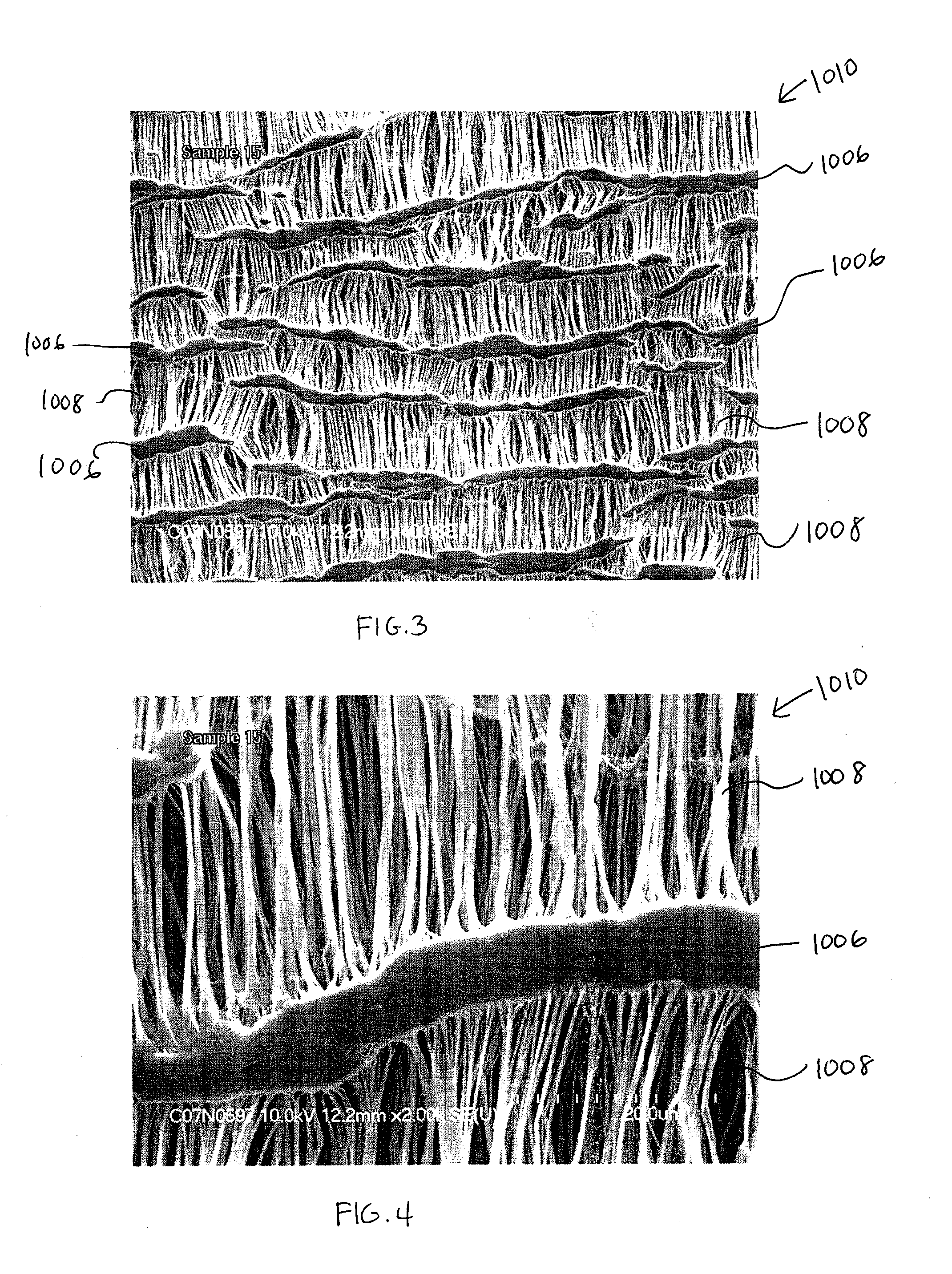

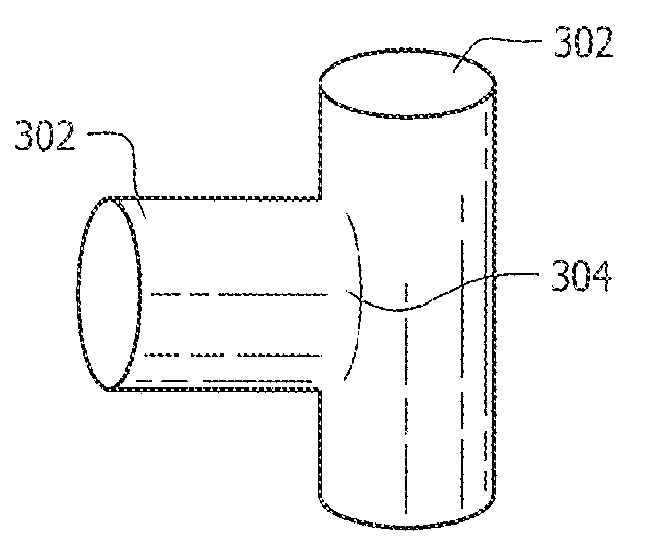

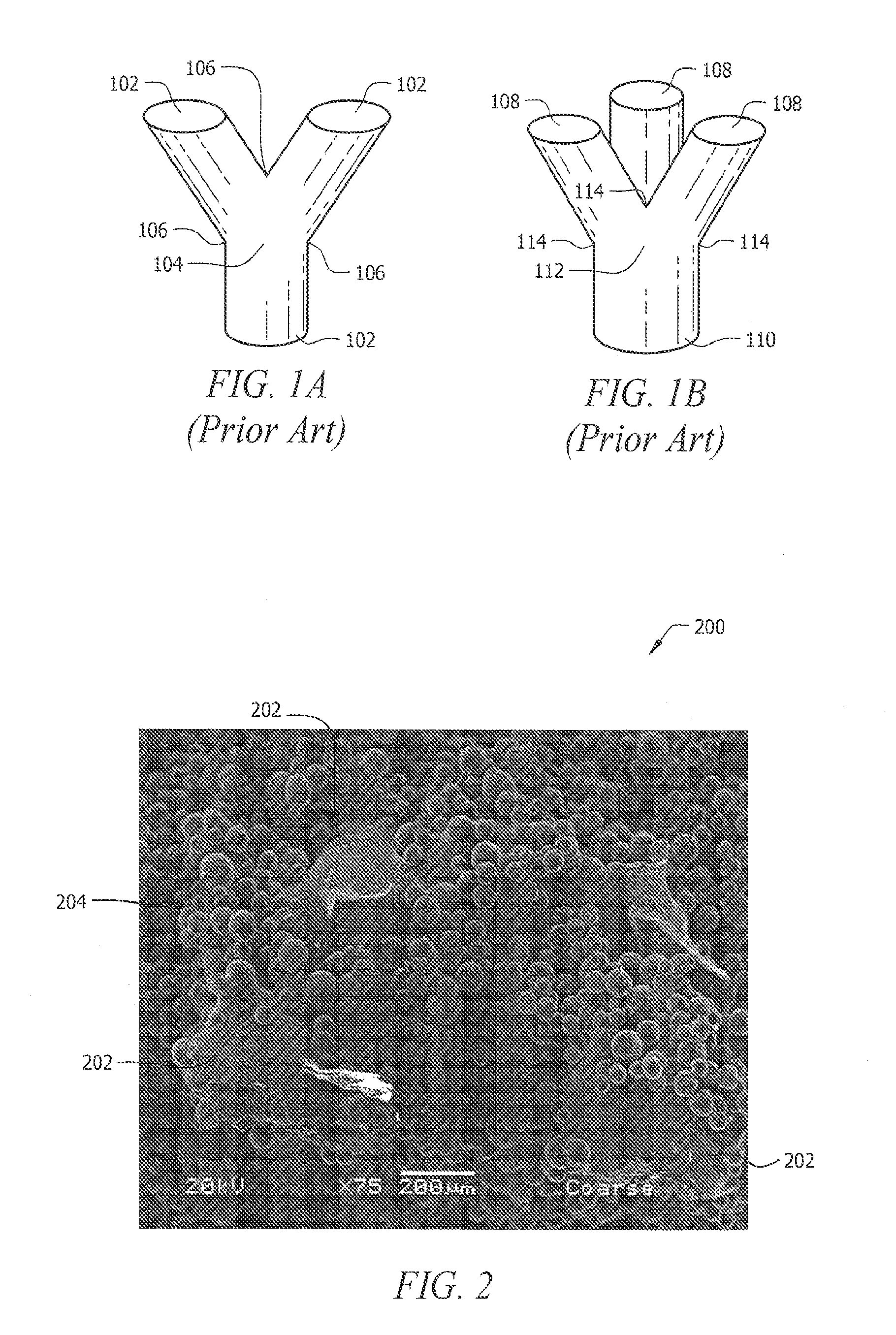

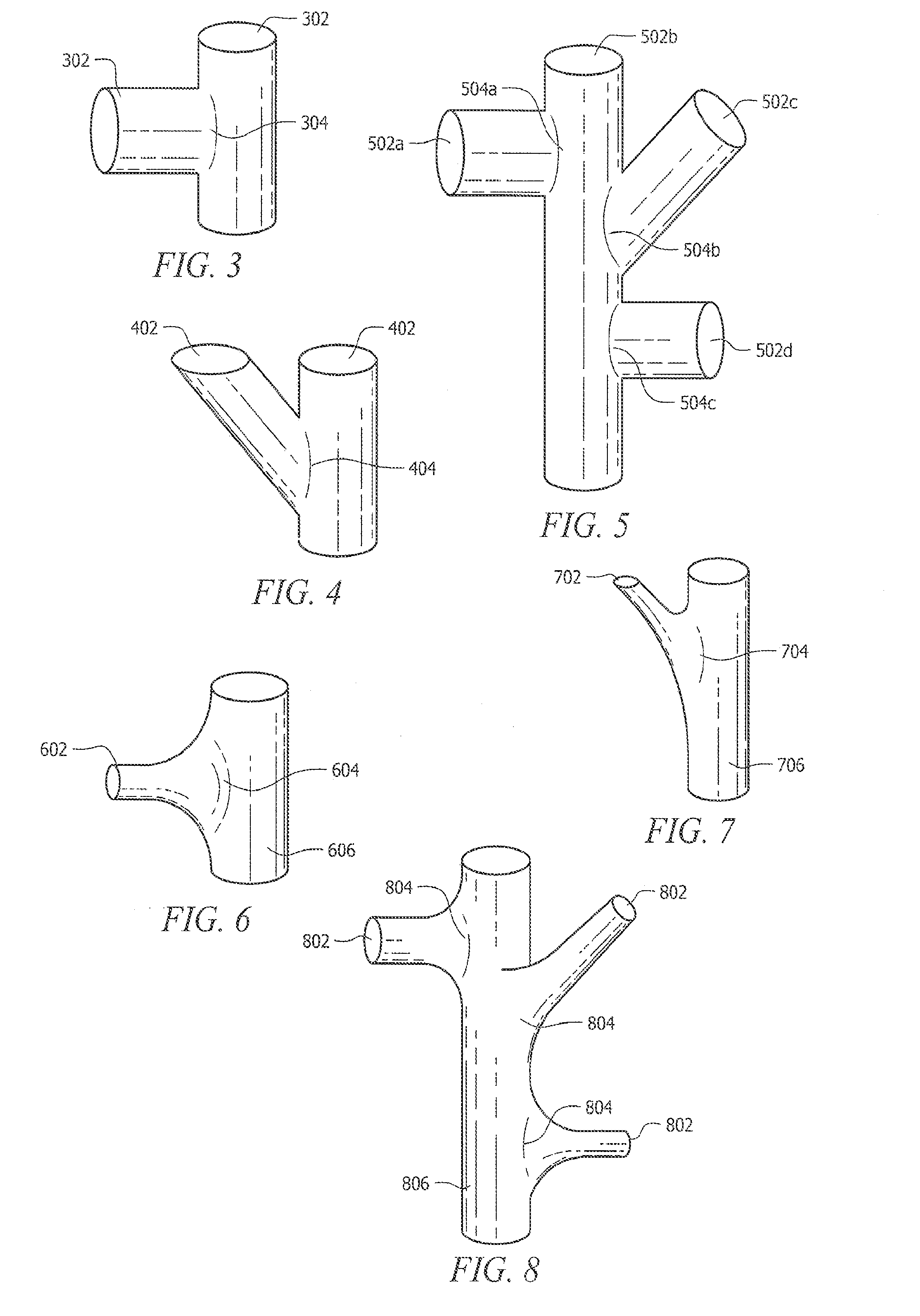

Porous implant with effective extensibility and methods of forming an implant

The implant includes an outer layer of ePTFE which exhibits extensibility normally not associated with ePTFE. The ePTFE is reduced in length by deforming the fibrils between the nodes while maintaining the nodes in a substantially flat configuration. Various implant configurations that can include the outer layer described are also disclosed.

Owner:EVERA MEDICAL

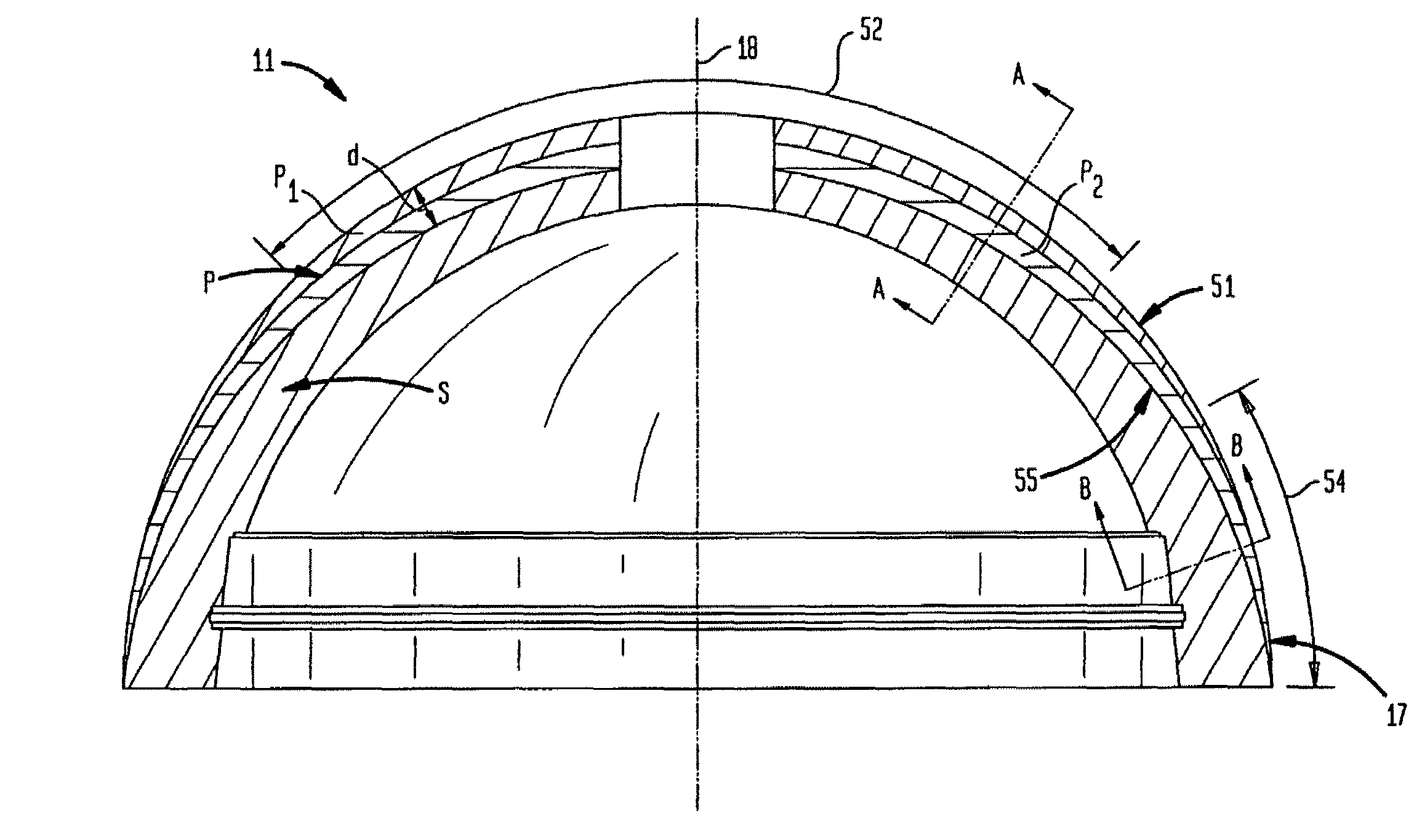

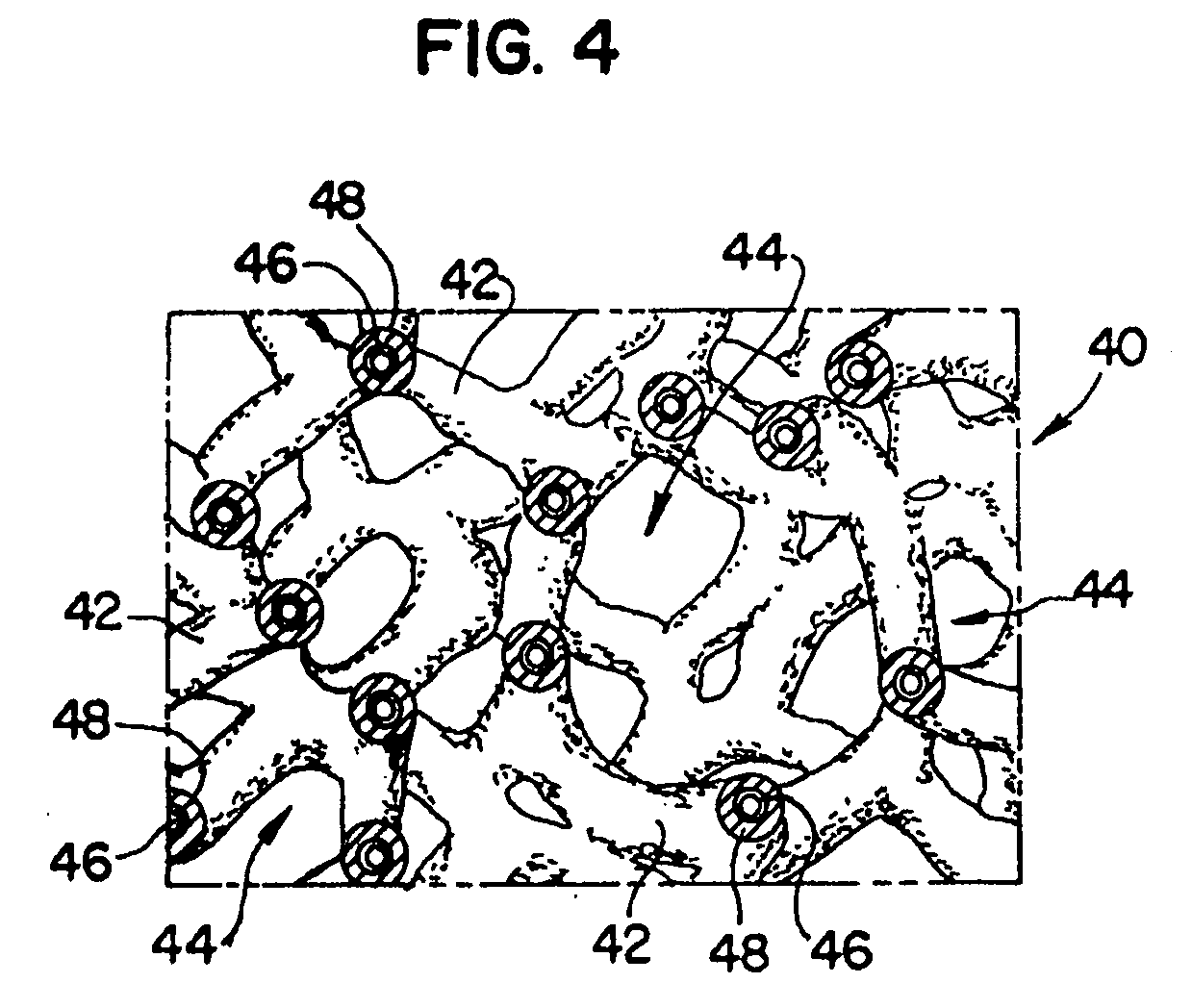

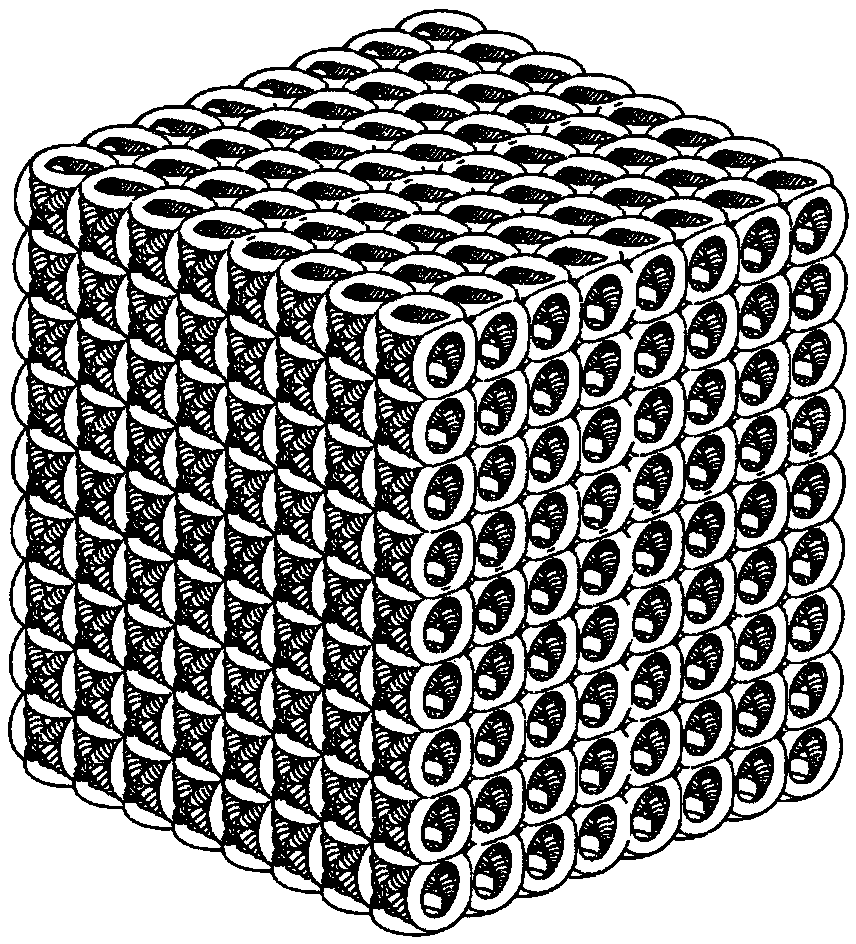

Gradient porous implant

ActiveUS7578851B2Optimizes various mechanical and biological requirements of the implants performanceIncreasing the thicknessAdditive manufacturing apparatusBone implantPorous implantMedical device

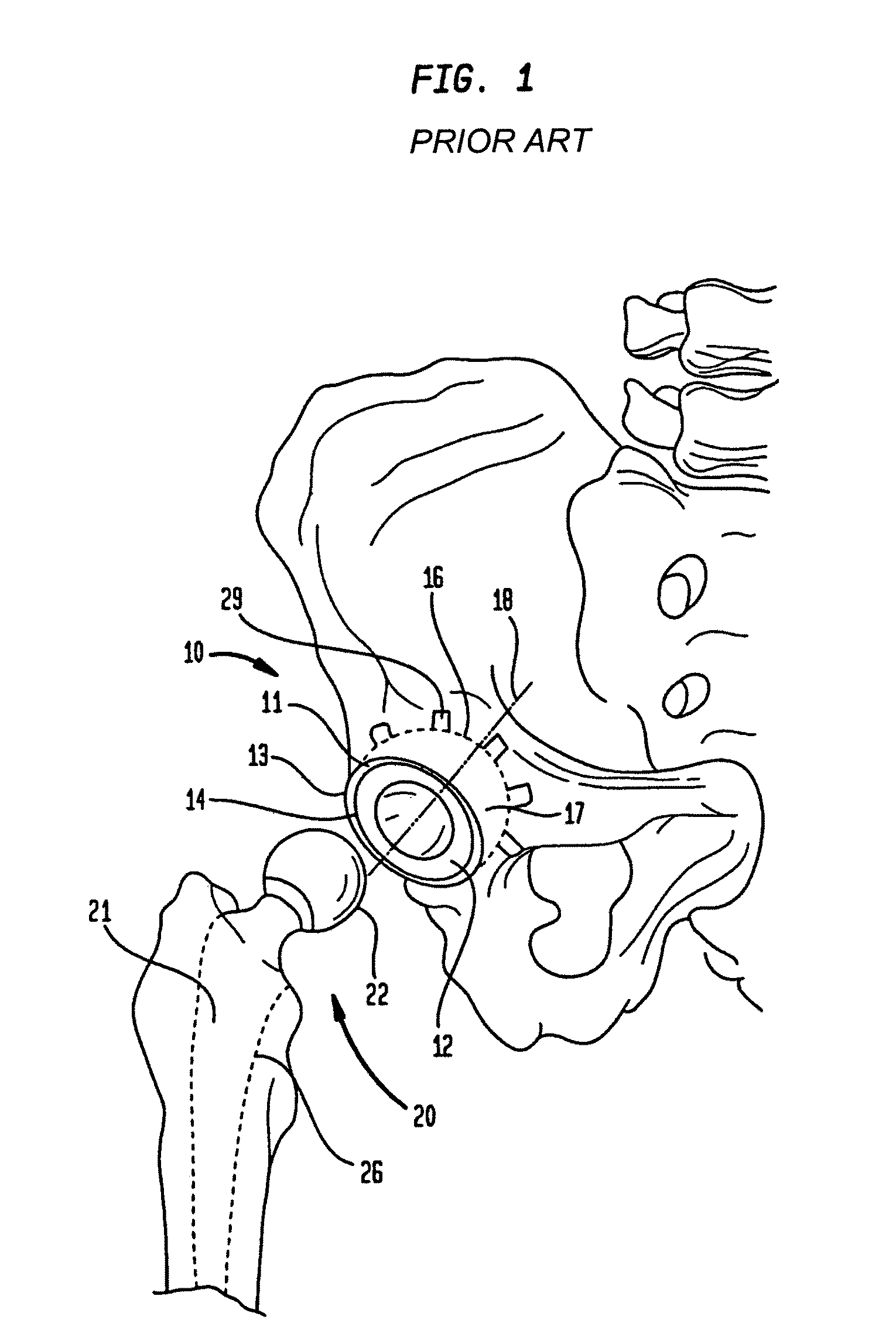

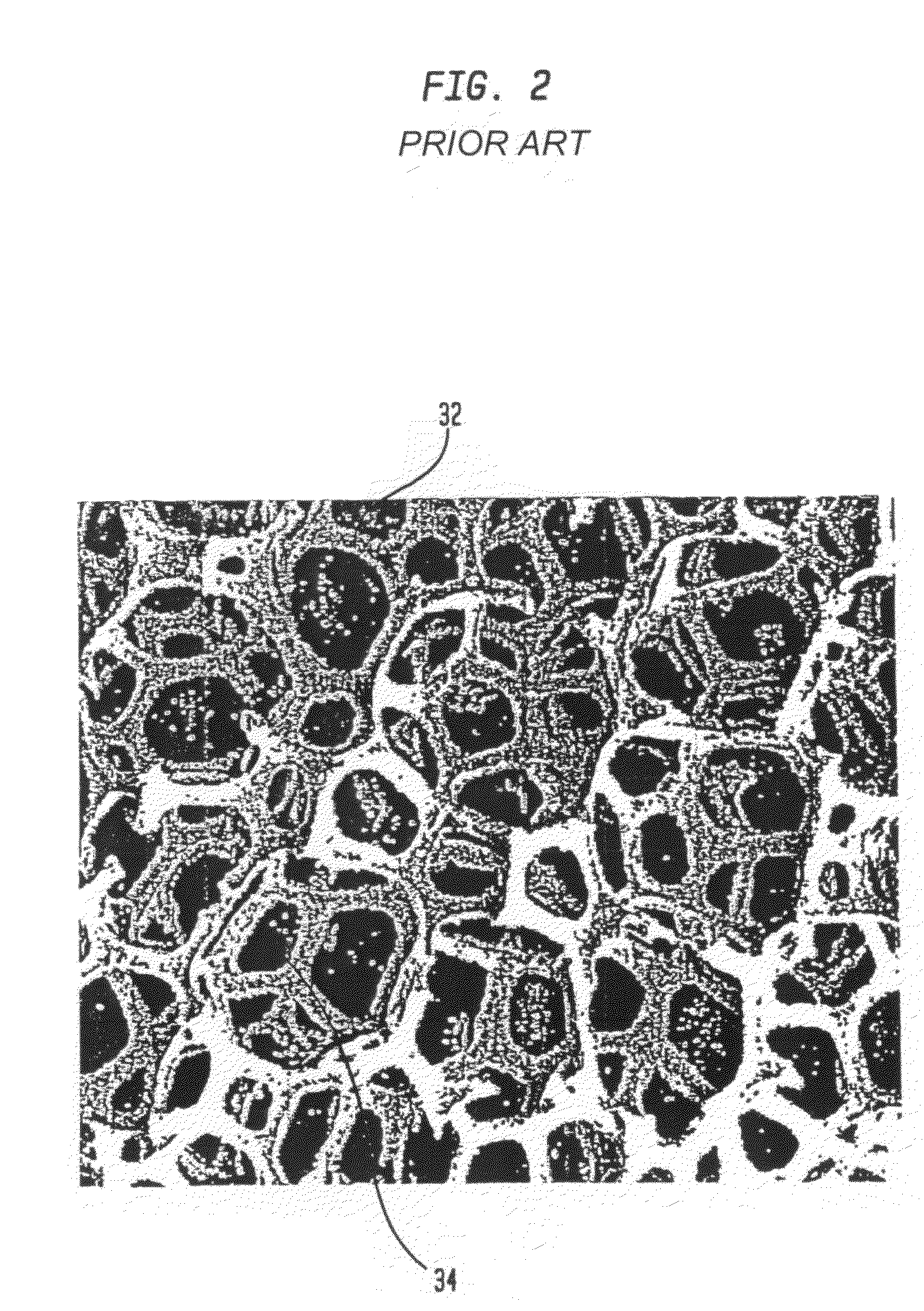

An implantable medical device includes a porous metal foam or foam-like structure having pores defined by metal struts or webs wherein the porous structure has directionally controlled pore characteristics. The pore characteristics controlled include one or more of the metal structure porosity, pore size, pore shape, pore size distribution and strut thickness. The pore characteristics may vary in one or more directions throughout the structure. Preferably the pore characteristics are controlled to match the porous metal structure to various mechanical and biological requirements of different regions of the structure in order to optimize aspects of the implants performance and may vary not only over the surface of the porous structure but through the depth of the porous structure. The thickness of the porous metal structure may also be modified to establish a thickness profile that optimizes mechanical and biological requirements of the implants performance. Acetabular cup embodiments of the invention are described. Various methods of manufacturing implants having directionally controlled pore characteristics are described.

Owner:HOWMEDICA OSTEONICS CORP

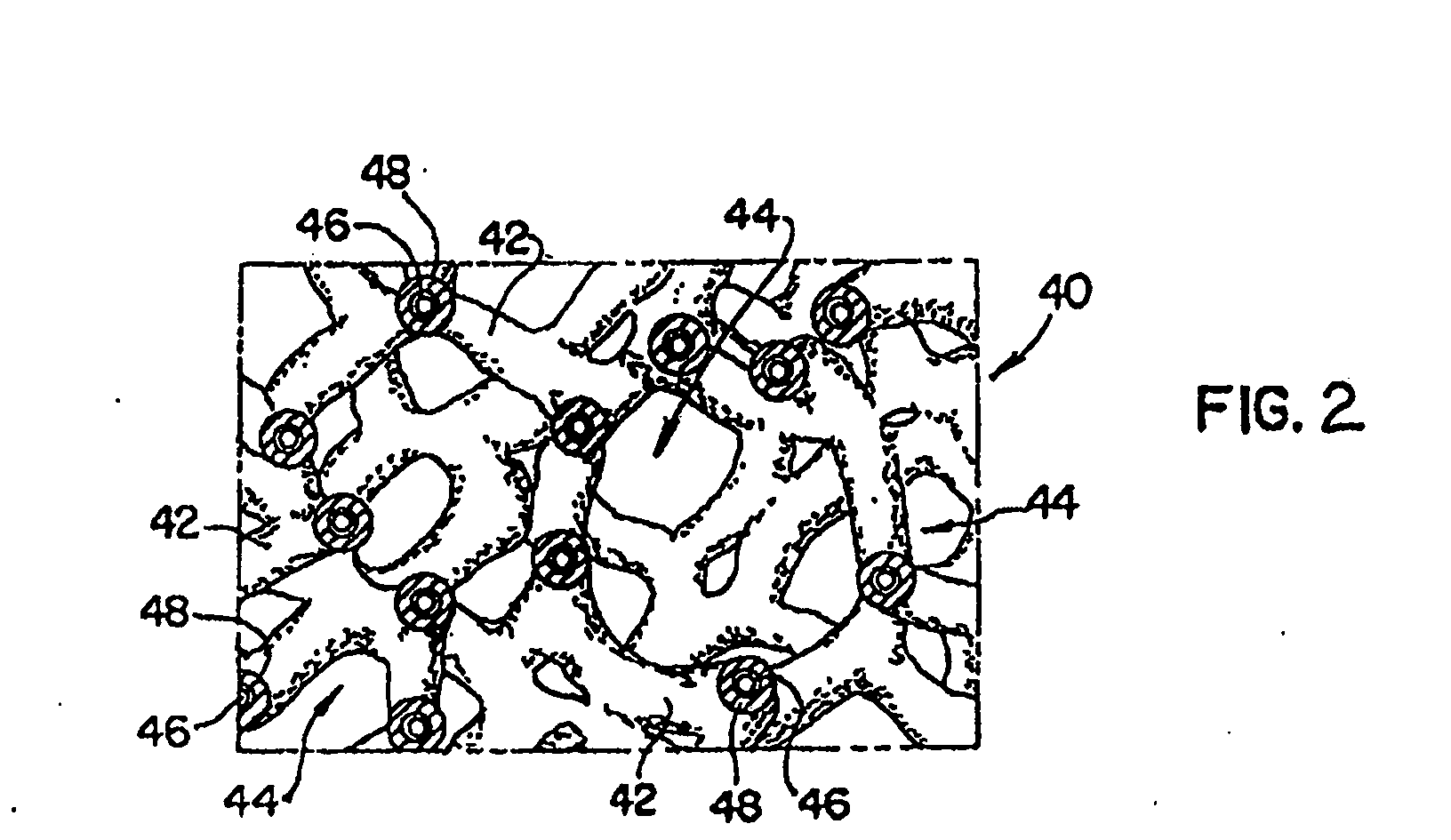

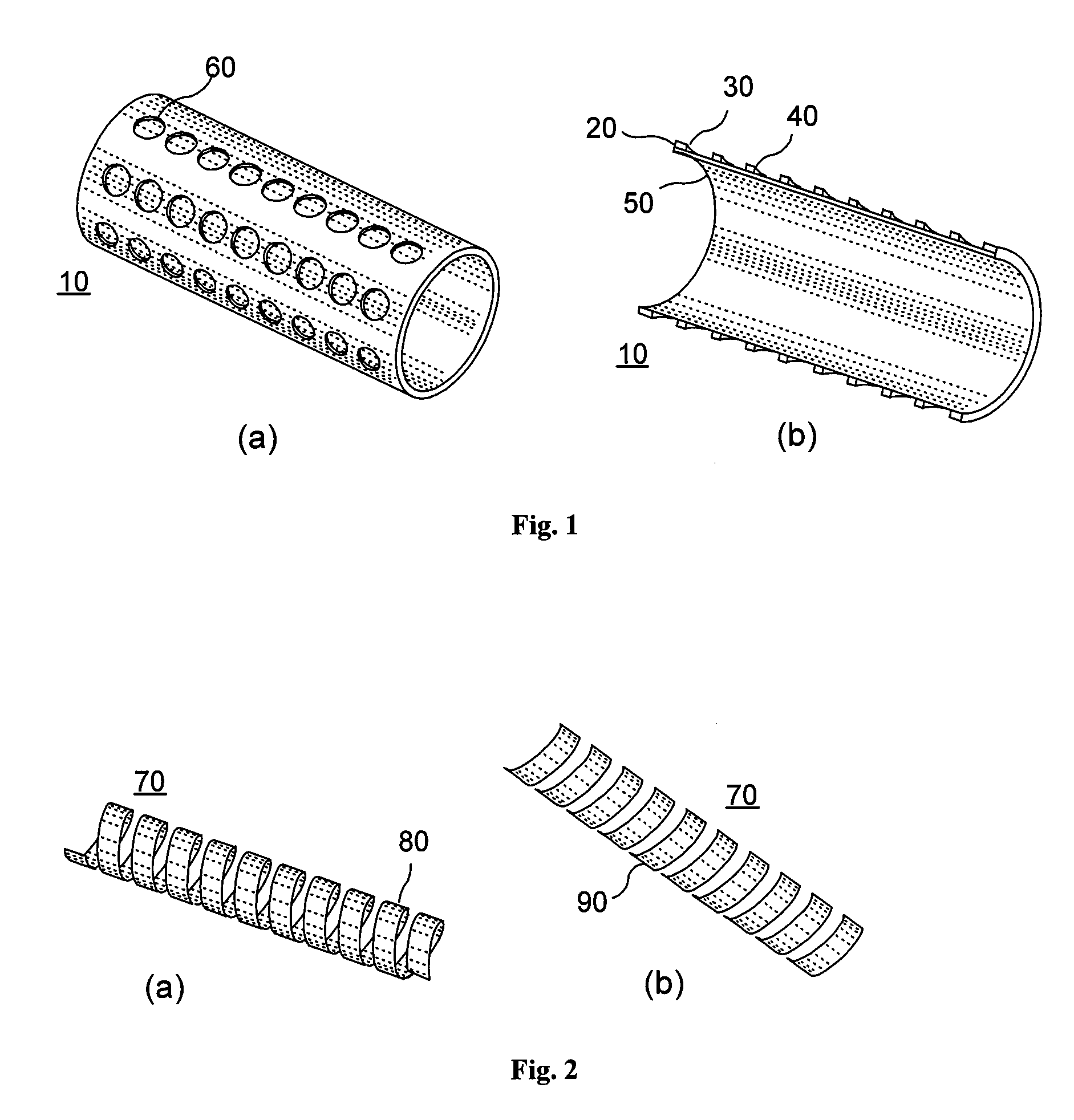

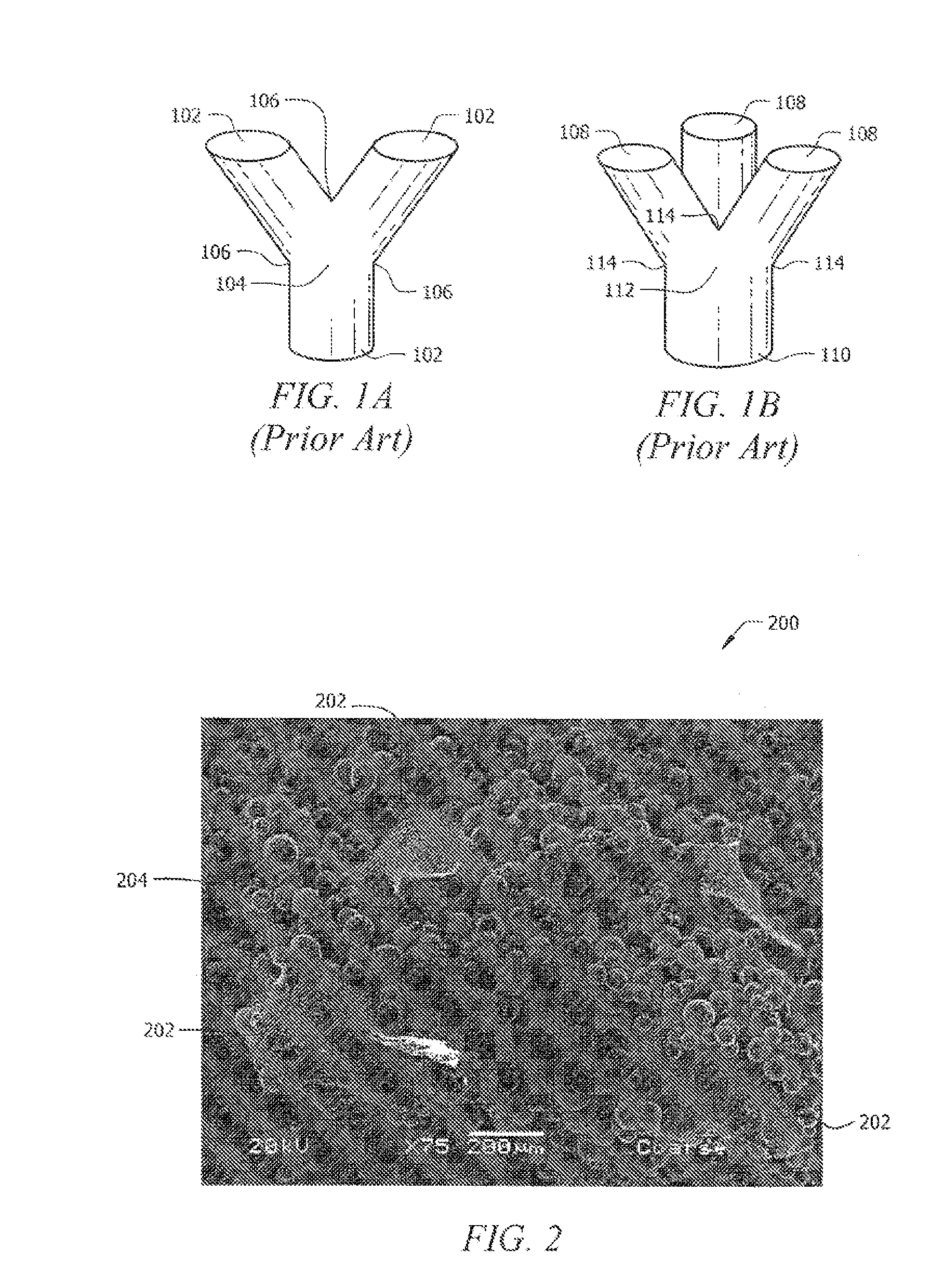

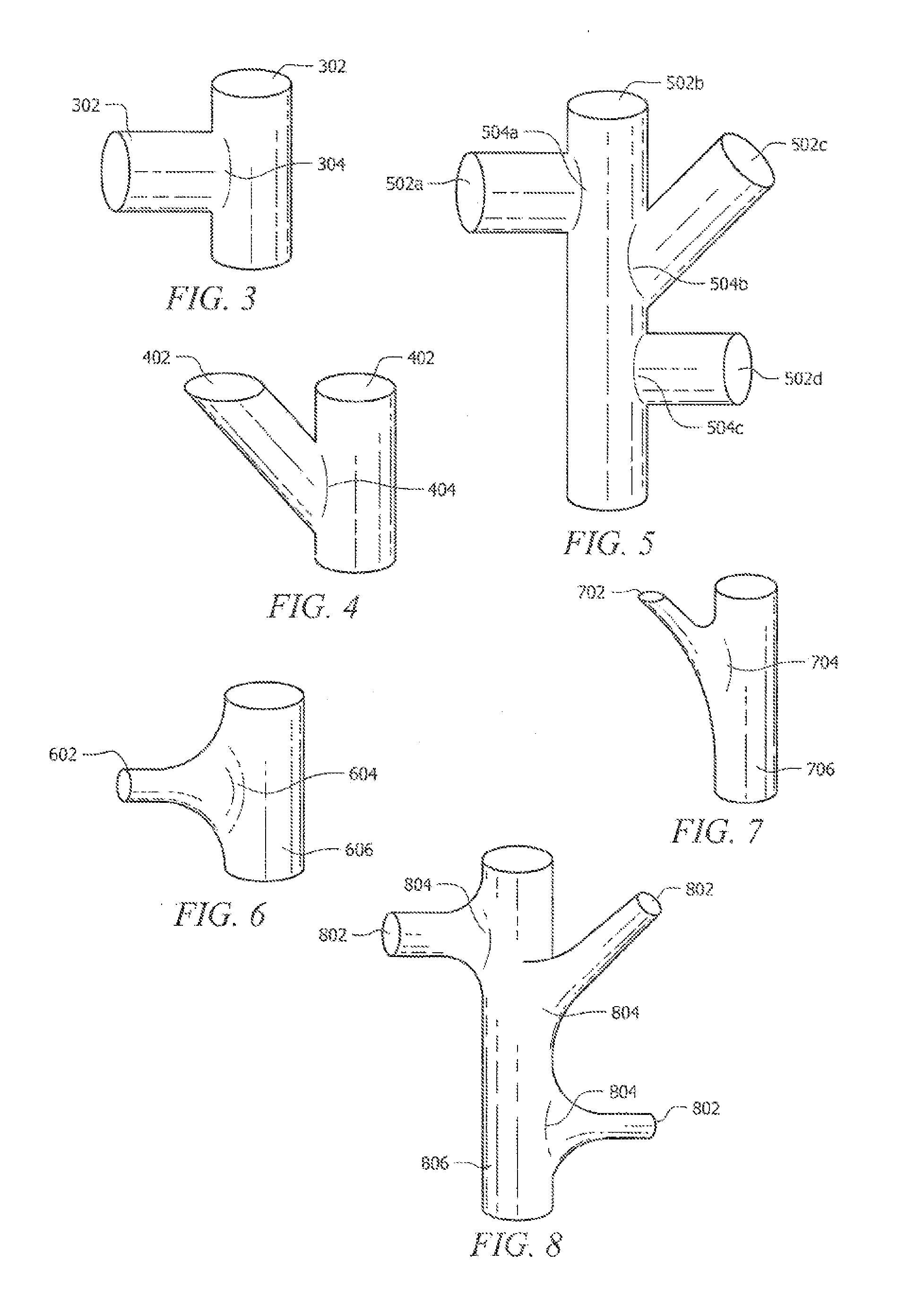

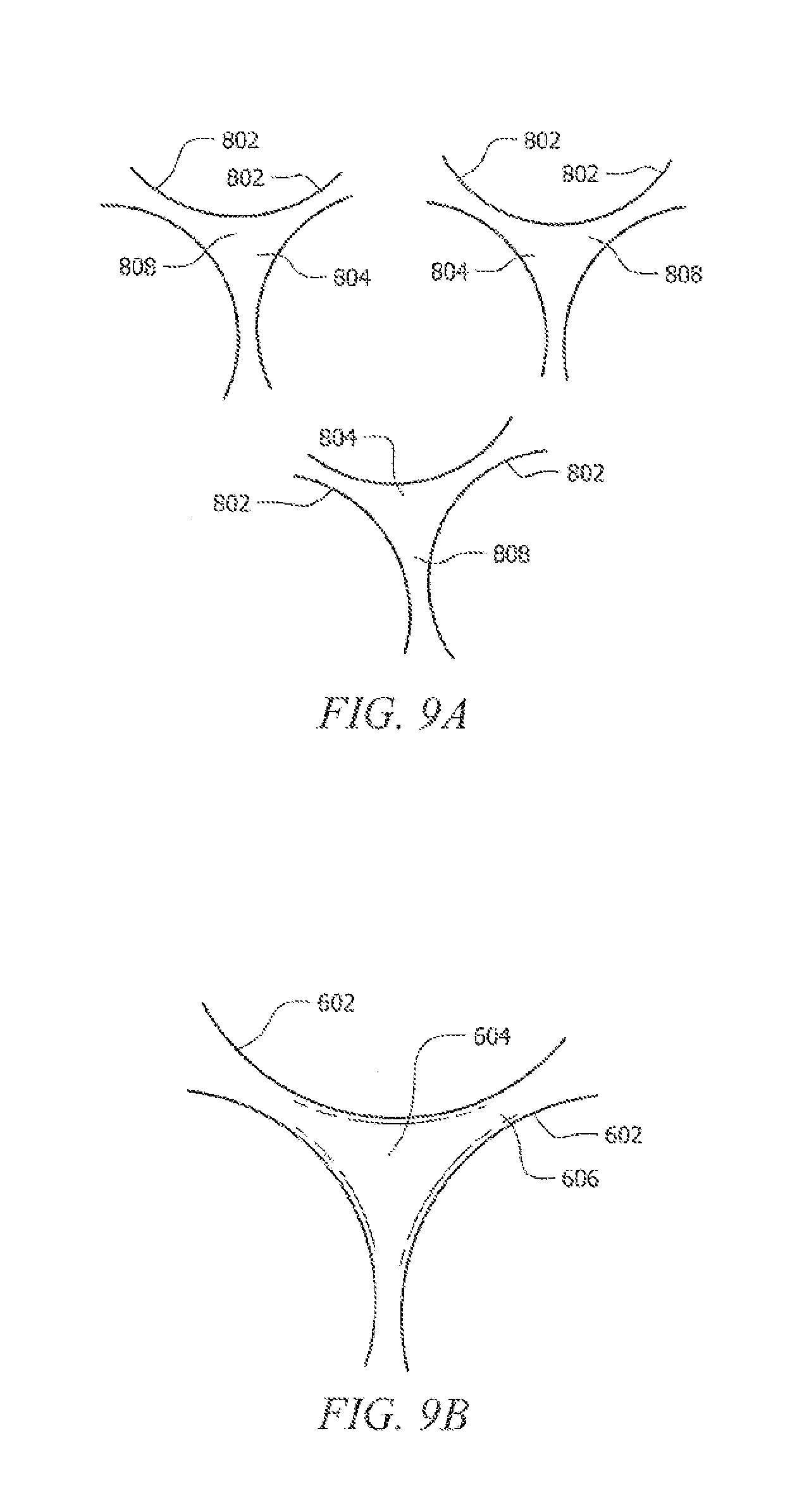

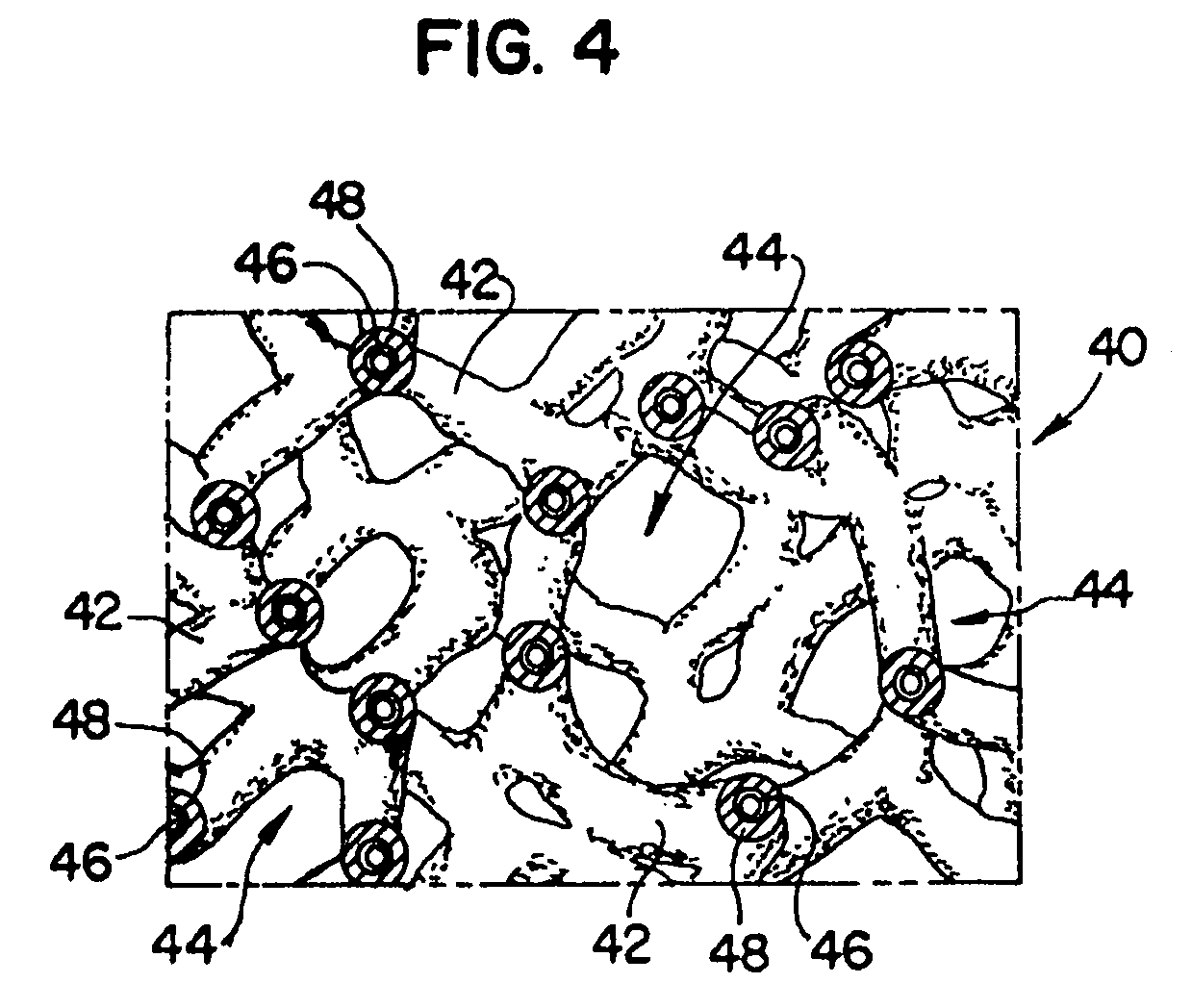

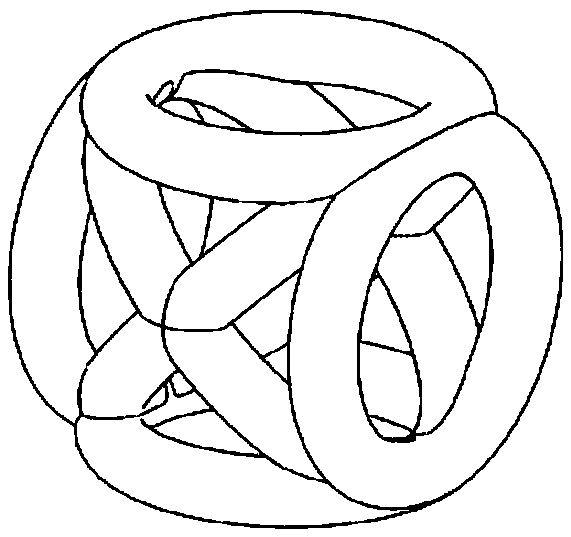

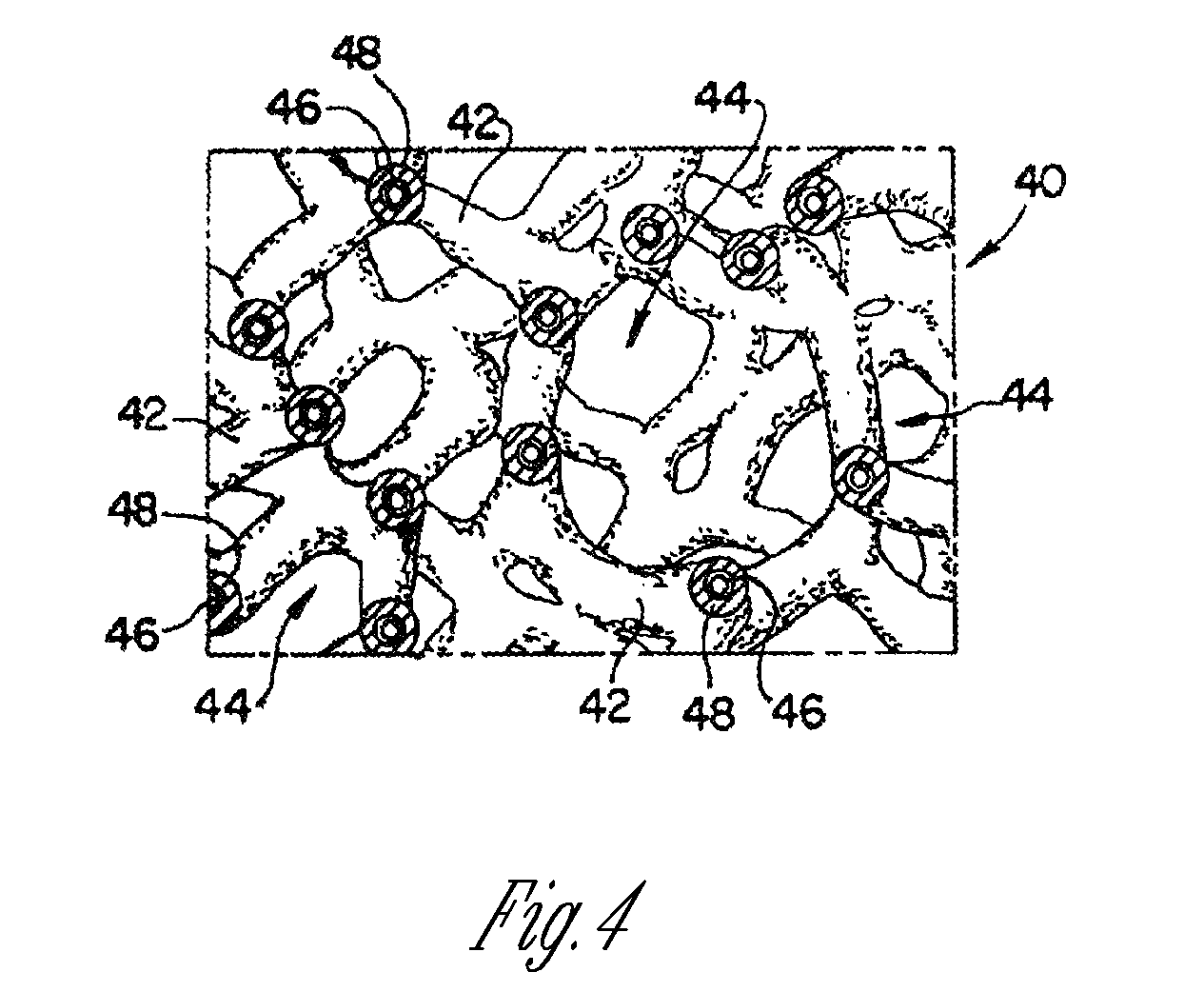

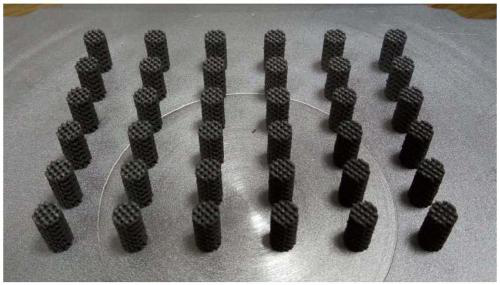

Porous implant structures

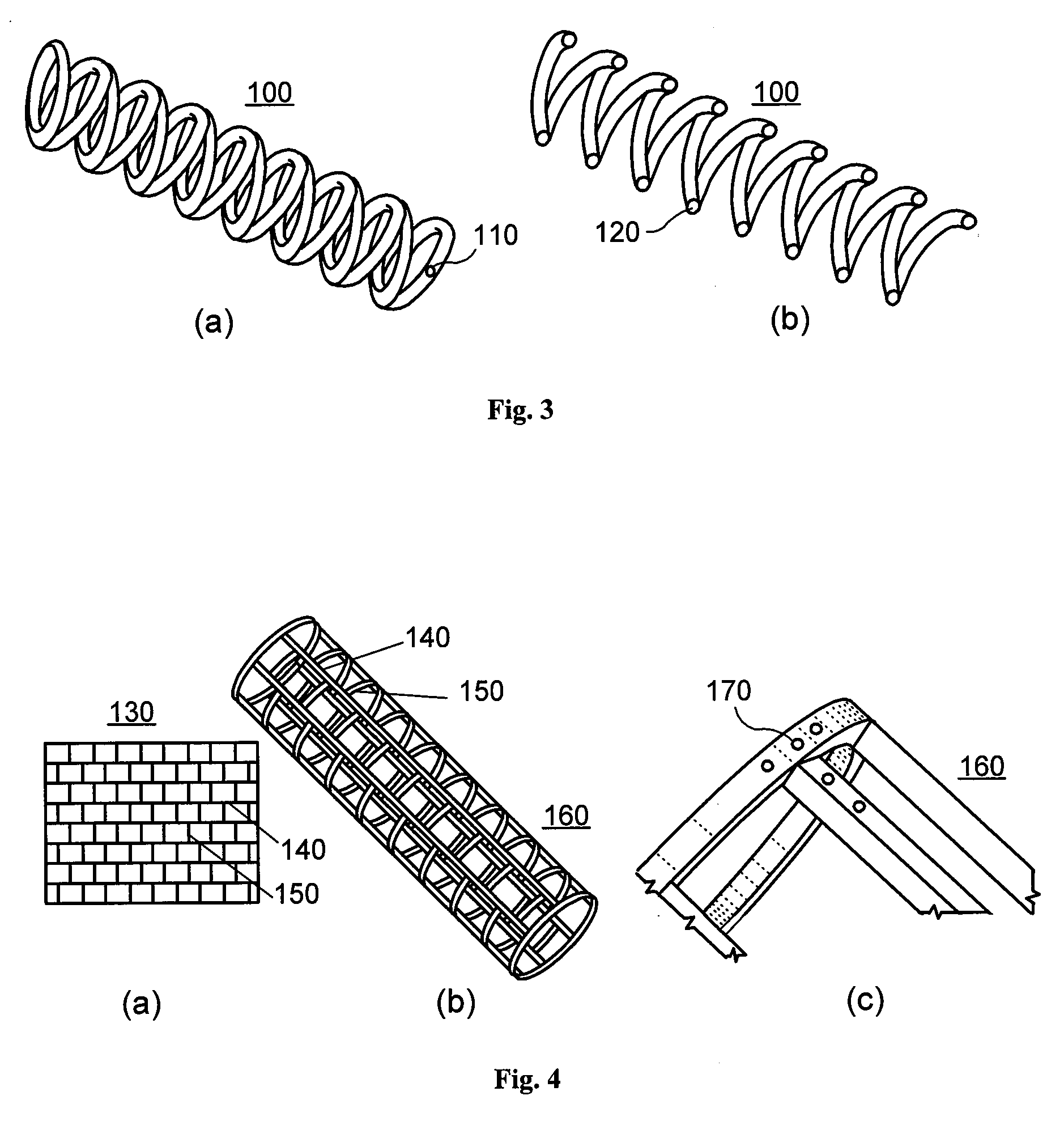

InactiveUS20120215310A1High porosityHigh strengthAdditive manufacturing apparatusSurgical adhesivesNODALManufacturing technology

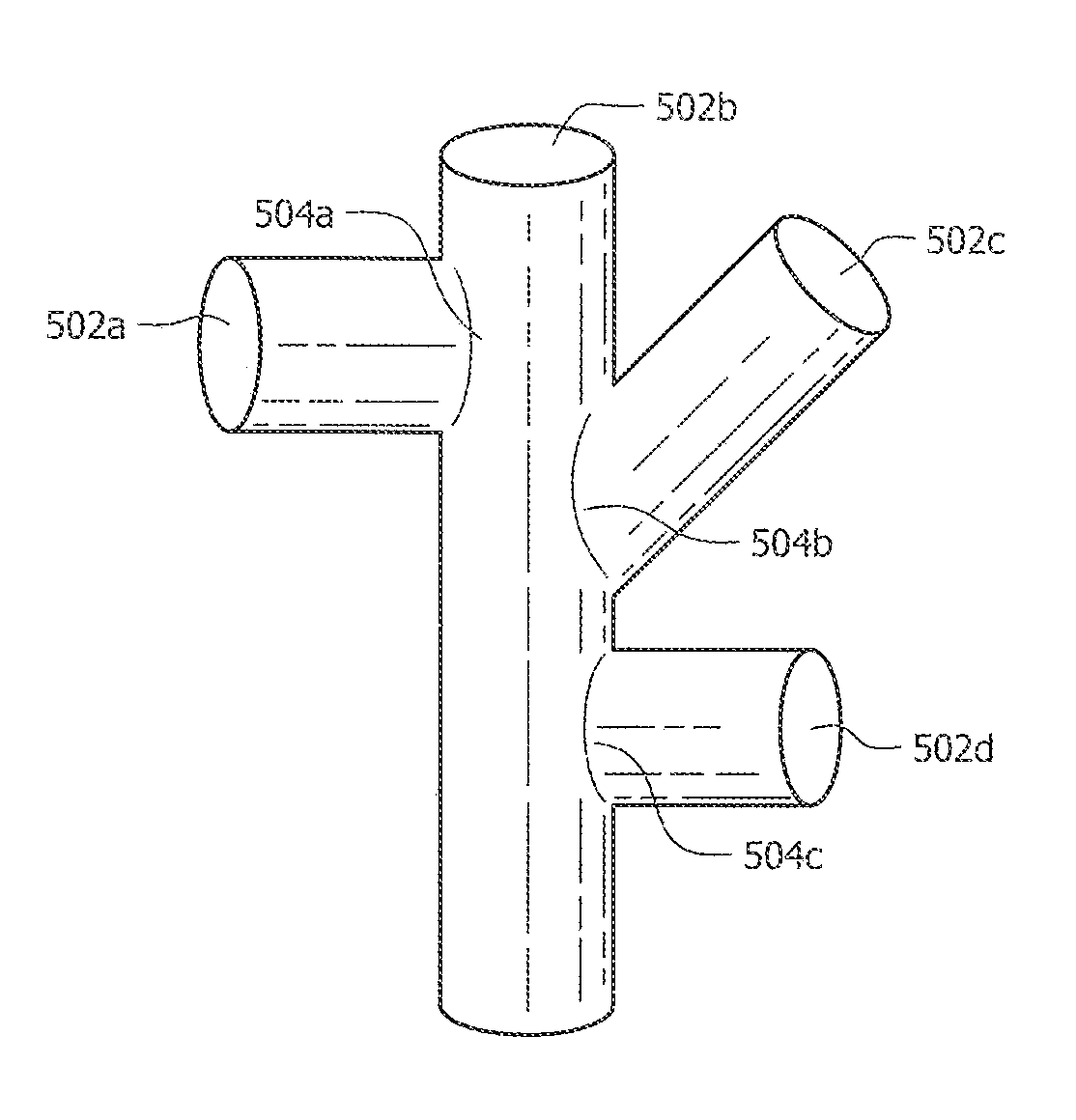

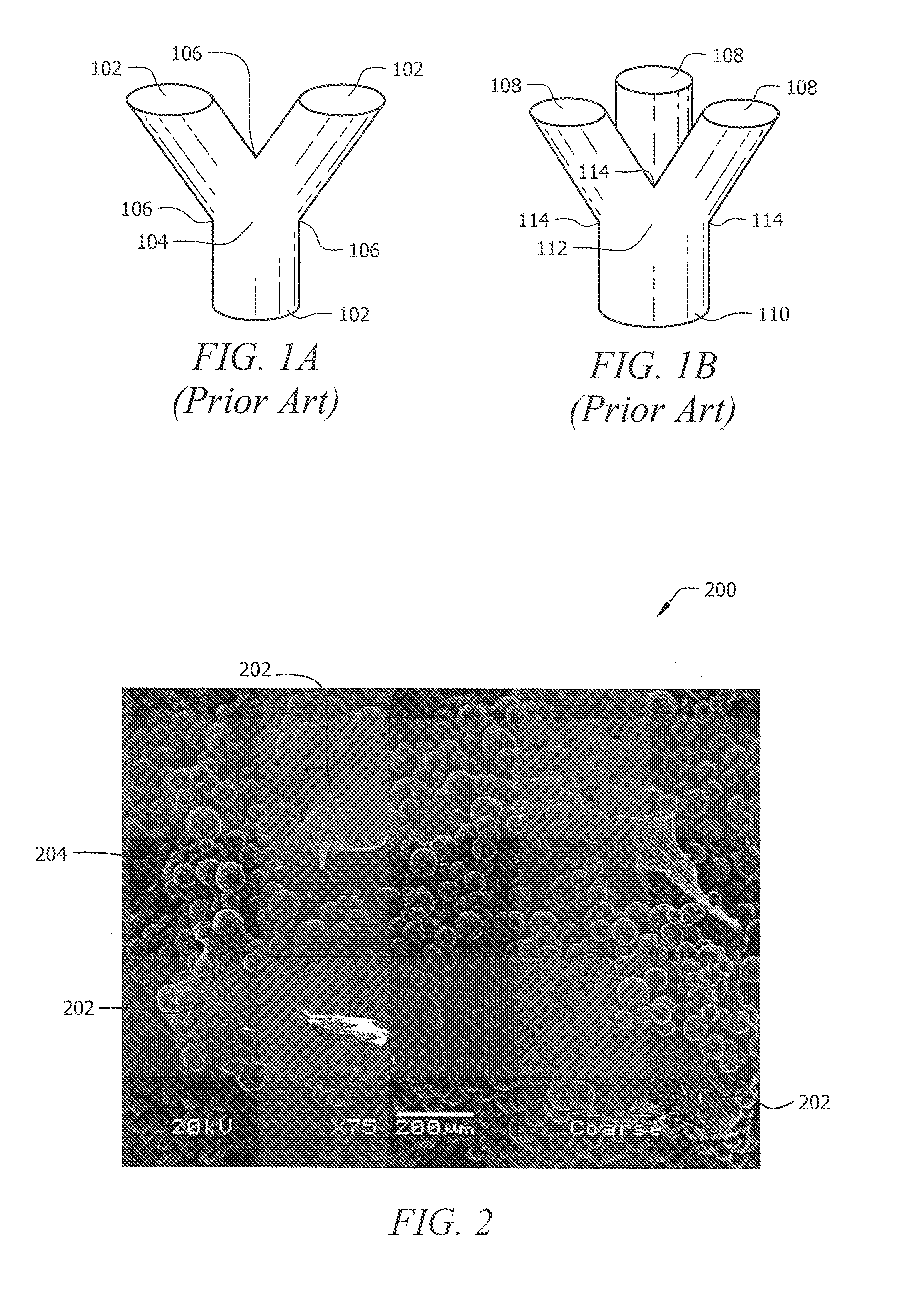

Porous biocompatible structures suitable for use as medical implants and methods for fabricating such structures are disclosed. The disclosed structures may be fabricated using rapid manufacturing techniques. The disclosed porous structures has a plurality of struts and nodes where no more than two struts intersect one another to form a node. Further, the nodes can be straight, curved, portions that are curved and / or straight. The struts and nodes can form cells which can be fused or sintered to at least one other cell to form a continuous reticulated structure for improved strength while providing the porosity needed for tissue and cell in-growth.

Owner:SMITH & NEPHEW INC

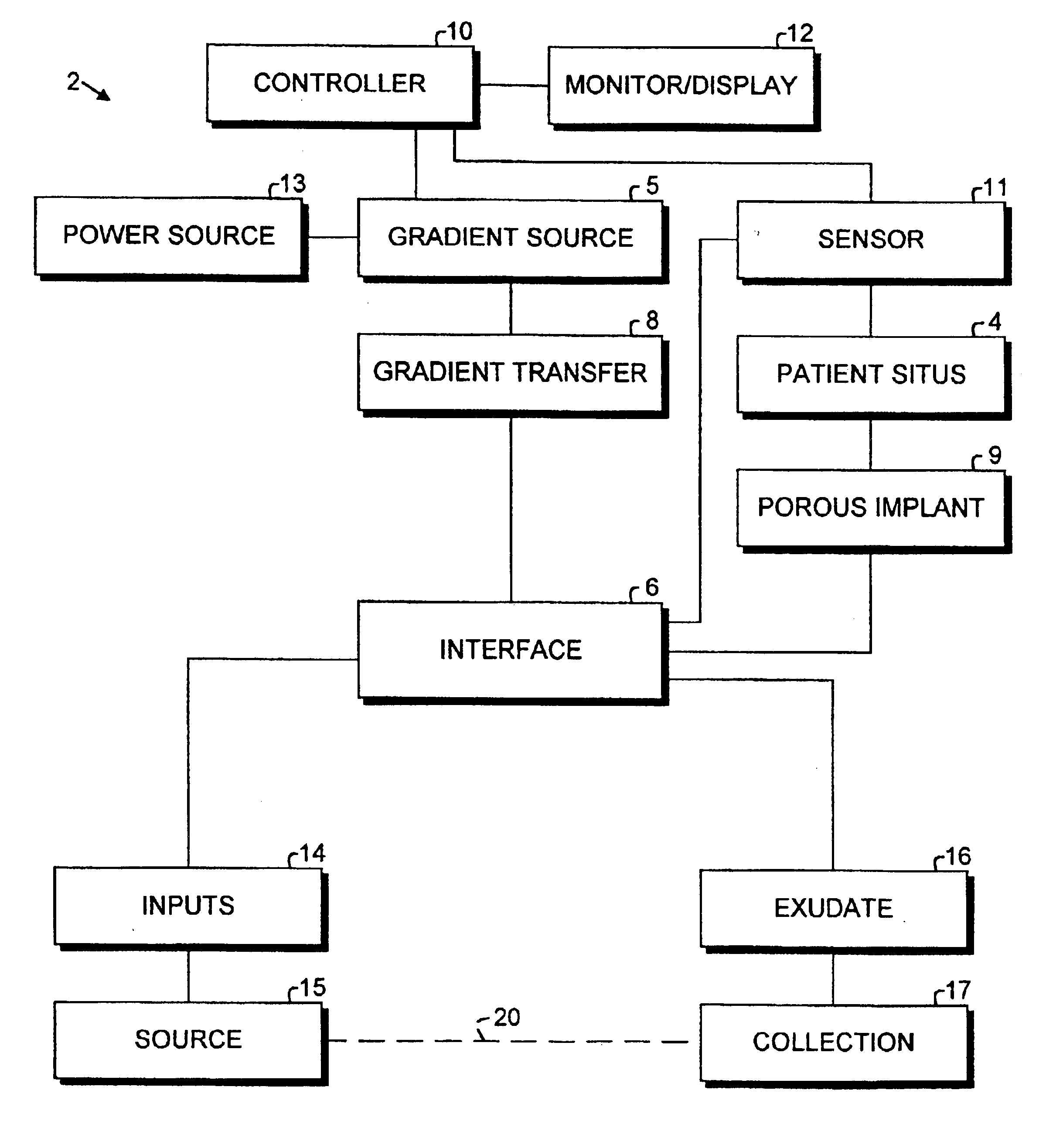

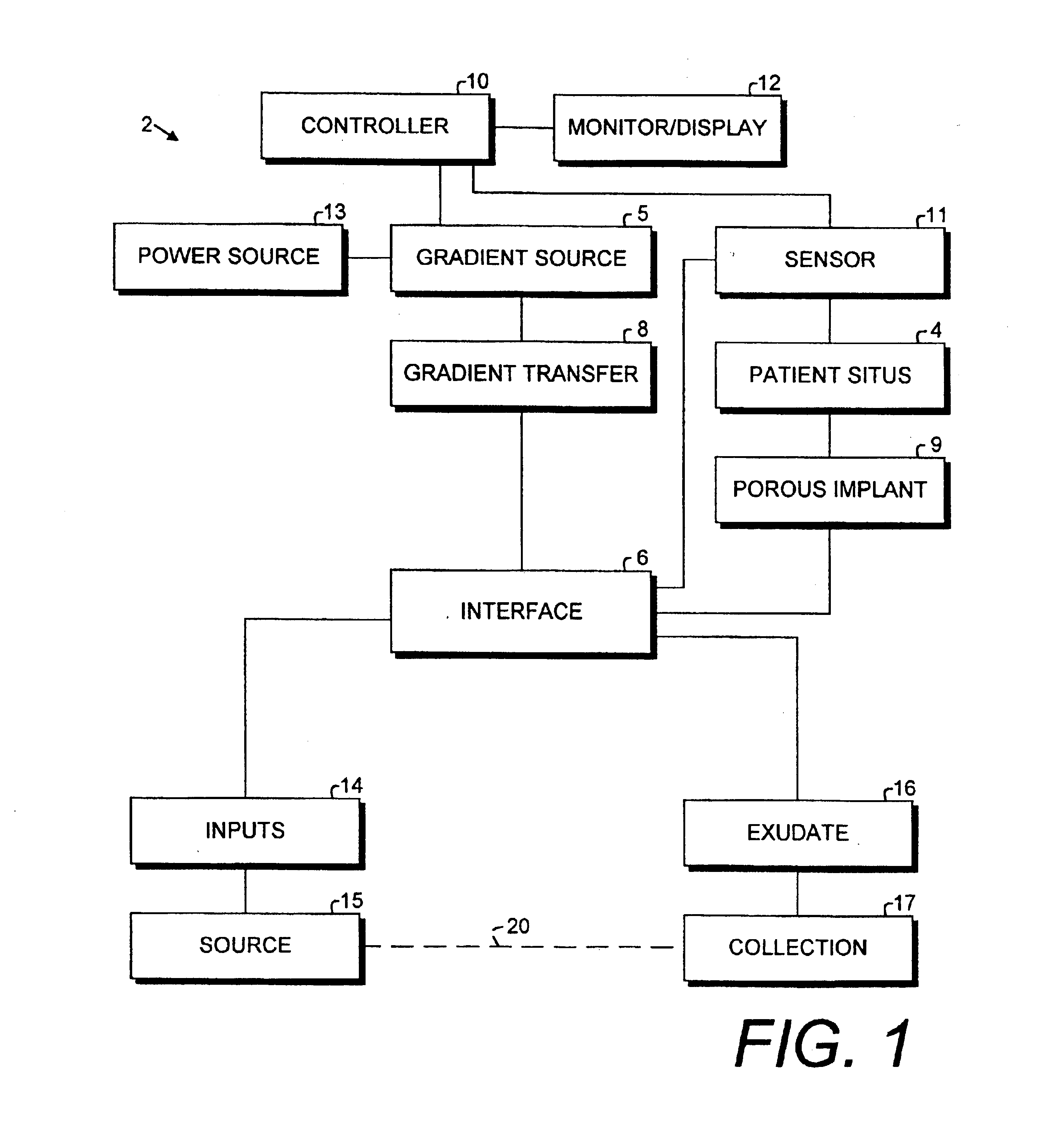

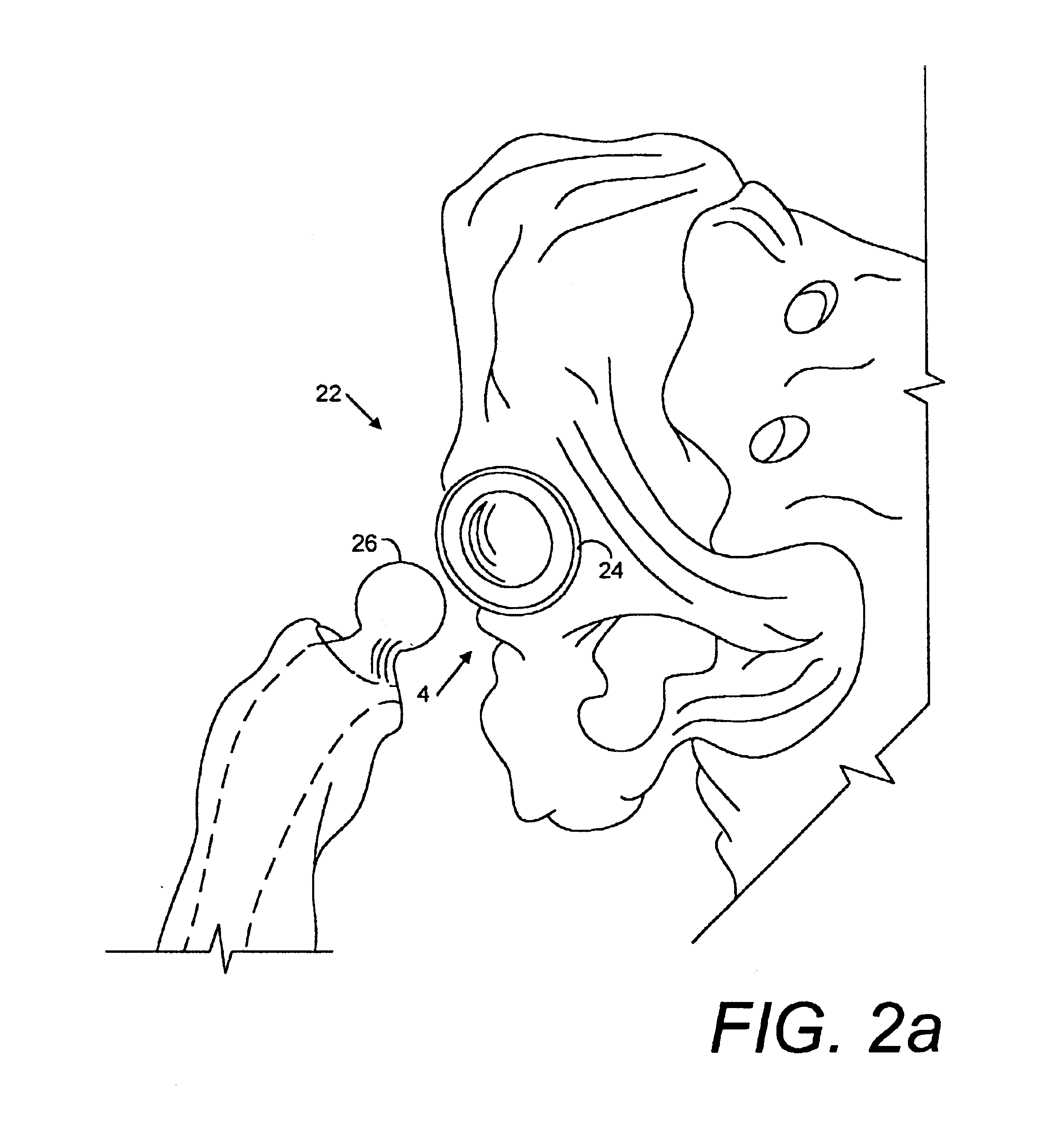

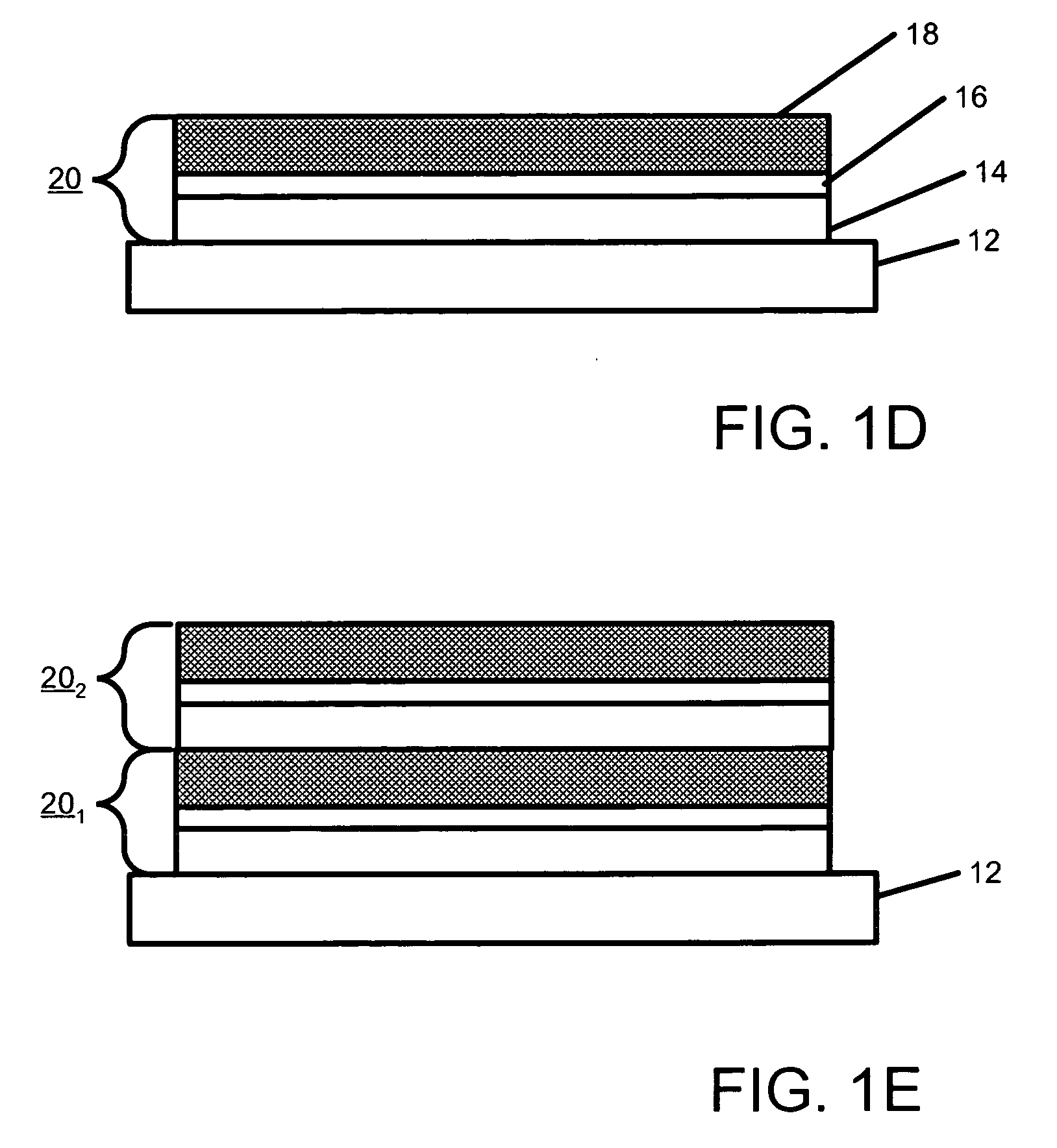

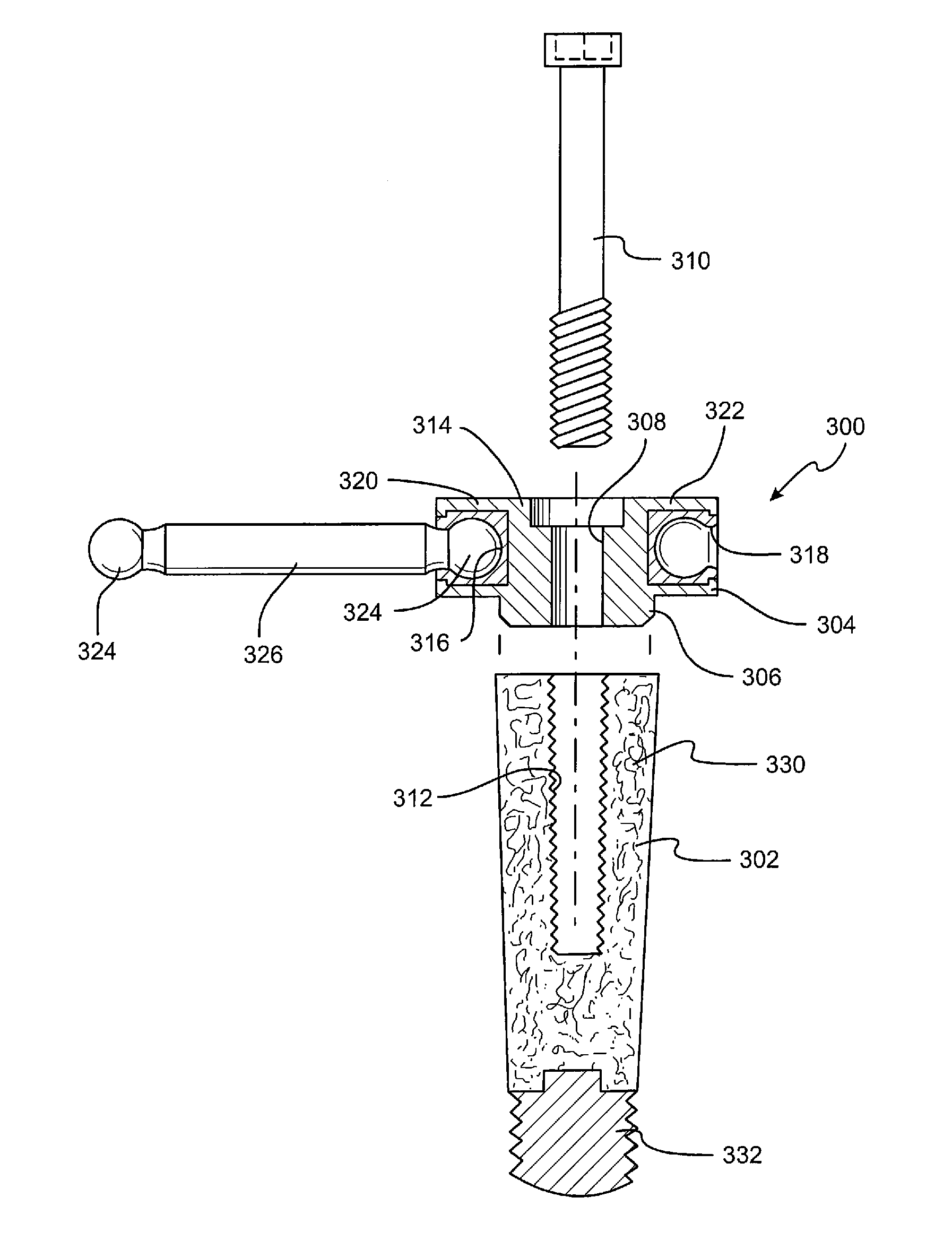

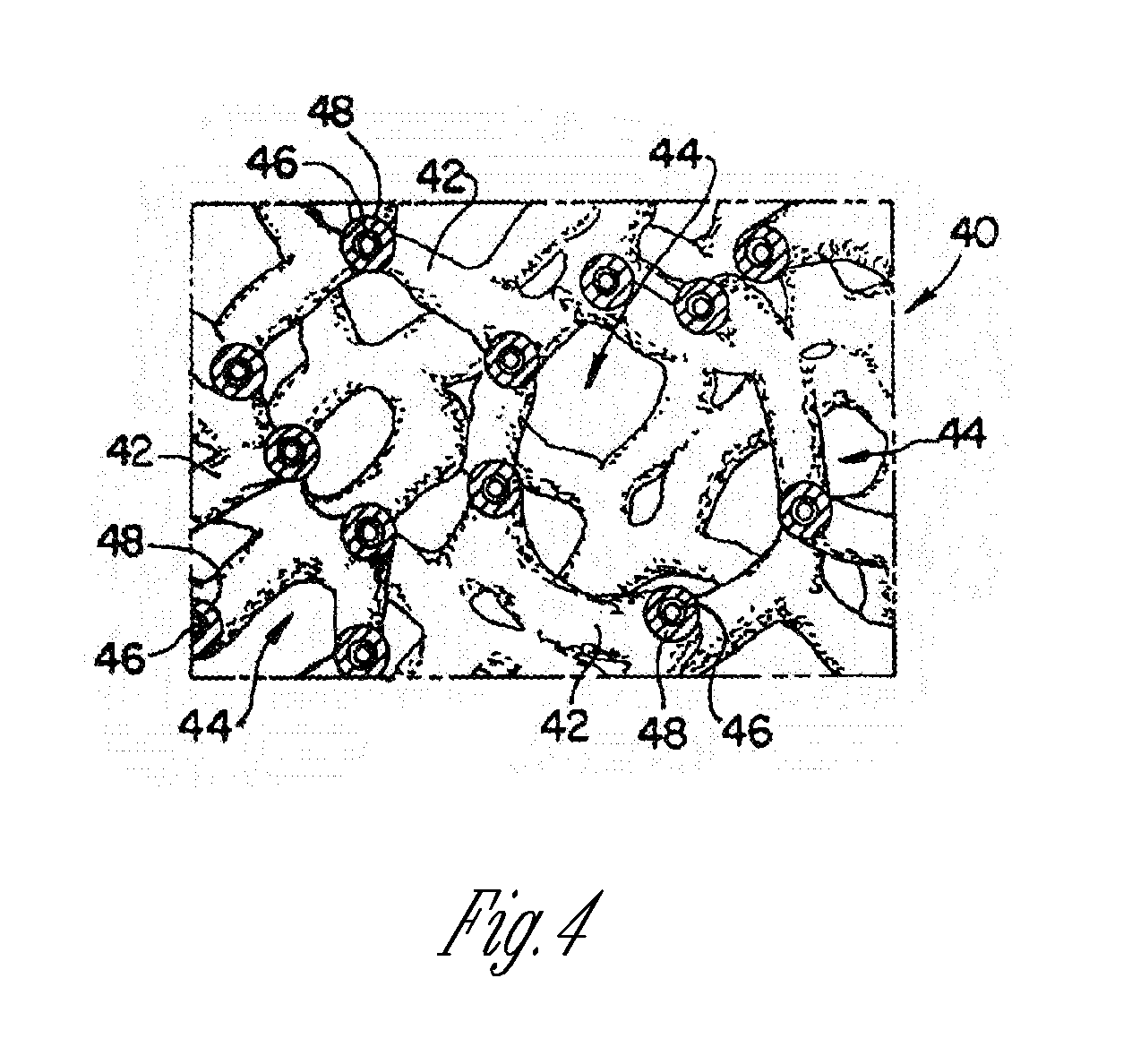

Porous implant system and treatment method

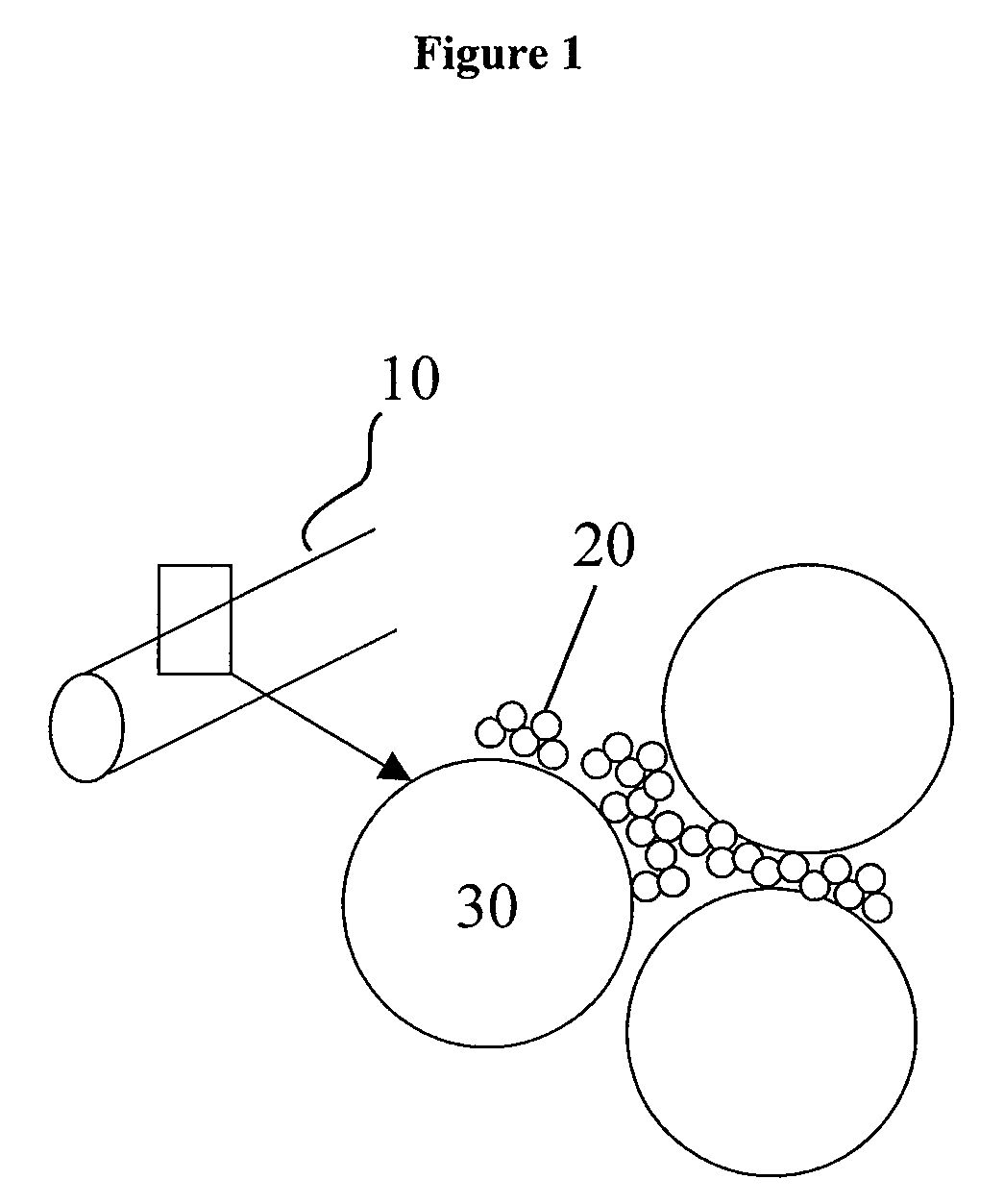

A porous implant system includes a gradient source adapted for transferring a gradient to an interface connected to an implant at a patient situs. The gradient source is controlled by a programmable controller. The implant is bonded to the patient by tissue ingrowth, which is facilitated by the gradient formed across the porous portion of the implant. A treatment method and includes the steps of providing a porous implant, connecting same to a gradient source through an interface, forming a gradient across the implant and controlling the operation of the gradient source according to a predetermined and preprogrammed treatment protocol.

Owner:BUBB STEPHEN K

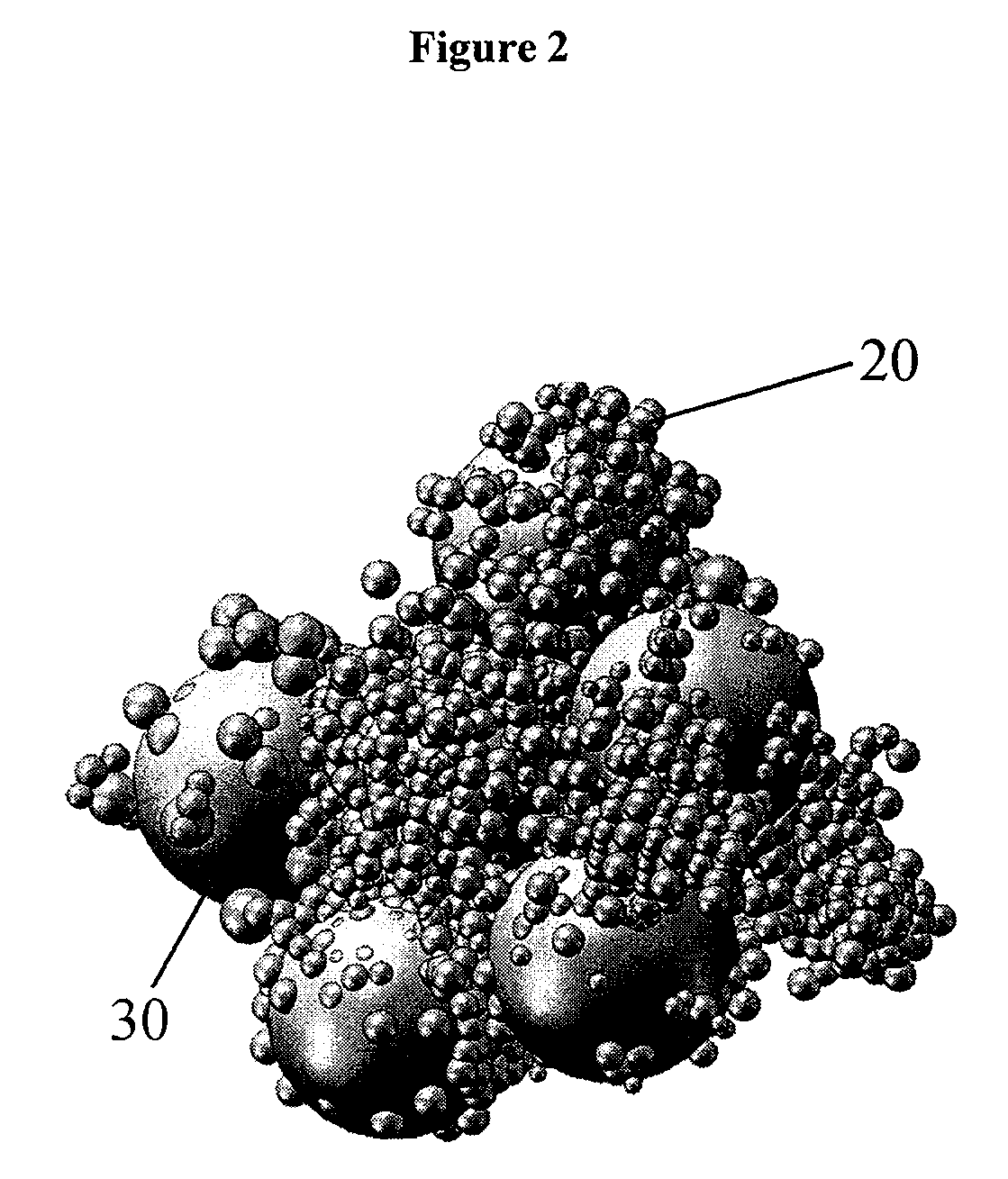

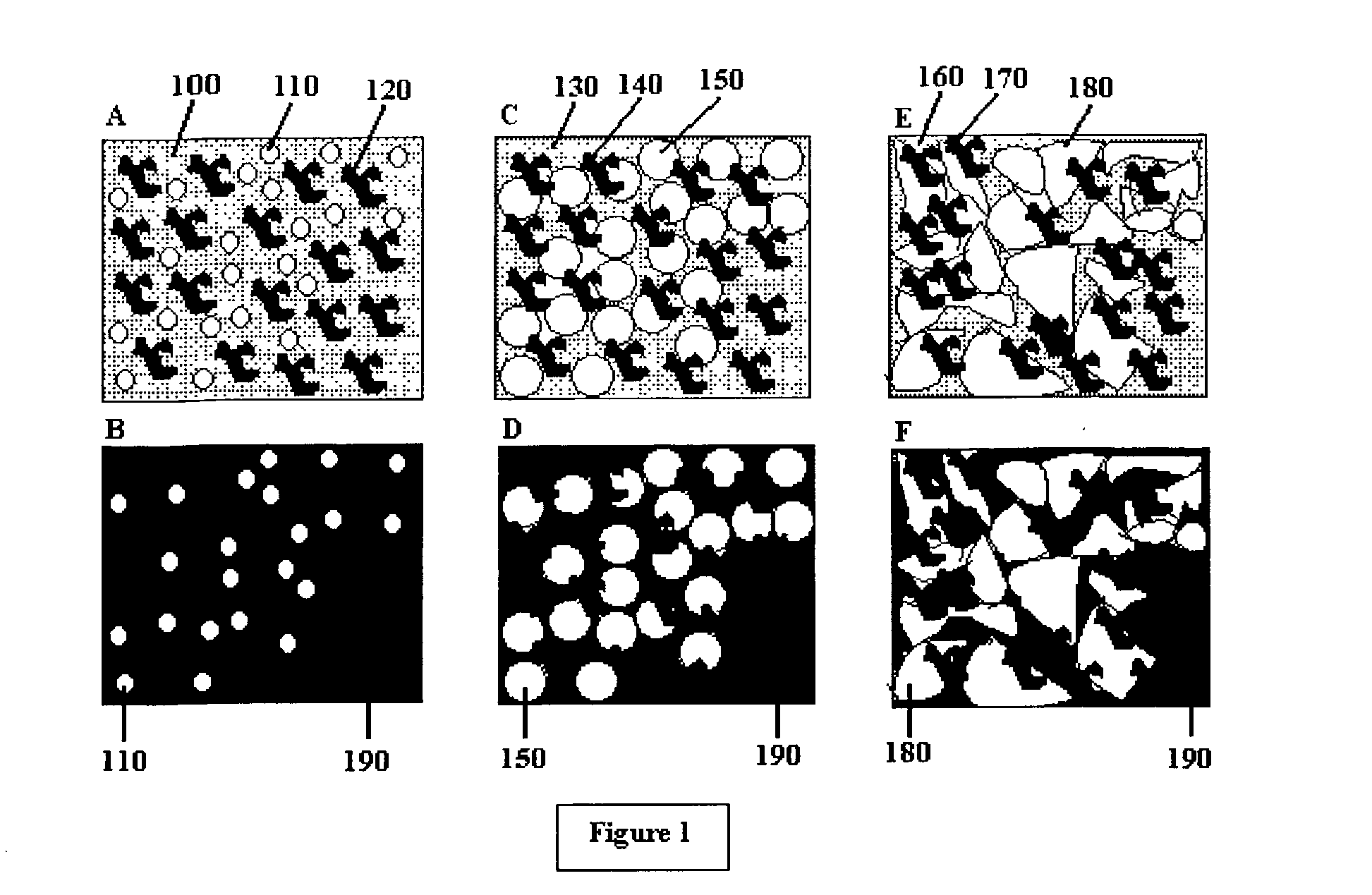

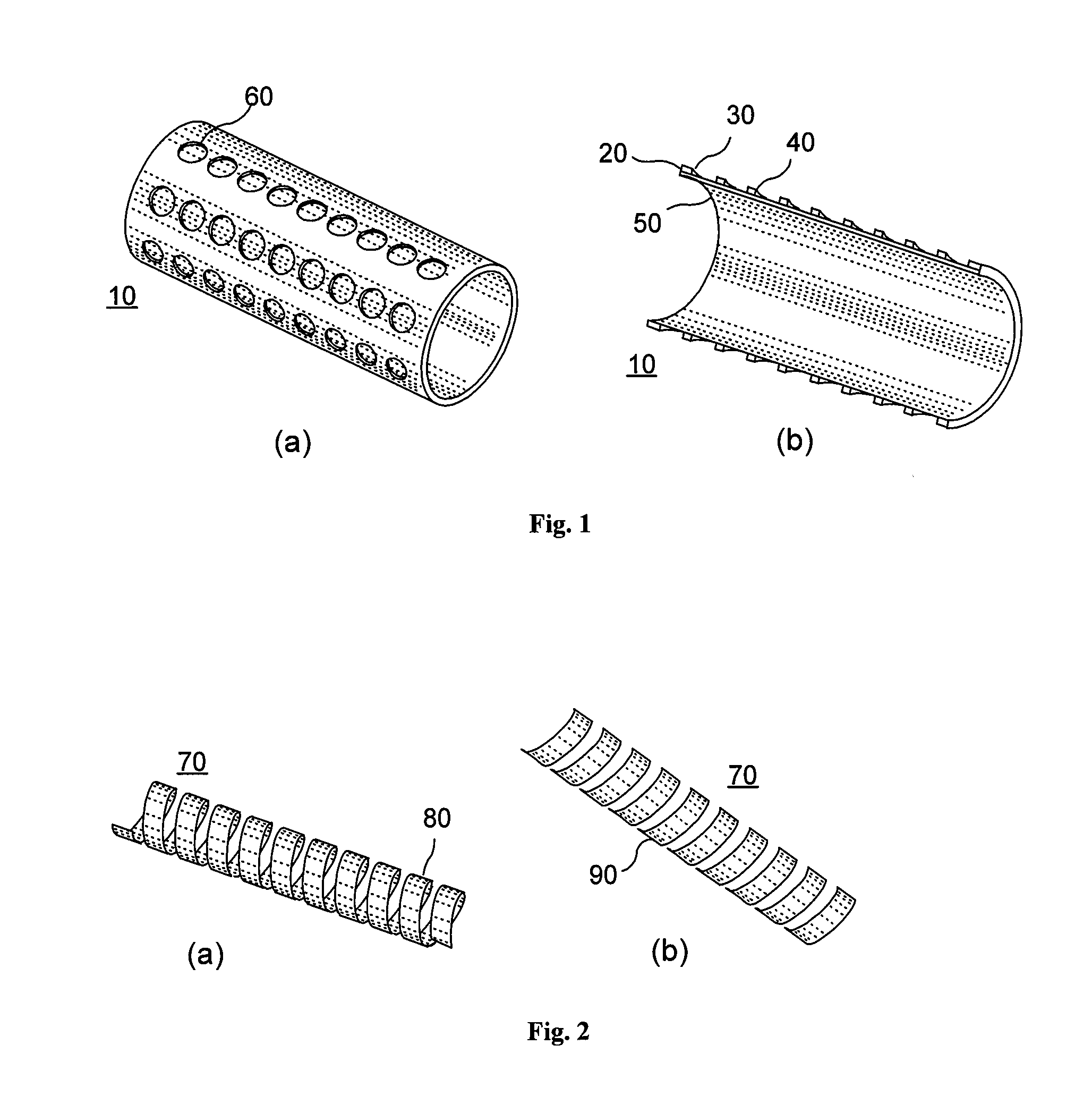

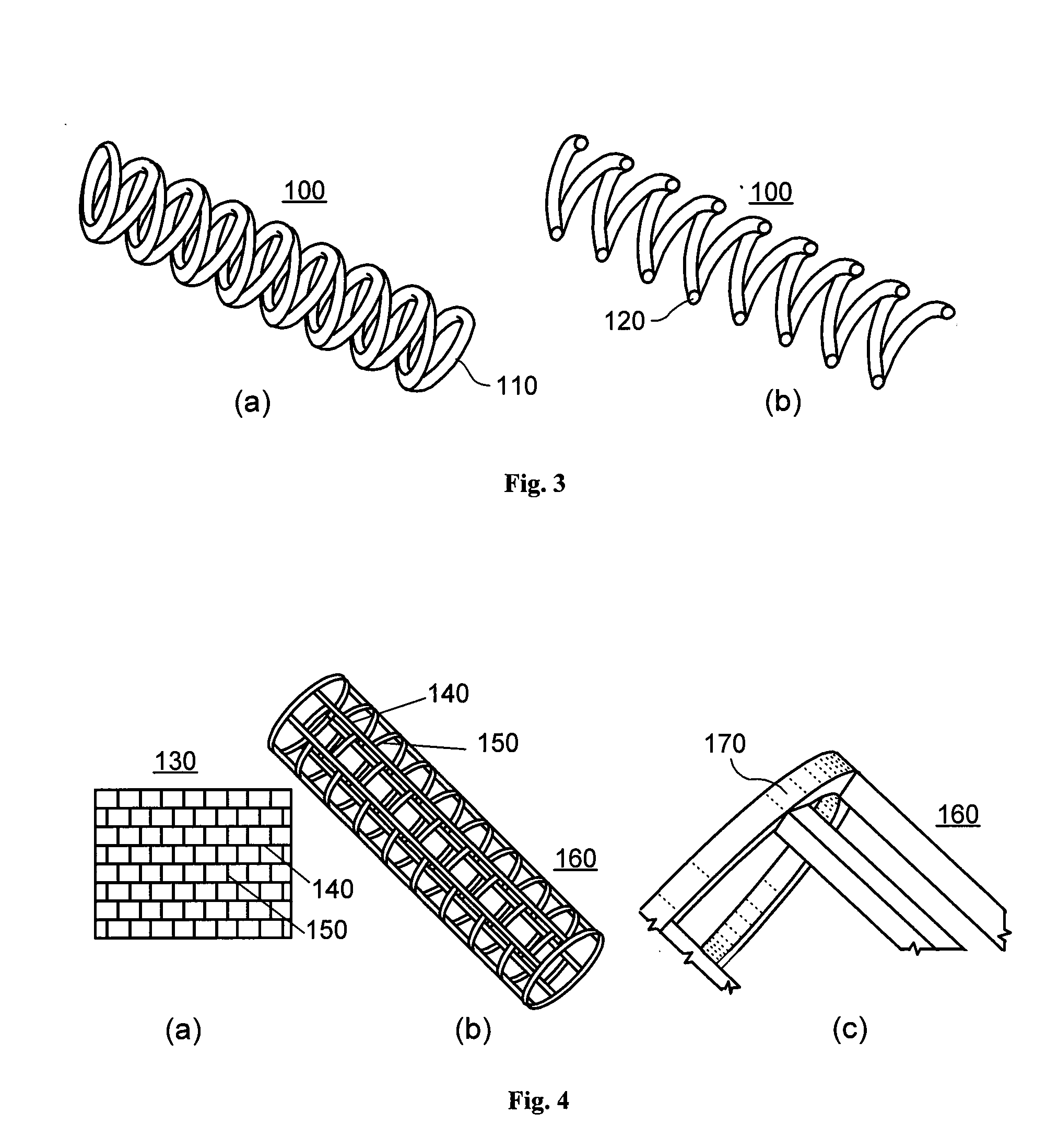

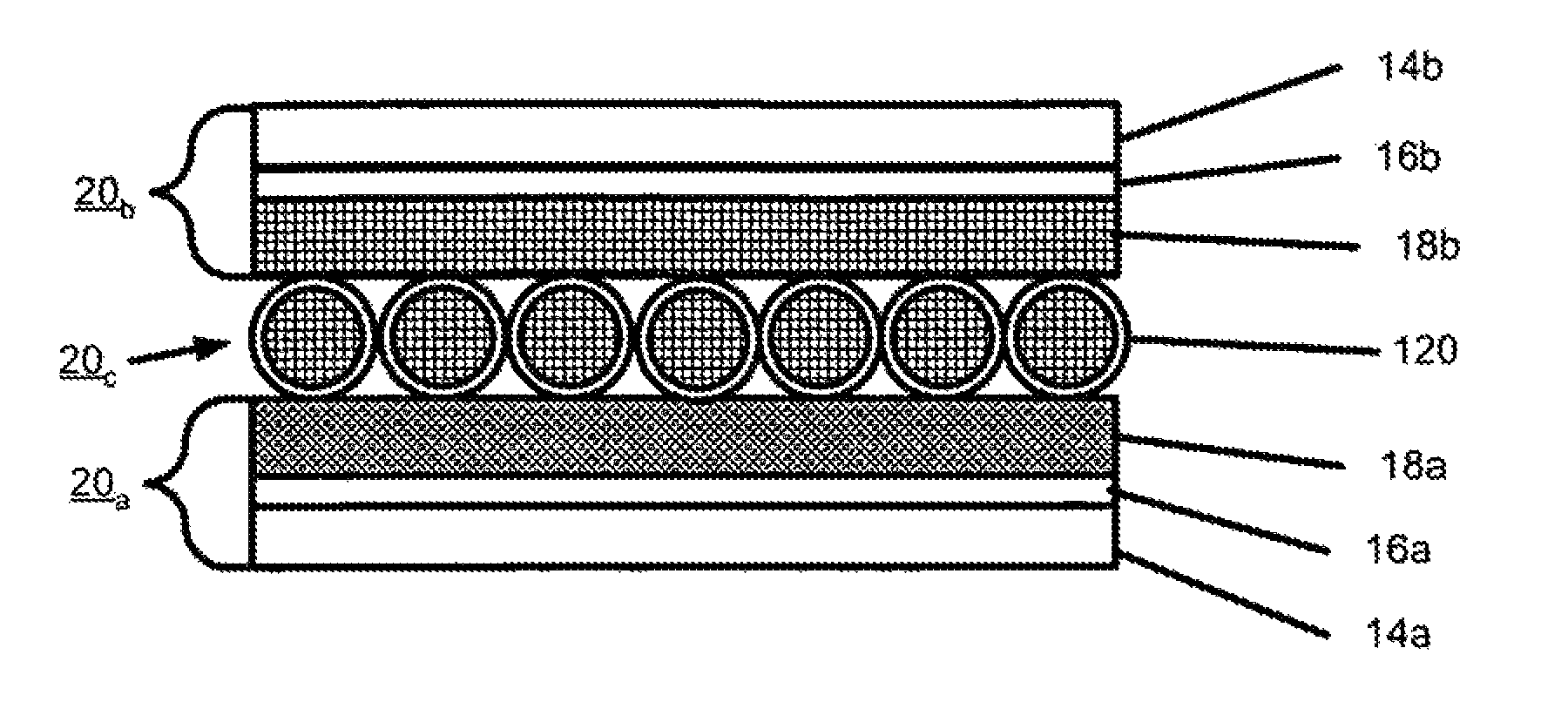

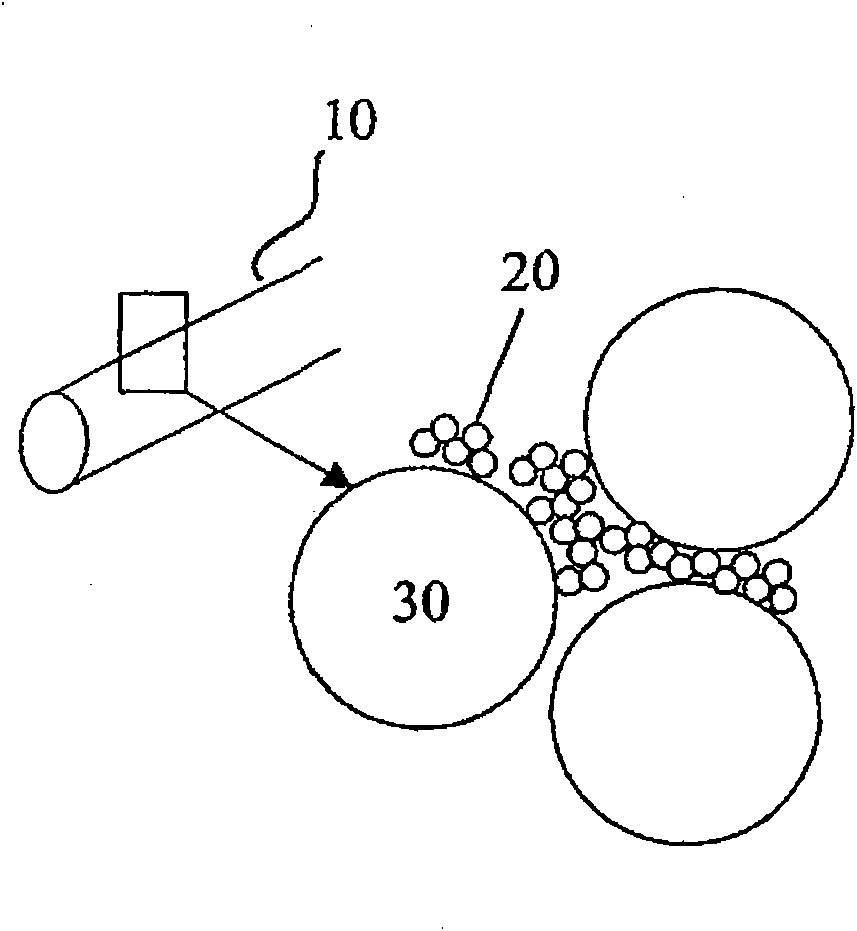

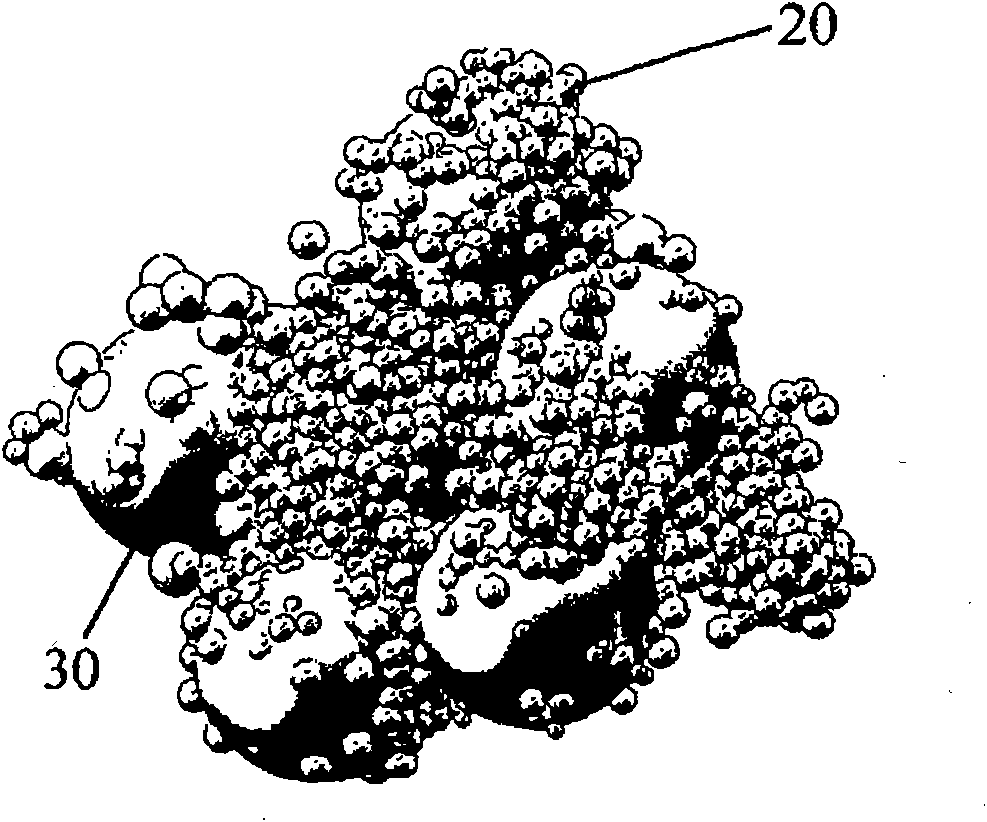

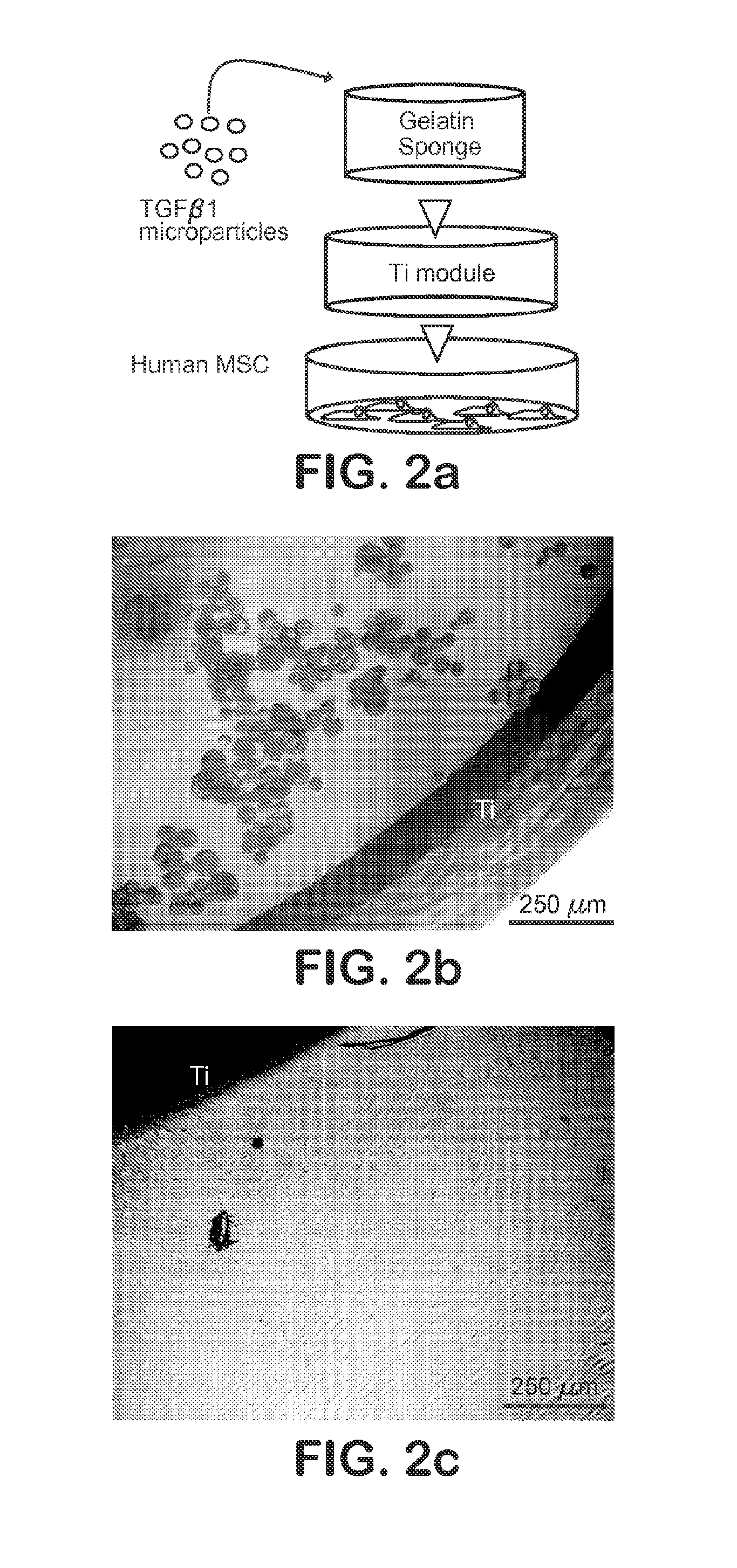

System and method for tissue generation and bone regeneration

ActiveUS20070061015A1Promotes bone formationIncrease surface areaImpression capsBone implantDamages tissueActive agent

A system and method for the repair of damaged tissue and bones, congenitally missing tissue / cosmetic reconstruction of tissue is described. The system has a layered porous structure with a sufficiently large area of exposed pores to promote neo-vascularization as well as bone and tissue formation. The disclosed porous implant system can contain bioactive agents necessary for rapid tissue formation and keep ingrowth of unwanted tissue out of the implant surgical site. The implant can be reinforced with an additional, stronger polymer layer and / or may include an endoskeleton or exoskeleton for dimensional stability.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

Porous, non-degradable implant made by powder molding

InactiveUS20080213611A1Sufficient pore volumeSufficient volumeLayered productsPharmaceutical delivery mechanismDecompositionShell molding

Owner:CINVENTION AG

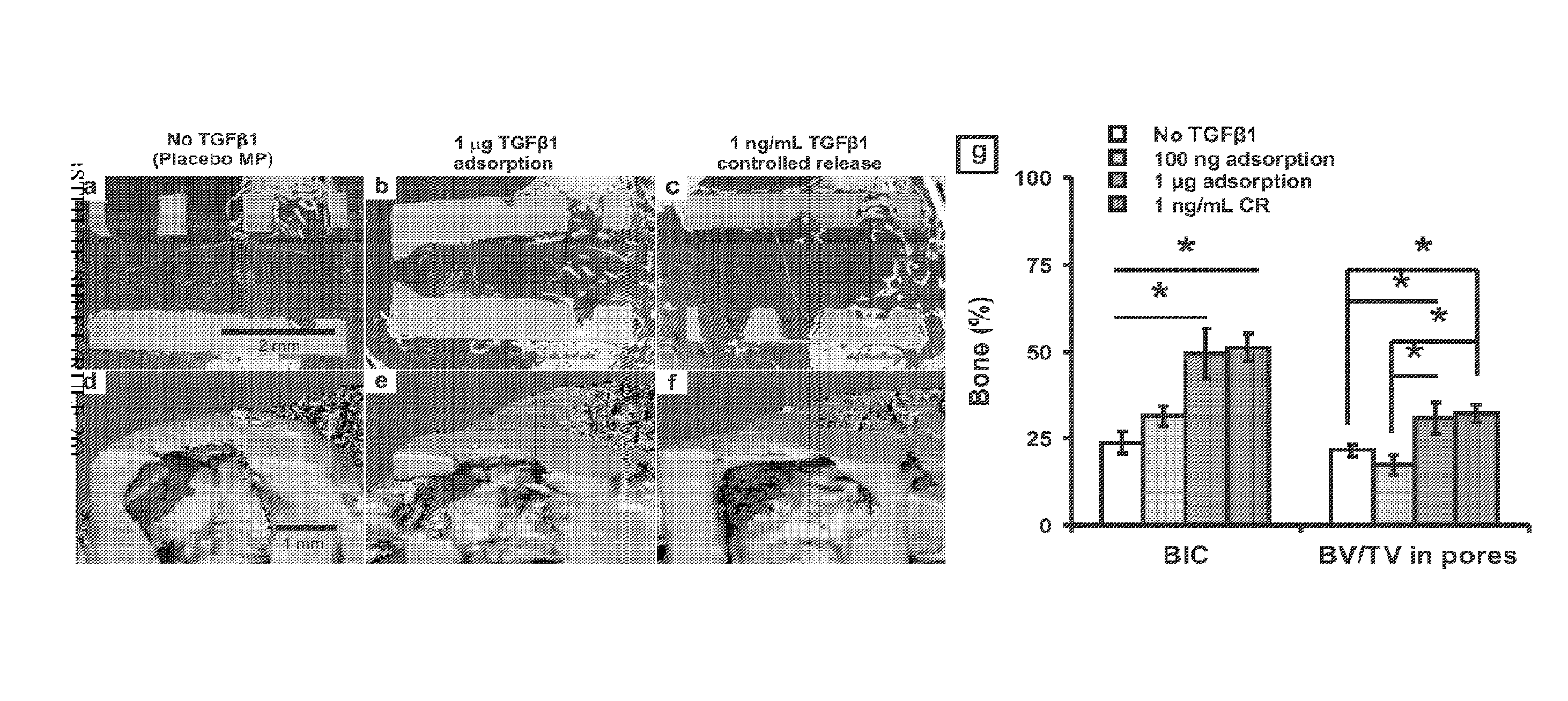

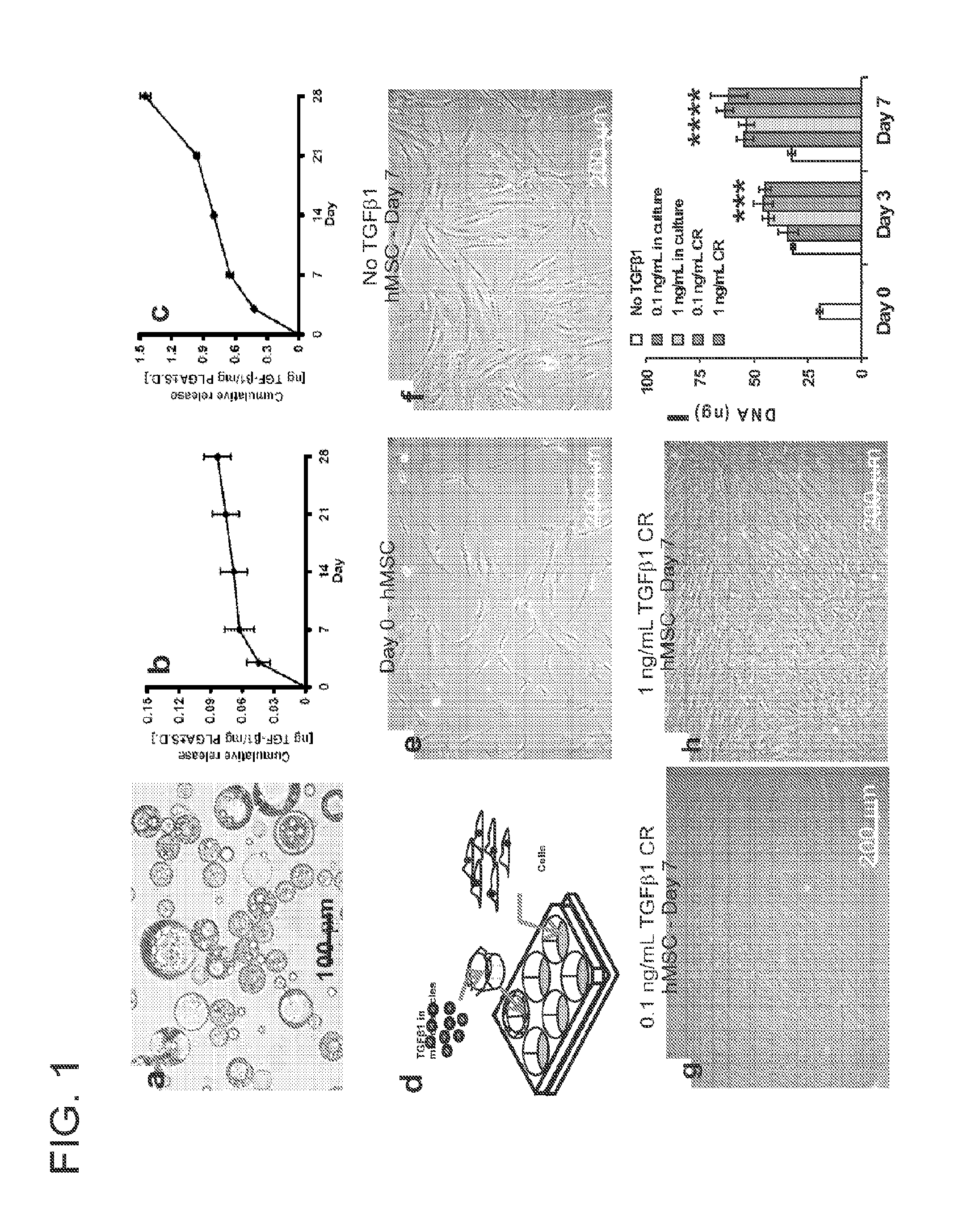

Implant improving local bone formation

InactiveUS20060188542A1Improve effectivenessBiocideDental implantsChemical LinkageCalcium biphosphate

A bone implant comprises an active agent on at least a portion thereof. The active agent is locally deliverable to bone proximate the implant in at least a two-phased release scheme. A first phase rapidly releases a first quantity of the active agent, and at least a second phase gradually releases a second quantity of the active agent, whereby bone formation stimulated by the active agent is modulated. In one embodiment, a porous implant comprises a porous portion coated with a calcium phosphate compound and which is contacted with a bisphosphonate compound to form a bisphosphonate layer chemically bound to the calcium phosphate at the surface of the porous portion and to form bisphosphonate molecules being non-chemically attached inside the pores of the porous portion. The non-chemically attached bisphosphonate molecules are released in the subject at a rate greater than that of the chemically bound bisphosphonate layer.

Owner:BOBYN JOHN DENNIS +1

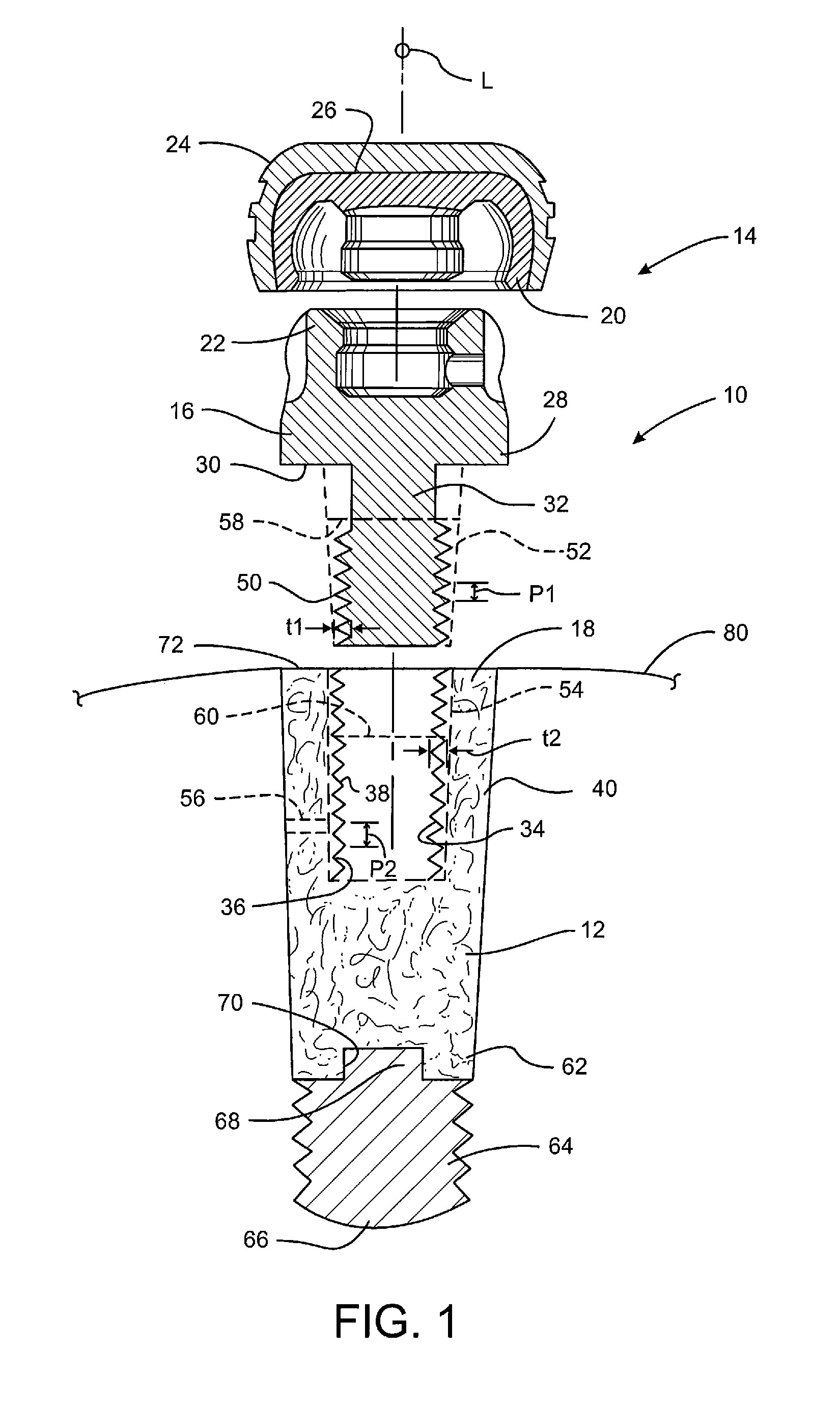

Porous Implant Device for Supporting a Denture

A dental implant device has an implant portion for being placed in a bore in bone. The implant portion has a coronal end portion and a porous metal portion. A metal coupling has a coronal end configured for connection to a denture support piece. The coupling also has an apical end integrally formed with the coronal end and engaging the porous metal portion. In one form, the coupling is attached to the porous metal portion in a threaded connection so that the coupling is removable from the porous portion without significantly damaging the porous metal portion sufficiently to re-engage another metal coupling.

Owner:ZIMMER DENTAL INC

Porous implant with a dried, lubricious when wet, in vivo absorbable coating

An apparatus including a medical implant is provided. The medical implant includes a porous outer portion, and the apparatus further includes a dried, lubricious when wet, in vivo absorbable coating covering the porous outer portion. A method for finishing a medical implant is also provided. The method includes forming a porous outer portion on the implant, covering the porous outer portion with a lubricious when wet, in vivo absorbable coating, and drying the coating.

Owner:ZIMMER TECH INC

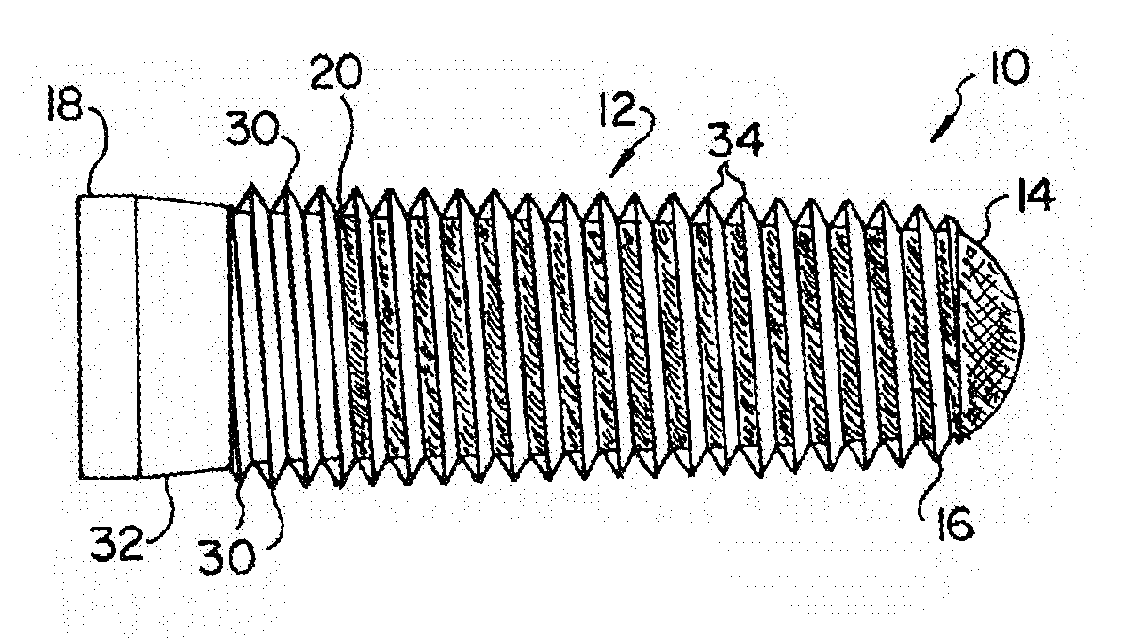

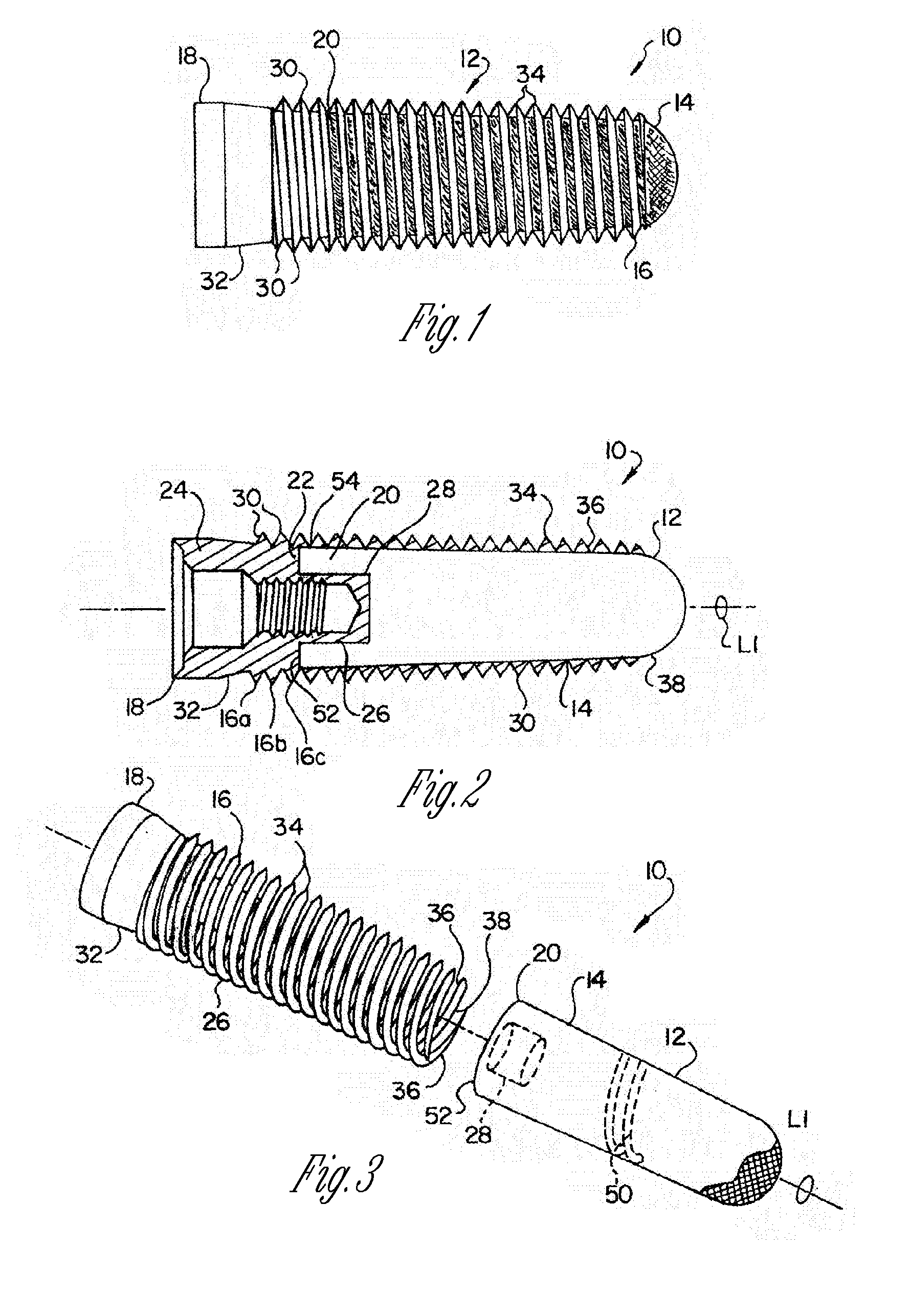

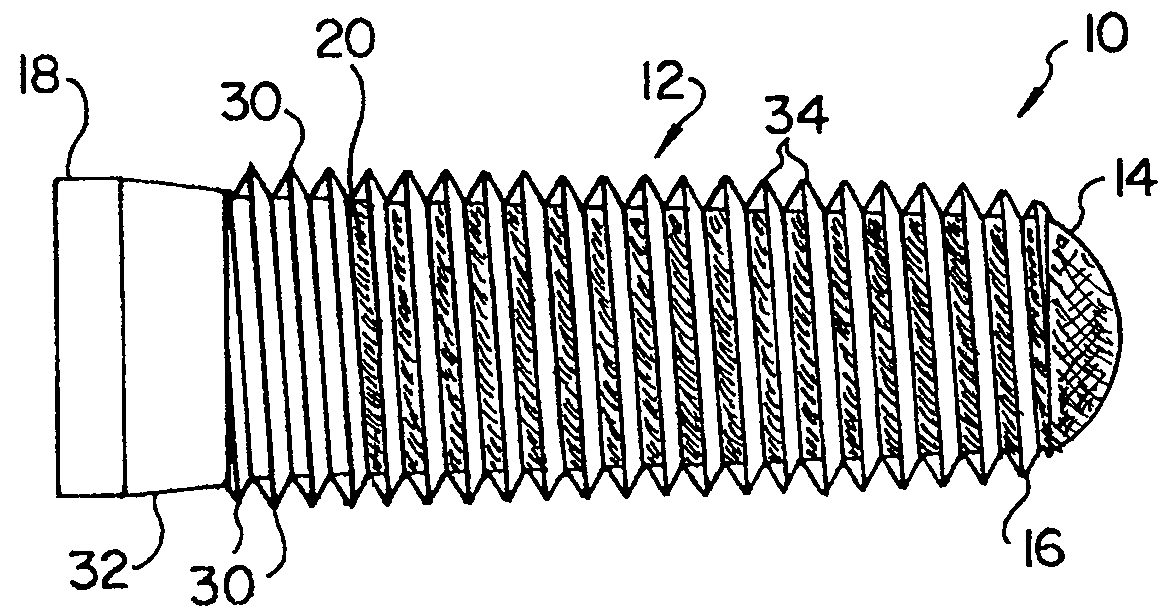

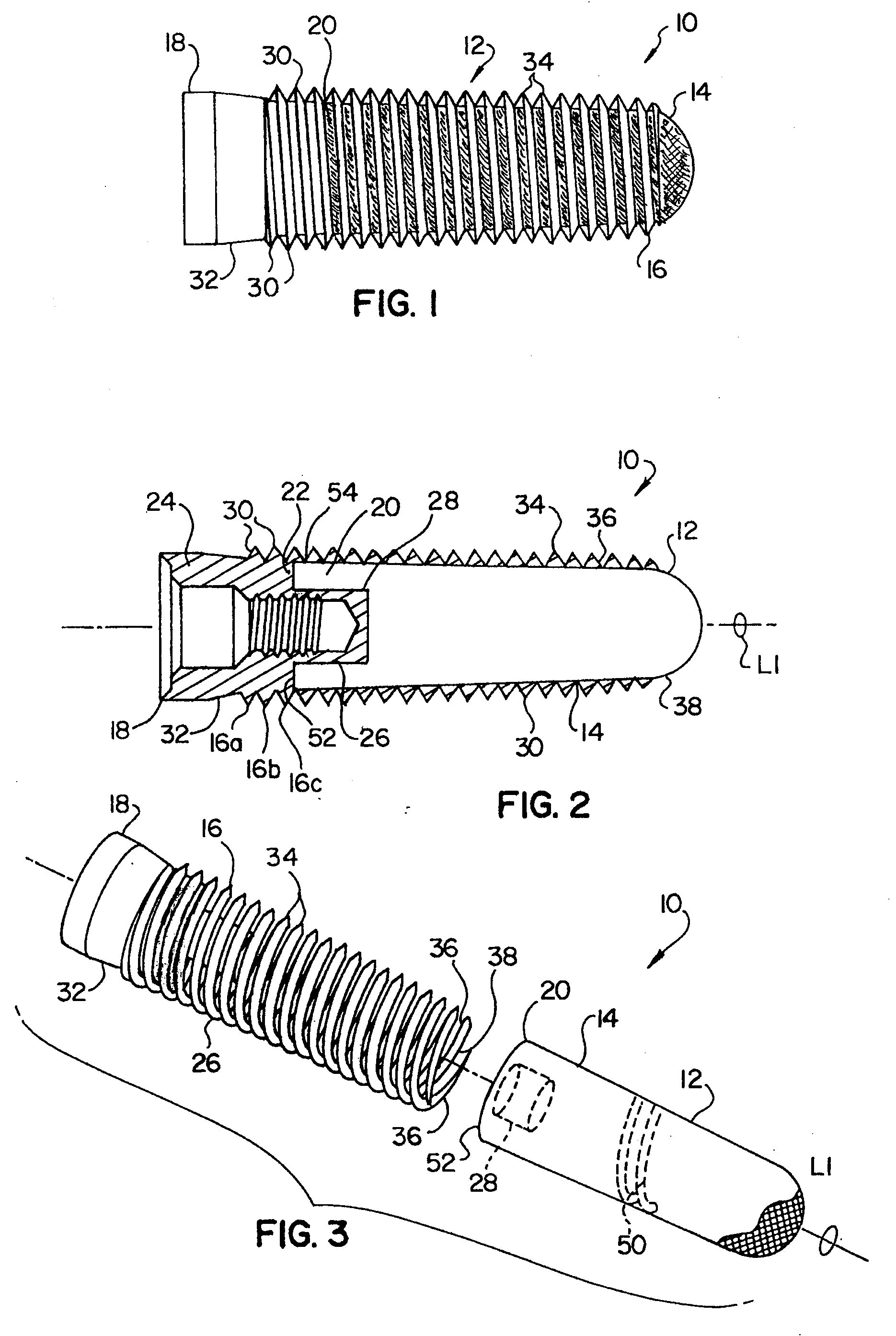

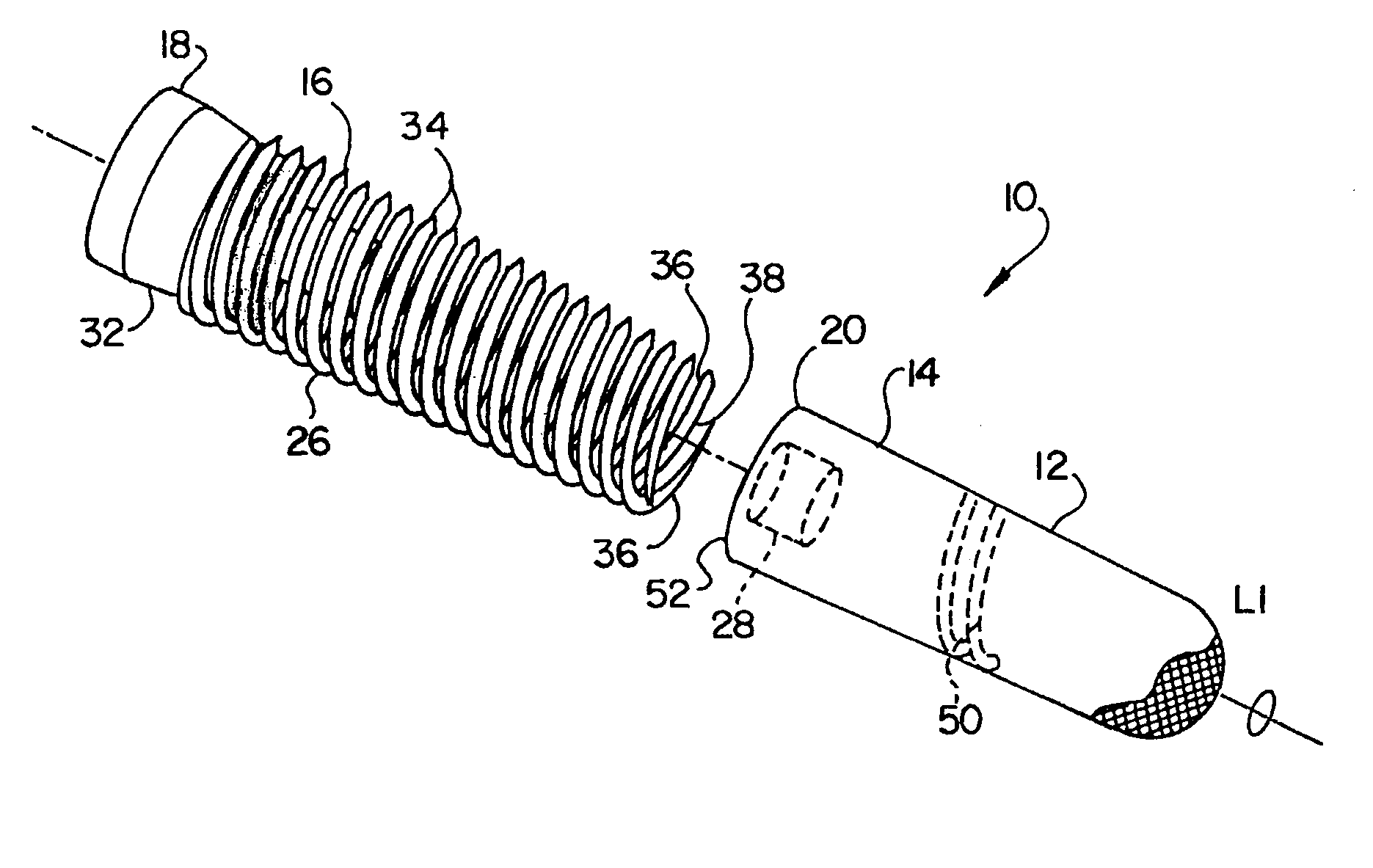

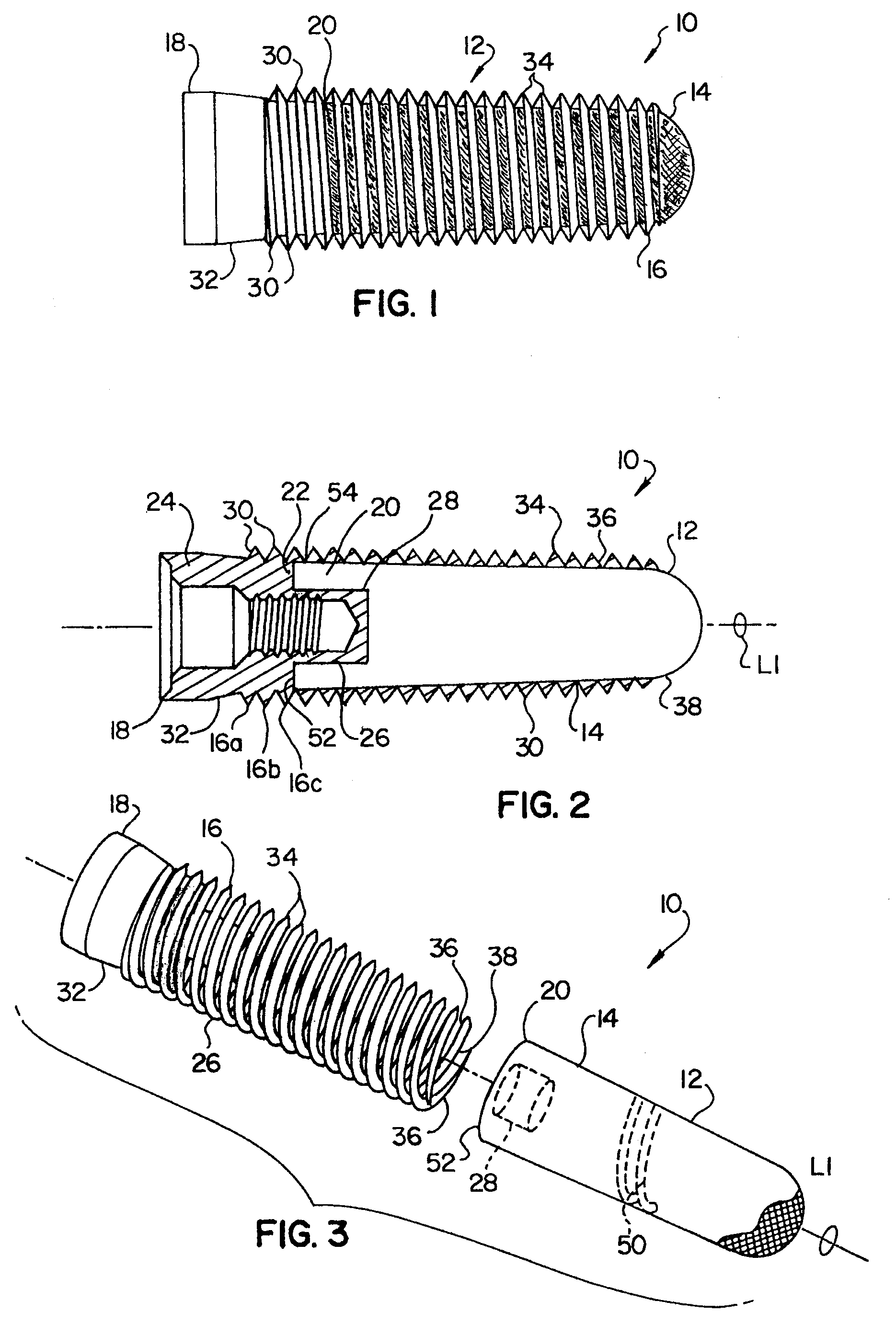

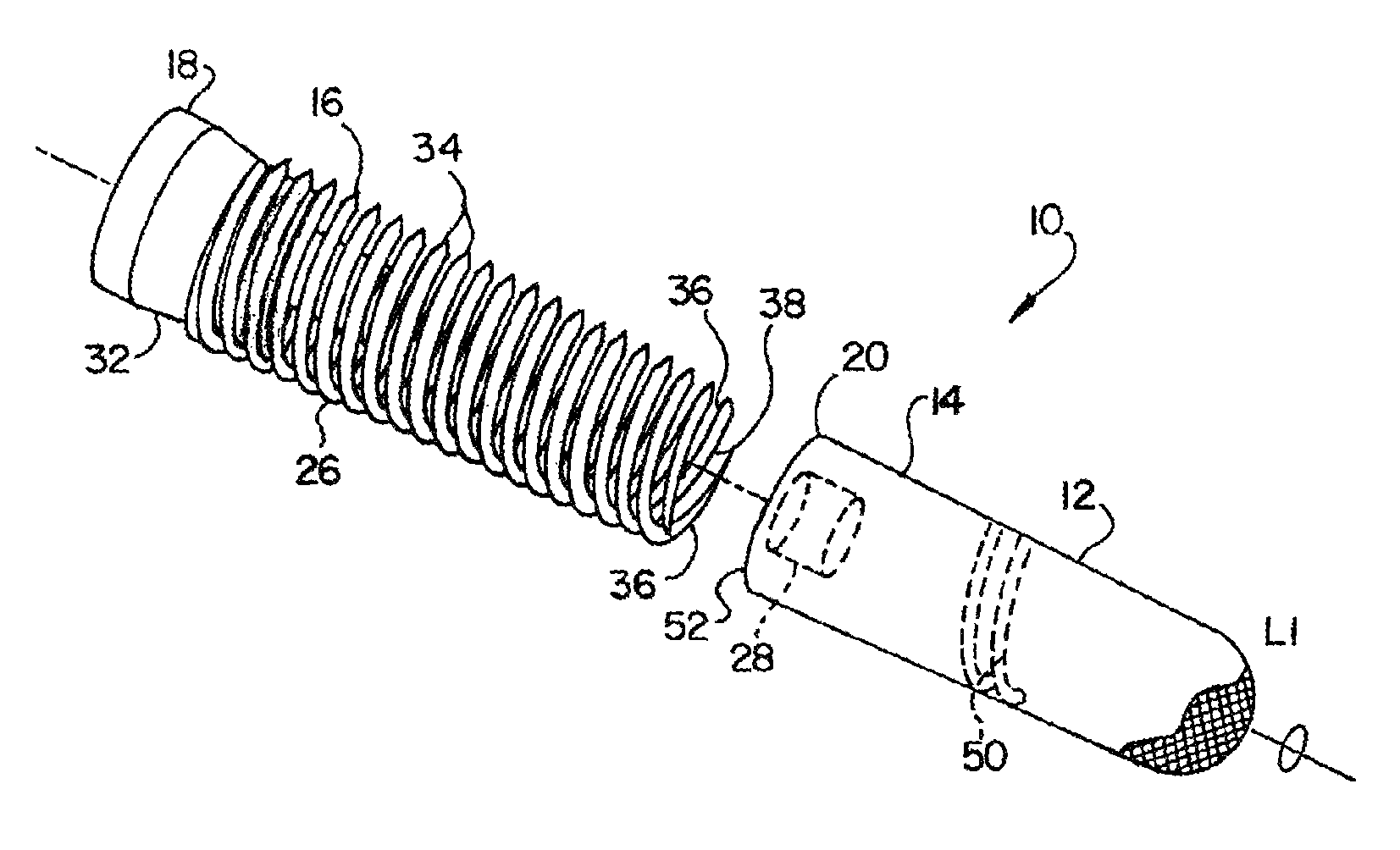

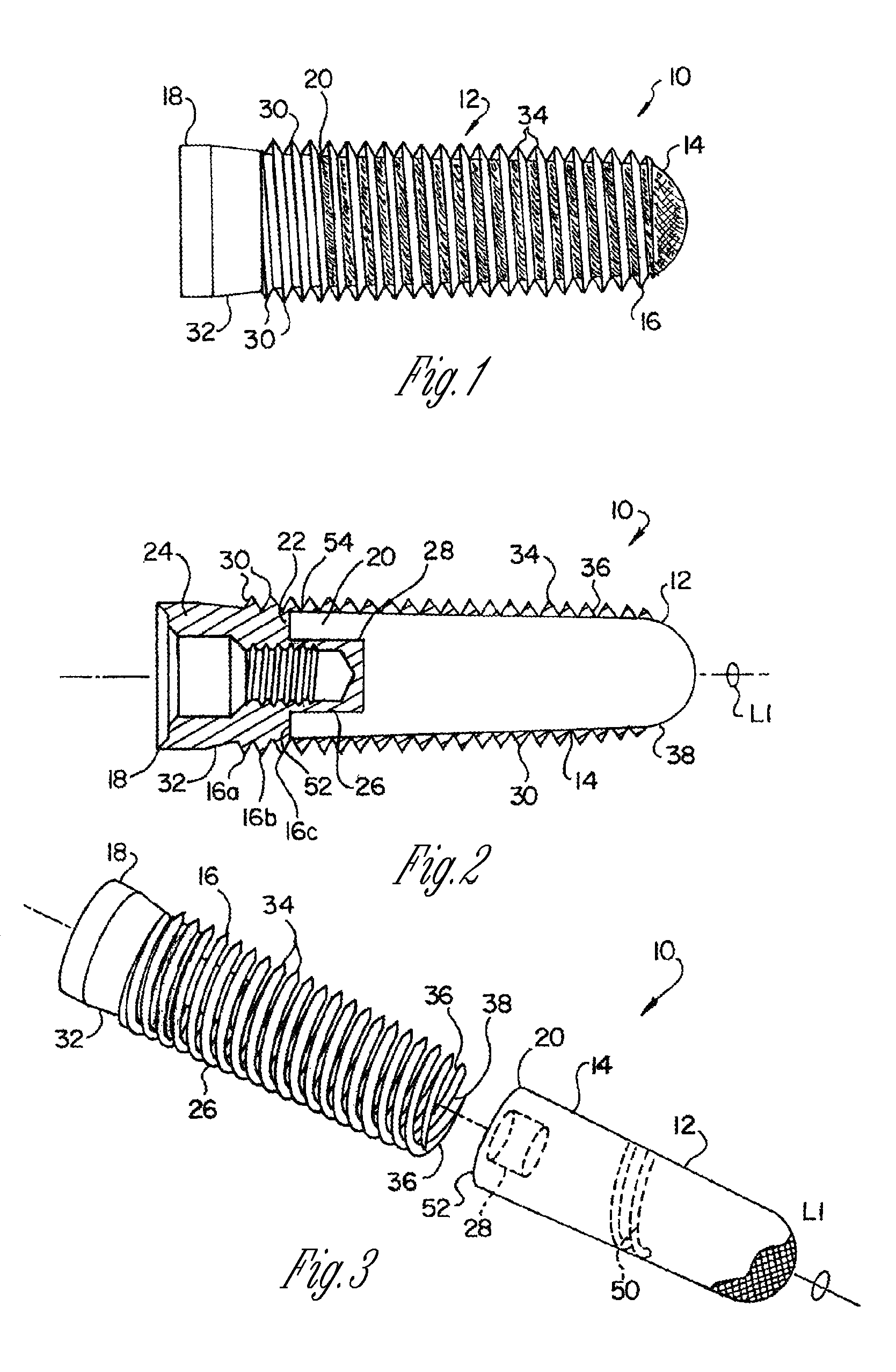

Porous implant with non-porous threads

InactiveUS20130022943A1Promote osseointegrationImprove short-term stabilityDental implantsPorous implantDental implant

A dental implant can comprise a shaft defining a longitudinal axis and having an apical end, a coronal end, and an exterior surface. A portion of the exterior surface can include a porous material. The dental implant can comprise at least one thread, including a non-porous material, having an interior surface and a bone-engaging surface. The interior surface can engage and wind around the exterior surface of the shaft and the bone-engaging surface can extend outwardly from the exterior surface of the shaft. The shaft can include one or more channels configured to communicate a flowable material, stored within the shaft, to the exterior surface. Each channel can include an opening at the exterior surface to release the flowable material. At least one channel can extend between a cavity of the shaft and the exterior surface and can optionally be angled toward the apical end.

Owner:ZIMMER DENTAL INC

Porous implant with non-porous threads

An implant which includes a shaft made of a first material and having an exterior surface, and at least one thread made of a second material different from the first material, engaging the exterior surface, and extending outwardly from the exterior surface for engaging bone. After implantation of the implant, bone tissue may osseointegrate into the porous shaft to anchor the implant within the surrounding bone. The first material may be a porous metal and include tantalum while the second material is non-porous.

Owner:ZIMMER DENTAL INC

Degradable porous implant structure

InactiveUS20080195198A1Efficient supplyFacilitate providing a stentSurgeryBlood vesselsInsertion stentPorous implant

Owner:CINVENTION AG

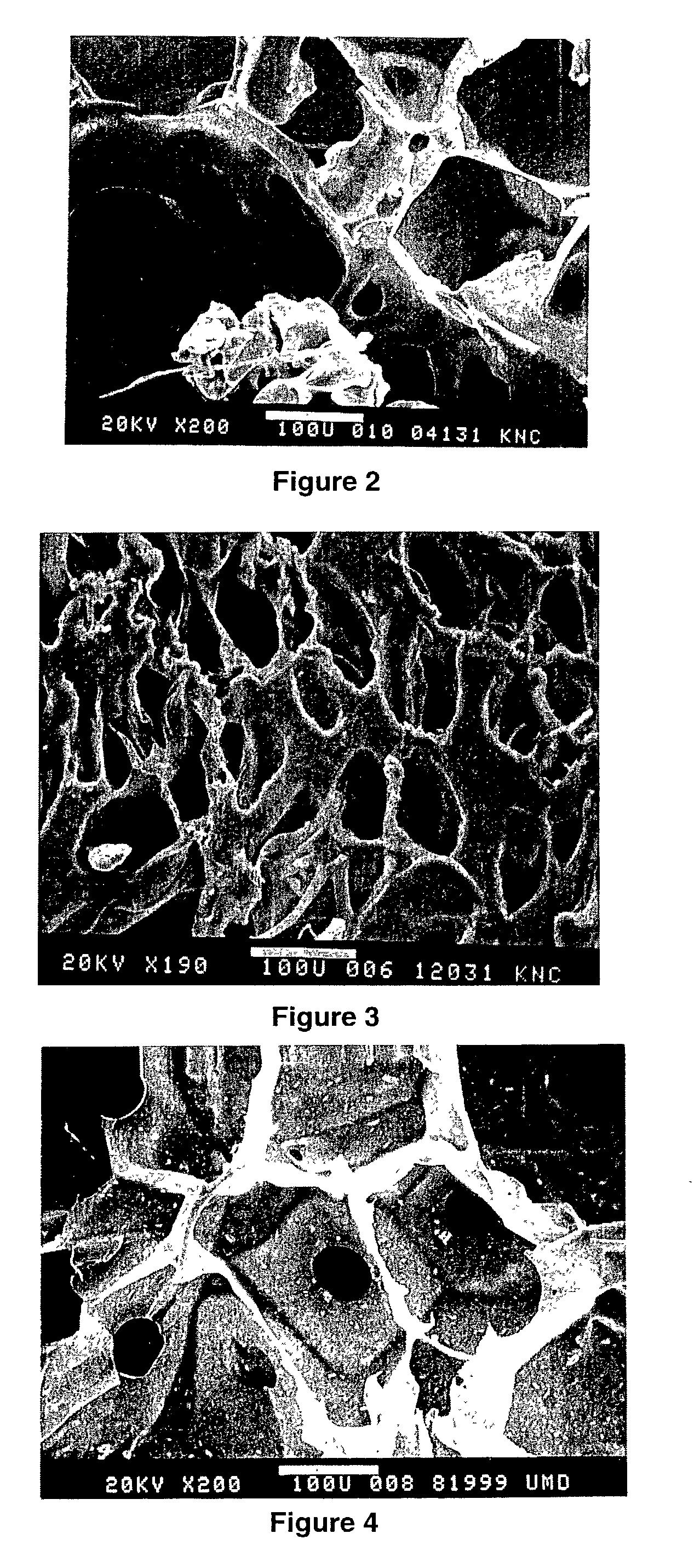

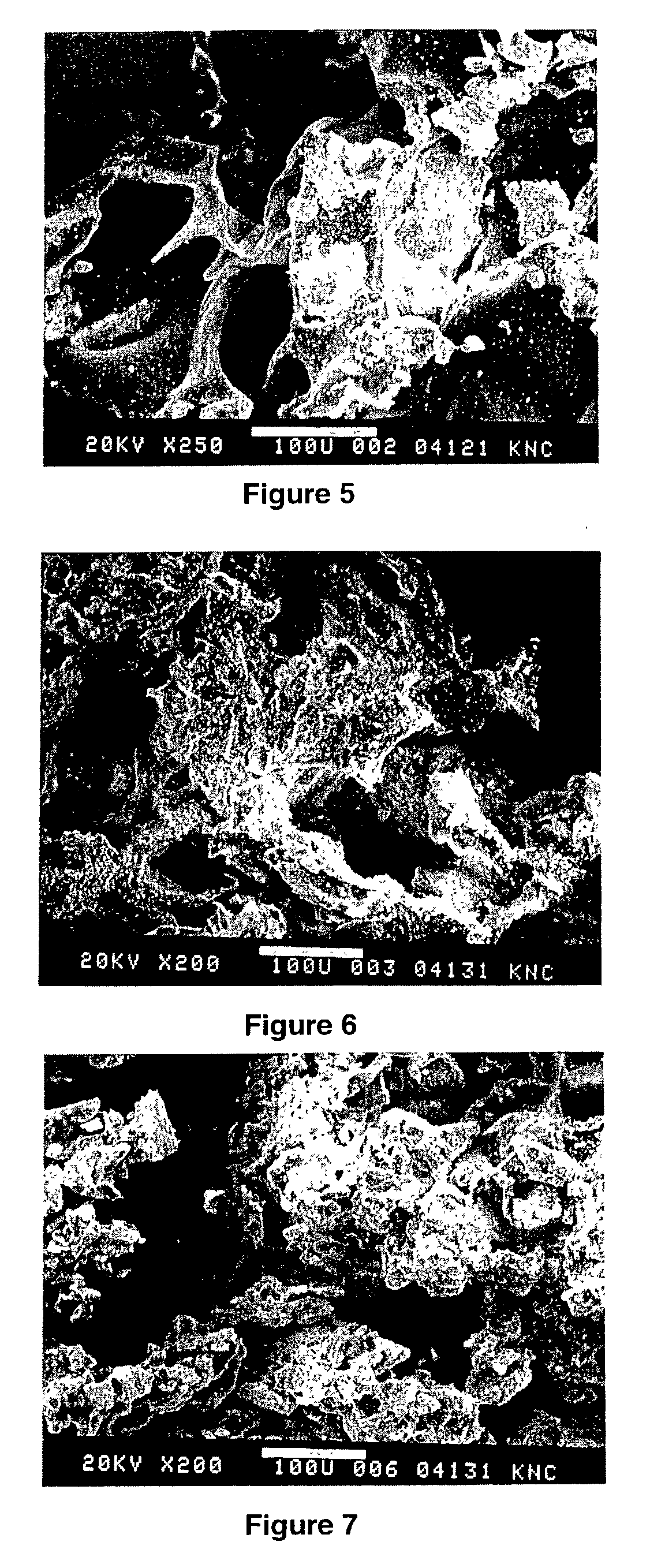

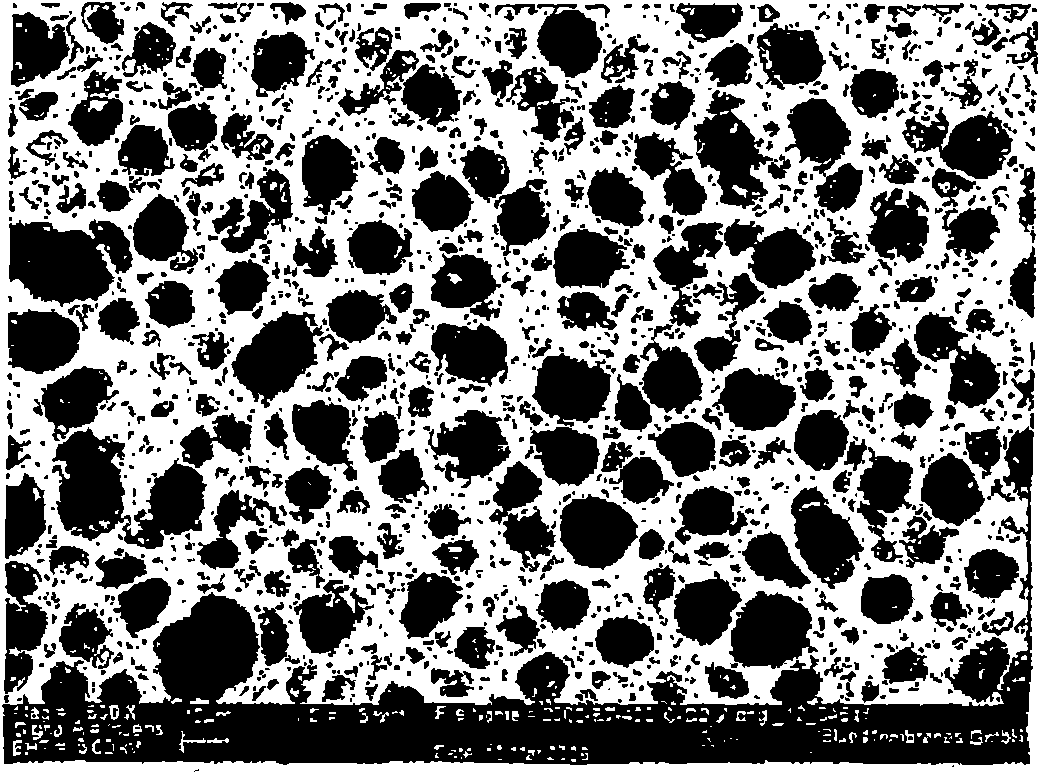

Resorbable structure for treating and healing of tissue defects

InactiveUS7049348B2Extended stayPreserve molecular weightSurgeryPharmaceutical delivery mechanismTissue defectPorous implant

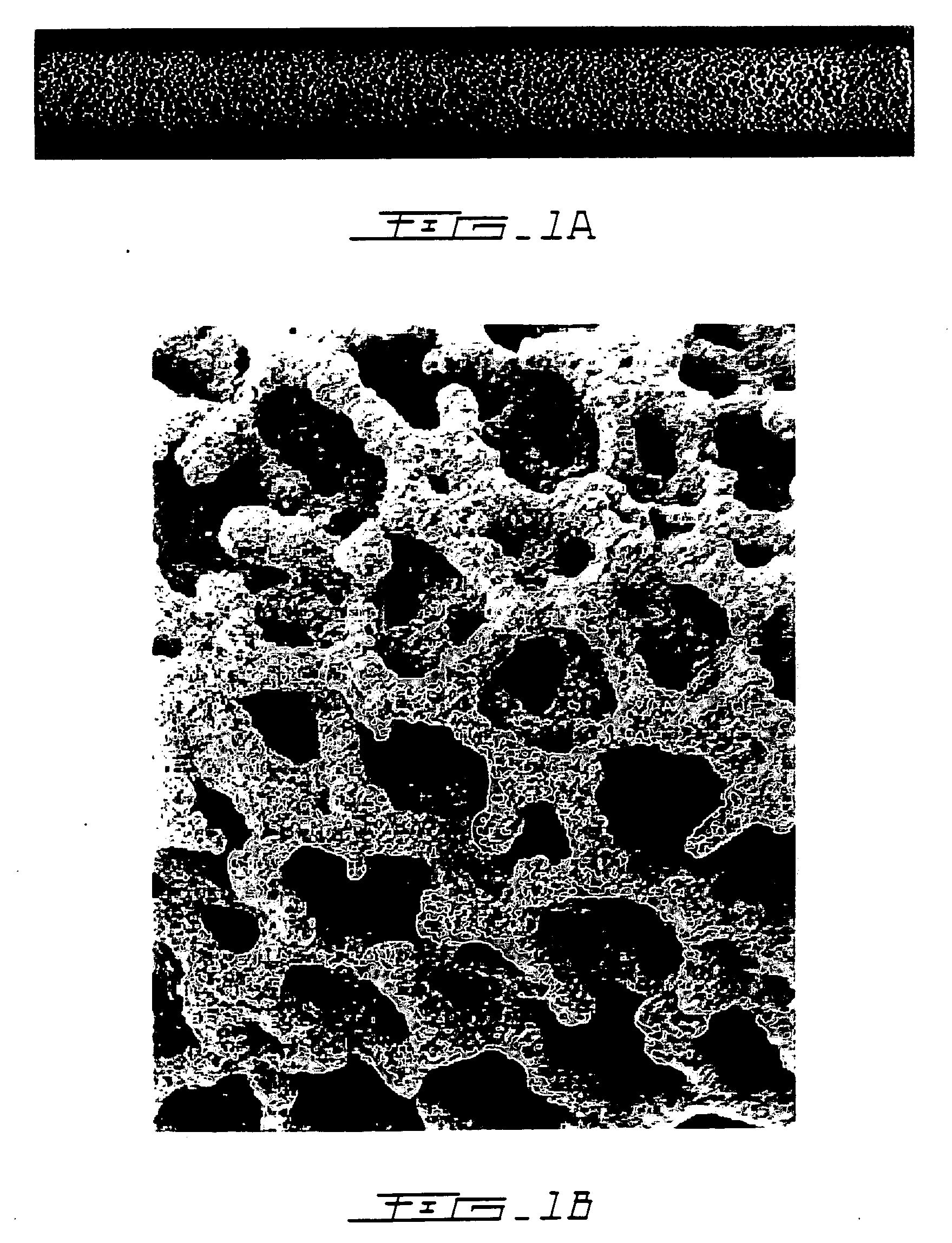

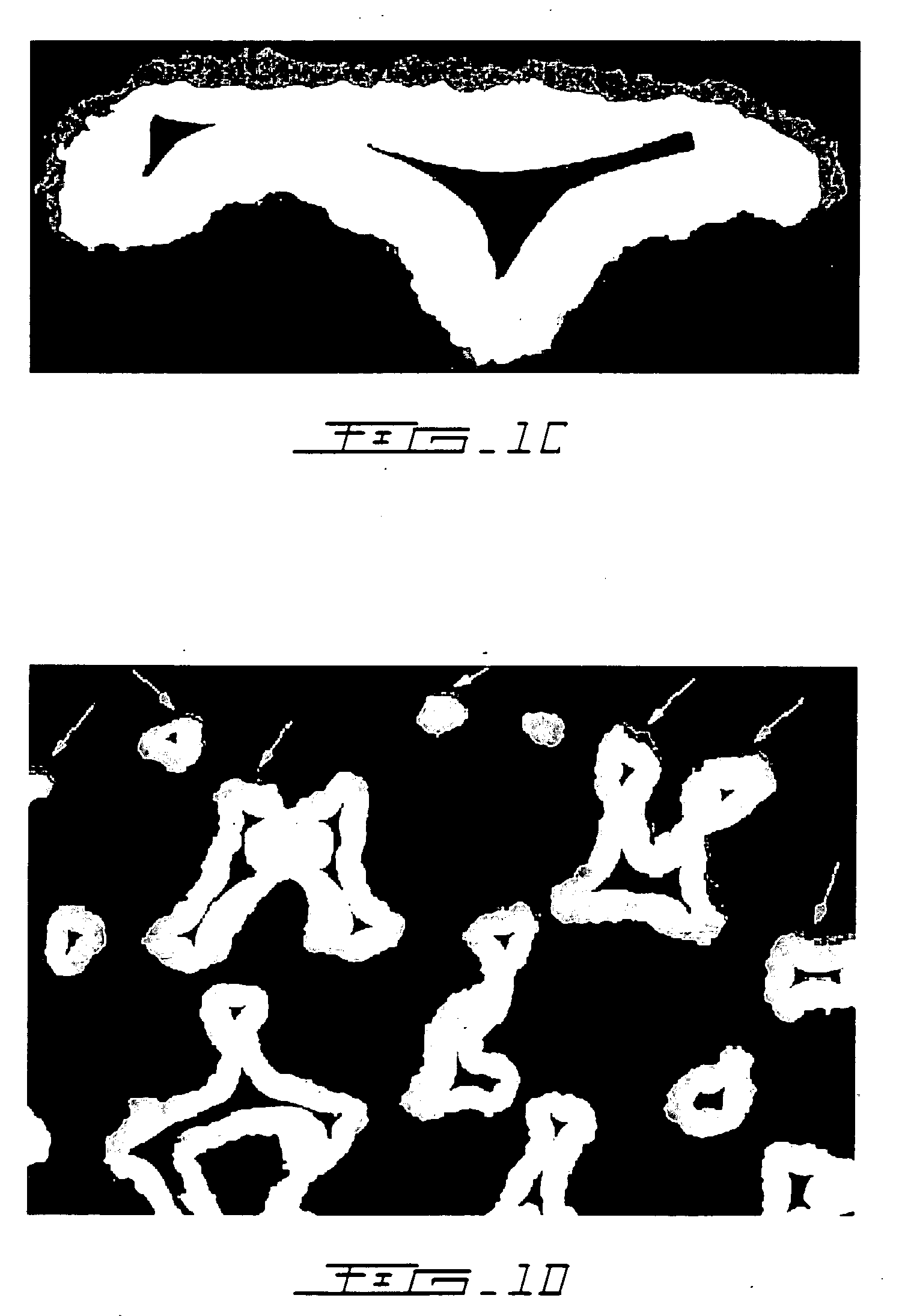

Devices and processes (e.g., improved Plasticized Melt Flow processes (PMF) or improved Phase Separation Polymer Concentration (PSPC), etc.) used to make resorbable and non-resorbable structures for treating and / or healing of tissue defects are disclosed. Among the advantages of using these improved processes are the preservation of molecular weight and the broadening of the processing conditions for temperature sensitive polymers and therapies This reduction in processing temperature, pressure and time can help to preserve the molecular weight and / or integrity of the final product or any additive incorporated therein. The present invention relates to an improved porous implant wherein the pores of the implant present a second modeling material on their surfaces. This second material provides a textured or roughened face to the internal surfaces of pores. Additionally, this second material can be incorporated in sufficient quantity to, among other things, create a microporous network connecting interior closed cell pores with the exterior of the device.

Owner:KENSEY NASH CORP

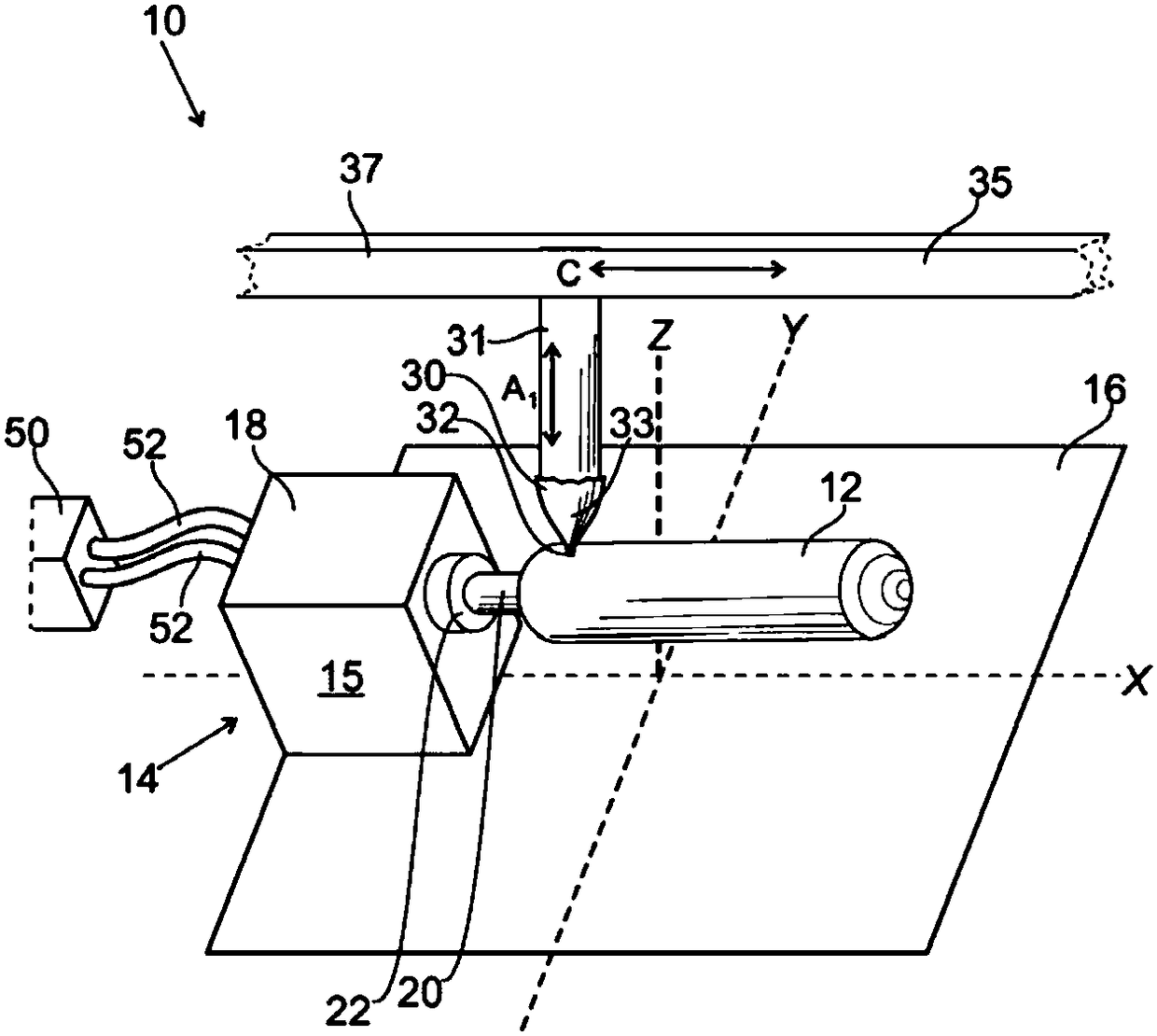

Method for preparing porous implant through gelcasting 3D printing and electroreduction

ActiveCN106421904AAchieve forming controlConvenient treatmentPharmaceutical delivery mechanismCoatingsOxide ceramicElectrolysis

The invention discloses a method for preparing a porous implant through gelcasting 3D printing and electroreduction. The preparation method comprises steps as follows: according to the human body features of a to-be-implanted part, a personalized gradient porous implant negative-type mold adopting a microstructure is designed by the aid of a medical image data reverse solution model; a gradient porous implant negative-type resin mold is prepared through photo-curing forming equipment; metal oxide ceramic slurry is injected into the negative-type resin mold through a gel injection mold and sintered at the high temperature, and a metal oxide ceramic porous scaffold is obtained; a primary porous metal implant is produced through molten salt in-situ reduction; a metal coating is deposited on the surface of the primary porous metal implant with a chemical vapor deposition method. The defects that implants with complex shapes, precise sizes and uncontrollable microstructures cannot be produced with a traditional porous implant preparation method are overcome, structure nanosizing can be realized, and a new way for preparing the porous implant is expected to be developed.

Owner:XI AN JIAOTONG UNIV

Porous implant structure

InactiveUS20090192592A1Efficient supplyFacilitate providing a stentStentsSurgeryPorous implantBiomedical engineering

Owner:CINVENTION AG

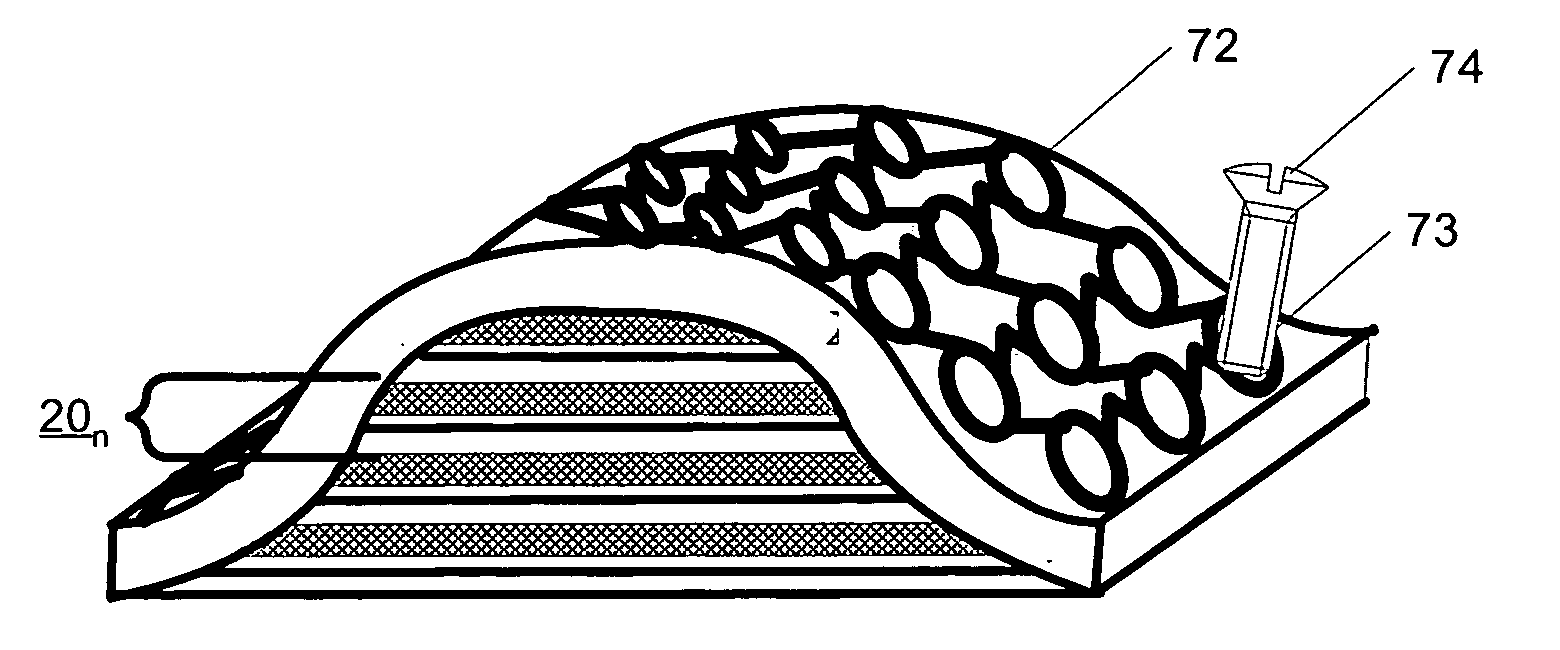

System and method for tissue generation and bone regeneration

ActiveUS8518123B2Promotes bone formationIncrease surface areaImpression capsBone implantDamages tissueSurgical site

A system and method for the repair of damaged tissue and bones, congenitally missing tissue / cosmetic reconstruction of tissue is described. The system has a layered porous structure with a sufficiently large area of exposed pores to promote neo-vascularization as well as bone and tissue formation. The disclosed porous implant system can contain bioactive agents necessary for rapid tissue formation and keep ingrowth of unwanted tissue out of the implant surgical site. The implant can be reinforced with an additional, stronger polymer layer and / or may include an endoskeleton or exoskeleton for dimensional stability.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

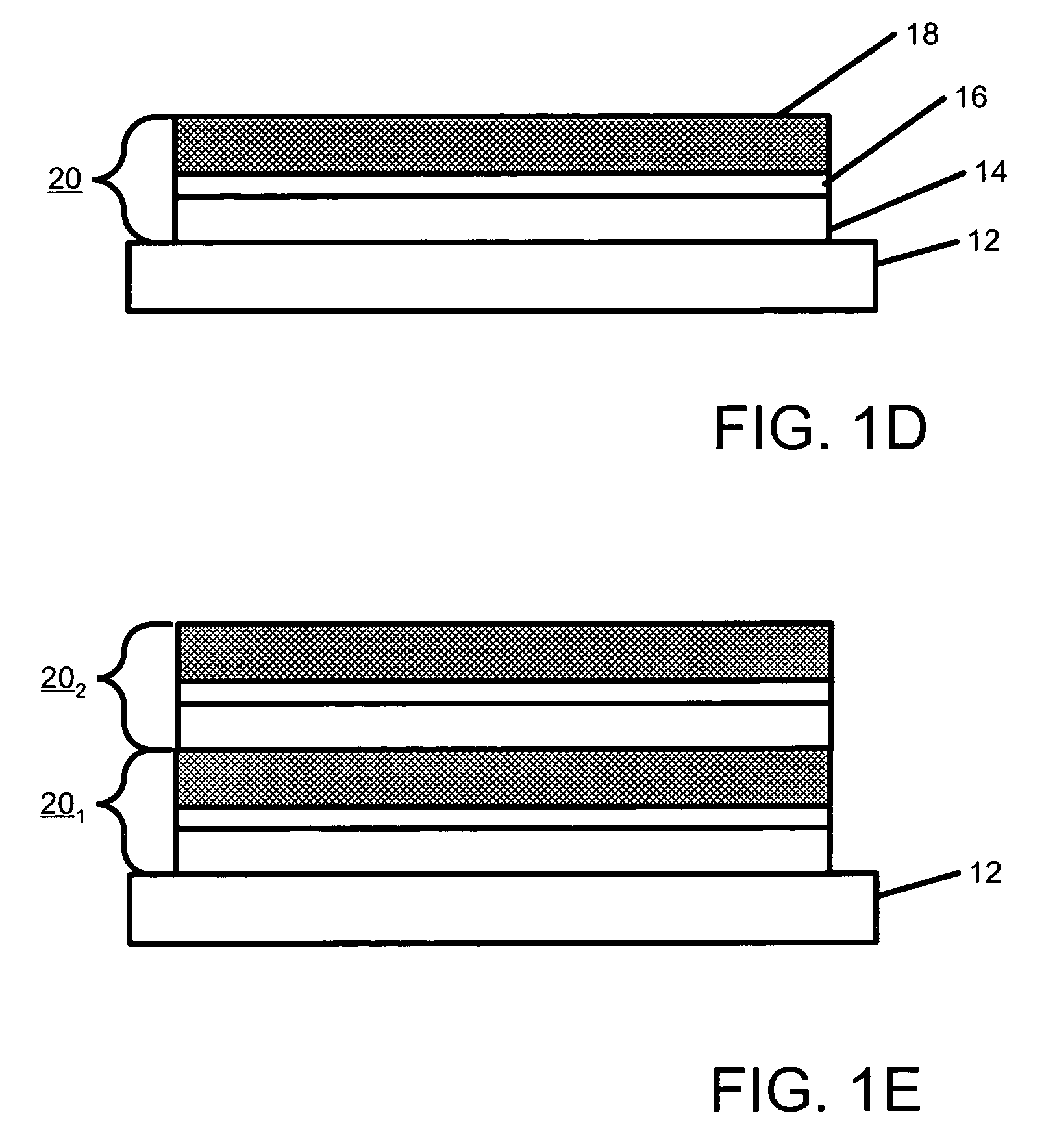

Method for preparing stainless steel biological porous implant material by selective laser sintering

The invention belongs to the field of biological medical porous metal implant materials, and provides a method for preparing a stainless steel biological porous implant material by selective laser sintering, which comprises the following steps: preparing thermoplastic polymer coated 316L stainless steel powder by a film coating method, and forming the powder by a selective laser sintering technique, thereby quickly preparing the biological medical porous metal implant material. The film coating technique mainly comprises the following steps: melting the thermoplastic polymer, coating the stainless steel powder, pulverizing, and screening the coated stainless steel powder. The method is simple and feasible; the coated 316L stainless steel powder has the advantages of favorable sintering property and high adhesive strength; and the selective laser sintering technology is utilized to form the coated stainless steel powder, and the after-treatment of degreasing and secondary sintering is combined to prepare the porous metal implant material. The microstructure and mechanical properties of the stainless steel biological porous implant material can be flexibly controlled by adjusting the technological parameters of the selective laser sintering and after-treatment, thereby achieving the goal of matching with natural bones. The technology has significant application value in the field of preparation of biological medical porous metal implant materials.

Owner:UNIV OF SCI & TECH BEIJING

3-d printing of porous implants

Computer implemented methods of producing a porous implant are provided including obtaining a 3D image of an intended tissue repair site; generating a 3D digital model of the porous implant based on the 3D image of the intended tissue repair site. The method also includes determining an implant material and an amount of a porogen to add to an implant material to obtain a desired porosity of the porous implant. The desired porosity is based on a combination of macropores, micropores and / or nanopores structures. The 3D digital model developed is stored on a database coupled to a processor, wherein the processor has instructions for combining the implant material with the porogen based on the stored 3D digital model and for instructing a 3D printer to produce the porous implant. A layered 3Dprinted porous implant prepared by the computer implemented method is also provided.

Owner:WARSAW ORTHOPEDIC INC

Porous implant structures

ActiveUS20170056178A1High porosityHigh strengthAdditive manufacturing apparatusSurgical adhesivesReticular formationPorous implant

Porous biocompatible structures suitable for use as medical implants and methods for fabricating such structures are disclosed. The disclosed structures may be fabricated using rapid manufacturing techniques. The disclosed porous structures have a plurality of struts and nodes where no more than two struts intersect one another to form a node. Further, the nodes can be straight, curved, portions that are curved and / or portions that are straight. The struts and nodes can form cells which can be fused or sintered to at least one other cell to form a continuous reticulated structure for improved strength while providing the porosity needed for tissue and cell in-growth.

Owner:SMITH & NEPHEW INC

Porous, non-degradable implant made by powder molding

The present invention is directed to porous implants and methods for the manufacture thereof which use powder molding techniques. Specifically, the methods include the steps of providing a suspensioncomprising a plurality of first particles of at least one organic polymer; a plurality of second particles of at least one metal-based material; and at least one solvent; wherein the first and secondparticles are substantially insoluble in the solvent; molding the suspension to form a green body comprising the first particles embedded in a matrix of compressed second particles; removing the firstparticles from the green body by thermally induced decomposition and / or evaporation; and sintering the green body to form the implant; wherein the step of removing the first particles is performed during sintering.

Owner:CINVENTION AG

Porous implant with non-porous threads

Owner:ZIMMER DENTAL INC

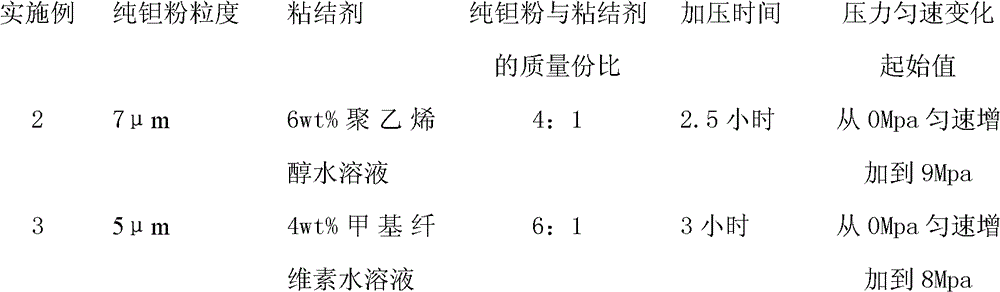

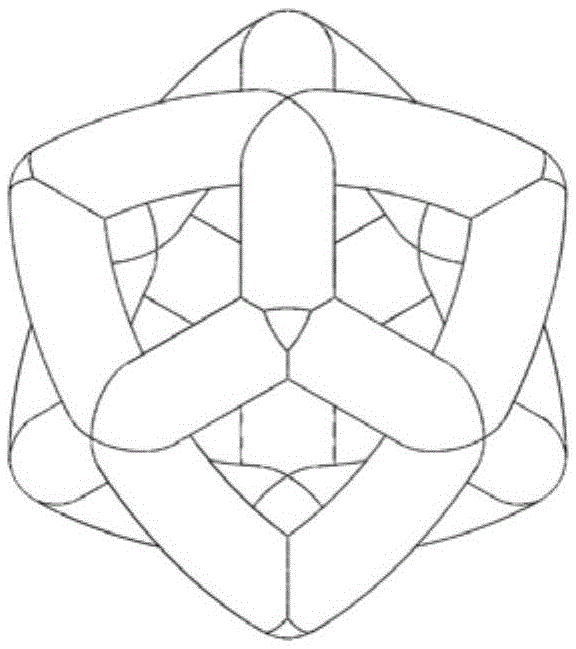

Method for preparing biological medical porous implant material

ActiveCN102796907AReduce sintering deformationStrong mechanical propertiesTransportation and packagingMetal-working apparatusBiocompatibility TestingSlurry

The invention discloses a method for preparing a porous tantalum biological medical implant material. The method comprises the following steps of: uniformly mixing pure tantalum powder and a binding agent to obtain tantalum powder slurry; placing a high polymer resin template support which has the porosity of 20 to 50 percent and of which pores are completely communicated in a three-dimensional way in a steel die; pouring the prepared tantalum powder into the steel die until the high polymer resin template support is immersed; slowly and uniformly applying pressure to the periphery of the steel die to ensure that the tantalum powder can be fully and completely filled into the high polymer resin template support, wherein the applied pressure is increased from 0 Mpa to10 Mpa at constant speed, and the time required by the pressure application process is 2 to 5 hours; performing chemical dissolution to remove the high polymer resin template support to obtain a green body framework of porous tantalum; and performing aftertreatment such as degreasing, sintering and the like to obtain the biological medical porous tantalum implant material. A product prepared by the method is a green body of the porous metal material of which pores are completely communicated in the three-dimensional way, and the green body is sintered to form the porous metal implant material of which the pores are completely communicated in the three-dimensional way, so that the porous metal implant material is high in biocompatibility.

Owner:CHONGQING RUNZE PHARM CO LTD

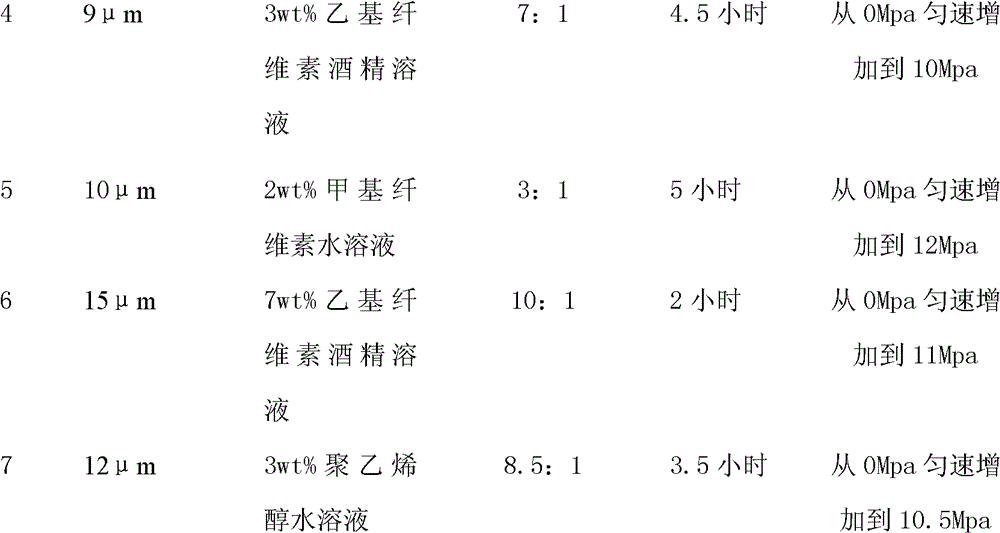

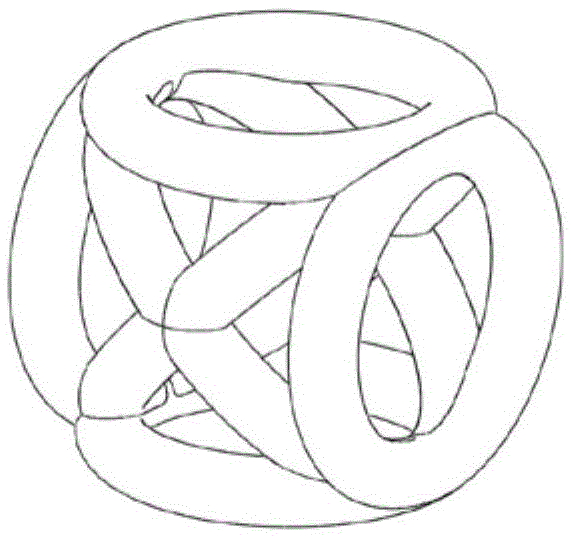

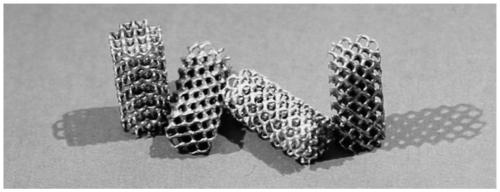

Preparation method of porous implant filled with O-intersecting lines units

InactiveCN105559947AThe preparation method is reliable and feasibleGreat potentialJoint implantsFemoral headsSand blastingPorous implant

The invention provides a preparation method of a porous implant filled with O-intersecting lines units. The preparation method comprises the following steps: drawing a three-dimensional model of the O-intersecting lines units, controlling the bore diameter, wall thickness and porosity of the three-dimensional model according to the given specific dimension so as to generate a unit structure cell body, carrying out array copying operation on the unit structure cell body, thus obtaining a space porous network body, introducing in a femoral three-dimensional surface model, scaling the model to reach the proportion actually needed, carrying out cutting and Boolean operation on the porous network body and the femoral three-dimensional surface, thus obtaining a porous main body part, drawing the femoral steam end and a bolt positioning hole part by utilizing three-dimensional modeling, combing the porous main body part to enable the porous main body part to form a single-output porous implant body, saving the single-output porous implant body into an output format file and transmitting the file to layering software, adding with a bottom surface support, printing the porous implant body by adopting a 3D printer, clearing a substrate plate, taking out the porous implant, carrying out sand blasting treatment on the porous implant, and packaging the porous implant. With the adoption of the preparation method, units which are regular and uniform and having no closure can be generated, and the stressing uniformity is guaranteed.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

Porous implant structures

ActiveUS20120232654A1High porosityHigh strengthAdditive manufacturing apparatusSurgical adhesivesNODALManufacturing technology

Porous biocompatible structures suitable for use as medical implants and methods for fabricating such structures are disclosed. The disclosed structures may be fabricated using rapid manufacturing techniques. The disclosed porous structures has a plurality of struts and nodes where no more than two struts intersect one another to form a node. Further, the nodes can be straight, curved, portions that are curved and / or straight. The struts and nodes can form cells which can be fused or sintered to at least one other cell to form a continuous reticulated structure for improved strength while providing the porosity needed for tissue and cell in-growth.

Owner:SMITH & NEPHEW INC

Porous implant filled with O-intersecting lines units

InactiveCN105496611AThe preparation method is reliable and feasibleGreat potentialJoint implantsTissue regenerationBone structureTissue fluid

A porous implant filled with O-intersecting lines units is mainly oriented to femoral stems and comprises a femoral stem end, a porous main body part and a screw positioning hole part, wherein the femoral stem end is used for positioning the porous implant, the screw positioning hole part is used for fixing the implant and a host, the porous main body part is a three-dimensional through porous network entity mainly formed by being filled with the O-intersecting lines units, the porous network entity comprises hollowed-out entities formed by scanning of O-intersecting lines unit cylinders penetrating through and crossing with one another in space, the hollowed-out entities are formed by pairwise perpendicular and linearly stacked O-intersecting lines unit cylinder surfaces, and the porous network entity has the pore diameter ranging from 400 mu m to 1,000 mu m, the unit wall thickness ranging from 80 mu m to 120 mu m and the porosity ranging from 55% to 85%. Thus, a porous network structure formed by stacking of the hollowed-out entities is close to a bone structure, has the high porosity, the high communication ratio and the larger surface contact area, is suitable for new bone ingrowth and circulation of nutrition tissue liquids and has the considerable clinical medical prospect.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

Porous implants and stents as controlled release drug delivery carriers

InactiveUS20110027339A1Improve efficiencyEffective treatmentOrganic active ingredientsBiocidePorous implantBone ingrowth

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

Porous implant with non-porous threads

InactiveUS9095396B2Promote osseointegrationImprove long-term stabilityDental implantsPorous implantDental implant

Owner:ZIMMER DENTAL INC

Preparation method of porous magnesium rare earth alloy implant based on laser selective melting (SLM) additive manufacturing technology

ActiveCN110394447AHigh strengthHigh modulusAdditive manufacturing apparatusIncreasing energy efficiencyManufacturing technologyRare earth

The invention provides a preparation method of a porous magnesium rare earth alloy implant based on a laser selective melting (SLM) additive manufacturing technology. The method comprises the following steps that 1, components of magnesium rare earth alloy powder are selected; 2, the magnesium rare earth alloy powder is preheated; 3, a substrate is preheated; 4, a three-dimensional model of the porous magnesium rare earth alloy implant is drawn; 5, a porous magnesium rare earth alloy implant entity is stored into an output format file in an STL format and transmitted to layering software, a bottom surface support is added, and slicing treatment is carried out; 6, the porous magnesium rare earth alloy implant entity is printed; 7, the porous magnesium rare earth alloy implant molding pieceand the substrate are cut and separated; and 8, electrochemical polishing treatment is carried out. The porous implant prepared by the method has uniform hole wall thickness, no crack defect and highoverall strength and modulus; and the porous implant prepared by the method is better matched with the strength and modulus of human bones.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing individualized porous implant through selective laser formation and electrolytic reduction

ActiveCN106390198AAchieve forming controlConvenient treatmentCoatingsProsthesisOxide ceramicSelective laser melting

The invention provides a method for preparing an individualized porous implant through selective laser formation and electrolytic reduction. The method comprises the following steps: according to human body characteristics of a part needing an implant, carrying out individualized porous implant design with a microstructure through utilizing a medical image data reverse model; preparing a metal oxide ceramic porous implant with a microstructure through utilizing a selective laser melting / sintering additive manufacturing method; carrying out the electrolytic reduction on molten chloride melt to obtain a primary porous metal implant with a nanostructure, and sintering at a high temperature; depositing the same metal coating on the surface of the primary porous metal implant by utilizing a chemical vapor deposition method. By adopting the method provided by the invention, the disadvantages of a traditional porous implant preparation method that the microstructure cannot be controlled and the difficulty of direct laser additive manufacturing is great are overcome; structure nano-crystallization can be realized, a new way for preparing the porous implant is hopefully explored; the method has an important meanning on promotion of clinical application of the porous implant.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com