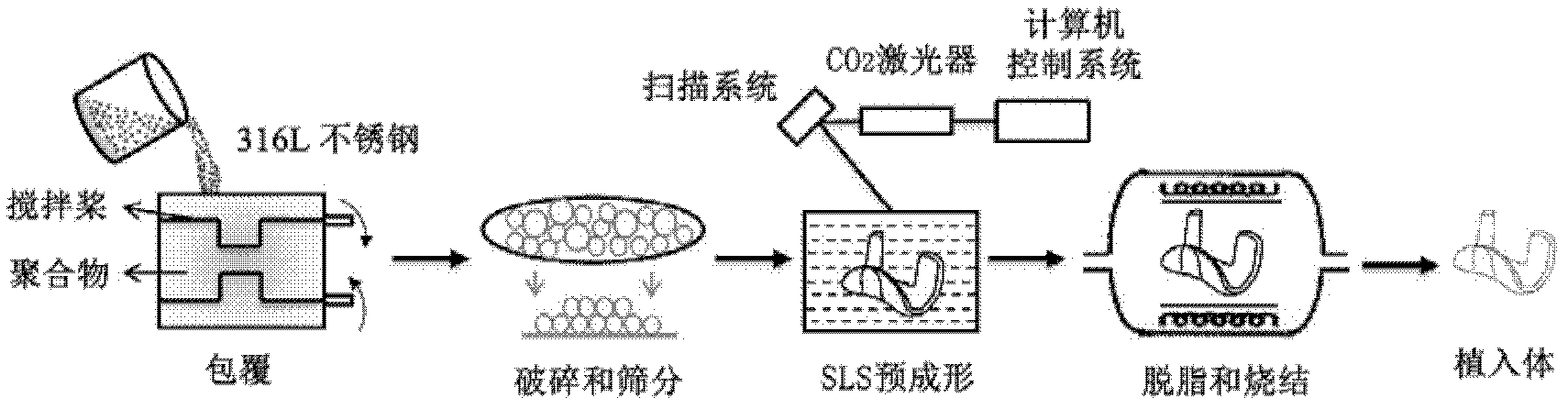

Method for preparing stainless steel biological porous implant material by selective laser sintering

A technology of implant materials and laser sintering, which is applied in the field of preparation of biomedical metal materials, achieves the effect of high forming precision, no pollution, and easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0025] (1) First weigh 500g of -200 mesh 316L stainless steel powder and 15g of high-density polyethylene powder; then add high-density polyethylene into the kneader and heat it. After it is completely melted, add 316L stainless steel powder and stir while heating 30min, so that the surface of the stainless steel particles is completely covered by high-density polyethylene; finally, through mechanical crushing and sieving to obtain -150 mesh coated 316L stainless steel powder;

[0026] (2) Firstly, CAD software is used to construct the three-dimensional structure of the implanted material, and after being sliced, it is transported to the SLS forming machine in STL format; then, the coated 316L stainless steel powder is laid on the workbench of the SLS forming machine, and heated by a laser Preheat to 60°C for 2 minutes, and then according to the slice information, the laser performs selective sintering on the powder bed with the process parameters of 15W laser power, 0.10mm sca...

Embodiment approach 2

[0030](1) First weigh 500g of -250mesh 316L stainless steel powder and 35g of polystyrene powder; then add polystyrene into the kneader and heat it. After it is completely melted, add 316L stainless steel powder and stir for 50 minutes while heating. The surface of the stainless steel particles is completely covered by polystyrene; finally, the -180 mesh coated 316L stainless steel powder is obtained by mechanical crushing and sieving;

[0031] (2) Firstly, CAD software is used to construct the three-dimensional structure of the implanted material, and after being sliced, it is transported to the SLS forming machine in STL format; then, the coated 316L stainless steel powder is laid on the workbench of the SLS forming machine, and heated by a laser Preheat to 90°C for 8 minutes, and then according to the slice information, the laser performs selective sintering on the powder bed with the process parameters of 25W laser power, 0.20mm scanning distance, 0.20mm slice thickness and...

Embodiment approach 3

[0035] (1) First weigh 500g of -400mesh 316L stainless steel powder and 25g of polyamide powder; then add polyethylene into the kneader and heat it. After it is completely melted, add 316L stainless steel powder and stir for 40 minutes while heating to make the stainless steel The surface of the particles is completely covered by polyethylene; finally, the -270 mesh coated 316L stainless steel powder is obtained through mechanical crushing and sieving;

[0036] (2) Firstly, CAD software is used to construct the three-dimensional structure of the implanted material, and after being sliced, it is transported to the SLS forming machine in STL format; then, the coated 316L stainless steel powder is laid on the workbench of the SLS forming machine, and heated by a laser Preheat to 70°C for 5 minutes, and then according to the slice information, the laser performs selective sintering on the powder bed with the process parameters of 30W laser power, 0.15mm scanning distance, 0.15mm sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com