Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

235 results about "Metal implant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The most commonly implanted metals used in orthopedic implants are cobalt/chrome, stainless steel, and titanium. All orthopedic implants are alloys, meaning they have several different metals in the implant. The base metal(s) are found in the highest quantities, but smaller amounts of other metals are also found in the implant.

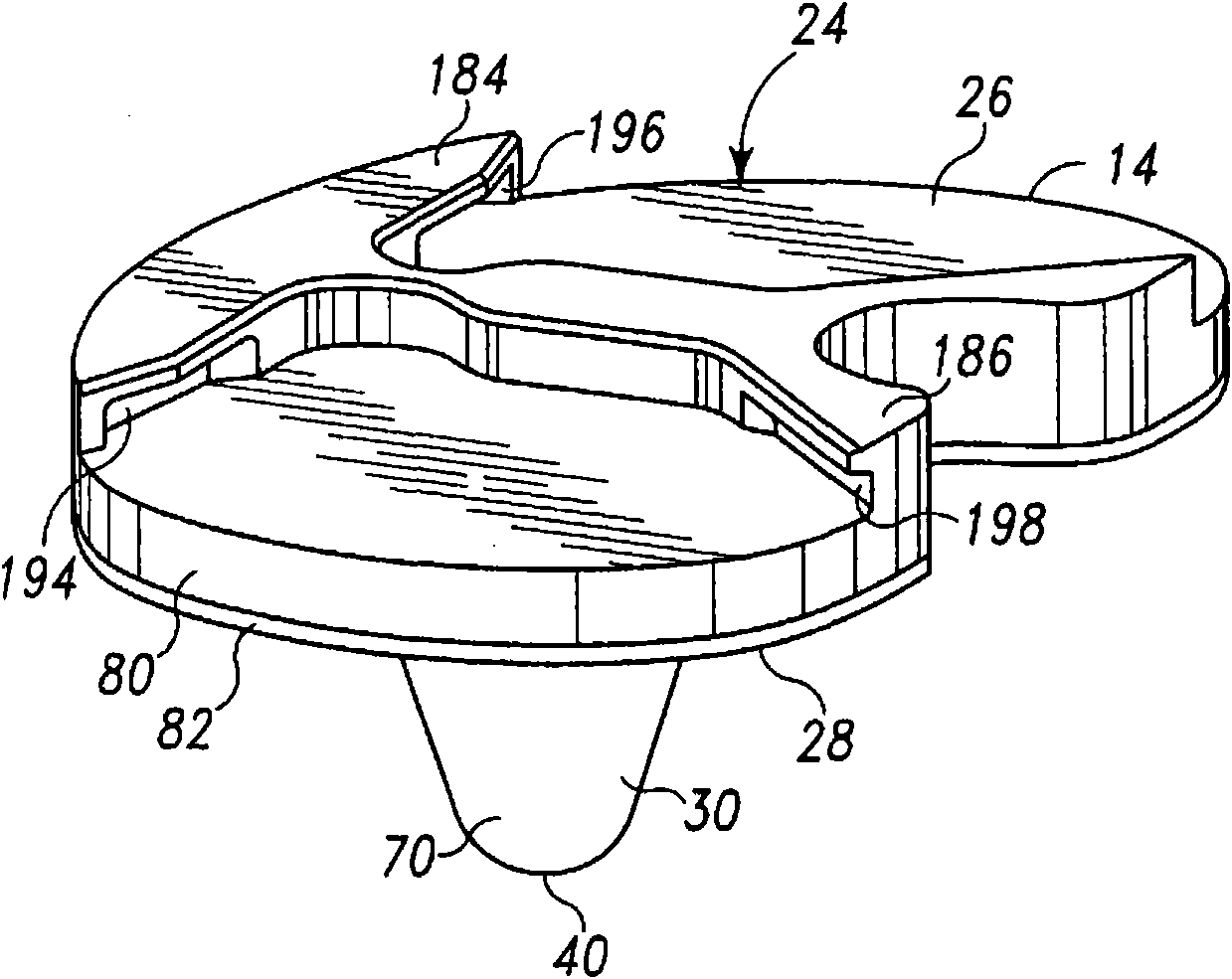

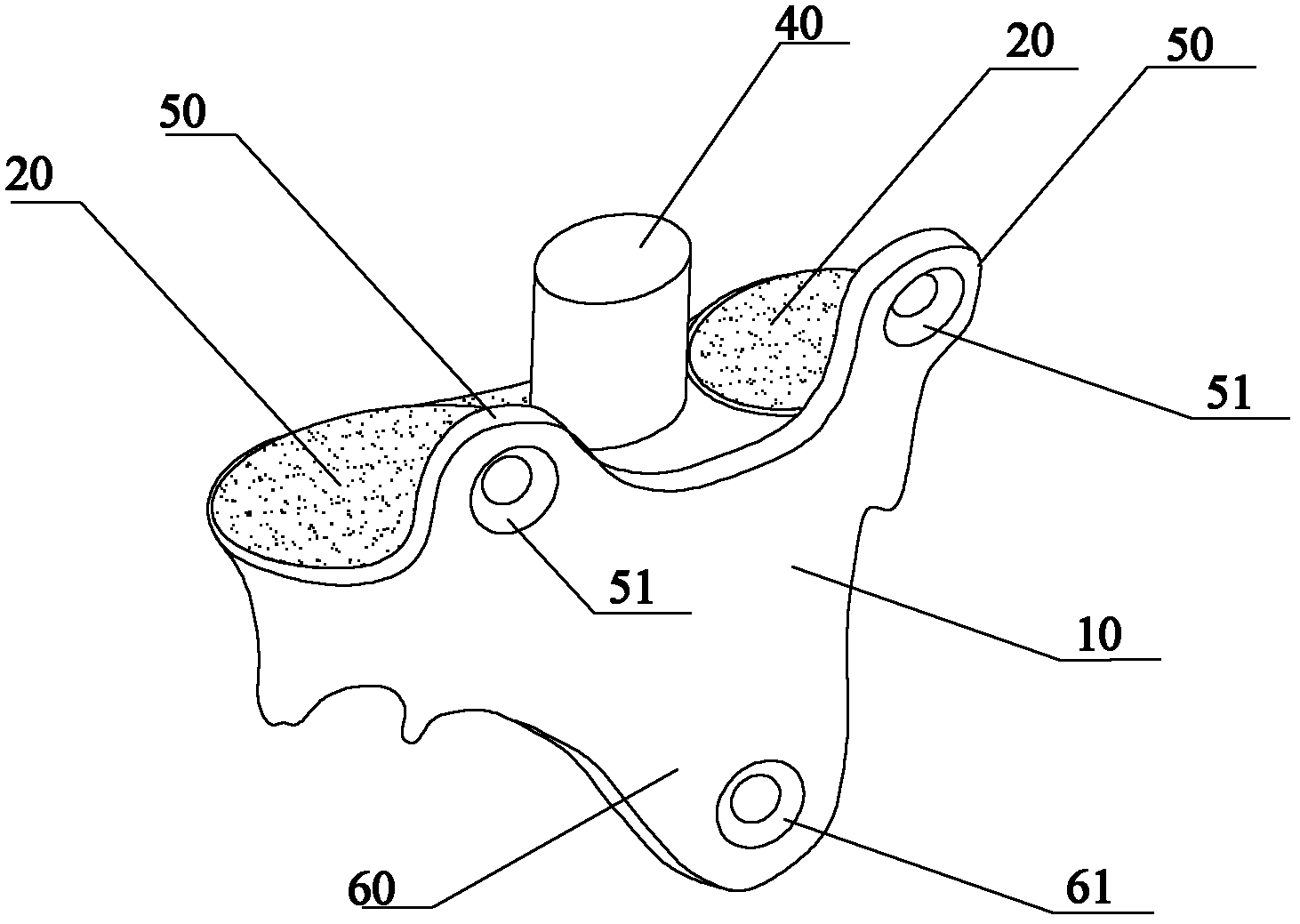

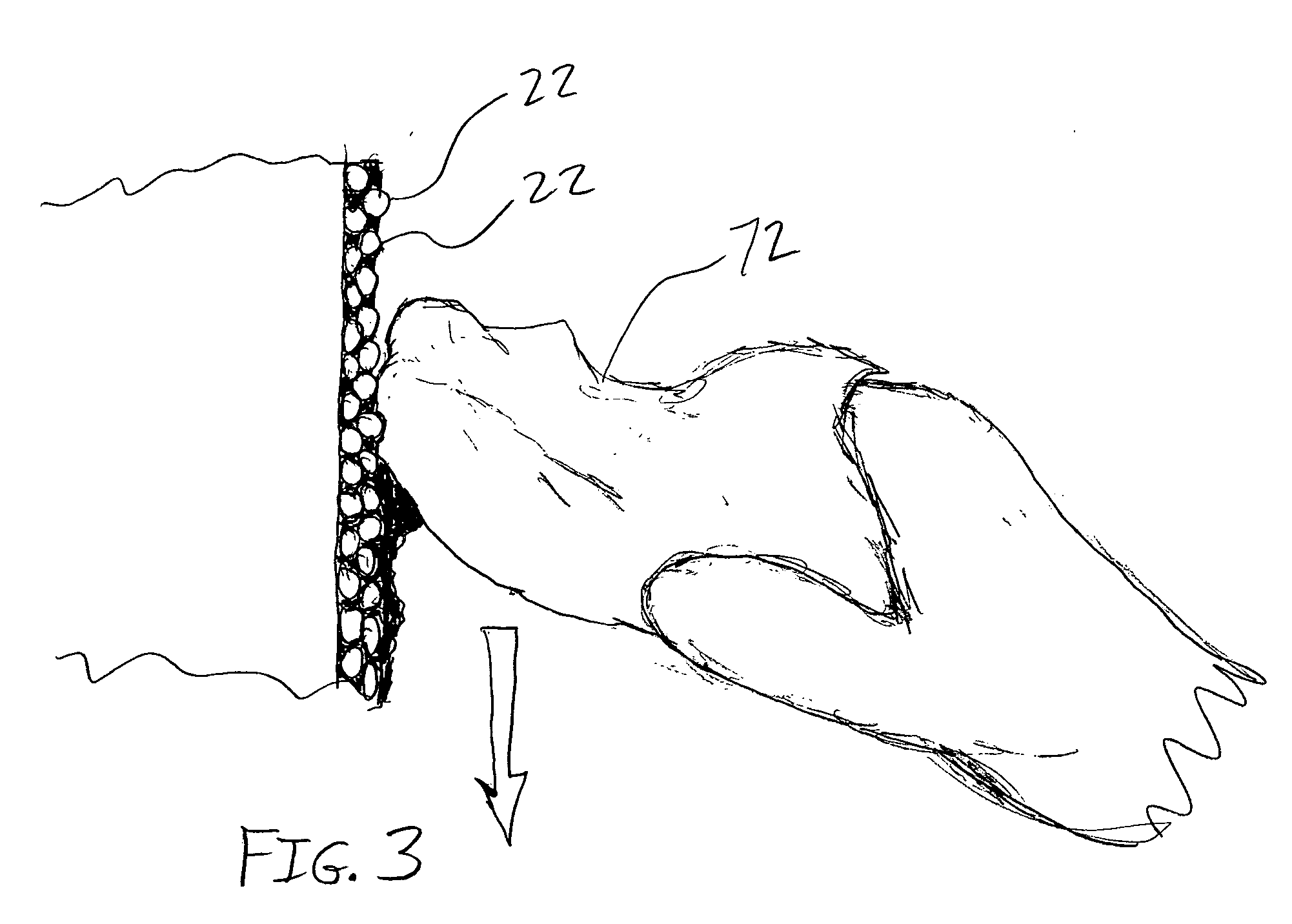

System and method for attaching soft tissue to an implant

ActiveUS20060105015A1Firmly connectedIncreased pull-out strengthAnodisationBiocideCell-Extracellular MatrixProsthesis

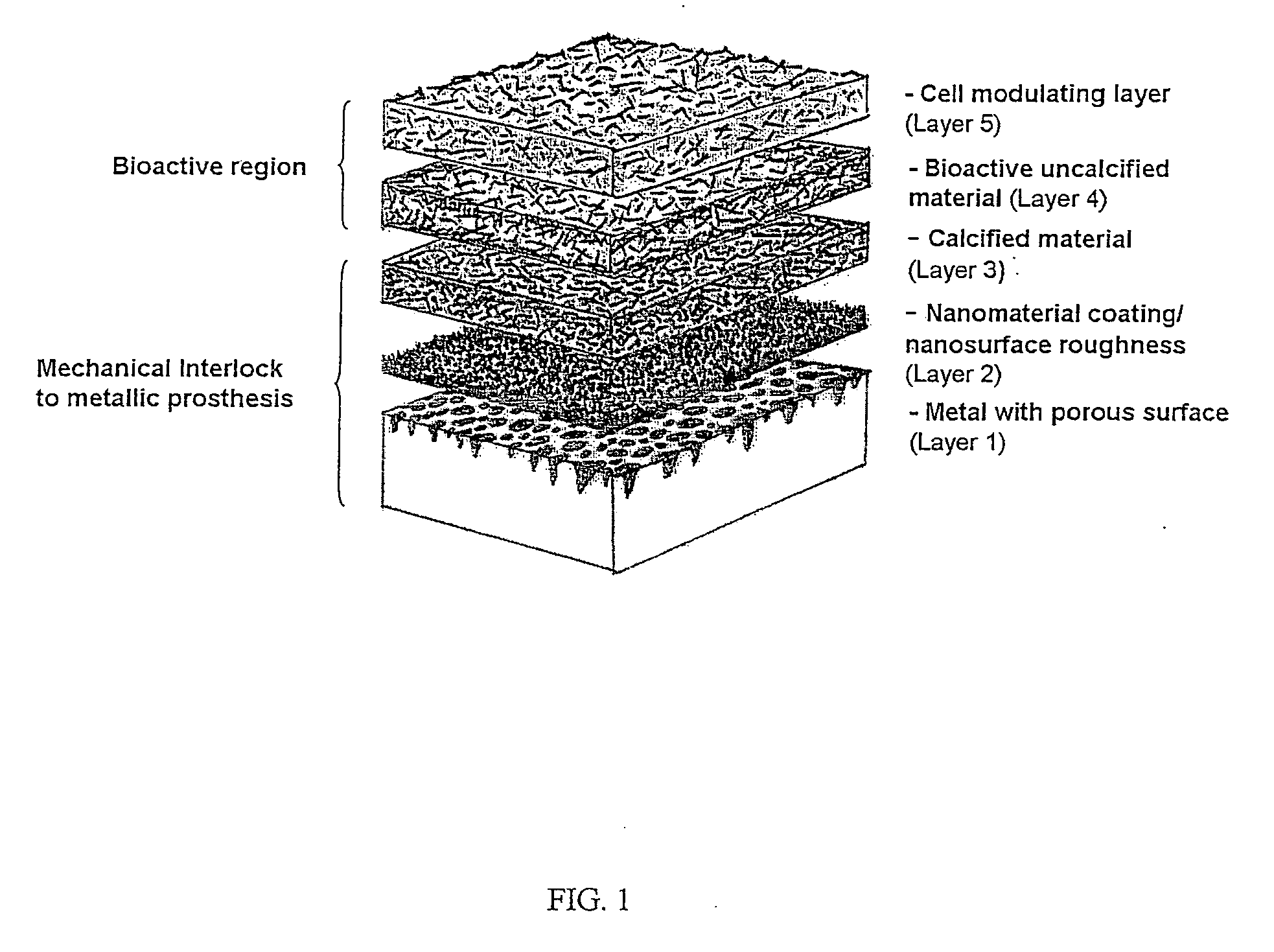

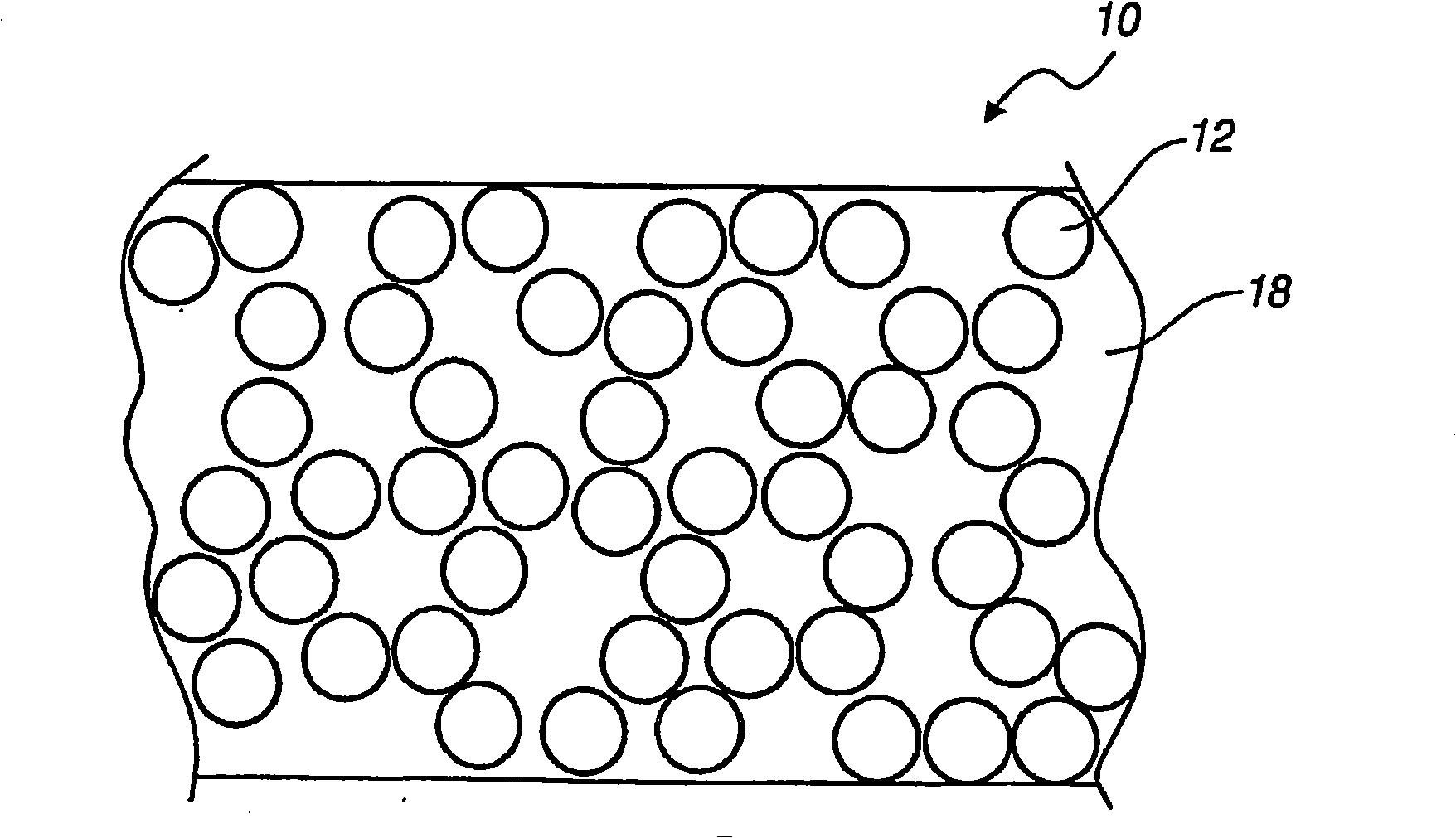

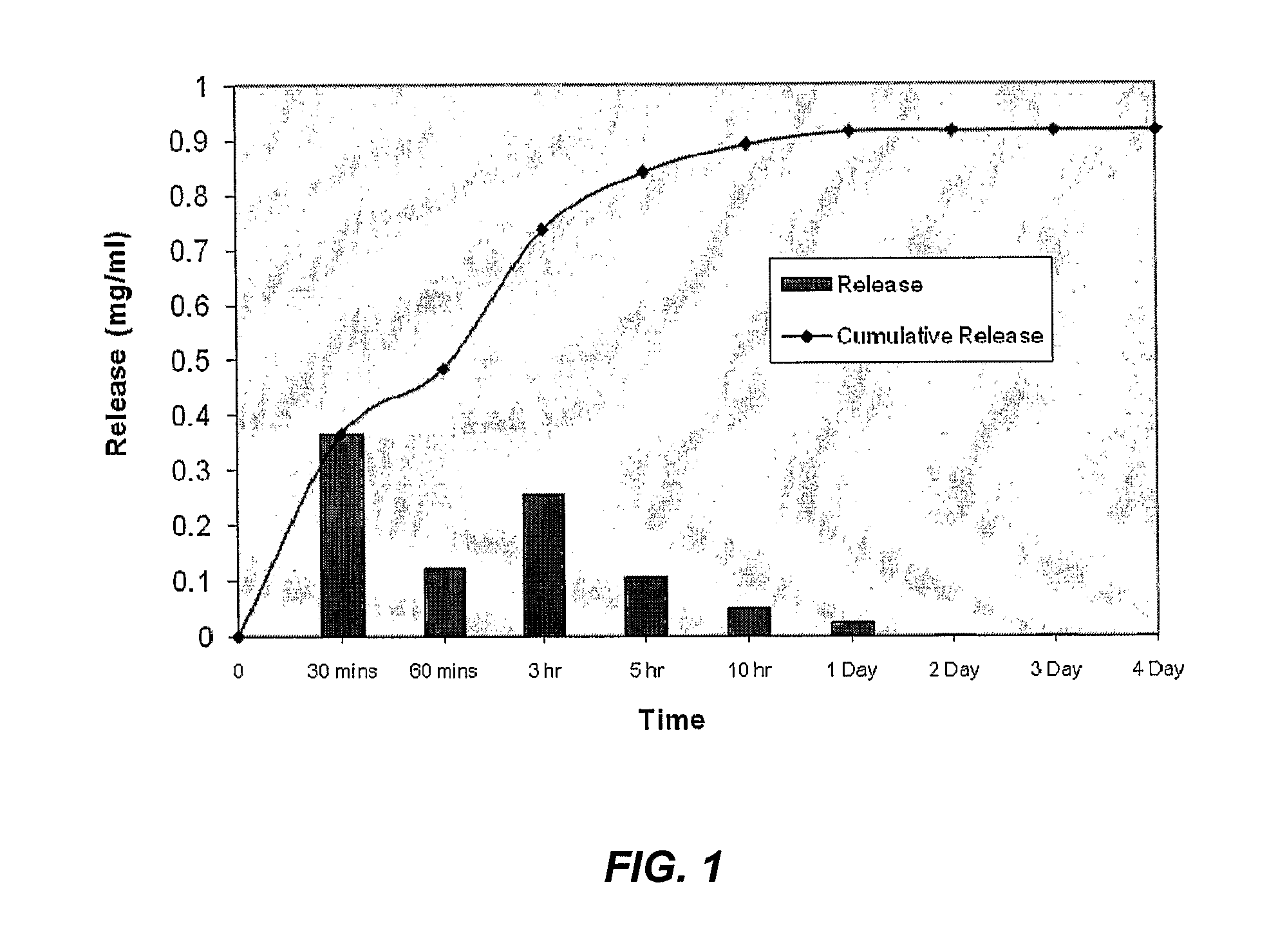

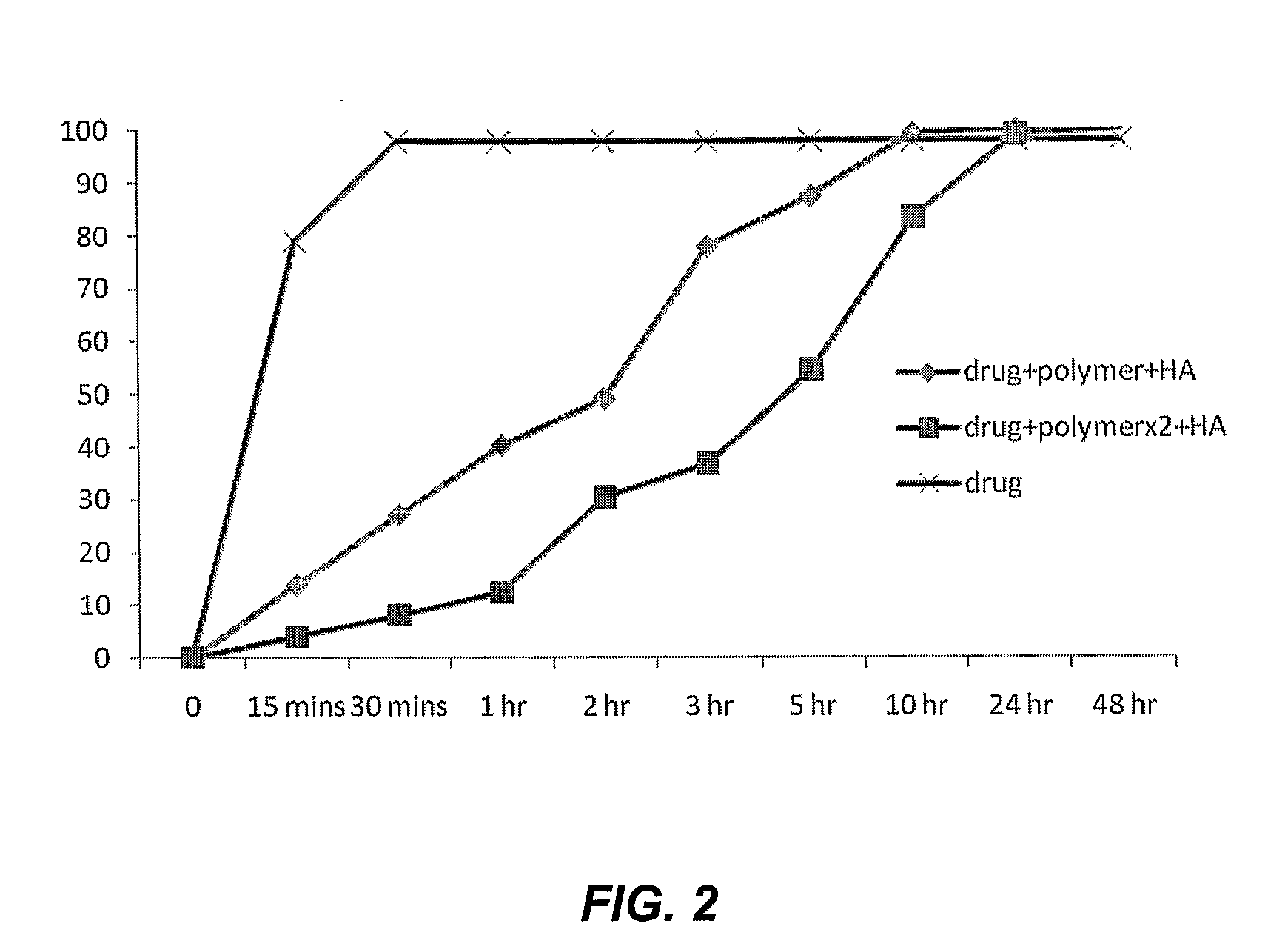

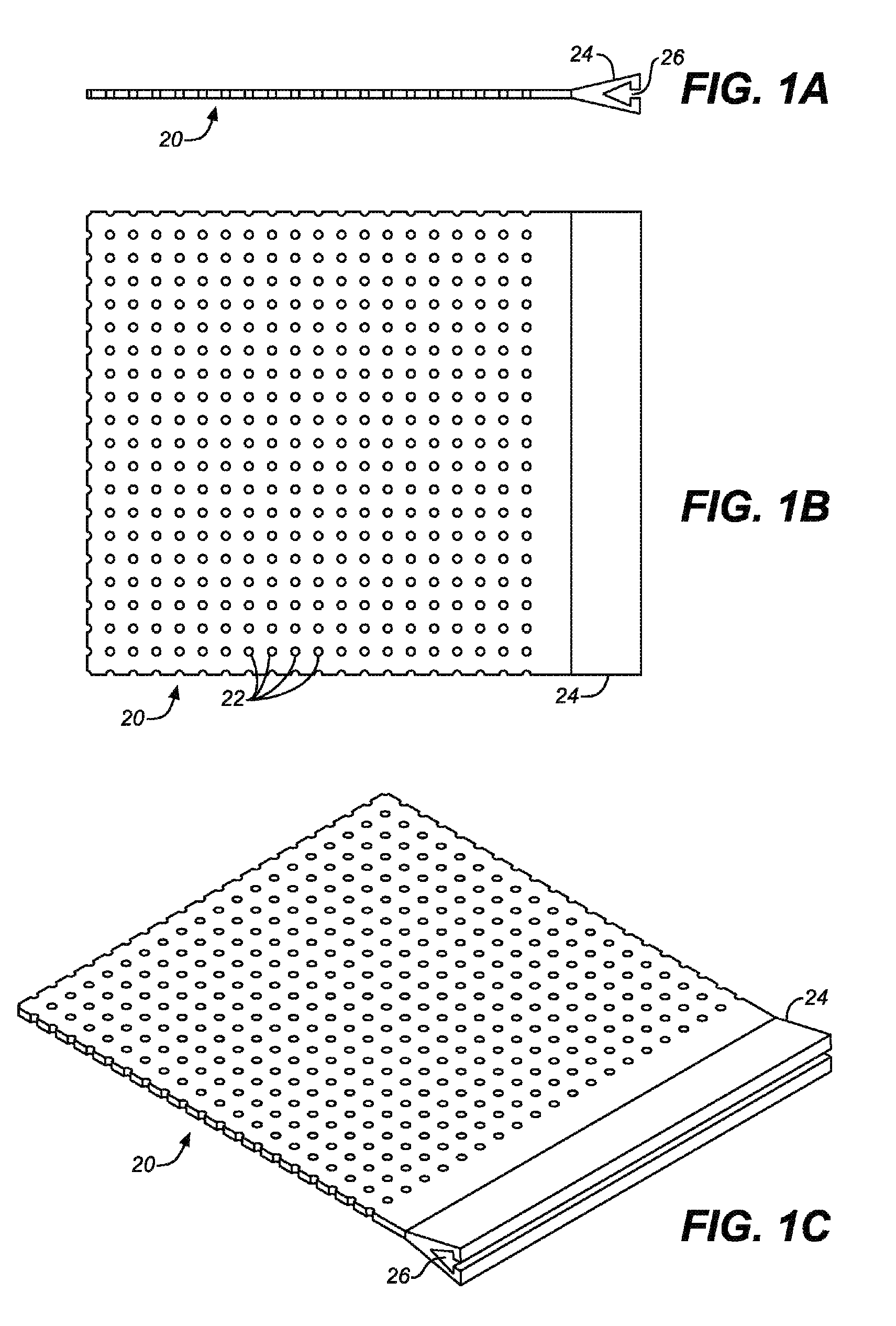

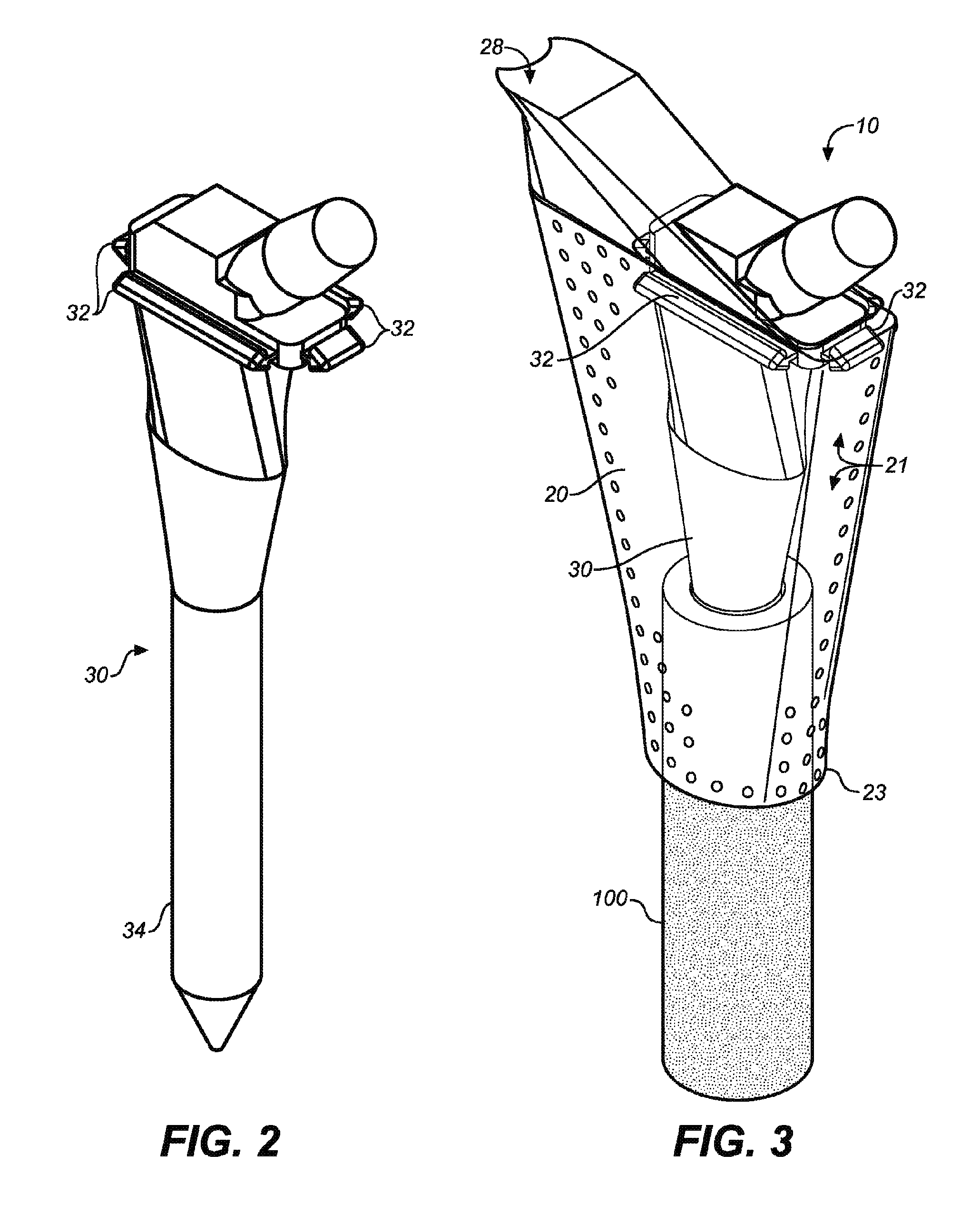

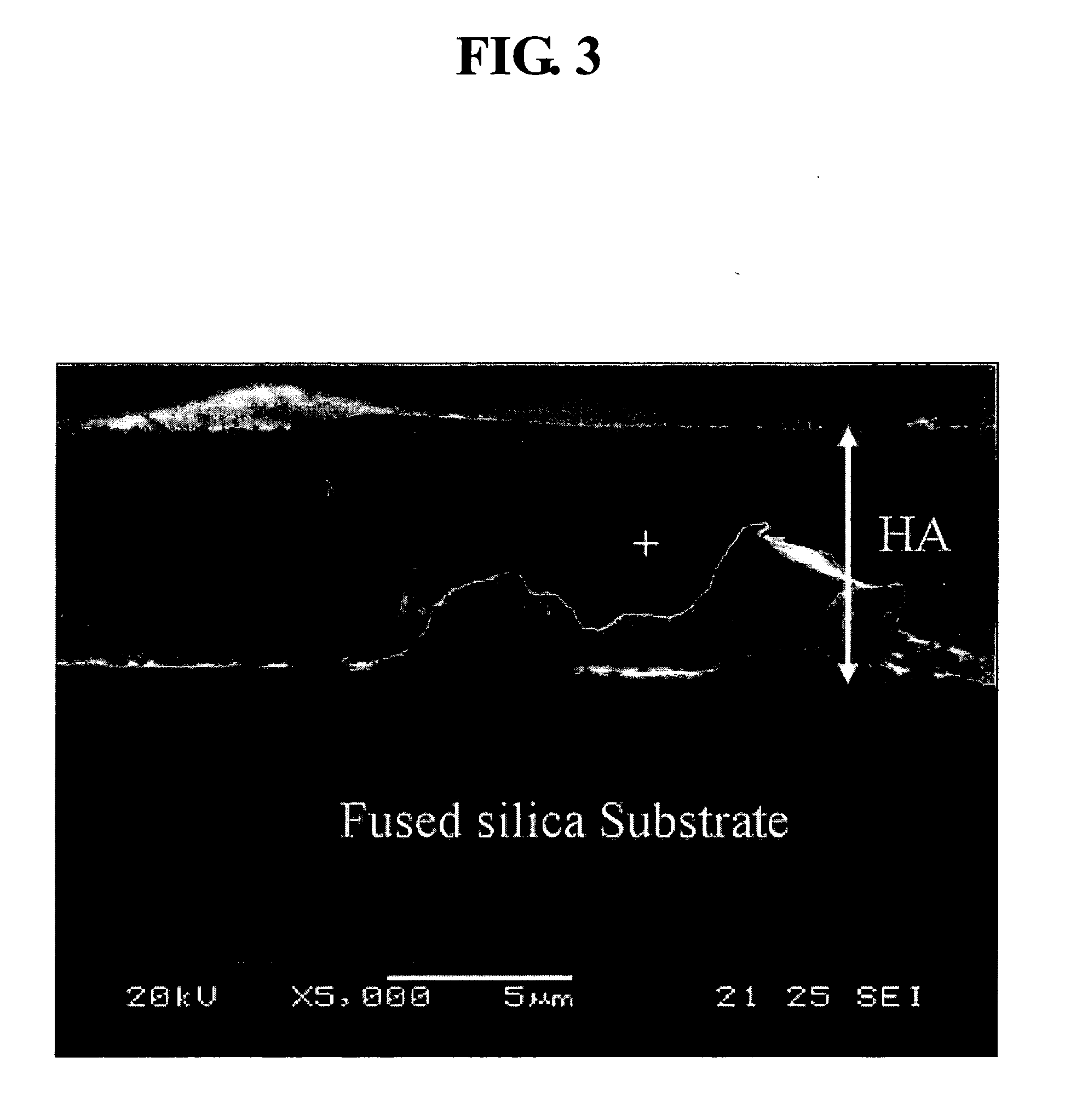

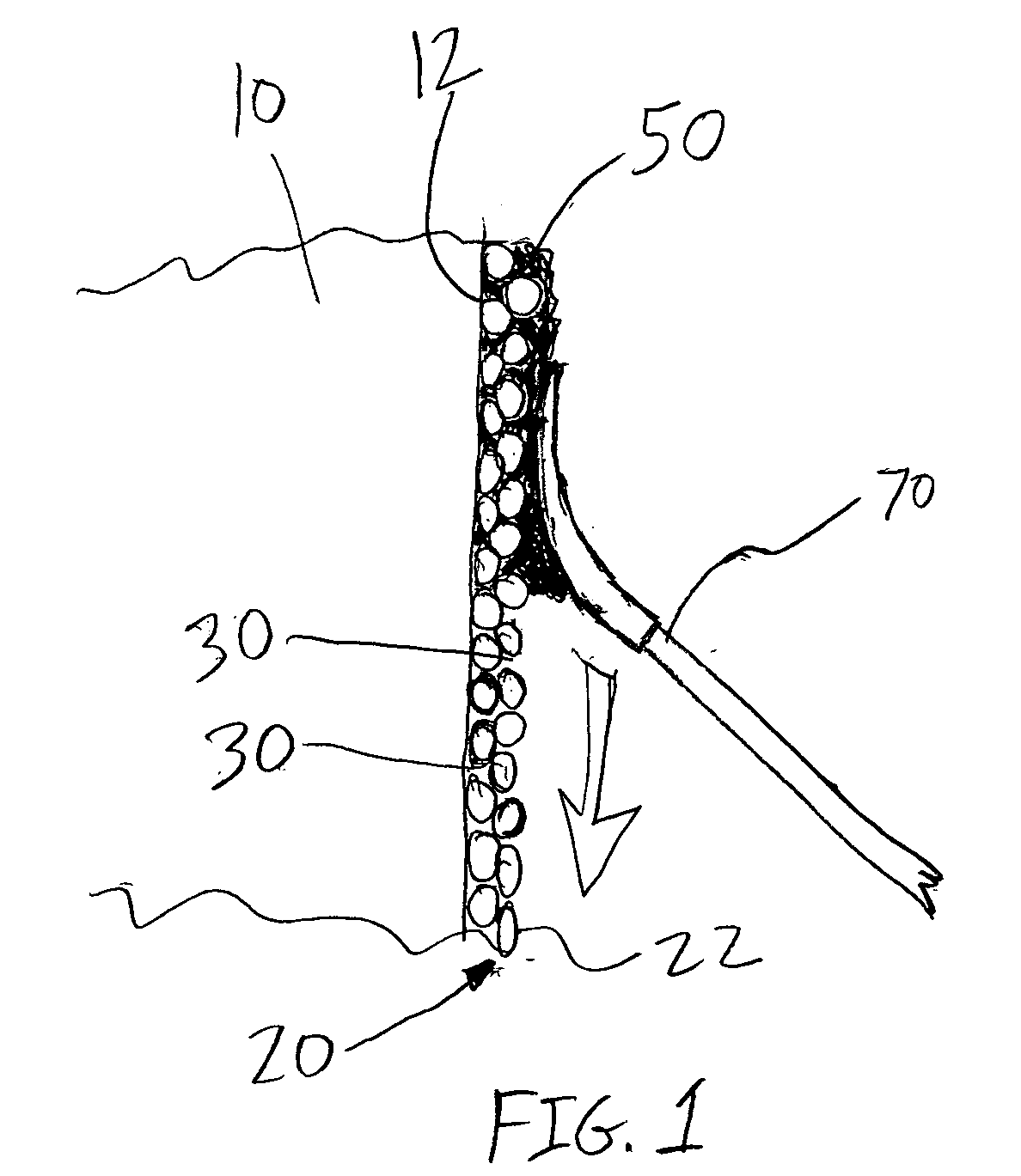

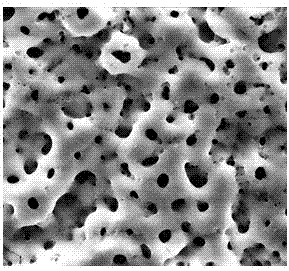

One embodiment of the present invention is directed to compositions and methods for enhancing attachment of soft tissues to a metal prosthetic device. In one embodiment a construct is provided comprising a metal implant having a porous metal region, wherein said porous region exhibits a nano-textured surface, and a biocompatible polymer matrix coating the nano-textured surface. The polymer matrix coating comprises a naturally occurring extracellular matrix with biocompatible inorganic materials distributed within the matrix, or a biocompatible polymer and an osteo-inductive agent.

Owner:DEPUY SYNTHES PROD INC +1

Dopamine-nanosilver composite coating and preparation method thereof

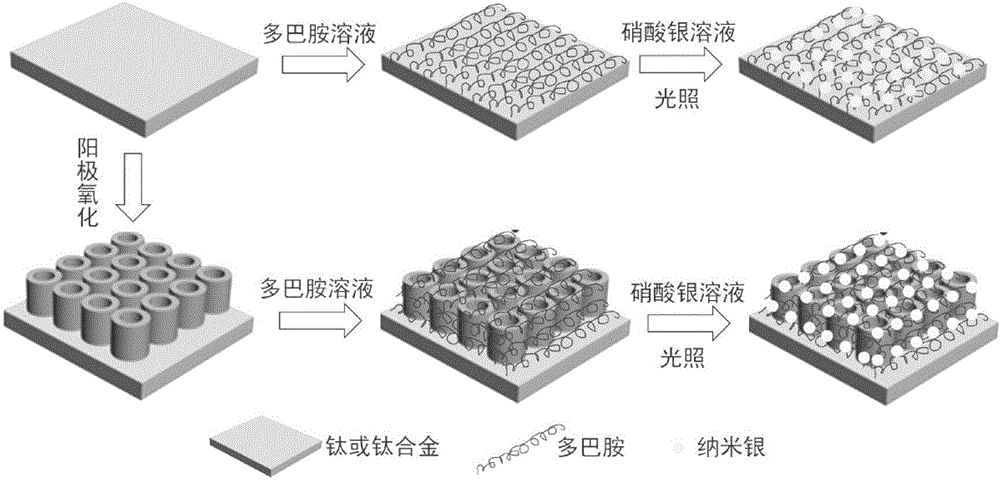

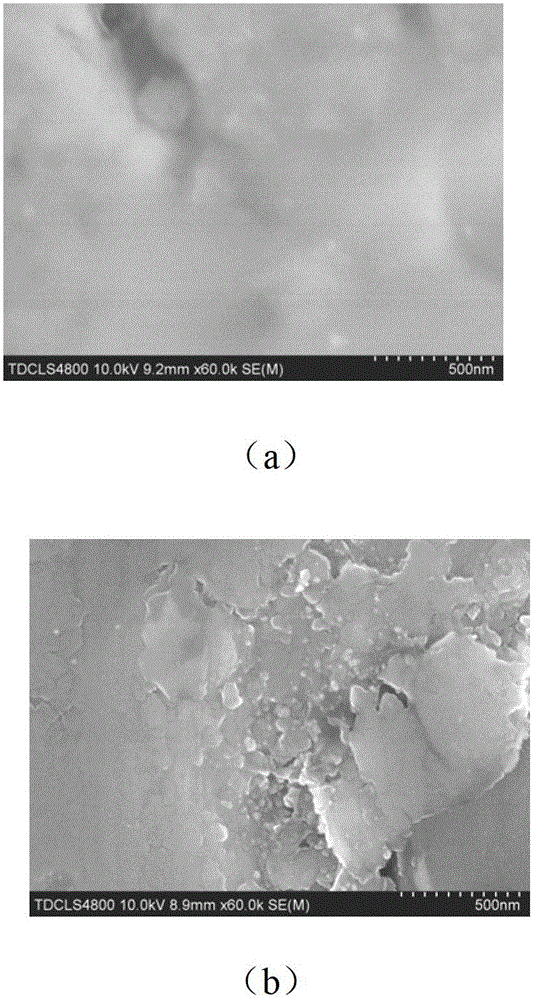

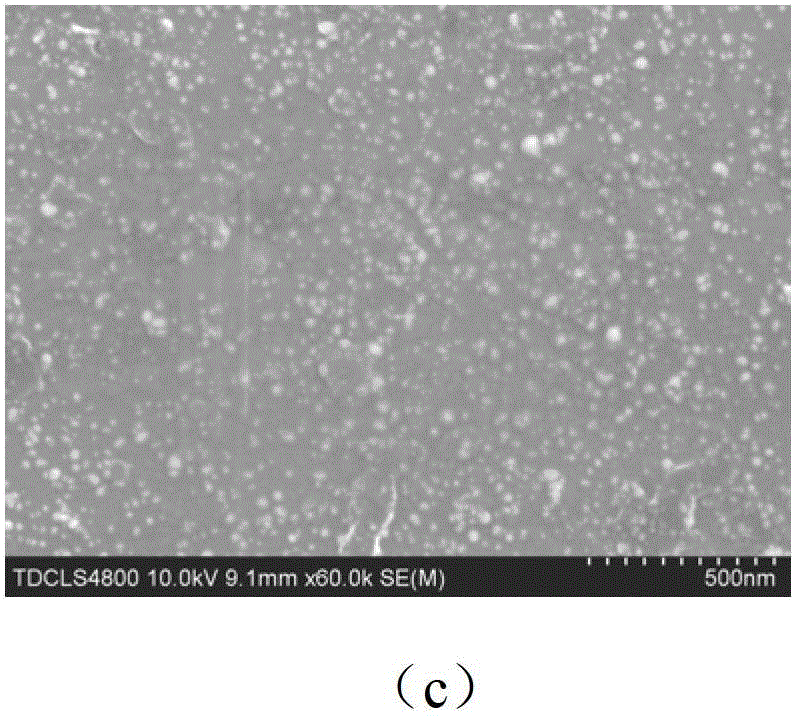

The invention discloses a dopamine-nanosilver composite coating and a preparation method thereof. Firstly, pure titanium or a titanium alloy with titanium dioxide nanotube arrays grown on the surface of the titanium alloy is put in a dopamine buffer solution, then the pure titanium loaded with the dopamine or the titanium alloy with the titanium dioxide nanotube arrays grown on the surface of the titanium alloy is put in a silver nitrate solution, and nanosilver particles are obtained by photoreduction. According to the dopamine-nanosilver composite coating and the preparation method thereof, the chelating property of the dopamine and metal ions and the reducibility in an auto polymerization process are utilized, and the antibacterial performance of material is improved by preparing the nanosilver coating on the surface of the titanium alloy, which has important application value and guiding significance for developing novel functional metal implant material.

Owner:TIANJIN UNIV

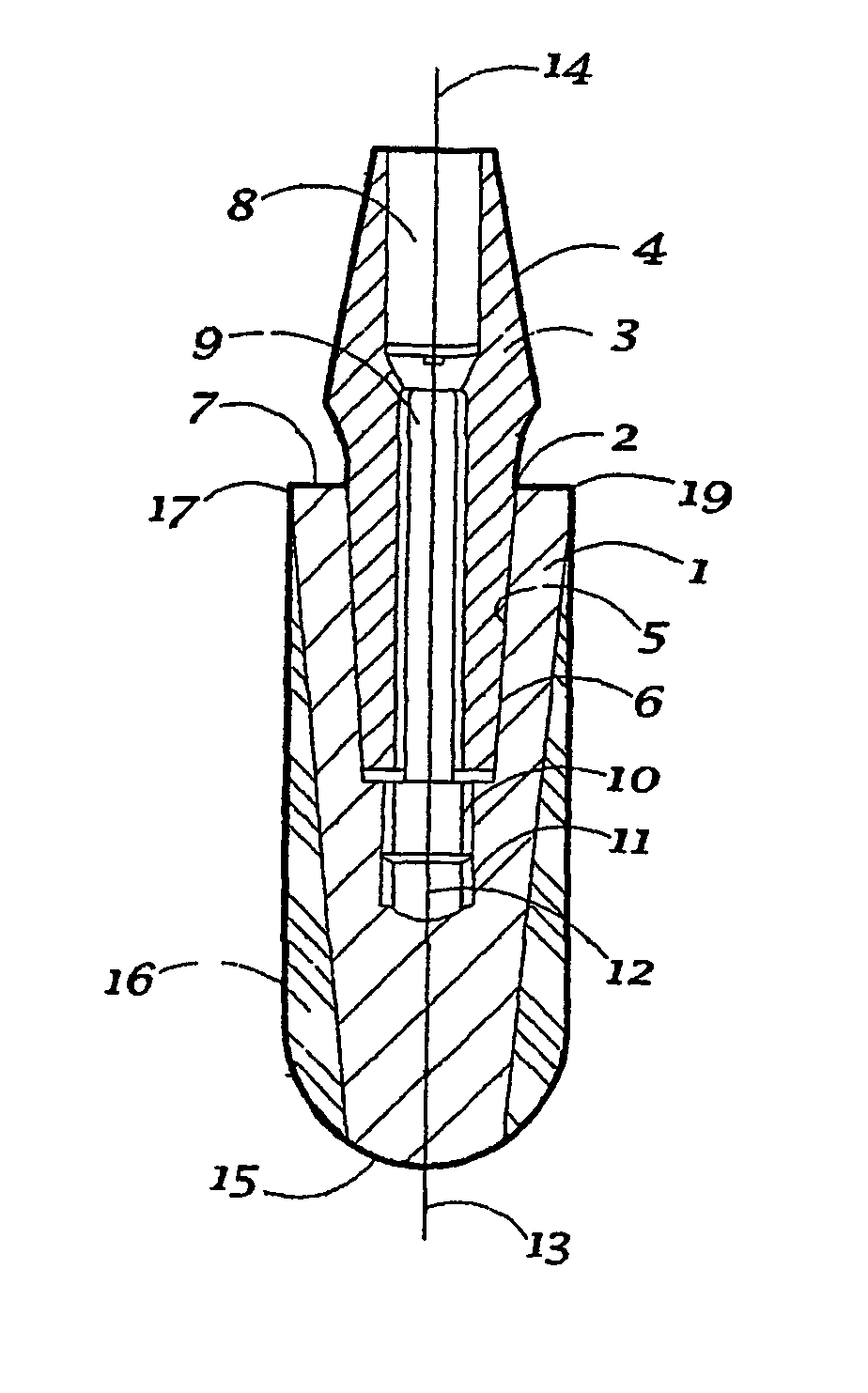

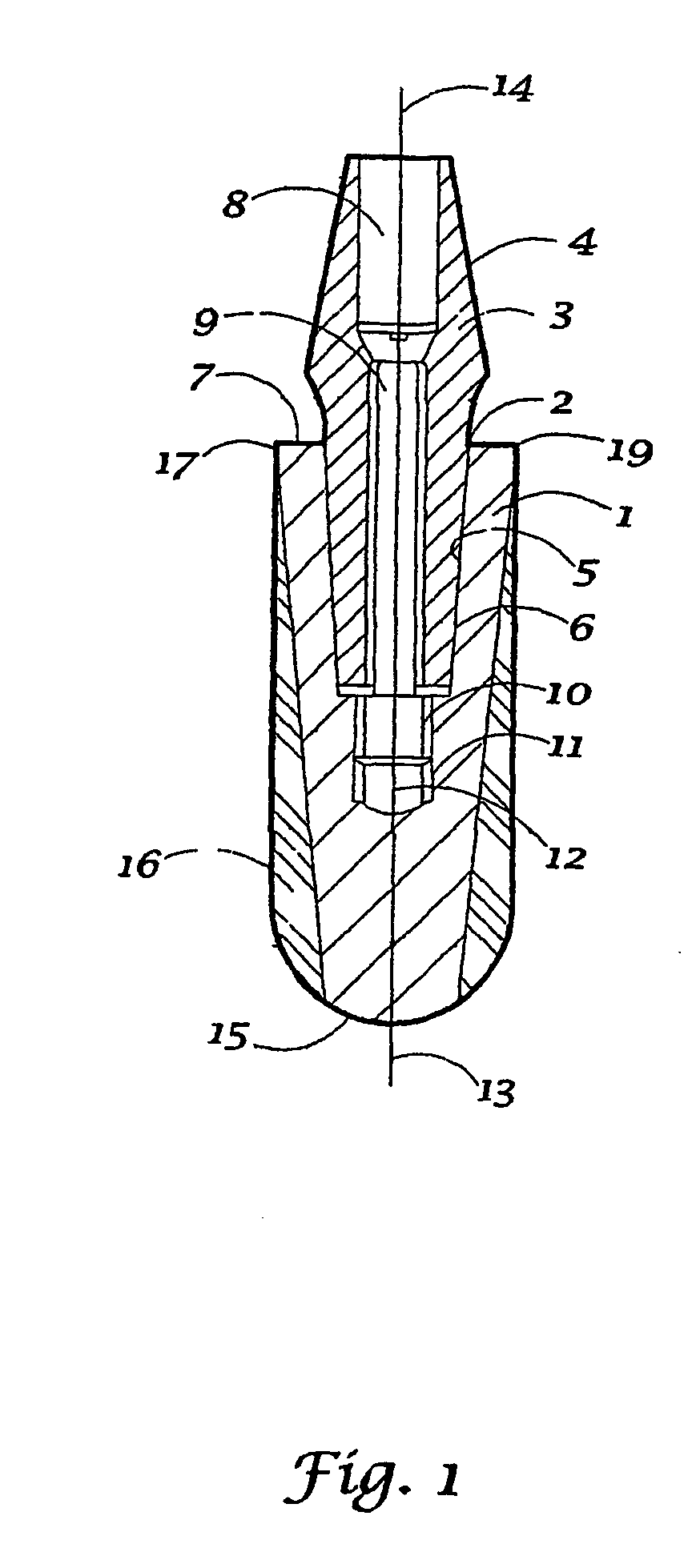

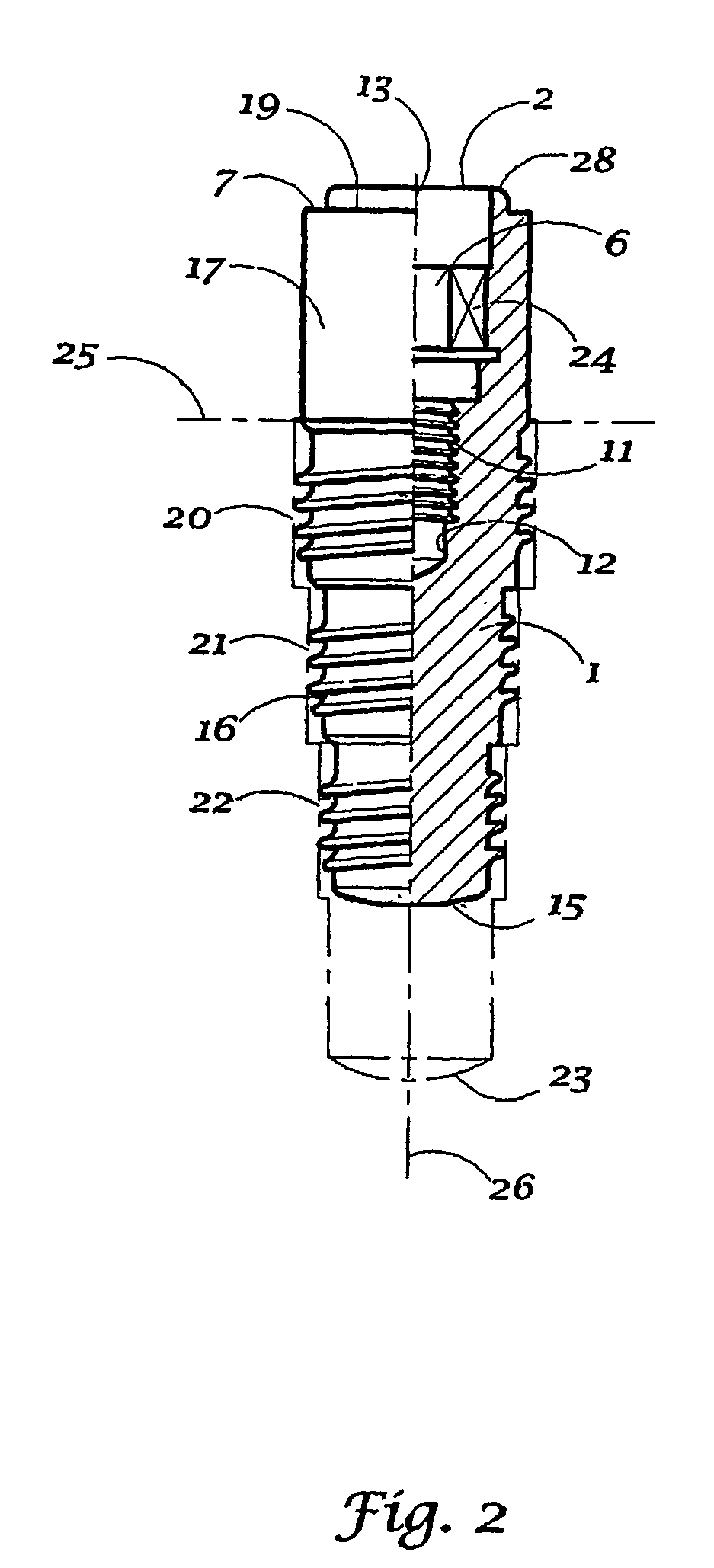

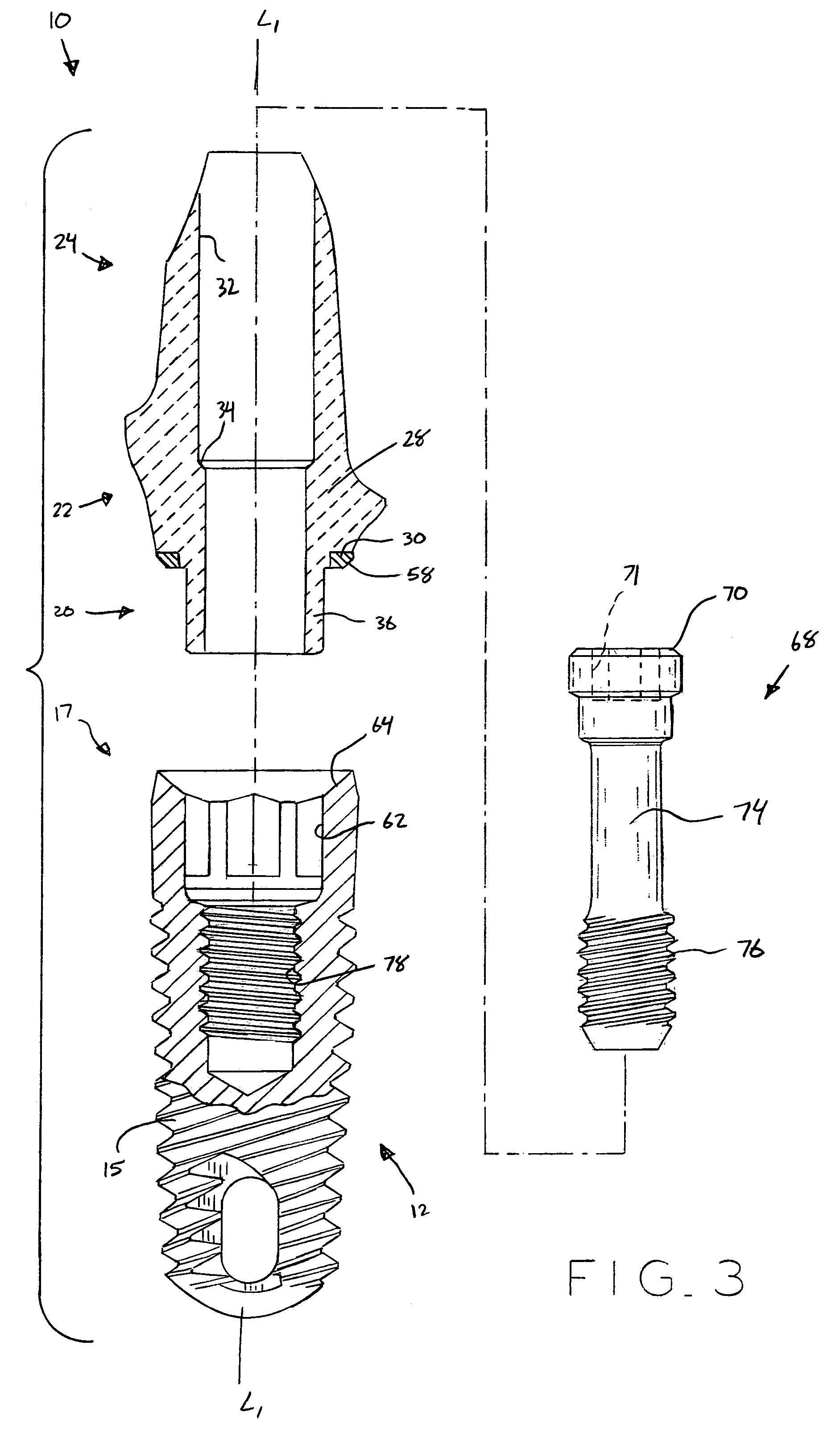

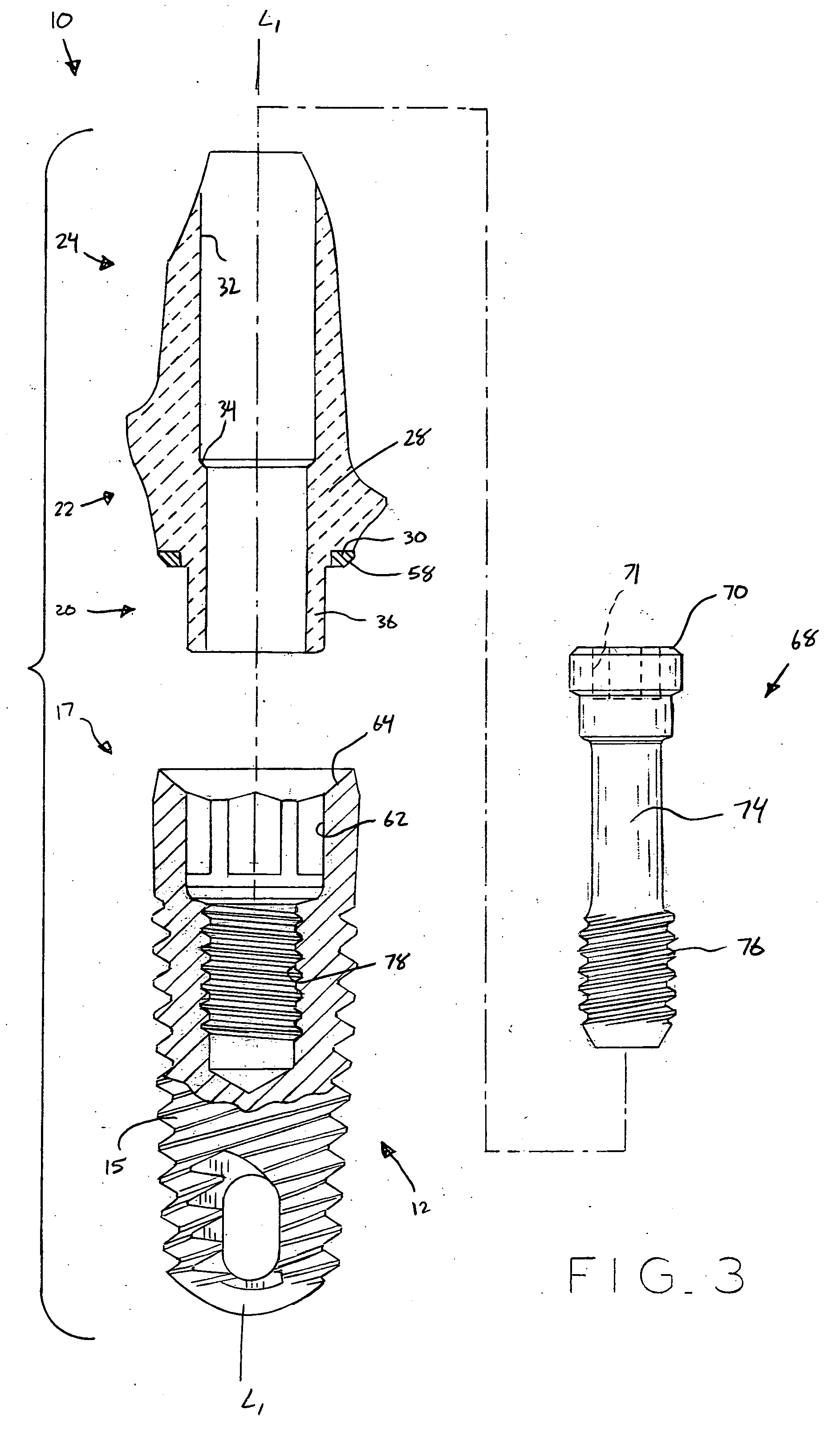

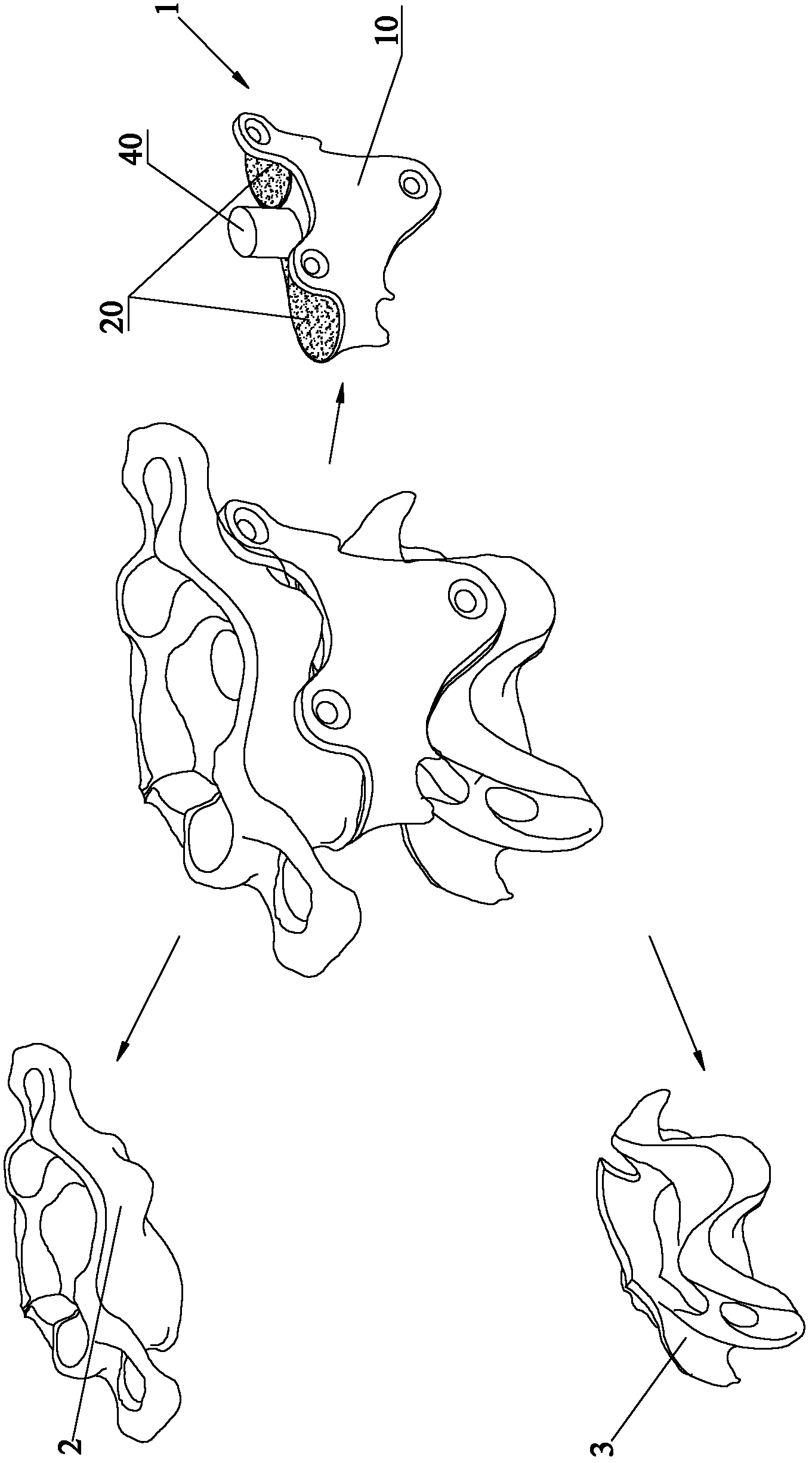

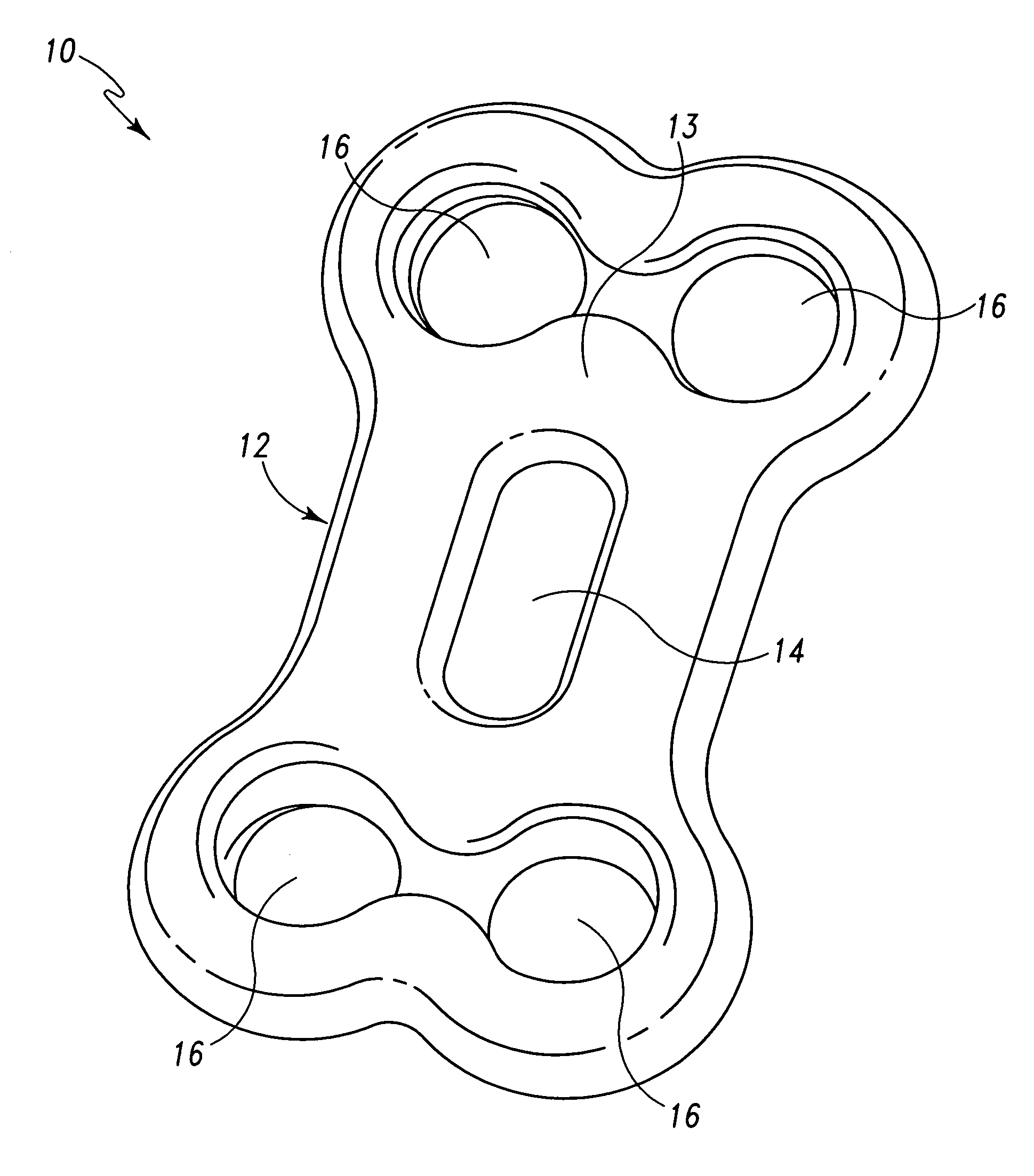

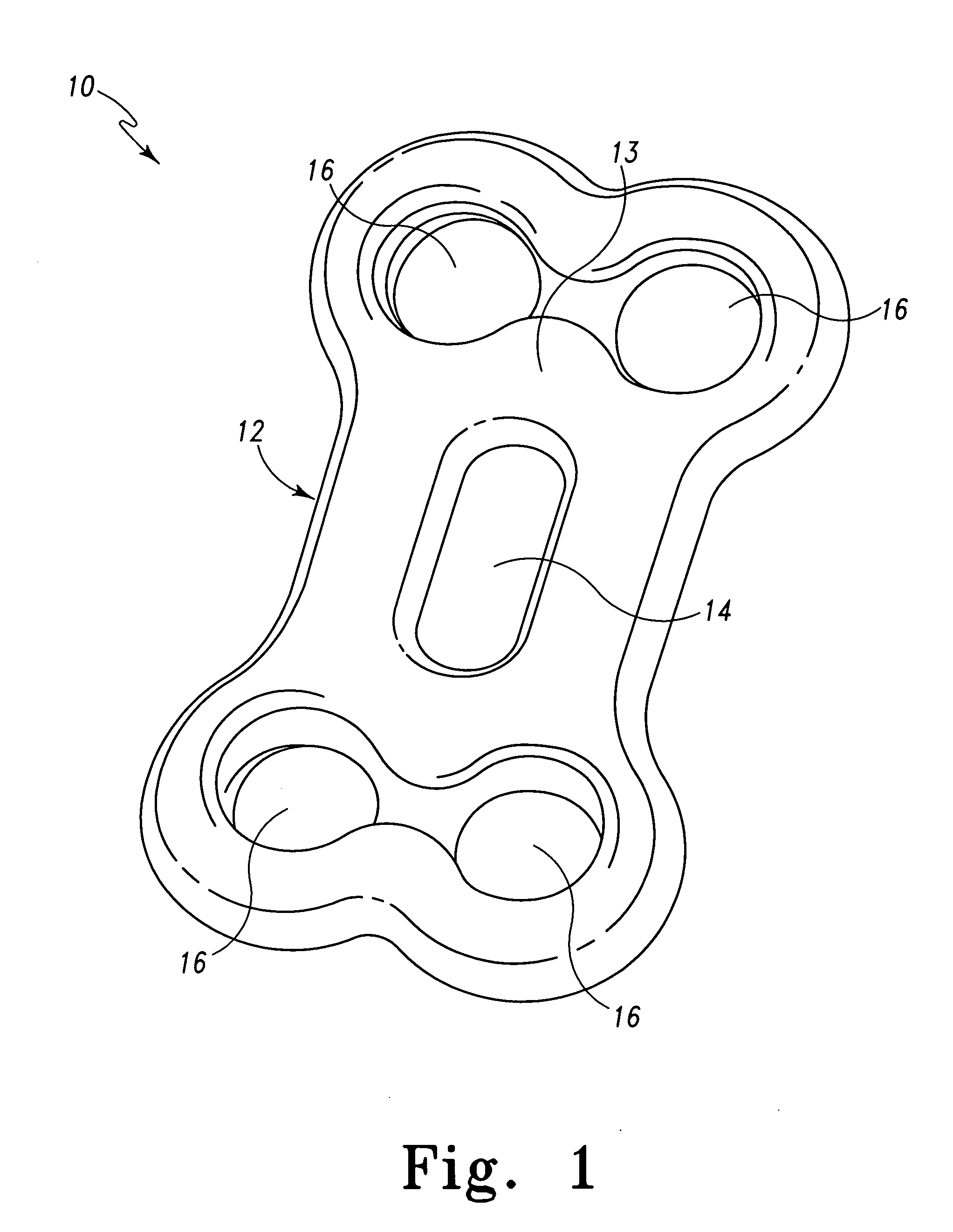

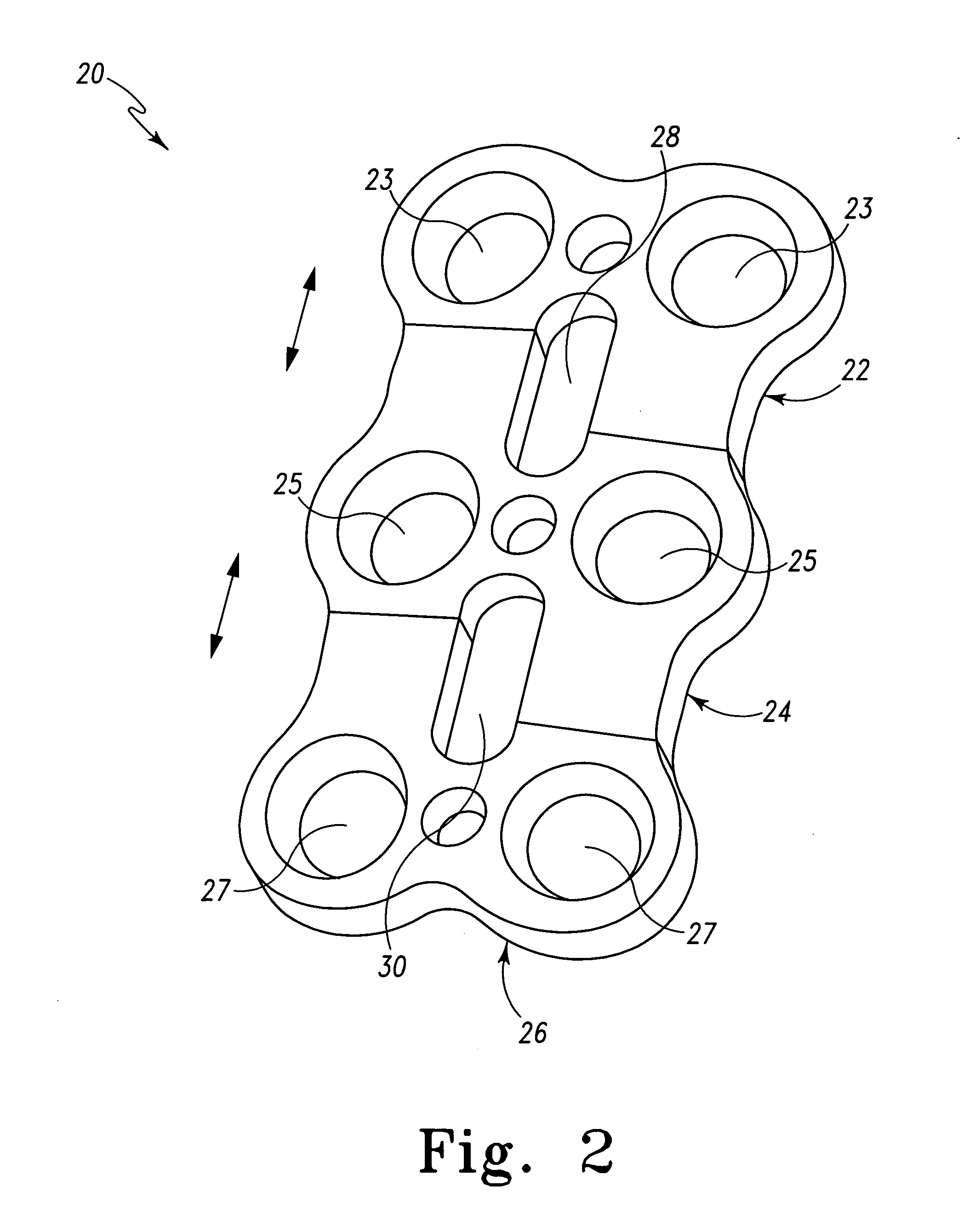

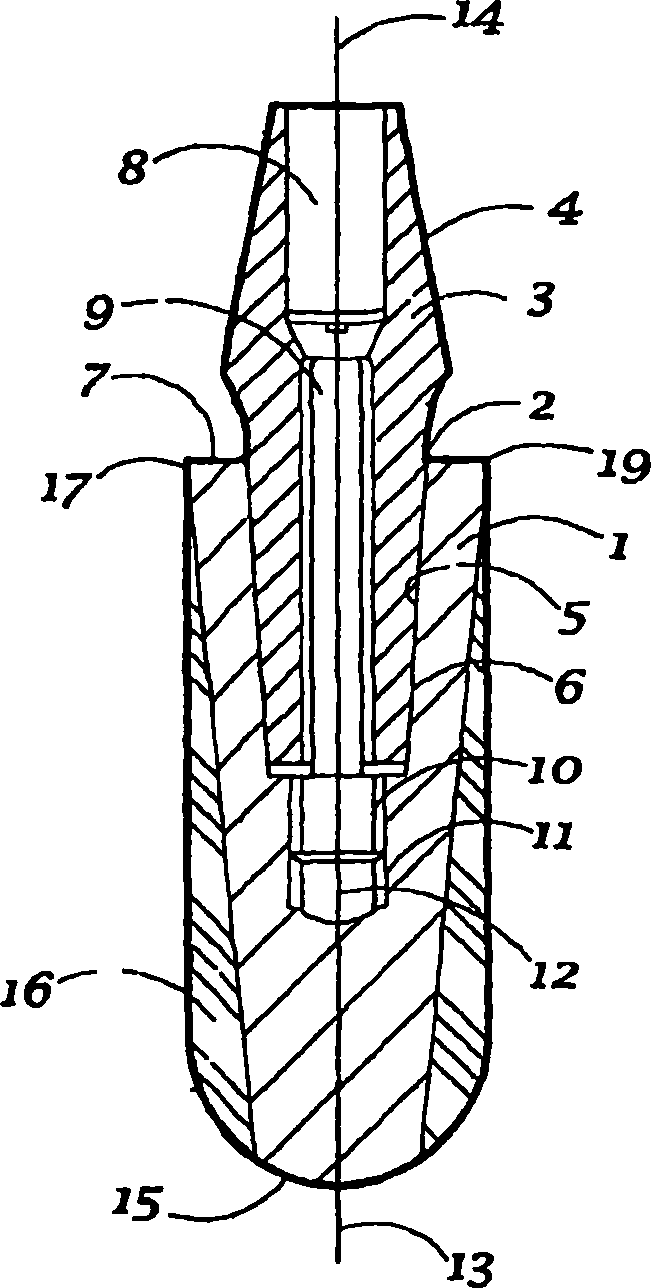

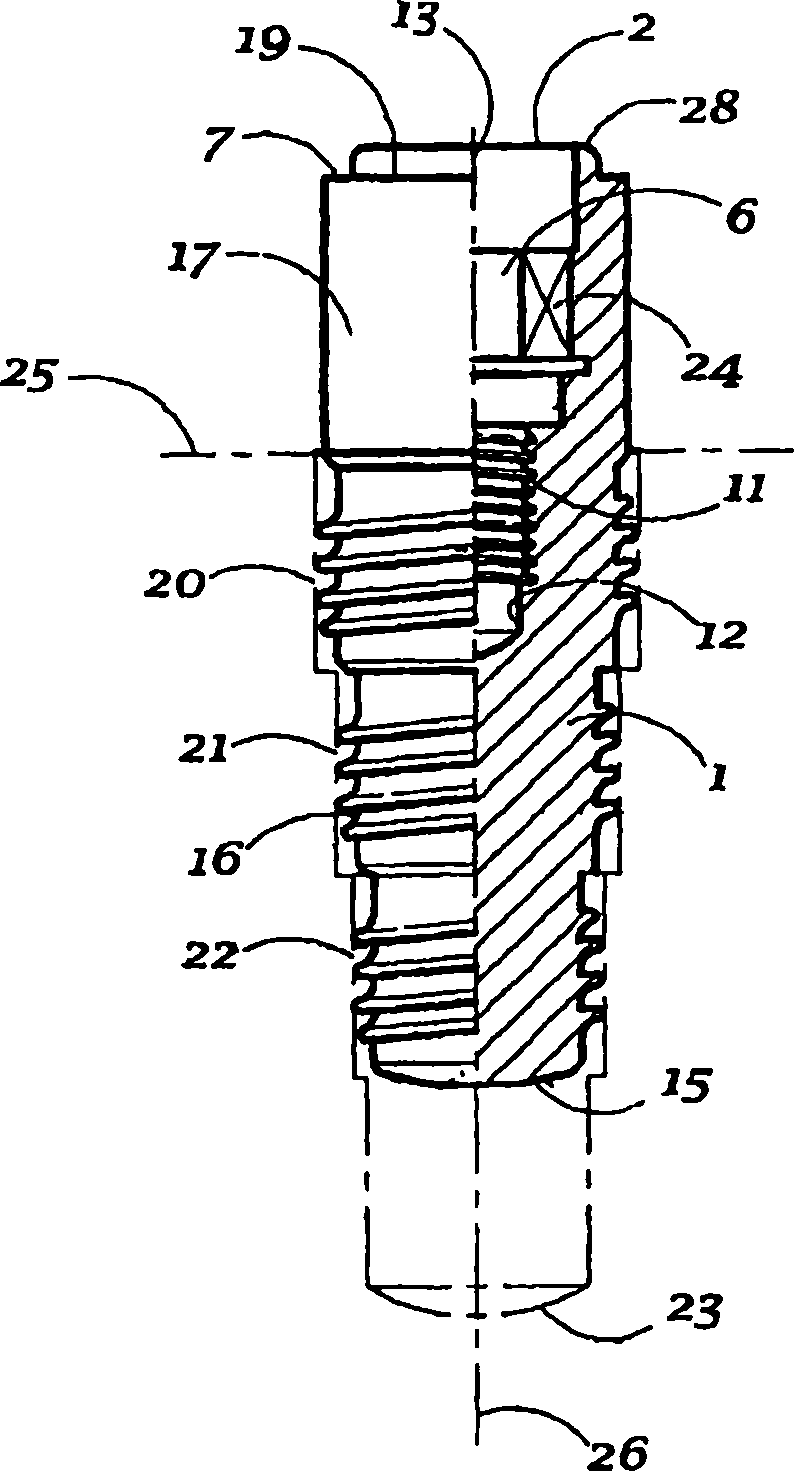

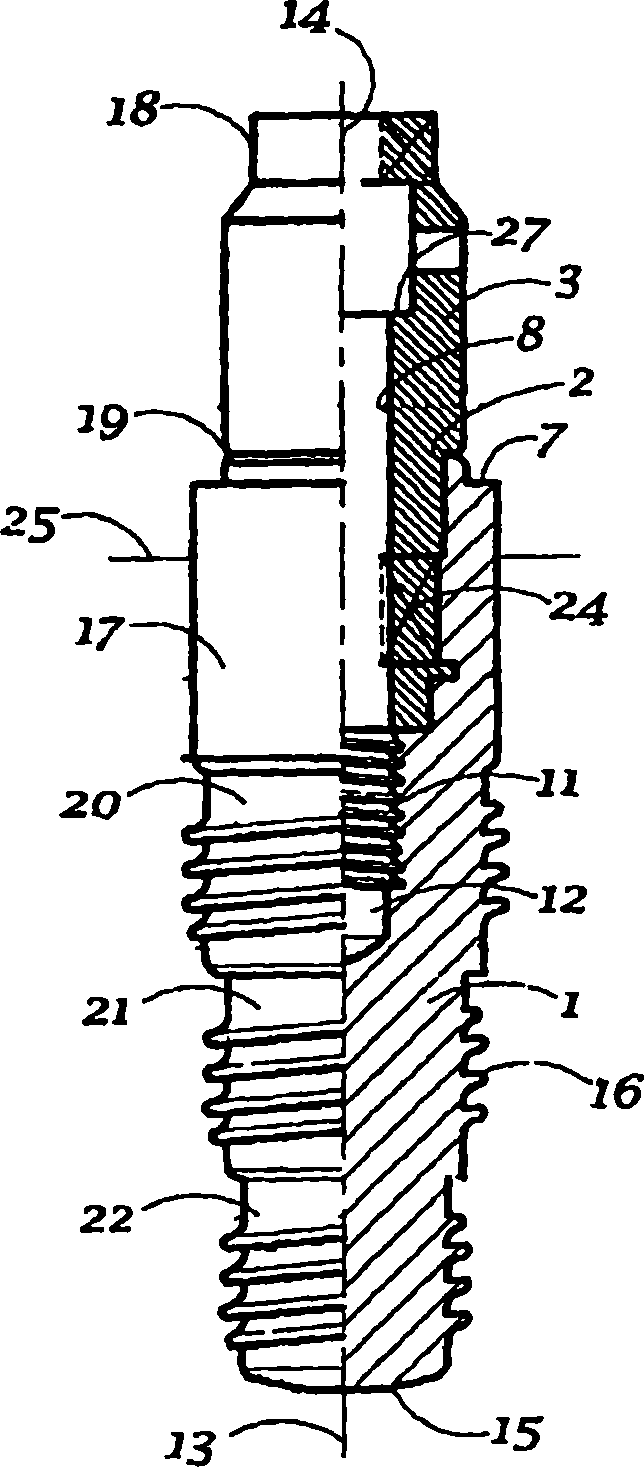

Multi part non metal implant

InactiveUS20060246397A1Good effectGood flexibilityDental implantsDental prostheticsAbutmentBiomedical engineering

An implant is disclosed comprising a fixture component (1) intended for insertion into a bone, and at least one further abutment component (3) for providing a base for a prosthetic superstructure, and a connecting element (9) for mechanically securing the abutment (3) to the fixture (1), wherein the fixture (1) comprises an external thread (16) or other protrusions for improving engagement between the fixture (1) and the bone, wherein the connecting element (9) detachably interconnects the fixture (1) and the abutment (3), and wherein at least the fixture (1) and the abutment (3) are made of non-metal material, and method of making the same.

Owner:FRIADENT

Biomedicine implant material with controllable degrading rate and its application

InactiveCN1857742AControl the rate of early degradationGuaranteed mechanical propertiesSurgeryProsthesisCardiovascular stentShort terms

The present invention relates to biomedicine metal implant material, and is especially biomedicine implant material with controllable degrading rate and its application. The biomedicine implant material with controllable degrading rate has a magnesium or magnesium alloy matrix and a coated degradable polymer layer with thickness controlled within 0.01-5 mm. The biodegradation is completed step by step so as to ensure the mechanical performance of the material during degradation and match the degradation rate with the service period of the implanted device. The biomedicine metal implant material of magnesium or magnesium alloy may be used in preparing temporary or short term implanted device, such as degradable blood rack and peripheral rack, bone fracture plate and bone nail for inner fixing, tissue engineering rack, etc.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

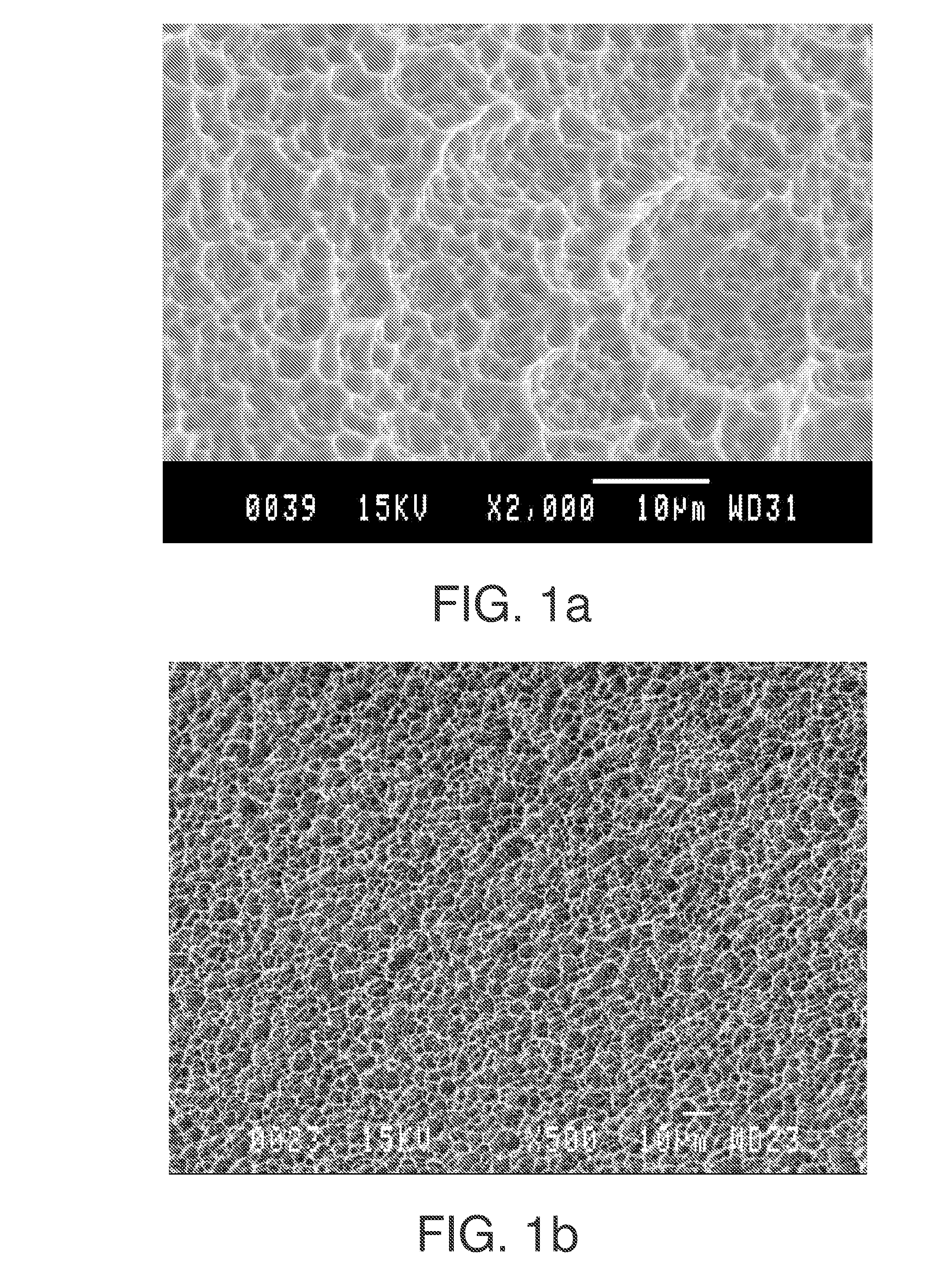

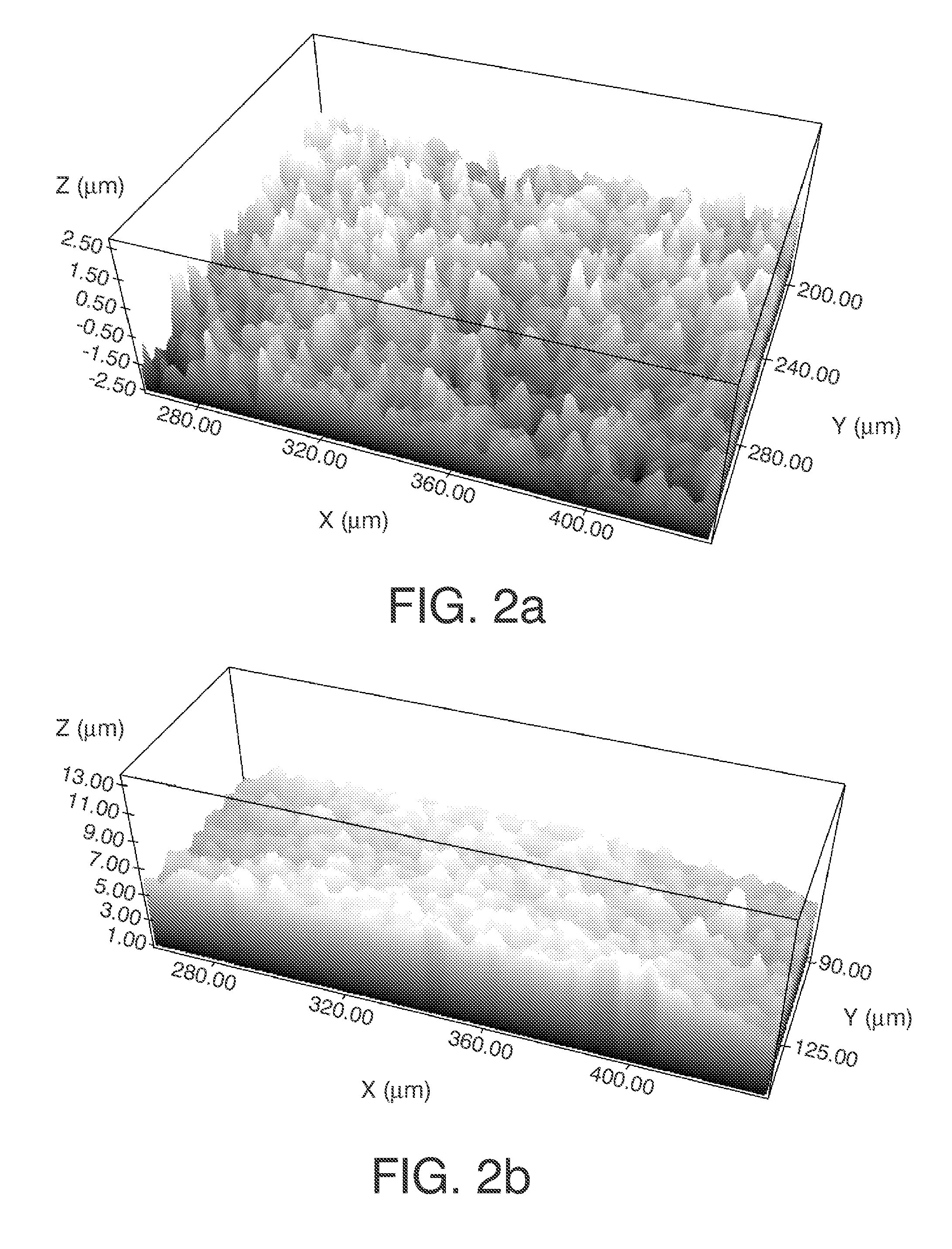

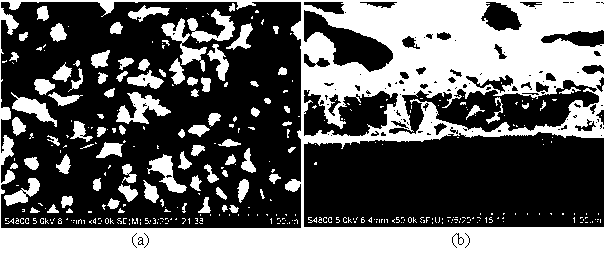

Method for obtaining a surface of titanium-based metal implant to be inserted into bone tissue

The invention relates to a method for obtaining a surface of a titanium-based metal implant intended to be inserted into bone tissue, comprising: (a) projecting particles of aluminium oxide under pressure on the external area of the implant; (b) chemically treating the sandblasted external area of the implant with an acid composition comprising sulfuric acid and hydrofluoric acid; and (c) thermally treating the sandblasted external area of the implant by heating at a temperature of 200-450° C. for 15-120 min. The invention likewise defines a metal implant having said surface. The surface thus obtained has good micrometer-scale roughness with a suitable morphology, as well as a composition which is virtually free of impurities and a thickness which is approximately three times the thickness of conventional surfaces, which characteristics provide it with very good osseointegration properties.

Owner:PHIBO DENTAL SOLUTIONS

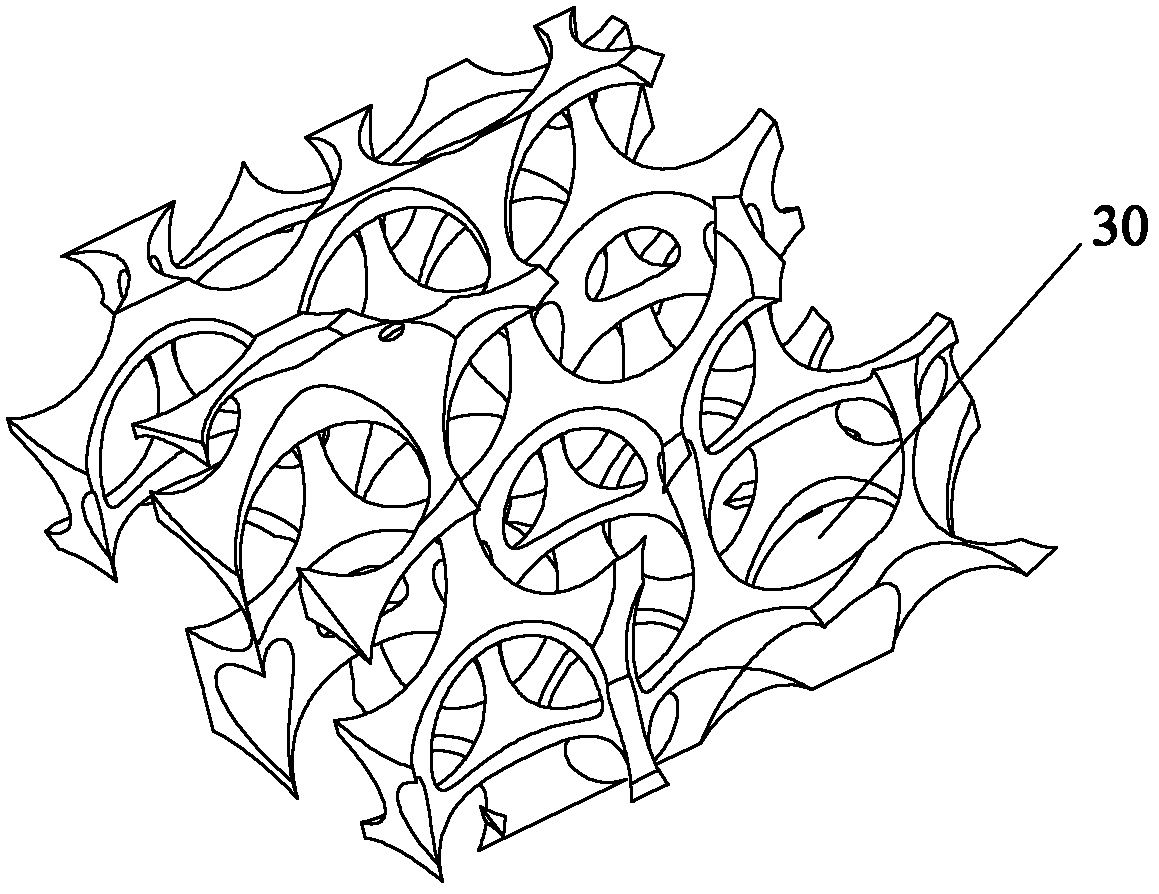

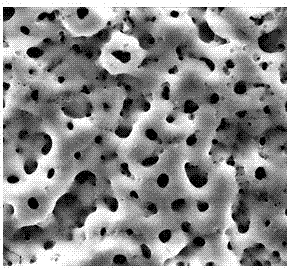

Method and apparatus for forming porous metal implants

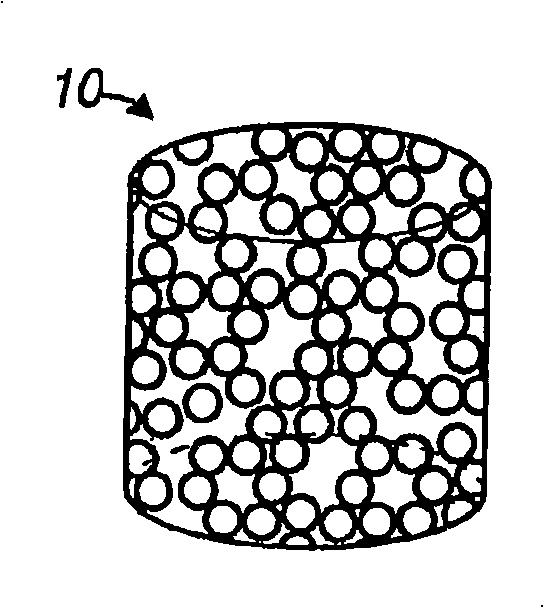

The present invention relates to a method for providing a porous metal implant. A mixture of a biocompatible metal, a spacing agent, and a binder is provided. The mixture is formed into a shaped the spacing agent is removed to form a plurality of pores in the implant. A shaped porous metal implant is also provided.

Owner:BIOMET MFG CORP

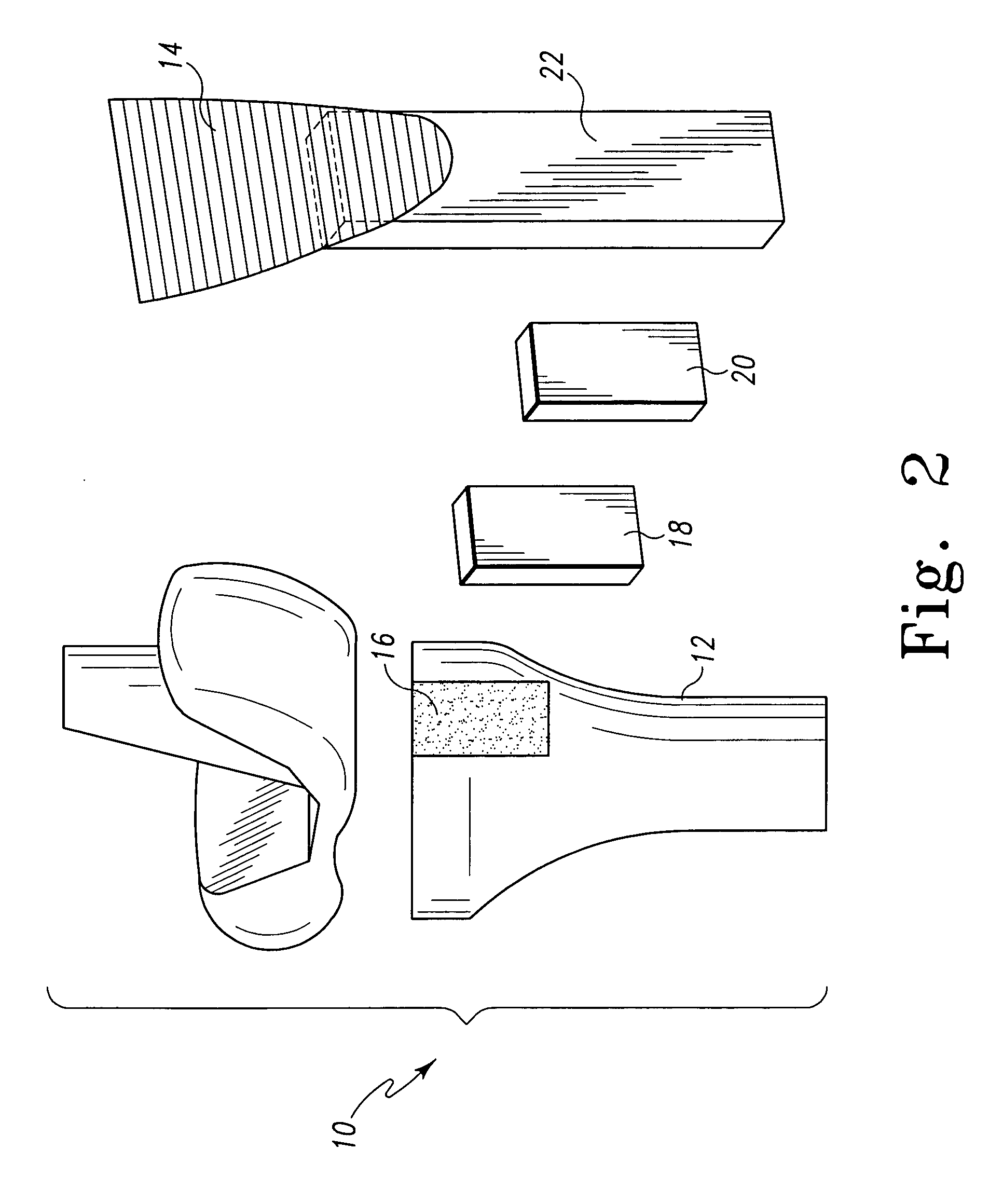

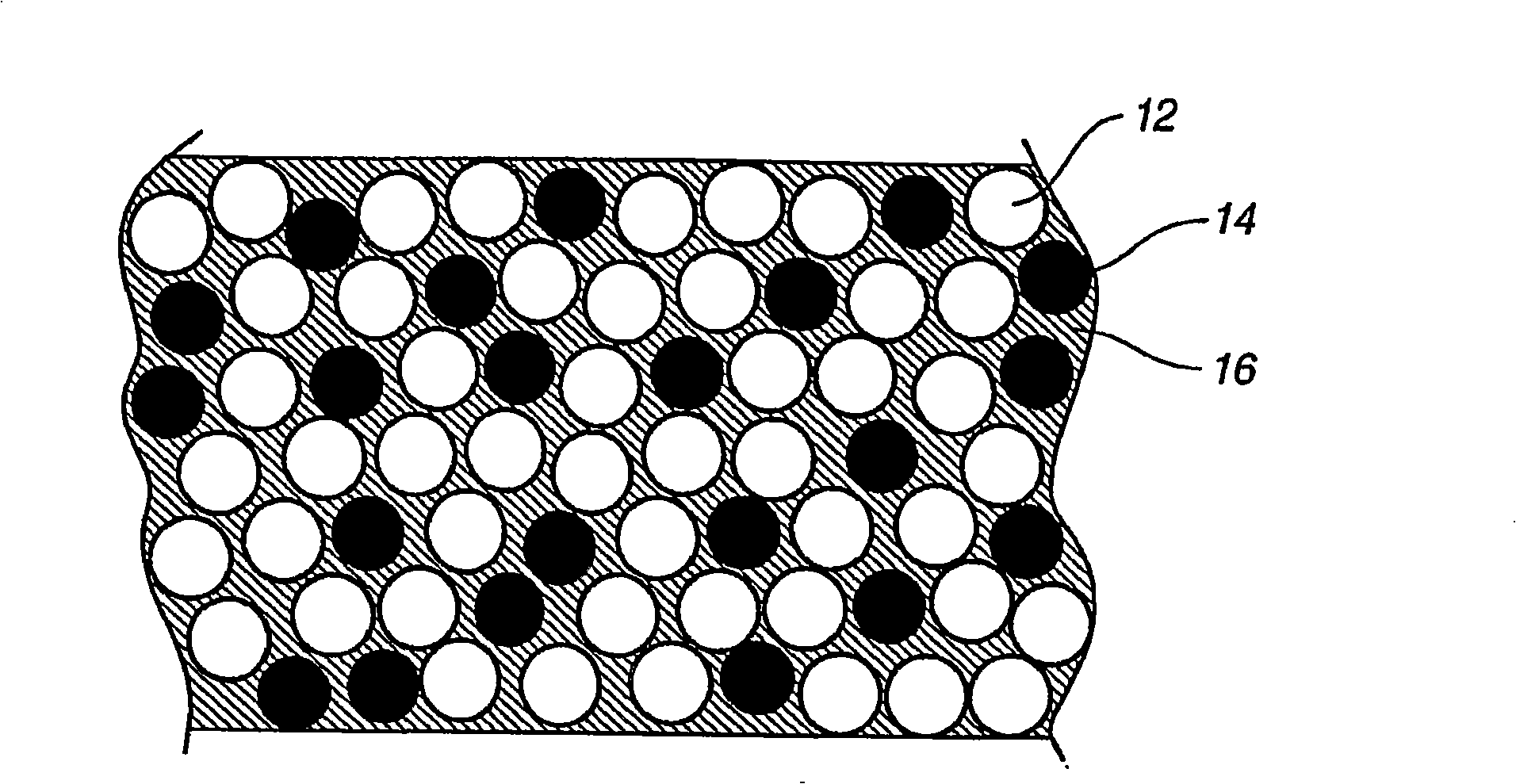

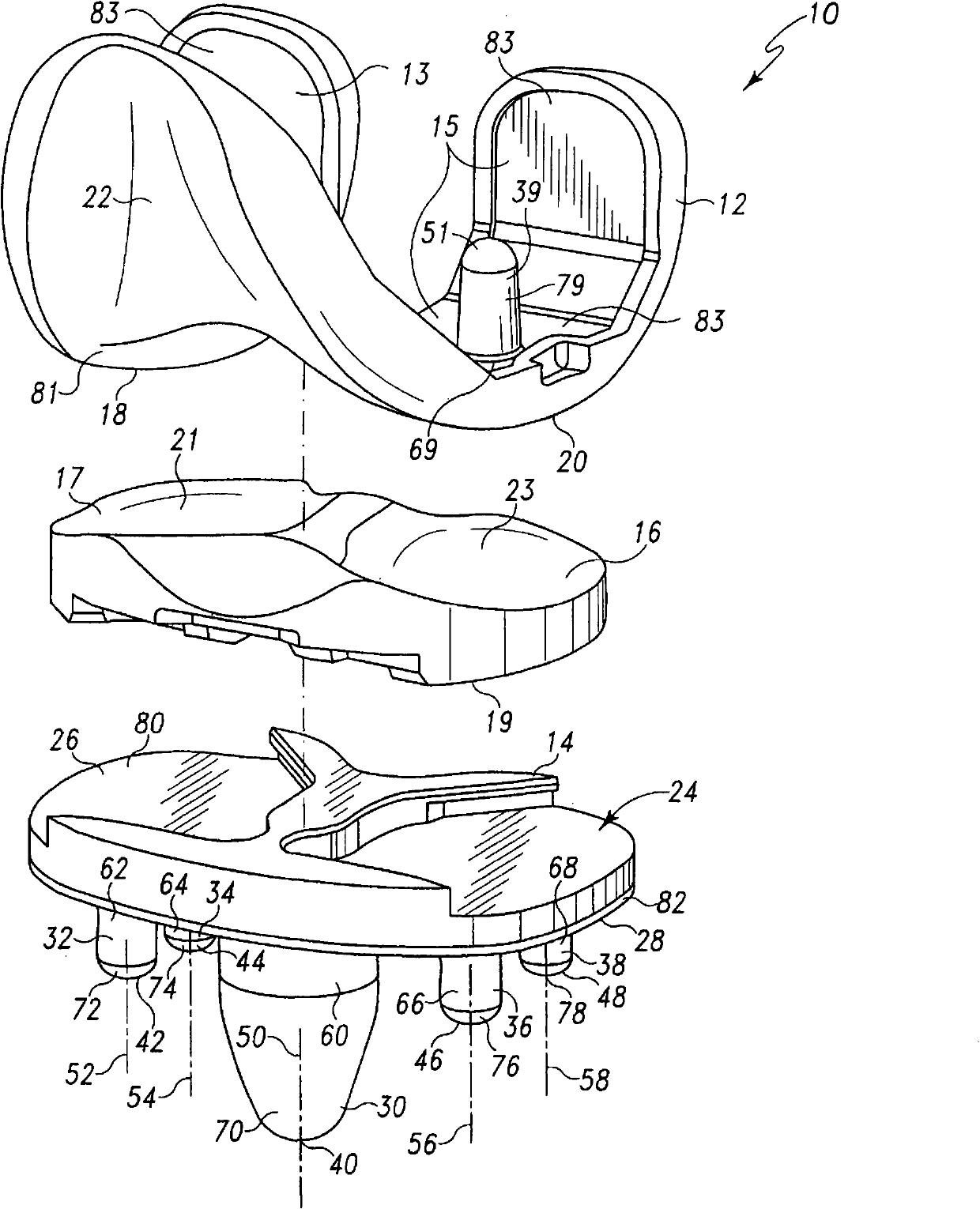

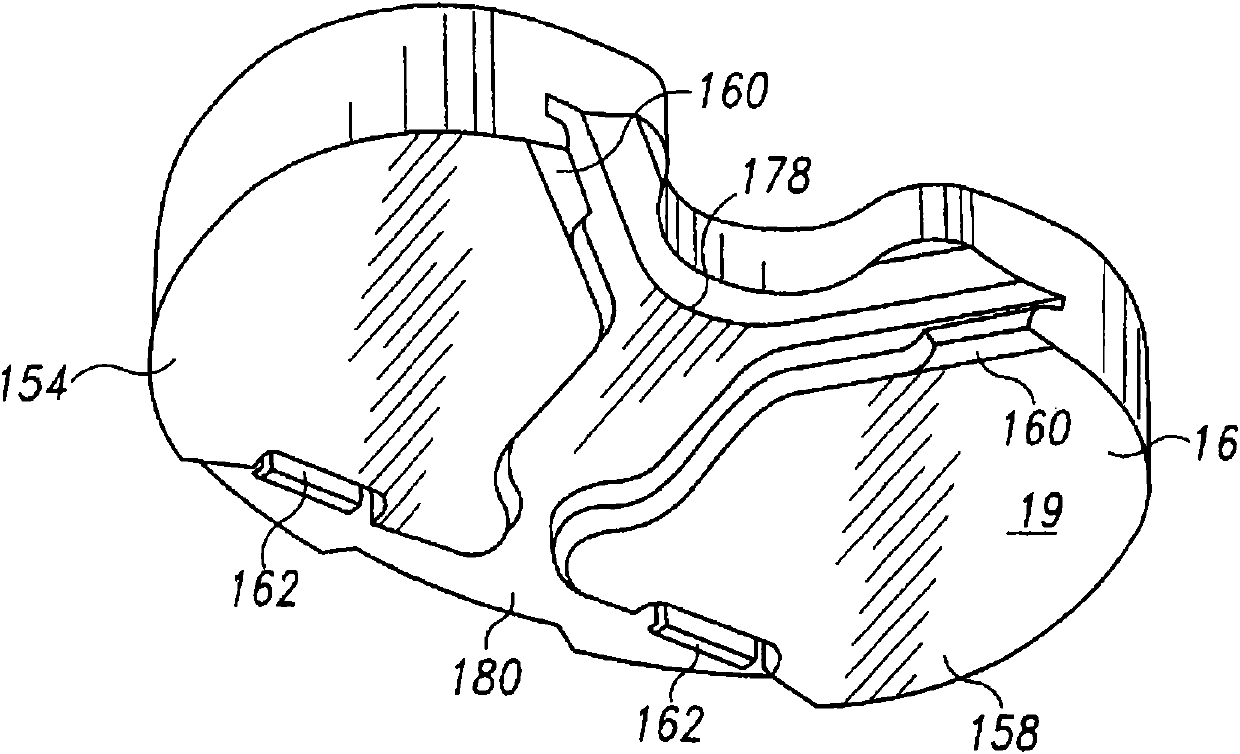

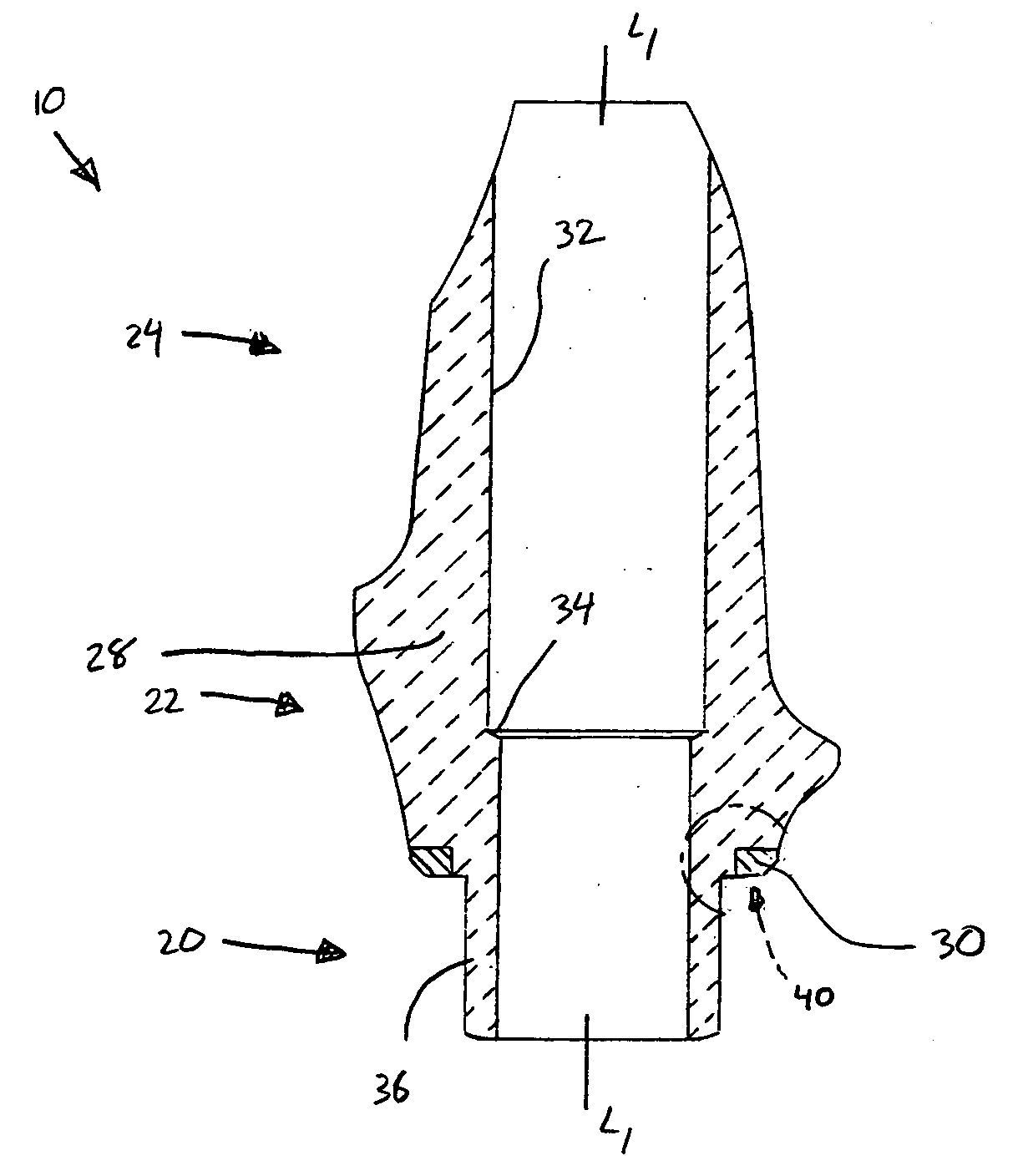

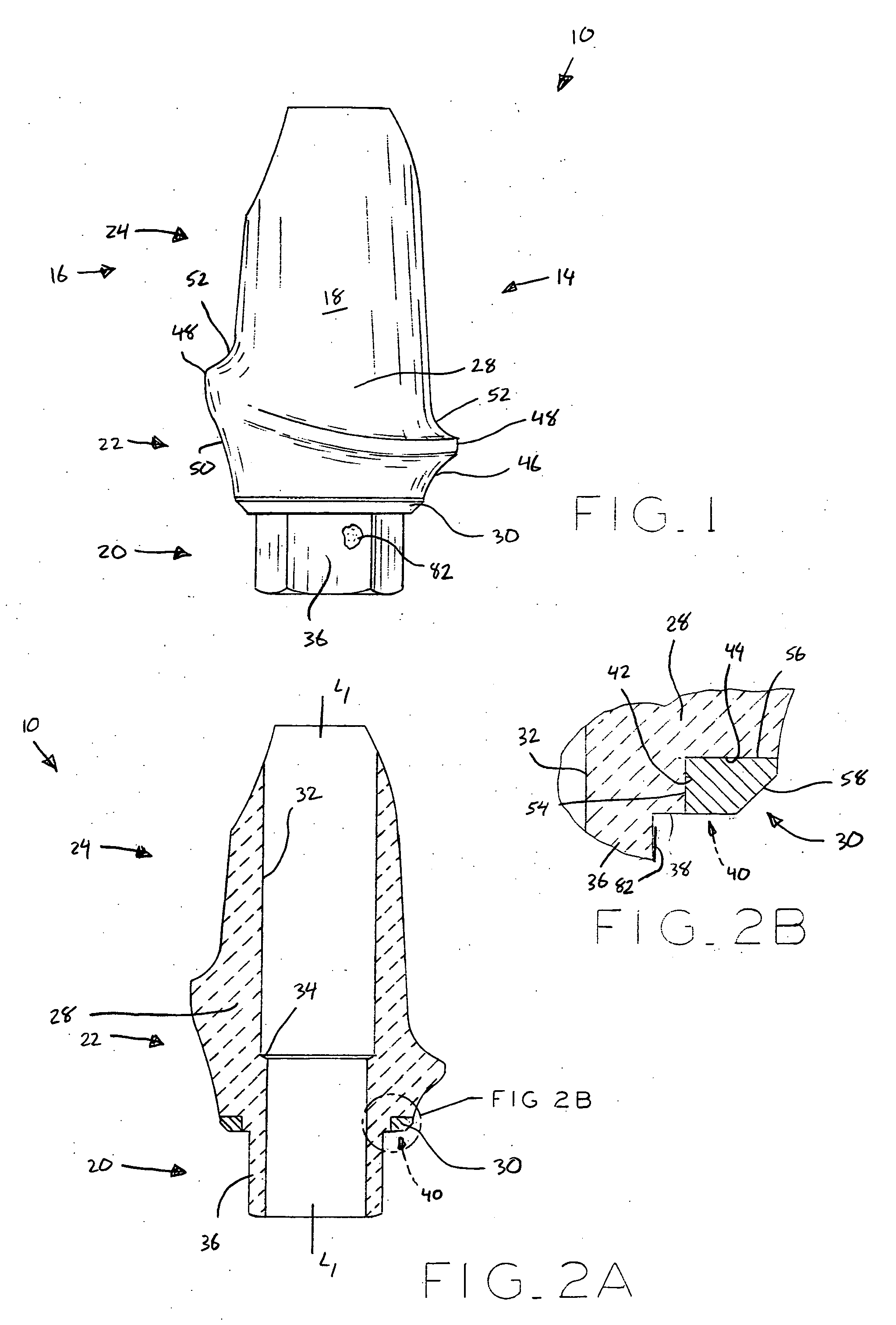

Prosthesis for cemented fixation and method for making the prosthesis

A joint prosthesis system (10) is suitable for cemented fixation. The system has two metal implant components (12,14) and a bearing (16). One of the metal implant components has an articulation surface (18,20,22) for articulation with the bearing. The other metal implant component has a mounting surface (26) for supporting the bearing. One of the metal implant components includes an extension (30,32,34,36,38,39), such as a stem or pegs, with an exposed outer surface (79). The metal implant component from which the extension extends comprises titanium and the exposed outer surface of the extension comprises a different form of titanium. A method of making the joint prosthesis is also disclosed.

Owner:DEPUY PROD INC

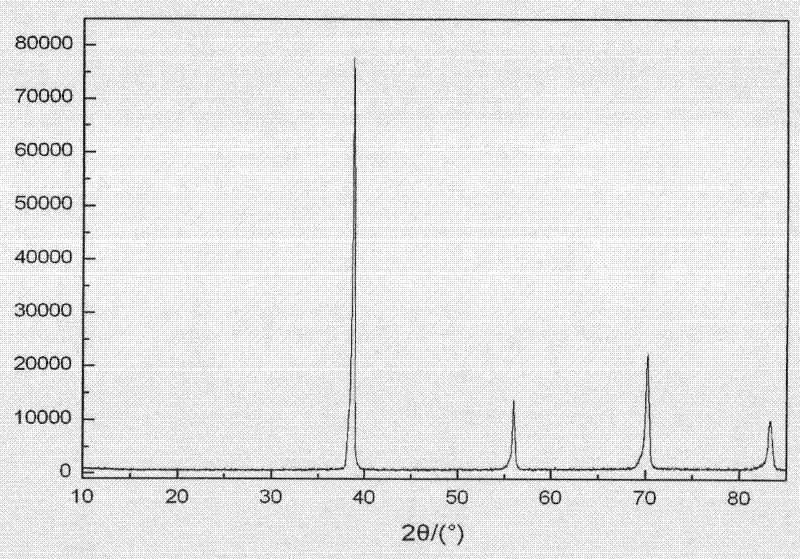

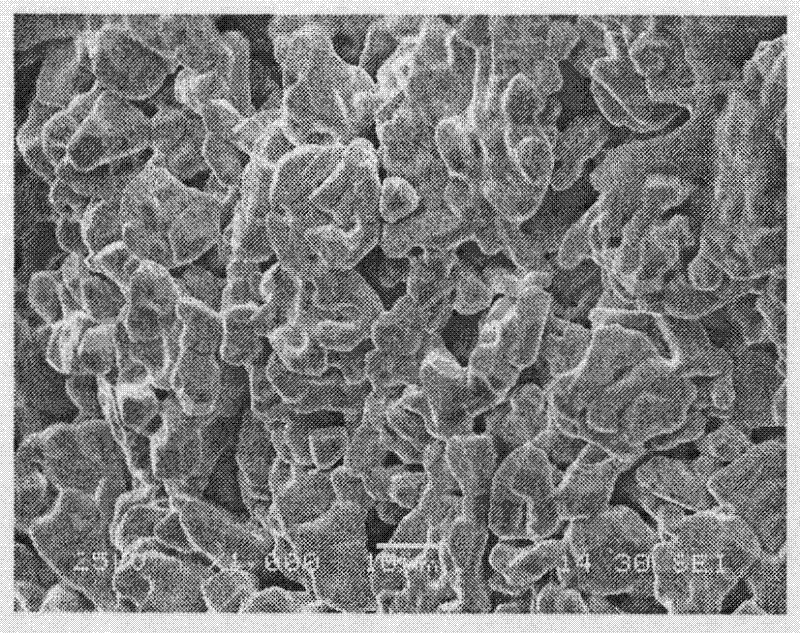

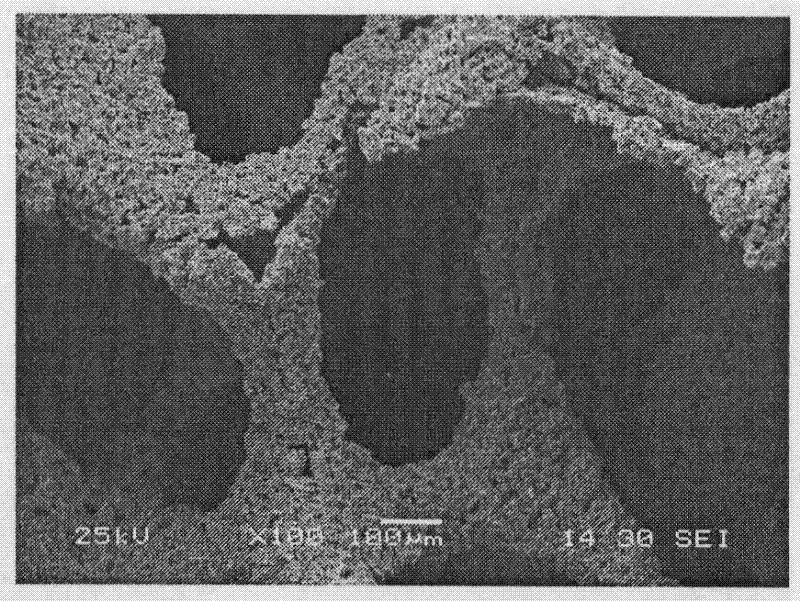

Porous tantalum serving as medical metal implanted material and preparation method thereof

ActiveCN102205144AReduce contentImprove mechanical propertiesMetal-working apparatusPharmaceutical delivery mechanismPorosityNeck structure

The invention relates to porous tantalum serving as a medical metal implanted material and a preparation method thereof. The porous tantalum has a pore three-dimensional communicating distribution foam structure, wherein a solution which is prepared from an organic adhesive and a dispersant and tantalum powder are adopted to prepare a tantalum powder slurry; the tantalum powder slurry is poured into an organic foam body and soaked until the tantalum powder slurry is filled in the pores of the organic foam body, drying is carried out so as to remove the dispersant in the organic foam body which is poured with the tantalum powder slurry, and ungreased treatment is carried out in the presence of inert gas so as to remove the organic adhesive and the organic foam body, and vacuum sintering is carried out so as to prepare the porous sintered body; on a foam framework which is formed by accumulated sintered pure tantalum powder, and a sintering neck structure exists among tantalum powder particles; and the tantalum powder is annealed in vacuum and subjected to conventional post-treatment. The porous tantalum has the advantages of high porosity, uniform and communicated porous distribution, uniform sintered microstructure particles, remarkable sintering neck, ensured excellent chemical performance and especially excellent ductibility.

Owner:CHONGQING RUNZE PHARM CO LTD

Method for coating metal implants with therapeutic mixtures

Disclosed herein are methods of treating an article surface. The method comprises delivering a polymer and drug to a medical implant having a porous surface and using at least one particle stream from at least one fluid jet to subsequently remove the polymer from the outer surface of the metal substrate, thereby retaining the therapeutic agent and polymer within the pores of the implant.

Owner:ENBIO

Metallic implants

InactiveUS20090204213A1Pharmaceutical delivery mechanismJoint implantsBiocompatibilityElectrochemistry

Disclosed is a method of preparing a medical implant. The biocompatible metal surface of the implant is subjected to electrochemical etching in an electrolyte solution to which a current has been applied.

Owner:DEPUY SYNTHES PROD INC

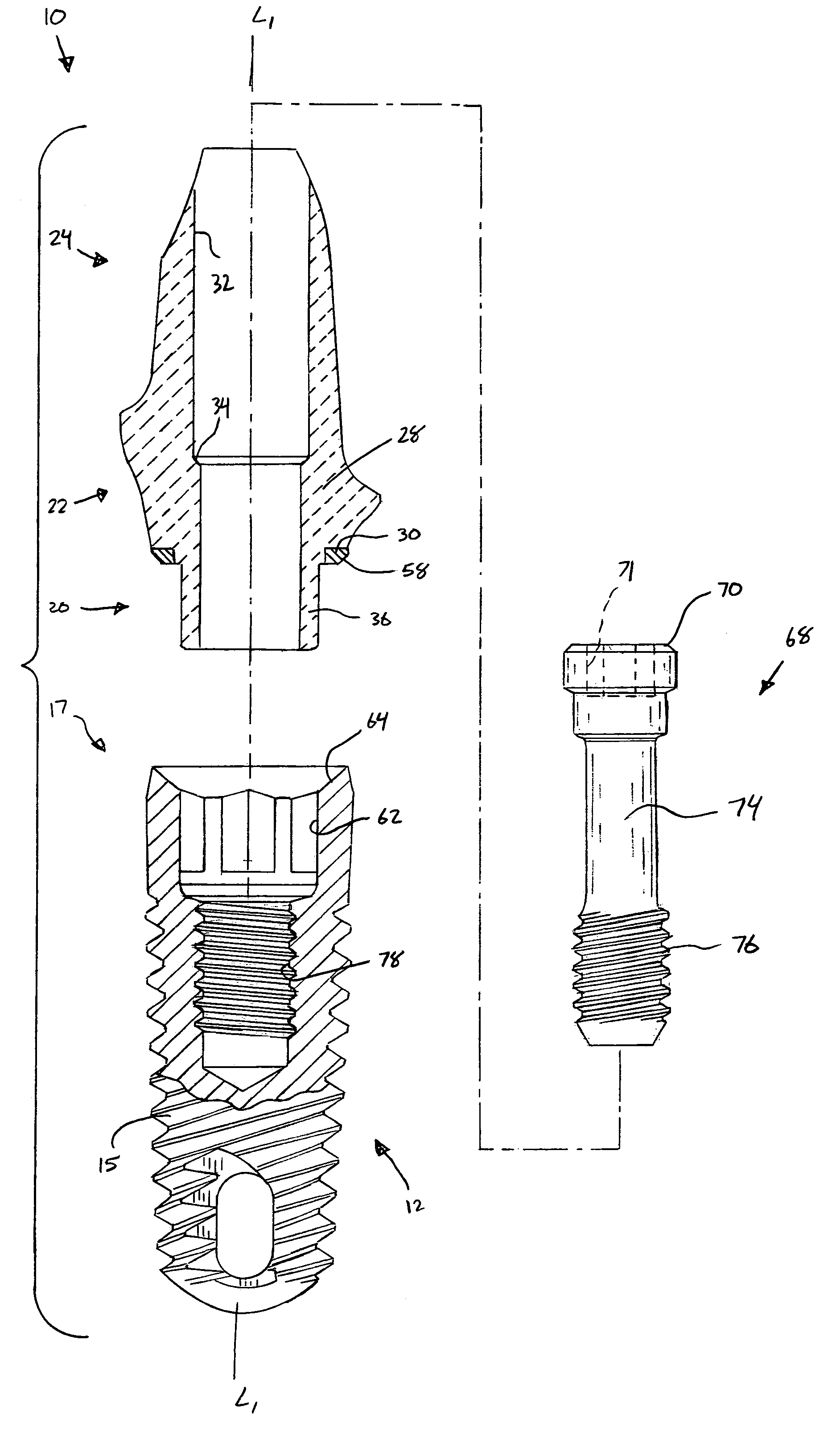

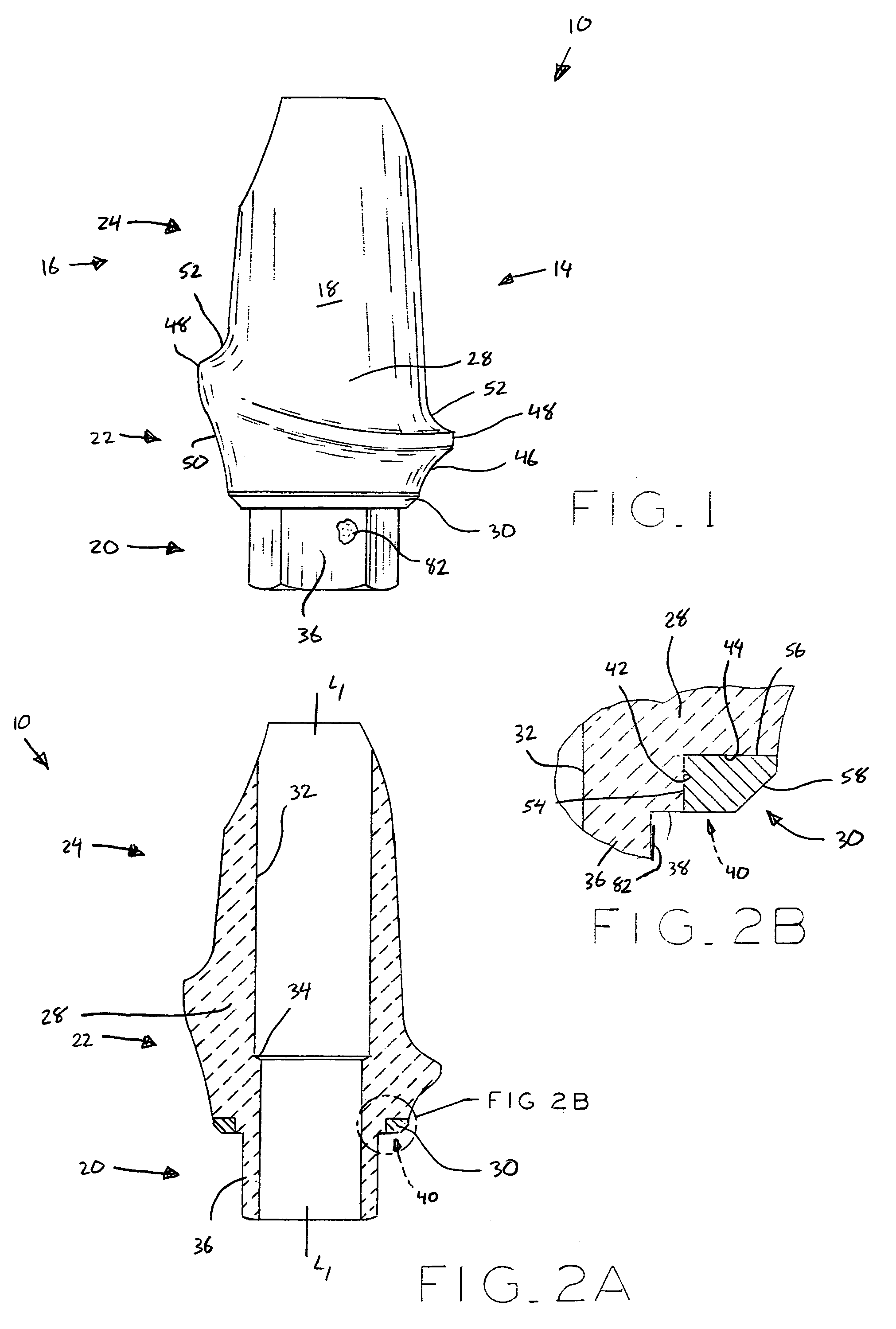

Ceramic/metallic dental abutment

A ceramic / metallic dental abutment for use with an implant, the abutment generally including a ceramic body portion having a base region, a transgingival region, and a supragingival region. The base region includes an anti-rotational implant interface, such as an external polygonal fitting, for engaging a cooperating internal polygonal fitting of an implant to prevent relative rotation between the abutment and the implant. The ceramic abutment body portion additionally includes a metal implant contact portion for contacting the implant and providing a load-bearing, metal-on-metal interface between the abutment and the implant.

Owner:ZIMMER DENTAL INC

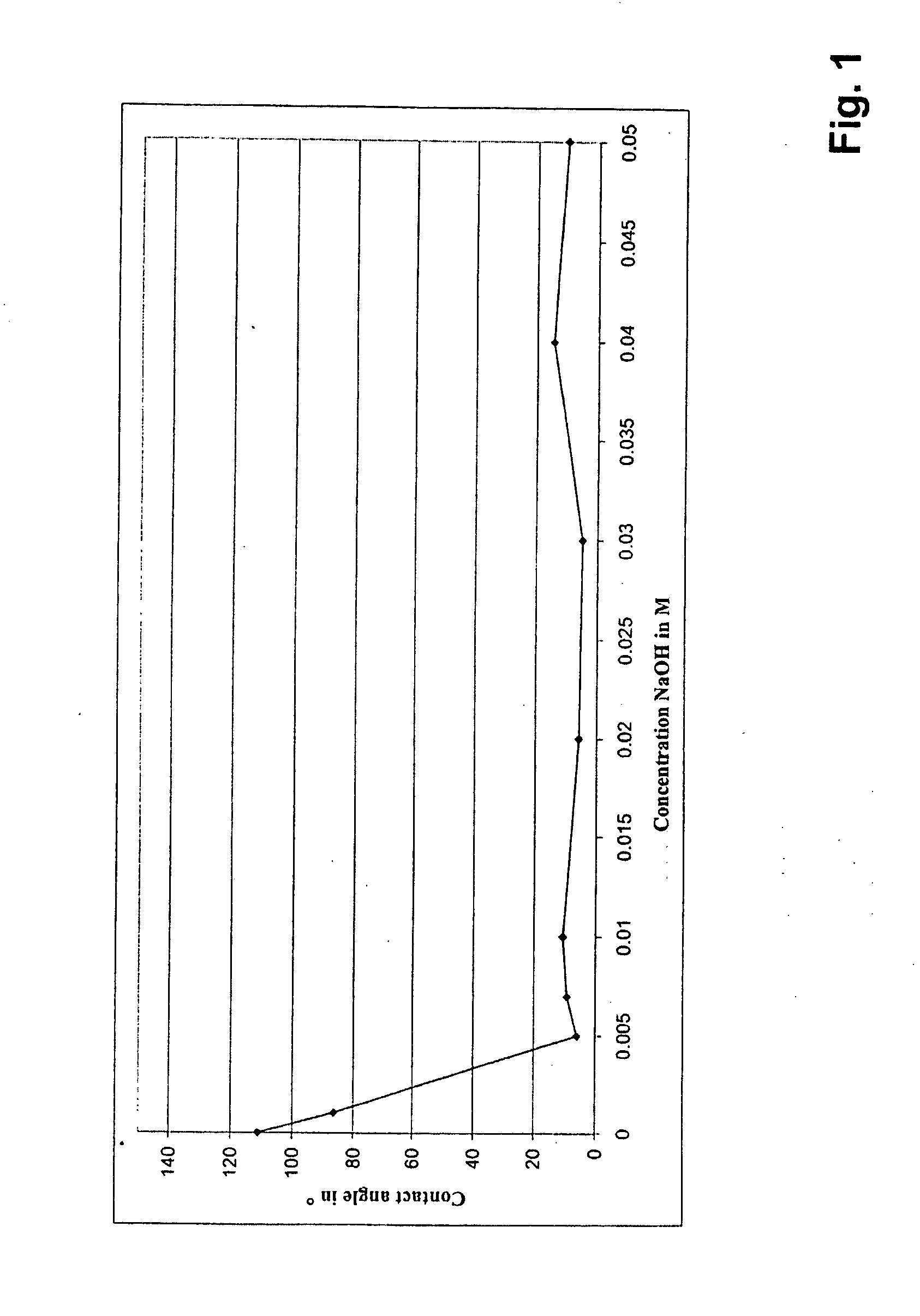

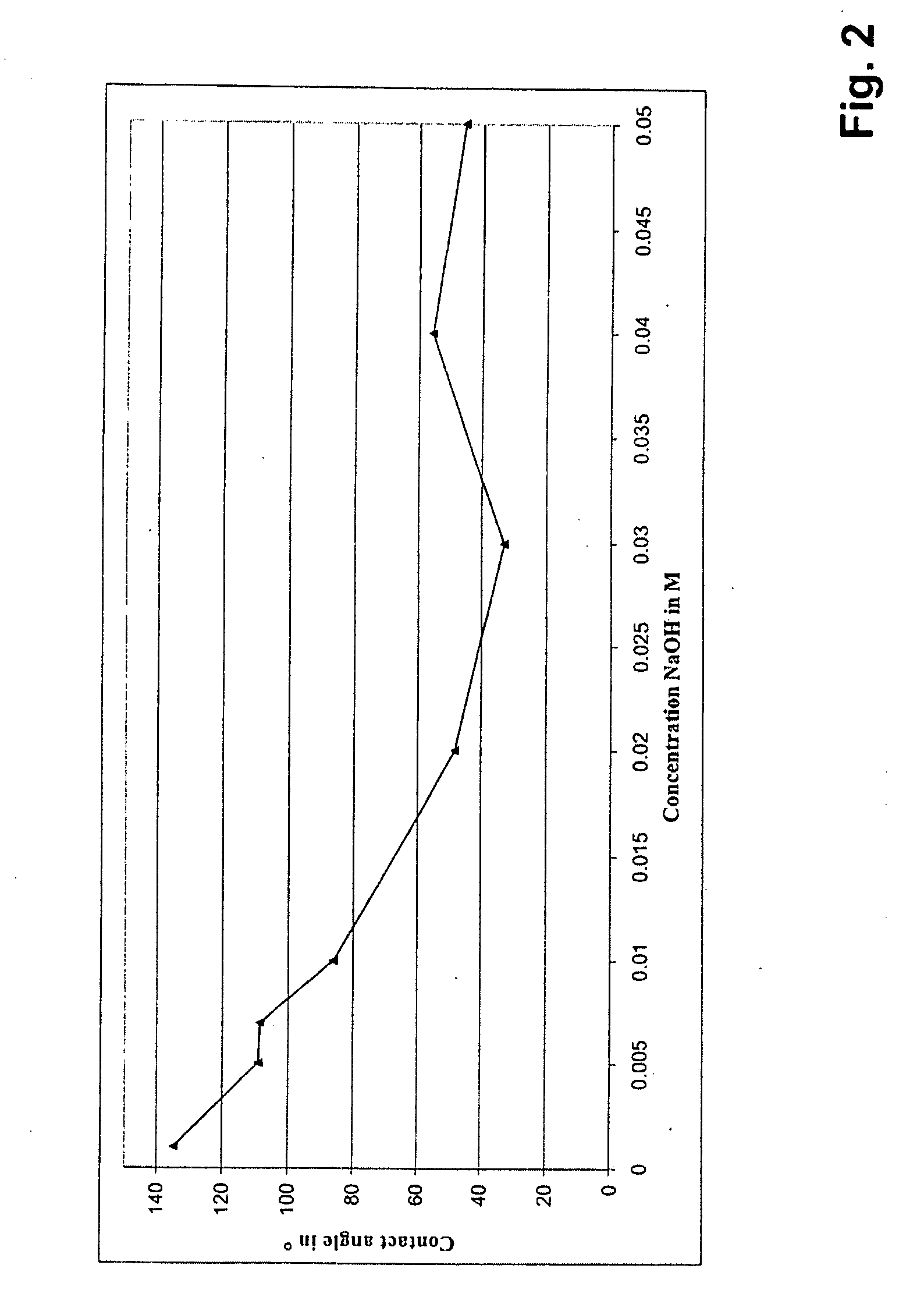

Implant, in particular dental implant

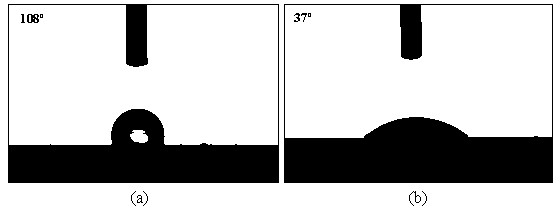

ActiveUS20100179665A1Quickly and lastingly anchored in hardGood osteointegrationDental implantsDiagnosticsOsseointegrationMaterial removal

A metal implant, in particular a dental implant, with a hydrophilic surface for at least partial insertion into a bone, and a method for the production of said implant are described. A particularly advantageous hydrophilic surface for improved osteointegration properties is made available if it is briefly treated, at least in some areas, in a weakly alkaline solution. These excellent osteointegration properties can be achieved in a method in which, optionally after a preceding mechanical surface modification by material removal and / or chemical surface modification, at least the areas exposed of this surface exposed to bone and / or soft tissue are chemically modified in an alkaline solution.

Owner:THOMMEN MEDICAL

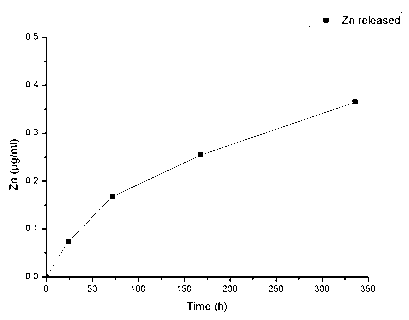

In-vivo controlled degradable bacteriostatic Mg-Ag-Zn-Mn magnesium alloy implant material and preparation method thereof

ActiveCN103614601AAvoid problems caused by non-degradableGood biocompatibilityProsthesisRare earthBiocompatibility Testing

The invention provides an in-vivo controlled degradable bacteriostatic Mg-Ag-Zn-Mn magnesium alloy implant material and a preparation method thereof. The material has an in-situ bacteriostasis function and comprises the following components in percentage by weight: 0.05-8.0% of Ag, 0.005-6.5% of Zn, 0.1-2.0% of Mn and the balance of Mg. The in-vivo controlled degradable bacteriostatic Mg-Ag-Zn-Mn magnesium alloy implant material not only can be used for solving the problem that the current clinic titanium and stainless steel metal implant materials are non-degradable in vivo, but also can be used for solving the problem that potential toxic elements such as rare earth or an aluminum element and the like exist in the traditional degradable biomedical magnesium alloy technology, has favorable biocompatibility and the mechanics and corrosion degradation matching performance, and also has a remarkable in-situ bacteriostasis effect so that the infection probability of an implanted part is effectively reduced.

Owner:SUZHOU ORIGIN MEDICAL TECH

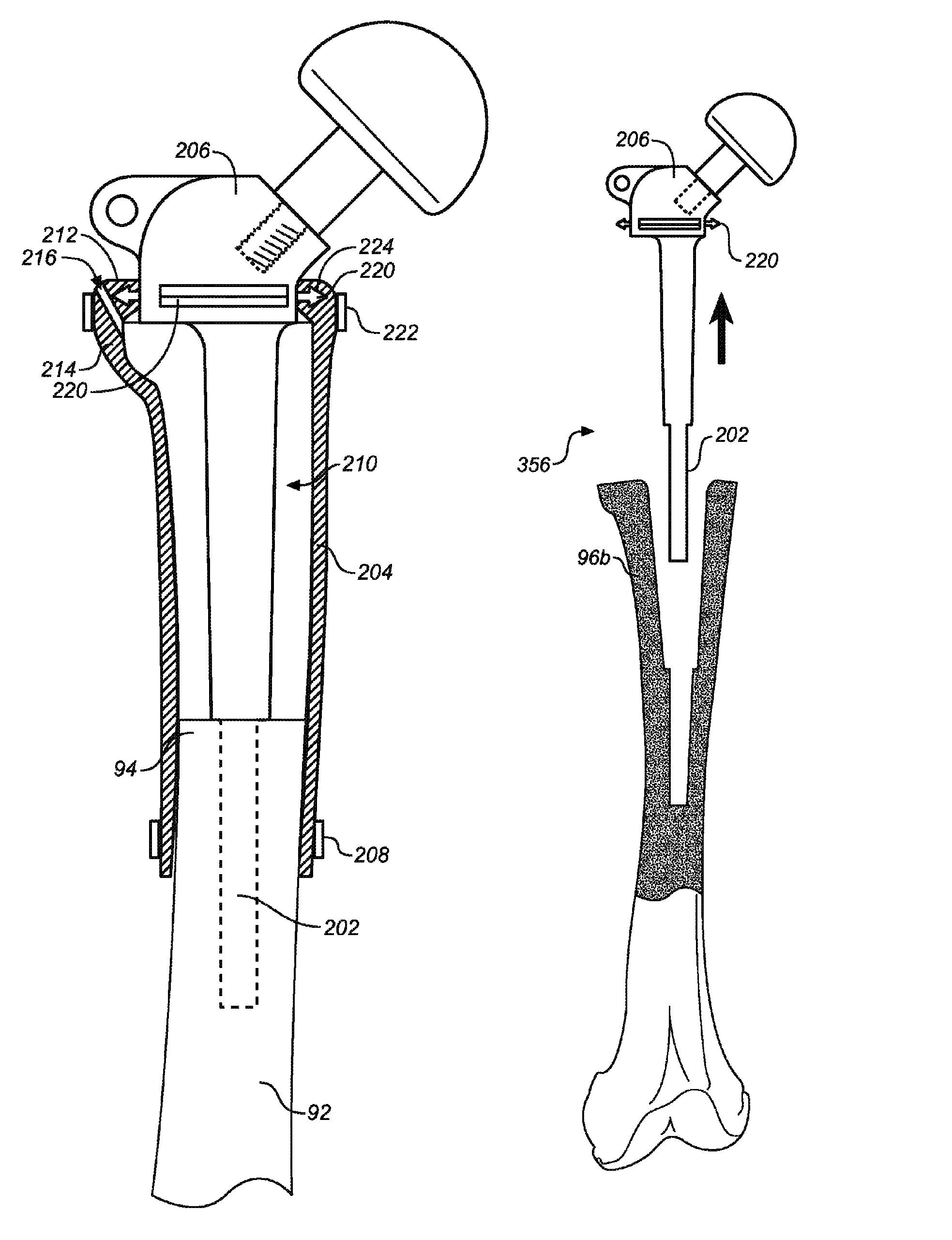

Device and method for reconstruction of osseous skeletal defects

ActiveUS8187336B2Immediate stabilizationSuture equipmentsAnkle jointsTotal knee replacementBone stock

A synovial joint implantable apparatus for the reconstruction of skeletal defects with a flexible member, which is preferably resorbable, attached to a rigid structural prosthesis such as a total hip or total knee replacement implant. The cavitary space defined and surrounded by the flexible member is filled with osteoconductive and / or inductive materials which eventually matures into new column of bone. The prosthesis is supported by the bed of graft material surrounding it and is gradually unloaded as the bed matures into solid bone. The fixation of the prosthesis into native bone depends on the specific implant and the anatomic area of its use. The flexible member is secured to the margins of the prosthesis using rails, runners, sutures, or other attachment devices that prevent the escape of the bone graft and maintain an initial column of support for the implant. Should the metal implant even need removal, the reconstituted bone can be separated from the implant in such a way as to restore bone stock and facilitate future revision surgical procedures.

Owner:JAMALI AMIR A

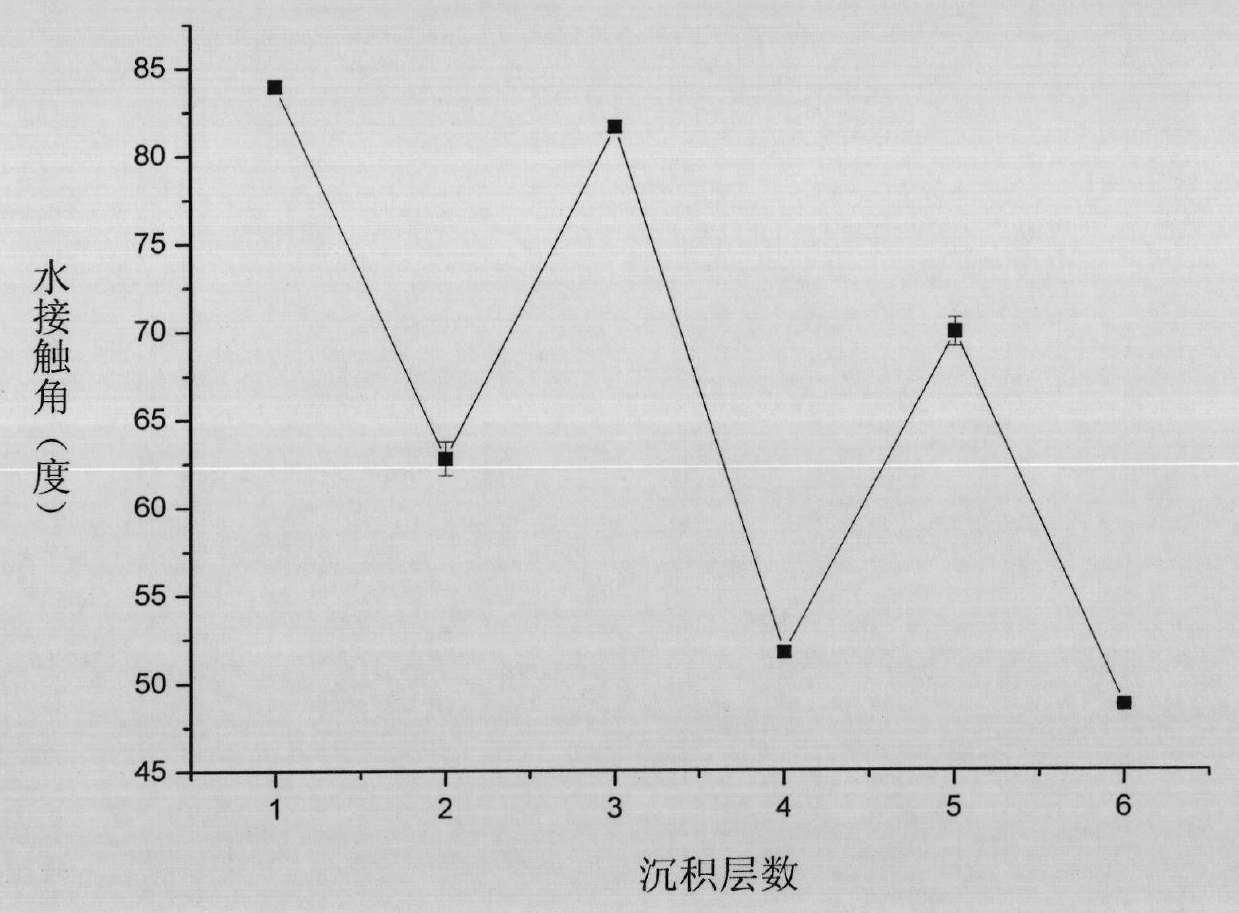

Biomedical calcium phosphate/zinc oxide nano-rod array composite coating on surface of medical metal and preparation method thereof

InactiveCN102793948AHydrophilic properties presentImprove biological characteristicsSolid/suspension decomposition chemical coatingProsthesisCalcium phosphate coatingDip-coating

The invention discloses a biomedical calcium phosphate / zinc oxide nano-rod array composite coating on the surface of a medical metal and a preparation method thereof. The biomedical calcium phosphate / zinc oxide nano-rod array composite coating is obtained by compounding biomedical calcium phosphate and a zinc oxide nano-rod array growing on the surface of a medical metal. One part of the biomedical calcium phosphate / zinc oxide nano-rod array composite coating comprises exposed zinc oxide nano-rod tips and the other part comprises calcium phosphate wrapping zinc oxide nano-rods. The biomedical calcium phosphate / zinc oxide nano-rod array composite coating has light-adjustable surface hydrophilicity and zinc ion slow-release properties. The preparation method comprises the following steps that a zinc oxide nano-rod array grows on the surface of a medical metal matrix with a zinc oxide crystal seed layer by a hydrothermal method; and a calcium phosphate coating is prepared by a sol-gel spin-coating method or a dip-coating method so that a part of zinc oxide nano-rods are exposed and calcium phosphate can wrap and strengthen the zinc oxide nano-rods. The biomedical calcium phosphate / zinc oxide nano-rod array composite coating has adjustable surface hydrophilicity and zinc ion slow-release properties and can be widely used for medical metal implants and other biomedical engineering fields.

Owner:ZHEJIANG UNIV

Ceramic/metallic dental abutment

InactiveUS20070202463A1Prevent rotationImprove wear resistanceDental implantsCeramic abutmentsCeramic metal

A ceramic / metallic dental abutment for use with an implant, the abutment generally including a ceramic body portion having a base region, a transgingival region, and a supragingival region. The base region includes an anti-rotational implant interface, such as an external polygonal fitting, for engaging a cooperating internal polygonal fitting of an implant to prevent relative rotation between the abutment and the implant. The ceramic abutment body portion additionally includes a metal implant contact portion for contacting the implant and providing a load-bearing, metal-on-metal interface between the abutment and the implant.

Owner:ZIMMER DENTAL INC

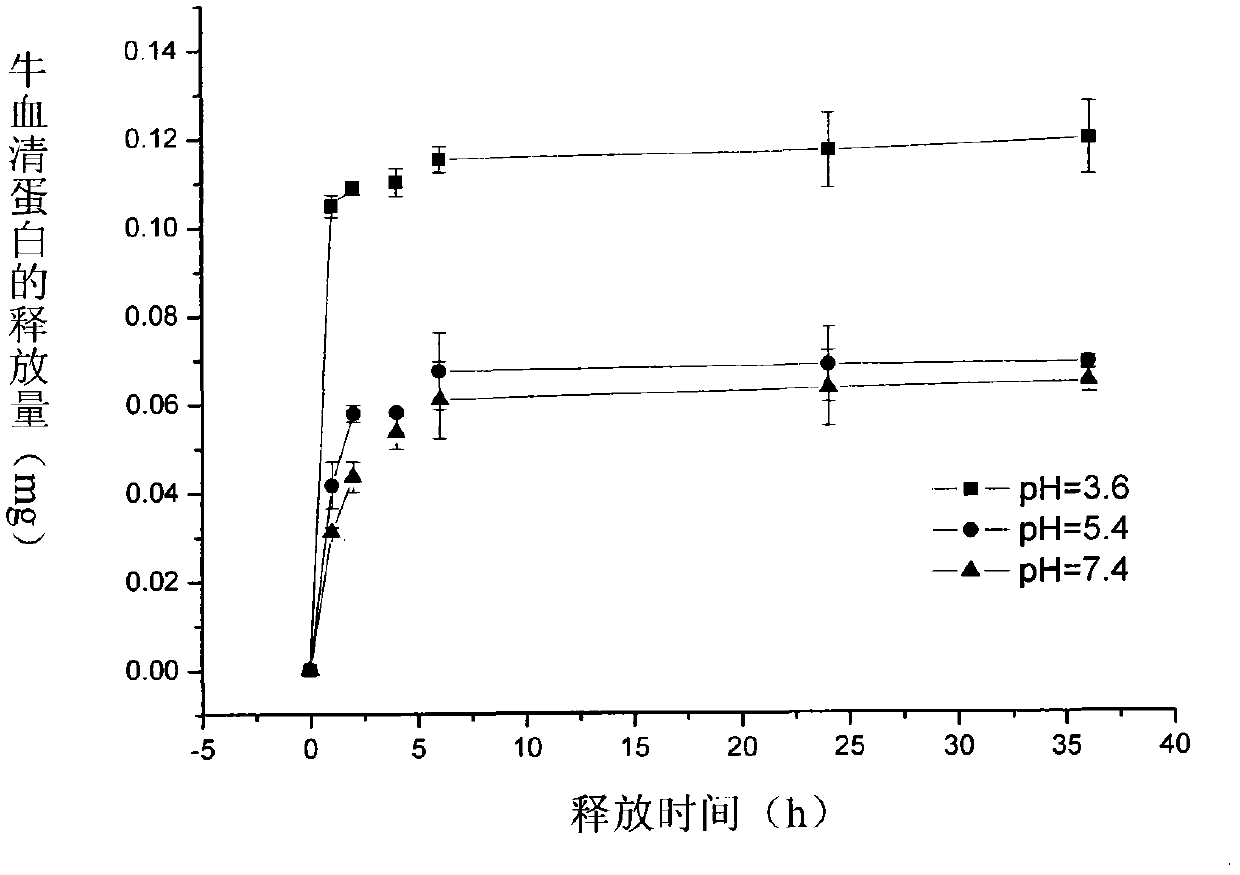

Metal implant with bioactive surface modification and preparation method thereof

InactiveCN102000360AProcess safetyMeet environmental protection requirementsSurgeryProsthesisComposite filmPolyetherimide

The invention discloses a bioactive surface modification method of a metal implant. In the method, chitosan and derivatives thereof with opposite charges are alternately assembled on the surface of the metal implant by a layered self assembly mode, wherein the thickness of a deposition film layer is less than 100nm. A preparation method of the metal implant comprises the following steps of: (1) placing the metal implant subjected to surface polishing and cleaning in a PEI(Polyetherimide) dilute solution and self-assembling to form a pretreatment layer with positive charges; (2) sequentially soaking the metal implant in chitosan and chitosan derivative dilute solutions with positive charges to obtain a multilayer self-assembling surface coating; and (3) continuously carrying out alternate assembly on effective active substances of growth factors, and the like and the chitosan derivatives with opposite charges on the surface of the self-assembling coating to obtain a composite film carrying active ingredients, wherein the active substances have slow release effect in the composite film. The coating of the invention improves the biocompatibility of the metal implant, and the preparation method is simple and accords with environmentally-friendly requirement.

Owner:SOUTH CHINA UNIV OF TECH

Fusion prosthesis

ActiveCN102319129APromote ingrowthGood for crawlingJoint implantsMachines/enginesArticular surfacesBone structure

The invention provides a fusion prosthesis. The fusion prosthesis is arranged between a first bone structure and a second bone structure to replace a bone structure between the first bone structure and the second bone structure; the fusion prosthesis comprises a prosthesis main body and a prosthesis fusion surface which is formed on the prosthesis main body; the prosthesis fusion surface is in fit with at least one of the first bone structure and the second bone structure; and the surface of the prosthesis fusion surface has a microcellular structure. The prosthesis main body is an equidimension metal implant which is manufactured according to computed tomography (CT) / magnetic resonance imaging (MRI) / ultrasound computed tomography (UCT) and other computed tomography data of a patient, the prosthesis fusion surface is built according to the replaced bone structure and is in fit with at least one of the first bone structure and the second bone structure; the microcellular structure of the surface of the prosthesis fusion surface contributes to crawling and ingrowing of bone cells; and after operation, the prosthesis fusion surface of the fusion prosthesis and at least one bony articular surface of at least one of the first bone structure and the second bone structure are subjected to sacralization so as to achieve long-term stability.

Owner:BEIJING AKEC MEDICAL

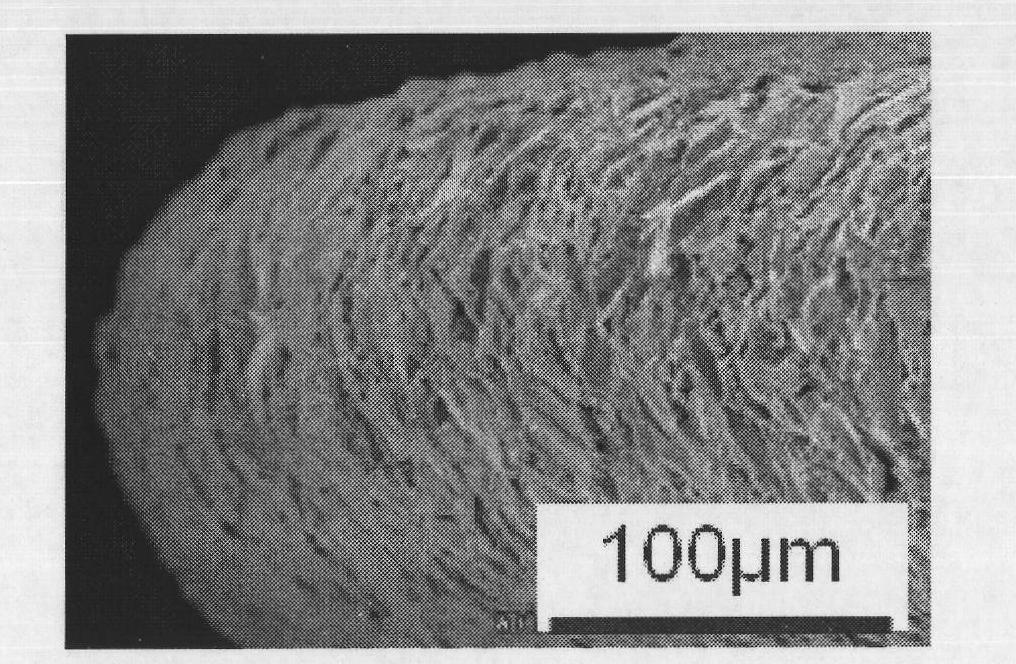

Method of fabricating medical devices and medical devices made thereby

A method of fabricating medical devices and medical devices made from the method of fabricating a medical device, the medical device, without being exhaustive, may be a medical instrument, an implant, a prosthetic, a body support structure or the like. The method includes work-hardening a work-hardenable metal to achieve a desired microstructure of the metal, then fabricating a medical device in accordance with the desired microstructure utilizing the work-hardened metal. In one form, the desired microstructure is an elongated grain structure. The medical device is created from the grain-elongated metal such that the medical device is oriented relative to the plane of grain elongation. In a particular form of the invention, the medical device is a curved spine plate wherein elongated grains of the work hardened metal are oriented in a plane normal to a curvature of the spine plate. Work-hardening includes forging, cold rolling or hot rolling, and annealing prior to use in medical device fabrication. This creates a metal implant stock that has more strength and flexibility in compression and bending than without undergoing the present work-hardening. These properties are exploited in medical device design, fabrication, fabrication orientation and / or the like to create medical devices such as super strong implants.

Owner:LIFE SPINE INC

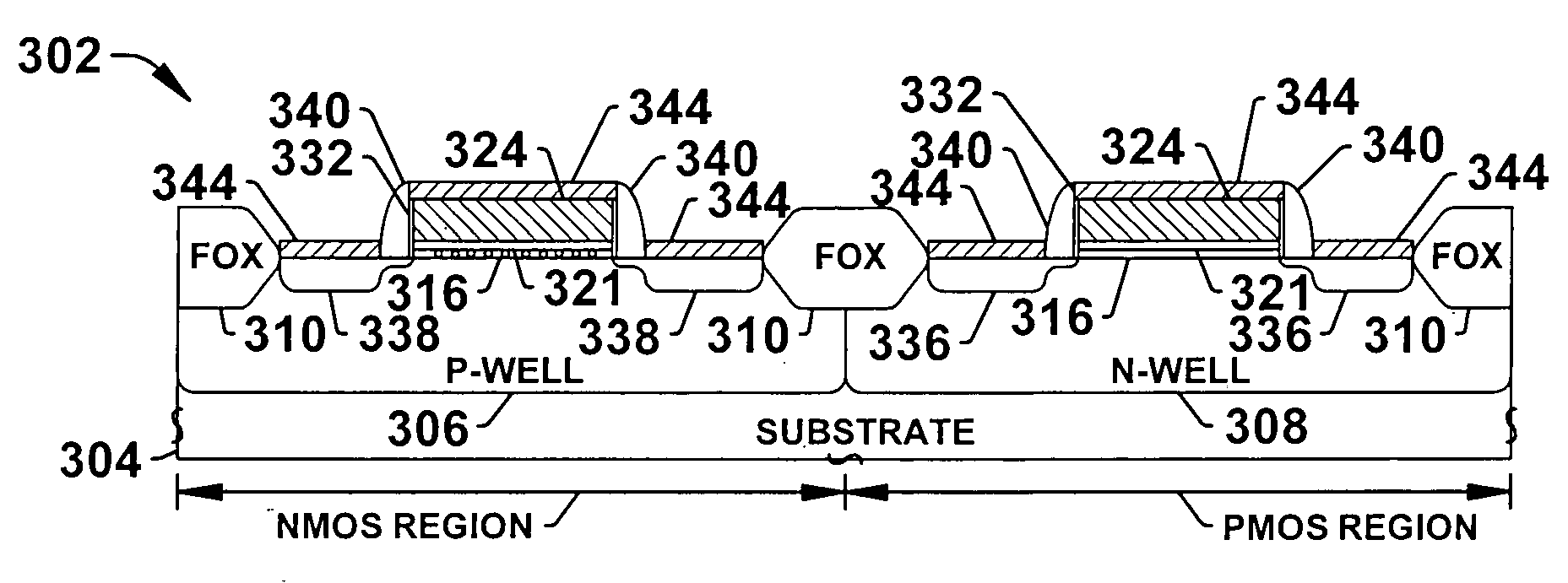

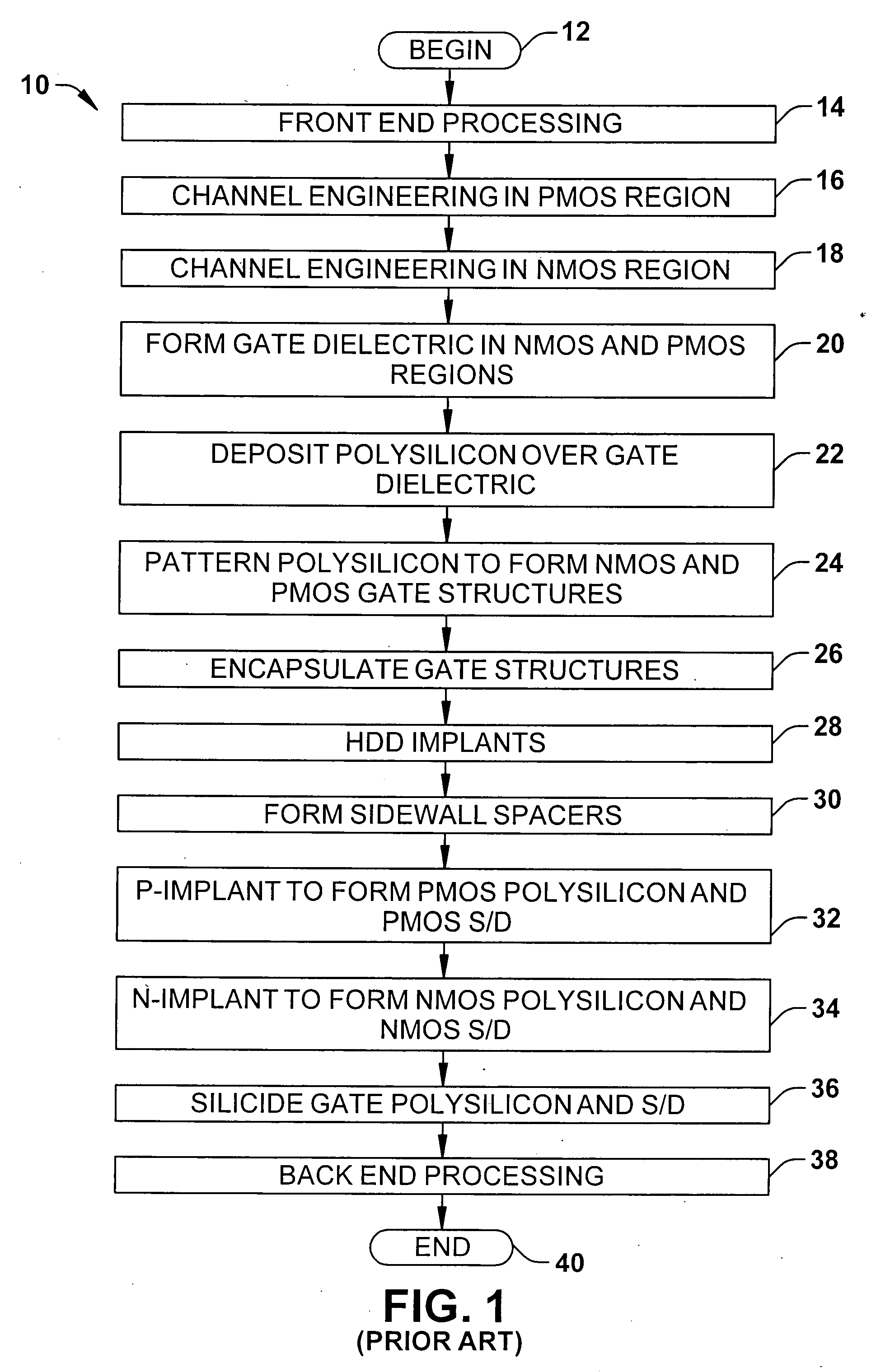

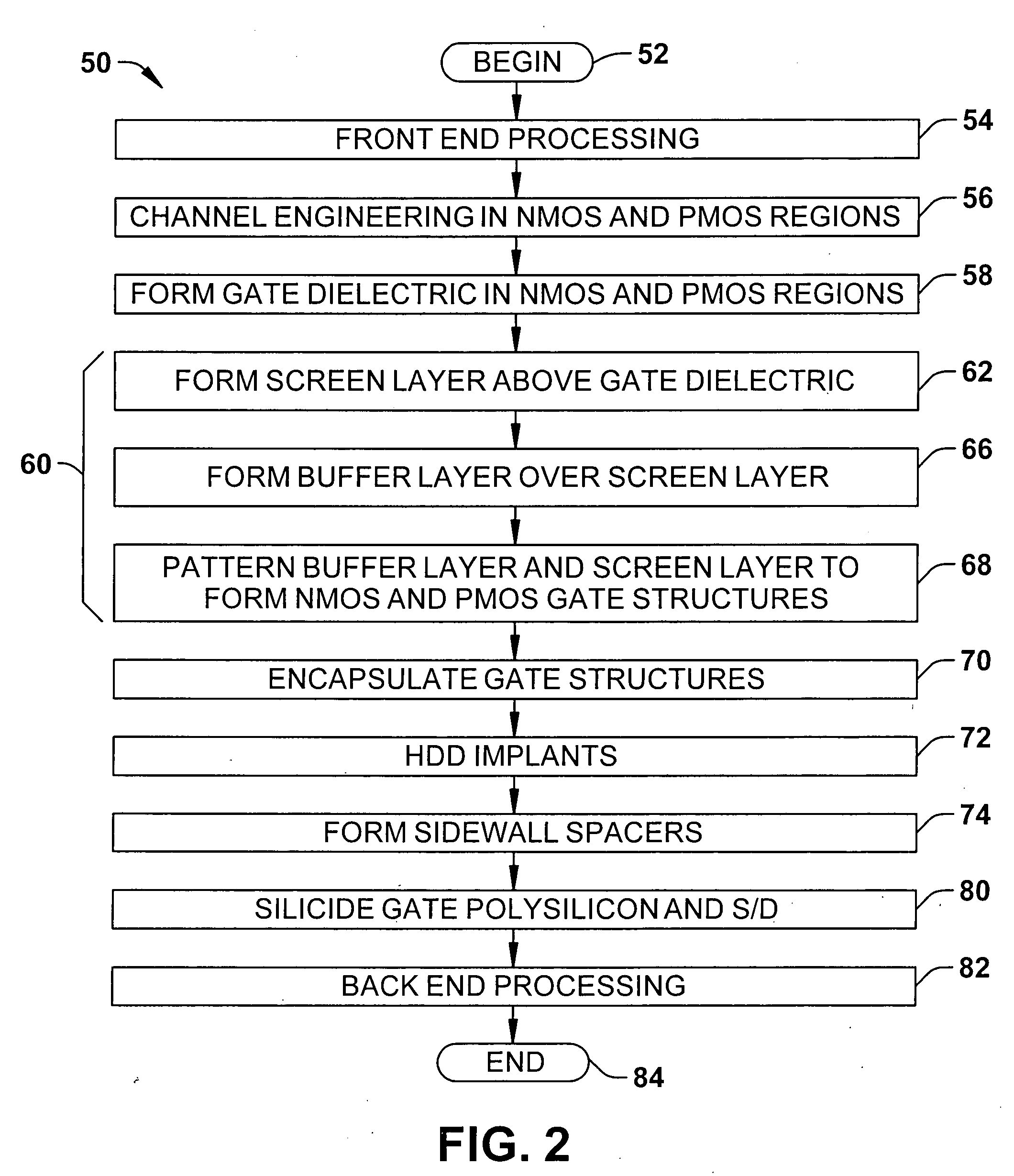

Lanthanide series metal implant to control work function of metal gate electrodes

Semiconductor devices and fabrication methods are provided, in which metal transistor gates are provided for MOS transistors. Metal nitride is formed above a gate dielectric. A lanthaide series metal is implanted into the metal screen layer above the gate dielectric. The lanthaide metal is contained in the screen layer or at the interface between the screen metal layer and the gate dielectric. This process provides adjustment of the gate electrode work function, thereby tuning the threshold voltage of the resulting PMOS or NMOS transistors.

Owner:TEXAS INSTR INC

Multi part non metal implant

An implant is disclosed comprising a fixture component (1) intended for insertion into a bone, and at least one further abutment component (3) for providing a base for a prosthetic superstructure, and a connecting element (9) for mechanically securing the abutment (3) to the fixture (1), wherein the fixture (1) comprises an external thread (16) or other protrusions for improving engagement between the fixture (1) and the bone, wherein the connecting element (9) detachably interconnects the fixture (1) and the abutment (3), and wherein at least the fixture (1) and the abutment (3) are made of non-metal material, and method of making the same.

Owner:FRIADENT

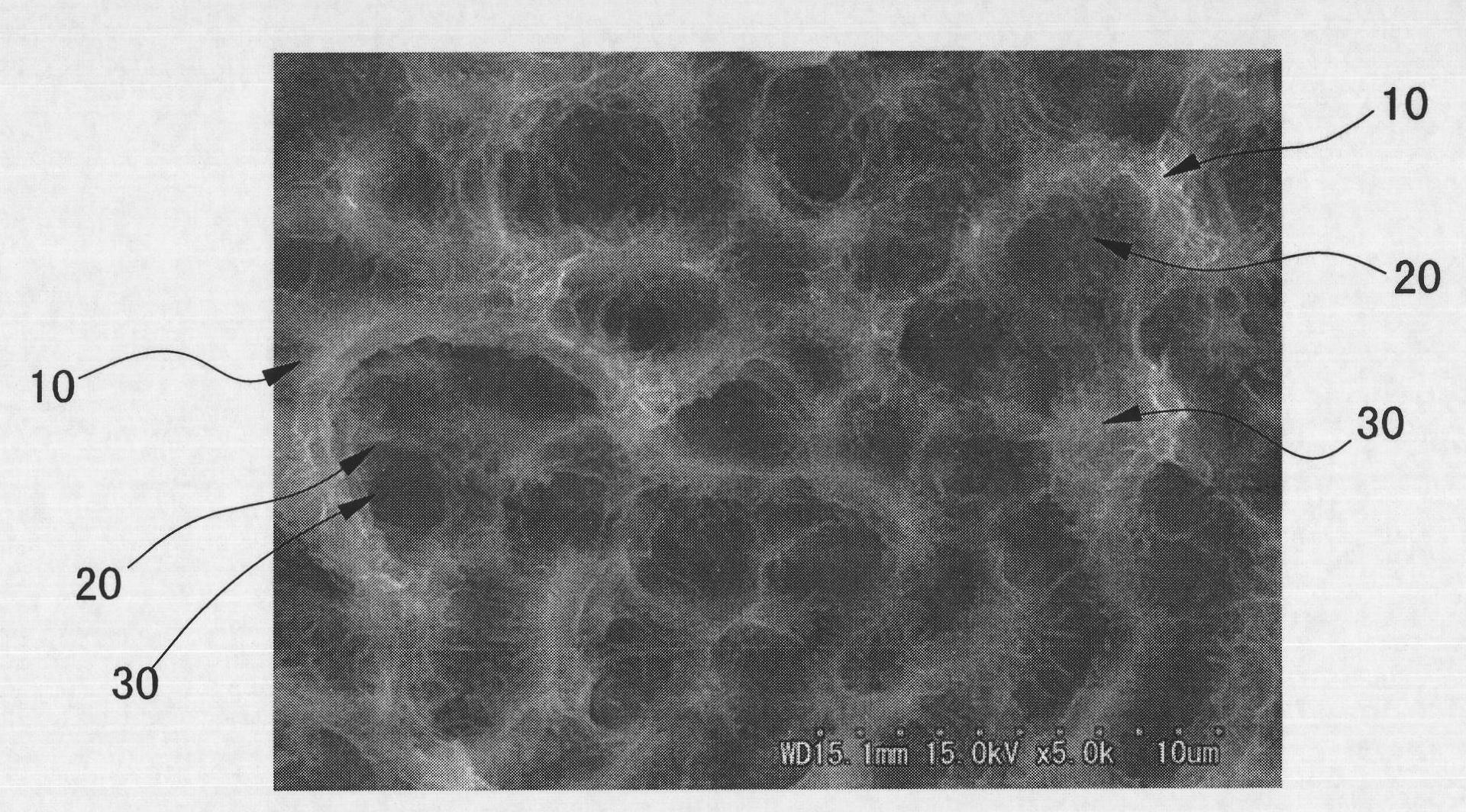

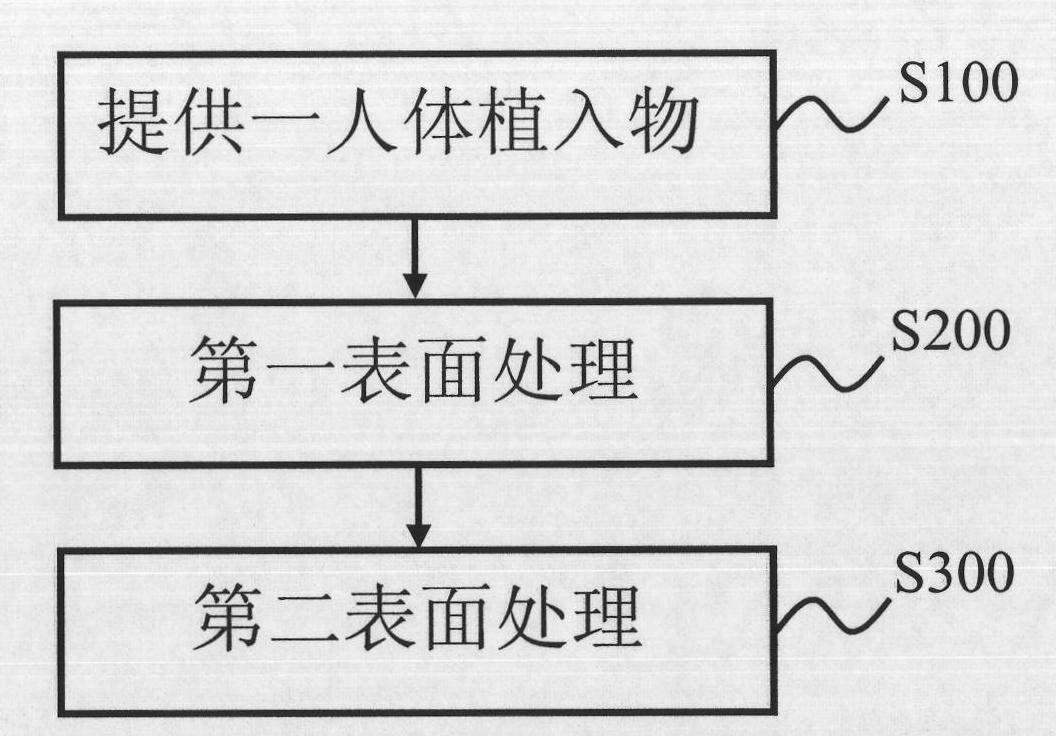

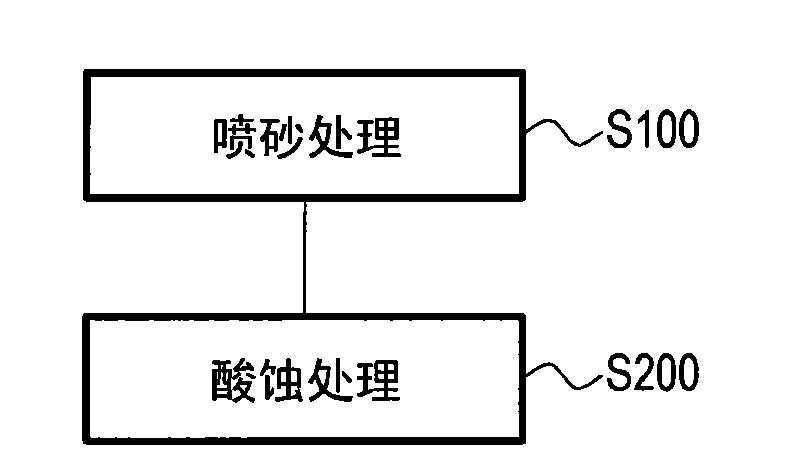

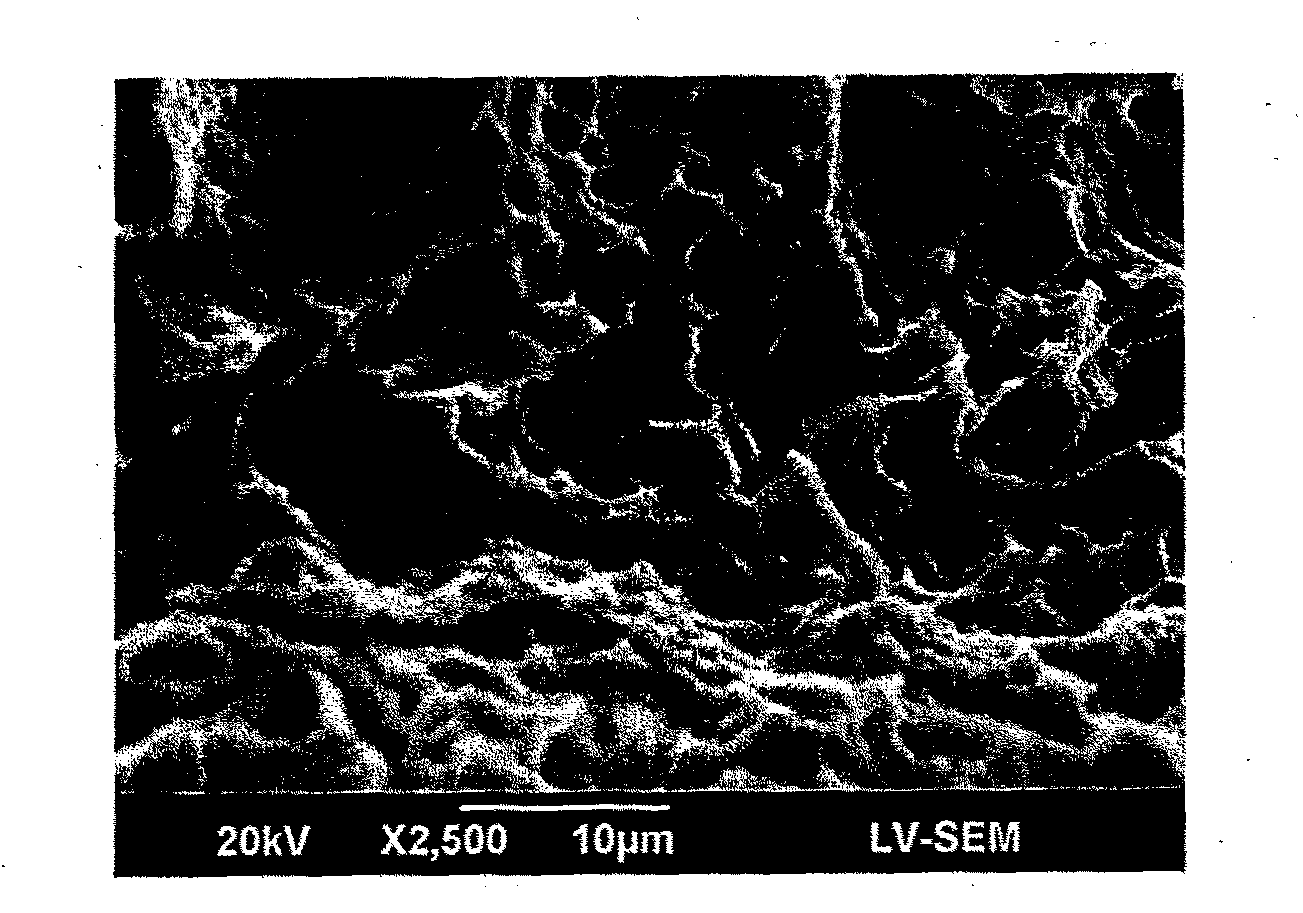

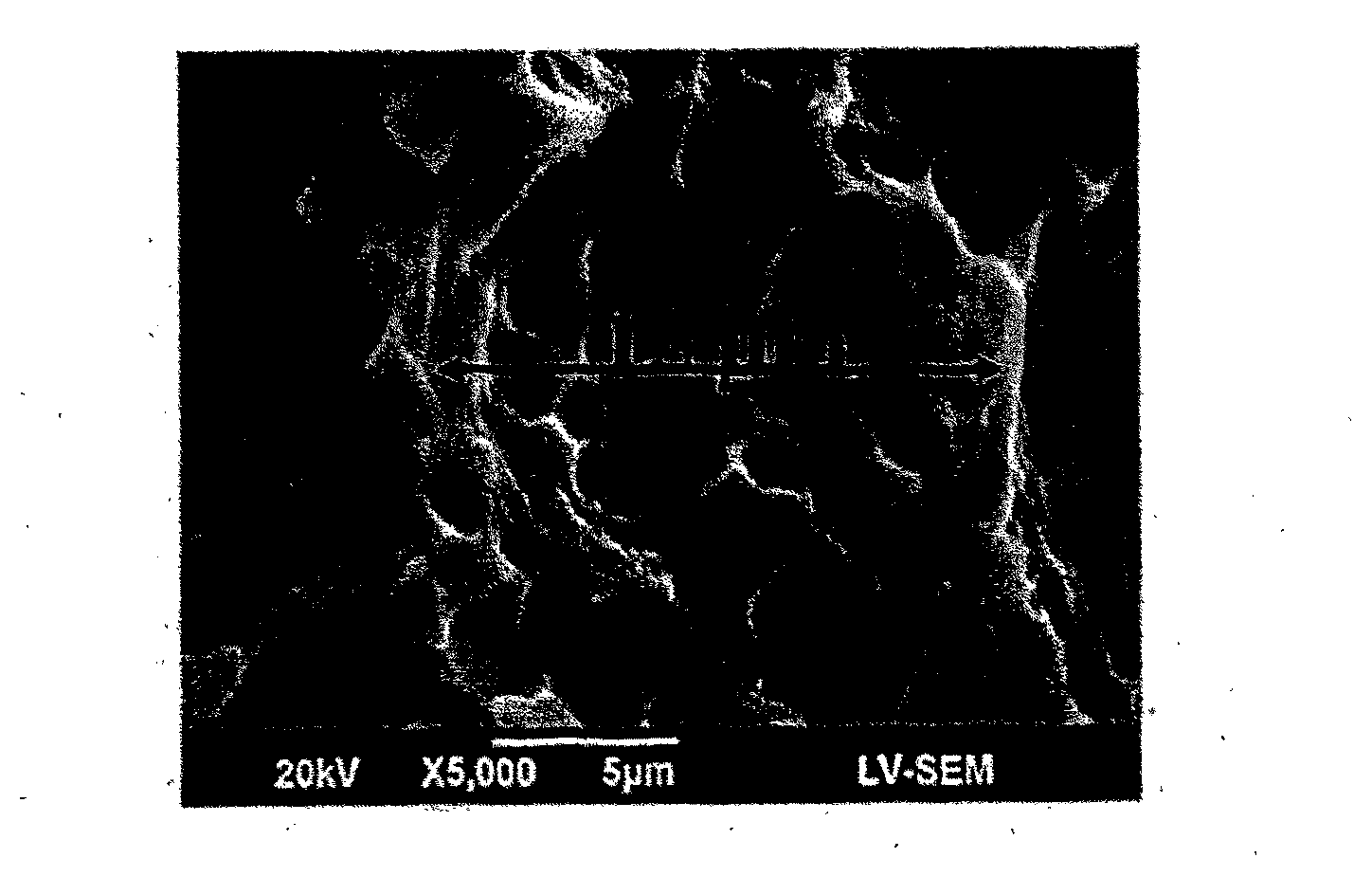

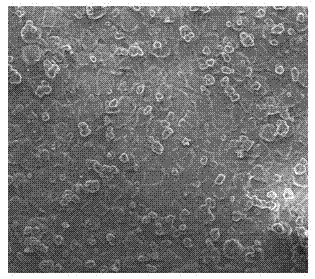

Metal implant and surface treatment method thereof

The invention discloses a metal implant and a surface treatment method thereof. A plurality of micron-sized pits are arranged on the surface of the metal implant, the micron-sized pits comprise a nano-sized fiber network, the aperture of the micron-sized pits is 1 micron to 100 microns, the nano-sized fiber network contains a plurality of nano-sized holes, and the aperture of the nano-sized holes is 10 nanometers to 1000 nanometers. The method comprises the following steps: providing the metal implant; performing primary surface treatment on the surface of the metal implant so as to form the plurality of micron-sized pits on the surface of the metal implant; and performing secondary surface treatment on the surface of the metal implant so as to form the nano-sized fiber network in the micron-sized pits, wherein the nano-sized fiber network contains the plurality of nano-sized holes, and the aperture of the nano-sized holes is 10 nanometers to 1000 nanometers. The external micro-sized pits can protect the structure of the nano-sized fiber network and reduce the risk of damaging the structure of the nano-sized fiber network during an implantation operation.

Owner:METAL INDS RES & DEV CENT

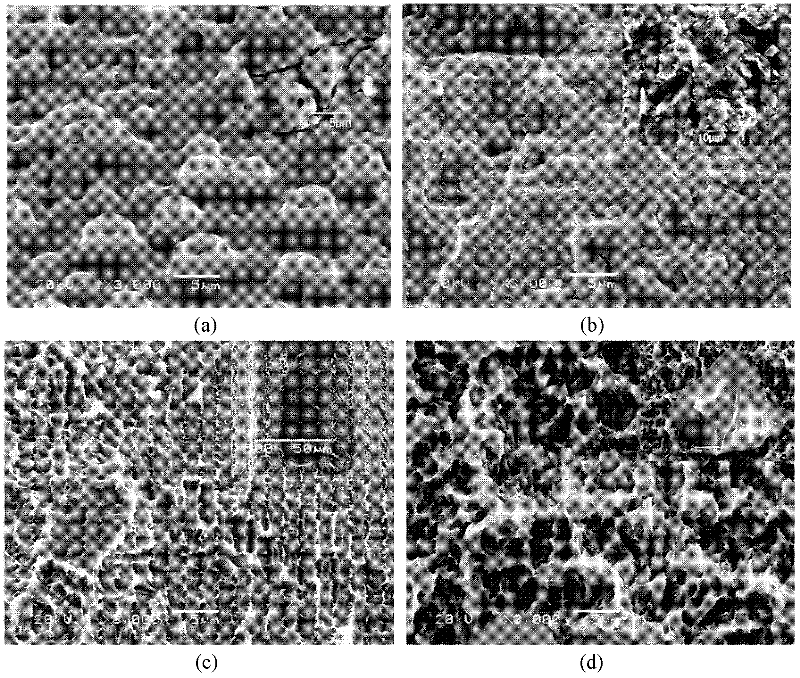

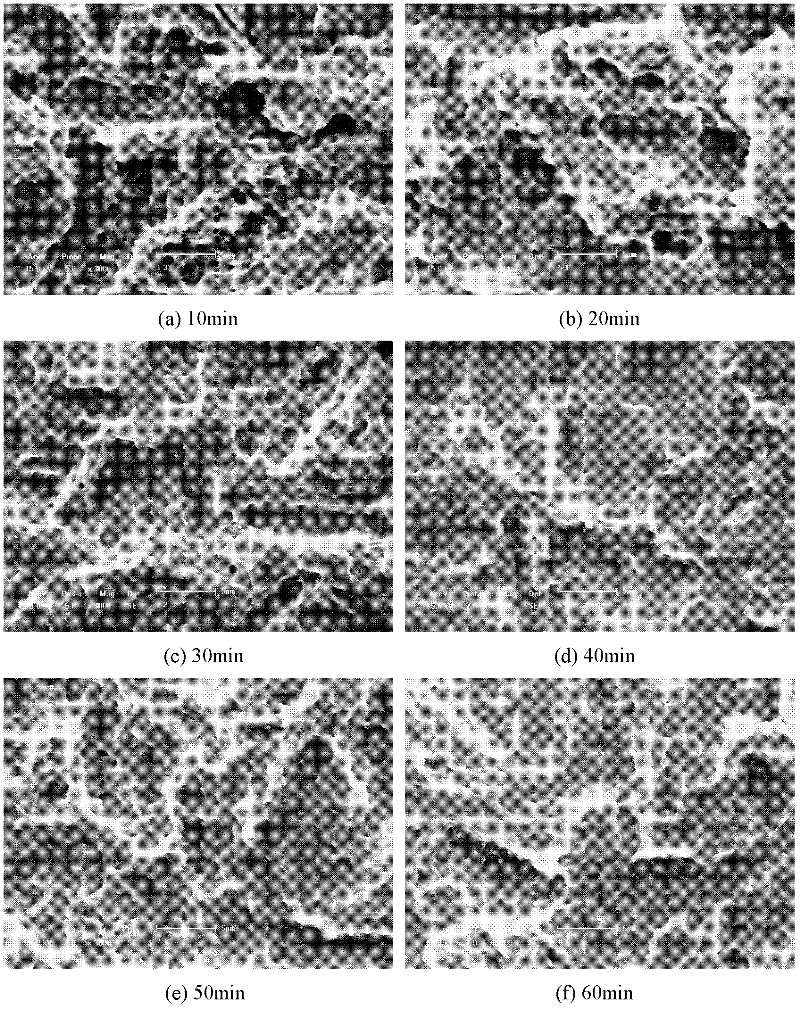

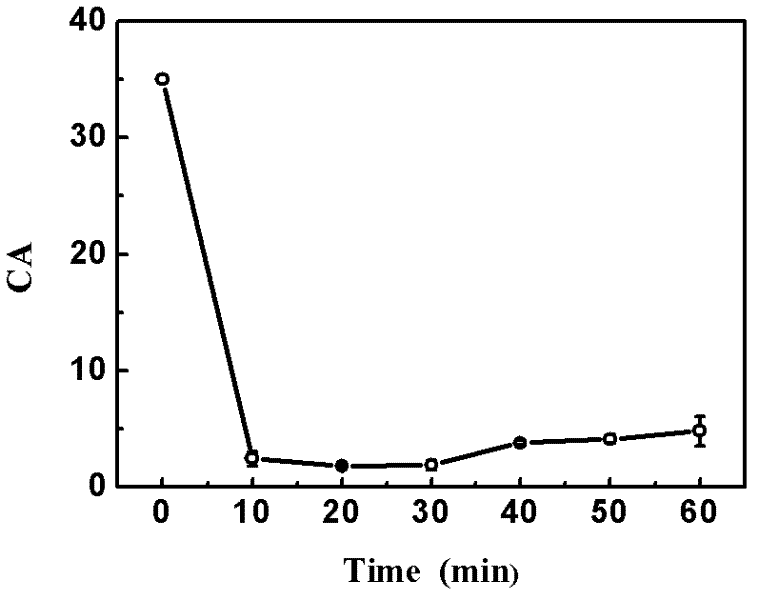

Preparation method for wettability controllable porous structure of titanium and titanium alloy surface

InactiveCN102345134AImprove bindingAchieve freedom of controlChemical vapor deposition coatingOsteoblast adhesionTitanium alloy

The invention discloses a preparation method for a wettability controllable porous structure of a titanium and titanium alloy surface, and belongs to the technical field of surface modification of biological implant materials. The method comprises the following steps of: performing roughening treatment on the titanium and titanium alloy surface by using a sand-blast, large-grit and acid-etch method (SLA) to prepare a super-hydrophilic surface with a micron-nano double-microcosmic pore structure; preparing a titanium oxide thin film with hydrophilic performance by using a plasma oxidation process, wherein osteoblast adhesion and proliferation experiments show that the surface prepared by the process method has excellent bioactivity; and finally, forming a hydrophobic surface on a rough titanium oxide surface by using a molecular self-assembly method and realizing mutual switching between hydrophilicity and hydrophobicity of the surface by using plasma treatment and ultraviolet irradiation. The hydrophilicity of the surface of an implant is obviously improved in the aspects of stability, durability and the like; and the binding force of the metal implant material and a surface coating can be obviously improved while the bioactivity of the titanium and titanium alloy surface is guaranteed.

Owner:蔺增

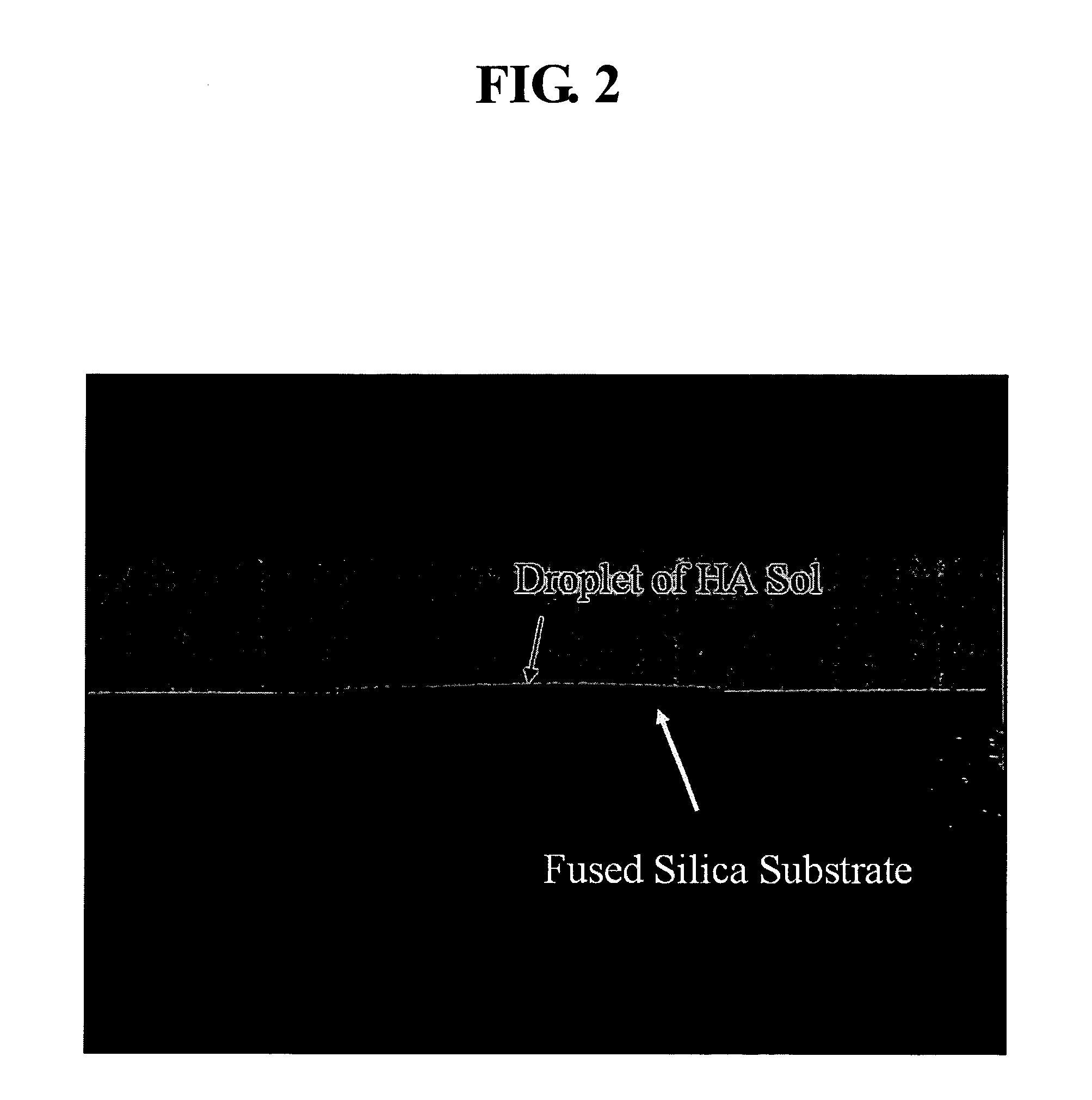

Method for producing polymeric sol of calcium phosphate compound and method for coating the same on a metal implant

ActiveUS20050158399A1Improve wettabilityExcellent bioactivityDental implantsBiocideTriethylphosphiteApatite

Disclosed is a method for producing a transparent and homogenized polymeric sol of a calcium phosphate compound, containing apatite and having excellent wettability and bioactivity, according to a sol-gel synthesis, and a method for coating the polymeric sol on a metal implant, in which the polymeric sol is coated on the metal implant and then heat-treated to form a dense coated layer strongly bonded to the metal implant. The polymeric sol is obtained by process of preparing a calcium salt solution, containing calcium ethoxide dissolved in organic acid, and a phosphate solution, containing triethyl phosphite or triethyl phosphate dissolved in the organic acid, mixing the calcium salt solution with the phosphate solution to produce a mixed solution, and aging the mixed solution.

Owner:SEOUL NAT UNIV R&DB FOUND

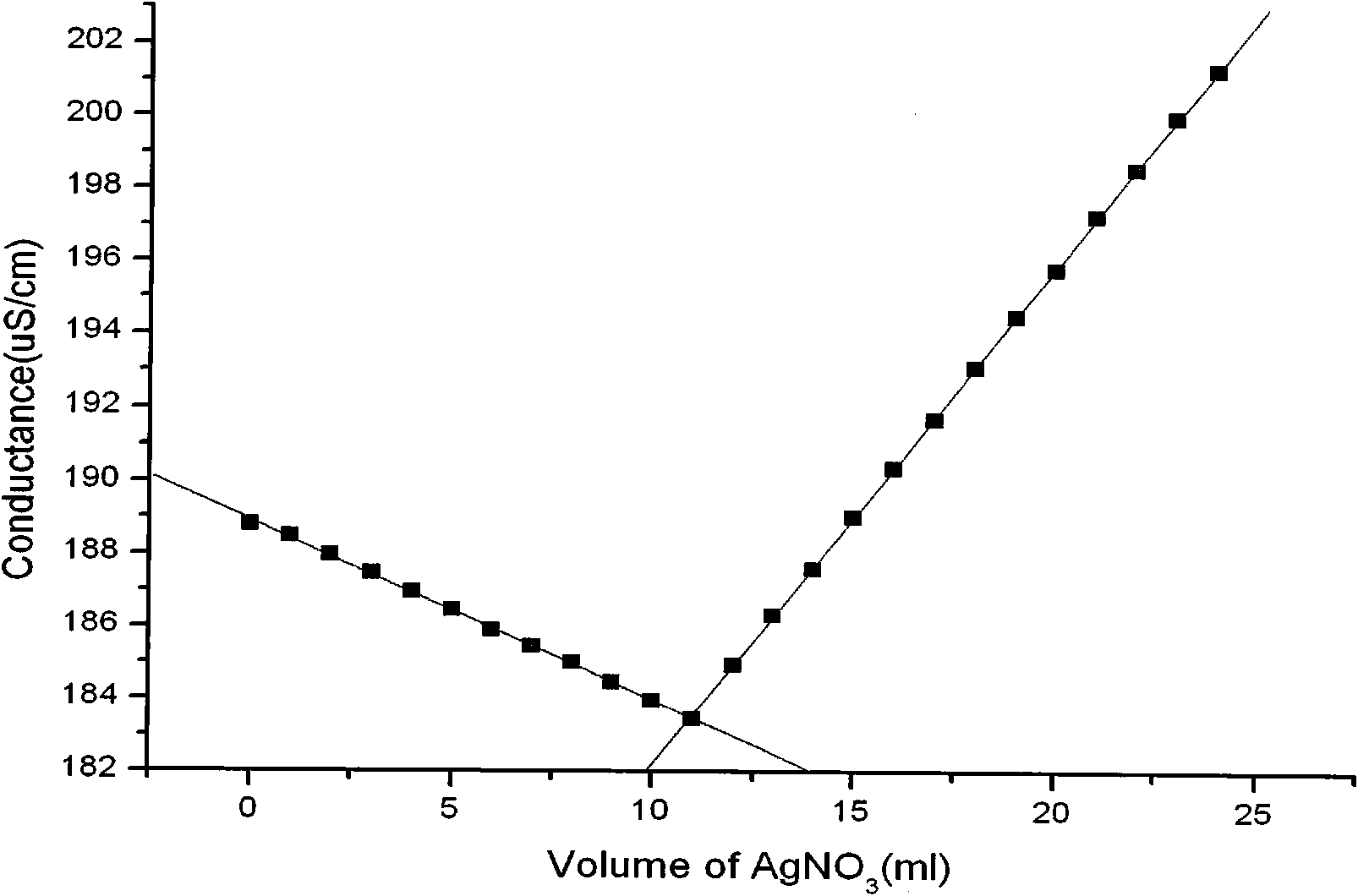

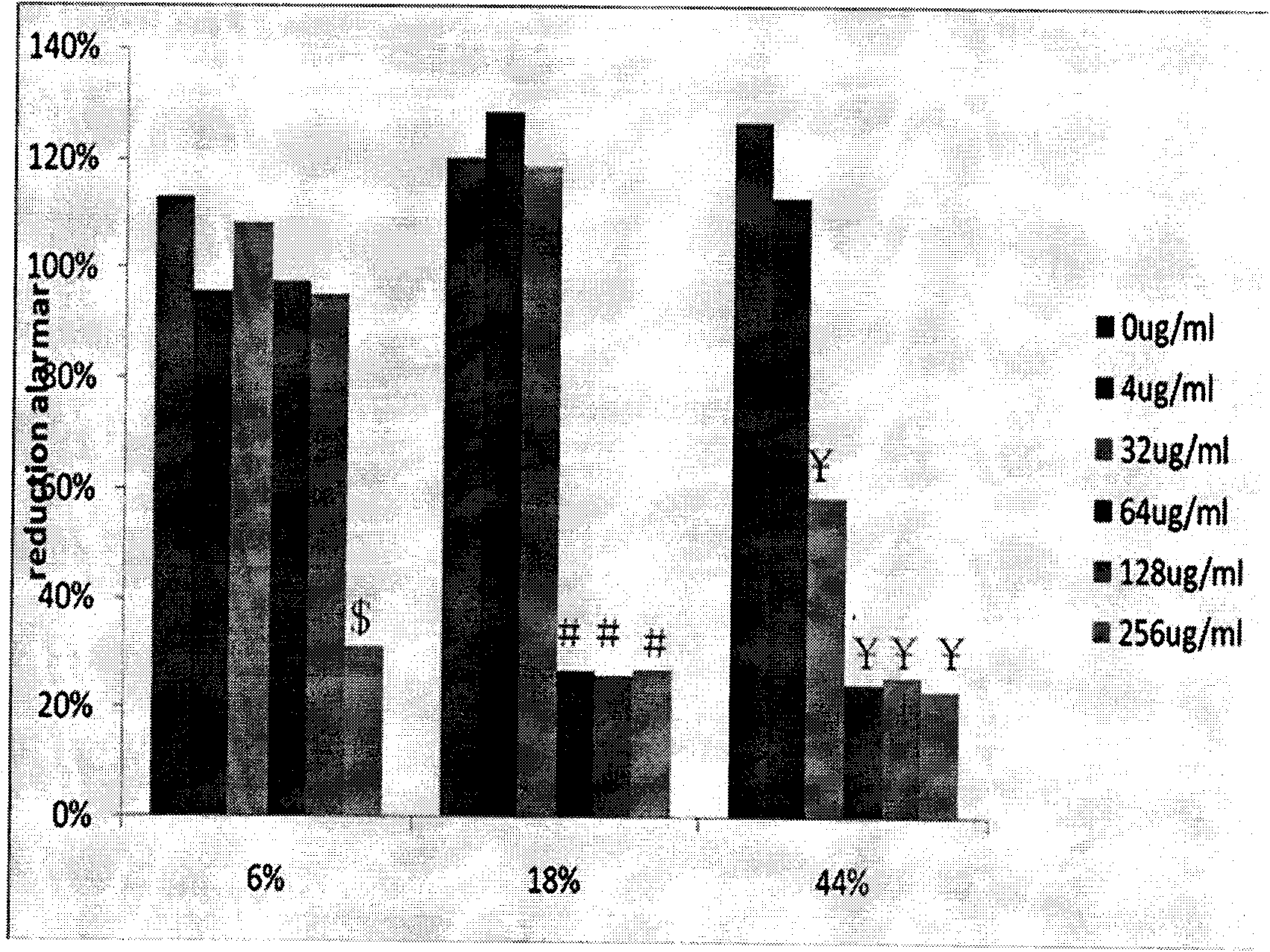

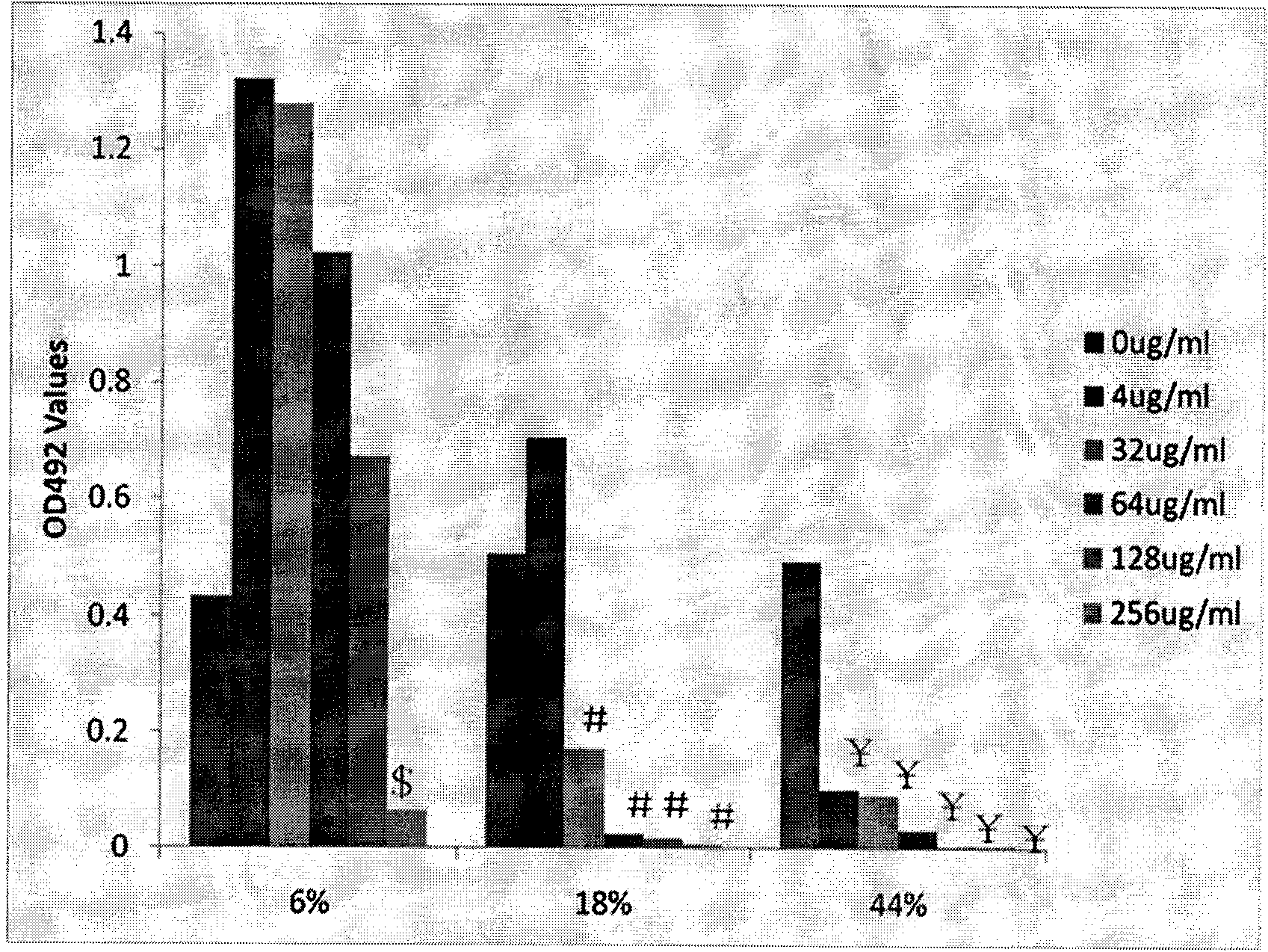

Quaternary ammonium salt of chitosan and application thereof

InactiveCN101935364APrevent mass colonizationReduce the risk of postoperative infectionCoatingsProsthesisOsseointegrationWound dressing

The invention relates to a quaternary ammonium salt of chitosan and application thereof. A substitution value of the quaternary ammonium salt of chitosan is 6-44 percent. As an optimized technical scheme, the substitution value of the quaternary ammonium salt of chitosan is 18 percent. The invention also provides new application of the quaternary ammonium salt of chitosan. The invention not only invents the anti-infective effect of the quaternary ammonium salt of chitosan with the substitution value of 6-44 percent, but also invents the influence on cell proliferation, osteogenic differentiation and osseointegration, thereby more comprehensively reflecting the application effect of the quaternary ammonium salt of chitosan with the substitution value of 6-44 percent. The quaternary ammonium salt of chitosan with the substitution value of 6-44 percent can be expected to exert the anti-infective function on surface coating layers of various metal implants of osteopathic joint prosthesis, nail plates, intramedullary nails, and the like and can be additionally used as bone substitute materials, wound dressing materials, and the like to play a role.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE +1

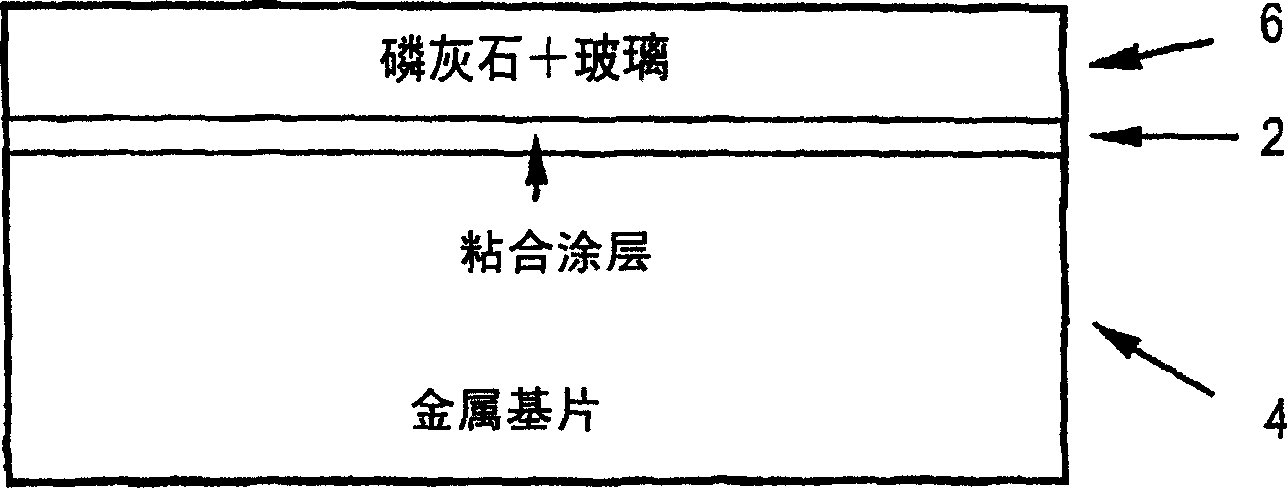

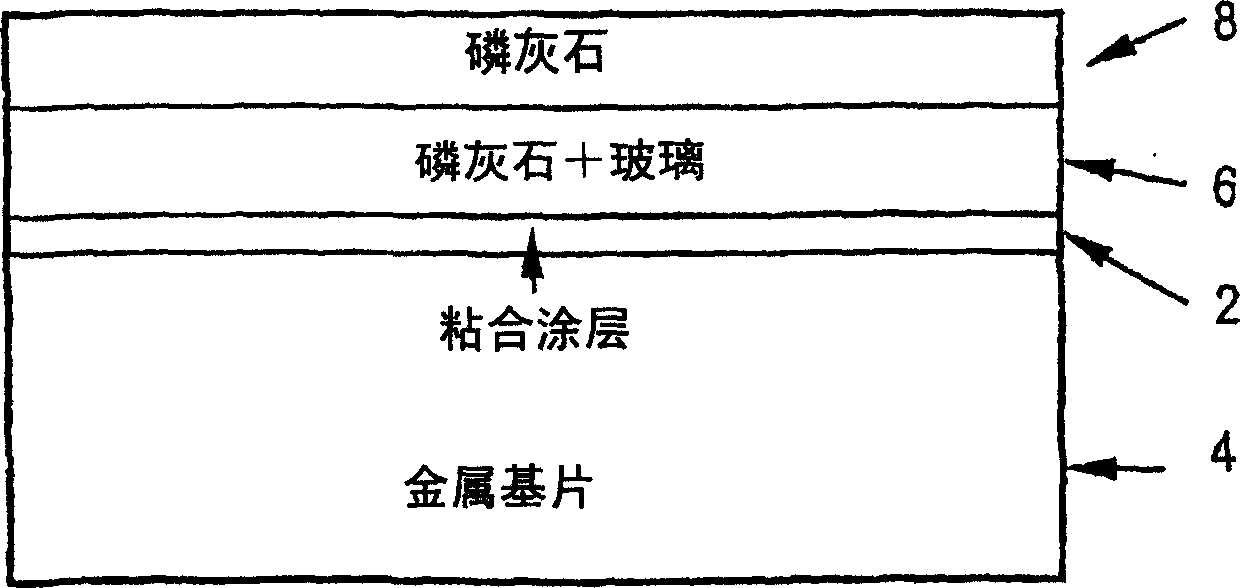

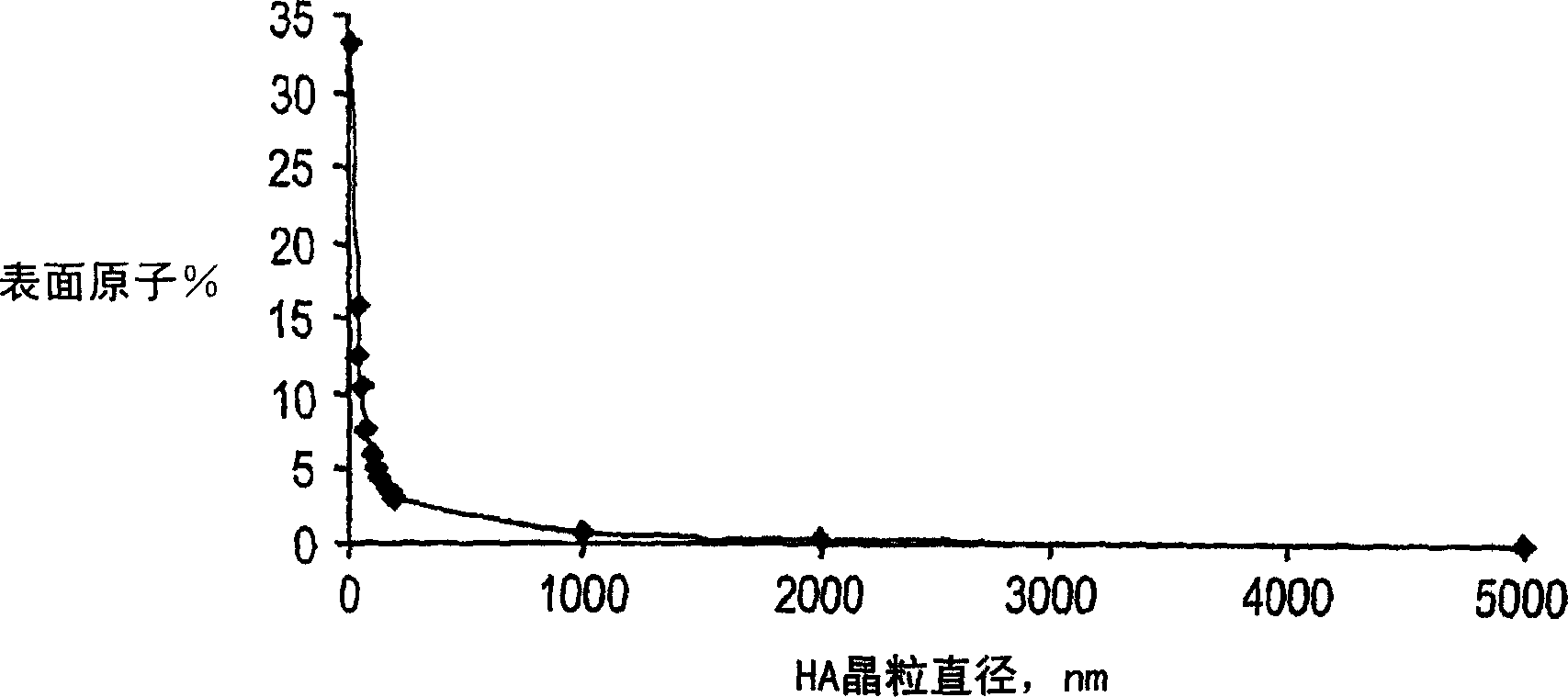

Coating, coated articles and methods of manufacture thereof

InactiveCN1589161AGood biological reactivityAvoid reactionCoatingsProsthesisThermal dilatationAdhesive

A multilayer coating especially suitable for coating implants, such as orthopedic and dental implants, especially metallic implants. The first layer includes a bond coat of a dense material that is insoluble and inert in body fluids. The second layer includes apatite and a binder. The first layer protects the metal implant from corrosion, dissolution of the apatite, and interfacial reactions with the apatite and the adhesive. The apatite in this second layer is a bioactive agent that osseobonds the tissue. Through this adhesive, the coefficient of thermal expansion between the coating and the metal substrate can be adjusted. The multi-layer coating has a high bonding strength to the implant and at the same time has excellent bioactivity to the surrounding body tissue.

Owner:美国英佛曼公司

Coating an implant for increased bone in-growth

ActiveUS20060188541A1Promotes increased bone in-growthEconomical and efficient methodImpression capsPretreated surfacesHemihydrate Calcium SulfateSulfate

A method of preparing an implant for bone in-growth comprising: providing a metal implant body, the metal implant body having a metal load bearing layer on an outer surface, the metal load bearing layer having a plurality of pores therein, the pores configured to promote bone in-growth into the load bearing layer; providing calcium sulfate hemi-hydrate; providing a diluent; mixing the calcium sulfate hemi-hydrate and the diluent to form a calcium sulfate paste; applying the calcium sulfate paste to the load bearing layer such that the calcium paste substantially impregnates at least a portion of the pores and forms an excess layer of the calcium sulfate paste on an outer surface of the load bearing layer; and wiping the calcium sulfate paste to remove the excess layer and thereby expose the outer surface of the load bearing layer while leaving the calcium sulfate paste impregnated in the pores.

Owner:WRIGHT MEDICAL TECH

Metal implant and surface processing method thereof

InactiveCN101904774APreserve surface morphologyTo achieve the effect of surface rougheningDental implantsCoatingsSurface roughnessBiomedical engineering

The invention discloses a metal implant. A plurality of micro-grade concave holes are formed on the surface of the metal implant and are internally provided with a plurality of submicro-grade concave holes, wherein the apertures of the micro-grade concave holes are between 1mu m and 100mu m; the apertures of the submicro-grade concave holes are between 100nm and 1000nm; and the surface average roughness of the metal implant is between 0.1mu m and 5mu m.

Owner:METAL INDS RES & DEV CENT

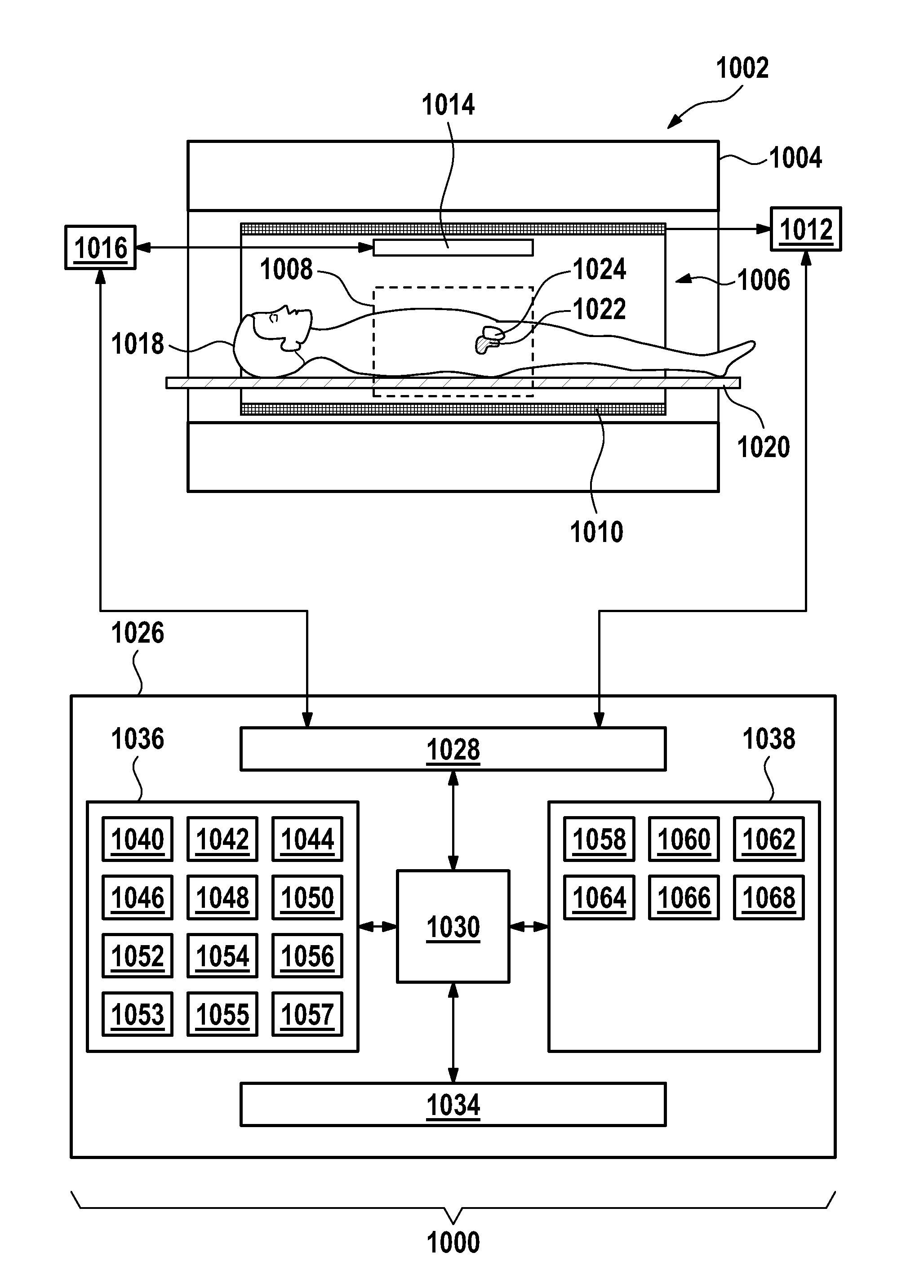

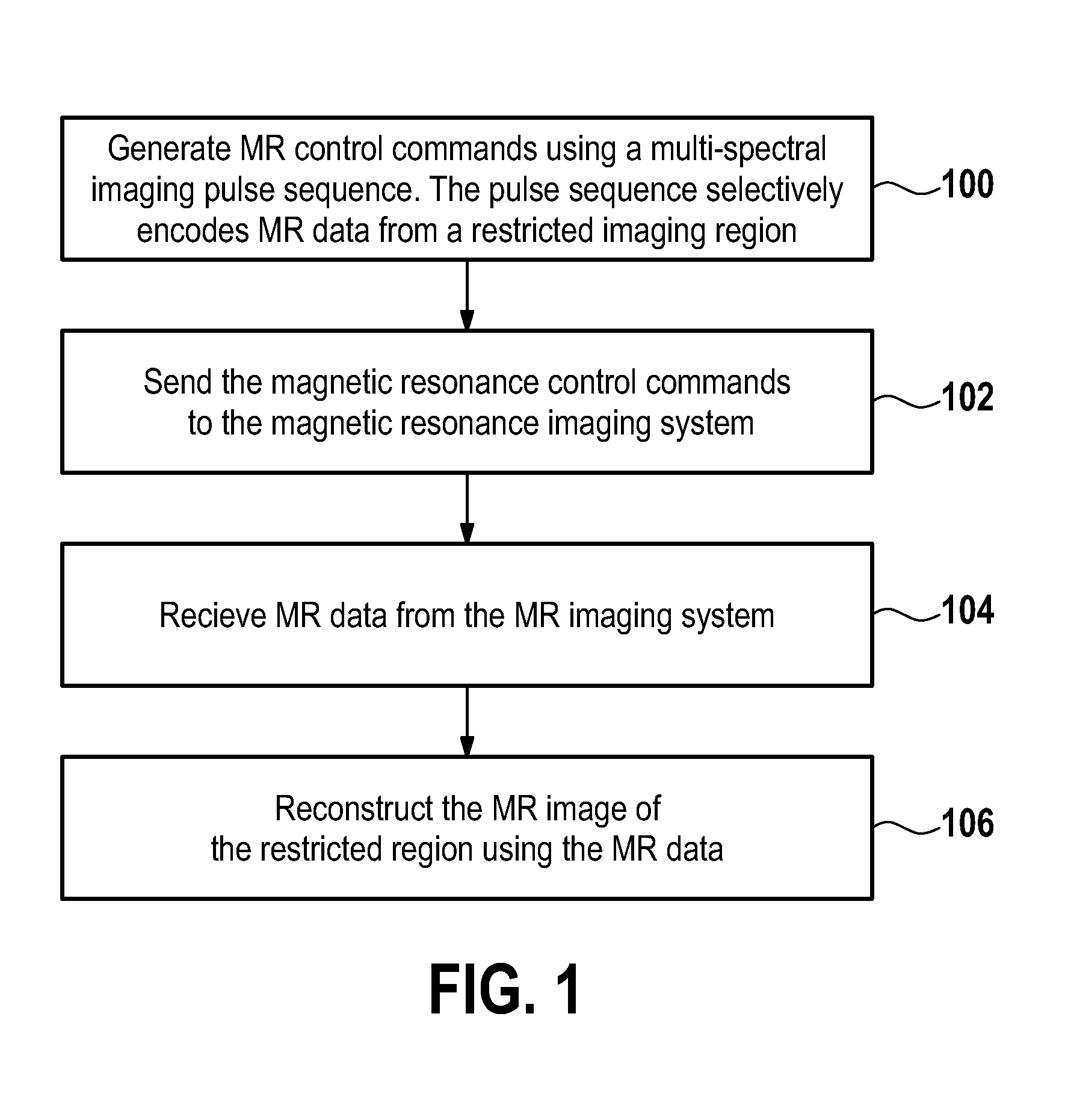

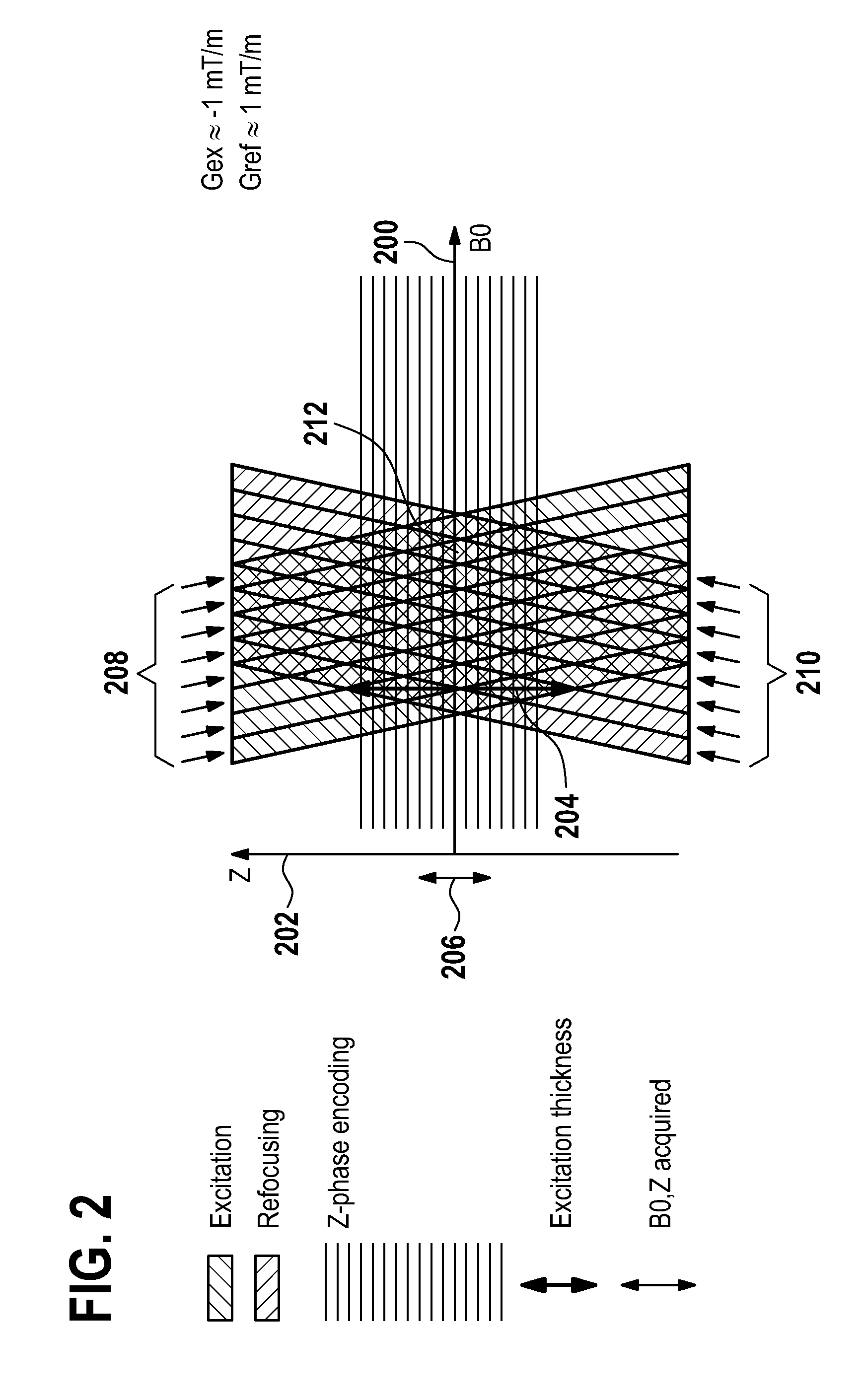

Restriction of the imaging region for MRI in an inhomogeneous magnetic field

ActiveUS20140002080A1Avoid distortionReduce noiseMeasurements using NMR imaging systemsElectric/magnetic detectionFat suppressionParallel imaging

The invention relates to magnetic resonance imaging in the vicinity of a metallic object (like, for instance, a metal implant) where severe spatial perturbations of the static magnetic field occur. In order to suppress the back-folding of distant off-resonant signals into the region of interest, the imaging volume is spatially restricted by means of selection gradients applied concurrently with the excitation and the refocusing RF pulses in a spin echo sequence. The selection gradient applied during the excitation pulse has an amplitude and / or a polarity different from that of the selection gradient applied during the refocusing pulse so that the respectively selected slices in an off-resonance frequency versus spatial coordinate diagram become tilted with respect to one another. The applied imaging technique may of the SEMAC or MAVRIC type and may incorporate compressed sensing, parallel imaging, fat suppression and / or SVD-based noise reduction.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Bioactive coating of metal implant and preparation method thereof

InactiveCN102409382AImprove oxidation efficiencyIncreasing the thicknessAnodisationMicro arc oxidationBiomedical engineering

The invention discloses a bioactive coating of a metal implant and a preparation method thereof. According to the invention, a medical metal implant subjected to deoiling and derusting is utilized as a positive pole to be subjected to micro-arc oxidation in a special micro-arc oxidation treatment liquid under the conditions that titanium or aluminum is used as a positive pole, stainless steel groove is used as a negative pole, direct current impulse micro-arc oxidation equipment is adopted, the current density is controlled at 2-4A / cm<2>, the duty ratio is 10-20%, and the time is 10-20 minutes; and the medical metal implant subjected to micro-arc oxidation is washed with deionized water and then naturally dried, so as to obtain the medical metal implant with the bioactive coating. Compared with the bioactive coating obtained by other methods, the bioactive coating prepared by the method disclosed by the invention has simple process and rapid bioactive coating growth speed, and is superior to the bioactive coatings prepared in the prior art in the aspects of growth efficiency of the bioactive coating, combination strength of the bioactive coating and the metal implant and the like.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com