Metal implant with bioactive surface modification and preparation method thereof

A surface modification and biological activity technology, applied in the field of biomedicine, can solve the problems such as failure to achieve growth factor embedding and controlled release, cumbersome surface modification method of chitosan, unsuitable for industrial production, etc. Improve biocompatibility and meet environmental requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

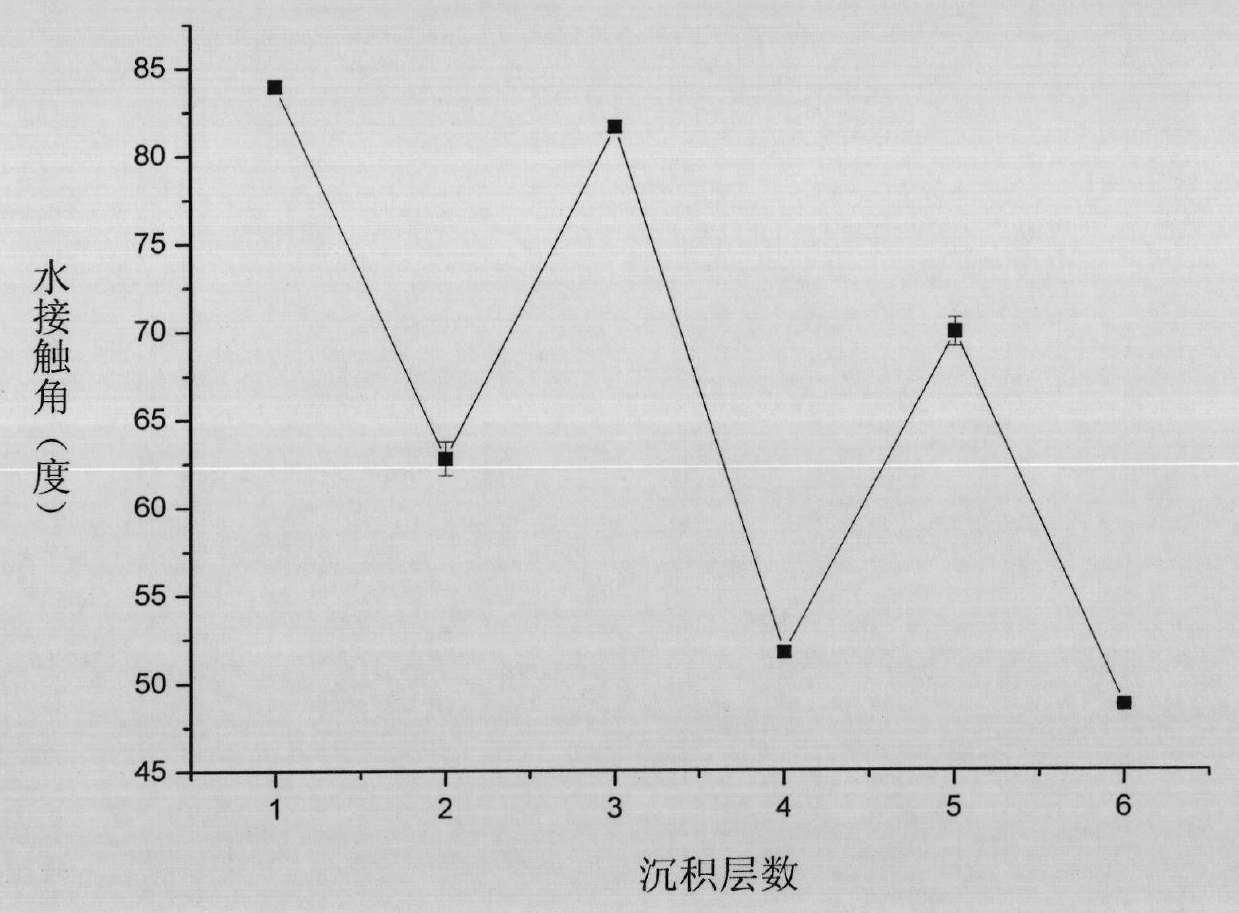

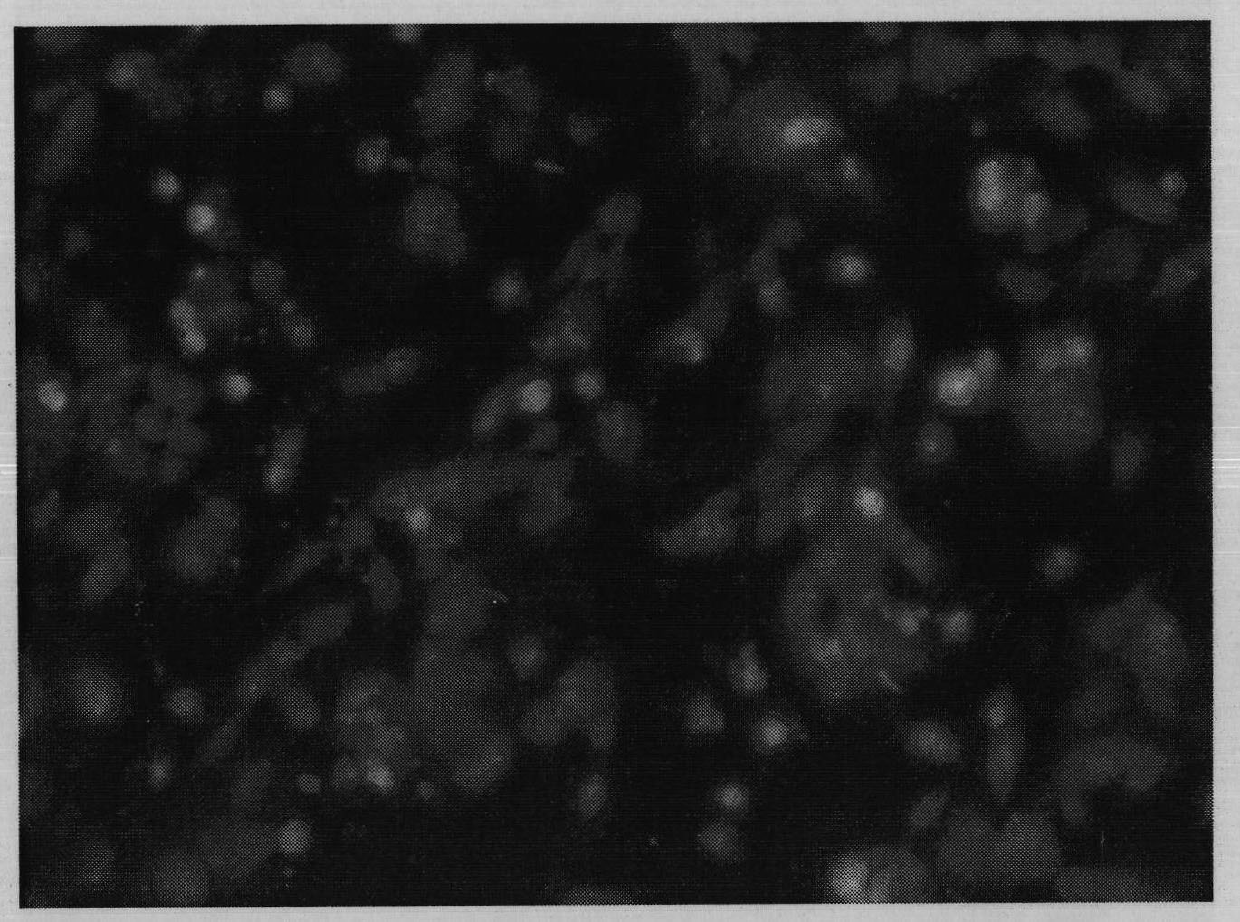

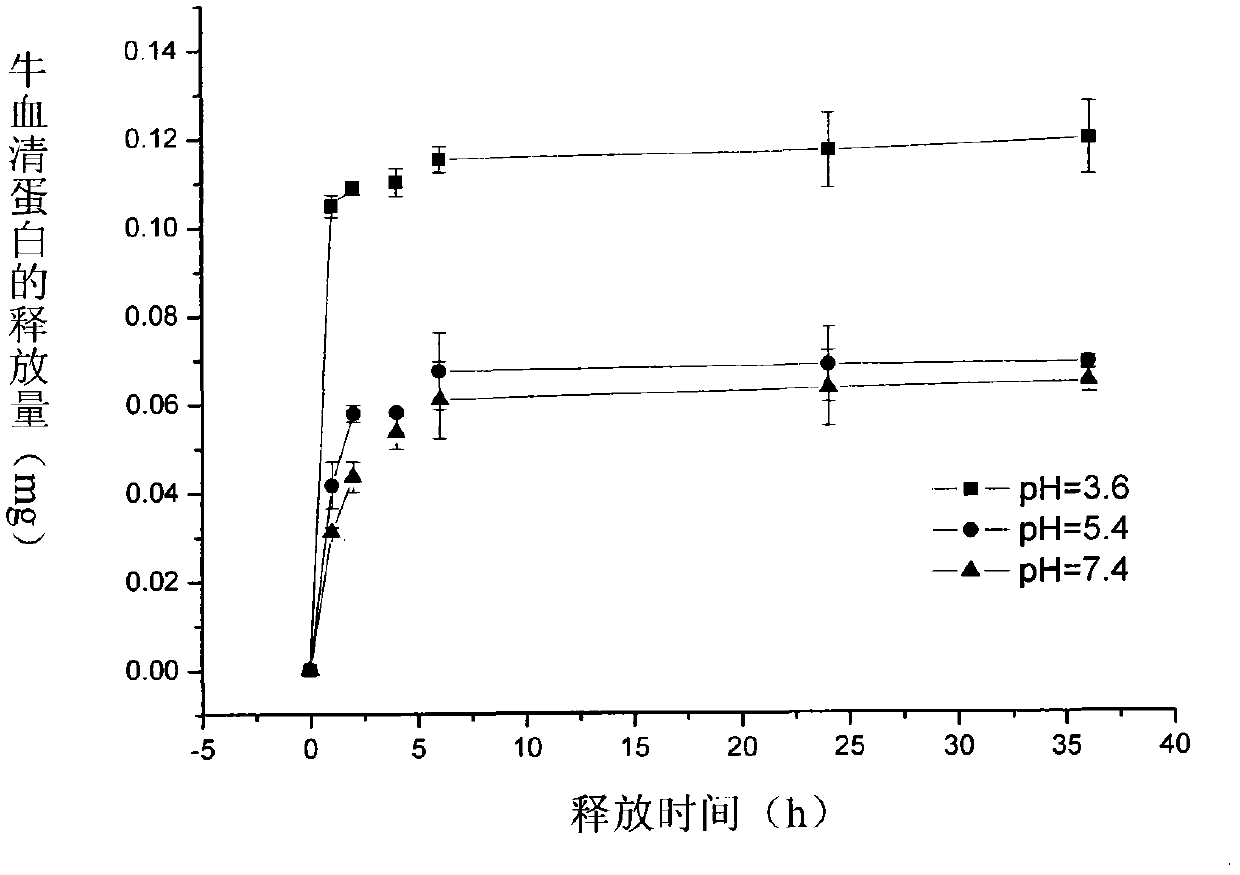

[0039] Use 400# and 600# metallographic sandpaper to polish the pure metal titanium dental implant (circular metal titanium sheet with a diameter of 9 mm and a thickness of 1 mm). Put the polished titanium sheet into distilled water, acetone, 70% ethanol, and distilled water in turn, and use ultrasonic cleaning for 20, 15, 20, and 20 minutes respectively. Vacuum dry. Dissolve sulfonated chitosan in deionized water containing 0.1MNaCl at room temperature to make a sulfonated chitosan solution with a concentration of 2mg / ml; dissolve chitosan in 1% (v / v) containing 0.1MNaCl In acetic acid, make a chitosan solution with a concentration of 2mg / ml; PEI is dissolved in deionized water containing 0.1MNaCl, and make a PEI solution with a concentration of 2mg / ml; 5mg / ml bovine serum albumin (BSA) with 0.1MNaCl solution. Soak the treated titanium sheet in PEI solution for 20 minutes, wash it twice in deionized water for 2 minutes each, and dry it with cold air to obtain a pretreatment l...

Embodiment 2

[0041] Use 400# and 600# metallographic sandpaper to polish the nickel-titanium alloy medical implant (circular metal sheet with a diameter of 9 mm and a thickness of 1 mm) in sequence. Put the polished nickel-titanium alloy sheet into distilled water, acetone, 70% ethanol, and distilled water in sequence, and clean it with ultrasonic waves for 20, 15, and 20 minutes respectively. Vacuum dry. At room temperature, carboxymethyl chitosan is dissolved in deionized water containing 0.1MNaCl to make a concentration of carboxymethyl chitosan solution of 2mg / ml; chitosan is dissolved in 1% (v / ml) containing 0.1MNaCl v) In acetic acid, the concentration is 2mg / ml chitosan solution; PEI is dissolved in deionized water containing 0.1MNaCl, and the concentration is 2mg / mlPEI solution; 5mg / ml bovine serum albumin (BSA) solution of 0.1MNaCl . Soak the treated nickel-titanium alloy sheet in PEI solution for 20 minutes, wash it twice in deionized water for 2 minutes each, and dry it with c...

Embodiment 3

[0043] Use 400# and 600# metallographic sandpaper to polish the stainless steel medical implant (circular metal sheet with a diameter of 9 mm and a thickness of 1 mm). Put the polished stainless steel sheet into distilled water, acetone, 70% ethanol, and distilled water in sequence, and clean it with ultrasonic waves for 20, 15, and 20 minutes, respectively. Vacuum dry. Dissolve carboxymethyl chitosan and chitosan quaternary ammonium salt in deionized water containing 0.1M NaCl respectively at room temperature to form two solutions with a concentration of 2 mg / ml; PEI is dissolved in deionized water containing 0.1M NaCl , Dubbed PEI solution with a concentration of 2mg / ml; 5mg / ml bovine serum albumin (BSA) solution of 0.1M NaCl. Soak the treated stainless steel sheet in PEI solution for 20 minutes, wash it twice in deionized water for 2 minutes each, and dry it with cold air to obtain a pretreatment layer with stable positive charge. Then soak the stainless steel sheet with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com