Multi part non metal implant

A technology of implants and non-metallic materials, applied in the field of implants, can solve problems such as high production costs and high costs, and achieve good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

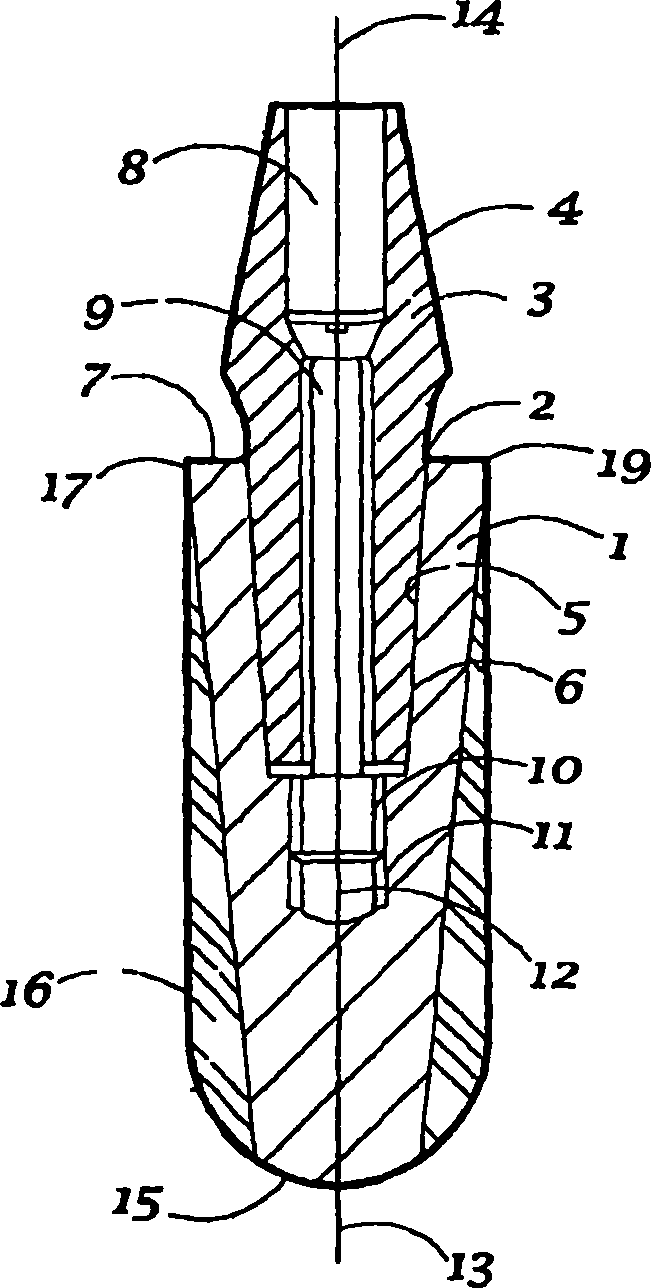

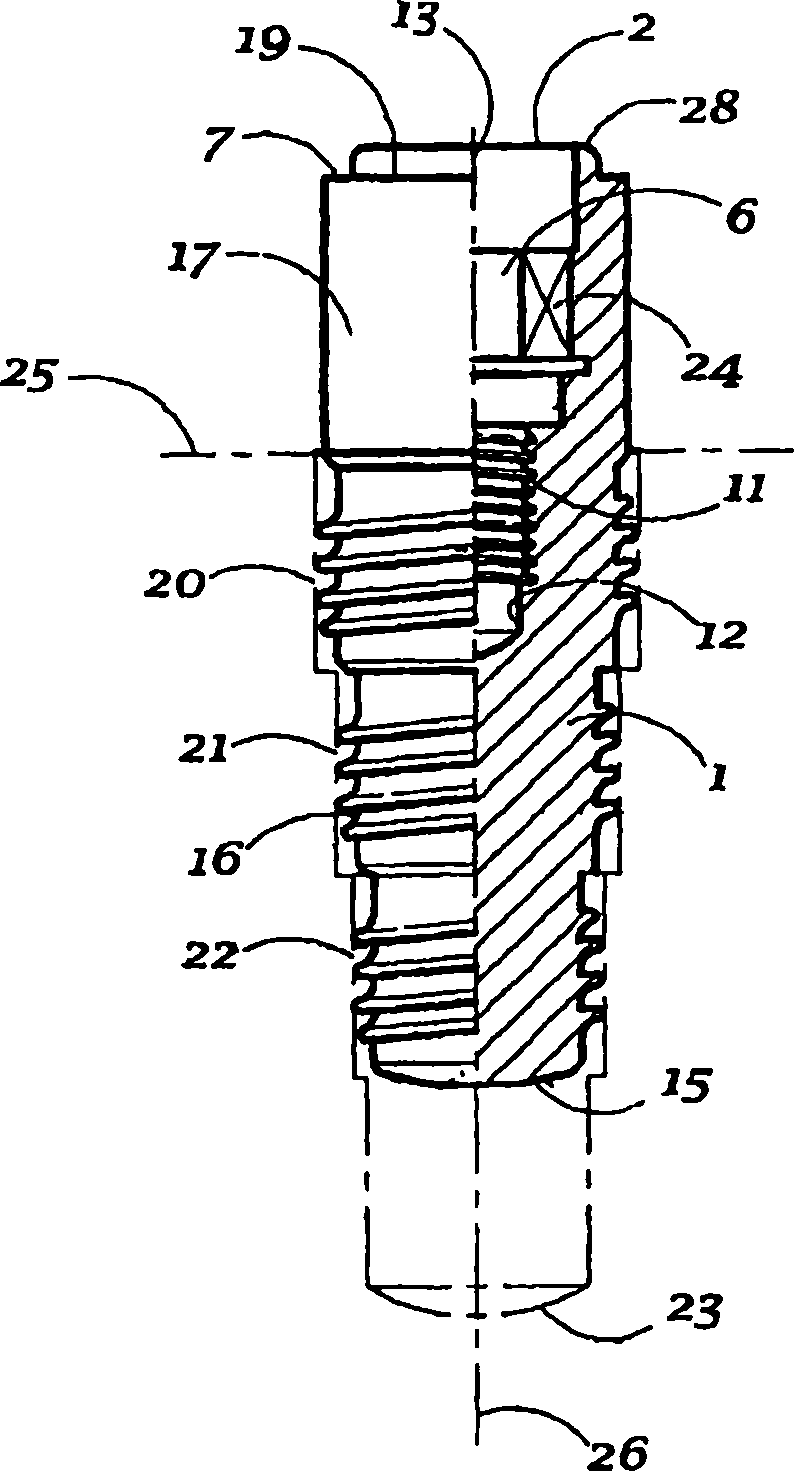

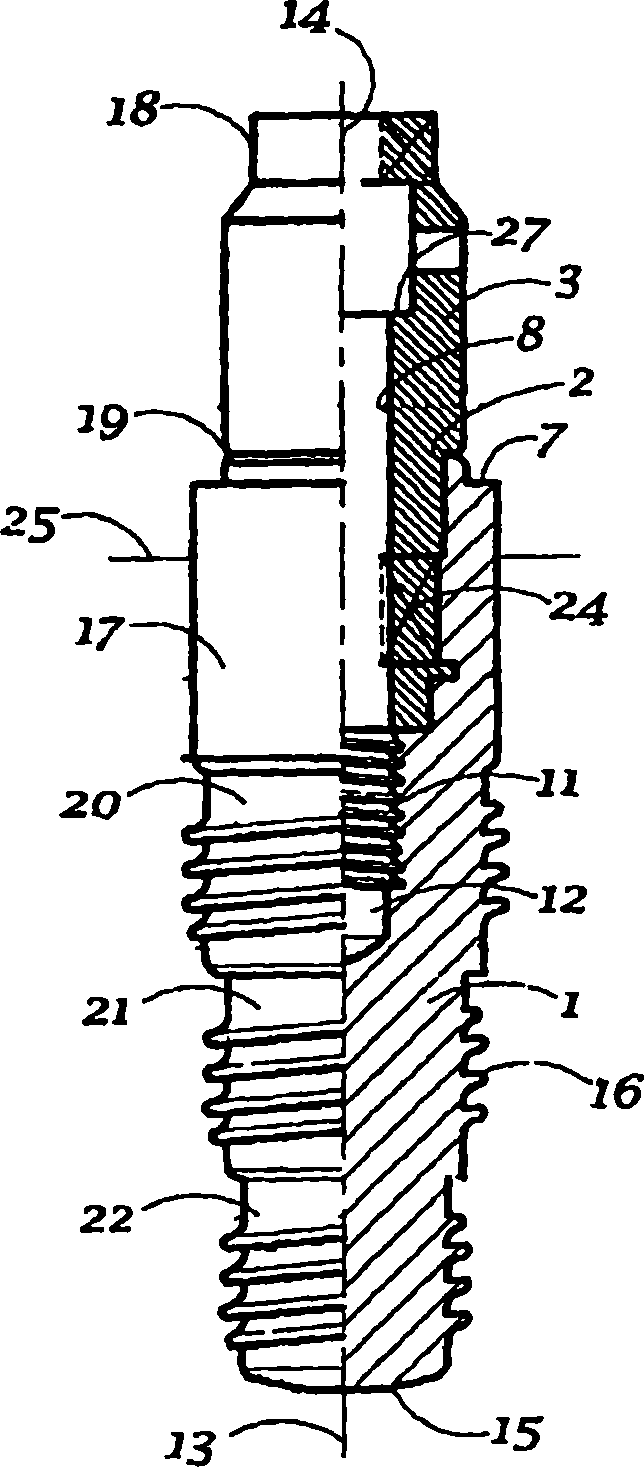

[0037] Figures 1 to 4 Various embodiments of dental implants are shown as examples of the invention. Features common to each embodiment have not been described in detail, although each embodiment has its own advantages in use. Accordingly, similar features in different embodiments will be denoted by the same reference numerals. All descriptions of these embodiments have been presented for purposes of illustration and are exemplary only in nature. Non-described parts or non-description at this point should be construed as limitations of the claims.

[0038] exist figure 1 , shows a two-stage, two-part dental implant which can be positioned steplessly in its direction of rotation, which comprises a first implant fixation part 1 having a central cavity opening 2. The fixing part 1 can be inserted into the jawbone, and the dental implant also includes a second implant abutment part 3, which can support a dental prosthesis superstructure (not shown) like a crown or a bridge. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com