Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

160 results about "Implant abutment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

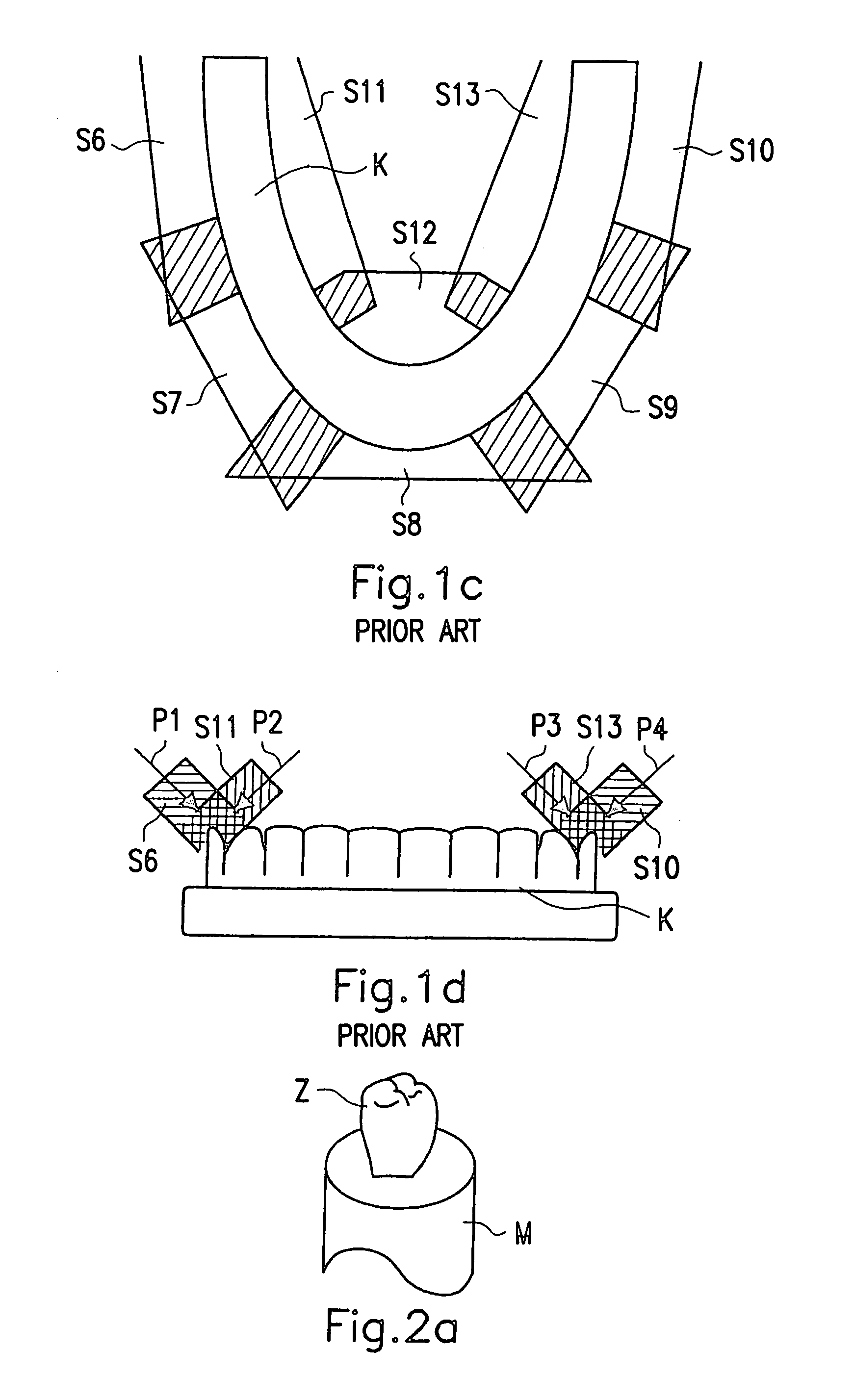

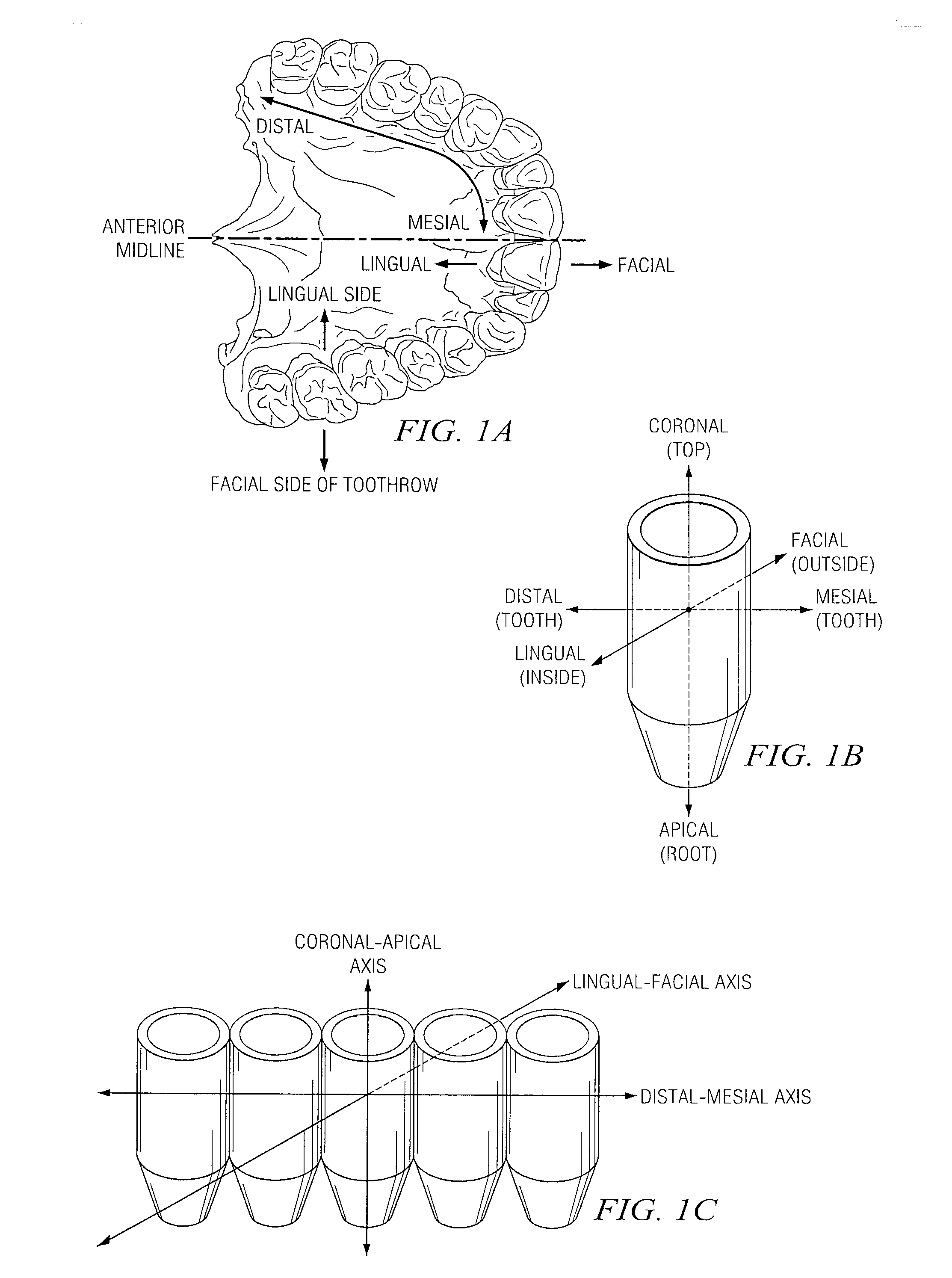

A dental implant abutment is an integral component of dental implants. During dental implantation, the dental implant abutment connects a titanium cylinder anchored in a patient's jaw to an artificial crown. During the healing time required during dental restoration, a temporary abutment ensures that no foreign materials enter the artificial cavity.

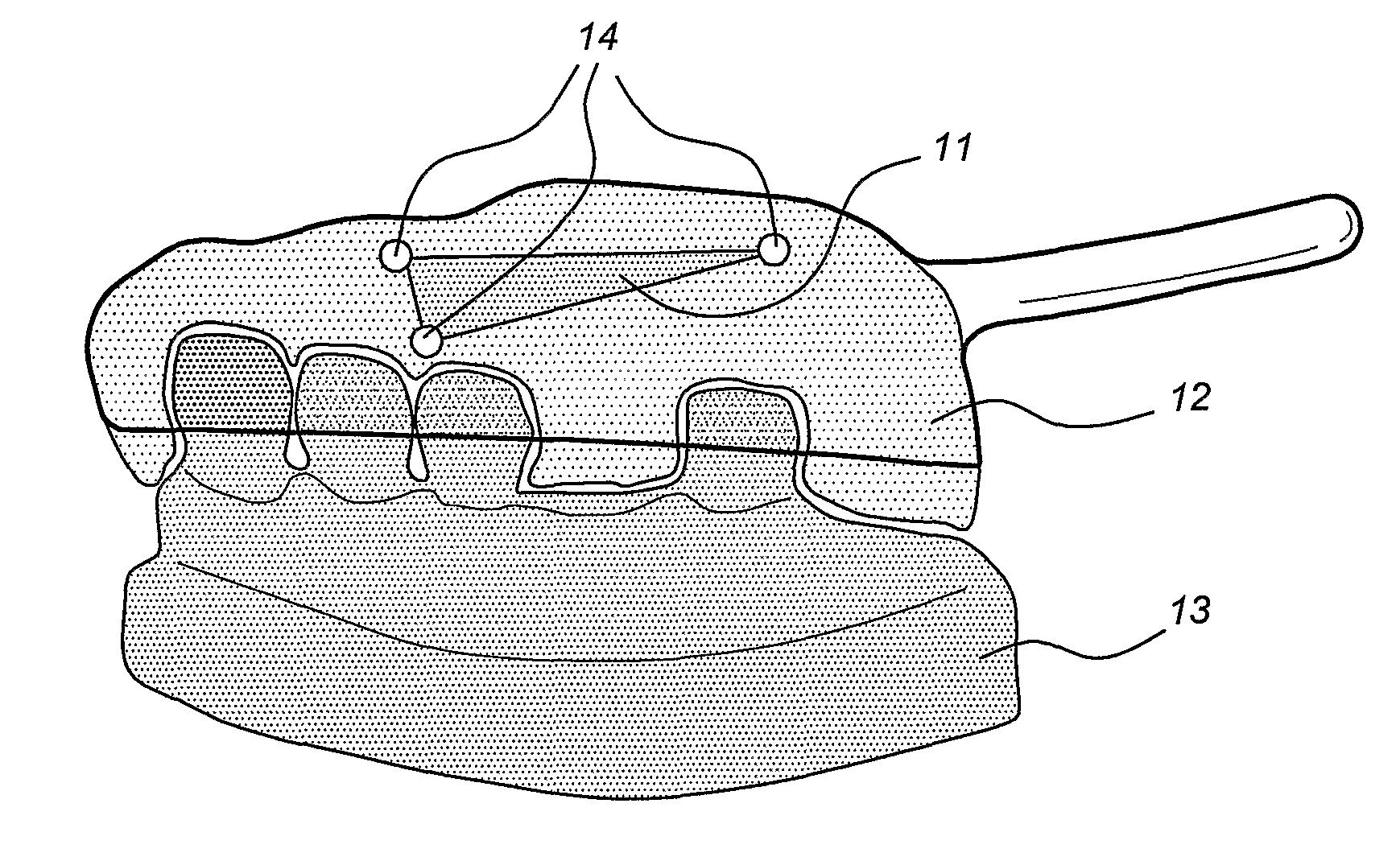

Method of Manufacturing and Installing a Ceramic Dental Implant with an Aesthetic Implant Abutment

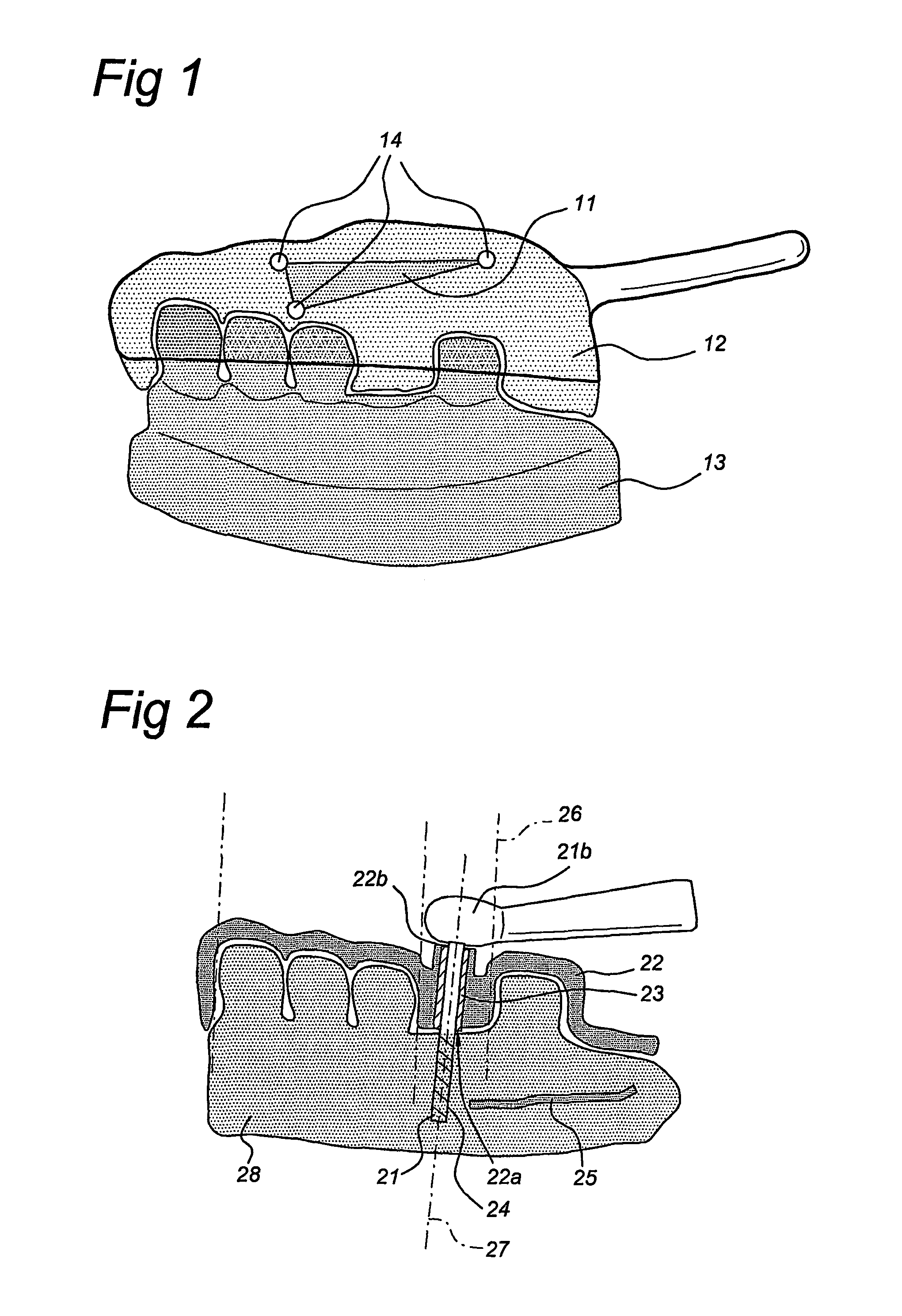

The present invention relates to a method for manufacturing a tooth prosthesis, for insertion in a jawbone, including an implant and an abutment on top of the implant. The method includes: defining a shape of the prosthesis and its location in the jawbone by using first data from a first CT scan image of the jawbone and second data from a second image of a gypsum cast, correlating first and second data by extracting from the first data first position reference data of a first reference in the first image, and from the second data second position reference data of a second reference in the second image, the second reference being identical to the first reference; performing a geometric transformation on the second data and / or the first data to have a coincidence of the second image with the first image and to combine the first and second data into composite scan data.

Owner:ORATIO

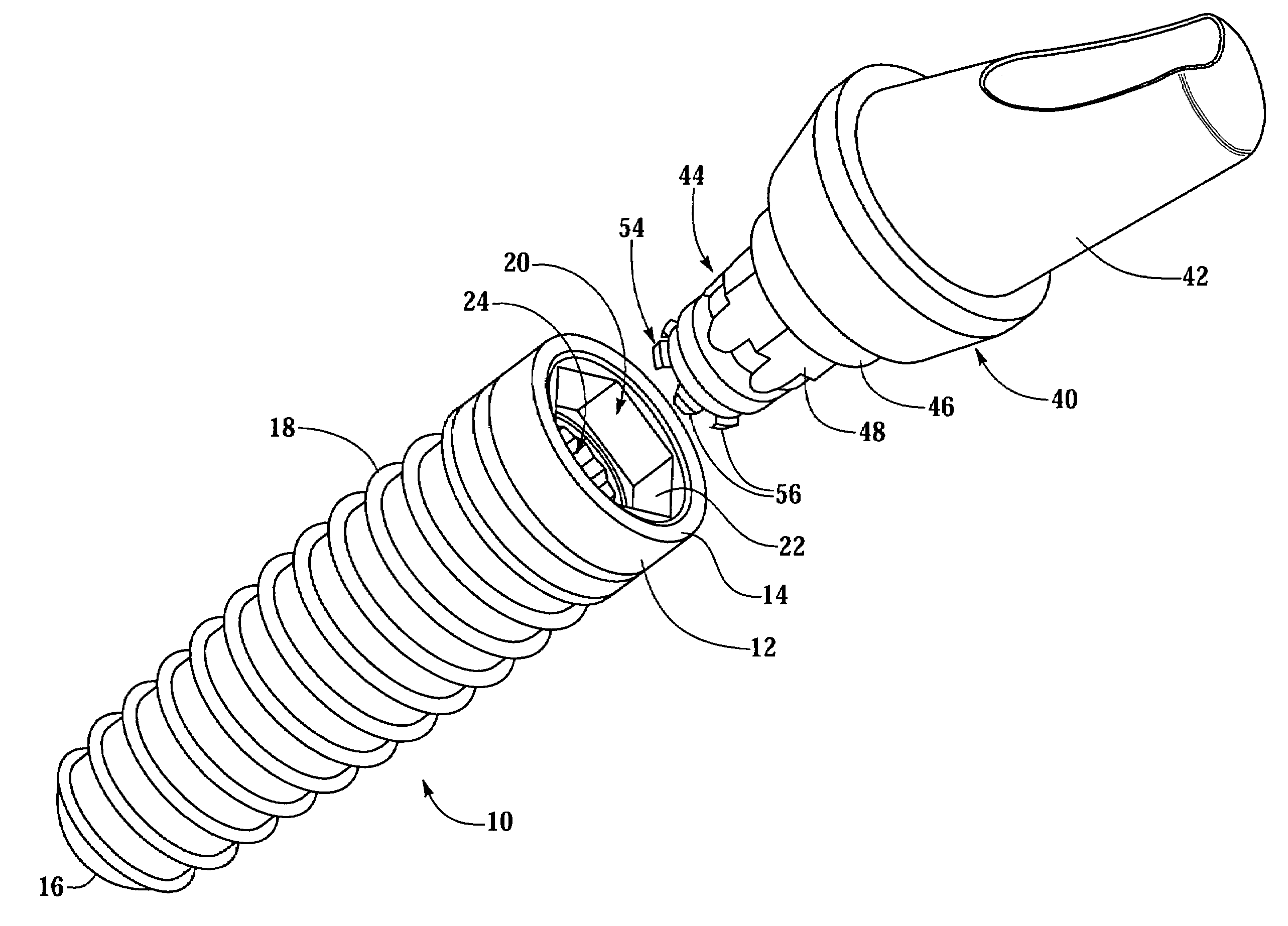

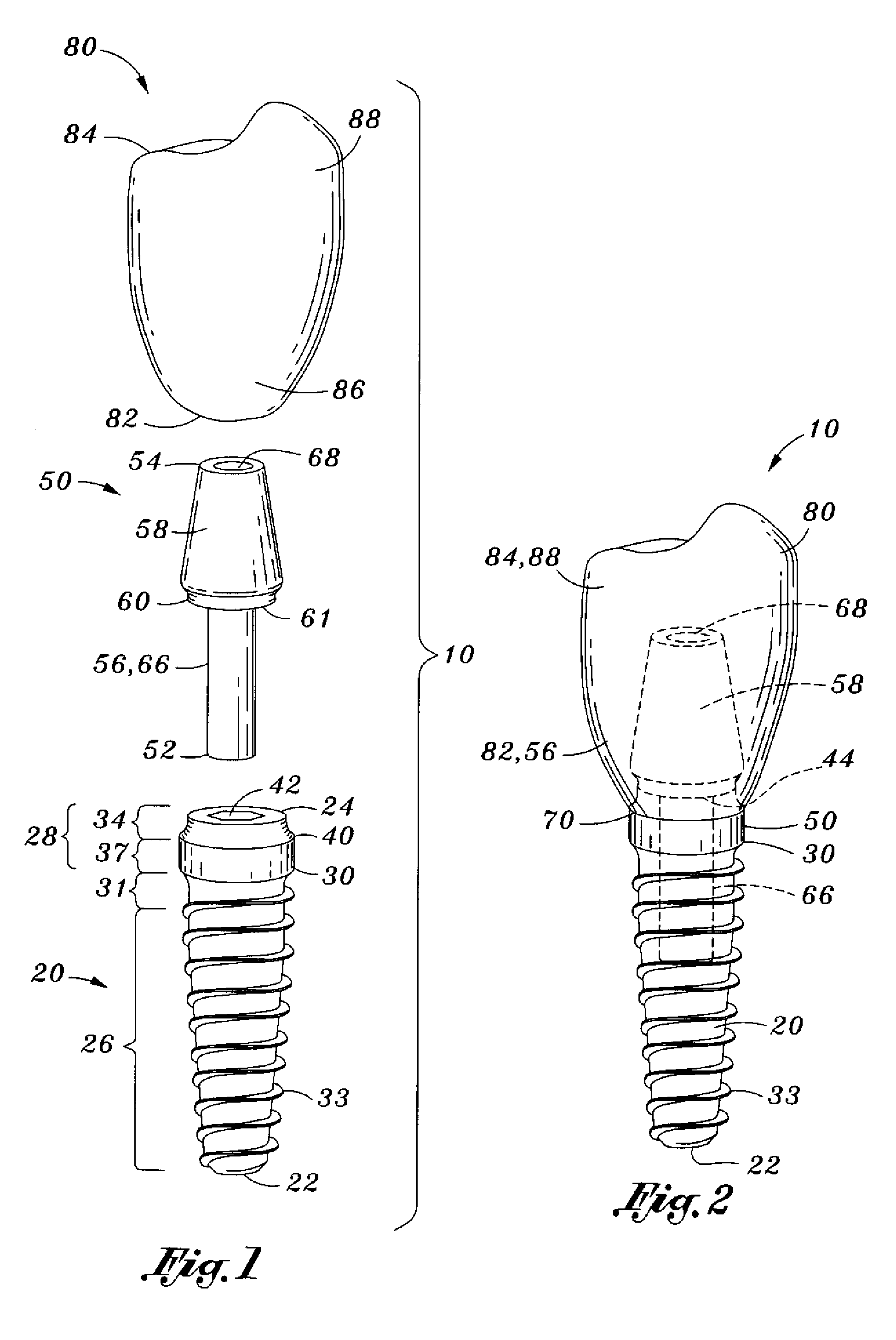

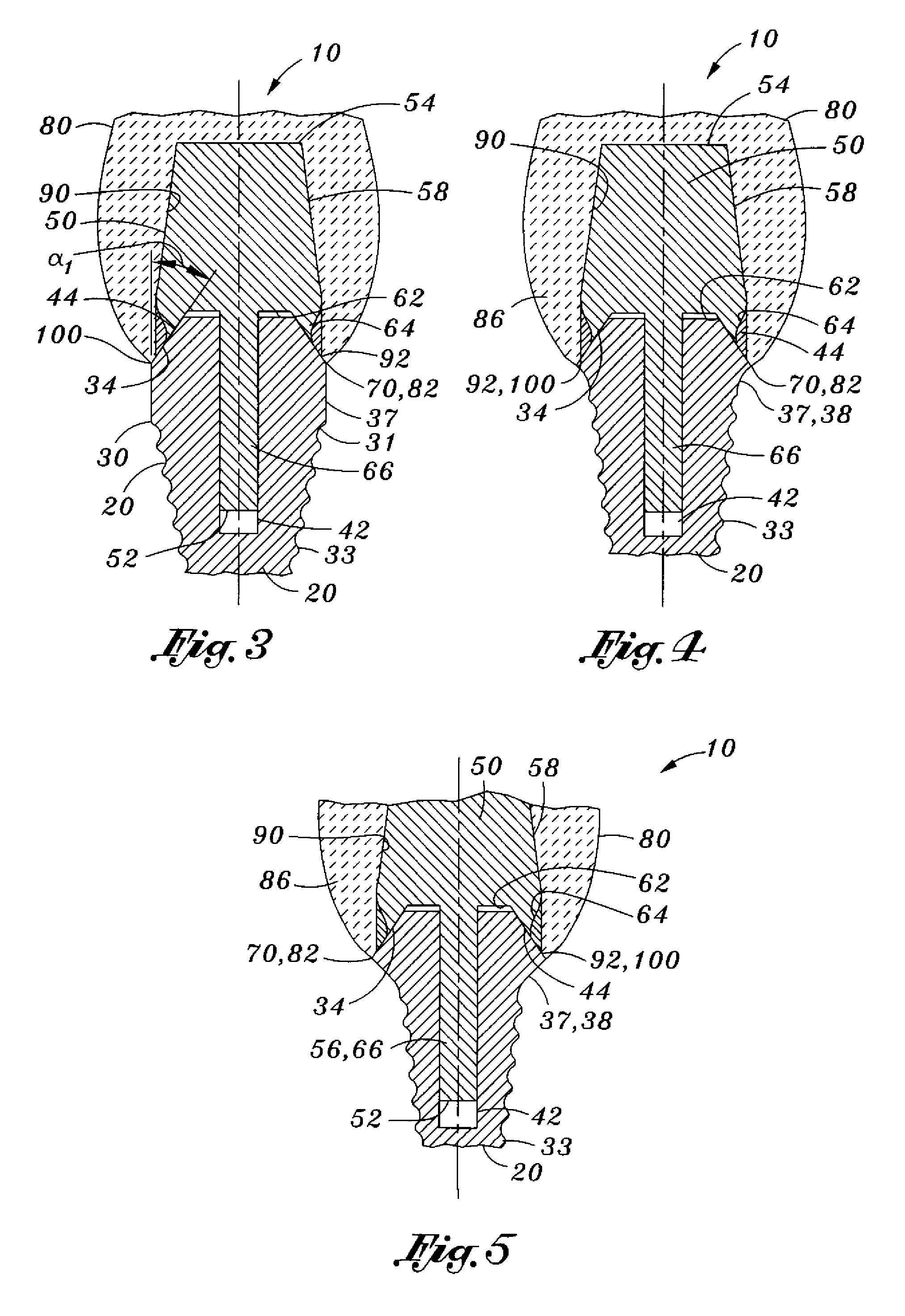

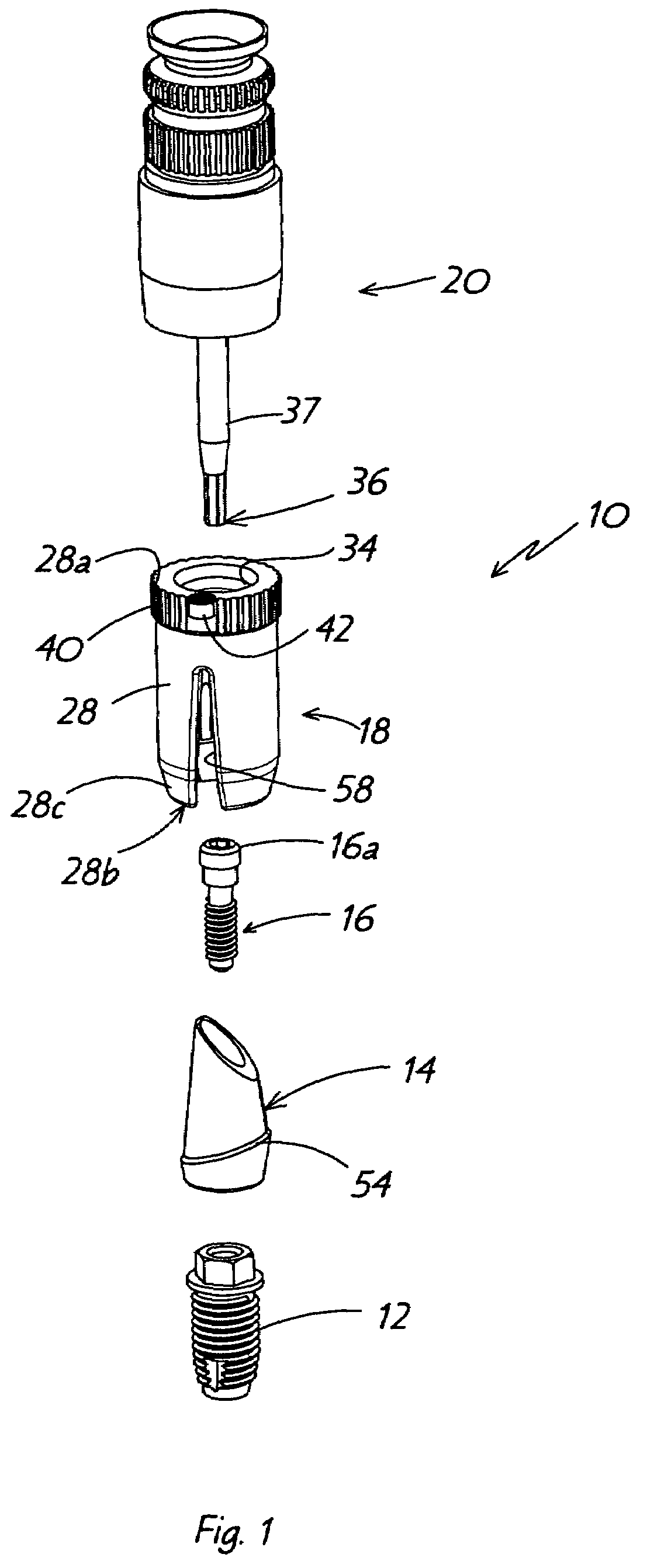

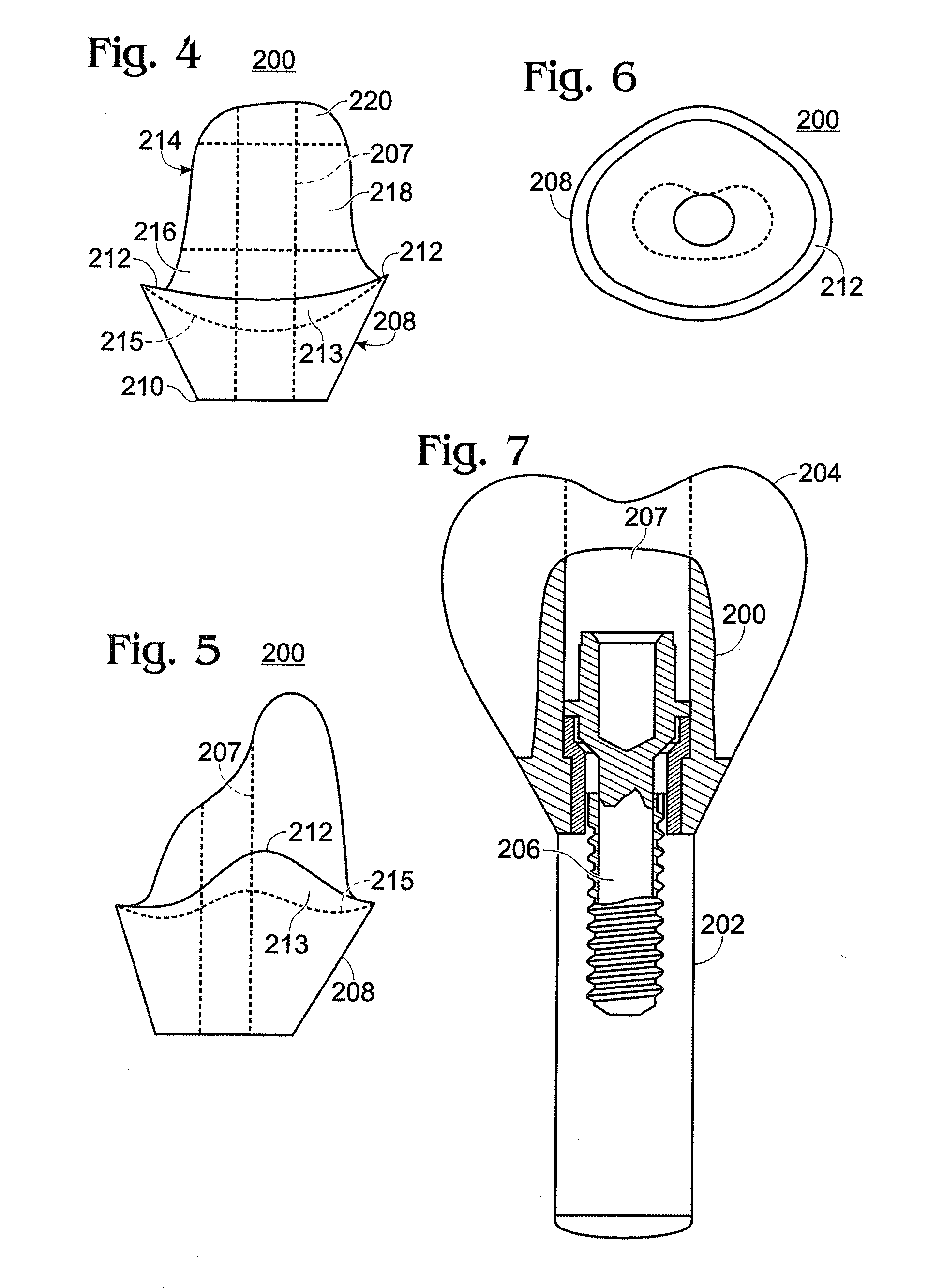

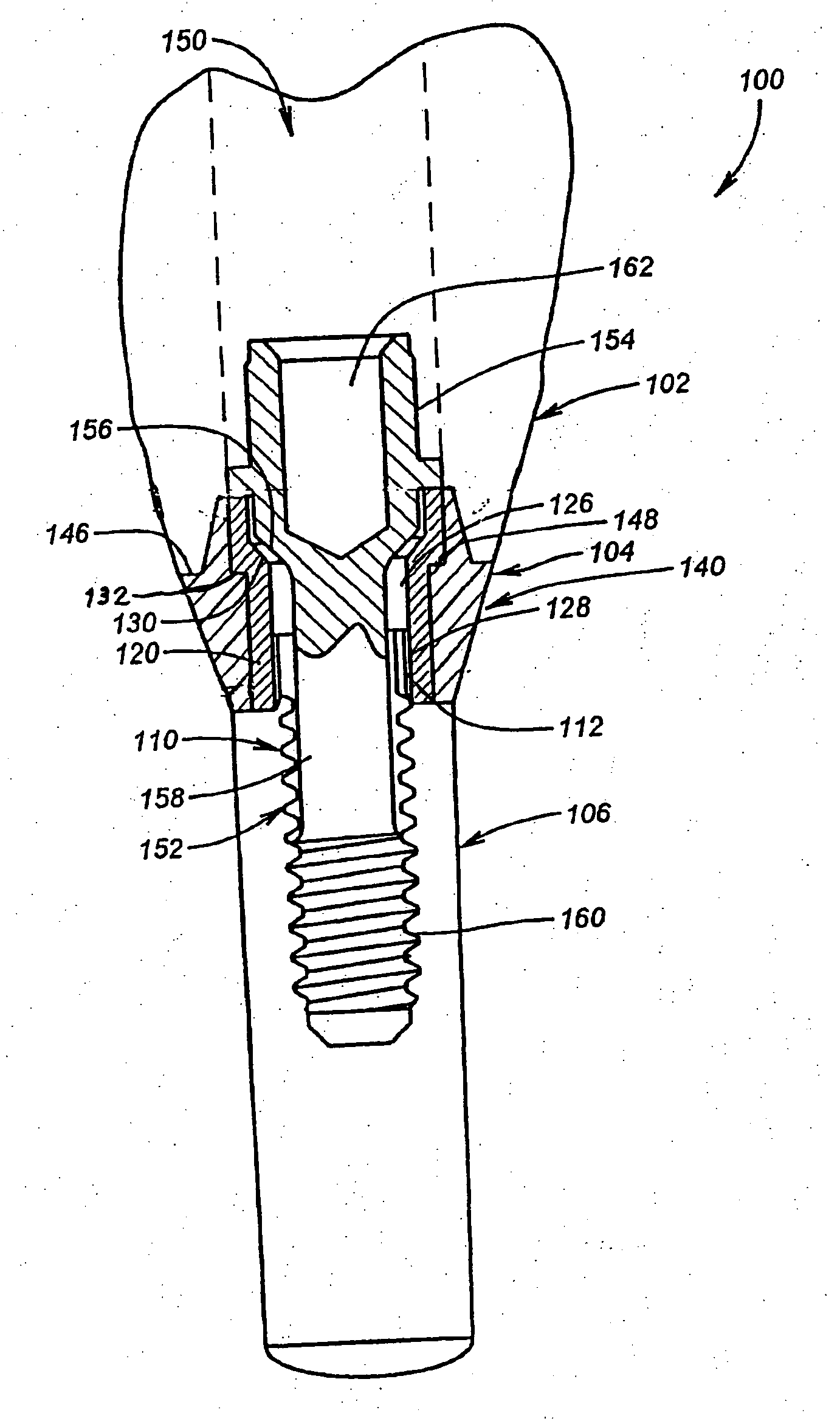

Dental implant system

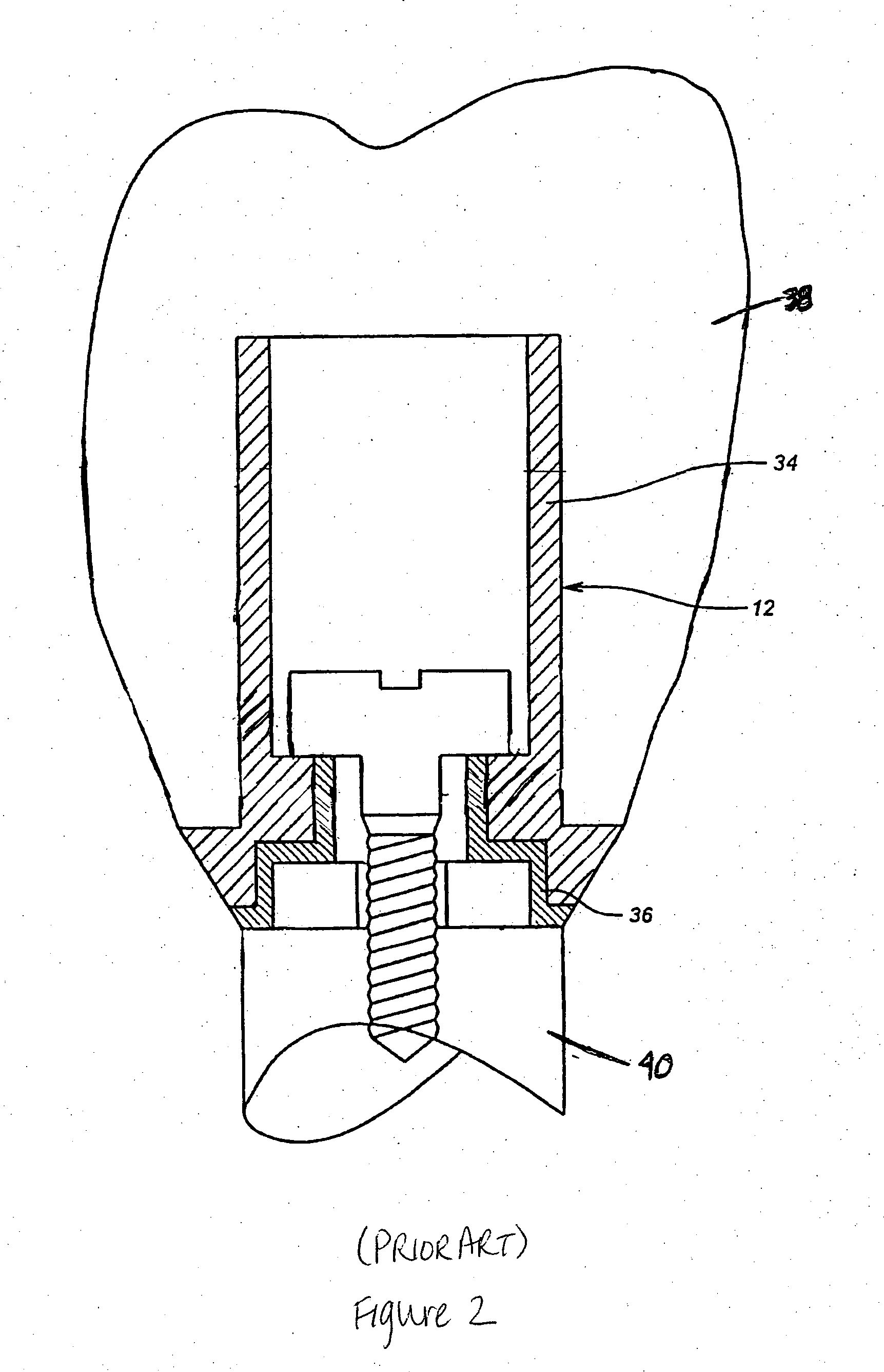

ActiveUS7338286B2Restrict movementDental implantsFastening prosthesisBiomedical engineeringImplant abutment

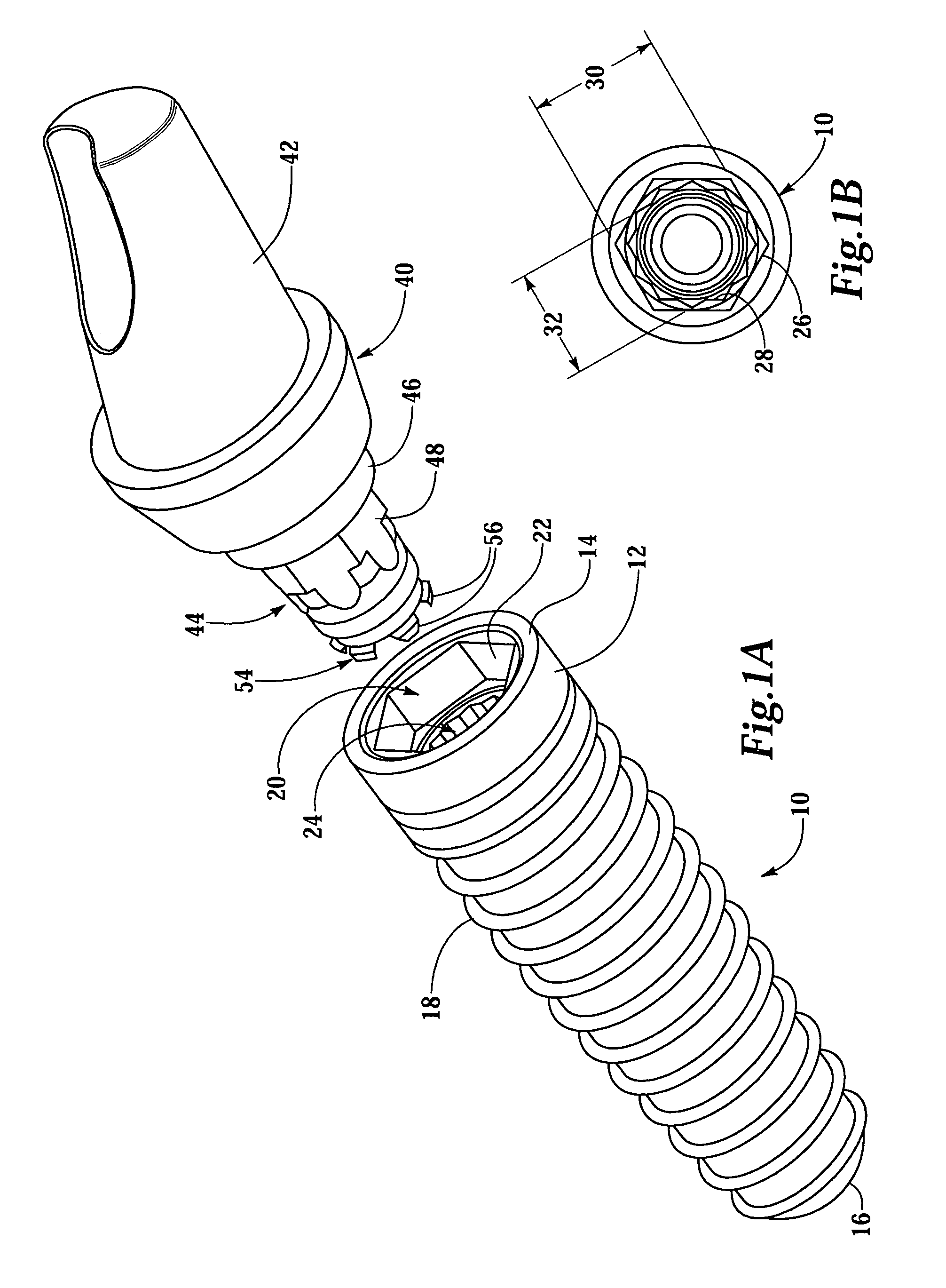

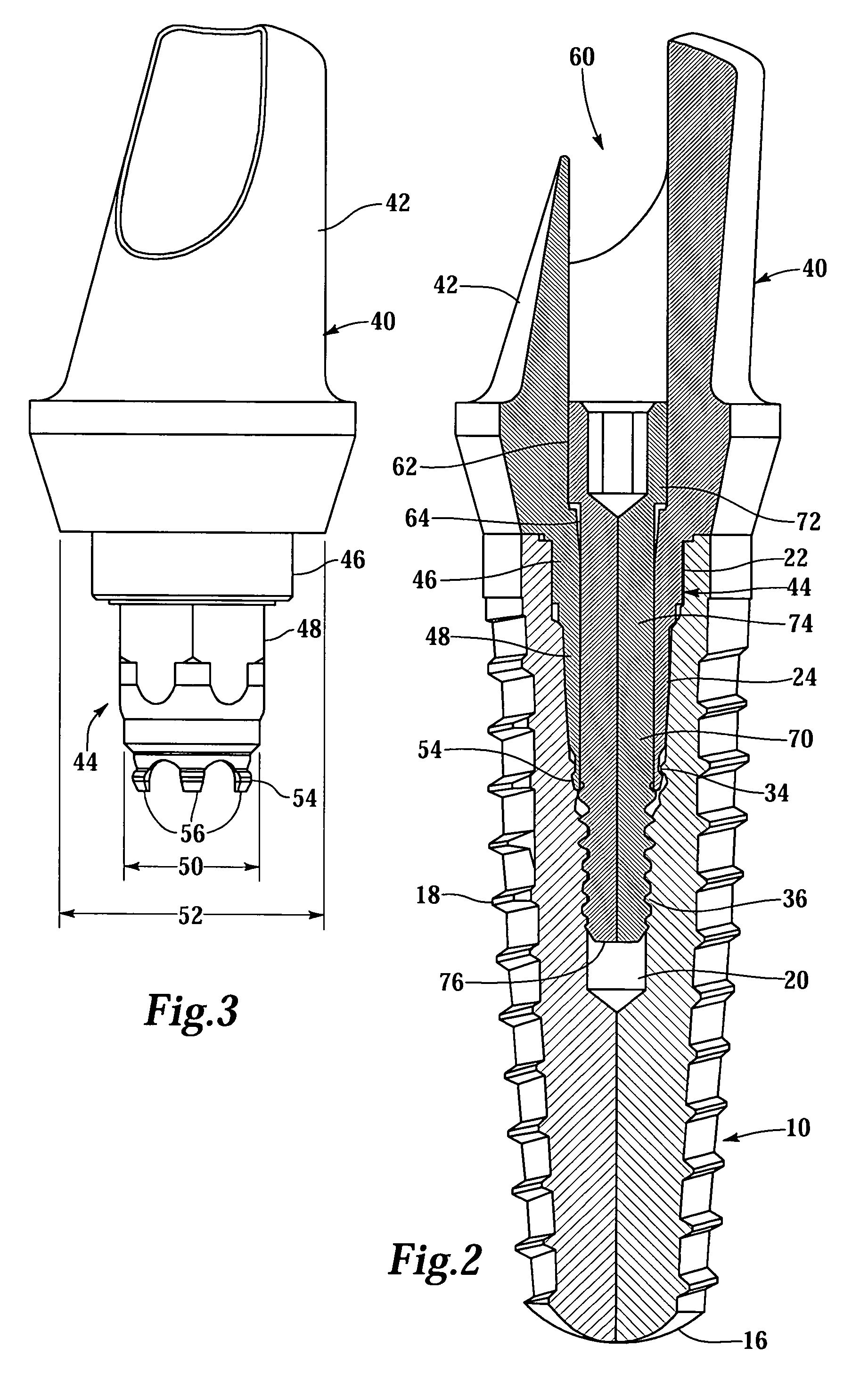

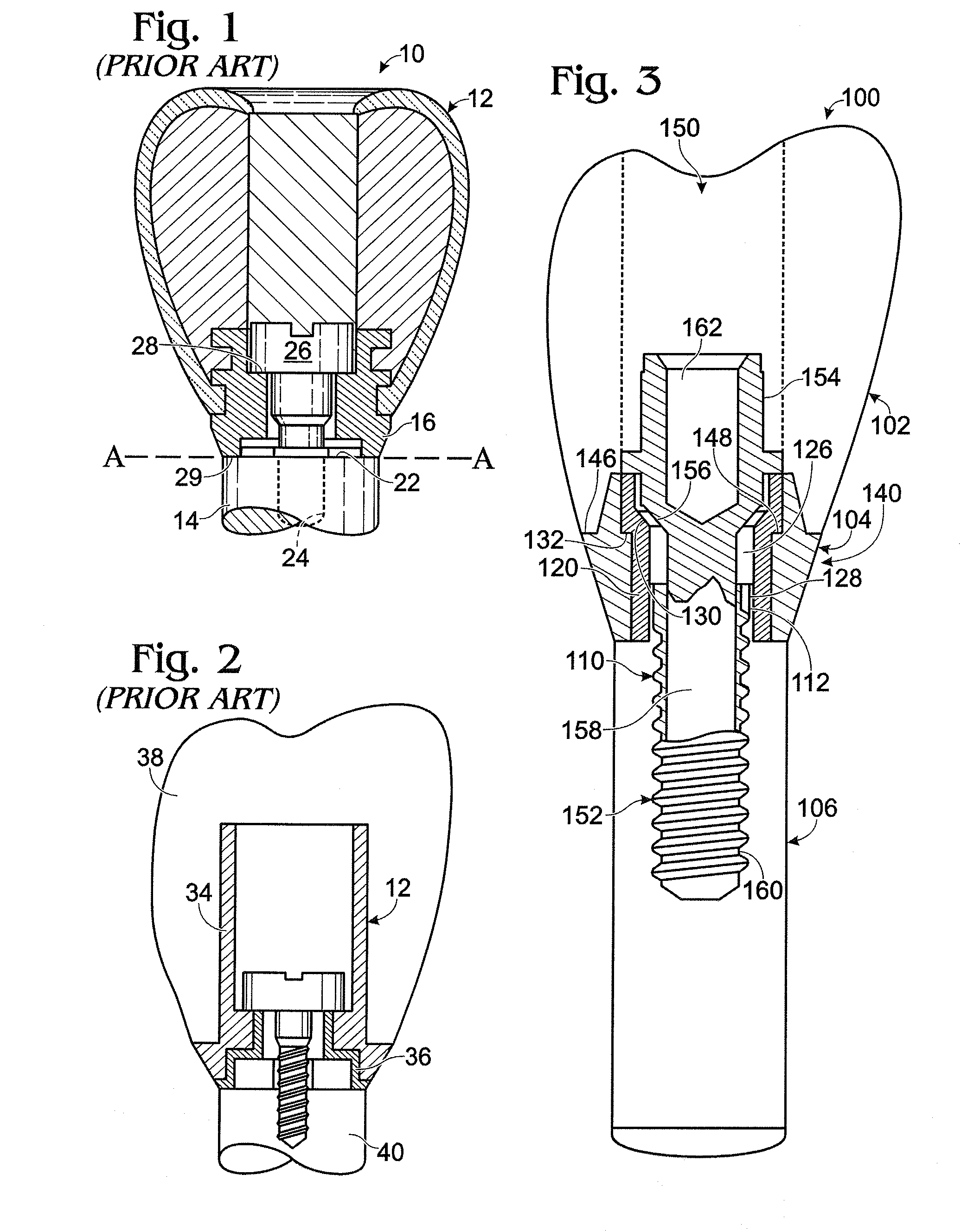

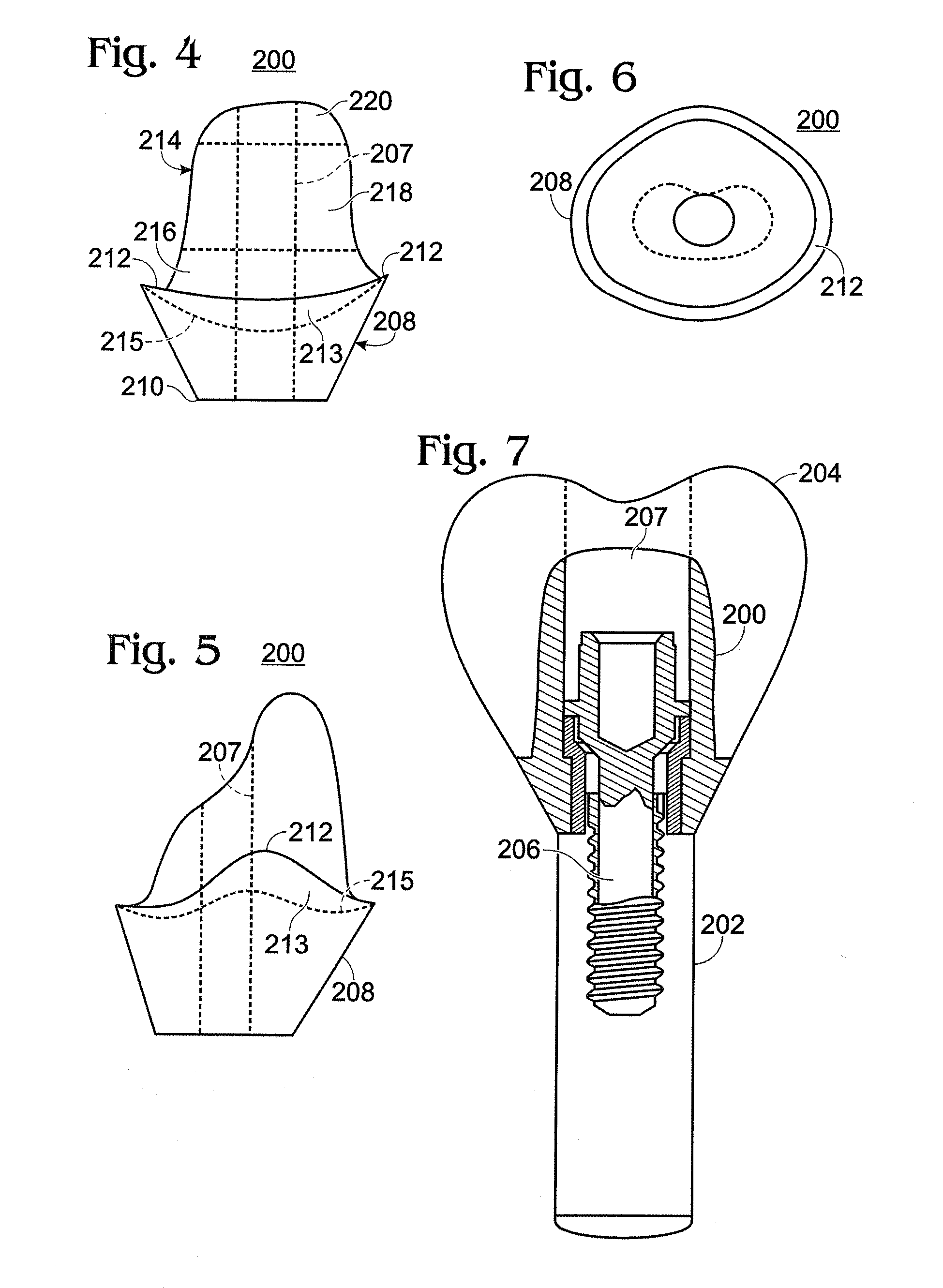

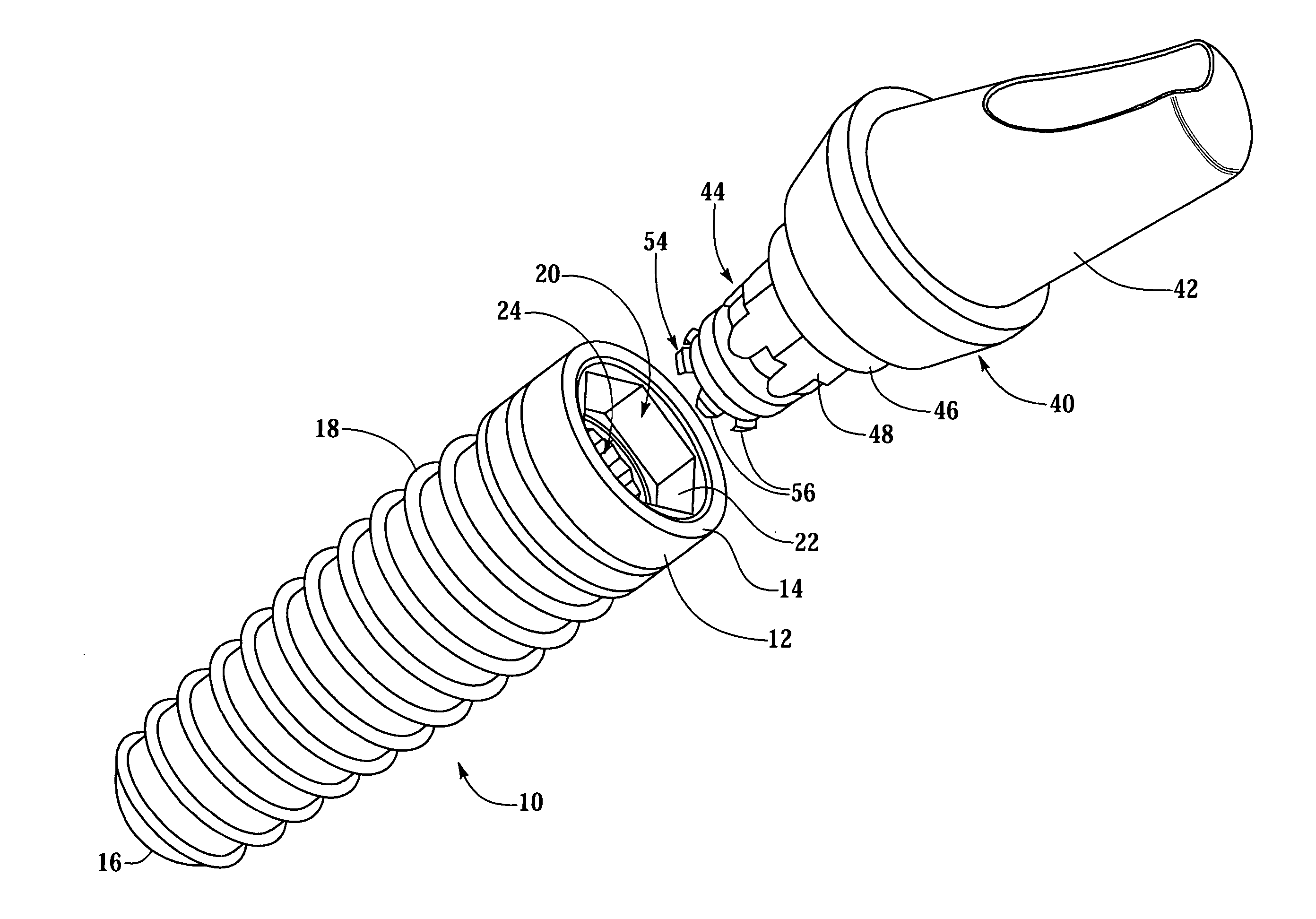

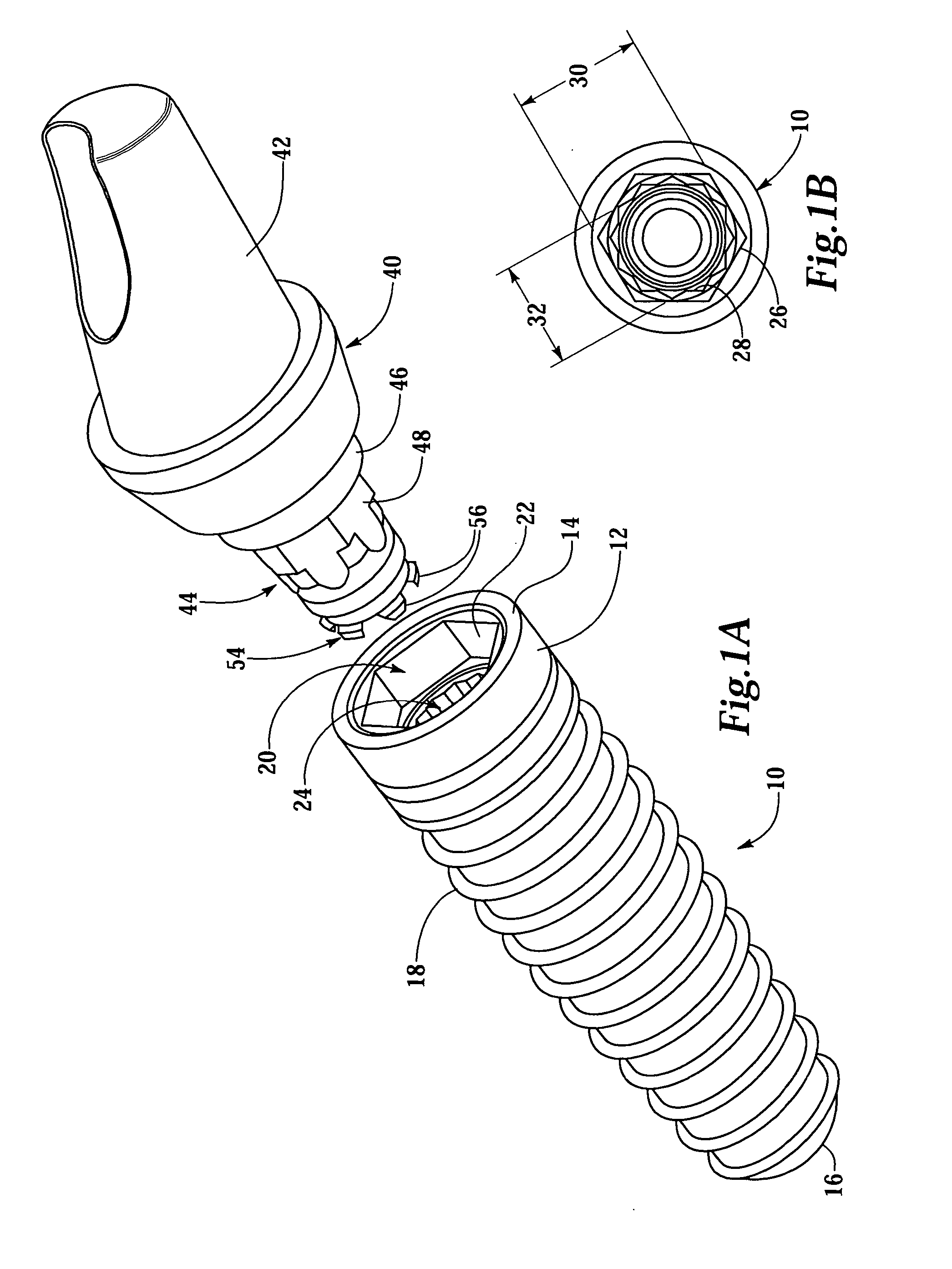

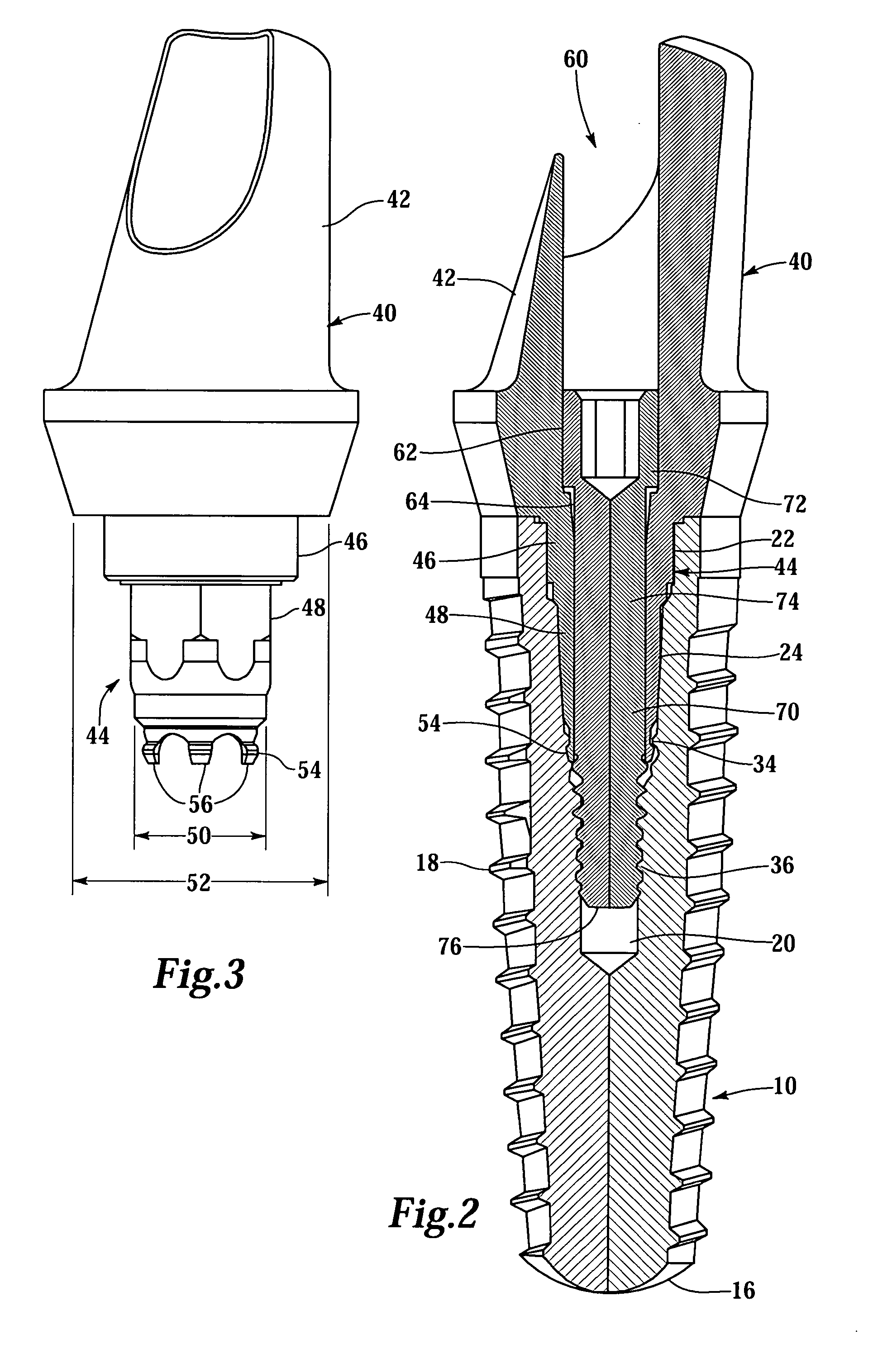

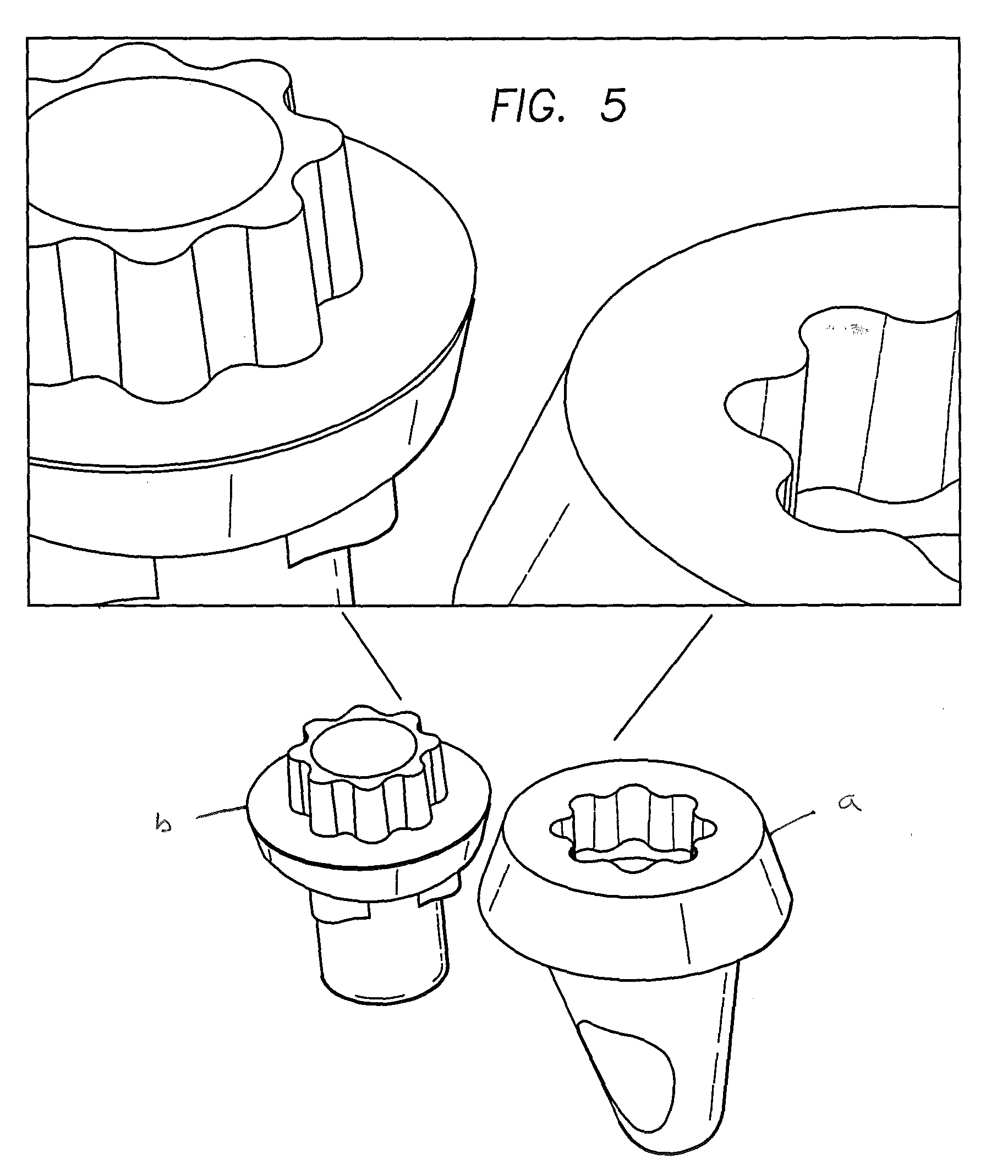

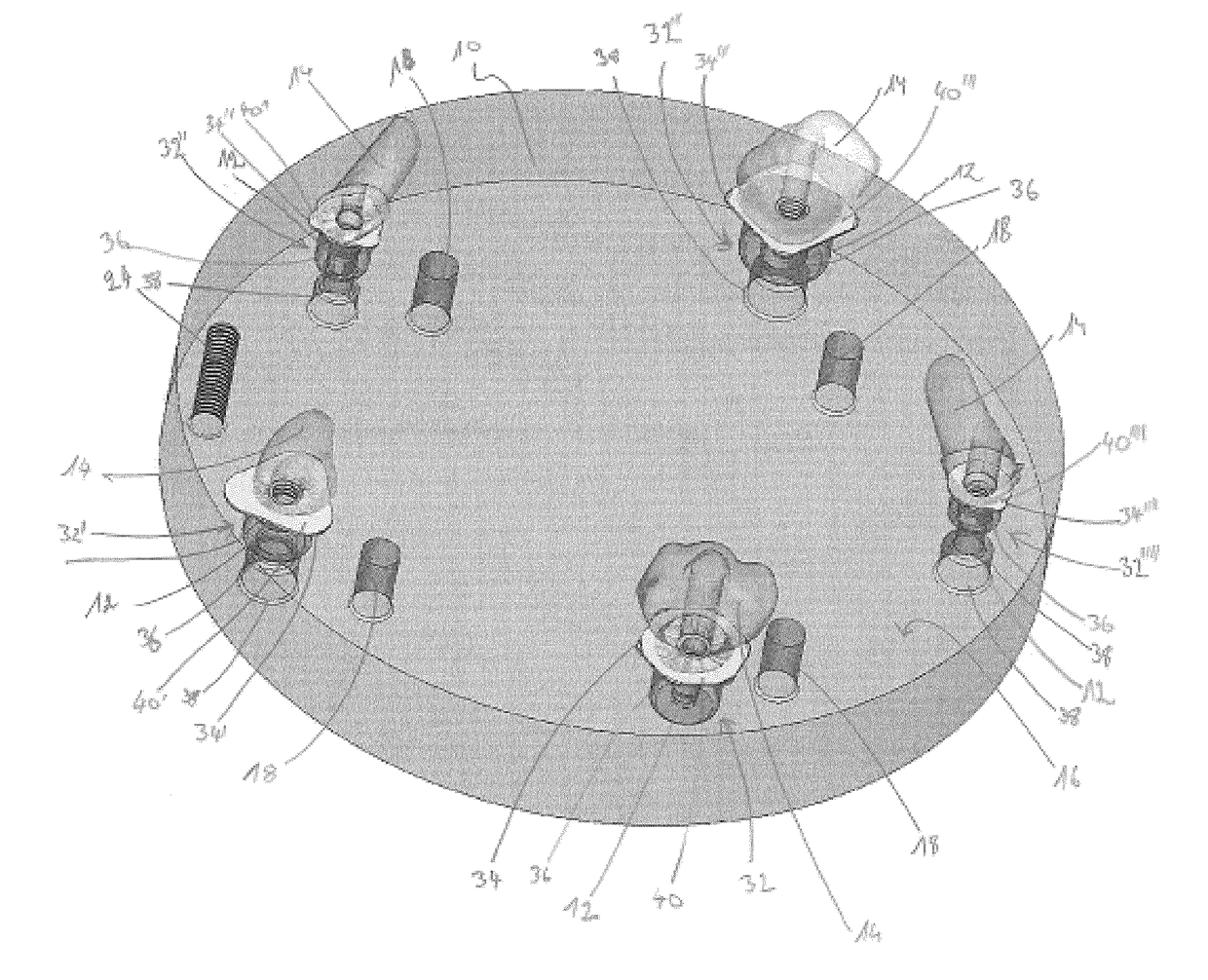

An implant comprising two internal anti-rotational features. One anti-rotational feature is adapted to engage a driving tool, while the other anti-rotational feature is adapted to engage an abutment. An implant abutment system is provided with an angled abutment adapted to mate with one of the anti-rotational features. A second, straight abutment is adapted to engage with the other anti-rotational feature. An abutment is provided with resilient fingers to interface with the implant and provide tactile and audible feedback indicating when the abutment is properly seated. An abutment screw extends through the abutment and engages the implant bore distal of the stem of the abutment. The abutment screw limits axial movement of the abutment relative to the implant. A driving tool comprising one of at least retention structure and visual alignment indicia is provided to facilitate screwing the implant into a patient's bone.

Owner:BIOMET 3I LLC

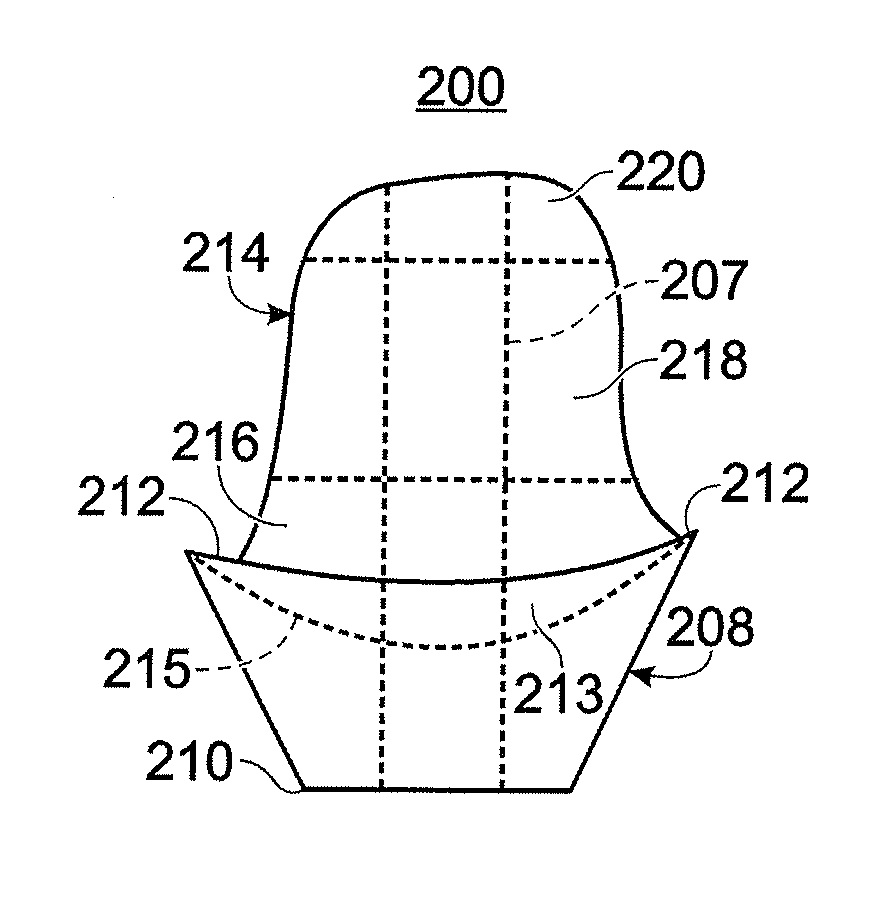

Dental Implant Abutment

A dental implant abutment for attaching a dental prosthesis within a patient's mouth. The abutment is a single unit structure fabricated of a ceramic material, multicolored throughout to match the color of the dental prosthesis, the surrounding dentition and the surrounding gingival tissue.

Owner:IVOCLAR VIVADENT AG

Method of manufacturing and installing a ceramic dental implant with an aesthetic implant abutment

The present invention relates to a method for manufacturing a tooth prosthesis, for insertion in a jawbone, including an implant and an abutment on top of the implant. The method includes: defining a shape of the prosthesis and its location in the jawbone by using first data from a first CT scan image of the jawbone and second data from a second image of a gypsum cast, correlating first and second data by extracting from the first data first position reference data of a first reference in the first image, and from the second data second position reference data of a second reference in the second image, the second reference being identical to the first reference; performing a geometric transformation on the second data and / or the first data to have a coincidence of the second image with the first image and to combine the first and second data into composite scan data.

Owner:CYRTINA DENTAL GROUP BV

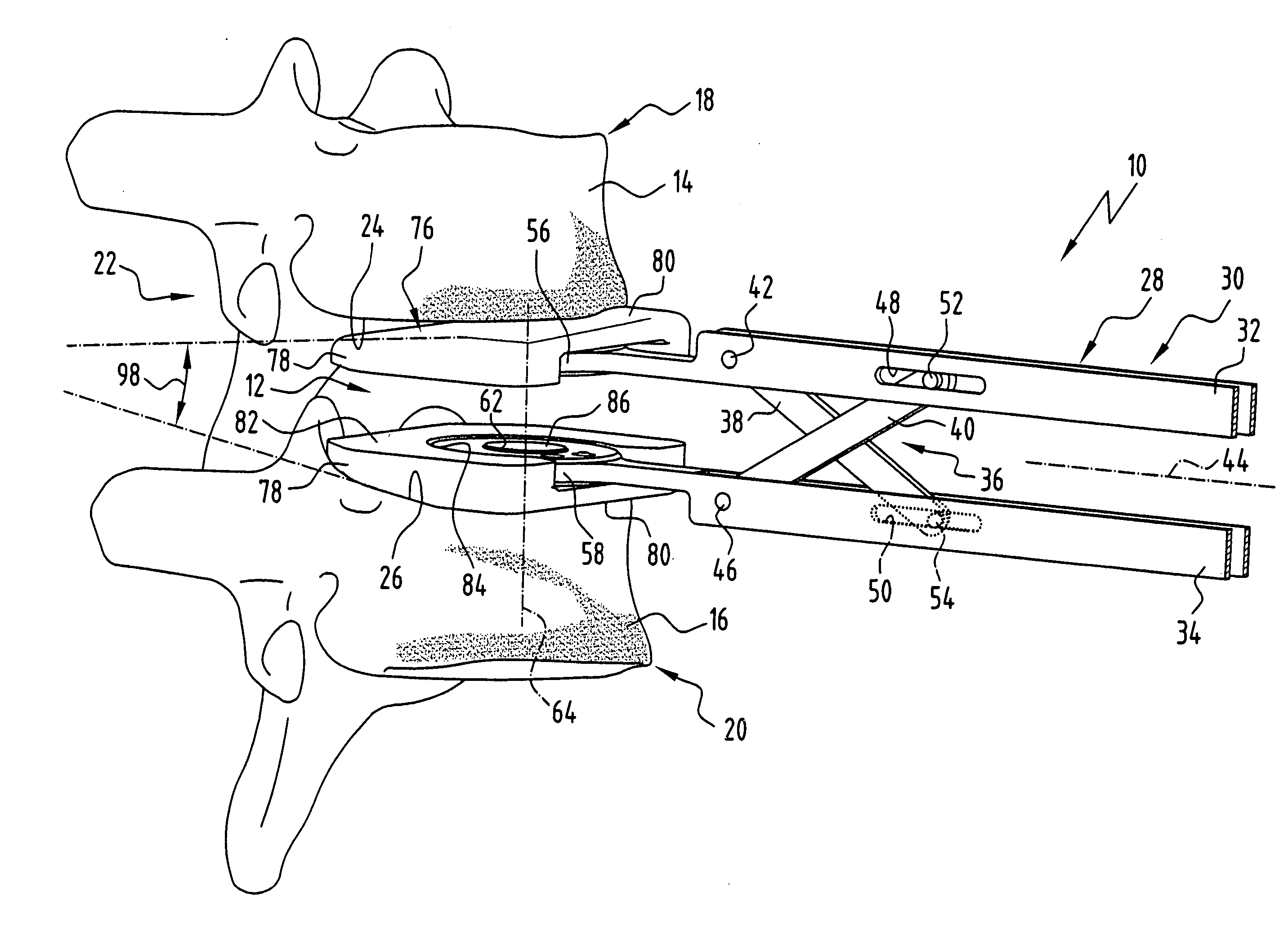

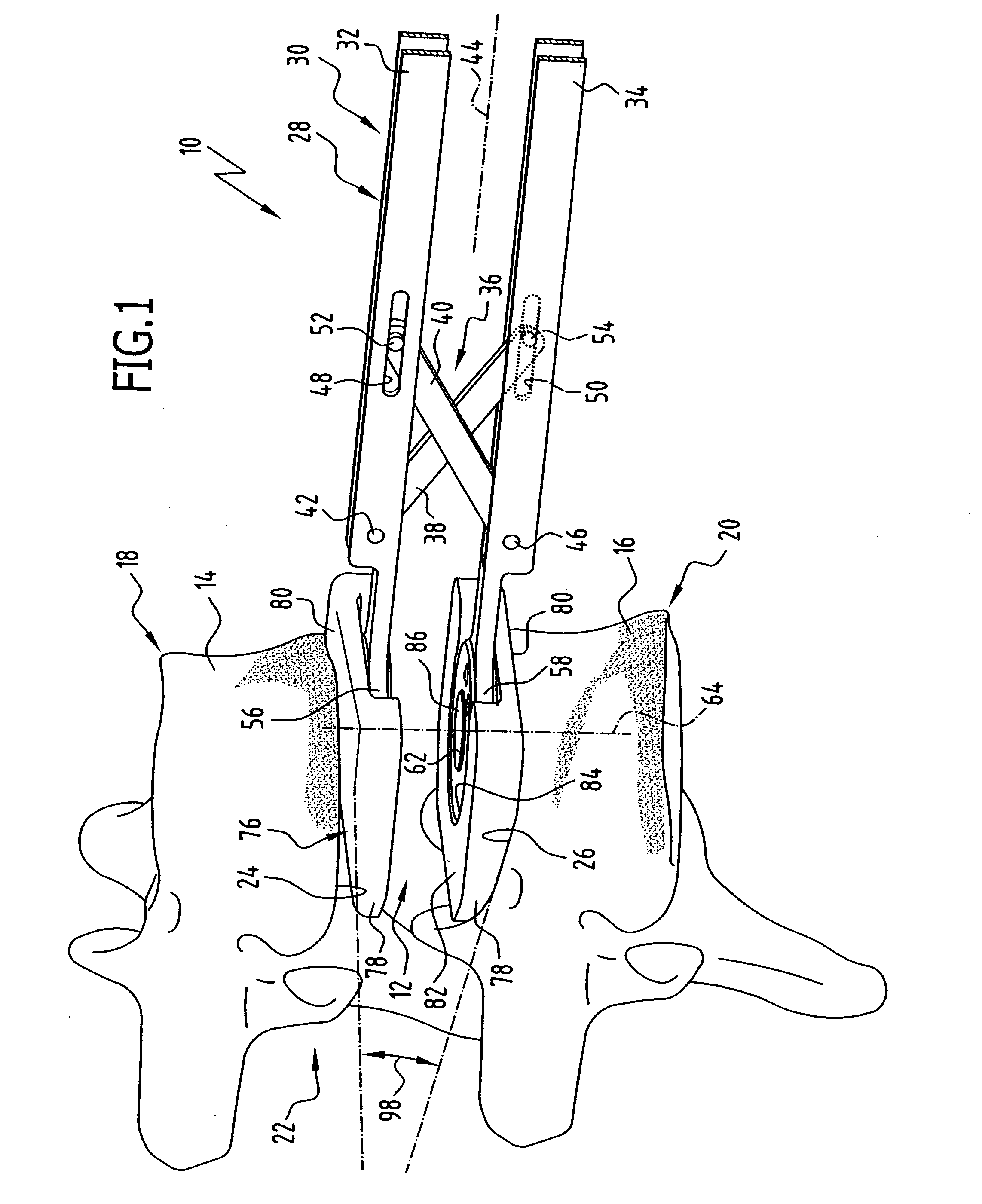

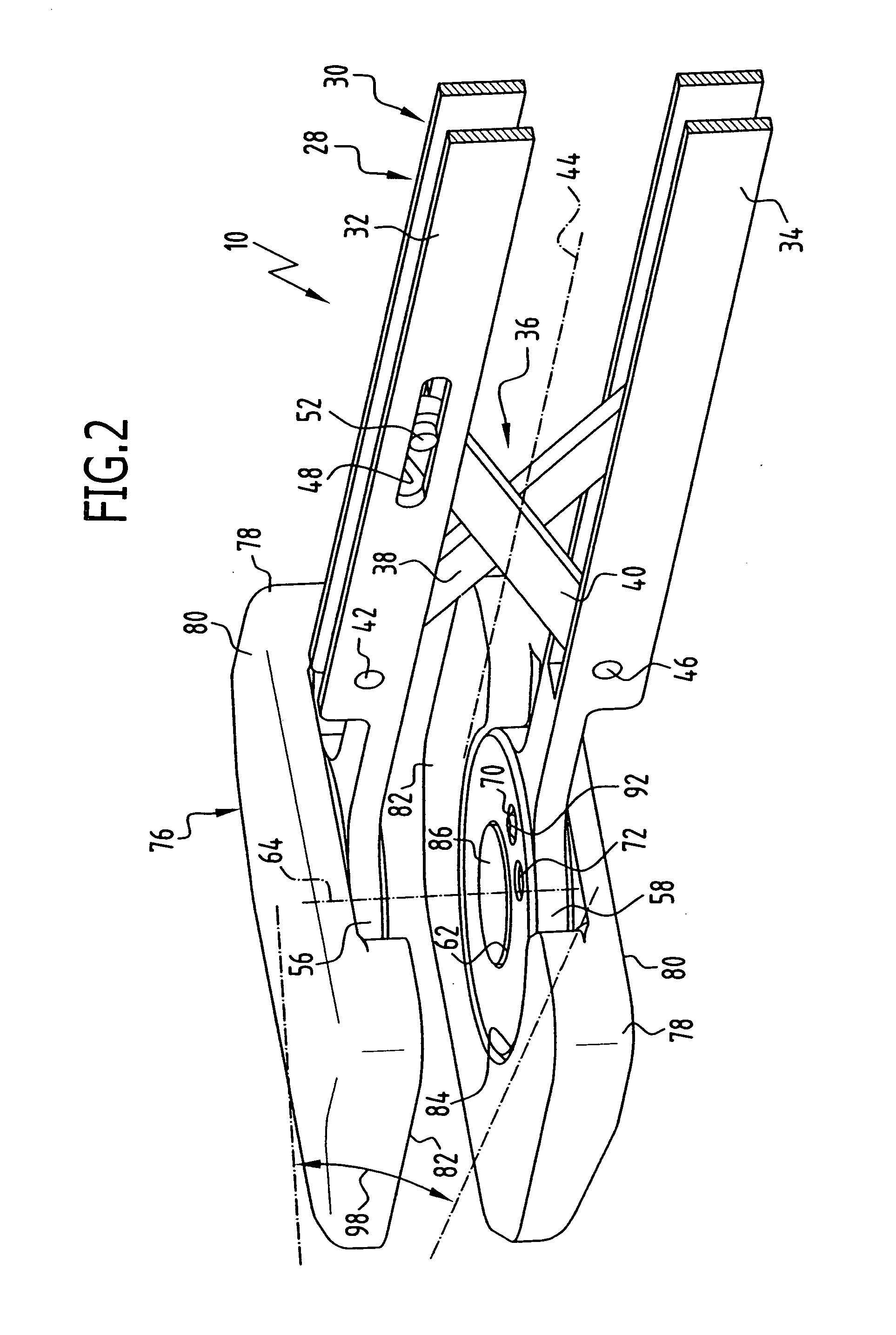

Surgical instrument

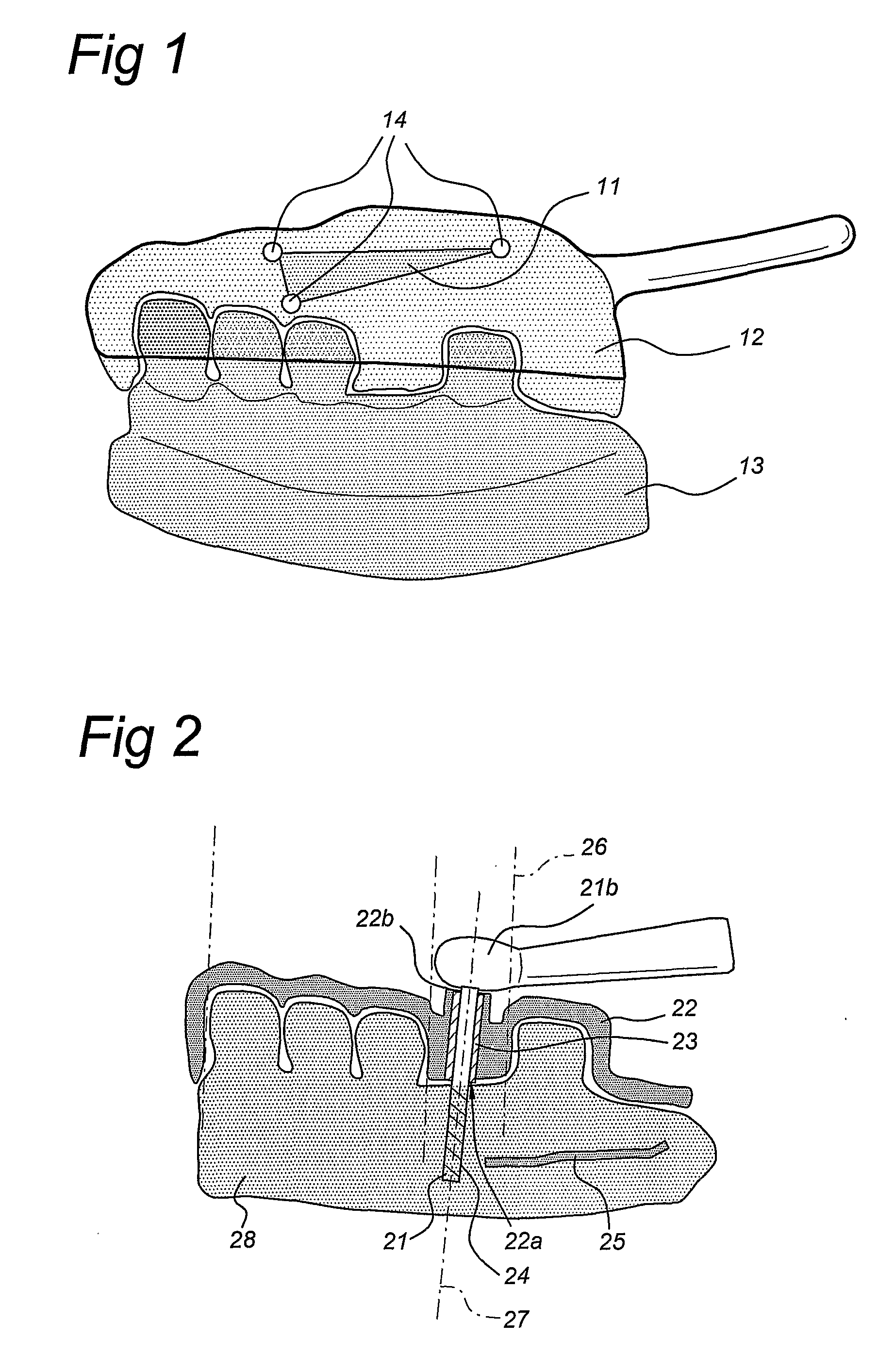

ActiveUS20070209222A1Reduce in quantityEasy to adjustMeasurement devicesPerson identificationArticular surfacesArticular surface

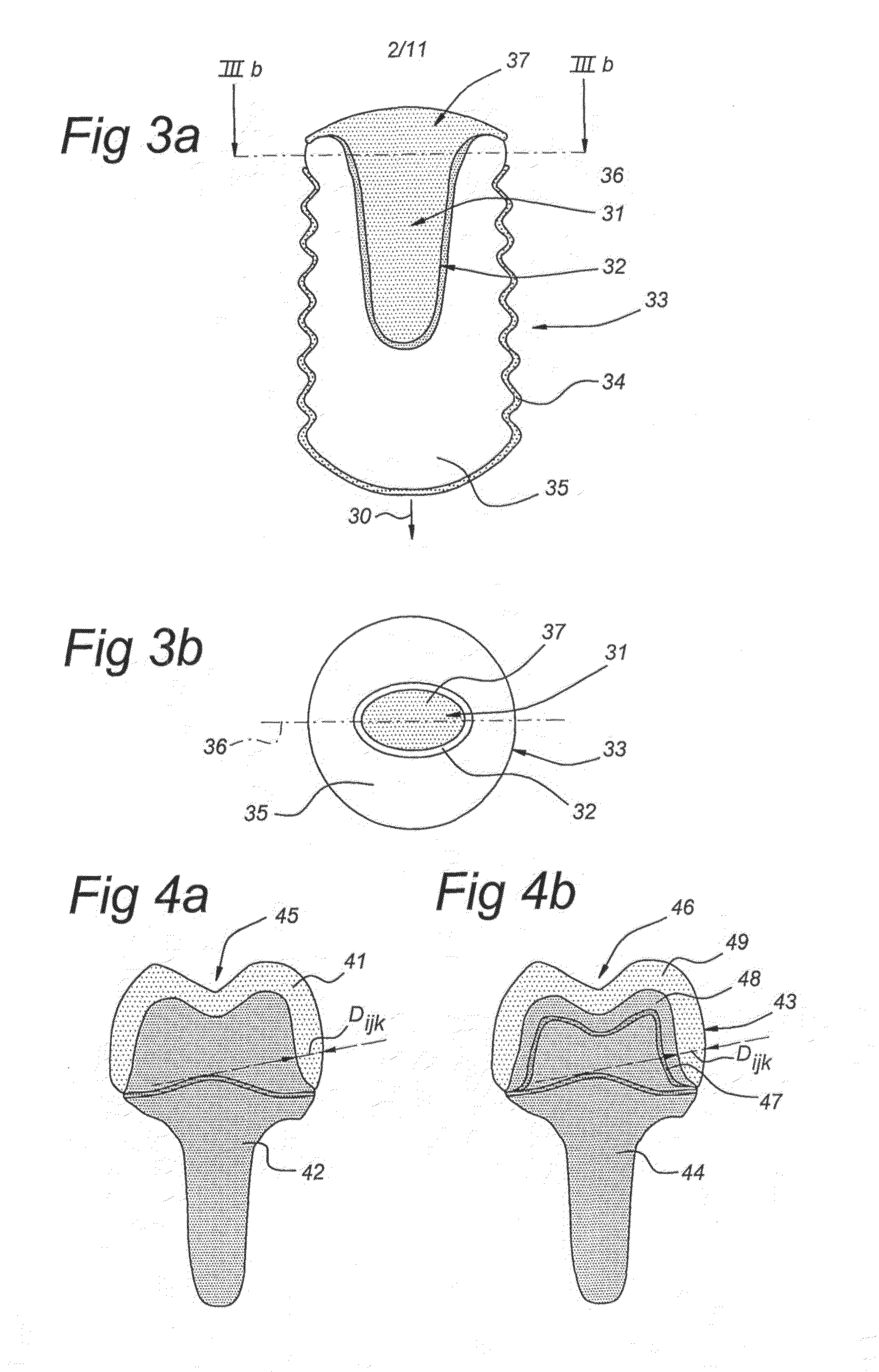

A surgical instrument is configured for determining the size and / or height of an intervertebral implant insertable into an intervertebral space between two adjacent vertebral bodies of two human or animal vertebrae. The implant includes a first abutment element for abutment against an articular surface of one of the two adjacent vertebral bodies and a second abutment element supported directly or indirectly on the first abutment element for abutment against an articular surface of the other of the two adjacent vertebral bodies. The instrument includes a holding part defining a longitudinal direction and at least one test implant, which includes a first and a second test-implant abutment element each having at least one abutment surface for abutment against one of the articular surfaces. A distal end of the holding part includes at least one abutment-element holding element for detachable connection to the at least one test implant 149.

Owner:AESCULAP AG

Method for fabricating a custom implant abutment

InactiveUS20120214133A1Facilitate precision millingSimple manufacturing processDental implantsTooth crownsCNC routerBiomedical engineering

A system and method for fabricating custom implant abutments uses an implant abutment connector to secure a partial blank with respect to a milling tool of a CNC milling machine. The implant abutment connector has an implant interface geometry of an implant. The partial blank can have a prefabricated implant abutment interface geometry of the implant abutment; and can thus mate with the implant, and the implant interface geometry of the implant abutment connector.

Owner:B & D DENTAL

Devices and methods for producing denture parts

Surface mapping and / or generation device is provided, with a device for mapping 3D data of at least one denture base object such as a tooth stump or an implantation abutment, and an environment thereof, as well as with a device for the data-based generation and production of a denture part incorporating the 3D data of the denture base object. Additionally provided are a device for determining and / or defining a placement direction of the denture part that is to be slipped onto the denture base object, and a device for determining and producing a primary part that is to be slipped onto the denture base object before the denture part and that yields a desired placement direction for the denture part which is different from the placement direction that exists for slipping the primary part onto the denture base object. The device for data-based generation and production of a denture part is designed to generate and produce the latter by incorporating the 3D data of the primary part. Surface mapping and / or generation method is provided, wherein 3D data from a denture base object such as a tooth stump or an implantation abutment and an environment thereof are mapped and then, based on this 3D data of the denture base object, a denture part to be slipped thereon is produced. Before production of the denture part, a placement direction of the denture part onto the denture base object is determined or defined. On the basis of this 3D data of the denture base object, a primary part is determined and produced, with which a desired placement direction that differs from the placement direction that exists for slipping the primary part onto the denture base object is created for the denture part. On the basis of the 3D data, the denture part is generated and produced based on data so as to fit when pushed onto the primary part.

Owner:INSTITUT STRAUMANN AG +1

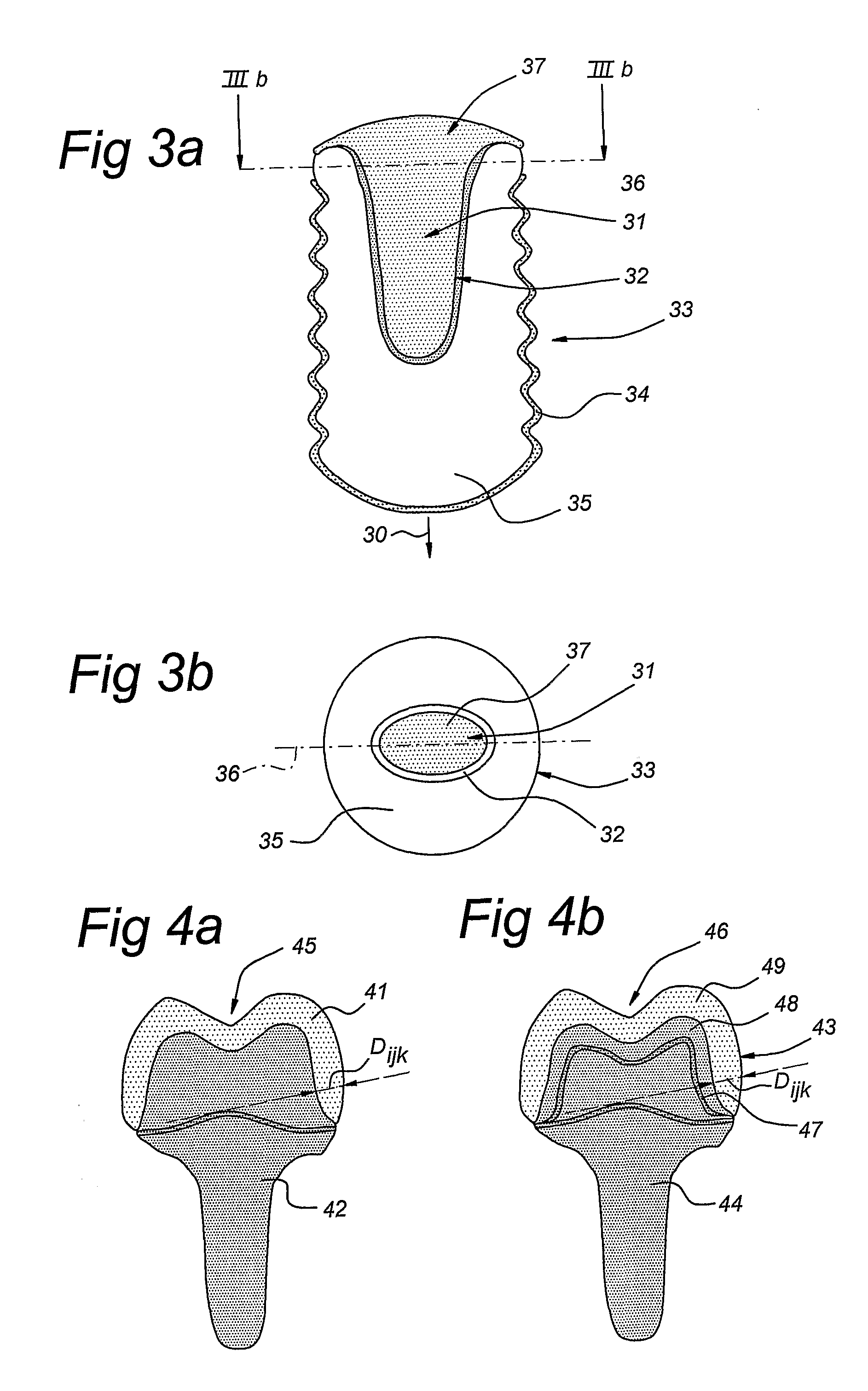

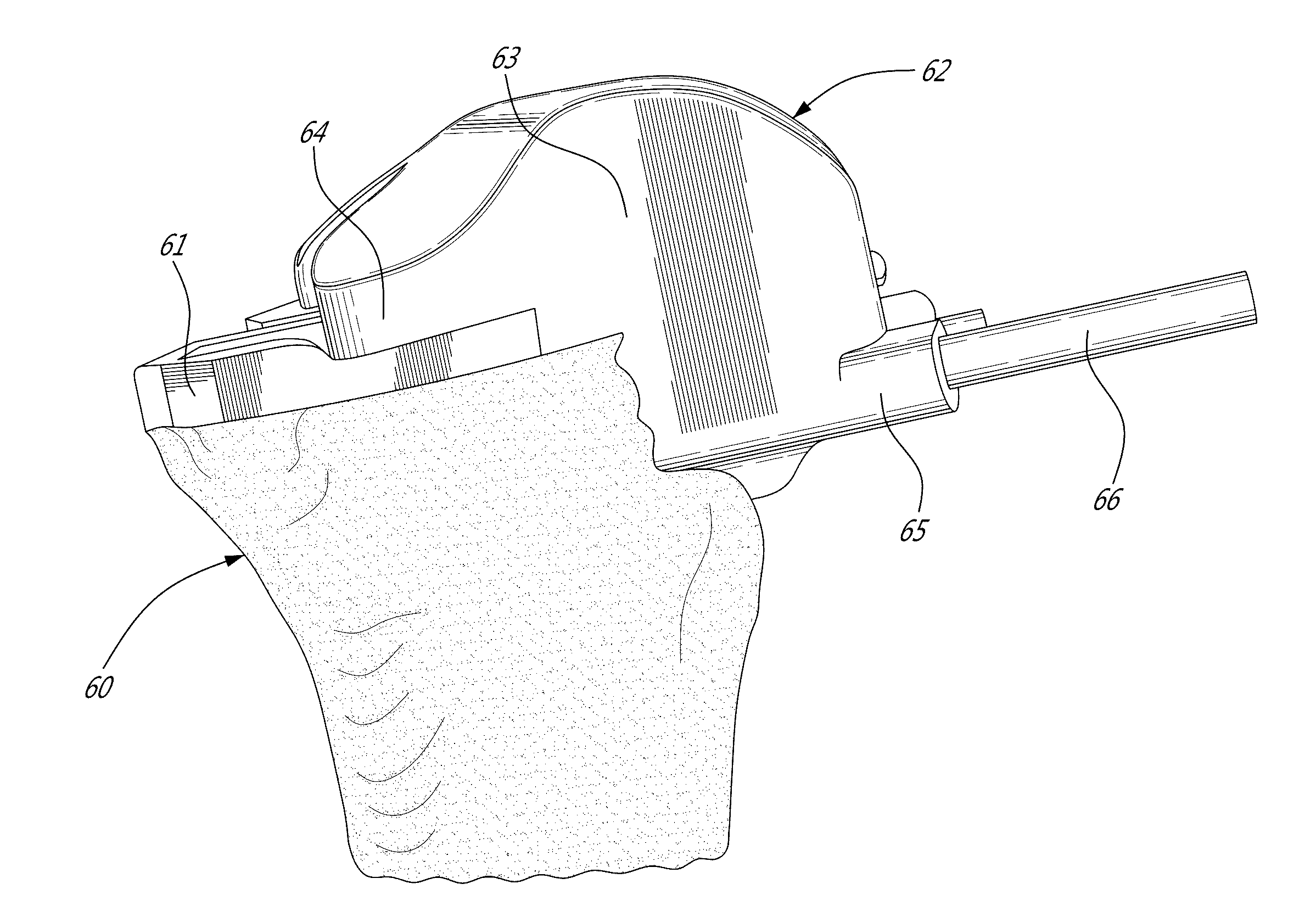

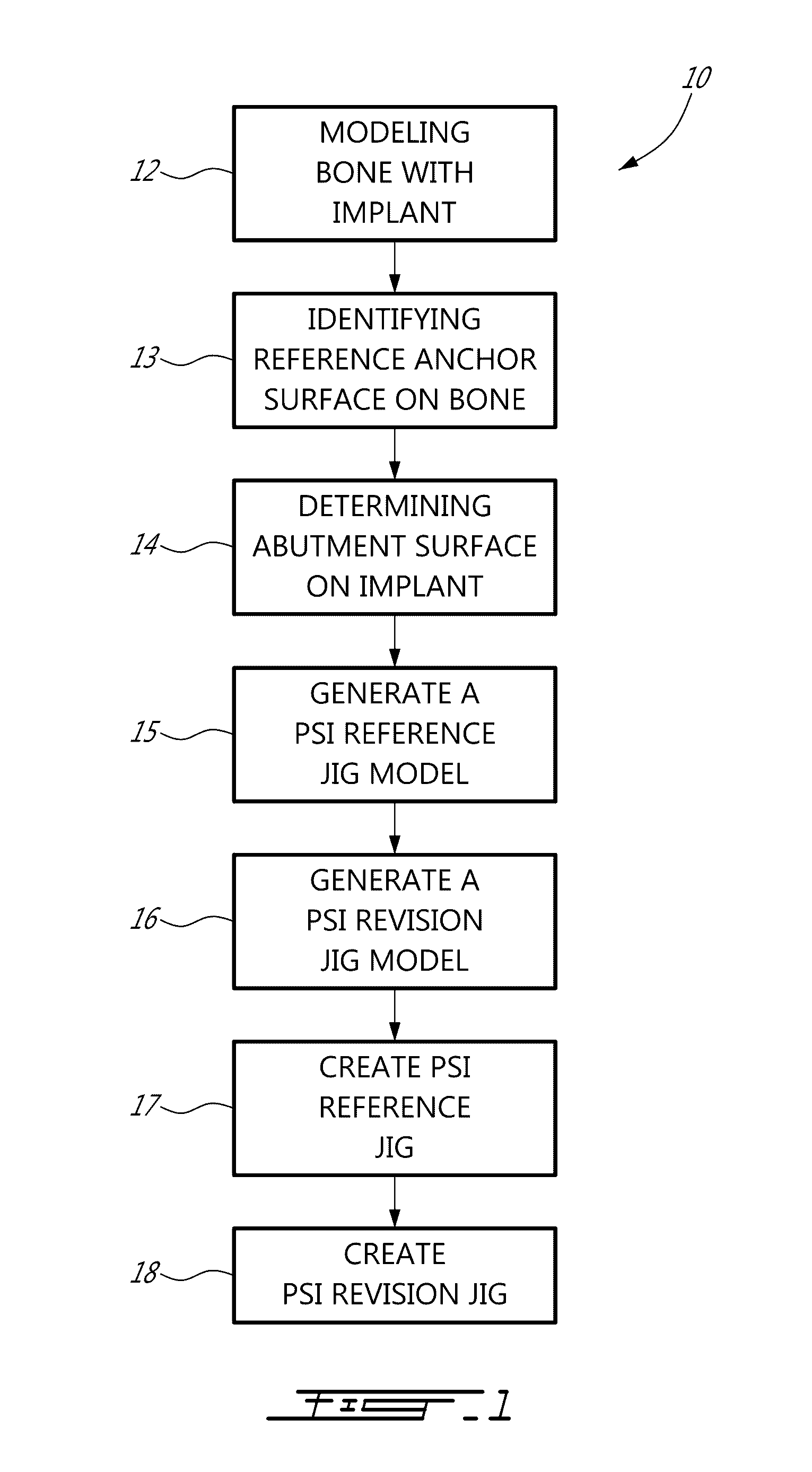

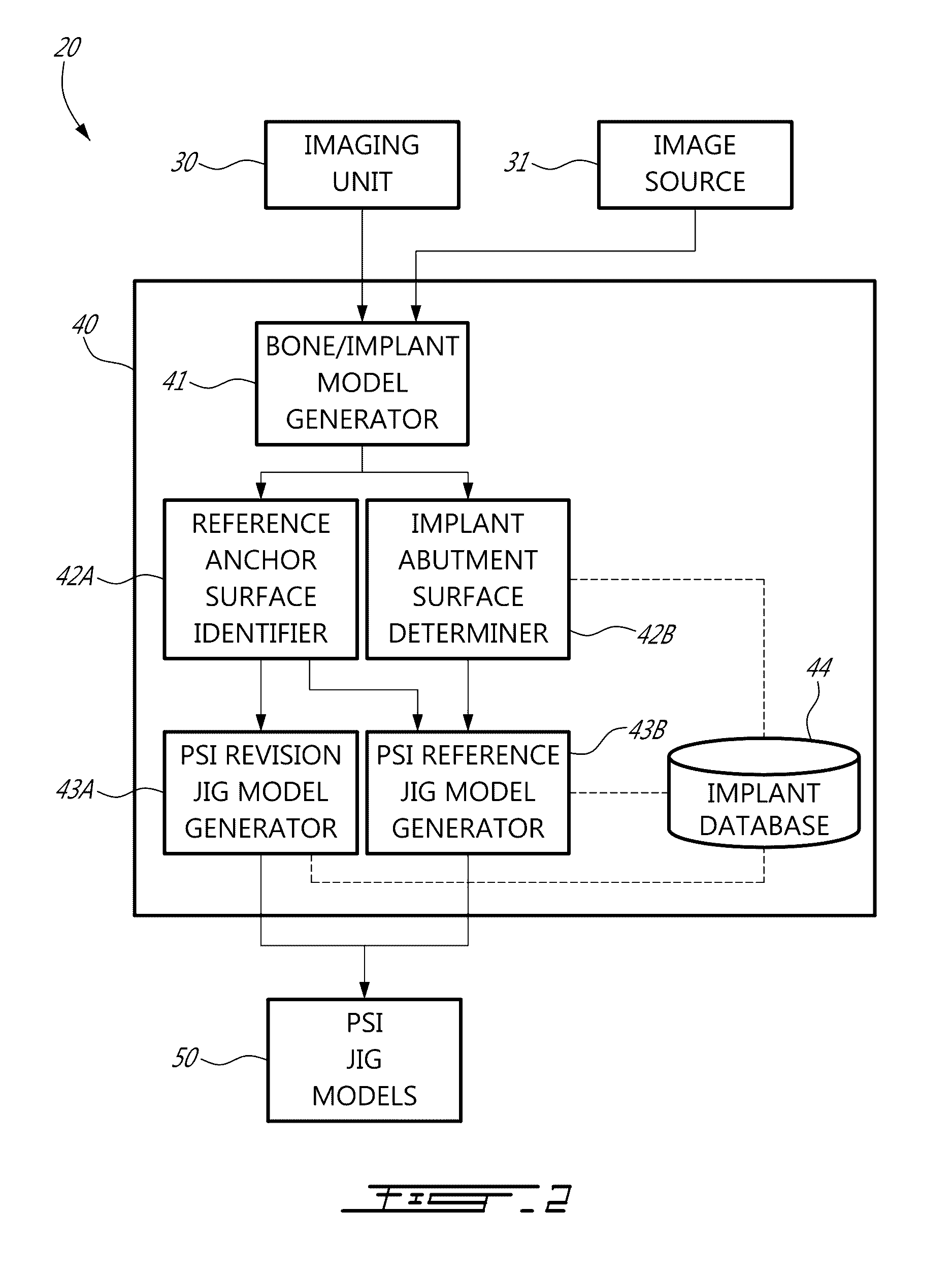

Patient-specific instrumentation for implant revision surgery

ActiveUS20170007331A1Joint implantsComputer-aided planning/modellingBiomedical engineeringInstrumentation

A system for generating a PSI jig model for implant revision comprises a reference anchor surface identifying module configured to identify at least one reference anchor surface from at least one patient specific image of a bone and of an implanted implant, the reference anchor surface configured to receive a guide reference(s). An implant abutment surface determining module determines an implant abutment surface from the patient specific bone image. A PSI reference jig model generator module generates and outputs a reference jig model using the identified reference anchor surface and the determined implant abutment surface, the reference jig model comprising contact surface(s) corresponding to the determined implant abutment surface for complementary connection with the determined implant abutment surface, guide interfacing portion(s) configured to guide a planting of the guide reference in the reference anchor surface, and a patient-specific geometry between contact surface(s) and the guide interfacing portion, so as to position and / or orient the guide interfacing portion relative to the reference anchor surface, for subsequently planting the guide reference(s) in the reference anchor surface as identified when the contact surface(s) is complementarily connected with the determined implant abutment surface. A method for creating patient-specific instrumentation jig for implant revision is also provided.

Owner:ZIMMER INC

Method of making a dental restoration

Blocks of material are prepared in a variety of shapes and sizes to be used in the fabrication of models for dental restorations. The material comprises a partially sintered ceramic material. The blocks are used to manufacture molds using CAD / CAM methods and equipment. The molds are useful in the manufacture of dental restorations using ceramics, metals, alloys, or powders thereof, and composite materials. The models milled from the blanks may be used to manufacture a variety of dental restorations including, but not limited to, crowns, bridges, space maintainers, tooth replacement appliances, orthodontic retainers, dentures, posts, jackets, inlays, onlays, facings, veneers, facets, implants, abutments, splints, partial crowns, teeth, cylinders, pins, and connectors.

Owner:IVOCLAR VIVADENT AG

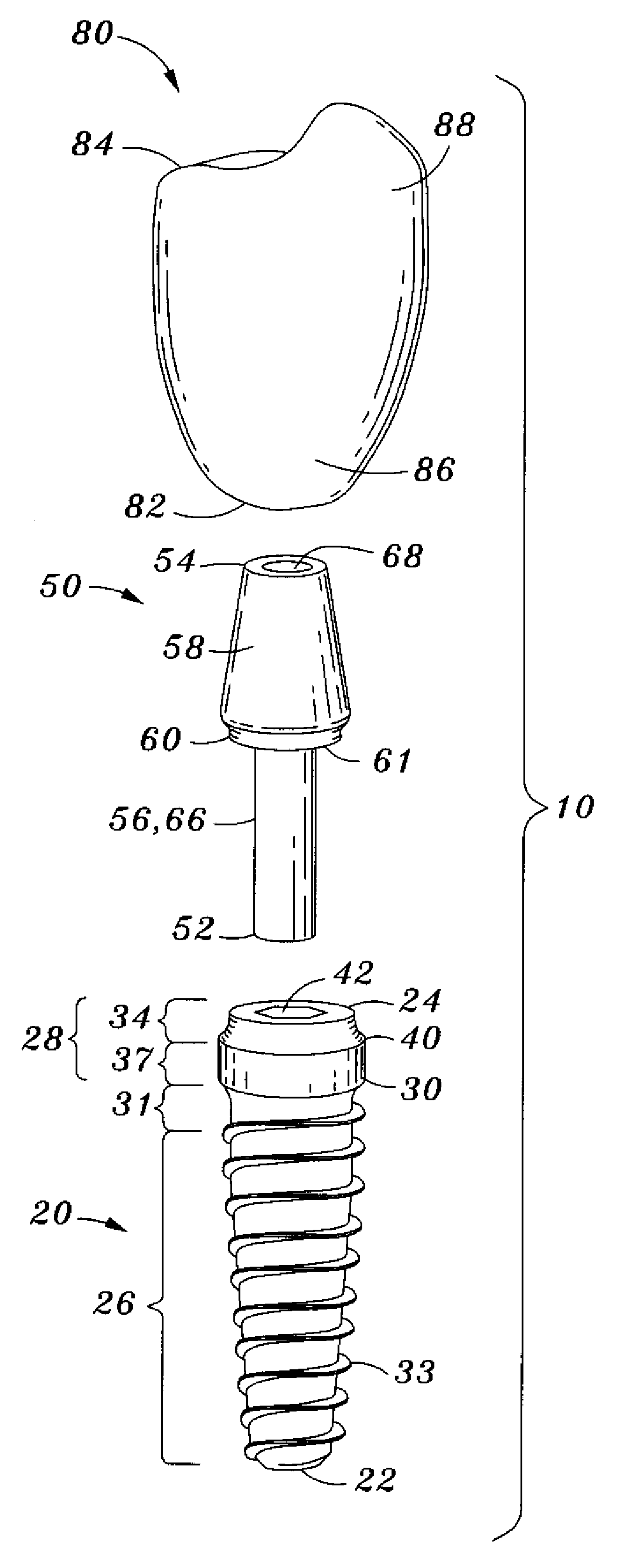

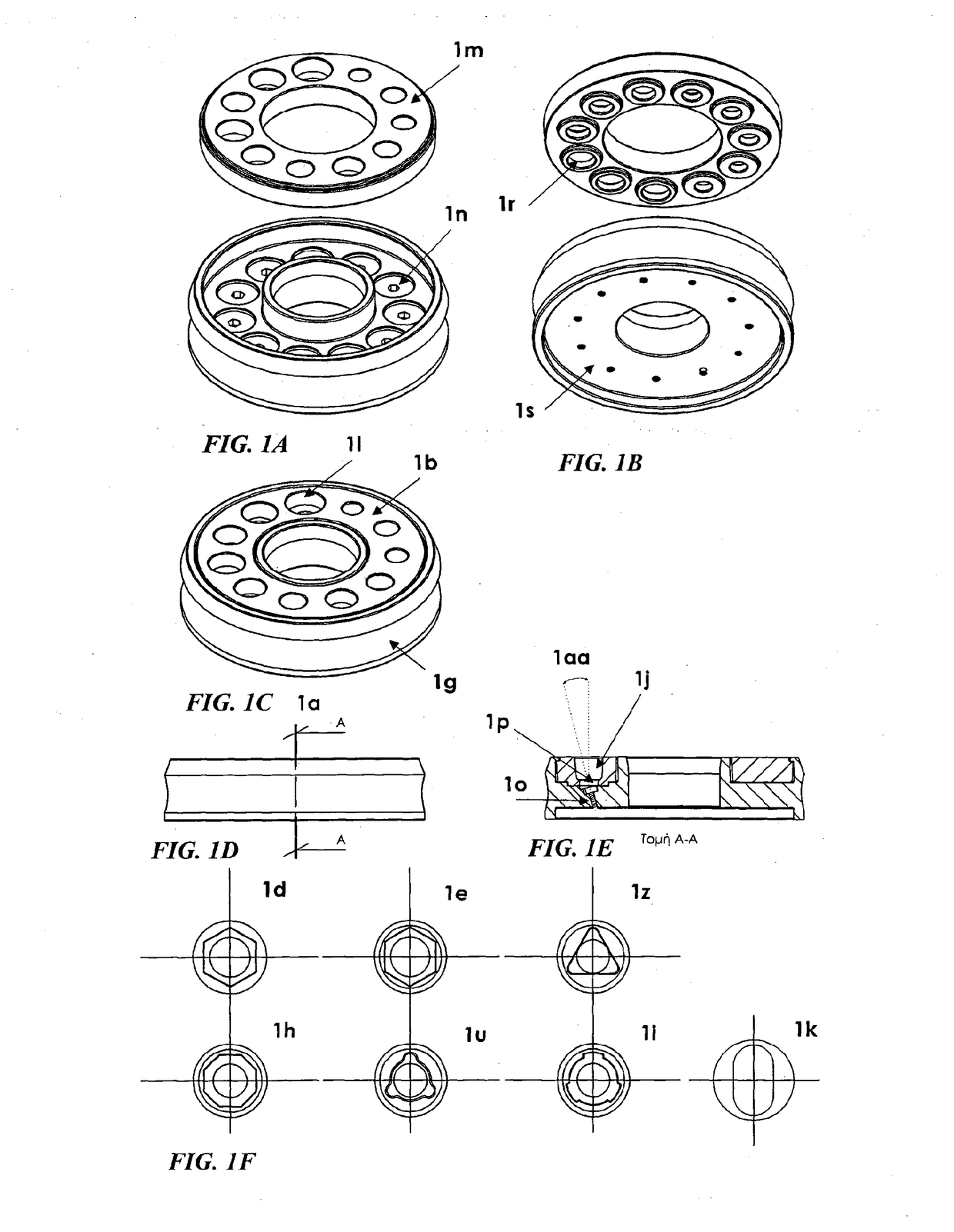

Dental Implant Device and Screw

InactiveUS20100261141A1Improve aestheticsPromotes Oral HealthDental implantsImplant retainerDental implant

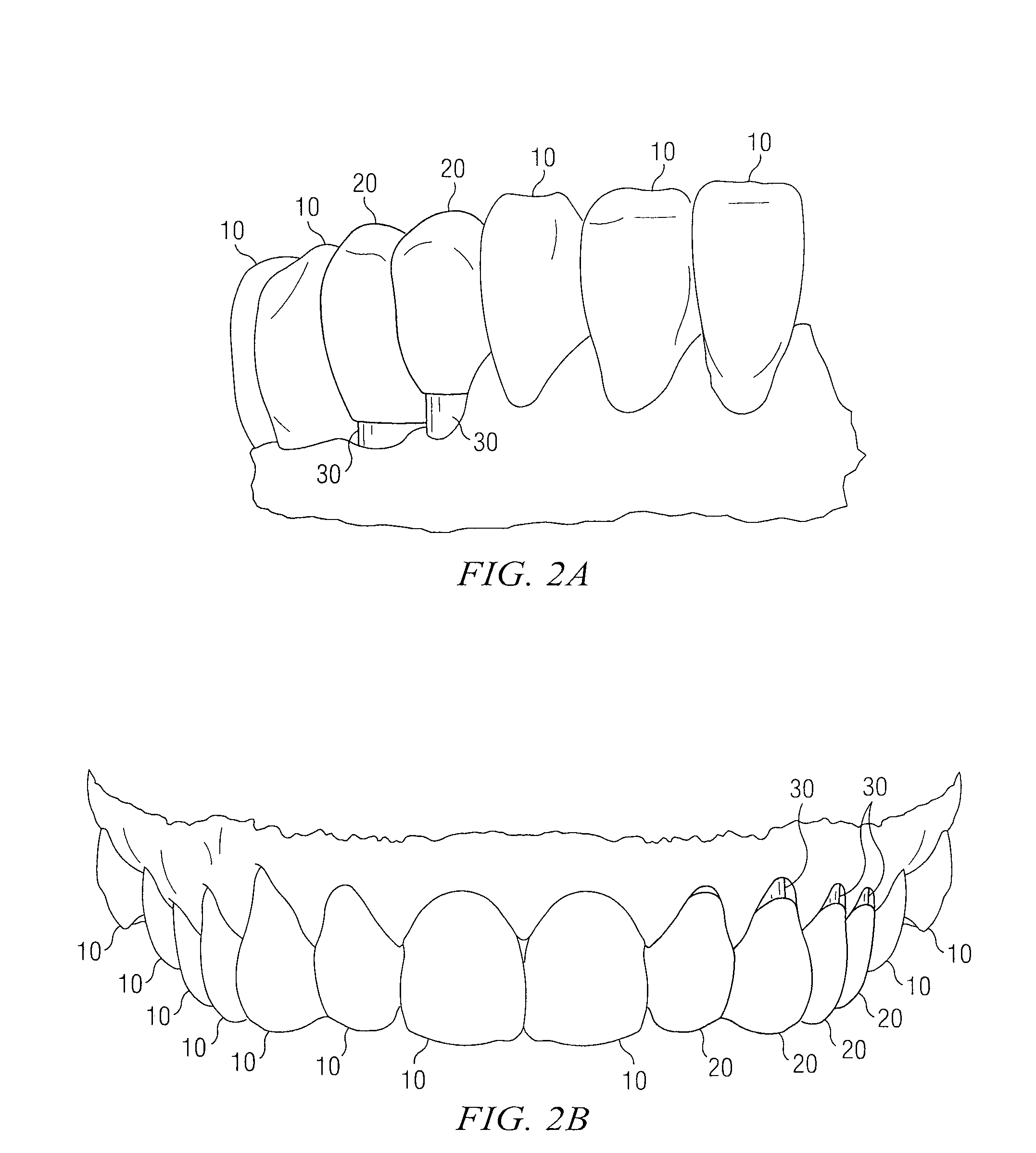

In one embodiment of the present invention, a dental implant may include an implant fixture capable of securing the dental implant in bone. An implant neck with a non-metallic coating may surround the coronal end of the implant fixture. An implant abutment attaches to the implant fixture at the implant fixture's coronal end. A crown attaches around the implant abutment and adjacent to the neck.

Owner:TEXAS A&M UNIVERSITY

Dental implant system

Owner:BIOMET 3I LLC

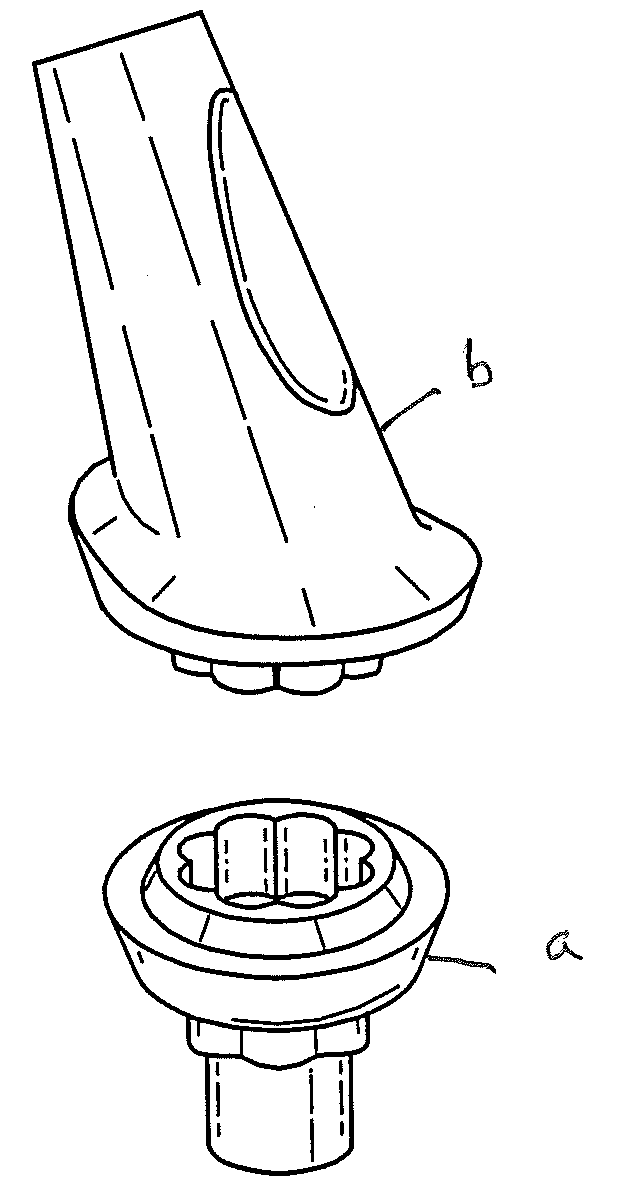

Two-part rotational dental implant abutment for use with existing implant bases

A two-part abutment for attachment between a dental implant and a restorative fixture may be oriented at an angle of between 0° and 35°, and manipulated between four to twelve directions or positions in addition to the directions in which the implant itself may be manipulated so that the restorative fixture may be oriented in the proper position within the mouth of a patient.

Owner:HINRICHSEN UWE

Dental implant

Owner:PERIOSEAL

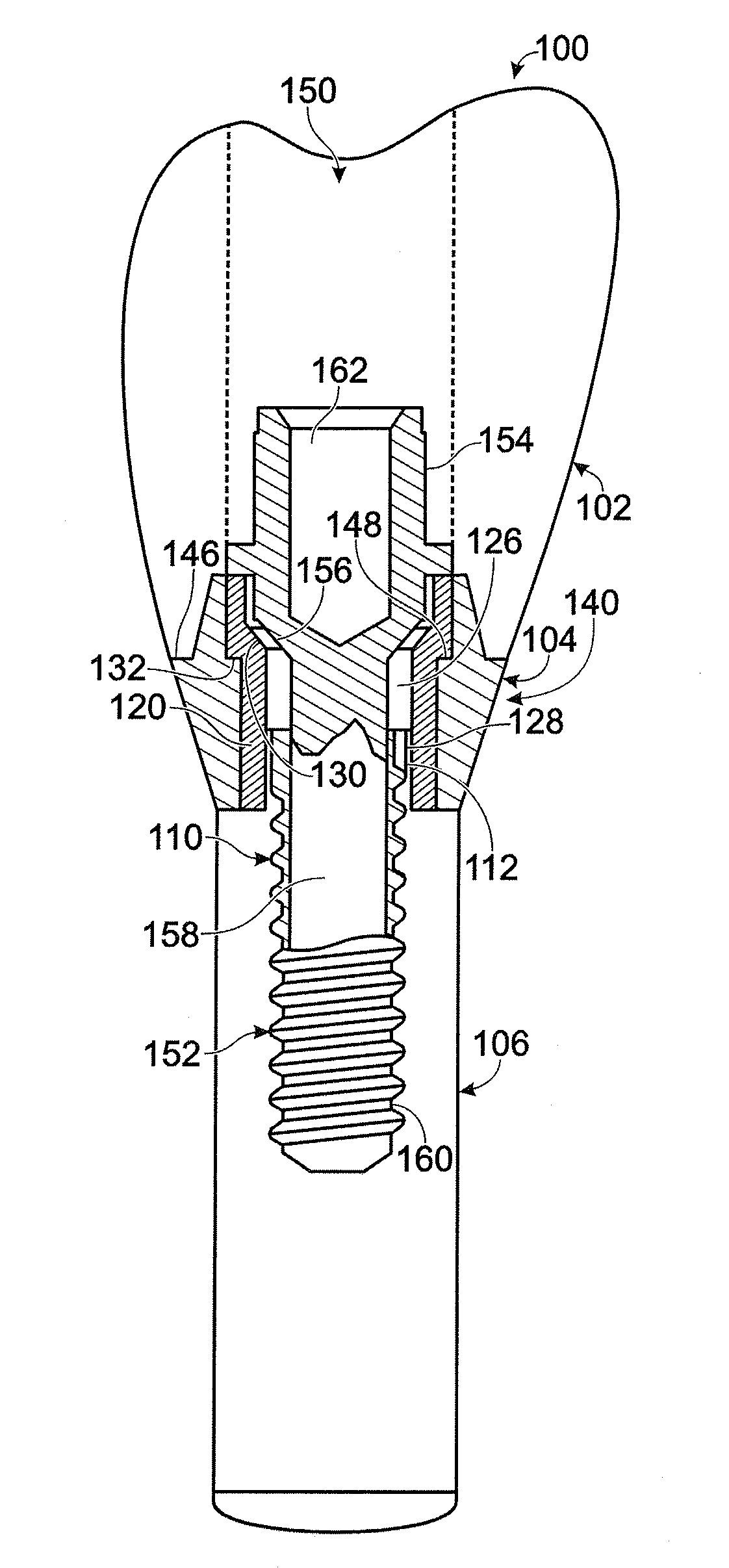

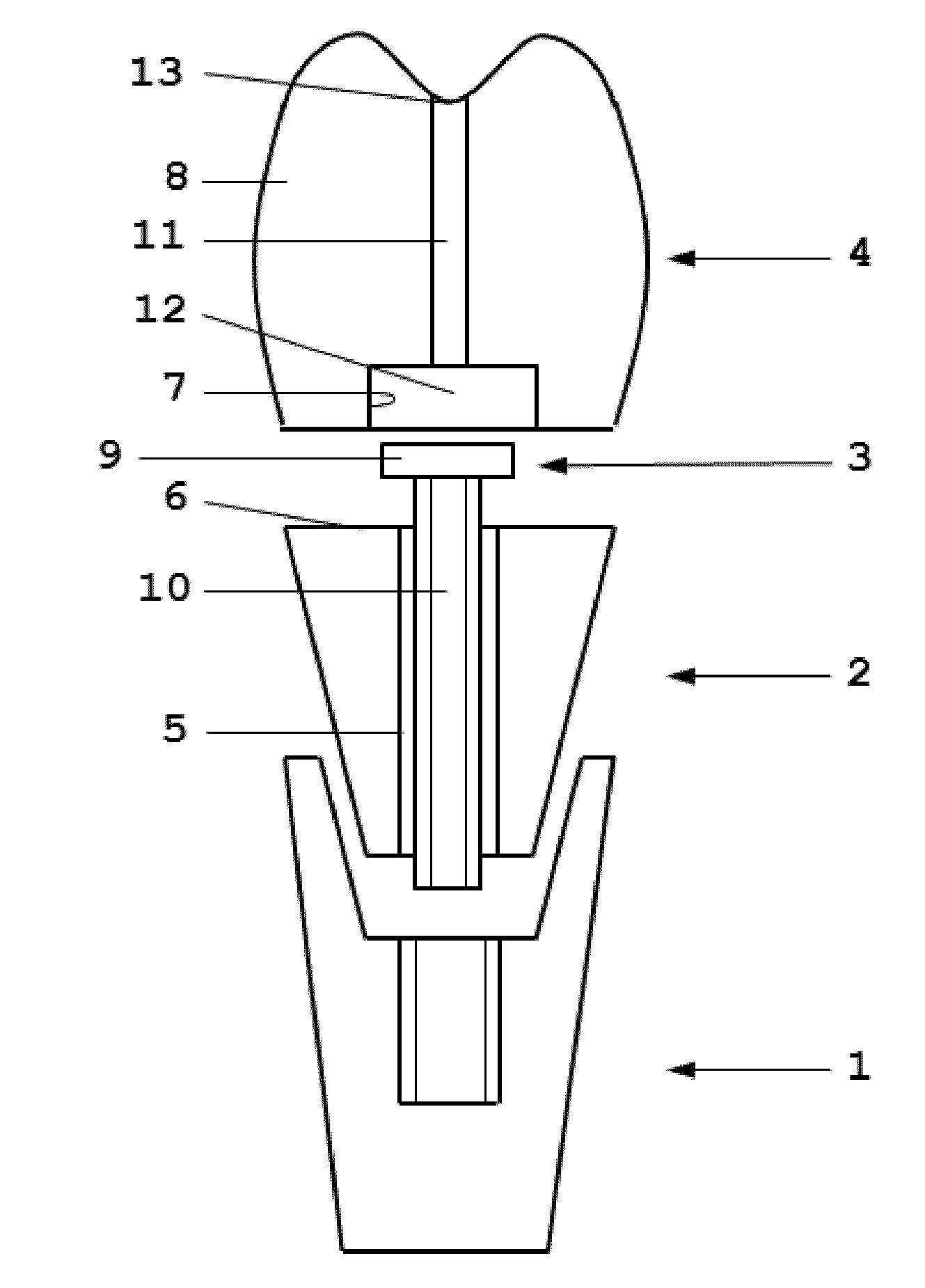

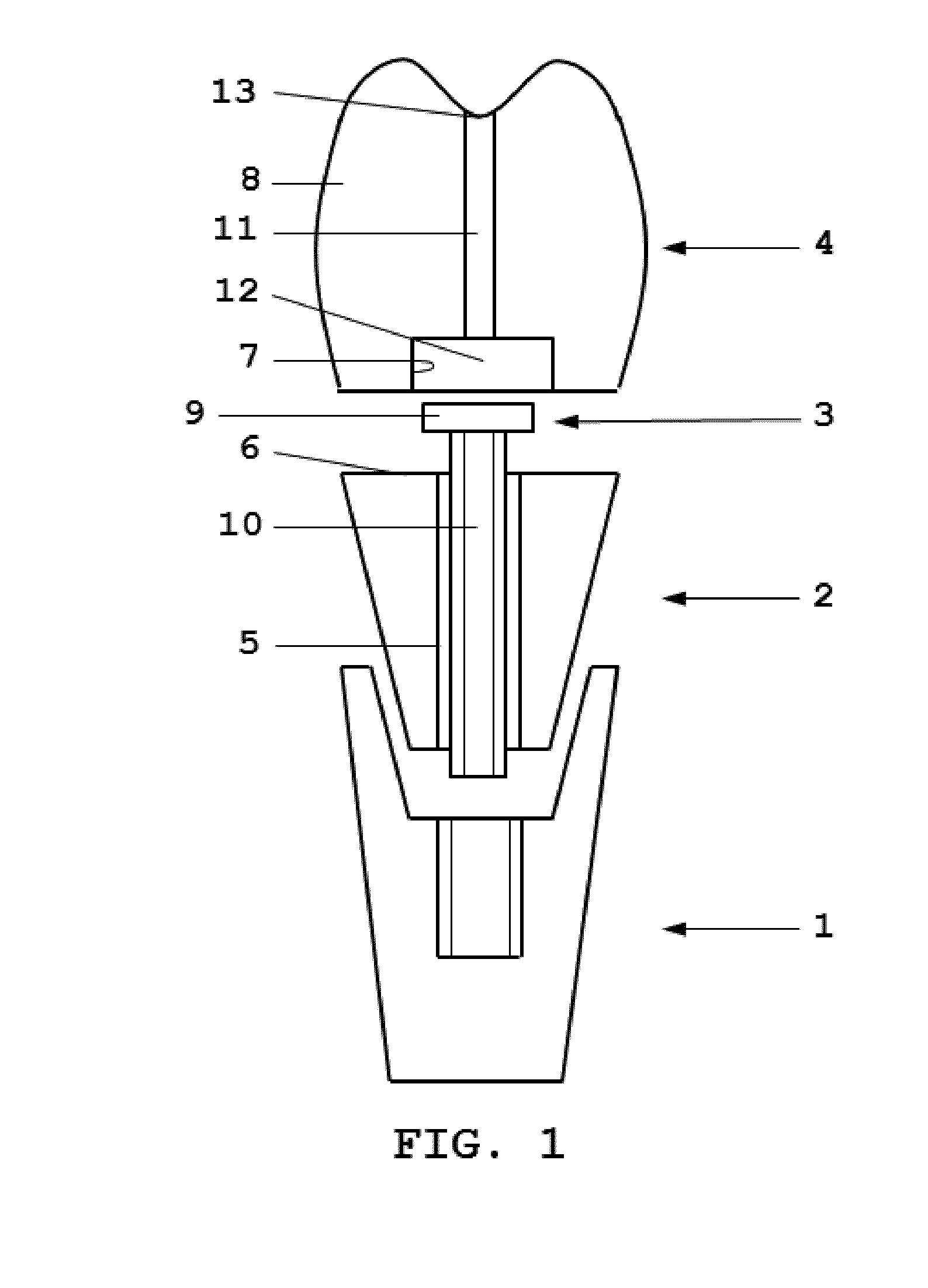

Dental kit-of-parts and method of assembling the same

The present invention describes a dental kit-of-parts comprising an implant abutment, a dental restoration and a screw. The head of the screw is provided in a recess formed in the kit-of-parts, with the screw shaft extending through a hole in the implant abutment. A channel in the dental restoration allows access to the screw head by a tool, wherein the diameter of the channel is smaller than the diameter of the screw head. The dental kit-of parts can be manufactured using rapid prototyping such that the captive screw is formed within the combination of the implant abutment and the dental restoration or through conventional means, with the dental abutment and the dental restoration being ex-situ connected to enclose the screw.

Owner:NOBEL BIOCARE SERVICES AG

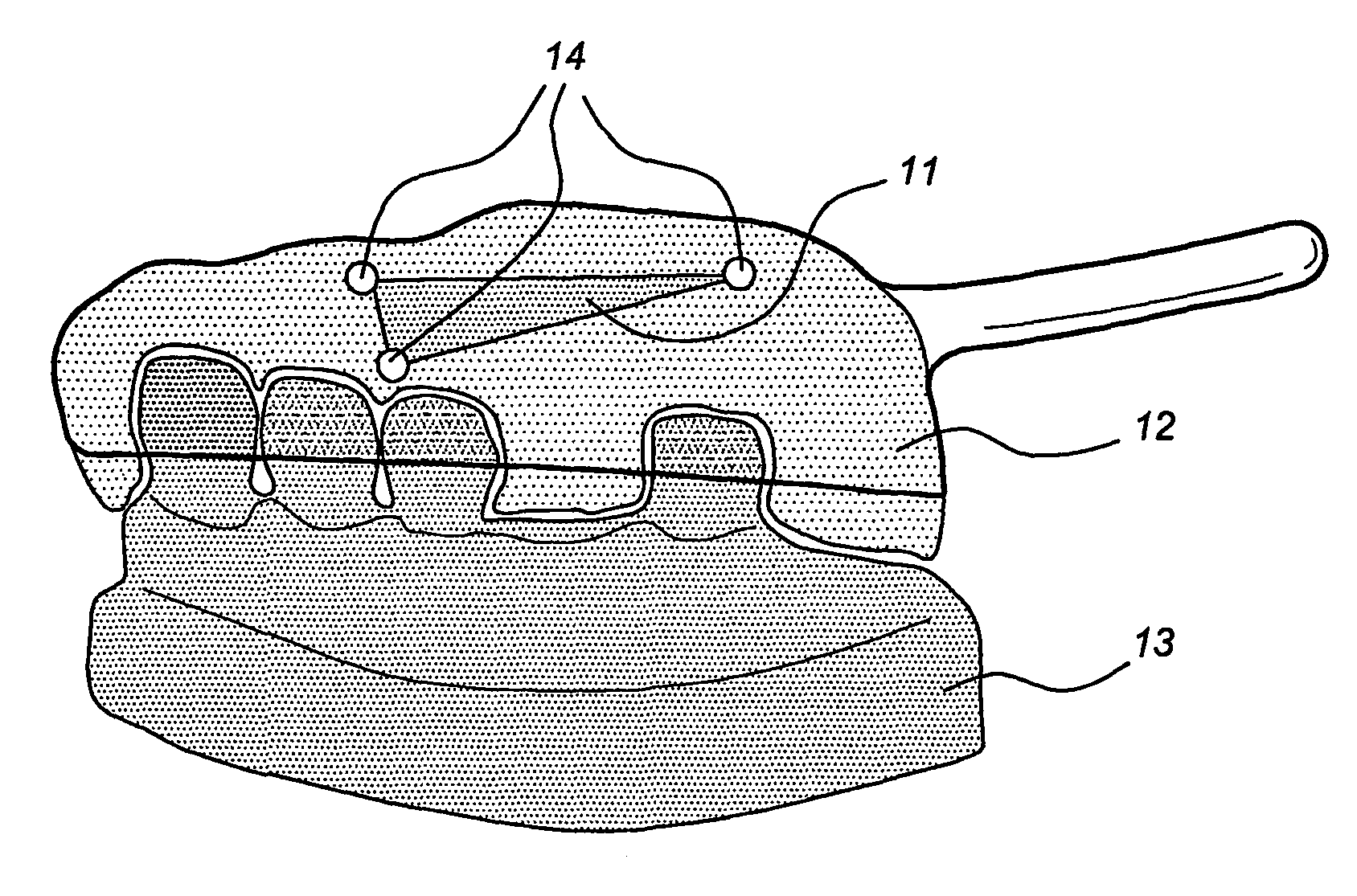

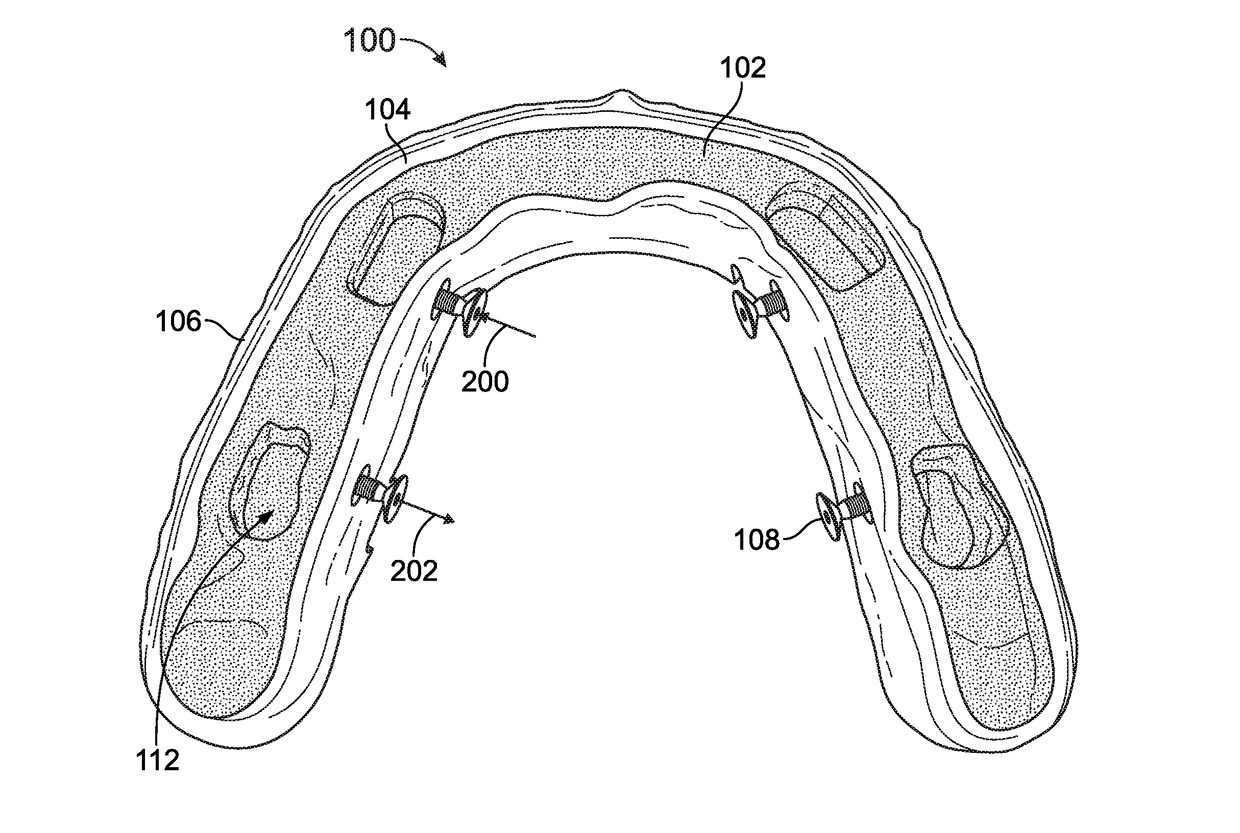

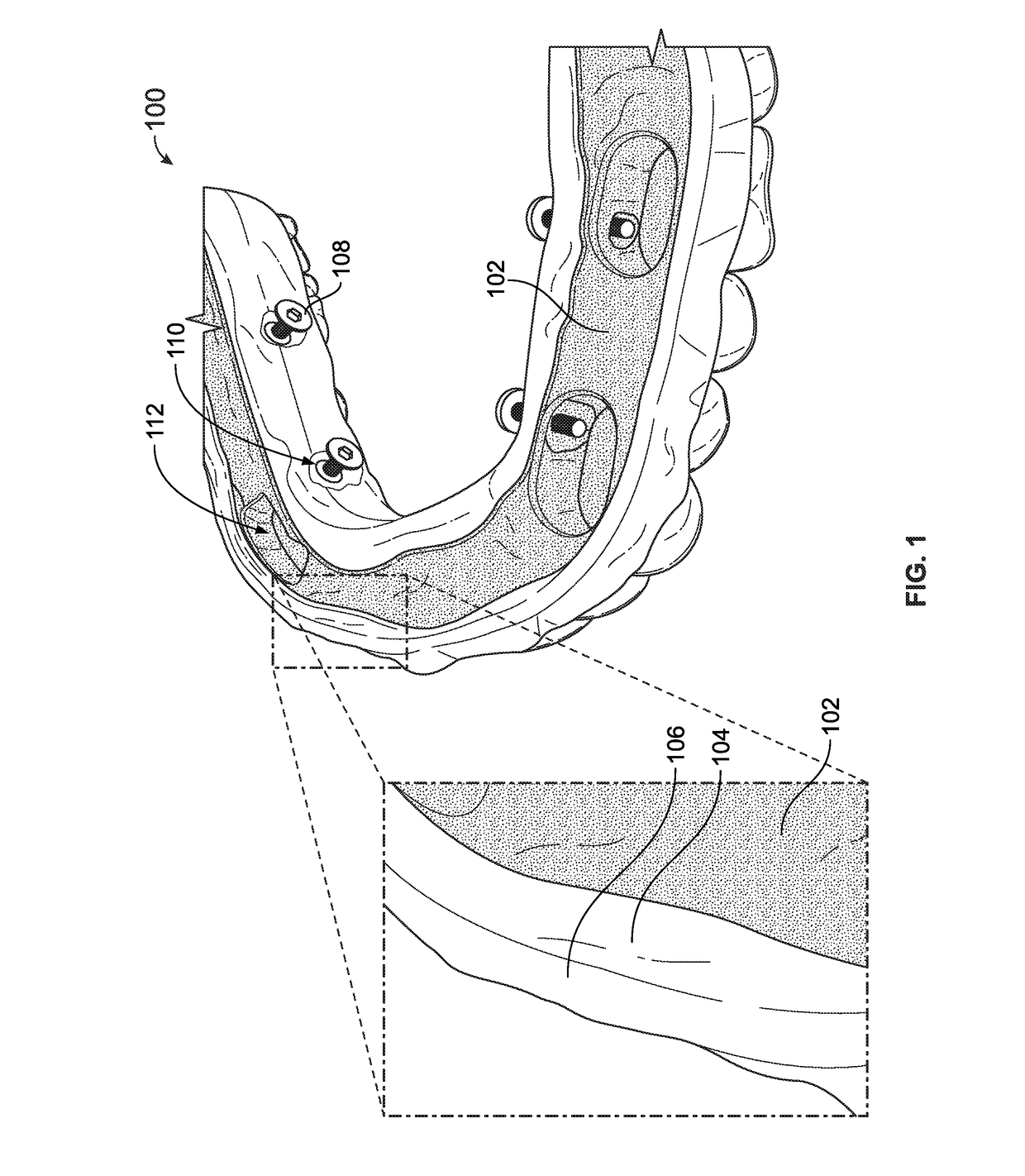

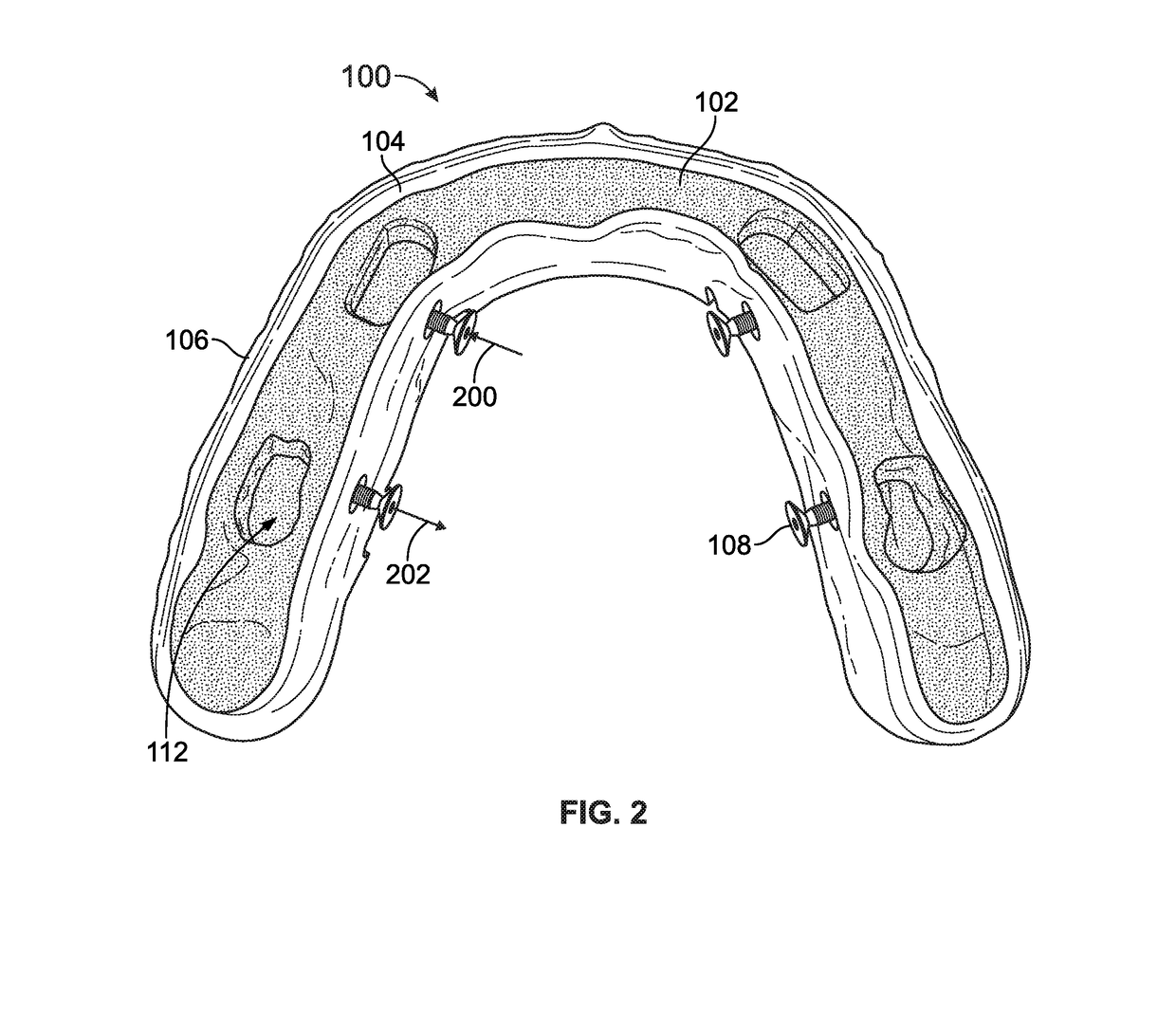

Dental prosthetic assemblies and coupling systems

A dental prosthetic assembly includes a semi-flexible reinforcement bar and a polymer and glass outer layer chemically luted to the semi-reinforcement bar outside of the reinforcement bar. The semi-flexible reinforcement bar forms an interior of the dental prosthetic assembly and at least a portion of the polymer and glass outer layer forms teeth of the dental prosthetic assembly. A coupling system of a dental prosthetic assembly includes pins disposed in openings extending into the dental prosthetic assembly and implant abutments configured to be coupled with a mouth of a patient. The implant anchors have horizontal holes configured to receive the pins. The pins secure the dental prosthetic assembly to the implant abutments by moving into the dental prosthetic assembly through the openings and into the holes of the implant abutments.

Owner:DENTAL MILLING SOLUTIONS LLC

Tools for customized design of dental restorations

ActiveUS20110224955A1Enhances dental restoration modelling experienceDental implantsAdditive manufacturing apparatusDental restorationImplant abutment

The present invention relates to tools in a system for the design of customized three-dimensional models of dental restorations for subsequent manufacturing. Dental restorations such as implant abutments, copings, crowns, wax-ups, bridge frameworks. Moreover, the invention relates to a computer-readable medium for implementing such a system on a computer.

Owner:3SHAPE AS

Implant abutment clips

An abutment clip for use in a dental implant system for orienting an abutment relative to features on a patient's teeth and jawbone so that a prosthesis, which is attachable to the abutment, will be correctly oriented. The abutment clip comprises a housing that includes a chamber sized to receive the abutment therein. The housing has at least one position indicator provided at one end thereof. The dentist engages the abutment clip over the abutment when it is still attached to a manufacturer's plaster model. He notes the position of the indicator on the housing in reference to features on the model and then detaches the abutment clip, abutment and abutment screw as a unit from the model. The combined abutment clip, abutment and screw are then positioned on an implant post in the patient's jaw bone and the position indicator is used to verify the orientation of the abutment before it is secured to the implant post.

Owner:IMPLANT INGENUITY

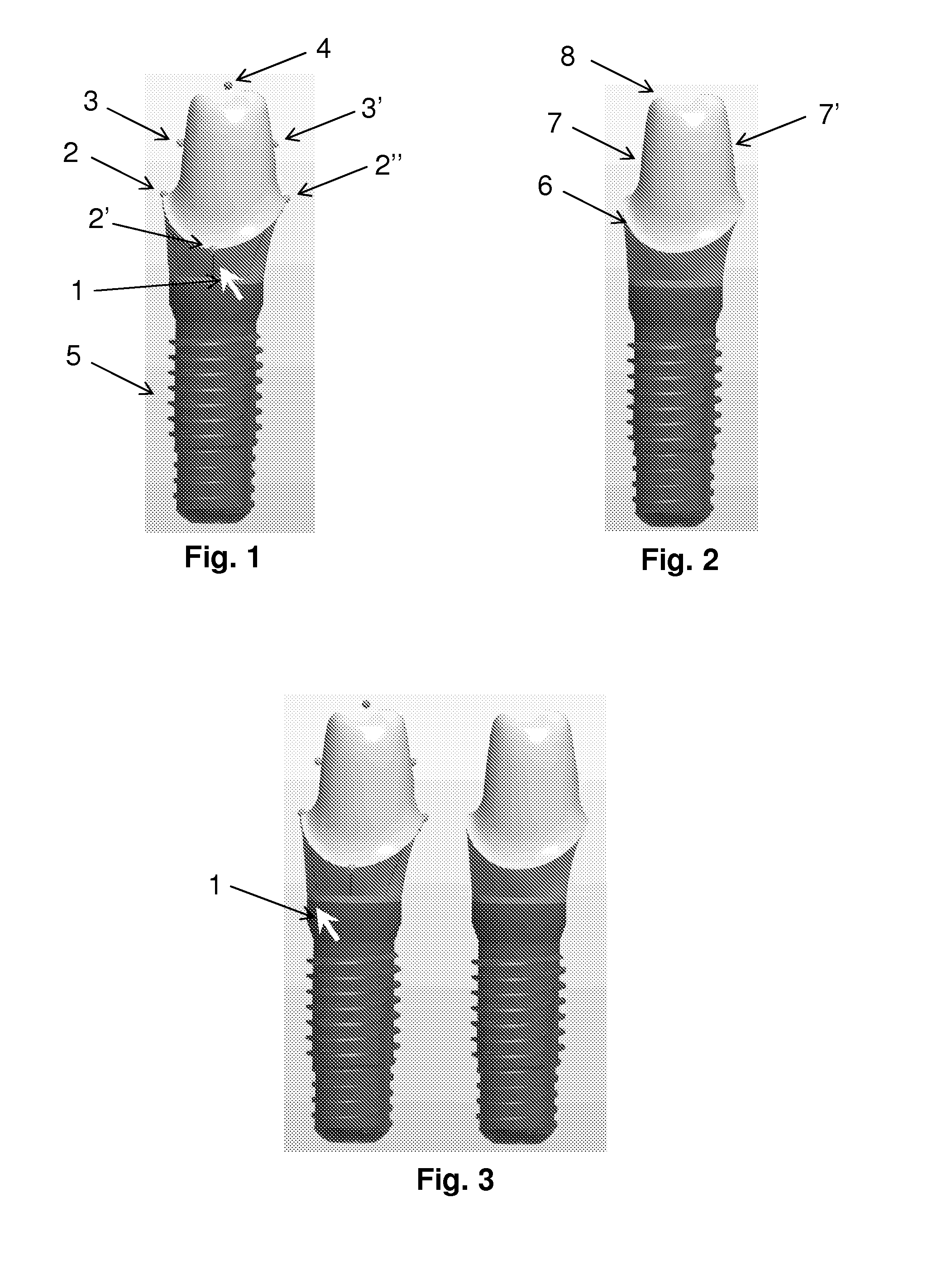

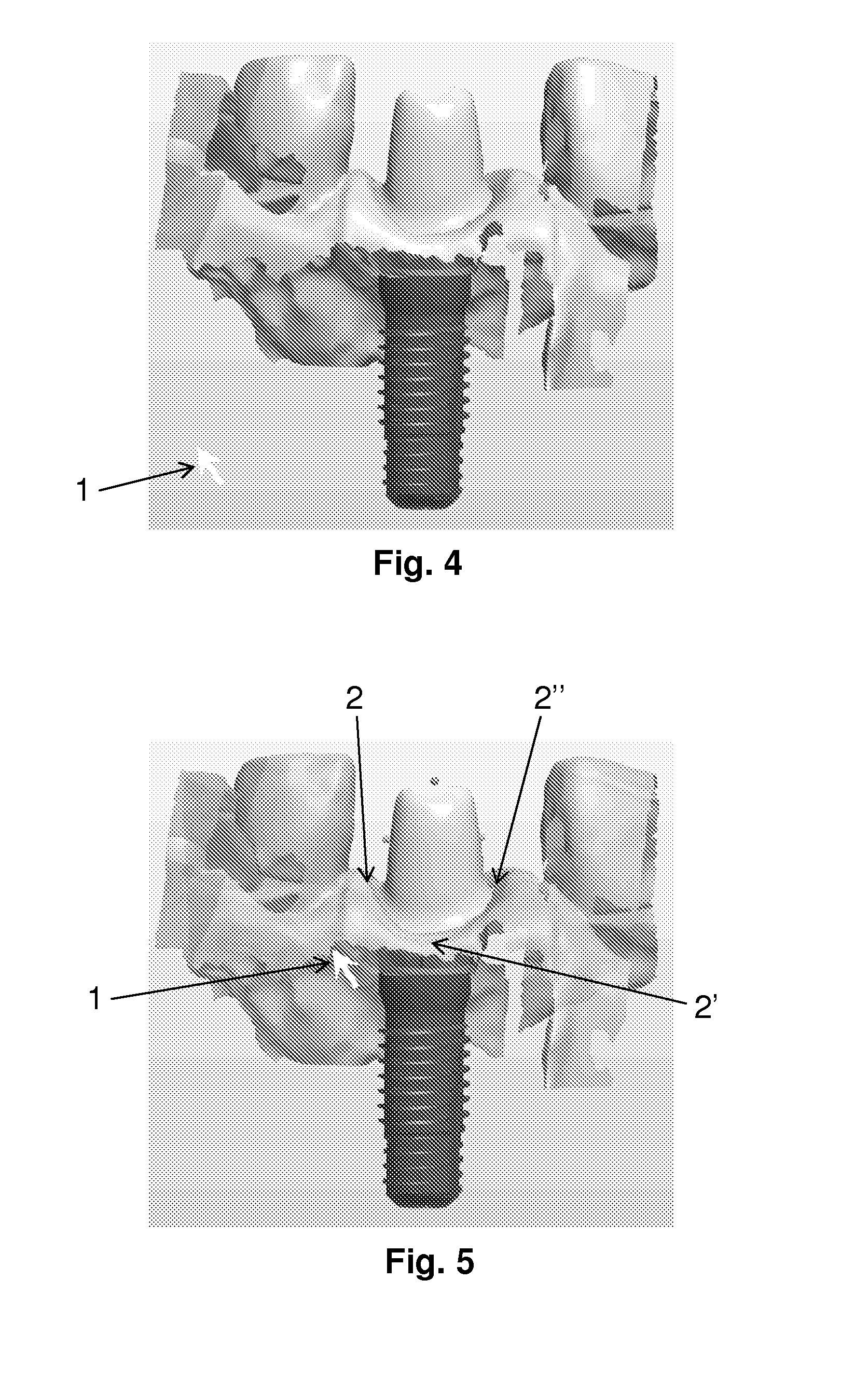

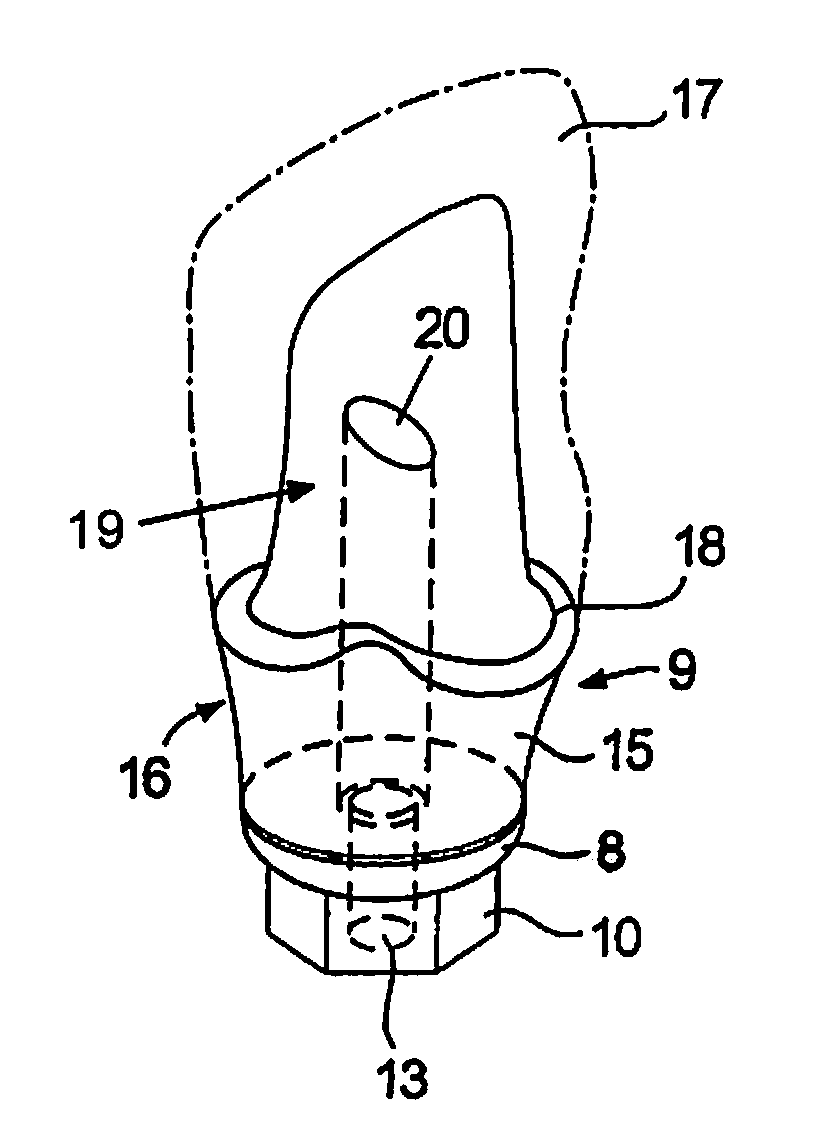

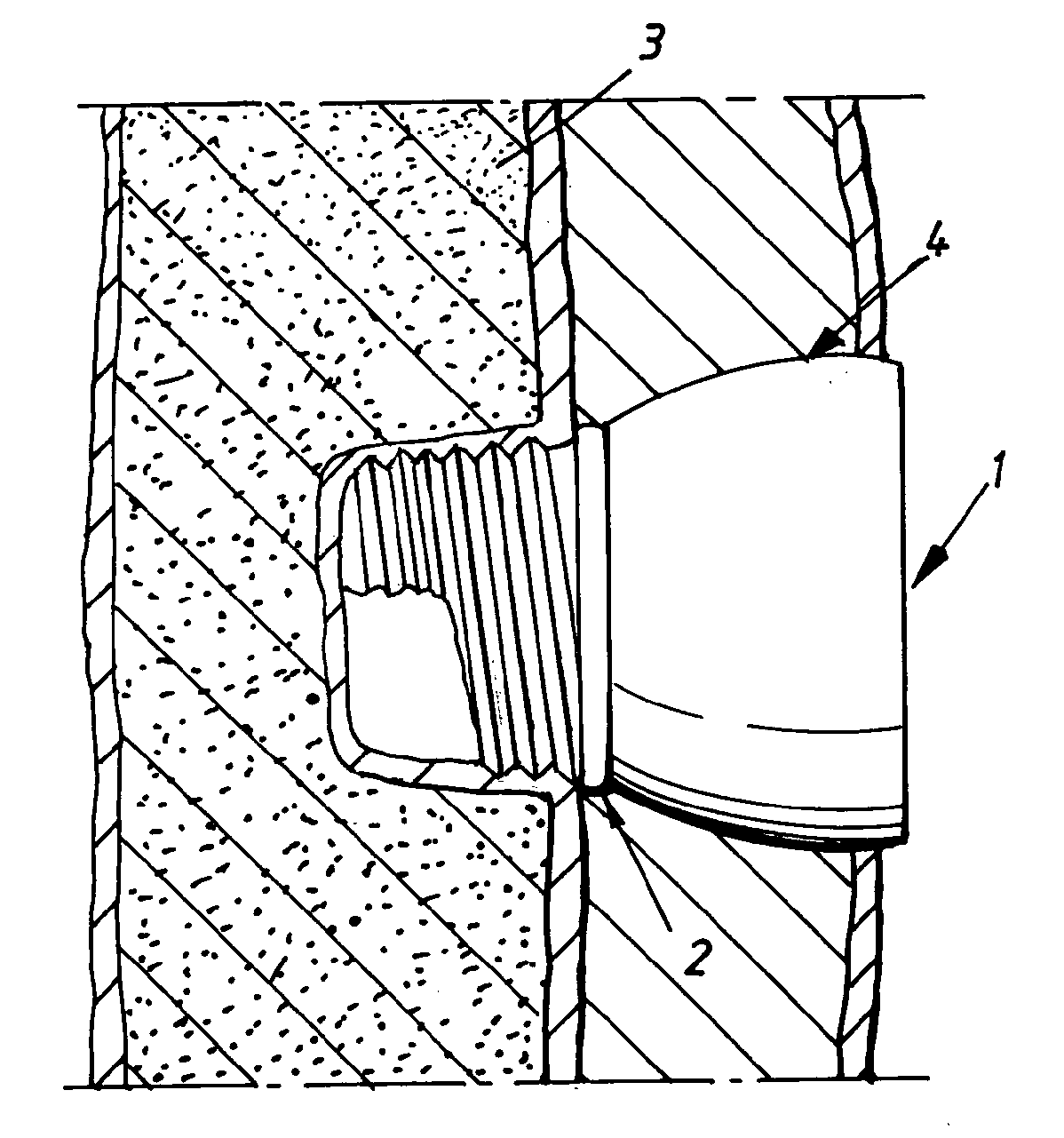

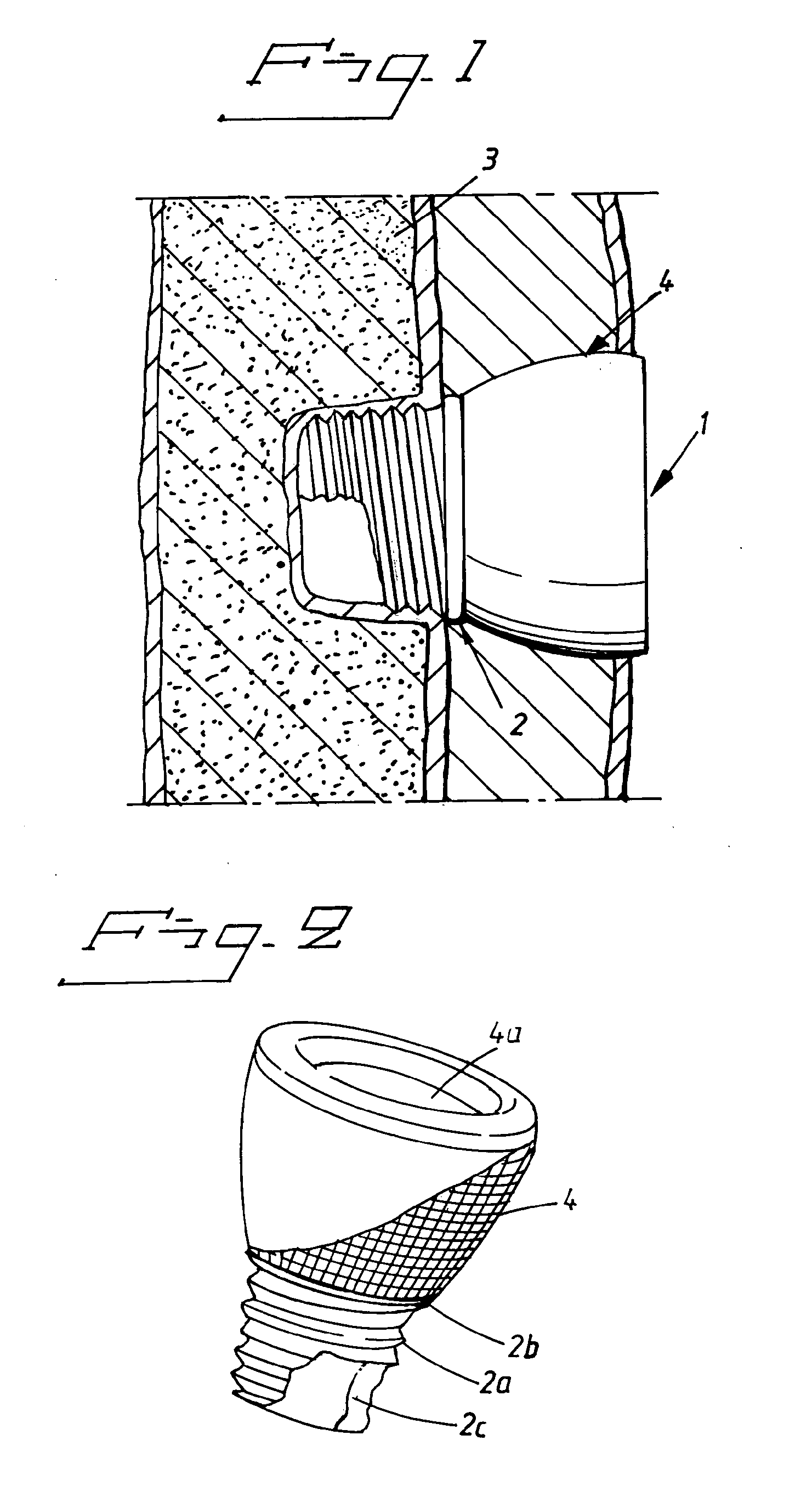

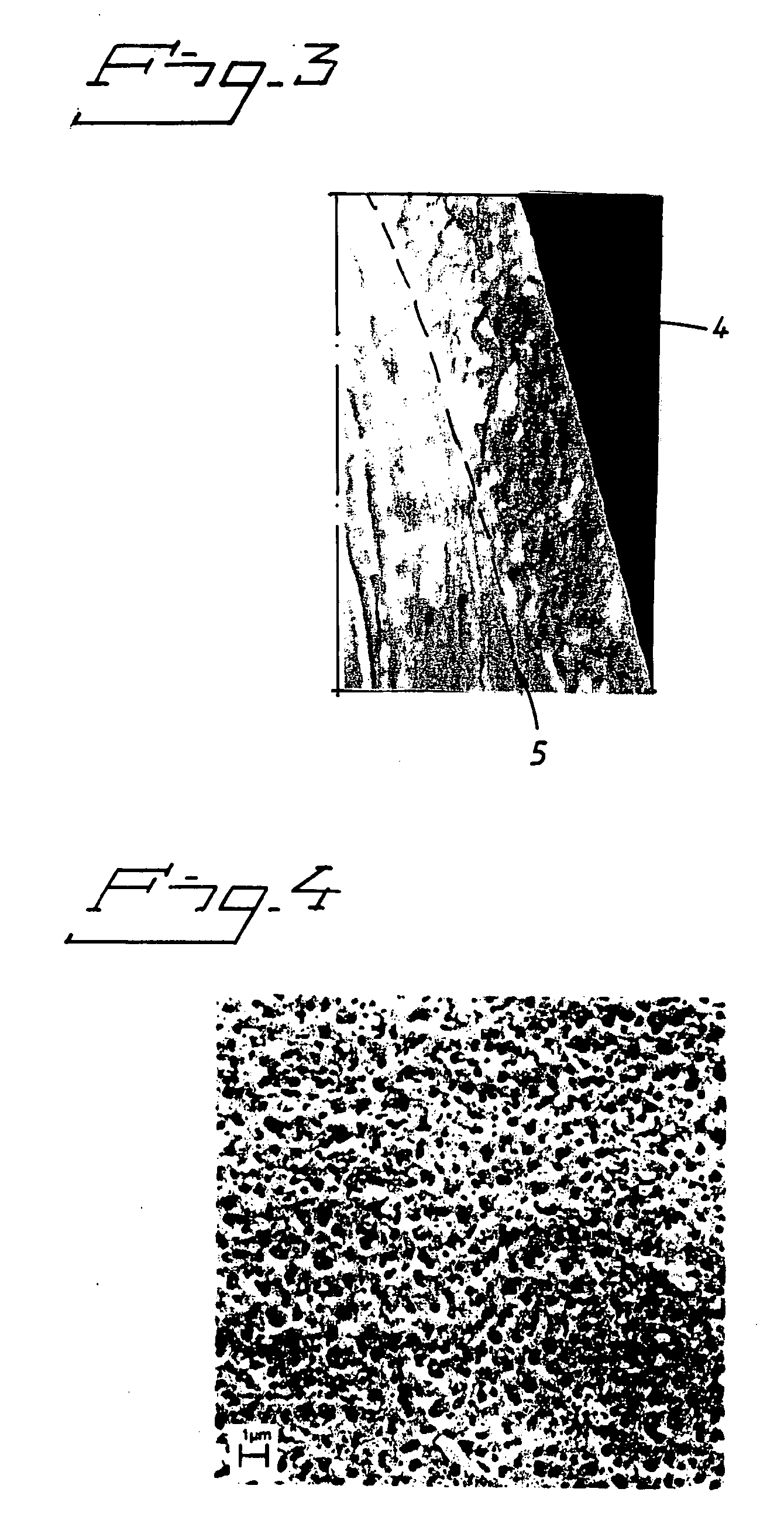

Method for manufacturing implant abutments for dental implants, and an implant abutment for a dental implant

ActiveUS8778443B2Improve aestheticsAvoid showingDental implantsImpression capsDental implantBiomedical engineering

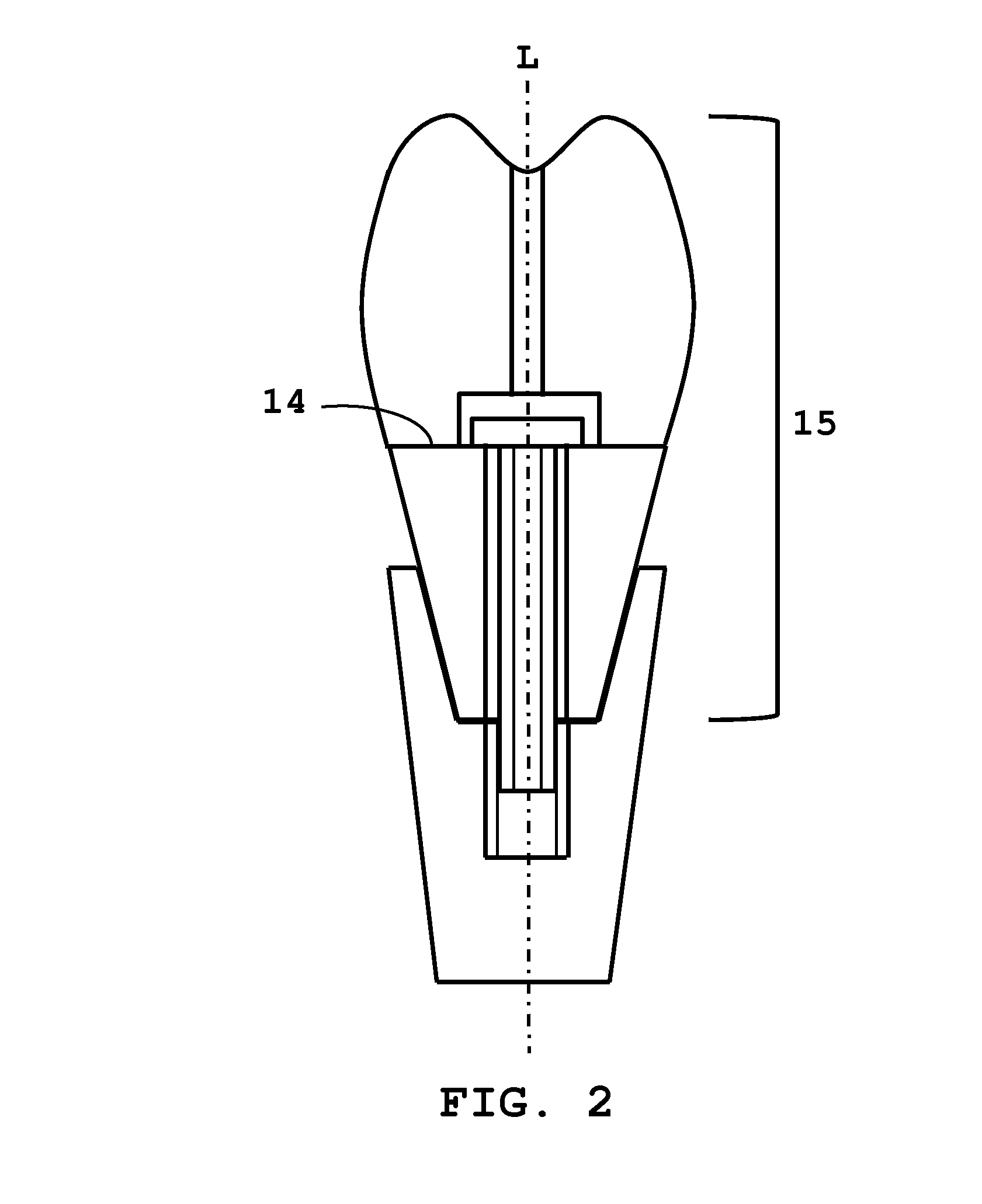

The invention relates to a method for manufacturing implant abutments 9 for dental implants 1, wherein the implant abutment 9 comprises a prefabricated base member 8 for joining the implant abutment to the dental implant 1, and a customized main body 15. The aim of the invention is to simplify this method of manufacturing. To this end, the main body 15 is formed by sintering and / or melting powdery material onto the base member 8 using laser sintering and / or laser melting. The invention relates also to an implant abutment manufactured by such a method.

Owner:BEGO MEDICAL

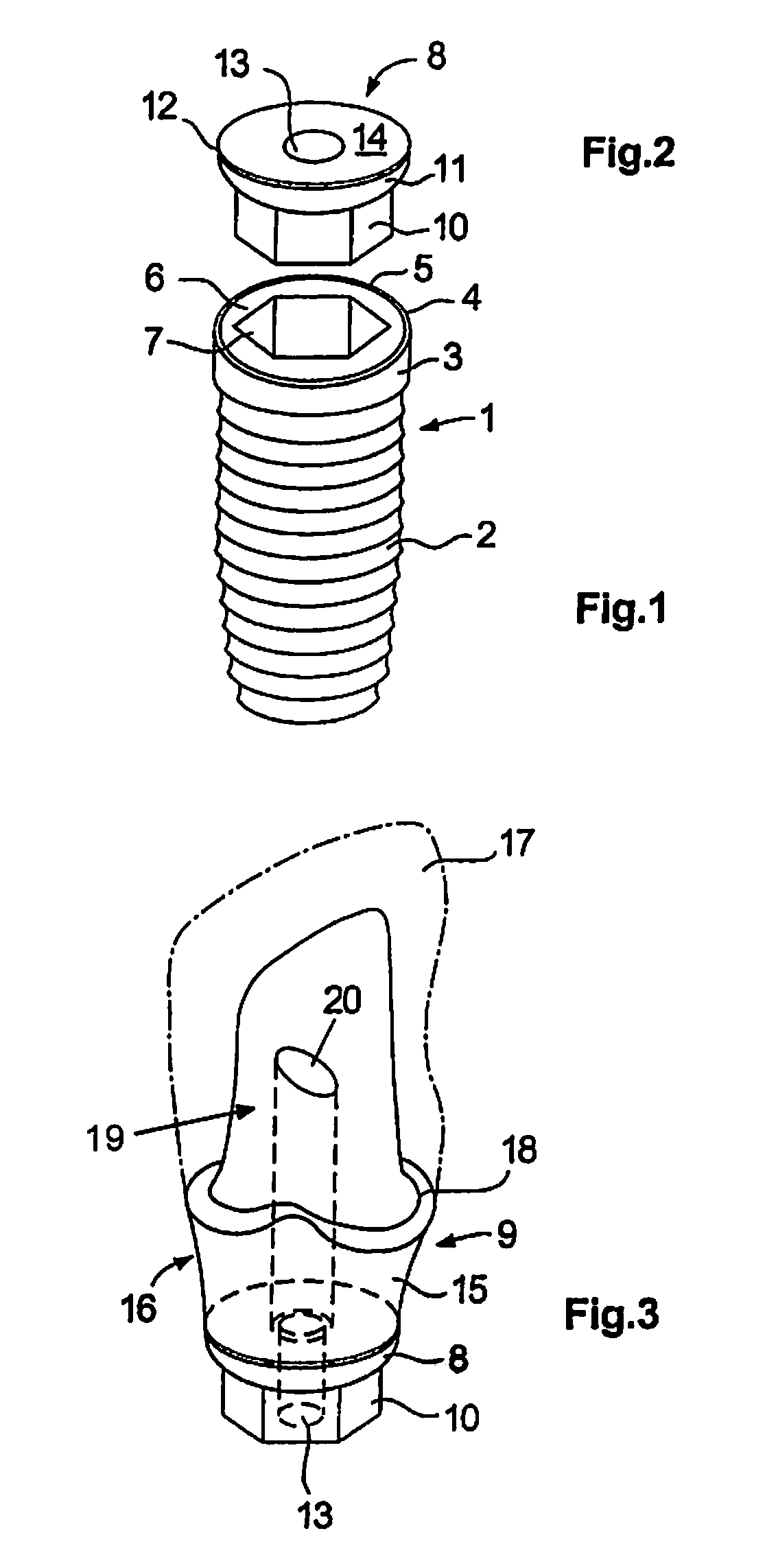

Molds for custom dental implant abutments and impression posts

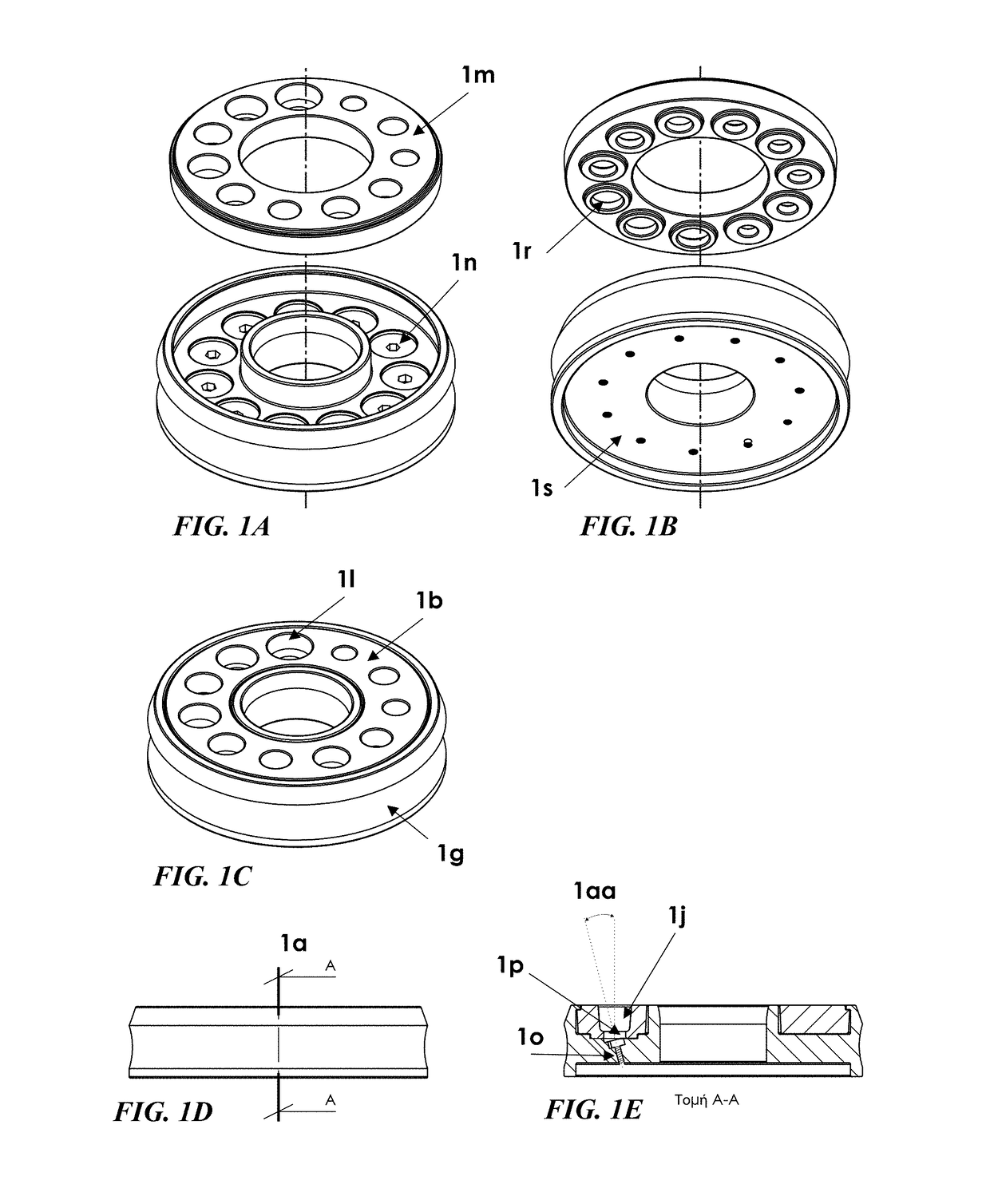

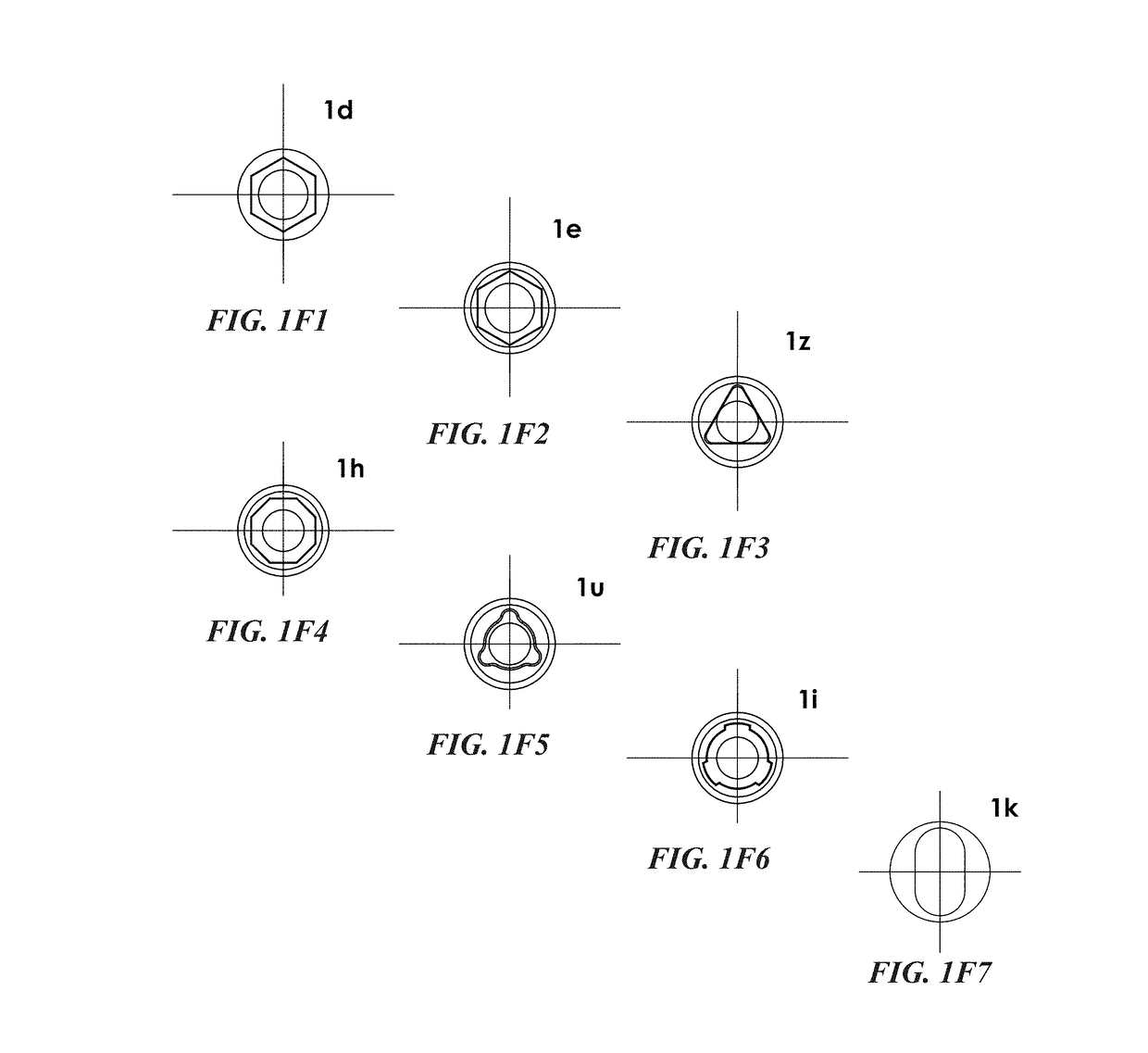

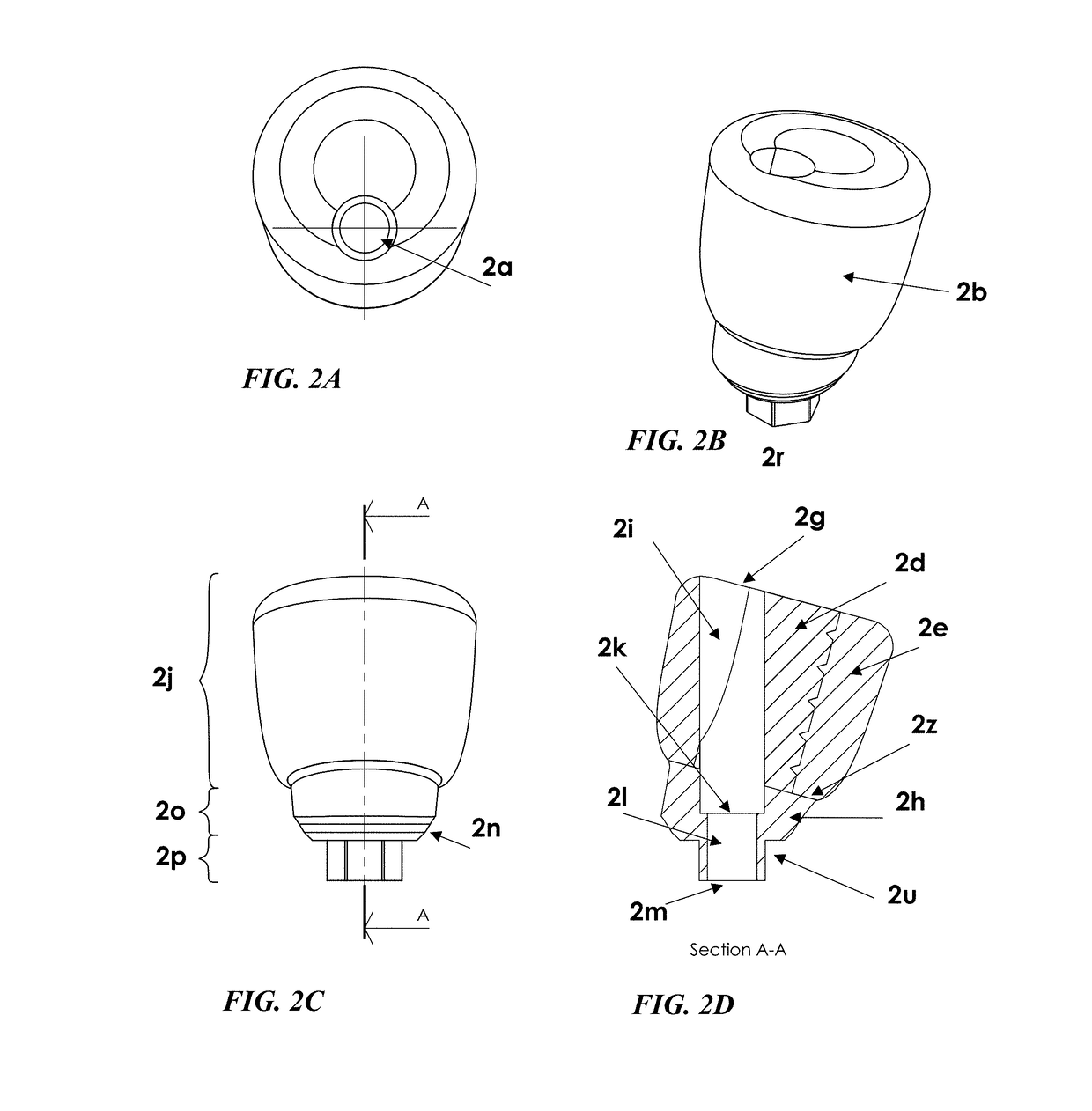

ActiveUS20170128176A1Improving final estheticImproving biological outcomeDental implantsImpression capsEngineeringDental implant

Molds for fabrication of custom and potentially modifiable abutments and impression posts for dental implants with various degrees of angulations (including zero degrees) and various dimensions are provided, with a generally oval shape that expands laterally upwards, a symmetrical or asymmetrical cross-section, and regular surfaces, that are fabricated as one piece, or as two coupling pieces snapping onto each other. Custom abutments achieve the development of a custom gingival emergence profile, three dimensionally, which is potentially modifiable according to the needs of each particular clinical case. Custom impression posts that correspond in dimensions and angulations to the abutments allow the accurate recording and transfer of the developed gingival emergence profile from the mouth onto the working cast, where the final implant prosthesis is fabricated. Custom abutments and impression posts have properties and design that allows their preparation and usage as temporary abutments for the cementation and support of temporary prostheses.

Owner:VP INNOVATO HLDG LTD

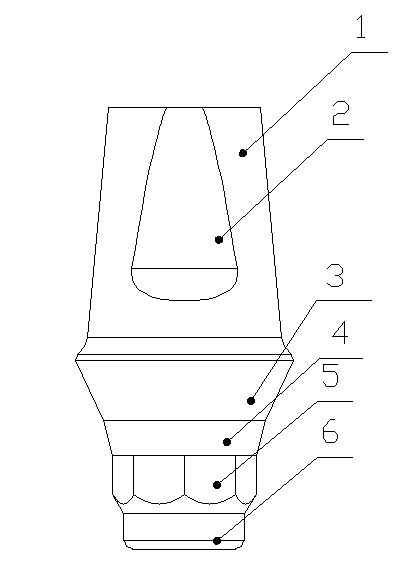

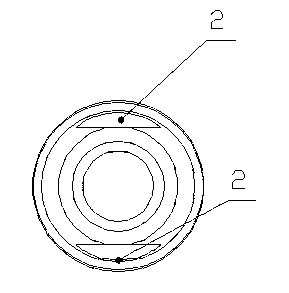

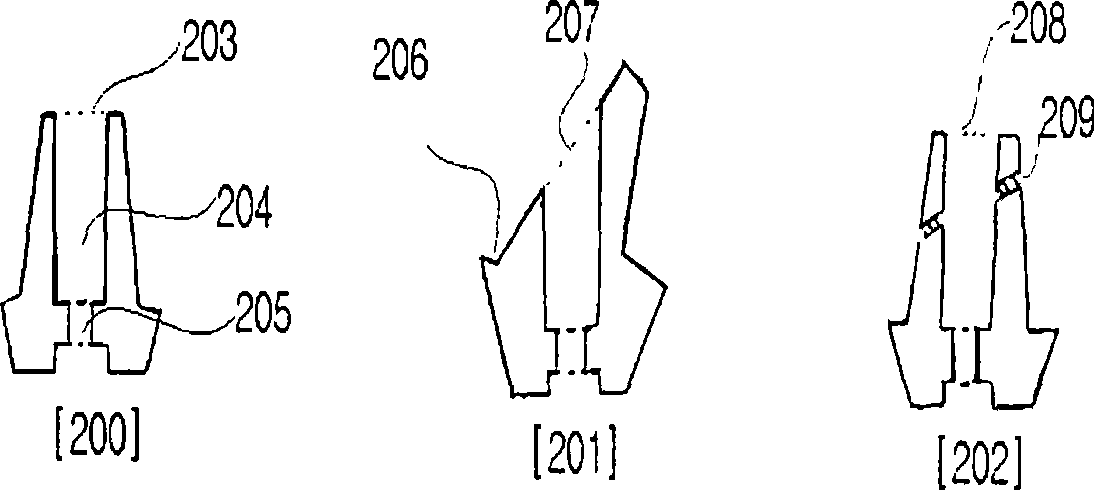

Implant abutment material for tailor-made and method for manufacturing abutment using the same

InactiveUS20110171603A1Fast preparationSimple working processDental implantsDental prostheticsCouplingBiomedical engineering

The present invention relates to an implant abutment material for tailor-made for manufacturing an abutment for tailor-made in consideration of individual characteristics of patients' teeth and which allows for mass production, and a method for manufacturing an abutment for tailor-made using the implant abutment material for tailor-made.For this purpose, an abutment material of the present invention is a product including: a cylindrical body; a grip integrally formed at the end of the body to be used to clamp the body to a machine when manufacturing a tailor-made abutment by machining the body; a coupling portion formed at the other end of the body and coupled with the fixture; and a fastening hole formed through the grip, the body, and the coupling portion, to be coupled to the fixture.

Owner:RAPHABIO

Dental implant abutment

A dental implant abutment for attaching a dental prosthesis within a patient's mouth. The abutment is a single unit structure fabricated of a ceramic material, multicolored throughout to match the color of the dental prosthesis, the surrounding dentition and the surrounding gingival tissue.

Owner:IVOCLAR VIVADENT AG

Dental implant abutment

The invention relates to a dental implant abutment, in particular relates to an abutment internally connected with an implant, and belongs to the fields of oral implant and repair. The connecting abutment consists of a crown connecting section, a middle trans-gingival section and an implant insertion section sequentially from top to bottom. The upper crown connecting section of the connecting abutment is a downward enlarged cone of which the taper is 6 degrees. A vertical cutting groove is formed in each of two lateral surfaces of the upper crown connecting section of the abutment, and the two cutting grooves are symmetrically distributed on the two lateral surfaces. The abutment can be used for positioning a crown, and plays a role in resisting rotation. A conical transition section is arranged between the abutment and a connector, and a silver-carrying TiO2 antibacterial coating is coated on the surface. After the abutment is inserted into the inner cavity of the implant, seal fit of conical surfaces, anti-rotating directional fit of eight-angular prism surfaces and pilot fit of cylindrical surfaces can be realized. The invention aims to provide the abutment internally connected with the implant, and the abutment is matched with the implant precisely and stably and has excellent anti-rotating performance.

Owner:DALIAN SANSHENG SCI & TECH DEV

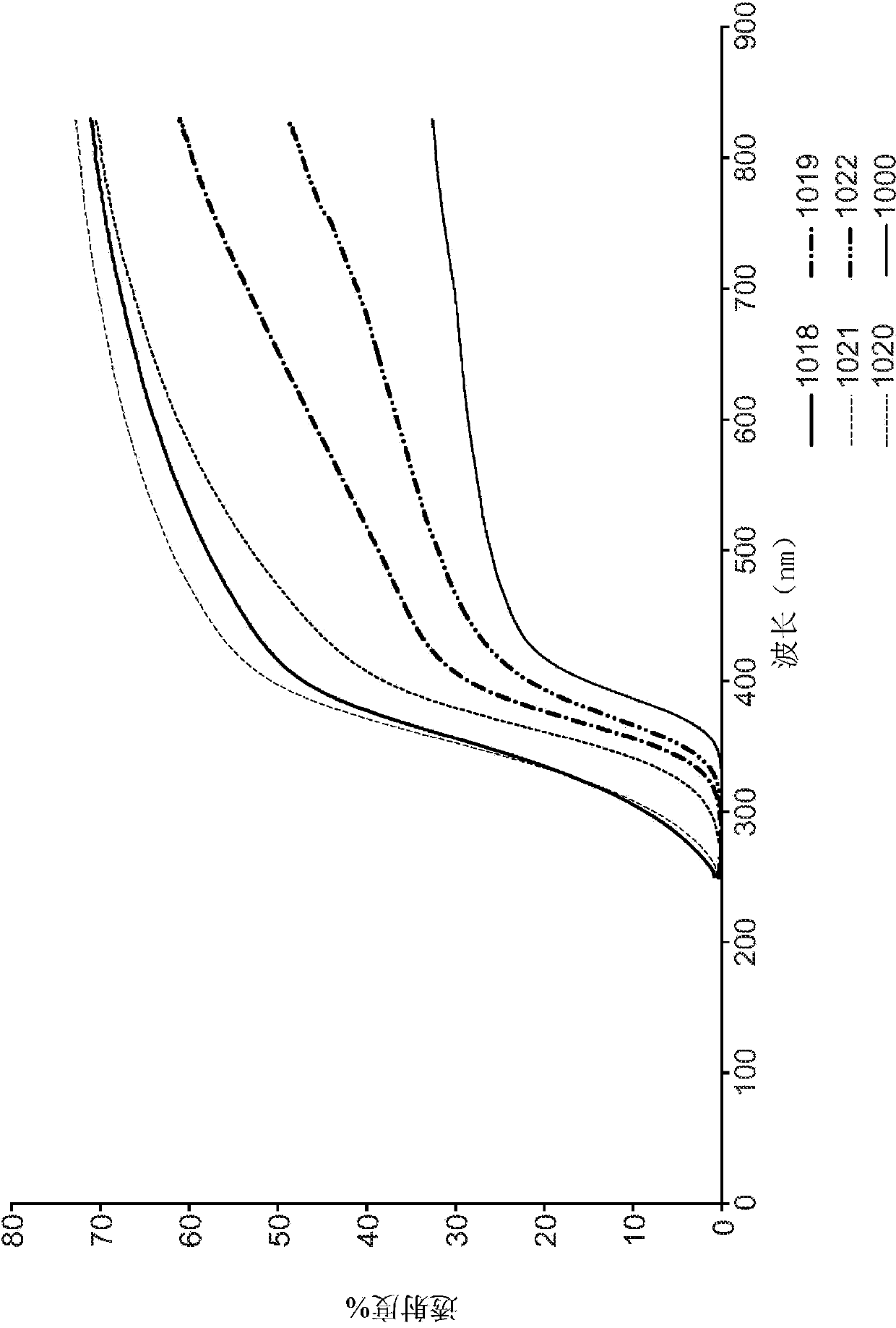

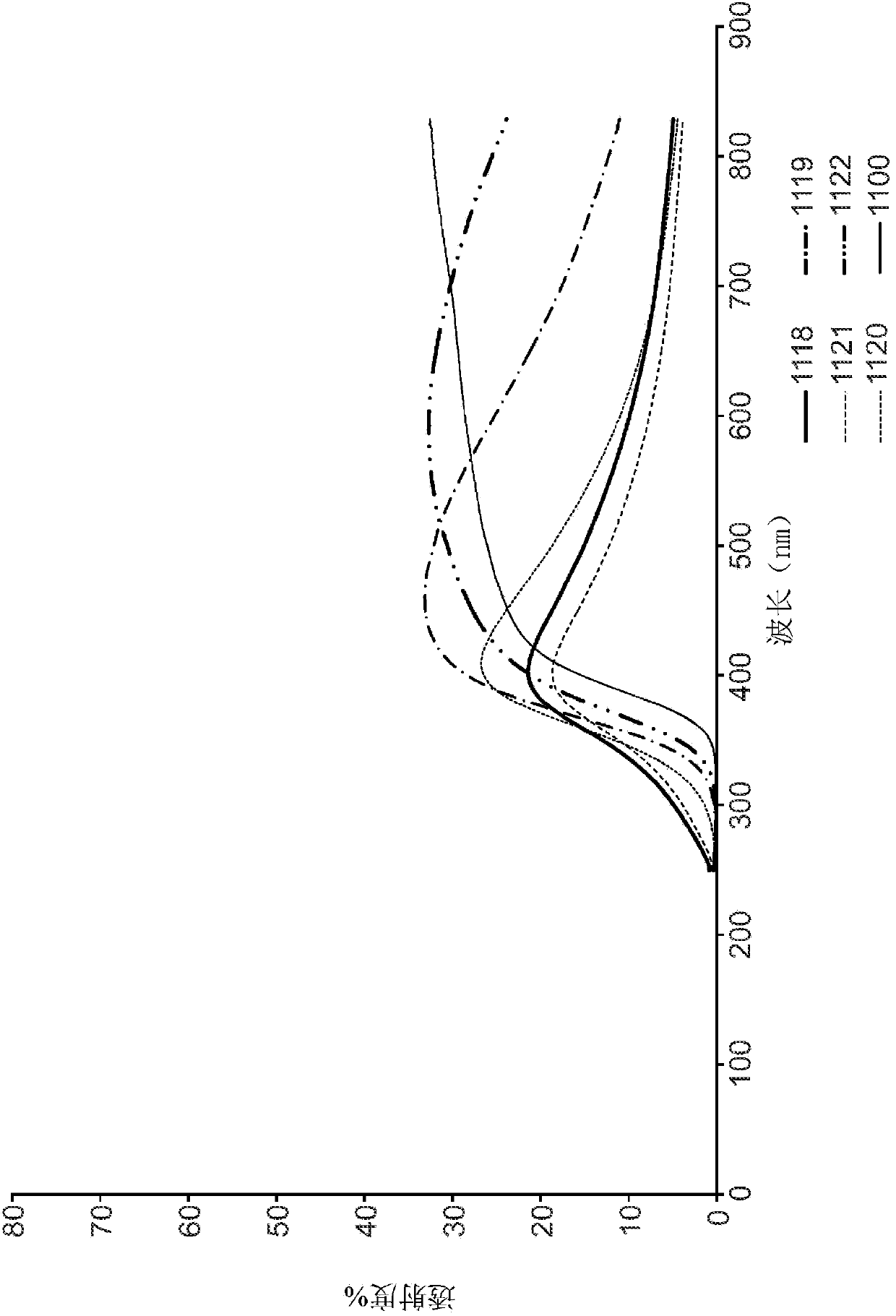

Aerogels, calcined and crystalline articles and methods of making the same

Aerogel, calcined articles, and crystalline articles comprising ZrO2. Exemplary uses of the crystalline metal oxide articles include dental articles (e.g., restoratives, replacements, inlays, onlays, veneers, full and partial crowns, bridges, implants, implant abutments, copings, anterior fillings, posterior fillings, and cavity liner, and bridge frameworks) and orthodontic appliances (e.g., brackets, buccal tubes, cleats, and buttons).

Owner:3M INNOVATIVE PROPERTIES CO

Abutment for dental implant

An implant abutment for attaching a dental prosthesis within a patient's mouth is disclosed. The abutment includes a core and a cuff surrounding the core, and the color of the cuff is matched to the color of the prosthesis. Dental restoration systems and methods for fabricating a dental implant restoration utilizing the abutment are also disclosed.

Owner:IVOCLAR VIVADENT INC

Molds for custom dental implant abutments and impression posts

ActiveUS10136974B2Increased durabilityEasy to operateDental implantsImpression capsEngineeringDental implant

Molds for fabrication of custom and potentially modifiable abutments and impression posts for dental implants with various degrees of angulations (including zero degrees) and various dimensions are provided, with a generally oval shape that expands laterally upwards, a symmetrical or asymmetrical cross-section, and regular surfaces, that are fabricated as one piece, or as two coupling pieces snapping onto each other. Custom abutments achieve the development of a custom gingival emergence profile, three dimensionally, which is potentially modifiable according to the needs of each particular clinical case. Custom impression posts that correspond in dimensions and angulations to the abutments allow the accurate recording and transfer of the developed gingival emergence profile from the mouth onto the working cast, where the final implant prosthesis is fabricated. Custom abutments and impression posts have properties and design that allows their preparation and usage as temporary abutments for the cementation and support of temporary prostheses.

Owner:VP INNOVATO HLDG LTD

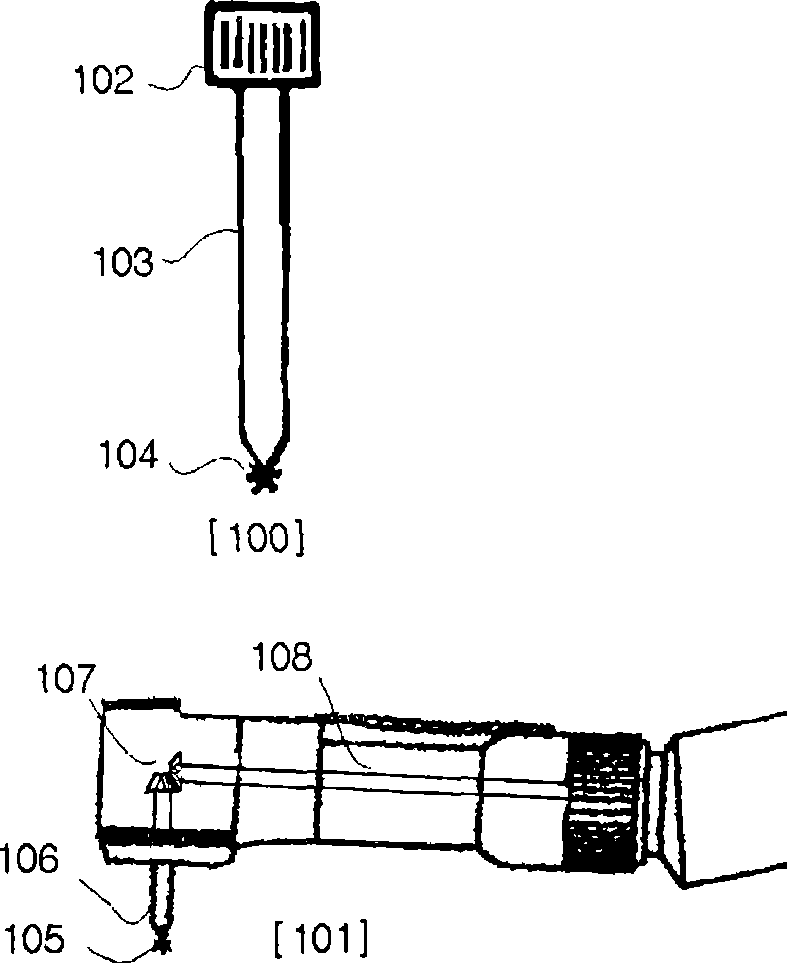

Implant abutment

InactiveUS20100249784A1Ear treatmentBone conduction transducer hearing devicesBone-anchored hearing aidSkin contact

The present invention relates to a percutaneous implant abutment for bone anchored implant devices adapted to be anchored in the craniofacial region of a person, such as bone anchored hearing aids. The abutment comprises a skin penetration body having a skin contacting surface. The skin contacting surface has been modified.

Owner:COCHLEAR LIMITED

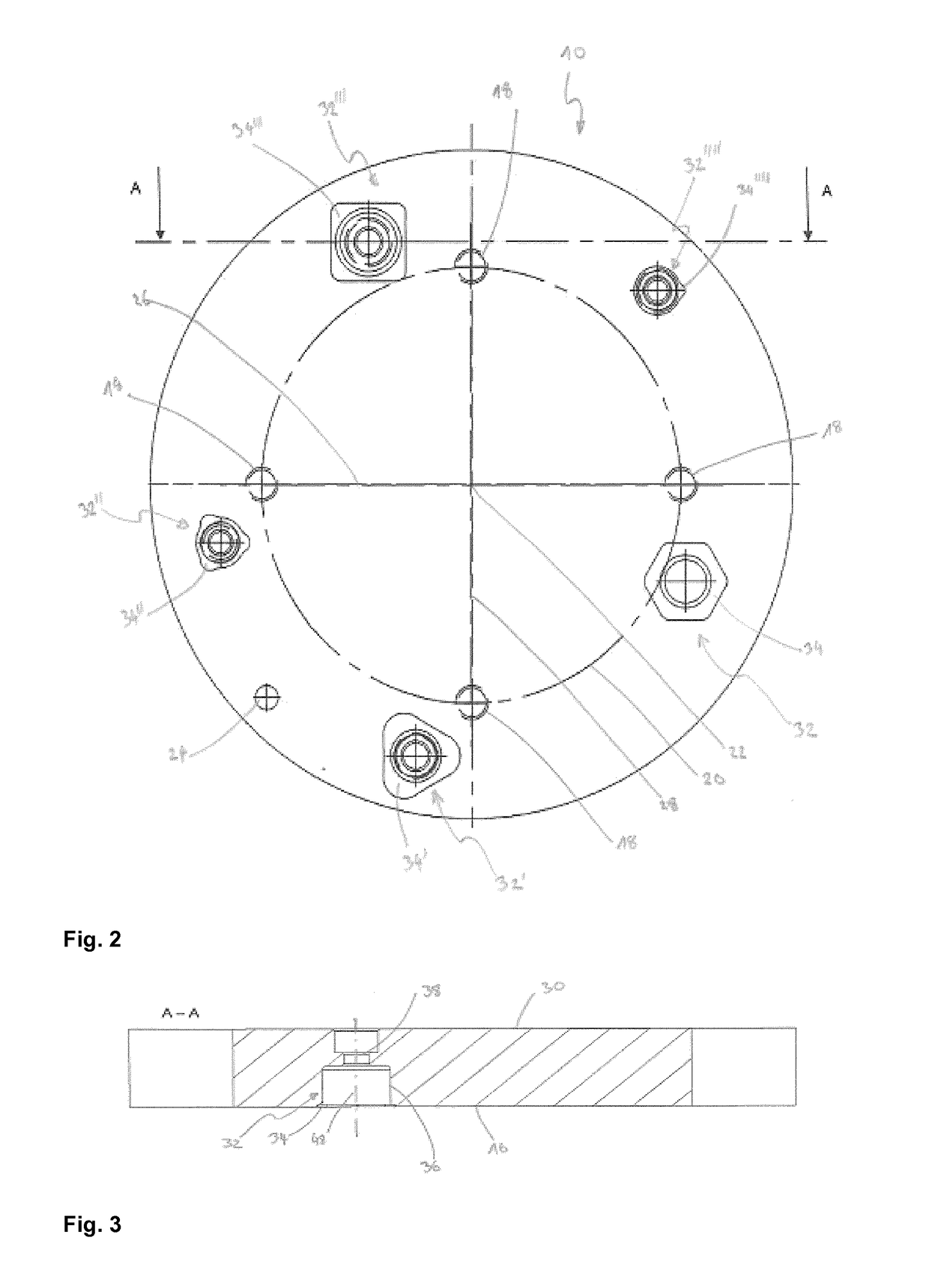

Plate for production of a dental implant and/or artificial prosthesis

ActiveUS20180333813A1Precise positioningNot more complicated or expensiveDental implantsAdditive manufacturing apparatusProsthesisDental implant

The present disclosure concerns a set for the production by 3D printing of implant abutments for dental implants, the set including at least one abutment having an elongated base member with an axis, and at least one positioning element fixed to the base member; a plate with at least one recess and a locking portion; where the recess is larger than the elongated base member and where the locking portion is configured to be in a form fit connection with the positioning element in order to vertically position the abutment, and lock the abutment in rotation around its axis.

Owner:JADE FINANCE S A R L

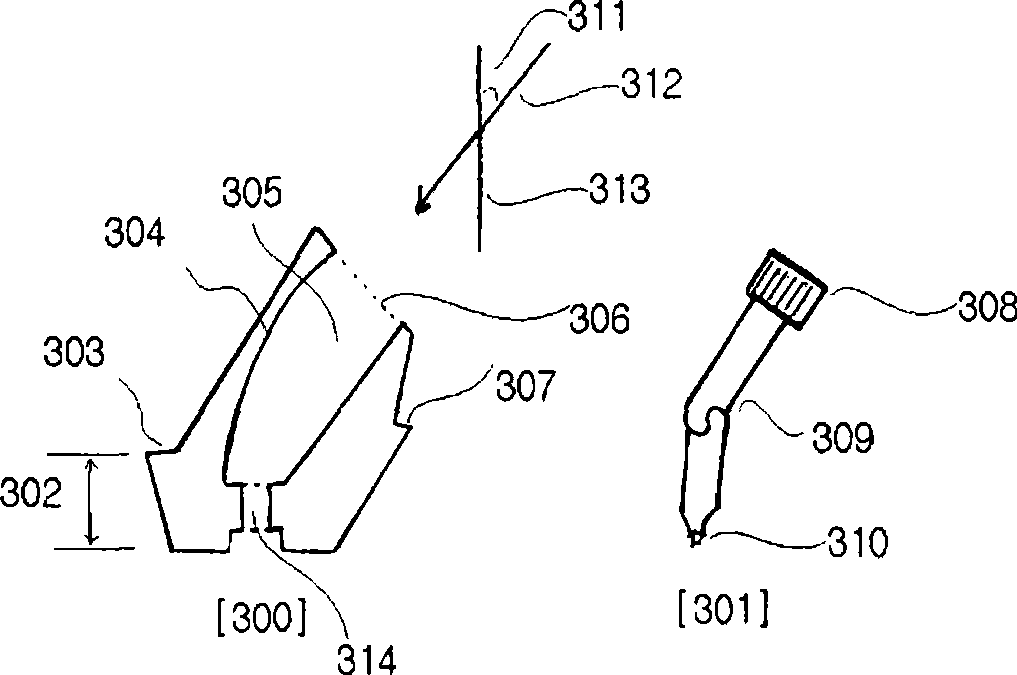

Free angled driver and free angled hole abutment

InactiveCN101365395AEasy to tightenEasy to loosenDental implantsWrenchesDental implantAnterior teeth

In case of straight driver, the entrance of screw inserting hole of implant prosthesis is on the same line with implant fixture's axis. Due to this position of the hole, final prosthesis has many difficulties. Thus. the free angled driver(301) is invented. For maxillay anterior teeth, we can move the screw hole to ligual surface of prosthesis(511). We can make esthetic and convenient prosthesis with capability of easy screwing and unscrewing. Also. I invented the free angled hole abutment(300) for the free angled implant driver,so we can move occlusal hole to the ideal position. It is an epoch-making change to solve many problems in the contemporary dental implant prosthetics.

Owner:李钟琥

Soft tissue preservation temporary (shell) immediate-implant abutment with biological active surface

An immediate dental implant shell has outer, multiple zones for engaging a soft tissue socket left immediately after tooth extraction from a bone socket. The zones have combinations of different biologic agents, macro- or micro-geometric, or micro- or macro-morphology irregularities to better engage gingival sulcus, junctional epithelium and dento-gingival fiber zones of the soft tissue socket. The shell may also have various guide markings and projections to aide drilling of the implant hole in the bone socket. A dental implant is placed in the drilled implant hole before or after the shell has been placed in the soft tissue socket, and has an axis that is independent of the shell axis so the shell and implant both sit in optimum positions in their respective soft and bone sockets.

Owner:EVOLLUTION IP HLDG

Digital three-dimensional construction and manufacturing method of personalized planting base station

ActiveCN111616821APersonalizeAvoid discomfortDental implantsAdditive manufacturing apparatusDental scanningDentistry

The invention relates to the technical field of artificial tooth implantation, and discloses a digital three-dimensional construction and manufacturing method of a personalized implant abutment, whichcomprises the following steps: s100, adjusting an implant interface by wearing a substitute of an implant; s200, designing a scanning rod three-dimensional diagram according to the adjusted plantinginterface, and exporting virtual scanning rod data according to the scanning rod three-dimensional diagram; s300, scanning the implant scanning rod physical model by adopting a dental scanner to obtain actual scanning rod data, and fitting the virtual scanning rod data with the actual scanning rod data to obtain the position of the implant and interface data; s400, designing a personalized map ofthe base station according to the gingival data and the occlusion relationship data in combination with the position of the implant and the interface data, and generating data of the personalized implant base station according to the personalized map of the base station; and S500, carrying out programming operation on the data of the personalized planting base station, controlling a machine tool to carry out processing by using the programming operation, and obtaining the personalized planting base station after the processing is completed. The individuation of the planting base station can berealized.

Owner:北京联袂义齿技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com