Metal implant and surface processing method thereof

A technology for surface treatment and implants, used in dental implants, coatings, medical science, etc., to solve problems such as ventricular arrhythmia, increased surface roughness, operator burns, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

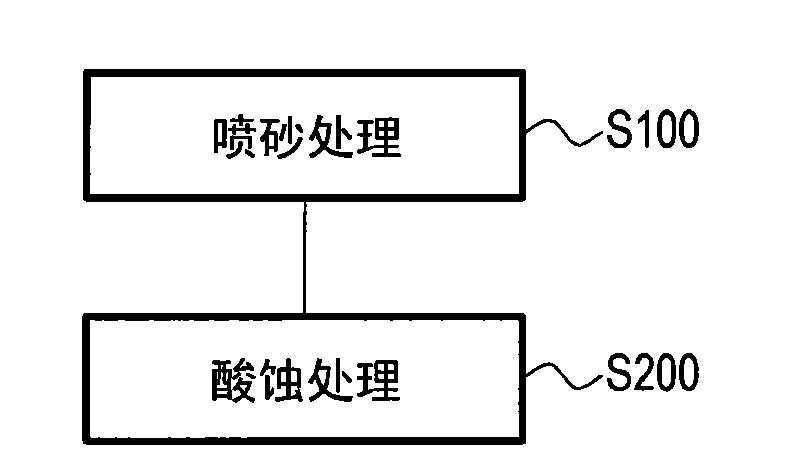

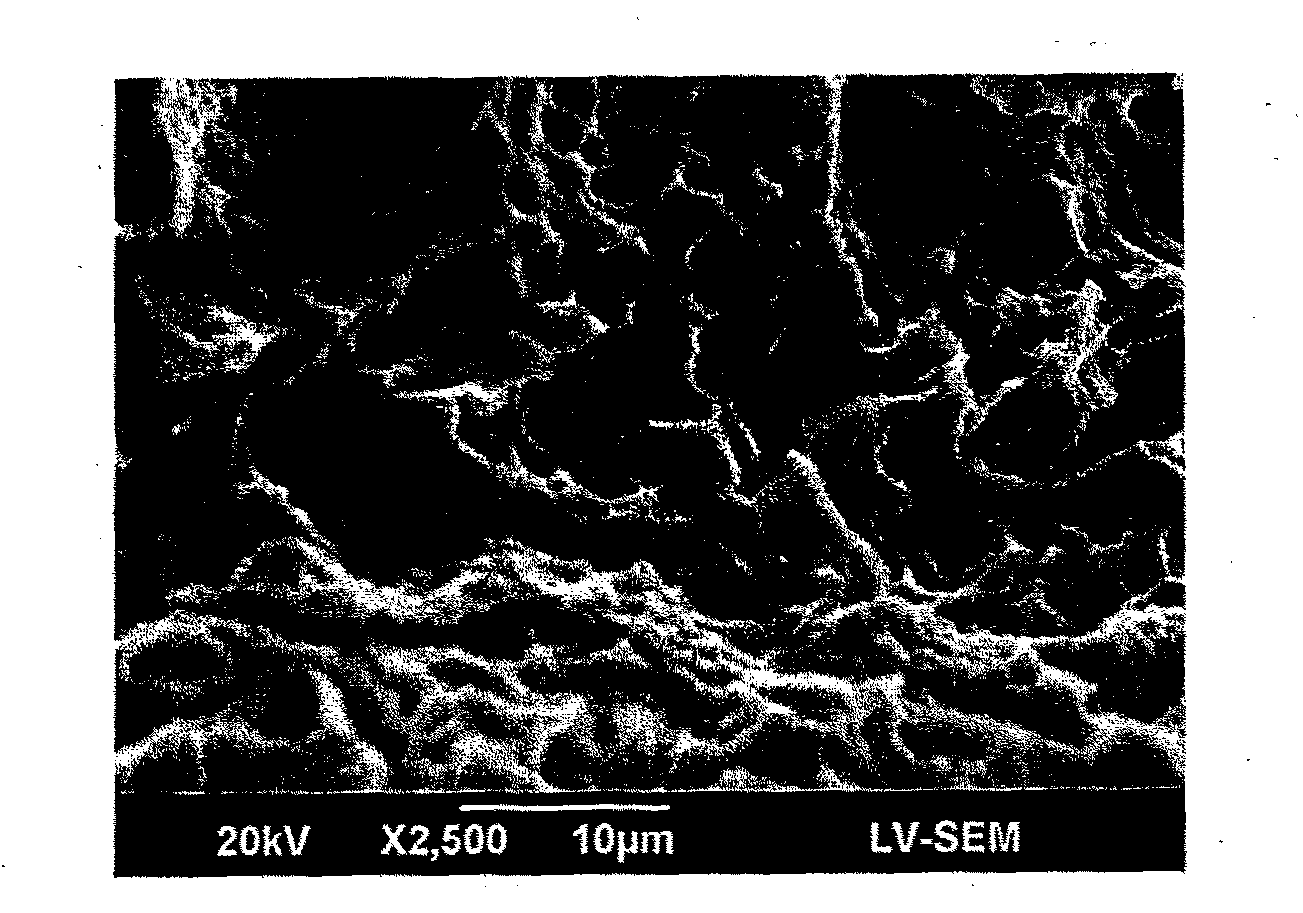

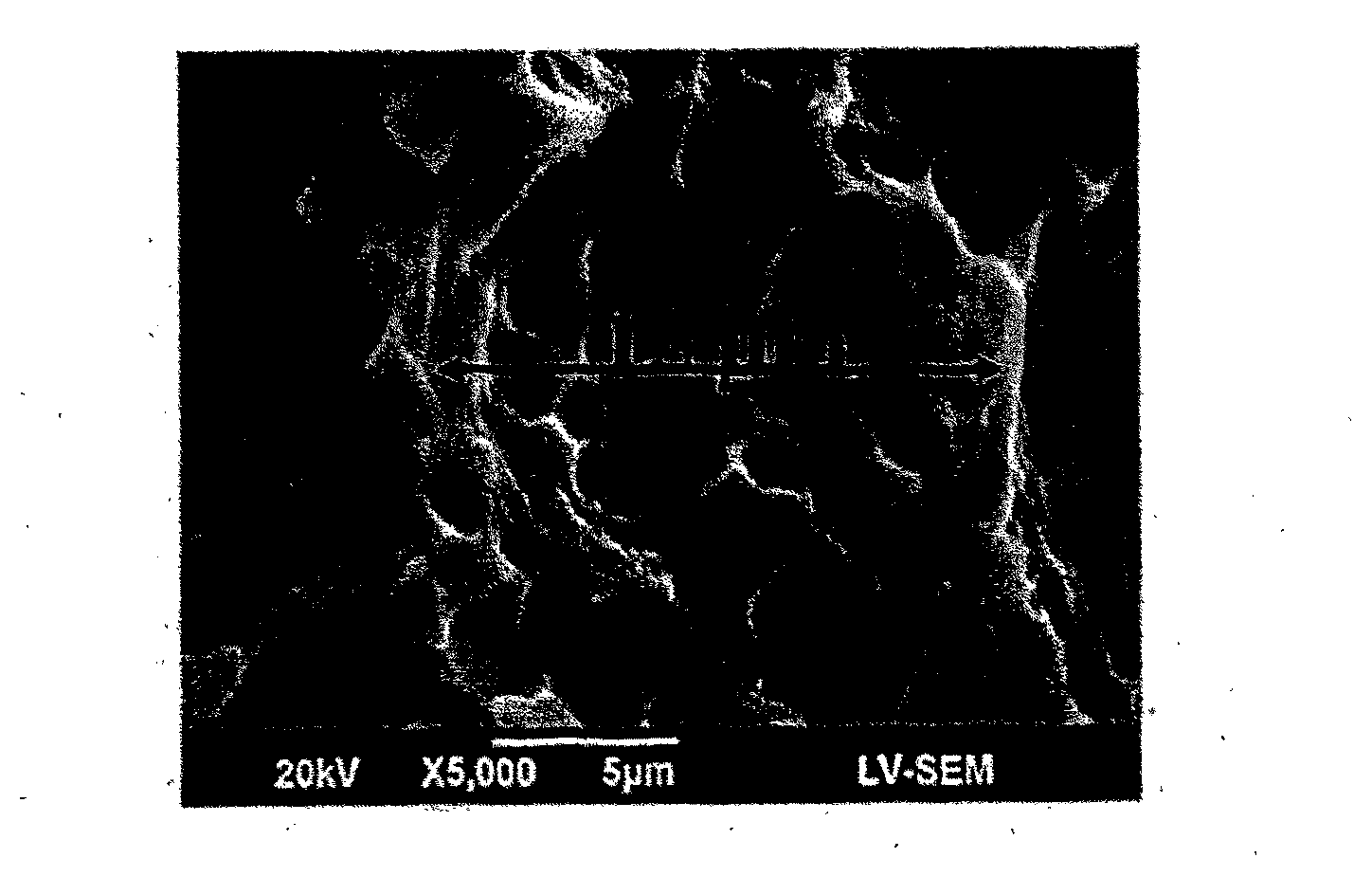

[0035] figure 1 It is a flowchart of the metal implant surface treatment method of the present invention. see figure 1 , the method for metal implant surface treatment comprises: first, carry out a sandblasting treatment (step S100), that is to say, carry out a sandblasting treatment to a metal implant with a sand body, so, after the sandblasting treatment The surface of the metal implant has a plurality of micron-scale pits.

[0036] The step of sandblasting in this embodiment is to sandblast the metal implant after the degreasing and cleaning procedures with ceramic sand bodies (such as alumina sand, titanium dioxide sand) with a particle size of 200 μm or less, and the sandblasting pressure is 2-200 μm. 4Kg / cm 2 , the sandblasting distance is 1-5 cm, and the sandblasting time is 20-40 seconds, wherein the material of the metal implant can be a titanium metal, a titanium alloy or a metal containing titanium.

[0037] After that, a deoxidation and reoxidation treatment (s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com