Method and equipment for preparing precursor body of poly carbon silane ceramics of containing zirconium

A technology of ceramic precursors and polycarbosilane, which is applied in the field of preparation of polycarbosilane ceramic precursors, can solve problems such as single function, complex process equipment, poor ultra-high temperature resistance of SiC ceramics and their fibers, etc., to achieve wide sources, The effect of simple process equipment and easy control of the reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Taking PSCS and zirconium acetylacetonate as raw materials, the mass ratio of the two (the proportions described in the following examples are all mass ratios) is: zirconium acetylacetonate: PSCS=4: 100, 420°C of reaction temperature, and 500°C of cracking temperature , after heat preservation reaction for 6 hours, dissolved in xylene, filtered, and the filtrate was distilled under reduced pressure at 390°C to obtain PZCS with a softening point of 215°C and a zirconium content of 1.31wt%, with a yield of 51.1%. N 2 Heat preservation at 1250°C for 1 hour under atmosphere, and the ceramic yield is 68.3%. Its reaction mechanism is shown in the following formula:

[0028]

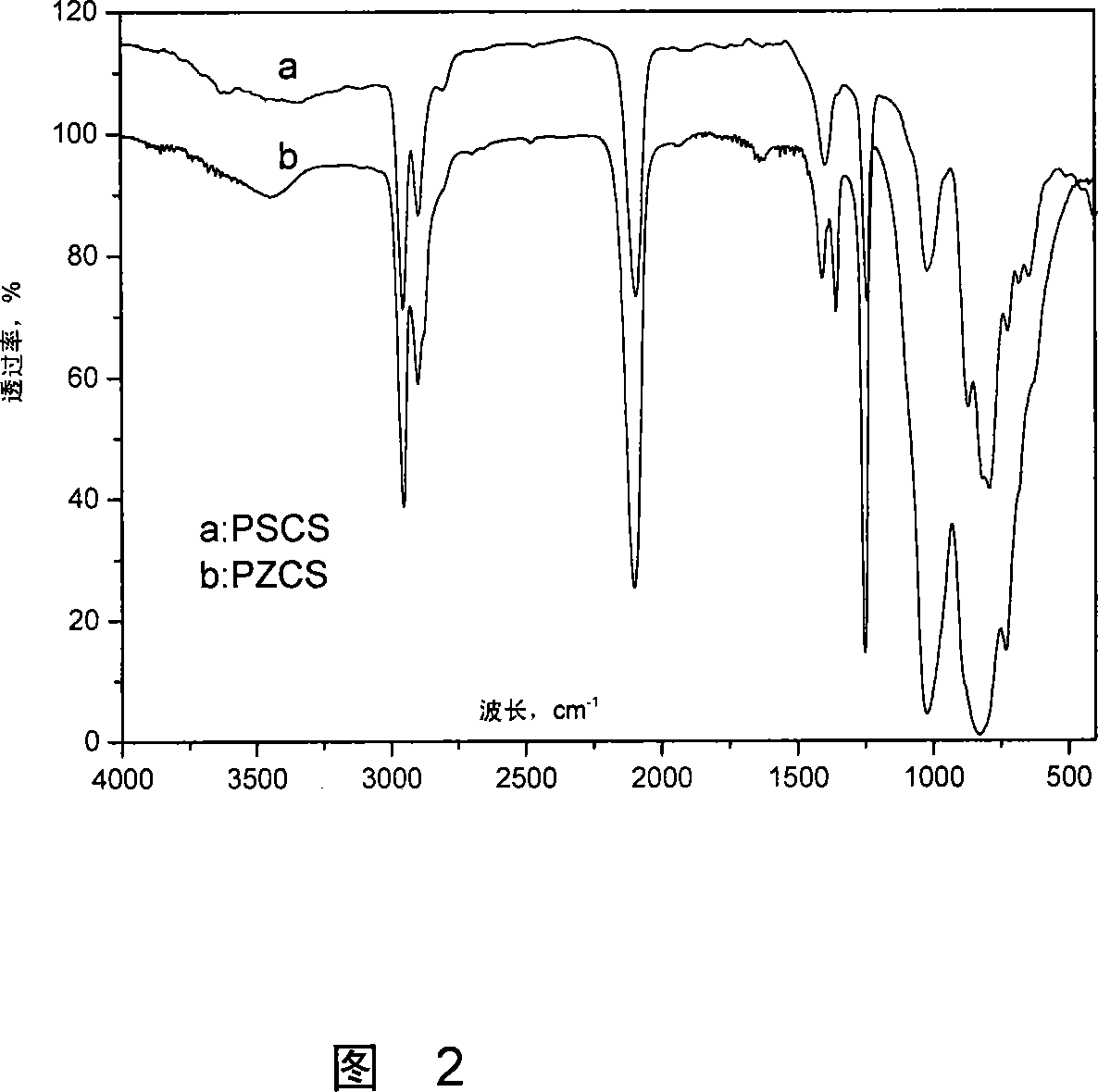

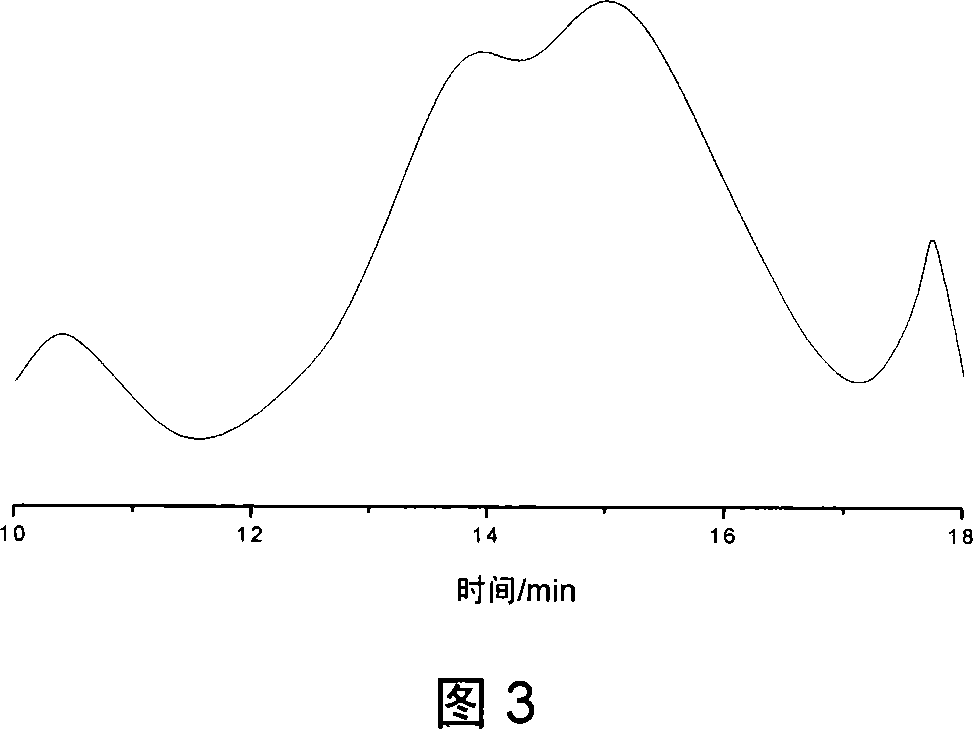

[0029] The infrared spectrum, GPC spectrum, and TG spectrum of the PZCS synthesized in this example are shown in Figure 2, Figure 3, and Figure 4, respectively.

Embodiment 2

[0031] Using PCS and tetraethoxy zirconium as raw materials, tetraethoxy zirconium: PCS = 1: 100, the reaction temperature is 450 ° C, the cracking temperature is 450 ° C, and after the reaction time of 1 hour, it is dissolved in xylene and filtered, and the filtrate is at 350 °C for vacuum distillation to obtain PZCS with a softening point of 242 °C and a zirconium content of 0.61 wt%, with a yield of 48.2%. N 2 Heat preservation at 1250°C for 1 hour under atmosphere, and the ceramic yield is 66.5%.

Embodiment 3

[0033] Use PS and zirconium acetylacetonate as raw materials, zirconium acetylacetonate:PS=20:100, reaction temperature 350°C, cracking temperature 550°C, heat preservation reaction time 20h, dissolve in xylene, filter, and distill the filtrate under reduced pressure at 370°C , the softening point is 195 DEG C, the PZCS containing 6.63wt% zirconium is obtained, and the yield is 46.8%. N 2 The temperature was kept at 1250° C. for 1 hour under the atmosphere, and the ceramic yield was 73.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com