Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

90results about How to "Good metal adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

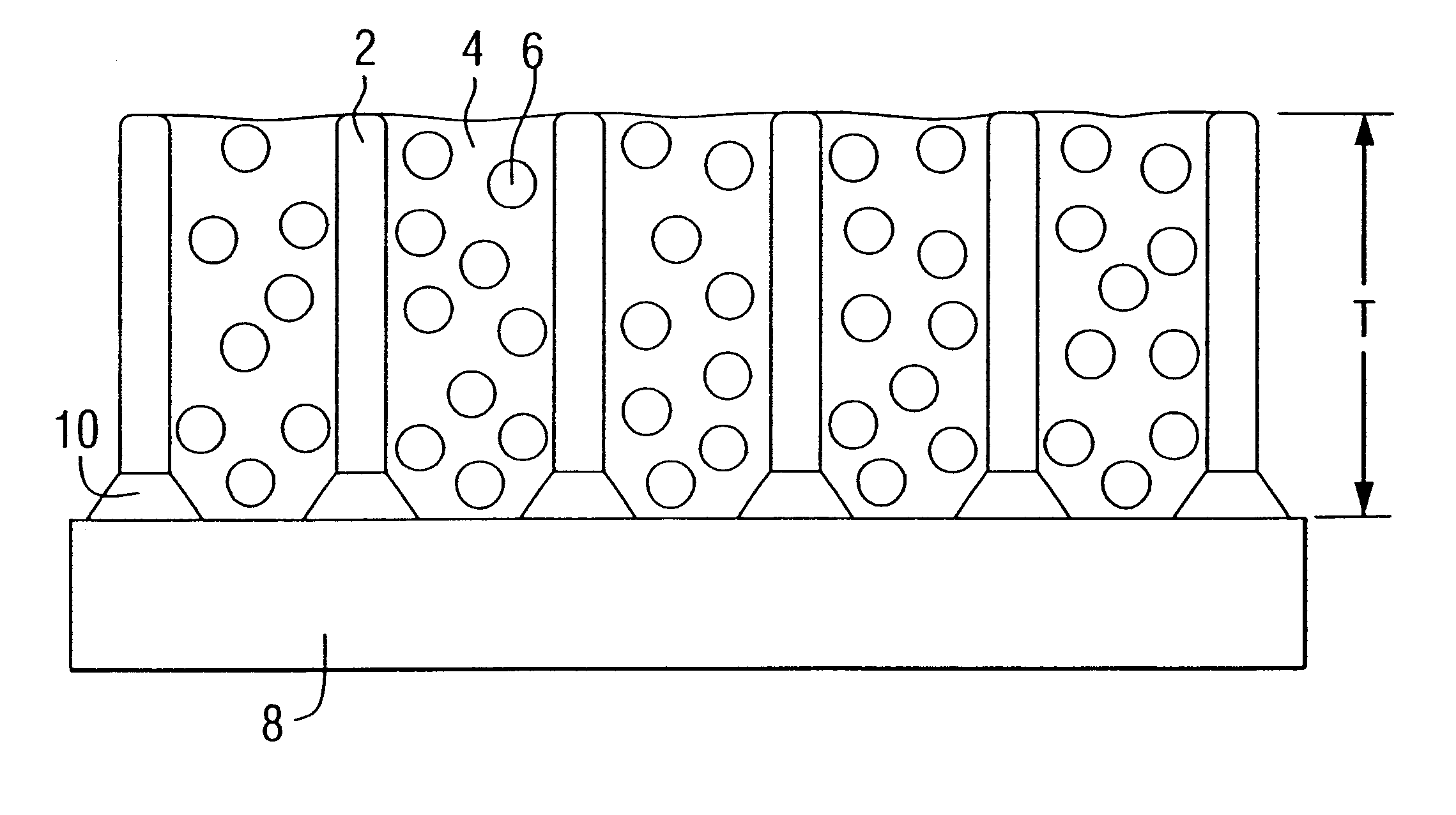

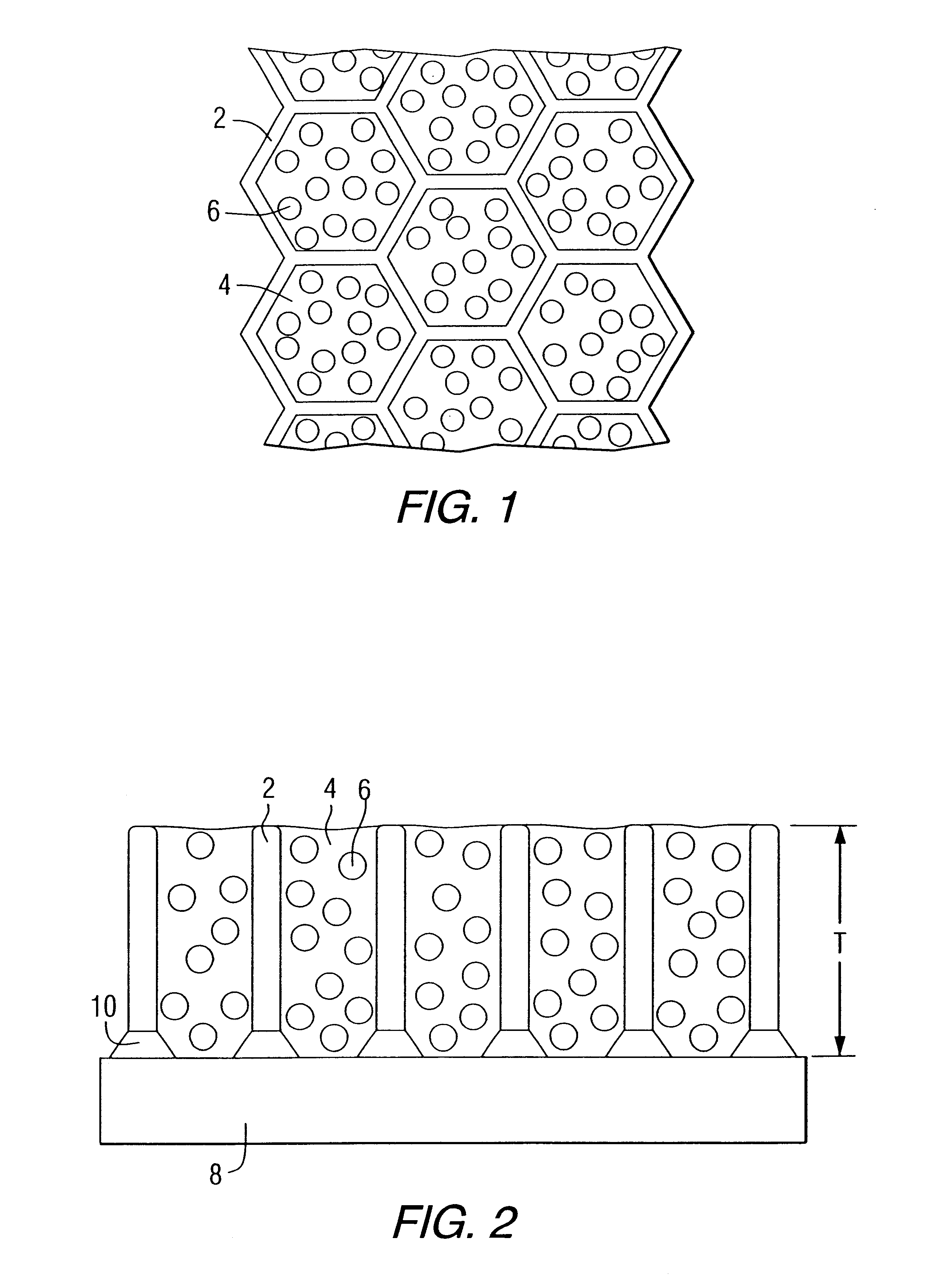

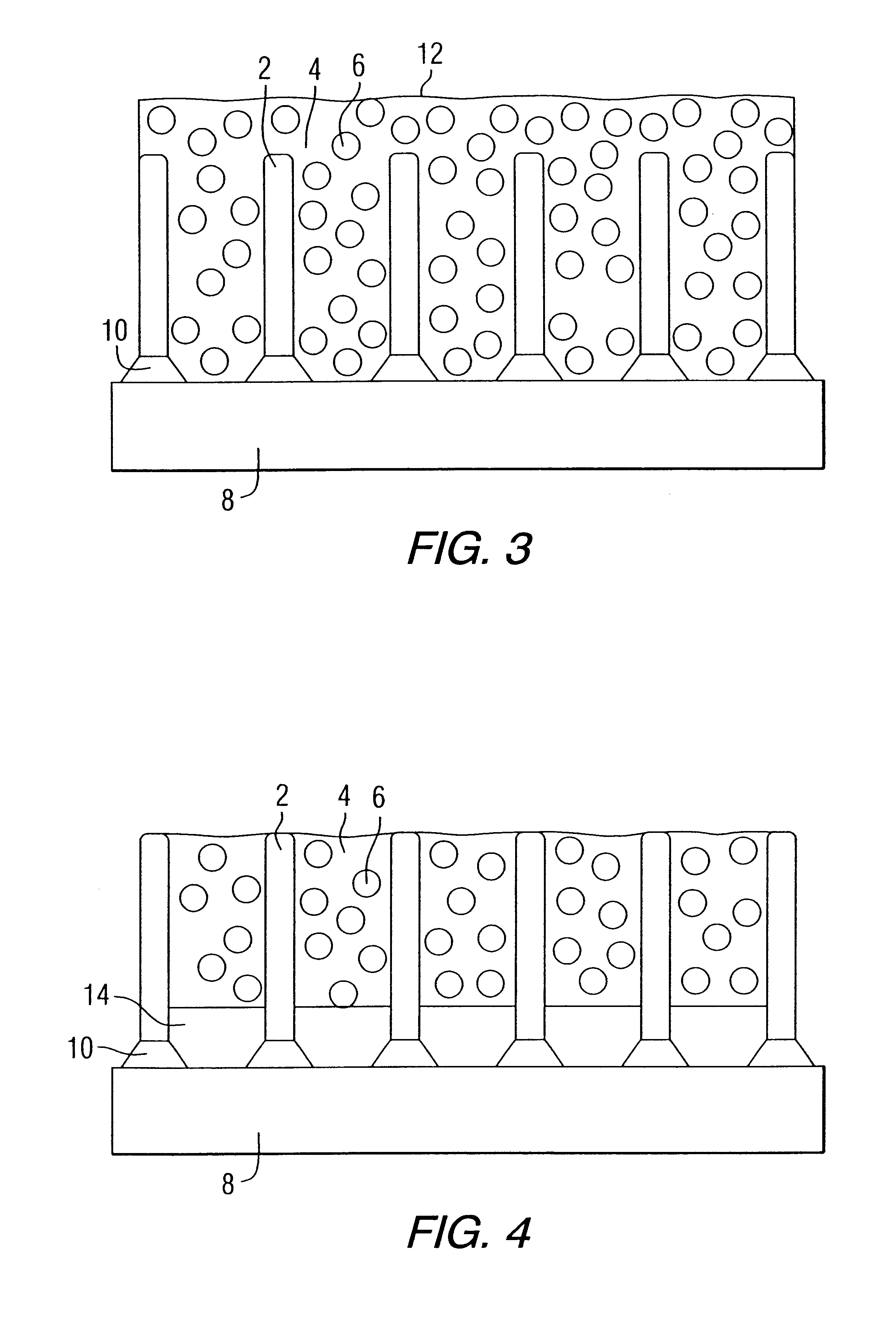

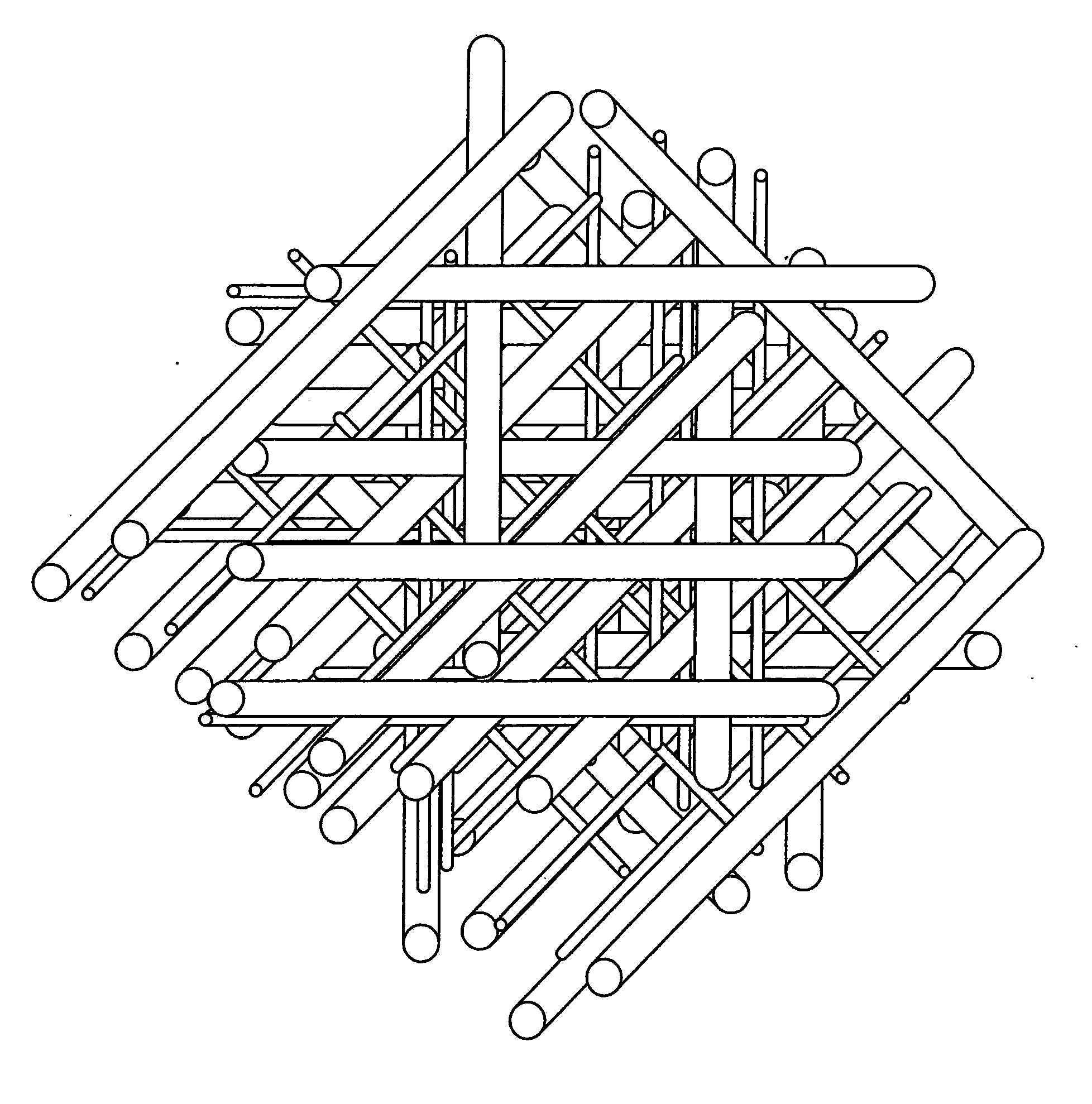

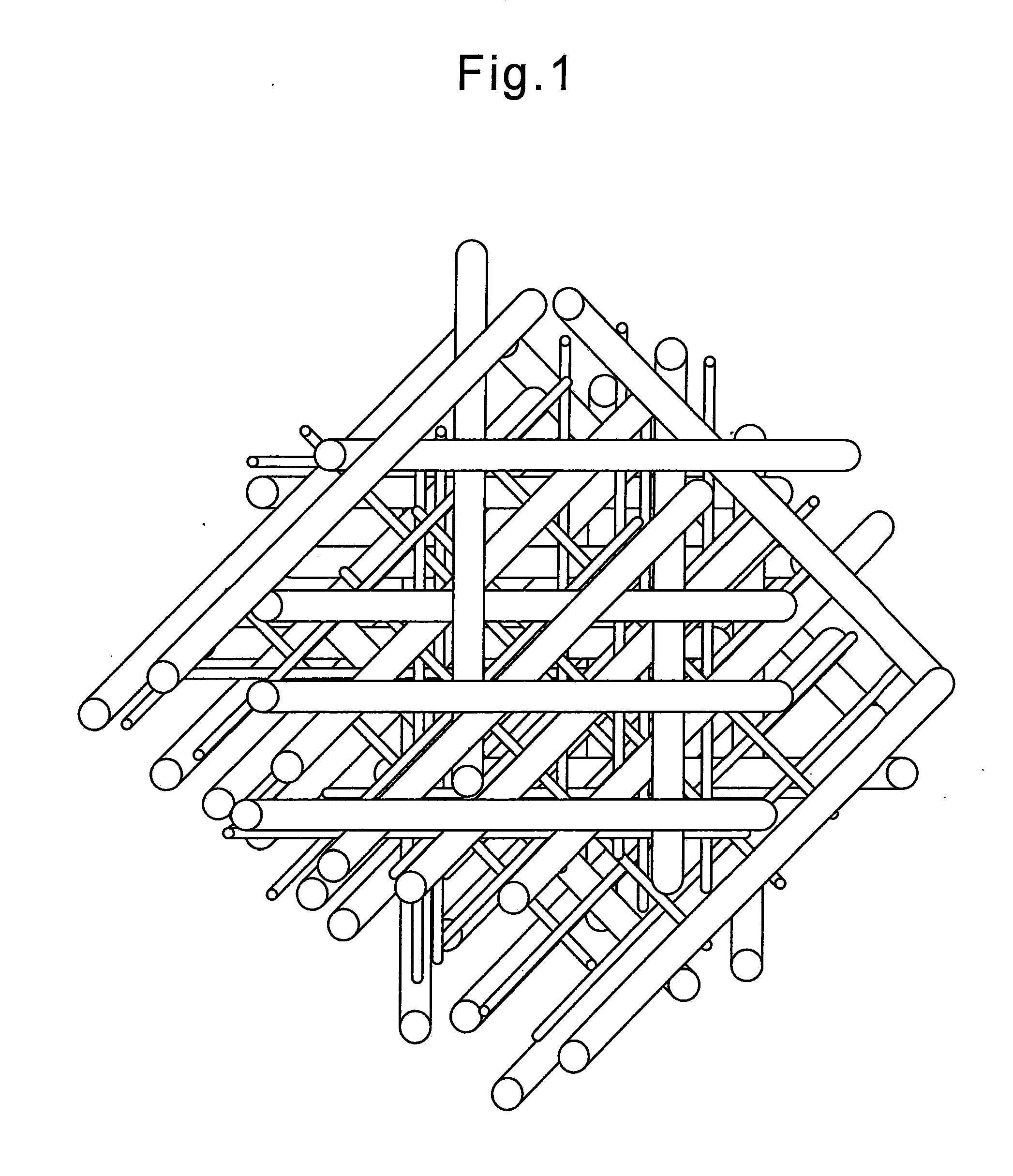

High temperature erosion resistant, abradable thermal barrier composite coating

InactiveUS6235370B1Improve wear resistanceImprove adhesionMolten spray coatingPump componentsCombustorHoneycomb

A composite thermal barrier coating system includes a honeycomb metallic structure filled with high thermal expansion ceramic hollow spheres in a phosphate bonded matrix. The composite thermal barrier coating system may be manufactured to thicknesses in excess of current thermal barrier coating systems, thereby imparting greater thermal protection. Superior erosion resistance and abrasion properties are also achieved. The composite thermal barrier coating is useful on combustion turbine components such as ring seal segments, vane segment shrouds, transitions and combustors.

Owner:SIEMENS ENERGY INC

Optical articles comprising isosorbide polyesters and method for making same

InactiveUS6126992AHigh light transmittanceEasy to copySynthetic resin layered productsPretreated surfacesPolyesterPolymer science

An optical article made of a transparent polymer which includes terephthaloyl moieties, optionally, other aromatic diacid moieties; ethylene glycol moieties; isosorbide moieties; and, optionally, one or more other diol moieties, wherein the polymer has an inherent viscosity of at least about 0.35 dL / g as measured on a 1% solution (weight / volume) in o-chlorophenol at 25 DEG C.

Owner:EI DU PONT DE NEMOURS & CO

Biaxially oriented polylactic acid film with high barrier

ActiveUS20100040904A1Good metal adhesionImproves the gas barrier of the metallized PLA filmSynthetic resin layered productsVacuum evaporation coatingMoisture barrierFood packaging

A multilayer film including a first layer including a polylactic acid polymer, a second layer of a metal primer, deposited upon one surface of the first polylactic acid polymer layer, and a third metal layer deposited on the second metal primer layer. This metal-primed and metallized polylactic acid film exhibits improved moisture barrier properties versus a non-metal-primed and metallized polylactic acid film and can be used as part of a lamination structure for food packaging applications.

Owner:TORAY PLASTICS AMERICA

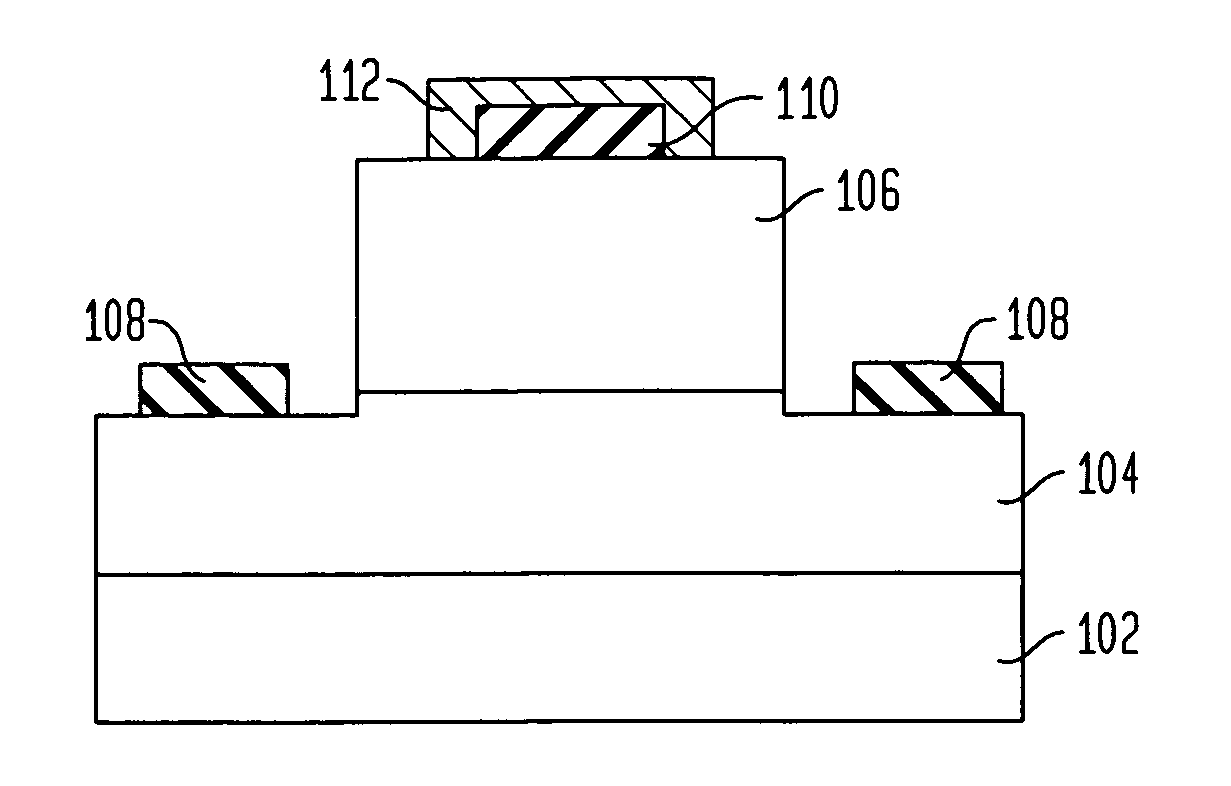

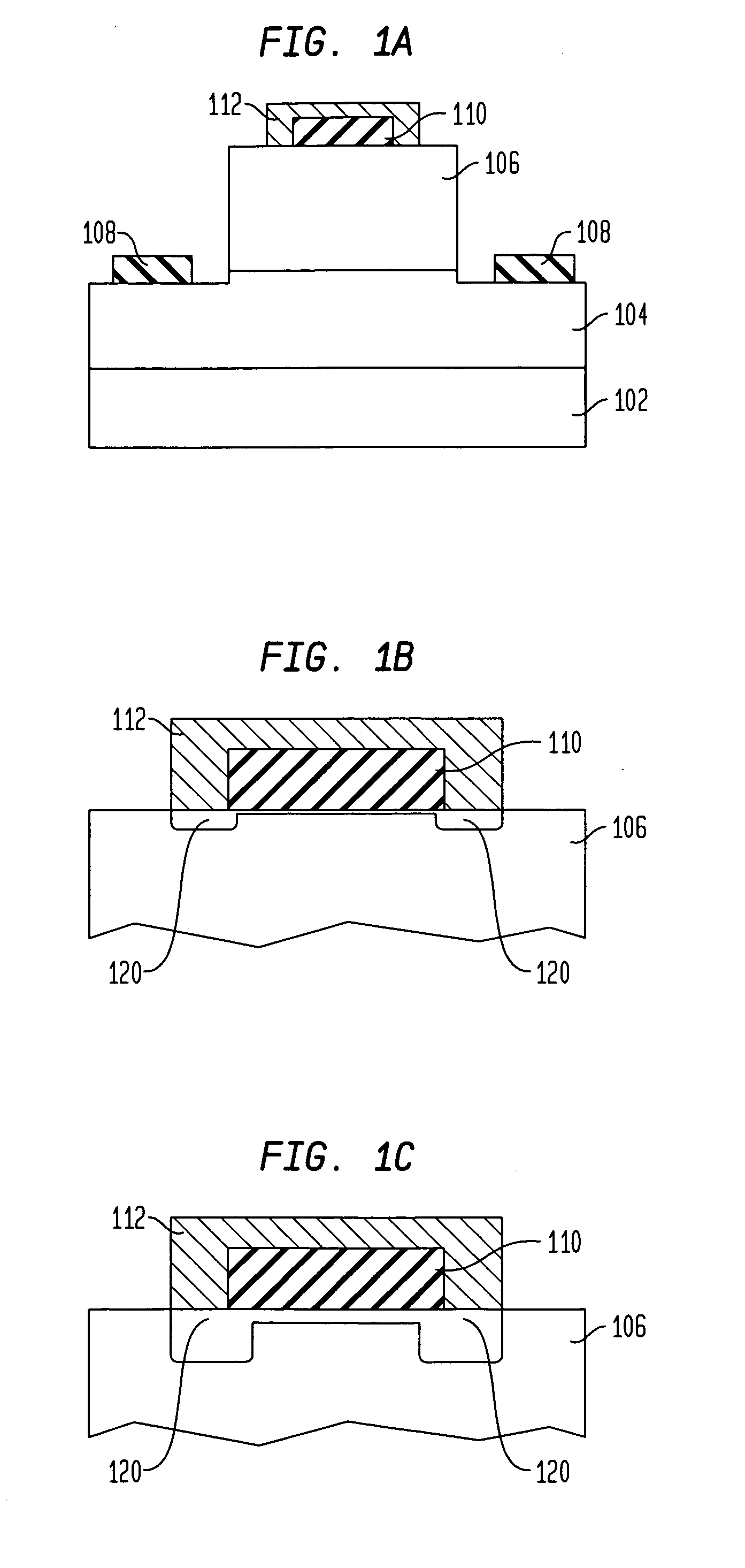

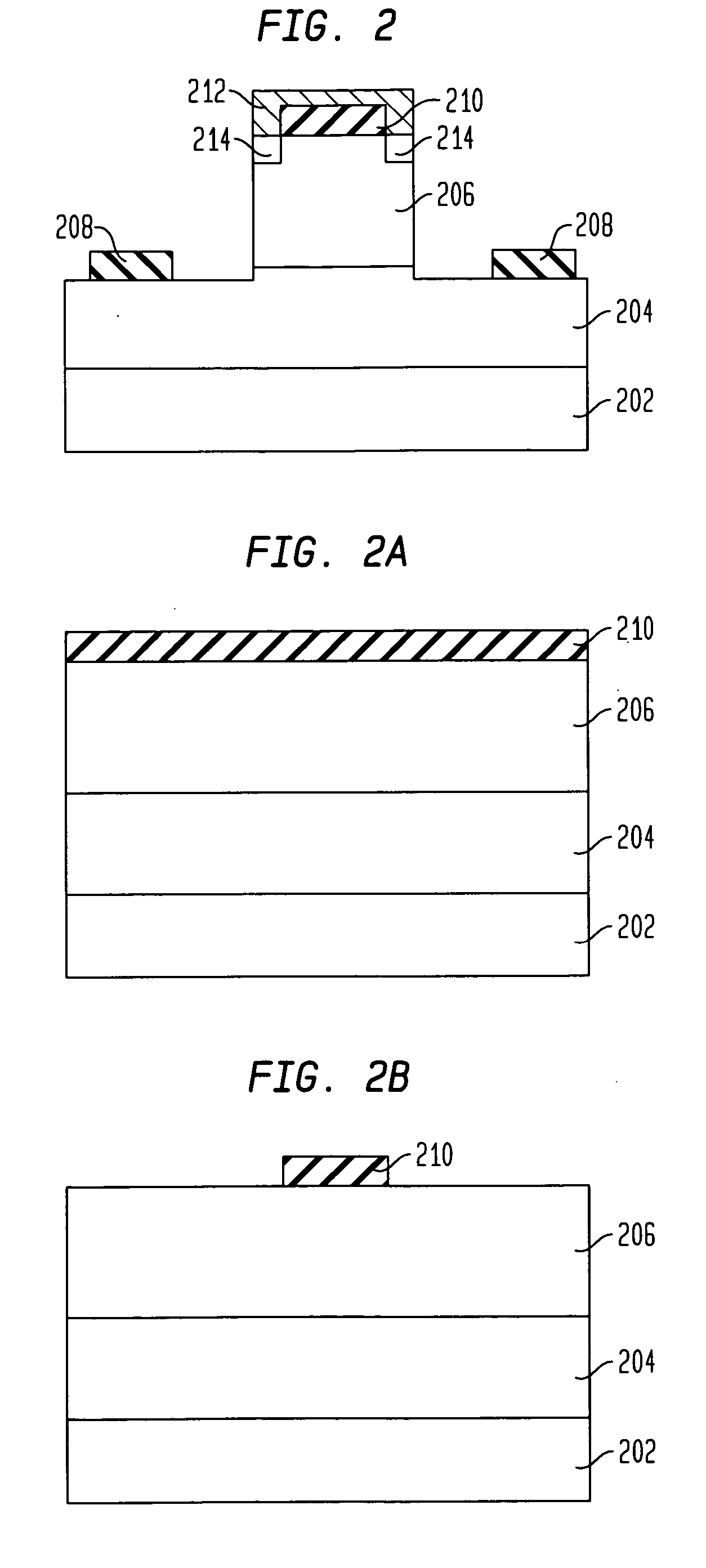

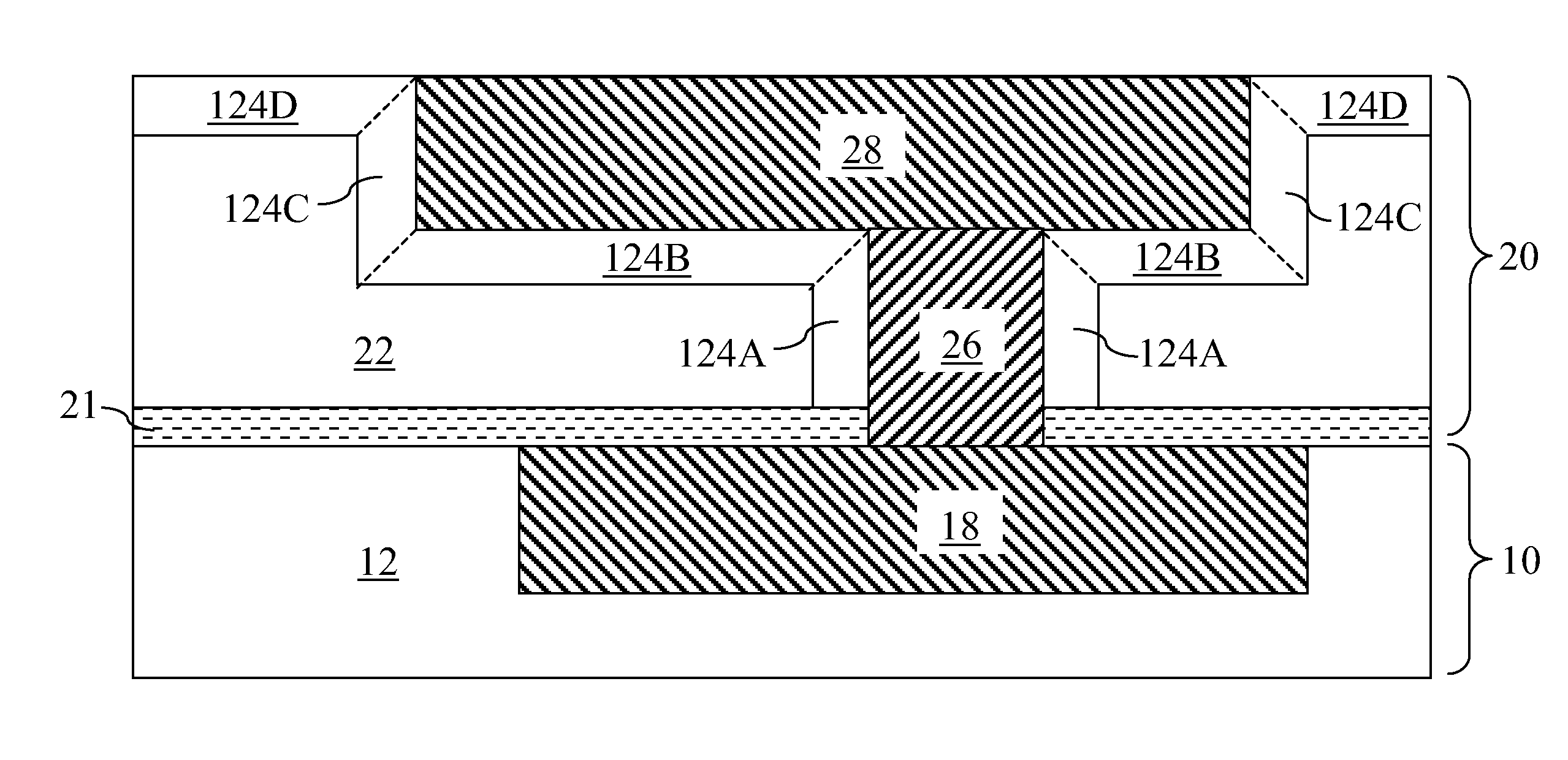

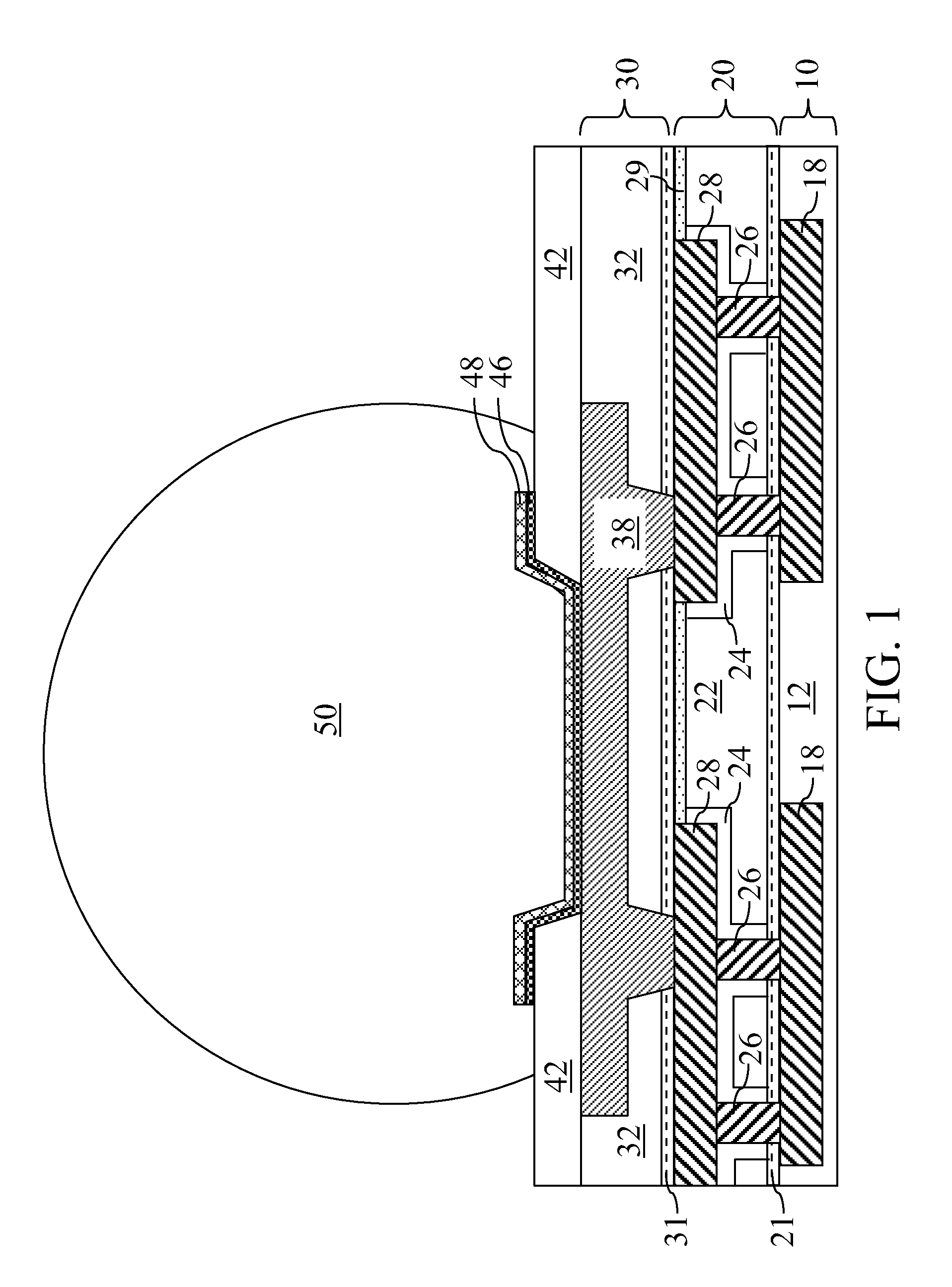

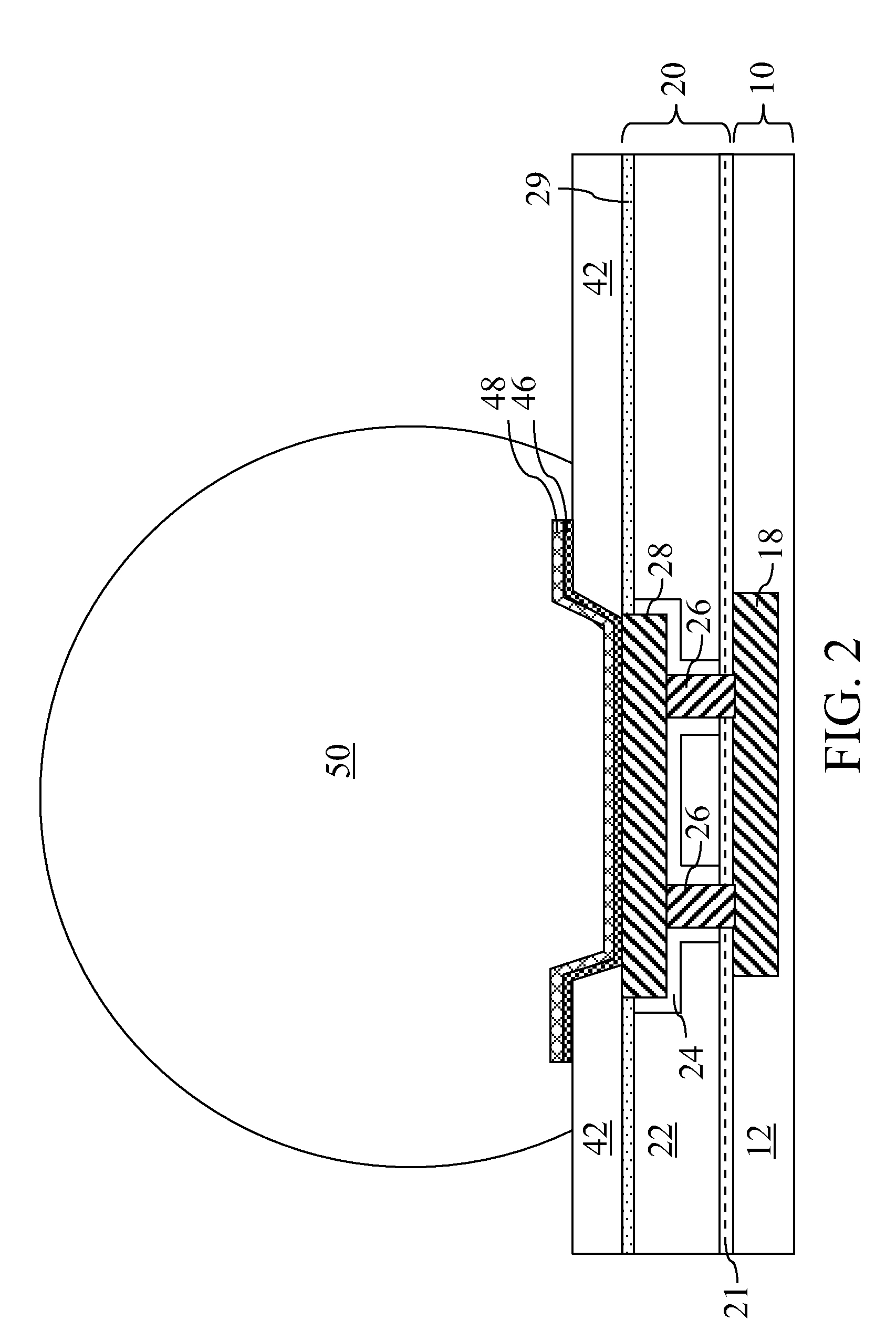

Second Schottky contact metal layer to improve GaN Schottky diode performance

InactiveUS20070108547A1Good metal adhesionImprove work functionSemiconductor/solid-state device manufacturingSemiconductor devicesSurface layerSemiconductor

A Schottky contact is disposed atop a surface of a semiconductor. A first Schottky contact metal layer is disposed atop a first portion of the semiconductor surface. A second Schottky contact metal is disposed atop a second portion of the surface layer and adjoins the first Schottky contact metal layer. The first Schottky contact metal layer has a lower work function than the second Schottky contact metal layer.

Owner:POWER INTEGRATIONS INC

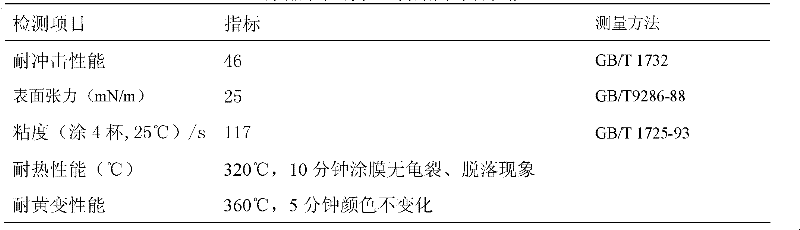

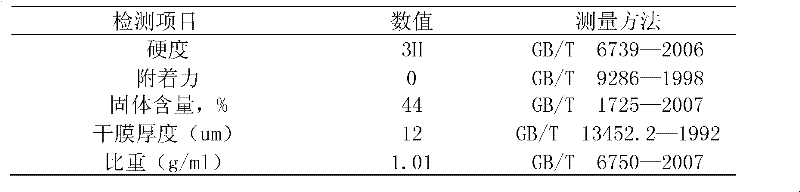

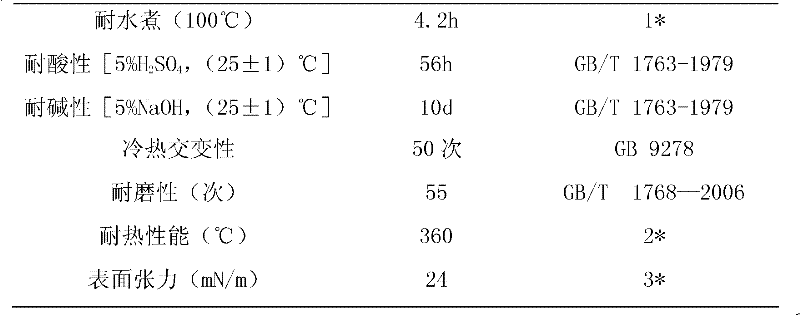

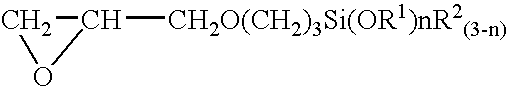

Method for preparing polyester modified organic silicon resin and coating containing the resin

ActiveCN102504265ALower surface energyLow surface energy coatings with good heat resistanceCoatingsPolyesterGlycidyl ethers

The present invention relates to a method for preparing polyester modified organic silicon resin which is prepared from 45-75 wt% of saturated polyester, 1-10 wt% of 3-glycidyl ether oxygen propyl trimethoxy silane and 20-45 wt% of organic silicon resin by reacting. The acid value of the saturated polyester is within a range of 60 to 120 mgKOH / g, and the weight-average molecular weight of the saturated polyester is within a range of 2000 to 6000. The weight-average molecular weight of an intermediate of the organic silicon resin is within a range of 800 to 2000, the content of alkoxy of the organic silicon resin is within a range of 2.5 to 15%, and the content of hydroxyl of the organic silicon resin is within a range of 3 to 20%. By combining with advantages of saturated polyester and organic silicon resin, the method has advantages of excellent heat resistant quality, good metal adhesion, low surface energy, excellent boiling resistant quality and acid-alkali resistant quality, and good temperature variation resistant quality. The polyester modified organic silicon resin prepared by the method can be used for preparing a high temperature resistant coating with low surface energy.

Owner:HANGZHOU JIHUA POLYMER MATERIAL CO LTD

Metal-coated resin molded article and production method therefor

InactiveUS20070190346A1Improve adhesionExcellent circuit adhesionPrinted circuit aspectsCoatingsPolyesterLiquid crystalline

A metal-coated resin molded article is provided, which has improved adhesion between a metal layer and a substrate of a resin composition as well as excellent moldability, heat resistance, electronic and mechanical properties. The resin composition comprises a liquid-crystalline polyester and an epoxy-group containing ethylene copolymer. The ethylene copolymer contains 50 to 99.9 wt % of an ethylene unit and 0.1 to 30 wt % of at least one of an unsaturated carboxylic acid glycidyl ester unit and an unsaturated glycidyl ether unit in the molecule thereof. A content of the ethylene copolymer is in a range of 0.1 to 25 parts by weight with respect to 100 parts by weight of the liquid-crystalline polyester.

Owner:MATSUSHITA ELECTRIC WORKS LTD +1

Anticorrosive coating containing rron oxide red

InactiveCN103173102AGood metal adhesionStructural pores are smallAnti-corrosive paintsEpoxy resin coatingsChemistryDibutyl tin dilaurate

The invention discloses an anticorrosive coating containing iron oxide red, which comprises two components A and B, wherein the component A comprises the following raw materials in parts by weight: 68-77 parts of epoxy resin E44, 20-25 parts of high chlorinated polyethylene resin, 5-7 parts of titanium dioxide, 5-7 parts of zinc borate, 2-3 parts of catechol, 1-2 parts of iron oxide red, 2-4 parts of sodium hexametaphosphate, 2-4 parts of dibutyltin dilaurate, 3-6 parts of propylene glycol, 2-4 parts of poly (butyl acrylate), 3-5 parts of stearic acid, 2-3 parts of polyacrylamide, 2-3 parts of diphenylamine, 2-5 parts of diethylene glycol dibenzoate, 3-4 parts of zinc stearate, 1-2 parts of hexamethylene tetramine, 10-25 parts of compound modifier, 25-30 parts of dimethylbenzene, 8-10 parts of n-butyl alcohol, 0.8-1 part of 3-(methacryloxy) propyl trimethoxy silane and 0.5-1 part of simethicone. The coating disclosed by the invention has the advantages of good metal adhesive force, small structural pore, compact structure, excellent adhesive force, good flexibility, high impact strength and good corrosion resistance and is capable of playing an efficient protection role to base metal.

Owner:ANHUI MINGZHU PIGMENT TECH

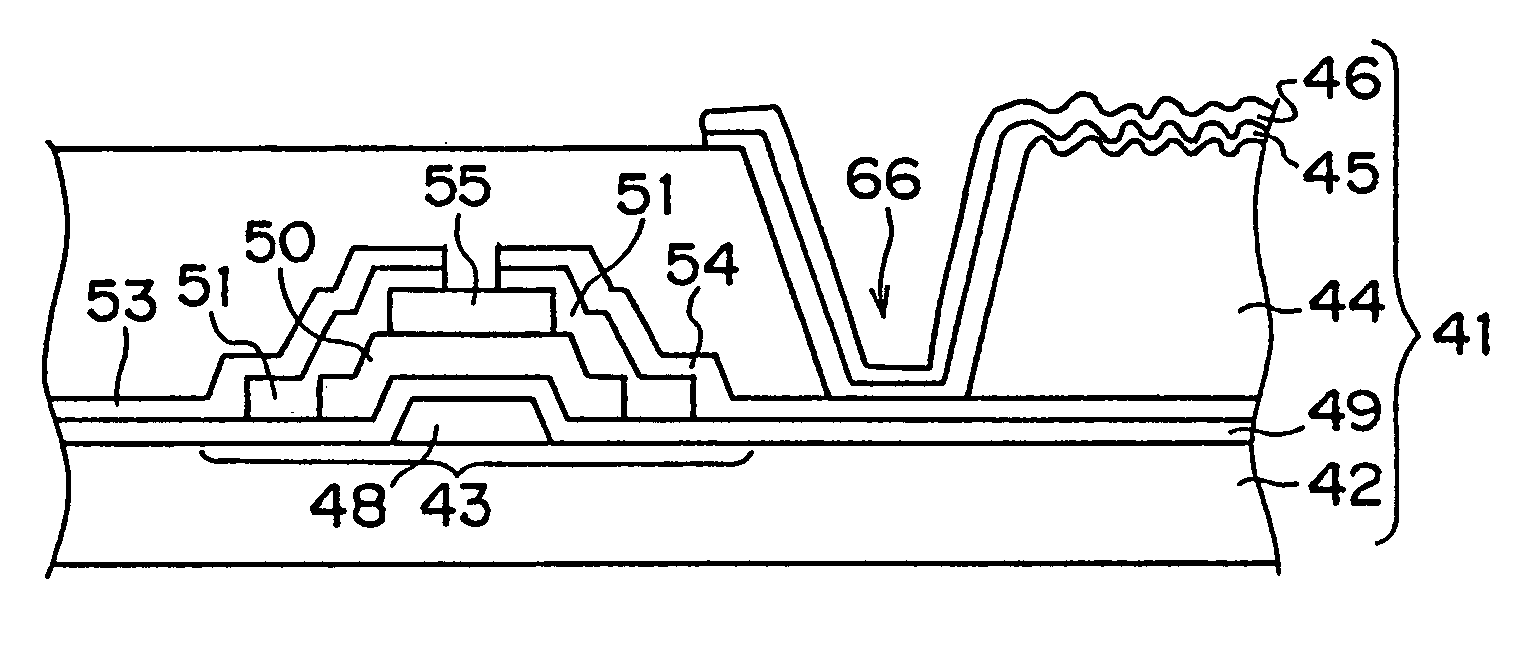

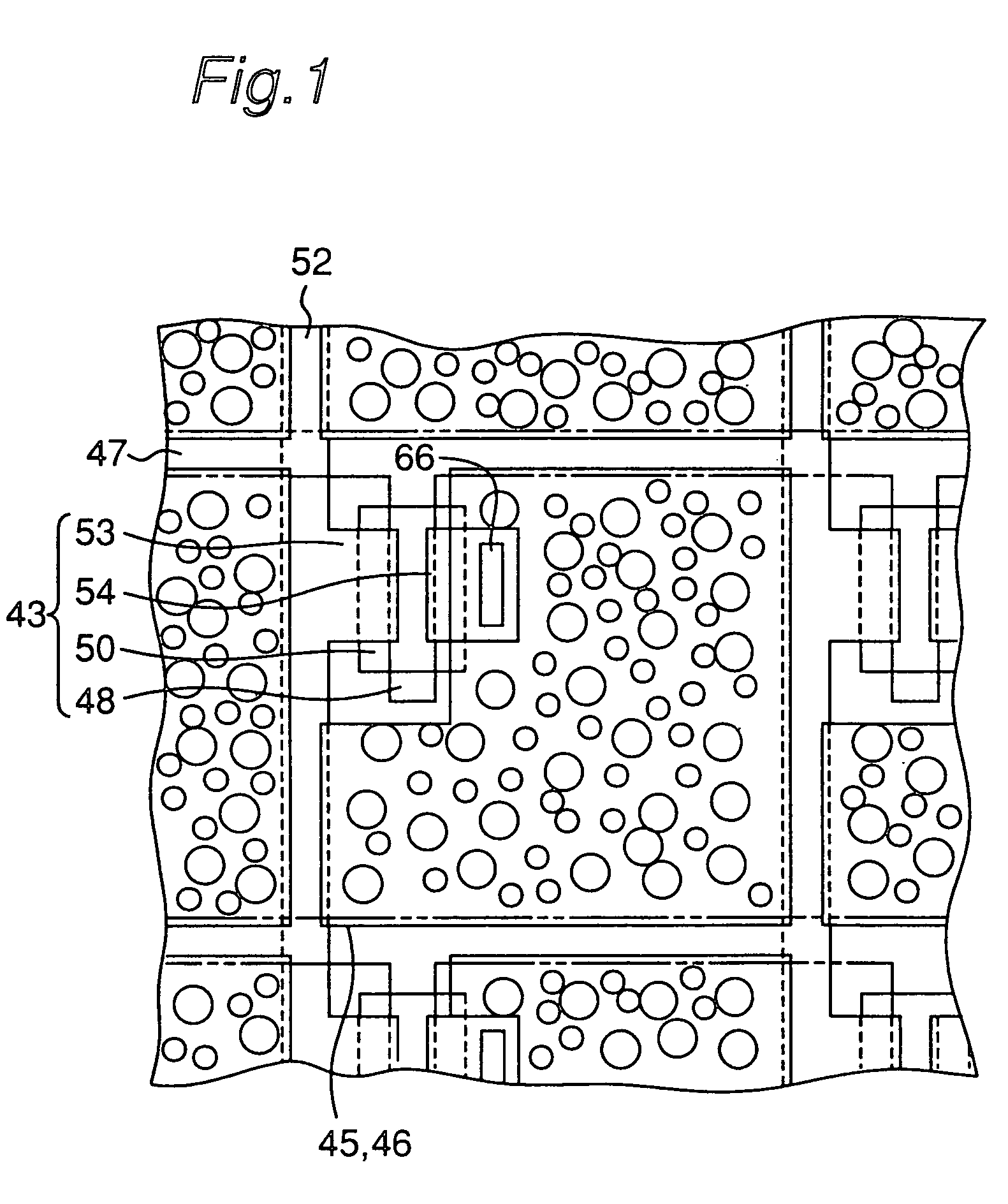

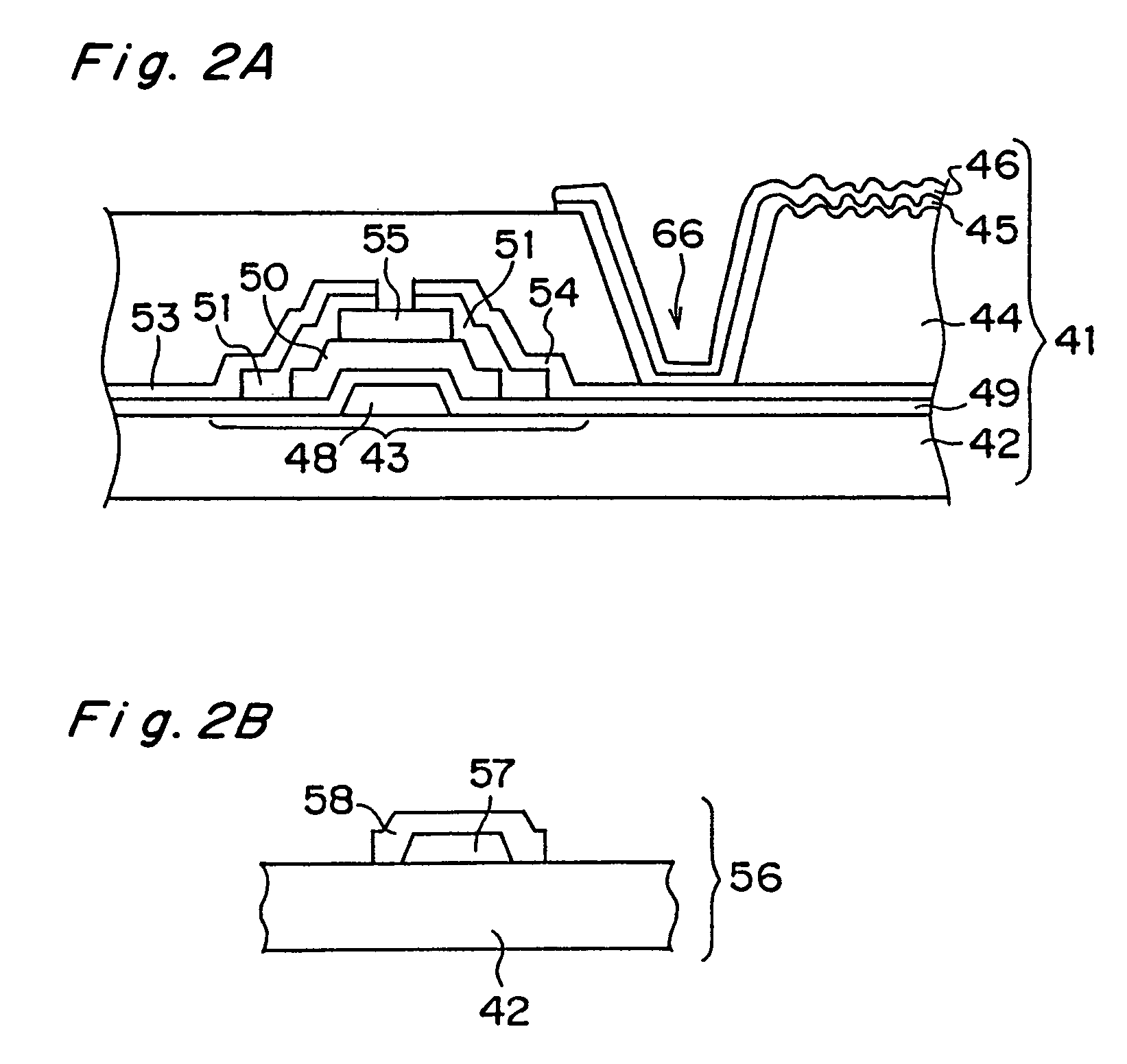

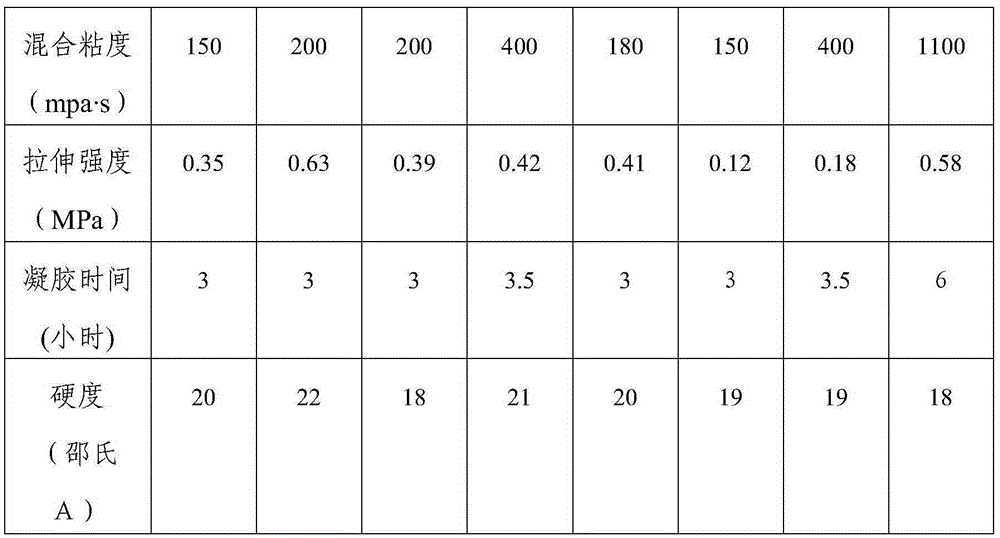

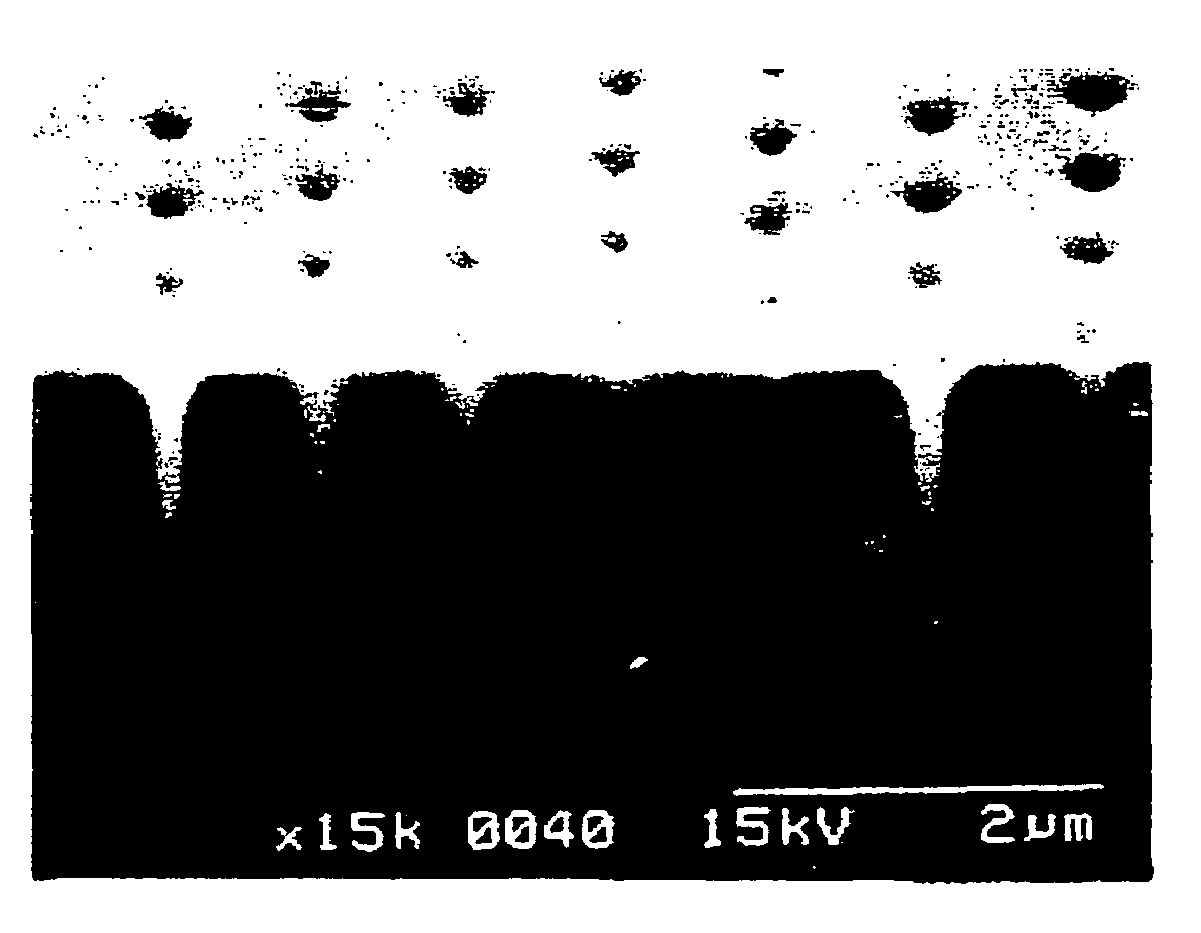

Patterned substrate and liquid crystal display provided therewith

InactiveUS7029727B1Improve reliabilityHigh yieldLiquid crystal compositionsStatic indicating devicesLiquid-crystal displayNitrogen

A thin film transistor (TFT) is formed on an insulating substrate, and a photosensitive resin film as an interlayer insulating film is formed so as to cover the TFT. Contact holes are formed in the photosensitive resin, and smooth concave and convex portions are provided on an upper surface of the resin. A film including molybdenum nitride (MoN) and a reflective pixel electrode film are successively laminated on the photosensitive resin. The nitrogen content in the MoN film may be between 5 atomic % and 30 atomic % inclusive.

Owner:SHARP KK

Metallizable and Metallized Polyolefin Films and a Process of Making Same

InactiveUS20110195259A1Good metal adhesionAcceptable barrier propertyPlastic/resin/waxes insulatorsSynthetic resin layered productsPolysilanePolyolefin

Owner:JINDAL FILMS AMERICAS LLC

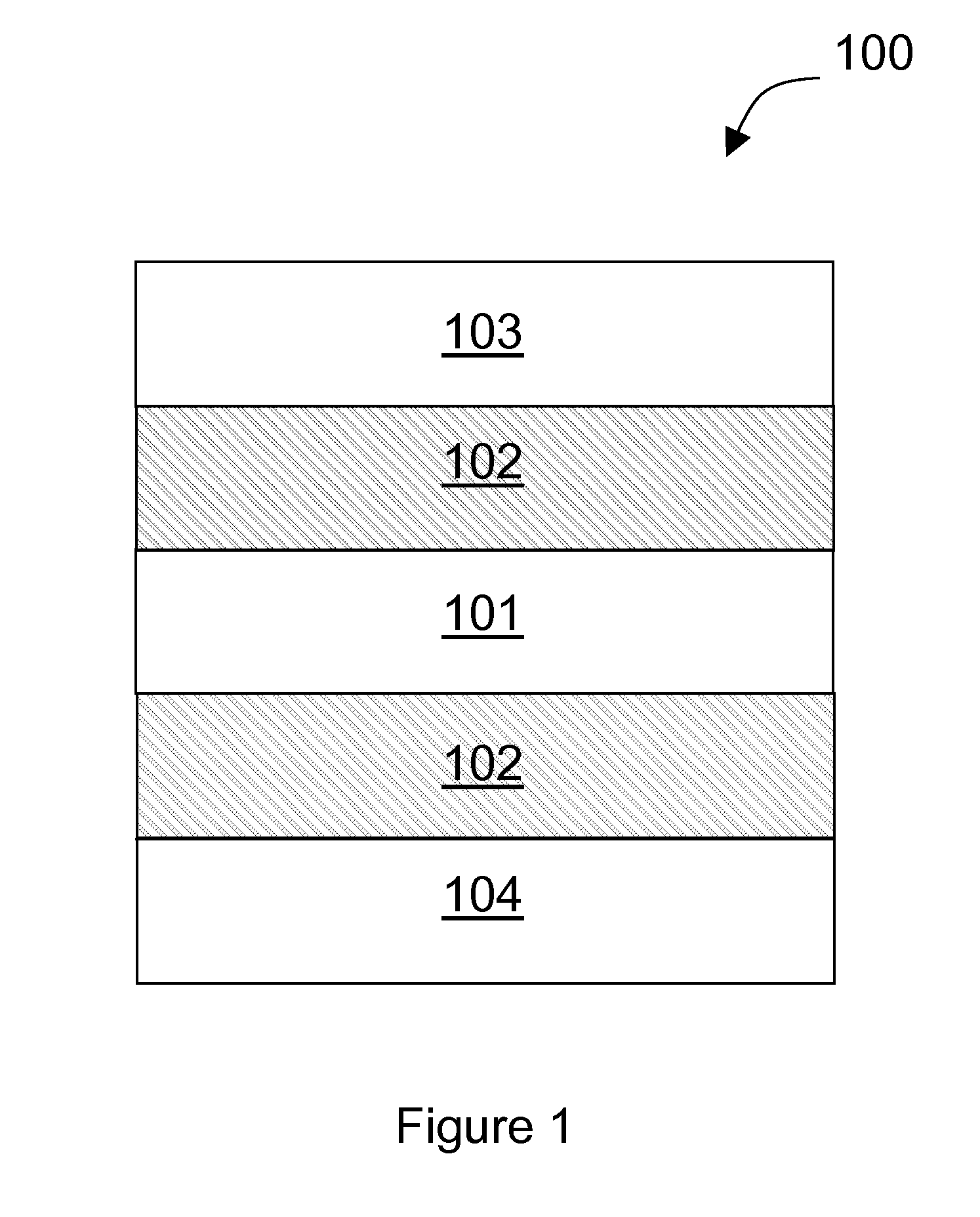

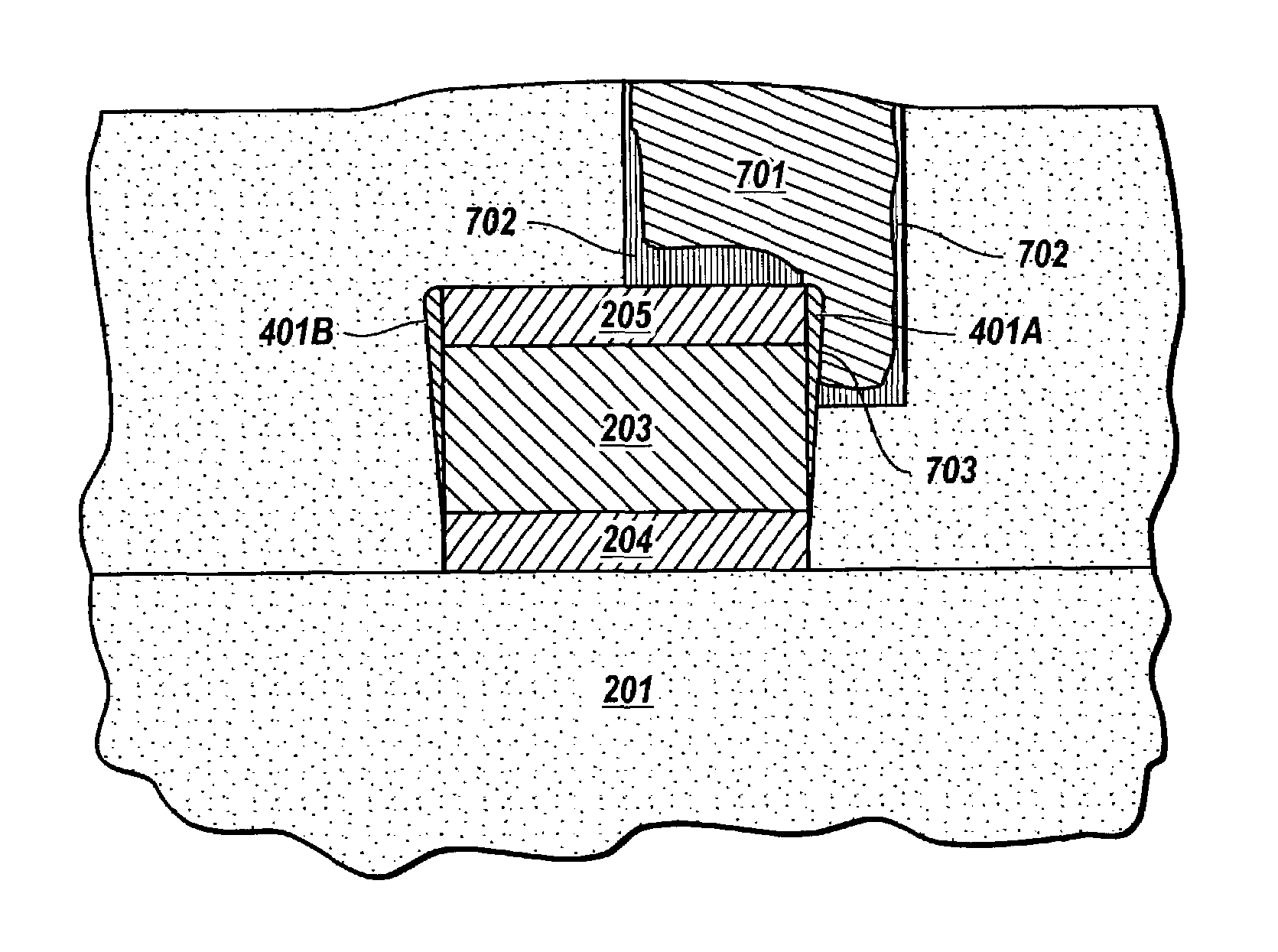

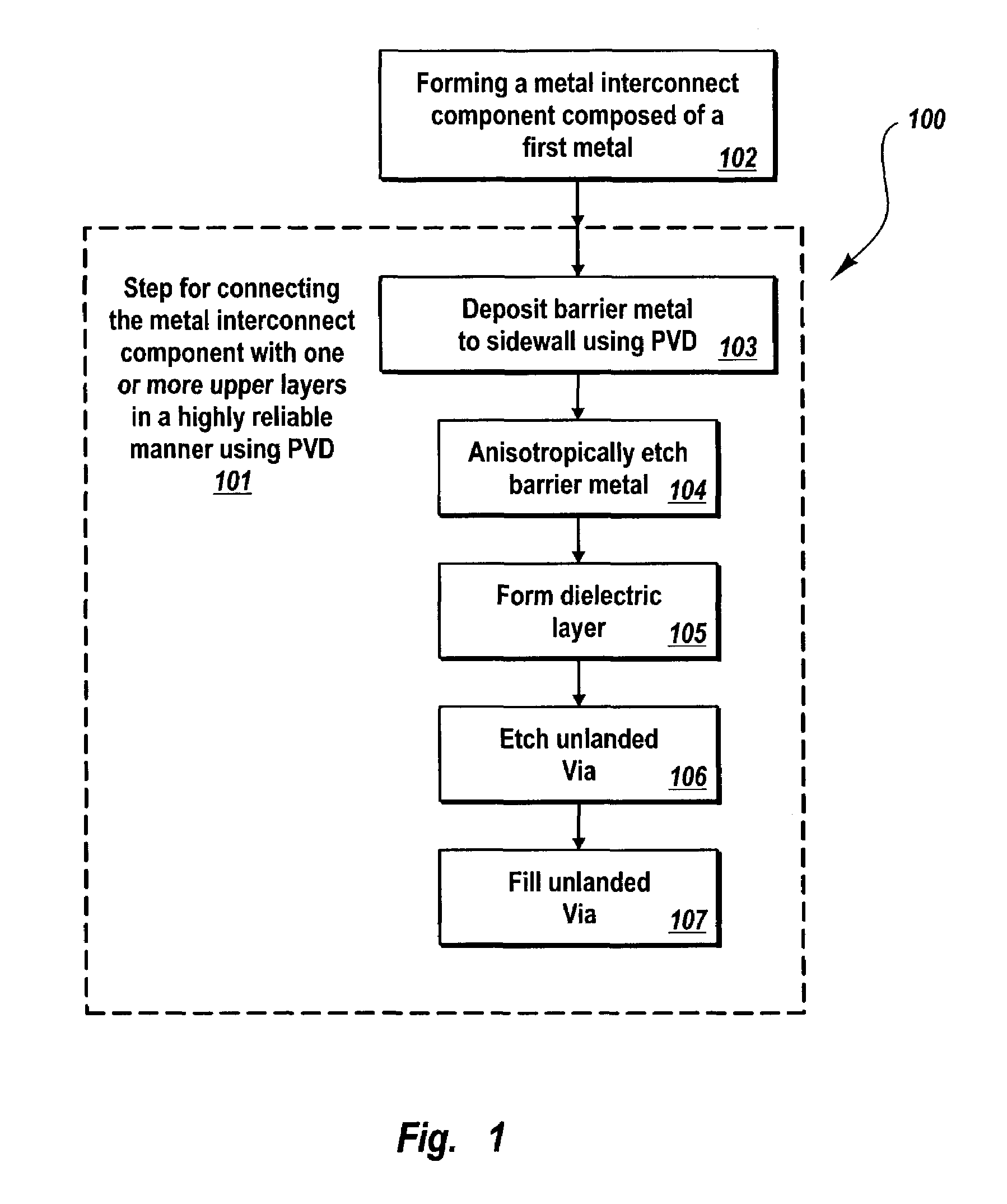

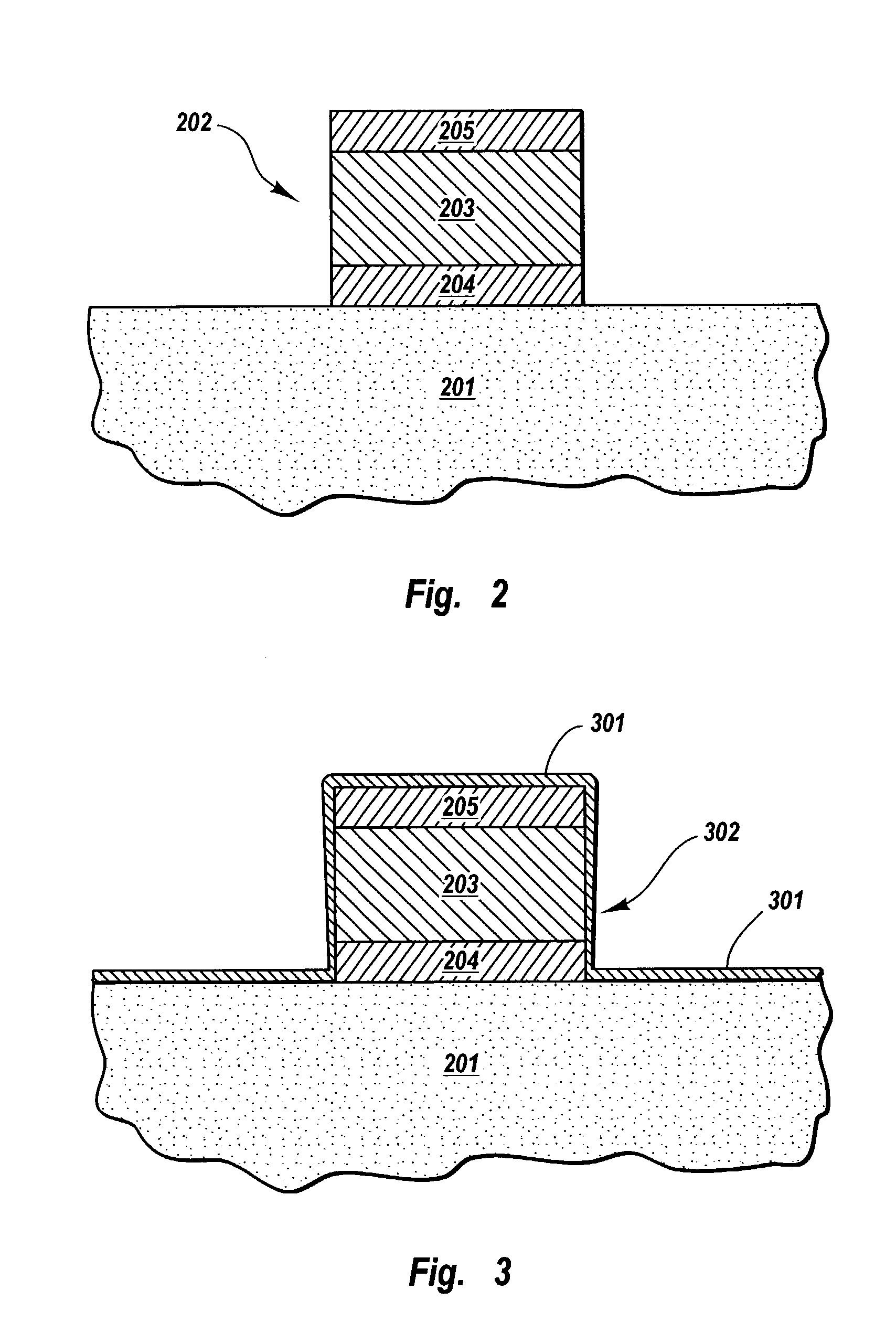

Methods for sidewall protection of metal interconnect for unlanded vias using physical vapor deposition

InactiveUS6960529B1Less-expensive sidewall protectionProtection is in progressSemiconductor/solid-state device manufacturingMetal interconnectMetallic materials

Methods for protecting the sidewall of a metal interconnect component using Physical Vapor Deposition (PVD) processes and using a single barrier metal material. After forming the metal interconnect component, a single barrier metal is deposited on its sidewall using PVD. A subsequent anisotropic etching of the barrier metal removes the barrier metal from the horizontal surface except for some that still remains on the top surface of the metal interconnect layer. A dielectric layer is then formed over the metal interconnect component and the barrier metal. The unlanded via is etched through the dielectric layer to the metal interconnect component, and then filled with a second metal to thereby allow the metal interconnect component to electrically connect with one or more upper metal layers.

Owner:SEMICON COMPONENTS IND LLC

Production of fast-drying water self-stripping metal heat treatment protecting coating

A method for producing fast-dry water self-stripping metal heat-treatment protective coating is carried out by putting boric acid 40.0-70.0 wt%, water resin 25.0-50.0 wt%, titanium pigment slurry 1.0-15.0 wt%, coloring pigment slurry 0.1-10.0 wt%, de-foaming agent 0.1-2.0 wt% and de-ionized water residue into stainless steel jar, high-speed dispersing to fineness below 50mu by agitator, filtering and packing to obtain final product. The precision metal work pieces have excellent oxidation and de-carbonizing resistances with air as medium for physical heat treatment, and have excellent cementation, aluminizing, siliconing and chromizing resistances with chemical substances as medium for chemical heat treatment. It has brushing and spraying functions, fast dry speed and better adhesion.

Owner:SHANGHAI JIAO TONG UNIV

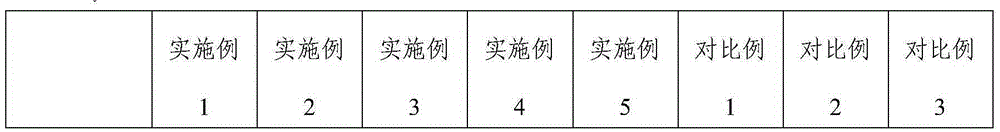

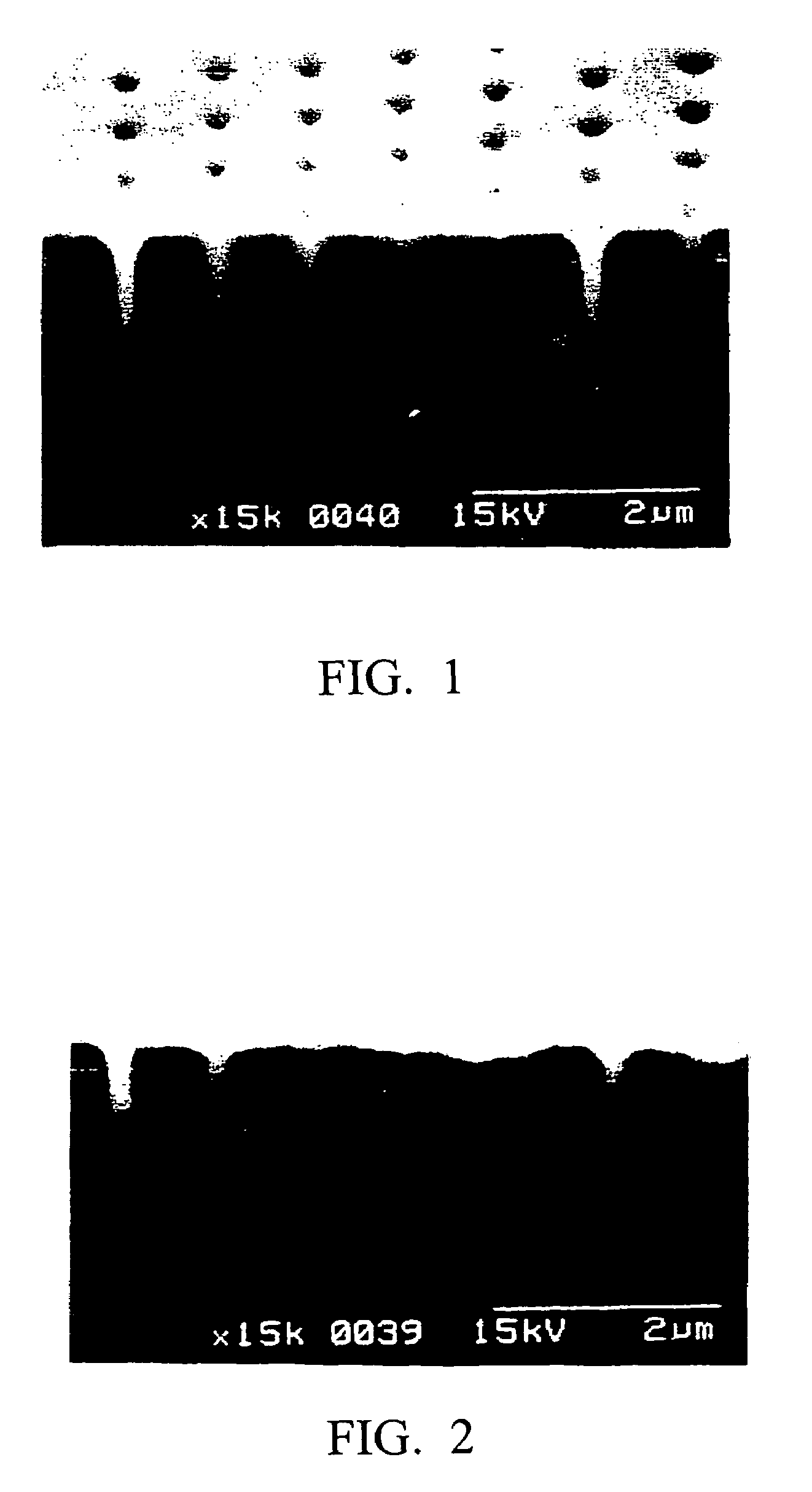

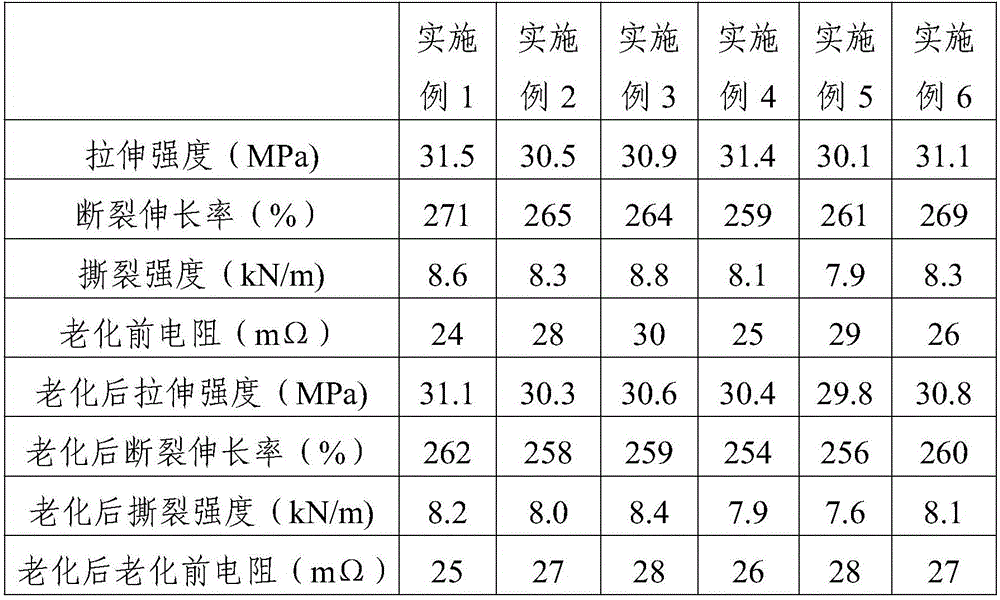

Polyurethane pouring sealant and preparation method thereof

ActiveCN105255432ALow viscosityReduce hardnessNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAntioxidantUltraviolet lights

The invention relates to a polyurethane pouring sealant. The polyurethane pouring sealant comprises a component A and a component B in a mass ratio of 1 to 1, wherein the component A is prepared from the following components in parts by weight: 80-100 parts of polymer polyol, 0-5 parts of small molecular alcohol, 0.1-1 part of an antioxidant, 0.1-1 part of an ultraviolet light absorber, 0.1-1 part of a light stabilizer, 0.5-8 parts of a catalyst, 0.1-1 part of a defoaming agent, 0.1-1 part of a coupling agent and 0-20 parts of a plasticizer; the component B is prepared from the following components in parts by weight: 20-50 parts of polyisocyanate and 40-80 parts of a plasticizer. The polyurethane pouring sealant has the characteristics of being low in viscosity and hardness, few in foams, capable of being cured at the normal temperature, high in curing speed and easy to operate; a cured product has good oxidation resistance and insulation and humidity resistance and relatively good metal bonding force.

Owner:BEIJING JINWEINA TECH CO LTD

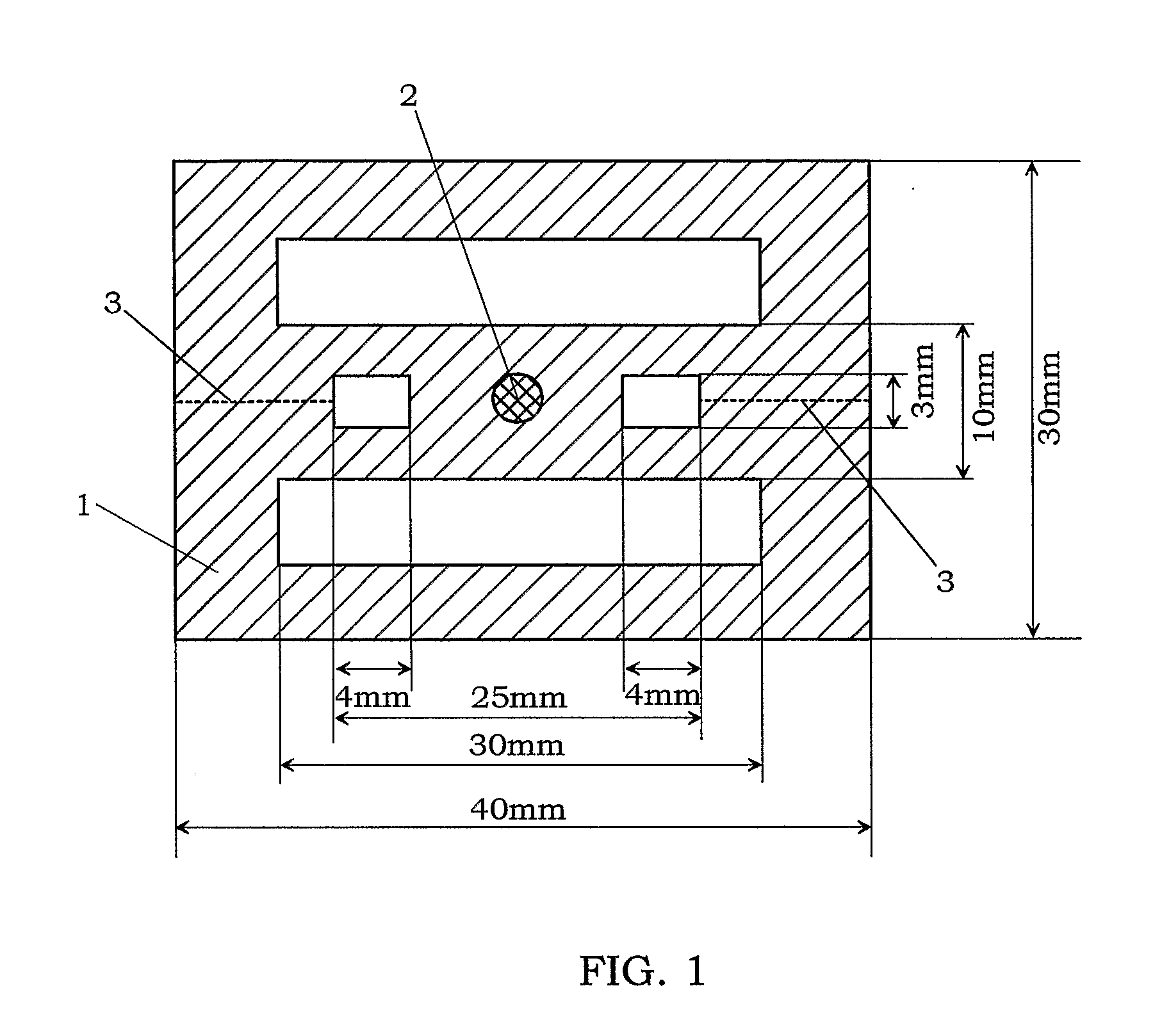

Metal plating method, pretreatment agent, and semiconductor wafer and semiconductor device obtained using these

InactiveUS7045461B2Inadequate coverageDifficult to coatPretreated surfacesSemiconductor/solid-state device manufacturingAzoleSemiconductor

Resin cloths, powders, specular bodies and other objects resistant to conventional plating can be plated with metals by a simple method.According to the metal plating method of the present invention, electroless plating is performed after the surface of a object to be plated is treated with a pretreatment agent obtained by reacting or mixing in advance a noble metal compound (catalyst) with a silane-coupling agent having functional groups capable of capturing metals. According to this method, metal plating can be securely applied to powders, resin cloths, semiconductor wafers, and other specular bodies. Moreover, the problem of the insufficient coverage of the seed layer on the inside walls of vias and trenches during the formation of fine wiring can be addressed by applying this method to semiconductor wafers. The silane-coupling agent may be a compound containing azole groups, preferably an imidazole.

Owner:JX NIPPON MINING& METALS CORP

Electromagnetic shielding sheet technical field

ActiveUS20120111627A1Good metal adhesionReducing increase in thickness of baseMagnetic/electric field screeningFibre typesMetal coatingElectromagnetic shielding

Disclosed is an electromagnetic shielding sheet that has a smaller increase in the thickness of a base after the formation of a metal coating film when compared with conventional electromagnetic shielding sheets, and which has excellent electromagnetic wave shielding properties despite a small amount of adhered metal. According to the present invention, the electromagnetic shielding sheet can endure metal working processes and has high electromagnetic wave shielding properties, resulting in a thin, very flexible fabric sheet. Specifically disclosed is an electromagnetic shielding sheet which is composed of a laminated non-woven fabric that has at least a first layer and a second layer, and which is characterized in that the first layer is a layer of thermoplastic synthetic fibers having a fiber diameter of 6 μm to 50 μm, the second layer is a layer of ultrafine fibers having a fiber diameter of 0.1 μm to 5.0 μm, and a metal is adhered to at least one surface of the sheet.

Owner:ASAHI KASEI FIBERS CORPORATION

Fluorine depleted adhesion layer for metal interconnect structure

ActiveUS20090212439A1Improve adhesionIncrease resistanceSemiconductor/solid-state device detailsSolid-state devicesHigh resistanceState of art

A line trough and a via cavity are formed within a dielectric layer comprising a fluorosilicate glass (FSG) layer. A fluorine depleted adhesion layer is formed within the line trough and the via cavity either by a plasma treatment that removes fluorine from exposed surfaces of the FSG layer, or by deposition of a substantially fluorine-free dielectric layer. Metal is deposited within the line trough and the via cavity to form a metal line and a metal via. The fluorine depleted adhesion layer provides enhanced adhesion to the metal line compared with prior art structures in which a metal line directly contacts a FSG layer. The enhanced adhesion of metal with an underlying dielectric layer provides higher resistance to delamination for a semiconductor package employing lead-free C4 balls on a metal interconnect structure.

Owner:TAIWAN SEMICON MFG CO LTD

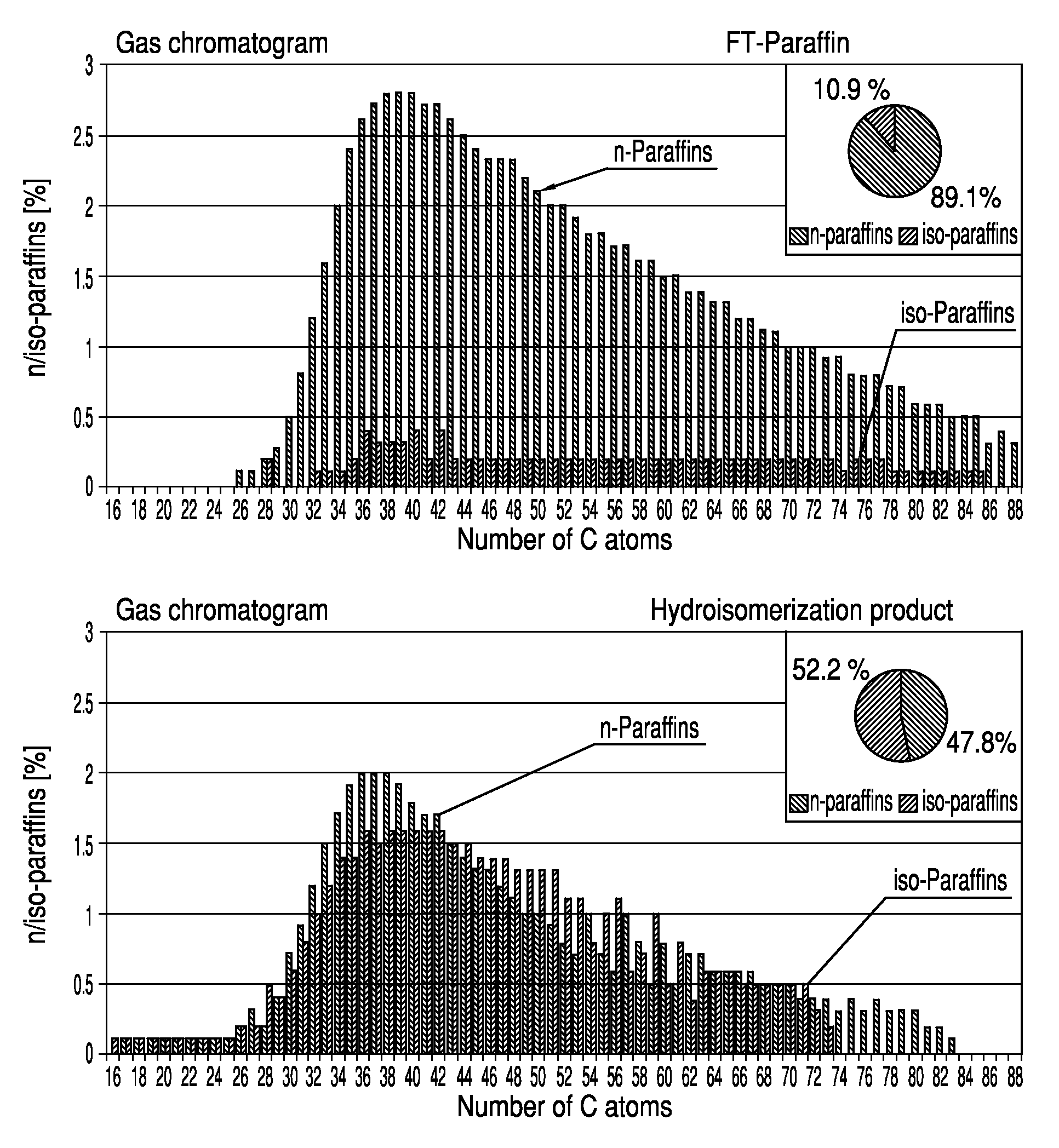

Microcrystalline paraffin

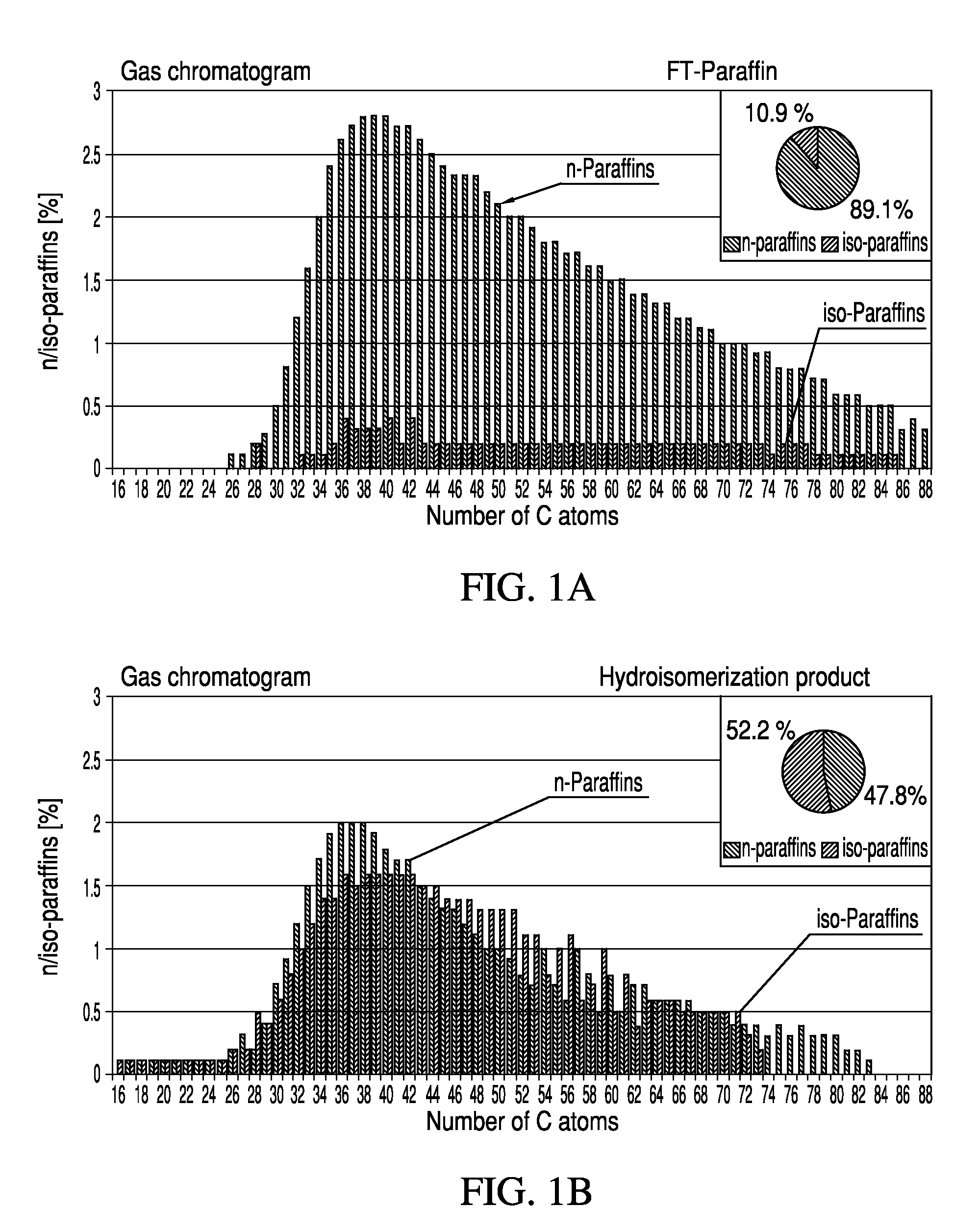

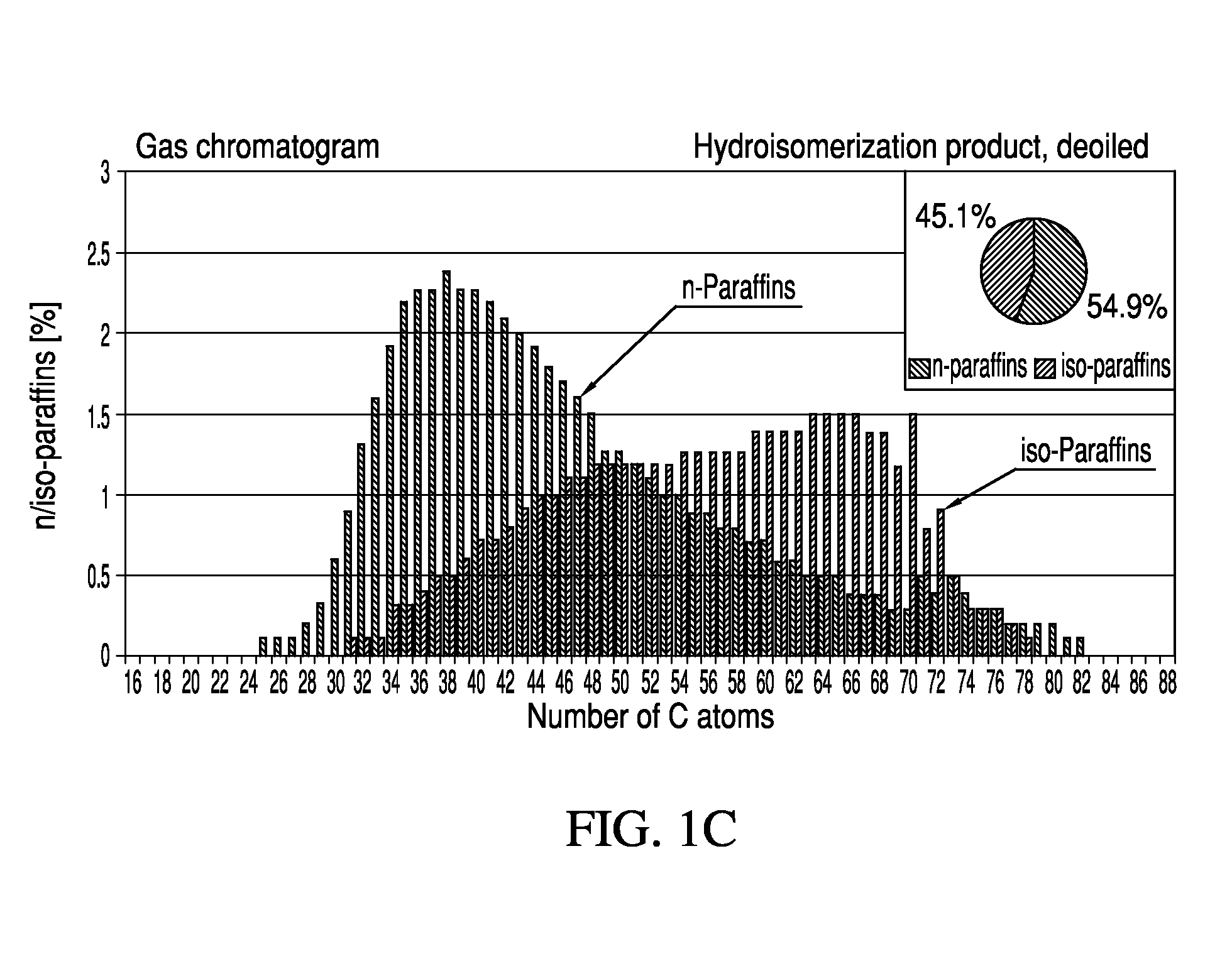

InactiveUS7875166B2Good metal adhesionLow pour pointCosmetic preparationsHydrocarbon by isomerisationParaffin waxAlkane

The invention relates to a novel and completely synthetic microcrystalline paraffin, said paraffin being obtained in a simple manner and with a high yield by the catalytic hydromerisation of paraffin FT comprising 20 to 105 carbon atoms. Said paraffins can be pasty to solid at room temperature and have a higher percentage of iso-paraffins than n-paraffins. Since they do not contain aromatic compounds they are particularly suitable for use in the pharmaceutical, cosmetic and food industries.

Owner:SASOL WAX GMBH

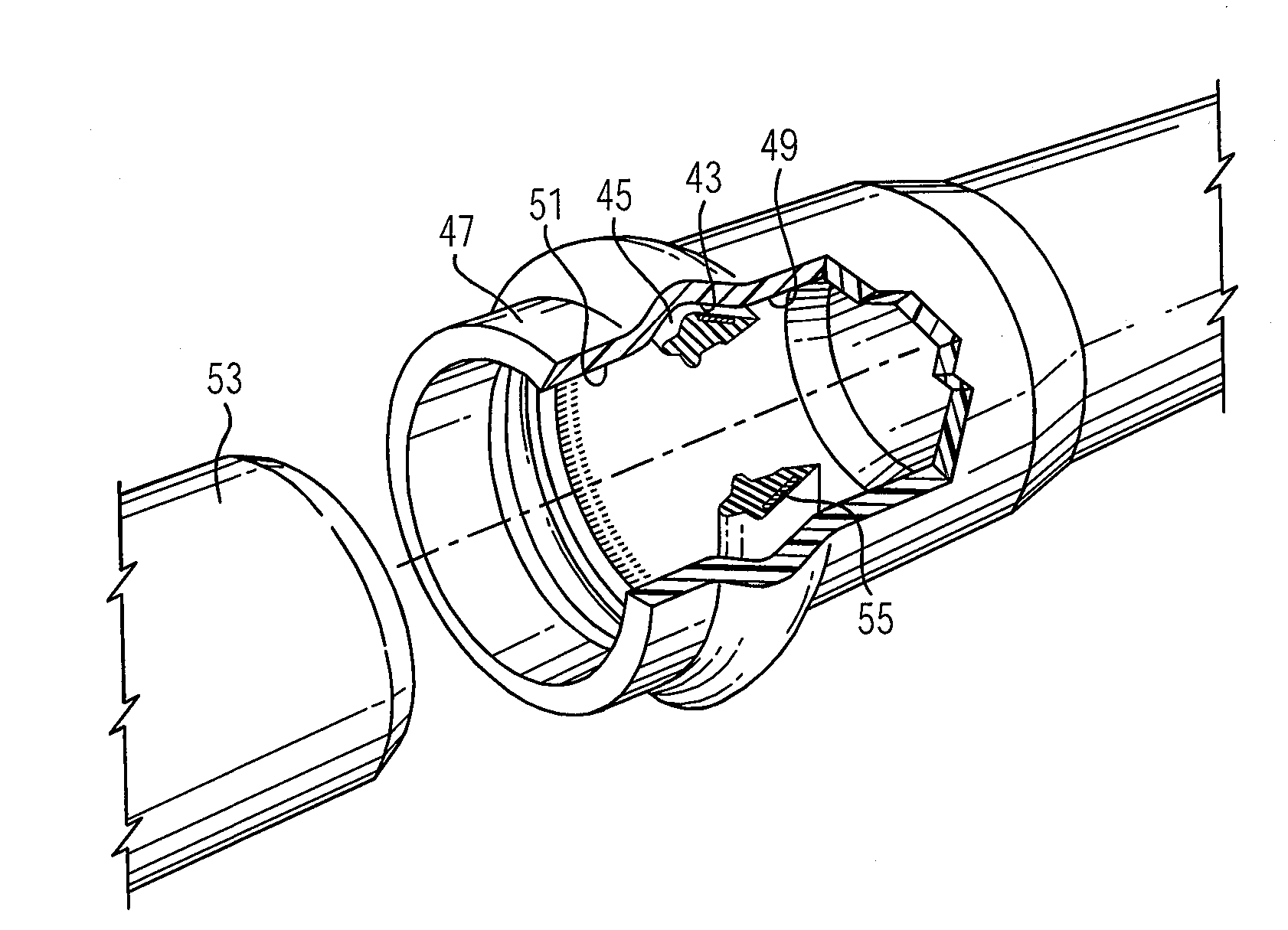

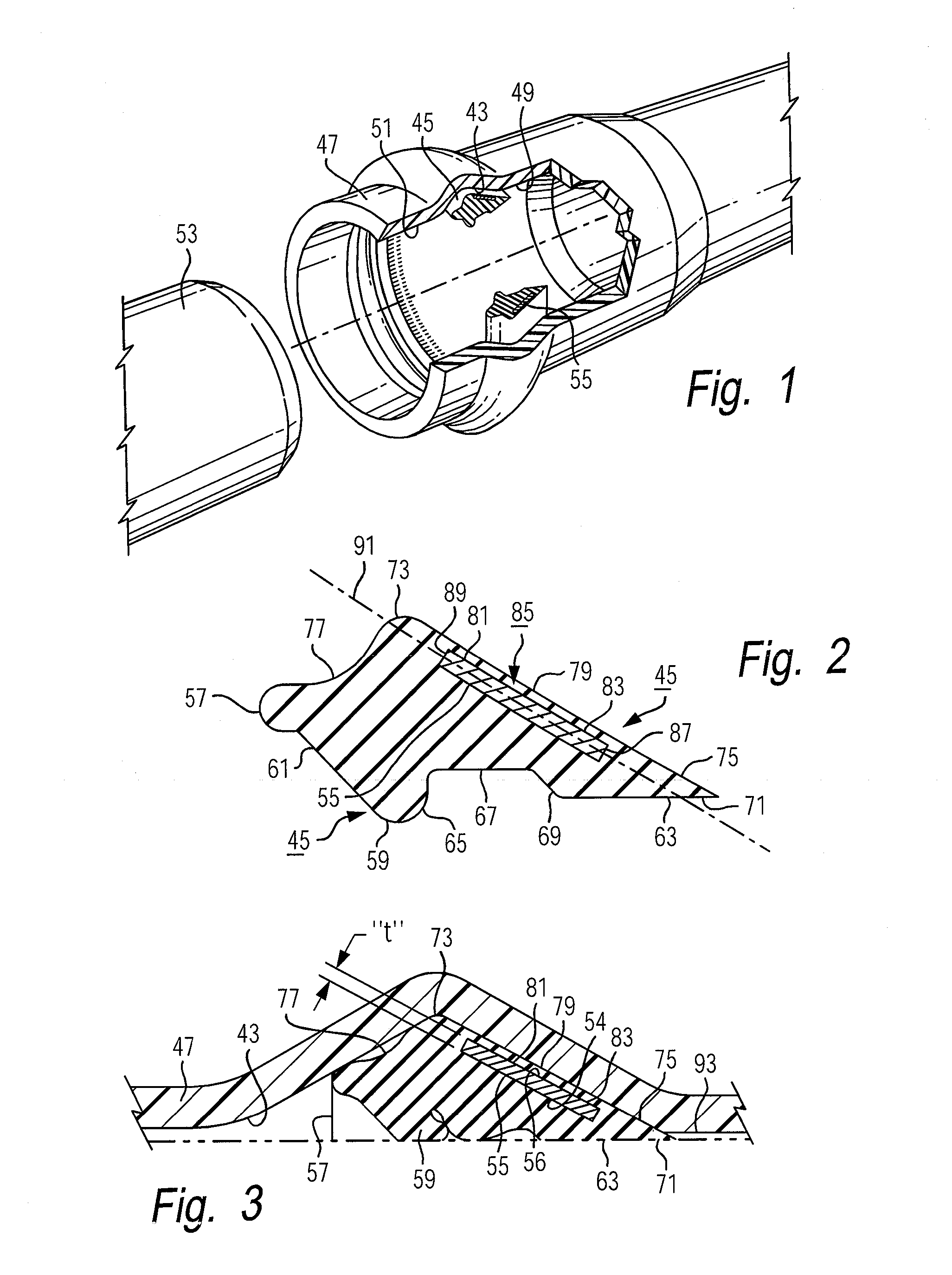

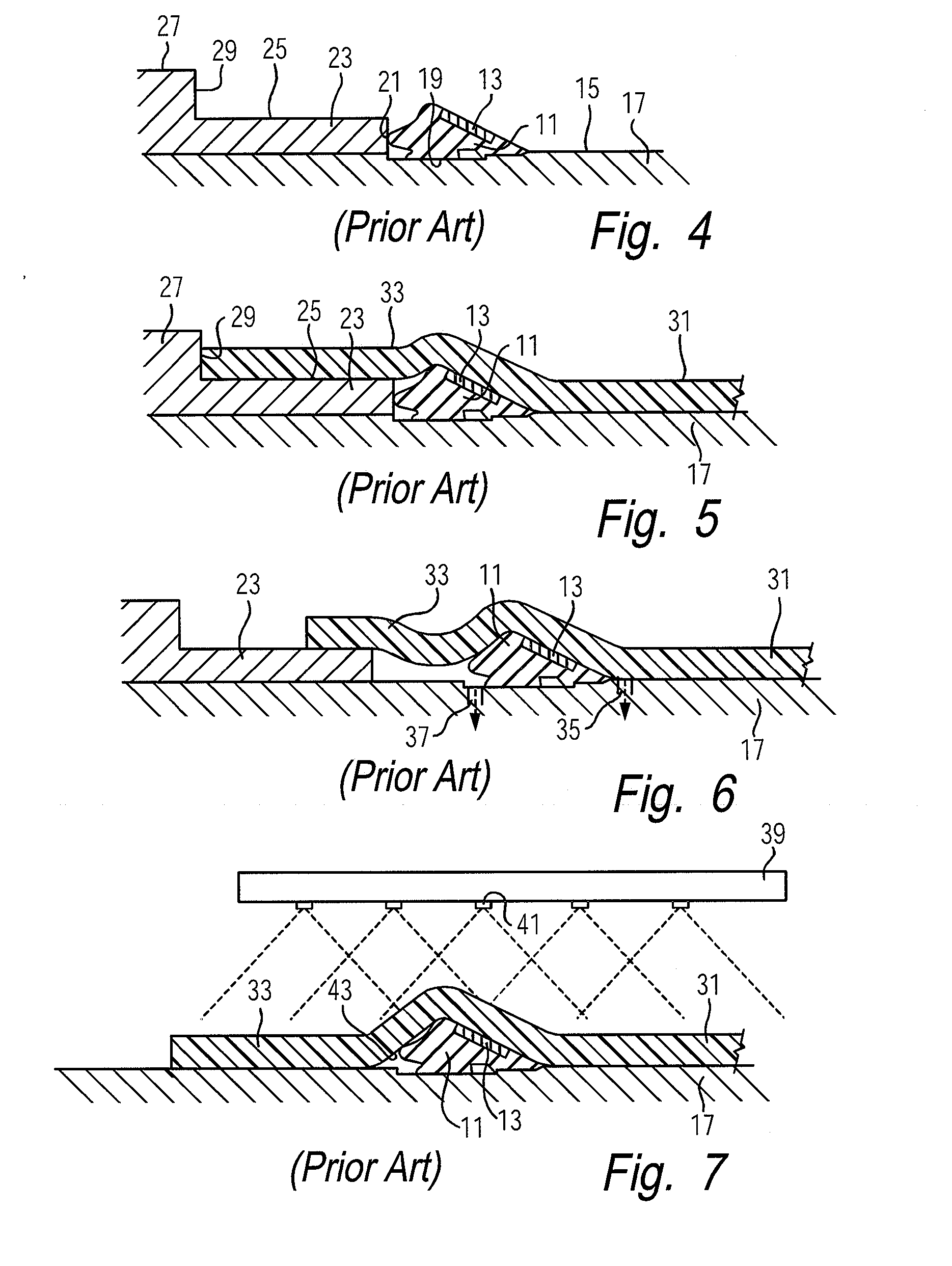

Method of Manufacturing a Pipe Gasket

A pipe sealing gasket is shown which is designed to be received within a groove provided within a socket end of a thermoplastic pipe such as PVC pipe used in municipal water and sewer installations. The gasket has a ring shaped body of an elastomeric material and includes a metal reinforcing band. The metal reinforcing band is entirely embedded within the body of elastomeric material during the gasket manufacturing process.

Owner:S & B TECHN PRODS

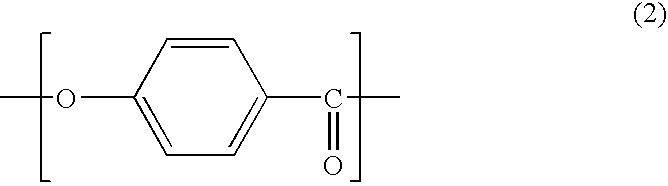

Multilayer, metalized or ceramic-coated, sealable, biaxially oriented polyester film, its use, and process for its production

InactiveUS6797359B2Good metal adhesionImprove performanceMagnetic materials for record carriersSynthetic resin layered productsPolyesterPolymer science

The invention relates to a metalized or ceramic-coated, biaxially oriented, sealable polyester film with at least one base layer (B), with a sealable outer layer (A), and with a further non-sealable outer layer (C). The sealable outer layer (A) has a minimum sealing temperature (fin) of not more than 110° C. and a seal seam strength (fin) of at least 1.3 N / 15 mm of film width. The two outer layers (A) and (C) are characterized by particular features. The film of the invention is particularly suitable for use in flexible packaging, and particularly and specifically for use on systems which operate in a vacuum.

Owner:MITSUBISHI POLYESTER FILM

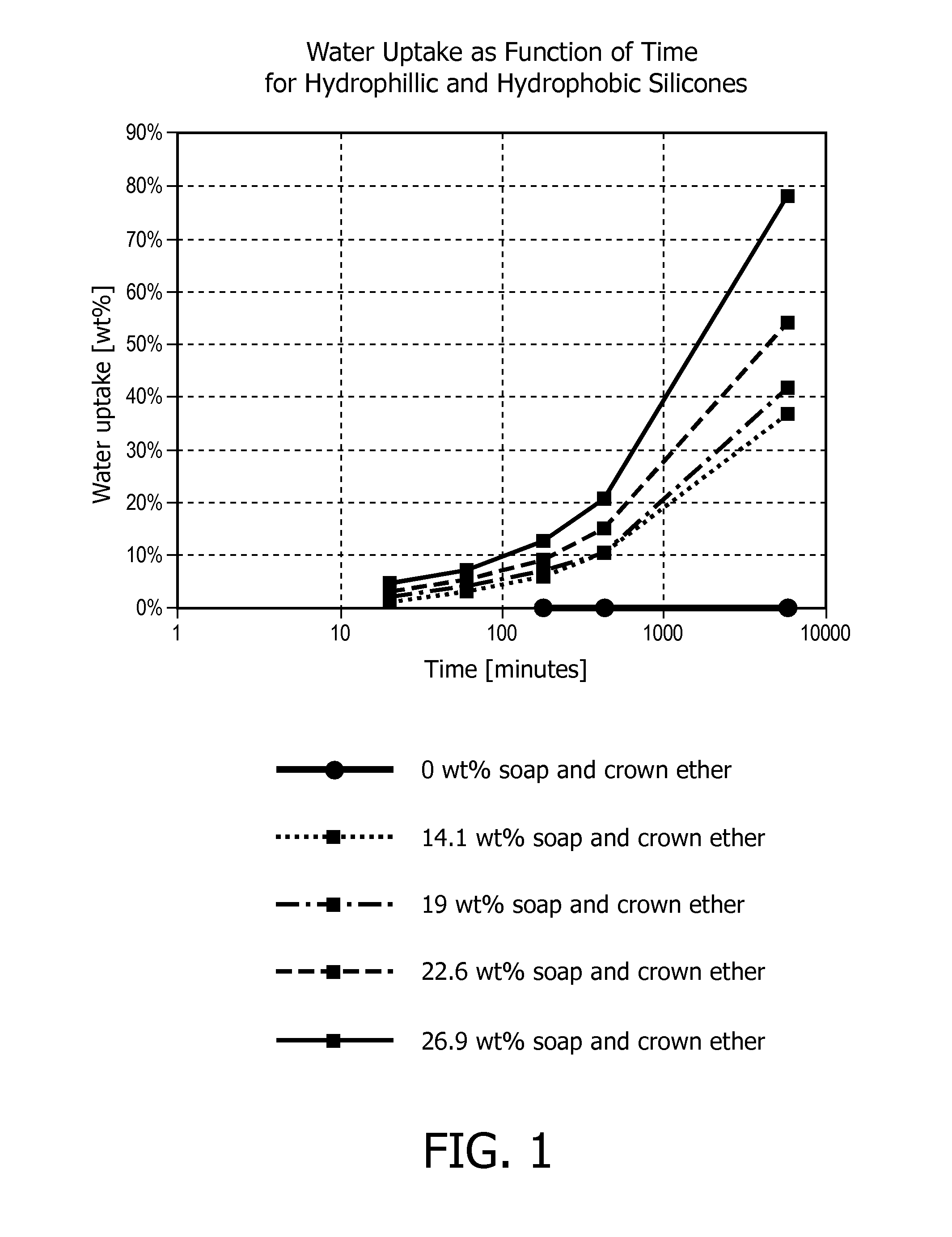

Medical and non-medical devices made from hydrophilic rubber materials

This invention relates to medical, health care and non-medical devices comprising a rubbery or elastomeric polymer material taking up more than 5% by weight of water and at most 500% by weight of water after immersion in demineralized water at room temperature for a sufficient time to reach saturation. The material may be in the form of a foam, or in the form of a coating adapted for adhesion to a substrate, or in the form of a sheet, or in the form of a fiber, and may comprise: —repeating units from one or more hydrophobic organic monomers, and —repeating units from one or more monomers (a) being modified with one or more hydrophilic side groups.

Owner:KONINKLJIJKE PHILIPS NV

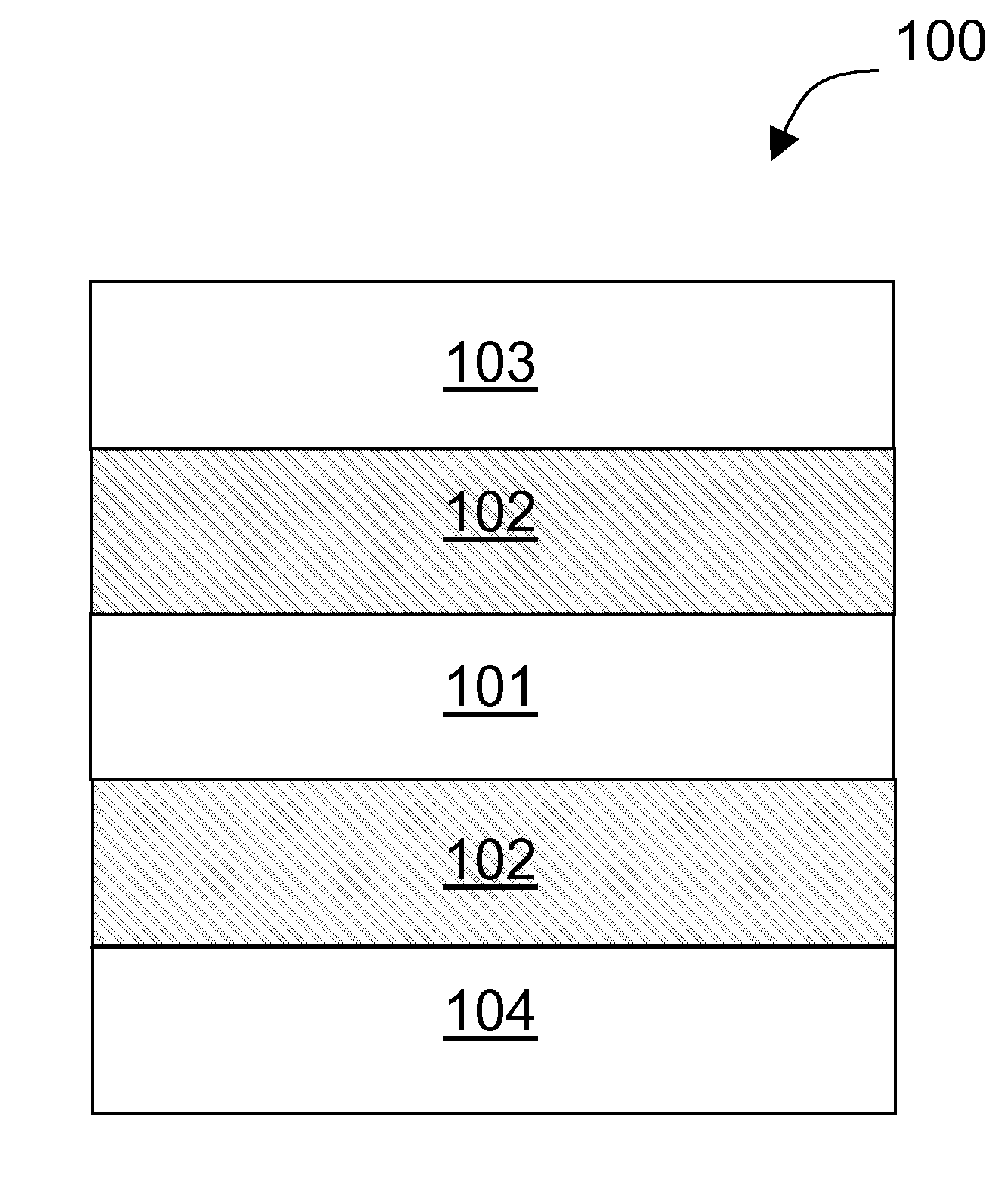

Biaxially oriented metallized polylactic acid film with high metal adhesion and high barrier properties

ActiveUS20100247886A1Improve performanceIncrease productivityRecord information storageMagnetic recordingPolymer chemistryMetal

Metallized multi-layer biaxially oriented polylactic acid base polymer (BOPLA) films that exhibits improved barrier properties and metal adhesion. The films include a core layer including crystalline polylactic acid base polymer, a first skin layer consisting essentially of amorphous polylactic acid base polymer, and a metal layer on the first skin layer. The films may include a second skin layer consisting essentially of amorphous polylactic acid base polymer.

Owner:TORAY PLASTICS AMERICA +1

Multi-layer high moisture barrier polylactic acid film

ActiveUS20130143057A1Excellent gas barrier performanceImprove barrier propertiesLiquid surface applicatorsPig casting plantsEmulsionMoisture barrier

Owner:TORAY PLASTICS (AMERICA) INC

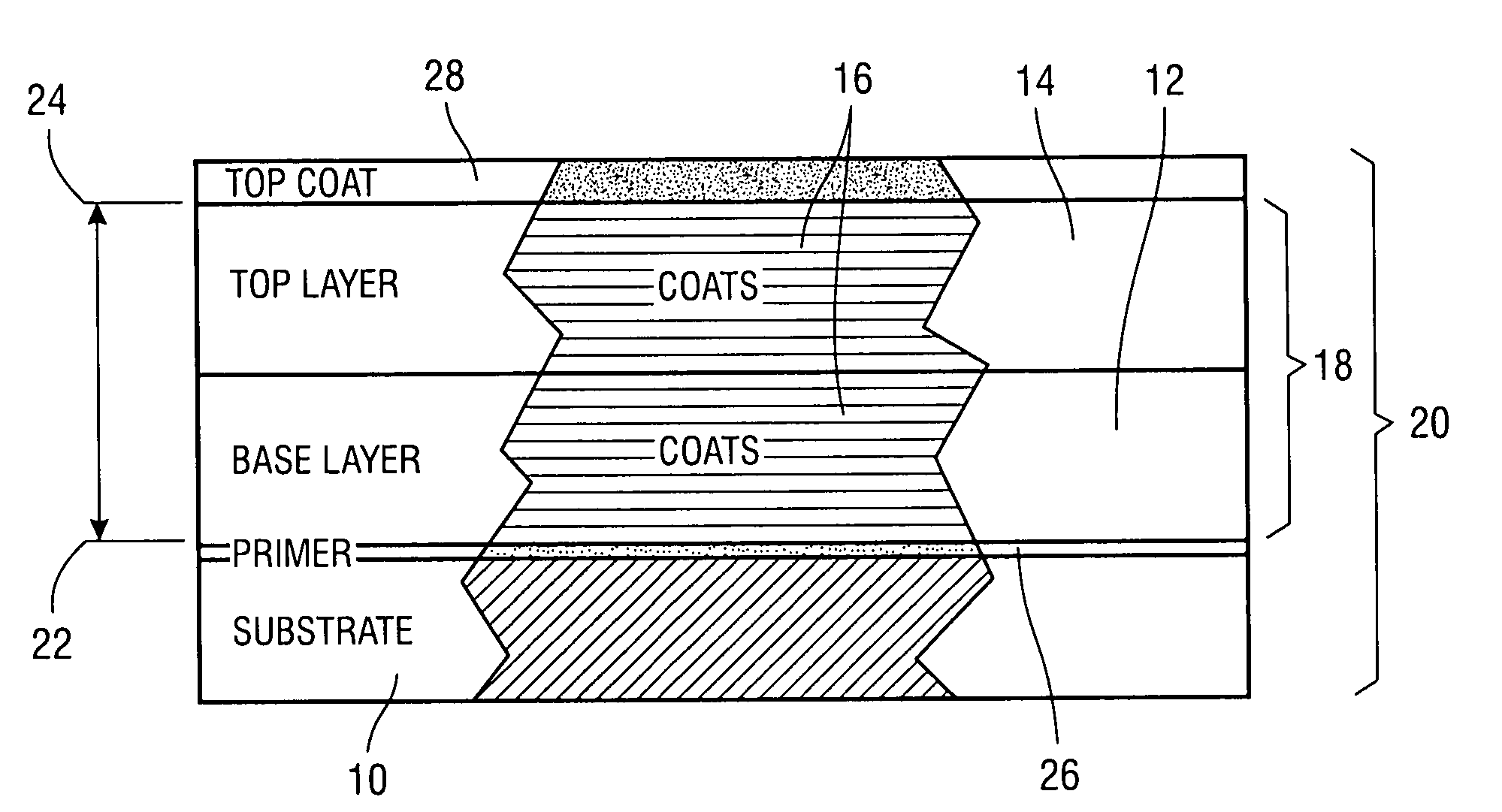

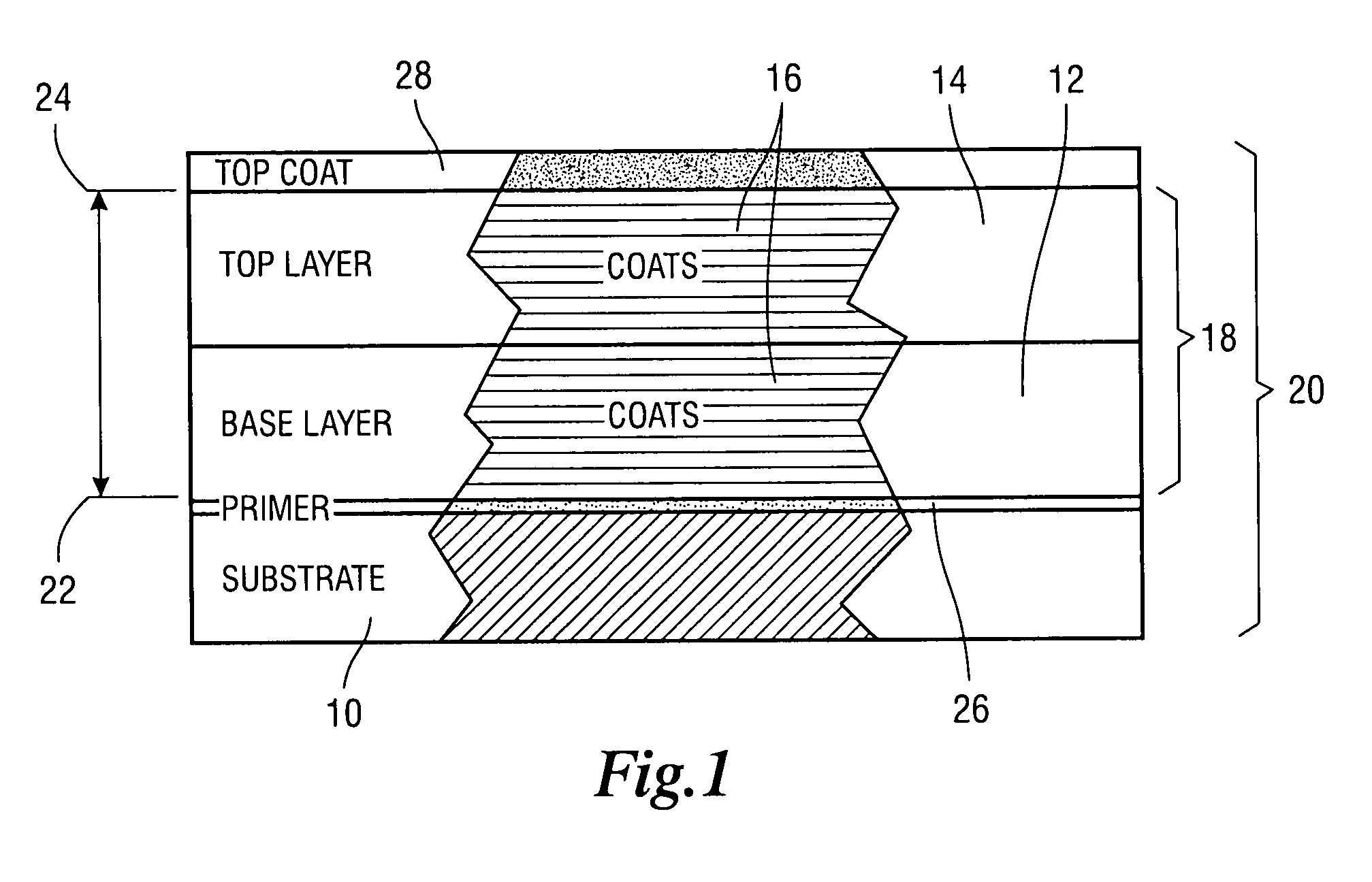

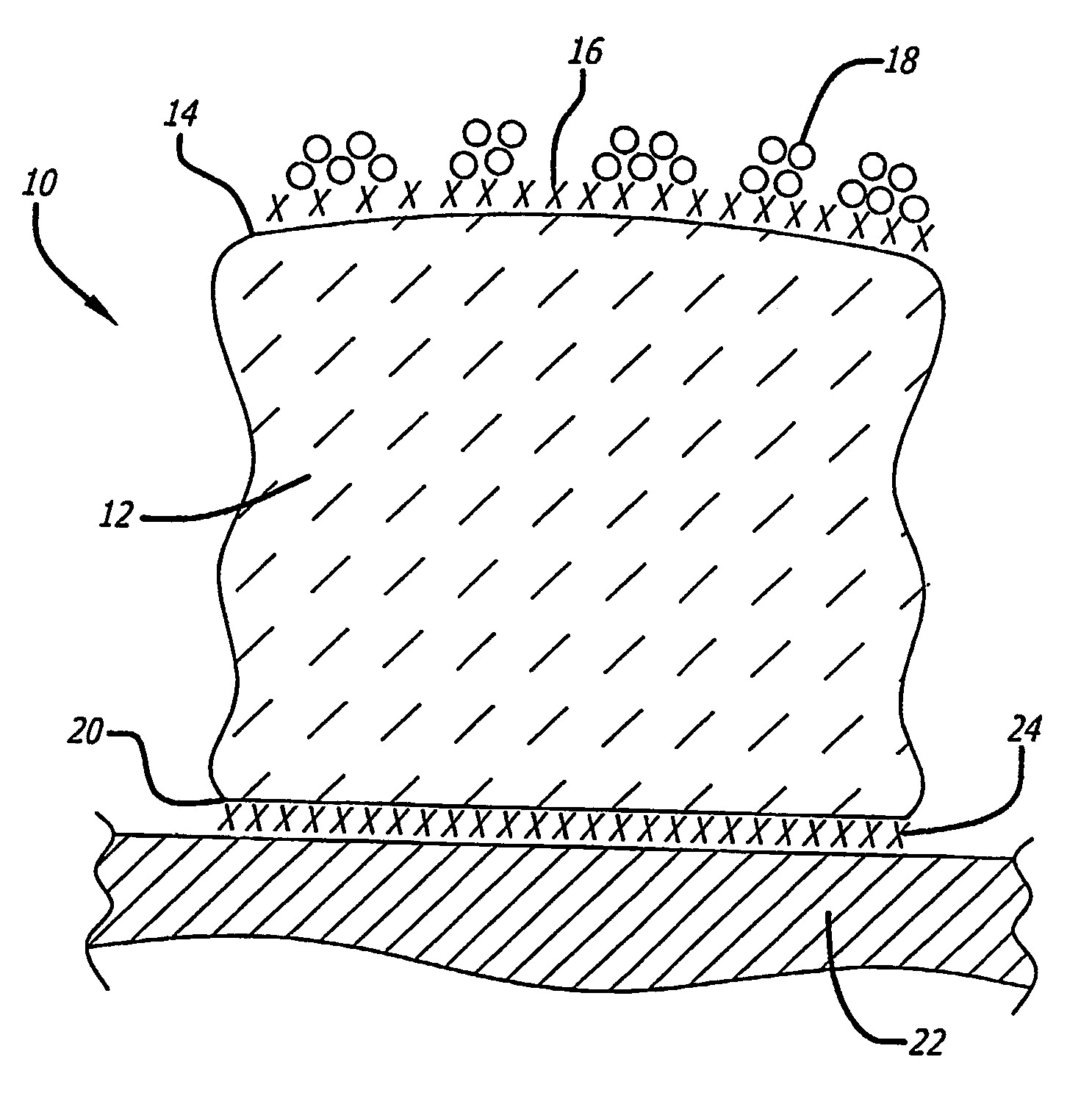

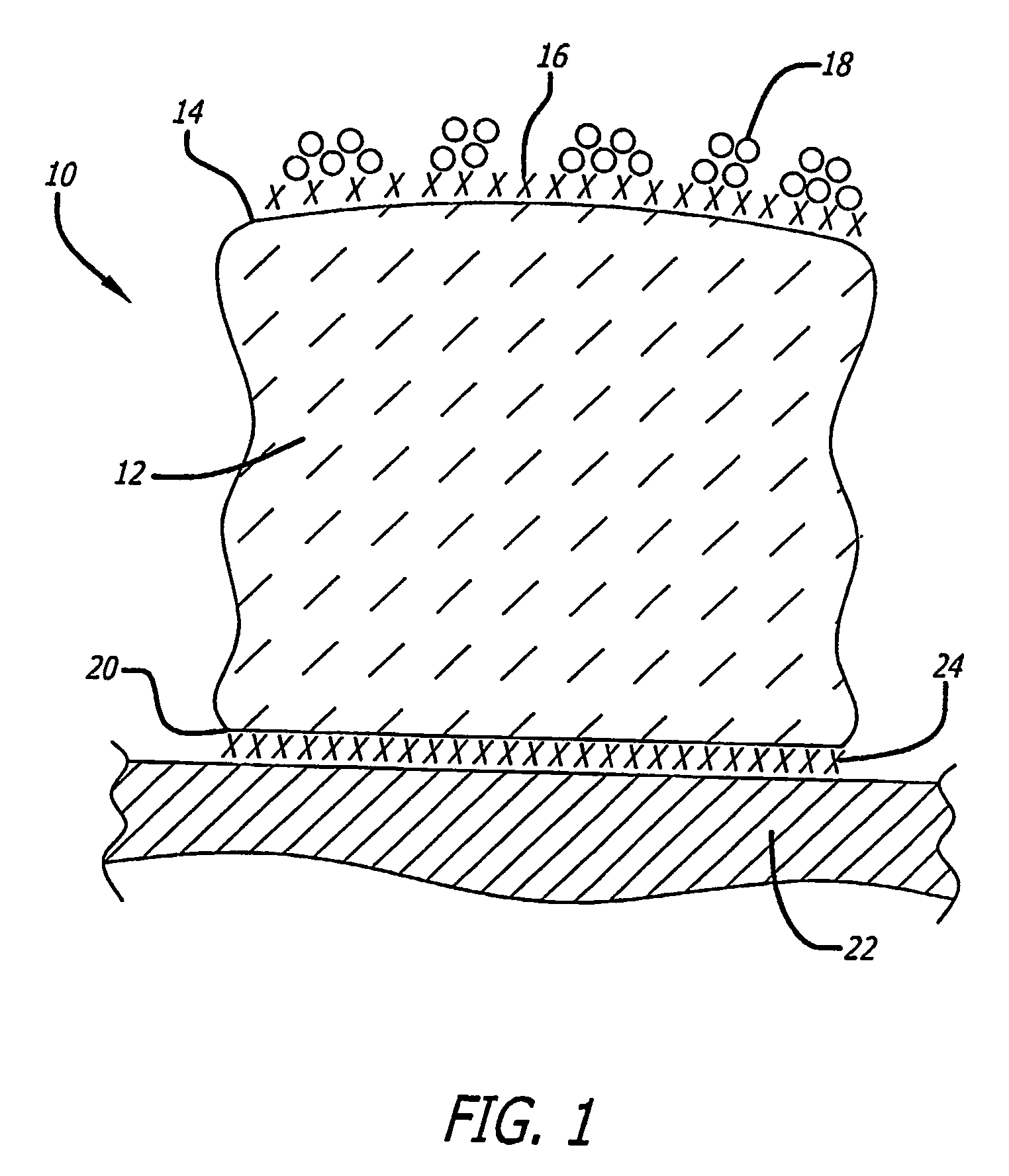

High temperature substrate protective structure

InactiveUS20090117356A1Easy to processImprove performanceLayered product treatmentSynthetic resin layered productsEnvironmental resistanceCompound (substance)

Substrate protective structures, including high performance polymers and polymer coatings from 1 to over 2500 mils thick, are disclosed. The structures protect metal and other surfaces with heat resistant, abrasion resistant, and chemical inert polymers. The structures are applied to the substrate in a manner that provides easy processing of curved and bent surfaces, increased adhesion of metal to polymer, greater resistance to mechanical and thermal stresses that cause cracking and de-lamination, and increased environmental resistance.

Owner:POLYMICS

Supported metal catalyst with improved thermal stability

InactiveUS7504355B2Improve adhesionGood metal adhesionCatalyst carriersCatalyst activation/preparationAdditive ingredientHafnium

Catalytic systems are provided that include a metallic catalyst attached to a ceramic support that has alumina as a principal ingredient. The ceramic support is doped with an adhesive agent so that the surface of the support includes the adhesive agent. The adhesive agent is designed to form an open-shell electronic structure at the interface between the metallic catalyst and the support. The open-shell structure promotes extended useful catalyst lifetimes. The adhesive agents are early transition metals that include titanium, zirconium, scandium, hafnium, lanthanum and yttrium. Doping of the ceramic support surface with the adhesive agent also increases the adhesion between the ceramic support and metallic monoliths to which the ceramic support may be attached.

Owner:PRINCETON UNIV

Polyimide film and laminate having metal layer and same

ActiveUS7267883B2Reduction factorHigh modulusSynthetic resin layered productsThin material handlingDynamic viscoelasticityPotassium hydroxide

A polyimide film of the present invention is a polyimide film having a dynamic viscoelasticity whose tan δ peak is located in a range of not less than 310° C. but not more than 410° C., and whose tan δ value at 300° C. is not more than 0.05, or a polyimide film prepared by copolymerizing (a) an acid dianhydride component including a biphenyltetracarboxylic dianhydride and a pyromellitic dianhydride, and (b) a diamine component, and the polyimide film having such an etching speed that one side thereof is etched with a 1N potassium hydroxide solution at an etching speed of 0.1 μm / minute (one side) or higher. The polyimide film of the present invention possesses film properties that are necessary for use in an electronic raw material for flexible printed circuit boards and the like, and is suitable as an electronic raw material.

Owner:KANEKA CORP

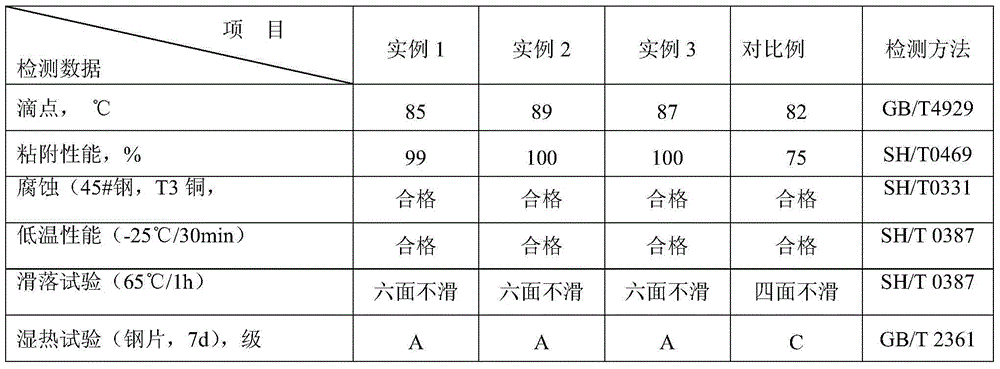

Heat-coating elevator steel wire rope grease and preparation method thereof

ActiveCN105733752APrevent slippingPrevent invasionLubricant compositionAdhesion forceMicrocrystalline wax

The invention discloses a heat-coating elevator steel wire rope grease and a preparation method thereof. The grease comprises 60-83% of high-viscosity high-aromatic-hydrocarbon-content mineral oil, 3-7% of microcrystalline wax, 3-10% of an amide thickener, 10-20% of a friction enhancing agent, and 1-8% of a rust inhibitor. The heat-coating elevator steel wire rope grease provided by the invention has good film-forming performance, metal surface adhesion force, and friction performance.

Owner:PETROCHINA CO LTD

Metallized biaxially oriented polypropylene film with high metal adhesion

ActiveUS8075985B2Good metal adhesionBright shiny reflectiveSynthetic resin layered productsVacuum evaporation coatingElastomerPolymer science

Described are laminate films including a polyolefin base layer, and a metal receiving layer including a blend of propylene homopolymer or mini-random propylene-ethylene copolymer, and an amorphous poly-alpha-olefin or ethylene-propylene elastomer. The metal receiving layer may also include an ethylene-propylene copolymer. The laminate film may also include additional layers such as an additional polyolefin resin-containing layer, a metal layer, or combinations thereof.

Owner:TORAY PLASTICS (AMERICA) INC

Conductive nitrile rubber and preparing method thereof

InactiveCN105820388AImprove high temperature resistanceImprove anti-aging propertiesMethacrylateSilver plate

The invention relates to the field of conductive rubber, in particular to a conductive nitrile rubber and a preparation method thereof. The conductive nitrile rubber is composed of the following raw materials in parts by weight: 80-110 parts of nitrile rubber, 22-28 parts of nano-rectorite , 10-15 parts of expanded graphite, 4-6 parts of carbon nanotubes, 18-22 parts of silver-plated copper powder, 4-6 parts of zinc oxide, 0.5-1.5 parts of stearic acid, 1-3 parts of titanate coupling agent , 2‑3 parts of dicumyl peroxide, 2‑3 parts of magnesium dimethacrylate, 2‑3 parts of tetramethylthiuram disulfide, 0.5‑1 part of sulfur, CuSO 4 5-8 parts of powder, 2-4 parts of modified nano-silicon nitride, nano-SiO 2 0.5-1 parts, N, N'-di-sec-butyl-p-phenylenediamine 1.5-3 parts, flame retardant 2-3 parts. The preparation method is simple and efficient, and mainly includes steps such as mixing and vulcanization. The conductive nitrile rubber of the invention not only meets the requirements of high strength and high conductivity, but also has good high temperature resistance, low temperature resistance, aging resistance and excellent mechanical properties.

Owner:安徽省含山县锦华氧化锌厂

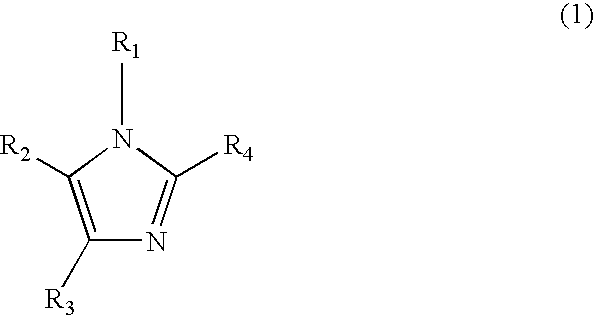

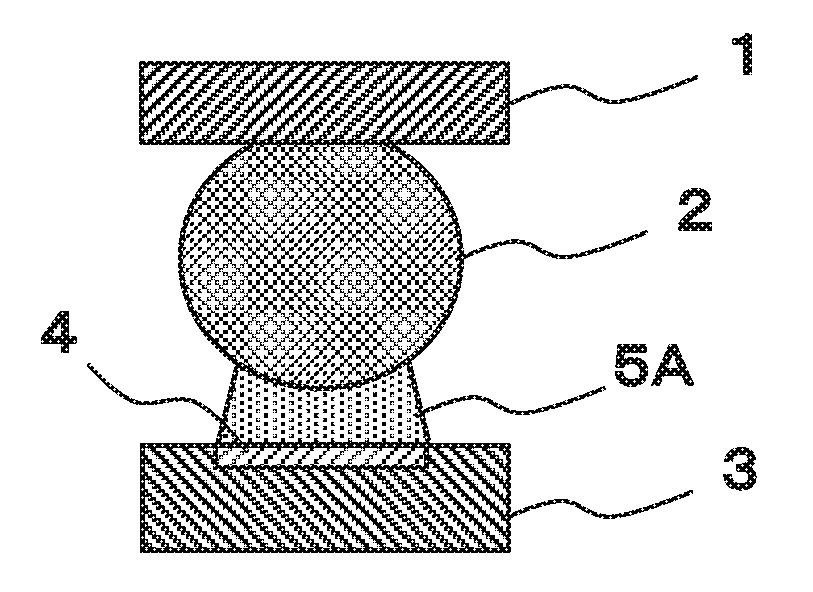

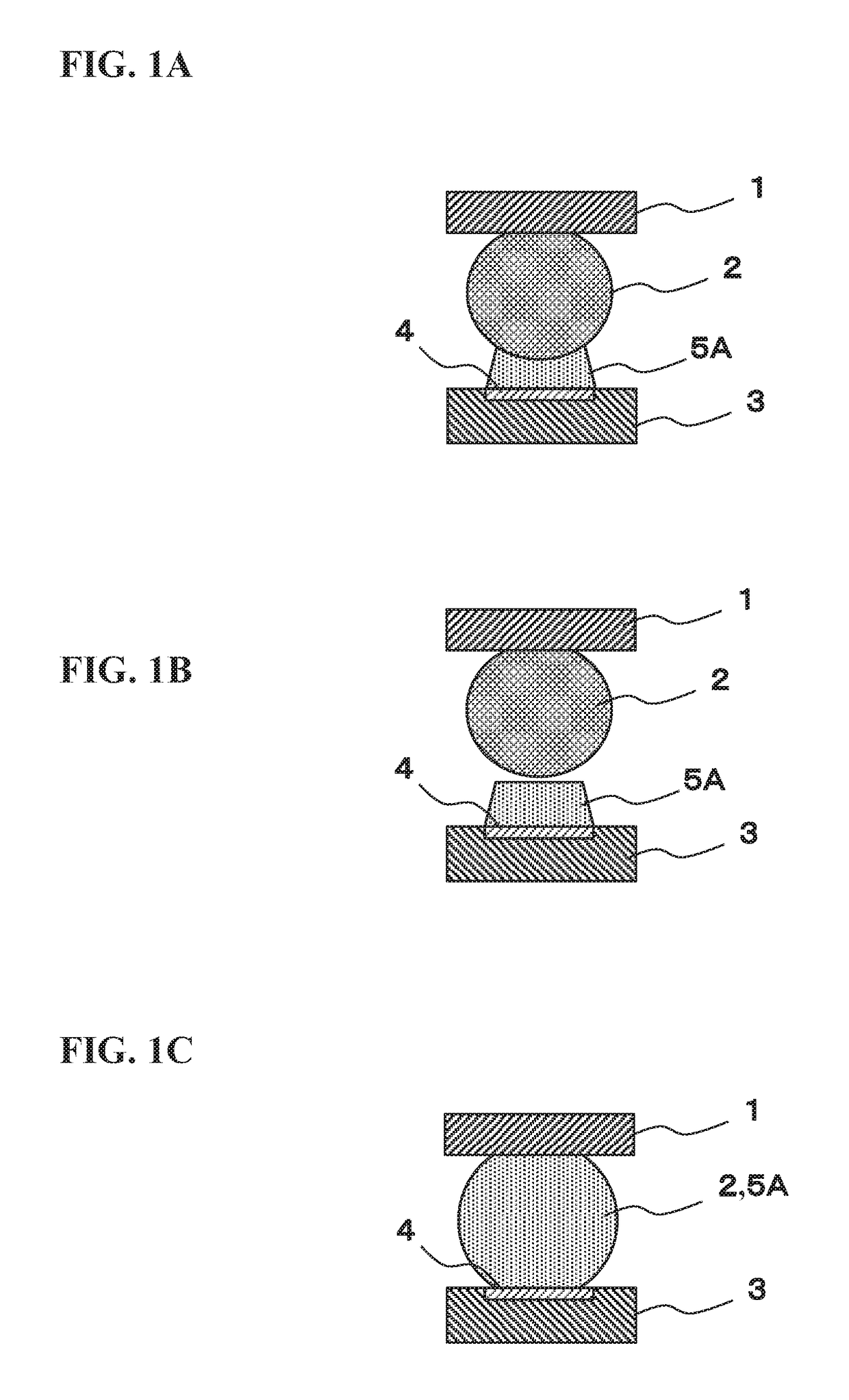

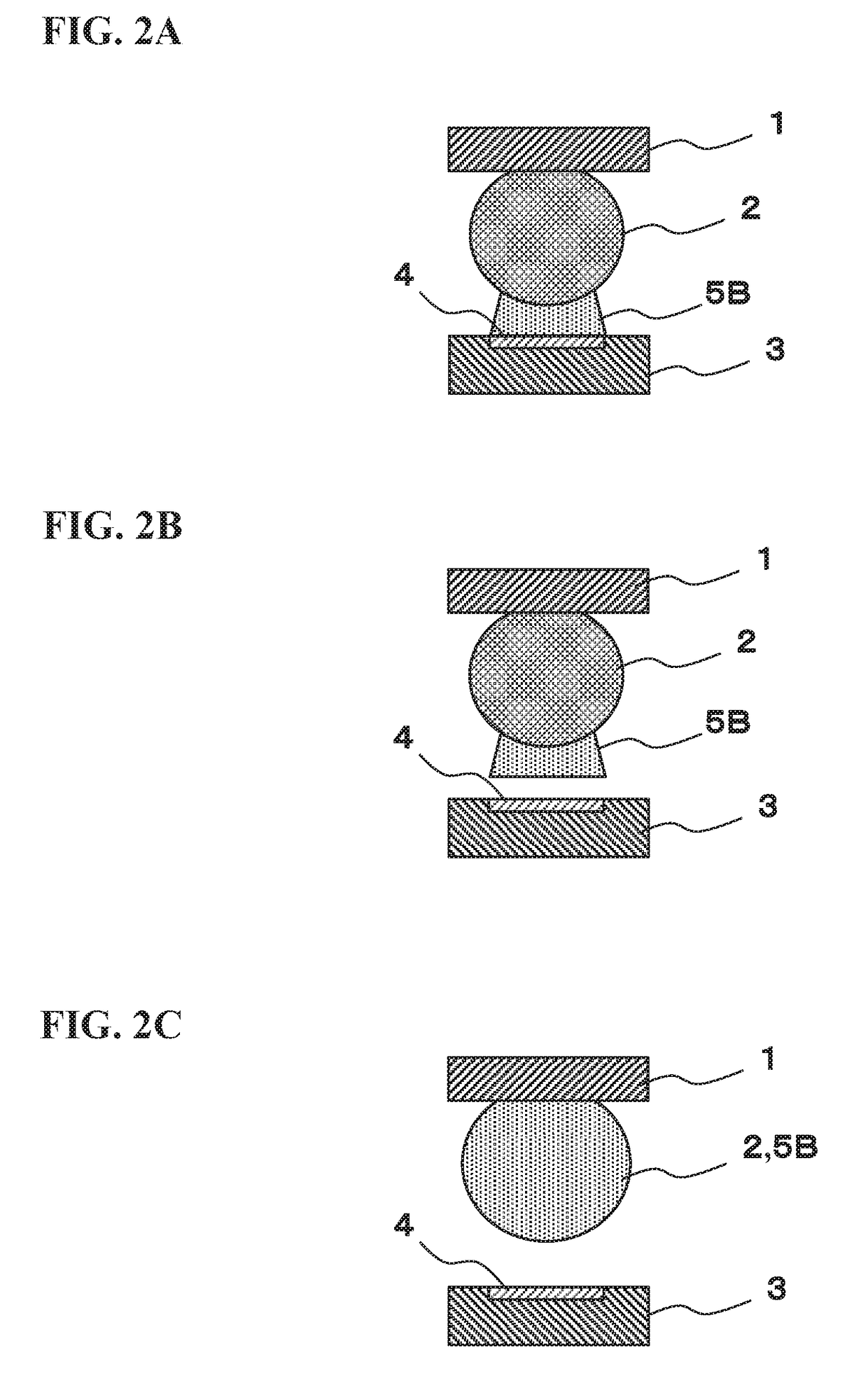

Solder Paste and Solder Joint

InactiveUS20170304961A1Prevent peelingGood metal adhesionSheet joiningWelding/cutting media/materialsOrganic acidHalogen

Provided is a flux for a solder paste that can prevent peeling from electrode, which is seen in a component, a thickness of which is reduced, such a semiconductor package like BGA. Rosin, a glycol-ether-based solvent, an organic acid, a thixotropic agent, a halogen compound, and an imidazole compound are contained and the halogen compound is either an amine hydrohalide or an organohalogen compound or a combination of them. Their addition amounts stay within a range satisfying a formula of 2.5-X-0.625Y≧0 in which the addition amount of the amine hydrohalide is indicated by X (weight %) and the addition amount of the organohalogen compound is indicated by Y (weight %). However, the addition amount X of the amine hydrohalide and the addition amount Y of the organohalogen compound are such that 0≦X≦2.5 and 0≦Y≦4, excluding a range of 0≦X<0.02 and 0≦Y<0.1.

Owner:SENJU METAL IND CO LTD

Electroplating of Metals on Conductive Oxide Substrates

InactiveUS20150259816A1Simple methodGood metal adhesionElectrolytic inorganic material coatingCopperZinc

A method of electroplating metal onto a transparent conductive oxide layer is described. The method comprises the steps of a) electroplating a zinc or zinc oxide seed layer directly onto the transparent conductive oxide layer and thereafter, b) electroplating one or more additional metal layers over the zinc layer. The one or more additional metal layers may include a cobalt strike layer electroplated over the zinc or zinc oxide seed layer and another metal layer such as copper, electroplated over the cobalt strike layer.

Owner:MACDERMID ACUMEN INC

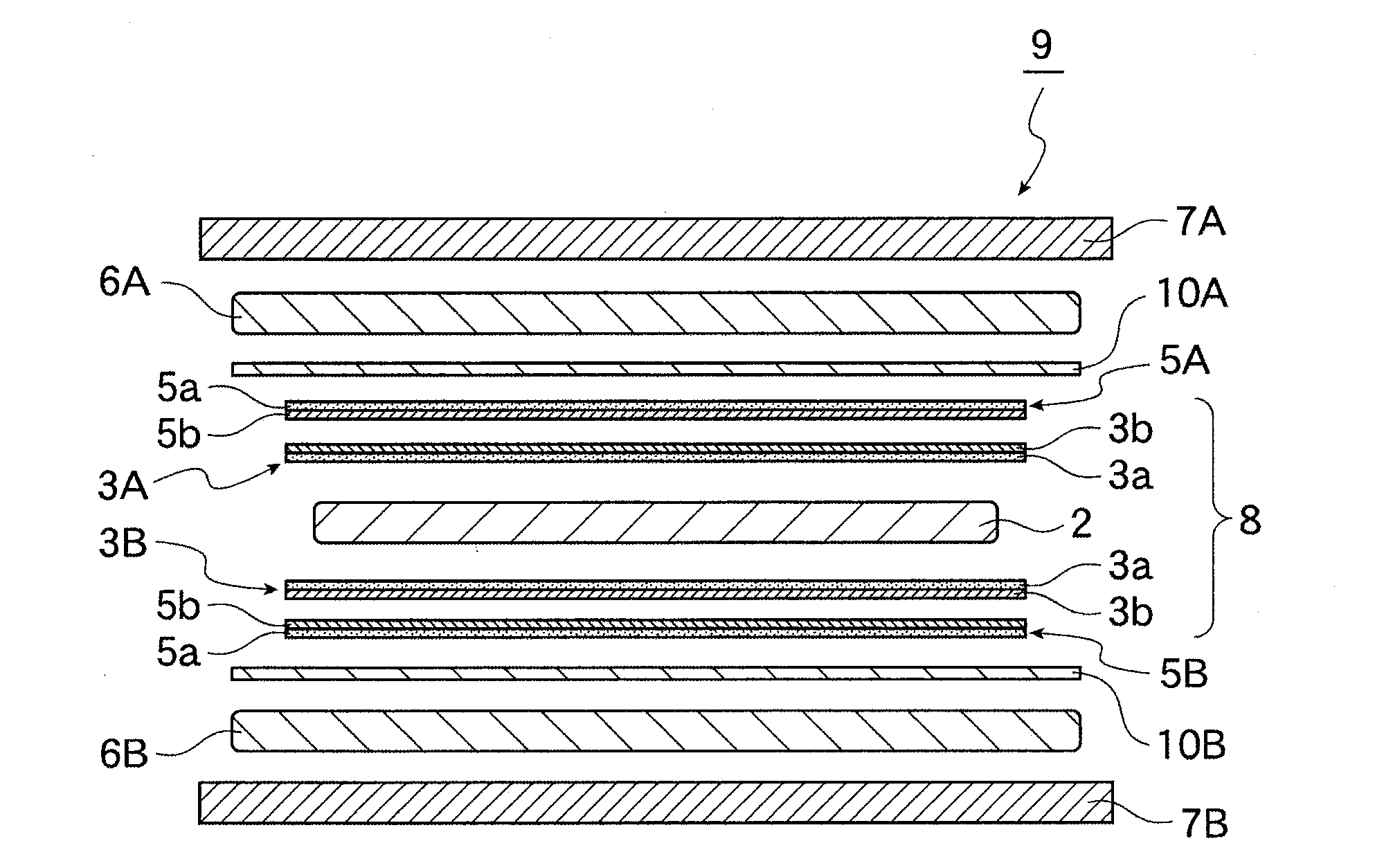

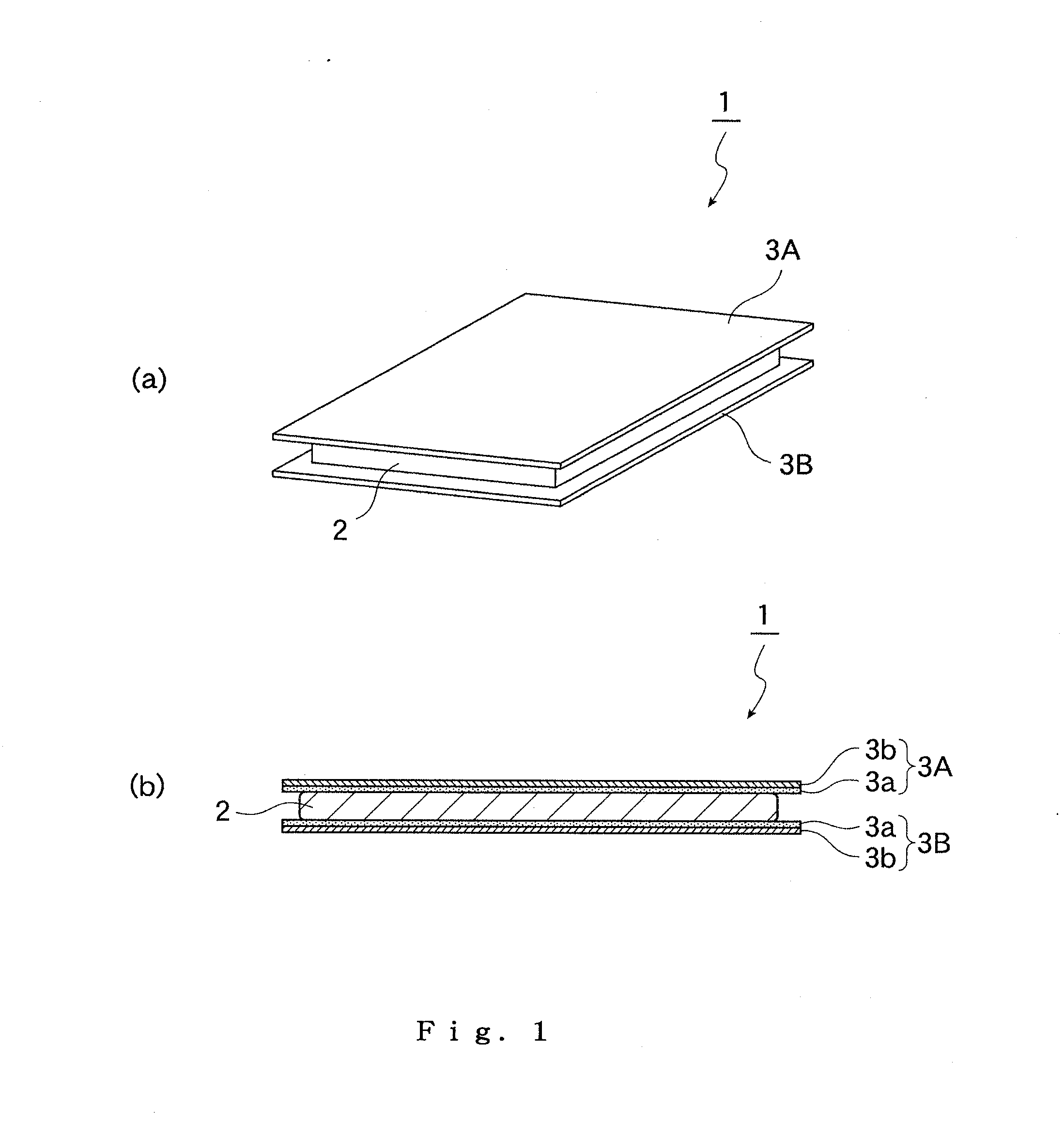

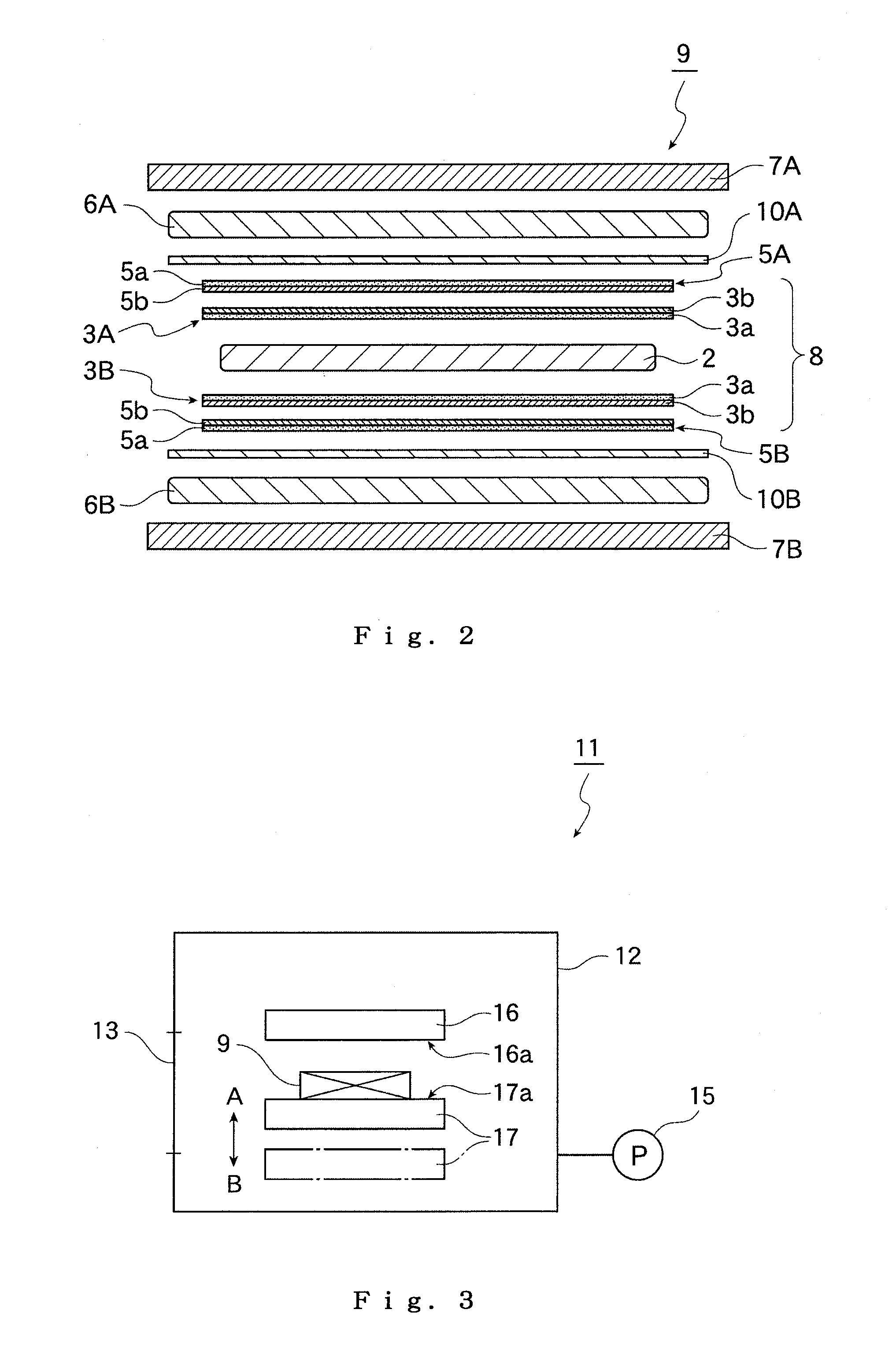

Method for producing metal foil laminate

InactiveUS20120006481A1Good metal adhesionImprove tight adhesionLayered product treatmentLaminationMetal foilComposite material

The present invention provides a method for producing a metal foil laminate, the method comprising sequentially interposing an insulating base material between a pair of metal foils and between a pair of metal plates, followed by heating and pressurizing to produce a metal foil laminate in which the pair of metal foils are attached on both sides of the insulating base material, wherein the ratio of an area of the insulating base material to that of each metal plate is from 0.75 to 0.95. According to the present invention, tight adhesion of a metal foil laminate is sufficiently increased even if the metal foil laminate has a large size.

Owner:SUMITOMO CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com