Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

263results about How to "Dense coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

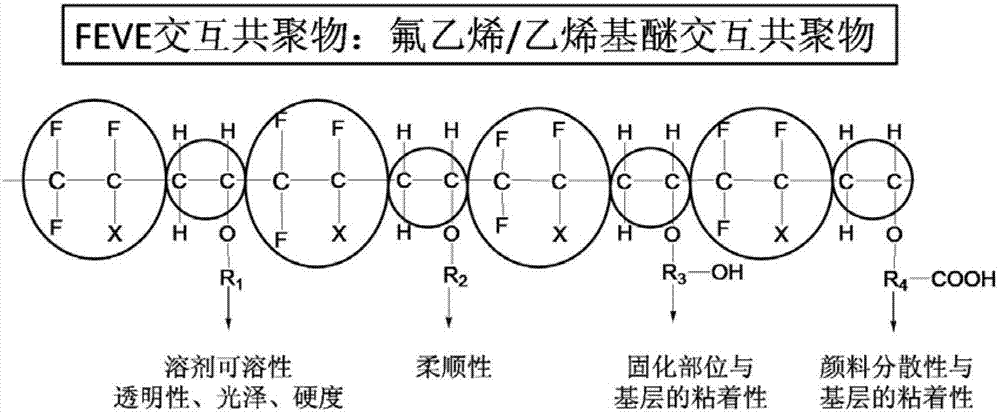

Self-cleaning super-weather-proof powder paint and preparation method thereof

ActiveCN103194140AImprove stabilityProtect against agingPowdery paintsPolyester coatingsPolyesterAging resistance

The invention belongs to the field of powder paints and particularly relates to a self-cleaning super-weather-proof powder paint. The self-cleaning super-weather-proof powder paint comprises a carboxyl-terminated polyester particle system and a fluorocarbon resin particle system in a weight part ratio of 4:1-1:4, wherein the fluorocarbon resin particle system contains TiO2 nano-particles. As carboxyl-terminated polyester is introduced into a pure fluorocarbon paint, the phase separation occurs in a solidification process, and the fluorocarbon resin floats up to the surface of a coating to serve as coating protection and ageing resistance; the carboxyl-terminated polyester and the like and a substrate can be well wetted, so that the coating and the substrate can be well adhered and can hardly crack and spall; as the TiO2 nano-particles only exist in a fluorocarbon phase, the resin on a bottom layer cannot be broken, and the excellent stability of the system is guaranteed; and the TiO2 nano-particles are scattered in a dry blending manner, and the complex preprocessing is avoided, so that the preprocessing process can be greatly shortened, the cost is lowered, and the efficiency is improved.

Owner:NINGBO SOUTH SEA CHEM

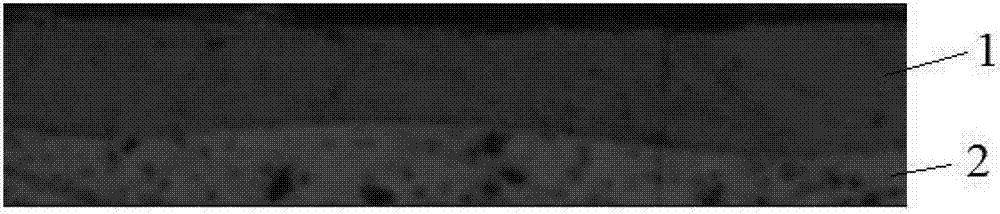

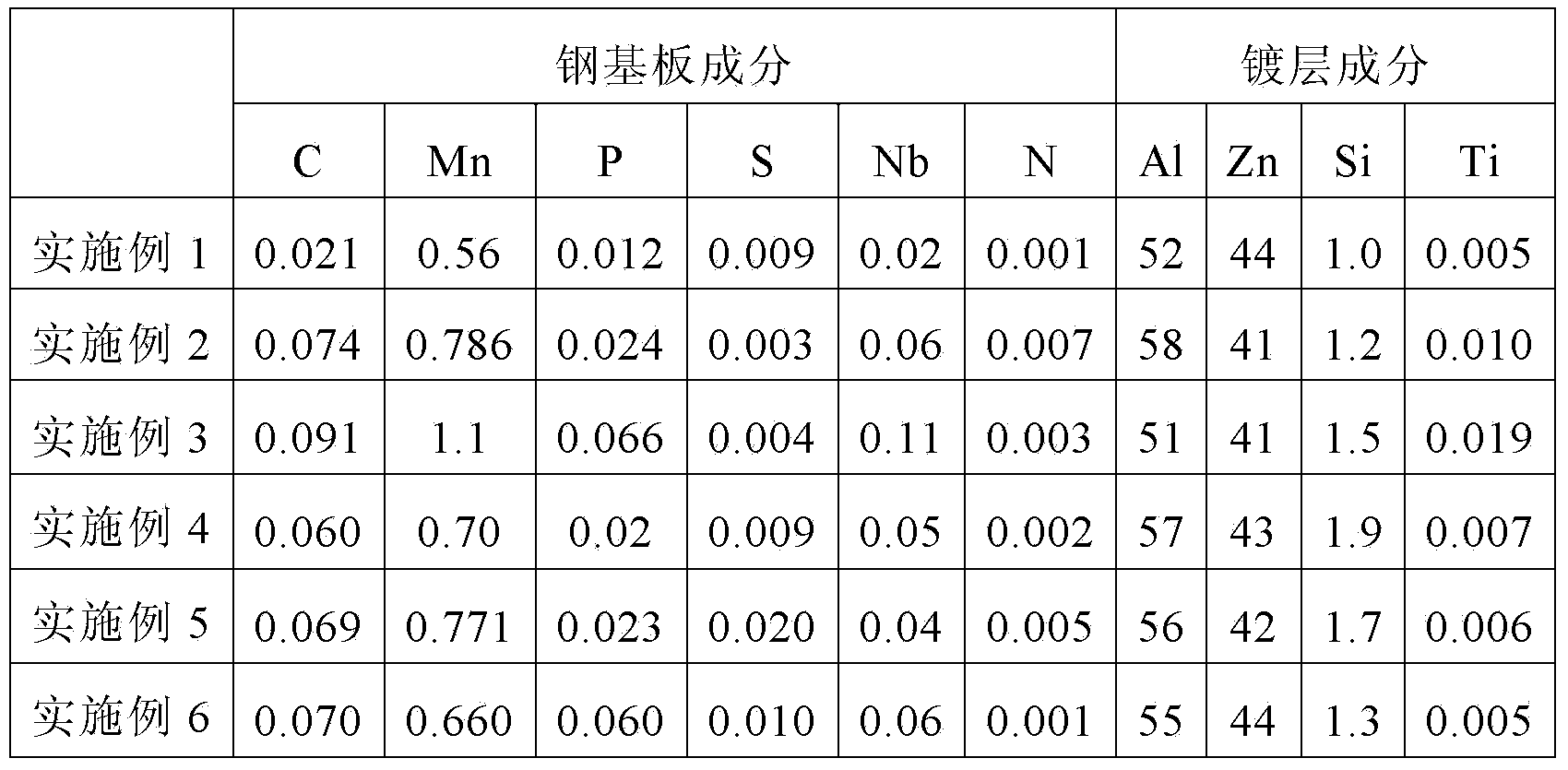

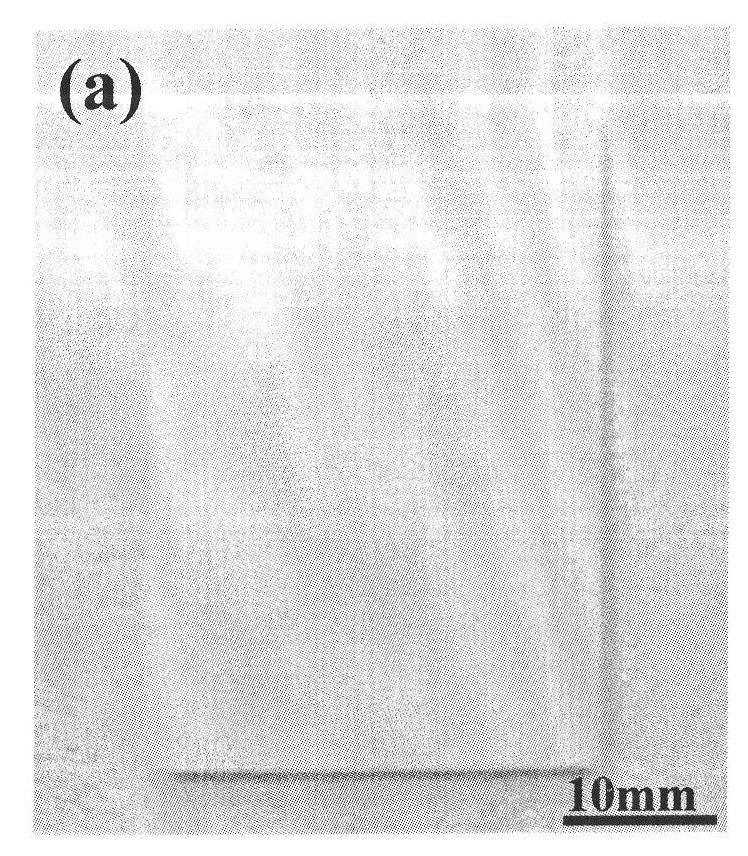

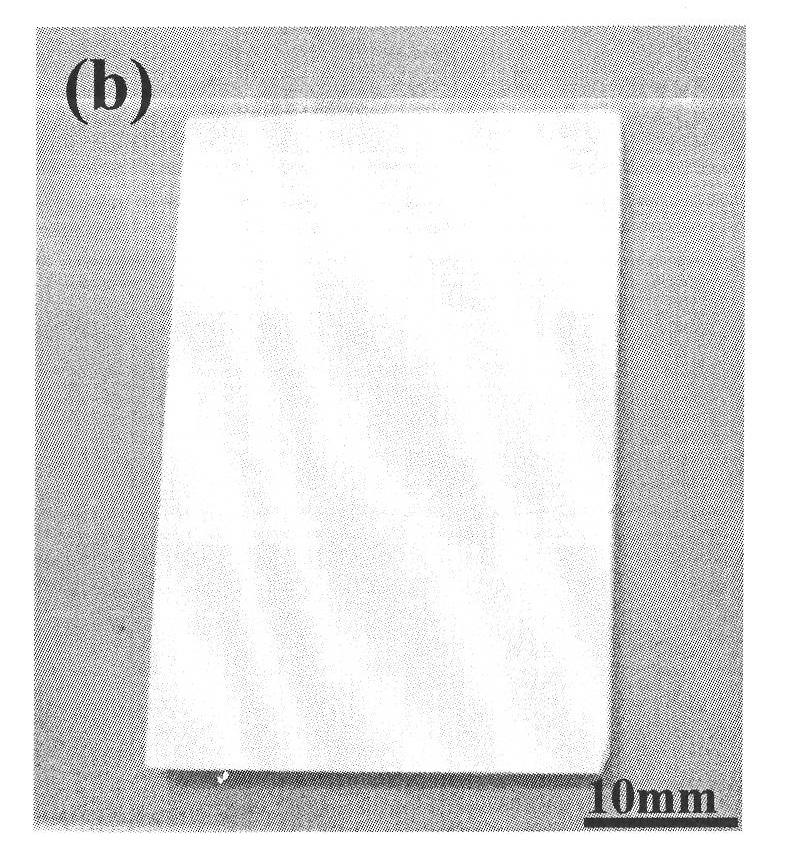

High-strength low-alloy hot-dip aluminized and galvanized steel strip and production method thereof

ActiveCN104264041AHigh strengthLow yield ratioHot-dipping/immersion processesAlloy coatingContinuous annealing

The invention relates to a high-strength low-alloy hot-dip aluminized and galvanized steel strip and a production method thereof. The hot-dip aluminized and galvanized steel strip comprises a steel base plate and an alloy coating, wherein the steel base plate comprises the following chemical components in percentage by weight: 0.02-0.10% of C, 0.5-1.2% of Mn, 0.01-0.07% of P, 0.01-0.12% of Nb, less than or equal to 0.0080% of N, less than or equal to 0.02% of S and the balance of Fe and inevitable impurities, wherein Nb-0.22C-1.1N is equal to or greater than 0.01% and less than or equal to 0.1% and Mn / 1.7S is equal to or greater than 8; the alloy coating comprises the following chemical components in percentage by weight: 50-58% of Al, 40-45% of Zn, 1.0-2.0% of Si, 0.005-0.020% of Ti and the balance of unavoidable impurities. According to the hot-dip aluminized and galvanized steel strip, by virtue of smelting, casting, carrying out hot rolling and cold rolling, continuously annealing and carrying out hot-dip aluminizing and galvanizing, the aluminum-zinc coating is evenly and densely adhered to the steel base plate, the obtained low-alloy hot-dip aluminized and galvanized steel strip has the yield strength of 410-570MPa, the tensile strength equal to or greater than 470MPa and elongation equal to or greater than 15% and has both good strength and toughness and excellent corrosion resistance. The production process is low in cost and high in steel plate yield.

Owner:BAOSHAN IRON & STEEL CO LTD

Neodymium-iron-boron magnet of aluminum or aluminum alloy composite coating and preparation method thereof

ActiveCN102031522AImprove processing efficiencyLow costVacuum evaporation coatingSputtering coatingHigh humidityAlloy composite

The invention discloses a neodymium-iron-boron magnet of an aluminum or aluminum alloy composite coating and a preparation method thereof. An aluminum or aluminum alloy film is deposited on the neodymium-iron-boron magnet by adopting multi-arc ion plating technology, and then phosphate treatment is performed. The coating is uniform and dense, and is well combined with a matrix. The neodymium-iron-boron magnet applied with the aluminum composite coating with thickness of 10 to 20 microns tolerates high pressure and high humidity (100 to 130 DEG C, 2 to 2.6atm, and 95 to 100 percent RH) for over 200 hours, and tolerates NaCl salt fog corrosion (3.5 to 5 weight percent of NaCl and 25 to 35 DEG C) for over 500 hours. The coating process has high efficiency and low cost; and the prepared composite coating has good corrosion resistance and adhesion performance, and has no influence on the magnetism of the neodymium-iron-boron matrix (mainly small-size magnet).

Owner:北京钐元新材料股份有限公司

Production of fast-drying water self-stripping metal heat treatment protecting coating

A method for producing fast-dry water self-stripping metal heat-treatment protective coating is carried out by putting boric acid 40.0-70.0 wt%, water resin 25.0-50.0 wt%, titanium pigment slurry 1.0-15.0 wt%, coloring pigment slurry 0.1-10.0 wt%, de-foaming agent 0.1-2.0 wt% and de-ionized water residue into stainless steel jar, high-speed dispersing to fineness below 50mu by agitator, filtering and packing to obtain final product. The precision metal work pieces have excellent oxidation and de-carbonizing resistances with air as medium for physical heat treatment, and have excellent cementation, aluminizing, siliconing and chromizing resistances with chemical substances as medium for chemical heat treatment. It has brushing and spraying functions, fast dry speed and better adhesion.

Owner:SHANGHAI JIAO TONG UNIV

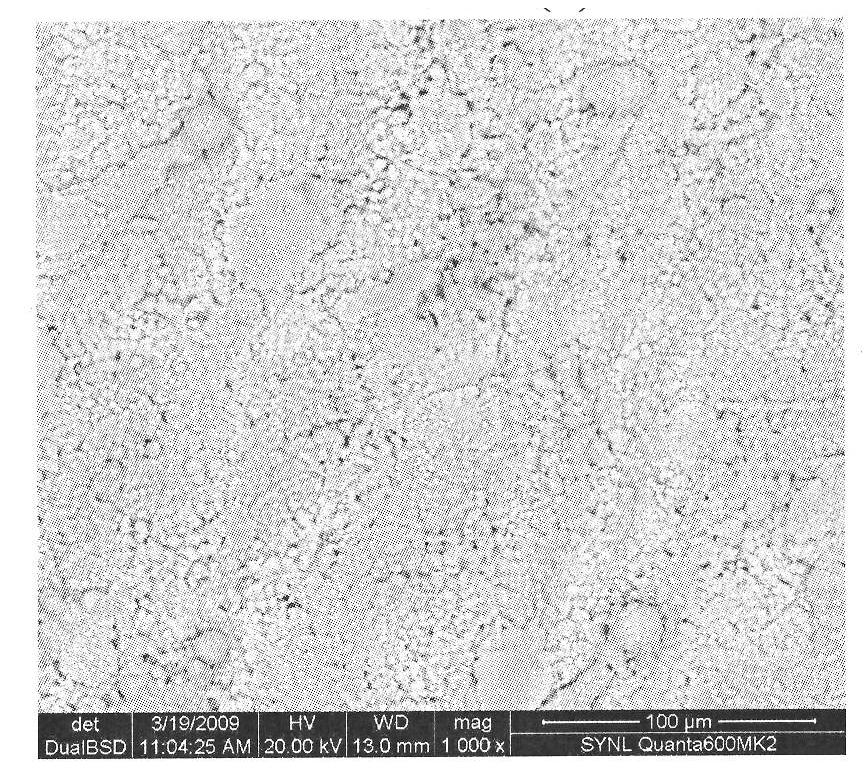

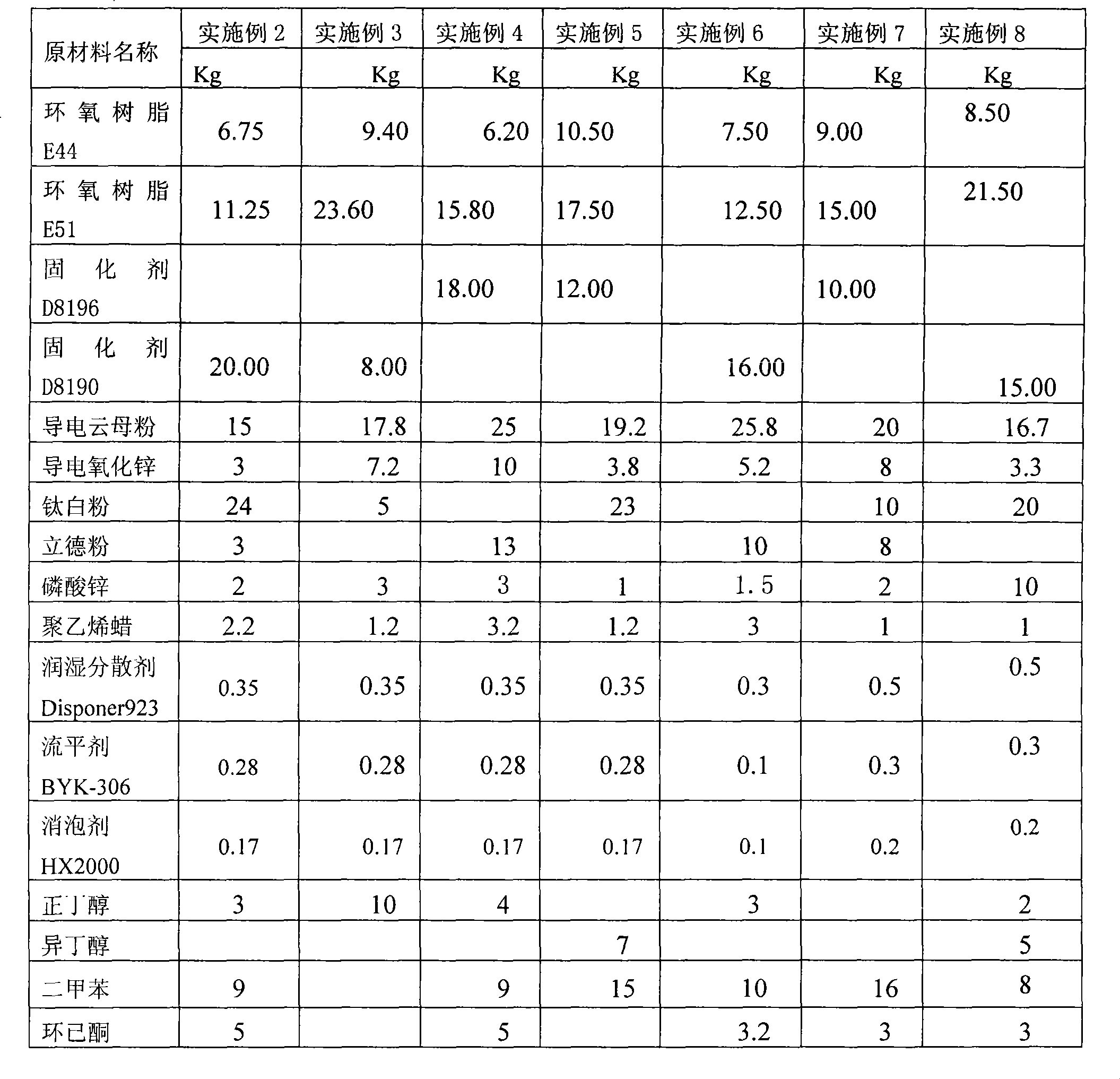

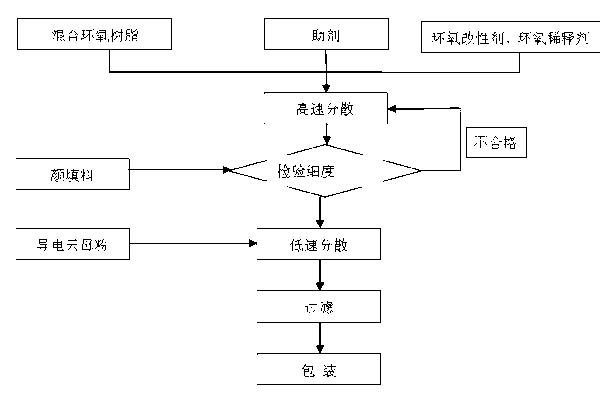

Methanol-resistant, static-conducting and anti-corrosive paint

InactiveCN101440251ADense coatingGood stability of electrostatic conductivityAnti-corrosive paintsEpoxy resin coatingsEpoxySurface resistivity

The invention discloses a methanol-resistant electrostatic conductive anticorrosive coating, which consists of the following raw materials according to the weight ratio: 18 to 33 of epoxy resin, 8 to 20 of modified arylated alkyl amine curing agent, 18 to 35 of electrostatic conductive filler, 1 to 30 of pigment, 1 to 30 of filler, 2 to 4 of auxiliary agent, and 10 to 30 of diluting agent, wherein the epoxy resin consists of an epoxy resin E44 and an epoxy resin E51 according to the weight ratio of 2-3:5; and the electrostatic conductive filler consists of conductive mica powder and conductive zinc oxide according to the weight ratio of 5:1-2. A final product has good electrostatic conductivity, and the resistivity on the surface of a paint film is between 10<6> and 10<7>omega; the final product has good corrosion resistance, can not seep particles when storing methanol for a long time, and has no pollution to the methanol; and the final product has good stability of electric conductivity, and the resistivity on the surface of the paint film has no obvious change through the soaking of the methanol.

Owner:石家庄市金达特种涂料有限公司

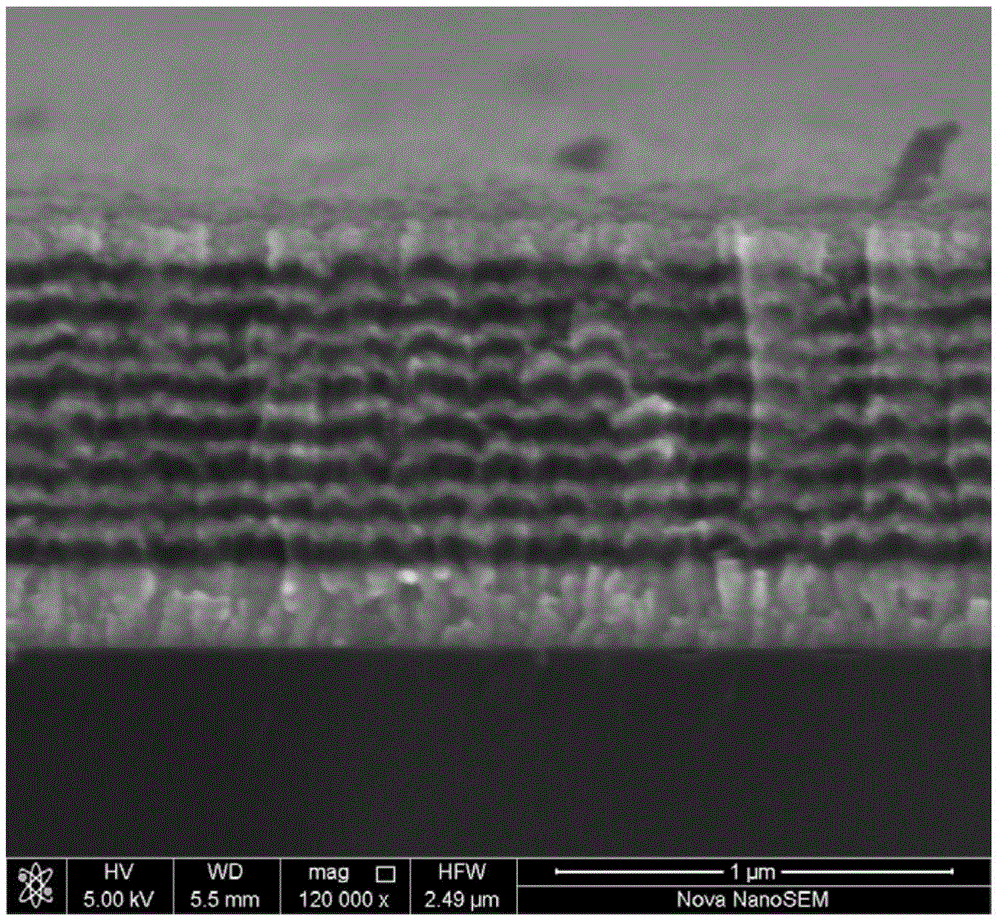

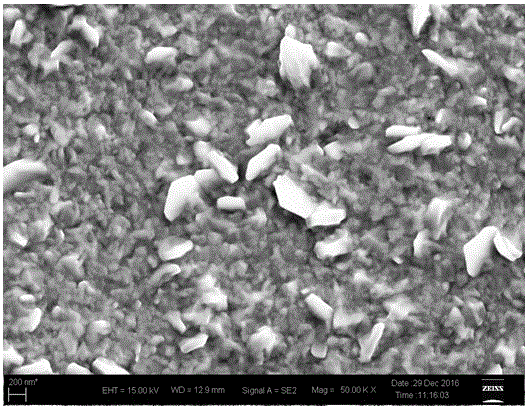

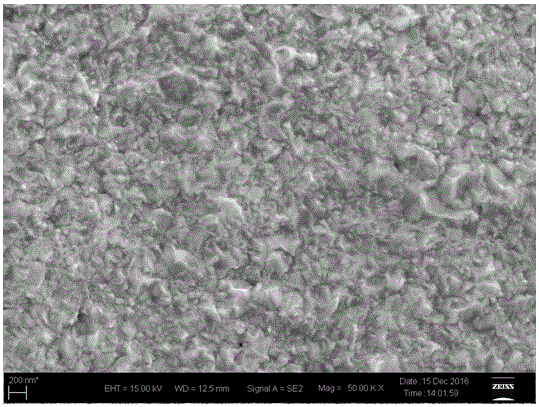

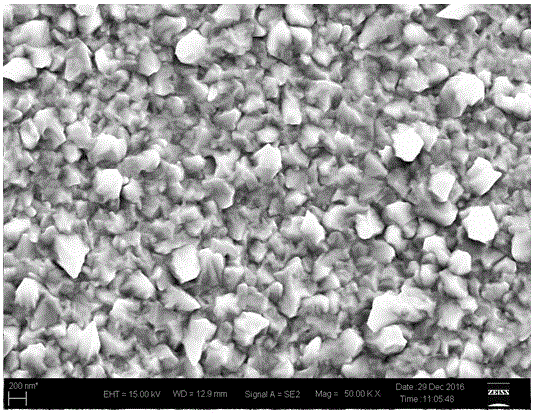

Preparation method of nano Sn/SiC composite plating

InactiveCN102051657AIncreased cathodic polarizationDense coatingElectrolytic coatingsCopper foilCorrosion

The invention discloses a preparation method of nano Sn / SiC composite plating, relating to a preparation method of Sn / SiC composite plating. The invention aims to solve the problems that the existing pure tin plating is easy to grow tin whisker and has poor mechanical property and codeposition of nano particles on a cathode can not be realized easily in the conventional nano composite plating technology. The preparation method comprises the following steps: 1, soaking SiC nano particles in methanesulfonic acid, then adding dispersant, stirring, and sequentially adding tin methanesulfonate, brightening agent, codeposition accelerant and main salt stabilizer to compose a plating solution; 2, parallelizing a cathode copper foil and a pure tin anode plate into the plating solution; and 3, adjusting the cathode current density, mechanically stirring and plating alternately, and keeping stirring under compressed nitrogen all the time, thus finishing preparing the nano Sn / SiC composite plating. The prepared nano Sn / SiC composite plating is obviously improved in inhibition of tin whisker growth, corrosion resistance, hardness and the like, and the preparation method can be applied to the field of weldable plating.

Owner:HARBIN INST OF TECH

Fiber reinforced type polymer cement waterproof paint

InactiveCN1718652AHigh tensile strengthDense coatingAntifouling/underwater paintsPaints with biocidesEmulsionDefoaming Agents

Owner:王立华

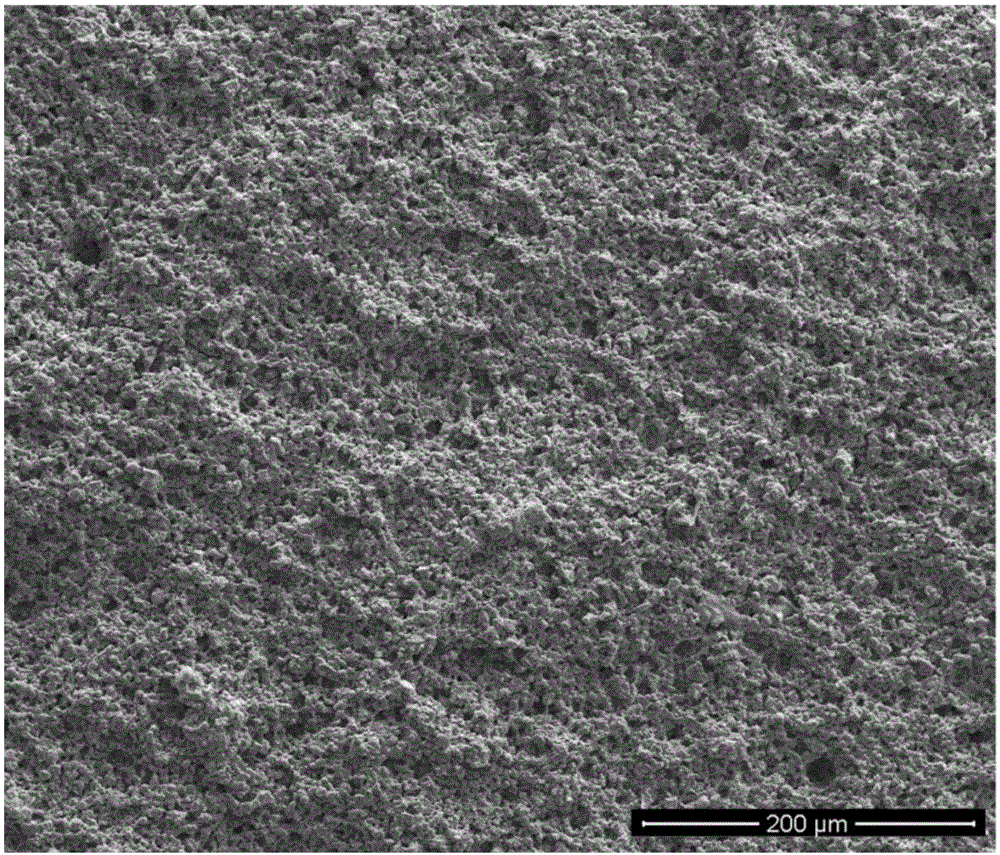

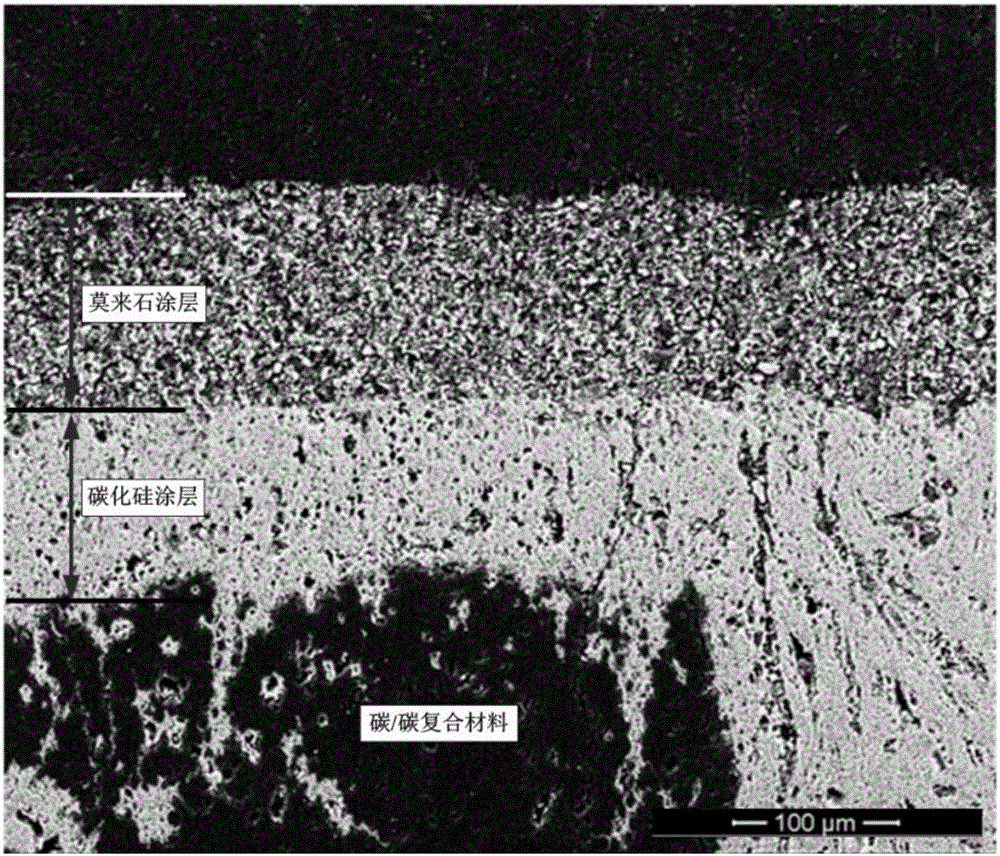

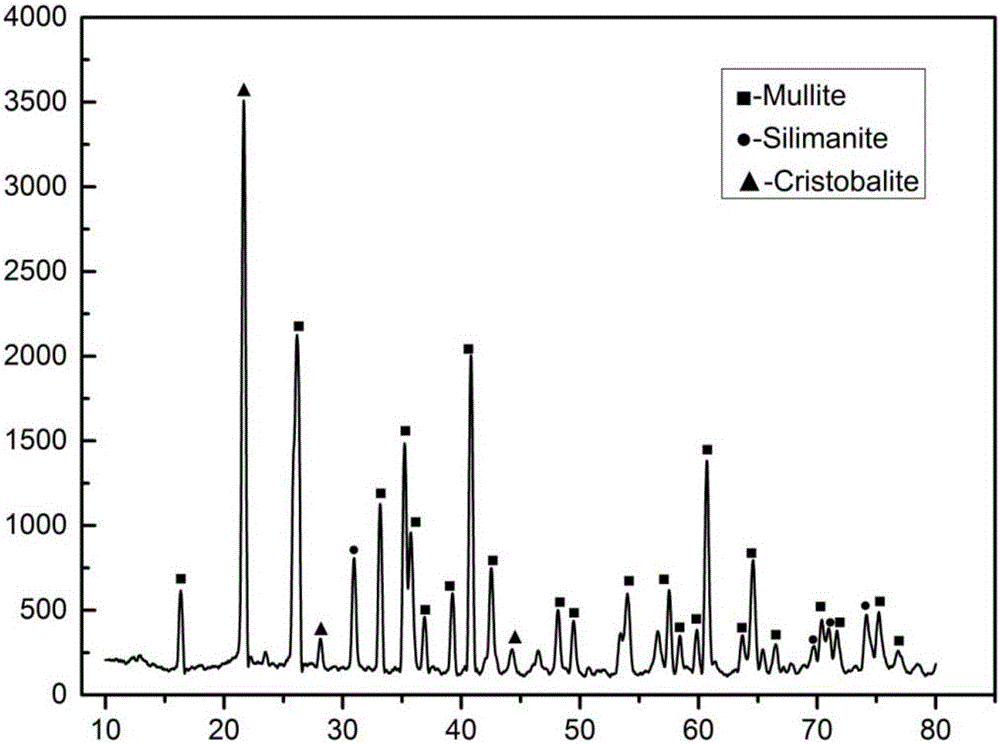

Preparation method of mullite oxidation resistant coating

The invention relates to a preparation method of a mullite oxidation resistant coating, particularly to a method for preparing a mullite / SiC bilayer-structure oxidation resistant coating on the surface of a carbon / carbon composite material. The preparation method comprises the following steps: pre-calcining mullite powder A and mullite precursor powder B according to the mass ratio of (4-6):1 to prepare pre-calcined mullite powder A and mullite precursor powder B, preparing a coalescing agent and a drying inhibitor according to certain ratio, uniformly mixing the pre-calcined mullite powder A, the pre-calcined mullite precursor powder B, the coalescing agent and the drying inhibitor to obtain a sizing agent, dipping a matrix in the sizing agent, performing sizing agent coating by adopting the dip-coating technology, and after the sizing agent coating, calcining at 1480-1515 DEG C to obtain the mullite oxidation resistant coating. According to the invention, the technology is simple, the raw material is cheap and available, the industrial production is facilitated, and the obtained coating has the advantages of high uniformity and compactness, excellent binding property, and high high-temperature oxidation resistant capacity.

Owner:HUNAN SHIXIN NEW MATERIALS CO LTD

Plastic lens for spectacles

ActiveUS7178919B2Prevent deterioration of resinsIncreasing the thicknessCoatingsOptical partsHardnessOptoelectronics

A plastic lens of a multilayer film structure forms an organosiloxane-based hard coating film formed on a surface of a lens substrate as a first layer, an inorganic oxide-based antireflection film formed on the hard coating film as a second layer, and a water-repellent thin film obtained by polycondensing an organosilicon compound and formed on the antireflection film as a third layer, pencil hardness of the surface of the lens on which these plural layer films are formed being from 3H to 7H, and an initial falling angle of oleic acid on the surface of the lens on which these plural layer films are formed being 20° or less.

Owner:TOKAI OPTICAL CO LTD

Thermally-grown Cr2O3 or Al2O3 film type M-Cr-Al nano composite coating and method for preparing same and application thereof

InactiveCN1880513ACompound composition controllableDense coatingElectrolytic coatingsCarbon steelNanometre

The invention discloses an M-Cr-Al nanometer composite coater and preparing method and application of heat-growing Cr2O3 or Al2O3 model, which is characterized by the following: containing nanometer size metal M and 5-20 percent nanometer metal Cr and 3-10 percent Al particle with dispersion allocating in the metal M, wherein M is Ni, Fe or Co; adopting Ni, Fe or Co, carbon steel or low-alloy steel as base material; adopting compound plating metal M and Cr and Al plater of conventional common battery depositing technology to produce Ni-Cr-Al, Fe-Cr-Al or Co-Cr-Al nanometer compound plater as anti-high temperature protective coater and anti-heat eroding protective coater.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Plastic lens for spectacles

A plastic lens of a multilayer film structure forms an organosiloxane-based hard coating film formed on a surface of a lens substrate as a first layer, an inorganic oxide-based antireflection film formed on the hard coating film as a second layer, and a water-repellent thin film obtained by polycondensing an organosilicon compound and formed on the antireflection film as a third layer, pencil hardness of the surface of the lens on which these plural layer films are formed being from 3H to 7H, and an initial falling angle of oleic acid on the surface of the lens on which these plural layer films are formed being 20° or less.

Owner:TOKAI OPTICAL CO LTD

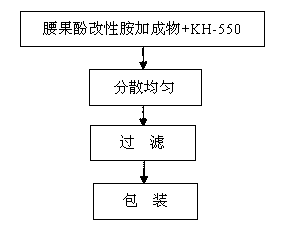

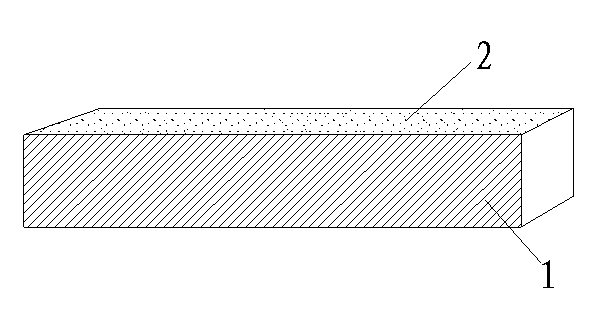

Light-color modified epoxy static conductive anticorrosion coating and preparation method thereof

ActiveCN103275596AGood value for moneyDense coatingAnti-corrosive paintsEpoxy resin coatingsPolymer scienceFirming agent

A light-color modified epoxy static conductive anticorrosion coating is formed by a component A and a component B, the component A comprises 5-10mass% of an E44 epoxy resin, 5-10mass% of an F-51 novolac epoxy resin, 7-17mass% of an epoxy resin modifier, 5-15mass% of an epoxy diluent 660A, 0.1-0.5mass% of a wetting dispersant BYK-110, 0.1-0.5mass% of an antifoaming agent BYK-A530, 1.0-1.5mass% of a silane coupling agent KH-560, 1.0-1.5mass% of a multifunctional thixotropic agent, 8-20mass% of conductive mica powder, 4-10mass% of active silica, and 12-35mass% of a pigment filler, and the component B comprises 10-20mass% of a cardanol modified amine adduct curing agent and 0.1-0.5mass% of a silane coupling agent KH-550. The coating has the advantages of wide application range, excellent application property, and high cost performance, has been industrially produced and applied, can compete with products of the same kind in China, and has a very large cost performance advantage.

Owner:XIAMEN SUNRUI SHIP COATING

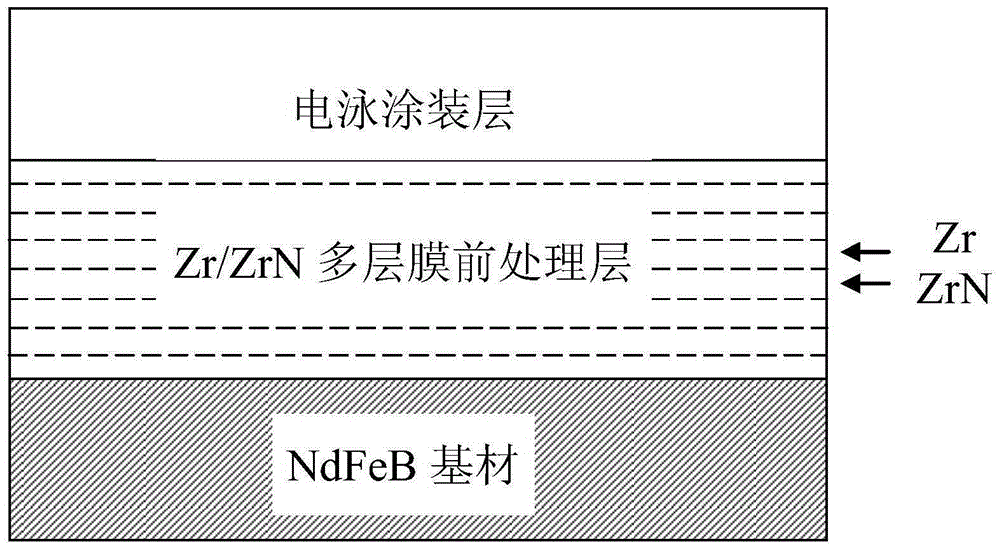

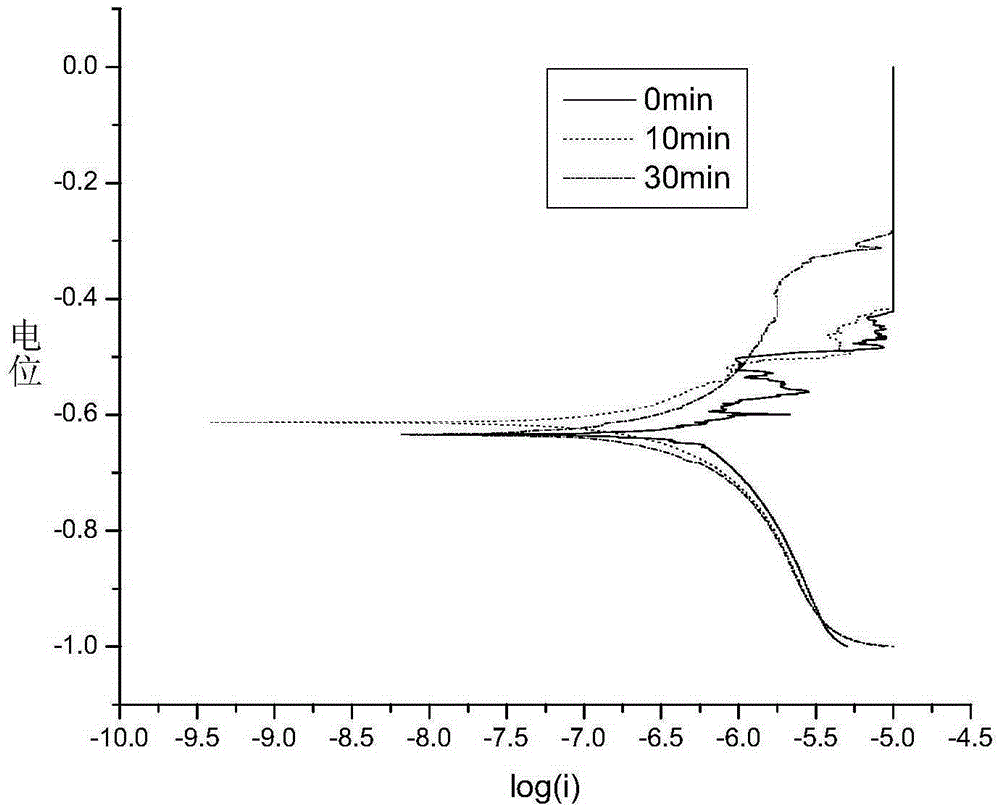

Vapor deposition method used for anticorrosion pretreatment of permanent magnet

InactiveCN105420669ANo magnetic damageOvercome the disadvantage of magnetic damageVacuum evaporation coatingSputtering coatingGas phaseElectrophoresis

The invention discloses a vapor deposition method used for anticorrosion pretreatment of a permanent magnet, and relates to the field of surface treatment of materials. The physical vapor deposition technology is adopted, and a nano multi-layer structural thin film is deposited on a NdFeB surface; before the nano multi-layer structural thin film is deposited on the NdFeB surface, the NdFeB surface can be passivated; after the nano multi-layer structural thin film is deposited on the NdFeB surface, an electrophoretic method is adopted to carry out coating deposition; and the invention discloses a method for carrying out pretreatment on the magnetic material NdFeB so as to replace phosphorization; and through the technology, the NdFeB magnetic performance damage caused by a phosphorization technology can be overcome. The method is green, free of pollution and wide in application prospect, and technological parameters are easy to control; combination performance of a transition metal / nitride composite coating prepared through the method and the NdFeB permanent magnet is excellent, the method is matched with the electrophoresis or plating process, and the anticorrosion performance of the NdFeB permanent magnet can be obviously improved.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

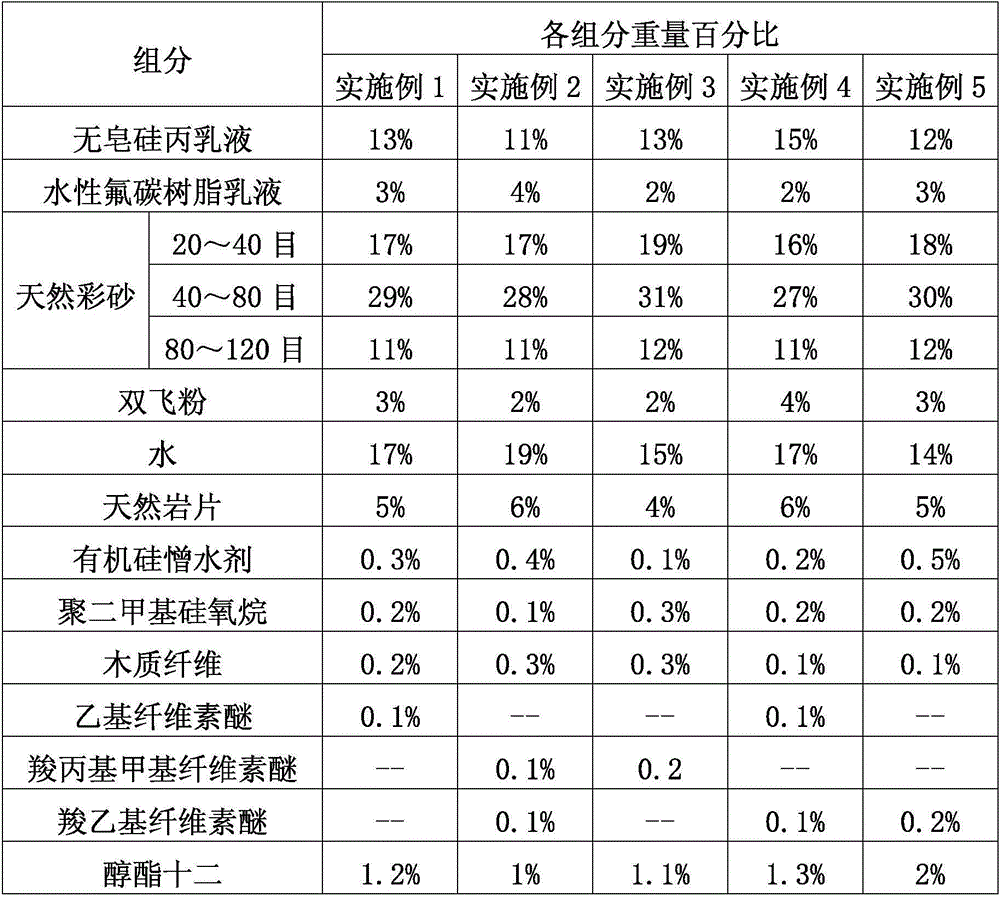

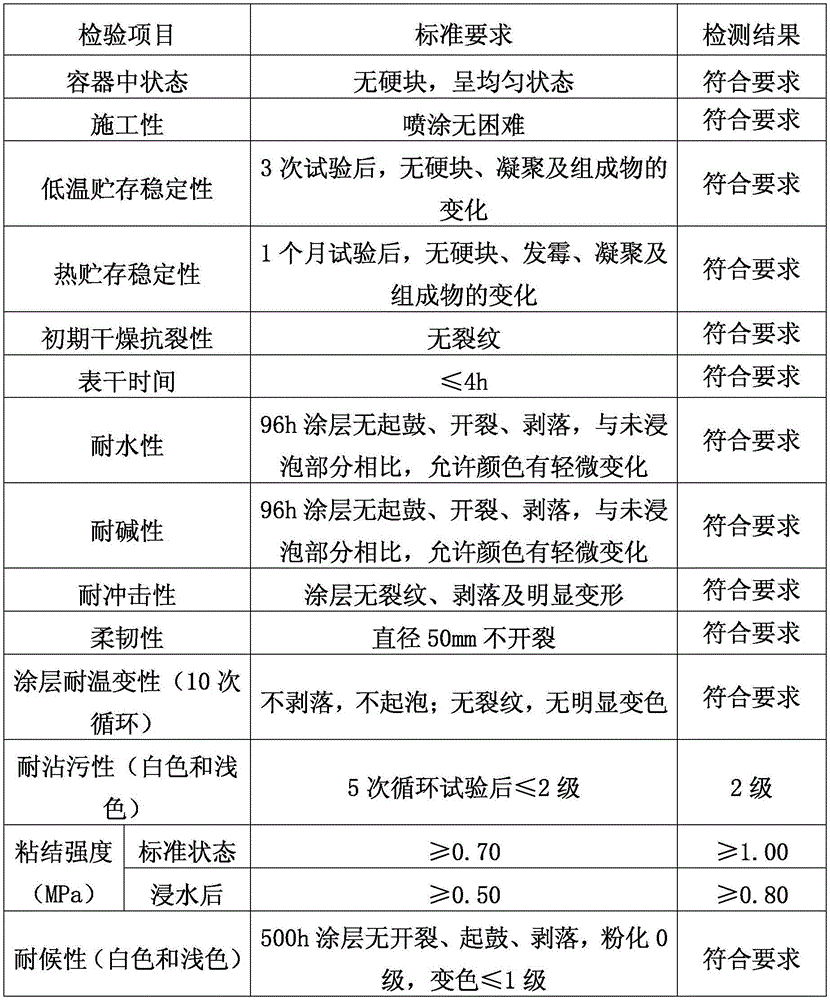

High-waterproof colorful stone-like paint

A high-waterproof colorful stone-like paint is composed of the following raw materials in percentage by weight: 11 to 15% of soap-free silicone acrylic emulsion, 2 to 4% of aqueous fluorocarbon resin emulsion, 54 to 63% of natural colorful sand, 2 to 4% of calcium carbonate and magnesium carbonate powder, 14 to 20% of water, 4 to 6% of natural rock sheets, 0.1 to 0.5% of water repellent, 0.1 to 0.3% of antifoaming agent, 0.1 to 0.3% of wood fiber, 0.1 to 0.2% of cellulose ether, and 1 to 2% of film-forming auxiliary agent. The soap-free silicone acrylic emulsion and aqueous fluorocarbon resin emulsion are mixed and used as the adhesive of the stone-like paint. Natural colorful sand with different finenesses is matched with natural rock sheet to prepare the stone-like paint. The prepared stone-like paint has the advantages of high waterproofness, natural color and luster, stone-like texture, good imitation effect, and high adhesive strength. The coating will not fade and become loosen and scratched. After drying, the paint film is compact, and moreover the paint has the advantages of strong adhesive force, large hardness, cracking resistance, alkali / acid resistance, corrosion resistance, no odor or toxicity, safety, and environment-friendliness.

Owner:黄美忠

Target magnetron sputtering device and film coating method used for powder particle surface film coating

InactiveCN103160795ATo vibrateFully exposedVacuum evaporation coatingSputtering coatingOperational costsVacuum chamber

The invention provides a target magnetron sputtering device and a film coating method used for powder particle surface film coating. The target magnetron sputtering device comprises a vacuum chamber, a roller with openings at two ends, two support rollers, a motor, a speed regulation device, two magnetron sputtering target frames and a sputtering power source, wherein each support roller is provided with a limiting inclined face. The support rollers are connected with the speed regulation device. The roller is directly placed on the support rollers and driven to rotate through the support rollers. Target materials are arranged at the positions of the openings at the two ends of the roller. During magnetron sputtering film coating, a grinding ball and powder are simultaneously placed into the roller, the rotating speed of the motor is regulated, the grinding ball and powder particles in the roller are enabled to drop in a parabola mode, sputtering stream injected from the openings of the roller is deposited on the falling powder, and film with good evenness is obtained after a certain period of time. The target magnetron sputtering device and the film coating method used for the powder particle surface film coating are large in technological handling capacity, low in operational cost and suitable for industrial production.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Thin type micro villus polyurethane certificate leather and preparation method thereof

The invention discloses thin type micro villus polyurethane certificate leather and a preparation method of the thin type micro villus polyurethane certificate leather. The preparation method of the thin type micro villus polyurethane certificate leather takes a 0.45 imitated micro fiber fabric base raising on a single face as a carrier and comprises the following steps: directly coating a polyurethane resin layer with a certain viscosity on the raised surface of the 0.45 imitated micro fiber fabric base, after coagulation, forming a polyurethane epithelium on the surface of the fabric base after cohesion, and during the film formation process, sequentially carrying out washing for displacing a DMF (dimethyl formamide) solvent, drying and shaping the polyurethane epithelium, so as to obtain a semi-finished product; carrying out oriented buffing and tentering on the surface layer of the semi-finished product, then carrying out aftertreatment and colour alternation, so that the thin type micro villus polyurethane certificate leather finished product is obtained. The thin type micro villus polyurethane certificate leather obtained by adopting the preparation method has the advantages of fine villus, soft handfeel, light weight, superior air permeability and downy feeling like micro fiber, a certificate leather lining made adopting the thin type micro villus polyurethane certificate leather shines with dazzling brilliance, is decent and has excellent protective properties, such as shakeproof, breakageproof and scratchproof properties, on a delicate article, and the thin type micro villus polyurethane certificate leather is especially applicable to linings of shells of a mobile phone, a computer and the like.

Owner:ANHUI ANLI MATERIAL TECH

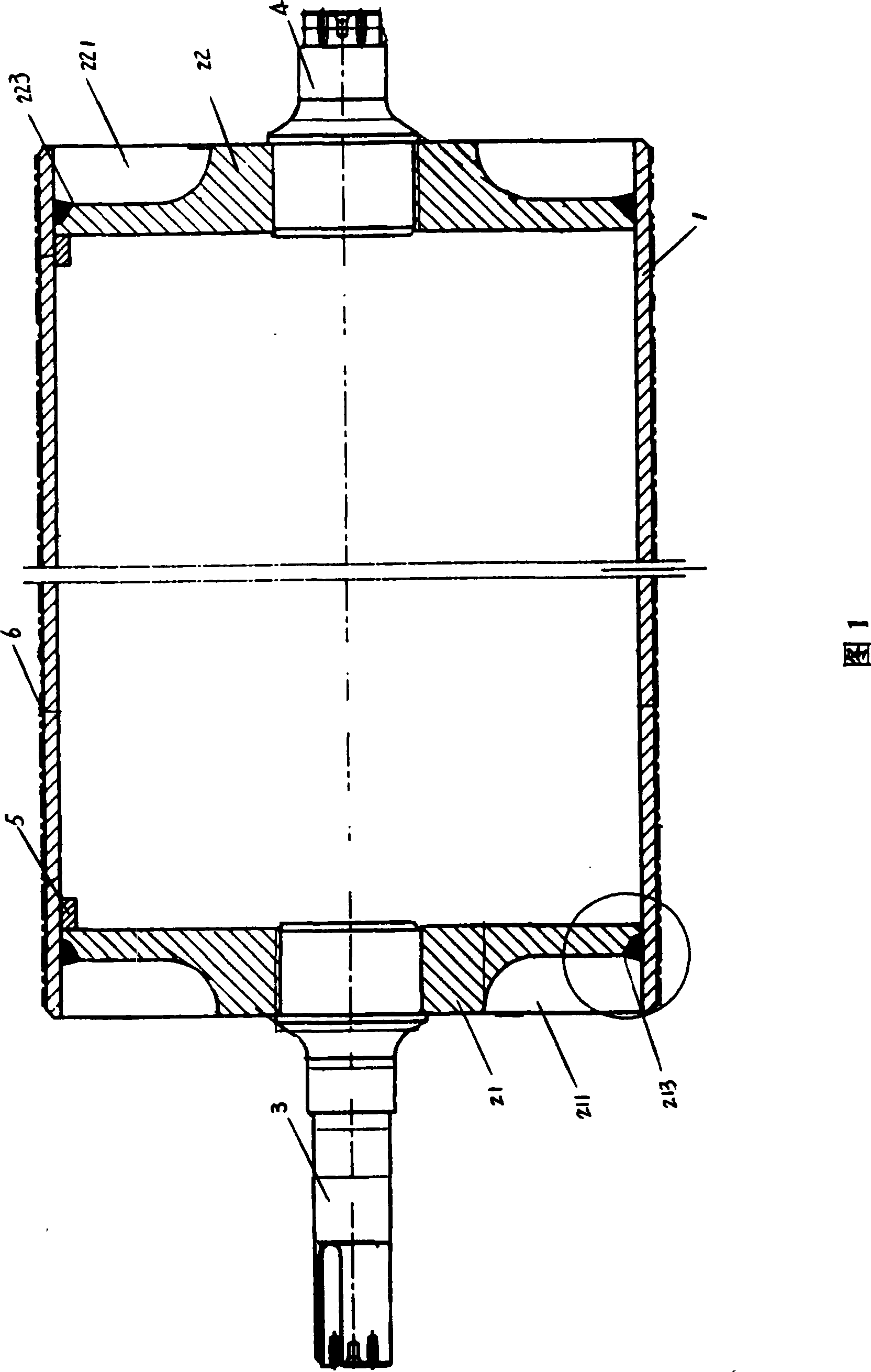

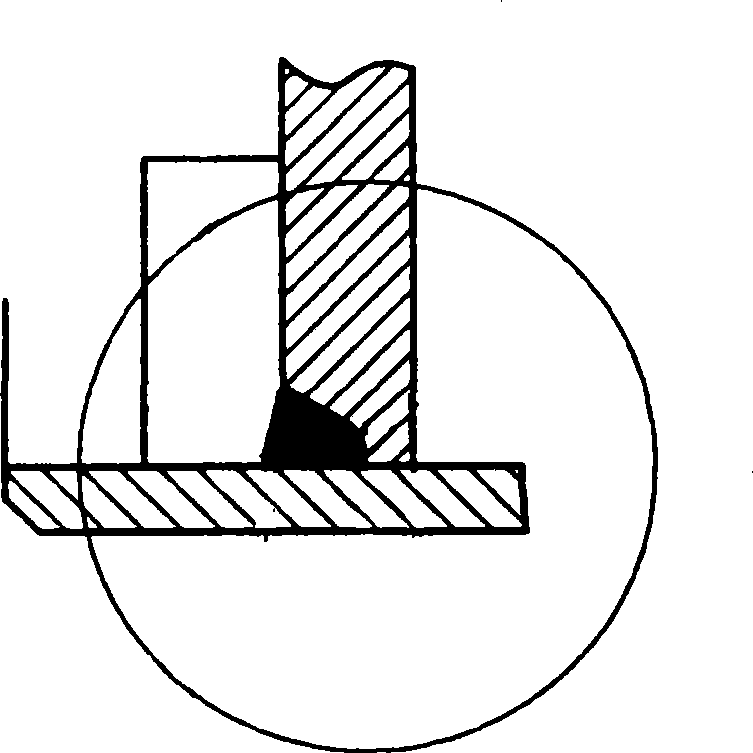

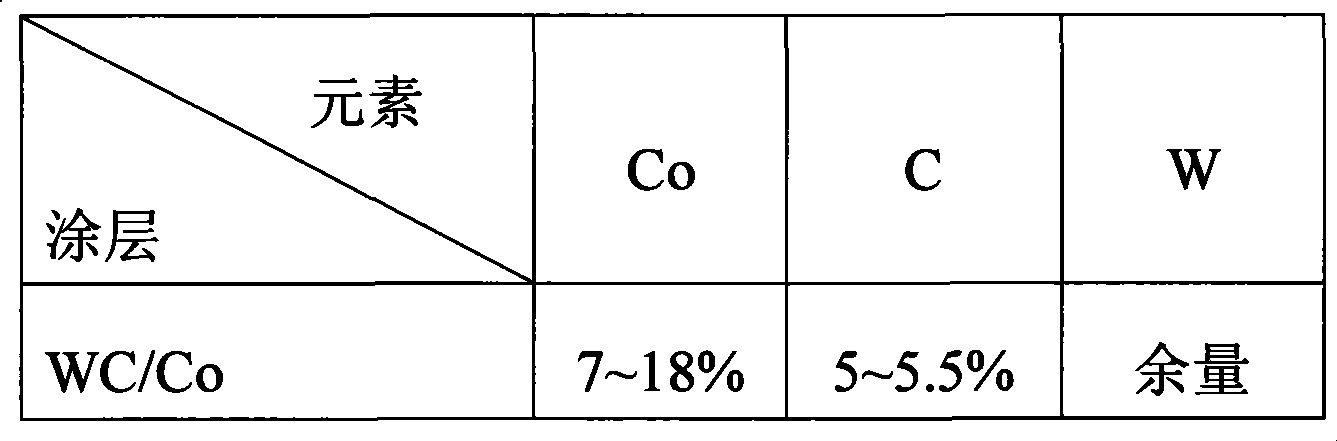

Hard-surface build-up welding strain roller and manufacture method thereof

ActiveCN101362151AHigh bonding strengthDense coatingMolten spray coatingRollsBrown iron oxideChromium

The invention relates to a hard-surface bead welding stretching roller and a production method thereof. The stretching roller comprises a drum and round side covers which are fixedly and closely covered at the openings of the two ends of the drum; the centers of the two side covers are in coupling connection with a left shaft head and a right shaft head respectively; the outer surface of the drum is covered with a spraying layer; the external sides of the two side covers are provided with sockets which stretch from the middle of the side covers to the edge; the external sides of the two sides covers are provided with chamfer angles in a surrounding way; the two side covers are welded with the inner walls at the two ends of the drum by the chamfer angles and the sockets; the spraying layer uses a functional metal ceramic coat which is composed of composite metal ceramic formed by WC / Co metal ceramics and metal or alloy. The roller solves the technical problems that as the external surface of the existing product roller surface is sprayed with hard plating, in the process of use, the coat is easy to produce pits or bumps owing to the press of sundries such as iron oxide, etc., and drawing stamps or stains are formed on the surface of finished product, strip steel, therefore, the surface quality of the strip steel is influenced; simultaneously, the technical problem that in the process of use, heat is easy to enter the inner side of the drum from the joint between the drum and the close cover is solved, therefore, the solution of the problems is beneficial to the longer service life of the stretching roller.

Owner:SHANGHAI JUSN SURFACE TECH ENG

Roller coating type simulated face brick coating and construction method

The invention relates to the technical field of coatings, and particularly relates to a roller coating type simulated face brick coating and a construction method. The roller coating type simulated face brick coating is prepared by dispersing the following components in parts by weight in a dispersing kettle: 10-20 parts of ethylene glycol, 2-6 parts of dispersing agents, 1-2 parts of AMP 95, 50-100 parts of 2% hydroxy ethyl cellulose solutions, 30-50 parts of 10% inorganic gels, 1-2 parts of wetting agents, 3-9 parts of defoaming agents, 500-600 parts of natural rock flour, 50-100 parts of rigid polymer emulsions, 50-100 parts of elastic polymer emulsions, 5-10 parts of film forming auxiliary agents, 5-10 parts of hydrophobic modified alkali swelling thickening type thickening agents, 1-6 parts of hydrophobic modified alkali swelling associating type thickening agents, 1-2 parts of sterilizing agents and 110-240 parts of water. According to the invention, a coated film grain obtained after roller coating is more similar to that of an exterior wall tile.

Owner:BAOJI JIALILAI BUILDING DECORATION

Real mineral varnish prepared from waste polystyrene foam plastic serving as partial raw material

The invention discloses a real mineral varnish prepared from waste polystyrene foam plastic serving as a partial raw material. The real mineral varnish comprises a component A and a component B, wherein the component A comprises the following raw materials in percentage by weight: 11%-15% of waste polystyrene foam plastic, 17%-22% of solvents, 1%-3% of an emulsifying agent, 1%-2% of dibutyl phthalate, 2-3% of sodium persulfate, 3%-6% of a modifying agent and 53%-61% of water; the component B comprises the following raw materials in percentage by weight: 85%-92% of natural colored sand, 3%-10% of talcum powder, 1%-2% of a defoaming agent, 0.5%-1.5% of hydroxyethyl cellulose ether and 3%-4% of a film forming aid; the mass ratio of the component A to the component B in the real mineral varnish is 1 to (2-3). According to the real mineral varnish, a selected emulsion is prepared from the waste polystyrene foam plastic which serves as the raw material, so that the problem of environmental pollution is solved, and a new path is provided for the comprehensive utilization of the waste polystyrene foam plastic.

Owner:广东神洲化学工业有限公司

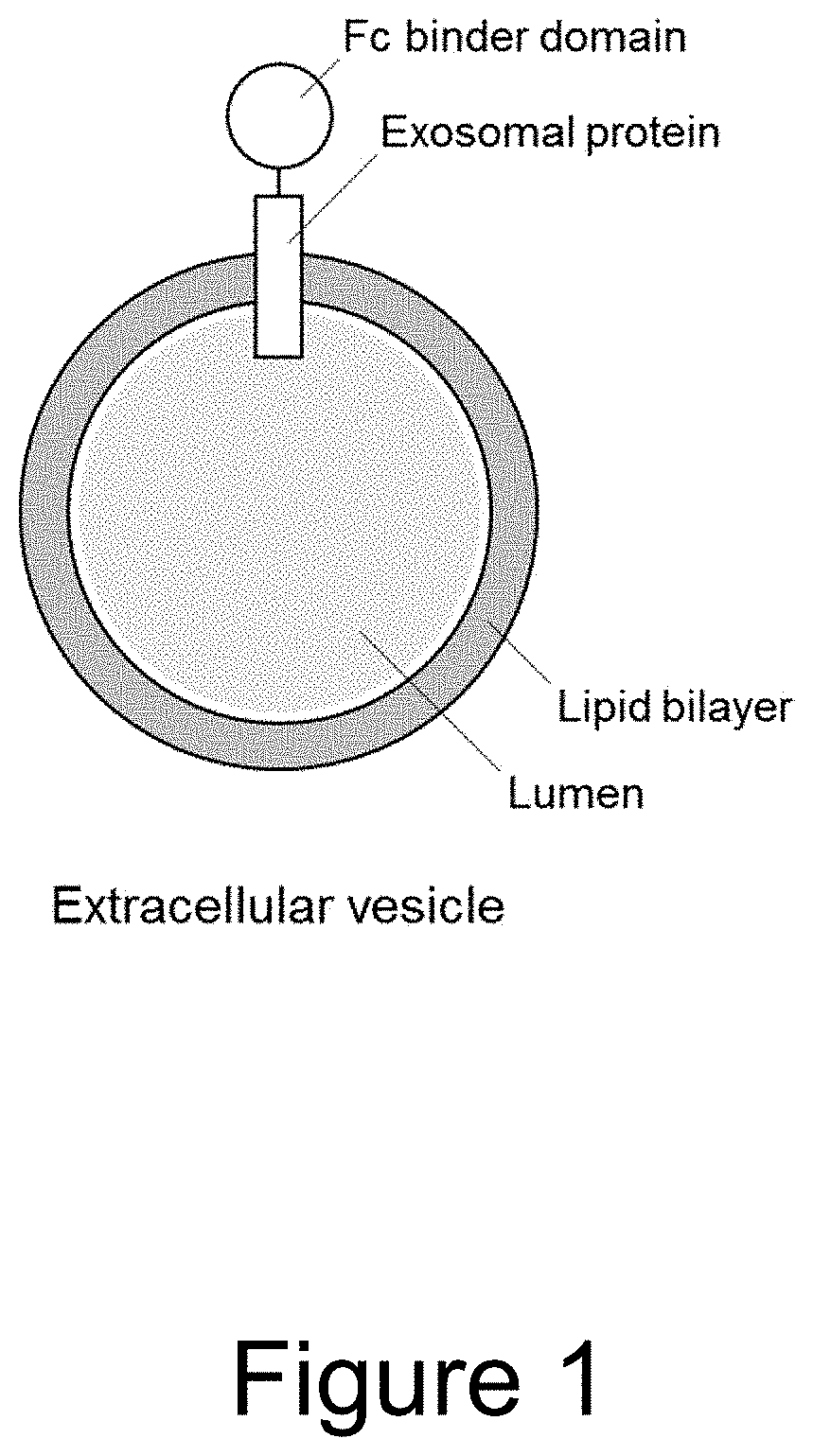

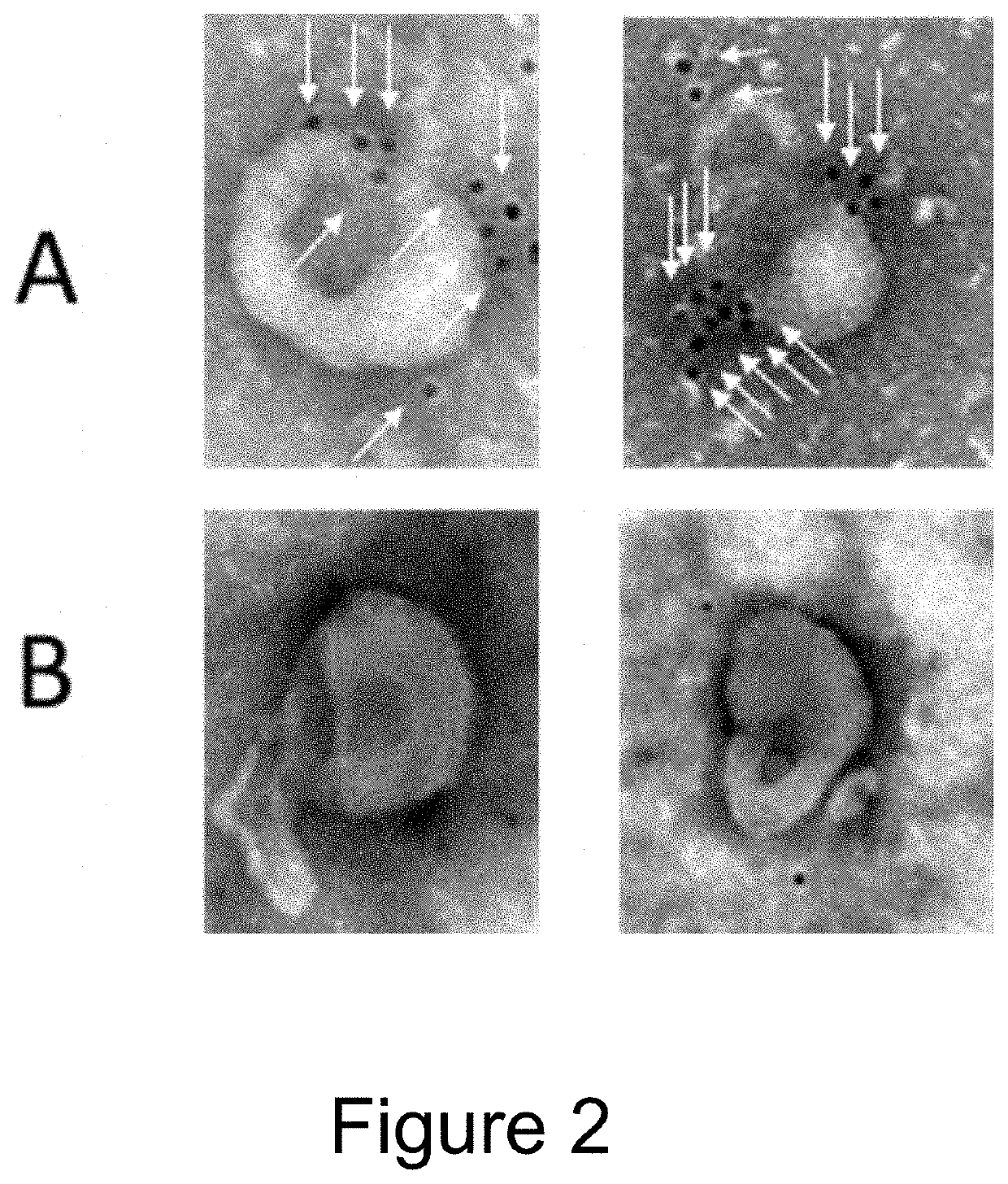

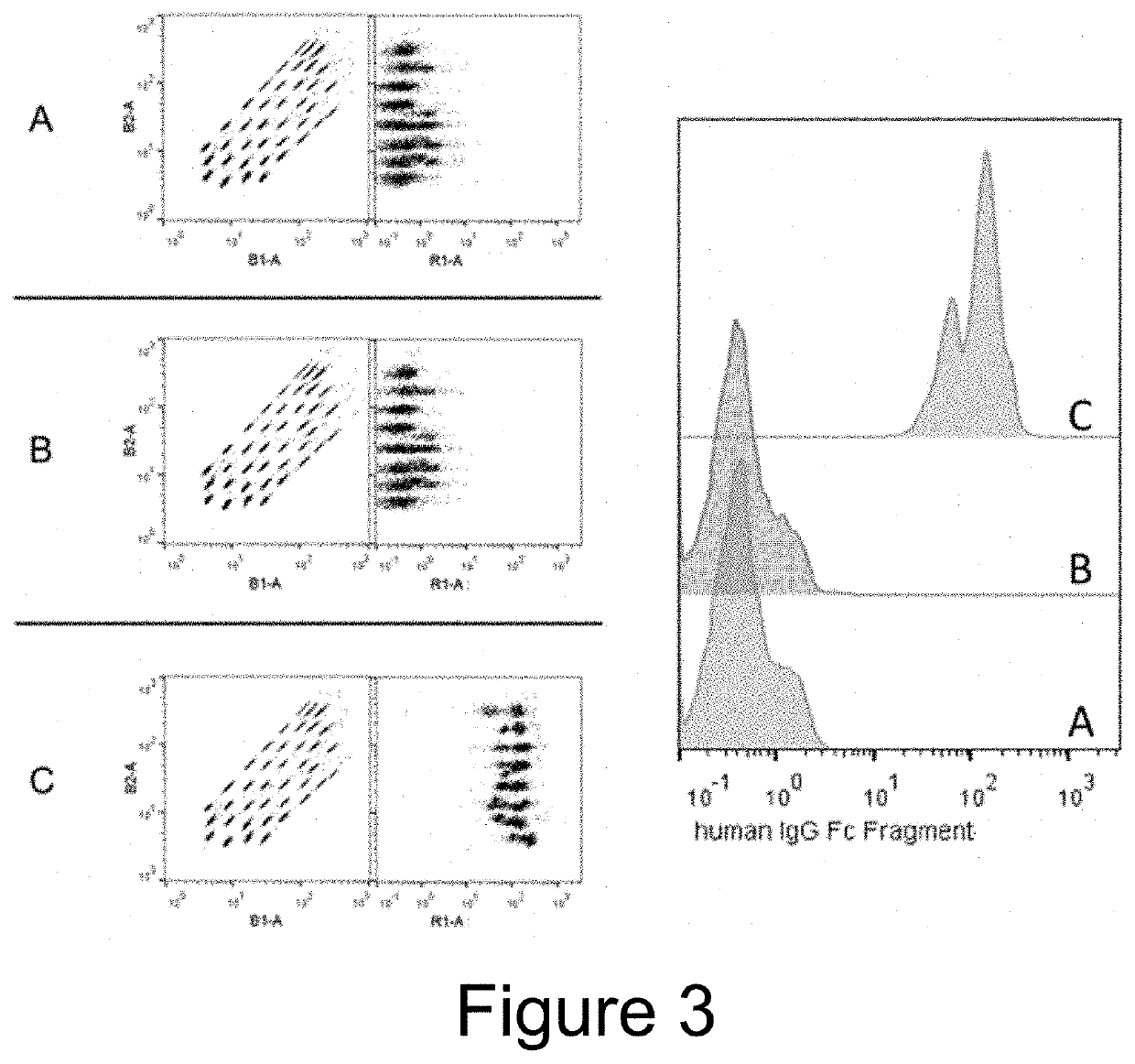

Extracellular vesicle comprising a fusion protein having fc binding capacity

ActiveUS20200109183A1Enhance therapeutic potentialOvercome problemsPeptide/protein ingredientsAntibody mimetics/scaffoldsExtracellular vesicleAntiendomysial antibodies

The present invention pertains to extracellular vesicle (EV) therapeutics, wherein the EVs are coated with proteins containing Fc domains (such as antibodies) for i.a. targeting and therapeutic applications. The coating of EVs is achieved through inventive protein engineering of EV polypeptides. The present invention thus relates to methods for coating of EVs, EVs per se, as well as pharmaceutical compositions and medical applications of such EVs coated with Fc containing proteins.

Owner:EVOX THERAPEUTICS LTD

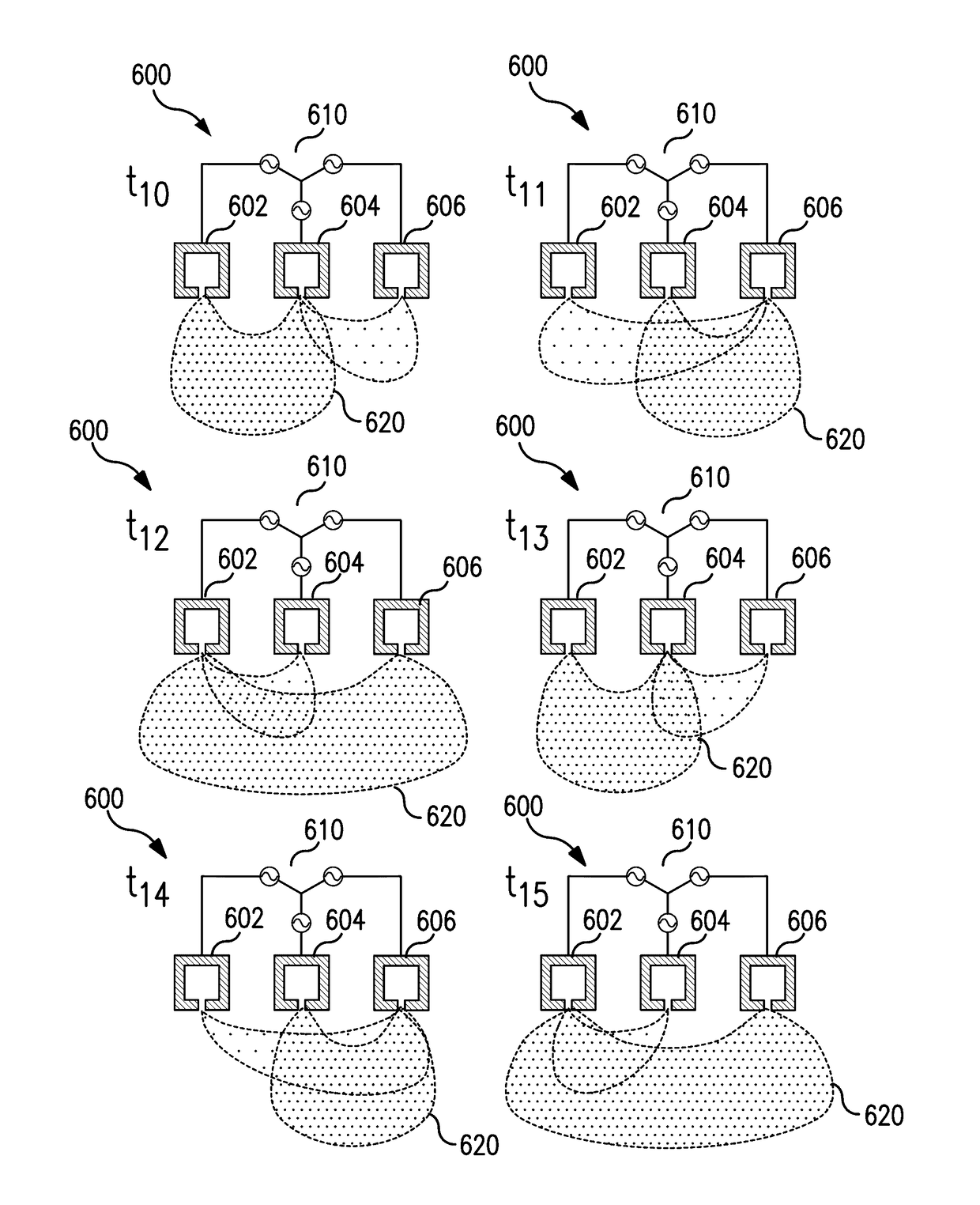

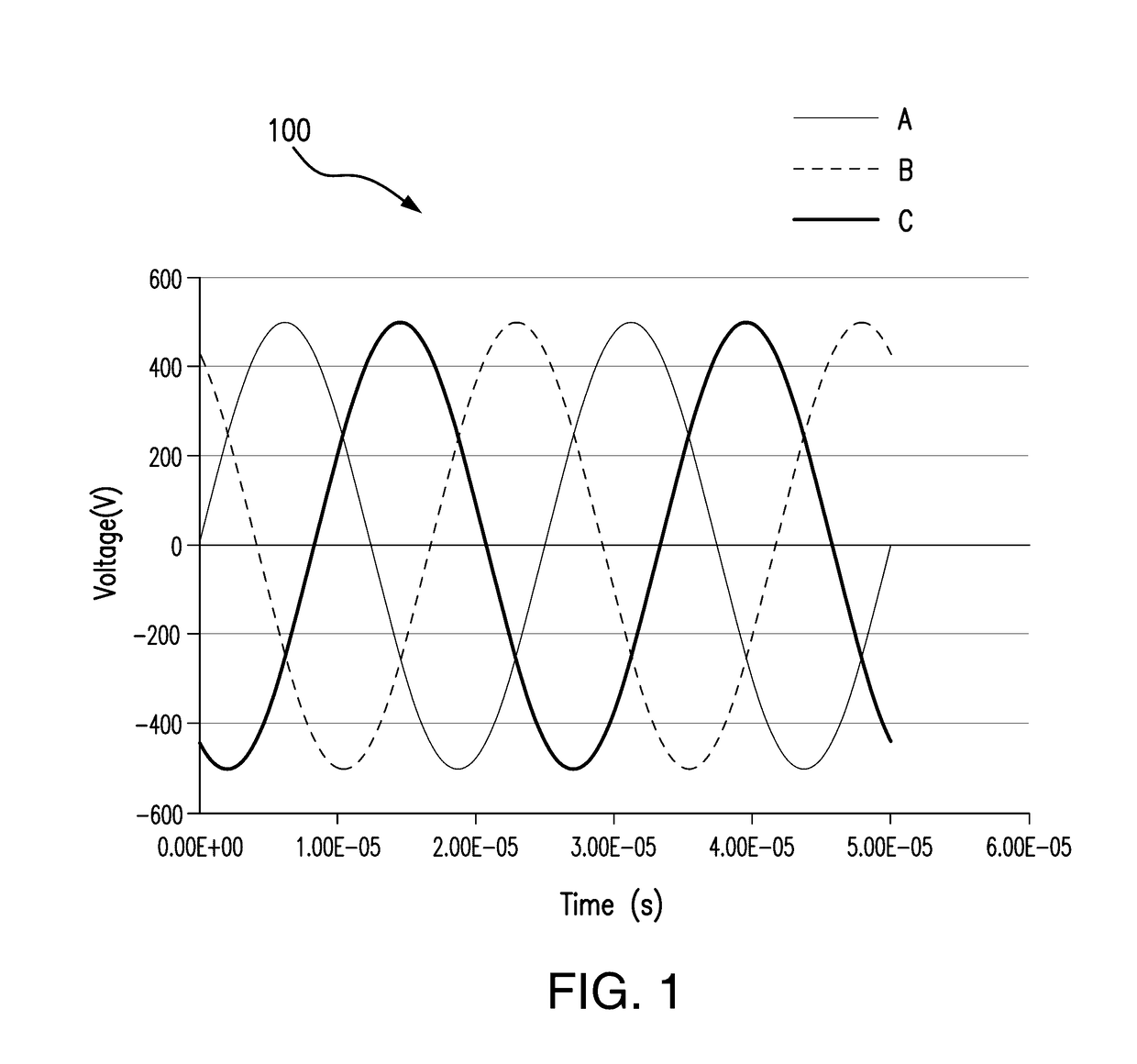

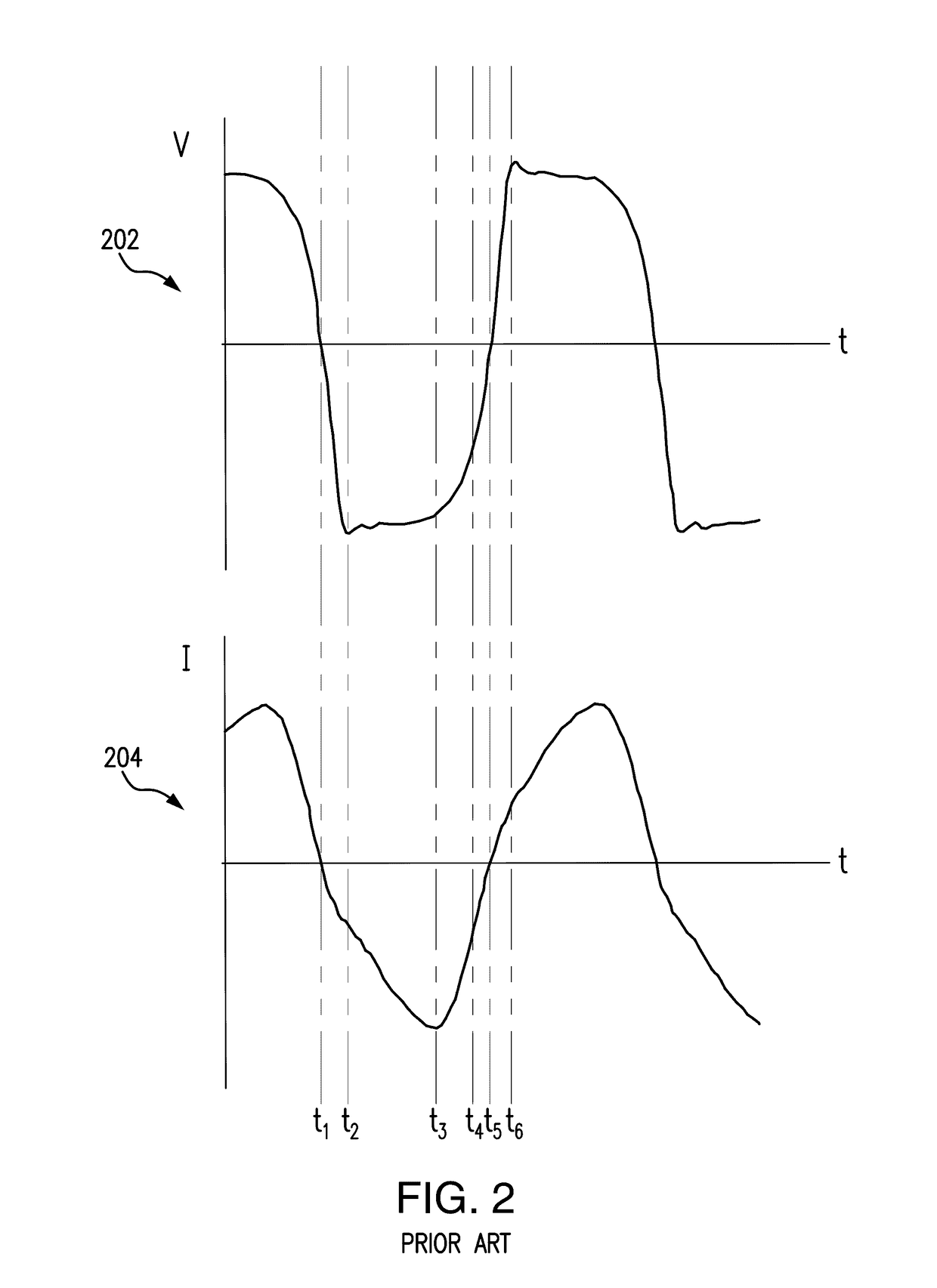

Plasma device driven by multiple-phase alternating or pulsed electrical current

InactiveUS20170140904A1Easy to operateIncreased disassociation energyElectric discharge tubesMulti phaseElectrical current

A plasma source is provided. The plasma source includes at least three hollow cathodes, including a first hollow cathode, a second hollow cathode, and a third hollow cathode, each hollow cathode having a plasma exit region. The plasma source includes a source of power capable of producing multiple output waves, including a first output wave, a second output wave, and a third output wave, wherein the first output wave and the second output wave are out of phase, the second output wave and the third output wave are out of phase, and the first output wave and the third output wave are out of phase. Each hollow cathode is electrically connected to the source of power such that the first hollow cathode is electrically connected to the first output wave, the second hollow cathode is electrically connected to the second output wave, and the third hollow cathode is electrically connected to the third output wave. Electrical current flows between the at least three hollow cathodes that are out of electrical phase. The plasma source is capable of generating a plasma between the hollow cathodes.

Owner:AGC FLAT GLASS NORTH AMERICA INC +2

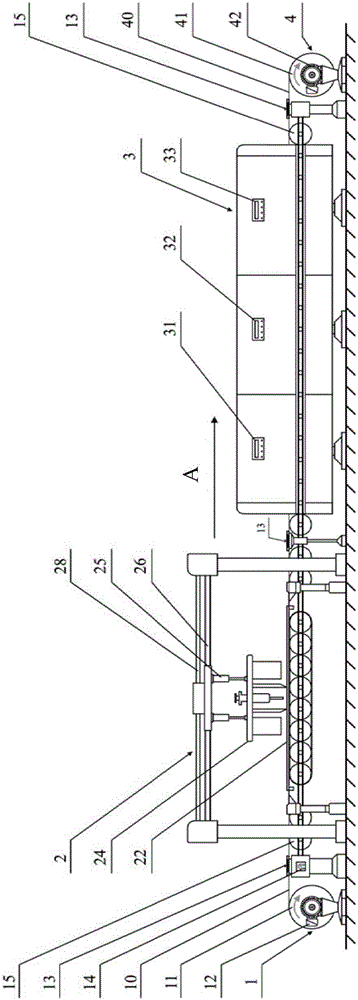

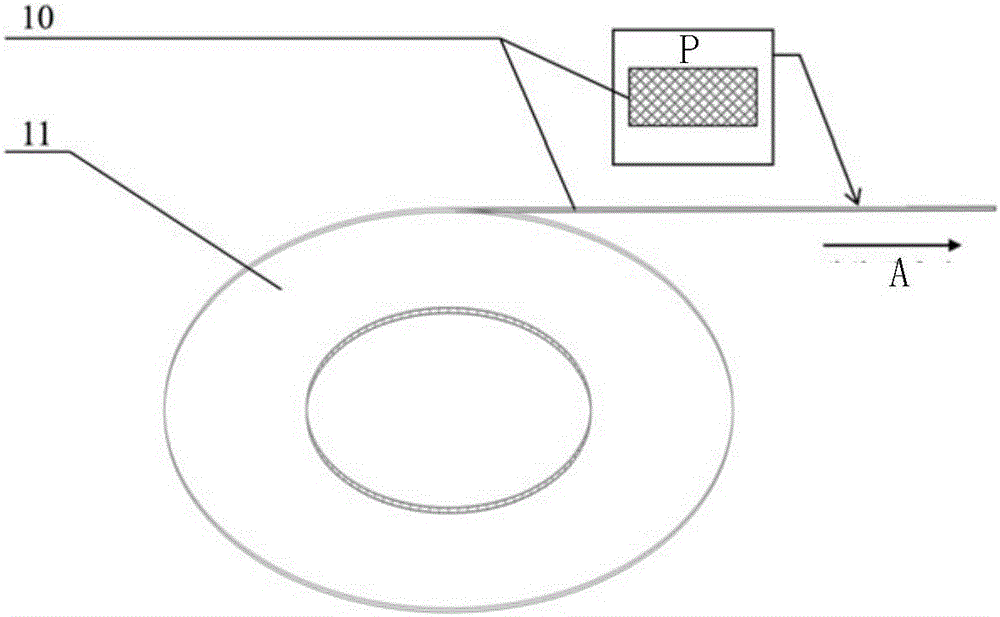

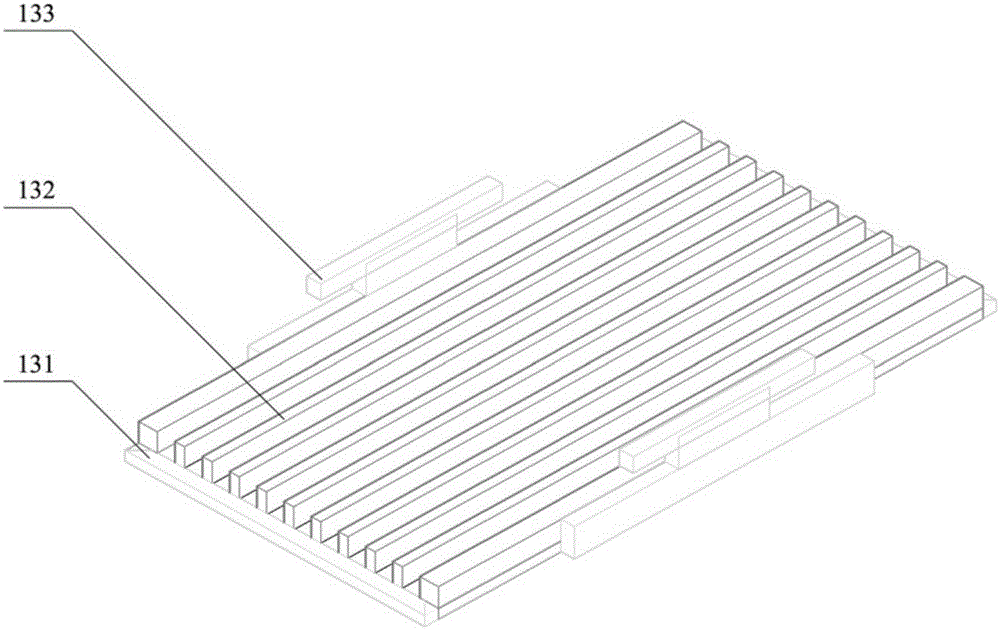

Continuous screen printing machine for ceramic substrate and printing method thereof

InactiveCN106696444AUniform coatingDense coatingScreen printersOther printing apparatusEngineeringPrinting press

The invention discloses a continuous screen printing machine for a ceramic substrate and a printing method thereof and relates to screen printing. The continuous screen printing machine for the ceramic substrate comprises a thin film conveying system, a printing system, a heat treatment system and a substrate film receiving system. The thin film conveying system, the printing system, the heat treatment system and the substrate film receiving system are arranged in sequence and placed on the ground. A transmission mechanism of the thin film conveying system is connected with the printing system and the heat treatment system. A locating mechanism is arranged between the printing system and the heat treatment system. A silicon carbide ceramic film is conveyed from the thin film conveying system, passes the locating mechanism, is conveyed to the printing system and the heat treatment system, passes the locating mechanism again and is reeled through the substrate film receiving system to form a finished substrate. Uniform coating of printing materials can be conducted on the surface of the silicon carbide ceramic film in a short time, and the printed printing materials are subjected to heat treatment and solidification, so that the silicon carbide ceramic film is made into the silicon carbide ceramic substrate with circuit patterns.

Owner:XIAMEN UNIV

Ionic liquid gold plating solution containing coordination agent and additive and gold plating method adopting ionic liquid gold plating solution

The invention discloses an ionic liquid gold plating solution containing a coordination agent and an additive and a gold plating method adopting the ionic liquid gold plating solution and belongs to the technical field of gold electroplating. The gold plating solution is prepared from a solvent [BMIm] [BF4], main salt chloroauric acid, the coordination agent and the additive. Gold electroplating mainly includes the steps of (1) a substrate pretreatment and nickel preplating process and (2) gold electroplating. The ionic liquid gold plating solution containing the coordination agent and the additive and the gold plating method adopting the ionic liquid gold plating solution have the advantages that the added coordination agent has a certain coordination relation to gold ions, the stability of a gold complex in the plating solution can be improved, cathodic polarization can be improved in the electroplating process, and the functions of refining grains and brightening plating coatings are achieved; the added additive cooperates with the coordination agent to a certain degree so that the grains can be further refined, the coatings can be more compact and the appearance can be brighter; and to sum up, the ionic liquid gold plating solution and the gold plating method have the best characteristic that by adding the coordination agent and the additive in an ionic liquid system, the stability of the gold complex in the gold plating solution and the stability of the gold plating solution are improved, and therefore the gold plating coatings and the gold plating solution which are good in properties are obtained.

Owner:HARBIN INST OF TECH

Aqueous chrome-free dacromet coating material, preparation method and use method thereof

The present invention discloses an aqueous chrome-free dacromet coating material and a preparation method thereof, and belongs to the technical field of metal anticorrosion. The technical scheme is that four components are separately prepared and are mixed according to a mass ratio of 4:3.5:2.5:1 so as to obtain the aqueous chrome-free dacromet coating material, wherein the component A preparation method comprises: mixing flaky zinc powder and aluminum powder, adding a dispersant, an organic solvent, water and a defoaming agent, stirring, and uniformly dispersing, the component B preparation method comprises: mixing potassium permanganate, titanyl sulfate, aluminium dihydrogen phosphate, boric acid, ammonium molybdate and water, and dissolving, the component C is an organosilicon hydrolyzate, and the component D is a thickener. According to the present invention, the prepared aqueous chrome-free dacromet coating material has characteristics of compact coating, high hardness and good corrosion resistance; the organic matter in the coating is less, such that the volatile matter has little effect on the environment; and the sintering temperature is low, and the energy source is saved.

Owner:佛山市高明区(中国科学院)新材料产业研究院 +1

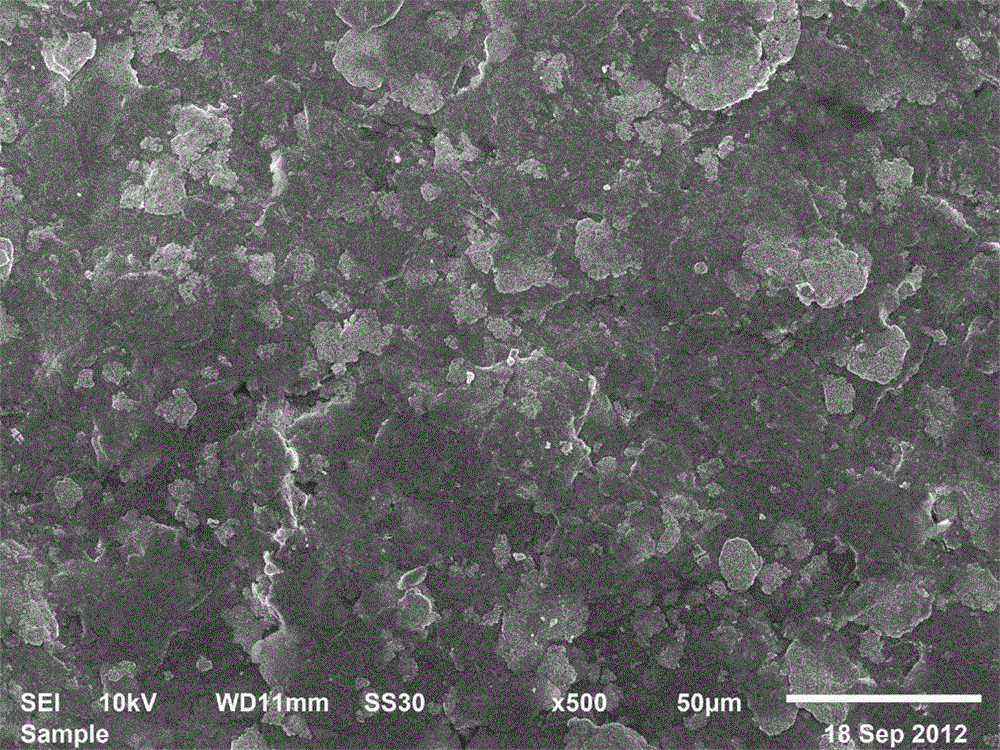

Preparation technique for thermal spraying nano-microcrystalline enamel

InactiveCN105463457AImprove corrosion resistanceDense coatingMolten spray coatingThermal sprayingFrit

The invention relates to a preparation technique for thermal spraying nano-microcrystalline enamel. The process comprises the steps that 1, an enamel glaze block is prepared, specifically, a raw material prepared according to a formula and mixed uniformly is fed into a high-temperature furnace to be melted sufficiently at the temperature of 1300-1500 DEG C and is subjected to water quenching to obtain the homogeneous enamel melted glaze block; 2, thermal spraying powder is prepared, specifically, the melted glaze block is smashed and ground, enamel pre-grinding powder is obtained, 5-30% of nano-silica is added into the pre-grinding powder, mixing granulation is carried out, and the nano-microcrystalline enamel powder for thermal spraying is obtained; and 3, thermal spraying and overall crystallization are conducted, specifically, the enamel powder is uniformly sprayed on the surface of a workpiece through a thermal spraying gun, and the powder is melted and liquefied in the process of being spayed out from the spraying gun and is cooled and solidified after being sprayed on the surface of the workpiece; the obtained enamel layer is a multiphase composite material with nanocrystallines, microlite and glass being interwoven together. The enamel layer has the characteristics of being good in corrosion resistance, high in density, good in toughness, high in impact resistance, capable of being formed at a time and low in manufacturing cost.

Owner:李训竹

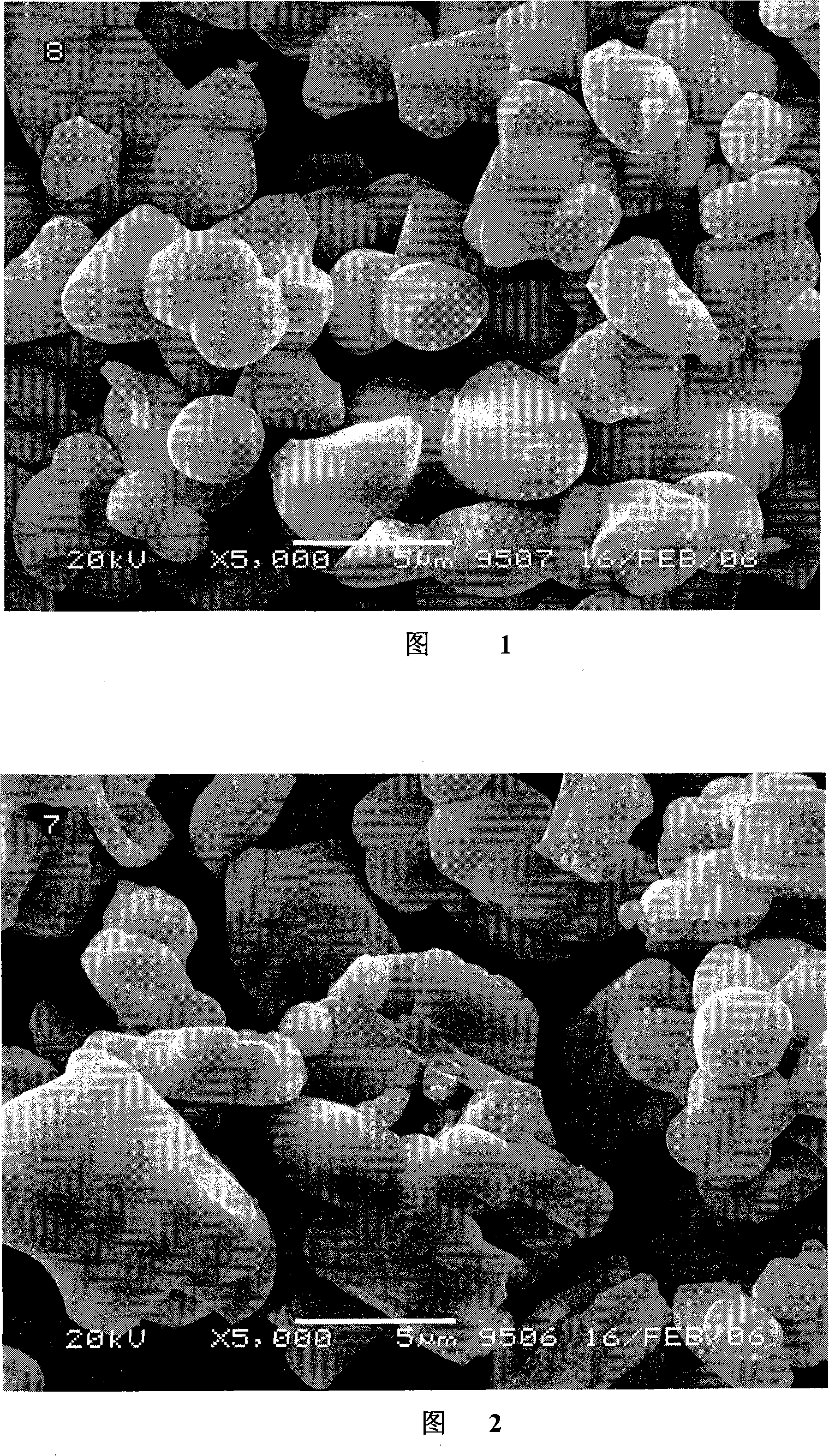

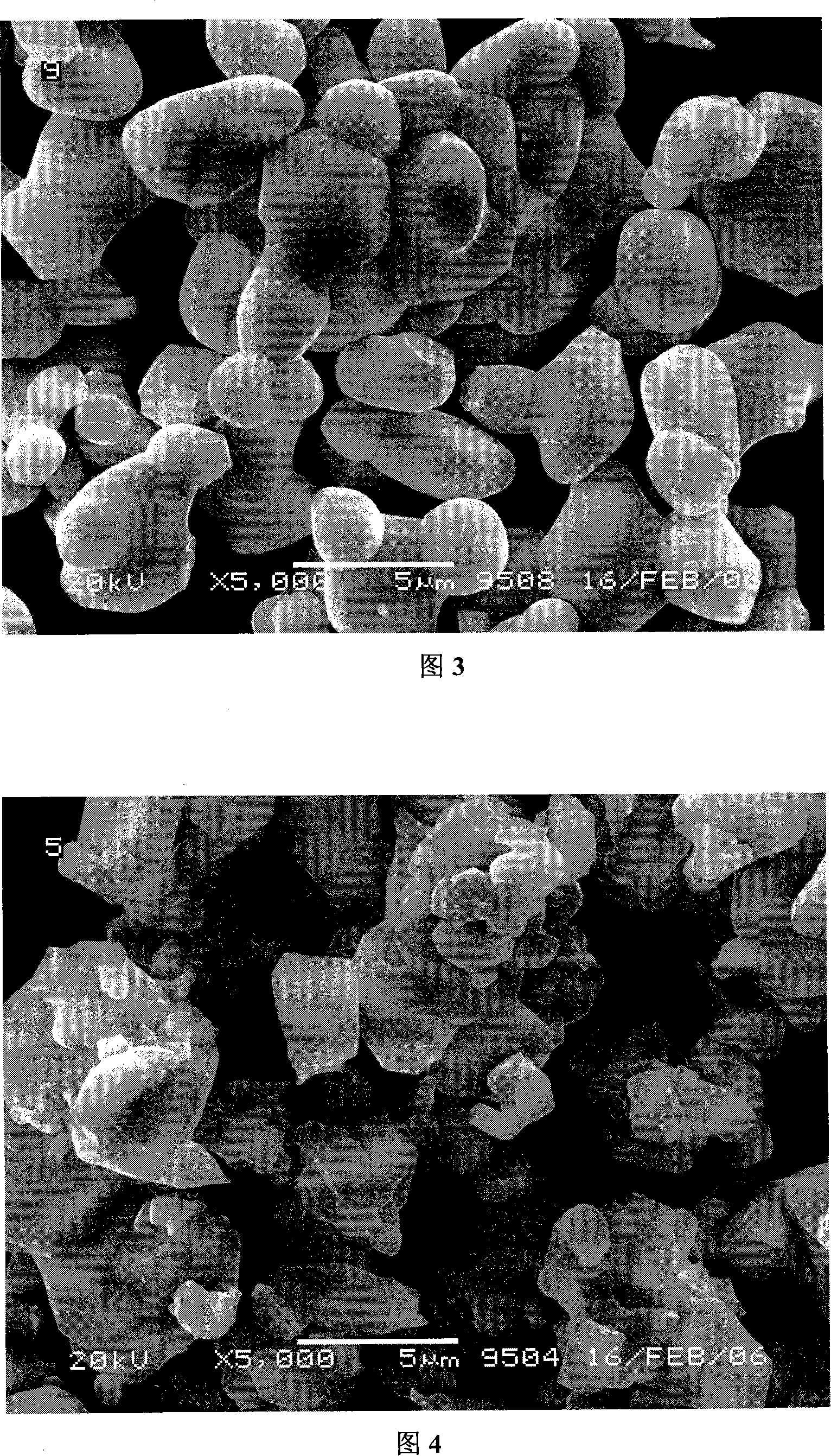

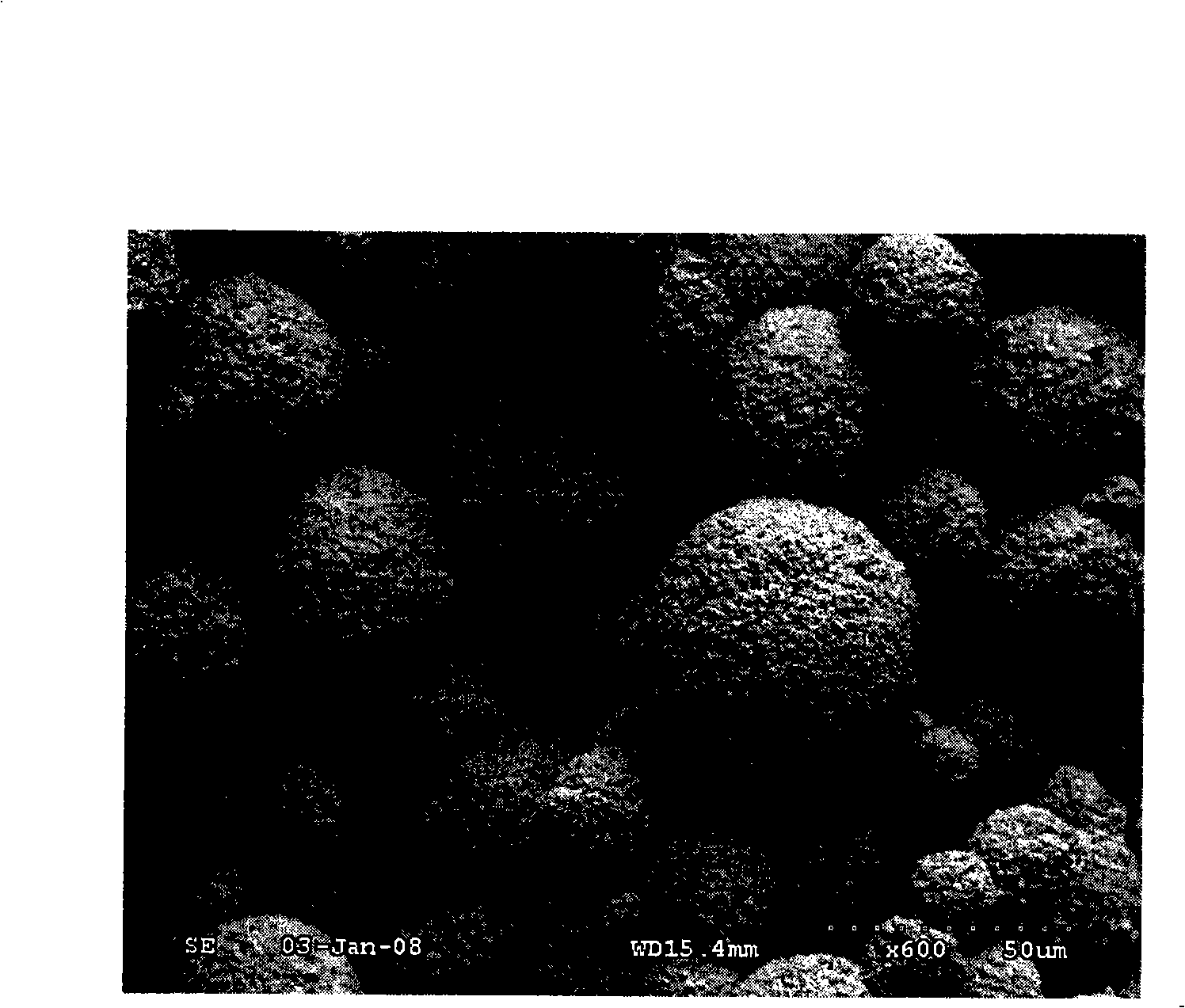

Method for preparing ball milling free spherical crystal type fluorescent powder

The no ball milling spherical crystal phosphor powder preparing process belongs to the field of light-emitting RE material technology and relates to preparation process of YAG phosphor powder and green-blue phosphor powder for LED. By using yttria, cerium oxide, magnesia, barium carbonate, manganese carbonate, barium fluoride and other materials and through one improved high temperature solid phase process, phosphor powder of 5.0-6.0 micron size for use in making LED may be prepared directly without need of ball milling. The present invention has simple technological process, low preparation cost, high yield, capacity of obtaining high purity and high performance phosphor powder and other advantages.

Owner:湖南信多利新材料有限公司

Non magnetic cemented carbide powder with nickel-vanadium alloys as binder phase and preparation

The invention relates to a non-magnetic hard alloy powder for heat spraying which is constituted by taking nickel-vanadium alloys as the binding phase and a preparation method. The preparation of the non-magnetic hard alloy powder for heat spraying is formed by taking nickel-vanadium alloy powder, nickel-vanadium-aluminum alloy powder or nickel-vanadium-chromium alloy power as the binding phase, taking tungsten carbide plus chromium carbide as the hard phase and carrying out clustering or spray drying and sintering. A coating which is prepared by using the non-magnetic hard alloy powder can improve and enhance multiple functions and the service life of a plurality of mechanical parts which require the non-magnetic or anti-magnetic and magnetic isolated work environment.

Owner:王哲 +1

Preparation method of SiC coating

ActiveCN112537962AHigh bonding strengthHigh temperature resistance and oxidation resistanceHigh densityOxidation resistant

The invention discloses a preparation method of a SiC coating. Polymethylsilane is adopted as a coating main body material, and active metal powder and inert ceramic powder are added, so that the prepared coating slurry can be used for preparing the SiC high-temperature-resistant coating on a high-density green body by adopting a brushing method, and the coating has the characteristics of compactness, high bonding strength, high temperature resistance and oxidation resistance. The SiC high-temperature-resistant coating prepared through the method is compact, high in bonding strength with a high-density green body, not prone to falling off and cracking and good in oxidation resistance at the temperature of 1,600 DEG C or below. The method is low in equipment requirement, short in manufacturing period, high in efficiency and safe and controllable in preparation process. Meanwhile, the prepared SiC coating has high bonding strength with a high-density green body, is compact, is not easy to fall off, has oxidation resistance, and can meet the requirements of high temperature resistance and oxidation resistance at 1600 DEG C.

Owner:HUNAN BOWANG CARBON CERAMIC CO LTD

Ceramic overflow pipeline inner wall wear-resistant coating

ActiveCN104195401AWith wear-resistant functionHigh temperature resistantPipe protection against damage/wearWear resistantTemperature resistance

The invention discloses a ceramic overflow pipeline inner wall wear-resistant coating which is prepared from the following components in parts by weight: 15-32 parts of Cr3C2-NiCr, 18-33 parts of WC-Co, 26-41 parts of NiCrBSi, 16-25 parts of silver-base solder, 11-17 parts of TaC and 13-19 parts of NbC. The ceramic overflow pipeline inner wall wear-resistant coating has the advantages of wear resistance, high temperature resistance, high compactness, high bonding strength, simple process preparation and flexible operation, and is suitable for painting the ceramic overflow pipeline inner wall.

Owner:NANTONG GAOXIN ANTIWEAR MATERIALS TECH CO LTD

Nano particle compound type anticorrosive coating and preparation method therefor

InactiveCN104974572ADense coatingNot easy to peel offAnti-corrosive paintsMaleic anhydrideCis-Butenedioic Acid

The invention discloses a nano particle compound type anticorrosive coating and a preparation method therefor. The nano particle compound type anticorrosive coating comprises the following components in parts by weight: 20-30 parts of polybutylene, 2-8 parts of maleic anhydride, 3-5 parts of acrylate resin, 0.2-0.6 part of dibenzoyl peroxide, 2-4 parts of pentaerythritol, 5-10 parts of nanosilicon dioxide, 1-4 parts of nanometer titania, 0.35-0.88 part of sodium dodecyl benzene sulfonate, 1-5 parts of amino silicon oil, 2-6 parts of diethylenetriamine, 3-5 parts of polystyrolsulfon acid, 1-5 parts of carboxyethyl cellulose, 5-10 parts of maleic anhydride, 1-3 parts of fire retardant, 1-3 pats of fireproof staple fiber, 2-5 parts of foaming agent and 0.8-2.5 part of reinforcing agent. The rigidity and strength of the coating are high, the adhesive force of a priming paint and a base material is high, and the mechanical strength is improved; the coating is more compact after coating and is unlikely to peel off, and the corrosion resistance is reinforced.

Owner:SUZHOU POLYMER NEW MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com