Aqueous chrome-free dacromet coating material, preparation method and use method thereof

A water-based and coating technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of insufficient density and corrosion resistance of coatings, and achieve the effect of small impact, high hardness, and less organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

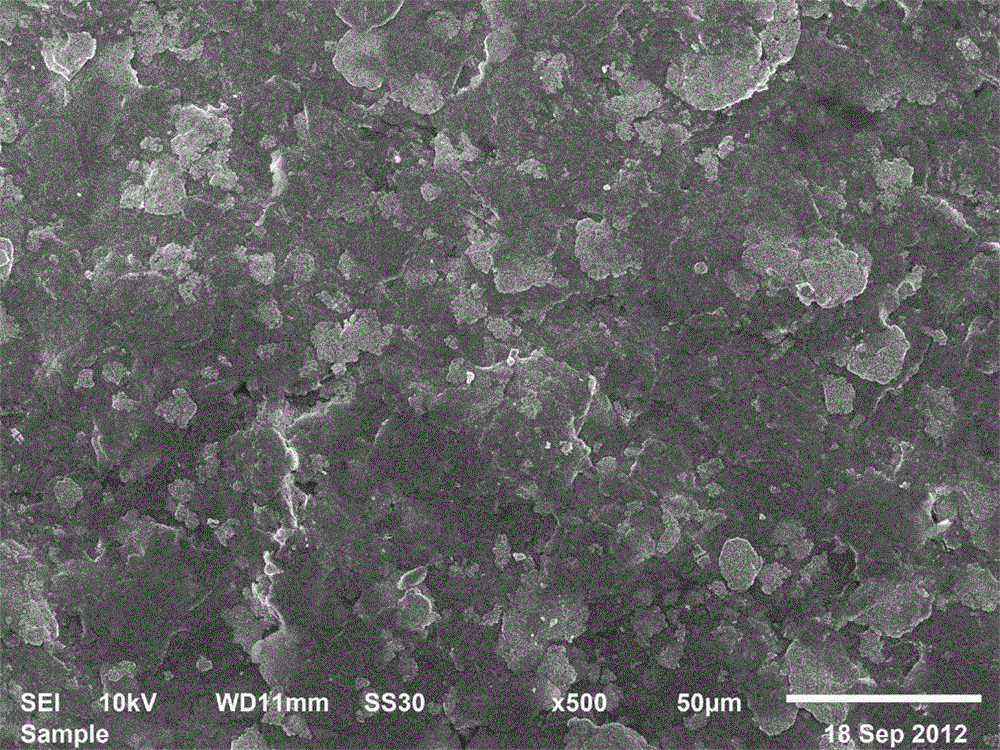

Image

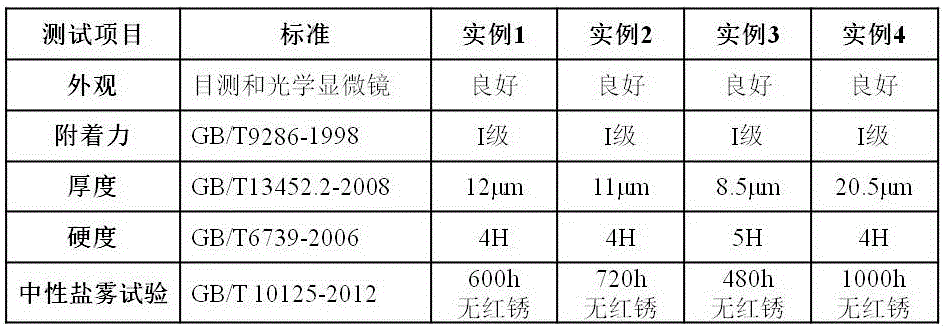

Examples

Embodiment 1

[0026] Weigh 21g of zinc powder, 4g of aluminum powder, 17g of ethylene glycol, 4.5g of op-10, 24g of water, 0.2g of defoamer, stir mechanically, and disperse evenly to prepare component A for use; weigh permanganate Potassium 0.4g, titanium oxysulfate 0.3g, aluminum dihydrogen phosphate 10g, boric acid 6.5g, ammonium molybdate 0.2g, cerium nitrate 0.05g, water 40g, ultrasonically dissolved to make B component, stand-by; weigh γ- Glycidyl etheroxypropyltrimethoxysilane 19g, water 19g, methanol 3.5g, under the condition of 50°C water bath, magnetically stirred until colorless and transparent, then added dropwise 1.0g of 1mol / L dilute hydrochloric acid, sealed and hydrolyzed for 10 hours, prepared Component C, ready for use; weigh 15.0 g of nonionic polyurethane associative thickener and 3.0 g of white carbon black, stir evenly, and set aside.

[0027] The four components are mixed according to the mass ratio of 4:3.5:2.5:1. The specific preparation method: under the condition o...

Embodiment 2

[0031] Weigh 20.0g of zinc powder; 5.0g of aluminum powder; 15.0g of ethylene glycol; 5.0g of op-10; 25.0g of water; Take 0.5g of potassium permanganate, 0.3g of titanyl sulfate, 10.5g of aluminum dihydrogen phosphate, 6.5g of boric acid, 0.2g of ammonium molybdate, 0.05g of cerium nitrate, and 40g of water, and ultrasonically dissolve it to make component B for use ;Weigh 20g of γ-glycidyl etheroxypropyl trimethoxysilane, 20g of water, 4.5g of methanol, under the condition of 50°C water bath, stir magnetically until it is colorless and transparent, then add 1.5g of 1mol / L dilute hydrochloric acid dropwise, seal Hydrolyze for 8 hours to prepare component C, which is ready for use; weigh 15.0 g of nonionic polyurethane associative thickener and 2.5 g of white carbon black, stir evenly, and set aside.

[0032] The four components are mixed according to the mass ratio of 4:3.5:2.5:1. The specific preparation method: Under the condition of continuous stirring at 500rmp, component ...

Embodiment 3

[0036] Weigh 20.0g of zinc powder; 5.0g of aluminum powder; 16.0g of ethylene glycol; 5.5g of op-10; 23.0g of water; Take 0.5g of potassium permanganate, 0.35g of titanyl sulfate, 11g of aluminum dihydrogen phosphate, 6.0g of boric acid, 0.25g of ammonium molybdate, 0.05g of cerium nitrate, and 40g of water, and ultrasonically dissolve it to prepare component B for use; Weigh 22g of γ-glycidyl etheroxypropyl trimethoxysilane, 19g of water, and 6.0g of methanol, and stir it magnetically until it is colorless and transparent in a water bath at 50°C, then add 2.0g of 1mol / L dilute hydrochloric acid dropwise, seal and hydrolyze After 12 hours, component C was prepared and set aside; 15.0 g of nonionic polyurethane associative thickener and 3.0 g of white carbon black were weighed, stirred evenly, set aside.

[0037]The four components are mixed according to the mass ratio of 4:3.5:2.5:1. The specific preparation method: Under the condition of continuous stirring at 300rmp, compone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com