Ionic liquid gold plating solution containing coordination agent and additive and gold plating method adopting ionic liquid gold plating solution

A technology of ionic liquid and complexing agent, which is applied in the field of gold plating, can solve the problems of limited ability to form complexes and has not been practically applied, and achieve the effects of bright appearance, improved cathode current efficiency, and increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

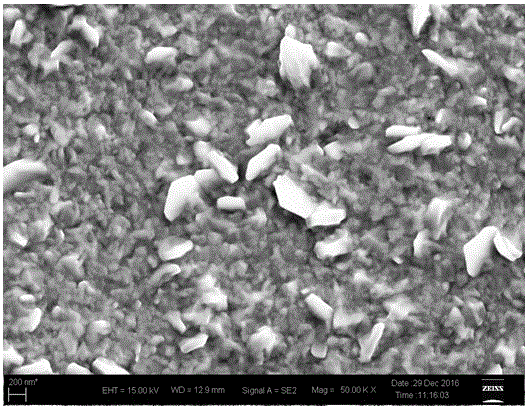

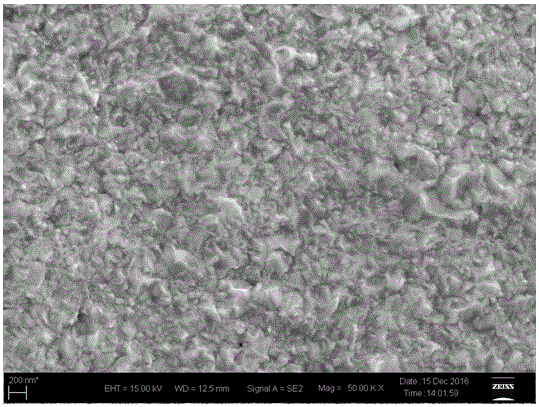

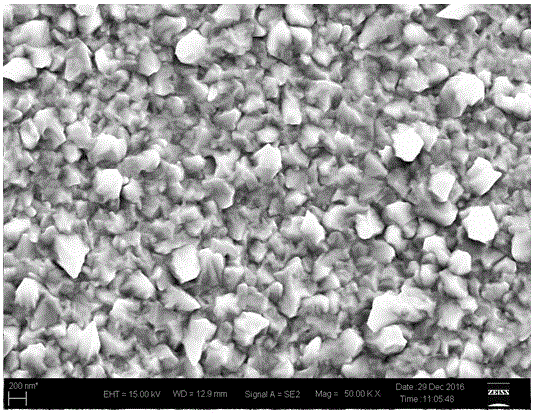

Image

Examples

specific Embodiment approach 1

[0023] Specific embodiment one: a kind of ionic liquid gold plating liquid that comprises complexing agent and additive, described gold plating liquid is made of solvent [BMIm] [BF 4 ], main salt chloroauric acid (HAuCl 4 ·3H 2 O), complexing agent and additives are mixed and prepared, wherein the concentration of main salt chloroauric acid is 1~50g / L, the concentration of complexing agent is 5~100g / L, and the concentration of additive is 0.5~20g / L .

[0024] Specific embodiment two: a kind of ionic liquid gold plating liquid that comprises complexing agent and additive described in specific embodiment one, described complexing agent is organic complexing agent, and described organic complexing agent is hydantoin, 3 -Hydroxymethyl-5,5-dimethylhydantoin, 5,5-diphenylhydantoin, 1,3-dichloro-5,5-dimethylhydantoin, 1- Aminohydantoin, 5,5-dimethylhydantoin, 2-thiohydantoin, 1,3-dibromo-5,5-dimethylhydantoin, 1,3- Dimethylol-5,5-dimethylhydantoin, 2-thio-5,5-dimethylhydantoin, t...

specific Embodiment approach 3

[0025] Specific embodiment three: a kind of ionic liquid gold-plating liquid that contains complexing agent and additive described in specific embodiment one or two, described additive is pyridine, 2,2-bipyridine, 4,4-bipyridine, 2- Aminopyridine, 3-aminopyridine, ethylenediamine, triethylenetetramine, tetraethylenepentamine, polyethyleneimine, triethanolamine, dopamine, polyvinyl alcohol, polyethylene glycol, adenine, guanine, hypoxanthine , cytosine, uracil, thymine, vanillin, piperonal, saccharin, uric acid, adenosine, theobromine, 3-hydroxy-2-pyridinecarboxylic acid, 2-pyridinecarboxylic acid, citric acid, ethylene glycol, methanol, butyl Alkynediol, succinimide, nicotinic acid, nicotinamide, L-methionine, imidazole, ethylenediaminetetraacetic acid, hydroxyethylethylenediaminetriacetic acid, 2-aminothiazole, thiosemicarbazide one or a mixture of several.

specific Embodiment approach 4

[0026] Specific embodiment four: a kind of method that utilizes the ionic liquid gold-plating solution that comprises complexing agent and additive described in any specific embodiment in specific embodiment one to three to carry out the method for electroplating gold, the step of the method for described electroplating gold is as follows:

[0027] Step 1: Pretreatment of the substrate and pre-nickel plating process (the pretreatment process is water washing, degreasing, pickling, and water washing in sequence, and then the pretreated substrate is placed in the nickel plating solution, and electroplated with a constant current power supply for 5~10min , to obtain a certain thickness of nickel plating layer, then wash it with distilled water and dry it with cold air);

[0028] Step 2: Electroplating gold: place the dried nickel-plated substrate in the prepared ionic liquid gold plating solution, and use a constant current method for electroplating. The process is: temperature is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com